Page 1

58ED,PB

HEATING A COOLING

Horizontal Gas-Fired Furnaces

Installation, Start-Up and Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS

GENERAL .................................................................1

INSTALLATION ....................................................2-13

Step 1 — Select Location ...........................................2

Step 2 — Provide Air For Combustion and

Ventilation..............................................................3

Step 3 — Assemble Furnace ......................................3

• DRAFT HOOD

Step 4 — Size Ductwork

Step 5 — Vent Furnace ..............................................4

• MASONRY CHIMNEY

• TYPE B-1 VENT

• ATTIC INSTALLATION

Step 6 — Connect Gas Piping

• BURNER ORIFICES

Step 7 — Make Electrical Connections

Step 8 — Install Filters

.............................................

Step 9 — Reverse Components

(if required) ........................................................ 11-13

START-UP AND ADJUSTMENT ........................13-15

SERVICE AND MAINTENANCE

SAFETY CONSIDERATIONS

These instructions are intended for use by qualified

personnel who have been trained in installing this type of

furnace. Installation of this furnace by an unqualified

person may lead to equipment damage and/or a

hazardous condition which may lead to personal injury

GENERAL

This furnace is designed for use with either natural or

liquefied petroleum (propane) gases and has been design

certified by the American Gas Association It is shipped

as a packaged unit, complete with burners and controls,

and requires only a line voltage ( 115-v) connection to the

................................

...........................................

...................................

.....................

.......................

1

4

5

6

II

15-17

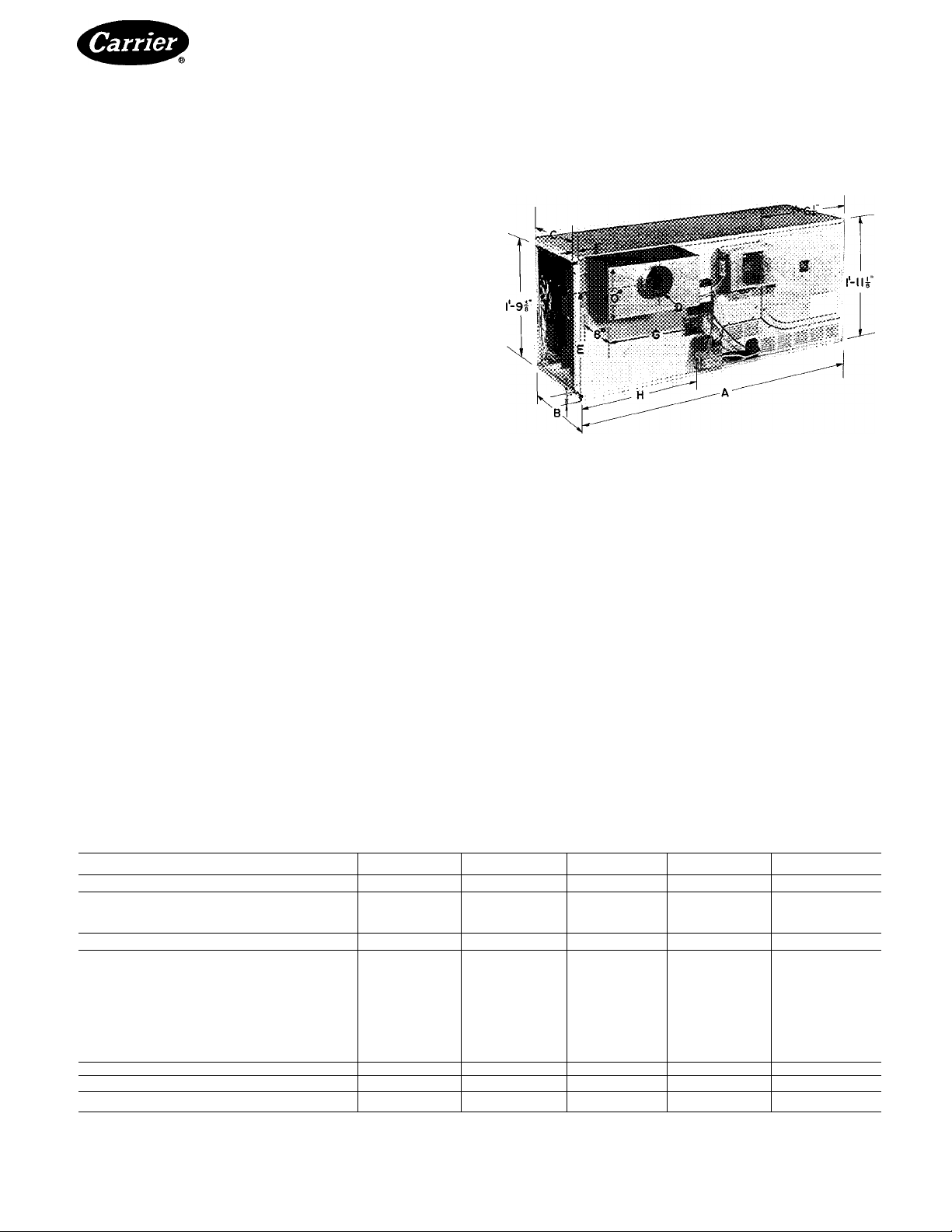

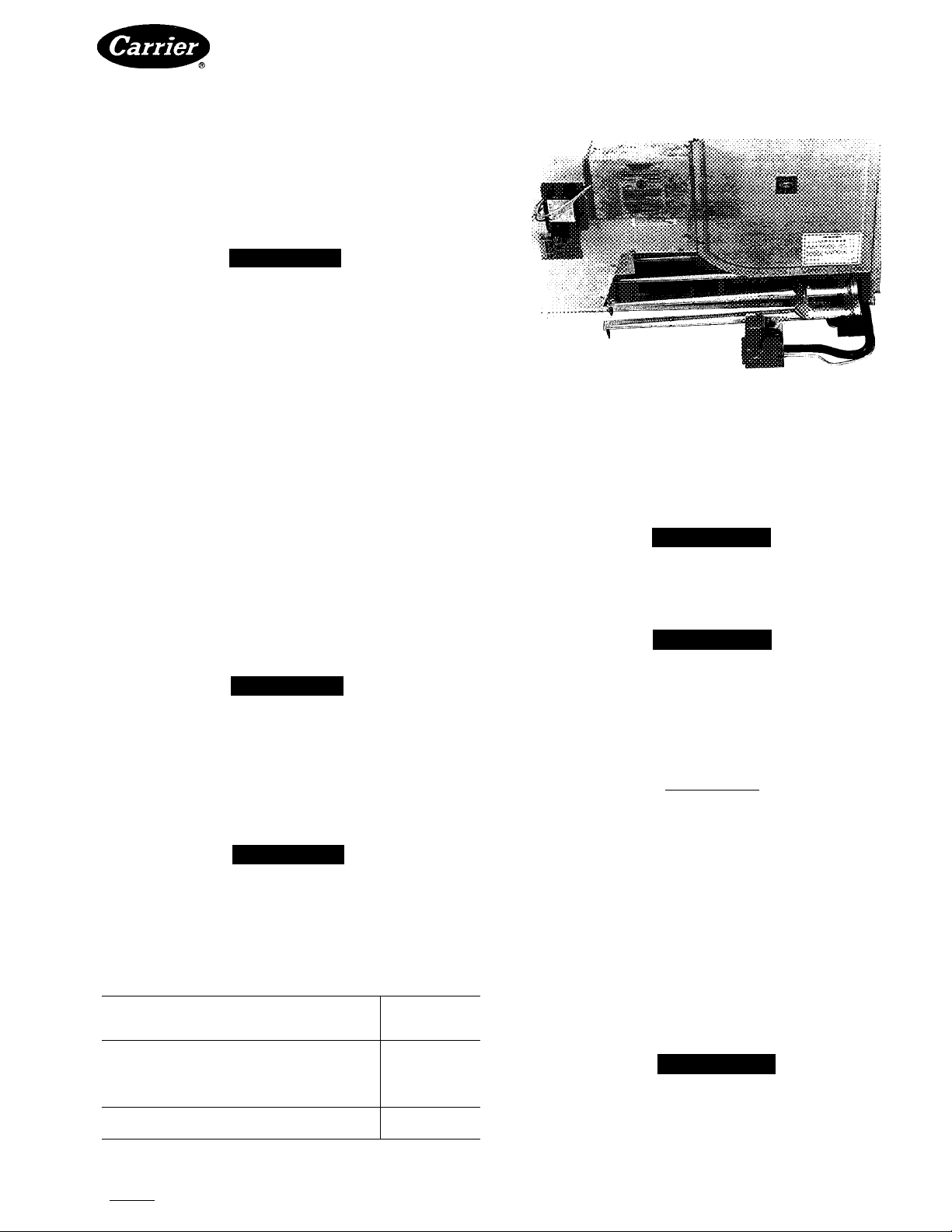

Fig. 1 — Furnace Dimensions

(Modei 58ED Shown)

junction box and a thermostat hookup as shown in the

wiring diagram. The design of the furnace is such that

the burners, controls and flue outlet can be assembled

on the same side to facilitate servicing for installations

where only limited access to the unit is available. (See

Step 9 — Reverse Components.) The 58ED furnace

(with intermittent electronic ignition) is shown in Fig. I.

This furnace has been designed to interface with splitsystem cooling equipment (approved by UL) to provide

year-round air conditioning. The blower is sized for

both heating and cooling. Table I provides physical

data and dimensions of the furnaces, and Table 2 pro

vides airflow data.

The furnace installation must conform with local

building codes or, in the absence of local codes, with the

National Fuel Gas Code, NFPA54-I984/ANSI Z223.I-

I984 For complete information on installation standards

consult the National Fuel Gas Code, obtainable at a

nominal cost from the National Fire Protection Associa

tion, Inc., Batterymarch Park, Quincy MA 02269 or the

Table 1 — Physical Data and Dimensions

SIZE 58ED/PB FURNACE

INPUT (1000 Btuh)*

HEATING CAPACITY (1000 Btuh)t

Non-Weatherized

Indoor

TEMPERATURE RISE (F)

DIMENSIONS (ft-ln.)

NUMBER OF BURNERS

SHIPPING WEIGHT (lb)

‘Ratings shown are for elevations up to 2000 ft above sea level.

For elevations above 2000 ft, deduct 4% of input capacity for

each 1000 ft above sea level

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book|1 |4 PC101 Catalog No 535-834 Printed in U S A Form 58ED,PB-1SI Pg 1 6-85 Replaces: 58PB-1 SI

Tab |6a|8a

Length A

Width B

Duct Opening C

Vent Diameter D

E

F

G

OSO

50

38

39

35-65

4-6

1- V/2

0-11 Ye 0-11 Ye 1-ЗУв

0-4

1- 8%

0- 8%

1-4

1- 9У4 1- 9'/4

1- 7%

2

155

For replacement items use Carrier Specified Parts.

075 100

75 100 125 140

56

58 77

40-70 40-70

4-6

1- VÁ

0-4 0-5

1- 8У4 1-8У4

0- 8% 0-6У8

1-4

1- 7У4 1-7У4 1- 5У4

3

165 190

fDetermined as per U S Government standard tests

75

4-6

1-5

1-4

1-9У4

4

125

94 105

96

40-70

4-8

1- 8Уг 2-0

1- 6Ув 1-10Ув

0-5 0-6

1- 8У4

0- 9У2 0- 9Уг

1- 5У4

1-11 '/4

5

230 250

140

108

40-70

4-8

1- 7У4

1- 5У4

1-11 '/4

1- 5'/4

6

Page 2

58ED,PB

HEATING A COOLING

American Gas Association, 1515 Wilson Boulevard,

Arlington, VA 22209.

A WARNING

The furnace cabinet must have an uninterrupted or

unbroken electrical ground to minimize personal

injury if an electrical fault should occur. The unit

must also be electrically grounded in accordance

with local codes, with the National Electrical Codes

ANSl/NFPA No. 70-1984 or the latest edition. Do

not use gas piping as an electrical ground.

INSTALLATION

Step 1 — Select Location — This furnace may be

located in an attic, basement crawl space, alcove or

suspended from the ceiling of a utility room or basement.

As shown in Table 3, the minimum clearances, or greater,

must be provided between the furnace and adjacent

construction.

A WARNING

Failure to comply with all the recommended clear

ances will result in a fire hazard.

If a furnace is to be installed in a residential garage, it

must be installed so the burners and the ignition source

are located not less than 18 in. above the floor and the

furnace must be located or protected to avoid physical

damage by vehicles.

The furnace should be located as close to the chimney

as possible in order to keep vent connections as short and

direct as possible. The furnace should also be located as

near to the center of the air distribution as possible, and

should be mounted level.

Horizontal Gas-Fired Furnaces

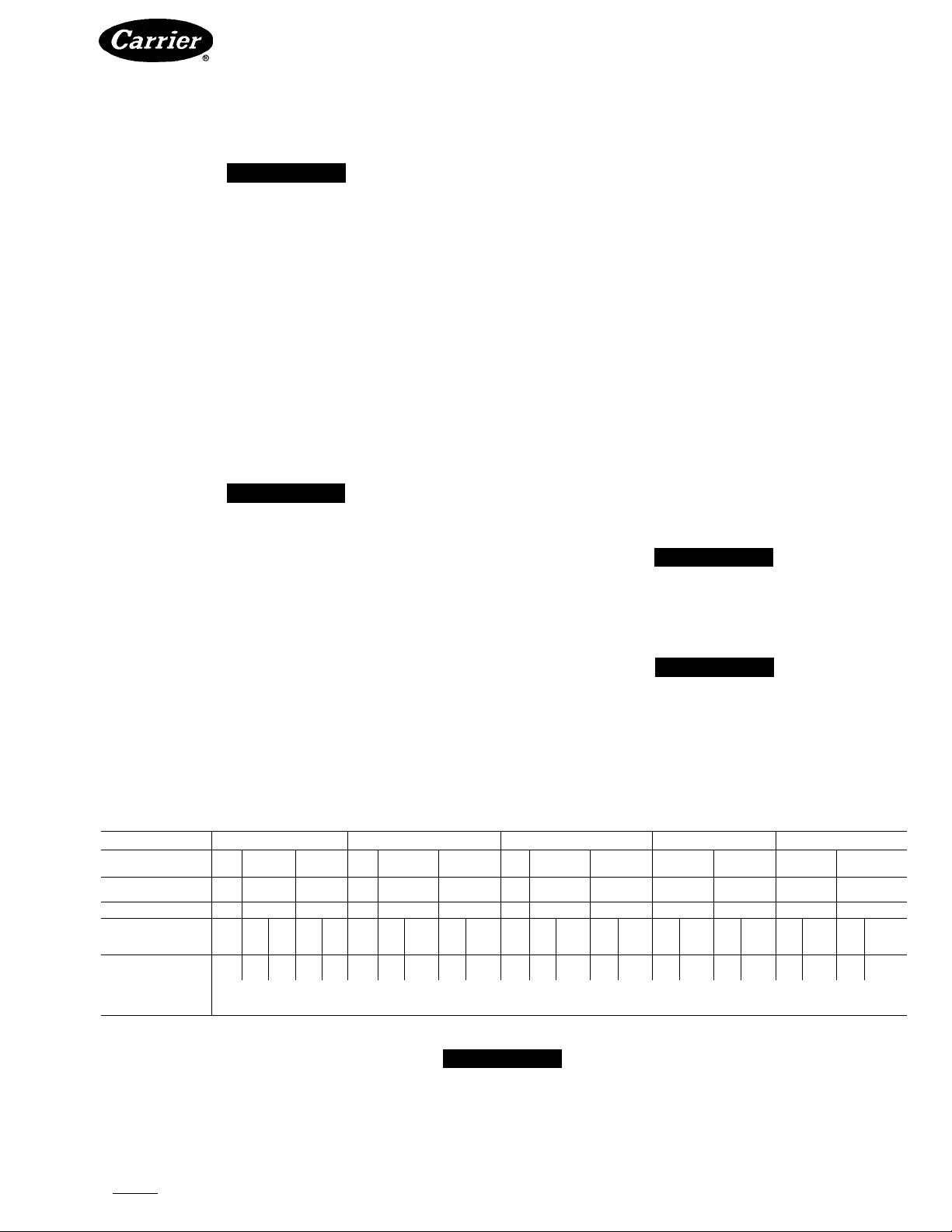

Since this furnace is suitable for attic installation, it

must not be installed directly on carpeting, tile or other

combustible material. Line contact is only permissible

between lines formed by the intersection of the furnace

top and two sides and the building joists, studs or

framing. See Fig. 2

A clearance of at least 30 in. should be provided at the

front of the furnace for combustion air and servicing.

For attic installations, the passageway and service area

adjacent to the furnace should have a floor installed.

The areas adjacent to the combustion air openings must

be covered with fireproof board or sheet metal extending

a minimum of 12 in. from the furnace. See Fig. 2.

If the furnace is to be installed in a crawl space, consult

local codes. Use of a concrete pad one to 2 in. thick is

recommended.

If the furnace is to be suspended from the ceiling, it is

necessary to use steel pipe straps around each end of the

furnace. These straps should be attached to the furnace

with sheet metal screws and bolted to the rafters. The

furnace may also be suspended by an angle iron frame

bolted to the rafters.

A WARNING

Do not place combustible material on or against

the draft hood.

A WARNING

The furnace is not watertight and is not designated

for outdoor installation.

Table 2 — Blower Data (Direct Drive)

FURNACE 58ED/PB

SERiES (15th Digit

of Model No.)

BLOWER SIZE (in)

DXW

MOTOR HP (PSC)

SPEED TAP

WIRE COLOR

BLOWER RPM

EXTERNAL STATIC

PRESSURE (in wg)

A

10x4 10x4

%

Hi

Lo

Red BIk

830 1070

20 50

930

765

050

B c

10x6 10x6

Va

Lo Hi

Red BIk

1080 700 920 1020

760

50 20

20

1220 790 1165

735

075 100

A B c A B c C

10x6 10x6

'/3 %

Lo Lo

Red Red BIk Blu BIk Blu Red

Va

Hi Med Hi

790

20 50 20 50 20 20

1130 995 1260 1090

'/3

Med Lo

1060 820 860

10x8

10x8 10x8

Va

'4

Hi

Med Hi Med

BIk Blu

990 730 1050

50 20 50

AIRFLOW (Cfm)

1290 1090 1530 1360 2010 I860

1310

'/3

BIk Blu

840 1070

20 50 20 50

Hi

BIk

125 140

D B c

12 X 9

'h

Med Hi

Blu BIk

12x9 12 X 12 12x12

3/4

Med Hi

820

Blu BIk Blu BIk Blu

920

1000

20 50 20 50 20

1810

2115

’/2

Med

1070 970

2100 1930

3/4

Hi Med

980 780

2350 2100

A WARNING

When operating furnace in heating mode, the static pressure

and the temperature rise (outlet air temperature minus room

temperature) must be within those limits specified on the

AGA rating plate.

Book|1 |4 PC101 Catalog No 535-834 Printed in U S A Form 58ED.PB-1 SI Pg 2 6-85 Replaces: 58PB-1 SI

Tab I6al8a

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without Incurring obligations.

For replacement Items use Carrier Specified Parts

Page 3

58ED,PB

HEATING A COOLING

Table 3 — Alcove Clearances (In.)

TOP

8 6

’With draft hood in front of furnace

tWith draft hood on back of furnace

SIDES

BACK

8*

18t

DRAFT

HOOD

Line

Contact

SINGLE

WALL VENT

6

Step 2 — Provide Air For Combustion and

Ventilation — For an unconfined space (more than

50 cu ft of volume per 1,000 Btu of aggregate input rating

of all appliances installed in that space) such as a base

ment or attic, infiltration air is normally adequate to

provide air for combustion, ventilation and dilution of

flue gases. Adjoining rooms may be included if there are

no doors between the rooms

For a confined space, where air is taken from an

interior space, 2 permanent openings of equal area are

required. One opening must be within 12 in. of the ceiling

and the other must be within 12 in. of the floor. Each

opening must have a free area of at least 1 sq in. per

1000 Btu of total input rating but not less than 100 sq

inches.

If the outside air is supplied to a confined space, then

the 2 openings must be equal and located as above and

the free area of each must be:

Horizontal Gas-Fired Furnaces

A CAUTION

Whenever this furnace is installed in an area along

with one or more gas appliances, the total Btu input

of all appliances must be included when determining

the free area requirements for combustion and

ventilation air openings.

When ducts are used, they must be of the same cross-

sectional area as the free area of the openings to which

they connect. The minimum dimension of rectangular

air ducts must not be less than 3 inches.

The free area through a design of louver or grille

should be used in calculating the size opening required

to provide the free area specified. If the design and free

area is not known, it may be assumed that wood louvers

have 20-25% free area and metal louvers and grilles have

60-75% free area. Screens used must not be smaller than

1/4 in. mesh and louvers shall be fixed in the open posi

tion or interlocked with the equipment so that they are

opened automatically during equipment operation.

A WARNING

Do not block the combustion air openings in the

furnace. Any blockage will result in improper com

bustion and may result in a fire hazard or unsafe

condition

1. Onesqin. per 4,000 Btu of total input rating when

the air is directly communicated from the outdoors.

2. One sq in. per 4,000 Btu of total input rating when

the air is brought in through vertical ducts.

3 One sq in. per 2,000 Btu of total input rating when the

air is transferred through horizontal ducts.

LINE CONTACT ONLY

PERMISSIBLE BETWEEN

TOP CORNERS OF FURNACE

AND BUILDING JOISTS.

STUDS OR FRAMING.

KEEP ALL INSULATING

MATERIAL CLEAR OF

FURNACE. INSULATING

MATERIALS MAY BE

COMBUSTIBLE.

METAL EXTENDING 12 IN, FROM

UNDER COMBUSTION CHAMBER

Fig. 2 — Attic Installation Showing Point Contact

A CAUTION

For an attic installation, keep insulation 12 in. or

more away from any furnace openings. Some types

of insulating materials may be combustible.

Step 3 — Assemble Furnace — The burner and

controls are shipped in place and the furnace high- and

low-voltage wiring is complete to facilitate the installa

tion. Low-voltage wiring to the field-supplied thermostat

is necessary to complete the unit wiring (see Step 7 —

Make Electrical Connections).

In order to accommodate all the possible field installa

tions that may exist, the unit is designed so that the gas

valve, controls and draft hood assembly may be

assembled on either side of the furnace. Refer to Com

ponent Reversal section for details. After reversal (if

required), return to this section.

A CAUTION

Remove cardboard shipping insert from eye of the

blower scroll before energizing blower.

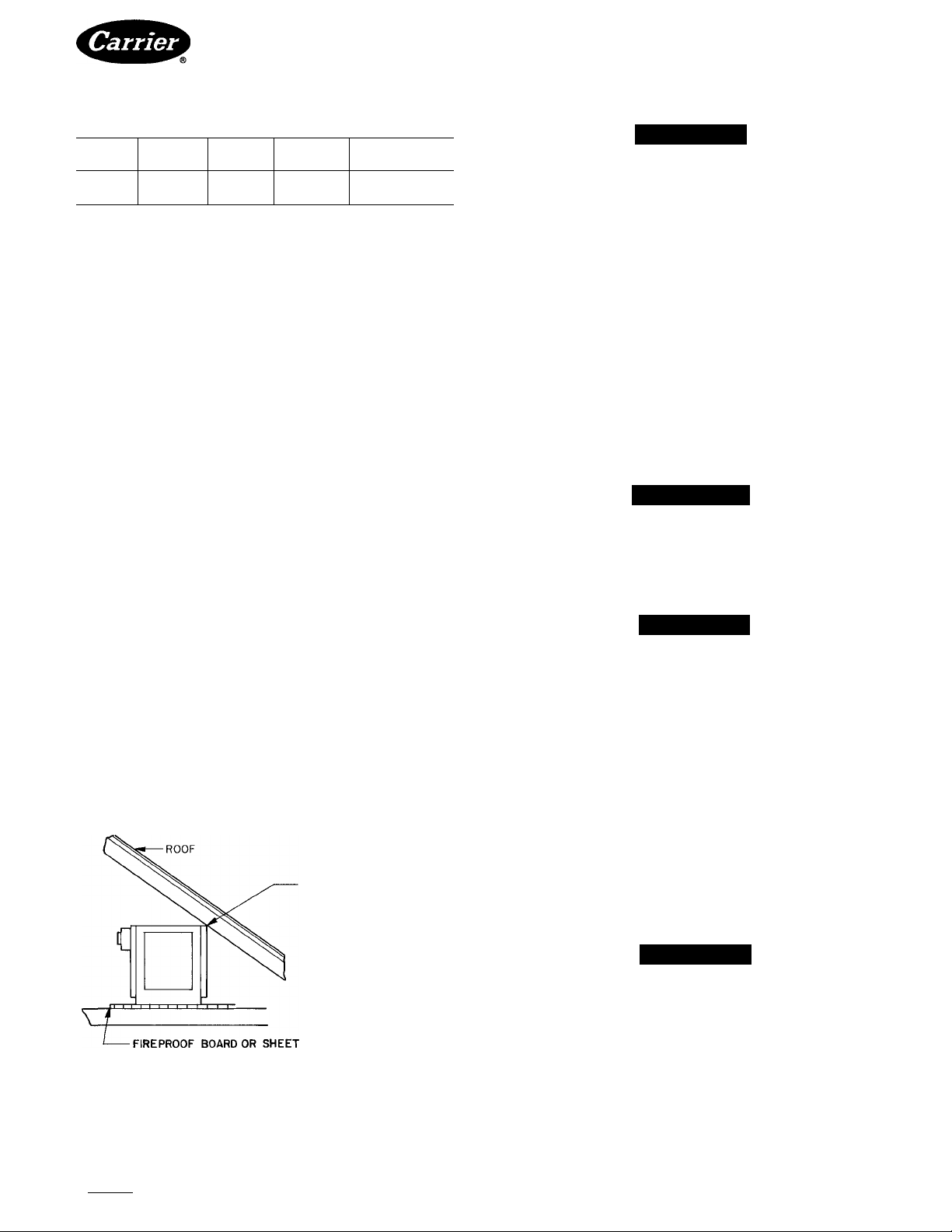

DRAFT HOOD — In order to save shipping space the

draft hood is shipped disassembled (on models 125 and

140 the left panel is spotwelded in place). Remove the

draft hood components from the blower compartment

(on some models the panels might be packed outside the

furnace jacket). On the models 50, 75 and 100 there will

Book|1 |4 PC101 Catalog No 535-834 PrintedinUSA Form 58ED.PB-1 SI Pg 3 6-85 Replaces: 58PB-1SI

Tab l6a|8a

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

For replacement items use Carrier Specified Parts

Page 4

r

58ED,PB

HEATING & COOLING

be a wrapper, 2 panels (one marked with an “R”, the

other marked with an “L”) and a hardware package.

Refer to Fig 3 to assemble the draft hood. Depending

on the model, one or both panels are slid into the proper

location in order to line up the 4 mounting holes. Secure

the panel(s) with the screws provided

After completing the draft hood assembly, it is

advisable to check the overall size with Table 4.

Install the draft hood over the selected flue opening by

placing it on top of the draft hood clip and securing it to

the furnace jacket with screws provided. Adhere to the

necessary clearances as shown in Table 3.

Table 4 — Draft Hood Dimensions (in.)

FURNACE

58ED/PB

050

075

100

125

140

LENGTH

16

16

16 10

17'/4

17'/4

HEIGHT

10

10

10

10

DEPTH

8

8

8

8

8

PIPE DIA.

4

4

5

5

6

Step 4 — Size Ductwork— Proper ductwork sizing

is necessary to ensure satisfactory heating operation

Ductwork should be in accordance with the latest editions

of NFPA-90A (Air Conditioning Systems) and NFPA-

90 B(Warm Air Heating and Air Conditioning Systems).

Follow these recommendations when installingductwork:

1. Install locking-type dampers in all branch or indi

vidual ducts to balance out system. Dampers should

be adjusted to impose the proper static pressure at

the outlet of the furnace.

2 Noncombustible flexible duct connectors are recom

mended to connect both the supply and return ducts

to the furnace

3 In cases where the return air grille is located close to

the fan inlet, there should be at least one 90 degree air

turn between fan and inlet grille. Further reduction

in sound can be accomplished by installing acoustical

air turning vanes and/ or lining the inside of duct with

acoustical material.

Horizontal Gas-Fired Furnaces

When installing the furnace with cooling equipment

for year-round operation, the following recommenda

tions should be followed for series or parallel airflow:

1. In series airflow applications, the coil is mounted

after the furnace in an enclosure in the supply air-

stream. The furnace blower is used for both heating

and cooling airflow.

A WARNING

The coil must be installed on the air discharge

side of the furnace. U nder no circumstance should

the airflow be such that cooled, conditioned air

can pass over the furnace heat exchanger. This

causes condensation in the heat exchanger and

possibly early failure due to rust.

2. In parallel flow installation, dampers must be pro

vided to direct air over the furnace heat exchanger

when heat is desired and over the cooling coil when

cooling is desired.

IMPORTANT: The dampers should be adequate

to prevent cooled air from entering the furnace,

and if manually operated, must be equipped with

means to prevent operation of either the cooling

unit or furnace unless the damper is in the

full cool or heat position.

Step 5 — Vent Furnace — This furnace must be

A CAUTION

Air openings in burner cover, return air grilles, and

warm air registers must not be obstructed.

A WARNING

When supply ducts carry air circulated by the furnace

to areas outside the spaces containing the furnace,

return air shall also be handled by a duct sealed to

the furnace casing and terminating outside the space

containing the furnace.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|1 14 PCiOl Catalog No 535-834 Printed in U S A Form 58ED,PB-1SI Pg4 6-85 Replaces: 58PB-1SI

Tab l6al8a

For replacement items use Carrier Specified Parts.

vented to the outside and in accordance with local codes

or requirements of the local utility. In the absence of local

codes, venting should conform to the requirements of

the National Fuel Gas Code (NFPA 54-1984/ANSI

Z223.1-1984 Part 7).

For additional venting information, refer to ANSI/

NFPA 211 Chimneys, Fireplaces, Vents and Solid Fuel

Burning Appliances.

This furnace must not be vented into a solid fuel

burning chimney. The chimney must be checked for

deterioration. Correct the condition before venting

the furnace into the chimney. The chimney must be

properly lined and sized per National Fuel Gas Code

(ANSI Z223.1-1984/NFPA-54, 1984).

Page 5

58ED,PB

HEATING A COOLING

MASONRY CHIMNEY — This furnace can be vented

into an existing masonry chimney. Normal connections

to a chimney are made using single wall pipe; however,

single wall pipe is not approved to pass through any attic,

inside wall or concealed space or through any floor. For

further information, consult venting section of National

Fuel Gas Code.

TYPE B-1 VENT — The furnace is also approved for

use with a Type B-1 vent that terminates through the roof

(horizontal venting through an outside wall is not

approved). The vent must be terminated with a listed

cap or roof assembly. This venting must be installed in

accordance with the vent manufacturer’s instructions

and be in accordance with all local codes.

ATTIC INSTALLATION — Attic and/or National Fuel

Gas installations require the use of Type B or Type L vent

material The following requirements are provided for

venting system;

1. Ensure the chimney flue is clear of any dirt or debris.

2. Ensure the chimney is not serving an open fireplace.

3. Never reduce the pipe size below the outlet size of

the furnace.

GAS

SUPPLY

Horizontal Gas-Fired Furnaces

4. All pipe should be supported using the proper clamps

and/ or straps

5. All horizontal runs of pipe must have an upward

slope of 1/4 in. per foot.

6. All runs of pipe should be as short as possible with

as few turns as possible.

7. Seams must be tightly joined and checked for leaks.

8 The flue pipe must not extend into the chimney,

but be flush with the inside chimney wall.

9. The chimney or gas vent must extend 3 ft above the

highest point where it passes through a roof of a

building and at least 2 ft higher than any portion of a

building within a horizontal distance of 10 feet. It

shall also extend at least 5 ft above the highest

connected equipment flue collar.

10 Check local codes for any variance.

Step 6 — Connect Gas Piping — Install gas piping

to provide a supply of gas sufficient to meet the maximum

demand without undue loss of pressure between the gas

meter and the furnace. The gas line to the furnace should

be a separate line direct from the meter, unless the

existing gas line is of ample capacity. Refer to Table 5

for sizing gas piping.

Use a joint compound (pipe dope) resistant to the

action of liquefied petroleum gases or to any other

chemical constituents of the gases to be conducted

through the piping.

Before any system of gas piping is finally put into

service, it should be carefully tested to determine if it is

gas tight. The piping must withstand a pressure of 6 in. Hg

for a period of 10 minutes or as required by local

authority.

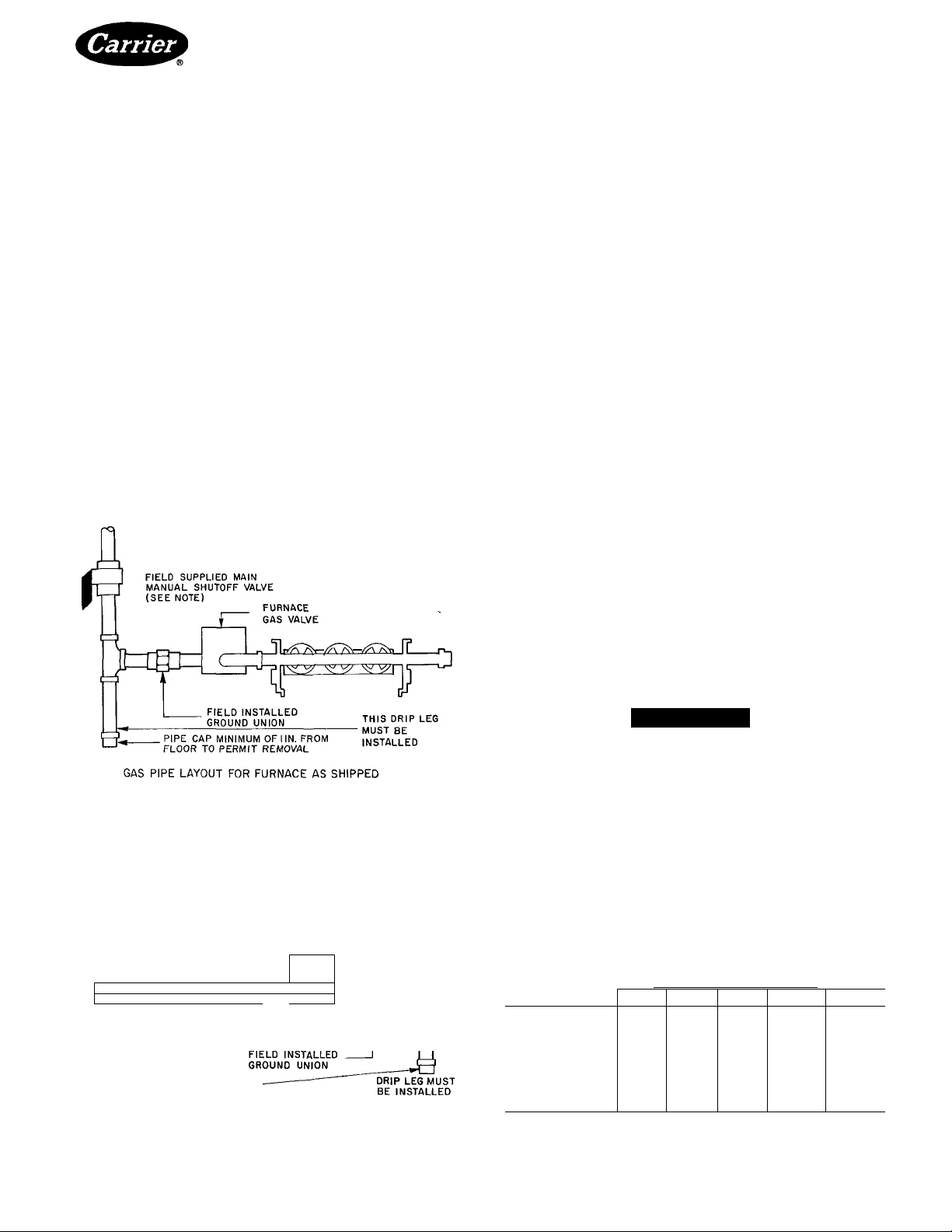

note:

LOCATE MANUAL SHUTOFF VALVE AS REQUIRED

BY THE LOCAL AUTHORITY OR CODE IN THE

ABSENCE OF SUCH A CODE, LOCATE THE

MANUAL MAIN

FROM THE FLOOR

FIELD SUPPLIED MAIN

MANUAL SHUTOFF VALVE

FURNACE

GAS VALVE -

Tl

CD

r'l

PIPE CAP MINIMUM OF I IN. FROM

FLOOR TO PERMIT REMOVAL

GAS PIPE LAYOUT AFTER REVERSING COMPONENTS

(SEE NOTE)

r

Lj

Fig. 4 — Gas Pipe Layout

A WARNING

The furnace and its individual shutoff valve must be

disconnected from the gas supply system during any

pressure testing of that system at test pressures in

excess of 1 / 2 psig. The furnace must be isolated from

the gas supply piping system at pressures equal to or

less than 1/2 psig.

GAS

SUPPLY

The recommended method for installing the gas piping

to the furnace is shown in Fig. 4. Also shown is correct

piping if the gas valve and controls have been reversed

in the field.

Table 5 — Gas Pipe Sizing (Cu Ft of Gas per Hour)'*

)

PIPE (ft)

10

20

30

40

50

75

100

150

* Based on gas pressures of 0 5 psig or less and pressure drop of

0 3 in wg and 0 60 specific gravity gas

DIAMETER OF PIPE — IPS (in.)

Vr % 1 IV4

132

278

92

190

73

152

63

130

—

115

—

—

_

520 1050

350 730

285 590

245 500

215 440

93 175 360

150 305

79

64 120 250

IV2

1600

1100

890

760

670

545

460

380

Manufacturer reserves the right to discontinue, or change at any time, specitications or designs without notice and without incurring obligations.

Book|1 |4 PC101 Catalog No 535-834 PrintedinUSA Form 58ED.PB-1SI Pg5 6-85 Replaces; 58PB-1 SI

Tab l6a|8a

For replacement items use Carrier Specified Parts

Page 6

58ED,PB

HEATING & COOLING

Support all gas piping independent of the furnace. For

propane gas, a tank regulator is required to reduce supply

pressure to 12-13in.wg. For manifold pressure, see

Table 6.

Check all piping for leaks using soapy water and a

brush.

A CAUTION

Never use an open flame when testing for gas leaks!

Use a soap and water solution

A 1/8 in. NPT plugged tap accessible for test gage

connection must be installed immediately upstream of

the gas supply connection to the furnace if one is not

supplied on gas valve.

BURNER ORIFICES — The furnace is supplied with

standard orifices for the gas shown on the rating plate.

Table 6 shows combinations of heating values and

specific gravities for various fuels, from which proper

input may be obtained

Regardless of the type of gas used, when installation is

at an elevation of 2000 ft or more above sea level, orifices

may need to be changed, depending on local gas value.

For operation at elevations above 2000 ft, input ratings

should be reduced at the rates of 4% for each 1000 ft

above sea level. To change orifices, remove the burner

removal cover on the gas valve side of unit. Remove

manifold locking device and slide the manifold tray back

until each burner is clear of heat exchanger tube. See

Fig. 5 Pull the manifold tray forward until burners are

clear of furnace. Remove the locking device from each

burner and pull each burner back off the orifice.

A CAUTION

Take care when removing the pilot burner not to

damage the pilot gas line.

Horizontal Gas-Fired Furnaces

Fig. 5 — Burners Removed From Furnace

After securing the manifold assembly, replace all other

components and/or wiring, being sure that all connec

tions and screws are tightened.

A WARNING

If it is necessary to adjust the manifold pressure

more than 0.3 in. wg, the orifices must be changed

A WARNING

Never set the furnace input rate above that shown

on rating plate.

Use the following formula to determine the furnace

input rate:

After removing orifices, ensure the new orifiees are

Input (Btuh) = Heating Value of Gas (Btu/cu ft)

seated properly and tightened. Replace burners correctly

and secure with the locking device before replacing and

securing the manifold assembly.

X 7200 sec/2 hr

Time in sec for 2 cu ft of gas

Example. If the heating value of natural gas is 1015

_______

______

Btu/cu ft and it takes 75 seconds to burn 2cuft of gas,

A CAUTION

The manifold must be properly positioned in order

to engage the locking mechanism

then:

Input (Btuh) = 1015 Btu/cu ft X 7200 sec/2 hr

75 sec/2 cu ft

Input = 97,440 Btuh

When checking rate, make sure all other gas appliances

are shut off except for pilot burners.

Table 6 — Burner Orifices

Step 7 — Make Electrical Connections — The

control system depends on the correct polarity of the

TYPE OF GAS

(Heating Value — SP GR)

BTU PER CU FT

NATURAL — MANIFOLD PRESS. 3.5 in. wg

800 — 0.6

900 — 0.6

1000 — 0.6

1100 — 0.6

PROPANE — MANIFOLD PRESS. 10 in. wg

2500 — 1.53

Book|1 |4 PC101 Catalog No 535-834 Printed in U S A Form 58ED.PB-1 SI Pg6 6-85 Replaces: 58PB-1SI

Tab l6al8a

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

ORIFICE SIZE

(Drill No.)

43

44

45

46

54

For replacement items use Carrier Specified Parts

power supply. Connect field power wiring and field

ground wire as shown in Fig. 6 and 7.

A WARNING

The unit cabinet must have a separate uninterrupted

or unbroken electrical ground to minimize personal

injury if an electrical fault should occur.

Page 7

“ü

o

(O

O 3

FIELD POWER SUPPLY C115-1-60)

CN0TE5 #2,3 g 4)

SCHEMATIC DIAGRAM

ORN

WHT

<i~I <ri^

ic

9 ij> o Cj)

PI

BLK

GRN

YEL

m

1

GV

(NOTES #2, 3 g 4)

GROUND

COMPONENT ARRANGEMENT

YEL

TB

MLS

g

FS

WHT

IFR

DS

TRAN

WHT

C--BLK-

GRN

RED-i

FM

BLK

BLU WHT

^ o>.1/ 3

Q. sS

« d' Ä

i c 3

E CO i®

= > 45

<D ^

3 O

« 2.

c S:

w o

O 0)

S "n 5’

q o 3

0 5*"

-» 3 o

W C71

•O 05 Q.

g m ®

2; O 2.

<5' <o

m 3

T3 r «

0) _L <

2. 05 S.

"D

CD

THERMOSTAT g SUB-BASE

(NOTE #1)

— Capacitor

Cap.

CC

— Cooling Compensator

DS — Door Switch

IC — Ignition Control

FM

— Fan Motor

FS — Fan Switch

GV

— Automatic Gas Valve

HA — Heat Anticipator

— Indoor Fan Relay

IFR

— Limit Switch

LS

— Mam Limit Switch

MLS

— Outdoor Relay

OR

P — Pilot

— Pilot Igniter

PI

— Spark Igniter

SI

— Terminal Board

TB

NOTES;

1 USE THERMOSTAT PART NO. HH01PD042 WITH SUB-BASE

2. USE COPPER CONDUCTORS ONLY.

3. TO BE WIRED IN ACCORDANCE WITH NATIONAL ELECTRIC

4 MAKE FIELD POWER SUPPLY CONECTIONS TO BLACK AND

5. IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE

6. IMPORTANT - UNIT HAS 5866 CONTROL, IF PILOT

7 DO NOT ATTEMPT TO LIGHT THE FURNACE MANUALLY

8. OR - OUTDOOR RELAY SUPPLIED WITH CONDENSING UNIT.

Fig. 6 — 58ED Furnace Wiring Label — Heat/Cool

LEGEND (FIG. 6 and 7)

Tran — Transformer

CommoH Potential (Not Actual Wiring)

_______Fieid Power Wiring

—Field Ground Wiring

______

Field Control Wiring

PART NO. HH93RZ03G OR ENG. EQUIVALENT.

(N.E.C ) AND LOCAL CODES. UNIT MUST BE GROUNDED

WHITE WIRES CAPRED WITH ORANGE WIRE NUTS.

FURNACE MUST BE REPLACED, IT MUST BE REPLACED

WITH WIRING MATERIAL HAVING A TEMPERATURE RATING

OF AT LEAST 105°C AND BE A MINIMUM OF 16 GA.AWG.

FLAME 15 NOT ESTABLI5HED, CONTROL WILL SHUT DOWN

THE SYSTEM. TO INITIATE A RE-IGNITION TRIAL,TURN

DOWN THERMOSTAT TO LOWEST SETTING, WAIT AT LEAST

60 SECONDS g THEN RESET THERMOSTAT TO ABOVE TEMP

o Component Connection (Unmarked)

O Component Connection (Marked)

Field Splice

—O— Junction

—•— Junction Thermostat to Subbase

T

o

Ñ'

o

3

O

fi)

0)

(D

Q.

T| cn

C 00

D o

c/) W

Page 8

58ED,PB

HEATING & COOLING

Horizontal Gas-Fired Furnaces

CC LU

I— O

o z

UJ 3

¿iJ

< C D O O <

ox cr 3 < Q 3

cn C 3 O 2

_( o

c r

<D

C L U

H- cn cn a: i:u

:3c 3

LU •

o cn

2 L U

< o

Q O

cr. o

o

O -j

a. cn OD

CD I—

3

o

2

z c

o cr

o o

cr :3c

2

3

Ln Q

LU

cr Cl

3 1 — < 2 X C

Q L U 3 ^

' n. ■< <C C 3 I

cn O L—

. 2 >— <

‘ 3 o

O ^ <C I— >

< L i_ t j_ — 1 z < O

O o I

O o I

Ln < o LH <D

3 2 cn

' cr 3

• 223

3 q : Q

) h- 3 2

•3X0

>- h- o

I 3 3

I X o o

h- Q 3

c

o

CO

0)

X

0)

n

(0

u

O)

c

o

(0

c

w

3

Li.

Q

LU

00

in

O

CO

Q>

C

o

d)

CTr

CL^r

3

Cno5

crcn

lU K

:3:(M

O it

Cl

3

Book 11 |4 PC101 Catalog No 535-834 Printed in U S A Form 58ED,PB-1 SI Pg 8 6-85 Replaces'. 58PB-1 SI

Tab I6al8a For replacement items use Carrier Specified Parts

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Page 9

58ED,PB

HEATING & COOLING

Horizontal Gas-Fired Furnaces

o

o

0

(0

a>

1

c

0)

SI

(0

-I

O)

c

u

CD

a

oo

lO

d>

a>

n>

c

Book 11 14 PC101 Catalog No 535-834 PrintedinUSA Form 58ED,PB-1 SI Pg9 6-85

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Tab !6al8a For replacement items use Carrier Specified Parts

Replaces: 58PB-1SI

Page 10

58ED,PB

HEATING & COOLING

Horizontal Gas-Fired Furnaces

>

C

O

(0

0)

X

0)

n

(0

_l

u>

c

0)

o

(0

c

3

u.

m

0.

00

IT)

c

o

o

d)

Bookll 14 PC101 Catalog No 535-834 Printed in U S A Form 58ED,PB-1Sl Pg 10 6-85 Replaces; 58PB-1 SI

Tab l6a l8a For replacement Items use Carrier Specified Parts

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without Incurring obilgations.

Page 11

58ED,PB

HEATING & COOLING

Use only copper wire for 115v supply service to

furnace. When replacing any original wiring, use only

105 C, 16 gage AWG copper wire.

Instructions for wiring the thermostat are packaged

with the thermostat (field supplied). Make connections

as shown in wiring labels at the 24 v terminal board

located on the electrical junction box. When installing

accessories to this furnace, follow manufacturer’s

instructions included with the accessory Except for

thermostat wiring, a minimum of typeT (63 F rise) must

be used.

Step 8 — Install Filters — Filters and racks are

available as accessories. See Fig. 8 for recommended

filter size rating and type.

IMPORTANT: All furnaces must be equipped with

a filter.

Step 9 — Reverse Components (if required).

A WARNING

Before proceeding with component reversal, make

sure that all power is turned off upstream of furnace

and all gas piping is shut off and disconnected from

furnace.

A CAUTION

Before proceeding with field reversing, ensure a

correct wiring diagram is available and/or be

prepared to mark all wiring as it is disconnected.

Horizontal Gas-Fired Furnaces

All references to left or right side of furnace refer to

the furnace looking at the heat exchanger (supply

air side).

The gas valve, pilot burner components and controls

may be reversed as follows:

1 Loosen burner removal cover screws and remove

both covers

2 Disconnect all wires to gas valve and unplug the

igniter cable from the ignition control (if so

equipped).

3. Remove the manifold locking device and slide the

burner and manifold assembly back towards the

furnace inlet until the burners are clear of the heat

exchanger tubes. See Fig. 5.

4. Slide manifold assembly towards the front of furnace .

until it clears the blower deck.

NOTE: Keep manifold assembly straight while

removing. If manifold is cocked, then the assembly

will bind in burner box.

5. Place manifold on a work area and disconnect the

pilot tubing and thermocouple, if equipped, from the

valve

6. Using 2 pipe wrenches (one on the gas valve and

one on the manifold extension pipe), remove the

gas valve

7. Remove the manifold extension pipe from the

manifold (it may be necessary to put a pipe wrench

on the manifold pipe while turning the extension).

8. Using 2 pipe wrenches (one on the manifold pipe

between the pipe cap and burner orifices and one on

the pipe cap), remove the pipe cap.

9. Clean the threads on manifold pipes, gas valve and

pipe cap of any old pipe dope.

NOTE: Use a joint compound (pipe dope) resistant

to the action of liquefied petroleum gases or to any

other chemical constituents of the gases to be

conducted through the piping.

10. Using a suitable joint compound and 2 pipe

wrenches, replace the manifold pipe extension where

the pipe cap was. The pipe extension should be

tightened and positioned so that it is pointing

towards the back of the burners.

11. Using 2 pipe wrenches (one on the manifold exten

sion and the other on the gas valve), tighten gas

INPUT

(iOOO BTUH)

50

75

100

125 20i

140 I5Î

A

(IN)

I4i

I6|

valve to the extension and position the valve so that

the manual knob is in the 12 o’clock position

12. Using 2 pipe wrenches (one on the pipe cap and the

other on the manifold pipe), tighten the pipe cap to

the other end of the manifold pipe

13. Remove the screws holding the pilot bracket to the

crossovers of the first 2 burners When removing

pilot assembly, be carelul not to damage the pilot

note;

FILTER RACK TO INLET

END OF FURNACE INSTALLED

INTO RETURN DUCTWORK.

Fig. 8 — Accessory Filter Rack Assembly

Manulacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|1 |4 PC 101 Catalog No 535-834 PrintedinUSA Form 58ED,PB-1SI Pgll 6-85 Replaces: 58PB-1SI

Tab I6al8a

For replacement items use Carrier Specified Parts

gas tubing and ignition cable (or thermocouple, if so

equipped).

NOTE This step is not required foi 050 size, as

there are only 2 burners

Page 12

58ED,PB

HEATING & COOLING

1415With the pilot bracket removed from burners, rebend

the pilot tubing and thermocouple at the second bend

per Fig. 10. Make sure there are no kinks in tubing.

Connect the 1/4 in. diameter pilot gas tubing (and

the thermocouple, if equipped on standing pilot

models) to the gas valve. Be careful not to kink the

aluminum tubing.

16. Check the pilot position as shown in Fig. 9 and 10.

17. Standing pilot models only: Mount the pilot bracket

on the crossovers of the first 2 burners on the side of

manifold where valve is now mounted (Fig. 10).

Connect thermocouple and the 1/4 in. diameter

pilot gas tubing to gas valve This requires adjust

ments to pilot tubing and thermocouple. It is ex

tremely important not to kink either the thermo

couple or aluminum tubing.

Insert the manifold tray back into the furnace and

18.

slide the burners into the heat exchanger tubes. The

locking device will not engage unless the manifold

is in the correct position.

Lock the manifold in place (on electronic ignition

19.

models, be sure the ignition cable or sensing lead

is not pinched under the burners).

Remove the junction box cover and disconnect the

20

motor leads.

21. Remove junction box. See Fig. 11. On standing

pilot models, remove 2 hole plugs from back side

of furnace and then remove junction hox.

IMPORTANT; Pull junction box straight out

from furnace until fan and limit is clear of side

panel.

22. Mount the junction box on the opposite side of

furnace. Ensure door switch is kept towards the

blower door when mounting junction box

Horizontal Gas-Fired Furnaces

EDGE OF PILOT HOOD TO BE FLUSH TO

NOTE; The fan and limit dial will be upside down

when junction box is properly reversed. This does

not affect the operation of fan and limit.

Remove the strain relief holding the motor wires,

23

route motor leads under blower, feed wires into back

of junction box and snap the strain relief into place.

Reconnect motor leads and replace junction box

24.

cover.

Replace hole plugs in openings where fan and limit

25

and motor leads were

26. Remove the draft hood and draft hood support clip

PILOT

TUBE

PILOT ASSEMBLY AS SHIPPED

FROM FACTORY

PILOT ASSEMBLY AFTER FIELD REVERSAL

PILOT LOCATION

Fig. 10 — Pilot Assembly

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book|1 [4 PC101 Catalog No 535-834 Printed in U S A Form 58ED.PB-1S1 Pg 12 6-85 Replaces: 58PB-1 SI

Tab i6al8a

For replacement Items use Carrier Specitied Parts

Page 13

58ED,PB

HEATING & COOLING

27. Remove the flue box cover and flue box cover gasket

and remount them where the draft hood was located.

See Fig. 12. Do not glue gasket to cover plate.

28. Replace the draft hood support clip and the draft

hood where the flue box cover plate was located.

NOTE; All controls, wiring, draft hood and the

AG A lighting instruction plates must be located

on the same side of the furnace as the automatic

main gas valve. Reattach all wires to gas valve and

check against wiring diagram.

29. Elect}onic ignition models only: Reattach all wires

to the gas valve and the ignition cable to the ignition

control.

Check all wiring against the wiring diagram. Fig.

6 and 7.

30. After the furnace components have been reversed,

return to Step 3, Assemble Furnace Draft Hood and

proceed with remainder of installation.

START-UP AND ADJUSTMENT

Standing Pilot Models

OPERATIONAL CHECKOUT — The automatic gas

valve controls the flow of gas to both the pilot and

main burners. The manual valve built into the automatic

valve body has 3 positions- OFF, PILOT, and ON.

SEQUENCE OF OPERATION — The furnace operates

automatically. It is controlled by a thermostat which is

set at the desired temperature. When indoor temperature

/ drops below this setting, the thermostat turns on the

system.

When the thermostat calls for heat, power from the

transformer energizes the main gas valve (the pilot must

be lit already) and gas flows through the valve to the

burners. The pilot flame lights the burners.

A heat sensing switch automatically energizes the

blower when heat buildup is sufficient. The air is moved

by the blower over the heating element, thus warming it,

and it goes through the ducts to room registers.

When the thermostat is satisfied, the circuit is broken,

de-energizing the main gas valve and stopping gas flow

to the main burners.

Horizontal Gas-Fired Furnaces

The blower continues to run until the heat in the heat

exchanger is removed and then the sensing switch shuts

off the blower.

All forced air furnaces are equipped with a high

temperature limit switch which prevents the furnace

from overheating. If the furnace overheats for any

reason, the high temperature limit opens, breaking the

circuit to the gas valve. The blower motor continues to

run. The main burners cycle on limit until the fault is

corrected.

A WARNING

If overheating occurs, or if the gas supply fails to

shut off, shut off the manual gas valve to the furnace

before shutting off the electrical supply.

Electronic Ignition Models

OPERATIONAL CHECKOUT — The automatic gas

valve controls the flow of gas to both the pilot and main

burners. The manual valve built into the automatic valve

body has 2 positions: OFF and ON.

SEQUENCE OF OPERATION — The furnace operates

automatically. It is controlled by a thermostat which is

set at the desired temperature. When indoor temperature

drops below this setting, the thermostat turns on the

system.

When the thermostat calls for heat, power from the

transformer simultaneously energizes the pilot gas valve

(inside the main gas valve) and the spark igniter. After

the pilot flame is established, the electrode ceases to

spark and the flame sensing probe acts to energize the

main gas valve, permitting gas flow to the burners.

A heat sensing switch automatically energizes the

blower when heat buildup is sufficient. The air is moved

by the blower over the heating element, thus warming it,

and it goes through the ducts to room registers.

When the thermostat is satisfied, the circuit is broken,

de-energizing the main gas valve and stopping gas flow

to the pilot and main burners. The blower continues to

run until the heat in the heat exchanger is removed and

then the sensing switch shuts off the blower.

JUNCTION

BOX

FLUE BOX

COVER

(GASKET IS

UNDERNEATH)

Fig. 11 — Junction Box

(Model 58ED Shown)

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

BookH 14 PC101 Catalog No 535-834 PrintedinUSA Form 58ED,PB-1SI Pg 13 6-85 Replaces: 58PB-1 SI

Fig. 12 — Flue Box Cover

Page 14

58ED,PB

HEATING & COOLING

All forced air furnaces are equipped with a high

temperature limit switch which prevents the furnace

from overheating. If the furnace overheats for any

reason, the high temperature limit opens, breaking the

circuit to the gas valve. The blower motor continues to

run. The main burners cycle on limit until the fault is

corrected.

A WARNING

If overheating occurs, or if the gas supply fails to

shut off, shut off the manual gas valve to the furnace

before shutting off the electrical supply.

The furnace is equipped with either Honeywell S86E or

S86G intermittent pilot control.

S86E control. If the pilot fails to light, the pilot valve

and spark gap remain energized until there is a successful

ignition.

S86G control: If the pilot fails to light, the control

will shut down the system. To initiate a reignition

trial, turn down the thermostat to lowest setting, wait

at least 60 seconds, and then reset thermostat to a setting

above room temperature.

Starting Procedure

STANDING PILOT MODELS

1. Set the manual gas shutoff valve at OFF position.

Wait 5 minutes.

2. Be sure all electrical power to furnace is off.

3 Check all wiring using proper wiring diagram on

inside of blower door.

4. Light the pilot by following instructions on lighting

plate. (Main burners should not light.)

a) Remove burner cover.

b) Turn manual gas shutoff valve to PILOT position.

c) Depress dial, light pilot with a match or taper.

Keep dial depressed until pilot remains lit after

dial is released (approximately 30-45 seconds).

If pilot does not remain lit, repeat operation,

allowing a longer period before releasing dial.

d) Replace burner cover.

5. Adjust pilot flame to envelop the thermocouple a

distance of 3/8 to 1/2 inch. The adjusting screw for

pilot flame is located on main gas control. With

standing pilot, rate is approximately 1000 Btuh.

See Pig. 13.

Fig. 13 — Pilot Thermocouple or Sensor Position

6. With the pilot lit, set thermostat above room

temperature.

7. Turn on power supply to furnace. This energizes

gas valve which should click open. The burners

should not light.

Horizontal Gas-Fired Furnaces

Open the manual gas valve on the automatic gas

valve. Burners should light and remain on.

Check for leaks in manual valve, gas control valve

and gas connections using soap and water solution.

A CAUTION

Never use an open flame when testing for leaks.

Use soap and water solution.

lO. Leave burners on for 15 minutes before making

combustion adjustment

ELECTRONIC IGNITION MODELS

1. Set the manual gas shutoff valve at OFF position.

Wait 5 minutes.

2. Be sure all electrical power to furnace is off

3 Check all wiring using proper wiring diagram on

inside of blower door.

4 Set thermostat above room temperature.

5. Turn on power supply to furnace. This energizes the

pilot valve and spark igniter. The burners should

not light.

6. Turn dial on gas valve to ON position. The pilot

should light. When the sensing probe detects the

presence of pilot flame, the control de-energizes

spark igniter and energizes main gas valve. Main

burners should light and remain on. (If system shuts

down on S86G control, a reignition trial is

necessary.)

7. Check for leaks in manual valve, gas control valve

and gas connections using a soap and water solution.

A CAUTION

Never use an open flame when testing for gas

leaks. Use a soap and water solution.

8 Leave burners on for 15 minutes before making a

combustion adjustment.

Combustion Adjustment

ALL FURNACES — A primary air shutter assembly is

provided on all furnaces. The shutters are factory set for

natural gas furnaces and a closed position for LP gas

furnaces. Readjustment may be required to obtain

optimum setting. Shutters are individual to each burner,

so adjustment of the burner flame must be done one

burner at a time. See Fig. 14.

Loosen the locking screw and close the air shutter.

This should cause the burner flame to glow bright yellow

Open the shutter until the flame turns blue. Lock the

locking screw. See Fig. 15 for proper flame. Repeat this

procedure until all burners are properly adjusted. A

visual check of the main burner and pilot flame should

be made at the beginning of each heating season.

Safety Pilot Check — For Standing Pilot Models

Only. After operating for 15 minutes, turn the valve to

the OFF position. The pilot switch should snap open

between 20 seconds and 3 minutes later. To re-ignite

pilot, follow the nameplate instructions.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|1 |4 PC101 Catalog No 535-834 Printed in U S A Form 58ED,PB-1SI Pg 14 6-85 Replaces: 58PB-1SI

Tab |6a|8a

For replacement items use Carrier Specified Parts

Page 15

58ED,PB

HEATING & COOLING

LOCATION OF SHUTTER

LOCKING SCREW

SHUTTER ADJUSTING TAB

NOTE; LOOSEN LOCKING SCREW BEFORE

ADJUSTING SHUTTER. RETIGHTEN SCREW

AFTER FINAL ADJUSTMENTS ARE MADE.

Fig. 14 — Air Shutter Adjustment

Manifold Pressure Adjustment — For natural

gas, best results are obtained with a manifold pressure of

3.0 in. to 3.5 in. wg. Remove pressure tap pipe plug from

the gas valve and connect to a water manometer. Measure

gas pressure with the furnace on.

Turn regulator adjusting screw in to increase pressure,

or out to decrease pressure.

For LP gases, a 10 in. wg pressure is required. Input

rate must be maintained at ± 2%.

Fan Adjustment Check — This furnace is equipped

with a 3-speed direct drive motor to deliver a temperature

rise within the range specified on the rating plate, between

the return and supply plenums at the external duct static

pressure noted on the AGA rating plate. Consult the

wiring diagram for speed changes on the direct drive

motor. Adjust fan speed so that temperature rise is within

rating plate specifications.

Fan and Limit Control Check — After the furnace

has been operating for at least 15 minutes, restrict the

return air supply by blocking the filters or closing the

return air registers and allow the furnace to shut down on

high limit. The fan must continue to run. Remove the

restriction and the burner should come on in a few

minutes.

The operational checkout is now complete. Be sure to

adjust the thermostat to the desired setting and inform

the owner how to operate the furnace system before

leaving the jobsite.

Stopping the Furnace— Follow these procedures to

shut down the furnace for the summer, if required.

1. Disconnect electrical power to all accessories.

2. To shut down main burner, turn gas cock dial clock

wise to OFF position

3. (Standing pilot models only): To shut down both

pilot and main burner, depress dial and turn clockwise

to OFF position

4. Turn off all electrical power to furnace.

5. Turn off water supply to humidifier, if so equipped.

Horizontal Gas-Fired Furnaces

Fig. 15 — Burner Flames

SERVICE AND MAINTENANCE

A CAUTION

The ability to properly perform maintenance on this

equipment requires certain mechanical skills and

tools. If you are at all uncertain, contact your Carrier

dealer for qualified maintenance and service.

A WARNING

Turn off all gas and electrical power to furnace

before performing any maintenance or service on

unit. Failure to take this precaution may result in

personal injury due to electrical shock or uncon

trolled gas leakage.

NOTE; Furnace is equipped with a blower door switch

which cuts electric power when blower door is removed.

Air Filter — In order to aequaint the user of the furnace

with proper procedure for inspecting and cleaning the

filter, the installer should instruct the user to locate,

remove, clean and replace the furnace filter(s).

NOTE: If furnace is equipped with accessory filter rack,

refer to section on page 11.

A CAUTION

Personal injury or property damage may result if

furnace is operated with the blower compartment

door removed. A lack of adequate combustion air

may cause the main burner flame to be drawn out of

the furnace unless blower compartment door is

secured.

After inspecting or replacing the filter, be sure that

the blower compartment door is securely fastened in

place. Never operate the furnace without a filter.

Lubricating Motors — Direct drive motor and

blower assemblies are factory lubricated and normally

do not require oiling.

Bookjl |4 PC101 Catalog No 535-834 Printed in U S A Form 58ED,PB-1SI Pg 15 6-85 Replaces: 58PB-1SI

Tab l6a|8a

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

For replacement items use Carrier Specified Parts

Page 16

58ED,PB

HEATING & COOLING

Cleaning Heat Exchanger and Venting System

— The heat exchanger and venting system should be

checked each year by a qualified dealer. If necessary,

the following procedures should be performed:

1. Make sure that all utilities are turned off upstream

of the furnace (both gas and electrical supplies),

2. Remove burner covers, manifold assembly with

burners, vent connectors and draft hood.

3. Clean flue box, flue ways, burner box and burners

with brush and/or vacuum cleaner.

4. After cleaning, check pilot for proper position.

Replace all parts.

Table 7 — Trouble Analysis Chart for Standing Pilot Models

Turn off gas and electrical supplies to furnace before servicing. (Unless specific

test requires gas and electrical supplies )

Horizontal Gas-Fired Furnaces

5. Turn on gas and electrical supplies. Test for leaks

using soap and water solution.

A CAUTION

Never use an open flame when testing for gas

leaks. Use a soap and water solution.

6. Check for proper operation of all controls.

A WARNING

SYMPTOM AND PROBABLE CAUSE

BURNERS WILL NOT IGNITE

1 Pilot light out

2 No 115-v power to furnace

3 No 24-v power to control circuit

4. Miswired or loose connections

5. No gas at main burners

6 Flame probe or connecting lead is shorted or open 6, Correct electrical shorting or open circuit

INADEQUATE HEATING

1 Furnace undersized for application

2 Gas input to furnace too low

3 Limit switch cycles main burners

ALDEHYDE ODORS (CO), SOOTING FLAME,

FLOATING FLAME

1 Incomplete combustion — poor flame characteristics

1 Relight pilot If pilot does not remain lit, replace

thermocouple

2. Connect to power supply. Check fuse, wiring or circuit

breaker.

3. Check transformer; replace.

4 Check all wiring and wirenut connections.

5 Check to see if main valve is operating Look for loose or

broken wiring connections If no deficiency is found, replace

valve assembly.

1 Replace with proper size furnace

2. Check gas pressure at manifold. Clock gas meter for input

If too low, increase manifold pressure, or replace with correct

orifices.

3 OFF setting of fan control set too high; reset.

Dirty air filters; clean and reinstall.

Blower speed too low; use faster speed tap

Registers closed, restricted ductwork, open or remove

restriction

Check heat anticipator setting on thermostat, readjust.

1 Air shutter on burners closed, adjust to soft, blue flame.

Check all screws aroundflueoutletsand burner compartment,

tighten

Lack of combustion air, see Installation section

Cracked heat exchanger; replace

Overfired furnace; reduce input or change orifices.

Check vent for restriction; clean as required

REMEDY

Bookp |4 PC101 Catalog No 535-834 PrintedinUSA Form 58ED.PB-1SI Pg16 6-85 Replaces: 58PB-1 SI

Tab I6al8a

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

For replacement items use Carrier Specified Parts.

Page 17

58ED,PB

HEATING & COOLING

Table 8 — Trouble Analysis Chart for Electronic ignition Modeis

Turn off gas and electrical supplies to furnace before servicing (Unless specific

test requires gas and electrical supplies.)

SYMPTOM AND PROBABLE CAUSE

PILOT WILL NOT LIGHT

1 No spark at electrode

2 Spark shorting out to main burner

3. No gas at pilot burner

BURNERS WILL NOT IGNITE

1 No 115-v power to furnace

2. No 24-v power to control circuit

3. Miswired or loose connections

4 No gas at main burners

5 Flame probe or connecting lead is shorted or open

INADEQUATE HEATING

1. Furnace undersized for application

2 Gas input to furnace too low

3 Limit switch cycles main burners

Horizontal Gas-Fired Furnaces

A WARNING

REMEDY

1 Check spark gap, refer to Start-Up and Adjustment section

Check if Induced draft motor is operating If not, check power

to motor

Check for any blockage in flue venting system and chimney,

thereby preventing pressure switch from closing Unblock

if necessary

Check moisture or dirt accumulation on electrode ceramic,

clean ceramic with cloth

Cracked ceramic, replace pilot electrode assembly

Check for loose or broken wiring at and between electronic

control box and electrode. Replace wire as necessary

Check fuse or circuit breaker for 115-v supply to furnace

Check 24 v input to electronic control box If you read 24 v,

and above steps have been completed, replace electronic

control box assembly

Check pressure switch and tube assembly for any blockage

that prevents pressure switch from operating

Check continuity to determine if pressure switch has

disengaged

2 Realign electrode tip away from main burner but maintain

spark gap to pilot burner as noted above

3 Check to see if pilot valve is opening Look for loose or broken

wiring connections If no deficiency is found, replace valve

assembly

1 Connect to power supply Check fuse, wiring or circuit

breaker

2 Check transformer; replace

3 Check all wiring and wirenut connections

4 Check to see if main valve is operating. Look for loose or

broken wiring connections If no deficiency is found, replace

valve assembly

5. Correct electrical shorting or open circuit

1 Replace with proper size furnace

2 Check gas pressure at manifold Clock gas meter for input.

If too low, increase manifold pressure, or replace with correct

orifices

3 OFF setting of fan control set too high, reset

Dirty air filters, clean and reinstall.

Blower speed too low, use faster speed tap

Registers closed, restricted ductwork, open or remove

restriction.

Check heat anticipator setting on thermostat; readjust

ALDEHYDE ODORS (CO), SOOTING FLAME,

FLOATING FLAME

1 Incomplete combustion — poor flame characteristics

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|1 [4 PC101 Catalog No 535-834 PrintedinUSA Form 58ED,PB-1SI Pg17 6-85 Replaces: 58PB-1 SI

1 Air shutter on burners closed, adjust to soft, blue flame

Check all screws around flue outlets and burner compart

ment; tighten

Lack of combustion air, see Installation section

Cracked heat exchanger, replace

Overfired furnace; reduce input or change orifices

Check vent for restriction; clean as required

>% Dorfo

Page 18

58ED,PB

HEATING A COOLING

Horizontal Gas-Fired Furnaces

t

t

BookM 14 PC101 Catalog No 535-834 Printed in U S A Form 58ED,PB-1Si Pg 18 6-85 Repiaces: 58PB-1Si

Tab IGaTSa For replacement items use Carrier Specified Parts

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Loading...

Loading...