Carrier 90MA-MF-MU User Manual

Marine/Industrial

Single Package

Cooling Unit

Models

90MA/MF/MU, Design Series Two

Beginning Serial Number C00400

62--10458--00

INSTALLATION

OPERATION & SERVICE

OPERATION AND SERVICE MANUAL

MARINE/INDUSTRIAL SINGLE PACKAGE

COOLING UNIT

MODELS

90MA/MF/MU, Design Series Two

Beginning Serial Number C00400

Carrier Refrigeration Operations, A member of the United Technologies Corporation family. Stock symbol UTX.

Carrier Transicold, Carrier Corporation, P.O. Box 4805, Syracuse, N.Y. 13221 U. S. A.

Carrier Corporation 2000 D Printed in U. S. A. 0700

SAFETY SUMMARY

GENERAL SAFETY NOTICES

The following general safety notices supplement the specific warnings and cautions appearing elsewhere in this

manual. They are recommended precautions that must be understood and applied during operation and maintenance

of the equipment covered herein. The generalsafety notices are presented in the following three sections labeled: First

Aid, Operating Precautions and Maintenance Precautions. A listing of the specific warnings and cautions appearing

elsewhere in the manual follows the general safety notices.

FIRST AID

An injury, no matter how slight, should never go unattended. Always obtain first aid or medical attentionimmediately.

OPERATING PRECAUTIONS

Always wear safety glasses.

Keep hands, clothing and tools clear of the evaporator and condenser fans.

No work should be performed on the unit until all circuit breakers, start-stop switches are turned off, and power supply

is disconnected.

Always work in pairs. Never work on the equipment alone.

In case of severe vibration or unusual noise, stop the unit and investigate.

MAINTENANCE PRECAUTIONS

Beware of unannounced starting of the evaporator fan. Do not open the evaporator access panels before turning power

off, disconnecting and securing the power source.

Be sure power is turned off before working on motors, controls, solenoid valves and electrical control switches. Tag

circuit breaker and power supply to prevent accidental energizing of circuit.

Do not bypass any electrical safety devices, e.g. bridging an overload, or using any sort of jumper wires. Problems

with the system should be diagnosed, and any necessary repairs performed, by qualified service personnel.

In case of electrical fire, open circuit switch and extinguish with CO

(never use water).

2

SPECIFIC WARNING AND CAUTION STATEMENTS

To help identify the label hazards on the unit and explain the level of awareness each one carries, an explanation is

given with the appropriate consequences:

WARNING -- means to warn against hazards or unsafe conditions which could result in severe personal injury or

death.

CAUTION -- means to warn against potential hazard or unsafe practice which could result in product or property

damage.

The statements listed below are applicable to the unit and appear elsewhere in this manual. These recommended

precautions must be understood and applied during operation and maintenance of the equipment covered herein.

WARNING

Never reach into unit while fan is running. Lock open and tag unit disconnect before working on fan.

Remove fuses and take them with you after noting this on tag.

WARNING

Follow all Safety codes. Wear safety glasses and rubber gloves when using inhibited hydrochloricacid

solution.

WARNING

Lock open and tag unit disconnect before working on fan motor. Remove fuses and take them with you

after noting this on tag.

CAUTION

Compressor crankcase heater must be energized for 24 hours prior to start up to prevent compressor

bearing damage.

Safety-1

62--10458--00

CAUTION

Sharp edges of coil fins are exposed. To prevent injury, cover top of evaporator with cardboard or a few

layers of heavy tape.

CAUTION

To avoid coil damage, cover evaporator face with plywood or other rigid sheet material. If any coil fins

are mashed or bent, straighten with a coil fin comb of the proper tooth spacing (refer to “coil fins/inch”

in Table 1 through Table 2). Check for refrigerant leaks.

CAUTION

Before attempting to remove fan motors or motor mounts, place a piece of plywood over evaporator

coils to prevent coil damage.

62--10458-- 00

Safety-2

TABLE OF CONTENTS

PARAGRAPH NUMBER Page

GENERAL SAFETY NOTICES Safety-1.....................................................

FIRST AID Safety-1......................................................................

OPERATING PRECAUTIONS Safety-1......................................................

MAINTENANCE PRECAUTIONS Safety-1..................................................

SPECIFIC WARNING AND CAUTION STATEMENTS Safety-1.................................

1. INTRODUCTION 1..............................................................

2. MODEL CHART 1...............................................................

3. INSTALLATION 1...............................................................

3.1 Inspect Unit 1................................................................

3.2 Protect Unit from Damage 1.....................................................

3.3 Provide Unit Support 1.........................................................

3.4 Install Accessory Heating Coil (if applicable) 1......................................

3.5 Rig and Place Unit 1...........................................................

3.6 Install Accessory Plenum (If Supplied) 1...........................................

3.7 Install Ventilation--Air Ductwork (If required) 1.....................................

3.8 Install Return Air Ductwork (If required) 1.........................................

3.9 Check Return--Air Filters 5......................................................

3.10 Align Fan Shaft and Wheel 5....................................................

3.11 Check Compressor Spring Mounts (008 & 012 size only) 6............................

3.12 Make Condenser C onnections 6..................................................

3.13 Install Condensate Drain Line 7..................................................

3.14 Make Electrical Connections 7...................................................

4. OPERATION 8..................................................................

4.1 To Start Unit 8...............................................................

4.2 T o Shut Down Unit 8..........................................................

4.3 Sequence Of Operation 8.......................................................

5. SERVICE 9.....................................................................

5.1 Return--Air Grille Removal 9....................................................

5.2 Access Panel Removal 9........................................................

5.3 Evaporator Fan Adjustment 9....................................................

5.4 Return--Air Filter 10............................................................

5.5 Condensate Drain 10............................................................

5.6 Evaporator Coil 10.............................................................

5.7 Water Regulating Valve 10.......................................................

5.8 Condenser 10.................................................................

5.9 Refrigerant Charging 11.........................................................

5.10 Evaporator Fan Motor Removal 12................................................

5.11 Pressure Relief Device 12........................................................

5.12 Crankcase Heater 12............................................................

5.13 Cycle--LocTM -- Protection Device 12..............................................

5.14 Discharge and Suction Pressure Switches 12.........................................

5.15 Oil Charge 12.................................................................

i 62--10458-- 00

LIST OF ILLUSTRATIONS

FIGURE NUMBER Page

Figure 1 Base Unit Interior Details (Typical) 1................................................

Figure 2 Unit Dimensions 5...............................................................

Figure 3 Horizontal Wheel Centering 5......................................................

Figure 4 Concentric Wheel Alignment 5.....................................................

Figure 5 Connection Locations 6...........................................................

Figure 6 Typical Condenser Water Piping 6...................................................

Figure 7 Condensate Drain Trap 7..........................................................

Figure 8 Fan Pulley Adjustment 9..........................................................

Figure 9 Gravity Flow Method 10...........................................................

Figure 10 Forced Circulation Method 11......................................................

Figure 11 Charging Charts 11...............................................................

Figure 12 Mounting Base 13...............................................................

Figure 13 Wiring Schematic -- 90MA/MF/MU004/006 14........................................

Figure 14 C omponent Arrangement -- 90MA/MF/MU004/006 15..................................

Figure 15 Wiring Schematic -- 90MA/MF/MU008/012 16........................................

Figure 16 C omponent Arrangement -- 90MA/MF/MU008/012 17..................................

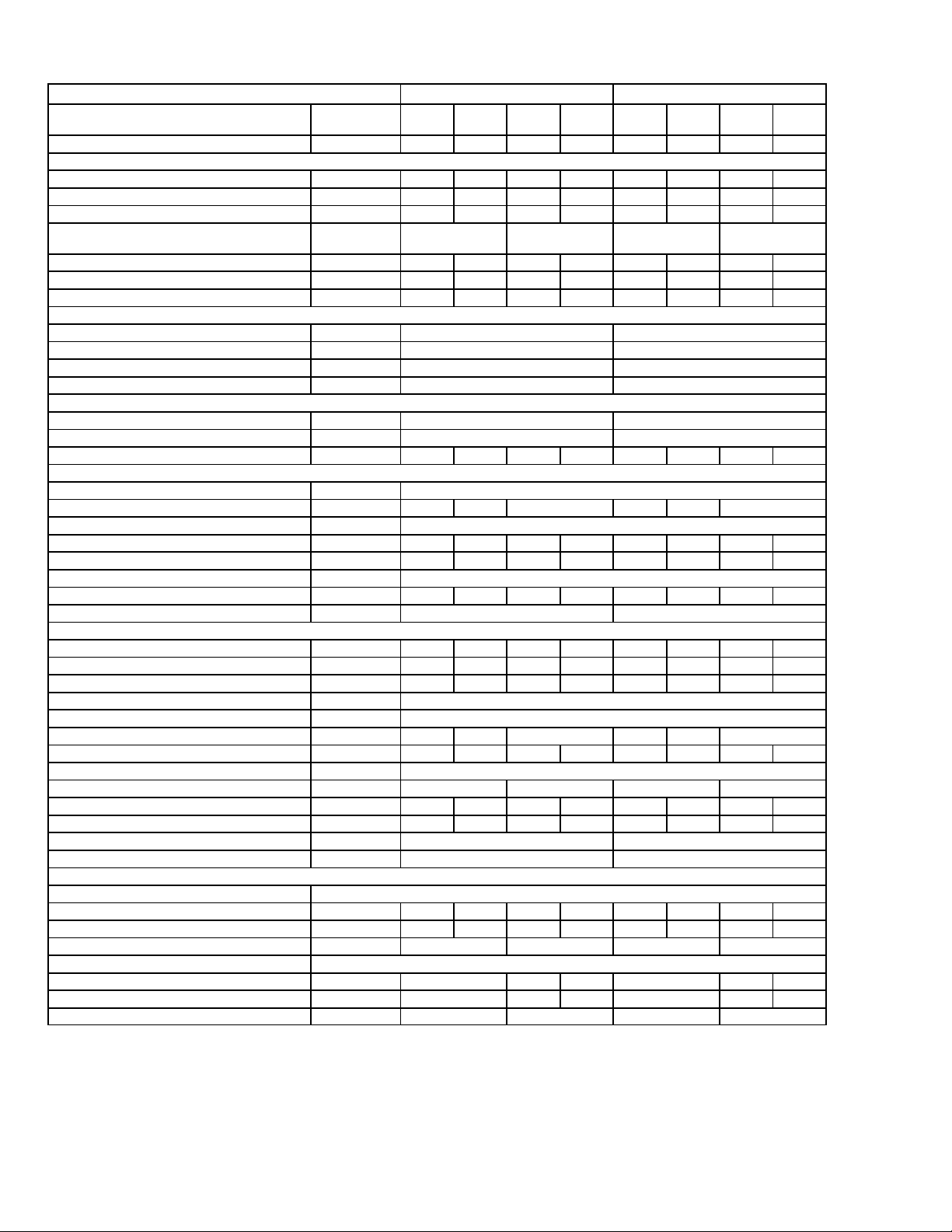

LIST OF TABLES

TABLE NUMBER Page

Table 1 90MA/MF/MU Physical Data -- Refrigerant 22 2.........................................

Table 2 90MA/MF/MU Physical Data -- Refrigerant 407C 3.......................................

Table 3 90MA/MF Physical Data -- Refrigerant 134a 4...........................................

Table 4 R ecommended Line Sizes, Remote Condenser 7.........................................

62--10458-- 00

ii

1. INTRODUCTION

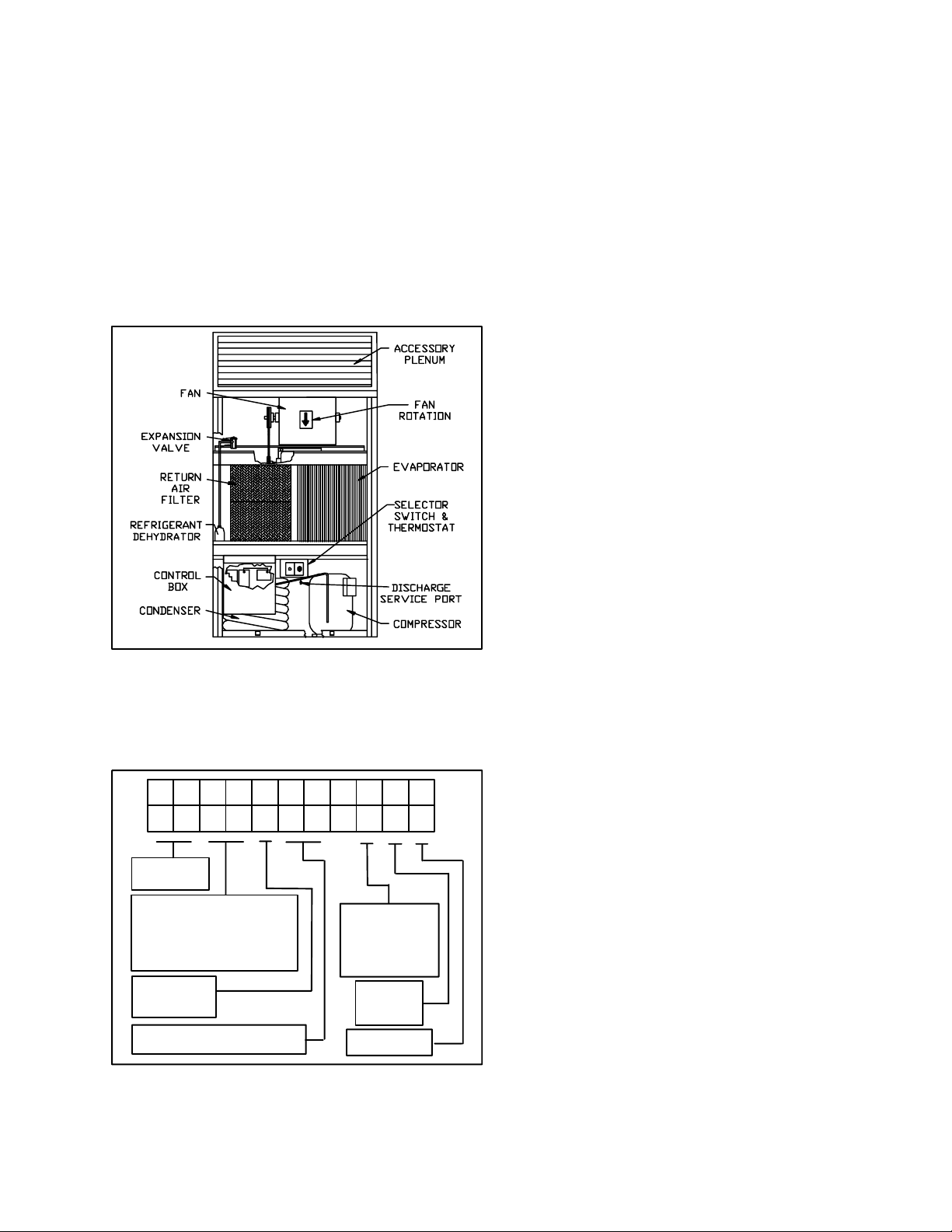

The 90M series single--package cooling units (See

Figure 1) are designed to provide air conditioning

aboard marine vessels and in industrial applications.

The 90MA units are fitted with sea water cooled

condensers while the 90MF units are fitted with fresh

water cooled condensers. Both units are factory

charged, wired and piped. The 90MU units are similar

except they are configured for use with a remote

mounted condenser.

An accessory discharge plenum may be installed to

provide free--blow into the conditioned space. Also, an

accessory electric, hot water or steam coil heater may be

installed to provide comfort heating.

3.1 Inspect Unit

Check unit against shipping order. Inspect carefully for

concealed shipping damage. If shipment is damaged or

incomplete,file claim w ith transportation company and

advise Carrier Transicold immediately.

3.2 Protect Unit from Damage

To maintain warranty, protect unit against adverse

weather, theft, or vandalism on j ob site.

3.3 Provide Unit Support

Refer to Figure 2 and Table 1 through Table 2 for unit

size and weight. If desired, construct a frame of I--beams

or angle iron that adequately supports unit. See

Figure 12.

3.4 Install Accessory Heating Coil (if applicable)

Electric heaters are installed at the top of the unit. Water

or steam coil must be installed through the back of the

unit as described in the Installation Instructions shipped

with the accessory coil.

3.5 Rig and Place Unit

NOTE

Install accessories before placing unit.

(90MA/MF

ONLY)

Figure 1 Base Unit Interior Details (Typical)

2. MODEL CHART

This manual covers 90M design series two units as

shown in the following model chart.

1 234 56 7891011

0MA

9

PRODUCT

CODE

MODEL

MA - 90/10 Copper Nickel

Condenser

MF - Copper Condenser

MU - Condenserless

2-R-22

3 - R-134a

4 - R-407C

NOMINAL COOLING

CAPACITY (R--22)

3 1 2 --- 6 2

VOLTAGE

5 - 208/230-3-60

6 - 460-3-60

9 - 400-3-50

DESIGN

SERIES

PACKAGING

1

3. INSTALLATION

To install the unit, do the following:

a. Provide space around unit for service, filter access,

and overhead clearance as indicated in Figure 2.

b. Move and store unit in upright position.

c. Useslings with spacer under base skid to prevent pan-

el damage when using hoist.

d. Units as shipped are adequately dampened against

vibration. If additional dampening is desired, place

sponge rubber or rubber mat, between deck and base

of unit or install vibration isolators.

e. Unit should be level. Unit leveling tolerance is 1/8

inch per linear foot in any direction.

3.6 Install Accessory Plenum (If Supplied)

Use plenum as template to mark hole locations in top

panel. Drill 5/32--in. (0.4 cm) holes in top panel at

marked locations and attach plenum with screws

supplied.

3.7 Install Ventilation--Air Ductwork

(If required)

Connect ventilation ducts to flanges on outside--air

supply opening (See Figure 2) using a flexible

connection. Attach ductwork to ship structure and

insulate with fiberglass and vapor barrier to reduce

sound transmission and prevent vapor condensation.

Weatherproof external ductwork, joints, and openings

in accordance with applicable codes. Ducts passing

through an unconditioned space must be insulated and

covered with a vapor barrier.

3.8 Install Return Air Ductwork (If required)

The unit back panel is to be field cut for alternate

return--air (or outdoor--air inlet) opening as indicated in

Figure 2. To install ductwork:

a. Cut out the alternate return--air opening as required.

1

62--10458-- 00

Table 1 90MA/MF/MU Physical Data -- Refrigerant 22

R--22 -- English Units R--22 -- Metric Units

BASE UNIT 90MA/MF/MU UNITS

NOMINAL CAPACITY Tons (kW) 3 5 7.5 10 10.5 17.6 26.4 35.1

OPERATING WEIGHT

Base Unit -- 90MA/MF Pounds (kg) 390 427 895 950 177 194 406 431

Base Unit -- 90MU Pounds (kg) 330 360 835 890 150 163 379 404

Discharge Plenum Pounds (kg) 25 25 50 50 11.3 11.3 22.7 22.7

COMPRESSOR TYPE Welded Hermetic

Quantity of Cylinders -- -- 4 6 -- -- 4 6

Quantity of Unloading Cylinders -- -- 0 2 -- -- 0 2

Quantity of Capacity Steps -- -- 1 2 -- -- 1 2

DISCHARGE PRESSURE SWITCH

Opens -- 90MA/MF psig (kPa) 39510 272569

Closes -- 90MA/MF psig (kPa) 29520 2034138

Opens -- 90MU psig (kPa) 4267 293748

Closes -- 90MU psig (kPa) 32020 2206138

SUCTION PRESSURE SWITCH

Opens psig (kPa) 274 18628

Closes psig (kPa) 677 46248

OPERATING CHARGE -- 90MA/MF pounds (kg) 3.1 5.3 11. 2 10 1.4 2.4 5.1 4.5

CONDENSER -- 90MA/MF

Number & Type 1....Tube In Tube

Water Volume gallon (liter) 0.39 0.86 2.42 1.48 3.3 9.2

EVAPORATOR AIR FAN Adjustable, Belt Driven Centrifugal: 1750 RPM Motor @ 60 Hz

Nominal Flow cfm (m3/h) 1200 2000 3000 4000 1698 2830 4245 5660

Standard Speed Range RPM 525-750 647-915 495-700 600-850 427-652 593-762 412-583 500-708

Maximum Allowable RPM 1050

Belt Quantity / Pulley Pitch Diameter inches (cm) 1/8.0 1/6.4 1/8.5 1/7.0 1 / 20.3 1 / 16.3 1 / 21.6 1 / 17.8

Motor Pulley Pitch Diameter Range inches (cm) 2.4to3.4 6.1to8.6

Motor Nominal Rating(@60 Hz)...Frame Size

Standard horse power 1/3...56 3/4...56 1...56 2...56 .25 / 56 .56 / 56 .75 / 56 1.5 / 56

Alternate(SeeNote1) horse power 3/4...56 1...56 2...56 3...56 .56 / 56 .75 / 56 1.5 / 56 2.2 / 56

Alternate(SeeNote1) horse power -- -- -- -- 3...56 -- -- -- -- -- -- 2.2 / 56 -- -EVAPORATOR COIL 3/8 (.95 cm) OD, Copper Tubes, Aluminum Fins

Tube Type Prime

Quantity of Rows...fin Spacing fins/inch(cm) 2...14.4 3...14.4 3...12.5 2...5.7 3...5.7 3...4.9

Face Area sq ft (sq m) 5 5 7.3 8.5 0.46 0.46 0.68 0.79

RETURN AIR FILTERS Factory Supplied, Cleanable

Quantity...Size inches (cm) 2...16 x 25 x 1 4...16 x 20 x 1 2...40.6x63.5x2.5 4...40.6x50.8x2.5

CONDENSER CONNECTIONS

Water Inlet (bottom) & Outlet (top) inches FPT 1/2 3/4 1 1 1/2 3/4 1 1

Maximum Working Pressure (refrigerant side) psig (kPa) 400 2758

CONDENSATE DRAIN CONNECTIONS inches FPT 3/4 3/4

ACCESSORY HEATING COILS

HOT WATER

Quantity of Rows...fin spacing fins/inch(cm) 1...15 1...15 2...14 2...14 1...5.9 1...5.9 2...5.5 2...5.5

Face Area sq ft (m) 5 5 6 6 0.46 0.46 0.56 0.56

Water Inlet (top) & Outlet Connection (bottom) inches (cm) 7/8 ODF 1--1/4 MPT 7/8 ODF 1-- 1/4 MPT

STEAM

Quantity of Rows...fin spacing fins/inch(cm) SeeNote2 1...14 1...14 SeeNote2 1...5.5 1...5.5

Face Area sq ft (m) SeeNote2 6.9 6.9 SeeNote2 0.64 0.64

Water Inlet (top) & Outlet Connection (bottom) inches (cm) SeeNote2 1--1/4 MPT SeeNote2 1--1/4 MPT

English (Metric)

LEGEND

FPT = Female Pipe Thread MPT = Male Pipe Thread ODF = Outside Diameter Female

204 206 208 212 204 206 208 212

Scroll

Semi--Hermetic

Reciprocating

Welded Hermetic

Scroll

Semi--Hermetic

Reciprocating

NOTES:

1. Motors and drives other than those furnished with unit must be purchased separately. Contact your Carrier Transicold representative.

2. Accessory heating coil in 004 and 006 units is combination hot water/steam. See hot water data.

62--10458-- 00

2

Loading...

Loading...