Page 1

Number One

Air Conditioning

l\^er

mstaflation, Start-Up

and Service Instructions

#

Carrier Parkway • Syracuse NY 13221

Single-Package Cooling Units

INSTALLATION

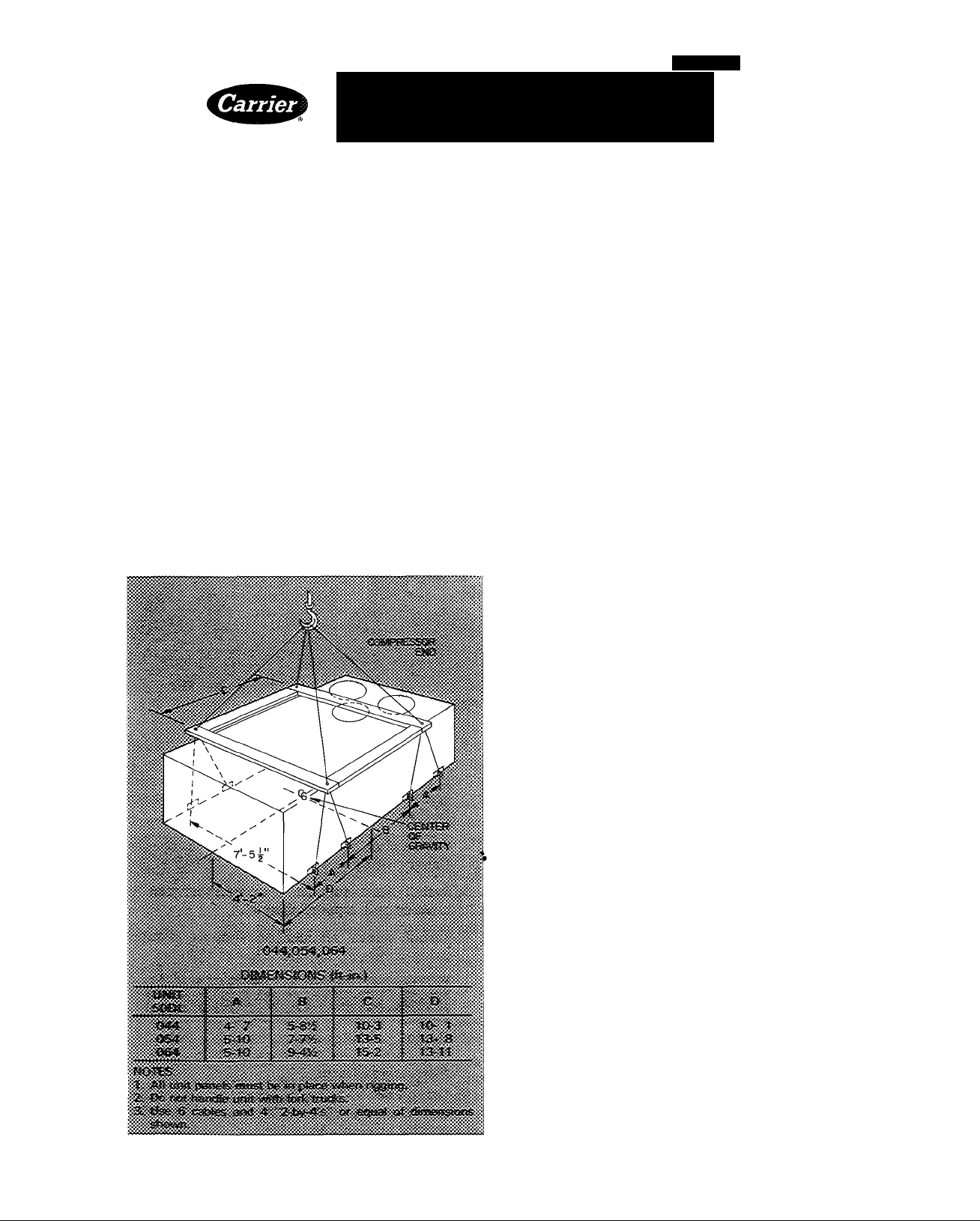

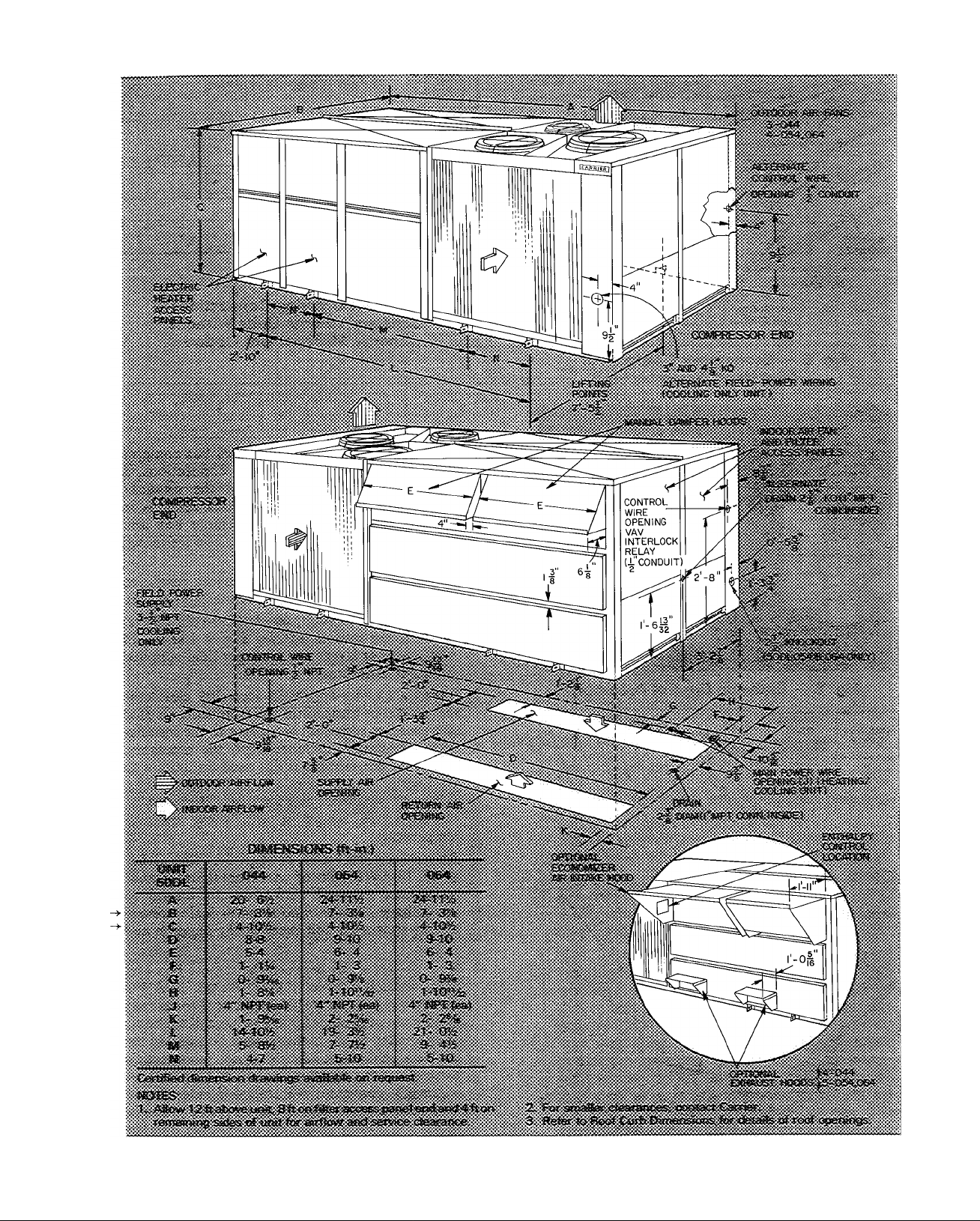

Rigging and Unit Placement — Inspect unit for

transportation damage. File claim with transporta

tion agency. Do not remove shipping skid until unit

is ready to be set in final location. Do not drop unit;

keep upright. Use spreader bars over unit to prevent

sling or cable damage. Rollers may be used to move

unit across a roof. Level by using unit frame as

reference. See Fig. 1 for additional information.

Unit weight is shown in Table 1.

Fig. 1 — Rigging Details

Units are designed to be hoisted only. However,

units with optional shipping skids may be moved

with a fork truck. Refer to Accessory Roof Curb

Installation Instructions for additional information

as required.

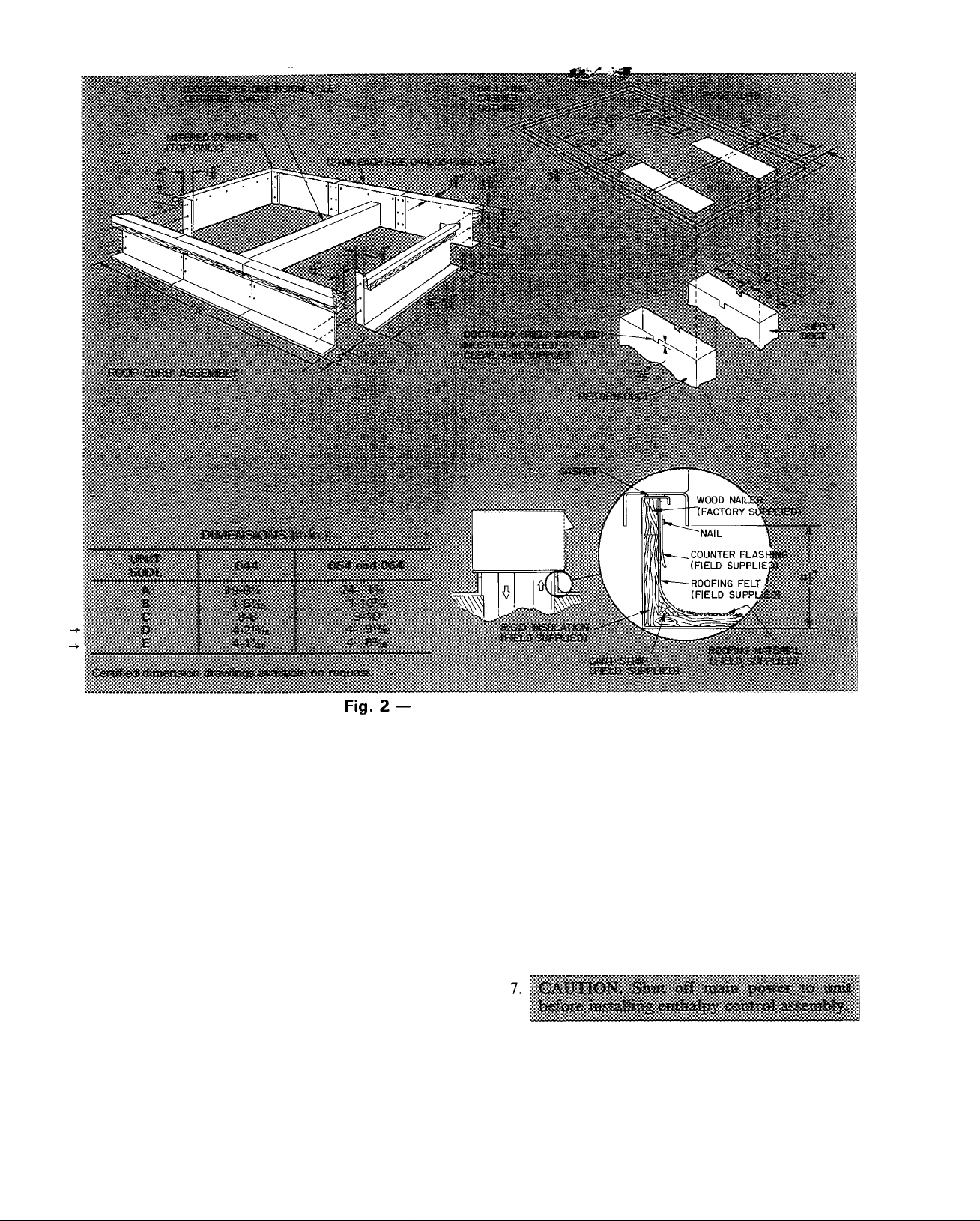

Roof Curb — Assemble and install as described in

instructions shipped with this accessory. Accessory

roof curb and information required to field fabricate

a roof curb of 2-in. x 14-in. planks is shown in Fig. 2.

Install insulation, cant strips, roofing and flashing as

required. For unit drains to function properly, curb

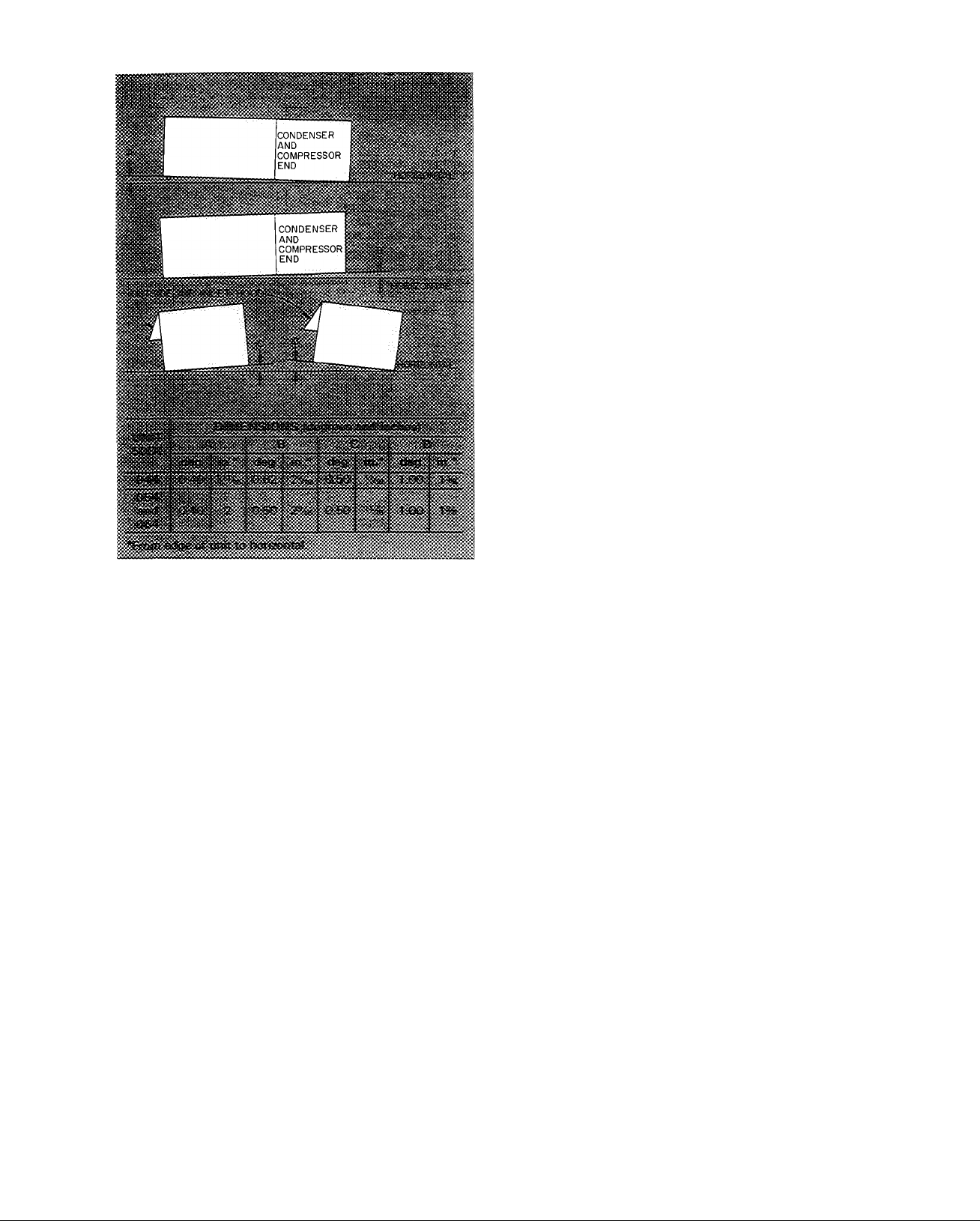

must be level or within tolerances shown in Fig. 3.

Roof Mount — Check building codes for weight

distribution requirements. Unit weight is shown

in Table 1.

Slab Mount — Provide a level concrete slab that

extends beyond unit cabinet at least 6 inches. Make

a slab 8 in. thick with 4 in. above grade. Use gravel

apron in front of condenser air inlet to prevent grass

and foliage from obstructing airflow.

Alternate Unit Support Methods — Where the

preferred curb or slab mount cannot be used,

support unit with sleepers on perimeter, using curb

support area. However, if sleepers cannot be used,

support long sides of unit (dimension “A,” Fig. 4)

with 4-in. X 4-in. pads equally spaced on each side.

Unit may sag if supported by corners only.

Positioning — Unit condenser air inlets and outlets

may be located in any compass direction since they

are not affected by wind. Provide clearances around

and above unit for airflow, safety and service

access (Fig. 4).

Do not install unit in an indoor location. Do not

locate air inlets near exhaust vents or other sources

of contaminated air.

Although unit is weatherproof, guard against

water from higher level runoff and overhangs.

Field-Fabricated Ductwork — Secure all ducts to

building structure. Use flexible duct connectors be

tween unit and ducts as required. Insulate and

weatherproof all external ductwork, joints and all

roof openings with flashing and mastic in accord

ance with applicable codes.

Carrier Corporation 1983 Form 50DL-1SI

Page 2

Roof Curb Dimensions

Insulate ducts passing thru unconditioned spaces

and cover with a vapor barrier.

Maintain one-in. minimum clearance between

supply air duct and any combustible material for at

least 3 ft of duct run from unit.

Unit is shipped set up for thru-the-bottom duct

connections. Ductwork openings are shown in

Fig. 4.

Economizer Section

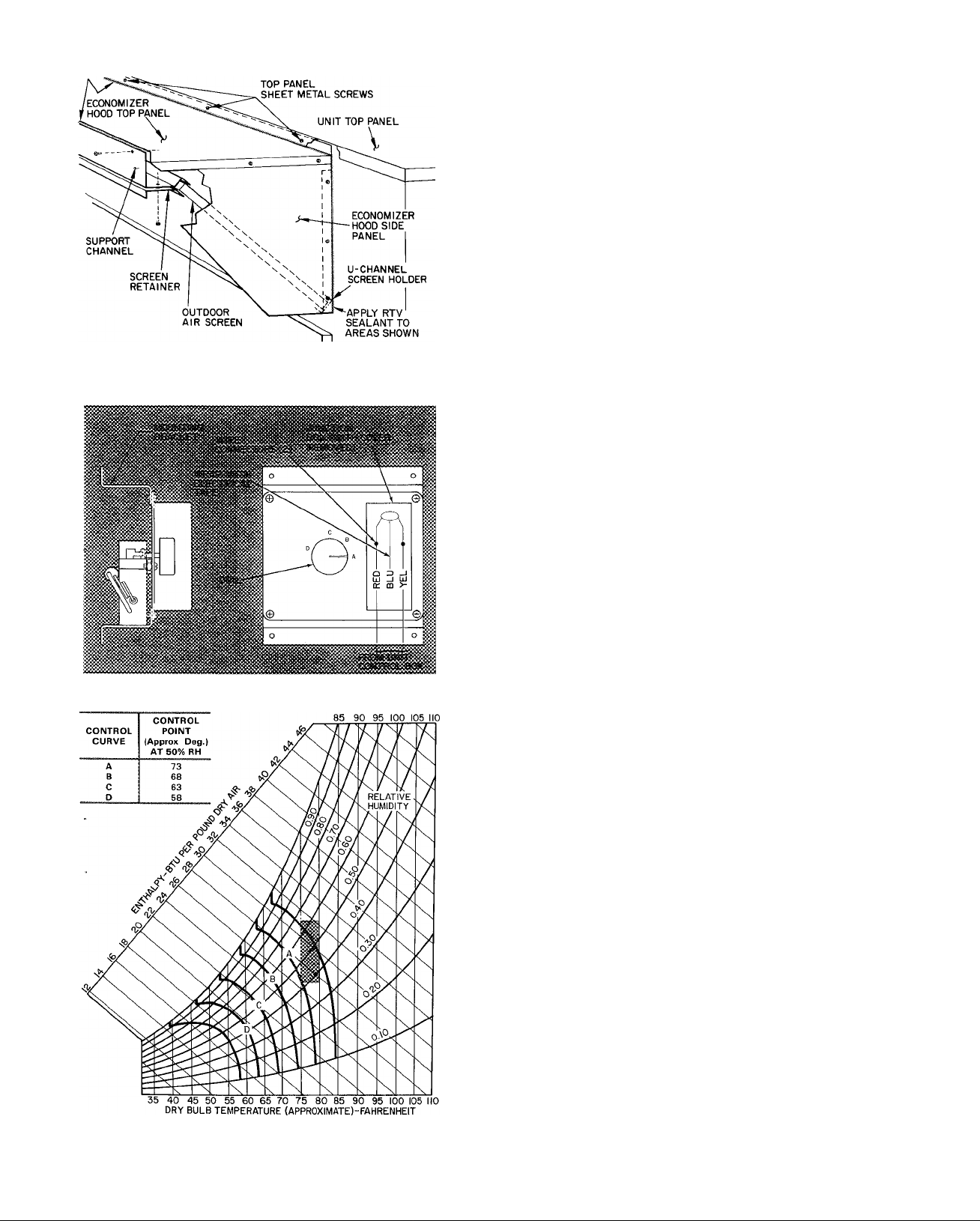

ECONOMIZER HOODS INSTALLATION (Fig.

5) — The economizer mechanism and all electrical

connections are factory installed and adjusted

except as noted below. Hood assembly, outdoor air

inlet screens and required hardware are shipped

separately and must be field installed. Units have 2

hood assemblies.

Install economizer hoods and enthalpy control

as follows:

1. Loosen unit top panel sheet metal screws above

outdoor air inlet opening.

2. Assemble hood top panel, side panels and

support channel.

288

3. Insert hood flange between unit top panel flange

and unit. Slots are provided in hood flange to

clear sheet metal screws. Tighten sheet metal

screws. Apply RTV sealant to surfaces as shown

in Fig. 5.

4. Secure hood side panels to outdoor air opening

flanges, using screws provided.

5. Install hood support bracket(s) between U-

channel and support channel.

6. Install screen retainer on support channel,

using screws in the slots. Do not tighten.

8. Remove enthalpy control assembly from ship

ping location on horizontal deck in return air

filter compartment.

9. Using 4 no. 10-1/2 screws from envelope in con

trol assembly junction box, mount enthalpy

control assembly to inside of economizer hood

side panel nearest condenser section (Fig. 4).

Page 3

Fig. 3 — Unit Leveling Tolerances

10. Route the red and yellow wires thru knockout in

side plate. Wrap end of blue wire with electrical

tape. Using wire connectors from envelope in

junction box, wire enthalpy control assembly as

shown in Fig. 6. Use strain reliefs from envelope

on side plate and junction box.

11. Install outdoor air screens.

12. Push retainer snugly against screens and tighten

screws.

Exhaust Air Hood Installation — The optional

power exhaust package hood damper assemblies

and required sheet metal screws are shipped in the

compartment at right of indoor air fan motor com

partment. Using screws provided, install a hood

damper assembly over each exhaust air opening as

shown in Fig. 4. Power exhaust is applied only to

economizer units using bottom duct connections.

Exhaust fan and motor assembly is factory wired

and adjusted. Refer to Service, Power Exhaust

Air Fan Adjustment if required.

Indoor Air Fans — The fan belt and pulleys are

factory installed and adjusted. If required, adjust

as described in Service, Indoor Air Fan Adjustment.

Condensate Drains — See Fig. 4 for drain loca

tions. Condensate drain is open to atmosphere and

must be trapped. Install a trapped drain line at con

nection to be used. Trap must be at least 3in. deep

and made of flexible material or be installed to pre

vent freeze-up.

Condensate drain pan under unit is fitted with a

one-in. FPT coupling. A gasket is shipped taped to

this drain. Install gasket in unit basepan opening or

alternate opening on end of unit.

Field Power Supply — Unit is factory wired for

voltage shown on nameplate. The main power ter

minal block is suitable for use with aluminum or

copper wire. Units have circuit breakers for com

pressors, fan motors and control circuit. If required

by local codes, provide an additional disconnect

switch.

If an external electrical source is used, unit must

be electrically grounded in accordance with local

codes, or in the absence of local codes, with the

National Electrical Code, ANSI Cl-1978.

All field wiring must comply with National Elec

trical Code and local requirements.

Install conduit connector in unit basepan or side

panel openings provided as shown in Eig. 4. Route

power lines thru connector to terminal connections

in control box as shown in Fig. 8, 9 and 10.

Affix crankcase heater sticker to unit disconnect

switch.

Voltage to compressor terminals during com

pressor operation must be within voltage range

indicated on unit nameplate. Also, see Tables 2 and

3. Phases must be balanced within 2%. Contact local

power company for correction of improper voltage

or phase unbalance. Failure due to operation of unit

on improper line voltage or with excessive phase

unbalance constitutes abuse and may cause damage

to unit electrical components.

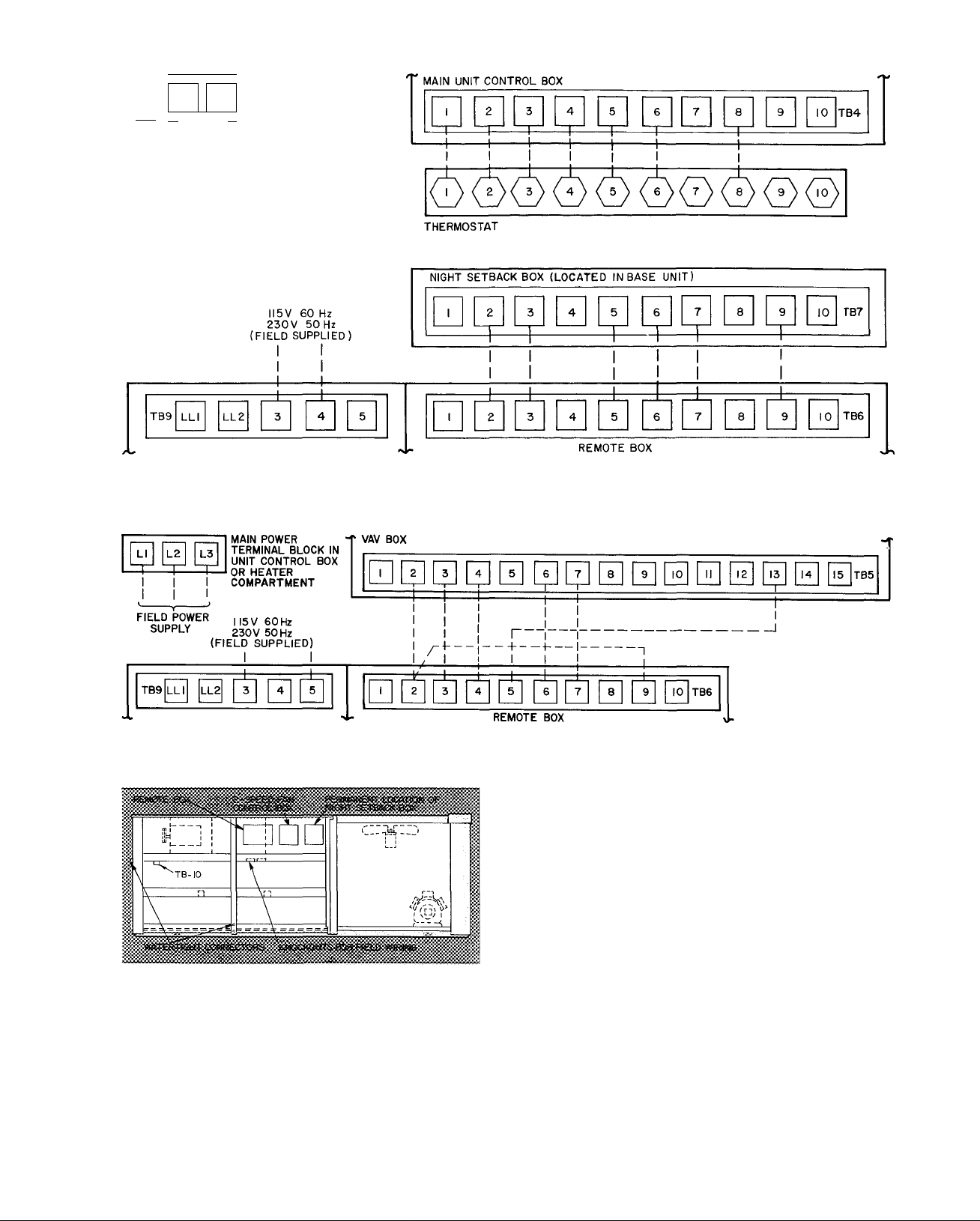

Field Control Wiring

STANDARD UNIT (WITHOUT ENERGY

MANAGEMENT OPTION) — Install a Carrier-

approved accessory electronic thermostat on a sub

base (or a transmitter on subbase if remote sensor is

used) per installation instructions included with the

accessory. Note that the subbase must be used oh

constant volume units without night setback. Locate

thermostat, or remote sensor, if used, in the condi

tioned space where it will sense average temperature.

Route thermostat cable or equivalent single leads

of no. 18 AWG colored wire from subbase terminals

thru connector on unit to low-voltage connections

in main control box as shown on unit wiring dia

gram and in Pig. 8.

UNITS WITH ENERGY MANAGEMENT

OPTION — In addition to the standard control

box, units with Energy Management option are also

equipped with a remote box and a night setback

box. The remote box contains a 7-day time clock,

a bypass switch that can manually bypass the time

clock for up to 5 hours, 6 indicator lights and 2

terminal blocks for field wiring connections. Mount

this box remote from the unit in an indoor or

Page 4

Table 1 — Physical Data

UNIT 50DL

OPERATING WEIGHT (lb)

Base Unit

Economizer 225 250

Roof Curb 200 225

COMPRESSOR

Quantity...Type

Quantity Cylinders (ea)...Rpm 4 1750 4 6 1750

Capacity Steps (%) (Standard) 50, 100 60, 100

With Accessory Unloaders 25, 50, 75, 100

Capacity Steps (%) (Variable Volume)

With Electric Unloaders

REFRIGERANT CHARGE

System 1...System 2 (lb) 37 0 37 0 53 0 42 0

OUTDOOR AIR FANS

Quantity...Diameter (in.) 3 30 4 30

Nominal Cfm 21,000

Motor Hp...Rpm 1 1050

CONDENSER COIL

Rows...Fins/in. 3 158

Total Face Area (sq ft)

INDOOR AIR FANt

Quantity...Size (in.)

Maximum Allowable Rpm

Nominal Cfm

Standard Motor and Drive

Motor Hp

Motor Frame Size

Single Speed

Two Speed

Fan Pulley Pitch Diameter (in.)

Fan Pulley Bore I’Me

Single-Speed Motor Rpm

Two-Speed Motor Rpm

Motor Pulley Pitch Diameter (in.)

Pulley A

Pulley B

Resulting Fan Rpm

Single-Speed with Pulley A. .B

Two-Speed with Pullley A...B

Alternate Motor and Drive

Motor Hp

Motor Frame Size

Single Speed

Two Speed

Fan Pulley Pitch Diameter (in.)

Fan Pulley Bore I'Me I'Me

Single-Speed Motor Rpm

Two-Speed Motor Rpm

Motor Pulley Pitch Diameter (in.)

Pulley A

Pulley B

Resulting Fan Rpm

Single-Speed with Pulley A...B

Two-Speed with Pulley A...B

EXHAUST FAN MOTOR Quantity...Hp

EVAPQRATQR CQIL

Rows...Fins/in

Total Face Area (sq ft)

ELECTRIC RESISTANCE HEATERS

HeatikW

INDQQR AIR FILTERS

No. ...Size

Standard; 2-in Throwaway

Bag Type; 12-in. (Optional)

044

5406 6100

Serviceable, Hermetic

2 06E 2. .06E*

20, 40, 60, 80, 100

25, 50, 75, 100 20, 40, 60, 80, 100

Type 22; Controlled by Thermostatic Expansion Valve

Direct Driven, Propeller Type

28,000

1 1050

61 0

Belt Driven, Centrifugal Type

4 15x9

4 15x11

1300

16,000

20,000

15

254T

284T

10 6

1750

1750/1170

1750/1170

6 5

5 6 60

1073 925

1073/751

925/617

1073 ..991

1073/751

991/661

20

256T

286T

80 80

1750

1750/1170

1750/1170

5 3

5 6

1159 1225* 1159 1225

1159/773.

1225/817

«

1159/773.

1225/817

2 3 2 3

4 15

30 2

Open Nichrome Wire Elements with Multiple-Stage Control

See Electrical Data tables

27 16x25

21 16x25

6 12x24

6 24x24 7 24x24

054 064

6485

250

225

2 06E

6 1750

50, 100

16, 33, 50, 67, 83, 100

16, 33, 50, 67, 83, 100

81 0 81 0

4 30

31,000

1 1150

3 158

81 5

1300

20

256T 284T

286T

106

I’Me

1750

6 5

25t

284T

286T —

4 15.8

81 25

4 15x11

1450

24,000

25

286T

80

1750

1750/1170

56

60

1225 1312

1225/817.

1312/875

30t

286T

10 6

1750

5 3

5 6

4 15

35 4

9 20x25

7 12x24

1750

1750/1170

8 0

1321 —

1321/881

2 3

4 139

35 4

9 20x25

21 16x25

**

*Unit contains one 06EA250 and one 06EA275 compressor

tStandard fan motor supplied with standard fan drive pulleys and

belts; alternate fan motor supplied with alternate fan drive

pulleys and belts Other combinations are field supplied Pulley

A is installed in unit; Pulley B is shipped with unit (044 and 054).

288

JDue to large frame size, the 25-hp, 208-230-volt and 30-hp

motors are available in single speed only

**The 50DL064 alternate drive is supplied with Pulley A only

Page 5

Fig. 4 — Base Unit Dimensions

5

288

Page 6

APPLY RTV SEALANT TO AREAS SHOWN

Fig. 5 — Economizer Outdoor Air

Inlet Hood Assembly

Fig. 6 — Enthalpy Control Assembly

Fig. 7 — Psychrometric Chart for

Enthalpy Control

MAIN POWER TERMINAL BLOCK IN UNIT CONTROL

BOX OR HEATER COMPARTMENT

^

FIELD POWER

SUPPLY

THERMOSTAT SUBBASE

NOTE Thermostat subbase required.

Fig. 8 — Field Wiring Connections

Constant Volume Units Without

Energy Management Option

TB4 MAIN CONTROL BOX

I I

weathertight space. The night setback box contains

a terminal block for field wiring connections, a

morning warmup thermostat and the setback/

setup module. The night setback box remains in

the unit. Shipping locations of remote box and

permanent location of night setback box are shown

in Fig. 11.

1. Remove remote box and mount in a restricted

access area (indoors or in a weathertight space).

2.

Run separate 115-volt, 60-Hz (230-volt, 50-Hz)

power to the remote box per Fig. 9. Use no. 14

AWG wire or larger and a proper field-supplied

electrical connector.

Install a Carrier-approved accessory electronic

thermostat or transmitter if remote sensor is used

(subbase not required) according to the installa

tion instructions included with the accessory.

Note that the subbase is not used on units with

the Energy Management option. Locate the ther

mostat or remote sensor, if used, in the condi

tioned space where it will sense average

temperature.

Route thermostat cable or equivalent single leads

of no. 18 AWG eolored wire from thermostat or

transmitter terminals thru connector on unit to

low-voltage (TB4) connections in main control

box as shown on unit label wiring diagram and

in Fig. 9.

4.

Run 24-volt wires between the remote box and

night setback box per Fig. 9. Use no. 18 AWG

wire for lengths up to 100 feet. Local codes may

dictate use of conduitfor low voltage. Knockouts

are provided in the night setback box and in the

fan deck separating heating section from section

containing the night setback box (Fig. 11). A

watertight connector is installed in side of unit.

Two rubber grommets are taped inside the night

setback box. Use grommets in knockouts in fan

deck and night setback box.

288

Page 7

MAIN POWER TERMINAL

L2

L3

~r~

NOTE Subbase not used

I

I I

FIELD POWER

SUPPLY

BLOCK IN UNIT CONTROL

LI

BOX OR HEATER

COMPARTMENT

Fig. 9 — Field Wiring Connections

Constant Volume Unit With Energy Management Option

Fig. 10 — Field Wiring Connections for 50DL VAV

Fig. 11 — Shipping Location — Remote Box

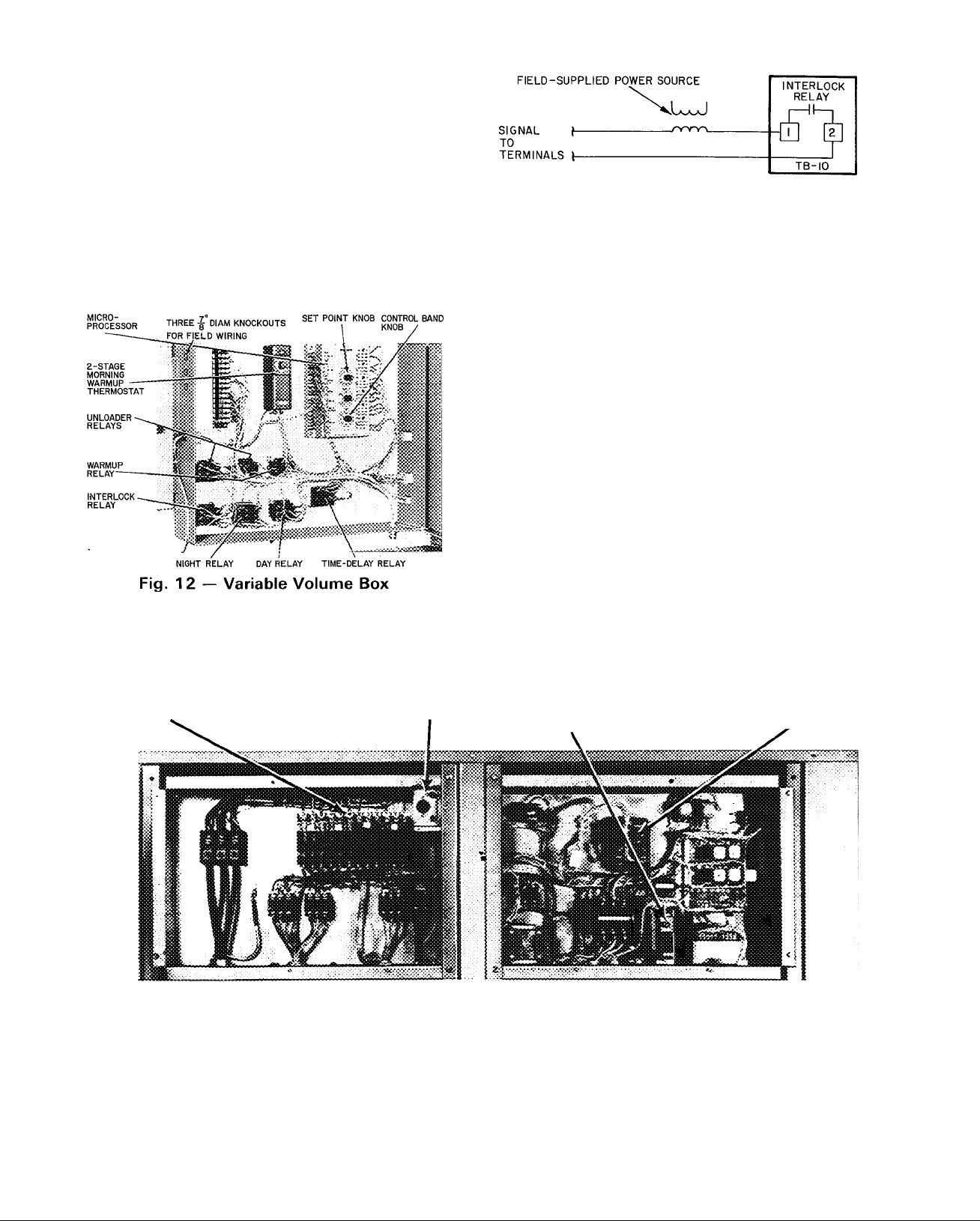

UNITS WITH VARIABLE VOLUME OPTION

— Units do not use room thermostats or sensors.

In addition to the main control box, units are

equipped with a remote box and a variable volume

box. Remote box is described above (Units With

Energy Management Option). The variable volume

box (Fig. 12) contains a microprocessor, a morning

warmup thermostat, a time-delay relay, 3 unloader

relays, an interlock relay, a night relay, a day relay

and a terminal block for field wiring. Shipping loca

tion of remote box is shown in Fig. 11.

1. Remove the remote box and mount in a restricted

access area (indoors or in a weathertight space).

2. Run separate 115-volt, 60-Hz (230-volt, 50-Hz)

power to the remote box per Fig. 10. Use no. 14

AWG wire or larger and proper electrical con

nector (field supplied).

3. Run 24-volt wires between remote box and

variable volume box per Fig. 10. Use no. 18 AWG

wire for lengths up to 100 feet. Run wire in con

duit to unit if local codes dictate. Knockouts are

provided in the variable volume box and the fan

deck separating heating section from section con

taining the variable volume box (Fig. 11). Water

tight connectors are installed in unit cornerpost

and side of unit. Two rubber grommets are

shipped taped inside variable volume box. Use

grommets in knockouts in fan deck and variable

volume box.

288

Page 8

4. If the unit is equipped with electric heat, the room

terminals must be controlled to go fully open

when unit goes into heating. An interlock relay is

provided in the variable volume box. When unit

goes into heating, the interlock relay energizes

providing switch closure to open the room ter

minals. Field connections for the interlock relay

are terminals 1 and 2 of the terminal block (TB10)

located in upper left corner of electric heat sec

tion (Fig. 11).

Route field-supplied power wiring thru watertight

connector supplied in unit cornerpost. Make TBIO

connections as shown in Fig. 13.

Return Air Filters — Check that return air filters

are of the correct type and size and installed in unit

filter racks. Filter data is shown in Table 1. Do not

operate unit without return air filters.

Fig. 13 — Morning Warmup Interlock

Outdoor Air Inlet Screens — Outdoor air inlet

screens must be in place before operating unit.

Compressor(s) — Loosen compressor holddown

bolts until sidewise movement of the washer under

each holddown bolt head occurs. Do not loosen

completely as bolts are self-locking and will main

tain their adjustment.

Open the compressor discharge and suction

service valves. Replace and tighten valve caps to

prevent leaks.

Liquid Line Service Valve — Open the liquid line

service valve. Replace and tighten valve cap to

prevent leaks.

Low Ambient Compressor Lockout (Fig. 14) —

All units are equipped with an adjustable low

ambient lockout thermostat to lock off the compressor(s) at low outdoor air ambients. Thermostat

is located in the main control box. Setting will

depend on specific installation but should be

approximately 50 F on VAV units and 55 F on

constant volume units.

Convenience Outlet — All units are equipped

with a 115-volt convenience outlet for handling

small power load or service light. See Fig. 14.

CIRCUIT BREAKERS CONVENIENCE OUTLET LOW AMBIENT LOCKOUT

Fig. 14 — Control Box

THERMOSTAT

LOGIC PANEL

Page 9

Table 2 — Electrical Data — 5ODL044 and 054

MODEL

NOMINAL

VOLTS-PH-HZ

50DL044

208/230-3-60

50DL044

460-3-60

50DL044

575-3-60

50DL054

208/230-3-60

50DL054

460-3-60

50DL054

575-3-60

VOLTAGE

RANGE NO. 1 NO 9

Min Max

187

414 508

518 632

187 254

414

518

COMPR

RLA LRA RLA

254

80 345 80

37 173 37

30 120

117 506

508 53

632 42 5

30

78 5

253 36

176

28 6 120 4

COMPR

LRA

345

173

120

345

173

OUTDOOR

FAN

MOTORS

Qty FLA

76 20

3

(ea)

3 3

3

(ea)

2 7

3

(ea) 20

7 6

4

(ea)

33

4

(ea)

2 7

(ea)

INDOOR

FAN

MOTOR

Hp

15

15

20

15

15

15 46 0 3 11

15

20

20

20

20

15 21 0

15 21 0 3 4 8

20

15 21 0

15 21 0

20

15 21 0

15 21 0

20

20

20 27 0

20

15 17

15 17 3

20 22

20

20

25

20

20

25 75

20 60 3 11

20

25

25

25

25

20 27

20 27

25 34

20 27

20

25 34

20

20

25 34

25

25 34

25 34

20

20

25

25

EXHAUST

FAN

MOTOR

FLA

46 0

Hp

— —

FLA

46 0 3

60 0

—

46 0

—■ — 45/54 9

46 0 —

60 0 3 11

11 — —

—

—

HEATERS

kW

—

—

60/73 2

— —

45/54 9

3 11

46 0

60 0

60 0

— —

—

60/73 2

45/54 9

_

60/73 2 166/184

60 0 3 11 45/54 9 125/184

60 0 3 11

60/73 2 166/184

— — — —

— —

—

27 0

27 0 3

27 0

27 0

27 0 3 4 8

22 —

60

60 3 11

75

60

60

— — —

—

—

4 8

4 8

3

3

48 73 2 92

—

— —

4 8

3

54 9 69

—

73 2 92

— —

54 9 69

54 9 69 121

73 2 92

54 9 69

73 2 92

_ __

3 9

—

3 3 9

_

—

—

— — —

—

—

—

—

3 11

— —

— — 101

—

—

— —

60/73 2 166/184

75/91 5

— —

—

60/73 2 166/184

60 3 11

—

75

— —

75

75 3 11

75 3 11

75/91 5

—

60/73 2 166/184

75/91 5

60/73 2 166/184

75/91 5

— — — —

3 48

—

—

__

—

— —

27

3

27 3

27 3

34

22 0

48

48 73 2 92

48 91 5 115

—

—

—

—

3

48 73 2 92

3

48 91 5 115 187

—

—

22 0 3 3 9

— —

27 0

27 0 3 3 9

—

— —

73 2 92

91 5

— — 158

73 2 92

91 5 115 187

— —

— —

—

— —

FLA

—

—

125/138

166/184

MCA

249

271

263

249

265/288

285

125/138

166/184

125/138

271

271/288

263

283/305

285

285/305

115

124

121

115

142

130

124

142

149

130

149

93

—

—

—

98

106

312

334

327

312

208/230

335/363

349

334

208/230

335/363

327

208/230

354/382

349

208/230 354/382

—

141

151

148

149

115 178

151

178

158

158

113

121

—

118

126

ruvvcn

SUPPLY

MOCP*

300

350

300

300

350/350

350

350

350

350

400

350

400

150

150

150

150

175

150

150

175

175

200

175

200

110

125

125

125

400

450

400

400

400/450

450

450

450

450

500

450

500

175

200

200

200

200

200

200

200

225

250

225

250

150

150

150

150

See Legend and Notes on page 10

Page 10

Table 3 — Electrical Data — 50DL064

MODEL VOLTAGE

NOMINAL

VOLTS-PH-HZ

50DL064

208/230-3-60

50DL064

460-3-60

Compr — Compressor

FLA — Full Load Amps

Hp — Nominal Horsepower

kW — Kilowatts

LRA — Locked Rotor Amps

MCA — Minimum Circuit Ampacity

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

*Fuse only.

NOTES (Tables 2 and 3)

1 All outdoor fan motors are single-phase motors

2 All heaters are 3-phase assemblies

3 Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase unbalance in supply volt

age is greater than 2% Use the following formula to determine

the % voltage unbalance

% Voltage Unbalance

100 X-

RANGE NO. 1

Min Max RLA LRA RLA LRA

187 254 119 506 119 506

414

LEGEND (Tables 2 and 3)

max voltage deviation from average voltage

COMPR

53

508

average voltage

COMPR

253 53

NO. 2

253

OUTDOOR

FAN

MOTORS

Qty FLA

6 6/6 0

4

4

30

INDOOR

FAN

MOTOR MOTOR

Hp

25 75

25 75

30 88

25 75

25 75

30

25 75 3

25

30

30

30 88 3

30 88 3

25 34

25 34 3 48

30

25

25 34

302540

25 34 3 48

30

30

30 40 3 48

30 40 3

EXHAUST

FAN

FLA

Hp

FLA

— —

—

11

3

— — — —

— —

— —

3 11

88

75 3

88

88

40

34

34334848

40

40

Example:

A B

Determine maximum deviation from average voltage

(AB) 457 - 452 = 5 volts

(BC) 464 - 457 = 7 volts

(AC) 457 - 455 = 2 volts

Maximum deviation is 7 volts

Determine % voltage unbalance

% Voltage Unbalance = 100 x - ~ = 1 53%

This amount of phase unbalance is satisfactory as it is below

the maximum allowable 2%

11 60/73 2

11

—

—

—

—

11

11

—

— — —

—

—

— —

— —

— —

—

—

48

Supply voltage is 460-3-60

“ 457

HEATERS

kW

—

60/73 2

75/91 5 208/230 370/382 500

_

75/91 5 208/230 392 500

60/73 2

75/91 5

60/73 2

75/91 5

—

— —

73 2

91 5 115 187 250

73 2 92

91 5 115 187 250

73 2 92 172 250

91 5 115 194 250

73 2

91 5

AB = 452 volts

BC = 464 volts

AC = 455 volts

FLA

—

—

166/184 370 450

_

166/184 392 450

166/184

208/230 383/398

166/184

208/230 405 500

—

92

92 181

115

Average Voltage =

POWER

SUPPLY

MCA

370 400

392

383 450

405 450

383

405 500

166 200

175 200

172 200

166 225

181

175

194 250

452 + 464 -r 455

1371

MOCP*

= 457

¿i

-gíítíf

450

500

500

200

225

250

START-UP

Constant Volume Units

COOLING (WITH OR WITHOUT ENERGY

MANAGEMENT OPTION)

1. Open compressor service valves. Make sure the

crankcase heater has been on for at least 24 hours

to remove liquid refrigerant from compressor

crankcase. Check compressor oil level. Oil sight

glass should be half full.

2. Be sure that the liquid line service valve is open

and that high- and low-side refrigerant service

ports are closed as applicable.

3. On units equipped with the Energy Management

option, move the COOL SETUP SELECT

jumper wire to the desired setting(5°, 8°, or 12°).

If cooling is not desired during the unoccupied

periods, move jumper wire from COOL SETUP

to COOL LOCKOUT. See Fig. 15.

4. Turn on power to unit. On standard units, set the

subbase selector switch to COOL. On units with

the Energy Management option, set the 7-day

time clock as required. Refer to 7-Day Time

Clock Adjustment. Check that compressor low

ambient lockout contacts and morning warm-up

contacts (on units with Energy Management

option) are closed.

10

Page 11

i

(A) HEATING SETBACK

Fig. 15 — Setback/Setup Module (Partial)

5. Remove cover from thermostat (or from trans

mitter if a remote sensor is used); note the red

diagnostic light-emitting diodes (LED’s). See

Fig. 16.

6. To call for cooling, move the thermostat or

transmitter cooling set point (blue lever) below

room temperature. Cooling LED on the righthand side of thermostat or transmitter should

begin to glow. Check the cooling effect at supply

duct outlets.If the mechanical cooling does not

come on, see Service, Electronic Component

Checkout.

7. Move the thermostat or transmitter cooling set

point above room temperature. The cooling

equipment should cycle off and the cooling

LED intensity should decrease to a faint glow

or go off completely. The economizer should

move to minimum position.

(B) COOLING SETUP OR LOCKOUT

To Shut Off Unit — For standard units, set the

subbase selector switch to OFF or set the cooling

temperature selector lever above room tempera

ture. For units with Energy Management option, set

the cooling temperature selector switch above

room temperature.

Do not shut off unit circuit breakers except

when unit is serviced. Crankcase heater is ener

gized only when unit power is on.

HEATING (Electric Heat Units)

1. Turn on unit power; set circuit breakers at ON.

2. On units with Energy Management option, posi

tion the HEAT SETBACK SELECT switch in

the setback/setup module to the desired position

(5°, 10°, or 15°). See Fig. 15.

3. Move the thermostat or transmitter heating set

point (red lever) above room temperature. The

HEATING

LEVER (RED)

COOLING

LEVER(BLUE)

COVER THERMOSTAT/TRANSMITTER

Fig. 16 — Electronic Thermostat/Transmitter (Without Subbase)

11

Page 12

heating LED on the left-hand side of thermo

stat or transmitter should begin to glow. Electric

heat should cycle on. Check supply duct outlets

for heat. If heating equipment does not cycle on,

see Service, Electronic Component Checkout.

4. Move the heating set point below room tempera

ture. The heating equipment should cycle off and

the heating LED intensity should decrease to a

faint glow or go off completely.

5. Return the heating and cooling set points to

desired settings and lock in place. On standard

units, return subbase switch to desired position.

On units with Energy Management option, an

adjustable morning warmup thermostat is used

to hold dampers closed until return air reaches

the setting on the thermostat located in the

night setback box.

To Shut Off Unit — Standard units, set the subbase

selector switch to OFF or set the heating tempera

ture selector lever below room temperature. For

units with Energy Management option, set the heat

ing temperature selector switch below room

temperature.

AUTOMATIC CHANGEOVER — Standard units

automatically switch from heating to cooling mode

when the subbase selector switch is set at AUTO,

and the temperature of the conditioned space rises to

the cooling selector lever setting. When the tempera

ture of conditioned space falls to heating selector

lever setting, the unit automatically changes from

cooling mode to heating mode.

The thermostat and unit are so connected that

cooling and heating systems do not operate

simultaneously.

On units with Energy Management option, with

dual set point thermostat or transmitter, changeover

is also automatic. There is a minimum 3 F deadband

between the heating and cooling set points.

ECONOMIZER OPERATION — If unit is

equipped with modulating outdoor air control

(economizer), set enthalpy control (Fig. 4 and 6) at

“A.” Unit capability to integrate economizer with

.mechanical cooling allows for a higher changeover

point than conventional economizer systems. Be

cause of this, outside air is desired whenever its

enthalpy (total heat content) is below return air

enthalpy. Typical return air conditions, shaded

portion of Fig. 7, indicate that setting “A” should

be used for maximum operating economy.

OPERATING SEQUENCE WITH ECONO

MIZER (without Energy Management option)

using thermostat with subbase.

Cooling — System switch set at AUTO, or COOL,

fan switch at ON or AUTO, (indoor air fan runs

intermittently). Thermostat set at desired setting.

When thermostat calls for cooling and outdoor

air enthalpy is below setting of enthalpy controller.

the economizer modulates open. (If outdoor air

enthalpy is above enthalpy set point, the outdoor

air dampers remain at minimum position.) Econo

mizer acts as the first stage of cooling, providing

“free cooling” with outside air. If outside air alone

cannot satisfy the cooling requirements of condi

tioned space, economizer cooling is integrated

with mechanical cooling.

Compressor(s), working simultaneously with

economizer, will come on in stages to meet the

cooling load.

As the conditioned space temperature approaches

the thermostat’s cooling set point, stages cycle off,

last stage first. After all stages of mechanical cool

ing are off, economizer modulates to minimum

position.

During the cooling cycle, a discharge air sensor

senses discharge air temperature. If discharge air

temperature drops below 62 F, economizer starts

to modulate toward minimum position. At 50 F dis

charge temperature, the economizer will be at mini

mum position.

Heating — System switch set at HEAT or AUTO.,

fan switch at ON or AUTO., thermostat set at

desired setting. When thermostat calls for heating,

one or 2 stages of heat energize to satisfy heating

demand.

As space temperature approaches the heating

temperature set point, heating stages cycle off.

During heating, economizer is limited to the

minimum position to provide outdoor air for

ventilation requirements.

OPERATING SEQUENCE WITH ECONO

MIZER AND ENERGY MANAGEMENT option

(using electronic thermostat or transmitter).

Clock in remote control box switches controls to

OCCUPIED mode. Indoor air fan runs continually

while in OCCUPIED mode.

If return air temperature is below the adjustable

setting of morning warmup thermostat, outdoorair dampers remain closed.

When return air temperature goes above setting

of morning warmup thermostat, economizer goes

to adjustable minimum position.

When thermostat calls for cooling and outdoor

air enthalpy is below setting of enthalpy controller,

economizer modulates open. (If outdoor air en

thalpy is above enthalpy set point, economizer

remains at minimum position.) The economizer acts

as the first stage of cooling, providing “free cooling”

with outside air. If outside air alone cannot satisfy

cooling requirements of the conditioned space,

economizer cooling is integrated with mechanical

cooling.

Compressor(s), working simultaneously with

economizer, will come on in stages to meet the

cooling load.

12

Page 13

m

As the conditioned space temperature approaches

the thermostat’s cooling set point, stages cycle off,

last stage first. After all stages of mechanical

cooling are off, economizer modulates to minimum

position.

During the cooling cycle, a discharge air sensor

senses discharge air temperature. If discharge air

temperature drops below 62 F, the economizer

modulates toward minimum position. At 50 F dis

charge temperature, the economizer will be at mini

mum position.

At the end of the DAY (OCCUPIED) mode on

the clock, unit controls enter the NIGHT (UN

OCCUPIED) mode. Economizer closes. Indoor air

fan runs only on a call for heating or cooling. Tem

perature controls go into HEATING SETBACK,

COOLING SETUP or COOLING SHUTDOWN

mode.

HEATING SETBACK is field selectable at the

unit for 5°, 10°, or 15° below set point on room

thermostat.

COOLING SETUP is field selectable at the unit

for 5°, 8°, or 12° above set point on room

thermostat.

During the UNOCCUPIED mode, unit continues

to use economizer cooling first and then integrates

economizer cooling with mechanical cooling to

meet cooling requirements.

A 5-hour bypass timer is located in the remote

control box to provide air conditioning during

normally unoccupied hours.

TWO-SPEED INDOOR FAN OPTION — Table 1

lists the 2-speed indoor fan motor hp, frame size and

shaft diameter. Due to the larger frame size, the

208/ 230-volt, 25-hp motors and all 30-hp motors are

available in single speed only.

The 2-speed motors are 2 winding (4 pole/6 pole)

design, with speeds of 1750/1170 rpm. Indoor fans

automatically operate at low speed until high speed

is necessary to maintain comfort conditions. No

field wiring or adjustment is necessary.

COOLING mode sequence of operation is out

lined in Table 4.

In HEATING mode, the indoor fan operates at

low speed for ventilation only, and operates at high

speed during active heating. A 2-heat/4-cool logic

panel provides the necessary fan control.

The circuit breakers, contactors, and relays re

quired for 2-speed motor control are located in the

2-speed indoor fan motor control box (Fig. 17).

POWER EXHAUST OPERATION — Units have

an auxiliary switch located on the damper motor.

This switch is factory set to prevent the power

exhaust fans from operating when the economizer

damper is less than 30% open.

If other than factory setting is desired, adjust

as follows:

Table 4 — Two-Speed Indoor Air Fan

Staging; Cooling Mode

ECONOMIZER COOLING (Enthalpy Permitting)

OPERATING

CONDITION

NO CALL FOR COOLING

(Ventilation Air)

CALL FOR

MINIMUM COOLING

STAGE 1 OF

LOGIC PANEL

(Economizer Cooling)

STAGE 2 OF

LOGIC PANEL

(Integrated Econ/Mech

Cooling)

STAGE 3 AND 4

OF LOGIC PANEL

(Integrated Econ/Mech

Cooling)

SPEED

ECONOMIZER

FAN

Low

Low

High Full Open

High

High Full Open

DAMPER

POSITION

Minimum

Position

Modulating

Between

Min and

Full Open

Full Open

COMPRESSOR

OPERATION

Off

Off

Off

Compr 1

Compr 1 and 2

MECHANICAL COOLING

(Enthalpy Not Permitting Economizer Cooling)

ECONOMIZER

OPERATING

CONDITION

NO CALL FOR COOLING

(Ventilation Air)

STAGE 1 OF

LOGIC PANEL

STAGE 2 OF

LOGIC PANEL

STAGE 3 OF

LOGIC PANEL

STAGE 4 OF

LOGIC PANEL

INDOOR FAN

FAN

SPEED

Low

Low

Low

Low

High

DAMPER

POSITION

Minimum

Position

Minimum

Position

Minimum

Position

Minimum

Position

Minimum

Position

REMOTE CONTROL PANEL

COMPRESSOR

OPERATION

Compr 1

Compr 1 and 2

Compr 1 and 2

Off *

Off

Fig. 17 — Two-Speed Fan Control Box

Location

NOTE: Adjustment does not require running the

motor.

1. Motor must be in the fully closed position.

2. Referring to Fig. 18, take off “C” clip and drive

bracket. Remove screws at 4 corners of housing.

Pull off return spring housing.

3. Remove spring on motor shaft.

4. Adjust switch as shown in Fig. 19.

5. After adjustment, replace spring on motor shaft

and reassemble return spring housing.

13

Page 14

Fig. 18 — Removing Return Spring

Mechanism

STARTING POSITON

NOTE POSITION

OF RED DOT

CENTERLINE

Each adjustment mark repre

sents 10 degrees of motor rota

tion Use marks and center of

cam roller as adjustment guide

Red dot will be to right of centerline if switch is properly adjusted

Fig. 19

Adjusting Switch Make and

Break Points

ADJUST CAMS

OPERATIONAL

Loosen operational cam adjust

ment screw Rotate both cams

clockwise the number of de

grees motor must travel before

switch makes Tighten screw

CAPACITY CONTROL, HEATING — Stages 1

and 2 of heaters are controlled by heating relays

HRl and HR2, respectively. Using a suitable

ammeter, check heater current draw for heating

assemblies or elements. When checking secondstage heater operation, be sure heating thermostat

is set high enough to activate second-stage heaters.

Also, check operation of outdoor air thermostats if

additional staging is provided.

Modu-Pac® Variable Volume Units — Units

suitable for use with Modu-Pac variable air volume

systems (i.e. Carrier 37 Series terminal units) are

equipped with electric unloaders on the no. 1 com

pressor and hot gas bypass on the no. 1 refrigerant

system.

Before starting unit, open compressor service

valves and liquid line shutoff valve. Be sure com

pressor crankcase heaters are on and crankcase oil

level is half full. See Compressor and Crankcase

Heaters as applicable.

CONTROL SEQUENCE CHECKOUT

1. Turn on unit main power supply. Be sure unit is

ready to operate. Turn off compressor circuit

breakers.

2. Set the control band knob (Fig. 12) on micro

processor to 8° (50DL044) or 6° (50DL054,064).

3. If unit is not in DAY (OCCUPIED) mode, turn

on unit by overriding time clock with manual

bypass switch on remote box cover.

4. To check for cooling, turn set point knob

(Fig. 14) on microprocessor to 40 F. As cor

responding stage of cooling come on, the LED’s

should glow. Indicator light, located on remote

box cover, should also be lit.

5. Turn set point knob on microprocessor to 90 F.

The LED’s on microprocessor should go out as

corresponding stages turn off (providing ambient

temperature is below 90 F).

6. To check for heating on units with electric heat,

set morning warmup thermostat (Fig. 12),

located in variable volume box, to its maximum

position. If return air temperature is below the

set point, first stage of heat should come on. The

outdoor dampers should be tightly closed. Light

marked HEATING on the cover of remote box

should come on. NOTE: If unit has been in cool

ing mode, it will be necessary to shut off unit

power momentarily in order to check out heating

mode; once unit goes into cooling mode, a hold

ing relay locks out heating mode.

7. The morning warmup thermostat is a 2-stage

device. When first stage is satisfied, control shuts

down electric heat (if used). An adjustable dead

band of 3F to 10 F exists between first and

second stage. In the deadband zone, indoor air

fan runs but cooling mode will not begin until

return air temperature exceeds adjustable set

point of the second stage. Note that the difference

between heating and cooling set points will

always be 3 F to 10 F.

8. When checkout is complete and unit operation is

satisfactory, turn off bypass switch, position the

set point knob on microprocessor to desired

setting (approximately 55 F) and replace all

unit panels.

ECONOMIZER OPERATION — Refer to Con

stant Volume Units, Economizer Operation.

7-DAY TIME CLOCK ADJUSTMENT

Setting ON and OFF Times (Fig. 20) — NOTE:

14 trippers (7 sets, one set for each day) are included.

If more than 7 ON-OFF operations per week are

required, additional trippers are needed.

1. To set ON (OCCUPIED) time, slip the ON

tripper over edge of time dial and position at

desired day of the week and time of the day (AM

or PM). (When switch is turned on, normally

open contacts close and normally closed con

tacts open.)

14

Page 15

Fig. 20 — Setting the 7-Day Time Clock

NOTE: Dial turns clockwise when power is

connected and time clock is operating.

2. Hold tripper firmly against the edge of dial and

tighten knurled screw by hand. (Do not use

pliers.)

3. To set OFF (UNOCCUPIED) operation, use

OFF tripper and repeat steps 1 and 2, setting

the time desired for the switeh to turn off.

(Normally open contacts open and normally

closed contacts close.)

4. Time cloek can be set for up to 3 ON-OFF oper

ations per day or 21 per week. To omit operation,

do not place trippers on the dial for that day(s).

NOTE: Minimum time from an ON operation to an

OFF operation is 3-1/2 hours.

Minimum time from an OFF operation to an ON

operation is 3-1/2 hours (limited by the width of the

trippers which cannot be set closer).

Setting the Time of Day (Fig. 20)

1. Apply power to timer motor.

2. Turn time dial clockwise until the TIME pointer

is aligned with correct time and day. Do not

turn time dial counterclockwise and do not

move the TIME pointer.

Time clock has a spring wound carryover me

chanism to keep timer on schedule during power

failure up to 10 hours. When power is restored,

mechanism automatically rewinds.

VARIABLE VOLUME OPERATING SE

QUENCE (with accessory electric heat) — Clock

in remote control box switches controls to DAY

(OCCUPIED) mode. Indoor air fan runs for one

minute before any other control can function. (This

allows sensing of unit discharge air to start from the

conditioned space ambient rather than initial unit

ambient.)

If return air is below adjustable set point of first

stage of the morning warmup thermostat, heaters

energize. Outdoor air dampers remain elosed.

Normally open contacts in base unit override the

field-supplied VAV terminal controls and room ter

minals remain open during heating.

When first stage of morning warmup thermostat

is satisfied, heaters shut down, indoor air fan runs

eontinuously and outdoor air dampers remain

closed.

When conditioned space temperature rises to

adjustable set point of second stage of morning

warmup thermostat, unit switches to COOLING

mode. Outdoor air dampers go to at least the mini

mum position. (Once the unit has gone into cooling

mode, heat cannot come on during OCCUPIED

time period set on the clock.)

If outdoor air enthalpy is below setting of

enthalpy controller, economizer modulates open.

(If outdoor air enthalpy is above enthalpy set

point, economizer remains at minimum position.)

Economizer acts as first stage of cooling, providing

“free cooling” with outside air. If outside air alone

eannot satisfy cooling requirements of the condi

tioned space, economizer cooling is integrated with

mechanical cooling.

Compressor(s) will start, stop, load and unload

and economizer will modulate to maintain an

average discharge air temperature. If outside air

temperature drops below the adjustable setting

(normally 50 F) of the low ambient lockout, the

compressor(s) will shut down.

At end of DAY (OCCUPIED) mode on the clock,

unit enters the NIGHT (UNOCCUPIED) mode.

The outdoor air damper closes and indoor fan and

compressors shut down.

If a field-supplied night thermostat is installed

in the conditioned space, indoor air fan runs only on

a call for heating or cooling. Dampers open only on

a call for cooling. On a call for cooling, economizer

cooling occurs first and then integrates with me

chanical cooling to meet the cooling requirement.-

A 5-hour, manual bypass timer is provided in

remote control box. This timer, when manually

set by building occupant, overrides the UN

OCCUPIED mode and places unit in OCCUPIED

mode for up to 5 hours.

Constant and Variable Volume Units

TIME GUARD® CIRCUIT — Timer sequence

for a particular unit depends on unit and com

pressor arrangement. The Time Guard device pro

vides a delay in compressor start-up after thermostat

closes. On normal unit start-up, outdoor air fans

energize 15 seconds before the compressor. If com

pressor shutdown is due to satisfied thermostat or

automatic resetting of a safety device, the com-

15

Page 16

pressor automatically restarts after a 5-minute inter

val. If compressor shutdown is due to tripped over

loads, the circuit breakers must be manually reset

before compressor will start.

Timer (Time Guard®) for second compressor has

a 6-minute interval to prevent compressors from

starting simultaneously.

Refer to unit label diagram for specific timer

sequence.

CRANKCASE HEATER — Unit main power

supply must remain on to provide crankcase heater

operation. Crankcase heater in each compressor

keeps oil free of refrigerant while compressor is off.

HEAD PRESSURE CONTROL — Each unit has a

fan cycling thermostat to shut off 2 outdoor fan

motors at 55 F. This permits unit to operate with

correct condensing temperatures down to 35 F out

door air temperature.

SERVICE

Electronic Component Checkout

CONSTANT VOLUME UNITS

The checkout procedures in this section will

determine whether;

1. The logic panel is controlling the heating and

cooling equipment properly.

2. System components are correctly wired to the

logic panel.

Prior to checking out control circuit, establish

setting on the low ambient lockout thermostat.

Compressors will not start below this setting (cool

ing mode only). Recommended setting is approxi

mately 50-55 F.

NOTE: To complete the electronic component

checkout, a volt-ohmmeter (Simpson 260 is

recommended) is required.

LOGIC PANEL (Fig. 21)

1. Check that 24 VAC is supplied to logic panel.

Connect meter to terminals TR.

2. Check thermostat supply voltage at STAT ter

minals 1 and 2. Reading should be 20 VDC.

3. Remove thermostat supply wires from STAT

terminals 1 thru 5 on logic panel.

4. Set meter to volts AC scale equal to relay switch

ing voltage (50-volt scale for 24 VAC).

5. To simulate a call for cooling, jumper between

STAT terminals 2 and 4. Normally open Logic

Panel contacts (Cool 1 and 2) should close and

cooling equipment should cycle on.

6. Connect meter leads to the normally open cool

ing contacts 1 and 2 on logic panel. Meter should

Fig. 21 — Logic Panel

read zero if contacts have closed and contacts

are made.

If meter is reading zero and cooling equipment

has not cycled on, logic panel is not at fault.

7. To simulate a call for heating, jumper between

STAT terminals 2 and 5. Normally open logic

panel contacts (HEAT 1 and 2) should close and

heating equipment should cycle on.

8. Connect meter leads to the normally open heat

ing contacts on logic panel. Meter should read

zero if contacts have closed.

If meter is reading zero and heating equipment

has not cycled on, logic panel is not at fault.

9. Replace thermostat wiring to terminals 1 thru 5.

DISCHARGE SENSOR

1. Set resistance on meter to R x 100.

2. Disconnect lead from SENSOR terminal T1 on

logic panel.

3. Connect one meter lead to logic panel terminal T

and the other meter lead to the loose lead wire

from the sensor.

4. Meter readings depend on temperature. Dis

charge sensor readings should be between 1500

and 4500 ohms. See Fig. 22.

THERMOSTAT/TRANSMITTER (Fig. 16)

1. Set meter to 20 VDC scale.

2. Check for power to thermostat. Connect negative

(-) lead to terminal 1 and positive (+) lead to

terminal 2. Meter should read 20 VDC.

3. Connect the negative (-) lead to terminal 1 and

the positive (+) lead to terminal 4.

4. Slowly move the cooling lever below room tem

perature to simulate a call for cooling. Meter

16

Page 17

reading should gradually increase to about

16 VDC. (See Fig. 23.)

5. Move the cooling lever above room temperature.

Meter reading should drop to less than 2 VDC.

6. Remove the (+) meter lead from terminal 4 and

connect it to terminal 5.

7. Slowly move the heating lever above room tem

perature to simulate a call for heating. Meter

5000

4800

4600

4400

4200

4000

3800

3600

3400

3200

3000

2800

2600

2400

2200

2000

1800

1600

1400

1200

1000

800

600

400

200

N

L

____

\

^30 OOnAT 77F( >50

60 65 70 75 80 85 90 95 100

(16) (18) (21) (24) (27) (29) (32) (35) (38)

TEMPERATURE DEGREES F (DEGREES C)

Fig. 22 — Resistance Range of

the Discharge Sensor

'

reading should gradually increase to about

16 VDC. (See Fig. 23.)

8. Move the heating lever below room temperature.

The meter reading should drop to less than

2 VDC.

ECONOMIZER (Motor Operation) — Check to

see 115 V is at the economizer motor. Remove wire

from the W terminal on damper motor. Dampers

should go fully open.

Short between R-W on motorterminals. Dampers

should go fully closed.

Logic Panel Economizer Signal

1. Disconnect terminal W on logic panel.

2. Connect meter (2.5 VDC scale) with negative (-)

lead to R and the positive (+) lead to W.

3. Set thermostat for a call for cooling. Meter

reading should rise to 1.5 VDC. If thermostat

was already calling for cooling, reading will be

1.5 V when meter is connected.

4. Turn thermostat up so that no cooling is called

for. Voltage should fall from 1.5 VDC to 0.

Conduct the above test with air temperature at

the discharge sensor (located at unit air dis

charge) above 62 F. If air is below 50 F, there will

be no voltage signal. If air is between 50 F and

62 F, voltage will be in the same proportions.

VOLTAGES NECESSARY TO ACTIVATE LOGIC PANEL

HEAT STAGE

1

2

Differential: 63 +

VOLT DC

4 63 1

5 88

07 volts

COOL STAGE

2

Tolerance: i 25 volts

Fig. 23 — Thermostat/Transmitter

Output Voltage Ramps

VOLT DC

5 00

5 88

Cleaning — Inspect unit interior at the beginning

of each heating and cooling season and during each

season as operating conditions require. Remove unit

top panel(s) and/ or side panels as required to expose

unit interior.

EVAPORATOR COILS — Clean with a stiff

brush, vacuum cleaner or compressed air.

CONDENSER COILS — Clean with a stiff brush

or vacuum cleaner. When cleaning with compressed

air or low-pressure water or steam, guard against

damaging compressor wiring and nearby controls.

Condenser fan motor(s) is drip-proof but not

waterproof.

CONDENSER SECTION DRAIN — Check that

area under coil is clear and drains freely.

CONDENSATE DRAIN — Check and clean

annually at start of cooling season. In winter, keep

drain and trap dry or protect against freeze-up.

FILTERS — Replace filters at start of each heating

and cooling season or as often as necessary during

each season, depending on operating conditions.

Refer to Table 1 for type and size of filter used.

Filter access panels are shown in Fig. 4. Return air

filter tracks will accept 2 layers of 1-in. thick filters

if 2-in. filters are not available. Do not install bag

filters in standard filter tracks. Do not install

17

Page 18

standard filters or 2-in. high-efficiency filters in bag

filter tracks.

OUTDOOR AIR INLET SCREEN(S) -- Clean

screens with steam or hot water and mild detergent.

Do not use throwaway filter in place of these

screens. Loosen fastening-bracket screws and slide

out screens.

Lubrication

COMPRESSORS — Each compressor is charged

with correct amount of oil at the factory. Oil level

should be between bottom and mid-level of sight

glass when compressor is warm. Refer to 06D or

06E Compressor Service Manual if additional infor

mation regarding compressor lubrication system

is required.

FAN SHAFT BEARINGS — Charge each grease

fitting with a suitable bearing grease at least once a

year. Do not overlubricate.

FAN MOTOR BEARINGS — No relubrication of

outdoor air fan motors is necessary for first 2 to 5

years of use, depending on operating conditions.

Annually thereafter, open, clean and repack each

bearing with a suitable bearing grease.

Indoor air fan motor bearings should be cleaned

and repacked with a suitable bearing grease

annually after initial unit installation.

Power Exhaust Air Fan Adjustment (if fitted) —

Adjust belt tension so that 1/8-in. deflection at 5-to

8-pounds pressure between pulley centers can be

obtained. To change tension, loosen motor mount

ing bolts, reposition motor and tighten mounting

bolts. Tighten locknut and bolt under motor

mounting plate to secure in fixed position.

Outdoor (Condenser) Air Fan Adjustment

(Fig. 24) — Shut off unit power supply. Remove fan

guard and loosen fan hub setscrews. Adjust fan

height using a straight edge laid across venturi.

Tighten setscrews and replace rubber hubcap to

prevent hub from rusting to motor shaft. Fill hub

‘recess with permagum if hub has no rubber hubcap.

Damper Vent Position Setting

1. On constant volume units, adjust thermostat or

transmitter so there is no call for cooling. On

variable volume units, adjust set point knob on

microprocessor so there is no call for cooling.

The economizer dampers go to minimum

position.

2. Remove cap from vent adjustment screw on top

of damper motor terminal box cover.

3. Turn adjustment screw slowly until dampers

assume desired vent position. Do not manually

operate damper motor. Damage to motor will

result.

POWER FAILURE — Dampers have a spring re

turn. In the event of a loss of power, dampers close

until power is restored. Do not manually operate

damper motor. Damage to motor will result.

Fig. 24 — Outdoor Air Fan Adjustment

Refrigerant Charge — Amount of refrigerant

charge is shown on unit nameplate and in Table 1.

When charging refrigerant system, refer to Carrier

Standard Service Techniques Manual, Chapter 1,

Refrigerants. When adding a complete charge,

evacuate the system using standard evacuating pro

cedures and weigh in specified amount of refrig

erant. A charging chart (Fig. 25, 26, and 27) is pro

vided on unit control box door above compressor

and may be used (use of sight glass not required).

When using refrigerant liquid line sight glass to

charge system:

1. Install a jumper on the low-pressure switch if

required.

2. Operate unit with restricted condenser airflow

to achieve an operating discharge pressure of

about 375 psig.

3. Slowly add refrigerant until sight glass clears.

4. Remove jumper from low-pressure switch and

remove condenser air restriction.

Indoor Air Fan Adjustment — Fixed fan speeds

are set as shown in Table 1. If other than available

fan speeds are required, select field-supplied motor

or pulleys, using data from Tables 5 and 6, and

Fig. 28 and 29.

PULLEY REMOVAL — Pulleys are of the fixed

type and have taper-lock bushings. To remove, shut

off unit power. Loosen fan motor mounting plate

and remove belt. Relocate taper-lock bushing bolts

in removal holes to loosen bushing. Remove pulley

from shaft.

After reinstalling pulley and belt, check pulley

alignment and belt tension as described below.

PULLEY ALIGNMENT — Loosen fan shaft pulley

bushing and slide pulley along shaft. Make angular

adjustment by loosening motor mounting plate and

repositioning it as required.

BELT TENSION — Adjust belt tension by moving

motor back until only a slight bow appears in the

belts on the slack side of the drive while running

under full load. Secure motor. Recheck belt tension

after 24 hours of operation, adjust as necessary.

18

Page 19

Page 20

COMPRESSOR SUCTION PRESSURE

Fig. 27 — Charging Chart; 50DL064, System 1 and System 2

Table 5 — Indoor Air Fan Pulley Data

UNIT

50DL

MOTOR

FAN

PULLEY

RPM

No Grooves - Type - In.

i 991Ì3-3V-6.0 ! 3-3V-10.6 ! 3-3V-750 I3-3V-770

044 ! 1093 Ì4-3V-50 i 4-3V- 8.0 l’4-3V.710j 4-3yj^710

! 1039 Ì5-3V-4.75Ì 5-3V- 8.0 Ì5-3V-710 Ì

054 ^

1093 i s-3V-5.0 ! 5-3V- 8.0I5-3V-710

FAN

PULLEY

SINGLE

SPEED

BELT

NO.-SIZE

-------------------

0 Ì4-3V-710

TWO-

SPEED

BELT

NO - SIZE

mmmm

825 4 -3V- 5 6

991 4 -3V- 6 0

5-3V-475 5-3V- 80

1039

4 - 3V- 6 5 4-3V-106

1073

1093

064

5 -3V - 5 0

1159 5-3V-5.3 5-3V- 8.0

■ •iSSSewH

4 - 3V - 10 6 4-3V-750

4-3V-106 4 - 3V - 750

5-3V- 80

5-3V-710 5-3V-710

4 - 3V - 750

5-3V-710

5-3V-710 5 • 3V - 720

WW«?KSS¥Sw!

Shaded values indicate standard or optional pulley

available as shown in Physical Data table All other

are field supplied

•Three belts are required. 4 may be used if desired

tRemove one belt

20

4 - 3V- 750

4 - 3V - 770

4 - 3V - 770

5 • 3V - 720

combinations

combinations

Page 21

Table 6 — Indoor Air Fan Data

UNIT

50DL

054,

064

CFM

8,000 467 1 22 546 1 61 628

9,000 508 1 65 575

10,000

11,000

12,000 642 3 60 688 4 00 738 4 48 791 5 07 847 5 78 902

13,000 689 4 52 730 4 93

044

14,000

15,000 783 6 79 818 7 24 855 7 74

16,000 831 8 18

17,000 879

18,000 927 11 52 956

19.000

20.000

10,000

11,000 519 1 90 601 2 30 679 2 84 750

12,000 554

13,000 590 3 04

14,000

15,000

1 6,000

17,000

18,000 780 7 83 820 8 09

19,000

20,000 859 10 69

21,000

22,000 938

23,000 978 16 18

24,000 1018

0.20

Rpm Bhp Rpm

552

2 18 609

596

2 83 648

736

5 57

9 75 910 10 24 941

976

13 48

15 67

1024

487

1 47 577 1 89 659 2 40 733

2 42

627 3 76 684

664 4 59 716 4 87 775 5 34

703 5 54 750

741 6 62 785 6 88

819 9 19 857 9 45

12 35 932 12 62 967

898

14 18

18 36 1047 18 64 1076

0 40

Bhp

2 02 649 2 54

2 56 674 3 06

3.21 704 3 70

774

6 00

864

8 65 898 9 17 933 9 74 971

12 03

14 02

1003

16 23

1050

626 2 77 702 3 34

654

3 35

4 05

5 81

894

10 95

970 14 45 1003 14 78

16 45 1040

1008

0.60 0.80

Rpm

775

814

986 12 58 1016

1031

1076

724

749

803

833 7 28 886

865

898 9 81 943

932

EXTERNAL STATIC PRESSURE (in. wg)

Bhp

Rpm Bhp Rpm Bhp

2 12 705

5 41

6 49

10 78

14 59

16 82

3 92

4 58 813

6 24 860

8 47 914

11 30

12 96

16 78 1073

18 97

2 66 774

721

3 14 789 3 75 852

741

3 67

764

4 32

822

5 98 873

857 7 06

8 31

894

974 11 36

1059

1103

770 3 95

791 4 57 852

836 6 02

973 11 77

1005

1039 15 21

1108

1008

13 18 1048 13 83

15 21

1089

17 45

1131

2 99 802

3 42 817

5 25

6 90

7 88

9 01

10 31

1018 1241 1064

13 40 1047

1077

17 20

1109 17 72

19 38 1141

806

825 5 01 883 5 75

902 7 72

935 8 96

833 4 62

873 5 96

894 6 77

917 7 66

940

965 9 77

991 11 00

1

00

3 24

4 35 867

6 68 924 7 46

10 38

12 00 1044

15 86

18 12

3 60

4 09 879 4 76 935

5 23

8 66 993

13 99

15 76

19 88 1177

1.20 1.

Rpm Bhp

839 3 85

949

978

11 11 1050

1009

12 72 1081 13 51

14 54

1081

1119

16 58

18 84

1159

863 4 21 922

895

910 5 97 967 6 77

928 6 69 982

949

970

1016 10 62

1039 11 86

13 24

14 76 1134

1090

16 47

1118

1146 18 38

20 50 1214 21 26

40

Rpm Bhp

900 4 47

4 40 911

5 03 924

6 54

8 51

9 70 1022

5 35

7 52

8 47

9 49 1042

5 08 967

5 73

939

6 50

956 7 35

975

8 28 1025

997

9 35 1045

10 57 1067

11 93

1115 15 31 1150 16 17

1151

17 35

19 61

1189

4 86 977 5 58

5 42

952

6 08 1003 6 79

7 49

1000 8 32 1051 9 18

1021

9 27 1069 10 12

10 35 1089 11.21 1134

1064

11 51 1110 12 42

1087

12 78

1110 14 17

15 70

17 35

1159

1186

19.20 1226 20 20 1266 21 27

1.

60

Rpm Bhp

956

5 09

5 77

978

6 48

992

7 26

1008

8 17

9 15 1074^

10 23

11 47

12 86 1134

1092

1119 14 40

1183 18 19

6 11

989

1020 7 57

1035 8 35

1132

13 74

1155 15 14

1178 16 69

1201 18 37

1252 22 19

1.80

Rpm Bhp

1010 5 72

1020 6 46

1031

7 24

1043 8.06

1057

8 99

10 04

1091

11 17

1111

12 40

13 82

1159

15 40

1186

17 12

1217

19 10

1030

6 27

1041

6 88

1054

7 54

1069

8 33

9 21

1085

1100 10 11

1116 11 05

12 11

1155

13 33

1176

14 69

1197 16 16

1220 17 72

1243 19 42

1290 23 28

UNIT

50DL

Bhp — Brake horsepower

Rpm — Revolutions per minute

CFM 2.00 2.20 2.40

Rpm Bhp Rpm Bhp Rpm Bhp

6 37 1110 7 04 1155

1061

8,000

1070 7 15

9,000

10,000

11,000

1 2,000

1 3,000

044

14,000

1 5,000

1 6,000

1 7,000

18,000

19.000

20.000

10,000

11,000 1090 7 67 1138

1 2,000

13,000

14,000

15,000 1148

16,000

054,

1 7,000 1178

064

18,000

19,000

20,000

21,000 1260

22,000 1283 20 51

23,000 1306

24,000 1329 24 39

1081 8 01 1128

1091 8 89 1139 9 73

1105 9 84 1150

1120 10 93

12 12

1137

1155 13 40 1198

1176 14 80

1198 1641 1238 17 45

1224 18 18 1261 19 25

1078 6 91 1125 7 63 1169

1102 8 33

1116 9 12

1132 10 05 1175

11 03 1193

1162 12 03 1208 13 01

13 09 1222

1197 14 29 1239

1218 15 65 1258

1239 17 17 1279 18 18

18 79 1300

22 38 1344 23 52

EXTERNAL STATIC PRESSURE (in. wg)

2.60

Rpm Bhp

7 87 1164

1118

8 78

10 72

1165

11 82 1208 12 76

1181 13 08 1223 14 04

14 42

1217 15 85 1257

8 43 1181

1149

9 18

1161 9 94 1206

10 88

11 94

14 13 1266

15 31 1281 16 40

16 66 1297 17 72

19 85 1338

1321 21 63 1359 22 74

1367 25 55 1403 26 75

NOTES 1 Fan performance has deductions for unit casing losses, wet coil and clean standard filters

7 69 1201

8 57

1173 9 54

1184

10 57

1195 11 63

1240 15 44

16 93 1297

1277

18 54

8 35 1210

9 12 1225

1194

10 05 1237

10 83 1249

1219 11 75

1234

12 81

1251

13 99 1291

15 17 1307

1317

19 23 1354

20 90 1375 22 01

24 69

1380

2 Fan motor bhp is based on minimum voltages and 80 F air access motor

3 Consult physical data and indoor air fan pulley data.for appropriate motor and pulleysizes with

corresponding rpm

4 For rpm's outside of published data, field-supplied drive may be required

8 38 1245

1209

9 33 1252

1218 10 34

1228 11 43

1238 12 55

1250

13 72

1264

15 00

1280

16 48

18 03

9 10

9 90 1266

10 87

11 76

1260 12 64

1275 13 72

14 95

16 22

1322

17 51

1337

18 85

20 33

1395

23 84

1416

25 85

1438

27 98

2.80

Rpm

Bhp

9 09

10 08

1260

11 13

1269 12 25

1280 13 46

1291

14 70

1253

9 89 1293

10 70 1303 11 50

1278 11 64

1290

12 70

1302

13 60 1342

1315 14 66

1329 15 87

1347

17 25

1362

18 61 1400 19 72

1376

20 02

1392

21 50

1410 23 14

1431

24 99

3 00

Rpm Bhp Rpm

1332

10 71

1318 12 45 1356

1330 13 60

1354 15 63

1368 16 86

1384

1415 21 19

1430

1446

1342

1369 14 45 1405

14 61

1380

1392

1405 17 87 1441 18 89

18 25 1419 19 24

1437

22 73

24 35

3.20 3.40

Bhp Rpm Bhp

1371

11 52

12 34 1380 13 22

13 32 1393 14 19

15 62

1418 16 60

16 66

1429 17 73

20 80

12 37

15 27

21

Page 22

о

о

ю

Ю'

K)

I

Оо

—о

zS

—СМ'

Og

ИЛм'

СЛ

СО

CÛO

0_-'

>—t)

h-O

<-■

со

N

N

о

—^

N

\

N

К

\

N

N

N

N

N

N.

N .

''

V

-V,

N,

N

N

N

N

о

N,

\

V.

2

s

.

s

V

N,

N,

s. Ч

V.

N ,

V

Ч

"N

s

N.

\. ;

N.

Ч

3

5

Ч

#

X

X

ч

s

Ч

ib-

S

Ч

VX

яг

¿.с

S

IL

1

J

12n

s.

S

ч

s

V

Ч

с

S

'S N_

ч

X

N

\

iv-

Ч

V

\ 1

!.,

_

V

s

го

S.

X

.5

ю

МАХ RPM“ МОО MIN RPM' 800 INCR RPM' 100 MIN НР = 2 МАХ НР= 25

I

CFMdOOO S) (STD AIR)

Fig. 28 — 50DL044 Indoor Air Fan Data

22

t

Page 23

N)

(Q

to

(O

OI

o

Q

rO

cn

0)

3

Q.

O

3

^

Q. —

O °

■b O

CO

0>

3

U

Q)

CO

—)

o

TOTAL STATIC PRESSURE IN WG

0

TOTAL STATIC PRESSURE IN WG *10

-3

>

::o

Page 24

For replacement items use Carrier Specified Parts

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

#

Book 1

Tab

1b

Form50DL-1SI New

Printed in U S A

288

6-83 PC 111 Catalog No 565-020

Loading...

Loading...