Carrier 58STX09010016, 58STX11010012, 58STX09010014, 58STX07010012, 58STX07010016 Installation Guide

...

Installation, Start-up, Operating and

Service and Maintenance Instructions

SAFETY CONSIDERATIONS ........................ 2

INTRODUCTION .................................. 3

CODES AND STANDARDS .......................... 4

Safety ......................................... 4

General Installation ............................... 4

Combustion and Ventilation Air ..................... 4

Duct Systems ................................... 5

Acoustical Lining and Fibrous Glass Duct ............. 5

Gas Piping and Gas Pipe Pressure Testing ............. 5

Electrical Connections ............................ 5

Venting ........................................ 5

LOCATION ....................................... 5

AIR FOR COMBUSTION AND VENTILATION ......... 7

INSTALLATION .................................. 10

Bottom Return Air Inlet .......................... 10

Side Return Air Inlet ............................. 10

Leveling Legs (If Desired) ........................ 11

Bottom Return Air Inlet .......................... 12

Suspended Furnace Support ....................... 12

Platform Furnace Support ......................... 12

Roll-Out Protection ............................. 12

Bottom Return Air Inlet .......................... 12

Side Return Air Inlet ............................. 12

General Requirements ............................ 13

Ductwork Acoustical Treatment .................... 13

Supply Air Connections .......................... 13

Return Air Connections .......................... 19

115-V Wiring .................................. 21

J-box Relocation ............................... 21

Electrical Connection to J-Box ..................... 21

Power Cord Installation in Furnace J-Box ............ 22

BX Cable Installation in Furnace J-Box .............. 22

24-V Wiring ................................... 24

Accessories .................................... 24

General Venting Requirements ..................... 24

Masonry Chimney Requirements ................... 25

Appliance Application Requirements ................ 27

Sidewall Venting ................................ 27

START-UP, ADJUSTMENT, AND SAFETY CHECK ..... 32

General ....................................... 32

Start-Up Procedures ............................. 32

Adjustments ................................... 37

Check Safety Controls ........................... 37

Checklist ...................................... 38

SERVICE AND MAINTENANCE PROCEDURES ....... 43

Introduction ................................... 43

Care and Maintenance ........................... 44

Sequence of Operation ........................... 47

Wiring Diagrams ............................... 48

Troubleshooting ................................ 48

PARTS REPLACEMENT INFORMATION GUIDE ....... 51

Always Ask For

Use of tile AIIR[ Cmlified 1-,i Mark indicates a

manulilcturer's pallicipation in the program. ]or

verification (if cellification lbr individual products,

go to www.ahridJreclory.org.

ISO9001

NOTE: Read the entire instruction manual before starting the

installation.

Portions of the text and tables are reprinted from NFPA 54/ANSI

Z223.1-2012©, with pernfission of Nation Fire Protection

Association, Quincy, MA 02269 and American Gas Association,

Washington DC 20001. This reprinted material is not the

complete and official position of the NFPA or ANSI on the

referenced subject, which is represented only by the standard in

its entirely.

SAFETY CONSIDERATIONS

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

iniury, death, or property damage.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause carbon monoxide poisoning,

explosion, fire, electrical shock, or other conditions which

may cause personal iniury or property damage. Consult a

qualified service agency, local gas supplier, or your

distributor or branch for information or assistance. The

qualified service agency must use only factory-authorized

and listed kits or accessories when modifying this product.

FURNACE RELIABILITY HAZARD

Failure to follow this caution may result in unit component

damage.

Application of this furnace should be indoors with special

attention given to vent sizing and material, gas input rate,

air temperature rise, unit leveling, and unit sizing.

CUT HAZARD

Failure to follow this caution may result in personal iniury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing, safety glasses and

gloves when handling parts, and servicing furnaces.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical shock, or

other conditions which may cause death, personal injury, or

property damage. Consult a qualified installer, service agency, or

your distributor or branch for information or assistance. The

qualified installer or agency must use factory-authorized kits or

accessories when modifying this product. Refer to the individual

instructions packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Have a fire extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions

include in literature and attached to the unit. Consult local

building codes, the current editions of the National Fuel Gas

Code (NFGC) NFPA 54/ANSI Z223.1 and the National

Electrical Code (NEC) NFPA 70.

Recognize safety information. This is the safety-alert symbol/_.

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal iniury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety-alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal iniury or death. WARNING signifies hazards

which could result in personal iniury or death. CAUTION is

used to identify unsafe practices which may result in minor

personal iniury or product and property damage. NOTE is used

to highlight suggestions which will result in enhanced

installation, reliability, or operation.

1. Use only with type of gas approved for this furnace. Refer

to the furnace rating plate.

2. Install this furnace only in a location and position as spe-

cified in the "Location" section of these instructions.

3. Provide adequate combustion and ventilation air to the

furnace space as specified in "Air for Combustion and

Ventilation" section.

4. Combustion products must be discharged outdoors. Con-

nect this furnace to an approved vent system only, as spe-

cified in the "Venting" section of these instructions.

5. Never test for gas leaks with an open flame. Use a com-

mercially available soap solution made specifically for the

detection of leaks to check all connections, as specified in

the "Gas Piping" section.

6. Always install furnace to operate within the furnace's in-

tended temperature-rise range with a duct system which

has an external static pressure within the allowable range,

as specified in the "Start-Up, Adjustments, and Safety

Check" section. See furnace rating plate.

7. When a furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space con-

taining the furnace, the return air shall also be handled by

duct(s) sealed to the furnace casing and terminating out-

side the space containing the furnace. See "Air Ducts" sec-

tion.

8. A gas-fired furnace for installation in a residential garage

must be installed as specified in the warning box in the

"Location" section.

9. The furnace may be used for construction heat provided

that the furnace installation and operation complies with

the first CAUTION in the LOCATION section of these in-

structions.

10. These Multipoise Gas-Fired Furnaces are CSA (formerly

A.G.A. and C.G.A.) design-certified for use with natural

and propane gases (see furnace rating plate) and for install-

ation in alcoves, attics, basements, closets, utility rooms,

crawlspaces, and garages. The furnace is factory-shipped

for use with natural gas. A CSA (A.G.A. and C.G.A.) lis-

ted accessory gas conversion kit is required to convert fur-

nace for use with propane gas.

11. See Fig. 1 for required clearances to combustible construc-

tion.

12. Maintain a 1-in. (25 mm) clearance from combustible ma-

terials to supply air ductwork for a distance of 36 in. (914

mm) horizontally from the furnace. See NFPA 90B or loc-

al code for further requirements.

13. These furnaces SHALL NOT be installed directly on car-

peting, tile, or any other combustible material other than

wood flooring. In downflow installations, factory access-

ory floor base MUST be used when installed on combust-

ible materials and wood flooring. Special base is not re-

quired when this furnace is installed on manufacturer's

Coil Assembly Part No. CNPV, CNRV, CAR or CAP or

when Coil Box Part No. KCAKC is used. See Fig. 1 for

clearance to combustible construction information.

f_7/8

1/16

[4a_

,,@/,°

51/2 _R_Ctt# _52/_

• --TOp OF¢.A_NG

[14a_

Q

_B

27 @/4

57/S--

[!;_;t

71_511/15

1

_ 21.6

tT,_,_1 [15sN

BOTTOM_T

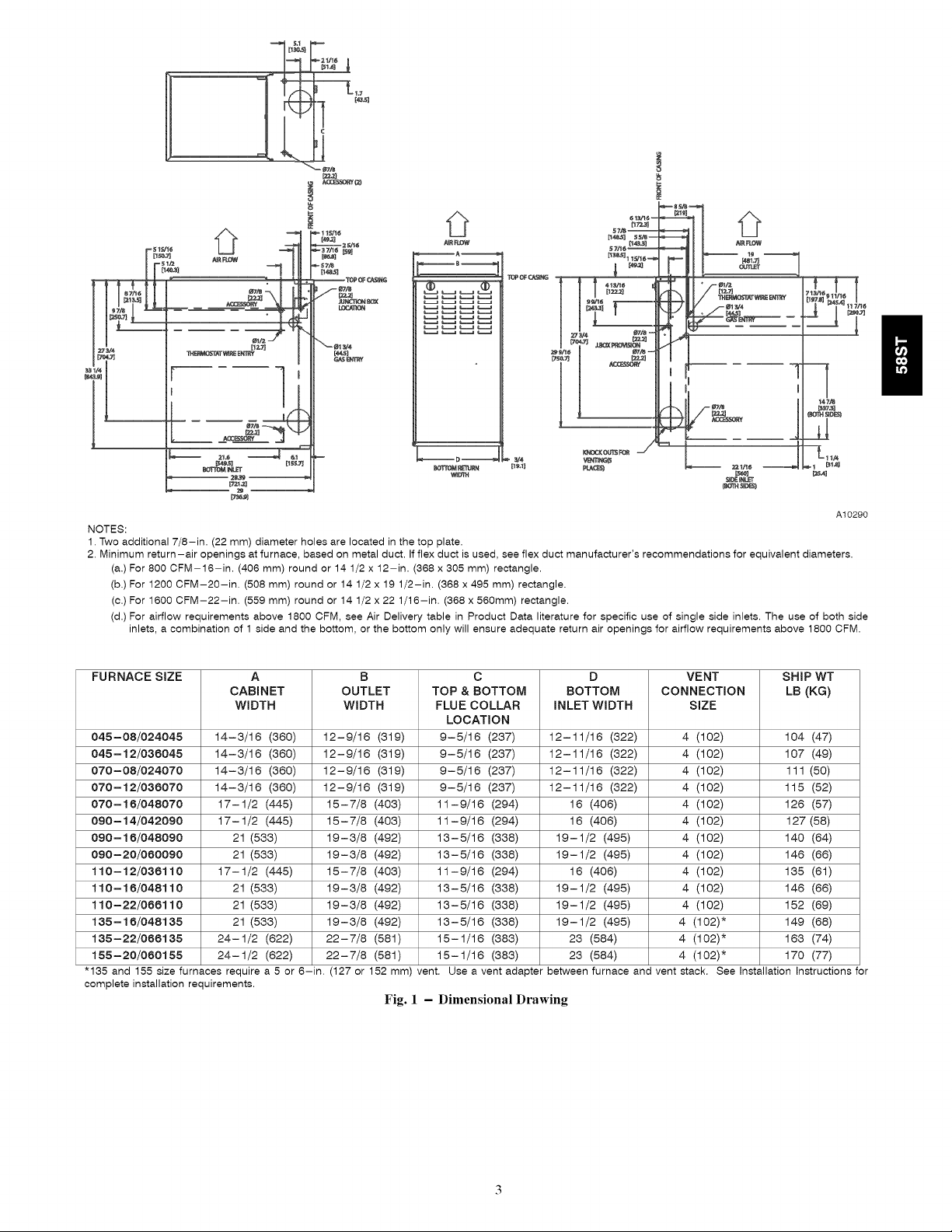

NOTES:

1. Two additional 7/8-in. (22 mm) diameter holes are located in the top plate.

2. Minimum return-air openings at furnace, based on metal duct. If flex duct is used, see flex duct manufacturer's recommendations for equivalent diameters.

(a,) For 800 CFM-16-in. (406 mm) round or 14 1/2 x 12-in. (368 x 305 mm) rectangle.

(b.) For 1200 CFM-20-in. (508 mm) round or 14 1/2 x 19 1/2-in. (368 x 495 mm) rectangle,

(c.) For 1600 CFM-22-in. (559 mm) round or 14 1/2 x 22 1/16-in. (368 x 560mm) rectangle.

(d.) For airflow requirements above 1800 CFM, see Air Delivery table in Product Data literature for specific use of single side inlets. The use of both side

inlets, a combination of 1 side and the bottom, or the bottom only will ensure adequate return air openings for airflow requirements above 1800 CFM.

FURNACE SIZE A B C D VENT SHIP WT

CABINET OUTLET TOP & BOTTOM BOTTOM CONNECTION LB (KG)

WIDTH WIDTH FLUE COLLAR INLET WIDTH SIZE

045 - 08/024045

045 - 12/036045

070 - 08/024070

070 - 12/036070

070 - 16/048070

090 - 14/042090

090 - 16/048090

090 - 20/080090

110-12/038110

110-16/048110

110-22/088110

135-16/048135

135 -22/088135

155 -20/080155

"135 and 155 size furnaces require a 5 or 6-in.

complete installation requirements.

14-3/16 (360) 12-9/16 (319) 9-5/16 (237) 12-11/16 (322) 4 (102) 104 (47)

14-3/16 (360) 12-9/16 (319) 9-5/16 (237) 12-11/16 (322) 4 (102) 107 (49)

14-3/16 (360) 12-9/16 (319) 9-5/16 (237) 12-11/16 (322) 4 (102) 111 (50)

14-3/16 (360) 12-9/16 (319) 9-5/16 (237) 12-11/16 (322) 4 (102) 115 (52)

17-1/2 (445) 15-7/8 (403) 11-9/16 (294) 16 (406) 4 (102) 126 (57)

17-1/2 (445) 15-7/8 (403) 11-9/16 (294) 16 (406) 4 (102) 127 (58)

21 (533) 19-3/8 (492) 13-5/16 (338) 19-1/2 (495) 4 (102) 140 (64)

21 (533) 19-3/8 (492) 13-5/16 (338) 19-1/2 (495) 4 (102) 146 (66)

17-1/2 (445) 15-7/8 (403) 11-9/16 (294) 16 (406) 4 (102) 135 (61)

21 (533) 19-3/8 (492) 13-5/16 (338) 19-1/2 (495) 4 (102) 146 (66)

21 (533) 19-3/8 (492) 13-5/16 (338) 19-1/2 (495) 4 (102) 152 (69)

21 (533) 19-3/8 (492) 13-5/16 (338) 19-1/2 (495) 4 (102)* 149 (68)

24-1/2 (622) 22-7/8 (581) 15-1/16 (383) 23 (584) 4 (102)* 163 (74)

24-1/2 (622) 22-7/8 (581) 15-1/16 (383)

(127 or

152 mm) vent. Use a vent adapter between furnace and vent stack. See Installation Instructions for

LOCATION

Fig. 1 - Dimensional Drawing

[15.1_

I N_N

23 (584) 4 (102)* 170 (77)

A10290

improper adjustment, alteration, service,

maintenance, or installation can cause

serious injury or death.

Read and follow instructions and

precautions in User's Information Manual

provided with this furnace. Installation

and service must be performed by a

qualified service agency or the gas

supplier.

Check entire gas assembly for leaks after

lighting this appliance.

iNSTALLATION

1. This furnace must be installed in

accordance with the manufacturer's

instructions and local codes. In the

absence of local codes, follow the National

Fuel Gas Code ANSI Z223.1 / NFPA54

or CSA B-149. 1 Gas Installation Code.

2. This furnace must be installed so there are

provisions for combustion and ventilation

air. See manufacturer's installation

information provided with this appliance.

OPERATION

This furnace is equipped with manual reset

limit switch(es) in burner compartment to

protect against overheat conditions that

can result from inadequate combustion air

supply or blocked vent conditions.

1. Do not bypass limit switches.

2. If a limit opens, call a quallified

serviceman to correct the condition

and reset limit switch.

Fig. 2 - Clearances to Combustibles

MiNiMUMiNCHESCLEARANCETOCOMBUSTIBLECONSTRUCTION

This forced air furnace is

equipped for use with natural

gas at altitudes 0 - 10,000 ft

(0 - 3,050m).

An accessory kit, supplied by

the manufacturer, shall be used

to convert to propane gas use

or may be required for some

natural gas applications.

This furnace is for indoor

installation in a building

constructed on site.

This furnace may be installed

on combustible flooring in alcove

or closet at minimum clearance

as indicated by the diagram

from combustible material.

This furnace may be used with

a Type B-1 Vent and may be

vented in common with other

gas fired appliances.

This furnace is approved for

UPFLOW, DOWNFLOW, and

HORIZONTAL installations.

Clearancearrows

donotchangewith

furnaceorientation.

Clearancein inches

Vent Clearance to combustibles:

For SingleWallvents 6 inches(6 po).

ForType B-1 venttype I inch (1 po).

MINIMUM INCHES CLEARANCE TO

COMBUSTIBLE CONSTRUCTION

DOWNFLOWPOSiTiONS:

1-

Installation on non-combustible floors only.

For Installation on combustible flooring only when installed on special

base, Part No. KGASB0201ALL or NAHA01101SB, Coil Assembly,

Part No. CAR, CAP, CNPV, CNRV, END4X, ENW4X, WENC, WTNC,

WENW OR WTNW.

18 inches front clearance required for alcove.

O

Indicates supply or return sides when furnace is in the horizontal

position. Line contact only permissible between lines formed by

intersections of the Top and two Sides of the furnace jacket,

and building joists, studs or framing.

IIIIIIIIIIIIIIIIIIIIIIIIIII

336996-161 REV. C

A10269

! MAX80°F/27C

o

FRONT

__ :_ MIN60°F/16C

A06745

Fig. 3 - Return Air Temperature

INTRODUCTION

This 4-way nmltipoise Category I fan-assisted furnace is CSA

design-certified. A Category I fan-assisted furnace is an

appliance equipped with an integral mechanical means to either

draw or force products of combustion through the combustion

chamber and/or heat exchanger. The furnace is factory-shipped

for use with natural gas. This furnace is not approved for

installation in mobile homes, recreational vehicles, or outdoors.

This furnace is designed for minimum continuous return-air

temperature of 60 °F (16 ° C) db or intermittent operation down to

55°F (13°C) db such as when used with a night setback

thermostat. Return-air temperature must not exceed 80 ° F (27 °C)

db. Failure to follow these return-air temperature limits may

affect reliability of heat exchangers, motors, and controls. (See

Fig. 3.)

For accessory installation details, refer to the applicable

instruction literature.

NOTE: Remove all shipping brackets and materials before

operating the furnace.

CODES AND STANDARDS

Follow all national and local codes and standards in addition

to these instructions. The installation nmst comply with

regulations of the serving gas supplier, local building, heating,

plumbing, and other codes. In absence of local codes, the

installation must comply with the national codes listed below and

all authorities having jurisdiction. In the United States, follow all

codes and standards for the following:

Step 1 mSafety

National Fuel Gas Code (NFGC) NFPA 54-2012/AN-

SI Z223.1-2012 and the Installation Standards, Warm

Air Heating and Air Conditioning Systems ANSI/

NFPA 90B

Step 2

Step 3

Step 4

Step 5

mGeneral Installation

Current edition of the NFGC and the NFPA 90B. For

copies, contact the National Fire Protection Association

Inc., Batterymarch Park, Quincy, MA 02269;

(www.NFPA.org) or for only the NFGC, contact the

American Gas Association, 400 N. Capitol Street,

N.W., Washington, DC 20001 (www.AGA.org).

mCombustion and Ventilation Air

Section 9.3 of the NFGC, NFPA 54 / ANSI

Z223.1-2012 Air for Combustion and Ventilation

_Duct Systems

Air Conditioning Contractors Association (ACCA)

Manual D, Sheet Metal and Air Conditioning Contract-

ors National Association (SMACNA), or American

Society of Heating, Refrigeration, and Air Condition-

ing Engineers (ASHRAE) 2001 Fundamentals Hand-

book Chapter 34 or 2000 HVAC Systems and Equip-

ment Handbook Chapters 9 and 16.

---Acoustical Lining and Fibrous Glass

Duct

• Current edition of SMACNA and NFPA 90B as tested

by UL Standard 181 for Class I Rigid Air Ducts

Step 6 _Gas Piping and Gas Pipe Pressure

Testing

• NFGC; NFPA 54 / ANSI Z223.1-2012 chapters 5, 6, 7

and 8 and National Plumbing Codes

Step 7 _Electrical Connections

• National Electrical Code (NEC) ANSI/NFPA 70-2011

Step 8 inVenting

• NFGC NFPA 54 / ANSI Z223.1-2012; chapters 12

and 13

ELECTROSTATIC DISCHARGE (ESD)

PRECAUTIONS PROCEDURE

FURNACE RELIABILITY HAZARD

Failure to follow this caution may result in furnace

component damage.

Electrostatic discharge can affect electronic components.

Follow the Electrostatic Discharge Precautions Procedure

listed below during furnace installation and servicing to

protect the furnace electronic control. Precautions will

prevent electrostatic discharges from personnel and hand

tools which are held during the procedure. These

precautions will help to avoid exposing the control to

electrostatic discharge by putting the furnace, the control,

and the person at the same electrostatic potential.

1. Disconnect all power to the furnace. Multiple disconnects

may be required. DO NOT TOUCH THE CONTROL OR

ANY WIRE CONNECTED TO THE CONTROL PRIOR

TO DISCHARGING YOUR BODY'S

ELECTROSTATIC CHARGE TO GROUND.

2. Firmly touch the clean, unpainted, metal surface of the fur-

nace chassis which is close to the control. Tools held in a

person's hand during grounding will be satisfactorily dis-

charged.

3. After touching the chassis, you may proceed to service the

control or connecting wires as long as you do nothing to

recharge your body with static electricity (for example;

DO NOT move or shuffle your feet, do not touch un-

grounded objects, etc.).

4. If you touch ungrounded objects (and recharge your body

with static electricity), firmly touch a clean, unpainted

metal surface of the furnace again before touching control

or wires.

5. Use this procedure for installed and uninstalled (ungroun-

ded) furnaces.

6. Before removing a new control from its container, dis-

charge your body's electrostatic charge to ground to pro-

tect the control from damage. If the control is to be in-

stalled in a furnace, follow items 1 through 4 before

bringing the control or yourself in contact with the fur-

nace. Put all used and new controls into containers before

touching ungrounded objects.

7. An ESD service kit (available from commercial sources)

may also be used to prevent ESD damage.

LOCATION

CARBON MONOXIDE POISONING AND UNIT

DAMAGE HAZARD

Failure to follow this warning could result in personal

injury or death, and unit component damage.

Corrosive or contaminated air may cause failure of parts

containing flue gas, which could leak into the living space.

Air for combustion must not be contaminated by halogen

compounds, which include fluoride, chloride, bromide, and

iodide. These elements can corrode heat exchangers and

shorten furnace life. Air contaminants are found in aerosol

sprays, detergents, bleaches, cleaning solvents, salts, air

fresheners, and other household products. Do not install

furnace in a corrosive or contaminated atmosphere. Make

sure all combustion and circulating air requirements are met,

in addition to all local codes and ordinances.

GENERAL

This multipoise furnace is shipped in packaged configuration.

Some assembly and modifications are required when used in any

of the four applications shown in Fig. 4.

This furnace must:

• be installed so the electrical components are protected

from water.

not be installed directly on any combustible material

other than wood flooring for upflow applications.

Downflow installations require use of a factory-ap-

proved floor base or coil assembly when installed on

combustible materials or wood flooring. (Refer to

SAFETY CONSIDERATIONS).

THE BLOWER IS LOCATED

TOTHE RIGHT OFTHE

BURNER SECTION, AND

AIR CONDiTiONED AiR IS

DISCHARGED TO THE LEFT.

t

AIRFLOW

d>

THE BLOWER IS

LOCATED BELOW THE

BURNER SECTION, AND

CONDiTiONED AIR IS

DISCHARGED UPWARD.

\

B

HORIZONTAL LEFT

THE BLOWER IS

LOCATED ABOVE THE

BURNER SECTION, AND

CONDITIONED AIR IS

DISCHARGED DOWNWARD

• be located as close to the chimney or vent and attached

to an air distribution system. Refer to Air Ducts section.

• be provided ample space for servicing and cleaning.

Always comply with minimum fire protection clear-

ances shown on the furnace clearance to combustible

label.

• The following types of furnace installations may re-

quire OUTDOOR AIR for combustion due to chemical

exposures:

• Commercial buildings

• Buildings with indoor pools

• Laundry rooms

• Hobby or craft rooms, and

• Chemical storage areas

If air is exposed to the following substances, it should not be used

for combustion air, and outdoor air may be required for

combustion:

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine based swimming pool chemicals

• Water softening chemicals

• De-icing salts or chemicals

• Carbon tetrachloride

• Halogen type refrigerants

_AIRFLOW

Fig. 4 - Multipoise Orientations

HORIZONTAL RIGH-'_AIR FL_OW

THE BLOWER IS

LOCATED TO THE LEFT

OF THE BURNER SECTION,

AND CONDiTiONED AIR IS

DISCHARGED TO THE RIGHT.

A02097

• Cleaning solvents (such as perchloroethylene)

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid

• Cements and glues

• Antistatic fabric softeners for clothes dryers

• Masonry acid washing materials

All fuel-burning equipment must be supplied with air for fuel

combustion. Sufficient air must be provided to avoid negative

pressure in the equipment room or space. A positive seal must be

made between the furnace cabinet and the return-air duct to

prevent pulling air from the burner area and from draft safeguard

opening.

FIRE AND EXPLOSION HAZARD

Failure to follow this warning could result in personal

iniury, death, and/or property damage.

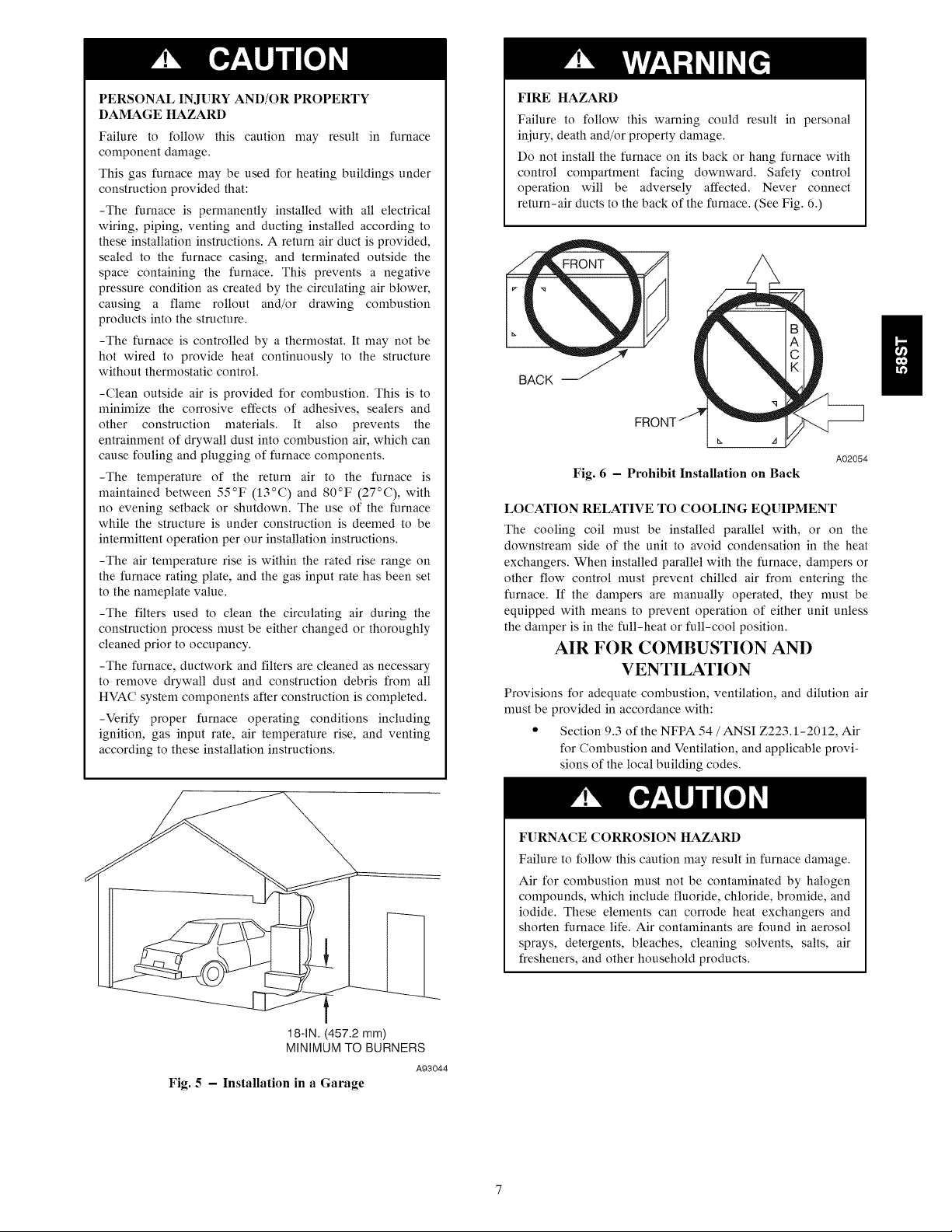

When the furnace is installed in a residential garage, the

burners and ignition sources must be located at least 18

inches above the floor. The furnace must be located or

protected to avoid damage by vehicles. When the furnace is

installed in a public garage, airplane hangar, or other

building having a hazardous atmosphere, the furnace must

be installed in accordance with the NFGC. (See Fig. 5.)

PERSONALINJURYAND/ORPROPERTY

DAMAGEHAZARD

Failureto follow this caution may result in furnace

component damage.

This gas furnace may be used for heating buildings under

construction provided that:

-The furnace is permanently installed with all electrical

wiring, piping, venting and ducting installed according to

these installation instructions. A return air duct is provided,

sealed to the furnace casing, and terminated outside the

space containing the furnace. This prevents a negative

pressure condition as created by the circulating air blower,

causing a flame rollout and/or drawing combustion

products into the structure.

-The furnace is controlled by a thermostat. It may not be

hot wired to provide heat continuously to the structure

without thermostatic control.

-Clean outside air is provided for combustion. This is to

nfininfize the corrosive effects of adhesives, sealers and

other construction materials. It also prevents the

entrainment of drywall dust into combustion air, which can

cause fouling and plugging of furnace components.

-The temperature of the return air to the furnace is

maintained between 55°F (13°C) and 80°F (27°C), with

no evening setback or shutdown. The use of the furnace

while the structure is under construction is deemed to be

intermittent operation per our installation instructions.

-The air temperature rise is within the rated rise range on

the furnace rating plate, and the gas input rate has been set

to the nameplate value.

-The filters used to clean the circulating air during the

construction process must be either changed or thoroughly

cleaned prior to occupancy.

-The furnace, ductwork and filters are cleaned as necessary

to remove drywall dust and construction debris from all

HVAC system components after construction is completed.

-Verify proper furnace operating conditions including

ignition, gas input rate, air temperature rise, and venting

according to these installation instructions.

FIRE HAZARD

Failure to follow this warning could result in personal

iniury, death and/or property damage.

Do not install the furnace on its back or hang furnace with

control compartment facing downward. Safety control

operation will be adversely affected. Never connect

return-air ducts to the back of the furnace. (See Fig. 60

BACK J

A

A02054

Fig. 6 - Prohibit Installation on Back

LOCATION RELATIVE TO COOLING EQUIPMENT

The cooling coil must be installed parallel with, or on the

downstream side of the unit to avoid condensation in the heat

exchangers. When installed parallel with the furnace, dampers or

other flow control must prevent chilled air from entering the

furnace. If the dampers are manually operated, they must be

equipped with means to prevent operation of either unit unless

the damper is in the full-heat or full-cool position.

AIR FOR COMBUSTION AND

VENTILATION

Provisions for adequate combustion, ventilation, and dilution air

must be provided in accordance with:

• Section 9.3 of the NFPA 54 / ANSI Z223.1-2012, Air

for Combustion and Ventilation, and applicable provi-

sions of the local building codes.

18-IN. (457.2 mm)

MINIMUM TO BURNERS

Fig. 5 - Installation in a Garage

FURNACE CORROSION HAZARD

Failure to follow this caution may result in furnace damage.

Air for combustion nmst not be contanfinated by halogen

compounds, which include fluoride, chloride, bronfide, and

iodide. These elements can corrode heat exchangers and

shorten furnace life. Air contanfinants are found in aerosol

sprays, detergents, bleaches, cleaning solvents, salts, air

fresheners, and other household products.

A93044

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

injury or death.

The operation of exhaust fans, kitchen ventilation fans,

clothes dryers, attic exhaust fans or fireplaces could create a

NEGATIVE PRESSURE CONDITION at the furnace.

Make-up air MUST be provided for the ventilation devices,

in addition to that required by the furnace. Refer to Carbon

Monoxide Poisoning Hazard warning in venting section of

these instructions to deternfine if an adequate amount of

make-up air is available.

The requirements for combustion and ventilation air depend

upon whether or not the furnace is located in a space having a

volume of at least 50 cu/ft, per 1,000 Btuh input rating for all gas

appliances installed in the space.

• Spaces having less than 50 cu/ft, per 1,000 Btuh re-

quire the OUTDOOR COMBUSTION AIR

METHOD.

• Spaces having at least 50 cu/fl, per 1,000 Btuh may use

the INDOOR COMBUSTION AIR, STANDARD or

KNOWN AIR INFILTRATION METHOD.

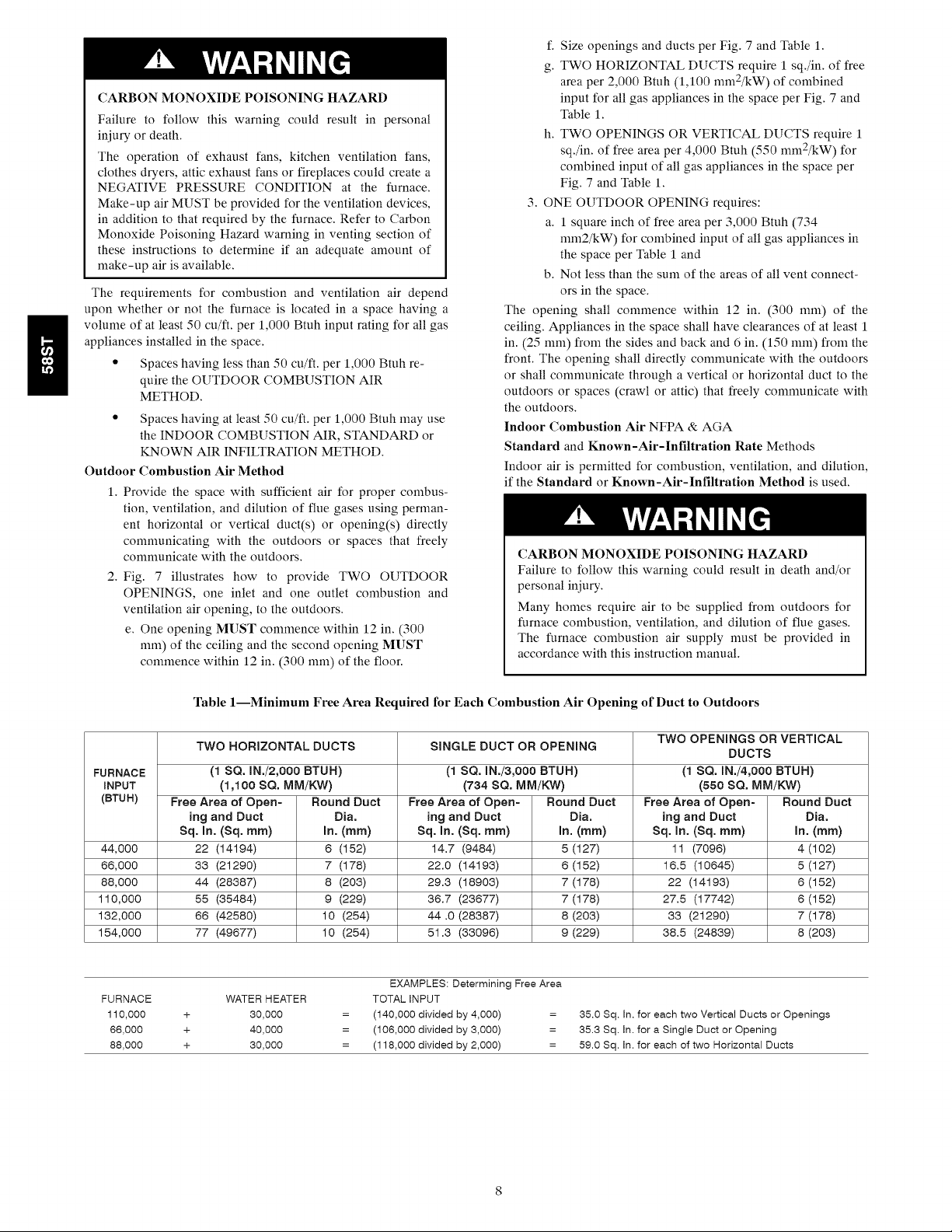

Outdoor Combustion Air Method

1. Provide the space with sufficient air for proper combus-

tion, ventilation, and dilution of flue gases using perman-

ent horizontal or vertical duct(s) or opening(s) directly

communicating with the outdoors or spaces that freely

communicate with the outdoors.

2. Fig. 7 illustrates how to provide TWO OUTDOOR

OPENINGS, one inlet and one outlet combustion and

ventilation air opening, to the outdoors.

e. One opening MUST commence within 12 in. (300

ram) of the ceiling and the second opening MUST

commence within 12 in. (300 ram) of the floor.

f. Size openings and ducts per Fig. 7 and Table 1.

g. TWO HORIZONTAL DUCTS require 1 sq./in, of free

area per 2,000 Btuh (1,100 mm2/kW) of combined

input for all gas appliances in the space per Fig. 7 and

Table 1.

h. TWO OPENINGS OR VERTICAL DUCTS require 1

sq./in, of free area per 4,000 Btuh (550 mm2/kW) for

combined input of all gas appliances in the space per

Fig. 7 and Table 1.

3. ONE OUTDOOR OPENING requires:

a. 1 square inch of free area per 3,000 Btuh (734

mm2/kW) for combined input of all gas appliances in

the space per Table 1 and

b. Not less than the sum of the areas of all vent connect-

ors in the space.

The opening shall commence within 12 in. (300 ram) of the

ceiling. Appliances in the space shall have clearances of at least 1

in. (25 ram) from the sides and back and 6 in. (150 ram) from the

front. The opening shall directly communicate with the outdoors

or shall conmmnicate through a vertical or horizontal duct to the

outdoors or spaces (crawl or attic) that freely communicate with

the outdoors.

Indoor Combustion Air NFPA & AGA

Standard and Known-Air-Infiltration Rate Methods

Indoor air is pernfitted for combustion, ventilation, and dilution,

if the Standard or Known-Air-Infiltration Method is used.

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in death and/or

personal iniury.

Many homes require air to be supplied from outdoors for

furnace combustion, ventilation, and dilution of flue gases.

The furnace combustion air supply must be provided in

accordance with this instruction manual.

Table 1--Minimum Free Area Required for Each Combustion Air Opening of Duct to Outdoors

TWO HORIZONTAL DUCTS SINGLE DUCT OR OPENING

FURNACE (1 SQ. IN./2,000 BTUH) (1 SQ. IN./3,000 BTUH) (1 SQ. IN./4,000 BTUH)

INPUT (1,100 SO. MMiKW) (734 SO. MMiKW) (550 SO. MMiKW)

(BTUH) Free Area of Open- Round Duct Free Area of Open- Round Duct Free Area of Open- Round Duct

ing and Duct Dia. ing and Duct Dia. ing and Duct Dia.

Sq. In. (Sq. ram) In. (ram) Sq. In. (Sq. ram) In. (ram) Sq. In. (Sq. ram) In. (ram)

44,000 22 (14194) 6 (152) 14.7 (9484) 5 (127) 11 (7096) 4 (102)

66,000 33 (21290) 7 (178) 22.0 (14193) 6 (152) 16.5 (10645) 5 (127)

88,000 44 (28387) 8 (203) 29.3 (18903) 7 (178) 22 (14193) 6 (152)

110,000 55 (35484) 9 (229) 36.7 (23677) 7 (178) 27.5 (17742) 6 (152)

132,000 66 (42580) 10 (254) 44.0 (28387) 8 (203) 33 (21290) 7 (178)

154,000 77 (49677) 10 (254) 51.3 (33096) 9 (229) 38.5 (24839) 8 (203)

EXAMPLES: Determining Free Area

FURNACE WATER HEATER TOTAL INPUT

110,000 + 30,000 = (140,000 divided by 4,000) = 35.0 Sq. In. for each two Vertical Ducts or Openings

66,000 + 40,000 = (106,000 divided by 3,000) 35.3 Sq. In. for a Single Duct or Opening

88,000 + 30,000 = (118,000 divided by 2,000) 59.0 Sq. In. for each of two Horizontal Ducts

TWO OPENINGS OR VERTICAL

DUCTS

Table 2--Minimum Space Volumes for 100 % Combustion, Ventilation, and Dilution from Indoors

OTHER THAN FAN-ASSISTED TOTAL FAN-ASSISTED TOTAL

(1,000'S BTUH GAS INPUT RATE) (1,000'S BTUH GAS INPUT RATE)

30 40 50 44 66 88 110 132 154

ACH Space Volume Ft3 (M 3)

0.60 (29.7) (39.6) (49.5) (31.1) (46.7) (62.2) (77.8) (93.4) (109.0)

0.60 (35.6) (47.5) (59.4) (37.3) (56.0) (74.7) (93.4) (112.1) (130.8)

0.40 (44.5) (59.4) (74.3) (46.7) (70.0) (93.4) (116.8) (140.1) (163.5)

0.30 (59.4) (79.2) (99.1) (62.2) (93.4) (124.5) (155.7) (186.8) (218.0)

0.20 (89.1) (118.9) (148.6) (93.4) (140.1) (186.8) (233.6) (280.3) (327.0)

0.10 (178.3) (237.8) (297.3) (186.8) (280.3) (373.7) (467.2) (560.6) (654.1)

0.00 NP NP NP NP NP NP NP NP NP

NP = Not Permitted

1,050 1,400 1,750 1,1 O0 1,650 2,200 2,750 3,300 3,850

1,260 1,680 2,1 O0 1,320 1,980 2,640 3,300 3,960 4,620

1,575 2,1 O0 2,625 1,650 2,475 3,300 4,125 4,950 5,775

2,1 O0 2,800 3,500 2,200 3,300 4,400 5,500 6,600 7,700

3,150 4,200 5,250 3,300 4,950 6,600 8,250 9,900 11,550

6,300 8,400 10,500 6,600 9,900 13,200 16,500 19,800 23,1 O0

PER 4000 CIRCULATING AIR

TO

OUTDOORS

(305mm) 12"MAX I _J

lSQiN _11:1

PER2000 IIB

©

BTUi"

DUCTS

OUTiOORS _

PER 2000 _ I:IAI

BTUH* T

305mm 12"MAX | .

*Minimum dimensions of 3-in. (76 mm).

NOTE: Use any of the following combinations of openings:

Fig. 7 - Air for Combustion, Ventilation, and Dilution for

i,

I

CIRCULATING AIR DUCTS

A&BC&DD&EF&G

TO PER 4000

OUTDOORS BTUH*

Outdoors

1SQ IN. !

BTUH* _DUCTS !1

12_ (305mm)

SO IN.

PER

4000

3TUH*

cO

n-

O

o

a

F-

o

SQ IN.

PER

4000

BTUH*

12" (305mm)

MAX

12" MAX

(305mm)

1 SQ IN.

A03174

VENT THROUGH ROOF

,, ,, ,, ,,,,

I I I I I

:305mm)

1 SQ IN.

PER 1000

BTUH* IN DOOR

ORWALL

INTERIOR

HEATED

SPACE

UNCONFINED

SPACE

6" MIN (152mm)

(FRONT)0

1 SQ IN.

PER 1000

BTUH* IN DOOR

-- OR WALL

L 12" MAX(305mm)

I

CIRCULATING AIR DUCTS

* Minimum opening size is 100 sq in. (64516 sq. mm)with minimum dimensions

of 3 in. (76 mm)

1-Minimum of 3 in. (76 mm) when type-B1 vent is used.

Fig. 8 - Air for Combustion, Ventilation, and Dilution from

Indoors

A03175

The Standard Method:

1. The space has no less volume than 50 cu/fl, per 1,000

Btuh of the maximum input ratings for all gas appliances

installed in the space and

2. The air infiltration rate is not known to be less than 0.40

air changes per hour (ACH).

The Known Air Infiltration Rate Method shall be used, if the

infiltration rate is known to be:

1. Less than 0.40 ACH and

2. Equal to or greater than 0.10 ACH

Infiltration rates greater than 0.60 ACH shall not be used. The

minimum required volume of the space varies with the number of

ACH and shall be deternfined per TaMe 2 or Equations I and 2.

Deternfine the minimum required volume for each appliance in

the space and add the volumes together to get the total minimum

required volume for the space.

Table 2 - Minimum Space Volumes were deternfined by using

the following equations from the National Fuel Gas Code ANSI

Z223.1-2012/NFPA 54-2012, 9.3.2.2:

1. For other than fan-assisted appliances, such as a draft

hood-equipped water heater:

Volume - 21ft3 L_ !°ther

2. For fan-assisted appliances such as this furnace:

Volume _ 15ft 3 _ I fan

If:

Iother = combined input of all other than fan-assisted

appliances in Btuh/hr

Ifan = combined input of all fan-assisted appliances in Btuh/hr

ACH = air changes per hour (ACH shall not exceed 0.60.) The

following requirements apply to the Standard Method and to the

Known Air Infiltration Rate Method.

1. Adjoining rooms can be considered part of a space if:

a. There are no closeaMe doors between rooms.

b. Combining spaces on same floor level. Each opening

c. Combining space on different floor levels. The

2. An attic or crawlspace may be considered a space that

freely conmmnicates with the outdoors provided there are

adequate permanent ventilation openings directly to out-

doors having free area of at least 1-in.2/4,000 Btuh of total

input rating for all gas appliances in the space.

3. In spaces that use the Indoor Combustion Air Method, in-

filtration should be adequate to provide air for combus-

tion, permanent ventilation and dilution of flue gases.

Other ACH H000 Btu/hr

A04002

Fan ACH 000 Btu/hr

A04003

shall have free area of at least I in.2/1,000 Btuh (2,000

mm2/kW) of the total input rating of all gas appliances

in the space, but not less than 100 in. 2 (0.06 m2). One

opening shall commence within 12 in. (300 ram) of

the ceiling and the second opening shall commence

within 12 in. (300 ram) of the floor. The minimum

dimension of air openings shall be at least 3 in. (80

ram). (See Fig. 8.)

volumes of spaces on different floor levels shall be

considered as conmmnicating spaces if connected by

one or more permanent openings in doors or floors

having free area of at least 2 in.2/1,000 Btuh (4,400

mm2/kW) of total input rating of all gas appliances.

However, in buildings with unusually tight construction,

additional air MUST be provided using the methods de-

scribed in the Outdoor Combustion Air Method section.

Unusually tight construction is defined as Construction with:

a. Walls and ceilings exposed to the outdoors have a con-

tinuous, sealed vapor barrier. Openings are gasketed or

sealed and

b. Doors and openable windows are weatherstripped and

c. Other openings are caulked or sealed. These include

joints around window and door frames, between sole

plates and floors, between wall-ceiling joints, between

wall panels, at penetrations for plumbing, electrical

and gas lines, etc.

Combination of Indoor and Outdoor Air

1. Indoor openings shall comply with the Indoor Combus-

tion Air Method below and,

2. Outdoor openings shall be located as required in the Out-

door Combustion Air Method mentioned previously and,

3. Outdoor openings shall be sized as follows:

a. Calculate the Ratio of all Indoor Space volume divided

by required volume for Indoor Combustion Air

Method below.

b. Outdoor opening size reduction Factor is 1 nfinus the

Ratio in a. above.

c. Minimum size of Outdoor openings shall be the size

required in Outdoor Combustion Air Method above

nmltiplied by reduction Factor in b. above. The nfin-

imum dimension of air openings shall be not less than

3 in. (80 mm).

INSTALLATION

UPFLOW INSTALLATION

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return-air opening. Remove and discard this panel when

bottom return air is used. To remove bottom closure panel,

perform the following:

1. Tilt or raise furnace and remove 2 screws holding bottom

filler panel. (See Fig. 90

Bottom

Closure Panel

Bottom Filler Panel

A10273

Fig. 9 - Removing Bottom Closure Panel

2. Rotate bottom filler panel downward to release holding

tabs.

3. Remove bottom closure panel.

4. Reinstall bottom filler panel and screws.

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return-air opening. This panel MUST be in place when

only side return air is used.

10

NOTE: Side return-air openings can be used in UPFLOW and

most HORIZONTAL configurations. Do not use side return-air

openings in DOWNFLOW configuration.

In upflow position with side return inlet(s), leveling legs may be

used. (See Fig. 10.) Install field-supplied, 5/16 x 1-1/2 in. (8 x

38 ram) (max) corrosion-resistant machine bolts, washers and

nuts.

NOTE: Bottom closure must be used when leveling legs are

used. It may be necessary to remove and reinstall bottom closure

panel to install leveling legs. To remove bottom closure panel, see

Item 1. in Bottom Return Air Inlet section.

(8mm)

I 3/4'

(44mm)

1 3/4"

(44mm)

4. If downflow subbase, KGASB is used, install as shown in

Fig. 12. If Coil Assembly Part No. CNPV, CNRV, CAR,

or CAP or Coil Box Part No. KCAKC is used, install as

shown in Fig. 13.

(8mm)

5/16"

(8mm)

(44mm) 1 3/4"

(44mm) I 3/4'_"_

A89014

Fig. 10 - Leveling Legs

Leveling Legs (If Desired)

To install leveling legs:

1. Position furnace on its back. Locate and drill a hole in

each bottom corner of furnace. (See Fig. 10.)

2. For each leg, install nut on bolt and then install bolt and

nut in hole. (Install flat washer if desired.)

3. Install another nut on other side of furnace base. (Install

flat washer if desired.)

4. Adjust outside nut to provide desired height, and tighten

inside nut to secure arrangement.

5. Reinstall bottom closure panel if removed.

DOWNFLOW INSTALLATION

NOTE: For downflow applications, this furnace is approved for

use on combustible flooring when any one of the following 3

accessories are used:

• Special Base, KGASB

• Cased Coil Assembly Part No. CNPV, CNRV, CAR,

or CAP

• Coil Box Part No. KCAKC

1. Determine application being installed from Table 3.

2. Construct hole in floor per Table 3 and Fig. 11.

3. Construct plenum to dimensions specified in Table 4 and

Fig. 11.

A96283

Fig. 11 - Floor and Plenum Opening Dimensions

NOTE: It is recommended that the perforated supply-air duct

flanges be completely folded over or removed from furnace when

installing the furnace on a factory-supplied cased coil or coil box.

To remove the supply-air duct flange, use wide duct pliers or

hand seamers to bend flange back and forth until it breaks off. Be

careful of sharp edges. (See Fig. 140

FURNACE

(OR COIL CASING

WHEN USED)

COMBUSTIBLE

FLOORING \

SUBBASE

SHEET METAL

PLENUM

FLOOR

OPENING

A96285

Fig. 12 - Furnace, Plenum, and Subbase Installed on a

Combustible Floor

11

FURNACE

APPROVED

COIL ASSEMBLY

OR

COIL BOX

COMBUSTIBLE

FLOORING

\\\\_

SHEET METAL _

PLENUM

I

Fig. 13 - Furnace, Plenum, and Coil Assembly or Coil Box

Installed on a Combustible Floor

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return-air opening. Remove and discard this panel when

bottom return air is used. To remove bottom closure panel,

perform the following:

1. Tilt or raise furnace and remove 2 screws holding bottom

filler panel. (See Fig. 9.)

2. Rotate bottom filler panel downward to release holding

tabs.

3. Remove bottom closure panel.

4. Reinstall bottom filler panel and screws.

HORIZONTAL INSTALLATION

FLOOR

OPENING 12

A08556

If the screws are attached to ONLY the furnace sides and not the

bottom, the straps must be vertical against the furnace sides and

not pull away from the furnace sides, so that the strap attachment

screws are not in tension (are loaded in shear) for reliable support.

Platform Furnace Support

Construct working platform at location where all required furnace

clearances are met, (See Fig, 2 and 170 For furnaces with 1-in,

(25 ram) clearance requirement on side, set furnace on non-

combustible blocks, bricks or angle iron, For crawl space

installations, if the furnace is not suspended from the floor joists,

the ground underneath furnace must be level and the furnace set

on blocks or bricks,

Roll- Out Protection

Provide a minimum 17-3/4 in, x 22 in, (451 x 559 ram) piece of

sheet metal for flame roll-out protection in front of burner area

for furnaces closer than 12 inches (305 ram) above the

combustible deck or suspended furnaces closer than 12 inches

(305 ram) to joists, The sheet metal MUST extend underneath the

furnace casing by 1 in, (25 ram) with the door removed,

The bottom closure panel on furnaces of widths 17-1/2 in, (445

ram) and larger may be used for flame roll-out protection when

bottom of furnace is used for return air connection, See Fig, 17

for proper orientation of roll-out shield,

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return-air opening, Remove and discard this panel when

bottom return air is used, To remove bottom closure panel,

perform the following:

1, Tilt or raise furnace and remove 2 screws holding bottom

filler panel, (See Fig, 90

2, Rotate bottom filler panel downward to release holding

tabs.

3. Remove bottom closure panel.

4. Reinstall bottom filler panel and screws.

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return-air opening. This panel MUST be in place when

side return air inlet(s) is used without a bottom return air inlet.

Not all horizontal furnaces are approved for side return air

connections. (See Fig. 20.)

FILTER ARRANGEMENT

FIRE, EXPLOSION, AND CARBON MONOXIDE

POISONING HAZARD

Failure to follow this warning could result in personal

injury, death, or property damage.

Do not install the furnace on its back or hang furnace with

control compartment facing downward. Safety control

operation will be adversely affected. Never connect

return-air ducts to the back of the furnace.

The furnace can be installed horizontally in an attic or crawl

space on either the left-hand (LH) or right-hand (RH) side. The

furnace can be hung from floor joists, rafters or trusses or

installed on a non-combustible platform, blocks, bricks or pad.

Suspended Furnace Support

The furnace may be supported under each end with threaded rod,

angle iron or metal plumber's strap as shown. (See Fig. 15 and

16.) Secure angle iron to bottom of furnace as shown.

Heavy-gauge sheet metal straps (plumber's straps) may be used

to suspend the furnace from each bottom corner. To prevent

screws from pulling out, use 2 #8 x 3/4-in. (19 ram) screws into

the side and 2 #8 x 3/4-in. (19 ram) screws in the bottom of the

furnace casing for each strap. (See Fig. 15 and 16.)

CARBON MONOXIDE AND POISONING HAZARD

Failure to follow this warning could result in personal

iniury, death and/or property damage.

Never operate a furnace without a filter or with filter access

door removed.

There are no provisions for an internal filter rack in these

furnaces.

Refer to the instructions supplied with accessory Media Cabinet

for assembly and installation options.

This furnace requires a field-supplied external filter rack or a

suitable field-supplied substitute, such as the media cabinet. See

the Product Data Sheet for accessory list.

Refer to the instructions supplied with external filter rack for

assembly and installation options.

12

Table 3--Opening Dimensions - In. (mm)

FURNACE

CASING

APPLICATION

WIDTH

Upflow Applications on Combustible or Noncombustible Floor- 12-11/16 21-5/8 13-5/16 22-1/4

Downflow Applications on Noncombustible Flooring (KGASB 12-9/16 19 13-3/16 19-5/8

14-3/16 Downflow applications on combustible flooring (KGASB sub- 11 - 18/16 19 18- 7/16 20- 5/8

(360) base required) (284) (483) (341) (600)

Downflow Applications on Combustible Flooring with CNPV,

CNRV, CAR, or CAP Coil Assembly or KCAKC coil box

Upflow Applications on Combustible or Noncombustible Floor- 16 21 -5/8 16-5/8 22-1/4

Downflow Applications on Noncombustible Flooring (KGASB 15-7/8 19 16-1/2 19-5/8

17-1/2 Downflow applications on combustible flooring (KGAS B su b- 15-1/8 19 16-3/4 20-5/8

(445) base required) (384) (483) (425) (600)

Downflow Applications on Combustible Flooring with CNPV,

CNRV, CAR, or CAP Coil Assembly or KCAKC coil box

Upflow Applications on Combustible or Noncombustible Floor- 19-1/2 21-5/8 20-1/8 22-1/4

Downflow Applications on Noncombustible Flooring (KGASB 19-3/8 19 20 19-5/8

21 Downflow applications on combustible flooring (KGASB sub- 18-5/8 19 20-1/4 20-5/8

(533) base required) (473) (483) (514) (600)

Downflow Applications on Combustible Flooring with CNPV,

CNRV, CAR, or CAP Coil Assembly or KCAKC coil box

Upflow Applications on Combustible or Noncombustible Floor- 23 21 - 1/8 28- 5/8 22-1/4

Downflow Applications on Noncombustible Flooring (KGASB 22-7/8 19 28-1/2 19-5/8

24-1/2 Downflow applications on Combustible flooring (KGAS B su b- 22-1/8 19 28- 3/4 20-5/8

(622) base required) (562) (483) (603) (600)

Downflow Applications on Combustible Flooring with CNPV,

CNRV, CAR, or CAP Coil Assembly or KCAKC coil box

ing (KGASB subbase not required) (322) (549) (338) (565)

subbase not required) (819) (483) (335) (498)

(KGASB subbase not required) (819) (483) (338) (508)

ing (KGASB subbase not required) (406) (549) (422) (565)

subbase not required) (403) (483) (419) (498)

(KGASB subbase not required) (394) (483) (419) (508)

ing (KGASB subbase not required) (495) (549) (511) (565)

subbase not required) (492) (483) (508) (498)

(KGASB subbase not required) (483) (483) (508) (508)

ing (KGASB subbase not required) (584) (537) (600) (565)

subbase not required) (581) (483) (597) (498)

(KGASB subbase not required) (572) (483) (597) (508)

PLENUM OPENING FLOOR OPENING

A B C D

12-5/16 19 13-5/16 20

15-1/2 19 16-1/2 20

19 19 20 20

22-1/2 19 28-1/2 20

AIR DUCTS

General Requirements

The duct system should be designed and sized according to

accepted national standards such as those published by: Air

Conditioning Contractors Association (ACCA), Sheet Metal and

Air Conditioning Contractors National Association (SMACNA)

or American Society of Heating, Refrigerating and Air

Conditioning Engineers (ASHRAE) or consult The Air Systems

Design Guidelines reference tables available from your local

distributor. The duct system should be sized to handle the

required system design CFM at the design external static pressure.

The furnace airflow rates are provided in Table 4 - AIR

DELIVERY-CFM (With Filter).

When a furnace is installed so that the supply ducts carry air

circulated by the furnace to areas outside the space containing the

furnace, the return air shall also be handled by duct(s) sealed to

the furnace casing and terminating outside the space containing

the furnace.

Secure ductwork with proper fasteners for type of ductwork used.

Seal supply- and return-duct connections to furnace with code

approved tape or duct sealer.

NOTE: Flexible connections should be used between ductwork

and furnace to prevent transmission of vibration. Ductwork

passing through unconditioned space should be insulated and

sealed to enhance system performance. When air conditioning is

used, a vapor barrier is recommended.

Maintain a 1-in. (25 ram) clearance from combustible materials

to supply air ductwork for a distance of 36 in. (914 ram)

horizontally from the furnace. See NFPA 90B or local code for

further requirements.

Ductwork Acoustical Treatment

NOTE: Metal duct systems that do not have a 90 degree elbow

and 10 ft. (3 M) of main duct to the first branch take-off may

require internal acoustical lining. As an alternative, fibrous

ductwork may be used if constructed and installed in accordance

with the latest edition of SMACNA construction standard on

fibrous glass ducts. Both acoustical lining and fibrous ductwork

shall comply with NFPA 90B as tested by UL Standard 181 for

Class 1 Rigid air ducts.

Supply Air Connections

For a furnace not equipped with a cooling coil, the outlet duct

shall be provided with a removable access panel. This opening

shall be accessible when the furnace is installed and shall be of

such a size that the heat exchanger can be viewed for possible

openings using light assistance or a probe can be inserted for

sampling the air stream. The cover attachment shall prevent leaks.

13

Table4--Air Delivery - CFM (with Filter)*

FURNACE RETURN-AIR SPEED EXTERNAL STATIC PRESSURE (In. W.C.)

SiZE INLET 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

045-08/ Bottom or High 1035 995 945 895 835 770 675 565 390 195

024048 Side(s) Med - High 865 830 790 745 690 625 545 440 250 195

045-12/ Bottom or High 1440 1375 1305 1240 1160 1070 975 870 730 560

036045 Side(s) Med - High 1360 1300 1240 1175 1115 1040 950 850 725 575

070-08/ Bottom or High 1030 1005 965 925 870 810 740 645 465 280

024070 Side(s) Med- High 835 815 790 755 710 660 590 480 325 205

070-12/ Bottom or High 1425 1375 1320 1265 1200 1125 1035 940 830 655

036070 Side(s) Med- High 1320 1280 1240 1205 1140 1075 995 905 790 620

070-16/ Bottom or High 1755 1700 1635 1570 1505 1435 1350 1260 1160 1055

048070 Side(s) Med- High 1550 1520 1475 1430 1375 1310 1240 1155 1070 970

090-14/ Bottom or High 1605 1570 1535 1465 1385 1285 1175 1055 895 645

042090 Side(s) Med - High 1470 1445 1410 1380 1300 1220 1115 990 830 600

090-16/ Bottom or High 1940 1880 1805 1720 1635 1540 1425 1290 1090 830

048090 Side(s) Med - High 1740 1700 1650 1590 1525 1440 1335 1195 1010 820

Bottom Only Med - High 2170 2110 2040 1970 1895 1785 1675 1565 1420 1260

090-20/ Both Sides or 1 High 2530 2450 2365 2270 2165 2065 1940 1805 1670 1505

060090 Side & Bottom Med - High 2230 2170 2110 2050 1985 1890 1780 1660 1525 1360

1Side Only Med - High 2105 2145 2070 2010 1940 1845 1735 1620 1475 1325

110-12/ Bottom or High 1600 1550 1490 1425 1355 1260 1135 990 785 530

036110 Side(s) Med- High 1475 1435 1395 1335 1285 1185 1070 890 725 450

110-16/ Bottom or High 1980 1915 1835 1750 1655 1495 1365 1185 965 700

048110 Side(s) Med-High 1745 1710 1650 1560 1450 1340 1205 1090 865 605

Bottom Only Med- High 2135 2100 2060 2000 1930 1860 1765 1670 1555 1425

110-22/

066110 or 1 Side & Bot- Med-High 2140 2100 2050 1990 1935 1865 1760 1670 1545 1410

A filter is required for each return-air inlet. Airflow performance included 3/4-in. (19 mm) washable filter media such as contained in factory-authorized ac-

cessory filter rack. To determine airflow performance without this filter, assume an additional 0.1 In. W.C. available external static pressure.

-- Indicates unstable operating conditions.

Bottom Sides High .... 2355 2285 2190 2090 1965 1850 1705 1535

tom Med - Low 1855 1840 1815 1775 1725 1675 1600 1510 1405 1290

1Side Only Med - High 2030 2025 2000 1950 1905 1850 1750 1660 1555 1425

Med - Low 760 720 680 635 580 520 445 345 220 195

Med - Low 1250 1210 1160 11 O0 1040 965 885 790 670 520

Med - Low 725 700 675 635 595 545 460 350 250 - -

Med - Low 1200 1175 1145 1105 1050 990 920 840 725 555

Med - Low 1355 1340 1310 1280 1240 1190 1125 1060 975 890

Med- Low 1310 1295 1265 1230 1195 1120 1025 915 710 565

Med - Low 1505 1505 1480 1440 1375 1300 1190 1045 890 740

High 2405 2310 2220 2130 2025 1920 1790 1660 1530 1350

Med - Low 1920 1875 1835 1780 1715 1630 1535 1420 1275 1135

Med - Low 1895 1890 1845 1815 1755 1685 1600 1480 1350 1180

High 2475 2395 2300 2200 2090 1985 1865 1730 1585 1425

Med - Low 1850 1860 1810 1770 1715 1650 1555 1445 1310 1150

Med - Low 1315 1295 1265 1220 1155 1080 985 810 675 440

Med- Low 1530 1515 1470 1400 1310 1215 1095 990 830 670

High 2485 2415 2340 2255 2160 2080 1950 1840 1720 1565

Med - Low 1855 1840 1815 1775 1725 1675 1600 1510 1405 1290

High 2495 2440 2370 2290 2205 2120 2015 1910 1775 1625

Med - Low - - 1735 1725 1695 1650 1595 1535 1455 1335 1230

14

Table 5---Air Delivery - CFM (with Filter)* (Continued)

FURNACE RETURN-AIR SPEED EXTERNAL STATIC PRESSURE (In. W.C.)

SIZE iNLET 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

135-16/ Bottom or High 2065 2000 1930 1835 1710 1590 1420 1235 1025 835

048135 Side(s) Med - High 1790 1755 1705 1640 1550 1465 1295 1145 945 775

Bottom Only Med - High 2130 2080 2025 1960 1880 1795 1690 1550 1405 1255

135-22/

066135 or 1 Side & Bot- Med-High 2120 2075 1995 1970 1905 1835 1735 1645 1515 1325

155-2o/

060155

A filter is required for each return-air inlet. Airflow performance included 3/4-in. (19 mm) washable filter media such as contained in factory-authorized ac-

cessory filter rack. To determine airflow performance without this filter, assume an additional 0.1 In. W.C. available external static pressure.

-- Indicates unstable operating conditions.

Bottom, Sides High .... 2355 2280 2160 2065 1930 1805 1655 1465

tom Med - Low 1860 1830 1800 1755 1725 1630 1530 1415 1280 1140

1 Side Only Med-High 2070 2015 1970 1935 1855 1765 1655 1550 1445 1265

Bottom Only

BothSidesOr I

Side& Bottom

ISideOnly

Med - Low 1480 1480 1480 1450 1380 1295 1160 1005 855 670

High 2445 2365 2280 2190 2085 1980 1850 1705 1520 1355

Med - Low 1860 1830 1800 1755 1705 1630 1530 1415 1280 1140

High .... 2215 2130 2030 1920 1795 1675 1540 1385

Med - Low 1860 1830 1800 1755 1725 1630 1530 1415 1280 1140

High 2465 2430 2375 2305 2215 2110 2000 1865 1715 1530

Med-High

Med - Low

High

Med-High

Med - Low

High

Med-High

Med - Low

2115 2095 2055 2005 1940 1845 1820 1675 1525 1390

1800 1790 1770 1735 1695 1640 1570 1465 1345 1225

.... 2375 2285 2185 2105 1995 1870 1720 1555

2155 2125 2075 2015 1935 1830 1780 1635 1485 1365

1800 1790 1770 1735 1695 1640 1570 1465 1345 1225

.... 2260 2180 2070 1975 1865 1740 1595 1440

2140 2085 2020 1950 1850 1745 1695 1545 1415 1290

1800 1790 1770 1735 1695 1640 1570 1465 1345 1225

/

U PFLOW DOWN FLOW HO REZO NTAL

I ......

YES

120°_

MIN

YES

\

YES 120°_ YES 120°_ YES

NO NO NO

/\ /\

MIN MIN

Fig. 14 - Duct Flanges

YES

A02020

15

ASSEMBLY

L.

8" (203mm) MtN

FOR DOOR REMOVAL

(2) HEX NUTS, (2) WASHERS & (2) LOCK WASHERS

REQ. PER ROD

_/4"(6mm) THREADED ROD

4 REQ.

SECURE ANGLE

IRON TO BOTTOM

OF FURNACE WiTH

3 #8 x3/4'' (19mm) SCREWS

TYPICAL FOR 2 SUPPORTS

1" (25ram) SQUARE, 1-1/4"x1-1/4"x1/8" (32x32x3mm)

ANGLE IRON OR UNI-STRUT MAY BE USED

OUTER DGOR

ASSEMB_

A10130

Fig. 15 - Horizontal Unit Suspension

22 GAUGE GALVANIZED

STRAPS TYPICAL

FOR 4 STRAPS

METHOD 2

&

BACK OF

FURNACE

METHOD 1

FOLD ALL STRAPS UNDER

FURNACE AND SECURE WTH

(4) #8 x 3/4 (t9 ram) SHEET METAL SCREWS

(2 SCREWS IN SIDE AND 2 SCREWS

IN BOTTOM).

USE (4) #8 x 3/4 (19 ram) SHEET

METAL SCREWS FOR EACH

STRAR THE STRAPS

SHOULD BE VERTICAL

AGAINST THE FURNACE

SIDES AND NOT PULL AWAY

FROM THE FURNACE

SIDES.

Fig. 16 - Horizontal Suspension with Straps

16

A10131

Loading...

Loading...