Page 1

Carrier

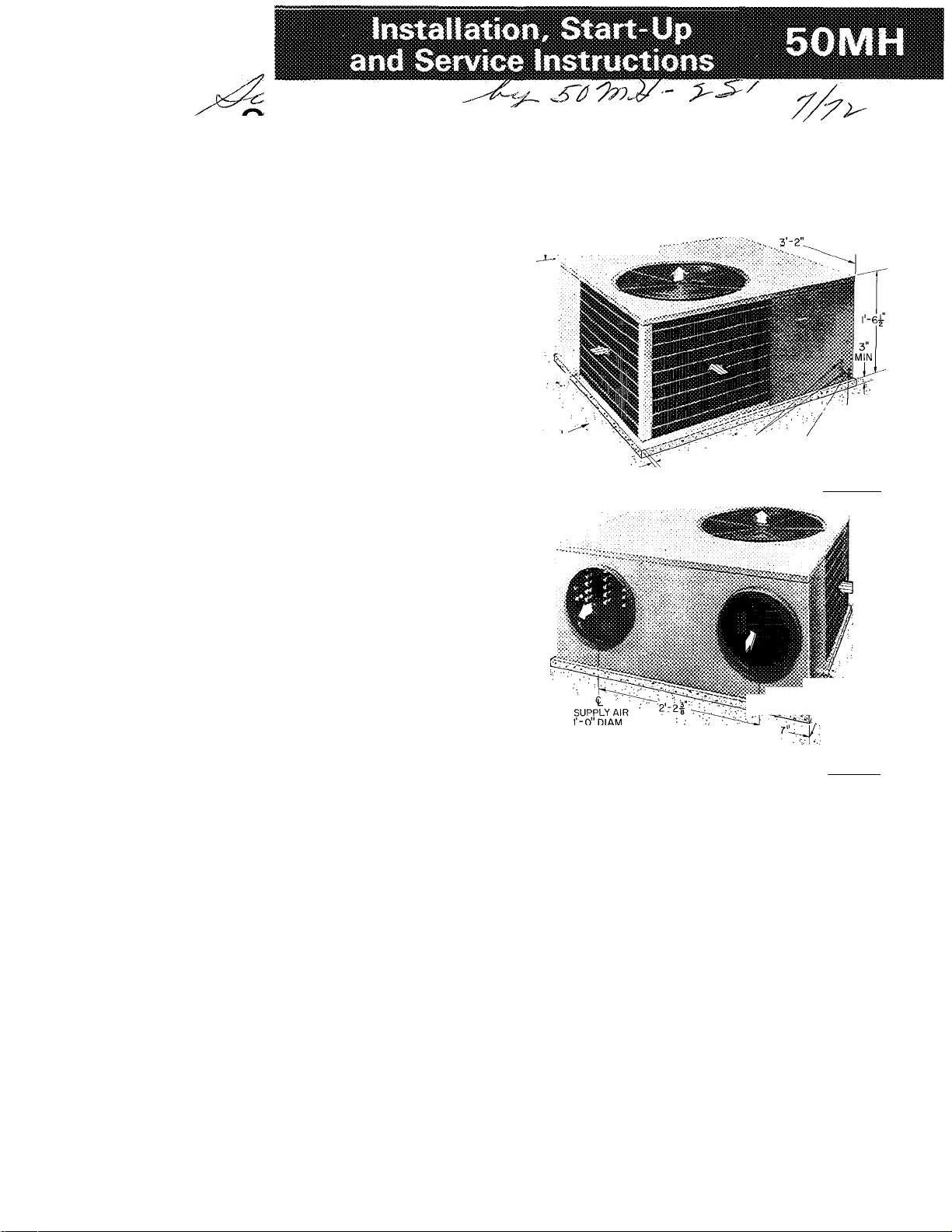

ingle-Packagé Cooling Units

(Mobile Home Unit)

INTRODUCTION

The 50MH unit is a complete cooling system,

with provision for addition of accessory electric

heaters. Units are air cooled, designed for outdoor

installation and may be connected into existing

duct system Required connections include air

ducts, condensate drain, line and control power

wiring, A field-supplied filter box must be installed

for return air.

TRANSPORTATION DAMAGE

File claim with shipping company if shipment is

damaged or incomplete. Move unit to installation

site in upright position.

PRELIMINARY SURVEY

Consult local building codes for special installa

tion requirements.

When installing unit, allow sufficient space for

condenser air-flow clearance, wiring, and servicing

unit (see Fig. 1). Position unit so water from roof

will not pour directly on top of unit.

Mounting Pad (Fig. 1) — Install unit on a solid,

level-poured concrete pad or equivalent. Construct

pad so top is a minimum of 3 in. above ground

level. Pad must not be more than one inch longer

or wider than unit. Extend a 24-in. gravel apron

completely around pad. Insert a sheet of tar-base

construction felt paper between unit and pad.

DUCTWORK

Design duct system to have a friction loss of

between .25 in. wg and .70 in. wg for proper unit

operation. Insulated flexible ductwork (1-ft inside

diameter) of weatherproof type is recommended.

Do not reduce duct inside diameter below 1 ft.

Combined length of supply and return ducts

should not exceed 20 ft with a minimum supply

duct length of 6 ft and a minimum return duct

length of 3 ft. Do not operate unit longer than 5

minutes without ductwork. If necessary, refer to

Carrier System Design Manual, Part 2, for air duct

design.

Flanges are provided on unit for attaching

ductwork. See Fig. 1 for connection sizes and Fig.

2 for typical duct installation.

Supply Air Connection — Connect flexible duct to

unit supply air connection. When unit is equipped

with electric heaters, insert a sheet metal sleeve

inside of flexible duct. Sleeve must extend 24 in.

from electric heater element. At approximate

4'-0" OVERHEAD

; AIR SPACE REQUIRED

I DIAM LOW

2-0

GRAVEL APRON

AROUND PAD :

OPERATING WT:

50MH003-275 LBS

50MH004-295 LBS

M POWER ® DIAM

A' MAX cnppi Y KNOCKOUT

(4 SIDES) KNOCKOUTS

li DIAM |3 nv,...

VOLTAGE CONN

FRONT VIEW

■'Mli

t

-

---

11^ EVAPORATOR AIR FLOW

^CONDENSER AIR FLOW

Fig. 1 — Dimensions and Connections

■ i"

<L ^

RETURN AIR

'-0" DIAM

ID

CONDENSATE

DRAIN

REAR VIEW

center of trailer, connect flexible duct to main

supply duct with a 90-degree sheet metal elbow.

Install turning vanes in main supply duct directly

above elbow connection using standard sheet metal

practices.

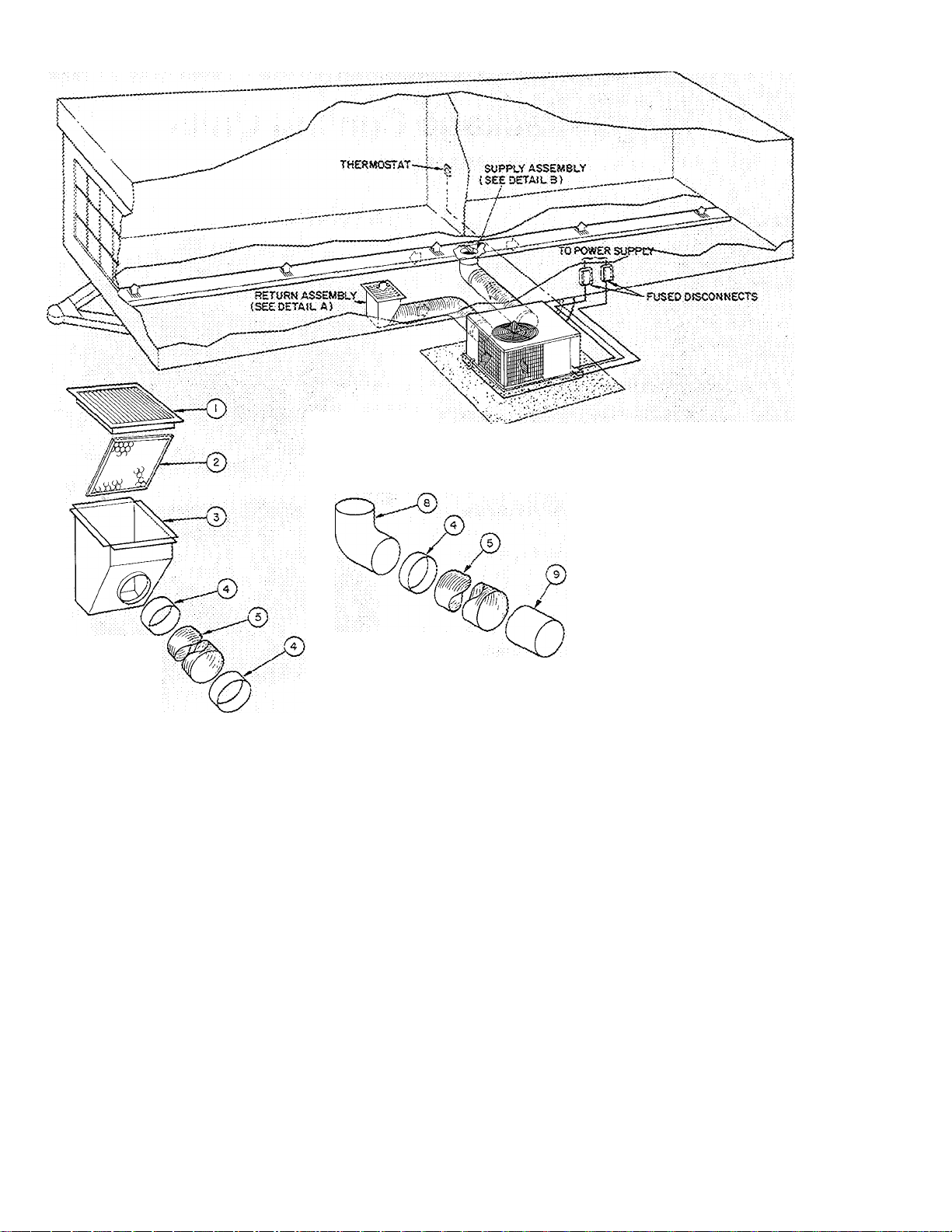

Return Air Connection — Purchase or field fabri

cate a filter box. Suggested minimum filter box

dimensions are shown in Fig. 3 (see page 3). At

approximate center of trailer, cut a return air

opening in floor. Locate opening where it will not

be obstructed by furniture. Size opening to accept

filter box. Cut hole in carpet or floor covering

same size as filter box floor opening. Ensure

electrical wiring or main structural supports are not

accidentally cut. Insert filter box thru floor open

ing. Weatherseal floor connection in accordance

with good construction practice. Insert filters in

filter box, and cover with return air grille.

® Carrier Corporation 1971

Form 50MH-1SI

Page 2

DETAIL A

(RETURN ASSEMBLY)

DETAIL B

(SUPPLY ASSEMBLY)

Fig. 2 — Typical Installation

(7) RETURN A5R REGISTER

( z ) l4*x25”;il“nETER(PERMANEN7

^ TYPE)

iT) RETURN AiR PLENUM

COLLAR

0

FLEXIBLE DUCT

:0! BAFFLE

(T) TAP*IN COLLAR

(e) INSULATED ELBOW

LINER

------

CONTROL WIRING

——POWER WIRING

^ CONDENSER AIR FLOW

evaporator air flow

Connect flexible duct to filter box. Extend

duct from filter box to unit return air connection.

If possible, insert a total of a 90-degree bend in

return air duct for sound dampening. Connect duct

to unit return air connection.

When existing furnace is kept in system:

During heating season, insert a sheet metal

panel beneath return air grille and over filter to

prevent air movement thru cooling unit.

When furnace is removed from system, blank

off original furnace floor connection.

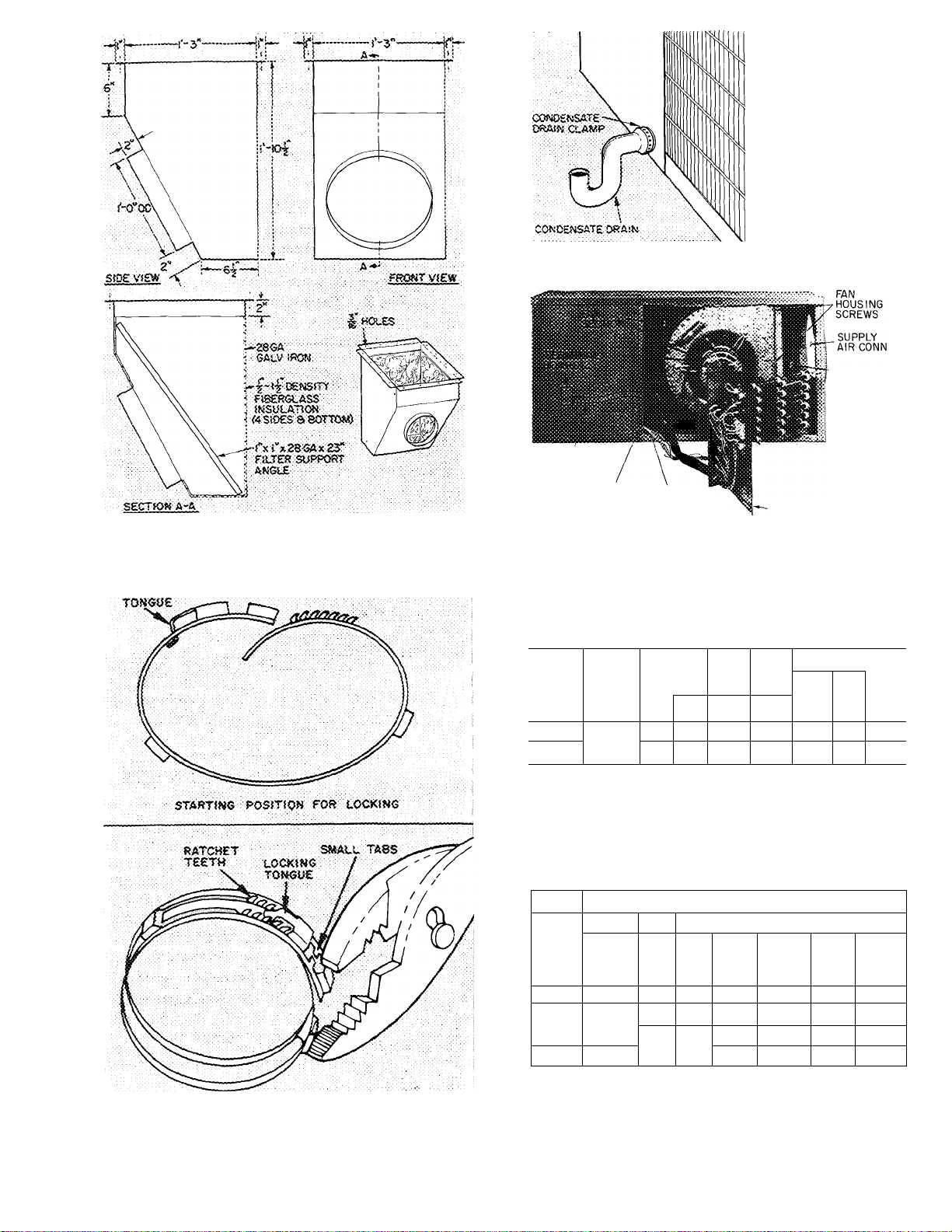

CONDENSATE DRAIN

A condensate trap is factory supplied and taped

to unit suction line for shipment. Connect trap to

unit condensate drain fitting with clamp provided.

See Fig. 4 and 5.

Applying Clamp

1. Pull ends apart.

2. Wrap around condensate trap with toothed end

beneath. Prelatch by compressing until last

ratchet teeth catch behind small tabs.

3. Grip adjacent bridges with pliers and compress

to tight position.

4. To remove, lift the locking tongue with

screwdriver.

ELECTRIC RESISTANCE HEATER

Remove fan section access panel and sheet

metal plate covering heater installation area (be

tween evaporator fan discharge and supply air

connection). See Fig. 6. Discard sheet metal plate

and insert heater into opening provided. Insert

heater support bar thru hole in side of fan

discharge duct. Fasten heater in place at top and

bottom with two sheet metal screws. See Wiring

section for power connection details.

Page 3

Fig. 3 — Minimum Dimensions Return Air

Filter Box

fRl

mi

RI

Fig. 5 — Condensate Drain Connection

LINE POWER

LEADS FROM

HEATER

CONTROL

WIRING

RECEPTACLE

Fig. 6 — Electric Resistance Heater Installation

CONTROL

LEADS

FROM HEATER

ELECTRIC HEATER

ASSEMBLY

HEATER

INSTALLATION

OPENING

i.0Ci(fN6

ELECTRICAL DATA AND WIRING

Table 1 — Unit Electrical Data

EVAP

COMPR

PH

LRA FLA FLA FLA

86.0 19.5 3.4 1 1 10 30

20 0

93 0

50MH

003

004

VOLTS/

230/1

MODEL

LRA — Locked Rotor Amps

FLA — Full Load Amps

NOTE:

Motors and controls will operate satisfactorily 10% above and 10%

below unit voltage. Control circuit voltage is 24 volts on all units.

COND

FAN

FAN

3 4 1 1 10 30 30

BRANCH CKT

Wire

Max

Size

Wire

(AWG)

Fuse

Ft

Amps

30

Table 2 — Electric Resistance Heater Data

ELECTRIC HEATER

UNIT

50MH

003

&

004

Volts/

Ph

240/1

KW

No.

1

5

1 41.7 6 30

10

15 2

Branch Circuit

FLA

(ea)

Wire

Size

(AWG)

20.8 10

20 8

41 7 6

10

Max

Ft

Wire

30

30 30

30 50

Fuse

Amps

30

50

CLA«P IN LOCKIXS POSJTiO«

Fig. 4 — Condensate Drain Clamp

Wiring — Field wiring must comply with local and

national codes. Install a branch circuit fused

disconnect of adequate size to handle unit starting

current. Provide a separate fused disconnect for

Page 4

each electric resistance heater. Voltage to unit

during operation must be within ± 10% of voltage

range indicated on nameplate.

THERMOSTAT’

&-

TERMINAL

BOARD 3

Failure due to operation of unit on improper

line voltage constitutes abuse ana is not covered

by Carrier Warranty.

LINE POWER — Bring line power leads from fused

disconnect thru hole provided (Fig. 1) into high

voltage section of control box. Connect line power

leads to Terminals 1 and 2 on Terminal Board 1.

See label diagram and Fig. 7. Aluminum field

wiring may be used when splice connected to

copper pigtails from unit with approved copper to

aluminum splice connectors.

Accessory Electric Fleater(s) — Connect line power

leads from fused disconnect(s) to Terminal Board 2

as shown in Fig. 7. Extend power leads (supplied

with electric heater) from heater thru fan section

and thru hole provided into high voltage section of

control box. Connect leads to Terminal Board 2

(Fig. 6 and 7).

№

&-

0

------------------------------------

Connect Terminal G to Terminal 2 for operation with electric

heater or Terminal 3 for operation without electric heater

_____

Field Wiring

*HH01 YA092 thermostat with HH93YZ096 subbase

Fig. 8 — Thermostat Connections

-a

-Q

a

TO

HEATER

FD

—

TO (-

HEATER <

FD 1-

FD — Fused Disconnect

______

Field Wiring

______

Factory-Supplied Wire (Field Connected)

<Q) Unmarked Terminals

”0—[aF

—

-0—0-

RED

BLK

YEL

BLU

(2

TO

)

10 Kw

HEATER

1 TO

> 5KW

1 HEATER

Fig. 7 — Line Power Connections

Evaporator Fan Motor is factory wired for high

speed operation as shown in Fig. 9. If medium or

low speed operation is desired, remove black motor

lead from Contactor Terminal 23 and replace with

blue motor lead for medium speed or red motor

lead for low speed. Tape unused leads separately.

THERMOSTAT LEADS (24 v) are brought thru

hole provided (Eig. 1) into low voltage section of

control box. Connect leads to Terminal Board 3 as

shown in Eig. 8 and 9.

Accessory Electric Heaters — Extend control leads

with plug (supplied with heater) thru fan section

and insert plug into receptacle located on side

panel of control box. See Fig. 6 and 9.

— Thermostat, Cooling

— Contactor

c

— Compressor TDR

Comp

— Fan Capacitor (1FM)

FC

FR — Fan Relay Tran — Transformer

— Indoor Fan Motor

IFM

— Low-Press. Switch

LPS

OFM — Outdoor Fan Motor

R — Relay

RC — Run Capacitor (Dual)

SC

— Start Capacitor

SFR — Safety Fan Relay

— Start Relay

SR

— Terminal Board

TB

NOTES

1. To be wired in accordance with NEC and local codes

2 Low-pressure cutout setting 27 0 ± 4 psig.

3. Terminations in junction box suitable for NEC Class 2 control

circuit, at 24 volts

4 Motor provided with inherent thermal protector,

5. Terminal G connects to terminal no 2 for operation with electric

heater.Terminal G connects to terminal no. 3 for operation with

out electric heater

TC

— Time-Delay Relay

TH — Thermostat, Heating

Field Power Wiring

—

___

. Field Control Wiring

NEC Class 2, 24 v.

Marked Connections

o

Unmarked Connections

O

Terminal Board Connections

□

Fig. 9 — Typical System Wiring Diagram

Page 5

START-UP

Adjust remote control center as follows:

1. Set selector switch at “Off.”

2. Fan switch at “Auto.” or “Fan.”

3. Turn on main disconnect switch(es) to unit.

4. Set thermostat dial to the desired temperature.

5. Selector switch at “Heat” or “Cool.”

Electric Resistance Heater Operation — When

thermostat calls for heating, evaporator fan and

heater no. 1 are energized immediately. Remaining

heaters are energized in 30 second intervals. When

thermostat is satisfied, the cycle reverses and

heaters are de-energized in 30-second intervals.

Evaporator fan motor shuts off with last heater.

SERVICE

Table 3 — Service Data

Manual, Chapter 1, pg 1-21, for oil recharging

procedure. Use Carrier PP33-1, Texaco Capella B

or Suniso 3G oil.

Fan Motor Bearings are prelubricated for three

years heavy duty or five years normal duty. When

lubrication is necessary, send motor to authorized

motor repair shop.

CONDENSER

Coil — Lift or remove unit top cover for access to

condenser coil. Inspect coil periodically. Clean

with brush, vacuum cleaner, low-pressure water,

steam or air.

Fan Position — Required fan position is shown in

Fig. 10. Adjust fan by loosening setscrews and

moving blades up or down.

#

UNIT 50MH003

R-22 CHG (Ib-oz)*

Refrig Control

COMPRESSOR

Type Start CSR

Oil Recharge (oz) 45 50

EVAP FAN

Rpm

Diam (in.) 10

Width (in.)

Nom Cfm

Norn Motor Hp

COND FAN

Rpm

Diam (in.) 18

Norn Cfm

Norn Motor Hp

CSR — Capacitor Start

* Factory refrigerant charge

3-0 3-11

TXV

38GC401404 51YA400524

Centrifugal —

1075 - 950 - 850

8

1125

Propel 1er —

1050

2400

%

50MH004

TXV

CSR

Direct Drive

10

8

1350

Di rect Drive

1050

18

2400

ke

REFRIGERANT CHARGING

Refrigerant System is factory charged. When

recharging is necessary, weigh in total charge

indicated in Table 3. Blow any refrigerant

remaining in system before recharging. Standard

1/4-in. Schraeder service connections provided on

high and low sides of refrigerant system for

evacuation and charging.

LUBRICATION

Compressor contains factory oil charge. Replace oil

when lost. See Table 3 for oil charge. If necessary,

refer to Carrier Standard Service Techniques

EVAPORATOR

Coil — Lift or remove unit top cover for access to

evaporator coil. Inspect coil periodically. Clean

with brush, vacuum cleaner or low-pressure air.

CONDENSATE DRAIN — Clean condensate drain

trap with bottle brush, then flush condensate pan

beneath evaporator coil with clean water. Ensure

water flows freely thru condensate drain.

Evaporator Fan Wheel should be centered in fan

housing. To adjust, loosen setscrews holding fan to

rhotor shaft. Adjust fan and retighten setscrews.

EVAPORATOR PAN REMOVAL - Disconnect

fan motor wiring. Remove two fan housing sheet

metal screws shown in Pig. 6 and slide out

complete fan and motor assembly.

RETURN AIR FILTER

Clean filter a minimum of twice yearly. Flush

permanent-type filter with hot water, steam or

soak in mild solution of soap or detergent and

water. Allow filters to dry and replace. Refer to

filter manufacturer’s instructions, as required, for

other types of filters.

«

Page 6

TROUBLESHOOTING CHART

Page 7

I

Û

lU

L.

CO

O

_J

O

UJ

a.

<

h-

cc

o

LU

« a

y S

Û- CO

< X

ifi

Q

Z

< z

LÜ LU

■y Û.

^ o

_J

w

X

hÜ

z

o

_J

<

u

<

CÛ

Q

_J

o

z

o

WARRANTY - EXTENDED PROTECTION PLAN

GENERAL WARRANTY STATEMENT - We warrant all

I

Carrier products to be free from defects in material and

workmanship under normal use and service Our obligation

shall be limited to repairing or supplying a replacement for

the defective part, assembly or portion thereof, which our

inspection shall show to be defective, F.O.B. Carrier factory.

PERIOD OF COVERAGE

First Year Warranty — The above warranty applies for one

year from date of original installation to all parts and

components in the Carrier product identified below

excepting refrigerant, air filters and filter-driers which are not

included in any part of this warranty.

Motor-Compressor Protection Plan — The above warranty

applies for five years from date of original installation to the

Hermetic Motor-Compressor only in the product identified

below Cartier will allow transportation for the Hermetic

Motor-Compressor between the factory and its authorized

distributor.

GENERAL CONDITIONS — This warranty does not cover

the cost of labor for any adjustments or service calls, nor

does it include the cost of labor for replacing defective parts

or components.

This warranty does not apply if the Carrier product or

any part thereof has been subjected to misuse, abuse, neglect,

accident oi alteration.

This warranty applies only to Carrier products installed

within the boundaries of the Continental United States,

Canada and Hawaii, and only applies- to parts supplied oi

designated by Carrier.

This warranty is in lieu of all other warranties expressed

or implied, and in no event shall Carrier be liable for any

special, indirect or consequential damages

IMPORTANT — Obligations of Purchaser (not included in

this warranty)

1. Failure to start due to voltage conditions, blown fuses or

other damage due to inadequacy or interruption of

electrical service.

2. Filter replacement or cleaning of evaporator coil, con

denser coil or heat exchanger.

3. Damage due to freezing of condensing water, inadequate

or interrupted water supply, use of corrosive water or

rearrangement of plumbing system.

4. Failure resulting from overfiring, use of incorrect fuel,

and improper burner or control adjustments.

5. Damage caused by accident, misapplication, abuse,

alteration, tampering or servicing by other than an

authorized agency.

6. Damage resulting from use of equipment in corrosive

atmosphere.

7. Damage due to lack of proper maintenance.

Carrier products are the result of years of research in

development laboratories. The most modern precision pro

duction methods, together with every precaution through

inspection and test, combine to insure long life and

economical service. The user of this product should assist in

maintaining this maximum of long life and economical

service by following the instructions contained in the

Instruction Packet included with the product

I

Service or other labor charges not included in this warranty may be covered by a service agreement through the seller at time of purchase.

Such agreement or contract shall be separate and apart from this factory equipment warranty.

CARRIER AIR CONDITIONING COMPANY • SYRACUSE, NEW YORK

Name of Owner ^ . . ....

Address of Installation

Unit Model No. . . . .......

Unit Serial No.

______

Date of I nstallation

Installed by

......

_____

....

............

____

............ .

...

..............

__________

........

............

.......... ........

. ________ ....

.

................. .

... ...

...............

____ _ . _________

___

........

___

.....

_

________

........

..

.

_

_________

_

_______ _

-

_____

_

-

Fill out warranty record and return to Carrier Air Conditioning Company,

Syracuse, N.Y. within 15 days after installation in order for this warranty to

be effective.

I

Page 8

FOLD BACK ALONG THIS LINE AND STAPLE, GLUE, OR TAPE CLOSED -

OPEN ON THIS END

cr Q

a: P

D

Q_

CD

*D

c o

> JD

ID

CQ

o

CD

D

Q-

O

O)

D

O

D

Q_

O

O

O

O

13

Q.

o'

O

O

CD

O

13

<

Q.

O

c

o

o

d

D

OD

X

D

03

C/3

o

03

d

W

03

Q-

X

—

Q_

D

□

□

o

I

o

CO

o

H

o

c

z

H

-<

,

c

73

00

m

H

m

o

H

S

m

30

z

>

CO

o

o

c

z

-<

D

H

m

73

> H

m

1"

m

m

H

73

2

>

m l~

,

□

□

□

in

o

CD <

□

o

CD

■D

C

ID

□

X

o

X

Qo

□

03

c

CD

O

X

o

3 .

CD 1

□

M

03

CO

d

H

_

>

H

X

m

O

3

CD ; 1

!

□

>

"O

CO

o

H

<

!

g

H

H

>

-<

H

m

1

1

1

'

CO

D

m

>

73

m

>

1“

z

z

V)

H

p

>

l-

m

O

BUSINESS REPLY ENVELOPE

FIRST CLASS PERMIT NO. 1005, SEC. 34.9 P.L. & R., SYRACUSE, N. Y.

CARRIER AIR CONDITIONING COMPANY

—!

o

D"

>

CD

O

o

>

z

CD

CT

C/3

H

CD

Q.

-<

33

<

m

CD

D

o

Q_

O

C

33

CD

D

j

1

-D

> .

H !

Z '

p

CARRIER PARKWAY

SYRACUSE, NEW YORK 13201

SERVICE ENG. DEPT. TR-20

FOLD LINE

□

O i

j ■

CD

□

o

CT

I

o

INSTRUCTIONS

N

N

•V

If any equipment deficiencies are found at the time of instal

lation, fill out the reverse side of this form giving a com

plete, explicit description. Use sketch if necessary. Make

out and mail a report every time a deficiency is found.

Page 9

For replacement items use Carrier specified parts.

Manufacturer reserves the right to change any product specifications without notice.

CARRIER AIR CONDITIONING COMPANY • SYRACUSE, NEW YORK

Tab 18 Form50MH-1SI New Printed in U.S A. 3-71 Codes D and MS Catalog No. 535—008

Loading...

Loading...