Page 1

Number One

AirConditbning

Maker

Instiillation, Start-U|5

I Division of

" Carrier Corporatio

Carrier Parkway • Syracuse NY 13221

and Service Instructions

Single-Package Cooling Units

SAFETY CONSIDERATIONS

Installation and servicing of air conditioning

equipment can be hazardous due to system pressure

and electrical components. Only trained and quali

fied service personnel should install, repair or

service air conditioning equipment.

Untrained personnel can perform basic mainte

nance functions of cleaning coils and filters and

replacing filters. All other operations should be per

formed by trained service personnel. When working

on air conditioning equipment, observe precautions

in the literature, tags and labels attached to the unit

and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and

work gloves. Use quenching cloth for unbrazing

operations. Have fire extinguisher available for all

brazing operations.

INSTALLATION

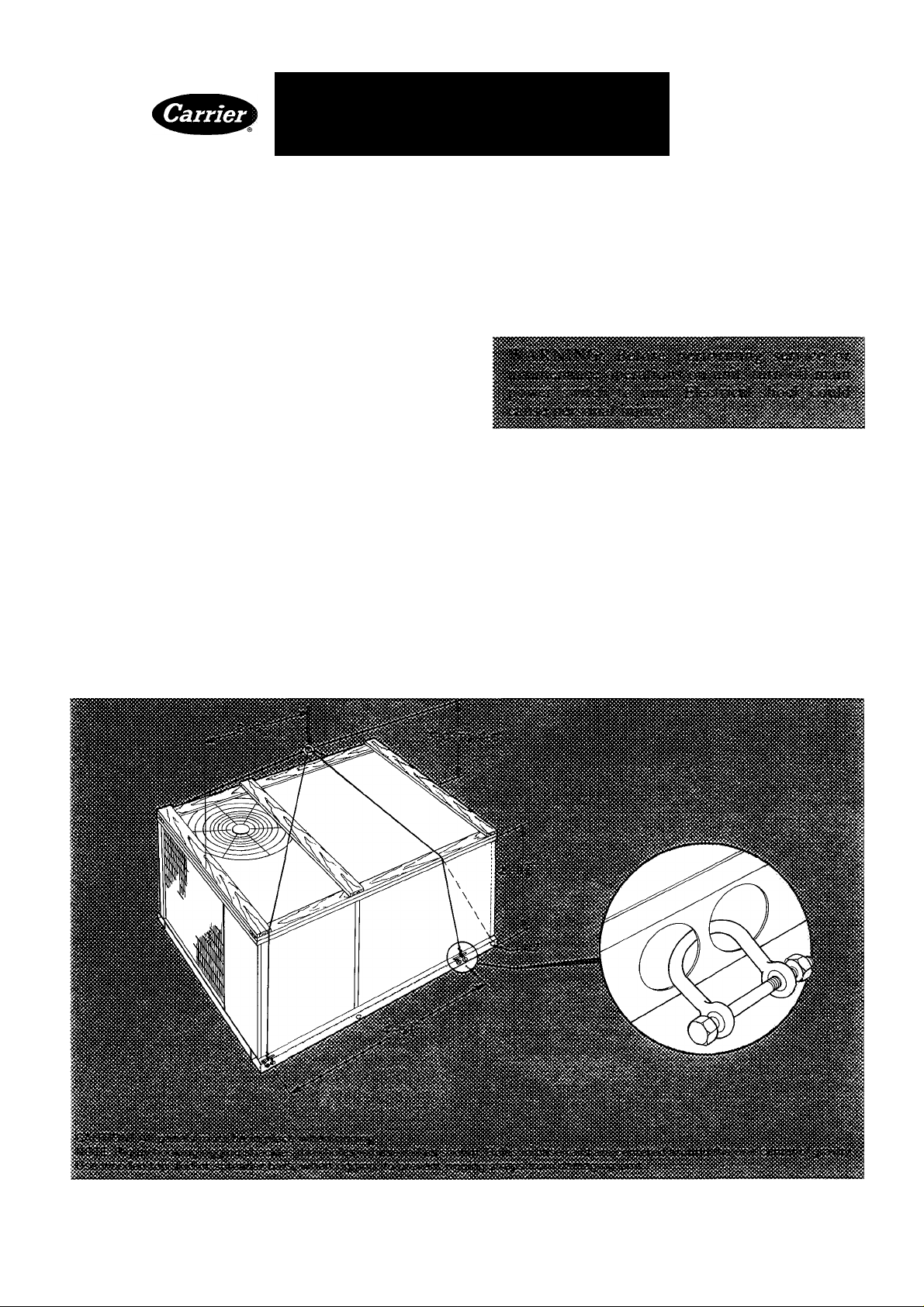

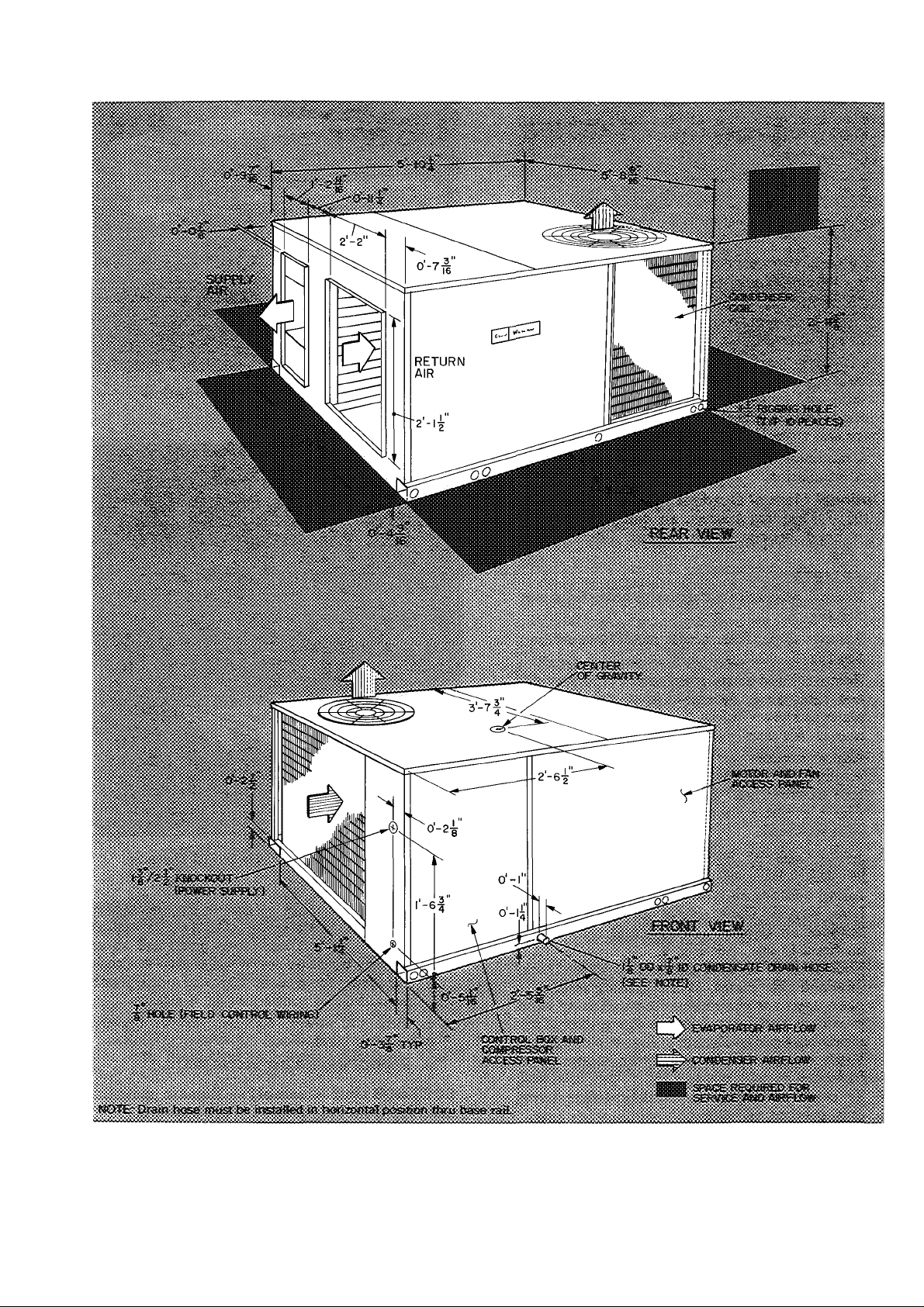

Unit Rigging and Placement — Inspect for trans

portation damage. File any claim with transporta

tion agency. Spreader bars are not required if top

crating is left on unit. Keep unit upright. Do not

drop unit (see Fig. 1). Rollers may be used to move

unit across a roof. Level by using frame as a refer

ence. Leveling tolerance is ± 1 / 16-in. per linear foot

in any direction. This is necessary for condensate

drain to function properly. Table 1 shows unit

weight. See Fig. 1 for rigging details.

Fig. 1 — Rigging Details

© Carrier Corporation 1983 Form 50CD-23SI

Page 2

Table 1 — Physical Data

UNIT SIZE

OPERATING WEIGHT (lb)

Unit

With Economizer* 790

Roof Curb* — 14 in. 120

COMPRESSOR

No. ...Type

Oil (oz)

REFRIGERANT (Capillary Control)

Charge (lb)

CONDENSER COIL Copper Tubes, Aluminum Fins

Rows

Fins/in.

Total Face Area (sq ft)

CONDENSER AIR FAN

Nominal Cfm

No. ...Diameter (in.)

Motor Hp (1075 Rpm)

EVAPORATOR COIL

Rows

Fins/in. 13 9

Total Face Area (sq ft)

EVAPORATOR AIR FAN

Quantity...Size (in )

Nominal Cfm

Minimum and Maximum Cfm (Standard Motor) 2250 - 3650

(Optional Motor) 2250 - 3750

Rpm Range

Maximum Allowable Rpm

Motor Pulley Pitch Diameter (in.)

Fan Pulley Pitch Diameter (in )

Belt No. ...Type

Speed Change per Full Turn of

Moveable Pulley Flange (Rpm)

Moveable Pulley Maximum Full Turns

from Closed Position

Factory Setting — Full Turns Open 3

Factory Speed Setting (Rpm) 760

Motor Hp (Service Factor) Standard 1 Hp (1 4)

Optional 1 5 Hp (1 3)

HIGH-PRESSURE SWITCH

Cutout (psig)

Reset (psig)

LOW-PRESSURE SWITCH (Liquid Line)

Cutout (psig)

Reset (psig)

OUTDOOR AIR INLET SCREENS*

Economizer, No . Size (in ) 2 19 X 31 X 1/2 — None on 50CH008

RETURN AIR FILTERS* (Type) Disposable — None on 50CH008

No. ...Size (in.)

»50CD008 only

50CD/CH008

730

1 — BRE2 Copeland

124

R-22

105

2

13 9

15 6

4100

1 22

1/2 Hp

Copper Tubes, Aluminum Fins

3

82

1 12x9

3000

652 - 924

924

2 4-3 4

12 7

1 A51

54

426 ± 7

320 ± 20

27 ± 4

67 ± 7

2 16 X 20 X 1

2 20 X 20 X 1

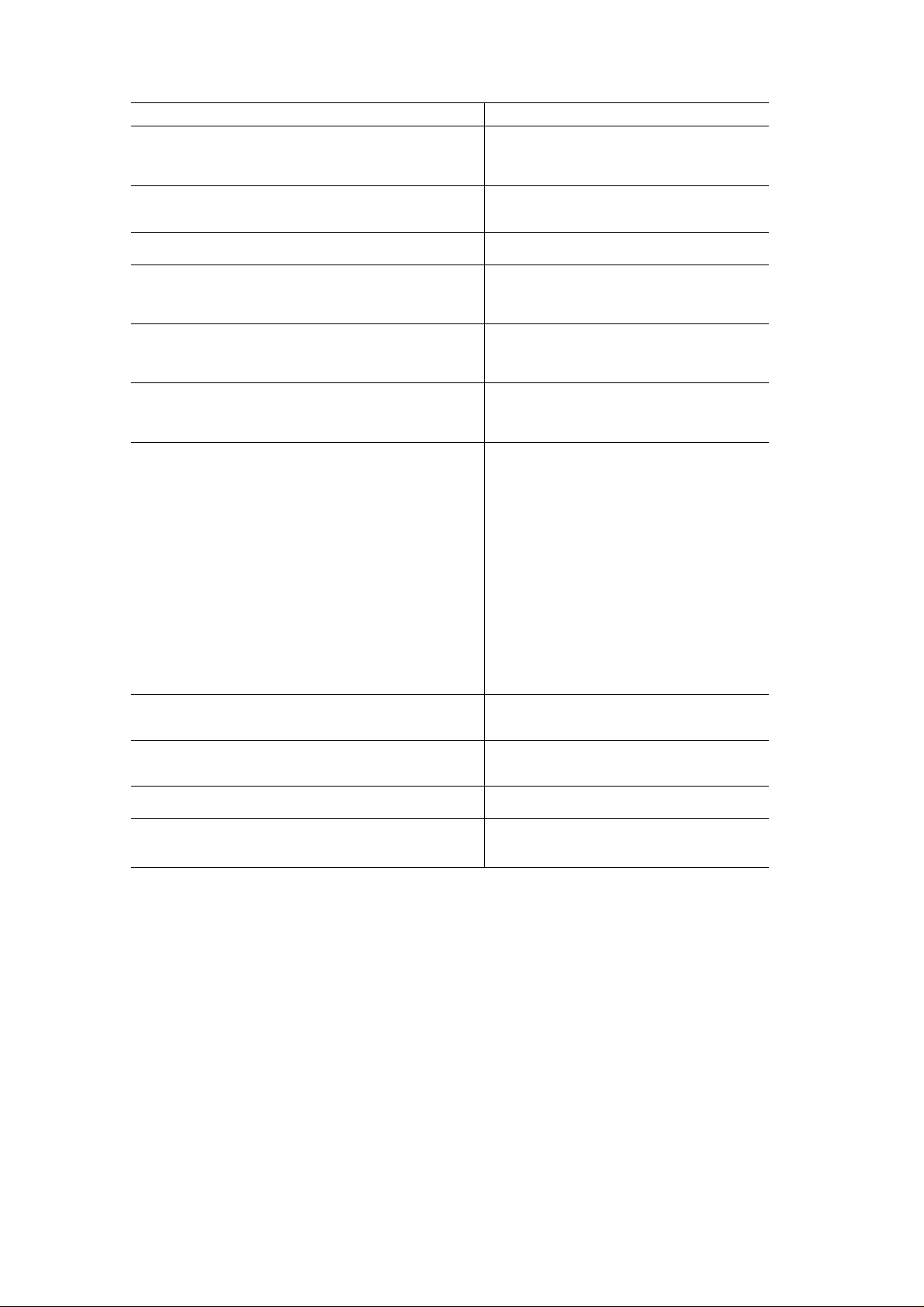

Accessory Roof Curb (50CD008) — See Fig. 2.

Assemble and install in aeeordance with instruetions

shipped with curb. Install insulation, cant strips,

roofing and flashing as required. Ductwork must

be attached to curb.

Unit gasketing to roof curb is critical for water

integrity. Make sure that gasketing material shipped

with the roof curb has been properly installed as

indicated in Fig. 2.

Roof Mount — Check building codes for weight

distribution requirements. Table 1 shows unit

weight.

Slab Mount (50CH008) — Provide a level con

crete slab the same width as unit that extends to ends

of base rails only. The slab should be 8 in. thick with

4 in. above grade. Install a gravel apron in front of

©

outdoor air inlet to prevent grass and foliage from

obstructing airflow. Allow a minimum of 6 in. under

outdoor coil for condensate drainage. In areas

where prolonged sub-freezing temperatures or

heavy snow occur, increase clearance to 12 in. mini

mum, 18 in. maximum.

Positioning — Position unit to prevent snowdrifts

from blocking condenser coil and outdoor air intake

(50CD008). Provide clearance around and above

unit for airflow, safety and service access.

Do not install unit in an indoor location. Do not

locate unit air inlets near exhaust vents or other

sources of contaminated air.

Although unit is weatherproof, guard against

water from higher level runoff and overhangs.

Page 3

Fig. 2 — 50CD008 Roof Curb Dimensions and Details

Page 4

t

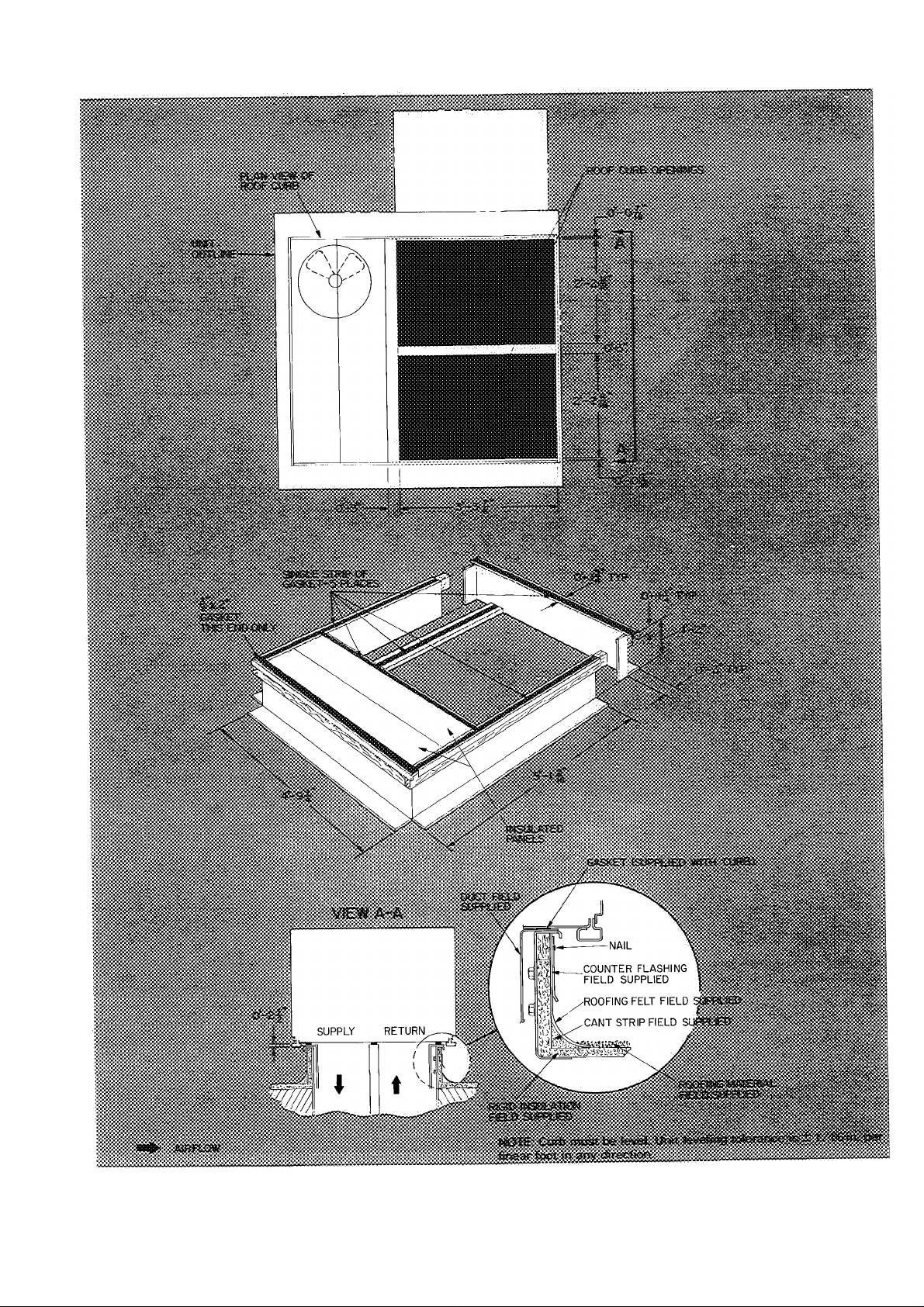

Fig. 3 — 50CD008 Base Unit Dimensions

4

t

Page 5

#

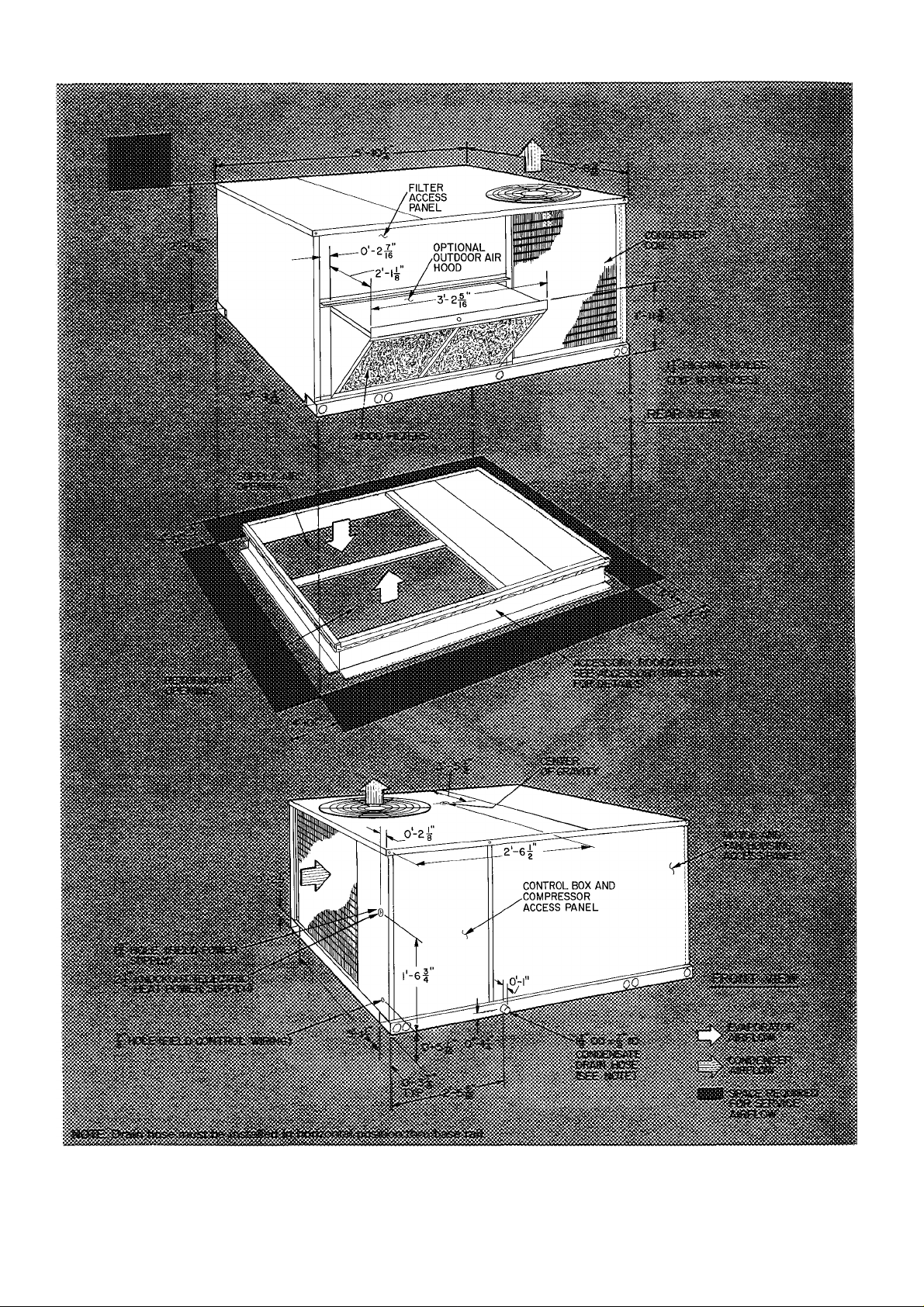

Fig. 4 — 50CH008 Base Unit Dimensions

Page 6

Outdoor Air Intake (50CD008) — The 50CD

can be equipped with an optional outdoor air

damper or an economizer that mixes outdoor air

with return air.

Field-Fabricated Ductwork

50CD — See Fig. 3. Secure all ducts to roof curb and

building structure before unit is placed on curb.

Do not connect ductwork to unit.

Cabinet return air static shall not exceed 0.35 in.

with economzier or 0.40 in. without economizer.

50CH — See Fig. 4. Secure all ductwork to flanges

on unit supply air and return air openings and

building structure.

50CD/CH — Insulate and weatherproof all ex

ternal ductwork, joints and roof/ wall openings with

flashing and mastic in accordance with applicable

codes. Insulate ducts passing thru an unconditioned

space and cover with a vapor barrier.

A minimum clearance is not required for any air

duct installation.

Optional Manual Outdoor Air Damper (50CD

008) — Optional outdoor air damper is shipped

with hood broken down in unit filter section.

See Fig. 5.

ASSEMBLY

1. Remove protective polyethylene cover from unit.

See Fig. 5.

2. Remove upper filter access panel (save screws).

See Fig. 5.

3. Remove hood parts from unit evaporator fan

and filter area. Assemble hood top and side

plates as shown in Fig. 6. Do not attach hood to

unit at this time.

4. Adjust outdoor air damper blade to desired

setting for outside air intake by releasing linkage

rod setscrew and adjusting linkage rod. See

Fig. 7. Secure damper blade in desired position

with setscrew.

5. Remove screws holding manual outdoor air

damper to unit. See Fig. 8.

Install outdoor air hood assembly, using screws

6.

from step 5. These screws secure the manual

outdoor air damper assembly and the outdoor

air hood to unit. See Fig. 9.

Slide outdoor air inlet screens into screen tracks

7.

on hood side plates. While holding screens in

place, fasten screen retainer to hood using screw

provided. Make sure bottom edge of screens rest

inside base rail as shown in Fig. 9.

Replace upper access panel with screws saved

8.

from step 2.

9. To check percentage of ventilation air entering

unit, proceed as follows:

a. If unit power is on, turn it off.

b. Jumper red and black wires in 24-v barrier

in main control box. See Fig. 10.

c. Turn on unit power to energize evaporator

(indoor) fan.

t

Fig. 5 — Access Panel Location

Fig. 6 — Outdoor Air Hood Details

d. Check percentage of ventilation air entering

unit. If percentage varies from that specified,

remove upper filter access panel and adjust

damper blade as described in step 4. Proce

dure may have to be repeated until proper

percentage of ventilation air is attained.

e. Turn off power. Remove jumper between

red and black wires.

f. Replace upper filter access panel.

50CH008 Unit Assembly — Remove packaging

and tape from evaporator fen drive system.

Evaporator Air Fan — Evaporator fan uses a belt-

drive motor which provides high static at nominal

airflow. The standard motor provides approxi

mately 0.95 in. static at nominal cfm and the alter

nate motor provides 1.0 in. static at nominal cfm.

Page 7

#

MANUAL OUTDOOR

air damper assembly

L/NKA6E

ROD SETSCREW

m

a; . •W

Fig. 7 — Damper Blade Adjustment

Fig. 8 — Manual Outdoor Air Damper

HOOD BASE UNIT

Condenser Air Fan and Motor are factory set.

LINKAGE ROD

•>

^,r

AIR SCREENS BASE RAIL

Fig. 9 — Outdoor Air Hood Assembled

to Base Unit (50 Series Shown)

Refer to Service, Condenser Air Fan Adjustment,

as required.

Condensate Drain — See Fig. 3 and 4 for drain

location. A 7/8-in. ID preformed drain hose is

Fig. 10 — Control Box Details

shipped clamped to the evaporator basepan. At

installation, reroute hose so that it passes thru the

hole in the evaporator basepan and the unit base

rail.

When installed properly, the hose protrudes thru

the base rail about 3in. on the 50CD008. On the

50CH008, hose protrudes thru the side of the base

rail about 1 inch.

Replace clamp over the hose where it passes thru

the basepan. This keeps the hose level. Use a trap at

least 4 in. deep and provide protection for trap

against freeze-up.

Field Power Supply — See Fig. 11 and Table 2.

Unit is factory wired for voltage shown on name

plate. On 208-volt installations, reconnect all trans

formers to 208- (200-) volt tap. Refer to unit label

diagrams. Pigtails are provided for field service on

units without electric heat (use factory-supplied

splices or UL-approved copper/aluminum con

nector). Units with electric heat are provided with

terminal block in single point box.

All field wiring must comply with National Elec

trical Code and local requirements.

Run power lines thru condenser coil end panel to

terminal connections as shown on unit wiring

diagram and in Fig. 3 and Fig. 4.

Operating voltage to compressor must be within

voltage range indicated on unit nameplate. On 3phase Units, voltages between phases must be

balanced within 2% and the current must be bal

anced within 10%.

Use the following formula to determine the %

voltage unbalance.

% Voltage Unbalance

_ max voltage deviation from average voltage

average voltage

Page 8

WITHOUT ELECTRIC HEAT

UNIT CONTROL BOX

WITH ELECTRIC HEAT

1

SINGLE POINT BOX

C — Contactor

Comp — Compressor

Gn*d*^ — Equipment Ground

— Fuse

Fu

— Terminal Block

TB

50CD/CH008

NOMINAL

V-PH-HZ

208/230-3-60

460-3-60

— Full Load Amps

FLA

— Horsepower

Hp

— Indoor Fan Motor

IFM

— Locked Rotor Amps

LRA

VOLTAGE

RANGE

Min Max RLA

187

414

. Factory Wiring

. Field Power Wiring

. Field Splice

Fig. 11 — Field Power Wiring Connections

COMPR OFM

LRA FLA

32 5 183 29 1 80

254

91 1 1 5 1 2 9

15 2

508

MOCP — Maximum Overcurrent Protection

OFM — Outdoor Fan Motor

RLA — Rated Load Amps

‘Fuse only

Table 2 — Electrical Data

ELECTRIC HEATERS

IFM

Hp

50CD008

Kw FLA Kw

FLA

9 3 20-23

186 40-46 158

28 1 59-68

9 7 11 7

160 193 160

194 23 4 31 5

29 6 35 7

— —

—

POWER SUPPLY

50CH008 50CD008 50CH008

Min Ckt

j

FLA

93 20-23 55/55 60/60 55/55 60/60

33-38

31 5 68-76 85/95

—

97 11 7

19 3 30

37 9 40

MOCP

55/55 60/60* 55/55 60/60*

60/70 60/70 55/60

80/90

25

25

50

Min Ckt j MOCP

Arr

)ps

95/105 90/100

35*

35 25

35 30

35 55

45

25

60/60

35*

35

35

45

Example; Supply voltage is 460-3-60.

ABC AB = 452 volts

BC = 464 volts

AC = 455 volts

Average Voltage

452 + 464 + 455

3

1371

= 457

Determine maximum deviation from average

voltage: (AB) 457 - 452 = 5 volts

(BC) 464 - 457 = 7 volts

(AC) 457 - 455 = 2 volts

Maximum deviation is 7 volts

Determine % voltage unbalance:

% Voltage Unbalance = 100 x

7

457

= 1.53%

This amount of phase unbalance is satisfactory

as it is below the maximum allowable 2%.

t

Page 9

THERMOSTAT ASSEMBLY

LOW-VOLTAGE THERMOSTAT CONNECTIONS IN UNIT CONTROL BOX

Fig. 12 — Field Control Thermostat Wiring

•#

Unit failure as a result of operation on improper

line voltage or excessive phase imbalance constitutes

abuse and may cause damage to electrical compo

nents. Such operation would invalidate any appli

cable Carrier warranty.

UNITS WITH ELECTRIC HEAT — When elec

tric heat is installed, connect the field power wires

to terminal block located in the single point box.

The single point box is attached to the corner post,

directly below the control box.

DISCONNECTS — A fused disconnect is required

only on units without electric heat. When electric

heat is installed, use a NEC disconnect of adequate

size. Provide fusing for disconnect if required by

local codes. The unit informative nameplate and

Table 2 list electric heat fuse and wire amperage.

Field Control Wiring — Install a Carrier-approved

accessory thermostat assembly according to instal

lation instructions included with accessory. Locate

thermostat assembly on a solid wall in the condi

tioned space to sense average temperature.

THERMOSTAT WIRES — Use 18 gage for 0- to

50-ft long wires, 16 gage for 50- to 75-ft wire

lengths. Route the control wires thru hole provided

in the corner post (see Fig. 3 and 4) and then feed

wires thru a raceway built into the corner post.

Route wires from the raceway into the 24-v barrier

located on the left side of the control box. Make

connections as shown in Fig. 12.

Set heat anticipator settings as indicated below.

Heat Anticipator Settings

1 St stage

2nd Stage with 2 Heaters and 2-Stage

Heat Thermostat*

‘Applies only to 50CD

9

3

Settings may be changed slightly to provide a

greater degree of comfort for a

particular

installation.

Refer to accessory remote control panel instruc

tions as required.

Return Air Filters (50CD008) — Make sure

correct filters are installed in filter tracks. See

Table 1. Do not operate unit without return air

filters.

Outdoor Air Inlet Screens (50CD008) — Out

door air inlet screen(s) must be in place before

operating unit.

Economizer Section (50CD008) — Optional

economizer is shipped with hood broken down in

unit filter section. See Fig. 13.

Fig. 13 — Access Panel Location

ASSEMBLY

1. Remove protective polyethylene cover from

unit. See Fig. 13.

2. Remove upper filter access panel (save screws).

See Fig. 13.

3. Remove hood parts from unit evaporator fan

and filter area. Assemble hood top and side

plates as shown in Fig. 14. Do not attach hood

to unit at this time. Put aside baffle, screen

retainer and retainer screw for later assembly.

4. Determine if vent air is required in building to

be conditioned. If so, check for percentage of

Page 10

vent air needed and record quantity for vent

adjustment in step 11.

5. Remove jumper plug from base unit receptacle

and discard. Insert economizer plug into recep

tacle. See Fig. 15.

Steps 6 thru 8 involve releasing and adjusting

indoor damper blades from factory set position.

Remove violet wire from economizer damper

motor and connect to terminal D on economizer

damper motor. See Fig. 17.

OUTDOOR BLADES (2)

DRIVE

SHAFT

OUTDOOR DRIVE LINKAGE

Fig. 16 — Economizer Details

INDOOR

BLADES (3)

Fig. 14 — Outdoor Air Hood Details

ECONOMIZER

PLUG

CLS — Cooling Lockout Switch

EC — Enthalpy Control

OAT. — Outdoor Air Thermostat

BASE UNIT

RECEPTACLE

OUTDOOR AIR

INLET SCREENS (3)

Fig. 15 — Economizer Installed in Unit

6. Release indoor blades’ drive linkage by loosen

ing linkage connector setscrew at indoor crank-

arm on drive shaft. See Fig. 16.

Remove pink wire from economizer damper

motor terminal D and temporarily tape bare

wire end.

PINK WIRE

VIOLET WIRE

TERMINAL D

Fig. 17 — Economizer Motor Connections

7. Jumper red (base unit 24-v power) and black

(evaporator fan motor) wires in 24-volt control

box compartment. See Fig. 10.

Turn on base unit power to energize evap

orator fan. The economizer’s outdoor blades

should open completely.

8. Adjust the indoor blades’ drive linkage so that

indoor blades are fully closed. Tighten the

linkage connector setscrew. Turn off base unit

power. Reconnect pink and violet wires to

economizer motor, as shown in Fig. 17.

9. If vent air is required, leave red and black wires

jumpered. If vent air is not needed, remove

jumper between red and black wires.

10. Fasten baffle to left side of damper plate with

round head screws provided. See Fig. 18.

t

10

Page 11

BASE RAIL

Fig. 18 — Baffle Installation Details

Fig. 19 — Vent Position Setting Details

11. If vent air is not required, go on to step 12. If

vent air is required, proceed as follows:

a. Turn on base unit power. This energizes the

evaporator fan motor.

b. Slide economizer out of unit so that access

hole to vent position setscrew is visible. See

Fig. 19.

c. Adjust vent opening by loosening vent posi

tion setscrew on left side of economizer

damper motor and setting vent position

lever to adjust damper. See Fig. 19. Move

vent position lever back toward evaporator

coil to close damper or forward to open

damper. When adjustment is eompleted,

retighten setscrew.

d. Turn off base unit power and remove jumper

from red and black wires.

e. Slide economizer assembly back into unit.

12. Remove tape from outdoor air thermostat

(OAT.) and cooling lockout switch (CLS), and

fasten to inside of hood with screws and speed

clips provided. Make sure terminals on OAT.

are up. See Fig. 20.

:i OUTDOOR AIR THERMOSTAT

«(TERMINALS ARE UP)

: COOLING LOCKOUT

SWITCH

1

ACCESSORY

: ENTHALPY,

CONTROL

cooling

LOCKOUT

SWITCH

HOOD

Fig. 20 — Outdoor Air Thermostat/

Enthalpy Control and Cooling Lockout

Switch Installation

11

Page 12

13. Fasten hood top and side plate assembly

(Fig. 9) and eeonomizer to unit with screws

supplied. Before attaching, make sure bottom

of hood assembly is resting on top of unit base

rail.

14. Place knob supplied with accessory economizer

on OAT. See Fig. 20. Set for 3 degrees below

indoor room thermostat setting.

If accessory enthalpy control (EC) (Fig. 20) is

used in lieu of OAT., refer to instructions

shipped with accessory enthalpy control for

installation and adjustment.

15. Connect OAT./EC and CLS per unit label.

See Fig. 21.

Connect 2 economizer wires to each switch

with quick-connects. Unit connecting wires are

shipped taped on outdoor blade. See Fig. 15.

16. Slide outdoor air inlet screens in hood screen

tracks. Secure screens with screen retainer

across hood front. Secure screen retainer with

screw provided. See Fig. 22.

17. Replace upper filter access panel with screws

saved from step 2.

18. Turn base unit power on.

PINK

F

CLS — Cooling Lockout Switch

EC — Enthalpy Control

OAT. — Outdoor Air Thermostat

NOTE; When Enthalpy Control (EC) is installed, outdoor air thermo

stat (OAT ) is removed from economizer

RED

-<T)o^t50-

CLS

-O^Q-

SEE NOTE

_ OAT _

PINK

BLUE

Fig. 21 — Wiring Connections for Outdoor

Air Thermostat/or Enthalpy Control

and Cooling Lockout Switch

AIR INLET SCREEN

RETAINER

OUTDOOR AIR

HOOD

BASE UNIT

BASE RAIL

Fig. 22 — Economizer and Outdoor Air Hood

Assembled to Unit

: *

START-UP

Unit Preparation — Make sure unit has been

installed in accordance with installation instruc

tions and applicable codes.

Compressor Mounting — Compressors are inter

nally spring mounted. Do not loosen or remove

compressor holddown bolts.

Internal Wiring — Check all electrical connections

in unit control boxes. . .tighten as required.

Refrigerant Service Valves — Eaeh unit system

has 2 Schrader type serviee ports, one on the suetion

line and one on the compressor discharge line. Be

sure that eaps on the ports are tight.

Crankcase Heater(s) are energized as long as there

is power to the unit. Energize heater(s) 24 hours

prior to base unit start-up.

Cooling — To start unit, turn on main power

supply. Set system selector switch to COOL and

fan switch at AUTO. Adjust thermostat to a setting

below room temperature. Compressor starts on

closure of contactor.

Check cooling effects at a setting above room

temperature. Cheek unit charge. Refer to Refrig

eration Charge in Service section.

Reset thermostat at a position above room tem

-i

perature. Compressor will shut off.

TO SHUT OFF UNIT — Set system seleetor switch

at OFF position or reset thermostat at a position

above room temperature. Units are equipped with

t

Cyele-LOC™ proteetion device. Unit shuts down on

any safety trip, and indicator light on thermostat

comes on. Cheek reason for safety trip.

Compressor restart is accomplished by manual

reset at the thermostat by turning the seleetor switch

to OFF and then to ON.

Heating — To start unit, turn on main power

supply. Refer to Crankcase Heaters.

Set thermostat at HEAT and a setting above

room temperature, fan at AUTO.

First stage of thermostat energizes the first-stage

eleetric heater; seeond-stage electric heater elements

if installed. Cheek heating effeets at air supply

grille(s).

TO SHUT OFF UNIT — Set system selector switch

at OFF or set heating selector lever below room

temperature.

Ventilation {Continuous Fan) — Set fan and sys

tem selector switches at ON and OFF, respectively.

Evaporator air fan operates continuously to provide

constant air circulation.

Economizer Operation {50CD008) — See

pages 9 thru 12 for start-up and checkout proce

dures. If unit is equipped with modulating out

door air control (economizer), it should operate as

follows;

COOLING MODE — Evaporator and condenser

fans and compressor energize when there is a call

12

Page 13

ф

for cooling and outdoor ambient temperature is

above outdoor air thermostat setting. The econo

mizer damper moves to VENT position.

Evaporator fan starts and economizer damper

opens fully upon a first-stage call for cooling when

outdoor ambient temperature is below the outdoor

air thermostat setting. Compressor remains off.

Compressor is energized and mechanical cooling

integrates with economizer cooling upon a secondstage call for cooling.

Mechanical cooling is locked out when ambient

temperature is below 50 F.

Economizer damper modulates when mixed air

temperature is below mixed air thermostat (non-

adjustable) setting.

An economizer control thermostat (ECT) is

located on the evaporator coil. This thermostat

guards against abnormally low suction tempera

tures while operating mechanical cooling in con

junction with economizer. Low suction tempera

tures can lead to frosting on the evaporator coil.

If frost buildup is detected, thermostat turns off

economizer, thus closing the outdoor air damper.

This raises air temperature entering the evaporator

coil and melts frost. Once frost is melted, the

economizer is re-energized.

During unoccupied periods, if a field-supplied

night switch is used and is opened, the outdoor air

damper closes.

HEATING MODE — Outdoor air damper stays at

VENT position while evaporator air fan runs. If

field-supplied night switch is used, the outdoor air

damper closes when switch is open.

Fig. 23 — Removing Top Panel

ф

SERVICE

Cleaning — Inspect unit interior at the beginning of

each heating and cooling season or as operating

conditions require. Remove unit side panels for

access to unit interior.

EVAPORATOR COIL

1. Turn unit power off.

2. Disconnect evaporator motor and electric

heater(s) from main control box.

3. Remove top panel screws shown in Fig. 23.

4. Remove screws from base of evaporator fan

housing and electric heater plate.

5. Pry up top panel to clear top of evaporator fan

housing. See Fig. 23.

6. Remove evaporator fan housing, heaters and

heater plate from unit.

7. Use commercial coil cleaner (Oakite 164), or

dishwasher detergent in a pressurized spray

cannister. Wash both sides of coil and flush with

clear water. For best results, backflush towards

return air section to remove foreign material.

Flush condensate pan after completion.

8. Replace evaporator fan housing, electric heater(s)

and all wires.

Fig. 24 — Cleaning Condenser Coil

CONDENSER COIL —^ Inspect coil monthly.

Clean condenser coil annually, or as required by

location or outdoor air conditions.

Fins are not continuous thru coil sections. Dirt

and debris may pass thru first section, become

trapped between the 2 rows of fins, and restrict con

denser airflow. Shine flashlight thru coil to deter

mine if dirt or debris has collected between coil

sections.

13

Page 14

Clean coil as follows:

1. Turn off unit power.

2. Remove top panel screws on condenser end of

unit. Remove screws from coil side of coil center

post. Do not remove center post.

3. Remove condenser coil corner post. See Fig. 24.

To hold top panel open, place coil corner post

between top panel and center baffle. See Fig. 25.

4. Remove device holding coil sections together at

return end of condenser coil. Carefully separate

the outer coil section 3 to 4 in. from the inner coil

section. See Fig. 26.

5. Use a water hose or other suitable equipment to

flush down between the 2 coil sections to remove

dirt and debris. Clean the outer surfaces with

a stiff brush in the normal manner.

6. Reposition the outer coil section, remove the coil

corner post from between the top panel and

eenter baffle. Secure the sections together. Install

the corner post, coil center post and replace

all screws.

CONDENSATE DRAIN — Check and clean each

year at start of cooling season. In winter, keep drain

and trap dry or protect against freeze-up.

FILTERS — Clean or replace at start of each heat

ing and cooling season, or more often if operating

conditions require it.

OUTDOOR AIR INLET SCREENS (50CD008) —

Clean screens with steam or hot water and a mild

detergent. Do not use throwaway filters in place of

screens.

Lubrication

COMPRESSORS — Each compressor is charged

with correct amount of oil at the factory.

LAN MOTOR BEARINGS — No lubrication of

condenser or evaporator fan motors is required

for first 5 years of operation.

Annually thereafter, clean and repack bearings

with a suitable bearing grease.

Condenser Air Fan Adjustment (Fig. 27) — Shut

off unit power supply. Remove condenser fan

assembly (grille, motor, motor cover and fan) and

loosen fan hub setscrews. Adjust fan height as

shown in Fig. 27. Tighten setscrews and replace

condenser fan assembly.

Fig. 25 — Propping Up Top Panel

Fig. 26 — Separating Coil Sections

Fig. 27 — Condenser Air Fan Adjustment

Manual Outdoor Air Damper (50CD008) — If

outdoor air damper blade adjustment is required,

see Optional Manual Outdoor Air Damper section

on page 6.

Economizer Adjustment (50CD008) — Refer

to Economizer section under Installation.

Refrigerant Charge — Amount of refrigerant

charge is listed on unit nameplate (also refer to

Table 1). Refer to Carrier Standard Service Tech

niques Manual, Chapter 1, Refrigerants.

Unit panels must be in place when unit is oper

ating during charging procedure.

14

i

Page 15

#

NO CHARGE — Use standard evacuating tech

niques. After evacuating system, weigh in the

specified amount of refrigerant. (Refer to Table 1.)

LOW CHARGE, COOLING — Using Cooling

Charging Chart, Fig. 28, vary refrigerant until the

conditions of the chart are met. Note the charging

chart is different from type normally used. Chart is

based on charging the units to the correct superheat

for the various operating conditions. Accurate pres

sure gage and temperature sensing device are re

quired. Connect the pressure gage to the service port

on the suction line. Mount the temperature

sensing device on the suction line and insulate it so

that outdoor ambient temperature does not affect

the reading. Indoor air cfm must be within the

normal operating range of the unit.

II- r

689

w

¿621-

o

in

0552-

—

§483

in

01414- i 60

bJ

z

o

1—

'"276-

_J

z345-

_ ___ __ _

<n

LiJ

§ 70

in

2 50

90

80

ni ITnnOR TFMP

(F) (C)

115 46

in*s 41

R5 PR

65 18

50 15

45

50

7

TO USE COOLING CHARGING CHART —

Take the outdoor ambient temperature and read the

suction pressure gage. Refer to chart to determine

what suction temperature should he. If suction tem

perature is high, add refrigerant. If suction tempera

ture is low, carefully blow some of the charge. Re

check the suction pressure as charge is adjusted.

Example; 50CD/CH008 (Fig. 28)

Outdoor Temperature ...........................................85 F

Suction Pressure............................................... 70 psig

Suction Temperature should be

............................

52 F

(Suction Temperature may vary ± 5 F.)

30-

207-

20 30 40 50 60 70

SUCTION LINE TEMPERATURE

-7 -i

SUCTION LINE TEMPERATURE

-4

( F)

lb 16 21 27

(C)

80

Fig. 28 — 50CD/CH008 Cooling

Charging Chart

If Chargemaster® charging device is used, tem

perature and pressure readings must be accom

plished using the charging chart.

15

Page 16

t

For replacement items use Carrier Specified Parts

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book

Tab

1 4

1b

6b

Form 50CD-23SI Supersedes 50CD-13SI

Printed in USA 5-83 PC111

Catalog No 565-018

Loading...

Loading...