Carrier 58DE User Manual

Number One

Air Conditioning

l\Mer

D

e

c

Carrier Parkway • Syracuse NY 13221

J .*•. S jyy,. ^

. ... .

: sv V :

SV.I'rtWiVrt'.Ov.'.N

Gas-Fired Counterflow Furnace

INTRODUCTION

Before installing the furnace, refer to “Procedure for Gas

Furnace Installation” (packaged with the furnace) for infor

mation concerning combustion, venting, piping, and other

standard installation practices. Further reference is made to

the current edition of the American National Standard

Z223.1 National Fuel Gas Code. This publication covers in

stallation, startup, and maintenance.

The Model 58DE Counterflow Gas-Fired Furnaces are

shipped from the factory completely assembled and internal

ly wired ready for indoor heating installation. The air condi

tioning models have a low-voltage terminal strip for con

venience of field wiring.

The design of the 58DE Gas-Fired Furnaces is A.G.A. cer

tified for installation on combustible flooring (with use of

optional combustible floor base) in alcoves, closets, or utility

rooms; with either natural or liquefied petroleum gas.

_

________ ________________________

CLEARANCE REQUIREMENTS

_______________________

(in inches)

Sides.......................................................................................1

Back........................................................................................0

Tbp......................................................................................... 1

Vent Connector (single wall)

Type B (double wall)

.................................................

.......................................................

6

1

Front....................................................................................... 6

Provide service clearance of 30 in. at front of unit.

INSTALLATION

For installation on a combustible floor, see instructions

packaged with the combustible floor base.

For installation on a noncombustible floor, place the furnace

over opening in the floor. Make a seal between the furnace

bottom and the floor to avoid excessive air leakage.

The furnace plenum opening in the floor should correspond

with Figure 5 and Table III.

Installation comprises the following:

*1. Inspection

*11. Location, Ventilation, and Air for Combustion

*III. Gas Piping

*IV. Venting

V. Electrical

VI. Sequence of Operation

VII. Filter Arrangement

VIII. Startup and Adjustment

IX. Care and Maintenance

*Tb perform these sections (or installation steps), refer to

the appropriate sections of “Procedures for Gas-Fired Fur

naces” booklet packaged with this unit.

For accessory installation details, refer to applicable in

stallation literature.

Figure 1 - Model 58DE080

V. ELECTRICAL CONNECTIONS

A. Line-Voltage Wiring

IMPORTANT: Before proceeding with the electrical connec

tions, make certain that voltage, frequency, and phase cor

respond to that specified on the unit rating plate. Also, check

to be sure that the service provided by the utility is sufficient

to handle the additional load imposed by this equipment. Re

fer to the unit rating plate for equipment electrical require

ments.

l^ecíssesí to «Itet.

Use a separate branch electrical circuit for this furnace. A

disconnecting means must be located within sight of, and

within 50 feet of, the furnace.

B. Low-Voltage Wiring

See Figure 3 for wiring diagram showing the proper field

low-voltage wiring. Make all electrical connections in ac

cordance with the National Electrical Code and any local

codes or ordinances that might apply.

© Carrier Corporation 1977

Form 58DE-1SI

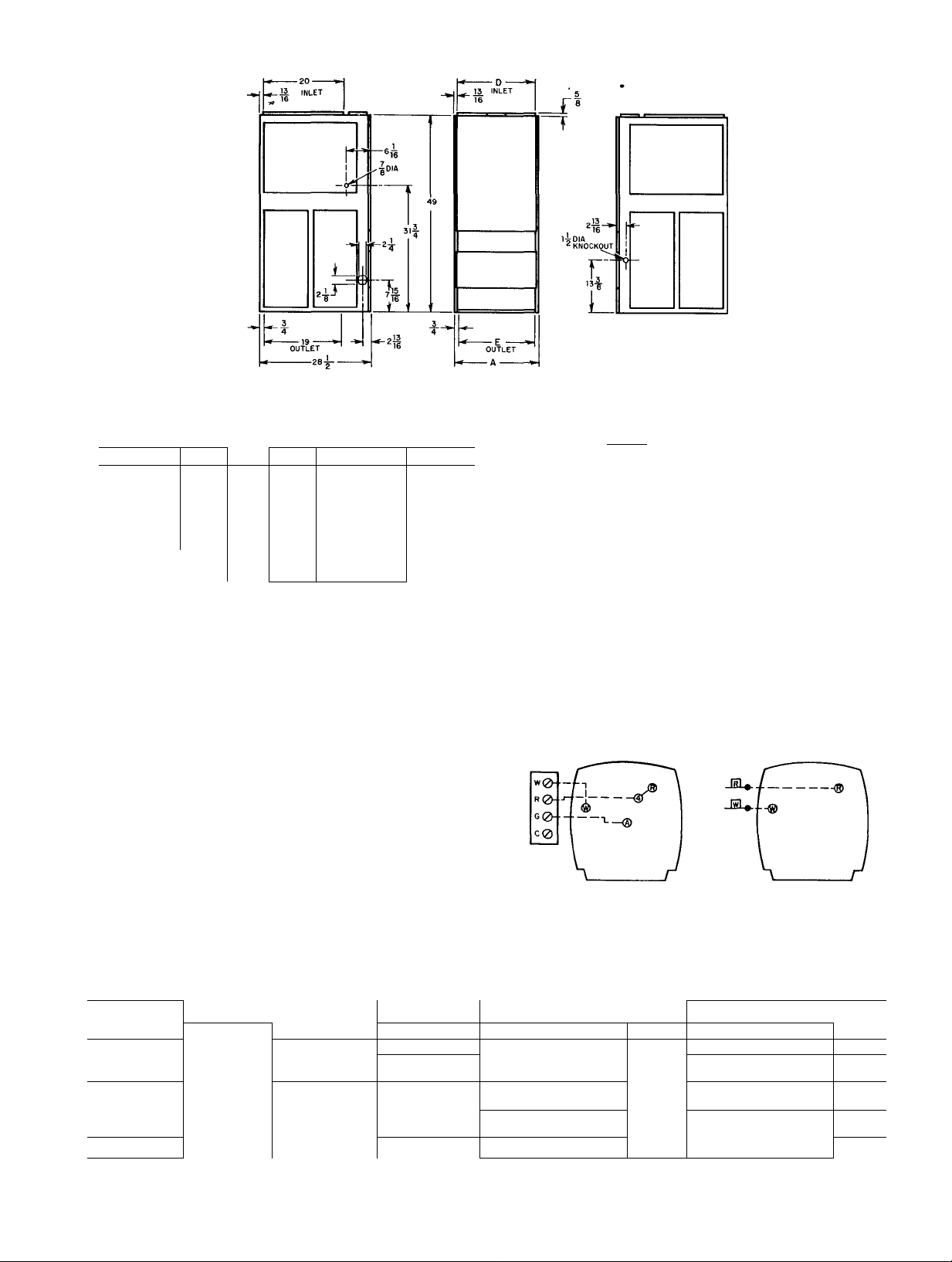

Figure 2—Dimensional Drawing

TABLE l-DIMENSIONS IN INCHES

SIZE 58DE

050-200

080-100

080-200

100-100 ]7%

100-200

125-100

125-200

150-200

14 Vs

1714

17У2

I7V2

21

21

24%,

A

D

]2%

12 У

16

Ì5V4

]5% 16

16 5 165

15У4

16

15У

19У,е

I9V4

19Уе

19У4

23

22У4

VENT SIZE SHIP WT

E

4 131

4 138

4

5 170

5 207

5 212

6 240

143

Make field low-voltage connections at the low-voltage ter

minal strip on units equipped with a cooling relay. On heat

ing-only units, two flagged wires are provided for making

the thermostat connections. See Figure 4.

Set the thermostat heat anticipator at 0.9. If additional con

trols are connected in the thermostat circuit, their amp

draw must he added to this setting. Failure to make the set

ting will result in improper operation of the thermostat.

The room thermostat should be located where it will be in

the natural circulating path of room air. Avoid locations

where the thermostat would be exposed to cold air infiltra

tion, drafts from windows, doors, or other openings leading

to the outside, or exposure to air currents from warm or cold

air registers; or to exposure where the natural circulation of

the air is cut off—such as behind doors, above or below man

tels, shelves, etc.

The thermostat should not be exposed to heat from nearby

fireplaces, radios, televisions, lamps, or rays from the sun.

Nor should the thermostat be mounted on a wall containing

pipes or warm air ducts, or a flue or vent that could affect its

operation and prevent it from properly controlling the room

temperature. Any hole in the plaster or panel through which

FIELD LOW-VOLTAGE WIRING — •

FIELD HIGH-VOLTAGE WIRINGFACTORY LOW-VOLTAGE WIRING-

o-||-o|

-------

_____

9.—

roxmrMCMr rating PLATE

CONTROL BOX HERTZ,& PHASE

0.

-----------

0-00--

FURNACE

___________

LOW-VOLTAGE

TERMINAL BOARD

Q (p (p

1—r

Figure 3—Heating and Cooling Application

Wiring Diagram

NOTE: If any of the original wire, as supplied, must be replaced,

use same type or equivalent wire

UNITS WITH COOLING RELAY HEATING ONLY UNITS

Figure 4—Thermostat Connections

Ш

m

1 I

I J

POWER SUPPLY

SEE UNIT

for voltage.

m

#

TABLE ll-RATINGS AND PERFORMANCE*

SIZE 58DE

050-200 50,000

080-100

080-200

100-100

100-200

125-100

125-200

150-200

*The above ratings are approved for altitudes to 2000 ft For elevations above 2000 ft, reduce ratings 4% for each 1000 ft above sea level

NATURAL AND LP

Input Btuh

80,000

100,000

125,000

150,000

Output Btuh

40,000

64,000

80,000

100,000

120,000

TEMP RISE

RANGE

45- 75

70-100

45-100

70-100

45-100

70-100

45-100

45- 75

Ext Static Pressure

HEATING COOLING

-

0.12 700

0.15 870

0.20

0.20

CFM

617

855 0.5

910

1100

1206

1736

Ext Static Pressure

0.5

0.5

0.5

0.5

CFM

800

1200

1400

1600

1920

t

Loading...

Loading...