Carrier 50AH024-060 User Manual

HEATING & COOLING

, ^pAH024-060

Ì-ÌOnzCintal Indoor Single-Package Cooling Units

Installation, Start-Up and Service Instructions

SAFETY CONSIDERATIONS

Installing and servicing air conditioning equipment

can be hazardous due to system pressure and electrical

components. Only trained and qualified service personnel

should install, repair or service air conditioning

equipment.

Untrained personnel can perform basic maintenance

functions such as cleaning coils and filters and replacing

filters. All other operations should be performed by

trained service personnel. When working on air condi

tioning equipment, observe precautions in the literature

and on tags and labels attached to unit.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations.

Have fire extinguisher available.

A WARNING

Before performing service or maintenance opera

tions on unit, turn off main power switch to unit.

Electrical shock can cause personal injury.

INTRODUCTION

The 50AH024,036,048 and 060 units are single

package, indoor ceiling-mounted air conditioners of 2, 3,

4 and 5 tons capacity respectively.

These units can be mounted as factory-shipped single

package units or can be separated and mounted as a

split system. If unit is split, the condenser section can be

mounted horizontally.

All units are designed to be ducted on both the con

denser and evaporator sides. Centrifugal blowers are

used to insure quiet air delivery in the conditioned space.

Sound level requirements should be determined before

final unit installation site is chosen.

Unit servicing is relatively simple as access to the

condenser and evaporator motors, blowers, belt and

pulley is gained through removable swing doors located

on bottom of unit. These doors may also be used for

cleaning of condenser coils. Unit side panels provicfe

access to control box and pressure switches.

Refrigeration cycle components (e.g., compressor,

filter drier, etc.) can be serviced upon removal of the base

unit from the space.

INSTALLATION

A WARNING

Determine building alterations required to run

piping, wiring and ductwork. Follow dimensional

drawings carefully for ductwork, piping locations,

electrical wiring and overall unit dimensions. Read

booklet before starting installation.

Step 1 — Receive and Inspect Unit — Unpack

and check unit against shipping order. Inspect carefully

for concealed shipping damage. If unit is damaged or

incomplete, file claim with transportation company and

advise Carrier immediately.

Step 2 — Protect Unit from Damage — To main

tain warranty, unit must be protected against theft and

vandalism and stored indoors at all times.

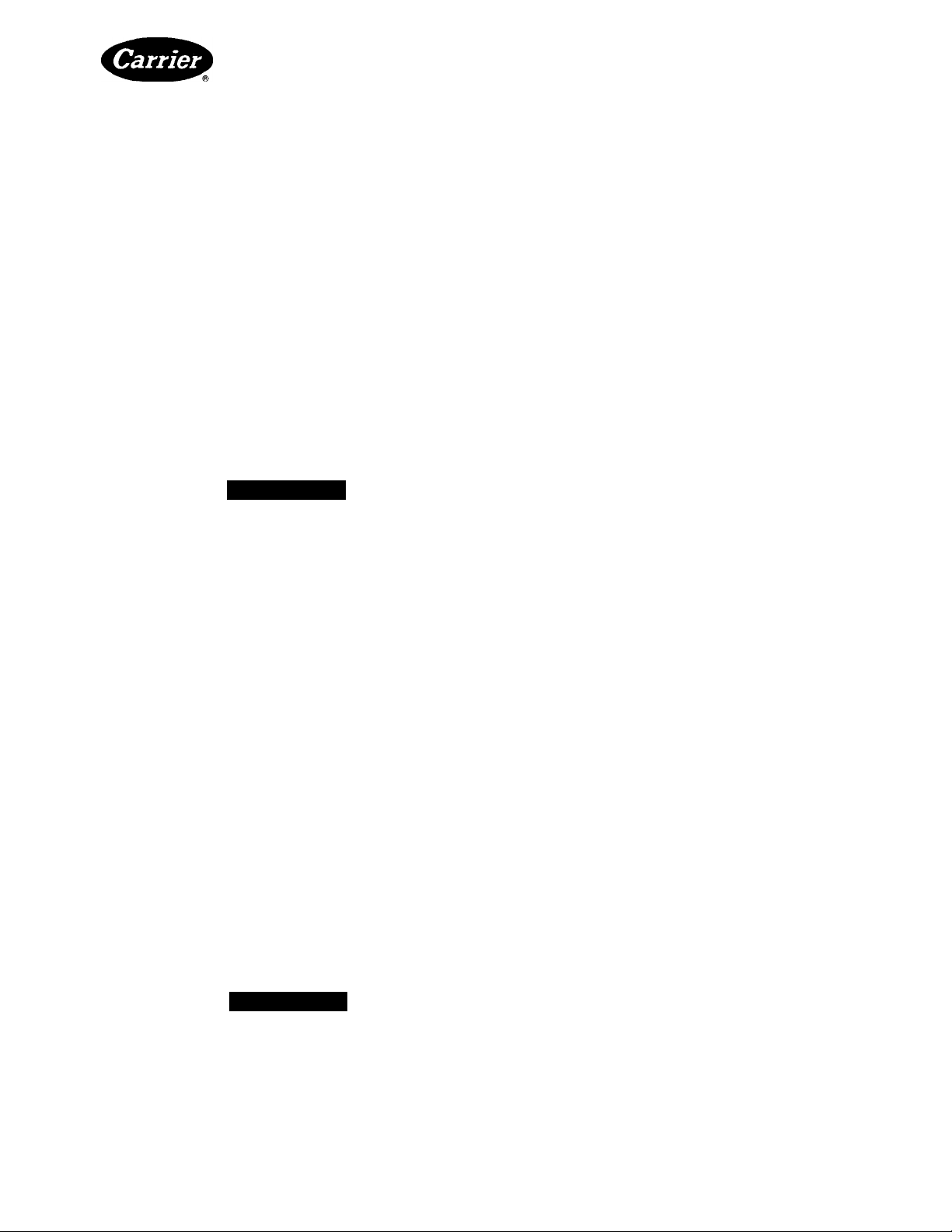

Step 3 — Provide Unit Support — Refer to Fig. 1

and 2 for unit dimensions and component locations.

Refer to Table 1 — Physical Data for unit sizes and

weights.

Each unit requires the following:

• 4 threaded suspension rods (3/8-in. - 16 SAE Grade 1

minimum)

• washers and locknuts

Install the 4 field-supplied rods by suspending from a

suitable ceiling support. Locate rods to mate with 4

outside corner rigging holes shown in Fig. 1.

The ceiling and ceiling supports of existing buildings

may require reinforcements; follow all applicable codes.

Step 4 — Rig and Place Unit — Move and store

unit in horizontal position. Provide space around unit for

service, filter access, ductwork and overhead clearance

as indicated in Fig. 1.

Using suitable hydraulic lift source, raise unit up to

meet bottom of the 4 threaded rods suspended from

ceiling. Center unit so that the 4 threaded rods can be

easily inserted into the factory-drilled holes at each end.

Refer to Fig. 3 for rigging details.

Apply washers and locknuts on ends of each of the

4 rods.

Tighten locknuts sufficiently so that unit weight is

supported entirely by the 4 rods. Level unit within the

space by adjusting locknuts.

IMPORTANT: Unit must be level to operate

properly.

NOTE: The 2 factory-drilled holes in the middle of unit

can be used for support if a split system application is

desired. If required, an accessory vibration isolator pack

age is available for use to dampen vibration that may be

transmitted to building structure.

Step 5 — Make Piping Connections — Two

3/4-m. pipe thread condensate drain connections are pro

vided below the evaporator coil. One 3/4-in. pipe thread

connection is provided for condenser coil washdown.

One of the evaporator drains is plugged at factory and

plug must be removed when making field connections.

The condenser washdown pan is plugged at factory. This

drain is to be used only when condenser coil is being

cleaned and plug must be replaced when cleaning is

completed.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|1 |4 PC111 Catalog No 565-040 PrintedinUSA Form60AH-2SI . Pg1 6-87 Replaces: 50AH-1SI

Tab l2a|7b

For replacement items use Carrier Specified Parts

r-5 MIN FOR

REMOVAL OF

PANEL

BOTTOM ACCESS'

PANEL (COND FAN

MOTOR a

BLOWER, COND

COIL WASHDOWN)

CONDENSER COIL

WASHDOWN DRAIN 5

DIMENSIONS (ft-in.)

UNIT

50AH

024

2-5

2-4%

036

048 2-5

2-4%

060

A

2-1% 1- 4%

2-2% 1-11%

FPT

C D E

B

2-2 1- 4% 1-2 1-1

1-11% 1-8% 1-7%

2-3

1-2 1-1

1-8% 1-7%

CORNER D

4'-o"

o

CORNER C

0'-4"-

TgDIA (TYP 8 PLACES)

RIGGING HOLES

I I

I I

I I

I I

1

> \

1

_ _ _

1

°

-2-4"-

COND SECT.

ACCESS PANEL

I "DIA HOLE FIELD

CONTROL WIRING

Fig. 1 — Dimensions

CONTROL BOX

FIELD POWER SUPPLY

JUNCTION BOX

0'-5"

r - i -

1

i r -

i i i

1 1 1

" " i

_ _ _ _

j i

/-~>COMPR !

{ '

1- —,

1

2- 1

o r~j--1

CONTROLS

coMPR a

ACCESS

PANEL

--

CORNERA

^EVAP

r 'COIL

■CORNER B

—0'-4"

EVAP COIL

ACCESS PANEL

FILTER

CONDENSATE DRAINS (2)

0'-3"MIN FOR P-TRAP

r-5" MIN FOR REMOVAL

\

___

, OF PANEL

BOTTOM ACCESS

PANEL(EVAR

■FAN MOTOR a

BLOWER, EVAR

COIL a

CONDENSATE

PAN)

FPT

- Center of Gravity

- Direction of Airflow

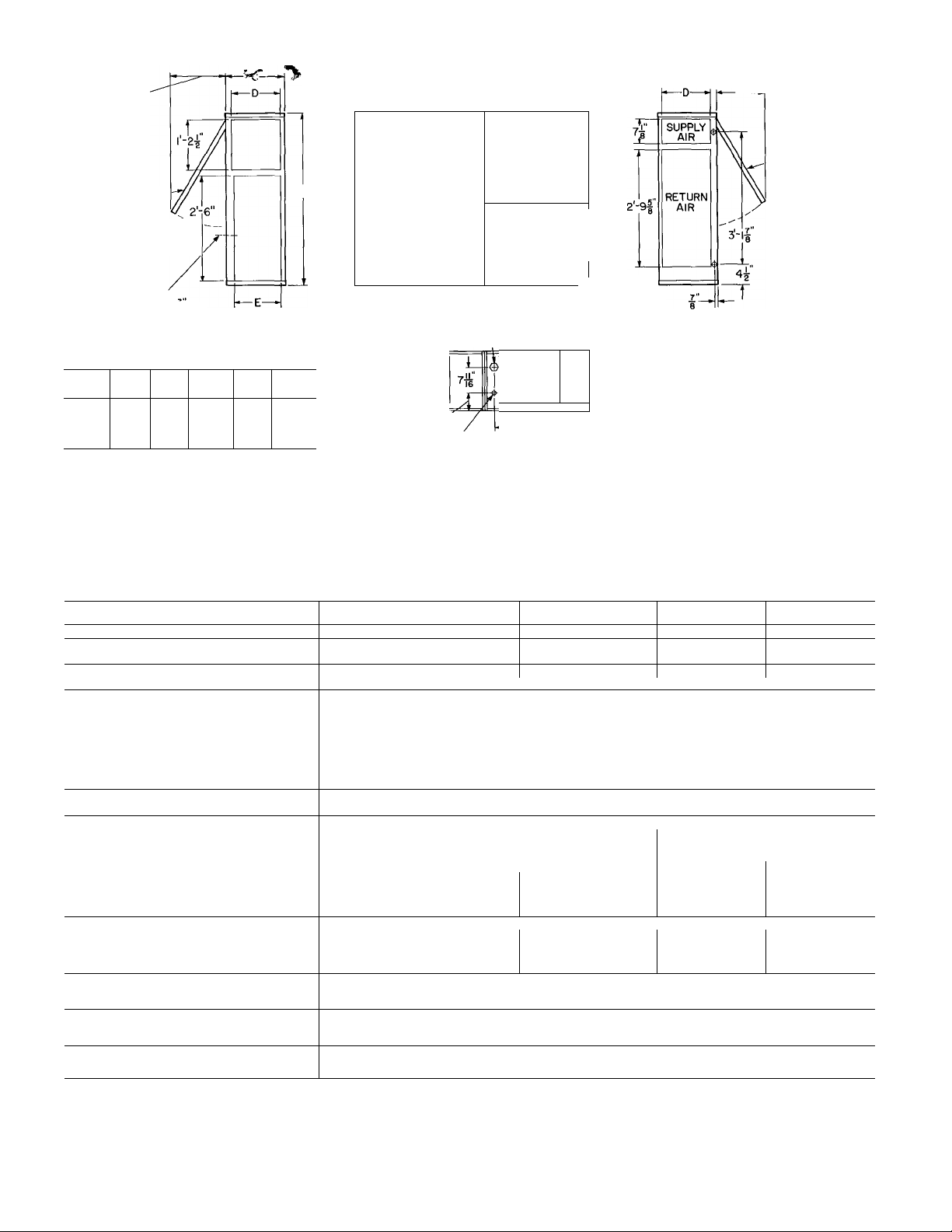

Table 1 — Physical Data

UNIT 50AH

SHIPPING WEIGHT (lbs) (Note 1) 600

OPERATING WEIGHT (lbs)

Base Unit

OPERATING CHARGE (lbs) (Note 2) 56

Refrigerant

COMPRESSOR — TYPE Hermetic

Quantlty...Model

Oil (oz)

HPS Setting (psig)

Cutout

Reset

LPS Setting (psig)

Cutout

Reset

CONDENSATE CONNECTION

Condensate Drain %...FPT

CONDENSER FAN

Nominal Cfm

Maximum Rpm

Blower Size On.)

Pulley Pitch Diameter (in.)

Blower None

Motor (Variable)

Motor Hp

Motor Rpm

EVAPORATOR FAN Centrifugal — Direct-Drive

Nominal Cfm

Maximum Rpm

Blower Size (in.)

Motor Hp

CONDENSER COIL Copper Tubes — Aluminum Fins

Size (L X H) (in.)

Number of Rows...Fins/in.

EVAPORATOR COIL

Size (L X H) (in.)

Number of Rows...Fins/in.

INDOOR AIR FILTERS

Number...Size (in.)

Centrifugal — Direct-Drive Centrifugal — Belt Drive

024 036 048

480 500 580

(1) AB5524H (1). AV5535H* (1).. P46

32 32 76

1350

1100

12 X 6

None 2 4-3 4

%

825 1725

800

1100

10 X 5 10 X 6

Vs

40 X 15 40 X 22

Copper Tubes — Aluminum Fins

34 X 15

Factory-Supplied Cleanable Type

620 700

5.5 80

R-22

426 ± 7

320 ± 20

27 ± 4

67 ± 7

Size (in.)...Type

60 60

% 1 0

1200

1150

Vi

4...13.6

4...14.4

(1) .1

060

710

590

76

(1)...P60

76

2250 2450

1 9-2 9 2 4-3 4

1725 1725

1600 2000

1050

10 X 8 10 X 8

1500

12 X 9

60

1 5

1050

%

34 X 22

%

CFM — Cubic Feet per Minute

FPT — Female Pipe Thread

PSIG — Pounds per Square Inch Gage

RPM — Revolutions per Minute

'Three-phase units use (1) AV5535E compressor

NOTES:

1 Shipping weights include base unit plus packaging

2. If components are to be split, additional refrigerant will be needed Refer to charging

charts found on page 5 and 6

3 If components are to be split, the maximum length of refrigerant tubing to be used is

75 ft, assuming components will be installed in same horizontal plane If components

are not to be installed in same horizonal plane, contact Carrier, Syracuse for more

information For additional piping information, refer to Carrier System Design Manual,

Part 3

Loading...

Loading...