Page 1

58SSB

... ..„„0 .0 Accessory Variable Speed Blower Kit

Installation Instructions

GENERAL

These instructions cover installation of an ECM blower

accessory on 2- and 3-ton cooling 58SSB 060 and 080

furnaces. ECM blower accessory Part No. 58SSB900131

is used on 2-ton cooling 58SSB060 furnace and Part No.

58SSB900141 is used on3-toncooling58SSB080furnace.

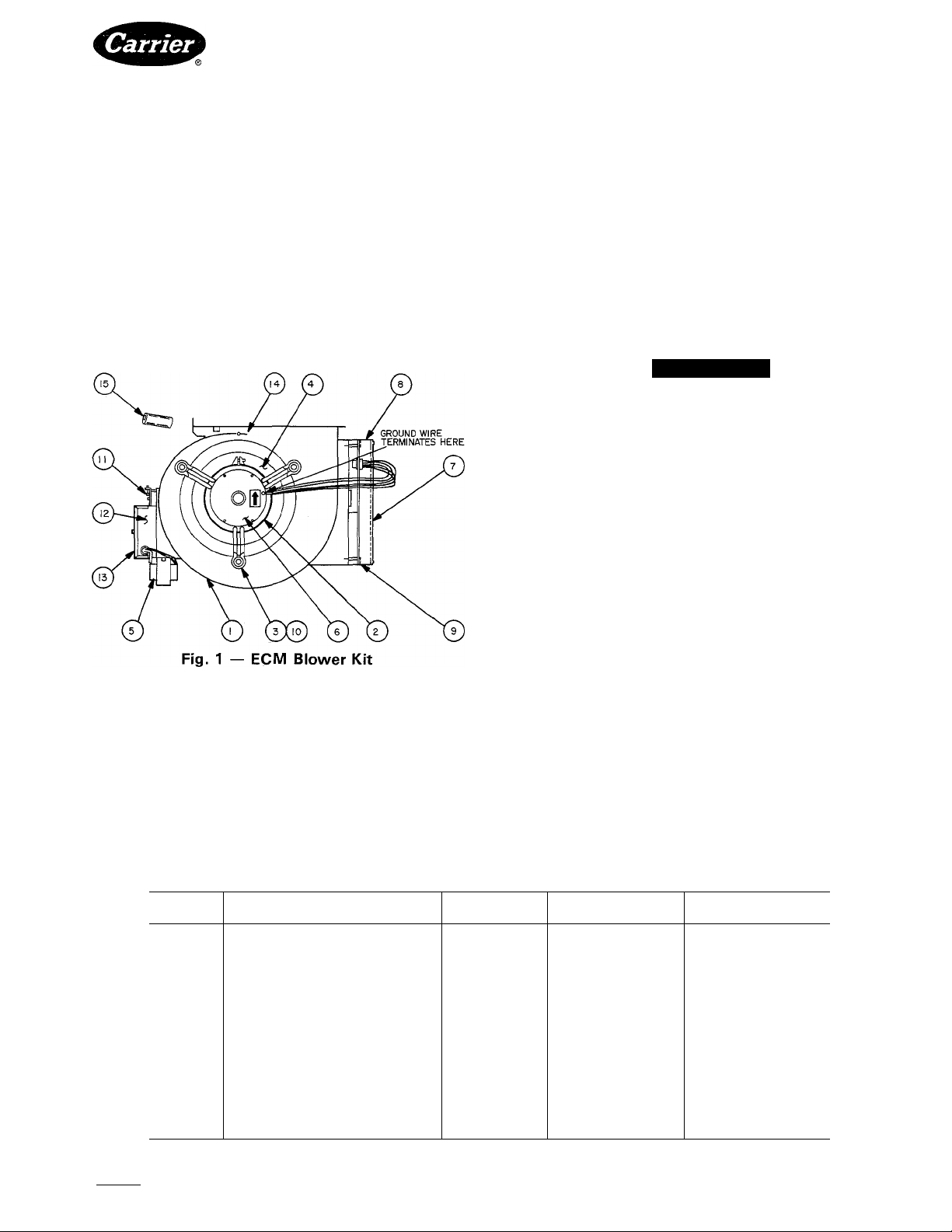

Each ECM blower kit comes completely assembled

with an ECM blower motor and controller, and interface

circuit board. See Table 1 for a list of parts in assembly

shown in Fig. 1.

ECM blower kit is used in conjunction with following

variable speed outdoor units:

38EV024320

38EV036320

38QV024320

38QV036320

This ECM blower is controlled by outdoor unit and

provides variable airflow across furnace coil in response

to variable demand on heat pump or air conditioner. For

emergency heat, interface circuit board allows furnace

control board to operate ECM blower at a fixed rate of

speed. This speed is normally adjusted to midpoint of

rating plate temperature rise range. Interface circuit

board also powers a Parker indoor thermostat. Part No.

HH05ZA001.

Installation of indoor coil expansion valve, and start

up and adjustment instructions are covered in Installa

tion, Start-Up and Service Instructions for the 38EV,QV

outdoor units. See detailed system operation and control

in the 38EV,QV system operation and troubleshooting

guide.

A WARNING

Turn off power at main disconnect switch before

starting installation to avoid possibility of electrical

shock.

TABLE OF CONTENTS

Page

INSTALLATION ..................................................................1-4

SEQUENCE OF OPERATION

TEMPERATURE RISE ADJUSTMENT

CARE AND MAINTENANCE

INSTALLATION

The following steps should be performed by a qualified

service person:

1. Turn off power at main disconnect.

2. Remove blower door.

3. Remove control box from bottom side of blower

shelf and position out of way.

4. Remove electrical leads from numbered side of

blower speed selector.

5. Remove screws securing blower assembly to blower

shelf and slide blower assembly out of furnace.

6. Unpackage ECM blower assembly and set the

minimum and maximum torque settings on ECM

blower control via access in lower mounting bracket

as shown in Fig. 2.

.........................................

....................

..........................................

5

6

6,7

Table 1 — ECM Blower Kit Parts List

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14 Cutoff, Blower 1

15

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book|1 14 PC101 Catalog No. 535-857 Printed in U.S.A. Form58SSB-5SI Pgl 4-87 Replaces:New

Tab |6a|8a

Housing-Blower

Band-Motor Mount

Arm-Motor Mount

Wheel-Blower

T ransformer

Motor (ECM) 1

ECM Motor Controller

Top Blower Control Bracket

Grommet-Isolator

Interface Board

Interface Box

Interface Box Cover

Electrical Noise Suppressor 1

DESCRIPTION

Bottom Blower Control Bracket

QUANTITY

1

1

3

1

1

1

1

1

3

1

1

1

58SSB900131

PART NO.

58SSB309891-701

HC98ZZ480

HC98ZZ242

LA22RA101

HT01AW232

HC42SE113

HR46KH001

58SSB308056-201

58SSB308056-202

09-0135

HK42FA002

58SSB309863-401

58SSB309864-301

79725-2

HK99FA001

58SSB900141

PART NO.

58SSB309891-702

HC98ZZ480

HC98ZZ248

LA22RA100

HT01AW232

HC42SE113

HR46KH001

58SSB308056-201

58SSB308056-202

09-0135

HK42FA002

58SSB309863-401

58SSB309864-301

79725-3

HK99FA001

Page 2

TORQUE SELECT

[ 1

pnnnnnnn

r)

pmnnnnf^

MIN.

LIMIT

, (WHITE)

FURNACE

SIZE

58SSB060 3 7

58SSB080

MIN

SETTING

3

Fig. 2 — Torque Setting

7. Slide ECM blower assembly into furnace and tighten

screws to secure blower assembly to the blower shelf.

8. Reinstall furnace control box on bottom side of

blower shelf.

9. Connect electrical leads from furnace control pre

viously used as blower speed selector taps to

numbered connector which is panel mounted on the

left side of the interface control box. Black lead to

position 1, red lead to position 2, white lead to posi

tion C.

10. Double-check to make sure main power disconnect

is off.

In steps 11 through 14, the 115-v power leads to ECM

blower icit connects in parallel with furnace 115-v power

supply. To do this:

11. Remove cover of auxiliary junction box.

|j

^ MAX.

LIMIT

(BLACK)

SETTING

MAX

10

12. Remove strain relief securing the power leads in place

on the auxiliary J-box.

13. Route power leads from ECM blower kit through

opening in back of auxiliary junction box. Dis

connect black lead from furnace control at door

switch, and connect black lead with 3/16-in. piggy

back quick-connect from ECM blower kit in its place.

Then reconnect black lead from furnace control to

3/16-in. male quick-connect provided on piggyback

connector. Remove wire connecting white lead of

furnace control to line voltage common line. Connect

white wire from ECM blower kit and reinstall wire

nut.

14.

Make sure all power leads are secured in place using

the strain relief provided with this kit.

Reinstall cover to auxiliary junction box.

15.

Disconnect all existing thermostat leads from the

16.

furnace control board if applicable.

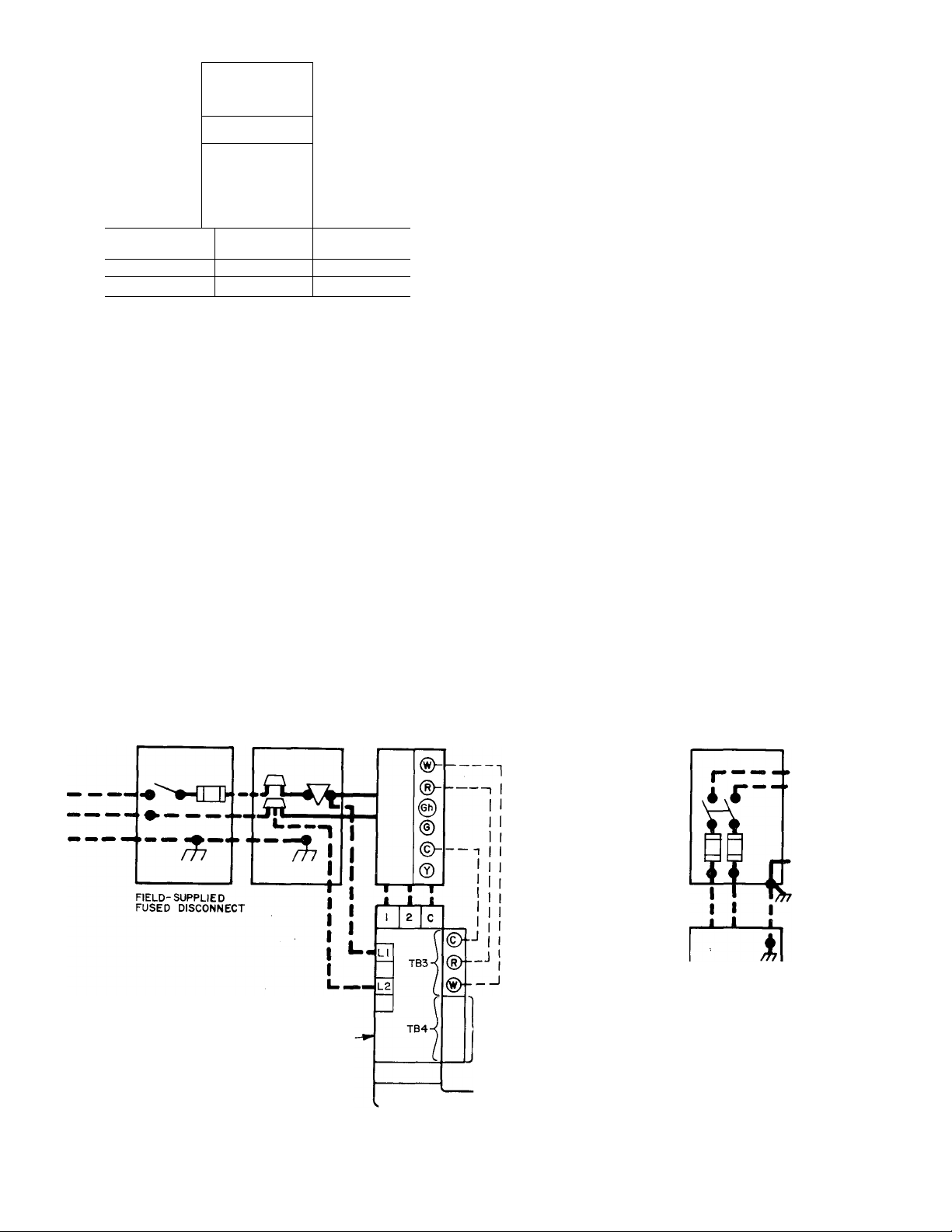

Connect W, R, and C from terminal block TB3

17.

labeled, HEAT, on interface circuit board located on

front of blower housing to their respective thermostat

connections on furnace control board, labeled (W,

R, C) using field-supplied thermostat wire cut 6 in.

in length and stripped 1 /4 in. on each end. See Fig. 3.

18.

Install thermostat following instructions included

with outdoor section. For single zone applications,

route 6-conductor thermostat wire into furnace

through one of the knock-outs in the cabinet. Multi

zone applications require only 3-conductor wire.

Slide electrical noise suppressor provided, over

19.

thermostat wire before making electrical connections

(see Fig. 3) at blower assembly.

NOTE; For electrical interference and noise, refer to

38EV,QV outdoor section Installation, Start-Up and

Service Instructions.

AUXILIARY

JUNCTION BOX

ECM BLOWER KIT

INTERFACE BOARD-

FIELD LOW-VOLTAGE WIRING

■ FIELD HIGH-VOLTAGE WIRING

FACTORY LOW-VOLTAGE WIRING

LOW-VOLTAGE

TERMINAL BLOCK

PARKER INDOOR

THERMOSTAT TERMINALS

ELECTRICAL

NOISE

SUPPRESSOR

----------------------

THERMOSTAT LINE

(SEE FIG. 4a OR FIG. 4b

FOR CONNECTIONS)

INTERFACE CABLE

► SINGLE

PHASE

VAR. SPEED

CONDENSING

1

UNIT

NOTE: If any of the original wire as supplied must be replaced, use same type or equivalent wire.

Fig. 3 — Field High- and Low-Voltage Wiring Diagram

Page 3

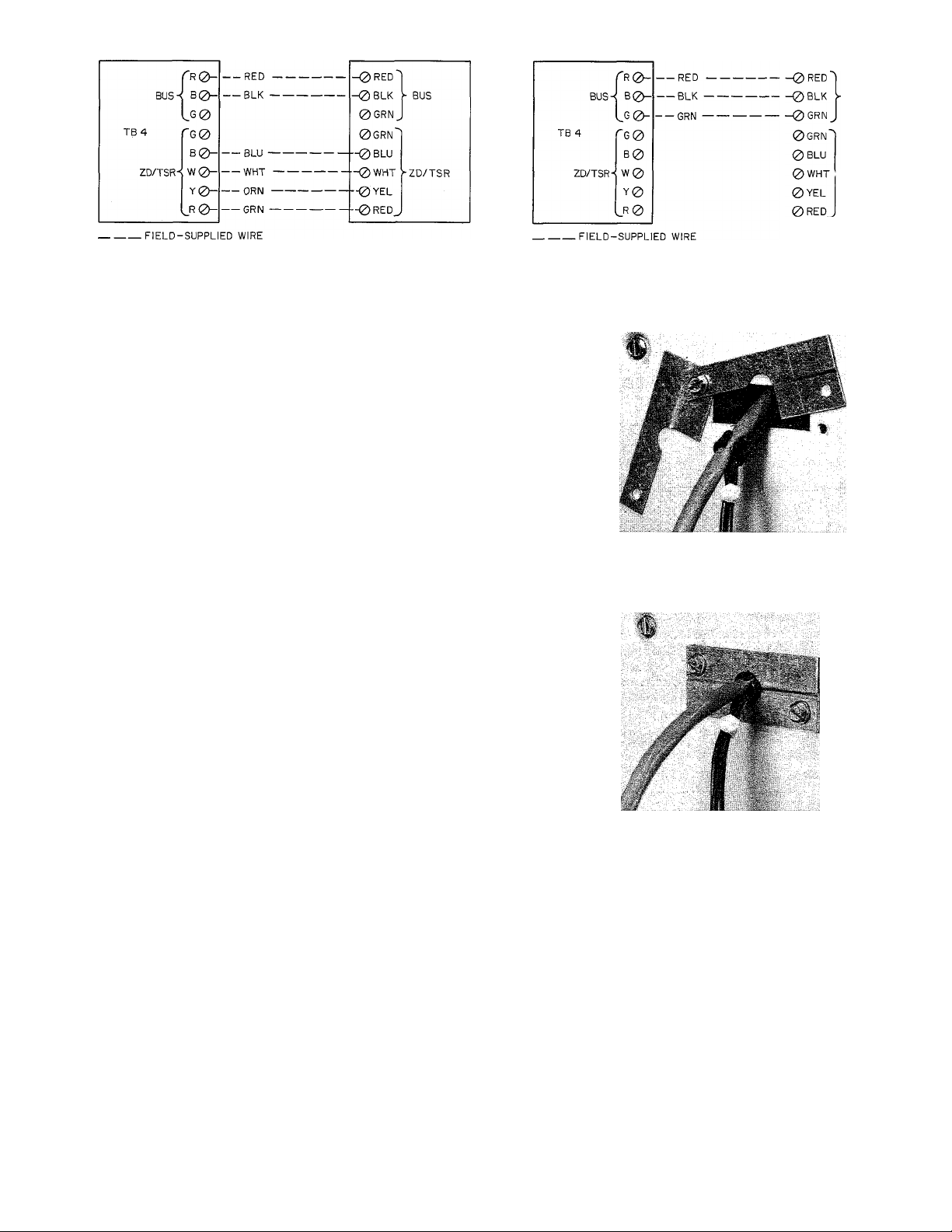

INTERFACE BOARD

PARKER

INDOOR THERMOSTAT INTERFACE BOARD

PARKER

INDOOR THERMOSTAT

BUS

VZD/TSR

4a — SINGLE ZONE

Fig. 4 — Thermostat Connections

20. Strip thermostat wire leads back 1/8-in. and make

connections to blower kit interface board as shown

in Fig. 4a or 4b. Slide noise suppressor down thermo

stat wire and position close to interface board.

21. Route interface cable provided with Model 38EV or

QV outdoor unit to furnace, as described in Model

38EV,QV installation instructions.

22. To permit routing of interface cable into furnace

blower compartment it is necessary to modify furnace

cabinet according to the following procedure,

referring to Fig. 5.

a. Provided with kit are 2 sheet metal covers, screws

and snap bushing. See Fig. 5. Use one cover as a

template. Mark and drill two 1/8-in. diameter

mounting screw holes in either side of furnace

cabinet.

NOTE: Be sure to locate cable entry hole where

cable does not interfere with interior furnace com

ponents. Also, before making hole be sure cable

reaches proper receptacle (PI) on blower acces

sory interface board.

b. Use a chassis punch or similar tool to cut a 1 /2-in.

X 1-5/8 in. rectangular cable entry opening

between the 2 sheet metal cover mounting screw

holes to permit passage of interface cable

connector.

c. Mount the 2 sheet metal covers loosely to cabinet

with one screw. See Fig. 5.

d. Route interface cable through cable entry hole

into furnace blower compartment to receptacle PI

of blower accessory interface board. Connector is

polarized so it cannot be mounted in wrong direc

tion. Be sure spring clips on connector lock in

place to secure connector. Secure cable ground

wire to convenient interface board mounting

screw.

e. Mount indoor coil solenoid expansion valve

(SEV) as described in Model 38EV,QV outdoor

section installation instructions. Route 4-lead

wire harness from SEV through interface cable

entry hole to interface board polarized recep

tacle P2.

f. Open snap bushing provided and install busliing

around interface cable and 4 SEV leads at cable

entry hole with large rim of bushing facing out

ward from cabinet.

g. Slide 2 sheet metal covers together around bush

ing and secure covers loosely with remaining

mounting screw. Adjust cable and leads to allow

slack inside cabinet for strain relief.

h. Tighten both sheet metal cover mounting screws

with bushing positioned to protect cable and

leads from metal edges of cable entry hole.

4b — MULTI-ZONE

COVER DISASSEMBLED WITH

SNAP BUSHING ATTACHED TO LEADS

COVER FULLY ASSEMBLED

Fig. 5 — Cable Entry Hole and Cover

23.

Peel off backing from wiring diagram and stick on

top of previous furnace wiring diagram located on

inside of blower access panel.

24.

Reinstall control and blower access panels. See Fig. 3

for a wiring diagram showing proper field high- and

low-voltage wiring. Make all electrical connections

in accordance with National Electrical Code and any

local codes or ordinances that might apply.

25.

Clean 2-in. x 3-in. area next to unit rating plate.

Peel backing from auxiliary rating plate and stick to

26.

clean area next to unit rating plate.

NOTE: DO NOT apply auxiliary rating plate on top

of the unit rating plate. Make sure both rating plates

are legible after installation.

Page 4

CONNECTION DIAGRAM

SCHEMATIC (NAT'L a PROP)

MOTOR INTERFACE

CONTROLLER BOX

PCBl PCB2

, INTERNAL FUSE

ши (WHEN USED)

lA-TRANSFORHER, 120VAC/24VAC

2D-RELAY, INDUCER MOTOR DPST-N.O.

2E-RELAY, HEATING BLOHER (HER) SPST-K.C.

2F-RELAY, COOLING BLOHER (CFR) DPDT

3A-H0T0R, INDUCER

5F-VALVE, GAS (REDUNDANT)

6CI-B0ARD. P.C. (FURNACE CONTROL)

6C2-B0AR0, P.C. (INDUCER CONTROL)

•6C3-L0CK0UT MODULE

6F-GENERAT0R, SPARK (SOLID STATEl

6H-SHITCH. PILOT FLAME SENSING SPOT (740A)

7H1-SHITCH, LIMIT SPST-N.C.

7H2-SHITCH, DRAFT SAFEGUARD(SPST-N.C.) MANUAL RESET

7H3-SHITCH, AUXILIARY LIMIT(SPST-N.C.) MANUAL RESET

(HHEH USED)

7P-PRESSURE SHITCK, H.O.

7V-SHITCH, FLOH SENSING SPDT

9G-SHITCH, BLOHER DOOR INTERLOCK SPST-li.f.

FACTORY HIRING (120VAC)

FACTORY HIRING(24VAC)

—— FIELD HIRING (120VAC)

- CONDUCTORS ON 6C1 (FURNACE CONTROL BOARD)

CONDUCTORS OH 6C2 (INDUCER CONTROL BOARD)

@ SCREH TERMINAL FOR FIELD HIRING

t=3 1/4 INCH QUICK CONNECT TERMINALS

10B1-CONNECT0R. EDGE (FURNACE CONTROL BOARD)

1OB2-CONNECT0R, EDGE (INDUCER CONTROL B0ARD-7CKT.)

10B3-COHNECTOR, EDGE (INDUCER CONTROL B0ARD-2CKT.)

10B4-CONNECT0R. PILOT

10B5-FACT0RY TEST POINTS (NOT FOR FIELD USE)

1DB6-CONNECTOR, BLOHER MOTOR (PL3 ON PCB2)

IIB-FUSE, IN LINE 2AMP (HHEN USED)

11C-LIHK, FUSIBLE (OVER TEMPERATURE) (1 REQD. ON UPFLOH t

3 REQD. OH DOHNFLOH/KORIZONTAL FURNACE

llE-GROUHDj EQUIPMENT

HTRl-MOTOR (ECM) BLOHER

PCBI-P.C. BOARD (ECM BLOHERCONTROL )

PCB2-P.C. BOARD (INTERFACE)

T-3-THERMISTOR

TP)-TEST POINT

TRAN-24VAC TRANSFORMER

SEV-SOLENOID EXPANSION VALV:

c@=

5/>S

T2-INTERNALLY CONNECTED TO EQUIPMENT GROUND SPARK GENERATOR (6F)

MOUNTING SCREhS.

RELAY (2E) CONTACTS ARE NORMALLY CLOSED UNTIL 120VAC IS APPLIED

TO FURNACE.

IF ANY OF Tl

IT MUST BE I

BLOHER MOTOR (HTR-1) HAS A THERMAL OVERLOAD SWITCH.

BLOHER MOTOR (MTR-1) FACTORY SPEED ADJUSTMENTS ARE FOR AVERAGE

CONDITIONS. SEE ECM BLOHER KIT INSTALLATION INSTRUCTIONS

USE COPPER WIRE ONLY BETWEEN THE DISCONNECT SWITCH AND THE UNIT.

SYMBOLS ARE AH ELECTRICAL REPRESENTATION ONLY.

PRESSURE SWITCH (7P) IS USED FOR PROPANE ONLY.

FUSIBLE LINK USAGE, 1 REQD. OH UPFLOH & 3 REQD. ON DOHHFLOK/

HORIZONTAL FURNACE.

LOCKOUT MODULE (6C3) IS USED FOR PROPANE OR 100« SHUTOFF

NATURAL GAS.

2AMP FUSE IN SECONDARY OF TRANSFORMER FOR CANADIAN UNITS ONLY.

...... .

.................. -

FOR DETAILS OH OPTIMUM SPEED SELECTION.

-------------------

О solid state time delay relay

----

-------------------------------------------1

-isisr*

_____________

I I

310736-401 Rev. A

Fig. 6 — Schematic Wiring Diagram

Page 5

PIN 6 FOR 115 VAC

PIN 9 FOR 208,230 VAC

rh

GND,

WHT cnsv)

WHT Cl 15V) BLUC208V) RED C230V) ,

PR1-2 L2

YEL C208.230)

Fig. 7 — ECM Blower Kit Line-to-Line Wiring Diagram

LE6END

BLOWER CTRL RELAY DPST

BCR

Dl-4

DIODE BRIDGE

GROUND

GND

ILK

SWITCH, BLOWER DOOR INTERLOCK

SPST-N.O. CGA5 FURNACE ONLY)

MTRl

MOTOR CECM) BLOWER

ONR

ON/OFF RELAY DPST

P.C. BOARD CECM BLOWER CTRL)

PCBl

PCB2

P.C. BOARD CINTERFACE)

PLl

CONNECTOR CECM BLOWER CTRL)

PL2

CONNECTOR CECM BLOWER MTR)

PL3

CONNECTOR CFURN./HEATPACK CTRL.)

PL4

CONNECTOR (OUTDOOR SECTION)

CONNECTOR (EXPANSION VALVE)

PL5

RESISTOR CADJ: TEMP. RISE)

RES

TB3

TERMINAL BLOCK (FURNACE CTRL)

TERMINAL BLOCK (THERMOSTAT)

TB4

TRANSFORMER, 120, 208-230VAC

TRAN

PRI/24VAC SEC

FIELD SPLICE

PLUG RECEPTACLE

^ >-

JUNCTION

TERMINAL PCB FACTORY CONN.

TERMINAL FIELD CONN.

FACTORY WIRING C120V AC)

FACTORY WIRING CLOW VOLTAGE)

FIELD WIRING

CONDUCTOR ON PCB2 (INTERFACE)

SCREW TERMINAL FOR FIELD CONN.

0

D.C. GROUND

EQUIP. GROUND

Hi

NOTES:

T2 INTERNALLY CONNECTED TO EQUIP

MENT GROUND.

REPLACED DAMAGE WIRE WITH AWH

C105"C) WIRE OR ITS EQUIVALENT.

BLOWER MTR CMTRl) HAS THERMAL

OVERLOAD SWITCH.

SYMBOLS ARE ELECTRICAL REPRESENTA

TION ONLY.

SOLID LINES INSIDE PCB2 ARE P.C.

5.

BOARD CONDUCTORS.

303892-301 REV. B

SEQUENCE OF FURNACE OPERATION

Heating Cycle — The control circuit of furnace

shown in schematic wiring diagrams, Fig. 6 and 7, results

in the following sequence of operation for the heating

cycle when used with ECM blower kit:

1. When blower door is in place, 120 volts is supplied

through blower door interlock 9G. Both transformers

lA and TRAN are energized supplying 24 volts to

heating blower relay coil 2E, interface circuit board

PCB2, and outdoor section. When heating blower

relay coil 2E is energized its normally closed contact

is opened.

2. The wall thermostat calls for heat which in turn

transmits necessary signal to CPU in outdoor section

which energizes R and W circuit. This closed circuit

supplies power to 24-volt safety circuit containing

limit switch 7H1, fusible link 11C, manual reset draftsafeguard switch 7H2, manual reset auxiliary switch

7H3 (when used), and energizes ECM blower motor

MTRl at a low blower speed.

3. Simultaneously, the pick coil of gas'valve 5F, spark

generator 6F, and inducer-motor relay coil 2D are

energized. Inducer-motor relay contacts 2D close

supplying 120 volts to start inducer blower motor 3A.

Also, another set of contacts in inducer-motor relay

2D close in 24-volt circuit, and lock in inducer-motor

relay coil 2D. The coil is locked in until R and W

circuit or safety circuit opens.

4. When pick coil of gas valve 5F is energized, gas flows

to pilot. Pilot gas is ignited by a spark produced by

spark generator 6F. Simultaneously, inducer motor

3A comes up to speed, actuating flow sensing switch

7V, energizing hold coil of gas valve 5F. Pick coil of

gas valve 5F and spark generator 6F are de-energized

when contacts of pilot-flame sensing switch 6H move

from normally closed position, breaking circuit to

pick coil and spark generator. In approximately 50 to

60 seconds, normally open contacts of pilot-flame

sensing switch 6H close, making circuit to MGV (main

gas valve) of gas valve 5F. Gas valve 5F opens in

approximately 10 seconds, allowing gas flow to main

burners, which are ignited by pilot 6H. Simul

taneously, time-delay circuit in furnace control board

is energized. Approximately 60 seconds after gas

valve 5F opens, heating relay coil 2E is de-energized,

which closes 120-volt contacts of heating relay 2E,

energizing blower control relay BCR and on/off relay

ONR on interface circuit board PCB2. This in turn

steps up ECM blower motor MTR 1 to its heating speed.

5. When thermostat is satisfied, the appropriate signal

is transmitted to CPU in outdoor section which de

energizes R and W circuit. This in turn de-energizes

gas valve 5F, inducer motor relay 2D, and solid-state

time-delay circuit on furnace control board. Gas flow

stops immediately to pilot and main burners. After

approximately 105 seconds, heating relay 2E is ener

gized, which opens heating relay contacts 2E supplying

120 volts to interface circuit board PCB2. This causes

blower control relay BCR and on/ off relay ONR to

de-energize allowing ECM blower motor MTRl

to stop.

NOTE: After a brief interruption of either electric or gas

supply, furnace will not resume operation until contacts

of pilot-flame sensing switch 6H move from normally

open to normally closed position.

Page 6

HEATING SPEED

TRIM POT

TO BLOWER'

Fig. 8 — Variable Speed Blower Interface Board

TEMPERATURE RISE ADJUSTMENT

Furnace must not be operated outside range of tem

perature rise specified on unit rating plate. Determine

air temperature rise as follows;

1. Place thermometers in return and supply ducts as

near furnace as possible. Be sure thermometers do not

see heating element so that radiant heat does not

affect readings. This practice is particularly important

with straight run ducts.

2. When thermometer readings stabilize, subtract returnair temperature from supply-air temperature to deter

mine air temperature rise.

NOTE: If outdoor section and system thermostat are

not installed, temperature rise can be determined by

jumpering R and W circuits on furnace control board.

3. Adjust temperature rise to midpoint of temperature

rise range specified on unit rating plate by adjusting

blower speed. To adjust blower speed locate heating

speed trimpot in interface circuit board (see Fig. 8).

Increase blower speed clockwise to reduce tempera

ture rise. Decrease blower speed counterclockwise to

increase temperature rise.

CARE AND MAINTENANCE

A CAUTION

Because of possible damage to the equipment or

personal injury, maintenance should be performed

by qualified persons only.

For long life, economy and high efficiency, clean

accumulated dirt and grease from blower wheel and

motor annually.

The following steps should be performed by a qualified

service person:

Some motors have prelubricated sealed bearings and

require no lubrication. These motors can be identified

by the lack of oil ports on each end of the motor. For

those motors with oil ports:

Lubricate motor every 5 years if motor is used on inter

mittent operation (thermostat FAN switch in AUTO,

position), or every 2 years if motor is in continuous

operation (thermostat FAN switch in ON position).

A WARNING

To avoid possibility of electrical shock, be sure to

disconnect electrical power before removing access

panels.

Clean and lubricate as follows:

1. Remove access panels.

2. Disconnect R, W, and C thermostat leads on furnace

control board.

3. Remove control box from bottom side of blower

shelf and position out of way.

4. Note location of wires for reassembly. Remove elec

trical leads from numbered panel mount connector

located on left side of interface box.

5. Disconnect 15-conductor cable on interface circuit

board.

6. Note location of thermostat wires for reassembly.

Remove electrical leads from terminal block,TB4 on

interface circuit board.

7. Remove cover of auxiliary junction box. Disconnect

power leads going to interface circuit board.

8. Remove screws securing blower assembly to blower

shelf and slide blower assembly out of furnace.

9. Squeeze release tabs on connector PL2 and pull from

ECM blower controller.

10. Mark blower wheel location on shaft and motor

support location on motor before disassembly to

ensure proper reassembly.

11. Loosen setscrew holding blower wheel on motor

shaft.

12. Remove bolts holding motor mount to blower hous

ing. Slide motor and mount out of housing.

13. Lubricate motor.

a. Remove dust caps or plugs from oil ports located

at each end of motor. If motor does not have these

caps or plugs, bearings are sealed and need no

further lubrication.

b. Use a good grade of SAE 20 nondetergent motor

oil. Put one teaspoon (5 cc, 3/16 oz or 16 to 25

drops) in each oil port. Use of other types or

grades of oil will damage motor. Excessive oiling

can cause premature bearing failures.

c. Allow time for total quantity of oil to be absorbed

by each bearing.

d. After oiling motor, wipe excess oil from motor

housing.

e. Replace dust caps or plugs on oil ports.

14. Remove blower wheel from housing.

a. Mark blower wheel orientation and cutoff plate

location to ensure proper reassembly.

b. Remove screws securing cutoff plate and remove

cutoff plate from housing.

c. Remove blower wheel from housing.

15. Clean blower wheel and motor by using a vacuum

with soft brush attachment. Be careful not to disturb

balance weights (clips) on blower wheel vanes. Do

not drop or bend wheel because balance will be

affected.

16. Reassemble blower by reversing steps 14a through c.

Be sure wheel is positioned for proper rotation and

motor oiling plugs are pointed up when motor is

installed.

Page 7

17. Reassemble motor and blower by reversing steps 9

through 12. If motor has ground wire, be sure it is

reconnected. Be sure wheel is centered in blower

housing. Spin blower wheel to check clearance.

18. Reinstall blower assembly in furnace.

19. Reconnect power leads from interface circuit board.

Reinstall auxiliary junction box cover.

20. Reconnect thermostat leads to terminal block TB4

on interface circuit board.

21. Reconnect 15-conductor cables.

22. Reconnect electrical leads from furnace control to

numbered panel mount connector located on left

side of interface box.

23. Reinstall control box on bottom side of blower shelf.

24. Refer to 38EV,QV outdoor section installation in

structions and inspect for proper blower operation.

Page 8

Manufacturer reserves the right to discontinue, or change at any lime, specifications or designs without notice and without incurring obiigations.

Book|1 |4 PC101 Catalog No. 535-857 Printed in U.S.A. Form58SSB-5SI Pg 8 4-87 Replaces:New

Tab |6a 8a

Loading...

Loading...