Page 1

Number One

AirConditbning

M^er

Division of

Carrier Corporation

CaTiier Parkway • Syracuse N Y 13221

Single-Package Cooling Units

SAFETY CONSIDERATIONS

The 50BA,BB Single-Package Cooling Units are

designed to provide safe and reliable service when

operated within design specifications. However, due

to system pressures, electrical components and

equipment location, some aspects of installation,

start-up and servicing of this equipment can be

hazardous.

Only trained, qualified installers and service

mechanics should install, start up and service this

equipment.

When working on the equipment, observe all pre

cautions on tags or labels attached to the unit,

safety notes in the literature and any other safety

precautions that apply.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use care in handling, rigging and placing bulky

equipment.

A DANGER

NEVER reach into unit while fan is running.

LOCK OPEN AND TAG fan motor power dis

connect before working on a fan. Remove the fuses

and take them with you after noting this on tag.

Page

Step 11 — Install return air ductwork

Step 12 — Check return-air filters

Step 13 — Check compressor spring

Step 14 — Make condenser

Step 15

Step 16

START-UP...............................................

Unit Size 50BA,BB004 and 006 ...

Unit Size 50BA,BB008 thru 064 ...

Service Valves........................................

Capacity Control Valve Adjustment

SERVICE

Indoor Air Fan Adjustment

Lubrication

Return-Air Filters

Condensate Drains ................................................. 20

Evaporator Coil

Water-Cooled Condenser...................................... 20

Air-Cooled Condenser........................................... 20

Charging the System

Return-Air Grille Removal

Access Panel Removal.......................................... 22

Indoor-Air Fan Motor Removal............................. 22

Pressure Relief Devices........................................ 22

Crankcase Heaters

High and Low Pressurestats

Time Guard® Control Circuit

(004-012 units).................................... II

mounts

connections.....................................11,14

Install unit drain line

Make electrical connections. ... 16-18

.................................................

.............................................................

..............................................

...................................................

......................................................

..........................................

................................................

.......................

........................

.........

.........

.........

.........

.........

.........

.........

.....................................

................................

................................

11

11

15

18

18

18

18

18

19

19

20

20

20

20,21

21

22

22

22

A WARNING

CHECK assembly and component weights to be

sure rigging equipment can handle them safely. Note

also any specific rigging instructions.

WHEN STEAM CLEANING COILS, be sure area

is clear of personnel.

CONTENTS

Page

SAFETY CONSIDERATIONS.................................... 1

INSTALLATION .......................................................1-18

General ...................................................................... 1

Step 1 — Receive and inspect unit

Step 2 — Protect units from damage

Step 3 — Provide unit support

Step 4 — Rig and place unit

Step 5 — Install accessory plenum,

Step 6 — Position fan section as desired. .. 7,8

if supplied

Step 7 — Install fan motor.................................. 9

Step 8 — Align fan shaft and wheel

Step 9 — Install heating coil, if supplied. .. 11

Step 10 — Install supply air (evaporator)

ductwork

.......................................

........................................

...................

...............

..........................

..............................

7

..........

10,11

11

I

1

4

4

INSTALLATION

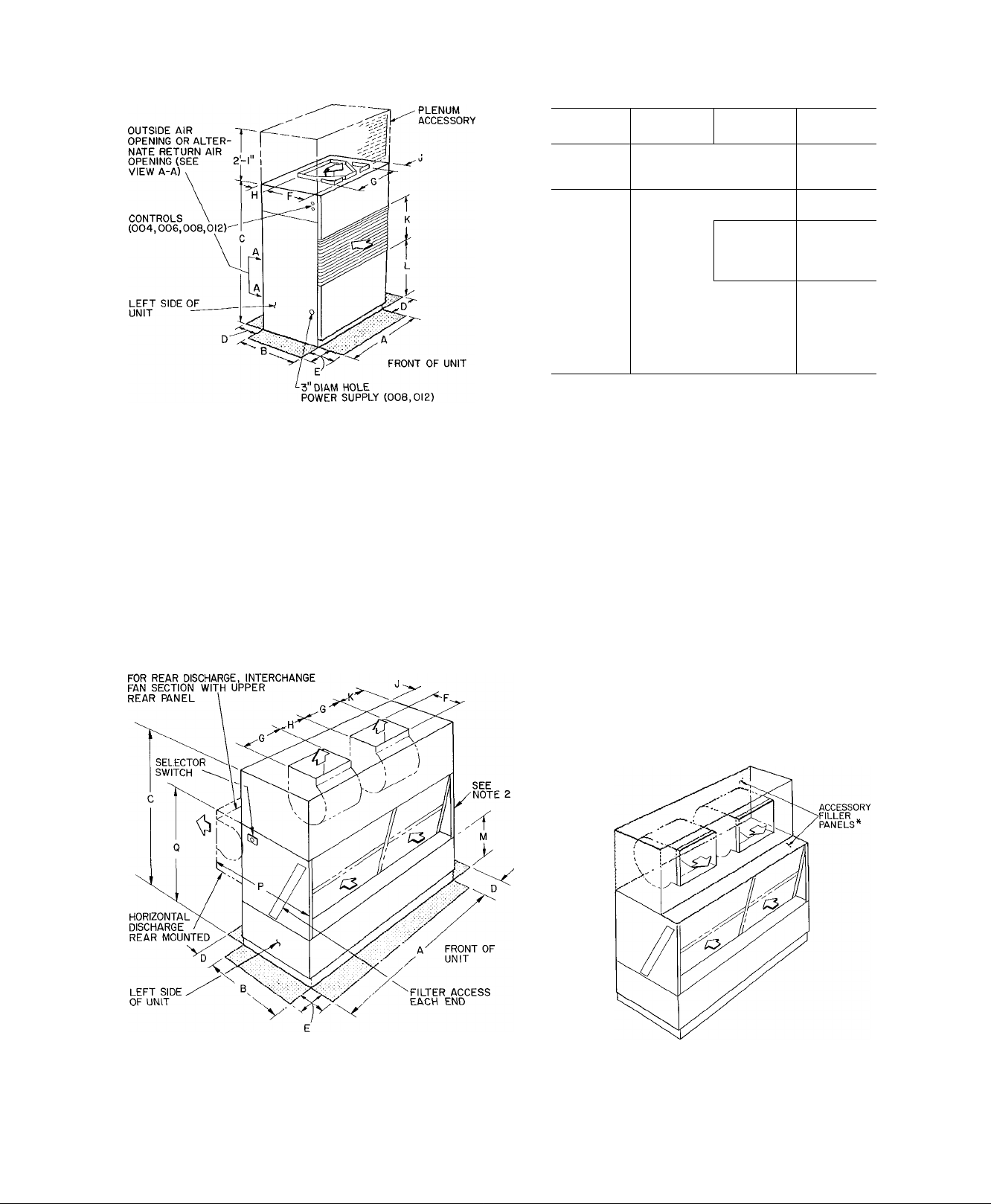

General — The 50BA,BB004 thru 024 units are self-

contained units arranged for vertical air discharge

and wired and piped at the factory.

Size 50BA,BB028 thru 064 units are self-

contained units consisting of a base section, fan

section, fan motor and fan drive package, each

shipped separately and field assembled. The base

section consists of factory-wired compressor/

evaporator coil unit. The fan section can be

mounted for vertical or horizontal air discharge

(Fig. 1).

^Step 1 — Receive and inspect unit.

Check unit against shipping order. Inspect care

fully for concealed shipping damage. If shipment is

damaged or incomplete, file claim with transporta

tion company and advise Carrier immediately.

>■ Step 2 — Protect units from damage.

To maintain warranty, protect unit against ad

verse weather, theft or vandalism on jobsite.

Carrier Corporation 1981

Page 2

--M ----

-v^

ALT REAR INLET

VIEW A-A

UNITS 50BA,BB004,006,008 AND 012«

UNIT

50BA.BB

A

B

C

D

E

F 1-1-13/16

G

H —

J

K 1- 9 1/8

L 2- 9-5/8

M 2- 7-7/8

N

P

Q

NOTES

Certified dimension drawings available upon request

1

Minimum required clearance at back and right side of

2

unit is zero Clearance above and at left of unit depends

on space required for accessory plenum, ductwork, con

denser piping, accessory heater piping, condensate drain

line power wiring, and access to unit control center

Clearance required at front of unit for service access and

free return airflow is 2 feet

Water and refrigerant connections for Unit Sizes 50BA,

BB004 thru 01 2 are located on the left side of unit See

Fig 1 6 for connection details

DIMENSIONS (ft-in )

004

3- 2-5/16

1-10-7/8

1 5- 3-7/8

See Note 2

1- 4-7/16

1-1-1/8

1-0-1/2 0-10-5/8

0- 2

0-10

1- 3-9/16 1-4

006

1-3

0 3/4

008,

012

4-0

2- 6-1/8

6-5

1-0

2-0

1- 7-3/8

1- 5-1/4

0- 1-1/4

0-11-7/8

1-11-1/4

2- 5-3/8

3-6

0-3

1- 0-1/2

i

ELOOR

-v^

*ALTERNATE RETURN AIR OR

OUTDOOR AIR INLET

UNITS 50BA,BB016 AND 024

OPTIONAL TOP HORIZONTAL DISCHARGE

(D

ACCESS AREA

AIRFLOW

0

‘For optional top-mounted horizontal discharge, use

accessory filler panel package as shown See instal

lation instructions in filler panel package

■Fig. 1 — Unit Dimensions

2

Page 3

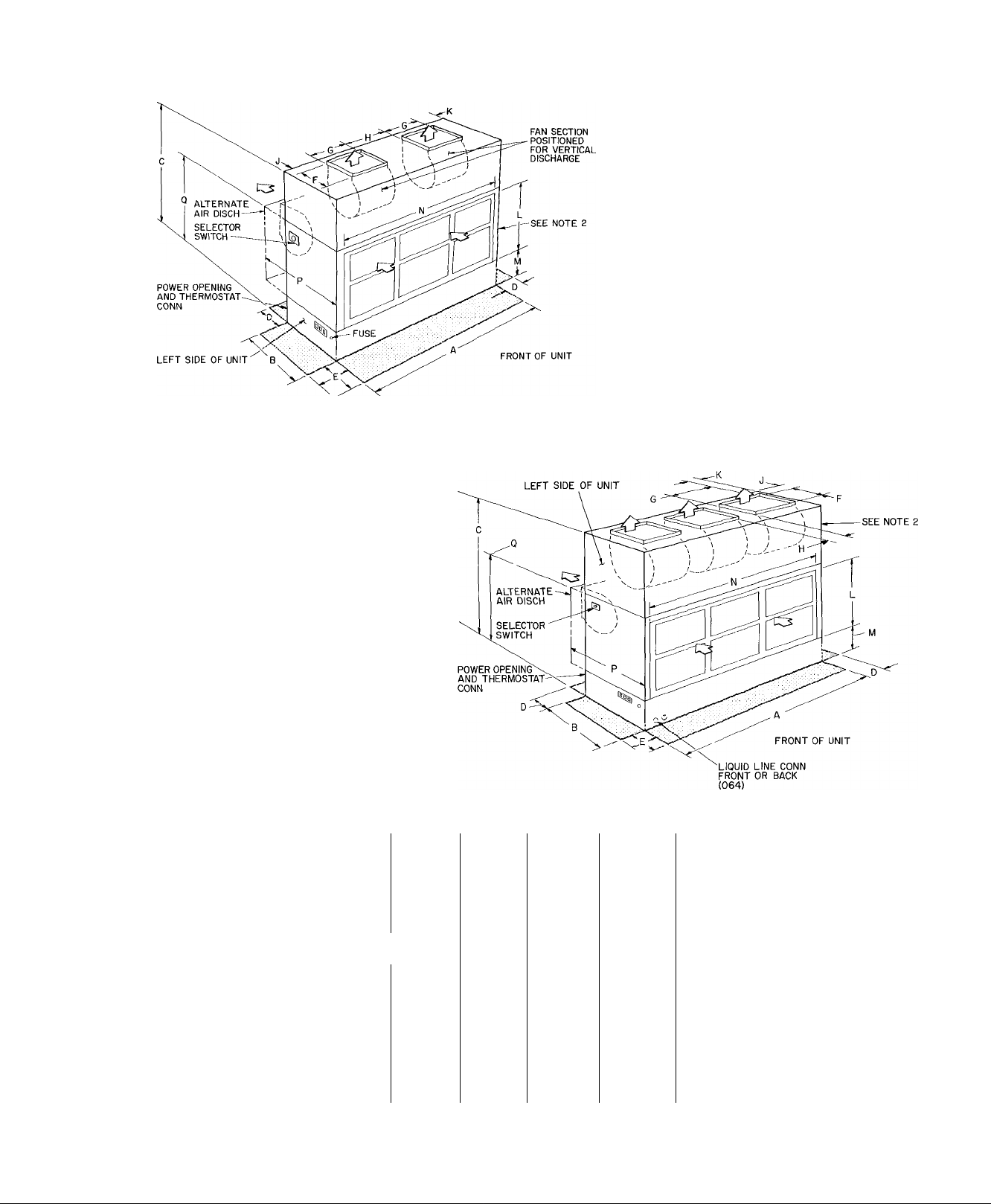

UNITS 50BA,BB028,034 AND 044

NOTES

1 Certified dimension drawings available on

request

2 Water and refrigerant connections for Unit Sizes

50BA,BB016 thru 064 are located on right side of

unit See Fig 1 6 for connection details

UNITS 50BA,BB054 AND 064

ACCESS AREA

AIRFLOW

[)

DIMENSIONS (ft-in

'■ ——

^10- g^3/g'

8- 0-1/8 8-10

2-0 2- 0

1-0

1- 8-7/8 1- 8-7/8

1- 8-7/8 1- 8-7/8

0- 2-3/a

3- 2-1/4

2- 1-1/8

7- 4-1/4 10- 0

'”o-3

2- 2-1/2

6- 4-5/8

. .. ...

- —-

054 064

1_-

3-10-1/4 3-10-1/4

9-9 10-1

3-0 3-0

3-0

3-10 4-9 4-9

1-0 3-0”

1- 8-7/8 1- 8-7/8

1- 8-7/8 1- 8-7/8

1- 5-5/8 1- 5-5/8

^ 0-3"^ 0-3

2- 2-1/2 2- 6-1/8

io-0 ^To-0

6- 4-5/8

UNIT

50BA.BB

A

B

C

D

E ~

F

G 1- 5-1/4

H

J

K

L

M

N

P

— ..—

016,024 028,034 044

" 6-8 7- 9-1/4

2- 5-1/4 2-11-1/4 3-10-1/4

6-10-1/2

2-0

. 3_Q

1- 7-1/4

1- 4-1/8 1- 7-7/8 2- 7-1/2

0- 1-5/8

1-7 1-4 2- 2-5/8 1- 2-1/4 1- 2-1/4

—

1-8

—

4- 4-5/8 5- 4-1/8

Q 4-1 1-1/2 5- 7-1/4 6- 3-5/8 7- 7-1/4 7- 7-1/4

"lol el/s'

6- 4-5/8

■Fig. 1 — Unit Dinrensions (cont)

3

Page 4

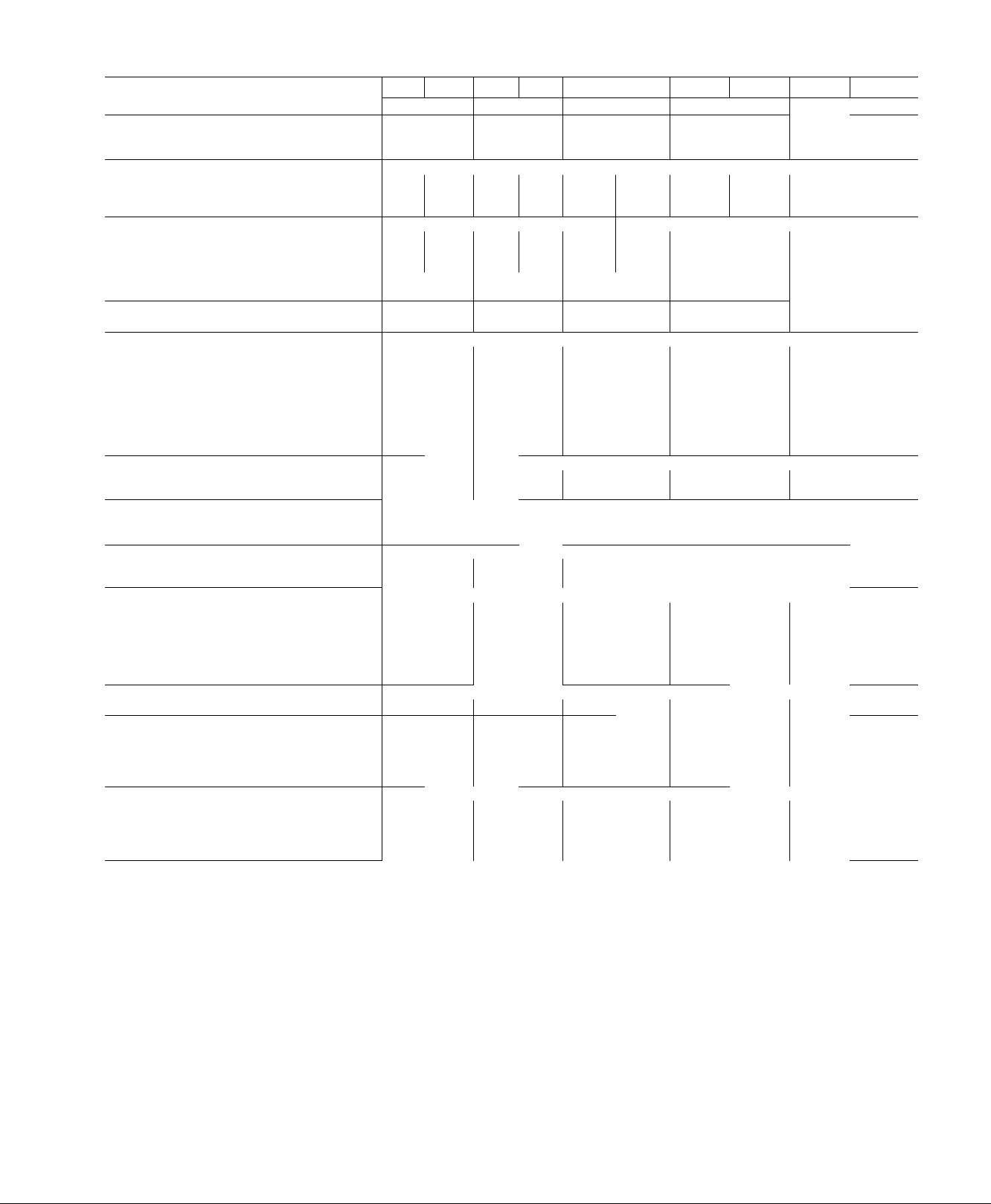

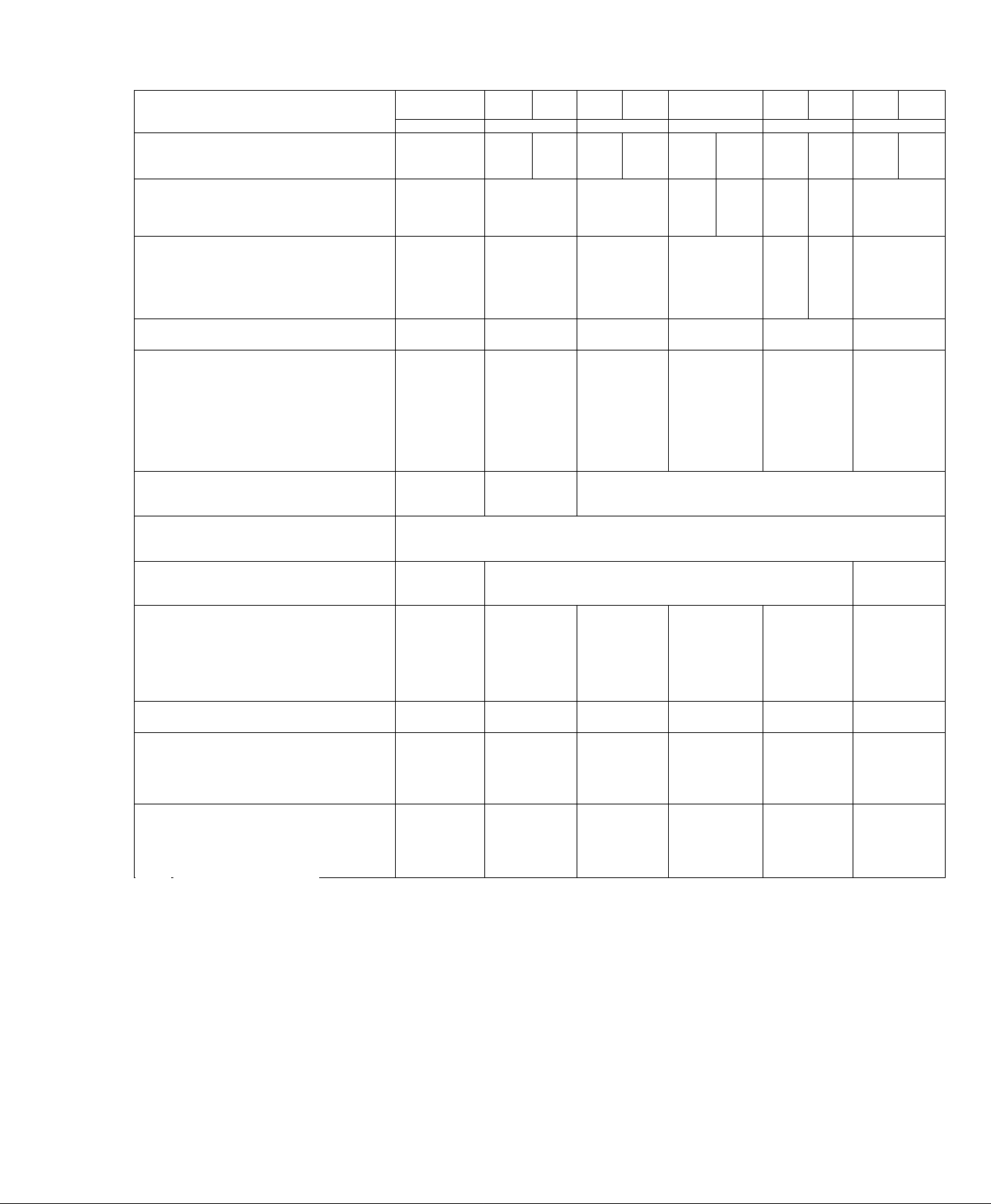

Table 1 — Physical Data

MODEL 50

OPERATING WEIGHT (lbs)

Base Unit

Discharge Plenum

OPERATING CHARGE (lbs) Refrigerant 22

System 1

System 2

System 3

COMPRESSOR — TYPE 06

System 1

System 2

System 3

No of Unloading Cylinders

No of Capacity Steps

CONDENSER (BA Only)

No. . Type

INDOOR FAN

Nominal Cfm

Standard Fan Speed Range (Rpm)

Maximum Allowable Rpm 1100 1100

No. of Belts . Fan Pulley PD (in )

Motor Pulley PDR (in )

Nom Hp Std...Frame Size 1/3 48

INDOOR COIL

No of Rows . Fins/in

Total Face Area (sq ft)

RETURN AIR FILTERS

No. ...Size (in.)

CONDENSER CONNECTIONS (BA Only)

Water Inlet — Manifolded

Water Outlet — Manifolded

REFRIGERANT CONNECTIONS (BB Only)

„ ^ - Hot Gas Line

System 1 Liquid Line

_ _ Hot Gas Line

System 2 Liquid Line

_ ^ _ Hot Gas Line

Systems Liquid Line

CONDENSATE CONNECTION

Condensate Drain

ACCESSORY HEATING COIL

Hot Water t , r- a /

„ Rows...Fins/in

HEATING COILS CONNECTIONS

Alt...Frame Size

Alt.. Frame Size

Rows ..Fins/in

Total Face Area (sq ft)

Total Face Area (sq ft)

Inlet

Hot Water r\ ^

Outlet

Outlet

BA BB

004

390 330 427

25

3 5

— —

—

Welded Hermetic, 3450 Rpm

M34 M34

—

— — —

0 0 0

1

1

TT

1200 2000

512-782

1 64

1 9-2 9 2 4-3 4

3/4 56 1

2

13 9

50

FPT 3/4

1/2

1/2 FPT 3/4 FPT

1/2 FI 1/2 FI

1/2 FI 1/2 FI

_

FPT 3/4

3/4

1

1~5

5 0 50

—

— —

1 7/8

1

7/8

1

7/8

1

7/8

2

—

—

2 16x25x1

BA

BB BA

006 008

360

25 140

46

—

—

P53

— — — — — —

1

TT

Adjustable, Belt-Driven Centrifugal; 1750 Rpm Motor

647-915

1

64

3/4 56

56

3 13 9

50

....... i

FPT

FPT

1

1 5

—

1

7/8

1

7/8 1

1

7/8 1

1

7/8

770

2 5 10

__

P67 P77

__

— —

—

— — — —

Copper Tubes, Aluminum Fins

Factory-Supplied Throwaway Type

......

BB

710

7

—

DA818

1

1 TT

3000

495-700 600-850

1100

1 8 5

2 4-3 4 2 4-3 4

1

56

145T

2

182T

3

3 12 1

7 3 8 5

4 16x20x1

.

Size (in ) . Type

1

1 FPT

Size (in.)...Type

3/4

5/8 ODF 5/8

3/4 FPT 3/4

2 14

1

No

1 1-1/4

1

(See Note 4)

FPT

ODF

_

—

—

—

Size (in ) Type

60

14

6 9

Size (in.) MPT

1-1/4

1-1/4

1-1/4

BA

950

10

—

—

Serviceable Hermetic, 1750 Rpm

DB724 DB824 DD337

....

.J...

BB

012

890

140

8

— —

—

2 2

2

1 TT

4000

1100

1

70

2 45T

3 182T 3

3 12 1

1 FPT

FPT

ODF

3/4

ODF

FPT 1

2 14

60 15 7

1 14

6 9

1 1-1/4 2

1-1/4 2

1

1-1/4 1

1

1-1/4 1

1

BA

1414

24

—

1 SC

568-720

1 11 4

3 7-4 7

2 145T

5 184T

3 106

3 16x25x2

3 20x25x2

2

1-1/8 ODM

5/8

2 11 3

1

BB

016

1221

140

15

— -

-

DD537

2

6000

1100

182T

16 9

FPT

FPT

i

ODM

FPT

14

144

1-1/2

1-1/2

1-1/4

1-1/4

Step 3 — Provide unit support.

Refer to Fig. I — Dimensions, and Table 1 —

Physical Data for unit size and weight.

Construct a stand or frame of I-beams or angle

iron that supports unit adequately, if desired. The

floor and floor joists of existing buildings may

require reinforcement; follow applicable codes.

Step 4 — Rig and place unit.

Provide space around unit for service, filter access

and overhead clearance as indicated in Fig. 1.

Move and store unit in upright position.

50BA,BB004 AND 006 — Use rollers under ship

ping rails. Unit may be moved by hand truck on any

side. Do not remove shipping rails until unit is in

final position.

50BA008 THRU 064 — Use slings with spacer under

base skid to prevent panel damage when using hoist.

Raise base skid on blocks and remove bolts. On 028

thru 064 units, unbolt fan section from skid.

Units as shipped are adequately dampened

against vibration. If additional dampening is de

sired, place sponge rubber, rubber mat or fiberglass

roof insulation between floor and base of unit or

install vibration isolators.

Page 5

MODEL 50

OPERATING WEIGHTlibir~~~~~

Base Unit

Discharge Plenum

OPERATING CHARGE (lbs)

System 1

System 2

System 3

DUMPHESSOR — TYPE 06

System 1

System 2

System 3

No. of Unloading Cylinders

No of Capacity Steps

CONDENSER (BA Onl^

No. . Type

llML/<^UK hAN "

...................................................

Nominal Cfm

Standard Fan Speed Range (Rpm)

Maximum Allowable Rpm

No of Belts...Fan Pulley PD (in )

Motor Pulley PDR (in.)

Norn HP Std...Frame Size

Alt .Frame Size

Alt. .Frame Size

INDOOR COIL

No. of Rows. .Fins/in.

Total Face Area (sq ft)

RETURN AIR FILTERS

No. ...Size (in )

CONDENSER CONNECTIONS (B^Onlv)

Water Inlet - Manifolded

Water Outlet — Manifolded

refrigerant CONNECTIONsTBB^iii^

System 1 Line

System 2 Line

System 3 Line

Liquid Line

Liquid Line

Liquid Line

CONDENSATE CONNECTION ~~~ ~-

Condensate Drain

ACCESSORY HEATING COIL

Hot Water Fins/in.

Total Face Area (sq ft)

Steam Flows. Fins/in.

_ Total Face Area (sq ft)

HEAIING COIL CONNECTIONS

Hot Water

Steam

FPT

— Female Pipe Thread

Hp

— Horsepower

MPT

— Male Pipe Thread

PD

— Pitch Diameter

PDR

— Pitch Diameter Range

SC

— Shell and Coil

ST

— Shell and Tube

— Tube in Tube

Outlet

Outlet

Table 1 — Physical Data (cont)

BA 1 BB

024

i

1894 i 1464

140

17 1 7

17 1 7

DA724I DA824

DA724I DA824

0

2

2 SC 2 SC 2 SC 2 SC

8000

700-875

1100

2 100

4 0-5 0

3 182T

5 182T

4 106

180

3 16x25x2 1 6 25x20x2 1 11 oc on 9 1 20x25x2

3 20x25x2 I 2 16x20x2 1 '' | 5.16x25x2

2-1/2 FPT

2-1/2 FPT

7/8 ODM

5/8 ODM

7/8 ODM

5/8 ODM

1 FPT 1-1/4 MPT

2 113

15 7

1 14

14 4

2 1-1/2

2 1-1/2

1 1-1/4

1 1-1/4

NOTES

1 50BB008 has serviceable hermetic 1750 rpm compressor

2 Operating charge for 50BB units does not include charge for remote air

cooled condenser or connecting pipe All 50BB units are shipped with a

holding charge Operating charge values are approximate See installa

tion instructions

3 Fan motor pulleys on 50BA,BB044,054 and 064 are fixed-pitch type

4 Field-supplied 2-in filters will fit

5 Motors and drives other than those furnished with unit must be purchased

locally Installation may require field modification Contact your local

Carrier representative

BA BB

028

2491

2397

24 1 15

17 112

DA3371DA537

DA7241DA824

0

2

Adjustable

10,000

605-750

1100

2 12 4

4 3-5 3

5 184T

7-1/2 213T

10 215T

4 89

22 6

BA

BB BA 1 BB

034

2598 2430 3800

Refrige

24 1 15

24 1 15

Serviceable Herr

DA337I DA537

DA337I DA537

0

2

;, Belt-Driven Ce

12,000

685-845

1100

2 11 0

4 3-5 3

5 184T

7-1/2 213T

10 ..215T

Copper Tubes — Aluminum Fins

Factory-Supplied Throwaway Type

Size (in ) ..Type

1-1/2, 2 FPTI 2,2 FPT I 3 FPT 1 3 FPT

1-1/2, 2 FPT 2,2 FPT 3 FPT 3 FPT

Size (in

1-1/8 ODS

5/8 ODS

7/8 ODS

5/8 ODS

1-1/8 ODS

5/8 ODS

1-1/8 ODS

5/8 ODS

Size (in

1-1/4 MPT

2 14

11 7

I 14

II 4

2 14

11 7

I 14

II 4

No .. Siz

2 1-1/2

2 1-1/2

2 1-1/2

2 1-1/4

2 1-1/2

2 1-1/2

2 1-1/2

2 1-1/4

044 054

3100

rant 22

24

24

17

netic, 1750 Rpm

DA3371DA537

DA337 DA537

DA7241 DA824

0

3

ntrifugal; 1750 R

16,000

627,672,717

1100

2 154

5 6,6 0,6 4

7-1/2 213T

10 215T

489 j 490 j 490 | 4 10 6

26.9 36 5 46.3 46.3

4100

15

15

11

DA337

DA337

DA337

pm Motor

.)...Type

1-1/8 ODM

5/8 ODM

1-1/8 ODM

5/8 ODM

7/8 ODM

5/8 ODM

.). .Type

1-1/4 MPT 1-1/2 MPT 1-1/2 MPT

2 113

35 0

1 10

32 6

s (in ) MPT

3 1-1/2

3 1-1/2

2 2-1/2

2 1-1/2

BA

BB

3300 4404

29

29

29

DA537

DA537

DA537

)

2 SC

20,000

650,695,762

1100

2 154

5 8,6 2,6 8

10 215T

15 254T

1-1/8 ODM

5/8 ODM

1-1/8 ODM

5/8 ODM

1-1/8 ODM

5/8 ODM

2 113

44 8

1 10

38 8

3 1-1/2

3 1-1/2

2 2-1/2

2 1-1/2

15

15

15

BA

BB

064

3550

52 1 25

52 1 25

EA275!EA275

E5275i E5275

4

6

2 ST

24,000

785,828,895

1100

2 154

7 0,7 4,8 0

15 254T

3 FPT

3 MPT

1-3/8 ODM

7/8 ODM

1-3/8 ODM

7/8 ODM

2 113

44 8

1 10

38 8

3 1-1/2

3 1-1/2

2 2-1/2

2 1-1/2

Page 6

isBKggggsas^iKssasìgagsasBgagaagMi

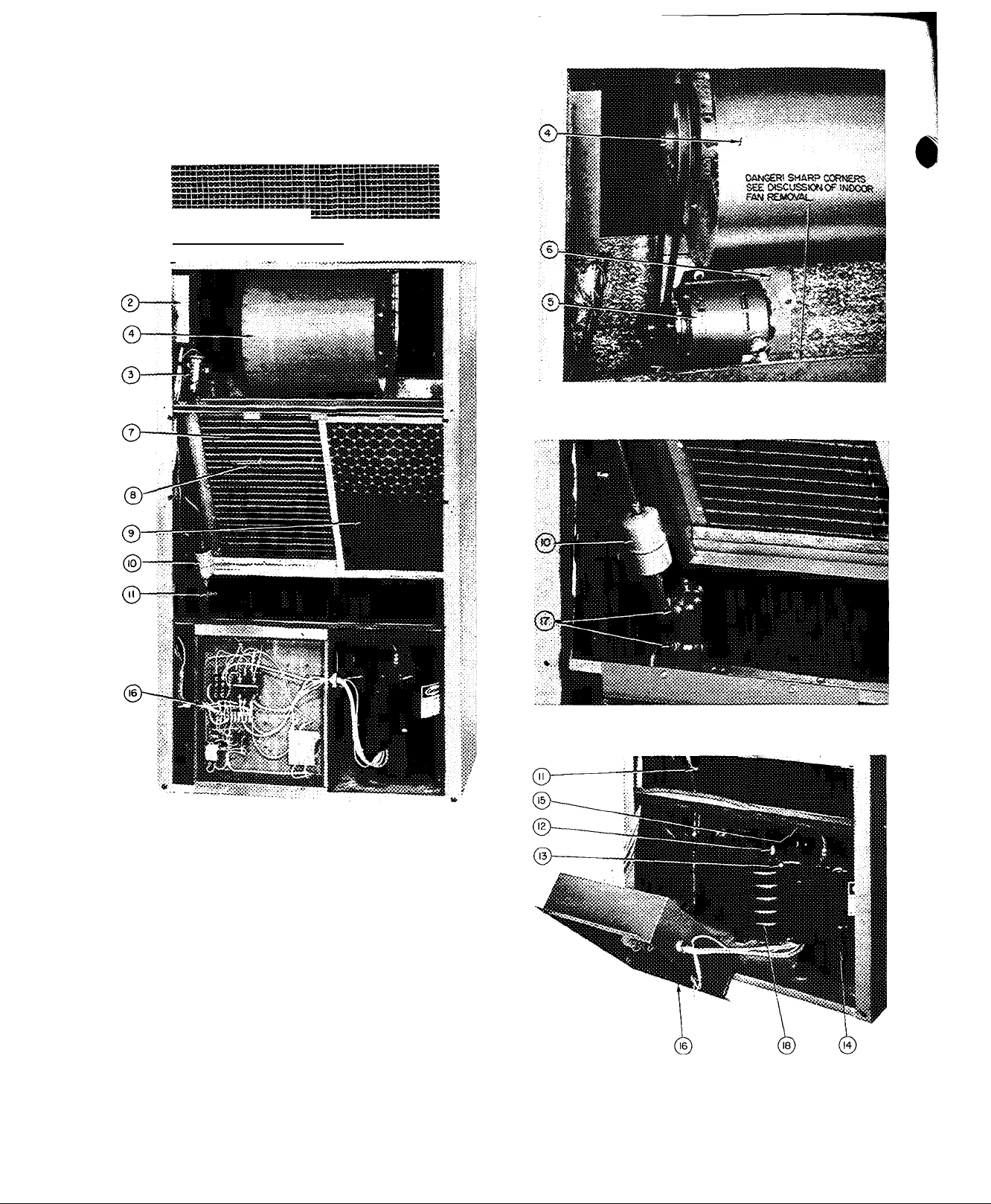

INDOOR AIR FAN DETAIL

BASE UNIT GENERAL VIEW

1 — Accessory Plenum

2 — Selector Switch and Thermostat

3 — Thermostatic Expansion Valve

4 — Indoor Air Fan

5 — Indoor Air Fan Motor

6 — Indoor Air Fan Motor Mounting Bracket

7 — Evaporator

8 — Thermostat Sensing Bulb

9 — Return Air Filter

10 — Refrigerant Filter-Drier

11 — Water Regulating Valve Fitting on Refrigerant Liquid Line (50BA)

12 — Low-Pressure Cutout Switch (50BA,BB006 only)

13 — Suction Pressure Gage Connection

14 — Compressor

15 — Discharge Pressure Gage Connection (50BA)

16 — Control Box

17 — Service Valves, Suction and Discharge, with Gage connections (50BB)

18 — Water-Cooled Condenser (50BA)

Fig. 2 — Base Unit Interior Details (50BA,BB004,006,008 and 012)

SERVICE VALVE DETAILS (50BB)

COMPRESSOR COMPARTMENT

Page 7

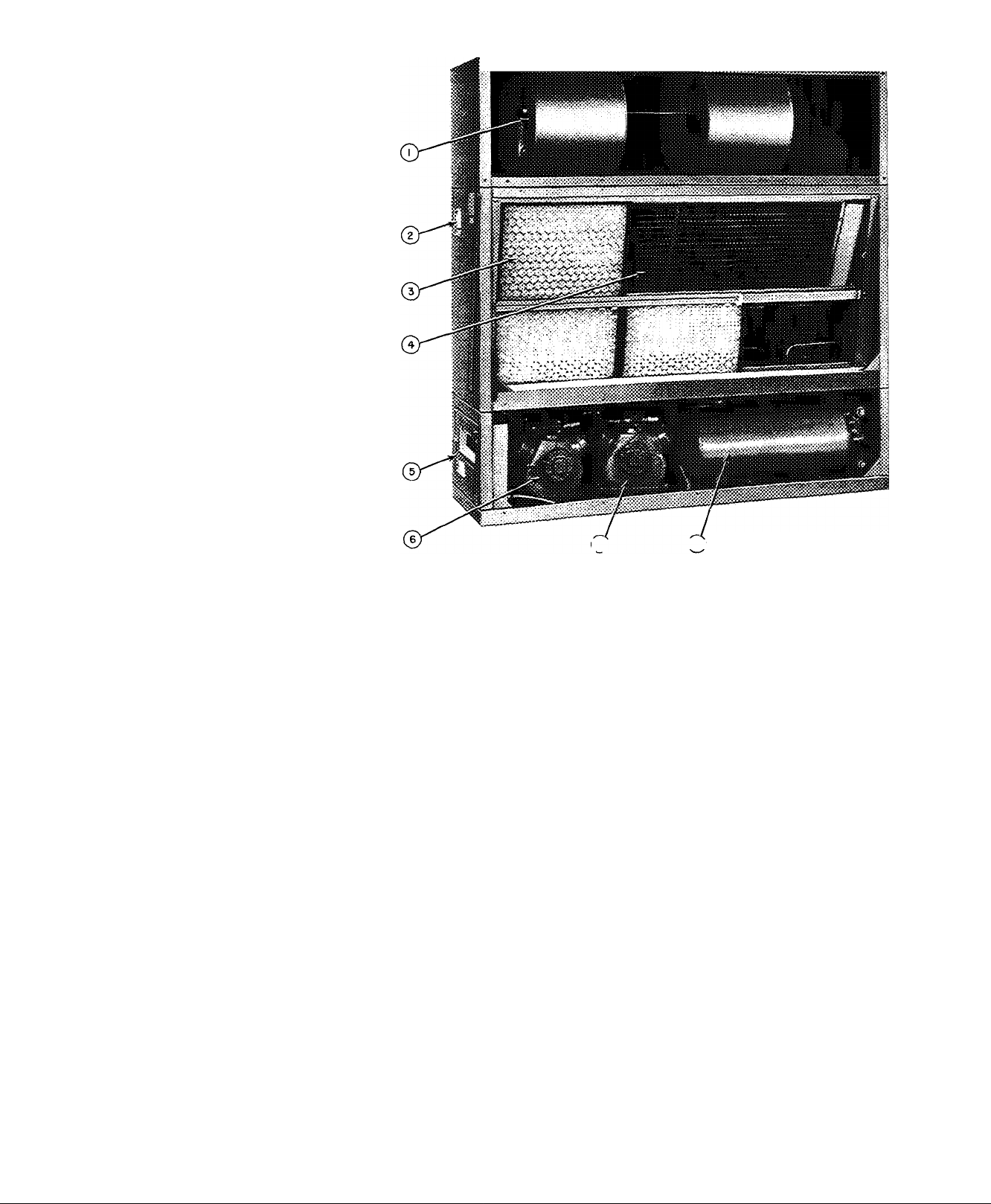

LEGEND FOR

50BA024 UNIT

1 — Indoor Air Fan

2 — Selector Switch

3 “ Return Air Filters

4 — Evaporator Coil

5 — Control Box

6 ^ Compressor No 1

7 — Compressor No 2

8 — Condensers

[7J (81

Fig. 3 — Base Unit Interior Details (50BA024 Unit Shown)

Step 5 — Install accessory plenum if supplied.

On unit Sizes 004 thru 024, holes in the unit top

panel match holes in plenum. Use screws (shipped

in cloth bag taped inside plenum) to attach plenum

to unit top. See Fig. 1 and 2.

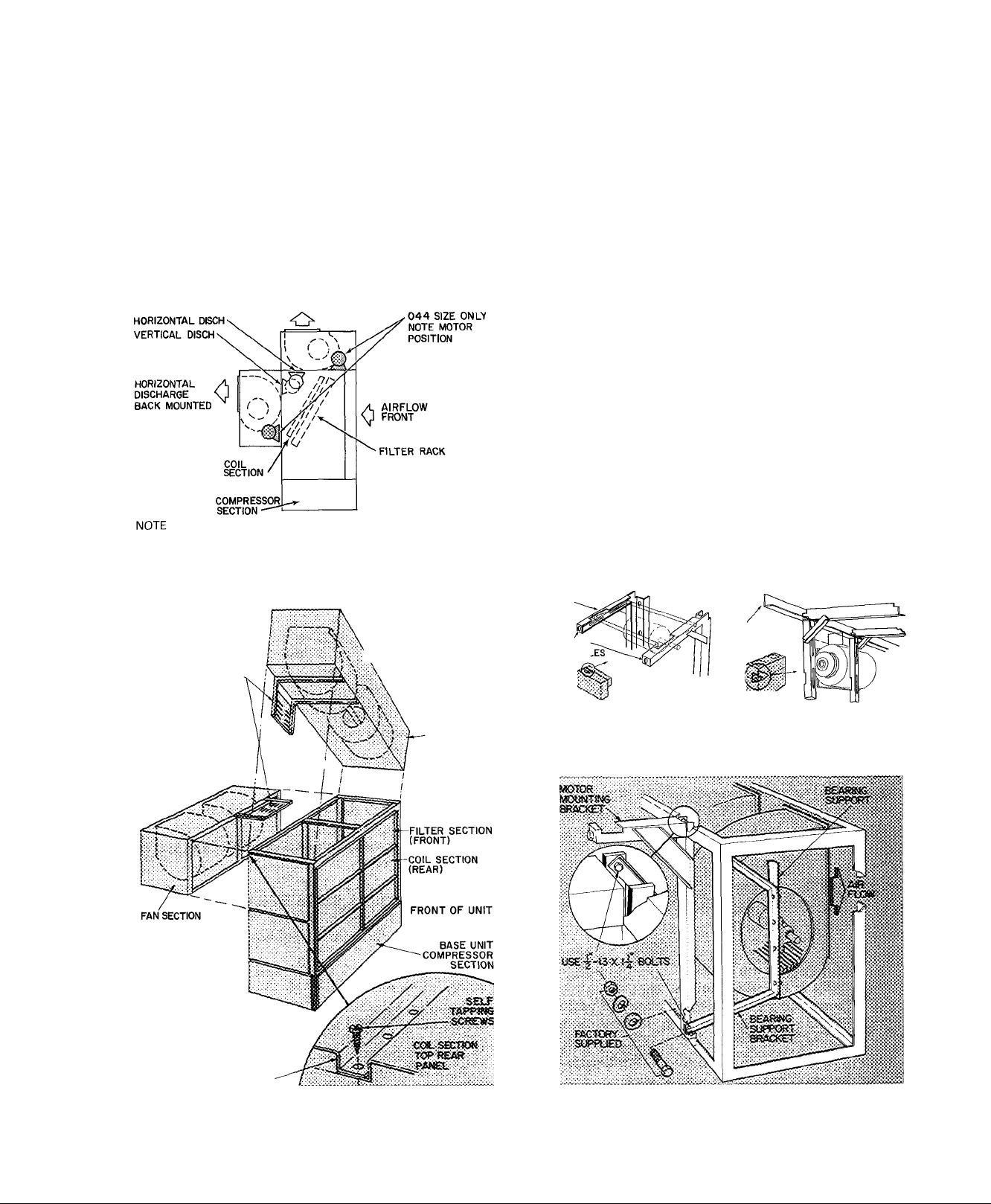

Step 6 — Position fan section as desired.

UNIT SIZES 50BA,BB004 THRU 024 are shipped

for vertical discharge. To set up these units for hori

zontal discharge, separately purchased accessory

filler panels must be field installed (see Fig. 1).

To set up unit Sizes 50BA,BB016 and 024 for

backmounted horizontal discharge (Fig. 1), proceed

as follows;

1. Remove;

a. Rear fan-section panel.

b. Upper rear coil-section panel.

c. Power connections from indoor fan motor.

d. Corner bolts holding fan section to coil

section.

2. Remove fan section and rotate it 180° lengthwise

so that motor is on left side of unit.

3. Place fan section on rear of coil section and

refasten.

4. Replace indoor fan motor power connections.

5. Adjust the following items per Installation

Step 8;

a. Shaft alignment.

b. Fan wheel position.

c. Pulleys.

d. Fan belt.

6. Replace panels as follows;

a. Upper rear coil-section panel on top of coil

section and fasten.

b. Rear fan-section panel on top of fan section

and fasten.

UNIT SIZES 50BA,BB028 THRU 064 are shipped

in sections as noted previously. They can be field

assembled for either vertical or horizontal discharge.

NOTE; Fan section panels may be removed for

easier lifting and to facilitate motor installation.

To set up Sizes 50BA,BB028 thru 064 for horizon

tal discharge (Fig. 4 and 5), proceed as follows;

1. Remove;

a. Upper rear and end panels of coil section.

b. End panels on fan section.

c. Fasteners holding lower rear edge of fan

panel.

Page 8

2.

Lift and position fan section on rear of coil section

(Fig. 4). Secure with fasteners provided.

3.

Install the following per Installation Step 7:

a. Motor mounting frame angles.

b. Motor on plate assembly.

c. Motor-plate assembly on frame angles.

d. Balance of drive package components.

4.

Adjust the following per Installation Step 8:

a. Shaft alignment.

b. Fan wheel position.

c. Pulleys.

d. Fan belts.

VERTICAL DISCH

TOP MOUNTED

Motor pulley on left side of unit — vertical discharge

Motor pulley on right side of unit — horizontal discharge

Fig. 4 — Fan and Motor Arrangements

50BA,BB028,034,044,054,064

REAR HORIZONTAL FAN

AND VERTICAL FAN

DISCHARGE SOBA.BB

028,034,044,054

MOTOR MOUNTING

BRACKETS (INSTALL

AFTER MOUNTING

fan SECTION)

\ AND 064

FAN SECTION

5. Replace panels as follows:

a. Rear coil section panel on top of coil section.

Rear holes will overlap fan section top panel.

Fasten, using hole vacated in Step Ic (see

Fig. 5).

b. All end panels.

NOTE; On Size 044 units, motor mounting channels

are factory installed and no angles, plates or

fasteners are necessary. In this position, the fan

motor is located on right side within fan section.

To set up Sizes 50BA,BB028 thru 064 for vertical

air discharge (Fig. 4 and 5):

1. Remove:

a. Front, rear and end panels of fan section.

Upper-rear and end panels of coil section.

b.

Filters from coil section.

c.

Fasteners holding filter frame top. Push frame

d.

out and away from coil section frame (on 028

and 034 units only).

2. Lift up and position fan section on coil section

(Fig. 5).

3. Fasten fan-section frame to coil-section frame

with fasteners provided, then (on 028 and 034

units) reposition and fasten the filter frame

moved in Step Id.

4. Install the following per Installation Step 7;

a. Motor mounting frame angles.

b. Motor on motor-plate assembly.

c. Motor-plate assembly on frame angles.

d. Balance of drive package components.

MOTOR MOUNTING

ANGLES

FAN SECTION

ADJUSTING

SCREW HOI

Fig. 6 — 028 and 034

Horizontal Fan Motor

Mounting Angles

FRAME

Fig. 7 — 054 and 064

Vertical Fan Motor

Mounting Angles

NO MOTOR MOUNTING

BRACKET USED WITH

044 SIZE UNIT

THREE FANS ON 054 AND

064 UNITS

REAR PANEL FAN SECTION

Fig. 5 — Fan Section Mounting

(50BA,BB028-064)

I

Fig. 8 — Fan Motor Mounting Detail

(50BA,BB054 and 064)

Page 9

FAN MOTOR

50BA,BB

028,034

MOUNTING

HOLES

PLATES

FOR

ADJUSTING

SCREWS

WELD

NUT

50BA,

BB044

50BA,BB

054,064

Fig. 9 — Motor Mounting

NOTE: On 044 units, motor mounting plate and

channels are factory installed within fan section. No

angle frame plates or fasteners are necessary. In this

position, motor is on right side of fan section.

5. Adjust the following per Installation Step 8:

a. Fan wheel alignment.

b. Shaft alignment.

c. Pulleys.

d. Fan belts.

SUPPORT CHANNEL

WELD NUT-

6. Replace panels as follows:

a. Rear coil-section panels, front and rear fan-

section panels.

b. All end panels.

Step 7 — Install fan motor.

This step applies to unit Sizes 50BA,BB028, 034,

054 and 064. Install items after fan-section frame

has'been placed in position on coil section.

NOTE: Place plywood over evaporator coil to pre

vent damage while installing motor and mounts.

To install motor:

1. Fasten motor mounting angle bracket to fan sec

tion. Use Fig. 4 or 5 for position reference and

Fig. 6, 7 and 8 for assembly guidance. Be sure

that lips of angle brackets are around fan-section

frame and that slots for motor mounting plate

face each other.

On Sizes 50BA,BB054 and 064, align bearing

support bracket holes with holes in motor

mounting bracket. Fasten with bolts, flat

washers, lock washers and nuts as shown in

Fig. 8.

2. Position motor on motor plate (Fig. 9) and fasten

with fasteners provided.

3. Fift motor-plate assembly and slide into motor

mounting angles as shown in Fig. 6. Plate fits into

angle slots. On vertical mounts, the motor-frame

assembly may be lowered to the bottom of the

support angle channels.

4. Assemble and install motor adjusting screws as

shown in Fig. 10. Drive roll pins into screws to

prevent screws from backing out during motor

position adjustment.

5. Adjust motor position. Fasten motor mounting

plate to mounting angles.

#

MOTOR

ADJUSTING

SCREW

Fig. 10 — Assembled Fan Motor

MOTOR

SUPPORT

ANGLE

Adjusting Screw

MOTOR

SUPPORT

CHANNEL

Table 2 — Alternate Fan Motors and Drives

UNIT

50BA,

BB

004 56 3/4 17.5 15.7

006 56 1

008,

012

016,

024

028,

034

044

054,

064

•Range of motor sizes unit will accept

NOTE Motors and drives other than those furnished with unit

must be purchased locally

NEMA

FRAME

SIZE*

184, 56, 145T 2

182T, 213

184, 56, 145T 2 11 8

213, 182T 3 11 8 8 4 1

184T, 215 5 11.8

182T, 213

184T, 215

254U, 213T

256U, 21 5T

213T

21 5T

21 3T 7-1/2

21 5T 10

254T 15

CENTER LINE

HP

7-1/2 33 3

7-1/2

DIST>

___

Max Min

17 1 15.4

102 6 8

102

3

34 4

3

34 4 28 8

5

33 3 29 8

10

14 3

14.3

10

33 5

33 5 29 0 1-7/16

33.5 29.0

(ir

XNCE

D..„„

10 1

10.1

6 8

8.4

28 8

29 8

29 0

FAfVI

SHAFT

DIAM

(in )

1/2

5/8

3/4

94

1-3/16

1-7/16

Page 10

Step 8 — Align fan shaft and wheel.

HORIZONTAL WHEEL CENTERING — All

wheels must be horizontally centered between the

inside edges of their fan scroll venturis (Eig. 11).

VENTURI

Fig. 11 — Horizontal Wheel Centering

WHEEL

/SCROLL

MUST BE EQUAL ALL AROUND

Adjust as follows:

Unit Sizes 50BA,BBQ04 thru 024

1. Loosen setscrews holding wheel support to shaft

(Eig. 12).

2. Center the wheel by sliding it horizontally.

3. Retighten setscrews.

CONCENTRIC ALIGNMENT Shaft and

wheels must be concentrically centered with the

venturi or air inlet of the fan housing (Fig. 13).

Unit Sizes 50BA,BB004 thru 024 — Shaft bearings

are supported by spider (Fig. 14). If shaft and wheels

are concentrically misaligned from shipping shock,

it is possible to rebend spider arms to original posi

tions. Replace the spider if it has been extensively

damaged by shipping shock.

Unit Sizes 50BA'BBQ28 thru 064

1. Loosen fan wheel locking clamps on each side

of fan support (Fig. 12).

2. Center the wheel by sliding it horizontally.

3. Retighten locking clamp bolts to torque speci

fied in Table 3.

Table 3 — Torque Requirements

BOLT SIZE (in.)

5/16

7/16

FAN CLAMP BOLT

RECOMMENDED TORQUE (Ib-ft)

15-18

30-35

VENTURI

LOCKING COLLAR

SHAFT

Fig. 14 — Fan Shaft Bearings — 004,006,

008,012,016,024

10

Page 11

Unit Sizes 5QBA028 thru 064 — Bearings are bolted

to an angle support fastened to fan scroll (Fig. 15).

To correct shaft and wheel concentric misalignment:

1. Loosen bearing support bolts and shim or move

as required.

2. Retighten bearing support bolts.

HORIZONTAL SHAFT ALIGNMENT (All units)

— If the shaft has moved and all wheels are off

horizontal center, recenter the shaft as follows:

1. Loosen the setscrews holding bearing locking

collar at each end of shaft (Fig. 14 or 15).

2. Slide shaft and wheel assembly horizontally until

wheels are horizontally centered (Fig. 11).

3. Slide the bearing locking collars against the bear

ing race and turn in direction of shaft rotation

until tight.

4. Retighten locking collar setscrews.

CUTOFF CLEARANCE (Unit Sizes 044, 054 and

064) — After centering and aligning the fan wheel,

loosen cutoff sheet (Fig. 13), adjust for 1-1/4 in.

clearance as shown and then tighten securely.

FAN, PULLEY AND BELT ADJUSTMENT

Refer to the Service section entitled Indoor-Air

Fan Adjustment.

PILLOW BLOCK

FAN SHAFT

BEARING.

SHAFT EXTENSION

LONGER ON

ONE END TO

ACCOMMODATE

DRIVE PULLEY

BEARING LOCKING

COLLAR 2 SET SCREWS

'SHIM IF NECESSARY

Fig. 15 — Horizontal Shaft Alignment

Step 9 — Install heating coil if supplied.

'HOLLOW SHAFT

3 FANS ON 028-064

On 50BA,BB004 and 006 units, any water or

steam heating coil must be installed thru the back

of the unit as described in the Installation Instruc

tions shipped with the accessory coil.

Step 10 — Install supply air (evaporator)

ductwork.

Connect supply ducts to flanges on air supply

opening (Fig. 1), using a flexible connection.

Attach ductwork to building structure and insu

late with fiberglass and vapor barrier to prevent

sound transmission and vapor condensation.

Weatherproof external ductwork, joints and

openings with flashing and mastic in accordance

with applicable codes.

Ducts passing thru an unconditioned space must

be insulated and covered with a vapor barrier.

Step 11 — Install return air ductwork (004 —

012 units).

The unit back panel is stamped to indicate alter

nate return air (or outdoor air inlet) opening as

indicated in Fig. 1.

1. Cut out the alternate return air opening as

required.

2. Attach a 1-in. flange to unit back panel or attach

a flanged, flexible duct connection directly to

unit as desired.

If an outdoor makeup air damper is to be in

stalled, attach it directly to unit back panel and

install flexible connection between damper

assembly and remaining ductwork.

Use accepted ductwork installation procedures.

Follow all applicable codes.

3. Restrict or completely blank off the standard

return air opening with a field-fabricated filler

panel. This panel must be removable for service

access. Refer to Service section entitled Return

Air Grille Removal as required.

Step 12 — Check return-air filters.

Be sure filters shipped with unit are the correct

size (see Table 1). Never operate unit without return-

air filters in place.

Step 13 — Check compressor spring mounts

(50BB008 and 50BA,BB012 thru 064).

The compressors are held rigid in shipment by

bolts extending thru a washer, grommet and com

pressor foot into a weld nut (for 064 unit, see para

graph below).

Loosen each bolt (4 per compressor) until com

pressor floats freely on springs. Then retighten bolts

until there is slight pressure on the neoprene gasket.

This will steady the compressor and prevent

start and stop rocking.

The 50BA,BB064 units are shipped with 4 special

flanged washers and neoprene grommets in a cloth

bag tied to the compressor. Remove the compressor

hold-down bolts. Then install the neoprene

grommets between the compressor feet and the

special washers. Reinstall the hold-down bolts and

tighten until there is slight pressure on the

grommets.

The compressors have reversible oil pumps that

operate in either direction; therefore the direction

of rotation need not be checked.

NOTE: Do not loosen bolts on 50BA008

compressor.

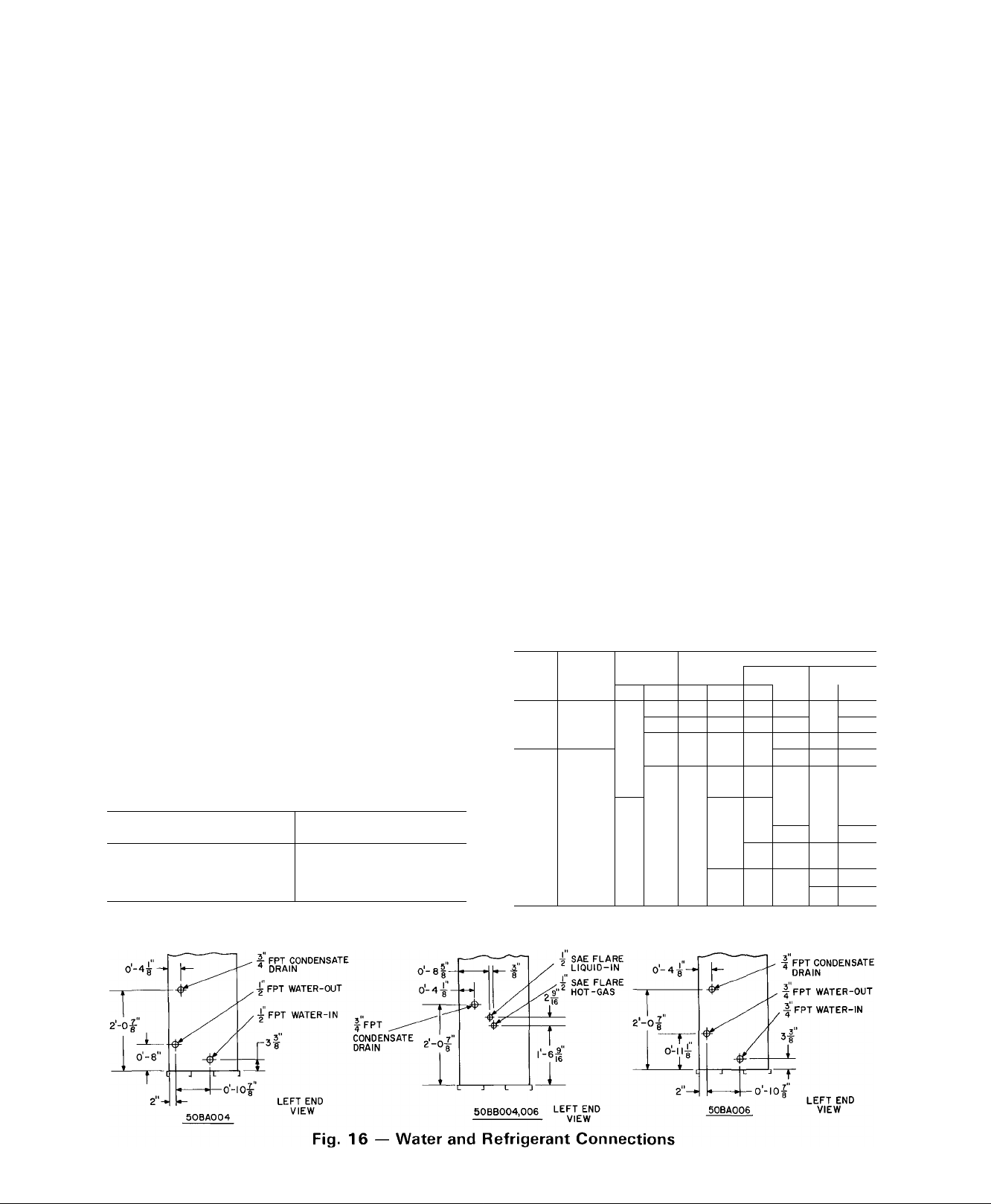

Step 14 — Make condenser connections.

WATER-COOLED (50BA) UNITS ^ GENERAL

— Condensers have water inlet and outlet connec

tions as shown in Fig. 16. Piping arrangements for

city, waste or recirculating water are shown in

Fig. 17 thru 24.

11

Page 12

WATER-COOLED UNITS, SIZE 50BA004

THRU 012 — Connect condenser water supply and

return lines as indicated in Fig. 16 and 17. When

connecting water lines, hold the condenser inlet and

outlet stubs firmly with a wrench at the FPT hex

fitting to prevent twisting. Do not use water lines

smaller than connection sizes shown in Fig. 17.

Observe all applicable plumbing and sanitary codes.

To assemble Carrier Compatible Fittings:

1. Cut tubing to length with tube cutter and remove

burrs.

2. Mark required insertion depth on tube (1-1/4 in.

for 5/8- and 3/4-in. OD tubing).

3. Remove plug from fitting and loosen nut one

turn.

4. Position and insert tube into fitting. Bottom

tube past depth mark.

5. Leave nuts on condenser end of tubing. Loosen

and purge one line at a time, using holding

charge in base unit.

6. Tighten nuts to stop on unit fitting collar.

7. Open all service valves.

Make sweat connections as follows:

1. Clean tube; then remove plug and nut from

fitting.

2. Remove O-ring from inside fitting with bent pin.

3. Wrap entire valve with wet rag.

4. Bottom tube in fitting and apply low temperature

solder, such as Allstate 430.

If specified, install field-supplied water-regulating

valve in water supply line outside cabinet as

follows:

1. Route the regulating valve capillary with its flare

nut to the fitting on refrigerant liquid line (Fig. 2),

using any convenient unused opening on side of

unit. Use a grommet in unit panel to prevent

chafing of capillary.

Table 4 — Maximum Water-Side

Working Pressure

UNIT SIZE 50BA

004,006,008,012 450 psig

016 550 psig

024,028,034,044,054, 150 psig*

064 250 psig

*550 psig if factory-installed dresser adapters are removed and

field-fabricated manifold is installed

MAXIMUM WORKING

PRESSURE

2. Remove cap from liquid line fitting.

3. Remove cotter pin taped to liquid line near

fitting. Insert pin, split end first, into water

regulating valve flare nut.

4. Connect flare nut to fitting. Round end of cotter

pin will depress core of fitting. The opened

fitting allows refrigerant pressure to act on water

regulating valve. Tighten flare nut to prevent

leakage.

The fitting automatically seals (closes) when flare

nut is removed; a slight amount of refrigerant is lost

each time, however. Do not lose cotter pin.

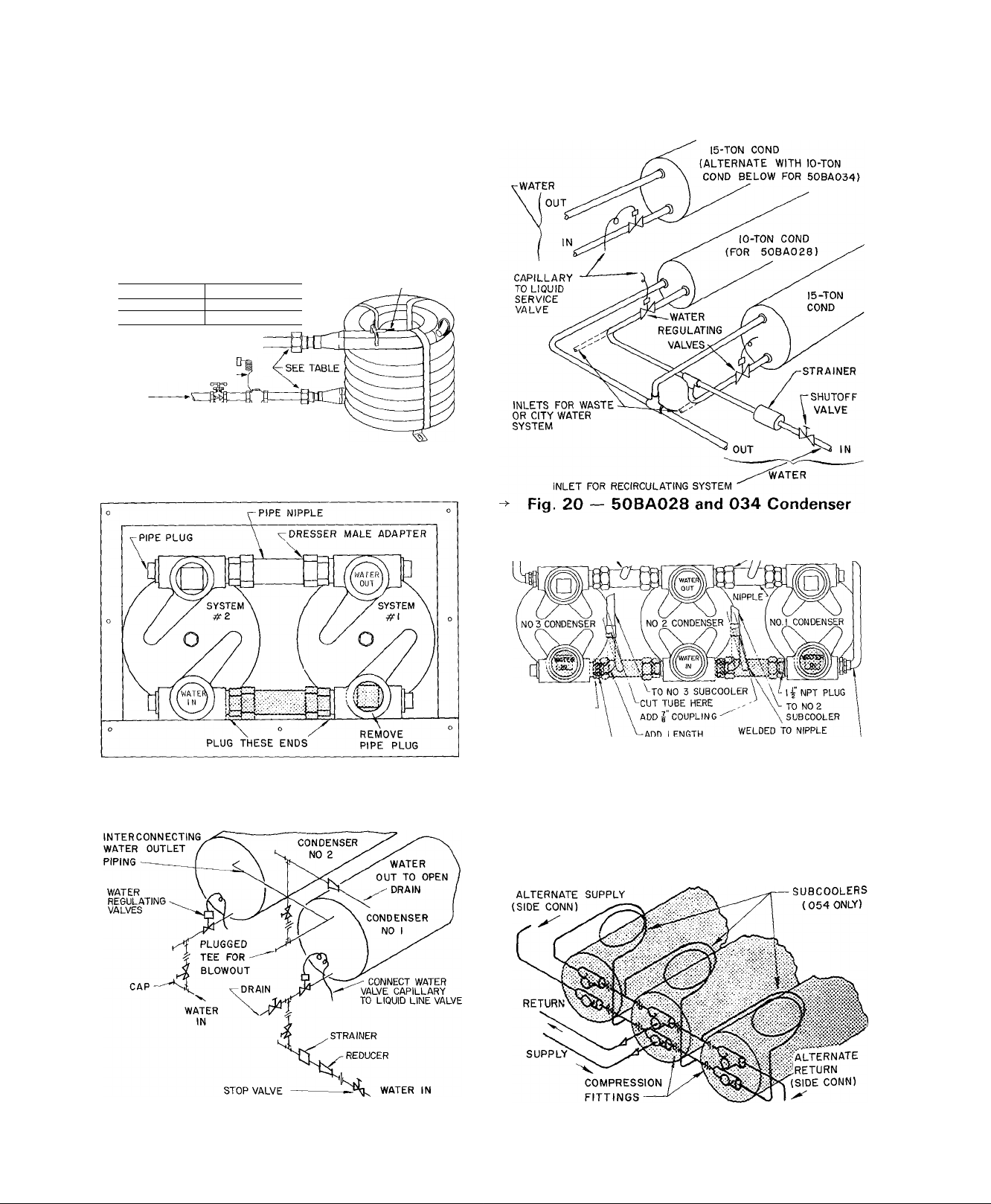

WATER-COOLED UNITS, SIZE 016 THRU 064

— Connect condenser water supply and return lines

as indicated in Fig. 16. Unit Size 50BA024, 044, 054

and 064 require field modification to condenser

piping when used on city or waste water. Refer to

Fig. 18, 21 and 24.

Install a water regulating valve on the inlet of each

condenser with any size unit used on waste or city

water (Fig. 19,20,22,23 and 24). Connect regulating

valve capillary to a back-seated liquid service valve.

Arrow on valve body must point in direction of

liquid flow. After connecting capillary, open

regulating valve one turn from back-seated position.

Adjust valve to maintain proper condensing

temperature.

Install a full size gate valve and strainer in water

supply line. Valve and strainer must be accessible.

See Table 4.

Table 5 — Recommended Line Sizes (in.)

(Condenserless Models)

UNIT

SYSTEM

50BB

004

006

008

012

016 —

024 1 & 2 5/8

028

034 1 & 2

044

054

064 1 & 2 7/8

HG — Hot Gas Line (OD

L — Liquid Line (OD in

—

—

—

1 & 2 5/8 1-1/8 5/8 1-1/8

1,2,3

CONN

SIZES*

L

1/2

1/2 1/2 1/2

1/2

5/8 7/8 5/8

-

5/8

5/8

1

5/8

2

5/8

5/8

3

5/8 1-1/8 5/8 1-1/8

L HG

HG

1/2

1/2

1/2

7/8

5/8

1-1/8

5/8

7/8

1-1/8 5/8 1-1/8

7/8 5/8 7/8

1-1/8 5/8 1-1/8

7/8 5/8 7/8

7/8

1-3/8

in )

)

LENGTH OF LINE

20

L HG L

1/2

1/2

1/2 7/8

7/8^

1/2 7/8

7/8

5/8 1-1/8 3/4 1-1/8

7/8

7/8 1-1/8

1-1/8

5/8

7/8

7/8 1-1/8

5/8 1-1/8 7/8

7/8 1-1/8 7/8

7/8 1-1/8

5/8 1-1/8

7/8 1-1/8

7/8 1-5/8

1-3/8

40

5/8 1/2 7/8

ï-i/8

*Sweat connections

5/8

1/2

7/8

7/8

7/8

7/8

7/8

7/8

7/8

60-80

1-3/8

1-1/8

1-3/8

1-1/8

1-3/8

1-3/8

1-1/8

1-3/8

1-5/8

HG

7/8

7/8

12

Page 13

2 DIA HOLE

FOR I "FPT COND

WATER INLET

(BA) CONN

50BA,BB008,0I2

W DIA KO FOR

f'oDF

LIQUID LINE

'dia hole for

|“fpt

CONDENSATE

CONN

2"DIA HOLES FOR

i"fpt cond water

OUTLET(BA)CONN

= HOT GAS

LINE (BB) :

LEFT END

VIEW

NOTE ■ ALL VIEWS ARE RIGHT END VIEWS EXCEPT AS INDICATED

(50BA, BB004 THRU 012 UNITS)

2 FPT water

OUTLET-

81/8" ;

t

' t

5 1/2"

---------------

"i-l'-9 1/2^

50BA0I6

T FPT

CONDENSATE

DRAIN CONN-

n

^

V.

-2 F PT

WATER

INLET

I 1/8 0 DM HOT

GAS CONN

50BB0I6

I" FPT

CONDENSATE

DRAIN CONN.

I ODM

LIQUID LINE

CONN

2 1/2" FPT

WATER OUTLET

2 1/2" FPT \

WATER INLET

HOT GAS

CONN.

7" ODS

8(028)

I^ODS

T

l"-5|-

FLOOR

LINE

50BB028 a034

50BA024

N

1 I

-T FPT

CONDENSATE

DRAIN CONN

-Ig ODS

/

■| ODS

<■2

16

HOT GAS

C0NN.(028

034)

LIQ LINE

C0NN.(028

034)

7/8 OD M HOT

GAS CONN.

4 3/4"

_L

S ODM

8

LIQ LINE

CONN.

2 FPT WATER

INLET-

FLOOR.

LINE

.2 FPT WATER OUTLET

1

pN

hi

1 V

4

50BA034

lEPT-“

CONDENSATE

DRAIN

CONN.

1^" FPT WATER INLET

FLOOR ^8

LINE

2

2'-2"-J

RIGHT END VIEW

50BA028

f

4

MOUNTING HOLES

2" FPT

WATER

INLET

50BA044,054

CONDENSATE

K..

(3 HOLES)

l-gODM

(50BB044

#

ONLY)

50BB044,054

MOUNTING HOLES

3"MPT WATER

I^MPT

'CONDENSATE

DRAIN CONN

Fig. 16 — Water and Refrigerant Connections (cont)

13

Page 14

ALL 50BB (AIR-COOLED) UNITS — Install air

cooled condenser in accordance with the installation

instructions provided with condenser. Connection

locations for liquid and hot gas service lines are

shown in Fig. 16. Recommended line sizes are given

in Table 5. Refer to Carrier System Design Manual,

Part 3, for standard refrigerant piping techniques.

Condenserless (50BB) units are shipped with a

holding charge. After refrigerant connections are

made, evacuate, leak test and charge system as

described in the Service section entitled. Charging

the System. Unit refrigerant operating charge is

listed in Table 1.

50BA004 1/2-in. FPT Conn,

50BA006

50BA008.012 1 -in FPT Conn

WATER

WATER

-—c

OUT

CONNECT TO

LIQUID SERVICE

VALVE GAGE PORT'

IN

WATER / /'WATER

SHUTOFF^ ^ REGULATING

VALVE

3/4-in. FPT Conn.

VALVE

Fig. 17 — Condenser Water Piping

(50BA004-012)

REMOVE SHADED FITTINGS

Fig. 18 — 50BA024 Condenser City Water

Piping Conversion

REFRIGERANT IN

Water Piping

/-FROM N0.3

SUBCOOLER

T'npt to

}"npt bushing

COUPLING

|"nPT-J"tUBE

A Remove shaded fittings

-^NOTE 50BA044 units same less subcoolers

1 Use one outlet for water discharge

2 Remove interconnecting nipples and "dresser” adapters on

inlet side of condensers

3 Remove 3-in plugs from no 1 and 3 condenser inlet headers

^FROM N0 2

\SUBCOOLER

----------------

' OfTuBE’ to no I subcooler (EXISTING)'

’’DRESSER” aFROM NO.I

adaptersn/v subcooler

Fig. 21 — Field Conversion to City or

Waste Water System (50BA044 and 054)

i

Fig. 19 — 50BA024 Typical Waste or

City Water Piping

Fig. 22 — Recirculating Water System Piping

(50BA044 and 054)

\A

Page 15

Step 15 — Install unit drain line.

Install a trapped condensate drain line at unit

drain connection (Fig. 16). The drain requires

standard pipe connected to condensate pan nipple

as shown in Table 6. Figure 26 shows proper trap

design.

Determine design negative static pressure. This

pressure is not the same as fan total pressure, which

includes pressure losses downstream as well as

upstream from the indoor air fan. Always assume

the worst conditions, such as having return air filters

clogged with dirt.

Referring to Fig. 26, Differential 1 must be equal

to or larger than negative static pressure at design

operating conditions. Store enough water in trap to

prevent losing seal (Differential 2). This differential

must be equal to or larger than one-half the maxi

mum negative static pressure. When the fan starts.

Differential 3 is equal to the maximum negative

static pressure.

Do not use drain line smaller than size listed in

Table 6. If required, cut hole in panel for drain line.

Pitch drain downward toward an open drain sump.

Provide a trap at least 3 in. high with plugged tee for

cleaning. Fill trap with water to make an air seal.

Observe all sanitary codes.

R£aRCUtAT{«6 SYBTeiiS - S£S NOTH )

NOTE For waste or city water, remove inlet manifold and supply

condensers individually

"Fig. 24 — 50BA064 Condenser Water Piping

Table 6 — Condensate Drain Connections (in.)

UNIT SIZE

004,006,

008,012

3/4 1 1-1/4

016,024

028,034,

044,054

1-1/2

064

50BA.BB* COIL NO. COMPR NO.

016

024,028,

034,064

044,054

*50BB units are condenserless

1 1

1, 2 1, 2

1, 2, 3

1,2,3

Fig. 25 — Refrigeration Circuits (016-064)

CONO NO.*

1

1, 2

1, 2, 3

Fig. 26 — Condensate Drain

IS

Page 16

UNIT

50BA.BB

004

006

VOLTS/PH/HZ

208-230/3/60

208-230/3/60

208-230/3/60

008

012

208-230/3/60

016

208-230/3/60 187 253 50 0

024

208-230/3/60 187

028

208-230/3/60

034 460/3/60

044t 460/3/60

054t

064

208-230/3/60

208-230/3/60

208-230/3/60

208-230/3/60

-> Table 7 — Electrical Data

VULI-

AGE

RANGE

COMPRESSOR NO. 1

RLA LRA

Min Max BA BB BA BB

230/1/60

460/3/60

230/1/60 207

460/3/60

575/3/60 518

460/3/60

575/3/60 518

460/3/60

575/3/60 518

460/3/60

575/3/60 518

460/3/60 414

575/3/60 518 632 12 9 16 0 50 0 62 0 129 16 0

460/3/60 414 506 22 2

575/3/60 518 632 180 23 0 69 0 96,0 130 170

575/3/60

575/3/60 518 632 180

460/3/60 414

575/3/60 518 632 180 —

460/3/60 414

575/3/60 518 632 38 0 50 0 176 0 176 0 38 0 50 0

207 253 19 8 19 8

187 253 13 0

414

528 5 5 5 5 30 0 30 0 — — — — 1/3

264

187 253 18 3 20 6

414 528

187 253 23 7 31 3 184 0 137 0

414 506 11 4 14 1 69 0 62 0

187 253

414 506

414 506 22 1

187 253 49 3

187 253

414 506

518

187

414

187

187

27 9 39 0 106 0

632

632

632 11 4 14 4 50 0 62 0

632

253

506

632 180 23 0 69 0 96 0 180 23 0

253

506 23 0 29 0

253

506 23 0

253

506

88

64

96 11 3 55 0

36 3

14 6

17 9 23 0 69 0 96 0

36 0 45 0 1370 170 0 36 0

16 0

49 3 64 0

22 2 29 0

50 0 64 0 191 0 266 0

50 0

102 0 1190 506 0 506 0 102 0 119 0

50 0 50 0 253 0

88 0 88 0

13 0

87 0 87 0

135 0

105 0

104

84 27 0 41 0

40 0 137 0 170 0

180

64 0

29 0

20 0

64 0

29 0

—

64 0

29 0 86 0 120 0 23 0 29 0 86 0

136 0

35 0 49 0

50 0

62 0

77 0

266 0

191 0

86 0

120 0

62 0 77 0 160 20 0

191 0 266 0 35 7 45 0

86 0

120 0

191 0 266 0 49 3 64 0

86 0 120 0 22 2 29 0

86 0

120 0

69 0

—

266 0

191 0

69 0

—

253 0

COMPRESSOR NO. 2

RLA LRA

BA

BB

_

_

_

— — —

—

__

—

— -_

—

_ _

—

_

_ _

— — — _

— —

—

_

— —

— —

— -—

—

— — ~ —

45 0 137 0 170 0 3 9 2

16 0 20 0 62 0 77 0

36 0

45 0

160 20 0 62 0 77 0

130

—

50 0 64 0 191 0

180

—

50 0 50 0 253 0

IIMUUUK

FAN

MOTOR*

BA BB

_

_

— —

_

—

—

—

— —

_

—

—

—

—

— —

—

—

62 0

77 0

50 0 62 0 3 3 4 32 9 40 0 45

137 0

170 0 5

50,0 62.0 5 5,6

191 0 266 0 5 16 2

86 0 120 0 5 6 6 57 6

69 0 96 0 5 5 6

137 0 170 0 7-1/2 21 6

50 0

—

266 0 10 28 0

120 0 10 13 0

69 0

506 0 506 0 15

176 0 176 0

—

253 0

FLA

Hp

33

1/3

3 3

1/3

0.8 7.7

3/4

5 3

3/4 7 1

3/4 7 6

3/4 1 1

1 40

1 6 15 9 194

1

1 4 134 15 5 20 25

1

2 60 52 0 56 0 80

2 2 8

2 23

2

2 3 1 31 0 40 0 50 50

2 2 5 25 0

3 46 40 8 49 8 50

16 2 1140 142 0 150

5

7-1/2 9 5 77 0 95 0 90 110

7-1/2

8 4 62 5

10

105

46 2 276 0

15

21 0

15 16 4 102 0 129 0 125 175

POWER SUPPLY

Min

Ckt

Ampst

BA BB

28 1 28 1 45

19 6

54 1 70

40 2

30 0 32 9

12 6

9 1 11,6 15 25

33 7 44 0 50

21 1

16 6 20.7

70 0

70

91 0 1110 125

51 4 63 9 60

66

41.0

128 0

161 0 175 200

46.0 57 9

171 0 211 0

191 0

236 0 225 300

88 0

107 0 100 125

69 5

314 0

134 0

134 0

19 6 30

7,7 15

14 6 20

25 9 35

87 0

32 0

51.9 45

72 9

—

—

MOCP

Ampst

BA

BB

45

30

15

90

45

50

25

70

25

30

90

40

25 35

110

150

40

35

150

60

45

200

70

70

60

80

50 80

200 250

80

—

80

350 400

175 175

~

FLA

Hp

LRA

MOCP

RLA

Full Load Amps

Horsepower

Locked Rotor Amps

Maximum Overcurrent Protective Device (See Note 1 )

Rated Load Amps

"Indoor fan motors are 3-phase motors of same voltage as unit except those

with FLA values in italics These motors are single-phase motors of same

voltage as unit

tMin Ckt Amps and MOCP Amps values per NEC (See Note 1 )

iUnits 50BA,BB044 and 054 have 3 compressors Compressor no 1 data

applies to Systems 1 and 2; compressor no 2 data applies to System 3

Table 8 — Maximum Wire Sizes for

Terminal Block (AWG or MCM)*

VOLT/

PHASE

008 012 016

024

208 230/3 00 00 00 00 350 0000 350 350

460/3 00 00 00

575/3

’Terminal block not supplied on 004 and 006 unit sizes Wire size to be selected per NEC and supply

wires to be connected to factory-supplied pigtail wire connectors

00 00 00 00 00 1 —

00

00

’Step 16 — Make electrical connections.

GENERAL — Provide an adequate fused dis

connect switch per NEC within sight of the unit.

Provision for locking switch open (OFF) is ad

visable to prevent power from being turned on when

unit is being serviced.

On 50BA,BB016 thru 064 size units, power may

be supplied thru a branch circuit. Branch circuit

protection is provided in these units by manual reset

NOTES;

• 1 In compliance with NEC requirements for multimotor and combination

load equipment (NEC Articles 430 and 440}, the overcurrent protective

device for the unit shall be fuse only

2 Phase imbalance must not exceed 2%

3 Fan motor power wiring, circuit breakers and other electrical components

are sized to accommodate special motors on the 50BA,BB016,024,028

and 034 units

4 Wire sizing amps are a sum of 125% of the FLA for largest motor plus

100% of FLA for all other motors in the unit

5 Maximum instantaneous current flow during starting is the sum of the

LRA for last compressor to start plus the FLA for all other compressors

in the unit

UNIT 50BA,BB

028,

034

044 054

BA 1 BB BA BB

064

BA BB

350 350 500

00 00 ÒÒÓ0 0000

00

0000 350

-

350

350 350

circuit breakers. Branch circuit must be in accord

ance with NEC or local code, whichever takes

precedence. Power supplied to auxiliary equipment,

such as fan motors for air-cooled condenser or for

cooling tower, must be run separately.

POWER WIRING — Conduit opening for 50BA,

BB004 thru 012 units is on left side of unit near

control box; for 50BA,BB016 thru 064 units, the

opening is on back of unit near control box.

i

Page 17

On 50BA,BB004 and 006 units, field power wires

are spliced to factory wires at the compressor

contactor. On all other sizes, field power connec

tions are made at a terminal block within the control

box (see Fig. 27). Refer to Table 8 for maximum

wire size at terminal block.

Supply voltage must be in accordance with name

plate voltage. On 3-phase units, voltage between

phases must be balanced within 2% and current

within 10% with compressor running. Contact your

local power company for correction of improper

voltage or phase imbalance (see Table 7). Failure of

unit because of phase imbalance constitutes abuse

and can void the warranty.

CONTROL WIRING — On extended voltage

(208-230-v) units, Sizes 50BA,BB006 thru 064, the

control transformer is factory wired for 208-v usage.

If unit is to be used on 230-v system, reconnect pri

mary wiring on transformer as shown on unit wiring

diagram.

m OFR ^ m

—(D—''—(D—

50BB004,006 (NOTE 2 AND 3)

FIELD

POWER

SUPPLY

-------

-------

NOTE Field power wiring connections on 004 and 006 unit sizes

are attached to factory wiring using factory-supplied wire

connectors

—

-----

♦{¡K@o

------♦{0}®°

50BA,BB008,0I2

FIELD WIRING

FACTORY WIRING

TBI

FIELD

POWER

SUPPLY

50BA,BB0l6-054

' L3

FIELD

POWER ( L2SUPPLY 1 , ,

-----------

LI

--------

508A,BB064

Fig. 27 — Field Power Wiring Connections

(008-064)

TO OUTDOOR FAN MOTOR

TB3

—[13-

Q]-

TB2

Wl

♦

---

!--1 I

1 5 [-t-t

_ ;

i

V

L—-{!}—

50BA,BB024

r

I T3

T2 I—I

-O^Q

I

1

1

-----------

A2

( NOTE 1 )

50BA, BB008,0I2

---

[_3j--i

-CXO

50BA.BB0I6

I Tl

Loÿ-

1

1

50BA,BB028

5

I

-Tl

50BA.BB064

IFC

50BA,BB044,054

CR — Control Relay

IFC — Indoor Fan Contactor

J — Jumper

OFR — Outdoor Fan Motor Relay

R — Condenser Fan Relay, 50BB; Pump Relay, 50BA

TorTC — Thermostat

TB — Terminal Board 23 _ Field Control Wiring Connections

NOTES

1 Condenser Fan Relay (OFR) shipped with 50BB008 and 012 units

2 Condenser Fan Relay contacts integral to control circuit with 50BB004

and 006 units

3 No provisions for pump relay connection on 50BA004 and 006 units

1 ~7

Page 18

Refer to Fig. 28 for field control wiring to pump

relay (50BA unit), condenser fan relay (5ÛBB unit)

and remote thermostat (unit sizes 016 thru 064).

On 50BA,BB004 thru 012 units, the thermostat is

factory installed with a sensing bulb in the return

air. To wire these units to a remote thermostat, or

to a remote control switch and thermostat, refer to

unit Wiring book or contact your Carrier

representative.

On 50BA,BB016 thru 064 units, a field-supplied

thermostat must be installed (Fig. 28). Table 9 lists

the recommended connecting sequence for a 2-step

thermostat.

Table 9 — Two-Step Thermostat Connection

for Capacity Control

UNIT THERMO

50BA.BB

012

016 Two 3 Liquid line solenoid

024

028

034

044

054

064

STEP CONN. ENERGIZED

One

One 3 Compressor No 2

Two

One 3 and 5 Compressor No 2 and 3

Two 2 Compressor No 1

One 3 and 6

Two 2

TERMINAL COMPONENT

2

2 Compressor No 1

Compressor

Capacity control solenoid

valve and liquid line

solenoid valve No 2

and compressor No 2

Liquid line solenoid No 1

and compressor No 1

FREEZE-PROTECTION THERMOSTAT — An

accessory freeze-protection thermostat is required

on Size 008,012 and 064 units when the low-pressure

switch setting (Table 1) is lowered or when a liquid

line low-pressure switch is installed for intermediate

or cold-weather operation. Installation instructions

are shipped with the thermostat.

HEATING COILS — Accessory heating coils are

available for field installation. Separate installation

instructions are shipped with the accessory.

START-UP

Unit Size 50BA,BB004 and 006

1. Set selector switch at OFF and thermostat at

highest setting.

2. Turn on unit power. On 50BB units, check that

crankcase heater is on. Compressor shell in

vicinity of heater should become warm to the

touch.

3. On 50BA unit, turn on condenser water supply.

On 50BB unit, open refrigerant line service

valves.

4. Set selector switch at FAN position. Check fan

speed (Table l)and rotation. Fan direction arrow

is attached to fan scroll. If fan requires adjust

ment, refer to Service section entitled, Indoor

Air Fan Adjustment.

5. On 50BA (water-cooled) units, set selector switch

on COOL and thermostat at lowest setting.

Compressor will start within 5 minutes.

On 50BB (condenserless) units, allow crankcase

heater to remain energized (unit power on) for at

least 6 - 8 hours; then set selector switch on

COOL and thermostat at lowest setting. Com

pressor will start within 5 minutes.

6. Set thermostat at highest setting to shut off

compressor.

7. Set thermostat at lowest setting. Compressor will

start within 5 minutes as described in the Service

section, Time Guard® Control Circuit.

On 50BB remote condenser unit, the outdoor air

fans cycle with compressor.

8. Set thermostat for comfort as desired.

^TO SHUT DOWN UNIT — Set selector switch at

OFF. Do not shut off main power except to service

unit. Crankcase heater (50BB unit) is operative only

when unit power is on (see Service section, Crank

case Heaters).

Unit Size 50BA.BB008 thru 064

1. Thoroughly clean and inspect unit.

2. Open compressor discharge and suction service

valves and liquid shutoff valves.

3. With selector switch in OFF position, turn circuit

breakers on. On 50BA008 and 064 unit, and

on all 50BB units, leave unit in this condition for

24 hours so that crankcase heater can drive off

any accumulated refrigerant.

4. Turn selector switch to COOL. Time Guard

circuit will delay unit start for 5 to 6 minutes.

5. Set thermostat at desired comfort temperature.

TO SHUT DOWN UNIT

1. If unit may be exposed to freezing temperatures,

drain water from condenser and all water piping.

2. Add a noncorrosive antifreeze to any residual

water in the system.

3. Turn selector switch to OFF position and turn

circuit breakers off.

4. If unit is to be used for winter heating, leave

circuit breakers on, set selector switch at FAN

position and turn cooling thermostat off.

Service Valves — Always be sure that compressor

suction and discharge service valves and liquid

shutoff valves are open before operating unit.

The liquid shutoff valves are accessible from the

rear of Size 064 unit and from front or rear of all

other units. To open valve, turn counterclockwise

(backseat). After opening, replace and tighten valve

cap to prevent leakage.

^Capacity Control Valve Adjustment (Fig. 29)

The capacity control valves are factory set as indi

cated in Table 10. If valve adjustment is required,

for any reason, use the following procedures.

The control set point (cylinder load point) is

adjustable from 0 psig to 85 psig. The pressure

differential between the cylinder load point and

cylinder unload point is adjustable from 6 psig to

22 psig (see Table 10).

t

I

Page 19

Table 10 — Factory Set Points (psig)

UNIT

50BA.BB

012

016

064

ACTION

Load

Unload

Load

Unload

Load

Unload

UNLOADER

NO. 1

69

58

69

58

77

58

UNLOADER

NO. 2

—

—

74

55

TO REGULATE CONTROL SET POINT

E Turn adjustment nut (Fig. 29) clockwise to its

bottom stop. Set point is now 85 psig.

2. Turn adjustment nut counterclockwise to reach

desired pressure. Each full turn decreases the set

point by 7.5 psig. (Approximately 11-1 /2counter

clockwise turns decreases set point to 0 psig.)

-CONTROL SET POINT

ADJUSTMENT NUT

POWER HEAD

VALVE BODY

PRESSURE DIFFERENTIAL

ADJUSTMENT SCREW

BYPASS RSTON RING

BYPASS PISTON

DIFFERENTIAL SCREW

SEALING CAP

REPLACE CAP TO PREVENT

REFRIGERANT LEAKAGE

Fig. 29 — Capacity Control Valve

TO ADJUST PRESSURE DIFFERENTIAL Turn differential adjustment screw (Fig. 29)

counterclockwise to its back-stop position. Differ

ential is now 6 psig.

Then turn screw clockwise to desired differential.

Each full turn increases differential by 1.6 psig.

(Approximately 10 clockwise turns increases

differential to 22 psig.)

SERVICE

Indoor Air Fan Adjustment — Observe fan com

partment CAUTION note above. The fan motor

pulleys are factory set at the fan speeds listed in

Table 1. Unit Sizes 50BA,BB044,054 and 064 have

fixed pulleys.

TO CHANGE FAN SPEED (004-034)

1. Shot off unit power .supply.

2. Loosen fan belt by loosening fan motor from

mounting bracket. Do not loosen fan motor

mounting bracket from unit.

3. Loosen movable pulley flange setscrew (Fig. 30).

4. Screw movable flange toward fixed flange to

increase fan speed and away from fixed flange to

decrease speed, using values shown in Table 1.

Increasing fan speed increases load on motor. Do

no! exceed maximum allowable fan speed (Table

I) or motor full load amps indicated on motor

nameplate and Table 7.

5. Set movable flange setscrew at nearest flat of

pulley hub and tighten setscrew.

6. Check Pulley Alignment and Belt Tension Ad

justment as described below.

7. Check fan operation. Repeat above procedure

as required.

PULLY ALIGNMENT — Shut off unit power

supply. Loosen fan motor pulley setscrews and

slide fan pulley along fan shaft. Make angular align

ment by loosening motor from mounting bracket.

See Fig. 30.

BELT TENSION ADJUSTMENT - Shut off

unit power supply. Loosen fan motor from

mounting bracket. Do not loosen motor mounting

bracket from unit. Move fan motor up or down until

proper belt tension is achieved (approximately

3/4-in. deflection with 8-lb tension at midpoint of

belt span).

MOVABLE FLANGES (004-034 ONLY)

STRAIGHT EDGE / \

MUST BE

PARALLEL

SETSCREWS

CAUTION: Before sert'icing fair compartment;

E Sharp edges of ex'aporator coU fms are ex

posed, To prevent arm injury, cover top edge

of evaporator with cardboard strip or a few

layers of heavy tape.

2. To avoid coil damage, ctjver evaporator coil

face with ply^vood or other rigid sheet

tnaterial. If any coil fins are mashed or bent,

straighien with a coil ftn comb of the proper

tooth spacing (see coil fins/in. in Table i).

Check for refrigerant leaks.

PULLEYS,

SETSCREWS'

;/ <1

^FIXEO flanges^

SINGLE-GROOVE TWO-GROOVE

MOTOR BFAN SHAFTS

MUST BE PARALLEL

Fig. 30 — Indoor Air Fan Pulley Adjustment

Page 20

Lubrication — Observe fan compartment

CAUTION note.

The fan motor bearings are factory lubricated and

will need no lubrication for the first 5 years of opera

tion (3 years at continuous service or excessively

dirty conditions).

Inspect bearings and relubricate or replace as

required. If heating coil is installed, oil bearings

every 6 months. Follow lubrication instructions on

special field-supplied motors.

Fan shaft bearings on 50BA,BB004 thru 034 units

are lubricated for the life of the bearings. The 50BA,

BB044, 054 and 064 units have alemite grease

fittings. Lubricate annually with a good grade of

mixed base grease or lithium base grease with rust

inhibitor. Add grease until air bubbles form under

the seal. Do not overgrease.

Return-Air Filters — Inspect filters twice monthly

and replace as often as required by operating condi

tions. Filter size and type are listed in Table 1.

If cleanable filters are used, flush them with hot

water or steam or soak them in a mild water solu

tion of soap or detergent. Refer to filter manu

facturer’s instructions as applicable.

Do not operate the unit at any time without

return-air filters in place. For access to filters, refer

to the Service sections entitled. Access Panel

Removal, and Return-Air Grille Removal as

required.

Condensate Drains — Clean the drain line and

unit drain pan at the start of each cooling season.

Check flow by pouring water into drain. Be sure trap

is filled as shown in Fig. 26 to maintain an air seal.

Evaporator Coil — Observe fan compartment

CAUTION note at the beginning of the SERVICE

section.

Remove dirt and debris from evaporator coil as

required by condition. Clean coil with a stiff brush,

vacuum cleaner or compressed air. Use a fin comb of

the correct fins/in. spacing (Table 1) when straight

ening mashed or bent coil fins.

When condenser is full, allow solution to remain

overnight, then drain condenser and flush with clean

water. Follow acid manufacturer’s instructions.

FORCED CIRCULATION METHOD(Fig. 32) —

Fully open vent pipe when filling condenser. The

vent may be closed when condenser is full and pump

is operating.

Regulate flow to condenser with a supply line

valve. If pump is a nonoverloading type, the valve

may be fully closed while pump is running.

For average scale deposit, allow solution to re

main in condenser overnight. For heavy scale

deposit, allow 24 hours. Drain condenser and flush

with clean water. Follow acid manufacturer’s

instructions.

i

Water-Cooled Condenser (50BA units) may

require cleaning of water-deposited scale.

Condensers are best cleaned with an inhibited

hydrochloric acid solution such as Oakite 32. The

acid can stain hands and clothing, attack concrete

and, without inhibitor, can attack steel. Cover

surroundings to guard against splashing. Vapors

from vent pipe are not harmful, but take care to

prevent liquid from being carried over by the gases.

Warm solution acts more readily but cold

solution is just as effective if applied for a longer

period.

GRAVITY FLOW METHOD (Fig. 31) -- Do not

add solution faster than vent can exhaust the

generated gases.

Fig. 32 — Forced Circulation Method

Air-Cooled Condenser (50BB units) — Inspect

and clean periodically, depending upon operating

conditions. Follow the service instructions provided

for the make of condenser used.

Charging the System — On unit Sizes 008 thru

064, sight glasses are provided at inlet of each expan

sion valve. These glasses are used in the field

charging procedure.

20

Page 21

->NOTE: Water regulating valve (water-cooled

condenser) or condenser airflow (air-cooled

condenser) must he properly set before checking

system charge.

UNIT SIZE 50BA004 AND 006 - Units are

shipped with full operating charge. If recharging is

necessary:

1.

Insert thermometer bulb in insulating rubber

sleeve on liquid line near filter-drier.

Add pressure gage to discharge line near

2.

compressor.

After unit conditions have stabilized, read head

3.

pressure on discharge line gage.

4.

From standard Pressure-Temperature chart for

R-22, find equivalent saturated condensing

temperature.

Read liquid line temperature on thermometer;

then subtract from saturated condensing tem

perature. The difference equals subcooling

temperature.

Compare the subcooling temperature with the

6.

normal temperature listed in the following table.

If subcooling is low, add charge; if high, remove

charge.

UNIT

50BÂ0ÏÏ4

50BA006

^Saturated condensing temperature at compressor minus

liquid line temperature

^B^COOLING*

25

22 + 2 F

EXAMPLE;

Head pressure (from gage) = 220 psig

Saturated cond temp (from chart) = 108 F

Liquid line temp (from thermometer) = 96 F

Subcooling (by subtraction) = 12 F

(add charge)

of the condenser subcooling feature. Add refrigerant

as follows;

50BA008 — 2.6 lb

50BA0I2 — 0.5 lb

On 50BA064 units, adding liquid refrigerant to

the level of condenser test cock will provide 12 to

15 F subcooling.

UNIT SIZE 50BB008 THRU 064 — These units,

with remote air-cooled condensers, are shipped with

a holding charge only. To charge;

1. Open suction and discharge line service valves.

2. Blow holding charge, evacuate and leakiest

system.

3. Add sufficient refrigerant vapor to permit con

tinuous operation after starting unit.

Start unit per Start-Up Section; then, using

4.

standard charging techniques, add refrigerant as

required to maintain normal operating

conditions.

Use charging chart supplied with condenser. If

information is not available, block off enough of

condenser coil to maintain 220 psig discharge

pressure and charge to a clear sight glass.

Return-Air Grille Removal (50BA,BB004-012) —

Loosen 2 screws visible thru grille at upper and

lower corner of one side. Slide grille side frame off

unit; then slide grille sideways and pull it away from

unit. To reassemble, reverse procedure.

UNIT SIZE 50BB004 AND 006 — Units are

shipped with a holding charge only. To charge;

1. Open suction and discharge line service valves.

2. Blow holding charge, evacuate and leakiest

system.

TEA

COMPRESSOR SUCTION PRESSURE (PSIG)

Temperature, Entering Air

3. Using standard refrigerant charging techniques

and the charts which follow (Fig. 33 and 34), add

refrigerant as required to maintain proper

operating conditions.

UNIT SIZE 50BA008 THRU 064 — These units,

with water-cooled condensers, are shipped with a

full operating charge. If recharging is necessary

(complete charge lost), weigh in amount of refrig

erant indicated on unit nameplate and Table 1.

If unit has partial charge, it may be charged with

«

sight glass using standard charging techniques. Ad

just the water regulating valve to maintain proper

saturated condensing temperature (168 - 226 psig).

Refrigerant can be added to 50BA008 and 012

units after sight glass is cleared to take advantage

COMPRESSOR SUCTION PRESSURE (PSIG)

TEA — Temperature, Entering Air

Fig. 34 — Charging Chart, 50BB006

21

Page 22

Access Panel Removal — On Size 004-012 units,

remove return air grille as described above. Remove

remaining grille side frame. Remove the panel

fastening screws now exposed.

TOP PANEL — Pull out and down.

BOTTOM PANEL — Pull out and up.

Indoor-Air Fan Motor Removal

A CAUTION

Before. aiiempttiJg:.to Totnove, faxt .ariotorjs.. of

motor mounts., p&ce a piece of piywo<Ki over

evaporator coiis to prevent coil damage,

50BA,BB004 THRU 012 — Motor power wires

need not be disconnected from motor terminals

before motor is removed from unit.

1. Shut off unit main power supply.

2. Loosen motor holddown bolts on mounting

bracket so that fan belt can be removed.

3. Loosen but do not remove the 2 motor mounting

bracket bolts on left side of bracket.

4. Slide motor/bracket assembly to extreme right

and lift out thru space between fan scroll and

side frame. Rest motor on a high platform such

as a step ladder. Do not allow motor to hang

by its power wires.

Field-Supplied Motors — The factory-installed

mounting bracket for a 48 frame motor will not fit

a 56 frame motor. If replacing 48 frame motor with

56 frame motor, use mounting bracket for 56 frame

motor.

50BA,BB016 AND 024 — Remove motor as

Follows:

1. Remove unit access panel and cover of motor

junction box.

’. Disconnect motor wires and remove conduit

connection.

. Remove motor base bolts and slide motor over so

that fan belt can be removed.

. Disconnect motor ground wire and remove

motor.

3BA,BB028 AND 034 — Proceed as follows:

Remove unit access panel and motor junction

box cover.

Disconnect motor wires and remove conduit

connection.

Remove the 2 motor adjusting screws and the fan

belt.

Slide motor assembly out thru slots in mounting

angles.

BA,BB044 THRU 064 — To remove motor:

Remove unit access panel and motor junction

box cover.

Disconnect motor wires and remove conduit

connection.

Remove bolts holding motor mounting plate to

channels.

Back out the motor adjusting screws, remove the

an belt and slide motor out thru channel lip

’uides.

TO REINSTALL MOTORS — Reverse the above

procedures. Align pulleys and adjust belt tension

as described in the section, Indoor-Air Fan

Adjustment.

Pressure Relief Devices — The 50BB (con

denserless) units are equipped with a fusible-plug

type safety relief device on the compressor. The

relief setting is 197 or 203 F on all units.

All 50BA (water-cooled) units, except Size

50BA064, have a frangible disc on each condenser.

Disc setting is 385 ± 5% psig.

The 50BA064 unit has a condenser pressure relief

valve set at 385 psig plus a pressure relief valve

on the compressor set at 450 psig.

Crankcase Heaters are supplied on all 50BB

(condenserless) units and on 50BA008 and 064

water-cooled units.

The heater prevents liquid refrigerant from accu

mulating in the compressor crankcase during

extended shutdown periods. Heater is automatically

energized whenever unit main power is on and

compressor is stopped. Heater is de-energized when

compressor starts.

Do not shut off unit main power supply for an

extended period except for servicing unit. Turn

on power supply for at least the following time