Page 1

HEATING & COOLING

© .

Variable-Speed Gas-Fired Condensing Furnaces

Service and Maintenance Instructions

For Sizes 060-100, Series 100

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Installing and servicing heating equipment can be hazardous

due to gas and electrical components. Only trained and qualified

personnel should install, repair, or service heating equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacing air filters. All other operations must

be performed by trained service personnel. When working on

heating equipment, observe precautions in the literature, tags, and

labels attached to or shipped with the unit and other safety

precautions that may apply.

Follow all safety codes, including NFPA 54/ANSI Z223.1-1988,

National Fuel Gas Code. Wear safety glasses and work gloves.

Have a fire extinguisher available during start-up and adjustment

procedures and service calls.

Recognize safety information. This is the safety-alert symbol ^ .

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal word —DANGER, WARNING, or CAU

TION. These words are used with the safety-alert symbol. DAN

GER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards that could

result in personal injury or death. CAUTION is used to identify

unsafe practices, which would result in minor personal injury or

product and property damage.

Fig. 1—Model 58VUA Upflow Furnace

58VCA

58VUA

A91128

A WARNING

Never store anything on, near, or in contact with the furnace,

such as:

1. Spray or aerosol cans, rags, brooms, dust mops, vacuum

cleaners, or other cleaning tools.

2. Soap powders, bleaches, waxes or other cleaning com

pounds, plastic or plastic containers, gasoline, kerosene,

cigarette lighter fluid, dry cleaning fluids, or other volatile

fluids.

3. Paint thinners and other painting compounds, paper bags or

other paper products.

Failure to follow this warning can cause corrosion of the heat

exchanger, fire, personal injury, or death.

CARE AND MAINTENANCE

For continuing high performance and to minimize possible equip

ment failure, it is essential that maintenance be performed annually

on this equipment. Consult your local dealer for maintenance and

the availability of a maintenance contract.

Fig. 2—Model 58VCA Downflow Furnace

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book 1 4

Tab 6a 8a

PC 101 Catalog No. 565-997

Printed in U.S.A. Form 58V-1SM

Pg1

О

6-92

A92095

Replaces: 58SXB-1SM

Page 2

A WARNING

The ability to properly perform maintenance on this equip

ment requires certain expertise, mechanical skills, tools, and

equipment. If you do not possess these, do not attempt to

perform any maintenance on this equipment other than those

procedures recommended in the User’s Manual. FAILURE

TO FOLLOW THIS WARNING COULD RESULT IN

POSSIBLE DAMAGE TO THIS EQUIPMENT, SERIOUS

PERSONAL INJURY, OR DEATH.

A WARNING

Turn OFF the gas and electrical supplies to the unit before

performing any maintenance or service. Follow the operating

instructions on the label attached to the furnace. Failure to

follow this warning could result in personal injury.

INSTALLATION

-POSITION

OF FILTERS

The minimum maintenance that should be performed on this

equipment is as follows:

1. Check and clean or replace air filter each month or as required.

2. Check blower motor and wheel for cleanliness and lubrication

each heating and cooling season. Clean and lubricate as

necessary. (See Step 2.)

3. Check electrical connections for tightness, and controls for

proper operation each heating season. Service as necessary.

4. Check for proper condensate drainage; clean as necessary.

5. Check for blockages of combustion-air and vent pipes.

A CAUTION

As with any mechanical equipment, personal injury could

result from sharp metal edges, etc. Be careful when removing

parts.

Step 1—Air Filter Cleaning and Replacement

The air filter arrangement may vary depending on the application.

A CAUTION

Never operate unit without a filter or with filter access door

removed. Failure to follow this warning could result in a fire

or personal injury.

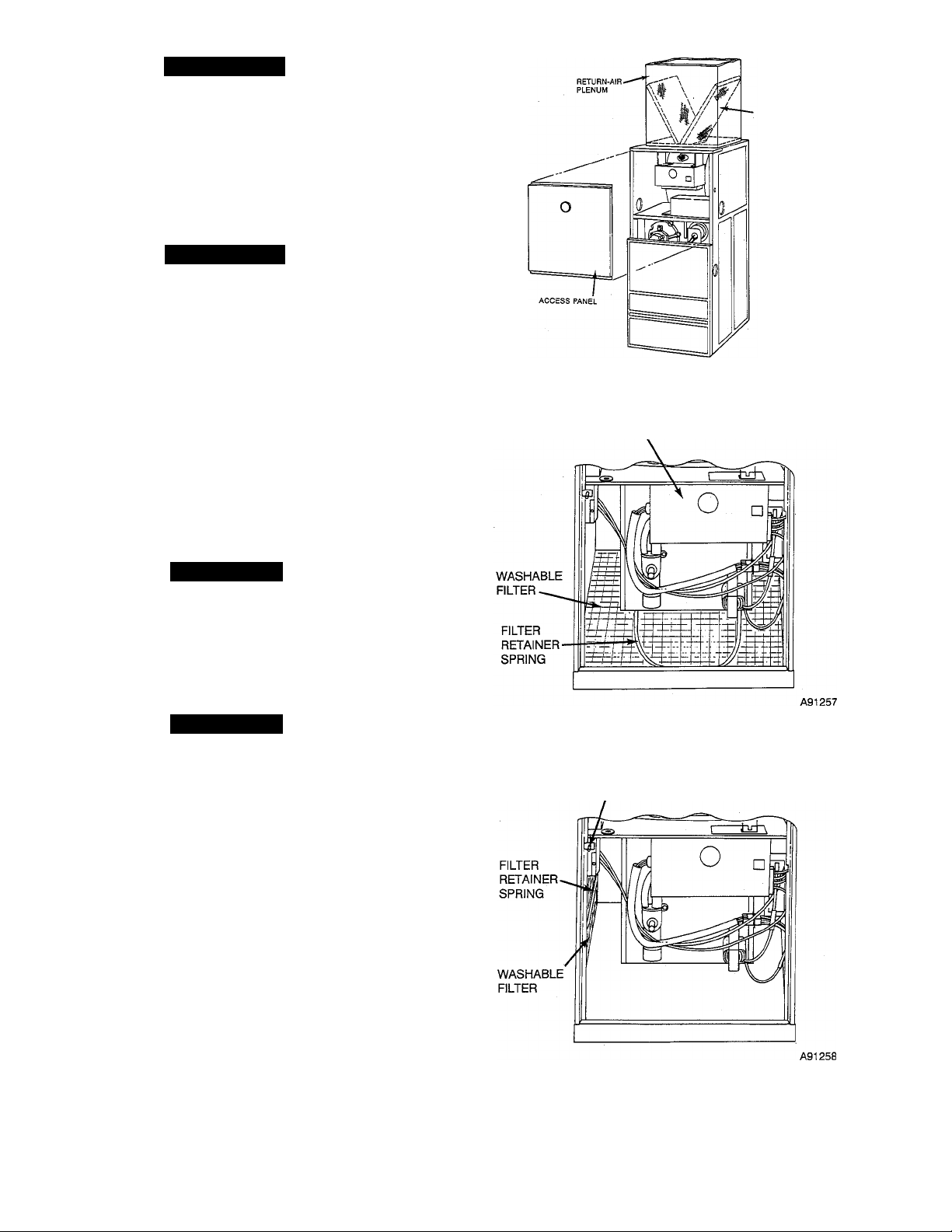

DOWNFLOW FURNACES ONLY - Each furnace accommo

dates 2 filters which are installed in the return-air duct. (See Fig.

3.) To clean or replace the filters, proceed as follows:

1. Turn OFF electrical supply to unit.

2. Remove blower access door.

3. Reaching up behind top plate, tilt filters toward center of

return-air plenum, remove filters, and replace or clean as

needed.

4. Furnaces are equipped with permanent, washable filters. Clean

these filters by spraying cold tap water through filter in

opposite direction of airflow.

5. Rinse filters and let dry. Oiling or coating of filters is not

recommended.

6. Reinstall filters with cross-mesh binding facing blower.

7. Replace access door.

8. Turn ON electrical supply to furnace.

UPFLOW FURNACES ONLY — To clean or replace the air

filter, proceed as follows:

1. Turn OFF electrical supply to unit.

A92117

Fig. 3—Position of Filters in Downflow Furnace

CONTROL

BOX

Fig. 4—Filter Installed for Bottom Inlet

AUX J-BOX

& BLOWER

DOOR SWITCH

Fig. 5—Filter Installed for Side Inlet

2. Remove access doors.

3. Release filter retainer spring from behind flange of furnace

casing. (See Fig. 4 and 5.)

4. Slide filter out.

WA

Page 3

5. Furnaces are equipped with permanent, washable filters. Clean

filter by spraying cold tap water through filter in opposite

direction of airflow.

6. Rinse filter and let dry. Oiling or coating of filter is not

recommended.

7. Place filter in furnace with cross-mesh binding either up or

facing blower.

8. Replace access doors.

9. Turn ON electrical supply to furnace.

Step 2—Blower Motor and Wheel Maintenance

For long life, economy, and high efficiency, clean accumulated dirt

and grease from blower wheel and motor annually.

The following items should be performed by a qualified service

technician:

Some motors have prelubricated, sealed bearings and require no

lubrication. These motors can be identified by the absence of oil

ports on each end of the motor. For motors with oil ports, lubricate

as follows:

Lubricate motor every 5 years if motor is used for intermittent

operation (thermostat FAN switch in AUTO position), or every 2

years if motor is in continuous operation (thermostat FAN switch

in ON position).

Clean and lubricate as follows:

1. Turn OFF electrical supply to unit.

2. Remove access doors.

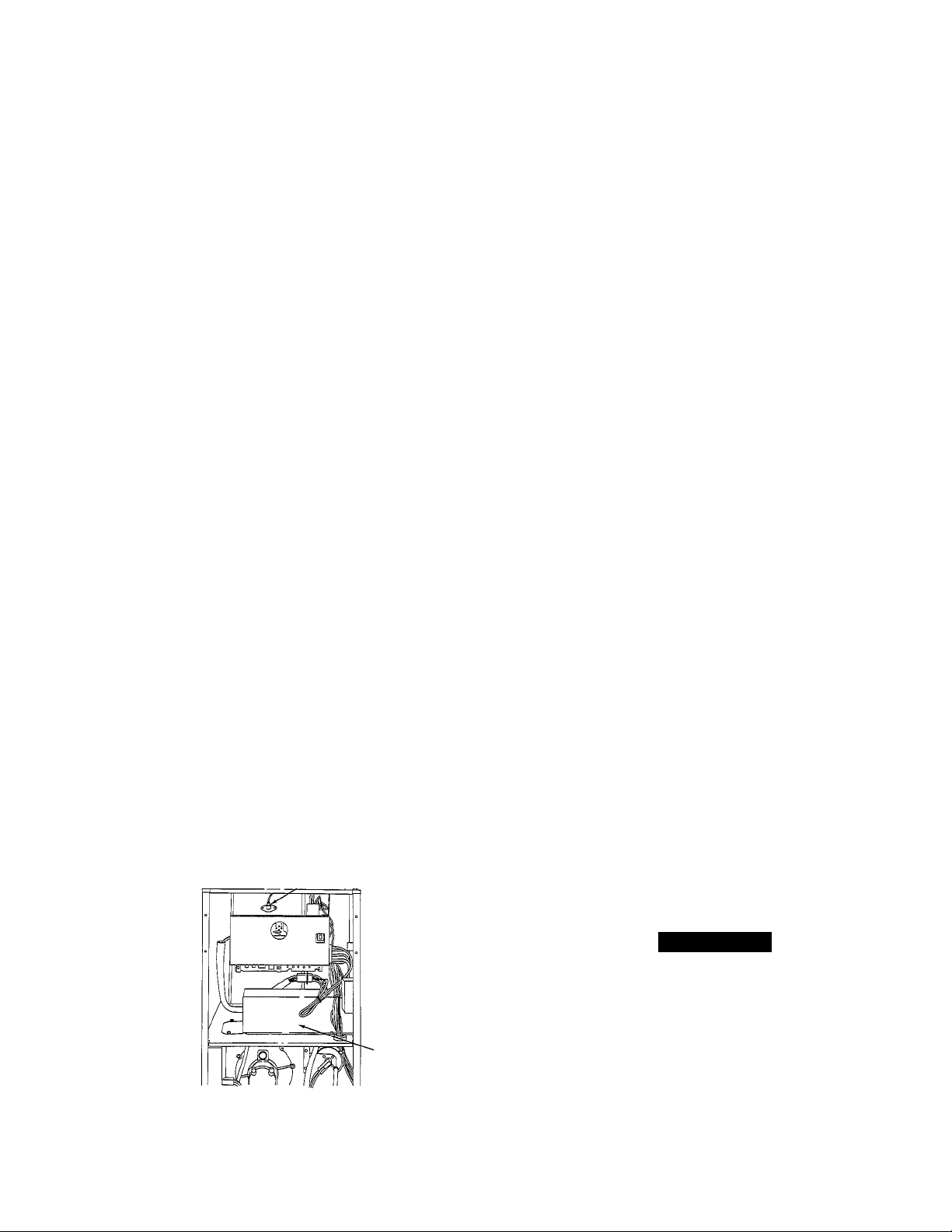

3. Upflow furnaces only —remove drain trap and control box:

a. Remove control box from bottom side of blower shelf and

position to 1 side.

b. Disconnect 9-circuit connector PL-13 from blower hous

ing.

c. Using backup wrench, disconnect drain pipe at coupling in

blower compartment.

d. Loosen hose clamp and remove 7/8-in. diameter drain hose

from drain trap.

e. Loosen hose clamp and disconnect 5/8-in. diameter drain

hose at bottom of inducer housing located under blower

shelf.

f. Remove screw securing drain trap assembly.

4. Downflow furnaces only — disconnect vent pipe, elbow, and

auxiliary limit switch. (See Fig. 6.)

a. Remove control box from top plate and position to 1 side.

AUXILIARY

UMIT

.SWITCH

c. Disconnect wires from auxiliary limit on blower housing.

d. Remove vent pipe enclosure from top side of blower shelf

and position to 1 side.

e. Loosen hose clamps on outlet elbow and remove elbow.

f. Loosen hose clamp on extension pipe outside of furnace

and remove pipe.

5. Remove screws securing blower assembly to blower shelf and

slide blower assembly out of furnace.

6. Squeeze side tabs of connector PL-13 and pull from blower

housing bracket.

7. Mark blower wheel location on shaft before disassembly to

insure proper reassembly.

8. Loosen setscrew holding blower wheel on motor shaft.

NOTE: Mark blower mounting arms and blower housing so each

arm is positioned at the same hole location during reassembly. This

will insure that oilers point up. ■

9. Remove bolts holding motor mount to blower housing and

slide motor and mounts out of housing.

10. Lubricate motor (when oil ports are provided).

a. Remove dust caps or plugs from oil ports located at each

end of motor. If motor does not have these caps or plugs,

bearings are sealed and need no further lubrication.

b. Use a good grade of SAE 20 nondetergent motor oil and

add 1 teaspoon (5 cc, 3/16 oz, or 16 to 25 drops) in each oil

port. The use of other types or grades of oil will damage the

motor. Excessive oiling can cause premature bearing fail

ures.

c. Allow time for total quantity of oil to be absorbed by each

bearing.

d. After oiling motor, wipe excess oil from motor housing.

e. Replace dust caps or plugs on oil ports.

11. Remove blower wheel from housing:

a. Mark blower wheel orientation and cutoff plate location to

insure proper reassembly.

b. Remove screws securing cutoff plate and remove cutoff

plate from housing.

c. Remove blower wheel from housing.

12. Clean blower wheel and motor using a vacuum with soft brush

attachment. Be careful not to disturb balance weights (clips)

on blower wheel vanes. Do not drop or bend wheel, as balance

will be affected.

13. Reassemble blower by reversing items ll.a. through ll.c.

Ensure wheel is positioned for proper rotation.

14. Reassemble motor and blower by reversing items 6 through 9.

If motor has ground wire, be sure it is reconnected.

Fig. 6—Downflow Furnace Blower Compartment

b. Disconnect 9-circuit connector PL-13 from blower hous

ing.

A92118

A CAUTION

Ensure the motor is properly positioned in the blower

housing. The motor oil ports must be at a minimum of 30°

above the horizontal centerline of the motor after the blower

assembly has been reinstalled in the furnace.

15. Reinstall blower assembly in furnace.

16. Upflow furnaces only — reinstall drain trap and control box:

a. Inspect drain trap and hoses to ensure they are not blocked

or restricted. Reinstall drain trap and hoses. Be sure to

tighten hose clamps.

b. Using backup wrench, attach drain pipe and tighten com

pression coupling.

Page 4

c. Reinstall control box on bottom side of blower shelf.

17. Downflow furnace only — reconnect vent pipe, elbow, and

auxiliary limit switch.

a. Reinstall outlet elbow and extension pipe. Be sure connec

tions are tight and leak proof.

b. Reinstall vent pipe enclosure.

c. Reconnect red wires to auxiliary limit switch.

d. Reinstall control box on top plate.

18. Connect 9-circuit connector PL-13 to blower harness. Note

that connections are polarized for correct assembly — do not

force.

19. Turn ON electrical supply and check for proper rotation and

speed changes between low- and high-heat and cooling.

Operate unit 10 minutes and carefully check for condensate

leaks.

Step 3—Cleaning Heat Exchangers

The following items should be performed by a qualified service

technician:

If it becomes necessary to clean the heat exchanger because of

carbon deposits, soot, etc., proceed as follows:

NOTE: Deposits of soot and carbon indicate a problem exists that

needs to be corrected. Action must be taken to correct the problem.

1. Turn OFF gas and electrical supplies to furnace.

2. Remove control and blower access doors.

3. Loosen hose clamps on combustion-air pipe and move air pipe

aside.

4. Using backup wrench, disconnect gas supply at ground joint

union. Remove gas pipe from valve.

5. Disconnect pilot leads at 3-circuit connector outside of burner

enclosure.

6. Disconnect high-voltage lead at spark generator.

7. Disconnect gas valve leads at 6-circuit connector on top of

valve.

8. Disconnect pressure tubing from right side of burner enclosure

and outlet end of gas valve.

9. Remove burner enclosure front.

10. Remove diffuser from inside top of burner enclosure. Remove

screws that secure burner enclosure to cell panel. These

screws are located Inside the burner enclosure.

11. Using care not to damage cell inlet panel gasket, remove gas

control assembly from furnace.

12. Remove vent pipe and drain.

a. Upflow furnace only:

(1.) Loosen hose clamps at vent pipe connection; discon

nect vent pipe and position to 1 side.

(2.) Loosen hose clamp and remove drain tube from

inducer outlet box.

b. Downflow furnace only:

(1.) Remove vent pipe enclosure.

(2.) Loosen hose clamps at vent pipe connection.

(3.) Loosen hose clamp and remove drain tube from

inducer outlet elbow.

13. Upflow furnace only —remove main control box.

a. Disconnect 15-circuit connector from main control box at

blower shelf.

b. Remove screws securing main control box to blower shelf

and position control box to 1 side.

14. Loosen hose clamp and remove drain tube from inducer

housing.

15. Disconnect both 6-circuit connectors from electronically com

mutated motor (ECM) inducer controller mounted on left side

of furnace.

16. Remove screws securing ECM inducer controller to mounting

plate attached to left side of furnace.

17. Disconnect 6-circuit connector from pressure switches.

18. Remove mounting screws securing inducer assembly to col

lector box and coupling box; remove inducer assembly and

remove all old sealant from parts.

19. Remove coupling box(es).

a. Upflow furnace only:

(1.) Remove screws securing coupling box and remove

from furnace. Remove all old sealant from parts.

b. Downflow furnace only:

(1.) Remove screws securing intake (upper) coupling box

and remove box from furnace. Remove all old sealant

from parts.

(2.) Remove screws securing primary (lower) coupling

box and remove box. Clean old sealant from parts.

20. Loosen hose clamp and remove 7/8-in. drain tube from trap.

21. Place bucket under 7/8-in. drain tube.

22. Using garden hose, flush each cell of the condensing heat

exchanger with water. Use care not to spray water onto

interior surfaces of control compartment. Dry all surfaces. Be

careful not to remove sealant around cell openings in cell

panel.

23. Using field-provided small wire brush, steel spring cable,

reversible electric drill, and vacuum cleaner, clean primary

heat exchanger cells. Do not use wire brush or other sharp

object to clean condensing heat exchanger. Failure of the

condensing heat exchanger will occur—flush with water only.

a. Assemble wire brush and steel spring cable.

(1.) Use 4 ft of 1/4-in. diameter high-grade steel spring

cable (commonly known as drain cleaning or Roto-

Rooter cable).

(2.) Use 1/4-in. diameter wire brush (commonly known as

25-caliber rifle cleaning brush).

NOTE: The materials required above can be purchased at local

hardware stores.

(3.) Insert twisted wire end of brush into end of spring

cable, and crimp tight with crimping tool or strike with

ball-peen hammer. Tightness is very important.

(4.) Remove metal screw fitting from wire brush to allow

insertion into cable.

b. Clean each primary heat exchanger cell:

(1.) Attach variable-speed, reversible drill to end of spring

cable (end opposite brush).

(2.) Insert brush end of cable into upper opening of cell

and slowly rotate with drill. Do not force cable.

Gradually insert at least 3 ft of cable into 2 upper

passes of cell. (See Fig. 7.)

(3.) Work cable in and out of cell 3 or 4 times to obtain

sufficient cleaning. Do not pull cable with great force.

Reverse drill and gradually work cable out.

(4.) Insert brush end of cable in lower opening of cell, and

proceed to clean 2 lower passes of cell in same manner

as 2 upper passes.

Page 5

A88489

Fig. 7—Cleaning Primary Heat Exchanger Cell

(5.) Repeat procedures (previous) until each furnace cell has

been cleaned.

(6.) Using vacuum cleaner, remove residue from each cell.

(7.) Using vacuum cleaner with soft brush attachment,

clean burner assembly.

Step 4—Reassemble Furnace (After Cleaning Heat Ex

changers)

1. Reinstall coupling box(es):

c. Apply sealant releasing agent (Pam) to coupling box flange

and cell panel where coupling box flange matches. (See

Fig. 8.)

APPLY RELEASE AGENT TO AREA

INDICATED BY SHADING

d. Install inducer assembly on collector box and support

bracket to coupling box.

e. Connect 6-circuit inducer motor connector to inducer

controller. Reconnect 6-circuit connector from pressure

switches to main harness. (See Fig. 18.)

f. Reconnect pressure tubes to pressure switch. (See Fig. 10 or

11.)

3. Connect small drain tube from top of trap to fitting on bottom

of inducer housing. (See Fig. 10 or 11.)

4. Connect 7/8-in. drain tube to trap and collector box; tighten

hose clamps. (See Fig. 10 or 11.)

COUPLING BOX

(INSIDE VIEW)

Fig. 8—Inside View of Coupling Box

d. Apply a generous bead (3/16-in. diameter) of G.E. RTV

122, 162, or Dow-Corning RTV 738 sealant (NO substi

tute is permissible) to flange of coupling box. (See Fig. 8.)

Your distributor/dealer should have G.E. RTV 122, 162, or

Dow-Corning RTV 738 sealants in stock.

e. Being careful not to smear sealant, position coupling box so

that slot in insulation is on left side and install coupling

box.

2. Reinstall inducer assembly.

a. Upflow furnace only —Be sure small round gasket(s) is in

place between blower shelf and inducer housing.

b. Apply sealant releasing agent (Pam) to collector box.

c. Apply 1/8-in. diameter bead of G.E. RTV 122, 162, or

Dow-Corning RTV 738 sealant to back of inducer housing.

Apply sealant around inlet air opening. (The sealant should

be about 1/4 in. from the edge of the inlet air opening.) (See

Fig. 9.)

Fig. 9—Back of Inducer Assembly Housing

A87318

Fig. 10—Upflow Furnace Pressure and Drain

Tubing Diagram

5. Reinstall vent pipe and drain tube,

a. Upflow furnace only;

(1.) Reconnect vent pipe. Be sure clamps are tight.

Page 6

13. Reconnect pressure tubes to gas valve and burner enclosure.

Be sure tubes are not kinked.

14. Using a backup wrench, install gas pipe in gas valve.

15. Reconnect gas pipe at ground joint union.

16. Reconnect combustion-air pipe. Tighten hose clamps.

17. Replace blower door only.

18. Turn ON gas and electrical supplies.

19. Check furnace operation through 2 complete operating cycles.

Lxjok through sight-glass in burner enclosure to check burners.

Burner flames should be clear blue, almost transparent. (See

Fig. 13.) p||_Q.^ flame burner flame

Fig. 11—Downflow Furnace Pressure and Drain

Tubing Diagram

(2.) Connect drain tube from collector box to inducer

outlet box.

b. Downflow furnace only:

(1.) Reconnect vent pipe. Be sure clamps are tight.

(2.) Reinstall vent pipe enclosure.

(3.) Connect drain tube from collector box to inducer

outlet elbow.

6. Upflow furnace only—reinstall main control box.

a. Reinstall main control box on blower shelf.

b. Reconnect 15-circuit connector at main control box on

blower shelf.

7. Check condition of gasket on cell inlet panel of burner

enclosure. Replace gasket if necessary. (See Fig. 12.)

Fig. 12—Burner Enclosure

8. Install gas control assembly in furnace.

9. Install diffuser and burner enclosure front.

10. Reconnect pilot leads at 3-circuit connector.

11. Reconnect high-voltage lead to spark generator.

12. Reconnect gas valve leads at 6-circuit connector.

A87301

A WARNING

Never use matches, candles, flame, or other sources of

ignition to check for gas leakage. Use a soap-and-water

solution. Failure to follow this warning could result in a fire,

personal injury, or death.

20. Check for gas leaks.

21. After condensate starts to drain, check for condensate leaks.

22. Replace control door.

Step 5—Clean Condensate Drainage System

1. Disconnect 5/8-in. drain tube from bottom of inducer housing.

(See Fig. 10 or 11.)

2. Disconnect 7/8-in. drain tube from collector box. (See Fig. 10

or 11.)

3. Disconnect condensate drain line from drain trap at compres

sion fitting.

4. Remove 1/4-in. screw(s) securing strap on drain trap.

5. Remove drain trap/hose assembly from furnace and flush with

water until clean.

6. Flush external condensate drain line with water until clean.

7. Reassemble condensate drainage system by reversing items 1.

through 5.

Step 6—Pilot Assembly

Check the pilot assembly and clean if necessary at the beginning of

each heating season. The pilot flame should be high enough for

proper impingement of the safety element and to light the burners.

Remove any accumulation of soot and carbon from the safety

element. Check spark electrode gap. (See Fig. 14 for proper spark

gap and Fig. 15 for correct pilot location.)

Step 7—Electrical Controls and Wiring

NOTE: There may be more than 1 electrical supply to the unit.

Page 7

Fig. 14—Position of Electrode to Pilot

(4.) Plug receiver into different outlet so that equipment

and receiver are on different branch circuits.

(5.) Slide Ferrite core electrical noise suppressor over

thermostat wire.

If necessary, the user should consult the dealer or an experienced

radio/television technician for additional suggestions. The follow

ing booklet prepared by the FCC may be helpful: “How to Identify

and Resolve Radio-TV Interference Problems.” This booklet is

available from the U.S. Government Printing Office, Washington,

DC 20402, Stock No. 004-000-00345-4.

SERVICE DIAGNOSTICS — This furnace has a light emitting

diode (LED) display to aid the installer, homeowner, or service

technician in installing or servicing the unit. (See Fig. 17.) The

display can be seen through the view port provided in the blower

door. To decipher the meaning of the display, refer to Fig. 17 or the

fault code label inside the control access door.

A79080

With power disconnected to the unit, check all electrical connec

tions for tightness. Tighten all screws on electrical connections. If

any smokey or burned connections are found, disassemble the

connection, clean all parts, strip wire, and reassemble properly and

securely.

Reconnect electrical power to the unit and observe unit through 1

complete operating cycle. Electrical controls are difficult to check

without proper instrumentation.

ELECTRICAL NOISE AND INTERFERENCE - This equip

ment generates and uses radio frequency energy and, if not

installed and used properly (in strict accordance with the manu

facturer’s instructions), may cause interference with radio and

television reception. The unit has been tested and found to comply

with the limits for a Class B computing device in accordance with

the specifications in Subpart J of Part 15 of Federal Communica

tions Commission (FCC) Rules, which are designed to provide

reasonable protection against such interference in a residential

installation. However, there is no guarantee that interference will

not occur in an installation. If this equipment does cause interfer

ence to radio or television reception (which may be determined by

turning the equipment off and on), the user is encouraged to try

correcting the interference by 1 or more of the following measures:

(1.) Reorient receiving antenna.

(2.) Relocate receiver with respect to equipment.

(3.) Move receiver away from equipment.

SETUP SWITCHES

BLOWER OFF DELAY COOLING AIRFLOW

ADJUSTMENT ADJUSTMENT

24V TERMINALS

A92099

Fig. 16—Microprocessor Control Center

View the display through the port provided in the blower door. If

YEL LED 3 is lit continuously, the furnace is operating in the

high-heat mode. If GRN LED 4 is lit continuously, the furnace is

operating in the low-heat mode. If the lower RED LED 1 is lit

continuously, the furnace is operating in the emergency-heat

mode. If the upper RED LED 2 is lit continuously, the micropro

cessor has malfunctioned.

DO NOT REMOVE THE BLOWER DOOR IF LED’s ARE

FLASHING; the fault code will be lost.

Alternate flashing of the YEL and GRN LED’s indicates that a

fault has occurred during operation. Count the number of times the

YEL LED flashes and then count the number of times the GRN

LED flashes. Once the fault code has been determined, refer to

Table 1 or the fault code label inside the control access door to

decipher the meaning of the display.

RED LED 2

MALFUNCTION

O

o

RED LED 1

EMER HT

COUNT THE

NO. OF ^

FLASHES '

I

(4)

Fig. 17—Fault Code LED’s

COUNT THE

NO. OF

FLASHES

I

■ = 42 FAULT

INDUCER OUTSIDE

VALID SPEED

RANGE

A87348

Page 8

When power is turned ON at the main disconnect, a microproces

sor self-test sequence will be completed in approximately 20 sec.

During this period the GRN LED will light for 12 sec, followed by

lighting of the YEL and GRN LED’s for 1 sec. After this period,

the unit will operate if a thermostat signal is initiated.

Table 1—Fault Code Descriptions

CODE

11

12

13 High limit lockout

14

DESCRIPTION

No faults in history display

Blower calibration lockout

Pilot proving lockout

21 Invalid model selection

22 Set-up error

23 Cooling capacity error

24

31

32 Low-pressure switch fault

33

34

41

42 Inducer outside valid speed range

43 Rpm ratio out of range

44

Fault Code Descriptions:

Code 11 — No fault in recent history display.

Indicates no faults have occurred within last 5 cycles.

To read recent fault history, put setup switch SW-1 in the ON

position.

To clear recent fault history, put setup switch SW-1 in the ON

position and jumper R, W, and Y simultaneously until a code 11 is

flashed.

Return setup switch SW-1 to the OFF position when complete.

Code 12 —Blower calibration lockout.

Indicates rpm calculated for low heat is less than 300 rpm or

greater than 1300 rpm on 2 successive attempts.

Check the following before referring to the trouble-shooting guide;

1. Excessive high- or low-static pressure could be caused by

dirty filters or undersized ductwork.

Code 13 —High-limit lockout.

Indicates the occurrence of 10 successive limit trips during high

fire or 3 successive limit trips during low fire.

Check the following before referring to the trouble-shooting guide:

1. Improper or misaligned limit and/or limit shield.

2. Improper high- or low-gas input adjustment.

3. Stuck high-fire solenoid in gas valve.

Code 14—Pilot-proving lockout.

Indicates pilot failed to prove in 5 minutes on 2 successive cycles.

It can also indicate the pilot was proven at the start of 2 successive

cycles.

Check the following before referring to the trouble-shooting guide:

1. Gas valve is turned OFF.

2. Main shutoff valve is turned OFF.

3. Wet pilot.

4. Restricted pilot orifice.

5. Open pilot circuit.

6. No spark at pilot.

7. Stuck pilot solenoid in gas valve.

Illegal thermostat input

High-pressure switch fault

High limit fault

Pilot proving fault

Blower outside valid speed range

Blower calibration fault

Code 21 — Invalid model selection.

Indicates personality connector is missing or incorrect.

See wiring diagram for correct connector jumper location.

Code 22 —Setup error.

Indicates setup switch SW-1, SW-2, or SW-3 is positioned

improperly.

The following combinations will cause the fault:

1. Thermostat call with SW-1 ON.

2. SW-2 and SW-3 ON together.

3. SW-1 and SW-2 ON together.

4. SW-1 and SW-3 ON together.

5. SW-1, SW-2, and SW-3 ON together.

Code 23 — Cooling capacity error.

Indicates improper A/C switch setting.

The 060-size furnace can deliver 1-1/2 to 3 tons of cooling airflow.

The 080-size furnace can deliver 1-1/2 to 3-1/2 tons of cooling

airflow. The 100-size furnace can deliver 2 to 5 tons of cooling

airflow.

If fault is flashing, unit will operate, but it will default to the

closest allowable airflow.

Code 24 — Illegal thermostat input.

Indicates thermostat terminals Y and W are both energized; unit

will default to cooling operation.

Code 31 —High-pressure switch fault.

Indicates high-pressure switch is closed at “call for heat,” is

closed in low-fire operation, fails to close after “call for heat,” or

opens in high-fire operation.

Check the following before referring to the trouble-shooting guide:

1. Plugged condensate drain.

2. Water in vent piping (possibly sagging piping).

3. Pressure switch wiring or tubing connections incorrect.

4. Failed or out-of-calibration pressure switches.

5. Pilot flame adjustment.

6. Failed or out-of-calibration pilot.

Code 32 — Low-pressure switch fault.

Indicates low-pressure switch is closed at “call for heat,” fails to

close after “call for heat,” or opens during operation.

Check the following before referring to the trouble-shooting guide;

1. Plugged condensate drain.

2. Water in vent piping (possibly sagging piping).

3. Pressure switch wiring or tubing connections inconect.

4. Failed or out-of-calibration pressure switches.

Code 33 — High-limit fault.

Indicates the high limit is open or the unit is operating in high- heat

only mode due to 2 successive low-fire limit trips.

Check the following before referring to the trouble-shooting guide;

1. Improper or misaligned limit and/or limit shield.

2. Improper low-gas input adjustment.

3. Stuck high-fire solenoid in gas valve.

Code 34—Pilot-proving fault.

Indicates pilot failed to prove within 5 minutes, the pilot opened

during the cycle, or the pilot was proven at the start of the cycle.

If this fault does not progress to a fault code 14, check the

following. Otherwise, refer to fault code 14:

Page 9

1. Combustion box diffuser plate missing or backwards.

2. Pilot flame adjustment.

3. Recirculation of combustion products at vent termination.

Code 41 —Blower outside valid speed range.

Indicates blower is not operating at the calculated or default rpm.

If this fault occurs in conjunction with fault code 44, check wiring

to motor—otherwise refer to the troubleshooting guide.

If this fault occurs by itself, check torque taps on motor. Normal

settings are White on pin-1, Black on pin-10, and Red on pin-11

unless used with a variable-speed cooling system.

Code 42—Inducer outside valid speed range.

Indicates inducer is not operating at the calculated rpm or has not

started within 10 sec after a “call for heat.”

Check the following before referring to the troubleshooting guide:

1. Continuous pilot spark.

2. High-tension lead too close to wiring harness.

Code 43 — Inducer rpm ratio outside valid range.

Indicates the low- and high-pressure switch “make” points during

purge are not within the calibration range.

Check the following before referring to the troubleshooting guide:

1. Plugged condensate drain.

2. Water in vent piping (possibly sagging piping).

3. Pressure switch wiring or tubing connections.

4. Failed or out-of-calibration pressure switches.

Code 44 —Blower calibration fault.

Indicates calculated blower speed is below 300 or above 1300 rpm.

Unit will default to either mode if possible.

If this fault occurs in conjunction with fault 41, check wiring to

motor. Otherwise, refer to troubleshooting guide.

If this fault occurs by itself, check for excessive static pressure

caused by dirty filters or undersized ductwork.

Using these fault codes, the owner may save the expense of a

service call by following the procedures provided in the User’s

Manual. A service technician can follow the steps furnished in the

appropriate section of the trouble-shooting guide when correcting

the problem.

NOTE: If the fault history is not cleared during servicing, the

microprocessor will clear it internally after 5 heating cycles have

been successfully completed without the fault occurring. This is

done to prevent the storage of useless fault codes in the service

history.

Step 8—Winterizing

A CAUTION

The unit must not be installed, operated, and then turned off

and left off in an unoccupied structure during cold weather

when the temperature drops to 32° F and below. Freezing

condensate left in the furnace will damage the equipment.

If the furnace will be off for an extended period of time in a

structure where the temperature will drop to 32° F or below,

winterize as follows:

1. Mix a solution of equal amounts of ethylene glycol (Prestone

II antifreeze/coolant or equivalent) and water.

2. Turn OFF electrical supply to furnace.

3. Remove control access door.

4. Disconnect drain tube from bottom of inducer outlet box/elbow.

5. Insert funnel in drain tube and pour antifreeze/water solution

into furnace until it is visible at point where condensate enters

open drain.

6. Reconnect drain tube to outlet box.

7. Replace control access door.

Page 10

Copyright 1992 CARRIER Corp. • 7310 W. Morris St. • Indianapolis, IN 46231

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book! 1 I 4 PC 101 Catalog No. 565-997 Printed in U.S.A. Form 58V-1SM Pg 10 6-92 Replaces: 58SXB-1SM

Tab |6a|8a

15055

Loading...

Loading...