42C,D,S,V Series

Fan Coil Air Conditioners

Installation, Start-Up and Service

Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . 1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

PRE-INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

Unpack and Inspect Units . . . . . . . . . . . . . . . . . . . . . . . . 3

Protect Units From Damage . . . . . . . . . . . . . . . . . . . . . . 3

Prepare Jobsite for Unit Installation. . . . . . . . . . . . . . 3

Identify and Prepare Units. . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-67

Step 1 — Place Units in Position . . . . . . . . . . . . . . . . 40

• 42C UNITS

• 42V UNITS

• 42D UNITS

• 42S UNITS

Step 2 — Make Piping Connections . . . . . . . . . . . . . 42

• VALVE PACKAGES

• 42C,D,V DRAIN CONNECTIONS

• 42C,D,V WATER SUPPLY/RETURN

CONNECTIONS

• 42C,D,V STEAM CONNECTIONS

• 42C,D,V DIRECT EXPANSION (DX) REFRIGERANT

PIPING

• TEST AND INSULATE

Step 3 — Make Electrical Connections . . . . . . . . . . 55

• STANDARD WIRING PACKAGES

Step 4 — Make Duct Connections . . . . . . . . . . . . . . . 66

Step 5 — Frame and Finish Unit. . . . . . . . . . . . . . . . . 66

Step 6 — Cut out Openings for Grilles and

Thermostats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Step 7 — Make Final Preparations. . . . . . . . . . . . . . . 67

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67,68

Excessive Condensation on Unit. . . . . . . . . . . . . . . . 67

To Clean Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Coil Air Vent (Manual or Automatic) . . . . . . . . . . . . . 67

Check Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Fan Motor Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Clean Fan Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Clean Electric Heater. . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Clean or Replace Air Filters . . . . . . . . . . . . . . . . . . . . . 68

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

START-UP CHECKLIST FOR 42C,D,S,V SERIES

FAN COIL AIR CONDITIONERS. . . . . . . . CL-1, CL-2

SAFETY CONSIDERATIONS

Installation of this unit can be hazardous due to electrical components and equipment location (such as a ceiling or elevated

structure). Only trained, qualified installers and service

mechanics should install and service this equipment.

When installing this unit, observe precautions in the literature,

labels attached to the equipment, and any other safety precautions that apply.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use care in handling and installing this accessory.

WARNING

ELECTRIC SHOCK HAZARD To avoid the possibility of

electrical shock, open and tag all service switches before

installing this equipment.

INTRODUCTION

This document contains general installation instructions for

the 42C,D,S,V unit fan coils. Refer to the unit-wiring diagram

installed on the blower housing or specific manufacturer literature for any other type of factory-mounted controls.

See drawings for unit configurations, dimensions, clearances,

and pipe connections. Refer to unit wiring label for all electrical

connections; follow NEC (National Electrical Code) and local

codes.

PHYSICAL DATA

Component weight data, shipping weights, and filter data of

the 42C,D,S,V units are provided in Tables 1-4.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53420004-01 Printed in U.S.A. Form 42-3SI Pg 1 12-09 Replaces: 42-2SI

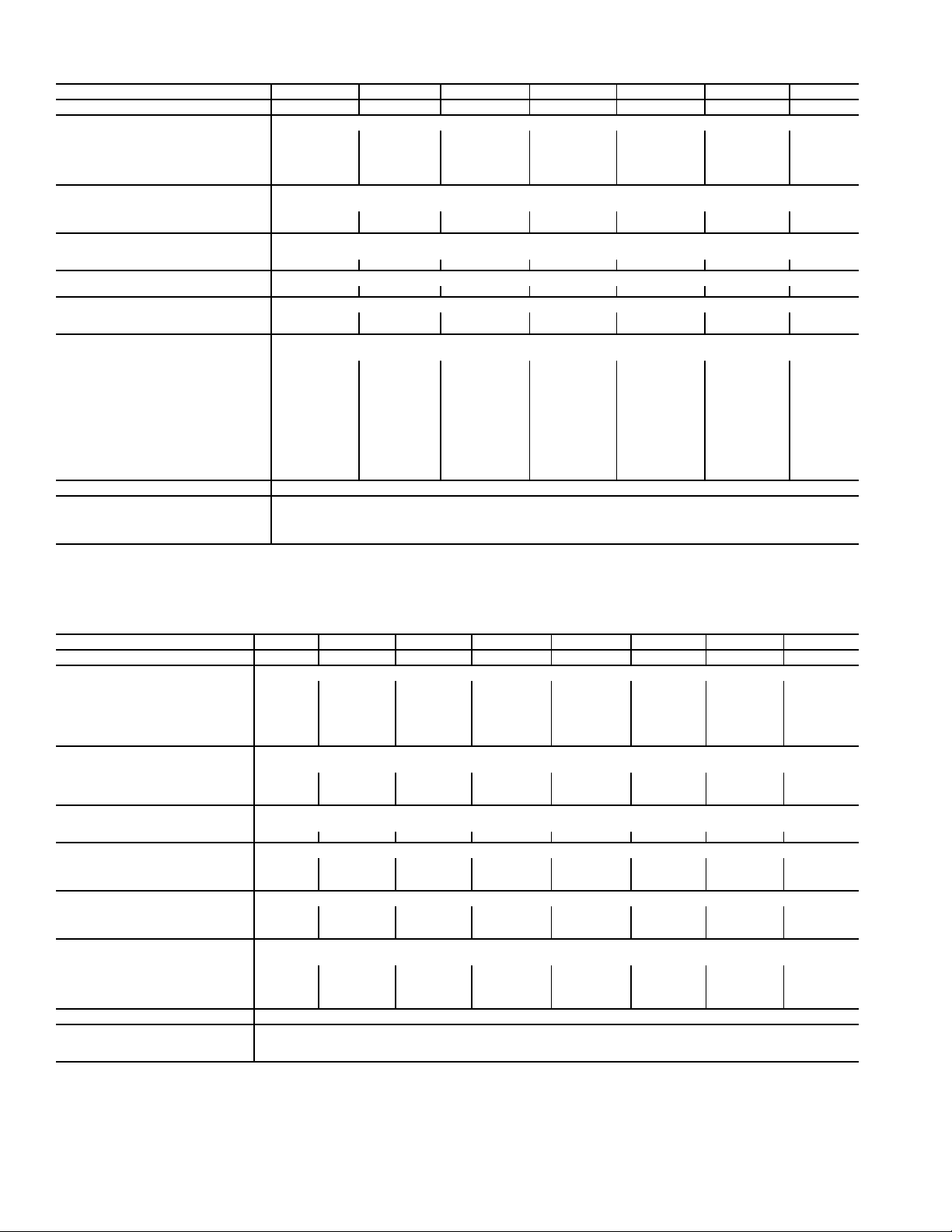

Table 1 — Physical Data — 42C Series Units

NOMINAL AIRFLOW (cfm) 200 300 400 600 800 1000 1200

UNIT SIZE 42C 02 03 04 06 08 10 12

SHIPPING WEIGHT (lb)*

42CA 36 39 49 59 64 95 107

42CE 55 60 70 82 95 135 154

42CF — — 84 97 110 163 —

42CG 98 118 126 168 176 215 245

42CK 115 120 135 150 155 227 241

COIL WATER WEIGHT

(Approx lb per row of coil)

42CA, CE, CG, CK 0.7 0.8 1.0 1.4 1.7 2.3 2.7

42CF — — 1.02 1.42 1.71 2.32 —

COILS

FPI 10 fins/inch

Coil Face Area (sq ft)† 0.8 1.1 1.4 1.9 2.3 3.2 3.7

MOTOR (qty)

42C Series 111 1 122

BLOWER (qty)

42CA, CE, CG, CK 112 2 244

42CF —— 2 2 2 4—

FILTERS

Nominal Size (in.) (1-in. thick)

42CA** 10 x 24 10 x 28 10 x 32 10 x 42 10 x 42 10 x 54 10 x 64

42CE†† 10 x 18 10 x 22 10 x 28 10 x 33 10 x 40 10 x 54 10 x 62

42CF††*** ——12

42CG

Bottom Return 10 x 23

Rear Return 8 x 23

42CK

Bottom Return 10 x 28 10 x 28 10 x 33 10 x 45 10 x 45 10 x 62 10 x 62

Rear Return 7 x 21 7 x 21 7 x 27 7 x 38 7 x 38 7 x 52 7 x 52

Rear Return with Duct Collar 6 x 18

Qty 111 1 111

1

/

2

1

/

2

3

/

4

10 x 28 10 x 321/

8 x 28 8 x 321/

6 x 183/

4

3

/4 x 28 123/4 x 33 123/4 x 40 123/4 x 54 —

10 x 37 10 x 41 10 x 541/

8 x 37 8 x 41 8 x 541/

6 x 353/

4

6 x 353/

4

6 x 493/4 6 x 493/

2

2

6 x 243/

2

2

4

10 x 63

8 x 63

4

SUPPLY DUCT COLLAR 1-in.

PIPING CONNECTIONS (Sweat) (in.)

Coil Outlet and Inlet

Drain Connection

Tell-Tale Drain

*Calculate operating weight of unit: shipping weight + coil water weight x

number of coil rows.

†42CF applies to sizes 04 to 10.

**Filter size for return-air grille location.

††Filter size if located in return-air plenum.

***With electric heater and bottom return, the 42CF unit filter width increases

from 12

5

/8 OD

7

/8 OD

5

/8 OD

3

/4 to 163/4.

Table 2 — Physical Data — 42V Series Units

NOMINAL AIRFLOW (cfm) 150 200 300 400 600 800 1000 1200

UNIT SIZE 42V 01 02 03 04 06 08 10 12

SHIPPING WEIGHT (lb)*

42VA — 65 80 90 112 115 140 170

42VB — 89 95 116 134 137 169 192

42VC — 50 60 72 110 — — —

42VE — 72 100 108 154 — — —

42VF — 92 98 122 141 144 178 205

42VG 40 — 74 — — — — —

COIL WATER WEIGHT

(Approx lb per row of coil)

42VA, VB, VC†, VF — 0.7 0.8 1.0 1.4 1.7 2.3 2.7

42VE — 0.9 1.2 1.6 2.3 — — —

42VG 0.4 — 1.0 — — — — —

COILS

FPI 12 fins/inch

Coil Face Area (sq ft) 0.8 0.8 1.1 1.4 1.9 2.3 3.2 3.7

MOTOR (qty)

42VA, VB, VF —11 1 1122

42VC, VE —1 1 1 2 — — —

42VG 1— 2 — — — — —

BLOWER (qty)

42VA, VB, VF —11 2 2244

42VC, VE —2 2 2 4 — — —

42VG 1— 2 — — — — —

FILTERS

Nominal Size (in.) (1-in. thick)

42VA, VB, VF —7

42VC, VE —7 x 21

42VG 10 x 141/

Qty 111 1 1111

3

/4 x 213/473/4 x 253/473/4 x 313/473/4 x 413/473/4 x 433/473/4 x 573/473/4 x 653/

3

/

7 x 263/

4

— 10 x 28 — — — — —

2

7 x 343/

4

7 x 483/

4

4

———

4

SUPPLY DUCT COLLAR 1-in.

PIPING CONNECTIONS (Sweat) (in.)

Coil Outlet and Inlet

Drain Connection

*Calculate operating weight of unit: shipping weight + coil water weight x

number of coil rows.

†Available in sizes 02-06.

5

/8 OD

3

/4 MPT

2

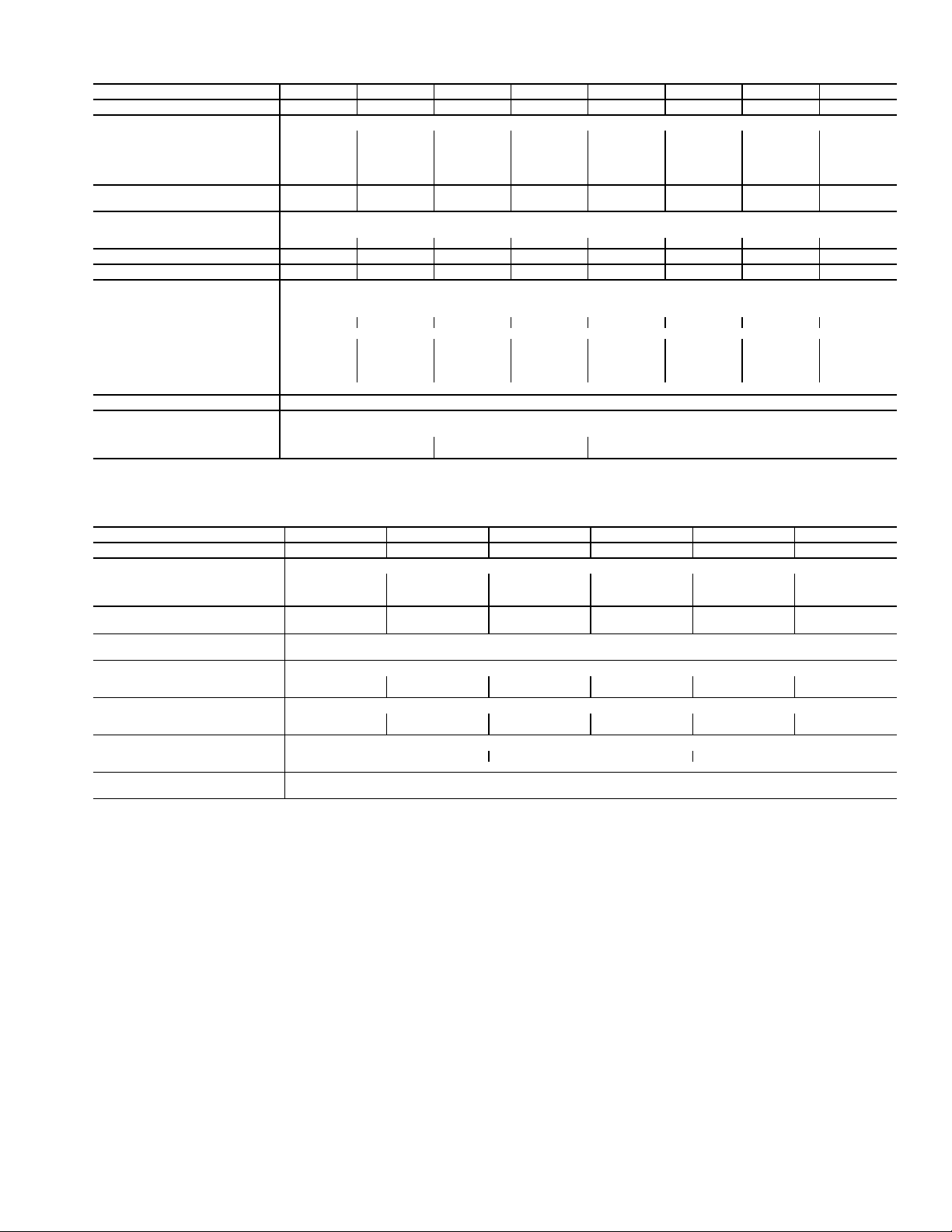

Table 3 — Physical Data — 42D Series Units

NOMINAL AIRFLOW (cfm) 600 800 1000 1200 1400 1600 1800 2000

SHIPPING WEIGHT (lb)*

42DA 64 79 93 110 119 129 137 155

42DC 94 107 150 169 174 178 195 220

42DD 150 163 176 195 220 235 240 247

42DE 135 155 165 184 199 215 232 243

42DF 157 167 177 199 215 229 249 258

COIL WATER WEIGHT

(Approx lb per row of coil)

COILS

FPI 10 fins/inch

Coil Face Area (sq ft) 1.62.12.53.03.54.14.65.0

MOTOR (qty) 11122222

BLOWER (qty) 11122222

FILTERS

Nominal Size (in.) (1-in. thick)

42DA NA

42DC 14 x 21 14 x 26 14 x 30 14 x 35 14 x 40 14 x 45 14 x 50 14 x 54

42DD

42DE 14 x 143/

42DF 14 x 14 14 x 20 14 x 24 14 x 28 14 x 34 14 x 38 14 x 44 14 x 48

Qty

SUPPLY DUCT COLLAR 1-in.

PIPING CONNECTIONS

(Sweat - 4-Row)

Inlet (in. OD)

Outlet (in. OD)

*Calculate Operating Weight of unit: Shipping Weight + Coil Water Weight x Number of Coil Rows.

UNIT SIZE 42D 0608101214161820

1.31.61.92.32.73.03.43.7

(Front Return) 12

(Bottom Return) 12

3

/4 x 21 123/4 x 26 123/4 x 30 123/4 x 35 123/4 x 40 123/4 x 45 123/4 x 50 123/4 x 54

3

/4 x 21 123/4 x 25 123/4 x 29 123/4 x 34 123/4 x 39 123/4 x 44 123/4 x 49 123/4 x 53

14 x 193/

4

5

/

8

5

/

8

14 x 233/

4

14 x 283/

4

7

/

8

7

/

8

14 x 333/

4

1

14 x 383/

4

14 x 433/

4

11/

8

11/

8

14 x 473/

4

4

Table 4 — Physical Data — 42S Series Units

NOMINAL AIRFLOW (cfm) 300 400 600 800 1000 1200

SHIPPING WEIGHT (lb)*

42SG,SU 180 225 240 260 280 305

42SH 202 247 262 286 311 336

42SJ 360 450 480 520 560 610

COIL WATER WEIGHT

(Approx lb per row of coil) 1.6 1.6 2.3 2.3 3.1 3.1

COILS

FPI 14 fins/inch

MOTOR (qty)

42SG,SH,SU 111111

42SJ 222222

BLOWER (qty)

42SG,SH,SU 111111

42SJ 222222

FILTERS

Qty 1†

PIPING CONNECTIONS

Inlet (in. OD)

*Calculate Operating Weight of Unit: Shipping Weight + Coil Water Weight x Number of Coil Rows.

†42SJ units require two filters.

UNIT SIZE 42S 03 04 06 08 10 12

1

Nominal Size (in.) (1-in. thick) 12

/2 x 241/

4

161/4 x 263/

1

/

2

4

201/2 x 291/

4

PRE-INSTALLATION

Unpack and Inspect Units —

from all units. Check the shipment against shipping order.

Make sure that furnished only items, such as thermostat,

grilles, etc., are accounted for, whether packaged separately or

shipped at a later date. If shipment is damaged or incomplete,

file claim with transportation company and advise Carrier immediately.

Remove shipping wraps

Protect Units from Damage — The equipment must

always be properly supported. Temporary supports used during

installation or service must be adequate to hold the equipment

securely. Equipment should always be stored in the proper orientation as marked on the carton. To maintain warranty, protect

units against adverse weather, theft, vandalism, and debris on

jobsite. Equipment covered in this manual is not suitable for

outdoor installations. Do not allow foreign material to fall into

drain pan. Prevent dust and debris from being deposited on motor and fan wheels. Manufacturer's warranty is void if foreign

material is allowed to be deposited on the motor or blower

wheels of any unit.

Prepare Jobsite for Unit Installation — To sav e

time and to reduce the possibility of costly errors, set up a complete sample installation in a typical room at jobsite. Check all

critical dimensions such as pipe, wire, and duct connection

requirements. Refer to job drawings and product dimension

drawings as required (see Fig. 1-36). Instruct all trades in their

part of the installation.

Identify and Prepare Units — Be sure power require-

ments match available power source. Refer to unit nameplate

and wiring diagram.

1. Check all tags on unit to determine if shipping screws are

to be removed. Remove screws as directed.

2. Rotate the fan wheel by hand to ensure that the fan is

unrestricted and can rotate freely. Check for shipping

damage and fan obstructions.

3

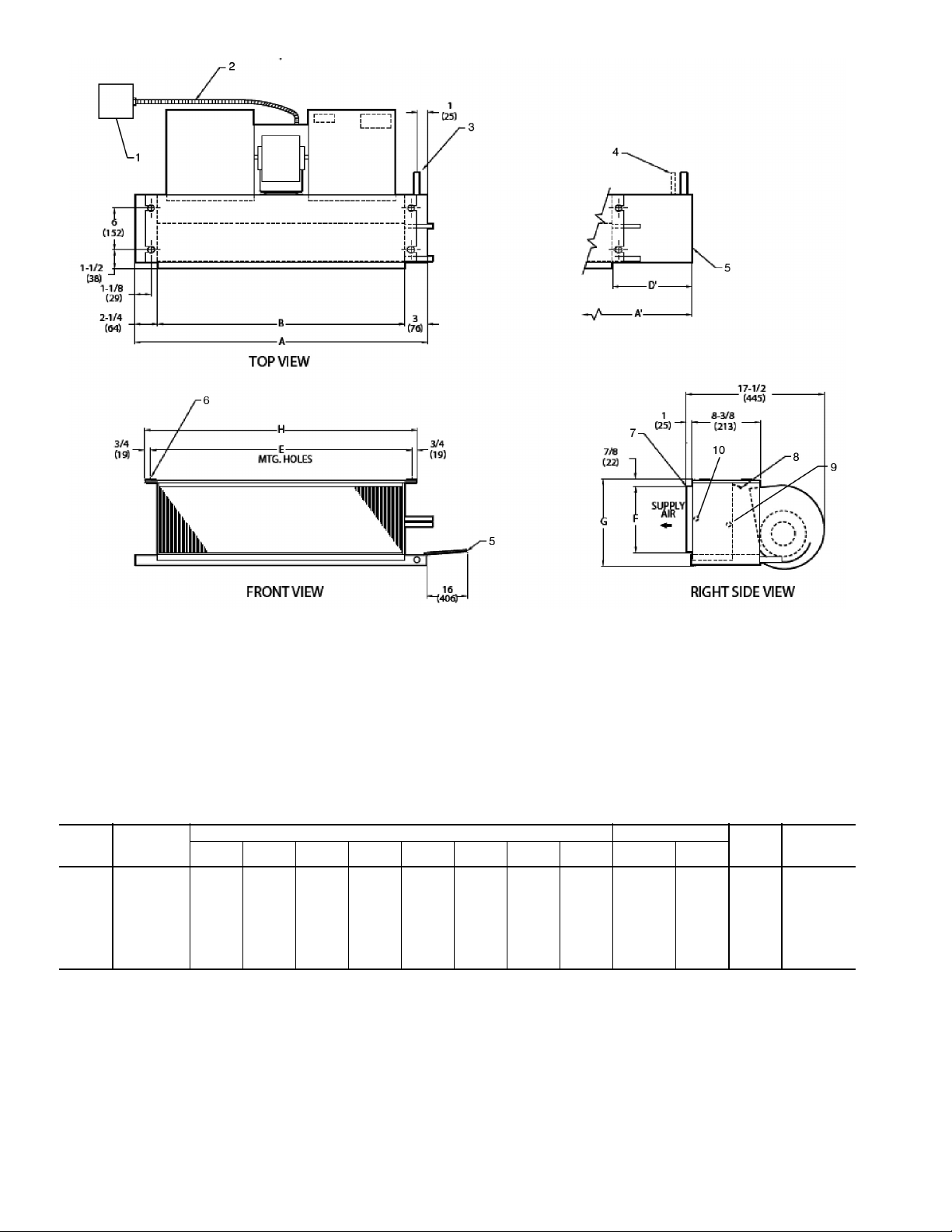

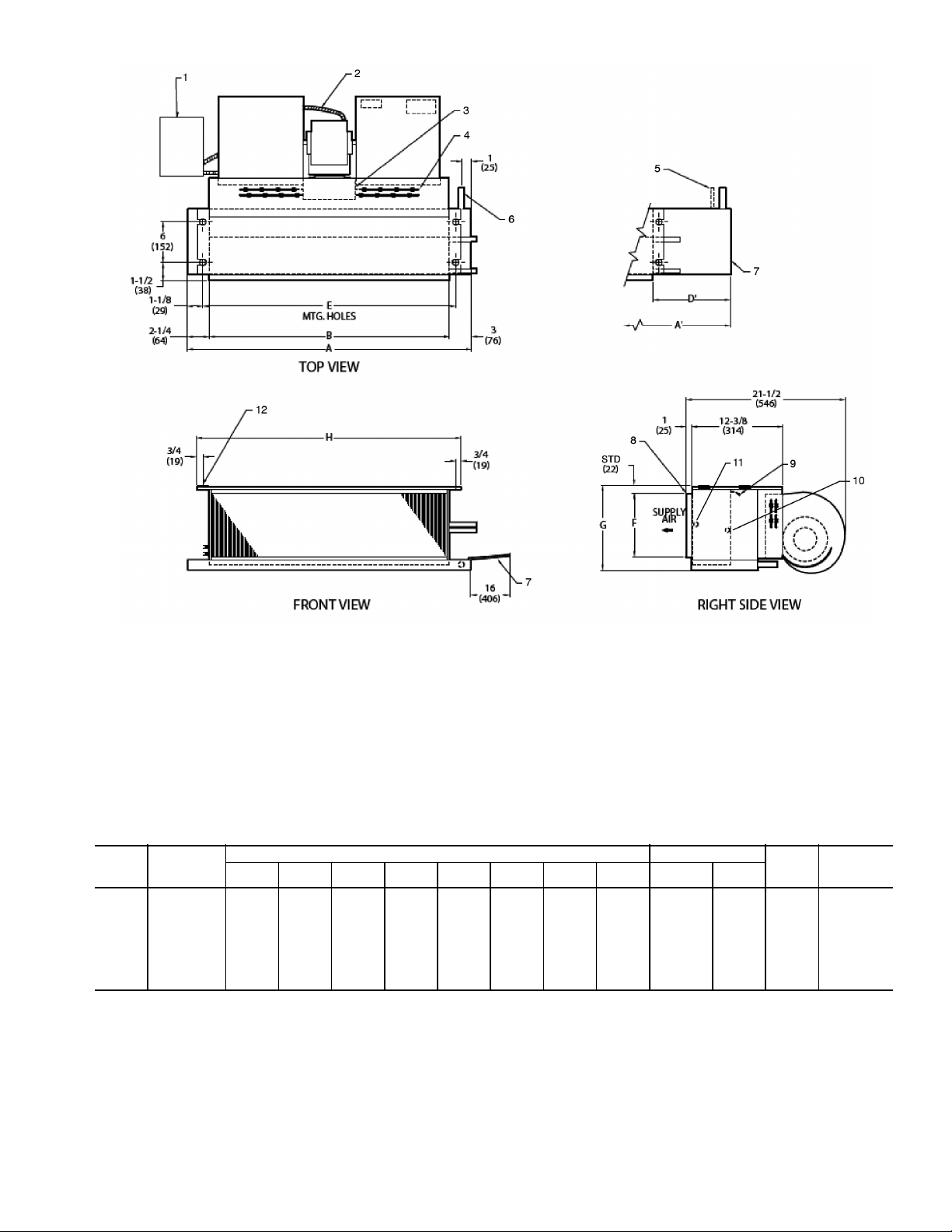

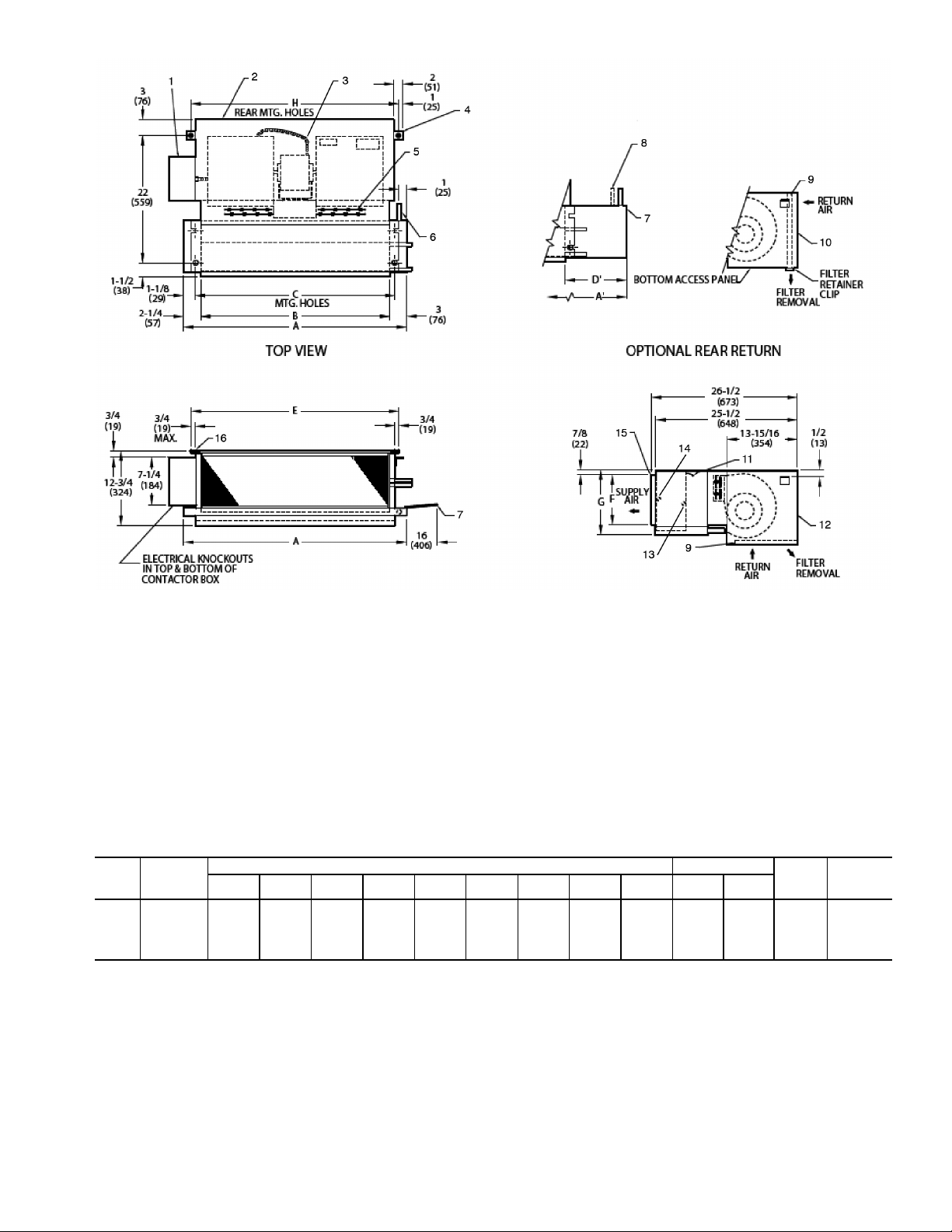

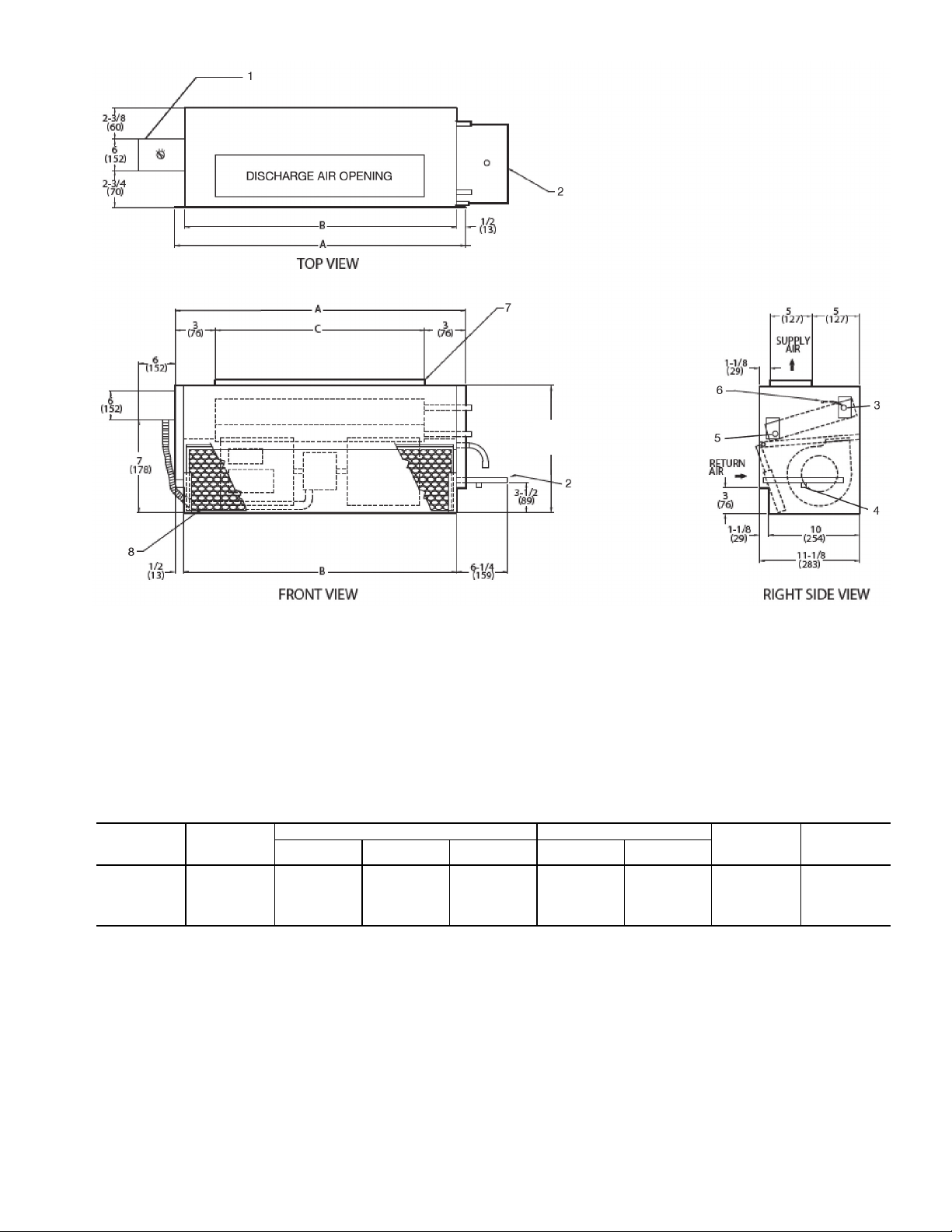

LEGEND

1—Junction Box (remote mount)

2—Flexible Metal Conduit

3—Drain Conn,

7

/8-in. OD

4 — Tell-Tale Drain Conn, 5/8-in. OD (optional)

5—Drip Lip (optional)

6—Hanger Slots (4), Rubber Grommet

has

3

/8-in. Diameter Hole

7—Supply Duct Collar, 1-in.

8—Air Vent,

1

/8-in. MPT

9—Return Conn, 5/8-in. OD

10 — Supply Conn,

5

/8-in. OD

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

AA’BD’E F GH

Blower Motor

02 200 21

1

/4311/

4

16 13 181/

4

61/

4

83/

4

193/

4

1 1 0.83 36

03 300 25

1

/4361/

4

20 14 221/

4

61/

4

83/

4

233/

4

1 1 1.08 39

04 400 31

1

/4431/

4

26 15 281/

4

61/

4

83/

4

293/

4

2 1 1.35 49

06 600 36

1

/4431/

4

31 10 331/

4

71/

2

10 343/

4

2 1 1.88 59

08 800 43

1

/4571/

4

38 17 401/

4

71/

2

10 413/

4

2 1 2.31 64

10 1000 57

1

/4651/

4

52 11 541/

4

71/

2

10 553/

4

4 2 3.16 95

12 1200 65

1

/4751/

4

60 13 621/

4

71/

2

10 633/

4

4 2 3.65 107

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-in.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04

through 08 have one motor, 2 blowers; sizes 10 and 12 have

2 motors, 4 blowers.

3. Standard 3-row coil shown.

4. Overall unit dimension increases by 4 in. with optional electric

heat.

5. Not shown: 3-speed fan switch; wall plate, closed cell foam on

main drain pan.

6. Units have galvanized finish.

7. For optional coil connections, view 42CA-203-1 using the Fan Coil

Builder.

8. Dimensions shown in inches (mm).

Fig. 1 — 42CA Furred-In Horizontal Unit Dimensions

a42-4099.eps

4

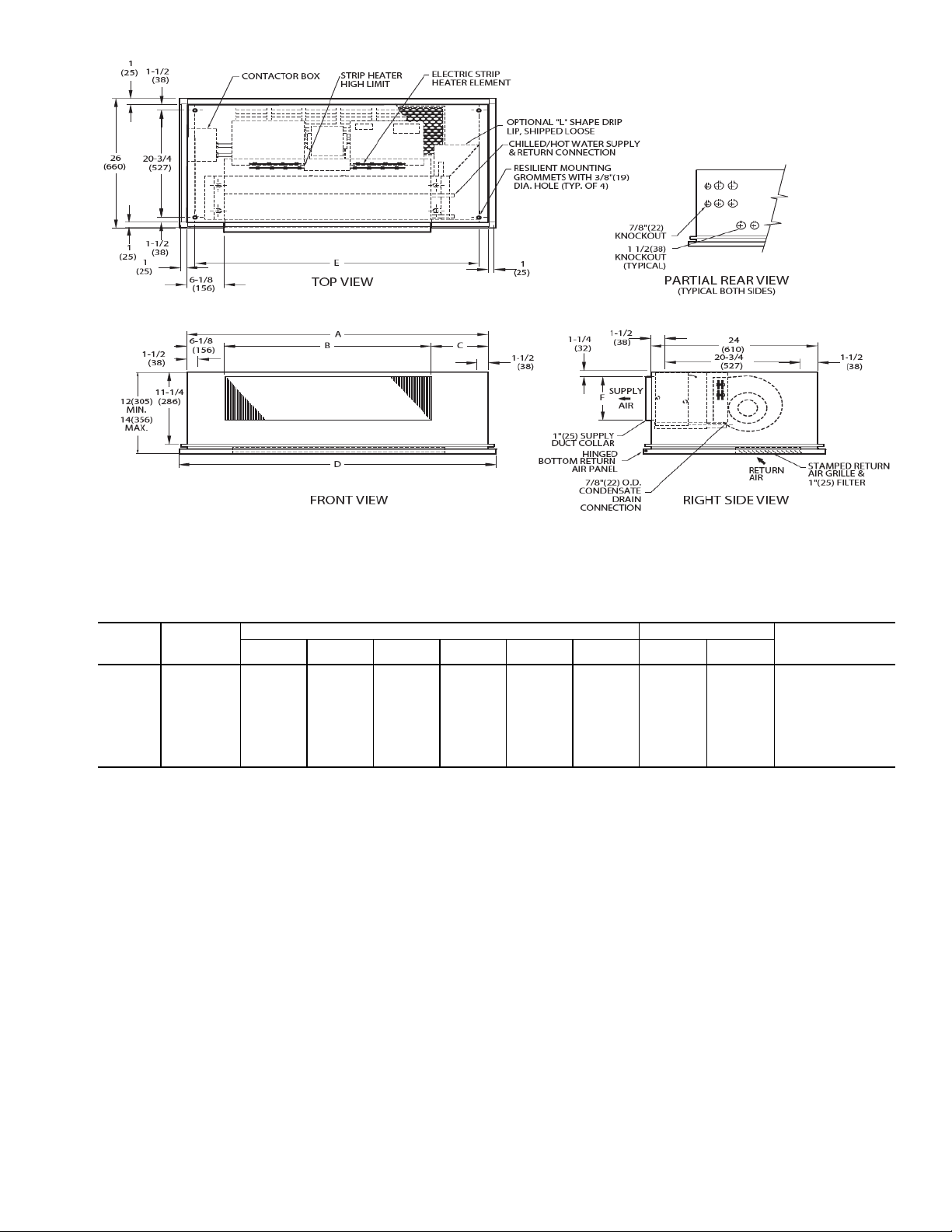

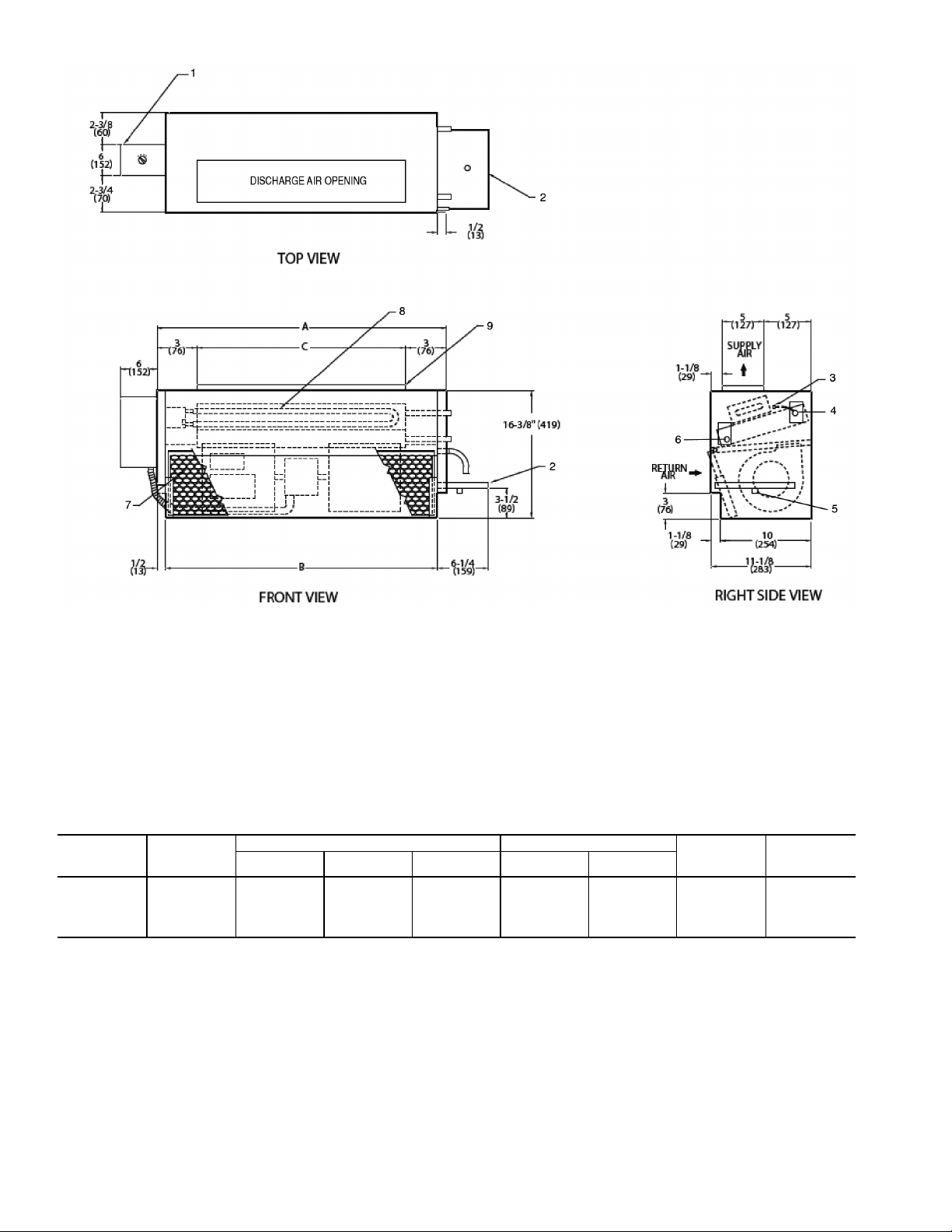

LEGEND

1—Junction Box (remote mount)

2—Flexible Metal Conduit

3 — Strip Heater High Limit

4 — Electric Strip Heater Element

5 — Tell-Tale Drain Conn,

5

/8-in. OD (optional)

6—Drain Conn, 7/8-in. OD

7—Drip Lip (optional)

8—Supply Duct Collar, 1-in.

9—Air Vent,

1

/8-in. MPT

10 — Return Conn,

5

/8-in. OD

11 — Supply Conn,

5

/8-in. OD

12 — Hanger Slots (4), Rubber Grommet

has

3

/8-in. Diameter Hole

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-in.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04

through 08 have one motor, 2 blowers; sizes 10 and 12 have

2 motors, 4 blowers.

3. Standard 3-row coil shown.

4. Overall unit dimension increases by 4 in. with optional electric

heat.

5. Not shown: 3-speed fan switch; wall plate, closed cell foam on

main drain pan.

6. Units have galvanized finish.

7. For optional coil connections, view 42CA-203-1 using the Fan Coil

Builder.

8. Dimensions shown in inches (mm).

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

AA’BD’E F GH

Blower Motor

02 200 21

1

/4311/

4

16 13 181/

4

61/

4

83/

4

193/

4

1 1 0.83 38

03 300 25

1

/4361/

4

20 14 221/

4

61/

4

83/

4

233/

4

1 1 1.08 41

04 400 31

1

/4431/

4

26 15 281/

4

61/

4

83/

4

293/

4

2 1 1.35 51

06 600 36

1

/4431/

4

31 10 331/

4

71/

2

10 343/

4

2 1 1.88 61

08 800 43

1

/4571/

4

38 17 401/

4

71/

2

10 413/

4

2 1 2.31 66

10 1000 57

1

/4651/

4

52 11 541/

4

71/

2

10 553/

4

4 2 3.16 97

12 1200 65

1

/4751/

4

60 13 621/

4

71/

2

10 633/

4

4 2 3.65 109

Fig. 2 — 42CA Furred-In Horizontal Unit with Electric Heat Dimensions

a42-4100.eps

5

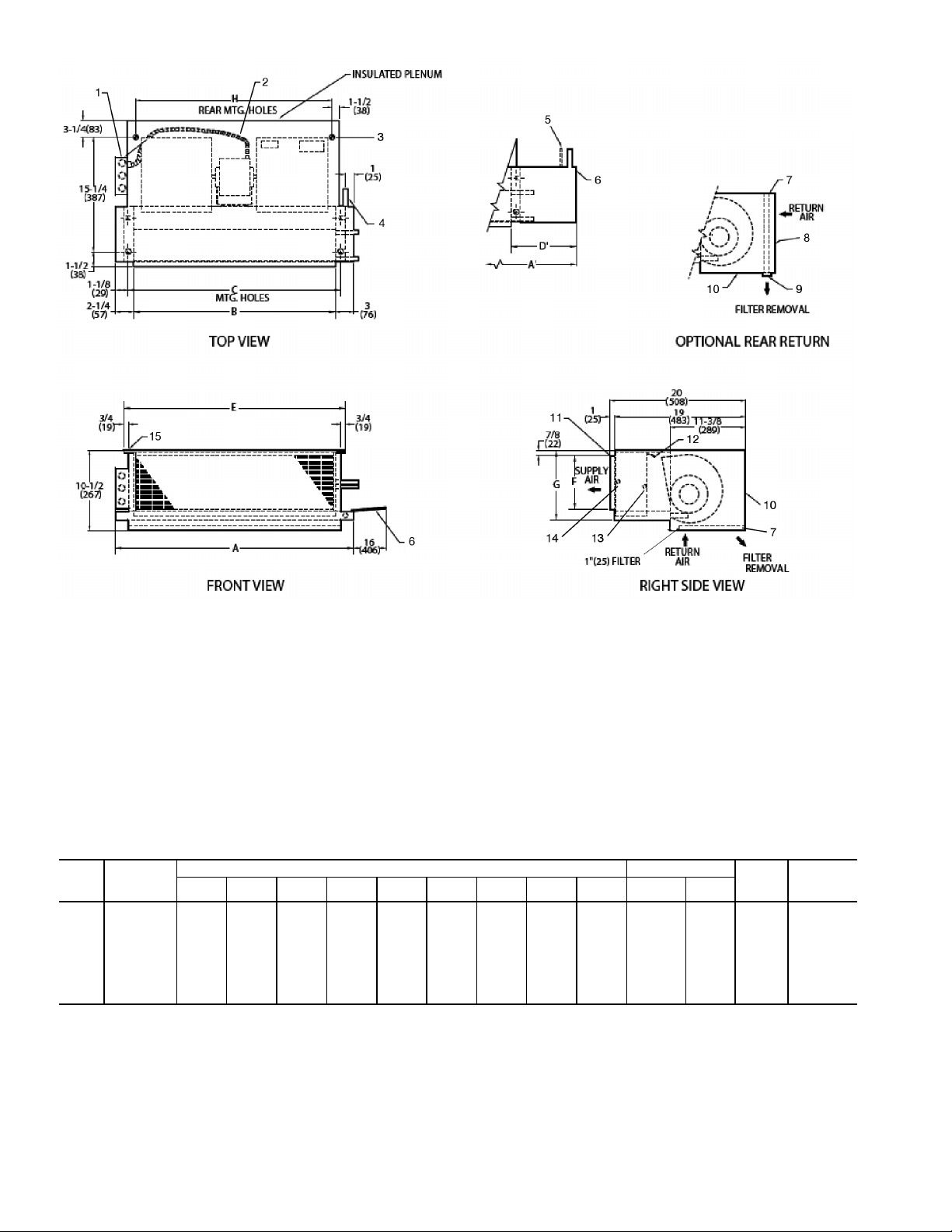

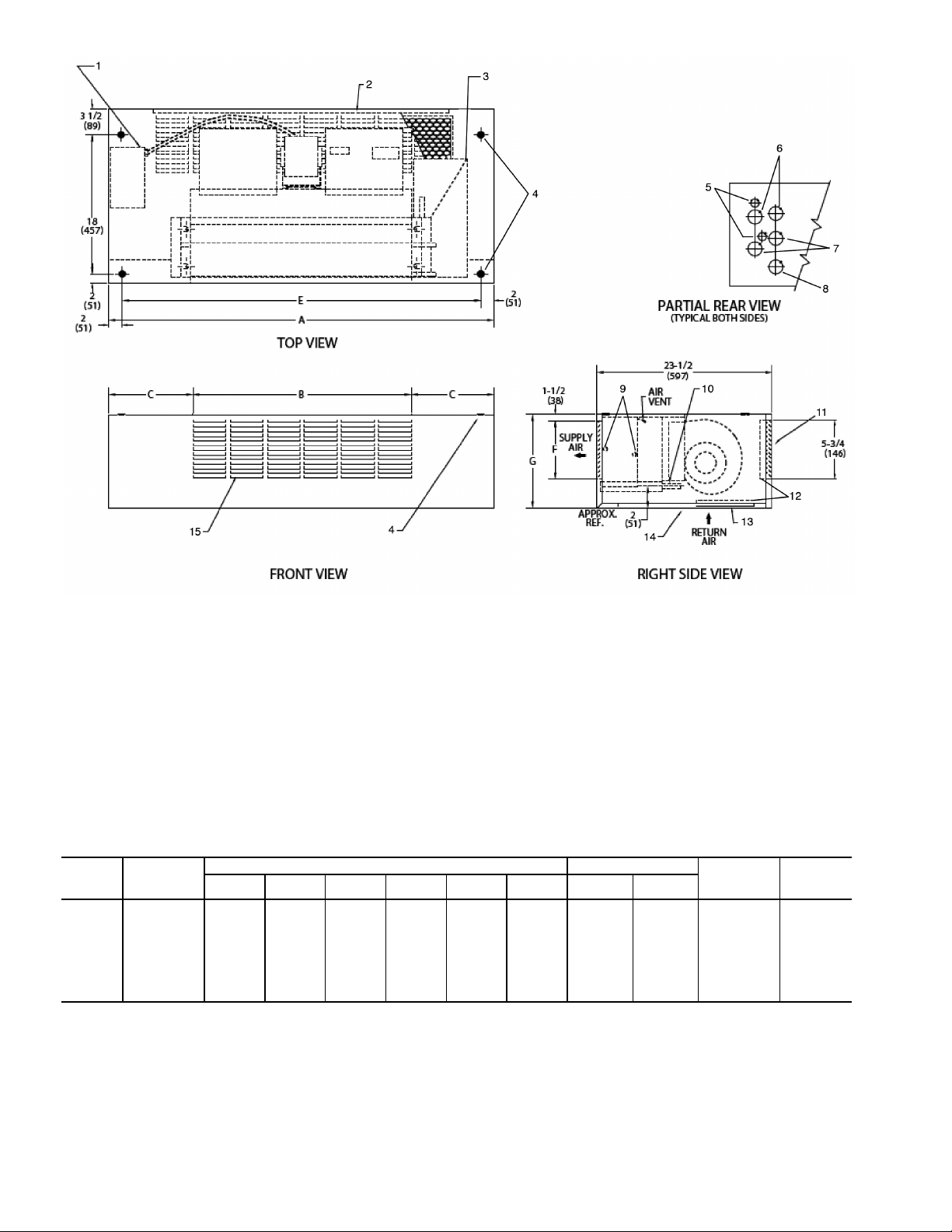

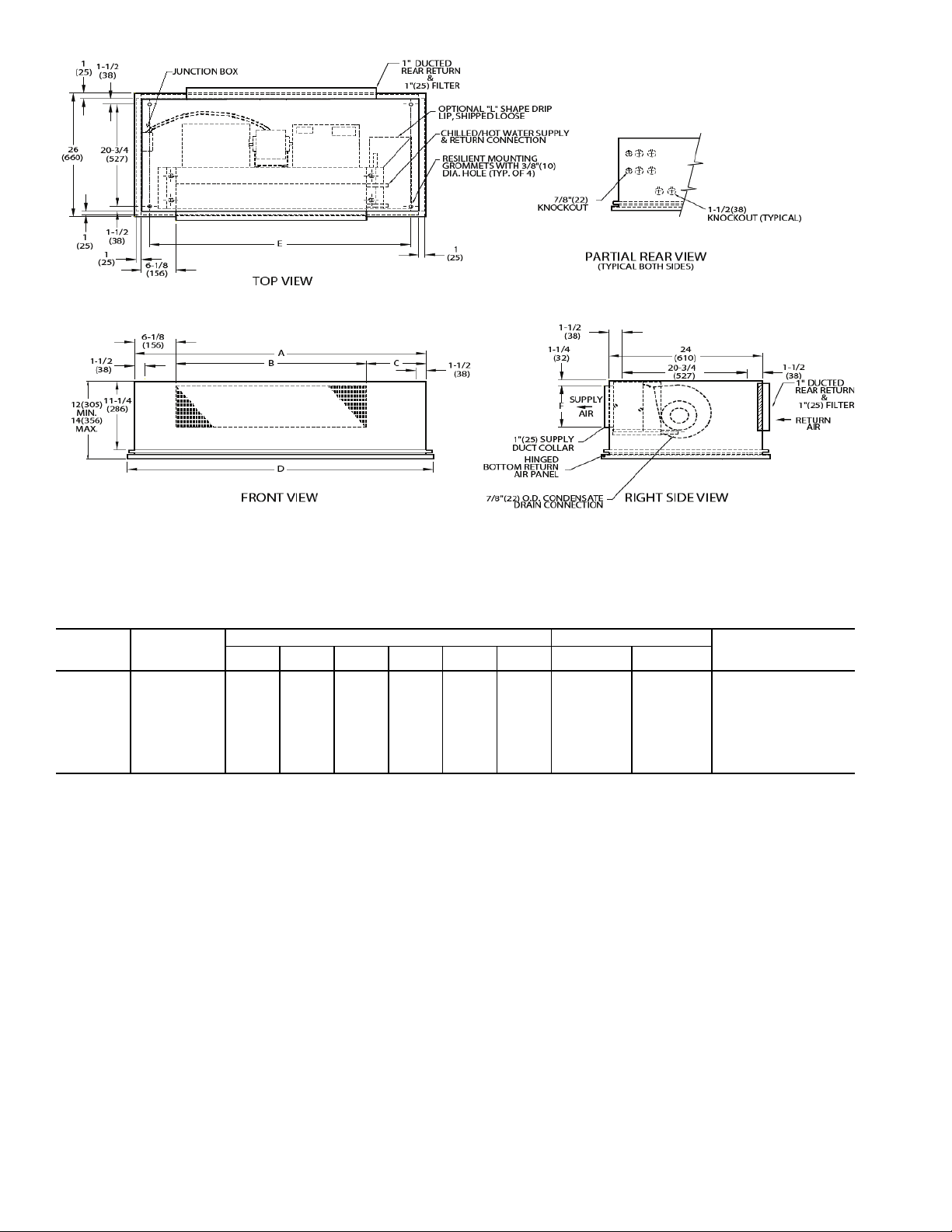

NOTES:

1. Right hand unit with standard 3-row coil shown; left hand unit opposite. Coil

connection locations are ±

5

/8-in.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04 through 08 have

one motor, 2 blowers; sizes 10 and 12 have 2 motors, 4 blowers.

3. Standard 3-row coil shown.

4. Unit available with bottom or rear return air.

5. Dimension increases by 4 in. with optional electric heat.

6. Not shown: 3-speed fan switch; wall plate,

1

/2-in. fiberglass insulation on

inside of plenum, closed cell foam on main drain pan.

7. Units have galvanized finish.

8. For optional coil connections, view 42CA-203-1 using the Fan Coil Builder.

9. Dimensions shown in inches (mm).

LEGEND

1— Junction Box, 4 in. x 4 in.

2— Flexible Metal Conduit

3— Mounting Bracket

4— Drain Conn,

7

/8-in. OD

5— Tell-Tale Drain Conn, 5/8-in. OD (optional)

6— Drip Lip (optional, shipped loose)

7— Filter

8— Return Duct Collar, 1-in.

9— Filter Access Panel

10 — Access Panel

11 — Supply Duct Collar, 1-in.

12 — Air Vent,

1

/8-in. MPT

13 — Return Conn,

5

/8-in. OD

14 — Supply Conn,

5

/8-in. OD

15 — Hanger Slots (4), Rubber Grommet has

3

/8-in. Diameter Hole

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

AA’B CD’E FGH

Blower Motor

02 200 21

1

/4311/

4

16 181/

4

13 193/461/

4

83/

4

153/

8

1 1 0.83 55

03 300 25

1

/4361/

4

20 221/

4

14 233/461/

4

83/

4

193/

8

1 1 1.08 60

04 400 31

1

/4431/

4

26 281/

4

15 293/461/

4

83/

4

253/

8

2 1 1.35 70

06 600 36

1

/4431/

4

31 331/

4

10 343/471/

2

10 303/

8

2 1 1.88 82

08 800 43

1

/4571/

4

38 401/

4

17 413/471/

2

10 373/

8

2 1 2.31 95

10 1000 57

1

/4651/

4

52 541/

4

11 553/471/

2

10 513/

8

4 2 3.16 135

12 1200 65

1

/4751/

4

60 621/

4

13 633/471/

2

10 593/

8

4 2 3.65 154

a42-4101

Fig. 3 — 42CE Furred-In Horizontal Unit with Plenum Dimensions

6

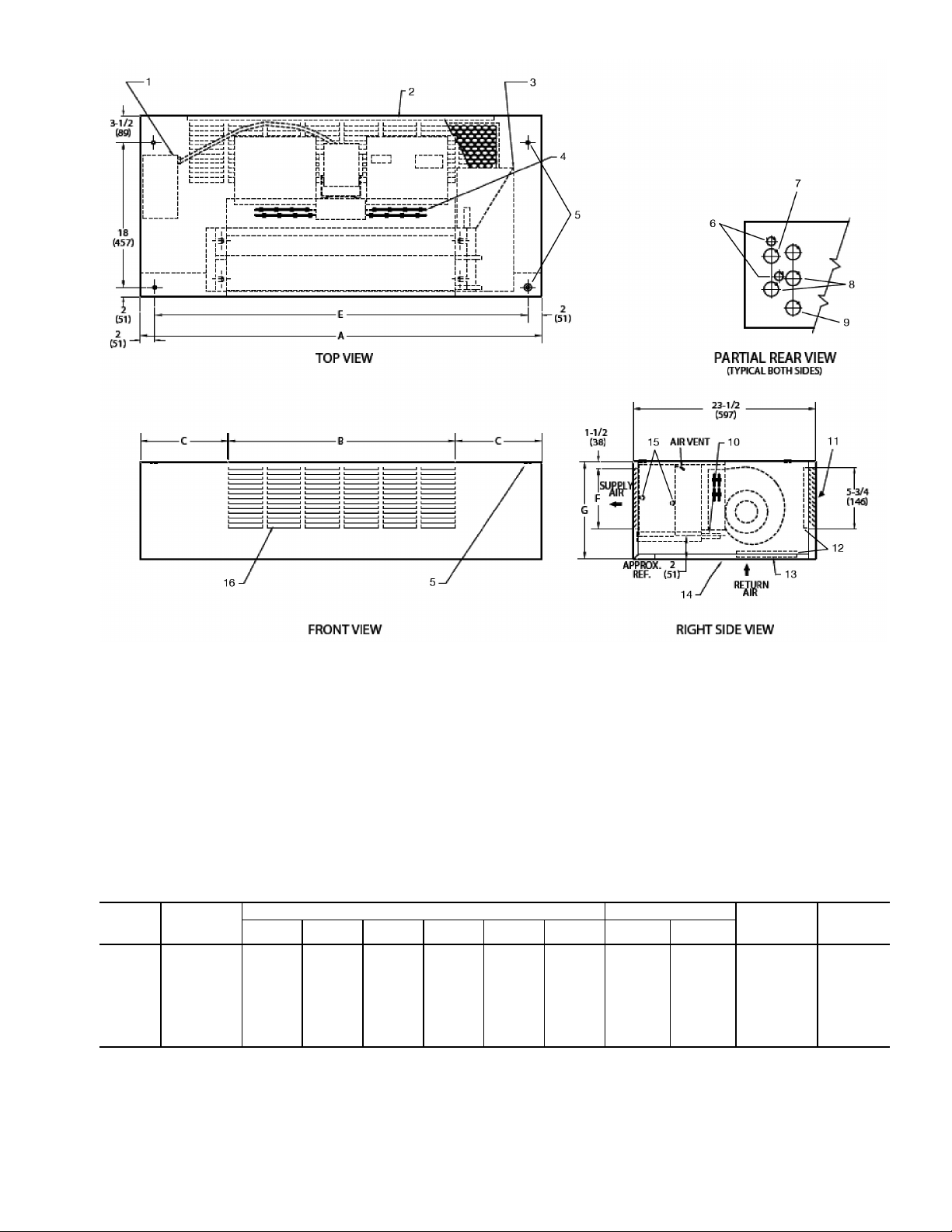

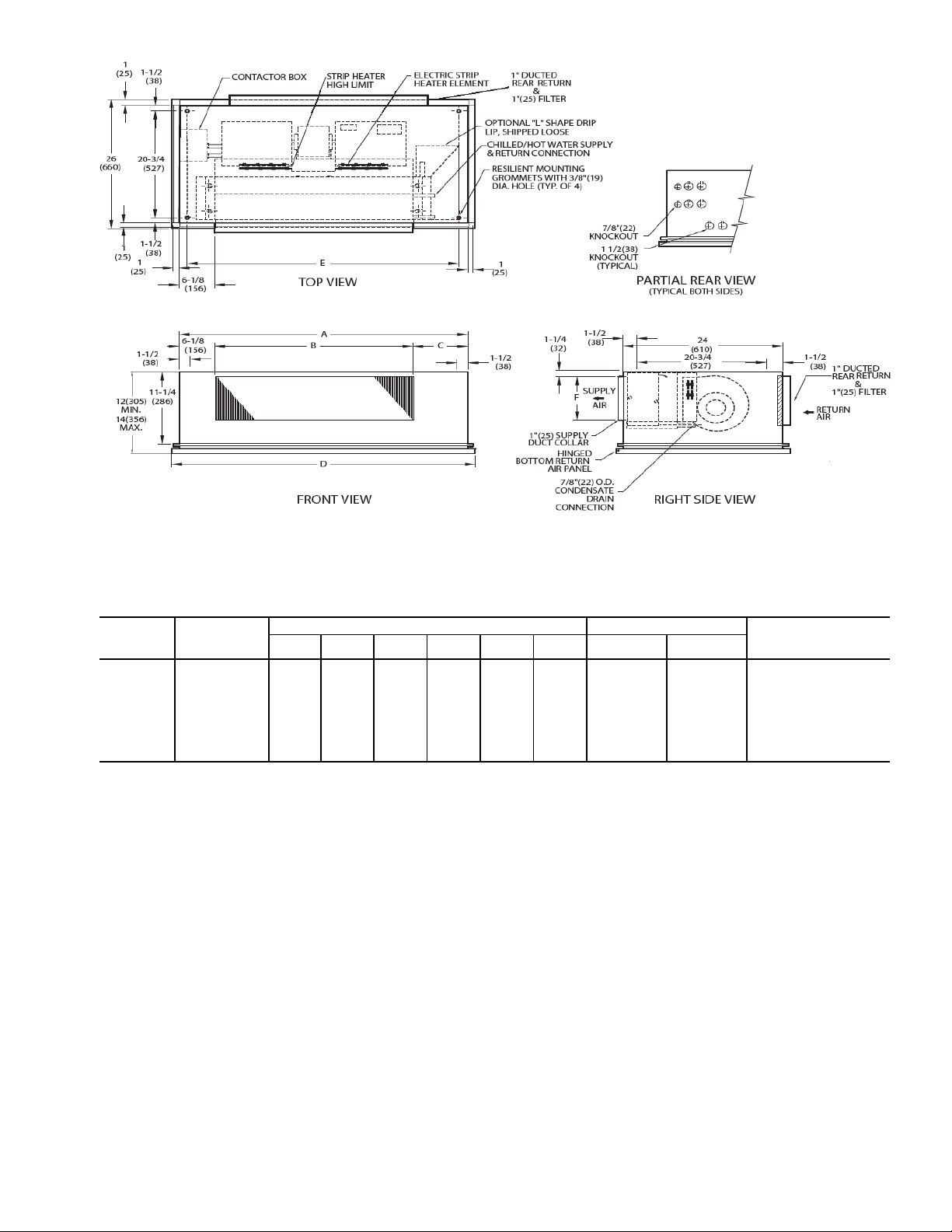

NOTES:

1. Right hand unit with standard 3-row coil shown; left hand unit opposite. Coil

connection locations are ±5/8-in.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04 through 08 have

one motor, 2 blowers; sizes 10 and 12 have 2 motors, 4 blowers.

3. Standard 3-row coil shown.

4. Unit available with bottom or rear return air.

5. Dimension increases by 4 in. with optional electric heat.

6. Not shown: 3-speed fan switch; wall plate,

1

/2-in. fiberglass insulation on

inside of plenum, closed cell foam on main drain pan.

7. Units have galvanized finish.

8. For optional coil connections, view 42CA-203-1 using the Fan Coil Builder.

9. Dimensions shown in inches (mm).

LEGEND

1— Junction Box, 4 in. x 4 in.

2— Flexible Metal Conduit

3— Mounting Bracket

4— Electric Strip Heater Element

5— Drain Conn,

7

/8-in. OD

6— Strip Heater High Limit

7— Tell-Tale Drain Conn,

5

/8-in. OD (optional)

8— Drip Lip (optional, shipped loose)

9— Filter

10 — Return Duct Collar, 1-in.

11 — Filter Access Panel

12 — Access Panel

13 — Supply Duct Collar, 1-in.

14 — Air Vent,

1

/8-in. MPT

15 — Return Conn,

5

/8-in. OD

16 — Supply Conn,

5

/8-in. OD

17 — Hanger Slots (4), Rubber Grommet has

3

/8-in. Diameter Hole

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

AA’B CD’E F G H

Blower Motor

02 200 21

1

/4311/

4

16 181/

4

13 193/461/

4

83/4153/

8

1 1 0.83 57

03 300 25

1

/4361/

4

20 221/

4

14 233/461/

4

83/4193/

8

1 1 1.08 62

04 400 31

1

/4431/

4

26 281/

4

15 293/461/

4

83/4253/

8

2 1 1.35 72

06 600 36

1

/4431/

4

31 331/

4

10 343/471/

2

10 303/

8

2 1 1.88 84

08 800 43

1

/4571/

4

38 401/

4

17 413/471/

2

10 373/

8

2 1 2.31 97

10 1000 57

1

/4651/

4

52 541/

4

11 553/471/

2

10 513/

8

4 2 3.16 137

12 1200 65

1

/4751/

4

60 621/

4

13 633/471/

2

10 593/

8

4 2 3.65 156

A42-4102

Fig. 4 — 42CE Furred-In Horizontal Unit with Plenum and Electric Heat Dimensions

7

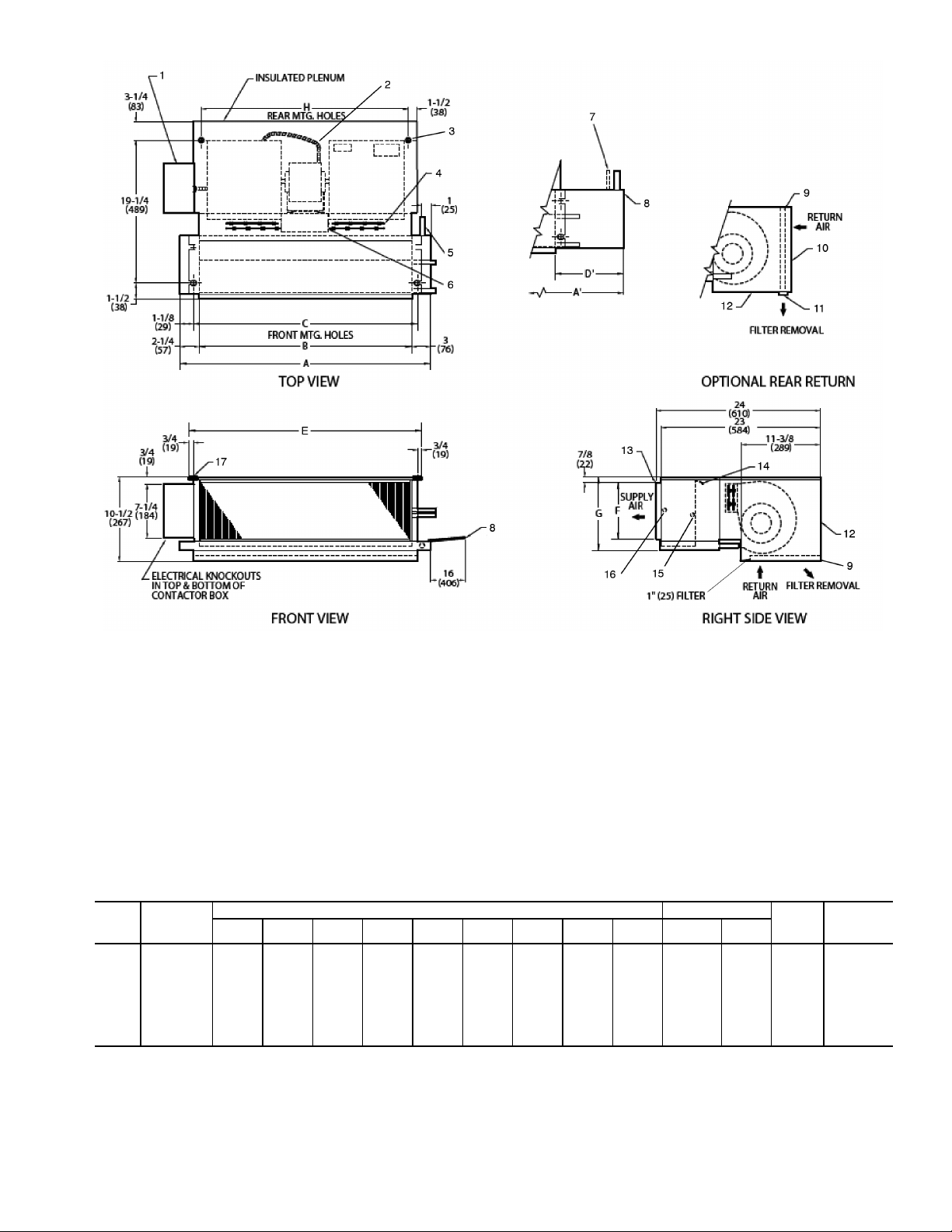

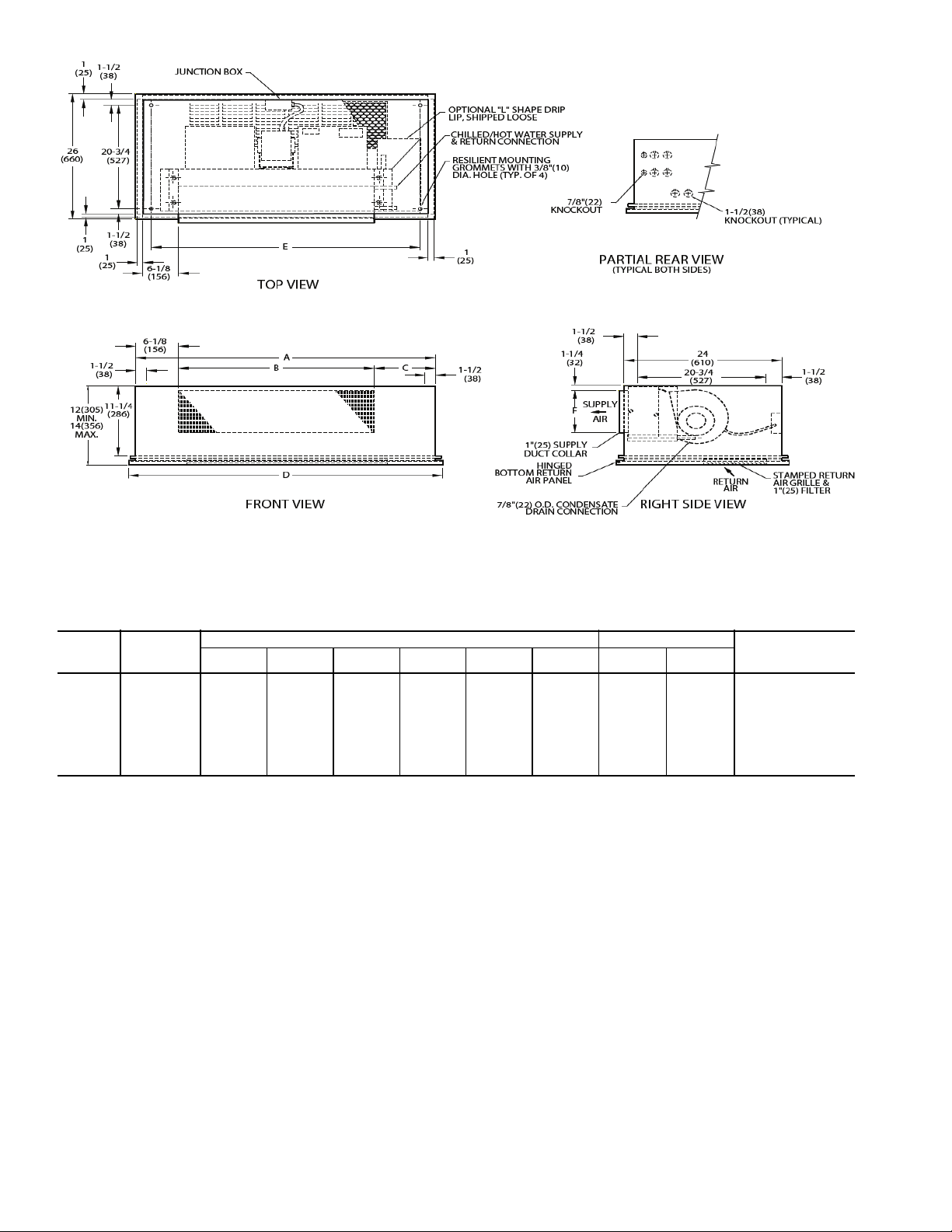

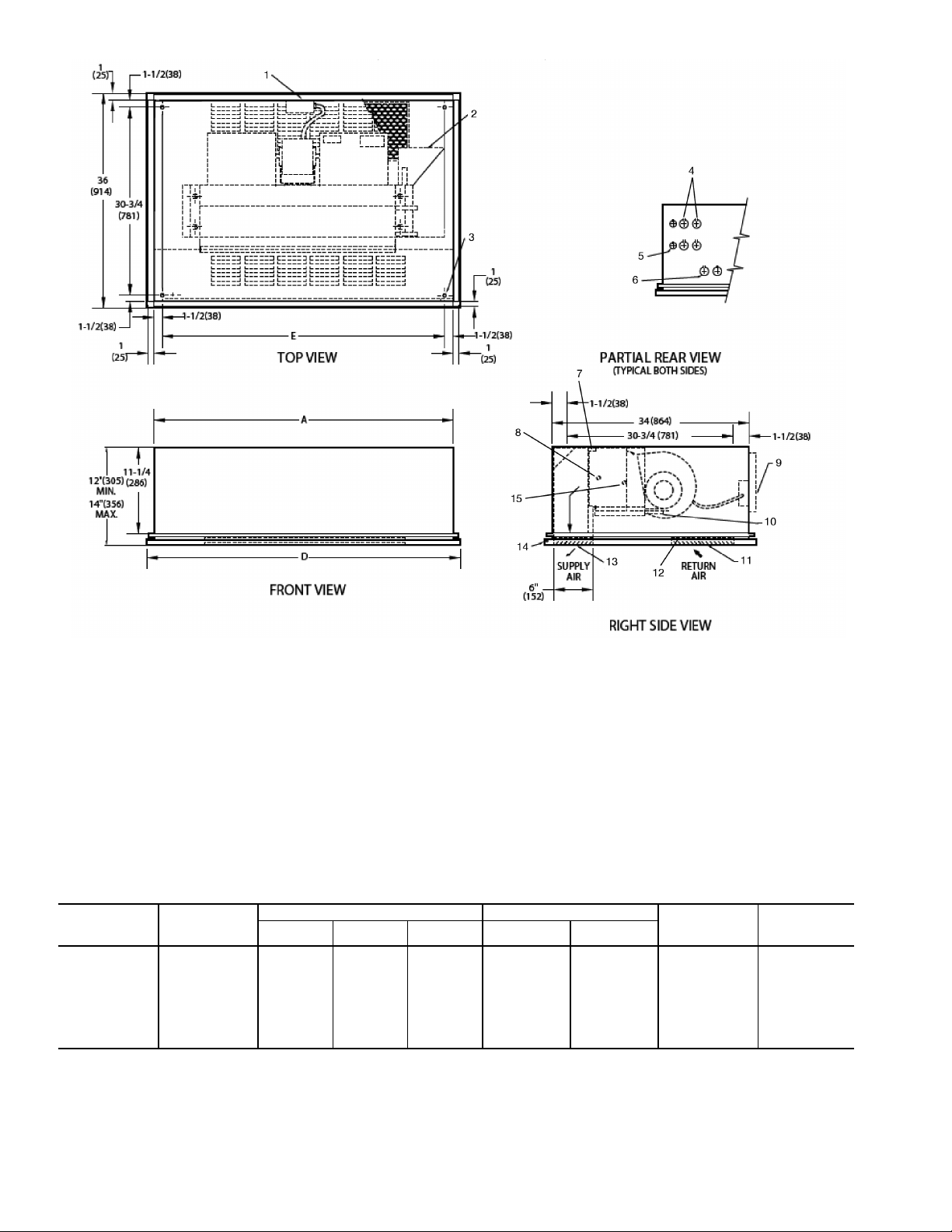

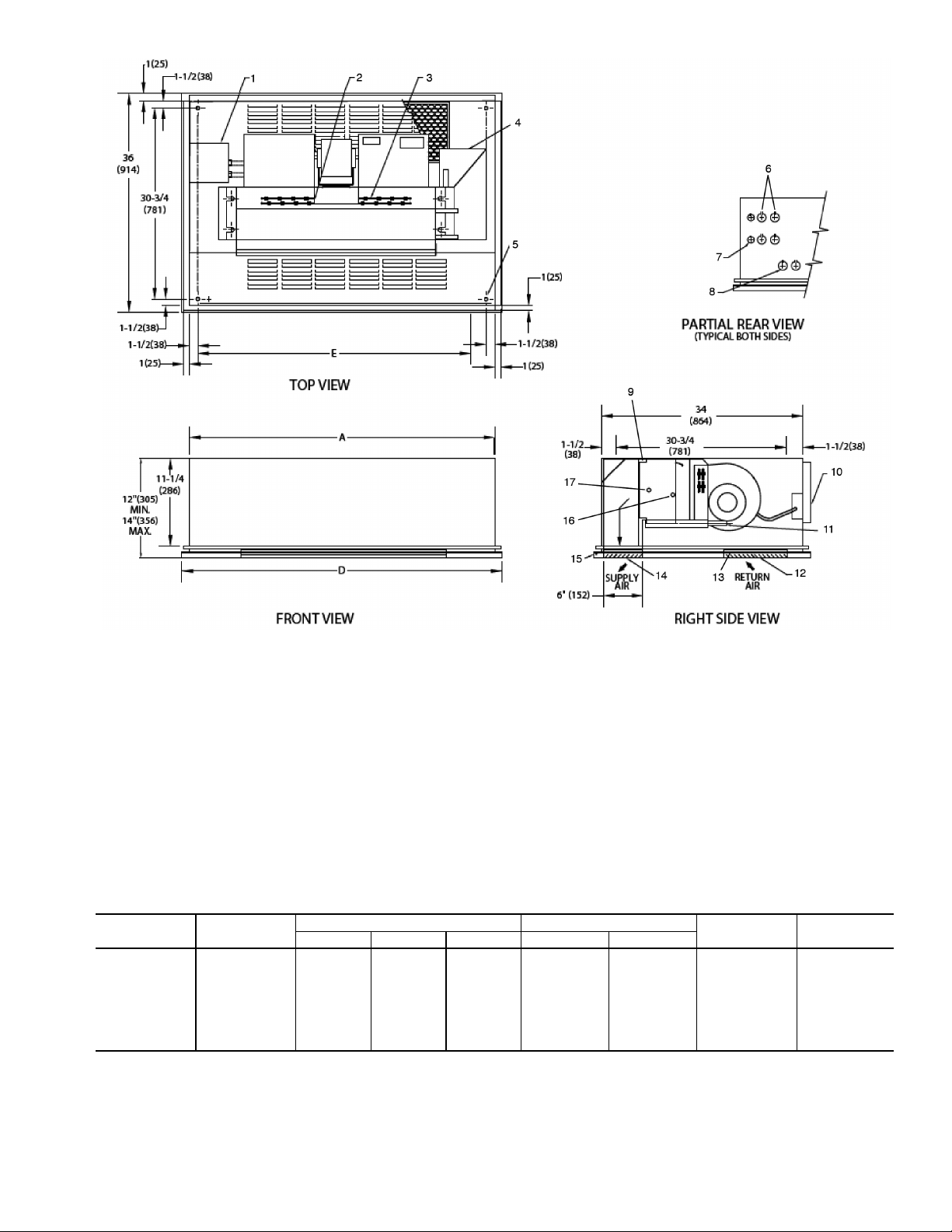

LEGEND

1— Junction Box, Installed with Plenum

2— Flexible Metal Conduit

3— Insulated Plenum

4— Mounting Bracket

5— Drain Conn,

7

/8-in. OD

6— Tell-Tale Drain Conn, 5/8-in. OD (optional)

7— Drip Lip (optional, shipped loose)

8— Filter

9— Return Duct Collar, 1-in.

10 — Access Panel

11 — Supply Duct Collar, 1-in.

12 — Supply Conn,

5

/8-in. OD

13 — Air Vent,

1

/8-in. MPT

14 — Return Conn,

5

/8-in. OD

15 — Hanger Slots (4), Rubber Grommet has

3

/8-in. Diameter Hole

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

AA’B CD’E F G H

Blower Motor

04 400 31

1

/4431/

4

26 281/

4

15 293/

4

61/

4

83/

4

301/

4

2 1 1.35 84

06 600 36

1

/4431/

4

34 331/

4

10 343/

4

71/

2

10 351/

4

2 1 1.88 97

08 800 43

1

/4571/

4

38 401/

4

17 413/

4

71/

2

10 421/

4

2 1 2.31 110

10 1000 57

1

/4651/

4

52 541/

4

11 553/

4

71/

2

10 561/

4

4 2 3.16 163

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-in.

2. Unit sizes 04 thru 08 have one motor, 2 blowers; size 10 has

2 motors, 4 blowers.

3. Refer to above figure for configuration of filter and track if

installed in optional plenum.

4. Dimension increases by 4 in. with optional electric heat.

5. Not shown: 3-speed fan switch; wall plate,

1

/2-in. fiberglass

insulation on inside of plenum (when installed), closed cell

insulation on main drain pan.

6. Units have galvanized finish.

7. For optional coil connections, view 42CA-203-1 using the Fan

Coil Builder.

8. Dimensions shown in inches (mm).

A42-4103

Fig. 5 — 42CF Furred-In High-Static Horizontal Unit with Plenum Dimensions

8

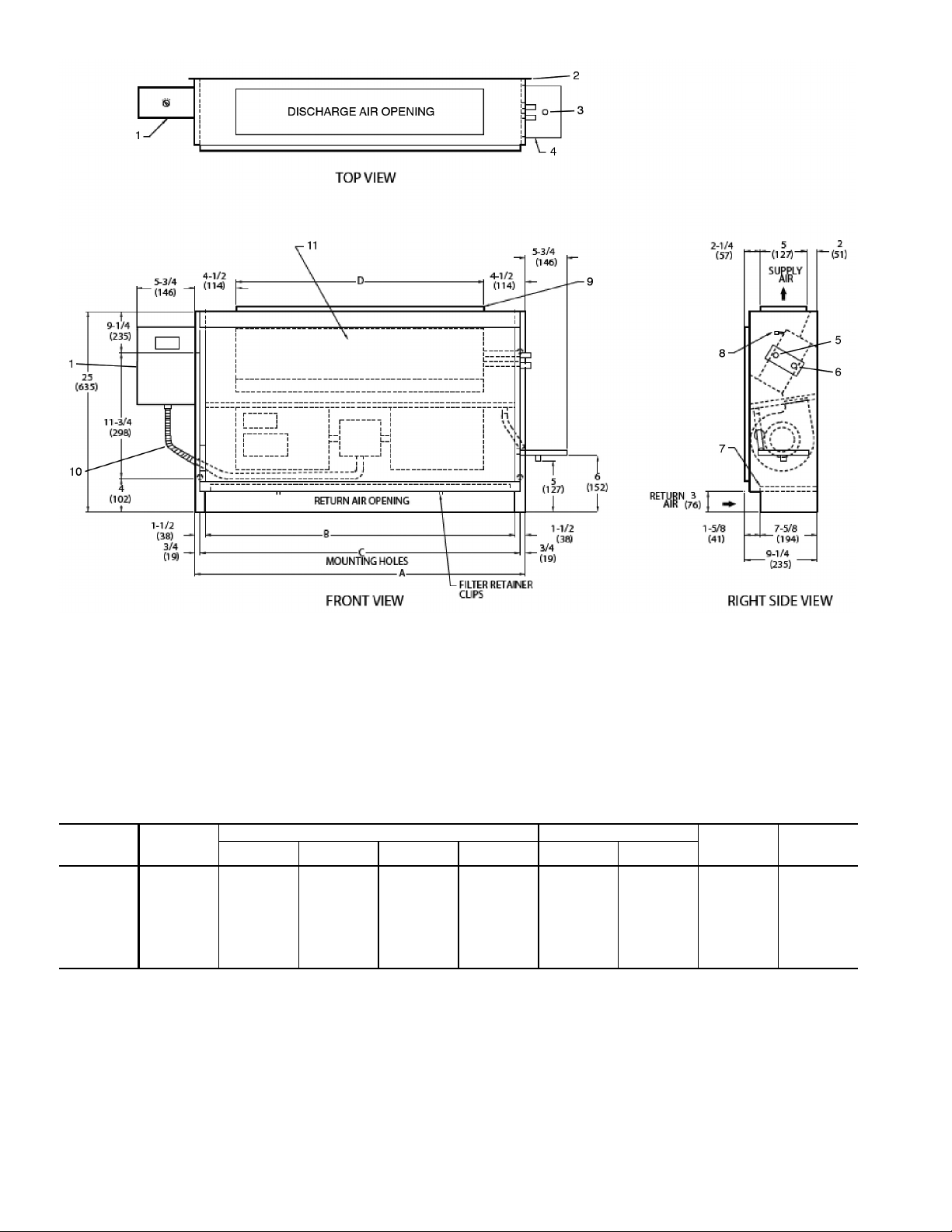

LEGEND

1— Junction Box, Installed with Plenum

2— Plenum

3— Flexible Metal Conduit

4— Mounting Bracket

5— Electric Strip Heater Element

6— Drain Conn,

7

/8-in. OD

7— Drip Lip (optional, shipped loose)

8— Tell-Tale Drain Conn, 5/8-in. OD (optional)

9— Filter

10 — Return Duct Collar, 1-in.

11 — Air Vent,

1

/8-in. MPT

12 — Access Panel

13 — Return Conn,

5

/8-in. OD

14 — Supply Conn,

5

/8-in. OD

15 — Supply Duct Collar, 1-in.

16 — Hanger Slots (4), Rubber Grommet has

3

/8-in. Diameter Hole

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-in.

2. Unit sizes 04 thru 08 have one motor, 2 blowers; size 10 has

2 motors, 4 blowers.

3. Refer to above figure for configuration of filter and track if

installed in optional plenum.

4. Dimension increases by 4 in. with optional electric heat.

5. Not shown: 3-speed fan switch; wall plate,

1

/2-in. fiberglass

insulation on inside of plenum (when installed), closed cell

insulation on main drain pan.

6. Units have galvanized finish.

7. For optional coil connections, view 42CA-203-1 using the Fan

Coil Builder.

8. Dimensions shown in inches (mm).

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

AA’B CD’E F GH

Blower Motor

04 400 31

1

/4431/

4

26 281/

4

15 293/

4

61/

4

83/

4

301/

4

2 1 1.35 84

06 600 36

1

/4431/

4

34 331/

4

10 343/

4

71/

2

10 351/

4

2 1 1.88 97

08 800 43

1

/4571/

4

38 401/

4

17 413/

4

71/

2

10 421/

4

2 1 2.31 110

10 1000 57

1

/4651/

4

52 541/

4

11 553/

4

71/

2

10 561/

4

4 2 3.16 163

A42-4104

Fig. 6 — 42CF Furred-In Horizontal Unit with Plenum and Electric Heat Dimensions

9

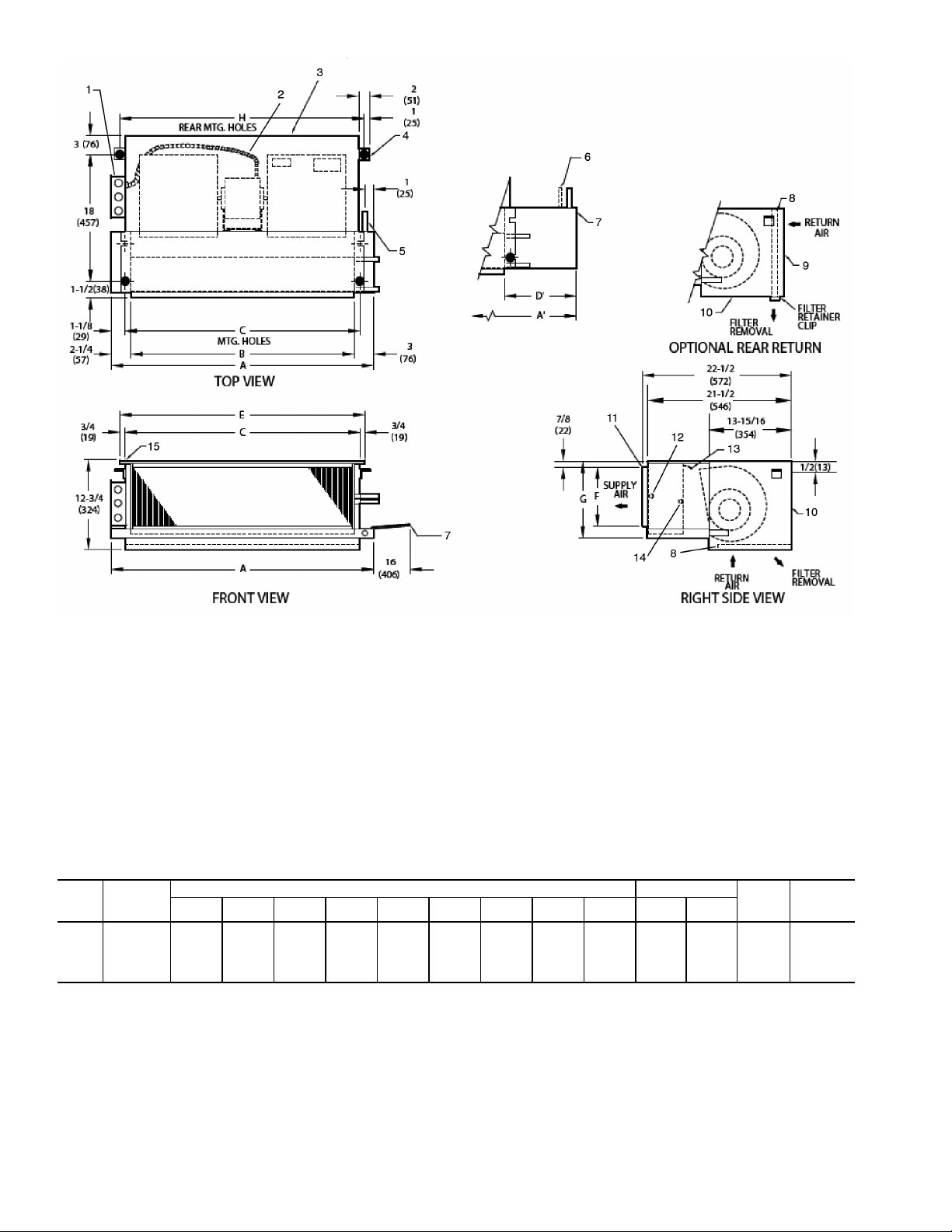

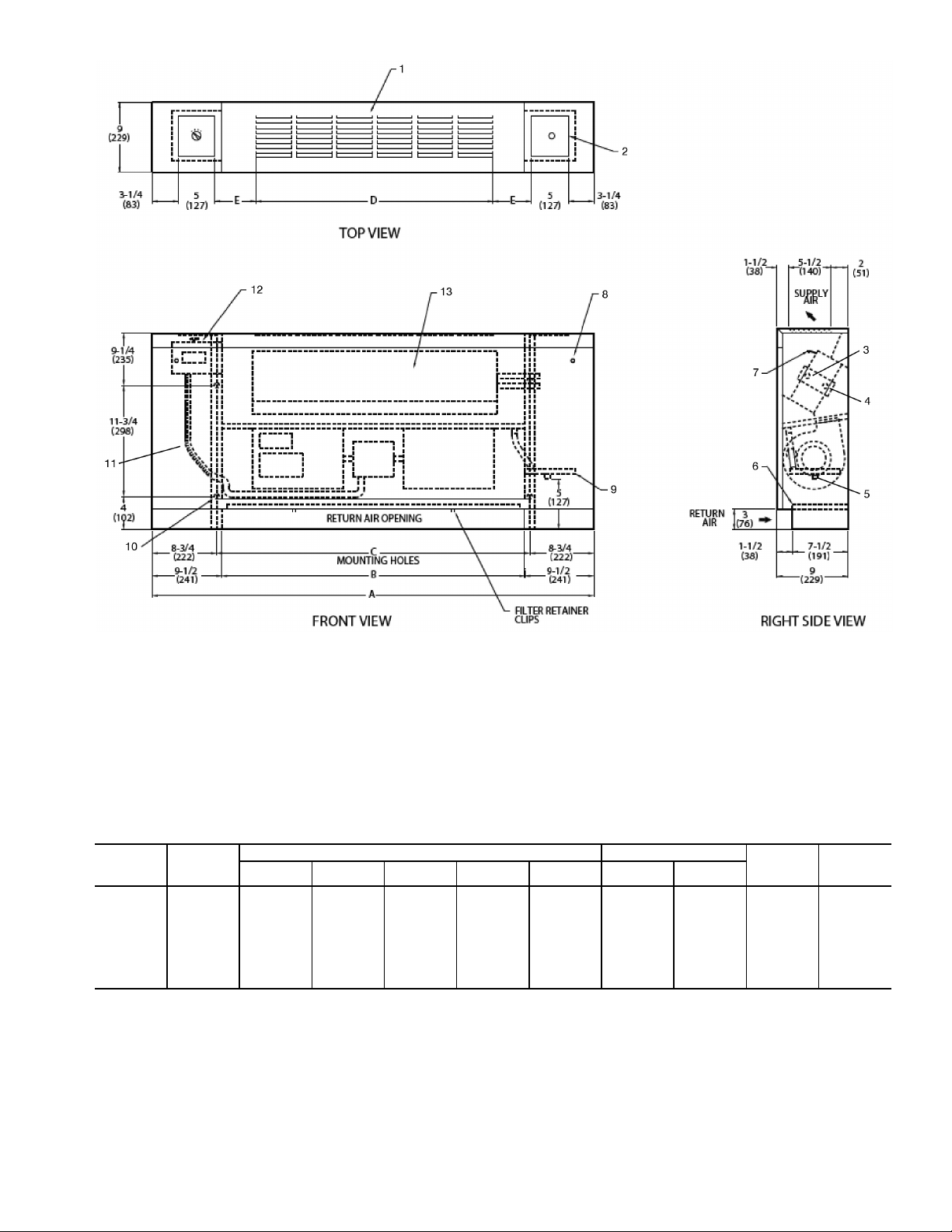

LEGEND

1— Junction Box, 4 in. x 4 in.

2— Optional Return Air Location

3— Optional Drip Lip, shipped loose

4— Mounting Holes (4), Rubber Grommets

have

3

/8-in. Diameter Hole

5— Electrical KO, 7/8-in. Diameter

6— Return KO, 1-in. Diameter

7— Supply KO, 1

1

/2-in. Diameter

8— Drain KO, 11/2-in. Diameter

9— Supply, Return Connections, 5/8-in. OD

10 — Drain Connection,

7

/8-in. OD

11 — Optional Valve Package (inside cabinet)

12 — Filter

13 — Standard Stamped-Return Air Grille

14 — Removable Hinged Access Panel

15 — Supply Grille, Stamped, Standard

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

ABCEFG

Blower Motor

02 200 38 17

1

/

8

107/

16

34 53/

4

11 1 1 0.83 98

03 300 42 21

1

/

2

101/

4

38 53/

4

11 1 1 1.08 118

04 400 48 25

7

/

8

111/

16

44 53/

4

11 2 1 1.35 126

06 600 53 34

5

/

8

93/

16

49 63/

4

12 2 1 1.88 168

08 800 60 39 10

1

/

2

56 63/

4

12 2 1 2.31 176

10 1000 74 52

1

/

8

1015/

16

70 63/

4

12 4 2 3.16 215

12 1200 82 60

7

/

8

109/

16

78 63/

4

12 4 2 3.65 245

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection locations

are ±5/8-in.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04 through 08

have one motor, 2 blowers; sizes 10 and 12 have 2 motors, 4 blowers.

3. Cabinet has an Arctic White baked finish.

4. Refer to supply and return connections above for coil stub-out locations.

5. Not shown: optional drip lip, 3-speed fan switch; wall plate,

1

/2-in. fiber-

glass insulation on inside of casing, closed cell foam on main drain pan.

6. For optional coil connections, view 42CA-203-1 using the Fan Coil

Builder.

7. Valve package is factory-installed inside the cabinet when ordered with

the unit (based on component size).

8. Dimensions shown in inches (mm).

A42-4105

Fig. 7 — 42CG Horizontal Cabinet Unit Dimensions

10

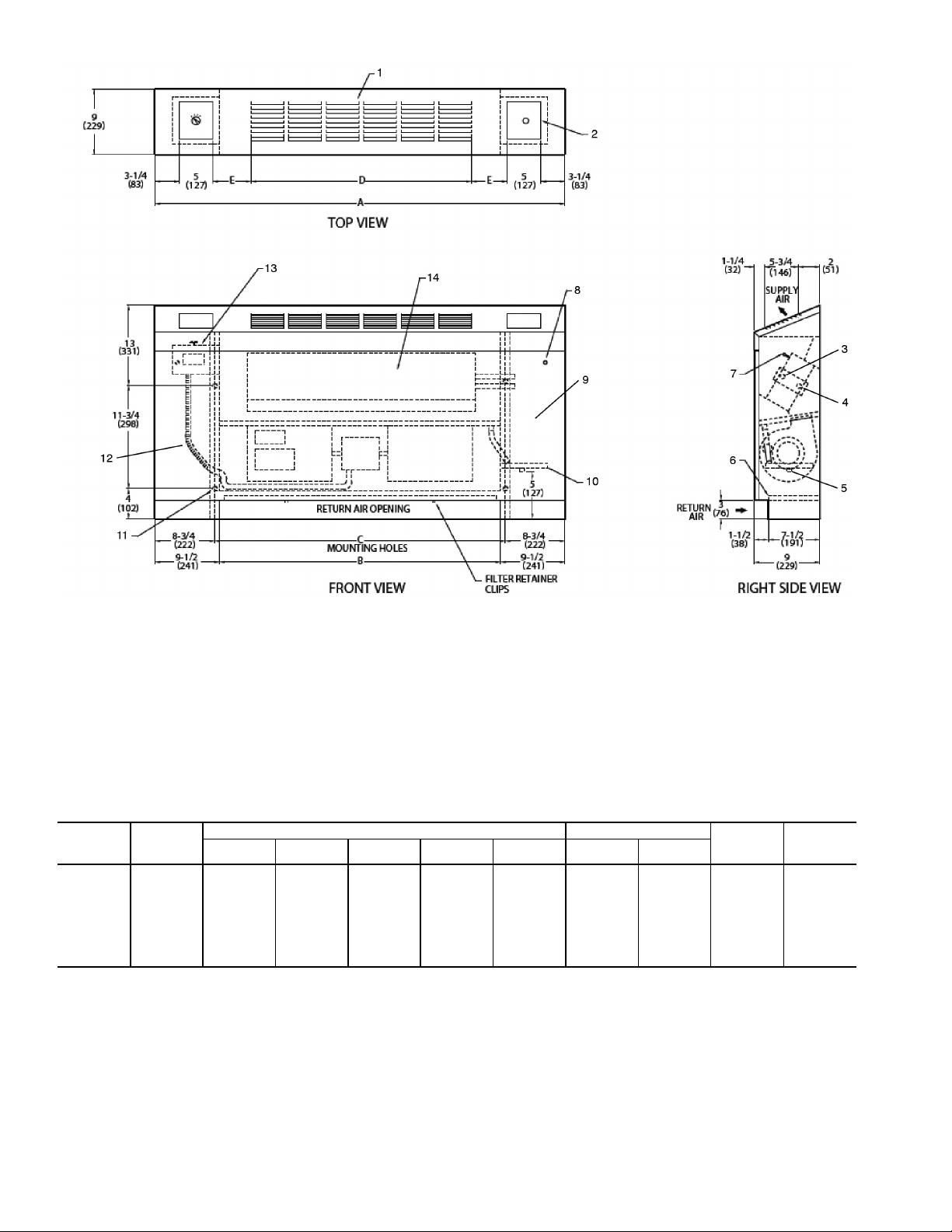

LEGEND

1— Junction Box, 4 in. x 4 in.

2— Optional Stamped Rear Return Grille

3— Optional Drip Lip, shipped loose

4— Electric Strip Heater Element

5— Mounting Holes (4), Rubber Grommets

have

3

/8-in. Diameter Hole

6— Electrical KO, 7/8-in. Diameter

7— Return KO, 1-in. Diameter

8— Supply KO, 1

1

/2-in. Diameter

9— Drain KO, 11/2-in. Diameter

10 — Drain Connection, 7/8-in. OD

11 — Optional Valve Package (inside cabinet)

12 — Filter

13 — Standard Stamped-Return Air Grille

14 — Removable Hinged Access Panel

15 — Supply, Return Connections,

5

/8-in. OD

16 — Supply Grille, Stamped, Standard

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-in.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04

through 08 have one motor, 2 blowers; sizes 10 and 12 have

2 motors, 4 blowers.

3. Cabinet has an Arctic White baked finish.

4. Refer to supply and return connections above for coil stub-out

locations.

5. Not shown: optional drip lip, 3-speed fan switch; wall plate,

1

/2-in. fiberglass insulation on inside of casing, closed cell foam

on main drain pan.

6. For optional coil connections, view 42CA-203-1 using the Fan

Coil Builder.

7. Valve package is factory-installed inside the cabinet when

ordered with the unit (based on component size).

8. Dimensions shown in inches (mm).

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

ABCE FG

Blower Motor

02 200 38 17

1

/

8

107/

16

34 53/

4

11 1 1 0.83 98

03 300 42 21

1

/

2

101/

4

38 53/

4

11 1 1 1.08 118

04 400 48 25

7

/

8

111/

16

44 53/

4

11 2 1 1.35 126

06 600 53 34

5

/

8

93/

16

49 63/

4

12 2 1 1.88 168

08 800 60 39 10

1

/

2

56 63/

4

12 2 1 2.31 176

10 1000 74 52

1

/

8

1015/

16

70 63/

4

12 4 2 3.16 215

12 1200 82 60

7

/

8

109/

16

78 63/

4

12 4 2 3.65 245

A42-4106

Fig. 8 — 42CG Horizontal Cabinet with Electric Heat Dimensions

11

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT

BOTTOM RETURN

FILTER SIZE, (in.)

ABCDEFBlowerMotor

02 200 35 16 12

3

/

4

37 32 6 1 1 10 x 28

03 300 35 20 8

3

/

4

37 32 6 1 1 10 x 28

04 400 41 26 8

3

/

4

43 38 6 2 1 10 x 33

06 600 53 31 15

3

/

4

55 50 7 2 1 10 x 45

08 800 53 38 8

3

/

4

55 50 7 2 1 10 x 45

10 1000 75 52 16

3

/

4

77 72 7 4 2 10 x 62

12 1200 75 60 8

3

/

4

77 72 7 4 2 10 x 62

NOTES:

1. Right hand unit shown; left hand unit opposite.

2. Internal factory valve package and drains may not align with

cabinet knockouts.

3. Dimensions shown in inches (mm). All dimensions are ±

1

/4 in.

4. Bottom panel is Arctic White polyester powder coat paint.

A42-4149

Fig. 9 — 42CK Horizontal Cabinet Unit with Telescopic Access Panel,

Front Supply, and Bottom Return Dimensions

12

NOTES:

1. Right hand unit shown; left hand unit opposite.

2. Internal factory valve package and drains may not align with

cabinet knockouts.

3. Dimensions shown in inches (mm). All dimensions are ±

1

/4 in.

4. Bottom panel is Arctic White polyester powder coat paint.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT

BOTTOM RETURN

FILTER SIZE, (in.)

A B C D E F Blower Motor

02 200 35 16 12

3

/

4

37 32 6 1 1 10 x 28

03 300 35 20 8

3

/

4

37 32 6 1 1 10 x 28

04 400 41 26 8

3

/

4

43 38 6 2 1 10 x 33

06 600 53 31 15

3

/

4

55 50 7 2 1 10 x 45

08 800 53 38 8

3

/

4

55 50 7 2 1 10 x 45

10 1000 75 52 16

3

/

4

77 72 7 4 2 10 x 62

12 1200 75 60 8

3

/

4

77 72 7 4 2 10 x 62

a42-4150

Fig. 10 — 42CK Horizontal Cabinet Unit with Telescopic Access Panel,

Front Supply, Bottom Return, and Heater Dimensions

13

NOTES:

1. Right hand unit shown; left hand unit opposite.

2. Internal factory valve package and drains may not align with

cabinet knockouts.

3. Dimensions shown in inches (mm). All dimensions are ±

1

/4 in.

4. Bottom panel is Arctic White polyester powder coat paint.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT

REAR RETURN

FILTER SIZE, (in.)

ABCDEFBlowerMotor

02 200 35 16 12

3

/

4

37 32 6 1 1 7 x 21

03 300 35 20 8

3

/

4

37 32 6 1 1 7 x 21

04 400 41 26 8

3

/

4

43 38 6 2 1 7 x 27

06 600 43 31 15

3

/

4

55 50 7 2 1 7 x 38

08 800 43 38 8

3

/

4

55 50 7 2 1 7 x 38

10 1000 75 52 16

3

/

4

77 72 7 4 2 7 x 52

12 1200 75 60 8

3

/

4

77 72 7 4 2 7 x 52

a42-4151

Fig. 11 — 42CK Horizontal Cabinet Unit with Telescopic Access Panel,

Front Supply, and Rear Return Dimensions

14

NOTES:

1. Right hand unit shown; left hand unit opposite.

2. Internal factory valve package and drains may not align with

cabinet knockouts.

3. Dimensions shown in inches (mm). All dimensions are ±

1

/4 in.

4. Bottom panel is Arctic White polyester powder coat paint.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT

REAR RETURN

FILTER SIZE, (in.)

ABCDEFBlowerMotor

02 200 35 16 12

3

/

4

37 32 6 1 1 7 x 21

03 300 35 20 8

3

/

4

37 32 6 1 1 7 x 21

04 400 41 26 8

3

/

4

43 38 6 2 1 7 x 27

06 600 43 31 15

3

/

4

55 50 7 2 1 7 x 38

08 800 43 38 8

3

/

4

55 50 7 2 1 7 x 38

10 1000 75 52 16

3

/

4

77 72 7 4 2 7 x 52

12 1200 75 60 8

3

/

4

77 72 7 4 2 7 x 52

a42-4152

Fig. 12 — 42CK Horizontal Cabinet Unit with Telescopic Access Panel,

Front Supply, Rear Return, and Heater Dimensions

15

LEGEND

1— Junction Box, 4 in. x 4 in.

2— Optional Drip Lip, shipped loose

3— Mounting Holes (4), Rubber Grommets

have

3

/8-in. Diameter Hole

4— Piping KO, 11/2-in. Diameter

5— Electrical KO,

7

/8-in. Diameter

6— Drain KO, 11/2-in. Diameter

7— Supply Duct Collar

8— Return Connection,

5

/8-in. OD.

9— Optional Rear Return. Consult factory for

collar dimensions.

10 — Drain,

7

/8-in. OD.

11 — Stamped Bottom Return Air Grille

12 — Filter

13 — Stamped Air Supply Grille

14 — Hinged Bottom Access Panel

15 — Supply Connection,

5

/8-in. OD.

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT

FACE AREA

(sq ft)

UNIT WEIGHT*

(lb)

ADE

Blower Motor

02 200 35 37 32 1 1 0.83 115

03 300 35 37 32 1 1 1.08 120

04 400 41 43 38 2 1 1.35 135

06 600 53 55 50 2 1 1.88 150

08 800 53 55 50 2 1 2.31 155

10 1000 75 77 72 4 2 3.16 227

12 1200 75 77 72 4 2 3.65 241

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±5/8-in.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04

through 08 have one motor, 2 blowers; sizes 10 and 12 have

2 motors, 4 blowers.

3. Bottom access panel has an Arctic White baked finish.

4. Refer to supply and return connections above for coil stub-out

locations.

5. Not shown: optional drip lip, 3-speed fan switch; wall plate,

1

/2-in. fiberglass insulation on inside of casing, closed cell foam

on main drain pan.

6. For optional coil connections, view 42CA-203-1 using the Fan

Coil Builder.

7. Valve package is factory-installed inside the cabinet when

ordered with the unit (based on component size).

8. Bottom return or bottom supply is an ETO (engineering to order)

request.

9. Dimensions shown in inches (mm).

A42-4107

Fig. 13 — 42CK Horizontal Cabinet Unit with Telescopic Access Panel

16

LEGEND

1— Junction Box, 4 in. x 4 in.

2— Strip Heater High Limit

3— Electric Strip Heater Element

4— Optional Drip Lip, shipped loose

5— Mounting Holes (4), Rubber Grommets

have

3

/8-in. Diameter Hole

6— Piping KO, 1

1

/2-in. Diameter

7— Electrical KO, 7/8-in. Diameter

8— Drain KO, 1

1

/2-in. Diameter

9— Supply Duct Collar

10 — Optional Rear Return. Consult factory for

collar dimensions.

11 — Drain,

7

/8-in. OD.

12 — Stamped Bottom Return Air Grille

13 — Filter

14 — Stamped Air Supply Grille

15 — Hinged Bottom Access Panel

16 — Supply Connection,

5

/8-in. OD.

17 — Return Connection, 5/8-in. OD.

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-in.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04

through 08 have one motor, 2 blowers; sizes 10 and 12 have

2 motors, 4 blowers.

3. Bottom access panel has an Arctic White baked finish.

4. Refer to supply and return connections above for coil stub-out

locations.

5. Not shown: optional drip lip, 3-speed fan switch; wall plate,

1

/2-in. fiberglass insulation on inside of casing, closed cell foam

on main drain pan.

6. For optional coil connections, view 42CA-203-1 using the Fan

Coil Builder.

7. Valve package is factory-installed inside the cabinet when

ordered with the unit (based on component size).

8. Bottom return or bottom supply is an ETO (engineering to order)

request.

9. Dimensions shown in inches (mm).

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT SIZE

NOM AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT

FACE AREA

(sq ft)

UNIT WEIGHT*

(lb)

ADEBlowerMotor

02 200 35 37 32 1 1 0.83 117

03 300 35 37 32 1 1 1.08 122

04 400 41 43 38 2 1 1.35 137

06 600 53 55 50 2 1 1.88 152

08 800 53 55 50 2 1 2.31 157

10 1000 75 77 72 4 2 3.16 229

12 1200 75 77 72 4 2 3.65 243

A42-4108

Fig. 14 — 42CK Horizontal Cabinet with Telescopic Access Panel and Electric Heat Dimensions

17

LEGEND

1— Optional Unit Mounted Control Box

2— Wall Mounting Holes (4),

3

/4-in. Diameter

3— Drain, 3/4-in. MPT

4— Drain Pan, Auxiliary, Shipped Loose

5— Supply Conn,

5

/8-in. OD

6— Return Conn, 5/8-in. OD

7— Filter

8— Air Vent,

1

/8-in. MPT

9— Discharge Opening

10 — Flexible Conduit

11 — Front Access Panel

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

ABCD

Blower Motor

02 200 25 22 23

1

/

2

16 1 1 0.83 65

03 300 29 26 27

1

/

2

20 1 1 1.08 80

04 400 35 32 33

1

/

2

26 2 1 1.35 90

06 600 45 42 43

1

/

2

36 2 1 1.88 112

08 800 47 44 45

1

/

2

38 2 1 2.31 115

10 1000 61 58 59

1

/

2

52 4 2 3.16 140

12 1200 69 66 67

1

/

2

60 4 2 3.65 170

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection locations

are ± 5/8-in.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04 through 08

have one motor, 2 blowers; sizes 10 and 12 have 2 motors, 4 blowers.

3. Standard 3-row coil shown.

4. Optional unit-mounted switch box and controls, when specified, are

installed on opposite side from cooling connections.

5. Not shown: 3-speed fan switch; wall plate,

1

/2-in. fiberglass insulation on

inside of casing, closed cell foam on main drain pan.

6. Units have galvanized finish.

7. For optional coil connections, view 42VA-203-1 using the Fan Coil

Builder.

8. Dimensions shown in inches (mm).

A42-4109

Fig. 15 — 42VA Furred-In Vertical Unit Dimensions

18

LEGEND

1— Standard Stamped Supply Grille

2— Access Door, Fan Switch

3— Supply Conn,

5

/8-in. OD

4— Return Conn, 5/8-in. OD

5— Drain,

3

/4-in. MPT

6— Filter

7— Air Vent, 1/8-in. MPT

8— Front Panel Fastener

9— Drain Pan, Auxiliary, Shipped Loose

10 — Wall Mounting Holes (4),

3

/4-in. Diameter

11 — Flexible Conduit

12 — Fan Switch, 3-speed

13 — Front Access Panel

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-in.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04 through

08 have one motor, 2 blowers; sizes 10 and 12 have 2 motors,

4 blowers.

3. Standard 3-row coil shown.

4. Cabinet has an Arctic White baked finish.

5. Stamped supply grille standard. Optional single or double deflection grilles available.

6. Not shown:

1

/2-in. fiberglass insulation on inside of casing, closed

cell foam on main drain pan.

7. For optional coil connections, view 42VA-203-1 using the Fan Coil

Builder.

8. Dimensions shown in inches (mm).

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

ABCDE

Blower Motor

02 20041 2223

1

/

2

171/

4

35/

8

1 1 0.83 89

03 30045 2627

1

/

2

211/

2

31/

2

1 1 1.08 95

04 40051 3233

1

/

2

26 41/

4

2 1 1.35 116

06 60061 4243

1

/

2

39 23/

4

2 1 1.88 134

08 80063 4445

1

/

2

39 33/

4

2 1 2.31 137

10 100077 5859

1

/

2

52 41/

4

4 2 3.16 169

12 120085 6667

1

/

2

61 33/

4

4 2 3.65 192

A42-4110

Fig. 16 — 42VB Vertical Cabinet Unit Dimensions

19

LEGEND

1— Standard Stamped Supply Grille

2— Access Door, Fan Switch

3— Supply Conn,

5

/8-in. OD

4— Return Conn, 5/8-in. OD

5— Drain,

3

/4-in. MPT

6— Filter

7— Air Vent, 1/8-in. MPT

8— Front Panel Fastener

9— Optional Valve Package (inside cabinet)

10 — Drain Pan, Auxiliary, Shipped Loose

11 — Wall Mounting Holes

3

/4-in. Diameter

12 — Flexible Conduit

13 — Fan Switch, 3 speed

14 — Access Doors

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-in.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04

through 08 have one motor, 2 blowers; sizes 10 and 12 have

2 motors, 4 blowers.

3. Standard 3-row coil shown.

4. Cabinet has an Arctic White baked finish.

5. Not shown:

1

/2-in. fiberglass insulation on inside of casing,

closed cell foam on main drain pan.

6. For optional coil connections, view 42VA-203-1 using the Fan

Coil Builder.

7. Valve package is factory-installed inside the cabinet when

ordered with the unit (based on component size).

8. Dimensions shown in inches (mm).

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

ABCDE

Blower Motor

02 200 41 22 23

1

/

2

171/

4

35/

8

1 1 0.83 92

03 300 45 26 27

1

/

2

211/

2

31/

2

1 1 1.08 98

04 400 51 32 33

1

/

2

26 41/

4

2 1 1.35 122

06 600 61 42 43

1

/

2

39 23/

4

2 1 1.88 141

08 800 63 44 45

1

/

2

39 33/

4

2 1 2.31 144

10 1000 77 58 59

1

/

2

521/

8

41/

4

4 2 3.16 178

12 1200 85 66 67

1

/

2

61 33/

4

4 2 3.65 205

A42-4111

Fig. 17 — 42VF Vertical Cabinet Unit with Slant Top Dimensions

20

LEGEND

1— Optional Unit Mounted Control Box

2— Drain Pan, Auxiliary, Shipped Loose

3— Supply Conn,

5

/8-in. OD

4— Drain, 3/4-in. MPT

5— Return Conn,

5

/8-in. OD

6— Air Vent, 1/8-in. MPT

7— Discharge Opening

8— Filter

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT

FACE AREA

(sq ft)

UNIT

WEIGHT* (lb)

ABC

Blower Motor

02 200 23 22 17 2 1 1.18 50

03 300 28 27 22 2 1 1.53 60

04 400 36 35 30 2 1 2.08 72

06 600 50 49 44 4 2 3.06 110

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-in.

2. Unit sizes 02 through 04 have one motor, 2 blowers; size 06

has 2 motors, 4 blowers.

3. Standard 2-row coil shown.

4. Optional unit-mounted switch box and controls, when specified,

are installed on opposite side from cooling connections.

5. Height increases by 2 in. with electric heat.

6. Not shown: 3-speed fan switch,

1

/2-in. fiberglass insulation on

inside of casing, closed cell foam on main drain pan.

7. Units have galvanized finish.

8. For optional coil connections, view 42VC-203-1 using the Fan

Coil Builder.

9. Dimensions shown in inches (mm).

A42-4112

14-3/8

(368)

Fig. 18 — 42VC Furred-In Lowboy Unit Dimensions

21

LEGEND

1— Unit-Mounted Control Box (Optional)

2— Drain Pan, Auxiliary, Shipped Loose

3— Air Vent,

1

/8-in. MPT

4— Supply Conn, 5/8-in. OD

5— Drain,

3

/4-in. MPT

6— Return Conn, 5/8-in. OD

7— Filter

8— Electrical Sheath Heater Element

9— Discharge Opening

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT

FACE AREA

(sq ft)

UNIT

WEIGHT* (lb)

ABC

Blower Motor

02 200 23 22 17 2 1 1.18 50

03 300 28 27 22 2 1 1.53 60

04 400 36 35 30 2 1 2.08 72

06 600 50 49 44 4 2 3.06 110

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-in.

2. Unit sizes 02 through 04 have one motor, 2 blowers; size 06 has

2 motors, 4 blowers.

3. Standard 2-row coil shown.

4. Optional unit-mounted switch box and controls, when specified,

are installed on opposite side from cooling connections.

5. Height increases by 2 in. with electric heat.

6. Not shown: 3-speed fan switch,

1

/2-in. fiberglass insulation on

inside of casing, closed cell foam on main drain pan.

7. Units have galvanized finish.

8. For optional coil connections, view 42VC-203-1 using the Fan Coil

Builder.

9. Dimensions shown in inches (mm).

A42-4113

Fig. 19 — 42VC Furred-In Lowboy Unit with Electric Heat Dimensions

22

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT

FACE AREA

(sq ft)

UNIT

WEIGHT*

(lb)

ABDC

Blower Motor

02 200 41

22

3

3

/

4

17 2 1 1.18 72

03 300 46

27

421

1

/

2

2 1 1.53 100

04 400 54

35

3

5

/

8

301/

4

2 1 2.08 108

06 600 68

49

4

1

/

16

433/

8

4 2 3.06 154

LEGEND

1— Fan Switch, 3-Speed, behind Access Door

2— Front Panel Fastener

3— Stamped Supply Grille

4— Supply Conn,

5

/8-in. OD

5— Return Conn, 5/8-in. OD

6— Stamped Return Grille

7— Filter

8— Air Vent,

1

/8-in. MPT

9— Optional Valve Package (inside cabinet)

10 — Drain Pan, Auxiliary, with

3

/4-in. MPT

Drain Connection

11 — Return Air Grille

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-in.

2. Unit sizes 02 through 04 have one motor, 2 blowers; size 06 has

2 motors, 4 blowers.

3. Cabinet has an Arctic White baked finish.

4. Height increases by 2 in. with electric heat.

5. Standard 2-row coil shown.

6. Not shown:

1

/2-in. fiberglass insulation on inside of casing,

closed cell foam on main drain pan.

7. For optional coil connections, view 42VC-203-1 using the Fan

Coil Builder.

8. Valve package is factory-installed inside the cabinet when

ordered with the unit (based on component size).

9. Dimensions shown in inches (mm).

A42-4114

14-3/8

(368)

Fig. 20 — 42VE Cabinet Lowboy Unit Dimensions

23

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT

FACE AREA

(sq ft)

UNIT

WEIGHT*

(lb)

ABCD

Blower Motor

02 200 41 22 3

3

/

4

17 2 1 1.18 72

03 300 46 27 4 21

1

/

2

2 1 1.53 100

04 400 54 35 3

5

/

8

301/

4

2 1 2.08 108

06 600 68 49 4

1

/

16

433/

8

4 2 3.06 154

LEGEND

1— Fan Switch, 3-Speed, behind Access Door

2— Electrical Sheath Heater Element

3— Stamped Supply Grille

4— Supply Conn,

5

/8-in. OD

5— Return Conn,

5

/8-in. OD

6— Stamped Return Grille

7— Filter

8— Air Vent,

1

/8-in. MPT

9— Front Panel Fastener

10 — Optional Valve Package (inside cabinet)

11 — Drain Pan, Auxiliary, with

3

/4-in. MPT

Drain Connection

12 — Return Air Grille

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-in.

2. Unit sizes 02 through 04 have one motor, 2 blowers; size 06 has

2 motors, 4 blowers.

3. Cabinet has an Arctic White baked finish.

4. Height increases by 2 in. with electric heat.

5. Standard 2-row coil shown.

6. Not shown:

1

/2-in. fiberglass insulation on inside of casing,

closed cell foam on main drain pan.

7. For optional coil connections, view 42VC-203-1 using the Fan

Coil Builder.

8. Valve package is factory-installed inside the cabinet when

ordered with the unit (based on component size).

9. Dimensions shown in inches (mm).

A42-4115

Fig. 21 — 42VE Cabinet Lowboy Unit with Electric Heat Dimensions

24

LEGEND

1— Supply Conn,

5

/8-in. OD

2— Air Vent,

1

/8-in. MPT

3— Filter

4— Return Air Grille, Stamped

5— Stamped Supply Grille

6— Return Conn,

5

/8-in. OD

7— Removable Front Panel

8— Drain Conn,

7

/8-in. OD

9— Auxiliary Drain Pan

10 — Valve Compartment

11 — Junction Box

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-in.

2. Front panel has an Arctic White baked finish.

3. Standard 2-row coil shown.

4. Unit size 01 has one motor, one blower; size 03 has 2 motors,

2 blowers.

5. Unit has

1

/2-in. flanges for mounting to wall surface.

6. Front panel hooks at top of unit, swing down and snap in at bottom

against a spring clip.

7. Not shown: 3-speed fan switch, wall plate,

1

/2-in. fiberglass insula-

tion on inside of casing, closed cell foam on main drain pan.

8. Dimensions shown in inches (mm).

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT UNIT

WEIGHT*

(lb)

ABCDE

Blower Motor

01 150 25

3

/

4

153/

4

14 11/

2

123/

4

1140

03 300 39

3

/

4

293/

4

28 115/

16

257/

8

2274

A42-4116

Fig. 22 — 42VG Furred-In Wall Unit Dimensions

25

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other

components.

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection locations are ±

5

/8 inches.

2. Sizes 06, 08 and 10 have one motor, one blower; sizes 12 through 20 have 2 motors, 2 blowers.

3. Standard 4-row coil shown. Other coil option dimensional data available on request.

4. For optional coil connections, view 42DA-203-1 using the Fan Coil Builder.

5. Fan switch, wall plate not shown.

6. Galvanized finish provided as standard.

7. Dimensions are in inches (mm).

UNIT

SIZE

NOM

AIRFLOW

(cfm)

DIMENSIONS (in. ±

1

/8) QTY/UNIT

UNIT

WEIGHT*

(lb)

A A’ B D’ E H Blower Motor

06 600 23 32 14 13

1

/217 181/

2

11 64

08 800 28 37 19 13

1

/222 231/

2

11 79

10 1000 32 42 23 14

1

/226 271/

2

11 90

12 1200 37 47 28 14

1

/231 321/

2

2 2 108

14 1400 42 52 33 14

1

/236 371/

2

2 2 119

16 1600 47 56 38 13

1

/241 421/

2

2 2 124

18 1800 52 62 43 14

1

/246 471/

2

2 2 141

20 2000 56 66 47 14

1

/250 511/

2

2 2 151

LEGEND

1— Motor Junction Box

2— Motor-Blower Assembly

3— Electric Strip Heater Element (optional)

4— Auxiliary Drip Lip (Optional, Shipped Loose)

5— Tell-Tale Drain (optional)

6— Drain Connection,

7

/8-in. OD

7— Air Vent, 1/8-in. MPT

8— Supply Connection

9— Supply Duct Collar, 1 inch

10 — Return Connection

11 — Mounting Holes (four,

3

/4-in. diameter) have

Rubber Grommets with

3

/8-in. holes.

a42-4120

Fig. 23 — 42DA Furred-In Ceiling Unit with Electric Heat Dimensions

26

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other

components.

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection locations are ±

5

/8 inches.

2. Sizes 06, 08 and 10 have one motor, one blower. Sizes 12 through 20 have 2 motors, 2 blowers.

3. Filter and filter rack are standard.

4. Standard 4-row coil shown. Other coil option dimensional data available on request.

5. For optional coil connections, view 42DA-203-1 using the Fan Coil Builder.

6. Fan switch, wall plate not shown.

7. Galvanized finish provided as standard.

8. Dimensions are in inches (mm).

UNIT

SIZE

NOM

AIRFLOW

(cfm)

DIMENSIONS (in. ±

1

/8) QTY/UNIT

UNIT

WEIGHT*

(lb)

A A’ B D’ E F G H Blower Motor

06 600 23 32 14 13

1

/217 21 251/4181/

2

11 94

08 800 28 37 19 13

1

/222 26 301/4231/

2

1 1 107

10 1000 32 42 23 14

1

/226 30 341/4271/

2

1 1 150

12 1200 37 47 28 14

1

/231 35 391/4321/

2

2 2 169

14 1400 42 52 33 14

1

/236 40 441/4371/

2

2 2 174

16 1600 47 56 38 13

1

/241 45 491/4421/

2

2 2 178

18 1800 52 62 43 14

1

/246 50 541/4471/

2

2 2 195

20 2000 56 66 47 14

1

/250 54 581/4511/

2

2 2 220

LEGEND

1— Motor Junction Box Opposite Piping

2— Insulated Return Air Plenum

3— Mounting Clips (Shipped Loose)

4— Electrical Strip Heater Element (optional)

5— Auxiliary Drip Lip (Shipped Loose) with

3

/8-in.

Hole

6— Tell-Tale Drain (optional)

7— Drain Connection,

7

/8-in. OD

8— Filter Retainer Angle

9— Access Panel

10 — Return Duct Collar, 2

1

/2 inches

11 — Air Vent,

1

/8-in. MPT

12 — Return Connection

13 — Filter, 1-in.

14 — Supply Duct Collar, 1 inch

15 — Supply Connection

16 — Mounting Holes (four,

3

/4-in. diameter) with

Rubber Grommet

A42-4121

Fig. 24 — 42DC Furred-In Ceiling Unit with Plenum and Electric Heat Dimensions

27

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other

components.

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection locations are ±

5

/8 inches.

2. Standard 4-row coil shown. Other coil option dimensional data available on request.

3. Sizes 06, 08 and 10 have one motor, one blower. Sizes 12 through 20 have 2 motors, 2 blowers.

4. Supply and return connections terminate within unit when valves are factory installed.

5. For optional coil connections, view 42DD-203-1 using the Fan Coil Builder.

6. Fan switch and wall plate are not shown.

7. Galvanized finish provided as standard.

8. Units with internal factory valve packages have external connections located in triangular section

above coil.

9. Consult Carrier for ducted front return air and external filter rack with 1-in. duct collar and throwaway

filters.

10. Units with electric heat require additional access on the side of unit for servicing contactor box.

11. With bottom return, access to filter is through the front access panel.

12. Dimensions are in inches (mm).

UNIT

SIZE

NOM

AIRFLOW

(cfm)

DIMENSIONS (in. ±

1

/8) QTY/UNIT UNIT

WEIGHT*

(lb)

ABC

Blower Motor

06 600 232115 1 1135

08 800 282620 1 1145

10 1000 32 30 24 1 1 155

12 1200 37 35 29 2 2 180

14 1400 42 40 34 2 2 190

16 1600 47 45 39 2 2 200

18 1800 52 50 44 2 2 215

20 2000 56 54 48 2 2 230

LEGEND

1— Motor Junction Box

2— Air Vent,

1

/8-in. MPT

3— Return Connection

4— Optional 6-in. Legs

5— Bottom Return (optional)

6— Return Air Opening

7— Supply Connection

8— Drain Connection,

7

/8-in. OD

9— Front Access Panel

10 — Filter, Throwaway

11 — Electric Strip Heater Element (optional)

12 — Supply Duct Connection, 1-in.

A42-4122

Fig. 25 — 42DD Vertical Unit with Full Casing and Electric Heat Dimensions

SEE NOTE 8

28

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves,

and other components.

NOTES:

1. Right hand unit shown; left hand unit opposite.

2. Coil stub-out location data available on request.

3. Unit fabricated of galvanized steel.

4. Internal parts fabricated of galvanized steel.

5. Sizes 06, 08 and 10 have one motor, one blower. Sizes 12 through 20 have 2 motors,

2 blowers.

6. Units must have drain line pitched and trapped externally.

7. For optional coil connections, view 42DA-203-1 using the Fan Coil Builder.

8. Fan switch, wall plate not shown.

9. Galvanized finished provided as standard.

10. Dimensions are in inches (mm).

UNIT

SIZE

NOM

AIRFLOW

(cfm)

DIMENSIONS (in. ±

1

/8) QTY/UNIT UNIT

WEIGHT*

(lb)

ABCD

Blower Motor

06 600 31 15 15 26 1 1 150

08 800 36 20 20 31 1 1 160

10 1000 40 24 24 35 1 1 170

12 1200 45 29 29 40 2 2 195

14 1400 50 34 34 45 2 2 205

16 1600 55 39 39 50 2 2 215

18 1800 60 44 44 55 2 2 230

20 2000 64 48 48 59 2 2 235

LEGEND

1— Motor Junction Box

2— Unit Mounting Channel (2), 14-gage; 4 Mounting

Slots,

1

/2-in. x 2-in.

3— Auxiliary Drip Lip (optional, shipped loose)

4— Side Access Panels

5— Electrical Strip Heater Element (optional)

6— Supply Air Duct Connection, 1 in.

7— Manual Air Vent

8— Filter, Throwaway, 1-in.

9— Return Air Duct Connection, 2

1

/2 in.

10 — Drain,

7

/8-in. OD

11 — Bottom Access Panel

12 — Drain Pan

13 — Coil Inlet, Copper Sweat Connection

14 — Coil Outlet, Copper Sweat Connection

A42-4123

Fig. 26 — 42DE Ceiling Unit with Full Casing and Electric Heat Dimensions

29

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other

components.

NOTES:

1. Right hand unit shown; left hand unit opposite.

2. Coil stub-out connection data available on request.

3. Units fabricated of galvanized steel with an Arctic White baked finish.

4. Internal parts fabricated of galvanized steel.

5. Sizes 06, 08 and 10 have one motor, one blower. Sizes 12 through 20 have 2 motors, 2 blowers.

6. Units must have drain line pitched and trapped externally.

7. Stamped supply and return grilles are not available.

8. Bottom return air is not available.

9. For optional coil connections, view 42DA-203-1 using the Fan Coil Builder.

10. Fan switch and wall plate are not shown.

11. Dimensions are in inches (mm).

UNIT

SIZE

NOM

AIRFLOW

(cfm)

DIMENSIONS (in. ±

1

/8) QTY/UNIT UNIT

WEIGHT*

(lb)

A B C D E Blower Motor

06 600 31 13

1

/214 26 81/

2

11150

08 800 36 18

1

/220 31 8 1 1 160

10 1000 40 22

1

/224 35 8 1 1 170

12 1200 45 27

1

/228 40 81/

2

22195

14 1400 50 32

1

/234 45 8 2 2 205

16 1600 55 37

1

/238 50 81/

2

22215

18 1800 60 42

1

/244 55 8 2 2 230

20 2000 64 46

1

/248 59 8 2 2 235

LEGEND

1—Junction Box

2—Return Air Grille, Hinged, Bar Type, with Filter

Frame (Anodized Aluminum Only)

3—Unit Mounting Channel (2), 14-gage; 4 Mounting

Slots,

1

/2 in. x 2-in.

4—Auxiliary Drip Lip

5—Electric Strip Heater Element (optional)

6—Coil Inlet, Copper Sweat Connection

7—Coil Outlet, Copper Sweat Connection

8—Manual Air Vent

9—Filter, Throwaway

10— Bottom Access Panel

11— Drain,

7

/8-in. OD

12— Drain Pan Insulated with Styrofoam

13— Side Access Panel (2)

14— Supply Air Grille (Double Deflection)

A42-4124

Fig. 27 — 42DF Exposed Ceiling Unit with Supply and Return Grille and Electric Heat Dimensions

30

*Drawing provided for reference only. Dimensions may vary with options ordered.

NOTES:

1. Units are fabricated of 18-gage galvanized steel with a 16-gage galvanized fan deck.

2. All risers are insulated with

1

/2-in. closed cell insulation.

3. Thermostats shipped loose for field connection.

4. Risers are piped to coil with valves as specified.

5. Blower, motor, valves, coil, and filter are accessible through the return air opening.

6. Unit and control box are insulated with 1/2-in. coated fiberglass insulation.

7. Riser length = [(floor to floor) +2 in.], maximum riser length = 115 inches.

8. Maximum riser size is 21/2-in. diameter. If larger sizes are required, please consult the factory.

9. Expansion loops in hot water heating circuits as required.

10. A 9-in. x 21/4-in. slot is provided in the inside back panel for coil connection penetration to permit expansion

and contraction of risers. Care must be taken to position the risers so that coil connection is at center of slot.

11. Drawing is pictorial (see unit arrangements for actual supply and return air orientation).

12. All dimensions are in inches.

†Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(cfm)

DIMENSIONS (in.)

UNIT

WEIGHT†

(lb)

Single Supply Double Supply Top Supply

EGH I

AB A BCD

03 300 14 8 14 6 14 10 17 1

1

/211/214 180

04 400 14 12 14 6 14 10 17 11/211/214 225

06 600 18 10 18 6 16 12 20 1 2 18 240

08 800 18 12 18 6 16 12 20 1 2 18 260

10 1000 — — 22 8 18 16 24 1 3 22 280

12 1200 — — 22 8 18 16 24 1 3 22 305

A42-4125

LEGEND

CR — Cold Water Return

CS — Cold Water Supply

D— Drain

HR — Hot Water Return

HS — Hot Water Supply

R— Return

S—Supply

**Factory-Installed.

††Field-Installed.

ITEM DESCRIPTION QTY

1 Electrical Knockouts 1

2 3-in. Expanded Section 3/5

3 Strip Heater (Optional) 1

4 Limit Switch**†† (Optional) 1

5

1

/2-in. Isolation Ball Valves**

2/4

6 Flexible Drain Tube/P-Trap 1

7 Coil

1

/2-in. OD Copper Tube

1

8 Filter, Throwaway, 1-in.** 1

9 Return Air Opening 1

10 Air Vent, Manual 1

11 Molex Connector for Field-Installed Stat 1

12 Control Box 1

13 Knockout (For Optional Remote Mounting) 2

14 Riser, Supply and Return (Copper) 2/4

15 Riser, Drain (Copper) 1

16 Drain Pan 1

17 Return Air Blockoff Panel (Optional) 1

18 Blower 1

19 Motor, 3-Speed, PSC, with Quick Connect 1

20 Access Panel (Control Box) 1

21 Control Opening (Surface Mount Stat) 1

22 Duct Collar, 1/2-in. Extension (Typical)

1/2/3

23 Supply Air Opening(s) 1/2/3

Fig. 28 — 42SG Furred-In Stack Dimensions

31

†Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(cfm)

DIMENSIONS (in.)

UNIT

WEIGHT†

(lb)

Single Supply Double Supply

CDE FG

ABAB

03 300 14 8 14 6 17 223/811/2221/8143/

4

202

04 400 14 12 14 8 17 223/811/2221/8143/

4

247

06 600 14 12 14 8 20 25

3

/82265/8173/

4

262

08 800 14 16 14 10 20 25

3

/82265/8173/

4

286

10 1000 18 16 14 12 24 293/83311/8173/

4

311

12 1200 18 16 14 12 24 29

3

/83311/8173/

4

336

*Drawing provided for reference only. Dimensions may vary with options ordered.

NOTES:

1. Units are fabricated of 18-gage galvanized steel with a 16-gage galvanized fan deck, painted with Arctic White.

2. 3-speed switch and thermostat are unit mounted.

3. Risers are piped to coil with valves as specified.

4. Blower, motor, valves, coil, and filter are accessible through the return air opening.

5. Unit is insulated with coated fiberglass.

6. Control box is insulated with 1/2-in. insulation for unit mounted controls.

7. Riser length = [(floor to floor) +2 in.], maximum riser length = 115 inches.

8. Maximum riser size is 21/2-in. diameter. If larger sizes are required, please consult the factory.

9. Expansion loops in hot water heating circuits as required.

10. A 9-in. x 2

1

/4-in. slot is provided in the inside back panel for coil connection penetration to permit expansion and

contraction of risers. Care must be taken to position the risers so that coil connection is at center of slot.

11. Drawing is pictorial (see unit arrangements for actual supply and retur n air orientation).

12. 42SHA available in front return only.

13. All dimensions are in inches.

A42-4126

**Factory-Installed.

††Field-Installed.

ITEM DESCRIPTION QTY

1 Full Riser Chase

1

2 Electrical Knockouts 1

3 3-in. Expansion Section 3/5

4 Strip Heater (Optional) 1

5 Limit Switch**†† (Optional) 1

61/2-in. Isolation Ball Valves**

2/4

7 Flexible Drain Tube/P-Trap 1

8 Drain Pan 1

9 Coil

1

/2-in. OD Tube

1

10 Filter, Throwaway, 1-in.** 1

11 Air Vent, Manual 1

12 Control Box 1

13 Cabinet Camloc

®

Fasteners 2

14 3-Speed Switch

1

15 Electrical Access Panel 1

16 Riser, Supply and Return (Copper) 2/4

17 Riser, Drain (Copper) 1

18 Return Air Panel 1

19 Return Air Blockoff Panel (Optional)

1

20 Motor, 3-Speed, PSC 1

21 Blower 1

22 Thermostat 1

23 Hinged Control Access Door 1

24 Double Deflection Steel Core Grille Assembly 1

LEGEND

CR — Cold Water Return

CS — Cold Water Supply

D— Drain

HR — Hot Water Return

HS — Hot Water Supply

R— Return

S—Supply

Fig. 29 — 42SH Cabinet Dimensions

32

†Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(cfm)

DIMENSIONS (in.)

UNIT

WEIGHT†

(lb)

Single Supply Double Supply Top Supply

EGHI J

ABA BCD

03 300 14 8 14 6 14 10 17 11/211/214 401/

4

360

04 400 14 12 14 6 14 10 17 1

1

/211/214 401/

4

450

06 600 18 10 18 6 16 12 20 1 2 18 461/

4

480

08 800 18 12 18 6 16 12 20 1 2 18 46

1

/

4

520

10 1000 ——22 81816241 322541/

4

560

12 1200 ——22 81816241 32254

1

/

4

610

*Drawing provided for reference only. Dimensions may vary with options ordered.

NOTES:

1. Units are fabricated of 18-gage galvanized steel with a 16-gage galvanized fan deck.

2. All risers are insulated with 1/2-in. closed cell insulation.

3. Thermostats shipped loose for field connection.

4. Risers are piped to coil with valves as specified.

5. Blower, motor, valves, coil, and filter are accessible through the return air opening.

6. Unit and control box are insulated with

1

/2-in. coated fiberglass insulation.

7. Riser length = [(floor to floor) +2 in.], maximum riser length = 115 inches.

8. Maximum riser size is 21/2-in. diameter. If larger sizes are required, please consult the factory.

9. Expansion loops in hot water heating circuits as required.

10. A 9-in. x 21/4-in. slot is provided in the inside back panel for coil connection penetration to permit expansion

and contraction of risers. Care must be taken to position the risers so that coil connection is at center of slot.

11. Drawing is pictorial (see unit arrangements for actual supply and return air orientation).

12. All dimensions are in inches.

**Factory-Installed.

††Field-Installed.

ITEM DESCRIPTION QTY

1 Electrical Knockouts

2

2

Gypsum Board,

5

/8-in. Type “X” 1

3 3-in. Expanded Section 3/5

4 Strip Heater**(Optional) 2

5 Limit Switch**†† (Optional) 2

6

1

/2-in. Isolation Ball Valves** 4/8

7

Thermafiber Insulation 2

8 Flexible Drain Tube/P-Trap 2

9 Coil

1

/2-in. OD Copper Tube

2

10 Filter, Throwaway, 1-in.** 2

11 Return Air Opening 2

12 Air Vent, Manual 2

13 Knockout (For Optional Remote Mounting) 2

14 Molex Connector for Field Installed Stat 2

15 Control Box 2

16 Riser, Drain (Copper) 1

17 Riser, Supply and Return (Copper) 2/4

18 Drain Pan 2

19 Return Air Blockoff Panel (Optional)

1

20 Blower 2

21 Motor, 3-Speed, PSC, with Quick Connect 2