Page 1

Carrier

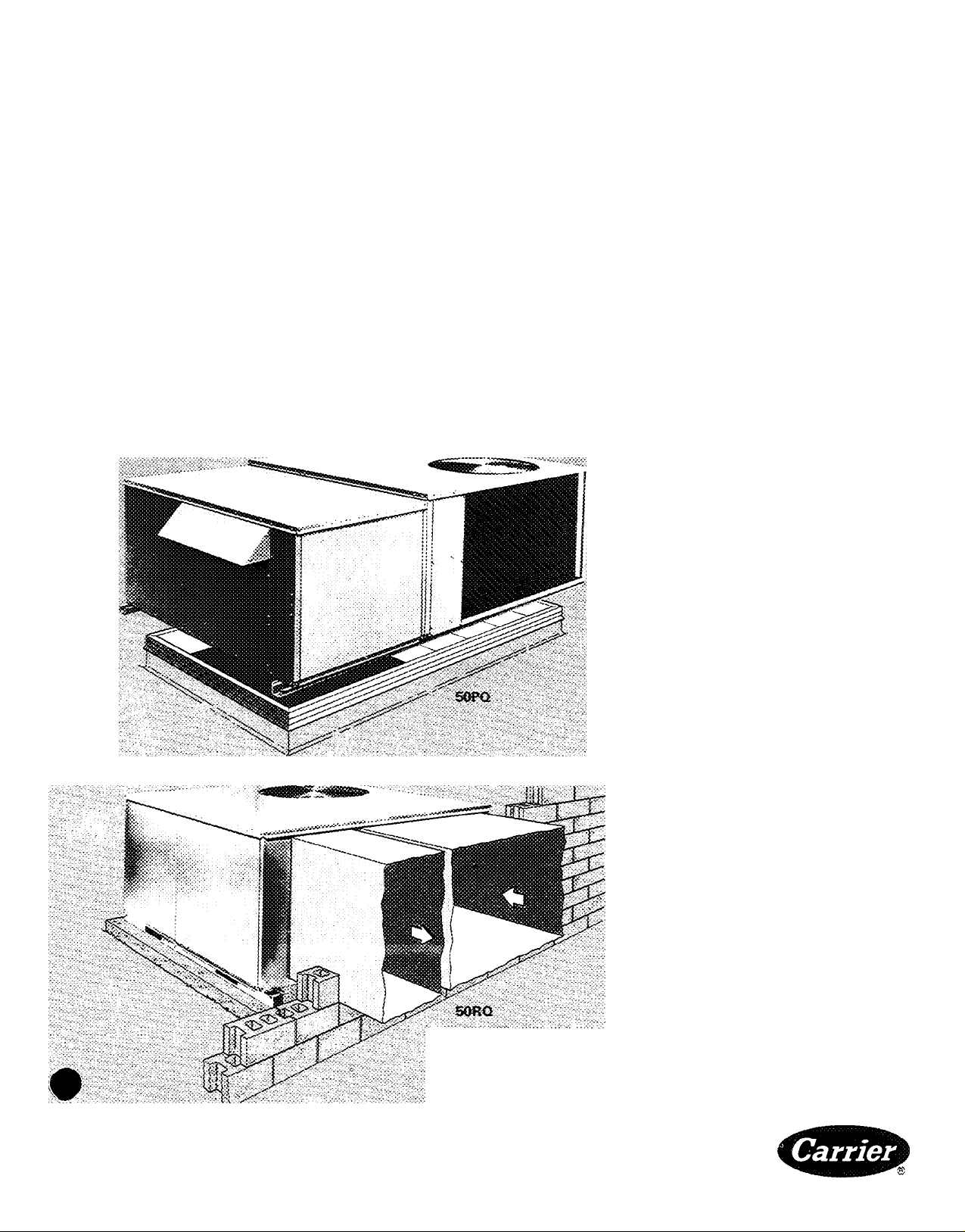

Single-Package

y-

Heat Pumps

The number 1

f<x heating & cooling camrr^rcy,

iixJustrial oc eckicational bialdlngsin 5, and 9 ton caf^ities.

4.

I

¿^ ! '0

I V

Jiy

50RQ,PQ

Heating 62,000 to 112,000 Btuh

Cooling 59,000 to 107,000 Btuh

© Carder Ccrpof3t5on 7977

Form 50RQ-3P

Page 2

The heat pump reverse cycle controls the weather all year round

The Carrier single package heat pump — compact,

efficient, reliable. It puts the weather to work for you

and lowers operating costs.

Thermodynamically, there is no difference be

tween a heat pump and an air conditioning unit or

refrigerator. The heat pump moves heat from a colder

heat source to a warmer heat sink thru the vapor

compression cycle. (The same as a refrigerator or air

conditioner.)

The difference, from a practical standpoint, is in

the heat pump's ability to reverse the roles of the

evaporator and condenser coils.

The heat pump takes advantage of the fact that

even cold winter air contains heat that can be

absorbed for heating a building. During cooling

season operation, the unit can be set to reverse the

evaporator and condenser coils, absorbing heat from

inside the building and discharging it outside — like a

standard air conditioner.

The operating cost advantage of the heat pump

occurs primarily during the heating mode. Depending

on outdoor temperature, the heat pump can actually

produce two to three units of heating energy for

every unit of electrical energy it uses.

The heat pump's cost saving reverse cycle prin

ciple uses refrigerant circulated within a compact,

closed circuit coil to absorb and transfer heat from

one area to another.

The process begins with the evaporator (cooling)

coil absorbing heat from the air around it. The

compressor then pumps the refrigerant to the con

denser where this heat is then rejected to the

surrounding air.

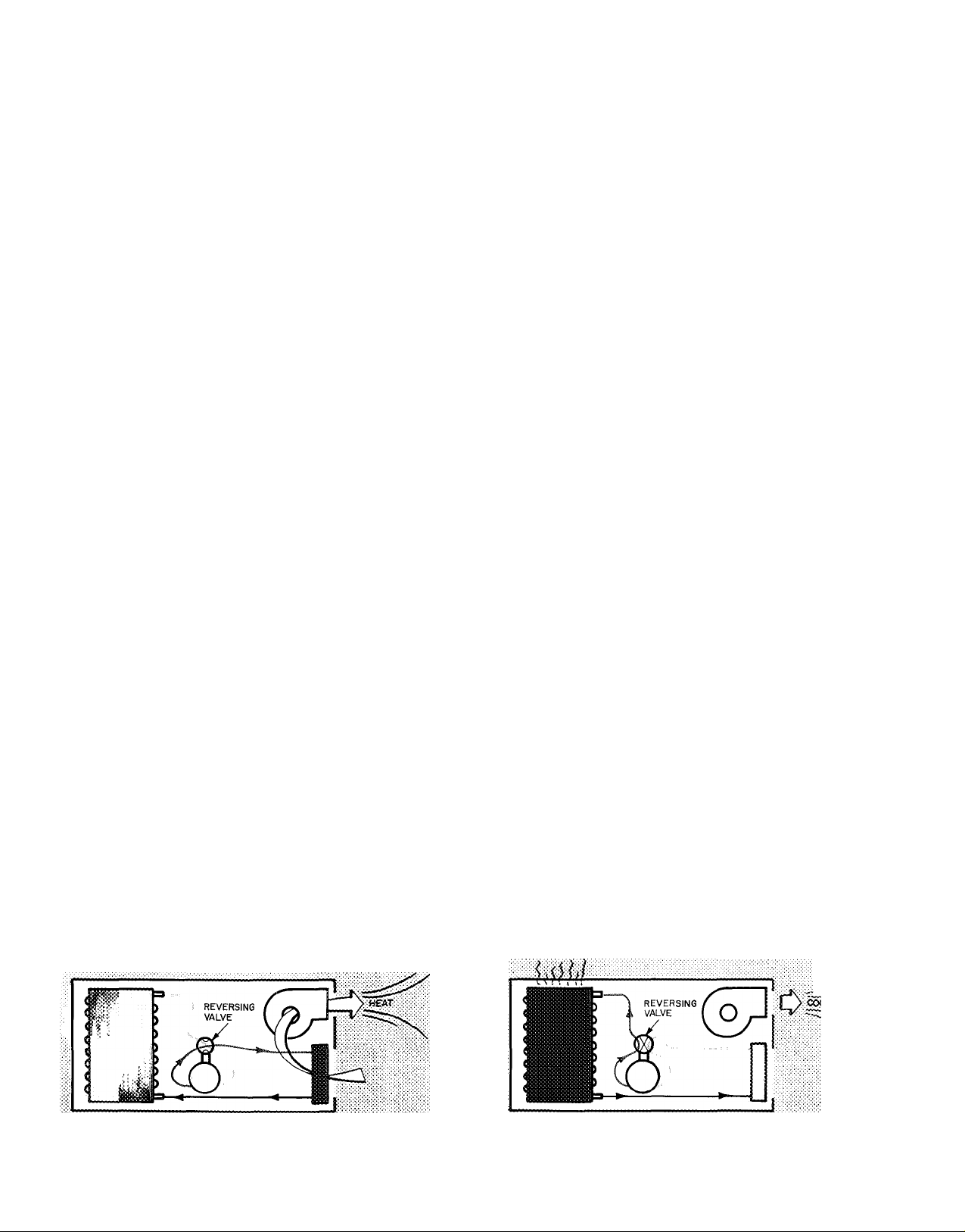

As shown in the diagram, the heat pump makes

double use of the two coils by means of a reversing

valve. The two coils alternate as evaporator or

condenser, depending on whether cooling or heating

is required.

Heating Cycle — Refrigerant enters ^ outdoor coil

(evaporator) at a lower temperature than the surrounding

outdoor air and heat is absorbed by refrigerant. The

refrigerant then passes thru tiie reversing valve and into the

compressor v^/here it is brouÿrt to a nigit temperature and

pressure. The hot refrigerant ieaves the compressor, fiows

thru the reversing valve to the indoor coil (condenser). Heat

is ihert rejected to the return air from the hot refrigerant as

the return air passes over the irxioorcoii (condenser).

Cooling Cycle — The two cotis exchange roles as evaporator

and coftdenser tftry tite action of the reversing valve.

Althougii reversed, system operation is exactly the same.

Refrigerant enters the evaporator (indoor coil) at a lower

temperature than the return air, heat is absorbed from

indoors, the cocker air is then distributed throughout the

building. Refrigerant ieaves the evaporator, flows thru the

reversing vaive and into tha compressor where it is brought

to a higher teinperature and pressure. The hot refrigerant

gas flows from the compressor^-ftiru the reversing valve and

into the outdoor coil (condenser). The outdoor coii (con

denser) rejects the heat from the hot refrigerant to the

cooler outdoor air as it passes over t)te coil The heat

transfer cycle is now ready to be repeated.

JL

Page 3

A great performer... with unmatched versatility

As the concern for energy grows

and grows, Carrier's 50RQ/PQ

single package heat pump looks

better and better. Short gas supply

and high cost electric power are no

problem with these versatile units

in operation. They're engineered

for a wide range of application . .

and installation is easy. For a

curbed heat pump with plenum, in

one piece ready to swing into place,

there's the 50PQ rooftop Or select

the RQ uncurbed ... on a slab for

horizontal air delivery. Or take the

RQ, attach the accessory plenum at

New and improved features for a lifetime of

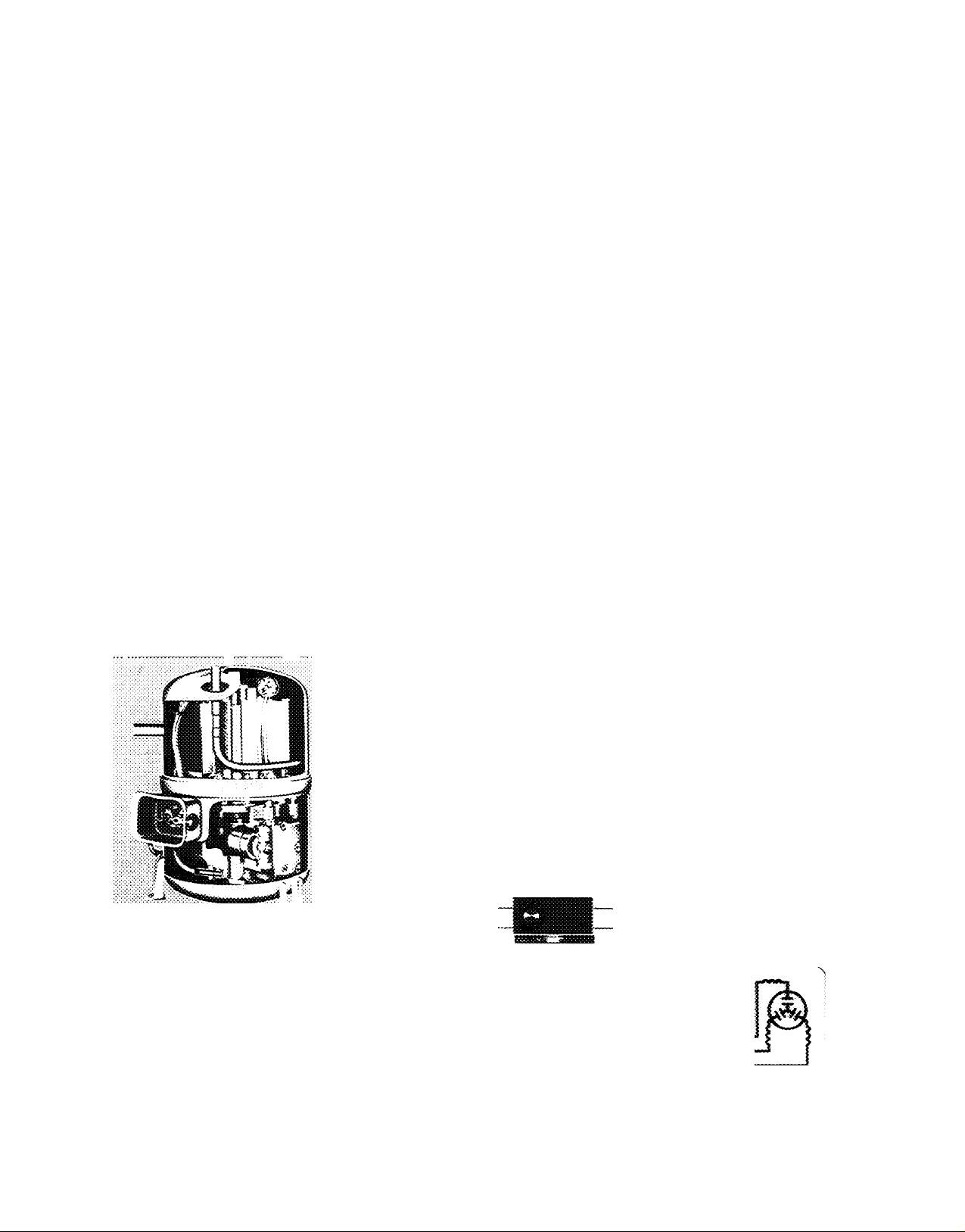

II New compressor for heavy duty

service — Carrier's new P compressor

more than meets the rigorous demands of

heat pump operation. Most efficient and

reliable hermetic in Carrier equipment

Thicker crankshaft Bigger bearing jour

nals. Larger valves. Extra large oil pump.

Crankcase heater.

the jobsite and it's a PQ

With an excellent cooling HER,

heating C.O P. among the highest in

industry, factory installed options

and field installed accessories, these

units will match specifications for

the most varied building

requirements

If you're looking for the reliable

one, the efficient one, the flexible

one . . the number 1 heat pump

on the market, LOOK TO

CARRIER!

dependable performance.

'I Signal-LOCTivi _ Carrier's new com

pressor protection system. Holds the

compressor off the line if any operational

or safety device trips the compressor

Operation of any one of the following

devices trips the compressor and lights an

indicator light on thermostat low-

pressure switch, high-pressure switch,

indoor coil freezeup thermostat, internal

line-break overload. Unit can be reset

manually at the thermostat Carrier

Exclusive.

11 Separate System capability (008,010

units) — Individual, independent refrig

eration systems. Operate circuit required

to maintain desired temperature. Provides

for stand-by operation. Less down time,

lowers service costs. Dual compressor

units with 2-stage heating and cooling —

operate with excellent part-load per

formance on heating and cooling. Elec

tric resistance heat is locked out above

40 F. This lowers demand charges and

costs Carrier Exclusive.

II Terminal strip — located in base unit

control box for easy connection to room

thermostat, outdoor thermostat(s),

emergency heat control, economizer and

electric heat

i> Exclusive, innovative variable circuit

refrigeration system — capacity and

COP are among the highest in industry

Maximizes refrigerant to air heat transfer

on both heating and cooling cycles No

other heat pump has it. Carrier Exclusive.

I' Automatic defrost system — Keeps

coil frost-free at temperatures below

40 F. Chrono-temp control activates de

frost system every 90 minutes if required

Automatically deactivates defrost cycle

when coil is clear or after a maximum of

10 minutes. Carrier Exclusive.

SSGNAL-LOC HEAT PUMP PROTECTOR

r—C

UNE8f5EAK

LI-I

L2-

L3-

Page 4

Accessories and factory installed options

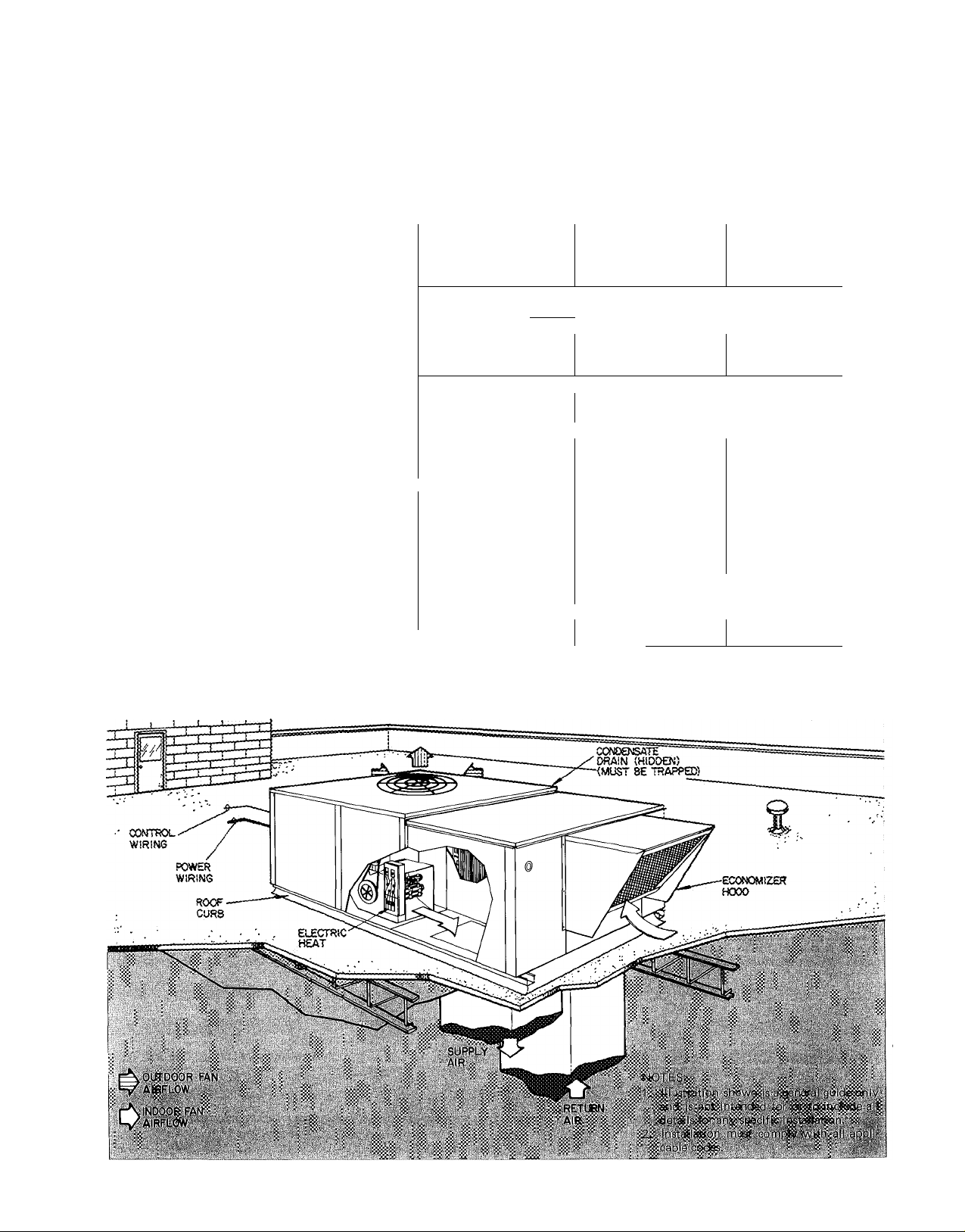

Economizer assembly is available; as s;

factory-installed option or field-installed;

accessory. Located in plenum, it provides;

low-cost cooling on in-between days,’

Automatically controlled dampers open;

to admit cool, filtered outdoor air The:

compressor(s) and outdoor air fan remain;

off to save energy if the outdoor tern-'

perature is low enough to satisfy cooling;

requirements without compressor;

operation. ^

I Remote control panel consists of a sep

"marate heating and cooling thermostat'

assembly plus a decorative wall-mounted '

■i-. rj panel In addition to switches for heating,*

:S|cooling and fan operation, the panel

‘i-^^.icontams 6 indicator lights and, for -

■ 4,1 economizer-equipped units, a ventilation.

] control knob.

Roof Curb with insulated base pans

supports PQ unit (RQ unit with accessory

plenum) and frames roof opening for

plenum and interior ductwork. Once curb

is in place, and ductwork connected, unit

can be placed anytime ~ to meet your

schedule. Curb design meets all National

Roofing Contractors Association (NRCA)

requirements.

Downturn plenum is standard equipmervL, ■

factory-installed on PQ units, field-;

installed accessory on RQ units. Directs ^

airflow downward and provides weather-;

proof openings for ductwork connec

tions. Unit with plenum is curb mounted.;

Thennostat and suUiase (24 V} Acces

sory package provides for selection of

heating, cooling, continuous or automatic

fan cçieratîoR. Works hand-in-fiand with

Signal-LOC circuit. Subbase has v^ming îîÿit (LK-OUT) to automaticaSiy in

dicate compressor lockout condition.

Occupant îs immedîaitely avrare if com

pressor is inoperative Sue to malfunction.

Emergency beat control — Accessory

emergency heat subbase and relay aliow

occupant to manually switch compressor

off and electric heat on if warning light

indicates system rnaifunction. Can be

used for quick morning warm-up or to

merely lock out compressor.

Electric resistance heaters — Available as

factory-installed option or for field in

stallation Complete with high temper

ature limit switches and overcurrent pro

tection. Qffered in 4 heating capacities

for each unit. Where heaters are factory

I installed, unit electrical input is single-

;j point at a factory-supplied terminal

J block. Connection point is suitable for

I copper or aluminum wire (except for

i200-v, 3-phase unit with 1.5 1 electric

:1 heat ratio which uses copper only).

Time Guard® circuit protects compressore

against thermostat "jiggling," automati-f

cally prevents compressor from restarting-;:

for at least 5 minutes after a shutdown.

Accessory prevents short cycling of com-:-;

pressor if thermostat is rapidly changec;

(field installed)

i Motormaster® Head Pressure Control —

i Units are designed to operate at outdoor ,

i temperatures down to 35 F on cooling;

I mode Below 35 F, accessory 32LT ;

I Motormaster control modulates outdoor;

! fan motor to maintain correct condensing >

1 temperature at outdoor temperatures;

down to -20 F.

^Alternate motor ;tnt( drive, a factory-

installed cation, provides extra perform

ance for instaiiaiioos requiring hi^sr

hors^jower die standard motor has

to offer.

Outdoor tfoemtostat($) — Used to lock

out electric heat above certain outdoor

temperature for economical operation.

Fietd-instaiied with wide range of adjust

ments availabie to suit building design

requirements.

Page 5

hysical data

UNIT 50RQ,PQ

OPERATING WEIGHT (lb)

Unit 50RQ (no plenum)

Unit 50PQ (plenum)

With Economizer

Roof Curb

006

460

590

620

175

008 010

765

925

955

225

825

1005

1035

225

No. ...Type 1 ,6P

Capacity Steps (%)

0, 100

REFRIGERANT R-22

Charge (lbs) Sys 1, Sys 2

OUTDOOR COIL

Total Face Area (sq ft)

OUTDOOR AIR FAN

Nominal Cfm

No. ...Diam (in.)

Motor Hp...Kw

INDOOR COIL

Total Face Area (sq ft)

9 2, -

2-Row, Copper Tube, 15 Aluminum Plate Fins/in

11.7

ropeller Type, Direct Drive

4000

1. 22 1 .26

Уг ..0.8

4 0

P

Copper Tube, 15 Aluminum Plate

Rows 4

INDOOR AIR FAN

One, Centrifugal Adjustable Belt Drive

Size (in.) 10x9

Nominal Cfm 2000

Rpm Range

Std 920-1300 690- 980

Alt

1070-1460

Max Allowable Rpm 1600

Fan Pulley Pitch Diam (in.)

Center Line Distance (in.)

Motor Hp (See note)

Max Bhp

INDOOR AIR FILTERS (50DP) TYPE

No. ...Size (in.)*

*Paciory inS'alled in plenum Dnii: 50RQ,PQ008 will accept 2-in thick filters, field supplied

NOTE: Nominal rpm for 50RQ,PQ006,008 is 3450; for 50RQ.PQ010 Is 1725

Std 9 0

Alt

9 0

15V4

Std

Alt

Std

Alt

1 18

1.69

2 20x25x1

%

1

1 0% efficient, Disposable Fibe

2...6P

0, 50, 100

R-22

6 4, 7 0

17.0

7000

1.1

6 56

12x11

3000

805-1093 800-1090

1500

12

12

1678

1

IV2

1 69

2.11

2 20x25x1

2...16x25x1

Fins/in.

.1--. .1. 4

____________

" Glass

2. P

0, 60, 100

R-22

10 5, 8 0

22 5

7000

1. 26

1.. 1.35

8 5

12x11

3600

690- 980

1500

6

6

1678

iVa

2

2 5

TJ

2 20x25x2

2 16x25x2

Typical piping and wiring

Page 6

Base unit dimensions

l| 0!AM KO

ACCESSORY

ELECTRIC HEATl

electrk: heat h

(OFTiONAL) CmTG'

i^ Ar t A

^ BOLT a NUT,.

FACTORY SUPPLIED

^ OUTDOOR COIL Alf?FLOW

C[)!NElOOR COiL AJfS^OW

i ¡SPACE REQUtREO FOR SERVICE

CLEARWCE AND AIRFLOW

U-V,, * :

^ D:AM

HOLE

DJM E NS S ON S { f t- i n. )

UH5 T ;

A

50R Q 00 6 I 3- g y.

50R Q 00 8 :

SO RQ O 10 i

5-

5- 0 *^ 4

SO PC t Q0 6 !

saP Q oo a •

50P Q & J0 : ;

7-> 0

8- 3 ii .

B

4-j y ,

i

1 4 - 8* ? i6

j 4- S '^ «; ,3 -2 - yt 6 i 2- 3 3

5-2%.

3-7 - y, 4

5-2%

5-2%

4-8 * y, 4

1 4 - 8^ 4

¡Die

3- 7 ^4i- 0? , i 2 - 0

}- 2- K s i 2 -3 5

; 3-3i 3-

: 3- 5‘ K .4 i 2 - 3 ^4

3-5 ^ 4 i 2 - 3 ^ 4

0-2 ^ 4

0-2 ^ 4

0-2X4

6%

0-3 3 4

0-3X4

0-3X4

Ce rt i if e ci cS f T> e «s i or i d r aw i ng s a r ea v ai t eb f eo f i r eq - ue s f.

C

1

” ^

I 1

2-0X4

x>2 - 3X < ^ '

Z2-9%:<

5-3

i 5- 3 1

! 6 - ; X 4 !

i 7- i i' X 4

i 0- 5X4 12-5V

■-

3-8X4

2-3 X

4

ROOF

OPERINSS

K

2-6 X

2-6 %

3-2 %

2-5X4

3-4

■ ■

%

2-5 % 43-4%

3-1X4

2-0

Page 7

Accessory dimensions

PLENUM (5OR0)

8AS£ i«!T

CA8!N£T

OUTLINE

BASE UN5T 50R0006

A

ROOF CURB DiMENSlONS

(ft-in.)*

A

B

C

0

E i-

F

G

4%

f 5 -

2-

i 7- 07 i a :

i: y.

6Va

i

4-G V s

2-3%^

■0- i 0- 1

i 1- 5^ ^ *:

1-

7%

i 2- O^ a

4%

■—i

-

L±£ l __ .

7-0 i (i

4-0 %

2-3 y :s

0-T . %a

2-0 ^ 6

2-0

B

C

D

E

F

G

*C ur b d im e ni o ns al s o a pp l y t o 5 0R Q u n it s w i th

fi et d -i n st a üe c i a cc e ss o ry pl e nu m .

PLENUM DiMENSlONS

(ft-in.)

50RCM)0850RQ010

2-

3‘

2-

9%a

4-

1-

ri

u-

1-

2-

V1

1%

6Va

T%:

1 ^ 6

5Xa

2%

5-

2-

3^X 6

0-

1%6

1-

5.*7i6

2-

11% «

1-

2S% OüTSiOE

a:b pamper

ANO HOOD

3-2 % e

5-2 %

2-3 % a

0- 1% a

1- 5^% a

3-1 % a

2- 7% a

BASE UNiT CORNER WEIGHTS <!b) FOR

ROOF fNSTALLATlON

50RQ

50PQ

A

UNÎT

006 i V34 ; 84 j ¡21

008 i 157 1 142 222 244

0)0 i 169 i 153 I 239 ^64

006 I 550 ; 108 i 126

B

150

576

356

ECONOMiZER HOOD DfMENSiONS

(ft-in.)

WWT

i 50RQ,P0006 Î 50R<J,FQ008 i SORQ,P<S010

A

B

1

......

1-3%«

! 1-7%« Î

.....

2-5% i 2-7%

1-7%« 1 2-3%

Page 8

Selection procedure (with example)

I Determine job requirements. IV Adjustments to capacities and Kw's for additional indoor fan

Estimated requirements motor heat for statics above 0.2 in. wg at listed cfm's.

Cooling load - total capacity

Outside air temperature (Cooling).....................................95 F operate at 2,000 cfm with 0.66 ESP to overcome the

- sensible capacity........................... 42,000 Btuh '"■ ^9 n"

Air entering indoor coil (Cooling) wb

Air quantity (cfm)........................................................2,000 1,208 rpm, 1,130 watts.

External static pressure - ESP (in. wg)

Heating load........................................................... 60,000 Btuh fable at required ESP.

Outdoor temperature (winter design)

Air entering indoor coil (Heating).......................................70 F 2,000 cfm *.2 83

Power supply

..............................................................

_ . . . (Diff in Kw) = 0 30

etermine unit size. ^ *NOTE Use motor Kw from RQ fan tables for .2 in ESP at

Select unit on cooling capacity. specified cfm for all plenum applications.

Enter the cooling capacity table at the given air quantity Adjust all capacities for additional IFM heat at higher

and evaporator entering wet bulb (2,000 cfm, 64 ewb). statics than .2 in. wg.

Read across table for net total capacity (TC) and net Diff (Btuh) = 3 413Btu/Kw x Kw

sensible capacity (SHC), under the condenser entering air ^ 3 413 x 30 = 1 024 Btuh

temperature (95 F) to find by interpolation TC of 56,000 rnni INC

and SHC of 47,400 at 2,000 cfm, 64 F wb for the , ,

RORonnK Adjusted TC = TC — Diff (Btuh)

Since these net capacities have been calculated at 0.2 in. wg Adjusted SHC = SHC — Diff (Btuh)

external static (ARI condition), for any additional static — ^ 4qq _ ^ Q24 = 4g 375

the net capacities must be adjusted to reflect the resulting Adjusted power input = Kw* + Diff '

IFM heat. To obtain the total required static,all accessory ^ 7 g + g 30 8 1 Kw

pressure drops must be calculated. Therefore, calculation *Kw-unit total from 'cooling capacity table at selected

of heater requirements must be made since pressure drop conditions

varies for each size of electric heater. HEATING

III Heating requirements — number of electric heaters required. Adjusted heating capacity = 18,000 -1- 1,024 = 19,024

Enter instantaneous/integrated heating ratings at 006 size Adjusted power input = Kw** -t Diff (Kw)

and 2,000 cfm. Under temperature at air entering outdoor =42-t 30 = 45 Kw

coil, -10 F, the Integrated heating capacity is 18,000 Btuh. **Kw from heating capacity tables of selected conditions.

The heating load is 60,000 Btuh, therefore, 42,000 Btuh V Corrections to SHC for dry bulb above or below 80 F - see

additional electric heat is necessary. Enter electric resist- SHC correction factor table. For this example, no correction

ance heater capacity table at 006 size and 230-3-60. The is necessary since the entering dry bulb is 80 F.

.754 heat ratio/or 13 Kw electric heater most closely Therefore, the final net capacities are

satisfies the electric heater requirement. SHC = 46,376 Btuh

13Kwor — 44,400 Btuh (from Electric TC = 54,976 Btuh

44,400 -t- 18,000 — 62,400 Btuh sensible capacity for the job application.

...................................

................................

54,000 Btuh The .754 electric heater resistance at 2,000 cfm is 0 26

64 F heater pressure drop.

gQ p From the fan tables at 2,000 cfm with 0.66 ESP requires

.................................

.............................

0.4 NOTE For PQ units or RQ units with plenums, use PQ fan

—10 F ESP IFM Kvy

230-3-60 .66 1.13

, , , , = 56,000-1,024 = 54,976 Btuh

Heating Capacities Table) The 50RQ at the required design conditions has enough

Performance data

COOLING

UNIT

CFM Cap. .

(Btuh)

50RQ

2000 59,000 7.5 62,000 2.8 35,000 2.0

006

50RQ

3000

008

SORQ

010

SOPQ

006

SOPQ

008

50PQ

010

88,000 7.8 91,000

3Ó00

108,000

2000 59,000

3000 87,000 7 6 92,000 2.8 52,000 2 0

3600

1 07,000 7 5 113,000 2.8 62,000 2 0

HTG (Hi -Temp)

EER

Cap.

(Btuh)

7.7

11 2,000 2.8 61,000 2 0

7.4 62,000

C.O.P.

2.8 51,000 2.0

2.8 35,000 1.9

(Btuh)

HTG(L

Cap.

ARI CAPACITY RATINGS

o-T emp)

C.O.P.

Rated in accordance with

ARI Standard 240-75.

Ratings are net values, reflecting the effects of circulating fan heat

Supplementary electric heat is not included, Ratings are based on:

Cooling Standard: 80 F db, 67 F wb indoor entering air temperature

and 95 F db air entering outdoor unit

Hi-Temp Heating Standard: 70 F db indoor entering air temperature

and 47 F db, 43 F wb air entering outdoor unit

Lo-Temp Heating Standard: 70 F db indoor entering air temperature

and 17 F db, 1 5 F wb air entering outdoor unit

Page 9

NET COOLING CAPACITIES"

UNIT

EVAP AIR CONDENSER ENTERING AIR TEMPERATURE (F)

Cfm

50RQ

006

008

010

Ewb

BF

72

1800

67

056

62

72

2000

67

063

62

72

2500

67 62 46

081

62 58 55 8 3

72

2700

67 92

048

62

72

3000

67

055

62

72

3700

67

070

62 90 85 11 3

72

3200

67

043

62

72

3600

67

050

62

72

4500

67 115 92

064

62

BF — Bypass Factor

Ewb _ Entering Wet Bulb

TC85SHC К w TC95SHC

66 32 7 7 64 3’

6'

42 7 4

56 51 7 1 52

66

32 7 9

62 43 7 6 59

57 53

33

66

100

48 11 0

64

84

77

101 50 11 1 97 49 11 8 94 48 12 0 92 47 12 4 85 45 12 9

94 67

86

81 10 4 81 78 10 9

101

51 11 8 98 51 12 6

95 71

123 63 13 8 117

113 80 13 2 107 78 13 8 103 77 14 1 99

103 97 12 7

124 65 14 0 119 63 4 7 115 62 15 0 112 62 15 4 104 58 15 9

115 85 13 5

106

102 13 0 99 98 13 6

124

67 15 2 118

108 107

58 41 7 7

64

54 51 7.7

7 3

64 32 9 1 62 32 9 3

8 6

59 46 8 8 57 45 8 9

8 4

56

96

10 7 87

10 3 79

88 65 11 3

10 8

90

11 5

86

97

108 83 14 1 105 81

14 8 108 90 15 4 105

14.3 102 102 15.0 99 99

Kw

8 0

7 4 51

5C

31 8 3

42 7 9 57 42 8 1

52 8 6

47

11 6

6'

11 2

74

10 8 76 73

12 1 87 69 12 4

7C

81 11 9

ÓÌ

14 5

13.3 94 91

93

Ó6 16 0 115 65

Kw — Total Power Input

SHC — Net Sensible Capacity

100

TC

62 31 8 2

56

62 31 8 5

52

54 51

93

84 61 n 4

84 64

79 76

96

83

114

96

К w TC

SHC

40 7 9

49 7 6 49 47 7 7

49 7 8 51 48 8 0 47 44 8 4

8 8 52

46

12 0 90 45 12 3 84 43 12 8

11 G

11 6 82

11 2

50 12 9 93 50 13 1

78 12 2 81 75 12 5 75 70 13 1

14 8

60

95 13 9

89

111 59 15 0 103

13 6 90

14 4

101

16 3

112

101 87 15 9 93 84

15 7

15.3 96 96 15.6 89 89 16 3

TC — Net Total Capacity

105

Kw

SHC

60 30

54 40 8 0 49 38 8 3

60 30

54 41

61

54

81

74 71

76

84

93

*Fan motor heat deducted

8 4

8 6

8 3 50

31 9 4

44 9 1 50 42

49 9 0 49

59

11 7

11 3

63

11 8

73

11 5 71 68

68 12 6 77 66 13 2

75 14 3

89

13 9

80 14 7 93 76 15 2

93 14 2 87 87 14 8

64 16 6 104 62 17 2

115

TC

SHC

56 29 8 7

46 44

56 29

39

56 30 9 7

45

74 57 12 2

69 ÓÓ 11 9

76

60 12 3

86

48

56

91 12

84 84 14 4

Kw

12 1

13 7

IS 6

14 9

16 5

8.0

8 9

8 5

NOTES:

1 Direct Interpolation is pelmissible Do not

9 4

9 3

extra polate

2 Tlie following formulas may be used:

t|db -tedb 1 09 X cfm

t|wb Wet-bulb temperature corresponding to en

thalpy of air leaving evaporator coil (h|yy[j).

sensible capacity (Btuh)

^ ^ total capacity (Btuh)

Iwb - ewb 4 5 X cfm

Where

hewb “ Enthalpy of air entering evaporator coil

3 SFIC is based on 80 F edb temp of air ent evap coil

Below 80 F edb, subtract (corr factor x cfm) from

SHC.

Above so F edb, add (corr factor x cfm) to SHC.

ENTERING AIR DRY-BULB TEMP (F)

79

BF

.04

.10 98

.15

Interpolation is permissible

Correction Factoi = 1 09 x (1 — BF) x (edb — 80)

Capacities are at 2 in wg ESP for cfm indicated for

006 units; at 25 in wg for 008 units, at 3 in wg

for 010 units

78

81

827783

1 05 2 09 3 14 4 19 5 23

1 96 2 94 3 92 4 91

,93 1.85 2.78 3.71 4.63

76

84

Correction

75

85

Factor

under 75

over 85

shown be

UNIT

50RQ

006

008

010

CFM

(Std

Air)

1800

2000

2500

2700

3000

3700

3200

3600

4500

]Instantaneous Rating

Cap.

14

13

15

14

18

17

20

18

21

19

24

22'

15

14

16

J5

20

18

-20

К w

3.8

3 9

4.8

5.4

5 5

5 9

6 2

6 3

^ ^ I 33

-10

Cap.

19

17

20

18

23

21

27

25

28

26

30

28

31

28

32

29

36

Cap. — Heating Capacity (1000 Btuh)

Kw — Total Power Input, includes

outdoor fan motor input, and

INSTANTANEOUS/INTEGRATED HEATING RATINGS

TEMPERATURE AIR ENTERING OUTDOOR COIL (F db at 70% rh)

Cap.

38

34_

39

„.35 ^

42

38

55

50

56

51

59

54

65

59

67

LI

71

75

17

К w

Cap.

46

5.1

40

47

5 2

41

50

6 1

44

7 5

7 6

83

9 1

72

84

9 1

73 '

89

10 2

77

NOTE Ratings are based on 70 F air entering indoor coil without

resistance heaters Integrated capacity is maximum (instarrtaneous)

capacity less the effect of frost on the outdoor coil and the heat re

quired to defrost it Ratings are at 2 in wg ESP for cfm indicated for

006 units, at 25 in wg for 008 units and, Sin wg for 010 rrnits

0

Kw

Cap.

К w

25

4.1

4 2

5 1

5 9

6 0

6 4

7 0

8 0

4.4

23"

26

4 5

24

29

5 4

27

34

6.4

31_

35

6 5

32

38

6 9

35

43

7 8

39

44

7 9

40

48

8 8

44

U Integrated Rating

, includes indooi fan motor heat

compressor motor power input,

indoor fan motor input

Cap.

31

28

32

29

35

32^

44

,40...,

45

.4L

48

44

56

J51_

57

52

61

56

10

Kw

4.7

4 8

5.7

6 9

7 0

7 6

8 6

9 1

10 2

30

40 47

Kw

5 6

5 7

6 7

8 2

8 7

10 2

10 3

1

К W

Cap.

54

6 c

54 61 64

55

6,1

55

58

7 1

58 65 69

80

8.8

80 90 94

81

8 9

81

85

9 5

85 94 99

97

1 1 0

97 110 116

99 112 118

99 112 118

104

104

Kw

Cap.

Ó1

62

62

65

90 94

91

91 95

94

no 116

118

118 124

6.4

6 5

7.6

9.5

9 6

10 0

12 6

Cap.

124

Ó4

65

65

69

95

99

50

Kw

6 7

6 8

7 7

9 8

9 9

10 2

1 2.1

12.1

12.9

Cap.

73

73

104

104

105

105

108

108

134

134

136

136

140

140

60

Kw

7 3

7 3

10.4

10 5

10 8

13.1

13 1

13 8

Page 10

Performance data (cont)

UNIT

CFM 0.1 0.2 0.3

Rpm Kw

_

1800

953 79 1003

2000

50RQ

2200 1031 .96

006

50PQ 2200

006 2300

SORQ

008

50PQ

008

50RQ

010

50PQ

010

1073

2300

1124 1.22 1169

2400

1176

2500

946

1800

1029

2000

1124

1180

1240

2400

2500 1296 1.66 1334

_

2700

2800

—

2900

— —

3000

— —

3200

3400 705 1.11

722

3500

741 1 .26 785 1 .36

3600

757 1.33 800

3700

697

2700

2800 718 .97 765 1.06 808 1 17

2900 738 1 .03 784 1.14

761

3000

800

3200

844

3400

870

3500

905

3600

3700 951 1.91

_ _

3200

- _

3300

752

3500

3700 782

3900 818 1.44 843 1.52

839

4000

859 1 .69

4100

899

4300

936 2.19

4500

748

3200

762

3300

3500 792 1 .17

829

3700

868 1.60

3900

890 1 .73 916

4000

911 1 .86 936 1.94

4100

947

4300

4500 978 2.35 1010 2.48

Rpm К w

927

1073

1121

1 .06

1.40 1227

72 997

85 1073 90

1170

1.09

1 .25 1223

I.44i 1283 1.54

_ _

— - —

—

—

690

721 1.08

752

767

1.18

93 746 98

806

1.11

844

1 .27

1.45 898 1 62

927

1 .57

959

1 .74

988 2.05

_ _

748 99 772 1.05

1 .06 774 1.12

1.22 804 1.28

1 .57 864 1 64

885 1.78

923

1 .95

956 2.27

773

.98

786

1 .03

817

857

1.35

896 1.69

969

2.10

Rpm Kw

975 74

71

1043 87

83

1121 1 09

1 00

1166 1 23

1 15

1220 1.39

1.30

1269 1.59(

1.48

1035 79

.75

1116 .97

1216 1.22

1.17

1274 1.45

1.31

1324

1.75

697 .93

710

—

724 1 01

738 1.06

98

767 1 18

795

1 21

1 29 811

828 1 48

844

1 44

790

828

849

1.22

894

1.35

943

976 1.90

1.77

997

1.89

1026 2.18

757 1.00

796 1.18

832 1.36

870 1.60

890 1 73

910 1 86

945

2 02

974

798

1 04

1 09 811

848 1 32

1 24

886 1 53

1 44

923 1.78

941

1.81

960 2.01

996 2.28

2 17

1-64:

-

.96

1.32

1.40

1.57

1 10

1.23

1.31

1 51

1 79

2.02

2.09

2.34

1 .10

1 15

1.89

4

Rpm

К w Rpm

1019

.77 1059 .81 1104 86

1085

.92

1168

1.17

1.29 1263

1211

1261

1.49' 1304

J304

1.68

1073

.82 1124 89

1164

1.05

1257

1.32 1309

1316

1.54

1365

1.74

- - - - - - - - - - -

746

98

759

1.04

770

1.10 815 1.21 860

784

1 17

810

1 29

839

1.44

859

1.53

878

1.64 944

1.86

931

835

1 .19 880 1 .29

853

1 25 904

874

1 33

898

1.44 943 1 .60 980 1 76

940

1.68

991

1.90 1029 2.02

1013

2.02 1052

1035

2.16

-

781

1 06

796

1.11 824

823

1.25

860

1 45

898

1.69

916

1.81

935

1.94

967

2.16

1005

2.46

828

1.16

844

1 .23 876 1.30

878

1.40

914

1 .62

948

1 85 974 1 92

967

1 .96

2.09

984

1026

2.39 1053

FAN PERFORMANCE

wg)

0.5 0.6 0.7 0.8

Rpm Kw

Kw

1133

1 00 1179 1 08

1213

1.24 1255 1 32

1304 1.52

1.42:

1.60'' 1347

1349

1 .79: - - - - - - - - - - - -

1209

1 12

1.45|1 1348 1.53

1357

1.64 1397 1.72

- - - - - - - - - - - -

790

1.10 835

1.16 846 1 24

804

828

1 27 874 1 37

855 1.40

891 1 60 941

916 1.72

1.83

967 2.00

1.38

1.47

922

991

1.80 1029

2.17

-

-

807

1.13 839 1.19 871

1.18

1 .33

854

889

1.54

1.78 950 1.85

924

941 1 .90 967 1.97

959 2.01 982

993 2.27 1023 2.38 1050 2.47

860

1 .23 893 1.30

1 49

908

1.70 970

942

993 2.04

1014 2 18

2 48,

1.70

1170 .96 1216 1.02 1261

1252 1 19

1.19

1 29 908 1 43

908 1.56 950

1 78

1.86

966

1.97 1020

982

2.13

1005

924 1.41 963 1 58

941 1.52

965 1 66

1.92 1072

1072 2.20

—

- - - -

857 1.26

884 1 42 914

1.63

917

2 08

907 1.38

?37 1 56 966 1.63

1.77 999

2 00 1032

1004

1023

2 13 1050

1043 2 28

—

Kw Rpm

Rpm

1150 .93 1198

1227 1.15

130^ 1.44 1345 1.521

1345

1 M

1387 1.79

1295 1.27 4339 1.36; 1377

1387 1.62 1430

1437 1.8Q

878 1 29 924

1.35 936

892

1 .51 961

922

1 72 1001 1 80 1039

1.89 1026 2.02

989

1.99 1042

1004

2.11

980 1.68 1037

1016

1.75

1.85 1076

1035

2.10

_

—

1 26

1 .33

888

1.50

1 .70

945

1 92

975

993 2.04 1023

1012

2 18 1041

1.37 953 1 44

926

938 1 45

1.85

2.08 1059

2.22

2.37 1093

1068

~ —

Kw

1 00 1243 1.07 1287

1 22 1303 1.31 1352 1.3¿- 1392

1267

1387 1.71 1427

- - - - - -

I 09 1303

1.70

- - - - - - - -

1 41 963

1.49 974 1 66

947 1 58 1005

1 68

2.13

~ - -

1020 1 .70 |1060 1.85

1 .78 1078 1.95

1 .90

1056

2.02

1 .33 937 1 40 969

905

920 1 .41 951

1 58 975

944

1 78

972

2.01

1005

2.13 1050

2.27 1067

969 1 52

1.70

995

1029

1.92

2.17

1075 2.31

2.46

0.9

Kw Rpm Kw Rpm

Rpm

1.61 1425

1381

1.79

1.16 1342 1.23

1.43 1419 1.51

__

1 58 1020 1 70

1.73 1043 1.85

1016

1 79 Í056 1.94

1.96 1082

2 18

1061

- - - - -

—

—

- - - -

1.46

1 65 1001 1.72

1002 1 81

2.09

1034

2.22 1075

2.36 1092

986

1 50 1027

1001 1 60

1028

1.79

1056

2 01

1085 2.26

__

-

1.

0

1.13..

1.69

_ '

-

_

-

1 76

1031

2.14

-

- - -

-

-

—

_

- -

- - -

- -

- - - -

-

-

1.46 WOO 4.56

978

1.55

1032

1.89 1059 2.02

1060

2.18

2.31

2.46

1.64

1038

1.71

1056

1 88

1082

2.10

- - -

- - -

: - :

1.

1

Kw

1326

1.20

1.46

- -

- -

1381

1.30

—

1060 1.85

1072 1.93

2.01

1085

-

-

_

_

—

- -

-

1016

1 64

1 .81

1035

2.27

1086

-

1058

1 73

1.79

1065

1082

1.97

—

—

-

-

—

_

-

—

-

-

—

I I Alternate motor and drive or field-supplied drive required

Kw — Kilowatts

Rpm — Revolutions per minute

Conversion — Kw to ВНР

BHP

IFM Kw

0.746 Kw/BHP

65 avg motor efficiency — (006 std)

70 avg motor efficiency — (008 std)

70 avg motor efficiency — (008 alt)

70 avg motor efficiency — (006 alt)

85 aVg motor efficiency — (010 std)

80 avg motor efficiency — (010 alt)

NOTES;

1. Fan performance is based upon wet coil and deducted casing losses

2. Special indoor fan motors are qualified for operation at the maximum con

ditions listed below (with original motor or Carrier specified parts):

50RQ,PQ006 50RQ,PQ008 50RQ,PQ010

ir. If if

3 Filter pressure drop is not included for RQ units; is included for PQ units

4 Electric heater pressure drop must be accounted for in fan rpm and Kw se

lection (see table, page 11)

5 Values in italics indicate that field-supplied drive may be used with standard

motor

10

Page 11

ACCESS/FIOP STATIC PRESSURE LOSSES (in. wg)

UNIT

50RQ,P<5

006

008

010

*Standaid on 50PQ, accessory on 50RQ Standard filter pressnie

drop included in plenum

CFM

Low

1800

2000 16 26 26 32

2500 24 42 42 48

2700 09 11 1 1 17

3000 10 13

3700 15 22 22

3200 .12

3600

I 4500 .29

13

.15 .20 20 .28

HEATERS

.75:1

.35 35 .45

1.0:1.0

21

15

1.5:1.0

21 25

13 20

15 .23

ELECTRIC HEATING CAPACITIES*

VOLTS/

UNIT

PHASE SIZE

230/ 75:1.0

1 1.0:1 0 20

200/ .75:1.0

50RQ,

3

PQ

006

50RQ,

PQ

008/

230/ 75:1.0 13 13

3

460/

3 1.0:1.0 20 13

200/

3

230/ .75:1.0

3 1.0:1.0

010

460/

I Available as an accessory only

‘Available as factory-installed option or field-installed accessory ex

cept as noted

I Available if outdoor thermostat is used.

HTR TOT.

Stage 1

KW

Low

i.i5:1.0

Low

1.0:1.0

1.5:1.0 26 13

Low

1.0:1.0 20

1.5:1.0

Low 5.2 5.2

.75:1.0

1.5:1.0

.75:1.0

1.0:1 0

1.5:1.0 39

1.5:1.0 39 13

.75:1.0 19 12 41.1

3 1.0:1.0 26 13

6.4

13

26

4.4 4 4

13 13

15

4.5

26

13

26 13

Low

Low 6.4 6.4

Low

6.5 6.5

20 10 34.2

26

19 12

26

6.4

39 13 44.4

BTUH KWt

KWt

(1000) Stage 2 (1000)

21.9

6.4

44.4

13

44.4 7

13

44.4

13

15.0

44.4

10 34.2 5 17.1

44.4 13

4.5

15.4

44.4

44.4

13

13 44.4

17.8

44.4

13

44.4 7 23 9

44.4 13

22.2

13 44.4 13

44.4

13

21.9

41.1 7

13 44.4

44.4 26 88 8

21.9

6 4

44.4 13 44.4

30

-

PLENUM*

14

17

25

^^21

25

41

16

.24

BTUH

—

23.9

44.4

13

—

- -

44.4

_ .

— —

23.9

7

13 44.4

—

- -

44.4

—

10 34.2

44.4

26 88.8

- -

24.0

44.4

13

—

24.0

7

26 88.8

INDOOR FAN DRIVE DATA

RPM

UNIT

50RQ,PQ

006

008

010

TYPE

0

Std

1224 1148 1072 996

1300

Alt 1460 1382 1304

Std

Alt

Std

Alt

980~

1093

978

1093

1035

1035 978

FAN

T urns

2

1

864 806 745

922

978

863 805 748

920

Open

4

3

1226 1148 1070

920 863 805

863 805

920

5

920

690

691

Electrical data

50RQ, PQ006

V-PH-HZ

Voltage

Range

-

-

COMPR

RLA

LRA

230-1-60

207-264

-

200-3-60

180-229

_

230-3-60

207-264

-

460-3-60

414-528

575-3-60

51S-660

Compr

FLA

Hp

IFM

Kw

LRA

OFM

RLA

‘Fuse only

Compressor

Full Load Amps

Horsepower

Indoor Fan Motor

Kilowatts

Locked Rotor Amps

Outdoor Fan Motor

Rated Load Amps

35 3

135

22.2

113

20.9

98

10.4

49

8.3

41

OFM

FLA

4.4

5.1

4.4

2.2

4.4

IFM

Hp

75

1.0 8.0

75 6.9

75 6.9

.75

1.0 8.0 6.4

1 0 8.0 13.0

1.0

.75

1 0 9 2

.75

75

75 7.9 15 0

.75

1.0

1 0 9.2

1.0 9.2

1.0 9 2 26 0

.75

1 0

.75 6 9 4.5

.75

75

75

1.0

1.0

1.0

1.0

.75 1.4

1 0

.75 1.4 5.2

.75

.75

.75

1 0 1.8 5 2

1 0

1.0 1.8 20.0

1.0 1 8

.75

1 0

FACTORY-

INSTALLED SUPPLY

HEATERS

FLA

Kw FLA

6 9

6.9

8 0

7.9

7.9 4.4 22 69 75

7.9 13.0

7 9

9.2 4.4

6.9

6.9

6.9 20.0

— —

-

6.4

13.0

20.0

20.0

_ —

— —

26.0

13.0

15.0

—

— —

8 0

13.0 48 98 100

26.0

6 9

8 0 4 5

13.0 48

8.0

20.0

8 0

8.0

26 0

_

_

1 8

13.0

1 4

20.0

1.4

26.0

1.4

1 8 13 0

26.0

1.1

1

_ _

- -

POWERt

Min

Max

Ckt

Fuse

Amps Amps

55

_

57

90

28

124 125

55

159

83

28 92

55

83 160

55 110 no

42

83

22

55

42

83

_

19 61 70

48 98

74 130 125

19 62 70

48

74 131

—

-

11

25 48

25 48

37

11

25

25 48

37

150

125

125

150

41 50

42 50

94

100

145

150

70

111 110

95 100

146 150

38

39 50

100

99 100

99 100

125

17

17

30

63

31

48

63 60

16

16 20

60

60

90

90

75

50

20

20

35

50

50

60

35

50

50

20

1 1

Page 12

Electrical data (cont)

50RQ,PQ008

v-PH-HZ

COMPR'

Voliago

Range

200-3-$0

i 80-229

230-3-60

207-264

460-3-60

414-32S

575-3-60

318—660

NO. 1,2

RLA

LRA

16 6

79

(ea)

14 3

67

(ea)

7 2

35

6 8

23

(ea)

OFM

FLA

4 5

4 5

1 9

4 5

Hp

1 0

1 5

1 G

1 C

1 0

1 0

1 5

1 5

1 5

1 5

1 0

1 0

1 0

1 0

1 5

1 5

1 5

1 5

1 C

1 5

1 G

1 C

1 0

1 0

1 5

1 0

IFM

FLA

9 2

11 5

9 2

9 2

9 2

9 2

11 5

11 5

11 5

11 5

8 0

10 0

8 0

8 0

8 0

8 0

10 0

10 0

10 0

10 0

1 8

2 6

1 8

1 8

1 8

1 8

2 6

2 6

2 6

2 5

1 4

2 1

FACTORY-

INSTALLED

HEATERS

Kw

FLA

6 5

33

65

20 0

83

26 0

113

39 0

33

6 5

65

20 0

83

26 0

113

39 0

29

6 4

49

19 0

75

26 0

99

39 0

29

6 4

19 0

49

75

26 0

99

39 0

15

6 4

26

19 0

26 0

39

51

39 0

6 4

15

26

19 0

39

26 0

51

39 0

POWER!

SUPPLY

Min

Ckt

Amps

51

53

93

135

162

196

95

13/

164

199

45 ’

47

82

108

142

171

84

no

144

173

20

21

39

52

69

83

40

53

69

84

21

22

Max

Fuse

Amps

60

60

100

125

150

1 50

100

125

1 50

150

60

60

80

100

125

150

80

no

125

150

25

25

40

50

60

70

40

50

60

70

25

25

50RQ,PQ010

V-PH-HZ

Voltage

COMPR

Range

200-3-60

180-229

230-3-60

207-264

460-3-60

414-328

S75-3-60

318-660

NO. 1

RLA

LRA

24

113

20 9

98

10 4

49

8 3

11

COMPR

NO. 2

RLA

LRA

18 3

87

16 4

70

8 8

35

6 4

27

OFM

FLA

7 7

6 6

3 3

6 6

Hp

I'e

2 c

1 'I

1 5

1 5

1 5-

2 0

2 0

0

2

2 (

1 5

2 0

1 5

1 5

1 5

1 5

2 0

2 0

2 0

2 C

1 Ъ

2 0

1 5

1 5

1 5

1 5

2 t

2 0

2 C

2 Г

1 '■

2 (

IFM

FLA

6 0

7 8

6 0

6 0

6 0

6 0

7 8

/ 8

7 8

7 8

5 2

6 8

5 2

5 2

5 2

5 2

6 8

6 8

6 8

6 8

2 б"

3 4

2 6

2 6

2 6

2 6

3 4

3 4

3 4

3 4

2 1

2 7

FACTORY-

INSTALLED

HEATERS_

Kw Vla

6 5

33

26 0

39 0

6 5

26 0

39 0

6 4

19 0

26 0

39 0

6 4

26 0

39 0

6 4

19 0

26 0

39 0

6 4

19 0

26 0

39 0

65

83

113

33

65

83

11 3

29

49

75

99

29

49

75

99

__ 180

15 45

26 58

39 74

51 88

15 46

26 59

39 75

51 89

20 0

20 0

1 9 0

POWER

SUPPLY*

Min

Ckt

Amps

62

64

102

142

170

202

104

144

172

204

54

56

91

116

148

178

92

117

150

28

29

21

22

Max

Fuse

Amps

60

no

150

150

150

no

150

150

150

60

60

90

no

150

150

90

no

150

150

35

35

50

60

70

80

50

60

70

80

25

30

Compr — Compressor

FLA — Full Load Amps

Hp — Horsepower

IFM — Indoor Fan Motor

Kw — Kilowatts

LRA — Locked Rotor Amps

OFM — Outdoor Fan Motoi

RLA — Rated Load Amps

*2 per unit, values apply to each

I Fuse only

Controls

Base unit operating sequence

Cooling — Witli unit main power on, therniostal at COOL and

desired room temperature, fan switch at AUTO

ALL UNITS — On a rise in room temperaLure, cooling contact

no 1 in thermostat closes, energizing compressor no 1

contactor on all units Compressor no 1 , indooi and outdor.ir

fan motors start Compressor no 1 cycles on demand of

thermostat to satisfy room conditions

50RQ/PQ008 — On 008 and 010 units with 2 compressors,

with an additional rise in room temperature, cooling contaot

no 2 in thermostat closes energiz ing compressor contactor no

2 Compressor no 2 starts Compressoi no 2 cycles on

demand of the thermostat to satisfy room conditions

Compr

FLA

Hp

IFM

Kw

LRA

OFM

RLA * Fuse only

Compressor

Full Load Arnjjs

Horsepower

Indoor Farr Motor

Kilowatts

Locked Rotor Amps

Outdoor Farr Motor

Rated Load Amits

Heating — Power on and tliermostat set at FI EAT and desired

temperature, fan at AUTO

On a drop in room temperature, heating contact no 1 in

the thermostat closes energizing compres.sor contactor no 1

and reversing valve, and starting compiessor no 1 Indoor fan

contactor and outdoor fan contactor are eneigized at the same

time for heat pump cycle

50RO/P0006 — On a further drop in room tcmipeiature,

heating contact no 2 in the thermostat doses energizing the:

electric resistance heat For heaters with 2 or more stages,

outdoor thermostats can be wiied into the control circuit to

energize electric heat elements in accordance with outdoor air

temperature Outdoor thermostats are set according to build

ing load requiremerrts and have an adjustable set point When

12

Page 13

outdoor ambient reaches the outdoor thermostat set point, the

heating element contactor is energized when thermostat

second stage heating contacts close, bringing on additional

electrical resistance heat

50RQ,PQ008/010 - On the 50RQ,PQ008 and 010, 2compressor units, when thermostat second stage heating

contacts close, compressor contactor no 2 energizes and

compressor no 2 is brought on Units have a built-in electric

resistance heat lock-out thru the defrost thermostat Above

40 F (approximate) outdoor temperature, electric resistance

heat is locked out and second stage heat is from compressor

no 2 Below 40 F (approximate) ambient, when thermostat

first stage heating contacts close, compressor contacts no 1

and no. 2 energize sequentially thru a time delay and both

compressors (no 1 and no 2) are brought on to satisfy heating

requirements

On a further drop in room temperature (outdoor ambient

below 40 F), thermostat second stage heating contacts close,

energizing electric resistance heat contactor and second stage

heat operates Electric heaters with 2 or more contactors can

have outdoor thermostats wired into the control circuit for

additional staging

Automatic changeover — When the system selection switch is

set at AUTO , unit automatically changes from heat operation

to cooling operation when the temperature of the conditioned

space rises to the cooling lever setting When the temperature

of the conditioned space fails to the heating lever setting, unit

automatically changes from cooling to heating operation (with

a 3 F deadband in between)

Continuous air circulation — Unit power on System control

set at OFF, fan switch set at ON Indoor fan contactor is

energized thru the thermostat switch and the indoor fan runs

continuously When controls are set at HEAT, COOL, or

AUTO , operation is as above and indoor fan runs

continuously.

Defrost cycle

50RQ/PQ006 — The defrost thermostat on the outdoor coil

activates a defrost timer which energizes electric resistance

heaters and de-energizes the reversing valve relay and the

outdoor fan motor When the defrost thermostat is satisfied or

when 10 minutes have elapsed, the reversing valve solenoid

energizes and electric heaters de-energize The defrost timer

prevents defrost again for 90 minutes

50RQ,PQ008/010 — Operation is same as above, except both

reversing valve relays de-energize or energize simultaneously

off the defrost timer and thermostat

On the 008 and 010 units, the defrost thermostat in

conjunction with a time delay relay prevent electric heat

operation above an ambient temperature of approximately

40 F (depends on coil frost conditions) If defrost thermostat

closes, the time delay relay energizes and pulls in compressor

contactor no 2 Both compressors now operate off of W1 and

W2 controls electric heat

Economizer operation

Unit power on, thermostat set at COOL or AUTO , outside

temperature below setting of outside air changeover

thermostat

Upon a rise in room temperature, cooling contact no 1 in

the thermostat closes Indoor fan motor starts and outside air

damper modulates to maintain mixture of outside air and

return air at present temperature Cooling is provided with

outside air Mechanical cooling is locked out

At temperatures above outdoor air changeover thermostat

setting, outdoor air damper moves to VENT position whenever

fan is running, and cooling operation is as described for base

unit When heat is energized, outdoor air damper moves to

VENT position Outdoor air damper closes when fan is not

operating

Signal-LOC^'^protection with "LK-OUT" light

If unit operation is interrupted by an open high-pressure

switch, low-pressure switch, indoor coil freezestat, or by the

compressor internal line break device (overcurrent or over

temperature), and the compressor is calling for either cooling

or heating, Signal-LOC simultaneously locks out the unit and

lights a warning light (LK-OUT) on the thermostat Unit is

restarted by manually turning room thermostat OFF and then

ON If any of the protective devices open again, unit continues

to lock out until corrective action is taken

Accessories

Emergency heat

If the compressor is inoperative due to a tripped safety device

(high pressure, low pressure, indoor coil freezestat, overcurrent

or over-temperature), Signal-LOC locks out the compressor and

lights the warning light (LK-OUT) on the room thermostat

When the switch is on, the thermostat is moved to the EM.

HT. position, the compressor circuit and the outdoor thermo

stats are bypassed and the second stage of the thermostat

energizes the indoor fan and the electric resistance heaters.

Time Guard®

The accessory Time Guard control circuit provides a 5-minute

delay of compressor restart after the desired space temperature

has been attained and the room thermostat has shutdown the

compressor Assuming that the compressor has been off for at

least 5 minutes due to room thermostat action, the Time

Guard control sequence is as follows

With the fan selector switch at AUTO , a call for cooling

from the room thermostat causes the indoor air fan to start

immediately, the compressor and outdoor air fan start 15

seconds later When the room thermostat is satisfied, the

compressor shuts off The Time Guard timer motor then runs

for 4 minutes and 45 seconds, at which point its internal

switches reset so the normal sequence can begin again

The base unit contains as standard equipment, a factory-

installed Signal-LOC compressor protection device If the

overload protector causes the compressor to shut off, the

compressor remains locked out until the control circuit is

manually reset Reset manually by moving the system selector

lever on the room thermostat to OFF momentarily and then

return it to the cooling position After the standard 5-minute

Time Guard delay, the compressor can restart

13

Page 14

Typical wiring schematic

(Unit 006 shown with electric heat option, economizer option and accessory emergency heat; schematic is for reference only,

do not use for wiring unit.)

UNIT MAIN POWER

#

AHA - Adjustable Heat Anticipator

C Contactor, Compressor

CC Cooling Compensator

CLO -

DFR -

Compressor Lock-Out

Defrost Relay

DR - Damper Relay

EH

FPT Fu

Emergency Heat o

Freeze-Up Protection Thermostat

Fuse

HC - Heater Contactor

HPS IFR L

LPS -

High Pressure Switch

Indoor Fan Relay

Lamp

Low Pressure Switch

MAT. - Mixed Air Thermostat

OAT. - Outdoor Air Thermostat

ODT - Outdoor Thermostat (Emer Heat)

RVR -

Reversing Valve Relay

LEGEND

14

TC

TH

TRAN -

□

o

o

__□__

-----

•—

______

______

M M M

Thermostat, Cooling

Thermostat, Heating

Transformer

Terminal Block Connection

Terminal (Unmarked)

Terminal (Marked)

Field Splice

Splice (Marked)

Wire Marker

Factory Wiring

Factory Splice

Accessory or Optional Wiring

Field Control Wiring

Field Power Wiring

To indicate common potential

not to represent wire

Page 15

Application notes

Filters — Plenum filter racks for 008 size units can accom

modate 2-in filters for higher filtration efficiency and/or

longer filter life. Filters other than 1-in standard must be field

supplied

Ductwork — At installer's option, ductwork may be attached

to the curb on 50PQ units (and 50RQ units with accessory

plenum) interior installation may proceed before unit is set in

place on roof

Field power connections — Accessory (field-installed) electric

heaters may require separate power entry to comply with local

codes Factory-installed electric heat allows single power entry

to unit for both heating and cooling

Condensate trap — Evaporator is draw-thru configuration. A

trap (minimum 4 in deep) must be field provided prior to

start-up on cooling cycle

Static pressure limits — When return air ductwork systems are

used, return side static pressures should be limited to 0 4

in. wg

Guide specifications

Operating limits — Cfm values indicated illustrate the oper

ating range of the indoor fan Operation above or below these

limits is not recommended Exception Operation of the

50RQ008 460-3-60 unit with 15 10 electric heat ratio,

minimum cfm is 2800 at 80 F return air temperature

Remote control panel - When use is required with emergency

heat, emergency heat switch, Carrier Part No HR59JP115

must be used Emergency heat subbase cannot be used with the

remote control panel

Low ambient cooling operation — Units are designed to

operate at outdoor temperatures down to 35 F At tempera

tures below 35 F, accessory Motormaster® will permit opera

tion at outdoor temperatures as low as —20 F

Roof curb — All curb installations must be counterflashed to

prevent water leakage.

Base unit — Furnish and install a one-piece, air-to-air electric

heat pump designed to function as a year-round air condi

tioning system. Unit shall be completely assembled, and tested

complete with refrigerant charge and ready to operate The

total unit shall be U L listed and carry a U.L label Unit shall

be designed for either slab mount (RQ) or single-piece curb

mount (PQ) PQ unit to have outdoor air inlet with filter, plus

factory-supplied 1-in throwaway return air filters

Cooling capacity (net) — Unit cooling cycle capacity shall be a

NET capacity with indoor fan motor heat deducted and shall

be

_____

Btuh or greater total,

tions of

______

cfm air entering indoor coil,

_

_____ F wet bulb, and _

The total unit cooling

rated in accordance with ARI Standard 240 for air-to-air heat

pumps

Heating capacity — Heating cycle capacity shall be

or greater (integrated rating) when rated at

ambient, with_______cfm and

(heating) coil The total unit C.O.P at above conditions shall

be

____

or greater The ARI heating C.O.P. shall be

47 F db outdoor ambient (hi-temp),

ambient (low temp) or greater when rated in accordance with

ARI Standard 240 for air-to-air heat pumps

Electric resistance heat — Electric resistance heaters shall be

supplied to offset building heat loss (at winter design

conditions) when the heat pump heating cycle capacity cannot

satisfy space requirements. Fleaters shall consist of open wire

nichrome elements with controls necessary for operation

Safety controls shall include primary overtemperature and

_________

___

F dry bulb entering outdoor coil

EER shall be

______

Btuh sensible at condi

________

______

F air entering the indoor

_________

.or greater when

_______

at 17 F db outdoor

F dry bulb.

_______

,F db outdoor

__________

Btuh

at

overcurrent protection. Heaters shall be U.L. listed when

factory installed

Unit compressor(s) shall be welded, fully hermetic with

crankcase heater(s) and suitable vibration isolators Com

pressors shall be of the same manufacture as unit and shall be

tested and designed in unit to operate to —20 F OAT on

heating cycle without shutting off. The standard unit shall be

capable of operating to 35 F OAT. on cooling cycle Com

pressors shall have a 5-year warranty

Coils — Indoor and outdoor coils shall be of nonferrous

construction with aluminum plate fins mechanically bonded to

seamless copper tubes with all joints brazed.

Fans and motors — Indoor air fan shall be forward curved,

centrifugal, belt-driven type capable of delivering

at

_____

in. wg external static pressure Motor pulley shall be

adjustable pitch. Indoor fan shall be

manently lubricated bearings. Outdoor fan shall be of the

propeller type, with direct driven permanently lubricated

motor of

Unit cabinet shall be constructed of galvanized steel, bonder-

ized and coated with a baked enamel finish Cabinet interior

shall be insulated with 1-in. thick neoprene coated fiberglass.

Cabinet panels shall be easily removable for service to' all

operating components. A condensate drain for the indoor coil

shall be provided.

Controls — The heat pump cooling/heating system shall be

protected with high pressurestat, low pressurestats, loss of

charge protection, indoor coil freezestats, and current and

temperature sensitive overload devices

_____

_hp or less. Fans shall discharge upward

____________

___________

hp with per

cfm

15

Page 16

Guide specifications (cont)

Each of these devices shall be wired thru the Signal-LOC^'^

circuit to prevent compressor restart until reset at the

thermostat The standard room thermostat shall contain a

"compressor malfunction light" designed to illuminate if any

of the beforementioned safety controls trip out the compres

sor thru the lockout circuit Two-compressor units shall have

separate and independent refrigeration and control systems

designed to allow for standby operation of either compressor

if one is locked out Two-compressor units shall have 2-stage

compressor heat and cool with built-in electric strip heat lock

out to prevent resistance heat operation above 40 F ambient

Defrost control — An outdoor coil defrost control system

(Chronotemp®) shall be incorporated into the base unit to

prevent frost accumulation during heating cycle The defrost

cycle shall function on the basis of time and coil temperature

A 90-minute timer shall actuate a defrost mode only if coil

temperature is low enough to indicate a heavy frost condition.

Defrost shall have a positive termination time of a maximum

of 10 minutes or when the defrost thermostat is satisfied to

prevent prolonged operation on a defrost cycle Electric

resistance heaters shall be operational automatically during the

defrost cycle

Unit electrical connections — Unit with factory-installed

electric heat shall have single point power connection to a

terminal block. Cabinet shall contain suitable openings for

routing of all utility connections The base unit shall contain a

terminal strip in the control compartment to allow for

terminal-to-terminal connection of room thermostat and field-

installed accessories

Maximum dimensions — Width

height

--------

inches.

Accessories and options

The following factory-installed options, (FlOP) or field-

installed accessories (accessory) shall be provided.

Roof curb shall be of the same manufacture as unit and shall

include an insulated panel under compressor section to prevent

condensation forming on the bottom Dimensions shall be

provided to allow for easy duct location and connection to

roof curb prior to unit placement Roof curb shall be a

minimum of 12 in high to allow for proper defrost meltage

run-off Curb design shall comply with National Roofing

Contractors Association requirements (accessory)

Economizer control shall include R.A. and O.A dampers,

outdoor air filter and hood, and fully modulating electric

control system with O.A. thermostat and adjustable mixed air

stat. Economizer control shall be capable of introducing up to

-----------------

in., depth

------------

in,

100% outdoor air The control changeover from mechanical

cooling to economizer operation shall be fully automatic thru

an adjustable outdoor air changeover thermostat. PQ units

(accessory or FlOP) RQ units with accessory plenum

(accessory).

Alternate motor and drive assembly to provide added cfm and

static pressure capability (FlOP)

Downturn plenum for use on RQ units designed to easily field

attach to the base unit to direct airflow downward thru the

roof. Plenum to provide for a weatherproof opening for

ductwork assembly (accessory only on RQ units)

Electric resistance heaters shall be available in 4 selections

(low, 75 1, 1 1,15 1 heat-to-cool ratio) and shall have open

wire nichrome elements with all necessary safety and operating

controls. Heaters shall be U.L. listed and approved for use

when factory installed. Units with factory-installed heat shall

have single power entry by terminal blocks suitable for copper

or aluminum wires (200-v, 3-phase unit with 39 Kw factory-

installed heat, copper only)

Thermostat assembly shall provide staged heating and cooling,

manual or automatic changeover and fan control Standard

subbase shall include "compressor malfunction light" (LK-

OUT) designed to illuminate if compressor lockout is activated

(accessory)

Emergency heat control shall consist of emergency heal

control box containing emergency heat relays and outdoor

thermostat(s), and an emergency heal thermostat subbase

(with warning light) Control shall allow for manual bypass of

compressor and outdoor thermostats if compressor becomes

inoperative, or for service Subbase light shall illuminate if

compressor lock-out is activated. Outdoor thermostats shall

provide for staging of electric resistance heal according to

outdoor temperature Thermostats shall be wired into the

electric heater contactors and shall have an adjustable set point

to provide economical resistance heat staging (accessory).

Remote control panel to provide central unit control of

heating, cooling, indoor fan and outdoor air damper Panel

shall contain indicator lights for up lo 6 unit functions

(accessory)

Time Guard® circuit to prevent compressor short cycling as a

result of a rapid change in thermostat setting. Also, auto

matically prevents compressor restart at least 5 minutes after

shutdown (accessory).

Head pressure control — A solid state outdoor fan speed

control (32LT) to maintain head pressure control down to

—20 F QAT on cooling cycle (accessory). (Inoperative during

heating cycle )

Number One

Air Conditioning

G

Division oi Carrier Corporation

Carrier Parkway • Syracuse NY 13221

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Tab 12 Form 50RQ-3P Supersedes 50RQ-2P Primed in U S A 10-77 PC 111 Catalog No 525—044

Book

1 4

Tab

5a 5a

Loading...

Loading...