Page 1

Number One

AirConditbninq

Maker

Division of

Carrier Corporation

Carrier Parkway • Syracus

N Y 13221

Combination Heating/Cooling Units

INTRODUCTION

The 48EL and EM combination heating/cooling

units are complete systems designed for outdoor

installation on slab or rooftop.

Installation consists of: rigging and mounting

the unit, attaching ductwork, making single gas,

electrical and condensate connections, and

attaching thermostat leads. A field-furnished filter

rack is required in the return airstream.

RECEIVING THE UNIT

Examine the unit carefully for any damage

incurred in shipment. If damaged, file claim with

transportation company immediately.

Check unit nameplate to ensure that unit

electrical requirements match available power

supply, and that unit is designed for use with the

proper gas type (natural or liquefied petroleum).

INSTALLATION

Check national and local gas and electrical

codes and local building codes for any special

installation requirements.

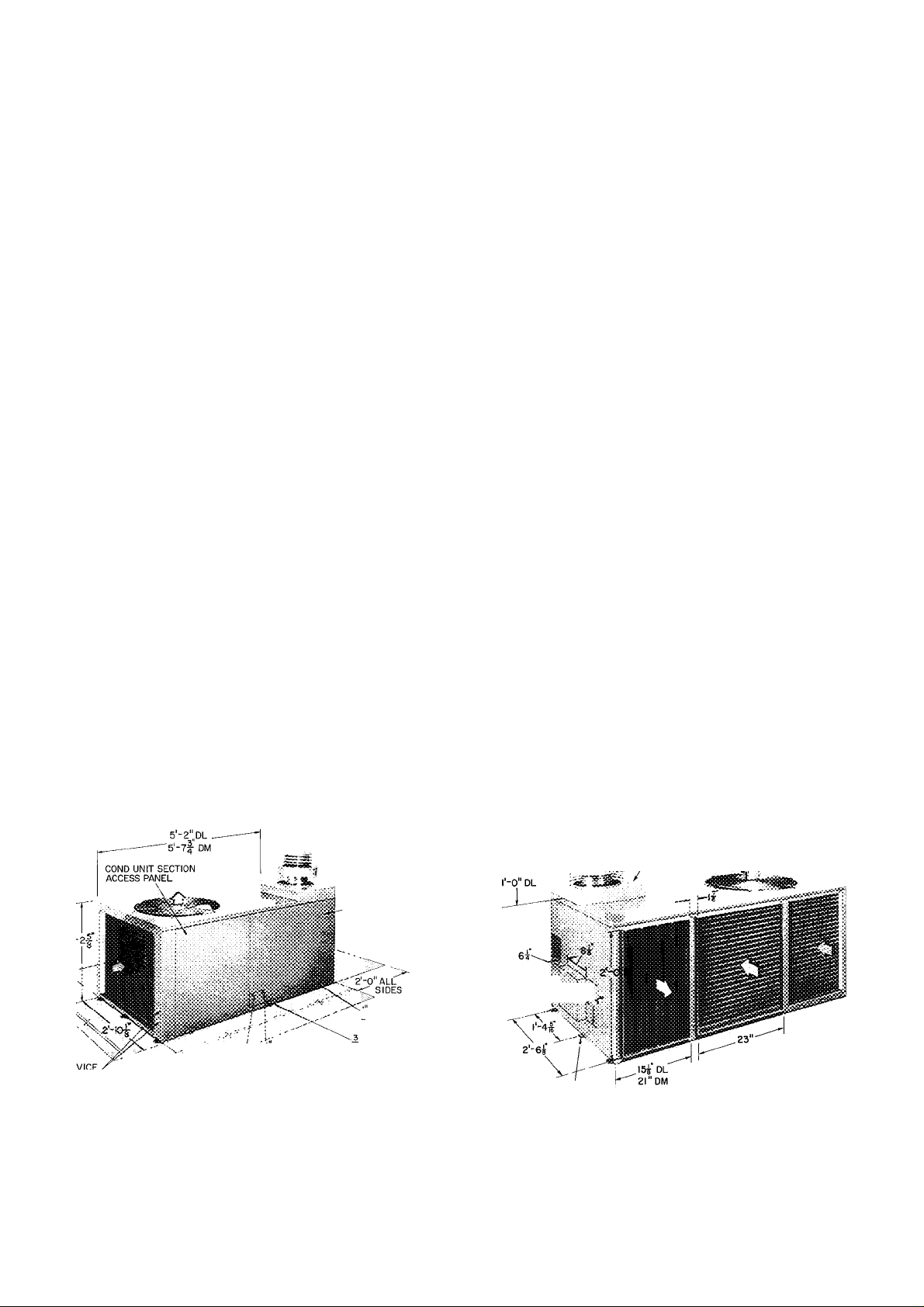

Unit Location — Install unit outdoors. Maintain

clearance of at least 2 ft from building. Unit may

face in any direction since neither the condenser

air inlet nor the flue outlet (Fig. 1) are affected by

wind. Do not locate unit near sources of con

taminated air.

Although the unit is weatherproof, position

unit so that water and ice from roofs or eaves

cannot fall directly on the unit. •

SPACE LIMITATIONS — Provide sufficient space

for unimpeded airflow and for wiring and servicing

unit (Fig. 1).

OUTSIDE AIR LIMITATIONS - Although there

are no restrictions on either the percentage or the

temperature of the outside air circulated thru the

unit, the rate of moisture condensation from the

combustion process increases significantly when

return air temperature drops below 50 F. Protect

the drain holes in the bottom pan against ice

buildup if outside air of below freezing tempera

ture is used.

VIBRATION ISOLATION - The unit compressor,

evaporator fan and condenser fan are mounted on

isolators to minimize vibration. Additional

isolation is not required for slab mounting. With

some types of roof construction, however, the use

of field-furnished rubber pad type isolators may be

advisable.

Unit Rigging

1. Sling the unit perpendicularly to shipping skid

runners. Use spreader bars to prevent damage

from sling or cable.

2. Raise unit to desired location and remove

shipping skid.

3. Mount and level the unit as indicated in Unit

Support and Mounting section.

Unit Support and Mounting

LEVELING THE UNIT - Level the unit from end

to end but pitch the unit slightly (3/8 to 1/2 in.)

towards the condensate drain on the service access

face of the unit (Fig. 1). Use the unit frame as a

leveling reference.

SLAB MOUNTING ^ Mount the unit on a

concrete pad, cement blocks, bricks or creosoted

wood of sufficient area and strength to support the

unit weight (Table 1) without distortion or damage

and maintain the drainage pitch recommended

above.

A gravel apron prevents grass and foliage from

obstructing the condenser air inlet (Fig. 1).

FLAT OR RECESSED ROOF MOUNTING should

be as close as possible to the roof duct opening.

Place the unit on at least 2 wooden 2 x 4 in. or 2 x

6 in. sleepers.

Sleepers may be perpendicular to or parallel to

the unit mounting rails, but must span at least 2

roof joists or purlins to distribute unit weight. Set

the sleepers in roof cement or mastic. Do not plug

drain holes in the compressor or furnace

compartment.

Do not support the unit by the ends of the base

rails, nor use vibration isolators at these points.

Unit will not be properly supported and could sag

in the middle.

PITCHED ROOF MOUNTING - Construct a

sturdy welded or bolted frame of 1-1/2 x 1-1/2 x

1/4 in. or larger angle iron, with frame members at

right angles to unit rails. Make provisions for

securing unit to frame. Use roof cement or mastic

where frame is in contact with roof.

© Carrier Corporation 1978

Form 48EL-1SI

Page 2

Table 1 — Physical Data

UNIT MODEL

OPERATil^ WEIGHT (lb)

REFRIG (22) CHGIIb-oz)

COMPRESSOR

Cylinders

Rpm (60-Hz)

CONDENSER FAN

Air Quantity (Cfm)

Motor Hp

evaporator fan

Size (in.)

Nominal Cfm

Rpm Range

Max Allowable Rpm

Fan Pulley Pitch Diameter (in.)

Motor Pulley Pitch Diameter (in.)

Belt

Speed Change per Full Turn of

Moveable Pulley Flange (Rpm)

Factory Setting — Full Turns Open

Motor Hp

CAPACITY (1000 Btuh)

Cooling

Heating Input/Bonnet*

MAX EXTERNAL STATIC PRESSURE

Heating (in. W.C.)

FILTERSt (1-in. thick)

Disposable — No. ...Size (in.)

Permanent^ — No. ...Size (in.)

HEAT TEMPERATURE RISE (F)

GAS CONNECTION (in.)

48EL006

48EM006

" soi

"^5”5

GB30K

___

010

2

3500

Propeller Type, Direct Drive; Vertical Discharge

2700

1/3

Centrifugal, Belt Drive: Horizontal Discharge

10x9

1900

820-1250

1500

80

1 9-2 9

4L40

90

2

3/4

58

110/82 5

150/112 5

2 16x20

2 16x20

45-75

1/2

’537'

5 5

58

1 20x25

1 25x25

1 20x25

1 25x25

^Ratings shown for elevations up to 2000 ft above sea level For elevations above 2000 ft deduct 4% capacity for each

1000 ft above sea level

fRecommended field-supplied filter

JBased on 0 055 in wg pressure drop or less thru filter

WIND CAP 4‘-0"OVERHEAD SPACE

COMBUSTION AIR REQUIRED FOR SERVICE

INLET BOX yTv AND AIRFLOW

2-0 \

ALL SIDES

li- DIAM HOLE FOR

i DIAM HOLE FOR

CONTROL WIRING

LINE POWER

WIRING

EVAPORATOR AND

HEATING SECTION

ACCESS PANEL

i- FPT GAS

VALVE CONN

CONDENSATE

’ DRAIN CONN

r-oi DM

SUPPLY GAS I:.; .

CONN HOLE^'

|DIAM(6MTG HOLES)

I

О INDOOR AIR

Ф CONDENSER AIR

Certified dimension drawings available on request

I

Space required for service Design certified by A G A for installation on

combustible-type floor with minimum space of 2'-0" on all sides

Fig. 1 — Physical Data and Dimensions

Page 3

Ductwork Installation — For air duct system design

information, refer to Carrier System Design

Manual, Part 2. System airflow must be within the

range of temperature rise and external static

pressure shown on the unit A.G.A. rating plate.

Bolt or screw ductwork to unit supply and

return air duct flanges and seal joints with sheet

metal flashing. Flange location and dimensions are

given in Fig. 1. Use flexible connectors between

ductwork and unit to dampen vibration. If a single

split duct is connected to the unit, use a gasket to

prevent air bypass between supply and return sides.

Insulate and weatherproof all external duct

work. Secure ducts to building structure and

weatherproof all duct openings in wall or roof.

Ducts passing thru unconditioned spaces must be

insulated and provided with a vapor barrier.

Filter Installation (Field-Supplied)

1. Locate filter in return air system. Convenient

location for filter is inside building behind

return air grille. Size and number of required

filters is given in Table 1.

2. Attach filter manufacturer’s instructions to

filter rack.

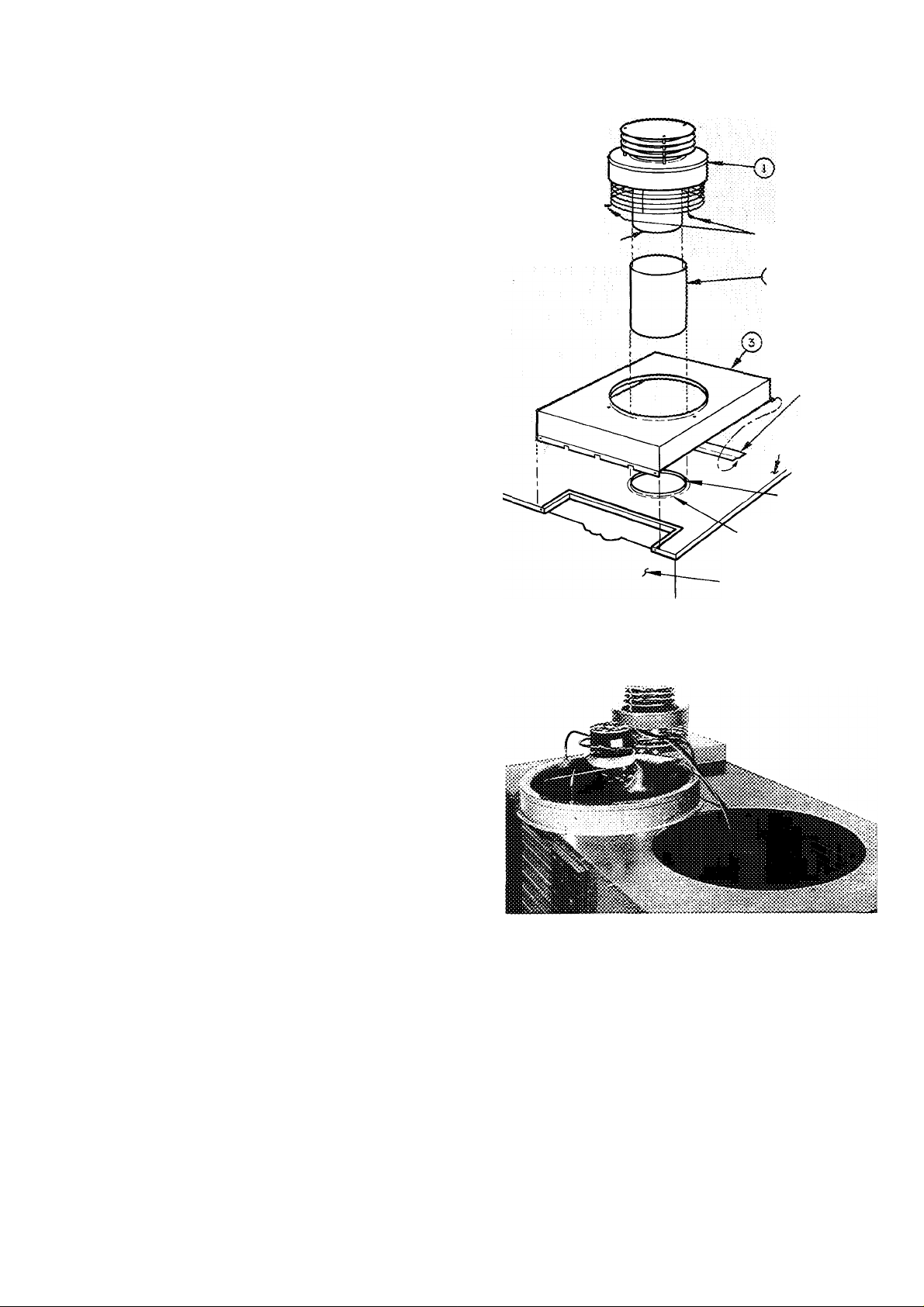

ASSEMBLE WIND CAP AND

COMBUSTION-AIR INLET BOX

WIND CAP

ASSSMSi-Y

auEPiPc

(PARTOF WiNOCAP

ASS£M8LY)

EY£L£TS(3)

« yHSATrSHfEXP

‘^^COLtAR

COMBUSTfON

AiR inlet BOX

RETAININS

CUP

TOP COVER

OF UNIT

!

TCP COVER

EXTRUSION

FLUE BOX

EXTRUSION

HEATING SECTION

ACCESS PANEL

Fig. 2 — Wind Cap and Air Inlet Box Assembly

Locate — The wind cap assembly, heat-shield collar

and combustion-air inlet box (items 1, 2 and 3 of

Fig. 2) are shipped within the condenser section

except 460 volt units.

On 460 volt units, only the combustion-air inlet

box is shipped within the condenser section. The

heat-shield collar and wind cap assembly are

shipped in a separate package.

Remove 6 sheet metal screws and lift condenser

fan, grille and orifice from the top of the con

denser section (Fig. 3). Remove and discard metal

banding securing the wind cap and/or inlet box and

remove the item(s) from the condenser section.

Before replacing the condenser fan, grille and

orifice, remove any shipping tape from the con

denser fan.

Assemble (Fig. 2)

1. Mount the combustion-air inlet box (item 3) by

sliding the horizontal box flange under the

retaining clip on the unit top cover. Fasten the

inlet box with sheet metal screws provided.

2. Place end of heat-shield collar and secure wind

cap assembly (item 1 ) with 3 sheet metal screws

thru wire cage eyelets.

PIPING AND WIRING

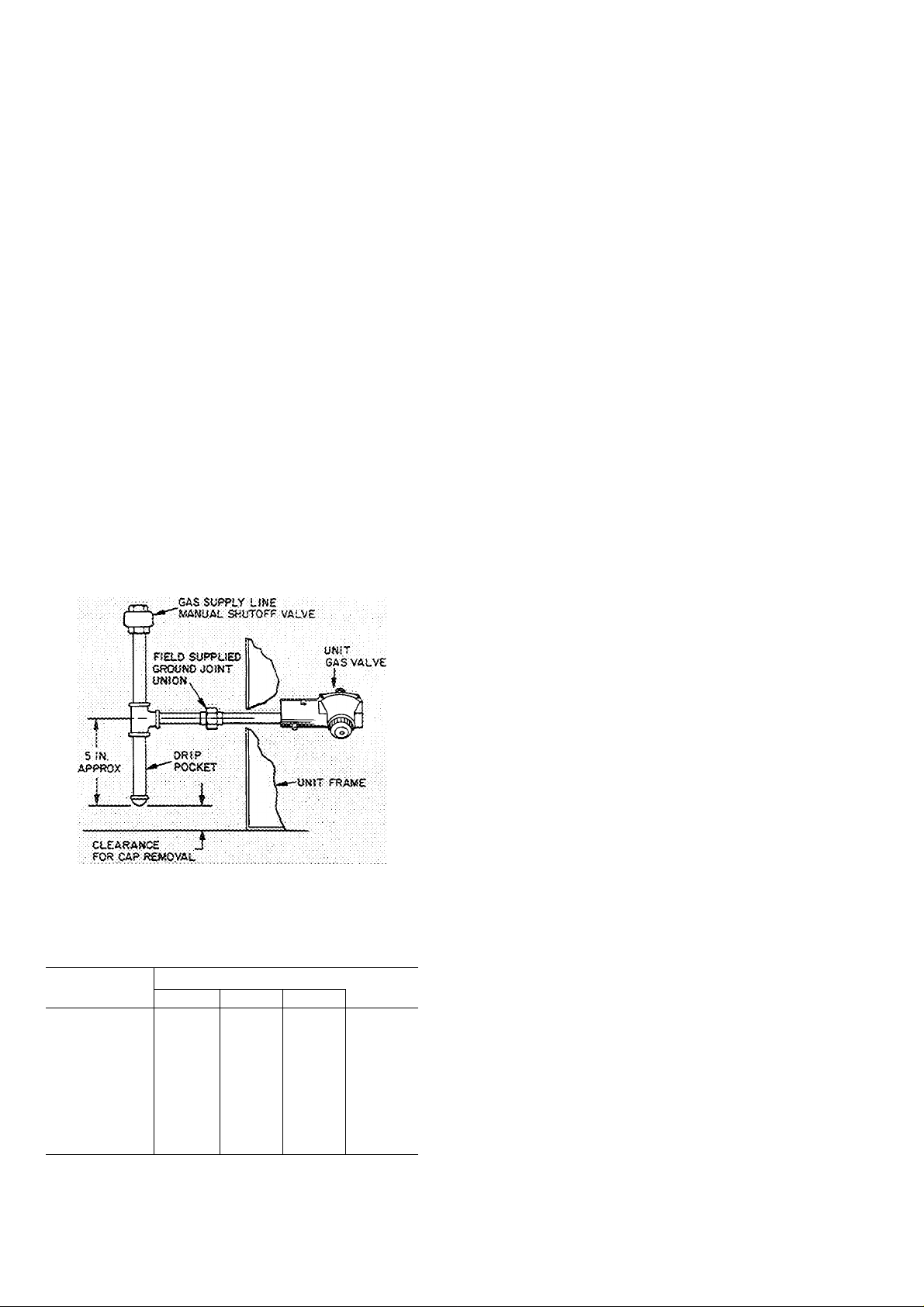

Gas Piping — Install piping per national and local

codes and ANSIZ223.1 entitled “National Fuel

Gas Code,” (published by American Gas Asso-

Fig. 3 — Removing Condenser Fan

and Orifice Assembly

ciation, 1515 Wilson Blvd., Arlington (Rosslyn),

VA 22209).

1. Furnish the gas line from the main gas supply

to the unit gas valve (Fig. 4). Connection at gas

valve is 1 /2 in. FPT.

2. Size the supply pipe for 0.3-in. wg maximum

pressure drop and for the volume of gas

required (Tables 2, 4 and 5). Pipe size must

equal or exceed size of gas connection at unit.

3. Use pipe dope approved for use with liquefied

petroleum (LP) gases.

Page 4

Pitch all horizontal pipe runs towards the unit

1 /4-in. per 15 ft to prevent trapping condensed

moisture.

5.

Support piping to maintain proper pitch,

prevent strain on unit controls, and prevent

accidental movement of piping.

Install a tee for attachment of a dirt and

moisture drip pocket (Fig. 4). Tee should be at

same level or below gas valve connection. Drip

pocket must be protected against freeze-up

7.

Install manual shutoff valve on gas piping per

local codes.

8. Provide a ground joint union in the gas supply

line near the unit gas valve.

9. Protect gas piping from freezing temperatures

Gas stoppage can result from failure to insulate

pipe against wide or sudden temperature

changes.

10. When piping is completed, check entire gas

assembly and field piping with soap and water

solution.

Never use an open flame for leak testing.

NOTE Connection to unit gas valve is 1/2 in FPT

Fig. 4 — Gas Piping Details

Table 2 — Maximum Pipe Cap. (cfh)*

PIPE

LENGTH (ft)

10

20

30 73

40

50

60

70

80

90

100

*Cfh — Cu ft/hr based on 0 3 in wg pressure drop and 0.6

gas specific gravity

NOTE: Correction is not necessary for normal number of

fittings nor for 0.7 gas specific gravity unless specified

NOMINAL PIPE SIZE (in.)

1/2

132 278 520

92 190 350

63

56 115

—

—

—

—

—

3/4

152

130

105 195

96 180

90

84

79

1 1-1/4

285 590

245 500

215 440

170 350

160 320

150 305

1050

730

400

370

Drain Piping — The condensate drain connection

(3/4-in. MPT) is on service access face of unit

(Fig. 1). Since drain is on the suction side of the

indoor (evaporator) fan, it must be trapped to

prevent leakage back into the unit. Trap should be

at least 3 in. deep and should be formed of flexible

material or in such a manner as to resist freeze-up

damage.

Wiring — The design center voltage for each unit is

stamped on the unit nameplate. The supply voltage

at the unit must be within maximum and minimum

limits shown on nameplate and in Tabled. Phase

unbalance on 3-phase units must be within 2%.

Contact local power company if correction is

necessary. Operation of the unit on improper line

voltage or with excessive phase unbalance is con

sidered abuse and is not covered by Carrier warranty.

Provide a branch circuit fused disconnect of

adequate size to handle unit starting current

(Table 3). Disconnect must be within sight of and

readily accessible from the unit in accordance with

Section 440-14 of the National Electrical Code

(NEC). Provision for locking switch at open (off)

position is advisable to prevent power from being

turned on while unit is being serviced.

Use only UL approved copper or copper-clad

aluminum power wires.

UNIT CONNECTION

1. Attach field power conduit to 1-1/8 in. hole at

front of high voltage (line wiring) junction box

(Fig. 1).

2. Run conduit so that access panels can be

readily removed.

3. Splice field power wires to the pigtail leads in

the junction box. Wire nuts are provided for

either copper or aluminum wire. These must be

field insulated.

4. Route the control-voltage field wiring thru the

7/8-in. hole in low-voltage junction box

(Fig. 1). If conduit is not used, protect wires by

inserting diaphragm grommet into the hole.

Make all connections to pigtail leads, but do

not use aluminum control wire for splice

connection to the copper pigtails.

Accessory Installation and Wiring

REMOTE CONTROL CENTER - The installation

instructions for this combination heating-cooling

thermostat and subbase are included with the

accessory.

Locate the thermostat on an inside wall or

column where it is affected only by the average

temperature of the room. The subbase has slots for

direct mounting on wall or on vertical outlet box.

Run the thermostat cable or equivalent single

leads of no. 18 colored wire from subbase ter

minals to 7/8-in. diameter hole in access side of

unit (Fig. 1) and attach to low voltage (control

wiring) terminals in junction box (Fig. 5).

Page 5

Table 3 — Electrical Data (60-Hz)

GE

230/1/60

460/3/60

VOLTA

Min-Max

207-264

187-253 22 7 132

414-528

UNIT MODEL

Norn V/Ph/Hz

48EL,EM006300,310

48EL,EM006500,510 208-230/3/60

49EL,EM006600,610

FLA — Full Load Amps LRA — Locked Rotor Amps

Table 4 — Gas Data — 48EL,EM006

TYPE

OF PER

GAS

Natural

Butane

Propane

Propane

BTU

CU FT

1000

1050

1100

3200

2500

2500

SPECIFIC

GRAVITY

60

65

60

60

_65^

2 00

1 53

1 53

Ml PR

CO

RLA

35 3 175

10.4

LRA

66 28

RLA — Rated Load Amps

MANIFOLD MAIN

PRESSURE BURNER

(in. wg) ORIFICE

3.3

3.5

30

3.2

27

2.9

12.2

OUTDOOR

FAN

MOTOR

FLA

2.8

28

_

108

INDOOR

FAN

MOTOR

FLA

6 9 55

6 9 40

6 9 20

#41 Drill

#54 Drill

#53 Drill

POWIEI

Min

Ckt

Amp

ORIFICE

.023 in

3 SUPPLY

Max

Fuse

Amps

70

50

25

PILOT

009 in

.009 in

THE RMOSTAT C OMBINA TIONS F OR ALL UNIT S

1 HH07AT0 74 A ND SUB BAS E HH 93A Z076

2 HH0IAD0 42 A ND SUBBASE HH 93A Z042

3 H H0IA D04 0 AN D S UBB ASE HH93AZ 040

I I I I I

I

BRN I BLK

I

RED BL U ORN

I 1

I I I I I

È * é I [È '

^ ^ FIELD POWER

FIELD CO NTR OL

WIR ES

I I Thermostat Connections

_$^Splice Connection

*Not connected when single-phase power input is used.

------------------

WIR ES

----------

BLU —

— B LK -

-YE L^

Field Power Wiring

Field Control Wiring

Factory Wiring

Fig. 5 — Remote Control Wiring

for Thermostat Combinations

When thermostat wiring is complete, mount

thermostat to subbase per instructions included

with the control. Do not turn on unit power at this

time; refer to Start-Up section of this publication.

Thermostat heat anticipator setting is 0.6 amps.

REMOVE SHIPPING TAPE on condenser fan, if

not previously removed.

CHECK COMPRESSOR HOLD-DOWN BOLTS -

Compressor is internally spring-mounted. Do not

loosen or remove hold-down bolts.

SET HEAT ANTICIPATOR on thermostat at 0.6

amps.

OPEN GAS SUPPLY LINE VALVE and purge line

by loosening ground joint union (Fig. 4). Tighten

union when gas odor is detected.

ADJUST BLOWER SPEED, if required, to main

tain heat temperature rise limits given in Table 1.

CHECK MAIN BURNERS

1. Measure and adjust main burner gas input as

described in Service section.

2. Turn main gas valve to ON position and operate

unit for at least 15 minutes with all access

panels in place.

3. With unit operating, remove heating section

access panel. Check burner flames. Flames

should be clear, almost transparent blue. If

flames appear yellow, a change to factory set

primary air adjustment has occurred. Refer to

Fig. 7 and readjust primary air as follows:

Loosen primary air spoiler locking screw.

Rotate adjustment tab counterclockwise

(slightly) until flame becomes blue. If flames

lift off burner ports, turn adjustment tab

clockwise. Retighten locking screw.

FINAL HEATING SYSTEM CHECKOUT - Move

thermostat dial above and below room temperature

setting several times, pausing at least 5 minutes

between cycles. Check pilot flame, main burner

ignition, flame characteristics and indoor (evap

orator) fan motor time delay relay operation.

Replace heating section access panel.

COOLING SYSTEM CHECKOUT

1. Turn power on.

Page 6

2. Set room thermostat selector switch at COOL

or AUTO, and dial setting below room

temperature.

3. Move thermostat dial above and below room

temperature several times, pausing at least 5

minutes between cycles. Check fan and com

pressor operation.

PILOT ADJUSTING SCREW CAP

MANUAL SHUTOFF VALVE

AND PILOT COCK

LOW VOLTAGE

CONNECTIONS

REGULATOR ADJUSTING

COVER (ADJUST Hi"

SIDE SCREW)

PILOT GAS LINE

CONNECTION

MAIN GAS CONNECTION

PRESSURE TAP

------------------

2. Set thermostat selector switch at HEAT posi

tion and set thermostat dial a few degrees above

room temperature.

3. Turn power on, and unit automatically operates

as described below.

AUTOMATIC SEQUENCE

1. Pilot valve opens, spark ignition and indoor fan

time delay relay energize.

2. Gas flows to pilot and ignites. Pilot flame

sensing probe permits energizing of the main

gas valve. Gas flows to main burner and ignites.

3. Time delay relay starts indoor fan motor in 30

— 45 seconds.

4. When thermostat setting is satisfied, main gas

valve and pilot gas valve close and flames are

extinguished.

5. Indoor fan motor stops in I - to 1-1/2 minutes.

CAUTION; l>o not use matches to li^t

pilof on iniennitient pilot units because of

electrical shock hazard-

Fig. 6 — Unit Gas Valve

AIR/GAS MIXTURE

ADJUSTMENT TAB

LOCKING SCREW

-.33

^^.^eCTROOE

:«LOr SOOT

¡¡—T

LOCKING SCREW' ^

Fig. 7 — Main Burner Adjustment Details

Start-Up Sequence, Natural and LP Gas Units With

Intermittent Spark Ignition of Pilot, indoor (evap

orator) fan motor time delay relay and Essex

SX242 gas valve.

MANUAL SEQUENCE

1. With power off turn manual gas valve knob to

ON position.

GENERAL OPERATING SEQUENCES

These sequences apply to both natural and EP gas

units in normal operation after initial start-up.

Operating Sequence-Heating

NATURAE GAS AND LP UNITS WITH INTER

MITTENT PILOT

1. Thermostat selector switch at HEAT or AUTO.

Thermostat dial set above room temperature.

2. Pilot gas valve opens. Gas flows to pilot and

ignites. Pilot flame sensing probe causes main

gas valve to open. Gas flows to main burner and

ignites.

3. TDR starts indoor fan motor in 30 — 45

seconds.

4. When thermostat is satisfied both pilot gas and

main gas valves close. Pilot and main burner

flames are extinguished.

5. TDR stops indoor fan motor in 1- to 1-1/2

minutes.

6. Pilot is on only when thermostat calls for

heating.

Operating Sequence — Cooling

1. Unit energized. Thermostat selector switch at

COOL or AUTO. Thermostat dial set below

room temperature.

2. Indoor and outdoor fans and compressor start.

3. When thermostat setting is satisfied, fans and

compressor stop.

Automatic Operation — Power and gas on. Room

thermostat (control center) set at AUTO. Fan

switch (on control center) set at AUTO.

Unit performs as described in the operating

sequences above on call for heating or cooling.

Page 7

Automatic changeover type thermostat is required.

Continuous Fan Operation — With power supplied

to unit and fan switch at ON position, indoor fan

remains on at all times.

Complete Shutdown or Change from Heating to

Cooling

1. Turn thermostat selector switch to OFF.

2. Remove heating section access panel.

3. Turn manual shutoff valve (Fig. 6) to PILOT.

Then depress valve and turn to OFF.

4. Turn off power. Replace access panel.

SERVICE

Adjusting Main Burner Gas Input (Refer to Fig. 4

and 6 and to Table 4 and 5) -- Need for adjustment

is determined by comparing measured gas input

(flow rate or manifold pressure) against the rated

input of a gas with a specific heating value. Check

local gas supplier for correct heating value (BTU’s

per cu ft). Before measuring, shut down all other

gas appliances.

Flow rate (cfm), the most accurate method, is

measured by gas meter and stop watch. Check

measured flow against rated flow in Table 5.

Refrigerant Charging — Standard 1/4-in. Schrader

service connections are provided on the high and

low sides of the refrigerant system for charging and

evacuation.

Amount of refrigerant charge is listed on unit

nameplate (also refer to Table 1). Refer to Carrier

Standard Service Techniques Manual, Chapter 1,

Refrigerants.

Unit panels must be in place when unit is

operating during charging procedure.

NO CHARGE — Use standard evacuating tech

niques. After evacuating system, weigh in the

specified amount of refrigerant.

LOW CHARGE — Using charging chart (Fig. 8),

add refrigerant until the conditions of the chart

are met. Charts are based on charging the units to

the correct superheat for the various operating

conditions. An accurate pressure gage and tem

perature sensing device are required. Connect the

pressure gage to the service port on the suction

line. Mount the temperature sensing device on the

suction line and insulate it so that outdoor

ambient temperature does not affect the reading.

Indoor air cfm must be within the normal

operating range of the unit.

^ Table 5 — Gas Rate (cfm)

UNIT

Natural 1000 1 83 2 50

Natural 1050 1 74 2 38

Natural 1100 1 66 2 27

Butane 3200 57

Propane 2500 73 1 00

48EL006 48EM006

78

Manifold pressure (in. wg) is measured as

follows:

1. Remove heating section access panel.

Shut down unit and close gas supply line valve

2.

(Fig. 4).

Remove pressure tap plug from main gas valve

3.

(Fig. 6) and install pressure tap.

4.

Attach U-tube water gage manometer to pres

sure tap and open gas supply line valve.

Start-iip heating system.

5.

6.

Measure gas pressure (in. wg) and compare with

rated pressure in Table 4.

To adjust pressure or flow rate:

1. Remove pressure regulator adjusting screw cap

on main gas valve (Fig. 6).

Turn screw slowly, clockwise to increase pres

2.

sure (flow), and counterclockwise to decrease.

Replace adjusting screw cap.

3.

4.

Shut down heating system.

Close gas supply line valve, remove manometer

5.

and replace pressure tap plug.

Open gas supply line valve and replace heating

6.

section access panel.

SUCTION LINE TEMPF

Fig. 8 — Charging Chart — 48EL,EM006

TO USE CHARGING CHART - Take the outdoor

ambient temperature and read the suction pressure

gage. Refer to chart to determine what the suction

temperature should be. If the suction temperature

is high, add refrigerant. If the suction temperature

is low, carefully blow some of the charge. Recheck

the suction pressure as charge is adjusted.

If Chargemaster® charging device is used, tem

perature and pressure readings must be accom

plished using charging chart. Fig. 8.

Page 8

Part Removal (Refrigerant System)

CAUTION: System contains oil and refiigerant

under pressure. Do not use torch to remove

component. Wear your protective gog^es.

1. Shut off electrical power to unit.

2. Relieve all pressure from system.

3. Cut connecting piping with tubing cutter.

4. Remove component from unit.

5. Unsweat piping stubs carefully. Oil may ignite

when exposed to torch flame.

WELDED HERMETIC COMPRESSOR - Make

certain that all safety codes are followed. Use

protective goggles, work gloves and water-soaked

quenching cloth.

1. Shut off electrical power and remove all wiring

from compressor.

2. Purge or remove all refrigerant and pressure

from system.

3. Cut suction and discharge lines with tubing

cutter at convenient place near compressor to

facilitate reassembly with copper slip

couplings.

4. Remove compressor from unit and carefully

unbraze piping stubs. Oil vapor in piping stubs

can ignite from torch flame, use quenching

cloth if necessary

5. Install old piping stubs on new compressor and

carefully braze in place.

6. Clean system. Add or replace liquid line filter

drier.

7. Install hew compressor in unit and braze in

place with field-supplied copper slip couplings.

Protect pressure relief plug in suction line with

wet rag if brazing near it.

8. Connect wiring; replace wire terminals if

necessary.

9. Attach caution sticker to new compressor.

10. Proceed with evacuation, charging and start

up. Procedures for evacuation and system

cleanout can be found in Carrier Standard

Service Techniques Manual, Chapter 1, Form

SM-1.

Part Removal Evaporator Fan (Blower Wheel) —

Remove fan as follows:

1. Shut off all electrical power to unit.

2. Remove heating section access panel.

3. Loosen 5 screws and remove interior panel.

4. Disconnect the 2 wires to the fan motor.

5. Remove screws holding the evaporator fan

housing and the support strap and slide housing

and fan from unit.

Spring Inspection

Disconnect electrical power before working

inside unit.

1. Inspect and clean (if required) fan blades and

housing, cooling coil, condensate pan and drain.

See below for cleaning details.

2. Inspect and clean air filter, and supply and

return air grilles.

3. Check electrical components and connections.

Checking procedures may be found in Carrier

Standard Service Techniques Manual,

Chapter 2, Form SM-2.

4. Inspect panels and ducts for air leaks.

Fall Inspection

Disconnect electrical power before working

inside unit.

1. Follow all steps under Spring Inspection.

2. Inspect and clean pilot, main burners, heat

exchangers and flues.

3. Check main gas valve operation.

Cleaning

HEAT EXCHANGER

1. Shut down unit.

2. Remove heating section access panel, heat

shield front upper panel, flue box and radiation

baffle over burners. Preserve all gaskets.

3. Clean soot from inside of heat exchanger and

other internal surfaces, especially the narrow

vertical sections of tubes. Use a long wire-

handled nylon-bristle brush and vacuum

cleaner.

4. Reassemble unit. Take care not to damage

gaskets.

INDOOR (EVAPORATOR) COIL - Clean with

stiff brush, vacuum cleaner or compressed air.

OUTDOOR (CONDENSER) COIL - Clean out

door coil annually or as required by location or

• outdoor air conditions. Inspect coil monthly —

clean as required.

Fins are not continuous thru coil sections. Dirt

and debris may pass thru first section, become

trapped between the 3 rows of fins, and restrict

condenser airflow. Use a flashlight to determine if

dirt or debris has collected between coil sections.

Clean coil as follows"

1. Turn off unit power.

2. Remove top cover screws and slide cover

toward the compressor end of unit and/or to

the side to expose top of condenser coil.

3. Remove screws that fasten the 3 sections of the

tube sheet together at the return bend end of

the condenser coil. Carefully spread the ends of

the coils apart (see Fig. 9).

Page 9

#

Fig. 9 — Outdoor Coil Cleaning

Using a water hose, or other suitable equip

4.

ment, flush down between the 3 sections of the

condenser coil to remove dirt and debris.

Clean the remaining surfaces in the normal

5.

manner.

Reposition the inner coil sections. Reinstall the

6

screws in the tube sheet and replace the top

cover.

CONDENSATE PAN AND DRAIN LINES - Clean

once a year, preferably in the spring. Drain off

water in the fall and keep trap dry or protect from

freeze-up thru the winter.

FILTERS — Inspect filters at start of each heating

and cooling season and as often during each season

as conditions warrant. Clean permanent filters per

manufacturer’s instructions. Throwaway filters

may be cleaned by vacuum or by tapping lightly

over newspaper. Replace filters with the cleaner

side facing downstream. After one cleaning, replace

throwaway filter.

INDOOR FAN ADJUSTMENT - Fan motor

pulley is factory set for speed shown in Table 1. To

change fan speed:

1. Shut off unit power supply.

2.

Slide fan housing from unit.

3.

Loosen fan belt by loosening fan motor

mounting plate bolts.

4.

Loosen movable pulley flange setscrew (see

Fig. 10).

5.

Screw movable flange toward fixed flange to

increase speed and away from fixed flange to

decrease speed. Increasing fan speed increases

load on motor. Do not exceed maximum fan as

specified in Table 1.

6.

Set movable flange at nearest key way of pulley

hub and tighten setscrew.

To align fan and motor pulleys, loosen fan

pulley setscrews and slide fan pulley along fan

shaft. Make angular alignment by loosening motor

from mounting plate (see Fig. 10).

Fig. 10

To Adjust Belt Tension — Loosen fan motor pivot

bolts. Move motor mounting plate for proper belt

tension (1/2-in. deflection with one finger) and

tighten pivot bolts. Adjust lock bolt and nut on

mounting plate to secure in fixed position.

OUTDOOR FAN ADJUSTMENT ^ The required

fan position is shown in Fig. 11. Loosen setscrews,

set fan at dimension indicated and retighten.

Adjusting Spark Ignition — If pilot fails to ignite,

check the spark ignition system as follows:

1. Shut off power to ignitor.

2. Check that spark gap is .12 inch. (See Fig. 7.)

3. Make sure that spark generator is .securely

grounded.

4. Check that high-voltage lead is securely con

nected between generator and electrode body.

5. Restore power. Check for 24-volt supply to

primary side of generator.

Indoor Air Fan Pulley Alignment

and Adjustment

Fig. 11 — Outdoor Fan Clearance

Page 10

Lubrication

FAN MOTOR BEARINGS are factory lubricated

and do not require service for 3 to 5 years,

depending upon type of service. When required,

clean and relubricate per motor manufacturer’s

instructions.

COMPRESSOR contains a factory oil charge. If oil

is lost thru leakage, refer to Carrier Standard

Service Techniques Manual SM-1, Chapter 1 for oil

recharging procedure.

TROUBLESHOOTING - HEATING SYSTEM

Burner Does Not Operate

Power failure — Power switch off; blown line

fuse; defective wiring. .

No power to controls — thermostat set too low,

dirty or defective; defective transformer, faulty

limit switch.

Burner does not ignite — no gas to unit; faulty

valve or pilot switch; faulty spark ignitor; dirty

pilot.

Burner Operates, But Heating is Inadequate

Unit undersized — unit size selected incorrectly

Fuel input too low ~ wrong orifice size,

regulator set too low

Thermostat opens too soon ~ wrong antici

pator setting, thermostat out of calibration,

wrong thermostat location; thermostat set

wrong.

Limit switch cycles burner

faulty fan switch or motor;

wrong; duct system restricted

Poor Combustion and Flame Characteristics

Smoky flame — insufficient air, flue restriction.

Noisy burner — too much air, incorrect input

TROUBLESHOOTING - COOLING SYSTEM

Compressor Does Not Start

Power failure — power switch off; blown line

fuse, defective wiring.

No power to controls ~ thermostat set too low;

or dirty or defective, defective transformer.

— dirty filters;

limit switch set

contactor coil open; loose leads from closed

contactor.

Power to compressor — motor windings open,

contactor closes, then opens

Compressor Runs But Cooling is Insufficient

Low suction pressure — restricted airflow;

capillary tubes restricted; low refrigerant

charge.

Low head and high suction pressure — defective

compressor valves.

Indoor fan stopped — loose or broken leads,

faulty capacitor; internal short circuit

Compressor Does Not Restart

Power failure — power switch off, blown line

fuse

Power at closed contactor — faulty start relay

or capacitor, contactor, run capacitor or com

pressor, low line voltage (must be within 10%

of nameplate voltage )

Compressor Cycles on Overload

Insufficient condenser air — check condenser

fan position in reference to orifice as in Fig 11.

Condenser air restricted ^ dirty coil, airflow

restricted

Condenser air recirculating — obstruction de

flecting airflow.

Improper line voltage — circuit overloaded;

loose electrical connections

Faulty run capacitor — capacitor shorted or low

on capacitance (mfd)

Noncondensables in system — moisture or air in

system

System overcharged — high head pressure

causes by excessive refrigerant.

No refrigerant in system — leak in system.

System restricted — capillary tubes restricted or

plugged, kinked tubing, dirty strainer

Fan slipping on motor shaft — setscrews either

loose or missing from fan.

Fan motor bearing seized — lack of oil or

bearing failure.

Fan motor defective — internal short circuit

Page 11

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book

Tab

1 4

1a

6a

Form48EL-1SI Supersedes48DL-1SI

Printed in U S A 11-78

PC 111

Catalog No 534-853

Loading...

Loading...