US

®

Owner's Manual

Air-cooled, Prepackaged

Automatic Standby Generators

Models:

ASPASICCA007 (6 kW NG, 7 kW LP)

ASPASICCA012 (12 kW NG, 12 kW LP)

ASPASICCA015 (13 kW NG, 15 kW LP)

©

Not intended for use as Primary Power in place of utility or in

life-support applications.

DEADLY EXHAUST FUMES. OUTDOOR INSTALLATION ONLY!!

INTRODUCTION

Thank you for purchasing this model of the Carrier

product line. This model is a compact, high performance,

air-cooled, engine-driven generator designed to

automatically supply electrical power to operate critical

loads during a utility power failure.

This unit is factory installed in an all-weather, metal enclosure

that is intended exclusively for outdoor installation. This

generator will operate using either vapor withdrawn liquid

propane (LP) or natural gas (NG).

• READ THIS MANUAL THOROUGHLY

If any portion of this manual is not understood, contact the

nearest Carrier Dealer for starting, operating and servicing

procedures.

Throughout this publication, and on tags and

decals affixed to the generator, DANGER, WARNING,

CAUTION and NOTE blocks are used to alert personnel

to special instructions about a particular operation that

may be hazardous if performed incorrectly or carelessly.

Observe them carefully. Their definitions are as follows:

After this heading, read instructions that, if not

strictly complied with, will result in serious

personal injury, including death, in addition to

property damage.

"_ WARNUNG _°

After this heading, read instructions that, if not

strictly complied with, may result in serious

personal injury or property damage.

"_ CAUTION

After this heading, read instructions that, if not

strictly complied with, could result in damage to

equipment and/or property.

NOTE:

After this heading, read explanatory statements

that require special emphasis.

These safety warnings cannot eliminate the hazards

that they indicate. Common sense and strict

compliance with the special instructions while

performing the service are essential to preventing

accidents.

Four commonly used safety symbols accompany the

DANGER, WARNING and CAUTION blocks. The type of

information each indicates follows:

The operator is responsible for proper and safe use

of the equipment. Carrier strongly recommends that the

operator read this Owner's Manual and thoroughly

understand all instructions before using this equipment.

Carrier also strongly recommends instructing other users

to properly start and operate the unit. This prepares them

if they need to operate the equipment in an emergency.

• CONTENTS

This manual contains pertinent owner's information,

including warranty, electrical diagrams, exploded views

and lists of repair parts, for three different Carrier models:

• ASPAS1CCA007 - 6 kW NG, 7 kW LP, single-cylinder

GH-410 Engine

• ASPAS1OCA012 - 12 kW NG, 12 kW LP, V-twin GT-

990 Engine

• ASPAS1COA015 - 13 kW NG, 15 kW LP, V-twin GT-

990 Engine

• OPERATION AND MAINTENANCE

It is the operator's responsibility to perform all safety

checks, to make sure that all maintenance for safe

operation is performed promptly, and to have the

equipment checked periodically by a Carrier Dealer.

Normal maintenance service and replacement of parts

are the responsibility of the owner/operator and, as such,

are not considered defects in materials or workmanship

within the terms of the warranty. Individual operating

habits and usage contribute to the need for maintenance

service.

Proper maintenance and care of the generator ensures a

minimum number of problems and keep operating

expenses at a minimum. See a Carrier Dealer for service

aids and accessories.

• HOW TO OBTAIN SERVICE

When the generator requires servicing or repairs, contact

a Carrier Dealer for assistance. Service technicians are

factory-trained and are capable of handling all service

needs.

When contacting a Carrier Dealer about parts and service,

always supply the complete model number and serial

number of the unit as given on its data decal, which is

located on the generator. See Figure 1.1 or Figure 1.2 in

Section 1.4 for decal location.

Model No. Serial No.

_This symbol points out important safety

information that, if not followed, could

endanger personal safety and/or property of

others.

_This symbol points out potential explosion

hazard.

_This symbol points out potential fire hazard.

Z_ This symbol points out potential electrical

shock hazard.

Carrier

Table of Contents

Carrier Air-cooled 7 kW, 12 kW and 15 kW Generators

Introduction ........................ Inside Front Cover

Read This Manual Thoroughly .............................. iFC

Contents ................................................................ iFC

Operation and Maintenance .................................. iFC

How to Obtain Service .......................................... IFC

Safety Rules ........................................................ 2

Standards Index ........................................................ 3

Section I - General Information .................. 4

1.1 Unpacking/Inspection .......................................... 4

1.2 Protection Systems .............................................. 4

1.3 NEC Requirement for Arc Fault Circuit

Interruption Breaker for Bedrooms ...................... 4

1.4 The Generator .................................................... 5

1.5 Specifications ...................................................... 6

1.6 System Set LED .................................................. 6

1.7 Fuel Requirements and Recommendations ........ 6

1.8 Fuel Consumption ................................................ 7

1.9 Location .............................................................. 7

1.10 Battery Installation .............................................. 8

1.11 The Battery .......................................................... 8

Section 3 - Maintenance .............................. 12

3.1 Fuses ................................................................ 12

3.2 Checking the Engine Oil Level .......................... 13

3.3 Changing the Engine Oil .................................... 13

3.4 Changing the Oil Filter ...................................... 14

3.5 Changing the Engine Air Cleaner ...................... 14

3.6 Spark Plug(s) .................................................... 14

3.7 Battery Maintenance .......................................... 15

3.8 Cooling System .................................................. 15

3.9 Corrosion Protection .......................................... 16

3.10 Attention After Submersion ................................ 16

3.11 Out of Service Procedure .................................. 16

Section 4 - Service .......................................... 17

4.1 Service Schedule .............................................. 17

Section 5 - Troubleshooting ........................ 18

5.1 Troubleshooting Guide ...................................... 18

Section 6 - Warranty ...................................... 19

Section 2 - Operation ...................................... 9

2.1 Break-in Procedure .............................................. 9

2.2 Using the Auto/Off/Manual Switch ...................... 9

2.3 Automatic Transfer Operation .......................... 10

2.4 Sequence of Automatic Operation .................... 10

2.5 Manual Transfer Operation ................................ 11

2.6 Setting the Exercise Timer ................................ 11

2.7 Protection Systems ............................................ 12

Carrier 1

SAFETYRULES

IMPORTANT SAFETY INSTRUCTIONS

CarrierAir-cooled 7 kW, 12 kW and 15 kW Generators

SAVE THESE INSTRUCTIONS - The manufacturer suggests that these rules for safe

operation be copied and posted near the unit's installation site. Safety should be stressed to all

operators and potential operators of this equipment.

Study these SAFETY RULES carefully before installing,

operating or servicing this equipment. Become familiar

with this Owner's Manual and with the unit. The generator

can operate safely, efficiently and reliably only if it is

properly installed, operated and maintained. Many

accidents are caused by failing to follow simple and

fundamental rules or precautions.

Carrier cannot anticipate every possible

circumstance that might involve a hazard. The warnings

in this manual, and on tags and decals affixed to the unit

are, therefore, not all-inclusive. If using a procedure,

work method or operating technique Carrier does not

specifically recommend, ensure that it is safe for others.

Also make sure the procedure, work method or operating

technique chosen does not render the generator unsafe.

_ Despite the safe design of this generator,

operating this equipment imprudently, neglecting

its maintenance or being careless can cause

possible injury or death. Permit only responsible

and capable persons to operate or maintain this

equipment.

_ Potentially lethal voltages are generated by

these machines. Ensure all steps are taken to

render the machine safe before attempting to

work on the generator.

GENERAL HAZARDS

• For safety reasons, Carrier recommends that the

installation, initial start-up and maintenance of this

equipment is carried out by a Carrier Dealer.

• The engine exhaust fumes contain carbon monoxide,

which can be DEADLY. This dangerous gas, if

breathed in sufficient concentrations, can cause

unconsciousness or even death. This exhaust system

must be installed properly, in strict compliance with

applicable codes and standards. Following

installation, do nothing that might render the system

unsafe or in noncompliance with such codes and

standards.

• Keep hands, feet, clothing, etc., away from drive belts,

fans, and other moving or hot parts. Never remove any

drive belt or fan guard while the unit is operating.

• Adequate, unobstructed flow of cooling and ventilating

air is critical to correct generator operation. Do not

alter the installation or permit even partial blockage of

ventilation provisions, as this can seriously affect safe

operation of the generator. The generator MUST be

installed outdoors.

• When working on this equipment, remain alert at all

times. Never work on the equipment when physically

or mentally fatigued.

• Inspect the generator regularly, and contact the

nearest Carrier Dealer for parts needing repair or

replacement.

• Before performing any maintenance on the generator,

disconnect its battery cables to prevent accidental

start up. Disconnect the cable from the battery post

indicated by a NEGATIVE, NEG or (-) first. Reconnect

that cable last.

• Never use the generator or any of its parts as a step.

Stepping on the unit can stress and break parts, and

may result in dangerous operating conditions from

leaking exhaust gases, fuel leakage, oil leakage, etc.

_ Parts of the generator are rotating and/or hot

during operation. Exercise care near running

generators.

2 Carrier

IMPORTANT SAFETY INSTRUCTIONS

CarrierAir-cooled 7 kW, 12 kW and 15 kW Generators

SAFETYRULES

/A

ELECTRICAL HAZARDS

• All generators covered by this manual produce

dangerous electrical voltages and can cause fatal

electrical shock. Utility power delivers extremely high

and dangerous voltages to the transfer switch as does

the standby generator when it is in operation. Avoid

contact with bare wires, terminals, connections, etc.,

while the unit is running. Ensure all appropriate

covers, guards and barriers are in place before

operating the generator. If work must be done around

an operating unit, stand on an insulated, dry surface to

reduce shock hazard.

• Do not handle any kind of electrical device while

standing in water, while barefoot, or while hands or

feet are wet. DANGEROUS ELECTRICAL SHOCK

MAY RESULT.

• The National Electrical Code (NEC) requires the frame

and external electrically conductive parts of the

generator to be connected to an approved earth

ground. Local electrical codes also may require proper

grounding of the generator electrical system.

• After installing this home standby electrical system, the

generator may crank and start at any time without

warning. When this occurs, load circuits are

transferred to the STANDBY (generator) power

source. To prevent possible injury if such a start and

transfer occur, always set the generator's

Auto/Off/Manual switch to its OFF position before

working on equipment and remove the 7.5A and 15A

fuses from the generator control panel.

• In case of accident caused by electric shock,

immediately shut down the source of electrical power. If

this is not possible, attempt to free the victim from the

live conductor. AVOID DIRECT CONTACT WITH THE

VICTIM. Use a nonconducting implement, such as a dry

rope or board, to free the victim from the live conductor.

If the victim is unconscious, apply first aid and get

immediate medical help.

• Never wear jewelry when working on this equipment.

Jewelry can conduct electricity resulting in electric

shock, or may get caught in moving components

causing injury.

A FIRE HAZARDS

• For fire safety, the generator must be installed and

maintained properly. Installation always must comply

with applicable codes, standards, laws and

regulations. Adhere strictly to local, state and national

electrical and building codes. Comply with regulations

the Occupational Safety and Health Administration

(OSHA) has established. Also, ensure that the

generator is installed in accordance with the

manufacturer's instructions and recommendations.

Following proper installation, do nothing that might

alter a safe installation and render the unit in

noncompliance with the aforementioned codes,

standards, laws and regulations.

• Keep a fire extinguisher near the generator at all times.

Extinguishers rated "ABC" by the National Fire

Protection Association are appropriate for use on the

standby electric system. Keep the extinguisher

properly charged and be familiar with its use. Consult

the local fire department with any questions pertaining

to fire extinguishers.

EXPLOSION HAZARDS

Do not smoke around the generator. Wipe up any fuel

or oil spills immediately. Ensure that no combustible

materials are left in the generator compartment, or on

or near the generator, as FIRE or EXPLOSION may

result. Keep the area surrounding the generator clean

and free from debris.

Gaseous fluids such as natural gas and liquid propane

(LP) gas are extremely EXPLOSIVE. Install the fuel

supply system according to applicable fuel-gas codes.

Before placing the home standby electric system into

service, fuel system lines must be properly purged and

leak tested according to applicable code. After

installation, inspect the fuel system periodically for

leaks. No leakage is permitted.

STANDARDS INDEX

In the absence of pertinent standards, codes, regulations

and laws, the published information listed below may be

used as installation guide for this equipment.

1. NFPA No. 37, STATIONARY COMBUSTION

ENGINES AND GAS TURBINES, available from the

National Fire Protection Association, 470 Atlantic

Avenue, Boston, MA 02210.

2. NFPA No. 76A, ESSENTIAL ELECTRICAL

SYSTEMS FOR HEALTH CARE FACILITIES,

available same as Item 1.

3. NFPA No. 54, NATIONAL FUEL GAS CODE,

available same as Item 1.

4. NFPA No. 58, AMERICAN NATIONAL STANDARD

FOR STORAGE AND HANDLING OF LIQUEFIED

PETROLEUM GAS, available same as Item 1.

5. NFPA No. 70, NFPA HANDBOOK OF NATIONAL

ELECTRIC CODE, available same as Item 1.

6. Article X, NATIONAL BUILDING CODE, available

from the American Insurance Association, 85 John

Street, New York, N.Y. 10038.

7. AGRICULTURAL WIRING HANDBOOK, available

from the Food and Energy Council, 909 University

Avenue, Columbia, MO 65201.

8. ASAE EP-3634, INSTALLATION AND

MAINTENANCE OF FARM STANDBY

ELECTRICAL SYSTEMS, available from the

American Society of Agricultural Engineers, 2950

Niles Road, St. Joseph, MI 49085.

9. NFPA No. 30, FLAMMABLE AND COMBUSTIBLE

LIQUIDS CODE, available same as Item 1.

Carrier 3

o • o

GENERAL

NFORMATON

_Only qualified electricians or contractors should

attempt such installations, which must comply

strictly with applicable codes, standards and

regulations.

Section 1 -- General Information

CarrierAir-cooled 7 kW, 12 kW and 15 kW Generators

1.1 UNPACKING/INSPECTION

After unpacking, carefully inspect the contents

for damage.

• This standby generator set has been factory supplied

with a weather protective enclosure that is intended for

outdoor installation only,

• This UL listed standby generator set is packaged with

an automatic transfer switch with built in load center.

The combination transfer switch and load center is

pre-wired with a two foot and 30 foot conduit. Circuit

breakers for emergency circuit connections are

included.

• This UL listed, 2-pole switch is rated at 100 AC

amperes at 250 volts maximum. This transfer switch

is for indoor use only.

",_ WARNnNG ,_°

_lf this generator is used to power electrical load

circuits normally powered by a utility power

source, it is required by code to install a

transfer switch. The transfer switch must

effectively isolate the electrical system from the

utility distribution system when the generator

is operating (NEC 700, 701 & 702). Failure to

isolate an electrical system by such means will

result in damage to the generator and also may

result in injury or death to utility power

workers due to backfeed of electrical energy.

If any loss or damage is noted at time of delivery, have

the person(s) making the delivery note all damage on the

freight bill or affix their signature under the consignor's

memo of loss or damage.

If a loss or damage is noted after delivery, separate the

damaged materials and contact the Carrier for claim

procedures.

"Concealed damage" is understood to mean damage to

the contents of a package that is not in evidence at the

time of delivery, but is discovered later.

1.2 PROTECTION SYSTEMS

Unlike an automobile engine, the generator may have to

run for long periods of time with no operator present to

monitor engine conditions. For that reason, the engine is

equipped with the following systems that protect it

against potentially damaging conditions:

1. Low Oil Pressure Sensor 3. Overcrank

2. High Temperature Sensor 4. Overspeed

There are LED readouts on the control panel to notify

personnel that one of these faults has occurred. There is

also a "System Set" LED that is lit when all of the

conditions describe in Section 1.3 are true.

1.3 NEC REQUIREMENT FOR ARC

FAULT CIRCUIT INTERRUPTION

BREAKER FOR BEDROOMS

In 2001, the National Electric Code (NEC) introduced a

requirement for new construction. This new requirement

indicates the need for Arc Fault Circuit Interrupters to be

used to protect the complete branch circuit that feeds a

dwelling bedroom. The actual NEC requirement is

indicated below.

SECTION 210.12 ARC FAULT CIRCUIT

INTERRUPTER PROTECTION

Definition: An arc fault circuit interrupter is a device

intended to provide protection from the effects of arc

faults by recognizing characteristics unique to arcing

and by functioning to de-energize the circuit when an

arc fault is detected.

2. Dwelling Unit Bedrooms: All branch circuits that

supply 125 volt, single-phase, 15 and 20 ampere

outlets installed in dwelling unit bedrooms shall be

protected by an arc fault circuit interrupter listed to

provide protection of the entire branch circuit.

Section 210.12 requires that AFCl protection be provided

on branch circuits that supply outlets (receptacle,

lighting, etc.) in dwelling bedrooms. The requirement is

limited to 15 and 20 ampere, 125 volt circuits. There is no

prohibition against providing AFCl protection on other

circuits or in locations other than bedrooms. Because

circuits are often shared between a bedroom and other

areas such as closets and hallways, providing AFCl

protection on the complete circuit would comply with

210.12.

If during the installation of the Carrier Home Standby

system the decision is made to provide back up power to

a bedroom branch circuit, then the circuit breaker in the

Carrier Transfer Switch should be replaced with an Arc

Fault Circuit Interrupter.

It is most important that breakers only be switched like for

like. For instance, if replacing a 15A breaker, it MUST be

replaced with a 15A AFCl breaker. Likewise, a 20A

breaker MUST be replaced with a 20A AFCl.

These AFCl breakers are available at the nearest

electrical wholesaler or hardware store.

Siemens Item #

Q115AF

Q120AF

Description

15A Single Pole AFCl

20A Single Pole AFCl

4 Carrier

CarrierAir-cooled 7 kW, 12 kW and 15 kW Generators

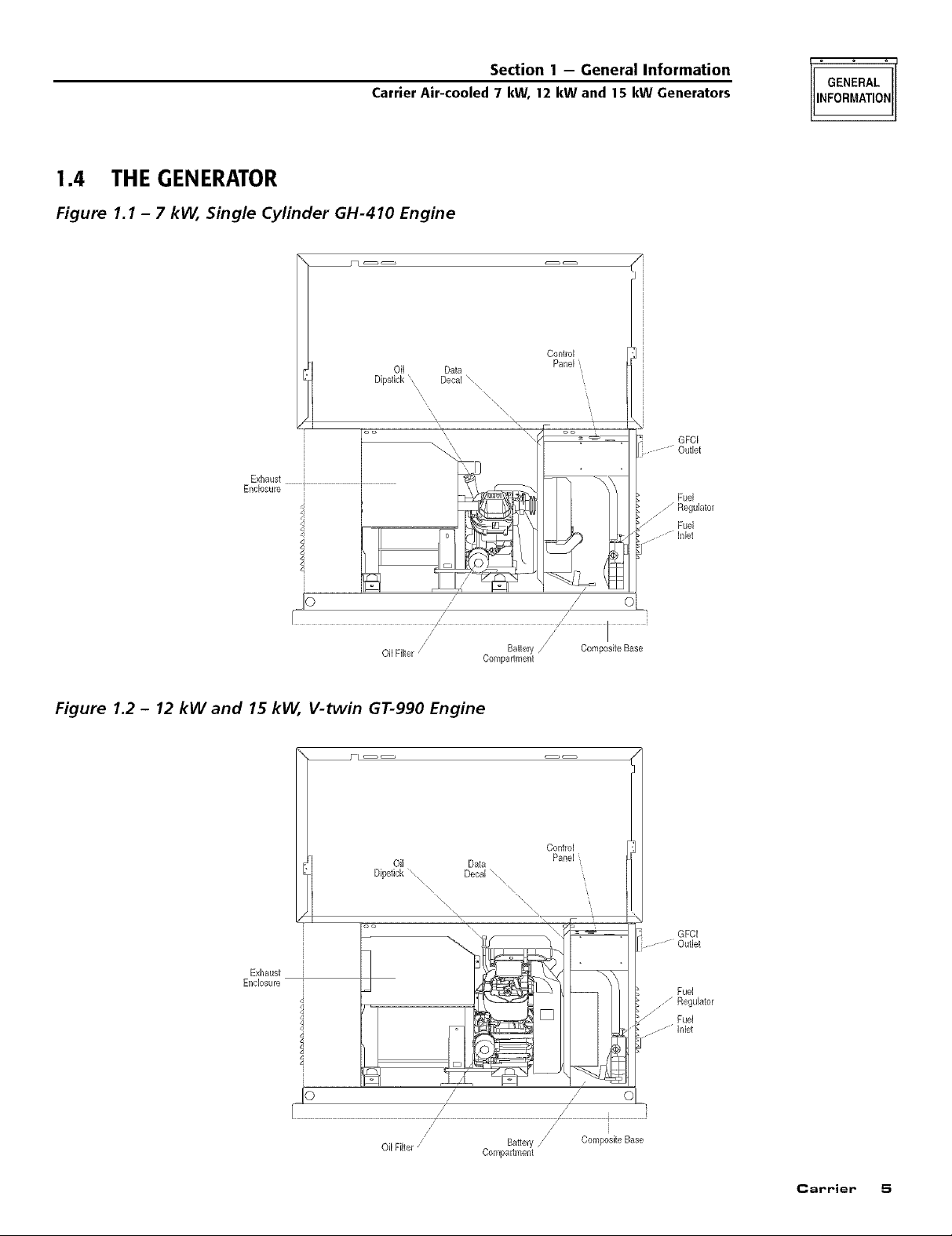

1.4 THE GENERATOR

Figure 1.1 - 7 kW, Single Cylinder GH-410 Engine

Oil Data

Dipsiick '\, Decal \,\

, \\

', \

, \

Exhaust

Enclosure

Section 1 -- General Information

Conirol

GFCI

........ Outlet

Fuel

-" Fuel

....." Inlel

GENERAL

INFORMATION

_0 /' C

Oil Filler " Battery / Composite Base

Figure 1.2 - 12 kW and 15 kW, V-twin GT-990 Engine

Oil Data Panel

Dipstick Deaa \

\ \\

\

Exhaust

Enclosure

Compadrnant

Contrd

/

GFCI

....... Outlet

Fuel

./ Regulator

/

/ Fuel

--" Inlet

/ /

/

Oil Filler/' _o@os.e

Comparlment

Base

Carrier 5

o • o

GENERAL

NFORMATON

Section 1 -- General Information

CarrierAir-cooled 7 kW, 12 kW and 15 kW Generators

1.5 SPECIFICATIONS

1.5.1 GENERATOR

Model

Rated Max. Continuous Power Capacity (Watts*)

Rated Voltage

Rated Max. Continuous Load Current (Amps)

120 Volts**

240 Volts

Main Line Circuit Breaker

Phase

Number of Rotor Poles

Rated AC Frequency

Power Factor

Recommended Air Filter

Battery Requirement

(At 0° F -17.8 ° C)

Weight

Output Sound Level @23 ft (7m) atfull load

Normal Operating Range

* Maximum wattage and current aresubject to and timltedby such factors as fuel atu content, ambient temperature, altitude, engine power and condition, etc. Maximum power decreases about 3.5

percent for each 1000 feet above sea level: and also will decrease about 1 percent for each 6" O (10° F) above 16° C (60° F) ambient temperature.

** Load current values shown for 120volts are maximum TOTAL values for two separate circuits.The maximum current in each circuit must not exceed the value stated for 240 volts.

1.5.2 ENGINE

Type of Engine

Number of Cylinders

Rated Horsepower

Displacement

Cylinder Block

Valve Arrangement

Ignition System

Recommended Spark Plug

Spark Plug Gap

Compression Ratio

Starter

Oil Capacity Including Filter

Recommended Oil Filter

Recommended Air Filter

Operating RPM

ASPAS1 CCA007

6,000 NG/7,000 LP

120/240

50.0 NG/58.3 LP 100.0

25.0 NG/29.2 LP 50.0

30 Amp

1

2

60 Hz

1

Carrier Part # 0C8127

Group 26

12 Volts and

350 Cold-cranking

Amperes Minimum

375 Pounds

68 db (A)

-20°F (-28.8°C) to 104°F (40°C)

ASPASICCA007

GH-410

1

14.5 @ 3,600 rpm

410cc

Aluminum w/Cast

iron Sleeve

Overhead Valves

Solid-state w/Magneto

RC14YC

0.76 mm (0.030 inch)

8.6:1

12 Vdc

Approx. 1.5 Qts

Carrier Part # 70185D

Carrier Part # 0C8127

3,600

ASPAS1CCA012

12,000 NG/12,000 LP

120/240

NG/100.0 LP 108.3

NG/50.0 LP 54.2

50 Amp

1

2

60 Hz

1

Carrier Part # 0C8127

Group 26

12 Volts and

525 Cold-cranking

Amperes Minimum

470 Pounds

70.5db (A)

ASPAS1CCA012

GT-990

2

30 @ 3,600 rpm

992cc

Aluminum w/Cast

iron Sleeve

Overhead Valves

Solid-state w/Magneto

RC12YC

0.508 mm (0.020 inch)

9.5:1

12 Vdc

Approx. 1.7 Qts

Carrier Part # 70185D

Carrier Part # 0C8127

3,600

ASPASICCA015

13,000 NG/15,000 LP

120/240

NG/125.0 LP

NG/62.5 LP

65 Amp

1

2

60 Hz

1

Carrier Part # 0C8127

Group 26

12 Volts and

525 Cold-cranking

Amperes Minimum

487 Pounds

71.5db (A)

ASPASlCCA015

GT-990

2

30 @ 3,600 rpm

992cc

Aluminum w/Cast

iron Sleeve

Overhead Valves

Solid-state w/Magneto

RC12YC

0.508 mm (0.020 inch)

9.5:1

12Vdc

Approx. 1.7 Qts

Carrier Part # 70185D

Carrier Part # 0C8127

3,600

1.6 SYSTEM SET LED

The "System Set" LED is lit when all of the following

conditions are true:

1. The AUTO/OFF/MANUAL switch is set to the AUTO

position.

2. The utility voltage being supplied to the unit is being

sensed by the PCB. If the utility sense voltage is not

connected to the unit or if it is below 168 volts AC,

then the system set light will flash rapidly. This

indicates that if the AUTO/OFF/ MANUAL switch is

placed in the Auto position, the generator will start.

3. The "Not In Auto" dip switch is set to the OFF position

on the control board.

6 Carrier

4. No alarms are present, for example, low oil pressure,

high temperature, etc.

1.7 FUEL REQUIREMENTS

AND RECOMMENDATIONS

With LP gas, use only the vapor withdrawal

system, This type of system uses the vapors formed

above the liquid fuel in the storage tank. The engine has

been fitted with a fuel carburetion system that meets the

specifications of the 1997 California Air Resources Board

for tamper-proof dual fuel systems. The unit will run on

natural gas or LP gas, but it has been factory set to run

on natural gas.

Loading...

Loading...