Page 1

yi..

тм

Hot Water/Glycol Heating 160,000 to'800,000 Btuh

Eiectric Cooling 180,000 to 360,000 Btuh

Electric Heating 180,000 to 540,000 Btuh

Gas Heating 480,000 to 720,000 Btuh

„ „ ,/йГ(1\ (eroRJlgjy/ KSnVV^lloro); ((U(eS3l!S|lil

Й1 d bib ul px eir i PJ ilo io ilt si oo V, йо хо )

0 ® Commercial buildings

:© Carrier Corporation 1982

Form 48MA/50ME-3P

Page 2

No hot decks. . .no cold decks. . . no zoning dampers. . .no energy waste!

It’s what you don’t get with Carrier’s

Zone-Mizer Modular Multizone unit

that sets it apart from all the others.

You don’t get hot decks or cold decks

because the Carrier design gives each

zone module its own cooling coil and

heating section. Each zone module

operates independently. One unit can

heat, cool, dehumidify, reheat, and

ventilate up to 12 different zones simul

taneously. All this means real energy

savings. . .there’s no wasteful duplica

tion of effort as in hot deck/cold deck

units. For still more energy savings,

Zone-Mizer provides up to 3 steps of

electric heat or gas heat with an inter

mittent pilot ignition in every zone.

Something else you don’t get. . .

zoning dampers. Since the Carrier de

sign doesn’t have hot and cold decks, it

doesn’t need zoning dampers. By elimi

nating them from the picture, you

eliminate the adjustments, service, and

operating problems that go along with

zoning dampers.

Five sizes, offering capacities to 37

tons, provide equipment flexibility and

economy. One large unit may serve

where 2 units were required before; or

units of different sizes may be mix/

matched to deliver the heating/cooling

capacity required in a specific applica

tion. And the choice of gas, elecfric or

hot water/glycol coils allows you to

select a unit that can deliver maximurn

operating economy and convenience by

taking advantage of an already available

heating plant or favorable area fuel

rates.

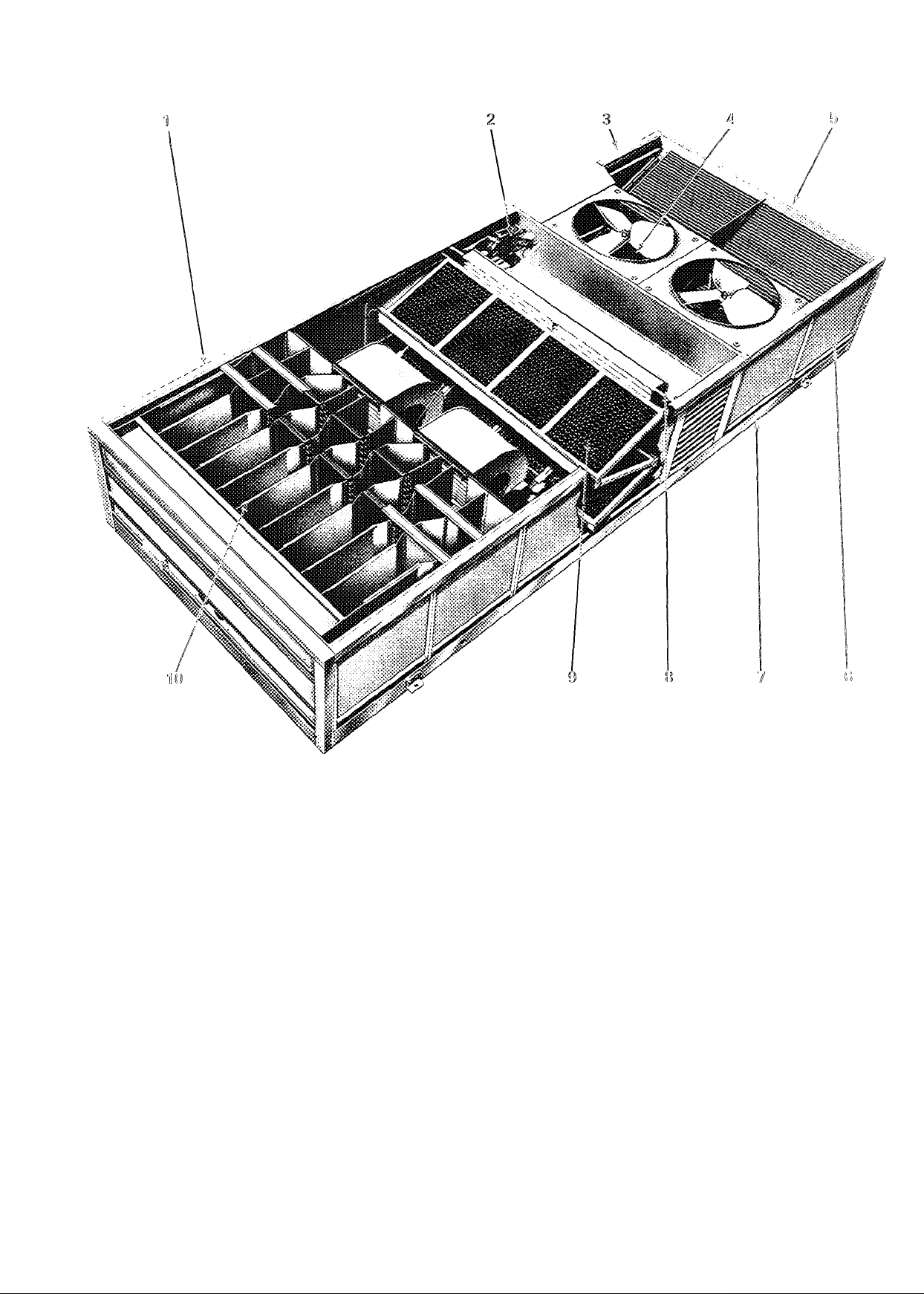

1 Etched solid copper circuit

panels have interchangeable plug-in

relays to minimize parts stocking Cir

cuit breakers that may be used as dis

connect switches, terminal boards to

simplify installation of accessories, a

control circuit shutoff switch and 24volt controls are all standard.

Motorized outdoor air inlet

damper — A simple rheostat adjust

ment on the unit (or on the optional re

mote control panel) sets the damper to

control the amount of outdoor air

admitted.

5 Dependable cooling — Each ser

viceable hermetic compressor system

has cylinder unloaders for capacity con

trol and electric power savings. Crank

case heaters, accumulators, filter driers

and low-ambient starting controls are

also standard.

Time Guard® electrical circuit pre

vents rapid cycling of the compressor if

occupant tampers with the thermostat.

Compressor cannot short-cycle on a

safety device, such as the low-pressure

switch, should someone forget to clean

the air filters.

Capacity control permits a wide oper

ating range. During light loads the com

pressor automatically unloads to re

duce operating costs and maintain

steady compressor operation. When

the load drops below the minimum

unloader stage, the hot gas bypass con

trol provides continuous cooling

operation.

Built-in safety controls prevent

damage to unit components. Included

are high- and low-pressure switches,

overtemperature limit switches and

overload protection for all motors.

When specifying a multizone unit,

choose the one that makes a point of

doing something about installation

problems. . .the Carrier Zone-Mizer

Modular Multizone. It’s a sturdy, onepiece unit — factory-wired, piped, and

charged. It arrives ready to be set in

place on the specially designed roof

curb. Make the power and control con

nections and that’s it. Initial adjust

ments are trouble free — you won’t

even need a factory engineer at start

up. The total package carries the UL

label or is design certified by AGA.

DG

3 Fused 115-volt convenience out

let in the control box provides power at

the unit for work lights and small power

tools.

4 Motormaster® solid-state con

denser fan speed control permits

year-round operation of refrigeration

system down to -20 F ambient.

6 Polyurethane foam sandwich

access panels are of Weather Armor

galvanneal steel. Their thermal resis

tance prevents sweating at outdoor

conditions up to 77 F dew point And

they are strong enough to support a

250-pound man.

Page 3

/ Rugged extruded aluminum

frames and protective grilles provide

strength and good looks. Unit will not

sag during rigging.

Low silhouette — The cabinet has no

vents or hoods to break up the clean

appearance. The curb-mounted unit

seldom requires a parapet to hide it

from street level view.

<5 Humidry® coil — This separate

cooling coil dehumidifies the outdoor air

before it is mixed with the return air to

prevent high indoor relative humidities

in humid weather and during partial

load operation.

‘ 5 Large filter area — Over 41 square

feet of standard filter area is factory

supplied. Filter tracks will accept

one-in. or 2-in., high- or low-velocity,

permanent or throwaway, standard or

high-efficiency filters.

10 Electric heater section (SOME)

— Each zone module has its own 2- or

3-stage electric heater assembly or hot

water/glycol heating coil. Electric

heaters have 24-volt relays and 115-volt

contactors. Each heating element has

circuit breakers and automatic thermal

reset. Each leg has its own heat limiter

(fusible link).

Each hot water/glycol heating coil

has its own solenoid operated shutoff

valve and balancing valve. All heating

coils are prepiped to supply and return

manifolds which also include a bleed

valve.

Gas heating (48MA) — Each zone

module has stainless steel burners,

Porcelon™ heat exchangers and its

own redundant gas valve. Natural gas

units also have a regulator for each

gas valve. Intermittent pilot ignition

and forced draft combustion are

standard on all units.

Page 4

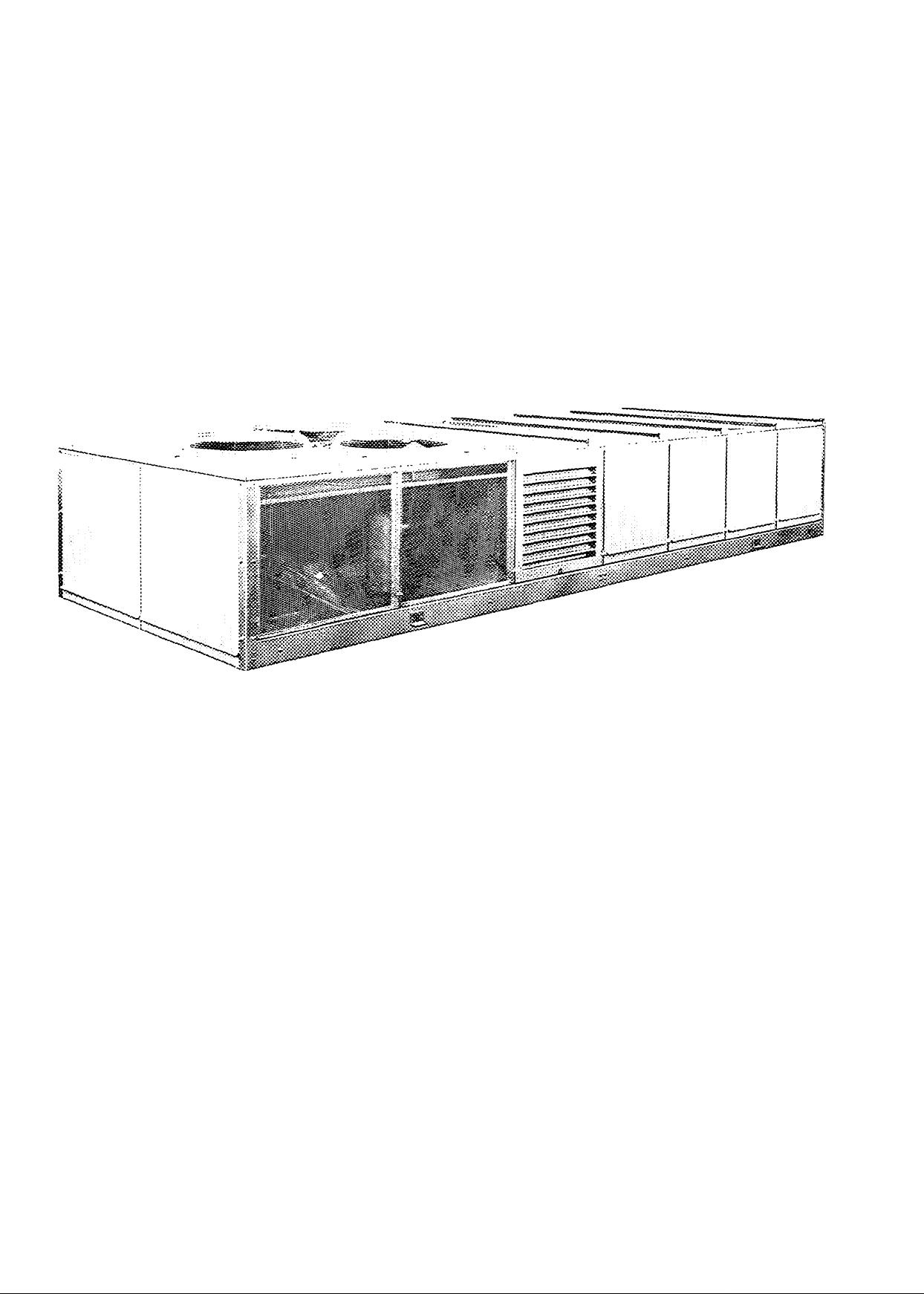

Zonc-Mizer^” Modular Multizone concept. How it works. . .

Outdoor air enterirvg the unit thru the

side louvers is filtered and then cooled

and dehumidified by the Humidry®

cooling coil when mechanical cooling is

operating. Return air entering the unit

from below is mixed with this condi

tioned air The mixture is then filtered.

After passing thru the indoor air fans,

the air is discharged into the individual

zone modules. The air passing thru

each zone module is either cooled or

heated in response to a signal from the

thermostat controlling that module.

This treated air then continues to the

individual zone duct systems, thus pro

viding a constant air pattern and volume

on each cooling coil and heating

assembly

Each zone module cooling coil has its

own solenoid valve to admit refrigerant

when needed. When 2 or more mod

ules are grouped for a larger zone re

t

quirement, 2-stage cooling can be

provided. . .and controlled by one

simple 24-volt mercury bulb thermostat

This condenser end view of unit (034

and 040) shows the 3 outdoor air fans

and the side condenser air inlet grilles.

The 2 end panels may be easily removed

for control box and compressor

accessibility.

SPLITS AIRSTREAM INTO ZONES

ADDS ADDS DIRECTS HEATED

SEPARATE OR SEPARATE OR COOLED AIR

COOLING HEATING TO INTERIOR ZONES

Page 5

and why it’s best.

Low operating costs

On partial load, the Carrier compres

sors unload cylinders to match com

pressor output to cooling needed with

up to 6 steps of reduction. To maintain

balanced operation, the hot gas bypass

system diverts hot refrigerant to the

outdoor air cooling coil as needed.

There is no mixing of warm and cold

airstreams in the modular design. Just

that amount of energy required to heat

or cool a given zone is used — and no

more.

Heating is available 3 ways. . .

Electric heating, provided by 2- or

3-stage electric heaters in each module,

gives up to 36 steps of capacity, again

using the minimum amount of energy.

Hot water/glycol heat may be speci

fied to utilize an already available

heating plant.

Gas heating models utilize inter

mittent pilot ignition in each module

designed to consume a minimum

amount of energy.

Low»temperature operating capa

bility. . .You can use the economizer

cycle with outdoor air for “free cooling,”

as with competing units. However, with

Carrier’s head pressure controlled re

frigeration system, you can often save

money by using refrigeration to cool

the space instead. So-called “free

cooling” is expensive if a large quantity

of cool outdoor air must be heated for

the zones which do not require cooling.

The Carrier refrigeration system can

operate at outdoor temperatures down

to -20 F. The Carrier modular design,

therefore, is not dependent on an

economizer cycle for cooling at low

outdoor temperatures.

Superior humidity control

One of the major concerns in multizone

applications has been the control of

humidity, especially in schools where

moisture comes from large groups of

people as well as from outdoor venti

lation air. The basic Carrier design elim

inates this problem. During mechanical

cooling, all outdoor air that passes thru

the Humidry® outdoor air cooling coil

is dehumidified whenever any zones

require cooling. The air is then further

dehumidified when it passes thru the

zone module cooling coil.

If further dehumidification should be

required for any or all zones, reheat can

be added easily. A humidistat, installed

in the conditioned space to override the

thermostat, energizes the cooling coil

for that zone.

Ease of service

The Zone-Mizer™ Modular Multizone

uses simple, familiar, commercial, ther

mostatic controls for each module,

eliminating the need for factory experts

and complex start-up and service

procedures. The printed control circuit

board has clearly marked terminals for

easy connection of standard 2-stage

heating and one- or 2-stage cooling

thermostats, which are located in

each zone.

Identical relays plug into the circuit

board. Modules can be easily combined

to serve larger spaces by placing

factory-supplied jumper wires on the

premarked terminals.

The entire control system is neatly

organized in one location. For excellent

accessibility, all circuit breakers project

outside so that any motor can be dis

connected without opening the highvoltage box. This often eliminates

the need for separate field-supplied

disconnects.

The handsome Carrier mercury bulb

type thermostats control heating and

cooling modes. They are available with

a locking device which requires an Allen

wrench for access, or you can allow

the zone occupant to set his own

temperature.

Access to the Zone-Mizer Modular

Multizone is thru removable side panels

held in place with simple fasteners. Top

panels may also be removed for com

plete access to unit interior.

In short, the local installing dealer or

contractor can handle all service and

will have available, from the nearest

Carrier distributor, any parts required.

Page 6

Accessories and factoryii'stalled options

Hot water/glycol heating (SOME) —

Often, such as when renovating existing

buildings, a heating plant is available.

For these applications, Carrier’s hot

water/glycol heating unit may be ideally

suited Each zone module has its own

high-capacity heating coil All controls,

solenoid operated shutoff valves and

balancing valves are included. No

internal piping or wiring required.

Heaters are designed for and in

tended to be operated with a glycol/

water solution of 20% minimum glycol

concentration for freeze-up protection.

(Factory-Installed Option).

Roof curb supports unit and frames

roof openings to provide a strong,

watertight interface between unit and

roof. Galvanized, 14-gage steel, 2-piece

construction minimizes installation time

and costs. (Accessory)

Modulating outdoor air control pro

vides year-round ventilation with out

door air. An outdoor air thermostat

locks out compressors to permit “free

cooling” with outdoor air. (FactoryInstalled Option)

Roll filter package includes 65 ft of

2-in. thick filter media, automatic media

advance switch and a motor. The run

out switch turns on the filter light in the

remote control center to show when the

media needs replacing (FactoryInstalled Option)

Powered exhaust damper has con

trols to operate outdoor air fans to

exhaust return air when unit is in “free

cooling” mode. (Factory-Installed

Option)

Cooling only unit (SOME) — Unit is

available with all heating controls but

without heater assemblies. Included are

24-volt control circuits and 115-volt

power terminals for 2-stage control of

steam heating coils field installed in the

unit or in the zone ductwork.

t

Electric heat (SOME) — Each zone

module is equipped with its own inde

pendent heater assembly. Two- and

3-stage heat is available to provide close

air temperature control without wide

temperature swings associated with

rapid-cycle, full-on, full-off systems.

Three heat-to-cool ratios are avail

able: .75.1, 1.1 and 1.5:1 to match

almost any heating load requirement.

(Factory-Installed Option)

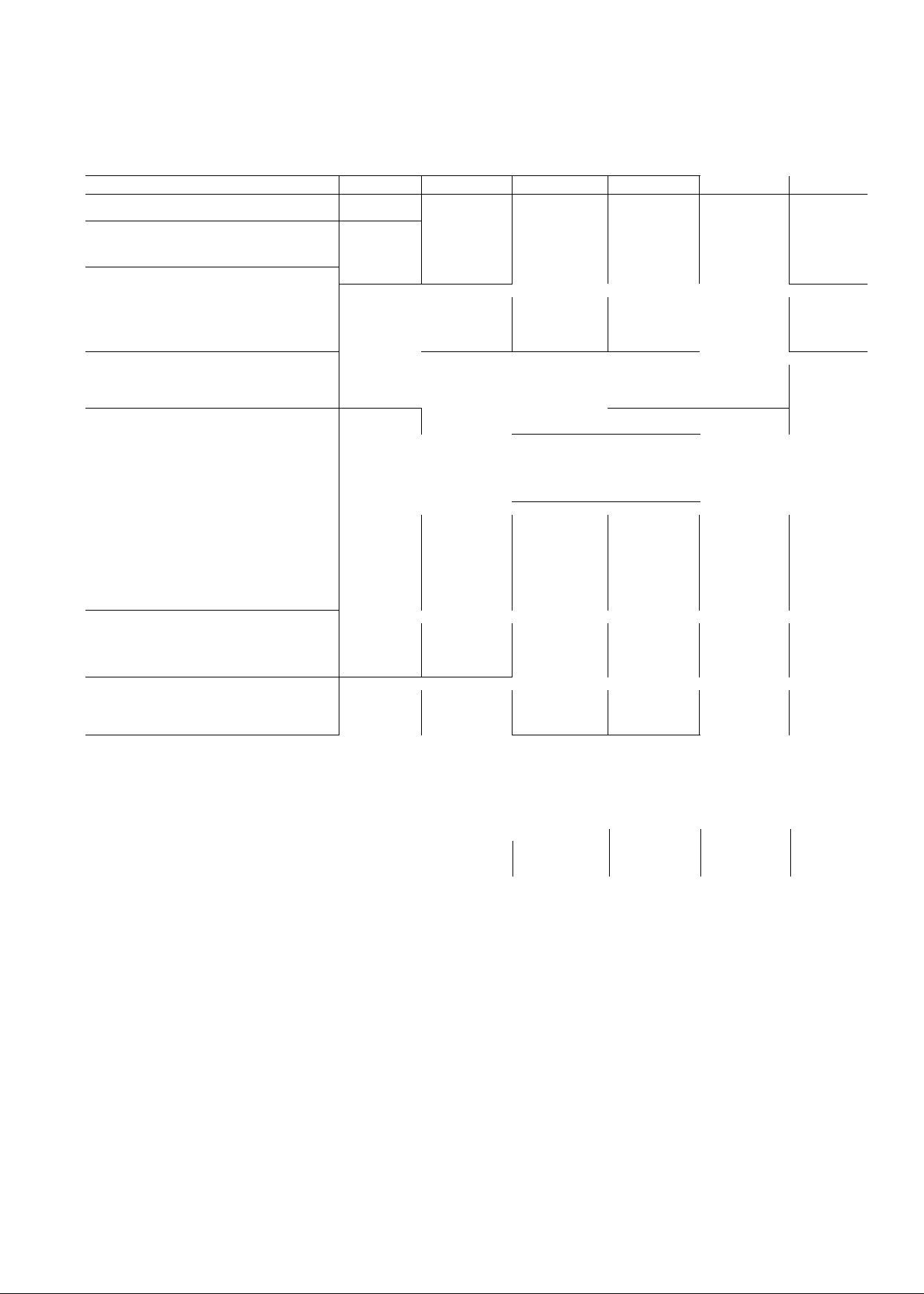

Zone thermostat (24 volts) provides 2-stage heating

and one- or 2-stage cooling for control of individual

modules. Matching subbases are available with or with

out tamperproof switches and automatic changeover.

(Accessory)

Remote control panel (24 volts) — This decorative

central control for the entire unit has switches for HEAT,

COOL, AUTOMATIC CHANGEOVER, OFF and

DAY/NIGHT settings; dial to adjust outdoor air damper

to rapidly ventilate conditioned spaces. A dirty filter

warning light and knockouts for additional warning lights

are also provided. (Accessory)

Page 7

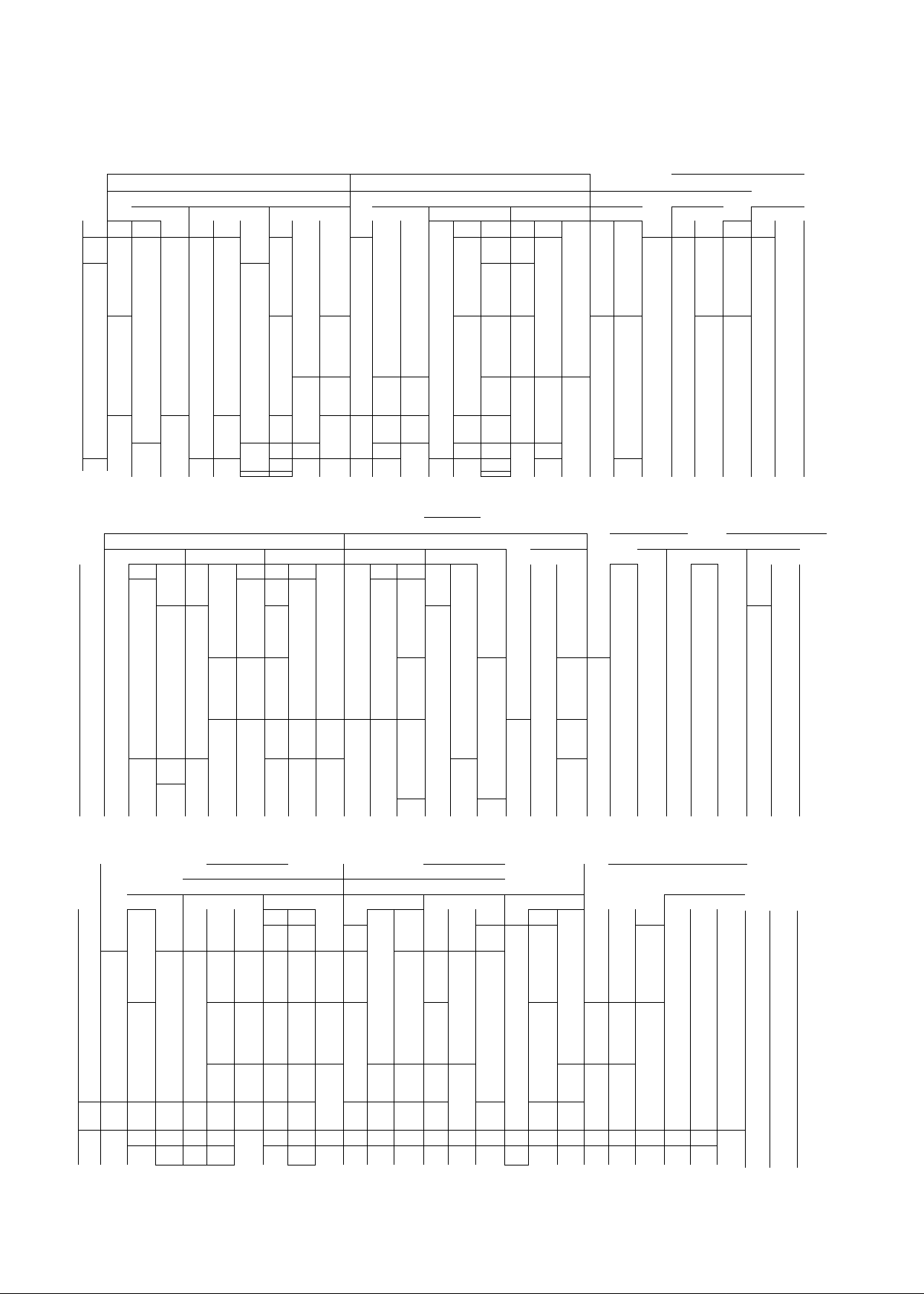

*hysiccd data

UNIT 48MA/50ME

Zone Modules

Nominal Cooling Capacity (tons) 15

OPERATING WEIGHT Tib)

Base Unit 48MA 3385

Base Unit SOME (with heat) 2985

Roof Curb 506

REFRIG CHARGE (lb, R-22) 28

COMPRESSOR

No. 1 Type

Cylinders. Unloaders 6 2

No. 2 Type

Cylinders (has no unloaders)

System Oil Charge (pts)

Unloader Settings (psig)

Left Bank

Right Bank

Capacity Steps (%) 100,67,33

OUTDOOR AIR FANS

Motor Hp .Rpm...Frame (NEMA)

Nominal Cfm

INDOOR AIR FANS

No. ...Size (in.)

Cfm (Nom) 6000

Motor Hp .Rpm

Fan Pulley

Outside Diameter (in )

Bore (in.)

Fan Belt No ..Size w/Std Mtr

Motor Pulley A

OutsideDiam(in.) w/Std Mtr

Bore (in.) 1-1/8

Resulting Fan Rpm w/Std Mtr 880

Motor Pulley B

Outside Diam (in.) w/Std Mtr 60

Resulting Fan Rpm w/Std Mtr

OUTDOOR AIR COOLING COIL

Face Area (sq ft)

Corrugated Fins/in ...Rows

EVAPORATOR COILS (zone)

No. ...Face Area (sq ft, ea)

Corrugated Fins/in .Rows

HEATING SECTION (48MA)

Rise Range

Input (1000 Btuh) Total

Bonnet Cap (1000 Btuh) Total

HEATING SECTION (SOME Electric)

Electric Heaters

No . .Elements (ea)

fiiMTNG SECWON (ici/ii*GTvcoii

Max Allowable Inlet Temp

Max Allowable Flow, Each Coil

Solution Mixture

Max Allowable Working Pressure

Total Internal Volume (gallons)

PRESSURE SWITCHES

Low-Pressure

High-Pressure

Indoor Airflow Switch (AFS 1

Factory Setting (cfm)

Adjustment Range (cfm)

INDOOR AIR FILTERS

Std No. ..Size (in )

High Efficiency (optional)

m

No. . Size (in )

Roll Media (optional)

OUTDOOR AIR FILTERS

No . Size (in )

No 1

No. 2

No 3

w/Opt Mtr

w/Opt Mtr

w/Opt Mtr

w/Opt Mtr

w/Opt Mtr

Each Module

Full Rate

Cutout

Cut-in

Cutout

Cut-in

016 024

8

06DE537

—

—

.... " .

— — —

16,500 15,000

2 15x15 2 15x15

5 1725

10 6

1-3/16 1-3/16

1 3V630 1 3V630

—

5 3

— — — —

—

—

995

—

68

13 2

8. .2 12

13 3

432

54

324

40 5

8 2 or 3

2 61

■ or 3-Stage, Nichrome, Open-Wire Flesistance Elements in Each Zone Module

8 10 10 12

20 25

3805

3405

506

32 43

06DE824

6.2 6 ..2

06DA824

6

22

100,83,67

50,33,17

8000 10,000 10,000

7-1/2 1725 10 1725 10 1725 15 1725

10 6 80 80

60 50 50

1-3/8 1-3/8 1-3/8 1-5/8 1-5/8

995

— —

69

— —

1145

—

Thermostatic Expansion Valve, Hot Gas Bypass

68

13 2

8. .2 12

13 3

432

54

324

40 5 40 5 40 5 40 5

8 2or3 J_ 10 2 or 3 I 10 2 or 3 [ 12 2 or 3 |

2 61

6000

4000-600

Same but with 36 5% efficiency (NBS Dust Spot Test)

2 20 X 25 X 1

028 030 034 040

4075

3665

506

Reciprocating Hermetic. 1725 Rpm

06DE537

06DA824 06DA537 06DA537

6 6

22 22 21

Compressor No 1 Only

71 0 ± 1 5

57 5 ±25

760 ± 1 5

62 5 ±25

100,80,60

40,20

Propeller, Direct Drive

1 1075 56(1-phase)

1 1140 56 (3-phase)

15,000

Centrifugal; Belt Drive

2 15x15 2.15x15 3..15x9 3. .15 X 9

1-3/16

2 3V560

—

Factory Installed

1095

Shipped With Unit

56

1230 1230 1230 1230

—

6 8

1

13 2 13 2 i

Solenoid Valve and Capillary Tube for each

I 10.212 I 10.212 I

Furnace Assembly in Each Zone Module

25 F to 55 F at 0 75 in wg ESP

540

54

405

One Heating Coil in Each Zone Module

3 15 3 15 3 76 3 76

65 ft of 2-in media

6 8

I

13 3 j 13 3

200 F

6 Gpm

20% Glycol

30 Psig

29 + 5 Psig

39 ± 5 Psig

400 ± 5 Psig

300 ± 5 Psig

12 20 x 25 x2

28 30

4080

3670 4400 5250

506

43

06DE537

6.2

100,80,60

40,20

-

15,000

1-3/16

2 3V560

—

1095

—

5 6 5 6

—

—

I

540

54

405

4800

630

57 66 1

06DE537 06EE250

6.2

6

75 5 ± 1 5

58 0 ± 2 5

100,83,67

50,33,17

1.1140 56 (3-phase)

24,000

12,000

20 1725

8.0

1-11/16 1-11/16

2 3V630 2 3V630

3 3V670

50

6.0

1095

1320

6 5

1425

102

13 2

12.201

12 3

648

54

486

9000

6000-9000

2 32 X 35 X 1

12

37

5700

630

4.1

06EA250

4

31

—

100,75,

50,25

23,000

12,000

15 1725

20 1725

80

3 3V670

50

6.0

1095

1320

56

6 5

1425

102

13 3

12.201

15 3

648

54

486

40 5

12 2or3

Page 8

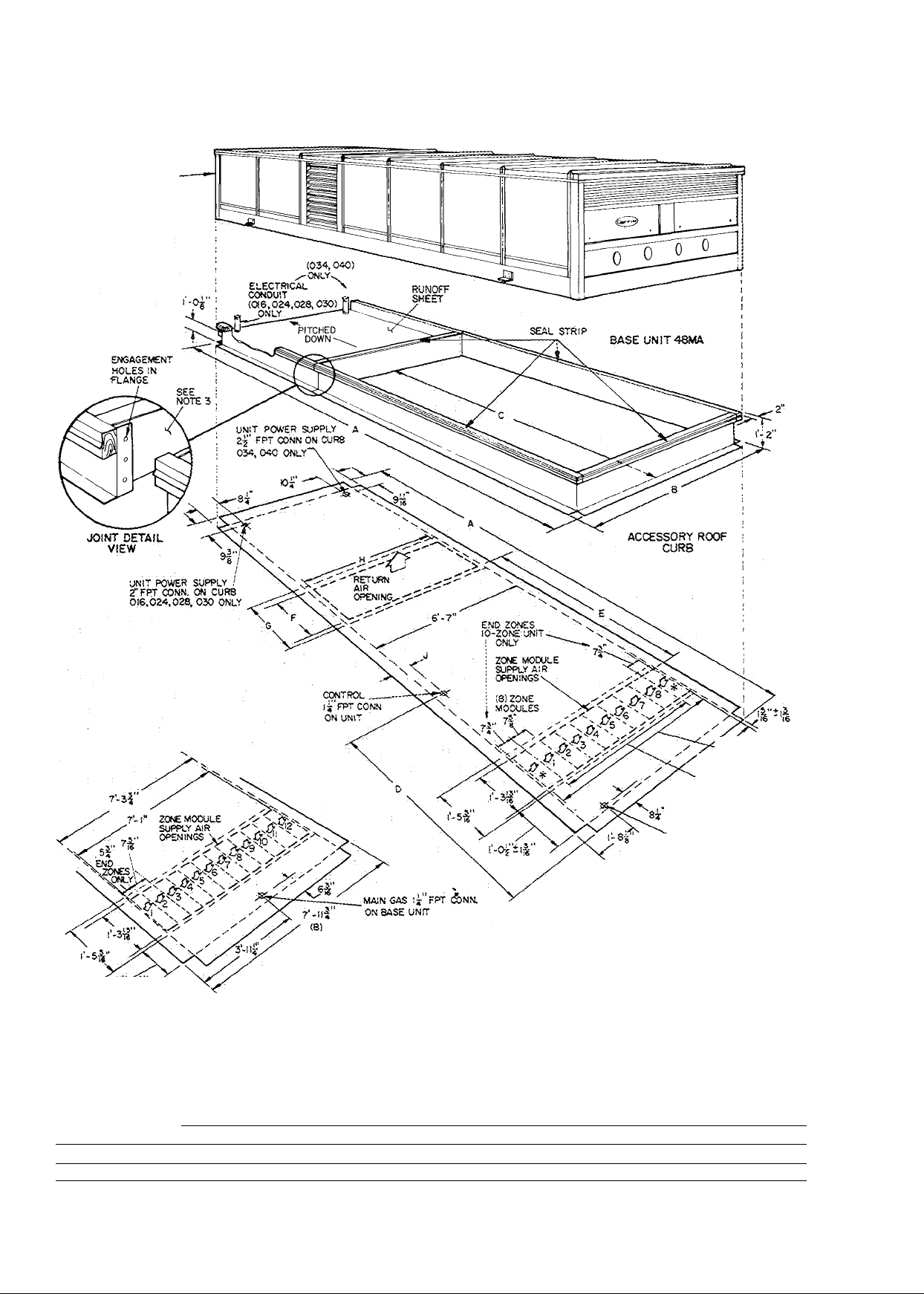

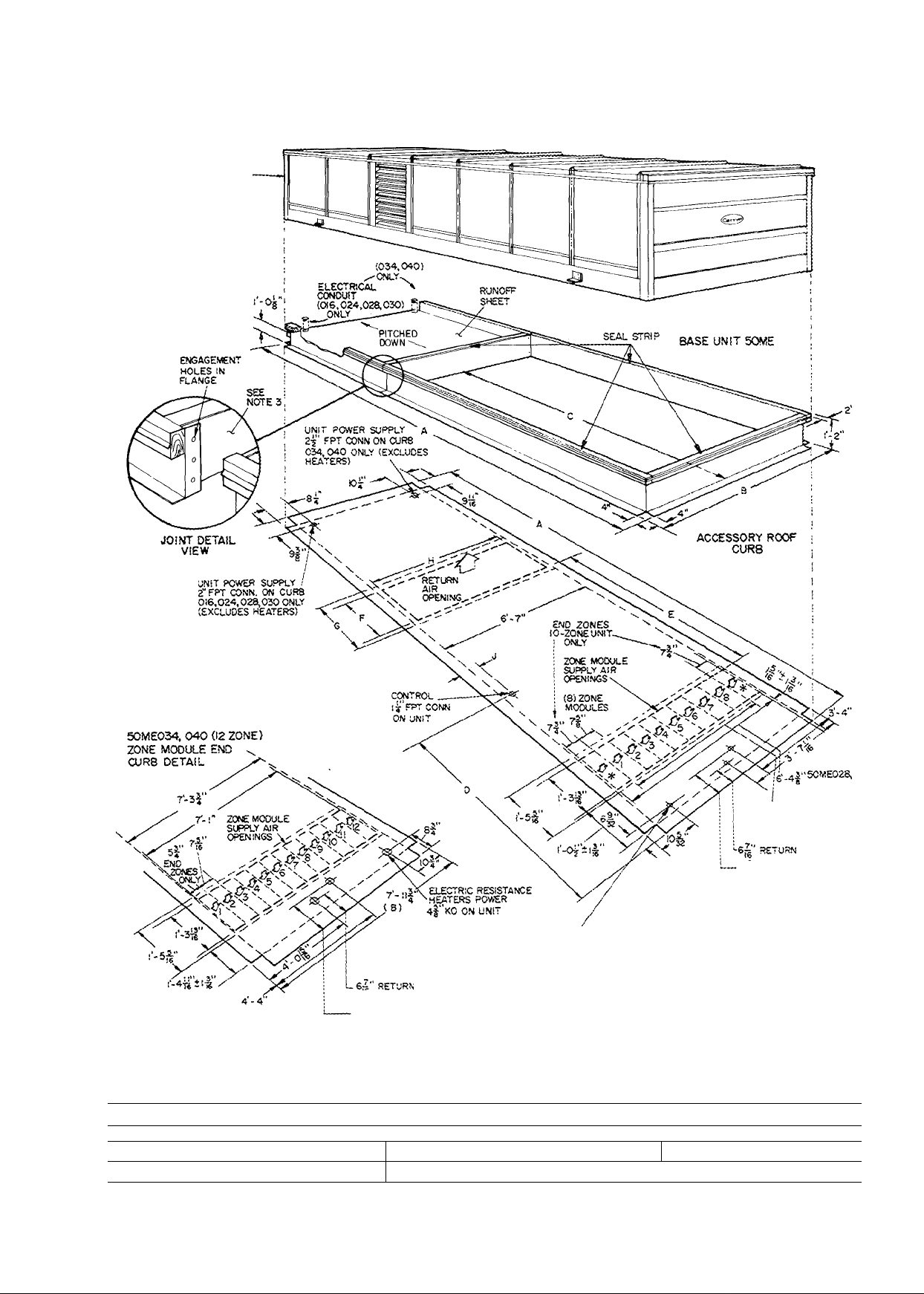

Roof curb dimensions (48MA)

COMPRESSOR, CONDENSER

AND CONTROL BOX END '

OF UNIT

Certified dimension drawings available on request.

UNIT

48MA 1

016,024,028,030

034,040 i

A 1 B

]B- 2% Î 7-3

21-1 r/j 1 7-ll-y<

48MA0M. 040 02 ZONE)

ZONE MODULE END

CURB DETAIL

I c

1 D

i n-9

Î 14-iy

DiMENSiONS (ft-in.)

i........E

.5-6 V,

6-7’/,,

......

i 7-2%

i 8-4%,

MAIN GAS l3 FPT CONN

ON SASE UNIT

evaporator (ZONE MODULE ¡AIRFLOW

* NOT USED ON 48MA0t6,024(8 ZONE

NOTES- I FOR additional INFORMATION SEE

; F

Î 1-10%,

Î 2- 9% j 3-1

module UNITS)

BASE UNIT PH.YSICAL DATA AND

DIMENSIONS

2 MAXIMUM ALLOWABLE UNIT PITCH IS

jlN IN lOFT IN ANY DIRECTION

3 REMOVE SHIPPING BRACE BEFORE

ASSEMBLING CURS SECTION

(LOCATION SHOWN).

i G

i H

1 2-2%, I 6-0%

! 6-8% i 0-10%,

'6'.4|"4SMA028,

'030 (10 ZONE MODULES)

5'-r 48MA016, 024

(8 ZONE MODULES)

1 J

1 C- 7%

Page 9

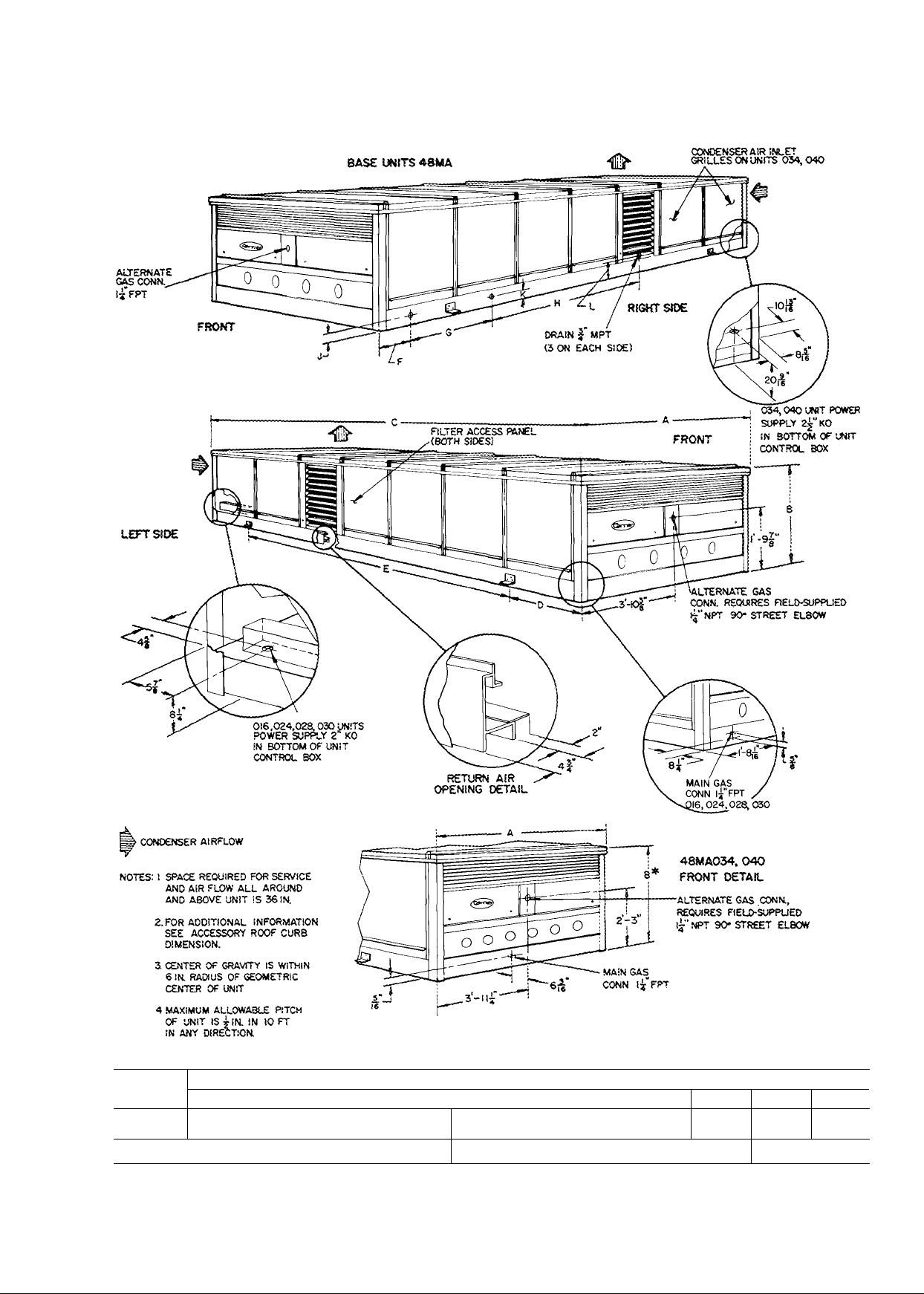

Base unit dimensions (48MA)

Certified diiTiension drawings avaiiabie on request

UNIT

m

48MA

016,024,

028,030

034,040

*Ovsra!i height: induces 1 3/4-in for fan guards WSMA034 an.d 040

i A

1 7- 21^

1 7-n

lJ

_______

i B I c

f

----------------

I 3-0%

1

“T

-----------------

i

; 21 - 9%«

; 0

1 2-2*%s

1 4-2

DIMENSIONS (ft-

1 !3-5%

i i3-5%

!

1 0- 9^6

in.)

1 G

i 2-10

i 3- 4%s

1 ”

1 7-3%« r /«

I 8-6% 1 0-3

i ■)

0-3%

K

L

0-3%

0-7%

Page 10

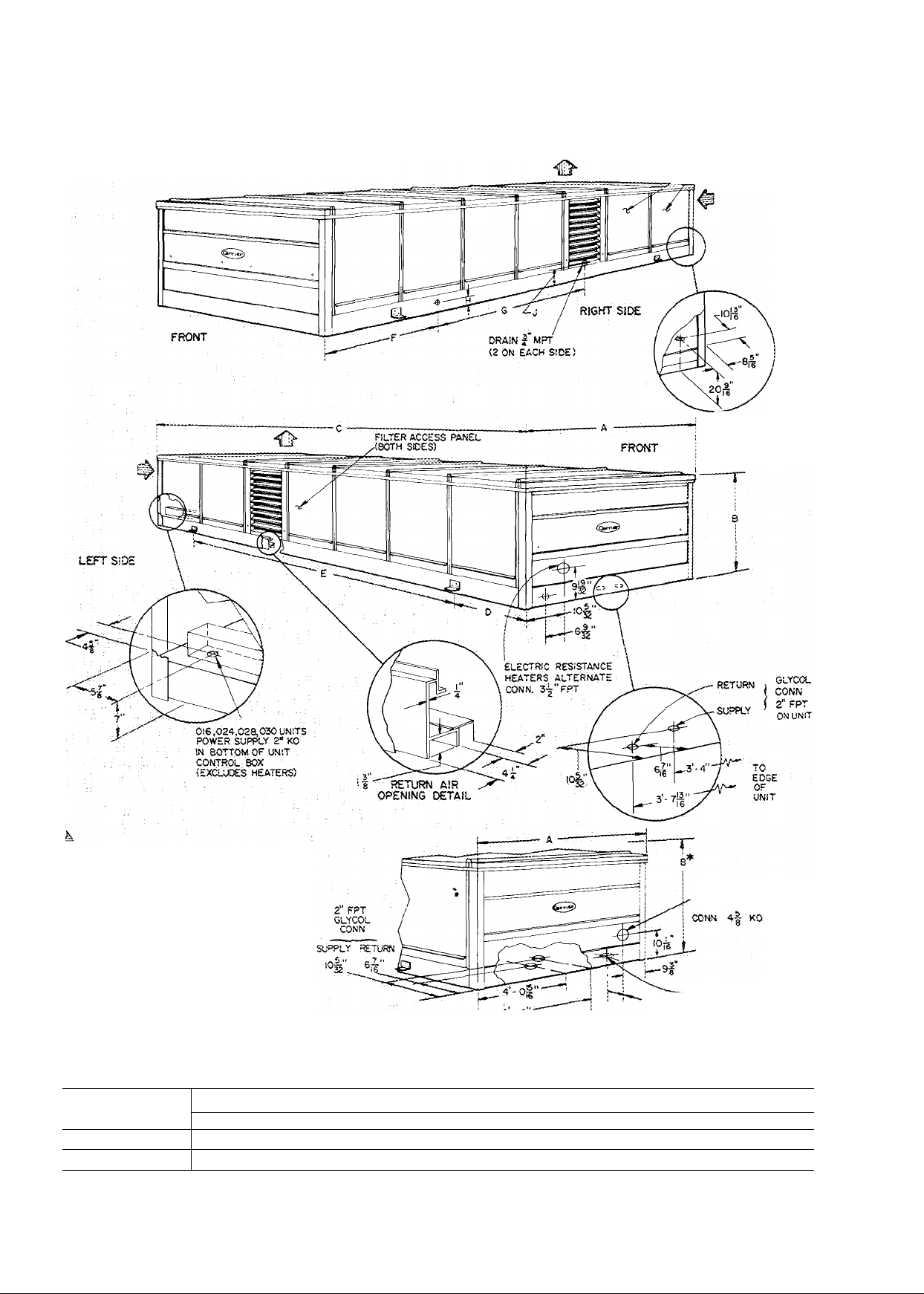

Base unit dimensions (SOME)

BASE UNfT SOME

CONO£NS£R AIR INLET

^ GRILLES ON UNITS

034,040 UNIT POWER

SUPPLY 24" KO

IN BOTTOM OF UN!T

CONTROL SOX

(EXCLUDES HEATERS)

034, 040

t

• CONDENSER AIRFLOW

notes: I SPACE REQUiRED FOR SERVICE

AND AIR FLOW ALL AROUND

AND ABOVE UNIT IS 36 iN.

2 FOR ADDITIONAL INFORMATION

SEE ACCESSORY ROOF CURS

DIMENSIONS.

3 CENTER OF gravity IS WITHIN

6IN RADIUS OF GEOMETRIC

CENTER OF UNIT

4 MAXIMUM allowable PITCH OF

UNIT IS -¿-IN. IN lOFT IN ANY

DIRECTION.

UNIT

SOME

016,024.028.030

034,040

^■Overaü r.eigdt, inciudes ' 3/4 in fc* fan guajds .(oOV-ЕОЗА and 0^0).

A

7- 2%

7-1 i

i ®

: 3-0^«

i 3-9”/.** 21- 9Мб i 4-2% ! 13-54 i

DIMENSIONS (ft-in.)

j 2-2^5<* 1 13-54 i

10

c i D . j E i

ELECTRIC RESISTANCE

HEATERS MAIN POWER

_

_______

G

ELECTRIC resistance

CONN. 4|" KO

: Я

i 0-2‘4б

T| heaters main POWER

Certifiées dimensior> drawir^gs avaueble ori request.

F

3-74* i 7-34* i 0-34

4-4 г 8-64

i J

i 0-34

i 0-74

Page 11

Roof curb dimensions (SOME)

COMPSeSSOR, CONDENSER

AND CONTROL SOX END

OF UNIT

Certified dimension drawings available on request

--------------------------—J

------------

UNIT 1

48MA A

016,024,028,030 1 IS- 2%

034,040 j 2i-n%

ELECTRIC resistance

HEATER POWER

Ag'KO ON UNIT

) GLYCOL CONN

-10Й SUPPLY’

I г"РРТ ON UNIT

DIMENSIONS {ft-in

В {

7- 3 !

n-9

i D i E i F

c

i S-6% 1 7-2% 1

7-11% : ;4-l% i 6-7%« i 8-4%« j

11

5' 50ME0I6.024

ЮЙ' SUPPLY GLYCOL CONN

2"PPT ON UNIT

if) evaporator (ZONE module; AIRP'lOW

* not used on 5CWE0I6,024(820NE

NOTES- 1 POR ADDITIONAL INFORMATION SEE

module UNITS)

BASE UNIT PHYSICAL DATA AND

DIMENSIONS

Z MAXIMUM ALLOWABLE UNIT PITCH IS

■jlN IN ЮРТ IN ANY DIRECTION.

3. REMOVE SHIPPING BRACE BEFORE

ASSEMBLING CURB SECTION

(LOCATION SHOV/N)

)

i G

i H

1-10%« i 6-0%

2- 9%

iilL

i 6-8%

030 OOZONE

MODULES)

¡8 ZONE

MODULES)

] J

I 0- 7%

i 0-10%«

Page 12

Selection procedure (with example)

Refer to Carrier’s Engineering Guide for Multizone Unit

Systems and contents of this booklet for typical multizone

design considerations. Using the Engineering Guide, cal

culate cooling and heating load estimates for the areas to

be served by the multizone unit. Divide each area into zones

based on the peak load and control requirements within

the area.

The resulting loads calculated for a typical building are;

Cooling

Grand Total Load (GTL)

........................................

272,440 Btuh

Sensible Load (SL) .................................................. 219,000 Btuh

Room Design .................................................... 75 F db/50% Rh

Outdoor Air (OA) Cfm............................................................1000

OA Ambient Temperature

..............................

95 F db/75 F wb

Electric Power Source...................................................... 460/3/60

Zone No. (RTL)/Zone (RSL)/Zone

1 19,000 Btuh 16,935 Btuh

2 25,000 Btuh 22,505 Btuh

3 25,000 Btuh 22,505 Btuh

4 70,000 Btuh 59,160 Btuh

5 22,000 Btuh 19,720 Btuh

6 25,000 Btuh 22,505 Btuh

7 40,000 Btuh 33,870 Btuh

Total 226,000 Btuh 197,200 Btuh

*Loads are peak loads

Room Total Load* Room Sensible Load

Heating (Electric Resistance Heat required)

Zone No. Heating Load/Zone Electric Resistance/Zone

1 34,000 Btuh 10 0 kw

2 44,000 Btuh 12 9 kw

3 44,000 Btuh 12 9 kw

4 111,000 Btuh 32 5 kw

5 42,000 Btuh 12.3 kw

6 44,000 Btuh 12 9 kw

7 81,000 Btuh 23 7 kw

Total* 400,000 Btuh 117 2 kw

*Zone Peak Capacities

Selection:

Base the multizone unit selection on cooling load require

ments. Enter the 48MA/50ME rating tables in the Per

formance Data Section and select the unit that meets or

exceeds the grand total load at the specified conditions.

(Interpolation may be necessary to obtain unit rating at

certain conditions; extrapolations are not advised. Contact

Carrier Application Engineering tor performance data at

points beyond the range of published tables.) Tbe 024 size

unit does not have sufficient capacity to meet load

requirements at any cfm. The 028 size exceeds load require

ments; however, it is the smallest unit that meets specifica

tions. Thus, the 48MA/50ME028at: 9000 cfm; 1000 cfm OA;

95 F/75 OA temperature; and 75 F/50% Rh room design has

a Total Capacity (TC) of 282,000 Btuh, Sensible Heat Ca

pacity (SHC) of 219,000 Btuh and a compressor kw of 27.5.

Calculate the Room Total Capacity (RTC) and the Room

Sensible Heat Capacity (RSHC) by deducting the outdoor

air load from the unit capacity. The outdoor air load with

respect to room conditions is:

Total Heat (OATH) = 4.5 (hoa - hroom) (OA cfm)

= 4.5 (38.61 - 28.29) (1000)

= 46,440 Btuh

Sensible Heat (OASH)

- 1.09 (toa - troom) (OA cfm)

= 1.09 (95 - 75) (1000)

= 21,800 Btuh

The unit capacity available to offset room loads is:

RoomTC = UnitTC - Outdoor Air TC

= 282,000 - 46,440

= 235,560 Btuh

Room SHC = Unit SHC - Outdoor Air Sensible Heat

= 219,000 - 21,800

= 197,200 Btuh

For comparison.

Actual Load

GTL = 272,440 Btuh

SL = 219,000 Btuh

RTL = 226,000 Btuh

RSL = 197,200 Btuh

Actual Unit Capacity

TC = 282,000 Btuh

SHC = 219,000 Btuh

RTC = 235,560 Btuh

RSHC = 197,200 Btuh

The 48MA/50ME size meets or exceeds the total and zone

load requirements at the specified conditions. The excess

RTC decreases space average relative humidity slightly

below the room design of 50%. By increasing air quantity

above 9000 cfm, this excess latent capacity can be

converted to additional sensible capacity if desired.

Since the modular multizone is a constant volume

machine, proportion the selected supply cfm per zone to

satisfy each zone’s peak load condition.

Divide room sensible capacities (RSC) equally among

the modules if an equal cfm is going to each. In this

example, the 48MA/50ME028 has 10 modules and the

nominal cfm is 900 cfm per module and equal cfm’s are not

going to each.

Vary the cfm to each zone (with field-supplied manual

dampers in zone ducts) to match different zone require

ments. Since the original rating was based on 9000 cfm

supply air, all variations must total 9000 cfm. When the cfm

is changed (by some percent) from the nominal in a specific

module, use the room capacity multipliers in the Zone

Cooling Capacity Multiplier Table to correct room TC and

room SHC for that zone. Capacity versus cfm changes for

the example is given in the Capacity vs Cfm Change

table.

By analyzing each zone’s ratio of deviation from equal

sensible heat allocation, determine the proper cfm change.

In the example, if building room SHC is 197,200 Btuh and

10 zones are used, each zone’s normal room SHC is

19,720 Btuh. But if Zone 3 has 22,505 Btuh room SHC, then

by ratio of 22,505: 19,720 or 1.14, the cfm change is +20%.

Correspondingly, if Zone 1 had 16,935 Btuh room SHC,

the cfm change is -20%.

In applications where the zone selection is not an incre

ment of the number of unit modules (i.e. one zone requiring

500 cfm in a 48MA/50ME028 with 10,000 cfm), refer to

Module Cfm Limits (page 36), Application Data section for

details on using cfm’s below 600 cfm/module.

Formulas required to use ratings are:

Outdoor Air Total Heat (OATH)

OATH = 4.5 (OA cfm) (hoa - hroom)

12

Page 13

CAPACITY VS CFM CHANGES

ZONE

NO.

NO. OF RSL/ZONE

MODULES

...

1

2

3 1

4

5

6

7

RSHC — Room Sensible Heat Capacity RSL —

10 197,200

PEAK LOAD (RSL/NOM UNIT RSHC) FROM NOMINAL UNIT RTC

1 16,935

1 22,505 22,505/19,720

3 59,160

1

1 22,505

2 33,870

22,505

19,720

22,505/19,720

59,160/3 X 19,720 =

22,505/19,720 1 .14 : +20 1080 1 11

33,870/2 X 19,720 =

% DEVIATION

16,935/19,720

19,720/19,720

.86*

1.14

1 .14

1 00

1.00

86

Room Sensible Load

ZONE COOLING CAPACITY MULTIPLIERS

%

CFM CHANGE*

+ 35

+ 20

+ 10

0

-10

-20

-35

*Must not be greater than 1200 cfm nor less than 600 cfm per module,

tlf resulting RSHC is greater than RTC, then RSHC equals RTC

ROOM TOTAL

CAPACITY

(RTC)

1.15

1.10

1.05

1.00

0 95

0 90

0 85

ROOM SENSIBLE

HEAT CAPACITY

(RSHC)

1.14t

1 07t

1.00

0 93

0.86

0.79

Outdoor Air Sensible Heat (OASH)

OASH = 1.09 (OA cfm) (toa - troom)

Room Total Capacity (RTC)

RTC = Unit TC - OATH

Room Sensible Heat Capacity (RSHC)

RSHC = Unit SHC - OASH

Leaving Air Temperature (LAT)

TAT + + RSHC

LAT = room temperature - ^ Q'^f^

Determine Heating Capacity:

The specified requirement for electric heat dictates the

selection of a 50ME028 unit with a kw option that meets

or exceeds the heating load.

The Electric Resistance Heater Data table (page 30) indi

cates that the 028 unit has heating capacity options of 66,

88 and 132 kw. The 132 kw option is selected as it provides

adequate heat for this application. The kw/zone and

number of heat stages available are:

Zone No. Load

1

2

3

4

5

6

7

Total

10.0

12 9 kw

12 9 kw

32 5

12 3 kw 13.2 kw

12 9

23 7

117 2 kw 132 0 kw

Zone Heating

Capacity

kw

kw

kw

kw 26.4 kw 6

13 2 kw 3

13 2 kw 3

13 2 kw 3

39 6 kw 9

31 2 kw

Stages

of Heat

3

3

30

% CFM CHANGE

-20 720 i 9

+20

+20 1080 1 11

0

0 900 ! 1 .0

-20 1440 1 .9

Stages of heat are controlled individually in the small zones

or collectively in large zones to provide flexible and

continuous control for each zone.

Determine fan requirements

For 48MA/50ME operation, cfm range per module is 600

to 1200 cfm. Lower flow volumes are permissible if only

first stage of heat is operated. Volumes above 1200 cfm

may cause water blow-off during cooling.

Since the various unit zones operate at different air

quantities and different external resistances, identify the

zone having the highest static pressure requirement for

the supply duct and supply outlet.

Usually, the longest duct run to the last outlet, with the

greatest number of offsets and elbows, has the greatest

static pressure requirement. Assume a duct friction analysis

has been made and the cfm and static pressure are:

Zone No. CFM

The total unit (02810or 030) cfm is 9000. Zones 4 and 7 have

3 and 2 modules, respectively, “ganged” together to comply

with the limitation of 1200 cfm per module

The cfm for Zone 2 is 1080 with an ESP of 0.8 in. wg. This

module appears to possess the highest friction loss. There

fore, the main fan static pressure is established at 8 in. wg

ESP.

Enter Fan Performance table at 9000 cfm, .8 in. wg ESP

and read: 1020 rpm and 5.4 bhp. The 028 indoor fan motor

data shows the standard 10 hp motor with a maximum bhp

of 11.5. Therefore, 5 4 bhp for this selection is satisfactory.

In the Physical Data table, 2 pulley selections are available

with the 028: Pulley A, shipped mounted; Pulley B, shipped

in the blower compartment. Pulley A has a fixed pitch and

at 1095 rpm is close enough to the required cfm and should

be used. Pulley B at 1230 rpm allows selection of the unit

at higher cfm’s and static pressures.

13

jUNIT TOTAL

CFM3 CAPACITY

Imultiplier

1080

1

11

2700 i 1 0

9000 j

RTC — Room Total Capacity

ESP (in. wg)

1

2 1080

3 1080

4 2700

5

6

7

Totals 9000

720

900

1080

1440

UNIT

NOMINAL

RTC/ZONE

X

23,556

X

23,556

X

23,556

X

3 X 23,556

X

23,556

X

23,556

X

2 X 23,556

No. Modules CFM/Module

6

8

5

6

4

4

5

1

1

1

3

1

1

2

ADJUSTED

21,200

25,912

25,912

70,668

23,556

25,912

42,400

235,560

720

1080

1080

900

900

1080

720

Page 14

Performance data

Room Design 75 F/50% Rh

OUTDOOR

R

Db

Wb

85

90

95

100

105

no

115

OUTDOOR

TEMP

Db Wb

65 204

85

70 204

65

70

90

73

75

65

70

95

75

78

80

70

100

75

78

70

105

75

110

78 183 133

115 75

0 750

TC SHC Kw

65

168

70

168 J18

65 164

70

164

73

164 116

75 164 116

65

I6U

70

160 114

75

160 114 16 0 173 121 16 6

78

160 114 16 0 175

80

160 114

70

156 112

75

156

78

156 112 16 5 171

70 152

75

152 no 17.0

78

148

75

144 107 18 0

TC SHC Kw TC

200 141

200 141

200 141

200 141

196 140

196 140

196

196

196 140

192 137

192

192 137

187 1 35 20 9

187

178 131 22 3 191 155 23 3 200

14 8 174

118

14.8

116 15 4 169

116 15 4 173

15 4 176

15 4

114

16 b

16 0 169 126 16 4

16.0

16 5"^

112 16 5 168 123 17 2

no 17 0 160 130 17 5

109

17 5

0

143

18 0

143

18.0

18 8 208 155 19 2

18 8

18 8

18 8

19 5 203 157

19 5

140 19 5 212

140 19 5

19 5

20 2

137 20 2 207 150 21 2 216

20 2 209 147

135 20 9 201

21 6

4,000

Outdoor Air Cfm

TC SHC Kw

126 15 1

178 122

177

165 131

177 116

164

164

161 124

155

Outdoor Air Cfm

212

217

212

215

216 146

207

214

216

202

197

199 150 22 8

15.3 184

129

15 7 172

124

15 9 179 131

121 16 0

119 16 1

16 2

118 16 8 186

16 9

128 17 0

120 17.4

125 17 8 172

18 5 171 139 19 1 154

130

18 8 162 152

5,000

750

SHC Kw

153 18 5 216 161 18 7

149

18 7

151 19 5 219

148 19 6

19 7 227

19 9

153

20 2

148 20 5 222 154

145 20 6

143 20 8 230

155 20 9 209

21 4 221 154

157 21 6 204

152

21 9 211 166

1500

TC

177 134 15 2

183 125

186 121

168

174 137 16 7

182 127 17 1 167

189

170 143

177 133 17 7 163 124

181 127 18 0 163 124 16 9

165 149 17 9

TC SHC

224

212 167

224 152 20 1 210 159

208 173 20 2 206 157

214

227

210 166 23 6

Kw

SHC

15 6

124

15 8

140

16 2

16 4

16 5

146 16 4

17 4

121

116 17 5 167

17 3

139 18 3 158 123 17 4

19 4

1500

Kw

19 1 215 161

152

19 4 210 159 19 3

158 19 9 210 159

148 20 3 210

164

20 6

21 1

148 21 4

144

21 6

170 21 3 201

160

21 8

22 1

176

22 1

22 6

24 0 186 149

178

0

TC

SHC Kw

130

176

176

130

171

128 15 8

171

128 15 8

171

128

171

128

167 126

167 126

126

167 126

126

163 124

158 123 17 4

121

149 119

0

TC

SHC Kw

215 161

206

206

206

206

201

201

196

196

191

18 6 222

18 6

19 3

19 3

159 19 3

20 1

157 20 1

157

20 1 220 1 66 21 0 229

157 20 1

157 20 1

155 20 8 211 172 21 5

155 20 8 214

155

20 8 217

153

21 5

153 21 5

151

22 2 206 168 23 3

22 9

COOLING CAPACITIES

TOTAL UNIT CFM

5,000

Outdoor Air Cfm

750

SHC K w TC SHC

TC

15 2

181 139 15 4 184 146 15 6 181 142 15 4 186

15.2 184 134

176

179 136 16 2

15 8 182 133

15 8

183

16 3

172

16 3

175 138 16 8

16 3

178 133 16 9 186 139

16 3

180 130 17 1

16 3

182 128 17 2

16 9

170

16 9

173 136 17 5

175 132 17 6

165 143 17 9

168 138 18 1 175 152 18 5

17 9 166 137

18 4

159

TOTAL UNIT CFM

Outdoor Air Cfm

TC

226 167 19 2

218

221 169 20 0 227 176

223

225

213

216

222 163 21 1

224

205

209

TW 173" 23 8 206

15 6 190 137 15 9

141

16 0 179 152 16 2 176 140 16 0

16 3

131

16 4 191 133 16 8 176

143 16 6 174 158 16 7

141

17 3

18 7 - - -

142 19 1

6,500

750

SHC Kw

171

19"0 226

173 19 8

166

20 1

164

20 2 234 166

175 20 5

171

20 7 222 182

160

21 2 236 162 21 9 212 174 20 5

21 7

168

164 21 9

174

22 2 212 193

169

22 4 217 184

1500 0

Kw TC SHC Kw

181 142

185 143

188

180 149 17 0

190 133 17 6

175 155 17 6

181

170 162 18 2

TC SHC Kw TC SHC Kw

233 170 19 5 222 178 19 0

222 Tss 2b"b 2i7 i76" T9" 7

231

217

233

217

223

227 172

215 184 24 0 197

16 4 176 140 16 0

137 16 6

- -

146 17 9 167

- - -

- -

1500

179

170

191

172 21 5 212 174 20 5

166

188

178

T95" TTT" 191

176

140 16 0

140

172

138

172

138

172

17 4

-

_

19 2

20 3

20 6

20 7

20 8

21 1

21 7

21 8

22 2

22 5

22 6

23 0 202 169 21 9

138

172

138 16 6 184

172

138

167 136

136

167 136 17 2

162 134

162 134 17 7

158 132 is 2 T69

153 130 18 7

222

178

217 176

217 176

217 176 19 7

212 174

212 174

212 174 20 5

207

172 21 2 216'

207

172 21 2 220

207 172 21 2

202

169 21 9

167 22 6

f65 23"3 202

15.4

16 0

16 6

16 6

16 6

16 6

\17 l74

17 2

T7T T69 154^

Outdoor A r Cfm

0

19 0"

229"

232

224

19 7 227

19 7 229

231

20 5 219

20 5

222 187

225

228 179

229 177

222 181 22 2

"2ll

214

210

48MA/50ME016

6,000

Outdoor Air Cfm

750

TC SHC

189 146 15 8 194

181

184

186

187

176

179 150

182

185

177

179 144 17 8

172

162 153‘

Kw

150 15 7

152 ibb 183 1641

148

145

143

155

145 17.1 189

142 17 2

140

152

147

149 18 3

T48

TC

188

16 4

189 155

16 5

192 149

16 6

194

178 170

16.8

183

17.0

17 3

17 5

178 '167

17 7

'18‘T 17l3 173

TF9

19 3

48MA/50ME024

8,000

750

TC

Kw

SHC

i 88"

183

l"90"

185

182

181

191 20 9

182 21 3 233 189

189"

184 22 0 227

19T

186 22 8

185 23 6

T89

TC

19 4

233" 196 19""6

19 5

239 187 19 9

20 1

228 202

20 3 233

20 4

237 187 20 8

20 5 239

223 207

21 1 227

21 4

21 5 - -

21 8 222

22 5"

"21 7 210"

221

24 1

1500

SHC

T58^

149

145

161

151

_

_

- -

__ _

- -

-

1500

SHC

20 4"

193 20 6

183 21 0

21 2

199 21 4

21 8

_

_

204

22 2

195 22 5

- - 22 9

201 23 3

_ _ _

- -

Kw

15^8'

26 1

T6^4'

16.6

16 8

16 9

T7V0

17 2

17 5

T7 8

18 4

kw

_

t

AIR

TFMP

Db

85

95 75

100

lO*'

no

lis

0

Wb

TC SHC Kw

65

265

70

65

70

73 259

75 259

65 254

70

78

80

70 248 182

75

78

70

75 242

78

75

190 24 6

265

190

259

188 24 9

259 188 24 9 274

188 24 9 277

188

185

254

185

254

185

254

185 25 8

254

185 25 8 279

248 182 26 7 266

248 182

242

180 27 6

180 27 6 259 201

236

177

230 174

—

24 0

24 9 279

25 8

25 8

25 8

26 7 261 205 27 6

26.7

28 4

29 2

7,000

Outdoor Air Cfm

1000

TC

SHC Kw

203

275

280 197

269

206

200 25 8 282

196 25 9

193 26 1

262

208 26 4

267

202 26 7

273 196

276

192

189 27.3 294

198 27 9 277 212

269 194

254

207 28 4 261

256

199

246

206

2000 0

Kw

TC

24 6

24 8 289

25 5 273

27 0 284

27 2 290 196

28.1 283

28 8 270 220 29 5 252

29 9 268 219

30 4 256 236 31 2

SHC

280 213

201 25 3 277

221 25 7 271

209 26 2 271

287

201 26 5 271 210

291 196

267 229

275 217

204 27 7 264

190 28 3

268 225

203

233

TC

24 8

277

271

26 7

264

26 6

264

27 1

264

28 0

264

258

28 0

28 6 258

29.0

258

252 202

28 9

245 199

30 8

239

TOTAL UNIT CFM

9,000

Outdoor A ir Cfm

1000 2000

SHC Kw

213 24 6

213 24 6

210

210 25 6

210

ToT 26 5

208 26 5

208

208 26 5

208

205 27 4

205

205

202

197

TC SHC K w

287 226 25 2

291 220

25 6 280 229 26 1 284 244

284

25 6 287 219 26 5

25 6

289

273

277 225 27 3 284

26 5

282

285

26.5 287 212 27.8

270 228

27 4

275 221 28 5 284 235 29 1

27.4

277 217 28.6

28 3 263 230 29 0

28 3 267

29 1

263

29 9

253

25 4

223

26 3 291

216 26 6

27 0 277

231

219 27 5

214

27 7 297 219 28 4

28 2

224 29 3 276

222

30 4 - -

229 31 0 262

14

— — —

TC

SHC

291 236

298 224 25 8 285 234

296 225 27 0 278 232 26 0

299 219 27 2 278 232

292 227 28 1

276

- - -

269 255 29 5

25 4

26 3 278 232 26 0

232 26 7 278

252 27 2

240 27 7

-

-

248

28 6

243 30 0 258 223

258 31 7

—

0

Kw TC

SHC

285 234

232

272 229 26 9

272 229 26 9

272 229 26 9

272 229 26 9

272

229 26.9 292

265 226 27 8 276

265 226

226

265

258 223 28.7 269

-

221 29 6

251

245 218 30 3

Kw

25 1 294

25 1

26 0 291

26.0 295

27 8

27 8

28 7 273

48MA/50ME028

11,000

Outdoor Air Cfm

1000

TC

298 242 25 8

287

293 241 26 9

280

284

288

291

280 243

283 239

268 243

258 250 31 4

SHC

25 6

248

"26 5

"250"

244 26 7

27 0

238

27 4

252

27 7

247

27 9

240

236 28 1

233 28 2

249 28 6

28 8

29 0

"29 5

252

29 7

245

30 8

Kw

2000

TC

SHC Kw

"298 "258 25 s'

305 246 26 1

"266 26 '7

297 254

302

304 241

"283

290

282 "269

274 274

27 1

246

27 3

27 5

273 27 6

262 28 0

28 9

29 8

Page 15

Performance data

Room Design 75 F/50% Rh

COOLING CAPACITIES

48MA/50ME030

OUTDUUK

Aik

TEMP

Db Wb TC SHC

65 298

оэ

70 298 215 29,7

292 212

65

292 212 30 7

70

292 212

73

292 212 30.7

75

65 285 209

70 285 209

95 75

100 75 279

no 78

115

285 209

285 209 31 8

78

80 285 209 31.8

279 207

70

279_ 207

70 273

273

75

266 201 34.6

261 199 35.5 279

75

- -

OUTDOOR

AIK

TEMP

Db Wb

95 75

100 75 293 240

110 78 279

115 75 273

TC SHC

314 248

65

70 314

307 245

65

70 307 245

307 245 31 8 326

73

75 307 245 31.8 328

65 300

70 300 242 32.8

300

300 242

78

80 300

293 240

70

_293

78

286 237 34 8 300 266

70

286 237 34.8

75

TOTAL UNIT CFM

8,000

Ou tdoor Air Cfm

0 1000 2000 2500 0

Kw TC SHC

215 29 7 311

317 223 30.9 326 228

30 7 304 231 31 6

309 225

30 7

313

315 219 32,3 328

31 8 297

31 8 302

31 8

308

311 217 33 6

314 215 33.8

32 8

207 32 8 300

204 33 7

204

295

.32,8

303

288

33.7 293

289

0

Kw

TC SHC

30 7

326

331 257 31 8 339 262 32.3 312 264

30.7

248

31 8

319

31 8 323

32 8 311

242

242

242

315

32 8 321

32 8 323 251 34 5

325

32,8

33 8 307

33 8 312

33:8 _ ^5

24Q_

304

234

35.7 300

231 36.6

289 264

Kw

229

222

234 32 6 303 255 33 0 305 264

228

222

230

224 34 4 312 237

220 34.7

232

226

224

231 37.1 291 260 38.2

---

Outdoor Air Cfm

1000

263

265 32 5 324 281 32 9

259 32 9 331 269 33 4

256

253

267

261 33 9 323 276 34 4

255

249

263 34.9

257 35 3

253

25?

257 37.4

TC SHC Kw TC SHC Kw TC SHC Kw TC

317

30 5

31 9 318

32 2 324

33 0 311

33 4 320 230 34 2

34 0 303

34 9

35.4

36.6 303 244 37.7

11,000

Kw TC SHC

31 5

33 1

33.2

33 9

34 3

34.6

35.5

35 9 309 290 36.6

36,3

38.0

240

30.9 319

309 247

326

330 216

.3L8.

297 258 35 7

304

—

332 273

336

339 256 33.9

317

330 263 35 0 334 267

335

-

315 283 35 5

322

327 263

3_13

300

31.5

31 9 312

235 32 5

228 32 9 328

222

33.2 333 234 33.5 303 235 31.5 325

243

33 6

222 34 7 332

34.9 337 216 35.4 296 232 32.5 322 237 34.4 336

34 6 307

250

35 3

229

,35J_

245 36.3 309 254 36.6

2000

Kw TC SHC

31.8 334 278 31 9 317 259 30 9 330

261 33 7 339 264

287 34 1 319 297 34 2 303 253 33 0 314 277

35 3

255

„

- - -

271 36 0 326 277 36 3 296 250 34 1 315 268 35.5

36.4

278_ 37,0 -

- ~ - -

293

38 9

245

329

230

254

322 240 32 8 303 235

230

314

250 33 8 296 232 32 5 312

234 34 6

325

223 35 1

260

317 244

324

. 23A

300 269 35 9 282 226 34 5 296 255

254

308

296

274

—

2500

326

288 33 1 310

334

274

343 257

325 283 34 6 303 253 33 0 319 272

_ -

292

318

302

311

- - -

31 0 309 238 30 4 322

31.7

309 238

32 1 303

33 2 303 235

33 2 296

296

296 232 32.5

34 9

289

35 6 289 229 33 5 304

36.1 .289

282 226

276

38.1

270 220 36 3 287 253 37.8

38 6

TOTAL UNIT CFM

—

—

—

Kw

TC SHC

32.5

317 259

33 6 310

33 9 310

34.2

310

303 253 33 0

35 2

303

-

303 253 33.0 328 258 34.8

296 250 34 1 310 274

35 7

296 250 34.1 318 263 35,7 - -

36 8 289 247 35 1 303 276

__

289 247 35J

282 244

276 241 36 8 292 275 38.3

10,000

Air Cfm

Outdoor

1000 2000 2500

30.4

235

31 5

31 5

31 5

232

32 5 307

232 32 5

229

33 5

33,5

229

34.5 301

35.4 297

223

SHC

252 31 2

246 31,5

327

254 32 3

315

320 248

323 245 32.8 332 251 33 5 336

242

256 33 3

251 33 7

244 34 0

317

320 240

304

253

246 35 0

242_ 35_.3_

312_

249 36.0

247 37.2

TC

Kw

328

335

320 270

32 6

328 258 33 1 331

33,0 336 245 33.7

314

319 266 34 2

328 253

34 2

333 244 35.1

34 7

312 273 35 2 315 282

319 260

32A

35 6

305 280

3J.1

- -

297

Kw

TC SHC

334 268

331

323 265

326 261 34 7

367

302

- -

12,000

Air Cfm

Outdoor

Kw

TC SHC

273 31 7 335 284 32 0

342

32.Q_

32 8

328

33 1

266 33 3

263 33 4

270

268

334

338

341

33 9

321

34 1

326 287 34.6 328

34.5 333 274 35 1

-

35 2

318 294 35 7 321 303

324

36 1 311

36.5 316

- - - - -

37 6

- - - - -

— —

0 1000 2000

30.9

256 32 0 322 275

256 32 0 327 270

256 32 0 329

256 32.0

253

33 0

36.0

Kw TC

SHC

263

31 6

251 32,1 339

32 7

SHC

330 267

322

340 246

277

238 35.4

252 36.2

268 36,8

282 38.7

316

33.8

322 273

34 8 332

324 267

35.8

36 3

308 291

3]5 276

302 296

Kw TC

—

- -

-

_

2500

SHC

337

2?2

291 33 1 330 298

280

272 33 9

267

298

_

- - - -

281 36 2

300 36 8 314

28? 37,2 - -

3A5

32,5

33 6 337 284

342

34.1 345 268

34 3 323 307

-

- _ -

-

r

253

277

263

253

286

257

289

274

275

294

312

31 7

32.3

32 8

33.3

33 7

34-0

33 9

34.4

35 1

_

35 5

36 1

36 6

37.1

39 1

32.1

32.7

33 3

33 8

34 1

34 3

34 4

34 8

-

35 9

-

-

37 0

#

Kw — Compressor Motor Power Input

SHC — Sensible Heat Capacity (1000 Btuh)

TC — Total Capacity (1000 Btuh)

NOTES: 1. No values are given where unit cannot maintain the assumed room

design relative humidity since the moisture content of the air leaving

the unit is higher than the assumed room moisture content

2. Ratings are gross and do not include fan motor heat deduction.

15

Page 16

Performance data

Room Design 75 F/50% Rh

COOLING CAPACITIES

48MA/50ME034

OUTDOOR

AIR

TEMP

Db

85

90

95 75

100

105

no

115 75

OUTDOOR

AIR

Db

85

90

95

100

105

110

115

_

Wb

tc

65 314

70

65 307

70

73 307

75 307

65

70

78

80

70 293

75 293

80 293

70

75

78

Wb

65 325 254

70

65 318 251

70

73 318 251

75 318

65 310

70

75 310

78

80

70 302

75 302

78 302

70 294

75

78 287

75 279

SHC

231

314

231 28.6

228 29 6

307

228 29 6 324

228 29 6

228 29.6

300 225

300

225

300

225

300

225

300

225 30 7 329

222 31 8

222 31 8 314

222

285

219 32 8

285

219 32 8

’2/8 215

271 212 34 7

TC SHC

325 254

318 251

251 30 2 339

247 31 3 324

310 247 31 3

247 31 3

310

247

310

247 31 3

244

244

244

241

294

241

238

234 35 4 296

0

kw

TC

28 6 326 246

332 240

318 248

328 239

330 236

311

30 7

30 7 316 244 31 6

30 7 322

30 7 326 234

308

31.8 318 236

300

306 242 34 1

33.8 301

290 246 36 1

0

Kw

TC SHC

29 1 336

29 1 341 262

30 2

328 ^270 30 8

30 2 334 264

30 2

337 261 31 3

325 267 32 2

331

31 3

334

337 253

32 4 317

32 4 322

32 4 325

33 4

308 270 34 3

33.4

313 264

34 4

308

__

9,000

0

utdoor Air Cfm

100(

Kw

SHC

29 2

333

29.5 342

30 3 325 264

242

30 6 334 253

30 8 341

30.9

250 31 3

238

231 32.4

246

240

248

345

322 275

326

32 0

336

32 2 343

348

32.7

318 267 33 3

33 1

328

33.3 334

33 8

314

319

240 35 4 316

306 280 37 3

n,ooo

Outdoor Air Cfm

1000

Kw

268 29 7

258 31 4

275 32 1

260 32 5

256

268 33.2

262 33 6

258 33 8

262

268

30 0

31 1

32.7

32 8

34.6

35.9

36 6

343

352

335

343

349

353

332

334

344

350

354

326

335

340

322

325

2000

TC

SHC

257 29 6

245

30.0

30 6

31 1

245 31 5

Kw

240 31.7

32 0

260 32 2

247 32 8

239 33 2

233

33.4

254

33 9

246

34.3 341

278 34 7

262 35 0

261

36 4

2000

TC

SHC

Kw

279 30 1

268 30.5

287 31 1

275 31 6

268 31 9

262 32.1

298 32 5 335

282 32 7

270 33.2 349

262

33.5 -

256

33 8

290 33 8 334

277 34 3

269 34.7

301 35 2 326

284 35.4 3_^

- - - - -

303

37 8

TOTAL UNIT CFM

2500

TC

SHC

336

262

347

247

327

272

339

257 31 4

346

248 31 7

351

242

325

286

330

267 32 4

342

252

350

241

356

234

321

277

333 261

251

319 291

324

271

- - -

312

295

TOTAL UNIT CFM

2500

TC

SHC

345 285

355

270 30 7 329

342 299

347

280 31 8

354

271 32 1

358 264

308 32.7

338

290 32 9

274 33 5

-

- 304 34 3

340 284

- - -

313 35 4

294

-

Kw

TC SHC

29 7

30.3

30 8

32.0

32 2

33 1

33 6

33 9

33T

34 2

34.7

35 0

35 3

243

320

320 243 28.9

313

240 29 9 324 259

313

240 29 9 329 253

313

240 29 9 333 250 31 0

313

240 29 9 335 247

305

237 31’ 0 3T9 ’264’

305

237 31 0 321 256

305

237 31 0

305 237

305 237

233''

298

298 233 32 1

298 233

290 230 33 1

290 230

283 227 34 1

37 8

275 224

Kw

TC

30.2 329

SHC

264 29 3

264 29 3

31 5 322

32.4

_

34 6 306

35.7

-

261

322 261

322

261 30.4 341

322 261 30.4

314

258

314

258

314

258 31 5

314

258

314

258 31 5

306 255

255

306

255

298 251 33 6 311

298 251

290

248 34 6 311 273

282

245 35 6 299

b" 1000

Kw

TC SHC

2ST 331 257 29 5

337 251

327 249 32 3

31 0

330 245 32 5

31.0 333 242

321

313" 257' 33 0

318 251 33 3 331

32.1

322 247

304 ’259”

33.1

310

253

305 251

35 1

0

Kw

TC

257

1000

SHC Kw

340 279

345 273 30 2

30.4 332

30 4

31 5

31 5

31 5

32 6 320 279

32 6 325 273

32.6

33.6 316 275

281

337 275

272 31 4

343

269

328 286 32 3

329

277 32 4

334 271 32 7

337

267

264

340

269

328

281 34 5

279 36 8

10,000

Outdoor Air Cfm

Kw

TC

33F

,348

29.8

30 6

330 276

30 9

340 264

345

31.2

349

31.8 328

31 9

331

340

347

32.6 351

’322

338

33.6

’341 ’

318

34.4

322

35 7 319

36 4 30^

12,000

Outdoor Air Cfm

TC

29.9 347

355

31 0

339

31 3

347

352 279

31,6

355 273

336 309

338 293

347

32 9

352

- - — _

33.0

33 5

329

33 8

337

-

34.0

325

34.8

328 295

36.1

- -

2000

SHC Kw

268

29.8 34T T73

257

30.3 352

30 9

31 4

257

31,7

251 31.9

287 32 3

271

32 5

259 33 0

250

33 4

245

33.6

279

33 6

266 34.1

258 34 5

290

35 0 323

273

35 2

272

36 6

292

37 6~’

2000

K w

SHC

290 30.3

279

30 7

297 ’31 3

286 31 8

32 0

32.2

32.8

32.9

280 33 4

272

33 7

300 34 0

288

34 5 342

_

_ _

312

35 4

35.6

_ _ _

-

2500

tc

SHC

259

338

288

343

269 31 6

350

260 32 0

355 253 39 9

331

297

335

279 32 7

346

263

353 253

326 289

337

273

344

263

302

328 283

_

_

315

307^

’38 0

2500

TC

SHC

349

295

359

^81

’346

3io

350

291

357

282

361

275

338

319

341

301

351

285

_

337

315

295

329

324

-

Kw

30.0

30.5

31 3

32 5

33.3

33 7

33 8

34 4

34 9

35 2

35.5

.. ^

Kw

30 4

30.9

3L7

32.0

32 3

32.5

32.9

33 1

33.6

34 4

34 8

35.6

16

#

Page 17

Performance data

Room Design 75 F/50% Rh

COOLING CAPACITIES

48MA/50ME040

OUTDOOR

AIR

TEMP

Wb TC SHC

Db

85

90

95

100 75 355

105

no

115

367

65

70 367 262

364

65

364 263 38 3

70

364

73

364

75

361 264 39.8

65

361 264

70

75 361

78 361 264 39 8

361 264 39.8

80

70

355

78 355

351 263 42 8

70

351 263 42.8

75

342 260

78

334

75

OUTDOOR

AIR

TEMP

Wb TC SHC

Db

85

95 75

100

no 78

115

371 273 36 9

65

371 273

70

369 276

65

369

70

369 276 38 5

73

369 276

75

367 279

65

367

70

367 279 40.0 408 311 43 4 418

367 279

78

80 367 279 40.0 415

362

70

75 362

78 362

357

70

357 281 43.1 379

75

349 279 44 7 364

342

75

--

0

Kw

TC

262 36 8

263

263 38 3

263

264 39 8 398

264

264 41 3 383 288 44 6 390

264

257 45.8

402 294 39 0 416 311

36.8 410 290

394 297

38 3

401 293 40 9 412

408

38,3 413 290 41.5

386 300

392

39.8

402 285 43 4 413

405 282 43 6 418

41 3 397

41 3 387

365

368

354

44.3

336 283

11,000

Outdoor

Air Cfm

1000

SHC kw

291

295

289 43 1 408

294

284

294

287 46.1 373 303 47.8 381

280

TC

39.5 426 300 40.8

403

40 4

41 4 419 298

425

390

41.8

42 3 398

43 9 381

44.9 397

364 316 46 9 366 338 48 0 354

45 5

48.2 360 298 50.1 373

49 4 338

TOTAL UNIT CFM

--

2000 3000

SHC Kw

316 41 6 404 330 42 3 366 270 38 4

304

293

321

309

296 44 6 416

287 45 2 427

281

313 45 4 384

300

291 46 7

309 51.3 347

TC

40 2

420

434 305 41.6 368

42 3 418

42 8 427 303 43 7

434 295 44 1

43 1

388

43 1

402 323 44 6

43 8

45 6

433

46 2 399

410

Kw

SHC

322 40 8 368 268

314

43 1

339

43 8

304

45 6

292 46 3 364 272

284 46 7 364 272

331

46 3 359 273

313 47 2 359 273

302 47 8 359 273

322 48.8 354

319 51,4 347 269

336 52 9

—

-

-------

— - --

0 1000

Kw

TC SHC

268

366

270

366

270

366

270

364 272

364 272 39 9 398 307

364 272 39 9

271 43 0 371

271

269 46 1 342

339

TC SHC

36 8 406 302

36.8 414

399 307 40 6

406 303

38 4

38 4 413 303

38.4

419 302

39 9 392 312

404

39 9

408

39 9 411 294

41 5 384 306

41 5 389 300

41 5

393 296

374 299 46.3 378

43.0

44.6

359 291

TOTAL UNIT CFM

13.000

Outdoor Air Cfm

0

Kw

36.9 417 307 39 8 437 322 41 2 446

38 5

276 38.5 409 312 41 2 423 328 42 6 430 338 43 5 371 282 38 6 412 321

38 5

40 0

279 40 0

40 0 412

41 6

280

41 6

280

280 41 6 397

281 43 1 376

46 3 347 305 49 9 350

278

1000 2000

TC SHC

409 310 39 2 426 333 40 5 432

402

416 311 41 7 431 321 43 2 439 327

423 312 41.8

395 320 42 1

401

388

394

Kw

TC

315 40 7 415 339 42 0 417 354 42 7 371 282 38 6 405 323 40 8 419 349

436 316 43.4

316

307 43 7 423 310 45 5 436 315

304

317 44 3 393 336 45 7

310 45 0 400 322 46 6

307

317 45 9

310 46.5 383 325 48.2

302

403 345

42 7 410 333

44.0 427

406 314 47.1 417 324 48 2 364 287

45 3

375

48 6 371

Kw

SHC

43 4 401

44 1 414 347

319 45 0

304

45 9 442

338 47 3 376 359

320

50 5 380

331 51.7

3000

TC SHC

445

427 328

395

408

390

359 354 53.3 345 287

Kw

345

41 1 374 279

329

42 0 374 279

44 0

319 44.3

362 44 2

45 0 369

46 0 369 286 40 1 412 321

46 6 369 286 40 1 416 317 43 8 428

307

47 0 369 286

353 46 7 364 287

47 6 364 287 41 7

336

48 4

344 49 2 359 289 43.2

341

51 7 352

0

Kw

SHC

TC

371 282 38 6 419 320

371 282

286 40 1 397

369

286 40 1 405 326 42 9

359 289 43 2 380 328

288

TC SHC

37.1

412 318

37 1

420 315 39.9

38 6 427 322

40 1 419 315

393

41 7

398

41.7

402 318

384

44 8

368 313 48.8

46 4

352

12,000

Outdoor

Air Cfm

2000 3000

Kw

TC SHC Kw

39 1 423 323 40 4 427 335

432 312 41 0 441

39 7

300

301

297

306 45 7 370 327

295 49 7

410

41 1

41.7

41 8 431 305 43 4 440

42 0 397 334 43 3 398

42.6

43.3

43 8 419 299 45 4 433 305 46 4

43 8

44 2

44 8

45 1 402 303 47 0

48 4

328

418 317

426

310 43 0

404

322

414

308

423 293

387 325

396 311

314

366

309 50 3

343

320

TC

41 8 411 343 42 5

42 5 425 326

434

44 0

409 335 44 8

44 9 423 316

45 8 438 296 46 9

45 6 390 342 46 5

46 5 404 325 47 4

414

47 1 371

385

48 0

376

51 6

353 347 53 1

14.000

Outdoor Air Cfm

1000

Kw TC

39 4 429

41 4 429

41 8 439

41 9

42 2 409 356

328

43 5

44 1

44 5 398

327

321 45 1 405 333

45 4 410

46 1

321 46.7 388 335 48 4

316 50 1 357 343

2000

Kw

SHC

342 40 6 438 356 41 3

442

333

339 42 8 435 349

332 43 3 443

440

328

416

345 44 2

422 330 45.2 431 339

321 45 7 438

431 315

347 45 9 400

325

380 349

377

330 50 7

TCiSHC

41 4

451 340

422 364

42 1

43 5 449

409

43 5

418 358 45 1

445 317

46.0

413 347

46 8

47 2 420 334

47 5 382

395

385 1 351

3651 362 53.6

51.8

SHC Kw

41 0

41 9

318

43 3

315 43 9

44 2

308

44 1

351

45 8

313

48 0

349 48 3

333 49 0

51 5

330

3000

Kw

42 2

42 8

43 6

44.2

338

330 44 5

44 4

373

46.1

326

46 7

47 1

364

46 9

47 7

48 3

369

48 6

355

49 3

51.8

Kw — Compressor Motor Power Input

SHC — Sensible Heat Capacity (1000 Btuh)

TC — Total Capacity (1000 Btuh)

NOTES: 1. No values are given where unit cannot maintain the assumed room

design relative humidity since the moisture content of the air leaving

the unit is higher than the assumed room moisture content

2. Ratings are gross and do not include fan motor heat deduction

17

Page 18

Performance data

Room Design 78 F/50% Rh

COOLING CAPACITIES

48MA/50ME016

R

IP

Db

Wb

65 183

85

70 _ 183

65 178 131 16 1 182

70

90

73 178 131

75 178

65 174

70 174

95

75

78

80 174

70 169 127

100

75

78 169 127 17,3 181 135 17.9

70

105

75

no

78 160

115

75

0

TC

SHC

132

132

178 131 16 1 185

131

129

129 16 7 180

174

129

174 129

129 16.7 187

169 127 17 3

165 125

165 125 17.8 173 140

123

156 121 18 9

Outdoor Air Cfm

Kw

TC

15 5 186 141

15,5

190 136 15,9 194 139_

16 1

187 136 16 6 193 139 16 9

16.1 188

16 7 177

16 7

183 136

16 7 186

17 3

175 143

178

17 8

170 145 18 2

18.4

170 139

164

OUTDOOR

AIR

TEMP

Db

85

90

95

100

105

110 78

115

- -

0

Wb TC

65 220 158

70 220 158 18 9 231 163

65

70 216 156

73

75

65

70 211 154

75 21 1 154 20 4 224 163 21 2 232

78

80 211 154

70

75

78

70 201

75

75

SHC

216

156 19 7 222 169

216 156

216 156 19.7

211 154 20 4 217 171 20 8 220 187 21 0 218

211

154 20 4 227 160

206 152 21 2

206

152 21 2

206

152 21 2

150

201 150 21 9

196 148 22 6

191

146 23 3 202 170

Outdoor Ai

K w TC

227

18 9

226 165 20 2

19 7

19 7 228 163

230 161 20 5 238

20 4 220 167

229

20 4

215 169 21 7 220

219 164

221 161

210 171 22 5

21 9

213 166 22 7

210

5,000 .

750

Kw

SHC

IS 7

16 3 183 154 16 4

143

16 5

138

16.6

134

16 9

145

17 0

140

17 2

17 4 1 94

133

17.4 196

130

17 6 179 157

17 8

1 38

18.4

19.1

19 5

144

6,000

r Cfm

750

K w

SHC

19 2

167

157

165

2 30

19 4 236 167 19 7

20 0

231

20 4 •^35

21 0 226 178 21 3

21 4 237 163 22 0

21 5 240

22 0 227 175

22 2 231

221 181

23.6 219

24 1

TOTAL UNIT CFM

1500

TC SHC

188

189

195 135 17.0 183 143 16 4

179 160 17 0

184

190

185 148 18 2 174

188

174 163

179

178

169

Kw

148 15 8

.16,]

145 16 7

151 17 3 178

141 17 6

135 17 7

131 17 8

17 8 174

141

18 4

18 4

154

18 8 169

154

19.5

166 19 9 159 133 19 2 167 156

- -

1500

SHC Kw TC SHC K w TC

TC

175 1 9 4

181 20 2

225

172 20 5

167

20 8

163 20.9 223

169 21 7

159

22 2 218

184

22 1 21 3

22 5 213 170 21 6 225

169

22 8 213

190 22 9

215

210

23 2

24 2

181

192 24 7

0

SHC

TC

144

188

J88^

183 143 16 4

183 143 16 4

183 143 16 4 191