Carrier 50PCH User Manual

AQUAZONE™

50PCH,PCV006-060

Compact High-Efficiency Water Source Heat Pumps

®

with PURON

Refrigerant (R-410A)

Installation, Start-Up, and

Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . .1,2

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Step 1 — Check Jobsite . . . . . . . . . . . . . . . . . . . . . . . . 2

Step 2 — Check Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

• STORAGE

•PROTECTION

•INSPECT UNIT

Step 3 — Locate Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

• FIELD CONVERSION OF DISCHARGE AIR

Step 4 — Mount the Unit . . . . . . . . . . . . . . . . . . . . . . . . . 8

• HORIZONTAL UNITS

• VERTICAL UNITS

Step 5 — Check Duct System . . . . . . . . . . . . . . . . . . . . 8

• SO U N D AT T E NUATI O N

• EXISTING DUCT SYSTEM

Step 6 — Install Condensate Drain . . . . . . . . . . . . . . . 8

• HORIZONTAL UNITS

• VERTICAL UNITS

• VENTING

Step 7 — Pipe Connections . . . . . . . . . . . . . . . . . . . . . . 9

• WATER LOOP APPLICATIONS

• GROUND LOOP APPLICATIONS

• INSTALLATION OF SUPPLY AND RETURN HOSE

KIT

Step 8 — Wire Field Power Supply . . . . . . . . . . . . . . 10

• POWER CONNECTION

• SUPPLY VOLTAGE

• 208-VOLT OPERATION

• 460-VOLT OPERATION

Step 9 — Wire Field Controls. . . . . . . . . . . . . . . . . . . . 20

• THERMOSTAT CONNECTIONS

• WATER FREEZE PROTECTION

• AIR COIL FREEZE PROTECTION

• ACCESSORY CONNECTIONS

• WATER SOLENOID VALVES

• WSHP OPEN WIRING

PRE-START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22,23

System Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PSC Blower Speed Selection . . . . . . . . . . . . . . . . . . 22

FIELD SELECTABLE INPUTS . . . . . . . . . . . . . . . .24,25

Complete C Control Jumper Settings. . . . . . . . . . . 24

Complete C Control DIP Switches. . . . . . . . . . . . . . 24

Deluxe D Control Jumper Settings . . . . . . . . . . . . . 24

Deluxe D Control DIP Switches . . . . . . . . . . . . . . . . 24

Deluxe D Control Accessory Relay

Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Water Valve (Slow Opening) . . . . . . . . . . . . . . . . . . . 25

Outside Air Damper (OAD) . . . . . . . . . . . . . . . . . . . . 25

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-33

Operating Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Scroll Compressor Rotation. . . . . . . . . . . . . . . . . . . . . 26

Unit Start-Up Cooling Mode . . . . . . . . . . . . . . . . . . . . . 26

Page

Unit Start-Up Heating Mode . . . . . . . . . . . . . . . . . . . . . 30

Unit Start-Up with WSHP Open Controls . . . . . . . . 30

Flow Regulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Cooling Tower/Boiler Systems . . . . . . . . . . . . . . . . . . 32

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-36

Power Up Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Units with Aquazone Complete C Control . . . . . . . 33

Units with Aquazone Deluxe D Control

Units with WSHP Open Multiple Protocol. . . . . . . . 33

COMPLETE C AND DELUXE D BOARD

SYSTEM TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36-38

Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

WSHP Open Test Mode. . . . . . . . . . . . . . . . . . . . . . . . . . 36

Retry Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Aquazone Deluxe D Control LED Indicators . . . . . 37

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38-40

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Water Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Condensate Drain Pans . . . . . . . . . . . . . . . . . . . . . . . . . 38

Refrigerant System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Fan Motors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Condensate Drain Cleaning . . . . . . . . . . . . . . . . . . . . . 38

Air Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Condenser Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Checking System Charge . . . . . . . . . . . . . . . . . . . . . . . 39

Refrigerant Charging. . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Air Coil Fan Motor Removal . . . . . . . . . . . . . . . . . . . . . 40

Replacing the WSHP Open Controller’s

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . 40-42

Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Control Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

WSHP Open Controller . . . . . . . . . . . . . . . . . . . . . . . . . . 40

APPENDIX A — WSHP OPEN SCREEN

CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . 43-48

50PCH,PCV START-UP CHECKLIST . . . . . CL-1, CL-2

IMPORTANT: Read the entire instruction manual before

starting installation.

. . . . . . . . . . 33

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters. All other

operations should be performed by trained service personnel.

When working on air-conditioning equipment, observe

precautions in the literature, tags and labels attached to the unit,

and other safety precautions that may apply.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53500094-01 Printed in U.S.A. Form 50PC-3SI Pg 1 3-11 Replaces: 50PC-2SI

Improper installation, adjustment, alteration, service, maintenance, or use can cause explosion, fire, electrical shock or other

conditions which may cause personal injury or property damage. Consult a qualified installer, service agency, or your distributor or branch for information or assistance. The qualified installer or agency must use factory-authorized kits or accessories

when modifying this product. Refer to the individual instructions packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have fire

extinguisher available. Read these instructions thoroughly and

follow all warnings or cautions attached to the unit. Consult

local building codes and the National Electrical Code (NEC)

for special installation requirements.

Understand the signal words — DANGER, WARNING,

and CAUTION. DANGER identifies the most serious hazards

which will result in severe personal injury or death. WARNING signifies hazards that could result in personal injury or

death. CAUTION is used to identify unsafe practices, which

would result in minor personal injury or product and property

damage.

Recognize safety information. This is the safety-alert

symbol ( ). When you see this symbol on the unit and in

instructions or manuals, be alert to the potential for personal

injury.

WARNING

Electrical shock can cause personal injury or death. Before

installing or servicing system, always turn off main power

to system. There may be more than one disconnect switch.

Turn off accessory heater power if applicable.

GENERAL

This Installation and Start-Up Instructions literature is for

Aquazone™ water source heat pump systems.

Water source heat pumps (WSHPs) are single-package horizontally and vertically mounted units with electronic controls

designed for year-round cooling and heating. Aquazone

WSHPs are available in the following unit configurations:

• PCH standard efficiency with horizontal airflow and

right, left or back discharge

• PCV standard efficiency with vertical airflow and top

discharge

IMPORTANT: The installation of water source heat pump

units and all associated components, parts, and accessories

which make up the installation shall be in accordance with

the regulations of ALL authorities having jurisdiction and

MUST conform to all applicable codes. It is the responsibility of the installing contractor to determine and comply

with ALL applicable codes and regulations.

INSTALLATION

Step 1 — Check Jobsite —

maintenance instructions are provided with each unit. Before

unit start-up, read all manuals and become familiar with the

unit and its operation. Thoroughly check out the system before

operation. Complete the inspections and instructions listed

below to prepare a unit for installation. See Table 1 for unit

physical data.

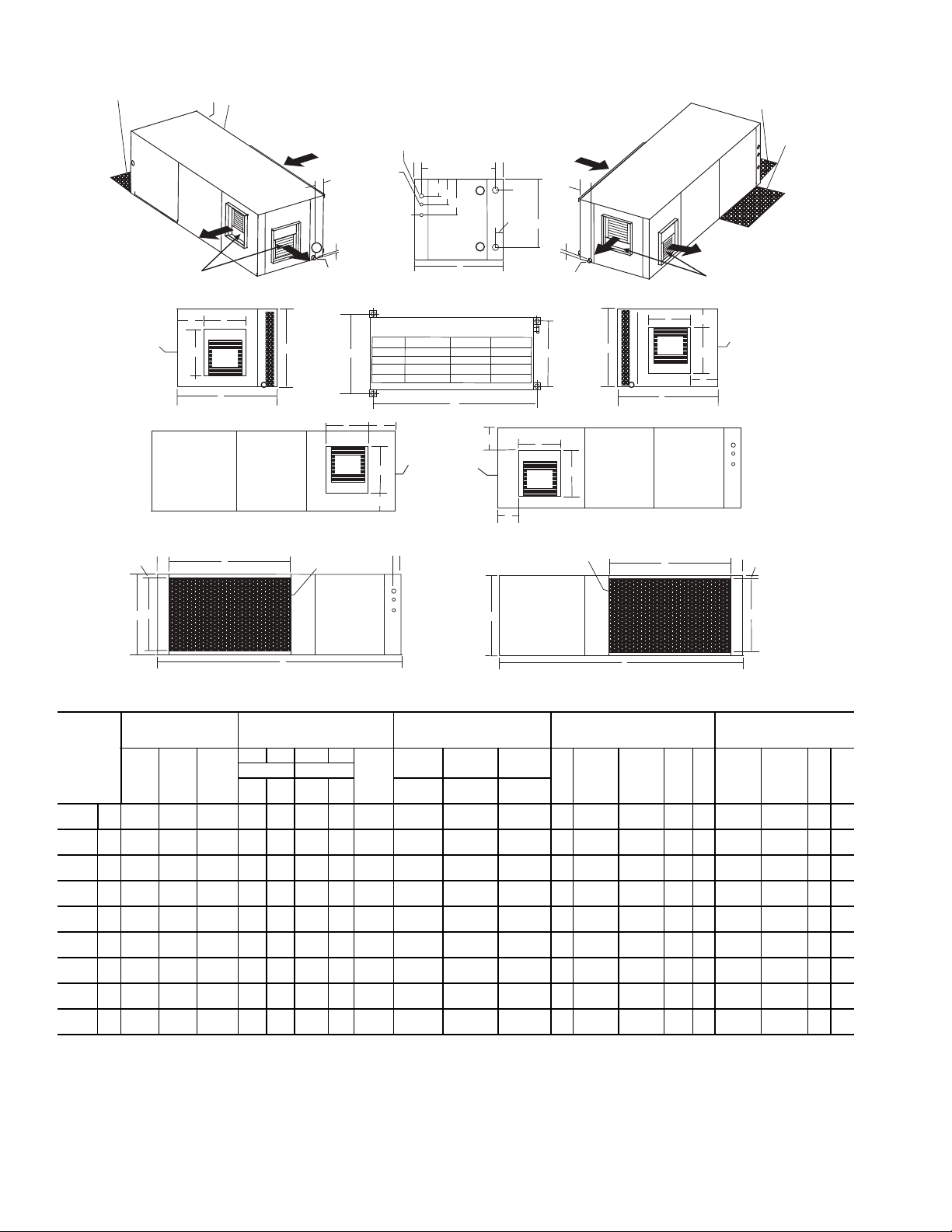

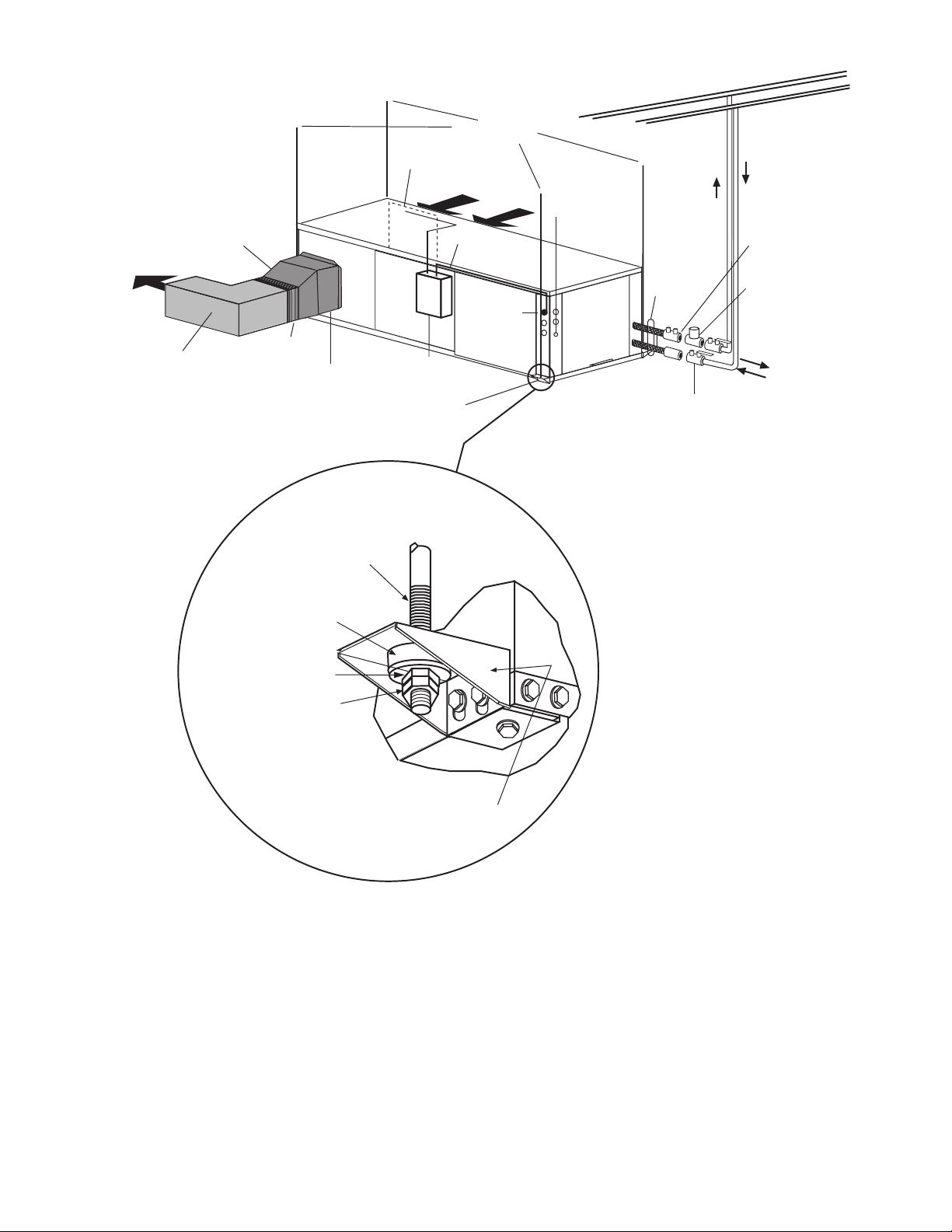

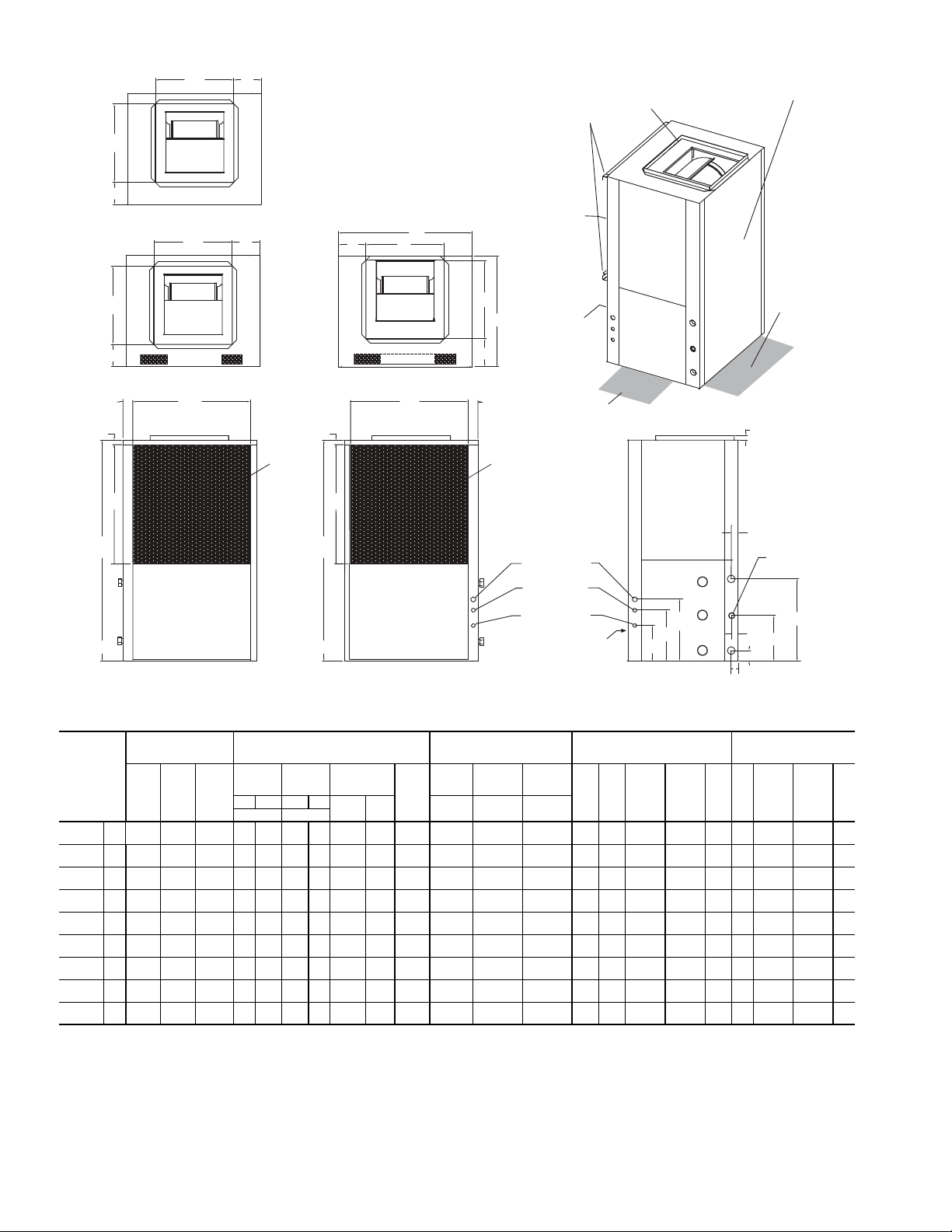

HORIZONTAL UNITS (50PCH) — Horizontal units are

designed for indoor installation only. Be sure to allow adequate

space around the unit for servicing. See Fig. 1 for overall unit

dimensions. Refer to Fig. 2 for an illustration of a typical horizontal installation.

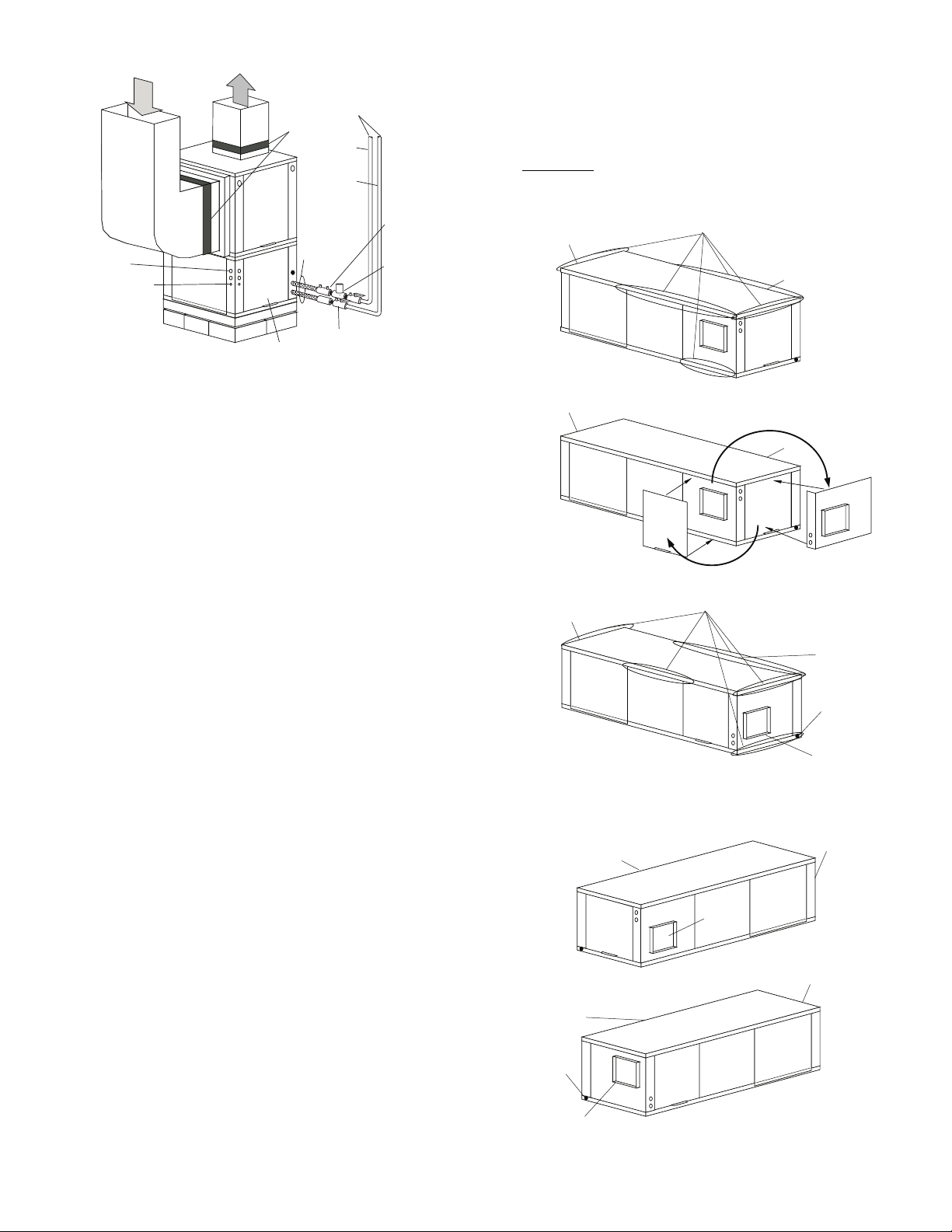

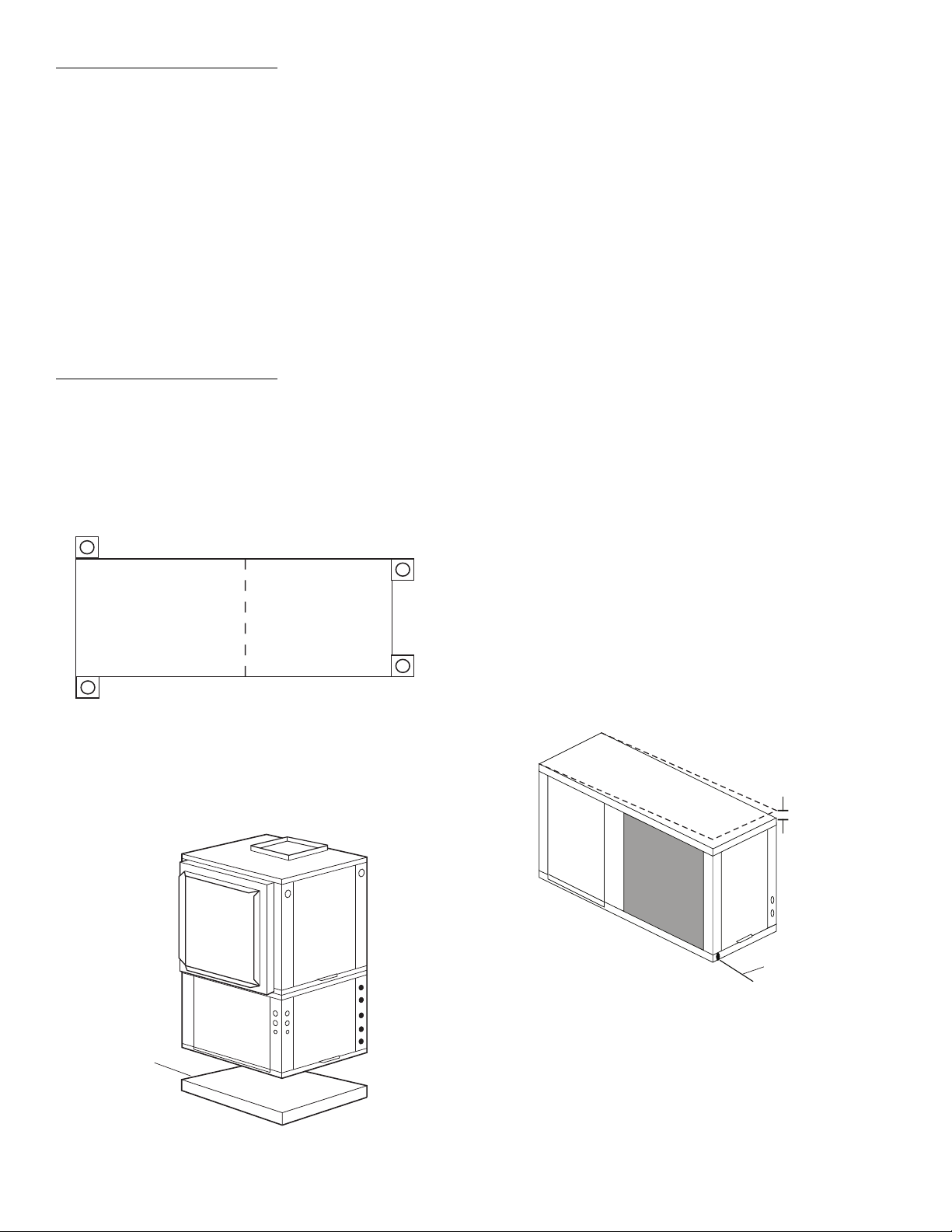

VERTICAL UNITS (50PCV) — Vertical units are designed

for indoor installations. While vertical units are typically

Installation, operation and

installed in a floor-level closet or a small mechanical room,

the unit access guidelines for these units are very similar to

those described for horizontal units. See Fig. 3 for overall dimensions. Refer to Fig. 4 for an example of a typical vertical

installation.

CAUTION

To avoid equipment damage, do not use these units as a

source of heating or cooling during the construction

process. The mechanical components and filters used in

these units quickly become clogged with construction

dirt and debris which may cause system damage.

Step 2 — Check Unit — Upon receipt of shipment at

the jobsite, carefully check the shipment against the bill of

lading. Make sure all units have been received. Inspect the carton or crating of each unit, and inspect each unit for damage.

Ensure the shipping company makes proper notation of any

shortages or damage on all copies of the freight bill. Concealed

damage not discovered during unloading must be reported to

the shipping company within 15 days of receipt of shipment.

NOTE: It is the responsibility of the purchaser to file all

necessary claims with the shipping company.

1. Verify unit is correct model for entering water temperature of job.

2. Be sure that the location chosen for unit installation provides ambient temperatures maintained above freezing.

Well water applications are especially susceptible to

freezing.

3. Be sure the installation location is isolated from sleeping

areas, private offices and other acoustically sensitive

spaces.

NOTE: A sound control accessory package may be used

to help eliminate sound in sensitive spaces.

4. Check local codes to be sure a secondary drain pan is not

required under the unit.

5. Be sure unit is mounted at a height sufficient to provide

an adequate slope of the condensate lines. If an appropriate slope cannot be achieved, a field-supplied condensate

pump may be required.

6. Provide sufficient space for duct connection.

7. Provide adequate clearance for filter replacement and

drain pan cleaning. Do not allow piping, conduit, etc. to

block filter access.

8. Provide sufficient access to allow maintenance and

servicing of the fan and fan motor, compressor and coils.

Removal of the entire unit from the closet should not be

necessary.

9. Provide an unobstructed path to the unit within the closet

or mechanical room. Space should be sufficient to allow

removal of unit if necessary.

10. Provide ready access to water valves and fittings, and

screwdriver access to unit side panels, discharge collar,

and all electrical connections.

11. Where access to side panels is limited, pre-removal of the

control box side mounting screws may be necessary for

future servicing.

STORAGE — If the equipment is not needed immediately at

the jobsite, it should be left in its shipping carton and stored in a

clean, dry area of the building or in a warehouse. Units must be

stored in an upright position at all times. If carton stacking is

necessary, stack units a maximum of 3 high. Do not remove

any equipment from its shipping package until it is needed for

installation.

PROTECTION — Once the units are properly positioned on

the jobsite, cover them with either a shipping carton, vinyl film,

2

or an equivalent protective covering. Cap open ends of pipes

stored on the jobsite. This precaution is especially important in

areas where painting, plastering, or spraying of fireproof material, etc. is not yet complete. Foreign material that accumulates

within the units can prevent proper start-up and necessitate

costly clean-up operations.

Before installing any of the system components, be sure to

examine each pipe, fitting, and valve, and remove any dirt or

foreign material found in or on these components.

CAUTION

DO NOT store or install units in corrosive environments or

in locations subject to temperature or humidity extremes

(e.g., attics, garages, rooftops, etc.). Corrosive conditions

and high temperature or humidity can significantly reduce

performance, reliability, and service life. Always move

units in an upright position. Tilting units on their sides may

cause equipment damage.

INSPECT UNIT — To prepare the unit for installation, complete the procedures listed below:

1. Compare the electrical data on the unit nameplate with

ordering and shipping information to verify that the

correct unit has been shipped.

2. Verify that the unit is the correct model for the entering

water temperature of the job.

3. Do not remove the packaging until the unit is ready for

installation.

4. Verify that the refrigerant tubing is free of kinks or dents,

and that it does not touch other unit components.

5. Inspect all electrical connections. Be sure connections are

clean and tight at the terminals.

6. Loosen compressor bolts until the compressor rides freely

on springs. Remove shipping restraints.

7. Remove the four

1

/4 in. shipping bolts from compressor

support plate (two bolts on each side) to maximize vibration and sound alternation.

CAUTION

Failure to remove shipping brackets from spring-mounted

compressors will cause excessive noise and could cause

component failure due to added vibration.

8. Remove any blower support cardboard from inlet of the

blower.

9. Locate and verify any accessory kit located in compressor

section.

10. Remove any access panel screws that may be difficult to

remove once unit is installed.

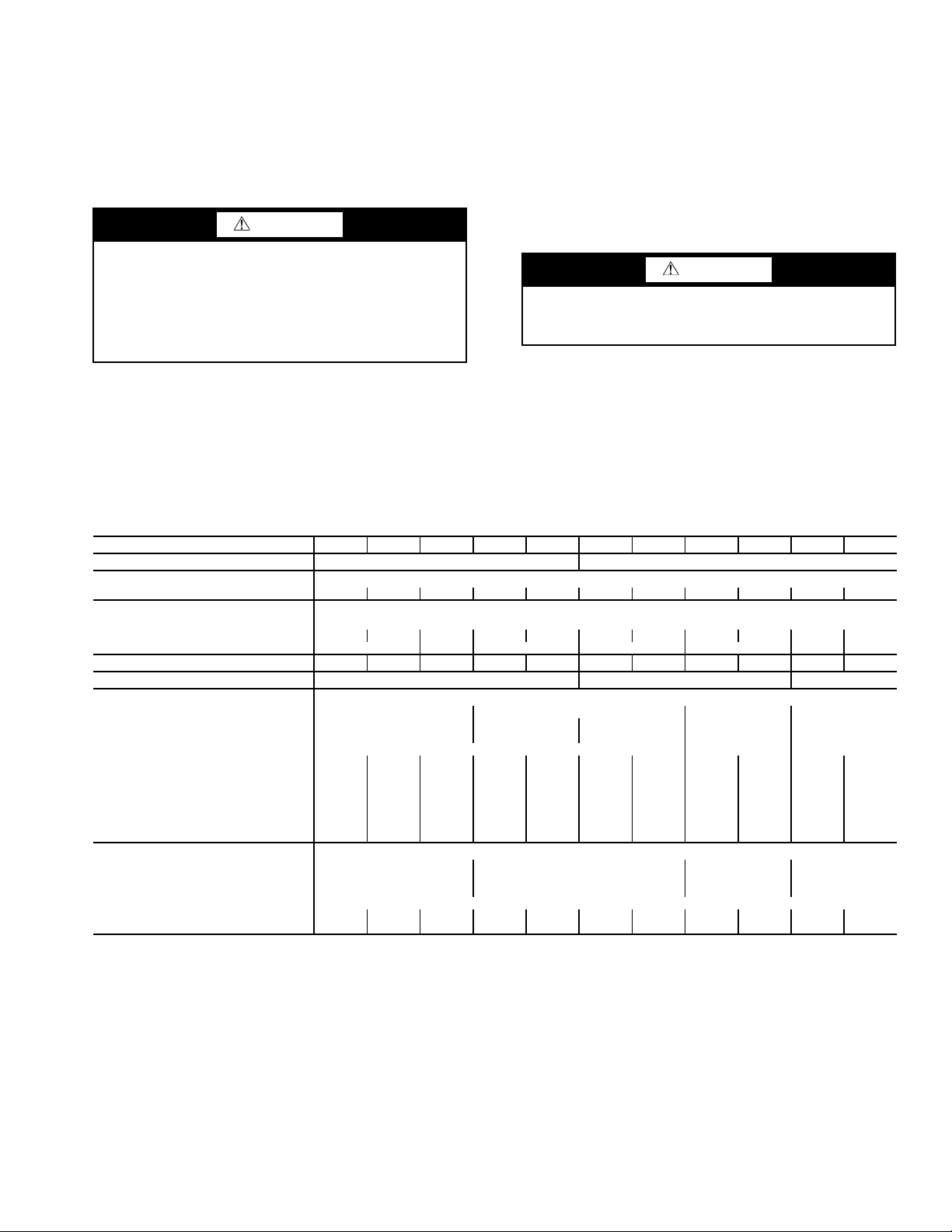

Table 1 — Physical Data — 50PCH,PCV Units

50PCH,PCV UNIT 006 009 012 015 018 024 030 036 042 048 060

COMPRESSOR (1 each) Rotary Scroll

REFRIGERANT TYPE R-410A

Factory Charge (oz) 1718.5233243434750707482

FAN MOTOR AND BLOWER

Fan Motor Type/Speeds PSC/3

Fan Motor (hp)

Blower Wheel Size (Dia x W) (in.) 5 x 5 6 x 5 8 x 7 9 x 7 9 x 8 10 x 10 11 x 10

COAX VOLUME (gal.) 0.123 0.143 0.167 0.286 0.450 0.286 0.323 0.323 0.890 0.738 0.939

WATER CONNECTION SIZE FPT (in.)

HORIZONTAL

Air Coil Dimensions (H x W)(in.) 10 x 15 16 x 22 20 x 25 20 x 35

Standard Filter - (Qty)

1 in. Throwaway

Weight (lb)

Operating 103 105 114 153 158 174 182 203 218 263 278

Packaged 113 115 124 158 163 179 187 209 224 270 285

Corner Weight (lb)*

Left-Front 37 38 42 53 55 62 67 75 81 98 103

Right-Front 24 24 26 36 37 40 41 47 50 60 64

Left-Back 23 23 25 34 35 39 40 44 48 58 61

Right-Back 19 20 21 30 31 33 34 37 39 47 75

VERTICAL

Air Coil Dimensions (H x W)(in.) 10 x 15 20 x 17.25 24 x 17.75 24 x 28.25

Standard Filter - (Qty)

1 in. Throwaway

Weight (lb)

Operating 103 105 114 153 158 189 197 203 218 263 278

Packaged 113 115 124 158 163 194 202 209 224 270 285

LEGEND *Front is located at control box end.

FPT — Female Pipe Thread

PSC — Permanent Split Capacitor

1

/

1

25

/

(1) 10 x 18 (1) 16 x 25 (1) 18 x 25

(1) 10 x 18 (1) 20 x 20 (1) 24 x 24

1

10

/

10

1

/

1

/

2

1

6

/

NOTES:

1. All units have grommet compressor mountings, and

3

2. Maximum water working pressure is 500 psig.

1

6

/4-in. electrical knockouts.

/

3

4

/

4

3

1

/

4

(1) 20 x 28 or

/

2

(2) 20 x 14

3

/

4

3

/

4

1

(1) 20 x 24,

(1) 20 x 14

(1) 14 x 24,

(1) 18 x 24

1

/2-in. and

1

3

F

RIGHT RETURN STRAIGHT DISCHARGE

FRONT

L

N

O

M

RIGHT RETURN

FRONT

LEFT/STRAIGHT

DISCHARGE

CSP

BACK

DISCHARGE

CONDENSATE

3 / 4" FPT

3.3"

[83.8 MM]

0.7"

[17.8 MM]

FRONT-VIEW

E

D

K

J

2

1

1.1 [27.9 MM]

A

CAP

BSP

RIGHT RETURN RIGHT VIEW -

AIR COIL OPENING

AIR COIL

C

T

S

B

R

Q

FRONT

L

N

O

M

LEFT RETURN STRAIGHT DISCHARGE

FRONT

BSP

LEFT RETURN RIGHT RETURN

AIR COIL

CSP

FRONT

LEFT RETURN LEFT VIEW -

AIR COIL OPENING

1.75 [44.5 MM]

C

T

R

QS

B

UNIT HANGER DETAIL

U

V

FRONT

W

MODEL U V W

015-030 43.1 [109.5] 22.2 [56.4] 18.0 [45.7]

036-042 47.1 [119.6] 22.2 [56.4] 18.0 [45.7]

048-060 54.1 [137.4] 26.2 [66.5] 22.0 [55.9]

RIGHT RETURN BACK DISCHARGE

A

AIR COIL SIDE

C

P

N

O

M

CSP

BSP

2 FT [610 MM] SERVICE

ACCESS

FRONT

LEFT RETURN

0.7" [17.8 MM]

3.3"

[83.8 MM]

CSP

CONDENSATE

3 / 4" FPT

2 FT [610 MM] SERVICE

ACCESS

AIR COIL SIDE

M

A

C

LEFT RETURN BACK DISCHARGE

N

O

P

BSP

BLOWER

OUTLET

BLOWER

OUTLET

BLOWER

OUTLET

BLOWER

OUTLET

OPTIONAL 2 FT

[610 MM]

SERVICE

ACCESS

OPTIONAL 2 FT

[610 MM]

SERVICE

ACCESS

G

H

006-012 34.1 [86.6] 21.1 [53.6] 18.9 [42.9]

NOTE: BLOWER SERVICE PANEL REQUIRES 2 FT SERVICE ACCESS

POWER SUPPLY

3 / 4" [19.1 MM] KNOCKOUT

1 / 2"

[12.7 MM]

KNOCKOUT

LOW VOLTAGE

1 / 2" [12.7 MM]

KNOCKOUT

3

RIGHT/STRAIGHT

DISCHARGE

BACK

DISCHARGE

NOTE: CHOOSE EITHER

BACK OR STRAIGHT DISCHARGE

NOTE: CHOOSE EITHER

BACK OR STRAIGHT DISCHARGE

50PCH006-060 UNITS

NOTES:

1. While clear access to all removable panels is not required, installer should

take care to comply with all building codes and allow adequate clearance

for future field service.

2. Horizontal units shipped with filter bracket only. This bracket should be

removed for return duct connection.

3. Discharge flange and hanger brackets are factory installed.

4. Condensate is

3

/4-in. (19.1 mm) FPT copper.

5. Blower service panel requires 2 ft (610 mm) service access.

6. Blower service access is through back panel on left or right discharge units

or through panel opposite air coil on back discharge units.

50PCH

UNIT

SIZE

OVERALL CABINET

WATER

CONNECTIONS

ELECTRICAL KNOCKOUTS

DISCHARGE CONNECTIONS

DUCT FLANGE

( 0.10 in., 2.5 mm)

RETURN CONNECTION

USING RETURN AIR

OPENING

A

WidthBDepthCHeight

12 34

Size

(IPT)

H

1

/2-in.

J

1

/2-in.

K

3

/4-in.

LMSupply

Height

N

Supply

Width

OPQReturn

Depth

R

Return

Height

ST

Loop In Loop Out

DE F G

Low

Vol ta ge

Low

Vol ta ge

Power

Supply

006-

012

in. 19.1 34.1 11.1 9.6 1.1 1.5 1.1

1

/

2

8.1 5.1 2.1 0.8 8.9 6.7 8.2 1.3 16.1 9.8 1.1 0.6

cm 48.5 86.6 28.2 24.3 2.7 3.8 2.7 1.3 20.6 13.0 5.4 1.9 22.7 17.0 13.3 3.3 41.0 25.0 2.7 1.5

015

in. 20.1 43.1 17.0 15.1 1.4 3.2 1.4

1

/

2

12.1 9.1 6.1 2.6 13.3 9.9 4.1 1.3 23.0 15.0 1.1 1.0

cm 51.1 109.5 43.2 38.4 3.4 8.1 3.5 1.3 30.8 23.2 15.6 6.6 33.8 25.1 10.5 3.3 58.4 38.1 2.8 2.5

018

in. 20.1 43.1 17.0 15.1 1.4 4.1 1.4

1

/

2

12.1 9.1 6.1 2.6 13.3 9.9 4.1 1.3 23.0 15.0 1.1 1.0

cm 51.1 109.5 43.2 38.4 3.4 10.4 3.5 1.3 30.8 23.2 15.6 6.6 33.8 25.1 10.5 3.3 58.4 38.1 2.8 2.5

024

in. 20.1 43.1 18.3 15.1 1.4 4.4 1.4

3

/

4

12.1 9.1 6.1 2.6 13.3 9.9 4.1 1.3 23.0 16.3 1.1 1.0

cm 51.1 109.5 46.5 38.4 3.4 11.3 3.5 1.9 30.8 23.2 15.6 6.6 33.8 25.1 10.5 3.3 58.4 41.4 2.8 2.5

030

in. 20.1 43.1 18.3 15.1 1.4 3.1 1.4

3

/

4

12.1 9.1 6.1 2.6 13.3 9.9 4.1 1.3 23.0 16.3 1.1 1.0

cm 51.1 109.5 46.5 38.4 3.4 7.8 3.5 1.9 30.8 23.2 15.6 6.6 33.8 25.1 10.5 3.3 58.4 41.4 2.8 2.5

036

in. 20.1 47.1 21.0 15.1 1.4 5.3 1.4

3

/

4

16.1 13.1 10.1 2.5 16.1 11.0 3.0 2.5 25.9 19.0 1.1 1.0

cm 51.1 119.6 53.3 38.4 3.4 13.4 3.5 1.9 41.0 33.3 25.7 6.3 40.9 27.9 7.7 6.4 65.8 48.3 2.8 2.5

042

in. 20.1 47.1 21.0 15.1 1.4 4.4 1.4

3

/

4

16.1 13.1 10.1 2.5 16.1 11.0 3.0 2.5 25.9 19.0 1.1 1.0

cm 51.1 119.6 53.3 38.4 3.4 11.3 3.5 1.9 41.0 33.3 25.7 6.3 40.9 27.9 7.7 6.4 65.8 48.3 2.8 2.5

048

in. 24.1 54.1 21.0 15.1 1.4 4.4 1.4 1 16.1 13.1 10.1 3.7 16.1 13.7 4.1 1.3 35.9 19.0 1.1 1.0

cm 61.2 137.4 53.3 38.4 3.4 11.1 3.5 2.5 41.0 33.3 25.7 9.5 41.0 34.8 10.3 3.2 91.2 48.3 2.8 2.5

060

in. 24.1 54.1 21.0 15.1 1.4 3.8 1.4 1 16.1 13.1 10.1 1.7 18.1 13.7 4.1 1.3 35.9 19.0 1.1 1.0

cm 61.2 137.4 53.3 38.4 3.4 9.7 3.5 2.5 41.0 33.3 25.7 4.4 46.0 34.8 10.3 3.2 91.2 48.3 2.8 2.5

Fig. 1 — 50PCH Unit Dimensions

a50-8695

LEGEND

BSP — Blower Service Panel

CAP — Control Access Panel

CSP — Compressor Service Panel

FPT — Female Pipe Thread

4

Return Loop

Fig. 2 — Typical Installation — 50PCH Units

UNIT HANGER ISOLATION DETAIL

a50-7842ef

Field-supplied transition to

minimize pressure loss

Supply Air

Insulated supply duct with

at least one 90 degree elbow

to reduce air noise

(field supplied)

Flexible

Connection

Accessory

Electric Heat

(if applicable)

3/8" Threaded

Rod (by others)

Filter Access

Power Wiring

Unit Power

Disconnect

Unit Hanger

3/8" threaded rods

(by others)

Return Air

(Ductwork

not shown)

Unit Power

Thermostat

Wiring

Supply Loop

ater In

W

Water Out

Accessory

stainless steel

braid hose

with integral

“J” swivel

Ball Valve Accessory with optional

integral P/T plug (typical for supply

and return piping)

Balancing Valve (Field

installed and calibrated

accessory)

Low Pressure Drop Water

Control Valve (optional) or

(field-installed accessory)

Water Out

Water In

Vibration Isolator

(white compressor end

and red blower end)

Washer

(by others)

Double Hex Nuts

(by others)

Integral hanger supportpre-attached in factory

5

O

50PCV006-060 UNITS

NOTES:

1. Shaded areas are recommended service areas. Installer should take care to comply with

all building codes and allow adequate clearance for future field service.

2. Front and side access is preferred for service access. However, all components may be

serviced from the front access panel if side access is not available except on 50PCV009030 with front return.

3. Discharge flange is field installed.

4. Condensate is 3/4 in. (19.1 mm) FPT.

5. Units shipped with filter rails. These rails should be removed for return duct connection.

See WSHP Accessory Price Page for accessory air filter frame with duct collar.

50PCV

UNIT

SIZE

OVERALL CABINET WATER CONNECTIONS ELECTRICAL KNOCKOUTS

DISCHARGE CONNECTION

DUCT FLANGE INSTALLED

(0.10 in., 2.5 mm)

RETURN CONNECTION

USING RETURN AIR

OPENING

A

WidthBDepthCHeight

12 3

Size

(IPT)

J

1/2-in.

(1.3 cm)

K

1/2-in.

(1.3 cm)

L

3/4-in.

(1.3 cm)

MNOSupply

Width

P

Supply

Depth

QRSReturn

Depth

T

Return

Height

U

DE FG

HI

Low

Vol ta ge

Low

Vol ta ge

Power

Supply

Loop In Loop Out

006-

012

in. 19.1 19.1 22.0 1.4 1.6 9.5 1.6 6.1 1.61/

2

2.9 5.9 8.9 8.9 5.1 9.0 9.0 5.5 2.1 16.2 9.9 0.7

cm 48.5 48.5 55.9 3.6 4.1 24.1 4.3 15.6 4.1 1.3 7.3 14.9 22.5 22.7 12.9 22.9 22.9 14.0 5.3 41.1 25.1 1.9

015

in. 21.5 21.5 39.0 1.9 1.4 13.8 1.4 8.1 1.4

1

/

2

4.1 7.1 10.1 6.4 3.8 14.0 14.0 5.3 2.3 18.3 20.9 0.7

cm 54.6 54.6 99.1 4.8 3.6 35.1 3.6 20.6 3.6 1.3 10.5 18.1 25.7 16.1 9.5 35.6 35.6 13.6 5.8 46.5 53.1 1.9

018

in. 21.5 21.5 39.0 1.9 1.4 12.9 1.4 8.1 1.41/

2

4.1 7.1 10.1 6.4 3.8 14.0 14.0 5.3 2.3 18.3 20.9 0.7

cm 54.6 54.6 99.1 4.8 3.6 32.8 3.6 20.6 3.6 1.3 10.5 18.1 25.7 16.1 9.5 35.6 35.6 13.6 5.8 46.5 53.1 1.9

024

in. 21.5 21.5 40.0 1.9 1.4 13.8 1.4 8.1 1.4

3

/

4

4.1 7.1 10.1 6.4 3.8 14.0 14.0 5.3 2.3 18.3 20.9 0.7

cm 54.6 54.6 101.6 4.8 3.6 35.1 3.6 20.6 3.6 1.9 10.5 18.1 25.7 16.1 9.5 35.6 35.6 13.6 5.8 46.5 53.1 1.9

030

in. 21.5 21.5 40.0 1.9 1.4 15.2 1.4 8.1 1.4

3

/

4

4.1 7.1 10.1 6.4 3.8 14.0 14.0 5.3 2.3 18.3 20.9 0.7

cm 54.6 54.6 101.6 4.8 3.6 38.6 3.6 20.6 3.6 1.9 10.5 18.1 25.7 16.1 9.5 35.6 35.6 13.6 5.8 46.5 53.1 1.9

036

in. 21.5 26.0 45.0 1.9 1.4 15.7 1.4 8.1 1.43/

4

4.1 7.1 10.1 6.4 3.8 14.0 14.0 5.1 2.3 22.8 23.9 0.7

cm 54.6 66.0 114.3 4.8 3.6 39.9 3.6 20.6 3.6 1.9 10.5 18.1 25.7 16.1 9.5 35.6 35.6 13.1 5.8 57.9 60.7 1.9

042

in. 21.5 26.0 45.0 1.9 1.4 16.6 1.4 8.1 1.4

3

/

4

4.1 7.1 10.1 6.4 3.8 14.0 14.0 5.1 2.3 22.8 23.9 0.7

cm 54.6 66.0 114.3 4.8 3.6 42.0 3.6 20.6 3.6 1.9 10.5 18.1 25.7 16.1 9.5 35.6 35.6 13.1 5.8 57.9 60.7 1.9

048

in. 24.0 32.5 46.0 1.9 1.4 16.6 1.4 8.1 1.4 1 4.1 7.1 10.1 6.9 7.3 16.0 18.0 5.1 2.3 29.3 22.5 0.7

cm 61.0 82.6 116.8 4.8 3.6 42.2 3.6 20.6 3.6 2.5 10.5 18.1 25.7 17.4 18.4 40.6 45.7 13.1 5.8 74.4 57.0 1.9

060

in. 24.0 32.5 46.0 1.9 1.4 16.7 1.4 8.1 1.4 1 4.1 7.1 10.1 6.9 7.3 16.0 18.0 5.1 2.3 29.3 22.5 0.7

cm 61.0 82.6 116.8 4.8 3.6 42.4 3.6 20.6 3.6 2.5 10.5 18.1 25.7 17.4 18.4 40.6 45.7 13.1 5.8 74.4 57.0 1.9

Fig. 3 — 50PCV Unit Dimensions

LEGEND

ASP — Alternate Service Panel

BSP — Blower Service Panel

CAP — Control Access Panel

CSP — Compressor Service Panel

FPT — Female Pipe Thread

HV — High Voltage

LV — Low Voltage

a50-8696

Q

AIR COIL AND FRONT SIDE

TOP VIEW-FRONT RETURN

FRONT

O

Q

TOP VIEW-RIGHT RETURN

R

U

P

P

AIR COIL SIDE

S

N

N

N

TOP VIEW-LEFT RETURN

U

B

P

AIR COIL SIDE

S

O

FRONT

A

M

R

FIELD INSTALLED

STANDARD FILTER BRACKET

AIR COIL

CSP

2 FT [610 MM]

DISCHARGE FLANGE

SERVICE

BSP

CAP

ISOMETRIC

VIEW

ACCESS PANELS

ASP

1.00 [25.4 MM]

OPTIONAL

2 FT [610 MM]

SERVICE

ACCESS

LEFT RTN

(RIGHT RTN

OPPOSITE

SIDE)

AIR COIL

T

C

T

C

BACKFRONT

RIGHT RETURN RIGHT VIEW

- AIR COIL OPENING

LEFT RETURN LEFT VIEW

- AIR COIL OPENING

AIR COIL

BSP

G

POWER SUPPLY

3/4" [19.1 MM] HV

KNOCKOUT

LOW VOLTAGE

1/2" [12.7 MM] LV

CSPCSP

FRONTBACK

KNOCKOUT

LOW VOLTAGE

1/2" [12.7 MM] LV

KNOCKOUT

CSP

J

2

CAP

3

L

K

1

FRONT-VIEW

E

I

D

6

CONDENSATE

3/4" FPT

F

H

Step 3 — Locate Unit — The following guidelines

Return

Air

Power

Thermostat

Wiring

Compressor

Access Panel

Balancing Valve

(field installed

and calibrated

accessory)

Field-supplied

stainless steel

braid hose

with integral

“ J” swivel

Low Pressure

Drop Water

Control Valve

(optional)

(field-installed

accessory)

Ball Valve with optional

integral P/T plug

(typical for supply and

return piping)

Water

Out

Water

In

Building

Loop

Supply Air

Flexible

Connection

NOTE: Ball valve with integral pressure temperature plug recommended.

Fig. 4 — Typical Vertical Installation of 50PCV Unit

a50-6803ef

Return Air

Remove Screws

Return Air

Rotate

Move to Side

Side Discharge

Return Air

Discharge Air

Drain

Back Discharge

Replace Screws

Water

Connection End

Water

Connection End

Water

Connection End

Fig. 5 — Conversion Left Return,

Side Discharge to Back Discharge

Water

Connection End

Supply

Duct

Return Air

Water

Connection End

Drain

Return Air

Discharge Air

Side Discharge

Back Discharge

Fig. 6 — Conversion Right Return,

Side Discharge to Back Discharge

a50-6257ef

should be considered when choosing a location for a WSHP:

• Units are for indoor use only.

• Locate in areas where ambient temperatures are between

40 F and 100 F and relative humidity is no greater than

75%.

• Provide sufficient space for water, electrical and duct

connections.

• Locate unit in an area that allows easy access and

removal of filter and access panels.

• Allow enough space for service personnel to perform

maintenance.

• Return air must be able to freely enter the space if unit

needs to be installed in a confined area such as a closet.

• Install the unit on a piece of rubber, neoprene or other

mounting pad material for sound isolation. The pad

should be at least

thickness. Extend the pad beyond all four edges of the

3

/8 in. [10 mm] to 1/2 in. [13 mm] in

unit.

• Provide adequate clearance for filter replacement and

drain pan cleaning. Do not block filter access with piping, conduit or other materials. Refer to Fig. 1 and 3 for

dimensional data.

• Provide access for fan and fan motor maintenance and

for servicing the compressor and coils without removing

the unit.

• Provide an unobstructed path to the unit within the closet

or mechanical room. Space should be sufficient to allow

removal of the unit, if necessary.

• In limited side access installations, pre-removal of the

control box side mounting screws will allow control box

removal for future servicing.

• Provide access to water valves and fittings and screwdriver access to the unit side panels, discharge collar and

all electrical connections.

NOTE: Correct placement of the horizontal unit can play an

important part in minimizing sound problems. Since ductwork is normally applied to these units, the unit can be

placed so that the principal sound emission is outside the occupied space in sound-critical applications. A fire damper

may be required by the local code if a fire wall is penetrated.

FIELD CONVERSION OF DISCHARGE AIR — The discharge air of the 50PCH horizontal units can be converted

between side and back discharge in the field. The conversion

process is the same for right and left return configurations. See

Fig. 5 and 6.

NOTE: It is not possible to convert return air between left or

right return models in the field due to refrigerant piping

changes.

Preparation

— The unit should be on the ground in a well lit

area for conversion. Hung units should be taken down to

ground level before converting.

7

Side to Back Discharge Conversion

Fig. 7 — Horizontal Hanger Bracket

(Factory Installed)

a50-8489

Vibration

Absorption

Pad

Fig. 8 — 50PCV Unit Mounted with

Vibration Absorption Pad

a50-6259ef

Fig. 9 — Horizontal Unit Pitch

1/4” Pitch for

Drainage

Drain Connection

Pitch Toward

Drain

a50-6260ef

1. Remove screws to free the top and discharge panels. See

Fig. 5.

2. Remove the access panel and set aside.

3. Lift the discharge panel from side of unit and rotate it to

back using care not to damage blower wiring.

4. Check blower wire routing and connections for undue

tension or contact with sheet metal edges. Re-route if

necessary.

5. Check refrigerant tubing for contact with other components. Adjust if necessary.

6. Reinstall top panel using screws set aside in Step 1.

NOTE: Location for some screws at bottom of discharge panel

may have to be changed.

7. Manually spin fan wheel to check for obstructions.

Adjust for any obstruction found.

8. Replace access panel.

Back to Side Discharge Conversion

— Follow instructions

above for Side to Back Discharge Conversion, noting the

panels would be reversed.

Step 4 — Mount the Unit

HORIZONTAL UNITS (50PCH) — Horizontal units should be

mounted using the factory-installed hangers. Proper attachment

of hanging rods to building structure is critical for safety. See

Fig. 2 and 7. Rod attachments must be able to support the

weight of the unit. See Table 1 for unit operating weights.

COMPRESSOR

SECTION

AIR HANDLER

SECTION

NOTE: Some codes require the use of a secondary drain pan

under vertical units. Check local codes for more information.

Step 5 — Check Duct System — Size the duct sys-

tem to handle the design airflow quietly.

NOTE: Depending on the unit, the fan wheel may have a shipping support installed at the factory. This must be removed

before operating unit.

SOUND ATTENUATION — To eliminate the transfer of

vibration to the duct system, a flexible connector is recommended for both discharge and return air duct connections on

metal duct systems. The supply and return plenums should include internal duct liner of fiberglass or be made of duct board

construction to maximize sound attenuation of the blower.

Installing the WSHP unit to uninsulated ductwork in an unconditioned space is not recommended since it will sweat and

adversely affect the unit’s performance.

To reduce air noise, at least one 90-degree elbow could be

included in the supply and return air ducts, provided system

performance is not adversely impacted. The blower speed can

also be changed in the field to reduce air noise or excessive airflow, provided system performance is not adversely impacted.

EXISTING DUCT SYSTEM — If the unit is connected to

existing ductwork, consider the following:

• Verify that the existing ducts have the proper capacity to

handle the unit airflow. If the ductwork is too small,

install larger ductwork.

• Check existing ductwork for leaks and repair as

necessary.

NOTE: Local codes may require ventilation air to enter the

space for proper indoor air quality. Hard-duct ventilation may

be required for the ventilating air supply. If hard ducted ventilation is not required, be sure that a proper air path is provided

for ventilation air to unit to meet ventilation requirement of the

space.

Step 6 — Install Condensate Drain

HORIZONTAL UNITS (50PCH) — Slope the unit toward

the drain at a

sible to meet the required pitch, install a condensate pump at

the unit to pump condensate to building drain.

1

/4 in. drop at drain end. See Fig. 9. If it is not pos-

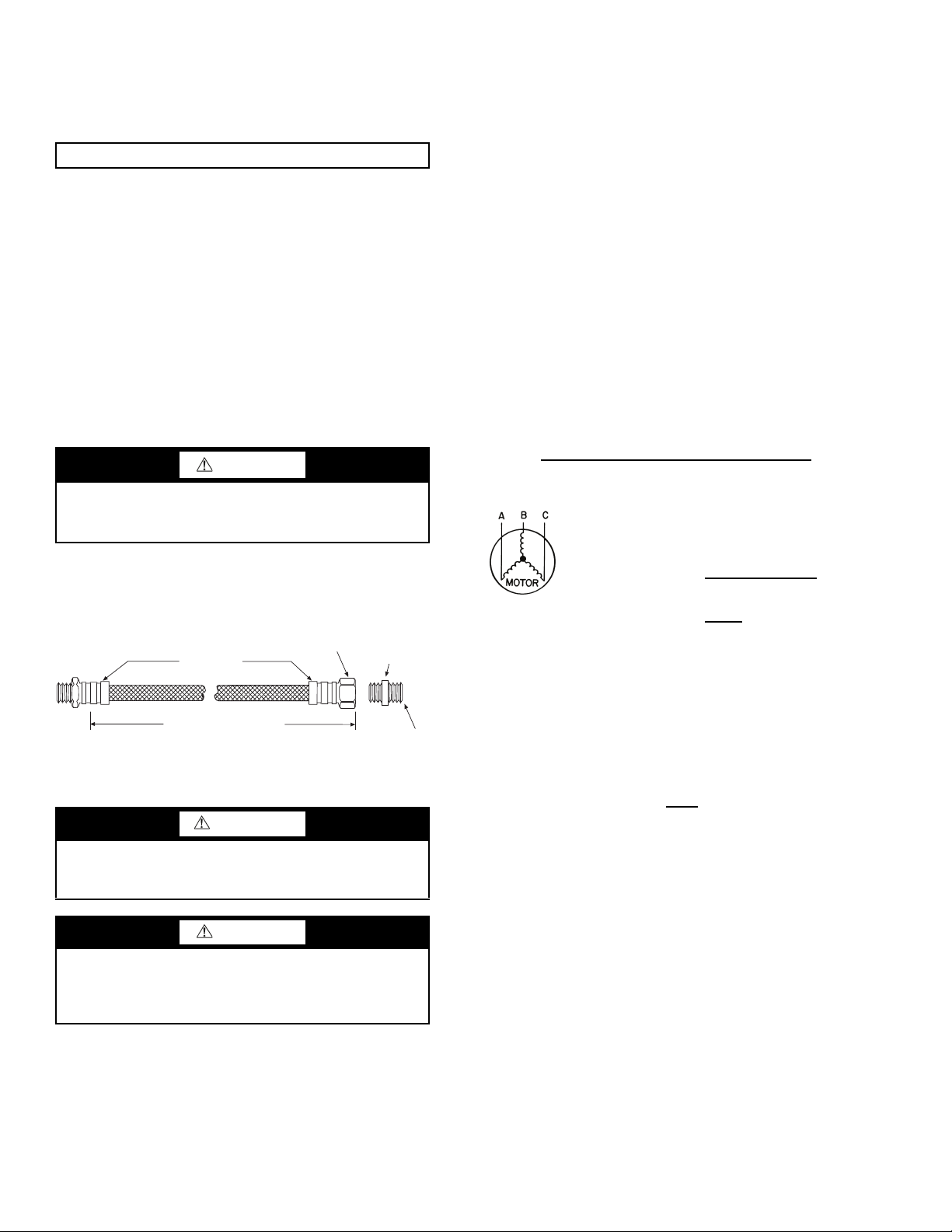

VERTICAL UNITS (50PCV) — Vertical units are available in

left or right return air configurations. See Fig. 3. Mount the unit

on a vibration absorption pad slightly larger than the entire base

to minimize vibration transmission. It is not necessary to mount

the unit on the floor. See Fig. 8.

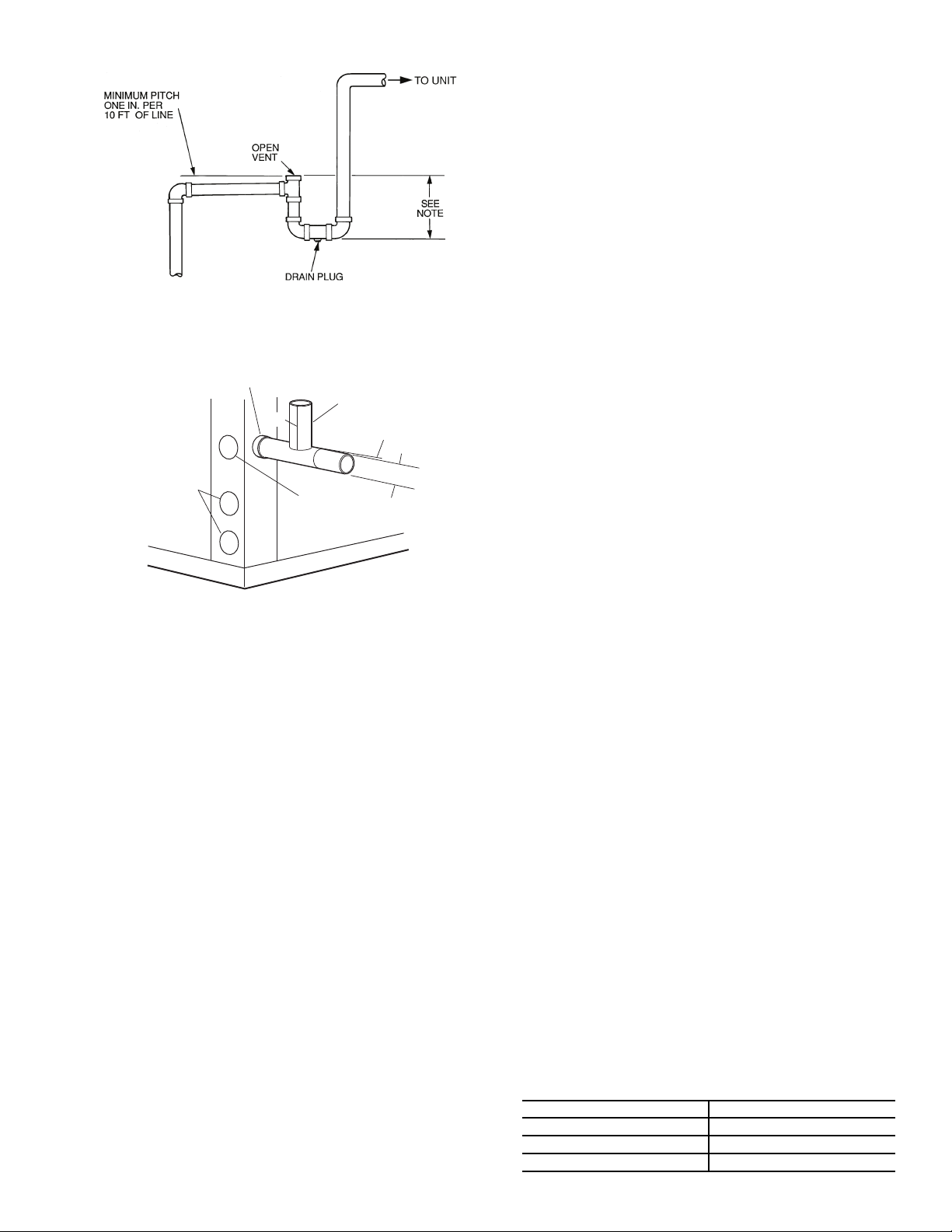

Horizontal units are not internally trapped, therefore an external trap is necessary. Install each unit with its own individual

trap and means to flush or blow out the condensate drain line.

Do not install units with a common trap or vent. For typical

condensate connections see Fig. 10.

NOTE: Never use a pipe size smaller than the connection.

VERTICAL UNITS (50PCV) — Each unit uses a condensate

hose inside all cabinets as a trapping loop, therefore an external

trap is not necessary and should not be used. See Fig. 11.

8

Each unit must be installed with its own individual vent and

NOTE: Trap should be deep enough to offset maximum unit static

difference. A 4-in. trap is recommended.

Fig. 10 — Trap Condensate Drain

a50-6261tf

Alternate

Condensate

Location

Vent

1/4” per foot

slope to drain

3/4” Copper FPT/PVC

Water

Connections

1/2”

1/2”

3/4” PVC

NOTE: Unit does not need to be sloped toward drain.

Fig. 11 — Vertical Condensate Connection

a50-6262ef

means to flush or blow out the condensate drain line. Do not install units with a common trap or vent.

VENTING — Install a vent in the condensate line of any

application that may allow dirt or air to collect in the line. Consider the following:

• Always install a vent where an application requires a

long horizontal run.

• Always install a vent where large units are working

against higher external static pressure and to allow

proper drainage for multiple units connected to the same

condensate main.

• Be sure to support the line where anticipated sagging from

the condensate or when “double trapping” may occur.

• If condensate pump is present on unit, be sure drain connections have a check valve to prevent back flow of condensate into other units.

Step 7 — Pipe Connections — Depending on the

application, there are 3 types of WSHP piping systems to

choose from: water loop, ground-water and ground loop. Refer

to Piping Section of Carrier System Design Manual for additional information.

thread fittings for water connections to prevent annealing and

out-of-round leak problems which are typically associated with

high temperature brazed connections. Refer to Table 1 for connection sizes. When making piping connections, consider the

following:

• Use a backup wrench when making screw connections to

All WSHP units use low temperature soldered female pipe

unit to prevent internal damage to piping.

• Insulation may be required on piping to avoid condensation in the case where fluid in loop piping operates at

temperatures below dew point of adjacent air.

• Piping systems that contain steel pipes or fittings may

be subject to galvanic corrosion. Dielectric fittings may

be used to isolate the steel parts of the system to avoid

galvanic corrosion.

WATER LOOP APPLICATIONS — Water loop applications

usually include a number of units plumbed to a common piping system. Maintenance to any of these units can introduce air

into the piping system. Therefore, air elimination equipment

comprises a major portion of the mechanical room plumbing.

The flow rate is usually set between 2.25 and 3 gpm per ton

of cooling capacity. For proper maintenance and servicing,

pressure-temperature (P/T) ports are necessary for temperature

and flow verification.

In addition to complying with any applicable codes, consid-

er the following for system piping:

• Piping systems using water temperatures below 50 F

require

1

/2-in. closed cell insulation on all piping surfaces

to eliminate condensation.

• Avoid all plastic to metal threaded fittings due to the

potential to leak. Use a flange fitted substitute.

• Teflon tape thread sealant is recommended to minimize

internal fouling of the heat exchanger.

• Use backup wrench. Do not overtighten connections.

• Route piping to avoid service access areas to unit.

• Flush the piping system prior to operation to remove dirt

and foreign materials from the system.

GROUND-LOOP APPLICATIONS — Temperatures between 25 and 110 F and a cooling capacity of 2.25 to 3 gpm of

flow per ton is recommended. In addition to complying with

any applicable codes, consider the following for system piping:

• Limit piping materials to only polyethylene fusion in the

buried sections of the loop.

• Do not use galvanized or steel fittings at any time due to

corrosion.

• Avoid all plastic to metal threaded fittings due to the potential to leak. Use a flange fitted substitute.

• Do not overtighten connections.

• Route piping to avoid service access areas to unit.

• Use pressure-temperature (P/T) plugs to measure flow of

pressure drop.

INSTALLATION OF SUPPLY AND RETURN HOSE

KIT — Follow these piping guidelines.

1. Install a drain valve at the base of each supply and return

riser to facilitate system flushing.

2. Install shutoff/balancing valves and unions at each unit to

permit unit removal for servicing.

3. Place strainers at the inlet of each system circulating

pump.

4. Select the proper hose length to allow slack between connection points. Hoses may vary in length by +2% to –4%

under pressure.

5. Refer to Table 2. Do not exceed the minimum bend radius

for the hose selected. Exceeding the minimum bend radius may cause the hose to collapse, which reduces water

flow rate. Install an angle adapter to avoid sharp bends

in the hose when the radius falls below the required

minimum.

NOTE: Piping must comply with all applicable codes.

Table 2 — Metal Hose Minimum Bend Radii

HOSE DIAMETER (in.) MINIMUM BEND RADII (in.)

1

/

2

3

/

4

15

21/

2

4

1

/

2

9

Rib Crimped

Length

(2 ft Length Standard)

Swivel

Brass

Fitting

Brass

Fitting

MPT

Fig. 12 — Supply/Return Hose Kit

A50-7734

Insulation is not required on loop water piping except where

the piping runs through unheated areas or outside the building

or when the loop water temperature is below the minimum expected dew point of the pipe ambient. Insulation is required if

loop water temperature drops below the dew point.

IMPORTANT: Do not bend or kink supply lines or hoses.

Pipe joint compound is not necessary when Teflon* threaded tape is pre-applied to hose assemblies or when flared-end

connections are used. If pipe joint compound is preferred, use

compound only in small amounts on the male pipe threads of

the fitting adapters. Prevent sealant from reaching the flared

surfaces of the joint.

NOTE: When anti-freeze is used in the loop, assure that it is

compatible with Teflon tape or pipe joint compound employed.

Maximum allowable torque for brass fittings is 30 ft-lb. If a

torque wrench is not available, tighten finger-tight plus one

quarter turn. Tighten steel fittings as necessary.

Optional pressure-rated hose assemblies designed specifically for use with Carrier units are available. Similar hoses can

be obtained from alternate suppliers. Supply and return hoses

are fitted with swivel-joint fittings at one end to prevent kinking during installation.

CAUTION

Backup wrench is required when tightening water connections to prevent water line damage. Failure to use a backup

wrench could result in equipment damage.

Refer to Fig. 12 for an illustration of a supply/return hose

kit. Male adapters secure hose assemblies to the unit and risers.

Install hose assemblies properly and check them regularly to

avoid system failure and reduced service life.

Step 8 — Wire Field Power Supply

WARNING

To avoid possible injury or death due to electrical shock,

open the power supply disconnect switch and secure it in

an open position during installation.

CAUTION

Use only copper conductors for field-installed electrical

wiring. Unit terminals are not designed to accept other

types of conductors. Failure to follow this safety precaution

could lead to equipment damage.

All field installed wiring, including the electrical ground,

MUST comply with the National Electrical Code (NEC) as

well as applicable local codes. In addition, all field wiring must

conform to the Class II temperature limitations described in the

NEC.

*Registered trademark of E. I. du Pont de Nemours and Company.

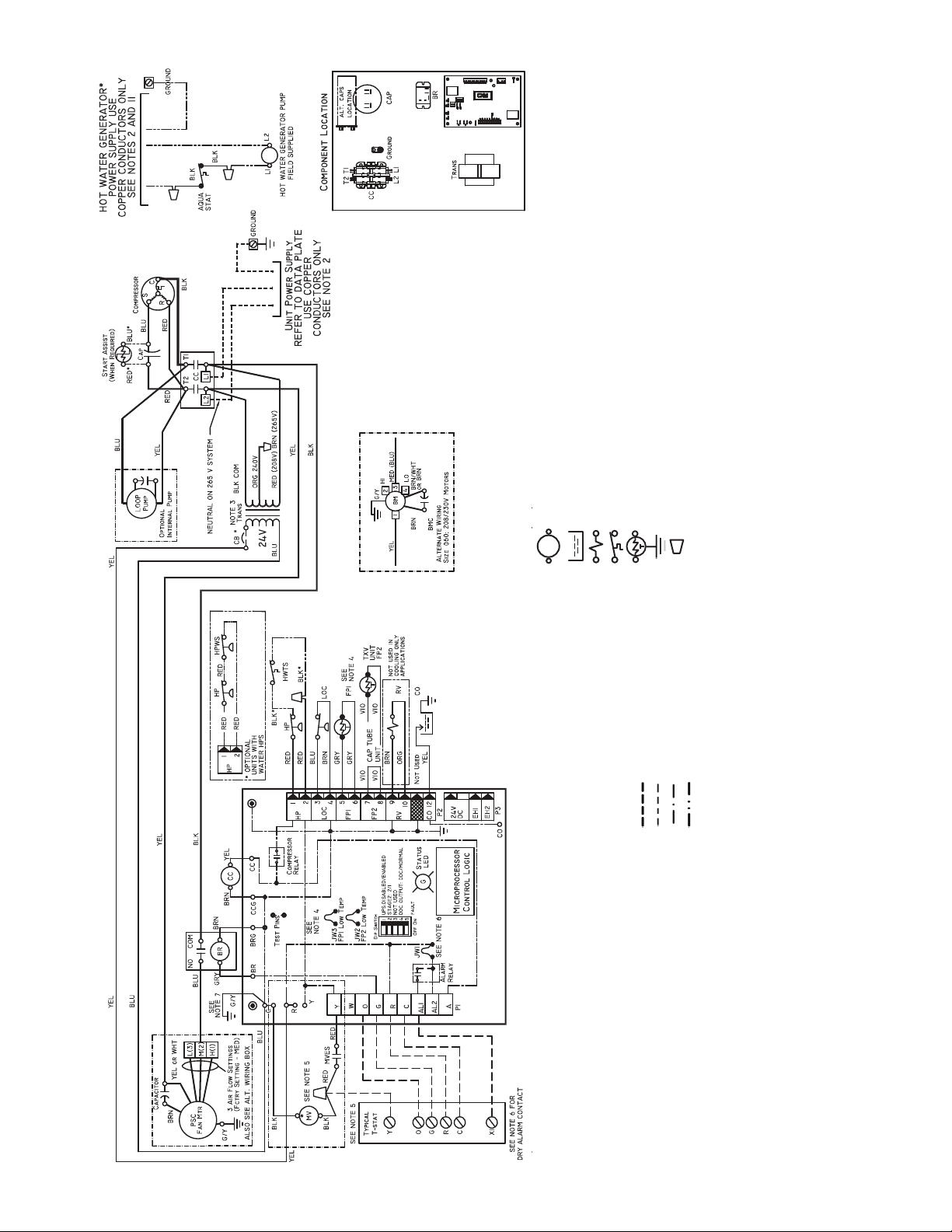

Refer to unit wiring diagrams Fig. 13-20 for a schematic of

the field connections, which must be made by the installing (or

electrical) contractor. Refer to Table 3 for fuse sizes.

Consult the unit wiring diagram located on the inside of the

compressor access panel to ensure proper electrical hookup.

The installing (or electrical) contractor must make the field

connections when using field-supplied disconnect.

Operating voltage must be the same voltage and phase as

shown in Table 3.

Make all final electrical connections with a length of flexible conduit to minimize vibration and sound transmission to

the building.

POWER CONNECTION — Make line voltage connection

by connecting the incoming line voltage wires to the L side

of the CC terminal as shown in Fig. 21. See Table 3 for correct wire and maximum overcurrent protection sizing.

SUPPLY VOLTAGE — Operating voltage to unit must be

within voltage range indicated on unit nameplate.

On 3-phase units, voltages under load between phases must

be balanced within 2%. Use the following formula to determine the percentage voltage imbalance:

% Voltage Imbalance

= 100 x

max voltage deviation from average voltage

average voltage

Example: Supply voltage is 460-3-60.

AB = 452 volts

BC = 464 volts

AC = 455 volts

Average Voltage =

452 + 464 + 455

3

1371

=

3

= 457

Determine maximum deviation from average voltage:

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent voltage imbalance.

% Voltage Imbalance = 100 x

7

457

= 1.53%

This amount of phase imbalance is satisfactory as it is

below the maximum allowable 2%.

Operation on improper line voltage or excessive phase

imbalance constitutes abuse and may cause damage to electrical components.

NOTE: If more than 2% voltage imbalance is present, contact

your local electric utility.

208-VOLT OPERATION — All 208-230 volt units are factory

wired for 208 volts. The transformers may be switched to

230-volt operation by switching the red (208 volt) wire with

the orange (230 volt) wire at the L1 terminal.

460-VOLT OPERATION — Units using 460-v and internal

secondary pump will require a neutral wire from the supply

side in order to feed accessory with 265-v.

10

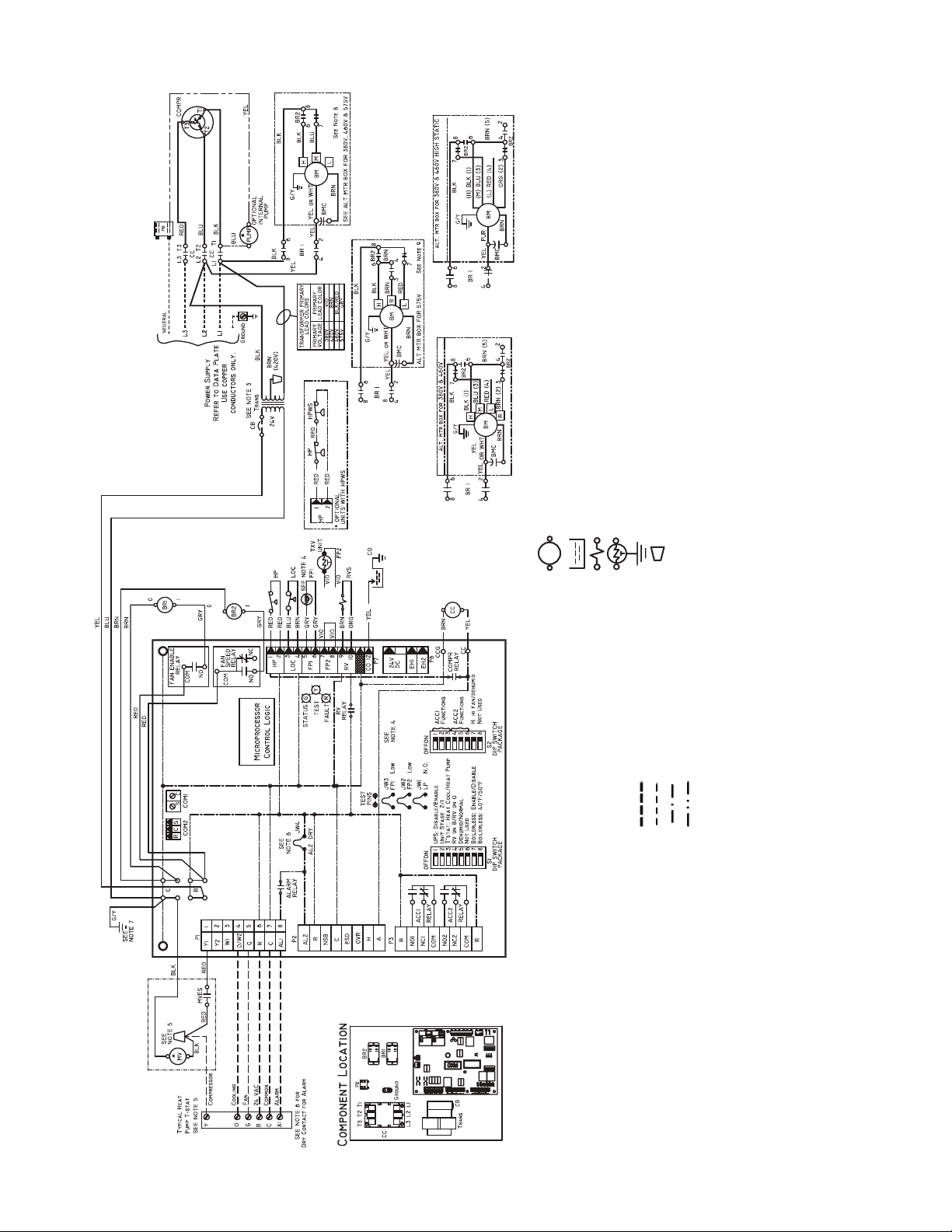

NOTES:

1. Compressor and blower motor thermally protected internally.

2. All wiring to the unit must comply with NEC and local codes.

3. Transformer for 208/230 v will be connected for 208 v operation. For

230 v operation, switch RED wire to ORG wire. Insulate open end of

RED lead. Transformer is energy limiting or may have circuit breaker.

4. FP1 thermistor provides freeze protection for water. When using anti-

freeze solutions, cut JW3 jumper.

5. Typical heat pump thermostat wiring shown. Refer to thermostat installa-

tion instructions for wiring to the unit. Wire “Y” from thermostat to “Y”

Complete C when a motorized valve is not used. “O” terminal is not used

in cooling only applications. Thermostat wiring must be Class 1 and volt-

age rating equal to or greater than unit supply voltage.

6. 24-v alarm signal shown. For dry alarm contact, cut JW1 jumper and for

anti-freeze solutions, cut JW3 jumper.

7. Transformer secondary ground via green wire with yellow stripe from “C”

terminal to control box.

8. Hot water generator pump only in models with hot water generation and

internal pump option.

9. For auxiliary staging options, consult electric heat installation manual.

10. Fan motors factory wired for medium speed. For high or low speed,

remove BLU wire from fan motor speed trap “M” and connect to “H” for

high speed or “L” for low speed.

11. Aquastat is with unit and must be wired in series with the hot leg to the

pump. Aquastat is rated for voltage up to 277 v.

a50-8490

Fig. 13 — 50PCH,PCV Units with Complete C Controller, Single-Phase

Complete C

*Optional.

AL — Alarm Relay Contacts

BM — Blower Motor

BMC — Blower Motor Capacitor

BR — Blower Relay

CAP — Compressor Capacitor

CB — Circuit Breaker

CC — Compressor Contactor

CO — Sensor, Condensate Overflow

FP1 — Sensor, Low Temperature Protection Water Coil

FP2 — Sensor, Low Temperature Protection Air Coil

HP — High-Pressure Switch

HPWS — High-Pressure Water Switch

HWTS — High Leaving Water Temperature Switch

JW1 — Jumper, Alarm

LEGEND

LOC — Loss of Charge Pressure Switch

MV — Motorized Valve

MVES — Motorized Valve End Switch

NEC — National Electrical Code

P1 — Field Wiring Terminal Block

PSC — Permanent Split Capacitor

RV — Reversing Valve Coil

TRANS — Transformer

TXV — Thermostatic Expansion Valve

Field Line Voltage Wiring

Field Low Voltage Wiring

Printed Circuit Trace

Optional Wiring

Relay/Contactor Coil

Condensate Pan

Solenoid Coil

Temperature Switch

Thermistor

Ground

Wire Nut

11

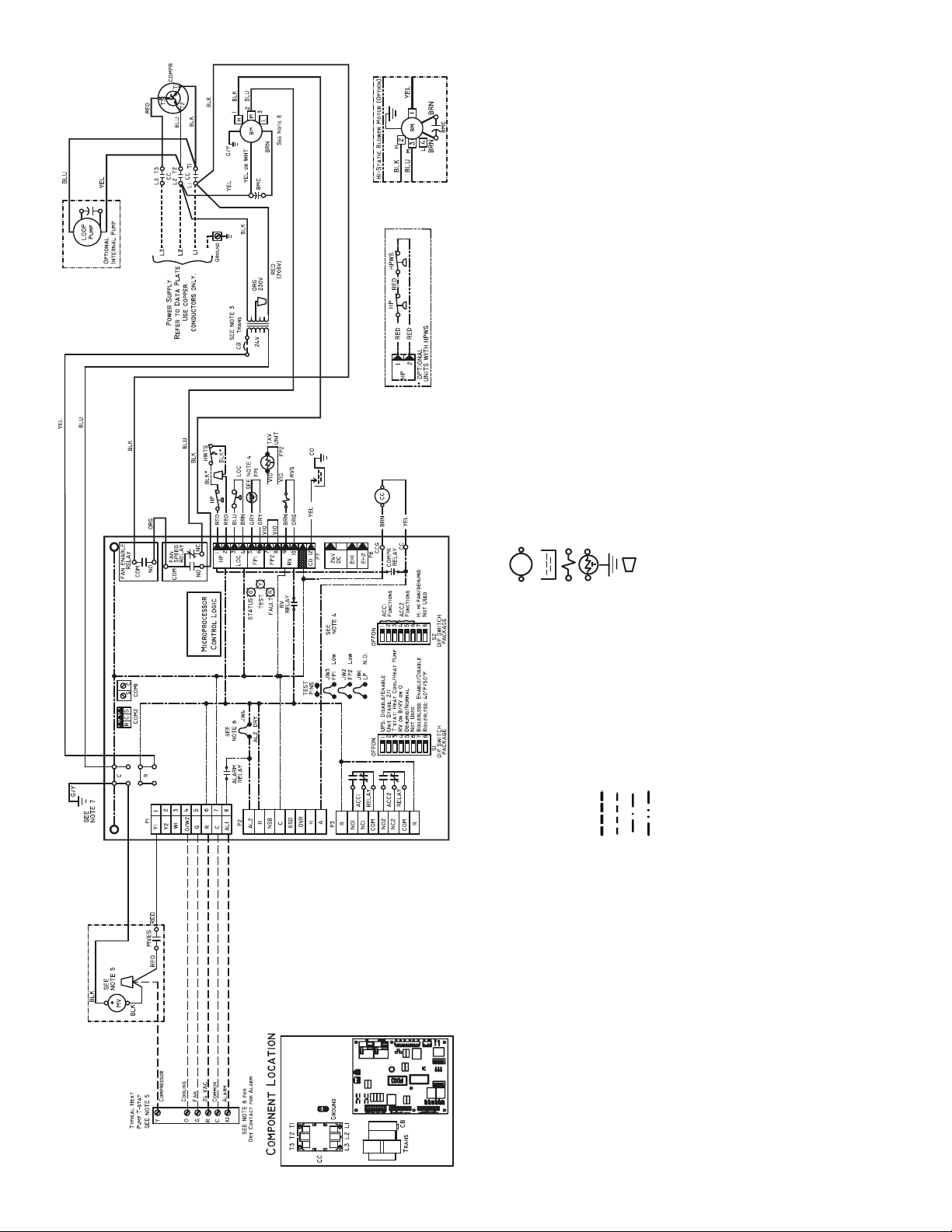

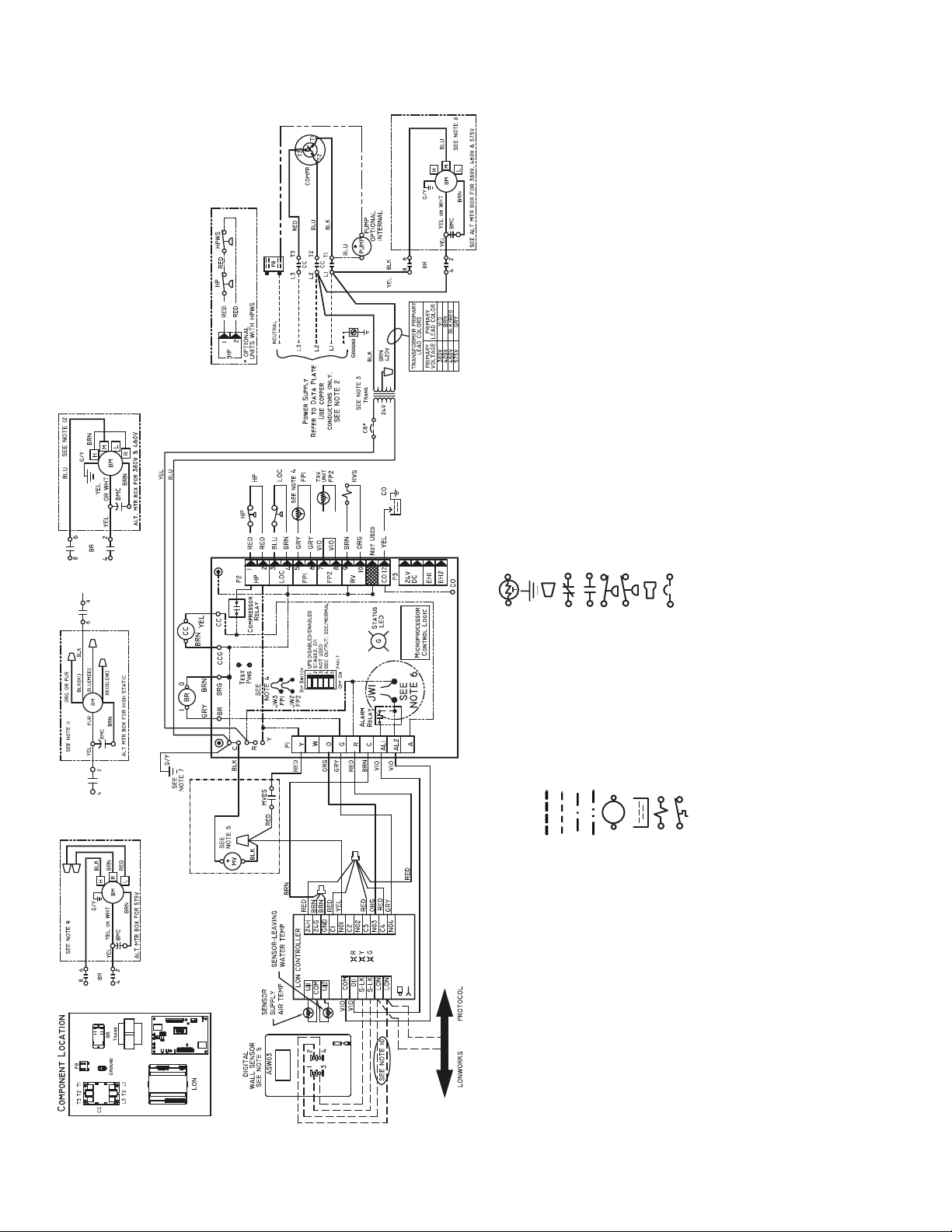

NOTES:

1. Compressor thermally protected internally.

2. All wiring to the unit must comply with NEC and local codes.

3. Transformer is wired to 208-v RED lead for 208-3-60 units. For 230-3-60,

switch RED and ORG leads at L1 and insulate RED lead. Transformer is

energy limiting or may have circuit breaker.

4. FP1 thermistor provides freeze protection for water. When using anti-

freeze solutions, cut JW3 jumper.

5. Refer to microprocessor control, LON, or thermostat installation instruc-

tions for wiring to the unit. Wire “Y” from thermostat to “Y1” Deluxe D

when motorized valve is not used. Thermostat wiring must be Class 1

and voltage rating equal to or greater than unit supply voltage. Heat/cool

thermostats not compatible with motorized water valve.

6. 24-v alarm signal shown. For dry alarm contact, cut JW4 jumper and dry

contact will be available between AL1 and AL2.

7. Transformer secondary ground via green wire with yellow stripe from “C”

terminal to control box.

8. Blower motor is factory wired for medium and high speeds. For any other

combination of speeds, attach black wire to the higher of the two desired

speed taps and the blue wire to the lower of the two desired speed taps.

a50-8491

Fig. 14 — 50PCH,PCV Units with Deluxe D Controller, Three-Phase (208/230 V)

LEGEND

Relay/Contactor Coil

Condensate Pan

Solenoid Coil

Thermistor

Ground

Wire Nut

*Optional.

AL — Alarm Relay Contacts

BM — Blower Motor

BMC — Blower Motor Capacitor

CB — Circuit Breaker

CC — Compressor Contactor

CO — Sensor, Condensate Overflow

FP1 — Sensor, Low Temperature Protection Water Coil

FP2 — Sensor, Low Temperature Protection Air Coil

HP — High-Pressure Switch

HPWS — High-Pressure Water Switch

HWTS — High Leaving Water Temperature Switch

JW1 — Jumper, Alarm

LOC — Loss of Charge Pressure Switch

MV — Motorized Valve

MVES — Motorized Valve End Switch

NEC — National Electrical Code

P1 — Field Wiring Terminal Block

RVS — Reversing Valve Solenoid

TRANS — Transformer

TXV — Thermostatic Expansion Valve

Field Line Voltage Wiring

Field Low Voltage Wiring

Printed Circuit Trace

Optional Wiring

Deluxe D

12

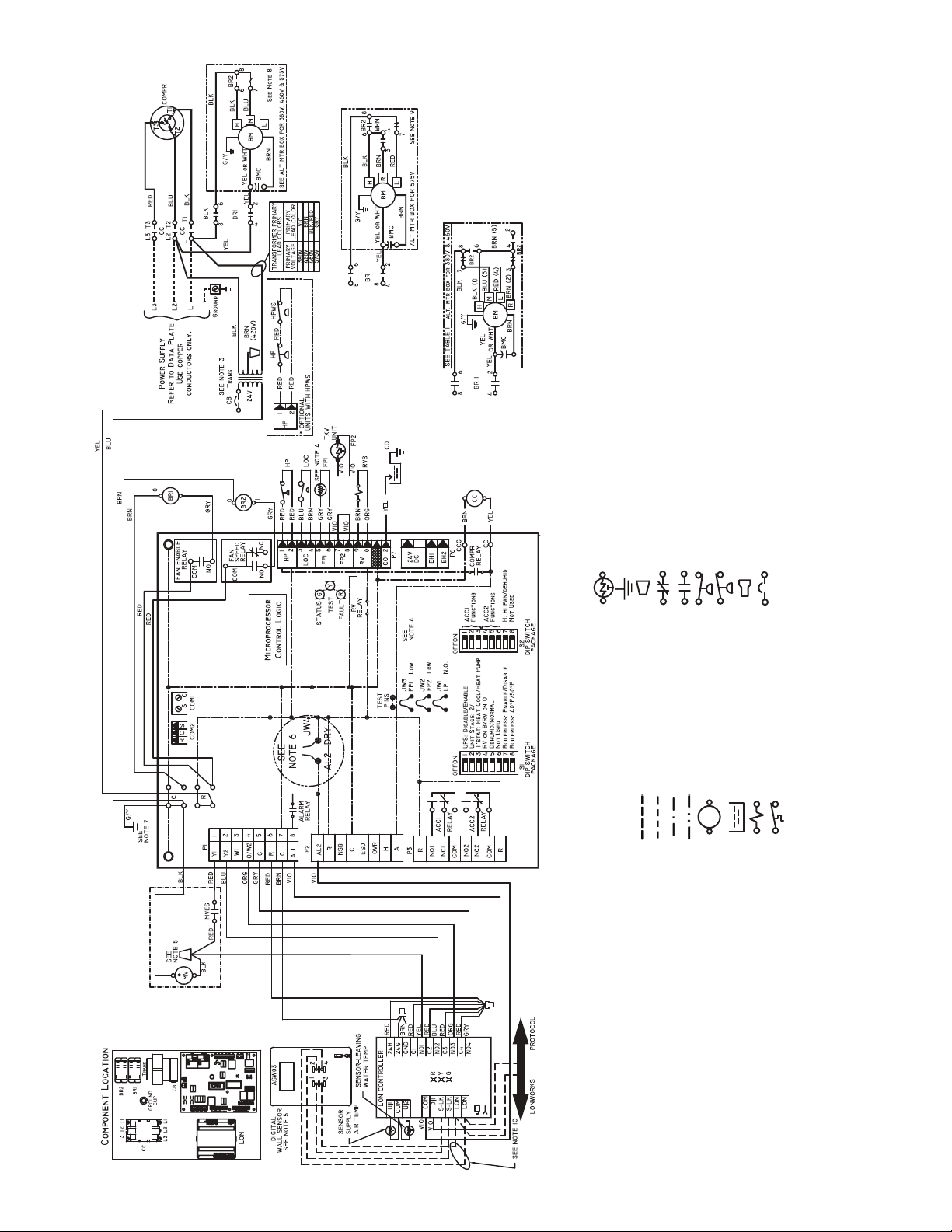

NOTES:

1. Compressor thermally protected internally.

2. All wiring to the unit must comply with NEC and local codes.

3. Transformer is wired to 460-v BLK/RED lead for 460-3-60 units or 575-v

GRY lead for 575-3-60 units. Transformer is energy limiting or may have

circuit breaker.

4. FP1 thermistor provides low temperature protection for water. When

using antifreeze solutions, cut JW3 jumper.

5. Refer to microprocessor control, LON, or thermostat installation instruc-

tions for wiring to the unit. Wire “Y” from thermostat to “Y1” Deluxe D

when motorized valve is not used. Thermostat wiring must be Class 1

and voltage rating equal to or greater than unit supply voltage. Heat/cool

thermostats not compatible with motorized water valve.

6. 24-v alarm signal shown. For dry alarm contact, cut JW4 jumper and dry

contact will be available between AL1 and AL2.

7. Transformer secondary ground via green wire with yellow stripe from “C”

terminal to control box.

8. Blower motor is factory wired for medium and high speeds. For any

other combination of speeds, attach black wire to the higher of the two

desired speed taps at the motor. Attach the blue wire to the lower of the

two desired speed taps.

9. Blower motor is factory wired for high and low speeds. No other combi-

nation of speeds is available.

10. The 460-v units using an internal secondary pump will require a neutral

wire from the supply side in order to feed the accessory with 265-v.

a50-8492

Fig. 15 — 50PCH,PCV Units with Deluxe D Controller, Three-Phase (460 V)

Deluxe D

LEGEND

Relay/Contactor Coil

Condensate Pan

Solenoid Coil

Thermistor

Ground

Wire Nut

*Optional.

AL — Alarm Relay Contacts

BM — Blower Motor

BMC — Blower Motor Capacitor

BR — Blower Relay

CB — Circuit Breaker

CC — Compressor Contactor

CO — Sensor, Condensate Overflow

FP1 — Sensor, Low Temperature Protection Water Coil

FP2 — Sensor, Low Temperature Protection Air Coil

HP — High-Pressure Switch

HPWS — High-Pressure Water Switch

JW1 — Clippable Field Selection Jumper

LOC — Loss of Charge Pressure Switch

MV — Motorized Valve

MVES — Motorized Valve End Switch

NEC — National Electrical Code

P1 — Field Wiring Terminal Block

PB — Power Block

RVS — Reversing Valve Solenoid

TRANS — Transformer

TXV — Thermostatic Expansion Valve

Field Line Voltage Wiring

Field Low Voltage Wiring

Printed Circuit Trace

Optional Wiring

13

Fig. 16 — 50PCH,PCV Units with Complete C and LON Controller (460 V)

a50-8493

LEGEND

AL — Alarm Relay Contacts

BM — Blower Motor

BMC — Blower Motor Capacitor

BR — Blower Relay

CB — Circuit Breaker

CC — Compressor Contactor

CO — Sensor, Condensate Overflow

FP1 — Sensor, Low Temperature Protection, Water Coil

FP2 — Sensor, Low Temperature Protection, Air Coil

HP — High-Pressure Switch

HPWS — High-Pressure Water Switch

JW1 — Clippable Field Selection Jumper

LOC — Loss of Charge Pressure Switch

LON — Local Operating Network

MV — Motorized Valve

MVES — Motorized Valve End Switch

NEC — National Electrical Code

*Optional Wiring.

P1 — Field Wiring Terminal Block

RVS — Reversing Valve Solenoid

TRANS — Transformer

TXV — Thermostatic Expansion Valve

Field Line Voltage Wiring

Field Low Voltage Wiring

Printed Circuit Trace

Optional Wiring

Relay/Contactor Coil

Condensate Pan

Solenoid Coil

Temperature Switch

Thermistor

Ground

Wire Nut

Relay Contacts - N.C.

Relay Contacts - N.O.

Low Pressure Switch

High Pressure Switch

Splice Cap

Circuit Breaker

NOTES:

1. Compressor and blower motor thermally protected internally.

2. All wiring to the unit must comply with NEC and local codes.

3. Transformer is wired to 460 v BLK/RED lead for 460-3-60 units. Trans-

former is energy limiting or may have circuit breaker.

4. FP1 thermistor provides low temperature protection for water. When

using antifreeze solutions, cut JW3 jumper.

5. Refer to microprocessor control, LON, or thermostat installation

instructions for wiring to the unit. Wire “N01” from LON to “Y1” Com-

plete C when a motorized valve is not used. Low voltage wiring must

be Class 1 and voltage rating equal to or greater than unit supply

voltage.

6. Factory cut JW1 jumper. Dry contact will be available between AL1 and

AL2.

7. Transformer secondary ground via green wire with yellow strip from “C”

terminal to control box.

8. Fan motors are factory wired for medium speed. For high or low speed,

remove BLU wire from fan motor speed tap “M” and connect to “H” for

high speed or “L” for low speed.

9. For low speed, remove BLK wire from BR “6” and replace with RED.

Connect BLK and BRN wires together.

10. Optional LON wires. Only connect if LON connection is desired at the

wall sensor.

11. For blower motors with leads. For medium or low speed, disconnect

BLK wire from BR “6”. Connect BLK and ORG/PUR wire together.

Connect RED for low or BLU for medium to BR “6”.

12. Blower motor factory wired to medium speed. For low speed remove

BLU wire from medium tap and connect to low speed tap. For high

speed, remove BLU wire from exisiting speed tap and remove BRN

jumper wire from high speed tap. Connect BLU wire to high speed tap.

Tape off unconnected end of BRN jumper.

13. The 460-v units using an internal secondary pump will require a neu-

tral wire from the supply side in order to feed the accessory with 265-v.

Complete C

14

NOTES:

1. Compressor and blower motor thermally protected internally.

2. All wiring to the unit must comply with NEC and local codes.

3. Transformer is wired to 460-v BLK/RED lead for 460-3-60 units. Trans-

former is energy limiting or may have circuit breaker.

4. FP1 thermistor provides low temperature protection for water. When

using antifreeze solutions, cut JW3 jumper.

5. Refer to microprocessor control, LON, thermostat installation instruc-

tions for wiring to the unit. Wire “N01” from LON to “Y1” Deluxe D when

motorized valve is not used. Thermostat wiring must be Class 1 and

voltage rating equal to or greater than unit supply voltage.

6. Factory cut JW4 jumper. Dry contact will be available between AL1 and

AL2.

7. Transformer secondary ground via green wire with yellow stripe from

“C” terminal to control box.

8. Blower motor is factory wired for medium and high speeds. For any

other combination of speeds, attach black wire to the higher of the two

desired speed taps at the motor, and attach the blue wire to the lower of

the two desired speed taps.

9. Blower motor is factory wired for high and low speeds. No other combi-

nation is available.

10. Optional LON wires. Only connect if LON connection is desired at the

wall sensor.

11. The 460-v units using an internal secondary pump will require a neutral

wire from the supply side in order to feed the accessory with 265-v.

Fig. 17 — 50PCH,PCV units with Deluxe D and LON Controller (460 V)

LEGEND

AL — Alarm Relay Contacts

BM — Blower Motor

BMC — Blower Motor Capacitor

BR — Blower Relay

CB — Circuit Breaker

CC — Compressor Contactor

CO — Sensor, Condensate Overflow

FP1 — Sensor, Low Temperature Protection, Water Coil

FP2 — Sensor, Low Temperature Protection, Air Coil

HP — High-Pressure Switch

HPWS — High-Pressure Water Switch

JW1 — Clippable Field Selection Jumper

LOC — Loss of Charge Pressure Switch

LON — Local Operating Network

MV — Motorized Valve

MVES — Motorized Valve End Switch

NEC — National Electrical Code

*Optional Wiring.

P1 — Field Wiring Terminal Block

RVS — Reversing Valve Solenoid

TRANS — Transformer

TXV — Thermostatic Expansion Valve

Field Line Voltage Wiring

Field Low Voltage Wiring

Printed Circuit Trace

Optional Wiring

Relay/Contactor Coil

Condensate Pan

Solenoid Coil

Temperature Switch

Thermistor

Ground

Wire Nut

Relay Contacts - N.C.

Relay Contacts - N.O.

Low Pressure Switch

High Pressure Switch

Splice Cap

Circuit Breaker

a50-8440

Deluxe D

15

WHSP-OPEN

FSD

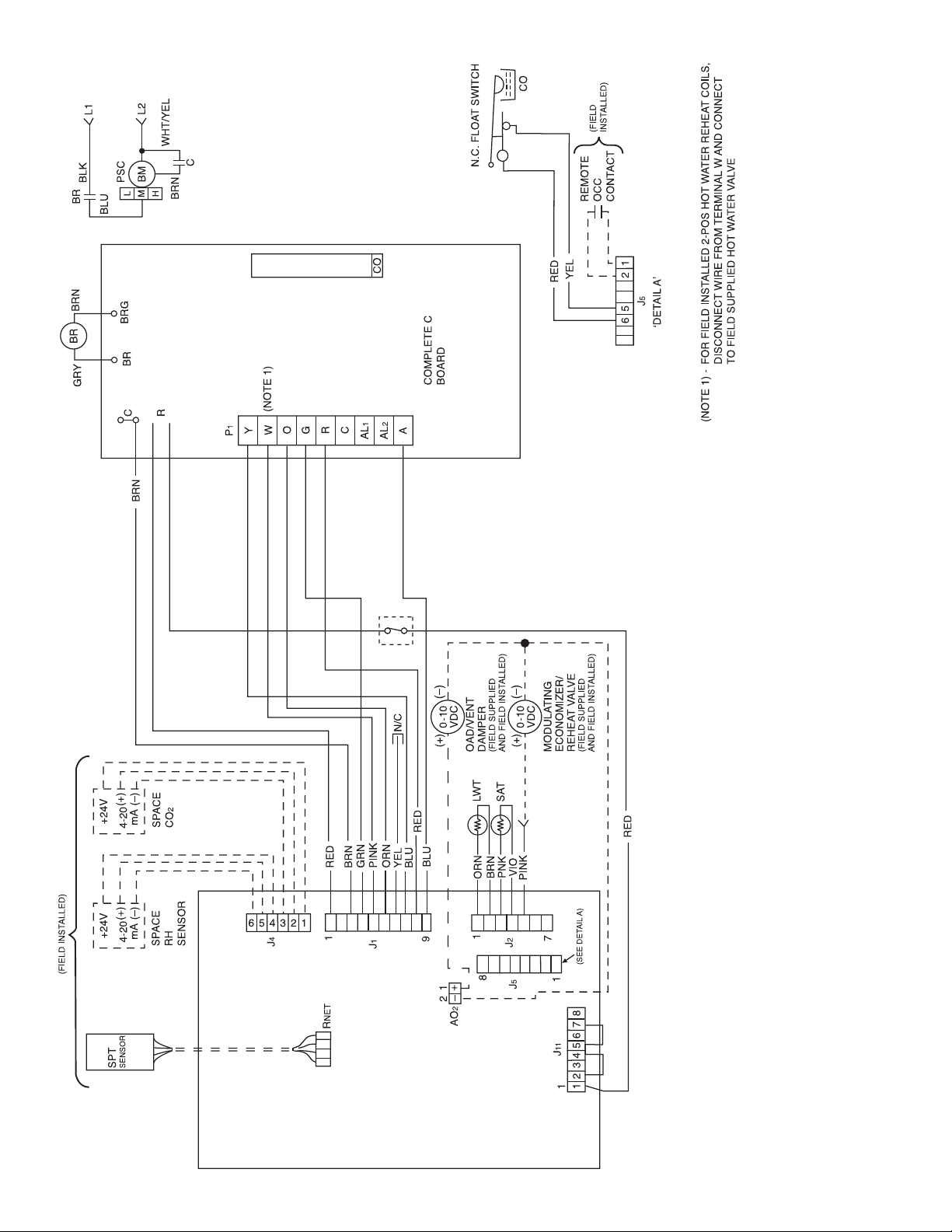

Fig. 18 — Units with Complete C and WSHP Open Multiple Protocol Controls

A50-8697

LEGEND

BM — Blower Motor

BR — Blower Relay

CO — Condensate Overflow

FSD — Fire Smoke Detector

LWT — Leaving Water Temperature

N.C. — Normally Closed

OAD — Outside Air Damper

OCC — Occupancy Input Contact

RH — Relative Humidity

SAT — Supply Air Temperature

SPT — Space Temperature

16

Loading...

Loading...