Page 1

Horizontal Indoor Single-Package Cooling Units

with PURON® Refrigerant (R-410A)

Installation, Start-Up, and

Service Instructions

ROOMTOP

50AH024-096

®

CONTENTS

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . 1

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Step 1 — Receive and Inspect Unit. . . . . . . . . . . . . . . 1

Step 2 — Protect Unit from Damage . . . . . . . . . . . . . . 1

Step 3 — Provide Unit Support . . . . . . . . . . . . . . . . . . . 1

Step 4 — Rig and Place Unit . . . . . . . . . . . . . . . . . . . . . 8

Step 5 — Make Condensate Piping

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Step 6 — Install Ductwork. . . . . . . . . . . . . . . . . . . . . . . . 8

Step 7 — Split Systems (Factory Option,

if Required). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Step 8 — Make Electrical Connections . . . . . . . . . . 10

• FIELD CONTROL WIRING

• THERMOSTAT WIRE

Step 9 — Adjust Fan Speed . . . . . . . . . . . . . . . . . . . . . 10

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17,18

SAFETY CONSIDERATIONS

Installing and servicing air-conditioning equipment can be

hazardous due to system pressure and electrical components.

Only trained and qualified service personnel should install,

repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance functions such as cleaning coils and filters and replacing filters. All

other operations should be performed by trained service personnel. When working on air-conditioning equipment, observe

precautions in the literature and on tags and labels attached to

unit.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations. Have

fire extinguisher available.

WARNING

Disconnect all power to the unit before performing maintenance or service. Electrical shock and personal injury could

result.

NOTE: Ensure voltage on unit agrees with voltage listed on

the unit rating plate.

GENERAL

The 50AH024-096 units are single-package, indoor, horizontally mounted air conditioners of 2 to 8 tons capacity. The

50AH units are ASHRAE (American Society of Heating, Refrigerating and Air Conditioning Engineers) 90.1 compliant.

These units can be mounted as factory-shipped singlepackage units or can be separated and mounted as a split

system. If unit is split, the condensing section must be mounted

horizontally.

All units are designed to be ducted on both the condenser

and evaporator sides. Centrifugal blowers are used to ensure

quiet air delivery to the conditioned space. Sound level

requirements should be determined before final unit installation site is chosen.

Unit servicing is relatively simple since access to the condenser and evaporator motors, blowers, belt, and pulley is

gained through access panels located on the sides of the unit.

These panels may also be used for cleaning of condenser coils.

Unit side panels also provide access to control box and pressure switches.

Refrigeration cycle components (e.g., compressor, filter

drier, etc.) can be serviced upon removal of the base unit from

the space.

INSTALLATION

WARNING

Determine building alterations required to run piping, wiring, and ductwork. Follow dimensional drawings carefully

for ductwork, piping locations, electrical wiring, and overall unit dimensions. Read all installation instructions before

starting installation.

The 50AH units are intended for indoor installation only.

Step 1 — Receive and Inspect Unit — Unpack and

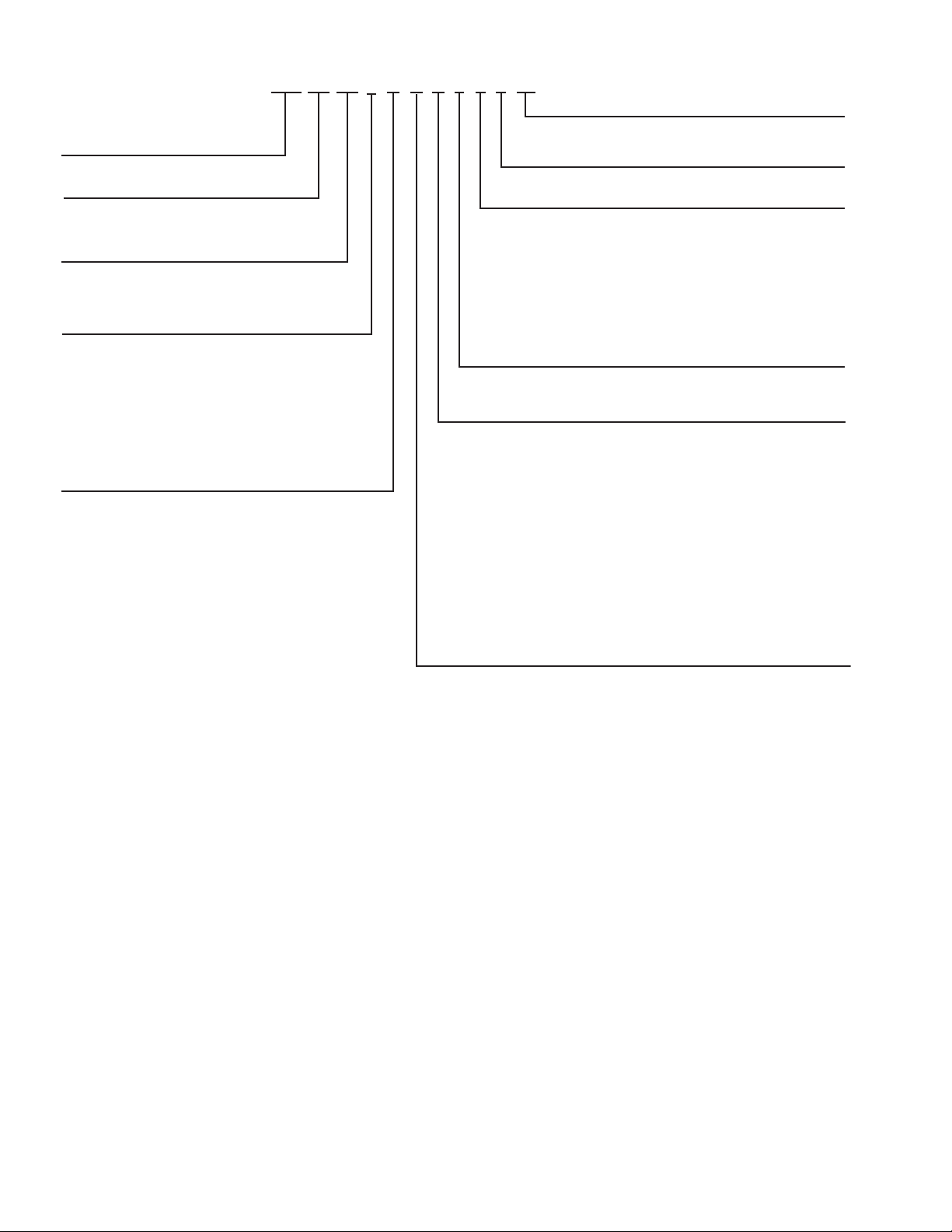

check unit against shipping order. See Fig. 1 for model number

nomenclature. Inspect carefully for concealed shipping damage. If unit is damaged or incomplete, file claim with transpor-

tation company and advise Carrier immediately.

Step 2 — Protect Unit from Damage — To main-

tain warranty, unit must be protected against theft and vandalism and stored indoors at all times.

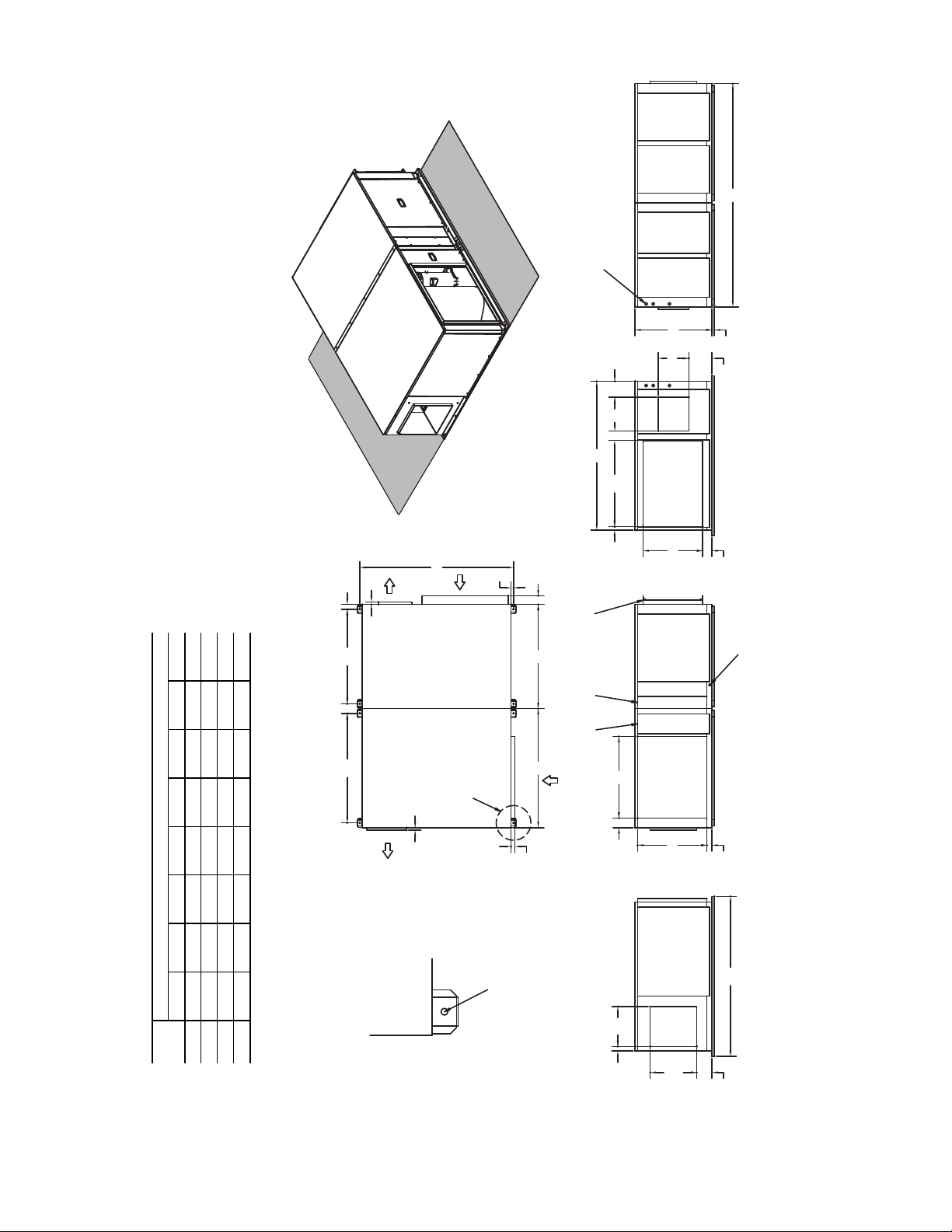

Step 3 — Provide Unit Support — Refer to Fig. 2-5

for unit dimensions. Refer to Table 1 for unit sizes and weights.

Each unit requires the following field-supplied items:

8 — threaded suspension rods (

minimum), 4 additional rods are needed if the unit

has a factory-installed air-side economizer

8—washers

8 — locknuts

Install the 8 field-supplied rods by suspending them from a

suitable ceiling support. Locate rods to mate with 8 outside corner rigging holes shown in Fig. 2-5. Unit center of gravity is

shown in Fig. 6.

The ceiling and ceiling supports of existing buildings may

require reinforcements; follow all applicable codes.

3

/8-in.-16 SAE Grade 1

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53500057-01 Printed in U.S.A. Form 50AH-14SI Pg 1 5-10 Replaces: 50AH-12SI

Page 2

Evaporator Configuration

Factory-Installed Options

50AH AC 048 5 – – – – 2 1 XX

50AH – Horizontal, Indoor

Single-Package Cooling Unit

Packaging

1 – Domestic

2 – Export

Voltage Description

5 – 208/230-3-60

6 – 460-3-60

Unit Size - Nominal Tons

024 –2

036 – 3

048 – 4

Compressor Options

AC – Air Cooled

060 –5

072 – 6

096 – 8

3 – 208/230-1-60

Condenser Configuration

Design Changes

2 – R-410A Original Design

Cabinet Type

S – Splittable*

– – Standard

Economizer and Hot Gas Options

A – Hot Gas Bypass†

B – Hot Gas Reheat†

– – None

C – Air-S

ide Economizer with Controls

E – Hot Gas Bypass and Air-Side Economizer†

F – Hot Gas Bypass, Air-Side Economizer, and

Hot Gas Reheat†

D – Hot Gas Bypass and Hot Gas Reheat†

G – Hot Gas Reheat and Air-Side Economizer†

B – Standard Motor with Alternate 2 Drive

A – Standard Motor with Alternate 1 Drive

– – Standard Motor with Standard Drive

E – Upgrade 1 Motor with Alternate 2 Drive

D – Upgrade 1 Motor with Alternate 1 Drive

C – Upgrade 1 Motor with St

andard Drive

H – Upgrade 3 Motor with Alternate 2 Drive

G – Upgrade 2 Motor with Alternate 2 Drive

F – Upgrade 2 Motor with Alternate 1 Drive

B – Standard Motor with Alternate 1 Drive

A – Standard Motor with Standard Drive, Flooded Condenser

– – Standard Motor with Standard Drive

E – Upgrade 1 Motor with Alternate 3 Drive

D – Upgrade 1 Motor with Alternate 2 Drive

C – Upgrade 1 Motor with Alternate 1 Drive

H – Upgrade 2 Motor with Alternate 3 Drive

G – Upgrade 2 Motor with Alternate 2 Drive

F – Upgra

de 2 Motor with Alternate1 Drive

J – Standard Motor with Alternate 1 Drive, Flooded Condenser

M – Upgrade 1 Motor with Alternate 3 Drive, Flooded Condenser

L – Upgrade 1 Motor with Alternate 2 Drive, Flooded Condenser

K – Upgrade 1 Motor with Alternate 1 Drive, Flooded Condenser

Q – Upgrade 2 Motor with Alternate 3 Drive, Flooded Condenser

P – Upgrade 2 Motor with Alternate 2 Drive, Flooded Condenser

N – Upgrade 2 Motor with Alternate1 Drive, Flooded Condenser

* Includes interconnecting kit and electrical box.

†Not available with splitable units.

a50-8546

Fig. 1 — Model Number Nomenclature

2

Page 3

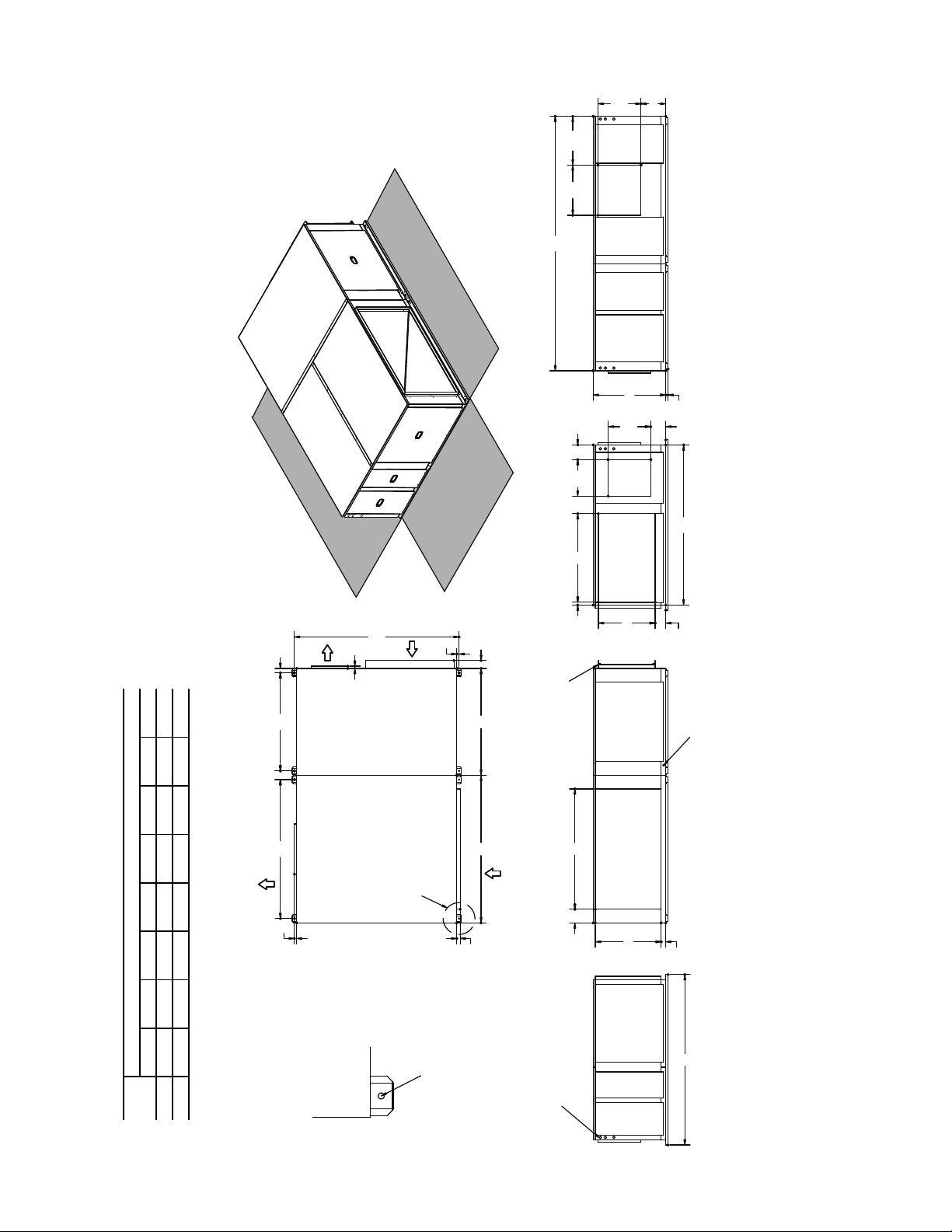

DETAIL A

CLEARANCE HOLE FOR

3/8" HANGING ROD

TYP 8 PLS

AIR

IN

COIL

ACCESS

FRONT

TOP

RIGHT

REAR LEFT

RETURN

AIR

SUPPLY

AIR

AIR

OUT

MOTOR

ACCESS

ELECT

BOX

ACCESS

BLOWER

ACCESS

EVAP

SECTION

COND

SECTION

ISOMETRIC VIEW

MOTOR

ACCESS

DETAIL "A"

ELECTRICAL

CONNECTIONS

TYP

CONDENSATE DRAIN

7/8" OD

FILTER

ACCESS

COMPRESSOR

ACCESS

QUICK

CONNECT

ACCESS

RA

LEFT

RIGHT

REAR

FRONT

26 IN. SERVICE

CLEARANCE

36 IN. SERVICE

CLEARANCE

31

90

6 7/16

13 5/8

34 3/4

1 3/8

9 5/16

12 3/8

60

24

3 3/4

3 13/16

33

2

28

64 1/2

6 1/8

18 3/4

1 3/4

16 1/8

48

42

2 1/4

3 1/2

62

1 15/16

38 1/8

3 7/8

44 1/8

1

1

1

A

B

C

DEG

FH

OSA

OPERATING WEIGHT DISTRIBUTION

UNIT

50AH

WEIGHT OF CORNER (lb)

ABCDEFGH

024 8711188 113 143 136 105 100

036 8711189 114 144 138 106 101

048 91 116 92 118 152 145 111 106

060 91 117 93 119 153 146 112 107

Fig. 2 — Unit Dimensions — 50AH024-060 Standard Units

NOTE: Dimensions are in inches.

a50-8547

LEGEND

OSA — Outside Supply Air

RA — Return Air

3

Page 4

64 1/2

6 1/8

183/4

1 3/4

16 1/

8

1 1/2

3 13/16

1 15/16

44 1/8

3 7/8

38 1/8

6 1/16

24 3/4

38 1/2

5 15/16

3 1/4

1/4

5 7/

8

13 5/8

9 5/16

12 3/

8

6 7/16

2 1/4

5 7/8

12

Fig. 3 — Unit Dimensions — 50AH024-060 Units with Factory-Installed Air-Side Economizer

a50-8548

NOTES:

1. Dimensions are in inches.

2. Economizer weight is 180 lb.

LEGEND

OSA — Outside Supply Air

RA — Return Air

4

Page 5

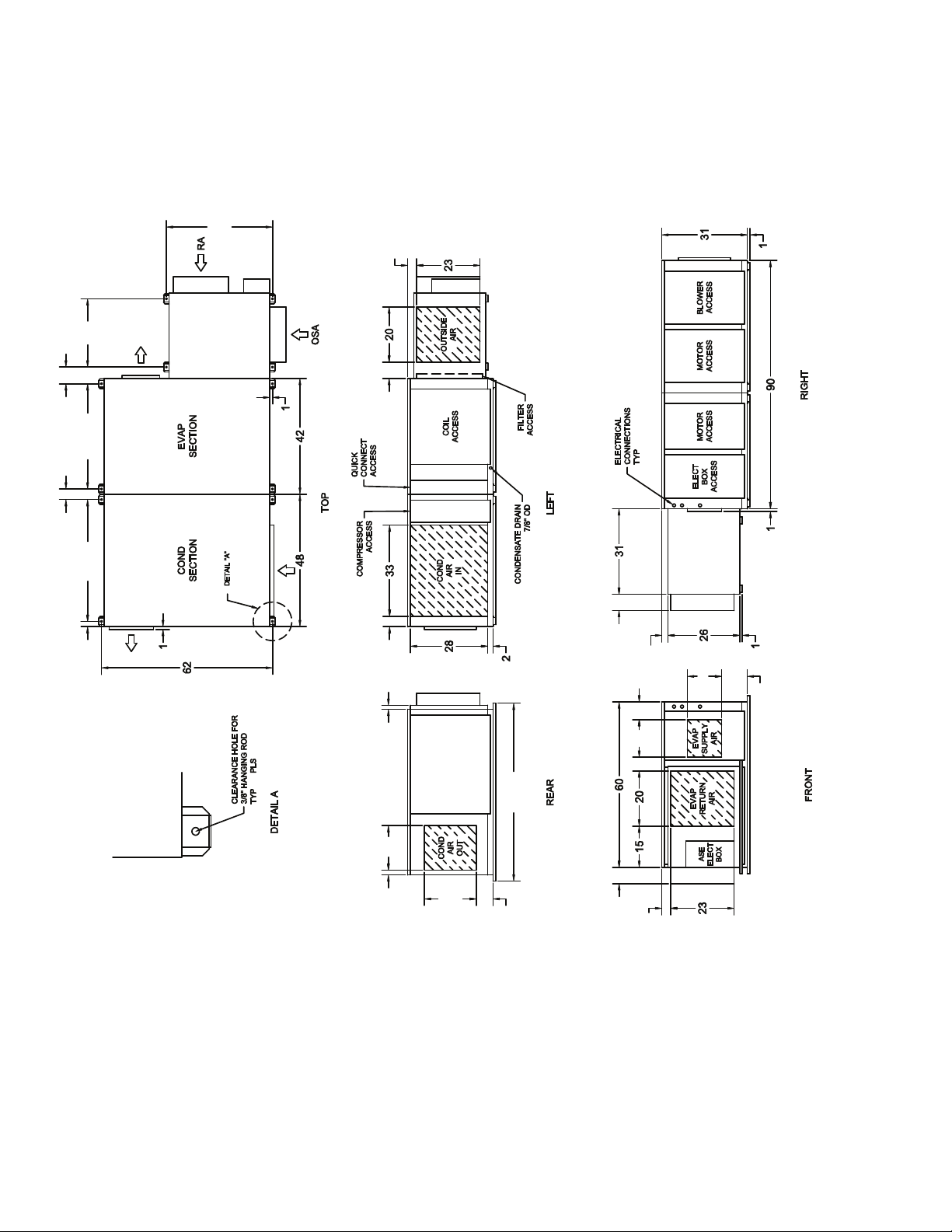

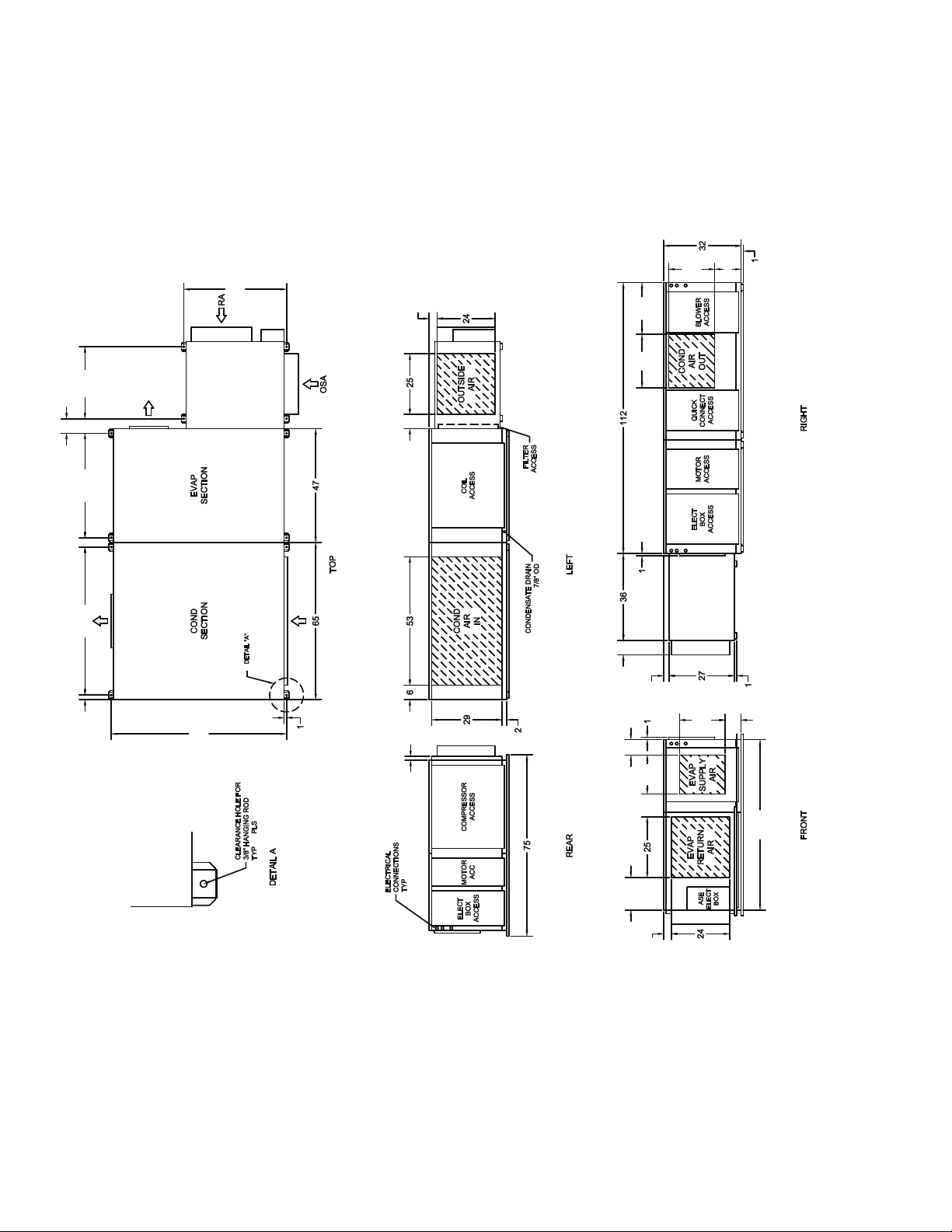

DETAIL A

CLEARANCE HOLE FOR

3/8" HANGING ROD

TYP 8 PLS

DETAIL "A"

AIR

IN

MOTOR

ACC

ELECT

BOX

ACCESS

COIL

ACCESS

COMPRESSOR

ACCESS

FILTER

ACCESS

CONDENSATE DRAIN

7/8" OD

FRONT

TOP

RIGHT

REAR LEFT

RETURN

AIR

SUPPLY

AIR

AIR

OUT

MOTOR

ACCESS

ELECT

BOX

ACCESS

BLOWER

ACCESS

QUICK

CONNECT

ACCESS

EVAP

SECTION

COND

SECTION

ELECTRICAL

CONNECTIONS

TYP

ISOMETRIC VIEW

21 7/16

22 1/8

18 15/16

10 7/8

32

112

25

3 5/8

39

1 1/4

16 1/16

6 7/16

18 3/4

6

70 1/2

29

653

2

2 1/4

3 1/2

47

65

72 1/2

1 15/16

43 1/8

3 7/8

61 1/8

75

26 IN. SERVICE

CLEARANCE

36 IN. SERVICE

CLEARANCE

36 IN. SERVICE

CLEARANCE

1

1

1

A

B

C

DEG

F

H

OSA

RA

REAR

RIGHT

LEFT

FRONT

OPERATING WEIGHT DISTRIBUTION

UNIT

50AH

WEIGHT OF CORNER (lb)

ABCDEFGH

072 125 128 149 152 126 128 188 192

096 126 129 149 153 139 142 208 212

NOTE: Dimensions are in inches.

a50-8549

Fig. 4 — Unit Dimensions — 50AH072,096 Standard Units

LEGEND

OSA — Outside Supply Air

RA — Return Air

5

Page 6

13 7/16

16 1/16

6 7/16

18 3/4

6 5/8

70 1/2

5 7/8

22 1/8 21 7/16

18 15/16

10 7/8

3 1/4

5 15/16

1 1/2

72 1/2

1 15/16 61 1/8

3 7/8

43 1/8

6 1/16

42 1/2

29 3/4

12

NOTES:

1. Dimensions are in inches.

2. Economizer weight is 200 lbs.

a50-8550

Fig. 5 — Unit Dimensions — 50AH072,096 Units with Factory-Installed Air-Side Economizer

LEGEND

OSA — Outside Supply Air

RA — Return Air

6

Page 7

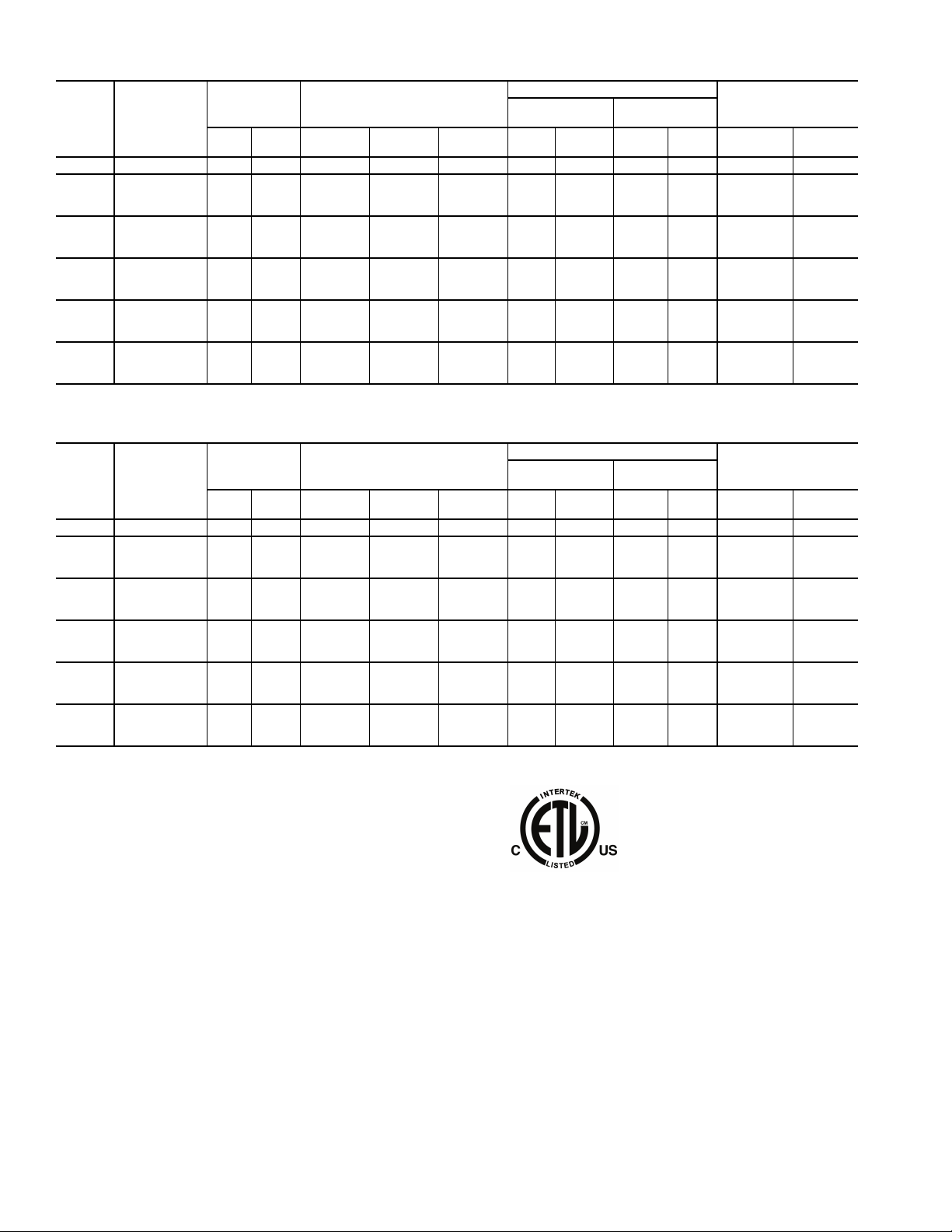

Table 1 — Physical Data

Fig. 6 — Rigging Details

CENTER OF GRAVITY

NOTE: Fasten threaded rods through holes in end frames as shown.

Use 4 rods on each side of unit for a total of 8.

UNIT 50AH

DIMENSIONS (in.)

AB

024 29.0 25.6

036 28.8 26.0

048 29.0 27.0

060 28.8 26.8

072 59.3 31.2

096 60.0 31.5

CAUTION

All panels must be in place when rigging.

UNIT 50AH 024 036 048

OPERATING WEIGHT (lb)

Base Unit 903 910 952

Evaporator/Condenser Sections 399/484401/489 417/515

SHIPPING WEIGHT (lb)* 1036 1043 1085

REFRIGERANT TYPE R-410A

Operating Charge (lb-oz)† 4-5 4-5 8-8

COMPRESSOR — TYPE Scroll

Quantity...Model 1...ZP20K5E 1...ZP31K5E 1...ZP38K5E

Oil (oz) 25 25 42

HPS Setting (psig)

Cutout 650 ± 7

Reset Manual Reset

LPS Setting (psig)

Cutout 75 ± 7

Reset 100 ± 7

CONDENSATE DRAIN CONNECTION

Size (in.)...Type

CONDENSER COIL Copper Tubes — Aluminum Fins

Size (L x H) (in.) 40 x 30 40 x 30 90 x 30

Number of Rows...Fins/in. 4...14 4...14 2...12

CONDENSER FAN Centrifugal — Belt Drive

Nominal Cfm 1700 2000 2500

Blower Size (in.) 15 x15 15 x 15 15 x 15

Motor Hp (Rpm)

Standard Motor 0.33 (1725) 0.33 (1725)

Upgrade 1 Motor ——

Upgrade 2 Motor ——

EVAPORATOR COIL Copper Tubes — Aluminum Fins

Size (L x H) (in.) 32 x 16 32 x 16 32 x 26

Number of Rows...Fins/in. 3...12 3...12 3...14

EVAPORATOR AIR FAN Centrifugal — Belt Drive

Nominal Cfm 800 1200 1600

Blower Size (in.) 12 x 9 12 x 9 12 x 9

Motor Hp (Rpm)

Standard Motor 0.25 (1725) 0.33 (1725)

Upgrade 1 Motor 0.33 (1725) 0.50 (1725)

Upgrade 2 Motor 0.50 (1725) 0.75 (1725)

Upgrade 3 Motor — 1.00 (1725)

INDOOR-AIR FILTERS Factory-Supplied Disposable Type

Number...Size (in.) 2...18 x 24 x 1 2...18 x 24 x 1 2...18 x 24 x 1

INTERCONNECTING TUBING SIZE

Suction (Qty...in.) 1...

Liquid (Qty...in.)

LEGEND

HPS — High-Pressure Switch

LPS — Low-Pressure Switch

*Shipping weights include base unit plus packaging.

†If components are to be split, additional refrigerant will be needed.

5

/

8

3

/

1...

8

NOTE: If components are to be split, the maximum length of refrigerant

tubing to be used is 50 equivalent ft, assuming components will be

installed in same horizontal plane. If components are not to be installed

in same horizontal plane, contact your Carrier representative for more

information. For additional piping information, refer to Carrier System

Design Manual, Part 3.

7

/8...OD

0.33 (1725)

0.50 (1725)

0.75 (1725)

0.33 (1725)

0.50 (1725)

0.75 (1725)

1.00 (1725)

1...5/

1...3/

8

8

1...7/

1...3/

8

8

7

Page 8

Table 1 — Physical Data (cont)

UNIT 50AH 060 072 096

OPERATING WEIGHT (lb)

Base Unit 960 1214 1283

Evaporator/Condenser Sections 421/519 554/634 556/701

SHIPPING WEIGHT (lb)* 1093 1647 1716

REFRIGERANT TYPE R-410A

Operating Charge (lb-oz)† 8-8 6-6 6-6

COMPRESSOR — TYPE Scroll

Quantity...Model 1...ZPKP51K5E 2...ZP31K5E 2...ZP38K5E

Oil (oz) 42 25 42

HPS Setting (psig)

Cutout 650 ± 7

Reset Manual Reset

LPS Setting (psig)

Cutout 75 ± 7

Reset 100 ± 7

CONDENSATE DRAIN CONNECTION

Size (in.)...Type

CONDENSER COIL Copper Tubes — Aluminum Fins

Size (L x H) (in.) 90 x 30 40 x 30 (2 coils) 40 x 30 (2 coils)

Number of Rows...Fins/in. 2...12 2...20 2...20

CONDENSER FAN Centrifugal — Belt Drive

Nominal Cfm 3000 5200 6400

Blower Size (in.) 15 x 15 18 x 18 18 x 18

Motor Hp (Rpm)

Standard Motor 0.33 (1725) 1.00 (1725)

Upgrade 1 Motor 0.50 (1725) 1.50 (1725)

Upgrade 2 Motor 0.75 (1725) —

EVAPORATOR COIL Copper Tubes — Aluminum Fins

Size (L x H) (in.) 32 x 26 46 x 28 46 x 28

Number of Rows...Fins/in. 3...14 3...14 3...14

EVAPORATOR AIR FAN Centrifugal — Belt Drive

Nominal Cfm 2000 2400 3200

Blower Size (in.) 12 x 9 15 x 15 15 x 15

Motor Hp (Rpm)

Standard Motor 0.33 (1725) 0.50 (1725)

Upgrade 1 Motor 0.50 (1725) 0.75 (1725)

Upgrade 2 Motor 0.75 (1725) 1.00 (1725)

Upgrade 3 Motor 1.00 (1725) 1.50 (1725)

INDOOR-AIR FILTERS Factory-Supplied Disposable Type

Number...Size (in.) 2...18 x 24 x 1 2...20 x 25 x 1 2...20 x 25 x 1

INTERCONNECTING TUBING SIZE

Suction (Qty...in.) 1...

Liquid (Qty...in.)

LEGEND

HPS — High-Pressure Switch

LPS — Low-Pressure Switch

*Shipping weights include base unit plus packaging.

†If components are to be split, additional refrigerant will be needed.

7

/

8

3

/

1...

8

NOTE: If components are to be split, the maximum length of refrigerant

tubing to be used is 50 equivalent ft, assuming components will be

installed in same horizontal plane. If components are not to be installed

in same horizontal plane, contact your Carrier representative for more

information. For additional piping information, refer to Carrier System

Design Manual, Part 3.

7

/8...OD

1...5/

1...3/

1.50 (1725)

2.00 (1725)

3.00 (1725)

0.75 (1725)

1.00 (1725)

1.50 (1725)

2.00 (1725)

8

8

1...7/

1...7/

8

8

Step 4 — Rig and Place Unit — Move and store unit

in horizontal position. Provide space around unit for service,

filter access, ductwork, and overhead clearance as indicated in

Fig. 2-5.

Using suitable hydraulic lift source, raise unit up to meet

bottom of the 8 threaded rods suspended from ceiling (12 rods

for units with air-side economizer). Center unit so that the 8 or

12 threaded rods can be easily inserted into the factory-drilled

holes at each end. Refer to Fig. 6 for rigging details.

Apply washers and locknuts on ends of each of the 8 or 12

rods.

Tighten locknuts sufficiently so that unit weight is support-

ed entirely by the 8 or 12 rods. Level unit within the space by

adjusting locknuts.

IMPORTANT: Unit must be level to operate properly.

NOTE: For split systems, 8 (or 12) suspension rods are

required (4 for each section and 4 for economizer if required).

Refer to Splitting Systems section below.

Step 5 — Make Condensate Piping Connections —

nection is provided for the evaporator section.

One 7/8-in. OD pipe thread condensate drain con-

Step 6 — Install Ductwork — Use flexible ductwork

to attach duct to unit and to help control transmission of vibrations to building structures. Attach ductwork to the return and

supply ends of both coils.

If unit is located with condenser close to outside of building,

install a field-supplied rainhood. Hood intake dimensions

should be same as condenser return-air dimensions. In addition, install a triple-layer bird screen over rainhood intake to

eliminate possibility of insects, birds, water, or debris from

entering unit. Ensure hood and/or louvers are installed correctly to avoid condenser air recirculation.

Step 7 — Split Systems (Factory Option, if

Required) — The Roomtop

2 sections, if desired, with condensing section mounted

remotely horizontally. The unit must be ordered with the

“Splittable” cabinet type as shown in the unit model number

nomenclature. See Fig. 1. All splittable units come with the

interconnecting tubing kit.

Sections installed in the same horizontal plane may be separated by up to 50 equivalent ft of tubing. Use type L copper or

better.

8

®

50AH units may be split into

Page 9

Condensing section must be located in same plane as, or

SELF-SEALING

COUPLING

(FEMALE HALF)

SELF-SEALING

COUPLING

(MALE HALF)

SELF-SEALING

FLANGE

SCREWS

Fig. 7 — Self Sealing Coupling

a50-8551

A — Male self-sealing fittings

B — Refrigerant piping between sections

C — Female self-sealing fittings

D — Schrader fittings

Fig. 8 — Tubing Installation

a50-8552

above, evaporator section to maintain the liquid refrigerant seal

at the expansion device. This permits expansion device to feed

liquid refrigerant to evaporator coil properly. To split sections

(some of the following steps may be eliminated depending on

particular application):

1. Disconnect all electrical power to unit.

2. Remove the 10 size 10 drive screws that hold on the top

tie strap.

3. Remove the 8 size

3

/8-in. drive bolts that hold on each

side angle.

4. Control panel access panels are held on with 2 size 10

drive screws for each panel. A standard 50AH024-060

unit has one control panel located in the evaporator section. A standard 50AH072 or 096 unit has a control panel

in both the evaporator and condenser sections.

5. Units have resealable fittings. Do not cut refrigerant piping. See Interconnecting Refrigerant Tubing section below for procedure on installing tubing.

6. Install evaporator and condensing sections in desired

locations.

7. Use sufficient length of refrigerant piping to reconnect

piping cut in previous step. Refer to Carrier System

Design Manual, Part 3, for additional piping data.

8. Recharge unit with R-410A. See Refrigerant Charge section on page 18 for more information.

After splitting sections, additional refrigerant must be added

to system to ensure proper refrigerant charge. The amount of

refrigerant to be added depends on length of tubing added to

system and operating temperatures of system. Refer to Carrier

System Design Manual, Chapter 3. Allow unit to operate at

least 10 minutes before adjusting refrigerant charge.

Since standard roomtop unit has negligible line losses, splitting the system can increase line loss and decrease system

capacity. Capacity reduction can be determined by referring to

Carrier System Design Manual.

INTERCONNECTING REFRIGERANT TUBING — The

interconnecting tubing kit comes with all factory-optional splittable units. After the separated sections have been installed, the

interconnecting tubing can be run, using the self-sealing couplings supplied in the interconnect tubing kit (see Fig. 7 and 8).

Perform the following procedure:

1. For condensing section, hand thread the female halves of

the self-sealing couplings (supplied with the interconnect

tubing kit) onto the male couplings (factory supplied and

installed on the condensing section). Turn union nut approximately 1 to 1

1

/2 turns. This is to make sure that the

interconnecting tubing will be routed and brazed with the

self-sealing couplings in their final proper location, so

that there will be no difficulty when the final coupling assembly is made.

2. For evaporator section, hand thread the male halves of the

self-sealing couplings (supplied with the interconnect

tubing kit) onto the female couplings (factory supplied

and installed on the evaporating section). Turn union nut

approximately 1 to 1

1

/2 turns. This is to make sure that the

interconnecting tubing will be routed and brazed with the

self-sealing couplings in their final proper location, so

that there will be no difficulty when the final coupling assembly is made.

3. Run the interconnecting tubing required.

NOTE: Installations may be made with up to 50 ft equiv-

alent line lengths by installing the recommended tube sizes and adding the necessary refrigerant. For equivalent

line lengths greater than 50 ft, contact Carrier for line sizing and additional accesories required.

IMPORTANT: On units with more than one refrigerant circuit, be careful not to intermix lines of the

various circuits. If the connections were labeled

before disconnecting the couplings, this should not

be a problem. Half couplings may be removed to

make brazing to the interconnecting tubing more

convenient.

D

B

B

C

D

C

A

CONDENSING

SECTION

A

C

EVAPORATOR

SECTION

C

D

A

D

A

For dual circuits, 2 kits are supplied. It is recommended that

some refrigerant oil be placed on the coupling threads to facilitate threading.

CAUTION

When brazing tubing to the self-sealing couplings, be sure

to use a wet rag, running water bath or chill blocks on the

quick-connects to prevent overheating the valves and damaging the seals

4. The interconnect tubing kit contains a sufficient number

of Schrader access valves to permit installation of one in

each end of both the liquid and suction lines of the fieldsupplied tubing. Each interconnecting line (suction, liquid, hot gas) must have one of the supplied Schrader access fittings installed into the field-supplied tubing, however, for short lengths of tubing, only one Schrader in

each line is necessary. Install the Schrader valve fittings

into the tubing before brazing the couplings onto the ends

9

.

Page 10

of the tubing. Use a

1

/4-in. hole to mount the valve. Clean

and debur the tubing before doing any brazing to ensure

that no chips or debris are left in the refrigerant circuit.

Remove the Schrader valve cap and core before doing

any brazing.

5. After brazing the tubing to the self-sealing coupling

halves, evacuate each line to 500 microns. Check to make

sure that each line holds a vacuum after removal of the

vacuum pump (indicating no leaks). Add the appropriate

charge of R-410A refrigerant using the Schrader valves.

Refasten male halves to outer back panel of evaporator

section with flanges and screws (if they were removed for

brazing to tubing). Wipe off coupling seals and threaded

surfaces with a clean cloth to prevent the inclusion of dirt

or foreign material into the system. Lubricate rubber seal

and metal seal in the male halves with refrigeration oil.

Thread coupling halves together by hand to ensure proper

mating of threads. Continue to handthread each half-coupling to its mating half until resistance is felt (approximately 1

1

/2 to 13/4 turns). Complete the connection of the

mating half-couplings with a wrench. The suction line

couplings (size 12) will be totally engaged after an addi-

1

tional 5

will be totally engaged after an additional 4

/2 to 53/4 turns. The liquid line couplings (size 8)

1

/2 to 43/

turns. Use a backup wrench to prevent the couplings from

twisting.

6. Refrigerant piping must be insulated in accordance with

local codes and/or applicable ASHRAE standards. Insulation exposed to weather must be suitable for outdoor

use. Provide protection from water and shielding from solar radiation as necessary.

7. Add refrigerant to the system to compensate for the additional interconnecting tubing. The suction line should be

pitched downward to the compressor, sloping approxi-

1

mately

/4-in. every 10 ft to facilitate oil return. P-traps

(field supplied) are required for all suction line risers every 15 ft. When the evaporator is above the condensing

section, an inverted P-trap should be incorporated as

close as possible to the evaporator (this minimizes floodback/oil slugging during the off cycle). If the condensing

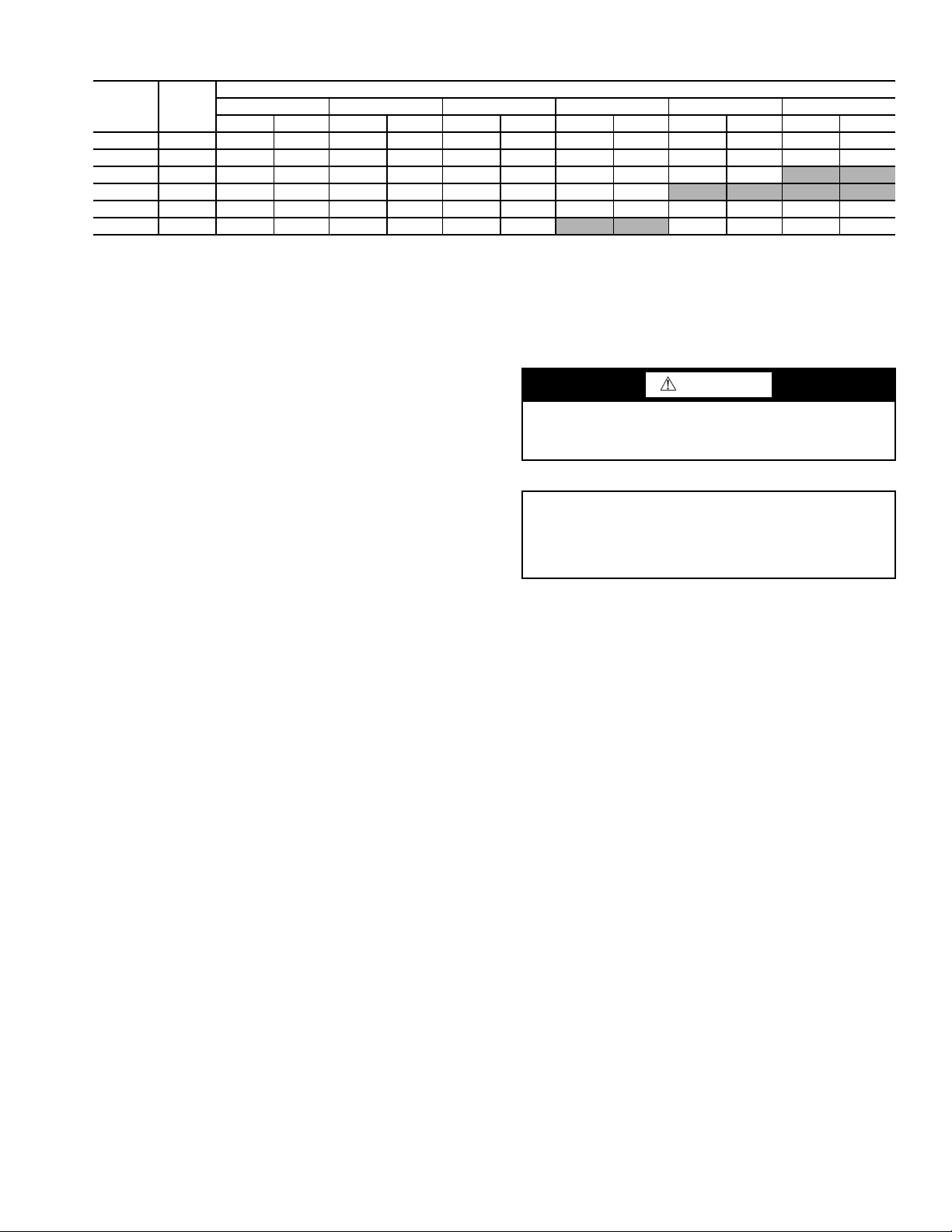

Table 2A — Electrical Data — Standard Evaporator Motor with Standard Condenser Motor

section is more than 50 ft above the evaporator, consult

Carrier for specific refrigeration components.

Step 8 — Make Electrical Connections — Con-

nect power wiring to junction box located on unit side near

control box access panel. All wiring must comply

with National Electrical Code (NEC) and all local code

requirements.

Operating voltage to compressor must be within voltage

range as indicated on unit nameplate. On 3-phase units, voltages between phases must be balanced within 2% and current

must be balanced within 10%. Contact local power company

for correction of improper voltage or phase imbalance. Unit

failure as a result of operation on improper line voltage or excessive phase imbalance constitutes abuse and may cause damage to electrical components. Such operation would invalidate

any applicable Carrier warranty.

Install a fused disconnect per NEC. Refer to unit nameplate

and Tables 2A-2L for fuse sizes and wire amperages for all

units.

FIELD CONTROL WIRING — Install a Carrier-approved

accessory thermostat assembly according to installation

instructions provided by thermostat manufacturer. Locate

4

thermostat assembly on a solid wall in the conditioned space

away from drafts to sense average room temperature.

Using thermostat cable or equivalent single leads of no. 18

AWG (American Wire Gage) colored wire, route cable or wire

from the subbase terminals, up and through connector on unit

side (below power lead junction box) and connect to low-voltage terminal block inside the control box.

THERMOSTAT WIRE — Use 18 gage for 0 to 50-ft long

wires and 16 gage for 51 to 75-ft wire lengths.

Step 9 — Adjust Fan Speed — Adjust fan speed to

meet jobsite conditions. Refer to Tables 3 and 4 to determine

fan speed settings. See Service section of this document for

instructions to adjust fan speed.

The evaporator and condenser fan motors on all units are

belt drive.

VOLTAGE

UNIT

50AH

024 208/230-1 187 254 1 13.5 58.0

036

048

060

072*

096*

HACR — Heating, Air Conditioning, and Refrigeration

Hp — Horsepower

FLA — Full Load Amps

LRA — Locked Rotor Amps

MOCP — Maximum Overcurrent Protection (HACR breaker)

RLA — Rated Load Amps

*Unit has two compressors.

V-PH

(60 Hz)

208/230-1 187 254

208/230-3 187 254 10.4 73.0

460-3 414 508 5.8 38.0

208/230-1 187 254

208/230-3 187 254 13.6 83.1

460-3 414 508 6.1 41.0

208/230-1 187 254

208/230-3 187 254 16.0 110.0

460-3 414 508 7.8 52.0

208/230-1 187 254

208/230-3 187 254 10.4 73.0

460-3 414 508 5.8 38.0

208/230-1 187 254

208/230-3 187 254 13.6 83.1

460-3 414 508 6.1 41.0

LEGEND

RANGE

Min Max QTY RLA LRA Hp FLA Hp FLA

COMPRESSOR

16.7 79.0

1

19.9 109.0

1

26.4 134

1

16.7 79.0

2

19.9 109.0

2

FAN MOTORS

Evaporator

(Standard)

1

/

1.25

4

1

/

3

1

/

3

1

/

3

1

/

3

1

/

3

1

/

3

1

/

3

1

/

3

1

/

3

1

/

2

1

/

2

1

/

2

3

/

4

3

/

4

3

/

4

Condenser

(Standard)

1

/

1.7 19.8 35

3

1.7

1.3

0.7

1.7

1.3

0.7

1.7

1.3

0.7

2.5 1 4.2 44.3 60

1.8 13.228.4 40

0.9 1 1.6 15.6 20

3.2 1 1/

2.4 1 1/

1.2 1 1/

1

/

1.7 24.3 40

3

1

/

1.3 15.6 25

3

1

/

0.7 8.6 15

3

1

/

1.7 28.3 50

3

1

/

1.3 19.6 35

3

1

/

0.7 8.9 15

3

1

/

1.7 36.4 65

3

1

/

1.3 22.6 40

3

1

/

0.7 11.1 20

3

6.5 54.5 75

2

4.8 37.8 50

2

2.4 17.3 25

2

POWER SUPPLY

Min Ckt

Amps

MOCP

Amps

10

Page 11

Table 2B — Electrical Data — Upgrade 1 Evaporator Motor with Standard Condenser Motor

UNIT

50AH

V-PH

(60 Hz)

VOLTAGE

RANGE

COMPRESSOR

Min Max QTY RLA LRA Hp FLA Hp FLA

024 208/230-1 187 254 1 13.5 58.0

036

048

060

072*

096*

208/230-1 187 254

208/230-3 187 254 10.4 73.0

460-3 414 508 5.8 38.0

1

208/230-1 187 254

208/230-3 187 254 13.6 83.1

460-3 414 508 6.1 41.0

1

208/230-1 187 254

208/230-3 187 254 16.0 110.0

460-3 414 508 7.8 52.0

1

208/230-1 187 254

208/230-3 187 254 10.4 73.0

460-3 414 508 5.8 38.0

2

208/230-1 187 254

208/230-3 187 254 13.6 83.1 1 3.2 1

460-3 414 508 6.1 41.0 1 1.6 1

2

16.7 79.0

19.9 109.0

26.4 134.0

16.7 79.0

19.9 109.0 1 4.2 1

Table 2C — Electrical Data — Upgrade 2 Evaporator Motor with Standard Condenser Motor

VOLTAGE

UNIT

50AH

V-PH

(60 Hz)

RANGE

Min Max QTY RLA LRA Hp FLA Hp FLA

024 208/230-1 187 254 1 13.5 58.0

036

048

060

072*

096*

208/230-1 187 254

208/230-3 187 254 10.4 73.0

460-3 414 508 5.8 38.0

208/230-1 187 254

208/230-3 187 254 13.6 83.1

460-3 414 508 6.1 41.0

208/230-1 187 254

208/230-3 187 254 16.0 110.0

460-3 414 508 7.8 52.0

208/230-1 187 254

208/230-3 187 254 10.4 73.0 1 3.2 1 3.2 29.8 40

460-3 414 508 5.8 38.0 1 1.6 1 1.6 16.3 20

208/230-1 187 254

208/230-3 187 254 13.6 83.1 11/

460-3 414 508 6.1 41.0 11/

LEGEND

HACR — Heating, Air Conditioning, and Refrigeration

Hp — Horsepower

FLA — Full Load Amps

LRA — Locked Rotor Amps

MOCP — Maximum Overcurrent Protection (HACR breaker)

RLA — Rated Load Amps

*Unit has two compressors.

COMPRESSOR

1

1

1

2

2

16.7 79.0

19.9 109.0

26.4 134.0

16.7 79.0 1 4.2 1 4.2 46.0 60

19.9 109.0 1

FAN MOTORS

Evaporator

(Upgrade 1)

1

/

1

/

1

/

1

/

1

/

1

/

1

/

1

/

1

/

1

/

3

/

3

/

3

/

1.7

3

2.5

2

1.8

2

0.9

2

2.5

2

1.8

2

0.9

2

2.5

2

1.8

2

0.9

2

3.2 1 4.2 45.0 60

4

2.4 1 3.2 29.0 40

4

1.2 1 1.6 15.9 20

4

FAN MOTORS

Evaporator

(Upgrade 2)

1

/

3

/

3

/

3

/

3

/

3

/

3

/

3

/

3

/

3

/

1

2

4

4

4

4

4

4

4

4

4

/

2

2

2

2.5

3.2

2.4

1.2

3.2

2.4

1.2

3.2

2.4

1.2

6.5 1 1/

4.8 1 1/

2.4 1 1/

Condenser

(Standard)

1

/

1.7 20.3 35

3

1

/

1.7 25.1 40

3

1

/

1.3 16.1 25

3

1

/

0.7 8.8 15

3

1

/

1.7 29.1 50

3

1

/

1.3 20.1 35

3

1

/

0.7 9.2 15

3

1

/

1.7 37.2 65

3

1

/

1.3 23.1 40

3

1

/

0.7 11.3 20

3

1

/

6.5 55.5 75

2

1

/

4.8 38.6 50

2

1

/

2.4 17.7 25

2

Condenser

(Standard)

1

/

1.7 21.1 35

3

1

/

1.7 25.8 40

3

1

/

1.3 16.7 25

3

1

/

0.7 9.1 15

3

1

/

1.7 29.8 50

3

1

/

1.3 20.7 35

3

1

/

0.7 9.5 15

3

1

/

1.7 37.9 65

3

1

/

1.3 23.7 40

3

1

/

0.7 11.6 20

3

6.5 57.880

2

4.8 40.2 55

2

2.4 18.5 25

2

POWER SUPPLY

Min Ckt

Amps

MOCP

Amps

POWER SUPPLY

Min Ckt

Amps

MOCP

Amps

11

Page 12

Table 2D — Electrical Data — Upgrade 3 Evaporator Motor with Standard Condenser Motor

FAN MOTORS

Evaporator

(Upgrade 3)

Condenser

(Standard)

POWER SUPPLY

Min Ckt

Amps

UNIT

50AH

V-PH

(60 Hz)

VOLTAGE

RANGE

COMPRESSOR

Min Max QTY RLA LRA Hp FLA Hp FLA

024 208/230-1 187 254 1 N/A N/A N/A N/A N/A N/A N/A N/A

1

/

036

048

060

072*

096*

208/230-1 187 254

208/230-3 187 254 10.4 73.0 1 2.4

460-3 414 508 5.8 38.0 1 1.2

1

208/230-1 187 254

208/230-3 187 254 13.6 83.1 1 2.4

460-3 414 508 6.1 41.0 1 1.2

1

208/230-1 187 254

208/230-3 187 254 16.0 110.0 1 2.4

460-3 414 508 7.8 52.0 1 1.2

1

208/230-1 187 254

208/230-3 187 254 10.4 73.0 1

460-3 414 508 5.8 38.0 1

2

208/230-1 187 254

208/230-3 187 254 13.6 83.1 2 6.0 1

460-3 414 508 6.1 41.0 2 2.9 1

2

16.7 79.0 1 3.2

19.9 109.0 1 3.2

26.4 134.0 1 3.2

1

/

16.7 79.0 1

6.5 1 4.2 48.3 65

2

1

/

4.8 1 3.2 31.4 40

2

1

/

2.4 1 1.6 17.1 25

2

N/A N/A N/A N/A N/A N/A N/A N/A

1

1

1

1

1

1

1

1

1.7 25.8 40

3

/

1.3 16.7 25

3

/

0.7 9.1 15

3

/

1.7 29.8 50

3

/

1.3 20.7 35

3

/

0.7 9.5 15

3

/

1.7 37.9 65

3

/

1.3 23.7 40

3

/

0.7 11.6 20

3

1

/

4.8 41.4 55

2

1

/

2.4 19.0 25

2

Table 2E — Electrical Data — Standard Evaporator Motor with Upgrade 1 Condenser Motor

FAN MOTORS

Evaporator

(Standard)

1

/

3

1

/

3

1

/

3

1

/

3

1

/

3

1

/

3

1

/

2

1

/

2

1

/

2

3

/

4

3

/

4

Condenser

(Upgrade 1)

1.7

1.3

0.7

1.7

1.3

0.7

2.5 1 1/

1.8 1 1/

1

1

1

1

1

1

0.9 1 1/

/

2.5 29.1 50

2

/

1.8 20.1 35

2

/

0.9 9.2 15

2

/

2.5 37.2 65

2

/

1.8 23.1 40

2

/

0.9 11.3 20

2

6.5 46.6 65

2

4.8 30.0 40

2

2.4 16.4 20

2

POWER SUPPLY

Min Ckt

Amps

2.4 2 6.0 39.0 55

1.2 2 2.9 17.8 25

UNIT

50AH

V-PH

(60 Hz)

VOLTAGE

RANGE

COMPRESSOR

Min Max QTY RLA LRA Hp FLA Hp FLA

024 208/230-1 187 254 1 N/A N/A N/A N/A N/A N/A N/A N/A

036

208/230-1 187 254

208/230-3 187 254 N/A N/A N/A N/A N/A N/A N/A N/A

1

N/A N/A N/A N/A N/A N/A N/A N/A

460-3 414 508 N/A N/A N/A N/A N/A N/A N/A N/A

048

208/230-1 187 254

208/230-3 187 254 13.6 83.1

1

19.9 109.0

460-3 414 508 6.1 41.0

060

208/230-1 187 254

208/230-3 187 254 16.0 110.0

1

26.4 134.0

460-3 414 508 7.8 52.0

072*

208/230-1 187 254

208/230-3 187 254 10.4 73.0

2

16.7 79.0

460-3 414 508 5.8 38.0

096*

208/230-1 187 254

208/230-3 187 254 13.6 83.1

2

N/A N/A N/A N/A N/A N/A N/A N/A

460-3 414 508 6.1 41.0

LEGEND

HACR — Heating, Air Conditioning, and Refrigeration

Hp — Horsepower

FLA — Full Load Amps

LRA — Locked Rotor Amps

MOCP — Maximum Overcurrent Protection (HACR breaker)

RLA — Rated Load Amps

*Unit has two compressors.

MOCP

Amps

MOCP

Amps

12

Page 13

Table 2F — Electrical Data — Upgrade 1 Evaporator Motor with Upgrade 1 Condenser Motor

FAN MOTORS

Evaporator

(Upgrade 1)

Condenser

(Upgrade 1)

POWER SUPPLY

Min Ckt

Amps

UNIT

50AH

V-PH

(60 Hz)

VOLTAGE

RANGE

COMPRESSOR

Min Max QTY RLA LRA Hp FLA Hp FLA

024 208/230-1 187 254 1 N/A N/A N/A N/A N/A N/A N/A N/A

036

048

060

072*

096*

208/230-1 187 254

208/230-3 187 254 N/A N/A N/A N/A N/A N/A N/A N/A

460-3 414 508 N/A N/A N/A N/A N/A N/A N/A N/A

1

208/230-1 187 254

208/230-3 187 254 13.6 83.1

460-3 414 508 6.1 41.0

1

208/230-1 187 254

208/230-3 187 254 16.0 110.0

460-3 414 508 7.8 52.0

1

208/230-1 187 254

208/230-3 187 254 10.4 73.0

460-3 414 508 5.8 38.0

2

208/230-1 187 254

208/230-3 187 254 13.6 83.1 1 3.2 2 6.0 39.8 55

460-3 414 508 6.1 41.0 1 1.6 2 2.9 18.2 25

2

N/A N/A N/A N/A N/A N/A N/A N/A

19.9 109.0

26.4 134.0

16.7 79.0

1

/

1

/

1

/

1

/

1

/

1

/

3

/

3

/

3

/

2

2

2

2

2

2

4

4

4

2.5

1.8

0.9

2.5

1.8

0.9

3.2 1 1/

2.4 1 1/

1.2 1 1/

1

/

2.5 29.9 50

2

1

/

1.8 20.6 35

2

1

/

0.9 9.4 15

2

1

/

2.5 38.0 65

2

1

/

1.8 23.6 40

2

1

/

0.9 11.6 20

2

6.5 47.3 65

2

4.8 30.6 40

2

2.4 16.7 20

2

N/A N/A N/A N/A N/A N/A N/A N/A

Table 2G — Electrical Data — Upgrade 2 Evaporator Motor with Upgrade 1 Condenser Motor

FAN MOTORS

Evaporator

(Upgrade 2)

/

/

/

/

/

/

3.2

4

2.4

4

1.2

4

3.2

4

2.4

4

1.2

4

1

/

4.8 2 6.0 41.4 55

2

1

/

2.4 2 2.9 19.0 25

2

Condenser

(Upgrade 1)

1

/

2.5 30.6 50

2

1

/

1.8 21.2 35

2

1

/

0.9 9.7 15

2

1

/

2.5 38.7 65

2

1

/

1.8 24.2 40

2

1

/

0.9 11.9 20

2

1

/

6.5 48.3 65

2

4.8 31.4 40

2

1

/

2.4 17.1 25

2

POWER SUPPLY

Min Ckt

Amps

UNIT

50AH

V-PH

(60 Hz)

VOLTAGE

RANGE

COMPRESSOR

Min Max QTY RLA LRA Hp FLA Hp FLA

024 208/230-1 187 254 1 N/A N/A N/A N/A N/A N/A N/A N/A

036

208/230-1 187 254

208/230-3 187 254 N/A N/A N/A N/A N/A N/A N/A N/A

1

N/A N/A N/A N/A N/A N/A N/A N/A

460-3 414 508 N/A N/A N/A N/A N/A N/A N/A N/A

048

060

072*

208/230-1 187 254

208/230-3 187 254 13.6 83.1

1

19.9 109.0

460-3 414 508 6.1 41.0

208/230-1 187 254

208/230-3 187 254 16.0 110.0

1

26.4 134.0

460-3 414 508 7.8 52.0

208/230-1 187 254

208/230-3 187 254 10.4 73.0 1 3.2 1 1/

2

16.7 79.0 1 4.2 1

3

3

3

3

3

3

460-3 414 508 5.8 38.0 1 1.6 1

096*

208/230-1 187 254

208/230-3 187 254 13.6 83.1 1

2

N/A N/A N/A N/A N/A N/A N/A N/A

460-3 414 508 6.1 41.0 1

LEGEND

HACR — Heating, Air Conditioning, and Refrigeration

Hp — Horsepower

FLA — Full Load Amps

LRA — Locked Rotor Amps

MOCP — Maximum Overcurrent Protection (HACR breaker)

RLA — Rated Load Amps

*Unit has two compressors.

MOCP

Amps

MOCP

Amps

13

Page 14

Table 2H — Electrical Data — Upgrade 3 Evaporator Motor with Upgrade 1 Condenser Motor

FAN MOTORS

Evaporator

(Upgrade 3)

Condenser

(Upgrade 1)

POWER SUPPLY

Min Ckt

Amps

UNIT

50AH

V-PH

(60 Hz)

VOLTAGE

RANGE

COMPRESSOR

Min Max QTY RLA LRA Hp FLA Hp FLA

024 208/230-1 187 254 1 N/A N/A N/A N/A N/A N/A N/A N/A

036

048

060

072*

096*

208/230-1 187 254

208/230-3 187 254 N/A N/A N/A N/A N/A N/A N/A N/A

460-3 414 508 N/A N/A N/A N/A N/A N/A N/A N/A

1

208/230-1 187 254

208/230-3 187 254 13.6 83.1 1 2.4

460-3 414 508 6.1 41.0 1 1.2

1

208/230-1 187 254

208/230-3 187 254 16.0 110.0 1 2.4

460-3 414 508 7.8 52.0 1 1.2

1

208/230-1 187 254

208/230-3 187 254 10.4 73.0 1

460-3 414 508 5.8 38.0 1

2

208/230-1 187 254

208/230-3 187 254 13.6 83.1 2 6.0 2 6.0 42.6 55

460-3 414 508 6.1 41.0 2 2.9 2 2.9 19.5 25

2

N/A N/A N/A N/A N/A N/A N/A N/A

19.9 109.0 1 3.2

26.4 134.0 1 3.2

1

/

16.7 79.0 1

2

1

/

2

1

/

2

6.5 1 1/

4.8 1 1/

2.4 1 1/

1

/

2.5 30.6 50

2

1

/

1.8 21.2 35

2

1

/

0.9 9.7 15

2

1

/

2.5 38.7 65

2

1

/

1.8 24.2 40

2

1

/

0.9 11.9 20

2

6.5 50.6 65

2

4.8 33.0 45

2

2.4 17.9 25

2

N/A N/A N/A N/A N/A N/A N/A N/A

Table 2I — Electrical Data — Standard Evaporator Motor with Upgrade 2 Condenser Motor

FAN MOTORS

Evaporator

(Standard)

1

/

3

1

/

3

1

/

3

1

/

3

1

/

3

1

/

3

3

/

4

3

/

4

POWER SUPPLY

Min Ckt

Amps

1.7

1.3

0.7

1.7

1.3

0.7

Condenser

(Upgrade 2)

3

/

3.2 29.8 50

4

3

/

2.4 20.7 35

4

3

/

1.2 9.5 15

4

3

/

3.2 37.9 65

4

3

/

2.4 23.7 40

4

3

/

1.2 11.6 20

4

2.4 3 8.4 41.4 55

1.2 3 4.0 18.9 25

UNIT

50AH

V-PH

(60 Hz)

VOLTAGE

RANGE

COMPRESSOR

Min Max QTY RLA LRA Hp FLA Hp FLA

024 208/230-1 187 254 1 N/A N/A N/A N/A N/A N/A N/A N/A

036

208/230-1 187 254

208/230-3 187 254 N/A N/A N/A N/A N/A N/A N/A N/A

1

N/A N/A N/A N/A N/A N/A N/A N/A

460-3 414 508 N/A N/A N/A N/A N/A N/A N/A N/A

048

208/230-1 187 254

208/230-3 187 254 13.6 83.1

1

19.9 109.0

460-3 414 508 6.1 41.0

060

208/230-1 187 254

208/230-3 187 254 16.0 110.0

1

26.4 134.0

460-3 414 508 7.8 52.0

072*

208/230-1 187 254

208/230-3 187 254 N/A N/A N/A N/A N/A N/A N/A N/A

2

N/A N/A N/A N/A N/A N/A N/A N/A

460-3 414 508 N/A N/A N/A N/A N/A N/A N/A N/A

096*

208/230-1 187 254

208/230-3 187 254 13.6 83.1

2

N/A N/A N/A N/A N/A N/A N/A N/A

460-3 414 508 6.1 41.0

LEGEND

HACR — Heating, Air Conditioning, and Refrigeration

Hp — Horsepower

FLA — Full Load Amps

LRA — Locked Rotor Amps

MOCP — Maximum Overcurrent Protection (HACR breaker)

RLA — Rated Load Amps

*Unit has two compressors.

MOCP

Amps

MOCP

Amps

14

Page 15

Table 2J — Electrical Data — Upgrade 1 Evaporator Motor with Upgrade 2 Condenser Motor

FAN MOTORS

Evaporator

(Upgrade 1)

Condenser

(Upgrade 2)

POWER SUPPLY

Min Ckt

Amps

UNIT

50AH

V-PH

(60 Hz)

VOLTAGE

RANGE

COMPRESSOR

Min Max QTY RLA LRA Hp FLA Hp FLA

024 208/230-1 187 254 1 N/A N/A N/A N/A N/A N/A N/A N/A

036

048

060

072*

096*

208/230-1 187 254

208/230-3 187 254 N/A N/A N/A N/A N/A N/A N/A N/A

460-3 414 508 N/A N/A N/A N/A N/A N/A N/A N/A

1

208/230-1 187 254

208/230-3 187 254 13.6 83.1

460-3 414 508 6.1 41.0

1

208/230-1 187 254

208/230-3 187 254 16.0 110.0

460-3 414 508 7.8 52.0

1

208/230-1 187 254

208/230-3 187 254 N/A N/A N/A N/A N/A N/A N/A N/A

460-3 414 508 N/A N/A N/A N/A N/A N/A N/A N/A

2

208/230-1 187 254

208/230-3 187 254 13.6 83.1 1 3.2 3 8.4 42.2 55

460-3 414 508 6.1 41.0 1 1.6 3 4.0 19.3 25

2

N/A N/A N/A N/A N/A N/A N/A N/A

19.9 109.0

26.4 134.0

1

/

1

/

1

/

1

/

1

/

1

/

2.5

2

1.8

2

0.9

2

2.5

2

1.8

2

0.9

2

3

/

3.2 30.6 50

4

3

/

2.4 21.2 35

4

3

/

1.2 9.7 15

4

3

/

3.2 38.7 65

4

3

/

2.4 24.2 40

4

3

/

1.2 11.9 20

4

N/A N/A N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A N/A N/A

Table 2K — Electrical Data — Upgrade 2 Evaporator Motor with Upgrade 2 Condenser Motor

FAN MOTORS

Evaporator

(Upgrade 2)

/

/

/

/

/

/

3.2

4

2.4

4

1.2

4

3.2

4

2.4

4

1.2

4

1

/

4.8 3 8.4 43.8 55

2

1

/

2.4 3 4.0 20.1 25

2

Condenser

(Upgrade 2)

3

/

3.2 31.3 50

4

3

/

2.4 21.8 35

4

3

/

1.2 10.0 15

4

3

/

3.2 39.4 65

4

3

/

2.4 24.8 40

4

3

/

1.2 12.2 20

4

POWER SUPPLY

Min Ckt

Amps

UNIT

50AH

V-PH

(60 Hz)

VOLTAGE

RANGE

COMPRESSOR

Min Max QTY RLA LRA Hp FLA Hp FLA

024 208/230-1 187 254 1 N/A N/A N/A N/A N/A N/A N/A N/A

036

208/230-1 187 254

208/230-3 187 254 N/A N/A N/A N/A N/A N/A N/A N/A

1

N/A N/A N/A N/A N/A N/A N/A N/A

460-3 414 508 N/A N/A N/A N/A N/A N/A N/A N/A

048

060

072*

208/230-1 187 254

208/230-3 187 254 13.6 83.1

1

19.9 109.0

460-3 414 508 6.1 41.0

208/230-1 187 254

208/230-3 187 254 16.0 110.0

1

26.4 134.0

460-3 414 508 7.8 52.0

208/230-1 187 254

208/230-3 187 254 N/A N/A N/A N/A N/A N/A N/A N/A

2

N/A N/A N/A N/A N/A N/A N/A N/A

3

3

3

3

3

3

460-3 414 508 N/A N/A N/A N/A N/A N/A N/A N/A

096*

208/230-1 187 254

208/230-3 187 254 13.6 83.1 1

2

N/A N/A N/A N/A N/A N/A N/A N/A

460-3 414 508 6.1 41.0 1

LEGEND

HACR — Heating, Air Conditioning, and Refrigeration

Hp — Horsepower

FLA — Full Load Amps

LRA — Locked Rotor Amps

MOCP — Maximum Overcurrent Protection (HACR breaker)

RLA — Rated Load Amps

*Unit has two compressors.

MOCP

Amps

MOCP

Amps

15

Page 16

Table 2L — Electrical Data — Upgrade 3 Evaporator Motor with Upgrade 2 Condenser Motor

FAN MOTORS

Evaporator

(Upgrade 3)

Condenser

(Upgrade 2)

POWER SUPPLY

Min Ckt

Amps

UNIT

50AH

V-PH

(60 Hz)

VOLTAGE

RANGE

COMPRESSOR

Min Max QTY RLA LRA Hp FLA Hp FLA

024 208/230-1 187 254 1 N/A N/A N/A N/A N/A N/A N/A N/A

036

048

060

072*

096*

208/230-1 187 254

208/230-3 187 254 N/A N/A N/A N/A N/A N/A N/A N/A

460-3 414 508 N/A N/A N/A N/A N/A N/A N/A N/A

1

208/230-1 187 254

208/230-3 187 254 13.6 83.1 1 2.4

460-3 414 508 6.1 41.0 1 1.2

1

208/230-1 187 254

208/230-3 187 254 16.0 110.0 1 2.4

460-3 414 508 7.8 52.0 1 1.2

1

208/230-1 187 254

208/230-3 187 254 N/A N/A N/A N/A N/A N/A N/A N/A

460-3 414 508 N/A N/A N/A N/A N/A N/A N/A N/A

2

208/230-1 187 254

208/230-3 187 254 13.6 83.1 2 6.0 3 8.4 45.0 55

460-3 414 508 6.1 41.0 2 2.9 3 4.0 20.6 25

2

N/A N/A N/A N/A N/A N/A N/A N/A

19.9 109.0 1 3.2

26.4 134.0 1 3.2

3

/

3.2 31.3 50

4

3

/

2.4 21.8 35

4

3

/

1.2 10.0 15

4

3

/

3.2 39.4 65

4

3

/

2.4 24.8 40

4

3

/

1.2 12.2 20

4

N/A N/A N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A N/A N/A

LEGEND

HACR — Heating, Air Conditioning, and Refrigeration

Hp — Horsepower

FLA — Full Load Amps

LRA — Locked Rotor Amps

MOCP — Maximum Overcurrent Protection (HACR breaker)

RLA — Rated Load Amps

*Unit has two compressors.

MOCP

Amps

UNIT

SIZE

50AH

CFM

RpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhp

900 509 0.11 632 0.14 739 0.19 833 0.24

024

800 495 0.07 623 0.12 733 0.17 829 0.22 915 0.28

700 470 0.06 604 0.10 717 0.14 814 0.19 901 0.25

1350 550 0.17 651 0.23 744 0.29 831 0.36

036

1200 526 0.14 635 0.19 734 0.25 825 0.31 908 0.38

1050 510 0.11 627 0.16 731 0.21 824 0.27 910 0.33 988 0.40

1800 607 0.29 685 0.36 760 0.43

048

1600 566 0.22 652 0.28 734 0.35 813 0.42

1400 537 0.17 632 0.23 722 0.29 806 0.35 886 0.42

2250 640 0.44

060

2000 588 0.32 670 0.40

1750 552 0.24 642 0.31 725 0.38

2700 461 0.36 543 0.47 619 0.60

072

2400 449 0.29 537 0.40 616 0.53 ——————

2100 435 0.24 529 0.34 611 0.47 683 0.61 ————

3600 555 0.74 618 0.87

096

3200 514 0.66 584 0.80 652 0.81

2800 448 0.37 552 0.51 626 0.64 695 0.79

LEGEND NOTES:

Bhp — Brake Horsepower

Table 3 — Evaporator-Fan Performance

EXTERNAL STATIC PRESSURE (in. wg)

0.2 0.4 0.6 0.8 1.0 1.2

919 0.30 997 0.37

993 0.34

979 0.31

912 0.43 — —

986 0.45

832 0.50 902 0.58 ——

888 0.49 960 0.56

962 0.49

715 0.52 786 0.61——————

747 0.48 819 0.56 889 0.64 — —

803 0.46 878 0.53 950 0.61

689 0.75 — — — —

680 1.01——————

707 0.94 769 1.10 — —

759 0.95 818 1.12

1. Refer to Table 1 for evaporator fan motor and drive information.

2. Upgrade 1 Static Motor is required for boldface values.

3. Upgrade 2 Static Motor is required for shaded values.

16

Page 17

Table 4 — Condenser-Fan Performance

UNIT

SIZE

50AH

024 1700 247 0.07 255 0.07 262 0.08 269 0.08 277 0.08 2840.09

036 2000 276 0.11 2820.11289 0.12 295 0.12 301 0.12 307 0.13

048 2500 251 0.17 305 0.18 357 0.22 408 0.27 456 0.32

060 3000 287 0.22 334 0.28 378 0.33 421 0.38

072 5200 367 0.68 438 0.89 464 0.98 490 1.07 516 1.16 542 1.25

096 6400 448 1.26 524 1.59 546 1.70

Bhp — Brake Horsepower

CFM

LEGEND NOTES:

0.0 0.1 0.2 0.3 0.4 0.5

RpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhp

START-UP

Unit Preparation —

accordance with installation instructions and applicable codes.

Make sure unit has been installed in

Compressor Mounting — Compressors are internally

mounted on rubber-in-shear (RIS) isolators. Do not loosen or

remove compressor holddown bolts.

EXTERNAL STATIC PRESSURE (in. wg)

568 1.81————

1. Refer to Table 1 for condenser fan motor and drive information.

2. Upgrade 1 Static Motor is required for boldface values.

3. Upgrade 2 Static Motor is required for shaded values.

Disconnect all power to the unit before performing maintenance or service. Electrical shock and personal injury could

result.

501 0.37

464 0.43 505 0.49

SERVICE

WARNING

Internal Wiring — Check all electrical connections in

unit control boxes and tighten as required.

Refrigerant Service Valves — Each unit system has

2 Schrader-type service ports, one on the suction line and one

on the compressor discharge line. Be sure that caps on the ports

are tight.

Compressor Rotation — On 50AH036-096, 3-phase

units, it is important to be certain compressor is rotating in the

proper direction. To determine whether or not compressor is

rotating in the proper direction:

1. Connect service gages to suction and discharge pressure

fittings.

2. Energize the compressor.

3. The suction pressure should drop and the discharge pressure should rise, as is normal on any start-up.

If the suction pressure does not drop and the discharge pres-

sure does not rise to normal levels:

1. Note that the condenser and evaporator fans may also be

rotating in the wrong direction.

2. Turn off power to the unit and tag disconnect.

3. Reverse any two of the unit power leads.

4. Reapply power to the unit; remove tag.

5. Verify correct refrigerant pressures.

The suction and discharge pressure levels should move to

their normal start-up levels.

NOTE: When the compressor is rotating in the wrong direc-

tion, the unit will sound louder than normal and will not

provide cooling.

Cooling — To start unit, turn on main power supply. Set

system selector switch at COOL position and fan switch at

AUTO. position. Adjust thermostat to a setting below room

temperature. Compressor, condenser and evaporator motors

start on closure of contactors.

TO SHUT OFF UNIT — Set system selector switch at OFF

position or reset thermostat at a position above room

temperature.

IMPORTANT: If repairs to refrigerant cycle components (e.g., compressor, filter drier, etc.) are required,

recover all refrigerant from the system by using both

high and low-pressure ports. Then remove base unit

from the space.

Filters —

Filters are disposable and should be inspected and

replaced at regular intervals monthly or as conditions require.

They are located in front of the evaporator coil and may be removed by sliding them horizontally out to edge of unit. See

Fig. 2-5. No tools are required for installation or removal of

filters.

Condenser Coil — The condenser coil is accessible

through the side access panel on condenser section, or through

side access panel on condenser section. Use a stiff brush when

cleaning coil. Be careful not to bend aluminum fins.

Evaporator Coil — The evaporator coil is accessible for

cleaning through the side access panel on evaporator section.

When necessary, wash coil with a commercial cleaner (Oakite

164) or dishwasher detergent using a pressurized spray canister. Flush coil from return-air duct side and take care not to get

water in ductwork or unit insulation.

Condensate Drain — Clean and empty drain pan at

least once a year to prevent sludge build-up.

Lubrication — Lubrication of the condenser and evapora-

tor motors is not necessary since both are equipped with

permanently lubricated bearings. Do not oil.

Unit Condenser Motor — All 50AH units contain

belt-driven adjustable-pulley fan systems. The unit fan motors

are shipped with adjustable pulley at 4 turns open.

Blower Wheel Servicing — In-space servicing is rec-

ommended for the evaporator and condenser blowers. Both are

removed by loosening and removing the 2 screws (sizes 024-

060) or 4 screws (sizes 072 and 096) that hold them in place. In

both cases, the entire assembly is then moved outside of the

base unit. Once outside, the blower wheel and condenser shaft

bearings and/or evaporator motor can be serviced.

17

Page 18

Blower Belt Adjustment — Inspect blower belt for

Fig. 9 — Sheave Alignment

a50-7135tf

BELT SPAN

LB FORCE

DEFLECTION

Fig. 10 — Fan Belt Tension

a50-7136ef

wear, proper belt tension, and pulley alignment as conditions

require or at the beginning of each heating and air conditioning

season.

Make sure that fan shafts and motor shafts are parallel and

level. The most common causes of misalignment are nonparallel shafts and improperly located sheaves. Where shafts are not

parallel, belts on one side are drawn tighter and pull more than

their share of the load. As a result, these belts wear out faster,

requiring the entire set to be replaced before it has given maximum service. If misalignment is in the sheave, belts enter and

leave the grooves at an angle, causing excessive belt and

sheave wear.

SHAFT ALIGNMENT — Check shaft alignment by measuring the distance between the shafts at 3 or more locations. If the

distances are equal, then the shafts are parallel.

SHEAVE ALIGNMENT

1. To check the location of the fixed sheaves on the shafts,

use a straightedge or a piece of string. If the sheaves are

properly aligned, the string will touch them at the points

indicated by the arrows in Fig. 9. Rotate each sheave a

half revolution to determine whether the sheave is wobbly or the drive shaft is bent. Correct any misalignment.

2. With sheaves aligned, tighten cap screws evenly and

progressively.

NOTE: There should be a

the mating part hub and the bushing flange. If the gap is

closed, the bushing is probably the wrong size.

3. With taper-lock bushed hubs, be sure the bushing bolts

are tightened evenly to prevent side-to-side pulley wobble. Check by rotating sheaves and rechecking sheave

alignment. When substituting field-supplied sheaves for

factory-supplied sheaves, only the motor sheave should

be changed.

BELT TENSION ADJUSTMENT — Using a gage, apply

4 lb of force to the center of the belt and adjust the tension until

a deflection of

1

/64-in. is achieved for every inch of shaft center

distance. See Fig. 10.

Ideal belt tension is the lowest value under which belt slip

will not occur at peak load conditions.

1

/8-in. to 1/4-in. gap between

Refrigerant Charge — Unit is shipped fully charged.

Amount of refrigerant charge is listed on unit nameplate (also

refer to Table 1). Refer to Carrier GTAC II; Module 5; Charging, Recovery, Recycling, and Reclamation manual.

Unit panels must be in place when unit is operating during

charging procedure. Unit must operate for at least 10 minutes

before adjusting charge. Use standard evacuating techniques.

After evacuating system, weigh in the specified amount of refrigerant. (Refer to Table 1.)

18

Page 19

Page 20

Copyright 2010 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53500057-01 Printed in U.S.A. Form 50AH-14SI Pg 20 5-10 Replaces: 50AH-12SI

Loading...

Loading...