Page 1

Carrier Corporation • Syracuse N Y 13221

Single-Package Heat Pumps

Chassis Only (Install ONLY after

50OT wall sleeve is in place)

CONTENTS

Page

SAFETY CONSIDERATIONS

INTRODUCTION .......................................................1

INSTALLATION.......................................................1-4

Step 1 — Check Equipment and Jobsite .. I

• UNPACK UNIT

• INSPECT EQUIPMENT

• INSPECT WALL SLEEVE

Step 2 — Install Chassis in Wall Sleeve.... 3

• SLIDE CHASSIS INTO SLEEVE

Step 3 — Install Thermostat and

Connect Thermostat Wiring....................................3

• TO MOUNT THERMOSTAT IN UNIT

• TO MOUNT THERMOSTAT

REMOTELY

COLD CLIMATE ACCESSORY

START-UP

SERVICE

.................................................................

.................................................................

..................................

................................

1

4

4

4-14

SAFETY CONSIDERATIONS

Installation and servicing of air conditioning

equipment can be hazardous due to system pressure

and electrical components. Only trained and quali

fied service personnel should install, repair or

service air conditioning equipment.

servke <ar

dixsr ’Tvm ^ feoatsr

mwst 4cfm bdoxa ^

WARNii^C: The 5QQT is.

uatt astd, thsr^ore, req«*res special casse m

liasEtdSas^ to lo asad

clastaags lo oast, Avcàé ìsspact visàì% or

other stapdmg «bjects whs® cissssim

INTRODUCTION

Install Model 50QT112, 115 and 118 heat pump

chassis in 50QT wall sleeve. Part No. 50QT900060;

and Model 50QT124 and 130 chassis in 50QT wall

sleeve. Part No. 50QT900080. Wall sleeves are

shipped separately with aecompanying installation

instructions. All electrical power, ductwork and

condensate drain hookups are made at time of wall

sleeve installation.

Untrained personnel can perform basic mainte

nance functions of cleaning indoor coil or replacing

filter. All other operations should be performed

by trained service personnel. When working on air

conditioning equipment, observe precautions in the

literature, tags and labels attached to the unit and

other safety precautions that may apply.

Follow all safety codes. Wear safety glasses

and work gloves. Use quenching cloth for brazing

operations. Have fire extinguisher available for

all brazing operations.

>P Carrier Corporation 1984

Bart

aad so '

is iiìsiaJled, isso? cm

pr^^per

<md<m m piace.

INSTALLATION

Step 1 — Check Equipment and Jobsite

UNPACK UNIT — Move to final loeation. Lift

eardboard carton off chassis taking special care not

to damage unit.

Form 50QT-10SI

Page 2

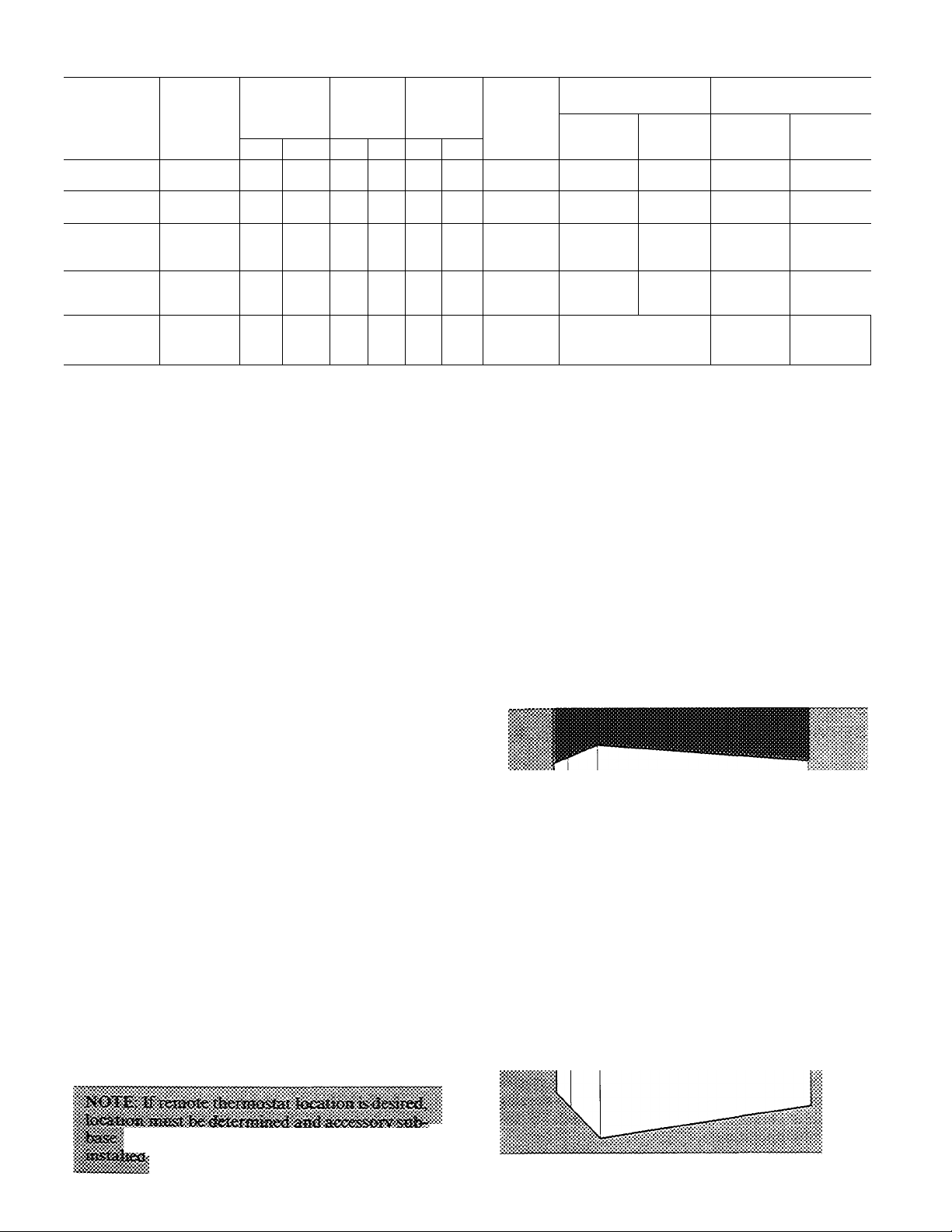

Table 1 — Electrical Data (&©^zt

MODEL

50QT

AB

112300 II

115300

AB

118300 AD

AF

AD

124300 AF

AG

AD

130300 AF

AG

♦Permissible limits of the voltage range at which units will

operate satisfactorily

fField wiring to be sized for NEC or local codes Use copper wire

only

^Maximum dual element fuse

♦♦Minimum voltage is 197 when outdoor ambient temperature

exceeds 105 F

NOTE: Dual values in this table (for example Electric Fleeter Amps

9 4/12 5) apply to 208- and 230-volt connections respectively

V/PH

208/230/1

208/230/1

208/230/1

208/230/1

208/230/1

OPER

VOLTAGE^

Max Min^*

254 187 37 6 8 1 5 1 0

254

254

254 187 59 13 0 2 0

254

187

187

187

COMPR

LRA

43 8 7

49

79

IFM OFM

RLA FLA

1 5

10 3

1 7

16 9 2 4

ELECTRIC

HEATER

AMPS

FLA

9 4/12 5

18.0/20.8

1 0

1 0

1 5

1 5

9 4/12 5

18 0/20 8

9 4/12 5

18 0/20 8

26 8/31 3

17 3/20 8

26 8/31 3

36 1/41.7

17 4/ 20 8

26 8/31 3

36 0/41 7

FLA — Full Load Amps

FIACR— Heating, Air Conditioning

IFM — Indoor Fan Motor

Max Fuse or

.....

These units require 2 separate supply circuits

Refer to BOTFI branch circuit charts for complete

electrical data

and Refrigeration

BRANCH CIRCUIT #1

(or Total Unit)t

HACR Ckt

Bkr Ampst

25/30

35/40

25/30

35/40

30/35

40/45

50/55

45/50

55/60

MCA

22 8/26 6

33.5/37.0

25 1/29 0

35.9/39.4

27 3/31 2

38 1/41 6

49 1/54 7

41 4/45 9

53.6/59.1

50/55 ^ 1 47.5/52J

BRANCH CIRCUIT #2

(When Used)t

Max Fuse or

HACR Ckt

Bkr Ampst

—

—

—

LRA — Locked Rotor Amps

MCA— Minimum Circuit

Amps

OFM — Outdoor Fan Motor

RLA — Rated Load Amps

MCA

—

—

—

1

♦INSPECT EQUIPMENT for damage prior to in

stallation. To remove plastic wrapper, grasp bottom

and pull out until velcro strips separate. To remove

metal cover plate, remove 6 screws. Eile claim with

shipping company if shipment is damaged or

incomplete.

Leave chassis bolted to skid and replace metal

cover plate, plastic wrapper, and carton until ready

for installation into wall sleeve.

INSPECT WALL SLEEVE installation for

damage. Condensate drain pan must be free of

debris and installed in accordance with local build

ing regulations. Electrical connector on left side of

sleeve should be free of dirt, grease, paint, etc.

Connector must be properly wired before chassis

installation. Duct connection panel must be level

and duct connections complete. Do not rest weight

of ductwork on duct connector panel. Inspect name

plate on sleeve to ensure wire and fuse sizing is

correct for model size to be installed.

At ^

-i

Fig. 1 — Chassis with Indoor Plastic Wrapper

©

Page 3

Step 2 — Install Chassis in Wall Sleeve —

Remove sleeve filler panel and save screws. Install

outdoor grille using these screws. Remove indoor

plastic wrapper as described in Step 1. Do not

handle cha.ssis with plastic wrapper in place.

SLIDE CHASSIS INTO SLEEVE — Chassis is

heavy. Portable lifting device must be used. Exercise

caution to make sure forks do not damage chassis

components (such as drain connections) while

lifting and installing. Guide chassis into sleeve on

indoor side by first placing chassis guide channels

onto sleeve guide channels at bottom of sleeve.

Slide chassis into sleeve until center partition peri

meter meets gasket provided around outer edge of

sleeve. Check electrical plugs for alignment as

chassis is slid into place.

Tighten chassis into place by driving 6 screws,

provided in separate bag with chassis, into nuts

provided on sleeve (see Fig. 3).

Electrical and condensate drain connections are

complete when chassis is installed correctly into

sleeve.

Step 3 — Install Thermostat and Connect

Thermostat Wiring — (Thermostat and subbase

are packaged separately with unit shipment.)

Thermostat can be installed in 50QT or in remote

location.

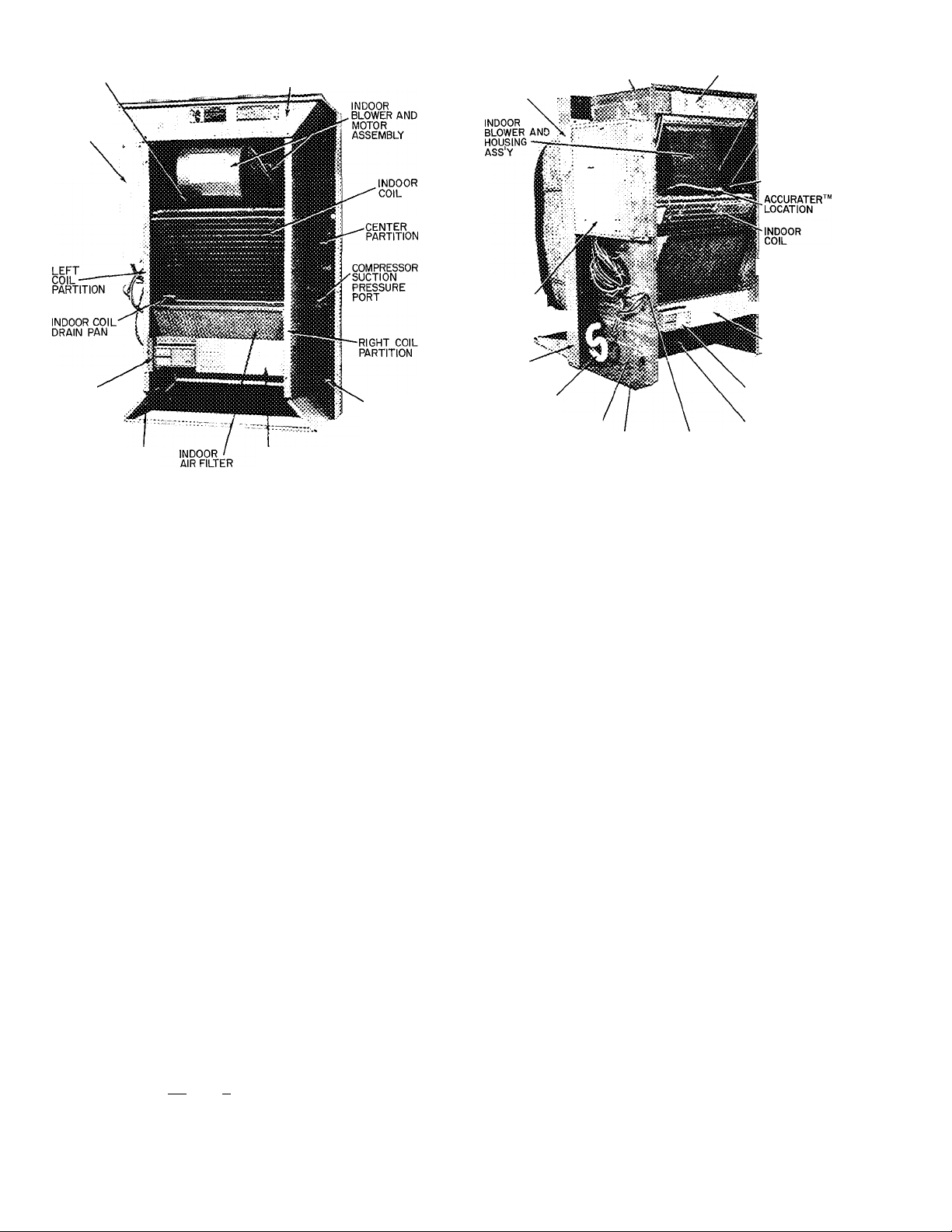

TO MOUNT THERMOSTAT IN UNIT;

1. Remove metal cover plate by removing 6 screws.

2. Locate and install subbase onto thermostat

bracket running between right and left coil par

tition (see Fig. 3). Push plug and wires through

hole provided.

3. Connect plug from subbase to mating socket

located on left coil partition (see Fig. 3).

4. Attach thermostat to subbase and snap on

thermostat cover.

5. Cut hole in stenciled area on back side of wrapper

with a sharp utility knife.

6. Cut and remove insulation from hole in metal

cover plate.

7. Replace metal cover plate.

TO MOUNT THERMOSTAT REMOTELY:

1. Pull subbase extension cord, previously installed,

up into the return air inlet. Plug cord into mating

socket on the left-hand coil partition. (See Fig. 3.)

FUSIBLE-

PLUG

CRANKCASE HEATER

THERMOSTAT

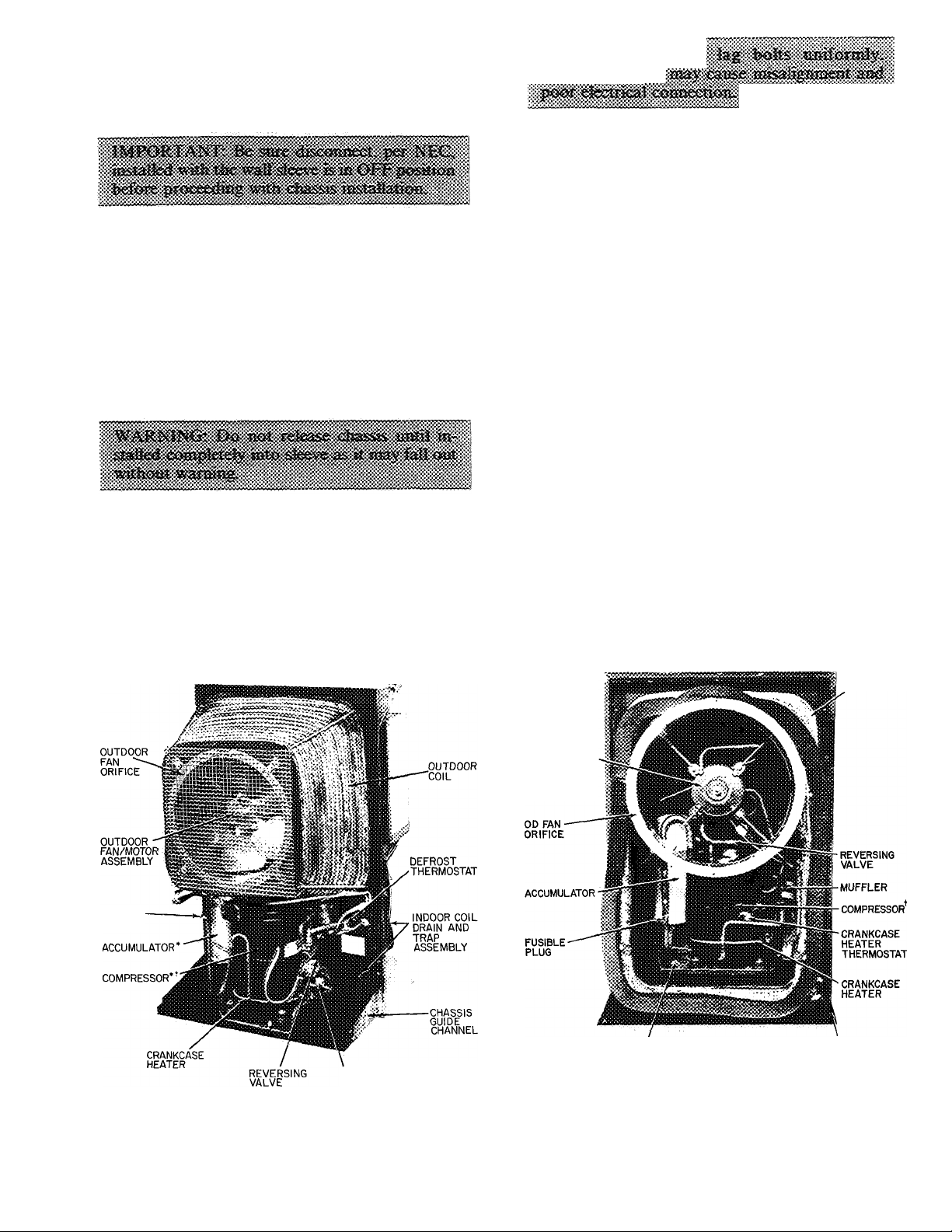

50QT112, 115, 118

^Accumulator and compressor location reversed on 50QT112

tCompressor guard removed

Fig. 2 — Outdoor Component Location

OUTDOOR

COIL

00 FAN MOTOR

(PROPELLER

FAN REMOVED

TO SHOW

MOTOR)

COMPRESSOR MOUNTING

PAN

CHASSIS GUIDE

CHANNEL

50QT124, 130

^Outdoor fan guard and compressor guard removed to show

components

Page 4

ACCURATER

LOCATION

MAIN

CONTROL BOX

COVER

MATING

SOCKET

LOCATION

INDOOR NAMEPLATE

LOCATION

THERMOSTAT

MOUNTING BRACKET

50QT112,115,118

ELECTRIC HEATER

CONTROL BOX COVER

CHASSIS

MOUNTING

BOLTS

(6 TOTAL)

SLEEVE ELECTRIC HEATER

JUNCTION LOCATION

BOX ACCESS

PLATE

MAIN

CONTROL

BOX

(SLIDES OUT

FOR servicing:

CENTER

PARTITION

INDOOR COIL

CONDENSATE

DRAIN

LEFT COIL PARTITION

INDOOR NAMEPLATE LOCATION

Fig. 3 — Indoor Component Location

THERMOSTAT PLUG

50QT124,130

ELECTRIC HEATER COVER

./INDOOR FAN

MOTOR

(NOT VISIBLE)

DEFROST

/THERMOSTAT ON

LIQUID LINE

LOW-PRESSURE

SWITCH

v(NOT SHOWN)

^COMPRESSOR

SUCTION

SERVICE PORT

BRIGHT COIL

■ PARTITION

ROOM THERMOSTAT

(CAN BE MOUNTED

REMOTELY)

INDOOR AIR FILTER

2. Plug other end of cord, hanging from the wall at

its remote location, securely into subbase.

3. Push plug and excess leads into wall hole. Cover

hole appropriately to avoid incorrect thermostat

readings.

4. Mount subbase onto wall.

5. Attach thermostat to subbase. Snap on cover

and install chassis indoor cover.

> COLD CLIMATE ACCESSORY

Cold climate accessory should be installed on

50QT100 units where the outdoor ambient tem

perature consistently falls below 30 F. Cold climate

accessory is available in both six packs and single

packs as indicated below: for 50QT112, 115, 118 —

accessory part no. 50QT90016106 (six pack) or

50QT900160 (single pack); for 50QT124, 130 —

accessory part no. 50QT90017106 (six pack) or

50QT900170 (single pack).

START-UP

Crankcase Heater — The 50QT compressor is

equipped with a crankcase heater that is thermo

statically activated in cold weather. (See Fig. 2 and

3.) If temperature is below 65 F, operate crankcase

heater 24 hours before starting unit. To energize

crankcase heater only, after chassis installation, set

thermostat to <C > ^position and turn on unit

power at disconnect switch.

Thermostat Anticipator — Room thermostat

anticipator settings for all 50QT heat pumps is

0.20 amps. This setting may be changed slightly to

provide a greater degree of comfort fora particular

installation.

To Start Unit — Check that main power is on and,

if temperature is below 65 F, that compressor

crankcase heater has been energized for at least

24 hours.

1. Set selector switch at*C •

2. Set fan switch as desired (FAN) (AUTO.).

3. Set thermostat lever at the desired temperature.

4. Set selector switch at HEAT or COOL. Check

system refrigerant charge. See Refrigerant

Charging.

SERVICE

Low-Pressure Switch (Safety Control) is lo

cated on liquid line downstream of AccuRater™

control during cooling mode (or upstream of Accu

Rater control during heating mode). Switch opens

at 5 psig and shuts down compressor to protect it

from overheating if refrigerant charge is too low.

High and low side pressure connections are acces

sible from the incloor portion of the unit for

charging. (See Fig. 3.)

High-Pressure Relief Valve (Safety Control) is

located in compressor. Relief valve opens at a pres

sure differential of approximately 450 ± 50 psi

between suction (low side) and discharge (high side)

to allow pressure equalization.

Internal Current and Temperature Sensitive

Overload (Safety Control) re.sets automatically

when compressor motor temperature drops to a safe

level (overloads may require up to one hour to reset).

#

Page 5

#

When an internal overload is suspected of being

open, check by using an ohmmeter or continuity

tester. If necessary, refer to Carrier Standard

Service Techniques Manual, Chapter 2, Electrical,

for complete instructions.

Defrost Control, consisting of a defrost timer,

defrost thermostat and defrost relay, interrupts

normal system heating operation to remove frost

and ice formation on outdoor coil. Frost impairs

unit performance. Defrost control simultaneously

stops outdoor fan, energizes reversing valve sole

noid to switch system into cooling cycle (outdoor

unit as condenser, indoor unit as evaporator),

and activates electric heater. Unit can defrost

every 90 minutes, but will do so only if outdoor

temperatures are in the frosting temperature zone.

For heat pump to defrost, 2 conditions are

necessary:

1. Defrost timer contacts must be closed.

2. Coil temperature must be cold enough to cause

defrost thermostat contacts to close.

Contacts close at 28 ±3 F (50QT112 - 118) and

35 ± 3 F (50QT124, 130). Every 90 minutes of

elapsed running time, the defrost timer contacts

close for 10 seconds. If the defrost thermostat

contacts are closed, the unit defrosts. The defrost

timer limits defrosting period to 10 minutes.

Normally the frost is removed and the defrost ther

mostat contacts will open to terminate defrosting

before 10 minutes have elapsed. Defrost thermostat

contacts open at 65 ±5F (50QT112 - 118) and

75 ±5F (50QT124,130). When defrosting is

terminated, the outdoor fan motor is energized

and reversing valve solenoid is de-energized, re

turning unit to heating cycle.

HEAT PUMP CIRCUITS shown in Fig. 4 are

refrigerant flow diagrams for heating and cooling

cycles.

Refrigerant Charging

CAtlTiOf^; To pfeveat persotial fejury. 'wear

safeij; giasoe» ao<3 giovfes ha»d3t»g

Do not overcharge system. An overcharge can

cause compressor flooding.

Unit refrigerant system is factory charged. When

recharging is necessary, weigh in total charge indi

cated in Table 2. (Charge must be weighed in during

heating season.) Remove any refrigerant remaining

in system before recharging. If system has lost com

plete charge, triple-evacuate system to 5000 microns

(29.7 in. vacuum) before recharging. Service port

connections are provided on unit suction and dis

charge lines for evacuation and charging. (See Fig. 4

for service port location.) Dial-a-charge charging

cylinder is an accurate device used to recharge

systems by weight. These cylinders are available at

refrigeration supply firms.

Table 2 — Service Data

UI\IIT50QT 112

MODEL

R-22 CHARGE* (lb) 2 7 2 7 3 2

Refrig Control AccuRater™ Bypass Type

INDOOR FAN Centrifugal Blower,

Rotationt

Rpm

Diameter (in )

Width (in.)

Range (cfm)

Motor Hp

OUTDOOR FAN

Cfm

Rpm 1125

Diameter (in )

Motor Hp Vs

ccw

cw

Counterclockwise

Clockwise

1580

430/

375

1700

115

300

300

Direct Drive, 2-Speed

CW CW CCW

CW

1550 1570 1675

6

6

550/ 575/

475 480

'A Vs.

'A

Propeller, Direct Drive, Single Speed

1700 1700 2000 2000

‘Factory refrigerant charge

fLooking at fan motor shaft

118

300

6

8

15

124 130

300 300

4 5

CCW

1675

7 7

885/

800

1025/

'/4 V4

47

960

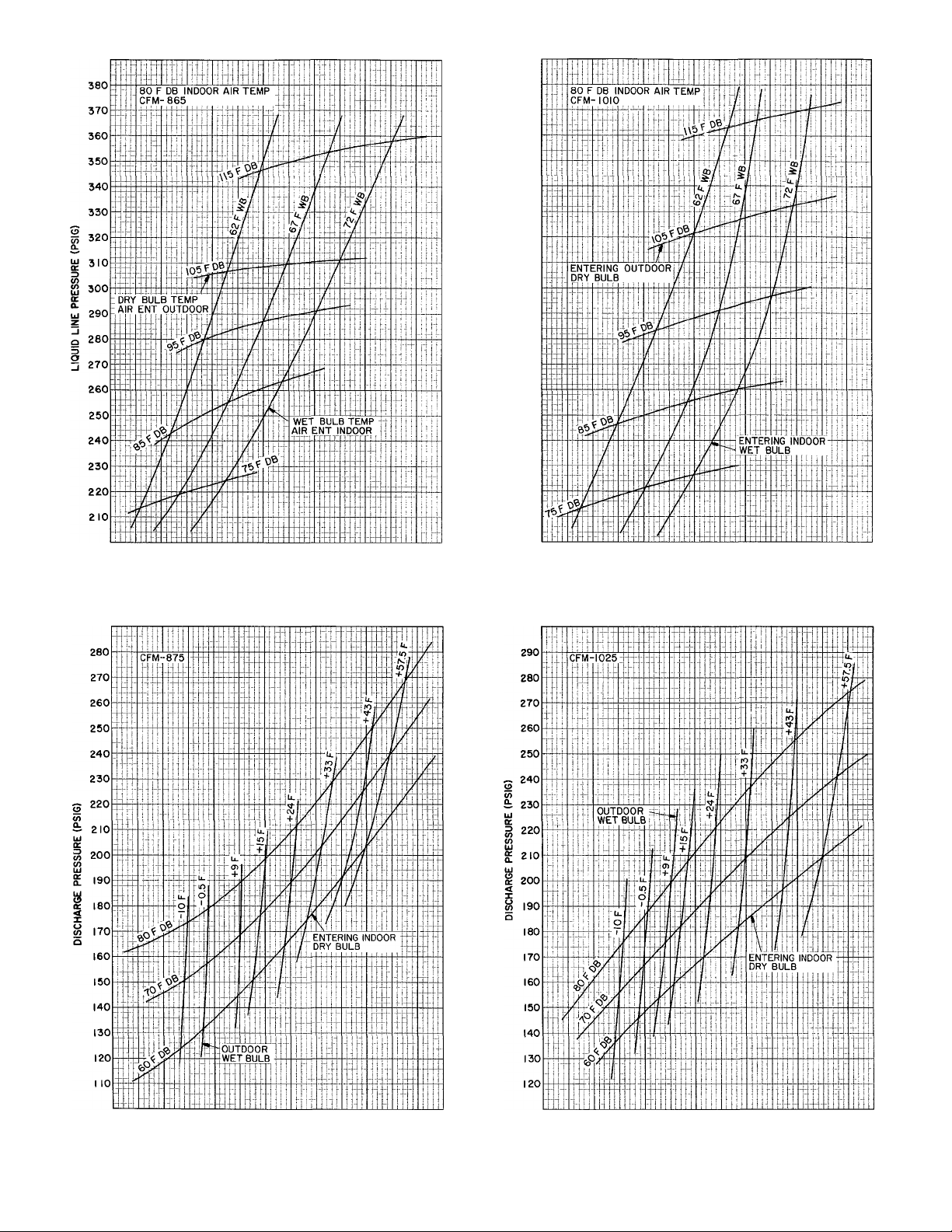

To check and/or adjust charge during cooling

season, use Cooling Cycle Charging Charts (Fig. 5,

7, 9, II, 13) and follow Charging Chart Method

below. The charging chart may also be used as an

alternate method of recharging system.

To check system operation during heating cycle,

use Heating Cycle Operation Check Chart (Fig. 6, 8,

10, 12, 14). These charts indicate whether a correct

relationship exists between system operating pres

sures and air temperatures entering unit. If pressure

and temperature lines do not intersect on chart,

the system refrigerant charge may not be correct

or other system abnormalities may exist. Do not

use Operating Check Charts to adjust refrigerant

charge. Weigh charge into system.

COOLING CYCLE CHARGING CHART

METHOD

1. Operate unit a minimum of 10 minutes before

checking charge, and after each charge

adjustment.

2. Measure suction pressure by attaching a gage to

unit suction service port. (See Fig. 4 for correct

service port location.)

3. Measure outdoor (coil inlet) air dry-bulb tem

perature. Use service thermometer.

4. Using a sling psychrometer, measure wet-bulb

temperature of air entering indoor fan coil.

5. Refer to Charging Chart. Locate on curves where

outdoor air dry-bulb and indoor air wet-bulb

temperature lines intersect.

6. From intersect point, project vertically down

ward to chart suction pressure line. Compare

chart suction pressure to unit suction pressure

(Step 2).

7. If unit suction pressure is lower than chart pres

sure, add refrigerant to system until chart

pressure is reached. If unit suction pressure is

higher than chart pressure, remove refrigerant

until chart pressure is reached.

Page 6

3 Unit Piping

t

Fig. 4 — 50QT Refrigerant Flow Diagrams

70 72 74 76 78 80 82 84 86 88 90 92

SUCTION PRESSURE (PSIG)

Fig. 5 — 50QT112 Cooling Cycle

Charging Chart

Fig. 6 — 50QT112 Heating Operation

Check Chart

Page 7

360

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

64 66 68 70 72 74 76 78 80 82 84 86

SUCTION PRESSURE (PSIG)

Fig. 7 — 50QT115 Cooling Cycle

Charging Chart

SUCTION PRESSURE (PSIG)

Fig. 9 — 50QT118 Cooling Cycle

Charging Chart

Fig. 8 — 50QT115 Heating Operation

Check Chart

Fig. 10 — 50QT118 Heating Operation

Check Chart

Page 8

390

380

370

360

350

340

330

320

310

300

290

280

270

260

250

240

230

220

70 72 74 76 78 80 82 84 86 88 90 92

SUCTION PRESSURE (PSIG)

Fig. 11 — 50QT124 Cooling Cycle

Charging Chart

68 70 72 74 76 78 80 82 84 86 88 90

SUCTION PRESSURE (PSIG)

Fig. 13 — 50QT130 Cooling Cycle

Charging Chart

10 20 30 40 50 60

SUCTION PRESSURE (PSIG)

Fig. 12 — 50QT124 Heating Operation

Check Chart

10 20 30 40 50 60

SUCTION PRESSURE (PSIG)

Fig. 14 — 50QT130 Heating Operation

Check Chart

Page 9

#

AccuRater™ Device (Dual-Piston Type)

Servicing — See Fig. 15 for dual-piston AccuRater

components. The pistons have a refrigerant meter

ing orifice through them. The retainers form a stop

for the pistons in the refrigerant bypass mode, and

a sealing surface for liquid line flare connection.

To clean or replace piston;

1. Shut off power to unit.

2. Protect area around unit to prevent damage to

interior, furnishings, etc.

3. Remove refrigerant from unit.

4. Remove liquid line flare connections from

AccuRater. See Fig. 3 for AccuRater location.

5. Note position of arrow on AccuRater body in

relation to unit.

6. Pull retainer out of body. Be careful not to

scratch flare sealing surface. If retainer does not

pull out easily, carefully use locking pliers to

remove retainer. Replace scratched or damaged

retainer.

7. Slide piston out by in.serting a small soft wire

through metering hole (18-gage thermostat

wire). Check that metering hole, sealing surface

around piston cones and fluted portion of

piston are not damaged.

8. See chart on indoor blower scroll for illustration

of proper arrangement and sizes of pistons.

9. Clean piston refrigerant metering orifice.

10. Replace retainer O-ring before reassembling

AccuRater. Carrier O-ring Part No. is

99CC501052.

LIQUID LINE STRAINERS (protect AccuRater),

are made of wire mesh and located in the liquid line

on each side of the AccuRater. The strainers are

pressed into the line. Remove strainer by threading

a #10 sheet metal screw into strainer and pulling

the screw with pliers.

Compressor Removal — (Refer to Fig. 2.)

caafsoi be

xaoVfiiS fmm aa btsislied cfesssis* Rmove

fnbi» sleeve, feratg. io &eTvice ijttcfe

or deales' sJiojr T^efore retaoviag coiap-ressor.

See Table 3 for compressor information. Follow

safety codes and wear safety glasses and work

gloves. Have quenching cloth available.

Table 3 — Compressor Data

UNIT 50QT

112

115

118

124

130

CONIPRESSOR

Copeland

RE-Z30150-PFV

Tecumseh

AB5515H

Copeland

CRB1-0175 PFV

Copeland

CRD-10200-PFV

Copeland

CRF1-0250-PFV

Compressor Removal — 50QT112, 115, 118

1. Shut off power to unit. Remove chassis indoor

cover, Fig. 1.

2. Remove chassis to truck or shop.

3. Remove refrigerant from unit using refrigerant

removal methods described in Carrier Standard

Service Techniques Manual, Chapter I,

Refrigerants.

4. Remove core from suction and discharge line

Schrader valves.

5. Remove compressor guard.

OIL RECHARGE

(oz)

20

32

51

51

51

#

CQCSL»i&

coociweEssTOii

mr

TO

i«>T£. are too&iec «sideciPAccvRiaw ssi cosi>t>0oeRt& ¡s ««(cai-fijr

iOQiTirtCATiOM

COOytiiS

STA»P££f

coupi.{(«5aocif ,

STRiawes

correct

Fig. 15 — AccuRater Device (Dual-Piston) Components

'50

(«BOOR

<m.

Page 10

6. Disconnect compressor wiring at compressor

terminal box.

7. Using a tubing cutter, cut suction and discharge

lines at convenient place near compressor for

easy reassembly to new eompressor with copper

slip couplings.

8. Remove crankcase heater from compressor

base.

9. Remove clamp holding accumulator to shell.

10. Remove compressor holddown bolts and lift

compressor out, sliding and tipping it towards

the outside.

11. Carefully unbraze suction and discharge line

piping stubs from compressor. If oil vapor in

piping stubs ignites, use quenching cloth.

12. Braze piping stubs (removed in step 11) on new

compressor, in .same position as before.

13. Install new compressor in unit. Braze suction

and discharge lines to compressor piping using

field-supplied copper couplings. Ensure com

pressor holddown bolts are in place. Reinstall

crankcase heater. Connect wiring.

14. Triple-evacuate to 5000 microns and recharge

unit. See Refrigerant Charging section.

15. Refer to NOTE at the end of this section for

important information.

Compressor Removal — 50QT124, 130

1. Shut off power to unit. Remove chassis indoor

cover. Fig. 1.

2. Remove chassis to truck or shop.

3. Remove refrigerant from unit using refrigerant

removal methods described in Carrier Standard

Service Techniques Manual, Chapter 1,

Refrigerants.

4. Remove core from suction and discharge line

Schrader valves.

5. Remove outdoor fan guard.

6. Remove outdoor compressor guard.

7. Remove outdoor propeller fan.

8. Remove outdoor fan orifice ring by removing 4

screws attaching it to outdoor fan motor

bracket.

9. Remove 3 of 4 outdoor fan motor bolts, leaving

bolt at upper right of fan motor in place. Rotate

motor up and out of the way by hinging it on

remaining bolt. Use wire or solder to tie outdoor

fan motor to outdoor coil support on top side

of coil.

10. Using a miniature tubing cutter, cut compressor

suction tube on short vertical run as tube enters

compressor.

11. Cut compressor discharge tube on horizontal

tubing run approximately 6 to 12 in. from where

it leaves the compressor. Keep crankcase heater

thermostat on right side of cut so it stays in

place when compressor is removed.

12. Disconnect compressor wiring at compressor

terminal box. Remove compressor wires and

crankcase heater splice from box.

13. Using an 18-in. long extension on ratchet

wrench, remove 4 compressor holddown bolts.

14. Slide compressor out to edge of pan. Remove

erankcase heater by loosening worm drive

clamp and sliding over top of compressor.

15. Remove compressor from pan.

16. Carefully unbraze suction and discharge line

piping stubs from compressor. If oil vapor in

piping stubs ignites, use quenching cloth.

17. Braze piping stubs (removed in step 11) on new

compressor, in same direction as before.

18. Using field-supplied copper couplings, install

new compressor in unit.

19. Reassembly is reverse of above procedure.

20. Triple-evacuate to 5000 microns and recharge

unit. See Refrigerant Charging section.

NOTE: If a compressor failure was caused by

motor winding burnout, the by-products of the

burnout must be separated from the circulating

refrigerant. This must be done before the by

products enter the reversing valve or aceumulator and render parts inoperative. Burnout

by-products can cause future system operating

problems if left in the system.

Clean the system by installing a suetion line

drier in the refrigerant line where the suction gas

enters the reversing valve. During the cooling

cycle, this is the line from the indoor eoil run

ning to the compressor compartment; during

heating cycle, install drier in line between

outdoor eoil and reversing valve. If possible,

run unit in cooling mode when cleaning system

as no defrosting occurs.

To provide protection for the 4-way valve,

do not place filter drier between 4-way valve

and accumulator. Since the suction drier works

on one mode only, temporarily wire the unit in

the seleeted mode (heating or cooling, based on

suction drier location). To insure cooling opera

tion only, install a jumper between terminals

no. 1 and no. 4 on receptaele no. 3. For heating

operation only, remove and insulate one of the

reversing valve solenoid leads. Run unit for

48 hours and check oil for acidity. If satis

factory, remove suction line drier. Refer to

and follow procedure under AccuRater™

Servicing for cleaning of AccuRater. Rewire

unit to normal condition.

Lubrication — Compressor contains factory oil

charge. Replace oil when lost. See Table 3 for oil

#

10

Page 11

recharge. If necessary, refer to Carrier Standard

Service Techniques Manual, Chapter 1, Refrig

erants, page 1-21, for oil recharging procedure. Use

Carrier PP33-1, Texaco WF-32 or Suniso 3GS oil.

FAN MOTOR BEARINGS — Oiling holes are pro

vided at each end of condenser fan motor. Remove

fan motor and lubricate motor with 32 drops (16

drops per hole) of SAE 10 nondetergent oil at

intervals described below:

a. Annually, when environment is very dirty,

ambient temperature is higher than 105 F and

average unit operating time exceeds 15 hours

a day.

b. Every 3 years when environment is reasonably

clean, ambient temperature is less than 105 F and

unit operating time averages 8 to 15 hours a day.

c. Every 5 years when environment is clean,

ambient temperature is less than 105 F and unit

operating time averages less than 8 hours a day.

INDOOR MOTOR — To oil indoor motor, remove

dust caps or plugs from oil holes located at each end

of the motor. Use a teaspoon, 5 cc (5 ml), 3/16 oz or

16 to 25 drops of a good grade of SAE 20 nondeter

gent motor oil in each oil hole. Allow time for total

quantity of oil to be absorbed into each bearing.

After oiling motor, be sure to wipe off excess oil

from housing and replace cap or plugs on oil port.

Outdoor Coil Cleaning — To be done at the

beginning of each cooling season or more often if

required.

4. If oil deposits are present, spray coil with liquid

household detergent. Wait 10 minutes, then

proceed to step 5.

5. Using garden hose, spray coil perpendicularly to

coil tubes with a constant stream of water at

moderate pressure (see Fig. 17). Keep nozzle at a

15 to 20 degree angle, about 3 in. from coil face

and 18 in. from tube. Spray so debris is washed

out and away from coil making sure water does

not contact components on side of chassis.

<iajiiage or re^val eati tessli

aot iiSre waiec, steam>

or voiatUe or coiro^xve oji tass m "

1. Shut off power to unit.

2. Remove chassis from sleeve by removing 6 bolts

and sliding chassis out. Transport chassis to an

appropriate cleaning location.

3. Clean coil using vacuum cleaner and its crevice

tool (see Fig. 16). Work crevice tool perpendicu

larly to coil tubes, making sure tool only touches

dirt on fins. To prevent fin removal, do not

“scrub” fins with tool or move tool parallel to

coil tube configuration.

w

Fig. 16 — Crevice Cleaning Tool

Fig. 17 — Positioning Hose to Spray Coil

II

Page 12

6. Make sure condensate pan drain is not clogged

with debris.

7. Reinstall chassis in sleeve.

8. Restore power to unit.

Indoor Coil and Condensate Pan Cleaning —

Clean and inspect indoor coil, condensate pan and

drain at same time outdoor coil is cleaned.

1. Use vacuum cleaner nozzle to clean the face

of coil.

2. Clean condensate pan with a brush similar to

that shown.

3. Hold pail under condensate pan drain connec

tion and flush pan by slowly pouring water on

coil. Do not overflow pan.

Indoor Air Filter Replacement (Refer to Fig. 3.)

— Replace filters at least 4 times per year especially

at the beginning of the heating and cooling seasons.

On 50QT112, 115 and 118, slide filter through

slots at bottom of left and right coil partitions.

Slide filter upward until top of filter reaches top of

filter brackets. Then, rest bottom of filter on

bottom flanges of left and right coil partitions.

On 50QT124 and 130, slide filter upward until

top of filter reaches top of filter brackets. Then,

rest bottom of filter on horizontal sheet metal shelf

between left and right coil partitions making sure

tabs at bottom of filter brackets hold filter in place.

Outdoor Fan Adjustment — Required fan posi

tion is shown in Fig. 18. Adjust position by loosen

ing setscrew on fan hub and moving in or out of

orifice.

Outdoor Fan/Motor Removal

1. Shut off power to unit.

2. Remove chassis from sleeve as described pre

viously in Outdoor Coil Cleaning section.

UNIT 50QT

112, 115, 118 2V2

124, 130 2

DIMENSION A

(in.)

Fig. 18 — Outdoor Fan Position

Remove 4 nuts from outer tip of coil support

rods and remove wire mesh guard.

Remove fan blade from motor shaft by loosening

4.

hub setscrews and slipping it off shaft.

5. Remove fan motor leads from electrical com

ponents in indoor side control box and pull

through bulkhead so they are loose in outdoor

machine compartment.

6. Remove nuts and bolts connecting 4 motor ears

to motor support struts.

7. Remove motor and leads.

8. Reassembly is reverse of above procedure. Make

sure guard is replaced and fan is positioned

correctly as in Fig. 2.

12

Page 13

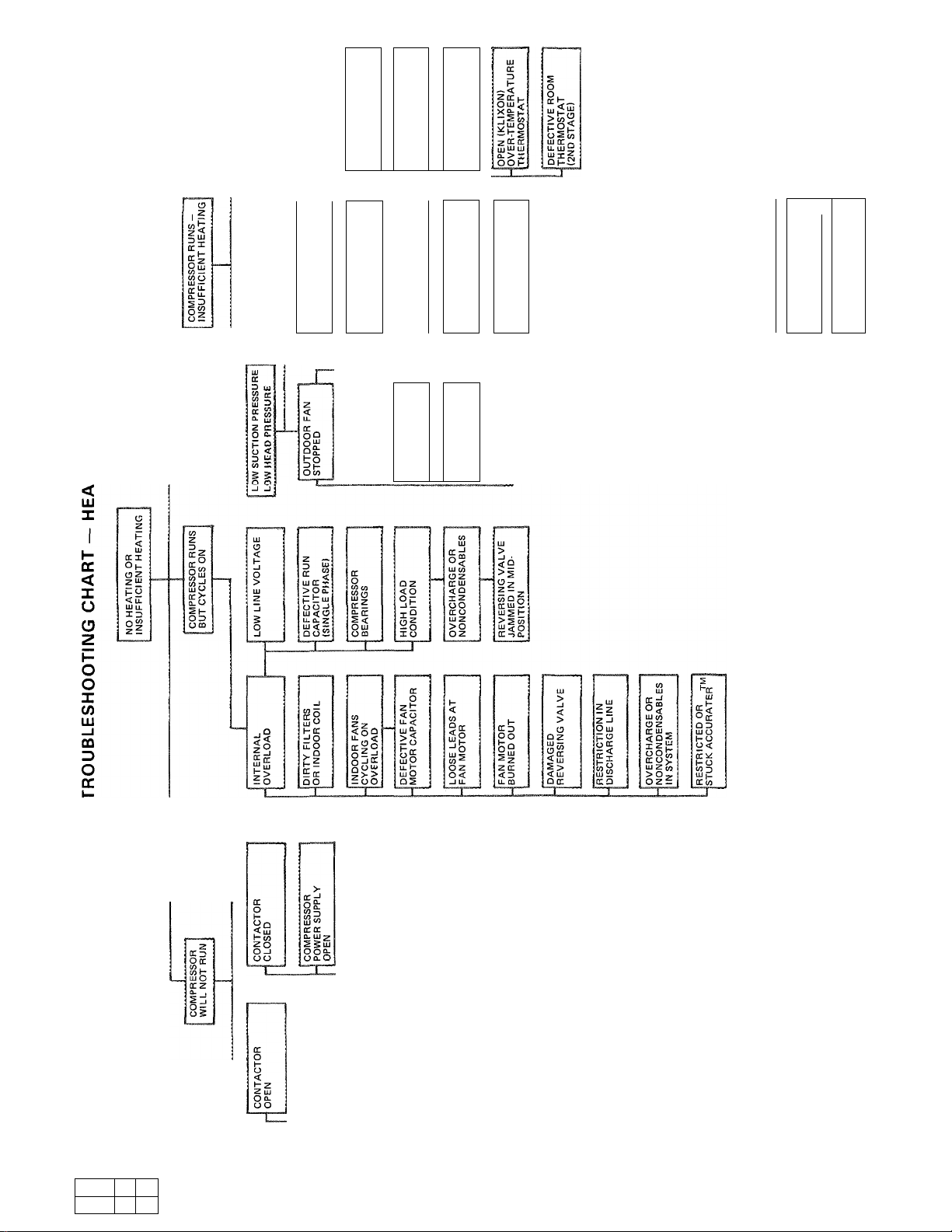

TROUBLESHOOTING CHART — COOLING CYCLE

#

Page 14

LU

o

>■

o

CD

tog

DC £

lij|_

b<

< CC

HI uj

X Q.

Q.O

<02

<o^

ljjy> I

ccOu-1

I— LU LU I

(0(00 I

Z

<

X

gg

o~

QZ

HZ

3D

OX X -i

X

Xiu

tUH

5<

OLU

X I

-h-i2

“t-z

2-uj

ZoS

LU ^ LU

X i _l

OGLU

O X

LUZ

EC2

H 3

(0/-1

III LU

Z

-J

to

3

X

z

g

o

-J

CO

5 CC

h OQ

ccqI^

LU S C5

HhO

<oo

oiSg

<0:9

<i

X X

_l -J

<x

Zq:

£°2

E50

X

H

<

LU

zz

LU LU

CQ LU

Q

X

(3

<

X

G

X

X

Q

Z

3

XD

oo

o°

2z

Z X

<3

X ffl

X

lLU H

X

3

to

X

f ^

X UJ

<o

Zx

X X

H^

5x

Ex

On

_l

lQ

X

Ov

H^

dE

OQ

ai

U. LU

LU I

OK

IL CC

0>(r

lu<E

U. U ¡c

LU LU £

OXh-

IW

!iJo

s?

[Xm

G CC

<|d

<

G?G

>

E^£

o

H<f G

z

^i=X

QGX

<XX'

XZ C

X

O

- E

a o

?cc

zm

LU 3

Q-O

O a.

(O CO

Q CO

<LU

Sec

“^5

wg

OK

_) <

LJ QJ

lU CC

>iuo

pou.

o <

lul-Z

Li. -i <

lUOX

Q>l-

k

So

O

o ^

Oi-

5

cc<

X

o

(O

to

LU

5d

ofe

5>

LU

(5 LL

Z LU

x>

LU <

> -I

8t

cc:?

Oco

Gqc

<o

Z LU

OQl

GO

X LU

LU>

X cu

QU-

LU

9q

2<

-JO

X

< xO

H. OZ

ZlunS

yccejo

Xh-XLU

X < LU X

OLUZ>

(OXLU&

So

X CC

Og

OJZ

X

o

X

<

For replacement items use Carrier Specified Parts

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book

1

Tab

5a

4

5a

Form 50QT-1OSI Supersedes 50QT-8SI

Printed in U S A

5-84

PC101 Catalog No 565-033

t

Loading...

Loading...