Page 1

50NQ

HEATING A COOLING

Single-Package Heat Pumps

Installation, Start-Up and Service Instructions

CONTENTS

Page

SAFETY CONSIDERATION

INSTALLATION

Step 1 —Moving and Setting Unit in Place

• ROOFTOP INSTALLATION

• GROUND-LEVEL INSTALLATION

• CLEARANCES

Step 2—Condensate Disposal....................................................4

Step 3—Duct Connections.........................................................6

Step 4—Electrical Connections

• HIGH-VOLTAGE CONNECTIONS

• PROCEDURES FOR 208V

• CONTROL VOLTAGE CONNECTIONS

• HEAT ANTICIPATOR SETTING

• CIRCUIT BREAKER

PREPARING UNIT FOR START-UP

START-UP AND ADJUSTMENTS

CARE AND MAINTENANCE...............................................10

NOTE TO INSTALLER: Leave these instructions and the

User’s ManurJ with the equipment user after installation.

Model 50NQ Packaged Heat Pump Units are fully selfcontained, heating/cooling units designed for outdoor instedlation. These units may be installed either on a rooftop or

ground-level slab. For rooftop downflow applications, an

accessory roof-mounting curb may be used.

Installing and servicing Eur conditioning equipment can be

hazardous due to system pressure and electrical compo

nents. Only trained and qualified service personnel should

install or service air conditioning equipment.

Untrained personnel can perform basic meiintenance func

tions such as cleaning coils and filters and replacing filters.

All other operations should be performed by trained service

personnel. When working on air conditioning equipmei^,

observe precautions in the literature and on tags and labels

attached to unit.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have

fire extinguisher available.

Recognize safety information: This is the safety-alert sym

bol A, when you see this symbol on the unit and in instruc

tions or manuals, be alert to the potential for personal

injury.

Understand the signal word—DANGER, WARNING or

CAUTION. These words are used with the safety-alert sym

bol. DANGER identifies the most serious hazards which

will result in severe personal injury or death. WARNING,

on the other hand could result in personal injury or death.

CAUTION is used to identify unsafe practices, which would

...................................................................

INTRODUCTION

SAFETY CONSIDERATIONS

..................................................

.............................

................................................

....................................

.........................................

1-7

1

4

6

7

9

Fig. 1 —Model 50NQ

result in minor personal injury or product and property

damage.

1. This installation must conform with eJI applicable local

and national codes.

2. The power supply (volts, hertz, and phase) must corre

spond to that specified on unit rating plate. (See Fig. 4

for location.)

3. The electrical supply provided by the utility must be

sufficient to handle load imposed by this unit.

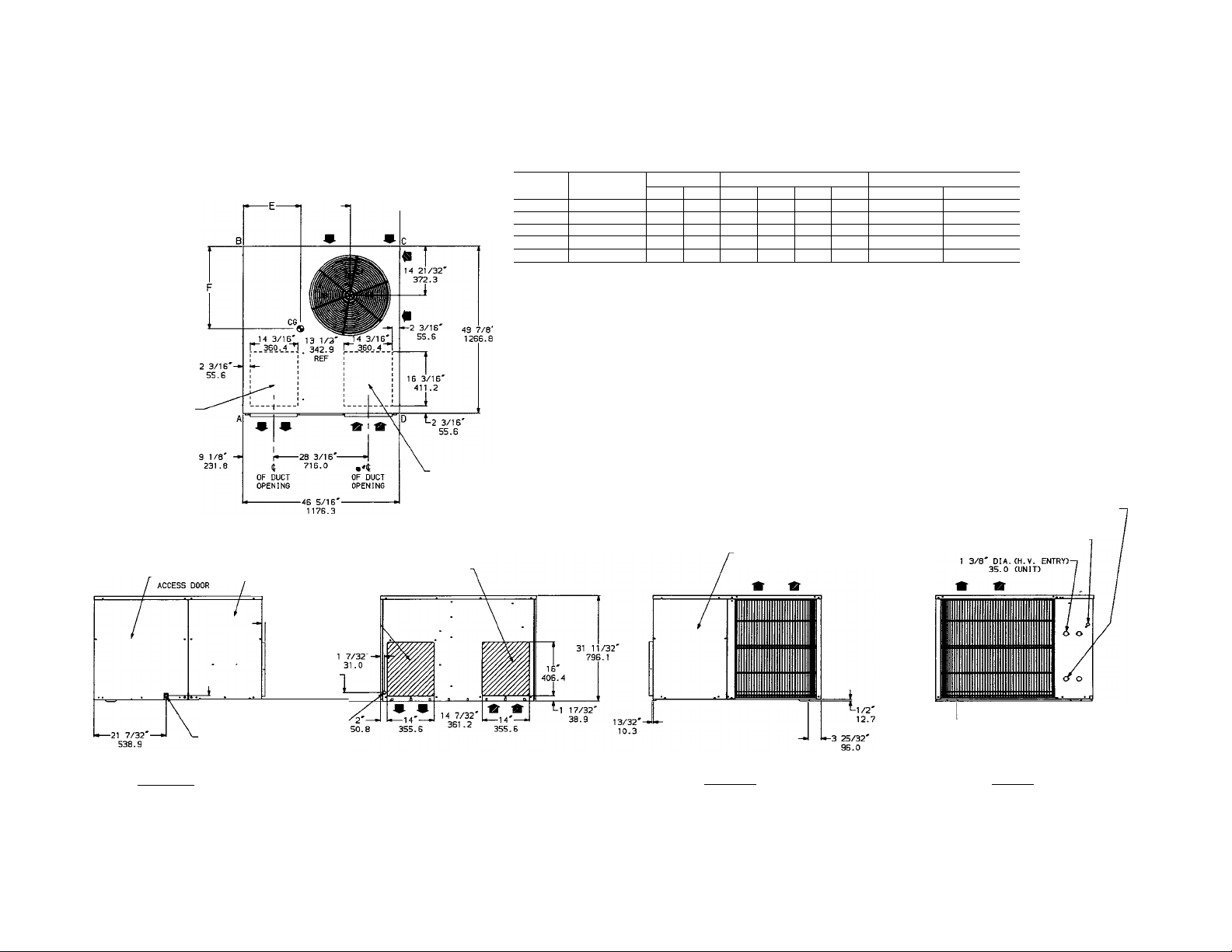

4. Refer to the dimensional drawings (Figs. 2 and 3) for

locations of electriceJ inlets, condensate drain, duct

connections, and required clearances before setting

unit in place.

5. Unit designed for outdoor installation on wood flooring

or on class A, B, or C roof covering materials.

GENERAL

Model 50NQ Packaged Heat Pump has been designed and

tested in accordance with ARI Standard 240, 270 and U.L.

Standard 559.

These units are factory-charged with R-22 refrigerant.

Installation is simple: connect air ducts, high- and low-

voltage wiring, condensate drain, and install a field-supplied

air filter.

All units can be connected into existing duct systems that

are properly sized and designed to handle an airflow of 375

to 450 Cfm per each 12,000 Btuh of rated cooling capacity.

Refer to pre-sale literature for detailed air delivery capacity.

NOTE: When installing any accessory item, see the manu

facturer’s Installation Instructions packaged with the

accessory. The Qualified Agency must use factory author

ized kits or accessories when modifying this unit.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book| 1 I 4 PC 101 Catalog No 565-116 Printed in U.S.A Form 50NQ-1SI Pg 1 7-89 Replaces: New

Tab 15a 15a

Page 2

N3

OPTIONAL SUPPLY

AIR OPENING

-CONTROL BOX

BLOWER ACCESS

DOOR

SUPPLY AIR-\

OPENING/DUCT ^

COVER

r-14 21/32

372.3

RETURN AIR-

0PENIN6/DUCT

COVER

OPTIONAL RETURN

AIR OPENING

UNIT CHARACTERISTICS LBS. KG.

ELECTRICAL UNIT WT. CORNER WT. LB./KG. CENTER OF GRAVITY

50NQ018 208/230/1/60 326 148

50NQ024 208/230/1/60

50NQ030 208/230/1/60 356 161 88/40

50NQ036 208/230/1/60 370 168 101/46 108/49 83/38 78/35 20" (508.0)

50NQ042 208/230/1/60 375

334 152

A B

100/45

102/46 63/29

102/46 108/49 63/29

103/47 89/40 76/34 21-1/4" (615.9) 22-3/4" (577.8)

170 102/46 112/51

UNIT TOP

..............................................

DUCT SIDE OF UNIT...6 MIN. CONTROL BOX ACCESS SIDE

SIDE OPPOSITE DUCTS.........................30 BOTTOM OF UNIT

NOTE. PROVISION MUST BE MADE FOR FRESH AMBIENT AIR TO REACH THE OUTDOOR

COIL WITHOUT RECIRCULATION OF THE AIR FROM THE OUTDOOR FAN DISCHARGE.

EVAP COIL

ACCESS PANEL

D E F

C

61/26 17-1/2" (444.5) 24-1/2" (622.3)

60/27

76/34 19-3/4" (501.6) 23-1/2" (596.9)

85/39

50NQ REQUIRED CLEARANCES CINCHES)

48 BLOWER ACCESS PANEL SIDE...........................................30

17" (431.8)

24" (658.6)

24" (658.6)

.............................................

...............................................................

1 3/8' DIA.CH.V. ENTRY3-

7/8' DIA.CL.V. ENTRY)-

22.2

30

0

35.0 (ACCESSORY

ELECTRIC HEAT)

RIGHT SIDE VIEW

^1 1/4'

31.7

3/4' NPT

19.0

DRAIN OUTLET

7/8' DIA K.O.-^

22.2

ELECT. ENTRY

ALT.

f

U-2 5/16 SQ.

3 25/32 -»1

96.0

LEFT SIDE VIEW FRONT VIEW

-

---------------------

58.7 TYP

38 3/8'

974.7

Fig. 2—Dimensional Drawing—Small Cabinet

Page 3

UNIT

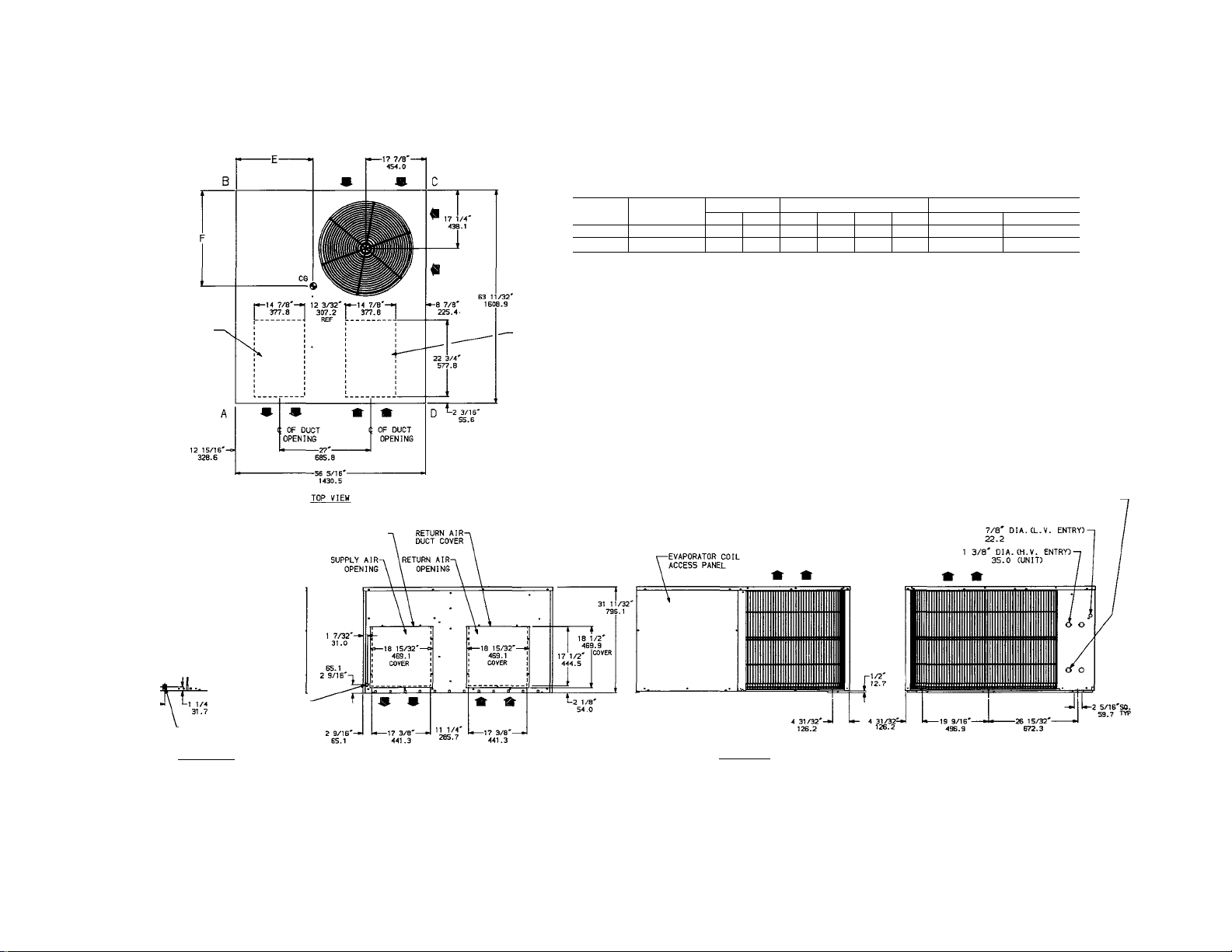

50NQ048 208/230/1/60 450 204

50NQ060 208/230/1/60

LBS. KG.

483

ELECTRICAL UNIT WT.

CHARACTERISTICS

A B C

120/54 147/67 101/46

219 128/58

CORNER WT. LB./KG. CENTER OF GRAVITY

170/77 106/48 80/36 21-1/2" 546.1 27-1/2" 698.5

82/37

D

E

22-3/4" 577.8 28-1/4" 717.5

F

CO

OPTIONAL SUPPLY-

-CONTROL BOX

ACCESS DOOR

AIR OPENING

3/4 NPT

19.0

DRAIN OUTLET

RIGHT SIDE VIEW

-BLOWER ACCESS

DOOR

7/8' DIA. K.O.-

22.2

ALT. ELECT. ENTRY

SUPPLY AIR

DUCT COVER

-OPTIONAL RETURN

AIR OPENING

50NQ REQUIRED CLEARANCES (INCHES)

UNIT TOP

..............................................

DUCT SIDE OF UNIT...6 MIN. CONTROL BOX ACCESS SIDE

SIDE OPPOSITE DUCTS

NOTES PROVISION MUST BE MADE FOR FRESH AMBIENT AIR TO REACH THE OUTDOOR

COIL WITHOUT RECIRCULATION OF THE AIR FROM THE OUTDOOR FAN DISCHARGE.

........................

LEFT SIDE VIEW

48 BLOWER ACCESS PANEL SIDE........................................30

30 BOTTOM OF UNIT

............................................

..............................................................

1 3/8' DIA.(H.V. ENTRY)-

30

0

35.0 (ACCESSORY

ELECTRIC HEAT)

Fig. 3—Dimensional Drawing—Large Cabinet

Page 4

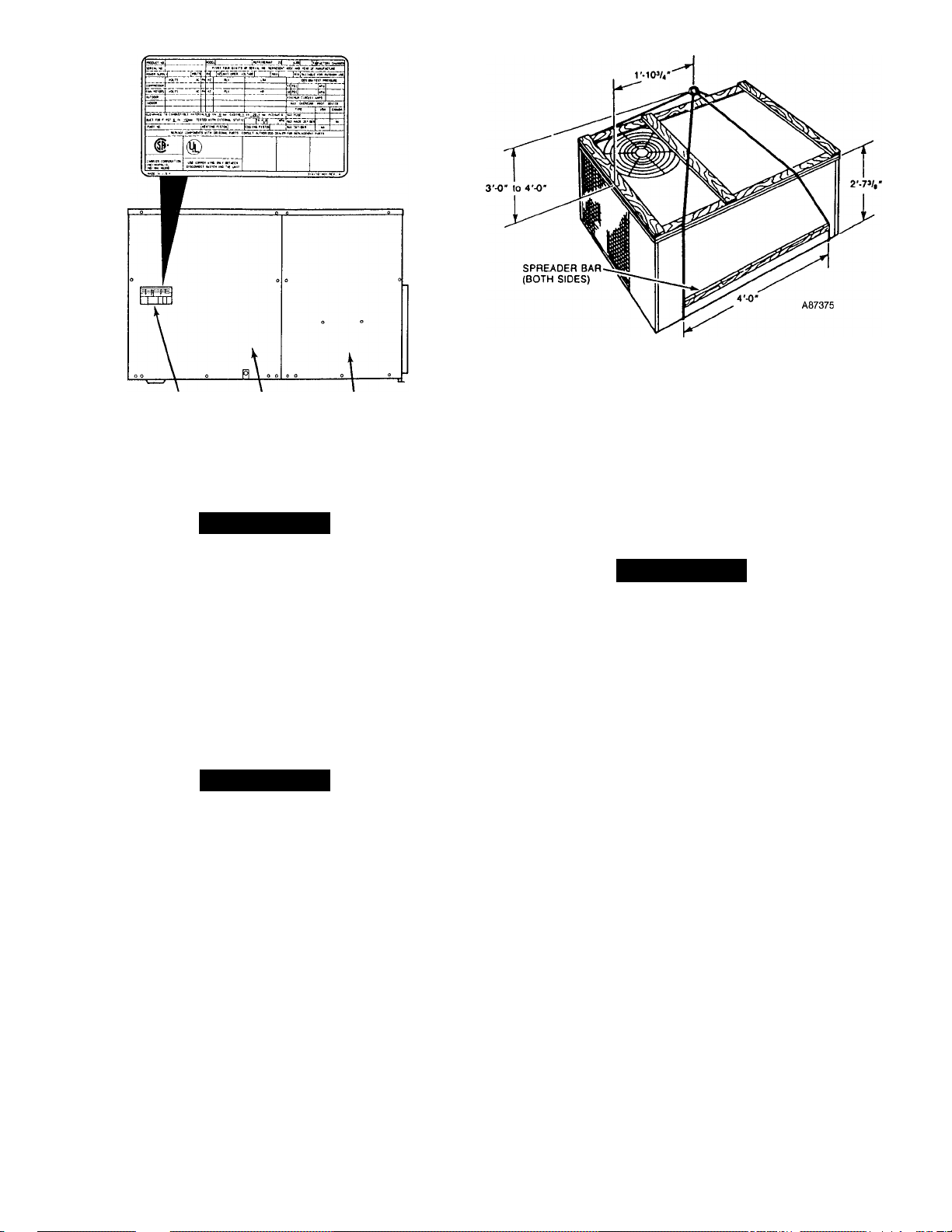

Fig. 5—Suggested Rigging

RATING CONTROL BOX BLOWER

PLATE ACCESS DOOR ACCESS

Fig. 4—Rating Plate Location

Step 1—Moving and Setting Unit in Piace

DOOR

A CAUTION

Use spreader bars and crate top when rigging the unit

to be lifted. Model 50NQ must be rigged for lifting as

shown in Fig. 5. Use extreme caution to prevent dam

age when moving the unit. Unit must remain in an

upright position during all rigging and moving opera

tions. The unit must be level for proper condensate

drainage; therefore, the ground-level pad or accessory

roof-mounting curb must be level before setting the

unit in place. When a field-fabricated support is used,

ensure that the support is level and properly supports

the unit.

ROOFTOP INSTALLATION

A CAUTION

When installing the unit on a rooftop, be sure that the

roof will support the additional weight. Refer to Figs. 2

and 3 for total weight and corner weight information.

For downflow applications, an accessory roof-mounting

curb may be installed on, and flashed into the roof before

unit installation. The instructions for installing the acces

sory curb are packaged with the curb.

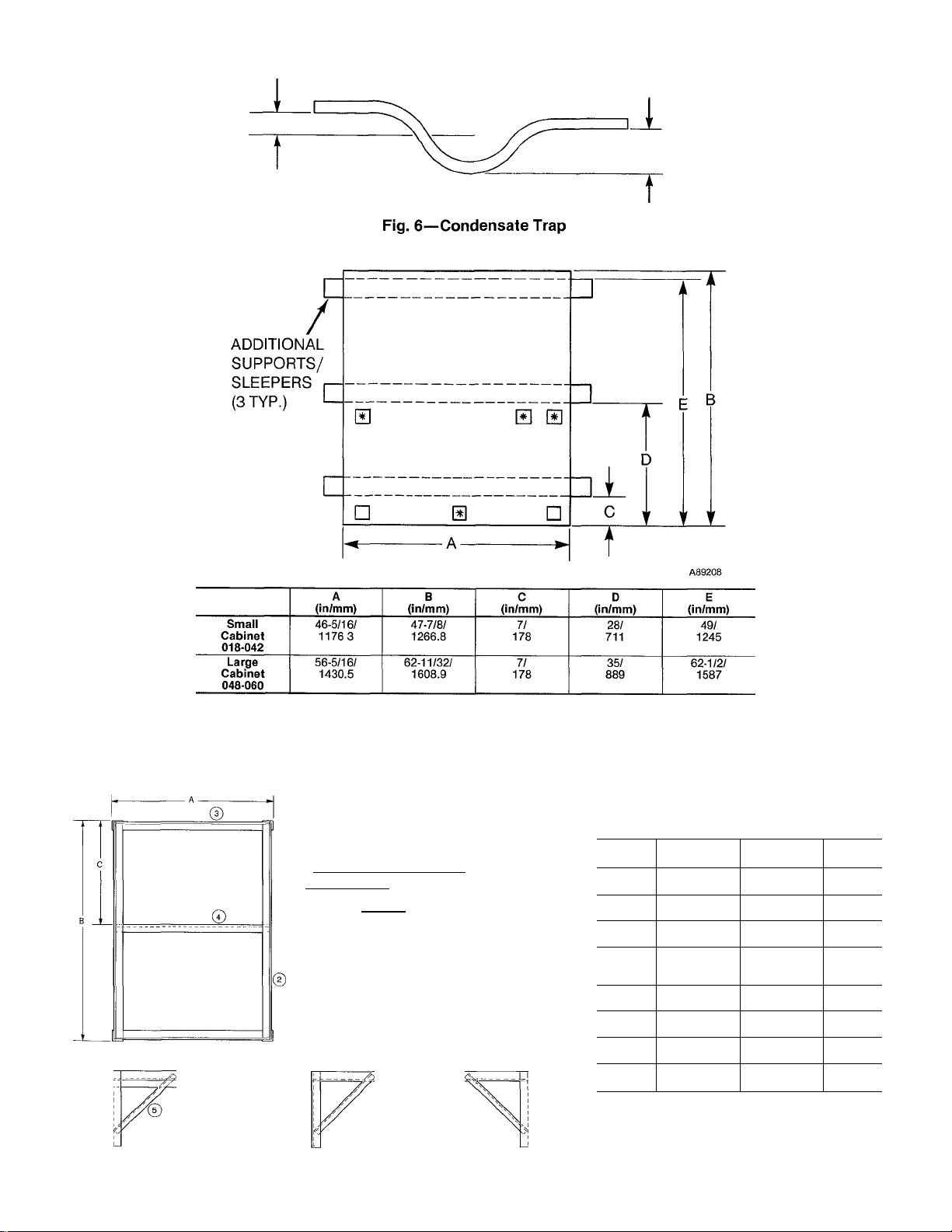

For end-discharge applications place the unit on a level base

that provides proper support. Refer to Fig. 7 for location of

additional supports/sleepers. On flat roofs, be sure that the

unit is located at least 4 ins. above the highest expected

water level on the roof to prevent flooding.

GROUND-LEVEL INSTALLATION

Place the unit on a solid, level, concrete pad that extends

approximately 2 ins. beyond the casing on all four sides of

the unit. Do not secure the unit to the pad except when

required by local codes. Ensure pad does not obstruct coil

drainage holes in bottom of unit. (Holes drain water during

cooling and defrost cycles.) In areas where prolonged sub

freezing temperatures or snowfall occur, increase clearance

to 12-18 ins. by constructing an angle-iron frame to support

the unit. The frame should be designed so as not to block

the drainage holes. See Fig. 8 and Table 1 for recommended

frame construction. Extend a 24-in. gravel apron around

pad for condensate and defrost water drainage.

CLEARANCES

The required minimum operating and service clearances are

shown in Figs. 2 and 3. Adequate condenser air must be

provided.

A CAUTION

Do not restrict condenser airflow. An air restriction at

either the outdoor-air inlet (the entire surface of the out

door coil) or the fan discharge can be detrimental to

compressor life.

The condenser fan discharges through the top of the unit.

Ensure that the fan discharge does not recirculate to the

condenser coil. Do not locate the unit in either a corner or

under a complete overhead obstruction. The minimum clear

ance under a partial overhang (such as a normal house roof

overhang) is 48 ins. above unit top. The maximum horizon

tal extension of a partial overhang must not exceed 48 ins.

Do not locate the unit where water, ice, or snow from an

overhang or roof will damage or flood the unit by falling on

the top. Do not locate the unit where grass, shrubs, or other

plants will interfere with the airflow either into or out of the

unit. Do not install the unit on carpeting, tile, or other com

bustible material other than wood flooring. Heat pump may

be installed on wood flooring or on Class A, B, or C roof cov

ering materieds.

Step 2—Condensate Disposal

NOTE: Ensure that condensate-water disposal methods

comply with IoceJ codes, restrictions, and practices.

Model 50NQ disposes of condensate water through a 3/4-in.

NPT drain fitting. See Figs. 2 and 3 for location.

Install a 3-in. trap at the dredn fitting to ensure proper

drainage. See Fig. 6. Meike sure that the outlet of the trap is

at least 1 in. lower than the unit drain pan connection to

prevent the pan from overflowing. Prime the trap with

water.

If the installation requires draining the condensate water

away from the unit, connect a drain tube using a minimum

of 7/8-in. OD copper tubing, 3/4-in. gedvemized pipe, or

3/4-in. plastic pipe. Do not undersize the tube. Pitch the

Page 5

1" MIN.

2" MIN.

A88130

♦These embossments are located on Large Cabinet Units (048-060 size only.)

Fig. 7—Additional Support/Sleeper

Location

©I" -------------®' I ~ I I

^ _j Ui_i/2" (38mm)

®^" — I

0 —ZZT—j

MATERIAL;

ANGLE IRON - 1-1/4" (31 8mm) TO 1-1/2" (38mm) COMM’L STD

WELD FRAME TOGETHER

PAINT WITH ZINC-RICH PAINT (RUSTPROOF)

—I [—1-1/2" (38mm)

Table 1—Mounting Frame

Dimensions

Large Cabinet

Item No.

A 50 in

B 60-1/2 in

C 30-1/4 in

1

2 60 in

3 49-1/2 in

4 49-1/2 in

5

Length

(1269mm)

(1535mm)

(766mm)

12 in (305mm)

to

24 in (610mm)

(1523mm)

(1257mm)

(1257mm)

16 in

(406mm)

Small Cabinet

Length

40-3/8 in

(1024mm)

47 in

(1193mm)

23-1/2 in

(597mm)

12 in (305mm)

to

24 in (610mm)

46-1/2 in

(1181mm)

39-7/8 in

(1012mm)

39-7/8 in

(1012mm)

16 in

(406mm)

Quantity

—

—

“

4

2

2

1

8

Fig. 8—Mounting Frame

Page 6

drain tube downward at a slope of at least 1 in, in every 10

ft of horizontal run. Be sure to check the dreun tube for

leaks.

Condensate water can be drained directly onto the roof in

rooftop installations (where permitted) or onto a gravel

apron in ground-level instaJlations. When using a gravel

apron, make sure it slopes away from the unit.

Step 3—Duct Connections

Model 50NQ has duct flemges on the supply and return mr

openings on the side and bottom of the unit except on sizes

048 and 060. 048 and 060 sizes do not have flanges on side

dischetrge openings. See Figs. 2 and 3 for connection sizes

and locations.

NOTE; The design and insteJlation of the duct system must

be in accordance with the standards of the National Fire

Protection Association for installation of nonresidence-type

air conditioning and ventilating systems, NFPA No. 90A or

residence type, NFPA No. 90B, and/or loced codes and

ordinances.

Adhere to the following criteria when selecting, sizing, and

installing the duct system:

1. Remove appropriate panels from unit to obtain either

horizontal or down discharge. If models 018 through

042 are installed in horizontal discharge applications,

remove side duct covers, save screws, and instedl the

covers on bottom duct openings. To install duct covers

on bottom duct openings, remove one flange which

interferes with heater mounting plate. For models 048

through 060 remove either side or bottom duct covers

as needed and discard.

2. Select and size ductwork, supply-air registers, and

return-air grilles according to ASHRAE recom

mendations. Refer to Tables 2 & 3 for static pressure

capability.

A CAUTION

When the duct-system fastening holes are being drilled

into side of unit instead of the unit duct flanges, use

extreme care to avoid puncturing the coil or coil tubes.

See Fig. 9.

3. Use flexible transition between rigid ductwork and unit

to prevent transmission of vibration. The transition

may be screwed or bolted to duct flemges. Use suitable

gaskets to ensure weather and edrtight seed.

4. Install external, field-supplied air filter(s) in return-air*

ductwork where it is easily accessible for service. Rec

ommended filter sizes are shown in Table 4.

5.

Size all ductwork for maximum required airflow (either

heating or cooling) for unit being installed. Avoid

abrupt duct size increases or decreases.

6.

Adequately insulate and weatherproof all ductwork

located outdoors. Insulate ducts passing through

unconditioned space and use vapor barrier in accor

dance with latest issue of SMACNA and ACCA mini

mum installation standards for heating and air condi

tioning systems. Secure edl ducts to building structure.

Flash, weatherproof, and vibration-isolate £dl openings

7.

in building structure in accordance with local codes and

good building practices.

8.

For Canadian Installations Only—An L-shaped

exhaust duct fabricated of sheet metal or a material

rated 94-5V shall be used in the case of downflow

applications.

Step 4—Electricial Connections

A WARNING

The unit cabinet must have an uninterrupted, unbro

ken, electrical ground to minimize the possibility of per

sonal injury if an electriced fault should occur. This

ground may consist of electrical wire connected to the

unit ground lug in the control compartment, or conduit

approved for electriced ground when instedled in accor

dance with the National Electrical Code ANSI/NFPA70 (in Canada, Canadian Electrical Code CSA C22.1)

and loced electriceil codes.

A CAUTION

A failure to follow these precautions could result in

damage to the unit being installed:

1. Meike all electrical connections in accordance with the

latest National Electrical Code, ANSI/NFPA-70 and

local electrical codes governing such wiring. In Canada,

all electrical connections must be in accordance with

CSA standead C22.1 Canadian Electrical Code part 1

and applicable local codes. Refer to Unit Wiring

Diagram.

2. Use only copper conductor for connections between

field-supplied electrical disconnect switch and unit. DO

NOT USE ALUMINUM WIRE.

3. Ensure that high-voltage power to unit is within oper

ating voltage range indicated on unit rating plate (Fig.

4). On 3-phase units, ensure that phases are voltage

and current balanced. Consult local power company for

correction of improper voltage and/or phase balance.

4. Insulate low-voltage wires for highest voltage con

tained within conduit when low-voltage control wires

are run in same conduit as high-voltage wires.

5. Do not damage internal components when drilling

through any panel to mount electriceil hardware, con

duit, etc.

CAUTION: DO NOT DRILL

OR SCREW IN SHADED AREA

«

SUPPLY

INLET/OUTLET PANEL

Cabinet Size

Smaii Cabinet

018-042

Large Cabinet 21-1/4"

048-060

Fig. 9—Location of Coii Area-

Not to be Drilied

5 0"-

RETURN

A

20-1/2"

O

Page 7

HIGH-VOLTAGE CONNECTIONS

The unit must have a separate electrical service with a field-

supplied, waterproof disconnect switch mounted at, or

within sight from the unit. Refer to the unit rating plate

(Fig. 4) for meiximum over-current device size and minimum

circuit amps (ampacity) for wire sizing.

The field-supplied disconnect switch box may be mounted

on the unit over the high-voltage inlet hole in the control

corner panel. See Figs. 2 and 3.

Proceed as follows to complete the high-voltage connections

to the unit:

1. Connect ground lead to chassis ground connection

when using separate ground wire.

2. Run high voltage leads into unit through inlet hole in

control box post, and to contactor through the hole in

the bottom of control box. The high voltage leads

should remain in conduit until entering control box and

a watertight termination should be made at bottom of

control box.

SPECIAL PROCEDURES FOR 208-V OPERATION

A WARNING

Make sure that the power supply to the unit is switched

OFF before making any wiring changes. Electrical

shock can cause personal injury or death.

For operation of 208 volts, disconnect the yellow

transformer-primary lead from the contactor. See the unit

wiring label. Remove the tape and cover from the termined

on the end of the blue tremsformer-primeiry lead. Save the

cover. Connect the blue lead to the contactor terminal from

which the yellow lead was disconnected.

Using the cover removed from the blue lead, insulate the

loose terminal on the yellow lead. Wrap the cover with elec

trical tape so that the metal terminal cannot be shorted.

Indoor blower motor speed taps should be changed for 208V

operation on 208/230v rated units. Interchange motor lead

at blower motor. See “Start-up and Adjustments” section

(page 9) and unit wiring label.

CONTROL VOLTAGE CONNECTIONS

Locate the room thermostat on an inside wall in the space to

be conditioned where it will not be subjected to either a cool

ing or heating source or direct exposure to sunlight. Mount

the thermostat 4 to 5 ft above the floor.

Use No. 18 AWG color-coded, insulated (35 C minimum)

wires to make the control voltage connections between the

thermostat and the unit. If the thermostat is located more

than 100 ft from the unit (as measured along the control

voltage wires), use No. 16 AWG color-coded, insulated (35 C

minimum) wires.

A grommeted control voltage inlet hole is located in the

panel adjacent to the control access panel. See Figs. 2 and 3.

Run the low-voltage leads from the thermostat, through the

inlet hole, and to the control voltage terminals. Connect the

thermostat leads to the terminals as shown in Fig. 10.

HEAT ANTICIPATOR SETTING

Factory thermostats have fixed heat anticipator settings.

No adjustment is required.

CIRCUIT BREAKER

Unit has manual reset circuit breaker which is located in the

low-voltage wiring box adjacent to low-voltage terminal

board. If unit fails to operate, first check breaker for tripped

position. If breaker is tripped, re-set and try to start unit. If

breaker continues to trip there is a problem in the lowvoltage electrical circuit (electrical short, ground, or tremsformer overload). Correct the condition and check for nor

mal unit operation.

PREPARING UNIT FOR START-UP

A WARNING

Failure to observe the following warnings could result

in serious personal injury:

1. Follow recognized safety practices and wear protec

tive goggles when checking or servicing refrigerant

system.

2. Do not operate compressor or provide any electric

power to unit unless compressor termined cover is in

place and secured.

3. Do not remove compressor terminal cover until edl

electrical sources have been disconnected.

4. Relieve all pressure from system before touching or

disturbing anything inside compressor termined box

if refrigerant leak is suspected eiround terminals.

5. Never attempt to repair soldered connection while

refrigerant system is under pressure.

6. Do not use torch to remove any component. System

contains oil and refrigerant under pressure. To

remove a component, wear protective goggles and

proceed as follows:

a. Relieve all pressure from system.

b. Cut component connecting tubing with tubing

cutter and remove component from unit.

c. Ceirefully unsweat remaining tubing stubs when

necessary. Oil can ignite when exposed to torch

flame.

PRESTARTUP PROCEDURES

Proceed as follows to inspect and prepare the unit for initial

startup:

1. Remove all access panels.

2. Read and follow instructions on all WARNING, CAU

TION, and INFORMATION labels attached to, or

shipped with, unit.

3. Make the following inspections:

a. Inspect for shipping and handling damages such as

broken lines, loose parts, disconnected wires, etc.

b. Inspect for oil at all refrigerant tubing connections

and on unit base. Detecting oil generally indicates a

refrigerant leak. Leeik-test all refrigerant tubing

connections using electronic leak detector, halide

torch, or liquid-soap solution. If refrigerant leak

is detected, see “Refrigerant Leaks” section on

page 9.

c. Inspect all field- and factory-wiring connections. Be

sure that connections are completed and tight.

d. Inspect coil fins. If damaged during shipping and

handling, carefully straighten fins with a fin comb.

4. Verify the following conditions:

a. Make sure that outdoor fan blade is correctly posi

tioned in fan orifice. Blades should clear fan motor

by no more than 1/4 in. The fan blade hub should be

flush with end of motor shaft.

b. Meike sure that air filter(s) is in place.

c. Make sure that condensate drain pan and trap are

filled with water to ensure proper drainage.

Page 8

THERMOSTAT

8 SUBBASE

(SEE BELOW)

UNIT

CONTROL WIRING

TERMINAL BOARD

THERMOSTAT

a SUBBASE

UNIT

CONTROL WIRING

TERMINAL BOARD

&

&

0-

0

-

B-

[£>

0-

COOLING AND ONE-STAGE HEATING

THERMOSTAT

a SUBBASE

(without Electric Heater)

UNIT

CONTROL WIRING

TERMINAL BOARD

0)

-<D

0)

<8>

-B)

ODT — Outdoor Thermostat

HR — Heater Relay

COOLING AND TWO-STAGE HEATING

(Unit equipped with Electric Heater, Supplemental

Heat, One Outdoor Thermostat)

THERMOSTAT

a SUBBASE

UNIT

CONTROL WIRING

TERMINAL BOARD

COOLING AND TWO-STAGE HEATING

(Unit equipped with Electric Heater, Supplemental

Heat, No Outdoor Thermostats)

Fig. 10—Control Connections

HR — Heater Relay

ODT — Outdoor Thermostat

COOLING AND TWO-STAGE HEATING

(Unit equipped with Electric Heater, Supplemental

Heat Relay, Two Outdoor Thermostats)

Page 9

d. Make sure that all tools and miscellaneous loose

parts have been removed.

Unit is now ready for initial steirtup.

REFRIGERANT LEAKS

Proceed as follows to repair a refrigerant leak and to charge

the unit:

1. Locate leak and ensure that refrigerant system pres

sure has been relieved.

2. Repeiir leak following accepted practices.

NOTE: Install a filter-drier whenever the system has been

opened for repair.

3. Add a small charge of R-22 refrigerant vapor to system

and leak-test unit.

4. Evacuate refrigerant system if additional leaks are not

found.

5. Charge unit with R-22 refrigerant, using a volumetriccharging cylinder or accurate scede. Refer to unit rating

plate for required charge. Be sure to add extra refriger

ant to compensate for internal volume of filter-drier.

START-UP AND ADJUSTMENTS

A CAUTION

Complete the required procedures given in “Preparing

Unit for Start-up,” page 7, before starting the unit.

Do not jumper any safety devices when operating the

unit.

Do not operate unit in the cooling mode when the out

door temperature is below 55 F (unless accessory lowtemperature kit is installed).

Do not operate unit in heating mode when outdoor tem

perature is above 60 F.

Do not rapid-cycle the compressor. Allow 5 minutes

between “on” cycles to prevent compressor damage.

The unit compressor is equipped with a crankcase heater. It

is recommended that heater be energized a minimum of 24

hours before starting unit. To energize heater only, set ther

mostat at OFF position; turn on unit main power at discon

nect switch.

TO START UNIT—Check that main power is on and that

compressor crankcase heater has been energized for at least

24 hours.

1. Check that heater main power is on as applicable.

2. Set selector switch at OFF.

3. Set fan switch as desired (FAN) (AUTO.).

4. Set thermostat dial at the desired temperature.

5. Set selector switch at HEAT or COOL. Check system

refrigerant charge as described in “Checking Charge”

section below.

CHECKING CHARGE-Factory Charge is shown on unit

rating plate (See Fig. 4).

A CAUTION

Compressor damage may occur if system is over

charged.

Adjust charge in cooling mode by following procedure

shown on the “superheat charging tables” located on unit.

Check charge in heating by following procedure shown on

“heating check chart” located on unit.

Page 10

INDOOR AIRFLOW AND AIRFLOW ADJUSTMENTS

A CAUTION

For proper operation, the recommended airflow is 375

to 450 CFM for each 12,000 BTUH of rated cooling

capacity. Minimum airflows may be different if supple

mental electric heaters are installed. See Table 5.

These units have direct-drive blower motors. Blower motors

are factory-connected to deliver the proper heating and cool

ing airflows at normal external static pressures.

Tables 2 and 3 show both heating and cooling airflows at

various external static pressures. Refer to these tables to

determine the airflow for the system being insteilled. See

Table 4 for the rated heating and cooling airflows.

NOTE: Be sure that all supply- and return-eur grilles are

open, free from obstructions, and adjusted properly.

A WARNING

Disconnect electrical power to the unit before changing

blower speed. Electrical shock can cause personal

injury or death.

The heating and/or cooling airflow of 208/230-V direct-drive

blower motors cem be changed by changing the lead connec

tions at the blower motor. The motor leads are color-coded

as follows:

black = high speed

blue = medium speed

red = low speed

UNIT CONTROLS

All compressors have the following internal-protection

controls:

1. High-pressure Relief Va/ue—This valve opens when the

pressure differential between the low and high side

becomes excessive.

2. Compressor Overload—This overload interrupts power

to the compressor when either the current or internal

temperature become excessive, and automatically

resets when the internal temperature drops to a safe

level. This overload may require up to 60 minutes (or

longer) to reset; therefore, if the internal overload is

suspected of being open, disconnect the electrical

power to the unit and check the circuit through the

overload with an ohmmeter or continuity tester.

SEQUENCE OF OPERATION

COOLING—On a call for cooling, thermostat makes circuit

R-0, R-Y and R-G. When room temperature rises to within 2

degrees of control setting of thermostat, circuit R-O makes,

energizing reversing valve solenoid (RVS). Unit is now in

standby condition for cooling. As room temperature rises,

the second-stage bulb makes, allowing a circuit (R-Y)

through low-pressure switch (LPS) to contactor (C), starting

compressor (COMP) and outdoor fan motor (OFM). Circuit

R-G energizes indoor fan relay (IFR) starting indoor fan

motor (IFM).

When thermostat is satisfied, contacts open de-energizing

contactor. Indoor fan relay, compressor and motor stop.

HEATING—On a call for heat, thermostat makes circuits

R-Y and R-G. Circuit R-Y is completed, allowing circuit

through low-pressure switch (LPS) to contactor (C), starting

compressor (COMP) and outdoor fan motor (OFM). Circuit

R-G also is completed, energizing indoor fan relay (IFR) and

starting indoor fan motor (IFM).

Should room temperature continue to fall, circuit R-W is

made through second-stage thermostat bulb. If optional

electric heat package is used, a sequencer is energized bring

ing on first bank of supplemental electric heat. When ther

mostat is satisfied, contacts open, de-energizing contactor

and sequencer. Motors and heaters de-energize.

DEFROST—Defrost board (DB) is a time/temperature con

trol which includes a field-selectable time period between

check if defrost is necessary (30, 50 and 90 minutes). Elec

tronic timer and defrost cycle start only when contactor is

energized and defrost thermostat (DFT) is closed.

Defrost mode is identical to cooling mode except outdoor

fan motor stops and a bank of optional electric heat turns

on to warm air supplying the conditioned space.

CARE AND MAINTENANCE

To ensure continuing high performance, and to minimize the

possibility of premature equipment failure, periodic mainte

nance must be performed on this equipment. This combina

tion heating/cooling unit should be inspected at least once

each year by a queilified service person.

NOTE TO EQUIPMENT OWNER: Consult your local Dealer

about the aveulability of a maintenance contract.

A WARNING

The ability to properly maintain this equipment

requires certain expertise, mechanical skills, tools, and

equipment. If you do not possess these, do not attempt

to perform any maintenance on this equipment other

than those procedures recommended in the Users Man

ual. A FAILURE TO HEED THIS WARNING

COULD RESULT IN SERIOUS PERSONAL

INJURY AND POSSIBLE DAMAGE TO THIS

EQUIPMENT.

The minimum maintenemce requirements for this equipment

are as follows:

1. Inspect Eur filter(s) each month. Clean or replace when

necessary.

2. Inspect cooling coil, drain pan, and condensate dreiin

each cooling season for cleanliness. Clean when

necessary.

3. Inspect blower motor and wheel for cleanliness each

heating and cooling season. Clean when necessary.

4. Check electrical connections for tightness on controls

for proper operation each heating and cooling season.

; Service when necessary.

A WARNING

A failure to follow these warnings could result in seri

ous personal injury.

AIR FILTER

A CAUTION

Never operate the unit without a suitable air filter in

the return-air duct system. Always replace the filter

with the same dimensional size and type as originally

installed. See Table 4 for recommended filter sizes.

Inspect air filter(s) at least once each month and replace

(disposable-type) or clean (cleemable-type) at least twice dur

ing each heating and cooling season or whenever the filter(s)

becomes clogged with dust and lint.

10

Page 11

Table 2—Models 50NQ Air Delivery (Cfm) in 208V-Horizontal Fiow Set-up at indicated

Externai Static Pressure & Voltage (Sizes 018, 024,030, 036, 048, 060)

UNIT

SIZE

018

024

VOLT/PHASE/HZ

208/1/60

208/1/60

030 208/1/60

036

208/1/60

042 208/1/60

048 208/1/60

060 208/1/60

MOTOR

SPEED

LOW

MED

HI

LOW

MED

HI

LOW

0.0 0.1 0.2 0.3

788 761 758

1195t

1184t 1160t

1425t 1375t 1359t

802 787 772 738

1211t

1473t

1200t 1190t 1169t 1138t

1444t 1418t 1377t 1339t

—

— — — —

MED 1225 1220 1211

HI 1483 1470 1450 1415

LOW

MED

HI

LOW

—

1421 1388 1343 1306

1882f

—

MED 1421

HI

1882t 1809t 1722t 1644t 1546T

— —

1809f

—

1388

1722t 1644t 1546t

1343 1306

LOW 1603 1584 1489

MED 2035 1985

HI

LOW

MED

HI

2304t 2262t 2139t

— — —

2205t 2198t 2190t 2188t 2122t

25811

2538t 2455t 2382t 2305t 2258t 2168t

1923 1851 1771 1678 1497

EXTERNAL STATIC PRESSURE—INCHES W.C.

734

1121t

675

1092t

1308t 1248t 1139t 1030t

702

0.4

0.5

644

987t

—

1061t

1260t

1177 1166 1105 1040

1372 1319

_

—

1252 1165

1386 1296

— —

_

1252

— — — — —

1386

— —

2046

1940

—

1815 1687

2084 2020

0.6

600

886

0.7 0.8 0.9 1.0

564

744

917t

525

724 667

786

—

702 647

— — — — —

993t

1195t

878

997t

913 —

1245

—

1058

1098 891

— — — —

_

1225

— —

1296

1225

__

—

1462

— — —

1943

2084

768 —

838 750

— — —

_

_

— —

_

_ _

—

__

1054

— — —

— — —

_

1863

1992

__

— —

—

1893

581

—

—

—

—

—

—

—

__

—

—

—

Tabie 3—Modeis 50NQ Air Deiivery (Cfm) in 230-V Horizontai Fiow Set-Up at indicated

External Static Pressure & Voltage (Sizes 018, 024, 030, 036, 048, 060)

UNIT

VOLT/PHASE/HZ

SIZE

018 230/1/60

024 230/1/60

030 230/1/60

MOTOR

SPEED

LOW

MED

HI

LOW

MED

HI

LOW

0.0

0.1

913t 905t

1366t 1336t

1584t

1552t

0.2 0.3 0.4

891 848 827 765 699

1302

1467t 1414t 1332t 1256t 1146t

950t 935t 926t

1414t 1399t 1373t 1333t

1652t

1614t

1556T

937 933 929 919 893

MED 1425 1413 1391 1358

HI

1670t 1576t 1552t 1533t

LOW 1088 1075 1050

036 230/1/60

042 230/1/60

048 230/1/60

MED

HI

LOW

MED

HI

1636t 1599t 1553t

2034t 1957t 1846t 1734t

—

1636t 1599t 1553t

2034t

LOW 1891

MED

HI

2230t 2155t

2385t 2304t 2183t

—

—

1957t 1846t 1734t

1852

1819 1746

2060

LOW 2027 2000 1993 1972 1940 1872

060

230/1/60

MED

HI

2546t 2508t 2448t

2837t 2758t

2652t

Air deliveries based on unit dry coil without air filter or optional electrical heaters. Deduct field supplied air filter and electric heater pressure drop to

obtain external static pressure available for ducting. Dashes indicate less than minimum airflow and coil icing may occur.

tAirflow exceeds maximum coil velocity. Condensate may be blown off of coil.

If supplemental electric heaters are used, refer to Table 5 for minimum air-flows. These airflows will be slightly greater than those required for unit

operation.

EXTERNAL STATIC PRESSURE—INCHES W.C.

0.6

1250t

1201t

900 885

0.5

1098t 982t

811 733

1289t 1229t 1148t

1520t

1440t 1375t 1277t

—

— — — —

1326 1268 1196

1468 1419 1324

—

—

1480 1393 1275

—

1602T

— —

1480 1393

1602f

1684

1989t

1885 1782

2097 1982

2382t

2297t 2234t 2150t

1571t

1275

1571t

1553

1863 1717

—

1158

1316

— —

1316

_

1630

—

2587t 2476t 2392t 2304t

0.7 0.8 0.9 1.0

651 606 575

898 776 676 609

101 Of

825 750 665

700 — — —

1015t

1098t

1071

811 747

876 799 701

875

— —

1134 920 875 —

1050

1225

1225

__

1483

1614

—

— —

—

1072

_

—

—

— __

— —

1493

— — —

_

— —

_

2070 1977 1870

2224t

2089 2003 1872

—

—

_

—

—

—

—

—

—

—

_

_

Table 4—Rated Airflow and Filter Sizes

Model

Size

Rated Airflow (Cfm)*

018300 024300 030300 036300 1 036500 1 036600 042300 1 042500 | 042600

675 900

1100

1300

Recommended Min f

Field Supplied

Filter Size

324 432 540 648

Disposable Type

Cleanableor High-

Capacity

216 288

360

432

♦Rated in accordance with U.S. Government D.O.E. test procedures and/or ARI Standard 210.

tRequired filter areas shown are based on the larger of the ARI-rated cooling or heating airflow at a velocity of 300 ft/min for disposable type or

450 ft/min for high-capacity type.

50NQ

048300 1 048500 | 048600

1500 1750

756

504 576

060300 1 060500 1 060600

864

11

2100

1030

720

Page 12

SIZE

AIRFLOW

(CFM)

Table 5—Minimum Airfiow for Safe

Electric Heater Operation

018

600

024 030 036 042 048 060

800 1000

1200

1400

1600 2000

Tabie 6—Wet Coil Pressure Drop

Unit Size Wet Coil P.D. (In. wc.)

018, 024 0.54

030 .060

036 .070

042 .075

048

060 .100

.086

UNIT TOP REMOVAL

A CAUTION

Condenser fan and motor eire fastened to the unit top.

When removing the top, use extreme care not to pull

the fan motor leads loose.

NOTE: When performing maintenance or service proce

dures that require removal of the unit top, be sure to per

form all of the routine maintenance procedures that require

top removal, including; coil inspection and cleaning, and

condensate drain pan inspection and cleaning.

Only qualified service personnel should perform mainte

nance and service procedures that require unit top removal.

Refer to the following top removed procedures:

1. Remove all screws that secure unit top, including

screws around four sides and those on top that screw

into internal divider panels. Save all screws.

2. Tape edl side panels at each seam near unit top. Use

tape strips that are at least 5 ins. long to prevent sides

from falling when top is removed.

3. Lift top from unit carefully. Set top on edge and ensure

that top is supported by unit side that is opposite duct

(or plenum) side.Use extreme care to prevent damage to

the fan blades, motor, and insulation.

4. Carefully replace and secure unit top to unit, using

screws removed in step 1, when maintenance and/or

service procedures are concluded. (Be sure to use origi

nal screws that have rubber washers to seal out water

when securing top to internal divider panels.)

INDOOR BLOWER AND MOTOR

For longer life, operating economy, and continuing effi

ciency; clean accumulated dirt and grease from the blower

wheel and motor annually.

A WARNING

Disconnect and tag electrical power to the unit before

cleaning the blower assembly. Failure to adhere to this

warning could cause personal injury or death.

Clean the hlower assembly as follows:

1. Remove and disassemble blower assembly as follows:

a. Remove blower access door.

b. Disconnect blower motor leads from their termina

tion points at motor. Disconnect yellow lead from

control box at capacitor.

c. Remove blower assembly from unit. Be careful not

to tear insulation in blower compartment.

d. Ensure proper reassembly by marking blower wheel

and motor in relation to blower housing before

disassembly.

e. Loosen setscrew(s) that secures wheel to motor

shaft, remove screws that secure motor mount

brackets to housing, and slide motor and motor

mount out of housing.

2. Remove and clean blower wheel as follows:

a. Ensure proper reassembly by marking wheel orien

tation and cutoff plate location.

b. Remove screws holding cutoff plate, and remove

plate from housing.

c. Lift wheel from housing. When handling and/or

cleaning blower wheel, be sure not to disturb bal

ance weights (clips) on blower wheel vanes.

d. Remove caked-on dirt from wheel and housing with

a brush. Remove lint and/or dirt accumulations

from wheel and housing with vacuum cleaner, using

soft brush attachment. Remove grease and oil with

mild solvent.

e. Reassemble wheel and cutoff plate into housing.

f. Reassemble motor into housing. Be sure setscrews

are tightened on motor shaft flats and not on round

part of shaft.

OUTDOOR COIL, INDOOR COIL, AND CONDENSATE

DRAIN PAN

Inspect the coils and condensate drain pan at least once

each year. Proper inspection and cleaning requires the

removal of the unit top. See “Unit Top Removal” section.

The coils are easily cleaned when dry; therefore, inspect and

clean the coils either before or after each cooling season.

Remove all obstructions, including weeds and shrubs that

interfere with the airflow through the outdoor coil.

Straighten bent fins with a fin comb. If coated with dirt or

lint, clean the coils with a vacuum cleaner using the soft

brush attachment. Be careful not to bend the fins. If coated

with oil or grease, clean the coils with a mild detergent-andwater solution. Rinse coils with clear water using a garden

hose. Be careful not to splash water on motors, insulation,

wiring, or air filter(s). For best results, spray outdoor coil

fins from inside to outside the unit. On units with an outer

and inner outdoor coil, be sure to clean between the coils. Be

sure to flush all dirt and debris from the unit base.

Inspect the drain pan and condensate drain line when

inspecting the coils. Clean the drain pan and condensate

drain by removing all foreign matter from the pan. Flush

the pan and drain tube with clear water. Do not splash

water on the insulation, motor, wiring, or air filter(s). If the

drain tube is restricted, clear it with a “plumbers snake” or

similar probe device.

OUTDOOR FAN

A CAUTION

Keep the outdoor fan free from all obstructions to

ensure proper operation. Never place articles on top of

the unit.

12

Page 13

FLARE

NUT

STRAINER

STAMPED ARROW ON

COUPLING BODY

COIL

RUBBER 0-RING

Fig. 11—Metering Device (Duai-Piston) Components

(TOWARD INDOOR COIL)

Inspect the fan blades for cracks or bends each year. Ensure

that blades clear the motor by no more than 1/4 in. The fan

blade hub should be flush with end of motor shaft. If the

blade assembly has slipped down the motor shaft, adjust the

fan position on the motor shaft by loosening the setscrew(s),

then moving the blade assembly up. Be sure that the setscrew(s) is on the flat(s) of the motor shaft before tightening.

ELECTRICAL CONTROLS AND WIRING

Inspect and check the electrical controls and wiring annu

ally. Be sure to turn off the electrical power to the unit.

Remove the control, blower, and compressor compartment

access panels to locate all the electrical controls and wiring.

Check all electrical connections for tightness. Tighten all

screw connections. If any smoky or burned connections are

noticed: disassemble the connection, clean all the parts,

restrip the wire end, and reassemble the connection properly

and securely.

After inspecting the electrical controls and wiring, replace

all the panels. Start the unit and observe at least one com

plete heating cycle and one complete cooling cycle to ensure

proper operation. If discrepancies are observed in either or

both operating cycles, or if a suspected malfunction has

occurred, check each electrical component with the proper

electrical instrumentation. Refer to the unit wiring label

when making these checkouts.

NOTE: Refer to the heating and/or cooling sequence of oper

ation in this publication as an aid in determining proper con

trol operation.

REFRIGERANT CIRCUIT

Inspect Eill refrigerant tubing connections and the unit base

for oil accumulations annually. Detecting oil generally indi

cates a refrigerant leak.

If oil is detected or if low cooling performance is suspected,

leak-test all refrigerant tubing; using an electronic leakdetector, halide torch or liquid-soap solution. If a refrigerant

leak is detected, see “Refrigerant Leaks” in this

publication.

If no refrigerant leaks are found and low cooling perfor

mance is suspected, refer to “Checking Charge” and unit

rating plate.

STRAINER

RETAINER

A87292

INDOOR AIRFLOW

The heating and/or cooling airflow does not require checking

unless improper performance is suspected. If a problem

exists, be sure that all supply- and return-air grilles are open

and free from obstructions, and that the air filter is clean.

When necessary, refer to “Indoor Airflow and Airflow

Adjustments,” page 10 of this publication to check the sys

tem airflow.

METERING DEVICE SERVICING

See Fig. 11 for metering device components. The pistons

have a refrigerant metering orifice through them. The

retainer forms a sealing surface for liquid line flare connec

tion. To check, clean or replace piston:

1. Shut off power to unit.

2. Remove refrigerant from unit using approved refriger

ant removal methods.

3. Remove liquid line flare connections from metering

device.

4. Note position of arrow on metering device body with

respect to unit.

5. Pull retainers out of body. Be careful not to scratch

flare sealing surfaces. If retainers do not pull out eas

ily, carefully use locking pliers to remove retainers.

Replace scratched or damaged reteuners.

Slide pistons out by inserting a small soft wire through

6.

metering hole (18-gauge thermostat wire). See that

metering hole, seeding surface around piston cones and

fluted portion of pistons are not damaged.

Chart on unit access panel illustrates proper arrange

ment and size of pistons.

Clean pistons refrigerant metering orifice.

Replacement retainer 0-ring Part No. is 99CC501052.

LIQUID LINE STRAINER

The Liquid Line Strainers (to protect metering device), are

made of wire mesh and are located in the liquid line on both

sides of the metering device. Strainers are pressed into the

line. Remove strainers by threading a No. 10 sheet metal

screw into strainers and pulling the screw with pliers.

13

Page 14

UNIT SINGLE-PHASE COMPRESSORS are equipped

with a Compressor Start Thermistor (PTC device). When

supply voltage is within 10% limit and compressor does not

start, check the start thermistor with an ohmmeter.

Checking Start Thermistor

1. Shut off all power to unit and wait 10 minutes for

thermistor to cool to ambient temperature.

2. Remove thermistor from circuit.

3. Measure resistance of thermistor with ohmmeter. Nor

mal resistance readings are 12.5 or 25 ohms -I- 20% at

75 F ambient temperature depending on your unit.

4. If ohmmeter resistance reading is not within ± 20%,

the thermistor is defective and must be replaced.

If start thermistor is good and compressor does not steu-t,

disconnect the thermistor from starting circuit and give

compressor a temporeiry capacitance boost. Run compressor

for 10 minutes, then shut off and allow system pressure to

equalize. Reconnect start thermistor and try restarting

compressor without boost capacitor. If after two attempts

the compressor does not start, remove thermistor and add

an accessory start capacitor and relay.

14

Page 15

TROUBLESHOOTING CHART—COOLING CYCLE

DEFECTIVE LOW

VOLTAGE

TRANSFORMER

SUPPLEMENTAL HEAT

RELAY ENERGIZED

OR WIRED WRONG

TROUBLESHOOTING CHART—HEATING CYCLE

LOW LINE VOLTAGE

OK UNBALANCED

3 PHASE LINE

COMPRESSOK

POWER supplì

OPEN

FAULTY START CAP

OR RELAY ISINGLE

PHASE) OR PTC

INDOOR IANS

CVCLINti ON

OVERLOAD

OVERCHARGE OR

NONCONDENSAOLES

IN SYSTEM

RESTHiCTED OR

STUCK

METERING DEVICE

OEFLCIIVE RUN

i;apaciioh

• SINCU E PHASE I

REVERSING VALVE

JAMMED IN MID

POSITION

LOOSE LEADS A

OUTDOOR FAN

MOTOR

INTERNAI FAN

MOTOR KLIXON

OPEN

DEFROST BOARD

N C CONTACTS

OPEN

METERING DEVICE

• RESTRICTED OR

ICE-CLOGGED

UNDERCHARGED

DEFROST T STAT

IN POOR PHYSICAL

CONTACT WITH LINE

DEFECTIVE DEFROST

RELAY OR DEFROST

TIMER

OUTDOOR

THERMOSTAT

DEFECTIVE

CAP TUBE PINCHED

OR BULB NOT

SENSING TRUE ODT

STRIP HEATER RELAY

OR CÜNIACTOH

DETECTIVE

OPENING IN POWER

CIRCUIT TO HEATER

ELEMENTS

OPEN (Kl IXON)

OVERTEMPERATURE

THERMOSTAT

DEFECTIVE ROOM

THEHMOSTAI

|?ND STAGEl

15

BAD ELECTRICAL CON

NECTION ANYWHERE

IN DEFROST CIRCUIT

A88431

Page 16

Manufacturer resenres the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

BookI 1 I 4 PC 101 Catalog No. 565-116 Printed in USA Form 50NQ-1SI Pg 16 7-89 Replaces: New

Tab 15a 15a

Loading...

Loading...