Page 1

50DF034

HEATING & COOLING

Installation, Start-Up and

Service Instructions

SAFETY CONSIDERATIONS

Installation and servicing of air conditioning

equipment can be hazardous due to system pressure and

electrical components. Only trained and qualified service

personnel should install, repair or service air conditioning

equipment.

Untrained personnel can perform basic maintenance

functions of cleaning coils and filters and replacing filters.

All other operations should be performed by trained

service personnel. When working on air conditioning

equipment, observe precautions in the literature, tags and

labels attached to the unit and other safety precautions

that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations.

Have fire extinguisher available for all brazing

operations.

Single-Package Cooling Units

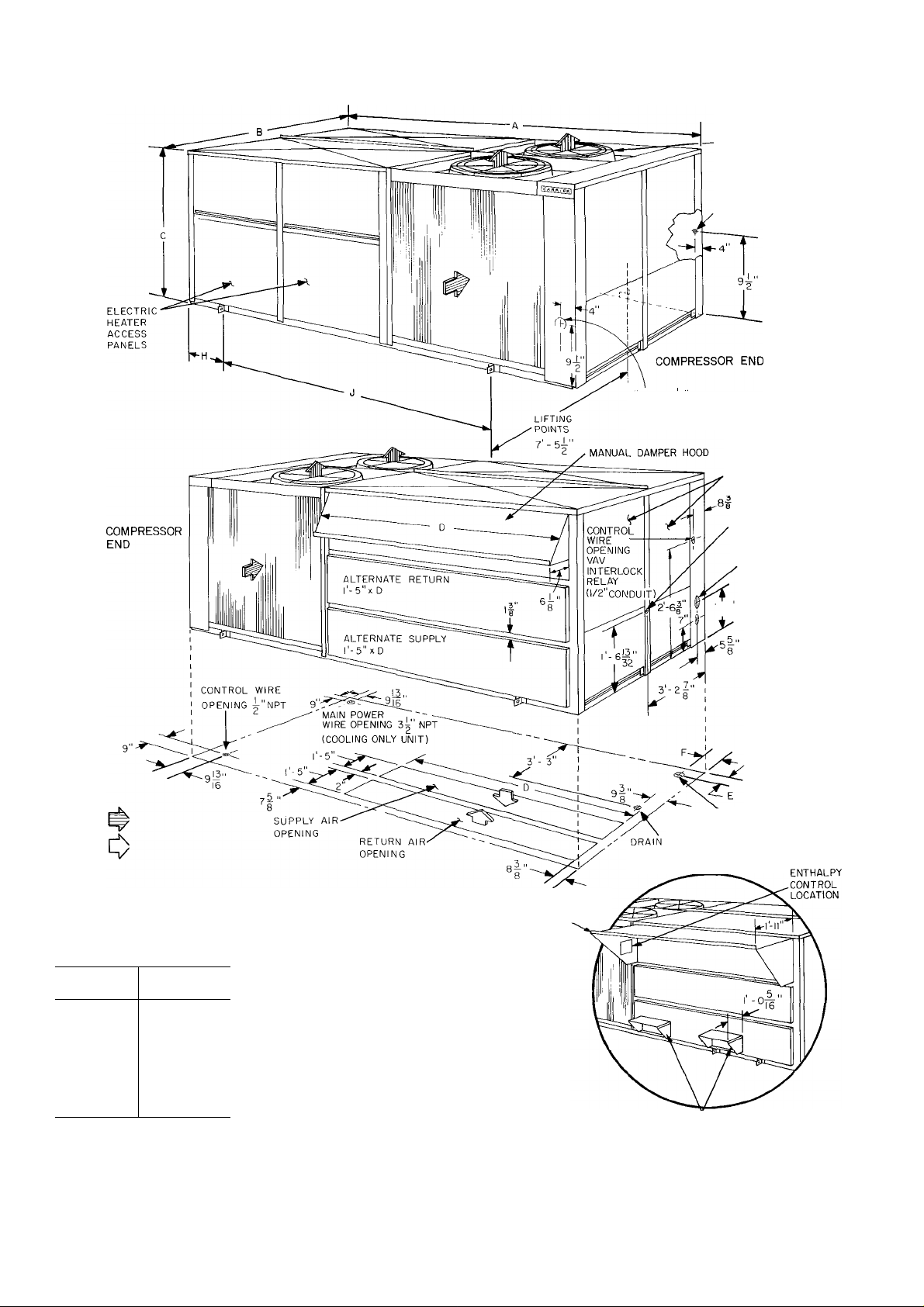

Alternate Unit Support Methods — Where the

preferred curb or slab mount cannot be used, support

unit with sleepers on perimeter, using curb support area.

However, if sleepers cannot be used, support long sides

of unit (dimension A, Fig. 4) with three 4-in. x 4-in. pads

equally spaced. U nit may sag if supported by corners only.

Positioning — Unit condenser air inlets and outlets

may be located in any compass direction since they are

not affected by wind. Provide clearances around and

above unit for airflow, safety and service access (Fig 4).

Do not install unit in an indoor location Do not locate

air inlets near exhaust vents or other sources of con

taminated air

Although unit is weatherproof, guard against water

from higher level runoff and overhangs.

A WARNING

Before performing service or maintenance operations

on unit, turn off main power switch to unit. Elec

trical shock could cause personal injury.

INSTALLATION

Rigging and Unit Placement — Inspect unit for

transportation damage. File claim with transportation

agency. Do not remove shipping skid until unit is ready

to be set in final location. Do not drop unit; keep upright.

Use spreader bars over unit to prevent sling or cable

damage. Rollers may be used to move unit across a roof.

Level by using unit frame as reference. See Fig. 1 for

additional information. Unit weight is shown in Table 1.

Units are designed to be hoisted only. However, units

with optional shipping skids may be moved with a fork

truck. Refer to Accessory Roof Curb Installation Instruc

tions for additional information as required.

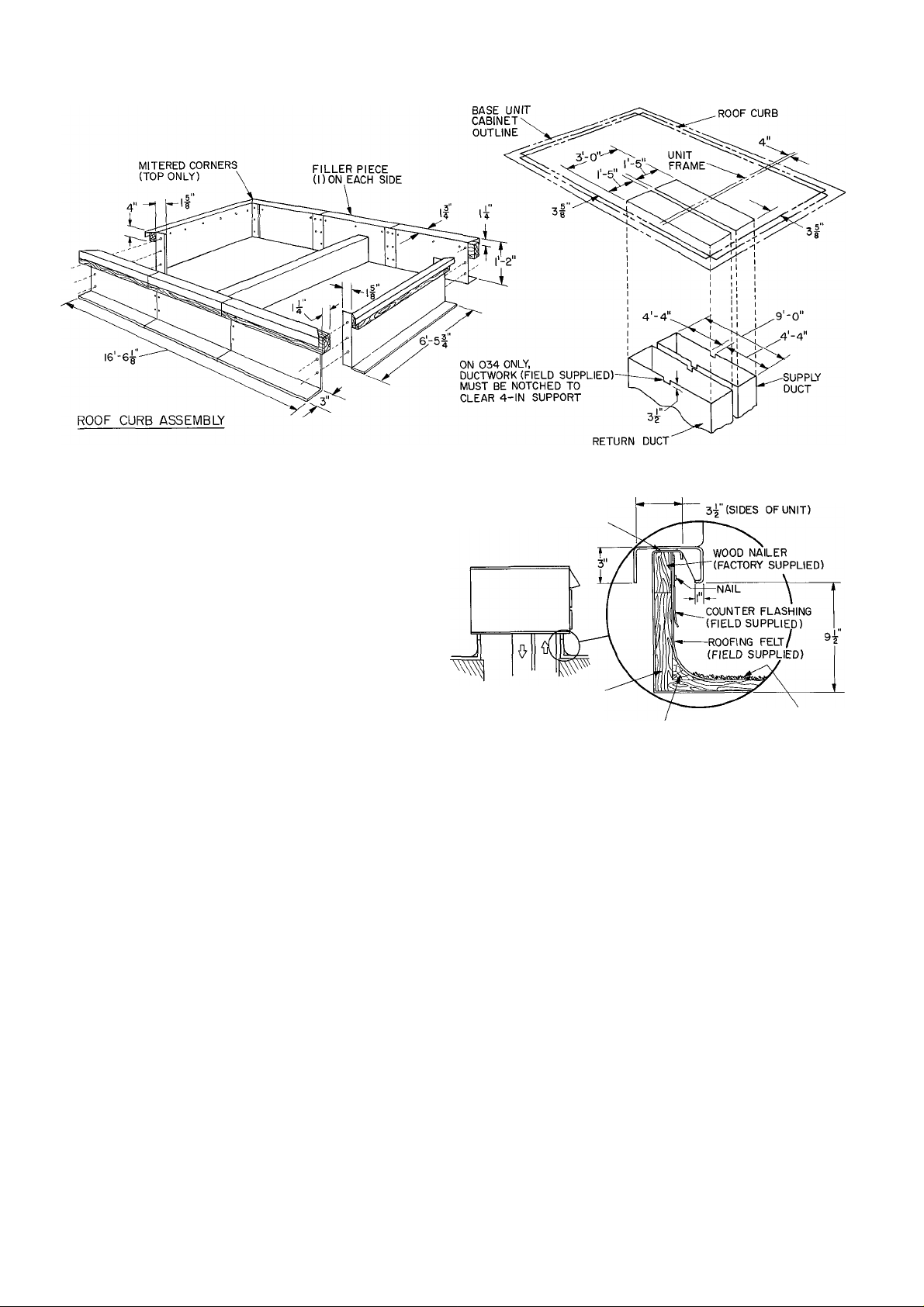

Roof Curb — Assemble and install as described in

instructions shipped with this accessory. Accessory roof

curb and information required to field fabricate a roof

curb of 2-in.

insulation, cant strips, roofing and flashing as required.

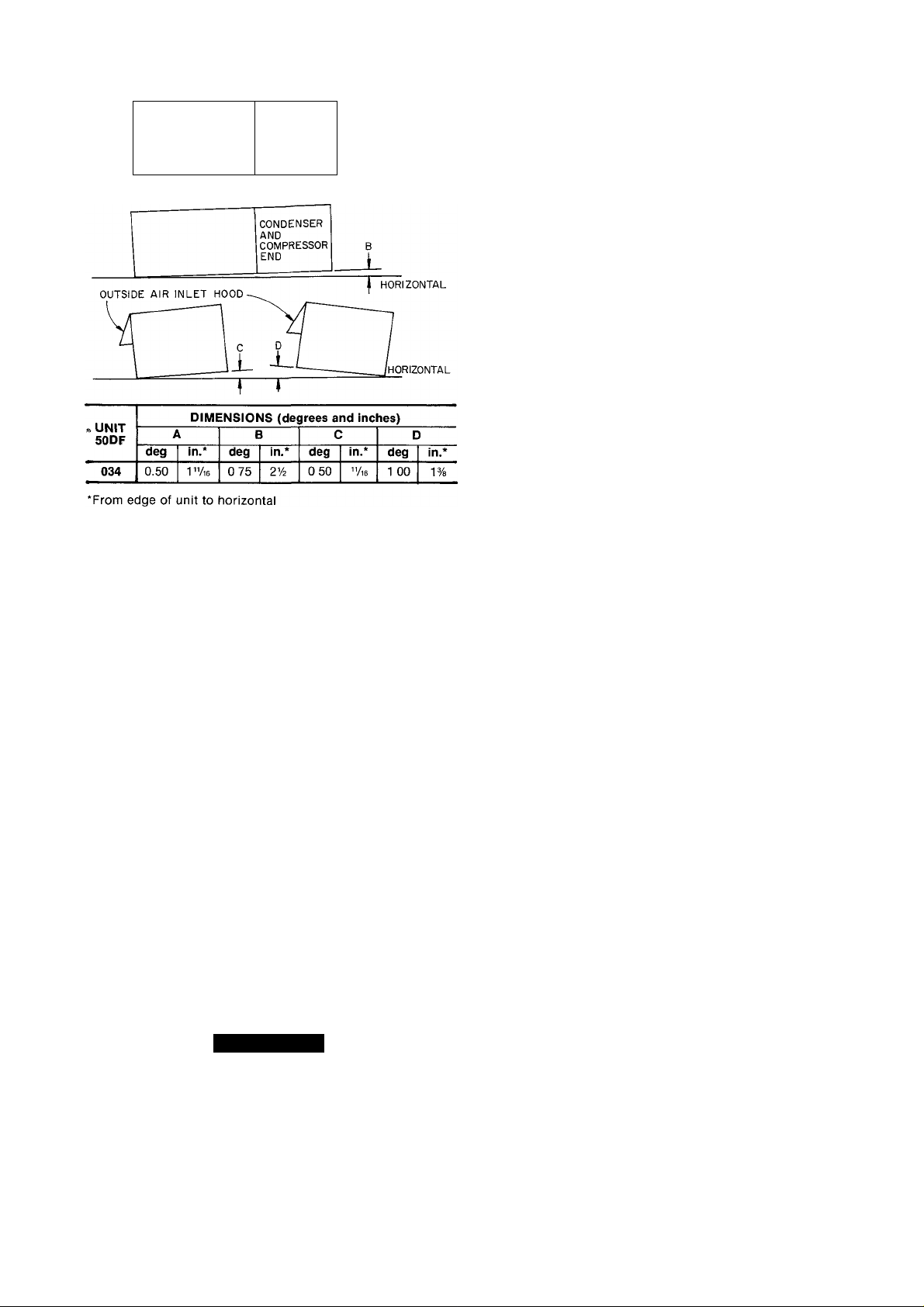

For unit drains to function properly, curb must be level

or within tolerances shown in Fig. 3.

Roof Mount — Check building codes for weight dis

tribution requirements Unit weight is shown in Table 1.

Slab Mount — Provide a level concrete slab that

extends beyond unit cabinet at least 6 inches. Make a slab

8 in. thick with 4 in. above grade. Use gravel apron in

front of condenser air inlet to prevent grass and foliage

from obstructing airflow.

X 14-in. planks is shown in Fig. 2. Install

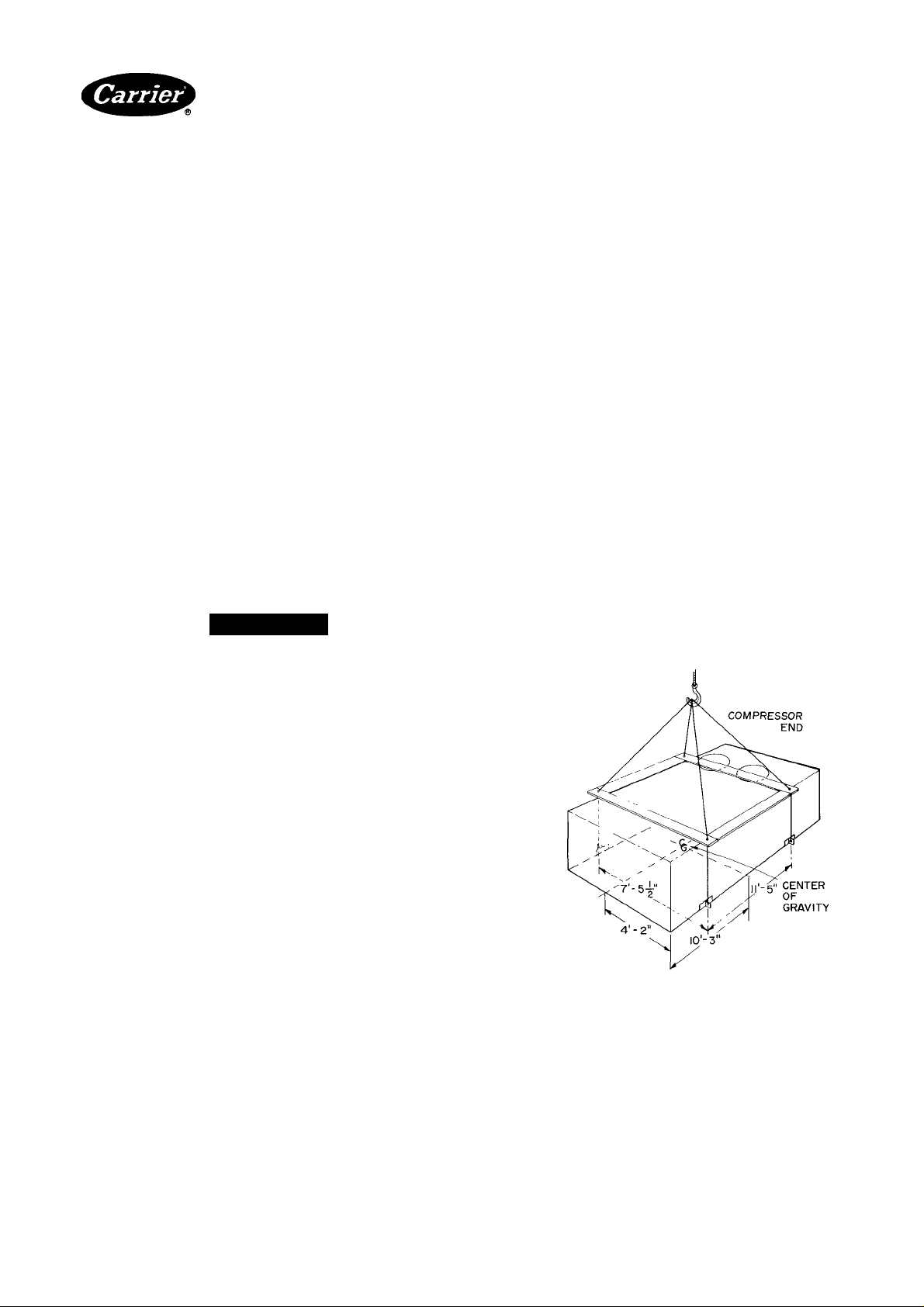

NOTES1 All unit panels must be In place when rigging.

2 Do not handle unit with fork trucks

3 Use 4 cables and four 2-by-4’s or 4-by-4's of dimensions

shown.

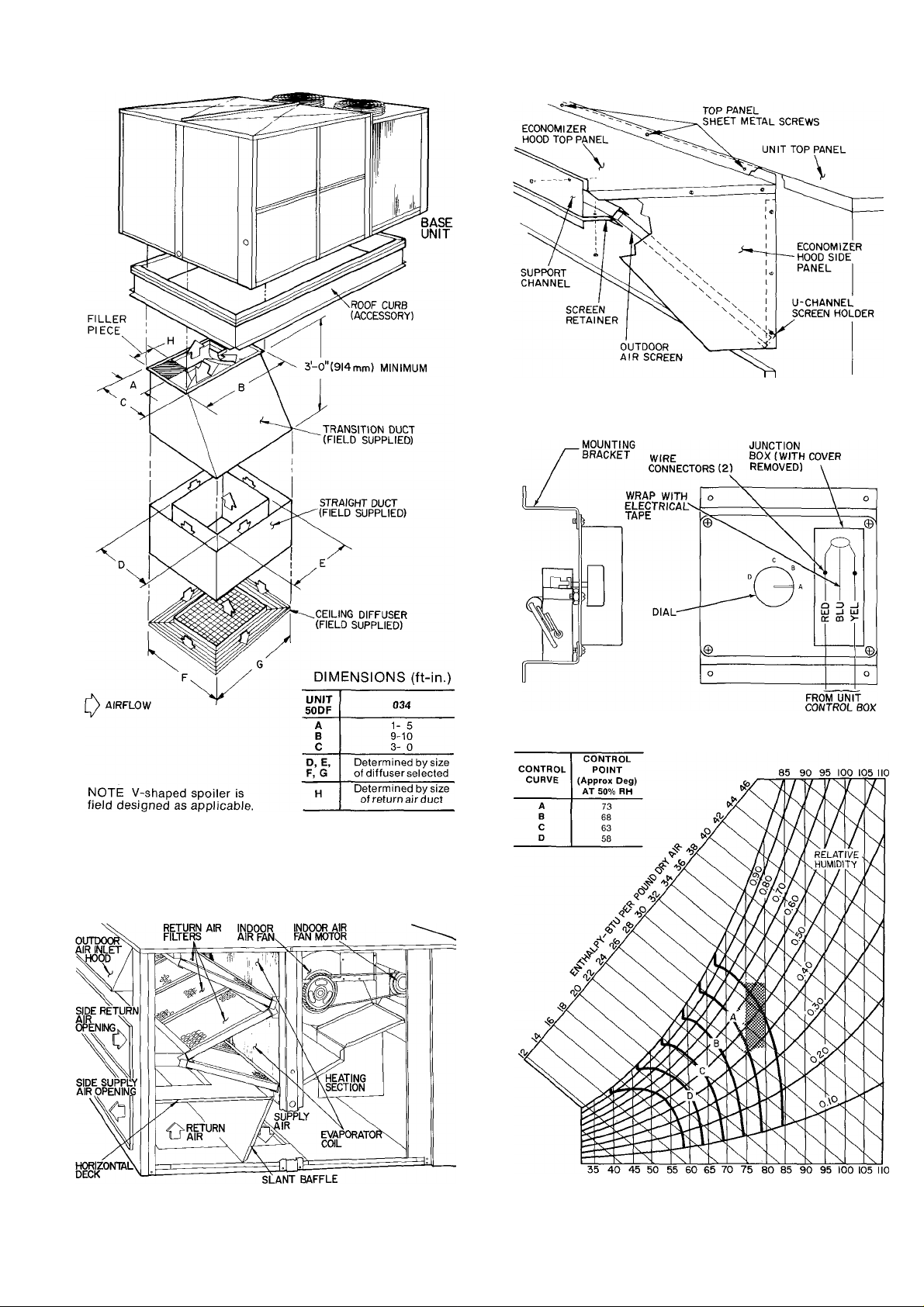

Fig. 1 — Rigging Details

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book|l PC111 Catalog No 565-032 PrintedinUSA Form 50DF-9SI Pgl 4-86 Replaces: 50DF-7SI

Tab lib

For replacement items use Carrier Specified Parts

Page 2

NOTE' Certified dimension drawings available upon request

Fig. 2 — Roof Curb Dimensions

GASKET

RIGID INSULATION

(FIELD SUPPLIED)

CANT STRIP

(FIELD SUPPLIED)

3-|"{ENDS OF UNIT)

ROOFING MATERIAL

(FIELD SUPPLIED)

Field-Fabricated Ductwork — Secure all ducts to

building structure. Use flexible duct connectors between

unit and ducts as required. Insulate and weatherproof

all external ductwork, joints and all roof openings with

flashing and mastic in accordance with applicable codes.

Insulate ducts passing through unconditioned spaces

and cover with a vapor barrier.

Maintain one-in. minimum clearance between supply

air duct and any combustible material for at least 3 ft of

duct run from unit.

Unit is shipped set up for through-the-bottom duct

connections. Ductwork openings are shown in Fig. 4.

Field-fabricated concentric ductwork may be connected

to units as shown in Fig. 5.

Modifications are required to convert unit for throughthe-side duct connections.

Do not use side duct connections on units with optional

power exhaust packages or accessory barometric relief

dampers.

To convert unit for through-the-side duct connection,

refer to Fig. 6 and perform the following procedure.

(Units without optional economizer);

1. Remove return air filter access panel.

2. Remove side air opening panels. Save sheet metal

screws.

3. Remove return air filters.

4. Remove slant baffle that separates bottom flow supply

and return air paths. Save screws.

5. Reinstall baffle on top of horizontal plenum deck

so that deck opening is covered. Face insulation side

of baffle down. Drill holes in horizontal plenum deck

using baffle holes as location guide Use sheet metal

screws removed in step 4 to secure baffle to deck.

6. Install side air opening panels in bottom air openings.

Face insulation side up Drill holes in unit basepan,

using panel holes as location guide. Use sheet metal

screws removed in step 2 to secure panels to basepan.

7. Reinstall return air filters. Be sure all relocated com

ponents are secure.

8. Open manual outdoor air inlet hood as described

below.

Manual Damper Hood Adjustment — Loosen

hood adjustment bolts, pull hood open to desired setting.

Tighten bolts. See Fig. 4.

Page 3

CONDENSER

AND

COMPRESSOR

END

Fig. 3 — Unit Leveling Tolerances

HORIZONTAL

10. Route the red and yellow wires through knockout

in side plate. Wrap end of blue wire with electrical

tape. Using wire connectors from envelope injunc

tion box, wire enthalpy control assembly as shown in

Fig. 8. Use strain reliefs from envelope on side plate

and junction box. Refer to Fig. 9 for Psychrometric

Chart for enthalpy control.

11. Install outdoor air screens.

12. Push retainer snugly against screens and tighten

screws.

Exhaust Air Hood Installation — The optional

power exhaust hood and damper assemblies and required

sheet metal screws are shipped in the compartment at

right of indoor air fan motor compartment. Using screws

provided, install a hood damper assembly over each

exhaust air opening as shown in Fig. 4. Power exhaust is

applied only to economizer units using bottom duct con

nections. Exhaust fan and motor assembly is factory

wired and adjusted. Refer to Service, Power Exhaust Air

Fan Adjustment if required.

Indoor Air Fans — The fan belt and pulleys are factory

installed and adjusted. If required, adjust as described

in Service, Indoor Air Fan Adjustment.

Economizer Section

ECONOMIZER HOOD INSTALLATION (Fig. 7) —

The economizer mechanism and all electrical connections

are factory installed and adjusted except as noted below.

Hood assembly, outdoor air inlet screens and required

hardware are shipped separately and must be field

installed.

Install economizer hood and enthalpy control as

follows:

1. Loosen unit top panel sheet metal screws above out

door air inlet opening.

2. Assemble hood top panel, side panels and support

channel.

3. Insert hood flange between unit top panel flange and

unit. Slots are provided in hood flange to clear sheet

metal screws. Tighten sheet metal screws. To insure

water tightness, apply RTV to edges as indicated

by shaded portions of Fig. 7.

4. Secure hood side panels to outdoor air opening

flanges, using screws provided.

5. Install hood support bracket(s) between U-channel

and support channel.

6. Install screen retainer on support channel, using

screws in the slots. Do not tighten.

7.

A CAUTION

Shut off main power to unit before installing

enthalpy control assembly.

8. Remove enthalpy control assembly from shipping

location on horizontal deck in return air filter

compartment.

9. Using 4 no. 10-1/2 screws from envelope in control

assembly junction box, mount enthalpy control

assembly to inside of economizer hood side panel

nearest condenser section (Fig. 4).

Condensate Drains — See Fig. 4 for drain locations.

Condensate drain is open to atmosphere and must be

trapped. Install a trapped drain line at connection to be

used. Trap must be at least 3 in. deep and made of flexible

material or be installed to prevent freeze-up.

Condensate drain pan under unit is fitted with a one-in.

FPT coupling. A gasket is shipped taped to this drain.

Install gasket in unit basepan opening or alternate open

ing on end of unit.

Field Power Supply — Unit is factory wired for

voltage shown on nameplate. The main power terminal

block is suitable for use with aluminum or copper wire.

See Fig. 10 and 11. Units have circuit breakers for

compressors, fan motors and control circuit. If required

by local codes, provide an additional disconnect switch.

If an external electrical source is used, unit must be

electrically grounded in accordanee with local codes, or

in the absence of local codes, with the National Electrical

Code, NFPA 70.

All field wiring must comply with National Electrical

Code and local requirements.

Install conduit connector in unit basepan or side panel

openings provided as shown in Fig. 4. Route power lines

through connector to terminal connections in control box

as shown in Fig. 10 and 11.

Affix crankcase heater sticker to unit disconnect

switch.

Voltage to compressor terminals during compressor

operation must be within voltage range indicated on unit

nameplate. Also, see Table 2. Phases must be balanced

within 2% Contact local power company for correction

of improper voltage or phase unbalance. Failure due to

operation of unit on improper line voltage or with exces

sive phase unbalance constitutes abuse and may cause

damage to unit electrical components.

Page 4

OUTDOOR AIR FANS

" (3)

ALTERNATE

CONTROL WIRE

OPENING

3 AND 4g- K 0

ALTERNATE FIELD-POWER WIRING

(COOLING ONLY UNIT )

INDOOR AIR FAN

AND FILTER

ACCESS PANELS

ALTERNATE

DRAIN 2|" KO d" MPT

L-2^" UNIT)

' CONDUIT

CONN INSIDE)

ALTERNATE

POWER WIRE

OPENING 3^“

(HEATING/COOLING

NPT

► OUTDOOR AIRFLOW

► INDOOR AIRFLOW

OPTIONAL

ECONOMIZER

AIR INTAKE HOOD

DSAM U"

^MPT CONN. INSIDE)

DIMENSIONS (ft-in :

UNIT

50DF

A

B

c

D

E 0-10yi6

F 0- 97a

G

H

J

Certified dimension drawings available on request

NOTES-

1. Allow 12 ft above unit, 8 ft on filter access panel end and 4 ft on remaining sides of unit for airflow and service clearance

2 For smaller clearances, contact manufacturer.

3 Refer to Roof Curb Dimensions for details of roof openings

034

17- 1

7- 3'/a

4-11

9- 0

4" NPT

2-10

11- 5

Fig. 4 Base Unit Dimensions

MAIN POWER WIRE

OPENING (G) (HEATING/

COOLING UNIT)

OPTIONAL

EXHAUST HOODS

(3)

V:

Page 5

Fig. 5 — Concentric Duct Details

Fig. 7 — Economizer Outdoor Air Inlet

Hood Assembly

Fig. 8 — Enthalpy Control Assembly

Fig. 6 — Manual Damper Unit Indoor Air Section

DRY BULB TEMPERATURE (APPROXIMATE)-FAHRENHEIT

Fig. 9 — Psychrometric Chart for Enthalpy Control

Page 6

MAIN POWER TERMINAL BLOCK IN UNIT CONTROL

BOX OR HEATER COMPARTMENT

FIELD POWER

SUPPLY

THERMOSTAT SUBBASE

NOTE. Thermostat subbase required

TB4

MAIN CONTROL BOX

Fig. 10 — Field Wiring Connections — Without Energy Management Accessory

L3

L2

_i—

FIELD POWER

SUPPLY

TB9

LLI

NOTE Subbase not used

MAIN POWER TERMINAL

BLOCK IN UNIT CONTROL

LI

BOX OR HEATER

COMPARTMENT

II5V 60 Hz

230 V 50 Hz

(FIELD SUPPLIED)

I I

I "-1

LL2

Fig. 11 — Field Wiring Connections — With Energy Management Accessory

±

MAIN UNIT CONTROL BOX

2

1

- 1- *

THERMOSTAT

NIGHT SETBACK BOX (LOCATED IN BASE UNIT)

1 2 3

1

1

3

*

4 5

4 5 6

REMOTE BOX

____1

Ц—* * Ц—^ — —----------------------------------------------------

___

9

8

7

1

1

1

1

6 7 8 9 10 TB4

10

TB7

10

TB6

10

Page 7

Table 1 — Physical Data

UNIT50DF

OPERATING WEIGHT (lb)

Base Unit (includes heaters)

Base Unit with Economizer

COMPRESSOR

Quantity...Model

Oil (3GS orBIUots)

REFRIGERANT CHARGE (R-22)

System 1...System 2 (lb)

OUTDOOR AIR FANS

Number...Hp

Frame (NEMA)

Rom

INDOOR AIR FANS*

Single-Speed Motor Hp...Shaft Diameter (in.)

1750 Rpm

Single-Speed Motor Frame Size

Motor Pulley Pitch Diameter (in.) A...B

Fan Pulley Pitch Diameter (in.)

Fan Speed (rpm) A...B

Fan Shaft Diameter (in.)

Maximum Allowable Fan Speed (rpm)

ELECTRIC HEATERS

HIGH-PRESSURE SWITCH

Cutout (psig)

Cut-in (psig)

LOW-PRESSURE SWiTCH

Cutout (psig)

Cut-in (psig)

INDOOR AIR FILTERS (in.)

Standard; Quantity...Size (in.)

Throwaway

Optional; Bag Type, 12 in.

AIR INLET SCREENS

Economizer; Quantity...Size (in.)

034

4400

Serviceable, Reciprocating Hermetic

4600

2...06DA

10 (ea)

29.0...29.0

Direct Drive, Propeller

3 .1

56

1050

Fixed-Speed Centrifugal

15 .

254T

53 56

8.0

1159 1225

1 "/i6

1300

Refer to Electrical Data table

400 ±5

300 ± 5

27 ±4

67 ±7

2

9 20 X 25

12 16x25

5 12x24

5...24 X 24

5. 20 X 25

‘Pulley A is installed in unit, pulley B is shipped with unit

790

Page 8

Table 2 — Electrical Data

NOMINAL

VOLTS/PH/HZ

VOLTAGE

RANGE

Min

208-230/3/60 187 254 63 5

460/3/60

414 508

575/3/60 518 660 22

Compr — Compressor

FLA — Full Load Amps

Hp — Nominal Horsepower

kW — Kilowatts

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

COMPR

Max RLA

27 5 120

NO. 1

LRA RLA LRA

266

63 5 266

27 5 120 3

96 22 96

COMPR

NO. 2

OUTDOOR

FAN MTR

FLA Hp

Oly

7 6

3

(ea)

3 3

(ea)

2 7

3

(ea)

*Fuse only

NOTES:

1 All outdoor fan motors are single-phase motors

2 All heaters are 3-phase assemblies

3 Circuit no. 2 is provided as indicated; total unit MCA is the sum of circuit

no 1 MCA and circuit no 2 MCA

4 Unbalanced 3-Phase Supply Voltage— Never operate a motor where a

phase imbalance in supply voltage is greater than 2% Use the following

formula to determine the % voltage unbalance

% Voltage Imbalance

max voltage deviation from average voltage

= 100 X ■

average voltage

INDOOR

FAN MTR

FLA

15 46 0

15

46 0 3 11

15

46 0

15

46 0

15

46 0

15

46 0

15

21 0

15

21 0

15

21 0

15

21 0

15

21 0

15

21.0 3

15

15

EXHAUST

FAN MTR

FLA kW FLA MCA

Hp

_ _ _ _

45-54 9

3 11

— —

3

45-54 9

75-91 5

11

75-91 5

_ _ _

3 4 8

3 4 8

— —

3

-

4.8

3 9

54 9

54 9

91 5

91.5

HEATERS

— —

125-138

125-138

208-230 212-212 250-250 156-173

208-230 223-223 250-250 156-173

214-230

223-230

_

— —

—

69

69

115 170

115

-

POWER SUPPLY*

Circuit 1 Circuit 2

MOCP

212 250

223 250

300-300

300-300

93 110

98 125

113

113

170 175

75

79

150

150

175

100

MCA

90

Example: Supply voltage is 460-3-60

AB = 452 volts

BC = 464 volts

AC = 455 volts

Average Voltage

452 + 464 + 455

3

1371

457

3

Determine maximum deviation from average voltage:

(AB) 457 - 452 = 5 volts

(BC) 464 - 457 = 7 volts

(AC) 457 - 455 = 2 volts

Maximum deviation is 7 volts

Determine % voltage imbalance:

% Voltage Imbalance = 100 x= 1 53%

This amount of phase imbalance is satisfactory as it is below the maxi

mum allowable 2%

MOCP

_

—

— —

175-200

175-200

— —

— —

__ __

— —

-

—

—

—

790

Í.

K

Page 9

f

Field Control Wiring

STANDARD UNIT (WITHOUT ENERGY MANAGE

MENT ACCESSORY) — Install a Carrier-approved

accessory electronic thermostat on a subbase (or a trans

mitter on subbase if remote sensor is used) per installation

instructions included with the accessory. Note that the

subbase must be used on constant volume units without

night setback. Locate thermostat, or remote sensor, if

used, in the conditioned space where it will sense average

temperature.

Route thermostat cable or equivalent single leads of

no 18 AWG colored wire from subbase terminals

through connector on unit to low-voltage connections in

main control box as shown on unit wiring diagram and

in Fig. 10.

UNITS WITH ENERGY MANAGEMENT ACCES

SORY — In addition to the standard control box, units

with energy management accessory are also equipped

with a remote box and a night setback box. The remote

box contains a 7-day time clock, a bypass switch that can

manually bypass the time clock for up to 5 hours, 6 indi

cator lights and 2 terminal blocks for field wiring con

nections. Mount this box remote from the unit in an

indoor or weathertight space. The night setback box

contains a terminal block for field wiring conneetions, a

morning warm-up thermostat and the setback/setup

module. The night setback box remains in the unit. Ship

ping locations of remote box and permanent location

of night setback box are shown in Fig. 12.

1. Remove remote box and mount in a restricted access

area (indoors or in a weathertight space).

2. Run separate 115-volt, 60-Hz (230-volt, 50-Hz) power

to the remote box per Fig. 11. Use no. 14 AWG wire

or larger and a proper field-supplied electrical

connector.

3. Install a Carrier-approved accessory electronic

thermostat or transmitter if remote sensor is used

(subbase not required) according to the installation

instructions included with the accessory. Note that

the subbase is not used on units with the energy

management accessory. Locate the thermostat or

rernote sensor, if used, in the conditioned space where

it will sense average temperature.

Route thermostat cable or equivalent single leads of

no. 18 AWG colored wire from thermostat or trans

mitter terminals through connector on unit to lowvoltage (TB4) connections in main control box as

shown on unit label wiring diagram and in Fig. 11.

4. Run 24-volt wires between the remote box and night

setback box per Fig. 11. Use no 18 AWG wire for

lengths up to 1000 feet. Local codes may dictate use

of conduit for low voltage. Knockouts are provided in

the night setback box and in the fan deck separating

heating section from section containing the night

setback box (Fig. 12). A watertight connector is in

stalled in side of unit. Two rubber grommets are taped

inside the night setback box. Use grommets in knock

outs in fan deck and night setback box.

REMOTE CONTROL

Fig. 12 — Shipping Locations — Remote Box

Return Air Filters — Check that return air filters are

of the correct type and size and installed in unit filter

racks. Filter data is shown in Table 1 Do not operate

unit without return air filters

Outdoor Air Inlet Screens — Outdoor air inlet

screens must be in place before operating unit.

Compressor(s) — Loosen compressor holddown

bolts until sidewise movement of the washer under each

holddown bolt head occurs Do not loosen completely

as bolts are self-locking and will maintain their

adjustment.

Open the compressor discharge and suction service

valves. Replace and tighten valve caps to prevent leaks.

Liquid Line Service Valve — Open the liquid line

service valve Replace and tighten valve cap to prevent

leaks.

Low Ambient Compressor Lockout(Fig. 13) —

All units are equipped with an adjustable low ambient

lockout thermostat to lock off the compressor(s) at low

outdoor air ambients. Thermostat is located in the main

control box. Setting will depend on specific installation

but should be approximately 55 F on constant volume

units.

Convenience Outlet — All units are equipped with

a 115-volt convenience outlet for handling small power

load or service light. See Fig. 13.

Page 10

CIRCUIT BREAKERS

MOVE SWITCH TO

POSITION FOR

DESIRED HEATING SETBACK

CONVENIENCE OUTLET LOW AMBIENT LOCKOUT

Fig. 13 — Control Box

THERMOSTAT

LOOIC PANEL

(A) HEATING SETBACK

Fig. 14

Accessory Setback/Setup Module (Partial)

Constant Volume Units

COOLING (WITH OR WITHOUT ENERGY

MANAGEMENT ACCESSORY)

1. Open compressor service valves. Make sure the crank

case heater has been on for at least 24 hours to remove

liquid refrigerant from compressor crankcase. Check

compressor oil level. Oil sight glass should be half full.

2. Be sure that the liquid line service valve is open and

that high- and low-side refrigerant service ports are

closed as applicable.

3. On units equipped with the energy management acces

sory, move the COOL SETUP SELECT jumper wire

to the desired setting (5°, 8°, or 12°). If cooling is not

desired during the unoccupied periods, move jumper

wire from COOL SETUP to COOL LOCKOUT. See

Fig 14.

4. Turn on power to unit. On standard units, set the

subbase selector switch to COOL. On units with the

energy management accessory, set the 7-day time clock

(B)COOLING SETUP OR LOCKOUT

START-UP

as required. Refer to 7-Day Time Clock Adjustment.

Check that compressor low ambient lockout contacts

and morning warm-up contacts (on units with energy

management accessory) are closed.

5. Remove cover from thermostat (or from transmitter

if a remote sensor is used); note the red diagnostic

light-emitting diodes (LED’s). See Fig. 15.

6. To call for cooling, move the thermostat or transmitter

cooling set point (blue lever) below room temperature.

Cooling LED on the right-hand side of thermostat or

transmitter should begin to glow. Check the cooling

effect at supply duct outlets If the mechanical cooling

does not come on, see Service, Electronic Component

Checkout.

7. Move the thermostat or transmitter cooling set point

above room temperature. The cooling equipment

should cycle off and the cooling LED intensity should

decrease to a faint glow or go off completely. The

economizer should move to minimum position.

10

Page 11

r

HEATING

LEVER(RED)

COOLING

LEVER (BLUE)

THERMOSTAT

CAPTIVE TERMINAL MOUNTING SCREWS

THERMOSTAT/TRANSMITTER

Fig. 15 — Electronic Thermostat/Transmitter (without subbase)

(Which must be ordered as an accessory)

To Shut Off Unit— For standard units, set the subbase

selector switch to OFF or set the cooling temperature

selector lever above room temperature. For units with

energy management accessory, set the cooling tem

perature selector switch above room temperature.

Do not shut off unit circuit breakers except when unit

is serviced. Crankcase heater is energized onlv when unit

power is on.

HEATING (Electric Heat Units)

1. Turn on unit power; set circuit breakers at ON.

2. On units with energy management accessory, position

the HEAT SETBACK SELECT switch in the setback/setup module to the desired position (5°, 10°,

15°). See Fig 14

3. Move the thermostat or transmitter heating set point

(red lever) above room temperature The heating LED

on the left-hand side of thermostat or transmitter

should begin to glow. Electric heat should cycle on.

Check supply duct outlets for heat. If heating equip

ment does not cycle on, see Service, Electronic Com

ponent Checkout.

4. Move the heating set point below room temperature.

The heating equipment should cycle off and the heating

LED intensity should decrease to a faint glow or go

off completely.

5. Return the heating and cooling set points to desired

settings and lock in place. On standard units, return

subbase switch to desired position. On units with

energy management accessory, an adjustable morning

warm-up thermostat is used to hold dampers closed

until return air reaches the setting on the thermostat

located in the night setback box.

To Shut Off Unit — Standard units, set the subbase

selector switch to OFF or set the heating temperature

selector lever below room temperature. For units with

energy management accessory, set the heating tempera

ture selector switch below room temperature

AUTOMATIC CHANGEOVER — Standard units

automatically switch from heating to cooling mode when

the subbase selector switch is set at AUTO, and the

temperature of the conditioned space rises to the cooling

selector lever setting When the temperature of con

ditioned space falls to heating selector lever setting, the

unit automatically changes from cooling mode to heat

ing mode.

The thermostat and unit are so connected that cooling

and heating systems do not operate simultaneously.

On units with energy management accessory, with

dual set point thermostat or transmitter, changeover is

also automatic. There is a minimum 3 F deadband

between the heating and cooling set points

ECONOMIZER OPERATION — If unit is equipped

with modulating outdoor air control (economizer), set

enthalpy control (Fig. 4 and 8) at “A.” Unit capability

to integrate economizer with mechanical cooling allows

for a higher changeover point than conventional econo

mizer systems. Because of this, outside air is desired

whenever its enthalpy (total heat content) is below return

air enthalpy. Typical return air conditions, shaded

portion of Fig. 9, indicate that setting “A” should be

used for maximum operating economy.

OPERATING SEQUENCE WITH ECONOMIZER

(without energy management accessory) using thermo

stat with subbase.

Cooling — System switch set at AUTO, or COOL, fan

switch at ON or AUTO, (indoor air fan runs inter

mittently). Thermostat set at desired setting.

When thermostat calls for cooling and outdoor air

enthalpy is below setting of enthalpy controller, the

economizer modulates open. (If outdoor air enthalpy is

II

Page 12

above enthalpy set point, the outdoor air dampers remain

at minimum position.) Economizer acts as the first stage

of cooling, providing “free cooling” with outside air. If

outside air alone cannot satisfy the cooling requirements

of conditioned space, economizer cooling is integrated

with mechanical cooling.

Compressor(s), working simultaneously with econo

mizer, will come on in stages to meet the cooling load.

As the conditioned space temperature approaches the

thermostat’s cooling set point, stages cycle off, last stage

first. After all stages of mechanical cooling are off, econo

mizer modulates to minimum position.

During the cooling cycle, a discharge air sensor senses

discharge air temperature. If discharge air temperature

drops below 62 F, economizer starts to modulate toward

minimum position. At 50 F discharge temperature, the

economizer will be at minimum position.

Heating — System switch set at HEAT or AUTO., fan

switch at ON or AUTO., thermostatset at desired setting.

When thermostat calls for heating, one or 2 stages of heat

energize to satisfy heating demand.

As space temperature approaches the heating tem

perature set point, heating stages cycle off.

During heating, economizer is limited to the minimum

position to provide outdoor air for ventilation

requirements.

OPERATING SEQUENCE WITH ECONOMIZER

AND ENERGY MANAGEMENT ACCESSORY

(using electronic thermostat or transmitter).

Clock in remote control box switches controls to

OCCUPIED mode. Indoor air fan runs continually while

in OCCUPIED mode

If return air temperature is below the adjustable setting

of morning warm-up thermostat, outdoor air dampers

remain closed.

When return air temperature goes above setting of

morning warm-up thermostat, economizer goes to adjust

able minimum position.

When thermostat calls for cooling and outdoor air

enthalpy is below setting of enthalpy controller, econo

mizer modulates open. (If outdoor air enthalpy is above

enthalpy set point, economizer remains at minimum

position.) The economizer acts as the first stage of cool

ing, providing “free cooling” with outside air. If outside

air alone cannot satisfy cooling requirements of the

conditioned space, economizer cooling is integrated with

mechanical cooling.

Compressor(s), working simultaneously with econo

mizer, will come on in stages to meet the cooling load.

As the conditioned space temperature approaches the

thermostat’s cooling set point, stages cycle off, last stage

first. After all stages of mechanical cooling are off, econo

mizer modulates to minimum position.

During the cooling cycle, a discharge air sensor senses

discharge air temperature. If discharge air temperature

drops below 62 F, the economizer modulates toward

minimum position. At 50 F discharge temperature, the

economizer will be at minimum position.

At the end of the DAY (OCCUPIED) mode on the

clock, unit controls enter the NIGHT (UNOCCUPIED)

mode Economizer closes. Indoor air fan runs only on a

call for heating or cooling. Temperature controls go into

HEATING SETBACK, COOLING SETUP or COOL

ING SHUTDOWN mode.

HEATING SETBACK is field selectable at the unit

for 5°, 10°, or 15° below set point on room thermostat.

COOLING SETUP is field selectable at the unit for

5°, 8°, or 12° above set point on room thermostat.

During the UNOCCUPIED mode, unit continues to

use economizer cooling first and then integrates econo

mizer cooling with mechanical cooling to meet cooling

requirements.

A 5-hour bypass timer is located in the remote control

box to provide air conditioning during normally un

occupied hours

POWER EXHAUST OPERATION — Units have an

auxiliary switch located on the damper motor. This

switch is factory set to prevent the power exhaust fans

from operating when the economizer damper is less than

30% open.

If other than factory setting is desired, adjust as follows:

NOTE. Adjustment does not require running the motor

1. Motor must be in the fully closed position.

2. Referring to Fig. 16, take off “C” clip and drive

bracket. Remove screws at 4 corners of housing. Pull

off return spring housing.

STARTING POSITION

NOTE POSITION

OF RED DOT

CENTERLINE

Each adjustment mark repre

sents 10 degrees of motor ro

tation Use marks and center

of cam roller as adjustment

guide

Red dot will be to right of centerline if switch is properly adjusted

Fig. 17 — Adjusting Switch Make and Break Points

ADJUST CAMS

OPERATIONAL

Loosen operational cam ad

justment screw Rotate both

cams clockwise the number

of degrees motor must travel

before switch makes Tighten

screw.

12

Page 13

3. Remove spring on motor shaft.

4. Adjust switch as shown in Fig. 17.

5. After adjustment, replace spring on motor shaft and

reassemble return spring housing.

CAPACITY CONTROL, HEATING — Stages 1 and 2

of heaters are controlled by heating relays H R1 and H R2,

respectively. Using a suitable ammeter, check heater

current draw for heating assemblies or elements. When

checking second-stage heater operation, be sure heating

thermostat is set high enough to activate second-stage

heaters Also, check operation of outdoor air thermo

stats if additional staging is provided

TIME GUARD® CIRCUIT — Timer sequence for a

particular unit depends on unit and compressor arrange

ment. The Time Guard device provides a delay in com

pressor start-up after thermostat closes. On normal unit

start-up, outdoor air fans energize 15 seconds before the

compressor. If compressor/shutdown is due to satisfied

thermostat or automatic resetting of a safety device, the

compressor automatically restarts after a 5-minute

interval. If compressor shutdown is due to tripped over

loads, the circuit breakers must be manually reset before

compressor will start.

Timer (Time Guard) for second compressor has a 6minute interval to prevent compressors from starting

simultaneously.

Refer to unit label diagram for specific timer sequence.

CRANKCASE HEATER — Unit main power supply

must remain on to provide crankcase heater operation.

Crankcase heater in each compressor keeps oil free of

refrigerant while compressor is off.

HEAD PRESSURE CONTROL — Each unit has a fan

cycling thermostat to shut off outdoor fan motors at 55 F.

This permits unit to operate with correct condensing

temperatures down to 35 F outdoor air temperature.

SERVICE

Electronic Component Checkout

A CAUTION

Control circuit must be checked with system power

on. Disconnect power before checking wiring and use

care to avoid electrical shock and prevent equipment

damage.

____________________

The checkout procedures in this section will determine

whether-

1. The logic panel is controlling the heating and cooling

equipment properly.

2. System components are correctly wired to the logic

panel.

Prior to checking out control circuit, establish setting

on the low ambient lockout thermostat. Compressors

will not start below this setting (cooling mode only).

Recommended setting is approximately 50-55 F.

NOTE: To complete the electronic component checkout,

a volt-ohmmeter (Simpson 260 is recommended) is

required.

LOGIC PANEL (Fig. 18)

I. Check that 24 vac is supplied to logic panel Connect

meter to terminals TR.

2 Check thermostat supply voltage at STAT terminals

1 and 2. Reading should be 20 vdc.

Fig. 18 — Logic Panel (Standard Unit)

3 Remove thermostat supply wires from ST AT ter

minals 1 through 5 on logic panel.

4. Set meter to volts ac scale equal to relay switching

voltage (50-volt scale for 24 vac).

5. To simulate a call for cooling, jumper between STAT

terminals 2 and 4. Normally open logic panel contacts

(COOL 1 and 2) should close and cooling equipment

should cycle on.

6. Connect meter leads to the normally open cooling

contacts 1 and 2 on logic panel. Meter should read zero

if contacts have closed and contacts are made.

If meter is reading zero and cooling equipment has

not cycled on, logic panel is not at fault.

7. To simulate a call for heating, jumper between ST AT

terminals 2 and 5. Normally open logic panel contacts

(HEAT 1 and 2) should close and heating equipment

should cycle on.

8. Connect meter leads to the normally open heating

contacts on logic panel. Meter should read zero if

contacts have closed.

If meter is reading zero and heating equipment has

not cycled on, logic panel is not at fault.

9. Replace thermostat wiring to terminals 1 through 5.

DISCHARGE SENSOR

1 Set resistance on meter to R x 100.

2. Disconnect lead from SENSOR terminal T1 on logic

panel.

13

Page 14

3. Connect one meter lead to logic panel terminal T and

the other meter lead to the loose lead wire from the

sensor.

4. Meter readings depend on temperature. Discharge

sensor readings should be between 1500 and 4500

ohms. See Fig. 19.

THERMOS!AT/TRANSMITTER (Fig. 15)

1. Set meter to 20 vdc scale.

2. Check for power to thermostat. Connect negative (-)

lead to terminal 1 and positive (+) lead to terminal 2.

Meter should read 20 vdc.

3. Connect the negative (-) lead to terminal 1 and the

positive (+) lead to terminal 4.

4. Slowly move the cooling lever below room tempera

ture to simulate a call for cooling. Meter reading

should gradually increase to about 16 vdc. (See

Fig. 20.)

5. Move the cooling lever above room temperature.

Meter reading should drop to less than 2 vdc.

6. Remove the (+) meter lead from terminal 4 and

connect it to terminal 5.

7. Slowly move the heating lever above room tempera

ture to simulate a call for heating. Meter reading

should gradually increase to about 16 vdc. (See

Fig. 20.)

8. Move the heating lever below room temperature. The

meter reading should drop to less than 2 vdc.

5000

4800

4600

4400

4200

4000

3800

3600

3400

3200

3000

2800

2600

2400

2200

2000

1800

1600

1400

1200

1000

800

600

400

200

\ 3000ÍIA1

60 65 70 75 80 85 90 95 100

(16) (18) (21) (24) (27) (29) (32) (35) (38)

TEMPERATURE DEGREES F (DEGREES C)

77F( 250

L

Fig. 19 — Resistance Range of the

Discharge Sensor

1

ECONOMIZER (Motor Operation) — Check to see 115 v

is at the economizer motor. Remove wire from the W

terminal on damper motor. Dampers should go fully

open.

Short between R-W on motor terminals. Dampers

should go fully closed.

Logic Panel Economizer Signal

Disconnect terminal W on logic panel.

Connect meter (2.5 vdc scale) with negative (-) lead to

R and the positive (+) lead to W.

Set thermostat for a call for cooling. Meter reading

3.

should rise to 1.5 vdc. If thermostat was already calling

for cooling, reading will be 1.5 v when meter is

connected.

4. Turn thermostat up so that no cooling is called for.

Voltage should fall from 1.5 vdc to 0.

Conduct the above test with air temperature at the

discharge sensor (located at unit air discharge) above

62 F. If air is below 50 F, there will be no voltage

signal. If air is between 50 and 62 F, voltage will be

in the same proportions.

A CAUTION

When servicing unit, shut off all electrical power

to unit to avoid shock hazard or injury from rotat

ing parts.

Cleaning — Inspect unit interior at the beginning of

each heating and cooling season and during each season

as operating conditions require. Remove unit top panel(s)

and/or side panels as required to expose unit interior.

EVAPORATOR COILS — Clean with a stiff brush,

vacuum cleaner or compressed air.

CONDENSER COILS — Clean with a stiff brush or

vacuum cleaner. When cleaning with compressed air or

low-pressure water or steam, guard against damaging

VOLTAGES NECESSARY TO ACTIVATE LOGIC PANEL

HEAT STAGE

1

2

Differential 63 ± .07 volts

VOLT DC COOL STAGE VOLT DC

4 63

5 88 2 5 88

1

Tolerance' ± 25 volts

5 00

Fig. 20 — Thermostat/Transmitter Output

Voltage Ramps

compressor wiring and nearby controls. Condenser fan

motor(s) is drip-proof but not waterproof.

CONDENSER SECTION DRAIN — Check that area

under coil is clear and drains freely.

CONDENSATE DRAIN — Check and clean annually

at start of cooling season. In winter, keep drain and trap

dry or protect against freeze-up.

FILTERS — Replace filters at start of each heating and

cooling season or as often as necessary during each

season, depending on operating conditions. Refer to

14

Page 15

Table 3 — Indoor Air Fan Data

UNIT

CFM 0.20

50DF

034

Boldface indicates aiternate or field-supplied fan motor or drive is required.

Bhp — Brake horsepower

Rpm — Revolutions per minute

NOTES:

1 Values in italics indicate that motor larger than optional fan motor is required

2 Fan performance has deductions for unit casing losses, wet coil and clean standard filters

3 Fan motor bhp is based on minimum voltages and 80 F air across motor

Rpm Bhp

9,000 690

720 3 29

9,500

10,000 751

782 4 28 842

10,500

814

11,000

845

11,500

12,000 877

12,500 909

941

13,000

973

13,500

1006

14,000

1038

14,500

1071

15,000

2 86

3 76

4 80 871

5 50

6 10 931

6 80 962 7 70 1010

7 60 992 8 50

8 50 1023 9 40

9 40 1054 10 40

10 30 1085 11.40

11 30 1116 12.40

0.40

Rpm

Bhp Rpm

755

3 40

784

3 88 839 4 42 891 4 95 940

813

4 40

4 96

5 60 923

901 6 20 952

7 00

0.60 0.80

Bhp Rpm

812

3 91 865

867 4 97

895 5 57

6 20 971

6 90

981

7 70

8 50

1039

9 40 1 1083

1069 10 30

1099 11.30

1129 12.30

1159 13.50

917 5 53

943 6 16

999 7 60 1042 8 20

1027

1055

1112

1141

1170

1200

EXTERNAL STATIC PRESSURE (in. wg)

1.00

Bhp Rpm

4 42 916

6 80 1016 7 50

8 40 1069 9 00

9 20 1097 9.90

10.10 1125 10.90

11.10 1153 11.90

12.10

13.20

14.40

Bhp

4 94

5 49

964 6 09

990 6 75

1181 12.90

1209

14.10

1238 15.30

Table 1 for type and size of filter used. Filter access panels

are shown in Fig. 4. Return air filter tracks will accept 2

layers of one-in. thick filters if 2-in. filters are not avail

able. Do not install bag filters in standard filter tracks.

Do not install standard filters or 2-in. high-efficiency

filters in bag filter tracks.

OUTDOOR AIR INLET SCREEN(S) — Clean screens

with steam or hot water and mild detergent. Do not use

throwaway filter in place of these screens. Loosen

fastening-bracket screws and slide out screens.

Lubrication

COMPRESSORS — Each compressor is charged with

correct amount of oil at the factory. Oil level should be

between bottom and mid-level of sight glass when com

pressor is warm. Refer to 06D or 06E Compressor Serv

ice Manual if additional information regarding com

pressor lubrication system is required.

FAN SHAFT BEARINGS — Charge each grease fitting

with a suitable bearing grease at least once a year. Do

not overlubricate.

FAN MOTOR BEARINGS — No relubrication of out

door air fan motors is necessary for first 2 to 5 years of

use, depending on operating conditions Annually there

after, open, clean and repack each bearing with a suitable

bearing grease

Indoor air fan motor bearings should be cleaned and

repacked with a suitable bearing grease annually after

initial unit installation.

1.20

Rpm Bhp Rpm

960 5 42

985 6 03

1010 6 67

1034 7 35

1059

8 10

1085 8.90

1110 9.70

1136 10.60

1163 11.60 1201

1191

12.60

1218 13.70 1254

1246 14.90

1275

16.10

1.40 1.60 1.80 2.00

Bhp Rpm

1006 5 94 1052

1026 6 54

1051

1076

1100 8.70

1125

1150

1176

1227

1282 15.70

7 22

7 96 1114

9.50

10.40

11.30

12.30

13.40

14.50

1071

1091 7.77

1139

1164

1188 11.10

1213

1238 13.10 12^

1264 14.10

1290 15.30

Bhp Rpm

6 48

7 10

8.51

9.30

10.20

12.00

Bhp Rpm Bhp

1094 7.02 1133

1114 7.67

1133 8.36 1174 8.97

1152 9.10 1193 9.73 1232 10.37

1174

9.90

1200 10.80

1225 11.80 1258 12.40

1249 12.80 1284 13.50

13.80

14.90

1298

7.57

8.24

1153

1212 10.50

1233 11.40

Rpm Bhp

1173 8.18

1190

1211 9.56

1250

1270 12.10

1291 13.10

After reinstalling pulley and belt, check pulley align

ment and belt tension as described below.

PULLEY ALIGNMENT — Loosen fan shaft pulley

bushing and slide pulley along shaft. Make angular

adjustment by loosening motor mounting plate and repo

sitioning it as required.

BELT TENSION — Adjust belt tension by moving

motor back until only a slight bow appears in the belts on

the slack side of the drive while running under full load.

Secure motor. Recheck belt tension after 24 hours of

operation, adjust as necessary.

Table 4 — Indoor Air Fan Pulley Data

UNIT

50DF

'Remove one belt

NOTE: Values shown indicate standard or optional pulley combinations

available as shown in Physical Data table All other combinations are field

supplied and shown in boldface type

FAN

RPM

1073 2-3V-6.5

1093

1141

1159 4-3V-5.3

1225 4-3V-5.6

1300

MOTOR

PULLEY

No. Grooves-Type-ln.

925 2-3V-5.6 2-3V-10.6

991 2-3V-6.0 2-3V-10.6

3-3V-5.0

4-3V-4.5

3-3V-6.0

FAN

PULLEY

2-3V-10.6

3-3V- 8.0

4-3V- 6.9

4-3V- 8.0

4-3V- 8.0

3-3V- 8.0

SINGLE-SPEED

BELT

NO.-SIZE

2-3V-750

2-3V-750

2-3V-750

3-3V-710

4-3V-670

4-3V-710

4-3V-710

3-3V-710

2.20

8.81

11.20

Indoor Air Fan Adjustment — Fixed fan speeds

are set as shown in Table 1. If other than available fan

speeds are required, select field-supplied motor or

pulleys, using data from Tables 3 and 4.

PULLEY REMOVAL — Pulleys are of the fixed type

and have taper-lock bushings. To remove, shut off unit

power. Loosen fan motor mounting plate and remove

belt. Relocate taper-lock bushing bolts in removal holes

to loosen bushing. Remove pulley from shaft.

Power Exhaust Air Fan Adjustment (if fitted) —

Adjust belt tension so that 1/8-in. deflection at 5- to

8-pounds pressure between pulley centers can be

obtained. To change tension, loosen motor mounting

bolts, reposition motor and tighten mounting bolts.

Tighten locknut and bolt under motor mounting plate

to secure in fixed position.

15

790

Page 16

Outdoor (Condenser) Air Fan Adjustment

(Fig. 21) — Shut off unit power supply Remove fan

guard and loosen fan hub setscrews Adjust fan height

using a straight edge laid across venturi. Tighten set

screws and replace rubber hubcap to prevent hub from

rusting to motor shaft. Fill hub recess with Permagum

if hub has no rubber hubcap.

Fig. 21 — Outdoor Air Fan Adjustment

Damper Vent Position Setting

1. On constant volume units, adjust thermostat or trans

mitter so there is no call for cooling. On variable

volume units, adjust set point knob on microprocessor

so there is no call for cooling. The economizer

dampers go to minimum position

2 Remove cap from vent adjustment screw on top of

damper motor terminal box cover

3. Turn adjustment screw slowly until dampers assume

desired vent position. Do not manually operate

clamper motor. Damage to motor will result.

POWER FAILURE — Dampers have a spring return.

In the event of a loss of power, dampers close until power

is restored Do not manually operate damper motor.

Damage to motor will result.

Refrigerant Charge — Amount of refrigerant charge

is shown on unit nameplate and in Table 1. When charg

ing refrigerant system, refer to Carrier Standard Service

Techniques Manual, Chapter 1, Refrigerants. When

adding a complete charge, evacuate the system using

standard evacuating procedures and weigh in specified

amount of refrigerant. A charging chart (Fig. 22) is pro

vided on unit control box door above compressor and

may be used (use of sight glass not required).

When using refrigerant liquid line sight glass to charge

system:

1. Install a jumper on the low-pressure switch if required.

2. Operate unit with restricted condenser airflow to

achieve an operating discharge pressure of about

375 psig.

3. Slowly add refrigerant until sight glass clears.

4. Remove jumper from low-pressure switch and remove

condenser air restriction.

Fig. 22 — Charging Chart; 50DF034, System 1 and System 2

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|l PC111 Catalog No 565-032 PrintedinUSA Form50DF-9SI Pg 16 790 4-86 Replaces: 50DF-7SI

Tab 1b

For replacement items use Carrier Specified Parts

Loading...

Loading...