Carrier 58ZAV User Manual

WeatherMaker 8000™

Downflow/Horizontal Induced-Combustion Furnaces

Visit www.carrier.com

Installation, Start-Up, and Operating Instructions

Sizes 050—135, Series 140

NOTE: Read the entire instruction manual before starting the

installation.

This symbol → indicates a change since the last issue.

Index Page

SAFETY CONSIDERATIONS.....................................................1

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

PROCEDURE...........................................................................2

INTRODUCTION.......................................................................3-4

Dimensional Drawing...............................................................2

Clearances From Combustible Materials.................................3

LOCATION....................................................................................4

General......................................................................................4

Location Relative to Cooling Equipment ................................4

Hazardous Locations.................................................................4

AIR FOR COMBUSTION AND VENTILATION...................4-5

Unconfined Space..................................................................4-5

Confined Space.........................................................................5

AIR DUCTS................................................................................5-6

General Requirements...............................................................5

Ductwork Acoustical Treatment...............................................5

Supply-Air Connections........................................................5-6

Return-Air Connections............................................................6

DOWNFLOW INSTALLATION..................................................6

HORIZONTAL ATTIC INSTALLATION...................................7

Construct a Working Platform .................................................7

Install Furnace...........................................................................7

HORIZONTAL CRAWLSPACE INSTALLATION....................7

FILTER ARRANGEMENT...........................................................8

GAS PIPING.............................................................................8-10

ELECTRICAL CONNECTIONS................................................10

115-v Wiring...........................................................................10

24-v Wiring.............................................................................11

Accessories..............................................................................11

VENTING ....................................................................................11

START-UP, ADJUSTMENT, AND SAFETY CHECK.......11-20

General...............................................................................11-13

Sequence Of Operation...........................................................13

Heating Mode..........................................................................13

Cooling Mode .........................................................................13

Continuous Blower Mode.......................................................13

Heat Pump Mode....................................................................13

Start-up Procedures.................................................................13

Adjustments .......................................................................15-20

Set Gas Input Rate..................................................................15

Set Temperature Rise............................................................ 18

Set Thermostat Heat Anticipator............................................19

Check Safety Controls............................................................20

Checklist..................................................................................20

®

REGISTERED QUALITY SYSTEM

SAFETY CONSIDERATIONS

Installing and servicing heating equipment can be hazardous due to

gas and electrical components. Only trained and qualified personnel should install, repair, or service heating equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacing air filters. All other operations must

be performed by trained service personnel. When working on

heating equipment, observe precautions in the literature, on tags,

and on labels attached to or shipped with the unit and other safety

precautions that may apply.

In the United States, follow all safety codes including the National

→

Fuel Gas Code (NFGC) NFPA 54-1996/ANSI Z223.1-1996 and

the Installation Standards, Warm Air Heating and Air Conditioning Systems (NFPA 90B) ANSI/NFPA 90B.

In Canada, refer to the CAN/CGA-B149.1- and .2-M95 National

→

Standard of Canada, Natural Gas and Propane Installation Codes

(NSCNGPIC).

Wear safety glasses and work gloves. Have fire extinguisher

available during start-up and adjustment procedures and service

calls.

Recognize safety information. This is the safety-alert symbol

When you see this symbol on the furnace and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, CAUTION,

→

and NOTE. These words are used with the safety-alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies a hazard

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which would result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability,

or operation.

These instructions cover minimum requirements and conform to

existing national standards and safety codes. In some instances,

these instructions exceed certain local codes and ordinances,

especially those that may not have kept up with changing residential construction practices. We require these instructions as a

minimum for a safe installation.

ama

58ZAV

CANADIAN GAS ASSOCIATION

APPROVED

R

.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 6a 8a

PC 101 Catalog No. 535-729 Printed in U.S.A. Form 58ZAV-10SI Pg 1 8-99 Replaces: 58ZAV-9SI

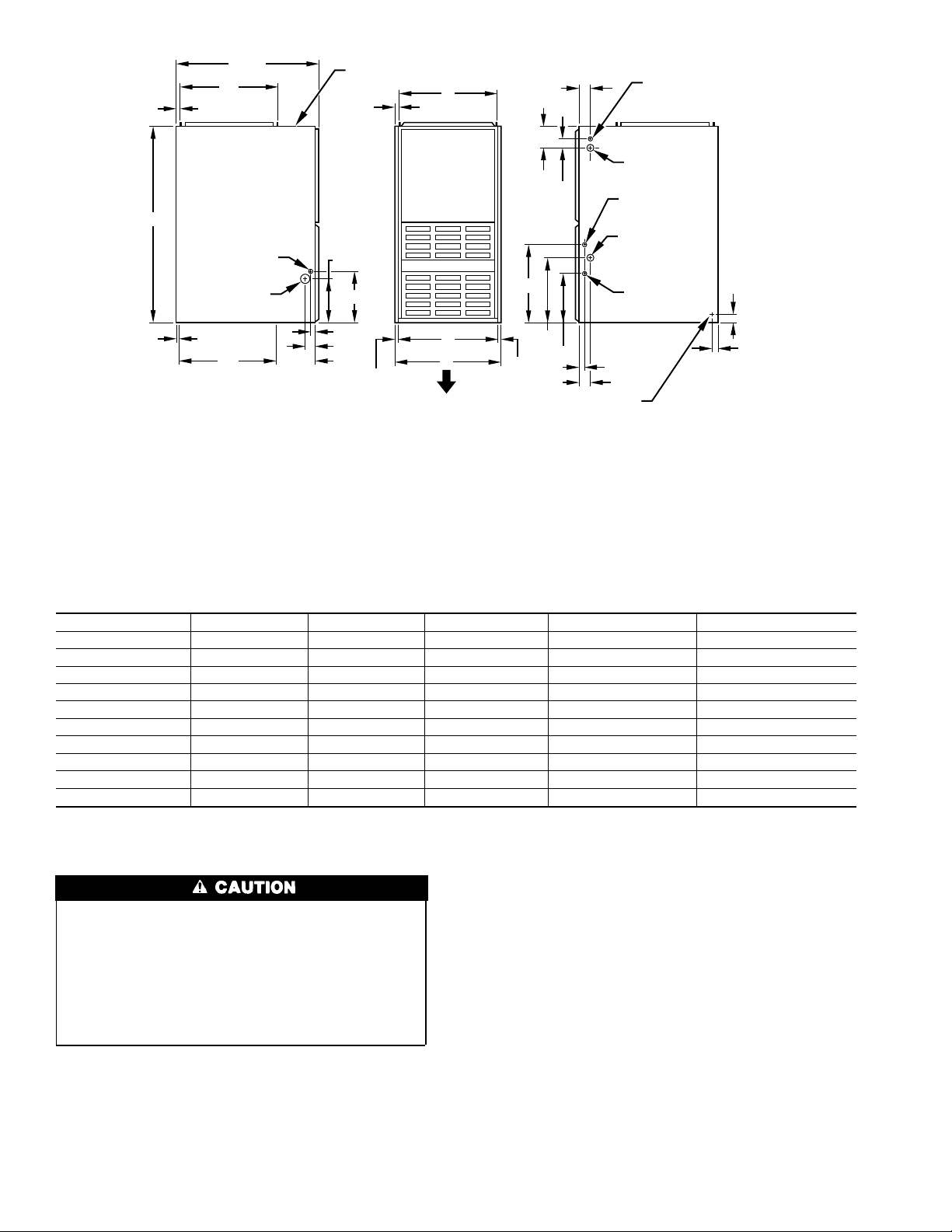

13

⁄16†

39 7⁄8†

11

⁄16†

28 1⁄2†

20†

INLET

7

⁄8† DIA

ACCESSORY

3

1

⁄4† DIA HOLE

GAS ENTRY

OUTLET

19†

NOTE:

ADDITIONAL

LOCA TED IN THE TOP PLA TE

AND BOTTOM PLATE

VENT CONNECTION

13

⁄16†

9 1⁄8†

10 1⁄4†

1 1⁄16†

2 1⁄8†

8 1⁄4†

11

⁄16†

7

⁄8† DIA K.O.’s ARE

D

E

A

AIRFLOW

1

⁄2† DIA

2†

4 3⁄16†

2 15⁄16†

16 1⁄16†

13 5 ⁄16†

10 1⁄4†

11

⁄16†

DIMPLES TO DRILL HOLES

FOR HANGER BOLTS (4 PLACES)

IN HORIZONTAL POSITION

THERMOSTAT

WIRE ENTRY

7

⁄8† DIA

ACCESSORY

7

⁄8† DIA HOLE

POWER ENTRY

1 1⁄2† DIA

R.H. GAS ENTRY

7

⁄8† DIA

ACCESSORY

1 1⁄16†

2 1⁄8†

† TYP

1

5

⁄8† TYP

NOTE:

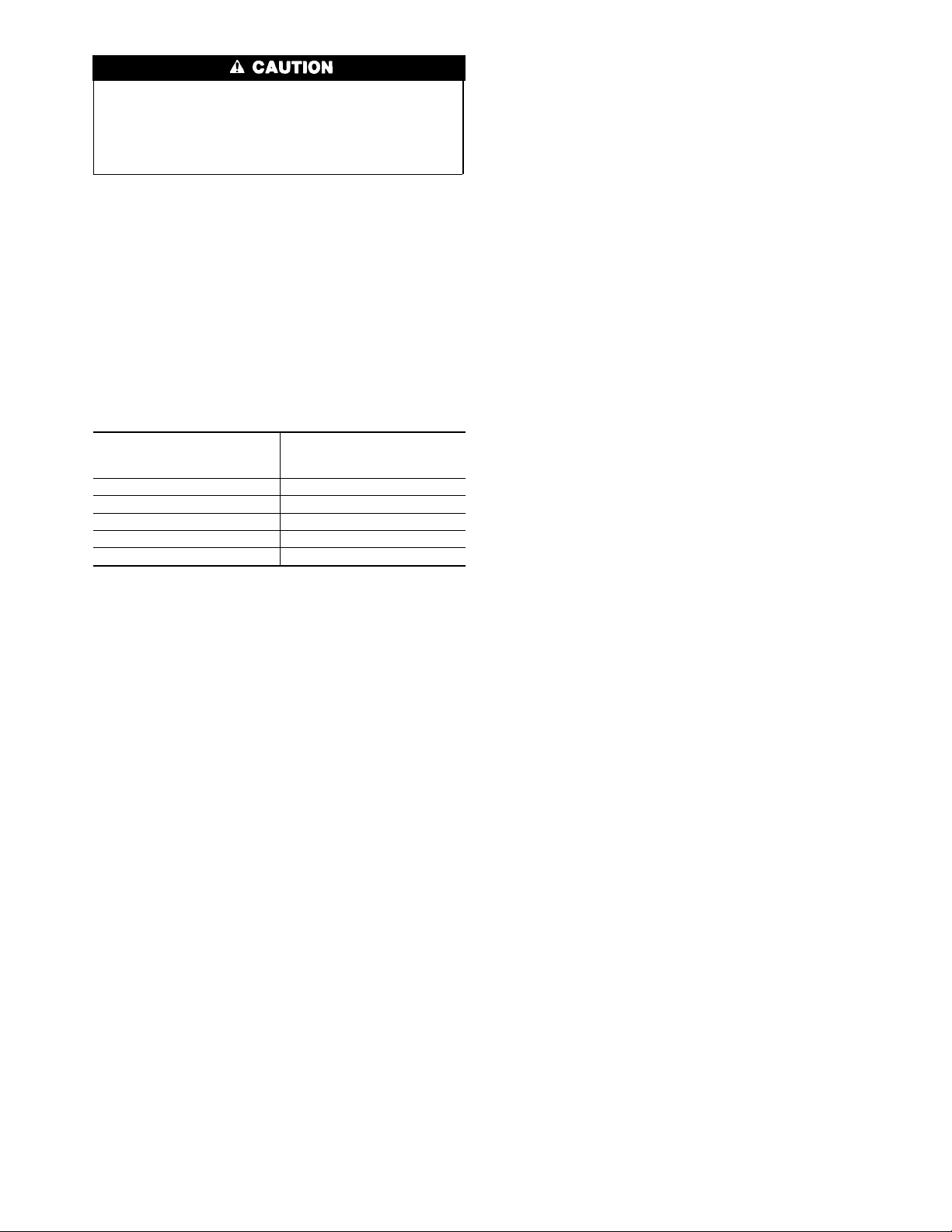

Minimum return-air openings at furnace, based on metal duct. If flex duct is used,

see flex duct manufacturer's recommendations for equivalent diameters.

a. For 800 CFM–16-in. round or 141⁄2 x 12-in. rectangle.

b. For 1200 CFM–20-in. round or 141⁄2 x 191⁄2-in. rectangle.

c. For 1600 CFM–22-in. round or 141⁄2 x 231⁄4-in. rectangle.

d. For airflow requirements above 1800 CFM, must use entire return air opening.

→Fig. 1—Dimensional Drawing

Table 1—Dimensions (In.)

UNIT SIZE A D E VENT CONN SHIP. WT (LB)

050-08 14-3/16 12-9/16 12-11/16 4 124

050-12 14-3/16 12-9/16 12-11/16 4 128

070-08 14-3/16 12-9/16 12-11/16 4 129

070-12 14-3/16 12-9/16 12-11/16 4 137

096-12 17-1/2 15-7/8 16 4 146

096-16 17-1/2 15-7/8 16 4 151

115-16 17-1/2 15-7/8 16 4 159

115-20 21 19-3/8 19-1/2 4 174

115-22 21 19-3/8 19-1/2 4 176

135-20 24-1/2 22-7/8 23 5 193

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

PROCEDURE

3. After touching the chassis you may proceed to service the

control or connecting wires as long as you do nothing that

recharges your body with static electricity (for example; DO

NOT move or shuffle your feet, DO NOT touch ungrounded

Electrostatic discharge can affect electronic components.

Take precautions during furnace installation and servicing to

protect the furnace electronic control. Precautions will prevent electrostatic discharges from personnel and hand tools

which are held during the procedure. These precautions will

help to avoid exposing the control to electrostatic discharge

by putting the furnace, the control, and the person at the same

electrostatic potential.

1. Disconnect all power to the furnace. DO NOT TOUCH THE

CONTROL OR ANY WIRE CONNECTED TO THE CONTROL PRIOR TO DISCHARGING YOUR BODY’S ELECTROSTATIC CHARGE TO GROUND.

2. Firmly touch a clean, unpainted, metal surface of the furnace

chassis which is close to the control. Tools held in a person’s

hand during grounding will be satisfactorily discharged.

objects, etc.).

4. If you touch ungrounded objects (recharge your body with

static electricity), firmly touch furnace again before touching

control or wires.

5. Use this procedure for installed and uninstalled (ungrounded)

furnaces.

6. Before removing a new control from its container, discharge

your body’s electrostatic charge to ground to protect the

control from damage. If the control is to be installed in a

furnace, follow items 1 through 5 before bringing the control

or yourself into contact with the furnace. Put all used AND

new controls into containers before touching ungrounded

objects.

7. An ESD service kit (available from commercial sources) may

also be used to prevent ESD damage.

2

A99288

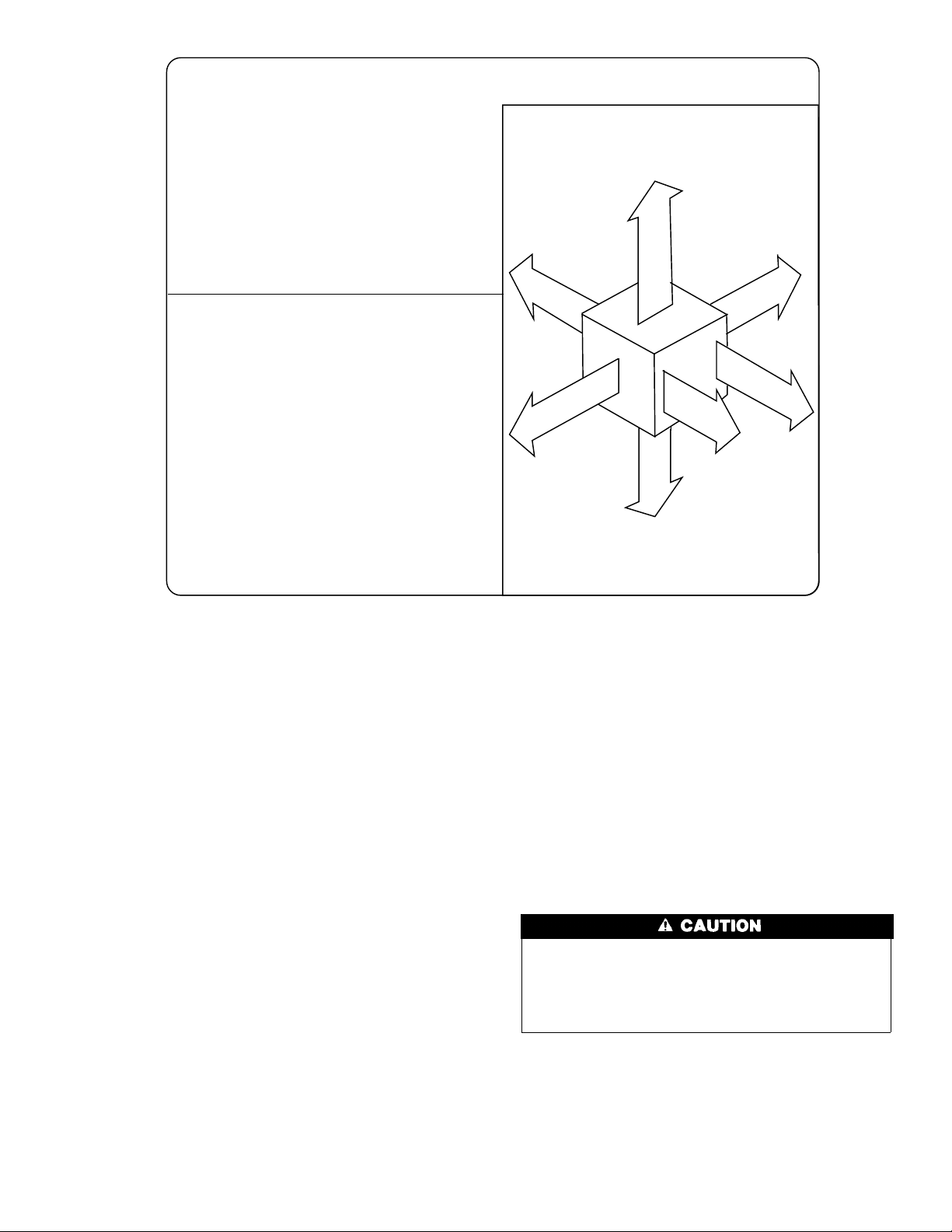

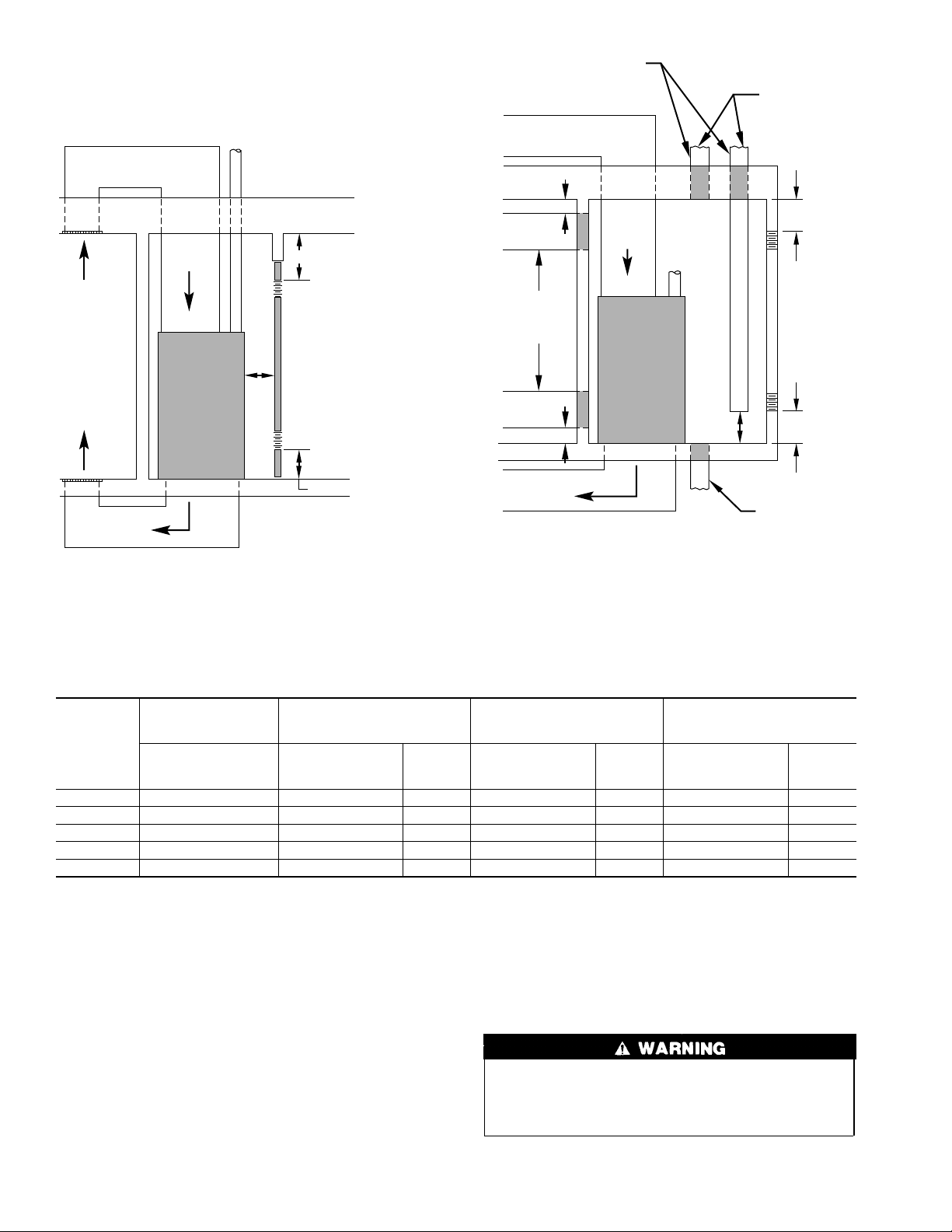

MINIMUM INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

This fo rced air furnace is equipped for use with natura l

gas at altitudes0-10,000ft (0-3,050m).

An accessory kit, supplied by the manu facturer,shall be

used to convert to propane gas use or may be required for

somenatura l gas applicatio ns.

This furnace is for indoor in stallatio n in a building

constructedonsite.

This furnace may be installed on combustible flooring in

alcove or closet at minimum clea rance from combustible

material.

This furnace may be used with a Type B-1 Vent and may

be vented in commonwithother gas-fired appliances.

For installation on non-combustible floorsonly.

†

For installation on combustible flooring only when

installedon special base, Part No. KGASB0201ALL,

Coil Assembly, Part No. CD5 or CK5, or Coil Casing,

Part No. KCAKC.

For furnaces wider than14.25 inches (362mm) may

#

be 0 inches.

18 inches front clearance requiredfor alcove.

Ø

Indicates supply or return sides whenfurnace isin

*

the horizontal position. Line contact only permissible

betweenlines formed by intersectionsof the Top and

two Sides of the furnace jacket, and building joists,

studs or framing.

For single wall vent type 6 inches.

##

For Type B-1 vent type 3 inches.

††

Clearance to Back 0 inches in downflowand

horizontal (attic/alcove& crawlspace) positionsand

3 inches in horizontal closet positions.

Fig. 2—Clearances to Combustibles

This f ur nace is approved f or DOWNFLOWand HORIZONTAL

installations.

Clearance arrows

do not change with

furnace orientation.

0"

†

†

B

A

C

K

E

D

I

S

1" #

*

Clearance in inches

1"

TOP / PLENUM

E

C

A

N

R

U

F

1

†

T

N

O

R

F

F

R

BOTTOM

#

"

S

O

N

T

##

Ø

1"

#

E

*

D

I

S

E

R

V

I

C

E

30"

Vent Clearance to combustibles:

For Single Wall vents 6 i nches.

For Type B-1 vent type 1 inch.

322286-101REV.F (LIT)

MIN

A99262

INTRODUCTION

The model 58ZAV Series 140 Furnaces are available in sizes

46,000 through 135,000 Btuh input capacities.

The design of the downflow/horizontal gas-fired furnace is

A.G.A./C.G.A. certified for natural and propane gases and for

installation on noncombustible flooring. The furnace is factoryshipped for use with natural gas. A factory accessory gas conversion kit, as listed on the furnace rating plate is required to convert

furnace for use with propane gas.

These furnaces SHALL NOT be installed directly on carpeting,

tile, or any other combustible material other than wood flooring. In

downflow installations, a factory accessory floor base, as listed on

the furnace rating plate MUST be used when installed on combustible materials and wood flooring. A factory base is not

required when this furnace is installed on manufacturer’s Coil

Assembly Part No. CD5 or CK5, or when Coil Box Part No.

KCAKC is used. This furnace is for installation in alcoves, attics,

crawlspaces, basements, closets, or utility rooms. The design of

this furnace line is not A.G.A./C.G.A. certified for installation in

mobile homes, recreation vehicles, or outdoors.

Before installing the furnace in the United States, refer to the

current edition of the NFGC and the NFPA 90B. For further

information, the NFGC and NFPA 90B are available from National Fire Protection Association Inc., Batterymarch Park,

Quincy, MA 02269; or the American Gas Association, 400 N.

Capitol St., NW, Washington DC 20001.

Before installing the furnace in Canada, refer to the current edition

→

of the NSCNGPIC. For a copy of the NSCNGPIC, contact

Standard Sales, CSA International, 178 Rexdale Boulevard, Etobicoke (Toronto), Ontario, M9W 1R3 Canada.

Installation must comply with regulations of serving gas supplier

and local building, heating, plumbing or other codes in effect in the

area in which installation is made. In absence of local building

codes, installation must conform with NFGC in the United States

and the NSCNGPIC and all authorities having jurisdiction in

Canada.

These instructions cover minimum requirements for a safe installation and conform to existing national standards and safety codes.

In some instances, these instructions exceed certain local codes

and ordinances, especially those that may not have kept pace with

changing residential construction practices. We require these

instructions as a minimum for a safe installation.

Application of this furnace should be indoors with special

attention given to vent sizing and material, gas input rate, air

temperature rise, and unit sizing. Improper installation or

misapplication of the furnace can require excessive servicing

or cause premature component failure.

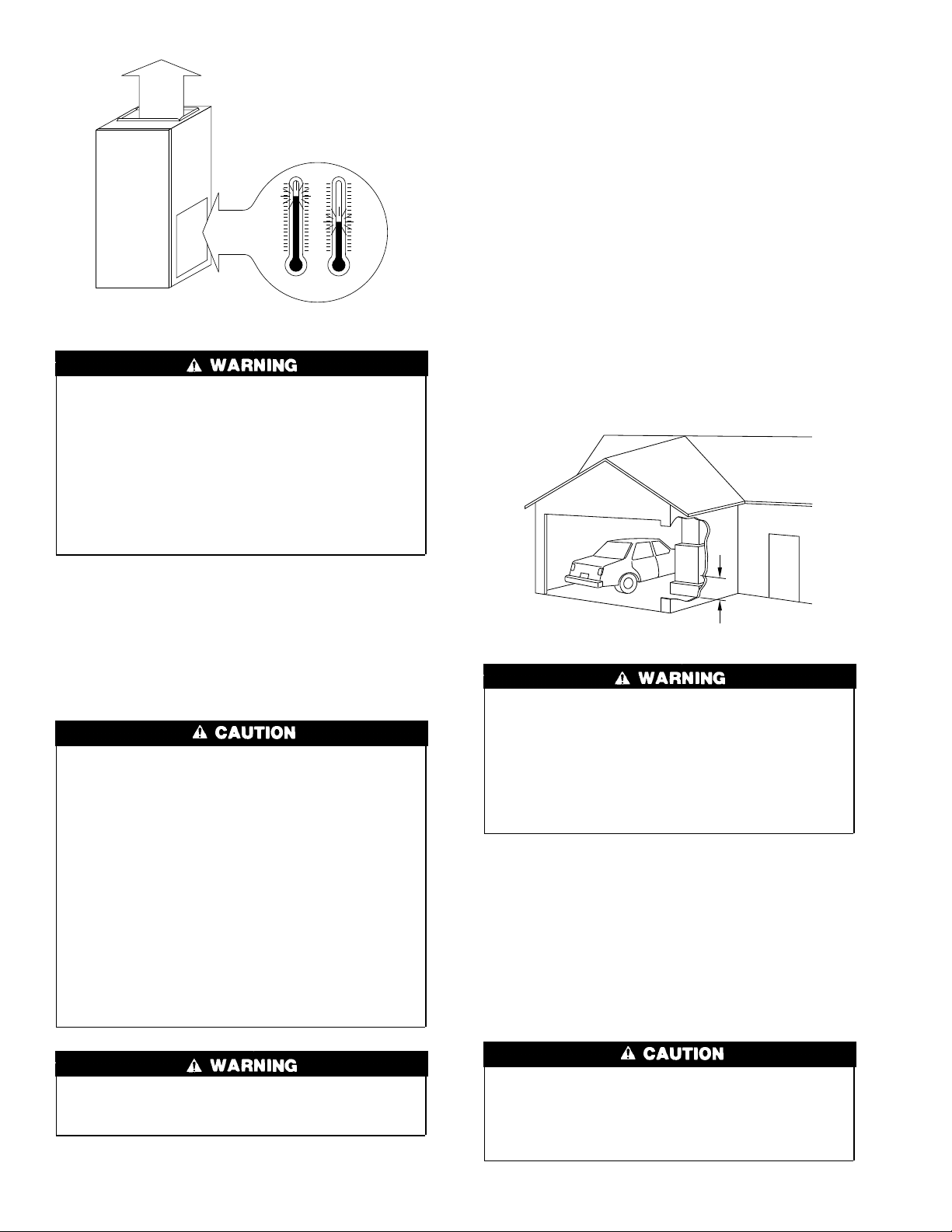

NOTE: These furnaces are designed for a minimum continuous

return-air temperature of 60°F or intermittent operation down to

55°F such as when used with a night setback thermostat. Return-air

temperature must not exceed a maximum of 85°F. Failure to

follow these return-air temperature limits may affect reliability of

heat exchangers, motors, and controls.

3

FRONT

°F °F

RETURN

AIR

MAX 85°F MIN 55°F

A93042

Improper installation, adjustment, alteration, service, maintenance, or use can cause carbon monoxide poisoning, explosion, fire, electrical shock, or other conditions which may

cause personal injury, loss of life, or property damage.

Consult a qualified installer, service agency, local gas supplier, or your distributor or branch for information or assistance. The qualified installer or agency must use only

factory-authorized and listed kits or accessories when modifying this product. Failure to follow this warning could result

in electrical shock, fire, personal injury, or death.

Locate the furnace as close to the chimney/vent and as near the

center of the air distribution system as possible. The furnace

should be installed as level as possible.

Provide ample space for servicing and cleaning. Always comply

with the minimum fire protection clearances shown on the unit

rating plate. This furnace shall not be installed directly on

carpeting, tile, or any combustible material other than wood

flooring. The furnace may be installed on combustible flooring

when installed with the accessory downflow subbase, which is

available from your distributor or branch when required.

LOCATION RELATIVE TO COOLING EQUIPMENT — The

cooling coil must be installed parallel with or on the downstream

side of the furnace to avoid condensation in the heat exchangers.

When installed parallel with a furnace, dampers or other means

used to control the flow of air must prevent chilled air from

entering the unit. If the dampers are manually operated, they must

be equipped with means to prevent operation of either unit unless

the damper is in the full-heat or full-cool position.

HAZARDOUS LOCATIONS

For accessory installation details, refer to the applicable installation literature.

NOTE: Remove all shipping brackets and materials before operating the furnace.

Step 1—Location

GENERAL

Do not install furnace in a corrosive or contaminated atmosphere. Make sure all combustion and circulating air requirements are followed, in addition to all local codes and

ordinances.

Do not use this furnace during construction when adhesives,

sealers, and/or new carpets are being installed. If the furnace

is required during construction, use clean outside air for

combustion and ventilation. Compounds of chlorine and

fluorine when burned with combustion air form acids which

cause corrosion of the heat exchangers and metal vent system.

Some of these compounds are found in paneling and dry wall

adhesives, paints, thinners, masonry cleaning materials, and

many other solvents commonly used in the construction

process.

Excessive exposure to contaminated combustion air will

result in safety and performance related problems.

18-IN. MINIMUM

TO BURNERS

A93044

When furnace is installed in a residential garage, it must be

installed so that burners and ignition sources are located a

minimum of 18 in. above floor. The furnace must be located

or protected to avoid physical damage by vehicles. When

furnace is installed in a public garage, airplane hangar, or

other building having a hazardous atmosphere, unit must be

installed in accordance with requirements of National Fire

Protection Association, Inc.

Step 2—Air For Combustion and Ventilation

Provisions for adequate combustion and ventilation air must be

provided in accordance with Section 5.3 of the NFGC, Air for

Combustion and Ventilation, or applicable provisions of the local

building codes.

Canadian installations must be installed in accordance with NSCNGPIC and all authorities having jurisdiction.

Do not install the furnace on its back; safety control operation

will be adversely affected. Failure to follow this warning

could result in fire, personal injury, or death.

This furnace must be installed so the electrical components are

protected from water.

Air for combustion must not be contaminated by halogen

compounds, which include fluoride, chloride, bromide, and

iodide. These elements are found in aerosol sprays, detergents, bleaches, cleaning solvents, salts, air fresheners, and

other household products.

4

The operation of exhaust fans, kitchen ventilation fans,

clothes dryers, or fireplaces could create a NEGATIVE

PRESSURE CONDITION at the furnace. Make-up air MUST

be provided for the ventilation devices, in addition to that

required by the furnace.

All fuel-burning equipment must be supplied with air for combustion of the fuel. Sufficient air MUST be provided to ensure there

will not be a negative pressure in the equipment room or space. In

addition, a positive seal MUST be made between the furnace

cabinet and the return-air duct to avoid pulling air from the burner

area and blocked vent safeguard opening.

The requirements for combustion and ventilation air depend upon

whether the furnace is located in an unconfined or confined space.

UNCONFINED SPACE — An unconfined space must have at

least 50 cu ft for each 1000 Btuh of input for all the appliances

(such as furnaces, clothes dryer, water heaters, etc.) in the space.

If the unconfined space is of unusually tight construction, air for

For Example:

58ZAV FURNACE

INPUT BTUH

46,000 307

69,000 460

92,000 613

115,000 767

135,000 920

MINIMUM SQ FT

WITH

7-1/2 FT CEILING

combustion and ventilation MUST come from either the outdoors

or spaces freely communicating with the outdoors. Combustion

and ventilation openings must be sized the same as for a confined

space as defined below. Return air must not be taken from the

room unless an equal or greater amount of air is supplied to the

room.

CONFINED SPACE

A confined space is defined as a space whose volume is less than

50 cu ft per 1000 Btuh of total input ratings of all appliances

installed in that space. A confined space MUST have provisions

for supplying air for combustion, ventilation, and dilution of flue

gases using 1 of the following methods. (See Fig. 3 and 4 and

Table 2.)

NOTE: In determining free area of an opening, the blocking

effect of louvers, grilles, and screens must be considered. If free

area of louver or grille design is unknown, assume that wood

louvers have a 20 percent free area and metal louvers or grilles

have a 60 percent free area. Screens, when used, must not be

smaller than 1/4-in. mesh. Louvers and grilles must be constructed

so they cannot be closed.

The size of the openings depends upon whether air comes from

outside of the structure or an unconfined space inside the structure.

1. All air from inside the structure requires 2 openings (for

structures not usually tight):

a. Each opening MUST have at least 1 sq in. of free area per

1000 Btuh of total input for all equipment within the

confined space, but not less than 100 sq in. per opening.

(See Fig. 3 and Table 2.) The minimum dimension of air

openings shall not be less than 3 in.

b. If building is constructed unusually tight, a permanent

opening directly communicating with the outdoors shall be

provided. See item 2 below.

c. If furnace is installed on a raised platform to provide a

return-air plenum, and return air is taken directly from

hallway or space adjacent to furnace, all air for combustion

must come from outdoors.

2. Air from outside the structure requires 1 of the following

methods:

a. If combustion air is taken from outdoors through 2 vertical

ducts, the openings and ducts MUST have at least 1 sq in.

of free area per 4000 Btuh of total input for all equipment

within the confined space. (See Fig. 4 and Table 2.)

b. If combustion air is taken from outdoors through 2 hori-

zontal ducts, the openings and ducts MUST have at least 1

sq in. of free area per 2000 Btuh of total input for all

equipment within the confined space. (See Fig. 4 and Table

2.)

c. If combustion air is taken from outdoors through a single

opening or duct (horizontal or vertical) commencing within

12 in. of the top of the confined space, opening and duct

MUST have at least 1 sq in. of free area per 3000 Btuh of

the total input for all equipment within the confined space

and not less than the sum of the areas of all vent connectors

in the confined space. (See Fig. 4 and Table 2.) Equipment

clearances to the structure shall be at least 1 in. from the

sides and back and 6 in. from the front of the appliances.

When ducts are used, they must be of the same cross-sectional area

as the free area of the openings to which they connect. The

minimum dimension of ducts must not be less than 3 in. (See Fig.

4.)

AIR DUCTS

Step 1—General Requirements

The duct system should be designed and sized according to

accepted national standards such as those published by: Air

Conditioning Contractors Association (ACCA), Sheet Metal and

Air Conditioning Contractors National Association (SMACNA) or

American Society of Heating, Refrigerating and Air Conditioning

Engineers (ASHRAE). Or consult factory The Air Systems Design

Guidelines reference tables available from your local distributor.

The duct system should be sized to handle the required system

design CFM at the design static pressure.

When a furnace is installed so that the supply ducts carry air to

areas outside the space containing the furnace, the return air must

also be handled by a duct(s) sealed to the furnace casing and

terminating outside the space containing the furnace.

Secure ductwork with proper fasteners for type of ductwork used.

Seal supply- and return-duct connections to furnace with code

approved tape or duct sealer.

Flexible connections should be used between ductwork and

furnace to prevent transmission of vibration. Ductwork passing

through unconditioned space should be insulated to enhance

system performance. When air conditioning is used, a vapor

barrier is recommended.

Maintain a 1-in. clearance from combustible materials to supply air

ductwork for a distance of 36 in. horizontally from the furnace. See

NFPA 90B or local code for further requirements.

Step 2—Ductwork acoustical treatment

Metal duct systems that do not have a 90 degree elbow and 10 ft

of main duct to the first branch take-off may require internal

acoustical lining. As an alternative, fibrous ductwork may be used

if constructed and installed in accordance with the latest edition of

SMACNA construction standard on fibrous glass ducts. Both

acoustical lining and fibrous ductwork shall comply with NFPA

90B as tested by UL Standard 181 for Class 1 Rigid air ducts.

5

VENT THROUGH ROOF

(CATEGORY I)

DUCTS TO

OUTDOORS

1 SQ IN.

PER 4000

BTUH

*

RETURN

AIR

INTERIOR

HEATED

SPACE

SUPPLY AIR

* Minimum opening size is 100 sq in. with

minimum dimensions of 3 in.

†

Minimum of 3 in. when type B-1 vent is used.

12″ MAX

1 SQ IN.

PER 1000

BTUH* IN DOOR

OR WALL

UNCONFINED

SPACE

6″ MIN

(FRONT)

1 SQ IN.

PER 1000

BTUH* IN DOOR

OR WALL

†

12″ MAX

A93387

Fig. 3—Confined Space: Air for Combustion and

Ventilation from an Unconfined Indoor Space

12″ MAX

1 SQ IN.

PER 2000

BTUH

*

DUCTS

TO

OUTSIDE

1 SQ IN.

PER 2000

BTUH

*

12″ MAX

SUPPLY AIR

Minimum dimensions of 3 in.

*

Use any of the following

NOTE:

combinations of openings:

A & B C & D D & E F & G

RETURN

A

B

AIR

D

VENT

THROUGH

ROOF

(CATEGORY I)

CONFINED

C

DUCT

TO

OUTDOORS

F

SPACE

G

E

12″ MAX

12″

MAX

1 SQ IN.

PER 4000

BTUH

OUTDOORS

1 SQ IN.

PER 4000

BTUH

12″

MAX

1 SQ IN.

PER 4000

BTUH

*

*

A93388

Fig. 4—Confined Space: Air for Combustion and

Ventilation from Outdoors

→Table 2—Minimum Free Area Of Combustion Air Opening

AIR FROM UNCON-

58ZAV

FURNACE

INPUT

(BTUH)

46,000 100 11.50 4 23.0 6 15.33 5

69,000 100 17.25 5 34.5 7 23.00 6

92,000 100 23.00 6 46.0 8 30.67 7

115,000 115 28.75 7 57.5 9 38.33 7

135,000 135 33.75 7 67.5 10 45.00 8

* Free area shall be equal to or greater than the sum of the areas of all vent connectors in the confined space. Opening area must be increased if other gas appliances

in the space require combustion air.

FINED INDOOR

SPACE

Free Area

of Opening

(Sq In.)

Step 3—Supply Air Connections

DOWNFLOW FURNACES

Connect supply-air duct to supply-air opening on furnace. The

supply-air duct attachment must ONLY be connected to furnace

supply/outlet or air conditioning coil casing (when used), when

installed on non-combustible material. When installed on combustible material, supply-air duct attachment must ONLY be connected to an accessory subbase or factory approved air conditioning coil casing. DO NOT cut main furnace casing to attach supply

side air duct, humidifier, or other accessories. All accessories

MUST be connected external to furnace main casing.

HORIZONTAL FURNACES

Connect supply-air duct to supply air opening on furnace. The

supply-air duct attachment must ONLY be connected to furnace

OUTDOOR AIR THROUGH

VERTICAL DUCTS

Free Area of

Opening and Duct

(Sq In.)

Round

Pipe

(In. Dia)

OUTDOOR AIR THROUGH

HORIZONTAL DUCTS

Free Area of

Opening and Duct

(Sq In.)

Round

Pipe

(In. Dia)

OUTDOOR AIR THROUGH

SINGLE DUCT

Free Area of

Opening and Duct

(Sq In.)

Round

Pipe

(In. Dia)

supply/outlet or air conditioning coil casing (when used). DO NOT

cut main furnace casing to attach supply side air duct, humidifier,

or other accessories. All accessories MUST be connected external

to furnace main casing.

Step 4—Return Air Connections

Do not install the furnace on its back or sides. Safety control

operation will be adversely affected. Never connect return-air

ducts to the back of the furnace. A failure to follow this

warning can cause a fire, personal injury, or death.

The return-air duct must be connected to return-air opening

provided as shown in Fig. 1. DO NOT cut into casing sides or back

6

Loading...

Loading...