Page 1

50JB-1SB

50JB034, 038, 044, 048, 054, 064

HORIZONTAL SUPPLY AND RETURN

SINGLE-PACKAGE COOLING UNITS

EXTENDED CHASSIS

CONSTANT VOLUME/VARIABLE VOLUME

PRODUCT INTEGRATED CONTROLS

CARRIER COMFORT NETWORK COMPATIBLE

— PERFORMANCE DATA

— TYPICAL FIELD WIRING

— CERTIFIED DIMENSION PRINTS

— CERTIFIED ROOF CURB

DIMENSION PRINTS

R 1997 Carrier Corporation • Syracuse, New York 13221

Form 50JB-1SB New Printed in U.S.A. 12-97 Catalog No. 515-074

Page 2

Date: Supersedes:

50JB034, 038, 044, 048, 054, 064

SINGLE-PACKAGE COOLING UNITS,

EXTENDED CHASSIS

PRODUCT INTEGRATED CONTROLS

50JB

JOB NAME: LOCATION:

BUYER: BUYER P.O. # CARRIER #

UNIT NUMBER: MODEL NUMBER:

PERFORMANCE DATA CERTIFIED BY: DATE:

DESCRIPTION

50JB units are completely packaged, pre-wired and precharged cooling only units with PRODUCT

INTEGRATED CONTROLS.

50JB units are built for horizontal supply and return applications. Their waterproof construction makes

them ideally suited for installation on the accessory roof curb which is NRCA approved or slab mounting.

Units are either CONSTANT VOLUME or VARIABLE AIR VOLUME depending on the factory-

installed options selected.

Units include space and coil tracks downstream of evaporator for field or factory installation of auxiliary

devices.

PRODUCT INTEGRATED CONTROL FEATURES

STANDARD CONTROL FUNCTIONS

Unit compatible with CARRIER COMFORTNETWORK or stand

alone operation.

Constant Volume or Variable Air Volume control.

Four to six stages of compressor unloading possible.

Supply fan control based on occupancy schedule using 365-day

electronic timeclock with holiday scheduling.

Time schedule override through the space temperature sensor

provided with the unit.

Compatible with 37H and 45 Series PIC terminals to form a

Digital Air Volume system (DAV).

Building pressurization control in conjunction with modulating power

exhaust option.

Supply duct static pressure controlled through inlet guide vanes or

field or factory supplied inverter.

Head pressure control to −20° F. Head pressure controlled by

saturated condensing temperature, low ambient control utilizes

Motormastert II fan cycling.

Lead-lag compressor control to even out run time.

Self-diagnostic run test confirms control and component operation

at unit commissioning. Self-diagnostic troubleshooting codes

indicate the reason unit tripped to expedite unit repair. Codes

expand to English Text.

Control of a two-speed supply fan motor on CV applications. (Twospeed motor available on Special Order.)

Building Purge Mode flushes building interior with outdoor air to

remove contaminants before occupancy.

Adaptive Optimal Start minimizes the amount of time and energy

required before entering the occupied mode.

Unoccupied Mode Free Cooling — units with optimal economizer

will utilize free cooling whenever possible to maintain the unoccupied set point.

Input/Output of data and monitoring of alarms can be done

remotely using Building Supervisor, or at the unit using the

accessory HSIO module.

Delayed Mechanical Cooling — units with optional economizer

will utilize cooling to cool the space 3 degrees below the occupied

set point to delay the need for mechanical cooling.

Rev.:

AVAILABLE THROUGH FACTORY-INSTALLED ‘‘OPTION MODULE’’

ADDITIONAL CONTROL FUNCTIONS

Provides a discrete output with occupancy control for use as specified by the customer.

Controls a field installed humidifier usinga4to20mAor2-stage

output. Requires accessory humidity sensor.

Smoke Control functions (Building Pressurization and Smoke Purge)

are provided through software. Terminals are provided to interface

with field supplied smoke/fire panel.

Providesa4to20mAoutput to direct or reverse proportional hot

water control valve for field supplied hydronic heating coil. Requires a field supplied freezestat to protect coil.

Factory installed suction and discharge pressure transducers and

suction temperature thermistors allow remote monitoring of these

parameters and superheat to provide enhanced remote diagnostics.

Differential enthalpy control can be provided using field installed

accessory humidity sensors.

2

Economizer control field configurable to:

— Maintain a minimum economizer set point position,

OR

— Maintain the minimum economizer position based on input from

an IAQ sensor (field supplied0-10volt),

OR

— Maintain a constant cfm of outdoor air intake (Requires

accessory Outdoor Air CFM package),

OR

— Look at all three above and maintain minimum economizer

position based on the dominant parameter.

Page 3

UNIT FEATURES

Large hinged access doors.

Standard one-year product warranty.

Standard unit as factory-assembled is listed by ETL and/or ETL,

Canada.

Units are rated in accordance with ARI Standard 360.

115-volt and 24-volt control circuit.

Semi-hermetic Carrier compressors.

Crankcase heaters.

Circuit breaker protection for all power components.

Compressor protection includes high and low pressure cutouts.

Single low rpm supply fan with 2-in. deflection springs under fan

sled.

PERFORMANCE DATA

Unit Operating Weight lb

Indoor Entering Air db

COOLING

Gross Total Cap. Btuh@ Condenser Air Temp F

Gross Sensible Capacity

Compressor Power Input

Indoor Fan Motor Size

Return Fan Motor Size

Fwb F

Btuh

kW

Hp

Hp

High efficiency indoor motors (supply and exhaust).

Tuff-Skin Rx anti-microbial insulation.

Sloped condensate pan.

Manual adjustable outside air intake for up to 25% outside air.

Cabinet made of prepainted galvanized steel.

Evaporator-fan motors are protected by circuit breakers.

Condenser-fan motors are internally protected.

Single-point electric service entry.

Dual refrigeration circuits.

Lifting lugs.

Two-inch disposable-type return air filters.

Cfm

Curb Weight

HEATING

External Static Pressure in. wg

NO UNIT MOUNTED HEAT AVAILABLE

lb

ELECTRICAL DATA

Power Supply to Unit Volts Phase Hertz

Minimum Circuit Amps Maximum Fuse Amps

OPTIONS AND ACCESSORIES

FACTORY-INSTALLED OPTIONS

M Control Option Module

M Two-inch Pleated Filters (30%)

M Bag Filters with Prefilters (90%)

M Inlet Guide Vanes or Variable Frequency Drives

M Alternate Motor and Drive

M Premium-Efficiency Motor and Drive (208/230, 460v)

M Alternate Premium-Efficiency Motor and Drive

(208/230, 460v)

M Economizer with Low Leak Dampers and Spring Return Motor

M Copper Condenser Coil

M Hot Gas Bypass

M Non-Fused Unit Disconnect

FIELD-INSTALLED ACCESSORIES

M Roof Curb with Full Perimeter Support (30, 35, 40, 45 ton)

M Roof Curb with Condenser and Support (50, 60 ton)

M Roof Curb to Enclose the Condenser Section (50, 60 ton)

M Outdoor Air Cfm Package

M Local Interface Device

M Differential Enthalpy Control Sensor

M Condenser Coil Guard

M Space Sensor with Set Point Adjustment

M Optional 4-Year Extended Compressor Warranty

x

M HSIO Keypad and Display Module (required for initial start-up)

M

M

M

3

Page 4

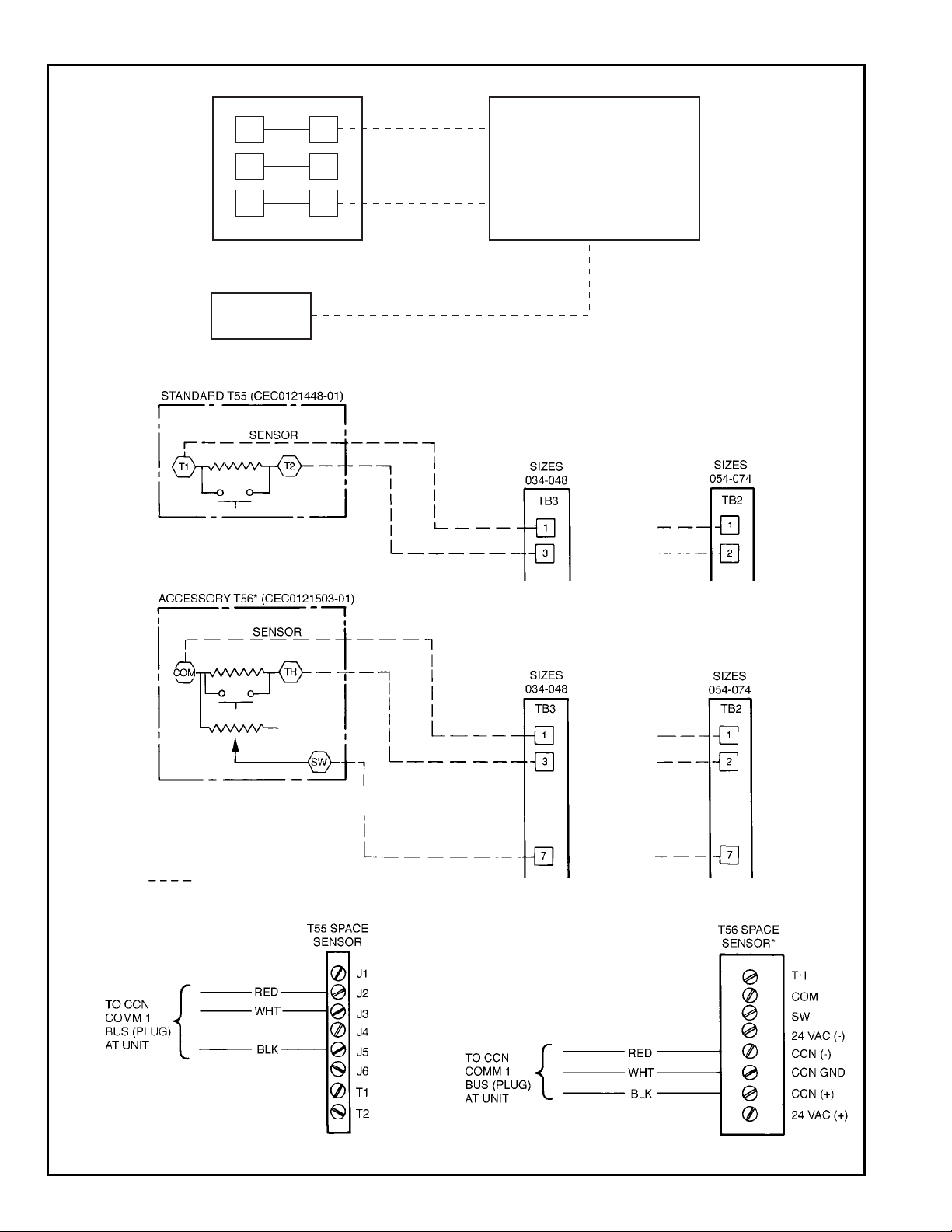

TYPICAL FIELD WIRING

FIELD POWER WIRING CONNECTIONS

21

22

23

EQUIP GND

11

12

13

DISCONNECT PER NEC

FIELD CONTROL WIRING

TYPICAL SPACE TEMPERATURE SENSOR WIRING

CCN COMMUNICATIONS BUS WIRING TO OPTIONAL SPACE SENSOR RJ11 CONNECTOR

CCN — Carrier Comfort Network

COM — Communications

GND — Ground

SW — Switch

T—Terminal

TB — Terminal Block

TH — Thermostat, Heating

*Constant Volume applications only.

LEGEND

4

Field Wiring

Page 5

----------------------------------------------------------------------------------------

CUT ALONG DOTTED LINE CUT ALONG DOTTED LINE

CERTIFIED DIMENSION PRINT

NOTES:

1. Dimensions in [ ] arein millimeters.

2. Center of Gravity includes economizer.Unit weight does

not include economizer or heating coil.

3. Unit clearances:

Top — Do not restrict condenser fans

Control Box End — 68-09

Sides — 68-09

Economizer End — 68-09 (except power exhaust units 108-09)

For smaller service and operating clearances, contact Carrier

Application Engineering Department.

4. Suggested field connections to be made inside or outside of

2.28 in. (32.5 mm) flange.

5. When the unit is slab mounted, plug the factory drilled auxiliary condensate drain holes.

6. Auxiliary heating coil is field supplied and installed.

7. Auxiliary heating coil dimensions (maximum):

Length (header included), 78-0

Width, 08-95⁄89 [244]

Height, 48-515⁄169 [1370]

8. Economizer side hoods are folded inside unit for

shipping.

1

⁄49 [2140]

50JB034 6470 2934 4418 14-5

50JB038 6595 2991 4474 14-81⁄

WEIGHT A

UNIT

SIZE

lb kg mm ft-in.

15

⁄

16

8

50JB034,038 (EXTENDED CHASSIS)

5

Page 6

6

CERTIFIED DIMENSION PRINT

NOTES:

1. Dimensions in [ ] are in millimeters.

2. Center of Gravity includes economizer. Unit weight does not include economizer

or heating coil.

3. Unit clearances:

Top — Do not restrict condenser fans

Control Box End — 68-09

Sides — 68-09

Economizer End — 68-09 (except power exhaust units 108-09)

For smaller service and operating clearances, contact Carrier

Application Engineering Department.

4. Suggested field connections to be made inside or outside of 1.28 in. (32.5 mm) flange.

5. When the unit is slab mounted, plug the factory drilled auxiliary condensate drain holes.

6. Auxiliary heating coil is field supplied and installed.

7. Auxiliary heating coil dimensions (maximum):

Length (header included), 78-0

Width, 08-95⁄89 [244]

Height, 48-515⁄169 [1370]

8. Economizer side hoods are folded inside unit for

shipping.

1

⁄49 [2140]

WEIGHT A

UNIT

SIZE

lb kg mm ft-in.

50JB044 7120 3229 5211 17-1

50JB048 7160 3247 5239 17-21⁄

1

⁄

8

4

50JB044, 048 (EXTENDED CHASSIS)

Page 7

----------------------------------------------------------------------------------------

CUT ALONG DOTTED LINE CUT ALONG DOTTED LINE

CERTIFIED DIMENSION PRINT

WEIGHT A B C D E F

UNIT

SIZE

50JB054 8800 3990 2959 9-8

50JB064 9100 4127 2959 9-81⁄26940 22-93⁄46393 20-1111⁄161163 3-925⁄3211 780 38-713⁄1612 164 39-107⁄

lb kg mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in.

1

⁄26940 22-93⁄46393 20-1111⁄161163 3-925⁄3211 780 38-713⁄1612 164 39-107⁄

NOTES:

1. Dimensions in [ ] are in millimeters.

2. Center of Gravity includes economizer. Unit weight does not include economizer or

8

8

heating coil.

3. Unit clearances:

Top — Do not restrict condenser fans

Control Box End — 68-09

Sides — 68-09

Economizer End — 68-09

For smaller service and operating clearances, contact Carrier Application Engineering

Department.

4. Suggested field connections to be made inside or outside of 1.28 in. (32.5 mm) flange.

5. When the unit is slab mounted, plug the factory drilled auxiliary condensate drain holes.

6. Auxiliary heating coil is field supplied and installed.

7. Auxiliary heating coil dimensions (maximum):

Length (header included), 78-0

Width, 08-95⁄89 [244]

Height, 48-515⁄169 [1370]

8. Economizer side hoods are folded inside unit for

shipping.

1

⁄49 [2140]

50JB054,064 (EXTENDED CHASSIS)

7

Page 8

8

CERTIFIED ROOF CURB DIMENSION PRINT

ROOF CURB — 50JB034, 038 (EXTENDED CHASSIS)

Page 9

----------------------------------------------------------------------------------------

CUT ALONG DOTTED LINE CUT ALONG DOTTED LINE

CERTIFIED ROOF CURB DIMENSION PRINT

ROOF CURB — 50JB044, 048 (EXTENDED CHASSIS)

9

Page 10

10

CERTIFIED ROOF CURB DIMENSION PRINT

ROOF CURB — 50JB054,064 (EXTENDED CHASSIS)

Page 11

----------------------------------------------------------------------------------------

CUT ALONG DOTTED LINE CUT ALONG DOTTED LINE

CERTIFIED ACCESSORY ROOF CURB DIMENSION PRINT

ACCESSORY ROOF CURB — 50JB054, 064

11

Loading...

Loading...