Page 1

90MA/MU

Single-Package Marine Cooling Units

Installation, Operation and Service Instructions

SAFETY CONSIDERATIONS

The 90MA/MU Units are designed to provide safe and

reliable service when operated within design specifications.

However, due to system pressures, electrical components,

and equipment location, some aspects of installation,

operation and servicing of this equipment can be hazardous.

Only trained, qualified installers and service technicians

should install, operate, and service this equipment.

When working on the equipment, observe all precautions

on tags or labels attached to the unit. Safety notes in the

literature, and any other safety precautions that apply.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use care in handling, rigging, and placing bulky

equipment.

WARNING

Never reach into unit while fan is running. Lock

open and tag power disconnect before working

on a fan. Remove the fuses and take them with

you after noting this on tag.

Check assembly and component weight to be

sure rigging equipment can handle them safely.

Note also any specific rigging instructions.

When steam cleaning coils, be sure area is

clear of personnel.

GENERAL

The 90MA/MU water cooled single-package cooling units

are designed to provide air conditioning aboard marine

vessels. The 90MA units are fitted with a water cooled

condenser and are factory charged, wired and piped. The

90MU units are similar to the 90MA except they are

configured for use of a remote mounted condenser.

An accessory discharge plenum may be installed to

provide free-blow into the conditioned space. Also, an

optional electric heater may be specified to provide comfort

heating.

INSTALLATION

Step 1 - Inspect Unit - Check unit against shipping order.

Inspect carefully for concealed shipping damage. If shipment

is damaged or incomplete, file claim with transportation

company and advise Carrier Transicold immediately.

CONTENTS Page

SAFETY CONSIDERATIONS........................................1

GENERAL .....................................................................1

INSTALLATION.............................................................1

Step 1- Inspect Unit .......................................................1

Step 2 - Protect Unit from Damage................................1

Step 3 - Provide Unit Support ........................................1

Step 4 - Rig and Place Unit............................................8

Step 5 - Install Accessory Plenum (If Supplied) ............8

Step 6 – Check Fan Shaft and Wheel Alignment...........9

Step 7 - Install Ventilation Ductwork (If Required)..........9

Step 8 - Check Return-Air Filters...................................9

Step 9 - Check Compressor Spring Mounts

(*08 & *12)................................................................9

Step 10 - Make Condenser Connections .......................9

Step 11 - Install Unit Drain Line ...................................11

Step 12 - Make Electrical Connections ........................12

OPERATION................................................................12

To Start Unit.................................................................12

To Shut Down Unit.......................................................12

Service Valves.............................................................12

SERVICE.....................................................................13

Return-Air Grill Removal..............................................13

Access Panel Removal................................................13

Evaporator Fan Adjustment .........................................13

Lubrication ...................................................................13

Return-Air Filters..........................................................13

Condensate Drains ......................................................13

Evaporator Coil............................................................14

Water Regulating Valve ...............................................14

Condenser ...................................................................14

Charging the System....................................................15

Evaporator Fan Motor Removal...................................15

Pressure Relief Device.................................................15

Crankcase Heater........................................................15

Cycle-LOC

Discharge And Suction Pressure Switches..................16

Oil Charge....................................................................16

WIRING SCHEMATIC - *04/*06...................................17

COMPONENT ARRANGEMENT - *04/*06..................18

WIRING SCHEMATIC - *08/*12...................................19

COMPONENT ARRANGEMENT - *08/*12..................20

UNIT SUPPORT DRAWINGS .....................................21

Step 2 - Protect Unit from Damage - To maintain warranty,

protect unit against adverse weather, theft, or vandalism on

job site.

Step 3 - Provide Unit Support - Refer to Figure 2 and

Tables 1A/B/C/2A/B/C for unit size and weight. If desired,

construct a frame of I-beams or angle iron that adequately

supports unit. See unit support drawings contained in this

document.

TM

Protection Device...................................15

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 1

Page 2

r

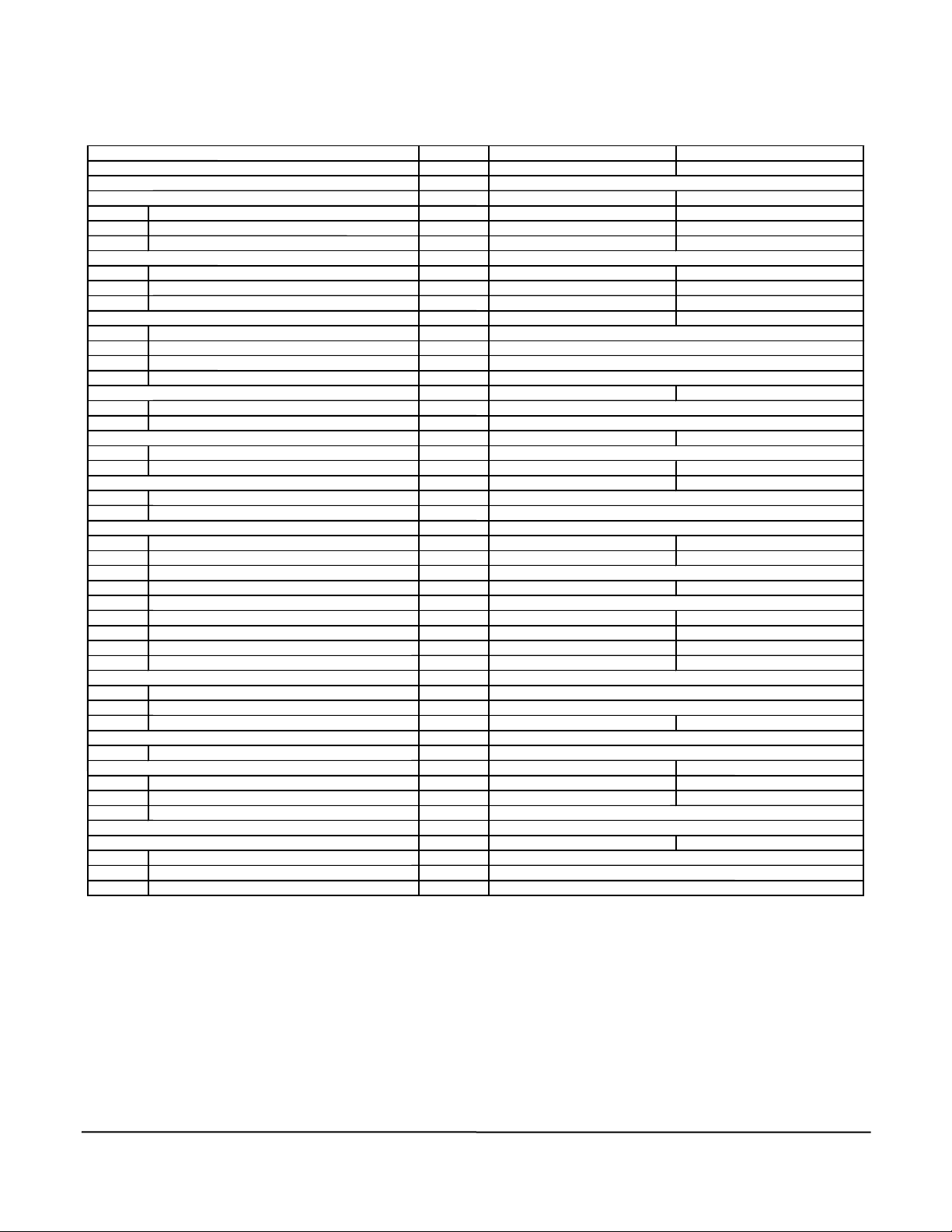

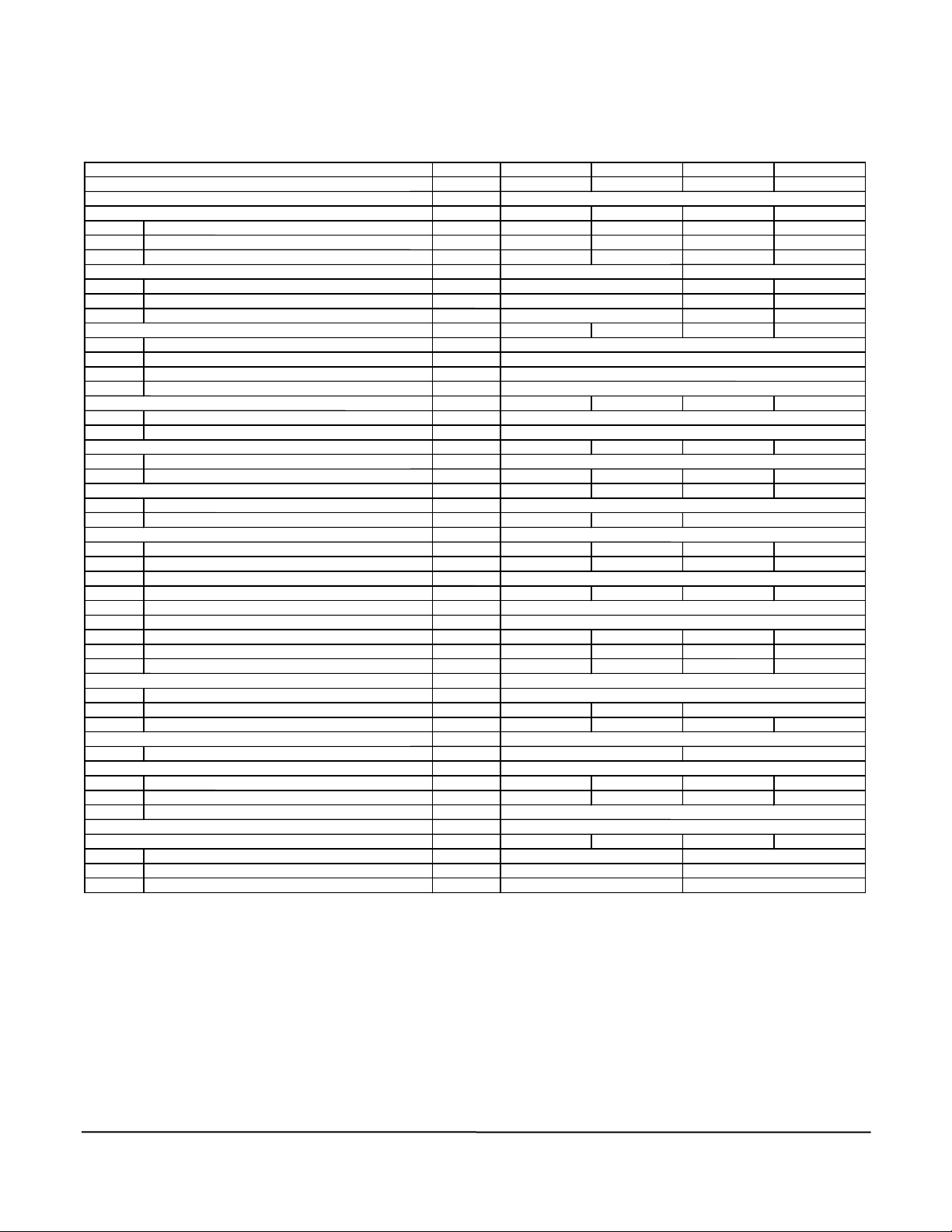

TABLE 1A - 90MA/MU PHYSICAL DATA – R-134A , ENGLISH UNITS (See Table 2A for SI units)

BASE UNIT (90MA/MU) UNITS 308 312

NOMINAL CAPACITY

REFRIGERANT

OPERATING WEIGHT

Base unit 90MA Pounds 895 950

Base Unit 90MU

Discharge Plenum

COMPRESSOR TYPE

Qty Cylinders 4 6

Qty Unloading Cylinders

Qty Capacity Steps

DISCHARGE PRESSURE SWITCH

Opens (90MA) PSIG

Closes (90MA)

Opens (90MU)

Closes (90MU)

SUCTION PRESSURE SWITCH

Opens PSIG

Closes

REFRIGERANT

Typ

Qty (90MA ONLY))

CONDENSER (90MA ONLY)

Number...Type

Water Volume Gallons

EVAPORATOR AIR FAN

Nominal Flow CFM 3000 4000

Standard Speed Range

Maximum Allowable Speed

Belt Qty/Pulley Pitch Diamete

Motor Pulley Pitch Diameter Range

Motor Nominal Rating (@ 60Hz)…Frame Size

Standard

Alternate (SeeNote 1)

Alternate (See Note 1)

EVAPORATOR COIL

Tube

Qty Rows…Fin Spacing

Face Area

RETURN AIR FILTERS

Qty…Size Inches

CONDENSER CONNECTIONS (90MA ONLY)

Water Inlet (bottom) Inches FPT 1 1

Water Outler (top)

Maximum Working Pressure (Refrigerant Side) PSIG

CONDENSATE DRAIN CONNECTIONS

ACCESSORY ELECTRIC HEAT

Capacity @ 460 volts Watts

Capacity @ 400 volts

Number of Electric Heat Stages

Tons 5.5 8

R-

Pounds N/ N/

Pounds 50 50

Semi-Hermetic, Recip

0 2

1 2

PSIG

PSIG

PSIG

335+/-10

235+/-10

N/

N/

PSIG

7+/-3

22+/-5

Pounds 11.2 10

R-

1…Tube in Tube

Adjustable, Belt Driven Centrifugal: 1750 RPM Motor@ 60hz

2.42

RPM 487-690 591-838

RPM

1250

Inches 1 / 8.5 1 / 7.0

Inches

2.4 to 3.4 inches

HP 1…56 2…56

HP 2…56 3…56

HP 3…56 N/

Fins/Inch

3/8 OD, Copper Tubes, Aluminum Fin

Prime

3…12.5

Sq Ft 7.3 8.5

Factory Supplied, Cleanable

4…16 x 20 x 1

Inches FPT 1 1

Inches FPT

400

3/4

Watts

17.5

13.4

2

LEGEND

FPT = Female Pipe Thread MPT = Male Pipe Thread ODF = Outside Diameter Female

NOTES:

1. Motors other than those furnished with unit must be purchased separately. Contact your Carrier Marine representative

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 2

Page 3

r

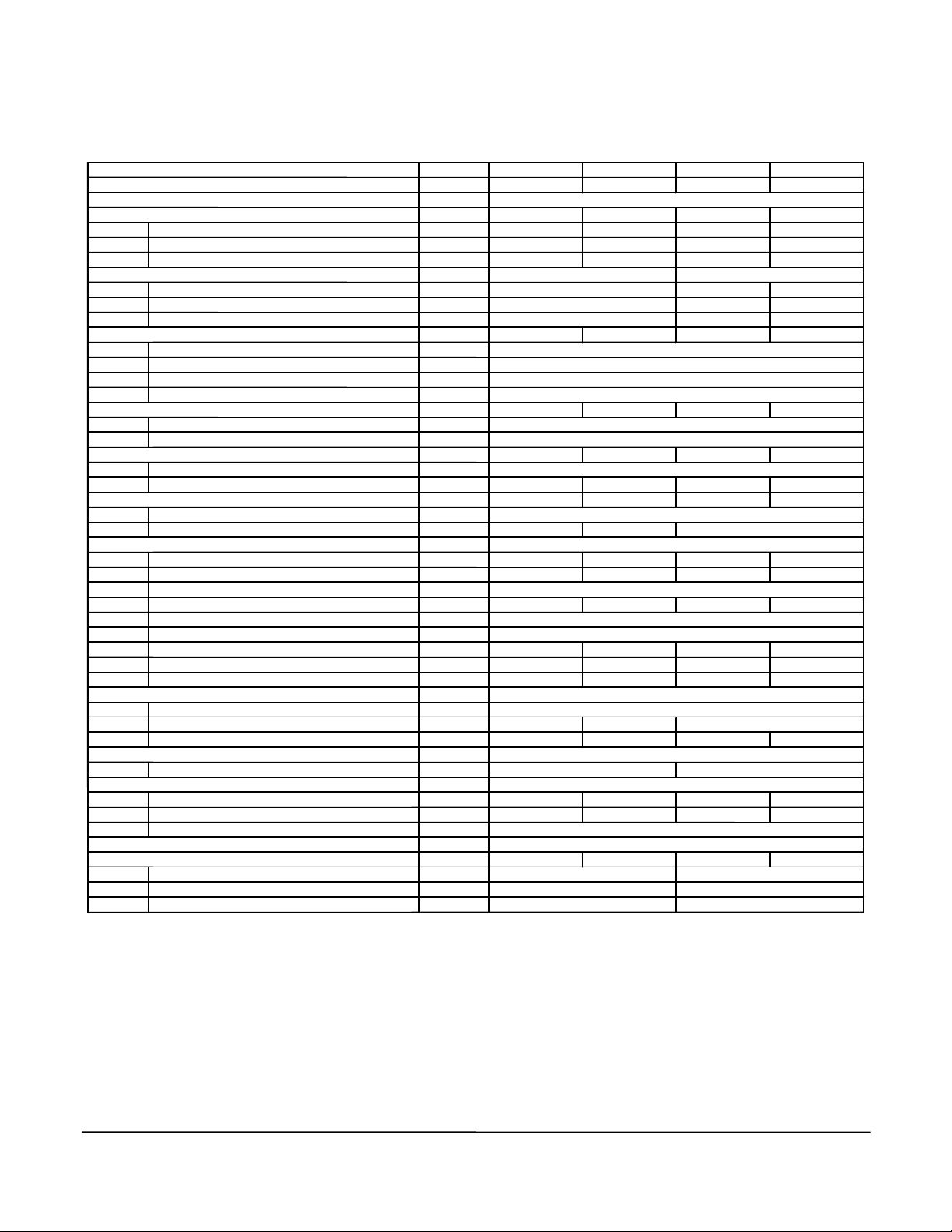

TABLE 1B - 90MA/MU PHYSICAL DATA – R-407C , ENGLISH UNITS (See Table 2B for SI units)

BASE UNIT (90MA/MU) UNITS 404 406 408 412

NOMINAL CAPACITY

REFRIGERANT

OPERATING WEIGHT

Base unit 90MA Pounds 390 427 895 950

Base Unit 90MU

Discharge Plenum

COMPRESSOR TYPE

Qty Cylinders 4 6

Qty Unloading Cylinders

Qty Capacity Steps

DISCHARGE PRESSURE SWITCH

Opens (90MA) PSIG

Closes (90MA)

Opens (90MU)

Closes (90MU)

SUCTION PRESSURE SWITCH

Opens PSIG

Closes

REFRIGERANT

Typ

Qty (90MA ONLY))

CONDENSER (90MA ONLY)

Number...Type

Water Volume Gallons 0.39 0.86

EVAPORATOR AIR FAN

Nominal Flow CFM 1200 2000 3000 4000

Standard Speed Range

Maximum Allowable Speed

Belt Qty/Pulley Pitch Diamete

Motor Pulley Pitch Diameter Range

Motor Nominal Rating (@ 60Hz)…Frame Size

Standard

Alternate (SeeNote 1)

Alternate (See Note 1)

EVAPORATOR COIL

Tube

Qty Rows…Fin Spacing

Face Area

RETURN AIR FILTERS

Qty…Size Inches

CONDENSER CONNECTIONS (90MA ONLY)

Water Inlet (bottom) Inches FPT 1/2 3/4 1 1

Water Outler (top)

Maximum Working Pressure (Refrigerant Side) PSIG

CONDENSATE DRAIN CONNECTIONS

ACCESSORY ELECTRIC HEAT

Capacity @ 460 volts Watts

Capacity @ 400 volts

Number of Electric Heat Stages

Tons 3 5 7.5 10

R-407C

Pounds 330 360 835 890

Pounds 25 25 50 50

0 2

1 2

Scroll Semi-Hermetic, Recip

N/

N/

1

PSIG

PSIG

PSIG

395+/-10

295+/-10

426+/-7

320+/-20

27+/-4

PSIG

67+/-4

R-407C

Pounds 3.1 5.3 11.2 10.0

1…Tube in Tube

Adjustable, Belt Driven Centrifugal: 1750 RPM Motor @ 60hz

2.42

RPM 647-914 647-915 487-690 591-838

RPM

1250

Inches 1 / 6.4 1 / 6.4 1 / 8.5 1 / 7.0

Inches

2.4 to 3.4 inches

HP 1/3…56 3/4…56 1…56 2…56

HP 3/4…56 1…56 2…56 3…56

HP N/ N/ 3…56 N/

Fins/Inch 2…14.4 3…14.4

3/8 OD, Copper Tubes, Aluminum Fin

Prime

3…12.5

Sq Ft 5 5 7.3 8.5

2…16 x 25 x 1 4…16 x 20 x 1

Factory Supplied, Cleanable

Inches FPT 1/2 3/4 1 1

Inches FPT

400

3/4

Watts

5.25

1 2

17.5

13.44.03

LEGEND

FPT = Female Pipe Thread MPT = Male Pipe Thread ODF = Outside Diameter Female

NOTES:

1. Motors other than those furnished with unit must be purchased separately. Contact your Carrier Marine representative

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 3

Page 4

r

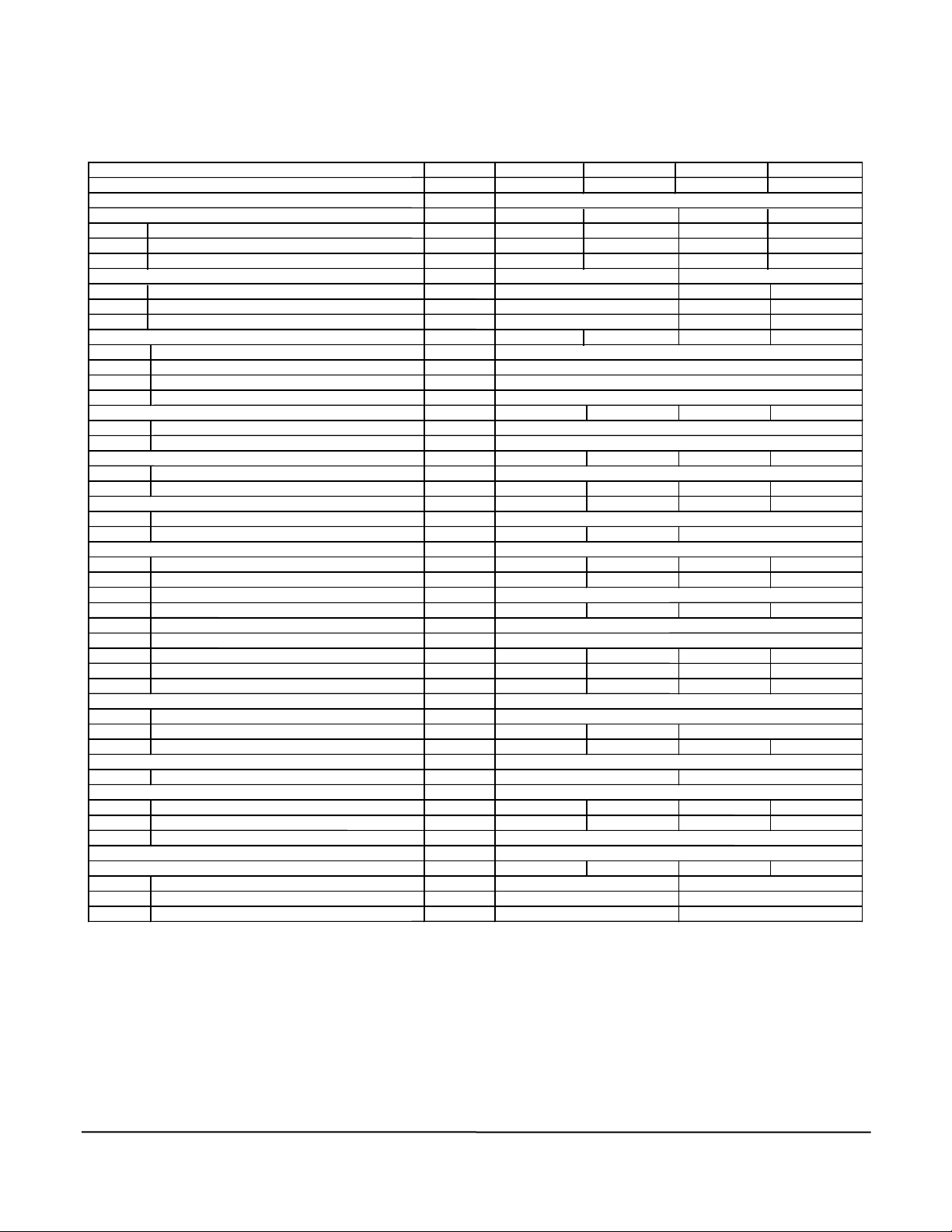

TABLE 1C - 90MA/MU PHYSICAL DATA – R-404A , ENGLISH UNITS (See Table 2C for SI units)

BASE UNIT (90MA/MU) UNITS 504 506 508 512

NOMINAL CAPACITY

REFRIGERANT

OPERATING WEIGHT

Base unit 90MA Pounds 390 427 895 950

Base Unit 90MU

Discharge Plenum

COMPRESSOR TYPE

Qty Cylinders 4 6

Qty Unloading Cylinders

Qty Capacity Steps

DISCHARGE PRESSURE SWITCH

Opens (90MA) PSIG

Closes (90MA)

Opens (90MU)

Closes (90MU)

SUCTION PRESSURE SWITCH

Opens PSIG

Closes

REFRIGERANT

Typ

Qty (90MA ONLY))

CONDENSER (90MA ONLY)

Number...Type

Water Volume Gallons 0.39 0.86

EVAPORATOR AIR FAN

Nominal Flow CFM 1200 2000 3000 4000

Standard Speed Range RPM 647-915 647-915 487-690

Maximum Allowable Speed

Belt Qty/Pulley Pitch Diamete

Motor Pulley Pitch Diameter Range

Motor Nominal Rating (@ 60Hz)…Frame Size

Standard

Alternate (SeeNote 1)

Alternate (See Note 1)

EVAPORATOR COIL

Tube

Qty Rows…Fin Spacing

Face Area

RETURN AIR FILTERS

Qty…Size Inches

CONDENSER CONNECTIONS (90MA ONLY)

Water Inlet (bottom) Inches FPT 1/2 3/4 1 1

Water Outler (top)

Maximum Working Pressure (Refrigerant Side) PSIG

CONDENSATE DRAIN CONNECTIONS

ACCESSORY ELECTRIC HEAT

Capacity @ 460 volts Watts

Capacity @ 400 volts

Number of Electric Heat Stages

Tons 3 5 7.5 10

R-

Pounds 330 360 835 890

Pounds 25 25 50 50

N/

0 2

1 2

N/

1

Semi-Hermetic, RecipScroll

PSIG

PSIG

PSIG

395+/-10

295+/-10

320+/-20

426+/-7

PSIG

27+/-4

67+/-4

Pounds 3.1 5.3 11.2 10.0

R-

1…Tube in Tube

Adjustable, Belt Driven Centrifugal: 1750 RPM Motor @ 60hz

2.42

591-838

RPM

1250

Inches 1 / 6.4 1 / 6.4 1 / 8.5 1 / 7.0

Inches

2.4 to 3.4 inches

HP 1/3…56 3/4…56 1…56 2…56

HP 3/4…56 1…56 2…56 3…56

HP N/ N/ 3…56 N/

Fins/Inch 2…14.4 3…14.4

3/8 OD, Copper Tubes, Aluminum Fin

Prime

3…12.5

Sq Ft 5 5 7.3 8.5

2…16 x 25 x 1 4…16 x 20 x 1

Factory Supplied, Cleanable

Inches FPT 1/2 3/4 1 1

Inches FPT

400

3/4

Watts

5.25

4.03

1

17.5

13.4

2

LEGEND

FPT = Female Pipe Thread MPT = Male Pipe Thread ODF = Outside Diameter Female

NOTES:

1. Motors other than those furnished with unit must be purchased separately. Contact your Carrier Marine representative

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 4

Page 5

r

r

r

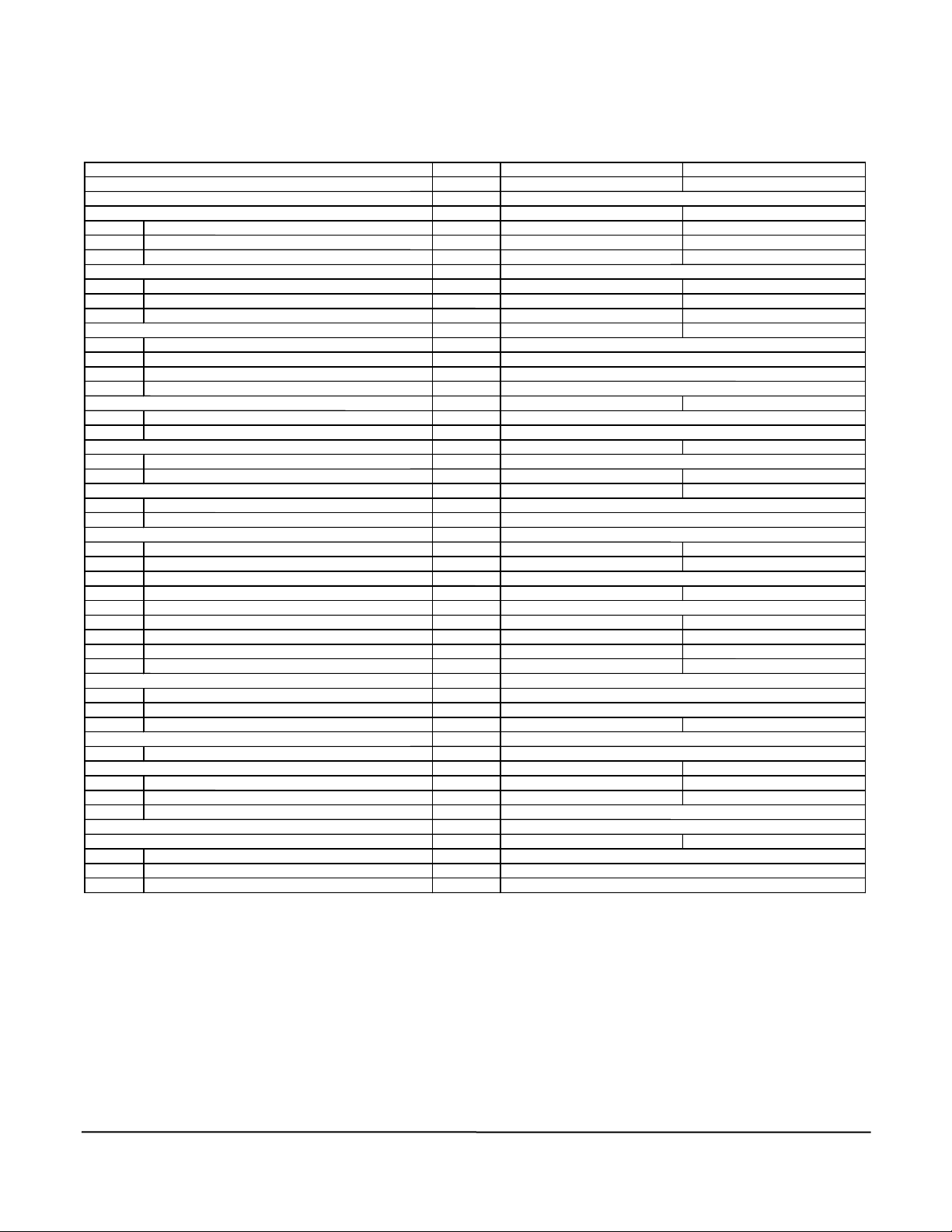

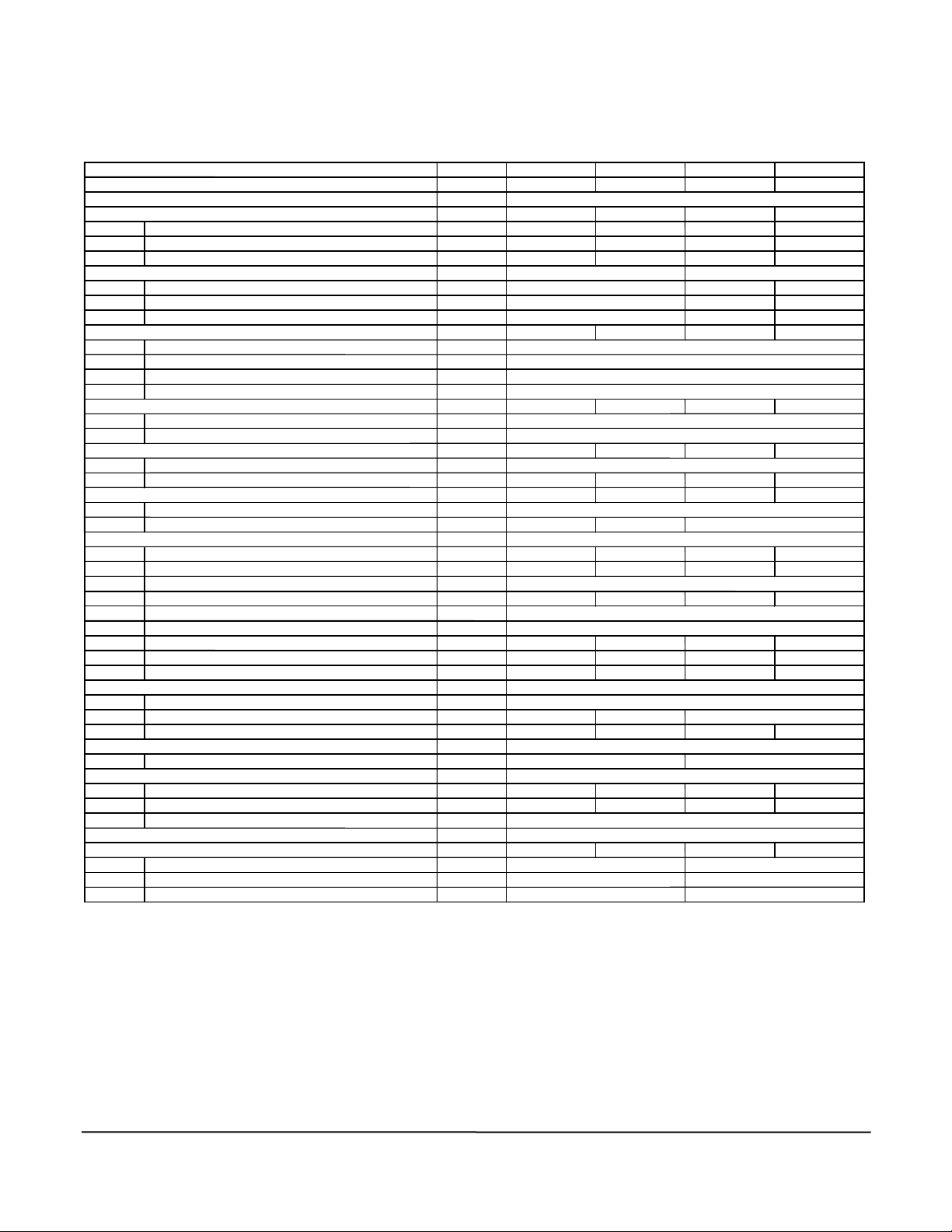

TABLE 2A - 90MA/MU PHYSICAL DATA – R-134A , SI UNITS

BASE UNIT (90MA/MU) UNITS 308 312

NOMINAL CAPACITY

REFRIGERANT

OPERATING WEIGHT

Base unit 90MA kg 406 431

Base Unit 90MU

Discharge Plenum

COMPRESSOR TYPE

Qty Cylinders 4 6

Qty Unloading Cylinders

Qty Capacity Steps

DISCHARGE PRESSURE SWITCH

Opens (90MA)

Closes (90MA)

Opens (90MU)

Closes (90MU)

SUCTION PRESSURE SWITCH

Opens kPa

Closes

REFRIGERANT

Typ

Qty (90MA ONLY))

CONDENSER (90MA ONLY)

Number...Type

Water Volume Lite

EVAPORATOR AIR FAN

Nominal Flow m3/h

Standard Speed Range

Maximum Allowable Speed

Belt Qty/Pulley Pitch Diamete

Motor Pulley Pitch Diameter Range

Motor Nominal Rating (@ 60Hz)…Frame Size

Standard

Alternate (SeeNote 1)

Alternate (See Note 1)

EVAPORATOR COIL

Tube

Qty Rows…Fin Spacing Fins/cm

Face Area

RETURN AIR FILTERS

Qty…Size cm

CONDENSER CONNECTIONS (90MA ONLY)

Water Inlet (bottom) Inches FPT 1 1

Water Outler (top)

Maximum Working Pressure (Refrigerant Side) kPa

CONDENSATE DRAIN CONNECTIONS

ACCESSORY ELECTRIC HEAT

Capacity @ 460 volts kW

Capacity @ 400 volts

Number of Electric Heat Stages

kW 19.3 28.1

R-

kg N/ N/

kg 22.7 22.7

Semi-Hermetic, Recip

0 2

1 2

kPa

kPa

kPa

kPa

2310+/-69

1620+/-138

N/

N/

kPa

48+/-12

152+/-35

kg 5.1 4.5

R-

1…Tube in Tube

9.2

Adjustable, Belt Driven Centrifugal:1750 RPM Motor @60hz

4245 5660

RPM 402-570 488-692

RPM

1250

cm 1 / 21.6 1 / 17.8

cm

6.1 to 8.6 cm

kW 0.75…56 1.5…56

kW 1.5…56 2.2…56

kW 2.2…56 N/

3/8 OD, Copper Tubes, Aluminum Fin

Prime

3…4.9

m2 0.68 0.79

Factory Supplied, Cleanable

4…40.6 x 50.8 x 2.5

Inches FPT 1 1

2758

Inches FPT

3/4

kW

17.5

13.4

2

LEGEND

FPT = Female Pipe Thread MPT = Male Pipe Thread ODF = Outside Diameter Female

NOTES:

1. Motors other than those furnished with unit must be purchased separately. Contact your Carrier Marine representative

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 5

Page 6

r

r

r

TABLE 2B - 90MA/MU PHYSICAL DATA – R-407C , SI UNITS

BASE UNIT (90MA/MU) UNITS 404 406 408 412

NOMINAL CAPACITY

REFRIGERANT

OPERATING WEIGHT

Base unit 90MA kg 177 194 406 431

Base Unit 90MU

Discharge Plenum

COMPRESSOR TYPE

Qty Cylinders 4 6

Qty Unloading Cylinders

Qty Capacity Steps

DISCHARGE PRESSURE SWITCH

Opens (90MA)

Closes (90MA)

Opens (90MU)

Closes (90MU)

SUCTION PRESSURE SWITCH

Opens kPa

Closes

REFRIGERANT

Typ

Qty (90MA ONLY))

CONDENSER (90MA ONLY)

Number...Type

Water Volume Lite

EVAPORATOR AIR FAN

Nominal Flow m3/h

Standard Speed Range

Maximum Allowable Speed

Belt Qty/Pulley Pitch Diamete

Motor Pulley Pitch Diameter Range

Motor Nominal Rating (@ 60Hz)…Frame Size

Standard

Alternate (SeeNote 1)

Alternate (See Note 1)

EVAPORATOR COIL

Tube

Qty Rows…Fin Spacing Fins/cm 2…5.7 3…5.7

Face Area

RETURN AIR FILTERS

Qty…Size cm

CONDENSER CONNECTIONS (90MA ONLY)

Water Inlet (bottom) Inches FPT 1/2 3/4 1 1

Water Outler (top)

Maximum Working Pressure (Refrigerant Side) kPa

CONDENSATE DRAIN CONNECTIONS

ACCESSORY ELECTRIC HEAT

Capacity @ 460 volts kW

Capacity @ 400 volts

Number of Electric Heat Stages

kW 10.5 17.6 26.4 35.1

R-407C

kg 150 163 379 404

kg 11.3 11.3 22.7 22.7

0 2

1 2

kPa

kPa

kPa

kPa

Scroll Semi-Hermetic, Recip

N/

N/

1

2725+/-69

2034+/-138

2937+/-48

2206+/-138

kPa

186+/-28

462+/-48

kg 1.4 2.4 5.1 4.5

R-407C

1.48 3.3

Adjustable, Belt Driven Centrifugal: 1750 RPM Motor@60hz

1698 2830 4245 5660

1…Tube in Tube

9.2

RPM 534-757 534-757 402-570 488-692

RPM

1250

cm 1 / 16.3 1 / 16.3 1 / 21.6 1 / 17.8

cm

6.1 to 8.6 cm

kW 0.25…56 0.56…56 0.75…56 1.5…56

kW 0.56…56 0.75…56 1.5…56 2.2…56

kW N/ N/ 2.2…56 N/

3/8 OD, Copper Tubes, Aluminum Fin

Prime

3…4.9

m2 0.46 0.46 0.68 0.79

2…40.6 x 63.5 x 2.5 4…40.6 x 50.8 x 2.5

Factory Supplied, Cleanable

Inches FPT 1/2 3/4 1 1

2758

Inches FPT

3/4

5.25 17.5

kW

4.03 13.4

1 2

LEGEND

FPT = Female Pipe Thread MPT = Male Pipe Thread ODF = Outside Diameter Female

NOTES:

1. Motors other than those furnished with unit must be purchased separately. Contact your Carrier Marine representative

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 6

Page 7

r

r

TABLE 2C - 90MA/MU PHYSICAL DATA – R-404A , SI UNITS

BASE UNIT (90MA/MU) UNITS 504 506 508 512

NOMINAL CAPACITY

REFRIGERANT

OPERATING WEIGHT

Base unit 90MA kg 177 194 406 431

Base Unit 90MU

Discharge Plenum

COMPRESSOR TYPE

Qty Cylinders 4 6

Qty Unloading Cylinders

Qty Capacity Steps

DISCHARGE PRESSURE SWITCH

Opens (90MA)

Closes (90MA)

Opens (90MU)

Closes (90MU)

SUCTION PRESSURE SWITCH

Opens kPa

Closes

REFRIGERANT

Typ

Qty (90MA ONLY))

CONDENSER (90MA ONLY)

Number...Type

Water Volume Lite

EVAPORATOR AIR FAN

Nominal Flow m3/h

Standard Speed Range

Maximum Allowable Speed

Belt Qty/Pulley Pitch Diameter

Motor Pulley Pitch Diameter Range

Motor Nominal Rating (@ 60Hz)…Frame Size

Standard

Alternate (SeeNote 1)

Alternate (See Note 1)

EVAPORATOR COIL

Tube

Qty Rows…Fin Spacing

Face Area

RETURN AIR FILTERS

Qty…Size cm

CONDENSER CONNECTIONS (90MA ONLY)

Water Inlet (bottom) Inches FPT 1/2 3/4 1 1

Water Outler (top)

Maximum Working Pressure (Refrigerant Side) kPa

CONDENSATE DRAIN CONNECTIONS

ACCESSORY ELECTRIC HEAT

Capacity @ 460 volts kW

Capacity @ 400 volts

Number of Electric Heat Stages

kW 10.5 17.6 26.4 35.1

R-

kg 150 163 379 404

kg 11.3 11.3 22.7 22.7

0 2

1 2

kPa

kPa

kPa

kPa

Scroll Semi-Hermetic, Recip

N/

N/

1

2725+/-69

2034+/-138

2937+/-48

2206+/-138

kPa

186+/-28

462+/-48

kg 1.4 2.4 5.1 4.5

R-

1.48 3.3

Adjustable, Belt Driven Centrifugal: 1750 RPM Motor@60hz

1698 2830 4245 5660

1…Tube in Tube

9.2

RPM 534-757 534-757 402-570 488-692

RPM

1250

cm 1 / 16.3 1 / 16.3 1 / 21.6 1 / 17.8

cm

6.1 to 8.6 cm

kW 0.25…56 0.56…56 0.75…56 1.5…56

kW 0.56…56 0.75…56 1.5…56 2.2…56

kW N/ N/ 2.2…56 N/

Fins/cm 2…5.7 3…5.7

3/8 OD, Copper Tubes, Aluminum Fin

Prime

3…4.9

m2 0.46 0.46 0.68 0.79

2…40.6 x 63.5 x 2.5

Factory Supplied, Cleanable

4…40.6 x 50.8 x 2.5

Inches FPT 1/2 3/4 1 1

2758

Inches FPT

3/4

kW

5.25 17.5

4.03

1 2

13.4

LEGEND

FPT = Female Pipe Thread MPT = Male Pipe Thread ODF = Outside Diameter Female

NOTES:

1. Motors other than those furnished with unit must be purchased separately. Contact your Carrier Marine representative

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 7

Page 8

Step 4 - Rig and Place Unit -

NOTE: Install accessories before placing unit.

a. Provide space around unit for service, filter access, and

overhead clearance as indicated in Figure 2.

b. Move and store unit in upright position.

c. Use slings with spacer under base skid to prevent panel

damage when using hoist.

d. Units as shipped are adequately dampened against

vibration. If additional dampening is desired, place

sponge rubber or rubber mat, between deck and base of

unit or install vibration isolators.

e. Unit should be level. Unit leveling tolerance is 1/8 in. per

linear ft in any direction.

Step 5 - Install Accessory Plenum (If Supplied) - Use

plenum as template to mark hole locations in top panel. Drill

0.154-in. holes in top panel at marked locations and attach

plenum with screws supplied.

FIGURE 1 - BASE UNIT INTERIOR DETAILS

(TYPICAL UNIT SHOWN)

UNIT *04 *06 *08,*12

A

B

C

D SEE NOTE 2

E 24(51)

F

G

H

J

K

L

M

NOTES:

1. Certified dimension drawings available upon request

2. Minimum required clearance at back of unit is zero.

Clearance above and at right (90MA*08,*12 only) and at

left of unit depends on space required for accessory

plenum, ductwork, condenser piping, accessory heater

piping, condensate drain line and power wiring

3. Water connections are located on left side of unit (Refer

to “Make Condenser Connections”, Condensate drain

connections are located on left side of unit for *04 & *06,

and on both sides of unit for *08 & *12.

11.25(286)

13.00 (330)

11.59(294)

36.13(918)

21.63(549)

59.25(1505)

0.75(19)

17.13(435)

20.38(519)

17.11(435)

13.50(343)

15.50(394)

0.75(19)

10.34(263)

48.26(1226)

29.88(759)

72.00(1828)

15.63(397)

18.38(466)

1.00 (25)

11.37(289)

24.20(615)

25.50(646)

17.11(435)

FIGURE 2 - UNIT DIMENSIONS

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 8

Page 9

DIMENSION “D” MUST BE

EQUAL ALL AROUND

FIGURE 3 - HORIZONTAL WHEEL CENTERING

FIGURE 4 - CONCENTRIC WHEEL ALIGNMENT

Step 6 – Check Fan Shaft and Wheel Alignment-

HORIZONTAL WHEEL CENTERING - All wheels must be

horizontally centered between the inside edges of their fan

scroll ventures (Figure. 3).

Adjust as follows:

a. Loosen set screws holding wheel to shaft.

b. Center the wheel by sliding it horizontally.

c. Re-tighten set screws.

CONCENTRIC ALIGNMENT - Shaft and wheels must be

concentrically centered with the venturi (Figure. 4). Shaft

bearings are supported by bearing supports. If shaft and

wheels are concentrically misaligned from shipping shock,

it is possible to re-bend bearing support arms to original

positions. Replace the bearing support if it has been

extensively damaged during shipping.

Step 7 - Install Ventilation-Air Ductwork (If required)Connect ventilation ducts to flanges on outside-air supply

opening (Figure. 2) using a flexible connection. Attach

ductwork to ship structure, insulate and cover with vapor

barrier to reduce sound transmission and prevent vapor

condensation.

Weatherproof external ductwork, joints, and openings

in accordance with applicable codes. Ducts passing

through an unconditioned space must be insulated and

covered with a vapor barrier.

Step 8 - Check Return-Air Filters - Ensure filters shipped

with unit are in place. Never operate unit without return air

filters in place.

Step 9 - Check Compressor Spring Mounts (*08 & *12

size only) - The compressors are held rigid in shipment by

bolts extending through a washer, grommet and

compressor foot into a weld nut.

Loosen each bolt (4 per compressor) until compressor

floats freely on springs. Then re-tighten bolts until there is

slight pressure on the neoprene gasket. This will steady

the compressor and prevent start and stop rocking.

The compressors have reversible oil pumps that

operate in either direction; therefore, the direction of

rotation need not be checked.

Step 10 - Make Condenser Connections

UNIT MOUNTED 90MA UNITS- Piping arrangements for

condenser cooling water are shown in Figure. 5.

Condensers have water inlet and outlet connections as

shown in Figure 6.

Connect condenser water supply and return lines as

indicated. When connecting water lines, hold the

condenser inlet and outlet stubs firmly with a wrench at the

female pipe thread hex fitting to prevent twisting. Do not

use water lines smaller than connection sizes shown in

Figure 6. Observe all applicable plumbing and sanitary

codes.

FIGURE 5 - TYPICAL CONDENSER WATER PIPING

Install water-regulating valve in water supply line

outside cabinet as follows.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 9

Page 10

a. Route regulating valve capillary with its flare nut to the

fitting on refrigerant discharge line (Figure. 1), using

any convenient unused opening on side of unit. Use a

grommet in panel to prevent chafing of capillary.

b. Remove cap from discharge line fitting.

c. Remove cotter pin taped to discharge line fitting. Insert

pin, split end first, into regulating valve flare

d. Hold flare tightly against fitting while connecting flare

nut. Round end of cotter pin will depress core of fitting.

The opened fitting allows refrigerant pressure to act on

water regulating valve. Tighten nut to prevent leakage.

Fitting automatically seals when nut is removed.

90MU UNITS-Install remote mounted condenser in

accordance with the installation instructions provided with

condenser. Recommended line sizes are given in Table 3.

Additional instructions can be found in Carrier System

Design Manual, Part 3, for standard refrigeration piping

techniques. On *08 and *12 size units, secure discharge

line to bracket at unit outlet using proper clamp from

supplied fastener package

Condenserless (90MU) units are shipped with a

refrigerant holding charge. After refrigerant connections

are made, leak test, reclaim refrigerant, evacuate, and

charge system as described in “Service, Charging The

System”.

A = Condensate, ¾ inch Female Pipe Thread,

D = Condenser Out, 1 Inch FPT

B = Electrical Opening,

C = Condenser In, 1 inch FPT,

FIGURE 6 - CONNECTION LOCATIONS

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 10

Page 11

TABLE 3 - RECOMMENDED LINE SIZES (INCHES) REMOTE CONDENSERS

UNIT

90MU

REFRIGERANT

TYPE

LENGTH OF RUN

DISCH LIQUID DISCH LIQUID DISCH LIQUID DISCH LIQUID

404 R-407C 1/2 3/8 5/8 3/8 5/8 3/8 5/8 3/8

406 R-407C 5/8 3/8 3/4 3/8 3/4 3/8 3/4 3/8

408 R-407C 3/4 1/2 3/4 1/2 7/8 1/2 7/8 1/2

412 R-407C 7/8 1/2 7/8 1/2 7/8 1/2 1-1/8 5/8

504 R-404A 5/8 3/8 5/8 3/8 3/4 3/8 3/4 3/8

506 R-404A 3/4 1/2 3/4 1/2 7/8 1/2 7/8 1/2

508 R-404A 7/8 1/2 7/8 1/2 1-1/8 1/2 1-1/8 5/8

512 R-404A 7/8 5/8 1-1/8 5/8 1-1/8 5/8 1-1/8 5/8

* Recommended line sizes correspond to 2 degree F drop.

NOTES:

1. Pipe sizes should never be smaller than cooling unit connection size.

2. Table is based on 2 degree F drop over entire length. Excessive (more than a few) elbows

and fittings will significantly affect pressure drop. If this situation exists, line sizing must be recalculated.

Step 11 - Install Unit Drain Line - Install a trapped

condensate drain line at unit drain connection The drain

requires standard pipe connected to condensate pan

nipple(s). Figure 7 shows proper trap design.

Determine design negative static pressure. This

pressure is not the same as fan total static pressure, which

includes pressure losses downstream as well as upstream

from the evaporator air fan. Always assume the worst

conditions, such as having return air filters clogged with

debris.

Referring to Figure 7, differential 1 must be equal to or

larger than negative static pressure at design operating

condition. Store enough water in trap to prevent losing

seal. Differential 2 must be equal to or larger than one-half

the maximum negative static pressure. To avoid loss of

seal when the fan starts, differential 3 must be greater

than the maximum negative static pressure.

Do not use drain line smaller than 3/4 inch. Use hole(s)

provided in panel for drain line. Pitch drain line downward

toward scupper. Installation of a plugged tee is

recommended for cleaning. Fill trap with water to make an

air seal. Observe all sanitary requirements.

FIGURE 7 - CONDENSATE DRAIN TRAP

76-10051-7526-500-25

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 11

Page 12

Step 12 - Make Electrical Connections

GENERAL - Provide an adequate fused disconnect switch

within sight of the unit. Provision for locking switch open

(OFF) is advisable to prevent power from being turned on

when unit is being serviced.

POWER WIRING - Conduit opening for all units is on left

side of unit near control box. Connect field power wires at

the compressor contactor.

Supply voltage must be in accordance with nameplate

voltage. Voltage between phases must be balanced within

2% and current within 10% with compressor running.

Correct improper voltage or phase imbalance. Unit failure

as a result of operation on improper line voltage or

excessive phase imbalance constitutes abuse and shall

void the Carrier warranty. Use the following formula to

determine the percent voltage imbalance.

CONTROL WIRING - On extended voltage (208/230-v)

units, the control transformer is factory wired for 208-v

usage. If unit is to be used on 230-v system, reconnect

primary wiring on transformer. See Figure 12

(90MA*04/*06) or figure 14 (90MA*08/*12).

On all units, the thermostat is factory installed. A

sensing element is provided in the return air. To wire these

units to a remote thermostat, or to a remote control switch

and thermostat, refer to unit Wiring Diagram or contact

your Carrier Transicold representative.

OPERATION

CAUTION

Compressor crankcase heater must be

energized for 24 hours prior to startup to

prevent compressor bearing damage.

To start unit:

1. Thoroughly inspect exterior of unit. Clean and dust up

debris, then wash with mild soap and water solution.

2. On 90MA*08 &*12 units, ensure compressor

discharge, suction and liquid service valves are open.

(Refer to “Operation - Service Valves.) Check oil level

in compressor sight glass. If level is below glass, add

oil to bring level to approximately 1/4 glass. If level is

above bottom of glass, do not remove any oil until the

crankcase heater has been energized for at least

twenty-four hours.

3. With selector switch in OFF position, turn main power

on. Leave power on for 24 hours so that crankcase

heater can drive off accumulated refrigerant.

4. If desired, the selector switch may be placed in the

FAN position during the crankcase warm-up period. On

first start-up, check fan speed (Tables 1A/B/C/2A/B/C)

and rotation (Figure 1). If fan requires adjustment, refer

to “Service, Evaporator-Fan Adjustment”.

5. Allow crankcase heater to remain energized (unit

power on) for at least 24 hours. Open any valves in

condenser cooling water supply lines and then set

selector switch at COOL position. If room temperature

is above thermostat setting compressor will start. On

first start-up, set water regulating valve. (Refer to

“Service, Water Regulating Valve.)

6. Set thermostat for comfort as desired.

To Shut Down Unit:

1. Turn selector switch to OFF position. Do not shut off

main power except to service unit. The crankcase

heater is operative only when main power is on. (Refer

to “Service, Crankcase Heater”).

2. If unit is to be used for winter heating, set selector

switch at HEAT position and re-set thermostat at

desired setting.

3. If unit may be exposed to freezing temperatures, drain

water from condenser and water piping. Add a noncorrosive antifreeze to residual water in system.

Service Valves - Always ensure that compressor suction,

and discharge service valves and liquid service valve are

open before operating unit.

The valves are accessible from the front of the unit. To

open valve, turn counterclockwise. After opening, replace

and tighten valve cap to prevent leakage.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 12

Page 13

SERVICE

WARNING

NEVER reach into unit while

fan is running. LOCK OPEN

AND TAG unit disconnect

before working on fan. Remove

fuses and take them with you

after noting this on tag.

CAUTION

1. Sharp edges of coil fins are exposed. To

prevent injury, cover top of evaporator

with cardboard or a few layers of heavy

tape.

2. To avoid coil damage, cover evaporator

face with plywood or other rigid sheet

material. If any coil fins are mashed or

bent, straighten with a coil fin comb of the

proper tooth spacing (refer to “coil

fins/inch” in Table 1). Check for

refrigerant leaks.

Return-Air Grille Removal

1. Pull grille out from top.

2. Pull grille up to release hinge pins from lower panel.

3. To reassemble, reverse procedure.

Access Panel Removal - Remove return-air grille as

described above.

Remove the panel fastening screws now exposed.

TOP PANEL - Pull out and down.

BOTTOM - Pull out and up.

Evaporator Fan Adjustment - Observe fan compartment

Caution note above. The fan motor pulleys are factory set

at the fan speeds listed in Table 1.

TO CHANGE FAN SPEED

1. Shut off unit power supply.

2. Loosen fan belt by loosening fan motor from mounting

bracket. Do not loosen fan motor mounting bracket

from unit.

3. Loosen movable pulley flange set screw (Figure. 8).

4. Screw movable flange toward fixed flange to increase

fan speed and away from fixed flange to decrease

speed. Increasing fan speed increases load on motor.

Do not exceed maximum allowable fan speed (Tables

1A/B/C/2A/B/C) or motor full load amps indicated on

motor nameplate.

5. Set movable flange set screw at nearest flat of pulley

hub and tighten set screw.

FIGURE 8 - FAN PULLEY ADJUSTMENT

6. Check pulley alignment and belt tension adjustment as

described below.

7. Check fan operation. Repeat above procedure as

required.

PULLEY ALIGNMENT - Shut off unit power supply.

Loosen fan motor pulley set screws and slide fan pulley

along fan shaft. Make angular alignment by loosening

motor from mounting bracket (See Figure. 8).

BELT TENSION ADJUSTMENT - Shut off unit power

supply. Loosen fan motor from mounting bracket. Do not

loosen motor mounting bracket from unit. Move fan motor

up or down until proper belt tension is achieved (approximately 3/4-in. deflection with 8-pound tension at midpoint

of belt span).

Lubrication - Fan motor and fan shaft bearings are

lubricated for the life of the bearings. No re-lubrication is

required

Return-Air Filters - Inspect filters twice monthly and clean

as required by operating conditions. Filter size and type

are listed in Tables 1A/B/C/2A/B/C. To clean filters flush

with hot water or steam or soak in a mild water solution of

soap or detergent. Refer to filter manufacturer's

instructions as applicable.

Do not operate unit without return-air filters in place.

Condensate Drains - Clean the drain line and unit drain

pan at the start of each cooling season. Check flow by

pouring water into drain. Be sure trap is filled as shown in

Figure. 7 to maintain an air seal.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 13

Page 14

Evaporator Coil - Observe fan compartment Caution note

at the beginning of the Service section.

Remove dirt and debris from evaporator coil as

required by condition. Clean coil with a stiff brush, vacuum

cleaner or compressed air. Use a fin comb of the correct

tooth spacing (Refer to Tables 1A/B/C/2A/B/C for coil

fins/inch) when straightening mashed or bent coil fins.

Water Regulating Valve

PREPARATION FOR OPERATION.

1. Open the water regulating valve inlet and outlet

isolation valves.

2. Close the water regulating valve bypass valve.

ADJUSTMENT

NOTE: Adjustments to the water regulating

valve must be made slowly, allowing ample

time for response and stabilization.

1. The compressor discharge pressure is controlled by

the water regulating valve and may be monitored by

observing liquid line pressure.

2. Install a calibrated gauge at the liquid line service port.

FOR 90MA: Operating liquid line range for R-407C

units is 200 to 215 psig, operating range for R-404A

units is 240 to 260 psig, operating range for R-134a

units is 122 to 130 psig.

FOR 90MU : Operating liquid line range for R-407C

units is 265 to 285 psig, operating range for R-404A

units is 290 to 315 psig, If pressure reading is below

operating range, rotate the square head adjusting

screw counterclockwise; this will increase spring

tension, decrease water flow and increase pressure.

If pressure reading is above operating range, rotate the

square head adjusting screw clockwise; this will

decrease spring tension, increase water flow and

decrease pressure.

3. Only the water regulating valve opening point is

adjustable. The closing point is 3 to 7 psig below the

opening point and is non-adjustable.

Condenser - Condensers may require cleaning of waterdeposited scale.

CAUTION

Follow all Safety codes. Wear safety glasses

and rubber gloves when using inhibited

hydrochloric acid solution.

Clean condensers with an inhibited hydrochloric acid

solution. The acid can stain hands and clothing, attack

concrete and, without inhibitor, can attack steel. Cover

surroundings to guard against splashing. Vapors from vent

pipe are not harmful, but take care to prevent liquid from

being carried over by the gases.

Warm solution acts faster, but cold solution is just as

effective if applied for a longer period.

FIGURE 9 - GRAVITY FLOW METHOD

GRAVITY FLOW METHOD (Figure. 9) -

1. Disconnect condenser piping at unit, including isolation

valves and water regulating valve.

2. Fill condenser as shown in figure 9. Follow acid

manufacturer's instructions. When condenser is full,

allow solution to remain overnight

3. Drain condenser and flush with clean water.

FORCED CIRCULATION METHOD (Figure. 10) -

1. Disconnect condenser piping at unit, including isolation

valves and water regulating valve.

2. Fill system as shown in figure 10. Follow acid

manufacturer's instructions. Fully open vent pipe when

filling system. The vent may be closed when system is

full and pump is operating.

3. Regulate flow to condenser with a supply line valve. If

pump is a non-overloading type, the valve may be fully

closed while pump is running. For average scale

deposit, allow solution to remain in condenser

overnight. For heavy scale deposit, allow 24 hours.

4. Drain condenser and flush with clean water.

FIGURE 10 - FORCED CIRCULATION METHOD

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 14

Page 15

g (ºF)

Charging the System (90MA) - These units are shipped

with a full operating charge. If recharging is necessary

(complete charge lost), weigh in amount of refrigerant

indicated on unit nameplate and in Table 1.

If unit has partial charge, it must be recharged by

removing existing charge and recharging by weighing in

the required amount of refrigerant. (Refer to Table

1A/B/C/2A/B/C)

Charging the System (90MU)

UNIT SIZES 90MU Units - These units, used with remote

condensers, are shipped with a holding charge only. To

charge:

1. Open discharge and liquid service valves.

2. Leak test, reclaim refrigerant and evacuate.

3. Using standard refrigerant charging techniques and

subcooling charts (Figure 11) add refrigerant as required

to maintain proper operating conditions. Subcooling is

determined by subtracting the actual temperature entering

the TXV from the saturated temperature entering the TXV.

IMPORTANT: Charge on both the HIGH and LOW side

simultaneously of idle compressors to prevent axial

loading of the scroll, which may cause a temporary no

start condition for the compressor. If this occurs, leave

the system off for approximately 30 minutes. Attempt

to restart the compressor; internal pressures should

equalize enough to allow compressor to start.

If removing the compressor, evacuate both the HIGH

and LOW side simultaneously.

Required

Subcoolin

10

15

20

25

Required

Subcooling (ºF)

10

15

20

25

Required

Subcooling (ºC)

10

13

Required

Subcooling (ºC)

10

13

0

5

0

5

0

3

5

7

0

3

5

7

R407C PRESSURE AT LIQUID LINE SERVICE VALVE PSIG

137 149 162 176 205 222 239 256 275 295 315 336 359

70 75 80 85 90 95 100 105 110 115 120 125 130

65 70 75 80 85 90 95 100 105 110 115 120 125

60 65 70 75 80 85 90 95 100 105 110 115 120

55 60 65 70 75 80 85 90 95 100 105 110 115

50 55 60 65 70 75 80 85 90 95 100 105 110

45 50 55 60 65 70 75 80 85 90 95 100 105

R404A PRESSURE AT LIQUID LINE SERVICE VALVE PSIG

150 163 176 190 205 221 237 255 273 292 313 334 356

70 75 80 85 90 95 100 105 110 115 120 125 130

65 70 75 80 85 90 95 100 105 110 115 120 125

60 65 70 75 80 85 90 95 100 105 110 115 120

55 60 65 70 75 80 85 90 95 100 105 110 115

50 55 60 65 70 75 80 85 90 95 100 105 110

45 50 55 60 65 70 75 80 85 90 95 100 105

R407C PRESSURE AT LIQUID LINE SERVICE VALVE kPa

1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300

23 26 29 32 34 37 39 42 44 46 48 50 52

20 23 26 29 31 34 36 39 41 43 45 47 49

18 21 24 27 29 32 34 37 39 41 43 45 47

16 19 22 25 27 30 32 35 37 39 41 43 45

13 16 19 22 24 27 29 32 34 36 38 40 42

10 13 16 19 21 24 26 29 31 33 35 37 39

R404A PRESSURE AT LIQUID LINE SERVICE VALVE kPa

1190 1288 1392 1503 1580 1701 1786 1918 2011 2107 2206 2308 2414

23 26 29 32 34 37 39 42 44 46 48 50 52

20 23 26 29 31 34 36 39 41 43 45 47 49

18 21 24 27 29 32 34 37 39 41 43 45 47

16 19 22 25 27 30 32 35 37 39 41 43 45

13 16 19 22 24 27 29 32 34 36 38 40 42

10 13 16 19 21 24 26 29 31 33 35 37 39

FIGURE 11 - CHARGING CHARTS

Evaporator-Fan Motor Removal - Motor power wires

need not be disconnected from motor terminals before

motor is removed from unit.

1. Shut off unit main power supply.

WARNING

LOCK OPEN AND TAG unit disconnect

before working on fan motor. Remove fuses

and take them with you after noting this on

tag.

CAUTION

Before attempting to remove fan motors or

motor mounts, place a piece of plywood over

evaporator coils to prevent coil damage.

2. Loosen motor hold down bolts on mounting bracket so

that fan belt can be removed.

3 Loosen but do not remove the 2 motor mounting

bracket bolts on left side of bracket.

4 Slide motor/bracket assembly to extreme right, remove

bolts and lift out through space between fan scroll and

side Rest motor on a high platform such as a step

ladder. Do not allow motor to hang by its power wires.

Pressure Relief Device - All units are equipped with a

fusible-plug type safety relief device an the refrigerant

tubing. The relief setting is 197 °F to 203 °F on all units.

Crankcase Heater - A Crankcase heater is supplied on

90MA,MU*08 and *12 size units. The heater prevents

liquid refrigerant from accumulating in the compressor

crankcase during extended shutdown periods. Heater is

automatically energized whenever unit main power is on

and compressor is stopped. Heater is de-energized when

compressor starts.

Do not shut off main power supply for an extended

period except for servicing unit. Turn on power supply for

at least 24 hours after an extended shutdown before

starting compressor. Refer to “Operation”.

Cycle-Loc

with Cycle-LOC current-sensing lockout relay. This device

will lock out the compressor after any safety trip (discharge

pressure switch, suction-pressure switch, or internal

overload of the compressor). Check reason for lockout

before resetting the device. Refer to unit label wiring

diagram. To reset, turn the system switch to OFF, then

back to COOL.

Discharge and Suction Pressure Switches - Refer to

Table 1 for opening and closing settings for these safety

devices.

The discharge pressure switch is located on the

compressor on 06DA compressor equipped units and on

the discharge line on all other units. The suction pressure

switch is located on top of the compressor on 06DA

TM

- Protection Device - All units are equipped

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 15

Page 16

compressor equipped units and on the suction line on all

other units.

Oil Charge - All units are factory charged with oil. On 06D

compressors, observe the oil level in the sight glass at

start-up. If unit oil level is below sight glass, add oil until

level reaches approximately 1/4 sight glass.

If oil charge is above sight glass, do not remove any oil

until the compressor crankcase heater has been energized

for at least 24 hours.

When additional oil or a complete charge is required,

use only the following Carrier approved oil.

R-407C, R-404A, and R-134a units

Castrol - Icematic SW68

ICI - Emkarate RL68HP

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 16

Page 17

FOR NOTES AND LEGEND, SEE FIGURE 13

FIGURE 12 WIRING SCHEMATIC - 90MA/MU*04/*06

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 17

Page 18

FIGURE 13 COMPONENT ARRANGEMENT - 90MA/MU*04/*06

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 18

Page 19

FOR NOTES AND LEGEND, SEE FIGURE 15

FIGURE 14 - ELECTRICAL SCHEMATIC - 90MA/MU*08/*12

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 19

Page 20

FIGURE 15 - COMPONENT ARRANGEMENT - 90MA/MU008/012

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 20

Page 21

FIGURE 16 – MOUNTING BASE ASSEMBLY – 90MA/MU*04/*06

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 21

Page 22

FIGURE 17 – MOUNTING BASE ASSEMBLY – 90MA/MU*08/*12

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 22

Loading...

Loading...