Page 1

AQUAZONE™

50PEC09-18

Water Source Heat Pump Console Unit with

®

PURON

Refrigerant (R-410A)

50 Hz

Installation, Start-Up and Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . .1,2

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Step 1 — Check Jobsite . . . . . . . . . . . . . . . . . . . . . . . . 2

Step 2 — Check Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 17

• STORAGE

• UNIT PROTECTION

Step 3 — Mount Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Step 4 — Wire Electrical Connections . . . . . . . . . . 17

• SUPPLY VOLTAGE

• EXTERNAL LOOP POWER CONNECTION

• 220-V OPERATION

Step 5 — Wire Low Voltage Connections . . . . . . . 25

• WATER FREEZE PROTECTION

• ACCESSORY CONNECTIONS

• WATER SOLENOID VALVES

• OPTIONAL WALL-MOUNTED THERMOSTAT

• OPTIONAL PREMIERLINK™ CONTROLLER

Step 6 — Install Supply and Return Piping. . . . . . 26

• SUPPLY AND RETURN HOSES

• SUPPLY AND RETURN PIPING

Step 7 — Install Condensate Piping . . . . . . . . . . . . 26

PRE-START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-29

System Cleaning and Flushing . . . . . . . . . . . . . . . . 27

System Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

FIELD SELECTABLE INPUTS . . . . . . . . . . . . . . . .29,30

Complete C Control Jumper Settings. . . . . . . . . . . 29

Complete C Control DIP Switches. . . . . . . . . . . . . . 29

Deluxe D Control Jumper Settings . . . . . . . . . . . . . 29

Deluxe D Control DIP Switches . . . . . . . . . . . . . . . . 29

Deluxe D Control Accessory

Relay Configurations . . . . . . . . . . . . . . . . . . . . . . . 30

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-32

Operating Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Unit Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Flow Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cooling Tower/Boiler Systems. . . . . . . . . . . . . . . . . 32

Ground Coupled, Closed Loop and Plateframe

Heat Exchanger Well Systems . . . . . . . . . . . . . . . 32

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32,33

Power Up Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Units with Aquazone Complete C Control. . . . . . . 32

Units with Aquazone Deluxe D Control . . . . . . . . . 32

COMPLETE C AND DELUXE D BOARD

SYSTEM TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . .33,34

Test Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Retry Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Aquazone Deluxe D Control LED Indicators. . . . . 33

SERVICE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34-36

Unit Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

System Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Water Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Refrigerant System . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Condenser Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Condensate Pans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Blower Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Safety Control Reset. . . . . . . . . . . . . . . . . . . . . . . . . . 35

Checking System Charge

Refrigerant Charging . . . . . . . . . . . . . . . . . . . . . . . . . 36

Air Coil Fan Motor Removal . . . . . . . . . . . . . . . . . . . 36

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . .36-38

Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Control Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

START-UP CHECKLIST. . . . . . . . . . . . . . . . . CL-1, CL-2

IMPORTANT: Read the entire instruction manual before

starting installation.

. . . . . . . . . . . . . . . . . . . . . 36

Page

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical components.

Only trained and qualified service personnel should install,

repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters. All other

operations should be performed by trained service personnel.

When working on air-conditioning equipment, observe precautions in the literature, tags and labels attached to the unit, and

other safety precautions that may apply.

Improper installation, adjustment, alteration, service, maintenance, or use can cause explosion, fire, electrical shock or other

conditions which may cause personal injury or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory-authorized kits or accessories when modifying this product. Refer to the individual

instructions packaged with the kits or accessories when

installing.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have fire

extinguisher available. Read these instructions thoroughly and

follow all warnings or cautions attached to the unit. Consult

local building codes and applicable electrical codes for special

installation requirements.

Understand the signal words — DANGER, WARNING, and

CAUTION. DANGER identifies the most serious hazards

which will result in severe personal injury or death. WARNING

signifies hazards that could result in personal injury or death.

CAUTION is used to identify unsafe practices, which would result in minor personal injury or product and property damage.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53500075-01 Printed in U.S.A. Form 50PEC-C1SI Pg 1 9-10 Replaces: New

Page 2

WARNING

Electrical shock can cause personal injury or death. Before

installing or servicing system, always turn off main power

to system. There may be more than one disconnect switch.

Turn off accessory heater power if applicable.

GENERAL

The 50PEC water source heat pump console unit is a decentralized room terminal designed for field connection to a

closed-circuit piping loop.

Units are typically installed in perimeter zones, usually under windows. Supply air is discharged directly into the conditioned space through discharge grilles located in the top of the

unit.

IMPORTANT: The installation of console water source heat

pump units and all associated components, parts, and accessories which make up the installation shall be in accordance

with the regulations of ALL authorities having jurisdiction

and MUST conform to all applicable codes. It is the responsibility of the installing contractor to determine and comply

with ALL applicable codes and regulations.

INSTALLATION

Step 1 — Check Jobsite —

stalled along an outside wall of the room. Refer to Fig. 1 and 2

for an illustration showing piping locations. Install units with

adequate clearance to allow maintenance and servicing. Refer

Units are typically in-

to Table 1 and Fig. 3-14. Locate the console unit so that it provides adequate air circulation throughout the room.

Installation, operation and maintenance instructions are

provided with each unit. Before unit start-up, read all manuals

and become familiar with the unit and its operation. Thoroughly

check out the system before operation. Complete the inspections

and instructions listed below to prepare a unit for installation.

1. Compare the electrical data on the unit nameplate with

ordering and shipping information to verify that the correct unit has been shipped.

2. Keep both the chassis and cabinet covered with the shipping carton until all plastering, painting, and finish work

is complete and it is time to install the chassis and cabinet.

3. Verify that the refrigerant tubing is free of kinks or dents,

and that it does not touch other unit components.

4. Inspect all electrical connections. Connections must be

clean and tight at the terminals.

CAUTION

To avoid equipment damage, do not use these units as a

source of heating or cooling during the construction process. The mechanical components and filters used in these

units quickly become clogged with construction dirt and

debris which may cause system damage.

CAUTION

To avoid the release of refrigerant into the atmosphere, the

refrigerant circuit of this unit must only be serviced by

technicians who meet local, regional, and national proficiency requirements.

Table 1 — 50PEC Physical Data

BASE UNIT 50PEC 09 12 15 18

COMPRESSOR (Qty)

REFRIG. CHARGE (R-410A)/CKT (kg)

No. of Circuits

BLOWER

Motor kW

Wheel Size D x W (mm) 2 each

WATER CONNECTION SIZE

OD Sweat (in.)

Optional FPT Fittings (in.)

Optional MPT Fittings (in.)

CONDENSATE CONNECTION SIZE (ID Vinyl) (in.)

Air Coil Size (h x w) (mm)

FILTER SIZE (h x w x d) (mm)

Bottom Return

Front Return

CABINET SIZE (h x w x d) (mm)

Bottom Return With Standard 127 mm Subbase

Front Return With No Subbase

UNIT WEIGHT (kg)

Shipping

Operating

Unit Maximum Working Pressure (kPa)

Base Unit

Internal Secondary Pump

Internal Motorized Water Valve

Internal Autoflow Valve

NOTES:

1. All units have grommet compressor mountings and TXV (thermostatic expansion valve) devices.

Rotary (1)

0.737

1

0.37

133 x 159

1

/

2

1

/

2

1

/

2

5

/

8

203 x 660 254 x 660 254 x 660 254 x 812

254 x 762 x 25

178 x 749 x 3

1219 x 660 x 305

1219 x 533 x 305

84

79

3100

999

2067

3100

2. All pipe sizes are in inches. Equivalent sizes in millimeters

follow:

0.822

1

0.62

133 x 159

1

/

2

1

/

2

1

/

2

5

/

8

254 x 762 x 25

178 x 749 x 3

1219 x 660 x 305

1219 x 533 x 305

86

82

3100

999

2067

3100

0.936

1

0.93

133 x 159

1

/

2

1

/

2

1

/

2

5

/

8

254 x 762 x 25

178 x 749 x 3

1219 x 660 x 305

1219 x 533 x 305

91

86

3100

999

2067

3100

in. mm

1

/

2

5

/

8

3

/

4

12.7

15.9

19.1

133 x 159

254 x 914 x 25

178 x 800 x 3

1372 x 660 x 305

1372 x 533 x 305

0.850

1

0.93

3

/

4

3

/

4

3

/

4

5

/

8

105

100

3100

999

2067

3100

2

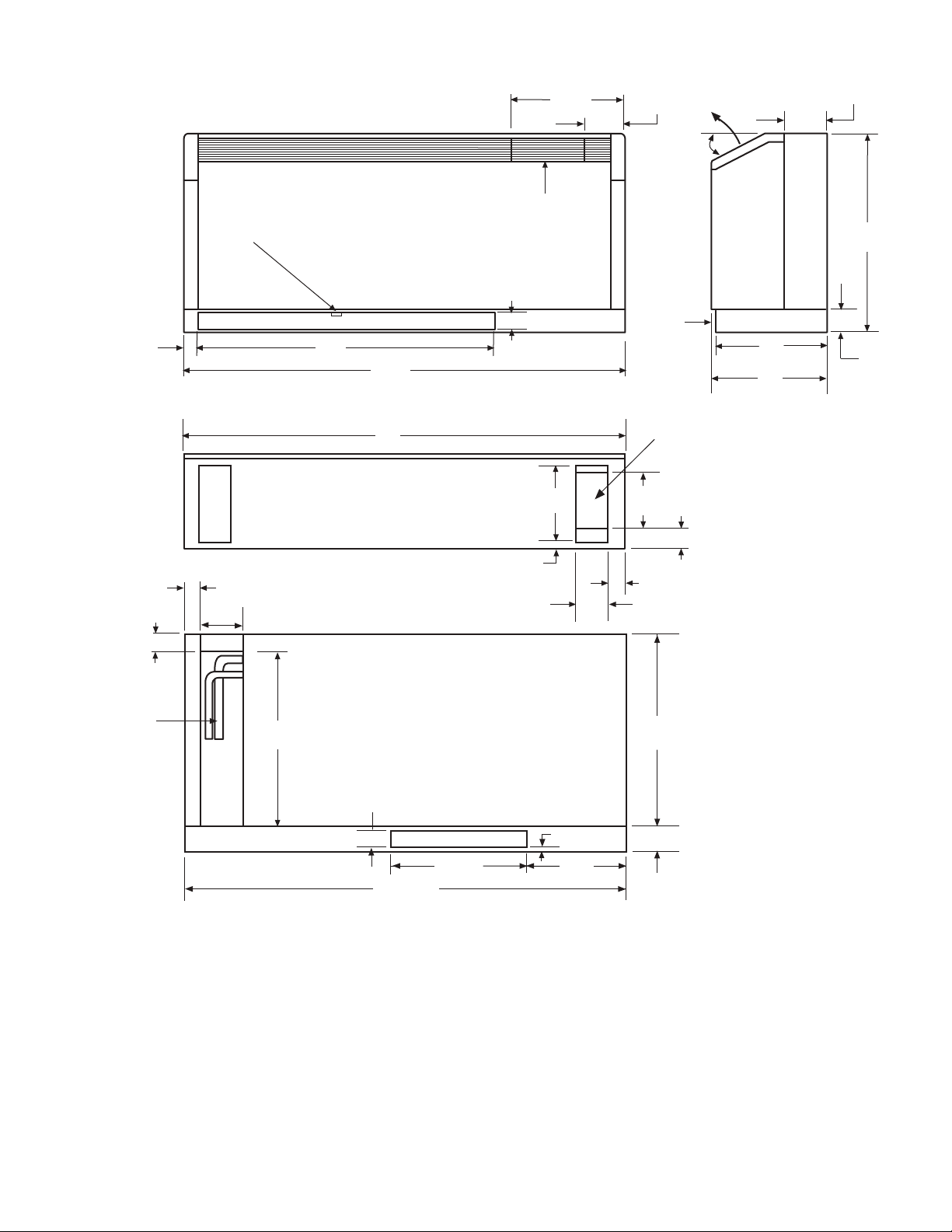

Page 3

LEGEND

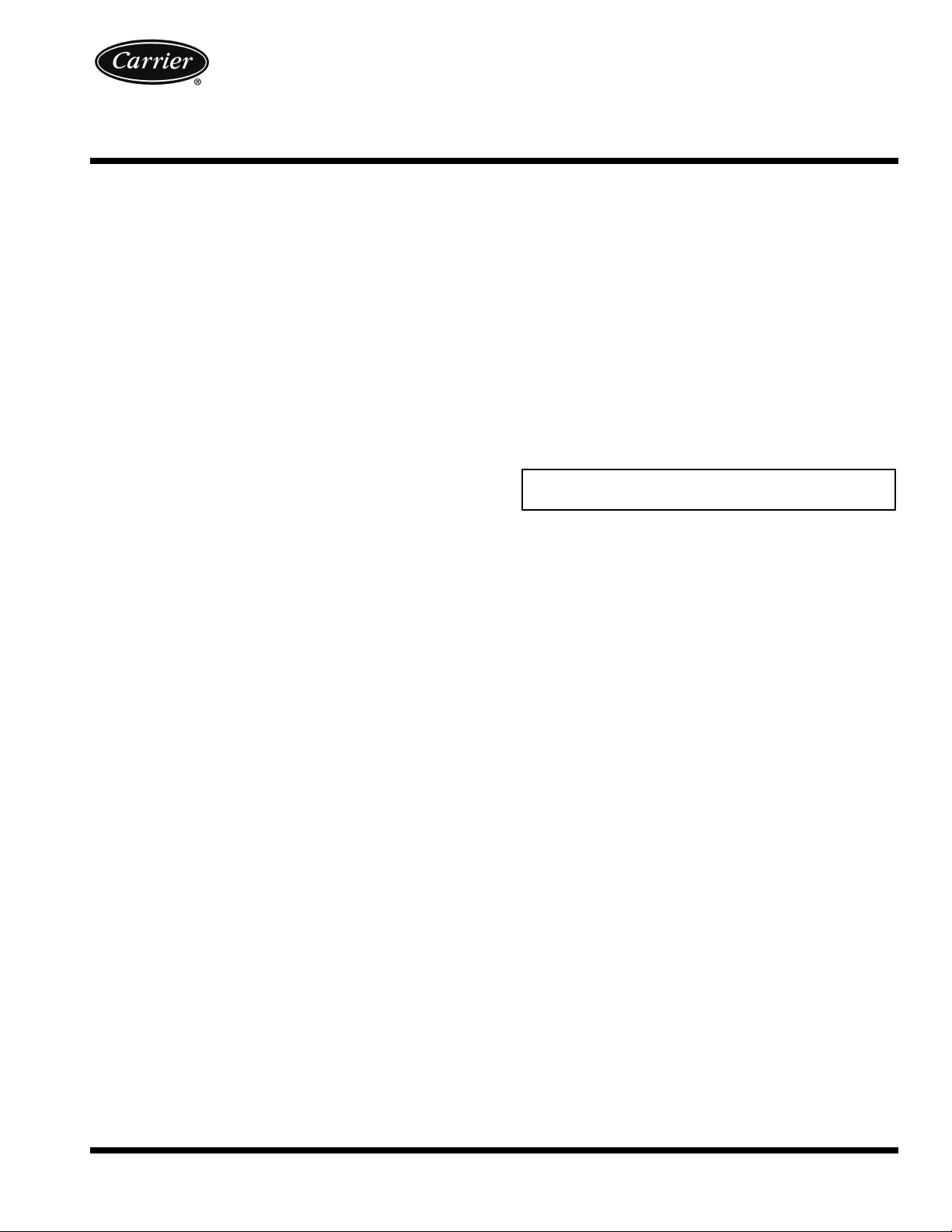

*Dimension reduced by fitting if selected.

NOTE: Dimensions shown are in inches. Dimensions in parentheses are in millimeters.

EPT — External Pipe Thread

IPT — Internal Pipe Thread

Fig. 1 — 50PEC09-15 Piping Dimensions

WATER IN

WATER OUT

COMPRESSOR

ACCESS

PANEL

CONTROL BOX

1.84

(77)

CONDENSATE

5/8" (15.9) ID

VINYL HOSE

OPTIO

MOTOR

WATER

OPTI

AUTO

VALV

WATER C

5/8" (15

OD COP

1/2" IPT

1/2" EP

OPTIONAL FLOW

REGULATOR

OPTIONAL

MOTORIZED

WATER VALVE

1.75 (44)

OUT

IN

WATER CONNECTIONS

5/8” (15.9) OD

COPPER, 1/2” IPT, OR

1/2” EPT

8.00 MIN

(203)

*

11.25 (286)

1.62 (41)

2.00

(51)

2.25

(57)

Right Hand Configuration

a50-8335

Left Hand Configuration

a50-8336

OUT

WATER IN

IN

AL

oW

vE

oNAL

IZED

aLVE

2.25

(57)

oNNECTIONS

AA)

eR,

or

CONDENSATE

5/8" (15.9) ID

VINYL HOSE

WATER CONNECTIONS

5/8” (15.9) OD

COPPER, 1/2” IPT,

OR 1/2” EPT

*

11.25 (286)

2.25

(57)

2.72

(96)

WATER OUT

2.00

(51)

8.00 MIN

(203)

3

1.50 (38)

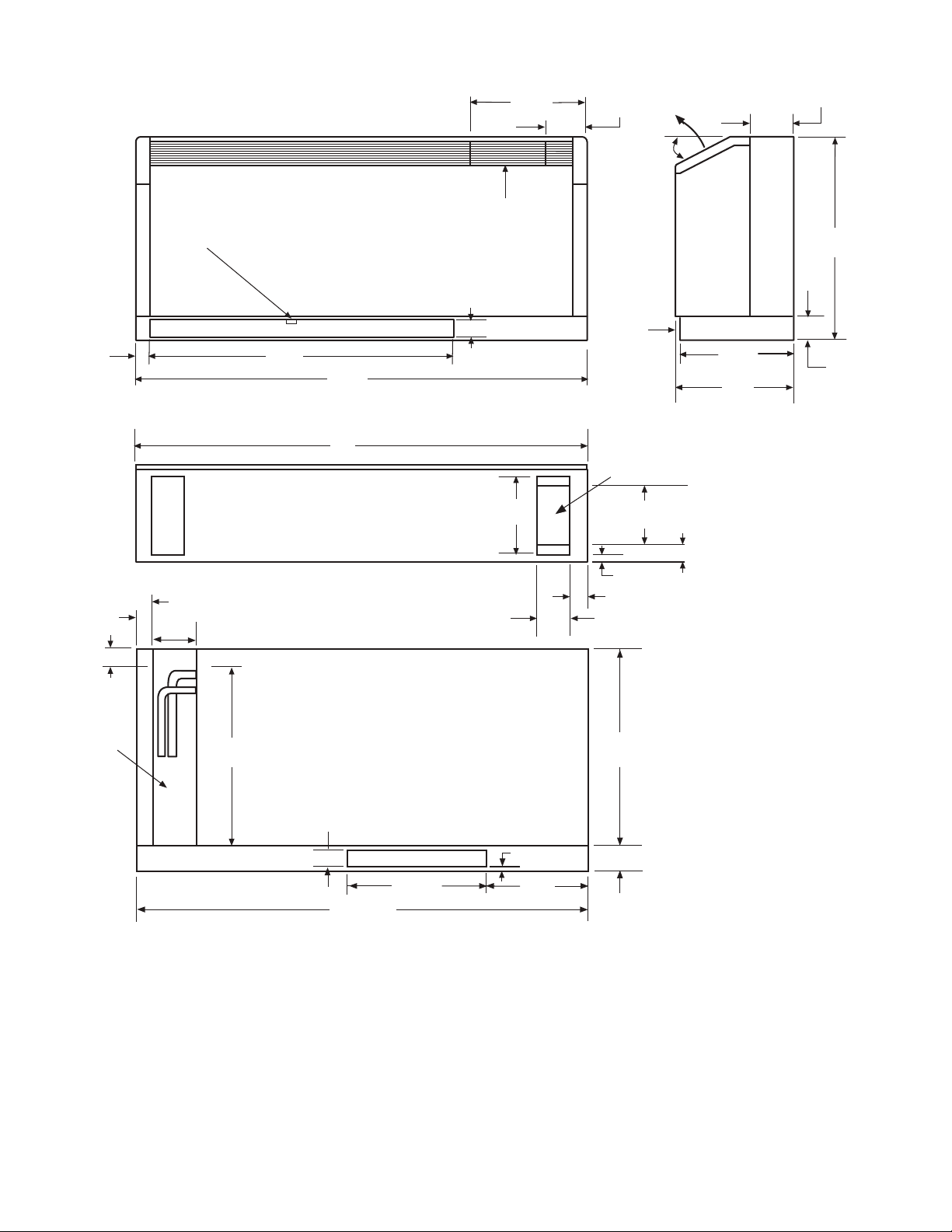

Page 4

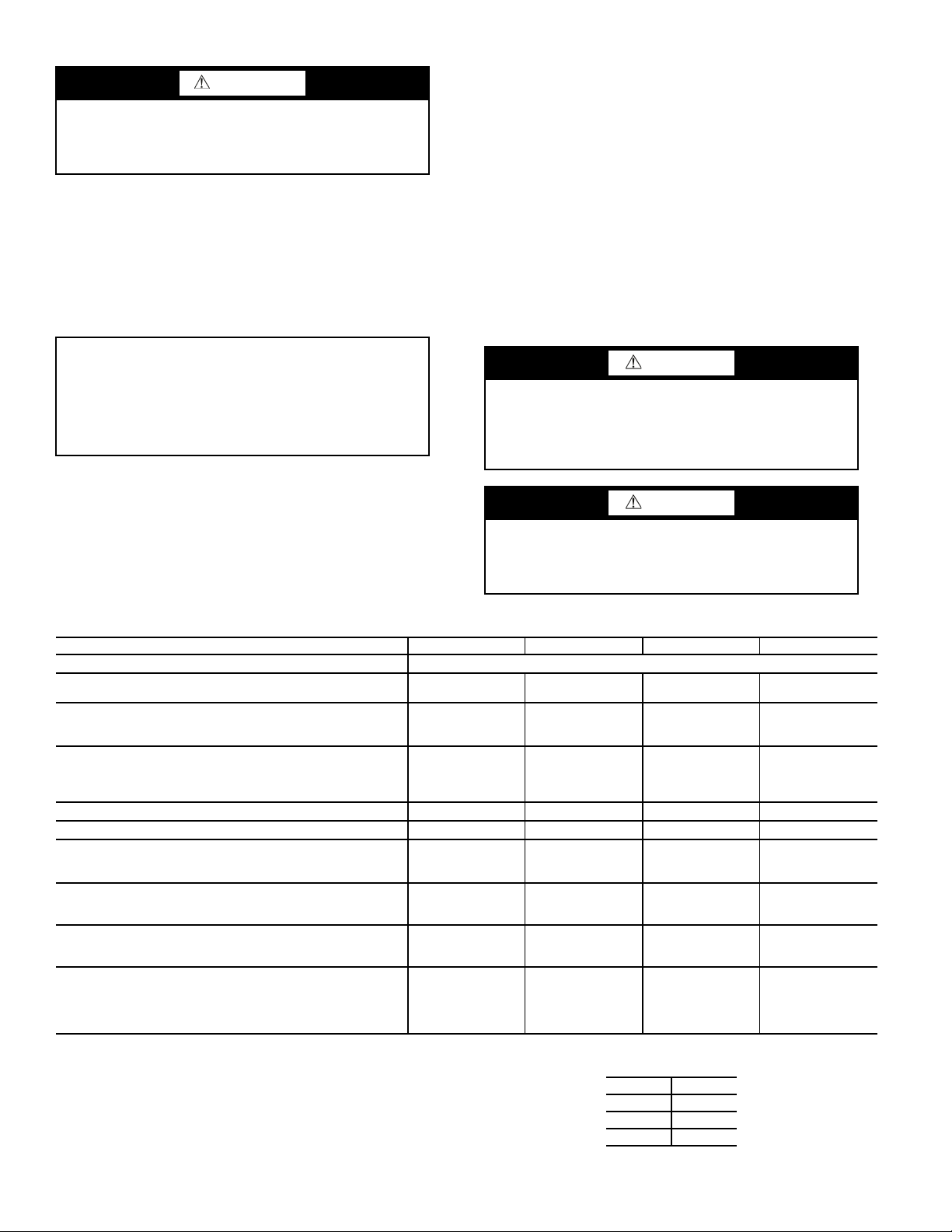

LEGEND

*Dimension reduced by fitting if selected.

NOTE: Dimensions shown are in inches. Dimensions in parentheses are in millimeters.

EPT — External Pipe Thread

IPT — Internal Pipe Thread

Fig. 2 — 50PEC18 Piping Dimensions

Right Hand Configuration

OPT

MOT

WAT

OPT

AUT

VALV

WATER

.875 (

OD C

3/4" IP

3/4" E

WATER

IN

WATER

OUT

COMPRESSOR

ACCESS

PANEL

CONTROL BOX

8.00 MIN

(203)

1.75 (44)

1.50

(38)

1.84

(47)

CONDENSATE

5/8" (15.9) ID

VINYL HOSE

OPTIONAL AUTO FLOW

VALVE

OPTIONAL

MOTORIZED

WATER VALVE

1.75 (44)

OUT

IN

WATER CONNECTIONS

7/8” (22.2) OD

COPPER, 3/4” IPT, OR

3/4” EPT

*

11.12 (282)

2.12

(54)

a50-8337

BLOWER DECK

BLOWER ACCESS PANEL

NS

OPTIONAL

MOTORIZED

WATER VALVE

OPTIONAL

AUTOFLOW

VALVE

WATER

IN

2.72

(96)

CONDENSATE

2.25

(286)

IN

OUT

5/8" (15.9) ID

VINYL HOSE

*

11.12 (282)

2.12

(54)

8.00 MIN

(203)

1.75 (44)

1.50

(38)

WATER

OUT

WATER

CONNECTIONS

7/8” (22.2) OD

COPPER, 3/4”

IPT OR 3/4” EPT

a50-8338

Left Hand Configuration

4

Page 5

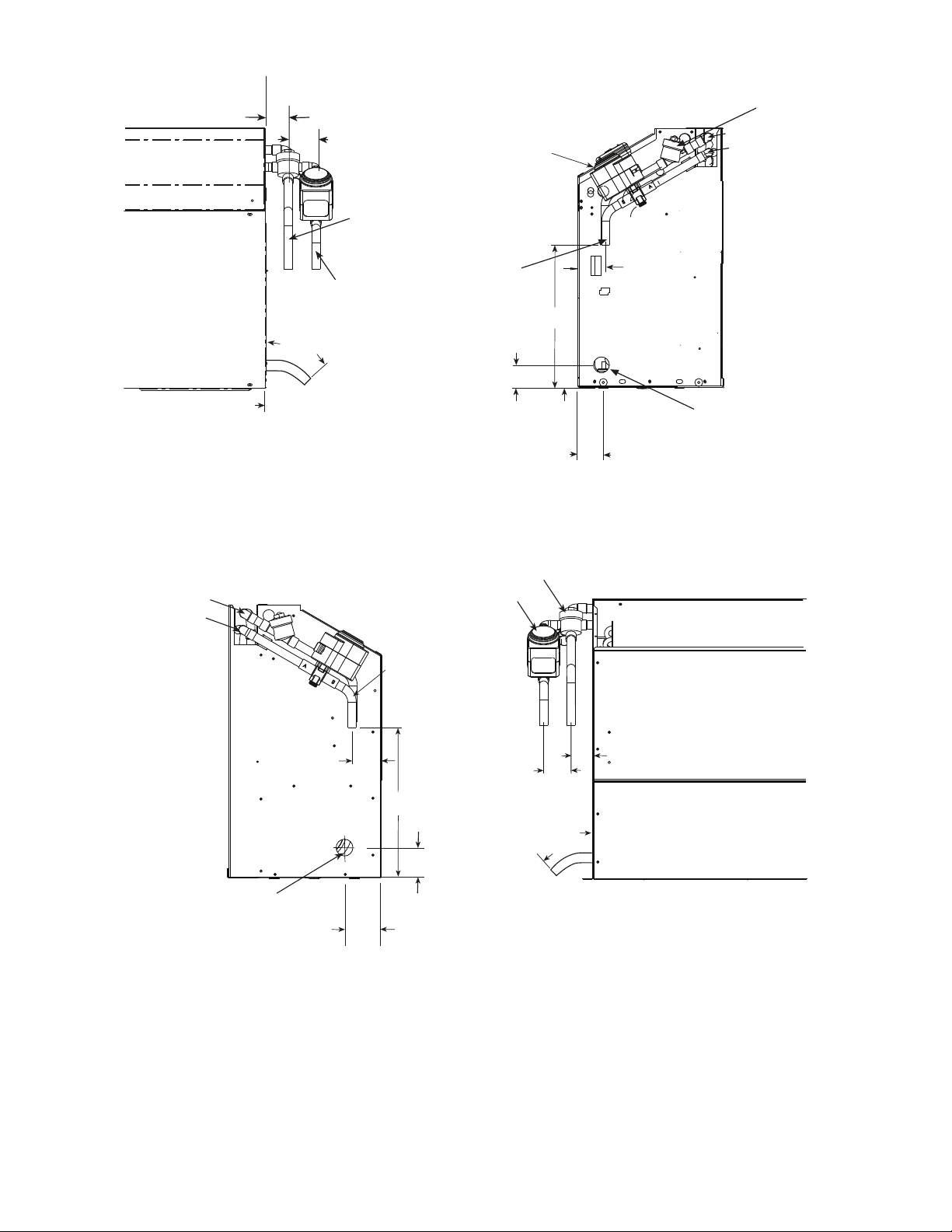

NOTES:

1. Dimensions are shown in inches. Dimensions in parentheses are in millimeters.

2. Access is reduced if optional disconnect box is selected.

3. Optional autoflow valve, motorized water valve and disconnect box are shown.

Fig. 3 — 50PEC09-15 Bottom Return Cabinet Dimensions — Right Hand Piping

a50-8339

Filter located inside and at

top of air inlet area. Rotate

filter latch forward, filter rack

can be pulled forward 75 to

100 mm for filter access

16.0

(406)

CONTROL ACCESS DOOR

FRONT VIEW

3.53

(90)

5.0

(127)

DISCHARGE

AIR

30

˚

VIEW

SIDE

3.5

(89)

(658)

25.9

1.75

(44.5)

1.0

1.0 (25)

R.H.

REAR

ACCESS

(NOTE 2)

(25)

4.5

(114)

AIR INLET AREA

20.0

(508)

33.5

(851)

BOTTOM VIEW

48.0

(1219)

48.0

(1219)

REAR VIEW

.75 (19)

3.00

(76)

10.0

(254)

AIR

INLET

(292)

12.0

(305)

R.H. PIPE AND

ELECTRIC AREA (NOTE 2)

6.88

(174)

2.12 (54)

1.75

(44)

21.0

(533)

11.5

4.9

(125)

1.63

(41)

DAMPER OPENING

48.0

(1219)

11.75

(298)

0.59

(15)

9.81

(249)

4.9

(125)

5

Page 6

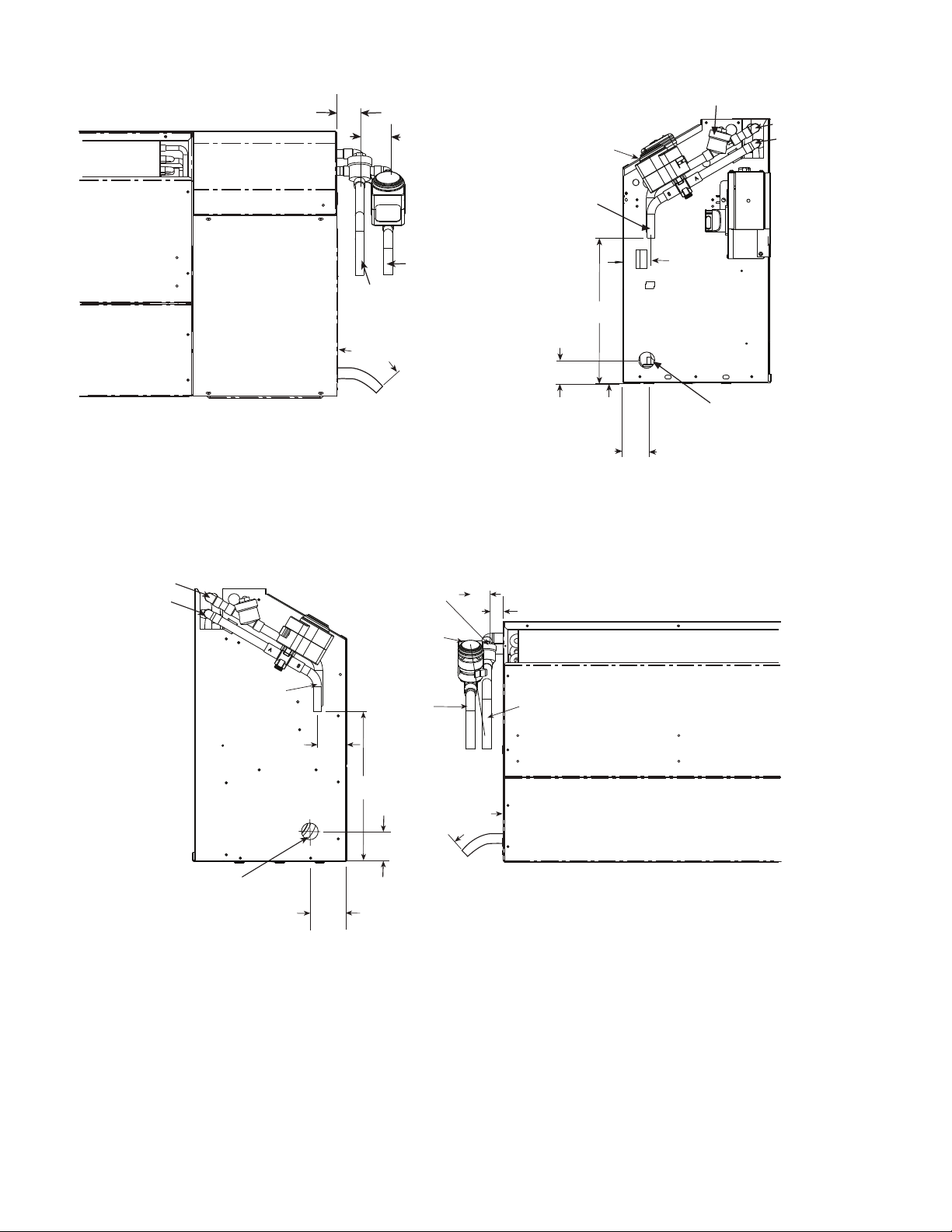

Fig. 4 — 50PEC18 Bottom Return Cabinet Dimensions — Right Hand Piping

NOTES:

1. Dimensions are shown in inches. Dimensions in parentheses are in millimeters.

2. Access is reduced if optional disconnect box is selected.

3. Optional autoflow valve, motorized water valve and disconnect box are shown.

a50-8340

30˚

11.50

(292)

4.90

(125)

3.50

(89)

25.90

(658)

DAMPER OPENING

54.00

(1372)

1.63

(41)

11.75

(298)

9.81

(249)

0.59

(15)

21.00

(533)

4.90

(125)

REAR VIEW

AIR

INLET

DISCHARGE

AIR

1.75

(44)

3.00

(76)

0.75 (19)

R.H. PIPE AND

ELECTRIC AREA

(NOTE 2)

1.00

(25)

1.00 (25)

4.50

(114)

20.00

(508)

12.00

(305)

10.00

(254)

BOTTOM VIEW

5.00

(127)

16.00

(406)

FRONT VIEW

CONTROL ACCESS DOOR

AIR INLET AREA

54.00

(1372)

39.50

(1003)

1.75

(44.5)

54.00

(1372)

3.53

(90)

SIDE

VIEW

RH REAR

ACCESS

(NOTE 2)

2.12 (54)

6.88

(174)

Filter located inside and at

top of air inlet area. Rotate

filter latch forward, filter rack

can be pulled forward 75 to

100 mm for filter access

6

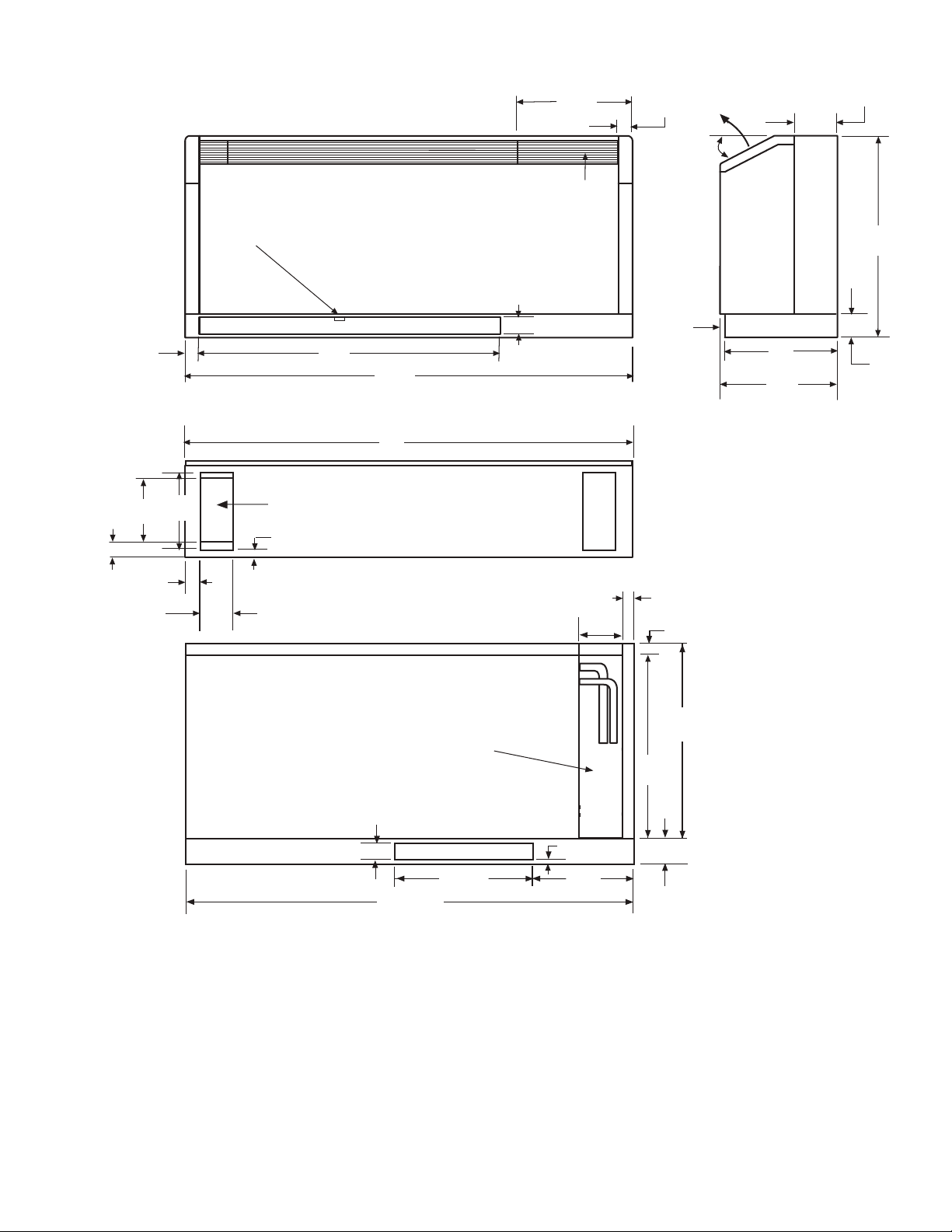

Page 7

a50-8341

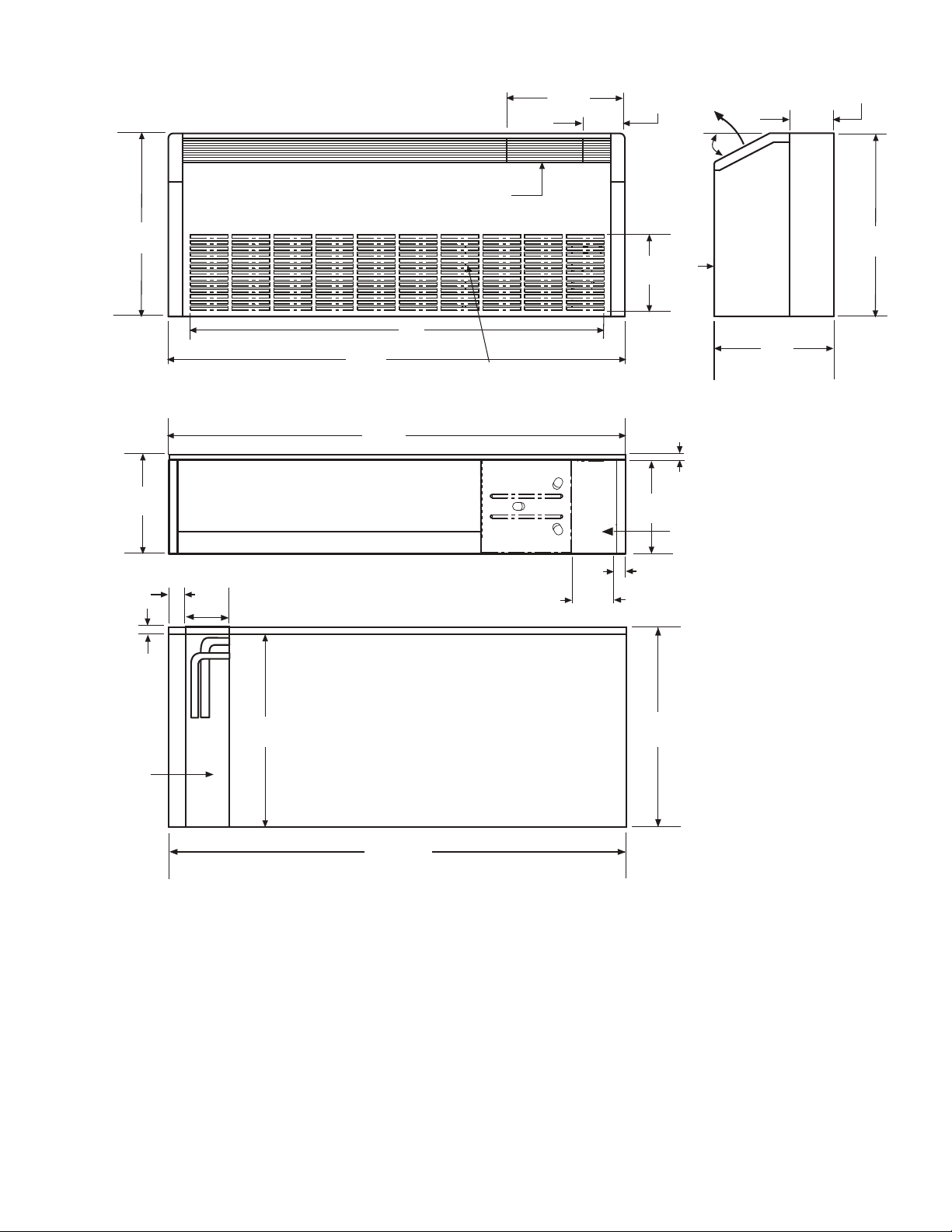

Fig. 5 — 50PEC09-15 Bottom Return Cabinet Dimensions — Left Hand Piping

NOTES:

1. Dimensions are shown in inches. Dimensions in parentheses are in millimeters.

2. Access is reduced if optional disconnect box is selected.

3. Optional autoflow valve, motorized water valve and disconnect box are shown.

30°

11. 5

(292)

4.9

(125)

3.5

(89)

25.9

(658)

DAMPER OPENING

48.0

(1219)

1.63

(41)

11.75

(298)

9.9

(251)

0.59

(15)

21.0

(533)

4.9

(125)

REAR VIEW

AIR

INLET

DISCHARGE

AIR

12.0

(305)

BOTTOM VIEW

12.6

(320)

FRONT VIEW

CONTROL ACCESS DOOR

AIR INLET AREA

48.0

(1219)

33.5

(851)

1.75

(44.5)

48.0

(1219)

1.5

(38)

3.53

(90)

1.75

(44)

3.00

(76)

0.75

(19)

L.H. PIPE AND

ELECTRIC AREA

NOTE 2

10.0

(254)

REAR

ACCESS

(NOTE 2)

1

(25)

1 (25)

4.5

(114)

20.0

(508)

SIDE

VIEW

L.H.

6.88

(174)

Filter located inside and at

top of air inlet area. Rotate

filter latch forward, filter rack

can be pulled forward 75 to

100 mm for filter access

7

Page 8

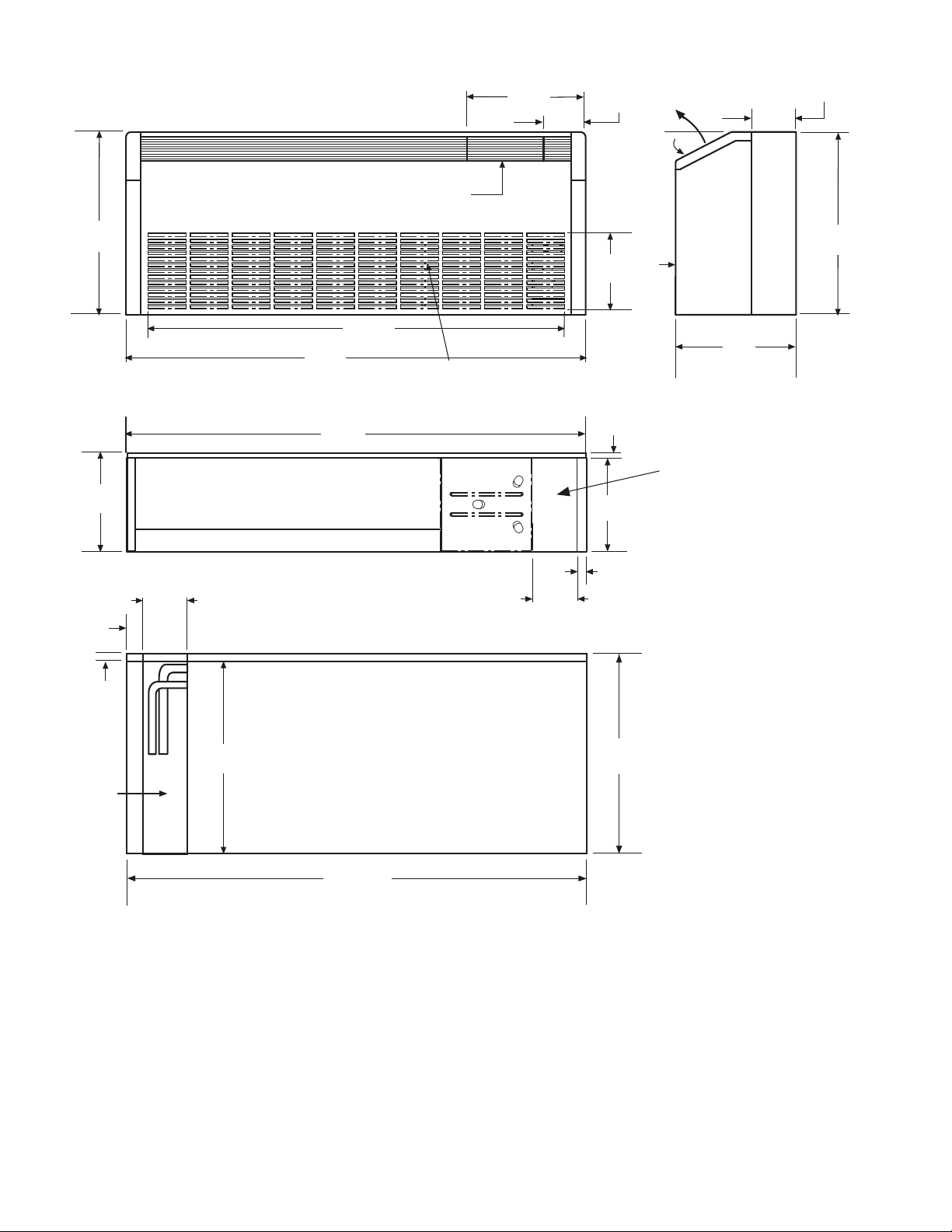

Fig. 6 — 50PEC18 Bottom Return Cabinet Dimensions — Left Hand Piping

NOTES:

1. Dimensions are shown in inches. Dimensions in parentheses are in millimeters.

2. Access is reduced if optional disconnect box is selected.

3. Optional autoflow valve, motorized water valve and disconnect box are shown.

a50-8342

30˚

11.50

(292)

4.90

(125)

3.50

(89)

25.90

(658)

DAMPER OPENING

54.00

(1372)

1.63

(41)

11.75

(298)

9.90

(251)

0.59

(15)

21.00

(533)

4.90

(125)

REAR VIEW

AIR

INLET

DISCHARGE

AIR

BOTTOM VIEW

12.60

(320)

FRONT VIEW

CONTROL ACCESS DOOR

AIR INLET AREA

54.00

(1372)

39.50

(1003)

1.75

(44.5)

54.00

(1372)

1.50

(38)

3.53

(90)

1.75

(44)

3.00

(76)

0.75

(19)

L.H. PIPE AND

ELECTRIC AREA

(Note 2)

10.00

(254)

REAR

ACCESS

(Note 2)

1.00 (25)

1.00 (25)

4.50

(114)

20.00

(508)

SIDE

VIEW

12.00

(305)

6.88

(174)

2.12 (54)

Filter located inside and at

top of air inlet area. Rotate

filter latch forward, filter rack

can be pulled forward 75 to

100 mm for filter access

8

Page 9

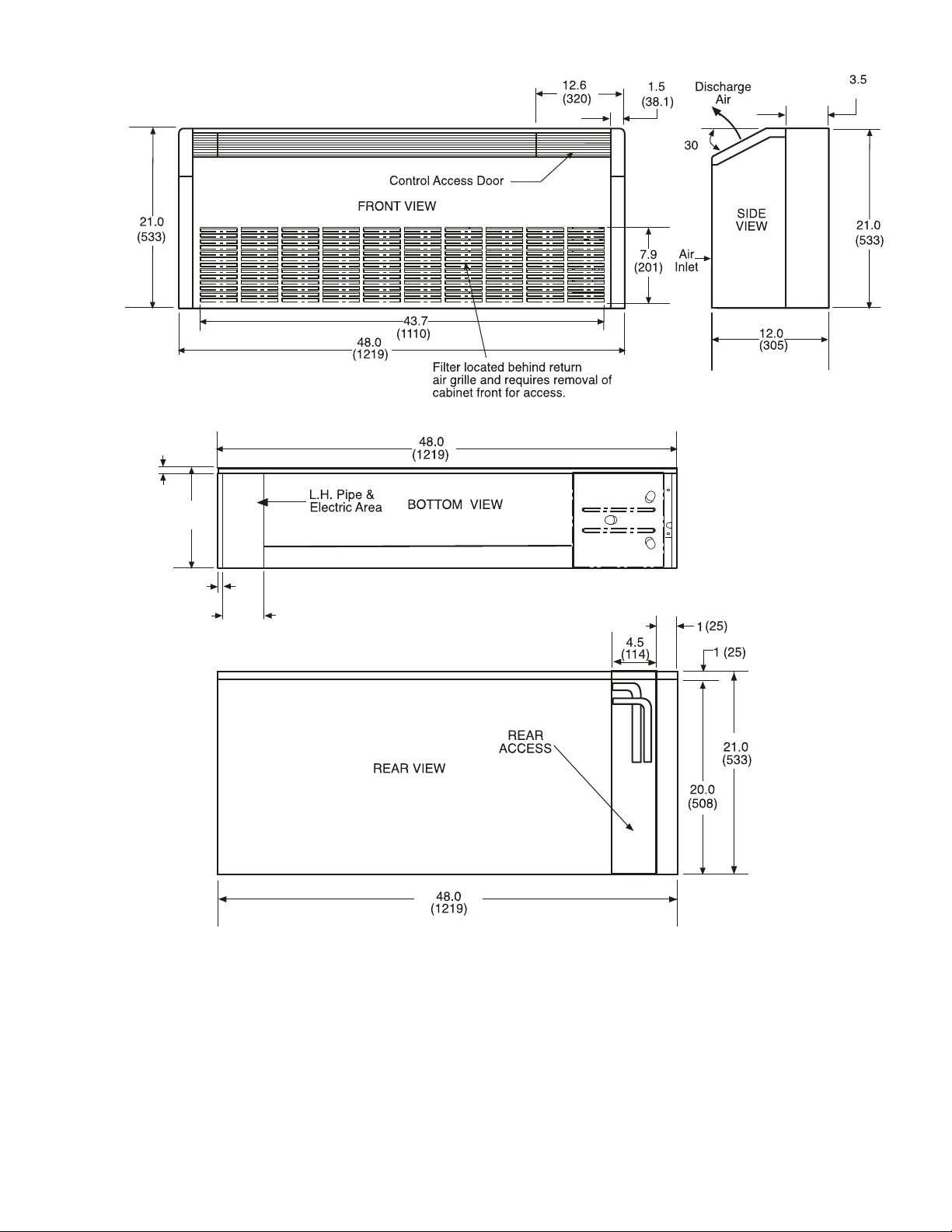

a50-8343

Fig. 7 — 50PEC09-15 Front Return Cabinet Dimensions — Right Hand Piping

NOTES:

1. Dimensions are shown in inches. Dimensions in parentheses are in millimeters.

2. Access is reduced if optional disconnect box is selected.

3. Optional autoflow valve, motorized water valve and disconnect box are shown.

21.0

(533)

CONTROL ACCESS DOOR

FRONT VIEW

16.0

(406)

5.0

(127)

7.9

(201)

DISCHARGE

30

˚

AIR

INLET

AIR

SIDE

VIEW

3.5

(89)

21.0

(533)

12.0

(305)

(25)

1.0

1.0 (25)

R.H.

REAR

ACCESS

(NOTE 2)

4.5

(114)

BOTTOM VIEW

20.0

(508)

(1110)

48.0

(1219)

48.0

(1219)

REAR VIEW

43.7

Filter located behind return

air grille and requires removal of

cabinet front for access.

4.12

(105)

11.50

(292)

R.H. PIPE AND

ELECTRIC AREA

.75 (19)

21.0

(533)

.50 (13)

12.0

(305)

48.0

(1219)

9

Page 10

a50-8344

Fig. 8 — 50PEC18 Front Return Cabinet Dimensions — Right Hand Piping

NOTES:

1. Dimensions are shown in inches. Dimensions in parentheses are in millimeters.

2. Access is reduced if optional disconnect box is selected.

3. Optional autoflow valve, motorized water valve and disconnect box are shown.

54.00

30˚

3.50

(89)

21.00

(533)

21.00

(533)

REAR VIEW

DISCHARGE

AIR

RH REAR

ACCESS

(NOTE 2)

1.00

(25)

1.00(25)

4.12

(105)

20.00

(508)

12.00

(305)

5.00

(127)

16.00

(406)

FRONT VIEW

CONTROL ACCESS DOOR

54.00

(1372)

48.00

(1219)

7.90

(201)

21.00

(533)

R.H. PIPE AND

ELECTRIC AREA

(NOTE 2)

(1372)

12.00

(305)

BOTTOM VIEW

54.00

(1372)

SIDE

VIEW

AIR

INLET

Filter located behind return

air grille and requires removal of

cabinet front for access.

.75 (19)

4.12

(105)

11.50

(292)

.50 (13)

10

Page 11

°

(89)

L.H.

(NOTE 2)

.50 (13)

11.50

(292)

.75

(19)

4.12

(105)

(Note 2)

a50-8345

Fig. 9 — 50PEC09-15 Front Return Cabinet Dimensions — Left Hand Piping

NOTES:

1. Dimensions are shown in inches. Dimensions in parentheses are in millimeters.

2. Access is reduced if optional disconnect box is selected.

3. Optional autoflow valve, motorized water valve and disconnect box are shown.

11

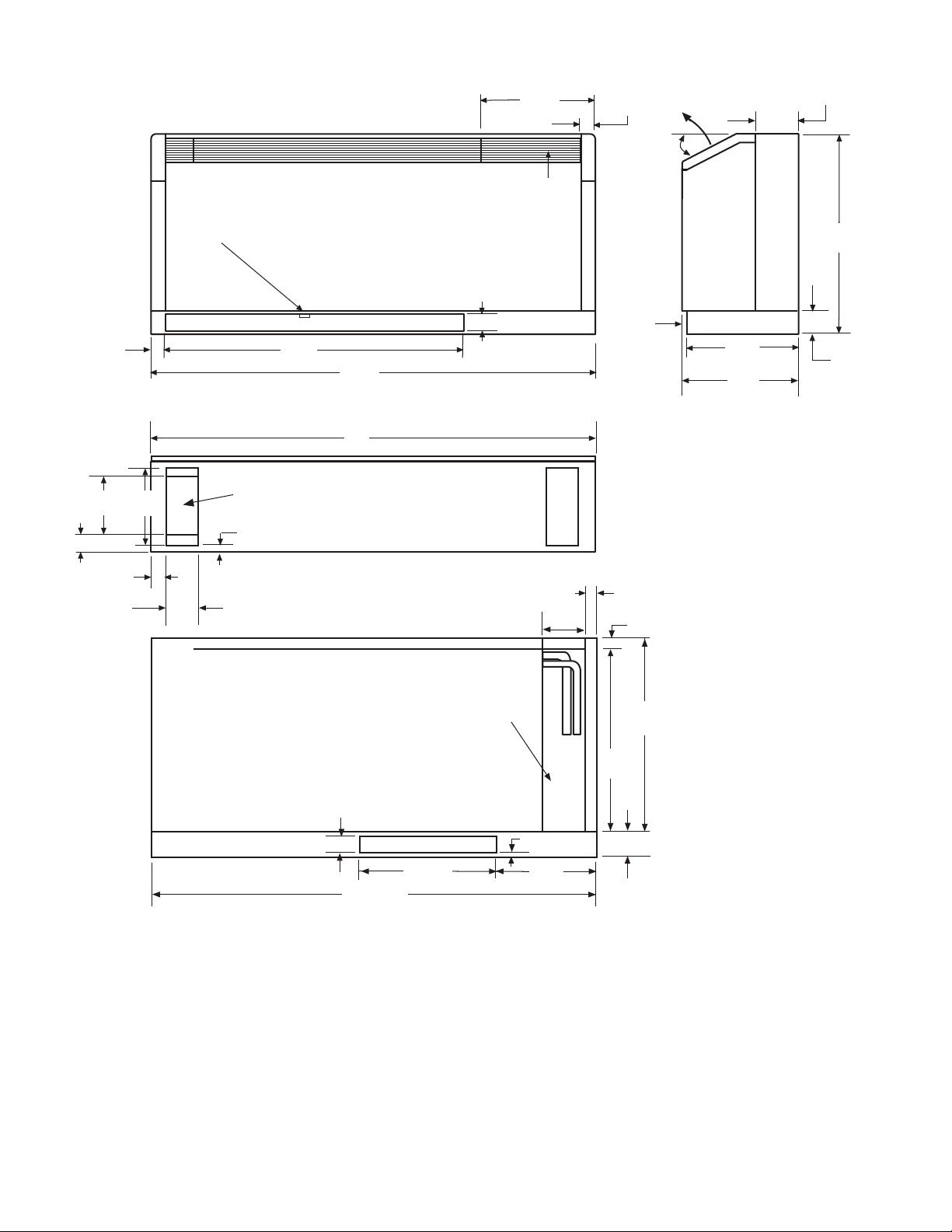

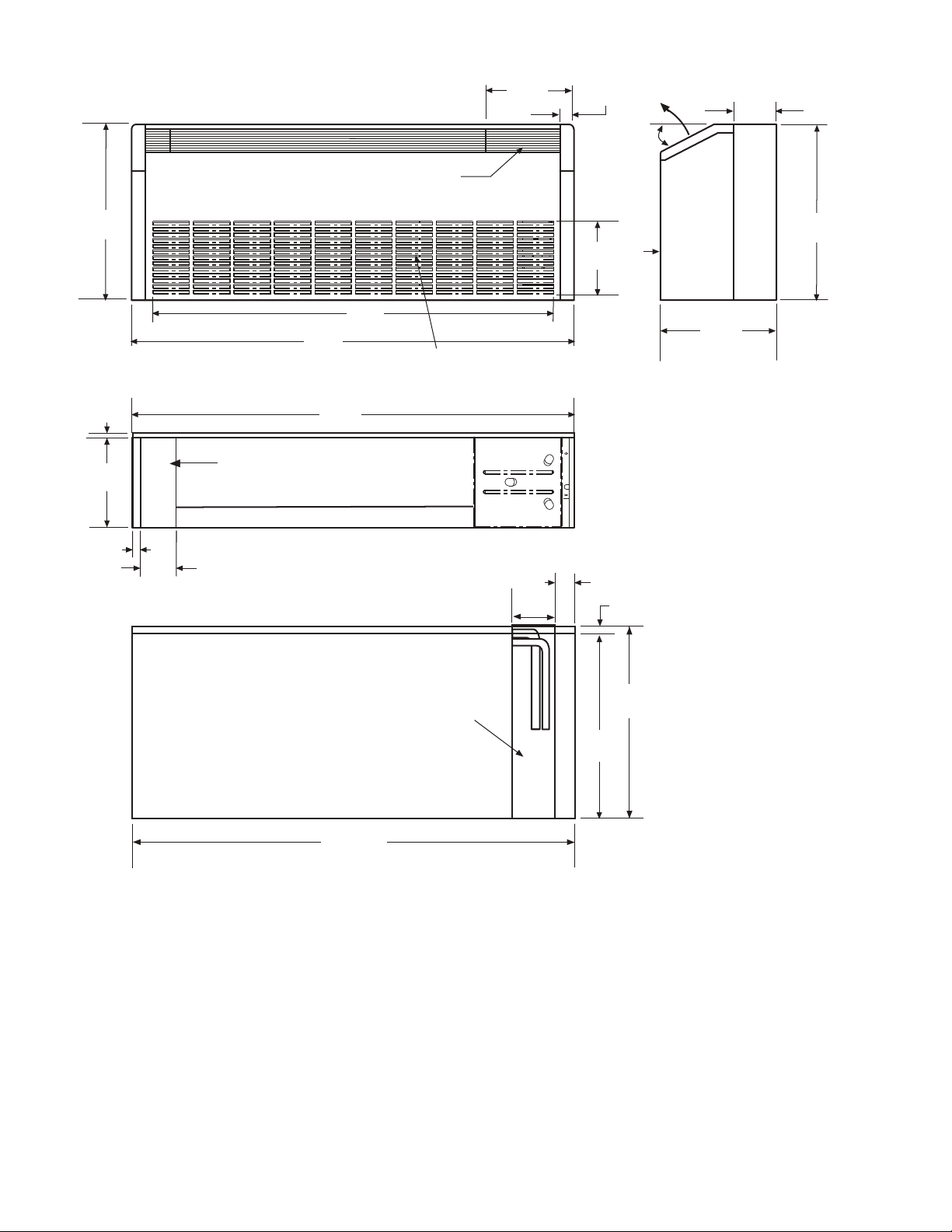

Page 12

a50-8346

Fig. 10 — 50PEC18 Front Return Cabinet Dimensions — Left Hand Piping

NOTES:

1. Dimensions are shown in inches. Dimensions in parentheses are in millimeters.

2. Access is reduced if optional disconnect box is selected.

3. Optional autoflow valve, motorized water valve and disconnect box are shown.

21.00

(533)

CONTROL ACCESS DOOR

FRONT VIEW

12.60

(320)

1.50

(38.1)

7.90

(201)

DISCHARGE

AIR

30˚

AIR

INLET

SIDE

VIEW

3.50

(89)

21.00

(533)

.50

(13)

11.50

(292)

.75

(19)

4.12

(105)

L.H. PIPE AND

ELECTRIC

(Note 2)

AREA

REAR VIEW

54.00

(1372)

54.00

(1372)

48.00

(1219)

Filter located behind return

air grille and requires removal of

cabinet front for access.

BOTTOM VIEW

REAR

ACCESS

(Note 2)

4.50

(114)

1.00 (25)

1.00 (25)

20.00

(508)

21.00

(533)

12.00

(305)

54.00

(1372)

12

Page 13

Power Supply

Blower Deck

Blower Access Panel

Compressor

Access

Panel

Control Box

40.98

(1041)

4.46

(113)

0.75

(19)

0.75

(19)

*

20.50

(521)

11.54

(293)

*16.66

(423)

30°

0.87

(22)

Hard Wire

Power Supply

Blower Deck

Blower Access Panel

Compressor

Access

Panel

Control Box

7.50

(191)

0.87

(22)

11.54

(293)

3.42

(87)

*16.66

(423)

30

°

3.01

(76)

5.36

(136)

0.75

(19)

0.75

(19)

4.46

(113)

*

20.50

(521)

40.98

(1040)

3.01

(76)

5.36

(136)

Optional

Motorized

Water Valve

Optional

Autoflow

Valve

Optional

Fused Disconnect Box

(mounted to cabinet

not chassis)

Optional

Motorized

Water Valve

Optional

Autoflow

Valve

*

3.56

(90)

7.50

(191)

3.42

(87)

*

3.56

(90)

Optional Fused

Disconnect Box

(mounted to cabinet

not chassis)

Power supply enters

Bottom of Box

Optional Disconnect

Only Box (All Configurations)

Power supply enters

Bottom of Box

4.46

(113)

4.56

(116)

Power supply enters

Bottom of Box

Left Hand Configuration

Right Hand Configuration

a50-8347

*If optional subbase is selected or if unit is installed raised above the floor, add 125 mm to dimension.

NOTES:

1. Dimensions shown are in inches. Dimensions in parentheses are in millimeters.

2. Optional autoflow valve, motorized water valve and disconnect box are shown.

Fig. 11 — 50PEC09-15 Chassis Dimensions — Bottom Return

13

Page 14

NOTES:

1. Dimensions shown are in inches. Dimensions in parentheses are in millimeters.

2. Optional autoflow valve, motorized water valve and disconnect box are shown.

3. Chassis can mount directly on floor.

Fig. 12 — 50PEC09-15 Chassis Dimensions — Front Return

not chassis)

Right Hand Configuration

a50-8348

Left Hand Configuration

Optional Fused

Disconnect Box

(mounted to cabinet

Optional

Autoflow

Valve

Power supply enters

Bottom of Box

Optional

Motorized

Water Valve

Power supply enters

Optional Disconnect

Only Box (All Configurations)

Bottom of Box

4.56

(116)

4.46

(113)

40.98

(1041)

Control Box

20.50

(521)

(19)

0.75

Panel

Access

Compressor

7.38

(187)

(762)

30.00

Blower Screen

(76)

3.01

5.36

(136)

°

30

Hard Wire

Power Supply

0.87

(22)

Control Box

16.66

(423)

(191)

Panel

7.38

(187)

3.56

(90)

4.46

7.50

(191)

Filter

3.56

(90)

4.46

(19)

0.75

(113)

(293)

11.54

Blower Deck

(87)

3.42

(293)

11.54

(423)

16.66

(19)

0.75

(113)

5.36

Power Supply

(136)

3.01

(76)

30°

0.87

(22)

3.42

(87)

7.50

Access

Compressor

40.98

(1040)

Blower Deck

(521)

20.50

Filter

Blower Screen

0.75

(19)

30.00

(762)

14

Valve

Optional

Autoflow

Optional

Motorized

Water Valve

Optional

not chassis)

(mounted to cabinet

Fused Disconnect Box

Bottom of Box

Power supply enters

Page 15

Fig. 13 — 50PEC18 Chassis Dimensions — Bottom Return

*If optional subbase is selected, add 125 mm to dimension.

NOTES:

1. Dimensions shown are in inches. Dimensions in parentheses are in millimeters.

2. Optional autoflow valve, motorized water valve and disconnect box are shown.

Blower Deck

Blower Access Panel

Compressor

Access

Panel

Control Box

46.98

(1193)

4.49

(114)

0.75

(19)

0.75

(19)

*

20.50

(521)

Hard Wire

Power Supply

Blower Deck

Blower Access Panel

Compressor

Access

Panel

Control Box

0.75

(19)

0.75

(19)

4.46

(113)

20.50

(521)

46.98

(1193)

Condensate

5/8" ID V

(15.8mm)

inyl Hose

Optional

Motorized

Water Valve

Optional

Autoflow

Valve

Optional

Disconnect Box

(mounted to cabinet

not chassis)

Optional

Motorized

Water Valve

Optional

Autoflow

Valve

7.5

(191)

0.87

(22)

11.54

(293)

3.43

(87)

*16.66

(423)

30˚

3.01

(76)

(136)

*

3.56

(90)

11.54

(293)

*16.66

(423)

30˚

0.87

(22)

3.01

(76)

5.36

(136)

Condensate

5/8" ID Vinyl Hose

7.50

(191)

3.42

(87)

*

3.56

(90)

Optional

Motorized

Water Valve

Optional

Autoflow

Valve

Optional Disconnect

Only Box (All Configurations)

Power supply enters

Bottom of Box

4.46

(113)

4.56

(116)

Optional Fused

Disconnect Box

(mounted to cabinet

not chassis)

Power supply enters

Bottom of Box

Power supply enters

Bottom of Box

Hard Wire

Power Supply

Right Hand Configuration

Left Hand Configuration

a50-8349

15

Page 16

Fig. 14 — 50PEC18 Chassis Dimensions — Front Return

NOTES:

1. Dimensions shown are in inches. Dimensions in parentheses are in millimeters.

2. Optional autoflow valve, motorized water valve and disconnect box are shown.

3. Chassis can mount directly on floor.

Blower Deck

Compressor

Access

Panel

Control Box

46.98

(1193)

4.49

(114)

0.75

(19)

0.75

(19)

20.50

(521)

Hard Wire

Power Supply

Blower Deck

Filter

Compressor

Access

Panel

Control Box

0.75

(19)

0.75

(19)

4.46

(113)

(521)

46.98

(1193)

Optional

Motorized

Water Valve

Optional

Autoflow

Valve

Optional

Disconnect Box

(mounted to cabinet

not chassis)

Optional

Motorized

Water Valve

Optional

Autoflow

Valve

7.5

(191)

0.87

(22)

11.54

(293)

3.43

(87)

16.66

(423)

30˚

3.01

(76)

3.56

(90)

11.54

(293)

16.66

(423)

30˚

0.87

(22)

3.01

(76)

5.36

(136)

7.50

(191)

3.42

(87)

3.56

(90)

Optional

Motorized

Water Valve

Optional

Autoflow

Valve

Optional Disconnect

Only Box (All Configurations)

Power supply enters

Bottom of Box

4.46

(113)

4.56

(116)

Optional Fused

Disconnect Box

(mounted to cabinet

not chassis)

Power supply enters

Bottom of Box

Power supply enters

Bottom of Box

Hard Wire

Power Supply

Blower Screen

Blower Screen

Filter

36.00

(914)

7.38

(187)

5.36

(187)

7.38

(187)

36.00

(914)

Right Hand Configuration

Left Hand Configuration

a50-8350

16

Page 17

SHIPPING

BOLTS

Fig. 15 — Remove 4 Shipping Bolts on

Compressor Isolator Plate

FIELD SUPPLIED

DISCONNECT SWITCH

ROOM THERMOSTAT

HEAT PUMP

A

B

A = Two power wires.

B = 1 heat/1 cool/manual or auto changeover remote 24-V thermostat.

NOTE: All customer-supplied wiring to be copper only and must conform to

national and local electrical codes. Wiring shown with dashed lines must be

field-supplied and field-installed. “B” wiring only required with systems using

remote-mounted thermostats.

Fig. 16 — Typical Field-Installed Wiring

WAR NING

Disconnect electrical power source to prevent injury or death from electrical shock.

CAUTION

Use copper conductors only to prevent equipment damage.

CAUTION

All refrigerant discharged from this unit must be recovered

without exception. Technicians must follow industry

accepted guidelines and all local, regional, and national

statutes for the recovery and disposal of refrigerants.

4. Select the proper fasteners to connect the backplate securely to the wall.

5. Fasten the backplate onto the wall through the screw holes

located in the back flange. Secure the subbase in place.

Step 4 — Wire Electrical Connections

WARNING

CAUTION

When a compressor is removed from this unit, system

refrigerant circuit oil will remain in the compressor. To

avoid leakage of compressor oil, the refrigerant lines of the

compressor must be sealed after it is removed.

Step 2 — Check Unit — Upon receipt of shipment at

the jobsite, carefully check the shipment against the bill of lading. Make sure all units have been received. Inspect the carton

or crating of each unit, and inspect each unit for damage. Ensure the shipping company makes proper notation of any shortages or damage on all copies of the freight bill. Concealed

damage not discovered during unloading must be reported to

the shipping company within 15 days of receipt of shipment.

NOTE: It is the responsibility of the purchaser to file all necessary claims with the shipping company.

STORAGE

CAUTION

DO NOT store or install console units in corrosive environments or in locations subject to temperature or humidity

extremes (e.g., attics, garages, rooftops, etc.). Corrosive

conditions and high temperature or humidity can significantly reduce performance, reliability, and service life.

Always move units in an upright position. Tilting units on

their sides may cause equipment damage.

To avoid possible injury or death due to electrical shock,

open the power supply disconnect switch and secure it in

an open position during installation.

CAUTION

Use only copper conductors for field-installed electrical

wiring. Unit terminals are not designed to accept other

types of conductors.

All field-installed wiring, including the electrical ground,

MUST comply with National Electrical Code (NEC, U.S.A.)

as well as all applicable local codes. In addition, all field wiring

must conform to the Class II temperature limitations described

in the NEC.

Consult the unit wiring diagram located on the inside of the

compressor access panel to ensure proper electrical hookup. The

installing (or electrical) contractor must make the field connections shown in Fig. 16 when using field-supplied disconnect.

Refer to unit wiring diagrams Fig. 17-24 for a schematic of

the field connections, which must be made by the installing (or

electrical) contractor. Operating voltage must be within voltage

range shown in Table 2.

Upon the arrival of equipment at the jobsite, immediately

store units in their shipping cartons in a clean, dry area. Store

units in an upright position at all times. Stack units a maximum of 3 units high. Use pallets to separate each layer of

units. DO NOT remove equipment from shipping cartons

until equipment is required for installation.

UNIT PROTECTION — Cover console units on the jobsite

with either shipping cartons, vinyl film, or an equivalent

protective covering. Cap the open ends of pipes stored on the

jobsite. In areas where painting, plastering, or the spraying of

fireproof material has not been completed, all due precautions

must be taken to avoid physical damage to the units and contamination by foreign material. Physical damage and contamination may prevent proper start-up and may result in costly

equipment clean-up.

Examine all pipes, fittings, and valves before installing any

of the system components. Remove any dirt found on these

components.

Step 3 — Mount Unit

1. Unpack the unit from the shipping carton. Remove the

2. Remove compressor isolation plate shipping bolts (4), as

3. Using a carpenter’s square and a level, ensure the unit

front cabinet by lifting up and away from the backplate.

Protect the cabinet from damage during installation by returning it to its original vinyl pack until required.

shown in Fig. 15.

is level. Shim the unit if necessary to assure proper

installation.

Poor or inadequate installation may result in noisy

unit operation or unattractive appearance.

17

Page 18

Fig. 17 — 50PEC Unit Manual or Auto Changeover with Complete C Controller Wiring

Complete C

10

Complete C

LEGEND

NOTES:

1. Compressor and blower motor thermally protected internally.

2. All wiring to the unit must comply with local

codes.

3. Transformer is wired to 240-V (ORG) lead for

240-1-50 units. For 220-1-50 operation, switch

the RED and ORG leads at L1 and insulate the

RED lead. Transformer is energy limiting or

may have a circuit breaker.

4. FP1 thermistor provides freeze protection for

water. When using anti-freeze solutions, cut

JW3 jumper.

5. For remote sensor, position jumper J1 on upper

2 pins.

6. For metric display, position jumper on 1 pin.

7. Transformer secondary ground via GRN/YEL

wire from C to control box.

8. Mate-N-Lok† plug is optional.

9. See view A for wiring of units with water valve

(part no. 23B00112N01) or view B for units with

water valve (part no. 23B00112N03).

10. Factory cut jumper (JW1). Dry contact will be

available between AL1 and AL2.

AL — Alarm Relay Contacts

BM — Blower Motor

BR — Blower Relay

CAP — Capacitor

CB — Circuit Breaker

CO — Sensor, Condensate Overflow

CR — Compressor Relay

DM — Damper Motor

ES — End Switch

FP1 — Sensor, Water Coil Freeze Protection

FP2 — Sensor, Air Coil Freeze Protection

HPS — High Pressure Switch

HPWS — High Presure Water Switch

JW1 — Jumper Wire for Alarm

LOC — Loss of Charge Pressure Switch

PDB — Power Distribution Block

RAS — Return Air Sensor

RVS — Reversing Valve Solenoid

TRANS

—

Transformer

WV

—

Water Valve

---------- Field Line Voltage Wiring

Field Low-Voltage Wiring

Printed Circuit Trace

Option Low Voltage Wiring

*Optional wiring.

†Registered trademark of AMP Incorporated.

Relay/Contactor Coil

Solenoid Coil

Thermistor

Circuit Breaker

Relay Contacts-N.O.

Switch-Temperature

Switch-High Pressure

Switch-Low Pressure

Ground

Wire Nut

Mate-N-Lok

>

>

18

Page 19

Fig. 18 — 50PEC Unit with Complete C and LON Controllers

Complete C

Complete C

LEGEND

*Optional wiring.

NOTES:

1. Compressor and blower motor thermally protected internally.

2. All wiring to the unit must comply with local

codes.

3. Transformer is wired to 240-V (ORG) lead for

240-1-50 units. For 220-1-50 operation, switch

the RED and ORG leads at L1 and insulate the

RED lead. Transformer is energy limiting or may

have a circuit breaker.

4. FP1 thermistor provides freeze protection for

water. When using anti-freeze solutions, cut JW3

jumper.

5. Low voltage wiring must be class 1 and voltage

rated equal or greater than unit supply voltage.

6. Factory cut jumper (JW1). Dry contact will be

available between AL1 and AL2.

7. Transformer secondary ground via GRN/YEL

wire from C to control box.

8. See view A for wiring of units with water valve

(part no. 23B00112N01) or view B for units with

water valve (part no. 23B00112N03).

AL — Alarm Relay Contacts

BM — Blower Motor

BR — Blower Relay

CAP — Capacitor

CB — Circuit Breaker

CO — Sensor, Condensate Overflow

CR — Compressor Relay

DM — Damper Motor

ES — End Switch

FP1 — Sensor, Water Coil Freeze Protection

FP2 — Sensor, Air Coil Freeze Protection

FSS — Fan Speed Switch

HP — High-Pressure Switch

HPS — High-Pressure Switch

HPWS — High-Pressure Water Switch

JW1 — Jumper Wire for Alarm

LOC — Loss of Charge Pressure Switch

LON — Local Operating Network

PB — Power Terminal Block

RVS — Reversing Valve Solenoid

TRANS — Tr a n sf o r me r

WV — Wate r Valve

---------- Field Line Voltage Wiring

Field Low-Voltage Wiring

Option Low-Voltage Wiring

Printed Circuit Trace

Relay/Contactor Coil

Solenoid Coil

Thermistor

Circuit Breaker

Relay Contacts-N.O.

Switch-Temperature

Switch-High Pressure

Switch-Low Pressure

Ground

Wire Nut

Mate-N-Lock

>

>

19

Page 20

Fig. 19 — 50PEC Unit with Deluxe D and LON Controllers

Deluxe D

AL — Alarm Relay Contacts

BM — Blower Motor

CAP — Capacitor

CB — Circuit Breaker

CO — Sensor, Condensate Overflow

CR — Compressor Relay

DM — Damper Motor

ES — End Switch

FP1 — Sensor, Water Coil Freeze Protection

FP2 — Sensor, Air Coil Freeze Protection

FSS — Fan Speed Switch

HP — High-Pressure Switch

HPS — High-Pressure Switch

HPWS — High-Pressure Water Switch

JW4 — Jumper Wire for Alarm

LOC — Loss of Charge Pressure Switch

LON — Local Operating Network

PB — Power Terminal Block

RVS — Reversing Valve Solenoid

TRANS — Transformer

WV — Water Valve

---------- Field Line Voltage Wiring

Field Low-Voltage Wiring

Printed Circuit Trace

LEGEND

Relay/Contactor Coil

Solenoid Coil

Thermistor

Circuit Breaker

Relay Contacts-N.O.

Switch-Temperature

Switch-High Pressure

Switch-Low Pressure

Ground

Wire Nut

Mate-N-Lock

>

>

*Optional wiring.

NOTES:

1. Compressor and blower motor thermally protected internally.

2. All wiring to the unit must comply with local

codes.

3. Transformer is wired to 240-V (ORG) lead for

240-1-50 units. For 220-1-50 operation, switch

the RED and ORG leads at L1 and insulate the

RED lead. Transformer is energy limiting or may

have a circuit breaker.

4. FP1 thermistor provides freeze protection for

WATER. When using anti-freeze solutions, cut

JW3 jumper.

5. Low voltage wiring must be class 1 and voltage

rated equal or greater than unit supply voltage.

6. Factory cut jumper (JW4). Dry contact will be

available between AL1 and AL2.

7. Transformer secondary ground via GRN/YEL

wire from C to control box.

8. See view A for wiring of units with water valve

(part no. 23B00112N01) or view B for units with

water valve (part no. 23B00112N03).

Deluxe D

20

Page 21

Fig. 20 — 50PEC Unit Manual or Auto Changeover and Deluxe D Controller

Deluxe D

9

Deluxe D

AL — Alarm Relay Contacts

BM — Blower Motor

BR — Blower Relay

CAP — Capacitor

CB — Circuit Breaker

CO — Sensor, Condensate Overflow

CR — Compressor Relay

DM — Damper Motor

ES — End Switch

FP1 — Sensor, Water Coil Freeze Protection

FP2 — Sensor, Air Coil Freeze Protection

HPS — High-Pressure Switch

HPWS — High-Pressure Water Switch

JW4 — Jumper Wire for Alarm

LOC — Loss of Charge Pressure Switch

NLL — Night Low Limit Switch

PB — Power Terminal Block

RAS — Return Air Sensor

RVS — Reversing Valve Solenoid

TRANS — Transformer

WV — Water Valve

---------- Field Line Voltage Wiring

Field Low-Voltage Wiring

Printed Circuit Trace

LEGEND

*Optional wiring.

Relay/Contactor Coil

Solenoid Coil

Thermistor

Circuit Breaker

Relay Contacts-N.O.

Switch-Temperature

Switch-High Pressure

Switch-Low Pressure

Ground

Wire Nut

Mate-N-Lock

>

>

NOTES:

1. Compressor and blower motor thermally protected internally.

2. All wiring to the unit must comply with local

codes.

3. Transformer is wired to 240-V (ORG) lead for

240-1-50 units. For 220-1-50 operation, switch

the RED and ORG leads at L1 and insulate the

RED lead. Transformer is energy limiting or may

have a circuit breaker.

4. FP1 thermistor provides freeze protection for

WATER. When using anti-freeze solutions, cut

JW3 jumper.

5. For remote sensor, position jumper J1 on upper

2 pins.

6. For metric display, position jumper on 1 pin.

7. Transformer secondary ground via GRN/YEL

wire from C to control box.

8. See view A for wiring of units with water valve

(part no. 23B00112N01) or view B for units with

water valve (part no. 23B00112N03).

9. Factory cut jumper (JW4). Dry contact will be

available between AL1 and AL2.

21

Page 22

Fig. 21 — 50PEC Unit Remote-Mounted Thermostat with Complete C Controller Wiring

Complete C

Complete C

AL — Alarm Relay Contacts

BM — Blower Motor

BR — Blower Relay

CAP — Capacitor

CB — Circuit Breaker

CO — Sensor, Condensate Overflow

CR — Compressor Relay

DM — Damper Motor

ES — End Switch

FP1 — Sensor, Water Coil Freeze Protection

FP2 — Sensor, Air Coil Freeze Protection

FSS — Fan Speed Switch

HPS — High-Pressure Switch

HPWS — High-Pressure Water Switch

JW1 — Jumper Wire for Alarm

LOC — Loss of Charge Pressure Switch

PDB — Power Distribution Block

RVS — Reversing Valve Solenoid

TRANS — Transformer

WV — Wate r Valve

---------- Field Line Voltage Wiring

Field Low-Voltage Wiring

LEGEND

Printed Circuit Trace

Option Low Voltage

Wiring

Relay/Contactor Coil

Solenoid Coil

Thermistor

Circuit Breaker

Relay Contacts-N.O.

Switch-High Pressure

Switch-Low Pressure

Ground

Wire Nut

Mate-N-Lock

>

>

*Optional wiring.

NOTES:

1. Compressor and blower motor thermally protected internally.

2. All wiring to the unit must comply with local

codes.

3. Transformer is wired to 240-V (ORG) lead for

240-1-50 units. For 220-1-50 operation, switch

the RED and ORG leads at L1 and insulate the

RED lead. Transformer is energy limiting or may

have a circuit breaker.

4. FP1 thermistor provides freeze protection for

water. When using anti-freeze solutions, cut

JW3 jumper.

5. Low voltage wiring must be class 1 and voltage

rated equal or greater than unit supply voltage.

6. Factory cut jumper (JW1). Dry contact will be

available between AL1 and AL2.

7. Transformer secondary ground via GRN/YEL

wire from C to control box.

8. See view A for wiring of units with water valve

(part no. 23B00112N01) or view B for units with

water valve (part no. 23B00112N03).

22

Page 23

Fig. 22 — 50PEC Unit Remote-Mounted Thermostat with Deluxe D Controller Wiring

Deluxe D

Deluxe D

AL — Alarm Relay Contacts

BR — Blower Relay

CAP — Capacitor

CB — Circuit Breaker

CO — Sensor, Condensate Overflow

CR — Compressor Relay

DM — Damper Motor

FP1 — Sensor, Water Coil Freeze Protection

FP2 — Sensor, Air Coil Freeze Protection

FSS — Fan Speed Switch

HP — High-Pressure Switch

JW4 — Jumper Wire for Alarm

LOC — Loss of Charge Pressure Switch

NLL — Night Low Limit

PB — Powe r Terminal Block

RVS — Reversing Valve Solenoid

TRANS — Transformer

WV — Water Valve

---------- Field Line Voltage Wiring

Field Low-Voltage Wiring

Printed Circuit Trace

Option Low Voltage Wiring

Relay/Contactor Coil

Solenoid Coil

Thermistor

Circuit Breaker

Relay Contacts-N.O.

Switch-High Pressure

Switch-Low Pressure

Ground

Wire Nut

Mate-N-Lock

>

>

*Optional wiring.

NOTES:

1. Compressor and blower motor thermally protected

internally.

2. All wiring to the unit must comply with local codes.

3. Transformer is wired to 240-V (ORG) lead for 2401-50 units. For 220-1-50 operation, switch the RED

and ORG leads at L1 and insulate the RED lead.

Transformer is energy limiting or may have a circuit

breaker.

4. FP1 thermistor provides freeze protection for

water. When using anti-freeze solutions, cut JW3

jumper.

5. Low voltage wiring must be class 1 and voltage

rated equal or greater than unit supply voltage.

6. Factory cut jumper (JW4). Dry contact will be available between AL1 and AL2.

7. Transformer secondary ground via GRN/YEL wire

from C to control box.

8. See view A for wiring of units with water valve (part

no. 23B00112N01) or view B for units with water

valve (part no. 23B00112N03).

LEGEND

23

Page 24

Y

W

O

G

R

C

AL1

AL2

A

CR

CMP1

FAN

PWR

HS1/EXH/RVS

PREMIER

LINK

CR

COMPLETE

C

CONTROL

J4

J6

J5

J8

J1

PWR

S

P

S

A

L

W

CMPSAFE

T

T

T

Y1

G

R

C

AL1

CMP1

FAN

PWR

PREMIER

LINK

DELUXE

D

CONTROL

J4

J8

J1

PWR

CMPSAFE

HS2

HS1

CMP2

Y2

W1

O/W2

J6

J5

S

P

T

S

A

T

L

W

T

LEGEND

NOTE: Reversing valve is on in Cooling mode.

CR — Control Relay

LWT — Leaving Water Temperature Sensor

SAT — Supply Air Temperature Sensor

SPT — Space Temperature Sensor

LEGEND

NOTE: Reversing valve is on in Cooling mode.

LWT — Leaving Water Temperature Sensor

SAT — Supply Air Temperature Sensor

SPT — Space Temperature Sensor

Fig. 23 — PremierLink™ Controller Applications with Complete C Control

Fig. 24 — PremierLink Controller Applications with Deluxe D Control

24

Page 25

Table 2 — Electrical Data — 50PEC Units

AQUAZONE CONTROL (Complete C Control Shown)

Fig. 25 — Typical Aquazone Control Board

Jumper Locations

a50-7467tf

Typical

Water

Valve

C

A

24 VAC

Terminal Strip

Fig. 26 — Typical Aquazone Accessory Wiring

Fig. 27 — AMV Valve Wiring

a50-8441

50PEC

UNIT SIZE

09 7 220/240-1-50 198-264 1 3.2 17 0.4 3.6 4.4 15.0

12 7 220/240-1-50 198-264 1 4.0 19 0.4 4.4 5.4 15.0

15 7 220/240-1-50 198-264 1 4.7 23 0.6 5.3 6.5 15.0

18 7 220/240-1-50 198-264 1 5.6 25 0.6 6.2 7.6 15.0

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

LRA — Locked Rotor Amps

RLA — Rated Load Amps

VO LTAGE

CODE

LEGEND

V-P h-Hz

MIN/MAX

VO LTAGE

COMPRESSOR

QTY RLA LRA

FAN MOTOR

FLA

TOTAL UN IT

FLA

MIN CIRCUIT

AMPS

Make all final electrical connections with a length of flexible conduit to minimize vibration and sound transmission to

the building.

SUPPLY VOLTAGE — Operating voltage to unit must be

within voltage range indicated on unit nameplate.

EXTERNAL LOOP POWER CONNECTION — If the unit

will be connected to an external loop pump or flow controller,

connect the pump to the loop pump terminal block PB1. The

maximum power handling is 4 amps at 240-v. The pumps will

automatically cycle as required by the unit.

220-V OPERATION — All 220/240-v units are factorywired for 240-v. The transformer wiring may be switched for

220-v operation (as illustrated on the wiring diagrams) by

switching the RED and ORG leads at L1.

Step 5 — Wire Low Voltage Connections

WATER FREEZE PROTECTION — The Aquazone™ control allows the field selection of source fluid freeze protection

points through jumpers. The factory setting of jumper JW3

(FP1) is set for water at –1.1 C. In earth loop applications,

jumper JW3 should be clipped to change the setting to 12.2 C

when using antifreeze in colder earth loop applications. See

Fig. 25.

WATER SOLENOID VALVES — An external solenoid

valve(s) should be used on ground water installations to shut

off flow to the unit when the compressor is not operating. A

slow closing valve may be required to help reduce water

hammer. Figure 26 shows typical wiring for a 24-vac external

solenoid valve. Figures 27 and 28 illustrate typical slow closing

water control valve wiring for Taco 500 Series and Taco ESP

Series valves. Slow closing valves take approximately 60 sec.

to open (very little water will flow before 45 sec.). Once fully

open, an end switch allows the compressor to be energized (only on valves with end switches). Only relay or triac based electronic thermostats should be used with slow closing valves.

When wired as shown, the slow closing valve will operate

properly with the following notations:

1. The valve will remain open during a unit lockout.

2. The valve will draw approximately 25 to 35 VA through

the “Y” signal of the thermostat.

IMPORTANT: Connecting a water solenoid valve can

overheat the anticipators of electromechanical thermostats. Only use relay based electronic thermostats.

MAX FUSE/

HACR

ACCESSORY CONNECTIONS — Terminal labeled A on

the control is provided to control accessory devices such as

water valves, electronic air cleaners, humidifiers, etc. This

signal operates with the compressor terminal. See Fig. 26.

Refer to the specific unit wiring schematic for details.

NOTE: The A terminal should only be used with 24-v signals

— not line voltage signals.

25

C

1

2

HEATER SWITCH

1Y

C

THERMOSTAT

1Y

AMV

3

TACO VALVE

Page 26

Fig. 28 — Taco SBV Valve Wiring

a50-8442

OPTIONAL WALL-MOUNTED THERMOSTAT —

The 50PEC water source heat pump units are built with standard internal thermostats in either manual changeover (MCO)

or automatic changeover (ACO) configuration. Refer to

Fig. 17-20.

When desired, the unit can be furnished with a 24-v control

circuit which is field wired to a Carrier-supplied accessory remote thermostat. Most heat pump thermostats can be used with

the controller. Use a thermostat with Y, G, O and W outputs.

Refer to unit wiring diagrams in Fig. 21 and 22 and Aquazone™ Controls, Operation, and Troubleshooting Instructions

for additional information.

Vendor installation instructions and additional installation

information is shipped with each thermostat.

NOTE: Low-voltage wiring between the unit and the wall thermostat must comply with all applicable electrical codes

(i.e., NEC and local codes), and be completed before the unit is

installed.

Table 3 lists recommended wire sizes and lengths to install

the thermostat. The total resistance of low-voltage wiring must

not exceed 1 ohm. Any resistance in excess of 1 ohm may

cause the control to malfunction because of high voltage drop.

4. Use pipe joint compound sparingly on the fitting adapters’ male pipe threads.

5. Prevent sealant from reaching the joint’s flared surfaces.

6. Do not use pipe joint compound when Teflon* thread

tape is pre-applied to hose assemblies or when flared-end

connections are used.

7. Maximum torque that may be applied to brass fittings is

40 Nm. When a torque wrench is not used, tighten brass

fittings finger-tight plus one quarter turn.

8. Tighten steel fittings as necessary.

9. Use shut-off/balancing valves, flow indicators, and drain

tees in the supply runout and return at each floor to aid in

loop balancing and servicing.

SUPPLY AND RETURN PIPING — System piping MUST

comply with all applicable codes.

1. Install a drain valve at the base of each supply and return

riser to enable system flushing at start-up and during routine servicing.

2. Install shut-off/balancing valves and unions at each unit

to allow unit removal for servicing.

NOTE: If flex hoses are used, unions are not necessary.

3. Install strainers at the inlet of each system circulating

pump.

IMPORTANT: Since loop temperatures are normally

between 15.6 C and 32.2 C, pipe sweating and heat loss do

not occur at normal ambient temperature conditions. Insulation must be installed on loop water piping on those sections that run through unheated areas or are located outside

the building. If loop temperatures are expected below the

ambient dew point, the optional internal insulation

(extended range) package must be ordered.

CAUTION

Table 3 — Recommended Thermostat Wire Sizes

WIRE SIZE MAX WIRE LENGTH*

18-Gage 20 m

16-Gage 35 m

14-Gage 60 m

*Length = Physical distance from thermostat to unit.

OPTIONAL PREMIERLINK™ CONTROLLER — This

direct digital controller (DDC) allows the water source heat

pump to be incorporated into a Carrier Comfort Network

(CCN) system installation. PremierLink control is factoryinstalled with the Complete C controller, or field-installed with

the Deluxe D control option. Refer to Fig. 23 and 24.

Step 6 — Install Supply and Return Piping

CAUTION

To ensure proper functioning of unit and system, be sure to

connect entering water to upper pipe on right-hand units.

On left-hand units, connect entering water to lower pipe.

Failure to do so could result in equipment damage.

SUPPLY AND RETURN HOSES — Optional pressure-rated

hose assemblies are available for use with units. Use the following guidelines when installing supply and return hose

assemblies.

1. Install supply and return hoses fitted with swivel-joint

fittings at one end to prevent the hose from twisting.

2. Use male adapters to secure the hose assembly to the unit

and the riser.

3. Do not allow the hose to twist during installation. Twisting may damage the hose wall or the rubber compound.

DO NOT bend or kink supply lines or hoses. Damage to

unit may result.

4. Before making the final water connections, flush the system as described in the Pre-Start-Up section of this

manual. After flushing the system, connect piping and

hoses to the proper supply, return and condensate connections of the unit.

NOTE: When necessary, use adapters to connect hoses.

®

5. Install any other system components, as required, following manufacturer’s instructions.

6. Reinstall the front cabinet by carefully lowering the front

cabinet over the chassis onto the backplate.

Step 7 — Install Condensate Piping — Connect

the unit condensate drain to the building condensate drain with

a flexible, nonpressure-rated

Avoid kinks in this hose to ensure an unobstructed flow of condensate from the unit to the drain.

The horizontal run of the condensate hose is usually too

short to pose any drainage problems, however, the horizontal

run of condensate line should be pitched at least 10 mm for every 1 m of run (in the direction of flow). Avoid low points and

unpitched piping since dirt collects in these areas and may

cause stoppage and overflow.

Field installation of a trap or vent is not required unless

specified by local codes. The 50PEC units are designed in a

blow-thru configuration. The condensate drain pan is located

on the outlet side of the blower so that the pressure in the drain

pan is higher than the atmospheric pressure.

* Registered trademark of DuPont.

26

5

/8-in. (16 mm) ID plastic hose.

Page 27

PRE-START-UP

1/2” Flexible Hose

Brass Adapter

(1/2” MPT x 1/2”

Male Flare)

Supply Valve

Floor Line

Return Valve

Fig. 29 — Temporary Connection for Flushing System Piping

NOTE: Use standard coupling (field-supplied)

and hose adapters to join 2 hoses.

System Cleaning and Flushing —

flushing the unit and system is the single most important step to

ensure proper start-up and continued efficient operation of the

system.

Cleaning and

WARNING

To prevent injury or death due to electrical shock or contact

with moving parts, open unit disconnect before servicing

unit.

Follow the instructions below to properly clean and flush

the system:

CAUTION

Do not flush system through the unit. Damage to unit could

result.

1. Verify that electrical power to the units is disconnected,

and that the circulation pump is deenergized.

2. Connect the supply hose directly to the return riser valve.

Use a single length of flexible hose, as shown in Fig. 29.

NOTE: If the length of hose is too short (i.e., the resulting connection would exceed the minimum bend radius of the hose),

substitute two lengths of flexible hose joined together with a

field-supplied, standard NPT coupling and the flare-fitting-topipe adapters provided with the hose kit (Fig. 29).

3. Open all air vents. Fill the system with water. Do not allow system to overflow. Bleed all air from the system.

Check the system for leaks and repair appropriately.

4. Check and adjust the water and air level in the expansion

tank.

5. Verify all strainers are in place. Start the pumps, and systematically check each vent to ensure all air is bled from

the system.

6. Verify make-up water is available. Adjust make-up water

appropriately to replace the air that was bled from the

system. Pressure test and inspect the system for leaks and

make any necessary repairs. Check and adjust the water

and air level in the expansion tank.

7. Open a drain at the lowest point in the system. Adjust the

make-up water replacement rate to equal the rate of bleed.

Continue to bleed the system until the water appears

clean or for at least three hours, whichever is longest;

then, completely drain the system.

8. Refill the system with clean, chemically treated water.

Since water varies for each locality, contact a local water

treatment company for the correct treatment chemicals to

use in the area. Set the boiler to raise the loop temperature

to approximately 29.4 C.

.

CAUTION

To avoid possible damage to piping systems constructed of

plastic piping DO NOT allow loop temperature to exceed

43.3 C.

Circulate the solution for a minimum of 8 to 24 hours. At

the end of this period, shut off the circulating pump and

drain the solution. Repeat system cleaning as necessary.

9. When the cleaning process is complete, remove the shortcircuited hoses. Connect the hoses to the proper supply

and return connections on each unit. Refill the system and

bleed off all air.

10. Test the system pH with litmus paper. The system water

should be slightly alkaline (pH 7.0 to 8.5). Add chemicals, as appropriate, to maintain acidity levels.

CAUTION

DO NOT use “Stop-Leak” or any similar chemical agent in

this system. Addition of these chemicals to the loop water

will foul the system and will inhibit unit operation.

11. When the system is successfully cleaned, flushed, refilled

and bled, check the main system panels, safety cutouts

and alarms. Set the controls to properly maintain loop

temperatures.

System Checkout — When the installation is complete

and the system is cleaned and flushed, follow the system

checkout procedure outlined below.

1. Voltage: Ensure voltage is within the utilization range

specifications of the unit compressor and fan motor.

2. System Water Temperature: Ensure temperature is within

an acceptable range shown in Table 4. (When conducting

this check, also verify proper heating and cooling set

points.)

27

Page 28

Table 4 — Air and Water Limits

50PEC UNIT COOLING (C) HEATING (C)

Min Ambient Air 10.0 10.0

Rated Ambient Air 26.7 21.1

Max Ambient Air 37.8 29.4

Min Entering Air 10.0 10.0

Rated Entering Air, dry bulb/wet bulb 26.7/19.4 21.1

Max Entering Air, dry bulb/wet bulb 37.8/28.3 26.7

Min Entering Water –1.1 –6.7

Normal Entering Water 29.4 21.1

Max Entering Water 43.3 32.2

NOTES:

1. Minimum air and water conditions can only be used at nominal flow rates.

2. 50PEC units may have up to two values at maximum or minimum with all

other parameters at normal conditions.

3. Operating limits shown are for start-up, not continuous operation. It is

assumed that such a start-up is for the purpose of bringing the space to

desired occupancy temperature.

Table 5 — Water Quality Guidelines

3. System Water pH: Verify system water is slightly alkaline

(pH = 7.5 to 8.5). Proper pH promotes the longevity of

the hoses and heat exchangers. See Table 5.

4. Closed-Type Cooling Tower (Open Tower with Heat Exchanger): Check equipment for proper temperature set

points and operation.

5. Balanced Water Flow Rate to Heat Pump: Record the

inlet and outlet water temperatures as each heat pump

unit is started. This check will eliminate nuisance unit

tripouts resulting from water velocities that are either too

low or too high; it can also prevent erosive water flow

rates.

6. Standby Pump: Verify the standby pump is properly installed and in operating condition.

CONDITION

Scaling Potential — Primary Measurement

Above the given limits, scaling is likely to occur. Scaling indexes should be calculated using the limits below.

pH/Calcium

Hardness Method

Index Limits for Probable Scaling Situations (Operation outside these limits is not recommended.)

Scaling indexes should be calculated at 150 F for direct use and HWG applications, and at 90 F for indirect HX use. A monitoring plan should be

implemented.

Ryznar Stability Index

Langelier Saturation Index

Iron Fouling

Iron Fe2+ (Ferrous)

(Bacterial Iron Potential)

Iron Fouling

Corrosion Prevention††

pH

Hydrogen Sulfide (H2S)

Ammonia Ion as Hydroxide,

Chloride, Nitrate and Sulfate

Compounds

Maximum Chloride Levels Maximum allowable at maximum water temperature.

Erosion and Clogging

Particulate Size and Erosion

Brackish

LEGEND

HWG — Hot Water Generator

HX — Heat Exchanger

N/A — Design Limits Not Applicable Considering Recirculating

NR — Application Not Recommended

SS — Stainless Steel

*Heat exchanger materials considered are copper, cupronickel, 304 SS

(stainless steel), 316 SS, titanium.

†Closed recirculating system is identified by a closed pressurized piping

system.

**Recirculating open wells should obser ve the open recirculating design

considerations.

Potable Water

HX

MATERIAL*

All N/A pH < 7.5 and Ca Hardness, <100 ppm

All N/A

All N/A

All N/A

All N/A

All

All N/A

All N/A

Copper N/A

Cupronickel N/A <150 ppm NR NR

304 SS N/A <400 ppm <250 ppm <150 ppm

316 SS N/A <1000 ppm <550 ppm <375 ppm

Titanium N/A >1000 ppm >550 ppm >375 ppm

All

All N/A

CLOSED

RECIRCULATING†

Monitor/treat as needed.

<10 ppm of particles and a

maximum velocity of 6 fps.

6 - 8.5

Filtered for maximum

800 micron size.

OPEN LOOP AND RECIRCULATING WELL**

6.0 - 7.5

If >7.5 minimize steel pipe use.

–0.5 to +0.5

Based upon 150 F HWG and direct well, 85 F indirect well HX.

If Fe2+ (ferrous) >0.2 ppm with pH 6 - 8, O2<5 ppm check for iron bacteria.

Minimize steel pipe below 7 and no open tanks with pH <8.

At H2S>0.2 ppm, avoid use of copper and cupronickel piping of HXs.

Copper alloy (bronze or brass) cast components are okay to <0.5 ppm.

50 F (10 C) 75 F (24 C) 100 F (38 C)

<20 ppm NR NR

<10 ppm (<1 ppm “sandfree” for reinjection) of par ticles and a maximum

velocity of 6 fps. Filtered for maximum 800 micron size. Any particulate that

is not removed can potentially clog components.

Use cupronickel heat exchanger when concentrations of calcium or sodium

chloride are greater than 125 ppm are present. (Seawater is approximately

25,000 ppm.)

††If the concentration of these corrosives exceeds the maximum allow-

able level, then the potential for serious corrosion problems exists.

Sulfides in the water quickly oxidize when exposed to air, requiring that

no agitation occur as the sample is taken. Unless tested immediately

at the site, the sample will require stabilization with a few drops of one

Molar zinc acetate solution, allowing accurate sulfide determination up

to 24 hours after sampling. A low pH and high alkalinity cause system

problems, even when both values are within ranges shown. The term

pH refers to the acidity, basicity, or neutrality of the water supply.

Below 7.0, the water is considered to be acidic. Above 7.0, water is

considered to be basic. Neutral water contains a pH of 7.0.

To convert ppm to grains per gallon, divide by 17. Hardness in mg/l is

equivalent to ppm.

If <–0.5 minimize steel pipe use.

<0.2 ppm (Ferrous)

<0.5 ppm of Oxygen

Above this level deposition will occur.

6 - 8.5

<0.5 ppm

Rotten egg smell appears at 0.5 ppm level.

<0.5 ppm

28

Page 29

7. System Control: To ensure no catastrophic system failures occur, verify system controls are functioning and the

sequencing is correct.

8. Freeze Protection for Water Systems: Verify freeze

protection is provided for the outdoor portion of the loop

water system. Inadequate freeze protection leads to

expensive repairs.

CAUTION

To avoid equipment damage, DO NOT leave system filled

in a building without heat during the winter unless antifreeze is added to system water. Condenser coils never

fully drain by themselves and will freeze unless winterized

with antifreeze.

9. System Water Loop: Verify all air is bled from the system. Air in the system impedes unit operation and causes

corrosion in the system piping.

10. Unit Filters: To avoid system damage and to provide

maximum performance, ensure the unit filter is clean.

11. Unit Fans: Manually rotate fans to assure free rotation.

Ensure fans are properly secured to the fan shaft. Do not

oil fan motors on start-up since they are lubricated at the

factory.

12. System Control Center: To ensure control of the temperature set points for operation of the system’s heat rejector

and boiler, examine the system control and alarm panel

for proper installation and operation.

FIELD SELECTABLE INPUTS

Jumpers and DIP (dual in-line package) switches on the

control board are used to customize unit operation and can be

configured in the field.

IMPORTANT: Jumpers and DIP switches should only

be clipped when power to control board has been turned

off.

Complete C Control Jumper Settings (See

Fig. 17, 18, and 21)

WATER COIL FREEZE PROTECTION (FP1) LIMIT

SETTING — Select jumper 3, (JW3-FP1 Low Temp) to

choose FP1 temperature limit of –12.2 C or –1.1 C. To select

–1.1 C as the temperature limit, DO NOT clip the jumper. To

select –12.2 C as the limit, clip the jumper.

ALARM RELAY SETTING — Select jumper 1 (JW1) for

connecting alarm relay terminal (AL2) to 24-vac (R) or to remain as a dry contact (no connection). To connect AL2 to R, do

not clip the jumper. To set as dry contact, clip the jumper.

Complete C Control DIP Switches — The Com-

plete C control has one DIP switch block with five switches.

See Fig. 17, 18, and 21.

PERFORMANCE MONITOR (PM) — DIP switch 1 will

enable or disable this feature. To enable the PM, set the switch

to ON. To disable the PM, set the switch to OFF.

STAGE 2 — DIP switch 2 will enable or disable compressor

delay. Set DIP switch to OFF for Stage 2 in which the compressor will have a 3-second delay before energizing.

SWITCH 3 AND SWITCH 4 — Not used.

FREEZE PROTECTION (FP1) — DIP switch 5 is used to

initiate one or 3 tries for the FP1 fault. If there is water freeze

protection for the water coil then DIP switch 5 can be set to

lock out on the FP1 fault after one try. ON = One try.

OFF = 3 tries.

Deluxe D Control Jumper Settings (See Fig. 19,

20, and 22)

WATER COIL FREEZE PROTECTION (FP1) LIMIT

SETTING — Select jumper 3, (JW3-FP1 Low Temp) to

choose FP1 temperature limit of –12.2 C or –1.1 C. To select

–1.1 C as the temperature limit, DO NOT clip the jumper. To

select –12.2 C as the limit, clip the jumper.

ALARM RELAY SETTING — Select jumper 4 (JW4-AL2

Dry) for connecting alarm relay terminal (AL2) to 24-vac (R)

or to remain as a dry contact (no connection). To connect AL2

to R, do not clip the jumper. To set as dry contact, clip the

jumper.

LOW PRESSURE SETTING — The Deluxe D control can

be configured for low pressure setting (LP). Select jumper 1

(JW1-LP Norm Open) for choosing between low pressure input normally opened or closed. To configure for normally

closed operation, do not clip the jumper. To configure for normally open operation, clip the jumper.

Deluxe D Control DIP Switches — The Deluxe D

control has 2 DIP switch blocks. Each DIP switch block has

8 switches and is labeled either S1 or S2 on the circuit board.

See Fig. 19, 20, and 22.

DIP SWITCH BLOCK 1 (S1) — This set of switches offers

the following options for Deluxe D control configuration:

Performance Monitor (PM)

able performance monitor. To enable the PM, set the switch to

ON. To disable the PM, set the switch to OFF.

Compressor Relay Staging Operation

able or disable compressor relay staging operation. The

compressor relay can be set to turn on with Stage 1 or Stage 2

call from the thermostat. This setting is used with dual stage

units (units with 2 compressors and 2 Deluxe D controls) or in

master/slave applications. In master/slave applications, each