Page 1

Number One

Air Conditioning

Maker

e

Division ot Carrier Corporatio

Syracuse New York

Single-Package Heat Pump Units

The 50MQ units are completely self-contained

cooling and heating systems with provision for

addition of accessory electric heaters. They are

air-to-air heat pumps designed for outdoor installa

tion. They may be connected into existing duct

systems which are properly sized and designed to

handle an air quantity of 400 to 500 cfm per ton

of cooling. Required connections include air ducts,

condensate drain, line and control power wiring.

Field-supplied filter must be installed in return air

duct. (See Table 1 for filter size.)

INSTALLER'S PRELIMINARY SURVEY

Step 1 — Inspect Equipment — File claim with

shipping company if shipment is damaged or

incomplete.

Step 2 — Complete or Consider the Following

before installing the 50MQ unit;

a. Consult local building codes for special installa

tion requirements.

b. Provide sufficient space for coil air flow clear

ance, wiring, and servicing unit. (See Fig. 1.)

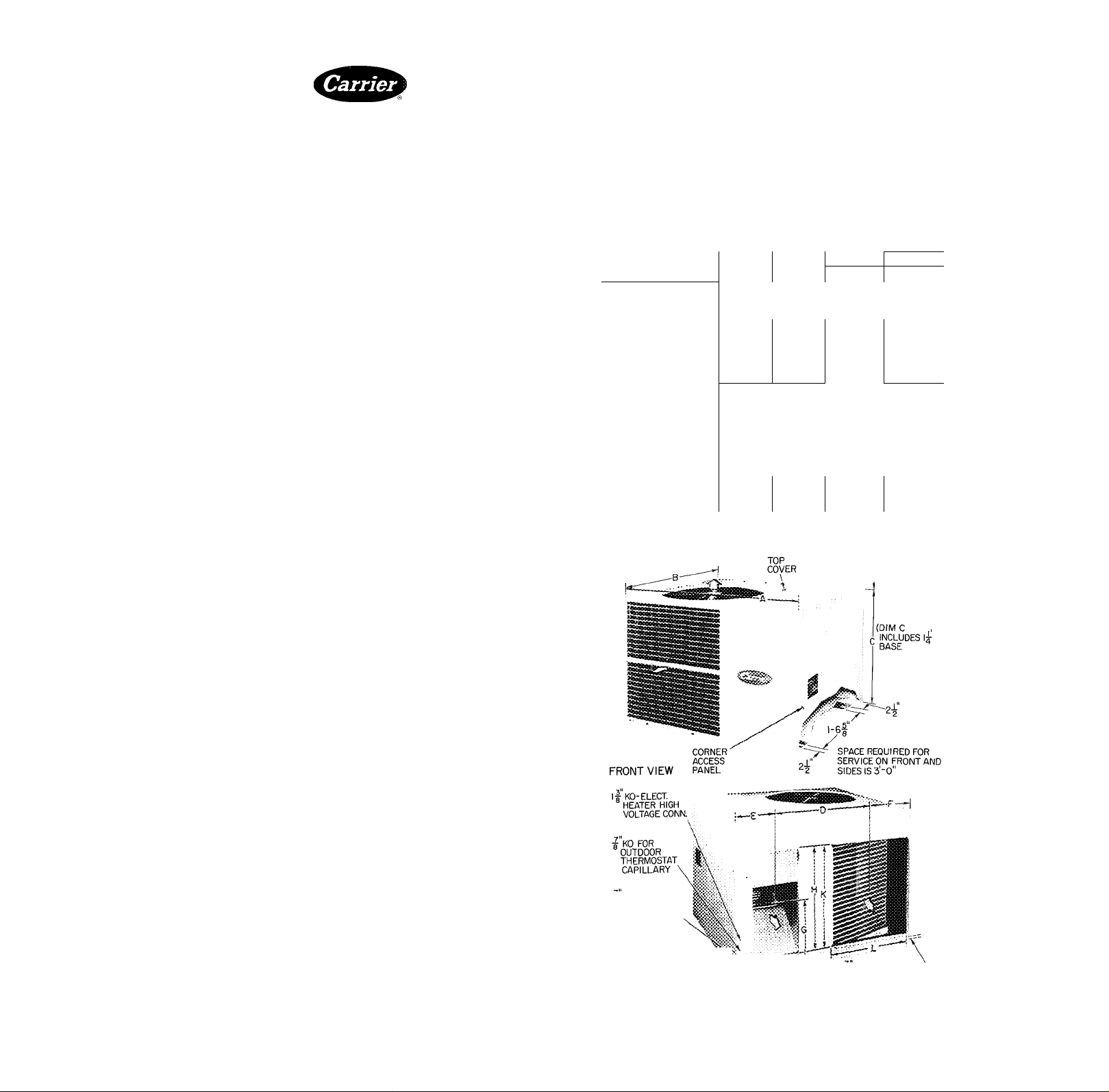

Table 1 — Installation Data (See Fig. 1.)

UNIT

OPER WT (lb)

DIMENSIONS

{ft-in») A

DUCT CONN.

(ft-in.)

Supply j

Return

FILTER SIZEt (in.)

Disposable

Permanent

‘Dimension "C"

t Recommended

50MQ022 50MQ027 50MQ032

315

B 3-

c*

2- 3Ys

D

1-1OY4

E

0- 6^6

F

0-10“/,6

G

1 -- 1 6

, , H

K

20 X 25

15 X 20

includes 1 1/4-in built-in base support channels (2)

field-supplied filters are 1-in. thick

330 340

2- 3%

1-1OV4

0-

0-10“/,6

1 — 1 6 1 — 1 ^/] 6

Sid e'b y- Si (d€ Rect an gu or

20 X 25 15 X 20(2)

20 X 20 20 X 20

6‘/4

3-

2

2- 3% 2- 7%

1-10^4

0- óV.e

0-10“/Ì6

1- 9%

0-

\QX

1 -

9%

1-

7%

, ,,T

4-0 OVERHEAD AIR

SPACE REQUIRED

50MQ037

353

1-1OY4

0- 6V,6

0-10“,(e

1-

1 5 X 20

20 X 20

20 X 25

c. Locate unit where supply and return air ducts

can be conveniently brought out to unit duct

connections.

d. Unit may be placed with duct side as close to

building as condensate drain, top removal, duct

connections and power connections will permit

Position unit so water or ice from roof will not

drop directly on top of unit or in front of coil

e. Make provisions for condensate drainage and

defrost water disposal. See Mounting Pad and

Cooling Cycle Condensate Disposal.

f. Roof installation method for 50MQ will depend

on building construction and special require

ments of local building codes. Ensure roof will

support unit weight. See Mounting Pad for

details.

a OIAM HOLE-

CONTROL

WIRING CONN

l| DIAM HOLE-UNIT

LINE WIRING CONN „

O SUPPLY AIR

^ RETURN AIR

Certified dimension drawings available on request

REAR VIEW

SPACE REQUIRED FOR SERVICE ON

REAR OF UNIT IS I'-O"

Fig. 1 — Dimensions and Connections

CHANNELS-2)

■g ID SIDE CONDENSATE

DRAIN FITTING

© Carrier Corporation 1974

Form No 50MQ-1SI

Page 2

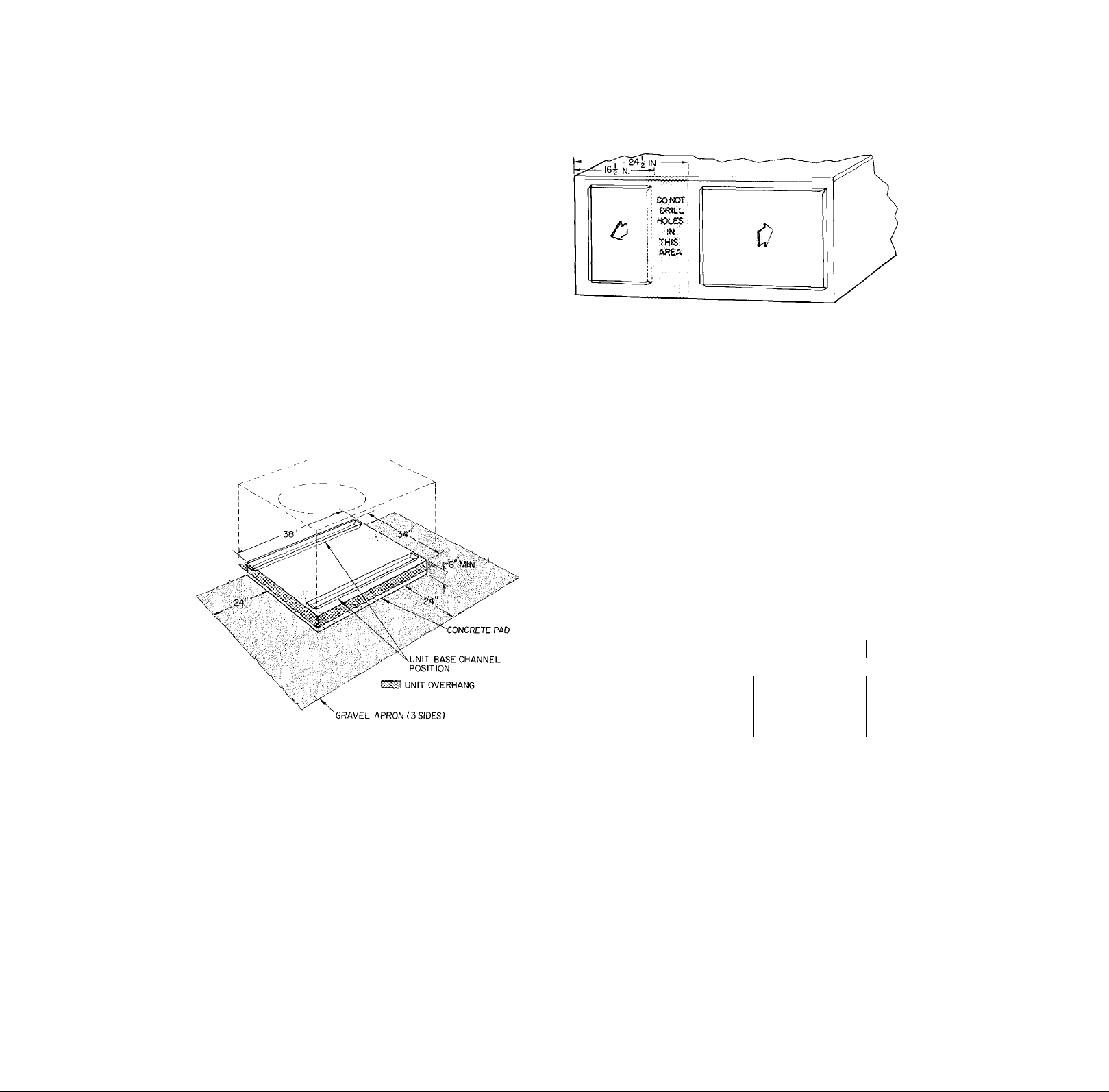

MOUNTING PAD

Step 3 — On the Ground: Mount Unit on a Solid,

Level Concrete Pad. See Fig. 2 for pad dimensions.

Ensure pad does not obstruct coil slots in unit base

pan. (Slots drain water during heating cycle).

Construct pad a minimum of 6 in. thick to provide

clearance under base pan coil slots for drainage and

ice buildup. In areas where prolonged subfreezing

temperatures, drifting or heavy snows occur, in

crease clearance to 12 to 18 inches. If climatic

conditions dictate, construct an angle iron frame to

support unit 12 to 18 in. off concrete base. Cross

angle of frame must not obstruct base pan coil

slots. Extend a 24-in. gravel apron around pad for

condensate and defrost water drainage field.

Step 4 — On the Roof: Mount Unit on a Level

Platform or Frame. Unit must be elevated for

proper clearance as described under ground in

stallation above. Roof design and water drainage

must be planned to prevent unit and its duct

flashing from sitting in water.

for system air duct design. When designing and

installing ductwork, consider the following.

a. When connecting ductwork to unit, do not drill

holes in area shown below. Coil may be

damaged.

b. All units should have field-supplied filters in

stalled in return air ductwork. Recommended

sizes for filters are shown in Table 1.

c Avoid abrupt duct size increases and reductions.

d. Use flexible connectors between ductwork and

unit to prevent transmission of vibration. When

electric heater is installed, use fireproof asbes-

• tos (or similar heat resistant material) con

nector between ductwork and unit discharge

connection. Heat resistant duct connector must

extend 24 in. from electric heater element.

e. Size ductwork for cooling air quantity (cfm).

The minimum air quantity for safe electric

heater operation is;

m

Fig. 2 — Concrete Pad Dimensions

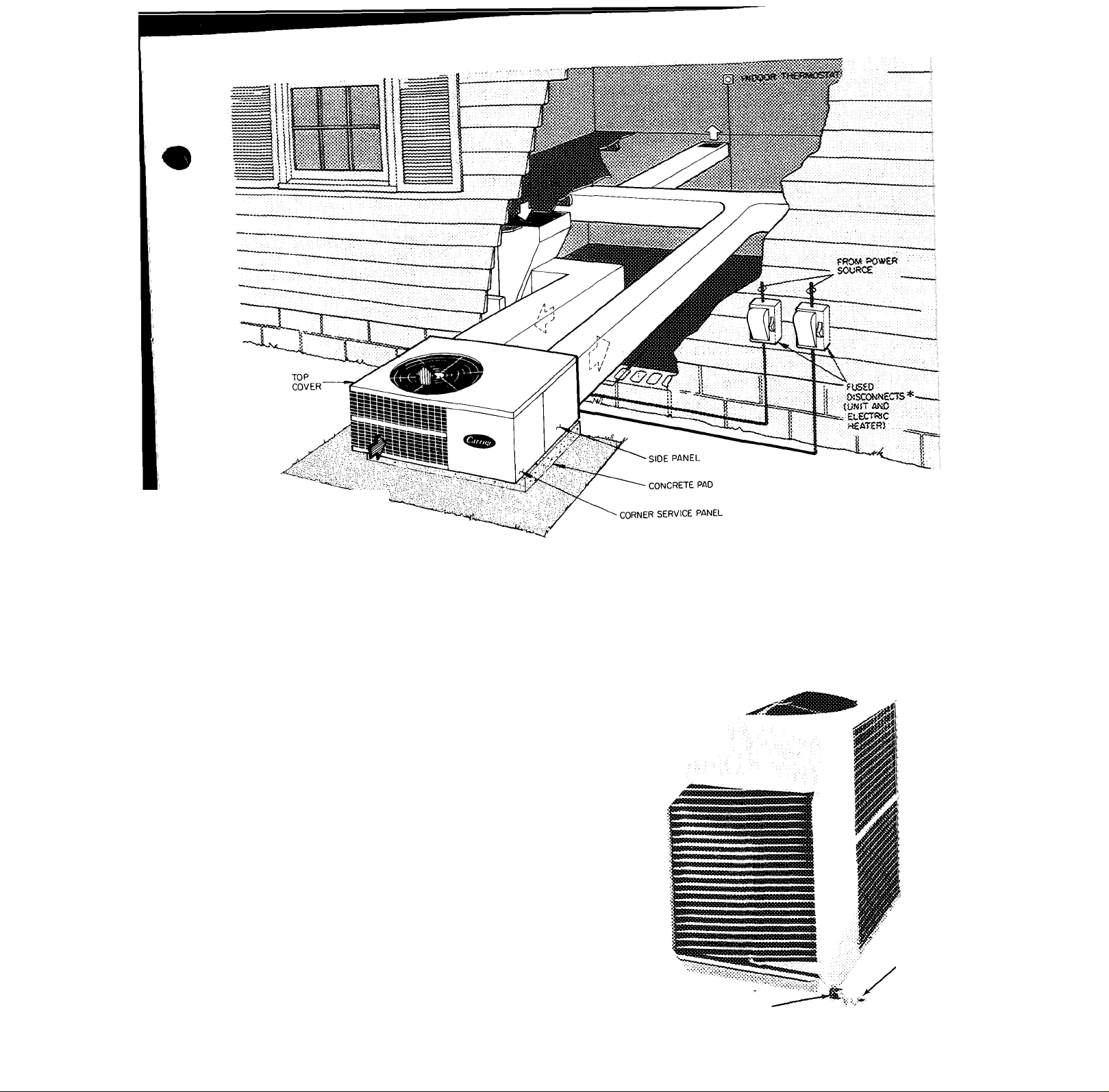

DUCTWORK

Step 5 — Connect Supply and Return Air Ductwork

to unit supply and return air duct connections. Refer

to Fig. 1 and Table 1 for unit supply and return air

connection sizes and locations.

Flanges are provided on unit for rectangular

duct connections. Fig. 3 shows a typical duct

system with 50MQ installed. Do not operate unit

longer than 5 minutes without ductwork. If neces

sary, refer to Carrier System Design Manual, Part 2,

INDOOR

UNIT FAN 5.0

SPEED

50MQ022

50MQ027 Med = H i 900

50MQ032

50MQ037

Med-Lo

Med-Lo

Med-Lo

ELECTRIC HEATER KW

7.5 1 10.0 j 15.0

Cfm

733 733 1

900 I 900

]068 1068 1

1230

1068 Í 1068

1230 ' 1230 j1230

20.0

733 j

-

-

1230

Heater limit switches may trip at air quantities

below those recommended.

f. All external ductwork must be insulated and

weatherproofed. Ducts passing thm uncondi

tioned space must be insulated and covered

with vapor barrier in accordance with the latest

issue of SMACNA’s (Sheet Metal and Air

Conditioning Contractors National Association)

and NESCA’s (National Environmental Systems

Contractors Association) minimum installation

standards for residential heating and air condi

tioning systems.

g. Secure all ducts to building structure. Weather

proof duct openings in wall or roof according

to good construction practices.

Page 3

— POWER WIRING

-------

CONTROL WIRING

OUTDOOR air flow

INDOOR AIR FLOW pUMP

«Separate fused disconnect required for electric heater.

Fig. 3 — Typical Installation

COOLING CYCLE CONDENSATE DISPOSAL

Condensate may be drained directly onto gravel

apron or connected by drain line(s) to a dry well

Condensate disposal methods must comply with

local codes and practices.

Step 6 - Connect a Drain Line to rubber conden

sate drain fitting on side of unit (see Fig. 1). Use

clamp provided. Install factory-supplied conden

sate trap (taped to indoor fan housing for ship

ment) at end of drain line. If a drain line is not

used, connect condensate trap to unit drain fitting

as shown in Fig 4.

ELECTRIC HEATER INSTALLATION

For complete heater installation data, including

accessory outdoor thermostat and emergency heat

switch, refer to accessory electric heater Installa

tion, Start-Up and Service booklet. Complete

control wiring connections are shown in this

booklet.

CONDENSATE DRAIN FITTING

WITFI CLAMP

Fig. 4 - Condensate Drain Connection

CONDENSATE

DRAIN TRAP

Page 4

ELECTRICAL DATA AND WIRING

Field wiring must comply with local and

national fire, safety and electrical codes. Voltage to

unit must be within ±10% of voltage indicated on

nameplate. On 3-phase units, phases must be

balanced within 2%.

Operation of unit on improper line voltage or ; with e.xcessive phase unbalance constitutes abuse and is not covered by Carrier Warranty.

See Table 2 for recommended wire and fuse sizes

Step 7 — Install a Branch Circuit Fused Disconnect

of adequate size to handle unit starting current.

Locate disconnect within sight of and readily

accessible from the unit. (Use a separate fused

disconnect(s) for each electric circuit as required.)

Step 8 — Bring Line Power Leads Into Unit.

Extend leads from fused disconnect thru hole pro

vided (Fig. 1) into line wiring splice box (Fig, 5).

Step 9 — Connect Ground Lead to Ground Lug in

Splice Box before connecting power wiring. See Fig.

6. Connect line power leads to yellow and black

pigtails on single-phase units or yellow, blue and

black pigtails on 3-phase units. Use wire nuts

'provided. Tape each connection. Wire nuts are

suitable for copper or aluminum wire since they

contain joint compound.

Step 10 — Set Indoor Fan Motor Speed — (Refer

to page 2 for minimum allowable air quantity for

safe electric heater operation). Four-speed indoor

fan motor is factory wired for high speed opera

tion. Fan motor is equipped with spade-type speed

selector terminals marked 1, 2, 3 and 4. For lower

fan speed, remove black unit lead from motor

spade terminal 1 and connect to spade terminal 2,

3 or 4. On alternate fan motors remove black

motor lead from unit connection and replace with

blue, orange or red motor lead.

MOTOR LEAD

MOTOR TERMINAL

FAN SPEED

Black

Hig h

B lue

2

Medium

Hig h

Orange Red

3

Med ium

Low

4

Low

Step 11 — Control Power Wiring (24 v) is brought

through 7/8-in. hole provided in unit. Fig. 1.

Extend leads to unit control wiring terminal board.

Fig. 5. Connect leads to terminal board as directed

in Fig. 7.

HEATER INSTALLATION

AREA

INDOOR FAN MOTOR

CONTROL WIRING

TERMINAL BOARD

WIRING KNOCKOUTS

■AND HOLES

(HIDDEN) SEE FIG t

LINE WIRING

SPLICE BOX

LINE VOLTAGE PIGTAILS

Fig. 5 — Unit Wiring Terminal Location

Table 2 — Unit Electrical Data

OPER

MODEL V/PH

50MQÒ22

50MQ027

S0MQ032

50MQ037

50MQ022

50MQ027

50MQ032

50MQ037

50MQ032

50MQ037

FLA — Full Load Amps

LRA — Locked Rotor Amps

IFM — Indoor Fan Motor

OFM — Outdoor Fan Motor

"Permissible limits of the voltage range at which the units will

operate satisfactorily.

tRequIred when using nonmetallic conduit.

■ —

200/1

230/1 254

200/230/3

200/230/3

VOLTAGE*

Max

220

254 180

254 180

Min

180

207

COMPRESSOR

LRA FLA FLA

75 14.1 2 2

80 16.2 2.2 2.2

99

112

68 12 8

72

88 18 0

100

75 13.0/11.5 3.6/3.1

80

IFM OFM

20.8 3.6 2 2

26.5

14 0

23.0 3.4

15.0/12 8

3.9 2.2 8 35 10

2.0 1 9 12 32

2.0

3 1

3.9/3.4

NO TE S :

1. Fan motors are 200w or 230-v, single-phase.

2. All units equipped with 24-v transformer for external control circuit.

3. Copper wire sizes based on 60 C. Aluminum field wiring may be used

when spiice connected to copper pigtails from unit with factorysupplied wire nuts. Use latest National Electrical Code for aluminum

wire sizing.

BRANCH CIRCUIT

Power Max Gnd Max

FLA

2.2 10 40 10

1.9 10

1 9

1.9 8 45 10

2.2/1.9 10/12 50/42 10/12 35/30

2.2/1.9

Wire Ft

Size

(AWG)

10

10

10/10 45/60 10/10 35/30

W ire

8

35 10

43

47 10

36 10 45

Wire Fuse

Sizet

(AWG)

10 50

12

Amps

35

40

60

30

35

50

Page 5

The 50MQ unit transformer supplies 24-v

power for complete system including accessory

electric heater up to 10 kw. Electric heaters over

10 kw are equipped with 24-v transformer used to

power heater controls.

HH07AT070 THERMOSTAT

HH93AZ076 SUBBASE

GROUND LUG

(IN SPLICE BOX)

Fig. 6 — Line Power Connections

UNIT CONTROL

WIRING TERMINAL BOARD

HH07AT070 THERMOSTAT

HH93AZ074 SUBBASE

50 MO

UNIT CONTROL

WIRING

TERMINAL BOARD

---------

Field Wiring, min 18 AWG

---------

Factory Supplied Wires

HR — Heater Relay

R — Relay

SEQ — Sequencer

Splice

Fig. 7 — Control Circuit Connections

5

Page 6

START-UP

The 50MQ units are equipped with a crankcase

heater. It is recommended that heater be energized

a minimum of 24 hours before starting unit. To

energize heater only, turn the thermostat to “Off’

position and close electrical disconnect to 50MQ

unit.

Heat Anticipator Settings for Room Thermostat

(HH07AT070) — Set anticipator settings for room

thermostat according to Table 3. These settings

may be changed slightly to provide a greater degree

of comfort for a particular installation.

Accessory Outdoor Thermostat provides adjustable

outdoor control of accessory electric heater over

10 kw. This thermostat makes contact when a drop

in outdoor temperature occurs. It energizes a

second stage of electric heat when the outdoor

temperature setting is reached, provided the room

thermostat is on the second stage of heating. Refer

to heat load of building for correct outdoor

thermostat setting. The accessory emergency heat

er relay is manually operated to lock out compres

sor and bypass the outdoor thermostat for electric

heater operation during heat pump shutdown. See

88EH electric heater Installation, Start-Up and

Service Instructions for installation of outdoor

thermostat and emergency heater relay.

To Start Unit — (Ensure crankcase heater has been

energized for 24 hours.) Adjust the thermostat as

follows;

1. Set selector switch at “Off.”

2. Set fan switch as desired (“Fan”) (“Auto.”).

3. Turn on main disconnect switch(es) to unit.

4. Set thermostat dial to the desired temperature.

5. Set selector switch at “Heat” or “Cool.” Check

system refrigerant charge. See Refrigerant

Charging.

50MQ Unit Single-Phase Compressors of the split

capacitor (PSC) type require an equalized system

pressure to start. When supply voltage is within

permissible limits and compressor does not start,

give compressor a temporary capacitance boost.

Use an 88-108 microfarad start capacitor with a

bleed resistor wired across the terminals. Connect

wires with insulated probes to each capacitor

terminal. Touch probes to each side of run

capacitor or to compressor motor terminals R and

S. Start compressor; pull probes away after 3

seconds Discharge start capacitor. (Two or more

bumps may be necessary to start compressor.) Run

compressor for 20 to 30 minutes, then shut off and

allow system pressure to equalize. Try restarting

without boost capacitor. If after 2 attempts (with

out boost capacitor) the compressor does not start,

add an accessory start capacitor relay package.

UNIT CONTROLS

High-Pressure Relief Valve (Safety Control) is

located in compressor. Relief valve opens at a

Table 3 — Thermostat Anticipator Settings

FIRST-STAGE

UNIT

50MQ022, 7.5

027,032,

037

ANTICIPATOR

SETTING

.4

ACCESSORY

ELECTRIC

HTR (Kw)

240 V

208 V

5.0 3.75"

5.6

10 0

15.0 1 1.3

20 0

7 5

15.0

SECOND-STAGE

ANTICIPATOR

SETTINGS i

4 *

56 !

56

.4 ;i

.4 1

pressure differential of approximately 600 psi

between suction (low side) and discharge (high

side) to allow pressure equalization. The valve also

permits pressure equalization when high-side —

low-side pressure differential reaches 90 psig at

shutdown. Compressor can then start unloaded. A

hissing sound during pressure equalization indicates

pressures are equalizing and does not indicate bad

valves.

Internal Current and Temperature Sensitive Over

load (Safety Control) resets automatically when

internal compressor motor temperature drops to a

safe level (overloads may require up to 45 minutes

to reset). When an internal overload is suspected of

being open, check by using an ohmmeter or

continuity tester. If necessary, refer to Carrier

Standard Service Techniques Manual, Chapter 2,

for complete instructions.

Defrost Control, consisting of a defrost timer,

defrost thermostat and defrost relay, interrupts

normal system heating operation if enough frost

forms on outdoor coil to impair unit performance.

Defrost control simultaneously stops outdoor fan,

de-energizes reversing valve solenoid to return

system to cooling cycle (outdoor unit as con

denser, indoor unit as evaporator), and activates

accessory electric heater. Unit can defrost every 90

minutes, but will defrost only if required.

For the heat pump to defrost, 2 conditions are

necessary:

1. Defrost timer contacts must be closed.

2. Refrigerant temperature from outdoor unit

must be cold enough to cause defrost ther

mostat contacts to close. Contacts close at 35

(+0, -6) F.

Every 90 minutes of elapsed running time, the

defrost timer contacts close for 10 seconds. If the

defrost thermostat contacts are closed, the unit

defrosts. The defrost timer limits defrosting period

to 10 minutes. Normally the frost is removed and

the defrost thermostat contacts will open to

terminate defrosting before 10 minutes have

elapsed. Defrost thermostat contacts open at 65

(+0, -6) F. When defrosting is terminated, the

outdoor fan motor and reversing valve solenoid are

energized returning unit to heating cycle.

HEAT PUMP CIRCUITS shown in Fig. 8 are

refrigerant flow diagrams for heating and cooling

cycles.

Page 7

Unit Piping

strainers

Fig. 8 — 50MQ Refrigerant Flow Diagrams

STRAINERS

SERVICE

Table 4 — Service Data

UNIT

R-22 CHG

(Ib-oz)*

Refrig Control

INDOOR FAN

Rpm

Diameter (in.)

Width (in.)

Range Cfm

Motor Hp

OUTDOOR FAN

Cfm

Rpm

Diameter (in.)

Motor Hp

»Factory refrigerant charge.

50MQ022 50MQ027

5.0 ) 5 7 5 7

733-915

1/4

50MQ032

Acc uR a ter ^

Cen tr ifu ga l — Dir ec t D r ive

1050-950-850-800

9

8

9 10

8 8

900-1125 1068-1332

1/4 1/3

Pro pe lle r — Di re ct D r ive

3000

1050

20

1/4

50MQ037

10

8

1230-1540

1/3

REFRIGERANT CHARGING

Unit refrigerant system is factory charged.

When recharging is necessary during heating or

cooling season, weigh in total charge indicated in

Table 4. (Charge must be weighed in during heating

season.) Blow any refrigerant remaining in system

before recharging. Standard 1/4-in. Schrader

Service Connections (Fig. 9) are provided on high

and low sides of refrigerant system for evacuation

and charging.

Dial-a-charge charging cylinder is an accurate

device used to recharge systems by weight. These

cylinders are available at refrigeration supply firms.

A Carrier Chargemaster® charging device

(Carrier Part No. 38GC680004) may be used to

check or adjust refrigerant charge during cooling

season The Chargemaster may also be used as an

alternate method of recharging system.

Chargemaster Operation — Operate unit 10 min

utes before using Chargemaster.

1. Tape Chargemaster feeler bulb to unit suction

line. Insulate bulb. Ensure suction line is clean

for good contact with bulb.

2. Connect refrigerant drum to Chargemaster inlet

port with drum in position for vapor charging.

3. Connect Chargemaster outlet port (loosely) to

unit suction line Schrader valve.

4. Crack valves on refrigerant drum and Charge-

master to purge lines from drum to suction line

Schrader valve. After purging lines, close valve

on Chargemaster only. Tighten Chargemaster®

connection at suction line Schrader valve.

5. Measure outdoor air dry-bulb temperature at

unit.

6. Read evaporator temperature at red needle

position on Chargemaster temperature gage and

suction line temperature at black needle

position

CAUTION: Do not read evaporator tem

perature with Chargemaster valve open.

7. Enter 50MQ Chargemaster Charging Chart,

Table 5, at outdoor air temperature (step 5)

and evaporator temperature (step 6). Find the

suction line temperature required for correct

system charge. If actual suction line tem

perature (step 6) is higher than table value, the

system is undercharged. If suction line tem

perature is lower than table value, the system is

overcharged.

Example- At outdoor air temperature of 85 F

and evaporator temperature of 40 F, the system

will be correctly charged at 48 F (±2 F) suctior

line temperature.

Page 8

8. Add charge by slowly opening Chargemaster®

valve. If necessary, reduce charge by bleeding at

liquid line Schrader valve. Check outdoor air

and evaporator temperature during procedure.

If they change, refer back to Chargemaster

Charging Chart for new value.

Correct use of Chargemaster ensures an opti

mum refrigerant charge will be in system when

conditions and system components are normal.

However, the Chargemaster does not solve or fix

system abnormalities It indicates correct charge

for condition of system. It will not make correc

tions for dirty filters, slow fans, excessively long or

short suction lines, or other abnormal conditions.

This charging device ensures that a correct relation

ship exists between outdoor temperature, evap

orator temperature, and suction line temperature

on a specific system.

Table 5 — 50MQ Chargemaster® Charging Chart

6. Remove compressor hold-down bolts. Lift com

pressor out.

CAUTION: Aluminum tubing is used in

50MQ unit coils. Do not overiieat or place

excessive strain on tubing or damage may

result.

Table 6 — Compressor Data

MODEL

50MQ022

50MQ027

50MQ032

50MQ037

50MQ022

50MQ027

50MQ032

50MQ037

5ÒMQ032

50MQ037

V/PH

200/1

230/1

200-230/3

PRODUCTION

COMPRESSOR

MB2423CB

MB2723CB

MB3423CB

MB4023CB

M52423CB

MD2723CB

MC3423CB

MC4023CB

MF3423CB ~

MF4023CB

OIL

RECHARGE (oz)

44

OUTDOOR

TEMP

(F)

60

65 40

70

75 37 46

80

85 42 -48

90 44

95 40 45 5 C

100 44

105

‘Saturated temperature which is the equivalent temperature of

pressure taken at the heat pump suction Schrader fitting.

EVAPORATOR TEMPERATURE (F)*

38 2ÏÔ

Te

Ó6

64

55

55

42 44

mperatu

62

54 61

49

42

28

30

32

Suet on Line

50

65

48

36

34

36,

72

56 Ó6

56

46

40

47

46 48 50|

res

60

55

55

50

60

54 59

50

54 58

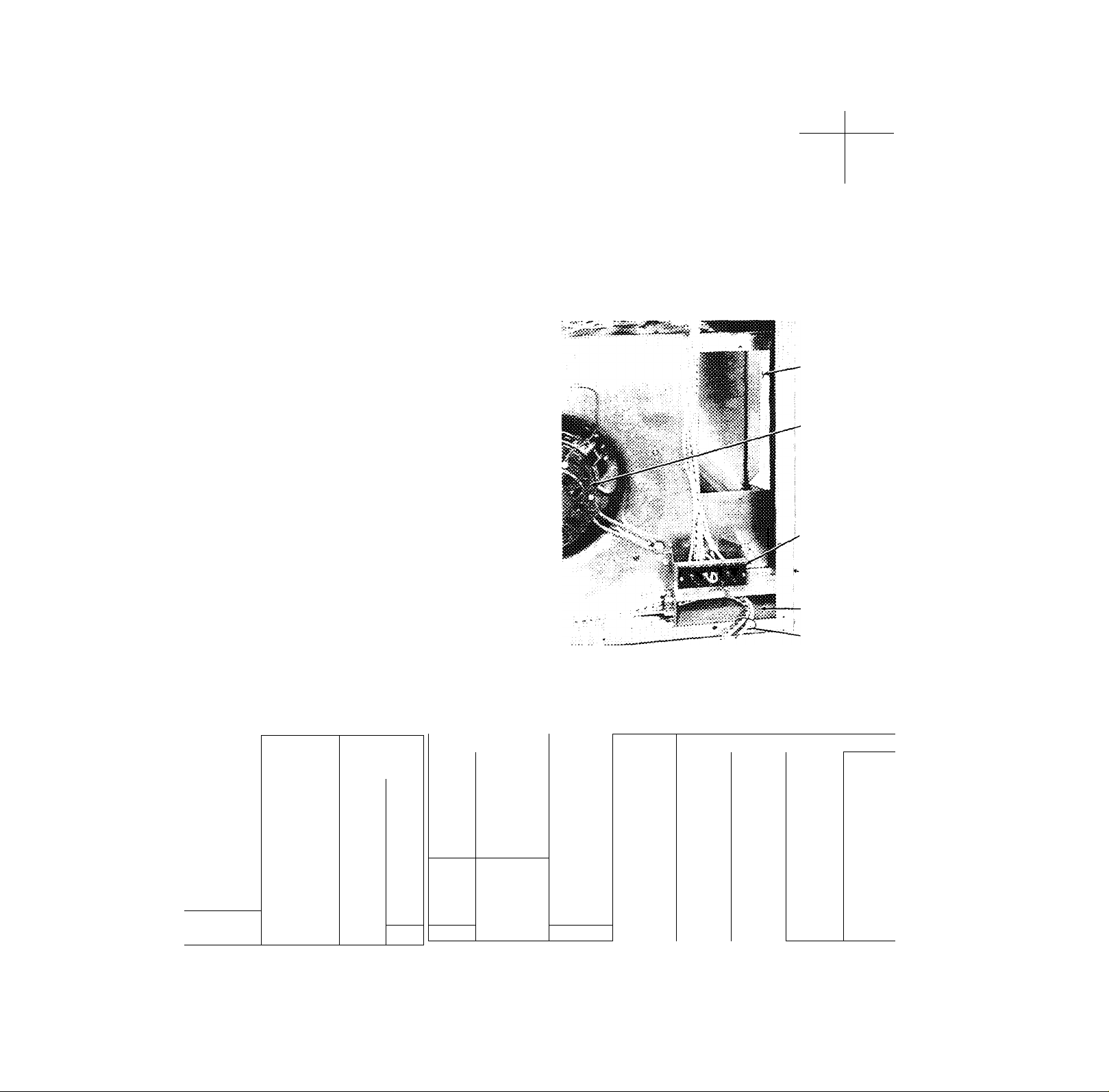

COMPRESSOR REMOVAL

See Table 6 for compressor information and

Fig 10 for component location.

1. Shut off power to unit. Vent refrigerant to

atmosphere or use refrigerant removal methods

shown in Carrier Standard Service Techniques

Manual, Chapter 1.

2. Remove unit corner access panel. Fig. 1.

3. Remove core from suction and discharge line

Schrader valves.

4. Disconnect compressor wiring at compressor

terminal box. Carefully unsweat suction and

discharge (hot gas) lines at compressor. Do not

stress or move compressor discharge line or it

may break at condenser connection.

CAUTION: Excessive movement of copper

lines at compresksor may cause a break where

lines connect to evaporator or condenser.

5. Remove crankcase heater from compressor

base.

Filter-Drier — Install a filter-drier in compressor

suction line when refrigerant system is opened for

service as described under Compressor Removal.

Fig. 9 shows suggested position of drier. Check

filter-drier pressure drop at drier service port and

unit suction line Schrader fitting. Ensure pressure

drop does not exceed 2 psi.

CONTROL BOX

4-WAY VaL^:

DISCHARGE LINcl

(HIGH SIDE)IS2!r

SCHRADER FITTING

$

FILTER-DRIER

SERVICE

FILTER-DRIER

(FIELD SUPPLIED)

SUCTION LINE

accumulator;

SUCTION LINE

(LOW SIDE)"

SCHRADER FITTING

COMPRESSO!

COMPRESSOR HOLD

DOWN BOLTS (4)

COMPRESSOR ’

TERMINAL BOX

Fig. 9 — Compressor Removal

MAINTENANCE

Lubrication

COMPRESSOR contains factory oil charge. Re

place oil when lost. See Table 6 for oil recharge. If

necessary, refer to Carrier Standard Service Tech

niques Manual, Chapter 1, pg 1-21, for oil re

charging procedure. Use Carrier PP33-1, Texaco

Capella B or Suniso 3G oil.

Page 9

FAN MOTOR BEARINGS are prelubricated for 3

years heavy duty or 5 years normal duty. When

lubrication is necessary, send motor to authorized

motor repair shop.

Evaporator (Indoor Coil)

OUTDOOR FAN AND MOTOR REMOVAL Remove screws holding outdoor coil fan grille in

place. Disconnect fan motor leads from controllers

and capacitor. Lift complete fan, motor and orifice

assembly (Fig. 10) out of unit. After replacing fan

motor assembly, reconnect fan motor leads.

CAUTION: Before performing recommended ;

maintenance, be sure main power switch to unit

is turned off.

COIL ” Lift or remove unit top cover for access to

indoor coil. See Fig. 10. Inspect coil periodically.

Clean as described under Condenser (Outdoor Coil)

below.

Condensate Drain

with bottle brush,

Clean condensate drain trap

then flush condensate pan

beneath evaporator coil with clean water. Ensure

water flows freely thru condensate drain.

INDOOR FAN WHEEL should be centered in fan

housing. To adjust fan, remove fan motor orifice

assembly as described below. Loosen setscrew

holding fan to motor shaft. Adjust fan and

retighten setscrew.

Indoor Fan Removal — See Fig. 10. Disconnect fan

motor wiring. Remove sheet metal screws (6)

holding fan orifice in place. Remove fan motor

bracket mounting screws (3). Slide out complete

fan, motor and orifice assembly.

Cleaning Indoor Fan Wheel — Remove caked-on

dirt from fan wheel and housing with brush;

remove grease with mild solvent. When replacing

blower assembly, ensure fan wheel is centered in

housing.

Condenser (Outdoor Coil)

COIL “ Lift or remove top cover for access to

outdoor coil. See Fig. 10. Inspect coil periodically.

Clean coil with water at the beginning of every

cooling season or more often if required. Use

ordinary garden hose at a pressure high enough to

clean efficiently. For best results, spray coil fins

from inside-to-outside the unit or top to bottom

between rows of tubing. Flush dirt from base pan

by spraying water thru top of unit. Avoid splashing

mud on coil or water on the fan motor.

OUTDOOR FAN POSITION - Required fan posi

tion is shown in Fig. 11. Adjust fan by loosening

setscrews and moving blades up or'down.

UNIT TOP CCVER

OUTDOOR FAN-ORIFICE

FAN MOTOR ASSEMBLY

NDOOR COIL

OUTDOOR COIL

4-WAY VALVE

CONTROL BOX

ACCUMULATOR

LINE WIRING

AIR FLOW

INDOOR FANORIFICE MOTOR

SPLICE BOX

Fig. 10 — Component Location

FANBLAOe

/

TOP OF

SLADE

L

------'------'------------

SETscf?ew

MOTOR

• -JiVMXl '

2,00 iri \

№

Fig. 11 — Outdoor Fan Position

Return Air Filter (Field Supplied) — Replace

throwaway filter twice a year. Clean permanent-

type filter a minimum of twice yearly. Flush

permanent filter with hot water, steam or soak in

mild solution of soap or detergent and water.

Allow filters to dry and replace. Refer to filter

manufacturer’s instructions, as required, for other

types of filters.

Page 10

TROUBLESHOOTING CHART - COOLING CYCLE

Page 11

TROUBLESHOOTING CHART - HEATING CYCLE

NO HEATING OR

INSUFFICIENT HEATING

CONTACTOR

OPEN

OPENING IN

POWER CIRCUIT

DEFECTIVE LOW

VOLTAGE

TRANSFORMER

REMOTE CONTROL

CENTER DEFECTIVE

CONTROL RELAY

COIL OR CONTACTS

DEFECTIVE

REVERSING VALVE

RELAY DEFECTIVE

CONTACTOR COIL

OPEN OR SHORTED

KLIXON OR OVER

LOAD DEFECTIVE

COMPRESSOR

WILL NOT RUN

CONTACTOR

CLOSED

COMPRESSOR

POWER SUPPLY

OPEN

LOOSE LEADS

AT COMPRESSOR

FAULTY START

CAPACITOR OR RELAY

SINGLE PHASE ONLY

COMPRESSOR

STUCK

INTERNAL

OVERLOAD

DIRTY FILTERS

OR INDOOR COIL

INDOOR FANS

CYCLING ON

OVERLOAD

DEFECTIVE FAN

MOTOR CAPACITOR

LOOSE LEADS AT

FAN MOTOR

FAN MOTOR

BURNED OUT

DAMAGED

REVERSING VALVE

RESTRICTION IN

DISCHARGE LINE

1

COMPRESSOR RUNS

BUT CYCLES ON

LOW LINE VOLTAGE

OR UNBALANCED

3-PHASE LINE

DEFECTIVE RUN

CAPACITOR

(SINGLE PHASE)

COMPRESSOR

BEARINGS

HIGH LOAD

CONDITION

OVERCHARGE OR

NONCONDENSABLES

REVERSING VALVE

JAMMED IN MID

POSITION

1

1 ■■ "

LOW SUCTION

LOW HEAD

OUTDOOR FAN

STOPPED

LOOSE LEADS AT

OUTDOOR FAN

MOTOR

INTERNAL FAN

MOTOR KLIXON

OPEN

FAN MOTOR

BURNED OUT

DEFROST RELAY

N.C. CONTACTS

OPEN

—1 p

COMPRESSOR RUNS -

INSUFFICIENT HEATING

OUTDOOR fan

RUNNING

RESTRICTED

LIQUID LINE

ACCU RATER '

RESTRICTED OR

ICE CLOGGED

UNDERCHARGED

OUTDOOR COIL

^ DIRTY

OUTDOOR COIL

HEAVILY FROSTED

DEFECTIVE DEFROST

THERMOSTAT

1

STRIP HEATERS

NOT OPERATING

OUTDOOR

THERMOSTAT

DEFECTIVE

ODT SETTING

TOO LOW

CAP TUBE PINCHED

OR BULB NOT

SENSING TRUE ODT

STRIP HEATER RELAY

OR CONTACTOR

DEFECTIVE

OPENING IN POWER

CIRCUIT TO HEATER

ELEMENTS

BLOWN FUSE LINK

BROKEN HEATER

ELEMENT

OVERCHARGE OR

NONCONDENSABLES

IN SYSTEM

DEFROST THERMOSTAT

IN POOR PHYSICAL

CONTACT WITH LINE

DEFECTIVE DEFROST

RELAY OR DEFROST

TIMER

REVERSING VALVE

STUCK

BAD ELECTRICAL CONNECTiON ANYWHERE IN

DEFROST CIRCUIT

4 INTERNAL PRESSURE

RELIEF OPEN

OPEN (KLIXON)

OVER-TEMPERATURE

THERMOSTAT

DEFECTIVE ROOM

THERMOSTAT

(2ND STAGE)

Page 12

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Tab 12

Form50MQ-1SI New

Printed in U.S.A.

12-74

Codes D and MS Catalog No 535-070

Loading...

Loading...