Page 1

38QP024/40RR024

Heat Pump System

HEATING & COOLING

Installation, Start-Up and Service Instructions

Piping Package No. 40RR900271

50/60 Hz

NOTE: Read and become familiar with these instructions

before beginning installation.

SAFETY CONSIDERATIONS

Installing and servicing air-conditioning equipment can

be hazardous due to system pressures and electrical com

ponents. Only trained and qualified service personnel should

install or service air-conditioning equipment. When work

ing on air-conditioning equipment, observe the precautions

provided in literature, and on tags and labels attached to the

unit.

A WARNING

Electrical shock can cause personal injury or death.

Before beginning any modification or installation of this

package, be sure the main electrical disconnect is in

the off position. Ensure power is disconnected to the

fan coil unit. On some systems both the fan coil and

the outdoor unit may be on the same disconnect. Tag

the disconnect switch with a suitable warning label.

GENERAL

The accessory heat pump piping package is designed for

use with the Carrier 38QP024 heat pump (outdoor section)

in combination with the 40RR024 fan coil unit (indoor

section) (see Fig. 1).

Special accessories are available for electrical control of

this system. Electric heaters for the 40RR024 are a fieldinstalled accessory. Ensure that all material required for

installation is available at the jobsite, including the 38QP024

outdoor section, the 40RR024 indoor section, piping pack

age, electrical control package, and 40RT electric heater

packages. The Sporlan part no. G8 nozzle is used for both

the upper (circuit no. 2) and lower (circuit no. 1) coil sec

tions of the indoor unit. Nozzles are shipped as standard

parts of the factory-installed 40RR distributor. Distributor

sizes are as follows:

COIL SECTION

Upper (Ckt 2)

Lower (Ckt 1)

DISTRIBUTOR SIZE

(in. OD)

7/8

7/8

OUTDOOR SECTION

38QP024

Fig. 1 — 38QP024/40RR024 Heat Pump System

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without Incurring obligations.

Book 11 PC 111 Catalog No 563-710 Printed in U.S. A Form 38QP-5SI Pg 1 11-92 Repiaces: New

Tab 5a

INDOOR SECTION

40RR024

Page 2

Accessories

PIPING PACKAGE — Contains check valves, thermo

static expansion valves (TXV’s), receiver, filter driers, and

tubing to connect the indoor coils for heat pump service.

THERMOSTAT HH07AT172 (HH07AT162 For Use on

Celsius Scale) — Used with subbase HH93AZ174, is a 2-stage

cool/2-stage heat thermostat with automatic changeover and

a lockout light. There is no provision for emergency heat.

THERMOSTAT HH07AT172 (HH07AT162 For Use on

Celsius Scale) — Used with subbase HH93AZ177, is a 2-stage

cool/2-stage heat thermostat. This combination has all the

features of HH07AT172 (HH07AT162)/HH93AZ174 plus

a provision for emergency heat.

SEQUENCER PACKAGE — Can be used with this system

when unloaders are added to the compressor(s). (Unloading

can be applied in the cooling cycle only. Unloading can

never be applied in the heating cycle.) The sequencer has

4-stage cooling capability.

ELECTRIC HEATERS — May be used with the 40RR in

door unit (see Table 1). Use a maximum of four 20-kW

(at 240 v) or 21.8-kW (at 480 v) electric heater assemblies.

ELECTRIC HEATER CONTROL PACKAGE 40RT900081

— Provides control for up to 3 stages of electric heat when

used with outdoor-air thermostat(s). Package must be used

whenever 40RT electric heaters are utilized. If a fourth

stage of electric heat is used, an additional field-supplied

heater control relay is necessary. This relay must have a

24-V coil with 230-v contacts. Outdoor thermostats

(part no. HH22QA040) are recommended for staging elec

tric heaters.

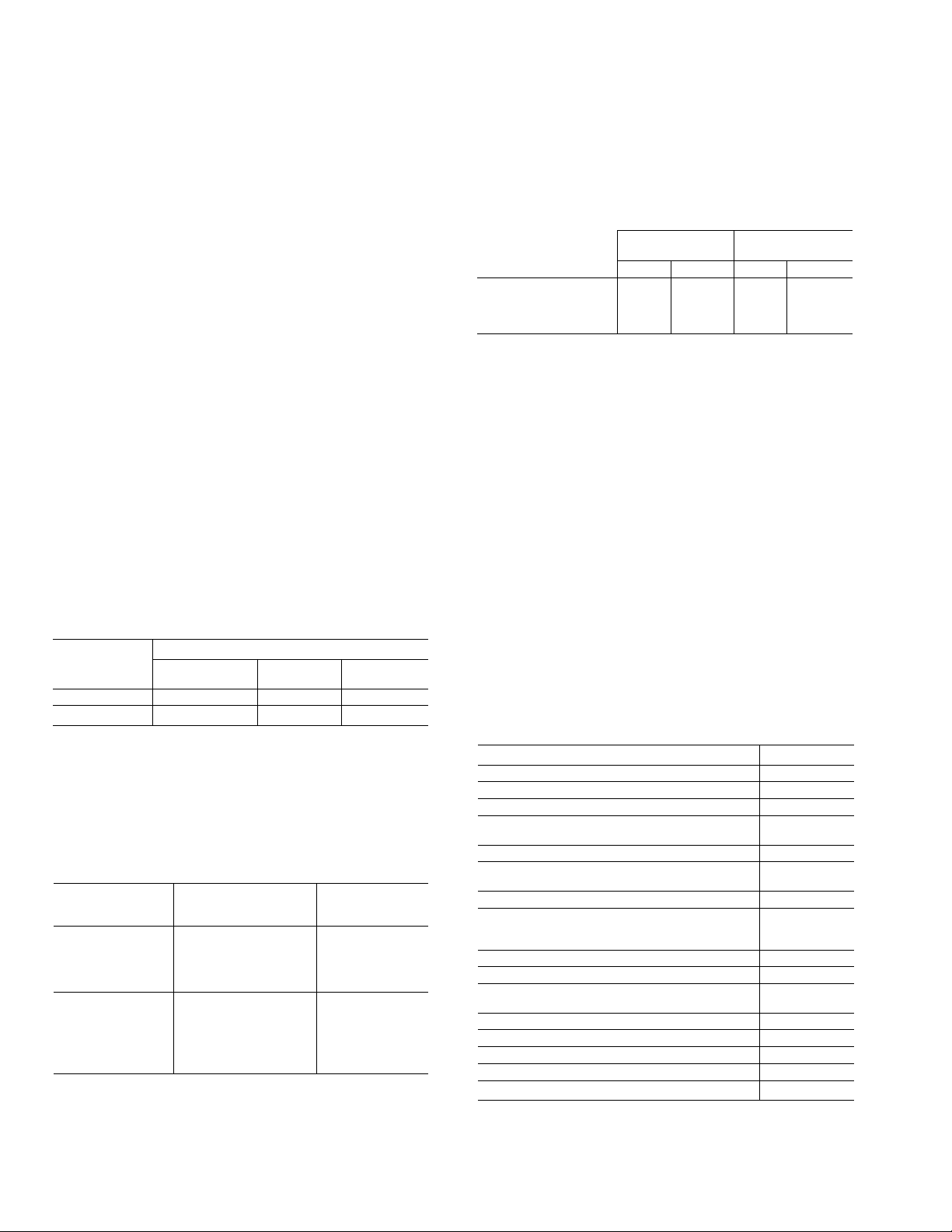

Table 1 — Unit 40RR Accessory Electric Heaters

PART NO.

40RT-900-101 240 20.0

40RT-900-111 480

LEGEND

FLA — Full Load Amps

NOTES;

1. A maximum of 4 electric heaters can be used with the 40RR024

unit.

2 Electric heaters are not UL (Underwriters’ Laboratories) listed for

the 38QP/40RR heat pump.

WATTAGE MULTIPLICATION FACTORS

Heater Voltage

Rating

240

480

Example: 20.0 kW (at 240 v) heater on 230 v

= 20.0 (0.92 multiplication factor)

= 18.4 kW capacity at 230 v

ELECTRIC HEATER (3 PHASE 50/60 Hz)

Rated

Voltage

Actual Heater

Voltage

(3 Phase, 50/60 Hz)

200 0.69

208 0.75

220

230

240 1.00

380

400 0 69

415

440

460

480 1.00

kW

21.8

FLA

48 0

26.0

Multiplication

Factor

0.84

0.92

0.63

0.75

0.84

0.92

INSTALLATION

Step 1 — Perform Outdoor and Indoor Unit

Installation — Follow the installation instructions pro

vided with each outdoor and indoor unit. See Table 2 for

maximum vertical elevation between the indoor and out

door sections.

Table 2 - Maximum Vertical Separation

HEIGHT OF INDOOR UNIT

SYSTEM

40RR024/38QP024,

60 Hz, Ckt 1 and 2

40RR024/38QP024,

50 Hz, Ckt 1 and 2

Above Outdoor

Unit

ft

59

58

m

180

17.7

Below Outdoor

Unit

ft m

59

58

18.0

17.7

Step 2 — Size Piping Lines — Employ one of the

following methods to size interconnecting refrigerant pip

ing between the 38QP and the 40RR:

1. Use the pipe sizes shown in Refrigerant (R-22) Charge

and Piping Selection table in the 38QP installation in

structions (when not using field-installed accessory un

loaders).

2. Use the Carrier System Design Manual, Part 3, Piping

Design (when using field-installed accessory

unloaders).

3. Use the piping sizing portion of the Carrier E20-II com

puter program (when using field-installed accessory

unloaders).

NOTE: Liquid line solenoid valves are not required; they

are factory-installed on the 38QP.

Step 3 - Check Contents of Piping Package

— Install heat pump piping package to convert indoor coil

for heat pump service. Table 3 lists the contents of the pip

ing package. Figure 2 shows the contents of the piping pack

age in the approximate order in which they are installed.

Table 3 — Heat Pump Piping Package Contents

DESCRIPTION

Receiver, Piping Assy (Ckt 1)

Piping Assy (Ckt 2)

Filter Drier (Ckt 1 and 2)

Receiver, Piping Assy Support Bracket

(Cktl)

Filter Drier Support Bracket (Ckt 2)

TXV (Thermostatic Expansion Valve)

(Ckt 1 and 2)

Screw, Receiver Strap*

Screws, No. 10 for Filter Drier Strap (4)

5/8" Tube Clamp (2), Filter Drier Support

Bracket (2)*

Tube, Filter Drier to TXV (Ckt 1)

Tube, Filter Drier to TXV (Ckt 2)

Strapping, 11" Long for Filter Driers

(Ckt 1 and 2)

Strapping, 10" Long for Receiver (Ckt 1)

Clamp for 5/8" OD Tube (Ckt 1)

Installation Instructions* 1

Strap for TXV Sensort

Screw and Nut for TXV Strapt

‘Items are included in a packet which accompanies piping package,

titems are packed together with TXV.

QUANTITY

1

1

2

1

1

2

1

8

1

1

2

1

1

2

2

Page 3

(CKT 2)

PIPING ASSY (CKT 2)

RECEIVER, PIPING

ASSY (CKT 1)

TXV — Thermostatic Expansion Valve

NOTE: Items listed in Tabie 1 and not shown on Fig 2 are inciuded

in packaging which accompanies piping package.

Fig. 2 - Heat Pump Piping Package Contents in Approximate Order of Installation

Page 4

Step 4 — Install Piping Package — install parts of

piping package as shown in Fig. 3.

CONNECT LIQUID AND VAPOR LINES - Run liquid

and vapor lines separately between the 38QP and the 40RR

units, because the 38QP has dual independent refrigerant

circuits. A label on the 38QP comer post identifies the

circuits.

CONNECT EQUALIZER LINE TO EACH THERMO

STATIC EXPANSION VALVE (TXV) - (See Fig. 4.)

Install a fitting for suction pressure readings near the indoor

section to allow for TXV superheat adjustments. (A fitting

can be installed in the equalizer line for this purpose.)

MOUNT TXV SENSING BULB - Locate TXV sensing

bulb on the suction line as shown in Fig. 4. Do not attach

bulb to suction manifold (header). Locate bulb on a vertical

riser where possible. If a horizontal location is necessary,

secure the bulb at approximately 4 o’clock or 8 o’clock

position. (See Fig. 5.)

Step 5 — Connect Power Wiring — All wiring

must comply with local and National Electrical Code re

quirements. See the installation instructions with each in

door and outdoor unit for recommended wire and fuse sizes.

See 38QP wiring book for wiring diagrams and Table 4 for

40RR wire MCA (minimum circuit amps) and MOCP (max

imum overcurrent protection). Perform charging instruc

tions per installation instructions provided with the outdoor

unit.

‘40RR024 Only.

Fig. 4

Equalizer Line and TXV Sensing Bulb

Locations

TXV — Thermostatic Expansion Valve

NOTE: Cut distributor side outlet tube to 1-5/16 in. (33.3 mm) length from OD of distributor.

Fig. 3 — Unit 40RR Piping Arrangement

Page 5

VAPOR LINE

TXV — Thermostatic Expansion Valve

NOTE: The 8 o’clock position is shown above

Fig. 5 — TXV Feeler Bulb Locations

Step 6 — Make TXV Adjustments.

A CAUTION

Wait 30 minutes between TXV adjustments to avoid

excessive superheat.

Make TXV adjustments on 40RR after installation of pip

ing package, verifying 10° F superheat.

Table 4 — Unit 40RR Electrical Data

FAN

V*-PH-HZ

UNIT

024

208-3-60

230-3-60

460-3-60t

LEGEND

40RR

FLA — Full Load Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

‘Motors are designed for satisfactory operation at ± 10% of nominai

voitages shown. Voitages should not exceed the limits shown in the

“Voltage Limits” column.

fMotors must be field wired for 460 v in accordance with directions

on nameplate of motor.

NOTE: Fan motors are field supplied on unit 40RR024 (575 v) and

on 50-Hz units.

VOLTAGE

LIMITS

180-220

207-253

416-528 5.0

MOTOR

FLA

Hp

3 10.8

10.1

3

POWER

SUPPLY

MCA

132

11.5

58

MOCP

(Amps)

15

15

NOTE: Because this split system uses TXV’s in the heating

cycle, refrigerant charge can be adjusted during heating op

eration. When properly charged, the 40RR has approxi

mately 32° F of state point subcooling leaving circuits no.

1 and 2 from the indoor coil in the heating cycle. Use charg

ing chart on unit to complete charging (in cooling cycle

only).

NOTE: Use refrigerant R-22 only.

NOTE: Since the 38QP unit contains 2 refrigeration

circuits, both circuits must be charged separately.

To charge system:

1. Regulate valve at refrigerant (R-22) tank to maintain suc

tion pressure at 80 psig (551.6 kPa) while charging. Charge

with vapor only at suction side of unit.

NOTE: Do not depend on sight glass when charging unit;

use charging charts which are attached to the inside of each

compressor access panel.

2. Measure line temperature close to the liquid service valve,

and measure the pressure at the Schrader port on the liq

uid line service valve. Plot point on the charging chart.

If point is above the line, add charge. If point is below

the line, remove and reclaim charge until operating point

falls on the curve.

3. Allow system to operate for 20 minutes. Take tempera

ture and pressure reading at liquid service valve and check

values with the charging chart.

4. Record final installed system charge in ink on unit

nameplate.

CHECK OIL CHARGE — Allow system to run for approx

imately 20 minutes. Stop system and check compressor oil

level. Ten pints is the proper oil charge amount for a 6D

compressor. Add oil only if necessary to bring oil into view

in sight glass. Use only Carrier-approved compressor oil:

Petroleum Specialties

Texaco, Inc

.......................................................

Witco Chemical Corp

..........................................

.........................................

Cryol 150A

Capella WE32

Sunisco 3GS

IMPORTANT: Do not reuse drained compressor oil

or oil that has been exposed to atmosphere. Proce

dures for adding oil are given in GTAC II, Module 5,

Charging, Recovery, Recycling, and Reclamation. To

remove oil: shut system off; isolate the compressor;

remove and reclaim the refrigerant in the compressor;

remove the compressor oil drain plug.

START-UP

Evacuate and Dehydrate — Evacuate and dehy

drate entire refrigerant system as shown in General Train

ing Air Conditioning (GTAC) II, Module 4, System

Dehydration.

A WARNING

To prevent personal injury, wear safety glasses and gloves

when handling refrigerant. Do not overcharge system

— this can cause compressor flooding. Never charge

liquid into the low-pressure side of the system. During

charging or removal of refrigerant, be sure indoor fan

system is operating.

Preliminary Charge — Refer to GTAC II, Module 5,

Charging, Recovery, Recycling, and Reclamation for charg

ing methods and procedures. Charge system per Table 1 in

GTAC II by the liquid charging method and charging by

weight procedure.

Charge System (Cooling Only) — Refer to GTAC

II, Module 5, Charging, Recovery, Recycling, and Recla

mation, and the following procedure.

SEQUENCE OF OPERATION

General — The heat pump contains 2 independent re

frigeration circuits. Each circuit has its own set of indepen

dent controls, compressor, liquid line solenoid valve, re

versing valve, crankcase heater, TXV, and accumulator.

Circuit breakers provide overcurrent protection for com

pressors (in both heating and cooling modes). These re

quire manual reset at the 38QP unit control box. The oil

pressure safety and crankcase heater also require reset at

the outdoor unit.

Cooling

NOTE: When power is supplied to a system that is off,

crankcase heaters are energized. The reversing valve may

or may not be energized depending on mode of operation

(heating or cooling) when thermostat was previously

satisfied.

The following cooling operating sequence has both heat

pump circuits connected to a single, 2-circuit fan coil. The

system is controlled by a single 2-stage heat/2-stage cool

thermostat.

Page 6

When the thermostat calls for first-stage cooling (TCI

closed), the indoor-fan motor starts immediately. Compres

sor no. 1 and outdoor fan no. 1 start after 3 seconds and

before 5 minutes depending on the length of time system is

off after thermostat was previously satisfied. (This time pro

cess is effective because of the 5-minute Time Guard® II

circuit.) The reversing valve solenoid (RVSl) deenergizes,

causing the reversing valve to shift to the cooling position.

The crankcase heater is off when the compressor is operat

ing. The liquid line solenoid valve in circuit no. 1 opens,

allowing refrigerant to flow.

When the thermostat calls for second-stage cooling (TC2

closed), compressor no. 2 and outdoor fan no. 2 start. The

reversing valve solenoid (RVS2) is deenergized, causing the

reversing valve to shift to the cooling position. The liquid

line solenoid in circuit no. 2 opens, allowing refrigerant

flow in circuit no. 2.

When the second stage of thermostat is satisfied (TC2),

compressor no. 2 shuts off and outdoor-fan motor no. 2

shuts off. When the first stage of thermostat is satisfied,

compressor no. 1, outdoor fan no. 1, and indoor fan shut

off. The liquid line solenoid valve closes in each refriger

ation circuit when the corresponding compressor shuts off.

The reversing valves do not shift but remain in the cooling

position until there is a call for heating.

The unit is equipped with a no-dump reversing valve logic.

When the unit is in the cooling mode, the reversing valve

remains in cooling mode position until the thermostat calls

for heating Conversely, when the unit is in the heating mode,

the reversing valve remains in heating mode position until

the thermostat calls for cooling.

NOTE: If a malfunction occurs, causing the high-pressure

switch (HPS), compressor overtemperature (COTP) safety,

or loss-of-charge switch (LCS) to open, the compressor in

the affected circuit is locked out by a Cycle-LOC™ circuit.

This causes the Signal-LOC™ warning light to come on at

the thermostat subbase. The remaining refrigeration circuit

continues to operate. The RVS remains deenergized on the

inactive circuit so reversing valve does not shift. These safe

ties are reset by adjusting the thermostat up to open TCI

and TC2, or by momentarily switching thermostat subbase

to OFF position. If the compressor oil pressure is lost, or if

oil pressure fails to build on start-up on either refrigeration

circuit, an oil-pressure safety switch shuts off the affected

compressor. The switch must be reset manually at the unit.

When the thermostat calls for heating (THl closed), the

indoor-fan motor starts. Compressor no. 1 and outdoor fan

no. 1 start after 3 seconds and before 5 minutes depending

on the length of time system is off after thermostat is sat

isfied. (The time process is effective because of the 5-minute

Time Guard II circuit.) The liquid line solenoid valve for

circuit no. 1 opens when compressor no. 1 operates and

closes when compressor no. 1 is off. The reversing valve in

circuit no. 1 shifts (RVSl energized) for heating operation.

When the thermostat for second stage of heating closes (TH2),

compressor no. 2 and outdoor fan no. 2 start, liquid line

solenoid no. 2 opens, and reversing valve in circuit no. 2

shifts (RVS2 energized).

When thermostat TH2 is satisfied, compressor no. 2 shuts

off, liquid line solenoid no. 2 closes, and outdoor fan no. 2

shuts off. When thermostat THl is satisfied, compressor

no. 1, outdoor-fan motor no. 1, and indoor-fan motor shut

off, and liquid line solenoid valve no. 1 closes. The revers

ing valves remain in the heating position until there is a call

for cooling.

If either circuit is locked out, the electric heater (if in

stalled) will be energized as long as the thermostat contin

ues to call for heat.

Defrost — An outdoor coil temperature of 28 F (-2 C)

triggers operation of the defrost timer logic on either circuit

so that defrost becomes automatic with a time sequence,

adjustable at 30, 50, or 90 minutes. As long as the outdoor

coil temperature remains below 28 F (-2 C), defrost occurs

every 30, 50, or 90 minutes on that circuit depending on

the time selected. When defrost is initiated, the heat pump

reverts to a modified cooling mode of operation (the out

door fan for the affected circuit shuts off). This modified

cooling mode utilizes heat rejection from the refrigerant to

melt any ice or frost on the outdoor coil. When defrost is

initiated on circuit no. 1, RVSl is energized and shifts the

reversing valve on this circuit. If defrost is not called for on

circuit no. 2, this circuit continues to run in heating until

enough frost or ice is built up on the coil to initiate defrost.

Circuits no. 1 and no. 2 reversing valves shift indepen

dently of one another, because the coil temperatures are sensed

independently. (TDFl [thermistor, defrost 1] is attached to

circuit no. 1, and TDF2 is attached to circuit no. 2.)

Defrost for circuits no. 1 and no. 2 is also terminated in

dependently. When temperature of either outdoor coil reaches

68 F (20 C) or length of defrost time exceeds 10 minutes,

the reversing valve on that circuit shifts back to heating mode

IMPORTANT: Do not reset more than once! If oil

pressure switch trips, determine cause and correct. Do

not bypass oil pressure safety switch.

of operation and the outdoor fan on that circuit restarts.

NOTE: If a malfunction occurs, causing the HPS, COTP,

or LCS to open, the compressor in the affected circuit is

locked out by a Cycle-LOC^“ circuit. This causes a Signal-

The crankcase heaters are in an electrical lockout circuit.

If a crankcase heater is defective, the compressor is locked

off. The compressor remains off until the crankcase heater

is replaced. This lockout circuit cannot be reset by adjust

ing the thermostat.

LOC™ warning light to come on at the subbase. The re

maining refrigeration circuit continues to operate. The RVS

remains energized so reversing valve does not shift. SignalLOC device resets by adjusting thermostat down to open

THl and TH2, or by momentarily switching thermostat sub

base to the OFF position. If compressor oil pressure is lost

or if oil pressure fails to build on start-up on either refrig

Heating

NOTE: When power is supplied to a system that is off, the

crankcase heaters are energized. The reversing valve may

or may not be energized depending on mode of operation

(heating or cooling) when the thermostat was previously

satisfied.

The following heating operating sequence has both heat

pump circuits connected to a single, 2-circuit fan coil. The

system is controlled by a single 2-stage heat/2-stage cool

thermostat.

Copyright 1992 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 11 PC 111 Catalog No 563-710 Printed in U S. A Form 38QP-5SI Pg 6 11-92 Replaces; New

Tab 5a

eration circuit, an oil-pressure safety switch shuts off the

affected compressor. The switch must be reset manually at

the unit.

IMPORTANT: Do not reset more than once! If oil

pressure switch trips, determine cause and correct. Do

not bypass oil pressure safety switch.

If crankcase heater is defective, the compressor in the af

fected circuit is locked off. The circuit remains off until the

crankcase heater is replaced.

Loading...

Loading...