48AJ,AK,AW,AY020-060

with Reciprocating Compressor

48EJ,EK,EW,EY024-068

Single Package Rooftop Units

Electric Cooling/Gas Heating

Installation, Start-Up and

Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-58

Step 1 — Provide Unit Support . . . . . . . . . . . . . . . . . . . 1

• ROOF CURB

• ALTERNATE UNIT SUPPORT

Step 2 — Rig and Place Unit . . . . . . . . . . . . . . . . . . . . . 2

• POSITIONING

• ROOF MOUNT

Step 3 — Field Fabricate Ductwork . . . . . . . . . . . . . . . 2

Step 4 — Make Unit Duct Connections . . . . . . . . . . . 2

Step 5 — Install Flue Hood . . . . . . . . . . . . . . . . . . . . . . 28

Step 6 — Trap Condensate Drain . . . . . . . . . . . . . . . . 28

Step 7 — Install Gas Piping . . . . . . . . . . . . . . . . . . . . . 28

Step 8 — Controls Options. . . . . . . . . . . . . . . . . . . . . . 29

• STAGED GAS UNIT APPLICATIONS

• THERMISTORS

• CONSTANT VOLUME APPLICATIONS

• VARIABLE AIR VOLUME (VAV) APPLICATIONS

Step 9 — Make Electrical Connections . . . . . . . . . . 33

•POWER WIRING

• FIELD POWER SUPPLY

• FIELD CONTROL WIRING

Step 10 — Make Outdoor-Air Inlet

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

• ECONOMIZER

• ECONOMIZER SETTINGS

Step 11 — Position Power Exhaust/Barometric

Relief Damper Hood. . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Step 12 — Install All Accessories . . . . . . . . . . . . . . . 54

Step 13 — Field Modifications. . . . . . . . . . . . . . . . . . . 57

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58-89

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89-102

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . 103-115

START-UP CHECKLIST . . . . . . . . . . . . . . . . . . . CL-1,CL-2

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should install, repair, or service air-conditioning equipment.

Untrained personnel can perform the basic maintenance

functions of cleaning coils and filters and replacing filters. All

other operations should be performed by trained service personnel. When working on air-conditioning equipment, observe

precautions in the literature, tags and labels attached to the unit,

and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations. Have

fire extinguishers available for all brazing operations.

Before performing service or maintenance operations on

unit, turn off main power switch to unit. Electrical shock

could cause personal injury.

1. Improper installation, adjustment, alteration, service,

or maintenance can cause property damage, personal

injury, or loss of life. Refer to the User’s Information

Manual provided with this unit for more details.

2. Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

What to do if you smell gas:

1. DO NOT try to light any appliance.

2. DO NOT touch any electrical switch, or use any

phone in your building.

3. IMMEDIATELY call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

4. If you cannot reach your gas supplier, call the fire

department.

Disconnect gas piping from unit when pressure testing at

pressure greater than 0.5 psig. Pressures greater than

0.5 psig will cause gas valve damage resulting in hazardous

condition. If gas valve is subjected to pressure greater than

0.5 psig, it must be replaced before use. When pressure

testing field-supplied gas piping at pressures of 0.5 psig or

less, a unit connected to such piping must be isolated by

closing the manual gas valve(s).

INSTALLATION

Step 1 — Provide Unit Support

1. All panels must be in place when rigging.

2. Unit is not designed for handling by fork truck.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1

Ta b 1 a

PC 111 Catalog No. 534-739 Printed in U.S.A. Form 48A,E-1SI Pg 1 107 11-01 Replaces: 48E-6SI

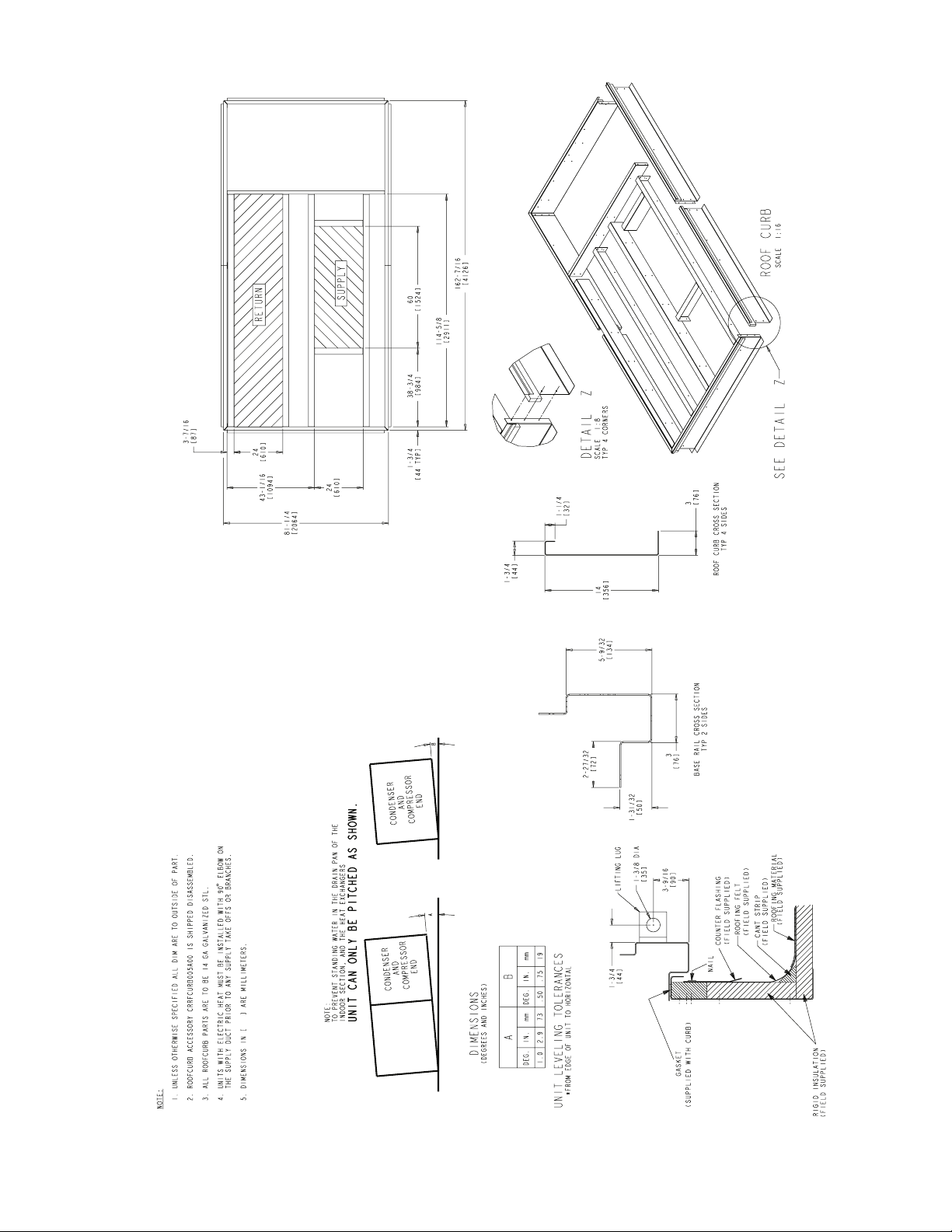

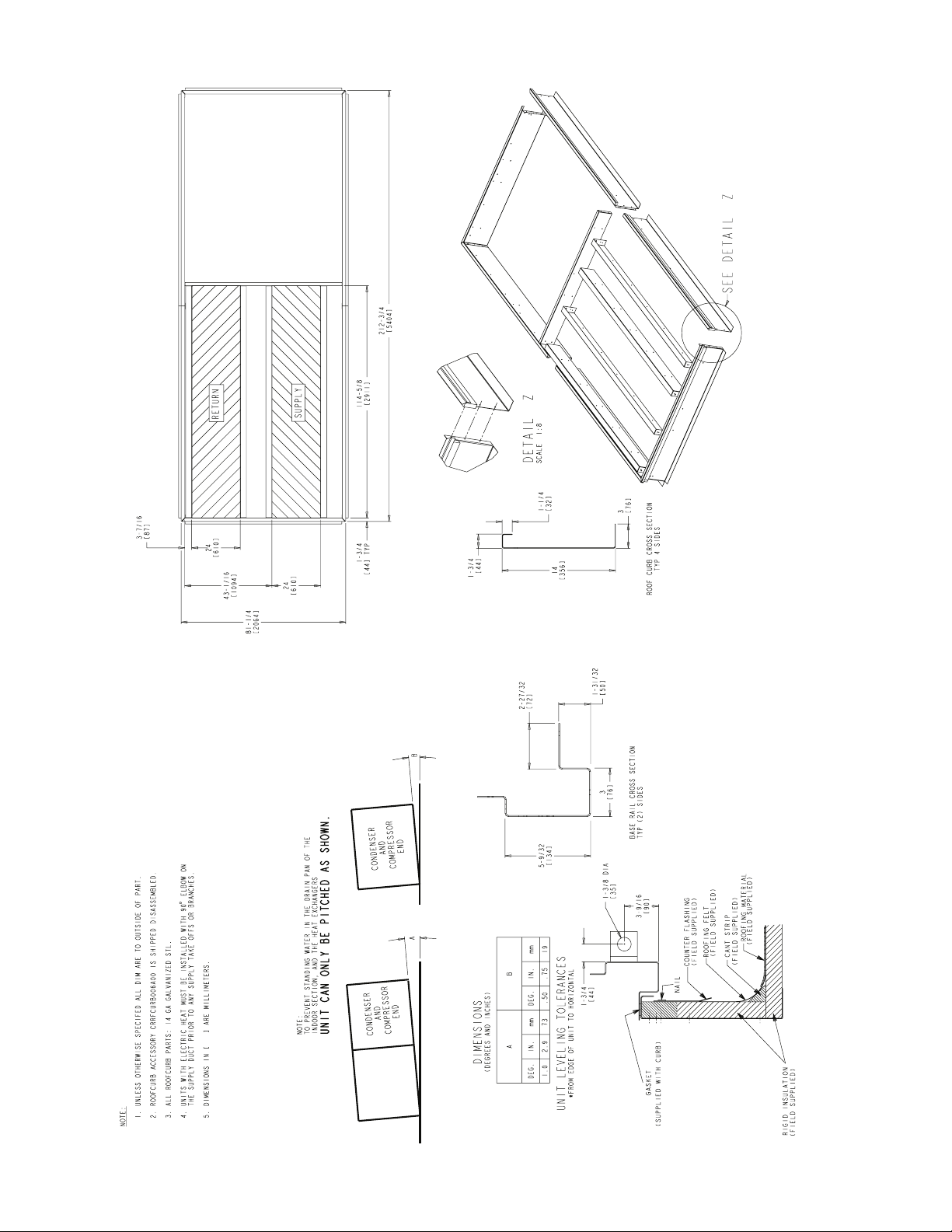

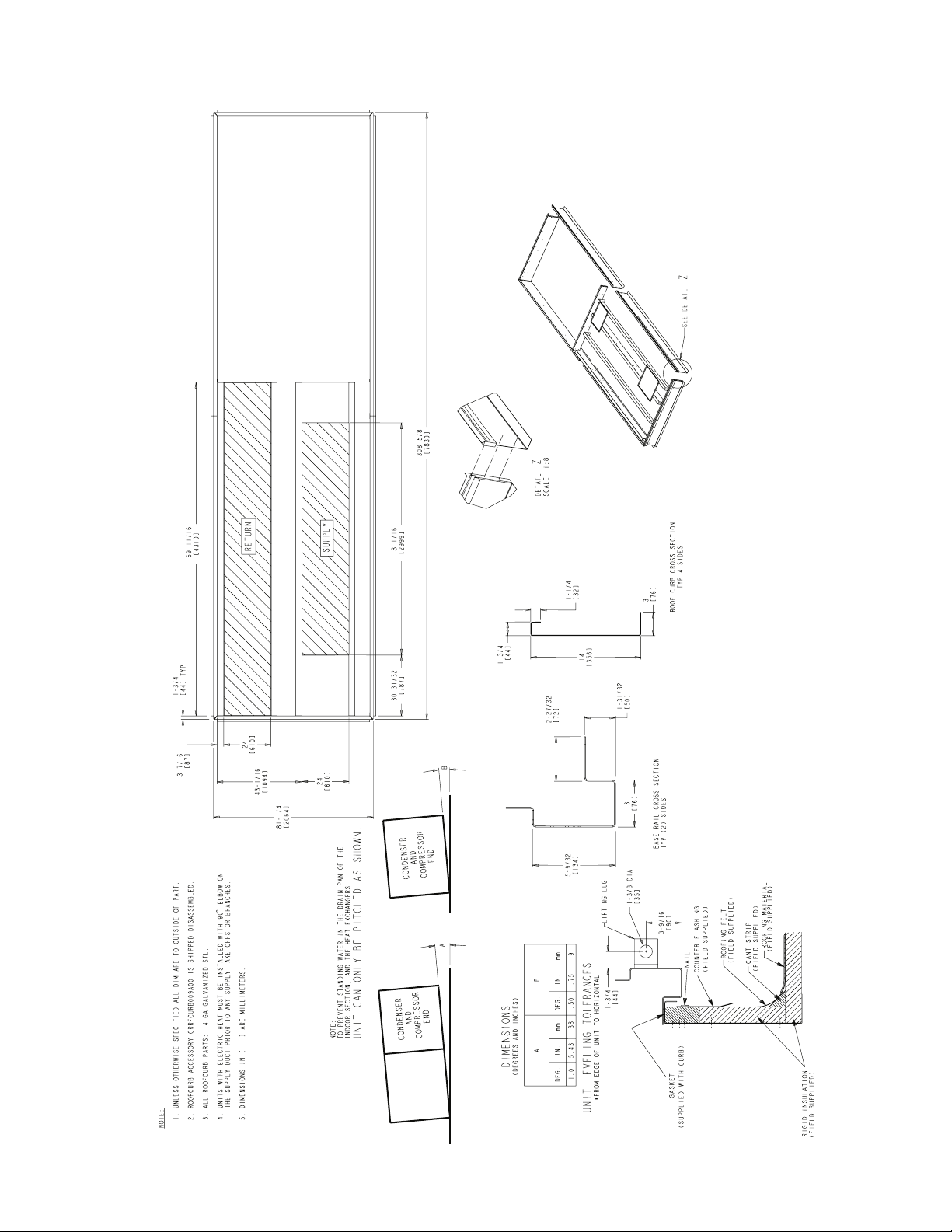

ROOF CURB — For vertical discharge units, assemble or install accessory roof curb in accordance with instructions

shipped with this accessory. See Fig. 1-4. Install insulation,

cant strips, roofing, and counter flashing as shown. Ductwork

can be installed to roof curb before unit is set in place. Curb

should be level. This is necessary to permit unit drain to function properly. Unit leveling tolerance is shown in Fig. 1-3.

Refer to Accessory Roof Curb Installation Instructions for

additional information as required. When accessory roof curb

is used, unit may be installed on class A, B, or C roof covering

material.

IMPORTANT: The gasketing of the unit to the roof curb is

critical for a watertight seal. Install gasket with the roof

curb as shown in Fig. 1-3. Improperly applied gasket can

also result in air leaks and poor unit performance.

ALTERNATE UNIT SUPPORT — When the preferred curb

or slab mount cannot be used, support unit with sleepers on perimeter, using unit curb support area. If sleepers cannot be

used, support long sides of unit (refer to Fig. 5-16) with a minimum number of 4-in. x 4-in. pads spaced as follows:

48AJ,AK,AW,AY020-030 and 48EJ,EK,EW,EY024-034 units

require 3 pads on each side; 48AJ,AK,AW,AY035-050 and

48EJ,EK,EW,EY038-048 units require 4 pads on each side;

48AJ,AK,AW,AY060 and 48EJ,EK,EW,EY054-068 units require 6 pads on each side. Unit may sag if supported by corners

only.

Step 2 — Rig and Place Unit — Inspect unit for

transportation damage. See Tables 1A and 1B for physical data.

File any claim with transportation agency.

Do not drop unit; keep upright. Use spreader bars over unit

to prevent sling or cable damage. Level by using unit frame as

a reference; leveling tolerance is shown in Fig. 1-3. See Fig. 17

for additional information. Unit operating weight is shown in

Table 2.

NOTE: On retrofit jobs, ductwork may be attached to old unit

instead of roof curb. Be careful not to damage ductwork when

removing old unit. Attach existing ductwork to roof curb

instead of unit.

Four lifting lugs are provided on the unit base rails as shown

in Fig. 5-16. Refer to rigging instructions on unit.

POSITIONING — Maintain clearance, per Fig. 5-16, around

and above unit to provide minimum distance from combustible

materials, proper airflow, and service access.

Do not install unit in an indoor location. Do not locate unit

air inlets near exhaust vents or other sources of contaminated

air. For proper unit operation, adequate combustion and ventilation air must be provided in accordance with Section 5.3 (Air

for Combustion and Ventilation) of the National Fuel Gas

Code, ANSI Z223.1 (American National Standards Institute).

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

Locate mechanical draft system flue assembly at least 4 ft

from any opening through which combustion products could

enter the building, and at least 4 ft from any adjacent building.

When unit is located adjacent to public walkways, flue assembly must be at least 7 ft above grade.

ROOF MOUNT — Check building codes for weight distribution requirements. See Fig. 17. Unit operating weight is shown

in Table 2.

Step 3 — Field Fabricate Ductwork — Secure all

ducts to building structure. Use flexible duct connectors between unit and ducts as required. Insulate and weatherproof all

external ductwork, joints, and roof openings with counter

flashing and mastic in accordance with applicable codes.

NOTE: Due to width of the horizontal supply/return ductwork,

provisions should be made for servicing of the outdoor air filters (i.e., catwalk over ductwork).

Ducts passing through an unconditioned space must be insulated and covered with a vapor barrier. Outlet grilles must not

lie directly below unit discharge. The return duct must have a

90-degree elbow before opening into the building space if the

unit is equipped with power exhaust.

To attach ductwork to roof curb, insert duct approximately

10 to 11 in. up into roof curb. Connect ductwork to 14-gage

roof curb material with sheet metal screws driven from inside

the duct.

For vertical supply and return units, tools or parts could

drop into ductwork and cause an injury. Install a 90-degree

elbow turn in the supply and return ductwork between the

unit and the conditioned space. If a 90-degree elbow cannot

be installed, then a grille of sufficient strength and density

should be installed to prevent objects from falling into the

conditioned space.

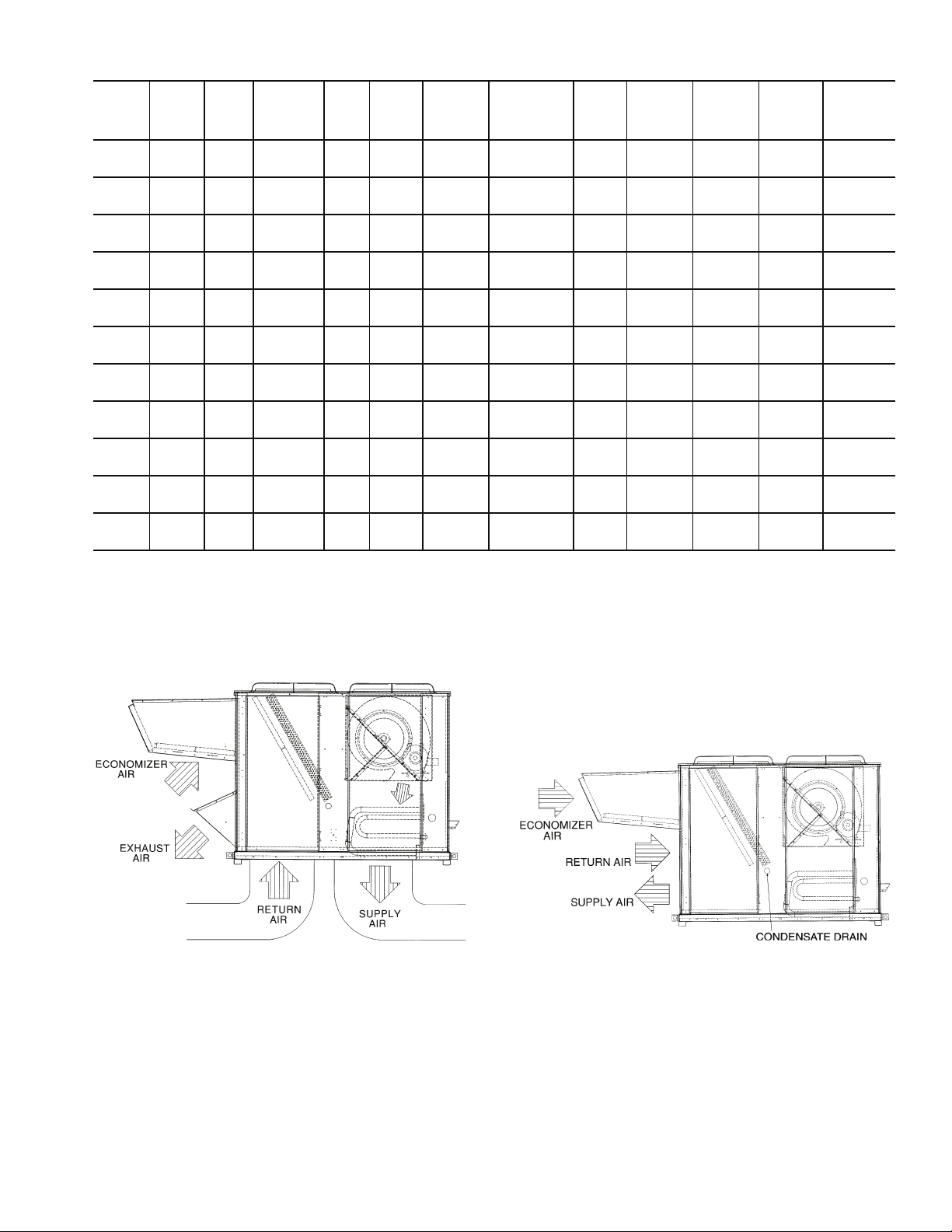

Step 4 — Make Unit Duct Connections

48AJ,AK,EJ,EK UNITS — Unit is shipped for through-thebottom duct connections. Field-fabricated ductwork should be

attached to the roof curb. Supply and return duct dimensions

are shown in Fig. 5-7 and 11-13. Air distribution is shown in

Fig. 18 and 19. Refer to installation instructions shipped with

roof curb for more information.

48AW,AY,EW,EY UNITS — Remove shipping covers from

supply and return air openings. Attach field-supplied ductwork

to unit. Connect to the unit with a single duct for all supply

openings and with a single duct for all return openings. Splitting of the airflow into branch ducts should not be done at the

unit. Sufficient duct length should be used prior to branching to

ensure the air temperatures are well mixed within the ductwork. See Fig. 8-10 and 14-16 for duct opening dimensions.

Secure all ducts to building structure. Air distribution is shown

in Fig. 8-10 and 14-16.

Install accessory barometric relief or power exhaust in the

field-fabricated return ductwork. Refer to Step 11 — Position

Power Exhaust/Barometric Relief Damper Hood section on

page 52 for more information.

Instructions continued on page 28.

2

Fig. 1 — Roof Curb — 48AJ,AK020-030 and 48EJ,EK024-034 Units

3

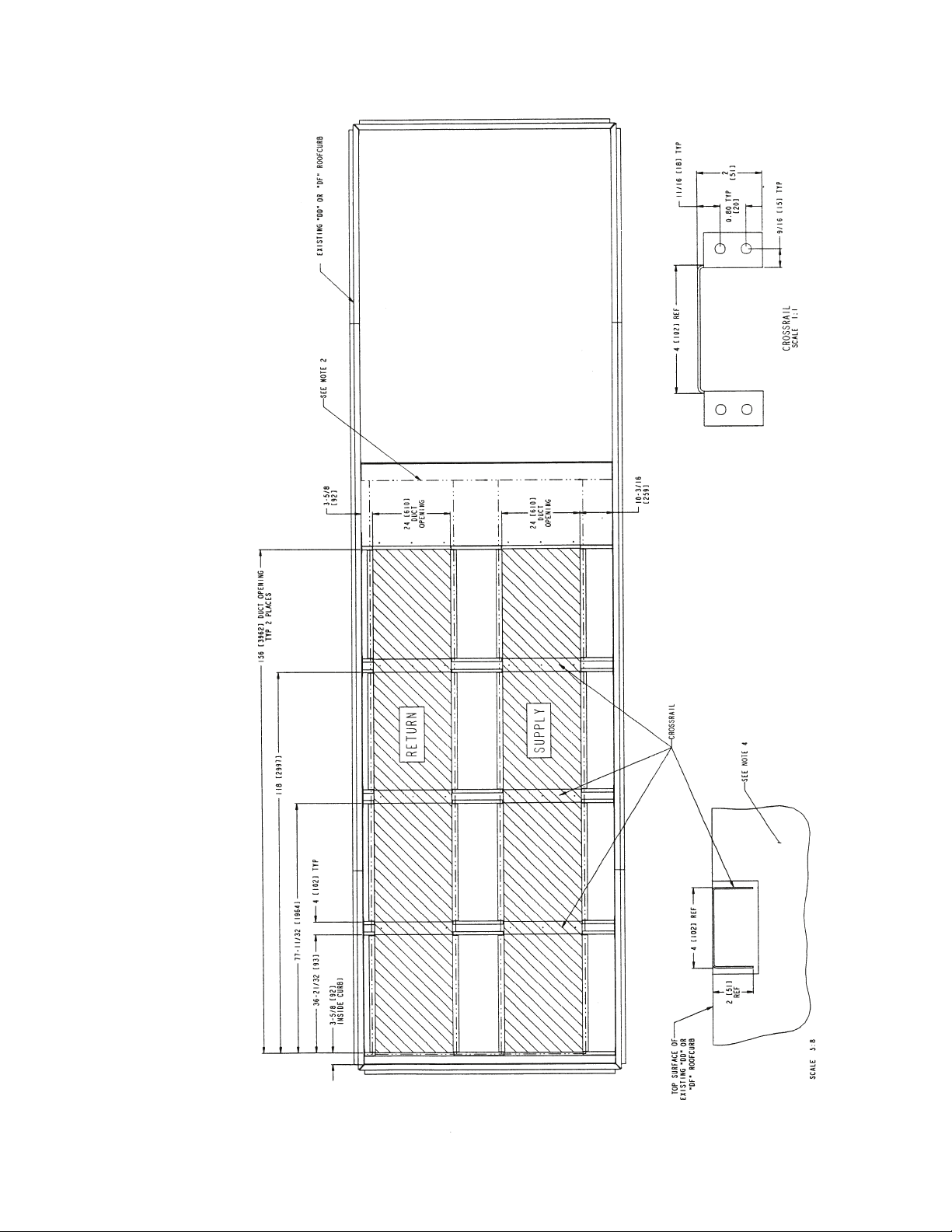

Fig. 2 — Roof Curb — 48AJ,AK034-050 and 48EJ,EK038-048 Units

4

Fig. 3 — Roof Curb — 48AJ,AK060 and 48EJ,EK054-068 Units

5

NOTES:

1. Unless otherwise specified, all dimensions are to outside of part.

2. Seal strip to be placed covering reference holes.

3. Phantom lines represent seal strip. Total length required is 75 linear ft.

length required is 62 linear ft.

self-tapping screws.

2.98″ at indoor motor end and 15.08″ at compressor end.

4. If existing seal strip around roof curb seems damaged, replace it. Total

5. Five crossrails are field located per dimensions shown and secured using

6. 48A and 48E series units will overhang existing “DD” or “DF” roof curbs by

7. Ductwork (field supplied) must be notched to clear three crossrails.

Fig. 4 — Roof Curb Adapter — (48AJ,AK060 and 48EJ,EK054-068 Units on 48DD,DF054-064 Retrofit, Part No. CRRCADPT005A00)

8. Dimensions in [ ] are millimeters.

6

1234

CORNER WEIGHT (lbs)

1082 1174 1502 1384

1126 1194 1494 1408

1135 1120 1516 1537

16

/

16

16

/

/

3

11

B

(ft-in.)

A

(ft-in.)

5

3-6

3-6

3-8 1103 1103 1511 1511

3-8

3-8 1123 1123 1539 1539

8

16

8

32

/

3

8

/

/

/

/

5

5

3

5

1234

1156 1140 1544 1565

16

/

5

3-8

32

/

3

5

CORNER WEIGHT (kg)

1156 1140 1544 1565

16

/

5

3-8 1123 1123 1539 1539

3-8

8

32

/

/

3

A (mm) B (mm)

(lbs)

WEIGHT*

OPERATING

UNIT SIZE

(kg)

WEIGHT*

OPERATING

UNIT SIZE

48AJ (High Heat) 020 5222 6- 1

48AJ (High Heat) 025 5308 5-10

48AJ (High Heat) 027 5405 5-10

48AJ/AK (Low Heat) 020 5142 6- 0

48AJ/AK (Low Heat) 025 5228 5- 9

48AJ (High Heat) 030 5405 5-10

48AJ/AK (Low Heat) 027 5325 5- 9

48AJ/AK (Low Heat) 030 5325 5- 9

48AJ (High Heat) 020 2369 1862 1085 511 542 678 639

48AJ (High Heat) 025 2408 1781 1125 515 508 688 697

48AJ (High Heat) 027 2452 1781 1125 524 517 700 710

48AJ/AK (Low Heat) 020 2332 1839 1072 491 533 681 628

48AJ/AK (Low Heat) 025 2371 1768 1118 500 500 686 686

48AJ (High Heat) 030 2452 1781 1125 524 517 700 710

48AJ/AK (Low Heat) 027 2415 1768 1118 509 509 698 698

48AJ/AK (Low Heat) 030 2415 1768 1118 509 509 698 698

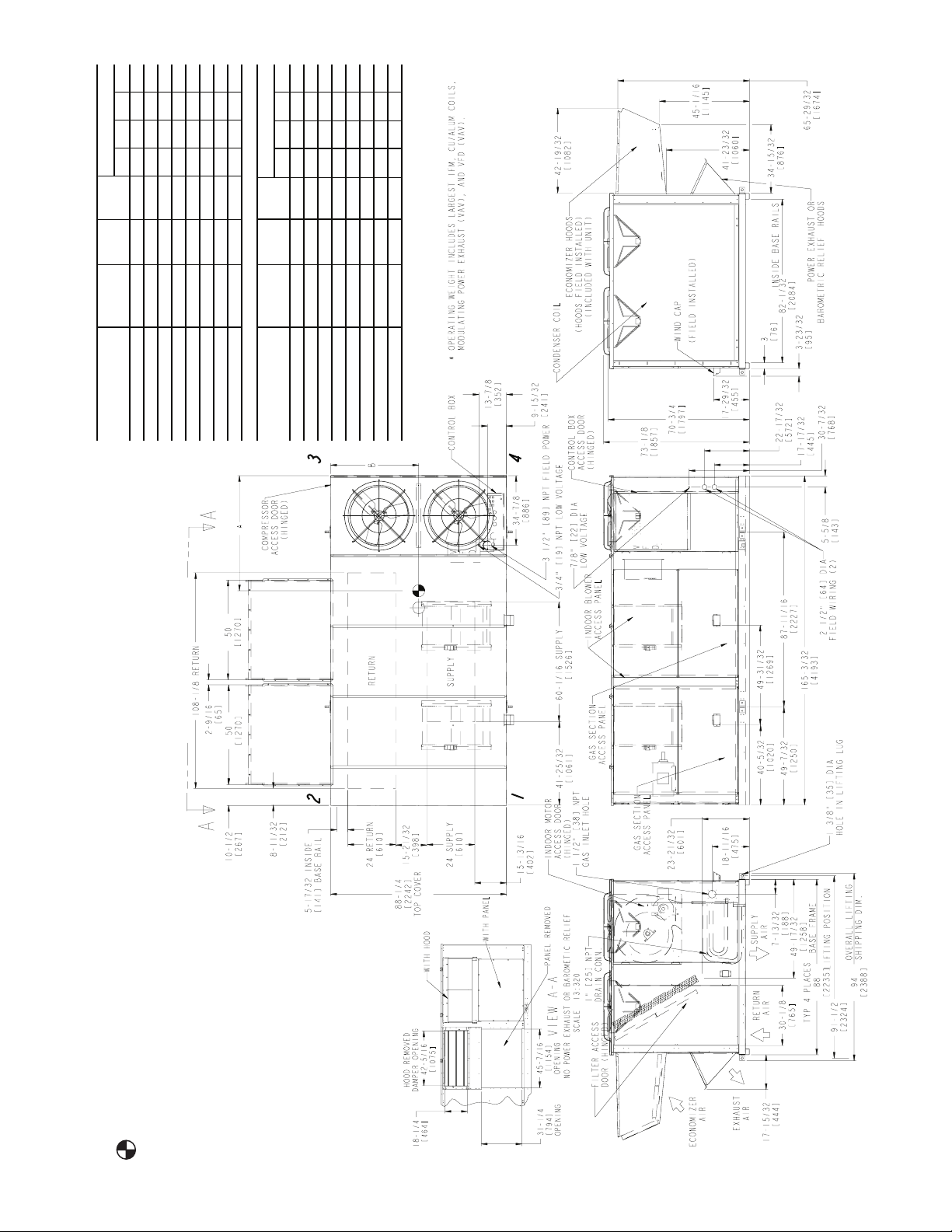

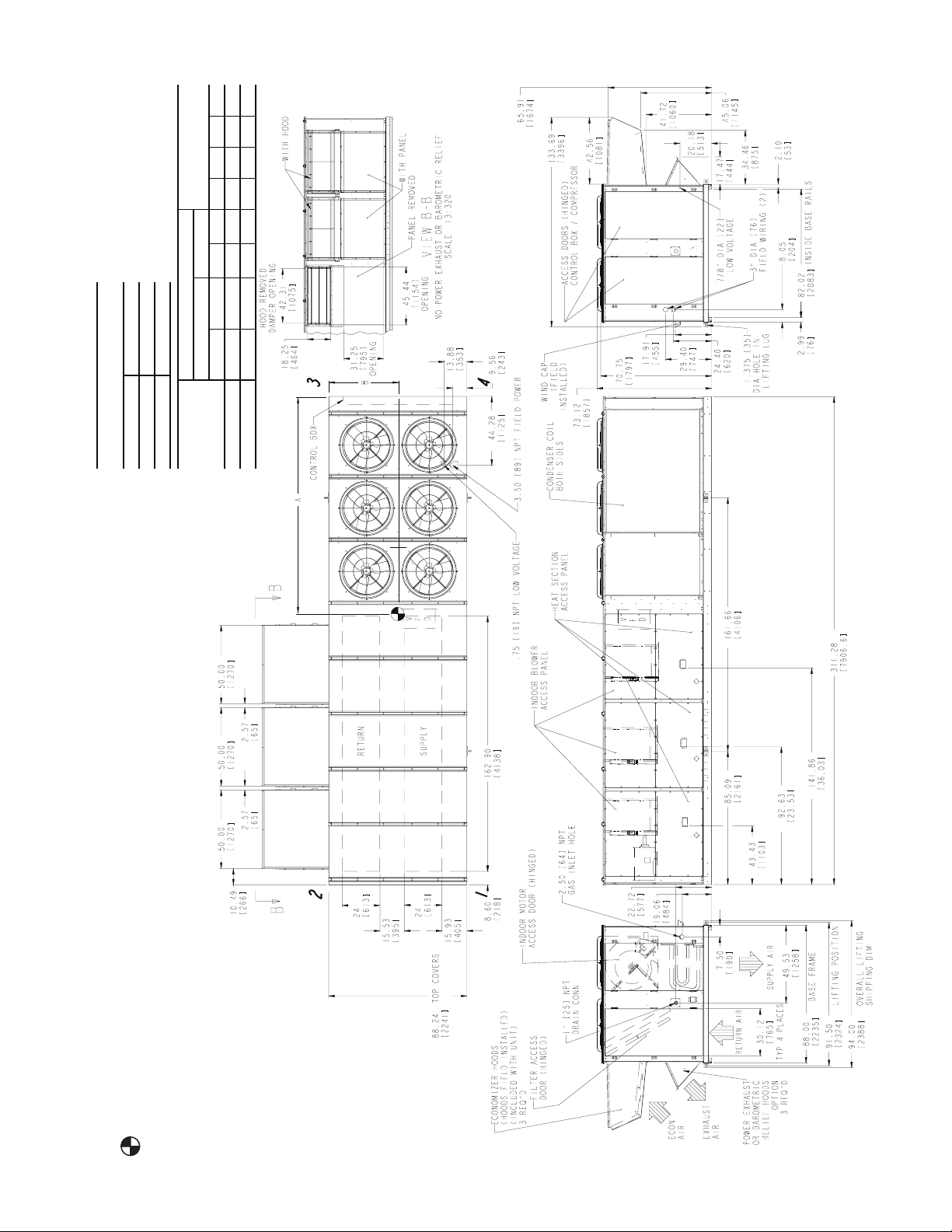

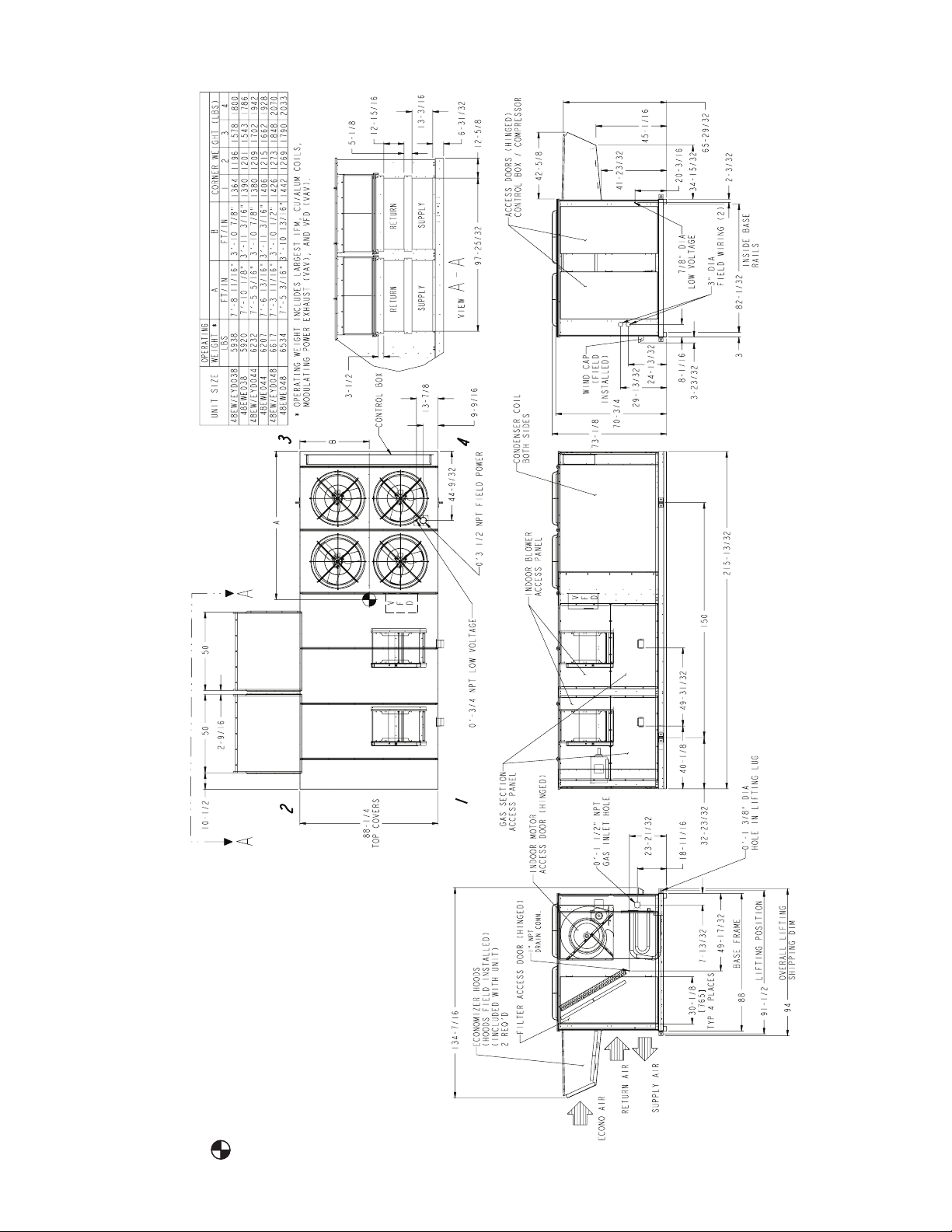

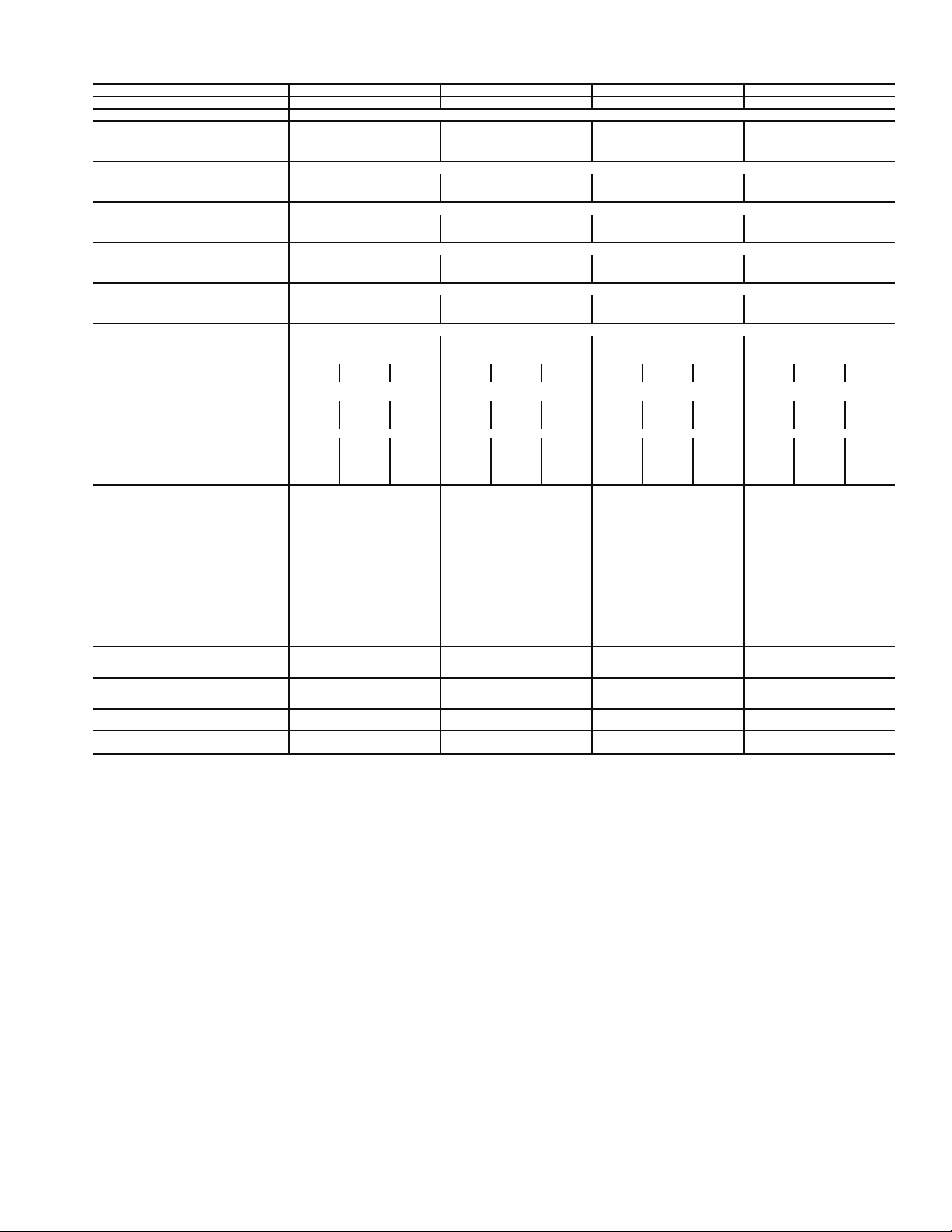

Fig. 5 — Base Unit Dimensions — 48AJ,AK020-030

Adjacent Units: 15′-0″ [4572].

Top of Units: No Overhang.

Condenser Coil: 4′-0″ [1219].

Economizer Side: 6′-0″ [1829].

Heat Side: 4′-0″ [1219].

inlet.

NOTES:

1. Weights include economizer (standard).

Min Clearances to be:

2. Center of Gravity.

3. Do not locate adjacent units with flue discharge facing economizer

Filter Access Side: 10′-0″ [3048]. (For removal of evaporator coil.)

cation Engineering Department.

mounted on dunnage, it is recommended the ducts must be sup-

ported by cross braces as done on accessory roof curb.

4. For smaller service and operational clearances contact Carrier Appli-

5. Bottom ducts designed to be attached to accessory roof curb. If unit is

6. Dimensions are in inches [mm].

7

1234

1380 1209 1595 1820

1447 1251 1607 1859

(ft-in.)

(ft-in.)

1442 1264 1779 2030

8

16

8

/

/

/

7

3

7

3-10

3-11

3-10

8

16

/

/

16

1

/

11

5

CORNER WEIGHT (lbs)

B

A

123 4

1512 1307 1787 2068

16

/

3

1

3-11

16

/

13

11

CORNER WEIGHT (kg)

1449 1294 1878 2104

1519 1337 1886 2142

16

/

2

/

13

3-10

3-10

16

/

16

/

3

A (mm) B (mm)

OPERATING

(lbs)

WEIGHT*

UNIT SIZE

(kg)

WEIGHT*

OPERATING

UNIT SIZE

48AJ (High Heat) 035 6164 7-10

48AJ (High Heat) 040 6674 7-6

48AJ/AK (Low Heat) 035 6004 7-8

48AJ (High Heat) 050 6885 7-5

48AJ/AK (Low Heat) 040 6514 7-5

48AJ/AK (Low Heat) 050 6725 7-3

48AJ (High Heat) 035 2796 2390 1199 656 567 729 843

48AJ (High Heat) 040 3027 2306 1199 686 593 811 938

48AJ/AK (Low Heat) 035 2723 2355 1191 626 548 723 826

48AJ (High Heat) 050 3123 2266 1189 689 607 856 972

48AJ/AK (Low Heat) 040 2955 2268 1191 654 573 807 921

48AJ/AK (Low Heat) 050 3050 2228 1181 657 587 852 954

NOTES:

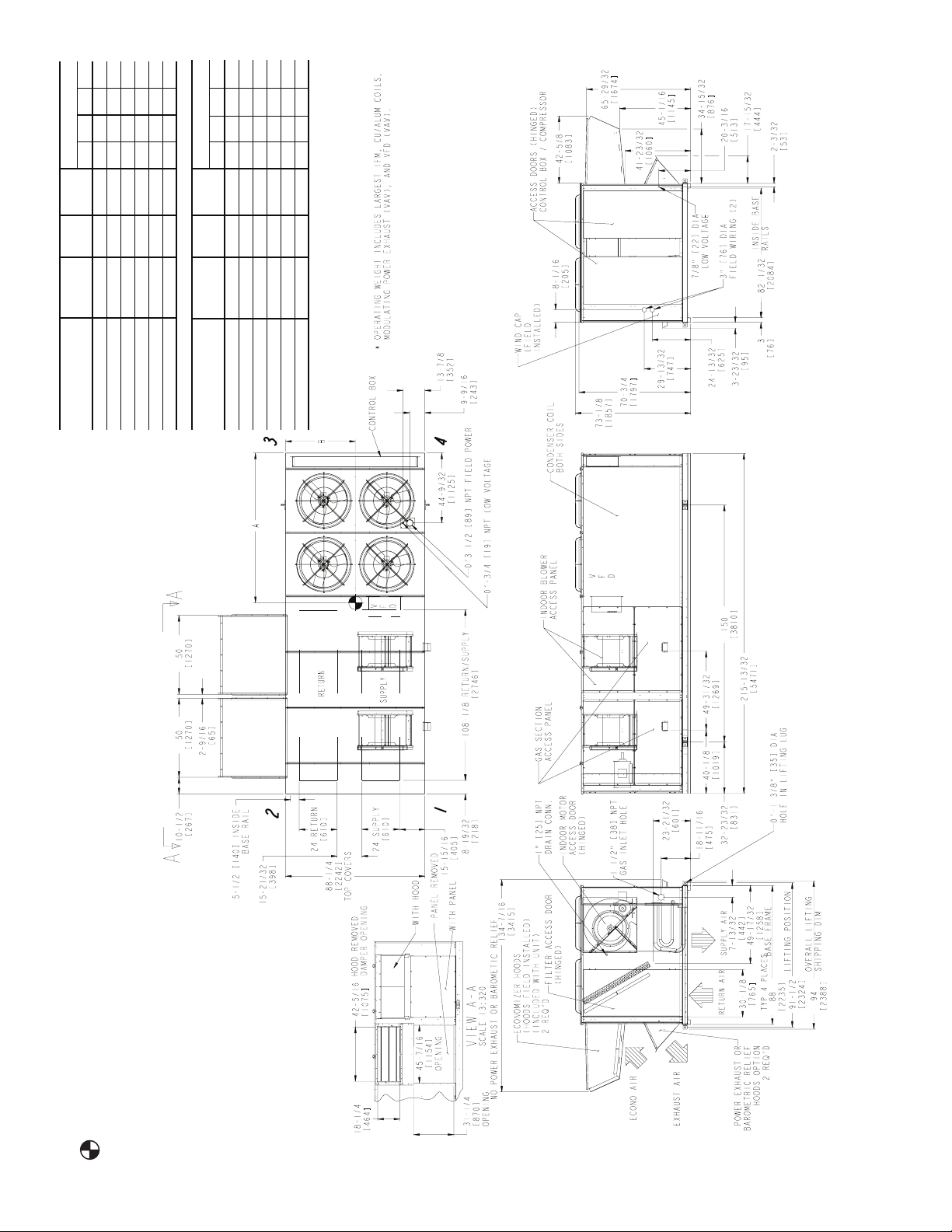

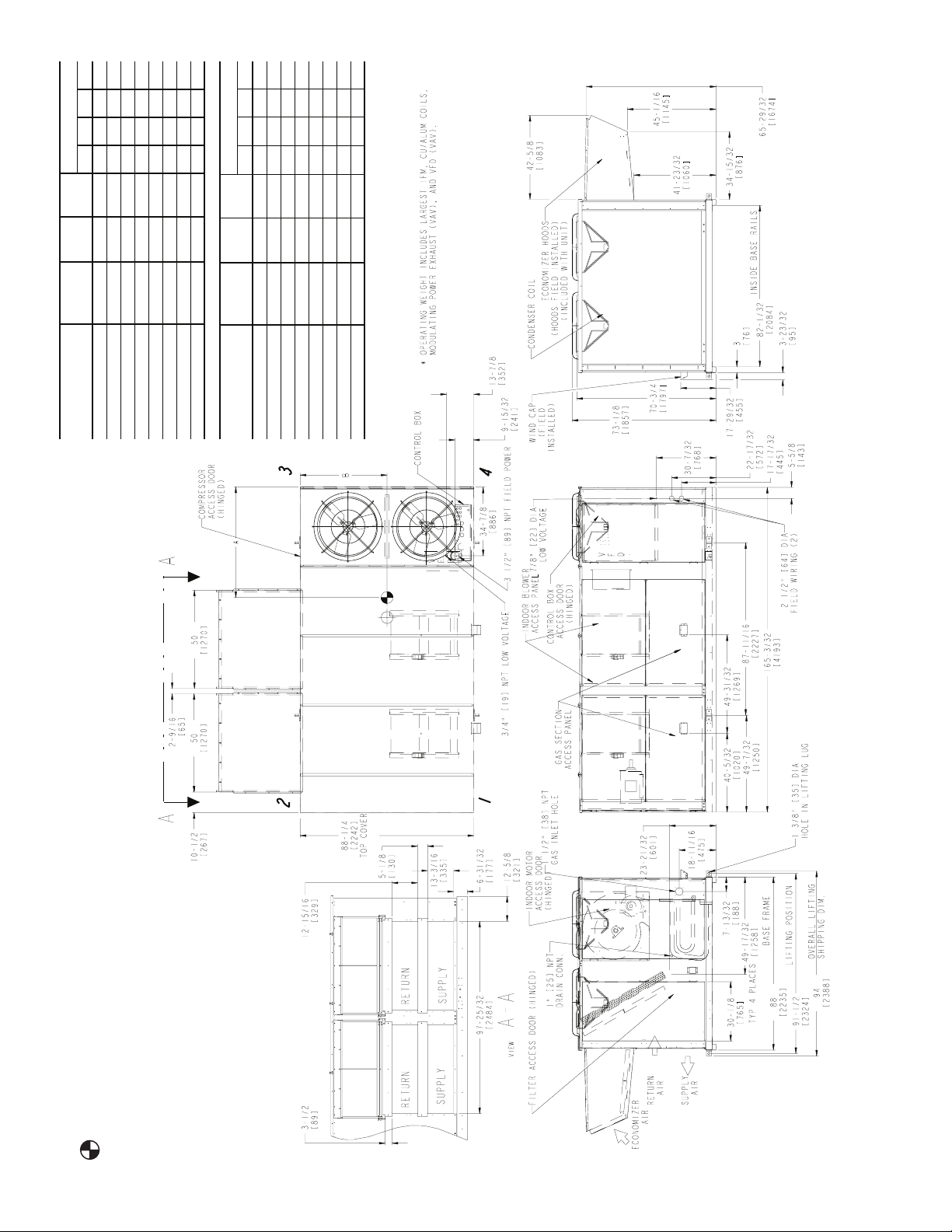

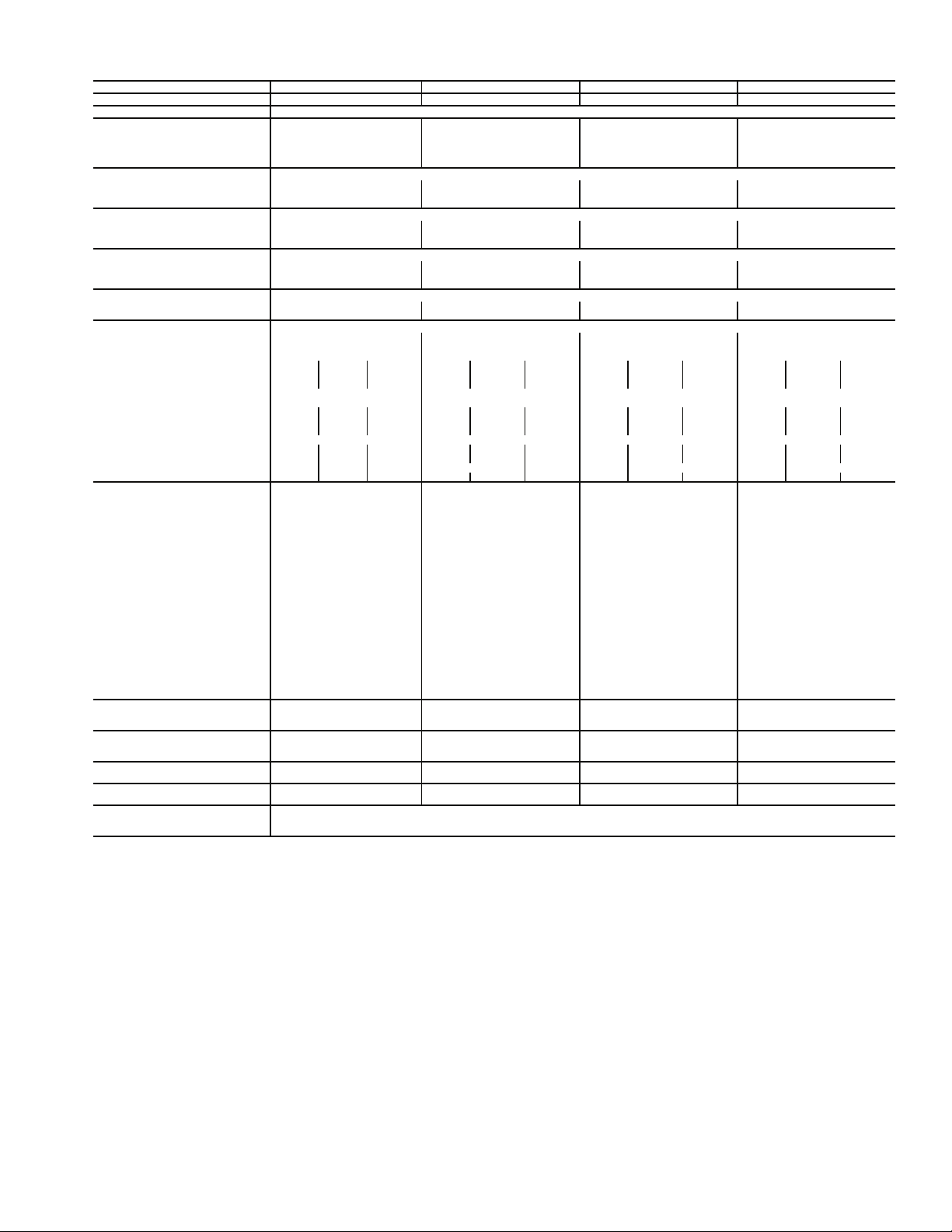

Fig. 6 — Base Unit Dimensions — 48AJ,AK035-050

Adjacent Units: 15′-0″ [4572].

Top of Units: No Overhang.

Condenser Coil: 4′-0″ [1219].

Economizer Side: 6′-0″ [1829].

Heat Side: 4′-0″ [1219].

inlet.

1. Weights include economizer (standard).

Min Clearances to be:

2. Center of Gravity.

3. Do not locate adjacent units with flue discharge facing economizer

Filter Access Side: 10′-0″ [3048]. (For removal of evaporator coil.)

cation Engineering Department.

mounted on dunnage, it is recommended the ducts must be supported

by cross braces as done on accessory roof curb.

4. For smaller service and operational clearances contact Carrier Appli-

5. Bottom ducts designed to be attached to accessory roof curb. If unit is

6. Dimensions are in inches [mm].

8

BASE UNIT WEIGHTS

(See Note 6) lbs (kg)

AT EACH CORNER

% OF TOTAL WEIGHT

3242 1184 21.7 19.3 27.7 31.2

3422 1235 23.9 19.4 25.4 31.3

32

/

19

32

/

19

3-10

060

48AJD/AKD 8930 (4051)

ft-in. Millimeters

CENTER OF GRAVITY

48AJE 9170 (4159)

UNIT SIZE

16

/

11

A B A B1234

48AJD/AKD060 10-7

4-

16

/

11

48AJE060 11-2

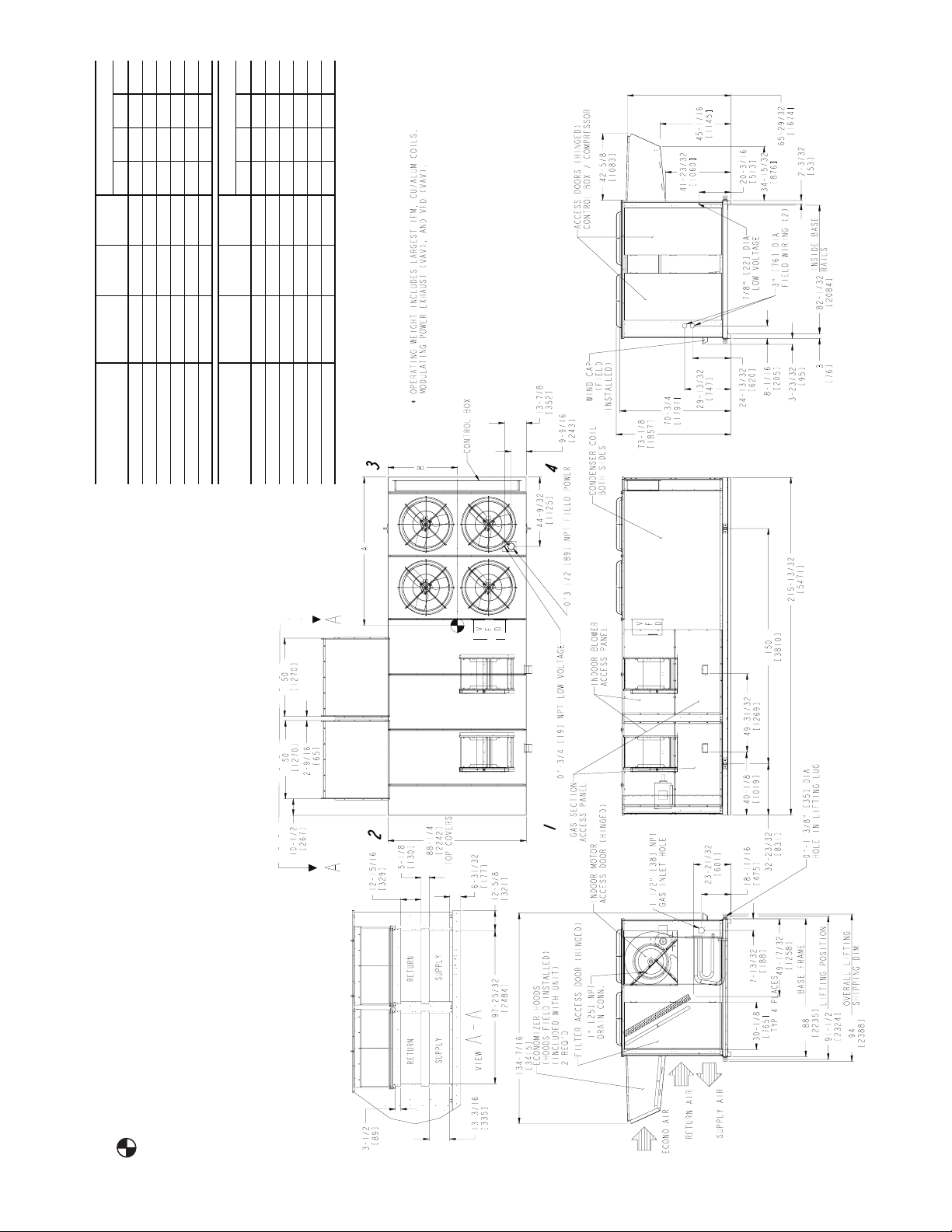

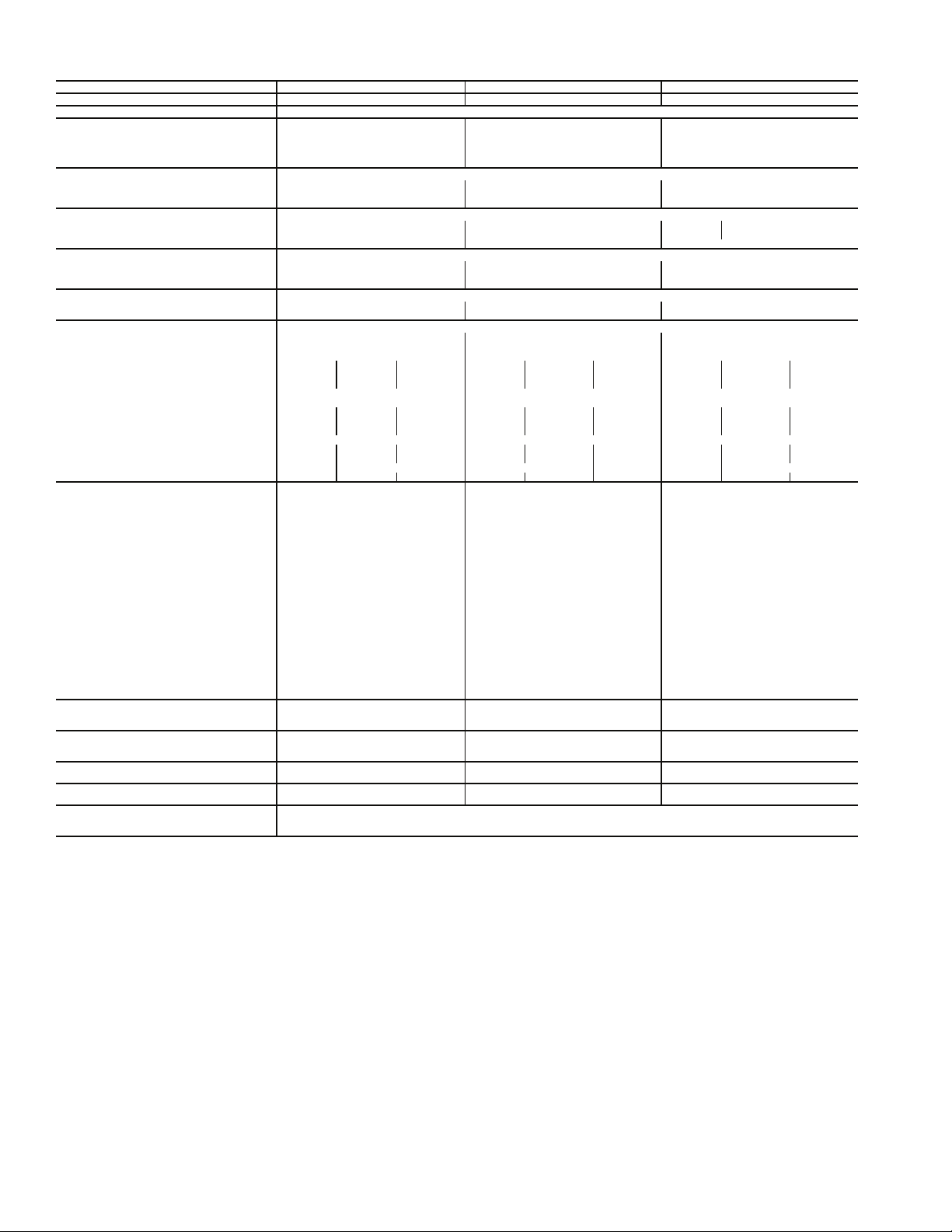

Fig. 7 — Base Unit Dimensions — 48AJ,AK060

on dunnage, it is recommended the ducts must be supported by cross braces as

done on accessory roof curb.

included). Add indoor motor, FIOPs and accessories for total operating weight.

5. Bottom ducts designed to be attached to accessory roof curb. If unit is mounted

NOTES:

1. Weights include economizer (standard).

VFD transducer and associated wiring.

6. Base unit weights include outdoor air hoods and filters (indoor fan motor is not

7. VAV motor weights include indoor motor, VFD, compressor electric unloaders,

8. Dimensions are in inches [mm].

Adjacent Units: 15′-0″ [4572].

Top of Units: No Overhang.

Condenser Coil: 4′-0″ [1219].

Economizer Side: 6′-0″ [1829].

Heat Side: 4′-0″ [1219].

Filter Access Side: 15′-0″ [4572]. (For

charge facing economizer inlet.

Min Clearances to be:

2. Center of Gravity.

3. Do not locate adjacent units with flue dis-

removal of evaporator coil.)

ances contact Carrier Application Engineer-

ing Department.

4. For smaller service and operational clear-

9

1234

CORNER WEIGHT (lbs)

1090 1183 1514 1395

1134 1203 1505 1419

1144 1128 1527 1548

16

/

16

16

/

/

3

11

B

(ft-in.)

A

(ft-in.)

5

3-6

3-6

3-8 1111 1111 1523 1523

3-8

8

16

8

8

/

/

/

/

3

5

5

1

1234

1165 1149 1555 1577

16

/

5

3-8 1132 1132 1551 1551

3-8

8

8

/

/

5

1

5

CORNER WEIGHT (kg)

1165 1149 1555 1577

16

/

5

3-8 1132 1132 1551 1551

3-8

8

8

/

/

1

A (mm) B (mm)

OPERATING

(lbs)

WEIGHT*

UNIT SIZE

(kg)

WEIGHT*

OPERATING

UNIT SIZE

48AW (High Heat) 020 5262 6- 1

48AW (High Heat) 025 5348 5-10

48AW (High Heat) 027 5445 5-10

48AW/AY (Low Heat) 020 5182 6- 0

48AW/AY (Low Heat) 025 5268 5- 9

48AW (High Heat) 030 5445 5-10

48AW/AY (Low Heat) 027 5365 5- 9

48AW/AY (Low Heat) 030 5365 5- 9

48AW (High Heat) 020 2387 1862 1085 515 546 683 644

48AW (High Heat) 025 2426 1781 1125 519 512 693 702

48AW (High Heat) 027 2470 1781 1125 528 521 705 715

48AW/AY (Low Heat) 020 2351 1839 1072 495 537 687 633

48AW/AY (Low Heat) 025 2390 1768 1118 504 504 691 691

48AW (High Heat) 030 2470 1781 1125 528 521 705 715

48AW/AY (Low Heat) 027 2434 1768 1118 513 513 704 704

48AW/AY (Low Heat) 030 2434 1768 1118 513 513 704 704

NOTES:

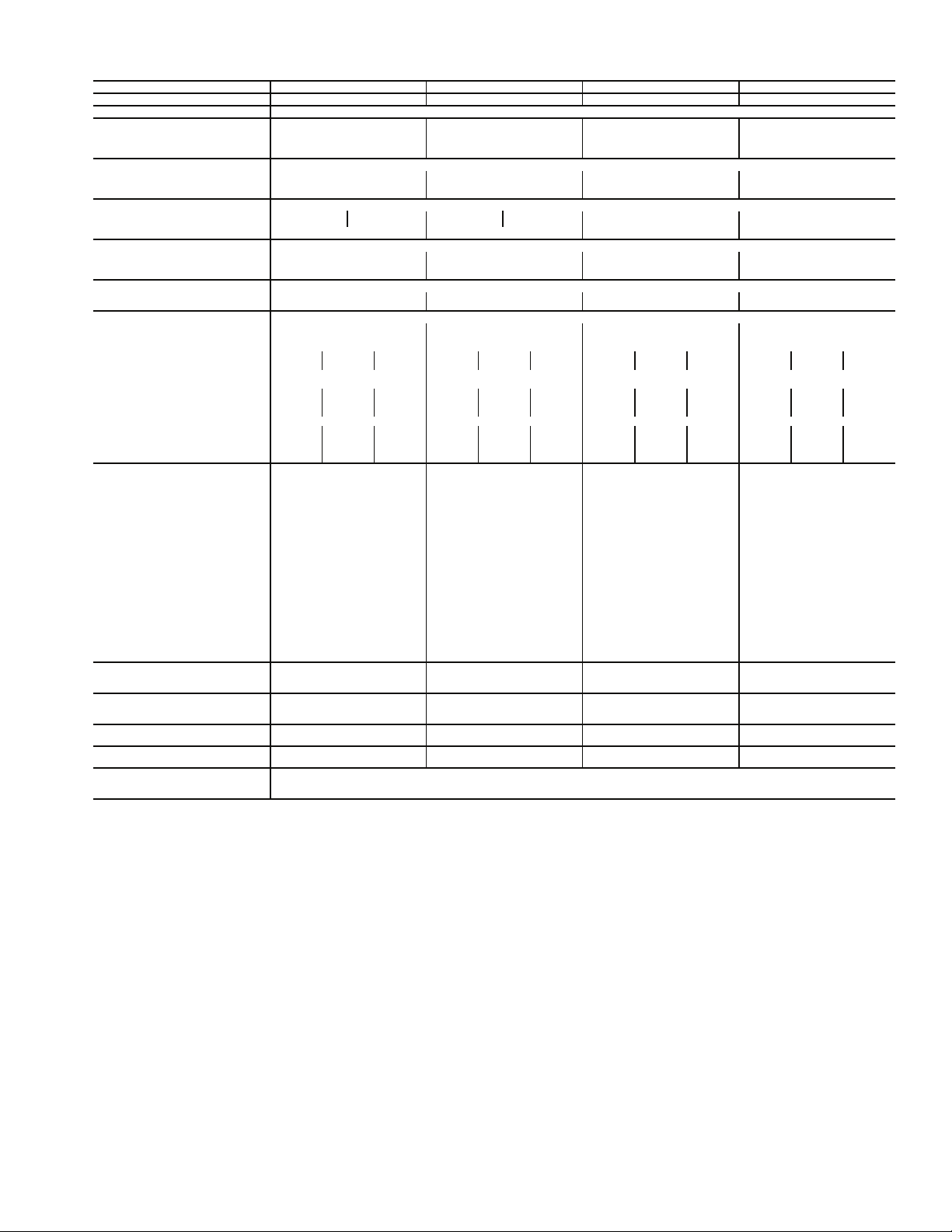

Fig. 8 — Base Unit Dimensions — 48AW,AY020-030

Adjacent Units: 15′-0″ [4572].

Top of Units: No Overhang.

Condenser Coil: 4′-0″ [1219].

Economizer Side: 6′-0″ [1829].

Heat Side: 4′-0″ [1219].

inlet.

1. Weights include economizer (standard).

Min Clearances to be:

2. Center of Gravity.

3. Do not locate adjacent units with flue discharge facing economizer

Filter Access Side: 10′-0″ [3048]. (For removal of evaporator coil.)

Application Engineering Department.

4. For smaller service and operational clearances contact Carrier

5. Dimensions are in inches [mm].

10

CORNER WEIGHT (lbs)

1234

1389 1217 1606 1832

1456 1259 1617 1871

1451 1271 1790 2042

1521 1315 1798 2080

1458 1301 1889 2117

1528 1345 1897 2155

16

8

16

/

/

B

7

3

(ft-in.)

3-10

3-11

16

/

8

/

11

1

A

(ft-in.)

/

8

16

2

/

/

/

7

3

1

13

3-10

3-11

3-10

3-10

16

16

16

/

/

/

16

/

11

13

11

3

CORNER WEIGHT (kg)

1234

A (mm) B (mm)

OPERATING

(lbs)

WEIGHT*

UNIT SIZE

(kg)

WEIGHT*

OPERATING

UNIT SIZE

48AW (High Heat) 035 6204 7-10

48AW (High Heat) 040 6714 7- 6

48AW/AY (Low Heat) 035 6044 7- 8

48AW (High Heat) 050 6925 7- 5

48AW/AY (Low Heat) 040 6554 7- 3

48AW/AY (Low Heat) 050 6765 7- 3

48AW (High Heat) 035 2814 2390 1199 661 571 734 849

48AW (High Heat) 040 3045 2306 1199 690 596 816 944

48AW/AY (Low Heat) 035 2741 2355 1191 630 552 728 831

48AW (High Heat) 050 3141 2266 1189 693 610 860 977

48AW/AY (Low Heat) 040 2973 2268 1191 658 577 812 926

48AW/AY (Low Heat) 050 3069 2228 1181 661 590 857 960

NOTES:

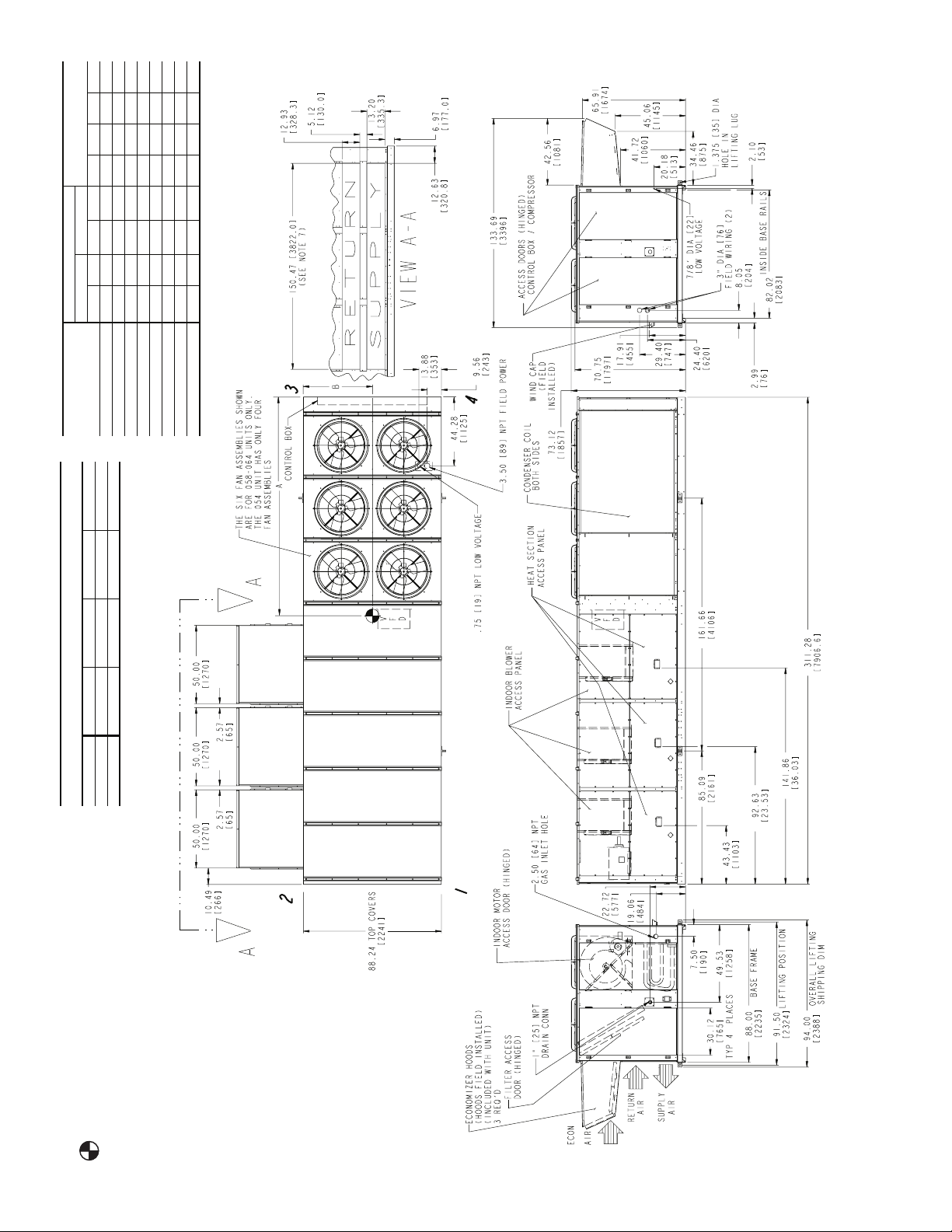

Fig. 9 — Base Unit Dimensions — 48AW,AY035-050

Adjacent Units: 15′-0″ [4572].

Top of Units: No Overhang.

Condenser Coil: 4′-0″ [1219].

Economizer Side: 6′-0″ [1829].

Heat Side: 4′-0″ [1219].

Min Clearances to be:

1. Weights include economizer (standard).

2. Center of Gravity.

3. Do not locate adjacent units with flue discharge facing economizer inlet.

Filter Access Side: 10′-0″ [3048]. (For removal of evaporator coil.)

4. For smaller service and operational clearances contact Carrier Application Engineering Department.

5. Dimensions are in inches [mm].

11

% OF TOTAL WEIGHT

060

(See Note 6) lbs (kg)

BASE UNIT WEIGHTS

CENTER OF GRAVITY

48AWE 9210 (4178)

48AWD/AYD 8970 (4069)

AT EACH CORNER

19

ft-in. Millimeters

11

A B AB1234

UNIT SIZE

3242 1184 21.7 19.3 27.7 31.2

32

/

3-10

16

/

48AWD/AYD060 10-7

3422 1235 23.9 19.4 25.4 31.3

32

/

19

4-

16

/

11

48AWE060 11-2

included). Add indoor motor, FIOPs and accessories for total operating weight.

5. Base unit weights include outdoor air hoods and filters (indoor fan motor is not

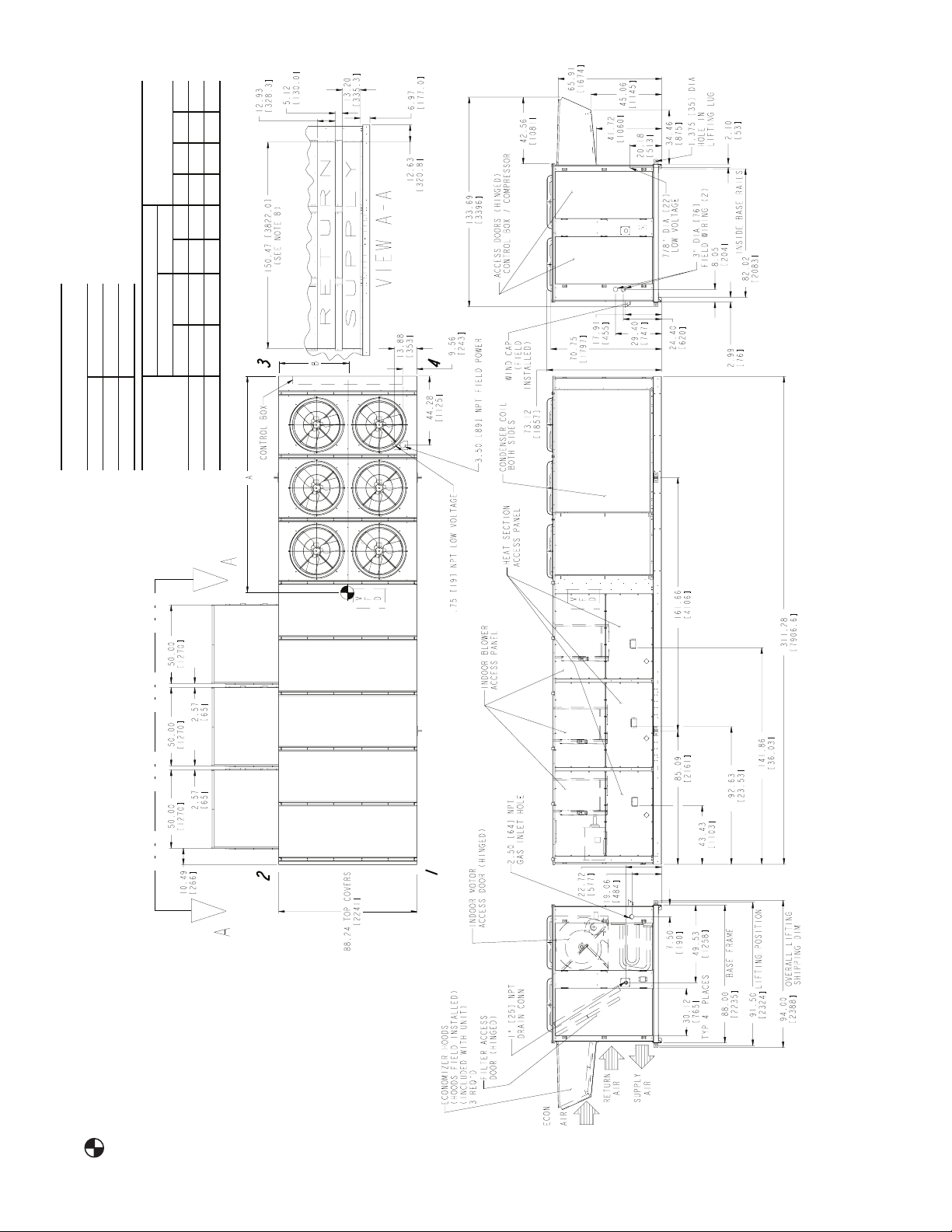

NOTES:

1. Weights include economizer (standard).

transducer and associated wiring.

6. VAV motor weights include indoor motor, VFD, compressor electric unloaders, VFD

2. Center of Gravity.

7. Dimensions are in inches [mm].

8. For side-supply/return applications, a single return and supply ductwork connection

charge facing economizer inlet.

3. Do not locate adjacent units with flue dis-

is recommended for covering all three return and all three supply openings. The

entire area around the duct openings is available for a 1.5″ duct flange attachment.

Adjacent Units: 15′-0″ [4572].

Top of Units: No Overhang.

Condenser Coil: 4′-0″ [1219].

Min Clearances to be:

Fig. 10 — Base Unit Dimensions — 48W,AY060

Economizer Side: 6′-0″ [1829].

Heat Side: 4′-0″ [1219].

Filter Access Side: 15′-0″ [4572]. (For

removal of evaporator coil.)

ances contact Carrier Application Engineer-

ing Department.

4. For smaller service and operational clear-

12

NOTES:

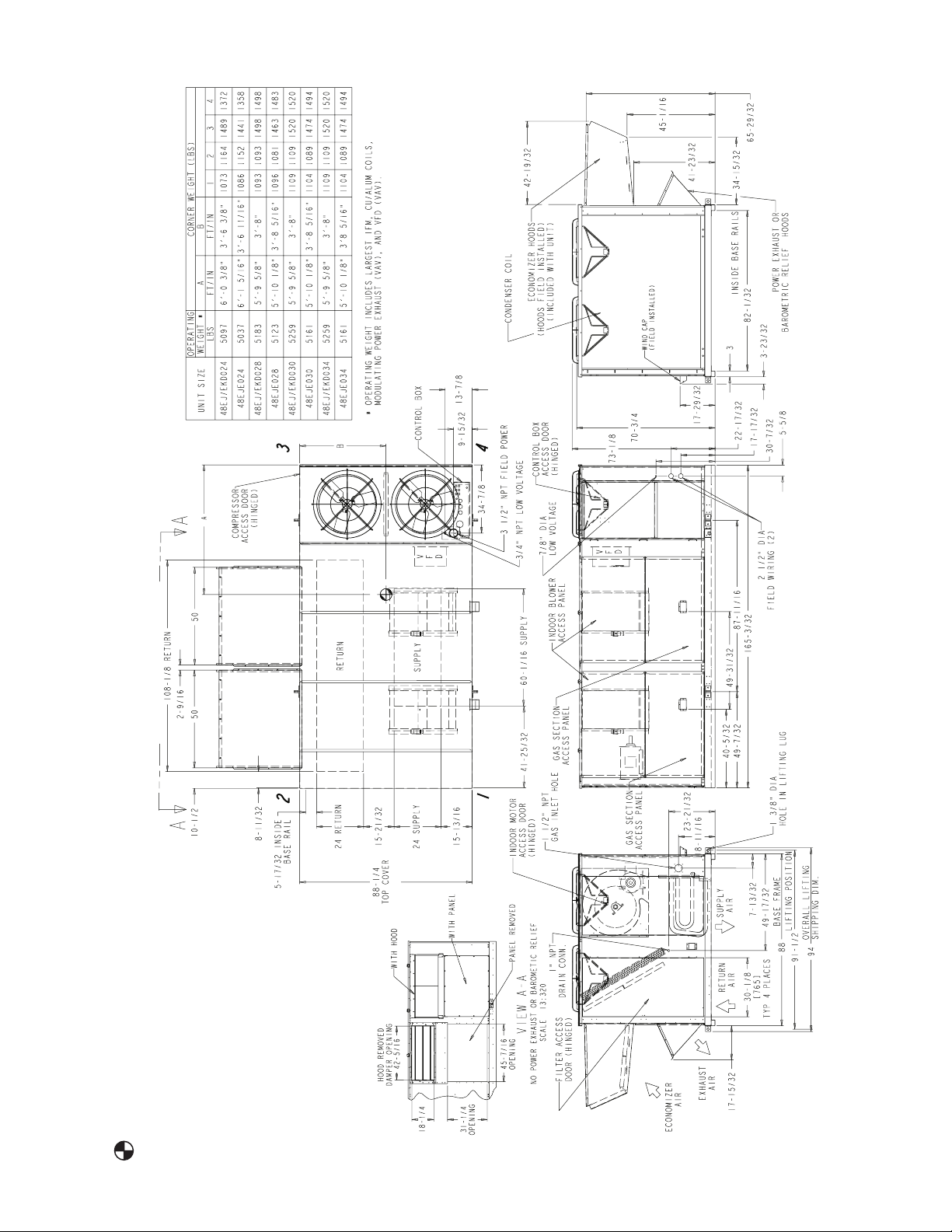

Fig. 11 — Base Unit Dimensions — 48EJ,EK024-034

Adjacent Units: 15′-0″ [4572].

Top of Units: No Overhang.

Condenser Coil: 4′-0″ [1219].

Economizer Side: 6′-0″ [1829].

Heat Side: 4′-0″ [1219].

inlet.

1. Weights include economizer (standard).

Min Clearances to be:

2. Center of Gravity.

3. Do not locate adjacent units with flue discharge facing economizer

Filter Access Side: 10′-0″ [3048]. (For removal of evaporator coil.)

cation Engineering Department.

mounted on dunnage, it is recommended the ducts must be supported

by cross braces as done on accessory roof curb.

4. For smaller service and operational clearances contact Carrier Appli-

5. Bottom ducts designed to be attached to accessory roof curb. If unit is

6. Dimensions are in inches [mm].

13

NOTES:

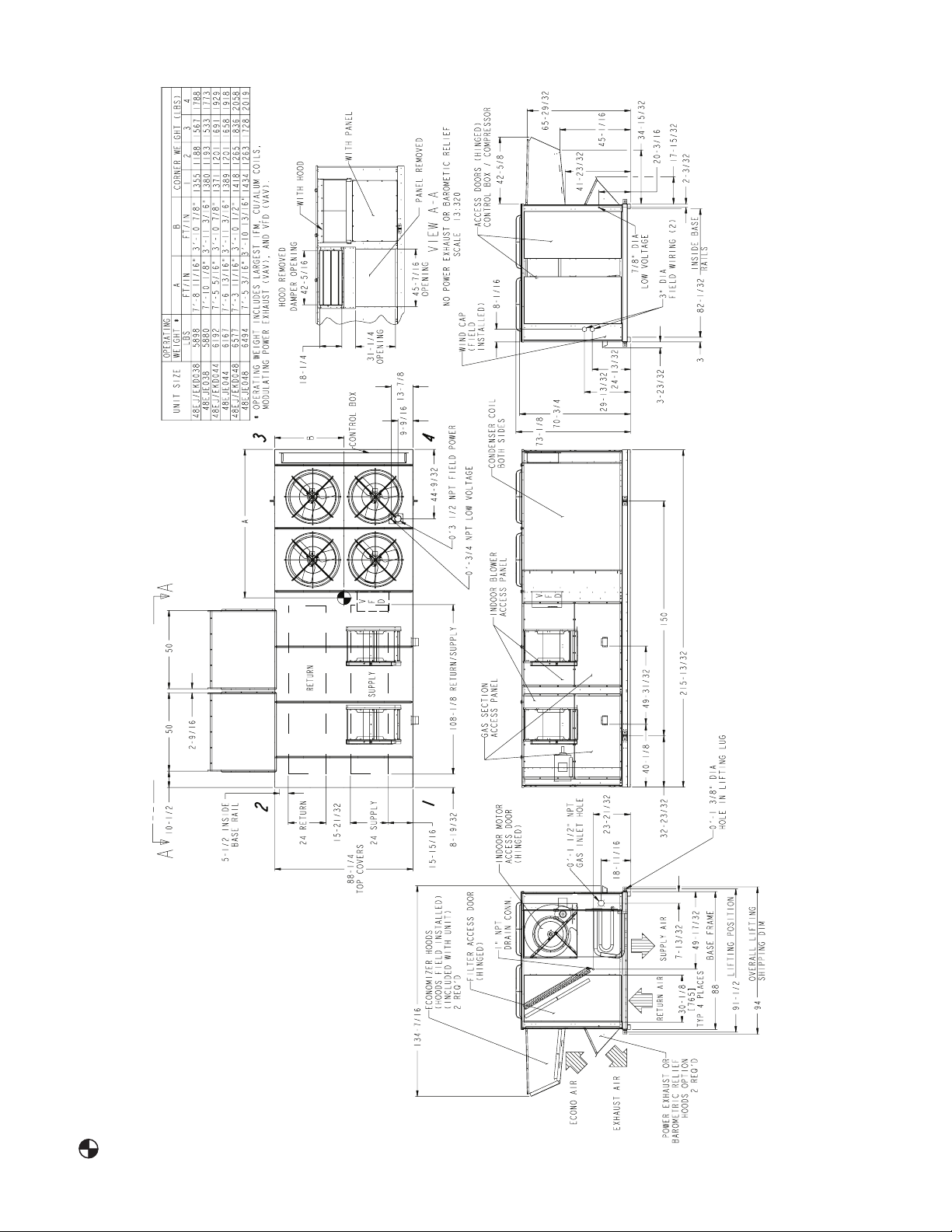

Fig. 12 — Base Unit Dimensions — 48EJ,EK038-048

Adjacent Units: 15′-0″ [4572].

Top of Units: No Overhang.

Condenser Coil: 4′-0″ [1219].

Economizer Side: 6′-0″ [1829].

Heat Side: 4′-0″ [1219].

inlet.

1. Weights include economizer (standard).

Min Clearances to be:

2. Center of Gravity.

3. Do not locate adjacent units with flue discharge facing economizer

Filter Access Side: 10′-0″ [3048]. (For removal of evaporator coil.)

cation Engineering Department.

mounted on dunnage, it is recommended the ducts must be supported

by cross braces as done on accessory roof curb.

4. For smaller service and operational clearances contact Carrier Appli-

5. Bottom ducts designed to be attached to accessory roof curb. If unit is

6. Dimensions are in inches [mm].

14

AT EACH CORNER

% OF TOTAL WEIGHT

CENTER OF GRAVITY

Inches Millimeters

UNIT SIZE

ABAB1234

48EJD/EKD054 130.9 46.9 3325 1192 22.4 19.6 27.0 30.9

48EJE054 133.8 47.4 3397 1204 23.1 19.8 26.3 30.7

48EJE058 139.5 49.6 3544 1260 25.3 19.6 24.1 31.1

48EJE064 132.2 47.2 3359 1199 22.8 19.7 26.7 30.8

48EJD/EKD058 132.1 47.5 3354 1207 22.9 19.5 26.5 31.1

48EJE068 134.7 48.6 3422 1235 23.9 19.4 25.4 31.3

48EJD/EKD064 125.3 45.2 3181 1149 20.7 19.6 29.1 30.7

48EJD/EKD068 127.7 46.6 3242 1184 21.7 19.3 27.7 31.2

BASE UNIT WEIGHTS

(See Note 6) lbs (kg)

054 058 064 068

48EJE 7045 (3196) 7295 (3309) 7545 (3422) 7720 (3502)

48EJD/EKD 6805 (3087) 7055 (3200) 7305 (3314) 7480 (3393)

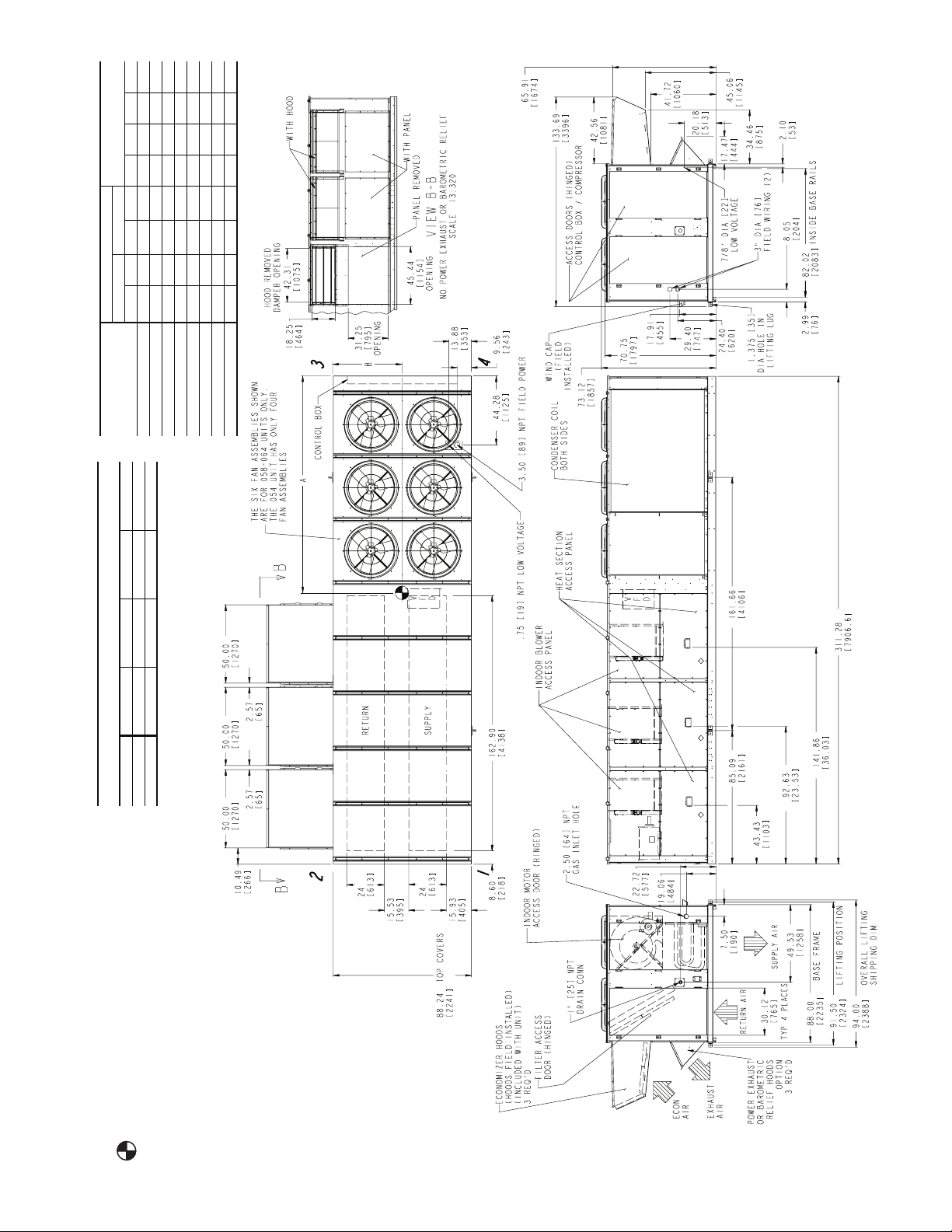

Fig. 13 — Base Unit Dimensions — 48EJ,EK054-068

Filter Access Side: 15′-0″ [4572]. (For removal of evaporator

Adjacent Units: 15′-0″ [4572].

mizer inlet.

NOTES:

1. Weights include economizer (standard).

Min Clearances to be:

2. Center of Gravity.

3. Do not locate adjacent units with flue discharge facing econo-

coil.)

Top of Units: No Overhang.

Condenser Coil: 4′-0″ [1219].

Economizer Side: 6′-0″ [1829].

Heat Side: 4′-0″ [1219].

Application Engineering Department.

unit is mounted on dunnage, it is recommended the ducts must

be supported by cross braces as done on accessory roof curb.

fan motor is not included). Add indoor motor, FIOPs and acces-

sories for total operating weight.

4. For smaller service and operational clearances contact Carrier

5. Bottom ducts designed to be attached to accessory roof curb. If

electric unloaders, VFD transducer and associated wiring.

6. Base unit weights include outdoor air hoods and filters (indoor

7. VAV motor weights include indoor motor, VFD, compressor

8. Dimensions in are in inches [mm].

15

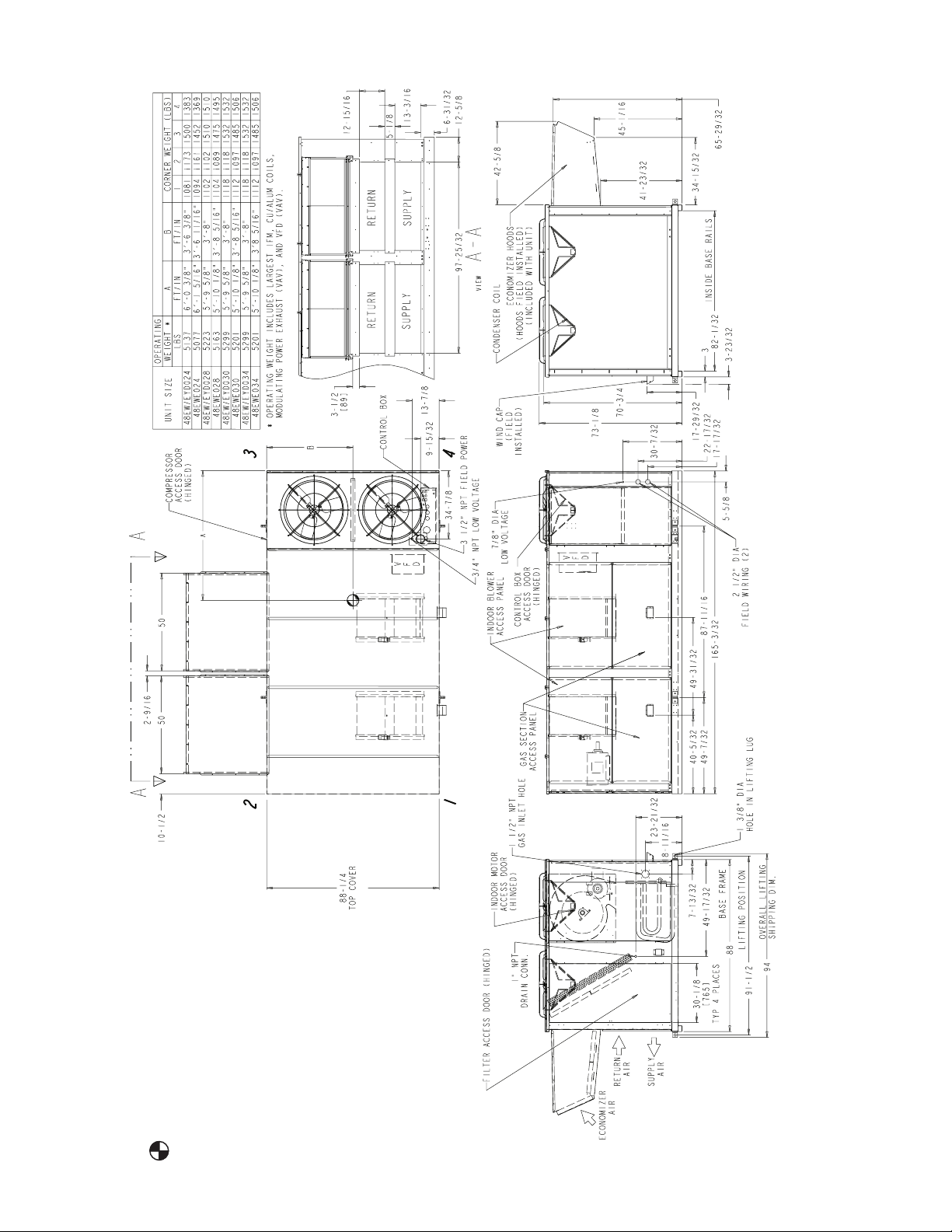

Fig. 14 — Base Unit Dimensions — 48EW,EY024-034

Filter Access Side: 15′-0″ [4572]. (For removal of evaporator

Adjacent Units: 15′-0″ [4572].

Min Clearances to be:

NOTES:

mizer inlet.

1. Weights include economizer (standard).

2. Center of Gravity.

3. Do not locate adjacent units with flue discharge facing econo-

coil.)

Top of Units: No Overhang.

Condenser Coil: 4′-0″ [1219].

Economizer Side: 6′-0″ [1829].

Heat Side: 4′-0″ [1219].

Application Engineering Department.

4. For smaller service and operational clearances contact Carrier

5. Dimensions in are in inches [mm].

16

NOTES:

Fig. 15 — Base Unit Dimensions — 48EW,EY038-048

Adjacent Units: 15′-0″ [4572].

Filter Access Side: 15′-0″ [4572]. (For removal of evaporator

coil.)

Top of Units: No Overhang.

Condenser Coil: 4′-0″ [1219].

Economizer Side: 6′-0″ [1829].

Heat Side: 4′-0″ [1219].

Min Clearances to be:

mizer inlet.

1. Weights include economizer (standard).

2. Center of Gravity.

3. Do not locate adjacent units with flue discharge facing econo-

4. For smaller service and operational clearances contact Carrier

Application Engineering Department.

5. Dimensions in are in inches [mm].

17

AT EACH CORNER

% OF TOTAL WEIGHT

CENTER OF GRAVITY

Inches Millimeters

UNIT SIZE

ABAB1234

48EWD/EYD054 130.9 46.9 3325 1192 22.4 19.6 27.0 30.9

48EWE054 133.8 47.4 3397 1204 23.1 19.8 26.3 30.7

48EWE058 139.5 49.6 3544 1260 25.3 19.6 24.1 31.1

48EWE064 132.2 47.2 3359 1199 22.8 19.7 26.7 30.8

48EWD/EYD058 132.1 47.5 3354 1207 22.9 19.5 26.5 31.1

48EWE068 134.7 48.6 3422 1235 23.9 19.4 25.4 31.3

48EWD/EYD064 125.3 45.2 3181 1149 20.7 19.6 29.1 30.7

48EWD/EYD068 127.7 46.6 3242 1184 21.7 19.3 27.7 31.2

BASE UNIT WEIGHTS

(See Note 6) lbs (kg)

054 058 064 068

48EWE 7085 (3214) 7335 (3327) 7585 (3441) 7760 (3520)

48EWD/EYD 6845 (3105) 7095 (3218) 7345 (3332) 7520 (3411)

Fig. 16 — Base Unit Dimensions — 48EW,EY054-068

Filter Access Side: 15′-0″ [4572]. (For

Adjacent Units: 15′-0″ [4572].

Top of Units: No Overhang.

facing economizer inlet.

NOTES:

1. Weights include economizer (standard).

Min Clearances to be:

2. Center of Gravity.

3. Do not locate adjacent units with flue discharge

removal of evaporator coil.)

Condenser Coil: 4′-0″ [1219].

Economizer Side: 6′-0″ [1829].

Heat Side: 4′-0″ [1219].

contact Carrier Application Engineering Depart-

ment.

and filters (indoor fan motor is not included).

Add indoor motor, FIOPs and accessories for

total operating weight.

compressor electric unloaders, VFD transducer

and associated wiring.

return and supply ductwork connection is rec-

ommended for covering all three return and all

three supply openings. The entire area around

the duct openings is available for a 1.5″ duct

4. For smaller service and operational clearances

5. Base unit weights include outdoor air hoods

6. VAV motor weights include indoor motor, VFD,

flange attachment

7. For side-supply/return applications, a single

8. Dimensions in are in inches [mm].

18

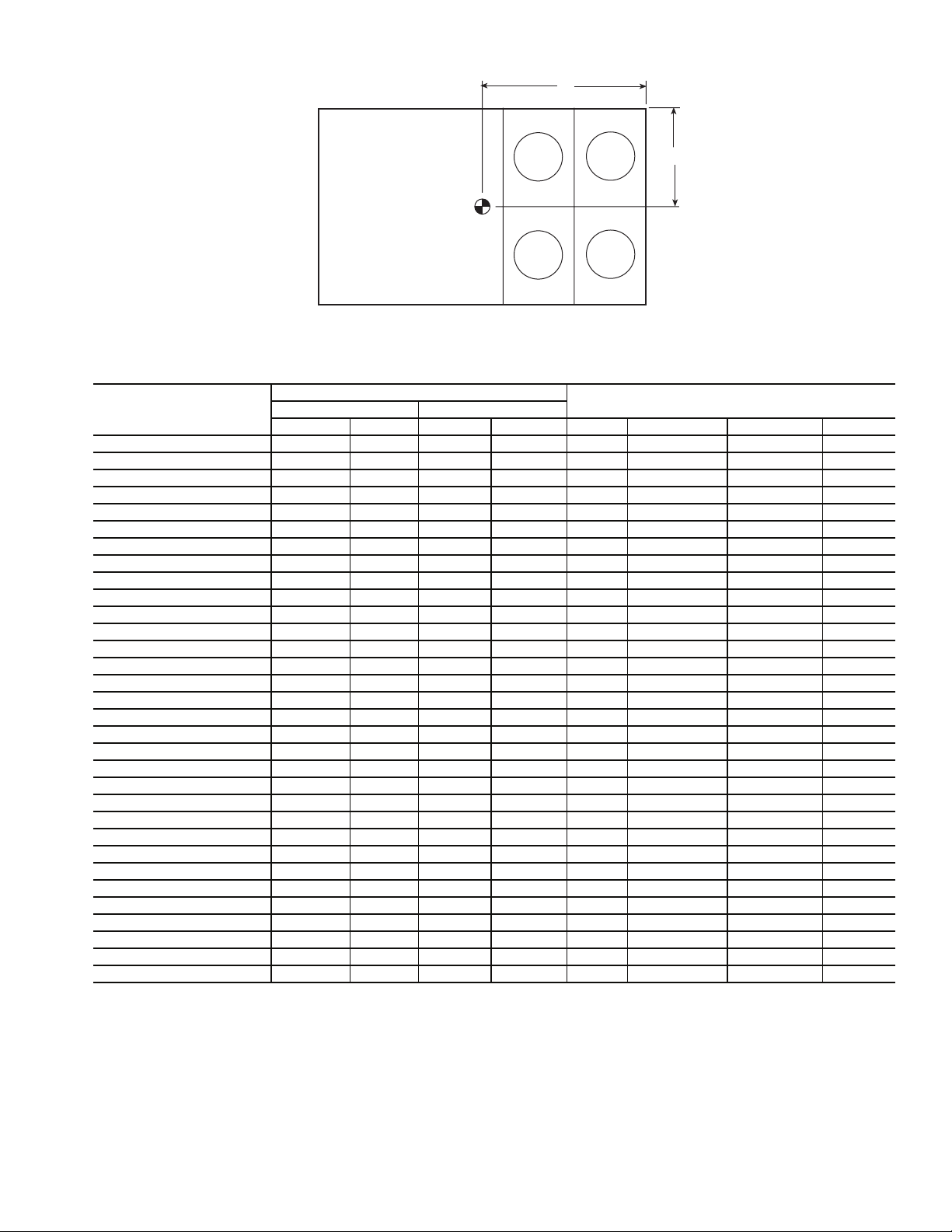

2

A

3

B

1

4

48AJ,AK,AW,AY UNITS

UNIT

CENTER OF GRAVITY

Inches Millimeters

PERCENT OF TOTAL WEIGHT

AT EACH CORNER (%)

ABAB1 2 3 4

48AJ,AKD020 72.4 42.2 1839 1072 21.0% 22.8% 29.2% 26.9%

48AJE020 73.3 42.7 1862 1085 21.6% 22.9% 28.6% 27.0%

48AW,AYD020 72.4 42.2 1839 1072 21.0% 22.8% 29.2% 26.9%

48AWE020 73.3 42.7 1862 1085 21.6% 22.9% 28.6% 27.0%

48AJ,AKD025 69.6 44.0 1768 1118 21.1% 21.1% 28.9% 28.9%

48AJE025 70.1 44.3 1781 1125 21.4% 21.1% 28.6% 29.0%

48AW,AYD025 69.6 44.0 1768 1118 21.1% 21.1% 28.9% 28.9%

48AWE025 70.1 44.3 1781 1125 21.4% 21.1% 28.6% 29.0%

48AJ,AKD027 69.6 44.0 1768 1118 21.1% 21.1% 28.9% 28.9%

48AJE027 70.1 44.3 1781 1125 21.4% 21.1% 28.6% 29.0%

48AW,AYD027 69.6 44.0 1768 1118 21.1% 21.1% 28.9% 28.9%

48AWE027 70.1 44.3 1781 1125 21.4% 21.1% 28.6% 29.0%

48AJ,AKD030 69.6 44.0 1768 1118 21.1% 21.1% 28.9% 28.9%

48AJE030 70.1 44.3 1781 1125 21.4% 21.1% 28.6% 29.0%

48AW,AYD030 69.6 44.0 1768 1118 21.1% 21.1% 28.9% 28.9%

48AWE030 70.1 44.3 1781 1125 21.4% 21.1% 28.6% 29.0%

48AJ,AKD035 92.7 46.9 2355 1191 23.0% 20.1% 26.6% 30.3%

48AJE035 94.1 47.2 2390 1199 23.5% 20.3% 26.1% 30.2%

48AW,AYD035 92.7 46.9 2355 1191 23.0% 20.1% 26.6% 30.3%

48AWE035 94.1 47.2 2390 1199 23.5% 20.3% 26.1% 30.2%

48AJ,AKD040 89.3 46.9 2268 1191 22.1% 19.4% 27.3% 31.2%

48AJE040 90.8 47.2 2306 1199 22.7% 19.6% 26.8% 31.0%

48AW,AYD040 89.3 46.9 2268 1191 22.1% 19.4% 27.3% 31.2%

48AWE040 90.8 47.2 2306 1199 22.7% 19.6% 26.8% 31.0%

48AJ,AKD050 87.7 46.5 2228 1181 21.6% 19.2% 27.9% 31.3%

48AJE050 89.2 46.8 2266 1189 22.1% 19.4% 27.4% 31.1%

48AW,AYD050 87.7 46.5 2228 1181 21.6% 19.2% 27.9% 31.3%

48AWE050 89.2 46.8 2266 1189 22.1% 19.4% 27.4% 31.1%

48AJ,AKD060 125.3 45.2 3181 1149 21.7% 19.3% 27.7% 31.2%

48AJE060 132.2 47.2 3359 1199 23.9% 19.4% 25.4% 31.3%

48AW,AYD060 127.7 46.6 3242 1184 21.7% 19.3% 27.7% 31.2%

48AWE060 134.7 48.6 3422 1235 23.9% 19.4% 25.4% 31.3%

Fig. 17 — Rigging Information

19

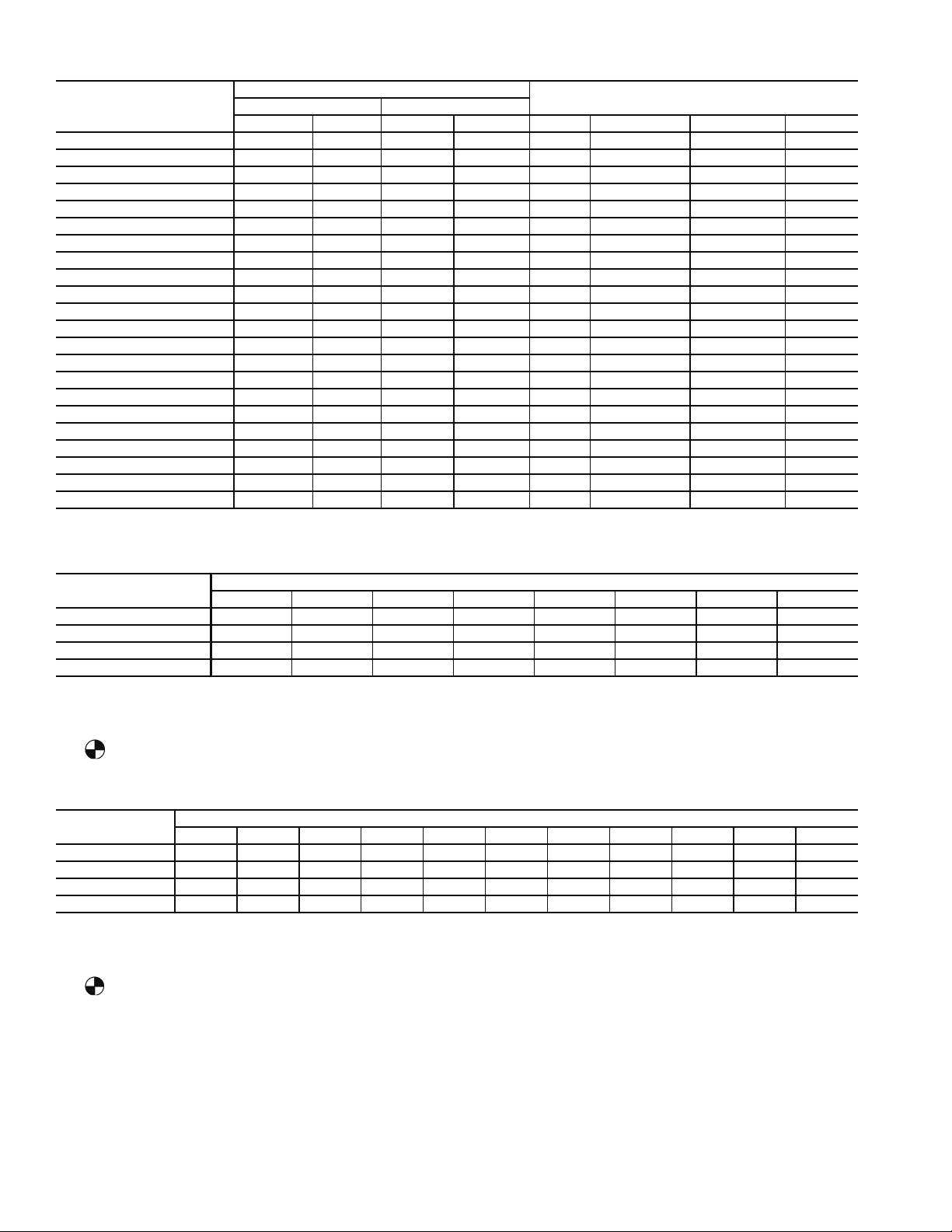

48EJ,EK,EW,EY UNITS

CENTER OF GRAVITY

UNIT

48EJ,EW,EK,EYD024 72.4 42.2 1839 1072 21.0 22.8 29.2 26.9

48EJ,EWE024 73.3 42.7 1862 1085 21.6 22.9 28.6 27.0

48EJ,EW,EK,EYD028 69.6 44.0 1768 1118 21.1 21.1 28.9 28.9

48EJ,EWE028 70.1 44.3 1781 1125 21.4 21.1 28.6 29.0

48EJ,EW,EK,EYD030 69.6 44.0 1768 1118 21.1 21.1 28.9 28.9

48EJ,EWE030 70.1 44.3 1781 1125 21.4 21.1 28.6 29.0

48EJ,EW,EK,EYD034 69.6 44.0 1768 1118 21.1 21.1 28.9 28.9

48EJ,EWE034 70.1 44.3 1781 1125 21.4 21.1 28.6 29.0

48EJ,EW,EK,EYD038 92.7 46.9 2355 1191 23.0 20.1 26.6 30.3

48EJ,EWE038 94.1 47.2 2390 1199 23.5 20.3 26.1 30.2

48EJ,EW,EK,EYD044 89.3 46.9 2268 1191 22.1 19.4 27.3 31.2

48EJ,EWE044 90.8 47.2 2306 1199 22.7 19.6 26.8 31.0

48EJ,EW,EK,EYD048 87.7 46.5 2228 1181 21.6 19.2 27.9 31.3

48EJ,EWE048 89.2 46.8 2226 1189 22.1 19.4 27.4 31.1

48EJ,EW,EK,EYD054 130.9 46.9 3325 1192 22.4 19.6 27.0 30.9

48EJ,EWE054 133.8 47.4 3397 1204 23.1 19.8 26.3 30.7

48EJ,EW,EK,EYD058 132.1 47.5 3354 1207 22.9 19.5 26.5 31.1

48EJ,EWE058 139.5 49.6 3544 1260 25.3 19.6 24.1 31.1

48EJ,EW,EK,EYD064 125.3 45.2 3181 1149 20.7 19.6 29.1 30.7

48EJ,EWE064 132.2 47.2 3359 1199 22.8 19.7 26.7 30.8

48EJ,EW,EK,EYD068 127.7 46.6 3242 1184 21.7 19.3 27.7 31.2

48EJ,EWE068 134.7 48.6 3422 1235 23.9 19.4 25.4 31.3

Inches Millimeters

ABAB1 2 3 4

PERCENT OF TOTAL WEIGHT

AT EACH CORNER (%)

RIGGING WEIGHTS

48AJ,AK,AW,AY UNITS

UNIT

48AJ,AKD 5142 5228 5325 5325 6004 6514 6725 8930

48AJ,AKE 5222 5308 5405 5405 6164 6674 6885 9170

48AW,AYD 5182 5268 5365 5365 6044 6554 6765 8970

48AW,AYE 5262 5348 5445 5445 6204 6714 6925 9210

*Includes outdoor-air hoods, filters, largest available indoor-fan

motor, modulating power exhaust, and the largest available variable

frequency drive (VFD).

NOTES:

1. Center of gravity.

2. On 020-050 includes 500 lbs and on 060 725 lbs for modulating

power exhaust.

020 025 027 030 035 040 050 060

MAXIMUM UNIT WEIGHTS (lb)*

3. On 020-050 includes 170 lbs and on 060 55 lbs for economizer

hoods. Includes 45 lbs for the economizer hood packaging.

4. Add 220 lbs for copper coil on the 020-030 size.

5. Add 284 lbs for copper coil on the 035 size.

6. Add 380 lbs for copper coil on the 040-050 size.

7. Add 651 lbs for copper coil on the 060 size.

48EJ,EK,EW,EY UNITS

UNIT

48EJ,EKD 5142 5228 5304 5304 5943 6237 6622 8029 8377 8755 8930

48EJE 5222 5384 5384 5384 6103 6397 6782 8269 8617 8995 9170

48EW,EYD 5182 5404 5344 5344 5983 6277 6662 8069 8417 8795 8970

48EWE 5262 5492 5424 5424 6143 6437 6822 8309 8657 9035 9210

*Includes outdoor-air hoods, filters, largest available indoor-fan

motor, modulating power exhaust, and the largest available variable

frequency drive (VFD).

NOTES:

1. Center of gravity.

2. Sizes 024-048 includes 500 lb and sizes 054-068 includes

725 lb for modulating power exhaust.

3. Sizes 024-048 includes 170 lb and sizes 054-068 includes

255 lb for economizer hoods.

024 028 030 034 038 044 048 054 058 064 068

MAXIMUM UNIT WEIGHTS (lb)*

4. Economizer hood packaging includes 45 lb.

5. For sizes 024-034 add 220 lb for copper coil.

6. For sizes 038-044 add 284 lb for copper coil.

7. For 048 size add 380 lb for copper coil.

8. For 054 size add 271 lb for copper coil.

9. For 058 size add 407 lb for copper coil.

10. For 064 size add 489 lb for copper coil.

11. For 068 size add 651 lb for copper coil.

Fig. 17 — Rigging Information (cont)

20

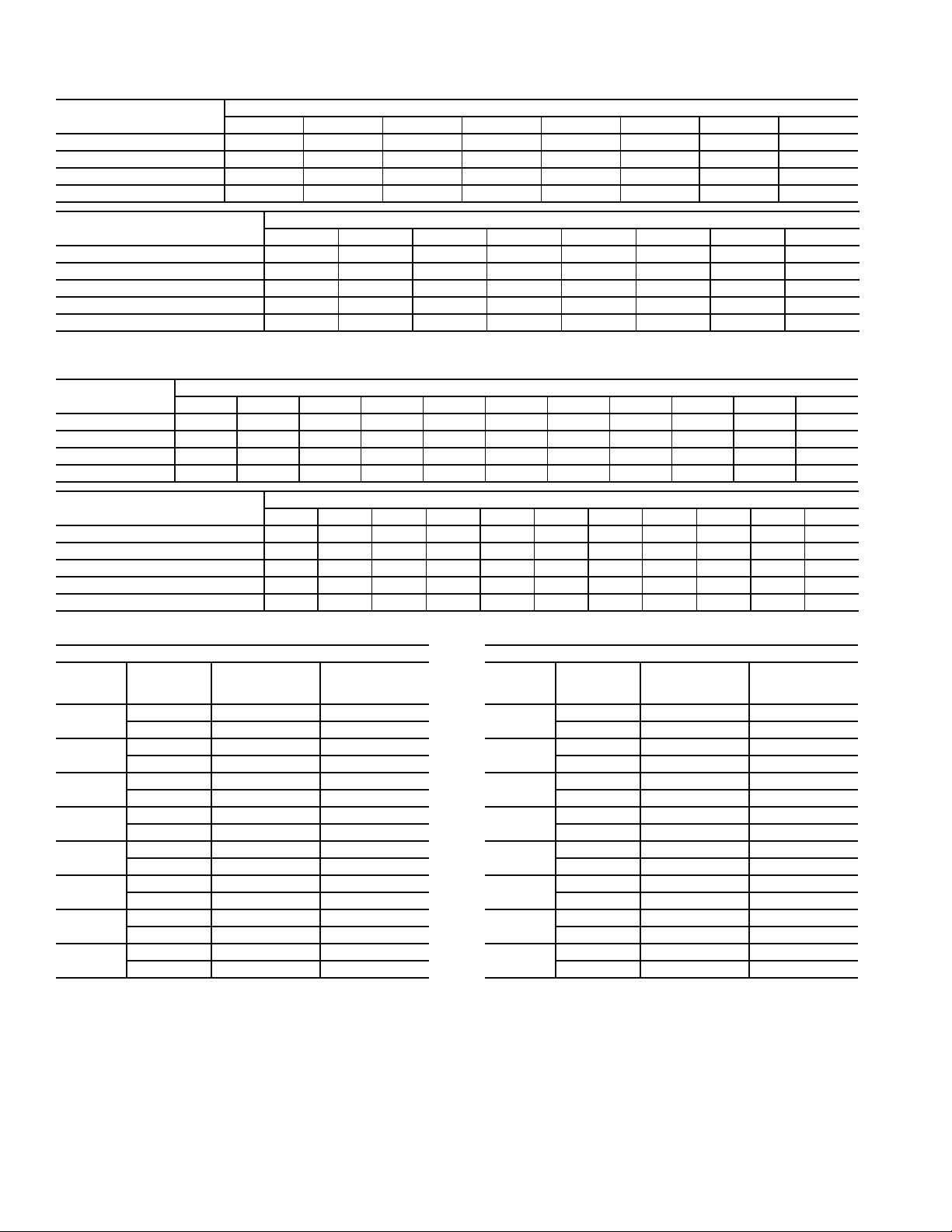

Table 1A — Physical Data — 48AJ,AK,AW,AY Units

UNIT 48AJ,AK,AW,AY 020D/E 025D/E 027D/E 030D/E

NOMINAL CAPACITY (tons) 20 25 27 30

BASE UNIT OPERATING WEIGHT (lb) See Operating Weights Table 2.

COMPRESSOR

Quantity...Type (Ckt 1 , Ckt 2) 1...06D328, 1...06D818 2...06D328 2...06D328 1...06D537, 1…06D328

Number of Refrigerant Circuits 2222

Oil (oz) (Ckt 1 , Ckt 2) 115, 88 115 ea. 115 ea. 115 ea.

REFRIGERANT TYPE R-22

Operating Charge (lb-oz)

Circuit 1 25-0 25-0 29-0 27-0

Circuit 2 31-0 25-0 28-0 29-0

CONDENSER COIL * Cross-Hatched

Quantity 1111

Rows...Fins/in. 4...15 4...15 4...15 4...15

Total Face Area (sq ft) 33.333.333.333.3

CONDENSER FAN Propeller Type

Nominal Cfm 13,420 13,420 13,420 13,420

Quantity...Diameter (in.) 2...30 2...30 2...30 2...30

Motor Hp 1111

EVAPORATOR COIL Cross-Hatched Copper Tubes, Aluminum Plate Fins

Tube Size (in.)

Rows...Fins/in. 4...15 4...15 4...15 4... 5

Total Face Area (sq ft) 31.731.734.734.7

EVAPORATOR FAN Centrifugal Type

Quantity...Size (in.) 2...20 X 15 2... 20 X 15 2... 20 X 15 2... 20 X 15

Type Drive Belt Belt Belt Belt

Nominal Cfm 8,000 10,000 11,000 12,000

Motor Hp 5 10 15 7.5 10 15 10 15 20 10 15 20

Motor Frame Size 184T 215T 254T 213T 215T 254T 215T 254T 256T 215T 254T 256T

Motor Bearing Type Ball Ball Ball Ball

Maximum Allowable Rpm 1200 1200 1200 1200

Motor Pulley Pitch Diameter 4.9 4.4 5.7 5.4 6.1 5.5 4.4 4.9 5.9 4.4 5.7 5.9

Nominal Motor Shaft Diameter (in.) 11/

Fan Pulley Pitch Diameter (in.) 12.4 8.6 9.1 12.4 11.1 8.7 9.4 8.1 8.7 9.0 9.1 8.7

Nominal Fan Shaft Diameter (in.) 115/

Belt Quantity 122112222222

Belt Type BX56 BX50 5VX530 BX56 5VX590 5VX570 BX50 5VX500 5VX530 BX50 5VX530 5VX530

Belt Length (in.) 56 63 53 56 59 57 50 50 53 50 53 53

Pulley Center Line Distance (in.) 16.0-18.7 15.6-18.4 15.0-17.9 15.6-18.4 15.6-18.4 15.0-17.9 15.6-18.4 15.0-17.9 15.0-17.9 15.6-18.4 15.0-17.9 15.0-17.9

Factory Speed Setting (rpm) 717 924 1096 773 962 1106 848 1059 1187 884 1096 1187

FURNACE SECTION

Rollout Switch Cutout

Temp (F) † 225 225 225 225

Burner Orifice Diameter (in. ...drill size)

Natural Gas Std .111...34 .111...34 .111...34 .111...34

Liquid Propane Alt .089...43 .089...43 .089...43 .089...43

Thermostat Heat Anticipator Setting

Stage 1 (amps) 0.10.10.10.1

Stage 2 (amps) 0.10.10.10.1

Gas Input (Btuh) Stage 1 262,500/394,000 262,500/394,000 262,500/394,000 262,500/394,000

Efficiency (Steady State) (%) 82 82 82 82

Temperature Rise Range 15-45/35-65 15-45/35-65 15-45/35-65 15-45/35-65

Manifold Pressure (in. wg)

Natural Gas Std 3.53.53.53.5

Liquid Propane Alt 3.53.53.53.5

Gas Valve Quantity 2222

HIGH-PRESSURE SWITCH (psig)

Cutout 426 426 426 426

Reset (Auto.) 320 320 320 320

LOW-PRESSURE SWITCH (psig)

Cutout 27 27 27 27

Reset (Auto.) 67 67 67 67

RETURN-AIR FILTERS

Quantity...Size (in.) 10...20 x 24 x 2 10...20 x 24 x 2 10...20 x 24 x 2 10...20 x 24 x 2

OUTDOOR AIR FILTERS 8...16 x 25 8...16 x 25 8...16 x 25 8...16 x 25

Quantity...Size (in.) 4...20 x 25 4...20 x 25 4..20 x 25 4...20 x 25

S t a g e 2 350,000/525,000 350,000/525,000 350,000/525,000 350,000/525,000

3

/

8

13/

8

8

16

LEGEND *Sizes 020-030: Circuit 1 uses the lower por tion of condenser coil, Circuit 2 uses the upper

Al — Aluminum

Bhp — Brake Horsepower

Cu — Copper

3

/8" Copper Tubes, Aluminum Lanced, Aluminum Pre-Coated, or Copper Plate Fins

3

/

8

13/

13/

8

13/

8

115/

15/

8

16

portion.

Sizes 035-050: Circuit 1 uses the left condenser coil, Circuit 2 the right. All units have

intertwined evaporator coils.

†Rollout switch is manual reset.

13/

8

3

/

8

15/

8

115/

15/

8

16

13/

8

3

/

8

15/

8

115/

15/

8

16

8

NOTE: High heat is for 48AJ,AW only.

21

Table 1A — Physical Data — 48AJ,AK,AW,AY Units (cont)

UNIT 48AJ,AK,AW,AY 035D/E 040D/E 050D/E 060D/E

NOMINAL CAPACITY (tons) 35 40 50 60

BASE UNIT OPERATING WEIGHT (lb) See Operating Weights Table 2.

COMPRESSOR

Quantity...Type (Ckt 1 , Ckt 2) 2...06D537 1...06D537, 1...06EA250 2…06EA250 2...06EA265

Number of Refrigerant Circuits 2222

Oil (oz) (Ckt 1 , Ckt 2) 115 ea. 115, 224 224 ea. 304 ea.

REFRIGERANT TYPE

Operating Charge (lb-oz)

Circuit 1 34-8 51-8 50-0 79-8

Circuit 2 34-8 49-8 50-0 79-8

CONDENSER COIL * Cross-Hatched

Quantity 2222

Rows...Fins/in. 3...15 4...15 4...15 4…15

Total Face Area (sq ft) 58.3 66.7 66.7 100

CONDENSER FAN Propeller Type

Nominal Cfm 27,064 27,064 27,064 43,900

Quantity...Diameter (in.) 4...30 4...30 4...30 6...30

Motor Hp 1111

EVAPORATOR COIL Cross-Hatched Copper Tubes, Aluminum Plate Fins

Tube Size (in.)

Rows...Fins/in. 4...15 6...15 6...15 4...17

Total Face Area (sq ft) 34.7 31.3 31.3 48.1

EVAPORATOR FAN Centrifugal Type

Quantity...Size (in.) 2...20 X 15 2...20 X 15 2...20 X 15 3...20 X 15

Type Drive Belt Belt Belt Belt

Nominal Cfm 14,000 16,000 20,000 24,000

Motor Hp 10 15 20 15 20 25 20 25 30 25 30 40

Motor Frame Size 215T 254T 25 6T 254T 256T 284T 256T 284T 286T 284T 286T 324T

Motor Bearing Type Ball Ball Ball Ball

Maximum Allowable Rpm 1200 1200 1300 1200

Motor Pulley Pitch Diameter 6.1 5.3 5.7 5.3 5.7 7.5 6.3 8.1 7.5 5.3 8.1 9.4

Nominal Motor Shaft Diameter (in.) 13/

Fan Pulley Pitch Diameter (in.) 13.7 9.5 9.5 9.5 9.5 11.1 11.1 12.5 11.1 9.1 12.5 13.6

Nominal Fan Shaft Diameter (in.) 115/

Belt Quantity 122222222332

Belt Type 5VX610 5VX530 5VX550 5VX530 5VX550 5VX590 5VX570 5VX630 5VX590 5VX530 5VX630 5VX650

Belt Length (in.) 61 53 55 53 55 59 57 63 59 53 63 65

Pulley Center Line Distance (in.) 15.6-18.4 15.0-17.9 15.0-17.9 15.0-17.9 15.0-17.9 14.6-17.6 15.0-17.9 14.6-17.6 14.6-17.6 15.2-17.5 14.7-17.2 14.2-17.0

Factory Speed Setting (rpm) 779 976 1050 976 1050 1182 993 1134 1182 1019 1134 1214

FURNACE SECTION

Rollout Switch Cutout

Temp (F) † 225 225 225 225

Burner Orifice Diameter (in. ...drill size)

Natural Gas Std .120...31 .120...31 .120...31 .120...31

Liquid Propane Alt .096...41 .096...41 .096...41 .096...41

Thermostat Heat Anticipator Setting

Stage 1 (amps) 0.1 0.1 0.1 0.1

Stage 2 (amps) 0.1 0.1 0.1 0.1

Gas Input (Btuh) Stage 1 300,000/600,000 300,000/600,000 300,000/600,000 582,000/ 873,000

Efficiency (Steady State) (%) 82 82 82 82

Temperature Rise Range 10-40/30-60 10-40/30-60 10-40/30-60 10-40/30-60

Manifold Pressure (in. wg)

Natural Gas Std 3.5 3.5 3.5 3.3

Gas Valve Quantity 2223

HIGH-PRESSURE SWITCH (psig)

Cutout 426 426 426 426

Reset (Auto.) 320 320 320 320

LOW-PRESSURE SWITCH (psig)

Cutout 27 27 27 27

Reset (Auto.) 67 67 67 67

RETURN-AIR FILTERS

Quantity...Size (in.) 10...20 x 24 x 2 10...20 x 24 x 2 10...20 x 24 x 2 16...20 x 24 x 2

OUTDOOR AIR FILTERS 8...16 x 25 8...16 x 25 8...16 x 25 12...16 x 25

Quantity...Size (in.) 4...20 x 25 4...20 x 25 4...20 x 25 6...20 x 25

S t a g e 2 400,000/800,000 400,000/800,000 400,000/800,000 776,000/1,164,000

3

/

8

15/

8

15/

8

16

LEGEND *Sizes 020-030: Circuit 1 uses the lower por tion of condenser coil, Circuit 2 uses the upper

Al — Aluminum

Bhp — Brake Horsepower

Cu — Copper

3

/8" Copper Tubes, Aluminum Lanced, Aluminum Pre-Coated, or Copper Plate Fins

1

/

2

15/

8

15/

8

115/

17/

8

16

portion.

Sizes 035-050: Circuit 1 uses the left condenser coil, Circuit 2 the right. All units have

intertwined evaporator coils.

†Rollout switch is manual reset.

15/

8

1

/

2

17/

8

115/

8

16

NOTE: High heat is for 48AJ,AW only.

1

/

2

17/

17/

8

17/

8

115/

21/

8

16

8

3.3 Liquid Propane Alt 3.5 3.5 3.5

22

Table 1B — Physical Data — 48EJ,EK,EW,EY Units

UNIT 48EJ,EK,EW,EY 024D/E 028D/E 030D/E 034D/E

NOMINAL CAPACITY (tons) 20 25 27.5 30

OPERATING WEIGHT (lb) For Operating Weights see Table 2.

COMPRESSOR

Typ e Ck t 1 06D328 06D328 06D537 06D537

Ckt 2 06D818 06D328 06D328 06D537

Number of Refrigerant Circuits 22 2 2

Oil (oz) (Ckt 1, Ckt 2) 115, 88 115 ea. 115 ea. 115 ea.

REFRIGERANT TYPE R-22

Operating Charge (lb-oz)

Circuit 1* 25-0 25-0 25-0 25-0

Circuit 2 31-0 25-0 25-0 25-0

CONDENSER COIL Cross-Hatched

Quantity 11 1 1

Rows...Fins/in. 4...15 4...15 4...15 4...15

Total Face Area (sq ft) 33.3 33.3 33.3 33.3

CONDENSER FAN Propeller Type

Nominal Cfm 13,420 13,420 13,420 13,420

Quantity...Diameter (in.) 2...30 2...30 2...30 2...30

Motor Hp (1075 Rpm) 11 1 1

EVAPORATOR COIL Cross-Hatched 3/8″ Copper Tubes, Aluminum Plate Fins, Intertwined Circuits

Rows...Fins/in. 4...15 4...15 4...15 4...15

Total Face Area (sq ft) 31.7 31.7 31.7 31.7

EVAPORATOR FAN Centrifugal Type

Quantity...Size (in.) 2...20x15 2...20x15 2...20x15 2...20x15

Type Drive Belt Belt Belt Belt

Nominal Cfm 8,000 10,000 11,000 12,000

Motor Hp 5 10† 15 7.5 10† 15 10 15† 20 10 15† 20

Motor Frame Size (Standard) S184T S215T D254T S213T S215T D254T S215T D254T S256T S215T D254T S256T

(High Efficiency) S184T S215T S254T S213T S215T S254T S215T S254T S256T S215T S254T S256T

Motor Bearing Type Ball Ball Ball Ball

Maximum Allowable Rpm 1200 1200 1200 1200

Motor Pulley Pitch Diameter 4.9 4.4 5.7 5.4 6.1 5.5 4.4 4.9 5.9 4.4 5.7 5.9

Nominal Motor Shaft Diameter (in.) 11/

Fan Pulley Pitch Diameter (in.) 12.4 8.6 9.1 12.4 11.1 8.7 9.4 8.1 8.7 9.0 9.1 8.7

Nominal Fan Shaft Diameter (in.) 115/

Belt, Quantity...Type 1...BX56 2...BX50 2...5VX530 1...BX56 1...5VX570 2...5VX530 2...BX50 2...5VX500 2...5VX530 2...BX50 2...5VX530 2...5VX530

Belt, Length (in.) 56 50 53 56 59 57 50 50 53 50 53 53

Pulley Center Line Distance (in.) 16.0-18.7 15.6-18.4 15.0-17.9 15.6-18.4 15.0-17.9 15.6-18.4 15.0-17.9 15.6-18.4 15.0-17.9

Factory Speed Setting (rpm) 717 924 1096 773 962 1106 848 1059 1187 884 1096 1187

FURNACE SECTION

Rollout Switch Cutout Temp (F)** 225 225 225 225

Burner Orifice Diameter

(in. ...drill size)

Natural Gas Std .111...34 .111...34 .111...34 .111...34

Liquid Propane Alt .089...43 .089...43 .089...43 .089...43

Thermostat Heat Anticipator

Setting (amps)

Stage 1 0.1 0.1 0.1 0.1

Stage 2 0.1 0.1 0.1 0.1

Gas Input (Btuh) Stage 1 Low 265,600 265,600 265,600 265,600

Efficiency (Steady State) (%) 82 82 82 82

Temperature Rise Range 15-45/35-65 15-45/35-65 15-45/35-65 15-45/35-65

Gas Pressure to Unit Range (in. wg) 5-13.5 5-13.5 5-13.5 5-13.5

Manifold Pressure (in. wg)

Natural Gas Std 3.5 3.5 3.5 3.5

Liquid Propane Alt 3.5 3.5 3.5 3.5

Gas Valve Quantity 22 2 2

Field Gas Connection Size

(in.-FPT) 1.5 1.5 1.5 1.5

HIGH-PRESSURE SWITCH (psig)

Cutout 426 426 426 426

Reset (Auto.) 320 320 320 320

LOW-PRESSURE SWITCH (psig)

Cutout 77 7 7

Reset (Auto.) 22 22 22 22

RETURN-AIR FILTERS (W x H x T)

Quantity...Size (in.) 10...20 x 24 x 2 10...20 x 24 x 2 10...20 x 24 x 2 10...20 x 24 x 2

OUTDOOR-AIR FILTERS 8...16 x 25 8...16 x 25 8...16 x 25 8...16 x 25

Quantity...Size (in.) 4...20 x 25 4...20 x 25 4...20 x 25 4...20 x 25

POWER EXHAUST Direct Drive, 3-Speed, Single-Phase Motor (Factory-Wired for High Speed) and Forward Curved Fan

Motor, Quantity...Hp 4...1

Fan, Diameter...Width (in.) 11...10

*Sizes 024-034: Circuit 1 uses the lower portion of condenser coil, Circuit 2 uses the upper portion.

Sizes 038-048: Circuit 1 uses the left condenser coil, Circuit 2 the right. All units have intertwined evaporator coils.

†Motor and drive shown will deliver approximately 2.5 in. wg net external static. For more information, see Table 3.

**Rollout switch is manual reset.

High 398,400 398,400 398,400 398,400

Stage 2 Low 350,000 350,000 350,000 350,000

High 525,000 525,000 525,000 525,000

13/

8

15/

8

16

NOTE: High heat is for 48EJ,EW only.

3

/8″ Copper Tubes, Aluminum Lanced, Aluminum Pre-Coated, or Copper Plate Fins

13/

8

13/

8

115/

15/

8

16

13/

8

15/

8

115/

15/

8

16

13/

8

15/

8

115/

15/

8

16

8

23

Table 1B — Physical Data — 48EJ,EK,EW,EY Units (cont)

NOMINAL CAPACITY (tons) 35 40 45

OPERATING WEIGHT (lb) For Operating Weights see Table 2.

COMPRESSOR

Typ e Ck t 1 06D537 06EA250 06EA265

Number of Refrigerant Circuits 22 2

Oil (oz) (Ckt 1, Ckt 2) 115 ea. 224 ea. 304, 224

REFRIGERANT TYPE R-22

Operating Charge (lb-oz)

CONDENSER COIL Cross-Hatched

Quantity 2211

Rows...Fins/in. 4...15 4...15 4...15 3...15

Total Face Area (sq ft) 58.3 58.3 66.7

CONDENSER FAN Propeller Type

Nominal Cfm 27,064 27,064 27,064

Quantity...Diameter (in.) 4...30 4...30 4...30

Motor Hp (1075 Rpm) 11 1

EVAPORATOR COIL Cross-Hatched 3/8″ Copper Tubes, Aluminum Plate Fins, Intertwined Circuits

Rows...Fins/in. 3...15 3...15 4...15

Total Face Area (sq ft) 34.7 34.7 34.7

EVAPORATOR FAN Centrifugal Type

Quantity...Size (in.) 2...20x15 2...20x15 2...20x15

Type Drive Belt Belt Belt

Nominal Cfm 14,000 16,000 18,000

Motor Hp 10 15† 20 15 20† 25 20 25† 30

Motor Frame Size (Standard) S215T D254T S256T D254T S256T S284T S256T S284T S286T

Motor Bearing Type Ball Ball Ball

Maximum Allowable Rpm 1200 1200 1200

Motor Pulley Pitch Diameter 6.1 5.3 5.7 5.3 5.7 7.5 6.3 8.1 7.5

Nominal Motor Shaft Diameter (in.) 13/

Fan Pulley Pitch Diameter (in.) 13.7 9.5 9.5 9.5 9.5 11.1 11.1 12.5 11.1

Nominal Fan Shaft Diameter (in.) 115/

Belt, Quantity...Type 1...5VX610 2...5VX530 2...5VX550 2...5VX530 2...5VX550 2...5VX590 2...5VX570 2...5VX630 2...5VX590

Belt, Length (in.) 61 53 55 53 55 59 57 63 59

Pulley Center Line Distance (in.) 15.6-18.4 15.0-17.9 15.0-17.9 14.6-17.6 15.0-17.9 14.6-17.6

Factory Speed Setting (rpm) 779 976 1050 976 1050 1182 993 1134 1182

FURNACE SECTION

Rollout Switch Cutout Temp (F)** 225 225 225

Burner Orifice Diameter

(in. ...drill size)

Thermostat Heat Anticipator

Setting (amps)

Stage 1 0.1 0.1 0.1

Stage 2 0.1 0.1 0.1

Gas Input (Btuh) Stage 1 Low 303,500 303,500 303,500

Efficiency (Steady State) (%) 82 82 82

Temperature Rise Range 10-40/30-60 10-40/30-60 10-40/30-60

Gas Pressure to Unit Range (in. wg) 5-13.5 5-13.5 5-13.5

Manifold Pressure (in. wg)

Gas Valve Quantity 22 2

Field Gas Connection Size

HIGH-PRESSURE SWITCH (psig)

Cutout 426 426 426

Reset (Auto.) 320 320 320

LOW-PRESSURE SWITCH (psig)

Cutout 77 7

Reset (Auto.) 22 22 22

RETURN-AIR FILTERS (W x H x T)

Quantity...Size (in.) 10...20 x 24 x 2 10...20 x 24 x 2 10...20 x 24 x 2

OUTDOOR-AIR FILTERS 8...16 x 25 8...16 x 25 8...16 x 25

Quantity...Size (in.) 4...20 x 25 4...20 x 25 4...20 x 25

POWER EXHAUST Direct Drive, 3-Speed, Single-Phase Motor (Factory-Wired for High Speed) and Forward Curved Fan

Motor, Quantity...Hp 4...1

Fan, Diameter...Width (in.) 11...10

*Sizes 024-034: Circuit 1 uses the lower portion of condenser coil, Circuit 2 uses the upper portion.

Sizes 038-048: Circuit 1 uses the left condenser coil, Circuit 2 the right. All units have intertwined evaporator coils.

†Motor and drive shown will deliver approximately 2.5 in. wg net external static. For more information, see Table 3.

**Rollout switch is manual reset.

NOTE: High heat is for 48EJ,EW only.

UNIT 48EJ,EK,EW,EY 034D/E 044D/E 048D/E

Ckt 2 06D537 06EA250 06EA250

Circuit 1* 34-0 35-0 41-0

Circuit 2 34-0 35-0 41-0

3

/8″ Copper Tubes, Aluminum Lanced, Aluminum Pre-Coated, or Copper Plate Fins

(High Efficiency) S215T S254T S256T S254T S256T S284T S256T S284T S286T

8

Natural Gas Std .120...31 .120...31 .120...31

Liquid Propane Alt .096...41 .096...41 .096...41

High 607,000 607,000 607,000

Stage 2 Low 400,000 400,000 400,000

High 800,000 800,000 800,000

Natural Gas Std 3.5 3.5 3.5

Liquid Propane Alt 3.5 3.5 3.5

15/

8

16

15/

8

15/

8

15/

115/

8

16

17/

8

15/

8

17/

115/

8

16

17/

(in.-FPT) 1.5 1.5 1.5

8

24

Table 1B — Physical Data — 48EJ,EK,EW,EY Units (cont)

UNIT 48EJ,EK,EW,EY 054D/E 058D/E 064D/E 068D/E

NOMINAL CAPACITY (tons) 50 55 60 65

OPERATING WEIGHT (lb) For Operating Weights see Table 2.

COMPRESSOR

Quantity...Type (Ckt 1, Ckt 2) 1...06EA265, 1...06EA250 1...06EA275, 1...06EA250 1...06EA275, 1...06EA265 2...06EA275

Number of Refrigerant Circuits 2222

Oil (oz) (Ckt 1, Ckt 2) 304, 224 304, 224 304, 304 304, 304

REFRIGERANT TYPE R-22

Operating Charge (lb-oz)

Circuit 1* 50-11 57-0 68-0 81-0

Circuit 2 46-8 48-6 68-0 73-0

CONDENSER COIL Cross-Hatched

Quantity 1 1 1 1 2 2

Rows...Fins/in. 3...15 2...15 3...15 2...15 3...15 4...15

Total Face Area (sq ft) 66.6 100.0 100 100

CONDENSER FAN Propeller Type

Nominal Cfm 30,000 43,900 43,900 43,900

Quantity...Diameter (in.) 4...30 6...30 6...30 6...30

Motor Hp (1075 Rpm) 1111

EVAPORATOR COIL Cross-Hatched 1/2″-in. Copper Tubes, Aluminum Plate Fins, Intertwined Circuits

Rows...Fins/in. 4...17 4...17 4...17 4...17

Total Face Area (sq ft) 45.0 45.0 48.1 48.1

EVAPORATOR FAN Centrifugal Type

Quantity...Size (in.) 3...20x15 3...20x15 3...20x15 3...20x15

Type Drive Belt Belt Belt Belt

Nominal Cfm 20,000 22,000 24,000 26,000

Motor Hp 15 20† 25 20 25† 30 25 30† 40 25 30† 40

Motor Frame Size S254T S256T S284T S256T S284T S286T S284T S286T S324T S284T S286T S324T

Motor Bearing Type Ball Ball Ball Ball

Maximum Allowable Rpm 1200 1200 1200 1200

Motor Pulley Pitch Diameter 4.7 6.1 8.1 5.9 6.7 7.5 5.3 8.1 9.4 6.7 5.9 9.4

Nominal Motor Shaft Diameter (in.) 15/

Fan Pulley Pitch Diameter (in.) 11.1 11.1 12.5 11.1 11.1 11.1 9.1 12.5 13.6 12.5 9.5 13.6

Nominal Fan Shaft Diameter (in.) 115/

Belt, Quantity...Type 2...5VX550 2...5VX570 2...5VX630 2...5VX570 2...5VX590 2...5VX590 3...5VX530 2...5VX630 2...5VX650 2...5VX610 3...5VX550 2...5VX650

Length (in.) 55 57 63 57 59 59 53 63 65 61 55 59

Pulley Center Line Distance (in.) 15.2-17.5 15.2-17.5 14.7-17.2 15.2-17.5 14.7-17.2 14.7-17.2 14.7-17.2 14.7-17.2 14.2-17.0 14.7-17.2 14.7-17.2 14.3-17.0

Factory Speed Setting (rpm) 741 962 1134 930 1056 1182 1019 1134 1214 938 1087 1214

FURNACE SECTION

Rollout Switch Cutout Temp (F)** 225 225 225 225

Burner Orifice Diameter

(in. ...drill size)

Natural Gas Std .120...31 .120...31 .120...31 .120...31

Liquid Propane Alt .096...41 .096...41 .096...41 .096...41

Thermostat Heat Anticipator

Setting (amps)

Stage 1 0.1 0.1 0.1 0.1

Stage 2 0.1 0.1 0.1 0.1

Gas Input (Btuh) Stage 1 441,000/ 873,000 441,000/ 873,000 441,000/ 873,000 441,000/ 873,000

Efficiency (Steady State) (%) 82 82 82 82

Temperature Rise Range 10-40/30-60 10-40/30-60 10-40/30-60 10-40/30-60

Gas Pressure to Unit Range (in. wg) 5 - 13.5 5 - 13.5 5 - 13.5 5 - 13.5

Manifold Pressure (in. wg)

Natural Gas Std 3.3 3.3 3.3 3.3

Liquid Propane Alt 3.3 3.3 3.3 3.3

Gas Valve Quantity 3333

Field Gas Connection Size

(in.-FPT) 2.5 2.5 2.5 2.5

HIGH-PRESSURE SWITCH (psig)

Cutout 426 426 426 426

Reset (Auto.) 320 320 320 320

LOW-PRESSURE SWITCH (psig)

Cutout 7777

Reset (Auto.) 22 22 22 22

RETURN-AIR FILTERS (W x H x T)

Quantity...Size (in.) 16...20 x 24 x 2 16...20 x 24 x 2 16...20 x 24 x 2 16...20 x 24 x 2

OUTDOOR-AIR FILTERS 12...16 x 25 12...16 x 25 12...16 x 25 12...16 x 25

Quantity...Size (in.) 6...20 x 25 6...20 x 25 6...20 x 25 6...20 x 25

POWER EXHAUST Direct Drive, 3-Speed, Single-Phase Motor (Factory-Wired for High Speed) and Forward Curved Fan

Motor, Quantity...Hp 6...1

Fan, Diameter...Width (in.) 11...10

*Circuit 1 uses the left condenser coil. Circuit 2 the right. All units have intertwined evaporator coils.

†Motor and drive shown will deliver approximately 2.5 in. wg net external static pressure. For more information see Table 3.

**Rollout switch is manual reset.

Stage 2 662,400/1,164,000 662,400/1,164,000 662,400/1,164,000 662,400/1,164,000

15/

8

8

16

NOTE: High heat is for 48EJ,EW.

3

/8″-in. Copper Tubes, Aluminum Lanced, Aluminum Pre-Coated, or Copper Plate Fins

17/

15/

8

17/

8

115/

17/

8

16

17/

8

17/

8

115/

21/

8

16

17/

8

17/

8

115/

21/

8

16

8

25

Table 2 — Operating Weights

48AJ,AK,AW,AY Units

UNIT

48AJD,AKD 4287 4373 4394 4394 5073 5515 5628 7480

48AJE 4367 4453 4474 4474 5233 5675 5788 7720

48AWD,AYD 4327 4413 4434 4434 5113 5555 5668 7520

48AWE 4407 4493 4514 4514 5273 5715 5828 7760

OPTION/

ACCE SSORY

Barometric Relief 300 300 300 300 300 300 300 450

Powe r Exhaust 450 450 450 450 450 450 450 675

Modulating Power Exhaust 500 500 500 500 500 500 500 725

Cu Tubing/Cu Fin Condenser Coil 220 220 220 220 285 285 380 651

Roof Curb (14-in. curb) 365 365 365 365 410 410 410 585

020 025 027 030 035 040 050 060

020 025 027 030 035 040 050 060

BASE UNIT WEIGHTS (Lb)*

OPTION/ACCESSORY WEIGHTS (Lb)

48EJ,EK,EW,EY Units

UNIT

48EJ,EKD 4287 4373 4373 4373 5012 5238 5525 6805 7055 7305 7480

48EJE 4367 4453 4453 4453 5172 5398 5685 7045 7295 7545 7720

48EW,EYD 4327 4413 4413 4413 5052 5278 5565 6845 7095 7345 7520

48EWE 4407 4493 4493 4493 5212 5438 5725 7085 7335 7585 7760

OPTION/

ACCE SSORY

Barometric Relief 300 300 300 300 300 300 300 450 450 450 450

Powe r Exhaust 450 450 450 450 450 450 450 675 675 675 675

Modular Power Exhaust 500 500 500 500 500 500 500 725 725 725 725

Cu Tubing/Cu Fin Condenser Coil 220 220 220 220 285 285 380 271 407 489 651

Roof Curb (14-in. curb) 365 365 365 365 410 410 410 585 585 585 585

024 028 030 034 038 044 048 054 058 064 068

024 028 030 034 038 044 048 054 058 064 068

BASE UNIT WEIGHTS (Lb)*

OPTION/ACCESSORY WEIGHTS (Lb)

CV MOTOR WEIGHTS (Lb)

MOTOR

HP

5

7.5

10

15

20

25

30

40

LEGEND

Cu — Copper

CV — Constant Volume

FIOP — Factory-Installed Option

HP — Horsepower

IFM — Indoor Fan Motor

VAV — Variable Air Volume

VFD — Variable Frequency Drive

*Outdoor-air hoods and filters included in base unit weights; indoor-

fan motors are NOT included.

UNIT

VOLTAGE

230/460 78 94

575 78 92

230/460 107 135

575 107 136

230/460 118 164

575 118 156

230/460 150 217

575 150 220

230/460 212 250

575 212 258

230/460 240 309

575 240 319

230/460 283 355

575 283 359

230/460 372 415

575 372 410

STANDARD

EFFICIENCY

IFM

HIGH

EFFICIENCY

IFM

VAV MOTOR WEIGHTS (Lb)

MOTOR

HP

5

7.5

10

15

20

25

30

40

NOTES:

1. Base unit weight includes outdoor-air hoods. Base unit weight

does NOT include indoor-fan motor. ADD indoor-fan motor,

FIOPs, and accessories for TOTAL operating weight.

2. The VAV motor weights include indoor fan motor and the VFD

(variable frequency drive), compressor electric unloaders, VFD

transducers, and associated wiring.

UNIT

VOLTAGE

230/460 125 141

575 163 177

230/460 183 211

575 193 222

230/460 204 250

575 204 242

230/460 238 305

575 240 310

230/460 348 386

575 304 350

230/460 377 446

575 375 454

230/460 480 552

575 418 494

230/460 637 680

575 587 625

STANDARD

EFFICIENCY

IFM

HIGH

EFFICIENCY

IFM

26

Table 3 — Evaporator Fan Motor Data

UNIT

SIZE

48AJ,AK,

AW,AY

020 024

025 028

027 030

030 034

035 038

040 044

050 048

— 054

— 058

060 064

— 068

NOTES:

1. Motor shaft speed is 1750 rpm. The fan shaft diameter is 115/16 inches.

2. All indoor fan motors meet the minimum efficiency requirements

as established by the Energy Policy Act of 1992 (EPACT), effective

October 24, 1997.

UNIT

SIZE

48EJ,EK,

EW,EY

MOTOR

MOTOR

SHAFT DIA.

HP

5 1.125 717 BK55 4.9 NONE — 1.125 1B5V124 12.4 B—1.9375 BX56 8

10 1.375 924 2BK50 4.4 NONE — 1.375 2B5V86 8.6 B—1.9375 (2) BX50 8

15 1.625 1096 2B5V56 5.7 B — 1.625 2B5V90 9.1 B—1.9375 (2) 5VX530 9

7.5 1.375 773 BK60H 5.4 H — 1.375 1B5V124 12.4 B—1.9375 BX56 10

10 1.375 962 1B5V60 6.1 H — 1.375 1B5V110 11.1 B—1.9375 5VX570 11

15 1.625 1106 2B5V54 5.5 B — 1.625 2B5V86 8.7 B—1.9375 (2) 5VX530 9

10 1.375 848 2BK50 4.4 NONE — 1.375 2B5V94 9.4 B—1.9375 (2) BX50 8

15 1.625 1059 2B5V48 4.9 B — 1.625 2B5V80 8.1 B—1.9375 (2) 5VX500 10

20 1.625 1187 2B5V58 5.9 B — 1.625 2B5V86 8.7 B—1.9375 (2) 5VX530 11

10 1.375 884 2BK50 4.4 H — 1.375 2B5V90 9.0 B—1.9375 (2) BX50 8

15 1.625 1096 2B5V56 5.7 B — 1.625 2B5V90 9.1 B—1.9375 (2) 5VX530 9

20 1.625 1187 2B5V58 5.9 B — 1.625 2B5V86 8.7 B—1.9375 (2) 5VX530 11

10 1.375 779 1B5V60 6.1 NONE — 1.375 1B5V136 13.7 B—1.9375 5VX610 12

15 1.625 976 2B5V52 5.3 B — 1.625 2B5V94 9.5 B—1.9375 (2) 5VX530 10

20 1.625 1050 2B5V56 5.7 B — 1.625 2B5V94 9.5 B—1.9375 (2) 5VX550 11

15 1.625 976 2B5V52 5.3 B — 1.625 2B5V94 9.5 B—1.9375 (2) 5VX530 10

20 1.625 1050 2B5V56 5.7 B — 1.625 2B5V94 9.5 B—1.9375 (2) 5VX550 11

25 1.875 1182 2B5V74 7.5 B — 1.875 2B5V110 11.1 B—1.9375 (2) 5VX590 11

20 1.625 993 2B5V62 6.3 B — 1.625 2B5V110 11.1 B—1.9375 (2) 5VX570 11

25 1.875 1134 2B5V80 8.1 B — 1.875 2B5V124 12.5 B—1.9375 (2) 5VX630 11

30 1.875 1182 2B5V74 7.5 B — 1.875 2B5V110 11.1 B—1.9375 (2) 5VX590 13

15 1.625 741 2B5V46 4.7 B — 1.625 2B5V110 11.1 B—1.9375 (2) 5VX550 11

20 1.625 962 2B5V60 6.1 B — 1.625 2B5V110 11.1 B—1.9375 (2) 5VX570 12

25 1.875 1134 2B5V80 8.1 B — 1.875 2B5V124 12.5 B—1.9375 (2) 5VX630 12

20 1.625 930 2B5V58 5.9 B — 1.625 2B5V110 11.1 B—1.9375 (2) 5VX570 13

25 1.875 1056 2B5V66 6.7 B — 1.875 2B5V110 11.1 B—1.9375 (2) 5VX590 14

30 1.875 1182 2B5V74 7.5 B — 1.875 2B5V110 11.1 B—1.9375 (2) 5VX590 14

25 1.875 1019 3B5V52 5.3 B — 1.875 3B5V90 9.1 B—1.9375 (3) 5VX530 12

30 1.875 1134 2B5V80 8.1 B — 1.875 2B5V124 12.5 B—1.9375 (2) 5VX630 14

40 2.125 1214 2B5V94 9.4 B — 2.125 2B5V136 13.6 B—1.9375 (2) 5VX650 15

25 1.875 938 2B5V66 6.7 B — 1.875 2B5V124 12.5 B—1.9375 (2) 5VX610 14

30 1.875 1087 3B5V58 5.9 B — 1.875 3B5V94 9.5 B—1.9375 (3) 5VX550 13

40 2.125 1214 2B5V94 9.4 B — 2.125 2B5V136 13.6 B—1.9375 (2) 5VX650 15

(in.)

FAN

SHAFT

SPEED

(rpm)

MOTOR

SHEAVE

MOTOR

SHEAVE

PITCH

DIAMETER

(in.)

BUSHING

DIAMETER

(in.)

FAN

SHEAVE

FAN

SHEAVE

PITCH

DIAMETER

(in.)

BUSHING

DIAMETER

(in.)

BELT

(Quantity)

BELT

TENSION

(lb at .25 in.)

Fig. 18 — Air Distribution — Thru-the-Bottom

Fig. 19 — Air Distribution — Thru-the-Side

27

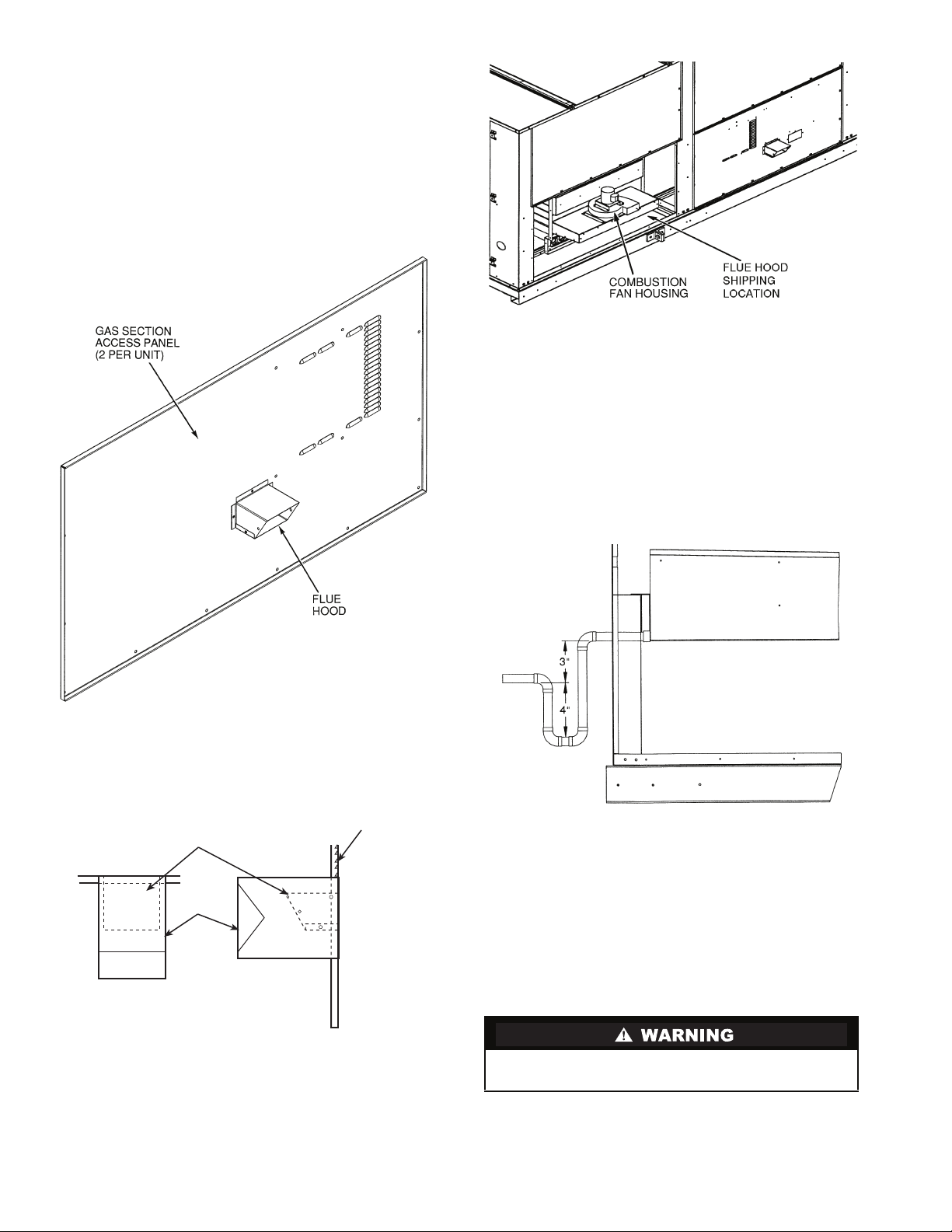

Step 5 — Install Flue Hood

48AJ,AK,AW,AY020-050 AND 48EJ,EK,EW,EY024-048

UNITS — Flue hood is shipped inside gas section of unit. To

install, secure flue hood to access panel. See Fig. 20A.

48AJ,AK,AW,AY060 AND 48EJ,EK,EW,EY054-068

UNITS — Flue hood and wind baffle are shipped inside gas

section of unit. To install, secure flue hood to access panel. Install the two pieces of the wind baffle over the flue hood. See

Fig. 20B.

NOTE: When properly installed, flue hood will line up with

combustion fan housing. See Fig. 21.

Fig. 21 — Combustion Fan Housing Location

Step 6 — Trap Condensate Drain — See Fig. 5-16

for drain location. Condensate drain is open to atmosphere and

must be trapped. Install a trapped drain at the drain location.

One 1-in. FPT coupling is provided inside the unit evaporator

section for condensate drain connection. A trap at least 4-in.

deep must be used. See Fig. 22. Trap must be installed to prevent freeze-up.

Condensate pans are sloped so that water will completely

drain from the condensate pan to comply with indoor air quality guidelines. The condensate drain pans are not insulated.

Fig. 20A — Flue Hood Location

(48AJ,AK,AW,AY020-050 and

48EJ,EK,EW,EY024-048 Units)

FLUE HOOD

WIND

BAFFLE

TOP VIEW SIDE VIEW

Fig. 20B — Flue Hood Location

(48AJ,AK,AW,AY060 and

48EJ,EK,EW,EY054-068 Units)

GAS SECTION

ACCESS PANEL

Fig. 22 — Condensate Drain Trap Piping Details

(Typical Roof Curb or Slab Mount Shown)

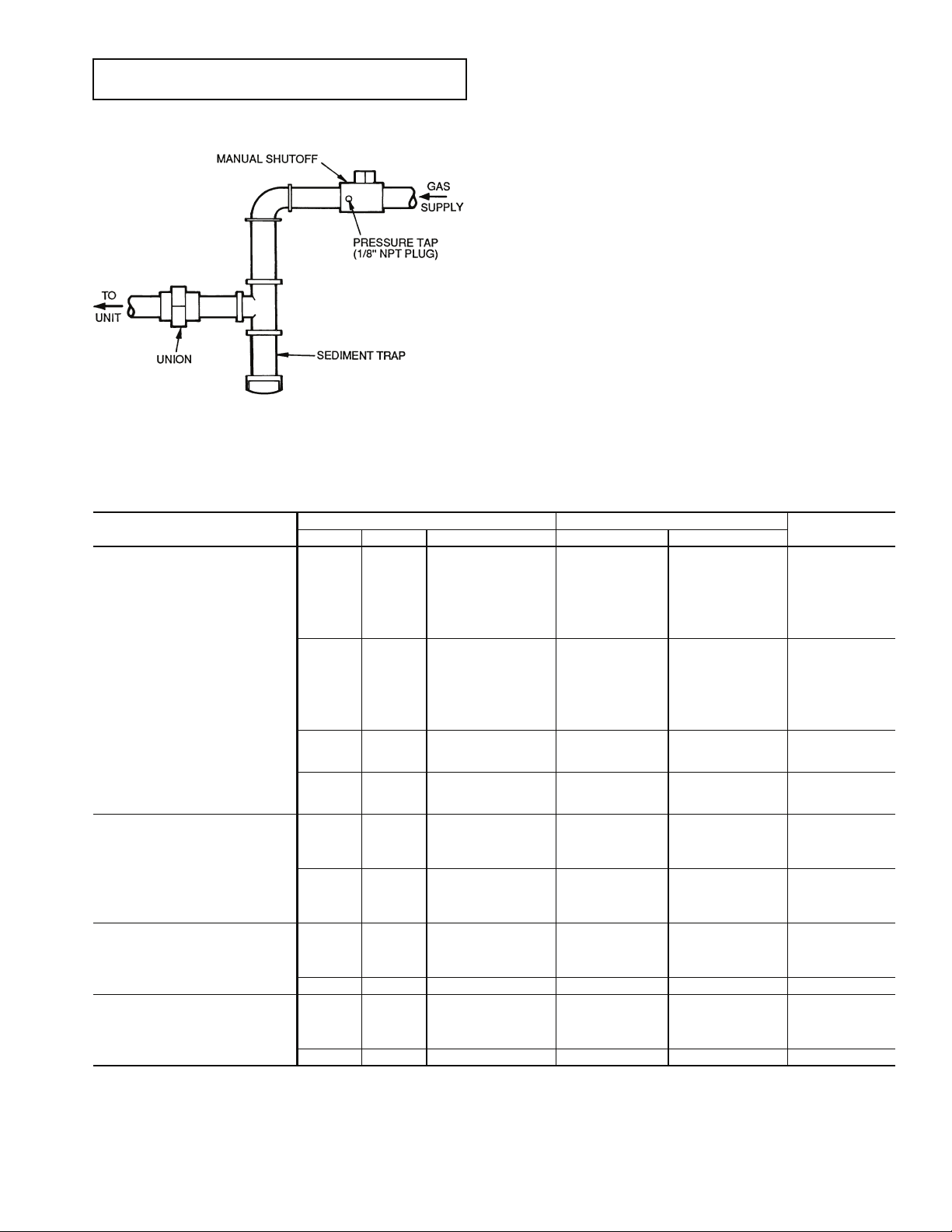

Step 7 — Install Gas Piping — Unit is equipped for

use with natural gas. Installation must conform with local

building codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1.

Install manual gas shutoff valve with a

tap for test gage connection at unit. Field gas piping must include sediment trap and union. See Fig. 23. An

also located on the gas manifold adjacent to the gas valve.

Do not pressure test gas supply while connected to unit.

Always disconnect union before servicing.

1

/8-in. NPT pressure

1

/8-in. NPT is

28

IMPORTANT: Natural gas pressure at unit gas connection

must not be less than 5 in. wg or greater than 13.5 in. wg.

Size gas-supply piping for 0.5-in. wg maximum pressure

drop. Do not use supply pipe smaller than unit gas connection.

Fig. 23 — Field Gas Piping

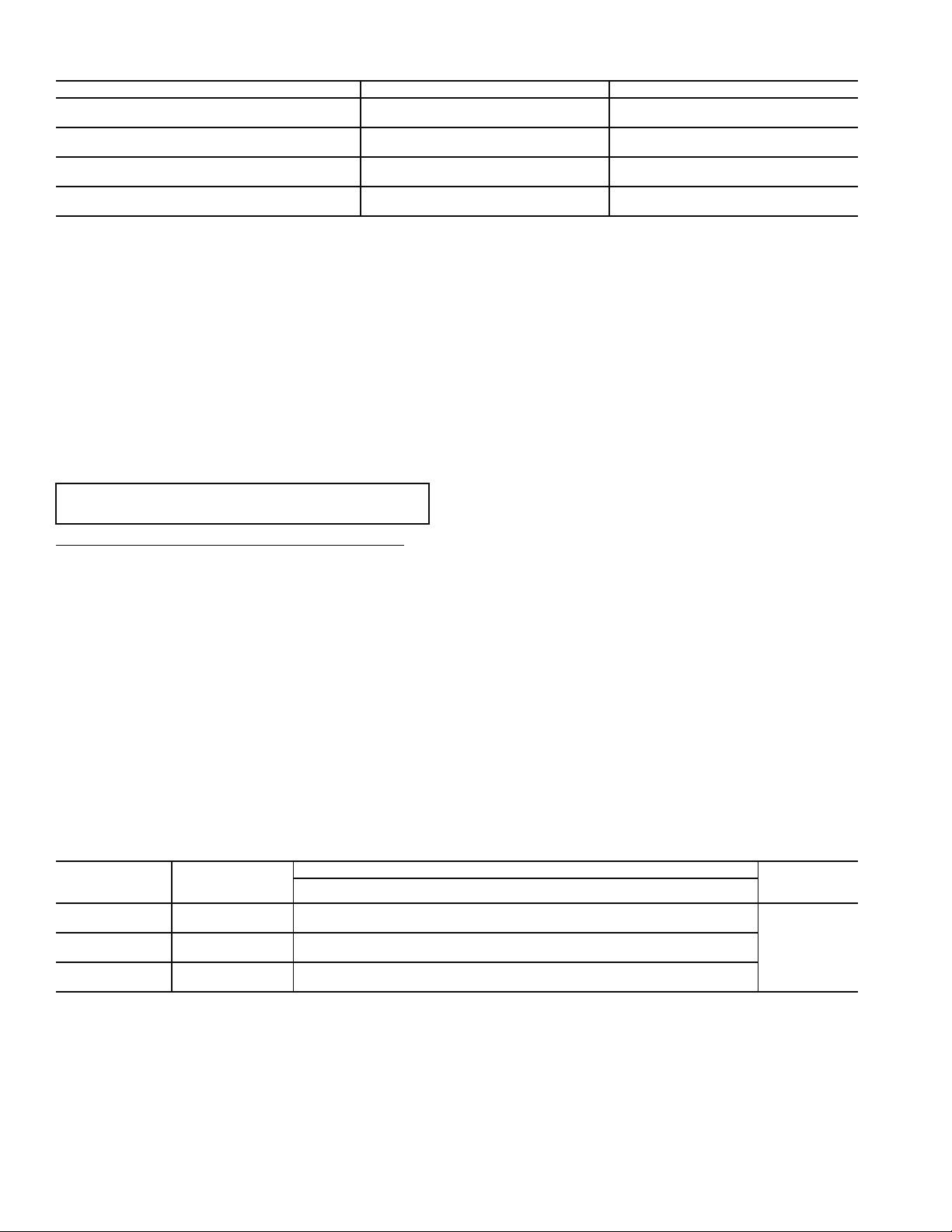

Table 4 — 48A,E Series Staged Gas Implementation

OPTIONAL STAGED GAS UNITS — The staging pattern

is selected based on Heat Stage Type (HTSTGTYP). Max

Capacity per changes default value is selected based on Capacity Maximum Stage (CAPMXSTG). See Table 4.

For complete information and service instructions for

Staged Gas Control Units, see Control Operation and Troubleshooting literature.

Step 8 — Controls Options — The control options

that the units can provide are based on the following parameters: CV (constant volume) or VAV (variable air volume) operation; stand-alone unit with field-supplied sensors installed

(CV or VAV); as a system via Carrier Comfort System (TEMP

or VVT® [Variable Volume and Temperature]); optional electronic expansion board installed (CV or VAV); linked to the

Carrier Comfort Network; availability of a computer and software (ComfortWORKS® Building Supervisor, and Service

Tool) or remote enhanced display accessory installed to access

the base control board; and optional factory-installed staged

gas control. See Table 5.

NOTE: Access to the base control board allows unit occupancy schedules, unit timeclock, and various set points to be

changed from their factory-defined default settings.

NUMBER OF STAGES

5 stages

7 stages

9 stages

11 stages

MODEL NUMBER POSITION POSITION

3 5 6,7,8 HTSTGTYP CAPMXSTG

024

028

ES

AS

ET

AT

ET

AT

ET

A T 060 Default=3 Default=15 High

ES

A S 060 Default=4 Default=15 Low

030

034

038

044

048

020

025

027

030

035

040

050

038

044

048

035

040

050

024

028

030

034

020

025

027

030

054

058

064

068

054

058

064

068

Default=1 Default=20 Low

Default=1 Default=20 Low

Default=1 Default=20 High

Default=1 Default=20 High

Default=2 Default=15 High

Default=2 Default=15 High

Default=3 Default=15 High

Default=4 Default=15 Low

HEAT SIZE

29

Table 5 — Controls Options and Configurations (Non-Thermostat Applications)

UNIT CONFIGURATION DEFAULT COOLING DEFAULT HEATING

CV or VAV Unit with SPT Sensor

CV Unit with SPT Sensor and Remote

Start/Stop Switch

VAV Unit Remote Start/Stop Switch Only

VAV Unit with SPT Sensor and Remote

Start/Stop Switch

LEGEND

CV — Constant Volume

NA — Not Available

RAT — Return-Air Temperature

SAT — Supply-Air Temperature

SPT Space Temperature

VAV — Variable Air Volume

*With DIP Switch No. 5 configured to OPEN (Occupied Heat Enabled).

NOTE: Space temperature sensor and remote start/stop switch are field-supplied.

Unoccupied Cooling — 90 F (32 C) (SPT)

Occupied Cooling — NA

Unoccupied Cooling — 90 F (32 C) (SPT)

Occupied Cooling — 78 F (26 C) (SPT)

Unoccupied Cooling — 90 F (32 C)(SPT)

Occupied Cooling — 55 F (13 C) SPT)

Unoccupied Cooling — 90 F (32 C) (SPT)

Occupied Cooling — 55 F (13 C) (SAT)

Unoccupied Heating — 55 F (13 C) (SPT)

Occupied Heating — NA

Unoccupied Heating — 55 F (13 C) (SPT)

Occupied Heating — 68 F (20 C) (SPT)

Unoccupied Heating — 55 F (13 C) (RAT)

Occupied Heating — 68 F (20 C) (RAT)*

Unoccupied Heating — 55 F (13C) (SPT)

Occupied Heating — 68 F (20 C) (RAT)*

STAGED GAS UNIT APPLICATIONS — The rooftop units

may be ordered with an optional factory-installed staged gas

control system that monitors heating operation of the rooftop

unit.

IMPORTANT: An accessory field-supplied Navigator display module is required for all staged gas control units.

Install Supply-Air Thermistors (Staged Gas Units Only)

—

Supply-air thermistors are a field-installed factory-provided

component. Three supply-air thermistors are shipped with

staged gas units and are inside the heating section. Thermistor

wires must be connected to SGC (staged gas controller) in the

heating section. See Table 6 and Fig 24. The supply-air thermistors should be located in the supply duct with the following

criteria:

• downstream of the heat exchanger cells

• equally spaced as far as possible from the heat exchanger

cells

• a duct location where none of the supply air thermistors

are within sight of the heat exchanger cells

• a duct location with good mixed supply air portion of the

unit.

Table 6 — Thermistor Designations

THERMISTORS — All units are equipped with a supply air

thermistor (SAT) located in the supply fan discharge and an

outdoor air thermistor (OAT) located in the outdoor air hood.

Variable air volume (VAV) units are supplied with a return air

thermistor (RAT) located on the return air damper support.

CONSTANT VOLUME APPLICATIONS — The units, as

shipped, are operable as stand-alone units, using either a standard (mechanical or electronic) 2-stage heat, 2-stage cool thermostat, or with an electronic room sensor and a timeclock to

establish unit start and stop times.

With a standard thermostat (programmable is optional),

heating and cooling operation is set by space temperature.

With a space sensor and timeclock, the machine will operate

at default values unless they are changed using appropriate input devices. The space sensor senses space temperature and

may be equipped with a timed override feature, which allows

unit operation during unoccupied periods.

The space sensors may be used in multiples of 4 or 9 to

achieve space temperature averaging. The use of a space sensor

also allows the unit to be turned on and off from a remote

signal.

THERMISTOR

SAT 1 J8 – 1,2 (SGC)

SAT 3 J8 – 5,6 (SGC)

CONNECTION

POINT

PIN

FUNCTION AND LOCATION

Thermistors

Supply Air Thermistor (SAT) — Inserted into supply section

underneath the gas heat section (factory-provided, field-installed)

Supply Air Thermistor (SAT) — Inserted into supply section

underneath the gas heat section (factory-provided, field-installed)

Supply Air Thermistor (SAT) — Inserted into supply section

underneath the gas heat section (factory-provided, field-installed)

30

PART NO.

HH79NZ016SAT 2 J8 – 3,4 (SGC)

Fig. 24 — Supply-Air Thermistor Connections

Features with Thermostat Control of Unit

• two-stage heating

• two-stage cooling

• control of unit using Y1, Y2, W1, W2, and G thermostat

inputs

• control of the indoor fan

• outdoor-air temperature/supply-air temperature

monitoring

• control of an outdoor air condenser fan based on outdoor-air temperature

• control of modulating economizer damper to provide

free cooling when outdoor conditions are suitable, using

supply-air temperature as a control point

• control of the economizer damper and indoor fan to

obtain unoccupied free cooling

• provide power exhaust output to an external power

exhaust controller

• support a field test for field checkout

• control of 2 stages of CV power exhaust

• compressor Time Guard® (power up, minimum off and

on times)

• compressor lockout during low supply-air temperature

Additional features are provided by accessing the standard

unit control board via software with a computer. These features

are:

• electronic expansion board features (if installed)

• control board diagnostics

• ability to change supply air set point (economizer control)

• ability to change high outdoor temperature lockout set

point (economizer control)

• ability to change power exhaust set points

NOTE: A CV unit without a thermostat requires a fieldsupplied sensor for operation.

Features with Sensor Control of Unit (Stand-Alone Applications — Unit control is limited to CV unoccupied default set

points, 90 F for cooling, 55 F for heating unless a computer has

been used to change the set points. There are 2 sensor options

available:

• T-55 sensor will monitor room temperature and provide

unoccupied override capability (1 hour)

• T-56 sensor will monitor room temperature, provide

unoccupied override capability (1 hour), and provide a

temperature offset of 5° F.

Standard features are:

• support of remote occupied/unoccupied input to start and

stop the unit

• cooling capacity control of 3 stages using economizer

and 2 compressors to maintain space temperature to an

occupied or unoccupied set point

• enable heating or cooling during unoccupied periods as

required to maintain space temperature within the unoccupied set points

• adjustment of space temperature set points of ±5° F when