Page 1

48GP (N) 024-060, 48JZ (N) 024-060

50GL 024-060, 50JZ 024-060

ICM FIOP Installation Instructions

Visit www.carrier.com

Installation, Start-Up, and Operating Instructions

NOTE: Read the entire instruction manual before starting the

installation.

TABLE OF CONTENTS

SAFETY CONSIDERATIONS .....................................................1

INTRODUCTION ..........................................................................2

RECEIVING AND INSTALLATION ..........................................2

ICM FIOP PRE-START-UP..........................................................2

Electrical Connections ..............................................................2

Control Voltage Connections ..............................................2

Standard Connection............................................................2

Easy Select™—48GP..........................................................2

48GP Sequence of Operation..............................................4

Easy Select™—48JZ...........................................................5

48JZ Sequence of Operation...............................................7

Easy Select™—50GL & 50JZ............................................7

50GL & 50JZ Sequence Of Operation...............................9

ICM FIOP START-UP ................................................................10

48GP Start-Up (ICM FIOP) ...................................................10

48JZ Start-Up (ICM FIOP) ....................................................10

50GL: Start-Up (ICM FIOP)..................................................11

50JZ: Start-Up (ICM FIOP) ...................................................11

ELECTRICAL DATA & SCHEMATICS—ICM FIOP.............12

Physical Data & Electrical Schematics..................................12

Tables For System Set-Up......................................................12

CARE AND MAINTENANCE...................................................12

TROUBLESHOOTING ...............................................................13

START-UP CHECKLIST............................................................13

NOTE TO INSTALLER — READ THESE INSTRUCTIONS

CAREFULLY AND COMPLETELY before installing this unit.

Also, make sure the Owner’s Manual and Service Instructions are

left with the unit after installation.

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be

hazardous due to system pressure and electrical components. Only

trained and qualified personnel should install, repair, or service

air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of

cleaning coils and filters. All other operations should be performed

by trained service personnel. When working on air-conditioning

equipment, observe precautions in the literature, tags, and labels

attached to the unit, and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth for unbrazing operations. Have fire extinguisher

available for all brazing operations.

Recognize safety information. This is the safety-alert symbol .

When you see this symbol on the product or in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words — DANGER, WARNING, CAUTION, and NOTE. Danger identifies the most serious hazards,

which will result in severe personal injury or death. Warning

indicates a condition that could cause serious personal injury or

death. Caution is used to identify unsafe practices, which would

result in minor personal injury or product and property damage.

NOTE is used to highlight suggestions which will result in

enhanced installation, reliability, or operation.

The power supply (volts, phase, and hertz) must correspond to that

specified on unit rating plate.

The electrical supply provided by the utility must be sufficient to

handle load imposed by this unit. Electrical supply must match the

voltage requirements listed on unit rating plate.

This installation must conform with local building codes and with

NEC (National Electrical Code). Refer to provincial and local

plumbing or waste water codes and other applicable local codes.

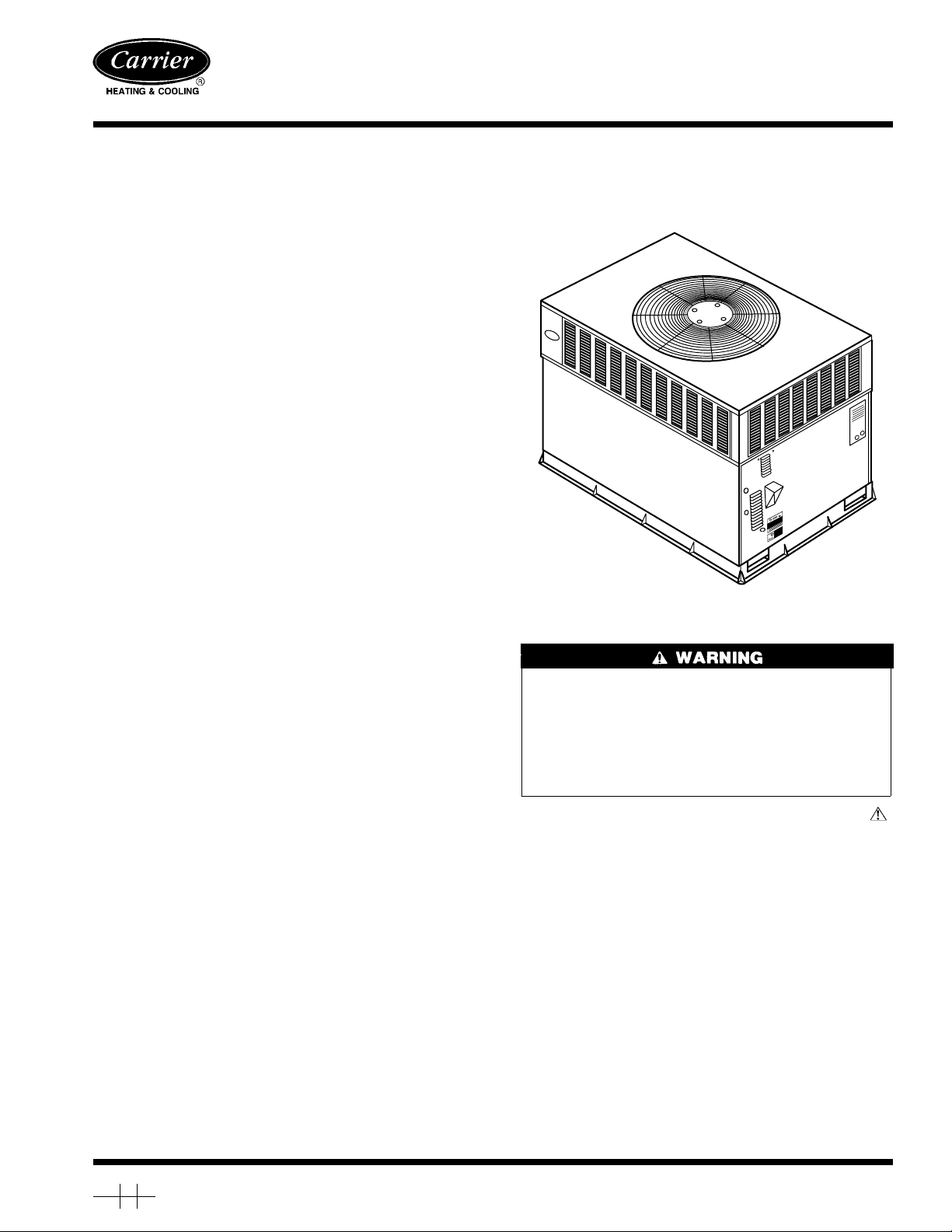

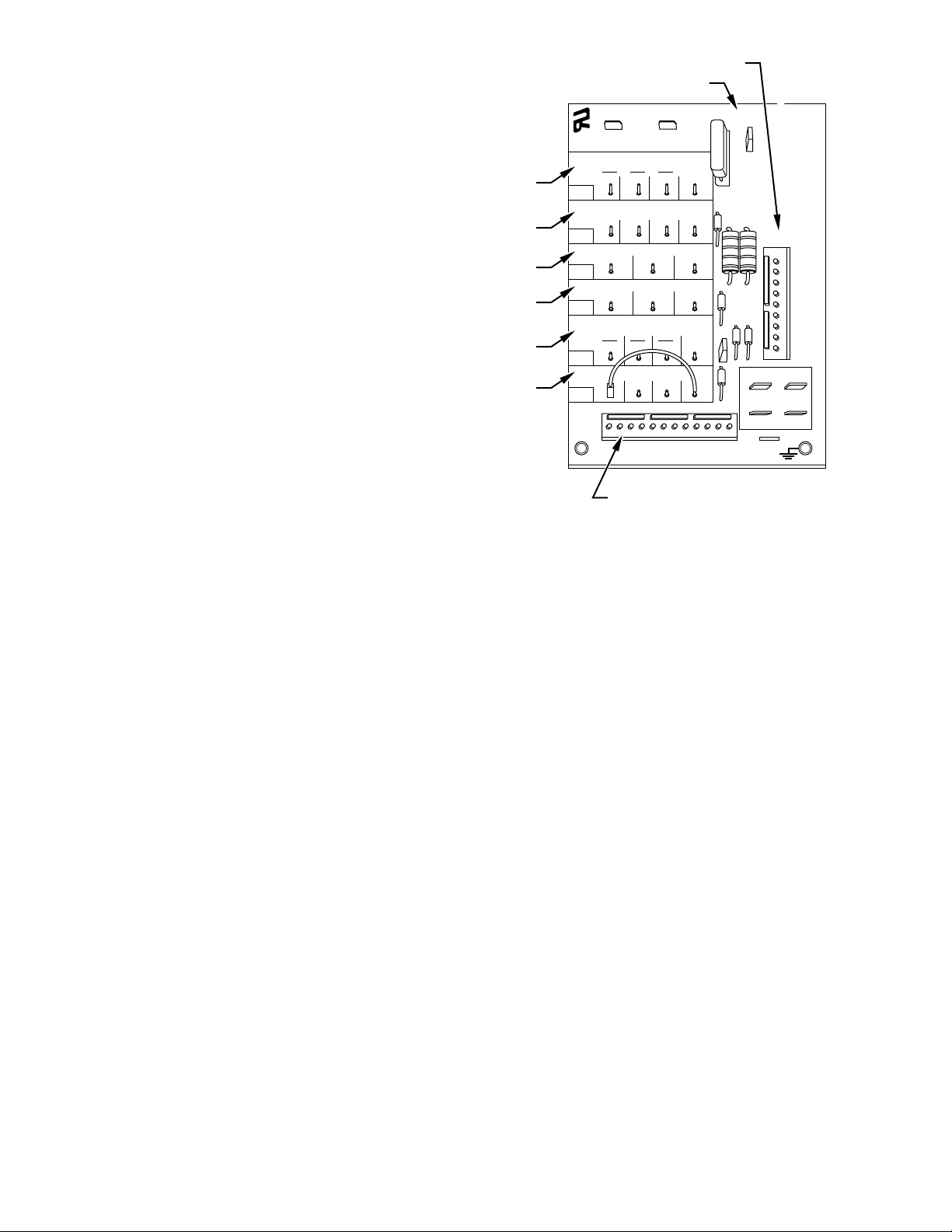

Fig. 1—Puron® Unit (48GP Shown)

Improper installation, adjustment, alteration, service, maintenance, or use can cause explosion, fire, electric shock, or

other occurrences, which could cause serious injury or death

or damage your property. Consult a qualified installer or

service agency for information or assistance. The qualified

installer or agency must use only factory-authorized kits or

accessories when modifying this product.

C99088

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 1a 1a

PC 101 Catalog No. 534-80085 Printed in U.S.A. Form 48–21SI Pg 1 10-01 Replaces: 48–20SI

Page 2

Approved for outdoor installation on wood flooring or on class A,

B or C roof covering materials.

Before performing service or maintenance operations on

system, turn off main power to unit and install lock-out tag.

Turn off accessory heater power switch if applicable. Electrical shock could cause severe injury or death.

Puron® (R-410A) systems operate at higher pressures than

standard R-22 systems. Do not use R-22 service equipment or

components on Puron® (R-410A) equipment. Ensure service

equipment is rated for Puron® (R-410A)

INTRODUCTION

NOTE: The minimum outdoor cooling operating temperature for

units using this ICM motor option is 55°F. To operate in cooling

at lower ambients the Motor Master™ II low ambient kit is

required.

These instructions cover the installation of a Carrier Small

Packaged Product with ICM motor-factory installed option

(FIOP). This option can be selected as a FIOP on gas

heating/electric cooling (48GP), dual fuel–electric heat pump with

gas heat back-up (48JZ), electric cooling (50GL) or electric heat

pump (50JZ) units with Puron®.

RECEIVING AND INSTALLATION

Refer to unit Installation Instructions.

ICM FIOP PRE-START-UP

Step 1—Electrical Connections

CONTROL VOLTAGE CONNECTIONS

NOTE: Do not use any type of power-stealing thermostat, without connecting the C (Common) terminal. Failure to follow this

note could result in unit control problems.

Use no. 18 American Wire Gage (AWG) color-coded, insulated

(35 C minimum) wires to make the control voltage connections

between the thermostat and the unit. If the thermostat is located

more than 100 ft from the unit (as measured along the control

voltage wires), use no. 16 AWG color-coded, insulated (35 C

minimum) wires.

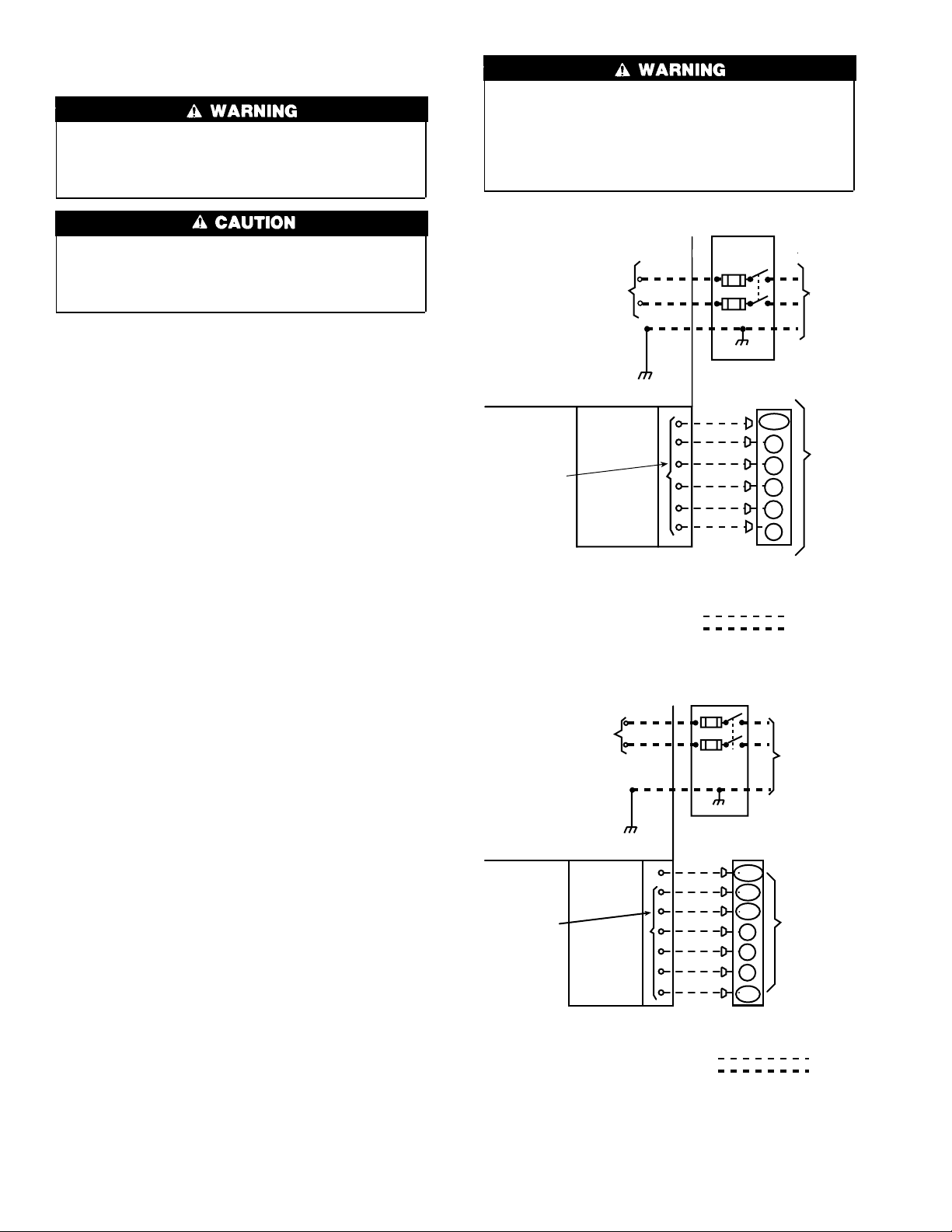

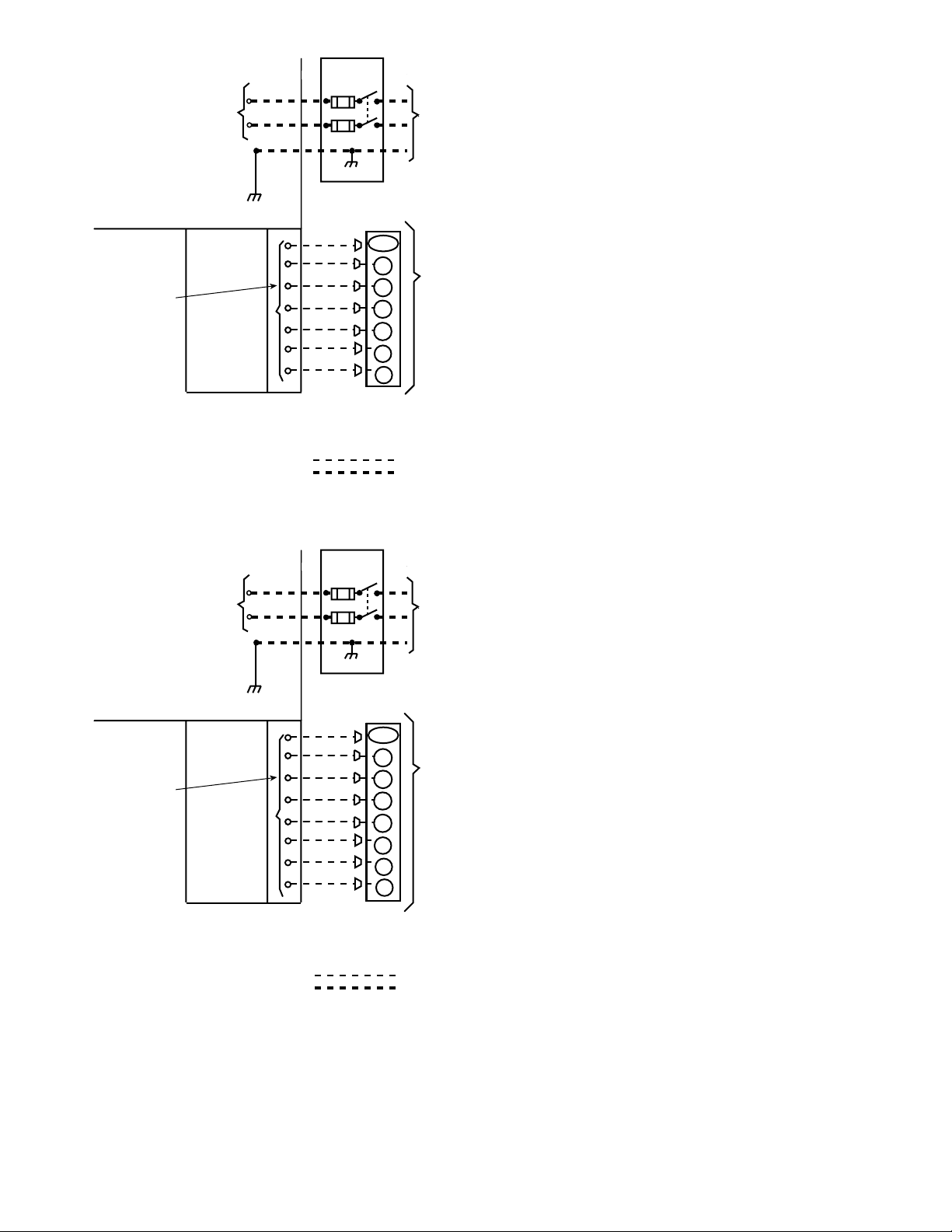

STANDARD CONNECTION

Remove knockout hole located in the heat section panel adjacent to

the service access panel (See unit installation package). Remove

the rubber grommet from the installer’s packet (included with unit)

and install grommet in the knockout opening. Provide a drip loop

before running wire through panel. Run the low-voltage leads from

the thermostat, through the inlet hole, and into unit low-voltage

splice box. Locate 18-gage wires leaving control box. These

low-voltage connection leads can be identified by colors (See Fig.

2, 3, 4 or 5). Ensure the leads are long enough to be routed into the

low-voltage splice box (located below right side of control box).

Route leads through hole in bottom of control box and make

low-voltage connections (See Fig. 2, 3, 4 or 5). Secure all cut

wires, so that they do not interfere with operation of unit.

SPECIAL PROCEDURES FOR 208–V OPERATION

Make sure that the power supply to the unit is switched OFF

before making any wiring changes. With disconnect switch

open, move yellow wire from transformer (3/16 in.) terminal

marked 230 to terminal marked 200. This retaps transformer

to primary voltage of 208-v. Electrical shock could cause

serious injury or death.

EASY SELECT™—48GP

HIGH VOLTAGE

POWER LEADS

(SEE UNIT WIRING

LABEL)

FIELD-SUPPLIED

FUSED DISCONNECT

BLK(DH)

YEL(Y)

GRN(G)

RED(R)

BRN(C)

WHI(W1)

DHUM

Y

G

R

C

W1

CONTROL BOX

LOW-VOLTAGE

POWER LEADS

(SEE UNIT

WIRING LABEL)

GND

SPLICE BOX

LEGEND

Field Control-Voltage Wiring

Field High-Voltage Wiring

Fig. 2—48GP High- and Control-Voltage

Connections

HIGH VOLTAGE

POWER LEADS

(SEE UNIT WIRING

LABEL)

CONTROL BOX

LOW-VOLTAGE

POWER LEADS

(SEE UNIT

WIRING LABEL)

FIELD CONTROL - VOLTAGE WIRING

FIELD HIGH - VOLTAGE WIRING

GND

SPLICE BOX

FIELD-SUPPLIED

FUSED DISCONNECT

BLK (DH)

WHT(W1)

YEL(Y)

GRN(G)

RED(R)

BRN(C)

ORN(O)

DHUM

W/W1

Y/Y2

G

R

C

O/W2

POWER

SUPPLY

THERMOSTAT

(THERMIDISTAT ™ )

Fig. 3—48JZ High- and Control-Voltage

Connections

POWER

SUPPLY

THERMOSTAT

(TYPICAL)

C01026

C01107

EASY SELECT™ CONFIGURATION TAPS FOR 48GP

Easy Select™ taps are used by the installer to configure a system.

2

Page 3

HIGH VOLTAGE

POWER LEADS

(SEE UNIT WIRING

LABEL)

CONTROL BOX

LOW-VOLTAGE

POWER LEADS

(SEE UNIT

WIRING LABEL)

Field Control-Voltage Wiring

Field High-Voltage Wiring

SPLICE BOX

LEGEND

GND

FIELD-SUPPLIED

FUSED DISCONNECT

BLK(DH)

YEL(Y)

GRN(G)

RED(R)

BRN(C)

WHI(W1)

GRA(W2)

DHUM

Y

G

R

C

W1

W2

POWER

SUPPLY

THERMOSTAT

(TYPICAL)

C01027

Fig. 4—50GL High- and Control-Voltage

Connections

HIGH VOLTAGE

POWER LEADS

(SEE UNIT WIRING

LABEL)

CONTROL BOX

LOW-VOLTAGE

POWER LEADS

(SEE UNIT

WIRING LABEL)

Field Control-Voltage Wiring

Field High-Voltage Wiring

SPLICE BOX

LEGEND

GND

FIELD-SUPPLIED

FUSED DISCONNECT

BLK(DH)

YEL(Y)

GRN(G)

RED(R)

BRN(C)

WHI(W1)

GRA(W2)

ORN(0)

DHUM

Y

G

R

C

W1

W2

O

POWER

SUPPLY

THERMOSTAT

(TYPICAL)

C01028

Fig. 5—50JZ High- and Control-Voltage

Connections

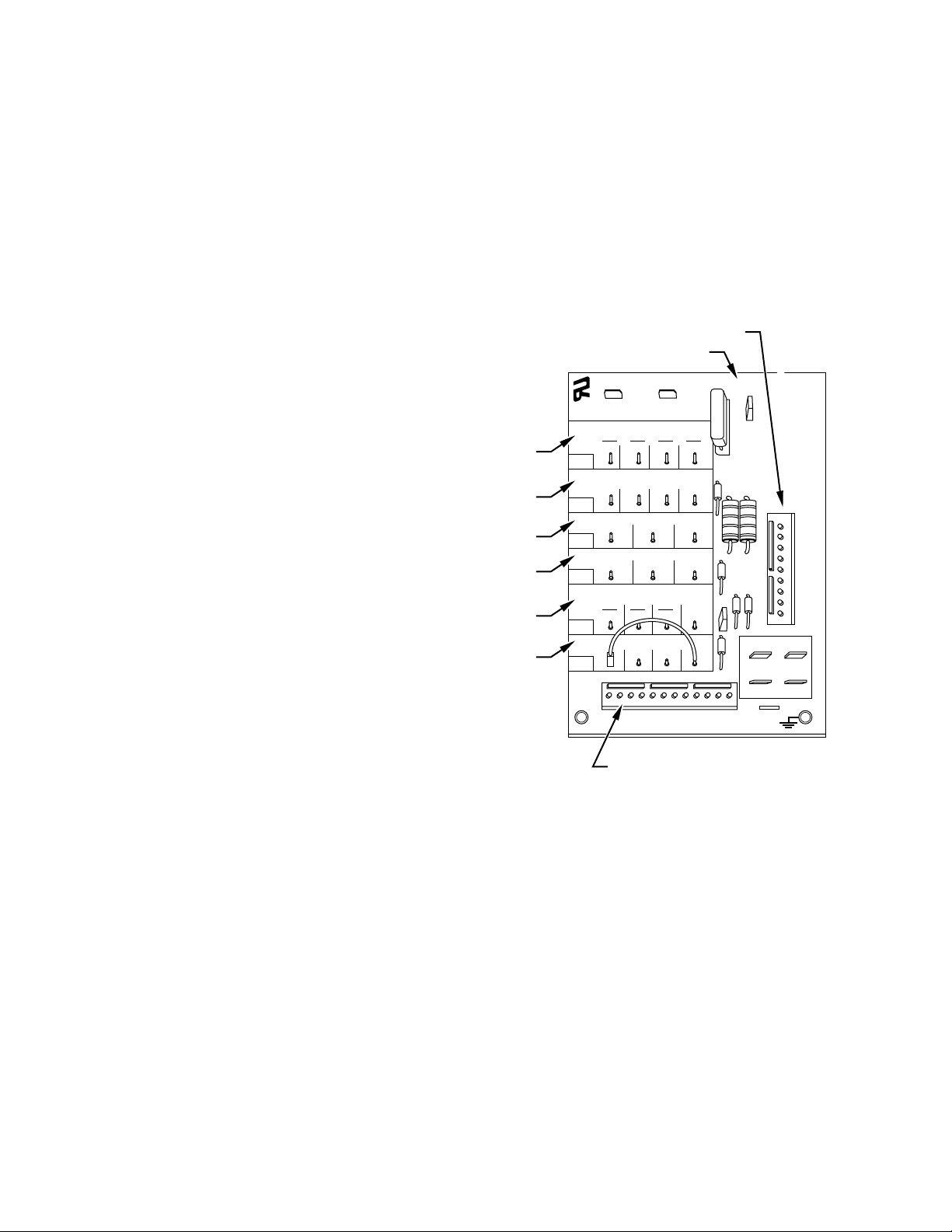

The ICM motor uses the selected taps to modify its operation to a

pre-programmed table of airflows.

The unit must be configured to operate properly with system

components with which it is installed. To successfully configure a

basic system (see information printed on circuit board label located

next to select pins), move the 6 select wires to the pins which

match the components used (See Fig. 8).

a. GAS HEAT/CFM—SELECT GAS HEAT INPUT SIZE

Factory selected gas heat size should correspond to unit label.

b. AC/HP SIZE—SELECT SYSTEM SIZE INSTALLED

Factory selected air conditioner size should correspond to

capacity of unit installed. Installer should verify air conditioner

size to ensure that airflow delivered falls within proper range

for the size unit installed. This applies to all operational modes.

c. SYSTEM TYPE—SELECT SYSTEM TYPE INSTALLED

Factory selected on 48GP for AC-Air conditioner.

For Gas Heat/Electric Cool Unit–AC must be selected.

d. AC/HP CFM ADJUST—SELECT NOMINAL, LOW, OR

HIGH AIRFLOW

The AC/HP CFM Adjust select is factory set to the High-HI

(NOM for 060) tap. The CFM Adjust selections NOM/LO will

regulate airflow supplied for all operational modes, except

non-heat pump heating modes. HI provides 15 percent airflow

over nominal unit size selected and LO provides 10 percent

airflow below nominal unit size selected. Adjust selection

options are provided to adjust airflow supplied to meet individual installation needs for such things as noise, comfort, and

humidity removal (See Fig. 8, D as indicated).

e. ON/OFF DELAY—SELECT DESIRED

TIME DELAY PROFILE

Four motor operation delay profiles are provided to customize

and enhance system operation (See Fig. 8, E as indicated).

Selection options are:

(1.) The standard 90 sec off delay (Factory Setting) at 100

percent airflow in cooling mode. In heating mode, IGC

will control 45 sec on delay with no airflow and 45 sec off

delay.

(2.) A 30 sec cooling delay with no airflow/ 90 sec off delay at

100 percent airflow profile is used when it is desirable to

allow system coils time to cool-down in conjunction with

the airflow in heating mode.

(3.) A no delay option used for servicing unit or when a

thermostat is utilized to perform delay functions in cooling

mode. In heating mode IGC will control 45 sec on delay

with no airflow and 45 sec off delay.

(4.) Not recommended for 48GP

f. CONTINUOUS FAN—SELECT DESIRED FAN SPEED

WHEN THERMOSTAT IS SET ON CONTINUOUS FAN

(1.) LO speed—Factory setting, 50 percent cooling mode

airflow.

(2.) MED speed—Move connector to MED, 65 percent cooling

mode airflow.

(3.) HI speed—Move connector to HI, 100 percent cooling

mode airflow (See Fig. 8, F as indicated).

g. LOW-VOLTAGE CIRCUIT FUSING AND REFERENCE

The low-voltage circuit is fused by a board-mounted 5–amp

automotive fuse placed in series with the transformer SEC2 and

the R circuit. The C circuit of the transformer is referenced to

chassis ground through a printed circuit run at SEC1 connected

to metal standoff marked with ground symbol.

h. BASIC UNIT CONFIGURATION

The following basic configuration of the indoor motor will

provide ARI rated performance of the 48GP. This BASIC

CONFIGURATION should be used when the rated ARI performance is required, or if system enhancements such as super

dehumidify are not needed.

(1.) HEAT-Factory selected to match heat input size.

3

Page 4

(2.) AC/HP Size-Factory selected to match system size, please

verify.

(3.) SYSTEM TYPE-Factory selected on 48GP system AC-

AIR CONDITIONER.

(4.) AC/HP CFM ADJUST-Select HIGH for 042 & 048, NOM

for 036 & 060, and LO for 024 & 030..

(5.) ON/OFF DELAY-Factory selected 0/90 profile.

(6.) CONTINUOUS FAN-Select desired fan speed when ther-

mostat is set to continuous fan.

i. COMFORT OPTIONS—SUPER DEHUMIDIFY (See Quick

Reference Guide)

The Super Dehumidify option is possible when this unit is

installed with a field supplied Thermidistat™ control (SuperDehumidify does not require an outdoor temperature sensor).

The following configuration is recommended for maximum

cooling/dehumidifying comfort. This configuration will improve the comfort provided by the air conditioning system if

more humidity removal is desired. While providing this improved comfort, the system will operate efficiently, but not at

the published ARI SEER efficiency. During cool-to-dehumidify

call, it provides maximum dehumidification by reducing airflow

to a minimum. The actual super dehumidify command from

Thermidistat™ control to the indoor unit is a “Y” signal without

a “G” signal in addition to dehumidify signal. The indoor unit

responds to this combination by reducing the airflow to a

minimum. All other characteristics of cool to dehumidify are the

same.

The following system configuration is recommended for maximum cooling/dehumidifying comfort (See Fig. 8).

(1.) HEAT-Factory selected to match gas heat size of unit

installed.

(2.) AC/HP Size-Factory selected to match system size, please

verify.

(3.) SYSTEM TYPE-Factory selected on 48GP system AC-

AIR CONDITIONER.

(4.) AC/HP CFM ADJUST-Select NOM (Lo for 060).

(5.) ON/OFF DELAY-Select ENH profile.

(6.) CONTINUOUS FAN-Select desired fan speed when ther-

mostat is set to continuous fan.

(7.) DEHUMIDIFY MODE-Remove J1 jumper to activate.

NOTE: J1 jumper should only be removed when a Thermidistat™, humidistat or capable zoning control is installed.

(8.) LOW VOLTAGE CONNECTIONS-Make connections as

shown in ELECTRICAL CONNECTIONS section.

(9.) CONFIGURE THERMIDISTAT™-Follow Thermidis-

tat™ (or capable zoning system) installation instructions

for Super Dehumidify operation.

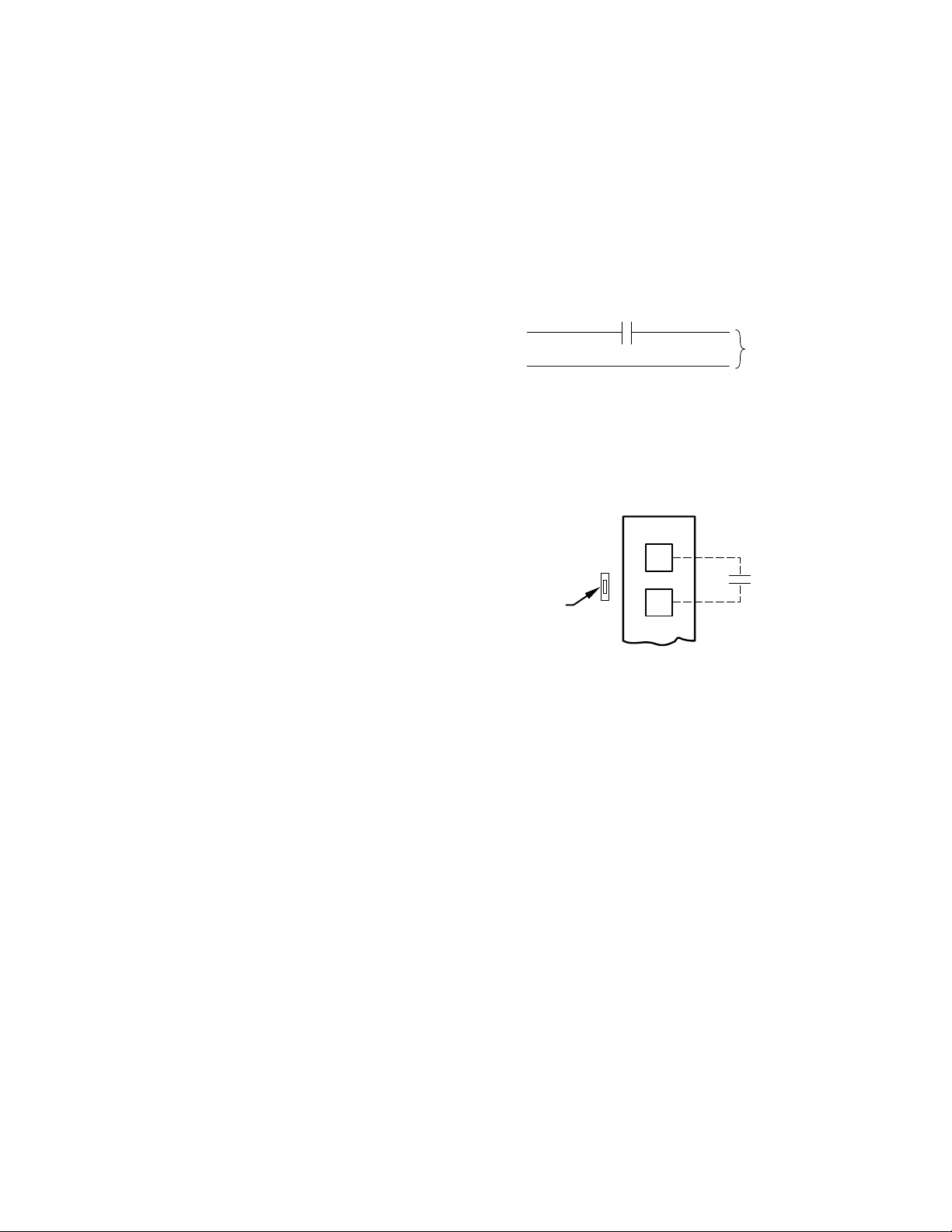

ACCESSORY INSTALLATION

a. AUXILIARY TERMINALS

The AUX and HUM terminals on the Easy Select™ Board are

tied directly to the G terminal, and provide a 24-v. signal

whenever the G terminal is energized (See Fig. 6). During

Super dehumidify mode, the G signal is not present and the

auxiliary terminals are not energized. If the installation includes

the use of this operating mode, do not use these terminals to

control accessories. See Electronic Air Cleaner and Humidifier

sections for further information.

b. ELECTRONIC AIR CLEANER CONNECTIONS

The AUX1 and AUX2 terminals are not always energized

during blower operations, as described above. When using an

electronic air cleaner with the unit, use Airflow Sensor P/N.

KEAAC0101AAA. The airflow sensor turns on electronic air

cleaner when the blower is operating.

c. HUMIDIFIER/HUMIDISTAT CONNECTIONS

Easy Select™ Board terminals HUM1 and HUM2 are provided

for direct connection to the low-voltage control of a humidifier

through a standard humidistat (See Fig. 6). These terminals are

energized with 24-v. when G thermostat signal is present (See

Fig. 6 & 7). Alternately, the 24-v. signal may be sourced from

the W and C on the 9 pin connector. When using a Thermidistat™ Control, Zone Comfort Plus or Comfort Zone II, the 24-v.

signal may be sourced directly from the Thermidistat™ HUM

terminal (See Fig. 6,7&8).

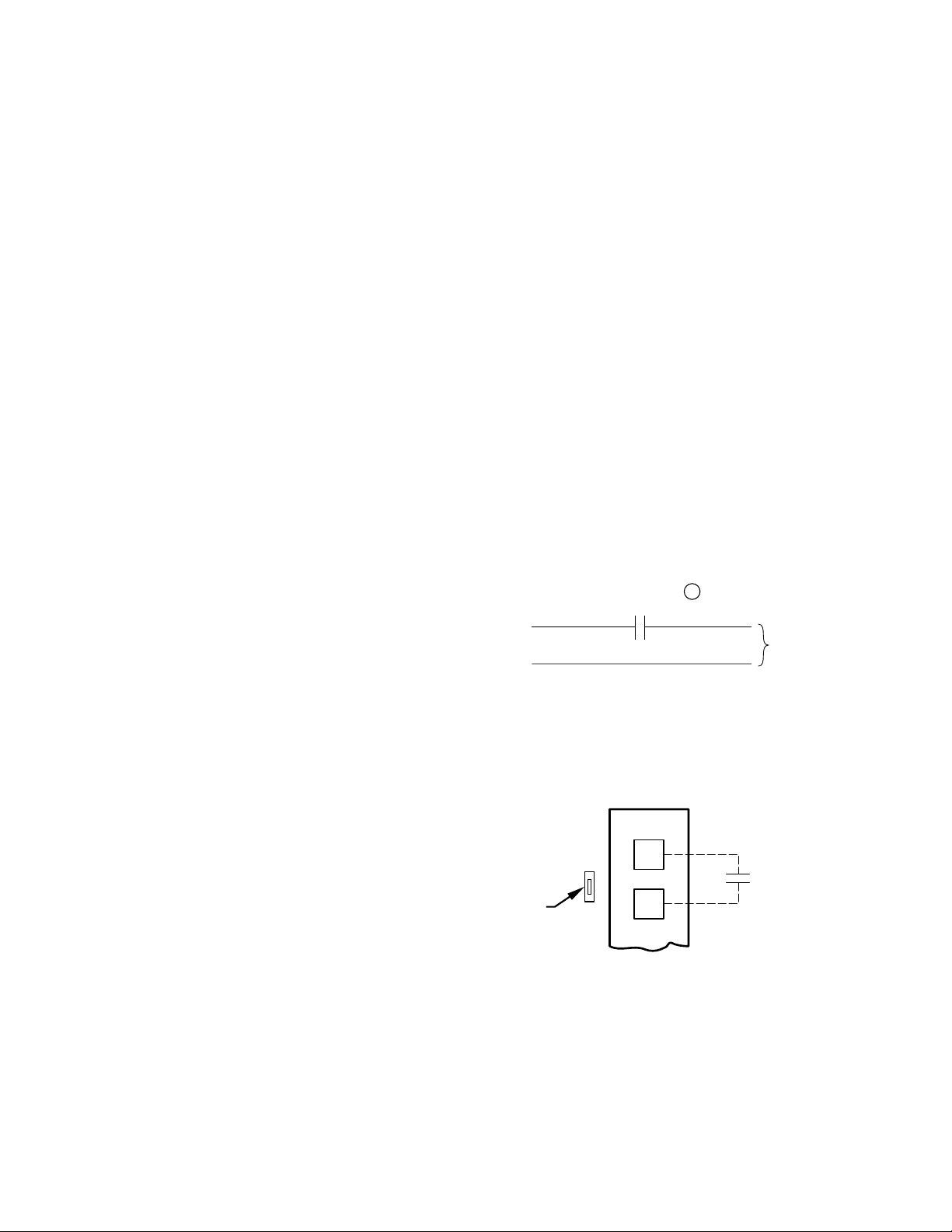

HUMIDISTAT

HUM 1

(C)

HUM 2

(G)

24-VAC

HUMIDIFIER WIRING

Fig. 6—Humidifier Wiring-48GP

EASY SELECT

BOARD TERMINAL

BLOCK

D

J1

REMOVE

JUMPER

H

R

Fig. 7—Humidistat Wiring for

De-Humidify Mode-48GP

d. DEHUMIDIFY CAPABILITY WITH STANDARD

HUMIDISTAT CONNECTION

Latent capacities for this unit are better than average systems. If

increased latent capacity is an application requirement, the ICM

board provides connection terminals for use of a standard

humidistat. The unit will detect the humidistat contacts opening

on increasing humidity and reduce its airflow to approximately

80 percent of nominal cooling mode airflow. This reduction

will increase the system latent capacity until the humidity falls

to a level which causes the humidistat to close its contacts.

When the contacts close, the airflow will return to 100 percent

of selected cooling airflow. To activate this mode, remove

jumper J1 and wire in a standard humidistat (See Fig. 7).

e. DEHUMIDIFY AND SUPER DEHUMIDIFY

CAPABILITIES

This model unit is capable of responding to a signal from indoor

system control (Thermidistat™ or capable zoning control) to

operate in comfort control modes such as Super Dehumidify

Mode. Consult literature provided with indoor system control to

determine if these operating modes are available, and to see

control set up instructions. No special setup or wiring of unit is

required.

48GP SEQUENCE OF OPERATION

a. CONTINUOUS FAN

(1.) Thermostat closes circuit R to G—The Blower runs at

continuous fan airflow

4

TO HUMIDIFIER

A95317

HUMIDISTAT

A95316

Page 5

b. COOLING MODE

(1.) If indoor temperature is above temperature set point and

humidity is below humidity set point, thermostat closes

circuits R to G, R to Y/Y2 and R to O—The unit delivers

single speed cooling airflow.

c. COOLING MODE-DEHUMIDIFICATION

(1.) If indoor temperature is above temperature set point and

humidity is above humidity set point, thermostat or Thermidistat™ closes circuits R to G, R to Y/Y2, R to O and

humidistat or Thermidistat™ opens R to DH—The unit

delivers airflow which is approximately 80 percent of the

nominal cooling airflow to increase the latent capacity of

the system.

d. COOLING MODE-SUPER DEHUMIDIFY OPERATION

(SEE QUICK REFERENCE GUIDE)

NOTE: The indoor control used, such as a Thermidistat™, must

be capable of providing Super Dehumidify operation mode and

control must be configured as outlined in its installation instructions. Consult indoor control literature to determine if control is

capable of providing Super Dehumidify inputs and for configuration instruction.

(1.) If the indoor temperature is below the temperature set

point and the humidity is above the humidity set point, the

Thermidistat™ closes circuit R to O, opens circuits R to

DH and R to G, and closes circuit R to Y/Y2. If circuit R

to G is closed (24-v.), the motor will deliver airflow at the

full cooling or cooling plus dehumidify mode requested

value. If circuit R to G is open (0–v.) for Super Dehumidify mode, the motor delivers reduced airflow to maximize the humidity removal of the system while minimizing

over cooling.

e. GAS HEATING MODE

(1.) Thermostat closes circuit R to W/W1—The unit delivers

the selected gas heat airflow. The IGC will control a 45

sec. blower “On” delay and a 45 sec. “Off” delay.

EASY SELECT™—48JZ

NOTE: Either the Carrier Thermidistat™ or Dual Fuel thermostat is required for operation of the dual-fuel (48JZ) units.

Be sure to follow the installation instructions supplied with the

Thermidistat™. Either indoor temperature control must use

an outdoor air sensor to properly control heating operation.

EASY SELECT™ CONFIGURATION TAPS FOR 48JZ

Easy Select™ taps are used by the installer to configure a system.

The ICM motor uses the selected taps to modify its operation to a

pre-programmed table of airflows.

The unit must be configured to operate properly with system

components with which it is installed. To successfully configure a

basic system (see information printed on circuit board label located

next to select pins), move the 6 select wires to the pins which

match the components used (See Fig. 8).

a. GAS HEAT/CFM—SELECT GAS HEAT INPUT SIZE

Factory selected gas heat size should correspond to unit label.

b. AC/HP SIZE—SELECT SYSTEM SIZE INSTALLED

Factory selected air conditioner size should correspond to

capacity of unit installed. Installer should verify air conditioner

size to ensure that airflow delivered falls within proper range

for the size unit installed. This applies to all operational modes.

c. SYSTEM TYPE—SELECT SYSTEM TYPE INSTALLED

Factory selected on 48JZ for HP-EFF.

SELECT OPTIONS

1. HP-COMFORT provides approximately 315 CFM/ton for

higher normal heating air temperature and provides approxi-

9 PIN CONNECTOR

ICM PRINTED CIRCUIT BOARD

SEC1 SEC2

EASY SELECT

GAS HEAT/CFM

090

060

1250

A

B

C

D

E

F

VIO

BLU

ORN

BLK

WHT

YEL

1100

AC/HP SIZE

036 030 024 018

SYSTEM TYPE

AC

AC/HP CFM ADJUST

NOM HI

ON/OFF DELAY

09030900

CONTINUOUS FAN

MED HI YELLO

TM

040

800

HP-COMFORT

HP-EFF

LO

0

HEATER/MOTOR

N/A

ENH

12 PIN CONNECTOR

J2

J1

AUX1 HUM1

AUX2

24VAC

GRY

D

R

W

W

Y

Y/ Y

G

O

C

HUM2

H

1

2

1

2

C01039

Fig. 8—Detail of SPP Printed-Circuit Board

mately 350 CFM/ton cooling airflow for good humidity removal

2. HP-EFF (factory selected) Provides equal airflow for heating

and cooling modes to increase overall heat pump efficiency.

Provides approximately 400 CFM/ton.

d. AC/HP CFM ADJUST—SELECT NOMINAL, LOW, OR

HIGH AIRFLOW

The AC/HP CFM Adjust select is factory set to the High-HI

(NOM for 036, 060) tap. The CFM Adjust selections NOM/LO

will regulate airflow supplied for all operational modes, except

non-heat pump heating modes. HI provides 15 percent airflow

over nominal unit size selected and LO provides 10 percent

airflow below nominal unit size selected. Adjust selection

options are provided to adjust airflow supplied to meet individual installation needs for such things as noise, comfort, and

humidity removal (See Fig. 8, D as indicated).

e. ON/OFF DELAY—SELECT DESIRED

TIME DELAY PROFILE

Four motor operation delay profiles are provided to customize

and enhance system operation (See Fig. 8, E as indicated).

Selection options are:

(1.) The standard 90 sec off delay (Factory Setting) at 100

percent airflow in cooling or heat pump heating mode. In

gas heating mode, IGC will control a 45 sec “On” delay

and a 45 sec “Off” delay.

(2.) A 30 sec cooling delay with no airflow/ 90 sec off delay at

100 percent airflow profile is used when it is desirable to

allow system coils time to cool-down/heat-up in conjunction with the airflow in cooling or heat pump heating

mode.

(3.) A no delay option used for servicing unit or when a

thermostat is utilized to perform delay functions. In gas

heating mode IGC will control 45 sec on delay with no

airflow and 45 sec off delay.

5

Page 6

(4.) ENH (enhanced) selection provides a 30 sec. cooling &

heat pump on delay with no airflow, plus 150 seconds at 70

percent airflow and no off delay for added comfort. This

will minimize cold blow in heat pump operation and could

enhance system efficiency.

f. CONTINUOUS FAN—SELECT DESIRED FAN SPEED

WHEN THERMOSTAT IS SET ON CONTINUOUS FAN

(1.) LO speed—Factory setting, 50 percent cooling mode

airflow.

(2.) MED speed—Move connector to MED, 65 percent cooling

mode airflow.

(3.) HI speed—Move connector to HI, 100 percent cooling

mode airflow (See Fig. 8, F as indicated).

g. LOW-VOLTAGE CIRCUIT FUSING AND REFERENCE

The low-voltage circuit is fused by a board-mounted 5–amp

automotive fuse placed in series with the transformer SEC2 and

the R circuit. The C circuit of the transformer is referenced to

chassis ground through a printed circuit run at SEC1 connected

to metal standoff marked with ground symbol.

h. BASIC UNIT CONFIGURATION

The following basic configuration of the indoor motor will

provide ARI rated performance of the 48JZ. This BASIC

CONFIGURATION should be used when the rated ARI performance is required.

(1.) HEAT-Factory selected to match heat input size.

(2.) AC/HP Size-Factory selected to match system size, please

verify.

(3.) SYSTEM TYPE-Factory selected on 48JZ system for

HP-EFF.

(4.) AC/HP CFM ADJUST-Select HIGH for 042 & 048, NOM

for 036 & 060, and LO for 024 & 030.

(5.) ON/OFF DELAY-Factory selected 0/90 profile.

(6.) CONTINUOUS FAN-Select desired fan speed when ther-

mostat is set to continuous fan.

i. COMFORT OPTIONS—SUPER DEHUMIDIFY (See Quick

Reference Guide)

The Super Dehumidify option is possible when this unit is

installed with a field supplied Thermidistat™ control (SuperDehumidify does not require an outdoor temperature sensor).

The following configuration is recommended for maximum

cooling/dehumidifying comfort. This configuration will improve the comfort provided by the air conditioning system if

more humidity removal is desired. While providing this improved comfort, the system will operate efficiently, but not at

the published ARI SEER efficiency.

The following system configuration is recommended for maximum cooling/dehumidifying comfort (See Fig. 8).

(1.) HEAT-Factory selected to match gas heat size of unit

installed.

(2.) AC/HP Size-Factory selected to match system size, please

verify.

(3.) SYSTEM TYPE-Factory selected on 48JZ system for

HP-EFF.

(4.) AC/HP CFM ADJUST-Select NOM (Lo for 060).

(5.) ON/OFF DELAY-Select ENH profile.

(6.) CONTINUOUS FAN-Select desired fan speed when ther-

mostat is set to continuous fan.

(7.) LOW VOLTAGE CONNECTIONS-Make connections as

shown in ELECTRICAL CONNECTIONS section.

(8.) CONFIGURE THERMIDISTAT™-Follow Thermidis-

tat™ installation instructions for Super Dehumidify operation.

ACCESSORY INSTALLATION

a. AUXILIARY TERMINALS

The AUX and HUM terminals on the Easy Select™ Board are

tied directly to the G terminal, and provide a 24-v. signal

whenever the G terminal is energized (See Fig. 9). During

Super dehumidify mode, the G signal is not present and the

auxiliary terminals are not energized. If the installation includes

the use of this operating mode, do not use these terminals to

control accessories. See Electronic Air Cleaner and Humidifier

sections for further information.

b. ELECTRONIC AIR CLEANER CONNECTIONS

The AUX1 and AUX2 terminals are not always energized

during blower operations, as described above. When using an

electronic air cleaner with the unit, use Airflow Sensor P/N.

KEAAC0101AAA. The airflow sensor turns on electronic air

cleaner when the blower is operating.

c. HUMIDIFIER / THERMIDISTAT™ CONNECTIONS

Easy Select™ Board terminals HUM1 and HUM2 are provided

for direct connection to the low-voltage control of a humidifier

through a standard Thermidistat™ (See Fig. 9). These terminals

are energized with 24-v. when G thermostat signal is present

(See Fig. 10). Alternately, the 24-v. signal may be sourced from

the W and C on the 9 pin connector. When using a Thermidistat™ Control the 24-v. signal may be sourced directly from the

Thermidistat™ HUM terminal (See Fig. 8, 9 & 10).

THERMIDISTAT ™

HUM 1

(C)

HUM 2

(G)

24-VAC

HUMIDIFIER WIRING

Fig. 9—Humidifier Wiring-48JZ

EASY SELECT

BOARD TERMINAL

BLOCK

D

J1

JUMPER

H

R

Fig. 10—Thermidistat™ Wiring for

De-Humidify Mode-48JZ

d. DEHUMIDIFY CAPABILITY WITH STANDARD

THERMIDISTAT™ CONNECTION

Latent capacities for this unit are better than average systems. If

increased latent capacity is an application requirement, the ICM

board provides connection terminals for use of a Thermidistat™. The unit will detect the Thermidistat™ contacts opening

on increasing humidity and reduce its airflow to approximately

80 percent of nominal cooling mode airflow. This reduction

will increase the system latent capacity until the humidity falls

6

TO HUMIDIFIER

C01108

THERMIDISTAT

C01109

Page 7

to a level which causes the Thermidistat™ to close its contacts.

When the contacts close, the airflow will return to 100 percent

of selected cooling airflow. To activate this mode wire in

Thermidistat™ see jumper in Fig. 10.

e. DEHUMIDIFY AND SUPER DEHUMIDIFY

CAPABILITIES

This model unit is capable of responding to a signal from

Thermidistat™ to operate in comfort control modes such as

Super Dehumidify Mode. Consult literature provided with

Thermidistat™ to determine if these operating modes are

available, and to see control set up instructions. No special

setup or wiring of unit is required.

48JZ SEQUENCE OF OPERATION

a. CONTINUOUS FAN

(1.) Thermostat closes circuit R to G—The Blower runs at

continuous fan airflow

b. COOLING MODE

(1.) If indoor temperature is above temperature set point and

humidity is below humidity set point, thermostat closes

circuits R to G, R to Y/Y2 and R to O—The unit delivers

single speed cooling airflow.

c. COOLING MODE-DEHUMIDIFICATION

(1.) If indoor temperature is above temperature set point and

humidity is above humidity set point, Thermidistat™

closes circuits R to G, R to Y/Y2, R to O and Thermidistat™ opens R to DH—The unit delivers airflow which is

approximately 80 percent of the nominal cooling airflow to

increase the latent capacity of the system.

d. COOLING MODE-SUPER DEHUMIDIFY OPERATION

(SEE QUICK REFERENCE GUIDE)

NOTE: Thermidistat™ is capable of providing Super Dehumidify operation mode and must be configured as outlined in its

installation instructions. Consult indoor control literature to determine if control is capable of providing Super Dehumidify inputs

and for configuration instruction.

(1.) If the indoor temperature is below the temperature set

point and the humidity is above the humidity set point, the

Thermidistat™ closes circuit R to O, opens circuits R to

DH and R to G, and closes circuit R to Y/Y2. If circuit R

to G is closed (24-v.), the motor will deliver airflow at the

full cooling or cooling plus dehumidify mode requested

value. If circuit R to G is open (0–v.) for super dehumidify

mode, the motor delivers reduced airflow to maximize the

humidity removal of the system while minimizing over

cooling.

e. GAS HEATING MODE

(Occurs if outdoor temperature is below outdoor temperature

change over setpoint.)

(1.) Thermostat closes circuit R to W/W1—The unit delivers

the selected gas heat airflow. The IGC will control 45 sec.

on delay with no airflow and 45 sec. off delay.

f. HEAT PUMP HEATING MODE

(Occurs if outdoor temperature is above outdoor temperature

change over setpoint.)

(1.) Thermidistat™ closes circuit R to G and R to Y/Y2–The

unit delivers selected heat pump heating airflow.

g. HEATING MODE—SUPER COMFORT HEAT OPERA-

TION

NOTE: The Thermidistat™ is capable of providing Super Comfort Heat operation mode and must be configured as outlined in its

installation instructions. The system must be installed with appropriate outdoor temperature sensor. Consult Thermidistat™ literature for configuration instructions. Consult sensor instructions for

sensor installation details.

If the outdoor temperature is in the range of 12° to 40° F, the

Thermidistat™ closes circuit R to Y/Y2 and opens circuit R to G.

If circuit R to G is closed (24-v.), the motor will deliver airflow at

the full heating requested value. If circuit R to G is open (0-v.) for

maximum heating comfort, the motor delivers reduced airflow to

maximize the temperature and minimize the draft effect of the

heated air leaving the unit.

EASY SELECT™—50GL & 50JZ

9 PIN CONNECTOR

ICM PRINTED CIRCUIT BOARD

SEC1 SEC2

EASY SELECT

AUX HEAT KW/CFM

0-30

0-20

1075

A

B

C

D

E

F

VIO

BLU

ORN

BLK

WHT

YEL

875

AC/HP SIZE

036 030 024 018

SYSTEM TYPE

AC

AC/HP CFM ADJUST

NOM HI

ON/OFF DELAY

09030900

CONTINUOUS FAN

MED HI YELLO

TM

0-10

725

HP-COMFORT

HP-EFF

LO

0

HEATER/MOTOR

ENH

0-5

625

12 PIN CONNECTOR

J2

J1

AUX1 HUM1

AUX2

24VAC

GRY

HUM2

D

R

W

W

Y

Y/ Y

G

O

C

H

1

2

1

2

C01033

Fig. 11—Detail of SPP Printed-Circuit Board

EASY SELECT™ CONFIGURATION TAPS FOR 50GL &

50JZ

Easy Select™ taps are used by the installer to configure a system.

The ICM motor uses the selected taps to modify its operation to a

pre-programmed table of airflows.

The unit must be configured to operate properly with system

components with which it is installed. To successfully configure a

basic system (see information printed on circuit board label located

next to select pins), move the 6 select wires to the pins which

match the components used.

a. AUX HEAT kW/CFM—SELECT HEATER RANGE FOR

SIZE OF ELECTRIC HEATER INSTALLED

Installer must select the auxiliary heat airflow approved for

application with kW size heater installed. If no heater is

installed, this step can be skipped. Each select pin is marked

with a range of heaters for which airflow (also marked), is

approved. For increased comfort, select the narrowest kW range

matching the heater size, for example, 0–10 for 10–kW heater.

This airflow must be greater than the minimum for CFM for

electric heater application with the size system installed for safe

7

Page 8

and continuous operation. (See Tables 16, 17 & 18 for airflow

delivery and minimum CFM.) Note that airflow marked is the

airflow which will be supplied in emergency heat mode and

heating mode on air conditioners when electric heat is the

primary heating source. In heat pump heating mode when

electric heaters are energized, the ICM will run the higher of

heat pump heating airflow and electric heater airflow to ensure

safe heater operation. The factory selection is the largest heater

range approved (See Fig. 11, A as indicated).

b. AC/HP SIZE—SELECT SYSTEM SIZE INSTALLED

The factory setting for air conditioner or heat pump size is the

size which matches the model of packaged unit installed.

Installer should verify air conditioner or heat pump size to

ensure that airflow delivered falls within proper range for the

size unit installed. This applies to all operational modes with

the exception of electric heat modes (See Fig. 11, B as

indicated).

c. SYSTEM TYPE—SELECT SYSTEM TYPE INSTALLED

The type of system will be factory selected (see below for

details):

(1.) AC-Air conditioner (Factory Selected for 50GL)

(2.) HP-COMFORT—Heat Pump Comfort provides approxi-

mately 315 CFM per ton for higher normal heating air

delivery temperature and provides approximately 350

CFM per ton cooling airflow for good humidity removal.

(3.) HP-EFF (Factory Selected for 50JZ)— Heat Pump Effi-

ciency provides same airflow for heating and cooling

modes to increase overall HP efficiency; approximately

350 CFM per ton.

d. AC/HP CFM ADJUST—SELECT NOMINAL, LOW, OR

HIGH AIRFLOW

The AC/HP CFM Adjust select is factory set to the High-Hi

(NOM for 060) tap. The CFM Adjust selections NOM/LO will

regulate airflow supplied for all operational modes, except

non-heat pump heating modes. HI provides 15 percent airflow

over nominal unit size selected and LO provides 10 percent

airflow below nominal unit size selected. CFM Adjust selection

options are provided to adjust airflow supplied to meet individual installation needs for such things as noise, comfort, and

humidity removal (See Fig. 11, D as indicated).

e. ON/OFF DELAY—SELECT DESIRED

TIME DELAY PROFILE

Four motor operation delay profiles are provided to customize

and enhance system operation (See Fig. 11, E as indicated).

Selection options are:

(1.) The standard 90 sec off delay (Factory Setting) at 100

percent airflow in cooling or heat pump heating mode.

(2.) A 30 sec cooling delay with no airflow/90 sec off delay at

100 percent airflow profile is used when it is desirable to

allow system coils time to heat-up/cool-down in conjunction with the airflow in cooling or heat pump heating

mode.

(3.) A no delay option used for servicing unit or when a

thermostat is utilized to perform delay functions.

(4.) ENH, enhanced selection, provides a 30 sec cooling on

delay with no airflow/ plus 150 sec at 70 percent airflow/

no off delay for added comfort.

This will minimize cold blow in heat pump operation

(50JZ only) and could enhance system efficiency.

f. CONTINUOUS FAN—SELECT DESIRED FAN SPEED

WHEN THERMOSTAT IS SET ON CONTINUOUS FAN

(1.) LO speed—Factory setting, 50 percent cooling mode

airflow.

(2.) MED speed—Move connector to MED, 65 percent cooling

mode airflow.

(3.) HI speed—Move connector to HI, 100 percent cooling

mode airflow (See Fig. 11, F as indicated).

g. LOW-VOLTAGE CIRCUIT FUSING AND REFERENCE

The low-voltage circuit is fused by a board-mounted 5–amp

automotive fuse placed in series with the transformer SEC2 and

the R circuit. The C circuit of the transformer is referenced to

chassis ground through a printed circuit run at SEC1 connected

to metal standoff marked with ground symbol.

h. BASIC UNIT CONFIGURATION

The following basic configuration of the indoor motor will

provide ARI rated performance of the System. This BASIC

CONFIGURATION should be used when the rated ARI performance is required, or if system enhancements such as super

dehumidify are not needed.

(1.) AUX HEAT kW/CFM-Select the heater range for the size

of electric heater installed (skip this step if no heater is

installed).

(2.) AC/HP SIZE-Factory selected to match system size in-

stalled, please verify.

(3.) SYSTEM TYPE-Factory selected AC (50GL) or HP-EFF

(50JZ).

(4.) AC/HP CFM ADJUST-Select HIGH for 042 & 048, NOM

for 036 & 060, and LO for 024 & 030.

(5.) ON/OFF DELAY-Select 0/90 profile.

(6.) CONTINUOUS FAN-Select desired fan speed when ther-

mostat is set to continuous fan.

i. COMFORT OPTIONS—SUPER DEHUMIDIFY (See Quick

Reference Guide)

The Super Dehumidify option is possible when this unit is

installed with a field supplied Thermidistat™ control (Super

Dehumidify does not require an outdoor temperature sensor).

The following configuration is recommended for maximum

cooling/dehumidifying comfort: This configuration will improve the comfort provided by the air conditioning system if

more humidity removal is desired. While providing this improved comfort, the system will operate efficiently, but not at

the published HSPF or ARI SEER efficiency.

The following system configuration is recommended for maximum heating and cooling/dehumidifying comfort (See Fig. 11).

(1.) AUX HEAT kW/CFM-Select the narrowest heater range to

match size of electric heater installed (skip this step if no

heater is installed).

(2.) AC/HP Size-Factory selected to match system size in-

stalled, please verify.

(3.) SYSTEM TYPE-Select system type HP-COMFORT (for

heat pump system) or AC (for air conditioner system).

(4.) AC/HP CFM ADJUST-Select NOM (Lo for 060).

(5.) ON/OFF DELAY-Select ENH profile.

(6.) CONTINUOUS FAN-Select desired fan speed when ther-

mostat is set to continuous fan.

(7.) DEHUMIDIFY MODE-Remove J1 jumper to activate.

(8.) LOW VOLTAGE CONNECTIONS-Make connections as

shown in ELECTRICAL CONNECTIONS section.

(9.) CONFIGURE THERMIDISTAT™ (or capable zoning

system)-Following its installation instructions for Super

Dehumidify and Super Comfort Heat operation.

8

Page 9

This configuration provides the following comfort enhancements:

(a.) A 30 sec blower on delay with 150 sec at 70 percent

airflow to allow the indoor coil to warm up or cool

down before the blower is asked to deliver 100 percent

airflow reducing the cold blow sensation at start up in

heating and allowing the indoor coil to more quickly

reach wet coil operating conditions in cooling.

(b.) A no blower off delay eliminates cold blow which may

be associated with running the blower after shut down

of the compressor and avoids re-evaporation of condensed moisture after cooling/dehumidifying operation.

(c.) Lower airflow while the compressor is running to

reduce draft effects and increase heating air temperature and improved humidity control during cooling

operation.

ACCESSORY INSTALLATION

a. ACCESSORY ELECTRIC HEATERS

Electric heaters may be installed with the 50GL & 50JZ units

per instructions supplied with electric heater package. See unit

rating plate for factory-approved electric heater kits.

b. AUXILIARY TERMINALS

The AUX and HUM terminals on the Easy Select™ Board are

tied directly to the G terminal, and provide a 24-v. signal

whenever the G terminal is energized (See Fig. 12). During

Super dehumidify mode, the G signal is not present and the

auxiliary terminals are not energized. If the installation includes

the use of the operating mode, do not use these terminals to

control accessories. See Electronic Air Cleaner and Humidifier

sections for further information.

c. ELECTRONIC AIR CLEANER CONNECTIONS

The AUX1 and AUX2 terminals are not always energized

during blower operations, as described above. When using an

electronic air cleaner with the unit, use Airflow Sensor P/N

KEAAC0101AAA. The airflow sensor turns on electronic air

cleaner when the blower is operating.

d. HUMIDIFIER/HUMIDISTAT CONNECTIONS

Easy Select™ Board terminals HUM1 and HUM2 are provided

for direct connection to the low-voltage control of a humidifier

through a standard humidistat (See Fig. 12). These terminals are

energized with 24-v. when G thermostat signal is present. (See

Fig. 11, 12 & 13). Alternately, the 24-v. signal may be sourced

from the W and C circuit board connections. When using a

Thermidistat™ Control, Zone Comfort Plus or Comfort Zone

II, the 24-v. signal may be sourced directly from the Thermidistat™ HUM terminal.

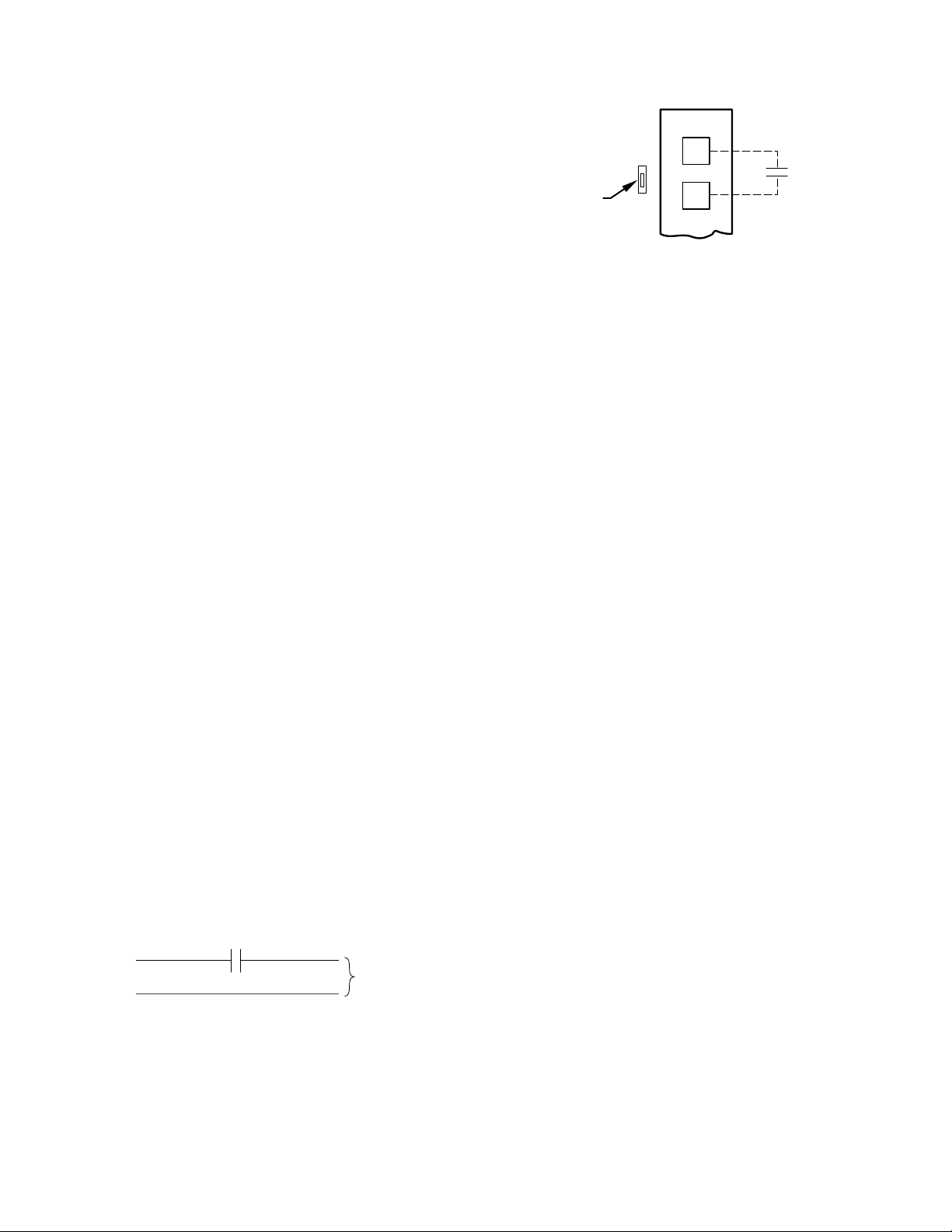

HUMIDISTAT

HUM 1

(C)

HUM 2

(G)

24-VAC

HUMIDIFIER WIRING

TO HUMIDIFIER

Fig. 12—Humidifier Wiring for 50GL & 50JZ

e. DEHUMIDIFY CAPABILITY WITH STANDARD

HUMIDISTAT CONNECTION

Latent capacities for these units are better than average systems.

If increased latent capacity is an application requirement, the

circuit board provides connection terminals for use of a

A95317

EASY SELECT

BOARD TERMINAL

BLOCK

D

J1

REMOVE

JUMPER

H

HUMIDISTAT

R

A95316

Fig. 13—Humidistat Wiring for De-Humidify Mode-

for 50GL & 50JZ

standard humidistat. The unit will detect the humidistat contacts

opening on increasing humidity and reduce its airflow to

approximately 80 percent of nominal cooling mode airflow.

This reduction will increase the system latent capacity until the

humidity falls to a level which causes the humidistat to close its

contacts. When the contacts close, the airflow will return to 100

percent of selected cooling airflow. To activate this mode,

remove jumper J1 and wire in a standard humidistat ( See Fig.

13).

f. DEHUMIDIFY AND SUPER DEHUMIDIFY CAPABILITIES

these models are capable of responding to a signal from indoor

system control (thermostat, Thermidistat™, zoning control) to

operate in comfort control modes such as Super Dehumidify

Mode. Consult literature provided with indoor system control to

determine if these operating modes are available, and to see

control set up instructions. No special setup or wiring of unit is

required.

50GL & 50JZ SEQUENCE OF OPERATION

a. CONTINUOUS FAN

(1.) Thermostat closes circuit R to G—The Blower runs at

continuous fan airflow.

b. COOLING MODE-LOW HUMIDITY

(1.) If indoor temperature is above temperature set point and

humidity is below humidity set point, thermostat closes

circuits R to G, R to Y/Y2 and R to O—The unit delivers

cooling airflow.

c. COOLING MODE-DEHUMIDIFICATION

(1.) If indoor temperature is above temperature set point and

humidity is above humidity set point, thermostat or Thermidistat™ closes circuits R to G, R to O, and R to Y/Y2

and humidistat or Thermidistat™ opens R to DH—The

unit delivers airflow which is approximately 80 percent of

the nominal cooling airflow to increase the latent capacity

of the system.

d. COOLING MODE-SUPER DEHUMIDIFY OPERATION (see

quick reference guide)

NOTE: The indoor control used, such as a Thermidistat™, must

be capable of providing Super Dehumidify operation mode and

control must be configured as outlined in its installation instructions. Consult indoor control literature to determine if control is

capable of providing Super Dehumidify inputs and for configuration instruction.

(1.) If the indoor temperature is below the temperature set

point and the humidity is above the humidity set point, the

Thermidistat™ closes circuit R to O, opens circuits R to

DH and R to G, and cycles circuit R to Y/Y2. If circuit R

to G is closed (24-v.), the motor will deliver airflow at the

full cooling or cooling plus dehumidify mode requested

9

Page 10

value. If circuit R to G is open (0–v.) for super dehumidify

mode, the motor delivers reduced airflow to maximize the

humidity removal of the system while minimizing over

cooling.

e. ELECTRIC HEATING MODE

(1.) Thermostat closes circuit R to W/W1, or W2—The unit

delivers the selected electric heat airflow. There are no on

or off delays.

f. HEAT PUMP HEATING MODE (50JZ only)

(1.) Thermostat closes circuits R to G and R to Y/Y2—The unit

delivers selected heat pump heating airflow.

g. HEAT PUMP HEATING WITH AUXILIARY

ELECTRIC HEAT (50JZ only)

(1.) Thermostat closes circuits R to G, R to Y/Y2 and R to

W/W1 or W2 (and R to O in the case of defrost).

In the event that electric heating is called for by the thermostat

while the heat pump is also operating in either heating or

defrost modes, the motor will modify its airflow output, if

necessary, to provide an airflow which is defined as safe for the

operation of the electric heater during heat pump operation.

That airflow is the greater of the heat pump heating airflow and

the electric heater only airflow.

h. HEATING MODE—SUPER COMFORT HEAT OPERA-

TION

NOTE: The indoor control used, such as a Thermidistat™, must

be capable of providing Super Comfort Heat operation mode and

control must be configured as outlined in its installation instructions. The system must be installed with appropriate outdoor

temperature sensor. Consult indoor control literature to determine

if control is capable and for configuration instructions. Consult

indoor control instructions and sensor instructions for sensor

installation details.

If the outdoor temperature is in the range of 12° to 40° F, the

Thermidistat™ closes circuit R to Y/Y2 and opens circuit R to G.

If circuit R to G is closed (24-v.), the motor will deliver airflow at

the full heating requested value. If circuit R to G is open (0-v.) for

maximum heating comfort, the motor delivers reduced airflow to

maximize the temperature and minimize the draft effect of the

heated air leaving the unit.

ICM FIOP START-UP

ICM General Start Up

CHECKING AND ADJUSTING REFRIGERANT CHARGE

The refrigerant system is fully charged with Puron® (R-410A)

refrigerant, and is tested and factory sealed.

NOTE: Adjustment of the refrigerant charge is not required

UNLESS the unit is suspected of not having the proper R-410A

charge.

The charging label and the tables shown refer to system temperatures and pressures. The temperatures and pressures are calculated

at rated airflow. When charging unit, set to rated airflow. A

refrigerant charging chart label is attached to the outside of the

compressor access door. The chart includes the required suction

line temperature at given suction line pressures and outdoor

ambients. An accurate superheat, thermocouple- or thermistor-type

thermometer, and gage manifold are required when using the

superheat charging method for evaluating the unit charge. Do not

use mercury or small dial-type thermometers because they are

not adequate for this type of measurement

IMPORTANT: When evaluating the refrigerant charge, an indicated adjustment to the specified factory charge must always be

very minimal. If a substantial adjustment is indicated, an abnormal

condition exists somewhere in the cooling system, such as insuf-

ficient airflow across either one or both coils.

Step 1—48GP Start-Up (ICM FIOP)

CHECKING COOLING CONTROL OPERATION-Start and

check the unit for proper cooling control operation as follows:

(1.) Place room thermostat SYSTEM switch in OFF position.

Observe that blower motor starts when FAN switch is

placed in ON position and shuts down when FAN switch

is placed in AUTO position. Note fan delay time setting

selected on the Easy Select™ board. (See Easy Select

Section.)

(2.) Place SYSTEM switch in COOL position and FAN switch

in AUTO position. Set cooling control below room temperature. Observe that compressor, condenser fan, and

evaporator blower motors start. Observe that cooling cycle

shuts down when control setting is satisfied. The evaporator fan will continue to run for the time setting selected

on Easy Select™ board. (See Easy Select Section.)

(3.) When using an auto-changeover room thermostat, place

both SYSTEM and FAN switches in AUTO position.

Observe that unit operates in heating mode when temperature control is set to “call for heating” (above room

temperature) and operates in cooling mode when temperature control is set to “call for cooling” (below room

temperature).

AIRFLOW AND TEMPERATURE RISE-The heating section for

each size unit is designed and approved for heating operation

within the temperature rise range stamped on the unit rating plate.

Table 15 shows the approved temperature rise range for each

heating input, and the air delivery (CFM) at various temperature

rise ranges.

The heating operation airflow must produce a temperature rise that

falls with in the approved range.

Refer to Indoor Airflow and Airflow Tables on the following

pages to adjust heating airflow when required.

CHECK HEATING CONTROL-Start and check the unit for

proper heating control operation as follows. (see furnace lighting

instructions located inside burner or blower access panel.):

(1.) Place room thermostat SYSTEM switch in the HEAT

position and the FAN switch in the AUTO position.

(2.) Set the heating temperature control of the thermostat above

room temperature.

(3.) The induced-draft motor will start.

(4.) After a call for heating, the main burner should light with

in 5 sec. If the burners still do not light, this sequence is

repeated. If the burners do not light within 15 minutes from

the initial call for heat, there is a lockout. To reset the

lockout control, break the 24-v. power to W.

(5.) The indoor fan will turn on 45 sec after the flame has been

established. The indoor fan will turn off according to time

delay selected on the Easy Select™ board (See Easy Select

Section) after the thermostat has been satisfied.

Step 2—48JZ Start-Up (ICM FIOP)

Also refer to the Thermidistat™ instructions for start up and

check out of the system.

(1.) FAN OPERATION—

The fan button on Thermidistat™ switches fan icon

between AUTO and ON. While ON is displayed, output

will be on, turning fan on. Allow up to 10 sec. after button

is pressed for fan to turn on and off. the fan will continue

to run for the time setting selected on the Easy Select™

board after AUTO icon is displayed.

10

Page 11

(2.) COOLING MODE—

Press MODE button on the Thermidistat™ until COOL

icon is displayed. Cooling begins within 10 sec. and

remains on for 4 minutes. Observe that compressor,

outdoor fan and indoor blower motors start after the call

for Cooling. At the end of 4 minutes, the cooling cycle

stops and the MODE reverts back to OFF. The Indoor

Blower continues to run for the time selected on the Easy

Select™ board after OFF icon is displayed.

(3.) HEAT PUMP HEATING—

Press MODE button on the Thermidistat™ until HEAT

icon is displayed. Heat pump heating begins within 10 sec.

and remains on for 4 minutes. Observe that the compressor, outdoor fan and indoor blower come on. At the end of

the 4 minutes, heating cycle stops and the MODE reverts

back to OFF. The indoor blower continues to run for the

time selected on the Easy Select™ Board after the OFF

icon is displayed. Heating maybe turned off anytime

during the 4 minute cycle by pressing MODE button until

OFF is displayed.

(4.) GAS HEAT MODE—

Press MODE button until E-HEAT(Emergency Heat or

Back-Up Heat) icon is displayed. Gas heating begins

within 10 sec. and remains on for 4 minutes. The induced

draft motor should start immediately. The burners should

light within 5 sec. of E-HEAT call. The indoor blower will

turn on 45 sec. after the flame has been established. Gas

heating stops at the end of 4 minutes and MODE reverts

back to OFF. The indoor blower continues to run for the

time selected on the Easy Select™ Board after the OFF

icon is displayed.

NOTE: If the burners do not light, this lighting sequence is

repeated for 15 minutes from the initial call for E-HEAT. If after

15 minutes the burners do not light, there will be a lockout. To

reset the burner lockout control, break the 24-v. power to “W”.

(5.) AUTOMATIC CHANGE-OVER—

To test AUTO CHANGE-OVER function between COOL

and HEAT:

Enable the AUTO CHANGE-OVER mode during Thermidistat™ set-up. Refer to the Thermidistat™ literature for

details. Observe that the unit operates in cooling when in

COOL MODE (when setting is below room temperature)

and HEAT MODE (when setting is above room temperature).

AIRFLOW AND TEMPERATURE RISE-The heating section for

each size unit is designed and approved for heating operation

within the temperature rise range stamped on the unit rating plate.

Table 15 shows the approved temperature rise range for each

heating input, and the air delivery (CFM) at various temperature

rise ranges.

The heating operation airflow must produce a temperature rise that

falls with in the approved range.

Refer to Indoor Airflow and Airflow Tables on the following

pages to adjust heating airflow when required.

Step 3—50GL: Start-Up (ICM FIOP)

CHECKING COOLING CONTROL OPERATION–Start and

check the unit for proper cooling control operation as follows:

(1.) Place room thermostat SYSTEM switch in OFF position.

Observe that blower motor starts when FAN switch is

placed in ON position and shuts down when FAN switch

is placed in AUTO position.

(2.) Place SYSTEM switch in COOL position and FAN switch

in AUTO position. Set cooling control below room tem-

perature. Observe that compressor, condenser fan, and

evaporator blower motors start. Observe that cooling cycle

shuts down when control setting is satisfied. The evaporator fan will continue to run for the selected off delay.

(3.) When using an auto-changeover room thermostat, place

both SYSTEM and FAN switches in AUTO positions.

Observe that unit operates in heating mode when temperature control is set to ‘‘call for heating’’ (above room

temperature) and operates in cooling mode when temperature control is set to ‘‘call for cooling’’ (below room

temperature).

NOTE: Once the compressor has started and then has stopped, it

will not start again until 5 minutes have elapsed. (The cooling

cycle remains ‘‘on’’ until the room temperature drops to point that

is slightly below the cooling control setting of the room thermostat.

At this point, the thermostat ‘‘breaks’’ the circuit between thermostat terminal R to terminals Y and G.) These open circuits

de-energize contactor coil C and ICM board. The condenser and

compressor motors stop. After the time delay setting selected on

the Easy Select™ board (See Easy Select Section) , the blower

motor stops. The unit is in a ‘‘standby’’ condition, waiting for the

next ‘‘call for cooling’’ from the room thermostat.

Step 4—50JZ: Start-Up (ICM FIOP)

CHECKING COOLING AND HEATING CONTROL OPERATION– Start and check the unit for proper control operation as

follows:

(1.) Place room thermostat SYSTEM switch or MODE control

in OFF position. Observe that blower motor starts when

FAN mode is placed in FAN ON position and shuts down

according to time delay selected on the Easy Select™

board (See Easy Select Section) when FAN MODE switch

is placed in AUTO position.

(2.) Thermostat:

When the room temperature rises to a point that is slightly

above the cooling control setting of the thermostat, the

thermostat completes the circuit between thermostat terminal R to terminals Y, O and G. These completed circuits

through the thermostat connect contactor coil (C) (through

unit wire Y) and ICM board (through unit wire G) across

the 24-v. secondary of transformer (TRAN).

Thermidistat™ or Thermostat and Humidistat:

When the room temperature rises to a point that is slightly

above the cooling control setting of the thermostat, the

thermostat completes the circuit between thermostat terminal R to terminals Y, O, DH, and G. These completed

circuits through the thermostat connect contactor coil (C)

(through unit wire Y) and ICM board (though unit wire G)

across the 24-v. secondary of transformer (TRANS).

(3.) Place system switch or MODE control in HEAT position.

Set control above room temperature. Observe that compressor, outdoor fan, and indoor blower motors start.

Observe that heating cycle shuts down according to time

delay selected on the Easy Select™ board (See Easy Select

Section) when control setting is satisfied.

(4.) When using an automatic changeover room thermostat,

place both SYSTEM or MODE control and FAN mode

switches in AUTO positions. Observe that unit operates in

Cooling mode when temperature control is set to “call for

Cooling” (below room temperature), and unit operates in

Heating mode when temperature control is set to “call for

Heating” (above room temperature).

NOTE: Once the compressor has started and then has stopped, it

should not be started again until 5 minutes have elapsed. The

11

Page 12

Table 1—ICM FIOP Physical Data—Unit 48GP

THIS DATA APPLIES TO 48GP UNITS WITH THE ICM INDOOR MOTOR FIOP

UNIT SIZE 48GP 024040 024060 030040 030060 036060 036090 042060 042090

NOMINAL CAPACITY (ton) 2 2 2-1/2 2-1/2 3 3 3-1/2 3-1/2

OPERATING WEIGHT (lb.) 290 290 313 313 321 321 382 382

COMPRESSORS

Quantity

REFRIGERANT (R-410A)

Quantity (lb.)

REFRIGERANT METERING DEVICE

Orifice ID (in.)

AccuRater™ Piston

CONDENSER COIL

Rows...Fins/in.

Face Area (sq ft)

CONDENSER FAN

Nominal Cfm

Diameter (in.)

Motor HP (Rpm)

EVAPORATOR COIL

Rows...Fins/in.

Face Area (sq ft)

EVAPORATOR BLOWER

Nominal Airflow (Cfm)

Size (in.)

Motor (HP)

FURNACE SECTION*

Burner Orifice No. (Qty...Drill Size)

Natural Gas

Burner Orifice No. (Qty...Drill Size)

Propane Gas

HIGH-PRESSURE SWITCH (psig)

Cutout

Reset (Auto)

LOSS-OF-CHARGE/LOW-

PRESSURE SWITCH

(Liquid Line) (psig)

Cutout

Reset (Auto)

RETURN-AIR FILTERS (in.)

Throwaway

* Based on altitude of 0 to 2000 ft.

5.0 5.0 5.5 5.5 6.9 6.9 9.0 9.0

.057 .057 .057 .057 .065 .065 .070 .070

1...17

10.9

2350

22

1/8 (825)

3...15

3.7

800

10X10

1/2

2...44

2...50

20X20X1 20X20X1 20X20X1 20X20X1 20X24X1 20X24X1 24X30X1 24X30X1

1...17

10.9

2350

22

1/8 (825)

3...15

3.7

800

10X10

1/2

2...38

2...46

1...17

12.7

2350

22

1/8 (825)

3...15

3.7

1000

10X10

1/2

2...44

2...50

1/8 (825)

1...17

12.7

2350

22

3...15

3.7

1000

10X10

1/2

2...38

2...46

610±15

420±25

Scroll

1

1/8 (825)

20±5

45±10

2...17

9.1

2350

22

3...15

3.7

1200

11X10

3/4

2...38

2...46

2...17

9.1

2350

22

1/8 (825)

3...15

3.7

1200

11X10

3/4

3...38

3...46

2...17

12.3

2350

22

1/8 (825)

3...15

4.7

1400

11X10

3/4

2...38

2...46

2...17

12.3

2350

22

1/8 (825)

3...15

4.7

1400

11 X 10

3/4

3...38

3...46

cooling cycle remains ‘‘on’’ until the room temperature drops to

point that is slightly below the cooling control setting of the room

thermostat. At this point, the thermostat ‘‘breaks’’ the circuit

between thermostat terminal R to terminals Y and G. These open

circuits de-energize contactor coil C and ICM board. The condenser and compressor motors stop. After the time delay setting

selected on the Easy Select™ board (See Easy Select Section) , the

blower motor stops. The unit is in a ‘‘standby’’ condition, waiting

for the next ‘‘call for cooling’’ from the room thermostat. The 5

minute compressor delay also applies to heat pump heating mode.

ELECTRICAL DATA & SCHEMATICS—ICM FIOP

Step 1—Physical Data & Electrical Schematics

Use the Physical Data and Electrical Tables on the following pages

for information that applies to Carrier Puron® units with the ICM

indoor motor FIOP.

AIRFLOW & TEMPERATURE RISE TABLES—ICM FIOP

Step 2—Tables For System Set-Up

Use the Airflow and Temperature Rise Tables on the following

pages for information that applies to Carrier Puron® units with the

ICM indoor motor FIOP.

CARE AND MAINTENANCE

Indoor Blower and Motor

NOTE: All motors are pre-lubricated. Do not attempt to lubricate

these motors. For longer life, operating economy, and continuing

efficiency, clean accumulated dirt and grease from the blower

wheel and motor annually.

Disconnect and tag electrical power to the unit before

cleaning and lubricating any blower motor and wheel. On

units with gas heat, turn off the gas supply before disconnecting the electrical power. Failure to adhere to this warning

could cause serious injury or death.

To clean the blower motor and wheel:

1. 1. Remove and disassemble blower assembly as follows:

a. Remove unit access panel.

b. Carefully pivot blower access panel outward towards the

electrical box. Route wiring above blower access panel.

c. Disconnect the 5 and 16 pin plugs at the blower motor.

d. On all units, remove blower assembly from unit. Remove

screws securing blower to vertical partition and slide

assembly out. Be careful not to tear insulation in blower

compartment.

e. Ensure proper reassembly by marking blower wheel and

motor in relation to blower housing before disassembly.

12

Page 13

Table 2—ICM FIOP Physical Data—Unit 48GP (Continued)

THIS DATA APPLIES TO 48GP UNITS WITH THE ICM INDOOR MOTOR FIOP

UNIT SIZE 48GP 048090 048115 048130 060090 060115 060130

NOMINAL CAPACITY (ton) 444555

OPERATING WEIGHT (lb.) 421 421 421 468 468 468

COMPRESSORS

Quantity

REFRIGERANT (R-410A)

Quantity (lb.)

REFRIGERANT METERING DEVICE

Orifice ID (in.)

AccuRater™ Piston

CONDENSER COIL

Rows...Fins/in.

Face Area (sq ft)

CONDENSER FAN

Nominal Cfm

Diameter (in.)

Motor Hp (Rpm)

EVAPORATOR COIL

Rows...Fins/in.

Face Area (sq ft)

EVAPORATOR BLOWER

Nominal Airflow (Cfm)

Size (in.)

Motor (HP)

FURNACE SECTION*

Burner Orifice No. (Qty...Drill Size)

Natural Gas

Burner Orifice No. (Qty...Drill Size)

Propane Gas

HIGH-PRESSURE SWITCH (psig)

Cutout

Reset (Auto)

LOSS-OF-CHARGE/LOW-PRESSURE SWITCH

(Liquid Line) (psig)

Cutout

Reset (Auto)

RETURN-AIR FILTERS (in.)

Throwaway

* Based on altitude of 0 to 2000 ft.

Scroll

1

9.5 9.5 9.5 10.0 10.0 10.0

.073 .073 .073 .086 .086 .086

2...17

12.3

3300

22

1/4 (1100)

4...15

4.7

1600

11X10

3/4

3...38

3...46

24X30X1 24X30X1 24X30X1 24X30X1 24X30X1 24X30X1

2...17

12.3

3300

22

1/4 (1100)

4...15

4.7

1600

11X10

3/4

3...33

3...42

2...17

12.3

3300

22

1/4 (1100)

4...15

4.7

1600

11X10

3/4

3...31

3...41

1/4 (1100)

610±15

420±25

20±5

45±10

2...17

16.4

3300

22

4...15

4.7

2000

11X10

1.0

3...38

3...46

2...17

16.4

3300

22

1/4 (1100)

4...15

4.7

2000

11X10

1.0

3...33

3...42

2...17

16.4

3300

22

1/4 (1100)

4...15

4.7

2000

11X10

1.0

3...31

3...41

Table 3—48GP with ICM FIOP Electrical Data

VOLTAGE

UNIT

SIZE 48GP

024 208/230–1–60 187 253 13.5 61.0 0.9 4.3 22.1 30

030 208/230–1–60 187 253 14.7 73.0 0.9 4.3 23.6 30

036 208/230–1–60 187 253 15.4 83.0 0.9 6.8 27.0 35

042 208/230–1–60 187 253 18.6 105.0 0.9 6.8 31.0 40

048 208/230–1–60 187 253 20.5 109.0 1.6 6.8 34.0 40

060 208/230–1–60 187 253 27.6 158.0 1.6 9.2 45.2 60

V-PH-HZ

RANGE

MIN MAX RLA LRA FLA FLA MCA

COMPRESSOR

f. Loosen set-screw that secures wheel to motor shaft, remove

screws that secure motor mount brackets to blower housing,

and slide motor and motor mount out of blower housing.

2. Remove and clean blower wheel as follows:

a. Ensure proper reassembly by marking wheel orientation.

b. Lift wheel from housing. When handling and/or cleaning

blower wheel, be sure not to disturb balance weights (clips)

on blower wheel vanes.

c. Remove caked-on dirt from wheel and housing with a

brush. Remove lint and/or dirt accumulations from wheel

and housing with vacuum cleaner, using soft brush attachment. Remove grease and oil with mild solvent.

OUTDOOR FAN

MOTOR

INDOOR FAN

MOTOR

POWER SUPPLY

d. Reassemble wheel into housing.

e. Reassemble motor into housing. Be sure set-screw(s) are

tightened on motor shaft flats and not on round part of

shaft.

f. Pivot blower access panel back into place. Adjust wire

assemblies so that wiring follows proper pathways.

g. Reinstall unit access panel.

3. Restore electrical power, then gas supply to unit. Start unit and

check for proper blower rotation and motor speeds during

heating and cooling cycles.

TROUBLESHOOTING

START-UP CHECKLIST

MAX FUSE

OR CKT. BKR.

13

Page 14

Fig. 14—ICM FIOP Electric Schematic—Unit 48GP

14

C01035

Page 15

Table 4—ICM FIOP Physical Data—Unit 48JZ

THIS DATA APPLIES TO 48JZ UNITS WITH THE ICM INDOOR MOTOR FIOP

UNIT SIZE 48JZ 024040 030040 030060 036060 036090 042060 042090

NOMINAL CAPACITY (ton) 2 2-1/2 2-1/2 3 3 3-1/2 3-1/2

OPERATING WEIGHT (lb.) 310 324 324 321 321 380 380

COMPRESSORS

Quantity

REFRIGERANT (R-410A)

Quantity (lb.)

REFRIGERANT METERING DEVICE

Orifice Indoor (in.)

AccuRater™ Piston

REFRIGERANT METERING DEVICE

Orifice Outdoor (in.)

AccuRater™ Piston

OUTDOOR COIL

Rows...Fins/in.

Face Area (sq ft)

OUTDOOR FAN

Nominal Cfm

Diameter (in.)

Motor Hp (Rpm)

INDOOR COIL

Rows...Fins/in.

Face Area (sq ft)

INDOOR BLOWER

Nominal Airflow (Cfm)

Size (in.)

Motor (HP)

FURNACE SECTION*

Burner Orifice No. (Qty...Drill Size)

Natural Gas

Burner Orifice No. (Qty...Drill Size)

Propane Gas

HIGH-PRESSURE SWITCH (psig)

Cutout

Reset (Auto)

LOSS-OF-CHARGE/LOW-

PRESSURE SWITCH

(Liquid Line) (psig)

Cutout

Reset (Auto)

RETURN-AIR FILTERS (in.)

Throwaway

* Based on altitude of 0 to 2000 ft.

7.0 8.9 8.9 9.3 9.3 9.5 9.5

0.061 0.061 0.061 0.067 0.067 0.073 0.073

0.032 (2) 0.040 (2) 0.040 (2) 0.040 (2) 0.040 (2) 0.038 (2) 0.038 (2)

2...17

8.5

2350

22

1/8 (825)

3...15

3.7

800

10X10

1/2

2...44

2...50

20X20X1 20X20X1 20X20X1 20X24X1 20X24X1 24X30X1 24X30X1

2...17

10.3

2350

22

1/8 (825)

3...15

3.7

1000

10X10

1/2

2...44

2...50

2...17

10.3

2350

22

1/8 (825)

3...15

3.7

1000

10X10

1/2

2...38

2...46

Scroll

1

2...17

10.3

2500

22

1/4 (1100)

4...15

3.7

1200

11X10

3/4

2...38

2...46

610±15

420±25

20±5

45±10

2...17

10.3

2500

22

1/4 (1100)

4...15

3.7

1200

11X10

3/4

3...38

3...46

2...17

13.5

2350

22

1/8 (825)

3...15

4.7

1400

11X10

3/4

2...38

2...46

2...17

13.5

2350

22

1/8 (825)

3...15

4.7

1400

11X10

3/4

3...38

3...46

15

Page 16

Table 5—ICM FIOP Physical Data—Unit 48JZ (Continued)

THIS DATA APPLIES TO 48JZ UNITS WITH THE ICM INDOOR MOTOR FIOP

UNIT SIZE 48JZ 048090 048115 048130 060090 060115 060130

NOMINAL CAPACITY (ton) 444555

OPERATING WEIGHT (lb.) 409 409 409 504 504 504

COMPRESSORS

Quantity

REFRIGERANT (R-410A)

Quantity (lb.)

REFRIGERANT METERING DEVICE

Orifice Indoor (in.)

AccuRater™ Piston

REFRIGERANT METERING DEVICE

Orifice Outdoor (in.)

AccuRater™ Piston

OUTDOOR COIL

Rows...Fins/in.

Face Area (sq ft)

OUTDOOR FAN

Nominal Cfm

Diameter (in.)

Motor Hp (Rpm)

INDOOR COIL

Rows...Fins/in.

Face Area (sq ft)

INDOOR BLOWER

Nominal Airflow (Cfm)

Size (in.)

Motor (HP)

FURNACE SECTION*

Burner Orifice No. (Qty...Drill Size)

Natural Gas

Burner Orifice No. (Qty...Drill Size)

Propane Gas

HIGH-PRESSURE SWITCH (psig)

Cutout

Reset (Auto)

LOSS-OF-CHARGE/LOW-PRESSURE SWITCH

(Liquid Line) (psig)

Cutout

Reset (Auto)

RETURN-AIR FILTERS (in.)

Throwaway

* Based on altitude of 0 to 2000 ft.

Scroll

1

10.6 10.6 10.6 12.4 12.4 12.4

.076 .076 .076 .088 .088 .088

0.046 (2) 0.046 (2) 0.046 (2) 0.052 (2) 0.052 (2) 0.052 (2)

2...17

13.5

3300

22

1/4 (1100)

4...15

4.7

1600

11X10

3/4

3...38

3...46

24X30X1 24X30X1 24X30X1 24X30X1 24X30X1 24X30X1

2...17

13.5

3300

22

1/4 (1100)

4...15

4.7

1600

11X10

3/4

3...33

3...42

2...17

13.5

3300

22

1/4 (1100)

4...15

4.7

1600

11X10

3/4

3...31

3...41

1/4 (1100)