Page 1

Product

Data

AQUAZONE™

50KQL07-19

Water Source Heat Pumps

Console Unit

1

/2to 11/2Nominal Tons

TM

Single-Package Console Water

Source Heat Pump with selfcontained line voltage thermostats.

• Suitable for either geothermal or

boiler/tower applications with

operating temperature range from

20 F to 110 F.

• Thermostatic expansion valve

(TXV) provides efficient and reliable

refrigerant flow

• Rubber grommet mounted

compressors for quiet operation

• Sloped top cabinet with powder

paint finish

• Right or left hand piping connection

• Multiple unit-mounted and remote

thermostat options

• Adaptable cabinet and subbase

configurations

• Factory-mounted flow regulators and

control valves for easy installation

• Flexible and reliable controls

accommodate all systems

Features/Benefits

Carrier’s Aquazone console

water source heat pumps are

a flexible, attractive

alternative for all finished

interior space, under-window

style installations.

Operating efficiency

Carrier Aquazone water source heat

pump (WSHP) units are designed for

quality and performance excellence

over their lifetime. Units offer standard

cooling EERs (Energy Efficiency

Ratios) up to 12.1 for boiler/tower

systems and as high as 19.5 for geothermal applications. Heating COPs

(Coefficient of Performance) are as

high as 4.9, among the highest in the

industry.

Copyright 2004 Carrier Corporation Form 50KQL-1PD

Page 2

Quiet operation

The Carrier Console WSHP provides

exceptionally quiet operation for maximum comfort.

Design flexibility

Aquazone™ Console WSHP units are

offered in 5 capacity sizes and 3 different voltages to meet individual zone

needs efficiently and effectively.

Standard and extended operating

range units are available to suit a

variety of application requirements.

Safe, reliable operation

Standard safety features include: high

and low pressure monitoring and field

selectable water and air coil freeze protection sensing. All safety controls may

be reset at the thermostat. Each unit is

tested and run at the factory to ensure

proper operation of all components

and safety switches.

All components are carefully

designed and selected for endurance,

durability, and carefree day-to-day

operation.

The water-to-refrigerant heat

exchanger has copper inner and steel

outer tubing which is painted on the

outside to provide corrosion resistance

protection. Cupronickel heat exchangers are available and should be used on

all open loop applications.

Units are rated and certified in

accordance with ARI/ISO/ASHRAE

13256-1 performance standard, and

are CSA/NRTL listed.

Installation ease

The unit is packaged for simple, low

cost handling, with minimal time required for installation. The console unit

arrives at the jobsite fully assembled to

minimize installation time and reduce

installation cost. All units are pre-wired

and factory charged with R-22

refrigerant.

Water connections are available in a

variety of configurations direct from

the factory. The standard configuration

5

is

/8 in. OD Sweat connections for

maximum flexibility in the field. Both

FPT and MPT are available as factoryinstalled options to improve installation

efficiency. Additionally, factoryinstalled motorized water shutoff

valves are available for use on energy

conserving systems employing a

variable pumping technique.

The standard electrical connections

are made quickly and directly to a power distribution terminal block. To further improve installation efficiency, a

fused or unfused disconnect switch as

well as a 20 amp plug and cord are

available as factory-installed options.

5

A

/8 in. ID vinyl condensate connection is provided for connection to

the field-installed condensate line.

Compact cabinet design dimensions are 12 in. deep, 48 in. wide and

24 in. tall (with 3 in. subbase). For flexibility, the controls can be mounted on

the top right or left side. Additionally,

the sloped top design discourages the

use of the unit as a shelf or coffee holder, preventing air blockage and any

spills from damaging the unit.

No-fuss maintenance and

serviceability

Regular maintenance or service to the

console WSHP units require little time.

Large service access panels enable

quick inspection for problem solving

and the control box swings down for

easy access to the controls.

Fan motor sleeve bearings are

permanently lubricated for worry-free

performance. If the unit does require

service, an easily removable cabinet

and slide out fan section make access

simple.

Refrigerant circuit protection is designed to result in fewer service calls.

Units are equipped with easily accessible service access ports on both the

suction and the discharge refrigerant

lines for on-site testing and environmentally correct refrigerant recovery.

Filter racks provide easy filter access

for cleaning.

Maximum control flexibility

Aquazone water source heat pumps

provide reliable control operation using

a standard microprocessor board.

Flexible alternatives for many direct

digital control (DDC) applications include the Carrier Comfort Network

(CCN) and open protocol systems.

Carrier’s Aquazone standard unit

solid-state control system, the Complete C, provides control of the unit

compressor, reversing valve, fan, safety

features, and troubleshooting fault indication features. The Complete C is

one of the most user friendly, low cost,

and advanced control boards found in

the WSHP industry. Many features are

field selectable to provide the ultimate

in field installation flexibility. The

overall features of this standard control

system include:

50 va transformer — Assists in

accommodating accessory loads.

Table of contents

Page

Features/Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ARI/ISO 13256-1 Capacity Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-13

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14,15

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-21

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22-24

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Typical Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25-31

Typical Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33-36

2

NRTL/C

As an ENERGY STA R ®Partner,

Carrier Corporation has determined that this product meets

the E

NERGY STA R guidelines

for energy efficiency.

Page 3

Features/Benefits (cont)

Anti-short cycle timer — Provides a

minimum off time to prevent the unit

from short cycling. The 5-minute timer

energizes when the compressor is

deenergized, resulting in a 5-minute

delay before the unit can be restarted.

Random start relay — Ensures a

random delay in energizing each different WSHP unit. This option minimizes

peak electrical demand during start-up

from different operating modes or after

building power outages.

High and low pressure refrigerant

protection — Safeguards against

unreliable unit operation and prevents

refrigerant from leaking.

Condensate overflow sensor —

Electronic sensor mounted to the drain

pan. When condensate pan liquid

reaches an unacceptable level, the unit

is automatically deactivated and placed

in a lockout condition. The sensor

recognizes thirty continuous seconds

of overflow as a fault condition.

High and low voltage protection —

Safety protection for excessive or low

voltage conditions.

Automatic intelligent reset — Unit

shall automatically restart 5 minutes

after shutdown if the fault has cleared.

Should a fault occur 3 times sequentially, lockout will occur.

Accessory output — In applications

such as variable speed pumping, a

24-v output cycles a motorized water

valve or damper actuator with

compressor.

Performance Monitor (PM) —

Unique feature monitors water temperatures to warn when the heat pump

is operating inefficiently or beyond

typical operating range. A field selectable switch initiates a warning code on

the unit display.

Water coil freeze protection

(selectable for water or antifreeze) — Field selectable switch for

water and water/glycol solution systems initiates a fault when temperatures exceed the selected limit for

30 continuous seconds.

Air coil freeze protection (check

filter operation) — Field selectable

switch for assessing excessive filter

pressure drop initiates a fault when

temperatures exceed the selected limit

for 30 continuous seconds.

Alarm relay setting — Selectable

24-v or pilot duty dry contact provides

remote alarm activation.

Electric heat option — Output pro-

vided on the controller for operating

two stages of emergency electric heat.

Service test mode with diagnostic

LED (light-emitting diode) — Tes t

mode allows service personnel to

check the operation of the WSHP and

control system efficiently. Upon entering Test mode, time delays speed up,

and the Status LED flashes a code

indicating the last fault. This mode

provides easy fault diagnosis; based on

the fault code the status LED flashes,

Carrier provided troubleshooting tables

provide easy reference to typical

problems.

LED visual output — An LED panel

indicates high pressure, low pressure,

low voltage, high voltage, air/water

freeze protection, condensate overflow, and control status.

Carrier PremierLink™ controller adds reliability, efficiency,

and simplification

The PremierLink direct digital controller can be ordered as a factory-installed

option. Designed and manufactured

exclusively by Carrier, the controller

can be used to actively monitor and

control all modes of operation as well

as monitor the following diagnostics

and features: unit number, zone tem-

perature, zone set point, zone humidity

set point, discharge air temperatures,

fan status, stages of heating, cooling

stages, outdoor-air temperature,

leaving-air temperature, leaving water

temperature, alarm status, and alarm

lockout condition.

This controller has 38.4K baud

communications capability and is compatible with ComfortLink™ Controls,

CCN and ComfortVIEW™ Software.

The Scrolling Marquee and Navigator

are optional tools used for programming and monitoring the unit for optimal performance. Adding the Carrier

CO

sensor in the conditioned space

2

provides ASHRAE 62-99 compliance

and Demand Control Ventilation

(DCV). A DCV control strategy is especially beneficial for a water source heat

pump system to minimize the energy

used to condition ventilation air. In

combination with energy efficient

Aquazone units, DCV may be the most

energy efficient approach ever developed for a water source heat pump

system.

The PremierLink peer-to-peer,

Internet ready communicating control

is designed specifically for Constant

Volume and Variable Volume Temperature applications. This comprehensive

controls system allows water source

heat pumps to be linked together, creating a fully functional HVAC (heating,

ventilation, and air conditioning) automation system.

3

Page 4

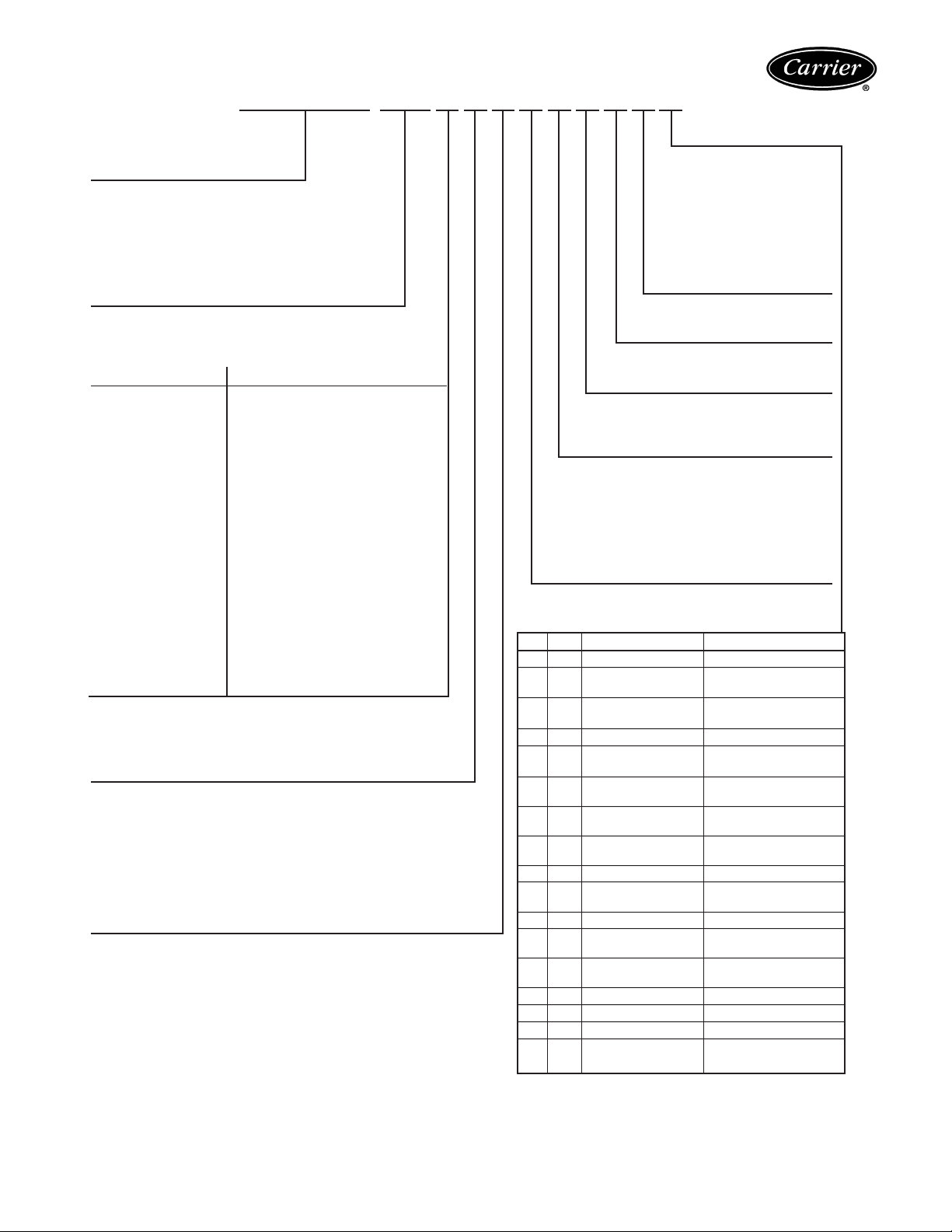

Model number nomenclature

50KQL07SAEC101AA

Aquazone™ High-Efficiency R-22

Water Source Heat Pump

50KQL – Console Unit

Size – Nominal Capacity (Tons)

07 – 1/2

09 – 3/4

12 –1

15 – 1 1/4

19 – 1 1/2

Water Circuit Options

Connection Type Valve Option

A – Sweat 2-Way Water Control Valve

B – Sweat Autoflow Regulator, 2.25 gpm/ton

C – Sweat Autoflow Regulator, 3.0 gpm/ton

D – Sweat 2-Way Water Control Valve with

E – Sweat 2-WayWater Control Valve with

F – FPT None

G – FPT 2-Way Water Control Valve

H – FPT Autoflow Regulator, 2.25 gpm/ton

J – FPT Autoflow Regulator, 3.0 gpm/ton

K – FPT 2-Way Water Control Valve with

L – FPT 2-Way Water Control Valve with

M – MPT None

N – MPT 2-Way Water Control Valve

P – MPT Autoflow Regulator, 2.25 gpm/ton

Q – MPT Autoflow Regulator, 3.0 gpm/ton

R – MPT 2-WayWater Control Valve with

S – Sweat None

T – MPT 2-Way Water Control Valve with

Water Supply Orientation

R – Right Hand

L – Left Hand

Control Options

A – Manual Changeover with Complete C

B – Manual Changeover with Deluxe D

C – Auto Changeover with Complete C

D – Auto Changeover with Deluxe D

P – PremierLink™ DDC Control†

R – Remote Thermostat with Complete C

S – Remote Thermostat with Deluxe D

*Right and left hand orientation is determined by looking at front of unit.

Right and left hand orientation is determined by looking at front of unit.

*

†Available with Complete C only.

†

For these options, unit must be hard wired (digit 15 must be “A”).

**20A plug and cord not available for 265V units.

††Sizes 07,09,12 only.

Autoflow Regulator, 2.25 gpm/ton

Autoflow Regulator, 3.0 gpm/ton

Autoflow Regulator, 2.25 gpm/ton

Autoflow Regulator, 3.0 gpm/ton

Autoflow Regulator, 2.25 gpm/ton

Autoflow Regulator, 3.0 gpm/ton

*

Power Termination

A – Field-Connected Hard Wired

B – 20A Plug and Cord**

D – Disconnect switch, 15A fuse

F – Disconnect switch, non-fused

H – 20A Plug, Cord, Receptacle,

Disconnect Switch, 15A Fuse

K – 20A Plug, Cord, Disconnect

Switch, No Fuse

Packaging

1 – Domestic

Revision Code

0 – Current revision

Power Supply

1 – 115V-1 Ph-60 Hz††

3 – 208/230V-1 Ph-60 Hz

4 – 265V-1 Ph-60 Hz**

Heat Exchanger and Operating Range

C – Copper heat exchanger, standard range

(60 to 95 F)

E – Copper heat exchanger, extended range (20 to 110 F)

F – Cupronickel heat exchanger, extended range

(20 to 110 F)

N – Cupronickel heat exchanger, standard range

(60 to 95 F)

Cabinet, Subbase and Mute Package Options

Std Mute Cabinet Subbase

AT Bottom return 3 in. Subbase

BU Bottom return 3 in. Subbase with

CV

DW Bottom return NO BASE

EY Bottom return 3 in. Subbase

FZ Bottom return 3 in. Subbase with

G1 Bottom return 5 in. Subbase with

H2 Bottom return NO BASE

J3 Front return NO BASE

K4 Front return NO BASE

L5 NO CABINET 3 in. Subbase

M6 NO CABINET 3 in. Subbase with

N7 NO CABINET 5 in. Subbase with

P8 NO CABINET NO BASE

Q9 NO CABINET 5 in. Subbase

R0 Bottom return 5 in. Subbase

SO Bottom return 5 in. Subbase

Bottom return

Locking control door

Locking control door Motorized Damper

Locking control door Motorized Damper

Locking control door

Locking control door

Locking control door

Motorized Damper

5 in. Subbase with

Motorized Damper

Motorized Damper

Motorized Damper

4

Page 5

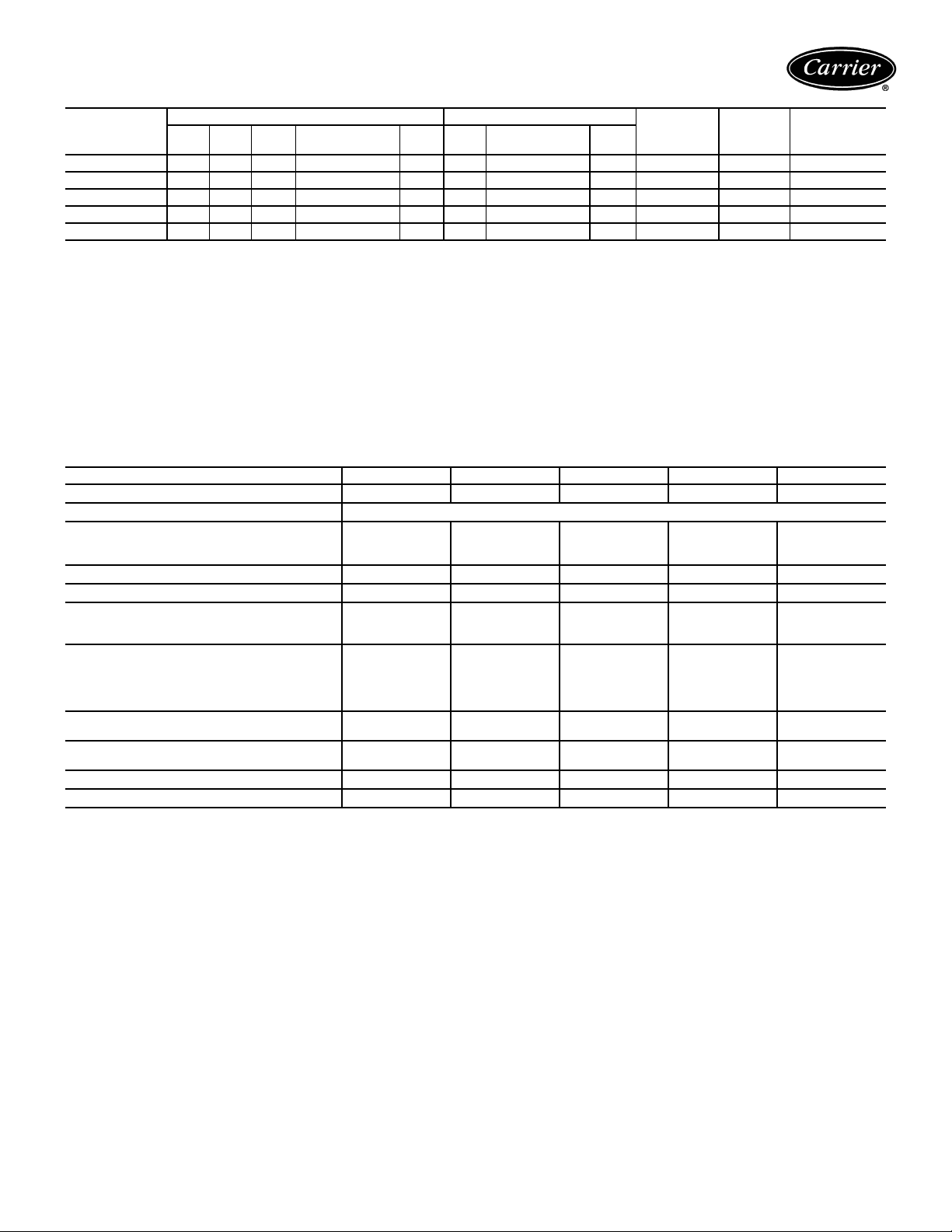

ARI/ISO 13256-1 capacity ratings

UNIT 50KQL

TC SC THR

COOLING HEATING

Input Power

(kW)

EER TC

Input Power

(kW)

COP

AIRFLOW

(cfm)

WATER

FLOW

(gpm)

PRESSURE

07 7.8 6.6 10.0 0.645 12.1 10.4 0.622 4.9 240 1.9 1.5

09 9.3 7.2 11.9 0.775 12.0 12.0 0.799 4.4 300 2.5 3.1

12 12.3 9.5 15.9 1.060 11.6 15.0 0.999 4.4 350 3.1 3.8

15 13.8 11.2 17.8 1.169 11.8 17.3 1.152 4.4 400 3.6 3.0

19 16.0 11.9 20.6 1.333 12.0 19.3 1.346 4.2 460 4.8 5.0

LEGEND NOTES:

ARI — Air Conditioning and Refrigeration Institute

COP — Coefficient of Performance

db — Dry Bulb Temperature

EER — Energy Efficiency Ratio

ISO — International Organization for Standardization

TC — Total Capacity (MBtuh)

THR — Total Heat of Rejection (MBtuh)

SC — Sensible Capacity (MBtuh)

1. Ratings are in accordance with and certified to ARI/ISO Standard

13256-1.

2. Cooling Standard: 80.6 F db, 66 F wb indoor entering air temperature, 86 F entering water temperature.

3. Heating Standard: 68 F db indoor entering air temperature, and

68 F entering water temperature.

wb — Wet Bulb Temperature

Physical data

BASE UNIT 50KQL 07 09 12 15 19

NOMINAL COOLING CAPACITY (Btuh)

COMPRESSOR

BLOWER

Motor Horsepower

Wheel Size D x W (in.) 2 each

FILTER SIZE (in.) Bottom Return

FILTER SIZE (in.) Front Return

UNITWEIGHT(lb)

Shipping

Operating

REF. TO AIR HEAT EXCHANGER

Face Area (sq ft)

No. of Rows Deep

Copper Tube Size OD (in.)

Fin Spacing (FPI)

REFRIG. CHARGE (R-22)/CKT (oz)

No. of Circuits

UNIT CABINET WITH STANDARD SUBBASE

WxHxD(in.) 48 x 24 x 12 48 x 24 x 12 48 x 24 x 12 48 x 24 x 12 48 x 24 x 12

WATER IN/OUT SIZE OD SWEAT (in.)

CONDENSATE SIZE ID VINYL (in.)

7,800 9,300 12,300 13,800 16,000

Rotary

51/4x61/

8x29

7x29

181

173

1

/

1.4

3

13

16

5

5

1

1

2

1

20

/2x3/

/2x1/

/

8

/

8

/

8

4

8

8

1

/

15

51/4x61/

8x291/2x3/

7x291/2x1/

185

177

1.4

2

3

/

8

13

16

1

5

/

8

5

/

8

1

/

15

4

8

8

51/4x61/

8x291/2x3/

7x291/2x1/

4

8

8

195

187

1.4

3

3

/

8

13

21

1

5

/

8

5

/

8

1

/

6

51/4x61/

8x291/2x3/

7x291/2x1/

201

193

1.8

3

3

/

8

13

27

1

5

/

8

5

/

8

4

8x291/2x3/

8

7x291/2x1/

8

51/4x61/

DROP

(ft wg)

1

/

6

206

198

1.8

3

3

/

8

12

24

1

5

/

8

5

/

8

4

8

8

5

Page 6

Options and accessories

Factory-installed options

Cupronickel heat exchangers are available for higher

corrosion protection for applications such as open tower,

geothermal, etc. Consult the water quality guidelines for

proper application and selection of this option.

Thermostat options include a unit mounted Manual

Changeover (MCO) or Auto Changeover (ACO) thermostat. The temperature set point knob and push button

switches for fan speed and cool/heat mode (MCO) selection are conveniently located on the top. The thermostat

senses the return-air temperature. The thermostat sends

the appropriate signal to the controller for cooling or heating mode of operation.

Options R and S allow connection to a remote wallmounted thermostat. The Complete C controller requires a

heat pump thermostat. The Deluxe D controller can be

configured for heat pump or heat/cool thermostat.

Extended range is provided to insulate the coaxial coil to

prevent condensation, and therefore potential dripping

problems, in applications where the entering water

temperature is below the normal operating range (less than

60 F).

Cabinet options include a locking control panel for

added security. Bottom or front return with left or right

hand configurations are available for ease of installation.

Available with 3 or 5 in. subbase, with or without motorized damper.

Motorized fresh air damper with the unit-mounted

thermostat. Opens when LOW or HIGH fan speed selections are made from the push button switches. When

STOP or FAN ONLY selections are made the spring return

on the damper motor closes the damper. With remote

thermostat the motorized fresh air damper opens when the

fan is running.

Piping connections can be provided on either the right

or left hand side of the unit, for easy installation. Orientation is determined by facing the unit from the front side.

Automatic flow regulators include internally mounted

2.25 or 3.0 gpm/ton automatic flow regulating valves for

easier install

Two-way motorized control valve can be provided with

a copper or cupronickel heat exchanger for applications

involving open type systems or variable speed pumping.

This valve will slowly open and close in conjunction with the

compressor operation to shut off or turn on water to the

unit. Standard two-way valve performance includes Cv of

2.9 and maximum operating pressure differential (MOPD)

of 125 psi.

Mute package includes high density noise suppression

material on front, right, and left sides of compressor

compartment and

insulated surfaces, for extra-quiet operation in the most

critical applications.

Deluxe D control system provides the same functions

as the Complete C while incorporating additional flexibility

and functions to include:

Thermostat input capabilities

shutdown mode and night setback with override (NSB)

potential. Night setback from low temperature thermostat

ation.

1

/2-in. fiberglass insulation on all

— Accommodate emergency

with 2-hour override is initiated by a momentary signal

from the thermostat.

Compressor relay staging

(units with 2 compressors and 2 Deluxe D controls) or in

master/slave applications.

Boilerless electric heat control system

changeover to electric heat at low loop water temperature.

Intelligent reversing valve operation

valve operation for extended life and quiet operation.

Thermostat type select (Y, O or Y, W)

work and select heat pump or heat/cool thermostats (Y, W).

Reversing valve signal select (O or B)

for heat pump O/B thermostats.

Dehumidistat input

dehumidification operation.

Multiple units on one thermostat/wall sensor

for communication for up to three heat pumps on one

thermostat.

Boilerless changeover temperature

boilerless changeover temperature set point.

Accessory relays

cations including fan and compressor cycling, digital night

setback (NSB), mechanical night setback, water valve operation, and outside air damper operation.

Night low limit

either the push button switches, remote thermostat or the

energy management system, it is possible that the space

temperature could drop uncontrollably. The Night Low

Limit feature, with Deluxe D controller, helps maintain the

space temperature at a level that is the best compromise

between energy consumption and a safe space temperature. A thermostat located near the return air filter

activates the blower and compressor operation when the

space temperature falls below 50 F. When return air temperature is raised above 55 F the compressor and blower

stop.

Override function

units operating in occupied/unoccupied mode under the

control of an external timeclock or an energy management

system. A contact closure from the timeclock or energy

management system shorts the NSB and C terminal on the

Deluxe D controller signaling an unoccupied mode.

For units with the unit-mounted thermostat, pressing

override switch (located under control access door) will

override the unoccupied mode and allow the occupied

mode of operation to continue for a period of two hours.

The units with the remote wall-mounted thermostat

require a digital thermostat with the override function. In

unoccupied mode an accessory relay is energized on the

Deluxe D controller. The NO/NC contacts of the relay can

be used as appropriate input to the digital thermostat to

signal occupied/unoccupied mode. The thermostat selects

cooling/heating set points based on occupied/unoccupied

mode.

PremierLink™ controller is compatible with the Carrier

Comfort Network (CCN) and other building automation

systems (BAS). This control is designed to allow users the

access and ability to change factory-defined settings thus

expanding the function of the standard unit.

— Provides operation of fan control for

— Allow configuration for multiple appli-

— If the unit operation is turned OFF from

— An Override function is available for

— Used with dual stage units

— Allows automatic

— Minimizes reversing

— Provides ability to

— Provides selection

— Provides

— Provides selection of

6

Page 7

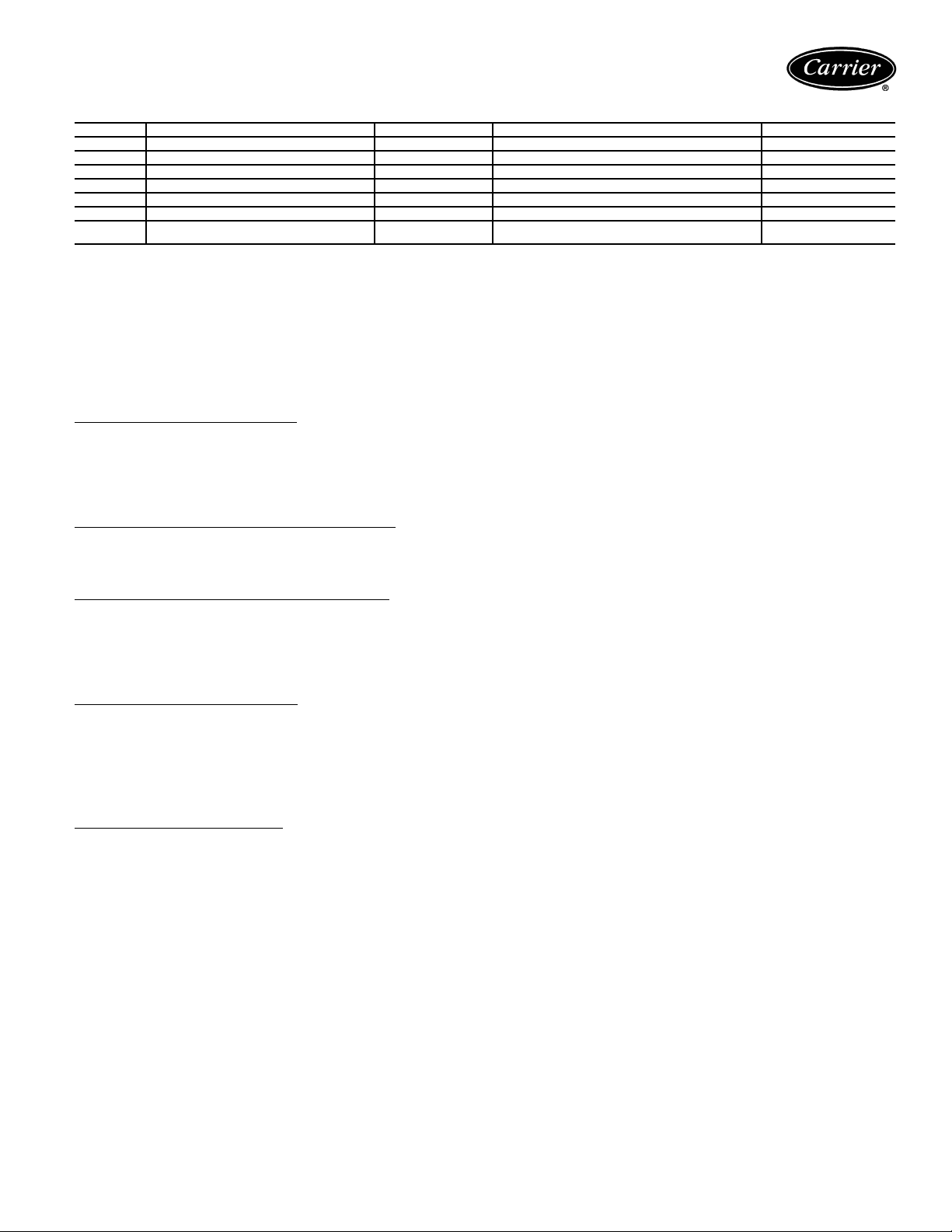

50KQL CONTROL OPTIONS TABLE

OPTION CONTROLLER THERMOSTAT FUNCTIONS TRANSFORMER

A Complete C MCO — 50 VA

B Deluxe D MCO NIGHT LOW LIMIT 2-HR OVERRIDE 75 VA

C Complete C ACO — 50 VA

D Deluxe D ACO NIGHT LOW LIMIT 2-HR OVERRIDE 75 VA

P Complete C with PremierLink™ LINKAGE DDC SYSTEM 50 VA

R Complete C REMOTE — 50 VA

S Deluxe D REMOTE

LEGEND

ACO — Auto Changeover

DDC — Direct Digital Controls

MCO — Manual Changeover

NIGHT LOW LIMIT2-HR

OVERRIDE

75 VA

Field-installed accessories

Carrier’s line of Aquazone™ thermostats (used with

remote thermostat units) are both attractive and multi-

functional, accommodating stand-alone water source heat

pump installations.

Programmable 7-day thermostat

2-stage cool, auto changeover, 7-day programmable with

copy command, 4 settings per day, fully electronic, 24 vac,

backlit LCD, keypad lockout, no batteries required,

5-minute compressor protection, NEVERLOST™ memory,

3 security levels, temperature display in degrees F or C.

Programmable 7-day light-activated thermostat

same features as the 7-day programmable thermostat and

includes occupied comfort settings with lights on, unoccupied energy savings with lights off.

Programmable 7-day flush-mount thermostat

same features as the 7-day programmable thermostat and

includes locking coverplate with tamper proof screws, flush

to wall mount, holiday/vacation programming, set point

limiting, dual point with adjustable deadband, O or B terminal, and optional wall or duct-mounted remote sensor.

Programmable 5-day thermostat

2-stage cool, auto changeover, 5-minute built-in compressor protection, locking cover included, temperature display

in degrees F or C, keypad lockout, backlit display, 5-1-1

programming, O or B terminal, dual set point with adjustable deadband, configurable display, self-prompting program, 4 settings per day.

Non-programmable thermostat

2 cool stages, auto changeover, 5-minute built in compressor

protection, locking cover included, temperature display in

degrees F or C, keypad lockout, large display, back-lit display, O or B terminal, dual set point with adjustable deadband, backplate with terminals.

Aquazone system control panel includes a preprogrammed, easy to use, Carrier Comfort Controller set

up for a WSHP system.

• Coordinates, monitors, and controls all WSHP units

and ancillary equipment including cooling towers, boilers, and system pumps.

• 50RLP model nomenclature is used to customize the

panel to control all WSHP system requirements.

• Panel can be ordered to include 2, 4, 6, or 8 stages of

system heat rejection.

• Panel can be ordered to include 2, 4, 6, or 8 stages of

system heat addition.

— Offers 2-stage heat,

— Offers

— Offers

— Offers 2-stage heat,

— Offers 2 heat stages,

• Panel can be ordered with unique WSHP zone operation

capabilities for stand alone systems (i.e., non-communicating)

to control 10 or 18 zones of WSHP units.

• Panel can be ordered to control variable frequency cooling tower fan operation.

• System pumping operation can be configured for start/

stop, lead/lag, or variable frequency pump operation.

• Direct Digital Control compatible using the Carrier

Comfort Network (CCN) and WSHP units utilizing

PremierLink CCN controllers.

Fire-rated hoses are 2 ft long and have a fixed MPT on

one end and a swivel with an adapter on the other end.

Hose kits are provided with both a supply and return hose

and can be either stainless steel or galvanized. Five sizes

are available (

1

/2, 3/4, 1, 11/4, 11/2 in.).

Ball valves (brass body) used for shutoff and balancing

water flow. Available with memory, memory stop, and

pressure temperature ports. UL-listed brass body, ball and

stem type with Teflon seats and seals. Five sizes are avail-

1

/2, 3/4, 1, 11/4, 11/2 in.).

able (

Y strainers (bronze body) are “Y” type strainers with a

brass cap. Maximum operating pressure rating of

450 psi. Strainer screen made of stainless steel. Available

with blow down valves. Five sizes are available (

1

/4, 11/2 in.).

1

1

/2, 3/4, 1,

Solenoid valves (brass body) offer 3.5 watt coil,

24 volt, 50/60 Hz, 740 amps inrush, .312 amps holding.

Slow operation for quiet system application. Five sizes are

available (

1

/2, 3/4, 1, 11/4, 11/2 in.).

Hose kit assemblies provide all the necessary components to hook up a water-side system. Supply hose

includes a ported ball valve with pressure temperature

(P/T) plug ports, flexible stainless steel hose with swivel

and nipple. Return hose includes a ball valve, preset automatic balancing valve (gpm) with two P/T ports, flexible

stainless steel hose with a swivel and nipple, balancing

valve, and low-pressure drop water control valve.

Remote sensors are available for Aquazone flush mount

thermostats. Sensors are available for wall (wired and wireless) or duct mounted applications.

PremierLink™ accessories are available to provide a

fully integrated WSHP DDC system. Accessories include

supply air temperature sensors (with override and/or setpoint adjustment), communicating room sensors, CO

sen-

2

sors (for use in demand control ventilation), and linkage

thermostats (to control multiple units from one thermostat).

7

Page 8

Options and accessories (cont)

CARRIER AQUAZONE™ THERMOSTATS

(FOR USE WITH REMOTE THERMOSTAT UNITS)

Carrier

®

Pm

AUTO

7-DAY PROGRAMMABLE/LIGHT-ACTIVATED

PROGRAMMABLE

COOL

HEAT

R

COOL

AUTO

HEAT

7-DAY PROGRAMMABLE FLUSH MOUNT

5-DAY PROGRAMMABLE/NON-PROGRAMMABLE

PREMIERLINK™ COMMUNICATING CONTROL

8

Page 9

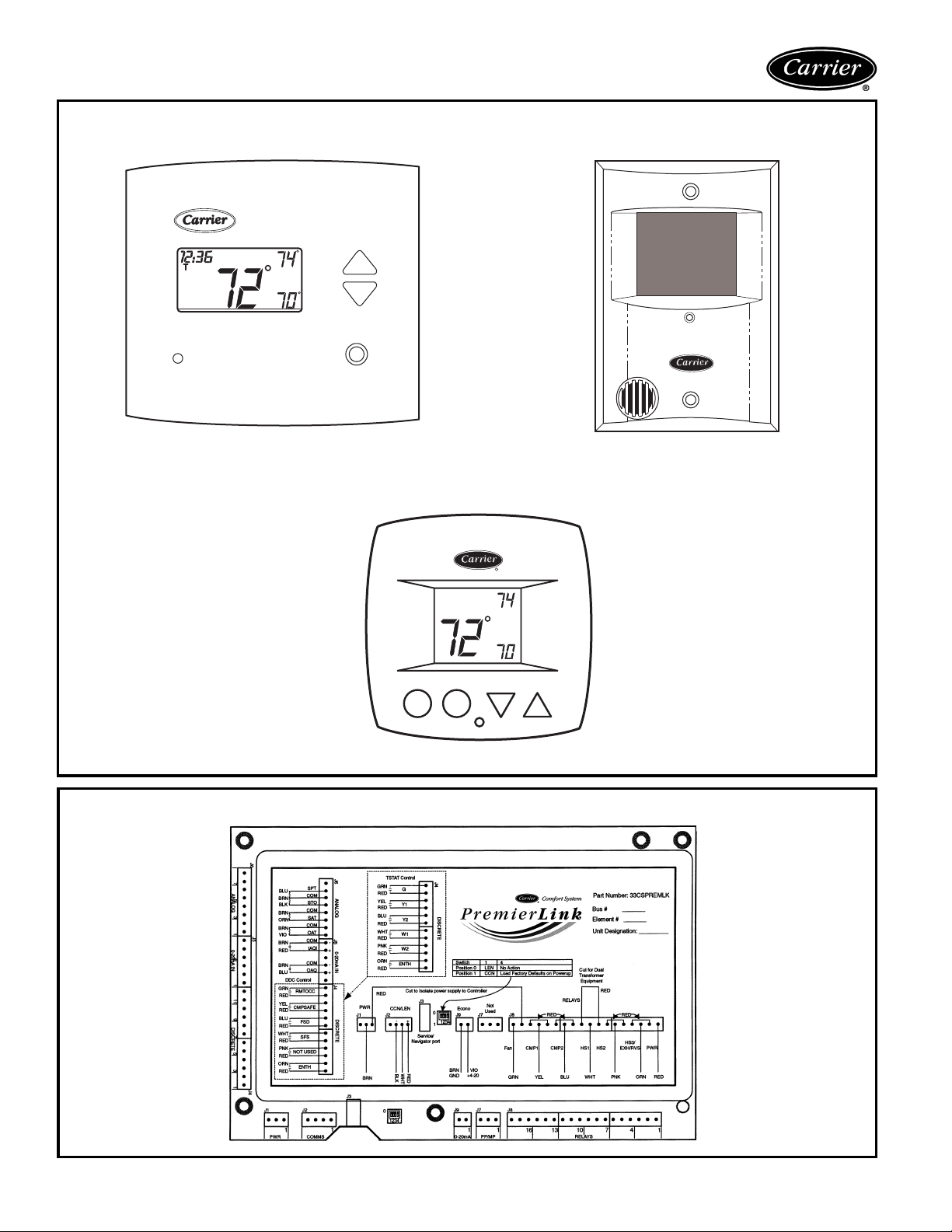

Dimensions

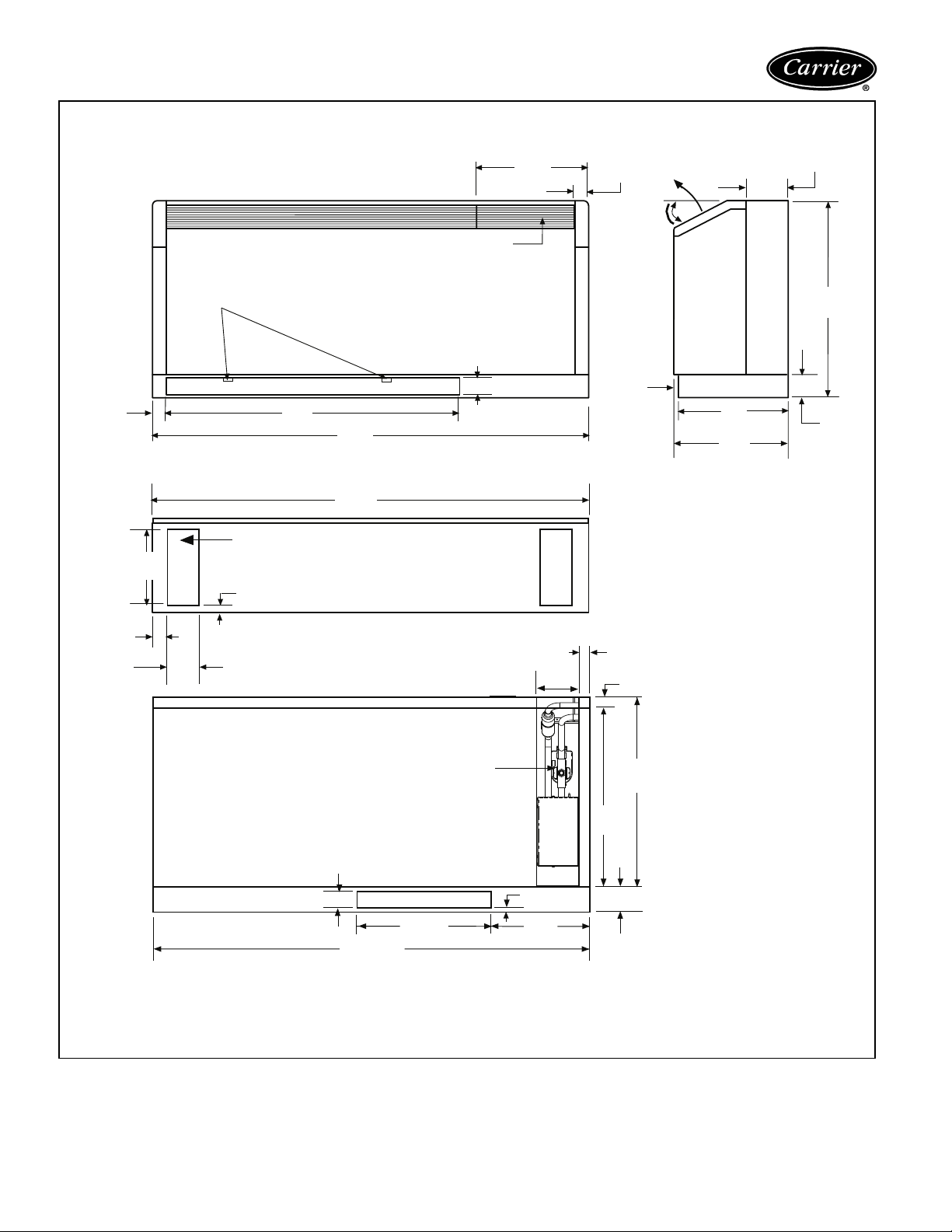

50KQL BOTTOM RETURN CABINET DIMENSIONS — RIGHT HAND PIPING

1.75

(44.5)

Filter located inside and at

top of air inlet area. Push

tabs back and down to release

filter for replacement.

AIR INLET AREA

33.5

(851)

Control Access Door

48.0

(1219)

48.0

(1219)

BOTTOM VIEW

FRONT VIEW

1.9

(48)

10.0

(254)

16

(406)

5

(127)

30

Air

Inlet

R.H. Pipe &

Electric Area

0.75

(19)

Discharge

Air

°

SIDE

VIEW

11.5

(292)

12.0

(305)

3.5

(88.9)

*23.9

(607)

*2.9

(74)

1 (25)

1 (25)

REAR

ACCESS

4.5

(114)

20

(508)

REAR VIEW

1.63

(41)

DAMPER OPENING*

48

(1219)

11.75

(298)

3.5

(89)

0.59

(15)

9.81

(249)

*Dimension shown is with 3 in. subbase. Add 2 in. to dimension shown for 5 in. subbase.

NOTES:

1. Dimensions are shown in inches. Dimensions in parentheses are in millimeters.

2. Optional autoflow valve, motorized water valve and disconnect box are shown.

Notes:

1. Dimensions shown are in inches. Dimensions in parentheses are in millimeters.

Shown is 76mm subbase. Add 50.8mm to dimension shown for 127mm subbase.

1.56

(40)

(533)

*2.9

(74)

21

9

Page 10

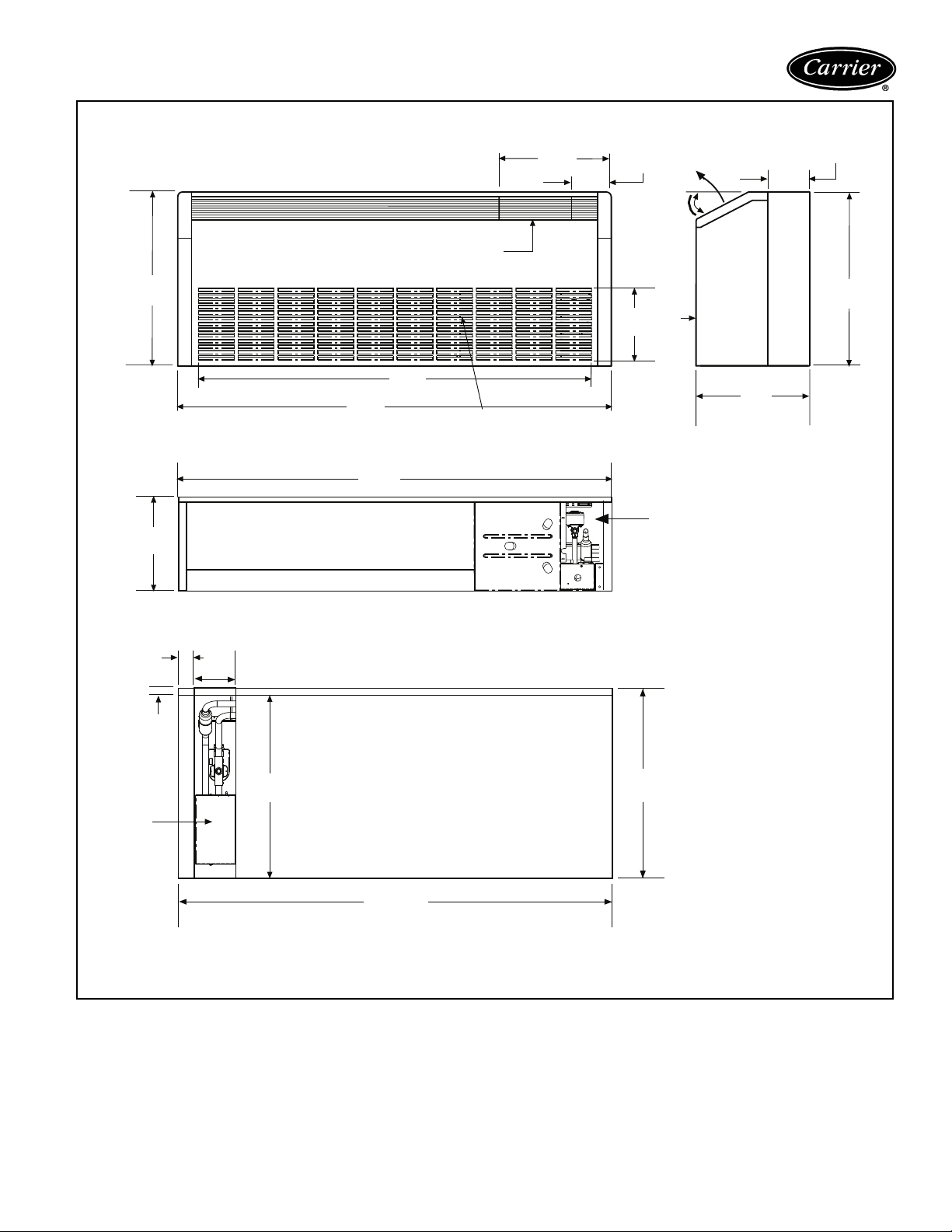

Dimensions (cont)

50KQL BOTTOM RETURN CABINET DIMENSIONS — LEFT HAND PIPING

1.75

(44.5)

Filter located inside and at top of air

inlet area. Push tabs back and down

to release filter for replacement.

L.H. Pipe &

10.0

(254)

Electric Area

0.75

(19)

AIR INLET AREA

33.5

(851)

48.0

(1219)

48.0

(1219)

BOTTOM VIEW

Control Access Door

FRONT VIEW

1.9

(48)

12.6

(320)

1.5

(38)

Air

Inlet

Discharge

Air

30°

SIDE

VIEW

11. 5

(292)

12.0

(305)

3.5

(88.9)

*23.9

(607)

*2.9

(74)

1.56

(40)

3.5

(89)

REAR VIEW

1.63

(41)

REAR

ACCESS

DAMPER OPENING*

11.75

48.0

(1219)

*Dimension shown is with 3 in. subbase. Add 2 in. to dimension shown for 5 in. subbase.

NOTES:

1. Dimensions are shown in inches. Dimensions in parentheses are in millimeters.

2. Optional autoflow valve, motorized water valve and disconnect box are shown.

Notes:

1. Dimensions shown are in inches. Dimensions in parentheses are in millimeters.

Shown 76mm subbase. Add 50.8mm to dimension shown for 127mm subbase.

2. Optional autoflow valve, motorized water valve and disconnect box are shown.

(298)

0.59

(15)

9.9

(251)

4.5

(114)

20.0

(508)

1 (25)

1 (25)

*2.9

(74)

21.0

(533)

10

Page 11

21.0

(533)

12.0

(305)

50KQL FRONT RETURN CABINET DIMENSIONS — RIGHT HAND PIPING

5

30°

Air

Inlet

R.H. Pipe &

Electric Area

Discharge

Air

SIDE

VIEW

FRONT VIEW

48.0

(1219)

BOTTOM VIEW

Control Access Door

43.7

(1110)

Filter located behind return

air grille and requires removal of

cabinet front for access.

48.0

(1219)

16

(406)

(127)

7.9

(201)

12.0

(305)

3.5

(88.9)

21.0

(533)

1 (25)

1 (25)

4.5

(114)

REAR VIEW

20.0

(508)

REAR

ACCESS

48.0

(1219)

NOTES:

1. All dimensions are shown in inches. Dimensions in parentheses are in millimeters.

Notes:

1.

All

2. Optional autoflow valve, motorized water valve and disconnect box are shown.

dimensions are shown in inches. Dimensions in parentheses are in millimeters.

2. Optional autoflow valve, motorized water valve and disconnect box are shown.

21.0

(533)

11

Page 12

Dimensions (cont)

50KQL FRONT RETURN CABINET DIMENSIONS — LEFT HAND PIPING

21.0

(533)

Control Access Door

FRONT VIEW

43.7

(1110)

48.0

(1219)

48.0

(1219)

12.6

(320)

Filter located behind return

air grille and requires removal of

cabinet front for access.

(38.1)

7.9

(201)

1.5

Discharge

30°

Air

Inlet

Air

SIDE

VIEW

12.0

(305)

3.5

(88.9)

21.0

(533)

12.0

(305)

L.H. Pipe &

Electric Area

BOTTOM VIEW

REAR

ACCESS

4.5

(114)

REAR VIEW

48.0

(1219)

NOTES:

Notes:

1. All dimensions are shown in inches. Dimensions in parentheses are in millimeters.

1.

All

dimensions are shown in inches. Dimensions in parentheses are in millimeters.

2. Optional autoflow valve, motorized water valve and disconnect box are shown.

2. Optional autoflow valve, motorized water valve and disconnect box are shown.

1 (25)

20.0

(508)

1 (25)

21.0

(533)

12

Page 13

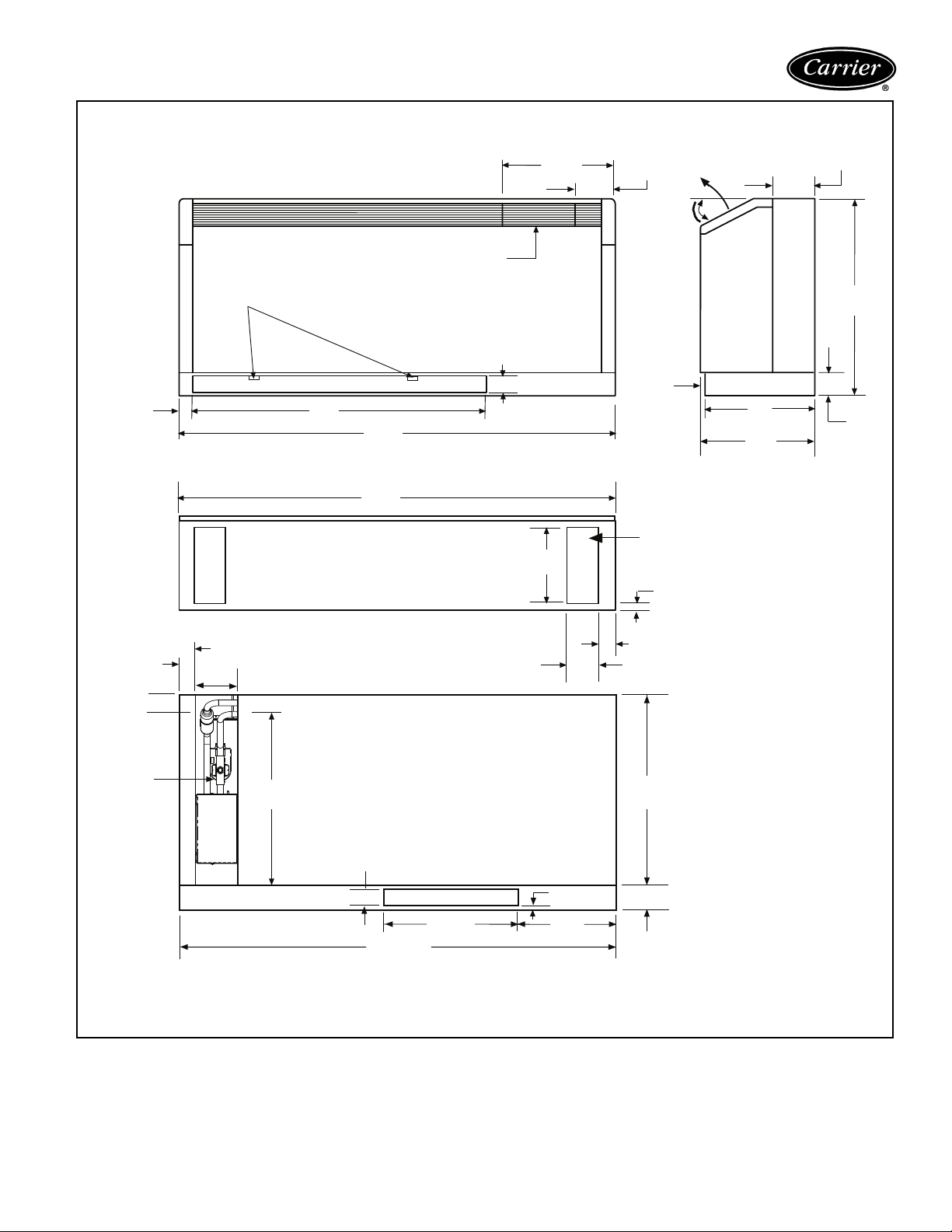

50KQL CHASSIS DIMENSIONS — SIZE 07, 09, 12, 15, 19

1.84

(47)

3.28

(83)

Water Out

Water In

Power Supply

30

°

40.98

(1040)

Control Box

5.36

(136)

3.01

(76)

0.87

(22)

20.50

(521)

0.75

(19)

Optional

Autoflow

Valve

Optional

Motorized

Water Valve

Water Connections

5/8” (15.9 mm)

OD Copper,

1/2” FPT or

1/2” MPT

5.36

(136)

3.01

(76)

0.87

(22)

Blower Deck

Blower Access Panel

Optional Disconnect Box

(mounted to cabinet not chassis)

Power Supply

Water Out

30°

Water In

Compressor

Access

Panel

4.46

(113)

0.75

(19)

Condensate

5/8” (15.9 mm)

ID Vinyl Hose

RIGHT HAND CONFIGURATION

3.50

(89)

1.93

(49)

40.98

(1041)

*16.66

(423)

*7.06

(179)

*1.94

(49)

3.88

(99)

11.5

(293)

Control Box

7.5

(191)

3.56

(90)

3.43

0.99

(87)

(25)

4

7.5

(191)

3.56

(90)

3.42

(87)

3.22

(82)

3.88

(99)

11.5

4

(293)

Optional Disconnect Box

(mounted to cabinet not chassis)

*16.66

(423)

*1.94

(49)

*7.06

(179)

Condensate

5/8” (15.9 mm)

ID Vinyl Hose

Optional

Autoflow

Valve

Optional

Motorized

Water Valve

Water Connections

5/8” (15.9 mm)

OD Copper,

1/2” FPT or

1/2” MPT

Blower Deck

Compressor

Access

Panel

20.44

(52)

Blower Access Panel

4.49

(114)

0.75

(19)

0.75

(19)

*For installed dimension, add to dimension shown 2.9 in. with 3 in. subbase and 4.9 in. for 5 in.

subbase.

Notes:

NOTES:

* For installed dimension, add to dimension shown 74mm with 76mm subbase and

124mm for 127mm subbase.

1. Dimensions shown are in inches. Dimensions in parentheses are in millimeters.

1. Dimensions shown are in inches. Dimensions in parentheses are in millimeters.

2. Optional autoflow valve, motorized water valve and disconnect box are shown.

2. Optional autoflow valve, motorized water valve and disconnect box are shown.

3. Water connection in same location regardless of connection type.

3. Water connection in same location regardless of connection type.

LEFT HAND CONFIGURATION

13

Page 14

Selection procedure (with 50KQL12 example)

I Determine the actual cooling and heating

loads at the desired dry bulb and wet bulb

conditions.

Assume cooling load at desired dry bulb 80 F and

wet bulb 66 F conditions are as follows:

Given:

Total Cooling (TC). . . . . . . . . . . . . . .11,750 Btuh

Sensible Cooling (SC) . . . . . . . . . . . . .8,650 Btuh

Entering-Air Temperature db . . . . . . . . . . . . 80 F

Entering-Air Temperature wb . . . . . . . . . . . . .66 F

II Determine the following design parameters.

Determine entering water temperature, water flow

rate (gpm), airflow (cfm), water flow pressure drop

and design wet and dry bulb temperatures. Airflow

cfm should be between 300 and 450 cfm per ton.

For applications using multiple units, the water pressure drop should be kept as close as possible across

units to make water balancing easier. Enter the

50KQL12 Performance Data tables and find the

proper indicated water flow and water temperature.

For example:

Entering Water Temp . . . . . . . . . . . . . . . . . 90 F

Water Flow (Based upon

10 F rise in temp) . . . . . . . . . . . . . . . . . . 3.1 gpm

Airflow Cfm . . . . . . . . . . . . . . . . . . . . . . 308 cfm

III Select a unit based on total cooling and total

sensible cooling conditions. Unit selected

should be closest to but not larger than the

actual cooling load.

Enter tables at the design water flow and water

temperature. Read the total and sensible cooling

capacities.

NOTE: Interpolation is permissible, extrapolation is

not.

For example:

Enter the 50KQL12 Performance Table at design

water flow and water temperature. Read Total

Cooling, Sensible Cooling and Heat of Rejection

capacities:

Total Cooling . . . . . . . . . . . . . . . . . .12,200 Btuh

Sensible Cooling . . . . . . . . . . . . . . . . 8,900 Btuh

Heat of Rejection . . . . . . . . . . . . . . .15,900 Btuh

NOTE: It is quite normal for water source heat

pumps to be selected on cooling capacity only since

the heating output is usually greater than the cooling

capacity. Heating capacity is selected based on

different entering water conditions than cooling

capacity.

IV Determine the correction factors associated

with the variable factors of dry bulb and wet

bulb using the Corrections Factor tables

found in this book.

Using the following formulas to determine the correction factors of dry bulb and wet bulb:

a) Corrected Total Cooling = tabulated total cooling

x wet bulb correction x airflow correction.

b) Corrected Sensible Cooling = tabulated sensible

cooling x wet/dry bulb correction x airflow

correction

V Determine entering air and airflow correction

using the Corrections Factor tables found in

this book.

The nominal airflow for 50KQL12 is 350 cfm. The

design parameter is 325 cfm.

308/350 = 88% of nominal airflow

Use the 88% row in the Nominal Cfm Correction

table.

The Entering Air Temperature wb is 66 F. Use the

66.2 F row in the Entering Air Correction table.

Using the following formulas to determine the cor-

rection factors of entering air and airflow correction:

Table Ent Air Airflow Corrected

Corrected

Total Cooling = 12,200 x 0.983 x 0.979 = 11,741

Corrected

Sensible Cooling = 89,900 x 1.036 x 0.936 = 8,630

Corrected

Heat of Rejection = 15,900 x 0.985 x 0.979 = 15,333

Compare the corrected capacities to the load

requirements established in Step I. If the capacities

are within 10% of the load requirements, the equipment is acceptable. It is better to undersize than

oversize as undersizing improves humidity control,

reduces sound levels and extends the life of the

equipment.

VI Water temperature rise calculation and

assessment.

Calculate the water temperature rise and assess the

selection using the following calculation:

Actual Temperature

Rise

Correction of Heat Rejection

=

gpm x 500

For example, using the Corrected Heat of Rejection

from the last step:

Actual Temperature

Rise

=

3.1 x 500

15,333

=9.9 F

If the units selected are not within 10% of the load

calculations, review what effect changing the gpm,

water temperature and/or airflow will have on the

corrected capacities. If the desired capacity cannot

be achieved, select the next larger or smaller unit

and repeat Steps I through VI.

14

Page 15

VII ARI/ISO 13256-1 Conversion

Performance standard ARI/ISO 13256-1 became

effective on January 1, 2000 and replaced the existing ARI Standards 320 Water-Loop Heat Pumps

(WLHP), 325 Ground-Water Heat Pumps (GWHP),

and 330 Ground-Loop Heat Pumps (GLHP).

The ARI/ISO Standard incorporates a consistent

rating methodology for including fan and pump

energy for calculating cooling capacity, heating

capacity, and energy efficiency ratios (EER). This

simplifies the use of rating data for heat pump performance modeling in seasonal energy analysis calculations, and allows for direct rating comparisons

across applications.

a) ISO Capacity and Efficiency Equations

The following equations are used to calculate and

correct cooling capacity, heating capacity, and

respective EER:

ISO Cooling Capacity = (Cooling Capacity in

Btuh) + (Fan Power Correction in Watts x 3.412)

ISO Cooling EER = (ISO Cooling Capacity in

Btuh/3.412)/(Power Input in watts – fan power

correction in watts + pump power correction in

watts) = Watts/Watts

NOTE: Do not divide ISO Cooling Capacity by

3.412 to obtain Btuh/Watts.

ISO Heating Capacity = (Heating Capacity in

Btuh) – (Fan Power Correction in Watts x 3.412)

ISO Heating EER = (ISO Heating Capacity in

Btuh/3.412)/(Power Input in watts – fan power

correction in watts + pump power correction in

watts) = Watts/Watts

NOTE: Do not divide ISO Heating Capacity by

3.412 to obtain Btuh/Watts.

b) Identify the design conditions corrected for air and

water conditions.

Airflow Cfm = 308 Cfm

Water Flow

(Based upon 10 F rise in temp) = 3.1 GPM

External Static Pressure = 0.0 in. wg (non-ducted

application)

Water Pressure Drop = 3.7 ft of head

Power input = 1,067 watts

Cooling Capacity = 11,741 Btuh

c) Perform Fan Power Correction Adjustment

Use the following formula to calculate Fan Power

Correction:

Fan Power

Correction = (Cfm x 0.472) x (External Static

Pressure x 249)/300 = Watts

= (308 x 0.472) x (0 x 249)/300

= 0 Watts

d) Perform Pump Power Correction Adjustment

Use the following formula to calculate Pump

Power Correction:

Pump Power

Correction = (GPM x 0.0631) x (Pressure Drop

x 2,990)/300

= Watts

= (3.1 x 0.0631) x

(3.7 x 2,990)/300

= 7.2 Watts

e) Perform capacity and EER calculations

Use the following formula to calculate capacity

and EER:

ISO Cooling

Capacity = (Cooling Capacity) + (Fan Power

Correction x 3.412)

= 11,741 + (0 x 3.412)

= 11,741 Btuh

f) Perform Corrections by using the ISO Equations

ISO EER = (ISO Cooling Capacity/3.412)/

(Power Input – Fan Power Correction + Pump Power Correction)

= Watts/Watts

NOTE: Do not divide ISO Cooling Capacity by

3.412 to obtain Btuh/Watts.

= (11,741/3.412)/(1,067 – 0 + 7.2)

= 3.20 Watts/Watt

= 10.93 Btuh/Watt

15

Page 16

Performance data

50KQL07 — NOMINAL AIRFLOW 240 CFM

EWT

GPM

(F)

1.0 1.6 1.8

20

1.4 2.5 2.7

1.9 3.7 4.2 5.5 0.50 3.8

1.0 1.4 1.6 9.7 6.9 0.71 0.36 10.9 6.0 0.51 4.3

30

1.4 2.2 2.4 9.8 6.9 0.70 0.33 10.9 6.3 0.52 4.5

1.9 3.3 3.7 9.9 6.9 0.70 0.31 10.9 6.4 0.52 4.7

1.0 0.9 1.0 9.4 6.8 0.72 0.41 10.8 6.9 0.53 5.1

40

1.4 1.4 1.7 9.6 6.9 0.71 0.37 10.9 7.2 0.54 5.4

1.9 2.1 2.5 9.7 6.9 0.71 0.36 10.9 7.4 0.55 5.6

1.0 0.9 1.0 9.0 6.7 0.74 0.46 10.6 7.8 0.56 5.9

50

1.4 1.4 1.6 9.3 6.8 0.73 0.42 10.8 8.2 0.57 6.3

1.9 2.0 2.5 9.5 6.8 0.72 0.40 10.8 8.4 0.57 6.5

1.0 0.8 0.9 8.6 6.5 0.76 0.52 10.4 8.7 0.58 6.7

60

1.4 1.3 1.5 8.9 6.6 0.74 0.48 10.5 9.2 0.59 7.2

1.9 1.9 2.4 9.1 6.7 0.74 0.46 10.6 9.4 0.60 7.4

1.0 0.7 0.9 8.1 6.3 0.78 0.58 10.1 9.6 0.61 7.6

70*

1.4 1.2 1.4 8.5 6.5 0.76 0.53 10.3 10.2 0.62 8.1

1.9 1.8 2.2 8.6 6.5 0.76 0.51 10.4 10.5 0.63 8.3

1.0 0.7 0.8 7.6 6.1 0.79 0.65 9.8 10.6 0.63 8.4

80

1.4 1.1 1.3 8.0 6.2 0.78 0.60 10.0 11.1 0.64 9.0

1.9 1.6 2.0 8.1 6.3 0.78 0.57 10.1 11.5 0.65 9.3

1.0 0.6 0.7 7.4 5.9 0.80 0.68 9.7 11.0 0.64 8.9

85*

1.4 1.0 1.3 7.7 6.1 0.79 0.63 9.9 11.6 0.65 9.4

1.9 1.5 1.9 7.9 6.2 0.78 0.61 10.0 12.0 0.66 9.7

1.0 0.6 0.7 7.2 5.8 0.81 0.72 9.6 11.5 0.65 9.3

90

1.4 1.0 1.2 7.5 6.0 0.80 0.67 9.8 12.1 0.66 9.9

1.9 1.4 1.9 7.6 6.1 0.79 0.64 9.8 12.5 0.67 10.2

1.0 0.6 0.7 6.7 5.5 0.81 0.81 9.5

100

1.4 0.9 1.1 7.0 5.7 0.81 0.75 9.6

1.9 1.3 1.7 7.2 5.8 0.81 0.72 9.6

1.0 0.5 0.7 6.4 5.2 0.81 0.91 9.5

110

1.4 0.9 1.1 6.6 5.4 0.81 0.84 9.5

1.9 1.3 1.7 6.7 5.5 0.81 0.81 9.5

LEGEND

DB — Dry Bulb

EAT — Entering Air Temperature (F)

EWT — Entering Water Temperature (F)

GPM — Gallons per Minute

MBtuh — Btuh in Thousands

SC — Sensible Capacity (MBtuh)

SHR — Sensible Heat Ratio

TC — Total Capacity

THA — Total Heat of Absorption (MBtuh)

THR — Total Heat of Rejection (MBtuh)

WB — Wet Bulb

WLHP — Water Loop Heat Pump

*ARI 320 points (bold printing) are shown for comparison purposes

only. These are not certified data points.

WATER PRESSURE DROP (ft wg) COOLING — EAT 80FDB/67FWB HEATING—EAT70F

Without Motorized

Val ve

With Cv = 2.9

MOPD = 125 psi

TC SC SHR

Input

Power

Operation not recommended

NOTES:

1. MOPD = Maximum Operating Pressure Differential (water pressure differential at unit cannot exceed MOPD or water valve cannot close)

2. Interpolation is permissible, extrapolation is not.

3. All entering air conditions are 80 F db and 67 F wb in cooling and

70 F db in heating.

4. All performance data is based upon the lower voltage of dual voltage rated units. See Performance Correction Tables on page 21

for operating conditions other than those listed above.

5. ARI/ISO 13256-1 (WLHP application) certified conditions are 86 F

EWT, 80.6 db and 66.2 F wb in cooling and 68 F EWT, 68 F db and

59 F wb in heating.

THR TC

Operation not recommended

Operation Not Recommended

Input

Power

THA

16

Page 17

50KQL09 — NOMINAL AIRFLOW 300 CFM

EWT

GPM

(F)

1.3 2.2 2.4

20

1.9 3.9 4.4

2.5 6.2 7.0 7.2 0.63 5.1

1.3 1.8 2.0 11.3 7.6 0.67 0.48 13.0 7.5 0.66 5.2

30

1.9 3.2 3.6 11.7 7.7 0.66 0.44 13.2 7.6 0.67 5.4

2.5 5.0 5.8 11.9 7.8 0.66 0.42 13.3 7.7 0.67 5.4

1.3 1.3 1.5 10.9 7.4 0.68 0.54 12.8 8.1 0.69 5.8

40

1.9 2.6 3.0 11.2 7.5 0.67 0.49 12.9 8.4 0.70 6.0

2.5 4.0 4.7 11.3 7.6 0.67 0.47 13.0 8.6 0.71 6.2

1.3 1.3 1.5 10.6 7.2 0.68 0.60 12.6 9.1 0.72 6.6

50

1.9 2.5 2.9 10.8 7.3 0.68 0.56 12.7 9.4 0.73 6.9

2.5 3.9 4.6 10.9 7.4 0.67 0.53 12.8 9.7 0.74 7.1

1.3 1.2 1.4 10.2 7.1 0.69 0.67 12.5 10.1 0.75 7.6

60

1.9 2.4 2.8 10.4 7.2 0.69 0.62 12.6 10.6 0.77 8.0

2.5 3.7 4.4 10.6 7.2 0.68 0.60 12.6 10.9 0.77 8.2

1.3 1.2 1.3 9.8 6.9 0.71 0.75 12.4 11.3 0.79 8.6

70

1.9 2.2 2.7 10.1 7.0 0.70 0.70 12.5 11.9 0.80 9.1

2.5 3.5 4.2 10.2 7.1 0.69 0.67 12.5 12.2 0.819.4

1.3 1.1 1.3 9.3 6.8 0.73 0.83 12.1 12.5 0.82 9.7

80

1.9 2.1 2.5 9.6 6.9 0.71 0.78 12.3 13.1 0.83 10.3

2.5 3.2 4.0 9.8 6.9 0.71 0.75 12.4 13.5 0.84 10.6

1.3 1.1 1.2 9.0 6.7 0.74 0.87 12.0 13.1 0.83 10.2

85

1.9 2.0 2.4 9.4 6.8 0.72 0.82 12.2 13.7 0.85 10.8

2.5 3.1 3.9 9.6 6.9 0.72 0.79 12.3 14.1 0.86 11.2

1.3 1.0 1.2 8.7 6.5 0.75 0.92 11.8 13.7 0.85 10.8

90

1.9 2.0 2.4 9.1 6.7 0.74 0.86 12.0 14.3 0.87 11.4

2.5 3.0 3.8 9.3 6.8 0.73 0.83 12.1 14.7 0.88 11.7

1.3 1.0 1.2 7.9 6.2 0.79 1.01 11.3

100

1.9 1.9 2.3 8.4 6.4 0.77 0.95 11.6

2.5 3.0 3.7 8.6 6.5 0.76 0.92 11.8

1.3 1.0 1.2 6.9 5.7 0.83 1.10 10.7

110

1.9 2.0 2.4 7.5 6.0 0.80 1.04 11.1

2.5 3.1 3.8 7.8 6.2 0.79 1.02 11.3

LEGEND

DB — Dry Bulb

EAT — Entering Air Temperature (F)

EWT — Entering Water Temperature (F)

GPM — Gallons per Minute

MBtuh — Btuh in Thousands

SC — Sensible Capacity (MBtuh)

SHR — Sensible Heat Ratio

TC — Total Capacity

THA — Total Heat of Absorption (MBtuh)

THR — Total Heat of Rejection (MBtuh)

WB — Wet Bulb

WLHP — Water Loop Heat Pump

*ARI 320 points (bold printing) are shown for comparison purposes

only. These are not certified data points.

WATER PRESSURE DROP (ft wg) COOLING — EAT 80FDB/67FWB HEATING—EAT70F

Without Motorized

Val ve

With Cv = 2.9

MOPD = 125 psi

TC SC SHR

Input

Power

Operation not recommended

THR TC

Operation not recommended

Input

Power

Operation Not Recommended

NOTES:

1. MOPD = Maximum Operating Pressure Differential (water pressure differential at unit cannot exceed MOPD or water valve cannot close)

2. Interpolation is permissible, extrapolation is not.

3. All entering air conditions are 80 F db and 67 F wb in cooling and

70 F db in heating.

4. All performance data is based upon the lower voltage of dual voltage rated units. See Performance Correction Tables on page 21

for operating conditions other than those listed above.

5. ARI/ISO 13256-1 (WLHP application) certified conditions are 86 F

EWT, 80.6 db and 66.2 F wb in cooling and 68 F EWT, 68 F db and

59 F wb in heating.

THA

17

Page 18

Performance data (cont)

50KQL12 — NOMINAL AIRFLOW 350 CFM

EWT

GPM

(F)

1.6 2.1 6.5

20

2.3 3.8 11.4

3.1 6.1 19.6 8.7 0.78 6.0

1.6 1.8 6.5 14.8 9.8 0.66 0.60 16.8 9.4 0.81 6.6

30

2.3 3.3 11.4 14.9 9.9 0.66 0.55 16.8 9.7 0.83 6.9

3.1 5.3 19.6 15.0 9.9 0.66 0.53 16.8 9.9 0.83 7.1

1.6 1.6 6.5 14.4 9.6 0.67 0.68 16.7 10.6 0.86 7.7

40

2.3 3.1 11.4 14.7 9.7 0.66 0.62 16.8 11.0 0.87 8.0

3.1 4.8 19.6 14.8 9.8 0.66 0.59 16.8 11.2 0.88 8.3

1.6 1.6 6.5 14.0 9.5 0.68 0.76 16.6 11.8 0.89 8.8

50

2.3 2.9 11.4 14.3 9.6 0.67 0.70 16.7 12.3 0.91 9.2

3.1 4.5 19.6 14.5 9.6 0.67 0.67 16.7 12.6 0.92 9.5

1.6 1.5 6.5 13.5 9.3 0.69 0.86 16.4 13.1 0.93 9.9

60

2.3 2.7 11.4 13.8 9.4 0.68 0.79 16.5 13.6 0.94 10.4

3.1 4.3 19.6 14.0 9.5 0.68 0.76 16.6 13.9 0.95 10.7

1.6 1.4 6.5 12.9 9.1 0.71 0.97 16.2 14.3 0.96 11.0

70

2.3 2.6 11.4 13.3 9.2 0.69 0.90 16.3 14.9 0.97 11.6

3.1 4.1 19.6 13.5 9.3 0.69 0.86 16.4 15.2 0.98 11.9

1.6 1.3 6.5 12.2 8.9 0.73 1.10 15.9 15.5 0.98 12.1

80

2.3 2.5 11.4 12.7 9.0 0.71 1.01 16.1 16.0 0.99 12.7

3.1 3.9 19.6 12.9 9.1 0.71 0.97 16.2 16.3 1.00 12.9

1.6 1.3 6.5 11.8 8.8 0.74 1.16 15.8 16.0 0.99 12.6

85

2.3 2.4 11.4 12.3 8.9 0.72 1.07 16.0 16.6 1.00 13.2

3.1 3.8 19.6 12.6 9.0 0.72 1.03 16.1 16.9 1.01 13.4

1.6 1.3 6.5 11.5 8.6 0.75 1.23 15.7 16.5 1.00 13.1

90

2.3 2.3 11.4 12.0 8.8 0.73 1.14 15.8 17.1 1.01 13.6

3.1 3.7 19.6 12.2 8.9 0.73 1.09 15.9 17.3 1.01 13.9

1.6 1.2 6.5 10.7 8.4 0.78 1.37 15.4

100

2.3 2.2 11.4 11.2 8.6 0.76 1.27 15.6

3.1 3.4 19.6 11.5 8.6 0.75 1.23 15.7

1.6 1.1 6.5 9.9 8.1 0.82 1.52 15.1

110

2.3 2.0 11.4 10.4 8.3 0.79 1.42 15.3

3.1 3.2 19.6 10.7 8.4 0.78 1.37 15.4

LEGEND

DB — Dry Bulb

EAT — Entering Air Temperature (F)

EWT — Entering Water Temperature (F)

GPM — Gallons per Minute

MBtuh — Btuh in Thousands

SC — Sensible Capacity (MBtuh)

SHR — Sensible Heat Ratio

TC — Total Capacity

THA — Total Heat of Absorption (MBtuh)

THR — Total Heat of Rejection (MBtuh)

WB — Wet Bulb

WLHP — Water Loop Heat Pump

*ARI 320 points (bold printing) are shown for comparison purposes

only. These are not certified data points.

WATER PRESSURE DROP (ft wg) COOLING — EAT 80FDB/67FWB HEATING—EAT70F

Without Motorized

Val ve

With Cv = 2.9

MOPD = 125 psi

TC SC SHR

Input

Power

Operation not recommended

NOTES:

1. MOPD = Maximum Operating Pressure Differential (water pressure differential at unit cannot exceed MOPD or water valve cannot close)

2. Interpolation is permissible, extrapolation is not.

3. All entering air conditions are 80 F db and 67 F wb in cooling and

70 F db in heating.

4. All performance data is based upon the lower voltage of dual voltage rated units. See Performance Correction Tables on page 21

for operating conditions other than those listed above.

5. ARI/ISO 13256-1 (WLHP application) certified conditions are 86 F

EWT, 80.6 db and 66.2 F wb in cooling and 68 F EWT, 68 F db and

59 F wb in heating.

THR TC

Operation not recommended

Operation Not Recommended

Input

Power

THA

18

Page 19

50KQL15 — NOMINAL AIRFLOW 400 CFM

EWT

GPM

(F)

1.8 1.4 1.8

20

2.7 3.0 3.9

3.6 4.9 6.5 9.9 0.93 6.7

1.8 1.2 1.6 16.5 11.2 0.67 0.68 18.8 10.4 0.95 7.2

30

2.7 2.6 3.4 16.6 11.1 0.67 0.62 18.7 10.7 0.96 7.4

3.6 4.2 5.7 16.6 11.0 0.67 0.60 18.6 10.9 0.97 7.6

1.8 1.3 1.6 16.3 11.1 0.68 0.76 18.9 11.6 0.99 8.2

40

2.7 2.3 3.1 16.5 11.2 0.68 0.70 18.9 12.1 1.00 8.7

3.6 3.6 5.1 16.5 11.2 0.67 0.67 18.8 12.3 1.01 8.9

1.8 1.2 1.6 15.8 11.0 0.70 0.85 18.7 13.1 1.03 9.6

50

2.7 2.2 3.1 16.2 11.1 0.69 0.78 18.8 13.7 1.05 10.1

3.6 3.5 5.0 16.3 11.1 0.68 0.75 18.9 14.0 1.05 10.4

1.8 1.2 1.6 15.2 10.8 0.71 0.94 18.4 14.7 1.07 11.1

60

2.7 2.1 3.0 15.6 10.9 0.70 0.87 18.6 15.4 1.09 11.7

3.6 3.4 4.9 15.8 11.0 0.69 0.84 18.7 15.8 1.09 12.1

1.8 1.1 1.5 14.3 10.5 0.73 1.04 17.9 16.4 1.10 12.6

70

2.7 2.0 2.9 14.9 10.7 0.72 0.97 18.2 17.2 1.12 13.4

3.6 3.2 4.8 15.2 10.8 0.71 0.94 18.4 17.6 1.13 13.8

1.8 1.1 1.5 13.4 10.2 0.76 1.16 17.3 18.0 1.13 14.1

80

2.7 2.0 2.8 14.0 10.4 0.74 1.08 17.7 18.8 1.15 14.9

3.6 3.1 4.6 14.3 10.5 0.73 1.05 17.9 19.3 1.15 15.3

1.8 1.1 1.5 12.9 10.0 0.78 1.21 17.0 18.8 1.14 14.8

85

2.7 1.9 2.8 13.5 10.3 0.76 1.14 17.4 19.6 1.15 15.6

3.6 3.0 4.6 13.9 10.4 0.75 1.10 17.6 20.0 1.16 16.0

1.8 1.0 1.4 12.3 9.9 0.80 1.27 16.7 19.5 1.15 15.5

90

2.7 1.9 2.7 13.0 10.1 0.78 1.20 17.1 20.2 1.16 16.3

3.6 3.0 4.5 13.4 10.2 0.76 1.16 17.3 20.6 1.16 16.6

1.8 1.0 1.4 11.1 9.4 0.85 1.40 15.9

100

2.7 1.8 2.7 11.9 9.7 0.82 1.32 16.4

3.6 2.9 4.4 12.2 9.8 0.80 1.28 16.6

1.8 1.0 1.4 9.8 8.9 0.91 1.53 15.0

110

2.7 1.8 2.7 10.6 9.2 0.87 1.45 15.5

3.6 2.9 4.4 11.0 9.4 0.85 1.41 15.8

LEGEND

DB — Dry Bulb

EAT — Entering Air Temperature (F)

EWT — Entering Water Temperature (F)

GPM — Gallons per Minute

MBtuh — Btuh in Thousands

SC — Sensible Capacity (MBtuh)

SHR — Sensible Heat Ratio

TC — Total Capacity

THA — Total Heat of Absorption (MBtuh)

THR — Total Heat of Rejection (MBtuh)

WB — Wet Bulb

WLHP — Water Loop Heat Pump

*ARI 320 points (bold printing) are shown for comparison purposes

only. These are not certified data points.

WATER PRESSURE DROP (ft wg) COOLING — EAT 80FDB/67FWB HEATING—EAT70F

Without Motorized

Val ve

With Cv = 2.9

MOPD = 125 psi

TC SC SHR

Input

Power

Operation not recommended

THR TC

Operation not recommended

Input

Power

Operation Not Recommended

NOTES:

1. MOPD = Maximum Operating Pressure Differential (water pressure differential at unit cannot exceed MOPD or water valve cannot close)

2. Interpolation is permissible, extrapolation is not.

3. All entering air conditions are 80 F db and 67 F wb in cooling and

70 F db in heating.

4. All performance data is based upon the lower voltage of dual voltage rated units. See Performance Correction Tables on page 21

for operating conditions other than those listed above.

5. ARI/ISO 13256-1 (WLHP application) certified conditions are 86 F

EWT, 80.6 db and 66.2 F wb in cooling and 68 F EWT, 68 F db and

59 F wb in heating.

THA

19

Page 20

Performance data (cont)

50KQL19 — NOMINAL AIRFLOW 460 CFM

EWT

GPM

(F)

2.4 3.0 3.7

20

3.6 6.0 7.5

4.8 9.7 12.5 11.2 1.05 7.6

2.4 2.1 2.8 20.1 13.2 0.66 0.81 22.8 12.2 1.09 8.5

30

3.6 4.2 5.8 20.5 13.4 0.66 0.76 23.1 12.6 1.10 8.9

4.8 6.8 9.6 20.7 13.5 0.65 0.74 23.2 12.8 1.11 9.0

2.4 2.0 2.7 19.4 12.9 0.66 0.90 22.5 13.8 1.14 9.9

40

3.6 3.8 5.4 19.8 13.1 0.66 0.84 22.7 14.3 1.16 10.3

4.8 6.2 9.0 20.0 13.2 0.66 0.82 22.8 14.5 1.17 10.6

2.4 2.0 2.6 18.7 12.5 0.67 1.00 22.1 15.5 1.21 11.4

50

3.6 3.7 5.2 19.2 12.7 0.66 0.94 22.4 16.0 1.23 11.9

4.8 6.0 8.8 19.4 12.8 0.66 0.91 22.5 16.3 1.24 12.1

2.4 1.9 2.5 18.0 12.1 0.67 1.11 21.8 17.2 1.27 12.8

60

3.6 3.5 5.1 18.5 12.4 0.67 1.04 22.0 17.8 1.30 13.4

4.8 5.8 8.5 18.7 12.5 0.67 1.01 22.1 18.1 1.31 13.6

2.4 1.8 2.4 17.2 11.8 0.68 1.23 21.4 18.8 1.34 14.2

70

3.6 3.3 4.9 17.7 12.0 0.68 1.16 21.6 19.4 1.36 14.8

4.8 5.5 8.2 17.9 12.1 0.67 1.12 21.8 19.8 1.37 15.1

2.4 1.7 2.4 16.3 11.4 0.70 1.36 20.9 20.3 1.40 15.6

80

3.6 3.2 4.7 16.8 11.6 0.69 1.28 21.2 20.9 1.42 16.1

4.8 5.2 7.9 17.1 11.7 0.69 1.24 21.3 21.3 1.43 16.4

2.4 1.6 2.3 15.8 11.2 0.71 1.43 20.7 21.0 1.42 16.2

85

3.6 3.1 4.6 16.4 11.4 0.70 1.35 21.0 21.6 1.44 16.7

4.8 5.0 7.8 16.7 11.5 0.69 1.31 21.1 21.9 1.46 16.9

2.4 1.6 2.3 15.3 11.0 0.72 1.50 20.4 21.7 1.45 16.7

90

3.6 3.0 4.6 15.9 11.2 0.71 1.42 20.7 22.2 1.47 17.2

4.8 4.9 7.7 16.2 11.3 0.70 1.38 20.9 22.5 1.48 17.4

2.4 1.6 2.2 14.1 10.5 0.75 1.65 19.8

100

3.6 2.9 4.5 14.8 10.8 0.73 1.56 20.1

4.8 4.8 7.5 15.1 10.9 0.72 1.52 20.3

2.4 1.6 2.3 12.8 10.0 0.78 1.81 19.0

110

3.6 3.0 4.5 13.6 10.3 0.76 1.72 19.4

4.8 4.9 7.6 13.9 10.5 0.75 1.68 19.6

LEGEND

DB — Dry Bulb

EAT — Entering Air Temperature (F)

EWT — Entering Water Temperature (F)

GPM — Gallons per Minute

MBtuh — Btuh in Thousands

SC — Sensible Capacity (MBtuh)

SHR — Sensible Heat Ratio

TC — Total Capacity

THA — Total Heat of Absorption (MBtuh)

THR — Total Heat of Rejection (MBtuh)

WB — Wet Bulb

WLHP — Water Loop Heat Pump

*ARI 320 points (bold printing) are shown for comparison purposes

only. These are not certified data points.

WATER PRESSURE DROP (ft wg) COOLING — EAT 80FDB/67FWB HEATING—EAT70F

Without Motorized

Val ve

With Cv = 2.9

MOPD = 125 psi

TC SC SHR

Input

Power

Operation not recommended

NOTES:

1. MOPD = Maximum Operating Pressure Differential (water pressure differential at unit cannot exceed MOPD or water valve cannot close)

2. Interpolation is permissible, extrapolation is not.

3. All entering air conditions are 80 F db and 67 F wb in cooling and

70 F db in heating.

4. All performance data is based upon the lower voltage of dual voltage rated units. See Performance Correction Tables on page 21

for operating conditions other than those listed above.

5. ARI//ISO 13256-1 (WLHP application) certified conditions are 86 F

EWT, 80.6 db and 66.2 F wb in cooling and 68 F EWT, 68 F db and

59 F wb in heating.

THR TC

Operation not recommended

Operation Not Recommended

Input

Power

THA

20

Page 21

CORRECTION FACTORS — ENTERING AIR

HEATING COOLING

EAT

DB

(F)

60 1.011 0.989 1.007 60 0.893 0.889 1.087 * * * * * 0.964 0.902

65 1.004 0.994 1.004 65 0.964 0.692 0.884 1.085 1.108 * * * 0.988 0.967

68 1.002 0.997 1.002 66.2 0.983 0.645 0.838 1.036 1.059 1.231 * * 0.995 0.985

70 1.000 1.000 1.000 67 1.000 0.613 0.806 1.000 1.027 1.199 * * 1.000 1.000

75 0.996 1.007 0.995 70 1.049 — 0.683 0.879 0.902 1.077 1.274 1.415 1.016 1.046

80 0.991 1.018 0.990 75 1.118 — — 0.676 0.698 0.866 1.068 1.266 1.037 1.106

*Sensible Capacity equals total capacity.

TC

Input

Power

THA

EAT

WB

(F)

TC

Sensible Capacity Entering Dry Bulb (F)

70 75 80 80.6 859095

Power

Input

CORRECTION FACTORS — AIRFLOW

THR

% OF

NOMINAL

AIRFLOW

75% 0.951 0.860 0.963 0.952 0.990 1.054 0.966

81% 0.964 0.894 0.973 0.965 0.993 1.035 0.977

88% 0.979 0.936 0.984 0.979 0.996 1.019 0.987

94% 0.990 0.969 0.992 0.990 0.998 1.008 0.994

100% 1.000 1.000 1.000 1.000 1.000 1.000 1.000

106% 1.010 1.033 1.008 1.010 1.002 0.994 1.005

113% 1.019 1.069 1.016 1.019 1.003 0.988 1.011

DB — Dry Bulb

EAT — Entering Air Temperature (F)

SC — Sensible Capacity

TC — Total Capacity

THA — Total Heat of Absorption

THR — Total Heat of Rejection

COOLING CORRECTIONS HEATING CORRECTIONS

TC SC

LEGEND

Input

Power

THR TC

Input

Power

50KQL CONSOLE BLOWER PERFORMANCE 60 Hz

50KQL

07 240 190 240

09 300 240 300

12 350 300 350

15 400 340 400

19 460 400 460

NOTES:

1. Fan speed is field adjustable.

2. All airflow is rated at lowest voltage if unit is dual voltage rated, i.e., 208 v for 208-230 v

units.

3. All units are ARI/ISO 13256-1 rated on high fan speed.

4. All units are designed and rated for zero external static pressure (non-ducted) application.

RATED

AIRFLOW

(cfm)

Low Speed High Speed

AIRFLOW (cfm)

THA

21

Page 22

Application data

Aquazone™ water source heat pump products are available

in a flexible, efficient array of models, which can be used in

all types of water loop, ground water, and ground loop

type systems. Use Aquazone products to provide optimal

energy efficient solutions and adapt to the most challenging design requirements.

AQUAZONE PRODUCT GUIDE

50 SERIES

50RHC,RVC

Horizontal/Vertical

50RHR,RVR

Horizontal/Vertical

50RHS,RVS

Horizontal/Vertical

50HQ,VQ

Horizontal/Vertical

50KQ

50RTG

50RWS

TYPE

SIZE (tons)

Standard

Efficiency

1

/2-5

High

Efficiency

1

/2-5

Premium

Efficiency

1

/4-6

1

Large Capacity

1

6

/2-25

Console

1

/2-11/

2

Rooftop

3-20

Water-to-

Water

3-30

APPLICATION

Efficient, compact, low cost

alternative for retrofit or new

boiler/tower systems.

Efficient, adaptable unit for

new boiler/tower, ground

water, or ground loop systems.

Premium, ultra efficient unit for

new boiler/tower, ground

water, or ground loop systems

Designed to handle large

zoned areas for all

applications.

Attractive design for finished

interior, under-window

installations.

Economical solution for IAQ

problems and tempering

ventilation air.

Used to pre-heat or cool

air and can be used as a

stand-alone or supplemental

boiler/chiller in most hydronic

heating applications. Also

conditions process fluids,

lubricants and refrigerants.

Water loop system

Water loop (or boiler/tower) system applications typically

include a number of units plumbed to a common piping

system. For optimal performance, design this system between 2.25 and 3 gpm per ton of cooling capacity. The

system is comprised of highly efficient packaged reverse

cycle heat pump units interconnected by a water loop. The

water circuit serves as both a sink and source for heat absorption and rejection and is designed for entering water

temperatures between 60 F and 90 F. Within this temperature range, units can heat or cool from the same water

source. Transferring heat from warm to cold spaces in the

building, whenever they coexist, conserves energy rather

than creating new heat.

Refer to the Carrier Water Source Heat Pump Sys-

tem Design Guide for assistance designing water loop

systems. The guide includes a practical approach for the

latest and most current design recommendations including:

• Horizontal, vertical, console, rooftop and water-to-

water product applications.

• Ventilation methods and system design including energy

recovery.

• Acoustical considerations for different product types.

• Addressing IAQ issues such as condensate removal,

humidity control.

• Air distribution design including diffuser selection/

layout and ductwork design.

• Hydronic system design including pipe sizing/layout

and boiler/tower sizing.

• Control configurations such as stand alone, DDC, DCV,

and VVT®.

• WSHP efficiency/operational cost comparison chart.

• System variations such as a system without a boiler,

variable pumping, and VAV for interior use.

Ground water systems

To use Aquazone units in ground water applications, you

should specify extended range. This will provide factoryinstalled coaxial coil insulation to prevent condensate from

dripping when entering water temperatures are below

60 F. In addition, the copper coaxial coil installed on the

Aquazone units may not be suitable for all water conditions. Refer to the Water Conditioning section for proper

coaxial coil material selection.

Surface water system — This system is typically located

near a lake or pond. In this application, the loop can be

submerged in a series of coils beneath the water surface.

The number of coils required depends on system load and

design. This application requires minimum piping and

excavation.

Open loop system — Use this system where ground

water is plentiful. In this application, ground water is

pumped through supply piping from the well to the building. The water is then pumped back into the ground

through a discharge well as it leaves the building. An additional heat exchanger is usually installed between the building water piping system and the ground water piping system. This design limits piping and excavation.

Aquazone units include a standard TXV and are rated to

extremely low temperatures to self-adjust the refrigeration

circuit. Therefore, open loop systems do not require water

regulating valves. Use a slow opening/closing solenoid

valve to conserve water.

Ground loop systems

There are many commonly specified designs for ground

loop applications. Typical designs include vertical loops

and horizontal loops. In some applications, water is piped

from the ground or lake directly to the water source heat

pump. This system only requires piping to get the water

from the source to the unit.

NOTE: When utilizing Aquazone water source heat pumps

in ground loop systems, refer to the design considerations

in the ground water system section.

Horizontal ground loop — Use this system when adequate space is available and trenching can be easily accomplished. A series of parallel pipes are laid out in trenches 3

to 6 feet below the ground surface, and then back-filled.

Often, multiple pipes are used to maximize each trench’s

heat transfer capability. Ground conditions, heating and

cooling requirements, and system design determine piping

requirements and ground loop field size.

Vertical ground loop — Use this system in vertical borehole applications. This design is well suited for retrofit

applications when space is limited or where landscaping is

already complete and minimum site disruption is desired.

The vertical ground loop system contains a single loop of

pipe inserted into a hole. The hole is back-filled and

grouted after the pipe is inserted. The completed loop is

22

Page 23

concealed below ground. The number of loops required depends on ground conditions, heating and cooling requirements, and the depth of each hole.

Hybrid systems — In some applications, it may be bene-

ficial to incorporate a cooling tower into the ground loop

system to reduce the overall cost. A Hybrid System discards excess heat into the air and increases the cooling

performance of the ground loop.

Condensate drainage

Connect the console unit condensate drain to the building

condensate drain with a flexible, non-pressure rate plastic

hose. Be sure to avoid kinks in this hose to ensure an unobstructed flow of condensate from the unit to the drain.

The condensate hose’s horizontal run is usually too short

to pose any drainage problems, however, make sure this

line is pitched at least 1 inch for every 10 feet of run (in the

direction of the flow.) Avoid low points and unpitched

piping since dirt collects in these areas and may cause stoppage and overflow.

Installing a trap or drain in the field is not required unless

specified by local codes. The 50KQL units are designated

in a blow-thru configuration. The condensate drain pan is

located on the outlet side of the blower so that the pressure

in the drain pan is higher than the atmospheric pressure.

Water conditioning

In some applications, maintaining proper water quality

may require higher corrosion protection for the water-torefrigerant heat exchanger. Water quality varies from location to location and is unique for each job. Water characteristics such as pH value, alkalinity, hardness, and specific

conductance are important when considering any WSHP

application. Water typically includes impurities and hardness that must be removed. The required treatment depends on the water quality as well as system type. Water

problems fall into three main categories:

1. Scale formation caused by hard water reduces the

heat transfer rate and increases the water pressure

drop through the heat exchanger. As water is heated,

minerals and salts are precipitated from a solution

and deposited on the inside surface of the pipe or

tube.

2. Corrosion is caused by absorption of gases from the

air coupled with water on exposed metal. Corrosion

is also common in salt-water areas.

3. Organic growths, such as algae, can reduce the heat

transfer rate by forming an insulating coating on the

inside tube surface. Algae can also promote corrosion

by pitting.

NOTE: In most commercial water loop applications, Aquazone™ WSHP units use copper water-to-refrigerant heat

exchanger. Units can also be equipped with a Cupronickel

heat exchanger for applications where water is outside the

copper heat exchanger’s standard contaminant limits.

WATER QUALITY GUIDELINES

CONDITION ACCEPTABLE LEVEL

pH

Total Hardness

Iron Oxides Less than 1 ppm.

Iron Bacteria No level allowable.

Corrosion*

Brackish