Page 1

50QQ

#

HEATING A COOLING

Single-Package Heat Pumps

Installation, Start-Up and Service Instructions

CONTENTS

Page

SAFETY CONSIDERATION

INSTALLATION..................................................................1-7

Step 1—Check Equipment and Jobsite............................. 1

• UNPACK UNIT

• INSPECT EQUIPMENT

• COMPLETE SYSTEM REQUIREMENTS

Step 2—Mount Unit.............................................................. 2

• ON THE GROUND

• ON THE ROOF

Step 3—Make Ductwork Connections

• CONNECT RETURN AND SUPPLY AIR

DUCTWORK

Step 4—Provide for Cooling Cycle

Condensate Disposal

• CONNECT DRAIN LINE

Step 5—Make Electrical Connections

• INSTALL A BRANCH CIRCUIT DISCONNECT PER

NEC

• ROUTE LINE POWER LEADS INTO UNIT

• CONNECT GROUND LEAD TO GROUND LUG

• SET INDOOR FAN MOTOR SPEED

• ROUTE CONTROL POWER WIRES

• ACCESSORY DUCT FLANGE KIT INSTALLATION

• ELECTRIC HEATER INSTALLATION

START-UP

SERVICE...........................................................................8-15

............................................................................

SAFETY CONSIDERATIONS

Installing and servicing air conditioning equipment can be

hazardous due to system pressure and electrical compo

nents. Only treuned and qualified service personnel should

install or service air conditioning equipment.

Untrained personnel can perform basic maintenance func

tions such as cleaning coils and filters and replacing filters.

All other operations should be performed by trained service

personnel. When working on air conditioning equipment,

observe precautions in the literature and on tags and labels

attached to unit.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have

fire extinguisher available.

.................................................

...............................

......................................................

...............................

1

2

4

5

8

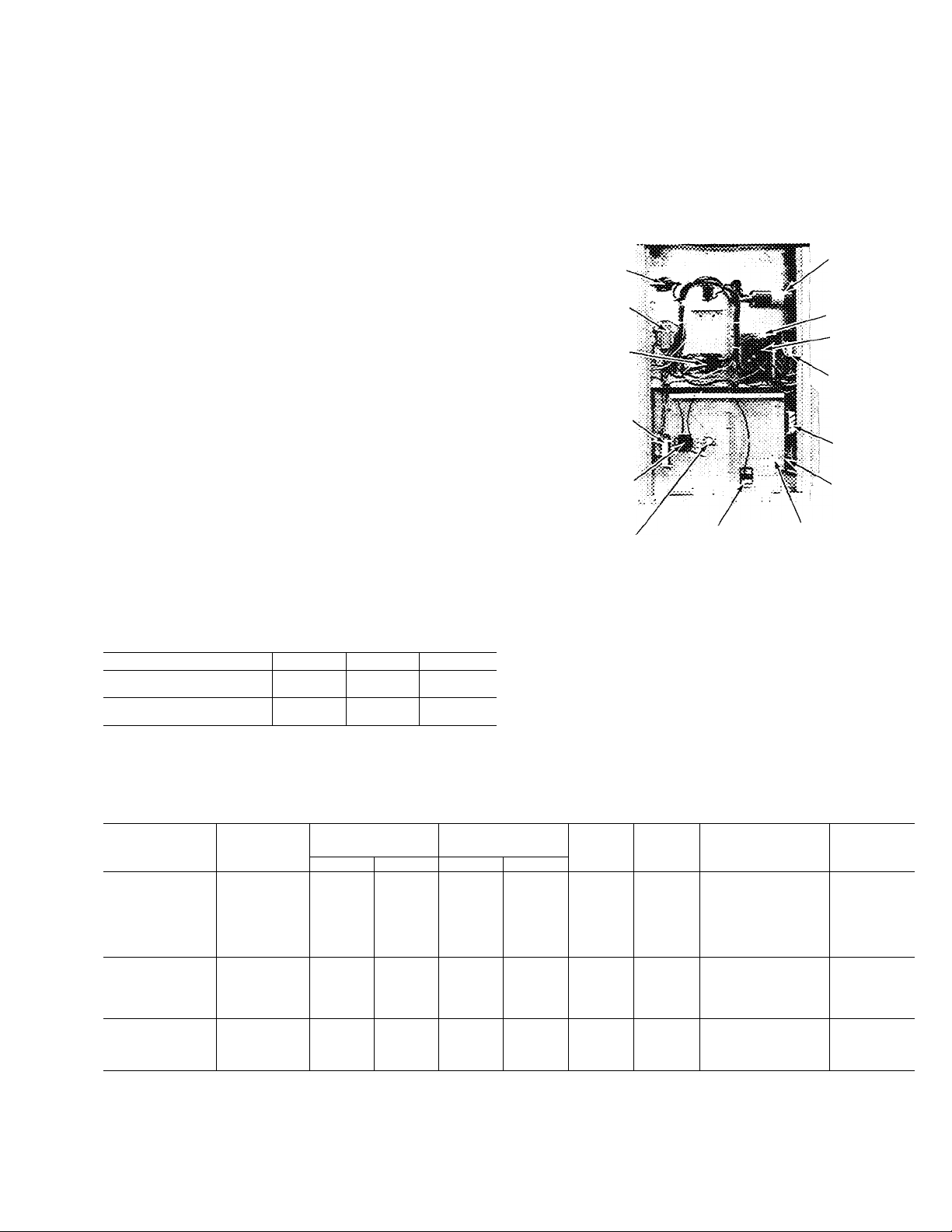

1-5/8” DIAM KNOCKOUT ELECTRIC HEAT

> OUTDOOR AIRFLOW

RIGHT-SIDE VIEW - MODEL 018 048(TYPICAL)

DUCT FLANGE

FOR 14”X28”

CONNECTION

A88061

A WARNING

Before performing service or maintenance operations on

7/8”

CONNECTOR^

system, turn off main power switches to unit. Turn off

accessory heater power switch if applicable. Electric

shock can cause personal injury.

INSTALLATION

Step 1—Check Equipment and Jobsite

1-3/8”DIAM

KNOCKOUT

LINE WIRING

CONN

RIGHT - SIDE VIEW • MODEL 060

1-5/8”DIAM KNOCKOUT

ELECTRIC HEAT

UNPACK UNIT—Move unit to final location. Lift off car

ton tEiking special care not to damage unit.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Bookl 1 I 4 PC 101 Catalog No 565-097 Printed in USA Form 50QQ-8Si 11/87 Pg 1 Replaces: 50QQ-7Si

Tab i5a 15a

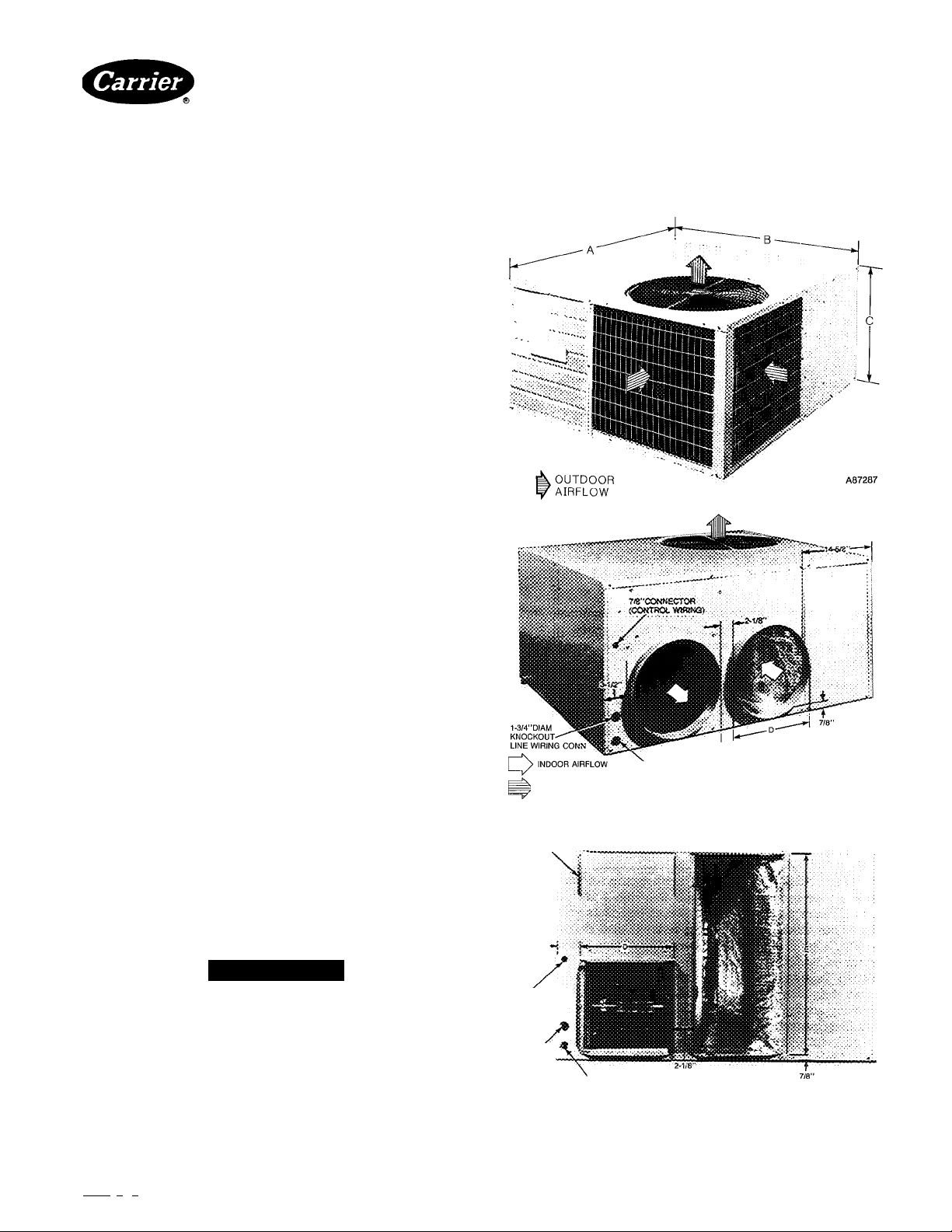

Fig. 1 —Dimensions and Connections

Page 2

Table 1—Physical Data and bimensions

MODEL 50QQ

REFRIGERANT (R-22)

Operating Charge (lb)

Refrigerant Control

SHIPPING WEIGHT (lb) 323 1 329 1 346 1 357 | 402 | 445 | 484

DIMENSIONS (in.)

DUCT CONNECTIONS (in.)

FILTER SIZE (in.)t

Disposable

Permanent

*Dimension C includes %-in built-in base support channels

tOptional square duct flanges are available as an accessory for 14-in x 14-in duct.

ijiRecommended field-supplied filters are one-in. thick.

A

B

C*

D

E

018 024

7 lbs 4 oz

20x25 20x25 (2)15x20

15x20 15x20 20x20

6 lbs 8 oz 8 lbs 0 oz

22'k 1 2472 1 29% 32%

030

Side-By-Side

Round!

036

7 lbs 4 oz

Piston

48

14

15x20

20x20 (2) 20 X 20

20x25

8 lbs 2 oz

INSPECT EQUIPMENT—File claim with shipping com

pany if shipment is damaged or incomplete.

COMPLETE SYSTEM REQUIREMENTS before

installing.

Consult local building codes and National Electrical Code

(NEC) ANSI/NFPA 70-1987 for special installation

requirements.

Provide sufficient space for coil airflow clearance, wiring,

and servicing unit. See Fig. 1 and 2. Locate unit where sup

ply and return air ducts can be conveniently brought out to

unit duct connections.

Unit may be placed with duct side as close to building as

top removal, duct connections and power connections per

mit. Position unit so water or ice from roof does not drop

directly on top of unit or in front of coil. Make provisions for

condensate drainage and defrost water disposal. Maintain a

4-ft clearance above unit for vertical air discharge.

Roof installation method for 50QQ depends on building con

struction and special requirements of local building codes.

Ensure that roof can support unit weight. Protect unit from

prevailing winds to ensure adequate defrost.

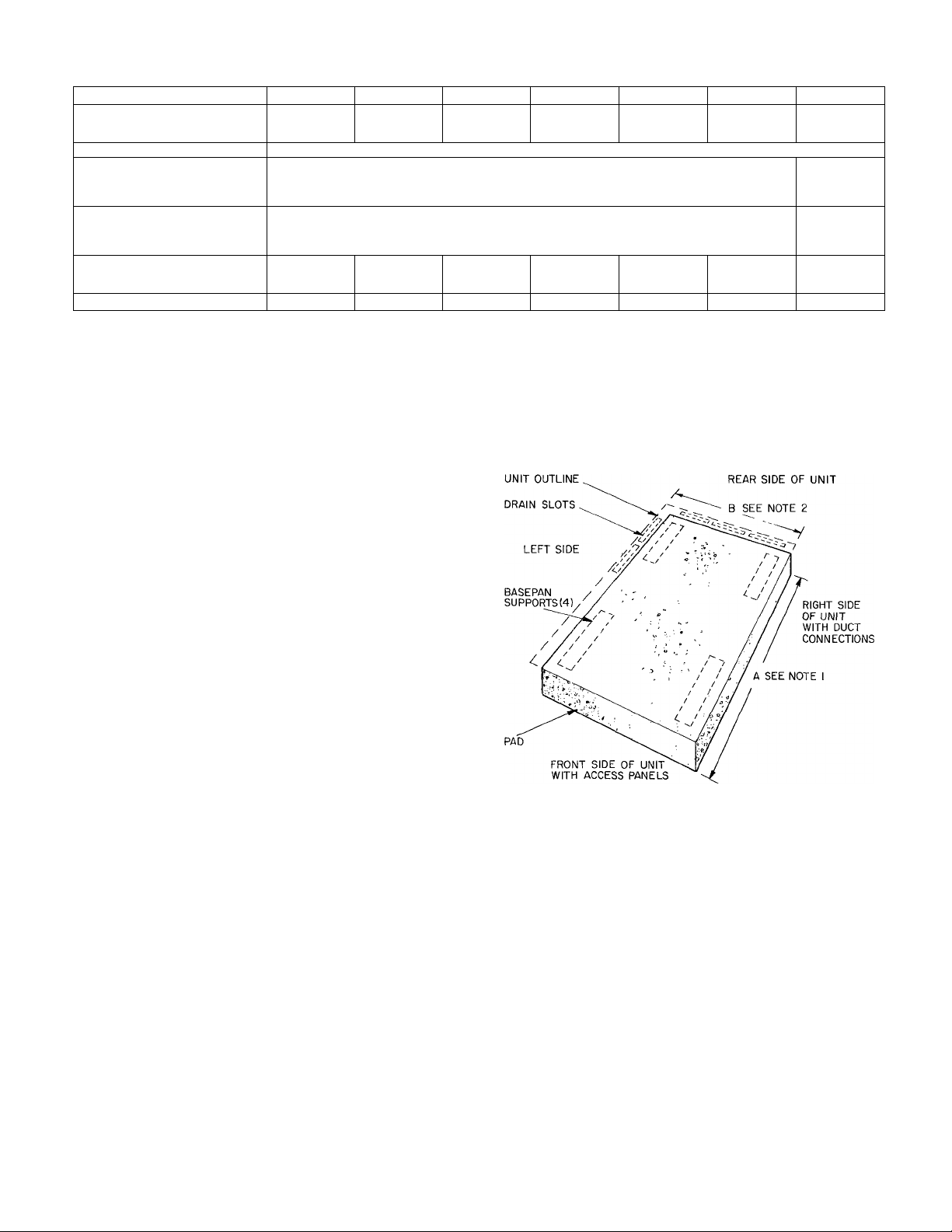

Step 2—Mount Unit

NOTES:

1

In areas of snowfall or subfreezing temperatures when elevated

frame Is used Dimension A is 48-in., Dimension B is 42-in. In areas

where elevated frame is not used Dimension A is 45-in , Dimension

B is 39-in

Allow a 3-ft service clearance at front and rear sides of unit

ON THE GROUND—Mount heat pump on an elevated

frame positioned on a level pad. See Fig. 2 for pad dimen

Fig. 2—Pad Dimensions

sions. Ensure pad does not obstruct coil slots in unit basepan. (Slots drain water during heating and defrost cycles.

See Fig. 2 for drain slot locations.) Construct pad to provide

clearance under basepan coil slots for drainage and ice

buildup. In areas where prolonged subfreezing temperatures

or snowfall occur, increase clearance to 12 to 18-in. by con

structing an angle-iron frame to support unit 12 to 18-in. off

base. Design cross angle of frame so as not to obstruct basepan coil slots. See Fig. 3 for recommended frame construc

tion. Alternate construction should follow dimensions.

Extend a 24-in. gravel apron around pad for condensate and

defrost water drainage field.

ON THE ROOF—Mount unit on a level platform or frame.

Elevate unit for proper clearance as described under ground

insteJlation above. Design roof and plan water runoff so as

to prevent unit and its duct flashing from sitting in water,

in accordance with eJl applicable codes.

Step 3—Make Ductwork Connections

CONNECT RETURN AND SUPPLY AIR DUCT

WORK—Connect ductwork to unit supply and return air

duct connections. Refer to Fig. 1 and Table 1 for unit supply

and return air connection sizes and locations.

Flanges are provided on Models 018-048 for round duct con

nections, on Model 060 for rectanguleu- duct connections.

Accessory duct flange kit is available for squeire or rectan

gular connections on 018-048 units. Refer to accessory

Installation Instructions on page 5 for connections to

ductwork.

Fig. 4 shows a typical duct system with 50QQ installed. Do

not operate unit longer than 5 minutes without ductwork or

damage to blower motor may result.

042

20x25

048

9 lbs 0 oz

20x25

20x20

(2) 15x 20 (2) 20 X 20

060

9 lbs 0 oz

Side-By-Side

Rectangular

13"/,eXl3’7,e

13"Ae X 277a

25x25

20x25

A88063

Page 3

I =\ = = = ^ 305 mm (12") TO 610 mm (24") (4) REQ

I

^ ----- —---------------------------------------------------------------------'(411") (2) REQ

' I ---------------1 I 959mm (37|")(2)REQ

^ I

----------------------

gj I I - |-^ 406 mm (16") (8) REQ

material:

ANGLE IR0N-3L8mm(l^) TO 38mm (1^) COMM'L STD

WELD FRAME TOGETHER

PAINT WITH ZINC-RICH PAINT (RUSTPROOF)

-| 959mm(375 )(l) REQ.

r 38 mm (1-5) 3"

#

Fig. 3—Heat Pump Mounting Frame

When designing and installing ductwork, consider the

following:

1. When connecting ductwork to 042, 048 and 060 units,

do not drill deeper than one inch in shaded area shown

below. Coil may be damaged.

2.

Install field-supplied filters in return air ductwork. Rec

ommended sizes for filters are shown in Table 1.

3.

Avoid abrupt duct size increases and reductions.

Abrupt change in duct size adversely affects air

performance.

4.

Use flexible connectors between ductwork and unit to

prevent transmission of vibration. When electric heater

is installed, use fireproof canvas (or similar heat resis

tant material) connector between ductwork and unit

discharge connection. If flexible duct is used, insert a

sheet metal sleeve inside duct. Heat resistant duct con

nector (or sheet meted sleeve) must extend 24-in. from

electric heat element.

5. Size ductwork for cooling air quantity (cfm). The mini

mum air quantity for proper electric heater operation is

listed below. Heater limit switches may trip at air

quantities below those recommended.

MODEL

50QQ

018

024

030

036

042

048

060

INDOOR FAN

SPEED SETTING

Low 1400

MIN CFM

675

875

875

1400

1700

1800

6. Insulate and weatherproof all external ductwork. Insu

late and cover with a vapor barrier all ductwork pass

ing through unconditioned spaces. Follow latest

SMACNA (Sheet Metal and Air Conditioning Contrac

tors National Association) minimum installation stand

ards for residential heating and air conditioning

systems.

7. Secure all ducts to building structure. Weatherproof

duct openings in wall or roof according to good con

struction practices.

Page 4

PARAT NO.

99TZ900521

99T2900571

50LQ90002106

50LQ90001106

38RQ900012

50LQ90000106 Outdoor Thermostat (Six 50LQ900001)

50LQ900031

32LT900301

32LT900611

50YM900051

88EM0050MA01

88EM0075MA01

88EM0100MA01

88EM0150MA01

88EM0200MA01

88EM0250MA01

88EM0100EA01

88EM0150EA01

88EM0200EA01

88EM0250EA01

88EM0100FA01

88EM0150FA01

88EM0200FA01

88EM0250FA01

HC95DE023

HC95DD058

HC95DE088

HC95DE208

HN61HB510

HN61KB021

HN61KB075

♦Available through Service Parts

NOTE: Electric heaters are rated at 240 and 480 volts

Thermostat 1 -stage cooling, automatic changeover

Subbase 2-stage heating, Carrier, Honeywell

Thermostat 2-stage cooling, manual changeover

Subbase 2-stage heating, Carrier, Honeywell

Solid-State Time Guard® Control (Six 50LQ900021)

Service Sentry (Six 50LQ900011)

Supplemental Heat Relay—Used with 25 kW heater and 2 outdoor thermostats

Reversible Filter Drier and AccuRater Assembly

Motormaster® Head Pressure Control

Motormaster Head Pressure Control

Duct Flange Kit

Electric Heater—5 kW, 240-1

Electric Heater—7.5 kW, 240-1

Electric Heater—10 kW, 240-1

Electric Heater—15 kW, 240-1

Electric Heater—20 kW, 240-1

Electric Heater—25 kW, 240-1

Electric Heater—10 kW, 240-3

Electric Heater—15 kW, 240-3

Electric Heater—20 kW, 240-3

Electric Heater—25 kW, 240-3

Electric Heater—10 kW, 480-3

Electric Heater—15 kW, 480-3

Electric Heater—20 kW, 480-3

Electric Heater—25 kW, 480-3

Start Capacitor^

Start Capacitor^

Start Capacitor^

Start Capacitor^

Start Relays

Start Relays

Start Relays

Table 2—Accessories

DESCRIPTION

MODEL

50QQ

All

All

All

All

060

All

All

All 208/230-v

All 460-v

018-048

All

All

All

030-060

036-060

060

030-060

030-060

042-060

060

036-060

036-060

036-060

060

018

024, 030

036-048

060

018

024-048

060

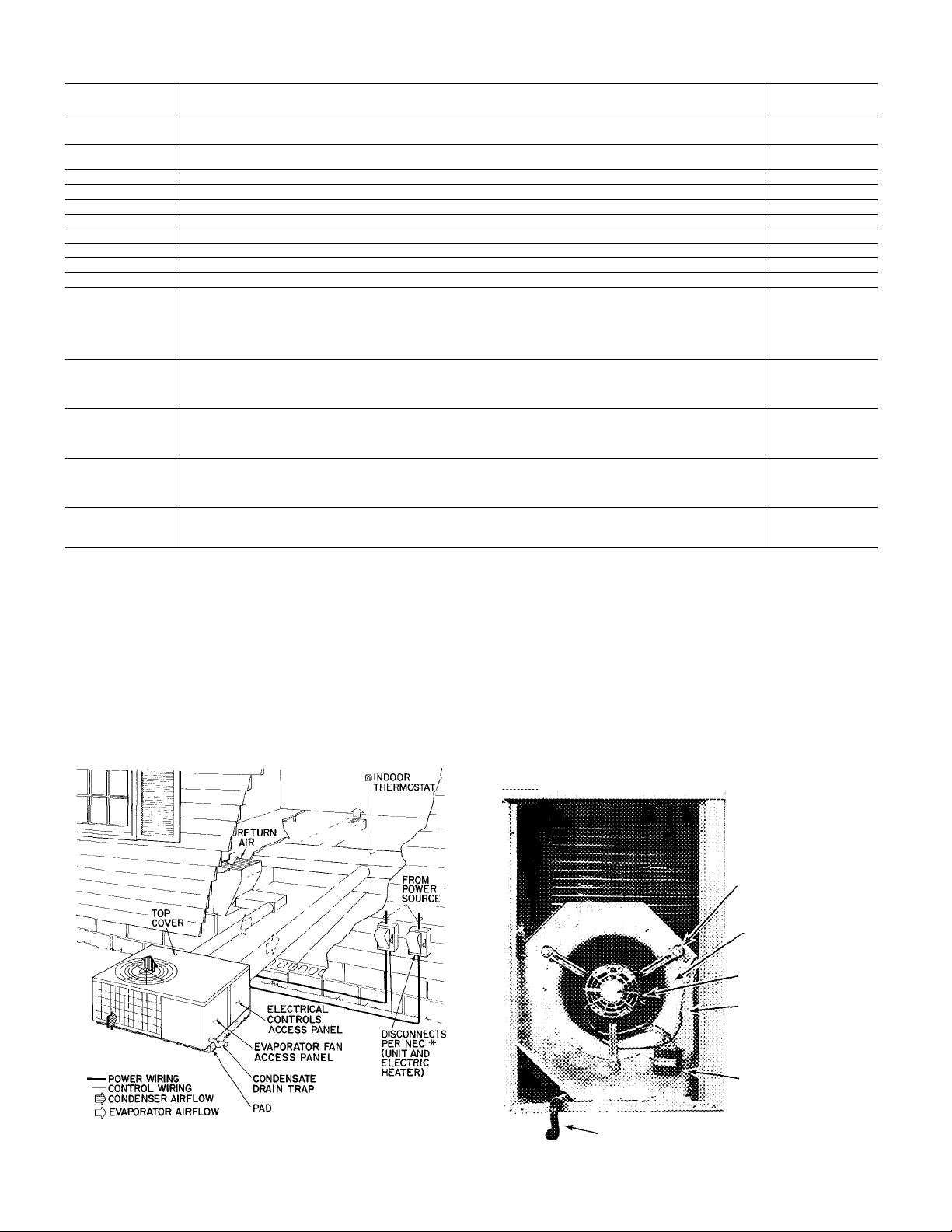

Step 4—Provide for Cooling Cycle condensate Disposal-

Condensate may be drained directly onto gravel apron or

connected by drain line(s) to a dry well. Follow local codes.

CONNECT DRAIN LINE to rubber condensate drain fit

ting on side of unit (see Fig. 5). Use clamp provided. Install

factory-supplied condensate trap (taped to indoor fan com

partment for shipment) at end of dredn line. If a drain line is

not used, connect condensate trap to unit drain fitting as

shown in Fig. 4.

FAN MOTOR

MOUNTING BOLTS

ORIFICE RING

FAN MOTOR

BLOWER

HOUSING

CAPACITOR

♦Separate disconnect per NEC required for electric heater

Fig. 4—Typical Installation

CONDENSATE TRAP

Fig. 5—Condensate Drain and Trap Details

Page 5

m

step 5—Make Electrical Connections—Install field wiring

in compliance with loced and national fire, safety and electri

cal codes. Be sure voltage to unit is within ± 10% of volt

age indicated on nameplate. Contact local power company

for correction of improper line voltage.

Operation of unit on improper line voltage constitutes

abuse and may cause unit damage that could affect war

ranty.

See Table 3 for recommended fuse sizes.

INSTALL A BRANCH CIRCUIT DISCONNECT PER

NEC of adequate size to handle unit starting current. Pro

vide a separate disconnect for unit and for each accessory

electric heater circuit as required. (See electric heater Instal

lation, Start-Up and Service Instructions.) Locate disconnect(s) within sight from and readily accessible from the

unit, per Section 440-14 of National Electriced Code (NEC).

ROUTE LINE POWER LEADS INTO UNIT-Extend

leads from disconnect per NEC through hole provided

(Fig. 1) into line wiring splice box. Use copper wire only.

CONNECT GROUND LEAD TO GROUND LUG in splice

box for safety. Connect power wiring. See Fig. 7. Connect

line power leads to yellow and black pigtails on single-phase

units.

SET INDOOR FAN MOTOR SPEED-Refer to page 3 for

minimum edlowable eiir quantity for safe electric heater

operation. Indoor fan motor is factory wired for low-speed

operation on all models. Fan motor is equipped with spadetype speed selector terminals marked 1, 2 and 3 on 3-speed

motors (042 and 048), and 1 and 2 on 2-speed motors (018,

024, 030, 036 and 060).

For electric heater operation, set motor at: LOW—sizes 018

through 042, and 060; MED—size 048.

MOTOR TERMINAL

FAN SPEED

(3-speed, 042, 048)

FAN SPEED

(2-Speed, 018-036, 060)

1

High

High

2

Medium

Low

3

Low

—

For air delivery performeuice, refer to Table 4.

ROUTE CONTROL POWER WIRES (24v) through 78-in.

connector provided in unit. Fig. 1. Extend leads to unit con

trol wiring terminal boeu-d in unit control box. Fig. 6. Con

nect leads to terminal board as shown in Fig. 8.

The unit transformer supplies 24-v power for complete sys

tem including accessory electric heater. A resettable circuit

breaker is provided in the 24-v circuit.

RUN

HEATER

CAPACITOR

CONTROL

VOLTAGE

CIRCUIT

BREAKER

CONTROL

BOARD

SUPPLE

MENTAL

HEAT

RELAY

SERVICE

SENTRY

UNIT

GROUNDING

LUG

START

THERMISTOR

TRANSFORMER

CONTACTOR

HEATER

CONTROL RELAY

TIME GUARD

LIM^i7cONTROL S^PLT^AGE GROUNDING

HEATER

connection

Fig. 6—Control Section

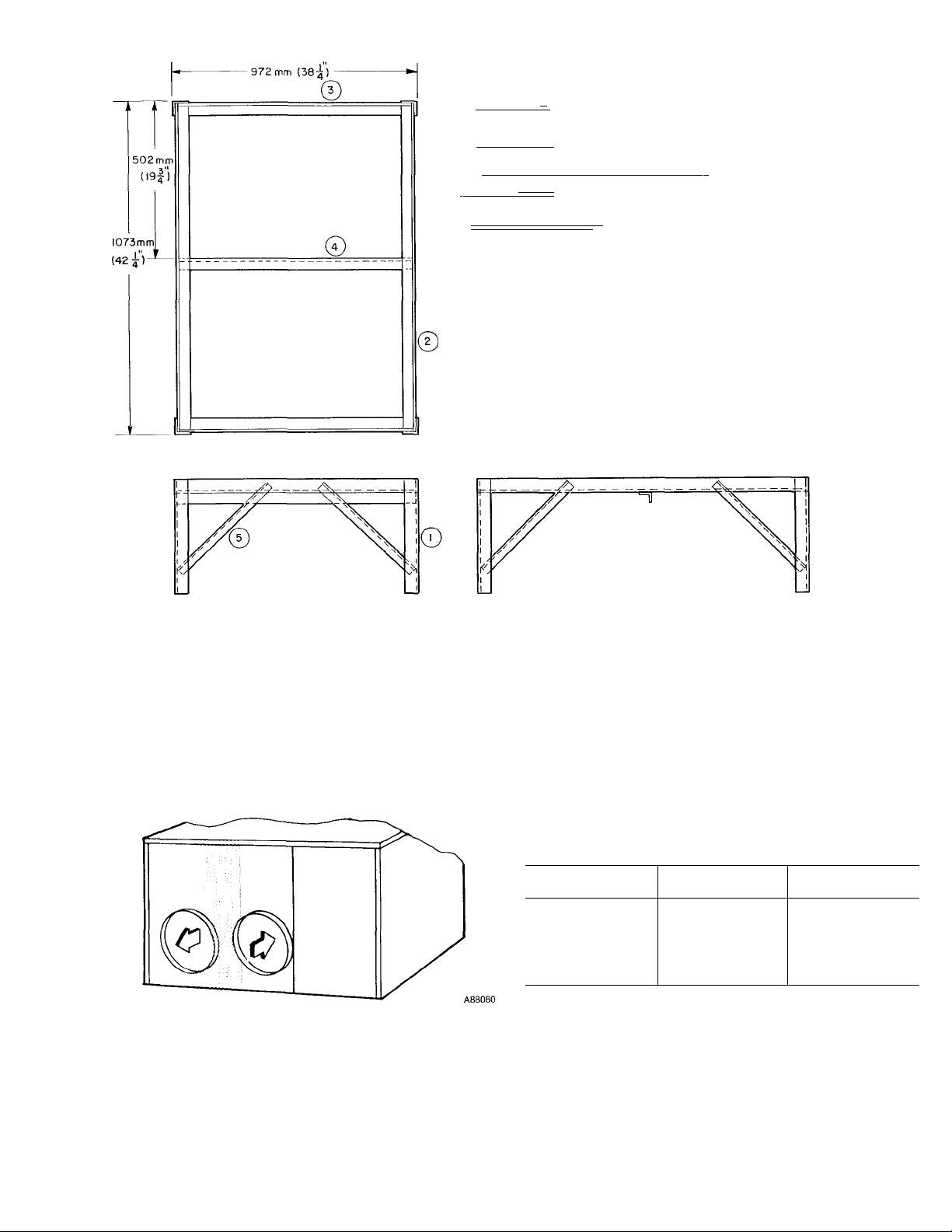

ACCESSORY DUCT FLANGE KIT INSTALLATION018-048

1. Refer to Fig. 8 for duct adapter dimensions and hole

locations.

2. Mark hole locations.

MODEL

5000

018

024

030

036

042

048

060

030

036

042

048

060

036

042

048

060

FLA —Full Load Amps

HACR—Heating, Air Conditioning, Refrigeration

IFM —indoor Fan Motor

LRA —Locked Rotor Amps

MCA —Minimum Circuit Amps

OFM —Outdoor Fan Motor

RLA —Rated Load Amps

V-PH

208/230-1 253 187 82 0

208/230-3 253 187 79 5

460-3

Max Min LRA

506 414 398

Table 3—Unit Electrical Data (60 Hz)

OPER

VOLTAGE*

COMPRESSOR

r RLA

50 0

53.0

65.0

106.0

1100

178.0

53 0

67 5

90.0

124.0

33.8

45 0

62.0

9.3 3.5 1 4

11 6 35

13.9

17.2

20 7 35

22.4 4.6 2.2

30.2 6.7

81

108

12.0

146 4.6

20.5 6.7

5.0

63 20

7.0 20

10.3

*Permissibie limits of the voltage range at which units will operate

satisfactorily.

tMaximum dual element fuse

NOTE: Use copper wire only.

IFM

FLA

35 1.4

35 22

35

35

46

1 7

3.4

OFM

FLA

1.4

22

2.8

1 4

2.2

2.2

22

2.8

07

1.3

1.3

1.3

MAX FUSEt

OR HACR CKT

BKR AMPS

25

30

35

40

50

50

60

20

25

30

35

45

15

15

15

25

MCA

165

19.4

22.2

27 2

31.6

34.8

47.3

15.0

19 2

21.8

25 0

35.1

8.7

11 2

12.1

17.6

Page 6

Table 4—Air Delivery (Cfm) Performance

MODEL

50QQ

018-10

024-10

030-

10&30

036-

10&30

042-10

042-30 230,

048-

10&30

060-

10&30

NOTES:

1. Air delivery values are based on 230- or 460-volt unit operating voltage without air filter or optional electric heaters Deduct field-supplied air filter and

electric heater pressure drop to obtain external static pressure available for ducting

2 Dashes indicate portions of table that are beyond blower motor capability,

3 Do not operate unit at a cooling airflow less than 350 cfm for each 12,000 Btuh of rated cooling capacity. Indoor coil icing may occur at airflows below

this point

UNIT

VOLTAGE

230 Wet

230

230

230,

460

460

230,

460

BLOWER

MOTOR

SPEED

Low Dry

High Dry

Low

High

Low Dry

High Dry

Low Dry

High

Low Dry 1850

Med

High

Low Dry 2395

High

COIL

Wet

Dry 1450

Wet 1390

Dry 1500

1460 1405 1350

Wet

Wet

Wet

Wet

Dry

Wet

Wet 1820

Dry 1960

1895 1880 1850 1795

Wet

Dry 2230

Wet 2145

Wet 2375

Dry 2570 2525 2470

Wet 2550

0.1 0.2 0.3

0.0

___

—

_

—

—

_

—

1410 1375

1340 1290 1225

1475

___ ___

— —

___ ___

_

—

__

___

—

___ ___

_

—

1810 1770 1725

1775 1730 1695

1915 1885 1830

2160

2105 2060 2000 1940

2365 2335 2290 2245

2325

2485

1435

1425 1360

1380

1500

1450

1440 1400

1400 1365 1290

1500

1465 1430

2120

2295

2435 2385

EXTERNAL STATIC PRESSURE (in. wc)

___ ___

—

— —

—

1320 1345 1175

1390 1335

1295 1255 1190

1315

1425 1245

1375 1295 1230

1460 1410

2070 2010

2250 2225

2425 2370

0.4 0.5 0.6

—

—

—

— 750 680

—

— 785 685

1165 1105

1295 1235

1250 1190 1125

1345 1290

1365

1685

1650

1780 1725

1745 1690

2345

800

820 680

1260 1180

1275 1190

1240

1345

1300

1640 1600

1610 1555

1950

1880 1820

2205

2180

2335 2265

2310 2235

0.7

640

730

550

550

575

1090

1020 915 740

1110

1160 1080

1145

1225

1185

1270

1230 1145 1020

1655

1620 1565 1510

1890 1820 1750 1675

2150 2100 2050

2135 2070 2020

985

1090 980

1020 870

1045 960

1120 1020

1080 985

1140 1040

1090 990

1195 1075

1535 1480

1500 1440 1385

1600

1750 1690 1615

2220 2160 2100

2190

1540

2130

0.9

0.8

_

—

— — —

— —

— —

760

850

_

840

—

995 925

895 790

935

905

930

890

930

890 —

1410

1470

1445

2000 1915

1960 1875

2075

1.0

—

_

—

—

815

830

805

—

—

—

1345

1320

1400

1375

1590

1540

2030

2000

3. Using duct flange as a template, make sure marked

locations line up with clearance holes on flanges.

4. At marked locations, drill screw engagement holes

using a #26 (.147-in.) twist drill.

GROUND LUG

(IN SPLICE BOX)

--GROUND LEAD

I - PHASE

CONN.

TO

DISCONNECT

PER NEC

3-PHASE

CONN.

TO

DISCONNECT

PER NEC

L2

L2

L3

__________

__________

- - GROUND LEAD -

----------------------

BLK

^

YEL

HEAT PUMP

GROUND LUG

(IN SPLICE BOX)

BLK

■BLU

-5^YEL - -s

HEAT PUMP

--------

--------

--------

A CAUTION

On 042, 048, do not drill deeper than one inch in shaded

area. Damage to refrigerant coil could result.

5. Attach duct adapters using #10B, V2-in. long screws

supplied in accessory kit.

6. Finished kit installation accommodates a 14-in. x 14-in

duct.

1

S

5

Fig. 8—Duct Fiange Kit Dimensions and Hoie Locations

A88058

#

Fig. 7—Line Power Connections

A88059

ELECTRIC HEATER INSTALLATION-For complete

heater installation data, refer to separate accessory electric

heater Installation, Start-Up and Service Instructions.

Page 7

THERMOSTAT

8 SUBBASE

(SEE BELOW)

0-

&

UNIT

CONTROL WIRING

TERMINAL BOARD

THERMOSTAT

a SUBBASE

UNIT

CONTROL WIRING

TERMINAL BOARD

B-

0

-

0

-

0

-

COOLING AND ONE-STAGE HEATING

THERMOSTAT

a SUBBASE

(without Electric Heater)

UNIT

CONTROL WIRING

TERMINAL BOARD

0)

<g>

^0

-0)

ODT—Outdoor Thermostat Assose

HR —Heater Relay

(Unit equipped with Eiectric Heater, Suppiemental Heat,

THERMOSTAT

a SUBBASE

COOLING AND TWO-STAGE HEATING

One Outdoor Thermostat)

UNIT

CONTROL WIRING

TERMINAL BOARD

(Unit equipped with Electric Heater, Supplemental Heat,

COOLING AND TWO-STAGE HEATING

No Outdoor Thermostats)

Fig. 9—Control Connections

SHR—Supplemental Heat Relay

HR —Heater Relay

ODT—Outdoor Thermostat

COOLING AND TWO-STAGE HEATING

(Unit equipped with Eiectric Heater, Supplemental

Heat Relay, Two Outdoor Thermostats)

A88054

Page 8

START-UP

The 50QQ unit compressors Eire equipped with crankcase

heaters. It is recommended that heater be energized a mini

mum of 24 hours before starting unit. To energize heater

only, set thermostat at OFF position; turn on unit main

power at disconnect switch.

Heat Anticipator Settings for Room Thermostat—Set

anticipator settings for room thermostat according to sepa

rate accessory electric heater Instedlation Instructions.

Accessory Outdoor Thermostat provides adjustable out

door control of accessory electric heaters of 15 kW and

leirger. This thermostat makes contact when a drop in out

door temperature occurs. It energizes a stage of electric

heat when the outdoor temperature setting is reached, pro

vided the room thermostat is on the second stage of heat

ing. An outdoor thermostat is recommended for the second

stage of electric heat. Refer to heat load of building and unit

capacity to determine the correct outdoor thermostat

setting.

The accessory supplemental heat relay is required when 2

outdoor thermostats are used. It is automaticeilly energized

by the manually operated supplementeil heat switch in the

indoor thermostat subbase. The indoor thermostat locks out

compressor and the relay bypasses the outdoor thermostats

for electric heater operation during heat pump shutdown.

When one outdoor thermostat is used, a supplemental heat

relay is not required. The supplemental heat switch in the

indoor thermostat subbase bypasses outdoor thermostat,

locks out compressor and activates electric heater.

MOUNT OUTDOOR THERMOSTAT-Locate maximum

of 2 outdoor thermostats in the controls section on the cen

ter post to the left of the electric heater. Fasten with screws

in holes provided. Route capillary tube per instructions in

thermostat package.

MOUNT SUPPLEMENTAL HEAT RELAY in low-voltage

section of control box to right of low-voltage connections,

using holes provided.

To Start Unit—Check that main power is on and that com

pressor crankcase heater has been energized for at least 24

hours.

1. Check that heater main power is on as applicable.

2. Set selector switch at OFF.

3. Set fan switch as desired (FAN) (AUTO.).

4. Set thermostat died at the desired temperature.

5. Set selector switch at HEAT or COOL. Check system

refrigerant charge as described under Service.

Unit Single-Phase Compressors are Equipped with a Com

pressor Start Thermistor (PTC device)—When supply volt

age is within 10% limit and compressor does not start,

check the start thermistor with an ohmmeter.

CHECKING START THERMISTOR

1. Shut off all power to unit and wait 10 minutes for

thermistor to cool to ambient temperature.

2. Remove thermistor from circuit.

3. Measure resistance of thermistor with ohmmeter. Nor

mal resistance readings are 25 ohms ± 20% at 75 F

ambient temperature.

4. If ohmmeter resistance reading is not within ± 20%,

the thermistor is defective and must be replaced.

If start thermistor is good and compressor does not start,

disconnect the thermistor from starting circuit and give

compressor a temporary capacitance boost. Run compressor

for 10 minutes, then shut off and eillow system pressure to

equalize. Reconnect start thermistor and try restarting

compressor without boost capacitor. If after 2 attempts the

compressor does not start, remove thermistor and add an

accessory start capacitor and relay.

SERVICE

A WARNING

Before installing or servicing unit, turn off main power

to system. There may be more than one disconnect

switch. Turn off accessory heater power if applicable.

Electrical shock can cause personal injury or death.

Unit Controls and Safety Devices

The following controls are used on all units:

HIGH-PRESSURE RELIEF VALVE (Safety Control) is

located in compressor. Relief valve opens at a pressure dif

ferential of approximately 450 psi between suction (low

side) and discharge (high side) to allow pressure

equalization.

INTERNAL CURRENT AND TEMPERATURE SENSI

TIVE OVERLOAD (Safety Control) resets automatically

when internal compressor motor temperature drops to a

safe level. When an internal overload is suspected of being

open, check by using an ohmmeter or continuity tester.

DEFROST CONTROL, consisting of a control board and

defrost thermostat, interrupts normeJ system heating oper

ation to remove frost and ice formation on outdoor coil.

Frost impairs unit performance. Defrost control simulta

neously stops outdoor fan, energizes reversing valve sole

noid to switch system into cooling cycle (outdoor unit as

condenser, indoor unit as evaporator), and activates acces

sory electric heater. Unit can defrost every 90 minutes, but

will do so only if outdoor temperatures are in the frosting

temperature zone.

For heat pump to defrost, 2 conditions are necessary:

1. Defrost timer contacts must be closed.

2. Refrigerant temperature must be cold enough to cause

defrost thermostat contacts to close. Contacts close at

27 ± 5 F.

Every 90 minutes of elapsed running time, the defrost timer

contacts close for 10 seconds. If the defrost thermostat con

tacts are closed, the unit defrosts. The defrost timer limits

defrosting period to 10 minutes. Normally the frost is

removed and the defrost thermostat contacts will open to

terminate defrosting before 10 minutes have elapsed.

Defrost thermostat contacts open at 80 ± 6 F. When

defrosting is terminated, the outdoor fan motor is energized

and reversing valve solenoid is de-energized, returning unit

to heating cycle.

The 90-minute period to check for defrost can be changed to

50 or 30 minutes by moving a jumper wire on the defrost

printed-circuit board.

HEAT PUMP CIRCUITS shown in Fig. 10 are refrigerant

flow diagrams for heating and cooling cycles.

Refrigerant Charging

A WARNING

Avoid contact with hot gas discharge line to prevent a

burn when working on compressor.

Page 9

COOLING STRAINERS HEATING

©

INDOOR

FAN

COOLING STRAINERS HEATING

Fig. 10—Refrigerant Flow Diagrams

Table 5—Service Data

MODEL 50QQ

R-22 CHARGE* (lb) 7 lbs 4 oz 6 lbs 8 oz 8 lbs 0 oz 7 lbs 4 oz

Piston Htg/cig.

INDOOR FAN

Rpm

Diameter (in.)

Width (in.)

Range (cfm)

Motor Hp

OUTDOOR FAN

Cfm

Rpm

Diameter (in.)

Motor Hp

•'Factory refrigerant charge

018

52/42

10

6

525-750 700-1000 875-1250

Va

2200

840

22

%

A WARNING

To prevent personal injury, wear safety glasses and

gloves when handling refrigerant.

Do not overcharge system. An overcharge can cause

compressor flooding.

024 030

61/49

840

Va

2200

840

22

67/32 76/63 78/70

2200

Centrifugal—Direct Drive

'h %

Propeller—Direct Drive

840 1100 1100

22 22

Vs

mode when temperature is below 65 F. If charge must be

checked in opposite mode, do not operate unit continually

for more them 10 minutes or damage to compressor may

result.

Refrigerant system is fully charged with R-22 refrigerant,

tested, and factory sealed. For more applications, factory

036

840 1100

1020-1450 1170-1670 1340-1920 1690-2420

2700 3200

74 74 74 V2

cheu-ge is the correct Eimount for best performance; however,

this charge may require a slight adjustment to atteun rated

performance.

Unit refrigerant system is factory charged. When recharg

ing is necessary, weigh in total charge indicated in Table 5.

NOTE: Adjustment of refrigeremt cheu-ge is not required

unless unit is suspected of not having proper R-22 charge.

(Charge must be weighed in during heating season.) Remove

any refrigerant remaining in system before recharging. If

system has lost complete charge, evacuate system to 5000

microns (29.7-in. vacuum) before recharging. Schrader fit

ting connections are provided on unit suction and discharge

lines for evacuation and charging. (See Fig. 12 for Schrader

fitting location.) Volumetric charging device is an accurate

device used to recharge systems by weight. These cylinders

When evaluating refrigerant charge, an indicated

adjustment to specified factory charge must always be

very minimal. If a substantial adjustment is indicated,

an abnormal condition exists somewhere in system,

such as insufficient airflow across either or both coils.

are available at refrigeration supply firms.

CHARGING AND ADJUSTING REFRIGERANT

CHARGE

NOTE: Check refrigerant charge in cooling mode when out

door temperature is above 65 F. Check charge in heating

Heating Mode

1. Remove gage port caps from both service valves and

attach gage manifold. Use hoses with valve core

depressors.

COOLING CYCLE

042

8 lbs 12 oz 9 lbs 0 oz 9 lbs 0 oz

12

6

V2

22 22 22

048

82/73 93/84

72

3200 3400

1100 1100

A CAUTION

A87291

060

1100

%

Page 10

Table 6—Field Charging Table—Fixed Restrictor

HEATING OPERATING PRESSURES PSIG (Pressures at High and Low Side Service Ports)

MODEL

50QQ

018

024

030

036

042

048

060

NOTE: Add charge if pressures are low Bleed out charge if pressures are high. Allow ± 5 psig tolerance on high-side pressure.

INDOOR

DRY BULB (F) 60

65 High 217

70 High

75 High 248 232

65

70

75 High 251 235

65 High 219 203

70 High 235 219

75 High 250 235

65 High 218 202

70 High 231 216

75

65 High 212 197

70 High 226 211

75 High 241 225

65 High 315 200

70 High 229 213 200 187

75 High 243

65

70 High 228 213

75 High 243

Low 77.2 65

Low

Low 78.4 65.9

High 219

Low 72.1

High 235

Low

Low

Low 70.5 58.9

Low 71.1

Low 71.5 59.9

Low 70.9 59.1

Low 71.4 59.6 49.3

High 246

Low 72 60.1

Low 69.6 58.1

Low

Low 70.7 59.2

Low 67.7 56.5

Low

Low 69

High 214 199 185 174 163

Low

Low 65.8 54.8

Low 66.4 55.4

232 217 203 192

77.8 65.4

72.6 60.9

73.2 61.4 51 41.6

70.2 58.7 48.6 39.7 31.9

68.3 57.1

65.2 54.2

OUTDOOR TEMPERATURE (F) DRY BULB

50 40

202 189

204 191 179

60.4 50.2 40.8 32.5

219

53.8 43.7 34.7

54.2 44 35

218

54.9

205

50.5

221 209 196

190 179 168

48.7

205

59.4

49.2

222

49.7

190

48.8

202

230 216

227 213

57.7 47.7 39 31.4 24.3 18.1

227 213

49.7 40.5 32.5

184

48

197

211

49.1 40.2 32.3

186

46.7 38.1 30.5

47.2

44.7

199

45.2

45.7

30

178

205

44.4

194

41.2

39.8

195

40.2

208

40.6

180

39.8

192 186

40.1 32.2 24.9

205

172

39.2

185

198

174

38.6

200

36.4 29

187

36.9

200

37.3

20

168

181

195

35.2 27.3

171 161

183

32.9

33.2 25.6

31.9

184 170

32.2 24.9

196

32.5

172 161

31.9 24.6

198

162

31.5

174

187

163 154

175 164

31 24 17.8

189 177

175

29.5 22.9

189 178

29.9 23.2

10

157

26.8

169 158

27 19.8

184 174

25.1

174 164

25.4 18.7

185

153 150

24.7

186 176

25.2 18.6

174

187

25.2

153

24.4 18

164 155 145

24.7 18.3 11.8

176 165

25 18.5

23.7 17.5 11.3

155 145

22.5 16.6

164 155 146

0

149 140

19.7 12.6

21.1

150

18.4

176 165

18.9

18.1 11.6

158

18.3

152

18.1

163 153

18.3 11.7

178 169

18.5 11.9

144 135

145 136

154 144

167 156

16.8 10.8

168 158

17.1 11.0

-10

147

12.9

165

13.2

139

11.7

154

12

12.1

141

145

11.7

167

11.9

142

11.6

11.6

155

12.1

11.5

11.8

136

10.8

COOLING DESIRED SUPERHEAT TEMP (F)

B

OUTDOOR

DBT

DGT(F) 54

60

65

70 7

75

60

85

90

95

100

105

110

115

*Do not attempt to charge system under these conditions or refrigerant

slugging may occur

NOTE: Add charge if actual superheat temperature is higher than chart

value. Remove if lower Allow ± 3 F for tolerance.

Unit is factory charged with R-22 in accordance with amount shown

on rating plate. This chart is intended for usage when minor unit

charge adjustments are required. For large charge adjustments, evac

uate unit and weigh in charge according to unit rating plate. Best per

formance will be achieved when unit operates with a suction gas

superheat at compressor inlet of 5 F at normal rating conditions of

Air Conditioning and Refrigeration Institute (ARI). This chart may be

used to approximate the charge if ARI rating conditions cannot be

obtained. ARI rating conditions are 95 F db outdoor. 89 F and 67 F

wb indoor. See Table 4 for required indoor airflow rates. Charge unit

with outdoor fan operating only on high speed.

12 15 18

10 13 16 19 21

if

*

■¥

* * *

♦

♦

♦

«

*

(Measured at Low-Side Service Port)

EVAPORATOR AIR INLET WBT (F)

56

58

60 62

21 24 27

10 13

6 9

*

*

* *

* «

* ♦

* *

♦ *

16

12

5 8 12

*

«

*

* *

*

* * ♦

« * * *

«

64

24 27 30

21 24 27

19

18 21 24

15

15

11

8

5

*

*

66 68 70

30

18

15

9

13

6

10

*

* * *

33

21

19 22 26

16

14

12

8

9

5

6

72

38 40 43

36

36

33

33

30

31 34 37

28

28 31 35

25

24

20

22

18

15 20 23

17

13

11 15 20

14

8

74

38

36

30

27 31

25

22 26

18

76

41

39

33

29

27

25

23

REQUIRED SUCTION TUBE (F) VS. DESIRED

(Measured at Low-Side Service Port)

DESIRED

SUPERHEAT

TEMP (F)

0 35

2 37

4 39

6 41

8

10

12 47

14 49

16 51

18

20

22 57

24 59

26 61

28 63

30

32 67

34 69

36 71

38

40

NOTE: Measure suction tube (F) with accurate superheat thermocouple

or thermistor-type thermometer.

FINAL DISPOSAL: CAUTION—CAREFULLY RELIEVE REFRIGERANT

PRESSURE WITHIN UNIT BEFORE FINAL DISPOSAL

SUCTION OR LOW-SIDE PRESSURE (psig)

61.5 64.2

37

39 43 43 45 47

41 43 45 47 49 51

43 45 47 49 51

45 47

43

47 49 51 53 55

45

49 51

51 53

53 55

53 55 57

57

55

59 61

61 63 65 67 69 71 73 75

63

65 67

67 69 71 73

65

69 71

71 73 75 77 79 81 83 85

73 75 77 79 81

75 77

73

77

75

SUPERHEAT (F)

AT SERVICE PORT

67.1

39

59 61 63 65

65 67 69 71 73 75

79

73

70

41

43 45

49 51 53

55 57

53

57 59

55

59

57

61 63

59

65 67 69

63

71

69

75

73

81 83 85 87 89

79

81 83

76

61

73

75

77

85

79.2 82.4

47 49 51

49

53

55 57 59

57

59

61

63

65 67

67

75 77

77 79 81

79

83

87 89 91

85.7

51 53

53

55

59

61 63

63 65

65

69

71

81

85

55

57

61

67

69

71

73

77

79

83

87

10

Page 11

2. Start unit and allow to operate until operating condi

tions stabilize and pressures level out.

3. Evaluate system performance and refrigerant charge

level by determining following conditions:

a. High- and low-side pressure gage reading.

b. Dry-bulb temperature of inlet air at outdoor coil.

c. Dry-bulb temperature of inlet air at indoor coil. This

may be read at central return-eiir grille.

d. Compare readings to those listed in Heating Operat

ing Pressures section of charging chart inside unit

(refer to Table 6, part A). The Heating Operating

Pressures portion of the chart is for checking charge

only when unit is in heating mode and outside tem

peratures are below 60 F.

If charge adjustment is necessary, charge can be adjusted

accurately only by blowing the charge, evacuating system,

and recharging unit with correct charge as listed on unit rat

ing plate. A volumetric charging device such as Dial-acharge is recommended for use when recharging.

Cooling Mode—A superheat charging label is affixed to elec

trical access door. The label includes a Field Superheat

Charging table (see Table 6, peirt B) and a Required Suction

Tube Temperature (F) chart (see Table 6, part C).

An accurate superheat-, thermocouple-, or thermistor-type

thermometer, a sling psychrometer, and a gage manifold are

required when using superheat charging method for evalu

ating unit charge. Do not use mercury or small dial-type

thermometers. They are not adequate for this type of

measurement.

Proceed as follows:

1. Remove caps from low- and high-pressure service

fittings.

Using hoses with valve core depressors, attach low-and

2.

high-pressure gage hoses to low- and high-pressure

service fittings, respectively.

Start unit in cooling mode. Let unit run until system

3.

pressures stabilize.

Measure and record following;

4.

Outdoor ambient air dry-bulb temperature (F).

a.

Evaporator inlet air wet-bulb temperature (F).

b.

Suction tube temperature (F) at low side service

fitting.

Suction (low side) pressure (psig).

d.

Using Field Superheat Charging table, compare out

5.

door air dry-bulb temperature (F) with evaporator inlet

air wet-bulb temperature (F) to determine desired sys

tem operating superheat temperature.

Using Required Suction Tube table, compare desired

6.

superheat temperature (F) with suction (low side) oper

ating pressure (psig) to determine proper suction tube

temperature.

Compare actueil suction tube temperature with proper

7.

suction tube temperature. Using a tolerance of ± 3 F,

add refrigerant if actual temperature is more than 3 F

higher than proper suction tube temperature, or

remove refrigerant if actueJ temperature is more than 3

F lower than required suction tube temperature.

Metering Device (Dual-Piston Type) Servicing—See Fig. 11

for dual-piston components. The pistons have a refrigerant

metering orifice through them. The retainers form a stop for

the pistons in the refrigerant bypass mode, and a sealing

surface for liquid line flare connection. To check, clean or

replace piston:

1. Shut off power to unit.

2. Remove refrigerant from unit using approved refriger

ant removal methods.

3. Remove liquid line flare connections from metering

device.

4. Note position of arrow on metering device body with

respect to unit.

5. Pull retainer out of body. Be careful not to scratch flare

sealing surface. If retainer does not pull out easily,

carefully use locking pliers to remove retainer. Replace

scratched or deimaged retainer.

6. Slide piston out by inserting a small soft wire through

metering hole (18-gage thermostat wire). See that

metering hole, sealing surface around piston cones and

fluted portion of piston are not damaged.

7. Chart on unit access panel illustrates proper arrange

ment and sizes of piston.

8. Clean piston refrigerant metering orifice.

9. Replace retainer 0-ring before reassembling metering

device. 0-ring Part No. is 99CC501052.

LIQUID LINE STRAINERS (to protect metering device),

are made of wire mesh and located in the liquid line on each

side of the metering device. The strainers are pressed into

the line. Remove strainer by threading a #10 sheet metal

screw into strainer and pulling the screw with pliers.

Compressor Removal—See Table 7 for compressor informa

tion and Fig. 12 for component location. Follow safety

codes, and wear safety glasses and work gloves. Have

quenching cloth available (step 8).

Table 7—Compressor Data

MODEL

SOQQ

018

024

030 JD30

036

042

048

060

*Refer to compressor nameplate for complete model number.

PRODUCTION

COMPRESSOR*

H22B173

JD25

JD37

JD42

JD45

H23A623

A CAUTION

OIL

RECHARGE (oz)

37

44

44

44

44

44

47

Copper tubing is used in unit coils. Do not overheat or

place excessive strain on tubing or damage may result.

1. Shut off power to unit. Remove compressor access

panel to expose compressor. See Fig. 12.

2. Remove refrigerant from unit using approved refriger

ant removal methods.

3. Remove core from suction and discharge line Schrader

fittings.

4. Disconnect compressor wiring at compressor terminal

box.

5. Using a tubing cutter, cut suction and discharge lines

at convenient place near compressor for easy reassem

bly to new compressor with copper slip couplings.

A CAUTION

Excessive movement of copper lines at compressor may

cause a break where lines connect to other system

components.

11

Page 12

FLARE

NUT

STRAINER

COOLING PISTON

IDENTIFICATION

HEATING

FLOW

RUBBER 0-RING

STAMPED ARROW ON

COUPLING BODY

COIL

COMPRESSOR HOLDDOWN BOLT

Fig. 12—Compressor Section

RUBBER 0-RING

Fig. 11—Metering Device (Dual-Piston) Components

TOWARD INDOOR COIL)

SUCTION

SCHRADER

FITTING

ACCUMULATOR

REVERSING

VALVE

DISCHARGE

SCHRADER

FITTING

CRANKCASE

HEATER

SWITCH

CRANKCASE

HEATER

A87293

6. Remove wraparound crankcase heater (if used) from

compressor base.

7. Remove compressor holddown bolts and lift compres

sor out.

8. Carefully unbraze suction and discharge line piping

stubs from compressor. If oil vapor in piping stubs

ignites, use quenching cloth.

A CAUTION

Muffler may contain quemtity of oil.

9. Braze piping stubs (removed in step 8) on new

compressor.

10. Install new compressor in unit. Braze suction and dis

charge lines to compressor piping stubs (at points

where cut, step 5) using field-supplied copper cou

plings. Ensure compressor holddown bolts are in place.

Connect wiring.

NOTE: Reinstall wraparound crankcase heater (if used)

on compressors.

STRAINER nUt'^^

RETAINER

A87292

11. Clean system. Add new suction line filter drier as

described below. Refer to Fig. 10.

NOTE: If a compressor failure was caused by motor

winding burnout, the byproducts of the burnout must

be separated from the circulating refrigerant. This

must be done before the byproducts enter the reversing

vedve or accumulator emd render peu-ts inoperative.

Burnout byproducts can cause future system operating

problems if left in the system.

Clean the system by installing a suction line drier in

the refrigerant line where the suction gas enters the

reversing valve. During the cooling cycle, this is the

line from the indoor coil running across the top of com

pressor compartment; during heating cycle, install

drier in line between outdoor coil and reversing valve.

If possible, run unit in cooling mode when cleaning sys

tem as installation of temporary suction drier is

simplified.

For drier installation during heating cycle, cut line

between outdoor coil and reversing valve, install fit

tings and tubing, and install suction filter drier. To pro

vide protection for the reversing valve, do not place fil

ter drier between reversing valve and accumulator.

Since the suction drier works in one mode only, tempo

rarily wire the unit in the selected mode (heating or

cooling, based on suction drier location). To ensure

cooling operation only, instiJl a jumper between termineds R and O on the low-voltage terminal board. For

heating operation only, remove and insulate one of the

reversing valve solenoid leads. Run unit for 48 hours

emd check oil for acidity. If satisfactory, remove suc

tion line drier. Refer to and follow procedure under

Metering Device Servicing for cleaning of pistons.

Rewire unit to normal conditions.

12. Triple-evacuate and recharge unit. See Refrigerant

Charging.

Filter Drier—Install an accessory reversible, liquid line filter

drier assembly, following the instructions in accessory

package.

NOTE: Follow instructions carefully as piston locations are

reversed from those shown when a filter drier is not used.

Lubrication

COMPRESSOR contains factory oil charge. Replace oil

when lost. See Table 7 for oil recharge. Use Carrier PP33-1,

Texaco Capella WF-32 or Suniso 3GS oil.

#

12

Page 13

FAN MOTOR BEARINGS are prelubricated for 3 years

heavy duty or 5 years normal duty. Oiling holes are pro

vided at each end of fan motor, remove fan motor and lubri

cate motor with 32 drops (16 drops per hole) of SAE 10

nondetergent oil at intervals described below:

a. Annually, when environment is very dirty, ambient

temperature is higher than 105 F and average unit

operating time exceeds 15 hours a day.

b. Every 3 years when environment is reasonably clean,

ambient temperature is less than 105 F and unit oper

ating time averages 8 to 15 hours a day.

c. Every 5 yeeirs when environment is clean, eunbient tem

perature is less than 105 F and unit operating time

averages less than 8 hours a day.

Indoor Coil

A WARNING

Before performing recommended maintenance, be sure

main power switch to unit is turned off. Electrical

shock can cause personal injury or death.

Lift or remove unit top cover for access to indoor coil.

Inspect coil periodically. Clean as described under Outdoor

Coil.

Condensate Drain—Clean condensate drain trap with bot

tle brush; then flush condensate pan beneath indoor coil

with clean water. Ensure water flows freely through conden

sate drain.

Indoor Fan Assembly (Fig. 2)—Fan wheel should be cen

tered in fan housing. To adjust fan, remove as follows;

Disconnect fan motor wiring. Remove 6 sheet metal screws

holding fan orifice in place. Remove 3 fan motor bracket

mounting screws. Slide out complete fan, motor and orifice

assembly.

Reassemble in reverse order.

To clean fan wheel and housing, use a brush, warm water

and detergent. Do not splash water on motor.

Outdoor Air Fan—Fan position is shown in Figs. 14 and 15.

Adjust fan by loosening setscrews and moving blades up or

down. To remove outdoor air fan and motor: disconnect

power, and remove screws holding discharge grille in place.

Disconnect fan motor leads from the motor. Lift complete

fan, motor, and orifice assembly (Fig. 16) out of unit. After

replacing fan motor assembly, reconnect fan motor leads.

DISCHARGE GRILLE

SET.

scae-A

TOP COVER

ORIRCÉ

ime

#

^ ■ Tinflnnir—■ _

-CONDENSATE TRAP

Fig. 13—Indoor Fan

Fig. 15—Fan and Motor

FAN MOTOR

MOUNTING BOLTS

ORIFICE RING

FAN MOTOR

BLOWER

HOUSING

CAPACITOR

Fig. 16—Fan and Motor Removed

13

Page 14

Return Air Filter (Field Supplied)—Replace disposable filter

4 times a year, clean permanent filter a minimum of 4 times

yearly or as required. Flush permanent filter with hot water,

steam or soak in mild solution of soap or detergent and

water. Allow filters to dry and replace. Refer to filter manu

facturer’s instructions, as required, for other types of

filters.

Outdoor Coil—Inspect outdoor coil regularly. A dirty coil

can lead to premature compressor failure and higher operat

ing costs. If cleaning is required, be sure power to system is

shut off before attempting to clean coil.

Outdoor coil may be cleaned with brush, vacuum cleaner, or

low-pressure water (weather permitting). Do not use indus

trial strength cleaning fluids for cleaning coils. If coil has 2

rows, make coil accessible by removing the top cover and

wash out with garden hose.

A WARNING

Be careful! Coil fins are sharp. Protect hands with

gloves when cleaning or handling coil.

Sequence of Operation (Refer to Figs. 17, 18, 19)—When

power is supplied to unit, transformer (TRAN) is energized.

If crankcase heater switch (CHS) is closed and outside tem

perature is below 65 F, crankcase heater (CH) will be

energized.

COOLING—On a call for cooling, thermostat makes circuit

R-0, R-Y and R-G. When room temperature rises to within 2

degrees of control setting of thermostat, circuit R-O makes,

energizing reversing vedve solenoid (RVS). Unit is now in

standby condition for cooling. As room temperature rises,

the second-stage bulb makes, allowing a circuit (R-Y)

through low-pressure switch (LPS) to contactor (C), starting

compressor (COMP) and outdoor fan motor (OFM). Circuit

R-G energizes indoor fan relay (IFR) starting indoor fan

motor (IFM).

When thermostat is satisfied, contacts open de-energizing

contactor. Indoor fan relay, compressor and motor stop.

HEATING—On a call for heat, thermostat makes circuits

R-Y and R-G. Circuit R-Y is completed, allowing circuit

through low-pressure switch (LPS) to contactor (C), starting

compressor (COMP) and outdoor fan motor (OFM). Circuit

R-G also is completed, energizing indoor fan relay (IFR) and

starting indoor fan motor (IFM).

Should room temperature continue to fall, circuit R-W is

made through second-stage thermostat bulb. If optional

electric heat package is used, a sequencer is energized bring

ing on first bank of supplemental electric heat. When ther

mostat is satisfied, contacts open, de-energizing contactor

and sequencer. Motors and heaters de-energize.

DEFROST—Defrost board (DB) is a time/temperature con

trol which includes a field-selectable time period between

check if defrost is necessary (30, 50 and 90 minutes). Elec

tronic timer and defrost cycle start only when contactor is

energized and defrost therniostat (DFT) is closed.

Defrost mode is identical to cooling mode except outdoor

fan motor stops and a bank of optional electric heat turns

on to warm air supplying the conditioned space.

14

Page 15

Fig. 18—Wiring Diagram—3 Phase 230V.

#

Fig. 19—Wiring Diagram—3 Phase 460V.

15

Page 16

POWEfI CinCU

SUPPLEMENTAL HEAT

RELAY ENERGIZED

OR WIRED WRONG

COMPRESSOR

POWER SUPPn

OPEN

FAULTY START CAP

OR RELAY ISINGLE

PHASEl OR PTC

TROUBLESHOOTING CHART-HEATING CYCLE

LOW LINE VOLTAGE

OH UNBALANCED

1 PHASF LINE

DEFFI IIVF HUN

(,APAî:HOH

iSINLiie PHASF I

INDOOR FANS

CYCLING ON

OVERLOAD

OVERCHARGE OR

NONCONDENSABLES

IN SYSTEM

RESTRICTED OR

STUCK

METERING DEVICE

REVERSING VALVE

JAMMED IN MID

POSITION

LOOSE LEADS A

OUTDOOR FAN

MOTOR

DEFROST BOARO

NC CONTACTS

OPEN

METERING DEVICE

RESTRICTED OR

ICE CLOGGED

UNDERCHARGED

DEFROST T STAT

IN POOR PHYSICAL

CONTACT WITH LINE

DEFECTIVE DEFROST

RELAY OR DEFROST

TIMER

OUTDOOR

THERMOSTAT

DEFECTIVE

CAP TUBE PINCHED

OR BULB NOT

SENSING TRUE OOT

STRIP HEATER RELAY

OR CONTACTOR

DEFECTIVE

OPENING IN POWER

CIRCUIT TO HEATER

ELEMENTS

OPEN (KLIXONI

OVERTEMPERATURE

THERMOSTAT

DEFECTIVE ROOM

THERMOSTAT

I2ND STAGE)

CONTACTOR OPEN

OPENING IN

POWER CIRCUIT

DEFECTIVE LOW

VOLTAGE

TRANSFORMER

CONTACTOR OR

COIL DEFECTIVE

INTERNAL OVERLOAD

OPEN

COMPRESSOR

WILL NOT RUN

CONTACTOR CLOSED

FAULTY START CAP

OR RELAY (SINGLE

PHASE) OR PTC

COMPRESSOR STUCK

TROUBLESHOOTING CHART—COOLING CYCLE

NO COOLING OR

INSUFFICIENT COOLING

COMPRESSOR RUNS

BUT CYCLES ON 8i OFF

INTERNAL OVERLOAD

OUTDOOR FAN STOPPED

OR CYCLING ON

OVERLOAD

LOOSE LEAD AT

FAN MOTOR

DEFROST BOARD

N C CONTACTS

MOTOR DEFECTIVE

OUTDOOR AIR

RESTRICTED OR

RECIRCULATING

DAMAGED

REVERSING

VALVE

RESTRICTED

DISCHARGE

LINE

OVERCHARGE OR

NONCONDENSABLES

IN SYSTEM

COMPRESSOR HOT

REVERSING VALVE

IN MID POSITION

LINE VOLTAGE

LOW LINE VOLTAGE

OR UNBALANCED

3 PHASE

DIRTY AIR FILTERS

DUCT RESTRICTED

COIL FROSTED

LIOUID LINE

SLIGHTLY

RESTRICTED

METERING DEVICE

RESTRICTED

BAD ELECTRICAL CON

NECTION ANYWHERE

IN DEFROST CIRCUIT

COMPRESSOR RUNS

INSUFFICIENT COOLING

HIGH SUCTION

LOW HEAD

PRESSURE

REVERSING VALVE

HUNG UP OR

INTERNAL LEAK

DEFECTIVE

COMPRESSOR

VALVES

INTERNAL

PRESSURE

RELIEF OPEN

RESTRICTED

OR STUCK

METERING DEVICE

COMPRESSOR

FLOODING

UNIT

OVERCHARGED

LOW

REFRIGERANT

CHARGE

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

BookI 1 I 4 PC 101 Catalog No. 565-097 Printed in USA Form 50QQ-8SI Pg 16 11-87 Replaces: 50QQ-7SI

Tab Isalsa

Loading...

Loading...