Page 1

Water-Cooled and Remote Air-Cooled

Indoor Self-Contained Systems and

Water-Cooled Heat Pumps

Installation, Start-Up and

Service Instructions

OMNIZONE™

50BV020-064

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . .1,2

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

MAJOR SYSTEM COMPONENTS . . . . . . . . . . . . . . . . . 2

Constant Volume (CV) Units. . . . . . . . . . . . . . . . . . . . . . 2

Variable Air Volume (VAV) Units . . . . . . . . . . . . . . . . . . 2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Step 1 — Complete Pre-Installation Checks . . . . . . 3

• EXAMINE THE UNIT

• UNIT STORAGE

• MODULAR UNITS

Step 2 — Rig and Place Unit . . . . . . . . . . . . . . . . . . . . . 3

• REMOVE PACKAGING

• UNIT LOCATION

• UNIT PLACEMENT

• ACOUSTICAL CONSIDERATIONS

• ASSEMBLING MODULAR UNITS

Step 3 — Install Ductwork. . . . . . . . . . . . . . . . . . . . . . . 19

• DUCT STATIC PRESSURE PROBE AND TUBING

( VAV O nl y)

• DUCT HIGH-STATIC (DHS) LIMIT SWITCH (VAV Only)

Step 4 — Make Piping Connections . . . . . . . . . . . . . 21

• CONDENSER WATER PIPING (Water-Cooled Only)

• EVAPORATOR CONDENSATE DRAIN

• HOT WATER HEATING COIL (Optional)

• WATER ECONOMIZER (Optional)

• REMOTE REFRIGERANT PIPING

(Remote Air-Cooled Only)

Step 5 — Complete Electrical Connections. . . . . . 24

• POWER WIRING

• CONTROL WIRING (CV Only)

• REMOTE CONDENSER FAN CONTACTOR WIRING

• CONTROL WIRING (VAV Only)

• SUPPLY AIR TEMPERATURE SENSOR (SAT)

• SMOKE DETECTOR/FIRE ALARM SHUTDOWN (FSD)

• ALARM (ALARM) AND WARNING (WARN) OUTPUTS

• REMOTE OCCUPANCY (ROCC)

• RETURN AIR TEMPERATURE SENSOR (RAS)

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-48

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

• CRANKCASE HEATERS

• CONFIRM THE INPUT POWER PHASE SEQUENCE

• INTERNAL WIRING

• RETURN-AIR FILTERS

• COMPRESSOR MOUNTING

• REFRIGERANT SERVICE PORTS

CV Unit Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

• EVAPORATOR FAN

•COOLING

• HEATING (Heat Pump Units Only)

VAV Unit Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

• PERFORM AUTOMATIC RUN TEST

•CHECK VFD

• POWER UP LID DISPLAY

• LOG ON TO THE LID DISPLAY

Page

• CHANGE THE DEFAULT PASSWORD

• SET THE CLOCK

• CONFIGURE SCHEDULES

• PROGRAM SET POINTS

• CHECK SYSTEM PARAMETERS

• DISPLAY ALARM HISTORY

• CONFIGURE THE CUSTOM PROGRAMMING

SELECTIONS

• SET CONTROLLER ADDRESS

• LOG OFF FROM THE CONTROLLER

Sequence of Operation (CV Only) . . . . . . . . . . . . . . . 47

• WATER ECONOMIZER COOLING

Sequence of Operation (VAV Only) . . . . . . . . . . . . . . 48

• SUPPLY FAN

• COMPRESSOR COOLING

• WATER ECONOMIZER COOLING

• COOLING RESET

Diagnostic Features (CV Only) . . . . . . . . . . . . . . . . . . 48

VAV Control and VFD Diagnostics. . . . . . . . . . . . . . . 48

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Compressor Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Fan Motor Replacement. . . . . . . . . . . . . . . . . . . . . . . . . 49

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49-51

Cleaning Unit Exterior. . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Coil Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Condensate Drains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Water-Cooled Condensers . . . . . . . . . . . . . . . . . . . . . . 49

• GRAVITY FLOW METHOD

• FORCED CIRCULATION METHOD

Fan Motor Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Fan Bearing Lubrication . . . . . . . . . . . . . . . . . . . . . . . . 50

Fan Sheaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

•ALIGNMENT

Evaporator Fan Performance Adjustment . . . . . . . 51

• BELT TENSION ADJUSTMENT

Charging the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

• REMOTE AIR-COOLED UNITS

Compressor Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . 51-65

Forcing and Clearing an Input or Output

(VAV only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

START-UP CHECKLIST . . . . . . . . . . . . . . . . . . .CL-1, CL-2

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air-conditioning

components and equipment can be dangerous. Only trained,

qualified installers and service mechanics should install, startup, and service this equipment.

When working on the equipment, observe precautions in

the literature and on tags, stickers, and labels attached to the

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53500001-01 Printed in U.S.A. Form 50BV-3SI Pg 1 10-08 Replaces: 50BV-2SI

Page 2

equipment. Follow all safety codes. Wear safety glasses and

work gloves.

WARNING

The 50BV units have removable access panels for easy

servicing. These panels allow access to controls, compressors,

condensers, VFD(s) (if applicable), evaporator motors, blowers, belts, pulleys, and refrigeration components.

Before performing service or maintenance operations on

unit, turn off main power switch to unit and open all disconnects. More than one disconnect switch may be

required to deenergize this equipment. Electric shock hazard can cause injury or death.

CAUTION

Use care in handling, rigging, and setting bulky equipment.

GENERAL

Omnizone™ 50BV indoor packaged units are very flexible

for a variety of applications. These self-contained units are

available as water-cooled or remote air-cooled air conditioning

units. The 50BV units are available with either constant volume (CV) or variable air volume (VAV) controls. In addition,

the 50BV unit is available as a water-cooled heat pump. Finally, Omnizone 50BV units are available in two cabinet styles.

Nominal 18 through 30-ton units are constructed in a singlepiece, unpainted galvanized cabinet. Nominal 30 through

60-ton units are available as modular units, and can be taken

apart for easier installation. Modular units are built using an unpainted, galvanized steel cabinet with steel framework, and can

be easily disassembled without breaking the refrigerant lines.

See Table 1 for a model number reference by application.

Each unit contains multiple scroll compressors piped in

separate refrigerant circuits. Each water-cooled circuit includes

a coaxial (tube-in-tube) condenser, TXV (thermostatic expansion valve), individual evaporator coils, and all interconnecting

piping. Water-cooled units are shipped fully charged with

refrigerant. Remote air-cooled units are shipped with a nitrogen

holding charge.

Each unit is equipped with one or two forward-curved centrifugal blowers, to ensure quiet air delivery to the conditioned

space. Constant volume units operate at a single, adjustable fan

speed and provide zone temperature control using a standard

commercial thermostat. For VAV applications, the unit is supplied with a variable frequency drive(s) (VFD) that automatically adjusts blower speed to maintain a constant, adjustable

duct static pressure. Compressors are automatically staged to

provide supply air temperature control (VAV applications) or

zone temperature control using a two-stage commercial thermostat (CV applications).

MAJOR SYSTEM COMPONENTS

Constant Volume (CV) Units

MAIN CONTROL BOARD (MCB) — The main control

board for the 50BVC, E, Q, T, U, and V units provides both

controls and diagnostics including:

• Condensate Overflow Protection

prevents unit operation in

the event that the drain pan clogs (optional sensors

required).

• Random Start

provides a programmable start with a range

of 30 to 60 seconds.

• Anti-short Cycle Timer

provides a 5-minute delay to pre-

vent compressor short cycling.

• Low Pressure Bypass Timer

bypasses the low-pressure

switch for 90 seconds to avoid nuisance trips during cold

start-up.

• High Pressure Switch Delay

is a one-second delay that pre-

vents nuisance trips at start-up.

• Brownout/Surge/Power Interruption Protection

is a

20-second moving scale that works in conjunction with the

random start timer to delay unit start when a nuisance lockout would otherwise have occurred. This allows the water

pumps to restart and establish water flow.

• Alarm Output

contacts provide remote fault indication.

• Test/Service Pin is a jumper that reduces all time delay

settings to 6 seconds during troubleshooting or operation

verification.

• Reset

occurs after a 5-minute delay when a fault condition

occurs. When the timer expires, the unit will restart. If the

same condition occurs a second time, the unit will be locked

out.

• Lockout Reset

requires that the unit power be cycled at the

unit controller via either the thermostat or unit disconnect.

NOTE: The refrigerant circuits on dual compressor models

are completely independent. If either stage has a fault condition the remaining stage will continue to operate without

interruption. A freeze (optional sensor required) or condensate

overflow lockout will shut down both refrigerant circuits.

• LEDs

are provided for diagnostic purposes.

Variable Air Volume (VAV) Units — The 50BVJ, K,

W, and X units come equipped with a Carrier 6400 Comfort

Controller and a VFD. Refer to the 50BV,XJ Controls, Operation and Troubleshooting manual for details.

NOTE: The VAV units utilize face split coils and should not

be operated below 50% of nominal airflow to prevent coil

freezing.

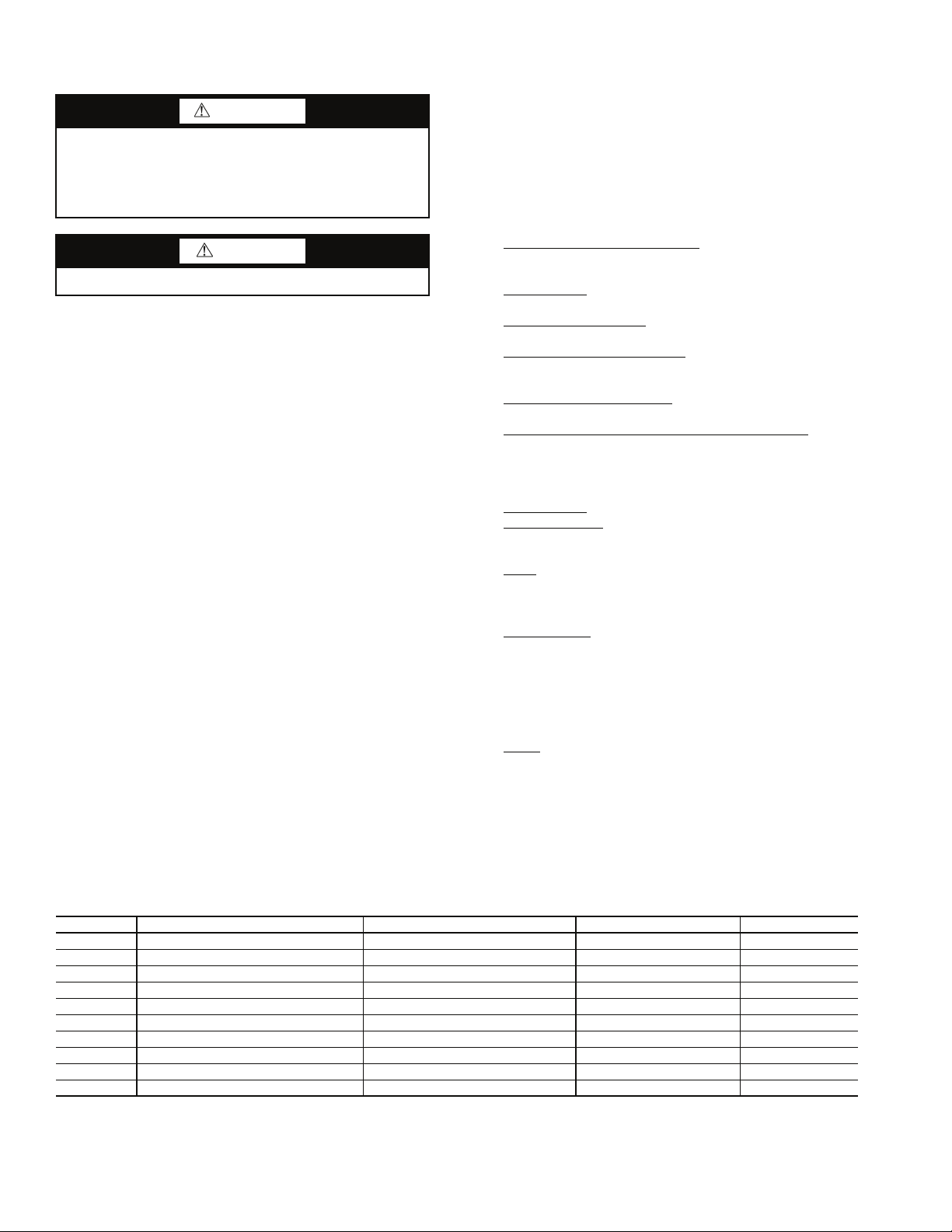

Table 1 — Model Number Reference By Application Type

MODEL TYPE* AVAILABLE CAPACITY CONSTRUCTION CONTROLS

50BVC Water-Cooled 18 to 30 nominal tons Single-piece CV

50BVE Remote Air-Cooled 18 to 30 nominal tons Single-piece CV

50BVQ Water-Cooled Heat Pump 18 to 30 nominal tons Single-piece CV

50BVJ Water-Cooled 18 to 30 nominal tons Single-piece VAV

50BVK Remote Air-Cooled 18 to 30 nominal tons Single-piece VAV

50BVT Water-Cooled 30 to 60 nominal tons Modular CV

50BVU Remote Air-Cooled 30 to 60 nominal tons Modular CV

50BVV Water-Cooled Heat Pump 30 to 60 nominal tons Modular CV

50BVW Water-Cooled 30 to 60 nominal tons Modular VAV

50BVX Remote Air-Cooled 30 to 60 nominal tons Modular VAV

LEGEND

CV — Constant Volume

VAV — Variable Air Volume

*All units are cooling only unless specified.

2

Page 3

INSTALLATION

Omnizone™ 50BV units are intended for indoor installation only. Determine building alterations required to run piping,

wiring, and ductwork. Read all installation instructions before

installing the unit.

Step 1 — Complete Pre-Installation Checks

EXAMINE THE UNIT — Examine the unit for shipping

damage. File a claim with the transit company if damage is

found. Check the shipment for completeness. Verify that the

nameplate electrical requirements match the available power

supply.

UNIT STORAGE — The 50BV units are designed and packaged for indoor storage and use only. If the equipment is not

needed for immediate installation upon its arrival at the job site,

it should be left in its shipping carton and stored in a clean, dry

area. Units must only be stored or moved in the normal upright

position, as indicated by the “UP” arrows on each carton, at all

times. DO NOT STACK UNITS.

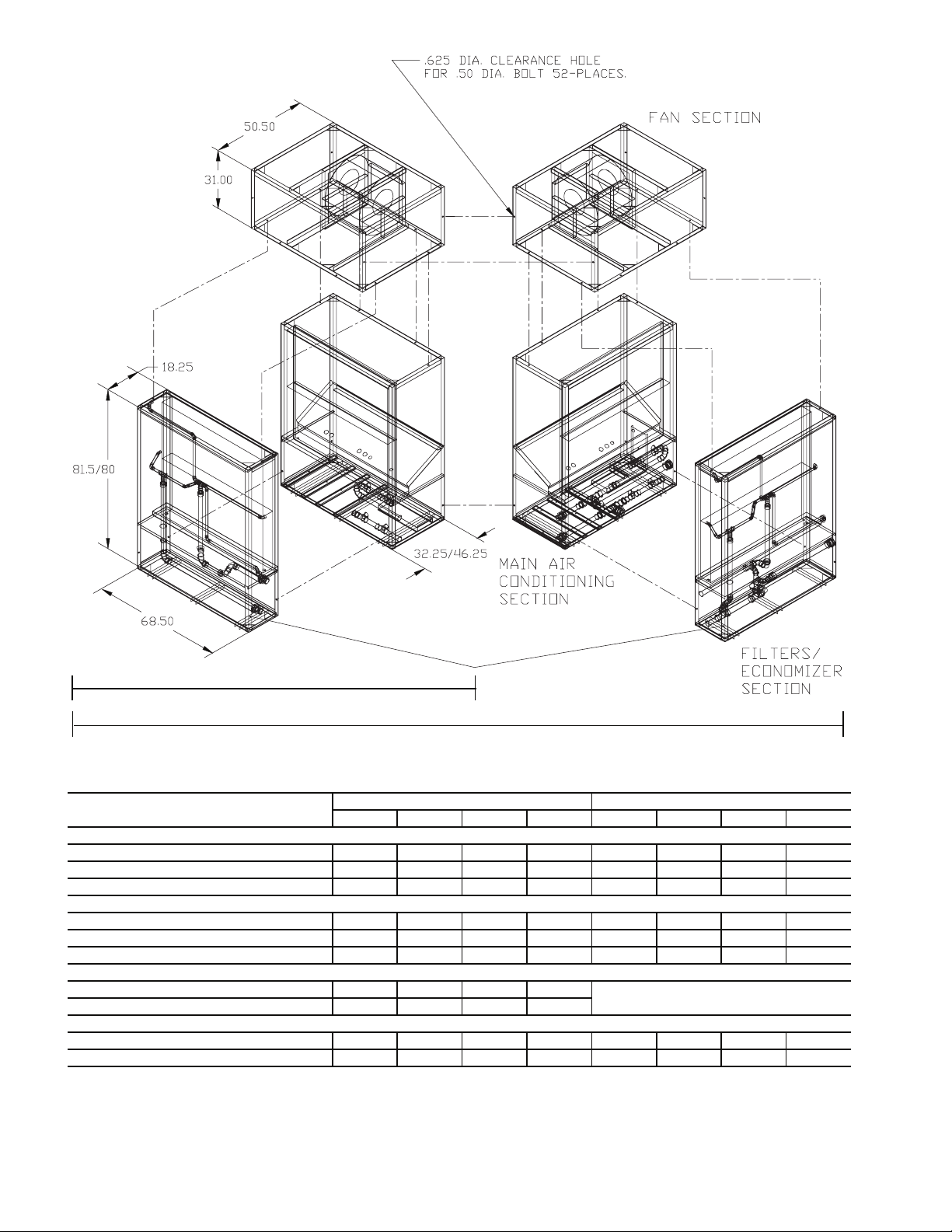

MODULAR UNITS — The 50BVT,U,V,W,X units are shipped

in multiple sections for easy movement and installation. The

separate modules will pass through a standard 36-in. steelframed door or service elevator. Circuit integrity is maintained

because none of the refrigerant piping requires disconnection.

Water piping connections are made with the use of heavy-duty

bronze-bodied unions so no field welding or brazing is required.

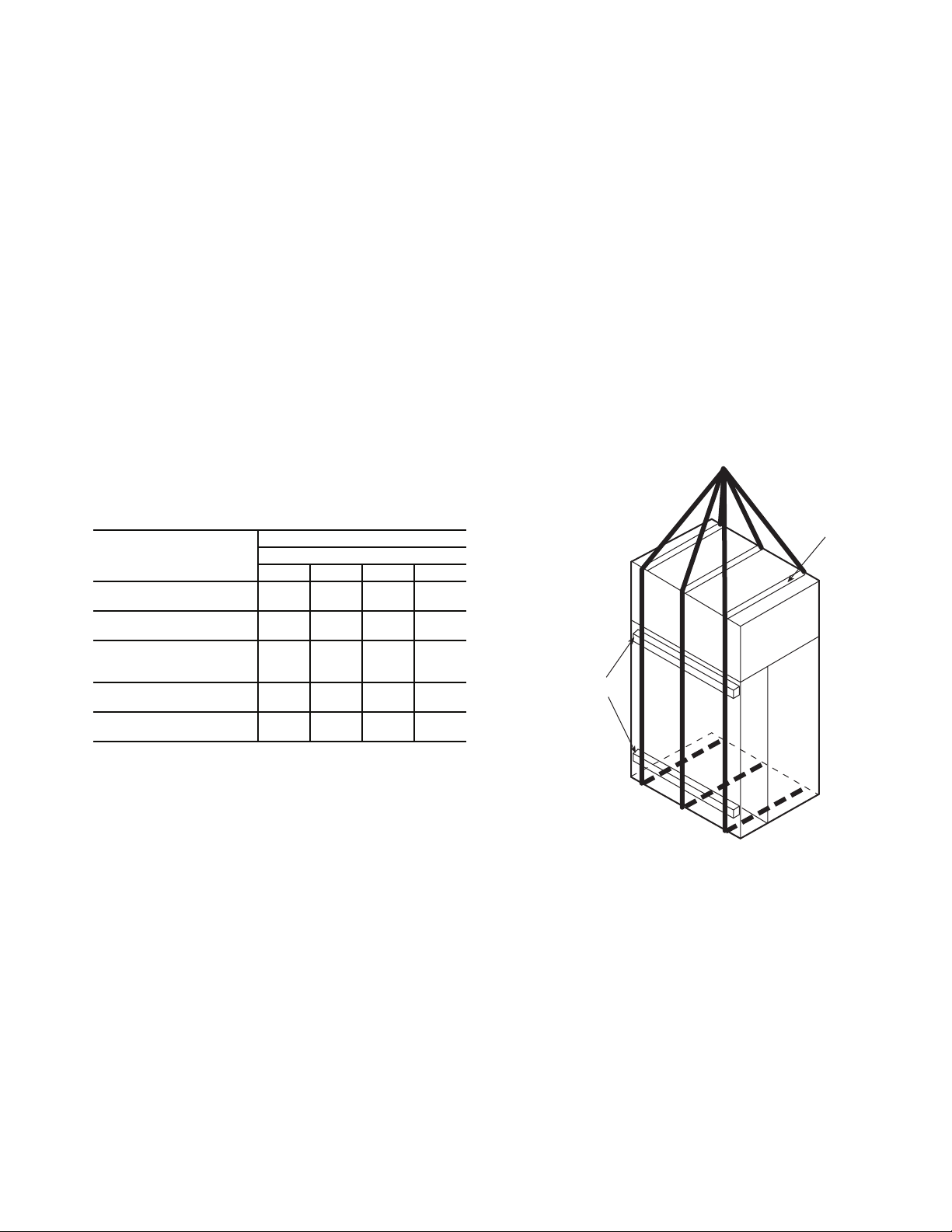

See Table 2 for the number of sections per unit.

Table 2 — Modular Unit Shipping Table

NUMBER OF SECTIONS

SECTIONS

Main Air Conditioning

Weight (lb) (each)

Reheat Coil Option

Weight (lb) (each)

Economizer/Filter

Filter Section Weight (lb)

Economizer Weight (lb)

Fan Section

Weight (lb) (each)

Tot al U ni t

Weight (lb)

50BVT, U, V, W, X

034 044 054 064

1

2100218252220022225

1

40

1

310

200

1

650

4

3300854008615086150

2

40

2

310

200

2

650

2

40

2

310

200

2

650

2

40

2

310

200

2

650

For single piece units, use spreader bars and rigging straps if

lifting with a crane to avoid damage to the unit. Otherwise,

move with a fork truck using the shipping pallet.

Refer to Fig. 2-14 for unit dimensions.

Refer to Tables 3A and 3B for physical data.

REMOVE PACKAGING — Remove all protective plastic,

remove and discard unit top cover protector, filter cover,

controller display protector, and water piping connection

packaging.

UNIT LOCATION — Locate the unit in an indoor area

that allows easy removal of the filters, access panels, and

accessories. Make certain enough space is available for service

personnel to perform maintenance or repairs. Provide sufficient

room to make all water, duct, and electrical connections. If the

unit is located in a small mechanical equipment room, make

sure adequate space is available for air to return freely to the

unit. These units are not approved for outdoor installations and

must be installed inside the structure. Do not locate in areas

that are subject to freezing.

UNIT PLACEMENT — Ensure that the floor is structurally

strong enough to support the weight of the equipment with

minimum deflection. A good, level floor is required for proper

unit operation and to ensure proper fit-up and alignment of all

bolt together and union coupled modules on modular units.

a50-7257ef

USE

SPREADER

BAR TO

PREVENT

DAMAGE

TO UNIT

4 X 4 ABOVE

AND BELOW

RETURN DUCT

CONNECTIONS

NOTE: Units ship with the main air conditioning, economizer/

filter, and, when selected, the reheat coil sections assembled

together. These can be easily disassembled, as required, in the

field. The fan section(s) always ships separately.

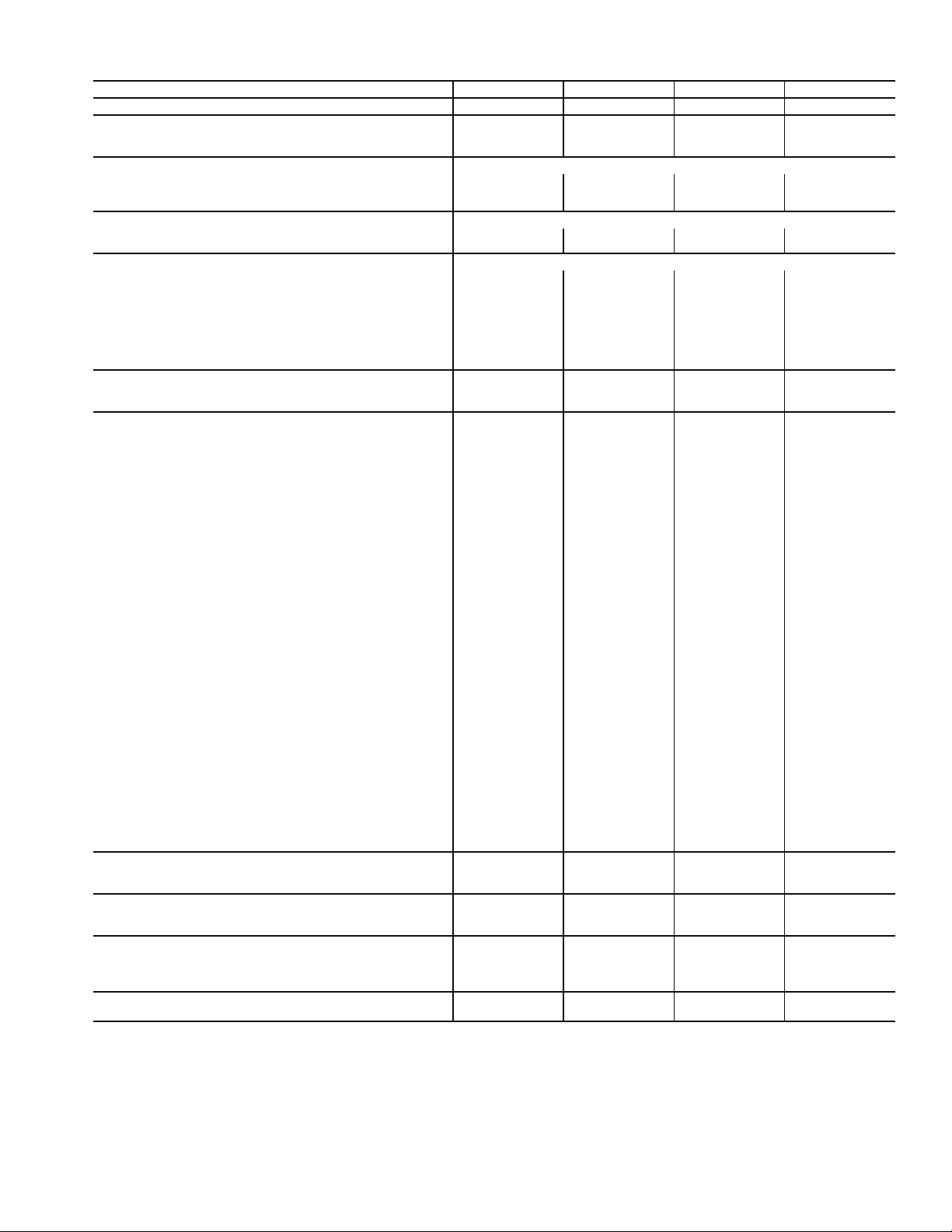

Step 2 — Rig and Place Unit — Use proper lifting

and handling practices to avoid damage to the unit. Move

modular units with a fork truck using the baserails provided, or

use spreader bars and lifting straps as shown in Fig. 1.

Fig. 1 — Modular Unit Rigging

3

Page 4

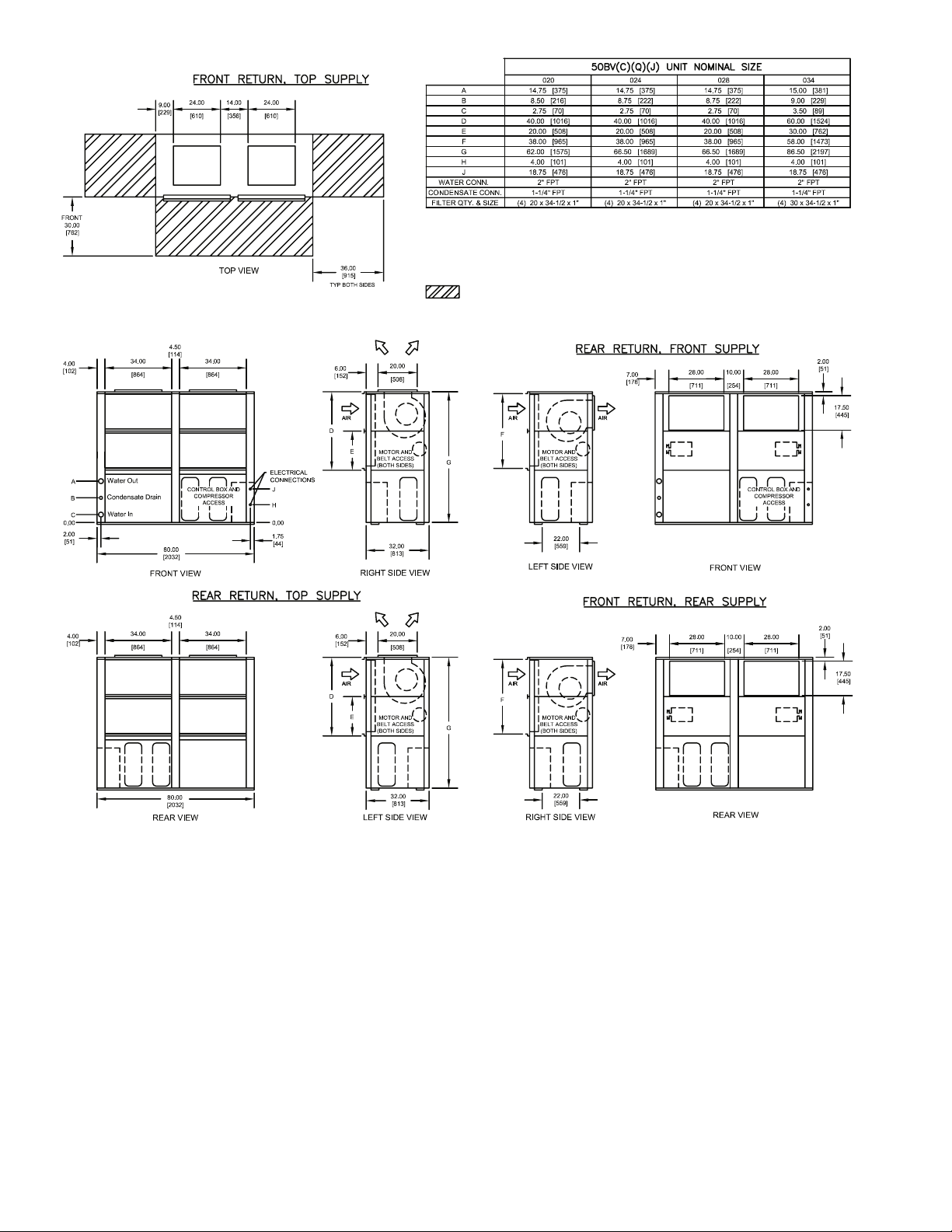

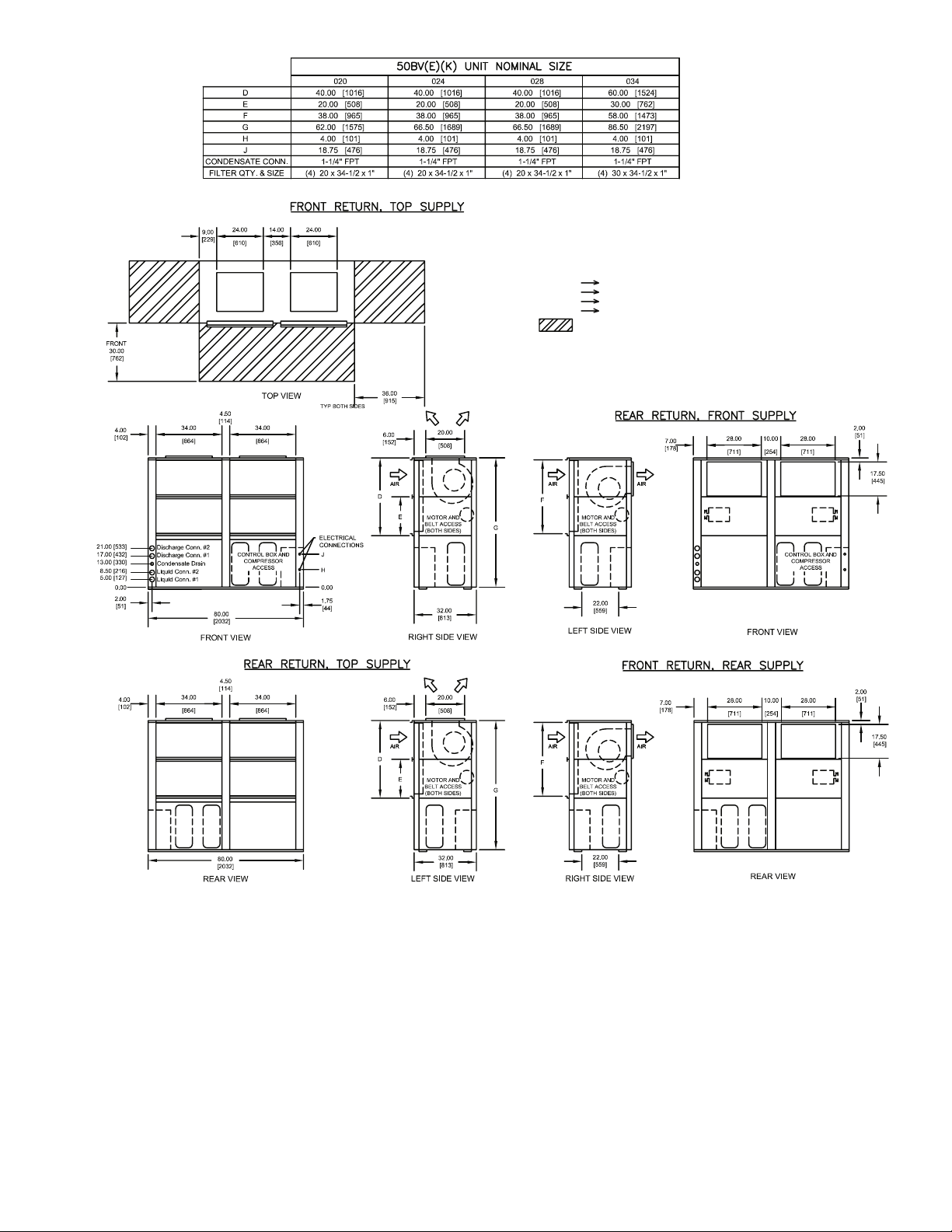

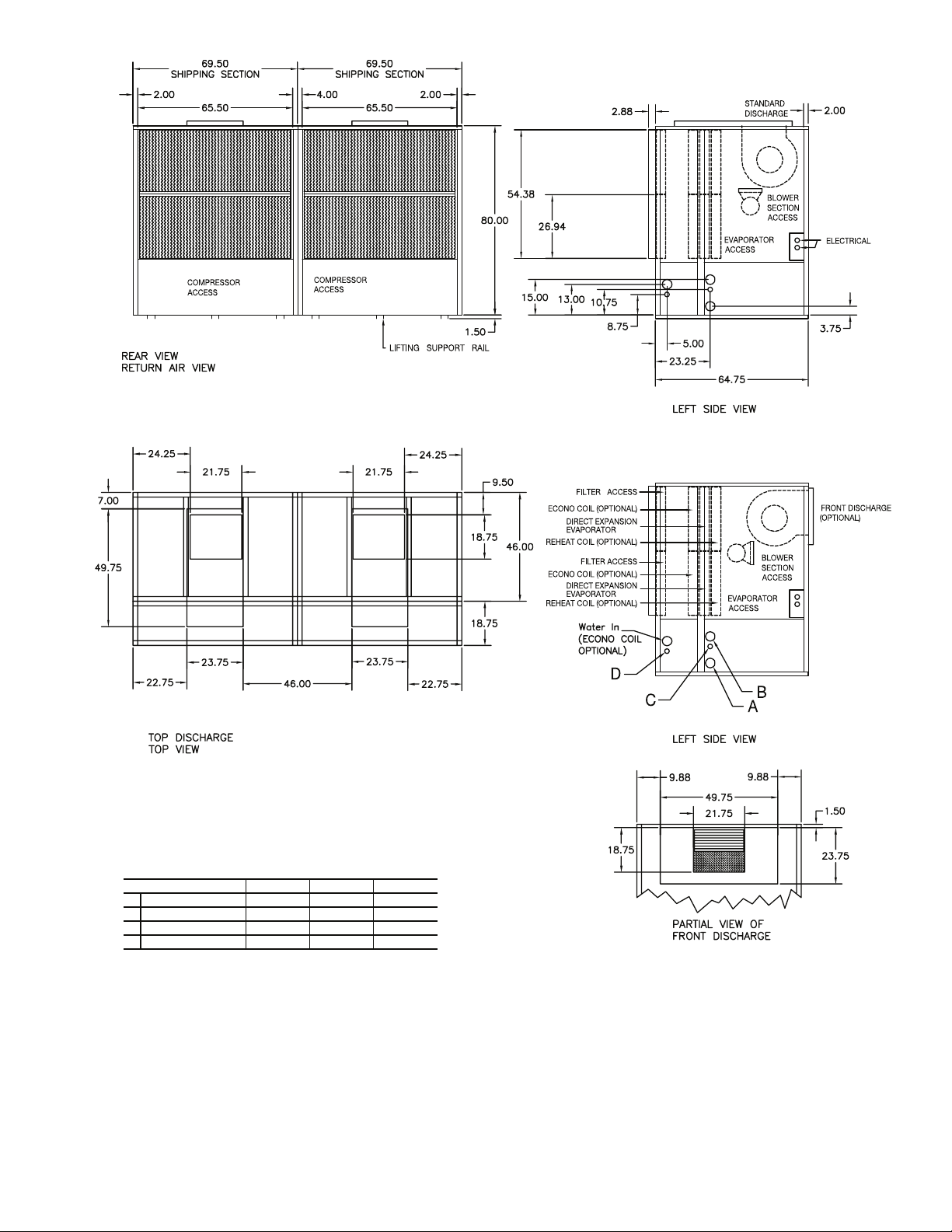

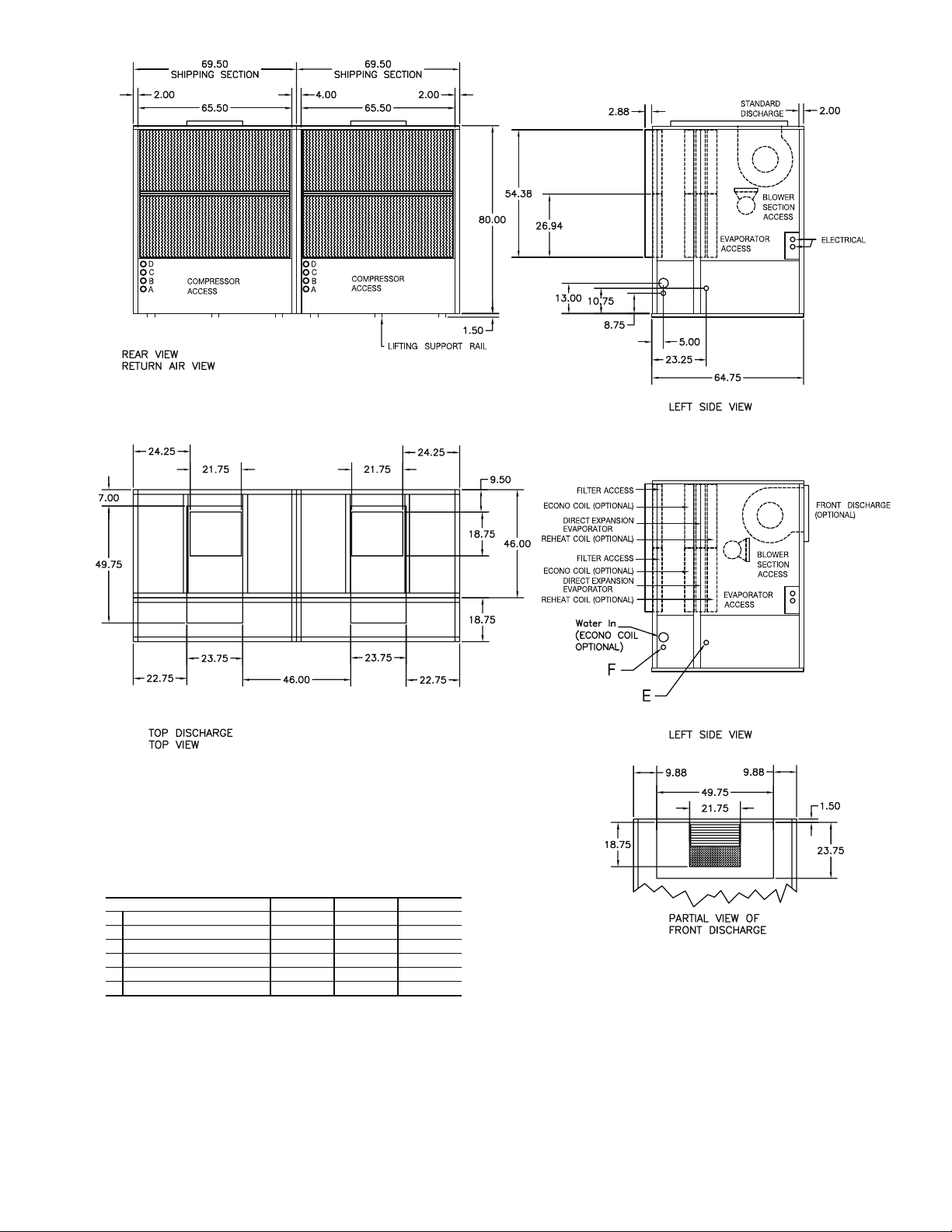

NOTES:

1. Dimensions in inches [mm].

2. VAV models (50BVJ) are rear return, top supply only.

3. Compressor, controls, and condenser access are through front panels.

4. Field power connections are 1-3/4 inches. Control connections are 7/8 inches.

5. Optional blower orientation is selected in model number nomenclature as option 9 in FIOP section

(digits 15 and 16).

Shows recommended minimum service clearances.

OPTIONAL

BLOWER

ORIENTATION

OPTIONAL

BLOWER

ORIENTATION

STANDARD

BLOWER

ORIENTATION

STANDARD

BLOWER

ORIENTATION

Fig. 2 — 50BVC,J,Q020-034 Dimensions

4

a50-8199

Page 5

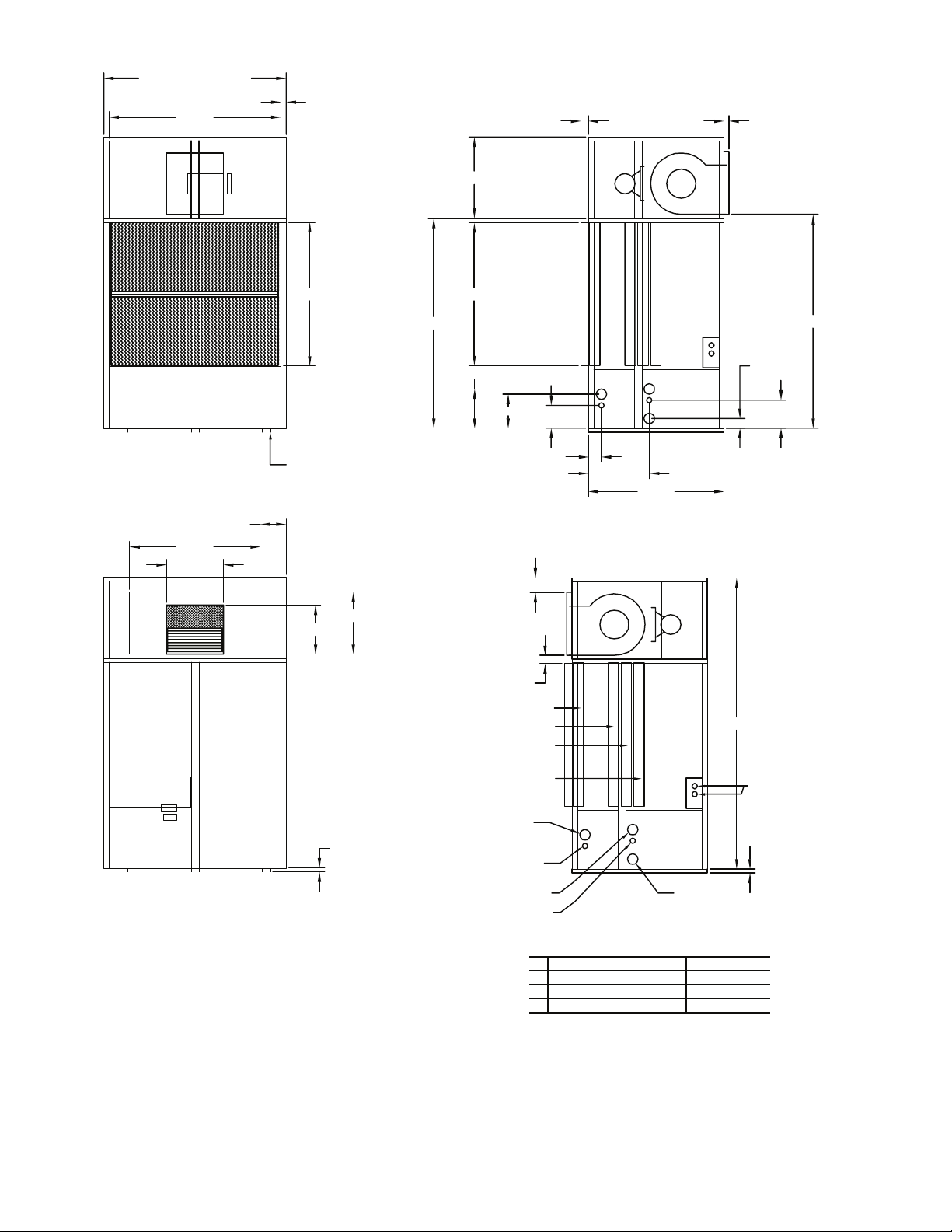

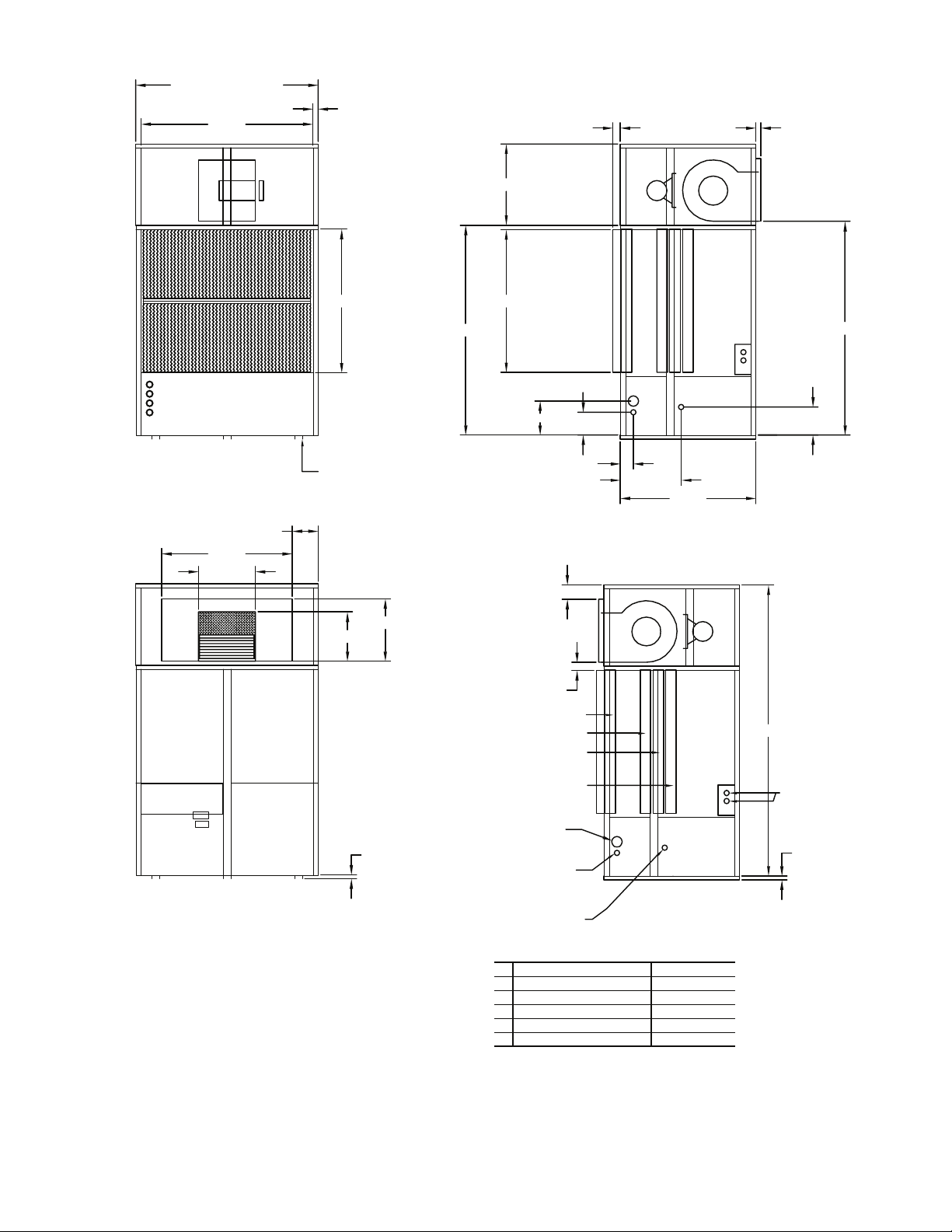

NOTES:

1. Dimensions in inches [mm].

2. VAV models (50BVK) are rear return, top supply only.

3. Compressor, controls, and condenser access are through front panels.

4. Field power connections are 1-3/4 inches. Control connections are 7/8 inches.

5. Discharge (hot gas) connections are 1-1/8 in. OD.

6. Liquid line connections are 7/8 in. OD.

7. Optional blower orientation is selected in model number nomenclature as

option 9 in FIOP section (digits 15 and 16).

RECOMMENDED CONDENSER MATCHES:

50BV020 one (1) 09DK020 (50/50 split each)

50BV024 one (1) 09DK024 (50/50 split each)

50BV028 one (1) 09DK028 (50/50 split each)

50BV034 one (1) 09DK034 (50/50 split each)

Shows recommended minimum service clearances.

OPTIONAL

BLOWER

ORIENTATION

OPTIONAL

BLOWER

ORIENTATION

STANDARD

BLOWER

ORIENTATION

STANDARD

BLOWER

ORIENTATION

Fig. 3 — 50BVE,K020-034 Dimensions

5

a50-8200

Page 6

69.50

SHIPPING SECTION

65.50

BLOWER

SECTION

ACCESS

2.00

54.75

31.00

54.38

2.88

BLOWER

SECTION

ACCESS

EVAPORATOR

ACCESS

2.00

STANDARD

DISCHARGE

COMPRESSOR

ACCESS

REAR VIEW

RETURN AIR VIEW

EVAPORATOR

ACCESS

49.75

21.75

9.88

EVAPORATOR

ACCESS

LIFTING SUPPORT RAIL

23.75

18.75

80.00

15.00

REAR DISCHARGE

(Optional)

FILTER ACCESS

ECONO COIL (Optional)

DIRECT EXPANSION

EVAPORATOR

13.00

3.19

5.50

8.75

5.00

23.25

51.63

LEFT SIDE VIEW

EVAPORATOR

ACCESS

BLOWER

SECTION

ACCESS

81.50

3.75

10.75

111.00

ELECTRICAL BOX

ELECTRICAL BOX

ACCESS

COMPRESSOR

ACCESS

1.50

FRONT VIEW

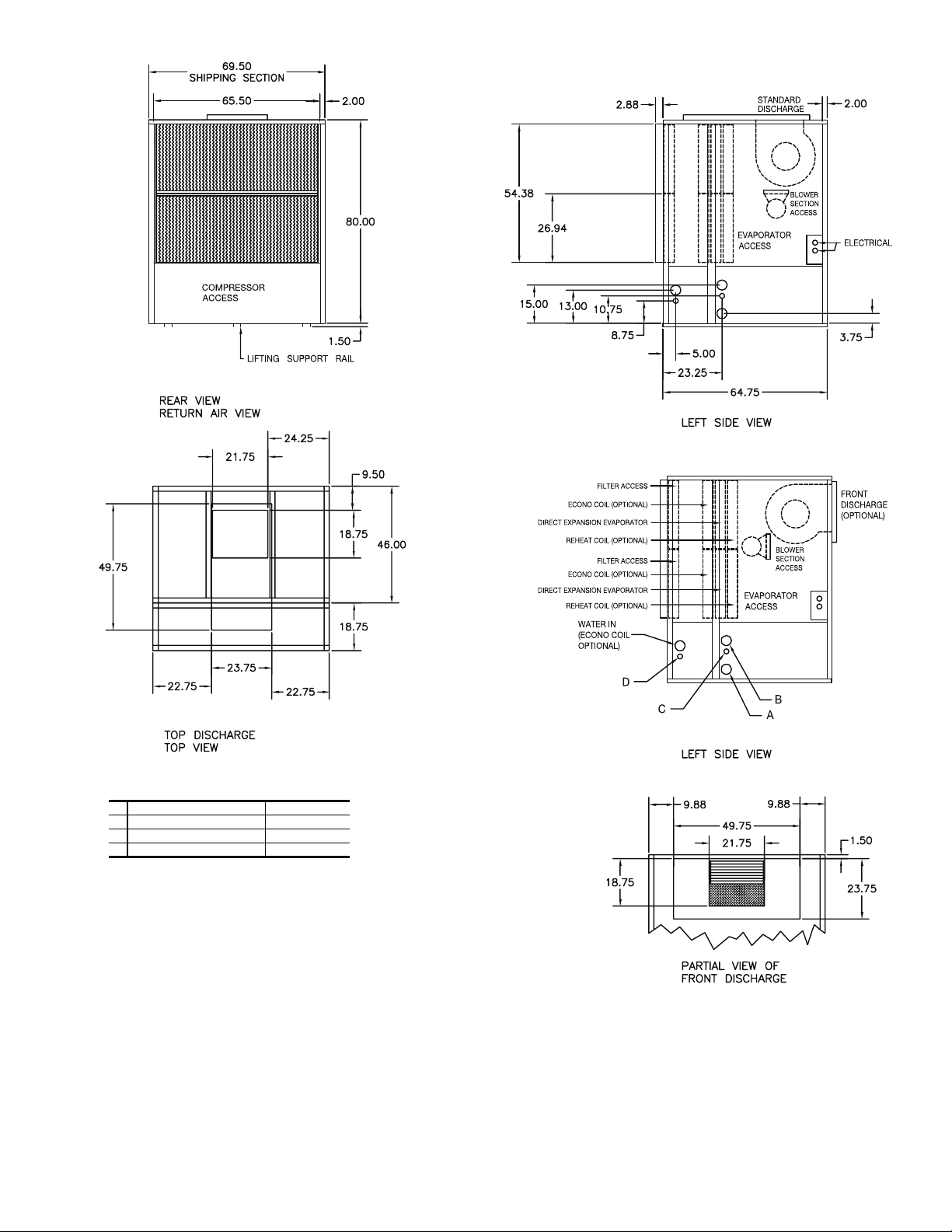

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. Constant volume units are available with front or rear air supply.

4. VAV units (50BVW) are available with rear supply only.

5. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left or right side — 65 in. (1651 mm) for coil removal

c. Side opposite coil removal — 20 in. (508 mm)

Fig. 4 — 50BVT,V,W034 (High-Boy) Dimensions

a50-8201

REHEAT COIL (Optional)

WATER IN

(ECONO COIL

OPTIONAL)

6

ELECTRICAL

1.50

D

A

B

C

CONNECTIONS

A WATER OUT 2-1/2 in. FPT

B WATER IN 2-1/2 in. FPT

C CONDENSATE DRAIN 1-1/4 in. FPT

D ECONOMIZER DRAIN 1-1/4 in. FPT

REPLACEMENT FILTERS : EIGHT (8) AT 17 x 27 x 4 INCHES.

LEFT SIDE VIEW

Page 7

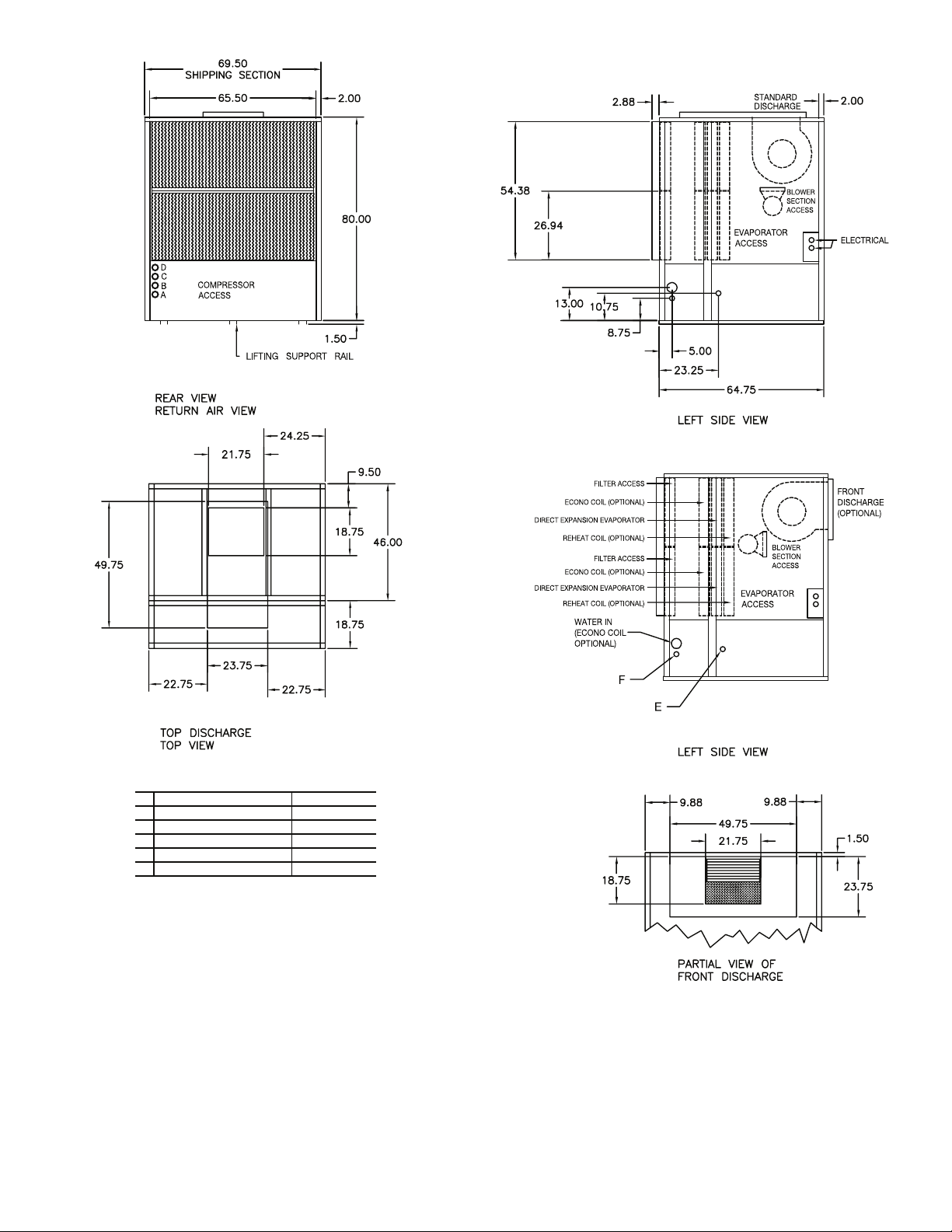

CONNECTIONS

A WATER OUT 2-1/2 in. FPT

B WATER IN 2-1/2 in. FPT

C CONDENSATE DRAIN 1-1/4 in. FPT

D ECONOMIZER DRAIN 1-1/4 in. FPT

REPLACEMENT FILTERS : EIGHT (8) AT 17 x 27 x 4 INCHES.

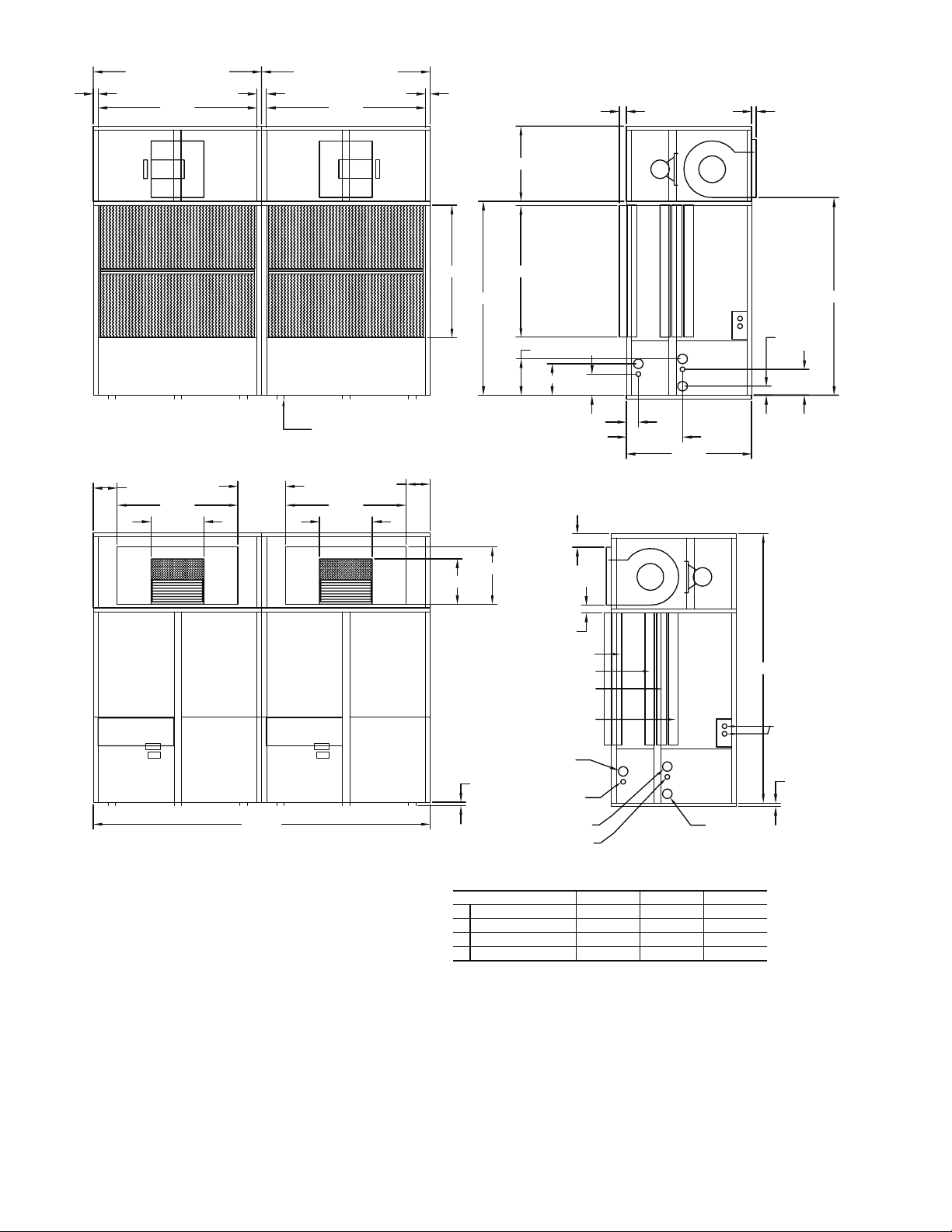

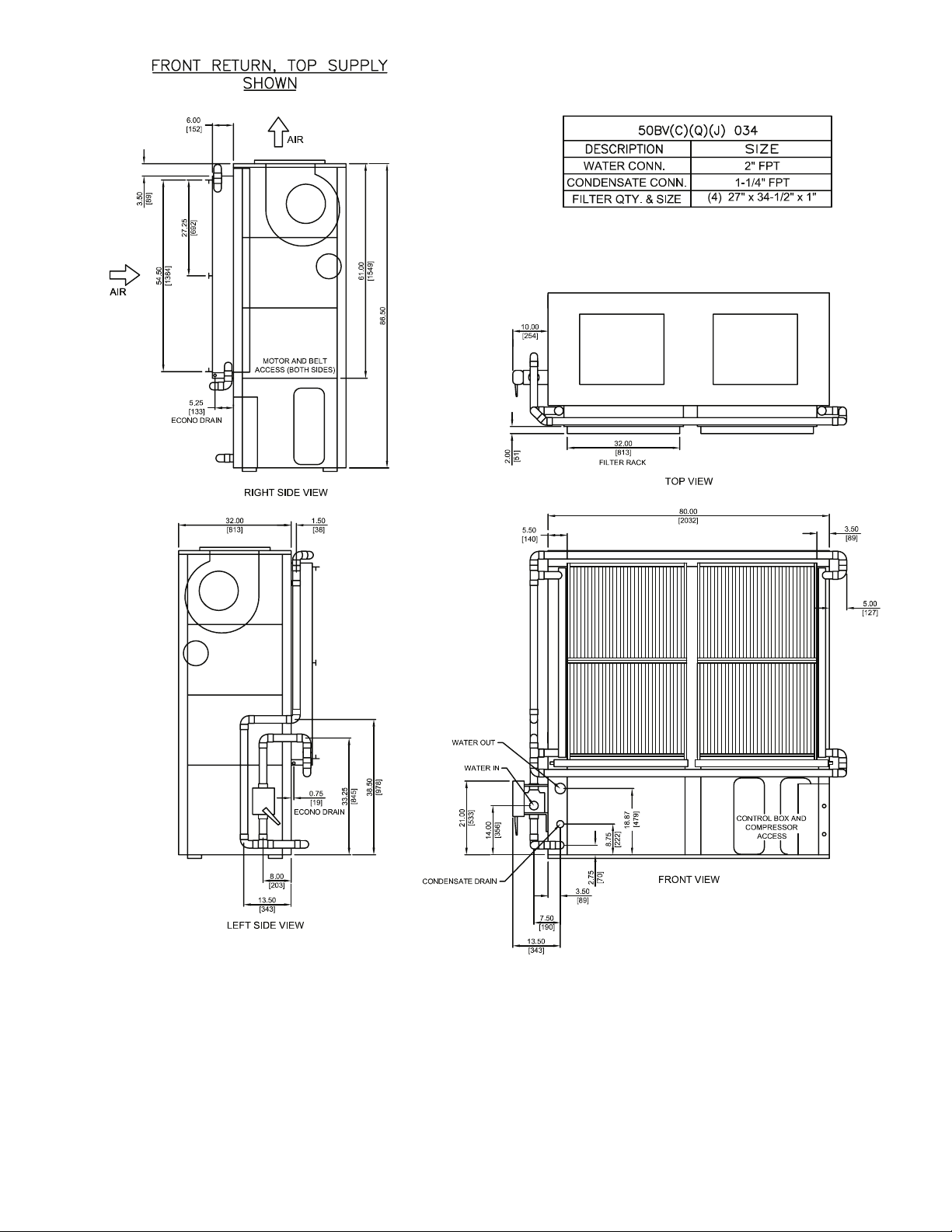

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left or right side — 65 in. (1651 mm) for coil removal

c. Side opposite coil removal — 20 in. (508 mm)

Fig. 5 — 50BVT,V,W034 (Low-Boy) Dimensions

a50-8202

a50-8202.eps

7

Page 8

69.50

SHIPPING SECTION

2.00 2.00

69.50

SHIPPING SECTION

4.00

65.50 65.50

BLOWER

SECTION

ACCESS

BLOWER

SECTION

ACCESS

54.75

80.00

31.00

54.38

2.88

BLOWER

SECTION

ACCESS

EVAPORATOR

ACCESS

2.00

STANDARD

DISCHARGE

81.50

COMPRESSOR

ACCESS

REAR VIEW

RETURN AIR VIEW

9.88

19.75

COMPRESSOR

ACCESS

LIFTING SUPPORT RAIL

49.75

21.75

EVAPORATOR

ACCESS

ELECTRICAL BOX

ELECTRICAL BOX

ACCESS

EVAPORATOR

ACCESS

COMPRESSOR

ACCESS

EVAPORATOR

ACCESS

ELECTRICAL BOX

ELECTRICAL BOX

ACCESS

139.00

FRONT VIEW

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. CV units are available with front or rear air supply.

4. VAV units (50BVW) are available with rear supply only.

5. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left and right sides — 65 in. (1651 mm) for coil removal

a50-8203

49.75

21.75

9.88

EVAPORATOR

ACCESS

COMPRESSOR

ACCESS

15.00

13.00

8.75

5.00

23.25

51.63

LEFT SIDE VIEW

18.75

23.75

5.50

REAR DISCHARGE

(OPTIONAL)

BLOWER

SECTION

ACCESS

3.19

FILTER ACCESS

ECONO COIL (OPTIONAL)

DIRECT EXPANSION

EVAPORATOR

REHEAT COIL (OPTIONAL)

WATER IN

(ECONO COIL

1.50

OPTIONAL)

EVAPORATOR

ACCESS

D

B

A

C

LEFT SIDE VIEW

CONNECTIONS

UNIT SIZE 044 054 064

A WATER OUT 2-1/2 in. FPT 3 in. FPT 3 in. FPT

B WATER IN 2-1/2 in. FPT 3 in. FPT 3 in. FPT

C CONDENSATE DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

D ECONOMIZER DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

REPLACEMENT FILTERS : SIXTEEN (16) AT 17 x 27 x 4 INCHES.

3.75

10.75

111.00

ELECTRICAL

1.50

Fig. 6 — 50BVT,V,W044-064 (High-Boy) Dimensions

8

Page 9

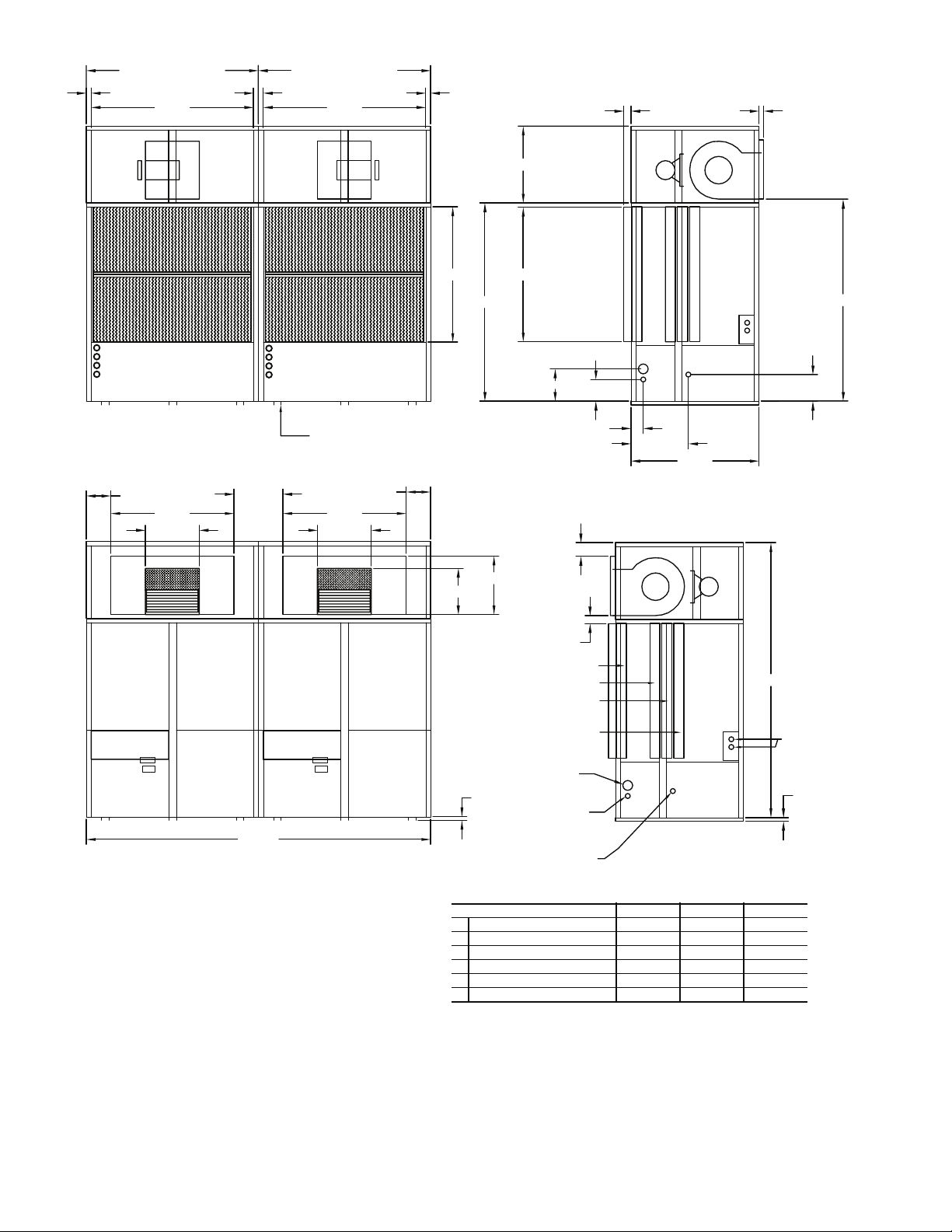

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left and right sides — 65 in. (1651 mm) for coil removal

CONNECTIONS

UNIT SIZE 044 054 064

A WATER OUT 2-1/2 in. FPT 3 in. FPT 3 in. FPT

B WATER IN 2-1/2 in. FPT 3 in. FPT 3 in. FPT

C CONDENSATE DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

D ECONOMIZER DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

REPLACEMENT FILTERS : SIXTEEN (16) AT 17 x 27 x 4 INCHES.

Fig. 7 — 50BVT,V,W044-064 (Low-Boy) Dimensions

a50-8204

9

Page 10

69.50

SHIPPING SECTION

65.50

BLOWER

SECTION

ACCESS

2.00

54.75

31.00

54.38

2.88

BLOWER

SECTION

ACCESS

EVAPORATOR

ACCESS

2.00

STANDARD

DISCHARGE

D

C

COMPRESSOR

B

ACCESS

A

REAR VIEW

RETURN AIR VIEW

EVAPORATOR

ACCESS

ELECTRICAL BOX

49.75

21.75

9.88

EVAPORATOR

ACCESS

LIFTING SUPPORT RAIL

23.75

18.75

80.00

13.00

REAR DISCHARGE

(Optional)

FILTER ACCESS

ECONO COIL (Optional)

DIRECT EXPANSION

EVAPORATOR

REHEAT COIL (Optional)

3.19

5.50

8.75

5.00

23.25

51.63

LEFT SIDE VIEW

EVAPORATOR

ACCESS

BLOWER

SECTION

ACCESS

81.50

10.75

111.00

ELECTRICAL

ELECTRICAL BOX

ACCESS

COMPRESSOR

ACCESS

1.50

FRONT VIEW

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. Constant volume units are available with front or rear air supply.

4. VAV units (50BVX) are available with rear supply only.

5. Recommended condenser match is ONE (1) 09DK034 (50/50 split).

6. Use proper piping practice for remote refr igerant connections. Refer to

Carrier System Design Manual Part 3.

7. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left or right side — 65 in. (1651 mm) for coil removal

c. Side opposite coil removal — 20 in. (508 mm)

Fig. 8 — 50BVU,X034 (High-Boy) Dimensions

WATER IN

(ECONO COIL

OPTIONAL)

F

E

CONNECTIONS

A LIQUID LINE CIRCUIT 1 7/8 in. OD

B LIQUID LINE CIRCUIT 2 7/8 in. OD

C DISCHARGE LINE CIRCUIT 1 1-1/8 in. OD

D DISCHARGE LINE CIRCUIT 2 1-1/8 in. OD

E CONDENSATE DRAIN 1-1/4 in. FPT

F ECONOMIZER DRAIN 1-1/4 in. FPT

REPLACEMENT FILTERS : EIGHT (8) AT 17 x 27 x 4 INCHES.

10

LEFT SIDE VIEW

1.50

a50-8205

Page 11

CONNECTIONS

A LIQUID LINE CIRCUIT 1 7/8 in. OD

B LIQUID LINE CIRCUIT 2 7/8 in. OD

C DISCHARGE LINE CIRCUIT 1 1-1/8 in. OD

D DISCHARGE LINE CIRCUIT 2 1-1/8 in. OD

E CONDENSATE DRAIN 1-1/4 in. FPT

F ECONOMIZER DRAIN 1-1/4 in. FPT

REPLACEMENT FILTERS : EIGHT (8) AT 17 x 27 x 4 INCHES.

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. Recommended condenser match is ONE (1) 09DK034 (50/50 split).

4. Use proper piping practice for remote refrigerant connections. Refer to

Carrier System Design Manual Part 3.

5. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left or right side — 65 in. (1651 mm) for coil removal

c. Side opposite coil removal — 20 in. (508 mm)

Fig. 9 — 50BVU,X034 (Low-Boy) Dimensions

a50-8206

a50-8206

11

Page 12

69.50

SHIPPING SECTION

2.00 2.00

69.50

SHIPPING SECTION

4.00

65.50 65.50

BLOWER

SECTION

ACCESS

BLOWER

SECTION

ACCESS

54.75

80.00

31.00

54.38

2.88

BLOWER

SECTION

ACCESS

EVAPORATOR

ACCESS

2.00

STANDARD

DISCHARGE

81.50

D

C

COMPRESSOR

B

A

ACCESS

REAR VIEW

RETURN AIR VIEW

9.88

49.75

21.75

EVAPORATOR

ACCESS

ELECTRICAL BOX

ELECTRICAL BOX

ACCESS

EVAPORATOR

ACCESS

COMPRESSOR

ACCESS

19.75

EVAPORATOR

ACCESS

ELECTRICAL BOX

ELECTRICAL BOX

ACCESS

D

C

COMPRESSOR

B

A

ACCESS

LIFTING SUPPORT RAIL

49.75

21.75

EVAPORATOR

ACCESS

COMPRESSOR

ACCESS

139.00

FRONT VIEW

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. CV units are available with front or rear air supply.

4. VAV units (50BVX) are available with rear supply only.

5. Use proper piping practice for remote refrigerant connections. Refer to

Carrier System Design Manual Part 3.

6. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left and right sides — 65 in. (1651 mm) for coil removal

a50-8207

9.88

13.00

8.75

5.00

23.25

51.63

LEFT SIDE VIEW

18.75

23.75

5.50

REAR DISCHARGE

(OPTIONAL)

BLOWER

SECTION

ACCESS

3.19

FILTER ACCESS

ECONO COIL (OPTIONAL)

DIRECT EXPANSION

EVAPORATOR

REHEAT COIL (OPTIONAL)

WATER IN

(ECONO COIL

1.50

OPTIONAL)

EVAPORATOR

ACCESS

111.00

F

E

CONNECTIONS

UNIT SIZE 044 054 064

A LIQUID LINE CIRCUIT 1, 2 7/8 in. OD 7/8 in. OD 7/8 in. OD

B LIQUID LINE CIRCUIT 3, 4 7/8 in. OD 7/8 in. OD 7/8 in. OD

C DISCHARGE LINE CIRCUIT 1, 2 1-1/8 in. OD 1-1/8 in. OD 1-1/8 in. OD

D DISCHARGE LINE CIRCUIT 3, 4 1-1/8 in. OD 1-1/8 in. OD 1-1/8 in. OD

E CONDENSATE DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

F ECONOMIZER DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

REPLACEMENT FILTERS : SIXTEEN (16) AT 17 x 27 x 4 INCHES.

LEFT SIDE VIEW

10.75

ELECTRICAL

1.50

Fig. 10 — 50BVU,X044-064 (High-Boy) Dimensions

12

Page 13

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. Use proper piping practice for remote refrigerant connections. Refer to

Carrier System Design Manual Part 3.

4. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left and right sides — 65 in. (1651 mm) for coil removal

CONNECTIONS

A LIQUID LINE CIRCUIT 1, 2 7/8 in. OD 7/8 in. OD 7/8 in. OD

B LIQUID LINE CIRCUIT 3, 4 7/8 in. OD 7/8 in. OD 7/8 in. OD

C DISCHARGE LINE CIRCUIT 1, 2 1-1/8 in. OD 1-1/8 in. OD 1-1/8 in. OD

D DISCHARGE LINE CIRCUIT 3, 4 1-1/8 in. OD 1-1/8 in. OD 1-1/8 in. OD

E CONDENSATE DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

F ECONOMIZER DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

REPLACEMENT FILTERS : SIXTEEN (16) AT 17 x 27 x 4 INCHES.

UNIT SIZE 044 054 064

Fig. 11 — 50BVU,X044-064 (Low-Boy) Dimensions

a50-8208

13

Page 14

NOTES:

1. Dimensions in inches [mm].

2. Refer to base unit certified drawing for additional unit dimensions, service

clearance, and alternate airflow configurations.

a50-7306ef

Fig. 12 — 50BVC,J,Q020-028 with Optional Waterside Economizer Dimensions

14

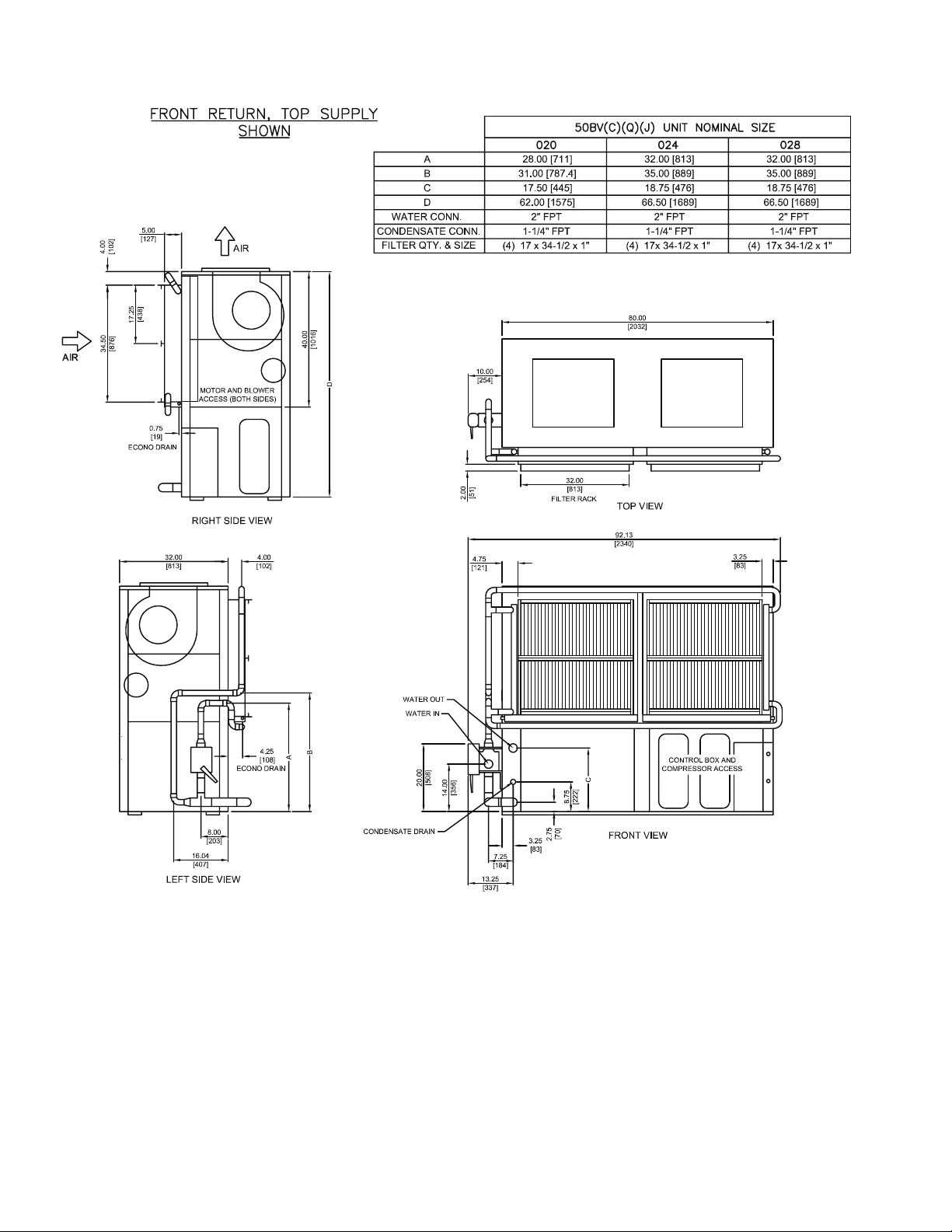

Page 15

NOTES:

1. Dimensions in inches [mm].

2. Refer to base unit certified drawing for additional unit dimensions, service

clearances, and alternate airflow configurations.

a50-7307ef

Fig. 13 — 50BVC,J,Q034 with Optional Waterside Economizer Dimensions

15

Page 16

a50-8235

*

*

Size 034 Units

Size 044-064 Units

Shipping Weights (lb)

50BVT,U,V,W,X UNIT

MAIN AIR CONDITIONING SECTION (EACH)

NUMBER OF SECTIONS 12221222

SECTION WEIGHT 1450 1175 1550 1575 2100 1825 2200 2225

REHEAT COIL OPTION 40 40 40 40 40 40 40 40

FILTER/ECONOMIZER SECTION (EACH)

NUMBER OF SECTIONS 12221222

FILTER SECTION 310 310 310 310 310 310 310 310

ECONOMIZER OPTION 200 200 200 200 200 200 200 200

FAN SECTION (EACH)

NUMBER OF SECTIONS 1222

FAN SECTION 650 650 650 650

TOTAL UN IT

NUMBER OF SECTIONS 36662444

UNIT WITH OPTIONS 2650 4750 5500 5550 2650 4750 5500 5550

*High-boy/low-boy.

034 044 054 064 034 044 054 064

Fig. 14 — Modular Shipping Weights — 50BVT,U,V,W,X

HIGH-BOY UNIT LOW-BOY UNIT

AIR CONDITIONING SECTION

INCLUDED IN

16

Page 17

Table 3A — Physical Data — 50BVC,E,J,K,Q

UNIT 50BVC,E,J,K,Q 020 024 028 034

NOMINAL CAPACITY (Tons) 18 20 25 30

OPERATING WEIGHT (lb)

50BVC,Q…50BVJ 1192…1227 1378…1413 1428…1473 1680…1725

50BVE…50BVK 1110…1145 1290…1325 1320…1365 1520…1565

COMPRESSOR Copeland Scroll

Quantity 2222

Number of Refrigerant Circuits 2222

Oil (ounces) Ckt 1…Ckt 2 85…85 110…110 110…110 140…140

REFRIGERANT TYPE R-22 or R-410A

Expansion Device TXVTXVTXVTXV

Operating Charge (lb) Ckt 1…Ckt 2 8.1…8.1 9.1…9.1 9.1…9.1 18.0…18.0

CONDENSER (50BVC,Q,J only) Tube-in-Tube Coaxial

Quantity of Manifolded Circuits 2222

Nominal Flow Rate (GPM) 54 60 75 90

Water Flow Range (GPM) 36-72 40-80 50-100 60-120

Max. Water Working Pressure (PSIG) 400 400 400 400

Max. Refrig. Working Pressure (PSIG) 450 (600*) 450 (600*) 450 (600*) 450 (600*)

Min. Entering Water Temp. (°F) 50 50 50 50

Max. Entering Water Temp. (°F) 110 110 110 110

Waterside Volume (gal) 3.6 4.0 5.0 6.0

EVAPORATOR COIL

Rows…Fins/in. 3…14 3…14 3…14 3…14

Total Face Area (sq ft) 18.1 18.1 18.1 22.0

EVAPORATOR FAN

Quantity…Size 2…15x15 2…15x15 2…15x15 2…15x15

Type Drive Belt Belt Belt Belt

Nominal CFM 7200 8000 10,000 12,000

Std Motor Qty…HP…Frame Size 2…1.5…56 2…2…56H 2…3…56HZ 2…5…56HZ

Alt 1 Motor Qty…HP…Frame Size 2…2…56H 2…3…56HZ 2…5…56HZ —

Alt 2 Motor Qty…HP…Frame Size 2…3…56HZ 2…5…56HZ — —

Alt 3 Motor Qty…HP…Frame Size 2…5…56HZ — — —

Motor Nominal RPM (1.5, 2, 3, HP) 1725 1725 1725 —

Motor Nominal RPM (5 HP) 3450 3450 3450 3450

Fan Drive RPM Range

Std Fan Drive (1.5, 2, 3 HP) 753-952 753-952 753-952 —

Std Fan Drive (5 HP) 967-1290 967-1290 967-1290 967-1290

Med Static Fan Drive (1.5, 2, 3 HP) 872-1071 872-1071 872-1071 —

Motor Bearing Type Ball Ball Ball Ball

Maximum Allowable RPM 1300 1300 1300 1300

Motor Pulley Pitch Diameter

Std Fan Drive (1.5, 2, 3 HP) 3.7-4.7 3.7-4.7 3.7-4.7 —

Std Fan Drive (5 HP) 2.9-3.9 2.9-3.9 2.9-3.9 2.9-3.9

Med Static Fan Drive (1.5, 2, 3 HP) 4.3-5.3 4.3-5.3 4.3-5.3 —

Motor Shaft Diameter (in.) (1.5, 2 HP)

Motor Shaft Diameter (in.) (3, 5 HP)

Belt, Qty…Type…Length (in.)

Std Fan Drive (1.5, 2 HP) 1…B…39 1…B…39 — —

Std Fan Drive (3 HP) 2…B…39 2…B…39 2…B…39 —

Std Fan Drive (5 HP) 2...BX…42 2...BX…42 2...BX…42 2...BX…42

Med Static Fan Drive (1.5, 2 HP) 1…B…40 1…B…40 — —

Med Static Fan Drive (3 HP) 2…B…40 2…B…40 2…B…40 —

Pulley Center Line Distance (in.) 10.1…10.9 10.1…10.9 10.1…10.9 10.1…10.9

Speed Change Per Full Turn of

Moveable Pulley Flange (RPM)

Std Fan Drive (1.5, 2, 3 HP) 33 33 33 —

Std Fan Drive (5 HP) 54 54 54 54

Med Static Fan Drive (1.5, 2, 3 HP) 33 33 33 —

Fan Shaft Diameter (in.) 1111

5

/

8

7

/

8

HIGH PRESSURE SWITCHES (PSIG)

Cutout 380 (420*) ± 10 380 (420*) ± 10 380 (420*) ± 10 380 (420*) ± 10

Reset (Auto) 300 (420*) ± 15 300 (420*) ± 15 300 (420*) ± 15 300 (420*) ± 15

LOW PRESSURE SWITCHES (PSIG)

Cutout 20 (40*) ± 3 20 (40*) ± 3 20 (40*) ± 3 20 (40*) ± 3

Reset (Auto) 40 (60*) ± 5 40 (60*) ± 5 40 (60*) ± 5 40 (60*) ± 5

REMOTE REFRIGERANT CONNECTIONS

(50BVE,K Only)

Discharge (Hot Gas) Connection (in.) Qty…Size 2…1

Liquid Connection (in.) Qty…Size 2…7/

1

/

8

8

RETURN AIR FILTERS

Quantity…Size (in.) 4…20x34.5x1 4…20x34.5x1 4…20x34.5x1 4…30x34.5x1

LEGEND *R-410A models.

TXV — Thermostatic Expansion Valve

5

/

8

7

/

8

2…11/

2…7/

——

7

/

8

8

8

2…11/

2…7/

8

8

7

/

8

2…11/

2…7/

8

8

17

Page 18

Table 3B — Physical Data — 50BVT,U,V,W,X

UNIT 50BVT,U,V,W,X 034 044 054 064

NOMINAL CAPACITY (Tons) 30 40 50 60

OPERATING WEIGHT (lb)

50BVT,V…50BVW 2580…2645 4334…4404 5198…5298 5230…5330

50BVU…50BVX 2420…2485 4094…4164 4938…5038 4970…5070

COMPRESSOR Copeland Scroll

Quantity 2444

Number of Refrigerant Circuits 2444

Oil (oz.)

Circuit 1…Circuit 2 140…140 110…110 140…140 140…140

Circuit 3…Circuit 4 — 110…110 140…140 140…140

REFRIGERANT TYPE R-22

Expansion Device TXV TXV TXV TXV

Operating Charge (lb)

Circuit 1…Circuit 2 18.0…18.0 10.0…10.0 18.0…18.0 18.0…18.0

Circuit 3…Circuit 4 — 10.0…10.0 18.0…18.0 18.0…18.0

CONDENSER (50BVT,V,W only) Tube-in-Tube Coaxial

Quantity of Manifolded Circuits 2444

Nominal Flow Rate (GPM) 90 120 150 180

Water Flow Range (GPM) 60-120 80-160 100-200 120-240

Max. Water Working Pressure (PSIG) 400 400 400 400

Max. Refrig. Working Pressure (PSIG) 450 450 450 450

Min. Entering Water Temp. (°F) 50 50 50 50

Max. Entering Water Temp. (°F) 110 110 110 110

Waterside Volume (gal) 6.0 9.0 11.3 13.5

EVAPORATOR COIL

Rows…Fins/in. 4…12 3…12 4…12 4…12

Total Face Area (sq ft) 23.2 46.4 46.4 46.4

EVAPORATOR FAN

Quantity…Size 1…18x18 2…18x18 2…18x18 2…18x18

Type Drive Belt Belt Belt Belt

Nominal CFM 12,000 16,000 20,000 24,000

Motor Option 1 Qty…HP…Frame Size 1…7.5…213T 2…7.5…213T 2…7.5…213T 2…7.5…213T

Motor Option 2 Qty…HP…Frame Size 1…10…215T 2…10…215T 2…10…215T 2…10…215T

Motor Option 3 Qty…HP…Frame Size 1…15…254T 2…15…254T 2…15…254T 2…15…254T

Motor Option 4 Qty…HP…Frame Size 1…20…256T — 2…20…256T 2…20…256T

Motor Nominal RPM 1750 1750 1750 1750

Fan Drive RPM Range

Standard (7.5 HP) 780-960 780-960 780-960 780-960

Standard (10, 15, 20 HP), Med Static (7.5 HP) 805-991 805-991 805-991 805-991

Med Static (10, 15, 20 HP), High Static (7.5 HP) 960-1146 960-1146 960-1146 960-1146

High Static (10, 15, 20 HP) 1119-1335 1119-1335 1119-1335 1119-1335

Motor Bearing Type Ball Ball Ball Ball

Maximum Allowable RPM 1450 1450 1450 1450

Motor Pulley Pitch Diameter

Std Fan Drive (7.5 HP) 5.2-6.4 5.2-6.4 5.2-6.4 5.2-6.4

Std Fan Drive (10, 15, 20 HP), Med Static (7.5 HP) 4.8-6.0 4.8-6.0 4.8-6.0 4.8-6.0

Med Static Fan Drive (10, 15, 20 HP), High Static (7.5 HP) 5.8-7.0 5.8-7.0 5.8-7.0 5.8-7.0

High Static Fan Drive (10, 15, 20 HP) 5.8-7.0 5.8-7.0 5.8-7.0 5.8-7.0

Motor Shaft Diameter (in.) (7.5, 10 HP) 1

Motor Shaft Diameter (in.) (15, 20 HP) 15/

Belt, Qty…Type…Length (in.)

Std Fan Drive (7.5 HP) 2…B…48 2...B...48 2…B…48 2…B…48

Std Fan Drive (10, 15, 20 HP), Med Static (7.5 HP) 2…B…46 2…B…46 2…B…46 2…B…46

Med Static Fan Drive (10, 15, 20 HP), High Static 7.5 HP) 2…B…48 2…B…48 2…B…48 2…B…48

High Static Fan Drive (10, 15, 20 HP) 2…B…45 2…B…45 2…B…45 2…B…45

Pulley Center Line Distance (in.) 10.2-11.4 10.2-11.4 10.2-11.4 10.2-11.4

Speed Change Per Full Turn of Moveable Pulley Flange (RPM)

Std Fan Drive (7.5 HP) 36 36 36 36

Std Fan Drive (10, 15, 20 HP), Med Static (7.5 HP) 31 31 31 31

Med Static Fan Drive (10, 15, 20 HP), High Static (7.5 HP) 31 31 31 31

High Static Fan Drive (10, 15, 20 HP) 36 36 36 36

Fan Shaft Diameter (in.) 1

HIGH PRESSURE SWITCHES (PSIG)

Cutout 380 ± 10 380 ± 10 380 ± 10 380 ± 10

Reset (Auto) 300 ± 15 300 ± 15 300 ± 15 300 ± 15

LOW PRESSURE SWITCHES (PSIG)

Cutout 20 ± 3 20 ± 3 20 ± 3 20 ± 3

Reset (Auto) 40 ± 5 40 ± 5 40 ± 5 40 ± 5

REMOTE REFRIGERANT CONNECTIONS (50BVU,X Only)

Discharge (Hot Gas) Connection (in.) Qty…Size 2…1

Liquid Connection (in.) Qty…Size 2…7/

RETURN AIR FILTERS

Quantity…Size (in.) 8…17x27x4 16…17x27x4 16…17x27x4 16…17x27x4

3

/

8

8

7

/

16

1

/

8

8

13/

15/

17/

16

4…11/

4…7/

8

8

8

8

13/

15/

17/

16

4…11/

4…7/

8

8

8

8

13/

15/

17/

4…11/

4…7/

8

8

16

8

8

18

Page 19

ACOUSTICAL CONSIDERATIONS — Proper acoustical

considerations are a critical part of every system’s design and

operation. Each system design and installation should be

reviewed for its own unique requirements. For job specific

requirements, contact an acoustical consultant for guidance and

recommendations.

In general, to reduce noise, consider the following:

• Locate mechanical room and ducts away from noise

sensitive locations. Whenever possible, work with the

architect to locate the equipment rooms around the

perimeters of restrooms, hallways, fire escapes, stair

wells, etc., to reduce noise transmission. This allows not

only for isolation from radiated sound but also enables

the contractor to route duct systems around sensitive

locations.

• Construct the equipment room of concrete block or use a

double offset stud wall with interwoven insulation. Seal

all penetrations.

• Design the system for low total static pressure.

• Use suitable vibration isolation pads or isolation springs

according to the design engineer's specifications.

• A flexible canvas duct connector is recommended on

both the supply and return air sides of units to be

connected to system ductwork.

• Use a minimum of 15 ft of return ductwork between the

last air terminal or diffuser and the unit.

• Insulate supply and return ducts with 2-in., 3-lb density

insulation.

• Round duct is recommended. If rectangular ductwork is

used, keep aspect ratios as small as possible (i.e., as close

to square as possible).

• Avoid any direct line of sight from return air grilles

into the unit's return. If return air is to be ducted to an

equipment room, an elbow should be installed within the

equipment room.

• Running a return air drop to near the floor of the room

will aid in sound attenuation.

• Do not exceed the recommended supply duct velocity of

2,000 fpm.

• Do not exceed the recommended return duct velocity of

1,000 fpm.

• Use turning vanes on 90-degree elbows.

• Place isolation springs under each corner and under each

compressor if utilized.

ASSEMBLING MODULAR UNITS — 50BVT,U,V,W,X

30 to 60 ton units ship in the number of pieces shown in Table

2. Reassemble the unit. Use the loose hardware provided in the

main air-conditioning section and the instructions below.

1. The filter/economizer section ships bolted to the main airconditioning section and can be removed in the field.

When reattaching the filter/economizer section to the

main air-conditioning section, place the filter side of the

filter/economizer section facing out and away from the

main air conditioning section.

2. If the unit has 2 filter/economizer and 2 main airconditioning sections (40 through 60 ton units), bolt the

remaining filter/economizer section and main airconditioning section together, as in Step 1.

3. For units with 2 filter/economizer and 2 main airconditioning sections, use the provided unions to assemble the water connections between the 2 additional

sections joined in Step 2.

4. For units with multiple air conditioning sections, connect

the condensate drain hoses from the “B” side of the unit

to the drain manifold on the “A” side of the unit.

5. For unit sizes 044-064, connect power wiring from the

main terminal block in the “A” side of the unit to the

power terminal block in the “B” side of the unit.

6. For VAV units only, connect the plenum tubing, coiled

behind the VAV control panel, to the bulkhead fittings

located in the discharge of the supply fan. This connects

the high pressure supply to the high side of the duct high

static pressure switch.

CAUTION

Remove all shipping blocks, if any, under blower housing

or damage to the fan may occur.

Step 3 — Install Ductwork — The VAV units must

use a “pair of pants” configuration as shown in Fig. 15. Refer

to the Carrier System Design Manual or ASHRAE (American

Society of Heating, Refrigerating and Air Conditioning Engineers) standards for the recommended duct connection to unit

with 2 fans.

A

NOTE: A = 11/2 to 21/2B

Fig. 15 — Typical Fan Discharge Connections for

Multiple Fan Units

A supply air outlet collar and return air duct flange are provided on all units to facilitate duct connections. Refer to dimensional drawings (Fig. 2-14) for connection sizes and locations.

A flexible canvas duct connector is recommended on both

supply and return air sides of the units to be connected to the

system ductwork.

All metal ductwork should be adequately insulated to avoid

heat loss or gain and to prevent condensation from forming on

the duct walls. Uninsulated ductwork is not recommended, as

the unit's performance will be adversely affected.

Do not connect discharge ducts directly to the blower

outlet(s). The factory filter should be left in place on a free

return system.

If the unit will be installed in a new installation, the duct

system should be designed in accordance with the System Design Manual, Part 2 and with ASHRAE (American Society of

Heating, Refrigeration and Air Conditioning Engineers) procedures for duct sizing. If the unit will be connected to an existing

duct system, check that the existing duct system has the capacity to handle the required airflow for the unit application at an

a50-8357.eps

B

19

Page 20

acceptable system static pressure. If the existing duct system is

too small, larger ductwork must be installed.

The duct system and diffusers should be sized to handle the

design airflow volumes quietly. To maximize sound attenuation

of the unit's blower(s), the supply and return air plenums should

be insulated for a length of at least 15 ft from the unit. Direct line

of sight from return air grilles into the unit's return should be

avoided. If return air is to be ducted to an equipment room, an

elbow should be installed within the equipment room. Running a

return air drop to near the floor of the room will aid in sound

attenuation. Avoid transmitting vibrations generated by the

movement of air in the ducting to the walls of the building. This

is especially important where ductwork penetrates walls. The

maximum recommended return air velocity is 1,000 fpm. Lower

return air velocities will result in lower sound power levels. The

use of round supply duct plenums should be considered, as it

will significantly reduce low frequency sound at the equipment

room. If rectangular supply plenums are used, the aspect ratio of

the duct should be kept as small as possible (i.e., as close to

square as possible). The large, flat surface areas associated with

large aspect ratio duct systems will transmit sound to the space,

and the potential for duct-generated noise is increased. The maximum recommended supply air duct velocity is 2,000 fpm.

Units with two fans should have a properly designed “pair

of pants” duct connection. An adequate straight length of

ducting from the unit should be allowed before elbows are

installed. If connecting an elbow directly to the fan outlet, a

minimum straight length of 2 fan diameters from the fan outlet

is recommended. Elbows should turn in the direction of fan rotation, if possible. Abrupt turns will generate air turbulence and

excessive noise. Turning vanes should be used in all short radius bends. Ensure that ducting does not obstruct access to the

unit for routine servicing.

DUCT STATIC PRESSURE PROBE AND TUBING (VAV

Only) — On VAV systems, the duct static pressure sensor and

tubing are field-mounted. The sensor tubing sensing point

should be located near the end of the main supply trunk duct in

a position free from turbulence effects and at least 10 duct diameters downstream and 4 duct diameters upstream from any

major transitions or branch take-offs. Incorrectly placing the

sensing point could result in improper operation of the entire

VAV s y st e m .

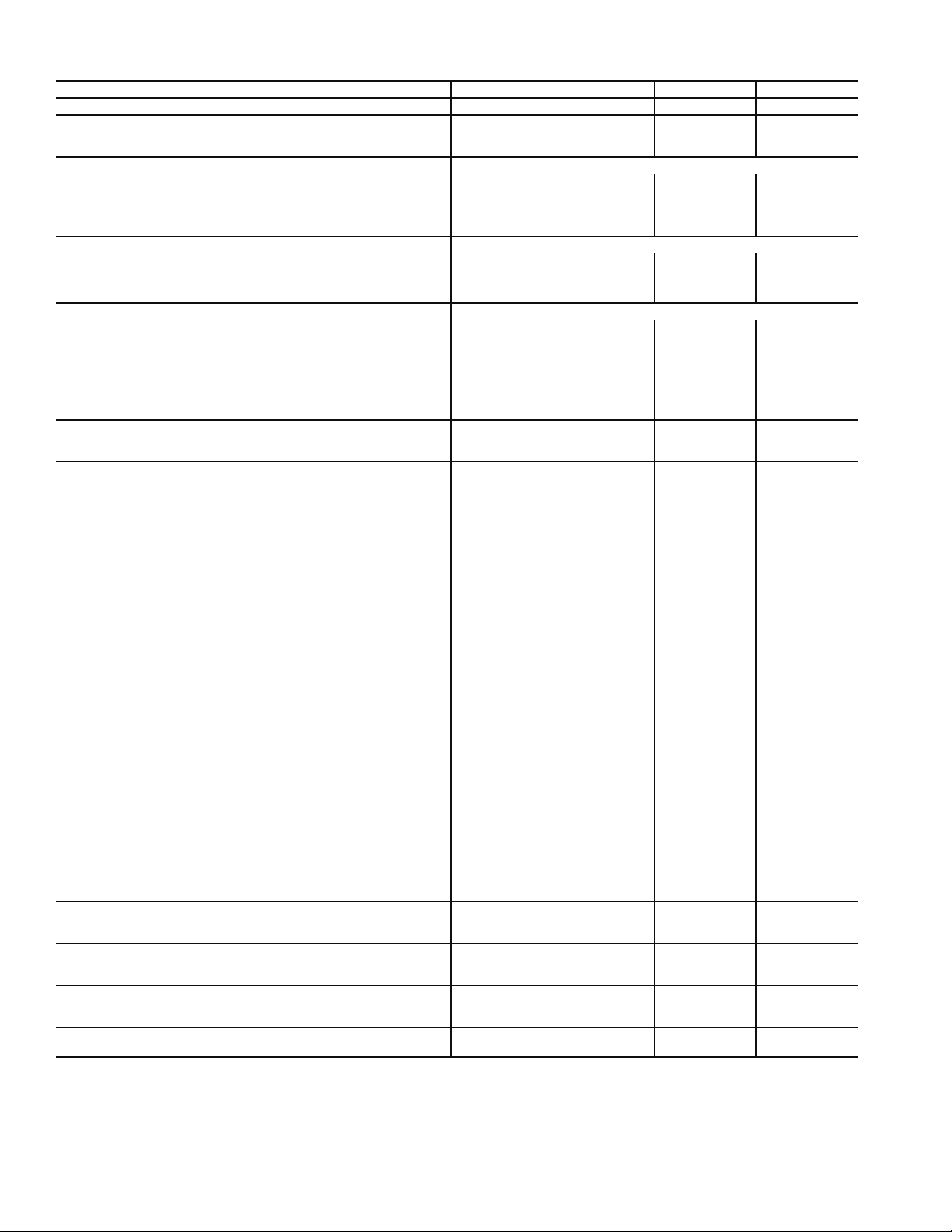

Install the factory-supplied duct static pressure probe with

the tip facing into the airflow. See Fig. 16.

AIRFLOW

PROBE

a50-7138ef

TUBING

Fig. 16 — Duct Static Pressure Probe

(P/N 39EK20462)

1

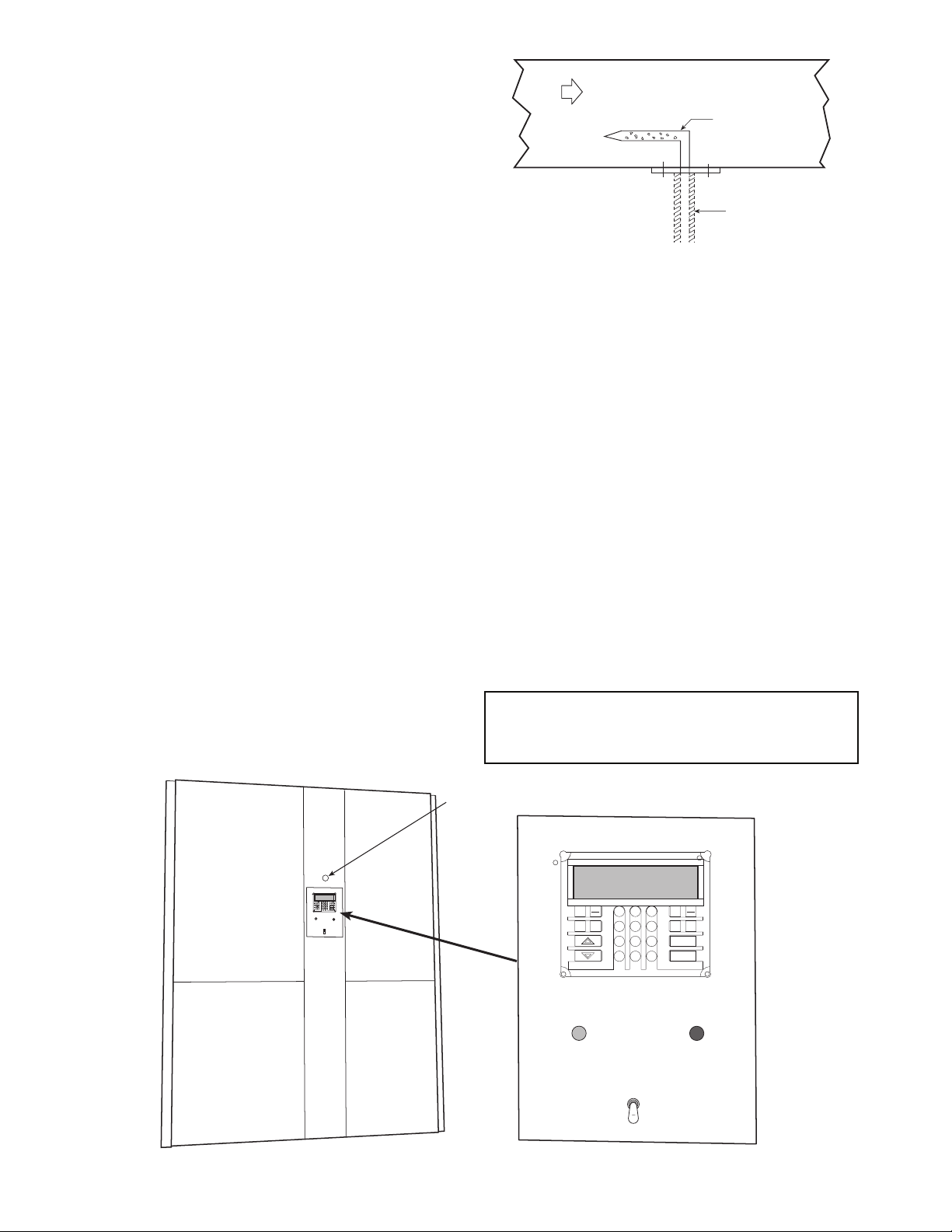

Use

/4-in. OD approved polyethylene tubing for up to

50 ft (3/8-in. OD for 50 to 100 ft) to connect the probe to the

bulkhead fitting mounted above the unit display panel

(Fig. 17). Carefully route the tubing from the probe to this

bulkhead fitting.

The static pressure control should be adjusted so that, at full

airflow, all of the remote VAV terminal boxes receive the

minimum static pressure required plus any downstream resistance. Control the system to the lowest static pressure set point

that will satisfy airflow requirements. Lower static pressure set

points reduce total required brake horsepower and reduce

generated sound levels.

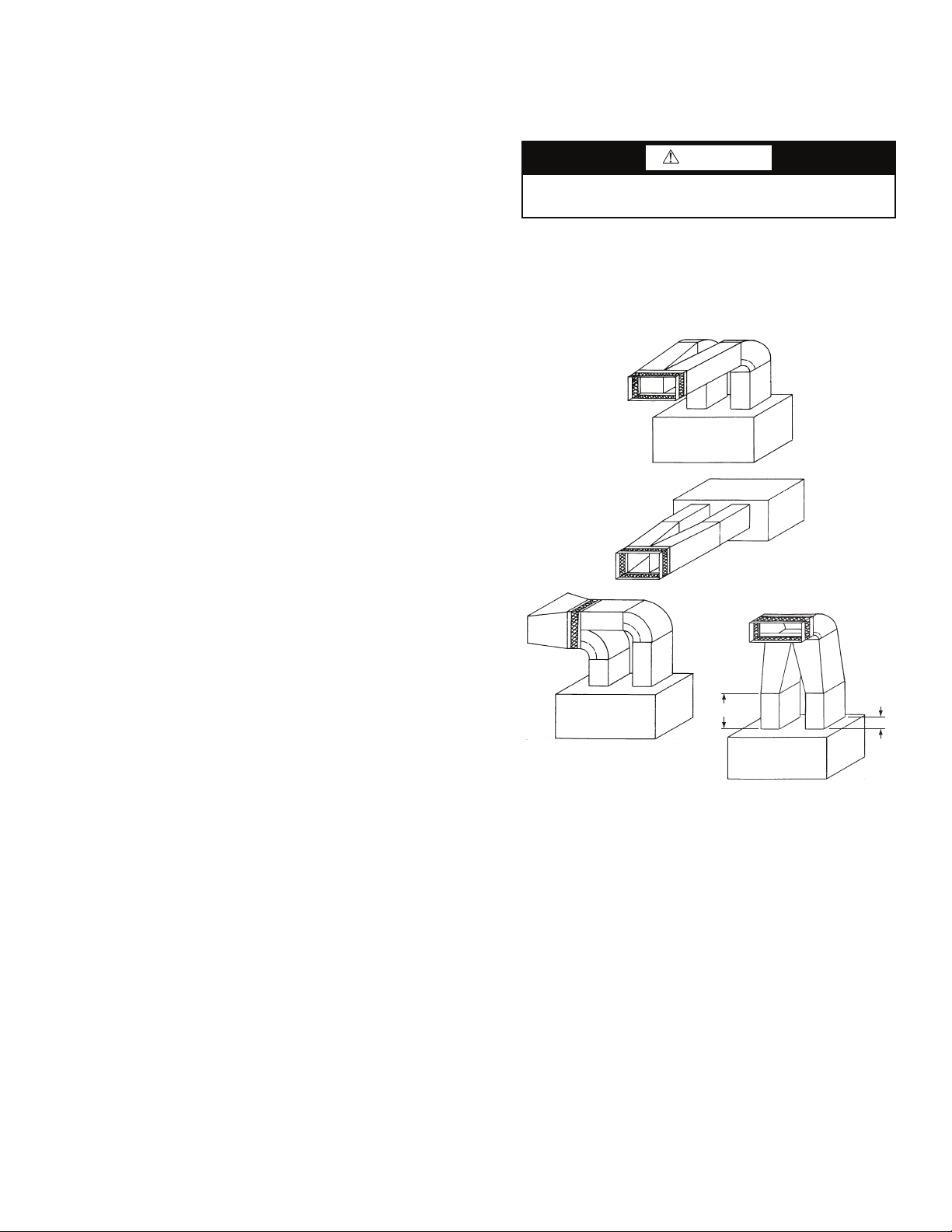

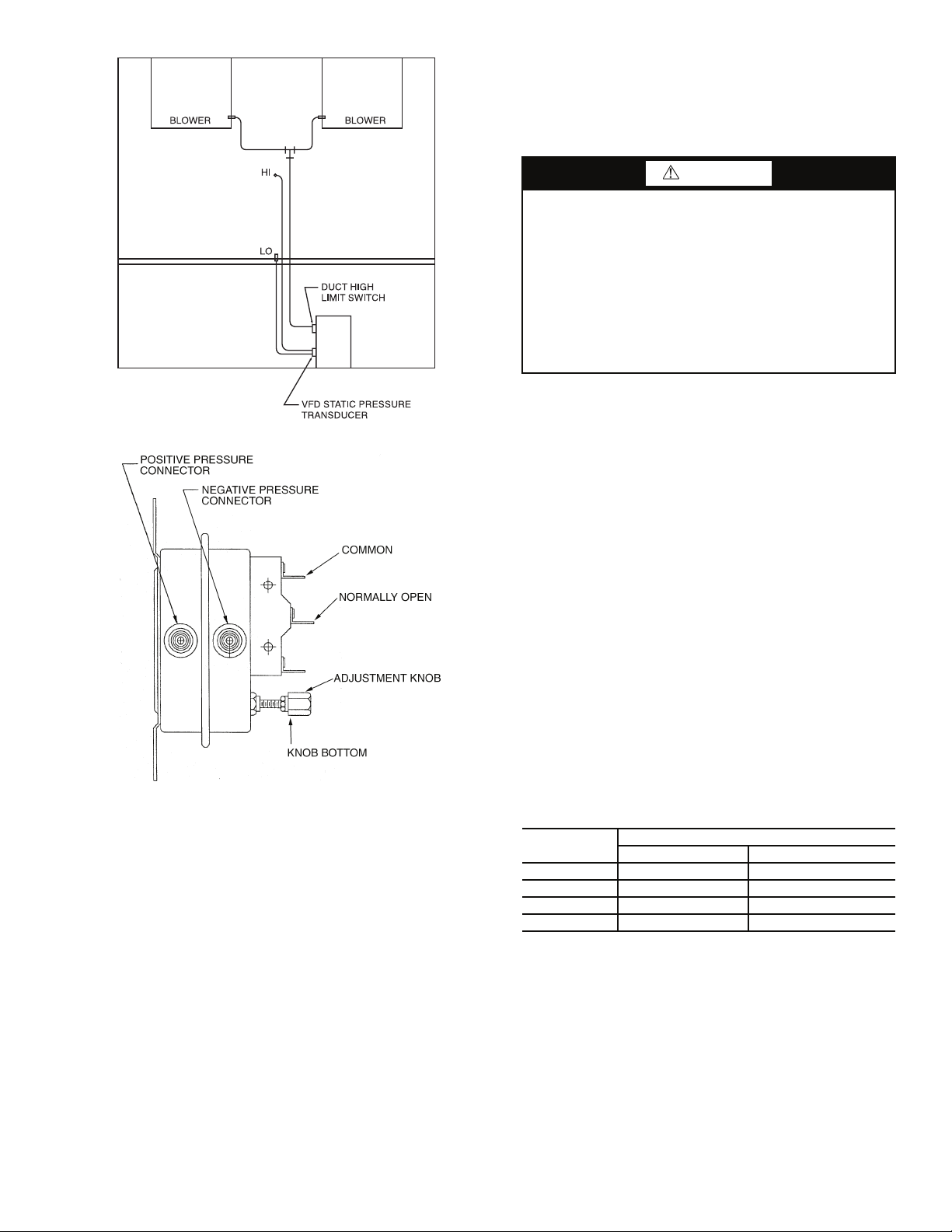

DUCT HIGH-STATIC (DHS) LIMIT SWITCH (VAV

Only) — The duct high static limit switch is a mechanical

safety that prevents duct overpressurization. The switch is located on the side of the VAV low voltage control panel

(Fig. 18) and is factory set at 3 in. wg. To make an adjustment

using an accurate differential pressure gage, connect low side

and high side to gage and pressure source. Place a voltmeter

across common and normally open contacts. Rotate the adjustment knob (Fig. 19) clockwise to increase pressure setting and

counterclockwise to decrease pressure setting. When the bottom of the adjustment knob is approximately

1

/8-in. from the

switch body, the switch will trip at approximately 3 in. wg.

IMPORTANT: Use tubing that complies with local codes.

Improper location or installation of the supply duct pressure tubing will result in unsatisfactory unit operation and

poor performance.

a50-7267ef

DUCT STATIC

PRESSURE

PROBE

BULKHEAD

FITTING

EXPN

TEST

STAT

3

2

1

SRVC

ALRM

EDIT

HISTALGO

SET

5

SCHD

6

4

CLEAR

8

9

7

ENTER

.

–

0

WARNING

ALARM

LOCAL

OFF

REMOTE

EXPN

STAT

SET

2

1

EDIT

5

SCHD

4

8

7

–

0

WARNING

LOCAL

REMOTE

Fig. 17 — Display Panel Location on Unit Front Panel

20

3

6

9

.

OFF

TEST

SRVC

ALRM

HIST ALGO

CLEAR

ENTER

ALARM

Page 21

a50-8253

Fig. 18 — DHS Pressure Limit Location

a50-7268tf

Fig. 19 — DHS Limit Switch (P/N 190060)

Step 4 — Make Piping Connections

CONDENSER WATER PIPING (Water-Cooled Only) —

Always follow national and local codes when installing water

piping to ensure a safe and proper installation. Connections to

the unit should incorporate vibration eliminators to reduce

noise and vibration to the building, and shutoff valves to facilitate servicing.

Prior to connecting the unit(s) to the condenser water

system, the system should be flushed to remove foreign

material that could cause condenser fouling. Install a screen

strainer with a minimum of 20 mesh ahead of the condenser

inlet to prevent condenser fouling and internal condenser tube

damage from foreign material.

Supply and return water piping must be at least as large as

the unit connections, and larger for long runs. Refer to the

System Design Manual, Part 3, and standard piping practice,

when sizing, planning, and routing water piping. See dimension drawings (Fig. 2-14) for water connection sizes and

locations.

Units are furnished standard with a copper heat exchanger.

A cupronickel heat exchanger is also available as a

factory-installed option. Copper is adequate for closed loop

systems where good quality water is available. In conditions

where scale formation or water treatment is questionable, the

optional cupronickel heat exchanger should be used. Where the

water is especially corrosive or could lead to excessive fouling,

intermediate plate frame heat exchangers are recommended.

CAUTION

Galvanized pipe or fittings are not recommended with

50BV units due to the possibility of galvanic corrosion

caused by dissimilar metals. When selecting piping

materials, use only approved piping materials that meet

applicable codes and that will handle the temperatures and

pressures that may be experienced in the application.

Piping systems will sweat if low temperature fluid is used

in the system. For these applications, supply and return

water piping should be insulated to protect from condensation damage. The minimum recommended entering water

temperature to the unit is 50 F.

The unit is capable of operating with entering water temperatures as low as 50 F, without the need for head pressure

control. If the entering water temperature is expected to be

lower, or more stable unit operation is desired, a field-supplied

water-regulating valve may be used.

This unit has multiple independent refrigerant circuits with

separate condensers. The individual condensers are manifolded

together on the waterside to provide easy, single-point water

connections. In order to achieve proper head pressure control

when a water-regulating valve is used, a temperature-actuated

valve is recommended. This allows any of the independent

refrigerant circuits to operate while still modulating condenser

water flow in response to loop water temperature.

A glycol solution should be used if ambient temperatures

are expected to fall below freezing or if the loop water temperature is below 50 F while operating in the reverse cycle heating

mode (heat pump units only). Refer to Table 4, which

lists freezing points of glycol at different concentrations. A

minimum concentration of 20% is recommended. Water

pressure drop will increase and unit performance will decrease

with increasing glycol concentrations.

Units with factory-installed waterside economizers have

cooling water passing through the economizer and condenser

in series while operating in the economizer mode. During

normal operation, water bypasses the economizer coil.

Table 4 — Glycol Freezing Points

% GLYCOL

20 18 19

30 79

40 –7 –5

50 –28 –27

Ethylene Glycol Proplylene Glycol

All manual flow valves used in the system should be of the

ball valve design. Globe or gate valves must not be used due to

high pressure drops and poor throttling characteristics.

Do not exceed recommended condenser fluid flow rates

shown in Tables 5A and 5B. Serious damage or erosion of the

heat exchanger tubes could occur. Piping systems should not

exceed 10 fps fluid velocities to ensure quietness and tube wall

integrity. Refer to Tables 5A and 5B for condenser water pressure drop versus flow rate. Flow rates outside of the published

range should not be used.

Ball valves should be installed in the supply and return lines

for unit isolation and water flow balancing.

FREEZE POINT (° F)

21

Page 22

Table 5A — Condenser Pressure Drop

50BVC,J,Q Units

FLOW RATE

(gpm)

35 9.1———

40 11.2 6.0 — —

45 13.5 7.5 — —

50 15.9 9.1 9.1 —

55 18.4 10.9 10.9 —

60 21.1 12.8 12.8 10.8

65 23.9 14.8 14.9 12.7

70 27.4 17.0 17.2 14.7

75 — 19.3 19.6 16.9

80 — 21.7 22.2 19.2

85 — — 24.9 21.7

90 — — 27.8 24.3

95 — — 30.8 27.1

100 — — 34.0 30.0

105 ———33.1

110 ———36.3

115 ———39.7

120 ———43.2

GPM — Flow Rate

PD — Pressure Drop (ft wg)

SIZE 020 SIZE 024 SIZE 028 SIZE 034

Pressure Drop (ft wg)

LEGEND

Table 5B — Condenser Pressure Drop

50BVT,V,W Units

FLOW RATE

(gpm)

60 8.7———

70 11.9———

80 15.5 6.3 — —

90 19.6 8.0 — —

100 24.2 9.9 6.0 —

110 29.3 12.0 7.3 —

120 34.9 14.3 8.7 8.7

130 — 16.7 10.2 10.2

140 — 19.4 11.8 11.8

150 — 22.3 13.6 13.6

160 — 25.3 15.5 15.5

170 — — 17.4 17.4

180 — — 19.6 19.6

190 — — 21.8 21.8

200 — — 24.2 24.2

210 — — — 26.6

220 — — — 29.2

230 — — — 31.9

240 — — — 34.8

GPM — Flow Rate

PD — Pressure Drop (ft wg)

SIZE 034 SIZE 044 SIZE 054 SIZE 064

Pressure Drop (ft wg)

LEGEND

Pressure and temperature ports are recommended in both

the supply and return lines for system flow balancing. These

openings should be 5 to 10 pipe diameters from the unit water

connections. For thorough mixing and temperature stabilization, wells in the water piping should extend at least

1

/2 pipe

diameter into the pipe. Measuring the condenser waterside

pressure drop and referring to Tables 5A and 5B can help to

properly set the water flow rate.

Improper fluid flow due to valving, piping, or improper

pump operation constitutes abuse that may result in voiding of

unit warranty. The manufacturer will not be responsible for

damages or failures resulting from improper piping design or

piping material selection.

EVAPORATOR CONDENSATE DRAIN — The condensate

drain connection is 1

1

/4-in. FPT and is located on the same side

of the unit as the condenser water connections. See dimension

drawings (Fig. 2-14) for exact location.

Drain lines should be pitched away from the unit with a

minimum slope of

1

/8-in. per foot and conform to all local and

national codes.

A trap must be installed in the condensate line to ensure free

condensate flow (units are not internally trapped). A vertical air

vent is sometimes required to avoid air pockets.

Install a condensate-trapping drain line at the units drain

connection. See Fig. 20 for correct drain layout.

a39-2371ef

P

1

1/2

P

Fig. 20 — Condensate Drain Layout

When calculating trap depth, remember that it is not the

total static pressure but the upstream or downstream static

resistance that is trapped against. For instance, when calculating the trap depth for a cooling coil condensate pan, trap

against the coil pressure drop in that coil section and any other

pressure drops upstream of it.

If calculating the trap depth for the cooling coil, use the total

static pressure drop (coil plus any other components upstream

of it) plus 1 in. (P

= negative static pressure + 1 in.), as shown

1

in Fig. 21.

Traps must store enough condensate to prevent losing the

drain seal at start-up. The “Minimum

1

/2 P1” dimension ensures

that enough condensate is stored.

Drain pans should be cleaned periodically to avoid the

build-up of dirt and bacterial growth.

HOT WATER HEATING COIL (Optional) — A factory-installed

one or 2-row hot water heating coil is available as an option. The

coil is supplied with hot water from a boiler through separate piping from the condenser water loop. All controls for heating operation are field-supplied.

Piping should be in accordance with accepted industry

standards and all components rated for the system pressure

expected. Pipe the coils so that they will drain, and provide a

drain and vent.

Always connect the supply to the top of the coil, and the

return to the bottom. Refer to Fig. 2-14 for hot water supply

and return piping locations.

Water coils should not be subjected to entering air temperatures below 38 F to prevent coil freeze-up. If air temperatures

across the coil are going to be below this value, use a glycol or

brine solution. Use a solution with the lowest concentration

that will match the coldest air expected. Excess concentrations

will greatly reduce coil capacity.

The return air duct system should be carefully designed to

get adequate mixing of the return air and outdoor air streams to

prevent cold spots on the coil that could freeze.

A 2 or 3-way, field-supplied modulating control valve, or a

simple 2-position on-off valve may be used to control water

flow. Select the valve based on the control valve manufacturer's

recommendations for size and temperature rating. Select the

control valve CV based on pressure drop and flow rate through

the coil. This information is available from the VPACBuilder

software program or Tables 6A and 6B.

1

22

Page 23

Table 6A — Hot Water Pressure Drop

50BVC,E,J,K,Q Units

FLOW RATE

(gpm)

10 0.7 0.7 0.7 —

15 1.5 1.5 1.5 —

20 2.6 2.6 2.6 —

25 4.0 4.0 4.0 —

30 5.8 5.8 5.8 0.1

35 7.8 7.8 7.8 0.1

40 10.2 10.2 10.2 0.1

45 12.9 12.9 12.9 0.2

50 15.8 15.8 15.8 0.2

55 ———0.3

60 ———0.3

65 ———0.4

GPM — Flow Rate

PD — Pressure Drop (ft wg)

SIZE 020 SIZE 024 SIZE 028 SIZE 034

Pressure Drop (ft wg)

LEGEND

Table 6B — Hot Water Pressure Drop

50BVT,U,V,W,X Units

FLOW RATE

(gpm)

45 2.4 — — —

50 3.0 — — —

55 3.6 — — —

60 4.3 — — —

65 5.0 — — —

70 5.7 — — —

75 6.6 — — —

80 7.4 — — —

85 8.4 — — —

90 9.3 2.5 2.5 2.5

100 — 3.1 3.1 3.1

110 — 3.7 3.7 3.7

120 — 4.4 4.4 4.4

130 — 5.1 5.1 5.1

140 — 5.9 5.9 5.9

150 — 6.7 6.7 6.7

160 — 7.6 7.6 7.6

170 — 8.6 8.6 8.6

180 — 9.6 9.6 9.6

GPM — Flow Rate

PD — Pressure Drop (ft wg)

SIZE 034 SIZE 044 SIZE 054 SIZE 064

Pressure Drop (ft wg)

LEGEND

Pipe sizes should be selected based on the head pressure

available from the pump. Water velocity should not exceed

8 fps. Design the piping system for approximately 3 ft of loss

per 100 equivalent ft of pipe. The piping system should allow

for expansion and minimize vibration between the unit and

piping system.

WATER ECONOMIZER (Optional) — The optional waterside

economizer (pre-cooling coil) is factory-installed and piped internally, in series with the condenser water circuit (Fig. 21). A diverting valve and factory controls are included with the option. Only

one set of field connections needs to be made for condenser water

and economizer water. In addition, when the unit is shipped with

the economizer option, the economizer drain must be connected

to a separate trap. Follow the same steps for the economizer drain

as described for the evaporator condensate drain. An Aquastat is

used to modulate water flow through the economizer. The controller is mounted to the low voltage control box. Electrical connections are factory installed and wired. The remote bulb is shipped

internal to the unit and requires field mounting. Care should be

taken not to dent the bulb or miscalibration may occur. The

Aquastat has a temperature range adjustment (–30 F to 100 F) and

is field set. See Fig. 2-14 for connection locations and sizes. See

Tables 7A and 7B for economizer waterside pressure drop data.

The waterside economizer can also be ordered without

factory-installed piping or controls. This offers additional

flexibility for specific applications. In this case, the coil is

factory mounted, but all supply and return piping and controls

are field supplied.

Table 7A — Economizer Pressure Drop Curve

(ft wg), 50BVC,E,J,K,Q Units

FLOW RATE

(gpm)

35 8.9 — — —

40 11.5 11.0 — —

45 14.4 13.8 — —

50 17.6 16.9 16.9 —

55 21.1 20.4 20.4 —

60 24.9 24.1 24.1 3.5

65 29.0 28.1 28.2 4.1

70 34.4 32.5 32.5 4.7

75 — 37.1 37.2 5.4

80 — 42.1 42.1 6.1

85 — — 47.4 6.9

90 — — 52.9 7.7

95 — — 58.7 8.5

100 — — 64.9 9.4

105 — — — 10.3

110 — — — 11.3

115 — — — 12.3

120 — — — 13.4

GPM — Flow Rate

PD — Pressure Drop (ft wg)

SIZE 020 SIZE 024 SIZE 028 SIZE 034

Pressure Drop (ft wg)

LEGEND

AQUASTAT

N.O.

FLUID IN

3-WAY MOTORIZED

BALL VALVE

“BULB STRAPPED

TO FLUID” IN LINE

(FIELD INSTALLED)

WATERSIDE

N.C.

ECONOMIZER

COIL

motor

MBV

N.O.

Fig. 21 — Optional Water Economizer

23

a50-7269ef

FLUID TO REFRIGERANT

HEAT EXCHANGER

POSITIVE SHUT-OFF SOLENOID

VALVE FOR VARIABLE SPEED

PUMPING SYSTEM

(FIELD INSTALLED)

Page 24

Table 7B — Economizer Pressure Drop Curve

(ft wg), 50BVT,U,V,W,X Units

FLOW RATE

(gpm)

60 13.1 — — —

70 17.9 — — —

80 23.5 5.8 — —

90 29.8 7.3 — —

100 36.9 9.1 9.0 —

110 44.8 11.0 11.0 —

120 53.4 13.1 13.1 13.1

130 — 15.4 15.4 15.4

140 — 17.9 17.9 17.9

150 — 20.6 20.6 20.6

160 — 23.5 23.5 23.5

170 — — 26.6 26.5

180 — — 29.8 29.8

190 — — 33.3 33.2

200 — — 36.9 36.8

210 ———40.7

220 ———44.7

230 ———48.9

240 ———53.3

GPM — Flow Rate

PD — Pressure Drop (ft wg)

SIZE 034 SIZE 044 SIZE 054 SIZE 064

Pressure Drop (ft wg)

LEGEND

REMOTE REFRIGERANT PIPING (Remote Air-Cooled

Only) — Carrier 50BVE,K,U,X units are supplied without

condensers. To complete the installation, these units must be

field connected to a suitable remote condenser. The 50BV units

from 18 to 30 tons contain 2 equally sized independent refrigerant circuits. Units from 40 to 60 tons have 4 separate equal capacity refrigerant circuits. It is important that the condenser circuiting be properly matched to the 50BV unit circuiting. Otherwise, unsatisfactory operation will result. Carrier will not be

responsible for improperly matched remote condenser selections. Recommended condenser matches are shown in Table 8.

Table 8 — Recommended Condenser Matches

for 50BVE,K,U,X Units

TRAP (MUST BE

ABOVE TOP OF

CONDENSER COIL)

SLOPE

TOWARD

CONDENSER

HOT GAS

LINE

50BV

UNIT

LIQUID

LINE

REMOTE

CONDENSER

a50-7270ef

Fig. 22 — System with Condenser

Above Evaporator

a50-7271ef

50BV

UNIT

HOT GAS

LINE

50BV

NO. OF

CKTS

020 2 09DK020 (1) 50/50%

024 2 09DK024 (1) 50/50%

028 2 09DK028 (1) 50/50%

034 2 09DK034 (1) 50/50%

044 4 09DK024 (2) 50/50% (each)

054 4 09DK028 (2) 50/50% (each)

064 4 09DK034 (2) 50/50% (each)

CONDENSER(S)

CONDENSER

CIRCUITING

Install the air-cooled condenser or condensers according to

the installation instructions provided with the condenser(s).

Connection locations and sizes for the hot gas and liquid lines

on the 50BV units are shown in Fig. 2-14, 22 and 23. For

50BV units up to 30 tons, there will be 2 hot gas lines and 2 liquid lines to install between the unit and the condenser. Above

30 tons, 4 hot gas lines and 4 liquid lines will be installed between the unit and the 2 condensers. Refer to the System Design Manual, Part 3 for standard refrigerant piping techniques.

Also see the air-cooled condenser installation instructions for

additional guidance.

Remote air-cooled 50BV units (only) are shipped with a dry

nitrogen holding charge. After refrigerant connections are

made, release nitrogen, evacuate, leak test, and charge the

system as described in Charging the System in the Maintenance section of this manual.

LIQUID

LINE

SLOPE TOWARD

CONDENSER

REMOTE

CONDENSER

Fig. 23 — System with Evaporator

Above Condenser

Step 5 — Complete Electrical Connections —

Verify that electrical requirements listed on the unit nameplate

match available power supply. The unit voltage must be within

the range shown in Tables 9A and 9B and phases must be

balanced within 2%. Contact the local power company for line

voltage corrections. Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

24

Page 25

For an unbalanced 3-phase supply voltage, use the follow-

ing formula to determine the percent of voltage imbalance:

Percent Voltage Imbalance

= 100 x

max voltage deviation from average voltage

average voltage

Example: Supply voltage is 460-3-60.

AB = 452 V

BC = 464 V

AC = 455 V

Average Voltage =

452 + 464 + 455

3

1371

=

3

= 457

Determine maximum deviation from average voltage:

(AB) 457 – 452 = 5 V

(BC) 464 – 457 = 7 V

(AC) 457 – 455 = 2 V

Maximum deviation is 7 V.

Determine percent of voltage imbalance:

% Voltage Imbalance = 100 x

= 1.53%

7

457

Table 9A — Electrical Data — 50BVC,E,J,K,Q

This amount of phase imbalance is satisfactory as it is be-

low the maximum allowable 2%.

IMPORTANT: If supply voltage phase imbalance is

more than 2%, contact the local electric utility company immediately.

POWER WIRING — Properly sized fuses or HACR (Heating, Air Conditioning and Refrigeration) circuit breakers must

be installed for branch circuit protection, according to the

national and applicable local codes. See unit nameplate and

Tables 9A and 9B for maximum overcurrent protection size.

These units are provided with single point, main power

supply terminal blocks. Refer to Fig. 2-14 for conduit connection locations. Connect the power leads as indicated on the unit

wiring diagrams (found in the Troubleshooting section) and be

certain to connect the ground lead to the ground lug in the unit

high voltage electrical box. Refer to Tables 9A and 9B for unit

electrical data.

UNIT SIZE

50BVC,E,J,K,Q

020

024

028

034

LEGEND

FLA — Full Load Amps

HP — Horsepower

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

NOMINAL

VOLTAGE

(3 Ph, 60 Hz)

208/230 187 253 32.9 195 32.9 195 2

460 414 506 16.5 95 16.5 95 2

575 518 633 13.6 80 13.6 80 2

208/230 187 253 33.6 225 33.6 225 2

460 414 506 18.6 114 18.6 114 2

575 518 633 13.6 80 13.6 80 2

208/230 187 253 53.6 245 53.6 245 2

460 414 506 20.7 125 20.7 125 2

575 518 633 16.4 100 16.4 100 2

208/230 187 253 59.1 425 59.1 425 2 5 12.2 157.4 200 142.6

460 414 506 26.4 187 26.4 187 2 5 6.1 71.6 90 65.0

575 518 633 20.5 148 20.5 148 2 5 5.4 56.9 70 51.8

VOLTAGE

RANGE

Min Max RLA LRA RLA LRA Qty

COMPRESSOR

No. 1 No. 2

INDOOR FAN MOTOR

HP

(ea)

1.5 5.0 84.0 110 75.8

1.5 2.5 42.1 50 38.0

1.5 2.0 34.6 45 31.2

FLA

(ea)

2 6.4 86.8 110 78.6

3 9.0 92.0 110 83.8

5 12.2 98.4 110 90.2

2 3.2 43.5 50 39.4

3 4.5 46.1 50 42.0

5 6.1 49.3 50 45.2

2 2.0 34.6 45 31.2

3 3.6 37.8 45 34.4

5 5.4 41.4 45 38.0

2 6.4 88.4 120 80.0

3 9.0 93.6 120 85.2

5 12.2 100.0 120 91.6

2 3.2 48.3 60 43.6

3 4.5 50.85 60 46.2

5 6.1 54.05 60 49.4

2 2.0 34.6 45 31.2

3 3.6 37.8 45 34.4

5 5.4 41.4 45 38.0

3 9.0 138.6 190 125.2

5 12.2 145.0 190 131.6

3 4.5 55.6 70 50.4

5 6.1 58.8 70 53.6

3 3.6 44.1 60 40.0

5 5.4 47.7 60 43.6

POWER

SUPPLY

MCA MOCP FLA

DISCONNECT

SIZE

25

Page 26

Table 9B — Electrical Data — 50BVT,U,V,W,X

UNIT SIZE

50BVT,U,V,W,X

034

044

054

064

LEGEND

FLA — Full Load Amps MCA — Minimum Circuit Amps

HP — Horsepower MOCP — Maximum Overcurrent Protection

LRA — Locked Rotor Amps RLA — Rated Load Amps

NOMINAL

VOLTAGE

(3 Ph, 60 Hz)

208/230 187 253 62.2 376 — — 1

460 414 506 27.6 178 — — 1

575 518 633 20.5 148 — — 1

208/230 187 253 42.0 239 42.0 239 2

460 414 506 19.2 125 19.2 125 2

575 518 633 12.4 80 12.4 80 2

208/230 187 253 47.1 318 47.1 318 2

460 414 506 22.6 158 22.6 158 2

575 518 633 17.3 125 17.3 125 2

208/230 187 253 62.2 376 62.2 376 2

460 414 506 27.6 178 27.6 178 2

575 518 633 20.5 148 20.5 148 2

VOLTAGE

RANGE

Min Max RLA LRA RLA LRA Qty

COMPRESSOR

No. 1 / No. 2 No. 3 / No. 4

INDOOR FAN MOTOR

HP

(ea)

7.5 19.4 159.4 200 143.8

10 25.8 165.8 225 150.2

15 38.6 178.6 225 163.0

20 49.6 189.6 250 174.0

7.5 9.7 71.8 90 64.9

10 12.9 75.0 100 68.1

15 19.3 81.4 100 74.5

20 24.8 86.9 110 80.0

7.5 7.8 53.9 70 48.8

10 10.3 56.4 70 51.3

15 15.4 61.5 80 56.4

20 19.8 65.9 80 60.8

7.5 19.4 217.3 250 206.8

10 25.8 230.1 250 219.6

15 38.6 255.7 250 245.2

7.5 9.7 101.0 110 96.2

10 12.9 107.4 125 102.6

15 19.3 120.2 125 115.4

7.5 7.8 68.3 80 65.2

10 10.3 73.3 80 70.2

15 15.4 83.5 90 80.4

7.5 19.4 239.0 250 227.2

10 25.8 251.8 250 240.0

15 38.6 277.4 300 265.6

20 49.6 299.4 300 287.6

7.5 9.7 115.5 125 109.8

10 12.9 121.9 125 116.2

15 19.3 134.7 150 129.0

20 24.8 145.7 150 140.0

7.5 7.8 89.1 100 84.8

10 10.3 94.1 110 89.8

15 15.4 104.3 110 100.0

20 19.8 113.1 125 108.8

7.5 19.4 303.2 350 287.6

10 25.8 316.0 350 300.4

15 38.6 341.6 400 326.0

20 49.6 363.6 400 348.0

7.5 9.7 136.7 150 129.8

10 12.9 143.1 150 136.2

15 19.3 155.9 150 149.0

20 24.8 166.9 175 160.0

7.5 7.8 102.7 110 97.6

10 10.3 107.7 125 102.6

15 15.4 117.9 125 112.8

20 19.8 126.7 125 121.6

FLA

(ea)

POWER

SUPPLY

MCA MOCP FLA

DISCONNECT

SIZE

26

Page 27

Modular Units

— For units with multiple main airconditioning sections, connect the high voltage compressor

power wiring to the line side of the high voltage terminal block

in the second section’s high voltage electrical box. This wiring

is located in the upper portion of the compressor compartment.

Connect the low voltage wiring, located in the compressor

compartment, between the two air conditioning sections using

the quick connects provided.

For the supply fan motor, connect the 3-phase high voltage

wiring, coiled behind the high voltage panel, to the line side of

the supply fan motor terminal block located in the fan compartment. For VAV units, connect the 3-phase high voltage wiring

to the line side of VFD.

For units with multiple fans, connect the control power

wiring with the quick connects provided at the fan compartment junction.

CONTROL WIRING (CV Only) — A standard commercial

thermostat controls constant volume units. These units turn

compressors on or off in response to zone temperature. The

50BV units provide 2 stages of cooling.

50BVC,E,Q020-034 and 50BVT,U,V034 Only

— These

models have 2 independent refrigerant circuits, each capable of

being staged independently. Thermostat wiring is connected to

the 6-position low voltage terminal block located in the unit

electrical box. The 50BV units have a 24-VAC control

transformer, which provides power to the control circuit and to

the thermostat. The thermostat connections and their functions

are as follows:

C Transformer 24-v ac Common

O Reversing Valve (heat pumps only)

Y1 1st Stage Compressor Contactor

Y2 2nd Stage Compressor Contactor

R Transformer 24-v ac Hot

G Indoor Fan Contactor

Select an appropriate commercial thermostat that has 2 stages of cooling control. If the unit is a heat pump, make sure the

thermostat is capable of heat pump control. Any of the

Debonair® series commercial thermostats will meet the requirements, and are available in a variety of attractive styles, in

programmable and non-programmable versions.

Install the thermostat in the space where the temperature is

being controlled, according to the instructions provided with

the thermostat.

WARNING

Before wiring the thermostat to the unit, make sure that

main power to the unit has been disconnected. Failure to

heed this warning could result in personal injury.

To wire the thermostat:

1. Connect the ‘C’ terminal from the 50BV unit to the ‘C’

terminal on the thermostat.

2. Wire the ‘Y1’ and ‘Y2’ terminals from the 50BV unit

to the ‘Y1’ and ‘Y2’ terminals, respectively, at the

thermostat.

3. Make a connection between the ‘G’ terminal on the unit

and the ‘G’ terminal on the thermostat.

4. Attach a wire from the ‘R’ terminal at the unit to the ‘R’

terminal at the thermostat.

5. 50BVQ and 50BVV ONLY: If the unit is a heat pump,