Page 1

42GW

U

A

Q

L

R

I

T

E

Y

T

S

I

G

E

R

S

'

D

Y

O

A

S

S

U

R

A

N

C

E

L

L

•

I

S

1

O

0

9

0

INST ALLATION MANU AL

Page 2

42 GW

“Hydronic Global Cassette” Fan Coil Units

Contents

Page

Dimensions and weights........................................................................ 2

Technical data........................................................................................ 3

General information............................................................................... 4

Avoid...................................................................................................... 5

Installation ............................................................................................. 6/8

Water connections................................................................................. 8

Motorized valve and control................................................................... 9/11

Electrical connections............................................................................ 11/12

Wiring diagram....................................................................................... 13

Fresh air renewal and conditioned air supply to adjacent room ............ 14/15

Maintenance .......................................................................................... 16

Models

C = 2-pipe

D = 4-pipe

42GWC004

42GWC008

42GWC010

42GWC012

42GWC016

42GWC020

42GWD004

42GWD010

42GWD020

Models

C = 2-pipe

D = 4-pipe

42GWC004H

42GWC008H

42GWC010H

42GWC012H

42GWC016H

42GWC020H

42GWD004H

42GWD010H

42GWD020H

Models

with

electric heater

42GWE004

42GWE008

42GWE010

42GWE012

42GWE016

42GWE020

42GWE004H

42GWE008H

42GWE010H

42GWE012H

42GWE016H

42GWE020H

42GWH004

42GWH008

Power supply

230V ~ 50Hz

ENGLISH

GB - 1

Page 3

42 GW

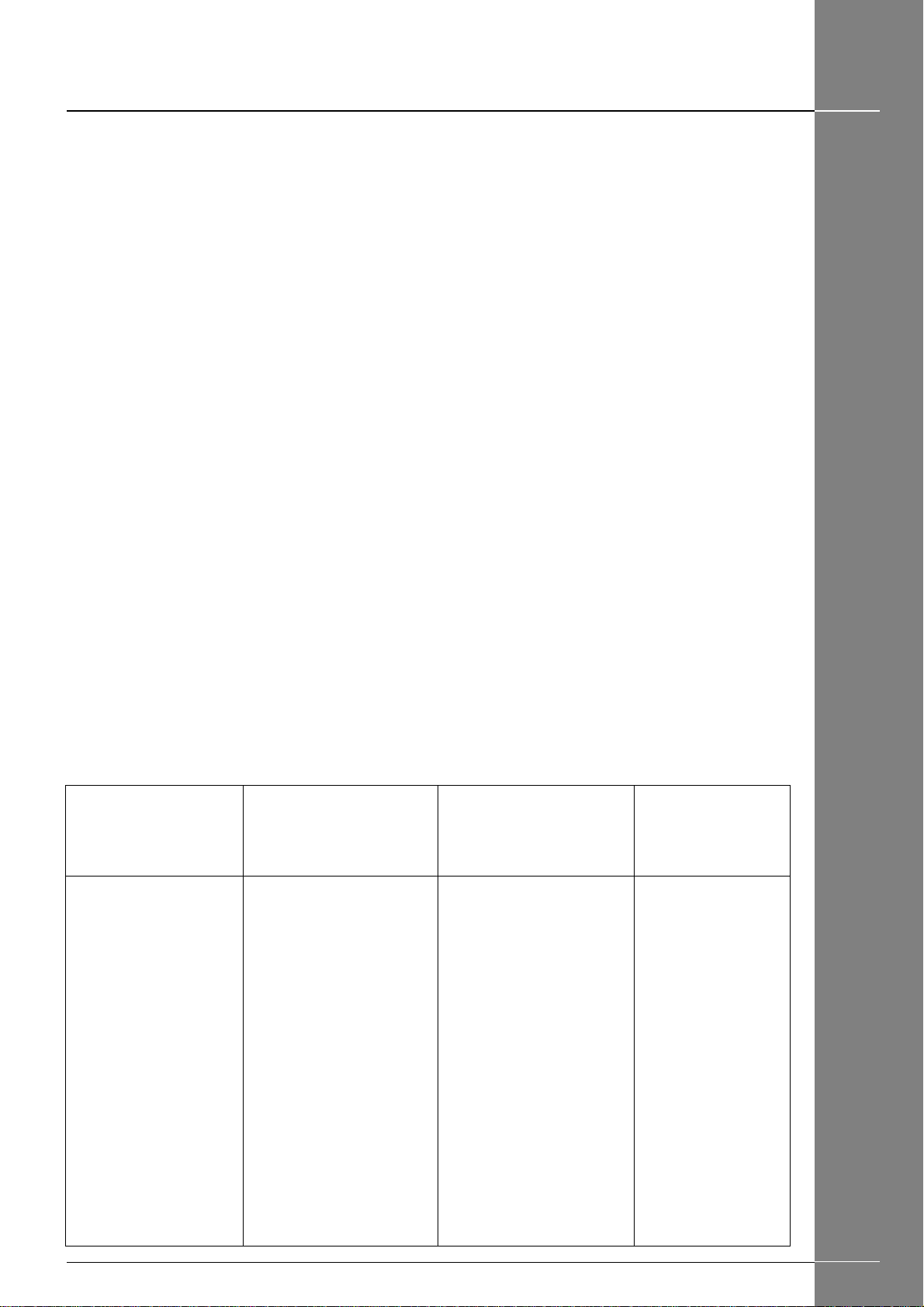

Dimensions and weights

225

298

280

42GW

004 - 008 - 010

575

Ø 150

440

Ø 25

120

515

158

Ø 70

575

720

550

100

52

50

90

110

160

155

298

237

150

Ø 100

42GW

012 - 016 - 020

ø150

825

62

825

120

0

25

Ø

595

125

70

88

112

160

960

813

42GW 004 008 010 012 016 020

Unit 17.5 19 19 36 38 38

Frame/Grille assembly 333555

GB - 2

kg

Page 4

42 GW

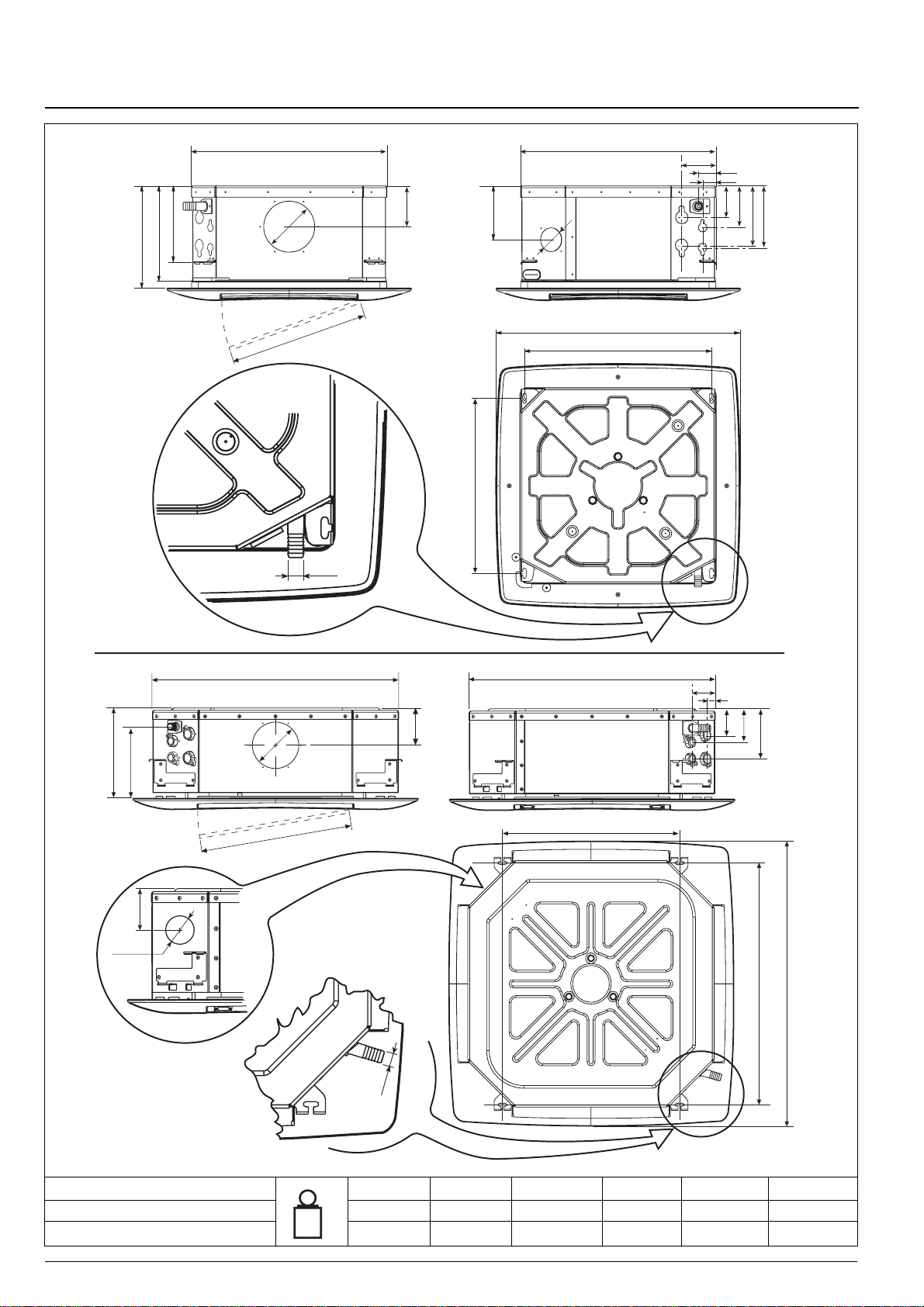

T echnical data

Table I: Nominal data

POWER INPUT

Models Cooling Heating

WA WA

42GWC004 42GWC004H 66 0.28 56 0.24

42GWC008 42GWC008H 78 0.34 68 0.29

42GWC010 42GWC010H 100 0.43 90 0.39

42GWC012 42GWC012H 97 0.42 87 0.38

42GWC016 42GWC016H 135 0.58 125 0.54

42GWC020 42GWC020H 197 0.85 187 0.81

42GWD004 42GWD004H 66 0.28 56 0.24

42GWD010 42GWD010H 100 0.43 90 0.39

42GWD020 42GWD020H 197 0.85 187 0.81

Note: 230V ~ 50Hz.

T able II: W ire section of connecting cable mm

Models L/R N/C

from 004 to 020 1.0 1.0

• The power cable to the electrical heaters must be type H07 RN-F.

• The unit power cable must be type H07 RN-F.

2

Models Cooling Heating

42GWE004 70 0.30 1560 6.8

42GWH004 70 0.30 560 2.4

42GWE008 65 0.28 2555 11.1

42GWH008 65 0.28 555 2.4

42GWE010 94 0.40 2584 11.2

42GWE012 123 0.53 3113 13.5

42GWE016 141 0.61 3131 13.6

42GWE020 233 1.00 3223 14.0

42GWE004H 70 0.30 1560 6.8

42GWE008H 65 0.28 2555 11.1

42GWE010H 94 0.40 2584 11.2

42GWE012H 123 0.53 3113 13.5

42GWE016H 141 0.61 3131 13.6

42GWE020H 233 1.00 3223 14.0

Table III: Technical data of electric heaters (if installed)

Mod. 004 H004 008 H008 010 012 016 020

Electric heater capacity kW 1.5 0.5 1.5+1.0

Supply voltage (ph) V

Max. power input A 6.50 2.1 10.8 2.1 10.8 7.5 7.5 7.5

Safety thermostat

Power supply cables mm23 x 1.5 3 x 1.5 3 x 2.5 3 x 2.5 3 x 2.5 5 x 1.5 5 x 1.5 5 x 1.5

Recommended fuse (Type gL) A 8 8 12 12 12 10 10 10

(*) In areas with a 2 kW limit for single-phase electric heaters it is possible to divide the power supply on two phases and

neutral of a three phase supply with neutral.

Use cable type HO7 RN-F - 4 x 1.5 mm

230 (1 ph) 230 (1 ph)

N° 1 Thermostat with automatic reset ST1 60°C

N° 1 Thermostat with manual reset(electric) ST2 100°C

2

- 400V 2N~

230 (*)

0.25+0.25

230 (1 ph)

1.5+1.0 2x1 + 2x0.5

230 (*) 400 400 400

POWER INPUT

WA WA

ENGLISH

IMPORTANT:

The electric heater must

always be factory

(mod. 42GWE/H...).

The use of other eletric

heaters is absolutely

prohibited.

Failure to follow this

safety requirement

causes unit damage and

voids the warranty.

installed

Table IV:

Material supplied

Description Q.ty Use

Installation instructions 1 Unit installation

Fresh air intake baffle 1 Air renewal

T able V : Operating limits

Water circuit Water- side maximum pressure Minimum entering water temperature: + 4°C

1400 kPa (142 m w.c.) Maximum entering water temperature: + 80°C

Room air Minimum temperature: 5°C (1)

Maximum temperature 32°C

Power supply

Notes: (1) If the room temperature can go down to 0°C, it is advisable to empty the water circuit to avoid damage caused by ice (see paragraph

on water connections).

Nominal single phase voltage 230V ~ 50Hz 60Hz Special Export Market

Operating voltage limits min. 198V – max. 264V min. 187V – max. 253V

Nominal three phase voltage 400V 3N~ 50Hz

Operating voltage limits min. 342V – max. 462V

Table VI: Accessories

Description Size / Code

004-008-010 012-016-020

2-pipe valve 42GW9003 42GW9007

4-pipe valve 42GW9004 42GW9008

Primary air 42GW9005 42GW9006

Air disch. closing

Active carbon filter 40GK-900---002-40 40GK-900---012-40

Electrostatic filter 40GK-900---001-40 40GK-900---011-40

Drain pan 42GW9009 42GW9010

Not to be used on units equipped with electric heater (mod.42GWE)

*

40GK-900---003-40 40GK-900---013-40

*

Description Size / Code

004-008-010-012-016-020

Water discharge pump 40GKX9001

Control 42GW9014

Control 42GW9015

Control 42GW9016

Control 42GW9017

Control CRC 33DFS-RM

Auxiliary board 42GW9013

GB - 3

Page 5

42 GW

General Information

Unit installation

Read this instruction manual thoroughly before starting

installation.

• This unit complies with the low-voltage (EEC/73/23) and

electromagnetic compatibility (EEC/ 89/336) directives.

• The installation should be carried out by a qualified installer.

• Follow all current national safety code requirements.

In particular ensure that a properly sized and connected ground

wire is in place.

• Check that the voltage and frequency of the mains power supply

are as required for the unit to be installed; the available power

source must be adeguate to operate all other appliances

connected to the same line.

Also ensure that national safety code requirements have been

followed for the main supply circuit.

• Where necessary, use field-supplied 25 mm I.D. PVC pipe of

appropriate length and with the correct thermal insulation for the

condensate drain extension.

• After installation thoroughly test system operation and explain all

system functions to the owner.

• Use this unit only for factory approved applications: the unit

cannot be used in laundry or steam pressing premises.

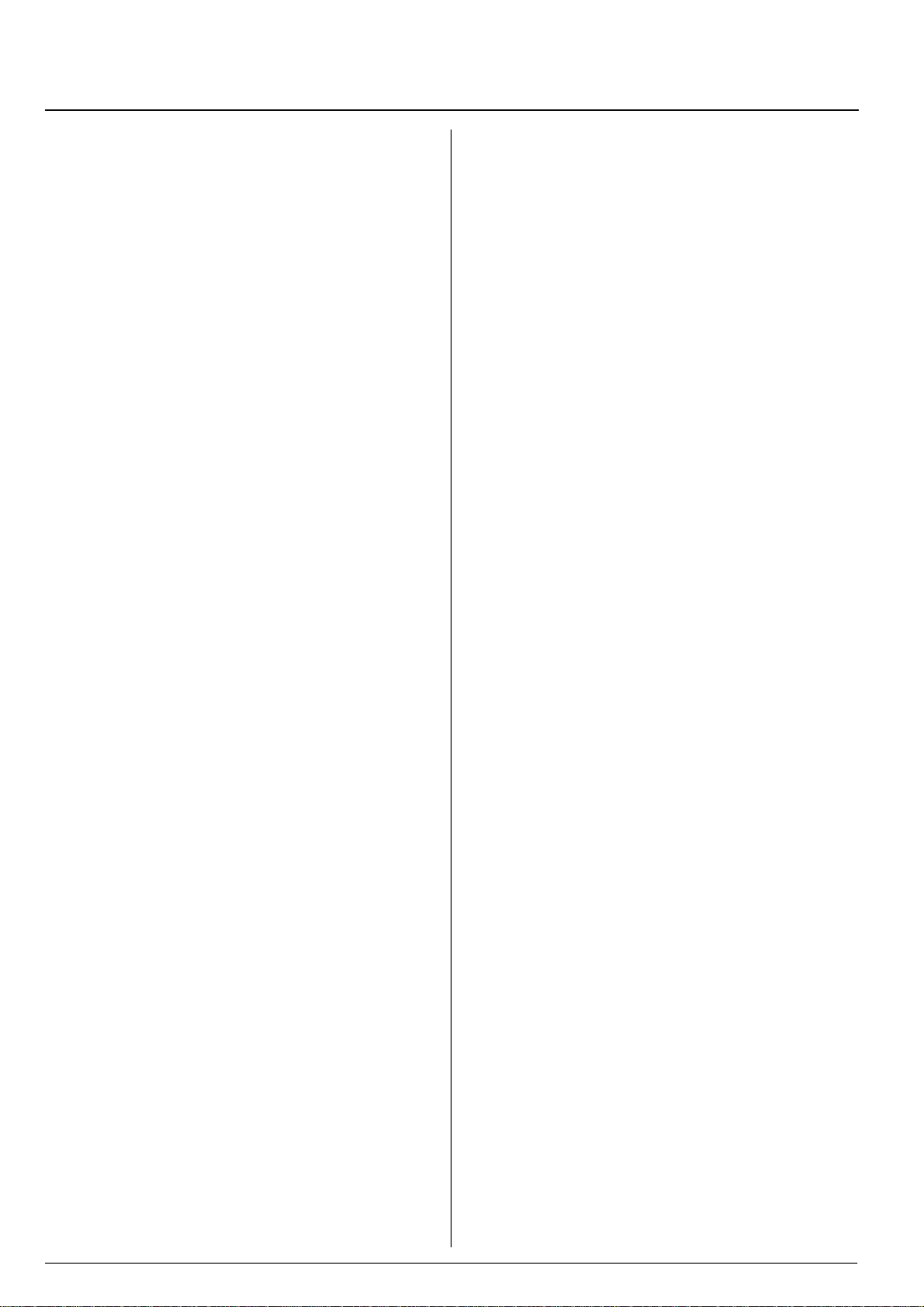

Choosing the installation site

Positions to avoid:

• Exposure to direct sunlight.

• Areas close to heat sources.

• On damp walls or in positions that may be exposed to water

hazard.

• Where curtains or furniture may obstruct free air circulation.

Recommendations:

• Choose an area free from obstructions which may cause uneven

air distribution and/or return.

• Consider using an area where installation is easy.

• Choose a position that allows for the clearances required.

• Look for a position in the room which ensures the best possible air

distribution.

• Install unit in a position where condensate can easily be piped to an

appropriate drain.

WARNING:

Disconnect the mains power supply switch before servicing

the system or handling any internal parts of the unit.

• The manufacturer declines any liability for damage resulting

from modifications or errors in the electrical or water

connections.

Failure to observe the installation instructions, or use of the

unit under conditions other than those indicated in Table

"Operating limits" of the unit installation manual, will

immediately invalidate the unit warranty.

• Failure to observe electric safety codes may cause a fire hazard in

the event of short circuits.

• Inspect equipment for damage during transport. In case of

damage file an immediate claim with the shipping company.

Do not install or use damaged units.

• In case of malfunction turn the unit off, disconnect the mains

power supply and contact a qualified service engineer.

• Maintenance must only be carried out by qualified personnel.

• All of the manufacturing and packaging materials used for

this appliance are biodegradable and recyclable.

• Dispose of the packaging material in accordance with local

requiremements.

GB - 4

Page 6

42 GW

Avoid...

MAX 3 m

... any obstruction of the unit air intake or supply grilles.

ENGLISH

MAX 3 m

... exposure to direct sunshine, when the unit is operating in the

cooling mode; always use shutters or shades.

... positions too close to heating sources which may damage the unit.

... exposure to oil vapours.

... installation in areas with high frequency waves. ... only partial insulation of the piping.

MAX. 200 mm

... connecting condensate piping to sewage system drain without

appropriate trap. Trap height must be calculated according to the

unit discharge head in order to allow sufficient and continuous

water evacuation.

Non-level installation which will cause condensate dripping.

... ascending sections of condensate drain piping.

These may only be used near the unit with a maximum height

difference of 200 mm from the top of the unit.

... horizontal sections or curves of condensate drain piping with less

than 2% slope.

... flattening or kinking the refrigerant pipes or condensate pipes.

...slack on electrical connections.

GB - 5

Page 7

42 GW

Installation

Max. 2 louvres closed

Heating: louvre position for

correct air flow.

Cooling: louvre position for

correct air flow.

• Install the unit as centrally as possible in the room, the air flow

direction can be controlled by manually regulating the louvres

position, according to the operating mode (cooling or heating): this

will ensure optimum distribution of the air in the room.

• During cooling mode operation the best position for the deflecting

louvres is one which allows air diffusion close to the ceiling

(Coanda effect). In heating mode, the louvres should be

positioned so that the air is directed towards the floor, in order to

prevent layers of hot air forming in the upper part of the room.

• In order to allow easy and rapid installation and maintenance,

make sure that in the selected position it is possible to remove

the ceiling panels or, if the ceiling is constructed of masonry,

that access to the unit is guaranteed.

ATTENTION:

Only restrict the air outlets as indicated in the drawing.

Prior to installation

Warning: To close one or two air outlets use the special kit

If plaster board ceiling panels are installed the maximum

dimensions of the unit housing must not exceed 660 x 660 mm

(mod. 004 - 008 - 010) and 900 x 900 mm (mod. 012 - 016 - 020).

In rooms with high humidity, brackets should be insulated by self

adhesive insulation supplied.

Installation

Mark the position of the hangers, connection lines and condensate

drain pipe, power supply cables and remote control cable (see

dimensions); the cardboard template (supplied with the kit) may

be of assistance for this operation. Depending on the type of

ceiling the hangers can be fixed as shown in the drawing.

It is advisable to place the unit as close as possible to the installation site

before removing it from the packaging. The grille panel and the control

are separately packed for maximum protection.

IMPORTANT:

Do not lift the unit by the condensate drain discharge pipe;

hold it by its four corners only.

Unit installation will be facilitated using a stacker.

GB - 6

Nut

Wooden frame

Threaded hangers

Washers

Nut

Washer

Threaded hangers

Washer

Nut

Nut

Once the threaded hangers have been positioned, do not tighten

the nuts, and insert the washers as shown in the drawing.

Page 8

42 GW

Installation

Threaded hangers

"T" bar

First position the connection lines , as described in the chapter

"Water connections".

Remove the "T" bar in order to facilitate installation operations.

(to be removed)

ENGLISH

Condensate drain pipe

2%

50

Suspension brackets

Carefully lift the unit (without the frame) using the four

suspension brackets (or the four corners), inserting it into the

false ceiling.

If the "T" bar cannot be removed the unit may need to be tilted

(this operation may only be carried out with false ceilings with a

minimum height of 300 mm).

mm

• To ensure correct condensate water flow, the drain pipe should

have a gradient of 2% without obstructions. Furthermore an

odour trap of at least 50 mm depth should be made to prevent

unpleasant odours from reaching the room.

False ceiling

Spirit level

Align and level the unit by adjusting the nuts and locknuts on

the threaded hangers, maintaining a distance of 25 -30 mm

between the sheet metal body and the underside of the false

ceiling.

Reposition the "T" bar and align the unit in relation to the bar by

tightening the nuts and locknuts.

After connection of the condensate drain line and the refrigerant

lines, carry out a final check to make sure that the unit is level.

• Condensate may be discharged at a maximum height of 200 mm

above the unit, as long as the ascending tube is vertical and

aligned with the drainage flange.

• If it is necessary to discharge the condensate from a level

above 200 mm, install an auxiliary water discharge pump and

float valve.

A float valve is recommended to stop the flow switch if there is

a fault at the auxiliary pump.

• The condensate pipe must be insulated with a condensationproof material such as polyurethane, propylene or neoprene of

5 to 10 mm thickness.

• If more than one unit is installed in the room, the drain system can

be made as shown in the drawing.

GB - 7

Page 9

42 GW

Installation

Frame pre-hooking support

Safety belt

Frame fixing screw

Installation of grille/frame assembly

Carefully unpack the assembly and check for damage sustained in

transit. Attach the assembly to the unit by using the two hooks.

Use the screws supplied to fix the frame in position.

A. Gasket "A"

B. Gasket "B"

A B

Air discharge

Ensure that the frame is not distorted by excessive tightening,

that it is aligned with the false ceiling and above all that there is

a seal between the air inlet and outlet.

In the drawing gasket "A" prevents return air from mixing with

the supply air and gasket "B" prevents the supply air from

leaking into the ceiling void.

On completion, the gap between the unit frame and the false

ceiling must not be more than 5 mm.

W ater connections

Water connections are fixed to the unit body to avoid damage

when pipes are connected; it is advisable to tighten the

connection with a spanner.

The upper coil connection is supplied with an air purge valve,

the lower connection with a water purge valve, suitable for a

10 mm wrench or screw-driver.

(The coil is only partially drainable; it it is advisable to

blow air into the coil for complete drainage).

Models Connections

004 3/4"

008 3/4"

010 3/4"

004

010

dimension (Ø)

*

*

1/2"

1/2"

Models Connections

012 1"

016 1"

020 1"

020

Hot water circuits, four-pipe version

*

dimension (Ø)

*

3/4"

It is necessary, when the installation is made, to insulate the

valve and the connection pipes with anti-condensate material

of polyethylene type or expanded neoprene.

Checking

Before unit operation pour a quantity of water into the external

auxiliary drain pan. Verify that the water flows into the internal

condensate drain pan and that the pump regularly drains the

liquid.

Otherwise check the pipe slope and look for possible

obstructions. Water connections are fixed to the unit body to

avoid damage when pipes are connected; it is advisable to

tighten the connection with a spanner.

Water inlet

Water outlet

Air purge valve

Water purge valve

GB - 8

Page 10

42 GW

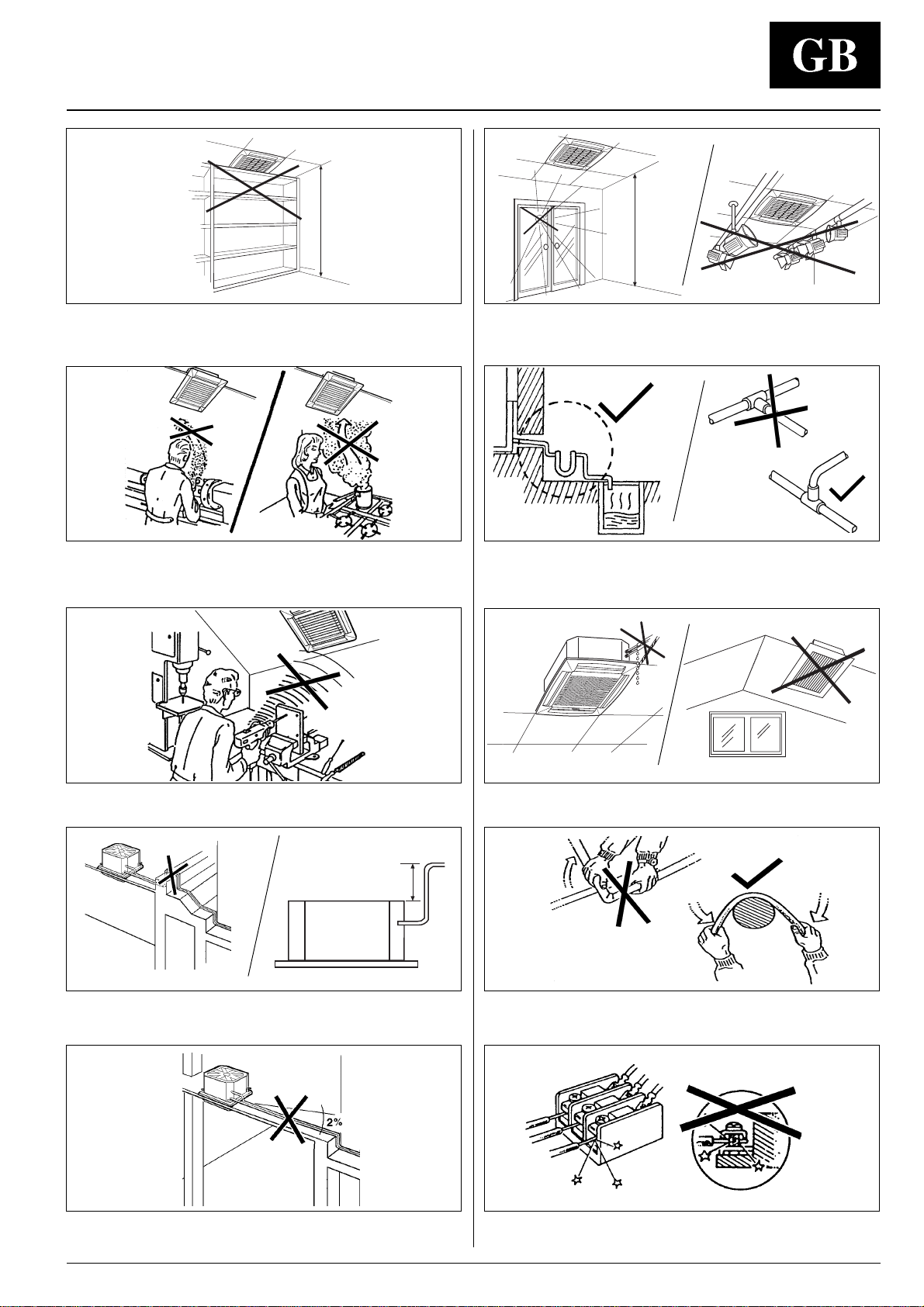

Motorized valve and control

• The unit control circuit only allows opening of the motorized

valve when the fan motor is working.

(See wiring diagrams)

• When the thermostat asks for cooling, terminal 1 of TB3 (cold

water) is supplied with 230V.

When it asks for heating, terminal 2 of TB3 (hot water or

electric heater) is supplied with 230V.

• The control circuit ensures that the condensate discharge

pump works continuously while the thermostat, asking for

cooling, keeps the cold water regulating valve open.

WARNING :

The valve is not only necessary to control the room

temperature, but also to stop the cold water flow to the coil

in case of an abnormal condensing water level rise in the

drain pan.

• If there is an abnormal condensing water rise in the drain pan

(for example: possible defective drain, pump malfunction, fan

motor not working) causing the opening of the float switch

contact (FS), the control circuit either operates the c

ondensate drain pump, or at the same time closes the

regulating valve, stopping the cold water flow towards the

coil and avoiding further condensation.

Control

The water flow has to be controlled:

• by installing the motorized thermo-electric valves supplied

as accessory

or

• by installing motorized field supplied valves.

Motorized thermo-electric valve assembly and components

A B

C

F

G

E

Water inlet Water outlet

004 012 004 020

Mod. 42GW 008 016 010

010 020

2-pipe 4-pipe

Ref. Description q.ty q.ty q.ty q.ty

A Adaptor 3/4 " gas with O-ring 2

Adaptor 1" gas with O-ring + 2+

Adaptor 3/4" gas with O-ring +

B Self tapping screw 3 3 3 3

C Clip 3 3 3 3

D Valve 1" gas pre-assembled 1

Valve 1" gas pre-assembled + 1+

Valve 3/4" gas pre-assembled 1

D1 Valve 3/4" gas pre-assembled 1

Valve 3/4" gas pre-assembled 1+

Valve 1/2" gas pre-assembled 1

E Auxiliary drain pan 1 1 1 1

F Insulating material 1 1 1 1

G Cable holder 1 1 1 1

D

D1

2

ENGLISH

Instructions for mounting of motorized

thermo-electric valve assembly

(see "Components" table)

• The thermo-electric valve must be mounted on the unit after

the unit installation.

For this operation follow figures, depending on model.

• Insert the clips supplied in the unit side slots.

Assembly

For models 42GWD (4-pipe), the valve assembly for the

cold water coil must be installed first.

•Gently grease the O-rings before fitting them into their

seats.

Sizes 004 - 008 - 010

Sizes 012 - 016 - 020

• Connect the valve assemble to the coil and fix it by a 30Nm

torque.

• Insulate the valve assembly.

• For 4-pipe hot water coil, repeat all the operations with gas

adaptors, as per the table.

• Pass cables through the cable holder G and fix them to the

case using the already pre-assembled screws.

• Mount the drain pan below the valve assembly, inserting the

discharge pipe into the special hole; align and fix it to the 3

clips previously assembled using the three screws supplied.

• Insulate the 3 screws and the drain pan lower part using the

insulating material F.

• To connect the steel pipes to the system, ensure they are

aligned and supported to avoid excess strain on the unit. If

the system is filled with water, check all fitting seals.

NOTE:

The seal efficiency of the valve assembly is factory tested.

Any system losses are therefore due to an incorrect

installation.

Electric connections

• To connect valves to the electric panel pass cables through

the electric panel grommet and connect them to the terminal

board TB3 as per the wiring diagrams.

Ring nut

O-ring

Coil coupling

See diagram supplied with

the kit..

Adaptor

O-ring

Coil coupling

Fit the reducers and O-rings

towards the coil connection.

GB - 9

Page 11

42 GW

Motorized valve and control

Automatic operation position

Thermo-electric valve

head

Valve body

004 - 008 - 010

012 - 016 - 020

Operation of the thermo-electric valve

• This 3-way valve is an ON-OFF type with a very slow stroke.

It is not a modulating valve so it has no PTC.

This valve is driven, as a sensible element, by the ambient

thermostat of the “cassette” unit.

• The thermo-electric valve is normally closed towards the coil

and open towards the bypass.

When the room temperature does not satisfy the thermostat,

an electric heater activates the heating of a thermostatic

element which causes the down-stroke of the piston; the

valve opens after about 3 minutes about to allow water to

circulate in the coil.

• If the room temperature satisfies the thermostat or if the

electric power has been switched off, the valve is closed after

about 3 minutes towards the coil and is opened towards the

bypass.

• If an emergency occurs, the valve may be manually opened,

removing the electric head, unscrewing the ring nut.

ON-OFF valves (230V)

• In this case the cold water valve must be controlled by the ONOFF signal from terminal 1 of TB3 and the hot water valve from

terminal 2 of TB3.

ON-OFF valves with other voltages than 230V

• If a room control listed in the accessories table is used, follow

the instructions in the previous paragraph and install two

230V relay at TB3 terminals 1, 2, 4 and 5 which will control

the valve opening.

230V valve connection or

230V valve relay connection

C

H

H Heating valve or heating valve relay

C Cooling valve or cooling valve relay

• If a low voltage control is used or if the control is not listed in

the accessories table, the connections must be made on the

unit terminal board.

When the emergency ends, remember to reset the valve to

automatic operation, repositioning the electric head;

failure to do this can result in condensate formation due

the water pipes, even if the unit is switched off.

Instructions for field supplied valves

Water connection

• Install valves following manufacturer's instructions; refer to the

relevant figures for connection to the unit.

• Carefully insulate pipes, valve assemblies and coil connections

(cold water side) to avoid condensation forming on the pipes

and dripping on the false ceiling.

Electrical wiring

• Connect the room control following instructions for the control

used.

WARNING:

Pass cables through the control panel cable-conduit.

• Connect valves as per the following instructions, using the

wiring diagram in this chapter.

• Valves, closing the unit water inlet when there is no

power supply, must be used.

Control connection

Fan speed

H = high speed

M = medium speed

L = low speed

Heat

Cool

GB - 10

Page 12

42 GW

Motorized valve and control

• If these connections are not made as described the drain

pan condensate may overflow.

• Valves should only open when the fan motor is working, i.e.

when one of TB1 terminals 1 or 2 or 3 is supplied from TB1

terminal 4.

• The optional electric heater (mod. 42GWE) which can only be

factory installed, must only be energized when the fan is

working.

• The optional electric heater which must be factory installed on

model 42GWE, works only if TB1 terminals 5-6 are supplied

from TB1 terminal 4.

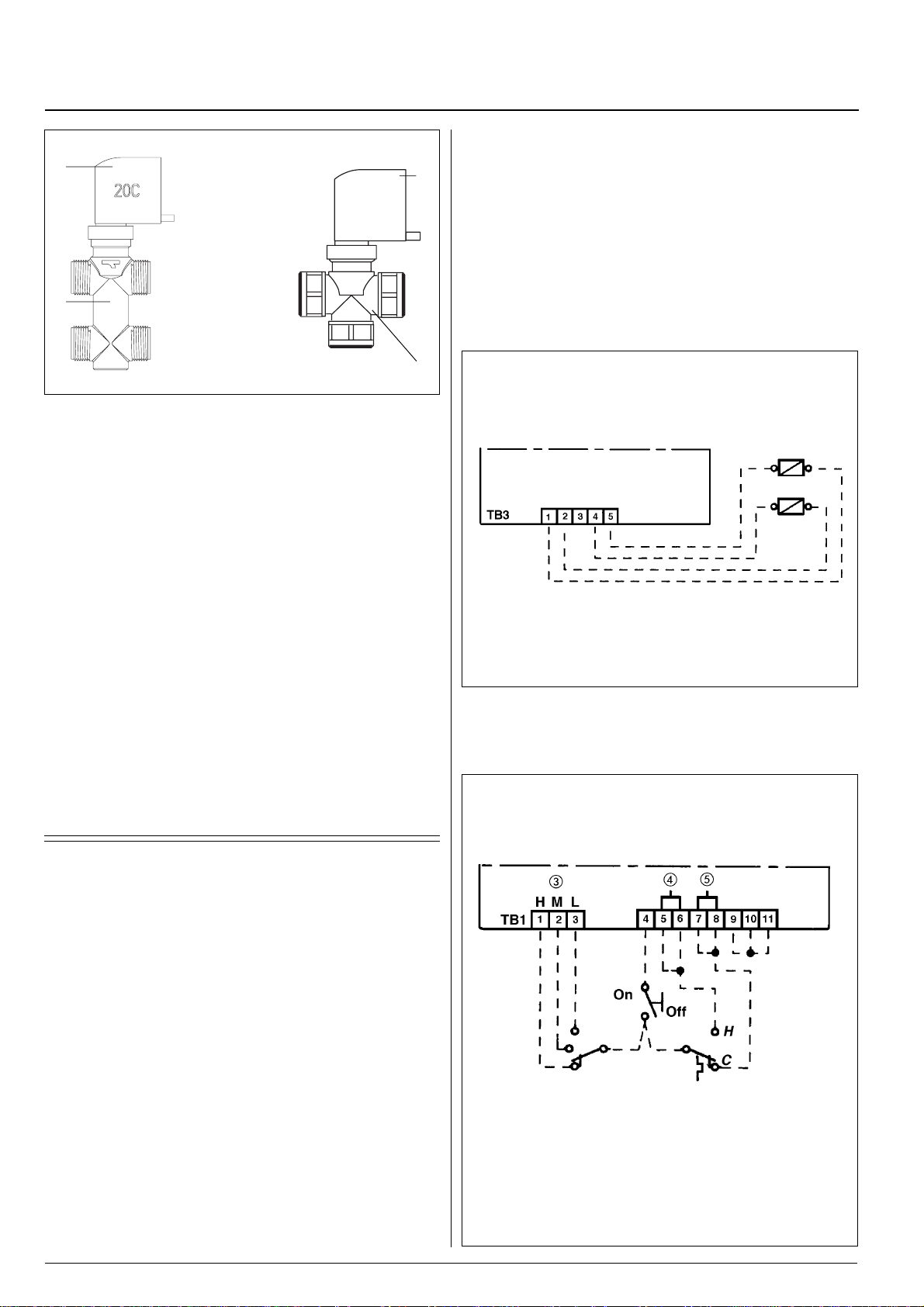

Electrical connections

We recommend to remove the main board from the electric

panelboard for better access to electric connections.

ST ANDARD version unit - Control panel

ENGLISH

• The water discharge pump should work every time the

cold water valve is opened, supplying TB1 terminal 7 and

8 from TB1 terminal 4.

• When the system is filled with water, verify all couplings

for tightness.

• The manufacturer does not accept responsibility for the

tightness of the field - installed valve assembly and this

is not tested in the factory. He declines any responsibility

for non functioning of these assemblies and for damage

due to dripping.

CV

C

CV

CP

CG

A

B

mod. 004 - 008 - 010

A

B

C

CG CP

mod. 012 - 016 - 020

Capacitor

Ground connection screw

Board

Relay board E-HTR (only on

models with electric heater)

Holes for panel fixing screws

Auxiliary board (accessory)

CV

Fan connector

Float connector

CG

CP

Pump connector

A. Electric heater supply connection

B. Unit power supply connection

C. Polarised connector

GB - 11

Page 13

42 GW

Electrical connections

The control panel can be reached by opening the grille and

removing the metal covers using the 3 or 4 screws.

IMPORTANT for units with electric heaters;

The unit is equipped with two thermostats: one with automatic

reset and one with manual (electric) reset that can be

reactivated by switching the power supply off and then on.

IMPORTANT:

• Make ground connection prior to any other electrical

connections.

• If the unit is fitted with an electric heater, this must have a

separate power supply.

Ensure that the mains supply connection is made through a

switch that disconnects all poles, with a contact gap of at least 3

mm.

• Fix the power cable of the electric resistance heaters under the

single cable clamp. Make certain that the YELLOW/GREEN

cable is stripped back further than the others.

Connect the power cables to terminal box connectors in

accordance with the wiring diagram and tighten firmly.

Wiring diagram legend

Factory wiring

Field wiring

Connector

Terminal on terminals

Normally closed contact

Normally open contact

Capacitor

FC Fan capacitor

FS Safety switch float

IFM Fan motor indoor unit

PR Drain pump relay

PS Drain pump

C1-3 Connectors

HR Heating relay

CR Cooling relay

CEV Electric valve (cooling)

HEV Electric valve (heating)

PCB Relay board

HTR Electric heater

ST Safety thermostat

T Timer

TB Terminal board

Low speed

Medium speed

High speed

Power supply line

Heating selection

Common thermostat (heating)

Cooling selection

Common thermostat (cooling)

Neutral fan

Neutral in

Neutral out

Neutral

Heating out

Cooling out

Cables colour

A Brown

B Blue

C Black

G Grey

R Red

W White

Y-G Yellow/Green

Connections

L Line phase

N Neutral

Warning:

Any warranty is declined in case of

field changes of factory wiring and

settings

Note

The connection sequence does not

represent the physical lay-out.

GB - 12

Page 14

42 GW

Wiring diagram, standard version unit

810

HR

B

C

G

TB3

TB3

TB3

햸

햹

햺

햻

햽

11

F1

TB2

L

N

TB3

5

4

3

2

1

T

PCB

W

Y-G

Y-G

2

1

543

6

65

4321

B

C

W

C3_F

C3_M

G

IFM

COOLING ONLY

-1-

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

CEV

-2-

CEV

-3-

HEV

(2 PIPE SYSTEM)

COOLING+HEATING

(2 PIPE SYSTEM)

COOLING+HEATING

(4 PIPE SYSTEM)

CEV

햷

햶

햵

햴

햳

햲

1

23

TB1

CR

PR

CN1

12

3

4

67

5

R

R

C2_F

C2_M

21

21

R

R

2

C1_F

C1_M

Y-G

1

1

FS

1

Valves connection:

select the diagram according to the

system type

PS

45 9

67

10

9

8

C

C

32

3

2

C

C

230V ~ 50Hz

햾

햿

헀

GND

Y-G

A

R

2

FC

1

Electric heater

supply

04–E / 04–H

230V ~ 50Hz

NL

230V ~ 50Hz

NL

230V

TAKEN FROM

400V 3N~ 50Hz

NRS T

400V 3N~ 50Hz

NRS T

230V 3N~ 60Hz

NRS T

25

PCB “TB3”

25

PCB “TB3”

25

PCB “TB3”

25

PCB “TB3”

25

PCB “TB3”

N

L3 L2 L1C HR N GND

E-HTR

08/10–E / 08-H

N

L3 L2 L1C HR N GND

E-HTR

08/10–E

N

L3 L2 L1C HR N GND

E-HTR

12/16/20–E

N

L3 L2 L1C HR N GND

E-HTR

12/16/20–E

N

L3 L2 L1C HR N GND

E-HTR

ENGLISH

R

ST1

R

C

ST2 ST1T3T2T1

C

ST2

1-HTR

R

ST1

R

C

ST2 ST1T3T2T1

C

ST2

2-HTR

1-HTR

R

ST1

R

C

ST2 ST1T3T2T1

C

ST2

2-HTR

1-HTR

R

ST1

R

C

ST2 ST1T3T2T1

C

ST2

4-HTR

2-HTR

3-HTR

1-HTR

R

ST1

R

C

ST2 ST1T3T2T1

C

ST2

4-HTR

2-HTR

3-HTR

1-HTR

GB - 13

Page 15

42 GW

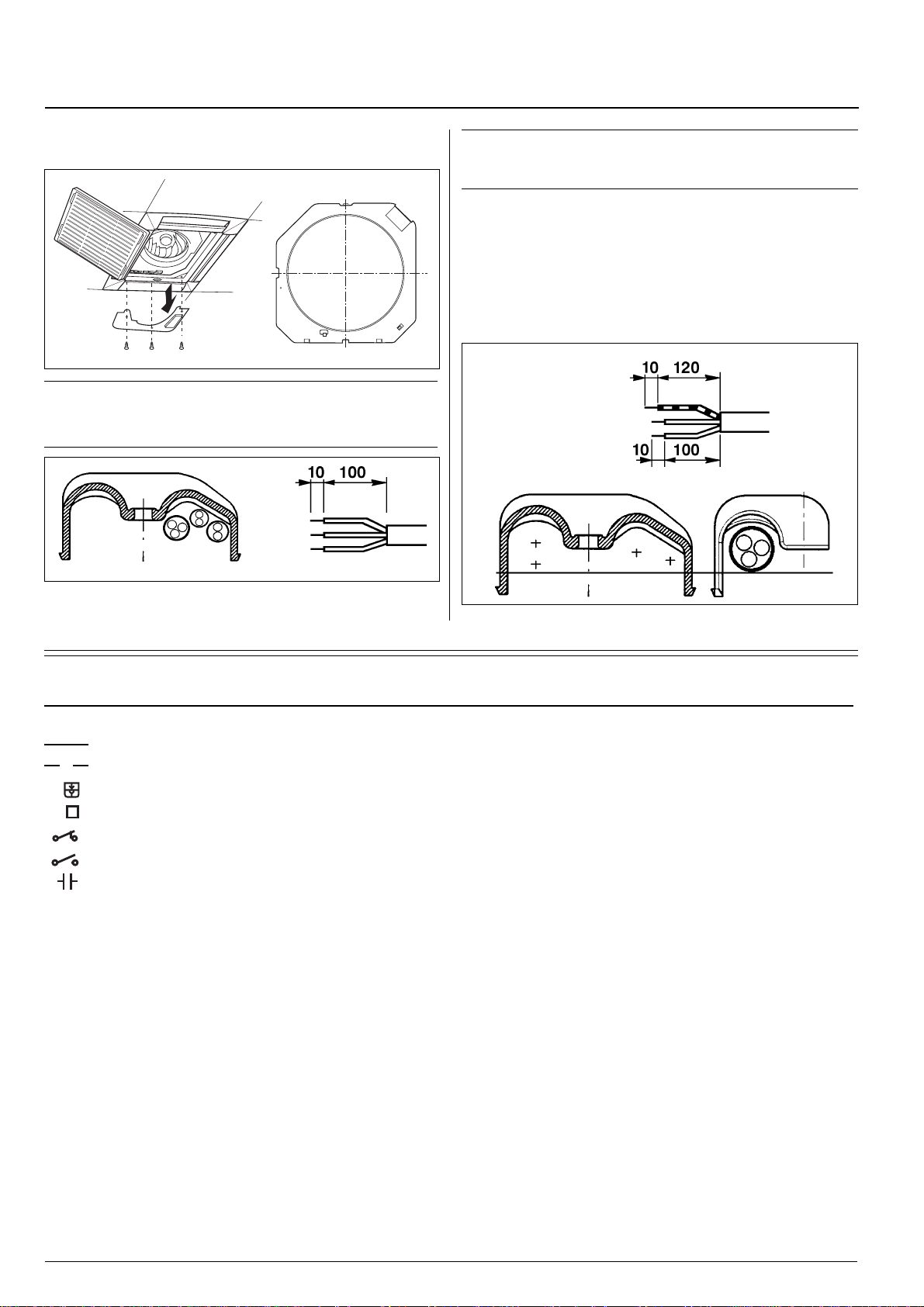

Fresh air renewal and conditioned air supply to an adjacent room

120

10549

C

Air intake grille

Ø A

216

Ø A

B

Duct connection flange

Clip

6 mm neoprene gasket

Model 004-008-010 012-016-020

Ø A mm 150 150

B mm 120 120

Ø C mm 70 100

Insulated flexible duct

Fresh air intake

Conditioned air supply to an

adjacent room

Polystyrene partition

Baffle

Frame

• Side knockouts allow connection of fresh air inlet ducts and ducts

to deliver conditioned air to an adjacent room.

• Remove the external prepunched anti-condensate insulation and

take away the knockout panels using a punch.

Air distribution to adjacent room

With a pencil, trace a line on the polystyrene around the inside

edges of the panel that was previously removed.

Cut away the polystyrene with a knife, taking care not to damage

the heat exchange coil.

Fresh air intake

Remove the polystyrene partition.

Introduce the baffle supplied after the frame has been hooked as

per above figure (ref. ).

Following that tighten the assembly frame/grille using the 4 screws.

Wall

Undercut door

Wall-fitted grille

Door-fitted grille

• Use locally purchased material, suitable for operating

temperatures of 60 °C (continuous).

Conduits can be of flexible polyester (with spiral core) or

corrugated aluminium, externally covered with anti-condensate

material (fibre glass of 12 +/- 25 mm thickness).

• To complete the installation, all non-insulated ducts must be

covered with anti-condensate insulation (ex. expanded neoprene,

6 mm thickness).

If these instructions are not observed, condensate may drip;

the manufacturer will not be held responsible for any damage

caused.

• The two prepunched side knockouts must not be used at the

same time to deliver conditioned air to an adjacent room.

• The return and supply duct lengths can be calculated in

accordance with the "air distribution to an adjacent room" and

"fresh air renewal" diagrams (also taking into account the

pressure drop through air diffusers, grilles and fresh air filters),

as well as the increase in noise caused by these ducts.

GB - 14

Page 16

42 GW

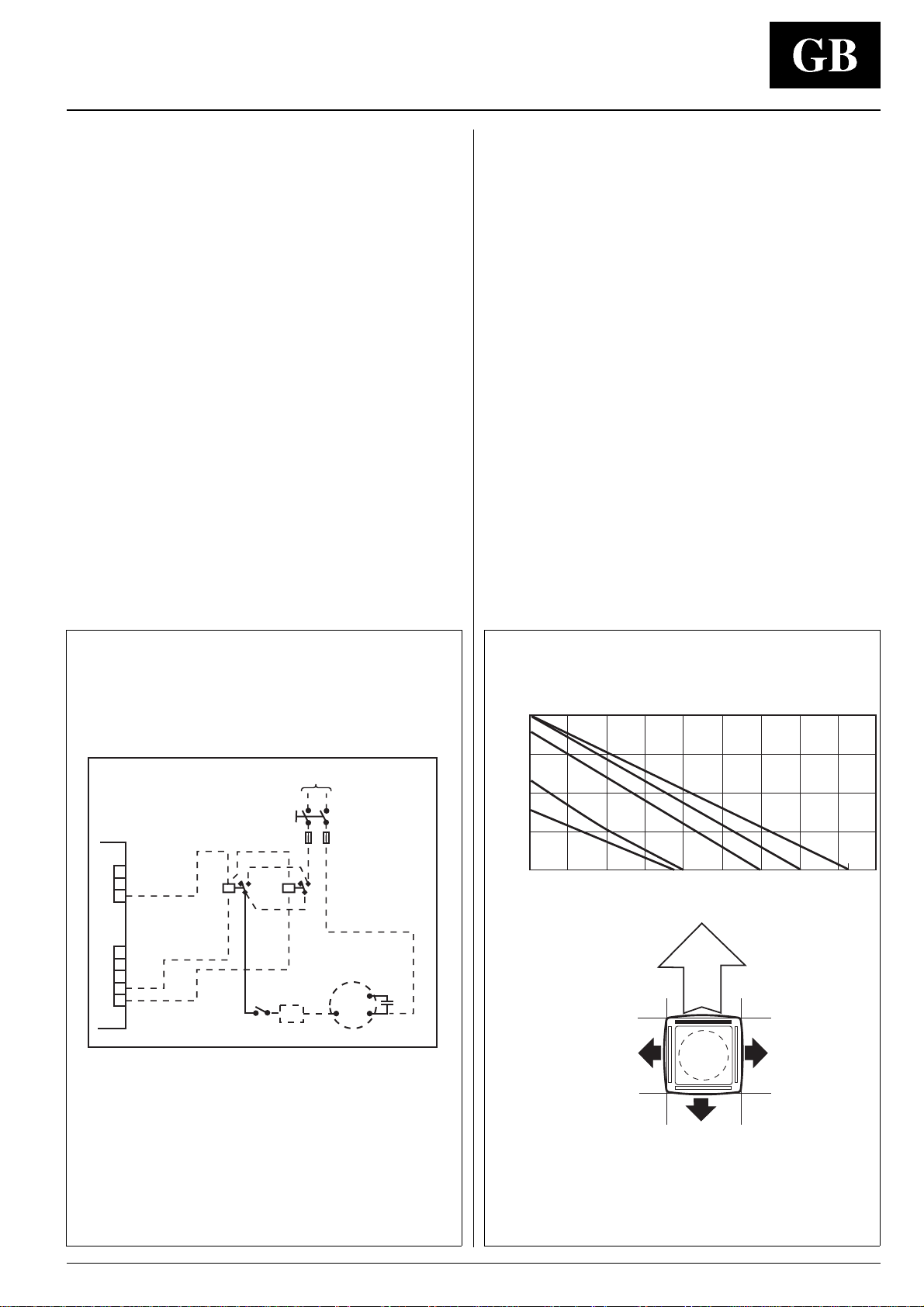

30

20

10

0

0

100

200

300 400

010/012

004

008

410

020

016

40

Fresh air renewal and conditioned air supply to an adjacent room

Fresh air renewal

• The optional supplementary fan for fresh air intake (field

supplied) has to be connected to terminal block as per

diagrams enclosed.

Fan motor operation is parallel to the thermo-electric control

valve, and the motor stops when the valve shuts off.

• For winter operation with fresh air intake, an anti-freeze

thermostat set at 2°C is recommended, with the bulb placed

on the water outlet pipe, before the supplementary fan.

• The fresh air flow must be less than 10% of the total air flow,

to avoid operating problems or eccessive noise.

For higher air flow a "primary air kit" is available which uses

the prepunched hole for air ducting to an adjacent room and a

baffle so that the fresh air is introduced into the room through

Conditioned air supply to an adjacent room

• Air supply to an adjacent room requires that the outlet

corresponding with the duct is closed, using the air

supply outlet obstruction kit supplied.

The kit cannot be used in units equipped with electric

heater (mod. 42GWE).

An air inlet grille must be fitted (if possible near the floor)

between the air conditioned room (where the unit is situated)

and the adjacent room or, alternatively, the door must be

undercut, as shown in the drawing.

• The duct lengths can be calculated in accordance with the “air

distribution to an adjacent room” diagram, also taking into

account the pressure drop through air diffusers and fresh air

filters.

ENGLISH

a diffuser.

• DO NOT use active carbon or electrostatic filter kits for

• Install an air inlet grille with filter inspection port to prevent

ducts towards adjacent rooms.

dust and dirt from entering and fouling the unit heat

exchanger.

Filter installation also makes the installation of a duct closing

damper during shut-down periods unnecessary.

Winter operation diagram with

fresh air intake

230V ~ 60Hz

TB2

L

N

Diagram of conditioned air supply to an

adjacent room: one louvre closed

Available static pressure - Pa

Air flow m3/h

TB3

5

4

3

2

1

Terminal board

Antifreeze thermostat

Speed controller

Fresh air fan motor

Relay 230V

Supply air duct to adjacent room

In case of two louvres closed, the fresh air flow towards the

adjacent room is 50% higher compared with only one louvre

closed (with equal static external pressure)

GB - 15

Page 17

42 GW

Maintenance and owner's guide

Maintenance

Cleaning and maintenance operations must be carried out by

specially trained personnel.

Before performing any service or maintenance operations,

turn OFF the main power switch.

To open the unit grille:

Turn the two screws through 90° (1/4 turn).

Filter cleaning

Clean filters in accordance with the actual operating

conditions and times (approximately every 6 months).

• The acrylic air filter is washable in water.

Electrostatic and active carbon filters (which can be used on

the unit) are not washable but must be replaced.

Additional maintenance

• The electric panel is easily accessible by removing the cover

panel.

The inspection or replacement of internal components such as:

fan motor, coil, condensate discharge pump, float switch, electric

heater (if fitted), involve the removal of the condensate drain pan.

Condensate drain pan removal

• During the removal operation of the condensate drain pan

protect the floor with a plastic sheet under the unit.

• Remove the frame-grille assembly by loosening the screws;

drain the condensate water contained in the drain pan into

a bucket of at least 10 litres capacity, using the special

drain with a rubber plug.

• Remove the electrical panel cover and disconnect the electric

connections, connectors C

ground wire (see drawing in “electrical connections”

section).

V, CG, CP and the yellow-green

Extract the filter.

Acrylic fibre

First vacuum clean the filter, then wash under tap water and

finally dry.

Replace the filter in the correct position.

Prolonged shutdown:

• Remove the four fixing screws on the side of the drain pan and

carefully remove the condensate drain pan.

Guide for the owner

When installation and tests are completed instruct the Owner on the

main operating modes of the air conditioner, such as:

• Turning the unit ON and OFF.

• Changing the operation modes.

• Temperature selection.

Leave the installation manual with the owner for future use during maintenance operations or for any other needs.

• Before starting the air conditioner:

- clean or replace the unit air filters.

- check and clean the drain pan and the condensate discharge of

the unit

- check tightness of electric connections.

GB - 16

Page 18

L010122H22 - 0405

Via R. Sanzio, 9 - 20058 Villasanta (MI) Italy - Tel. 039/3636.1

The manufacturer reserves the right to change any product specifications without notice.

Order No. 14207-74M10, April 2005. Supersedes Order No. 14207-74M10, December 2004. Printed in Italy

Loading...

Loading...