Page 1

48KHA,KLA

Packaged Heating/Cooling Units

Installation, Start-Up and Service Instructions

NOTE TO INSTALLER: After installation, leave these instructions, Owner’s Manual and Peurts Replace

ment Guide with equipment owner.

CONTENTS

Page

SAFETY CONSIDERATIONS

GENERAL..........................................................................1,2

INSTALLATION

Step 1—Rig and Place Unit..............................................2-4

.................................................................

...............................................

1

2-8

• ROOFTOP INSTALLATION

• GROUND LEVEL INSTALLATION

• CLEARANCES

• CONDENSATE DISPOSAL

• VENTING

Step 2—Make Gas Piping Connections

Step 3—Make Duct Connections........................................6

Step 4—Make Wiring Connections

..........................

.................................

5,6

6,7

• HIGH-VOLTAGE CONNECTIONS

• SPECIAL PROCEDURES FOR

208-V OPERATION

• LOW-VOLTAGE CONNECTIONS

• HEAT ANTICIPATOR SETTING

START-UP........................................................................9-16

SERVICE........................................................................16-19

TROUBLESHOOTING CHARTS

SAFETY CONSIDERATIONS

...................................

20,21

A WARNING

Improper installation, adjustment, eJteration, service,

maintenance or use can cause carbon monoxide poison

ing, explosion, fire, electric shock or other occurrences

which may injure you or damage your property. Con

sult a qualified instedler, service agency or the gas sup

plier for information or assistance.

NOTE: Installation of this unit must conform to the guide

lines presented in these Installation Instructions. Read and

become familiar with this publication before starting

installation.

Only trained, qualified installers and service mechanics

should install, start-up and service this equipment. Consult

the User’s Manual for routine maintenance. All other opera

tions should be performed by tredned service personnel,

personnel.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use care in handling, rigging and setting bulky equip

ment.

• Observe precautions in these instructions and on equip

ment tags, stickers and labels.

* •

A WARNING

Do not disconnect electric power to this appliance with

out first turning off gas supply. Be sure power to equip

ment is shut off before meuntenance or service.

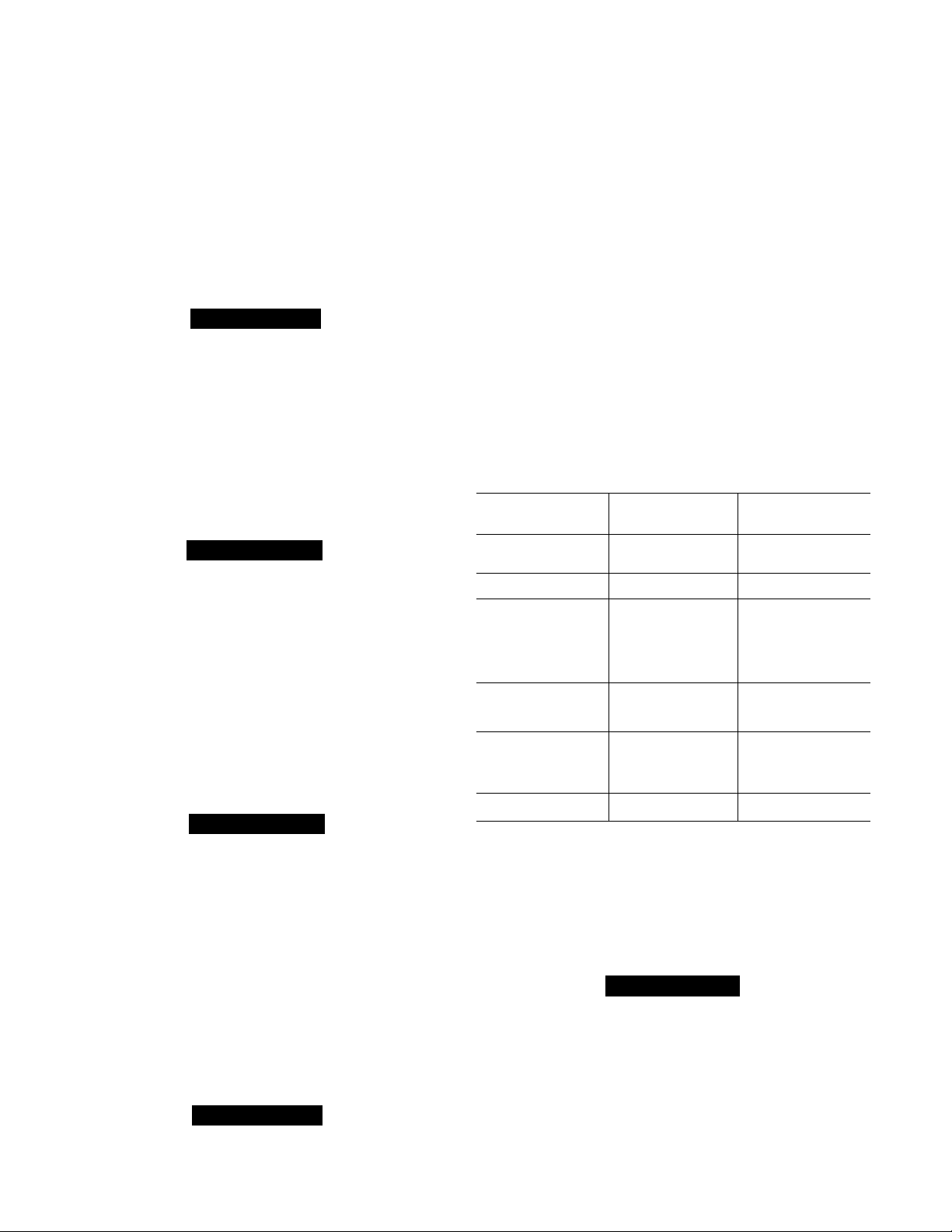

Fig. 1—Model 48KHA,KLA

GENERAL

Models 48KHA,KLA packaged gas/electric units (Fig. 1) eire

design certified in accordance with ANSI Z21.47B-1986,

ARI Standeird 210-81 and ARI Stemdard 270-84. The units

are design certified by the American Gas Association

(AGA) for use with natural or propane gases with appropri

ate controls or orifices. See Table 1 for heating input rat

ings. Models 48KHA,KLA units are fully self-contedned,

combination gas-heating/electric-cooling units designed for

outdoor installation on either a rooftop or ground-level slab.

May be instedled directly on wood flooring or on Class A,

Class B or Class C roof covering materials.

These units are equipped with an energy-saving automatic,

intermittent, electric spark ignition system that does not

have a continuously burning pilot. All units are manufac

tured with natural gas controls.

Units with number 1 in the 4th digit location of model num

ber in Table 1 meet California oxides of nitrogen (NOx) max

imum emission requirements.

Units are factory charged with R-22 refrigerant. To install:

connect gas supply, air ducts, high- and low-voltage wiring

and condensate drain, and install a field-supplied air filter in

the return-air ductwork.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

BookI 1 I 4 PC 101 Cataiog No 534-862 Printed in USA Form 48KH,KL-19Si Pg 1 1-88 Replaces: 48KH,KL-17SI

Tab ila 11a For replacement items contact distributor.

Page 2

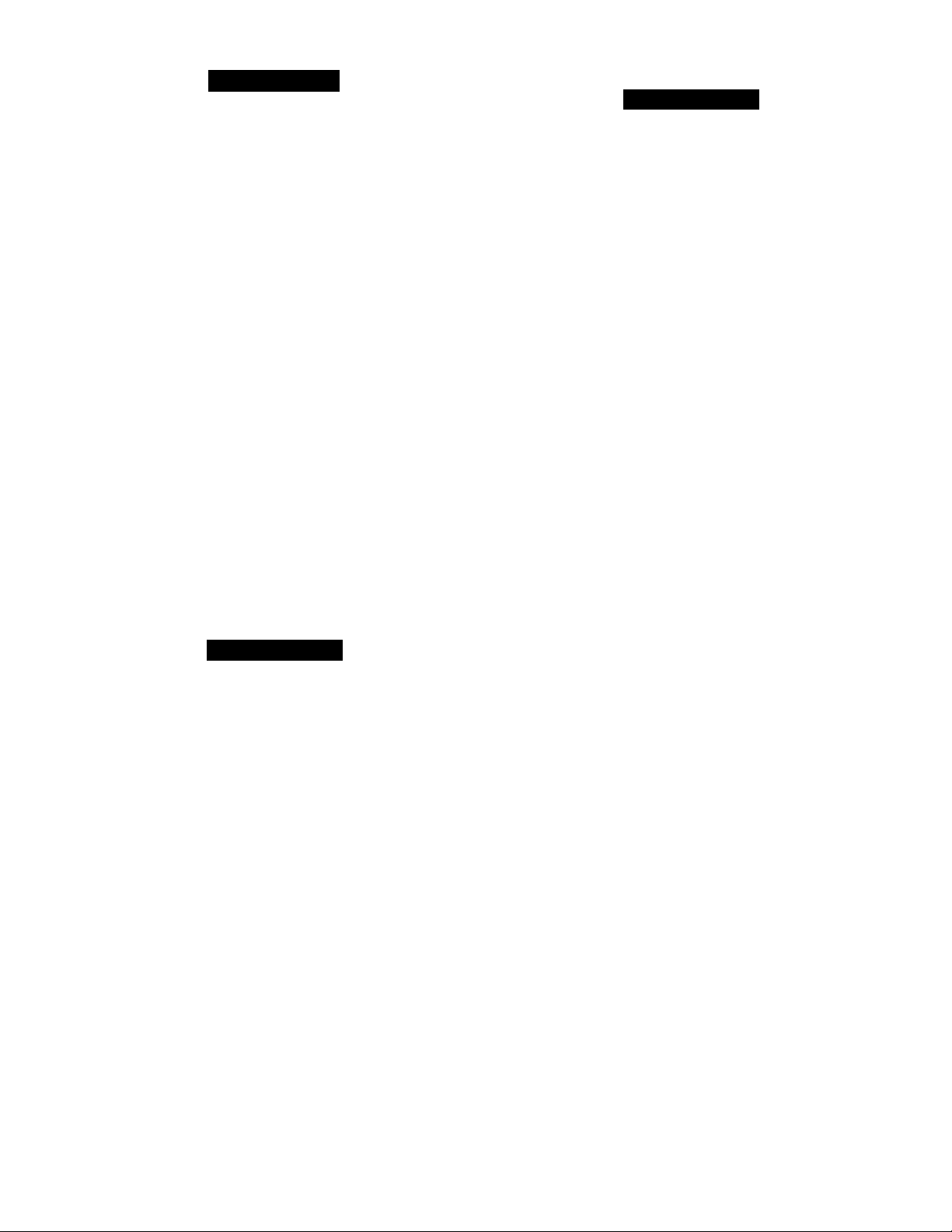

Table 1—Performance Data

COOLING

MODEL 48-

KLA118310BE

KLA124310BE

KHA024310BF

KLA130310BE

KHA030310BF

KLA136310BE

KLA136510CE

KLA136610CE

KHA136310BE

KHA136S10CE

KHA036310BF

KHA036510CF

KLA142310BE

KLA142510CE

KHA042310BF

KHA042510CF

KLA148310BE

KLA148510CE

KLA148610CE

KHA048310BE

KHA048510CF

KLA160310BE

KHA060310BF

♦Rated in accordance with U S. Government D.O.E. test procedures and/

or ARI Standard 210-81.

tSound rating per ARi 270-84.

tThe capacity ratings of singie-phase units are in accordance with U.S.

Government D.O.E. test procedures and/or AGA certification require

ments. For 3-phase units, the efficiency rating is a product thermai effi

ciency rating determined under continuous operating conditions, inde

pendent of any installed system.

CAPACITY

(Btuh)*

17,800 40,000 32,000

23,800 40,000

24,000 75,000

29,600

29,600 75,000 58,000

36,000 60,000

36,000

36,000 60,000

36,000

36,000

36,000

36,000

42,000 60,000

42,000 60,000

42,000

42,000 125,000

49,000

49,000

49,000

49,000

49,000

60,000

60,000

RATED

HEATING

INPUT

(Btuh)

40,000 32,000

60,000

100,000 79,000

100,000 75,000

125,000

125,000

125,000 97,000

80,000 63,000

80,000 60,000

80,000 60,000

125,000 97,000

125,000 93,750 8.4*

100,000* 79,000* 8.4*

150,000* 116,000* 8.4*

OUTPUT

CAPACITY

(Btuh)

32,000

58,000

47,000

45,000

45,000

97,000

93,750

47,000

45,000

93,750

ARI*

SOUND

RATING

(Bels)

7.8

7.8

8.0

7.8

7.8

8.0

8.0

8.0

8.0

8.0

8.0

8.0

78

7.8

7.8

7.8

8.4*

8.4*

8.4*

8.4*

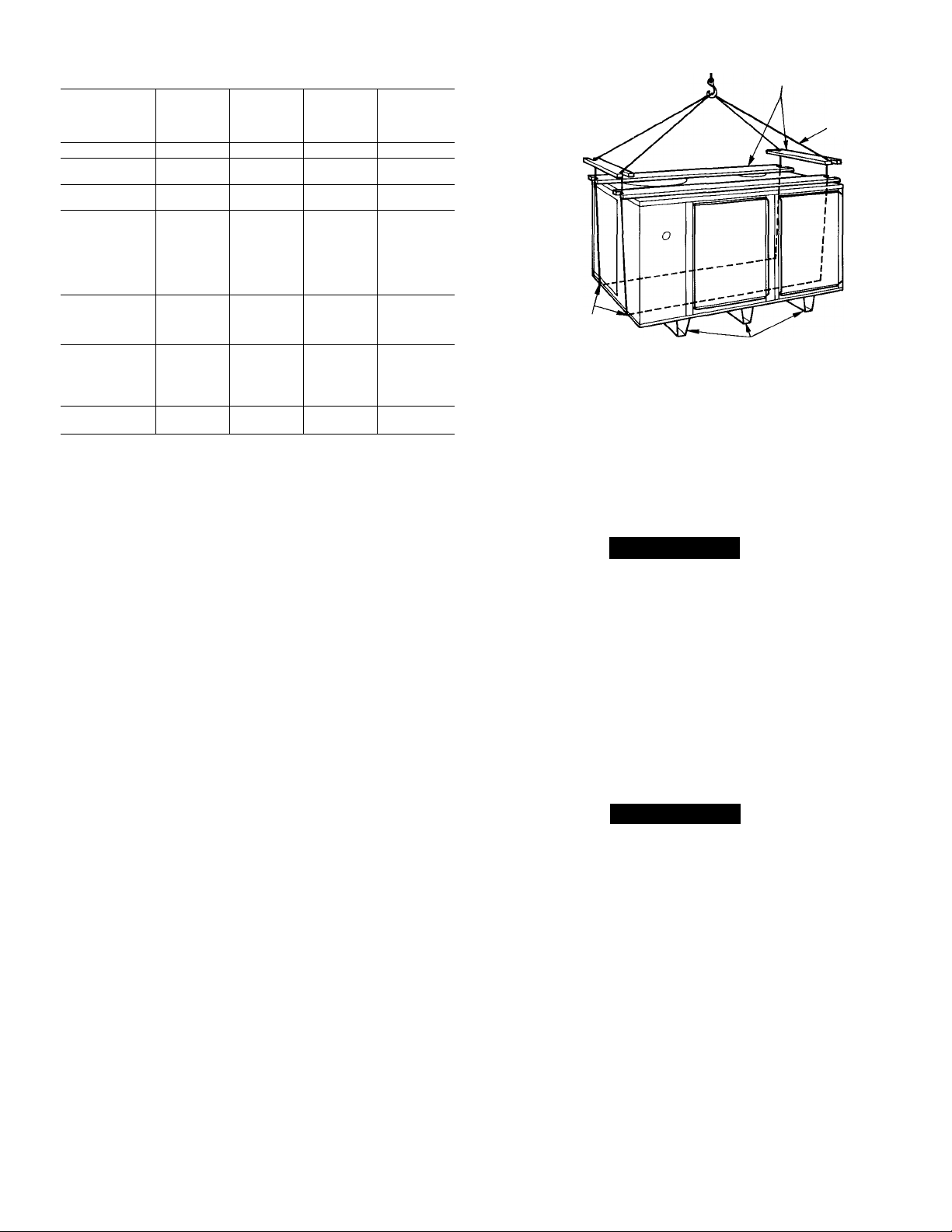

SPREADER OARS' ^

(2)2x4xUNIT LENGTH PLUS 10"WITH

11 DEEP 90° NOTCHES EACH END

(2) 2x4xUNIT WIDTH WITH l^

DEEP 90° NOTCHES

EACH END

LOCATE CHAINS THROUGH

HOLES IN BASE

CHANNELS

Fig. 2—48KHA,KLA Suggested Rigging

INSTALLATiON

Step 1—Rig and Place Unit

A CAUTION

SPREADER BARS

TWO OR THREE BASE

CHANNELS ATTACHED TO

BOTTOM OF UNIT

CHAIN

All units can be connected into existing duct systems that

are properly sized and designed to handle an airflow of 350

to 450 cfm per each 12,000 Btuh of rated cooling capacity.

See Table 8 for cooling euid heating airflow requirements.

NOTE: When insteJling any accessory item, see Installation

Instructions packaged with accessory.

IMPORTANT-

READ BEFORE INSTALLING

1. This instEdlation must conform with all applicable

local and nationed codes.

2. Power supply (volts, hertz and phase) must corre

spond to that specified on unit rating plate.

3. Electrical supply provided by utility must be suffi

cient to handle load imposed by unit.

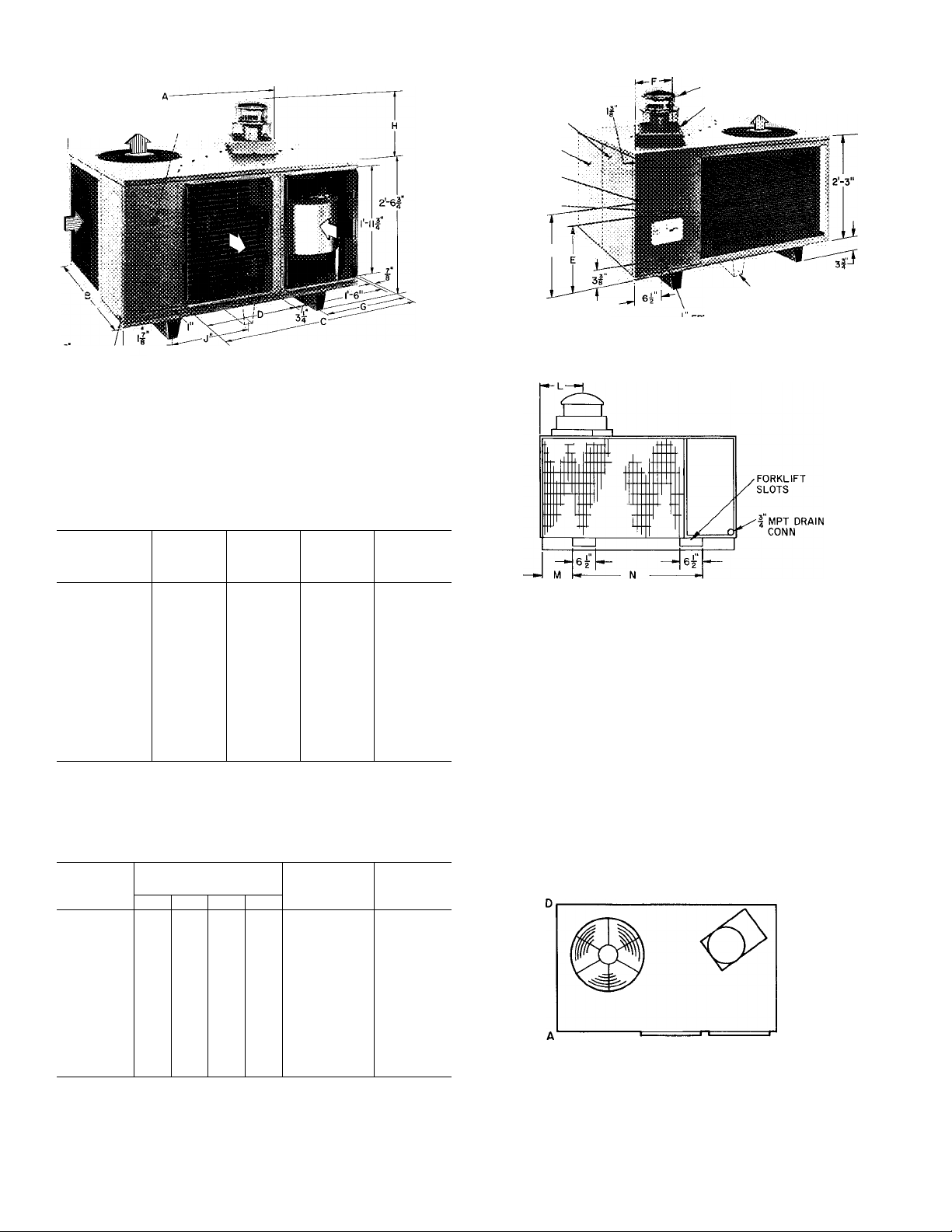

4. Refer to Fig. 4 for locations of gas inlet, electrical

inlets, condensate drain, duct connections, and

required clearances before setting unit in place.

5. Locate unit where vent cap will be a minimum of 4 ft

from openable windows or doors.

6. Installation must conform with local building codes

and with National Fuel Gas Code, NFPA 54-1984/

ANSI Z223.1-1984.

IMPORTANT: On some models, the high-voltage igni

tion cable is not connected to the spark generator termi

nal on the control head/gas valve assembly when shipped

from the factory. The cable is fastened to the manifold on

these models. Push the boot toward center of the cable to

expose the connector on the end of the cable. Attach the

connector securely to the terminal on the end of the con

trol head/gas vedve assembly. Push the boot over connec

tor to insulate the high-voltage connection.

When rigging unit to be hfted, use spreader bars to pro

tect top and sides. Rig unit as shown in Fig. 2. Use

extreme caution to prevent damage when moving unit.

Unit must remain in upright position during all rigging

and moving operations. Unit must be level for proper

condensate drainage; therefore, the ground-level pad or

accessory roof-mounting curb must be level before set

ting unit in place. When a field-fabricated support is

used, ensure that support is level and properly supports

unit and plenum.

ROOFTOP INSTALLATION

A CAUTION

When installing a unit on a rooftop, be sure roof will

support the additioneil weight. Refer to Fig. 4 to obtain

total weight and corner weight information.

When installing a Model 48KHA,KLA end discharge unit

with a field-supplied downflow plenum, a field-supplied roof

mounting curb must be installed on emd flashed into roof

before unit installation. When installing a Model

48KHA,KLA end discharge unit without a downflow ple

num, place unit on a level base that provides proper sup

port. On flat roofs be sure unit is located at least 4 in. above

highest expected water level on roof to prevent flooding.

Consult local codes for additional installation requirements.

GROUND LEVEL INSTALLATION-Place unit on a

solid, level concrete pad that is a minimum of 4 in. thick and

that extends approximately 2 in. beyond casing on all sides

of unit. Do not secure unit to pad except when required by

local codes.

CLEARANCES—Required minimum operating and service

clearances are shown in Fig. 4 for providing adequate com

bustion, ventilation emd condenser edr.

Page 3

A CAUTION

Do not restrict condenser airflow. An air restriction at

either outdoor-edr inlet (the entire surface of the outdoor

coil) or fan discharge can be detrimental to compressor

life.

Condenser fan discharges through top of unit. Ensure that

fan discharge does not recirculate to condenser coil. Do not

locate unit in either a corner or under a complete overhead

obstruction. Minimum clearance under a partial overhang

(such as a typical house roof overhang) is 3 ft above vent

cap. Maximum horizontal extension of a partial overhang

must not exceed 4 feet.

Do not locate unit where water, falling ice or snow from an

overhang or roof will damage or flood the unit. Do not locate

unit where grass, shrubs, or other plants will interfere with

the airflow either into or out of unit. Do not install unit on

carpeting, tile or other combustible material other than

wood flooring.

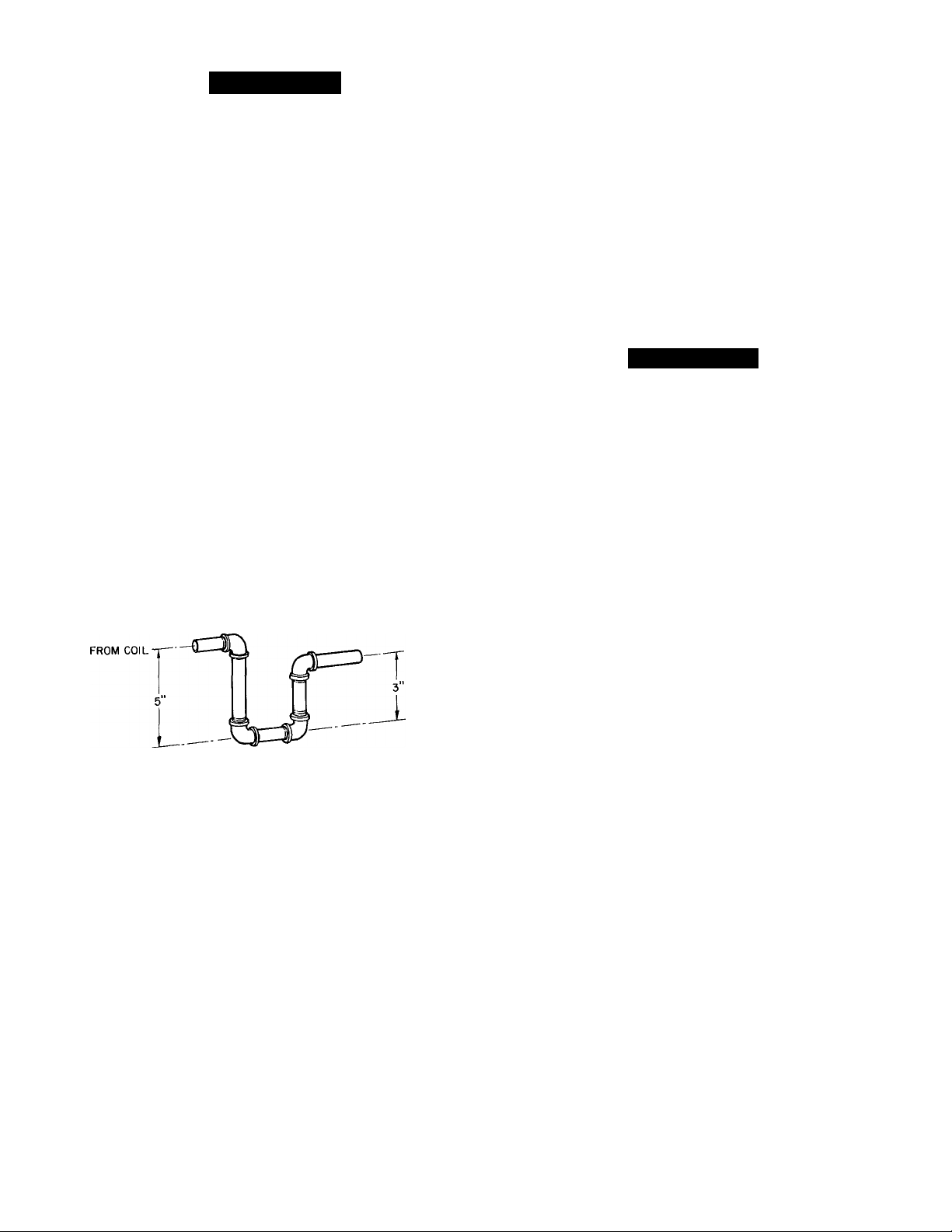

CONDENSATE DISPOSAL

NOTE: Be sure condensate water disposed methods comply

with local codes, restrictions and practices.

Models 48KHA,KLA dispose of condensate water through

a %-in. MPT drain fitting. See Fig. 4 for location.

Install a 3-in. trap at the drain fitting to ensure proper

drainage. See Fig. 3. Make sure trap outlet is at least 2 in.

lower than unit dredn pan connection to prevent pan from

overflowing. Prime trap with water.

TO DRAIN

Fig. 3—Condensate Trap

If installation requires draining the condensate water away

from unit, connect a dredn tube using a minimum of 7s-in. OD

copper tubing, %-in. galvanized pipe or 7s-in. plastic pipe. Do

not undersize the tube. Pitch drain tube downward at a

slope at least one in. for every 10 ft of horizontal run. Be

sure to check drain tube for leaks.

Condensate water can be drained directly onto roof in roof

top installations (where permitted) or onto a gravel apron in

ground level installations. When using a gravel apron, make

sure it slopes away from the unit.

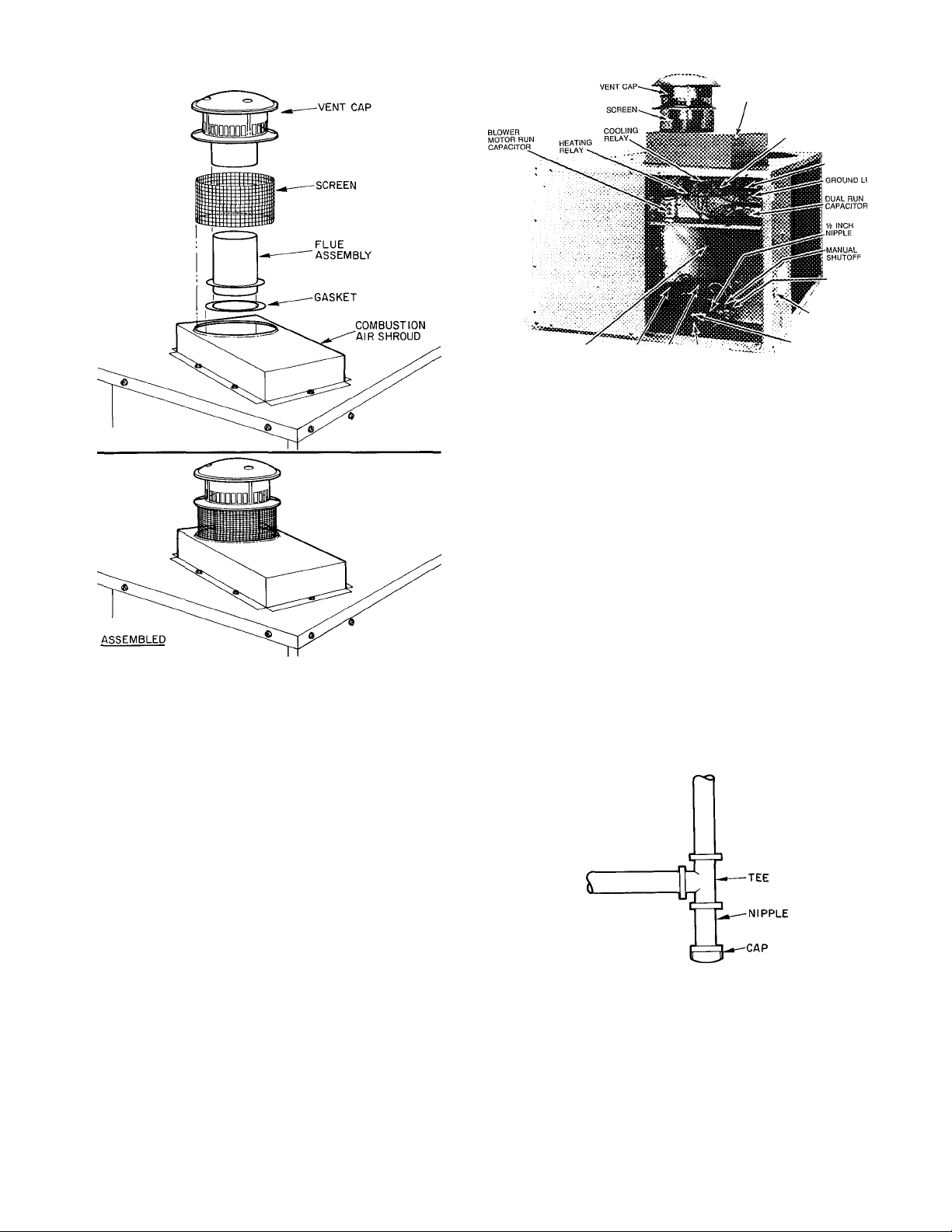

VENTING—The vent cap, combustion air shroud and flue

assembly are shipped in either the blower or control com

partment. Vent screen is taped to blower housing. Remove

access doors to locate assemblies. See Fig. 4 for door

locations.

A CAUTION

Venting system is designed to ensure proper venting.

Vent cap assembly must be installed as indicated

below.

NOTE: Screw holes in flue assembly and unit top eire posi

tioned to ensure proper orientation when installed. Refer to

Fig. 5 emd instedl vent cap as follows:

1. Place combustion air shroud over combustion air open

ing in unit top, and line up screw holes in shroud with

holes in top. Secure shroud to top, using screws with

rubber washers (provided).

2. The flue gasket is shipped in the literature assembly

envelope. Place gasket and flue assembly through hole

in combustion air shroud, orient screw holes in base of

flue assembly with holes in unit top, and secure gasket

and flue assembly to unit top, using screws provided.

3. Form flat wire screen (provided) into circular shape

around protruding lip of combustion-air shroud and

bend wire ends through holes of screen mesh to secure

screen in place. Make sure that no sharp edges are left

exposed.

4. Place vent cap sleeve inside flue assembly. Orient

spring chp of vent cap with slot in assembly. Be sure

clip snaps into slot to secure clip onto assembly.

Page 4

i MPT / U-—G

DRAIN CONN

PLUGGED ACCESS HOLE

FOR REFRIGERANT

PRESSURE GAGE HOSES

*NOTON MODELS48KLAII8THROUGH

I36i KHA024 THROUGH 030

CONTROL ACCESS

DOOR

BLOWER ACCESS

DOOR

I LOW VOLTAGE

INLET

K HIGH VOLTAGE

INLET

T-4Í

C> EVAPORATION AIRFLOW

^CONDENSER AIRFLOW

VENT CAP

COMBUSTION AIR INLET BOX

■NOT ON MODELS

48KLAII8 THROUGH 136;

KHA024 THROUGH 030

MODEL 48-

Dimensions

(ft-in.)

A

B

C

D

E

F

G

H

J

K

L

M

N

MODEL

48-

KLA118 82

KLA124

KHA024

KLA130

KHA030 97

KLA136

KHA136 122

KHA036

KLA142

KHA042

KLA148 130 135 137

KHA048 134 139 144

KLA160

KHA060

KLA118

KLA124

4-5% 4-5% 5-5%

2-6% 3-4% 3-8%

3-2'/a

1-4 1-7 2-0

1-4 1-4

0-7'/4

0-11% 0-10% 0-10%

1-3’A

—

0-1 %2 0-1% 0-1% 0-1%

0-1%

0-47,6

1-10 2-4 2-4

CORNER WT (ib)

A B

83 81

96 94

97 93

98 97 92

122 120 116 117 475 485

108 105 102

113 111 107

148 144 139

155 151

C D

79

93 91 94 375 385

120 116 117

148 151 605

KHA024

KLA130

KHA030

KLA136

3-57s 3-107e

0-8?8

1-374 1-874

—

0-17e

0-67,6

79 81 320 330

82

79

91 94 375 385

90 92 372 382

93 380

105 420

109 440

133 535

138 555

144 575

KHA136

KHA036

KLA142

KHA042

1-174

0-8%

1-1 O'732

1-4

0-87,6 0-87,6

TOTAL

OPERATiNG

WT (ib)

325 335

475

KLA148

KHA048

KLA160

KHA060

6-0%

3-8%

4-6%

2-8

1-174

0-8%

0-11%

1-8%

2-0=»/32

1-5

2-4

TOTAL

SHiPPING

WT (ib)

390

485

430

450

545

565

585

615

Above flue vent........................................................................................................3-0

Duct side of unit .....................................................................................................0-6

Side opposite ducts................................................................................................2-6

Biower access panel side.

Side opposite biower access panel.

Bottom of unit.................................................

NOTE: Provision must be made for fresh ambient air to reach the

outdoor coil without recirculation of the air from the outdoor fan

discharge

Weight Data

VIEW AA

CLEARANCES (ft-in.)

2-6

2-6

0

Fig. 4—Dimensions and Ciearances (ft-in.)

Page 5

Fig. 5—Vent Cap Assembly

COMBUSTION-AIR SHROUD

CONTROL

TRANSFORMER

COMPRESSOR

CONTACTOR

GAS INLET

PRESSURE TAP

(BACK SIDE)

‘GAS PIPE

ENTRANCE HOLE

REGULATOR

LOW VOLTAGE SECONDARY p. pf'TpoNIC \

WIRES air SHIELD ^^)n7rOL GAS VALVE

HEAD

ADJUSTING SCREW

Fig. 6—Model 48KLA136—Side View

(Partiai) with Access Doors Removed

2. Protect all segments of piping system against physiceJ

and thermal deimage. Support all piping with appropri

ate hangers, etc. Use a minimum of one hanger in every

6 feet. For pipe sizes larger them V2-in., follow recom

mendations of national codes.

Apply joint compound (pipe dope) speiringly and only

3.

to male threads of joint when meiking pipe connections.

Use only pipe dope that is resistant to action of lique

fied petroleum gases as specified by local and/or

nationeJ codes. Never use pipe thread tape.

InsteJl a sediment trap in riser leading to the heating

4.

section. See Fig. 7. This drip leg functions as a trap for

dirt and condensate. Install trap where condensate can

not freeze. Install this sediment trap by connecting a

piping tee to riser leading to heating section, so that

straight-through section of tee is vertical. Then, con

nect capped nipple into lower end of tee. Extend

capped nipple below level of gas controls.

Step 2—Make Gas Piping Connections—A manual shutoff

vedve is shipped loose in the burner compartment or blower

compartment. Connect one end of a field-supplied V2-in.

streught nipple to the gas valve inlet. Connect the other end

of the nipple to the manual shutoff valve as shown in Pig. 6.

The gas supply pipe enters unit through access hole pro

vided. See Fig. 4 for location. The gas connection to unit is

made to the V2-in. FPT gas inlet on manual shutoff. See Fig.

6 for inlet location.

Install a separate gas supply line that runs directly from

meter to heating section. Do not use cast-iron pipe. Check

local utility for recommendations concerning existing lines.

Choose a supply pipe that is large enough to keep pressure

loss as low as practical. Never use pipe smaller than the ^¡¿-in.

FPT gas inlet on unit manual shutoff.

When installing gas supply line, observe local codes pertain

ing to gas pipe installations. Refer to National Fuel Gas

Code, NFPA 54-1984/ANSI Z223.1-1984 in absence of local

building codes. Adhere to following pertinent recom

mendations:

1. Avoid low spots in long runs of pipe. Grade all pipe %-

in. in every 15 ft to prevent traps. Grade all horizonteJ

runs downward to risers. Use risers to connect to heat

ing section and to meter.

Fig. 7—Sediment Trap

5. Install an accessible, external, manual shutoff valve in

gas supply pipe within 6 ft of heating section.

NOTE: The unit manual shutoff valve has a Vs-in. tap

ping on the inlet side of this shutoff for measuring gas

input pressure.

6. Install ground-joint union close to heating section

between unit manual shutoff and external manual main

shutoff valve.

Page 6

7. Pressure-test all gas piping in accordance with loceil

and national plumbing and gas codes before connecting

piping to unit.

NOTE: When pressure-testing the gas supply system

after the gas supply piping has been connected to the

unit gas valve, the supply piping must be disconnected

from the gas valve during any pressure testing of the

piping systems at test pressures in excess of 0.5 in.

psig. When pressure testing the gas supply piping sys

tem at test pressures equal to or less than 0.5 in. psig,

the unit heating section must be isolated from the gas

piping system by closing the external main manual

shutoff valve and slightly opening ground-joint union.

A CAUTION

Unstable operation may occur, peirticularly under highwind conditions, when gas valve and manifold assembly

are forced out of position while connecting improperly

routed, rigid gas piping to gas valve. Use a backup

wrench when making connection to avoid strain on, or

distortion of, gas control piping.

2. Use a flexible transition between rigid ductwork and

unit to prevent transmissions of vibration. The transi

tion may be screwed or bolted to duct flanges. Use suit

able gaskets to ensure a weathertight and air-tight

seal.

3. Install external, field-supplied air filter(s) in return-air

ductwork where it is easily accessible for service. Rec

ommended filter sizes are shown in Table 2.

4. Size all ductwork for maximum required airflow (either

heating or cooling) for unit being installed. Avoid

abrupt duct size increases or decreases.

5. Adequately insulate and weatherproof all ductwork

located outdoors. Insulate ducts passing through an

unconditioned space, and use a vapor barrier in accord

ance with the latest issue of SMACNA and NE SC A

minimum installation standards for heating and air

conditioning systems. Secure all ducts to building

structure.

6. Flash, weatherproof and vibration-isolate all openings

in building structure in accordance with local codes and

good building practices.

8. Where permitted by local codes, use an approved corru

gated metal tubing gas connector between rigid gas

piping and unit manual shutoff.

A WARNING

Never use a match or other open flame when checking

for leaks. Failure to adhere to this warning may cause

an explosion.

9. Check for gas leeiks at eJl field-installed and factoryinstalled gas lines after all piping connections have

been completed. Use soap-and-water solution (or

method specified by local codes and/or regulations).

Step 3—Make Duct Connections—Model 48KHA,KLA

has duct flanges on the supply- and return-air openings on

side of unit. See Fig. 4 for connection sizes and locations.

A WARNING

The design and installation of duct system must be in

accordance with standards of National Fire Protection

Association for installation of non-residence type air

conditioning and ventilating systems. NFPA No. 90; or

residence-type NFPA No. 90B; and/or local codes and

ordinances.

Table 2—Filter Sizes (Field Supplied),

(Sq In.)*

MODEL 48-

KLA118310BE

KHA024310BF

KLA124310BE

KHA030310BF

KLA130310BE

KHA036310BF

KHA136510CE

KHA036510CF

KHA136310BE

KLA136510CE

KLA136610CE

KLA136310BE

KHA042310BF 694

KHA042510CF 694

KLA142510CE

KLA142310BE 672

KHA048310BF 768

KHA048510CF 768

KLA148510CE 768

KLA148610CE

KLA148310BE

KHA060310BF 960

KLA160310BE 960

*Required air filter areas shown are based on the ARI-rated cooling air

flow or the heating airflow at a velocity of 300 fpm depending on

whichever value is larger. Air filter pressure drop should not exceed 0 08

, in wg

STANDARD CLEANABLEOR

DISPOSABLE HIGH CAPACITY

TYPE

302 202

454

384 257

480 320

480 320

694

576

694

576

576

576 384

576 384

672

768 512

768 512

TYPE

303

462

384

462

384

384

462

462

448

448

512

512

512

640

640

Step 4—Make Wiring Connections

Adhere to the following requirements when selecting, sizing

tmd installing duct system;

1. Select and size ductwork, supply-air registers and

return-£ur grilles according to ASHRAE recommenda

tions emd as presented in Carrier System Design Man

ual, Part 2.

A CAUTION

When duct system fastening holes are drilled into side

of Model 48KHA,KLA instead of the unit duct flanges,

use extreme care to avoid puncturing coil or coil tubes.

A WARNING

Unit cabinet must have an uninterrupted, unbroken

electrical ground to minimize the possibility of personeil

injury if an electrical fault should occur. This ground

may consist of electrical wire connected to unit ground

lug in control compartment, or conduit approved for

electrical ground when installed in accordance with

National Electrical Code ANSI/NFPA 70-1984 and

local electriced codes. Do not use gas piping as an elec

trical ground. Failure to follow this warning could

result in the installer being held liable for personal

injury of others.

Page 7

A CAUTION

Feiilure to follow these precautions could result in dam

age to unit being installed.

1. Make all electrical connections in accordance with

National Electrical Code ANSI/NFPA 70-1984 and

local electrical codes governing such wiring.

2. Use only copper conductor for connections between the

field-supplied electrical disconnect switch and the unit.

Do not use aluminum or copper-clad aluminum wire.

3. Ensure that high-voltage power to unit is within oper

ating voltage range indicated on unit rating plate. On

3-phase units, ensure that phases are balanced within

2%. Consult local power company for correction of

improper voltage and/or phase balance.

4. When low-voltage control wires are run in same conduit

as high-voltage wires, insulate low-voltage wires for

highest voltage contained within conduit.

5. Do not damage internal components when drilling

through any panel to mount electrical hardware, con

duit, etc.

HIGH-VOLTAGE CONNECTIONS-Unit must have a

sepeirate electriceil service with a field-supplied, waterproof,

fused disconnect switch per NEC mounted near, and within

sight from, the unit. Refer to unit rating plate for maximum

fuse size and minimum circuit amps (ampacity) for wire siz

ing. Table 3 shows recommended wire sizes and lengths

based on rating plate data.

The field-supplied disconnect switch box may be mounted

on unit over the high-voltage inlet hole in control corner

pemel. See Fig. 4.

A WARNING

Label Part No. A74191B, which is shipped loose in bag

of parts, must be affixed to the disconnect switch box.

This label states: "DO NOT DISCONNECT THE

ELECTRICAL POWER TO THIS APPLIANCE

WITHOUT FIRST TURNING OFF THE GAS

SUPPLY.”

Proceed as follows to complete the high-voltage connections

to unit:

1. Connect ground lead to chassis ground connection

when using a separate ground wire.

2. Run high-voltage leads into unit control box and con

nect to contactor. See unit wiring label and Fig. 6

and 8.

NOTE; On 3-phase units, connect third high-voltage lead to

brown high-voltage pigtail lead. See unit wiring label and

Fig. 8.

SPECIAL PROCEDURES FOR 208-V OPERATION

A WARNING

Make sure power supply to unit is switched OFF before

making any wiring changes. Electrical power may cause

personal injury or death.

For operation on 208 volts, disconnect orange transformer

primary lead from contactor. See unit wiring label and

Fig. 6. Remove tape emd cover from terminal on end of red

transformer-primary lead. Save cover. Connect red lead to

contactor terminal from which orange lead was dis

connected.

Using cover removed from red lead, insulate loose terminal

on orange lead. Wrap cover with electricEd tape so that

metal terminal cannot be seen.

NOTE: For some 48KHA,KLA units, the factory-wired

blower-motor speed connections may require changing for

208-v operation to ensure adequate airflow at the rated

external static pressure. See unit wiring label. Insulate all

unused motor leads following same procedures described for

tremsformer leads.

LOW-VOLTAGE CONNECTIONS-Use a suitable room

thermostat as specified on unit wiring label.

Locate room thermostat on an inside wall in space to be con

ditioned where it will not be subjected to either a cooling or

heating source, or direct exposure to sunlight. Mount ther

mostat 4 to 5 ft above floor.

Use no. 18 AWG color-coded, insulated (35 C minimum)

v/ires to make low-voltage connections between thermostat

and unit. If thermostat is located more than 100 ft from

unit (as measured along the low-voltage wires), use no. 16

AWG color-coded, insulated (35 C minimum) wires.

A grommeted, low-voltage inlet hole is located in the panel

adjacent to control access panel. See Fig. 4. Run low-voltage

leads from thermostat, through inlet hole and to low-voltage

flagged pigtail leads that run through a hole in bottom of

unit control box. See Fig. 6. Connect thermostat leads to

pigtail leads as shown in Fig. 8

HEAT ANTICIPATOR SETTING—Room thermostat heat

anticipator must be properly adjusted to ensure proper

heating performance. Set heat anticipator, using ammeter

to determine exact required setting.

NOTE: For thermostat selection purposes, use 1.0 amps for

approximate required setting.

Failure to make a proper heat anticipator adjustment will

result in improper operation, discomfort to occupants of

conditioned space and inefficient energy use; however,

required setting may be changed slightly to provide a

greater degree of comfort for a particular installation.

Page 8

MODEL

48-

KLA118

SERIES

310BE 208/230-1 197

VOLTSPHASE

KLA124 310BE 208/230-1

KHA024 310BF

KLA130

KHA030

KLA136

KLA136

KLA136

KHA136

KHA036

310BE 208/230-1

310BF 208/230-1 197

310BE 208/230-1

510CE 208/230-3

610CE

310BE

310BF

KHA136 510CE,CF

KHA036 510CF

KLA142

310BE 208/230-1

208/230-1 197

460-3 414

208/230-1

208/230-3 187 253

208/230-3 187

KLA142 510CE 208/230-3

KHA042

310BF 208/230-1

KHA042 510CF 208/230-3

KLA148 310BE

KLA148

510CE 208/230-3

KLA148 610CE

KHA048

KHA048

KLA160

KHA060

310BF

510CF 208/230-3

310BE 230-1

310BF

208/230-1 197

460-3 414

208/230-1 197

230-1 207

AWG—American Wire Gage

FLA —Full Load Amps

IFM —Indoor Fan Motor

LRA —Locked Rotor Amps

MCA—Maximum Circuit Ampacity

OFM —Outdoor Fan Motor

RLA —Rated Load Amps

Table 3—Electrical Data (60 Hz)

OPERATING

VOLTAGE* COMPR

Min Max RLA LRA

253 8.7 49.0 1.2

197 253

197 253

197 253

187 253

197 253

197 253

187

197 253

187

187 253

187 253

207 253

11.7 63.0 1.7 1.0

253 11.7 63.0

13.7

253 13.7 76.0 2.9

506 5.1 32.8 1.9

253

253

253

253

506

253

253

*Voltage limits between which the unit will operate satisfactorily

tif other than 75 C copper wire is used, determine size from unit ampacity and the National Elec

trical code. Voltage drop of wire must be less than 2% of unit rated voltage Maximum wire

length is for one way along the wire path from unit to service panel

:(;Maximum dual element size

76.0

17.6 88.0 4.6

11.5 65.1 4.7 1.0 20.1

17.6 88.0 3.8 0.8 26.6

65.1 5.6 1.0 21.0 18.1

11.5

11.5 65.1 5.6 1.0 21.0 18.1

95.4 4.1

23.9

15.3 82.0 5.6 1.0 25.8 21.9

95.4 3.9 0.8 34.6 28.6 50

23.9

15.3 82.0 5.0 1.0

23.7 116.0 4.5

14.7 92.0 7.8

7.0

23.7 116.0

14.7

130.0 6.2 1.9 42.9 35.9

27.8

27.8 130.0 6.5

MAX FUSE

FLA

IFM

3.0 1.0

3.1 1.0

46.0 3.3 1.2 13.3 11.5 20

3.7 1.9 35.3 29.3 50 8

92.0 5.8 2.2 26.4 22.7 35

MCAt

OFM

1.0 13.1 10.9

1.0 21.0

1.0 27.6 23.2

0.6 8.9 7.6 15

0.8

1.9 36.1 30.1 50 8

2.2

1.9 43.2 36.2 60

MAX

AMPS

17.4 14.4 25

18.7 15.7 25

21.2 17.8 30 10 115

34.8 28.8 50

25.2 21.3 35 10

28.4

17.6 30 10 116

17.2 25

22 2 40

24.7 35 10

SIZE

(Amps)t

20

40 10

25 10 130

25 10 130

35 10 108

60 8

MIN WIRE

SIZE (AWG)t

(75C Copper)

14

12

12

10

14 272

10

8 113

8 114

14 180

10

8 99

MAX

WIRE

LENGTHt

76

89

82

88

137

92

111

108

96

111

104

100

SINGLE-STAGE HEAT S COOL-

MANUAL CHANGEOVER

. Field Low-Voltage Wiring

.Field High-Voltage Wiring

. Factory Low-Voltage Wiring

, Factory High-Voltage Wiring

SINGLE-STAGE HEAT S COOL-

AUTOCHANGEOVER

JUMPER-H

NOTE: For manual changeover applications, use thermostat part no. HH01AD042 with

subbase part no HH93AZ042, or thermostat part no HH01AD040 with subbase part no

HH93AZ040

For automatic changeover, use thermostat part no. HH07AT174 with subbase part no.

HH93AZ096; or thermostat part no HH10AD041 with subbase part no HH93AZ041.

-------------------

HIGH-VOLTAGE

PIGTAIL LEAD

1

—♦frrw^

-------

3-PHASE

UNITS ONLY

CONTACTOR TERMINALS

(SEE UNIT WIRING LABEL)

---

'

>n-rvri —

FIELD-SUPPLIED

DISCONNECT PER NEC

Fig. 8—High- and Low-Voitage Connections

Page 9

STARTUP

Unit Preparation

A WARNING

Failure to observe the following warnings could result

in serious personal injury;

1

Follow recognized safety practices and wear protective

goggles when checking or servicing refrigerant system.

Do not operate compressor or provide any electric

2.

power to unit unless compressor terminal cover is in

place and secured.

3.

Do not remove compressor terminal cover until all elec

trical sources have been disconnected.

4.

Relieve all pressure from system before touching or dis

turbing anything inside terminal box if a refrigerant

leak is suspected around compressor terminals.

5. Never attempt to repair a soldered connection while

refrigerant system is under pressure.

6. Do not use a torch to remove any component. System

contains oil and refrigerant under pressure. To remove

a component, wear protective goggles and proceed as

follows:

a. Shut off gas supply first, and then electrical power

to unit.

b. Relieve all pressure from system.

c. Use tubing cutter to cut tubing that connects com

ponent, and remove component from unit.

d. Carefully unsweat remaining tubing stubs when

necessary. Oil can ignite when exposed to torch

flame.

PRE-START-UP PROCEDURES-Proceed as follows to

inspect and prepare unit for initial start-up:

Remove edl access panels.

Read and follow instructions on all WARNING, CAU

TION and INFORMATION labels attached to or Heating Section Start-Up and Adjustments

shipped with the unit.__________________________________________________________________

3.

Make following inspections:

a. Inspect for shipping and handling damages such as

broken lines, loose parts, disconnected wires, etc.

b. Inspect for oil at all refrigerant tubing connections

and on unit base. The presence of oil generally indi

cates a refrigerant leeik. Leak-test all refrigerant

tubing connections using electronic leak detector,

halide torch or liquid soap solution. If refrigerant

leak is detected, see Refrigerant Leaks in next

section.

c. Inspect all field- and factory-wiring connections. Be

sure connections are completed and tight.

d. Inspect coil fins. If damaged during shipping and

handling, carefully straighten fins with a fin comb.

c. Maike sure air filter(s) is in place.

d. Make sure condensate dredn pan is filled with water

to ensure proper drainage.

e. Make sure all tools and miscellaneous loose parts

have been removed.

5. Replace all access panels. Unit is now ready for initial

start-up.

REFRIGERANT LEAKS—Proceed as follows to repair a

refrigerant leak and to charge the unit.

A WARNING

Never attempt to repair a soldered connection while

refrigerant system is under pressure. Severe bodily

injury may result. Always wear protective goggles

when servicing the refrigerant system.

1. Locate leak and ensure that refrigerant system pres

sure has been relieved.

2. Repair leak following accepted practices.

NOTE; Install a filter drier whenever system has been

opened for repair.

3. Add a small cheu-ge of R-22 refrigerant vapor to system

and leEik-test unit.

4. Evacuate refrigerant system if additioned leaks are not

found.

5. Charge unit with R-22 refrigerant, using a volumetric-

charging cylinder, such as Dial-a-Charge, or accurate

scale. Refer to unit rating plate for required charge. Be

sure to add extra refrigerant to compensate for interned

volume of filter drier.

NOTE: See Cooling Section Start-Up and Adjustments—

Checking and Adjusting Refrigerant Charge.

A CAUTION

Complete required procedures given in Unit Prepara

tion section before starting unit.

Do not jumper any safety devices when operating unit.

Ensure that burner orifices are properly aligned. Unstable

operation may occur when the burner orifices in the mani

fold are misedigned. To ensure correct burner orifice edignment, check orifice angle with a machinist’s protractor or

other suitable device. The orifice angle must be from hori

zontal to 3 degrees down, as measured from unit base.

Follow instructions on heating section operation label

(located in unit near the gas valve) or in Owner’s Manual, to

start the heating section.

A WARNING

Do not purge gas supply into combustion chamber. Do

not use a match or other open flame to check for gas

leaks. Failure to adhere to this warning may cause an

explosion.

4. Verify the following conditions:

a. Meike sure gas supply has been purged, and all gas

piping has been checked for leaks.

b. Make sure outdoor fan blade is correctly positioned

in fan orifice. Blades should clear fan motor by no

more than % inch.

CHECKING HEATING CONTROL OPERATION-Start

and check unit for proper heating control operation as

follows:

Place room thermostat selector switch in HEAT position

and fan switch in AUTO, position. Set heating temperature

control of thermostat above room temperature. Observe

that after built-in time delays, the pilot automatically

lights, burners light and blower motor starts. Observe that

burners and pilot are extinguished, and that after a built-in

delay, blower motor stops when heating control setting of

thermostat is satisfied.

_____

_

Page 10

GAS INPUT

A CAUTION

These units are designed to consume the rated gas

inputs using the fixed orifices at specified manifold

pressures as shown in Table 4. DO NOT REDRILL

ORIFICES UNDER ANY CIRCUMSTANCES.

The rated gas inputs shown in Table 4 are for altitudes from

sea level up to 2000 ft above sea level. These inputs are

based on natureJ gas with a heating value of 1050 Btu/cu ft

at 0.65 specific gravity, or propane gas with a heating value

of 2500 Btu/cu ft at 1.5 specific gravity. For elevations

above 2000 ft, reduce input 4% for each 1000 ft above sea

level. When gas supply being used has a different heating

value or specific gravity, refer to Carrier training manuals,

national and local codes, or contact your Carrier distributor

or dealer to determine required orifice size.

ADJUSTING GAS INPUT-The gas input to unit is deter

mined by measuring the gas flow at the meter or by measur

ing the manifold pressure. Measuring the gas flow at the

meter is recommended for natured gas units. Manifold pres

sure must be measured to determine the input of propane

gas units.

Measuring Gas Flow at Meter Method—Natural Gas

Units—Minor adjustment can be made by changing mani

fold pressure. Manifold pressure must be maintained

between 3.2 and 3.8 in. wg. If larger adjustments are

required, change main burner orifices following recommen

dations of national and loced codes.

NOTE: All other appliances that use the same meter must

be turned off when gas flow is measured at meter.

Proceed as follows:

1. Turn off gas supply to unit.

2. Remove pipe plug on bottom of gas vedve, then connect

water manometer at this point. Turn on gas to unit.

3. Record number of seconds for gas meter test dial to

make one revolution.

4. Divide number of seconds in step 3 into 3600 (number

of seconds in one hour).

5. Multiply result of step 4 by the number of cu ft shown

for one revolution of test dial to obtain cu ft of gas flow

per hour.

6. Multiply result of step 5 by Btu heating value of gas to

obtain toted measured input in Btuh. Compare this

value with heating input shown in Table 4. Consult

local gas supplier if the heating value of gas is not

known.

Example: Assume that the size of test dial is one cu ft, one

revolution takes 30 seconds and the heating value of the gas

is 1050 Btu per cu ft, then proceed as follows;

a. 30 seconds to complete one revolution.

b. 30 divided into 3600 equals 120.

c. 120 times one equals 120 cu ft of gas flow per hour.

d. 120 times 1050 equals 126,000 Btuh input.

If the desired gas input is 125,000 Btuh, only a minor

change in the manifold pressure is required.

Observe manifold pressure and proceed as follows to adjust

gas input:

1. Remove cover screw over REG ADJ screw on gas

valve.

2. Turn regulator adjustment screw clockwise to increase

gas input, or turn regulator adjustment screw counter

clockwise to decrease input. Manifold pressure must be

between 3.2 and 3.8 in. wg. UNSAFE OPERATION

OF THE UNIT MAY RESULT IF MANIFOLD

PRESSURE IS OUTSIDE THIS RANGE.

3. Replace vented seal on gas valve.

4. Turn off gas supply to unit. Remove manometer from

pressure tap. Replace pipe plug on gas valve. Turn on

gas to unit. Check for leaks.

Measuring Manifold Pressure—Propane Gas Units—The

main burner orifices on a propane gas unit are sized for the

unit rated input when manifold pressure is 10.5 in. wg.

Proceed as follows to adjust gas input on propane gas unit:

1. Turn off gas to unit.

2.

Remove pipe plug on gas valve outlet identified as

PRESS. TAP, then connect manometer at this point.

3.

Turn on gas to unit.

4. Remove cover screw over REG ADJ screw on gas

valve.

5.

Adjust regulator adjustment screw for a manifold pres

sure reading of 10.5 in. wg. Turn adjusting screw clock

wise to increase manifold pressure, or turn adjusting

screw counterclockwise to decrease manifold pressure.

Replace cover screw.

6.

7.

Turn off gas to unit. Remove manometer from pressure

tap. Replace pipe plug on gas valve, then turn on gas to

unit. Check for leaks.

Table 4—Rated Gas Inputs at Indicated Manifold Pressures

GAS SUPPLY NATURAL GAS PROPANE GAS

NUMBER

MODEL 48-

KLA118,124,130

KLA136,142 3 5.0

KHA024,030

KLA148

KHA136,KLA160

KHA036,042,048 5 5.0

KHA060 6 5.0

♦Based on altitudes from sea level up to 2000 ft above sea level. For alti

tudes above 2000 ft, reduce input rating 4% for each 1000 ft above sea

levei

OF Natural

ORIFICES Min Max

2 5.0 13.6 11.0

3 5,0

4 5.0 13.6

5 5.0 13.6

PRESSURE (in. wg) PRESSURE

13.6 11.0

13.6 11.0

13.6 11.0

13.6 11.0 13.0 3.5 10.5

Propane (in. wg)

Max Natural

Min

13.0 3.5 10.5

13.0 3.5 10.5

13.0 3.5

13.0 3.5

11.0

11.0 13.0 3.5 10.5

13.0 3.5

Orifice

Propane

10.5 LH32DB207(42) 75,000 LH32DB060(53) 75,000

10.5 LH32DB205(45) 80,000 LH32DB201(55)

10.5

fWhen KLA is converted to propane, all

See kit instructions

Part No. Input Part No. input

(Size)

LH32DB204(45) 40,000 LH32DB201(55)

LH32DB205(45) 60,000 LH32DB201(55)

LH32DB205(45)

LH32DB207(42) 125,000

LH32DB207(42) 150,000

Heating

(Btuh)* (Size) (Btuh)*

100,000 LH32DB201(55)

Orifice

LH32DB060(53)

LH32DB060(53)

NOx burners must be modified

10

Heating

40,000t

60,000t

80,000t

ioo,ooot

125,000

150,000

Page 11

ADJUSTING BURNER AIR SHUTTERS-After burners

have operated at full input for at least 10 minutes, adjust

primary air to each burner to ensure optimum heating per

formance. Make these adjustments when unit is being

installed and during routine maintenance inspections at

beginning of each heating season. Be sure each burner is

clean and free of deposits before adjusting primary air.

Primary air to each burner is regulated by burner air shut

ter on each burner. See Fig. 9 (Burner Flames, Standard) for

location of burner air shutter. With all burners operating,

adjust primary air to each burner as follows:

1. Loosen locking screw that secures air shutter in place

on burner, then partially close air shutter until a slight

yellow tip appears on top of burner flames.

2. Open air shutter very slowly until yellow tip just disap

pears, then secure air shutter in place with locking

screw.

3. Repeat steps 1 and 2 for each burner.

After air shutter adjustments have been completed, observe

that flames on each burner are light blue and soft in appear

ance, and that flames are same height along entire length of

each burner. See Fig. 9.

CARRYOVER

AIR

SHUTTER

STANDARD

MANIFOLD

Fig. 9—Burner Flames

BLOWER HEAT-RELAY OPERATION-Heating relay

(see Fig. 6 and unit wiring diagram) is located in the control

box and adjusts to permit either longer or shorter OFF

cycles. The ON cycle automatically adjusts as OFF cycle

changes. Adjusting level on relay is factory-set at center

position to provide optimum performance for most installa

tions. On unusual installations, or where line voltage is con

siderably above or below rated voltage, an increase or

decrease may be required for length of time blower remains

on. To increase blower operation time, move adjusting lever

toward right-hand position. To decrease blower operation

time, move lever toward left-hand position.

AIRFLOW AND TEMPERATURE RISE-The heating

section of each size of unit is designed and approved for

heating operation within temperature rise range stamped on

unit rating plate.

Table 5 shows approved temperature rise range for each

unit and air delivery (cfm) at various temperature rises.

Heating operation airflow must produce a temperature rise

that falls within the approved range. Refer to Cooling Sec

tion Start-Up and Adjustments—Indoor Airflow emd Air

flow Adjustments to adjust heating airflow when required.

HEATING SEQUENCE OF OPERATION—See Fig. 10

Models 48KHA,KLA have an intermittent electric-spark

ignition system without a standing flame. When manual

shutoff is opened, gas flows to gas valve. On a call for heat

ing by the thermostat, unit terminal R makes to unit termi

nal W. Pilot veJve solenoid of gas valve and spark generator

are energized. Gas flows to pilot and the pilot is ignited

within 4 seconds. The flame sensor proves the presence of

pilot flame within 0.8 seconds after pilot ignition. The inter

nal switching of gas valve de-energizes spark generator,

energizes meun valve solenoid and energizes heating delay

relay. Gas flows to medn burners and is ignited by pilot

flame. Contacts of heating relay close between 60 and 90

seconds after burners are ignited, and blower motor starts.

Heating cycle is now in normeil operation. Unit will continue

operating in heating cycle until thermostat is satisfied.

When this occurs, the thermostat switching removes 24-volt

control circuit voltage instantly; however, contacts of de

energized heating relay remain closed and keep blower

motor running for an additional 2 to 3 minutes. Contacts of

heating relay open after 2- to 3-minute delay and blower

motor stops. Heating section is now in a standby condition

wmting for another call for heating from thermostat.

Table 5—Air Delivery (cfm) at Indicated Temperature

MODEL 48-

KLA118

KLA124 40,000 794 751 712 678 646

KHA024 75,000

KLA130

KHA030

KLA136

KHA036/136

KHA036 125,000

KLA142 60,000 1190

KHA042 125,000

KLA148 80,000

KHA048

KLA160 100,000

KHA060 150,000

NOTE: Bolder ratings in table fall

range of the unit Dashed areas of

HTG

INPUT TEMPERATURE RISE(F)

(Btuh)

40,000 794 751 712 678

40,000 794 751 712

75,000

60,000 1190 1126

100,000

125,000

35 37 39 41 43 45 47

— — — — 1212 1158

—

1984 1877 1781 1694 1615

— — —

1128

— — ~

1502

1587

— —

1877

1984

— - — — —

678

—

1271

1016 969

1068

2117

1068 1016

—

1355

1425

2326 2117

1781 1694

below the approved temperature rise

the tabie faii beyond the air delivery

Rise and Rated Heating Input

49

646 617

617

617

646

1212 1158

926 887

1543

2019 1930 1846 1771

926

969

_

1930 1846

1292 1235 1182

1930

2019

1815 1543 1478

2325 2226

567 545 524

591

591 567 545

1063 1022 983

1109

591 567

1063 1022 983 947 914 883

1109

850

1417 1362 1310

1478

850 817 786 758 731 706 683 661

887

1771 1702 1638 1579 1523

1134 1089 1048 1010 975

1771 1702

1846

1417 1362

2135 2051

51 53

545 524

817 786

1701 1638

1638

1310

1974

capabiiity of the unit within the operating voitage range for aii voltage

options for each size unit.

57 59 61 63 65 67

55

505 487 471

947 914 883 854 827 809

505 487 471

758 731

1263 1218

1579 1523

1579

1263

1902

706

1177

1472

1482

942 911 —

1472

1523

1177

1218

1835 1773 1715 1660

441

455

455

854

683

1102 1068 1036 1006 978 951 926

1138

1378 1336 1296 1258 1223 1189 1158

1423

1378 1326 1296 1258 1223

1423

1423 1378

1102

1138

71 73 75

69

_

—

427

778

641 622 604 587 571 556

—

—

1336 1296

—

—

1561

1609

—

—

— — —

—

— —

—

—

_

—

1493 1483 1395

1516

11

—

1189

— —

—

—

—

—

—

Page 12

C — Contactor

Cap. — Capacitor

Comp — Compressor

GV — Gas Valve

IFM — Indoor Fan Motor

IFMC — Indoor Fan Motor Capacitor

IFR — Indoor Fan Relay (Cooling)

IFSS — Indoor Fan Safety Switch

LS — Limit Switch

OFM — Outdoor Fan Motor

P — Pilot (Safety, Flame Sensing)

PI — Pilot Igniter

QT — Quadruple Terminal

ST — Start Thermistor

TDR — Time-Delay Relay (Adjustable) (Heating)

Tran — Transformer

Fig. 10—Typical Wiring Diagram (48KHA030310 shown)

H— Wire Sleeve

O Component Connection (Unmarked)

o Component Connection (Marked)

------

— — Field Wiring

________

Field Ground Wiring

--------------Field Power Wiring

-Pl- Field Splice

• ■ Junction

-----

®— Junction (Thermostat to Subbase)

— ——— Alternate Start Thermistor Wiring

•

12

NOTES:

1 Use copper conductors only.

2 Compressor and fan motors thermally protected

3 Transformer pigtails: red208v; orange 230v;

insulate unused lead

4 Neutral for 240/416-v system for Canada only

5 If any of the original wire furnished must be

replaced, it should be replaced with wire of the

same type or its equivalent

6 Fan motor pigtails; red low, black high, insulate

unused lead

Page 13

UNIT

MODEL

48-

KLA118

KLA124

KHA024 208-

KLA130

KHA030

KLA136

KLA136

KHA036

KHA136

KHA036

KHA136 230-3

KLA142

KHA042

KLA148 208-

KLA148

KHA048

(See next page for applicable notes )

VOLTS- MOTOR

PHASE (60 Hz) SPEED

208- Coolt

230-1 High Heat):

208-

230-1 High Heat

230-1

208-

230-1

208-

230-1

208-

230-1

208/

230-3

460-3 Cool 1165

208- Coolf:

230-1

208/

208-

230-1

208/ Cool 965 960 955 940 930

230-3 High Heat

208-

230-1 High Heat 1705

208/ Cool

230-3 High Heat

230-1 High Heat

208/ Med Heat 1805 1800 1785 1765 1735

230-3

460-3 Cool 1490

208-

230-1

BLOWER EXTERNAL STATIC PRESSURE (in. wg)

Low

Low

Low Heat

High Highf:

Low Heatf:

High Heat

Low

High Heat

Low Heatf:

High Heat

Low Heatf:

High

Low Heat): 1185

High Heat 1535

Low Heat

High HeatL

Low Heat

Med Heat

High Heatf:

Low Heatt

High Heat

Low

Low Heat

Low Heatf:

Low HeatL

Low Heat):

High Heat

Low Heatt 1500

High Heat 2040

Low

High Heat

Table 6—Model 48KHA,KLA Air Delivery (cfm)*

at Indicated External Static Pressure and Voltage

COILt

0.0 0.1

Heat

740 700 660

700 665 625

795 750 705

Cool

745

Heatf:

895 850

Cool

865

980 930 875

Coolt

940

995 925 890

Cool);

935

1125

Cool

1080 1035 990

700

Cool

690 670 650 630 605 580

1325 1270 1210

Coolf:

1270 1220 1165

Heatt

1125

Cool

1085

1225 1165 1105

Cool

1175 1120 1065

950 945 940 930 915 900

Cool

945 940 935 925 910 890 — — —

1570 1500 1425

Coolf:

1475 1410 1345

1165 1155 1140

Cool

1155 1145 1125 1110 1085 1050 1015 960 855

Heat

1525

Cool):

1475

Cool): 1485

1280 1260 1240

1265 1245

1825 1765 1700 1630

Cool

1735 1670

1275 1270 1260 1240 1220 1195 1165 1135 1100

Coolf:

1270 1260

1625 1605 1575 1540 1500 1455 1400 1350 1295

Cool

1590 1565 1530 1490

2035 1980 1920 1855 1785

Cool

1915 1860 1800 1740 1675

855 850 835

Cool

855 845 830

1700 1635 1565 1495 1425

Cool):

1635 1575 1505 1440

Heatf: 970 965 960 945 935

2040 1980 1915 1850

Coolf:

1950 1890 1835

1410 1385 1355 1315 1255 1175

Cool

1390 1365 1330 1280 1215 1120 — — — 1535

Cool):

1650 1590 1535 1465

1405 1400 1395 1385 1365

1400 1395

1725 1710 1685 1655 1615

Cool):

1705 1685 1655 1615 1570 1515 1455 1390 1320 1870

1180 1170

Cool

1175 1165

1780

Coolf: 1770 1710 1645 1590 1525

1200 1195

Cool

1195 1190 1180 1170 1160

Cool

1800 1790 1770 1745 1715

2200 2155 2110 2055 2000 1940 1880 1815 1755 2325 2275 2220 2160

Coolf:

2155 2110

Cooli|: 2000 1960 1910 1855

Heatt

1690

Cool

1685 1640 1585

1890 1820

CoolL

1880

0.2

705 665

800 750 700 645

820 775 725 675 620

895 845 790 730 665

900 870

1075 1030 980 930 880

680 655

1070 1015

1035 985

1490 1450 1415 1375

1440 1405 1370 1325

1220 1195 1165

1595 1515 1410

1245 1225 1205

1650

1590 1525 1450

1385 1370 1345

1160

1155 1130 1075

1720 1660 1610 1550

1190 1180 1170

2060 2005 1950

1650 1600 1545

1760 1690 1625 1560

1810 1745 1670 1600 1530

208V

0.3 0.4 0.5 0.6 0.7

615 565 510

580 535 480

660 610 555

620 570

820 760

855 815

835 800

950 900

635 610

1150 1090 1020

1110 1045

955 900

925 870

1040 980

1005 945

1355 1280

1275 1205

1125

1100 1075 1040 995 930 1365 1345 1320 1295 1265 1225

1215 1190

1540

1445

820 795

815 790

1375

1785

1770 1705

1390

1090

1140

1480

1525 1455

_

_

— —

— —

—

520

700

780

766

855

585

975

840

815 — — —

915

885

1200

1140

1330

1280 1225

1160

1130

1425

1270

1175 1145 1110

1395 1350 1300 1245

1715

1610 1545

760

750

1355

1305

910 880 835 780

905 870

1715 1640 1550 1450 2145

1635 1555 1465 1380 2030 1970 1905 1840

1365

1300 — — — 1705 1640 1580 1510 1435

1335 1295 1240

1310 1260 1205 1145 1630 1605 1575 1540 1495

1565 1505 1440

980

960 — — —

1500

1470

1150 1145 1135 1115

1145

1700 1665

1680

1890 1835 1775 1710

1420

1390

—

_ — —

__

— — 920

_

_

— —

—

— —

— —

— —

_

—

_ —

—

—

_

_

—

—

— _

_

—

_

_

— —

— —

_

—

1280 1220 1135 1620

1155 1045 1560

_

_

—

_ —

— — — 1790

1645 1570 1495 2130

1480 1410 1995

— — —

—

— — 1030

_

_

__

— — 1695 1630 1560 1480 1405

820 765 1190

_

_

— _

—

— — _

— _

_

— —

1140 1130 1110 1415

1625 1585 2080

1640 1605 1565 2050

_ — _

—

— — 1750 1690 1630

— —

“ — —

0.0 0.1 0.2 0.3

0.8

_

805

—

—

—

—

— 985 935 885 835

—

—

_

—

—

_

_

—

—

_

—

_

—

_

1075 1490

_

—

1175 1650

1370 1935

—

_

765 725

760 720

870 825 780

810 775 730 690

950

1030 975 920 865

1030 990 955 920 880 840

1000

1160

1120 1075 1030 980 935

850

835

1370 1310 1245 1180

1305 1245 1190 1125

1175

1130

1260

1205

1250

1210

1610

1510

1345

1510

1475

1905

1505

1845

1770

1035

1770

1190

1580

1770

1350 1340 1330 1310

1345

1920

1860

1420

2265

1790

1975

1915

680

905 855

875 825

965 935

1115 1065

795 765 735 705

820

810 785

1115 1050

1070 1010

1140 1080 1020 955

1200

1155 1100

1205 1160 1115

1165 1125 1080 1035 990

1540 1470 1400

1450 1390

1320 1295 1265

1540 1495 1450 1405

1580

1475 1435

1520

1160 1135 1110 1095

1175

1135 1120 1095 1060

1155

1500 1460

1450 1415

1445 1400 1340 1275

1480

1440 1395

1845 1775

1725 1655

1490 1470

1470 1445

1805 1760 1710

1725 1675

2010 1940

2070

1875 1815 1745

1940

1025 1010

1020 1005 990

1635 1555

1705

1185 1175

1170 1155 1135 1105

1180

2010 1940

2080

1475 1420 1360

1530

1435 1380 1315 1240 — — —

1485

1710 1645

1635 1610

1885 1835

1770 1720 1665 1610 1550 1470 1360

1820

1335 1325 1300 1255 1120 — —

1845 1770

1790 1725 1655

1410 1400 1390

1395 1385 1380 1365 1350 1320 1285

1405

2015 1970 1920 1865 1805

2050

1975 1930 1880 1820 1765 1705 1640

2020

2215 2160

1480 1460

1450 1425 1395 1370

1470

1950 1895 1835 1775

1995

1665 1600

1730

1820

1900

1845 1770

230V or 460V

0.4

675 625 565

635 585 525 — — —

735 685 630

640 590

800 745 680

770 715 650

810 755

780 725

890 860 820 — — —

1015 965 915

755 725 695 —

1110 1035

1060 990

985 925 855

950 890 830

1040 985 925 — — —

1065 1015

1330 1255

1325 1260 1190

1235 1190 1135

1390 1345 1295

1425 1385 1340 1290 1230 1145

1380 1335 1290

1345 1280 1210 — —

1700 1595 1475

1565 1455 1320 — — —

1445 1415 1375 1330

1415 1375 1330 1285 1235 1185

1655 1595 1535

1625 1575 1520 1465

1870 1800 1725

995 975 950

965 935 —

1470 1385

1165 1145

1865 1790 1705

1770 1695 1610

1575 1500 1415

1585 1545 1500 1445 1380 1305

1780 1730 1670

1275 1190

1696 1625 1550

1585 1515 — —

1385 1370 1355

2095 2030 1965

2100 2040 1975 1910 1840 1770

1435 1410 1380 1350 1325 1295

1795 1735 1670

1530 1450

1565 1495 1410

1745 1665 1590

1696 1625

0.6

0.5

—

— — _

— — —

— —

—

—

_

— — —

—

885

— — —

—

— _

—

—

— — —

— _ —

—

— — —

—

_

1180

1355

1060

1015

1235

—

—

1680 1615

— _

— — _

1325

— — —

1120 1080

1055

—

1290

__

1345

— —

1445 1385

1610

—

_ _ _

1340

1710

—

— —

— — —

1550

—

0.7 0.8

— _

—

— —

_

_

— —

_

—

_ —

— —

_

—

—

_ —

_

_

_

_

_

—

1120 1020

1060 900

1300 1230

1235 1155

1005 940

970 895

1165 1055

— _

—

_ —

1230

1280

1415

1480

1350

1405

1645 1570

1545 1475

—

— —

1020 940

990 910

1610 1500

1515 1400

— _

_ _

—

1320 1250

1540 1455

_

—

_

1330 1300

1745 1680

1895 1825

1310 1280

1580

1645

1540

1610

—

—

—

—

—

13

Page 14

Table 6—Model 48KHA,KLA Air Delivery (cfm)*

at Indicated External Static Pressure and Voltage (cont)

MODEL

48-

KHA048 208/

KLA160

KHA060

*Air delivery values are without air filter. Deduct field-supplied air filter

pressure drop to obtain external static pressure available for ducting

tHeating airflow values are with a dry coil Cooling airflow values are with

a wet coil.

frThese airflow values are at the factory heating and cooling motor speed

setting.

A dash (—) indicates portions of the table that are beyond the blower

motor capability or that are not applicable

UNIT

VOLTS—

PHASE (60 Hz)

230-3

230-1

230-1

BLOWER

MOTOR

SPEED

Low Heat

Med Heat

High

Low

High

Low

Med

High

COILt

Cool

Cooli

Heat

Cool

Heatt

Cool

Heat

Coolj:

Heat

Cool

Heat^:

Cool

Heat

Coolj:

0.0

1440

1435

1755

1745

1950

1925

0.1

1435

1430

1740

1730

1920

1890

0.2

1425

1420

1725

1710

1880

1850

0.3 0.4

1415

1410

1700

1680

1940

1810

208V

1400

1395

1665

1645

1795

1765

EXTERNAL STATIC PRESSURE (in. wg)

0.6 0.7

0.5

1365

1385

1355

1380

1625

1580

1550

1600

1700

1750

1715

1665

NOTE: Do not operate the unit at a cooling airflow that is less than 350

fpm per each 12,000 Btuh of rated cooling capacity Indoor coil frosting

may occur at airflows below this point.

1340

1330

1530

1500

1645

1615

0.8

0.0 0.1 0.2 0.3

1305

1730

1290

1725

1470

1970

1440

1950

1590

2175

1560

2130

1610

1595

2375

2270

1880

1875

2130

2075

2345

2255

1720

1710

1945

1920

2130

2085

1600

1585

2280

2185

1875

1865

2075

2025

2260

2175

1700

1685

1910

1880

2085

2035

1580

1575

2185

2100

1860

1840

2015

1965

2180

2100

230V or 460V

0.4

1675

1645

1660

1625

1875

1825

1840

1790

2030

1970

1980

1920

1560

1530

1550

1515

2095

2000

2015

1930

1825

1770

1790

1725

1955

1890

1900

1835

2095

2010

2020

1945

0.5

1601

1585

1775

1735

1905

1855

1495

1475

1905

1840

1700

1650

1810

1760

1930

1865

0.6 0.7

1560

1545

1720

1685

1840

1790

1520

1495

1660

1625

1765

1720

0.8

1470

1445

1600

1570

1695

1650

NOTE: The igniter continues to spark for approximately 10

seconds after burners are ignited.

LIMIT AND PRESSURE SWITCHES-Furnace limit

switch (see Fig. 10) closes gas valve if leaving-air tempera

ture exceeds 175 F.

Normally closed limits switch completes control circuit

through pigtail lead W to gas valve 5F. See Fig. 10. Should

leaving-air temperature rise to 175 F, switch opens and W

control circuit breaks. Any interruption in W control circuit

instantly closes gas valve and stops gas flow to burners and

pilot. Blower motor continues to run until time-delay

sequence of heat relay is completed.

When air temperature at limit switch drops to the low-tem

perature setting of limit switch, switch closes and com

pletes W control circuit. Electric-spark ignition system

cycles emd unit returns to normeil heating operation.

BLOWER SAFETY SWITCH-BIower safety switch is a

temperature-actuated switch connected in parallel with con

tacts of heat relay. Function of switch is to activate blower

should gas valve fail to close when thermostat is satisfied.

Safety switch is mounted on blower divider panel. When

temperature at safety switch reaches approximately 175 F,

switch closes to start blower. Switch opens when tempera

ture at switch drops to approximately 116 F.

Cooling Section Start-Up and Adjustments

A CAUTION

Complete required procedures given in Unit Prepara

tion section before starting unit.

Do not jumper any safety devices when operating unit.

Do not operate compressor when outdoor temperature

is below 55 F (single-phase units) or 40 F (3-phase

units).

Do not permit compressor to rapid cycle. Allow 5 min

utes between cycles to prevent compressor damage.

CHECKING COOLING CONTROL OPERATION-Start

and check unit for proper cooling control operation as

follows:

1. Place room thermostat selector switch in OFF position.

Observe that blower motor starts when fan switch is

placed in ON position and shuts off when fan switch is

placed in AUTO, position.

2. Place selector switch in COOL position and fan switch

in AUTO, position. Set cooling control below room tem

perature. Observe that compressor, condenser fan and

evaporator blower motors start. Observe that cooling

cycle shuts down when control setting is satisfied.

3. When using an automatic changeover room thermo

stat, place both selector and fan switches in AUTO,

positions. Observe that unit operates in heating mode

when temperature control is set to call for heating

(above room temperature) and operates in cooling mode

when temperature control is set to call for cooling

(below room temperature).

CHECKING AND ADJUSTING REFRIGERANT

CHARGE—Refrigerant system is fully charged with R-22

refrigerant, tested and factory sealed. For most applica

tions, factory charge is the correct amount for best perform

ance; however, this charge may require a slight adjustment

to attain rated performance.

NOTE: Adjustment of refrigerant charge is not required

unless unit is suspected of not having proper R-22 charge.

For all applications, correct R-22 charge for best perform

ance is charge that results in a suction gas superheat of 5 F

at compressor inlet when unit is operating at ARI rating

conditions of 95 F db outdoor and 80 F db/67F wb indoor.

A superheat charging label is attached to outside of com

pressor access door. Label includes a Field Superheat

Charging Table and a Required Suction-Tube (F) tempera

ture chart.

Table 7 is intended for use when minor unit charge adjust

ments are required. For large adjustments, evacuate unit

and weigh in cheirge according to unit rating plate. Use

Table 7 to approximate charge if ARI rating conditions can-

14

Page 15

#

#

not be obtained. Refer to required eurflow rates in Table 8.

Charge unit with outdoor fan operating only at high speed.

An accurate superheat-, thermocouple-, or thermistor-type

thermometer, a sling psychrometer and a gage manifold are

required when using superheat cheirging method for evalu

ating unit charge. Do not use m ercury o r small dial-typ e

th erm o m eters b eca use they are not ade qua te for this type of

m easuremen t.

A CAUTION

When evaluating refrigerant charge, an indicated

adjustment to specified factory charge must always be

minimal. If a substantial adjustment is indicated, an

abnormal condition exists somewhere in cooling sys

tem, such as insufficient airflow across either or both

coils.

Proceed as follows:

1. Remove caps from low- and high-pressure service fit

tings. See Fig. 4 for location of entrance for refrigerant

pressure gage hoses.

2. Using hoses with valve core depressors, attach low-

and high-pressure gage hoses to low- and high-pressure

service fittings, respectively.

3. Start unit in cooling mode and let unit run until system

pressures stabilize.

4. Measure and record the following:

a. Outdoor ambient-air temperature (F db).

b. Evaporator inlet-air temperature (F wb).

c. Suction-tube temperature (F) at low-side service

fitting.

d. Suction (low-side) pressure (psig).

5. Using Field Superheat Charging Table, compare

outdoor-air temperature (F db) with evaporator inlet-air

temperature (F wb) to determine desired system oper

ating superheat temperature.

6. Using Required Suction-Tube (F) table, compare

desired superheat temperature with suction (low-side)

operating pressure (psig) to determine proper suction

tube temperature.

7. Compare actual suction-tube temperature with proper

suction tube temperature. Using a tolerance of ±3 F,

add refrigerant if actual temperature is more than 3 F

higher than proper suction tube temperature, or

remove refrigerant if actual temperature is more than

3 F lower than required suction-tube temperature.

NOTE: If the problem causing inaccurate readings is a

refrigerant leak, see Unit Preparation, Refrigerant Leaks

section of these instructions.

INDOOR AIRFLOW AND ADJUSTMENTS

A CAUTION

For cooling, recommended airflow is 350 to 450 cfm for

each 12,000 Btuh of rated cooling capacity. For heating,

airflow must produce a temperature rise that falls

within the range stamped on unit rating plate.

Models 48KHA,KLA end-discharge units have direct-drive

blower motors. All motors are factory-connected to deliver

proper heating and cooling airflows at normal external

static pressures (except for some 208-v applications).

Table 7—Refrigerant Charging Label

DESIRED SUPERHEAT TEMPERATURE (F)

(Measured @ Low-Side Service Port)

OUTDOOR

AMBIENT

EDB (F)

65

70

75

80

85

90

54 56 58 60

10 13 16 19

7 10 13 16 19

_

_

— —

—

95

100

—

105

110

115

NOTES:

1 Dashed Areas; Do not attempt to charge system under these condi

tions or refrigerate siugging may occur

2 Add charge if actual superheat temperature is higher than chart value

and remove if lower Allow ± 3 F for tolerance

EVAPORATOR AIR INLET EWB (F)

6 9 12 15

—

5

—

— — —

—

—

__

64 66 68

62

24 27 30 33 36 38

21

21

18 21

15 18

12

8

11 15 19 22 26 30 33

8

5 9

6

—

—

—

70

24 27

13 16

10 14

—

30

24

28 31

21

25 28 31

20

18

12

8

5 9 13

15

6 11 15 20 25

8

74 76

72

33 36 39

34 37

24 27 31

22 25 29

20 23 27

17 22 26

14

18

41

35

23

REQUIRED SUCTION-TUBE TEMPERATURE (F) vs.

DESIRED SUPERHEAT TEMPERATURE (F)

(Measured @ Low-Side Service Port)

DESIRED

SUPERHEAT

TEMP(F) 61.5

0

2 37

4

6

8