Page 1

Number One

AirConditbning

M^er

’.', wv V.*.'. .'.W

f ^ <‘‘^

^^2 Division of

Carrier Corporation

•

Carrier Parkway • Syracus

N Y 13221

■rt'.'rt'.v»v.'iV.'rt'.'.virtS'i'.'wC\"<ViVi'>»»%’iVi'i'»'*>..L»^r.:.riro:i'.^:

Single-Package Cooling Units

SAFETY CONSIDERATIONS

The 50BJ,BK Single-Package Cooling Units

are designed to provide safe and reliable service

when operated within design specifications.

However, due to system pressures, electrical

components and equipment location, some

aspects of installation, start-up and servicing

of this equipment can be hazardous.

Only trained, qualified installers and service

mechanics should install, start up and service

this equipment.

When working on this equipment, observe

all precautions on tags or labels attached to

the unit, safety notes in the literature and any

other safety precautions that apply.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use care in handling, rigging and placing

bulky equipment.

A DANGER

NEVER reach into unit while fan is running.

LOCK OPEN AND TAG fan motor power

disconnect before working on a fan. Remove

the fuses and take them with you after noting

this on tag.

A WARNING

CHECK assembly and component weights to

be sure rigging equipment can handle them

safely. Note also any specific rigging

instructions.

WHEN STEAM CLEANING COILS, be sure

area is clear of personnel.

Step 4 — Rig and Place Unit with

Accessories ...........................................................2

Step 5 — Position Fan Section As

Desired

Step 6 — Install Fan Motor

Step 7 — Route Fan Motor Wire

Step 8 — Align Fan Shaft and Wheel

..................................................................

......................................

.............................

______

2

5

6

6

Step 9 — Install Field-Fabricated

Ductwork ...............................................................8

Step 10 — Check Return Air Filters

.......................

9

Step 11 — Check Compressor Spring

Mounts ...................................................................9

Step 12 — Make Condenser

Connections..........................................................9

Step 13 — Install Unit Drain Line

..........................

11

Step 14 — Make Electrical

Connections

START-UP

.......................................................

............................................................

12

14,15

General ..................................................................... 14

Prior to Unit Start .................................................... 14

Control Sequence Checkout .................................. 14

SERVICE ...............................................................15-17

Fan Rotation ............................................................ 15

Indoor-Air Fan Adjustment

Lubrication

Return-Air Filters

Condensate Drains

Evaporator Coil

..............................................................

....................................................

.................................................

......................................................

Water-Cooled Condenser(s)

...................................

..................................

15

16

16

16

17

17

Air-Cooled Condensers .......................................... 17

Sight Glasses

..........................................................

17

Charging the System .............................................. 17

Indoor-Air Fan Motor Removal .............................. 17

Pressure Relief Devices ......................................... 17

Crankcase Heaters................................................. 17

High and Low Pressure Switches

........................

17

Time Guard® Control Circuit ................... 17

CONTROL SEQUENCE ........................................... 18

CONTENTS

Page

SAFETY CONSIDERATIONS

#

INSTALLATION .............................................................1-13

.......................................

1

General ..............................................................................1

Step 1 — Receive and Inspect Unit

...........................

2

Step 2 — Protect Unit From Damage ... 2

Step 3 — Provide Unit Support

© Carrier Corporation 1983

..................................

2

General — The 50BJ water-cooled condenser type

units and the 50BK condenserless units are single

package, vertical air conditioning units designed

specifically for application with 35B Modubox and

37A Moduline® variable volume air terminals. For

air terminal installation and service refer to the

separate 35B and 37A installation booklets.

INSTALLATION

Form 50BJ,BK-4SI

Page 2

Sizes 50BJ,BK016 and unite are shipped

with all components assembled, piped and wired.

Sizes 50BJ,BK028 and 034 are shipped as follows:

1. Base unit — containing evaporator coil unit,

compressors and condensers (50BJ unit only).

2. Fan section.

3. Fan motor and drive.

Sizes 50BJ,BK044,054 and 064 are shipped with

all components assembled, piped and wired.

Step 1 — Receive and Inspect Unit

Check unit against shipping order. Inspect care

fully for concealed shipping damage. If shipment is

damaged or incomplete, file claim with transporta

tion company and advise Carrier Corporation

immediately.

Step 2 — Protect Unit From Damage

To maintain warranty, protect unit against ad

verse weather, theft or vandalism on jobsite.

Step 3 — Provide Unit Support

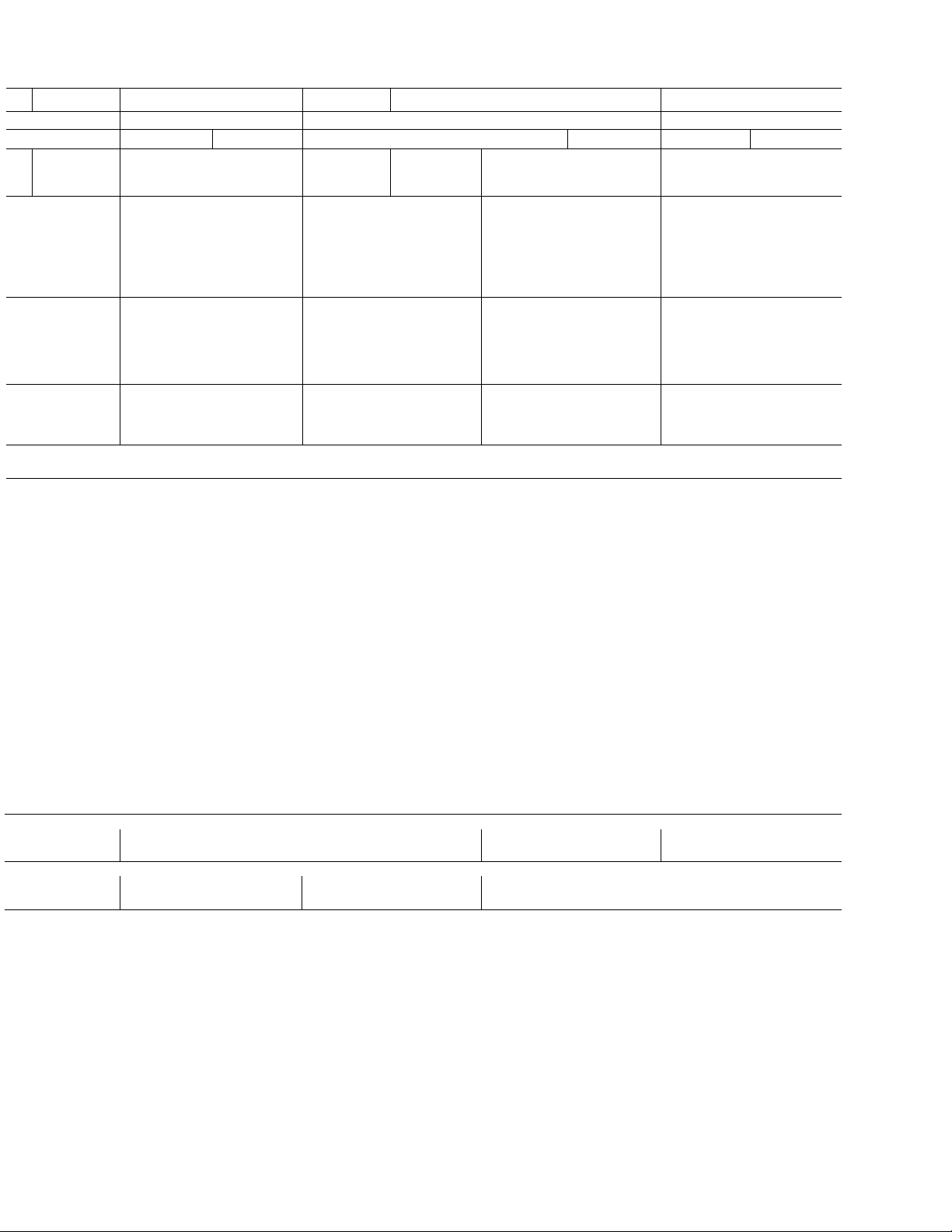

Refer to Fig. 1 — Unit Dimensions, and Table 1 —

Unit Physical Data for unit size and weight. Floor

unit loading should be adequate to support unit.

Step 4 — Rig and Place Unit With Accessories

Collect all unit parts together and move them to

actual installation site. Provide space around unit

for service, filter access and overhead clearance as

indicated in Fig. 1.

Move and store unit in upright position. Do not

remove shipping package or skids until unit is at

final position. Follow rigging label instructions

to prevent cabinet damage during unit positioning.

DO NOT USE CHAINS. Raise base skid on blocks

and remove bolts. Unbolt fan section from skid

(028 and 034 units only).

If any 39E accessories (eg. filters) are to be used

on 50BJ,BK044-064 units, refer to latest 39E

Installation Instructions. The 50BJ,BK044-064

units do not contain installed filters or racks. Bolts

to secure filter rack are shipped secured to base unit

compressor basepan.

Units as shipped are adequately dampened

against vibration. If additional dampening is de

sired, place sponge rubber, rubber mat or fiberglass

roof insulation between floor and base of unit or

install vibration isolators.

Step 5 — Position Fan Section As Desired

UNIT SIZES 50BJ,BK0I6 and 024 are shipped for

vertical discharge. To set up these units for topmounted horizontal discharge, accessory filler

panels must be field installed (see Fig. 1).

To set up unit sizes 50BJ,BK016 and 024 for

back-mounted horizontal discharge (Fig. 1), pro

ceed as follows:

1. Remove:

a. rear fan-section panel.

b. upper rear coil-section panel.

c. flexible conduit and wires from motor.

d. corner bolts holding fan section to coil section.

2. Remove fan section and rotate it 180° lengthwise

so that motor is on left side of unit.

3. Place fan section on rear of coil section and

refasten.

4. Replace motor wire and conduit.

5. Adjust the following items per Installation Step 8:

a. Shaft alignment.

b. Fan wheel position.

c. Pulleys.

d. Fan belt.

6. Replace panels as follows:

a. Upper rear coil-section panel on top of coil

section and fasten.

b. Rear fan-section panel on top of fan section

and fasten.

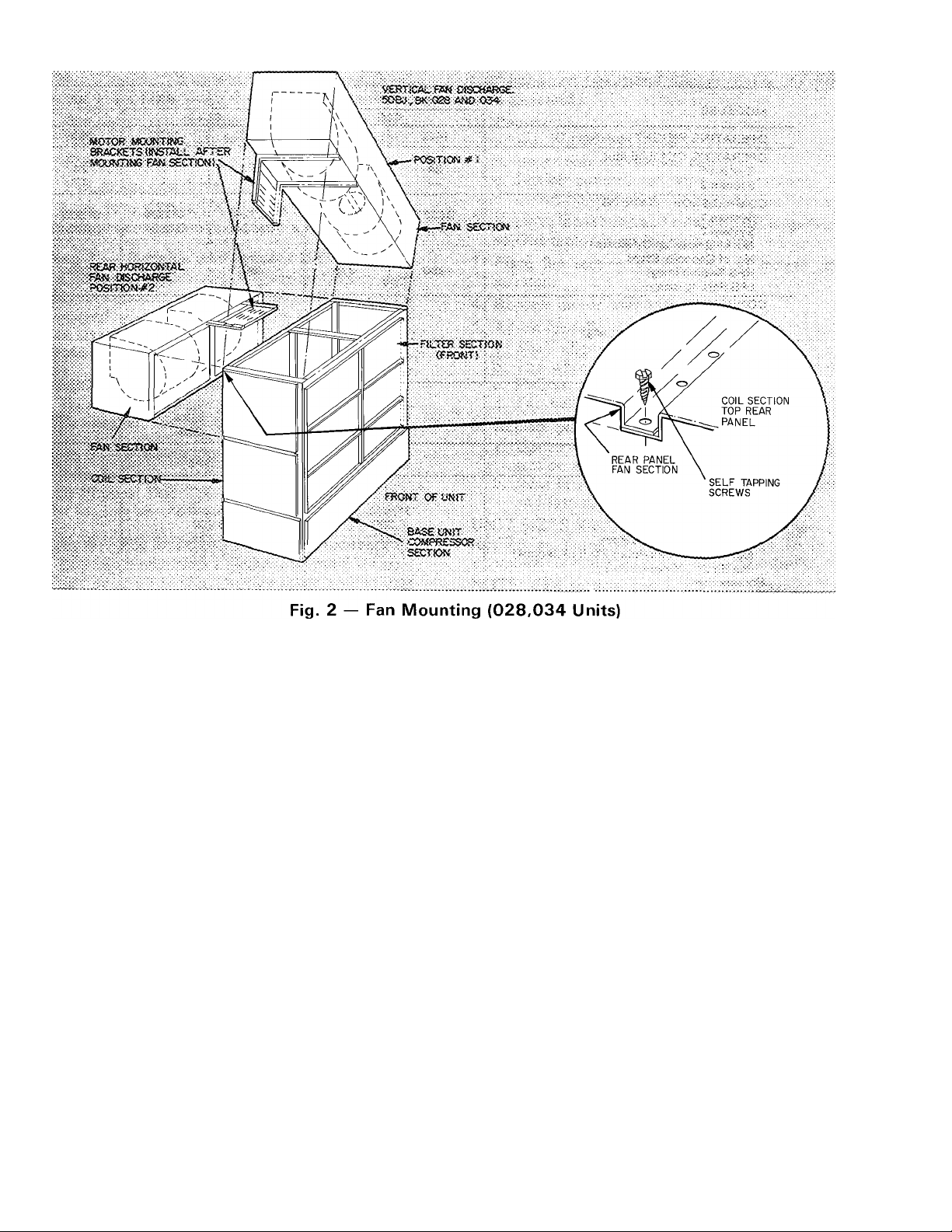

UNIT SIZES 50BJ,BK028 AND 034 are shipped in

sections as noted previously. They can be field

assembled for either vertical or horizontal discharge.

NOTE: Fan section panels may be removed for

easier lifting and to facilitate motor installation.

To set up sizes 50BJ,BK028 and 034 units for

horizontal discharge (Fig. 2), proceed as follows:

1. Remove:

a. Upper rear and end panels of coil section.

b. End panels on fan section.

c. Fasteners holding lower rear edge of fan panel.

2. Eift and position fan section on rear of coil

section (Fig. 2). Secure with fasteners provided.

3. Install the following per Installation Step 6:

a. Motor mounting frame angles.

b. Motor on plate assembly.

e. Motor-plate assembly on frame angles.

d. Balance of drive package components.

4. Adjust the following per Installation Step 8:

a. Shaft alignment.

b. Fan wheel position.

c. Pulleys.

d. Fan belts.

5. Replace panels as follows:

a. Rear coil section panel on top of coil section.

Rear holes will overlap fan section top panel.

Fasten using hole vacated in step Ic (see

Fig. 2).

b. All end panels.

Page 3

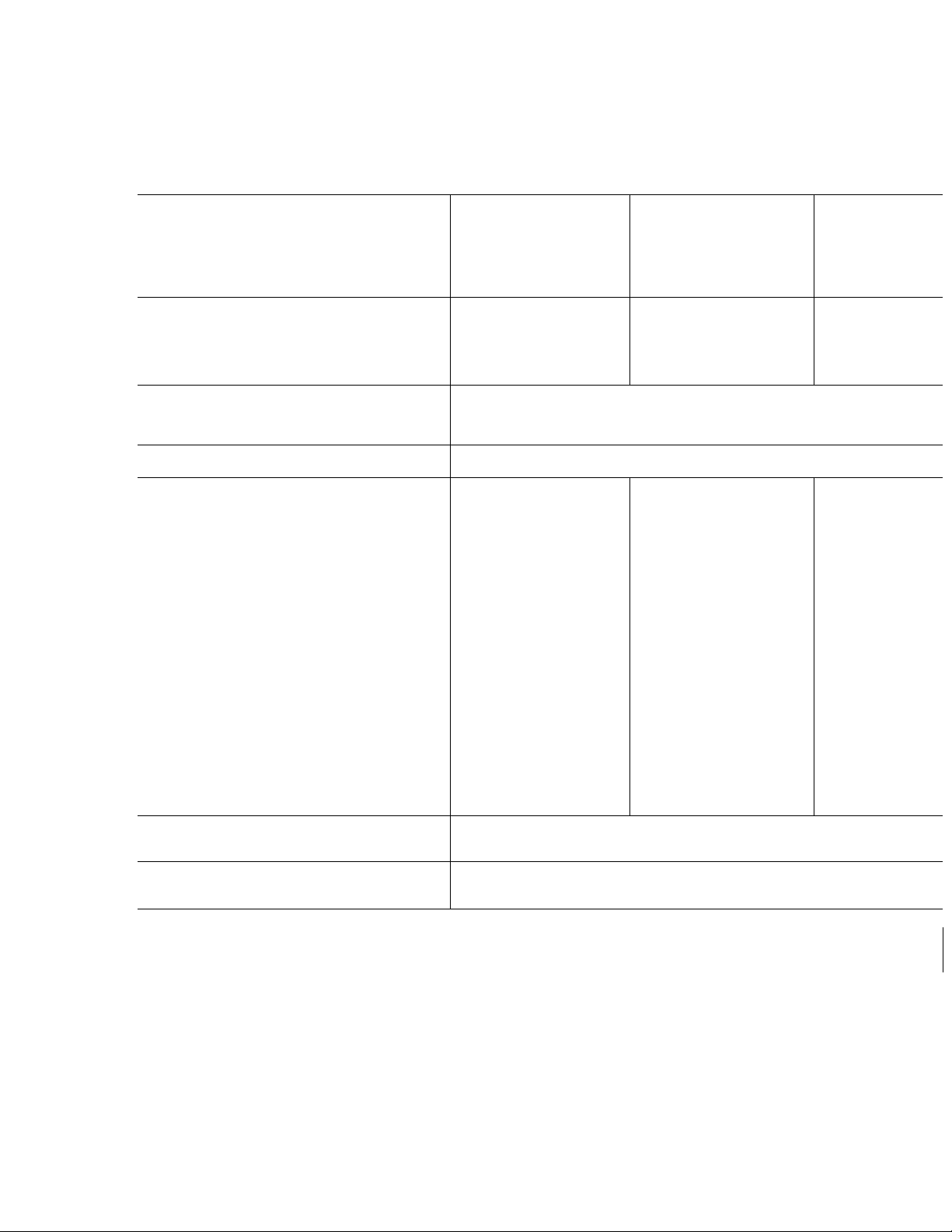

-> Table 1 — Unit P

MODEL50

OPERATING WEIGHT (lbs) (Note 1)

BJ

016

1420

OPERATING CHARGE (lbs)

System 1

24

System 2

COMPRESSOR — TYPE 06

System 1

System 2

No. of Unloading Cylinders

No. of Capacity Steps

HPS Setting (psig)

LPS Setting (psig)

DC337 1 DC537

4

3

280 j 376

27

CONDENSER (BJ Only)

No. ...Type

Max. Working Pressure (psig)

1 SC

550

Connection Size - (in.)

Water Inlet

Water Outlet

(1)2 FPT

(1)2 FPT

CONDENSER (BKOnly)

Connection Size - (in.)

Liquid

Discharge

% ODM (2)5/8 ODM

1У8 ODM

CONDENSATE CONNECTION

Condensate Drain

1 FPT 1 FPT

INDOOR FAN (Note 3)

Number

Size (in.)

Nominal Cfm

Maximum Allowable Rpm

No of Belts...Fan Pulley PD (in.) (Note 4)

Fan Shaft Diameter - (in.)

2 2

15x11 15x11

6,000 8,000

1200 1200

1 90 2 90

1^^

Horsepower

Standard...Frame Size

Motor Pulley A Diameter

Motor Pulley B Diameter

Motor Efficiency (%)

Motor Shaft Diameter (in.)

3 182T

4 5-5 5

—

79

1У8

Center To Center (standard and horizontal) 8 8-11 1

Center To Center (alternate top discharge)

— —

Fan Speed Range (Rpm)

Pulley A

875-1069

Pulley B

Alternate...Frame Size

Motor Pulley A Diameter

Motor Pulley B Diameter

Fan Speed Range (Rpm)

Pulley A

Pulley B

5 184T

—

— —

___

—

INDOOR COIL

No of Rows... Fins/in. 3 110

Total Face Area (sq ft)

16 3

RETURN AIR FILTERS

No. . .Size (in.)

3 16x25x2

3 20x25x2

Cfm — Cubic Feet Per Minute ODM — Outside Diameter Male

FPT — Female Pipe Thread ODS — Outside Diameter Solder

Hp — Horsepower PD — Pitch Diameter

MPT — Male Pipe Thread PDR — Pitch Diameter Range

BK BJ BK

024

1225 1900 1470

15 17

17

DC724 1 DC824

DA724 1 DA824

4

6

280 1 376

27

2 SC

150 (Note 2)

(1)2 5 FPT

(1)2 5 FPT

(2)У8 ODM

Р/б V'Ae

5 .184T

4 6-5 6

84 84

1У8 1%

8 8-11 1 29 8-33 3

894-1089 925

—

7 5.213T 10 215T

— —

— —

4 110

17 4

3. 16x25x2

3 20x25x2

Rpm — Revolutions Per Minute NO

SC — Shell and Coil

TT — Tube-in-Tube

BJ

028

2500

24

17

DC337 j DC

DA724 j da

280 1 3

2 SC

15 + 2 FPT

15 + 2 FPT

(2)% ODM

1У8 ODM

1У4 MPT

18x18

10,000

1100

2 124

7 5 213T

1073

4 90

21 9

6. 25x20x2

2 16x20x2

4

6

27

550

5 6

6 5

__

23

A

2

1 1

1

2.

t

Page 4

- Unit Physical Data

BJ

034

2610 2440

Refrigerant 22

24 1 15

24 15

c

lerviceable Hermetic, 1750 Rpn

DC337 1 DC537

DA337

4

e

280 376

27

2

550

(2)2

(2)2 FPT

Size (in ) Type

(2) Ув ODM

(2) 1 Ув ODM

Size (in

1У4

028

4

27

2

SC

550

5 + 2 FPT

5 + 2 FPT

)Ув

ODM

Ув

ODM

P/4

MPT

BK

2335

15

12

DC537

DA824

376

Adjustable, Belt-Driven Centrifugal; 1750 Rpm Motor

2 2

18x18 18x18

10,000 12,000

1100 1100

2 12 4 2 11 0

I'Me VVu

SC

FPT

) Type

MPT

BK

DA537

BJ

3660

30

30

1

E2150

EA150

2

(2) 2Ув

(1)ЗУв

(2) Ув

(2) 1 Ув

1У2

BK BJ

044

3155

18

18 35

Е2250

ЕА250

2

4

395

27

TT 2

400

ODS

ODS (1)ЗУв ODS

ODS

ODS

FPT

2888 3298 4030

45 18

E7265

EA150 ЕА250

(2) 2Ув

(2) Ув

(2)1з/в

1У2 FPT

054

395

400

2

20 X 10

16,000

1200

2 187

1'Me

20 X 18

20,000

1200

2 18 7

^"Ae

BK

18

Е7265

1

\ 4

27

TT 2

ODS

ODS

ODS (2) 1Ув

2

^ BJ

_______

40

40

E7175

EF175 EF275

(2) 2Ув

(1)ЗУв

(2) Ув

1У2 FPT

BK

064

3305

18

18

Е7275

e

395

27

TT

400

ODS

ODS

ODS

ODS

2

20 X 18

24,000

1200

2 18 7

1"4б

'5 213T 7 5 213T

5 6 5 6

6 5 6 5

84 84

1 % 1 %

>9 8-33 3 29 8-33 3

925

1073

10 215T

Copper Tubes, Aluminum Plate Fins

4 90 4 90

21 9 26 2

Factory Supplied — Throwaway

25x20x2 6 25x20x2

16x20x2 2 16x20x2

NOTES

1 Operating charge for 50BK units does not include charge for

matching air-cooled condenser or refrigerant connecting

piping All 50BK units are shipped with a holding charge

Operating charge values are approximate

2 Condenser working pressure is 550 psig if factory installed,

dresser adapters are removed and field-fabricated manifold is

installed

925

1073

10 215T

15 254T

9 0

10 3

85

1%

17 9-21 1

18 4-22 0

840

961

20 264T

10 9

11 8

1023

1107

3 15

37 5

None

(See Note 5)

20 264T

9 8

10 9

87

1%

17 9-21 1

18.4-22.0

915

1023

25 284T

10 9

11 8

1032

1117

4 15 4 15

37 5

None None

(See Note 5) (See Note 5)

Motors and drives other than those furnished with units

016-034 must be purchased locally Installation may require

field modification

Fan motor pulleys on 50BJ,BK028,034,044,054,064 are fixed

pitch type The smaller of the 2 pulleys is factory installed

Refer to 39E Series literature (size 39E32) for accessory

information

25 284T

9 8

10 9

89

1%

17 0-20 4

17 6-21 5

922

1032

30 286T

10 9

11 8

1029

1114

37 5

Page 5

OPTIONAL TOP HORIZONTAL DISCHARGE

*For optional top-mounted horizontal discharge, use

accessory filler panel package as shown

DIMENSIONS (ft-in.)

UNIT

50BJ.BK

A 6-8 7- 9V4

B 2-4 2-11V4

C

D

E

F

G

H 1- 4V4

016

6-10'/2

2-0

3-0

3%

11- 2%

024

028 j 034

8- OVe

2-0

3-0

1- 8Vb

1- 8%

1- 7Vs

NOTES:

1 Certified dimension drawings available on request

2 Water and refrigerant connections located on right side of unit.

UNITS 50BJ,BK028 AND 034

UNITS 50BJ,BK004, 054, AND 064

Fig. 1 — Unit Dimensions

UNIT 1

50BJ.BK 1

J

K 2-0

L

p 4- 4% 5-41/8

Q

016 1 024 028 1 034

0-1%

M 1 1-8 2-1 Vs

IM j

—

—

4-11'/2

ACCESS AREA

AIRFLOW

0-2%

1-4

3-2V4

7-41/4

5-71/4

0

NOTES:

1 Certified dimension drawings available on request

2 Water and refrigerant connections for unit sizes

50BJ,BK044 thru 064 are located on right side of

unit See Fig 12 for connection details

3 Filters are not supplied with base unit. All models

are directly compatible with 39E (size 32) air

handling unit components Refer to 39E literature

for physical data for accessories

ve

2.

3.

4.

5.

6.

4

Page 6

To set up sizes 50BJ,BK028 and 034 units for

vertical discharge (Fig. 2):

1. Remove:

a. Front, rear and end panels of fan section.

b. Upper-rear and end panels of coil section.

c. Filters from coil section.

d. Fasteners holding filter frame top. Push out

frame away from coil section frame.

2. Lift up and position fan section on coil section

(Fig. 2).

3. Fasten fan-section frame to coil-section frame

with fasteners provided; then reposition and

refasten the filter frame moved in step Id.

4. Install the following per Installation Step 6:

a. Motor mounting frame angles.

b. Motor on motor-plate assembly.

c. Motor-plate assembly on frame angles.

d. Balance of drive package components.

5. Adjust the following per Installation Step 8:

a. Fan wheel alignment.

b. Shaft alignment.

c. Pulleys.

d. Fan belts.

6. Replace panels as follows:

a. Rear coil-section panels, front and rear fan-

section panels.

b. All end panels.

Unit sizes 50BJ,BK044,054 and 064 are shipped

with vertical discharge as standard. Other fan posi

tions are available as a factory-installed option.

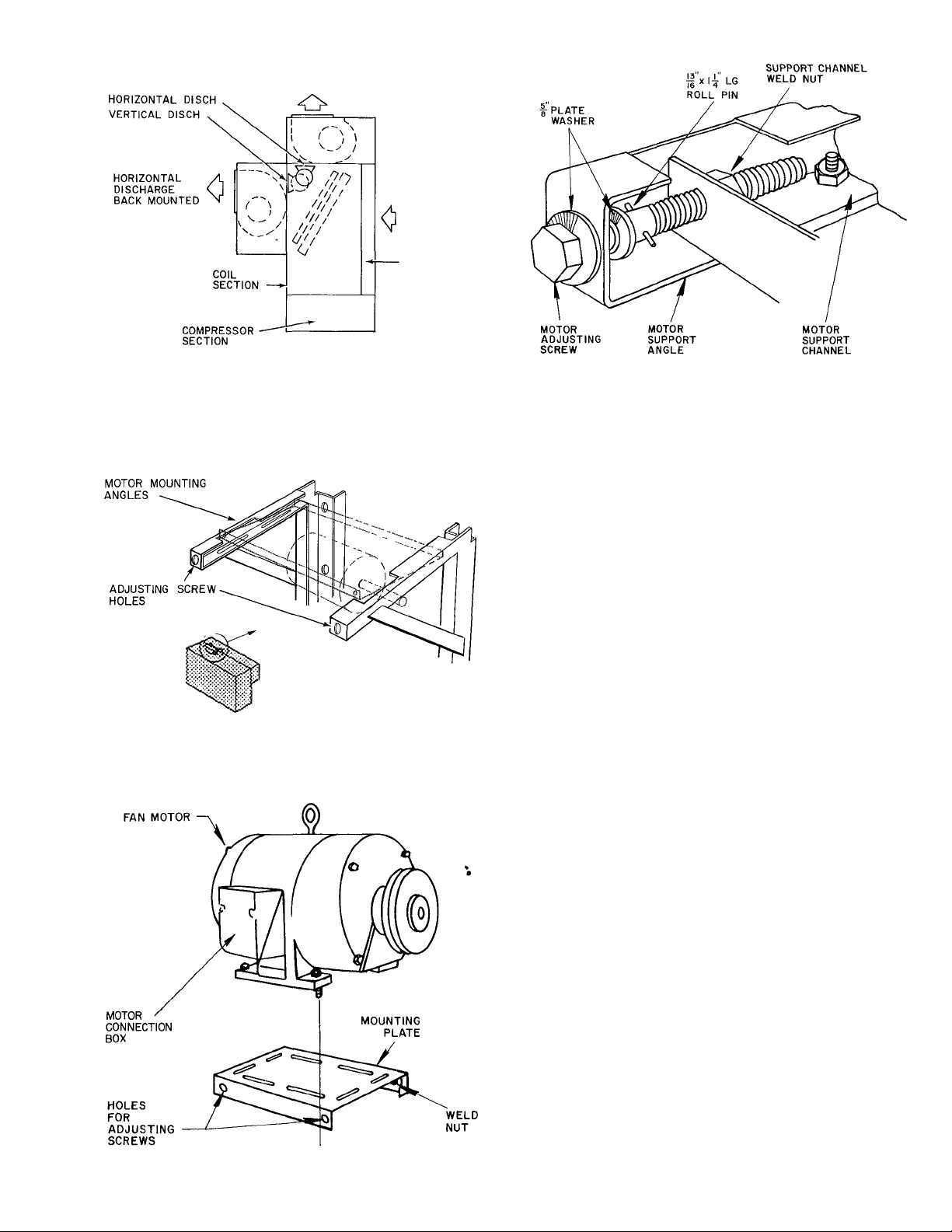

Step 6 — Install Fan Motor. Unit 50BJ,BK028

and 034 only. (All other units have factory-installed

motors.) Install items after fan section frame has

been placed in position on coil section.

NOTE: Place plywood over evaporator coil to

prevent damage while installing motor and mounts.

To install motor:

1. Fasten motor mounting angle bracket to fan

section. Use Fig. 2 or 3 for position reference

and Fig. 4 for assembly guidance. Be sure that

lips of angle brackets are around fan section

frame and that slots for motor mounting plate

face each other.

2. Position motor on motor plate (Fig. 5) and

fasten with fasteners provided.

3. Lift motor-plate assembly and slide into motor

mounting angles as shown in Fig. 4. Plate fits in

angle slots. On vertical mounts, the motor

mounting assembly can be lowered to bottom of

motor support channels.

4. Assemble and install motor adjusting screws as

shown in Fig. 6. Drive roll pins into screws to

prevent the screws from backing out during

motor position adjustment.

t

Page 7

VERTICAL DISCH

FAN MOTOR POSITION

NOTE.

Motor pulley on left side of unit — vertical discharge

Motor pulley on right side of unit — horizontal discharge

TOP MOUNTED

Fig. 3 — Fan and Motor Arrangements

50BJ.BK028.034

AIRFLOW

FRONT

■ FILTER RACK

Fig. 6 — Assembled Fan Motor

Adjusting Screw

5. Adjust motor position. Fasten motor mounting

plate to mounting angles.

Step 7 — Route Fan Motor Wire (Unit 50BJ,BK

028 and 034 only)

Fan motor must be field wired. Proper wire rout

ing is essential to the operation of these units.

Follow wire routing instructions carefully.

Fig. 4 — 50BJ,BK028 and 034 Horizontal

Fan Motor Mounting Angles

Fig. 5 — 50BJ,BK028 and 034 Motor

Mounting

CAUTION: Ttira t^ïricaï power to base

before cot-ttiag mriog to few matm.

CHECK EQUIPMENT — Refer to Fig. 7 and 8 for

location of base unit components. Fan motor wiring

is shipped coiled on top of evaporator coil. Wire tie

locations are shown in Fig. 7, 8 and 9.

ROUTE WIRING

CAUTiON: with aafScaeiit

to pertmi motor a<3|ssii»esi£. not

be pfecbed^ toecli zm moviiig parts or sharp

odgra.

VERTICAL DISCHARGE (Fig. 2. Position #1)

Run wiring thru wire tie# 1 (Fig. 9) on motor mount

ing bracket to the fan motor and secure. Route

wiring from wire tie around motor side of mounting

bracket to fan motor connection box on top of

motor (Fig. 5). Cut off and discard excess wire.

Refer to base unit label diagram for wiring connec

tion details.

HORIZONTAL DISCHARGE (Fig. 2, Position

#2) — Run wiring thru wire ties #2 and 3 (Fig. 9) to

the fan motor and secure. Run wiring to connection

box at back of motor (Fig. 5). Cut off and discard

excess wire. Refer to unit label diagram for wiring

connection details.

Step 8 — Align Fan Shaft and Wheel

HORIZONTAL WHEEL CENTERING — All

wheels must be horizontally centered between the

inside edges of their fan scroll venturis (Fig. 10).

Page 8

Fig. 7 — Typical 50BJ,BK028,034 Unit — Vertical Discharge

fA« MOTOR

Piti SECTiON

£V^«=<»ArOi? CCiL

Fig. 8 — Typical 50BJ,BK028,034 Unit — Horizontal Discharge

Page 9

Table 2 — Setscrew Torque Requirements

BOLT SIZE

(in.)

%

Vs

A VsfmCAL DfSC^íARS£

1 RECOMMENDED

TORQUE (Ib-ft)

1 15-18

1 22-25

Fig. 9 — Wire Tie Locations

WHEEL

CONCENTRIC ALIGNMENT—Shaft and wheels

must be concentrically centered with the venturi or

air inlet of the fan housing.

7SCROLL

VENTURI

ALL UNIT SIZES — Bearings are bolted to sup

ports. To correct shaft and wheel concentric

misalignment:

1. Loosen bearing support bolts and shim or move

as required.

2. Retighten bearing support bolts,

HORIZONTAL SHAFT ALIGNMENT (All

Units) — If the shaft has moved and all wheels are

off horizontal center, recenter the shaft as follows:

1. Loosen setscrews holding bearing locking collar

at each end of shaft.

DIMENSION "d"

MUST BE EQUAL ALL AROUND

Fig. 10 — Horizontal Wheel Centering

2. Slide shaft and wheel assembly horizontally until

wheels are horizontally centered (Fig. 10).

3. Slide the bearing locking collars against the

bearing race; turn in direction of shaft rotation

until tight.

Adjust as follows:

Units 50BJ,BK0I6 and 024

1. Loosen setscrews holding wheel support to shaft

(Fig. 11).

2. Center the wheel by sliding it horizontally

(Fig. 10).

3. Retighten setscrews.

Units 50BJ,B1C028,034,044,054 and 064

#

1. Loosen fan wheel square head setscrews on each

side of fan support (Fig. 11).

2. Center wheel by sliding it horizontally (Fig. 10).

3. Retighten locking setscrews to torque specified

in Table 2.

4. Retighten locking collar setscrews.

FAN, PULLEY AND BELT ADJUSTMENT —

Refer to the Service section entitled Indoor-Air

Fan Adjustment.

Step 9 — Install Field-Fabricated Ductwork

Connect ducts to unit, using flexible connections

as required. Duct angles are supplied with each

50BJ,BK044,054 and 064 unit. Install duct angles

at duct openings using flexible connections. Connect

supply ducts to flanges. Supply ducts should not be

manifolded together for at least 4 feet.

Attach ductwork to building structure and in

sulate. Add a vapor barrier to prevent sound trans

mission and vapor condensation.

Page 10

Weatherproof external ductwork, joints and

openings with flashing and mastic in accordance

with applicable codes.

Ducts passing thru an unconditioned space must

be insulated and covered with a vapor barrier.

Step 10 — Check Return Air Filters Unit 50BJ.BK (016-034 only)

Be sure that the filters are the correct size; refer to

Table 1. Do not operate the unit without these

filters in place.

Step 11 — Check Compressor Spring Mounts

The compressors are held rigid in shipment by

bolts extending thru a washer, lockwasher and

compressor foot into a weld nut.

Loosen and remove each bolt (4 per compressor)

until compressor floats free on springs. Remove and

discard washer and lockwasher. Take bag provided

with compressor and remove grommet and new

washer. Install grommet and new washer. Replace

and tighten bolts so that there is slight pressure

on grommet. This will steady compressor and pre

vent start and stop rocking.

The compressors have reversible oil pumps that

operate in either direction; therefore the direction

of rotation need not be checked.

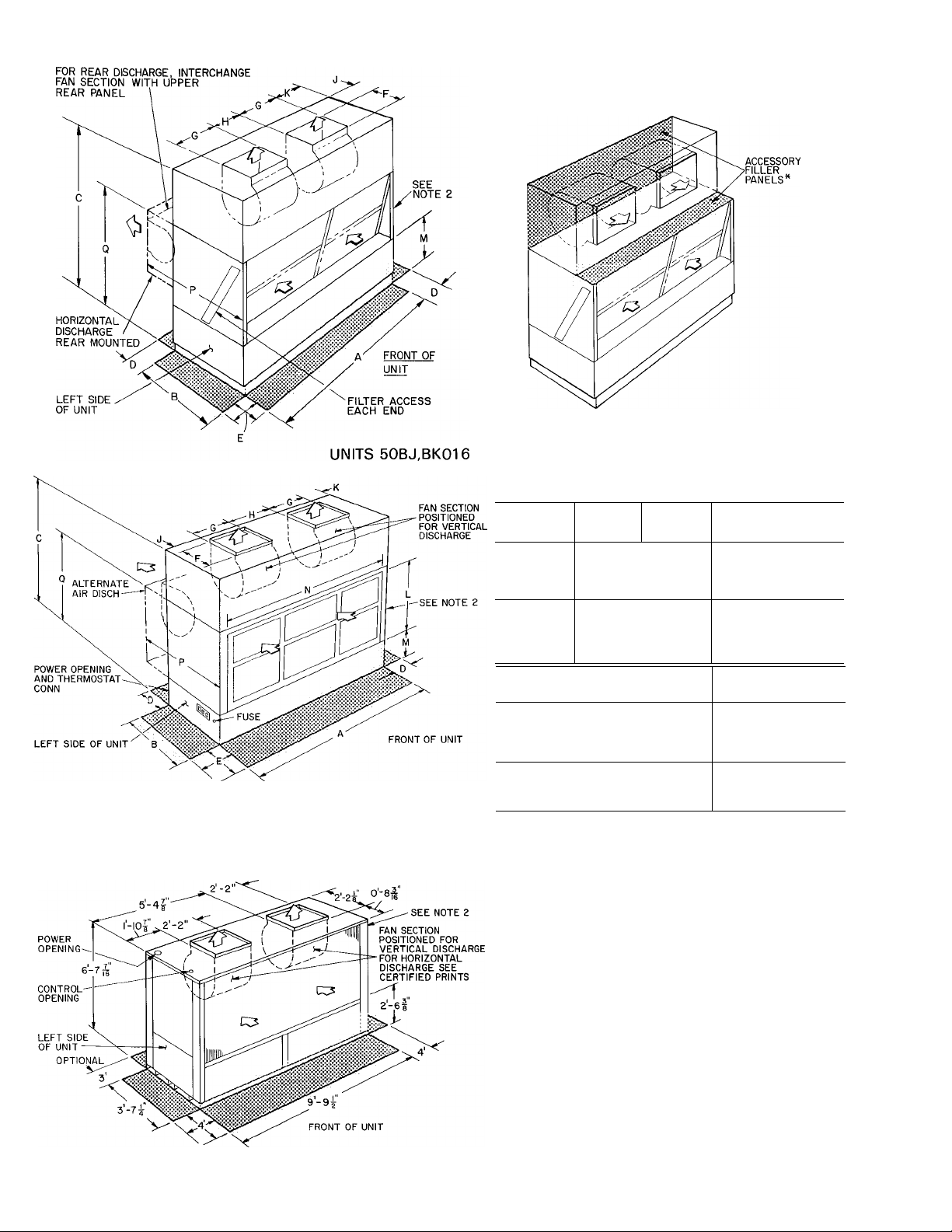

Step 12 — Make Condenser Connections

WATER-COOLED (50BJ unit) — Condensers

have water inlet and outlet connections as shown in

Fig. 12. Piping arrangements for city, waste or

recirculating water are shown in Fig. 13 thru 16.

Recirculating systems with low-temperature

water returning to the condenser may require a

water regulating valve. Units used on waste or city

water must have a regulating valve on the inlet of

each condenser and will require field modification

for separate condenser piping. Refer to Fig. 13, 14,

15, 16 and 17 for typical applications and

conversions.

2“FPT WATER

5OBJ0I6

50BK0I6

l" FPT

7/8" ODM HOT

50BK024

HOT GAS \

CONN 1

7"0DS

8 (028) f ^

I^ODS )

°t034) ^

l"-5 —

FLOOR 1

LINE T'

50BJ028

ё'

A

1 i"

♦ 1-4%

2

50BK028 a 034

‘•^Гб'

-Ig ODS

I

8

LIQ LINE

C0NN.(028

034)

HOT GAS

CONN (028

034)

NOTE: RIGHT SIDE VIEW OF UNIT SHOWN

Fig. 12

liEP.T CONDENSATE

DRAIN CONN.

2-|T , '

^ '/* 1-10,4

Water and Refrigerant Connections

50BJ044,054,064

9

3g IDS

WATER

RETURN

I^FPT

CONDENSATE

DRAIN CONN.

^ '4|б|"®2

50BK044,054,064

I ID LIQ

TUBE

(CKTI)

l|"l,D

HOT GAS

TUBE

(CKT I )

f I D HOT GAS

TUBE (CKT 2)

Page 11

CONNECT WATER REGULATING

VALVE TO COMPRESSOR

Fig. 13

50BJ024 City Water Condenser

Piping Conversion

1X1-

i|HXl-RETURN

CONNECT TO»rn

COMPRESSOR y

{X1-—dJo—

HXh

Nominal supply and return lines must be sized to provide required

gallons per minute at condenser All supply piping and valves are

2 in Return piping is 3 in Condensate drain is 1

supplied and installed external trap is required

-Cxi-

^^STRAINER

------

l||-C]— SUPPLY

Distrainer

'/2 in FPT Afield-

Fig. 16 — 50BJ,BK044,045 & 064

Condenser Water Piping

Install a water regulating valve on the inlet of each

condenser with any size unit used on waste or city

water (Fig. 14, 15 and 16).

Connect the regulating valve capillary to a back-

seated liquid service valve. Arrow on valve body

must point in direction of water flow. After con

necting capillary, open regulating valve one turn

from back-seated position. Adjust valve as required

to maintain proper condensing temperature.

Install full size gate valve and strainer in the water

supply line. See maximum working pressures in

Table 3. Valve and strainer must be accessible.

Fig. 14 — 50BJ024 Typical Waste or

City Water Piping

Table 3 — Maximum Water-Side

Working Pressure

UNIT SIZE 50BJ.BK

016 550

024

028,034

044,054,064

*550 psig if factory-installed dresser adapters are removed and

field-fabricated manifold is installed

MAXIMUM WORKING

PRESSURE (psig)

150*

550

400

AIR-COOLED (50BK units) — Install air-cooled

condenser in accordance with the Installation

Instructions shipped with condenser.

Consult Carrier System Design Manual for

standard refrigerant piping techniques. Connection

locations for liquid and hot gas service lines are

shown in Fig. 12. Recommended line sizes are

listed in Table 4.

Condenserless (50BK) units are shipped with a

holding charge. After refrigerant connections are

made, evacuate, leak test and charge the system as

described in the Service section entitled Charging

the System. Refer to Table 1 for approximate unit

charge.

10

Page 12

Table 4 — Recommended Line Sizes (in.)

(50BK Condenserless Models)

UNIT

50BK

HG — Hot Gas Line (OD in ]

L — Liquid Line (OD in )

‘Sweat connections

SYSTEM

016 —

024

028

034

044

054

064

1 & 2 % Vs Yb ys Ye

1 & 2 1 %

1 & 2 % IVs Vb V/a

1 & 2 % lys Vb

1 & 2

1

2 Ys ys

CONN.

SIZES*

L

% ^Ve Ve

% ^Vв Va

ys ^Уe

HG L HG

r/s Yb

LENGTH OF LINE (ft)

20

1'/s ys

1'/s Vb

ys Ya p/s

Yb

1 Vb Va

P/s Vb

P/s Va p/s ys

Vb

40

L

HG L

P/s .

P/s ys

p/s ys'

p/s ys p/s

Vb

p/s ys

p/s ys

60-80

ys

Ps

HG

P/s

P/s

p/s

p/s

p/s

p/s

p/s

Step 13 — Install Unit Drain Line

Install a trapped condensate drain line at unit

drain connection (Fig. 12). The drain requires

standard pipe connected to condensate pan nipple

as shown in Table 5. Figure 18 shows proper

trap design.

Determine design negative static pressure. This

pressure is not the same as fan total pressure,

which includes pressure losses downstream as well

as upstream from the indoor air fan. Always assume

the worst conditions, such as having return air

filters clogged with dirt.

Referring to Fig. 18, Differential 1 must be equal

to or larger than negative static pressure at design

operating conditions. Store enough water in trap to

prevent losing seal (Differential 2). This differential

must be equal to or larger than one-half the maxi

mum negative static pressure. When the fan starts.

Differential 3 is equal to the maximum negative

static pressure.

Table 5 — Condensate Drain Connections (in.)

UNIT SIZE : 016,024

PIPE SIZE ;

1 P/4

028,034

044,054,064

P/2

50BJ.BK044-064 UNITS

Fig. 17 — Refrigerant Systems (016-064)

TRAP CONDITION WHEN FAN STARTS

Fig. 18 — Condensate Drain

II

Page 13

Do not use drain line smaller than size listed in

Table 5. If required, cut hole in panel for drain line.

Piteh drain downward toward an open drain sump.

Provide a trap at least 3 in. high with plugged tee for

cleaning. Fill trap with water to make an air seal.

Observe all sanitary codes.

unbalance in supply voltage is greater than 2%. Use

the following formula to determine the % voltage

unbalance:

max voltage deviation

% Voltage _ jQQ from average voltage

Unbalance ~ average voltage

Step 14 — Make Electrical Connections

GENERAL — Provide an adequate fused dis

connect switch per NEC within sight from the unit.

Provision for locking switch open (OFF) is ad

visable to prevent power from being turned on when

unit is being serviced.

On all units, power may be supplied thru a branch

circuit. Branch circuit protection is provided in these

units by manual reset circuit breakers. Branch

circuit must be in accordance with NEC or local

code, whichever takes precedence. Power supplied

to auxiliary equipment, such as fan motors for air

cooled condenser or for cooling tower, must be

run separately.

^POWER WIRING — Conduit opening for 016-034

units is on back of unit near control box. Conduit

opening for 044-064 units is on top of unit near

control box. On all sizes, field power connections

are made at a terminal block within the control box

(see Fig. 19). Refer to Table 6 for maximum wire

size at terminal block.

50BJ,BKOI6-034

BLU

YEL

BLK

----------------

—7

FIELD

POWER

SUPPLY

FIELD

POWER

SUPPLY

---------------------------------------0L3 0-

------

O L2 O-

-----------

OLI O-

-01

EQUIP. GND.

L3

L2

LI

-------------------

--------------------

50BJ.BK 044-064

—

FIELD WIRING

FACTORY WIRING

TBI

IfTl—1

iV 1 1

EQUIP. GND,

llU

ÜU

rm

ÜU

Fig. 19 — Field Power Wiring Connections

Supply voltage must be in accordance with name

plate voltage. On 3-phase units, voltage between

phases must be balanced within 2% and current

within 10% with compressor running. If supply

voltage is not in accordance with nameplate voltage,

a phase unbalance may occur. Voltage at com

pressor must be within the minimum and maximum

shown in Table 7.

Contact local power company for line voltage

corrections. Never operate a motor where a phase

Example; Supply voltage is 240-3-60.

A B r, AB = 243 volts

BC = 236 volts

AC = 238 volts

Average Voltage =

Average Voltage

243 + 236 + 238

717

= 239 volts

Determine maximum deviation from average

voltage:

(AB) 243 — 239 = 4 volts

(BC) 239 — 236 = 3 volts

(AC) 239 -- 238 = 1 volt

Maximum deviation is then 4 volts. To determine

the % voltage unbalance:

1 Voltage Unbalance = 100 x

4

239

= 1.7%

This amount of phase unbalance is satisfactory

since it is below the maximum allowable of 2%.

IMPORTANT: ff supply voRage phase «abalaace h more than 2%, contaci your local

electric tiiility company immedjaieiy.

^ Compressor operation on improper line voltage

or excessive phase unbalance may be considered

abuse and anv resulting damage may not be covered

by Carrier warranty.

All wiring must be in accordance with local or

NEC regulations.

EIELD CONTROL WIRING — On extended volt

age (208-230-v) units, control transformer is factory

wired for 208-v usage. If unit is to be used on 230-v

system, reconnect primary wiring on transformer as

shown on unit wiring diagram.

When accessory timer control panel is used,

connect panel to factory-supplied control panel

as indicated on unit label diagram.

^WINTER START-UP PACKAGE — On 50BK

044-064 units, an accessory winter start-up package

is available for providing a 3-minute time delay by

shorting out the low-pressure switch on each com

pressor. This enables each compressor to start even

during low ambient conditions.

^HEATING COILS — Accessory heating coils are

available for field installation. Separate installation

instructions are shipped with the accessory (016-034

only). For 50BJ,BK044-064 units, refer to latest

39E (size 32) literature.

12

Page 14

Table 6 — Maximum Wire Size for

Power Terminal Block*

VOLTS/PHASE

208-230/3

460/3

016

2/0

2/0

575/3 2/0 2/0 2/0

024

UNIT 50BJ.BK

028,034

2/0 350

2/0 2/0

054,064t

044t

350

350

350 350

500

350

Table 7 — Unit Electrical Data

VOLTAGE

UNIT

50BJ016

50BJ024

50BJ028

50BJ034

50BJ044

50BJ054

50BJ064

50BK016

50BK024

50BK028

50BK034

50BK044

50BK054

50BK064

FLA — Full Load Amps

Hp — Nominal Horsepower

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection Device (amps)

RLA — Rated Load Amps

*Minimum circuit amps (MCA) for wire sizing complies with NEC Section

430-24

fin compliance with NEC requirements for multi motor and combination load

equipment (Ref NEC Articles 430 and 440), the overcurrent protective

device for the unit shall be fuse only

NOTES:

1 Compressor circuit breakers are current sensitive and temperature

compensated to ensure compressor cutoff if current draw becomes

excessive Breakers must be manually reset

VOLTS/PH/HZ

208-230/3/60

460/3/60

575/3/60 518

208-230/3760 n

460/3/60 414 508 160 62

575/3/60

208-230/3/60 187

460/3/60

575/3/60 518

208-230/3/60 187

460/3/60

575/3/60 518

208/230/3/60

460/3/60

575/3/60 518

208/230/3/60

460/3/60

575/3/60 518

208/230/3/60 187

460/3/60 414 508 42 6

575/3/60 518

208-230/3/60 187

460/3/60

575/3/60 518

208-230/3/60

460/3/60

575/3/60 518

208-230/3/60

460/3/60

575/3/60 518

208-230/3/60

460-3-60 414 508 29 0

575/3/60 518

208/230/3/60

460/3/60

575/3/60

208/230/3/60

460/3/60

575/3/60 518

208/230/3/60

460/3/60

575/3/60 518

RANGE

Min Max RLA LRA

187 254 50 0

414

187

518

414 508 22 2

414

187

414 508 26 5 142 26 5

187

414 508 35 8

414

187

414 508 20 0 77

187 254

414 508 29 0

187

187

414 508 35 8

518

187

414

187 254

414 508 56 5

508

632 17 9

254

632

254

632

254

508

632

254

632 22 2

254

632

254

632

254

508 29 0 120

632

254

632

632

254

632

254

632

254

508 48 6

632

632

COMP #1

22 1 86

36 0 137

129

^ 49 3 191 35 7

180 69 13 0

49 3 191

22 2

180

57 9

80 8

30 0

91 5 446 91 5

32 2 164 32 2

64 0 266

23 0 96

45 0

160 62

64 0 266 45 0

23 0 96 17 0 62 T/2

64 0

23 0 96

77 2

30 0

101 5

38 6 164

120 0 506 120 0 506

42 9 176 42 9

*Select wire size per NEC and connect supply wires to factory-

supplied pigtail wire connectors

tMaximum wire size for 50BJ,BK044 units with alternate drive

package is 500 MCM

IMaximum wire size for 50BJ.BK054 units with standard drive

package is 350 MCM

COMP #2

RLA

191

69

50 12 9 50 5

86 16 0 62

86 22 2

69 18 0 69 I'h 8 7

283 57 9 283 15 46 2

98

446

223 26 5 142 20 27 0

164 22 2

253

170 45 0

120 20 0

266

120 29 0 120 I'h

345 77 2 345 15 46 2

173 35 8 173 15 21 0

VO 30 0 120 15 15.4

446 77 2 345 20 59 4

223 37 9 173 20 27 0

253 56 5

—

—

—

36 0 137 5 13 2

160 62 5 6 6 42 6

49 3 191 IVi 22 0

22 2

60 0 283 20 59 4

42 6

— —

—

—

20 0 77 5

16 0 62 5

64 0

23 0 96 I'h 8 7

30 0 120 20 20 0

Discharge gas thermal protection or internal protection with automatic

reset de-energizes the control circuit if extreme compressor motor

temperature should occur from excessive gas temperature or motor

overloading

Low- and high-pressure switches automatically shut off compressor(s)

if refrigerant pressure exceeds switch settings This action protects

against loss of charge

Indoor fan motor circuit breaker protects against motor overload Breaker

requires manual reset

The 50BJ,BK units are ETL listed at 208/230 and 460 v and C S A certi

fied at 575 V

Phase imbalance shall not exceed 2%

Wire sizing amps are a sum of 125% of the FLA for the largest motor plus

100% of FLA for all other motors in the unit

Maximum instantaneous current flow during starting is the sum of the

LRA for last compressor to start plus the FLA for all other compressors in

the unit

LRA

—

_

—

137 T/2 22 0

50 I'h 8 7

86 I'A

142 15 21 0

98 15 15 4

98 20 20 0

446 25 74 8

253 25

164 25

_

—

170

170

77

266 T/2 22 0

253 25 34 0

176 25 25 6

INDOOR

FAN MOTOR

Hp

I'h 11 0 54 8

Th

T/2

25

FLA MCA*

3

3 4 6 32 2

3 3 7 26 2

3 9 2

3 4 6

3

5

9 2

5 6 35 1

11 0 61 0

34 0 131 9

25 6 100 1

3 7 32 5 50

13 2

6 6 51 6

5 6 41 6

22 0 147 4

11 0

8 7 54 7

11 0 76 3

74 8

71 7 110

94 2 125

Ì2Ó0 150

44 2

132 9

49 2

178 5 225

82 7

64 7

222 4

100 3 125

81 5 110

282 7

89 2 150

40 9 60

114 5 150

67 3 70

166 0

60 5

221 9

103 6 125

84.9

265 5 350

127 7

100 3

346 8 450

163 2

124 2

POWER

SUPPLY

MOCPt

50

40

50

45

70

60

175

80

60

100

80

300

350

150

125

70

50

200

70

200

100

80

250

110

175

125

200

150

13

Page 15

START-UP

General — The 50BJ,BK. units are designed for use

in Modu-Vac Variable Air Volume Systems using

Carrier 37A Moduline® and 35B Modubox Air

Terminals. For air terminal installation and adjust

ment, refer to 37 A or 35B literature as required.

CAPACITY CONTROL — The units are equipped

with electrie unloaders on the lead compressor

(Fig. 17) and hot gas bypass on the no. 1 refrigerant

system. (Size 016 units have only one refrigerant

system.)

Unit capacity is monitored and controlled by a

Honeywell W7100 microprocessor (Fig. 20). This

controller provides the number of capacity control

steps as shown in Table 8.

Table 8 — Capacity Control Steps

Fig. 21 — Accessory Timer Control Panel

UNITS

50BJ.BK I (No. Steps)

016

024,028,034

044 4

054,064

I CAPACITY CONTROL

I 3

6

6

Fig. 20 — Honeywell Microprocessor

TIMER CONTROL — Carrier strongly recom

mends use of an accessory timer control panel with

the 50BJ,BK units. Installation and adjustment of

this device (Fig. 21) is covered in separate Installa

tion, Start-Up and Service Instructions included in

the accessory package.

If accessory timer is not used, install field-installed

manual switch between TB3 terminals [~T~| and

in the variable volume eontrol box for the 016-034

units. Switeh is factory-installed on the 044-064

units.

MOISTURE INDICATORS are located ahead of

thermal expansion valves. They must be full of

liquid to properly indicate moisture content.

Operate system for 30 minutes before determining

moisture content.

SERVICE VALVES (50BK) — Valves use teflon

seat washers to ensure position seal with minimum

stem torque (10 Ib-ft max). Do not overtighten valve

stem. Use wet rag on valve when soldering. If refrig

erant has been lost, midseat valve. Always replace

stem cap.

Prior to Unit Start

1. Clean and inspect the unit.

2. Open (backseat) compressor service valves and

liquid line shutoff valves. Replace and tighten

valve caps to prevent leakage.

3. On 50BK (air-cooled condenser) units, turn on

indoor fan motor circuit breaker. Check that

compressor crankease heaters are energized and

crankcase oil level is half full.

4. Leave crankcase heaters energized for 24 hours

to ensure safe oil/ refrigerant mixture in crank

cases for unit start-up.

Control Sequence Checkout

1. Perform all applicable steps described above

under Prior to Unit Start.

2. Turn on unit main power supply.

^3. Set the control band knob on microprocessor

(Fig. 20) at 2.

4. Turn on indoor fan motor circuit breaker.

5. If unit is equipped with accessory timer control

panel and 7-day clock is not calling for cooling,

turn on unit by overriding clock with manual

bypass switch (see Start-Up General section

entitled, TIMER CONTROL).

6. Close compressor circuit breakers.

7. Check for cooling by turning microprocessor

SETPOINT knob to 40 F. Light-emitting diodes

14

Page 16

(LEDs) should glow as corresponding cooling

stages come on. In addition, indicating lights on

cover of aecessory timer eontrol panel should

light.

^ NOTE: Depending on job eonditions and dif

ferential between setpoint and discharge tem

peratures, minimum time for all stages to eome

on is 22 minutes.

8. Turn mieroprocessor SETPOINT knob to 90 F.

The LEDs on mieroproeessor and indieating

lights on aceessory timer control panel should

go off as corresponding cooling stages drop out.

Ambient temperature must be less than 90 F for

this test.

9. When checkout and unit operation are satis

factory, turn off manual bypass switch (step 5),

position microprocessor SETPOINT knob at

desired temperature (approximately 55 F) and

replace all unit panels.

SERVICE

WARNING; Lock open and tag unit disconnect

before servicing equipment.

CAUTION: Before serv'icing fan compartment.

L Sharp edge.s of evaporator coil fms are ex

posed. To prevent arm inj ury., cover top edge

of evaporator with strip of cardboard or a

few layers of heavy tape.

2. To avoid coil damage, cover coil face with a

piece of plywood or other suitable rigid sheet

material. If any coil fms are mashed or bent,

straighten with a coil fin comb. Check for

refrigerant leaks.

Fan Rotation — Correct fan rotation in respect to

fan outlet is shown in Fig. 22. To check for proper

fan rotation, remove service access panels and jog

fan motor switch. If fan rotation is incorrect, it must

be reversed.

1. Pulleys and fan belts should be aligned and

adjusted as shown in Fig. 23-25.

2. Tighten motor holddown bolts.

3. Replace service access panels.

Indoor-Air Fan Adjustment — Fan motor pulley

is factory set for speed shown in Table 1. Unit sizes

028-064 have fixed pulleys. A second pulley is

shipped with drive package.

Increasing fan speed increases load on motor;

Do not exceed maximtim allowable fan speed

(Table I) or motor fuB load amps shown on

motor nameplate and in Table 7.

TO CHANGE FAN SPEED

1. Shut off power supply.

2. Loosen fan belt by loosening fan motor on

mounting bracket. Do not loosen mounting

bracket from unit.

3. Loosen movable pulley flange setscrew (016,024).

See Fig. 25.

4. Select motor pulley diameter. See Table 1.

5. To increase fan speed, screw movable flange

towards fixed flange; to decrease speed, screw

movable flange away from fixed flange. Use

values shown in Table 1 (016,024).

6. Set movable flange setscrew at nearest pulley

hub flat and tighten (016,024).

7. Check pulley alignment and adjust belt tension

as described below.

8. Check fan operation. Repeat above procedure

as required.

V-BELT INSTALLATION AND TENSIONING

(See Fig. 23, 24, 25 and 26) — Use the following

steps when installing drive belts:

CORRECT

ALIGNMENT

OFF SET

(INCORRECT)

PIGEON TOED

(INCORRECT)

n

ANGLE

(INCORRECT)

Fig. 22 — Fan Rotation

To reverse the direction of rotation of a 3-phase

fan motor reverse any 2 of the power leads. Refer to

the connection diagram on the inside of motor

terminal box cover for proper reversing procedure

of single-phase motor.

Fig. 23 — Fan Belt Alignment

Step 1 — Sheave Conditions — Check condition of

all new and old sheaves. Sheave must have smooth

finish and no sharp edges or burrs. Check for groove

uniformity. Excessively worn sheaves or improperly

machined grooves can lead to early belt failure.

Non-uniformity of grooves will create an unequal

load distribution in matched set of belts.

Step 2 — Mounting Sheaves — Mount sheaves as

close to bearing as possible. Excessive overlap may

cause bearing failure.

15

Page 17

Step 3 — Matched Set of Belts — Always use

matched set of belts. NEVER mix new and used

belts andjor mix belts from different manufacturers.

Step 4 — Belt Installation:

a. Move pulleys together to facilitate belt installa

tion. NEVER pry or roll belt on to pulleys as this

may cause serious damage to belts.

b. Work belts around pulleys by hand. All belts

should be slack on same side of drive. Mixing

slack and tight sides together may result in

.serious damage to belts when drive is tensioned.

THIS OR THIS NEVER THIS

Fig. 24 — Fan Belt Adjustment

c. Move pulleys apart until belts are snug. Make

preliminary check of sheave and shaft alignment.

Operate drive at no load for several minutes to

seat belts and then check belt tension. Excessively

high or low tensions adversely affect the life and

operation of V-belts.

d. Check sheave and shaft alignment after belt

tension is applied.

PULLEY ALIGNMENT — Shut off unit power

Make sure motor and fan shafts are parallel.

Align shafts by loosening motor on mounting

bracket if required. Then loosen fan pulley set

screws, slide pulley along fan shaft and align with

straightedge as shown in Fig. 25.

MOVABLE Flanges

STRAIGHT EDGE MUSt/

SE PARALLEL

WITH BELT /

A

/ ■

\ SETSCREWS

/

A l/

PULLEYS

: SETSCREWS--

SINGLE-GROOVE T-WO-GRC'O'VE

MOTOR a FAN SHAFTS

' ^ MUST BE PARALLEL

nXED FLANGES

Fig. 25 — Indoor Air Fan Pulley

Adjustment and Alignment

TENSIONING (See Fig. 26) — Use the following

steps when adjusting belt tension:

Step 1 — Measure belt span in inches.

Step 2 — Use spring scale at center of span to deflect

belt 1/64 inch for every inch of span length. Record

scale reading.

Example: For span of 10 inches — deflection will be

10 5 . .

tt or inch.

64 32

Step 3 — Spring scale reading should be in range of

12 to 18 pounds. Maximum tension for a new belt

is 18 pounds.

Step 4 — Adjust tension to maximum after 15

minutes. Check belt tension after 2 to 4 hours of

operation.

Step 5 — After 24 to 48 hours of operation, check

drive to see if normal tension is obtained. Exces

sively high or low tension will adversely affect life

and operation of V-belt.

Lubrication — Shut off power Protect

coil from damage.

Fan motor bearings are factory lubricated and

will need no lubrication for the first 5 years of

operation (3 years with continuous service or ex

cessively dirty conditions).

Inspect bearings and relubricate or replace as

required. Follow manufacturer’s instructions for

lubrication of special field-supplied motors.

Fan shaft bearings on 50BJ,BK016 and 024 units

are lubricated for the life of the bearings. Bearings

for 50BJ,BK028 thru 064 units have grease fittings.

On 50BJ,BK044-064 units the fan shaft universal

joint requires the same lubrication as the bearings.

Lubricate annually with a good grade of mixed base

grease or lithium base grease with rust inhibitor.

Add grease until air bubbles form under the seal.

Do not overgrease.

Return-Air Filters — Inspect filters twice monthly

and replaee as often as required by operating condi

tions. Filter type and size is given in Table 1.

If field-supplied, cleanable filters are used, flush

them with hot water or steam, or soak them in a

mild solution of soap or detergent and water. Refer

to filter manufacturer’s instructions as applicable.

Never operate the unit without return-air filters

in place.

Condensate Drains — Clean drain line and unit

drain pan at start of each cooling season. Check

flow by pouring water into drain. Be sure trap is

filled to maintain air seal (Fig. 18).

16

Page 18

Evaporator Coil — Protect coil when working

inside unit. (See screened CAUTION note, page 15.)

Remove dirt and debris from evaporator coil as

required. Clean with a stiff brush, vacuum cleaner

or compressed air. Straighten mashed or bent coil

fins with a fin comb of the correct spacing. Table 1

lists the fins per inch for each coil.

Water-Cooled Condenser(s) may require clean

ing of scale (water deposits). Contact local water

treatment company for best results.

Air-Cooled Condensers — Periodically inspect

and clean depending on operating conditions.

Follow the service instructions provided with the

air-cooled condenser used.

Sight Glasses are provided at the inlet of each

expansion valve. Units may be field charged by

using the sight glass (see Charging the System).

'Charging the System

UNITS WITH WATER-COOLED CONDENSER

(50BJ) — Units are shipped with a full operating

charge of refrigerant. If recharging is necessary

(complete charge lost) weigh in amount of refrig

erant indicated on unit nameplate and Table 1.

If unit has a partial charge, unit may be charged

with sight glass using standard charging techniques.

See Carrier Standard Service Techniques Manual

entitled Chapter 1, Refrigerants for applicable

procedures.

Adjust the water regulating valve to proper

saturated condensing temperature (168 to 226 psig).

UNITS WITH AIR-COOLED CONDENSER

(50BK) — Units are shipped with a holding charge

only. To charge:

1. Open suction and discharge line service valves.

2. Blow holding charge, evacuate and leaktest

system.

3. Add sufficient refrigerant vapor to permit con

tinuous operation after starting unit.

4. Start unit per Start-Up Section; then, using

standard charging techniques, add refrigerant as

required to maintain normal operating

conditions.

Use charging chart supplied with condenser. If

information is not available, block off enough of

condenser coil to maintain 220 psig discharge

pressure and charge to a clear sight glass.

Indoor-Air Fan Motor Removal

Sim oif artd lockout ouit power swply.

A CAUTION

Biotor î3ao«îî£&, place a pjece of i^wooá over

ALL 50BJ,BK UNITS — Remove motor as follows:

1. Remove unit access panel and cover of motor

junction box.

2. Disconnect motor wires and remove conduit

connection.

3. Remove motor bolts and slide motor over so

that fan belt can be removed.

4. Disconnect motor ground wire (if present) and

remove motor.

TO REINSTALL MOTORS — Reverse the above

procedures. Align pulleys and adjust belt tension as

described in the section, Indoor-Air Ean

Adjustment.

Pressure Relief Devices — The 50BK (condenser

less) and 50BJ,BK044-064 units are equipped with

a fusible-plug type safety relief device on the com

pressor. The relief setting is 197 or 203 E on all units.

All 50BJ (water-cooled) units have a frangible

disc on each condenser. Disc setting is 385 ± 5% psig.

^Crankcase Heaters are supplied on all 50BK

(condenserless) units and on 50BJ044-064 watercooled units.

The heater reduces the possibility of liquid refrig

erant from accumulating in the compressor crank

case during extended shutdown periods. Heater is

automatically energized whenever unit main power

is on and compressor is stopped. Heater is de

energized when compressor starts.

Do not shut off unit main power supply for an

extended period except for servicing unit. After an

extended shutdown period, turn power supply on at

least 24 hours prior to starting compressor.

If 50BJ units are installed in unheated rooms,

they should be equipped with crankcase heaters. All

units equipped with crankcase heaters require 24

hours warm up time.

High-and Low-Pressure Switches — The high-

pressure switch is located in the electrical panel.

The low-pressure switch is located on top of

compressor.

Time Guard® Control Circuit provides auto

matic reset protection (except circuit breaker),

time delay in starting and controlled cycling. If

compressor shuts down for any reason, the control

circuit prevents restart for time periods as follows:

UNIT

50BJ.BK

016 1 5

024,028,

034

044,054

064 1 1 and 2 64

CIRCUIT

NO.

1 64

1 2

1 2

A

Full Cycle

(minutes)

5

5

B

Delayed Start

(seconds)

15

19

15

15

19

Column B shows time delay between compressor

starts under normal thermostat cycling.

17

Page 19

CONTROL SEQUENCE

All 50BJ,BK Units — The indoor fan circuit

breaker (IFCB) must be closed for the control

circuit to be energized. When breaker is closed, the

SYSTEM light will be on.

The 044-064 units are equipped with a switch

labeled STANDBY. When switch is closed, the

indoor fan contactor (IFC) is energized and the

indoor fan will start and run continuously. A light

labeled FAN will come on. To use accessory timer

control, switch must be put in STANDBY position.

All units are equipped with the improved Honey

well W7100 discharge air controller. Controller has

3 control knobs: set point, reset and control band.

Controller regulates the leaving air temperature to

the set point. A setting below 50 F may decrease

unit efficiency due to use of hot gas bypass at light

loads. The reset knob adjusts reset control range

from 5 F to 20 F. The reset feature requires fieldsupplied components and wiring. The control band

knob adjusts controller for the required number of

stages. The control band should be set at 6 F for the

016-034, 054 and 064 units, and 8 F for the 044 units.

Increasing control band setting above these recom

mended settings will decrease compressor cycling

and increase leaving air temperature variations.

Decreasing setting will not reduce discharge air

temperature variations but will increase compressor

cycling.

The controller is also factory equipped with 2

fixed resistors. One resistor corrects for the number

of steps. This is done by placing a 1/4-watt, 5%-

8

m

on micro-resistor across terminals m and

processor. A 3-stage, 300-ohm resistor is used on the

016 unit. A 4-stage, 400-ohm resistor is used on 044

units and a 600-ohm resistor is used on 024-034,

054 and 064 units. A second 510-ohm resistor is

connected between terminals 0 and [V] to indi

cate unit does nt have an economizer. These units do

not have a factory-supplied eeonomizer. If a fieldsupplied economizer is added, remove the 510-ohm

resistor. Consult Carrier Corporation for more

details.

If the discharge air deviates 1°F above or below

the control band while unit is running, a cooling

capacity stage will either be added or removed

according to the loading sequence table found on

page 18. Additional capacity steps will be turned on

or off until discharge air temperature is within

control band or is charging at a rate that will allow

it to be within control band within 10 minutes. The

controller also has a fixed guaranteed minimum

on and off time of 4 minutes to prevent compressor

cycling.

These units are equipped with a Time Guard®

circuit. This circuit prevents compressor no. 1 from

restarting until 4 minutes, 45 seconds have elapsed

from last shutdown. Compressor no. 2 will not

restart until 6 minutes, 10 seconds have elapsed.

Each compressor is equipped with a high-pressure

switch (HPS), discharge gas thermostat (DGT) or

internal protection (IP) and low-pressure switch

(EPS). If any of these “trip”, the compressor will

shut down. If, after 4 minutes, 45 seconds for com

pressor no. 1 and 6 minutes, 10 seconds for compres

sor no. 2, the switch resets, compressor no. 1 will

restart within 15 seconds and compressor no. 2

within 19 seconds.

The 50BK condenserless units are equipped with

a liquid line solenoid (ELS). When a stage calls for

compressor shutdown, the liquid line solenoid will

close first. The compressor will continue to run until

the low-pressure switch opens.

Loading Sequence

MODEL

50BJ.BK

016 33%

024 17%

028

034 17%

044 25% 50%

054 19% 38%

064 17% 34% 50% 67% 84%

1 2 3 4

67% 100%

34%

17% 34% 50% 67%

34%

STAGE

50% 67% 84%

50% 67% 84%

75%

57%

— —

100%

63% 84%

84%

-

-----

5

6

—

100%

100%

100%

—

100%

100%

18

Page 20

For replacement items use Carrier Specified Parts

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Book 1

Tab

2a

Form 50BJ,BK-4SI Supersedes 50BJ,BK-2SI Printed in U S A 6-83 PC 111

Catalog No 535-031

Loading...

Loading...