Page 1

Product

Data

50AH

Horizontal Indoor

Single-Package

Cooling Units

2to5NominalTons

Single Package Cooling Units

Featuring:

• compact design

• flexibility

• easy maintenance

• high quality and reliability

• quiet and efficient scroll compressor

technology

Features/Benefits

All in one package — high

cooling efficiency,

installation convenience,

ease of accessibility for timesaving maintenance.

Space and cost saving design

Model 50AH is specifically designed to

provide the building owner with truly outof-sight cooling, because it installs inside

the ceiling. That’s why we call it the Carrier ROOMTOP® unit. The compact design and low silhouette enable it to fit

easily and securely above the conditioned

space. Single-package construction

makes it easy to install with minimal time

and cost.

Application flexibility

If desired for particular applications, the

unit can also be installed as a split system

with the condenser section mounted horizontally. Centrifugal fans permit ducting

of both evaporator and condenser air.

Quiet operation

Commercial end users appreciate the extra comfort of quiet operation. Carrier

engineers met the challenge by specifying heavy insulation, vibration-resistant

construction and operating components

that function at low noise levels, all of

which keep system sound at a minimum

level.

Easy maintenance

When it comes to maintenance, the

50AH rates high in accessibility. Indoor

Copyright 2002 Carrier Corporation Form 50AH-6PD

Page 2

location is ideal for the maintenance

technician, and five access panels, easily

removed, provide quick and convenient

access to all components when needed.

As an added plus, all required service/

maintenance access can be from one

side allowing the unit to be located

against a wall or ceiling plenum obstruction, an obvious space-saving idea.

Carrier quality and reliability

The Carrier 50AH ROOMTOP® units

have much to offer the cost- and

efficiency-conscious commercial owner.

Every unit is thoroughly run tested at the

factory and equipped with safety controls

designed to monitor and protect over the

life of the unit.

Table of contents

Page

Features/Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,2

Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ARI Capacity Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Field-Installed Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

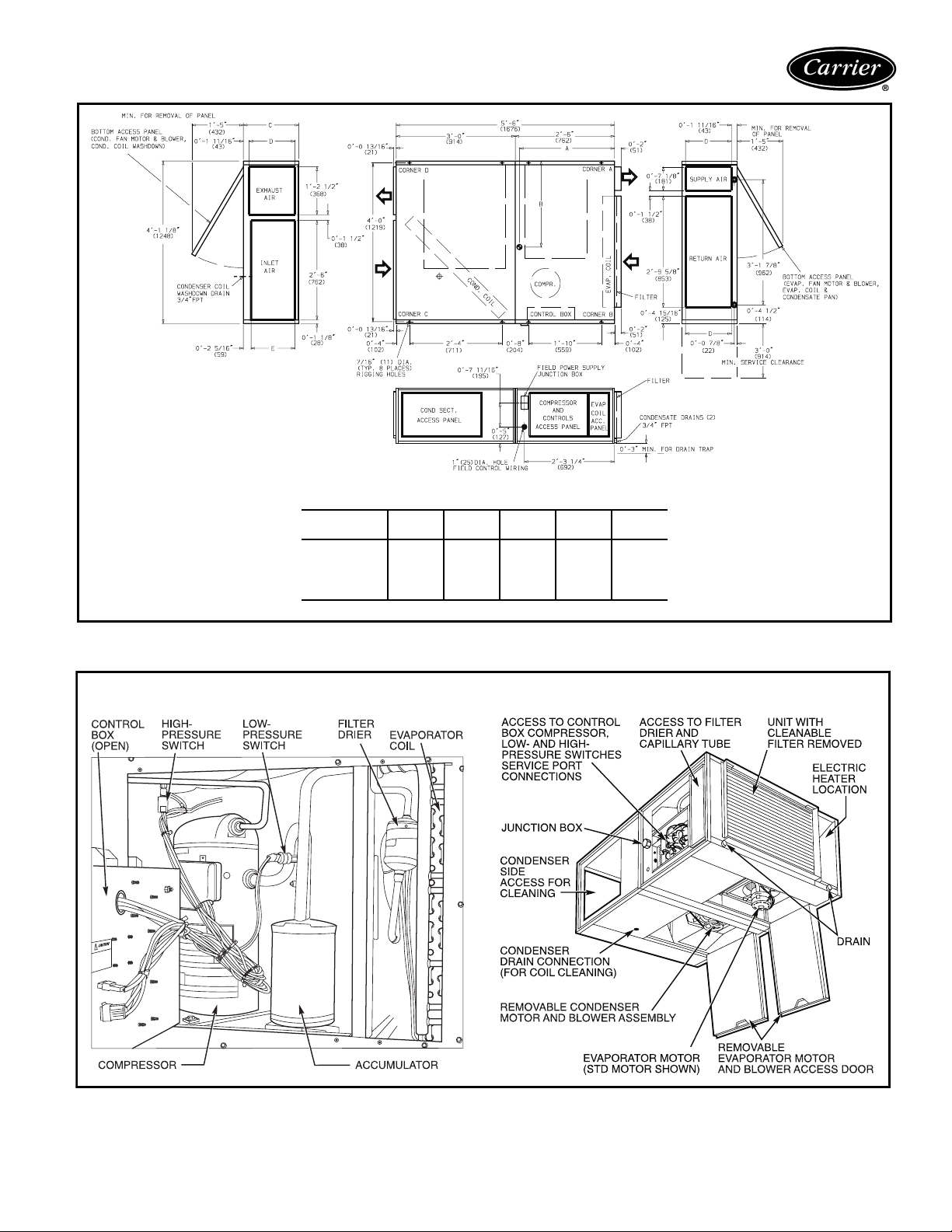

Base Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9,10

Typical Wiring Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11,12

Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14,15

Scroll compressor technology

Scroll compressors are designed for high

efficiency and are internally spring

mounted to minimize vibration noise.

Each compressor is hermetically sealed

against contamination to promote longer

life and dependable operation. Scroll

compressors are standard on all units.

Quality Assurance

®

I

S

O

9

0

0

1

:

2

5

2

3

2

A

#

0

0

0

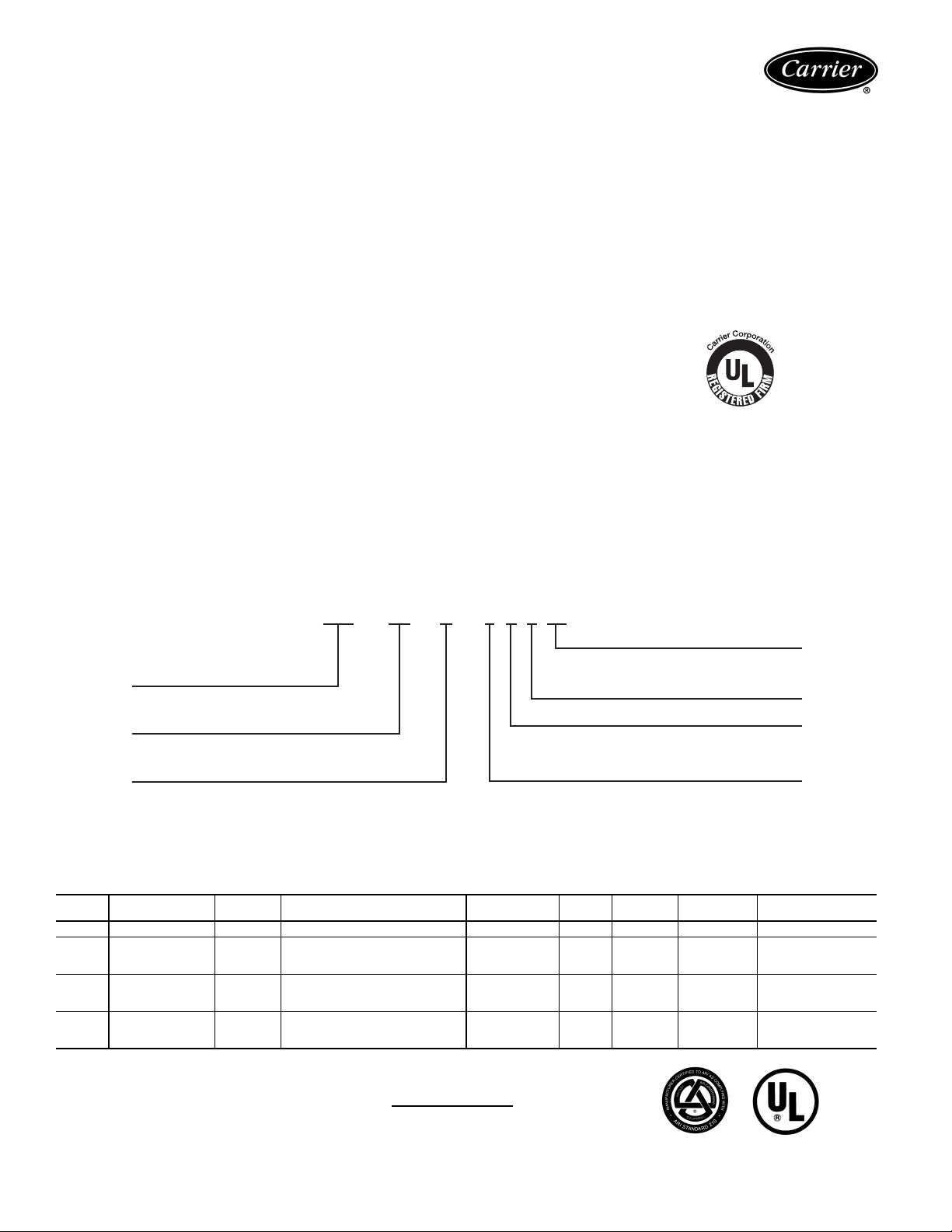

Model number nomenclature

50AH–048–M–541XX

Model Designation –

50AH Horizontal,

Indoor Single-Package

Cooling Unit

Nominal Tons

024 – 2

036 – 3

Indoor Fan Motor

– – Standard Motor

M – 1.5 hp Optional Motor

*FIOP — Factory-Installed option, contact your Carrier representative for details.

048–4

060–5

FIOP*

Packaging

1 – Domestic

2 – Export

Design Revision

Voltage

3 – 230-1-60

5 – 208/230-3-60

6 – 460-3-60

ARI* capacity ratings

UNIT

50AH

024 230-1-60 2.56 24,800 800 — — 10.50† 78

036

048

060

dB — Decibels

EER — Energy Efficiency Ratio

SEER — Seasonal Energy Efficiency Ratio

TDR — Time-Delay Relay 2. EER =

*Air-conditioning and Refrigeration Institute.

†TDR is standard.

V-P H- Hz

230-1-60

460-3-60 8.40 — —

230-1-60

460-3-60 8.80 — —

230-1-60

460-3-60 8.50 — —

LEGEND

TOTAL

kW

4.3 36,000 1200

5.63 49,500 1600

6.9 58,500 2000

NET TOTAL

COOLING CAP. (Btuh)

NOTES:

1. Ratings are at zero condenser air static and rated in

accordance with ARI Standard 210.

NET CAPACITY (Btuh)

TOTAL WATTS

NOMINAL

CFM

EER SEER

— 10.00 10.00

—— 10.00†

—9.7010.00

SEER

(with TDR)

SOUND RATING

(dB)

82208/230-3-60 8.40 — —

82208/230-3-60 8.80 — —

82208/230-3-60 8.50 — —

2

Page 3

Physical data

UNIT 50AH 024 036 048 060

SHIPPING WEIGHT (lb)* 560 590 690 700

OPERATING WEIGHT (lb)

Base Unit, Evaporator/Condenser Section 450, 193/256 480, 206/274 580, 250/330 590, 254/336

REFRIGERANT TYPE R-22

Operating Charge (lb)† 5.4 5.5 7.4 7.6

COMPRESSOR — TYPE Scroll

Quantity...Model (1)...ZR23 (1)...ZR34 (1)...SR48 (1)...ZR57

Oil (oz) 24 42 70 54

HPS Setting (psig)

Cutout 426 ± 7

Reset 320 ± 20

LPS Setting (psig)

Cutout 27 ± 4

Reset 67 ± 7

CONDENSATE DRAIN CONNECTION

Size (in.)...Type

CONDENSER COIL Copper Tubes — Aluminum Fins

Size (L x H) (in.) 40 x 15 40 x 16 40 x 22

Number of Rows...Fins/in. 4...13.6 4...17 4...13.6

CONDENSER FAN Centrifugal — Direct Drive Centrifugal — Belt Drive

Nominal Cfm 1350 1350 2250 2450

Maximum Rpm 1100 1500

Blower Size (in.) 12 x 6 12 x 9

Pulley Pitch Diameter (in.)

Blower None 5.0 6.0 6.0

Motor (Variable) None 2.4-3.4 1.9-2.9 2.4-3.4

Motor Hp

Motor Rpm 825 1725 1725 1725

EVAPORATOR COIL Copper Tubes — Aluminum Fins

Size (L x H) (in.) 34 x 15 34 x 16 34 x 22

Number of Rows...Fins/in. 4...14.4 4...15 4...14.4

EVAPORATOR AIR FAN (Standard) Centrifugal — Direct Drive

Nominal Cfm 800 1200 1600 2000

Max Rpm 1100 1150 900/1050**

Blower Size (in.) 10 x 5 10 x 6 10 x 6

Motor Hp (Rpm)

EVAPORATOR AIR FAN (Optional)

Nominal Cfm 1600 2000

Max Rpm 1300

Blower Size (in.) 10 x 8

Motor Hp 1

Motor Rpm 1725

Pulley Pitch Diameter (in.)

Blower 4.2

Motor (Variable) 2.4-3.4

INDOOR-AIR FILTERS Factory-Supplied Cleanable Type

Number...Size (in.) 1...14 x 34 x 1 1...21 x 34 x 1

INTERCONNECTING TUBING SIZE (in.)††

Hot Gas

Liquid

HPS — High-Pressure Switch

LPS — Low-Pressure Switch

*Shipping weights include base unit plus packaging.

†If components are to be split, additional refrigerant will be needed.

**Two-speed motor.

††Use Type L copper only.

LEGEND

1

1

/6(850)

1

3

/

2

Not

Available

/

2

/

8

3

/

4

1

/2(1075)

1

/

2

3

/

8

NOTE: If components are to be split, the maximum length of refrigerant tubing to be

used is 50 equivalent ft, assuming components will be installed in same horizontal plane.

If components are not to be installed in same hor izontal plane, contact your Carrier representative for more information. For additional piping information, refer to Carrier

System Design Manual, Part 3.

3

/4...FPT

11

3

/4(1050)

Centrifugal Belt Drive

1

/

2

1

/

2

3

/

8

1

/

2

1

/

2

3

/

8

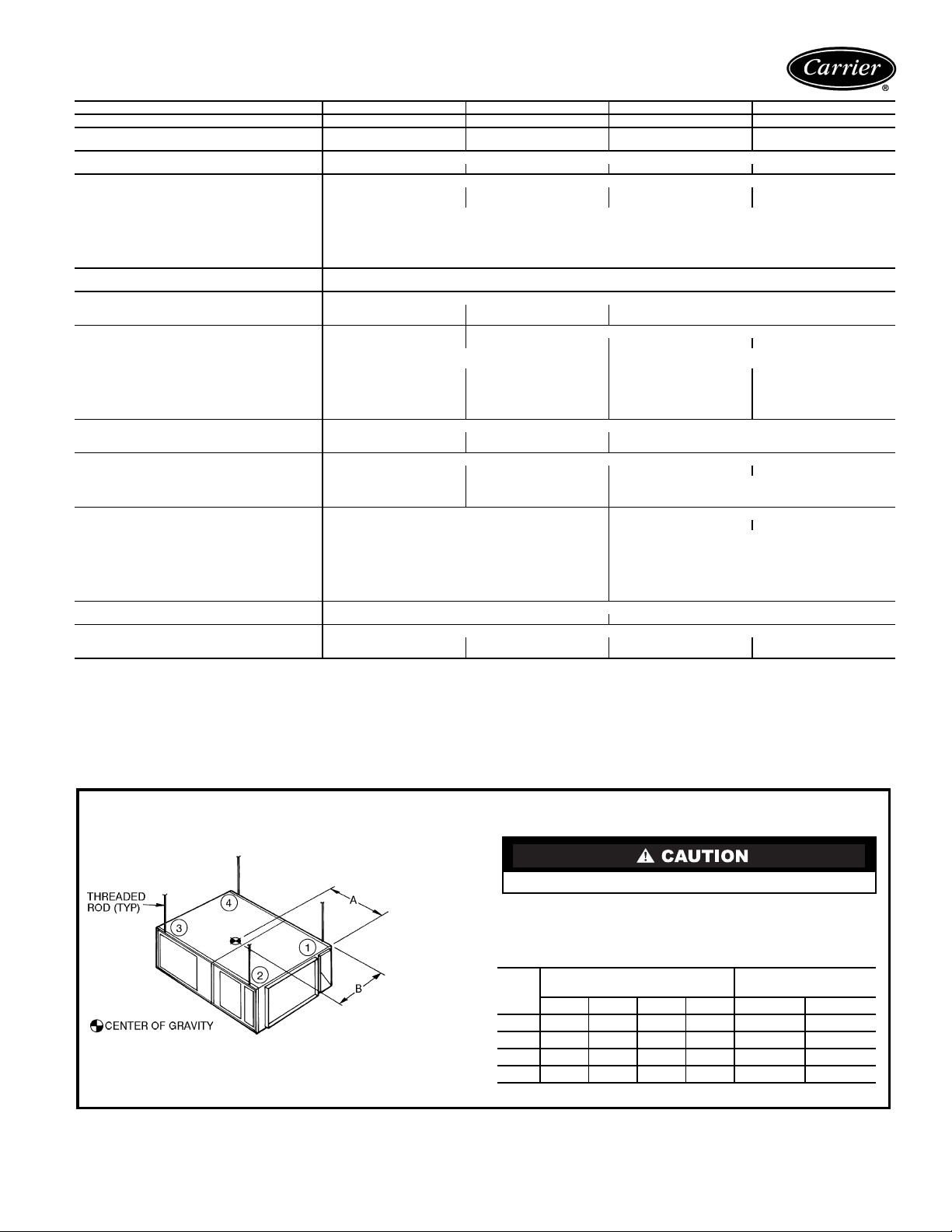

NOTE: Fasten threaded rods through holes in end frames. Use 2 rods

on each side of unit for a total of 4.

All panels must be in place when rigging.

OPERATING WEIGHT DISTRIBUTION AND

CENTER OF GRAVITY

UNIT

50AH

WEIGHT (lb/kg)

OF CORNER

1 234 A B

024 93/42 108/49 139/63 120/54 2-5 /737 2-1

036 95/43 113/51 148/67 124/56 2-4

048 112/51 143/65 183/83 142/64 2-5 /737 2-3 /686

060 114/52 143/65 186/84 147/67 2-4

DIMENSIONS

(ft-in./mm)

5

3

/4/730 2-2 /660

3

/4/730 2-23/4/679

/8/651

3

Page 4

Field-installed accessories

Thermostat and subbase — Attractive wall-mounted

24-v accessory provides precise temperature control.

Automatic and Manual changeover models available. A

thermostat subbase is available that works with CycleLOC™ circuitry. If a safety device trips, compressor locks

out and subbase warning light (LK OUT) alerts occupant.

Three models available: One stage cool/two stage heat;

two stage cool/two stage heat; one stage cool/one stage

heat.

Time Guard® II circuit (standard on single-phase

units) — Time Guard II device prevents short cycling of

compressor if thermostat is rapidly changed; automatically

prevents compressor from restarting for 5 minutes after

shutdown.

Electric heaters — A wide range of models is available

from 5 to 30 kW, 208-, 240- and 480-v, single- and 3-ph

units. The heaters mount easily on 50AH discharge opening. The heater control box is accessible from the bottom

of heater.

Condensate pump — The condensate pump is used

when the distance and slope to the nearest drain is far

enough to prevent the natural drainage of unit. The pump

is mounted remotely from the unit and includes a signal

light (field-installed) which illuminates when the reservoir

rises beyond a certain level. The unit automatically shuts

down when this reservoir level is achieved.

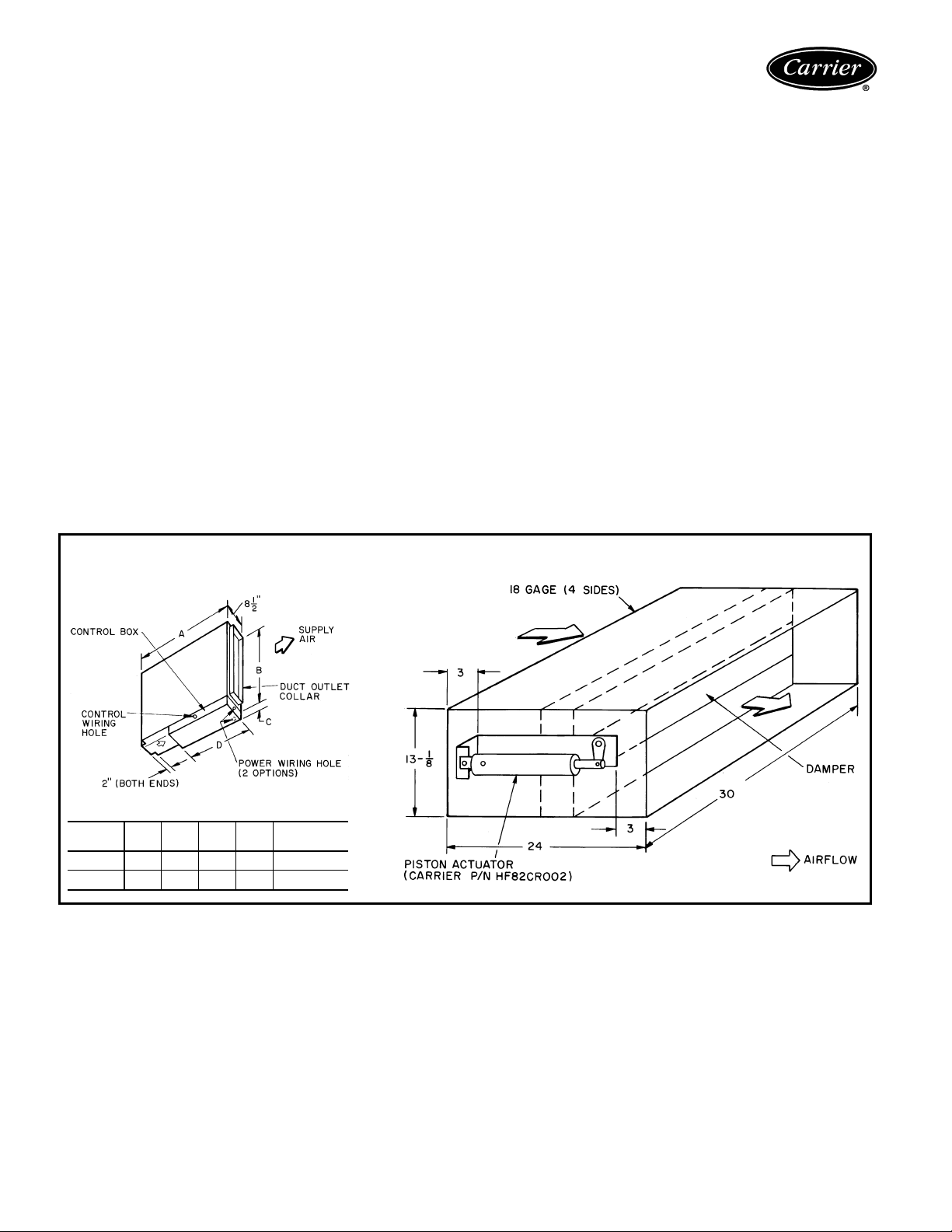

Head pressure control damper — This accessory is

duct mounted and allows unit to mechanically cool down to

0° F.

Damper dimensions fit 024, 036 sizes.

NOTE: For use with 048 and 060 size units, ductwork

from unit to damper must be reduced in size to fit damper

dimensions.

Vibration isolators — Package of four isolators used for

dampening any unit vibration so that vibrating sounds are

not transmitted to building structure. Isolators are spring,

ceiling type.

88EN ELECTRIC HEAT MODULE

UNIT

50AH

024,036 13

048,060 24 21

ACCESSORY

DIMENSIONS (in.)

ABCD

1

/216 21/281/271/8x14

3

/431971/8x207/

HEAD PRESSURE CONTROL DAMPER (in.)

DUCT

OPENING

8

4

Page 5

Base unit dimensions

DIMENSIONS (ft-in.)

UNIT

50AH

024 2-5 2-1

036

048

060

ABCDE

5

3

/42-2 1- 53/41-2 1-1

2-4

2-5 2-3 1-11

3

2-4

/42-23/41-115/81-87/81-77/

/81- 53/41-2 1-1

UNIT COMPONENT LOCATIONS

5

/81-87/81-77/

8

8

5

Page 6

Selection procedure (with example)

I Determine cooling requirements at design

conditions.

Given:

Gross Cooling Capacity

Required (TC) . . . . . . . . . . . . . . . . . .39,000 Btuh

Sensible Heat Capacity (SHC) . . . . . .30,500 Btuh

Temperature of Air Entering Condenser . . . . .95 F

Temperature of Air Entering

Evaporator . . . . . . . . . . . . . . . 80 F edb/67 F ewb

Evaporator Air Quantity. . . . . . . . . . . . 1,200 cfm

External Static Pressure:

Condenser . . . . . . . . . . . . . . . . . . .0.50 in. wg

Evaporator (includes static pressure

drop of factory-supplied filter

of 0.06 in. wg) . . . . . . . . . . . . . . .0.20 in. wg

II Select unit based upon required cooling

capacity.

Enter cooling capacity table at temperature of air

entering condenser of 95 F. The 50AH036 unit at

1200 cfm and 67 F ewb will provide a Total

Capacity (TC) of 44,200 Btuh and a Sensible Heat

Capacity (SHC) of 31,300 Btuh. Since the entering

air is 80 F edb, an SHC correction is not required.

III Determine evaporator fan performance.

Enter Evaporator Fan Performance table at

1200 cfm and 50AH036 data. The external static

pressure shown (0.23 in. wg) will exceed the

0.20 in. wg required. The fan motor will require

0.52 kW.

IV Determine condenser fan performance and

motor pulley setting requirements.

Enter Condenser Fan Performance table at

the selected cfm and required static pressure of

0.50 in. wg. The fan motor will require 0.73 kW

and the motor pulley should be set at 2 turns open

at 1350 cfm of condenser air required.

NOTE: Unit 50AH024 contains a direct-drive condenser fan assembly.

Performance data

50AH024

Temp

Air Ent

Condenser

(F)

85

95

105

115

See Legend on page 7.

7267 62 7267 62 7267 62

TC 27.1 25.3 23.0 27.7 26.4 24.6 27.8 26.9 25.8

SHC 13.5 17.0 20.2 14.7 19.4 23.7 15.6 21.5 25.8

kW 1.64 1.62 1.61 1.65 1.63 1.62 1.65 1.64 1.63

TC 26.6 24.5 20.8 27.4 25.8 22.9 28.0 26.5 25.2

SHC 13.4 16.7 19.1 14.7 19.4 22.8 16.0 21.7 25.2

kW 1.85 1.84 1.80 1.86 1.85 1.82 1.87 1.85 1.84

TC 25.8 22.3 18.4 27.1 24.5 21.2 27.7 25.6 23.6

SHC 13.1 15.8 17.9 14.7 18.9 21.2 16.2 21.5 23.6

kW 2.09 2.05 1.99 2.11 2.08 2.04 2.12 2.10 2.07

TC 24.6 19.9 16.5 26.1 22.0 19.8 26.8 23.6 22.3

SHC 12.7 14.8 16.5 14.4 17.9 19.8 16.0 20.7 22.3

kW 2.36 2.29 2.22 2.39 2.33 2.29 2.39 2.35 2.33

Evaporator Air Quantity — Cfm/BF

600/0.02 800/0.03 1000/0.04

Evaporator Air Ewb Temp (F)

GROSS COOLING CAPACITIES

50AH036

Temp

Air Ent

Condenser

(F)

TC 45.0 41.1 37.3 45.8 42.3 38.6 46.5 43.4 39.8

85

SHC 22.5 27.7 32.6 23.6 29.9 35.6 24.6 32.0 38.3

kW 3.19 3.07 2.96 3.22 3.11 3.00 3.25 3.14 3.04

TC 43.0 38.8 34.3 44.1 40.1 35.8 45.0 44.2 37.4

95

SHC 21.8 26.8 31.1 23.1 29.1 34.1 24.4 31.3 36.8

kW 3.42 3.28 3.15 3.46 3.33 3.20 3.49 3.37 3.25

TC 40.4 35.8 29.6 41.6 37.1 31.3 42.6 38.2 33.2

105

SHC 20.9 25.6 28.5 22.3 27.9 30.8 23.7 30.2 33.2

kW 3.63 3.48 3.38 3.68 3.53 3.44 3.73 3.58 3.49

TC 37.7 30.6 25.8 38.7 31.6 37.8 39.7 32.8 29.7

115

SHC 19.9 23.3 25.8 21.3 25.5 27.8 22.7 27.8 29.7

kW 3.85 3.71 3.59 3.90 3.76 3.67 3.94 3.80 3.73

Evaporator Air Quantity — Cfm/BF

900/0.011050/0.011200/0.02

Evaporator Air Ewb Temp (F)

7267 62 7267 62 7267 62

6

Page 7

Performance data (cont)

GROSS COOLING CAPACITIES (cont)

50AH048

Tem p

Air Ent

Condenser

(F)

TC 56.0 52.1 47.9 44.4 57.7 54.5 50.6 49.6 59.4 56.0 52.7 52.3

85

SHC 27.8 34.8 41.6 44.4 30.2 39.6 48.0 49.6 32.8 43.9 52.5 52.3

kW 3.77 3.68 3.59 3.53 3.81 3.74 3.66 3.64 3.85 3.77 3.70 3.69

TC 54.0 50.1 45.7 42.4 55.7 52.3 48.6 47.3 57.4 53.8 51.0 50.9

95

SHC 27.1 34.0 40.4 42.4 29.6 38.8 47.0 47.3 32.4 43.2 50.9 50.9

kW 4.21 4.11 4.01 3.95 4.25 4.18 4.09 4.07 4.31 4.21 4.15 4.15

TC 51.8 47.9 42.3 40.2 53.6 50.0 45.1 45.0 54.6 51.4 48.9 48.6

105

SHC 26.3 33.1 38.8 40.2 29.0 38.0 44.8 45.0 31.3 42.4 48.9 48.6

kW 4.69 4.58 4.45 4.40 4.75 4.65 4.54 4.53 4.77 4.69 4.63 4.63

TC 49.5 45.5 38.6 37.7 51.2 47.6 41.9 42.1 52.2 49.1 45.8 45.8

115

SHC 25.5 32.2 37.0 37.7 28.3 27.3 41.8 42.1 30.7 42.0 45.8 45.8

kW 5.21 5.09 4.92 4.89 5.27 5.17 5.03 5.03 5.30 5.23 5.14 5.14

BF — Bypass Factor

Ewb — Entering Wet-Bulb

kW — Compressor Motor Power Input (kilowatts)

SHC — Gross Sensible Heat Capacity (1000 Btuh)

TC — Gross Total Cooling Capacity (1000 Btuh)

NOTES:

1. Performance based on nominal condenser airflow listed in physical data table

on page 3.

2. SHC is based on 80 F db temperature of air entering the coil.

Below 80 F db, subtract (corr factor x cfm) from SHC.

Above 80 F db, add (corr factor x cfm) to SHC.

BYPA SS

FAC TOR

(BF)

.025 1.07 2.12 3.19 4.25 5.32

.05 1.04 2.07 3.11 4.14 5.18

.10 .98 1.96 2.94 3.92 4.90

.20 .87 1.74 2.62 3.49 4.36

.30 .76 1.53 2.29 3.05 3.82

.35 .71 1.42 2.13 2.83 3.54

Correction Factor = 1.10 x (1 – BF) x db – 80)

1200/0.06 1600/0.08 2000/0.10

7267 62 577267 62 577267 62 57

Evaporator Air Quantity Cfm/BF

Evaporator Air Ewb Temp (F)

LEGEND

ENTERING AIR DRY-BULB TEMPERATURE (F)

79 78 77 76 75Under75

81 82 83 84 85 Over 85

Correction Factor

Use formula

shown below

50AH060

Tem p

Air Ent

Condenser

(F)

85

95

105

115

The following formulas may be used:

t

ldb=tedb

= Wet-bulb temperature corresponding to enthalpy of air leaving

t

lwb

h

lwb=hewb

Where:

h

= Enthalpy of air entering evaporator coil

ewb

7267 62 7267 62 7267 62

TC 64.8 58.5 52.9 68.0 61.5 56.3 68.9 62.5 58.0

SHC 33.2 41.1 48.5 37.2 47.3 55.7 38.9 50.0 57.7

kW 4.49 4.29 4.13 4.59 4.83 4.22 4.62 4.41 4.27

TC 61.9 55.7 50.2 65.1 58.7 54.0 66.1 59.7 55.8

SHC 32.3 40.1 47.3 36.4 46.5 54.0 38.2 49.3 55.8

kW 4.94 4.72 4.57 5.04 4.81 4.67 5.07 4.84 4.72

TC 58.5 52.4 47.2 61.5 55.2 51.4 62.6 56.3 53.3

SHC 31.1 38.8 45.8 35.2 45.2 51.4 37.1 48.1 58.2

kW 5.41 5.20 5.04 5.51 5.28 5.16 5.55 5.32 5.22

TC 54.9 49.0 44.1 57.8 51.7 48.7 58.7 52.6 50.4

SHC 29.8 37.5 44.0 34.0 43.9 48.7 35.9 46.7 50.4

kW 5.93 5.72 5.56 6.04 5.80 5.70 6.07 5.83 5.75

sensible capacity (Btuh)

–

evaporator col (h

total capacity (Btuh)

–

Evaporator Air Quantity — Cfm/BF

1500/0.06 2000/0.09 2250/0.10

Evaporator Air Ewb Temp (F)

1.10 x cfm

).

lwb

4.5 x cfm

EVAPORATOR FAN PERFORMANCE

UNIT SIZE — 50AH

CFM

ESP Fan kW ESP Fan kW ESP Fan kW ESP Fan kW

600 .60.20——————

700 .54.22——————

800 .43.24——————

900 .29.26.69.44————

1000 .11.29.57.46————

1100 — — .42 .49 1.10 .45 1.11 .52

1200 — — .23 .52 1.01 .49 1.045 .55

1300 ————.90.51.97.57

1400 ————.79.55.88.59

1500 ————.67.58.78.62

1600 ————.54.61.67.64

1700 ————.39.64.53.67

1800 ————.22.67.52.70

1900 ————.03.70.40.74

2000 ——————.28.78

ESP — External Static Pressure (in. wg)

kW — Total Fan Motor Power Input (kilowatts)

*Standard direct drive indoor (evaporator) fan motor (IFM). For optional

belt drive IFM performance, see table on page 8.

NOTES:

1. Above fan performance is based on wet coil and deducted casing

losses, and clean factory-installed permanent cleanable filter.

024 036 048* 060*

LEGEND

2. Evaporator fans are direct drive (except 048, 060 special order

evaporator-fan motor option). Refer to Belt Drive Evaporator Fan

Performance table on page 8.

3. Interpolation is permissible, do not extrapolate.

4. For units installed with accessory electric heaters, see Electric

Heater Static Pressure Drop table for additional performance losses.

7

Page 8

Performance data (cont)

BELT DRIVE EVAPORATOR FAN PERFORMANCE

(Special Order Only, Pricing and

ordering on related price pages.)

UNIT SIZE — 50AH

CFM

1800 ————

1850 ————

1900 ————

1950 .81 1.03 — —

2000 .72 1.05 — —

2050 .63 1.07 — —

2100 .55 1.08 1.02 1.17

2150 .47 1.11 .93 1.21

2200 .42 1.14 .84 1.24

2250 .34 1.17 .75 1.27

LEGEND

ESP — External Static Pressure (in. wg)

kW — Total Fan Power Motor Input (kilowatts)

NOTE: Pulley setting must be adjusted to limit cfm to 450 cfm/ton

maximum.

condensate problems.

Unit operation beyond that limit may result in blow-off and

048 060

ESP Fan kW ESP Fan kW

CONDENSER FAN PERFORMANCE

UNIT

50AH

024

036

048

060

COND

CFM

1525 Note 4 .66 ————————————

1475 — — Note 4 .64 ——————————

1400 ————Note4.63————————

1350 ——————Note4.62——————

1300 ————————Note4.62————

1650 2 .84 ————————————

1600 — — 2 .82 ——————————

1550 ———— 2 .80————————

1500 3 .72 ———— 2 .781 .84————

1450 4 .63 3 .70 ———— 2 .761 .83——

1400 — — 4 .61 3 .68 —————— 1 .81

1350 5 .51 ———— 3 .67—— 2 .73——

1300 — — 5 .50 4 .57 — — 3 .65 — — 2 .71

2700 2 .90 ————————————

2600 — — 2 .87 ——————————

2550 3 .81 ————————————

2450 — — 3 .77 2 .83 1 .89 ——————

2350 —————— 2 .801 .86————

2300 4 .68 — — 3 .74 ———— 0 .90——

2200 — — 4 .66 ———— 2 .771 .820 .86

3100 3 1.34 ————————————

3000 — — 3 1.32 ——————————

2900 —————— 21.39——————

2850 4 1.11 — — 3 1.24 ————————

2750 — — 4 1.07 ———— 21.32————

2700 —————— 31.17——————

2650 ———————————— 11.37

2600 5 .95 — — 4 1.01 ———— 21.26——

2550 ———————— 31.12————

2500 — — 5 .92 ——————————

2450 —————— 4 .97———— 21.21

2400 ———— 5 .90———— 31.08——

0.0 0.1 0.2 0.3 0.4 0.5 0.6

Turn s kW Turns kW Tur ns k W Turn s kW Tur ns k W Turn s kW Tu rns kW

EXTERNAL STATIC PRESSURE (in. wg)

LEGEND

kW — Total Fan Motor Power Input (kilowatts)

NOTES:

1. Above fan performance is based upon coil and deducted casing

losses only.

2. External static pressure (ESP) is measured in inches water gage

(in. wg).

3. Interpolation is permissible. Do not extrapolate.

4. Condenser fan on unit size 024 only, is direct drive.

8

5. Minimum one turn open of motor pulley is required on unit sizes 036

and 060.

6. Number of turns open applies to field setting of motor pulley.

7. Factory setting as follows: 036, 4 turns open; 048, 2 turns open; 060,

5 turns open.

8. Care should be taken when hoods and/or louvers are installed to

avoid condenser air recirculation.

Page 9

ELECTRIC HEATER STATIC PRESSURE DROP (in. wg)

ELECTRIC HEATER

UNIT 88EN

0500CA01

0075CA01 510.03.06.10.16—————

0115CA01 620

0075EA01 320

1150EA01 720

0100EA01

0150EA01 1240

0200EA01 1350

0300EA01 1220

0300CA01 1220

0100FA01 1130

0150FA01 1360

0200FA01 1350

0300FA01 1270

NOTE: Above electric heaters are

listed for use with optional high-static evaporator-fan motor (048, 060 units only).

UNIT

50AH

024, 036

1-stage

heat

048, 060

2-stage

heat

MIN

CFM

400.02.04.06.10—————

970

not

UL (Underwriters’ Laboratories) or CSA (Canadian Standards Association)

600 800 1000 1200 1400 1600 1800 2000 2200

.04.08.13.19—————

— — — .04 .06 .08 .12 .15 .17

— — — .08 .11 .14 .18 .22 .26

— — — .04 .06 .08 .12 .15 .17

— — — .08 .11 .14 .18 .22 .26

UNIT CFM

Controls

Operating sequence

Cooling — Thermostat calls for cooling. Indoor (evapora-

tor) fan relay is energized and starts evaporator fan. Compressor contactor is energized to start compressor and

condenser fan (up to a 5-minute delay on single-phase

units). When room thermostat is satisfied, the evaporator

fan, compressor, and condenser fan shut off.

Continuous fan operation — The thermostat can be

set for continuous operation by setting the fan switch to

ON.

Electrical data

UNIT

50AH

024 230-1 207 254 11.4 56 .17 1.10 .50 3.40 19.0 25

036

048

048*

060

060*

HACR — Heating, Air Conditioning, and Refrigeration

Hp — Horsepower

FLA — Full Load Amps

LRA — Locked Rotor Amps

MOCP — Maximum Overcurrent Protection (HACR breaker)

RLA — Rated Load Amps

*Optional evaporator-fan motor nameplate data.

V-P H

(60 Hz)

230-1 207 254 17.2 96 .50 3.20 .75 6.06 29.5 40

208/230-3 187 254 10.3 77 .50 3.20 .75 3.93 19.9 25

460-3 414 508 5.1 40 .50 1.50 .75 1.97 8.9 15

230-1 207 254 24.4 150 .75 4.00 1.0 8.35 42.9 60

208/230-3 187 254 15.5 105 .75 4.00 1.0 3.93 27.3 35

460-3 414 508 7.4 55 .75 2.15 1.0 1.97 13.4 20

208/230-3 187 254 15.5 105 1.5 5.60 1.0 3.93 28.9 35

460-3 414 508 7.4 55 1.5 2.80 1.0 1.97 16.3 20

230-1 207 254 28.8 169 .75 4.00 1.5 9.50 49.5 60

208/230-3 187 254 17.3 123 .75 4.00 1.5 4.82 30.4 40

460-3 414 508 9.0 62 .75 2.15 1.5 2.41 15.8 20

208/230-3 187 254 17.3 123 1.5 5.60 1.5 4.82 32.0 40

460-3 414 508 9.0 62 1.5 2.80 1.5 2.41 16.0 20

VOLTAGE RANGE COMPRESSOR

Min Max RLA LRA Hp FLA Hp FLA

LEGEND

Evaporator Condenser

FAN MOTORS POWER SUPPLY

Min Ckt

Amps

MOCP

Amps

9

Page 10

Electrical data (cont)

ELECTRIC HEATER DATA

ELECTRIC HEATER

UNIT 88EN

0050CA01

0075CA01 240-1 7.5 31.3 39.1 40

0115CA01 240-1 11.5 47.9 59.9 60

0075EA01

1150EA01

0100EA01

0150EA01

0200EA01

0300EA01

0300CA01 240-1 30.0 124.0 155.0 175

0100FA01 480-3 10.0 12.0 15.0 15

0150FA01 480-3 15.0 18.1 22.6 25

0200FA01 480-3 20.0 24.1 30.1 35

0300FA01 480-3 30.0 36.1 45.1 50

LEGEND

MCA — Minimum Circuit Ampacity

MOCP — Maximum Overcurrent Circuit Protection

*May be field converted to single-phase units, see electric heat installation instructions.

NOTE: Separate power source is required for all heaters. Control from base unit 50AH (24 v).

(Fuses or Circuit Breaker)

USED WITH

UNIT 50AH

024, 036

1-Stage Heat

048, 060

2-Stage Heat

V-P H

(60 Hz)

240-1 5.0 20.8 26.0 30

208-3 5.6 15.6 19.5 20

240-3 7.6 18.0 22.6 25

208-3 11.3 31.2 39.0 40

240-3 15.0 36.1 45.1 50

208-3 7.5 20.8 26.0 30

240-1* 10.0 41.7 52.1 60

240-3 10.0 24.1 30.1 35

208-3 11.3 31.2 39.0 40

240-1* 15.0 62.5 78.1 80

240-3 15.0 36.1 45.1 50

208-3 15.0 41.7 52.1 60

240-1* 20.0 83.3 104.2 110

240-3 20.0 46.9 58.6 60

208-3 22.5 62.5 78.2 80

240-3 30.0 72.2 90.2 100

CAP. (kW)

Heater Amps MCA MOCP (Amps)

BRANCH CIRCUIT

10

Page 11

Typical wiring schematic

50AH048,060 — 230-1-60 UNITS

AHA — Adjustable Heat Anticipator

C—Contactor Compressor

CB — Circuit Breaker

CC — Cooling Compensator

EQUIP GND — Equipment Ground

HPS — High-Pressure Switch

HR — Heater Relay

IFC — Indoor (Evaporator) Fan Contactor

IFR — Indoor (Evaporator) Fan Relay

JB—Junction Box

L—Light

LPS — Low-Pressure Switch

NEC — National Electrical Code

PL — Plug Assembly

TB — Terminal Block

TC — Thermostat-Cooling

TH — Thermostat-Heating

TRAN — Transformer

LEGEND

Marked Wire

Denotes connection point between subbase and thermostat

Terminal (Marked)

Terminal (Unmarked)

Terminal Block

Field Splice

Splice (Marked)

Factory Splice

Factory Wiring

Accessory or Optional Wiring

Field Control Wiring

Field Power Wiring

To indicate common potential only not to represent wiring

11

Page 12

Typical wiring schematic (cont)

50AH036,048,060 — 208/230-3-60 UNITS

AHA — Adjustable Heat Anticipator

C—Contactor Compressor

CB — Circuit Breaker

CC — Cooling Compensator

CLO — Compressor Lockout

CT — Current Transformer

EQUIP GND — Equipment Ground

HPS — High-Pressure Switch

HR — Heater Relay

IFC — Indoor (Evaporator) Fan Contactor

IFR — Indoor (Evaporator) Fan Relay

JB—Junction Box

L—Light

LOR — Lockout Relay

LPS — Low-Pressure Switch

NEC — National Electrical Code

PL — Plug Assembly

TB — Terminal Block

TC — Thermostat-Cooling

TH — Thermostat-Heating

TRAN — Transformer

LEGEND

Marked Wire

Denotes connection point between subbase and thermostat

Terminal (Marked)

Terminal (Unmarked)

Terminal Block

Field Splice

Splice (Marked)

Factory Splice

Factory Wiring

Accessory or Optional Wiring

Field Control Wiring

Field Power Wiring

To indicate common potential only not to represent wiring

12

Page 13

Typical piping and wiring

LEGEND

NEC — National Electrical Code

NOTES:

1. Wiring and piping shown are not intended for or to include all

details for specific installation.

2. All wiring must comply with applicable local and national codes.

3. All piping must follow standard refrigerant piping techniques. Refer

to Carrier System Design Manual, Part 3, for details.

4. For other installation details refer to Installation Instructions.

5. If unit sections are field split, 8 threaded support rods are required.

6. Ensure condenser air recirculation is minimized.

Application data

OUTDOOR-AIR TEMPERATURE OPERATING LIMITS (F)

UNIT 50AH 024 036 048 060

Without Head Pressure Control Minimum 35 35 40 40

With Head Pressure Control Minimum 0000

Field splitting instructions — If components are split,

maximum length of refrigerant tubing to be used is 50 ft,

assuming components are installed in same horizontal

plane. Condenser may be mounted up to 12 ft above evaporator. Liquid line tubing is

1

discharge line is

/2-in. OD copper tubing. For additional

piping information, refer to Carrier System Design Manual, Part 3. Units should always be within line of sight from

each other, or separate NEC (National Electrical Code)

Maximum 126 126 126 126

Maximum 126 126 126 126

3

/8-in. OD copper tubing, and

disconnects will be required. Junction boxes should be

installed in both the evaporator and condenser sections

adjacent to D-shaped grommets, to provide a location to

splice the outdoor-fan motor factory wiring (no. 16 AWG

[American Wire Gage],

ing should be a minimum of no. 16 AWG,

insulation. Check all applicable electrical codes to ensure

proper compliance.

4

/64-in. thick insulation). Field wir-

4

/64-in. thick

13

Page 14

Guide specifications

Indoor Packaged Unit

HVAC Guide Specifications — Section 15787

Size Range: 2 to 5 Tons, Nominal

Carrier Model Number: 50AH

Part 1 — General

1.01 SYSTEM DESCRIPTION

Indoor mounted, electrically controlled packaged

horizontal cooling unit utilizing a hermetic type

scroll compressor.

1.02 QUALITY ASSURANCE

A. Unit shall be certified in accordance with ARI

Standard 210.

B. Unit shall be UL listed and carry a UL label.

C. Unit shall be CSA approved (except 3 ton, 3-phase

units).

D. Unit shall be factory run-tested to ensure proper

performance prior to delivery.

1.03 DELIVERY, STORAGE, AND HANDLING

A. Unit shall be shipped completely assembled and

ready to operate.

B. Unit shall be shipped factory charged with refriger-

ant R-22.

C. Unit shall be stored and handled in accordance with

the unit manufacturer’s instructions.

Part 2 — Products

2.01 EQUIPMENT

A. General:

Factory assembled horizontal, single piece, air

cooled, indoor, ceiling plenum mounted electric

cooling unit. Contained within the unit enclosure

shall be all factory wiring, piping, controls, refrigerant charge (R-22), and special features required

prior to start-up.

B. Unit Cabinet:

1. Constructed of galvanized steel.

2. Interior shall be insulated with

prene coated fiberglass. Insulation shall be

bonded to interior surfaces by sprayed water

reduceable adhesive.

3. Equipped with 3 same side access panels and

2 bottom hanging removable doors to facilitate

ease of maintenance. Side panels allow access

to the control box, refrigeration components,

and condenser coil. Control box shall be hinged

allowing access to the compressor and pressure

switches. Bottom doors shall allow access to

and easy removal of the condenser and evaporator motors and blower assemblies.

4. Equipped with two

drain connections below the evaporator coil

and one

denser coil wash down. Connections shall be

factory plugged for field removal.

3

/4-in. threaded connection for con-

3

/4-in. threaded condensate

1

/2-in. thick neo-

5. Field splittable through the removal of 4 bolts

and extending refrigerant piping and wiring to

allow remote horizontal or vertical condenser

mounting.

6. Unit shall have an integral hanging bracket

requiring only 4 threaded rods (8 if unit is split)

run to the top flange of the unit for hanging,

eliminating need for external hanger brackets.

7. Contains junction box for power connection

and opening for routing of control wiring.

C. Fans:

1. Evaporator:

a. Blower shall be of the forward-curved, cen-

trifugal, direct-drive type or belt drive (4 and

5 tons only).

b. Motor shall have permanently lubricated

bearings.

c. Unit sizes 048, 060 shall be available with

an optional 1.5 hp fan motor.

2. Condenser:

a. Blower shall be of the forward-curved, cen-

trifugal, direct-driven type (024 only), or belt

drive (036,048,060).

b. Motor shall have permanently lubricated

bearings.

D. Compressor:

1. Fully hermetic scroll type.

2. Mounted on suitable spring vibration isolators.

3. Equipped with internal line break protection.

E. Coils:

Evaporator and condenser coils shall be of nonferrous construction with aluminum fins mechanically bonded to seamless copper tubes with all joints

brazed.

F. Refrigerant Components:

Refrigerant components shall include:

1. Capillary tube feed system.

2. Refrigerant filter-drier.

G. Filter Section:

Filter section shall consist of factory-installed, permanent, cleanable air filter, removable from the

same side as the access panels without the use of

tools.

H. Controls and Safeties:

Control system shall include a high-pressure switch,

a low-pressure switch, and a compressor lockout

feature which upon tripping of any safety device

shall prevent compressor from restarting until reset

at the thermostat (on all 3-phase units and 036

single-phase units only).

Time Guard® II device (single-phase only) shall prevent the compressor from restarting for a minimum

of 5 minutes after shutdown.

14

Page 15

I. Operating characteristics:

1. Unit shall operate using refrigerant R-22.

2. Unit shall be designed for indoor suspended

horizontal mounting and operation.

J. Electrical Requirements

Unit shall have single point power connection to

leads in terminal box.

K. Special Features:

Certain standard features are not applicable when

the features designated by * are specified. For assistance in amending the specifications, your local

Carrier Sales Office should be contacted.

* 1. Electric Heat Module:

a. Provides encased heater elements that shall

attach directly to the base unit discharge.

b. Shall have bottom access.

c. UL listed.

2. Thermostat Assembly:

Provides cooling and fan control. Standard sub-

base shall include ‘‘Compressor malfunction

light’’ designed to illuminate if compressor lockout is activated.

3. Time Guard® II Device Compressor Cycle

Delay:

Prevents compressor from restarting for a minimum of 5 minutes after shutdown.

*4.Condensate Pump:

Unit shall be equipped with remotely located

condensate pump. A field-installed light shall

illuminate when reservoir rises above a preset

level. Unit shall shut down upon reservoir light

illumination.

* 5. Head Pressure Control Package:

Allows unit to mechanically cool down to 0° F

ambient temperature. Package shall include

damper operating device and all necessary

hardware.

6. Vibration Isolation Package:

Shall provide 4 spring hangers for ceiling

mounted unit to damper vibration that may be

transmitted to building structure.

15

Page 16

Carrier Corporation • Syracuse, New York 13221 204 9-02

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Ta b 2 b 7 a

Book 1

New Pg 16 Catalog No. 525-00039 Printed in U.S.A. PC 111 Form 50AH-6PD

Ta b I P 1a

Replaces: 50AH-5PD

Loading...

Loading...