Page 1

50LJ008-014

HEATING & COOLING

Single-Package Rooftop Cooling Units

Installation, Start-Up and Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS

INSTALLATION

Step 1 — Provide Unit Support

• ROOF CURB

• SLAB MOUNT

Step 2 — Field Fabricate Ductwork ....................... 2

Step 3 — Install External Trap for

Condensate Drain ................................................ 2

Step 4 — Rig and Place Unit

• POSITIONING

Step 5 — Make Electrical Connections

• FIELD POWER SUPPLY

• FIELD CONTROL WIRING

• HEAT ANTICIPATOR SETTINGS

Step 6 — Adjust Evaporator-Fan Speed .... 9

START-UP

SERVICE ............................................................... 16-18

.....................................................

.............................................................

................................

............................

.................................

................

1

1-14

2

2

2

15,16

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations. Have

fire extinguishers available for all brazing operations.

A WARNING

Before performing service or maintenance operations

on unit, turn off main power switch to unit. Electrical

shock could cause personal injury.

INSTALLATION

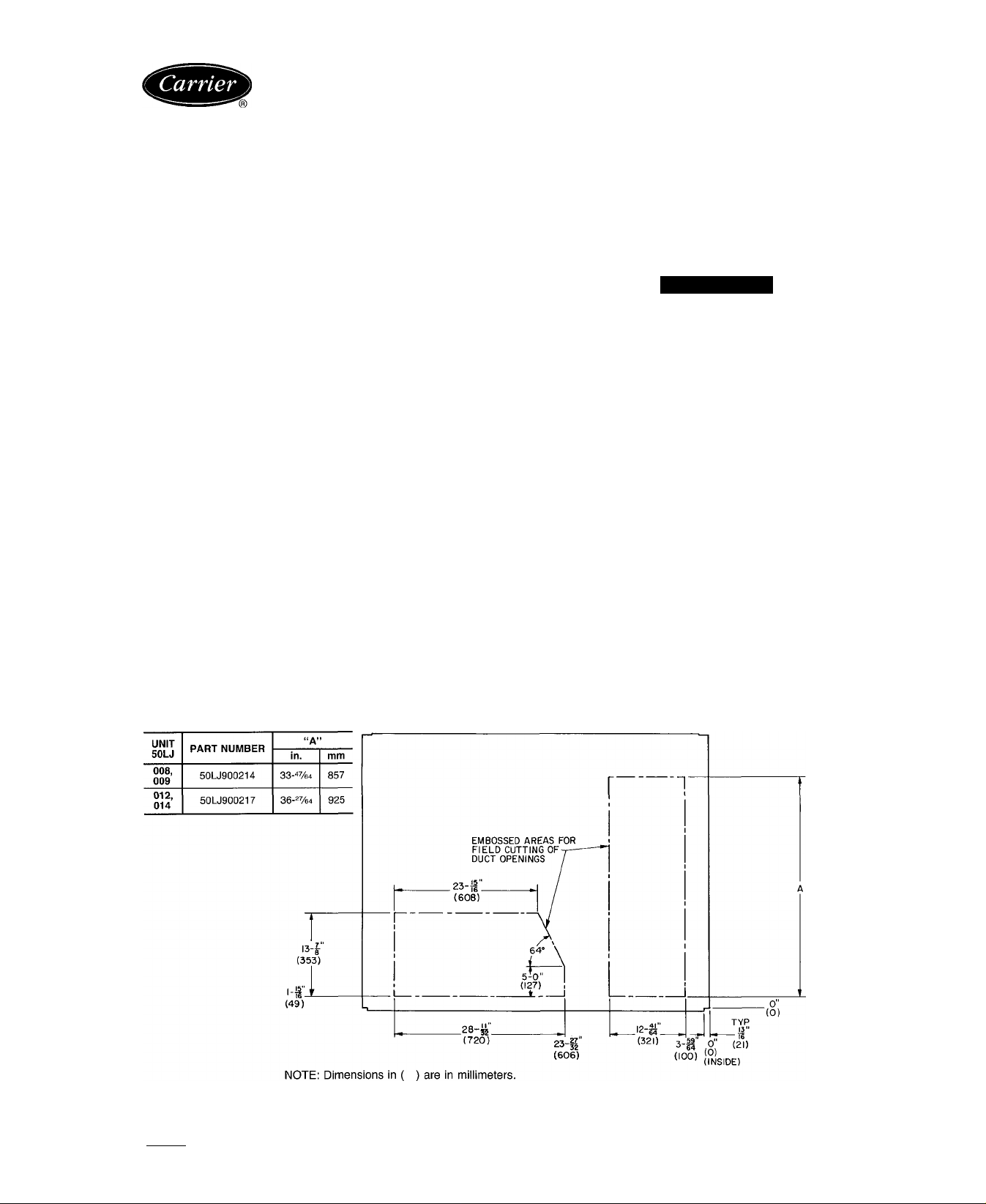

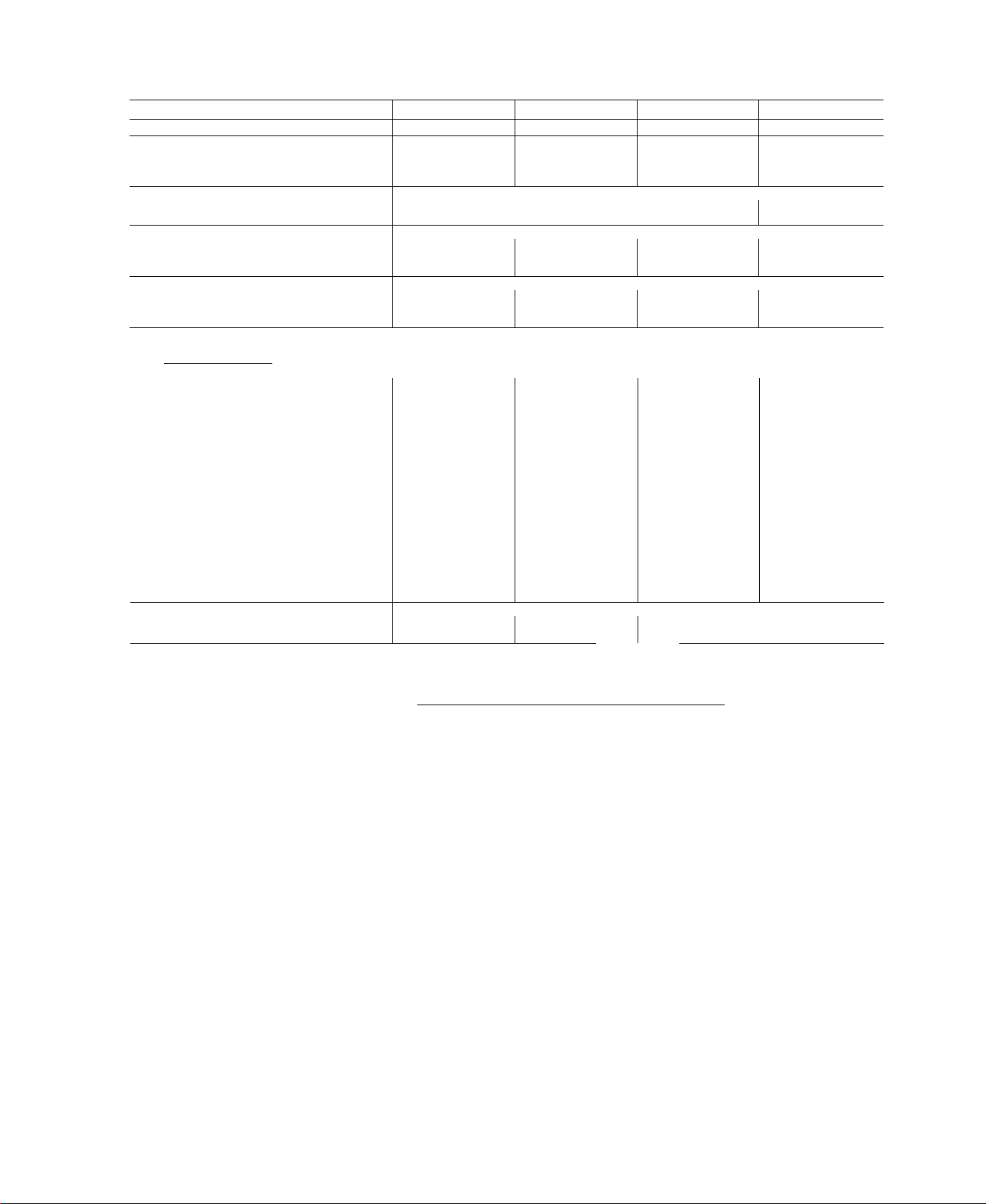

Unit is shipped in the vertical discharge configuration.

To convert to horizontal discharge application, cut imprint

area from front panels using sheet metal cutters. See Fig. 1

Duct openings in basepan must be covered by panels pro

vided in the Accessory Duct Cover Package, part no.

50LJ900214 (50LJ008,009) or 50LJ900217 (50LJ012,014).

Using screws provided in accessory package, install cov

ers on duct openings in basepan of unit with insulation-side

down. Seals around opening must be tight.

SAFETY CONSIDERATIONS

Installation and servicing air conditioning equipment can

be hazardous due to system pressure and electrical compo

nents. Only trained and qualified service personnel should

install, repair or service air conditioning equipment.

Untrained personnel can perform basic maintenance func

tions of cleaning coils and filters and replacing filters. All

other operations should be performed by trained service per

sonnel. When working on air conditioning equipment, ob

serve precautions in the literature, tags and labels attached

to the unit, and other safety precautions that may apply

IMPORTANT: An external filter kit MUST be used

or the filters MUST be field-installed outside the unit

on horizontal applications with accessory economizer

or two-position damper. Otherwise, the economizer

or two-position damper must be partially removed to

access the filters. The area of the field-installed fil

ters should be equal to the area of the factoryinstalled filters.

1-15"

' 16

(49)

Fig. 1 — Horizontal Conversion Imprint Dimensions

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book|1 |4 PC 111 Catalog No 565-004 Printed in U S A Form 50LJ-4SI Pg 1 11-91 Replaces: 50LJ-2SI

Tab 1b 6b

Page 2

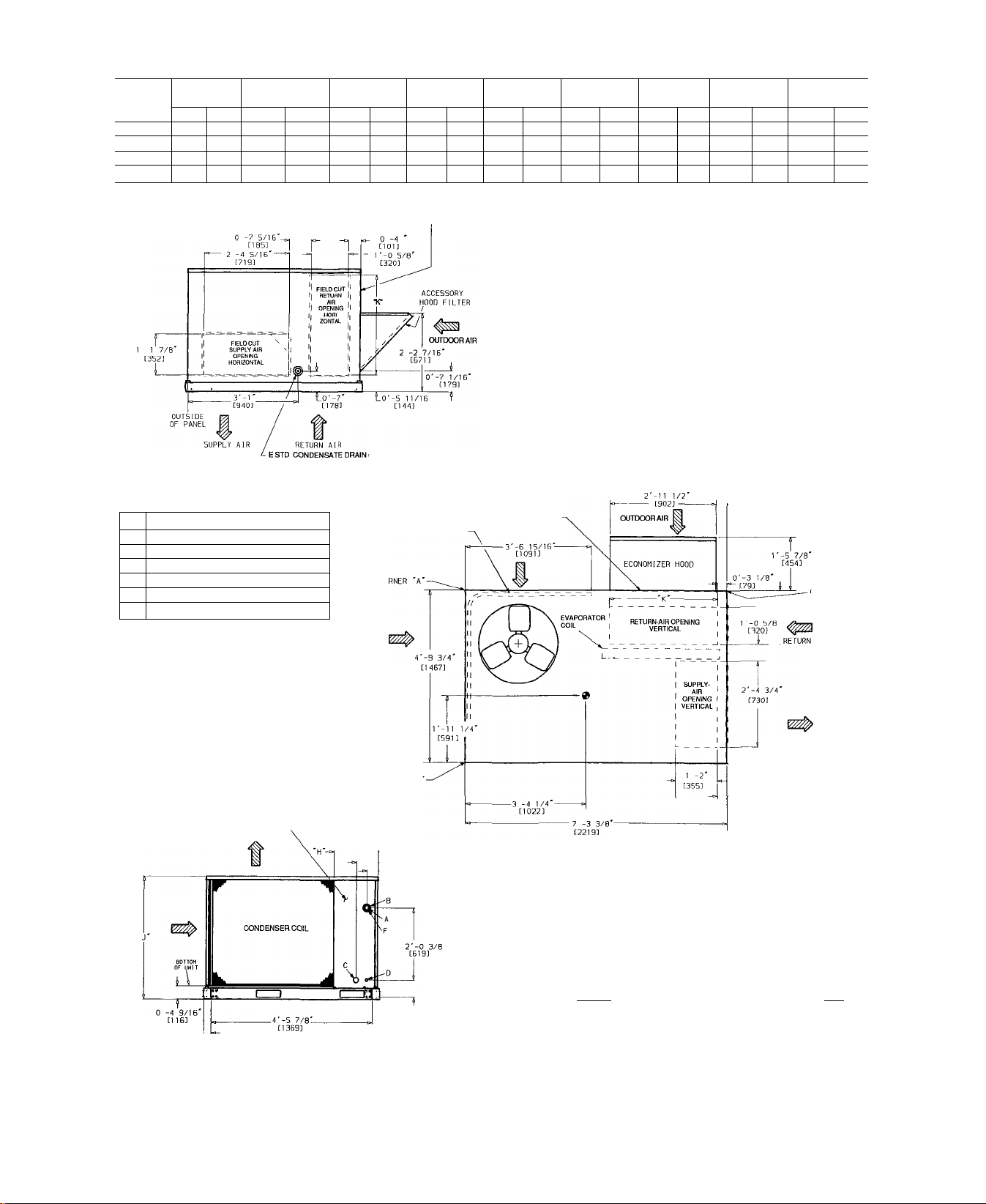

Step 1 — Provide Unit Support

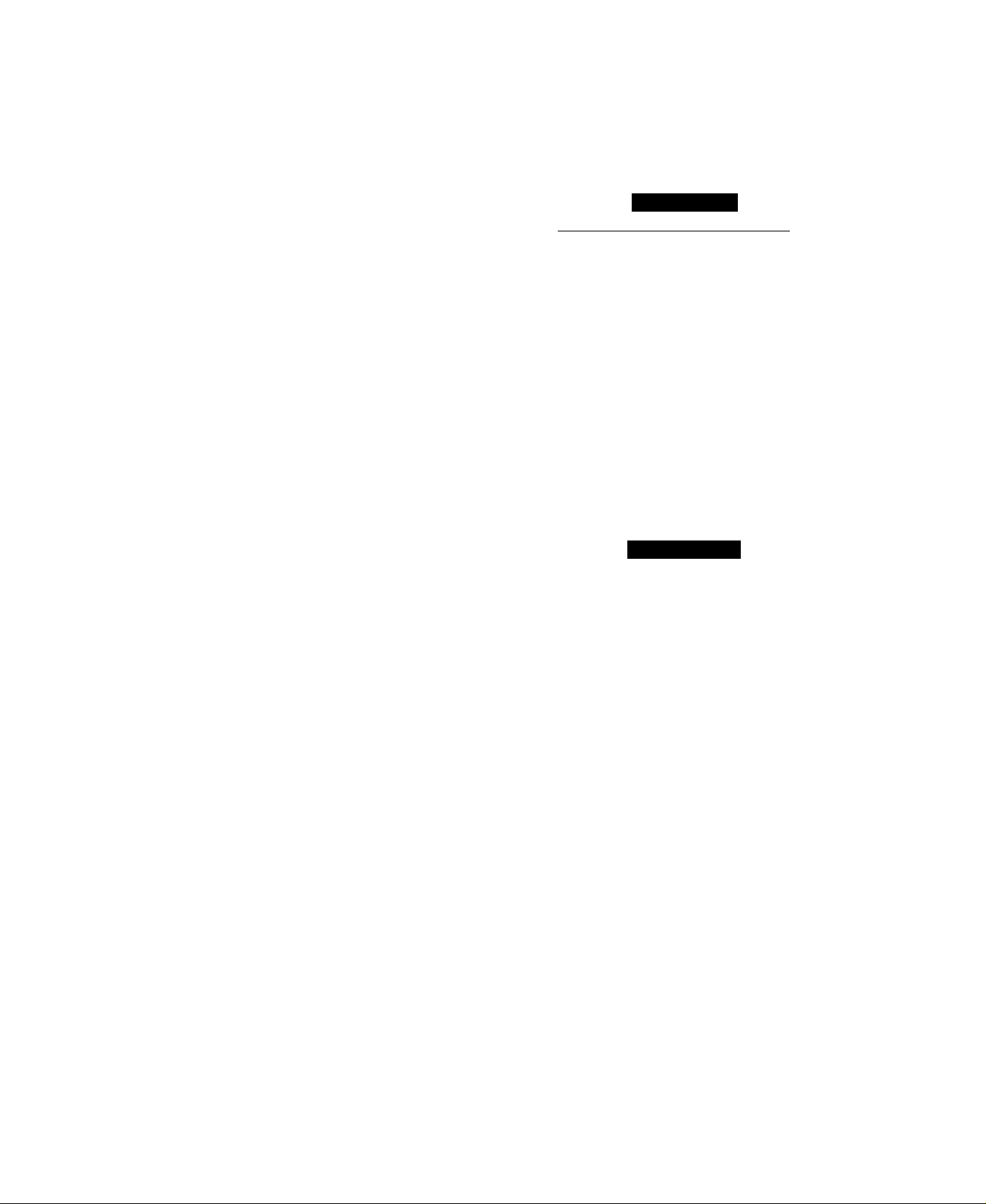

ROOF CURB — Assemble and install accessory roof curb

in accordance with instructions shipped with curb. See

Fig. 2. Install insulation, cant strips, roofing and counter

flashing as shown. Ductwork must be attached to curb, not

to unit. If electric or control power is to be routed through

the curb, attach the accessory thru~the-curb service connec

tion plates to the roof curb in accordance with the accessory

installation instructions. Connection plates must be in

stalled before unit is set on roof curb.

IMPORTANT: The gasketing of the unit to the roof

curb is critical for water integrity. Install gasket sup

plied with the roof curb as shown in Fig. 2. Improp

erly applied gasket can also result in air leaks and

poor unit performance.

Curb should be level. This is necessary for unit drain to

function properly. Unit leveling tolerances are shown in

Fig. 3. Refer to Accessory Roof Curb Installation Instruc

tions for additional information as required.

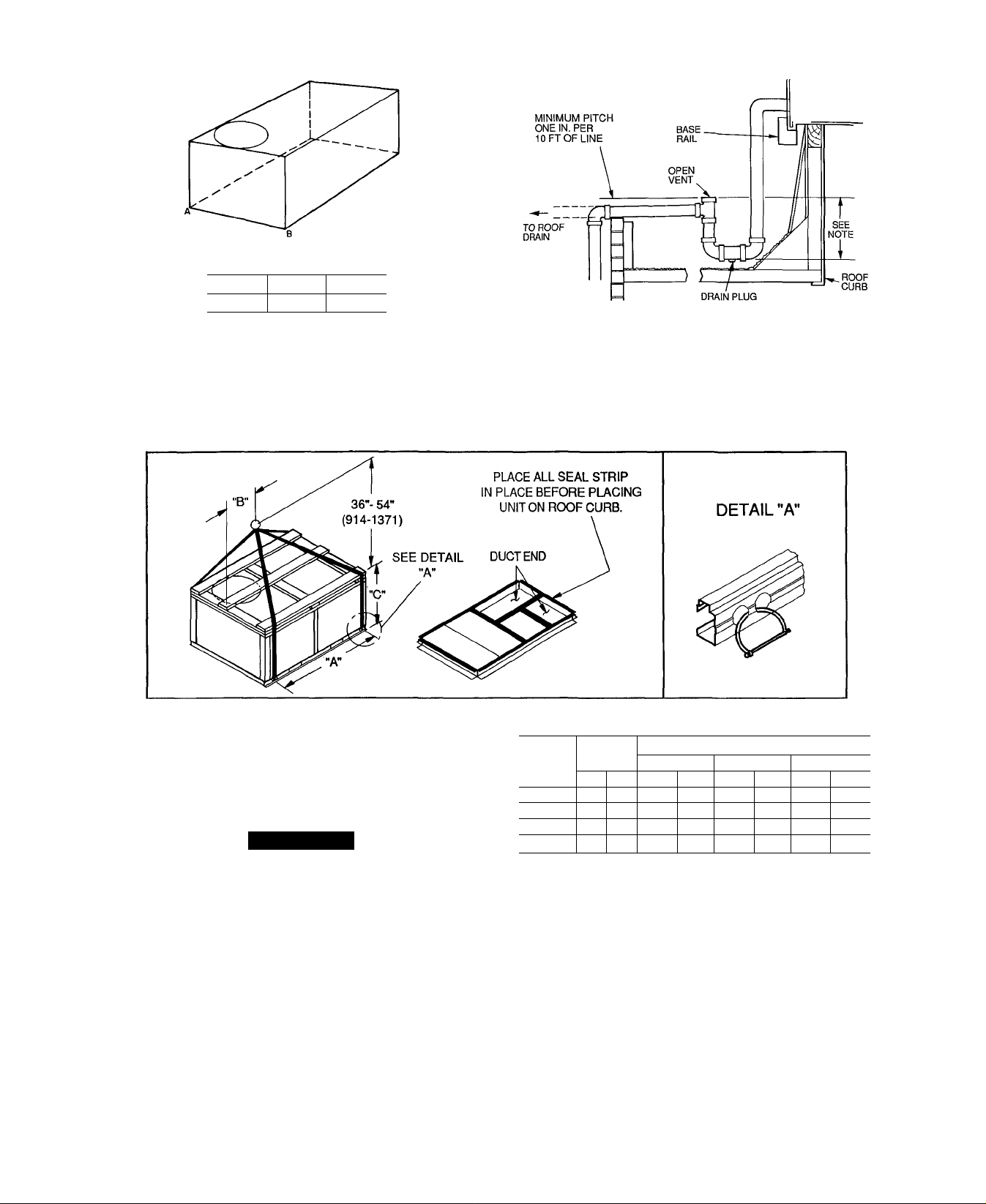

SLAB MOUNT (Horizontal Units Only) — Provide a level

concrete slab that extends a minimum of 6 in. beyond unit

cabinet. Install a gravel apron in front of outdoor-coil air

inlet to prevent grass and foliage from obstructing airflow.

NOTE: Horizontal units may be installed on a roof curb if

required.

are not required i.^’ top crpting is left on unit. Rollers may be

used to move unit across a roof. Level by using unit frame

as a reference. See Table 1 and Fig 5 for additional infor

mation. Operating weight is shown in Table 1 and Fig. 5.

Lifting holes are provided in base rails as shown in Fig.

5 and 6. Refer to rigging instructions on unit.

A CAUTION

I

______

All panels must be in place when rigging.

POSITIONING — Maintain clearance around and above

unit to provide proper airflow and service access. See

Fig. 6

Position unit on roof curb so that the following clear

ances are maintained: ‘A-in. clearance between roof curb

and base rails on each side and front of unit; U/32-in. clear

ance between roof curb and rear of unit (see Fig. 2, section

C-C).

Do not install unit in an indoor location. Do not locate

unit air inlet near exhaust vents or other sources of contam

inated air.

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

After unit is in position, remove polyethylene shipping

wrapper and rigging skid.

_________

|

Step 2 — Field Fabricate Ductwork — On verti

cal discharge units, secure all ducts to roof curb and build

ing structure. Do not connect ductwork to unit. For hori

zontal applications, field-supplied flanges should be attached

to horizontal discharge openings and all ductwork attached

to the flanges. Insulate and weatherproof all external duct

work, joints and roof openings with counter flashing and

mastic in accordance with applicable codes.

Ducts passing through an unconditioned space must be

insulated and covered with a vapor barrier.

If plenum return is used on a vertical unit, the return should

be ducted through the roof deck to comply with applicable

fire codes.

A minimum clearance to combustibles is not required around

ductwork on vertical discharge units. On horizontal dis

charge units, a minimum clearance of one in. is required

for the first 12 in. of ductwork. Cabinet return-air static

shall not exceed —.35 in. wg with economizer or —.45 in.

wg without economizer

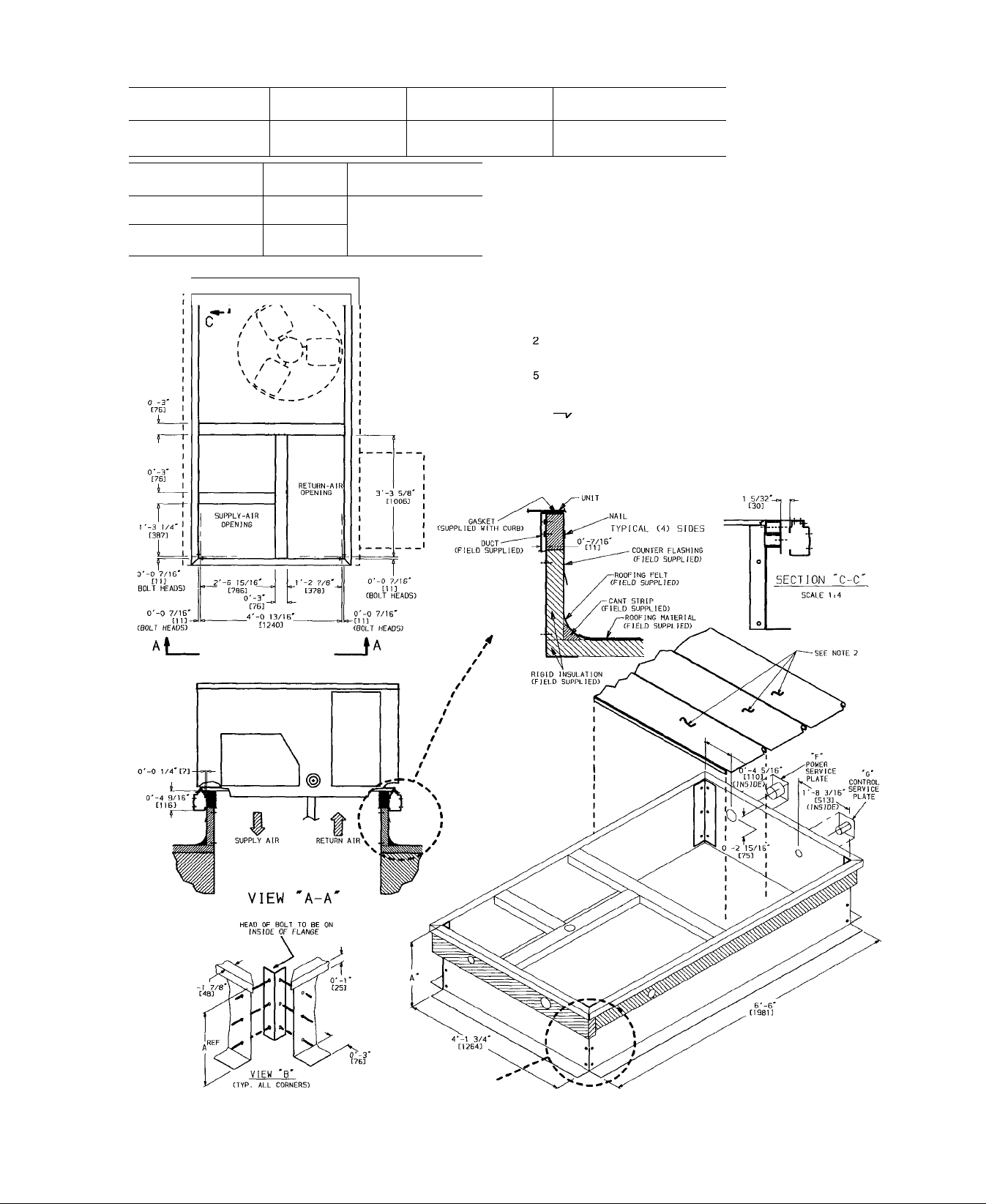

Step 3 — Install External Trap for Condensate

Drain — All units must have an external trap added. A

y4-in. NPT connection is located on the side of the unit.

Use a trap at least 4-in. deep, and protect against freeze-up.

See Fig. 4.

If drain line is run to a drain, pitch line away from unit at

one in. per 10 ft of run. Do not use a pipe size smaller than

the unit connection.

Step 4 — Rig and Place Unit — inspect unit for

transportation damage. File any claim with transportation

agency. Keep unit upright and do not drop. Spreader bars

Step 5 — Make Electrical Connections

A WARNING

Unit cabinet must have an uninterrupted, unbroken elec

trical ground to minimize the possibility of personal in

jury if an electrical fault should occur. This ground may

consist of electrical wire connected to unit ground lug

in control compartment, or conduit approved for elec

trical ground when installed in accordance with NEC

(National Electrical Code) ANSI (American National

Standards Institute) /NFPA (National Fire Protection As

sociation) 70-1987 and local electrical codes. Failure

to follow this warning could result in the installer be

ing liable for personal injury of others.

FIELD POWER SUPPLY - All units except 208/230-v

units are factory wired for the voltage shown on the name

plate. If the 208/230-v unit is to be connected to a 208-v

power supply, the transformer must be rewired by moving

the black wire from the 230-v red wire on the transformer

and connecting it to the 200-v blue wire from the trans

former. The end of the red wire then must be insulated.

Refer to unit label diagram for additional information.

Pigtails are provided for field wire connections. Use factory-

supplied splices or UL (Underwriters’ Laboratories) ap

proved copper/aluminum connector.

When installing units, provide a disconnect per NEC.

All field wiring must comply with NEC and local require

ments. In Canada, electrical connections must be in accor

dance with CSA (Canadian Standards Association) C22.1

Canadian Electrical Code Part One.

t

Page 3

UNIT SIZE

50LJ008, 009,

012 & 014

“F” POWER

1" [25] NPT or

2" [51] NPT

SERVICE PLATE SIZES

“G” CONTROL

%" [19] NPT

CONNECTOR PKG.

ACY.

50DJ901311

ROOF CURB

ACCESSORY

50DJ901371

50DJ901381

- - - -1- -

V----------------

“A” UNIT SIZE

1'-2"

[356]

2'-0"

50LJ008, 009,

012 & 014

[610]

NOTES:

1. Roof curb accessory is shipped unassembled.

Insulated panels.

3. Dimensions in [ ] are in millimeters.

4. Roof curb, galvanized steel.

Attach ductwork to curb (flanges of duct rest on curb ).

6. Service clearance 4 ft on each side.

7. Direction of airflow

SEE VIEW

Fig. 2 — Roof Curb

Page 4

MAXIMUM ALLOWABLE

DIFFERENCE (in.)

A-B B-C A-C

0.5 1 0 1 0

Fig. 3 — Unit Leveling Tolerance

NOTE: Trap should be deep enough to offset maximum unit static

difference. A 4-in trap is recommended.

Fig. 4 — External Trap Condensate Drain

NOTES-

1 Dimensions in ( ) are in miiiimeters

2. Hook rigging shackles through holes in base rail, as shown in

detail “A” Holes in base rails are centered around the unit cen

ter of gravity. Use wooden top skid when rigging to prevent rig

ging straps from damaging unit

3. Unit weights do not include economizer. See Table 1 for econ

omizer weights.

A CAUTION

All panels must be in place when rigging

Fig. 5 — Rigging Details

MAX

UNIT

50LJ008 755

50LJ009 760 345 77.42

50LJ012

50LJ014

WEIGHT

lb

915

930

in.

kg

342 77 42

415 77.42

422

77.42

“A”

DIMENSIONS

mm

in. mm

1967

40 25

1967

40 25 1022 41.31

1967

40.25 1022 49.31

1967

40 25

“B” “C”

in. mm

1022 41.31 1050

1022 49.31

1050

1253

1253

t

Page 5

Table 1 — Physical Data

BASE UNIT 50LJ

NOMINAL CAPACITY (tons)

OPERATING WEIGHT (lb)

Unit 755

With Economizer 799

Roof Curb 143

COMPRESSOR

Quantity 2

Oil (oz) (each compressor) 55

REFRIGERANT TYPE

Operating Charge (Ib-oz)

Circuit 1 7- 0 7-0 9-7

Circuit 2 5-12

CONDENSER FAN Propeller

Qty...Diameter (in.) 1 ..26 1...26 1 . 26 1...26

Nominal Cfm

Motor Hp...Rpm % ..1100

CONDENSER COIL

Rows...Fins/in.

Total Face Area (sq ft)

Size (in.) 15 X 15

Type Drive

Nominal Cfm 3000

Maximum Continuous Bhp

Motor Frame 56

Fan Rpm Range 590-840

Motor Bearing Type

Maximum Fan Rpm

Motor Pulley Pitch Diameter A/B (in.)

Fan Pulley Pitch Diameter (in.)

Belt — Type...Length (in.) A...48

Pulley Center Line Distance (in.)

Speed Change per Full Turn of 50

Movable Pulley Flange (rpm)

Movable Pulley Maximum Full Turns 5

From Closed Position

Factory Setting — Full Turns Open 5

Factory Speed Setting (rpm) 590

Fan Shaft Diameter at Pulley (in.)

EVAPORATOR COIL

Rows...Fins/in. 3. 15

Total Face Area (sq ft)

OUTDOOR-AIR INLET SCREENS

Qty...Size (in.)

RETURN-AIR FILTERS

Qty...Slze (In.)

008

71/2

6500 6500 7000 7200

2.17

18.0

Enhanced Copper Tubes, Aluminum Lanced Fin

Belt Belt Belt

2.4

Ball

2100 2100 2100 2100

2.4/3 4

7.0

16.75-19.25

1

Enhanced Copper Tubes, Aluminum Double-Wavy Fin

80

4..16x20x2 I 4...16x20x2 | 4 20 x 20 x 2 4 20 X 20 X 2

009

8V2

760 915 930

804

143 143 143

Hermetic

2 2

55

R-22

6-2

%...1100

2. 17 I 2...17 I 2.. 17

20 5 25.0 25.0

15 X 15 15 X 15

3400 4000 5000

2.4

56

590-840 690-935 860-1080

Ball

2 4/3.4

70

A .48

16 75-19.25

50 50 44

5

5

590 690 860

1 1 1

3. .15 3 .15 4...15

80 100 11.1

Cleanable

1 20 X 25 X 1

1.. 16 X 25 X 1

Disposable

012 014

10

959

70

8-6

1100

2.4

56 56

Ball Ball

2.8/3.8 4.0/5 0

70 8.0

A...51

18.25-20 75 18.25-20 75

5 5

5 5

LEGEND

Bhp — Brake Horsepower

I2V2

974

2

70

8- 3

8-11

%...1100

15 X 15

Belt

42

A...57

Page 6

UNIT

50LJ008

50LJ009

50U012 915

50U014 930

755

760 345

STD. UNIT

WEIGHT

Lb

342

415

422

Kg

ECONOMIZER

WEIGHT

Lb

44

44

44

44

CORNER

WEIGHT (A)

Lb

Kg

164

20

165 75

20

199

20

202

20

CORNER

WEIGHT (B)

Lb

Kg

74

140

141 64

90 170

92 172 78

FILTER ACCESS PANEL

(DISPOSABLE FILTERS)

CORNER

WEIGHT (C)

Lb

208

209

252

256

Kg

94 243 110

94 245 111

114

116

Kg

64

77

NOTES:

1 Dimensions in [ ] are in millimeters

CORNER

WEIGHT (D)

Lb

Kg

294 134

300 136

“H” “J

Ft-ln.

mm Ft-ln.

2-0% 632

1-2%

378

1-2%

378

1-2% 378

mm

3-5¥i6

1050

3-5¥ie

1050

4-1 yi 6 1253

4-15/16

1253

Ft-in.

2-9"/ie

2-9”/i6

3-0%

3-0%

“K”

mm

856

856

924

924

Center of gravity

3 Direction of airflow

4 On vertical discharge units, ductwork to be attached to accessory roof curb

only For horizontal discharge units, field-supplied flanges should be aftached fo horizontal discharge openings and all ductwork should be at

tached to the flanges.

5 Minimum clearance (local codes or jurisdiction may prevail):

a Bottom to combustible surfaces (when not using curb) zero in on ver

tical discharge units, and one in on horizontal discharge units,

b. Condenser coil, for proper airflow, 36 in. one side, 12 in. the other The

side getting the greater clearance is optional

c Overhead, 60 in to assure proper condenser fan operation

d Horizontal supply and return end, zero inches,

e Between units, control box side, 42 in per NEC

f Between unit and ungrounded surfaces, control box side, 36 in. per NEC

g Between unit and block or concrete walls and other grounded surfaces,

control box side, 42 in per NEC

6 With the exception of the clearance for the condenser coil as stated in Notes

5b and c, a removable fence or barricade requires no clearance

7 Units may be installed on combustible floors made from wood or class A,

B, or C roof covering material.

RIGHT SIDE

CONNECTION SIZES

1%" dia [35] field power supply hole

A

2y2” dia [64] power supply knockout

B

1%" dia [44] charging-port hole

C

%" dia [22] field control wiring hole

D

%”-14 NPT condensate drain

E

2" dia [51] power supply knockout

F

ELECTRICAL

DISCONNECT LOCATION

LEFT SIDE

0'-7 3/8

■ [187]

- 0 -3 13/16'

FILTER/ECONOMIZER ACCESS PANEL

CONDENSER COIL

[97]

REAR

FRONT

0'-3 9/16'

C90J

,__, 0 -5 1/2

] i_ [140]

SUPPLY AIR

"L 0'-5 7/16'

\H38]

0'-3 1/8' ^CORNER 'C'

[79]

O'-O 3/8'

[10]

AIR

r

0'-2 9/16^

[65] TYP

LEFT SIDE

ÍB©©

0'-5 3/4'

[146]

Fig. 6 - Base Unit Dimensions

CONTROL BOX AND

COMPRESSOR ACCESS PANEL

EVAPORATOR-FAN MOTOR,

BLOWER AND ELECTRIC

HEAT ACCESS PANEL

FORK LIFT SLOTS

FRONT

©B

0'-2 1/4' [57]

(TYP 8 PLACES)

t

Page 7

Install conduit through side panel openings. Install con

duit between disconnect and control box. Install power lines

to terminal connections as shown in Fig. 7.

Voltage to compressor terminals during operation must

be within voltage range indicated on unit nameplate (see

Table 2). On 3-phase units, voltages between phases must

be balanced within 2% and the current within 10%. Use the

formula shown in Table 2, Note 2 to determine the % volt

age imbalance. Operation on improper line voltage or ex

cessive phase imbalance constitutes abuse and may cause

damage to electrical components. Such operation would in

validate any applicable Carrier warranty.

FIELD CONTROL WIRING — Install a Carrier-approved

accessory thermostat assembly according to installation in

structions included with the accessory. Locate thermostat

assembly on a solid wall in the conditioned space to sense

average temperature in accordance with thermostat instal

lation instructions.

Route thermostat cable or equivalent single leads of col

ored wire from subbase terminals to low-voltage connec

tions on unit (shown in Fig. 8) as described in Steps 1-4

below.

NOTE; For wire runs up to 50 ft, use no. 18 AWG (Amer

ican Wire Gage) insulated wire (35 C minimum). For 50 to

75 ft, use no. 16 AWG insulated wire (35 C minimum).

For over 75 ft, use no. 14 AWG insulated wire (35 C min

imum). All wire larger than no. 18 AWG cannot be directly

connected to the thermostat and will require a junction box

and splice at the thermostat.

1. If unit is mounted on roof curb and accessory thru-thecurb service plate connection is used, route wire through

connection plate.

2. Pass control wires through the hole provided on unit (see

connection D, Connection Sizes Table, Fig. 6).

3. Feed wire through the raceway built into the corner post

to the 24-v barrier located on the left side of the control

box. See Fig. 9. The raceway provides the UL-required

clearance between the high- and low-voltage wiring

4. Connect thermostat wires to screw terminals of lowvoltage connector.

HEAT ANTICIPATOR SETTINGS - Set heat anticipator

settings as shown in Table 3.

#

50LJ008-014. 575-3-60

LEGEND

C

COMP(S)

IFC

NEC

TB

Contactor

Compressor(s)

Indoor (Evaporator) Fan Contactor

National Electrical Code

Terminal Block

Terminal Block Connection

Splice Connection

Field Wiring

Factory Wiring

BLK

YEL I

<g>

^ <i>

DISCONNECT

PER NEC

I BLU

I 1

' !

' 1

' '

50LJ014, 208/230-3-60

TO COMPS

'v'

TB2 I

--

1

50LJ008-012, 208/230-3-60; 50LJ008-014.460-3-60

DISCONNECT

PER NEC

Fig. 7 — Power Wiring Connections

BLK

YEL I

<£>

<§)

FIELD POWER SUPPLY

! DÌSCONNÌCT I

I

___

ft

' ! 1

' '

' 1

1 1

___________

TO COMPS

BLU

<§>

I

Page 8

Table 2 — Electrical Data

UNIT

SOLJ

008

(7% Tons)

009

(81/2 Tons)

012

(10 Tons)

014

(121/2 Tons)

NOMINAL

VOLTAGE

(60 Hz)

208/230

(3-phase)

460

(3-phase)

575

(3-phase)

208/230

(3 phase)

460

(3-phase)

575

(3-phase)

208/230

(3-phase)

460

(3-phase)

575

(3-phase)

208/230

(3-phase)

460

(3-phase)

575

(3-phase)

VOLTAGE

RANGE

Max

Min

187

414 508

518 632 49

187 254 162

414

518 632 61

187 254

414 508

518

187 254

414

518 632

COMPR

(each)

RLA

254

13.7 82 3.0 5 8

6.9 41

OFM IFM

LRA FLA FLA

1 5 26

30 1 5 2.6

84 30 5.8

508 8.0 42 1 5 26

33 1 5

26

192 105 30 58

55 1 5 26

96

632

22 3

508

45

83

137

1.5 26

30 120

104 69 1 5 54

96 55 1 5

54

ELECTRIC HEAT*

Nominal

kW**

7.8/10 4

12 0/16 0

18 6/24 8

24.0/32 0

31.8/42 2

13.9

165

27 8

33 0

41.7

180

36 0

7 8/10 4

12 0/16 0

18 6/24 8

24 0/32 0

31 8/42.4

139

16.5

27.8

33.0

41.7

180

36 0

7 8/10 4

12.0/16 0

24 0/32.0

31 8/42 4

37.5/50 0

165

27 8

33 0

41 7

50.0

18.0

36.0

54 0

7 8/10.4

12.0/16.0

24 0/32.0

31 8/42 4

37 5/50 0

165

27 8

33 0

41 7

50 0

180

36 0

54 0

LEGEND

FLA

HACR

IFM

LRA

MCA

MOCP

OFM

RLA

‘Heaters are field installed only.

fUsed to determine minimum disconnect size per NEC

“Heater capacity (kW) Is based on heater voltage of 240 v, 480 v or 575 v If power

distribution voltage to unit varies from rated heater voltage, heater kW will vary

accordingly

ttFuse or HACR circuit breaker

([Fusing in single point box provides the required branch circuit protection

NOTES;

1 In compliance with NEC requirements for multimotor and combination load equip

2 Unbalanced 3-Phase Supply Voltage

Full Load Amphull Load Allies

Heating, Air Conditioning and Refrigeration

Indoor (Evaporator) Fan Motor

Locked Rotor Amps

Minimum Circuit Amps

Maximum Overcurrent Protection

Outdoor (Condenser) Fan Motor

Rated Load Amps

ment (refer to NEC Articles 430 and 440), the overcurrent protective device for

the unit shall be fuse or HACR breaker The CSA units may be fuse or circuit

breaker

N e v e r o p e r a t e a m ot o r w h e r e a p h a s e im b a lan ce in sup p ly volt a g e is g rea ter

than 2% Use the following formula to determine the % voltage imbalance

% Voltage imbalance

= 100 x

max voltage deviation from average voltage

average voltage

POWER SUPPLY DISCONNECT SIZEt

= 457

42/ 42

42/ 42

45/ 50

66/ 75

83/ 92

108/124

47/ 47

47/ 47

47/ 50

66/ 75

83/ 92

108/124

108/124

127/145

115/131

134/152

3

FLA

21

22

26

38

46

58

16

23

42

23

23

26

38

46

58

19

23

42

54/ 54

54/ 54

54/ 54

83/ 92

27

27

41

46

58

69

24

24

42

59

69/ 69

69/ 69

69/ 69

91/102

32

32

45

52

64

75

30

30

45

65

LRA

223/223

112

90

227/227

114

96

269/269

140

120

376/376

189

161

FLA MCA

21 7/ 25 0

33 4/ 38 1

51 7/ 59 7

66 7/ 74 2

88 4/102.0

167

19.8

33 4

39 7

50 2

170

34.0

21.7/ 25 0

33 4/ 38 1

51 7/ 59 7

66 7/ 74.2

88 4/102.0

16.7

19.8

33 4

39 7

50 2

170

34.0

21 7/ 25 0

33 4/ 38 1

66 7/ 74 2

88 4/102 0

104 1/120 2

198

33 4

39 7

50.2

60 1

170

34 0

51 0

21 7/ 25 0

33 4/ 38 5

66 7/ 77 0

88 4/102 0

104 2/120 3

198

33 4

39 7

50 2

60 1

170

34 0

51 0

Example: Supply voltage is 460-3-60

Determine maximum deviation from average voltage

(AB) 457 - 452 = 5 V

(BC) 464 - 457 = 7 V

(AC) 457 - 455 = 2 V

Maximum deviation is 7 v

Determine % voltage imbalance

% Voltage imbalance = 100 x — = 1 53%

^ 457

This amount of phase Imbalance is satisfactory as it Is below the maximum al

lowable 2%

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact

your local electric utility company immediately

39 7/ 39 7

39 7/ 39 7

48 9/ 54 9

71 9/ 81 8

90 6/100 0

117 7/134 8

196

24 1

28 1

45 0

52 9

65 9

15 1

24 5

45 7

45 4/ 45.4

45 4/ 45.4

48 9/ 54 9

71 9/ 81 8

90.6/100 0

117.7/134 8

22 1

24 1

28 1

45 0

52 9

65 9

178

24 5

45 7

52 1/ 52 1

52.1/ 52 1

52.1/ 54 9

90.6/100 0

117 7/134 8

137.4/127 4

25.7

28.1

45 0

52 9

65 9

63 4

22 8

24 5

45 7

67 0

65 3/ 65 3

65 3/ 65 3

65 3/ 65 3

98 4/111 2

125 5/142 5

145 3/135 3

30 3

31 6

48 5

56 4

69 4

66 9

28 5

28 5

49 2

70 5

AB = 452 V

BC = 464 V

AC = 455 V

Average Voltage = •

MOCPtt

45/ 45

45/ 45

50/ 60

80/ 90||

100/10011

125/15011

50/ 50

50/ 50

50/ 60

80/ 9011

100/10011

125/15011

60/ 60

60/ 60

60/ 60

100/100

125/150

150/150

80/ soil

80/ 8011

80/ 8011

100/12511

150/15011

150/15011

7

7011

7011

7011

7011

7011

25

25

30

50

60

20

25

50

25

25

30

50

60

20

25

50

30

30

50

60

30

30

50

35

35

50

60

70«

80«

35

35

50

80«

452 + 464 455

1371

3

i

Page 9

Table 3 — Heat Anticipator Settings

208/230 460

UNIT

Heater kW 1 Stage 2 Stage Heater kW 1 Stage

104, 160 03

32 0, 24 8 06 0.3 03

50LJ

42 4, 50 0 0 9 06

Configuration

Stage 1 Stage 1

NA NA

Stage 2 Stage 1

139, 165

27 8, 33 0

03

41 7, 50 0 06 03 03

UNIT VOLTAGE

Configuration

Stage 1

03

NA NA

2 Stage

Stage 2

575

Configuration

Heater kW 1 Stage 2 Stage

Stage 1 Stage 1 Stage 2

18 0, 36 0 0.3 NA NA

54.0 0.6 03 03

THERMOSTAT CONNECTIONS

BAT - Battery

C — Contactor

DAT — Discharge-Air Thermistor

EWIC/EMFC — Energy Management Closed

EMO/EMFO — Energy Management Open

EQUIP — Equipment

GND — Ground

IFC — Indoor-Fan Contactor

THERMOSTAT

THREE-PHASE

POWER SUPPLY

LEGEND

IFR — Indoor-Fan Relay

OFC — Outdoor (Condenser) Fan Contactor

P — Plug

TB — Terminal Block

TRAN — Transformer

----------

Field Wiring

Factory Wiring

Fig. 8 — Control Wiring Connections

RACEWAY-

HOLE IN

END PANE!

(HIDDEN)

Fig. 9 — Field Control Wiring Raceway

Step 6 — Adjust Evaporator-Fan Speed — Adjust

evaporator-fan speed to meet jobsite conditions.

For units with electric heating, required minimum cfm is

2250 for 50LJ008; 2550 for 50LJ009; and 3000 for 50LJ012

and 014 with the following exceptions.

UNIT

50LJ012

and 014

50LJ008-

014

UNIT

VOLTAGE

208/230

208/230 50.0 Horizontal 3200

460

575

HEATER

kW

42 4

50.0

180

36 0

UNIT

CONFIG-

ATION

Horizontal 3200

Horizontal

or

Vertical

Horizontal

or

Vertical

REQUIRED

MINIMUM

CFM

3200

2800

2350

Table 4 shows fan rpm motor pulley settings, Table 5

shows motor efficiencies and Table 6 gives accessory static

pressure drops. Refer to Tables 7-12 to determine fan speed

settings. Fan motor pulleys are factory set for speed shown

in Table 1.

Page 10

008,

009

012 935

014

1080 1060 1035 1015 990 970 950 930 905

Table 4 — Fan Rpm at Motor Pulley Settings

MOTOR PULLEY TURNS OPEN

0 V2 1 IV2 2 2V2 3 3V2 4 4V2 5

840 815 790

910 890 865

765 740 715 690 665

840 815 790 765

640

740

615 590

715

885 860

Table 5 — Evaporator-Fan Motor Efficiency

MOTOR

50LJ008-012 83

50LJ014

NOTE: Convert bhp to ’

„ 746 X Bhp

Watts =-^——^77T^-----

Motor Efficiency

EFFICIENCY (%)

85

690

f

Table 6 — Accessory Static Pressure Drop (in. wg) 50LJ008-014

COMPONENT

1 Heater Module 020 030 .050 .065 .080 .100 120 140

2 Heater Modules .030 .050

Economizer

2200 2500

.020 .020 030 040 .050 060 .070 .080

3000 3500

070 .090

CFM

4000

4500 5000

.120 140

.160

5500 6000

190

.155

210

090

I

10

Page 11

Table 7 — Fan Performance, 50LJ008,009 — Vertical Discharge Units

LEGEND

— Brake Horsepower

Bhp

NOTES:

1. Boldface indicates field-supplied drive required

2 indicates field-suppiied motor and drive required.

3 Maximum usabie bhp is 2.4. Extensive motor and electrical test

ing on the Weathermaker® I units ensures that the full horse

power range of the motor can be utilized with confidence Using

Table 8 — Fan Performance, 50LJ012 - Vertical Discharge Units

IRFLOW

(Cfm)

3000

3100

3200

3300

3400

3500 596

3600 609

3700

3800

3900

4000

4100

4200

4300

4400 715

4500 729 1.83

4600 742 1.94

4700

4800

4900 783

5000

0.2

Rpm Bhp

532

544

557

570

583

622 1.09 686

635

649

662

675 1.42

689 1.52

702 1.61 759 1.88

756 2 06 810

770 2 18

mm

0.64 605 0.81 670

0.70 616 0.86 680

0.75 628

0.81 639 0.99 700 1 18

0.88

0.94 663 1.14 721

1.01

1.16 698 1 39

1.25 710 1 48

1.33 722

1 72

2.31 mm

0.4

Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm

0.93

1.06

651

0.6

0.97

1.03

690 1 10 746 1.28 796

711

1 25 767 1 44 815 1 61

1.33

674 1.22 732 1 42 787 1.61 836

1.30 744

1.57

1.67

734

746 1 77

1 50

755

1.59 808 1.80

767

1.68 818 1 90

778 1 78 829 2.01 878

790

1.89

1 99 851

801

813 2 11

772

1.99 825 2.22

785 2 10

797 2.22

837

mm

2.35

ms

2.34

mm

iiaas:

mm

LEGEND

Bhp — Brake Horsepower

NOTES:

1 Boldface indicates field-supplied drive required

2. indicates field-supplied motor and drive required

3. Maximum usable bhp is 2.4. Extensive motor and electrical test

ing on the Weathermaker I units ensures that the full horsepower

EXTERNAL STATIC PRESSURE (in. wg)

0.8

725 1.12 778 1 28

735 1 20

757

1.36 805

711 1.52 826

797

1.70

839 2.12

2 23

862 2.34

mM

S8& 029

89© a.72:

ms

SM

your fan motors up to the horsepower ratings shown will not re

sult in nuisance tripping or premature motor failure. Unit warranty

wiil not be affected

Use of field-supplied motor may affect wire sizing Contact your

Carrier representative to verify

Values include losses for filters, unit casing and wet coils.

Motor drive range is 590 to 840 rpm. All other rpms require a

field-supplied drive

1.2

Bhp

825

1.43

835 1 52

787

1.0

1.36

1.44 844 1 61

1.52 854

1.71

1.80

1.70

863

1.79

871 1 88

880 1 98

847 1 91 890 2.09

857 2.01 901 2 20

867 2.11

912 2.32

2 22

888 2.33

mm

■Z.SS:1

90©

0S®|3

2.7?,

STSSl.

S40

iysei

as'i

— —

~

-

range of the motor can be utilized with confidence. Using your

fan motors up to the horsepower ratings shown will not result in

nuisance tripping or premature motor failure Unit warranty will

not be affected.

Use of field-supplied motor may affect wire sizing. Contact your

Carrier representative to verify.

Values include losses for filters, unit casing and wet coils

Motor drive range is 690 to 935 rpm. All other rpms require a

field-supplied drive.

1012J 2.36

—

11

Page 12

Table 9 — Fan Performance, 50LJ014 — Vertical Discharge Units

AIRFLOW

(Cfm)

3700

3800 668

3900 683

4000

4100

4200 726

4300 741

4400

4500

4600

4700

4800

4900 829

5000

5100

5200

5300 888

5400

5500

5600

5700

5800

5900

6000

6100

6200 .4^eз

6300

Rpm

654 1.12

697

711

755

770 1.89

784 2.00

799 2.13

814 2.25 863

843

858

873

903 3.13 949

918

933

948

963

978 4.00

■m&i

iGáaí f4m

0.2

Bhp

1.20

1.28

1.37

1.46

1.56

1.66 794 1.91

1.77 808 2.03

0.4

Rpm Bhp Rpm Bhp Rpm ^Bhp Rpm

714

1.31 767 1.50 815

727

1.40

741

1.49 793

754

1.59 806

767

1.69

780

1.80

821 2.15

835 2.27

849 2.40

2 53 910

877 2.67 923 2.92 967

2.39

2.52 892 2.81

2.67 906 2 95 950

2.82

920

3.10

2 97 934 3 26

3 43 991 3 75

3.30 963 3.59

3 47 978

3.65 992

3.83 1006

3 77

3.95

4.14

43ÍJ

AS«!

V&7S-'

1830

ÍÍ«S

Am"

«m i-ñ7

0.6

780 1.60 827

1.70 839 1.88 884 2 05

1.80

1.90

819

832 2.01 877

845 2.12

858

2.24

871 2.37

884

2 49 928

897

2.63

2.77 954 3.02

937

3.08

3 24

963

3.40

977

3.57

1004

3.92

4.11

1018

‘ms'

4,SSi

4.88 ;s>£S3.

554’

EXTERNAL STATIC PRESSURE (in. wg)

0.8 1.0

851

864

889

902 2.48

915 2.61 955

941 2.88 981 3.11

980 3 32

993

1006 3.65

1019 3.82

1032 4 00

1045 4.18

W

iiiSSi

LEGEND

Bhp

NOTES:

1

Brake Horsepower

Boldface indicates field-supplied drive required

indicates field-supplied motor and drive required.

Maximum usable bhp is 4.2. Extensive motor and electrical test

ing on the Weathermaker® I units ensures that the full horse

power range of the motor can be utilized with confidence Using

Bhp Rpm

1.67 861 1 85

1.77

1.99

2.10

2 22

^35 931

1.95 916 2 18

873

2.16 938 2 38

895

907 2.28

2 41

919

2.54 971 2 72 1011

2 68

943

2 82

2.75

3.17

2.96

968

3.27 1030 3 48

993

1006 3.43

3 60

1019

3.48 1032 3.76

3 93 1081 4.19

1045

4.11

1058

mmi

IS

42»

tm mm

1.2

Bhp Rpm Bhp Rpm

906

2.08

927

2.28

949 2 49

960 2.60

983 2.86

995

3 01

1006

3 17

1018 3.32

1.4 1.6 1.8

Bhp Rpm

2.27 991 2.47 1030 2 65

950

959 2.38

969

979

989

1000

1022 3.10

1001 2 58 1040 2.78

2,50 1010

2.70 1049 2 91

2 62 1020 2.83

2.74

2.86

2 97

2.96

1029

3 10

1039

1049 3.23

3 37 1097

1059

1033 3.23 1070 3 51

1044 3.37

1056

3 52

3.64 1117

1081

1092 3.78

Bhp

1059 3.04

1068

3 18 1105

1077

3 31 1114

1087

3.46

3.61

1107

3.76

3.92

1127 4.07

2.0

Rpm

1064

1075

1085

1095

1124

1133

1143

1152

¥«SS3i

1067 3.69 1103 3.93

3.87 1114

4 00 mm

pM

1079

4.05

T4m

ptm

BM

■i&m

1043 3.65

1055 3.82 1091

1068

Wm

IS

— —

_

your fan motors up to the horsepower ratings shown will not re

sult in nuisance tripping or premature motor failure. Unit warranty

will not be affected.

Use of field-supplied motor may affect wire sizing. Contact your

Carrier representative to verify

Values include losses for filters, unit casing and wet coils

Motor drive range is 860 to 1080 rpm All other rpms require a

— — ~ — — — — —

—

—

—

— —

WM-

PÜPS

mm.

—

—

—

4.09

ÉM

— — — — —

— — — —

—

wM

mm

PM

Wi

mm

— — — —

—

MM

— —

w;

ÍÍÍ2S7::

mM

field-supplied drive

Bhp

2 82

2,96

3.11

3.25

3.39

3.54

3.69

3.84

4.00

4.17

_

_

#

12

Page 13

Table 10 — Fan Performance, 50LJ008,009 — Horizontal Discharge Units

AIRFLOW

(Cfm)

2200 459 0.42

2250

2300

2400

2500

2550 501

2600

2700

2800 533

2900

3000 559

3100

3200 585

3300 598

3400 610

3500 623 1 17

3600 636 1 25

3700

3750

3800

3900

4000

4100

4200

4250

4300

— Brake Horsepower

Bhp

Boldface indicates fieid-suppiied drive required.

Maximum usable bhp is 2.4. Extensive motor and eiectrical test

ing on the Weathermaker I units ensures that the fuil horse

power range of the motor can be utilized with confidence. Using

0.2

Rpm Bhp Rpm

465 0.43

471 0.45 559 0.66

482 0.50 569

494

Ò.54 581 0.76

0.57 587 0.79 659

507 0.59

520

0.65

0.71 615 0.95 683 1.20 747 1.49 802 1 75

0.77 626 1.02 693 1 27 756

546

0.83

572 0.90 648 1 17 715 1 43

0.96 660 1.24

1.03 671 1.32 739

1.10 682

649 1 33

655 1 37

661 1 41 733 1 82

674 1.49 746 1 93

1.57

687

1 66 772 2 17

699

1.75

712

1.80 792

719

1.85

725

LEGEND

indicates field-supplied motor and drive required.

0.4

Bhp Rpm

549 0.62 625 0 83 691

554 0.64 630 0 86 695

0.71 645 0 95

592

0.82 663 1.08 727

604

0.89

637

1.09

1.41

694

1.50

707

1 60

720 1.71 783

727

1 77

759 2 05

2.30

785

2.37

0.6 0.8 1.0

Bhp Rpm Bhp Rpm Bhp

635 0 89

654

1 01

1.05 722

1 14 737

672

704 1 35 765

727 1.52 785 1 83 841 2.15 ¥^35

1.62 795 1 91 851 2.26 S83

750 1.72 806

761 1.82

772

1.93

2.03 840

789

2.09

795

2.15

806

2.26

817

2.38

»46 2,’?1

,Z77SOS

asa

EXTERNAL STATIC PRESSURE (in. wg)

699

708 1 18 768 1.44

717 1.25 776 1.51

775

817 211

828 2.23

862

865

S&7 347 #;39';

soa a.16

1.2

Rpm Bhp Rpm

1 58 842

1 06 753 1.31

757 1.34 810

1.09

1.12

760 1.37

780 1 55

1.29

1.32 784 1.58 839

793 1.66 646 1.95

1.40

1.57

813 1.84

1.66

823 1.94

1.74 832 2.05 882 2.33

2 01

860 2.36 ma

2.35

: iS96i;iiaSiSi,

■3S6i|aSSl

805

1 62 850 1.91 873

1 65 859

816

824 1 72 872 2.01 909

832

1 79

836 1 83

1 87 891

855 2.04

863 2.13

872 2.22

iS^

ima

;SÉS7;

Mm

iSiSSfi

—

— — — — — — — — —

— 1 —

— —

S.i?

- 1 -

—

your fan motors up to the horsepower ratings shown will not re

sult in nuisance tripping or premature motor failure. Unit warranty

will not be affected.

Use of field-supplied motor may affect wire sizing Contact your

Carrier representative to verify.

Values include losses for filters, unit casing and wet coils

Motor drive range is 590 to 840 rpm All other rpms require a

field-supplied drive.

1.4 1.6 1.8

Bhp Rpm Bhp Rpm

1.87 857

1.94

882 2.09

887

2.13

2.17

898 2.26

2.35

906

ma

ma

ssgii

ami

mm

im

— — — — — — — —

— —

2.16 f:¥;ggli msi mesa

2.20 iiS^i

888 2.24 iiiààéfe

2.32 ami

2.40

925

iSiSSSi

iiisss;. iMS:

2SB SSr

S67 SS7 pm

ama

0m

rniinmi

ama

asm -

mi. -

' —

—

_

_ _

_ —

— — — — —

Bhp Rpm Bhp

MM

ami.

Wà MM

■2M-iàm

mè

— — —

— —

~ — —

— — —

— — —

2.0

ììskì?;

am:

572

mp

am

mm.

— —

— —

— —

— — ~ — — — — —

— — — — — — — —

— —

_ _

—

—

am-

ass

_

—

13

Page 14

Table n — Fan Performance, 50LJ012 — Horizontal Discharge Units

AIRFLOW

(Cfm)

3000

3100

3200

3300

3400

3500

3600

3700

3800

3900 582

4000 593

4100 605

4200 616

4300 628

4400 639

4500

4600 662 1.91

4700 674

4800 686

4900

5000

Rpm Bhp

484

495 0.61

505 0.66

516 0.72 589

527 0.78 599 0.93 664

537

548 0.92

560 1.00 629

571 1.08 639

651

698

mM

0.2

0.55

0.85

1.16 649

1.25 659

1.35 670

1.45 680

1.56

1.67 701 1.73 757 1.92

1.78

2.03 733

2.17

0.4 0.6 0.8 1.0 1.2

Rpm Bhp Rpm Bhp Rpm

560 0.70 631

570 0.76 638

579

0.81

0.87

609 0.99 672 1.18 731

619 1.05 680

1.12 688 1.31 747 1 51 802

1.19

1.27

1.35 717 1.56 773 1.78 823 1 98

1.44 727 1,65 781 1 86 832

1.53 737

1.63 747

690

1 84 767 2.02 817

712

1.95 777

722

0.87 690 1 03

0.92

646 0.98 708 1.16

1.05

655

1.11 724 1.30 775 1.48 827

1.24

1 39 756 1 60 810 1.81

698

1 47 764 1 69 816 1.89 865

708

1.74

1.83

2 13

2 07 787 2 24

744 2 20

797

2.36 S!®

2 31 755 2.33 80S ■.SS6 '

iW

SIS : 868 O&f. Z3&

EXTERNAL STATIC PRESSURE (in. wg)

Bhp Rpm Bhp Rpm Bhp

1,10

699

717

1.23

1,36 784

738 1.43

789 1 95 841

798 2 05

807

2.16

2.27

827

2.38

"^836

LEGEND

Bhp — Brake Horsepower

NOTES:

1. Boldface indicates field-supplied drive required

2 indicates field-supplied motor and drive required

3 Maximum usable bhp is 2 4 Extensive motor and electrical test

ing on the Weathermaker® I units ensure that the full horse

power range of the motor can be utilized with confidence. Using

747

755

1 20 800

1.27

805

1 38

1.44

761 1 34 812 1 51

767 1.40

819

1.59

1.67

794

1,56

1.64

1,75 880

833

840 1,83

1 73 847 1 92

856 2.02

2 12 908 2.32

875 2 22

883 2.32

2 08

2 18

849

88#

2.30 SQ& I

S83

Ì2.4Ì

2;02.

888 Z74

374 S34

2L7Sj

m

m

ZBT

33S zmi

003

your fan motors up to the horsepower ratings shown will not re

sult in nuisance tripping or premature motor failure Unit warranty

will not be affected

4. Use of field-supplied motor may affect wire sizing. Contact your

Carrier representative to verify.

5. Values include losses for filters, unit casing and wet coils,

6. Motor drive range is 690 to 935 rpm. All other rpms require a

field-supplied drive.

1.4

Rpm

Bhp

850

1.52

857

1 63

862

1.71

867

1 78

873

1 85

1,94 926

888

2.04

895

2.13 938

901

2.23

mM

SSi 2^

■96S- 3.11

:

3,23

[333L

m

—

1.6

Rpm

Bhp

879

1.38

896

1.66

908

1 85

915

1 98

920

2 07

2 15

931

2.23

2.33

I'M

Mm

— — — —

—

— —

Rpm

s-sssiS

—

1.8 2.0

Bhp Rpm Bhp

925

1.81 964 1.92

935

1.93 975 1.98

944

2.01

952

2.11

963

2.21

970

2.36

SitiSSSS

_

_

—

—

—

—

—

—

984

993

,1001

—

__

__

_ —

—

—

2.09

2.22

2.31

iyvsyxy

_

__

—

-

Table 12 — Fan Performance, 50LJ014 - Horizontal Discharge Units

AIRFLOW

(Cfm)

3700

3800

3900 636

4000 650

4100 665

4200 680

4300

4400 711

4500

4600

4700

4800

4900

5000

5100

5200

5300

5400 869

5500 885

5600

5700

5800

5900

6000

6100

6200

6300

0.2

Rpm Bhp Rpm

607 0.97 670 1.18

621 1.05

1.13 693

1.21 705

1.30 717 1.48 772

1.39 728

1.49 739 1.66

696

1.60 750 1.75 805

1.70 762 1.85 817

727

1.82

742

1.94 786

758

2.06 799 2.18

773

2.19 812 2.30 863

789

2.32

805

2.47 840

821

837 2.61

853 2.76 868

2 92

3 09

901 3 26

917 3 44 926 3.50

933 3.62

949 3 81

4.01 972

965

4.21’

99-7

i4AZ

1014 4,S4 Ida 4.68

0.4 0.6

Bhp Rpm Bhp Rpm Bhp Rpm Bhp

681 1.25 742 1.45 795 1.66 842

774

732 1.37

1.32 751 1.53 808 1.76 851

1.40 761

1.57

1.96 828

2.07

1.61 819

1.71 830 1.96

783 1.81 839

794

1.91 848

2.02 857

2.12 867 2.35

2.23 877 2,46 929 2 75

2.34 888 2 59 938

840

852 2.46

2.57

2.43 875 2.70 921 2 99 966 3.24

826

2.57

854 2.71 898 2 96 943 3 28

882

897 3 17 932

911 3 33

887 2 83 932

2 85 909

3 01

3 09

920 3 24 967 3.57 1009 3.86 1051

3.38

943 3.54 990 3.87

956

3.70

941 3,68 968 3 87 1013

956 3.87

4 05 4.?4-

981

4.06 995 • 4J83

’9S7

•L26 t1<308 4A2

■toos 4.46 it022

: leaa

:4.62 10S8

4.83

LEGEND

Bhp — Brake Horsepower

NOTES:

1, Boldface indicates field-supplied drive required.

2 indicates field-supplied motor and drive required.

3. Maximum usable bhp is 4 2, Extensive motor and electrical test

ing on the Weathermaker I units ensures that the full horse

EXTERNAL STATIC PRESSURE (in. wg)

0.8 1.0

782 1.56 833

1.86

2.05 883 2.25

2.14 896 2 38

2.24

899 2.72

910 2 86

3 13

955 3.42 998

978 3 72 1020

1002

4 03

4.20 Mm

ÌBS7

■4.SS

i04T

4;73- iosa 5,16

4,91 1160

TOTC

5.1-f 1112

1.2

Rpm Bhp Rpm

1.73 879

1.82 889 2.03

1.92

1.95 927 2 17 973 2.38 1013

2.12

898

861 2 02 908 2 21 950

871

917 2 32 960 2.55 1001

2.13

925 2 44 969 2 65 1009

935 2.56 979

908 2.51 945 2.68

2.63 955 2.82

919

947

957 3.11 1003

976 3 38

987

2.87

2.98

3,53

3.69

967

980

992 3 26

1005 3.16

2.96

3.11 1015

1025 3 45

3.41 1036 3.61 1073

1014

1024

1033

1042

3.56

3 71

3.84

3 98

1049

1061 3 96

1073

4.14

4 03 liSgifS-

1031 4.20

:464

iiésì?

MSSi lisa

iO/6

Mm

Mm-

4.S2

hii4 ;S,254 t-tsa:.

T125'

SiS

.iim i.5.©§

&4S

power range of the motor can be utilized with confidence. Using

your fan motors up to the horsepower ratings shown will not re

sult in nuisance tripping or premature motor failure. Unit warranty

will not be affected

Use of field-supplied motor may affect wire sizing Contact your

Carrier representative te verify.

Values include losses fer filters, unit casing and wet coils

Motor drive range is 860 to 1080 rpm All other rpms require a

.-ft 42-

-

field-supplied drive

1.4 1.6 1.8

Bhp Rpm Bhp Rpm Bhp Rpm Bhp

2.57 1046

934 2.26 980 2.48 1022 2 69

2 36 987 2.59 1030 2 81 1068 3.01

942

2.46 994

2.70

1037

2.92

2 81 1045 3.04 1085 3.27

2 92 1051 3 17 1092 3.40

2.77

988

2 89

996 3 02

3 30

3 79

4.14

1018 3.03

1028 3.14

1037

1046

1056 3 52

1064

1083 4.00

1093

Mm.

1058 3.29 1100 3.53

1066 3 41 1106 3.67

1074

3,25

3.38

3.54 1113 3.81

1084

3.66

1093 3.79 1129 4.09

3.67 1103 3.92

4.07

1112

3.83

iSMi;

MMi

MZ.

Mm MM

psaSi iiiiSSS

MM;\

MM:

534

mm

514

Mm

MM.

Mm

— ~ — — — —

— ~ — ~ — —

MM

— — —

— —

—

-

-

2.0

1058 2.87

1077

1121 3.95

SiSSE;

IW?

nS7

mm

Mèi-

Mm

Mm

Mm.

MM

— —

2 73

3.14

—

14

Page 15

#

To change fan speed;

1. Shut off unit power supply.

2. Loosen belt by loosening fan motor mounting plate nuts

(see Fig. 10).

3. Loosen movable pulley flange setscrew (see Fig 11)

4. Screw movable flange toward fixed flange to increase

speed and away from fixed flange to decrease speed. In

creasing fan speed increases load on motor. Do not ex

ceed maximum speed specified in Table 1.

5. Set movable flange at nearest key way of pulley hub and

tighten setscrew (see Table 1 for speed change for each

full turn of pulley flange).

To align fan and motor pulleys;

1. Loosen fan pulley setscrews.

2. Slide fan pulley along fan shaft

3 Make angular alignment by loosening motor from mount

ing plate.

To adjust belt tension (see Fig. 10);

1, Loosen fan motor mounting nuts.

2. Slide motor mounting plate away from fan scroll for proper

belt tension (Vi-in. deflection with one finger) and tighten

mounting nuts. Tension can be applied using ‘/2-in. drive

ratchet engaged into ‘/2-in. square hole on motor mount

ing plate.

3. Adjust bolt and nut on mounting plate to secure motor

in fixed position.

START-UP

IMPORTANT; Energize crankcase heaters 24 hours

prior to base unit start-up to remove entrapped refrig

erant from oil. Heaters are energized as long as there

is power to unit.

Unit Preparation — Make sure that unit has been in

stalled in accordance with these installation instructions and

applicable codes.

Return-Air Filters — Make sure correct filters are in

stalled in unit (see Table 1). Do not operate unit without

return-air filters.

Compressor Mounting — Compressors are inter

nally spring mounted. Do not loosen or remove compressor

holddown bolts.

Internal Wiring — Check all electrical connections in

unit control boxes; tighten as required

Refrigerant Service Ports — Each refrigerant sys

tem has 3 Schrader-type service gage ports; one on the suc

tion line, one on the liquid line and one on the compressor

discharge line. Be sure that caps on the ports are tight.

—

..........

11—r r ?_i: f.i "

MOTOR

Fig. 10 — Belt-Drive Motor Mounting

.™Jli

Cooling — To start unit, turn on main power supply.

Set system selector switch at COOL position and fan switch

at AUTO, position. Adjust thermostat to a setting below

room temperature. Compressor starts on closure of

contactor.

Check unit charge. Refer to Refrigerant Charge section

on page 17.

Reset thermostat at a position above room temperature.

Compressor will shut off.

TO SHUT OFF UNIT — Set system selector switch at OFF

position Resetting thermostat at a position above room tem

perature shuts unit off temporarily until space temperature

exceeds thermostat setting.

Heating (If Accessory Heater is Installed) — To

start unit, turn on main power supply.

Set thermostat at HEAT position and a setting above room

temperature, and set fan at AUTO, position.

First stage of thermostat energizes the first-stage electric

heater; second stage energizes second-stage electric heater

elements if installed. Check heating effects at air supply

grille(s)

If unit does not energize, reset limit switch (located on

evaporator-fan scroll) by pressing button located between

terminals on the switch.

TO SHUT OFF UNIT — Set system selector switch at OFF

position. Resetting heating selector lever below room tem

perature will shut unit off temporarily until space tempera

ture falls below thermostat setting

Safety Relief — A soft solder joint in the suction line

at the low-pressure service port provides pressure relief un

t

Fig. 11 — Evaporator-Fan Pulley Adjustment

der abnormal temperature and pressure conditions.

Ventilation (Continuous Fan) — Set fan and sys

tem selector switches at ON and OFF positions, respec

tively. Evaporator fan operates continuously to provide air

circulation.

15

Page 16

Operating Sequence

SERVICE

COOLING, UNITS WITHOUT ECONOMIZER - When

thermostat calls for cooling, terminals G and Y1 are ener

gized. The indoor (evaporator) fan contactor (IFC), and com

pressor contactor no. 1 (Cl) are energized and evaporatorfan motor, compressor no. 1 and condenser fan start. The

condenser-fan motor runs continuously while unit is cool

ing. If the thermostat calls for a second stage of cooling by

energizing Y2, compressor contactor no. 2 (C2) is ener

gized and compressor no. 2 starts.

HEATING, UNITS WITHOUT ECONOMIZER (If Acces

sory Heater is Installed) — Upon a call for heating through

terminal Wl, IFC and heater contactor no. 1 (HCl) are en

ergized. On unit equipped for 2 stages of heat, when addi

tional heat is needed HC2 is energized through W2.

COOLING, UNITS WITH ACCESSORY ECONOMIZER

— When the outdoor-air temperature is above the OAT

(outdoor-air thermostat) setting and the room thermostat calls

for cooling, compressor contactor no. 1 is energized to start

compressor no. 1 and the condenser-fan motor. The evaporatorfan motor is energized and the economizer damper moves

to the minimum position. Upon a further call for cooling,

compressor contactor no. 2 will be energized, starting com

pressor no. 2. After the thermostat is satisfied, the damper

moves to the fully closed position.

When the outdoor-air temperature is below the OAT set

ting and the thermostat calls for cooling, the economizer

dampers move to the minimum position. If the dischargeair temperature is above 54 F, the damper continues to open

until it reaches the fully open position. (The damper will

open for 5 seconds and remain stationary for 30 seconds

during this period.)

When the discharge-air temperature falls to between 54 F

and 50 F, the damper will remain at an intermediate open

position. If the discharge-air temperature falls below 50 F,

the damper will modulate back to the minimum position.

When the thermostat is satisfied, the damper will move to

the fully closed position.

If the outdoor air alone cannot satisfy the cooling require

ments of the conditioned space, economizer cooling is in

tegrated with mechanical cooling, providing second-stage

cooling. Compressor no. 1 and the condenser fan will be

energized and the position of the economizer damper will

be determined by the discharge-air temperature. Compres

sor no. 2 is locked out.

When the second stage of cooling is satisfied, the com

pressor and condenser-fan motor will be deenergized. The

damper position will be determined by the discharge-air

temperature.

When the first stage of cooling is satisfied, the damper

will move to fully closed position.

A CAUTION

When servicing unit, shut off all electrical power to

unit to avoid shoek hazard or injury from rotating parts.

Clssning Inspect unit interior at the beginning of each

heating and cooling season or as operating conditions

require.

EVAPORATOR COIL

1. Turn unit power off. Remove evaporator coil access panel.

2. If accessory economizer is installed, remove eeonomizer by disconnecting Molex plug and removing econ

omizer mounting screws. Refer to Accessory Economizer

Installation Instructions for more details.

3. Slide filters out of unit.

4. Clean coil using a commercial coil cleaner or dish

washer detergent in a pressurized spray canister. Wash

both sides of coil and flush with clean water. For best

results, backflush toward return-air section to remove

foreign material.

5. Flush condensate pan after completion.

6. Reinstall economizer and filters.

7. Reconnect wiring.

8. Replace access panels.

CONDENSER COIL — Inspect coil monthly. Clean con

denser eoil annually, and as required by location and outdoorair conditions.

Two-Row Coils — Clean coils as follows:

1.

Turn off unit power.

Remove top panel screws on condenser end of unit.

2.

Remove condenser coil comer post. See Fig. 12. To hold

3.

top panel open, place coil corner post between top panel

and center post. See Fig. 13.

4.

Remove device holding coil sections together at return

end of condenser coil. Carefully separate the outer coil

section 3 to 4 in. from the inner coil section. See

Fig. 14.

5.

Use a water hose or other suitable equipment to flush

down between the 2 coil sections to remove dirt and de

bris. Clean the outer surfaces with a stiff brush in the

normal manner.

CONDENSER

FAN

CONTROL BOX

CORNER POST

i

HEATING, UNITS WITH ACCESSORY ECONOMIZER

(If Accessory Heater is Installed) — When the room ther

mostat calls for heat through terminal W1, the evaporatorfan contactor and heater contactor no. 1 are energized. On

units equipped for 2 stages of heat, when additional heat is

needed, heater contactor no. 2 is energized through W2.

The evaporator-fan motor is energized 45 seconds after heat

ing begins, and the economizer damper moves to the min

imum position. When the thermostat is satisfied, the damper

moves to the fully closed position.

16

COIL CENTER

POST

Fig. 12 — Cleaning Condenser Coil

CONDENSER

COIL

REMOVE COIL

CORNER POST

i

Page 17

COIL CORNER CENTER BAFFLE

TOP PANEL

6. Reposition the outer coil section and remove the coil

corner post between the top panel and center post. Se

cure the sections together. Install the coil comer post

and coil center post, and replace all screws.

CONDENSATE DRAIN — Check and clean each year at

start of cooling season. In winter, keep drain dry or protect

against freeze-up.

FILTERS — Clean or replace at start of each heating and

cooling season, or more often if operating conditions re

quire it. Replacement filters must be same dimensions as

original filters.

Lubrication

COMPRESSORS — Each compressor is charged with cor

rect amount of oil at the factory.

FAN-MOTOR BEARINGS — Fan-motor bearings are of

the permanently lubricated type. No further lubrication is

required. No lubrication of condenser- or evaporator-fan

motors is required.

Fig. 15 — Condenser-Fan Adjustment

Refrigerant Charge — Amount of refrigerant charge

is listed on unit nameplate (also refer to Table 1). Refer to

Carrier Standard Service Techniques Manual, Chapter 1,

Refrigerants section.

Unit panels must be in place when unit is operating dur

ing charging procedure.

NO CHARGE — Use standard evacuating techniques. Af

ter evacuating system, weigh in the specified amount of re

frigerant (refer to Table 1).

LOW CHARGE COOLING — Use Cooling Charging Charts,

Fig. 16-19. Vary refrigerant until the conditions of the ap

propriate chart are met. Note the charging charts are differ

ent from type normally used. Charts are based on charging

the units to the correct superheat for the various operating

conditions. Accurate pressure gage and temperature sens

ing device are required. Connect the pressure gage to the

service port on the suction line. Mount the temperature sens

ing device on the suction line and insulate it so that outdoor

ambient temperature does not affect the reading. Indoor-air

cfm must be within the normal operating range of the unit.

TO USE COOLING CHARGING CHARTS - Take the

outdoor ambient temperature and read the suction pressure

gage. Refer to appropriate chart to determine what suction

temperature should be. If suction temperature is high, add

refrigerant. If suction temperature is low, carefully blow

some of the charge. Recheck the suction pressure as charge

is adjusted.

Example: (Fig. 16)

Outdoor Temperature.........................................................85 F

Suction Pressure............................................................70 psig

Suction Temperature should be

.........................................

42 F

(Suction Temperature may vary ±5° F.)

If Chargemaster® charging device is used, temperature

and pressure readings must be accomplished using the charg

ing charts.

Condenser-Fan Adjustment (Fig. 15)

1. Shut off unit power supply.

2. Remove condenser-fan assembly (grille, motor, motor

cover and fan) and loosen fan hub setscrews.

3. Adjust fan height as shown in Eig. 15.

4. Tighten setscrews.

5. Replace condenser-fan assembly.

17

Page 18

Fig. 16 — Cooling Charging Chart, 50LJ008

Fig. 18 — Cooling Charging Chart, 50LJ012

Fig. 17 — Cooling Charging Chart, 50LJ009

Fig. 19 — Cooling Charging Chart, 50LJ014

18

Page 19

t

Copyright 1991 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book|1 |4 PC 111 Cataiog No 565-004 Printed in U S A. Form 50LJ-4Si Pg 20 11-91 Repiaoes: 50LJ-2Si

Tab 1b 6b

Loading...

Loading...