Page 1

SERVICE & MAINTENANCE MANUAL

2005

Page 2

TABLE OF CONTENTS

Precautions for Service & Maintenance 2

1.

2. Split System Description 3

3.

Unit Model Designation & Identification 4

PAGE NO.

4. Unit Models & Part Numbers

4

5. System Operating Limits 5

6. System Safety Protections 5

Exploded View of Indoor Unit 6

7.

8. Part List of Indoor Unit 7

9. Exploded View of Outdoor Unit 9

10. Part List of Outdoor Unit 10

11. Wiring Diagrams 11

12. Field Electrical Connections Matching 13

13. Refrigeration Cycle 14

14. Self Diagnostic Function 16

15. Replacing Batteries of Remote Control 17

16. Emergency Operation of Air-Conditioner 17

17. Air Filter Cleaning 18

18. Periodical Checks 19

19. Trouble Shooting 20

1

Page 3

1. PRECAUTIONS FOR SERVICE AND MAINTENANCE

SAFETY CONSIDERATIONS

• Service and maintenance of air conditioning equipment can be hazardous due to system

pressures and electrical components. Only trained and qualified service personnel should

install, repair or service the air conditioning equipment.

• When working on air conditioning equipment, observe precautions in the literature, tags and

labels attached to the unit and other safety codes.

• Wear safety glasses and gloves. Use quenching cloth and have fire extinguisher available for all

brazing operations

WARNING

• This manual describes the service and maintenance of Carrier split room air conditioner

consisting of an outdoor unit and an indoor unit manufactured by Carrier.

What is not covered in Carrier warranty?

1- Failure due to Misuse: Abusing, overloading, careless handling and negligence.

2- Failure due to Accident / Weather: Natural catastrophe, accident due to bad weather (Hail Storm,

Sand Storm, lightning, Flooding, Acid Rain and Air Borne fallout, etc).

3- Failure due to Damages during transport.

4- Failure due to modification:Any modifications done on the unit without Carrier consent.

5- Failure due to Improper Installation: Installation should be performed according to standard.

The decision of Carrier in ascertaining the same will be final. Carrier or its approved dealer

should do installation.

6- Failure due to Improper Maintenance: Lack of professional maintenance, improper adjustments,

use of improper consumables, filters, spare parts other than specified in the Carrier manuals.

7- Failure due to use of non-genuine Carrier Parts, substitute other than Carrier parts.

8- Refrigerant normal noise, wear and tear of deterioration.

9- Inconvenience or commercial loss is not covered.

The decision of Carrier in ascertaining the same will be final. Any such repairs will be carried out

at the expense of the purchaser.

2

Page 4

,

2. SPLIT SYSTEM DESCRIPTION

(d) SUPPLY AIR FROM INDOOR UNIT

cool or warm air comes out of supply air outlet

(c) RETURN AIR TO INDOOR UNIT

The return air from the space to be air-

conditioned passes through the return grille

and then through the anti-bacteria filters to

clean the air from dust and foreign particles

(g) DRAIN HOSE

• Drains the water condensated in the indoor

unit during cooling operation to the outside.

Fig. (1)

CONSOLE & UNDERCEILING SPLIT SYSTEM

53KLE-H SERIES HEAT PUMP

53KLE-E SERIES COOL/ELECTRIC HEAT

53KLE-C SERIES COOL ONLY

(a) INDOOR UNIT

• Mounted inside the space to be air-conditioned.

• In summer it filters, dehumidifies and cools air.

• In winter it filters and heats air.

(e) WIRELESS REMOTE CONTROL (LCD)

Controls power, mode, fan speed, temperature,

and timer, swing and sleep functions.

(f) REFRIGERANT PIPING LINES

Insulated copper piping through which the

refrigerant R22 flow connects the indoor and

outdoor units.

(b) OUTDOOR UNIT

• Mounted outside the space to be air-conditioned.

• It contains compressor, fan, motor, condenser coil

copper tubing and electrical components.

3

Page 5

3. UNIT MODEL DESIGNATION & IDENTIFICATION

42 = Indoor Unit

38 = Outdoor Unit

42

38

UNIT MODEL DESIGNATION IDENTIFICATION (ID)

KLE

Unit Family

28

Compressor

Cooling Capacity

in MBTU/HR

at ASHARE

Conditions

4. UNIT MODELS & PART NUMBERS

INDOOR UNIT

HEAT PUMP COOL ONLY

Model P/N ID Model P/N ID

42KLE14-H 46302213 H 42KLE14-C 46302214 C

42KLE22-H 46302216 H 42KLE22-C 46302217 C

42KLE28-H 46302219 H 42KLE28-C 46302231 C

42KLE32-H 46302222 H 42KLE32-C 46302223 C

COOL/ELECTRIC HEAT 42KLE39-C 46302225 C

Model P/N ID

42KLE39-E 46302243 E

OUTDOOR UNIT

HEAT PUMP COOL ONLY

Unit

Model

38KLE14-H 46303305 H 38KLE14-C 46303309 C

38KLE22-H 46303366 H 38KLE22-C 46303368 C

38KLE28-H 46303367 H 38KLE28-C 46303369 C

38KLE32-H 46303308 H 38KLE32-C 46303312 C

38KLE39-C 46303313 C

P/N ID

Unit

Model

H

E

C

Unit Type

H = Heat Pump

E = Cool/Electric Heat

C = Cool Only

P/N ID

4

Page 6

5. SYSTEM OPERATING LIMITS

COOLING HEATING

Difference

Indoor temperature

Maximum

Minimum

Outdoor temperature

Maximum

Minimum

* When the system is operated above or below these limits for a long time, system diagnostics may detect a malfunction

and the unit will not operate properly.

Dry Bulb

Temp. C°

32

21

55

21

Wet Bulb

Temp. C°

23

15

-

-

MAIN POWER SUPPLY

Nominal

Power Supply

V/1PH/50HZ

200-240 180 264

Difference

Indoor temperature

Maximum

Outdoor temperature

Maximum

Minimum

Voltage

Maximum

Voltage

Dry Bulb

Temp. C°

27

21

Wet Bulb

Temp. C°

-

-

6. SYSTEM SAFETY PROTECTION

6-1 FOR HEAT PUMP SYSTEM

PROTECTION TYPE PROTECTION EFFECT OPERATION MODE WHEN ON

Cold draft prevention Indoor fan off Heating mode During unit operation

Defrost cycle Indoor fan off Heating mode During unit operation

Indoor coil

Freeze protection

Against frequent

Compressor cycling

6-2 FOR COOL ONLY SYSTEM

PROTECTION TYPE PROTECTION EFFECT OPERATION MODE WHEN ON

Indoor coil

Freeze protection

Against frequent

Compressor cycling

WARNING:

During heat pump operation the system will undergo several defrost cycles to remove ice that might

collect on the outdoor unit in very low ambient temperature. In these cycles, the indoor fan will be

automatically off and cannot operate until defrost cycle is completed.

Compressor off Cooling mode During unit operation

Compressor

Time delay

Cooling or heating

modes

At unit start-up or change

of operating mode

Compressor off Cooling mode During unit operation

Compressor

Time delay

Cooling mode

At unit start-up or change

of operating mode

5

Page 7

7. EXPLODED VIEW OF INDOOR UNIT

12/1

2

3/9

7

7

12/2

3/8

3/7

12/4

12/3

Pour 42KLE39

3/5

3/6

&

3/4

12/5

12

3/3

9

1

1/6

11 10

3/1

3/2

5/6

4

5/1

6

5/3 5/4

8

5/2

5/5

6

Page 8

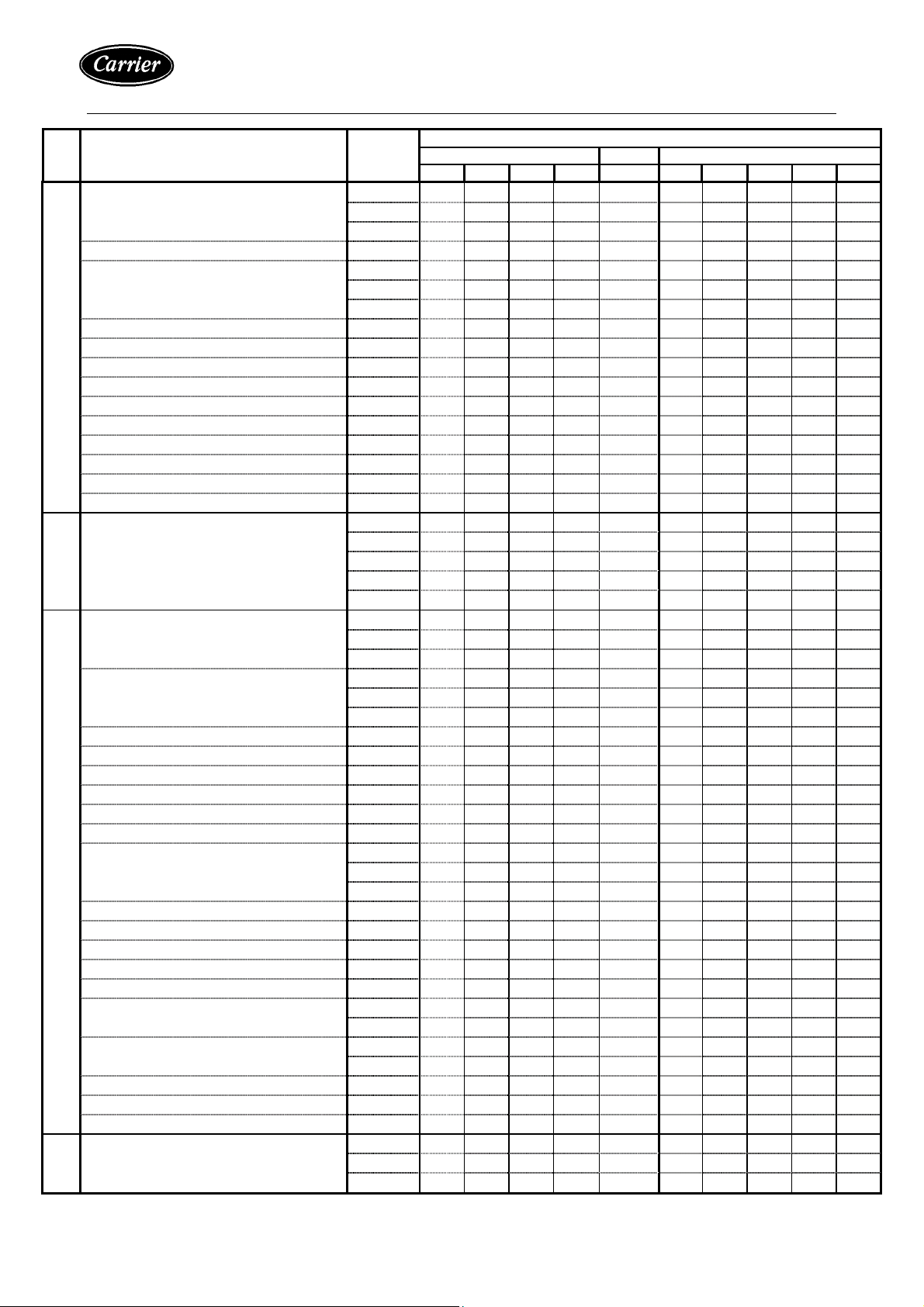

8. PART LIST OF INDOOR UNIT

SR. DESCRIPTION

1 Chassis Subassy 363-13331 1 1 1 1

363-13332 1 1 1 1

363-13333 1 1

1.1 Chassis Side LH Subassy 363-13327 1 1 1 1 1 1 1 1 1 1

1.2 Chassis Back 063-01800 1 1 1 1

063-01801 1 1 1 1

063-01802 1 1

1.3 Fan Deck Support 028-02318 2 2 2 2 2 2 2 2 2 2

1.4 Plug 028-02319 1 1 1 1 1 1 1 1 1 1

1.5 Chassis Side RH Subassy 363-13329 1 1 1 1 1 1 1 1 1 1

1.6 Motor Capacitor

1.6.1 Capacitor 3MFD +/- 5 % , 450 VAC 024-00302 1 1 1 1

1.6.2 Capacitor 5MFD +/- 5 % , 450 VAC 024-00332 1 1 1 1 1 1

1.7 Capacitor Clamp 028-04077 1 1 1 1 1 1 1 1 1 1

1.8 Terminal Block

1.8.1 Terminal Block 6 Poles-30Amps 025-01433 1 1 1 1

1.8.2 Terminal Block 4 Poles-30Amps 025-01413 1 1 1 1 1

2 Evaporator Coil & Headers Subassy 026-00180 1 1

026-00181 1 1

026-00182 1 1

026-00119 1 1

026-00120 1 1

3 Blower Deck Subassy 363-13319 1 1 1 1

363-13320 1 1 1 1

363-13396 1 1

3.1 Blower Deck 063-01807 1 1 1 1

063-01808 1 1 1 1

063-01809 1 1

3.2 Blower

3.2.1 Blower 155 mm Diam x 177.8 mm Width 028-02324 2 2 2 2

3.2.2 Blower 155 mm Diam x 228.6 mm Width 028-02325 2 2 3 2 2 3

3.2.3 Socket Set Screw – Blower 021-00317 2 2 2 2 3 2 2 2 2 3

3.3 Thermistor Clip Nylon 021-00846 1 1 1 1 1 1 1 1 1 1

3.4 Rubber Ring For Housing 028-00685 8 8 8 8 12 8 8 8 8 12

3.5 Motor Support 063-01810 1 1 1 1

063-01625 1 1 1 1

063-07403 1 1

3.6 Motor Clamp Kit C/W Screw & Nut 021-00913 2 2 2 2 2 2 2 2 2 2

3.7 Evaporator Motor

3.7.1 Motor 1/15 HP – 1200/1100/950/800 RPM 024-00096 1 1 1 1

3.7.2 Motor 1/10 HP – 1200/1100/950/800 RPM 024-00097 1 1 1 1

3.7.3 Motor 1/8 HP – 1220/1100/950 RPM 024-00178 1 1

3/8 Blower Housing RH 028-02328 2 2 2 2

028-02329 2 2 3 2 2 3

3.9 Blower Housing LH 028-02326 2 2 2 2

028-02327 2 2 3 2 2 3

3.10 Complement – Motor Shaft 024-00203 1 1

3.11 Coupling Rubber/Metal – Motor 024-00204 1 1

3.12 Bearing & Support Assy – Motor 024-00205 1 1

4 Drain Pan Subassy 363-13334 1 1 1 1

363-13335 1 1 1 1

363-13336 1 1

PART

NUMBER

42KLE-H 42KLE-E 42KLE-C

14 22 28 32 39 14 22 28 32 39

QTY./UNIT

7

Page 9

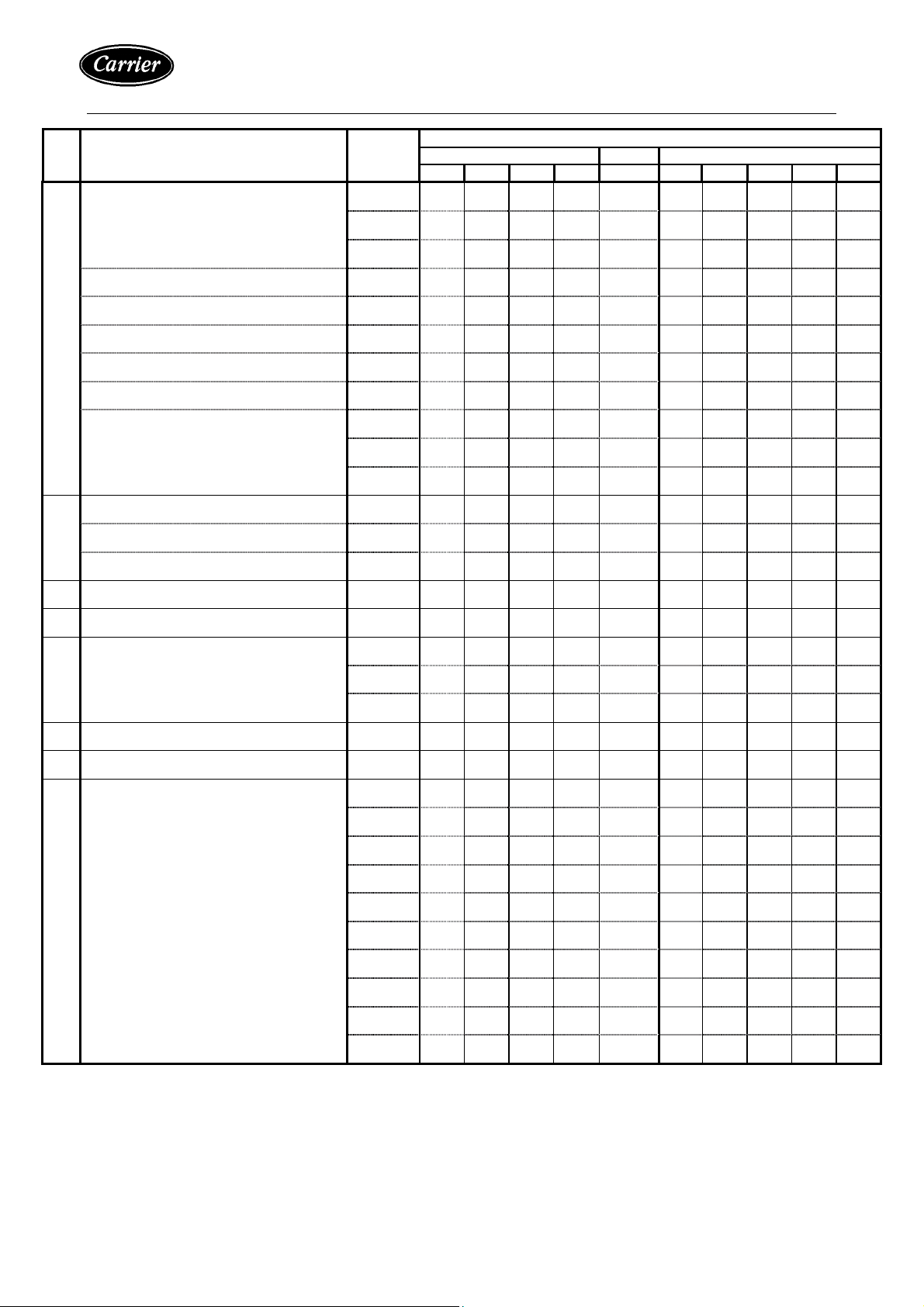

PART LIST OF INDOOR UNIT (Cont.)

SR. DESCRIPTION

PART

NUMBER

42KLE-H 42KLE-E 42KLE-C

14 22 28 32 39 14 22 28 32 39

5 Electrical Box Subassy 363-13338 1 1 1 1 1 1 1 1

363-13364 1 1

5.1 Main PCB 025-03019 1 1 1 1 1 1 1 1 1 1

5.2 Room Sensor 530 ± 30 mm 025-03102 1 1 1 1 1 1 1 1 1 1

5.3 Indoor Coil Sensor 530 ± 30 mm 025-03119 1 1 1 1 1 2 2 2 2 2

5.4 Cable Main PCB – Led PCB 025-01566 1 1 1 1 1 1 1 1 1 1

5.5 Cable Main PCB Step Motor 025-01567 1 1 1 1 1 1 1 1 1 1

5.6 Evap. Electrical Box 028-02334 1 1 1 1 1 1 1 1 1 1

5.7 Set of Cables 025-00883 1 1

025-00884 1 1 1 1

025-00885 1 1 1 1

6 Cabinet Subassy 363-13303 1 1 1 1

QTY./UNIT

(See Details Pages 5 & 6) 363-13304 1 1 1 1

363-13305 1 1

7 Air Filter-Anti Bacteria 028-02303 3 3 4 4 5 3 3 4 4 5

8 Spring for Return Grille 063-01829 1 1 1 1 1 1 1 1 1 1

9 Return Grille Subassy 363-13300 1 1 1 1

363-13301 1 1 1 1

363-13302 1 1

10 Wireless Remote Control 025-03100 1 1 1 1 1 1 1 1 1 1

11 Battery 1.5 Volt Size AAA - Alkaline 025-01125 2 2 2 2 2 2 2 2 2 2

12 Electric Heater Subassy

(Only For 42KLE39-E) 363-19007 1

12.1 Electric Heater Aluminum 4.0 kW 025-00181 1

12.2 Heater Fuse – One Shot 025-01100 1

12.3 Heater Thermostat – Manual Reset 025-01101 1

12.4 Power Relay Heater G7L-2A-T 024-00451 1

12.5 Bracket For Relay 024-00456 1

12.6 Heater Support RH 063-01628 1

12.7 Heater Support LH 063-01627 1

12.8 Heater Support Cover 063-01629 1

8

Page 10

EXPLODE VIEW AND PARTS LISTOF INDOOR UNIT (Cont.)

(A) EXPLODED VIEW

14

3

13

18.1

18.2

1

10

9

8

5

18.3

10

SEE DETAILS

4

6

2

DETAILS

4 & 6

9

Page 11

EXPLODE VIEW AND PARTS LISTOF INDOOR UNIT (Cont.)

(B) PART LIST

SR. DESCRIPTION

PART

NUMBER

42KLE-H 42KLE-E 42KLE-C

14 22 28 32 39 14 22 28 32 39

1 Cabinet Front Subassy 363-13312 1 1 1 1

363-13313 1 1 1 1

363-13314 1 1

2 Cabinet Side RH 028-02305 1 1 1 1 1 1 1 1 1 1

3 Holder Support 028-02321 1 1 1 1 1 1 1 1 1 1

4 Display & Receiver PCB 025-01561 1 1 1 1 1 1 1 1 1 1

5 Cable Main PCB – Led PCB 025-01563 1 1 1 1 1 1 1 1 1 1

6 Receiver Cover 028-02323 1 1 1 1 1 1 1 1 1 1

7 Half Moon Nameplate 029-00108 1 1 1 1 1 1 1 1 1 1

8 Step Motor MP35EAM 024-00167 1 1 1 1 1 1 1 1 1 1

QTY./UNIT

9 Motor Support 028-02314 1 1 1 1 1 1 1 1 1 1

10 Gear 028-02315 1 1 1 1 1 1 1 1 1 1

11 Spacer For Step Motor 063-01839 1 1 1 1 1 1 1 1 1 1

12 Support RH – Flap 028-02311 1 1 1 1 1 1 1 1 1 1

13 Carrier Logo 035-00092 1 1 1 1 1 1 1 1 1 1

14 Cabinet Side LH 028-02304 1 1 1 1 1 1 1 1 1 1

15 Holder Support 028-02321 1 1 1 1 1 1 1 1 1 1

16 Support LH – Flap 028-02309 1 1 1 1 1 1 1 1 1 1

17 Bearing LH – Flap 028-02316 1 1 1 1 1 1 1 1 1 1

18 Flap Subassy 363-11309 1 1 1 1

363-11310 1 1 1 1

363-11311 1 1

18.1 Flap 028-02306 1 1 1 1

028-02307 1 1 1 1

028-02308 1 1

18.2 Blade 028-02312 12 12 16 16 20 12 12 16 16 20

18.3 Blade Bar 028-02313 3 3 4 4 5 3 3 4 4 5

10

Page 12

9. EXPLODED VIEW OF OUTDOOR UNIT

17

1

19/2

4

19/1

19/3

20

2

3

19/5

19/4

15

19/8

19/3

20

21

5

18

16

6

12

8

9

10

13

7

11

14

11

Page 13

10. PART LIST OF OUTDOOR UNIT

SR. DESCRIPTION

PART

NUMBER

38KLE-H 38KLE-C

14 22 28 32 14 22 28 32 39

1 COMPRESSOR C/W GROMMETS & SPACERS

1.1 Mitsushita Comp. 2KS206DSBB04 01500235 1 1

1.2 Mitsushita Comp. 2JS324D3AB07 01500240 1 1

1.3 Mitsushita Comp. 2JS438D3FE02 01500241 1 1

1.4 Copeland Comp. CR37KQ-PFT 01500256 1 1

1.5 Copeland Comp. CR47KQ-PFZ 01500172 1

2 COND. BASE 08107402 1 1 1 1 1 1 1 1 1

3 SUPPORTING LEG ASSY 36314043 4 4 4 4 4 4 4 4 4

4 COND. PARTITION 06307407 1 1 1 1 1 1 1 1

06307436 1

5 CONDENSER COIL SUBASSY.

5.1 Cond. Coil 1 Row – 33.46” x 22” - 12FPI 02600227 1 1

5.2 Cond. Coil 1 Row – 33.46” x 22” - 15FPI 02600228 1 1

5.3 Cond. Coil 2 Row – 33.15” x 22” - 14FPI 02600229 1 1

5.4 Cond. Coil 2 Row – 33.15” x 22” - 15FPI 02600234 1 1

5.5 Cond. Coil 2 Row – 33.15” x 28” - 15FPI 02600231 1

6 CONDENSER MOTOR SUPPORT SUBASSY. 36318880 1 1 1 1 1 1 1 1 1

7 CONDENSER MOTOR

7.1 Motor 1/10 HP-880 RPM 02400154 1 1 1 1 1 1 1 1

7.2 Motor 1/5 HP-860 RPM 02400179 1

8 PROPELLER C/W SOCKET SCREW 8X8MM 02600441 1 1 1 1 1 1 1 1 1

9 ORIFICE PROPELLER 02803112 1 1 1 1 1 1 1 1 1

10 COND. SHROUD 08107406 1 1 1 1 1 1 1 1

06307435 1

21 CARRIER LOGO 02900615 1 1 1 1 1 1 1 1 1

12 HANDLE 02803110 1 1 1 1 1 1 1 1 1

13 GUARD PROPELLER 02803113 1 1 1 1 1 1 1 1 1

14 COND. BACK PANEL 06307409 1 1 1 1 1 1 1 1

06307434 1

15 COUPLING PANEL 06307410 1 1 1 1 1 1 1 1 1

16 SERVICE DOOR 02803106 1 1 1 1 1 1 1 1 1

17 COIL GUARD 02803114 1 1 1 1 1 1 1 1

02803115 1

18 COND. COVER 08107400 1 1 1 1 1 1 1 1 1

QTY./UNIT

12

Page 14

PART LIST OF OUTDOOR UNIT (Cont.)

QTY./UNIT

SR. DESCRIPTION PART NUMBER

14 22 28 32 14 22 28 32 39

19 ELECTRICAL BOX SUBASSY 36314064 1

36314019 1

36314020 1

36314045 1

36313908 1

36313904 1

36314021 1

36314022 1

36313907 1

19.1 DUAL CAPACITOR

19.1.1 Dual Capacitor 35 + 5 MFD/370 VAC 02400376 1 1

19.1.2 Dual Capacitor 45 + 5 MFD/370 VAC * 02400644 1 1

19.1.3 Dual Capacitor 50 + 5 MFD/440 VAC 02400379 1 1 1 1

19.1.4 Dual Capacitor 60 + 5 MFD/440 VAC 02400377 1

19.2 CONTACTOR FOR COMPRESSOR

19.2.1 Contactor 2 poles – 25 Amps 02400580 1 1 1 1 1 1 1 1

19.2.2 Contactor 2 poles – 30 Amps 02400572 1

19.3 TERMINAL BLOCKS

19.3.1 Terminal Block 6 Poles-30 Amps 02501433 1 1 1 1

19.3.2 Terminal Block 4 Poles-30 Amps 02501405 1 1 1 1 1

19.3.3 Terminal Block 3 Poles-30 Amps 02501315 1 1 1 1 1 1 1 1 1

19.4 COND. ELECTRICAL BOX 06307405 1 1 1 1 1 1 1 1 1

19.5 CAPACITOR CLAMP 06301283 1 1 1 1 1 1 1 1 1

19.6 SUPPORT - CABLES 02802523 1 1 1 1 1 1 1 1 1

19.7 ELECTRICAL WIRE HARNESS 02500886 1 1

02500887 1 1 1 1

02500888 1 1

02500873 1

19.8 STARTER FOR COMPRESSOR

19.8.1 PTC Starter Model SPP POW-R-PAK * 02501579 1 1

19.8.2 PTC Starter Model SPP5 02501578 1

20 REVERSING VALVE & ELECTRIC COIL

02200405 1 1 1

02200404 1

21 ACCUMULATOR 02301012 1

22 SENSOR – OUTDOOR COIL 02503121 1 1 1 1

23 TUBING

36319212 1

36319215 1

36319216 1

36319217 1

36319218 1

36319219 1

36319220 1

36319223 1

36319224 1

36319225 1

38KLE-H 38KLE-C

* Option for sizes 14,22 and 28

13

Page 15

11. WIRING DIAGRAM

INDOOR UNIT 42KLE-H SERIES HEAT PUMP

WIRING DIAGRAM

INDOOR UNIT 42KLE-C SERIES COOL ONLY

WIRING DIAGRAM

14

Page 16

WIRING DIAGRAM (CONT.)

INDOOR UNIT 42KLE39-E COOL/ELECTRIC HEAT

WIRING DIAGRAM

15

Page 17

WIRING DIAGRAM (CONT.)

OUTDOOR UNIT 38KLE-H SERIES HEAT PUMP

WIRING DIAGRAM

OUTDOOR UNIT 38KLE-C SERIES COOL ONLY

WIRING DIAGRAM

16

Page 18

12. FIELD ELECTRICAL CONNECTIONS MATCHING

HEAT PUMP SYSTEM COOL ONLY SYSTEM

200-240V ~ 50Hz

200-240V ~ 50Hz

LEGEND

➊ Outdoor Unit

➋ Indoor Unit

➌ Main Switch

➍ Time-delay fuse or circuit breaker

Earth

L Live power supply.

N Neutral power supply.

R Live connection indoor/outdoor unit.

C Neutral connection indoor/outdoor unit.

Y Compressor control.

O Reversing Valve Control (Only for heat pump system).

W2 Outdoor Unit Motor Control (Only for heat pump system).

S1 Outdoor Coil Sensor (Only for heat pump system).

Note: The mains supply must be connected to the outdoor unit.

S2 Outdoor Coil Sensor (Only for heat pump system).

17

Page 19

13. REFRIGERATION CYCLE

HEAT PUMP SYSTEM

18

Page 20

REFRIGERATION CYCLE (Cont.)

COOL ONLY SYSTEM

19

Page 21

14. SELF-DIAGNOSTIC FUNCTION

14-1 INTRODUCTION

- Self-diagnostic function is the key for success of air conditioner.

- The printed circuit boards existing inside the indoor unit are equipped with self-diagnostic function to detect

malfunction and automatically stops the operation at the air conditioner.

14-2 EXPLAINATION OF SELF-DIAGNOSTIC FUNCTION

Once a malfunction is detected, the diagnostic control section will force the system mode to OFF for 3

minutes. After the OFF delay, system mode releases and allowed returning to its normal state. The system

will be allowed to restart on its own. The diagnostic control section will allow the system to fail 5

consecutive times before shutting down the system. If the system is performing an active defrost, both the

compressor drive and reversing valve malfunction test will be cancelled and reinitiated after the following

compressor OFF-ON cycle. The Unit on lamp is scanned every half-second and the error codes are

displayed by the flashing frequency of unit on lamp. The error codes are displayed during SHUT-OFF (3

minutes off and after the 5

14-3 SELF-DIAGNOSTIC FUNCTION DESCRIPTION FOR HEAT PUMP SYSTEMS

The self-diagnostic function included in the control system detects malfunctions of the following

components:

(1) Return Air Sensor (4) Compressor Drive

(2) Indoor Coil Sensor (5) Reversing Valve

(3) Outdoor Coil Sensor

(Rank)

14-4 SELF-DIAGNOSTIC FUNCTION DESCRIPTION FOR COOL ONLY SYSTEMS

The self-diagnostic function included in the control system detects malfunctions of the following

components:

(1) Return Air Sensor (3) Compressor Drive

(2) Indoor Coil Sensor

If more than two errors, the highest rank codes are displayed.

If the highest rank error is cleared, the next rank error codes are displayed.

th

retry failure).

N

UUNNIITT OON

R

TTIIMMEER

CCOOMMP

P

PPOOWWEER

R

No.

1 Return Air Sensor Malfunction 2 Fan Only Mode

2 Indoor Coil Sensor Malfunction 3 Fan Only Mode

3 Outdoor Coil Sensor Malfunction 4 Fan Only Mode

4 Compressor Drive Malfunction 5 Fan Only Mode

5 Reversing Valve Malfunction 6 Fan Only Mode

No.

(Rank)

1 Return Air Sensor Malfunction 2 Fan Only Mode

2 Indoor Coil Sensor Malfunction 3 Fan Only Mode

3 Compressor Drive Malfunction 5 Fan Only Mode

Error

Contents

Error

Contents

Flashing

Frequency

Flashing

Frequency

Allowed

Modes

Allowed

Modes

NOTE

20

Page 22

15. REPLACING BATTERIES OF REMOTE CONTROL

(a) Mount Batteries

Remove the cover of battery compartment at the

bottom back of the remote control by sliding it out in

the direction of the arrow.

(b) Close the cover of the battery compartment

Mount the two-battery size AAA 1.5 Volt supplied with

the remote control.

Note:

During mounting of batteries check battery

symbols (+, -) indicated in batteries

compartment.

(c) Press the RESET button of the wireless remote control

with an object not sharp to operate the remote control.

16. EMERGENCY OPERATION OF AIR-CONDITIONER

EMERGENCY button:

Can be used when the remote control is lost or in operative

N : Position for using the unit via remote control.

C : Emergency position for cooling operation.

H : Emergency position for heating operation.

21

Page 23

17. AIR FILTER CLEANING

- The air filters supplied with the unit are high-efficiency washable and recyclable filters.

- To establish, how frequently these should be cleaned, the operating conditions must be taken in to account.

- REMOVAL OF AIR FILTERS FOR CLEANING:

Open the return grille without removing the two screws and the central

clamp from their position.

Remove acrylic-fiber filters, carbon filter and photocatalytic filter for

cleaning.

- CLEANING OF ACRYLIC-FIBRE STANDARD FILTERS:

First clean the filter with a vacuum cleaner every month. Rinse filter under running water, and dry it

Notes: (1) After cleaning, put the filters back in the correct positions.

(2) Before operating the air conditioner, check that air filters are in their places inside unit.

22

Page 24

18. PERIODICAL CHECKS

For a good operation of the air conditioner it is recommended to carry out checks and maintenance as

indicated.

Recommended maintenance intervals may very depending on the installation environment, e.g. dusty zones,

etc.

Indoor Unit Every Month Every 4 Months Every Year

Clean air filter

Clean drain pipe (2) ●

Change controller batteries ●

Outdoor Unit Every Month Every 4 Months Every Year

Clean outdoor coil from outside (2) ●

Clean outdoor coil from inside ●

Blow air over electric parts (2) ●

Check electric connection tightening (2) ●

Clean fan wheel (2) ●

Check fan tightening (2) ●

Clean drain pan (2) ●

(1) Increase frequency in dusty zones.

(2) Operations to be carried out by qualified service personnel.

●

(1)

23

Page 25

19. TROUBLE SHOOTING

TROUBLE REASON ACTION

Compressor and outdoor fan will not

start

Compressor will not start, but outdoor

fan runs

Compressor runs bur cycles on

internal overload (other than normally

satisfying thermostat)

Compressor operates continuously System undersized for load

Excessive head pressure Dirty outdoor coil

Power failure

Fuse blown or / and circuit breaker tripped

Detective contactor

Low line voltage

Incorrect or loose wiring

Temp. setting too low

Faulty wiring or loose connections in

compressor circuit

Compressor motor burned out, stuck or

internal over-load open

Detective run capacitor

Refrigerant over or under charge

Air or non condensable refrigerant in

system

Detective compressor

Low or too high line voltage

Blocked outdoor coil

Outdoor fan stopped

Detective run capacitor

Faulty fan motor of outdoor section

Restriction in refrigerant system

Capillary or Accurate restricted or ice

clogged.

Temp. setting too low

Defective outdoor fan

Air or non condensable refrigerant in

system

Air restricted or indoor section filter dirty

Detective outdoor fan

Refrigerant over charged

Air or non condensable refrigerant in

system

Outdoor section air restricted

Call power company

Replace fuse or reset circuit breaker

Replace

Determine cause and eliminate

Check wiring diagram and rewire correctly

Reset temp. setting

Check wiring and repair or correct

Replace compressor and determine cause

Replace

Blow refrigerant, evacuate system and

recharge

Blow refrigerant, evacuate system and

recharge

Replace and determine cause

Determine cause and correct

Determine cause and replace

Determine cause and replace

Replace

Replace

Locate restriction and remove

Blow refrigerant, evacuate system and

recharge

Decrease load or increase system size

Reset temp. setting

Check for source and replace

Blow refrigerant, evacuate system and

recharge

Clean filter or remove restriction

Clean coil

Replace

Purge excess refrigerant

Blow refrigerant, evacuate system and

recharge

Remove restricted

24

Page 26

TROUBLE SHOOTING (Cont.)

TROUBLE REASON ACTION

Head pressure too low Low refrigerant charge

Check for leaks, repair and recharge

Restriction in liquid tube

Indoor section air filter dirty

Excessive section pressure Reversing valve hung up or internal leak

Internal pressure relief open

Refrigerant over charged

Suction pressure too low Low refrigerant charge

Indoor unit frosted

Low indoor air or short cycling

Restriction in suction tube

Capillary or accurate restricted or ice clogged

Outdoor fan stopped or cycling on

overload

After batteries have been placed into

Detective fan motor capacitor

Loose leads at fan motor

Fan motor burned out

Motor bearing sized

Batteries are exhausted or have the wrong

Remove restriction

Clear filter

Replace

Check for source and eliminate

Purge excess refrigerant

Check for leaks, repair and recharge

See next trouble

Eliminate cause, check for fan

working

Locate restriction and remove

Blow refrigerant, evacuate system

and recharge

Replace

Check for cause and eliminate

Replace

Check for cause and eliminate

Replace batteries or check polarity.

the remote control, the display is not lit.

When pressing the recessed lock

adjustment button, hour figures on

display do not flash.

appear on display.

When pressing start button, unit does

not acknowledge signal with a beep.

polarity.

Recessed button has not been pressed

correctly.

Recessed button for time setting is blocked due

to excessive pressure during use.

Remote control has been irreversibly damaged. Replace with a new one.

Main switch is OFF. Switch it to ON position.

Remote control batteries are exhausted. Replace batteries.

Remote control has not been pointed correctly to

the receiver of indoor unit.

There are obstacles (curtains, walls, etc.)

between the remote control and the indoor unit

Receiver on the indoor unit or the remote control

is under intense sun radiation.

Signal transmission is obstructed by severe

interference from an electromagnetic field.

Press with a round point, avoid

exerting strong pressure

Check and repair. When pressing any button, all symbols

Turn remote control OFF and repeat

the operation in the correct direction.

Repeat the operation after having

removed the obstacles.

Avoid direct sun on the unit, shut

curtains or shades.

Avoid sending signals when

computers or household appliances

25

(Food processors, coffee makers,

etc.) are operating close by cellular

or cordless telephones may also

interfere with the control.

Page 27

TROUBLE CHART (Cont.)

TROUBLE REASON ACTION

When pressing stop button, unit does

Remote control batteries are exhausted. Replace batteries.

not acknowledge signal with a beep.

When pressing any function button,

the remote control shows the function

requested on the display, but unit

does not acknowledge signal receipt

with a beep and does not carry out the

function.

Remote control has not been pointed

correctly to the receiver of indoor unit.

There are obstacles (curtains, walls, etc.)

between the remote control and the

indoor unit

Receiver on the indoor unit or the remote

control is under intense sun radiation.

Signal transmission is obstructed by

severe interference from an

electromagnetic field.

Main switch is OFF. Switch it to ON position.

Remote control batteries are exhausted. Replace batteries.

Remote control has not been pointed

correctly to the receiver of indoor unit.

There are obstacles (curtains, walls, etc.)

between the remote control and the

Turn remote control OFF and repeat the

operation in the correct direction.

Repeat the operation after having

removed the obstacles.

Avoid direct sun on the unit, shut curtains

or shades.

Avoid sending signals when computers or

household appliances (Food processors,

coffee makers, etc.) are operating close

by cellular or cordless telephones may

also interfere with the control.

Turn remote control OFF and repeat the

operation in the correct direction.

Repeat the operation after having

removed the obstacles.

When pressing any button, display will

not change

Air conditioner will not start.

indoor unit

Receiver on the indoor unit or the remote

control is under intense sum radiation.

Signal transmission is obstructed by

severe interference from an

electromagnetic field.

The triangle symbols 2 ▲is on, as

another signal is being transmitted.

Main supply switch is OFF Switch to ON

Fuses or main switch are blown Replace fuses

Protection against frequent compressor

cycling is ON

Selected temperature is higher than the

room temperature in the cooling mode (or

lower in the heating mode).

Avoid direct sun on the unit, shut curtains

or shades.

Avoid sending signals when computers or

household appliances (Food processors,

coffee makers, etc.) are operating close

by cellular or cordless telephones may

also interfere with the control.

Wait for signal 2 ▲ to disappear and

repeat the operation.

Wait for 3 minutes.

Correct selected temperature.

26

Page 28

TROUBLE CHART (Cont.)

TROUBLE REASON ACTION

Air conditioner is not supplying

enough cooling.

Air conditioner is not supplying

enough heating.

Green LED is flashing System malfunction contact service

Air flow cannot circulate freely Remove obstructions.

Dirty filters reduce air quantity circulating. Clean air filters

Doors and/or windows are open. Close doors and windows

Fan speed has been set to “Low” Set fan speed at high speed.

Air flow direction is not correct Adjust airflow direction as per the mode

Selected temperature is higher than the

room temperature in the cooling mode.

Air flow cannot circulate freely Remove obstructions.

Dirty filters reduce air quantity circulating. Clean air filters

Doors and/or windows are open. Close doors and windows

Fan speed has been set to “Low” Set fan speed at high speed.

Air flow direction is not correct Adjust airflow direction as per the mode

Selected temperature is Lower than the

room temperature in the heating mode.

chosen.

Correct selected temperature.

chosen.

Correct selected temperature.

Refer to the installation manual for fault

A slight mist is emitted from the

indoor unit during cooling

A slight whistling noise is heard when

is heard when the air conditioner

starts or stops.

Water vapor (mist) emanating from the

outdoor unit.

Unpleasant smells coming from the

indoor unit.

center after having made the following

checks:

• Air filters are clean.

• Air circulation is not

obstructed.

• Outdoor unit coil is not

obstructed with a service

reduction of air circulation.

The cool air from the indoor unit is coming

into contact with the room air.

This is due to the refrigerant beginning to

circulate or an adjustment of the

refrigerant pressures.

It is normal in heat pump operation, when

defrost is automatically activated.

Unpleasant smells can be caused by

substances accumulated in the air filters

code reading to be notified to service

center.

Restart air conditioner after having

corrected the faults.

Normal operation

Normal operation

Normal operation

Switch the system OFF and contact an

authorized service center to have the

filters cleaned.

Restart unit in the ventilation (fan only)

mode and open windows to change room

air.

27

Page 29

TROUBLE CHART (Cont.)

TROUBLE REASON ACTION

Strange noises coming from the

indoor unit.

Starting in heating mode for heat

pump systems

Occasionally the indoor unit can emit

some strange short noises during

operation or when it has stopped.

These are generally due to the of

temperature changes on the plastic parts.

If the system starts at low ambient

temperatures, it takes a little while to

reach a comfortable room temperature.

When the system is started by the remote

control, it emits a signal beep, but the

louvre does not swing and the fan does

not run until the operating temperature

has been reached.

Normal operation

Normal operation

28

Loading...

Loading...