Carrier 8000 58WAV User Manual

Weathermaker 8000^*^

HEATING & COOLING

Induced-Combustion Furnaces

Installation, Start-Up, and Operating Instructions

Sizes 045-155, Series 110

NOTE: Read the entire instruction manual before starting the

installation.

Index Page

SAFETY CONSIDERATIONS ............................................................................. 1

Clearances From Combustibles

......................................................................

1

INTRODUCTION...................................................................................................1-2

LOCATION ............................................................................................................... 3

General .................................................................................................................3

Relative to Cooling Equipment ....................................................................... 3

Hazardous Locations......................................................................................... 3

AIR FOR COMBUSTION AND VENTILATION

.........................................

3-4

Unconfined Space ...............................................................................................3

Confined Space .............................................................................................. 3-4

FILTER ARRANGEMENT ............................................................................... 4-5

LEVELING LEGS..................................................................................................5-6

GAS PIPING.......................................................................................................... 6-7

ELECTRICAL CONNECTIONS........................................................................7-8

115-v Wiring.........................................................................................................7

24-v Wiring...........................................................................................................8

Accessories........................................................................................................... 8

VENTING ................................................................................................................ 8

START-UP, ADJUSTMENT, AND SAFETY CHECK................................ 8-9

General .............................................................................................................. 8

Sequence Of Operation .................................................................................... 8

Heating Mode ..................................................................................................... 8

Cooling Mode

........................

,........................................................................... 8

Continuous Blower Mode ................................................................................ 8

Heat Pump Mode ........................................................................................... 8-9

START-UP PROCEDURES .................................................................................. 9

ADJUSTMENTS ................................................................................................ 9-13

Set Gas Input Rate ....................................................................................... 9-12

Set Temperature Rise ............................................................................... 12-13

Set Thermostat Heat Anticipator ................................................................. 13

CHECK SAFETY CONTROLS ......................................................................... 13

CHECKLIST .......................................................................................................... 13

Installing and servicing heating equipment can be hazardous due to

SAFETY CONSIDERATIONS

gas and electrical components. Only trained and qualified person

nel should install, repair, or service heating equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacing air filters. All other operations must

be performed by trained service personnel. When working on

heating equipment, observe precautions in the literature, on tags,

and on labels attached to or shipped with the unit and other safety

precautions that may apply.

Follow all safety codes. In the United States, follow all safety

codes including the National Fuel Gas Code NFPA No. 541992/ANSI Z223.1-1992 (NFGC). In Canada, refer to the current

edition of the National Standard of Canada CAN/CGA-B149.1and .2-M91 Natural Gas and Propane Gas Installation Codes

(NSCNGPIC). Wear safety glasses and work gloves. Have fire

extinguisher available during start-up and adjustment procedures

and service calls.

a

Recognize safety information. This is the safety-alert symbol ^ .

When you see this symbol on the furnace and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal word DANGER, WARNING, or CAU

TION. These words are used with the safety-alert symbol. DAN

GER identifies the most serious hazards which will result in severe

personal injury or death. WARNxNG signifies a hazard that could

result in personal injury or death. CAUTION is used to identify

unsafe practices which would result in minor personal injury or

product and property damage. NOTE is used to highlight sugges

tions that will result in enhanced installation, reliability, or

operation.

These instructions cover minimum requirements and conform to

existing national standards and safety codes. In some instances,

these instructions exceed certain local codes and ordinances,

especially those that may not have kept up with changing residen

tial construction practices. We require these instructions as a

minimum for a safe installation.

Table 1—Minimum Clearances From

Combustible Materials (In.)

UNIT SIZE

Sides Single-Wall Vent

Type B-1 Double-Wall Vent

Back

Top of Plenum

Vent Connector Single-Wall Vent

Type B-1 Double-Wall Vent 1 1

Front Single-Wall Vent 6

Type B-1 Double-Wall Vent

NOTES;

1. Provide 30-in. front clearance for servicing. An open door in front of the

furnace can meet this requirement.

2, A minimum clearance of 3 in. must be provided in front of the furnace for

combustion air and proper operation.

INTRODUCTION

The Model 58WAV, Series 110 Furnaces are available in sizes

45,000 through 155,000 Btuh input capacities.

The design of the upflow gas-fired furnace is A.G.A./C.G.A.

certified for natural and propane gas and for installation on

combustible flooring, in alcoves, attics, basements, closets, or

utility rooms. The design of this furnace line is not A.G.A./C.G.A.

certified for installation in mobile homes, recreation vehicles, or

outdoors.

EFFICIENCY

RATING

CERTIFIED

ama

Service 30

58WAV

045 AND 070

1

0

0 0

1 1

6 6

3 3

091-155

0

0

6

30

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

BookI 1 I 4 PC 101 Catalog No. 535-850 Printed in U.S.A. Form 58WAV-2SI Pg 1 10-93 Replaces; 58WAV-1S1

Tab |6a|8a

39-7/8

-28-1/2

7/8 DIA '-—»LL

ACCESSORY

1-3/4 DIA HOLE

GAS ENTRY

1/2 DIA HOLE"

THERMOSTAT

WIRE ENTRY

H3/16

2-3/8

—-1-1/2 DIA

^ R.H. GAS ENTRY

7/8 DIA

ACCESSORY

1/2 DIA

THERMOSTAT

WIRE ENTRY

-13/16

SIDE INLET

11/16-

24-5/16 11/16-*-

NOTE: 2 ADDITIONAL 7/8 DIA KNOCKOUTS

ARE LOCATED IN THE TOP PLATE

NOTE; AIR DELIVERY ABOVE 1800 CFM REQUIRES THAT BOTH SIDES OF FURNACE

BE USED, OR A COMBINATION OF 1 SIDE AND BOTTOM, OR BOTTOM ONLY FOR

RETURN AIR.

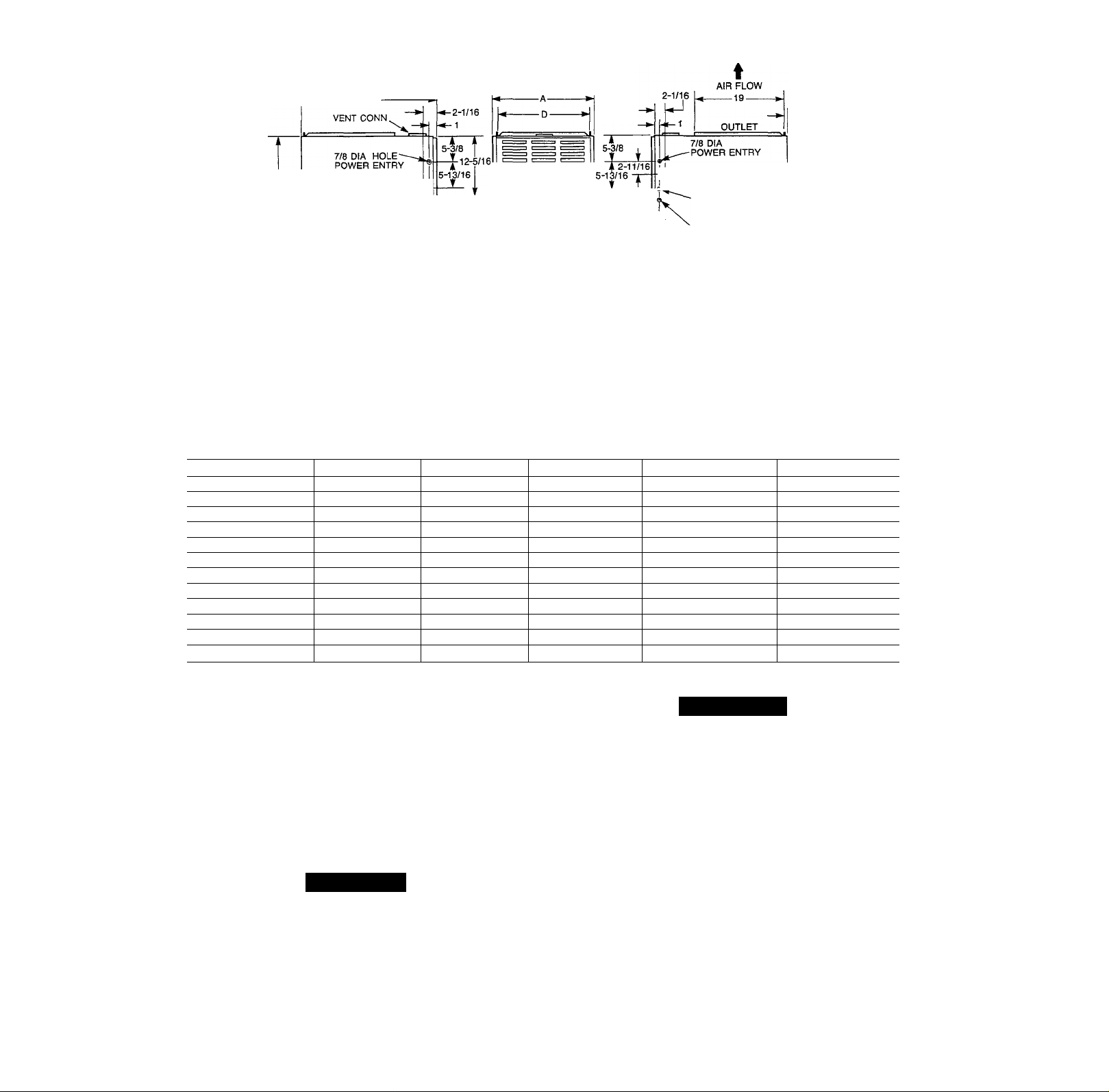

Table 2—Dimensions (In.)

UNIT SIZE

045-08

045-12 14-3/16

070-08

070-12

091-14 17-1/2 15-7/8 16

091-16

111-12 17-1/2 15-7/8 16

111-16

111-20

136-16

136-20

155-20

A

14-3/16 12-9/16

14-3/16 12-9/16 12-11/16

14-3/16 12-9/16 12-11/16

21 19-3/8 19-1/2 4

21

24-1/2 22-7/8 23

21

24-1/2 22-7/8 23

24-1/2 22-7/8 23 5

D E VENT CONN

12-9/16

19-3/8 19-1/2 4 166

19-3/8 19-1/2 5

Fig. 1—Dimensional Drawing

12-11/16

12-11/16

-11/16

SIDE INLET

INLET

-23-1/4-

4

4

4

4

4 150

4 160

4

5

14-1/2

1-3/4

SHIP. WT

A88367

122

124

132

134

154

184

178

194

204

Before installing the furnace, refer to the current edition of the

NFGC. Canadian installations must be installed in accordance with

NSCNGPIC and all authorities having jurisdiction. For further

information, the National Fuel Gas -Code is available from Na

tional Fire Protection Association Inc. Batterymarch Park, Quincy,

MA 02269, American Gas Association, 1515 Wilson Boulevard,

Arlington, VA 22209, or from Literature Distribution.

Installation must conform to the regulations of the serving gas

supplier and the local building, heating, and plumbing codes in

effect in the area in which the installation is made, or in the

absence of local codes with the requirements of the NFGC.

A CAUTION

Application of this furnace should be indoors with special

attention given to vent sizing and material, gas input rate, air

temperature rise, and unit sizing. Improper installation or

misapplication of the furnace can require excessive servicing

or cause premature component failure.

This furnace is designed for a minimum continuous return-air

temperature of 60°F db or an intermittent operation down to 55°F

db such as when used with a night setback thermostat. Return-air

temperature must not exceed a maximum of 85°F db.

WA

A WARNING

Improper installation, adjustment, alteration, service, mainte

nance, or use can cause carbon monoxide poisoning, explo

sion, fire, electrical shock, or other conditions which may

cause personal injury or property damage. Consult a qualified

installer, service agency, local gas supplier, or your distribu

tor or branch for information or assistance. The qualified

installer or agency must use only factory-authorized and

listed kits or accessories when modifying this product. A

failure to follow this warning can cause electrical shock, fire,

personal injury, or death.

For accessory installation details, refer to the applicable instruction

literature.

NOTE: Remove all shipping brackets and materials before

operating the furnace.

step 1—Location

GENERAL

A CAUTION

Do not install furnace in a corrosive or contaminated atmo

sphere. Make sure all combustion and circulating air require

ments are met, in addition to all local codes and ordinances.

A CAUTION

Do not use this furnace during construction when adhesives,

sealers, and/or new carpets are being installed. If the furnace

is required during construction, use clean outside air for

combustion and ventilation. Compounds of chlorine and

fluorine when burned with combustion air form acids which

will cause corrosion of the heat exchangers and metal vent

system. Some of these compounds are found in paneling and

dry wall adhesives, paints, thinners, masonry Ci-aning mate

rials, and many other solvents commonly used in ihe con

struction process.

This furnace must be installed so the electrical components are

protected from water.

Locate the furnace close to the chimney/vent and as near the center

of the air distribution system as possible. The furnace should be

installed as level as possible.

When a furnace is installed so that the supply ducts carry air to

areas outside the space containing the furnace, the return air must

also be handled by a duct(s) ’ sealed to the furnace casing and

terminating outside the space containing the furnace.

Provide ample space for servicing and cleaning. Always comply

with the minimum fire protection clearances shown on the unit

rating plate.

LOCATION RELATIVE TO COOLING EQUIPMENT - The

cooling coil must be installed parallel with or on the downstream

side of the furnace to avoid condensation in the heat exchangers.

When installed parallel with a furnace, dampers or other means

used to control the flow of air must prevent chilled air from

entering the unit. If the dampers are manually operated, they must

be equipped with means to prevent operation of either unit unless

the damper is in the full-heat or full-cool position.

HAZARDOUS LOCATIONS - When the furnace is installed in

a residential garage, it must be installed so that the burners and

ignition source are at least 18 in. above the floor. The furnace

should be protected from physical damage by vehicles. When a

furnace is installed in public garages, airplane hangars, or other

buildings having hazardous atmospheres, the unit must be installed

in accordance with the recommended good practice requirements

of the National Fite Protection Association, Inc.

Step 2—Air For Combustion and Ventilation

Provisions for adequate combustion and ventilation air must be

provided in accordance with Section 5.3, Air for Combustion and

Ventilation, of the NFGC or applicable provisions of the local

building codes.

Canadian installations must be installed in accordance with NSCNGPIC and all authorities having jurisdiction.

A CAUTION

Air for combustion must not be contaminated by halogen

compounds, which include fluoride, chloride, bromide, and

iodide. These elements are found in aerosol sprays, deter

gents, bleaches, cleaning solvents, salts, air fresheners, and

other household products.

All fuel-burning equipment must be supplied with air for combus

tion of the fuel. Sufficient air MUST be provided to ensure there

will not be a negative pressure in the equipment room or space. In

addition, a positive seal MUST be made between the furnace

cabinet and the return-air duct to prevent pulling air from the

burner area and draft safeguard opening.

A CAUTION

The operation of exhaust fans, kitchen ventilation fans,

clothes dryers, or fireplaces could create a NEGATIVE

PRESSURE CONDITION at the furnace. Make-up air MUST

BE PROVIDED for the ventilation devices, in addition to that

required by the furnace.

Combustion air requirements are determined by whether the

furnace is in an UNCONFINED or CONFINED space.

UNCONFINED SPACE — An unconfined space must have at

least 50 cu ft for each 1000 Btuh of input for all the appliances

(such as furnaces, clothes dryer, water heaters, etc.) in the space.

For Example:

58WAV FURNACE

INPUT BTUH

44,000 293

66,000 440

88,000

110,000 733

132,000 880

154,000 1026

If the unconfined space is of unusually tight construction, air for

combustion and ventilation MUST come from either the outdoors

or spaces freely communicating with the outdoors. Combustion

and ventilation openings must be sized the same as for a confined

space. A minimum opening with a total of at least 1 sq in. per 5000

Btuh of total input rating for all equipment must be provided.

Return air must not be taken from the room, unless an equal or

greater amount of air is supplied to the room.

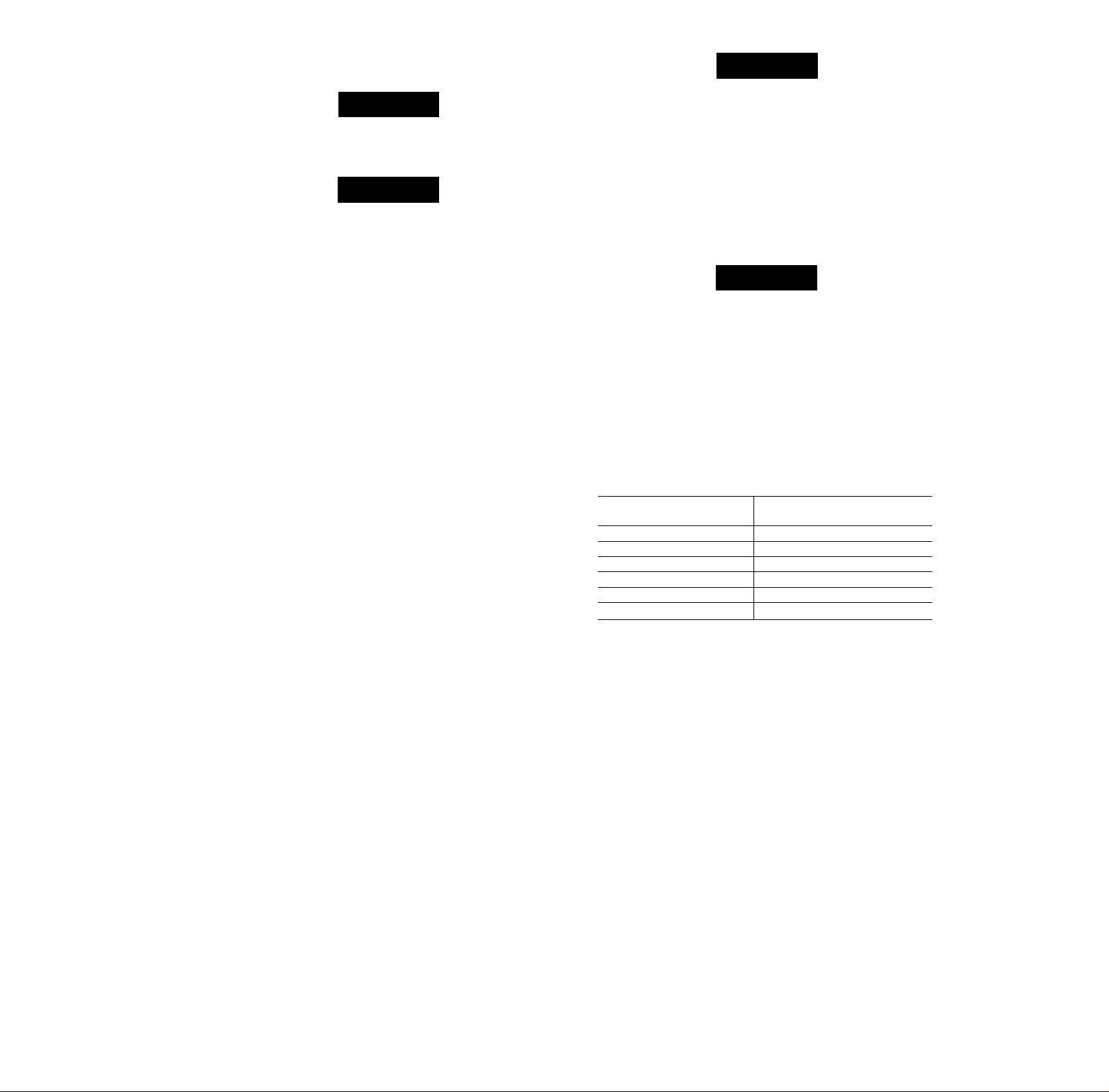

CONFINED SPACE — A confined space is one whose volume is

less than 50 cu ft per 1000 Btuh of the total output rating for all

appliances installed in that space. A confined space MUST have 2

permanent openings, 1 within 12 in. of the ceiling and the other

within 12 in. of the floor. (See Fig. 2.)

NOTE: In determining the free area of an opening, the blocking

effect of the louvers, grilles, and screens must be considered. If the

free area of a louver or grille design is unknown, it may be

assumed that wood louvers have a 20 percent free area and metal

louvers or grilles have a 60 percent free area. Screens, when used,

must not be smaller than 1/4-in. mesh. Louvers and grilles must be

constructed so they cannot be closed.

The size of the openings depends upon whether the air comes from

inside or outside of the structure.

1. All air from inside the structure:

Each opening MUST have at least 1 sq in. of free area per

1000 Btuh of the total input for all equipment within the

confined space, but not less than 100 sq in. per opening. (See

Fig. 2.)

MINIMUM SQ FT WITH

7-1/2 FT CEILING

587

SUPPLY

AIR

VENT THROUGH ROOF

(OATEGORY I) OR WALL

(CATEGORY III)

! I I

I I I

I I I

_12 MAX

1 1 SO IN.

Ш PER 1000

BTUH*

6 IN. MIN

(FRONT) +

1 SO IN.

PER 1000

BTUH*

INTERIOR

HEATED

SPACE

For Example:

58WAV FURNACE

INPUT BTUH

44,000 11.0

66,000

88,000 22.0

110,000 27.5

132,000 33.0

154,000

FREE AREA PER OPENING

(SQ IN.)

16.5

38.5

ROUND PIPE

(IN. DIA)

b. If combustion air is taken from the outdoors through

horizontal ducts, the openings and ducts MUST have at

least 1 sq in. of free area per 2000 Btuh of the total input

for all equipment within the confined space.

For Example:

58WAV FURNACE

INPUT BTUH

44,000 22.0

66,000 33.0

88,000 44.0

110,000

132,000 66.0 10

154,000 77.0

FREE AREA PER OPENING

(SQ IN.)

55.0 9

ROUND PIPE

(IN. DIA)

4

5

6

6

7

7

6

7

8

10

* Minimum opening size is 100 square in. with

minimum dimensions of 3 in.

+ Minimum of 3 in. when type-B vent is used.

A89012

Fig. 2—Air For Combustion and Ventilation

(Inside Air)

For Example:

58WAV FURNACE

INPUT BTUH

44,000

66,000

88,000

110,000

132,000

154,000

FREE AREA PER OPENING

(SQ IN.)

100

100

100

110

132

154

If the building is constructed unusually tight, a permanent opening

directly communicating with the outdoors should be provided.

This opening shall have a minimum free area of 1 sq in. per 5000

Btuh of total input rating for all equipment in the enclosure.

If the furnace is installed on a raised platform to provide a

return-air plenum, and return air is taken directly from the hallway

or space adjacent to the furnace, all air for combustion must come

from outdoors.

2. AJil air from outside the structure:

a. If combustion air is taken from outdoors through vertical

ducts, the openings and ducts MUST have at least 1 sq in.

of free area per 4000 Btuh of the total input for all

equipment within the confined space. (See Fig. 3.)

When ducts are used, they must be of the same cross-sectional area

as the free area of the openings to which they connect. The

minimum dimension of rectangular ducts must not be less than 3

in. (See Fig. 3.)

A WARNING

Do not install the furnace on its back; safety control operation

will be adversely affected. Never connect return-air ducts to

the back of the furnace. A failure to follow this warning can

cause a fire, personal injury, or death.

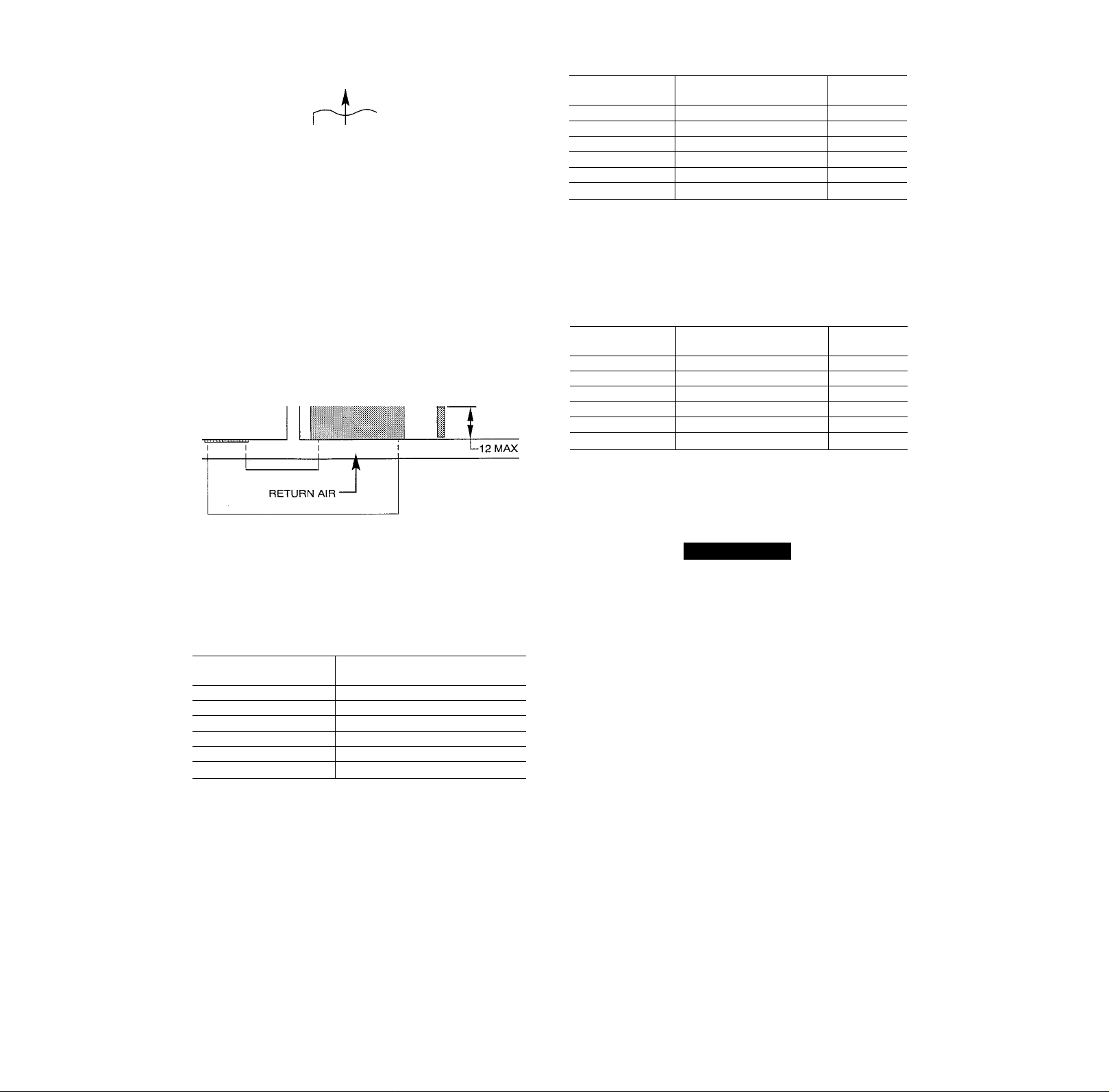

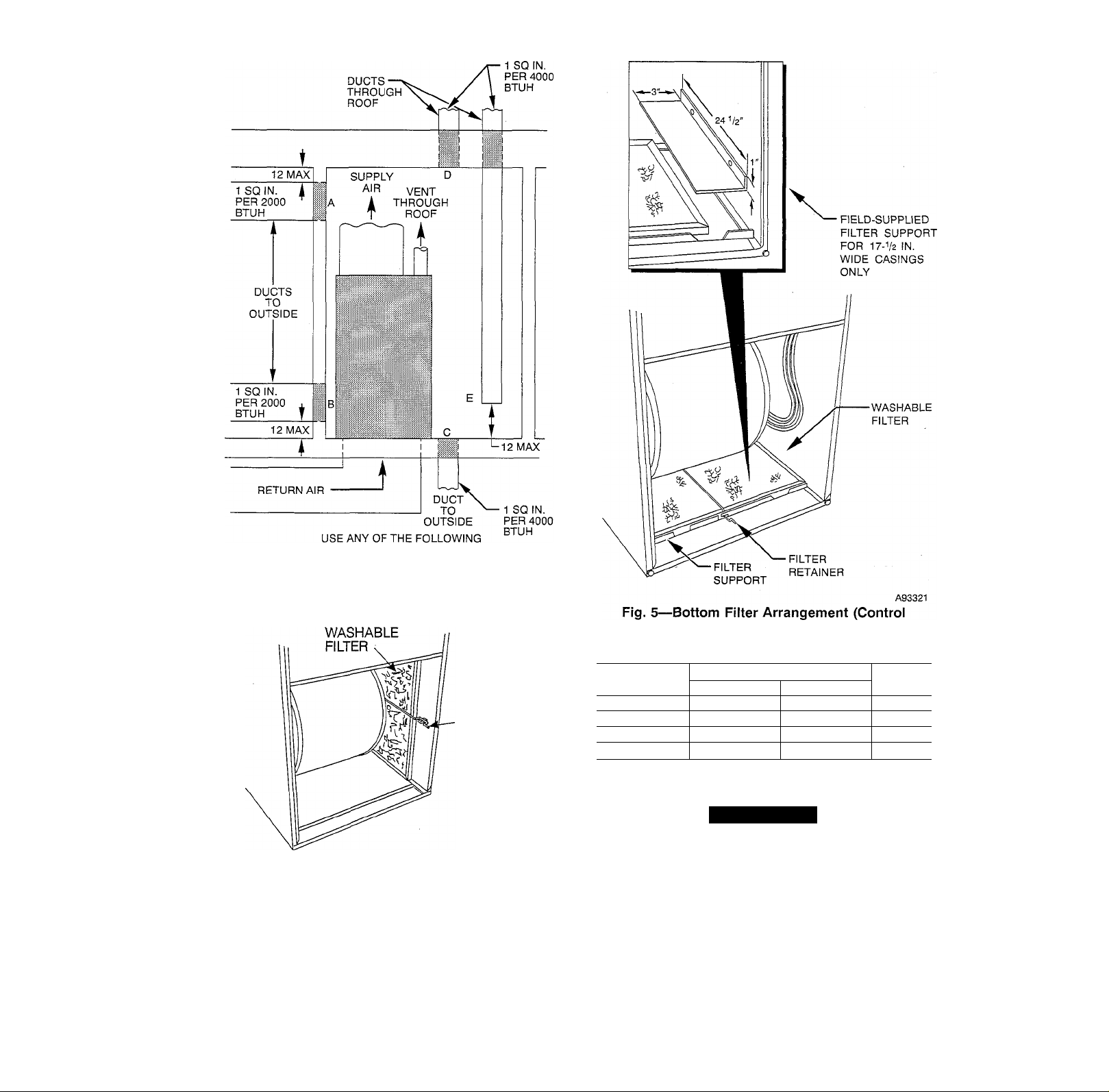

Step 3—Filter Arrangement

The factory-supplied filter(s) is shipped in the blower compart

ment. Determine location for the filter and move filter retaining

hardware, if necessary, before attaching the return-air duct. After

the return-air duct has been connected to the furnace, install the

filter(s) inside the furnace blower compartment. See Fig. 4 for side

return application and Fig. 5 for bottom return application.

A bottom closure panel is factory installed in the bottom of the

furnace. When bottom return inlet is desired, remove and discard

the enclosure panel.

Filter retaining brackets, supports, and retainers are factory as

sembled and shipped installed for side return application, with 1

set of all required hardware on each of the furnace. (See Fig. 4.)

For bottom return applications, remove the brackets (front and

back) and supports from each side. The back bracket(s) are

installed in the rear of the furnace casing (dimples are provided to

mark mounting screw locations).

The front bracket(s) are installed on the bottom front plate as

shown in Fig. 5, once the bottom enclosure has been removed.

Rotate filter supports 180° so filter will rest on support, and

reinstall. (Do not reinstall in 17-1/2 in. casing.) Install the filter

retaining rod (small U-shaped end) in the rear bracket, and the

front of the filter retainer rod as shown in Fig. 5. Two sets of

hardware are needed for furnaces in 24-1/2 in. casings using 2

filters for bottom return. All hardware is provided for filter

installation.

COMBINATIONS OF OPENINGS:

A&B C&D D&E

A89013

Fig. 3-

-Air For Combustion and Ventilation

(Outside Air)

•FILTER

RETAINER

SPRING

A93045

Fig. 4—Side Filter Arrangement (Control Removed

for Clarity)

NOTE: Furnaces with a 17-1/2 in. wide casing require an

additional procedure when locating the filter for bottom return-air

application. Field-fabricate a sheet metal filler strip 1 X 3 X 24-1/2

in. and install it along side of the filter as shown in Fig. 5. Drive

2 screws through the casing side and into the filler strip to secure

it in place. The filter is to rest on top of the filler strip when

installed.

Removed for Clarity)

Table 3—Filter Information (In.)

FURNACE

CASING WIDTH

14-3/16

17-1/2

21

24-1/2

* Filters can be field modified by cutting the frame as marked and folding to the

desired size. Alternate sizes can be ordered from your distributor or deaier.

t Factory provided virith the furnace.

(1) 16 X 25 X It

(1) 16 X 25 X It

(1) 16X25X 1 (1) 20 X 25 X ItCleanable

(2) 16 X 25 X 1t

FILTER SIZE*

Side Return

Bottom Return

(1) 14X25X1

(1) 16 X 25 X 1

(1) 24 X 25 X 1

FILTER

TYPE

Cleanable

Cleanable

Cleanable

A WARNING

Never operate unit without a filter or with filter access door

removed. Failure to follow this warning can cause fire,

personal injury, or death.

Step 4—Leveling Legs (If Required)

When the furnace is used with side inlet(s) and leveling legs are

required, refer to Fig. 6 and install field-supplied, corrosionresistant 5/16-in. machine bolts and nuts.

NOTE: The maximum length of the bolt should not exceed 1-1/2

in.

1. Lay furnace on its back. Locate and drill 5/16-in. diameter

hole in each bottom comer of furnace as shown in Fig. 6.

2. Install nut on bolt and install bolt and nut in hole. (Install flat

washer if desired.)

Loading...

Loading...