Page 1

HFATUNG & COOLING

%isitx__ _.¢arrier.com

Installation, Start-Up and Service instructions

50JZ 7-t4 kW (024-048)

SingMe-Package 50Hz Heat Pump Units

with Puron® (R-410A) Refrigerant

NOTE: Read the entire instruction manual be%re starting the

installation.

TABLE OF CONTENTS

SAFETY < ONSIDERATIONS 1

Introduction 2

Receiving and Installation .............................................................. 2

(heck Equipment ...................................................................... 2

Identify Unit ........................................................................ 2

Inspect Shipment ................................................................. 2

Provide -Unit Support ................................................................ 2

Roof Curb ............................................................................ 2

Slab Mount ..................................... 2

Ground Mount .................................... 2

Provide Clearances ................................... 2

Rig and Place Unit ................................... 3

Inspection ..................................... 4

Installation .......................................... 4

Select and Install Ductwork ........................... 5

Converting Horizontal Discharge Units To

Downflow (Vertical) Discharge Units ................. 7

Provide for Condensate Disposal 7

Install Electrical Connections ................................................... 9

High-Voltage Connections .......................... 9

Routing Powm Leads into Lnit .................... 1l

Connecting Ground Lead to Ground Lug ............. 1l

Routing Control Power Wires (24-V) i 1

PRE-START-UP !4

START-UP 14

(beck f_r Refrigerant Leaks 14

Start-Up Adjustments 14

Checking Cooling and Heating Control Operation .......... 14

Checking and Adjusting Refi'igerant Charge .................... 16

Refi'igerant Charge ........................... 16

No ( harge .................................... !6

Low Charge Cooling ........................... 16

Heating Mode Change 16

To Use Cooling Charging Charts i6

Indoor Airflow and Airflow Adjustments ........................ 16

Defiost ( ontrol ....................................................................... 18

Quiet Shift ..................................... 18

Defiost ........................................ !8

MAINTENANCE .................................... 20

Air Filter .......................................... 20

Indom Blower and Motor ........................... 21

Outdoor (oil, Indoor Coil, and Condensate D*ain......... 21

Outdoor Fan ...................................... 2l

Eleckical Controls and Wiring ...................... 22

Refrigerant Circuit ................................. 22

Indoor Airflow ................................... 22

PURON_R:Systems Items .......................... 22

System Infbnamtion .............................. 24

Phase Monitor Control .......................... 24

Loss of Charge S_itch 24

Check Defiost Them_ostat 24

TROL BLESHOOTING ............................................................... 24

Start°L p Checklist ........................................................................ 24

NOTE TO INSTALLER READ THESE INSTRUCTIONS

CAREFULLY AND COMPLETELY befbre installing this unit.

Also, nmke sure the Owner's Manual and Se*vice Instructions are

left with the unit afle* installation

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be

hazardous due to system pressure and electrical components Only

trained and qualified personnel should install, repair, or service

air-conditioning equipment.

Untrained personnel can perfbrm basic nmintenance functions of

cleaning coils and filters. All other operations should be performed

by trained service personnel. When working on air-conditioning

equipment, observe precautions in the literature, tags, and labels

attached to the unit, and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth fbr unbrazing operations. Have fire extinguisher

available for all brazing operations.

Improper installation, adjustment, alteration, service, nmiute°

nance, or use can cause explosion, fire, electric shock, or

other occurrences, which could cause serious injury or death

or danmge your proper U. Consult a qualified installer or

service agency for infbrmation or assistance. The qualified

installer or agency must use only fhctory-authorized kits or

accessories when modifying this product

Recognize safety information. This is the safhty-alert symbol/\.

When you see this symbol on d'*e product or in instructions or

manuals, be alert to the potential fbr personal injury

Understand die signal words DANGER, WARNING, (AU°

TION, and NOTE Danger identifies the most serious hazards,

which will result in severe personal injury or death. Warning

indicates a condition that could cause serious personal injury or

death. Caution is used to identif}' unsaf_ practices, which would

result in minor personal injmy or product and property damage.

NOTE is used to highlight suggestions which will result in

enhanced installation, reliabili w, or operation.

1. The power supply (volts, phase, and hertz) must correspond to

that specified on unit rating plate.

2. The electrical supply provided by the utility must be sufficient

to handle toad imposed by this unit.

3. This installation must confbrm with local building codes and

with IE( (International Electrical (ode). Refer to provincial

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

PC 101 Catalog No. 005-00027 Printed in U.S.A. Form 50JZ-C2SI Pg 1 7-02 Replaces: 50JZ-C1SI

Page 2

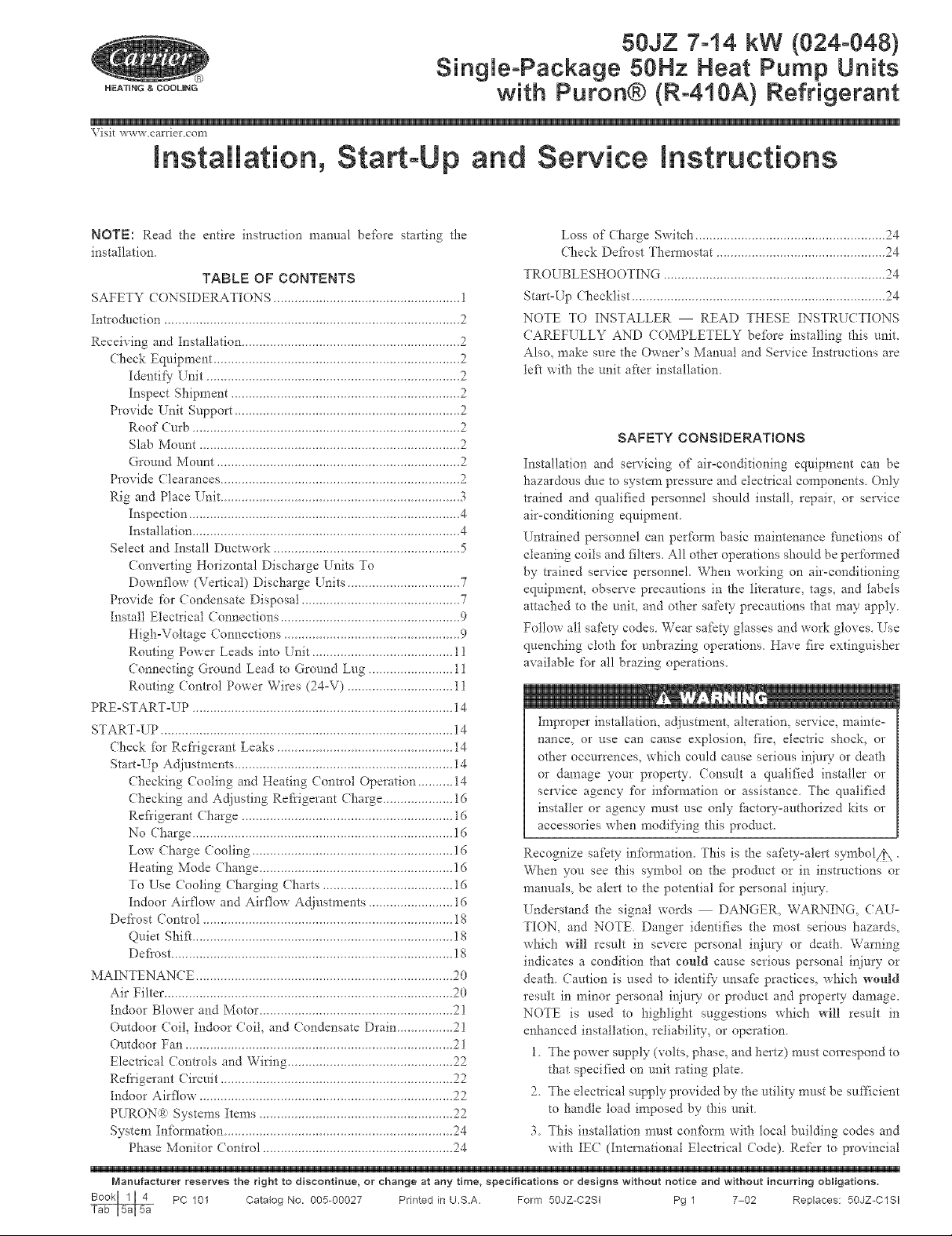

Fig. 1--UNt 50JZ (50 Hz)

and local plumbing or _xaste water codes and other applicable

local codes

Be%re per%rming service or maintenance operations on

system, turn off main power to unit. Turn off accessory heater

power switch if applicable Electrical shock could cause

severe injury or death

Puron (R-410A) systems operate at higher pressures than

standard R=22 systems. DO not use R=22 service equipment

or components on Pnron (R-410A) equipment. Ensure service

equipment is rated for Puron (R-4IOA)

INTRODUCTmON

The 50JZ (50 Hz) heat pump is fhlly selfocontained and designed

fbr otttdoor installation (See Fig. 1) Standard units are shipped in

a horizontal-discharge configuration for installation on a ground=

level slab Standard units can be converted to downflow (vertical)

discharge configurations for rooftop applications

RECEIVING AND INSTALLATION

Step 1--Check Equipment

IDENTIFY UNIT

The unit model number and serial nm'nher are stamped on the unit

rating identification plate. Check this infbrmafion against ship=

ping papers.

INSPECT SHIPMENT

Inspect tbr shipping damage while unit is still on shipping pallet

If unit appears to be damaged or is torn loose ti'om its anchorage,

have it examined by transportation inspectors be%re removal.

Fopxard claim papers directly to transportation company. Manu=

fitcmrer is not responsible fbr any damage incurred in transit.

Check all items against shipping list. Immediately notify the

nearest ( mTier Air Conditioning once if any item is missing. To

prevent toss or damage, leave all parts in original packages until

installation.

C99064

Step 2--Provide Unit Support

ROOF ([RB

Install accessory roof curb in accordance with instrt/cfions shipped

with curb. (See Fig. 5) Install insulation, cant strips, roofing, and

flashing Ductwork must be attached to cuIS.

INPORTANT: The gasketing of the nnit to the roof cm:b is critical

for a watertight seal Install gasketing material supplied with the

roof curb Improperly applied gasketing also can result in air leaks

and poor unit perfbrmance

Curb should be level (See Fig. 6) to within 1/4 in. (6.4 ram). This

is necessa_" t'or unit &ain to fimction properly. Refkr to accessow-

roof curh installation instructions for additional infbrmation as

required.

SLAB MOUNT

Place the unit on a solid, level concrete pad that is a minimum of

4 in. (102 ram) thick with 2 in. (51 ram) above grade. (See Fig. 7)

The slab should extend approximately 2 in. (51 ram) beyond the

casing on all 4 sides of the unit. Do not secure the unit to the slab

except when required by local codes.

GROUND MOUNT

The unit may be installed either on a slab or placed directly on the

ground if local codes permit. Place the unit on level ground

prepared with gravel fbr condensate discharge.

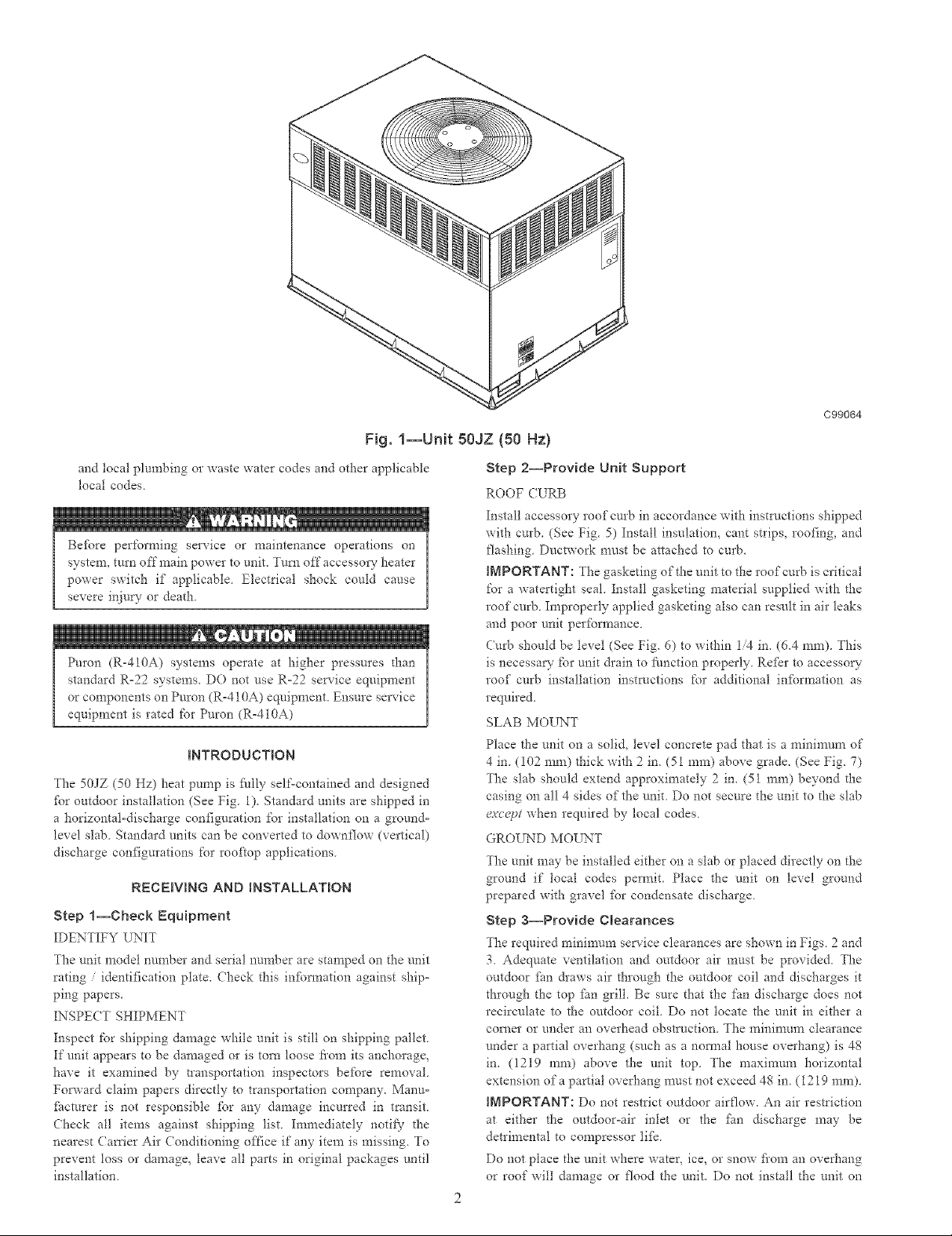

Step a--Provide Clearances

The required minimum service clearances are shown in Figs 2 and

3 Adequate ventilation and outdoor air must be provided. The

outdoor fire &aws air through the outdoor coil and discharges it

through the top fYn grill. Be sure that the fan discharge does not

recirculate to the outdoor coil. Do not locate the unit in either a

corner or under an overhead obstruction. The minimum clearance

under a partial overhang (such as a nom_al house overhang) is 48

in. (1219 ram) above the unit top. The maximum horizontal

extension of a partial overhang must not exceed 48 in. (1219 ram).

IMPORTANT: Do not restrict outdoor airflow. An air restriction

at either the outdoor=air inlet or the fire discharge may be

detrimental to compressor tifk

Do not place the unit where water, ice, or snow fi'om an overhang

or roof will damage or flood the unit Do not install the unit on

Page 3

il..........................r LLLo vE l

Tt

406 5

[_6 60]

EVAP l

TOP VIEW

RE'G_RED CLEARANCES TO COMBtIS_BLE MA'n-

TOP OF UNIT ............................................. 3556 [1400]

DUCT SiDE OF RNIT ......................................... 508 {200]

SIDE OPPOSITE DUCTS ..................................... 3556 [14001

BOTTOM OF UNIT ............................................ 127 {0501

ELECTRIC HEAT PANEL ..................................... 9144 [36001

NED. REQUIRED CLEARANCE&

BETWEEN UNITS, POWER ENTRY SIDE ........................ 10668 [4200]

UNiT AND UNGROUNDED SORTADES, POWER ENTRY SIDE .......... 914¸0 [3600]

UNiT AND BLOCN OR CONCREIE WAILS AND OTHER

GROUNDED SURFACES, POWER ENTRY SIDE .................. 1066¸8 [4200]

{31 44/

_IEIR _NTRY

S£RV_CE PORTS

• 11939

loiH

i" -n

MiLLiMETERS [iN]

MIllIMETERS [IN]

[47 O0

4020

[_583]

SUPP{ Y

DUCT

OPENING

i ;

177

Y

{463]

}

885 ....................................

[3¸48}

D_EeN_LEARANG_TO_ ORERM_'_ON AND SERVICINB

EVAP COIL ACCESS SIDE .................................. 914¸0 [36¸001

POWER ENTRY Si0E ........................................ 914¸0 [36.001

(EXCEPT HOH NEE REOUIREWENTS)

UNIT TOP ................................................ 914¸0 [36¸001

SiDE OPPOSITE 00GTS ..................................... 914¸0 [36¸001

DUCT PANEL .............................................. 304¸8 [12061,

*NININON DISTANCES:IF UNiT IS P{ACED LESS THAN 3048 [JRO0] FRON WALL

SYSTEM,IHEN SYSIEN PER;ORNANCE NAY_E COMPROMISER

24£¸6

I983]

I

_5505

REAR VIEW

t I

[2167]

NILLIMETERS [IN1

RETURN

DUCT

OPENING

[9831

A

i I i _

[168]

[2851

_12851

13212]

LCO_PRESSOR, BLOWER, EtECJRIC HEAY

& ELECTRICAL ACCESS PANgL

................................................._2263 ..........................................................

[48 281

LEFT SIDE VIEW FRONTVIEW RIGHT SIDE VIEW

UNiT

80JZ024

80JZO30

50JZ036

ELECTRICAL CHARACTERiSTiCS

400-3-50

400-3-50

400-3-50

UNIT WE_GHT

Ib kg

299 135.6

320 145.2

328 148.8

Fig. 2--50JZ024-036 Unit Dimensions

carpeting or other combustible materials Slab=mounted malts

should be at least 4 in. (101.6 ram) abo_e the highest expected

v, ater and runoff levels Do not use unit if it has been under water.

Step 4--Rig and Place Unit

Rigging and handling of this equipment can be hazardmEs %r many

reasons due to the installation location (roo£q, elevated structures,

etc,)

-}..LO..i

..62 l ' _

.......i [IO 87} 13_ / ........ ,

7 4 _-- 445 { 75] DIA K 0

{4 81]

C00160

UNIT HEBGHT

IN.(MM)

"A"

35.02 (889.5)

37.02 (940.3)

37.02 (940.3)

Only trained, qnalified crane operators and ground support staff

should handle and install this equipment,

When working with this equipment, obseza'e precautions in tlae

literature, on tags, stickers, and labels attached to the equipment,

and any other safety precautions that might apply.

Follow all applicable safety codes. Wear safety shoes and work

gloves.

19.0 (482.6) 18.3 (463.6) 16.0 (406.4)

20.0 (508.0) 19.3 (489.0) 17.6 (447.0)

20.0 (508.0) 19.0 (462.6) 16.5 (419.1)

CENTER OF GRAVITY

IN.(MM)

X Y Z

Page 4

. FULL LOUV[R

J

I

EVAP c011

° /

CO_l) COil

TOP VIEW

REQ4JIRB_CLEARANCES TO COr_BIJSTIBLE MAll..

lOP OF UNIT ........................................... 3556 [1400]

DUCT SIDE OF UNIT ......................................... 508 [?OO]

SIDE OPPOSITE DUCTS ..................................... 355¸6 [14OO]

_OTTOM OP UNIT ............................................ 127 [OSO]

ELECTRIC NEAT PANEl..................... 9}4¸4 {36 00}

NEC. REel]RED CLEARANCES.

BETWEEN UNITS, POWER ENTRY SIDE ........................ 10668 [420DI

UNIT AND UNGROUNDED SURFACES, POWER ENTRY SIDE .......... 9}4¸0 [3DOO]

UNIT AND BLOCK OR CONCRETE WALES AND OTHER

GROUNDED SURFACES, POWER ENTRY S{DE ...... {066 8 {42 00]

.............................................I090_ ............................................

[4294]

FULL _OUV#R

SERVICE PORTS

F_E_D [NTRY_

....................................... I

MILLIMETERS IIN]

MILL!ME]ENS [IN]

................................................ 11_39 ...................................................

[47 00)

4020

[5831

t

117 7

SUPPLY RETURN

DUCT DUCT

OPEN NG OPEN NG

,il'

l i J

_81,2 _3AYS

1S,431 IIS 6YI

_351 ? _ _331,2

I13_DSI I13_831

REAR VIEW

REQUIRED CLEARANCE FOR OPERATION AND SB_IVICING

EVAP CO{L ACCESS SIDE ................................. 914¸0 [36¸001

POWER ENTRY SIDE ........................................ 914D [36¸001

{EXCEPT FOR NED REQUIREMENTS}

UNIT TOP ................................................ 9140 [36¸00I

SIDE OPPOSITE DUCTS ............................... 914¸0 [36¸001

DUCT PANZL ............................. 304 8 {I?OO}_

_MINIMNM D!STANDES:IF UNIT IS PLACED LESS THAN 3048 [!DOO] FROM WALL

SYSTEM,THEN SYSTEM PERFORMANCE MAYDE COMPROMISED

DIMENSIONS IN {} ARE IN INCHES

MILLIMETERS [IN}

FULL LOUVZR

620 2

'14.'i

[48 28

FRONT VIEW

UNIT

50JZ048

ELECTRICAL CHARACTERiSTiCS IN. (Mivl}

400-%50 355 161.0 40.98 (1040.9)

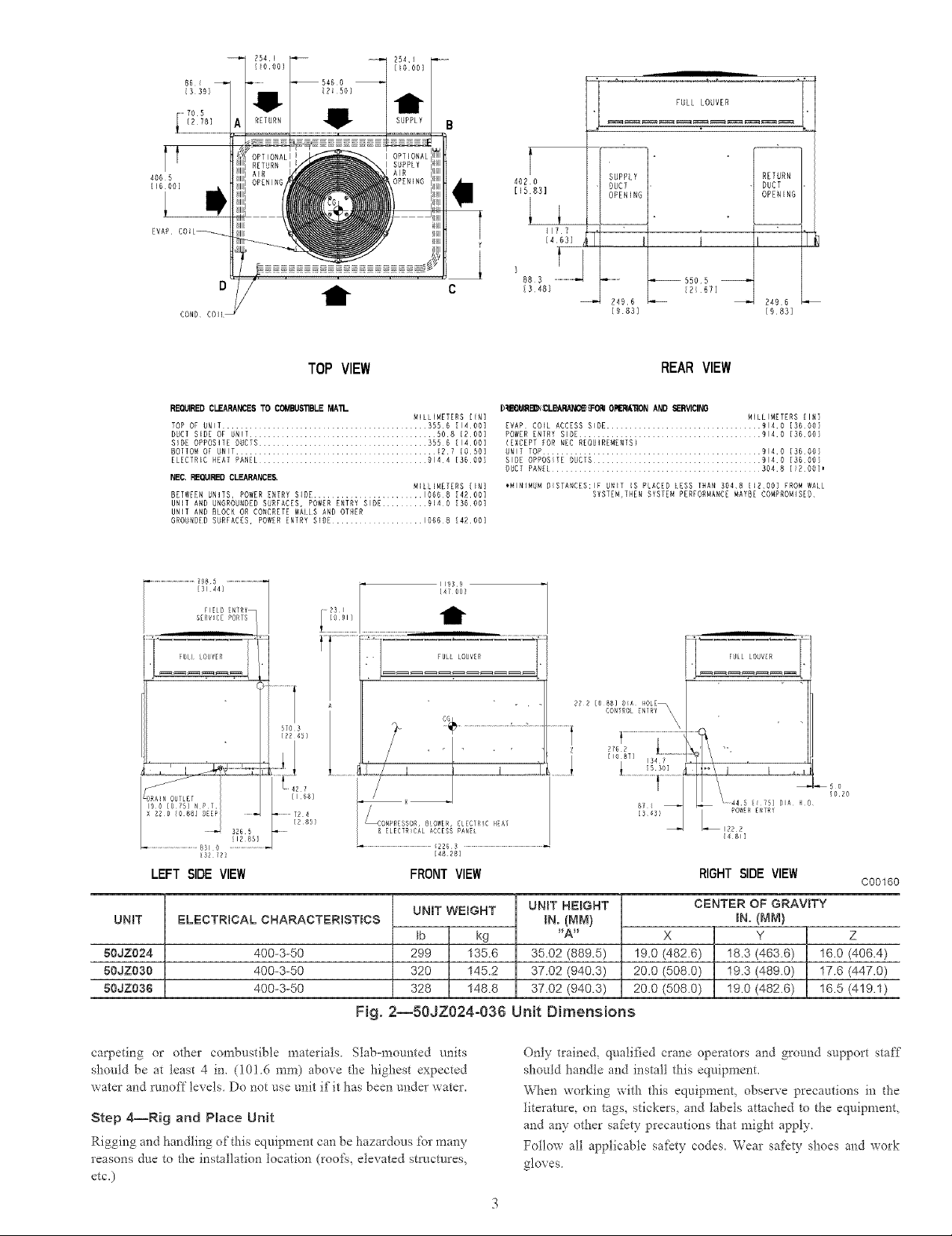

[NSPE(TION

Prior to initial use, and at monthly intervals, all rigging brackets

and straps should be visually inspected for any damage, evidence

of wear, structural deformatiom or cracks. Pa_1icular attention

should be paid to excessive wear at hoist hooking points and load

support areas. Brackets or straps showing any kind of wear in these

areas must not be used and should be discarded.

[NSTALLATION

1, Remove unit li'ona shipping carton. Leave top shipping skid on

the unit as a spreader bar to prevent the rigging straps flora

UNIT WEIGHT UNIT HEIGHT

tb kg "A"

Fig. 3--50JZ 048 Unit Dimensions

44 5 [{ 75101A K O_

POWER _NTRY

.............. 4

0 161

'2;'- L_

[4 81 RIGHT SIDE VIEW

CENTER OF GRAVITY

IN. {MN)

X Y Z

200 (508.0) 21.3 (539.8) 18.0 (457.2)

damaging the unit. If the wood skid is not available, use a

spreader bar of sufficient length to protect unit fi'orn damage.

2,

Position the ti_ing bracket assembly around the base of the

unit. Be sure the strap does not twist

3,

Place each of the 4 metal lifting brackets into the rigging holds

in the composite unit base

4,

Thread lifting bracket strapping around bottom perimeter of

unit as follows:

a Open lever of tension buckle (ratchet type)

b. Feed strapping through tension buckle as shown in Fig 8

C00161

Page 5

1

Y

4 x 3

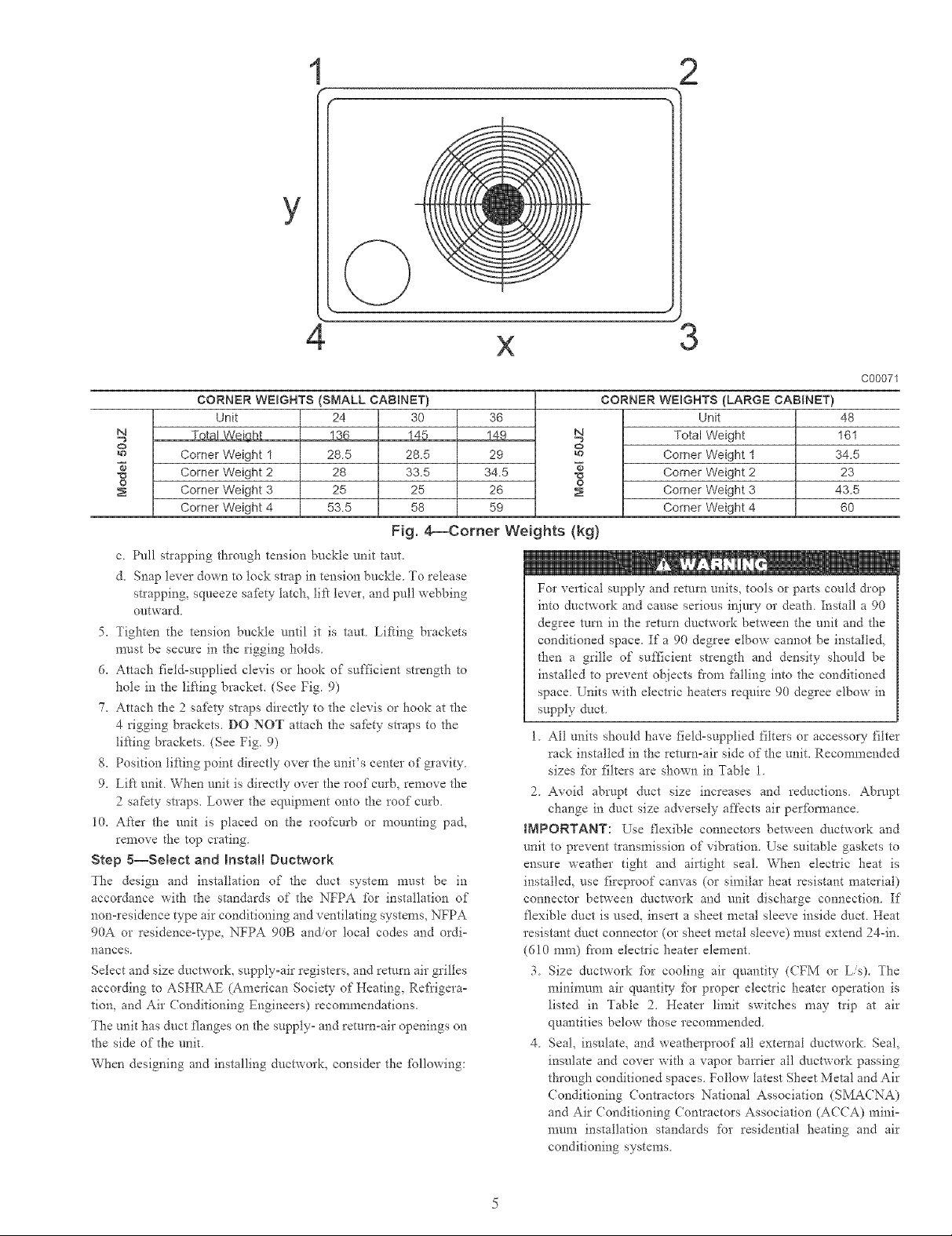

CORNER WEIGHTS (SMALL CABRNET)

N

O

o

c Pull strapping through tension buckle unit taut.

d. Snap lever down to lock strap in tension buckle. To release

strapping, squeeze safkty latch, lift lever, and pull webbing

outward

5. Tighten the tension buckle until it is taut Lifting brackets

n-rest be secure in the rigging holds

6. Attach field-supplied clevis or hook of sufficient strength to

hole in the lifting bracket. (See Fig 9)

7. Attach the 2 safkty straps directly to the clevis or hook at the

4 rigging brackets. DO NOT attach the safkty straps to the

lifting brackets. (See Fig 9)

8. Position lifting point directly over the unit's center of gravity

9. Lift unit When unit is directly over the roof curb, remove the

2 safBty straps. Lower the equipment onto d3e roof curb

10. After the unit is placed on the roofcurb or mounting pad,

remove [he top crating.

Step 5--Select and hstaH Duetwork

The design and installation of the duct system must be in

accoIdance with [he standards of [he NFPA for installation of

non-residence type air conditioning and ventilating systems, NFPA

90A or residence-Vpe, NFPA 90B an_or local codes and ordi-

nances

Select and size ductworl% supply_air registers, and return air grilles

according to ASHRAE (American Society of Heating, Ret'rigerao

tion, and Air Conditioning Engineers) recommendations.

The unit has duct flanges on the suppty_ and returnoair openings on

the side of [he unit.

When designing and installing ductwork, consider the _bllowing:

Unit

Total Weiqh_

Corner Weight 1

Corner Weight 2

Corner Weight 3

Corner Weight 4

24 30

18_ 14_

28.5 28.5

28 33.5

25 25

53.5 58

Fig. 4_Comer Weights (kg)

CORNER WEIGHTS (LARGE CABINET)

36

149

29

34.5

26

59

IMPORTANT: Use flexible connectors between ductwork and

unit to prevent transmission of vibration. Use suitable gaskets to

ensure weather tight and airtight seal. When electric heat is

installed, use fireproof canvas (or similar heat resistant material)

connector between ductwork and unit discharge connection. If

flexible duct is use& insert a sheet metal sleeve inside duct. Heat

resistant duct connector (or sheet metal sleeve) must extend 24-in.

(610 ram) fi'om electIic heater element.

N

O

o

For vertical supply and return units, tools or parts could &op

into dnctwork and cause serious injury or death Install a 90

degree mrn in the return ductwork between the unit and the

conditioned space. If a 90 degree elbow cannot be installed.

then a grille of sufficient strength and density should be

installed to prevent objects fiom fi_lling into the conditioned

space Units with electric heaters require 90 degree elbow in

supply duct

1 All units should have field-supplied filters or accessory filter

rack installed in the return-air side of the unit. Recommended

sizes _br filters are shown in Table 1

2. Avoid abrupt duct size increases and reductions. Abrupt

change in duct size adversely affects air per_bm_ance.

3. Size ductwork _br cooling air quantity (CFM or L/s). The

minimum air quantity fbr proper electric heater operation is

listed in Table 2. Heater limit switches may trip at air

quantities below those recommended.

4. Seal, insulate, and weatherproof all external ductwork. Seal,

insulate and cover with a vapor battier all ductwork passing

through conditioned spaces. Follow latest Sheet Metal and Air

(onditioning Conkactors National Association (SMACNA)

and Air ( onditioning Contractors Association (AC(A) mini-

mum installation standards for residential heating and air

conditioning systems.

Unit

Total Weight

Corner Weight 1

Corner Weight 2

Corner Weight 3

Corner Weight 4

C00071

48

161

34.5

23

43.5

60

Page 6

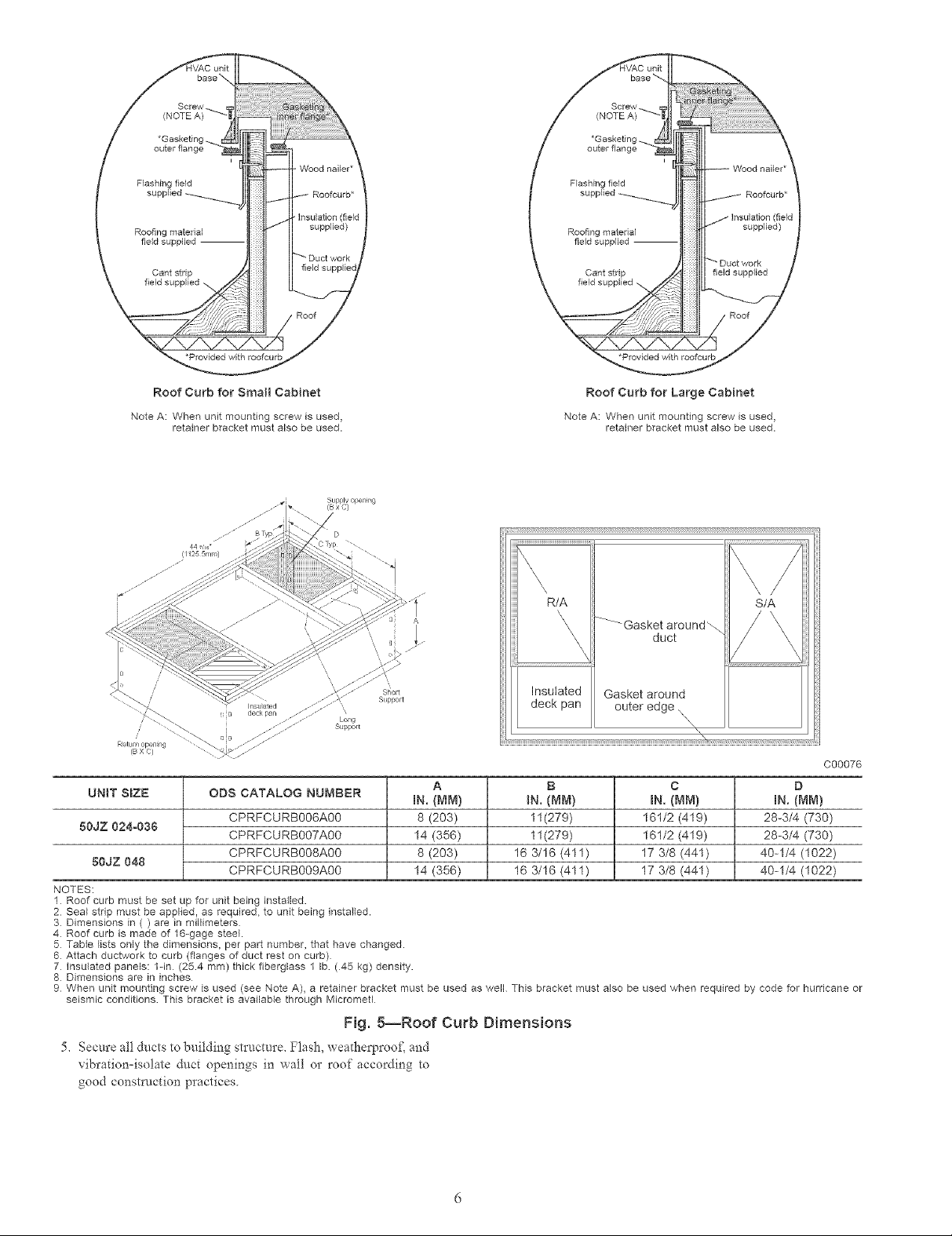

Roof Curb for Smart Cabinet

Note A: When unit mounting screw is used,

retainer bracket must also be used.

01255mm)

Roof Curb for Large Cabinet

Note A: When unit mounting screw is used,

retainer bracket must also be used.

\

R/A

A

_Gasket around_

\

\

\

\

duct

S/A

/2

s ipport

Loug

Support

Retur iopen ng

(B X C)

UNIT SBZE ODS CATALOG NUMB_::R

50JZ 024-036

80dZ 048

NOTES:

1 Roof curb must be set up for unit being instalbd.

2 Seal strip must be applied, as required, to unit being installed.

3 Dimensions in ( ) are in milfimeters

4 Roof curb is made of 16-gage steel.

5 Table lists only the dimensions, per part number, that have changed.

6 Attach ductwork to curb (flanges of duct rest on curb)

7 insulated panels: ldn (254 mm) thick fiberglass 1 Ib (45 kg) density.

8 Dimensions are in inches

9 When unit mounting screw is used (see Note A), a retainer bracket must be used as well This bracket must also be used when required by code for hurricane or

seismic conditions This bracket is available through Micrometl

CPRFCURB006A00 8 (203) 11(279) 161/2 (419) 26-3/4 (730)

CPRFCURB007A00 14 (356) 11(279) 161/2 (419) 28-3/4 (730)

CPRFCURB008A00 8 (203) 16 3/16 (411) 17 3/8 (441) 40-1/4 (1022)

CPRFCURB009A00 14 (356) 16 3/16 (411) 17 3/8 (441) 40-1/4 (1022)

A B C D

IN. {MM) IN. (MM) IN. {MN} IN. (NM)

Insulated

deck pan

Gasket around

outer edge \

\"\4

'\

C00076

Fig. 5--Roof Curb Dimensions

5, Secure ai! ducts to building structure, Flash, _ eatherproof, and

_ibration=isolate duct openings in _xall or roof according to

good construction practices

Page 7

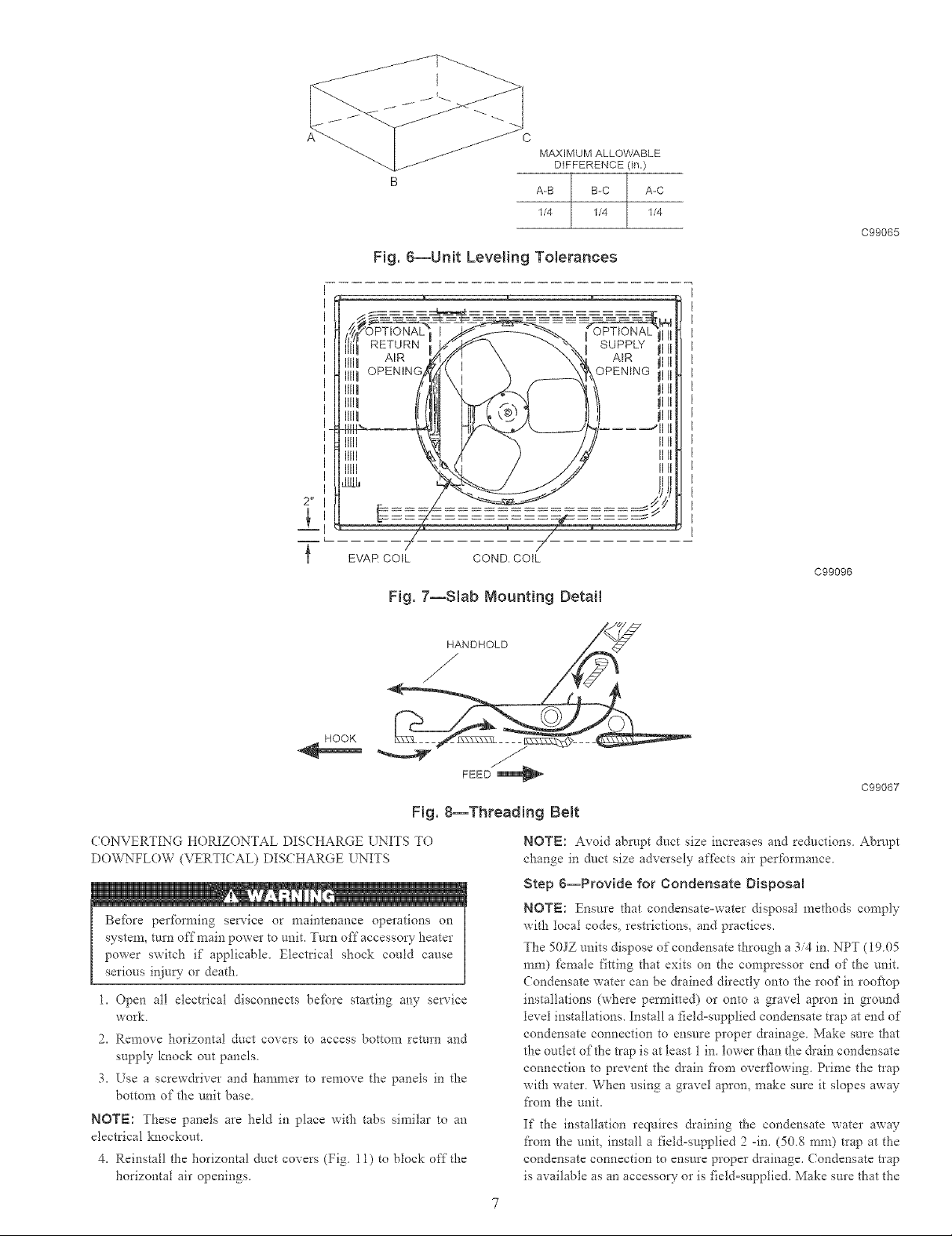

3

MAXIMUM ALLOWABLE

DIFFERENCE (in.)

A-B B-C A-C

1/4 1/4 1/4

C99065

Fig. 6--UnBt Leveling ToMrances

Illll

Itlll

Illll

I1111

It111

It111

2 _r

mL

EVAR COIL COND. COIL

C99096

Fig. 7--Slab Mounting Detail

HANDHOLD

/

HOOK

Fig. 8--Threading Be{t

CONVERTING HORIZONTAL DISCHARGE UNITS TO

DOVv%*FLOW(VERTICAL) DISCHARGE LNITS

Before perfc_rming service or maintenance operations on

system, trim off main power to unit. Turn off accessory heater

power switch if applicable. Electrical shock could cause

serious injury or death.

1. Open all electrical disconnects before starting any service

work

2. Remove horizontal duct covers to access bottom remm and

supply knock out panels.

3. Use a screwdriver and hammer to remove the panels in the

bottom of the unit base.

NOTE: These panels are held in place with tabs similar to an

electrical knockout

4. Reinstall the horizontal duct covers (Fig. 11) to block offthe

horizontal air openings.

FEED

C99067

NOTE: Avoid abrupt duct size increases and reductions Abrl/pt

change in duct size adversely affects air performance.

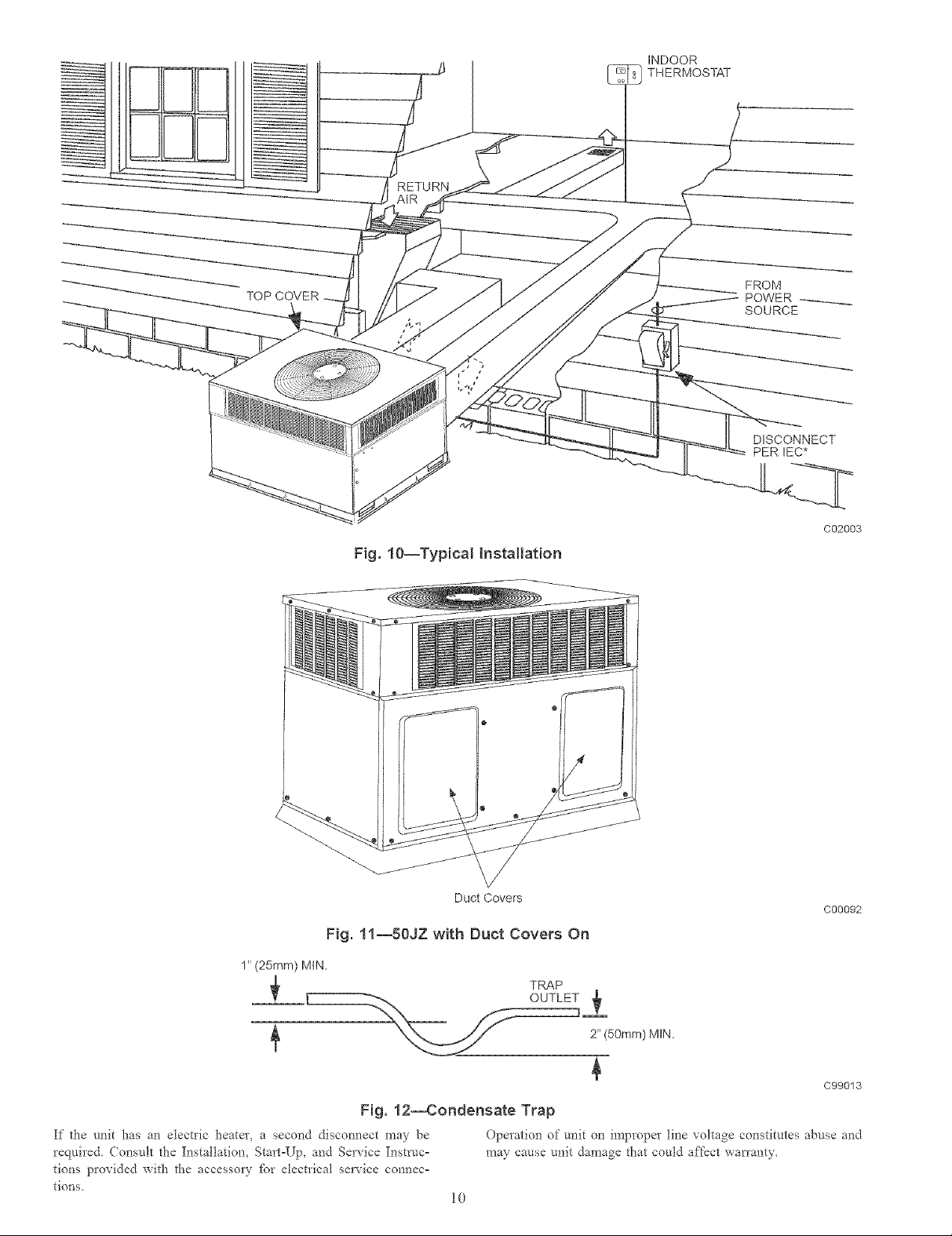

Step 6--Provide for Condensate Disposal

NOTE: Ensure that condensate-water disposal methods comply

with local codes, restrictions, and practices.

The 50JZ units dispose of condensate through a 3/4 in. NPT (I9.05

ram) f_male fitting that exits on the compressor end of d'*e unit.

Condensate water can be drained directly onto the roof in rooflop

installations (where permitted) or onto a gravel apron in ground

level installations. Install a field-supplied condensate trap at end of

condensate connection to ensure proper drainage. Make sure that

the outlet of the trap is at least 1 in. lower than the &ain condensate

connection to prevent the drain fi'om overflowing. Prime the trap

with water. When using a gravel apron, make sure it slopes away

I_'om the unit.

If the installation requires draining the condensate water away

from the unit, install a field-supplied 2 -in. (50.8 ram) trap at the

condensate connection to ensure proper &ainage. Condensate trap

is available as an accessory or is field-supplied. Make sure that the

Page 8

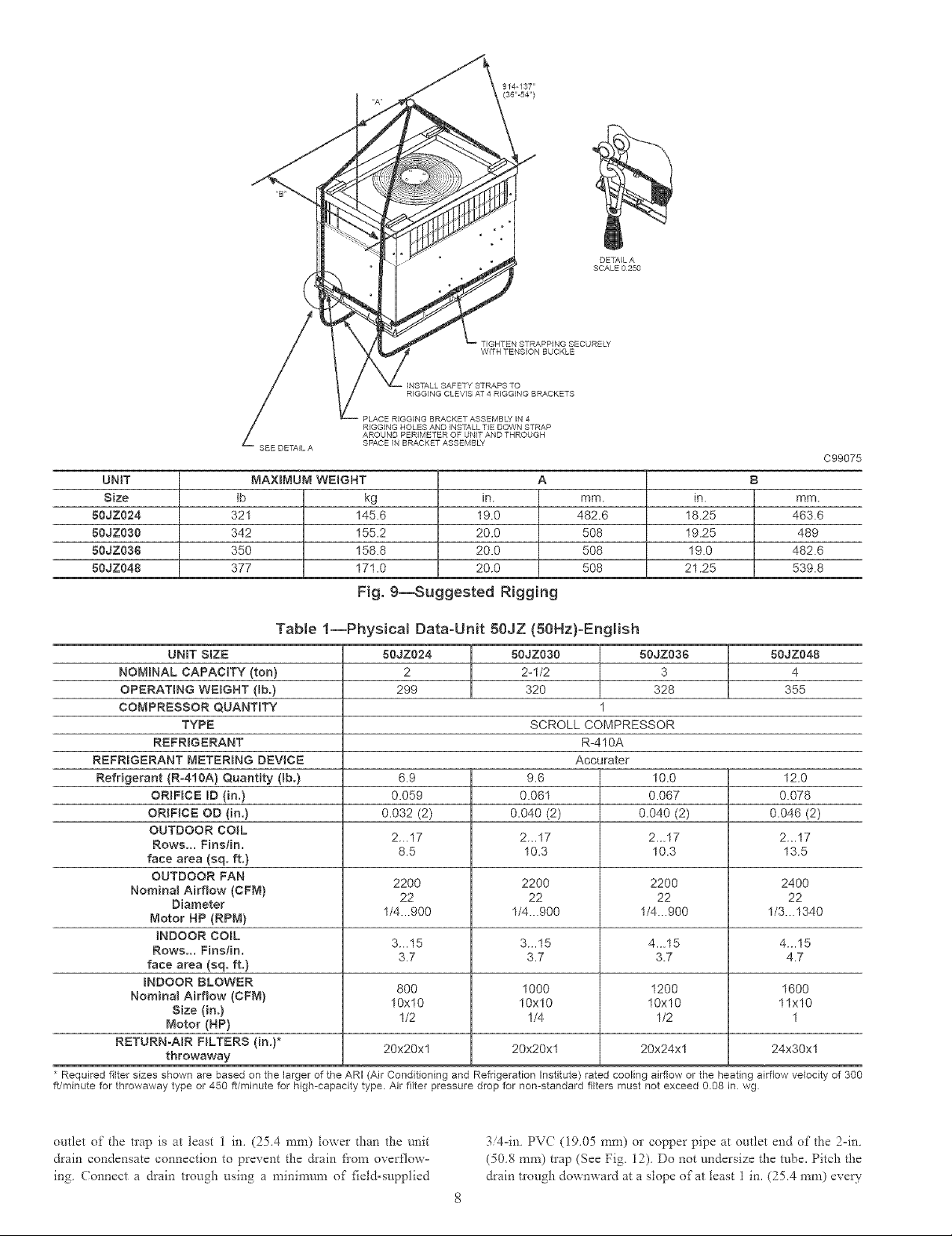

DETAIL A

SCALE 0250

TIGHTEN STRAPPING SECURELY

WITH TENSION BUCKLE

= INSTALL SAFETY STRAPS TO

RIGGING CLEVIS AT 4 RIGGING BRACKETS

PLACE RIGGING BRACKET ASSEMBLY IN 4

RIGGING HOLES AND INSTALL TIE DOWN STRAP

AROUND PERIMETER OF UNIT AND THROUGH

SPACE IN BRACKET ASSEMBLY

in.

19.0

20.0

20.0

20.0

C99075

A

mm.

482.6

5O8

5O8

5O8

in.

18.25

19.25

19.0

21.25

B

mm.

463.6

489

482.6

539.8

UNiT

Size

80JZ024

80JZ0S0

80JZ036

80JZ048

SEE DETAIL A

MAXBMUMWEJGHT

tb kg

321 145.6

342 155.2

350 158.8

377 171.0

Fig. 9--Suggested RiggBng

Table 1--Physicam Data-UnR 50JZ (50Hz}-English

UNIT SIZE

NOMINAL CAPACITY (ton}

OPERATING WEBGHT (lb.)

COMPRESSOR QUANTITY

TYPE

REFRIGERANT

REFRBGERANT METERBNG DEVICE

Refrigerant (R-41OA} Quantity (lb.)

ORIFICE ID (in.}

ORIFICE OD (in.}

OUTDOOR CO_L

Rows... Finslin.

face area (sq. ft.}

OUTDOOR FAN

Nomina_ Airflow (CFM}

Diameter

Motor HP (RPM)

_NDOOR COBL

Rows... Fins/in.

face area (sq. ft.}

mNDOOR BLOWER

Nomina_ Airflow (CFM)

Size (in.)

Motor (HP}

RETURN-AIR HLTERS (in,)*

throwaway

Required filter sizes shown are based on the larger of the ARI (Air Conditioning and Refrigeration Institute) rated cooling airflow or the heating airflow velocity of 300

ft/minute for throwaway type or 450 if/minute for high-capacity type. Air filter pressure drop for non-standard filters must not exceed 0.08 in wg

80JZ024

2

299

50JZ08O 50JZ088

2-1/2 3

320 328

80JZ048

4

355

1

SCROLL COMPRESSOR

R-410A

Accurater

6.9

0.059

0.032 (2)

2...17

8.5

2200

22

1/4...900

3...15

3.7

800

10x10

1/2

9.6

0.061

0.040 (2)

2...17

10.3

2200

22

1_...900

3...15

3.7

1000

10x10

1/4

10.0

0.067

O.040 (2)

2...17

10.3

22OO

22

1/4...900

41..15

3.7

1200

10x10

1/2

12.0

0.078

0.046 (2)

2...17

13.5

2400

22

1/3...1340

4...15

4.7

1600

11x10

1

20x20x1 20x20xl 20x24xl 24x30xl

outlet of the tlap is at least 1 in, (25,4 mnx) lower than the unit

drain condensate connection to prevent the &ain flora overflow°

ing (onnect a drain tlough using a n_inil*num of _ield-supplied

3/4=in PVC (19,05 ram) o1"copper pipe at outlet end of the 2=in

(508 nxm) trap (See Fig 12) Do not undersize the tube, Pitch the

drain t*ough downward at a slope of at 1east 1 in, (254 mnx) eve W

Page 9

Table 2--PhysicN Data-UNt 50JZ (50 Hz)-SI

UNIT SiZE

NOMINAL CAPACBTY (kW}

OPERATING WEBGNT (kg}

COMPRESSOR QUANTITY

TYPE

REFRBGERANT

REFRIGERANT METERBNG DEVtCE

Refrigerant (R-410A) Quantity (kg)

ORIFICE ID (ram)

ORIFICE OD (ram)

OUTDOOR COiL

Rows.,. Finstin.

Face Area (sq. m)

OUTDOOR FAN

Nomina_ Airflow (L/s)

Diameter (ram)

Motor HP (rls)

iNDOOR COraL

Rows... Finstm.

Face Area (sq. m)

RNDOOR BLOWER

Nominal Airflow (Lls)

Size (m)

Motor (r/s)

RETDRN-ABR FBLTERS (ram)

* Required filter sizes shown are based on the larger of the ARI (Air Conditioning and Refrigeration Institute) rated cooling airflow or the heating airflow velocity of 91.5

m/min, for throwaway type or 137 m cu../min for high-capacity type Air filter pressure drop for non-standard filters must not exceed 203 mm wg

throwaway

50JZ024

7

135

3.2

1.55

0.81

2...659

8.5

1038

556.8

.167...15

3...590

0.34

378

0.254x0.254

186...17.9

508x508

50JZ030 50J2:03$

8.8 10.6

145 149

1

SCROLL COMPRESSOR

R-410A

Accurater

4.0

1.55

1.02

2...669

10.3

1036

558.8

.167...15

3...590

0.34

472

0.254x0.254

373...21.7

508x508

2_.669

558.8

.187...15

3...590

0.254x0.254

373...21.9

508x508

4.2

1.70

1.02

10.3

1038

0.34

566

50JZ048

14.1

161

4.8

1.93

1.17

2...669

13.5

1133

558.8

.249...22

4...590

0.44

7O8

0.254x0.254

746...20.5

610x762

Table 3--MiNmum Airflow for Reliable Electric Heater Operation

ABRFLOW

CFM

L/s

10 ft. (3.05 m) of horizontal run. Be sure to check the drain trough

for leaks Prime tile trap at the beginning of tile cooling season

start=up.

Step 7--Install Electrical Connections

The unit cabinet must have an uninterrupted, unhroken

electrical ground [o minimize the possibility of personal

injury if an electrical _imlt should occur. This ground may

consist of an electrical wire connected to the unit ground lug

in the control compartment, or conduit approved for electrical

ground when installed in accordance with IEC, ANSI NFPA

American National Standards Institute/National Fire Protec-

tion Association (latest edition) and local electrical codes.

Failure to adhere to this warning could result in serious inju_'

or death.

50JZ024 80JZ030 50JZ036

800 1000 1200

378 472 567

50JZ648

1600

756

Failure to %llow these precautions could result in damage to

the unit being installed:

1_ Make all electrical connections in accordance with IEC

ANSINFPA (latest edition) and local electrical codes

governing such wiring.

2_ Use only copper conductor for connections between

field-supplied electrical disconnect switch and unit. DO

NOT USE ALUMINUM WIRE.

3. Be sure that high-voltage power to unit is within operating

voltage range indicated on unit rating plate. On 3-phase

units_ ensure phases are balanced within 2 percent. ( onsult

local power company fbr correction of improper voltage

and/or phase imbalance.

4. Insulate low-voltage wires for highest voltage contained

within conduit when low=voltage control wires are in same

conduit as high-voltage wires.

5. De not dan?age internal components when drilling through

any panel to mount electrical hardware, conduit, etc_

HIGH-VOLTAGE ( ONNECTIONS

The unit must have a separate electrical service with a field-

supplied, waterproof disconnect switch mounted at. or within sight

from the unit. Refer to the unit rating plate, IE( and local codes tbr

maximnm _i/seicircuit breaker size and minin-mm circuit amps

(ampacity) fbr wire sizing (See Table 4 for electrical data).

The field=supplied disconnect may be mounted on the unit over the

high=voltage inlet hole (See Figs. 2 and 3).

Page 10

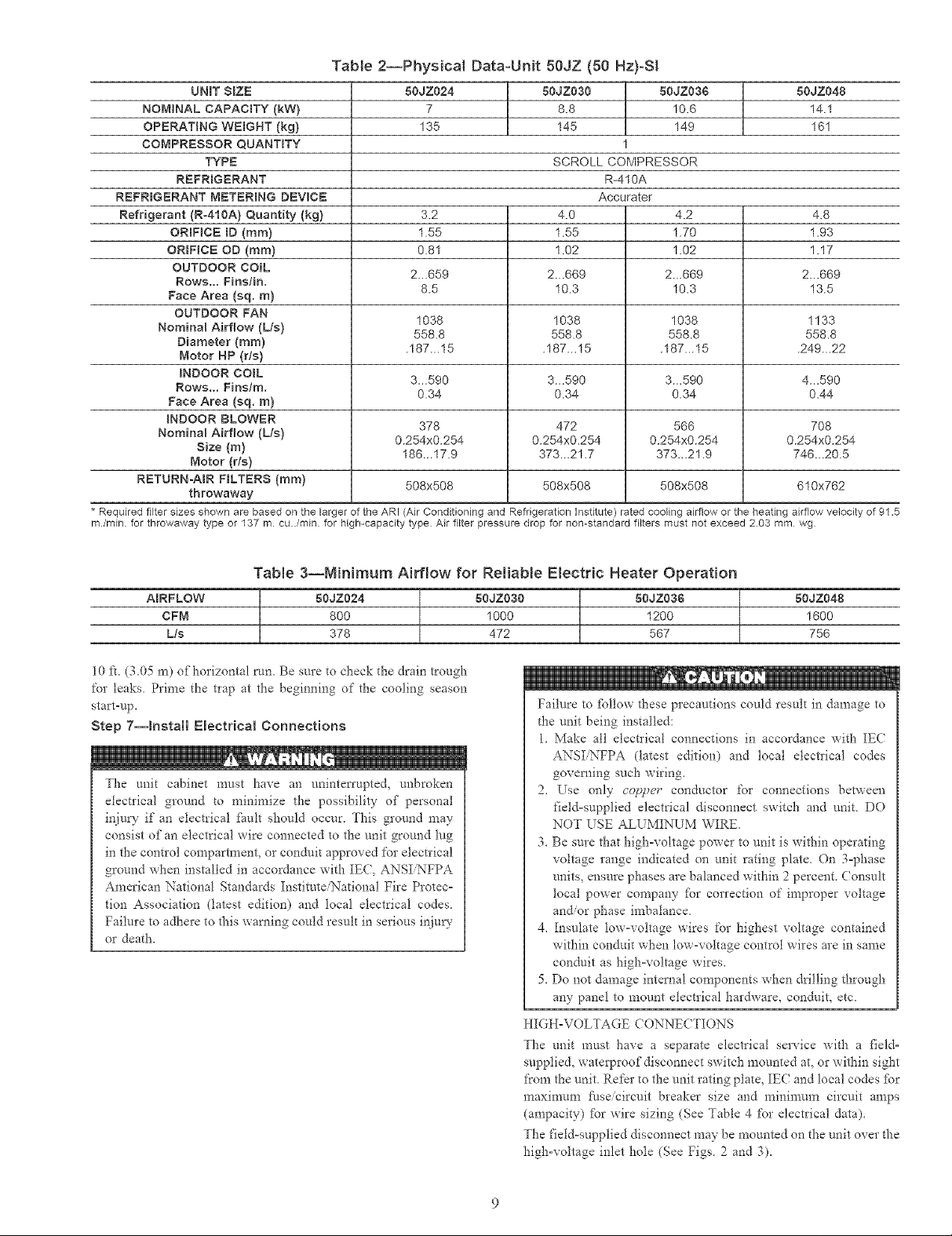

TOP COVER

INDOOR

THERMOSTAT

RETURN

DISCONNECT

PERIEC*

Fig. 10--Typical Installation

Duct Covers

Fig. 11--50JZ with Duct Covers On

C02003

C00092

TRAP

_.,__ 2" (50ram) MIN.

C99013

Fig. 12--Condensate Trap

If the unit has an electric heateL a second discom_ect may be Operation of unit o_1 improper line voltage co_lstitutes abuse and

required. Consult the Installation, Start°Up, and Service Iustruc° may cause unit damage that could affect warranty.

tions provided with the accessory fc_r electrical service connec=

tions.

10

Page 11

Table 4_ElectricN Data--50JZ {50Hz)

UNiT 50JZ

SIZE

O24

030

03G

O48

(See legend following ElectricN Data charts /

FLA -- Futt Load Amps

LRA -- Locked Rotor Amps

MCA -- Minimum Circuit Amps

MOCP -- Maximum Overcurrent Protection

RLA -- Rated Load Amps

CKTBKR -- Circuit Breaker

NOTES:

1. In compliance with IEC(International Electrical Code) requirements

for multimotor and combination toad equipment (refer to IEC

Artictes 430 and 440), the overcurrent protective device for the

unit shalt be Power Supply fuse.

2. Minimum wire size is based on 60 C copper wire. If other than

60 C wire is used, or if length exceeds wire length in table,

determine size from tEC.

3. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply volt-

age is greater than 2%. Use the following formula to determine

the percentage of voltage imbalance.

% Voltage imbalance

V-PH-HZ

400-3-50

400-3-50

400-3-50

400-3-50

= 100 x max vottage deviation from average voltage

VOLTAGE

RANGE

Min Max

380 420

380 420

380 420

380 420

LEGEND

average voltage

COMPRESSOR OFM IFM ELECTRIC HEAT

RLA LRA FLA FLA

4.5 32.0 0.8 1.1

5.2 35.0 0.8 1.7

6.5 46.0 0.8 2.0

6.7 50.0 1.3 3.9

Nominal Kw FLA

6.5 9.4

8.7 12.6

6.5 9.4

8.7 12.6

13.0 18.8

6.5 9.4

8.7 12.6

13.0 18.8

6.5 9.4

8.7 12.6

13.0 18.8

17.4 25.1

EXAMPLE: Supply vottage is 400-3-50.

A B C AB = 393 v

Determine maximum deviation from average voltage.

(AB) 397- 393=4v

(BC) 403- 397 = 6 v

(AC) 397 - 396 = 1 v

Maximum deviation is 6 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x --

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

more than 2%, contact your local etectdc utility company

IMPORTANT: If the supply voltage phase imbalance is

immediately.

POWER SUPPLY DISCONNECT SBZE

iMCA FUSE ORCKT. BKR MOCP

7.5 10 --

19.2 20 --

23.2 25 --

9.0 10 --

20.7 20 --

24.7 25 --

32.5 35 --

10.9 15 --

22.7 25 --

26.6 30 --

34.4 35 --

13.6 15 --

25.3 30 --

29.3 30 --

37.0 40 --

45.0 45 --

AC = 396 v

Average Voltage = 393 + 403 + 396

BC = 403 v

1192

= 397

6

397

= 1.5%

FLA LRA

7 35

18 44

22 48

9 39

20 49

23 52

30 59

11 51

21 61

25 64

32 70

14 58

24 67

28 71

35 77

43 83

3

3

Fig. 13--Electrical Data Legend

ROUTING POWER LEADS INTO "kNIT

Use only copper wire between disconnect and unit The high-

voltage leads should be in a conduit until they enter the duct panel;

conduit termination at the duct panel must be watertight. Run the

high-voltage leads through the power entry knockout on the power

entry side panel, (See Fig, 2 arid 3 for location and size) When the

leads are inside the uriit, run leads up the high-voltage raceway to

the line wiring splice box (See Fig, 13 through 15),

CONNECTING GROUND LEAD TO GROUND LUG

Refer to Fig, 18, Connect the ground lead to the chassis using the

ground lug in the wiring splice box,

ROUTING CONTROL POWER WIRES (24-V)

Form a &ip-toop with the them_ostat leads before routing them

into the unit, Route the thermostat leads through grommeted,

C02002

tow=voltage hole provided in unit into unit control power splice

box, (See Fig 2 arid 3) Connect thermostat leads to unit control

power leads as shown in Fig, 16 & 17,

The unit transfbm_er supplies 24-v power for complete system

including accessory electrical heater, An automatic-reset circuit

breaker (See Fig 17) is provided in the 24=v circuit; see the caution

label on the tIansl\_rmer or Fig, 18

11

Page 12

MAXIMUM WIRE

SIZE 6 AWG, TBI

FIELD

POWER

SUPPLY

SCHEMATIC

I I L 1 _)_BRN_

(BLK)_ I _ W8 BLN_ QT

Ij,

OPTION ONLY. I I

5,10,15& 20 KW

MAXIMUM WIRE

SIZE 2 AWG.

ON G

L 28 _

FAr

H I-(_D f- W43 BLK

Wll BLK W15 BLK •

IL:: PN.

J

IFC--WiDBL_?-t_;_WI4 BLK_

W12 BLK Wl60RN

Wl3 BLK WIT BLU

BLK _

W41 YEL

.

IFM

&

TRAN I

W33 GRN YEL

__ W34 GRN YEL

HPS LPS

W39 BRN-

W38 BRN-

OFC

c

OFC

PRM

IFC

RVS

TRAN

IF

THI ON (

AUTO SW

L I

SUPPLHEAT

FIELD THERMOSTAT

SEE NOTE#2

UNIT COMPONENTARRANGEMENT

OUTDOOR FAN

SECTION

INDOOR FAN

SECTION

50JZOAS& 060

--W200 PNK-

-- W203 GRA--

_[ _W32 BAN-- W207 BAN

-- -- -- FIELDCONTROLWIRING DB BEFROSTBOARD

CONTROL BOX AREA

ELECT HEAl

_C _

IFC

OFC

EQUIP. TRAN TRANSFORMER

/GND

24V PO_ER ENTRY _mE FROMIFR 21AND CONNECTBLK_IIE FRO_IF_

i i FIELD POWERWIRING DFT DEFROSTTHERMOSTAT CTD (TI,T2) COMPRESSORDELAY

I ACCESSORyOR OPTIONAL DR DEFROSTRELAY I i , i F

I TO INDICATECOMMON Hp_ HIGH PRESSURES_ITCH CI Cl

ACCESSORY ELECTRIC

HAl & 2 (10 KW) I 5 BAN

..... 6 BRN

-'.... _W204 BR#--_

HAl 2 3 & 4 (20 KW)

HEAT'_.X_ IIV38BRN-

HAl (5 KW]_,_[_W204 BR_-

---- _W207 BAN--

LEGEND

Z_'FIELD SPLICE _HA ADJUSTABLEHEATANTICIPATOR

C3TERMINALCMARKED) CONTACTOR

o TERMINAL(UNMARKED) CAP CAPACITOR

O SPLICE CB CIRCUIT BREAKER

C)SPLICE (MAR_ED_ CCN CRANKCASEHEATER

FACTORYWIRING CTD COMPRESSORTIMEDELAY

WIRING EQUIP EQUIPMENT

POTENTIALONLY: HR HEATERRELAY CLOSES OPENS

NOT TO REPRESENT_IRINGHTR HEATER TSAT

NOTES:

I IF _N_ OF THE ORI61N_L _IRES FURNISHED A_E _EPL_CED,

IT NU_T_E REPLACED_ITH T_PE_0 DEGREEC _IRE OR

IT'S EOUIV_LENT

_. SEE PtlCE PA_E$FORTHERMOSTATANDIUBBASEI

3 USE lS _EGREECOPPERCONDUCTORSFORFIEL_ INSTALLATION

4 FORHIGHSPEE_IFM,DI$CONNECTlED

FOREDlU_ SPEED,_ISCONNECTRE_HE

FROMIFRZl AN_CONNECTBLU_IRE FROMIFM

5 _EFROSTTI_ERm BE SET AT 9_ _INUTESEXCEPT

FOR50J$O4B060 HODEL$IETAT 50 HINUTES.

COMP COMPRESSORMOTOR

6N_ GROUN_ 0 5 SECT T+5 MIN

IFM INDOORFANMOTOR

IFC INDOORFANCONTACTOR

LPS LOW PRESSURESWITCH

OFM OUTDOORFAN _OTOR

OFC OUTDOORFAN CONTACTOR

PRM PHASE ROTATIONMONITOR

OT QUADRUPLETERMINAL

RVS REVERSINGVALVESOLENOID

TC THERMOSTATCOOLING

TH THERMOSTATHEATING 0 _ T:30 _+I0 MIN

LAST DFROST T:50 MAXIMUM

TRAM

CYCLE T:90

Fig. 14--Wiring Schematics

12

Page 13

©--

®

©

L_

Lii

_ --[__ _¢z.__wHT-

THERMOSTAT UNIT CONTROL POWER

AND SUBBASE SPLICE BOX

Fig. 15--Control Connections

GROUND LUG

GROUND

LEAD

L1 ........ /L_.,_ BLK--

L2 ....... zL__ YEL-

L3

LEGEND

IEC = International Electrical Code

- - - Field Wiring

Splice Connections

NOTE: Use copper wire only,

C99056

IN SLPICE BOX

C02005

Fig. 16--Line Power Connections

C99070

13

Page 14

TRANSFORMER CIRCUIT CONTAINS A MANUAL

RESET OVERCURRENT PROTECTOR

IT WILL NOT AUTOMATICALLY RESET

DISCONNECT POWER PRIOR TO

SERVICING

THIS COMPARTMENT MUST BE CLOSED

EXCEPT WHEN SERVICING

Fig. 18--Transformer Label

PRE-STAR%UP

Failure to obsela'e the %tlowing warnings could result in

serious personal injury or death:

1 Follow recognized safety practices and wear protective

goggles when checking or servicing refrigerant system

2. Do not operate compressor or provide any electric power to

unit unless compressor terminal cover is in place and

secured.

3 Do not remove compressor terminal cover until all electri=

cal sources are disconnected

4. Relieve and recover all refiigerant fi'om both high- and

low-pressure sides of system befbre touching or disturbing

anything inside terminal box if refiigerant leak is suspected

around compressor temainals.

5. Never attempt to repair soldered connection while refi'ig=

erant system is under pressure.

6. Do not use torch to remove any component. System

contains oil and refrigerant under pressure.

To remove a component, wear protective goggles and

proceed as follows:

a. Shut off electrical power to unit.

b. Relieve and reclaim al! refrigerant from system using

both high- and low-pressure ports.

c Cut component connecting robing witk robing cutter and

remove component fiom unit.

d. Carefully unsweat remaining tubing stubs when neces-

saN-. Oil can ignite when exposed to torch flame.

Use the Start=Up Checklist supplied at the end of this book and

proceed as fbllows to inspect and prepare tke unit fbr initial

start-up:

1. Remove all access panels.

2. Read and foilow instructions on all DANGER, WARNING,

CAI. TION, and INFORMATION 1abels attached to, or

shipped with, unit.

3. Make the following inspections:

a. Inspect fbr shipping and handling damages such as broken

lines, loose parts, disconnected wires, etc.

b. Inspect for oil at all refi'igerant robing connections and on

unit base Detecting oil generally indicates a refrigerant

leak. Leak-test all refrigerant robing connections using

electronic leak detector, or liquid=soap solution It" a tel'rig=

erant leak is detected, see following Check for Refrigerant

Leaks section

c. Inspect all field and factow-wiring connections Be sure

tkat connections are completed and tight.

d. Inspect coil fins. If damaged during shipping and handling,

carefully straighten fins with a ['in comb.

4. Verif}' the fbllowing conditions:

a. Make sure that outdoor-fan blade is correctly positioned in

f_n orifice

b. Make sure that air filter(s) is in place.

c. Make sure that condensate drain and trap are filled witk

water to ensure proper &ainage.

d. Make sure that all tools and miscellaneous loose parts have

been removed.

5,

Compressors are internally spring mounted. Do not loosen or

remove compressor hold=down bolts

6.

Each unit system has 2 Schrader=type ports, one tow=side

Schrader fitting located on the suction line, and one high=side

Schrader fitting tocated on the compressor discharge line Be

sure that caps on the ports are tight.

START-UP

Using the Start-Up Checklist supplied at the end of this book,

proceed as fbltows:

Step l--Check for Refrigerant Leaks

Locate and repair refrigerant leaks and charge the unit as fbllows:

1. Use both high- and tow-pressure ports to relieve system

pressure and reclaim remaining ret'rigerant.

2. Repair leak fbltowing accepted practices.

NOTE: Install a bi-flow filter &ier whenever the system has been

opened fbr repair.

3. (beck system fbr leaks using an approved method.

4. Evacuate refrigerant system and reclaim refi'igerant if" no

additional leaks are found

5. Charge unit witk R=410A refrigerant, using a volumetric=

charging cylinder or accu*ate scale. Refer to unit rating plate

fbr required charge

Step 2--Start°Up Adjustments

Complete the required procedures given in the Pre=Start=tp

section be_bre starting the unit Do not jumper any sat'cry devices

when operating the unit Do not operate the unit in Cooling mode

when tke outdoor temperature is below 55°F (12.7%), unless

accessory low=ambient kit is installed. Do not rapid=cycle the

compressor Allow 5 rain between "on" cycles to prevent corn=

pressor damage

CHE(KING (70()LING AND HEATING CONTROL OPERA=

TION

Start and check the unit for proper control operation as follows:

1. Place room themmstat SYSTEM switch or MODE control in

OFF position. Observe that blower motor starts when FAN

mode is placed in FAN ON position and sitars down aker

proper _hn off delay, when FAN MODE switch is placed in

AUTO position.

14

C99058

Page 15

1/8" (3.175mm) MAX BETWEEN MOTOR SHAFT

MOTOR AND FAN HUB

Fig. 19--Fan Blade Cmearance

C99009

LEGEND

HPS - High Pressure Switch

LCS - Loss of Charge Switch

Accurater _ Metering Device

Arrow indicates direction of flow

Fig. 20--TypicN Heat Pump Operation, Heating Mode

OUTDOOR COIL

OUTDOOR COIL

Metering

Position

Bypass

Position

Metering

Position

C00095

INDOOR COIL

LEGEND

HPS - High Pressure Switch

LCS - Loss of Charge Switch

Accurate€ Metering Device

] Arrow indicates direction of flow

Fig. 21--TypicN Heat Pump Operation, CoNing Mode

2. Place system switch or MODE contlol iu HEAT position. Set

control above room temperature, Observe d_at compressor,

outdoor fire, and indoor blower motors start. Observe that

heating cycle shuts down when control setting is satisfied,

3, When using an automatic changeover room thermostat, place

both SYSTEM or MODE contlol and FAN mode switches in

AUTO positions, Observe that unit operates in ( ooling mode

Bypass

Position

when temperature conuol is set Go "call for (ooling" (below

room temperature), and unit operates in Heating mode when

temperature control is set to "call for Heating" (above room

temperature),

IMPORTANT: Three=phase, scroll compressors are direction ori-

euted Unit must be checked to ensure proper compressor 3=phase

power lead orientation, If not corrected within the phase monitor

15

C00096

Page 16

Table 5--Wet Coil Air Delivery=English

Unit 50JZ 024=048"

UNiT

024

030

038

048

Air delivery values are based on operating voltage of 400-v, wet coil, without filter or electric heater. Deduct filter and electric heater pressure drop (see Tables 5 and

6) to obtain static pressure available for ducting

NOTES:

1 Do not operate the unit at a cooling airflow that is less than 350 cfm for each 12,000 Btuh (165 L/s for each 35 kW) of rated cooling capacity Evaporator coil frosting

may occur at airflows below this point.

2 Dashes indicate portions of table that are beyond the blower motor capadty or are not recommended.

MOTOR SPEED

Low

High

Low

High

Low

High

Low

High

Watts 303 305 303 300 .......

Cfm 969 879 785 687 .......

Watts .... 435 428 428 422 -- -- --

Cfm .... 963 833 758 676 -- -- --

Watts -- 814 853 889 921 954 1002 ....

Cfm -- 1189 1115 1041 971 903 833 ....

Watts ....... 700 683 688 755

Cfm ....... 1223 1142 1075 1058

Watts 552 540 529 523 514 480 .....

Cfm 1296 1237 1167 1097 1029 952 .....

Watts ..... 782 765 736 721 780 1002

Cfm ..... 1467 1398 1321 1237 1165 1137

Watts 692 686 678 664 652 664 736 ....

Cfm 1571 1509 1444 1370 1295 1240 1237 ....

Watts -- -- 1112 930 856 834 825 811 793 -- --

Cfm -- -- 1693 1670 1601 1521 1447 1378 1294 -- --

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

(See Fig. 25) will not provide the unit with power, A red light on

the phase monitor will blink_ The 3-phase power leads to the unit

must be reversed to correct rotation,

(HECKING AND ADJ[ STING REFRIGERANT CHARGE

The refi'igerant system is _idly charged with R-410A rel'rigerant

and is tested and _ctory sealed

NOTE: Adjustment of the refrigerant charge is not required

unless the unit is suspected of not having the proper R-410A

charge. The charging label and d'*e tables shown refer to system

temperatures and pressures in Cooling mode, only. A refrigerant

charging label is attached to the outside of the service access door.

If charge level is suspect in Heating mode, reclaim all refrigerant

and charge to nameplate amount. (This information may be

obtained ]:iom the physical data table also.) The charging label and

the tables shown refkr to system temperatures and pressures in

( ooling mode only. A refi'igerant charging label is attached to the

outside of the service access door. If charge level is suspect in

Heating mode, reclaim all refrigerant and charge to nameplate

amount. (This information may be obtained fi'om the physical data

table also.)

mNPORTANT: When evaluating the rd:i'igerant charge, an indio

cared adjustment to the specified factoQ' charge must always be

very minimal. If a substantial adjustment is indicated, an abnomaal

condition exists somewhere in the cooling system, such as insuf-

ficient airflow across either coil or both coils.

REFRIGERANT CHARGE

The amount of refi'igerant charge is listed on the unit nameplate

and/or the physical data table Refer to the Re_i'igeration Service

Techniques Manual, Rd:_'igerants Section

NO CHARGE

Check for leak. "Use standard evacuating techniques Aiier evacuo

ating system, weigh in the specified amount of refi'igerant (refer to

system data plate),

EXTERNAL STATIC PRESSURE (IN, WG}

LOW CHARGE COOLING

Use Cooling Charging Table. Vary refi'igerant until the conditions

of the table are met Note that charging tables are different from

type normally used. Tables are based on charging the units to

correct superheat for the various operating conditions Accurate

pressure gauge and temperature sensing devices are required.

Connect the pressure gauge to the service port on the suction line

Mount the temperature sensing device on the suction line and

insulate it so that the outdoor ambient does not affect the reading

Indoor air (FM (L/s) must be within the normal operating range of

the unit,

HEATING MODE CHANGE

Do not attempt to adjust charge by cooling methods while in

Heating mode. When charging is necessaw in Heating mode,

recover refi'igerant and weigh in according to unit data plate

refrigeration data.

TO USE COOLING CHARGING (}HARTS

Take the outdoor ambient temperature and read the suction

pressure gauge Re_kr to the chart to determine what the suction

temperature should be.

NOTE: If the problem causing the inaccurate readings is a

refrigerant leak, refer to Check for Re_?igerant Leaks section.

INDOOR AIRFLOW AND AIRFLOW ADJUSTMENTS

? = Le _ m

For heating and cooling operation, the recommended airflow

is 350 to 450 cfm for each 12,000 Bmh (165 Lis to 212 for

each 3.5 kW) of rated cooling capacity. For units with

optional electric heat, the airflow must not be reduced below

the levels stated in Table 2

Table 5 and Table 6 show both heating and cooling airflows at

various external static pressures Refer to these tables to determine

the airflow for the system being installed

16

Page 17

Table 6--Wet Coil Air Delivery-SI

Unit 50JZ 024-048*

UNIT

O24

030

036

O48

* Air delivery values are based on operating voltage of 400-v, wet coil, without filter or electdc heater. Deduct filter and electric heater pressure drop (see Tables 5 and

6) to obtain stafic pressure available for ducfing

NOTES:

1. Do not operate the unit at a cooling airflow that is less than 165 L/s for each 3.5 kW of rated cooling capacity Evaporator coil frosting may occur at airflows below

this point.

2. Dashes indicate portions of table that are beyond the blower motor capacity or are not recommended.

MOTOR SPEED

Low

High

Low

High

Low

High

Low

High

0 25 50 75 100 125 150 175 200 225 250

Watts 303 305 303 300 .......

L/s 458 415 371 324 .......

Watts .... 435 428 428 422 -- -- --

L/s .... 455 393 358 319 -- -- --

Watts -- 814 853 889 92I 954 1002 ....

L/s -- 561 526 491 458 426 393 ....

Watts ....... 700 683 688 755

L/s ....... 577 539 508 499

Watts 552 540 529 523 514 480 .....

L/s 612 584 551 518 486 449 .....

Watts ..... 782 765 736 721 780 1002

L/s ..... 693 660 624 584 550 536

Watts 692 686 678 664 652 664 736 ....

L/s 741 712 681 647 611 585 584 ....

Watts -- -- 1112 930 856 834 825 811 793 -- --

L/s -- -- 799 788 756 718 683 650 611 -- --

EXTERNAL STATIC PRESSURE (PA)

Table 7--Filter Pressure Drop (in. wg)-English

FILTER SBZE CFM

(iN.) 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700

20 X 20 X 1 0.05 0.07 0.08 0.10 0.12 0.13 0.14 0.15

20X24X1 0.09 0.10 0.11 0.13 0.14 0.15 0.16

24X30X1 0.07 0.08 0.09 0.10 0.11 0.12

1800 1900 2000 2100 2200 2300

0.13 0.14 0.15 0.16 0.17 0.18

Table 8--Filter Pressure Drop (Pa)-SI

FILTER S_ZE L/S

(MM} 236 283 330 378 425 472 519 566 614 661 707 755

508 x 508 12.4 17.4 19.9 24.9 29.9 32.3 34.8 37.3

508 x $10 .... 22.4 24.9 27.4 32.3 34.8 37.4 39.9

610 x 752 -- 17.4 19.9 22.4 24.9 27.4

802 850 896 944 991 1038

29.9 32.3 34.8 37.3 39.8 42.3

Table 9--Accessory Electric Heat Pressure Drop (in. wg)-ENGLISH

HEATER

KW 2000 2200

6.5-t7.4 0.067 0.075

HEATER WS

KW 283 378 472 569 661 755 850 944 1038

&8-17.4 7.5 8.2 9.2 10.4 11.7 12.9 14.9 16.7 18.7

NOTE: Be sure that all supply-and return-air grilles are open_ free

from obstIT./ctions, and adjusted properly.

Airflow can be changed by changing the lead connection of the

blower motor,

To change the speed of the indoor _bn motor (IFM), remove the fSn

motor speed leg lead tiom the indoor _Sn contactor (IF(7). To

600 800 1000 1200 1400 1600 1800

0.030 0.033 0.037 0.042 0.047 0.052 0.060

Table 10--Accessory Electric Heat Pressure (Pa)-Sl

CFM

change the speed, remove and replace with lead fbr desired blower

motor speed. Insz_/atc lhe *'emo*ed lead to avoid contact with

chassis parts

For 400-v Motors The motor leads are color coded as _bllows:

3-SPEED

Black high

White common

Blue medium

Red low

17

Page 18

SUPERHEAT

TEMP

(°C)

0

1

2

a

4

6

7

8

9

10

tt

12

t3

14

t5

16

t7

18

t9

20

21

22

Table 11--Required Suction=Line Temperature (Metric)

SUCTION PRESSURE AT SERVICE PORT {KPA)

424

1.7

2.8

3.9

5.0

6.1

7.2

8.3

9.4

10.6

11.7

12.8

13.9

15.0

16.1

16.7

17.2

18.3

19.4

20.6

21.7

22.8

23.9

443

2.8

3.9

5.0

6.1

7.2

8.3

9.4

10.6

11.7

12.8

13.9

15.0

16.1

17.2

17.8

18.3

19.4

20.6

21.7

22.8

23.9

25.0

463

3.9

5.0

6.1

7.2

8.3

9.4

10.6

11.7

12.8

13.9

15.0

16.1

17.2

18.3

18.9

19.4

20.6

21.7

22.8

23.9

25.0

26.1

483

5.0

6.1

7.2

8.3

9.4

10.6

11.7

12.8

13.9

15.0

16.1

17.2

18.3

19.4

20.0

20.6

21.7

22.8

23.9

25.0

26.1

27.2

503

6.1

7.2

8.3

9.4

10.6

11.7

12.8

13.9

15.0

16.1

17.2

18.3

19.4

20.6

21.1

21.7

22.8

23.9

25.0

26.1

27.2

28.3

524

7.2

8.3

9.4

10.6

11.7

12.8

13.9

15.0

16.1

17.2

18.3

19.4

20.6

21.7

22.2

22.8

23.9

25.0

26.1

27.2

28.3

29.4

546

8.3

9.4

10.6

11.7

12.8

13.9

15.0

16.1

17.2

18.3

19.4

20.6

21.7

22.8

23.3

23.9

25.0

26.1

27.2

28.3

29.4

30.6

568

9.4

10.6

11.7

12.8

13.9

15.0

16.1

17.2

18.3

19.4

20.6

21.7

22.8

23.9

24.4

25.0

26.1

27.2

28.3

29.4

30.6

31.7

591

10.6

11.7

12.8

13.9

15.0

16.1

17.2

18.3

19.4

20.6

21.7

22.8

23.9

25.0

25.6

26.1

27.2

28.3

29.4

30.6

31.7

32.8

TaNe 12--Superheat Charging Table (Metric)

OUTDOOR EVAPORATOR ENTERING ABR TEMPERATURE (°C WB)

TEMP

(°C) 10 11 12 13 14 15 16 17 18

13 5.0 6.7 7.8 9.4 11.1 11.9 12.8 14.4 16.1

16 3.9 5.6 6.7 8.3 10.0 10.8 11.7 13.3 15.0

18 - 3.3 5.6 7.2 8.9 9.7 10.6 11.7 13.3

2t - - 3.9 5.6 7.2 8.1 8.9 10.6 11.7

24 - - 3.3 5.0 5.8 6.7 8.3 10.0

27 - - 2.8 3.6 4.4 6.7 8.3

29 ..... 4.4 6.1

32 ..... 2.8 5.0

38 ..... 3.3

a8 ......

4t ......

48 ......

4G ......

Where a dash (-) appears, do not attempt to charge system under these conditions, or refrigerant

NOTE: Superheat °C is at low-side service port

2 SPEED

Black high

Red low

Yellow common

To change the speed of the indoor fan motor (IFM), remove f_n

motor speed lead fi'om the indoor fire contactor (IF() and replace

with the lead for the desired blower motor speed. The motor speed

lead is attached to tem_inal BM. Insulate removed lead end to

avoid contact with chassis parts.

Step 3--Defrost Control

QUIET SHIFT

Quiet Shill is a field-selectable defiost mode, which will eliminate

occasional noise that could be heard at the start of defrost cycle

and restarting of heating cycle. It is selected by placing DIP switch

3 (on defrost board) in ON position.

When Quiet Shit't switch is placed in ON position, and a de_i'ost is

initiated, the fbllowing sequence of operation will occur. Revers-

ing valve will energize, outdoor fire will mrn off, compressor will

mrn off for 30 sec and then mm back on to complete defrost. At

the start of heating after conclusion of defiost reversing valve will

de-energize, compressor will turn off for another 30 sec, and the

outdoor fan will stay off for 40 sec, before starting in the Heating

l'node,

DEFROST

The defi'ost control is a time/temperature control (See Fig_ 23)

which includes a field=selectable time period (DIP switch 1 and 2

on the board) between defi'ost cycles of 30, 50 or 90 minutes

(ihctory set at 30 minutes).

To initiate a forced defrost, two options are available depending on

the status of the defrost thermostat.

19 20 21 22 23 24

17.8 19.4 20.6 22.2 23.3 25.0

16.7 18.3 20.0 21.1 22.2 23.9

15.0 16.7 18.3 20.0 21.1 22.8

13.3 15.0 16.7 18.3 20.0 21.7

11.7 7.8 15.6 17.2 18.9 20.6

10.0 11.7 13.9 15.6 17.2 19.4

8.3 10.6 12.2 14.4 16.7 18.3

7.2 8.9 11.1 13.3 15.0 17.2

5.6 7.8 10.0 12.2 13.9 16.1

4.4 6.7 8.3 11.1 12.8 15.0

2.8 5.0 7.2 9.4 12.2 14.4

- 3.3 6.1 8.3 11.1 13.9

- - 4.4 7.8 10.0 12.8

slugging

may occur Charge must beweighed in.

18

Page 19

Table 13--Required Suction=Line Temperature (English)

SUPERHEAT SUCTION PRESSURE AT SERVICE PORT (PSBG)

TEMP

(°F) 61.5 64.2 67.1 70.0 73.0 76.0 79.2 82.4 85.7

0 35 37 39 41 43 45 47 49 51

2 37 39 41 43 45 47 49 51 53

4 39 41 43 45 47 49 51 53 55

6 41 43 45 47 49 51 53 55 57

8 43 45 47 49 51 53 55 57 59

10 45 47 49 51 53 55 57 59 61

t2 47 49 51 53 55 57 59 61 63

14 49 51 53 55 57 59 61 63 65

t6 51 53 55 57 59 61 63 65 67

18 53 55 57 59 61 63 65 67 69

20 55 57 59 61 63 65 67 69 71

22 57 59 61 63 65 67 69 71 73

24 59 61 63 65 67 69 71 73 75

26 61 63 65 67 69 71 73 75 77

28 63 65 67 69 71 73 75 77 79

30 65 67 69 71 73 75 77 79 81

32 67 69 71 73 75 77 79 81 83

34 69 71 73 75 77 79 81 83 85

36 71 73 75 77 79 81 83 85 87

38 73 75 77 79 81 83 85 87 89

40 75 77 79 81 83 85 87 89 91

TaNe 14_Superheat Charging TaNe (English)

OUTDOOR EVAPORATOR ENTERING ABR TEMPERATURE (°FWB)

TEMP

(OF} 50 52 54 56 58 60 62 64 66 68 70 72 74 76

58 9 12 14 17 20 23 26 29 32 35 37 40 42 45

60 7 10 12 15 18 21 24 27 30 33 35 38 40 43

68 -- 6 10 13 16 19 21 24 27 30 33 36 38 41

70 -- -- 7 10 13 16 19 21 24 27 30 33 36 39

78 -- -- -- 6 9 12 15 18 21 24 28 31 34 37

80 .... 5 8 12 15 18 21 25 28 31 35

85 ...... 8 11 15 19 22 26 30 33

90 ...... 5 9 13 16 20 24 27 31

98 ....... 6 10 14 18 22 25 29

100 ........ 8 12 15 20 23 27

105 ........ 5 9 13 17 22 26

110 ......... 6 11 15 20 25

11S .......... 8 14 18 23

Where a dash (-) appears, do not attempt to charge system under these conditions, or refrigerant slugging may occur. Charge must be weighed in.

NOTE: Superheat °F is at low-side service port

If de['rost them_ostat is closed, speedup pins (J1) must be shorted

by placing a flat head screw driver in between for 5 sec and

releasing, to observe a complete defiost cycle. When the Quiet

Shi_ switch is selected, compressor will be mined off _br two 30

sec intervals during this complete defi'ost cyctQ as explained

previously When Quiet Shift switch is in bactory default OFF

position, a normal and complete defrost cycle will be observed.

If defrost them_ostat is in open position, and spee&/p pins are

shorted (with a flat head screw driver) for 5 sec and re]eased_ a

short defi'ost cycle will be observed (actual length is dependent

upon the selected Quiet Shift position) When Quiet Shift switch is

in ON position, the length of defiost is 1 minute (30 sec

compressor off period _bllowed by 30 sec of del:i'ost with com_

pressor operation) On return to heating operation, compressor will

again mm off _br an additional 30 sec and the outdoor _hn for 40

sec When the Quiet Shift is in OFF position, only a brief 30 sec

cycle will be observed

If it is desirable to observe a complete defrost in warmer weather,

the det'rost thermostat must be closed as follows

1 Turn off power to outdoor unit and install lockout tag

2. Disconnect outdoor _im motor tead flora OF2 on control

board. (See Fig. 23) Tape to prevent grounding.

3. Restart unit in Heating mode, allowing I:i'ost to accumulate on

outdoor coil.

4. Aker a few minutes in Heating mode, liquid line temperate/re

should drop below closing point of defi'ost thermostat (ap-

proximately 30_>F/- 1. I _>().

NOTE: Uit will remain in defrost until defrost thermostat

reopens at approximately 80°F (26.7°C) coil temperature at liquid

line or remainder of defrost cycle time up to a maximum defi'ost

time of 10 minutes.

19

Page 20

_@, @@

5 @, @@

4@, @@

o

o

3@, @@

CL

_D

C

N

0J

i 20,0@

ff

I@,0@

_lance Point Workmheet _ _limh

_m_ _ In_r _nt_ing Air of 7@ F. and,P.at_C_

@, 0@

-20

=I@ @ I@ 2@ 3@ 4@ 5@ 6@

_t_r Air _, (D_g F)

Fig, 22A--80JZ BaMnce Point Worksheet-English

5. Tm'n off power tag disconnect to outdoor and reconnect fire

motor tend to OF2 on control board after above forced defrost

cycle.

MAINTENANCE

_o ensure continuing high perfbrmance, and to minimize the

possibility of premature equipment fitilure, periodic maintenance

must be pert'ormed on this equipment. This heat pump unit should

be inspected at least once each year by a qualified service person.

To troubleshoot unit, refer to Troubleshooting (hart at the end of

these instructions

NOTE TO EQ(IPMENT OWNER: Consult your local dealer

about the availability of a maintenance contlact.

The ability to properly perfbrm maintenance on this equip=

ment requires certain expertise, mechanical skills, tools and

equipment. If you do not possess these, do not attempt to

perfbrm any maintenance on this equipment, other than those

procedures recommended in the User's Manual. FAILURE

TO HEED THIS WARNING COULD RESULT IN SERI=

OUS INJURY OR DEATH AND POSSIBLE DAMAGE TO

THIS EQUIPMENT.

7@

C02006

Failure to _bllow these warnings could result in serious injury

or death:

1. Turn off electrical power to the unit and install lockout mg

befbre perfbrming any maintenance or selwice on this unit.

2. Use extreme caution when removing panels and parts. As

with any mechanical equipment, personal injury can result

ti'om sharp edges,

3 Never place anything combustible either on, or in contact

with, the unit

Errors made when reconnecting wires may cause improper

and dangerous operation. Label all wires prior to disconnect=

ing when servicing

The n_ininmm maintenance requirements fbr this equipment are as

follows:

1. Inspect air filter(s) each month. Clean or replace when

necessa1%/

2. Inspect indoor coil, &aim and condensate drain line each

cooling season for cleanliness. (;lean when necessary.

3. Inspect blower motor and wheel fbr cleanliness each cooling

season. Clean when necessary.

4. (heck electrical connections fbr tighmess and controls _br

proper operation each cooling season. Service when neces=

sa_

Step l--Air FHter

IMPORTANT: Never operate the unit without a suitable air filter

in the return=air duct system Always replace the filter with the

2O

Page 21

Balance Point Worksh_t - _tr±c

I$

_ _n _r _t_Ting Air of 21 C, and _at_ C_

14

12

o

CL

8

C

0J

212

.,=_ g

c

0

=30

=25 =20 =15 =10 -5 @ 5 !0 15

Fig, 22B--80JZ Balance Po{nt VVorksheet-SI

same dimensional size and type as originally installed See Table

1 for recommended filter sizes.

Inspect air filter(s) at least once each month and replace

(throwaway=type) or clean (cteanable-type) at least twice during

each cooling season and twice during d_e heating season, or

whenever the filter becomes clogged with dust arid tint

Step 2--Indoor Blower and Motor

NOTE: All motors are prelubricate& Do not attempt to lubricate

these motors.

For longer life, operating economy, and continuing efficiency,

clean accumulated dirt and grease fiom the blower wheel and

motor annually.

Disconnect and tag electrical power to the unit before

cleaning and lubricating the blower motor arid _heel Failure

to adhere to this warning could cause personal il_iury or death

Step 3--Outdoor Coi!, hdoor Coil, and Condensate

Drain

Inspect the condenser coil, evaporator coil, and condensate drain at

least once each year.

The coils are easily cleaned when &y; therefore, inspect and clean

the coils either be_bre or after each cooling season. Remove all

obstructions, including weeds and shrubs, that interfere with the

airflow through the condenser coil.

Stlaighten bent fins with a fin comb. If coated with dirt or tint,

clean the coils with a vacuum cleaner, using the soft brush

attachment. Be caret\d not to bend the fins. If coated with oil or

grease, clean the coils with a mild detergent=and-water solution.

20

C02011

Rinse coils with clear water, using a garden hose. Be carefi/l not to

splash water on motors, insulation, wiring, or air filter(s) For best

results, spray condenser coil fins fi'om inside to outside the unit.

On units with an outer and inner condenser coil, be sure to clean

between the coils Be sure to flush all dirt and debris from the unit

base

Inspect the drain and condensate &ain line when inspecting the

coils, Clean the drain and condensate &ain tine by removing all

foreign matter fiom the &ain Flush the &ain and &ain trough

with clear water Do not splash water on the insulation, motor,

wiring, or air filter(s) It"the &ain trough is restricted, clear it with

a "plumbers snake" or similar probe device,

Step 4--Outdoor Fan

Keep the condenser fan t'ree t'rom all obstructions to ensure

proper cooling operation. Never place articles on top of the

unit. Damage to unit may result.

1 Remove 6 screws holding outdoor grille and motor to top

COVer,

2. Turn motor/grille assembly upside down on top cover to

expose fire blade.

3. Inspect the _im blades t'or cracks or bends.

4. If fan needs to be removed, loosen setscrew and slide _m off

motor shaft.

5. When replacing thn blade, position blade so that the hub is 1/8

in. (3A75 ram) away fiom the motor end (See Fig. 19).

6. Ensure that setscrew engages the flat area on the motor shaft

when tightening,

2i

Page 22

O <-"b_

Q'--P:b

--< Q_

C) <:_

O

7q

bO

CD__

o

©

r 1

r 1

C 1

r ]

r ]

C 1

C

CESO130076-00

©

--3

3

3

]

3

3

3

3

Speedup

Pins

Quiet rost interval

Shift DI P switches

Fig. 23--Defrost Control

7. Replace grille.

Step 5--Electrical Controms and Wiring

Inspect and check [he electrical contlols and wiring armually. Be

s_me to t_t's_ q{/the e/ectrica/ yo_ e_' to i/Tezmit a_cl inst_dl loci_o_t

ldt_,

Remove access panel [o locate all the electrical controls and

wiring. Check all electrica! connections for rightness. Tighten a11

screw connections. If any smoky or burned connections are

notice& disassemble the connection, clean all the parts, restrip the

wire end and reassemble the connection properly and securely.

After inspecting the electrical controls and wiring, replace all the

panels. Start the unit, and obsela-e at least one complete cooling

cycle to ensure proper operation. If discrepancies are observed in

operating cycle, or if a suspected malt\ruction has occurred, check

each electrical component with the proper electrical instromentao

tion. Refer to the unit wiring label when making these checkouts.

Step 6--Refrigerant Circuit

Inspect all refrigerant robing connections and the unit base Ibroil

accumulation annually. Detecting oil generally indicates a refrigo

erant leak.

If oil is detected or if tow pertbmaance is suspected, leakotest all

refrigerant robing using an electronic leak detector, or tiquidosoap

solution. If a refrigerant leak is detected, refer to Check for

Re_iJgerant Leaks section.

If no refl'igerant leaks are %und and low performance is suspected,

refer to (hecking and Adjusting Refrigerant Charge section.

A99442

Step 7--hdoor Airflow

The heating and/or cooling airflow does not require checking

unless improper perfbm_ance is suspected tya proMem e_i._ts, /_e

.sz_re that a// szlppl)- and _'em_'n-air gH/les are oi_eI_ w_d free _'om

obst_'zzction.s, and that the ai_' fi]ter is c]ea_. When necessm?-, refer

to Indoor Airflow and Airflow Adjustments section to check the

system airflow.

Step 8--PURON® Systems Items

The Following items should be taken into consideration when

maintaining your PuronR; System.

Metering Deviees-Aeeurater Piston

This metering device is a fixed orifice and is contained in the brass

hexobody in the liquid line _)eding the indoor and outdoor coils.

Pressure Switches

Pressure switches are protective devices wired into control circuit

(low voltage). They shut off compressor if abnom_ally high or tow

pressures are present in the refi'igeration circuit. These pressure

switches are specifically designed to operate with Puron (R-410A)

systems. R-22 pressure switches must not be used as replacements

for the Puron (Ro410A) system.

Loss of Charge Switch

This switch is located on the liquid line and protects against tow

suction pressures caused by such events as toss of charge, low

airflow across indoor coil., dirty filters, etc. It opens on a pressure

drop at about 20 psig (138 kpa). If system pressure is above this,

switch should be closed. To check switch:

22

Page 23

Fig. 24_Refrigerant Circuit

C99097

1. Turn off all power to unit and install lockout tag

2. Disconnect leads on switch

3. Apply ohm meter leads across switch. You should have

continuity on a good switch.

NOTE: Because these switches are attached to refrigeration

system under pressure, it is not advisable to remove this device for

troubleshooting unless you are reasonably certain that a problem

exists. If switch must be removed, remove and recover all system

charge so that pressure gauges read 0 psi. Never open system

without breaking vacuum with dw nitlogen.

High-Pressure Switch

The high=pressure switch is located in the discharge line and

protects against excessive condenser coil pressure. It opens at (510

psig (4205 kpa). High pressure may be caused by a dirty outdoor

coil, gtiled fan motor, or outdoor air recirculation.

To check switch:

1. Turn off all power to unit and install lockout tag.

2. Disconnect leads on switch.

3. Apply ohm meter leads across switch. You should have

continuity on a good switch.

Cepeland Scroll Compressor (Puren Refrigerant)

The compressor used in this product is specifically designed to

operate wRh Puron (R-410A) refrigerant and cannot be inter-

changed.

The compressor is an electrical (as well as mechanical) device.

Exercise extreme caution when working near compressors. Power

should be shut off: if possible, fbr most troubleshooting tech-

niques. Refrigerants present additional sa_ty hazards.

Wear safety glasses and gloves when handling refrigerants

Keep torches and other ignition sources away fi'om refl'iger=

ants and oils. Failure to _bltow this warning can cause a fire,