Ceiling-Suspended Fan Coil Units

Installation, Start-Up

and Service Instructions

40QA024-060

CONTENTS

Page

SAFETY CONSIDERATIONS ................. 1

INSTALLATION ............................1-13

Step 1 − Complete Pre-Installation Checks ...3

• UNPACK UNIT

• INSPECT SHIPMENT

• BEFORE INSTALLATION

Step 2 − Select Location ....................4

Step 3 − Mount Unit ........................6

• TO MOUNT UNIT

• TO INSTALL REMOTE THERMOSTAT

Step 4 − Connect Refrigerant Piping ........7

Step 5 − Connect Condensate Drain Line ...10

Step 6 − Make Electrical Connections ......11

Step 7 − Install Remote Thermostat ........12

Step 8 — Make Connections Between

Indoor and Outdoor Units ................12

• COOLING ONLY SYSTEMS

• HEAT PUMP SYSTEMS

START-UP ...............................13-15

After Extended Shutdown ..................13

Seasonal Changeovers .....................13

Adjusting Airflow ..........................14

Operating Mode Memory ...................14

Automatic Operation (Auto.) Mode ..........14

Operating Sequence .......................14

• FAN OPERATION

• COOLING MODE OPERATION

• HEAT PUMP OPERATION (40QAE ONLY)

• DEFROST (40QAE ONLY)

• SYSTEM SAFETIES

• SPECIAL OPERATION, HEATING

CLEANING AND MAINTENANCE ...........15,16

Lubrication ................................15

To Remove and Clean or Replace

Air Filters ...............................15

• TO REMOVE AIR FILTERS

• TO CLEAN OR REPLACE FILTERS

To Clean Indoor Unit Bottom Panel .........16

To Clean Indoor Coil .......................16

To Clean Outdoor Coil (Outdoor Unit) .......16

To Clean Condensate Drains ................16

• TO CLEAN OR REPLACE DRAIN PAN

SERVICE ..................................16

Before Calling for Service ..................16

• IF SYSTEM FAILS TO OPERATE

FRESH AIR INSTALLATION OPTIONS .......16

Ventilation-Air Accessory ...................16

TROUBLESHOOTING .....................17-20

START-UP CHECKLIST ..............CL-1, CL-2

SAFETY CONSIDERATIONS

Installing and servicingair-conditioning equipment can be

hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install or service air-conditioning equipment.

Untrained personnel can perform basic maintenance, such

as cleaning and replacing filters. All other operations should

be performed by trained service personnel. When working

on air-conditioning equipment, observe precautions in literature and on tags and labels attached to unit.

Follow all safetycodes. Wearsafety glasses and work gloves.

Use quenching cloth for brazing operations. Have fire extinguisher available. Read these instructions thoroughly.Consult local building codes and National Electrical Code (NEC)

for special installation requirements.

Before installing or servicing system, always turn off

main power to system. There may be more than one disconnect switch. Turn off accessory heater power if applicable. Electrical shock can cause personal injury.

INSTALLATION

The 40QAB ceiling-suspended fan coil unit (Fig. 1) is typically installed with the 38HDC or 38HDS outdoor condensing unit, and the 40QAE unit is typically installed with the

38QRC heat pump.

NOTE: The 40QAE unit can also be installed with either the

38HDC or HDS condensing units. Refer to Table 1 to make

sure the correct indoor unit(s) is installed with the correct

outdoor unit.

Installation instructions for 40QA fan coil units are contained in this manual. Refer to this manual for proper installation of the complete system. Note that the outdoor units

are shipped with installation and service instructions for basic installation of the outdoor section. Be sure to make the

connections in Cooling-Only Systems and Heat Pump Systems sections on page 12 of this literature so that the unit

will operate properly with the 40QA mircoprocessor control

system.

Fig. 1 — 40QA Ceiling-Suspended Fan Coil Unit

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 3d 2d

PC 111 Catalog No. 534-052 Printed in U.S.A. Form 40QA-3SI Pg 1 4-96 Replaces: 40QA-1SI

Table 1 — Acceptable System Combinations for Indoor and Outdoor Units

OUTDOOR UNIT INDOOR UNIT

Type Model Number 38 Type Model Number 40QA

HDC018

HDC024 B024

HDC030 B036

HDC036 B036

HDC048 B048

Cooling Only

Cooling Only

Multi-Split*

Heat Pump

*Multi-split systems can accommodate up to 4 fan coil units of vari-

ous types with one condensing unit.The combinations listed in this

tableare those combinations which use only ceiling-suspendedunits

(not combined with any other type of fan coil unit). Refer to system

presale literature or Price Pages for more details on other system

combinations.

†Units must be field reconfigured for 1

tion. See Before Installation section on page 3 for details.

HDC060 B060

HDC018

HDC024 E024

HDC030 E036

HDC036 E036

HDC048 E048

HDC060 E060

HDS024

HDS048

HDS024

HDS048

QRC018

QRC024 E024

QRC030 E036

QRC036 E036

QRC048 E048

QRC060 E060

1

⁄2ton (18,000 Btuh) opera-

B024

Cooling Only

E024

Heat Pump

(2) B024†

Cooling Only

Heat Pump

Heat Pump

**One circuit (2 units) unit must be field reconfigured for 1

(18,000 Btuh) operation. See Before Installation section on page 3

for details.

NOTES:

1. If your particular application requires a heat pump outdoor unit

matched with a cooling-only fan coil unit, contact your local representative for more details.

2. Numbers in ( ) indicate quantities when there is morethan one fan

coil unit in the system.

(4) B024†

(3) B024**

(2) B024

(2) E024†

(4) E024†

(3) E024**

(2) E024

E024

1

⁄2ton

Be sure unit will be operated within the application guidelines shown in Table 2. When installing the 38QRC or HDC

units, note that for cooling operation when the outdoor-air

temperature is below 55 F,the accessory low ambient or winter start kit will be required. Systems using 38HDS units can

operate down to 40 F outdoor-airtemperature as shipped from

the factory. If operation at outdoor ambients between 40 F

and −20 F is desired, an accessory winter start kit will be

required for the 38HDS unit.

To install this system, you will need:

• 1 (or more)* 40QAB or 40QAE fan coil unit(s) with stand-

ard remote thermostat

• 1 38HDC, HDS, or QRC outdoor unit

• 1 low ambient kit or 1 winter start kit (if required for your

application)

• 1 power ventilation kit (if required for your application)

• 1 condensate pump kit (if required for your application)

*More than 1 fan coil unit may be used with the 38HDS

multi-split units. Refer to 38HDS unit Price Pages for complete details.

NOTE: Refrigerant pipe, drain pipe, wire, etc., are also required to install unit and are field-supplied.

Be sure you have the required parts before beginning installation. The 40QA unit utilizes a standard 24 v control system (see Tables 3Aand 3B) for ultimate flexibility while delivering optimal levels of comfort and efficiency. Be sure to

follow these instructions carefully to obtain proper functioning of the unit.

Table 2 — Application Range

COOLING

Maximum Minimum

Indoor Outdoor Indoor Outdoor

95FDB 125FDB 67FDB 55FDB*

71FWB 57FWB 40FDB†

HEATING (Heat Pump Systems Only)

Maximum Minimum

Indoor Outdoor Indoor Outdoor

80FDB 75FDB 55FDB 220FDB

71FWB 65FWB

LEGEND

DB — Dry Bulb

WB — Wet Bulb

*This value is for 38HDC, QRC systems. The 38HDC or QRC unit

may be equipped with an accessory low-ambient control or winter

start kit that will allow operation down to 220 F.

†This value is for38HDS systems. The 38HDSunit may be equipped

with an accessory winter start kit that will allow operation down to

−20 F.

2

Table 3A — Physical Data, 40QAB Cooling-Only Units

UNIT 40QAB 024* 024 036 048 060

NOMINAL CAPACITY (Tons) 1

1

⁄

2

23 4 5

NOMINAL SIZE (Btuh) 18,000 24,000 36,000 36,000 60,000

OPERATING WEIGHT (lb) 108 108 117 149 179

MOISTURE REMOVAL RATE (Pints/Hr) 5.8 7.1 9.5 13.4 15.1

FINISH GM Motorhome White with Black Trim

REFRIGERANT R-22

Control (Cooling) AccuRaterT Piston in Fan Coil Unit/TXV in Condensing Unit

System Charge Required (lb)† 3.7 5.5 5.6/5.4** 7.4 13.6

INDOOR FAN Direct Drive Centrifugal

Rpm...Cfm High 862...500 862...500 1275...840 1435...1200 1275...1600

Rpm...Cfm Medium 690...400 690...400 972...740 1388...1160 972...1220

Rpm...Cfm Low 552...320 552...320 830...640 1315...1100 830...1040

High Speed Watts 92 92 282 425 564

Quantity...Motor Hp 1...

Blowers — No. ...Size (in.) 2...6 x 8 2...6 x 8 2...6 x 8 3...6 x 8 4...6 x 8

INDOOR COIL Copper Tube, Aluminum Fin

Face Area (sq ft) 2.2 2.2 2.6 3.0 4.0

No. of Rows 44 4 4 4

Fins/in. 14.9 14.9 14.9 14.9 14.9

Circuits 44 4 8 8

FILTERS Cleanable

(Quantity) Size (in.) (4) 12 x 8

AIRSWEEP

Horizontal —

Vertical Automatic

CONTROLS

Control Voltage 24-v Provided in Control

Auto. Restart Yes

Fan Speed High/Medium/Low

Condensate Pump Safety Yes (Accessory)

Outdoor Coil High Temperature (Cooling Modes) Outdoor Coil Temperature greater than 144 F; Resets at 104 F

Filter Change Indication 250 Hours of Indoor Fan Operation (through thermostat)

REFRIGERANT LINES

Connection Type Flare

Liquid Line OD (in.)

Vapor Line OD (in.)

Maximum Length (ft) 200/50 \

Maximum Lift Fan Coil (Above Outdoor) (ft) 65/30 \

Maximum Lift Fan Coil (Below Outdoor) (ft) 150/30 \

1

⁄

15

5

⁄

8

1...1⁄

3

⁄

4

15

5

⁄

8

1...1⁄

6

(5) 105⁄8x83⁄

3

⁄

8

3

⁄

4

4

2...1⁄

15

(4) 105⁄8x83⁄

(2) 12 x 83⁄

7

⁄8††

4

4

2...1⁄

6

(6) 12 x 83⁄

7

⁄8††

CONDENSATE DRAIN CONNECTION Pipe Thread (MPT)

CONDENSATE DRAIN SIZE (in.)¶

LEGEND

TXV — Thermostatic Expansion Valve

*Field reconfigured to 18,000 Btuh (1

tion section on this page for details.

†Outdoor unit is shipped with a full charge for the smallest system

configuration. Refer to unit nameplate (on the unit) for details on

specific system charge required.

**When matched with a size 030 outdoor unit/when matched with a

size 036 outdoor unit.

1

⁄2tons). See Before Installa-

††The valve connection size is

7

is

⁄8inch.

\ Whenmatched with a 38HDC coolingonly unit/when matched with

a 38HDS multi-split unit.

¶ Flexible tubing (

is used.

3

⁄

4

3

⁄4inch. The recommended line size

5

⁄8in.)isrequired when accessory condensate pump

4

Step 1 — Complete Pre-Installation Checks

UNPACK UNIT — Store fan coil unit in the original packaging until it is moved to the final site for installation. When

removing unit from carton, lift unit by its 4 corners; DO NOT

lift unit by its plastic parts.

INSPECT SHIPMENT — Upon receipt of shipment, check

fan coil unit for damage. Forward claim papers directly to

the transportation company. Manufacturer is not responsible

for damage incurred in transit.

Check all items; if any item is missing, notify your Carrier distributor. To prevent loss or damage, leave all parts in

original packages until installation.

BEFORE INSTALLATION — Perform the following steps

before installing indoor fan coil unit. Place the indoor unit

upside down on the floor, then:

1. Remove side panels by sliding forward, then away from

sides of unit (Fig. 2). Reinstall prior to unit start-up.

2. Remove air filters from inlet grilles; then remove and re-

tain screws securing inlet grilles to indoor unit. Reinstall

prior to unit start-up.

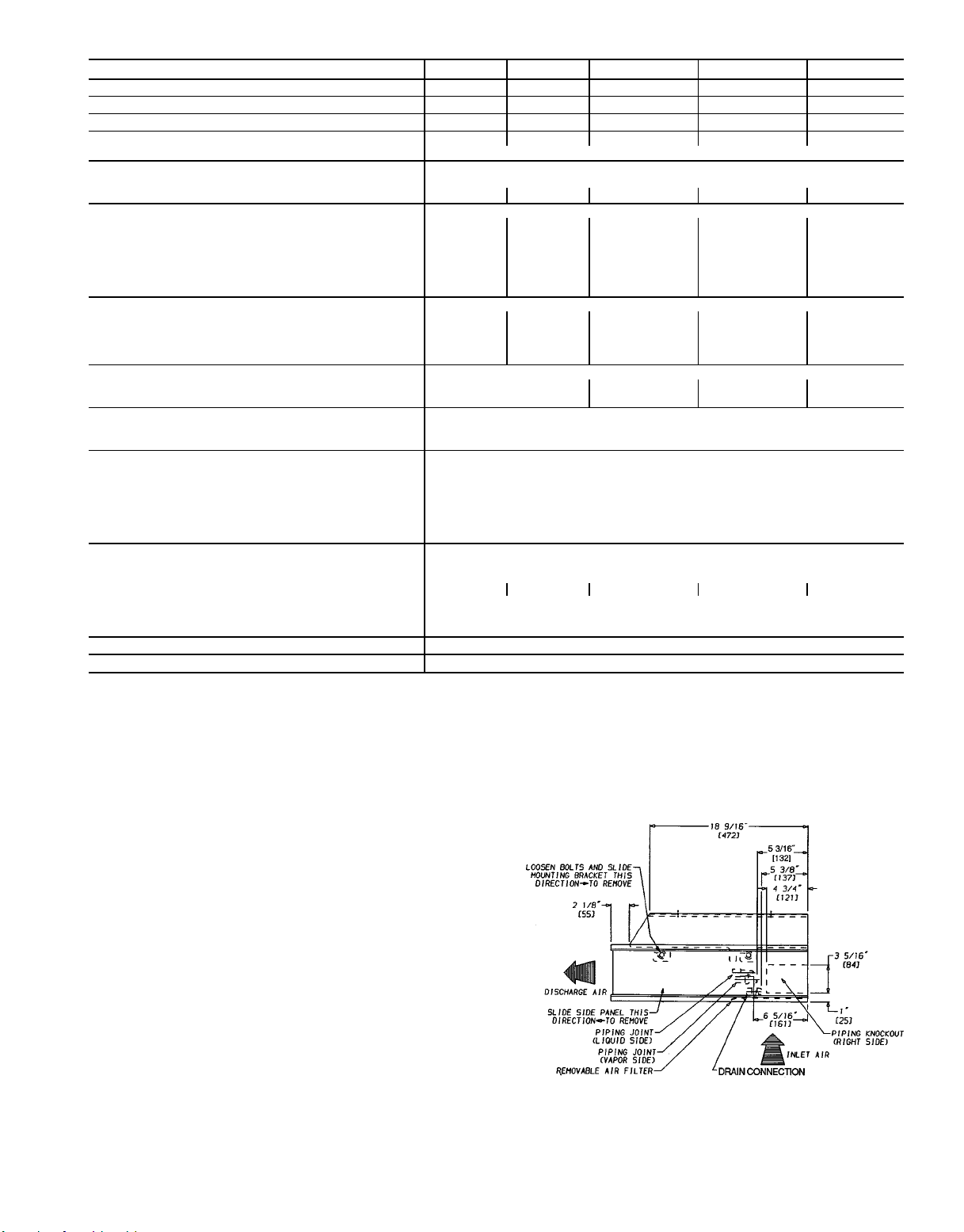

NOTE: Dimensions shown in brackets [ ] are in mm.

Fig. 2 — Removal of Mounting Brackets

from Indoor Unit

3

Table 3B — Physical Data, 40QAE Heat Pump Units

UNIT 40QAE 024* 024 036 048 060

NOMINAL CAPACITY (Tons) 1

1

⁄

2

23 45

NOMINAL SIZE (Btuh) 18,000 24,000 36,000 48,000 60,000

OPERATING WEIGHT (lb) 110 110 119 151 181

MOISTURE REMOVAL RATE (Pints/hr) 5.8 7.1 9.5 13.4 15.1

FINISH GM Motorhome White with Black Trim

REFRIGERANT R-22

Control (Cooling) AccuRater® Piston in Fan Coil Unit

Control (Heating) AccuRater Piston in Outdoor Unit

Holding Charge (lb)† 2.0 2.0 2.0/2.5** 2.5 2.5

INDOOR FAN Direct Drive Centrifugal

Rpm...Cfm High 862...480 862...480 1275...870 1435...1130 1275...1600

Rpm...Cfm Medium 690...400 1200...480 972...750 1388...975 972...1220

Rpm...Cfm Low 552...320 1050...400 830...630 1315...820 830...1040

High Speed Watts 92 92 282 425 564

Motor Quantity...Hp 1...

Blowers Quantity...Size (in.) 2...6 x 8 2...6 x 8 2...6 x 8 3...6 x 8 4...6 x 8

INDOOR COIL Copper Tube, Aluminum Fin

Face Area (sq ft) 2.2 2.2 2.6 3.0 4.0

No. of Rows 44 4 4 4

Fins/in. 14.9 14.9 14.9 14.9 14.9

Circuits 44 4 8 8

FILTERS Cleanable

Quantity...Size (in.) 4...12 x 8

AIRSWEEP

Horizontal

Vertical

1

⁄

15

3

⁄

1...1⁄

15

4

4...12 x 83⁄45...105⁄8x83⁄

1...1⁄

6

4

2...1⁄

15

4...105⁄8x83⁄

2...12 x 83⁄

4

4

2...1⁄

6

6...12 x 83⁄

4

—

Automatic

HEATER (kW) 2.0 2.0 3.0 4.0 5.0

CONTROLS

Defrost Method Timed

Manual Defrost Diagnostics Yes

Dehumidification Yes

Auto. Restart Yes

Control Voltage 24-v Provided in Control

High Indoor Coil Temperature Indoor Coil Temperature greater than 144 F; Resets at 104 F

Fan Speed High/Medium/Low

Freeze Protection Indoor Coil Less than 28 F, Resets at 50 F

Condensate Pump Safety Yes (Accessory)

Outdoor Coil High Temperature (Cooling Modes) Outdoor Coil Temperature greater than 144 F; Resets at 104 F

Filter Change Indication 250 Hours of Indoor Fan Operation (through thermostat)

REFRIGERANT LINES

Connection Type Flare

Liquid Line OD (in.)

Vapor Line OD (in.)

Maximum Length (ft) 200

Maximum Lift (Fan Coil Above) (ft) 65

Maximum Lift (Fan Coil Below) (ft) 150

5

⁄

8

5

⁄

8

3

⁄

8

3

⁄

4

7

⁄8††

7

⁄8††

CONDENSATE DRAIN CONNECTION Pipe Thread (MPT)

CONDENSATE DRAIN SIZE (in.) |

*Field reconfigured to 18,000 Btuh 11⁄2tons. See Before Installation

section on page 3 for details.

†Outdoor unit is shipped with a holding charge. Refer to unit name-

plate (on unit) for details on specific system charge required.

**When matched with 030 outdoor unit/when matched with 036 out-

door unit.

††The valve connection size is3⁄4inch. The recommended line size

is7⁄8inch.

\ Flexible tubing (5⁄8in.) is required when the accessory condensate

pump is used.

3

⁄

4

3. Remove inlet grilles from indoor unit by sliding forward.

Reinstall prior to unit start-up.

4. If necessary, reconfigure the 24,000 Btuh fan coil unit to

18,000 Btuh as follows:

a. The plug to the motor is located just outside the con-

trol box. Refer to the label diagram on the plug for

wiring for both 18,000 Btuh and 24,000 Btuh units.

b. Remove the black, blue, yellow, and red wires from

the plug. The white wire is the common and remains

in the same position.

c. Insert the blue wire into pin number 1.

d. Insert the yellow wire into pin number 2.

e. Insert the red wire into pin number 3.

f. Insert the black wire into pin number 4.

g. Check all connections to ensure they are secure.

h. Reinstall grilles using the screws removed in Step b.

i. Reinsert filters removed in Step a.

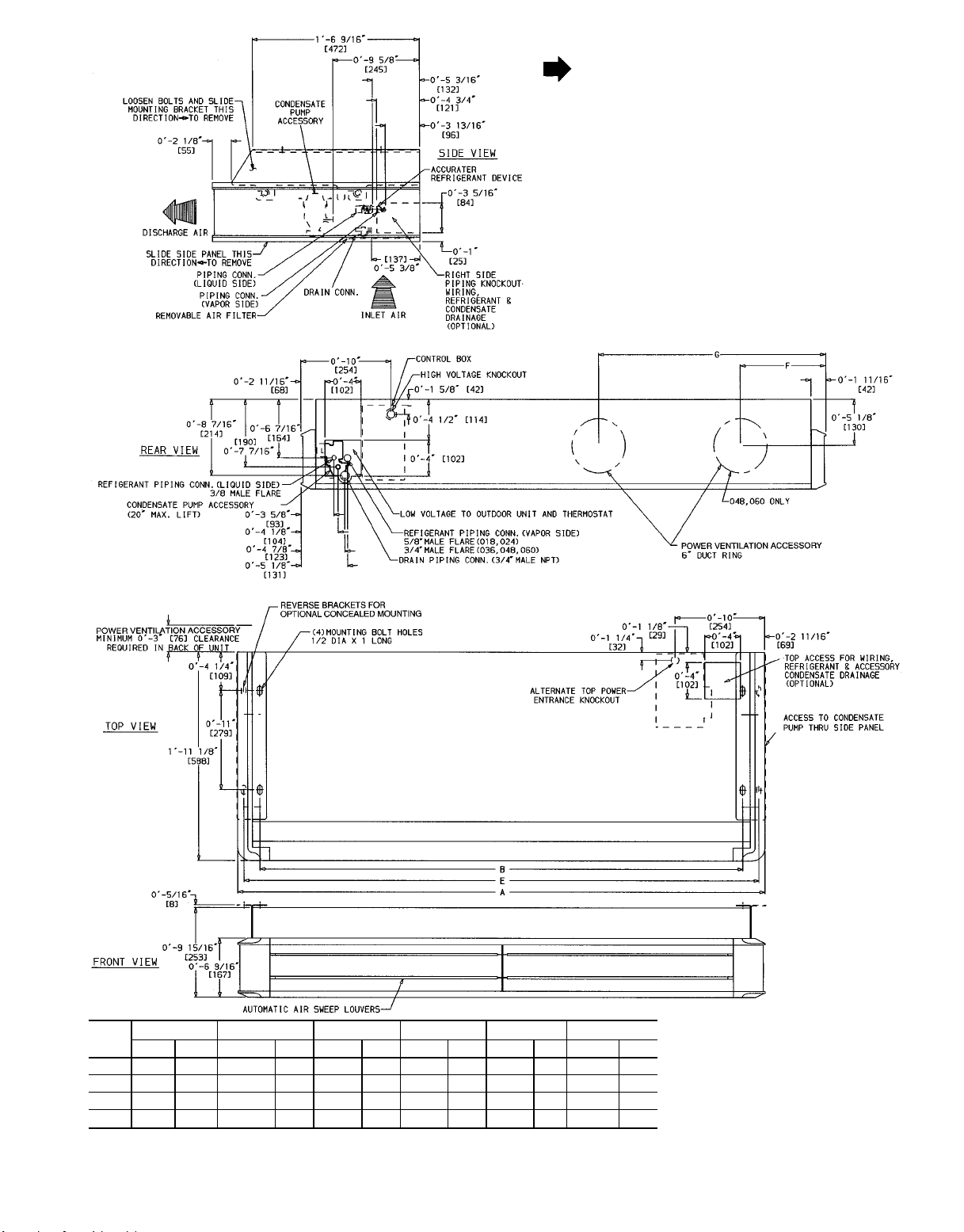

Step 2 — Select Location — Consult local building

codes and NEC for special installation requirements. See

Fig. 3 and 4 for unit dimensions and required clearances.

There are several ways the unit may be installed to different types of ceiling construction. These instructions do

not cover all installation methods. As a typical installation,

these instructions focus primarily on mounting the unit to

metal in new construction. Plan your installation carefully

before you begin. Listed below are some guidelines that should

be followed when determining location for the unit.

1. Place unit adjacent to an outside wall if fresh air is

required, ensuring that location allows for complete air

distribution.

4

NOTES:

1. Dimensions in [ ] are in millimeters.

2. Direction of airflow.

3. Standard unit clearances are as follows:

•09on top and rear

•39on left side

•129on right side

•369on bottom

(When facing unit discharge)

WEIGHT (lb) A B E F G

UNIT

40QA

QAB QAE ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm

024 108 110 4- 2

036 117 119 4-10

048 149 151 5-11

060 179 181 7- 8 2336 7- 3 2211 7- 6

15

⁄161294 3-10 1169 4- 15⁄81260 — — 1- 95⁄8549

13

⁄161493 4- 57⁄81368 4- 91⁄21459 — — 2- 11⁄2648

9

⁄161817 5- 65⁄81692 5-101⁄41783 1- 97⁄8555 3- 31⁄16992

5

⁄82302 1-115⁄8601 4-119⁄161512

Fig. 3 — 40QA Base Unit Dimensions

5

Fig. 4 — 40QA Clearances

2. Locate the thermostat in an area which is not subjected to

drafts or direct sunlight through windows. Locate thermostat on an interior wall whenever possible.

3. Allow sufficient clearance for airflow, wiring, refrigerant

piping, and servicing unit (Fig. 3 and 4).

4. Make sure the unit is easily accessible to electrical power.

5. Run refrigerant piping as directly as possible, and avoid

any unnecessary turns or bends.

6. Condensate piping can be directed through the inside wall

to an approved drain or straight outside.

NOTE: The piping hole for condensate line must slope at

a minimum pitch of

1

⁄4in. per foot to ensure proper drainage. If proper pitch cannot be achieved, install accessory

condensate pump at this time.

Step 3 — Mount Unit — Refer to Fig. 4 for clearances

and dimensions. Use mounting template included inside box

to locate mounting bolt holes, piping holes, electrical connections, and accessory outdoor-air intake, if used.

Select proper type of hardware from the guidelines below.

See Fig. 5.

Solid structure in ceiling must be used due to the weight

of the unit.

Wooden Structure — Install hanging bolts on a square wooden

piece placed over beams.

Newly Built Concrete Slab — Install hanging bolts with inserts, embedded bolts, etc.

Metal Structure — Install hanging bolts utilizing an existing

angle or by installing a new support angle.

Previously Built Concrete Slab — Install hanging bolts with

expansion anchor.

Fig. 5 — 40QA Unit Mounting Methods

(Hardware is Field Supplied)

TO MOUNT UNIT:

1. Remove mounting bracket and reinstall the 2 hex-head

bolts (factory supplied) into each side of indoor unit as

shown in Fig. 6. Allow approximately 3/8-in. space between bolt head and unit.

2. Determine installation position, paying particular attention to piping lengths, wiring connections, clearances, etc.

See Fig. 3 for connection locations, Fig. 4 for clearances,

and Fig. 7 and 8 for bolt locations.

3. Open knockout if right-side piping connections are required (Fig. 9), by removing the pre-slit portion in the

rear of the right side panel with a saw or cutter knife.

NOTE: If accessory fan coil unit louver guard is used, install at this time. Refer to installation instructions packaged

with this accessory.

4. Mount hanging brackets on ceiling (Fig. 10) for either

concealed or exposed bolt hanging position.

6

Fig. 6 — Installing Hex-Head Mounting Bolts

in 40QA Unit

DIMENSIONS (in.)

UNIT 40QA A B C

024 50

036 5813⁄

048 719⁄

060 92 87 905⁄

15

⁄

16

16

16

46 495⁄

537⁄

8

665⁄

8

571⁄

701⁄

Fig. 7 — 40QA Unit Hanging Dimensions

5. Lift the unit into place, and fit the hex-head bolts on sides

of indoor unit into mounting slots of mounting brackets

(Fig. 11). Ensure unit is mounted level to assure proper

drainage.

6. Tighten indoor unit hex-head bolts securely.

TO INSTALL REMOTE THERMOSTAT:

If there is at least 3/8 in. of space between the back of indoor

unit and wall:

1. Route remote thermostat wires (field supplied) through

slot in right side of rear panel of indoor unit (Fig. 3).

2. Route wires over refrigerant and drain piping as shown

in Fig. 12.

IMPORTANT: Do not route wires under the piping, or

wires could impede air filter removal.

If there is less than 3/8 in. of space between back of indoor

unit and wall:

1. Cut rear bottom of the right-side panel.

2. Route remote thermostat wires through new opening.

See Step 7 — Install Remote Thermostat section on page 12

for remainder of remote thermostat installation details.

Step 4 — Connect Refrigerant Piping — Fan coil

8

2

4

8

units may be connected to outdoor units using field-supplied

refrigerant grade piping. Refer to Tables 3A and 3B for the

correct size piping. The length of refrigerant pipe depends

on the unit placement and building structure; run pipes as

directly as possible. For piping requirements over 50 ft of

total run, or more than 25 ft of lift, consult the long line

application guidelines in the System Product Data literature.

DIMENSIONS (in.)

UNIT 40QA B C

024 46 49

036 537⁄

048 665⁄

060 87 905⁄

*Exposed mounting holes.

†Reverse bracket holes (concealed mounting).

8

8

571⁄

701⁄

5

⁄

8

2

4

8

Fig. 8 — Mounting Template Included

with 40QA Unit

Fig. 9 — Removing Rear Knockout in Side Panel

If Right-Side Piping Connection in Used

DO NOT BURY MORE THAN 36 IN. OF REFRIGERANT PIPE IN THE GROUND. If any section of pipe

is buried, there must be a 6-in. vertical rise to the valve

connections on the outdoor unit. If more than the recommended length is buried, refrigerant may migrate to

the cooler, buried section during extended periods of unit

shutdown, causing refrigerant slugging and possible compressor damage at start-up.

To connect piping:

1. Install insulation. Insulate supply and return refrigerant

lines on heat pumps (38QRC) and mult-split condensing

(38HDS) units to prevent condensation. It is extremely

important that all refrigerant lines and the AccuRatert

metering device be insulated on heat pumps. On 38HDC

cooling only units, the liquid line may be left uninsulated. Use any acceptable heat resistant closed-cell foam

insulation (minimum 3/8-in. wall thickness). When insulating piping, cap ends and slide insulation over the piping. Insulation can also be cut and placed over piping.

2. Run liquid and gas refrigerant piping.

a. Run pipes as directly as possible, and avoid any un-

necessary turns and bends.

b. Suspend refrigerant pipes so that the insulation is

not damaged and vibrations are not transmitted to the

structure.

c. Leave slack in the refrigerant pipe between the struc-

ture and the unit to absorb vibrations.

d. For 38HDC and QRC systems only, install flare con-

nection on tubing to liquid line at fan coil unit. A piston is shipped in the AccuRater device body (Fig. 13)

with the 40QA unit. Use Tables 4-6 to verify that you

have the required piston size for the system being

installed.

7

Fig. 10 — Mounting Hanging Brackets

MOUNTING

SLOT

Fig. 11 — Hanging 40QA Unit

HEX-HEAD

BOLT

*Factory supplied.

Fig. 12 — Routing Wires Over Piping

IMPORTANT: The factory-supplied piston MUST

be installed as shown in Fig. 13.

NOTE: DO NOT install a piston on 38HDS systems. Refrigerant control is handled by a TXV (thermostatic expansion valve) in the 38HDS unit in these systems.

For special applications, such as long lines or raised elevations, consult the Application Data section of the Product Data literature for specific system requirements. The

arrow on theAccuRatert device body must face away from

the indoor coil.

e. On heat pump (38QRC) installations, install factory-

supplied piston (enclosed in a bag taped inside the outdoor unit) into the AccuRater metering device located

in the service valve on the outdoor unit (Fig. 14).

IMPORTANT:The factory-supplied piston MUST

be installed as shown in Fig. 14.

Make sure Teflon seal on the piston faces toward the

outdoor unit. Use Table 5 to verify you have the required piston size for the system being installed. For

special applications, such as long lines or raised elevations, consult the Application Data section of the Product Data literature for specific system requirements.

8

NOTE: Arrow onAccuRater® body points in

from the indoor coil.

free flow

direction away

Fig. 13 — AccuRater Metering Device in Liquid

Line (Bypass Type Components), 38HDC and QRC

Systems Only

f. Refer to 38HDC, 38HDS, and 38QRC Installation,

Start-Up and Service Instructions for additional outdoor unit installation information.

g. Install a liquid line filter drier near the 38HDC or QRC

outdoor unit. On heat pump systems, a bi-flow filter

drier must be used.

3. Insulate and caulk wall openings to reduce air infiltration

and refrigerant pipe vibrations on structure.

4. Evacuate piping, if necessary. If either refrigerant piping

or the indoor coil is exposed to atmospheric conditions,

it must be evacuated to 1000 microns to eliminate contamination and moisture in the system. Refer to Carrier’s

Standard Service Techniques Manual, Chapter 1, Sections 1-7.

Table 4 — Required Piston Size for AccuRater Metering Device, Cooling-Only Systems

NOTE: Teflon Seal must face toward the outdoor heat pump unit.

Fig.14 —AccuRaterMetering Deviceat ServiceValve

(Bypass Type Components),

38QRC Systems Only)

INDOOR

UNIT 40QAB

024† 018 53 3.7

024 024 57 5.5

036

048 048 84 7.4

060 060 93 13.6

*Charge is based on 25 ft of interconnecting tubing. Charge may need to be added for longer tubing runs or when used with certain fan coil units.

†Unit is field reconfigured for 18,000 Btuh operation. See Before Installation section on page 3 for reconfiguration details. Check outdoor unit name-

plate for required charge.

NOTES:

1. All pistons are Chattleff 9B9 type.

2. All cooling units have a full factory charge for the smallest possible system combination.

3. Service valves are front-seating type.

OUTDOOR

UNIT 38HDC

030 65 5.6

036 70 5.4

PISTON SIZE

REQUIRED

REQUIRED SYSTEM

CHARGE (lb)*

Table 5 — Required Piston Size for AccuRater Metering Device, Heat Pump Systems

INDOOR

UNIT 40QAE

024† 018 55 49 4.3

024 024 55 49 6.3

036

048 048 84 78 10.0

060 060 96 82 11.9

*Charge is based on 25 ft of interconnecting tubing. Charge may need to be added for longer tubing runs or when used with certain fan coil units.

Check outdoor unit nameplate for required charge.

†Unit is field reconfigured for 18,000 Btuh operation. See Before Installation section on page 3 for reconfiguration details. Check outdoor unit

nameplate for required charge.

**Single phase/3 phase.

NOTES:

1. All pistons are Chatleff 9B9 type.

2. All heat pumps have a holding charge only as shipped from the factory.

OUTDOOR

UNIT 38QRC

030 63 55 6.4

036 63 61 7.5/8.7**

INDOOR PISTON

SIZE (COOLING)

OUTDOOR PISTON

SIZE (HEATING)

REQUIRED SYSTEM

CHARGE (lb)*

9

Step 5 — Connect Condensate Drain Line

Observe all local sanitary codes when installing conden-

—

sate drains. Refer to Fig. 3 and 15 for drain pipe connection

from indoor unit.

1. Use hardpolyvinyl chloride (PVC) pipe material with nominal ID of 3/4 in. to connect at drain line. Use pipe insulation 1/4-in. thick, such as Armaflex insulation, on exposed piping inside the conditioned space.

2. To ensure regular flow of condensate water,the drain pipe

should be pitched toward an open drain or sump at a downward slope of at least 1/4-in. per ft.

3. Attach plate with screws under piping hole.

4. Attach drain pipe with nylon wire tie passing through hole

(Fig. 16).

NOTE: Do not fasten nylon wire ties tight enough to deform the insulation, as this affects its performance.

5. Insulate condensate drain line(s) that are located in or above

an occupied area with a condensate-proof material such

as polyurethane or neoprene.

6. Install an external trap at the end of the condensate line.

NOTE: Should your particular installation require one,

a condensate pump may be ordered as a field-installed

accessory.

Table 6 — Required Piston Size for AccuRaterT Metering Device, Cooling-Only Condensing Units With

Heat Pump Fan Coil Units

INDOOR

UNIT 40QAE

024† 018 52 3.6

024 024 53 6.2**

036

048 048 84 7.4

060 060 93 13.6

*Charge is based on 25 ft of interconnecting tubing. Charge may need to be added for longer tubing runs or when used with certain fan coil units.

Check outdoor unit nameplate for required charge.

†Unit is field reconfigured for 18,000 Btuh operation. See Before Installation section on page 3 for reconfiguration details. Check outdoor unit

nameplate for required charge.

**Combination may require charge in addition to what is factory supplied.

NOTES:

1. All pistons are Chattleff 9B9 type.

2. All cooling units have a full factory charge for the smallest possible system combination.

3. Service valves are front-seating type.

OUTDOOR

UNIT 38HDC

030 63 5.6

036 65 5.6

PISTON SIZE

REQUIRED

REQUIRED SYSTEM

CHARGE (lb)*

1—Air Delivery Louvers

2—Air Filters

3—Remote Thermostat

4—Drain Pipe

5—Interconnecting Tubing and Wire

6—Outdoor Unit (38HDC Shown)

7—Outdoor Unit Disconnect Switch

8—Indoor Unit Disconnect Switch

Fig. 15 — Component Location (Typical Ceiling-Suspended System)

10

Fig. 16 — Routing Drain Piping

Step 6— Make Electrical Connections — Be sure

field wiring complies with local building codes and NEC,

and unit voltage is within limits shown in Table 7.

Contact local power company for correction of improper

line voltage.

To avoid personal injury or damage to unit, do not make

electrical connections until all power sources are shut

down, locked out, and tagged off. Failure to do so could

result in personal injury or unit damage.

Operation of unit on improper line voltage constitutes

abuse and could affect warranty. Refer to Table 7 for

permissible operating limits. Do not install unit in system where voltage may fluctuate above or below permissible limits.

NOTE: Use copper wire only between disconnect switch(es)

and unit.

NOTE: Install branch circuit disconnect of adequate size to

handle unit starting current per NEC. Locate disconnect within

sight from and readily accessible from unit, per Section 440-14

of NEC. Some codes allow indoor unit to share disconnect

with outdoor unit if disconnect can be locked; check local

code before installing in this manner.

1. Route ground and power wires.

According to NEC and most local codes, the unit must

have an uninterrupted, unbroken ground to minimize personal injury if an electric fault should occur. The ground

may consist of electrical wire or metal conduit when installed in accordance with existing electrical codes. Failure to follow this warning could result in an electric shock,

fire, or death.

2. Route line power leads (see Fig. 17) from indoor disconnect to the fan coil unit. Place wire through hole on the

control box (Fig. 18). Connect wire to high voltage terminal board (TB1) and ground screw. When routing the

wire in the unit, use care to keep the wire away from refrigerant and condensate piping and any sharp edges. The

208/230 V units are factory wired for 230 V to 24-V transformer operation. For 208 V to 24-V operation, interchange blue (208 V) and red (230 V) wires. Cap any unused wires with wire nuts.

Table 7 — Electrical Data

UNIT

40QA

B024†

B036

B048

B060 208/230 187 253 1.3

E024† 208/230 187 253 0.5

E036 208/230 187 253 1.3

E048 208/230 187 253 1.0

E060 208/230 187 253 1.3

AWG — American Wire Gage

FLA — Full Load Amps

MCA — Minimum Circuit Amps per NEC Section 430-24

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

*Permissible limits of the voltage range at which units will operate satisfactorily.

†Electrical data is the same for both the 24,000 Btuh 024 unit and the 024 unit which has been field-reconfigured for 18,000 Btuh. Refer to Before

Installation section on page 3 for reconfiguration details.

Volts

(Single-Ph,

60 Hz)

115 104 127 1.2

208/230 187 253 0.5

115 104 127 4.0

208/230 187 253 1.3

115 104 127 2.2

208/230 187 253 1.1

MINIMUM

OPERATING

VOLTAGE*

LEGEND

MAXIMUM

OPERATING

VOLTAGE*

Motor 1 Motor 2

FLA Hp FLA Hp kW FLA MCA MOCP FLA

FAN

1

⁄

15

− − − − 1.50 15 1.20 14

1

⁄

15

− − − − 0.63 15 0.50 14

1

⁄

6

− − − − 5.00 15 4.00 14

1

⁄

6

− − − − 1.60 15 1.30 14

1

⁄

15

1.01⁄

1

⁄

15

0.51⁄

1

⁄61.3

1

⁄

15

1

⁄

6

1

⁄

15

1

⁄61.3

1

− − 2.00 8.66 9.29 15 11.29 14

− − 3.00 13.00 17.70 20 14.30 14

0.51⁄154.00 17.40 23.80 25 19.00 12

1

HEATER POWER

15

− − 4.00 15 3.20 14

15

− − 2.00 15 1.60 14

⁄

6

− − 3.30 15 2.60 14

⁄65.00 21.70 28.70 30 24.30 10

MIN

WIRE

SIZE

(AWG)

11

Step 7— Install Remote Thermostat— The 40QA

unit is equipped with a remote thermostat which operates

the system. The thermostat monitors the system operation

and controls the operating mode. To change settings or modes

of operation, use the thermostat (see Fig. 19).

Mount thermostat to a wall in the occupied space using

2 field-supplied screws. Locate the thermostat in an area which

is not subjected to drafts or direct sunlight through

windows. Locate thermostat on an interior wall whenever

possible.

Step 8 — Make Connections Between Indoor

and Outdoor Units —

TB — Terminal Block

Fig. 17 — Line Power Connections

The thermostat is wired

between the indoor and outdoor units to make the system

complete.

Wirethermostat to fancoil unit according to Fig. 20 (coolingonly systems or condensing units matched with heat pump

fan coil units) or Fig. 21 (heat pump only systems). Refer to

Cooling-Only Systems and Heat Pumps Systems sections below to wire thermostat from fan coil unit to outdoor unit.

COOLING ONLY SYSTEMS — The following connections must be made to the 38HDC or HDS unit for it to operate as a system with the indoor unit:

Route 2 wires of field-supplied 18-gage AWG (American

Wire Gage) thermostat cable between the low-voltage terminal block of the fan coil unit and the 38HDC unit lowvoltage terminal block. Connect the wires Y1 to Y and C to

C. See Fig. 20.

HEAT PUMPSYSTEMS —The following connections must

be made to the 38QRC unit for it to operate as a system with

the indoor unit:

Route 6 wires of field-supplied 18-gage AWG thermostat

cable between the low-voltage terminal block of the fan coil

and the 38QRC unit low-voltage terminal block. Connect Y1

to Y, R to R, O to O, G1 to G, W2 to W2, and C to C with

the wires. See Fig. 21.

The 38QRC heat pump unit uses a timed defrost method.

The timed defrost can be field set for 30, 50, or 90 minutes.

The timed defrost is factory set for 90 minutes.

ASM — Air Sweep Motor

ASR — Air Sweep Relay

EQUIP GND — Equipment Ground

FL — Fuse Link

FPT — Freeze Protection Thermostat

HP — Heat Pump

HR — Heater Relay

HTR — Heater

HTT — Heater Temp. Thermostat

IFM — Indoor-Fan Motor

NOTES:

1. If any of the original wire furnished must be replaced, it must be

replaced with type 90 C wire or its equivalent.

2. Wire in accordance with NEC and local codes.

NEC — National Electrical Code

PCB — Printed Circuit Board

PL — Plug

TB — Terminal Board

TRAN — Transformer

Terminal (Marked)

Terminal (Unmarked)

Splice

Fig. 18 — Control Circuit Connections Arrangement

Terminal Block

Factory Wiring

Field Power Wiring

Field Control Wiring

Printed Circuit Board

Accessory or Optional Wiring

3. Transformer is thermally protected and will reset automatically.

4. Indoor-fan motor(s) are inherently thermally protected.

12

Mode

Fan

Air Sweep

Day/Night

Fig. 19 — Remote Thermostat

START-UP

Never operate unit without a filter or with grille removed; damage to the unit or personal injury may result.

Make the followingchecks and complete the Start-Up Checklist on pg CL-1 before system start-up. Refer to 38HDC,

38HDS, or 38QRC Installation, Start-Up and Service Instructions

for system start-up instructions and refrigerant charging

methods.

1. Check condensate drainage system:

a. Remove grille and frame from the unit.

b. On the opposite side of the drain connection, insert a

water bottle up into the fan coil unit and fill drain pan.

Refer to Fig. 22.Watermust flow steadily; if not, check

the pipe slope or inspect for any pipe restrictions.

TB — Terminal Block

*Heat pump units only.

Fig. 20 — CoolingOnly Systems or Condensing Unit

Matched with Heat Pump Fan Coil Unit Thermostat

Wiring

2. Make sure that all wiring connections are correct and that

they are tight.

3. Check that all barriers, covers, and panels are in place.

Ensure that the filters and return-air grilles have been

installed and that the discharge louvers are positioned

correctly.

After Extended Shutdown — If the system has been

turned off for more than 12 hours, turn on the indoor and

outdoor unit disconnect switches to supply power to the system for 12 hours BEFORE starting the system.

SeasonalChangeovers — When changing heat pump

system from cooling to heating or heating to cooling, or before starting cooling only system after it has been out of use

for the winter season, perform the following steps BEFORE

starting the system:

1. Inspect and clean the outdoor unit, particularly the coil.

2. Clean or replace the air filters in the indoor unit.

3. Clean the indoor unit drain pan and drain pipe, and remove any obstructions.

4. Turn on indoor and outdoor unit disconnect switches to

supply power to the system 12 hours before starting the

system.

13

LEGEND

DFB — Defrost Board

DFT — Defrost Thermostat

TB — Terminal Block

Fig. 21 — Heat Pump System Thermostat Wiring

Fig. 22 — Inserting Water into Drain Pan

Adjusting Airflow

AUTOMATIC AIR SWEEP — All units are equipped with

an automatic air sweep feature which automatically directs

the airflow louvers up and down to provide optimum room

air circulation. If the auto. sweep feature is not desired, temporarily start the auto. sweep using the remote thermostat

(press Air Sweep button). When the louvers are in the desired position, turn the auto. sweep off (press Air Sweep button again) to hold them in that position.

OperatingMode Memory — After the system is turned

off or after a power failure, the system remains in the last

operating mode selected. When the system is turned back

on, or when power is automatically restored, operation continues in the same operating mode as when the system shut

down.

AutomaticOperation (Auto.) Mode— If auto. mode

is selected, the system automatically switches over the 40QAE

operating mode from heating to cooling, or from cooling to

heating (heat pump system only) depending on the selected

temperature.Auto. mode also controls fan speed if not manually overridden.

NOTE: Between the cooling cycle and the heating cycle there

is a neutral zone of approximately 2° F above and 2° F below the selected temperature when only the fan is operating.

OperatingSequence — Ceiling-suspended fan coil units

have a relay board which controls system operation in response to a room thermostat. The user may manually select

any one of 3 fan speeds for unit operation. Ceiling-suspended

systems may be equipped with an accessory power ventilation kit and/or condensate pump.

FAN OPERATION — Fan speed can be selected by pressing the fan button (high, medium, or low speed choices).

The fan(s) is capable of operation when unit mode is set on

either cooling, heating, or auto. mode. When the fan(s) is

operating in medium or high speed and the unit is equipped

with the power ventilation kit, the ventilation fan will operate to provide fresh air. If the mode is set to the AUTO.

position, then the fan will operate with the outdoor unit compressor.

COOLING MODE OPERATION — When the room thermostat senses a demand for cooling, the fan coil relay board

is energized. The indoor fan(s) will start in the selected speed

(if it is not already operating). The reversing valve (40QAE

only) will energize and switch to the cooling position.

The internal condensate pump (if so equipped) runs whenever the reversing valve is energized (40QAE only) and/or

the unit is in cooling. As long as the condensate float switch

and freeze protection thermostat are closed, the cooling relays in the fan coil unit will close. This energizes the compressor and outdoor fan in the outdoor unit.

The compressor will continue to operate until the room

thermostat is satisfied. When the cooling demand is satisfied, the compressor and outdoor fan will stop. If the outdoor unit is equipped with accessory Time Guardt device,

the unit will not allow a new call for cooling for 5 minutes.

If the system is in the AUTO. position, the indoor fan will

stop with the compressor. If the unit has the accessory ventilation kit, the ventilation fan will operate whenever the indoor fan is set for medium or high speed.

HEAT PUMPOPERATION (40QAE Only) — When the room

thermostat senses a demand for heating, the fan coil relay

board is energized. The indoor fan will start in the selected

speed (if not already operating), and the reversing valve will

not be energized. The internal condensate pump (if supplied) and freeze protection thermostat are not operated during heating operation. The control relay (CR2) closes, and

the compressor and outdoor fan are energized through the

defrost board (DFB), which is located in the outdoor unit.

The microprocessor logic in the DFB is energized when the

compressor starts, and the defrost timer runs. Once every

90 minutes (factory default setting) of compressor run time,

the DFB logic checks the defrost thermostat (DFT). If the

DFT is open, the unit continues in heating operation. If the

DFT is closed, the DFB switches the unit to defrost mode.

The timing on the DFB may be set at either 30, 50, or 90

minutes.

14

DEFROST (40QAE Only) — The DFB energizes the RVS

(reversing valve solenoid), and the reversing valve switches

to the cooling position. The K1 relay on the DFB opens and

the outdoor fan stops. The W2 contact on the DFB is also

energized, which in turn energizes the defrost relay on the

fan coil relay board, turns off the electric heater and stops

the indoor fan.

The DFB logic checks the 10-minute defrost timer and

the DFT. If the DFT opens in less than 10 minutes, the DFB

switches the unit back to normal heating operation. If the

DFT remains closed, the DFB switches the unit back to heating operation after 10 minutes. When the DFB changes back

to heating mode, the RVR (reversing valve relay) is deenergized and the reversing valve switches back to heating operation. Both the outdoor and indoor fans come back on, and

if necessary, the electric heater also turns on.

SYSTEM SAFETIES — The system is equipped with the

following safety devices to protect system components:

A. Indoor coil freeze protection thermostat (40QAE unit cool-

ing cycle only) — If a coil temperature of 28 F or lower

is sensed, the compressor and outdoor fan will be shut

down until the coil temperature exceeds 28 F. The indoor fan will continue to run.

B. Condensate float switch (40QA units equipped with ac-

cessory condensate pump, cooling cycle only) — If the

level of condensate in the drain pan rises too high, the

condensate float switch will turn off the compressor and

outdoor fan until the condensate level returns to normal.

The indoor fan will continue to run.

C. Outdoor Unit Safeties — These units are protected by

the following devices:

• high-pressure switch

• low-pressure switch (condensing units only)

• compressor internal overloads

• outdoor-fan motor internal overload

NOTE: Outdoor units with scroll compressors are also

protected by a high discharge gas temperature sensor and

a 2-minute timer to prevent possible reverse rotation of

the compressor.

Should any of these devices trip after the compressor is

energized, the Cycle-LOC™ protection device will lock out

the outdoor unit (turn it off) to prevent cycling on a safety

device.

SPECIALOPERATION,HEATING— Outdoorcooling units

may be matched with heat pump ceiling-suspended fan coil

units to provide supplemental electric heat. All other operation is the same as a cooling-only system, except these units

have heating capability as follows:

When the room thermostat initiates a call for heating, the

electric heater is turned on. The indoor unit fan will start at

the same time if it was not already running.

When the heating requirement is satisfied, the room thermostat will open, and the heater will turn off.

CLEANING AND MAINTENANCE

Do not wash filter in water over 120 F (to avoid shrinkage). Do not expose filter to fire (to avoid fire damage).

Do not expose filter to direct sunlight. Clean filter more

frequently when air is extremely dirty.

Do not attempt to clean or service components in control box.

For proper system operation, perform the cleaningand main-

tenance operations in Table 8.

Lubrication— The indoor-fan, automatic air sweep, and

the outdoor-fan motors are factory lubricated and require no

oiling.

To Remove and Clean or Replace Air Filters

(Fig. 23)

Operating your system with dirty air filters may damage

the indoor unit and, in addition, can cause reduced cooling performance, intermittent system operation, frost

build-up on the indoor coil, and blown fuses. Inspect

and clean or replace the air filters monthly.

TO REMOVE AIR FILTERS — Remove filters by pulling

them straight out.

Fig. 23 — Cleaning Filters

To avoid the possibility of electric shock, before performing any cleaning and maintenance operations, always turn off power to the system by pressing the mode

button on the remote thermostat until the display shows

‘‘OFF,’’ and turning off the outdoor disconnect switch

located near the outdoor unit. If the indoor unit is on a

separate switch, be sure to turn this disconnect off as

well.

15

Table 8 — Cleaning and Maintenance Schedule

TASK MONTHLY QUARTERLY YEARLY

INDOOR UNIT

Clean Air Filters X

Clean Drain Pipe X

Clean Condensate Drain Pan X

Clean Indoor Coil X

Clean Indoor Unit Front Panel X

OUTDOOR UNIT

Clean the Fins From Outside X

Open the Unit and Clean Fins Inside X

Remove Dust From Electrical Parts X

Check Electrical Connections are Tight X

Clean Outdoor Fan X

Clean Outdoor Coil X

Check that Outdoor Fan Assembly is Tight X

Clean Drain Pan X

NOTE: Maintenance procedures for the outdoor units are in the 38HDC, HDS, and QRC installation instructions.

TO CLEAN OR REPLACE FILTERS — Filters can be vacuumed or washed in warm water. Shake filter to remove any

excess water, and replace by sliding filter behind grille until

filter snaps in place.

If the filter has begun to break down or is torn, replace it.

Replacement filters are available through your Carrier

distributor.

To Clean Indoor Unit Bottom Panel — If the bot-

tom panel of the unit becomes dirty or smudged, wipe the

outside of the panel with a soft dry cloth. Use a mild liquid

detergent and wipe off carefully with a dry cloth.

To Clean Indoor Coil — To clean the coil, remove in-

door unit bottom panel and vacuum the coil fins, using care

not to bend or damage fins.

To Clean Outdoor Coil (Outdoor Unit)

Some metal parts and sharp fins of outdoor unit coil can

cause personal injury during cleaning. Clean coil carefully.

To clean the outdoor coil:

1. Remove any dirt or obstruction from discharge opening.

2. Use a garden hose to spray water on the coil. Debris that

collects between coil fins inhibits heat transfer — direct

the water spray between coil fins to flush out debris.

ToClean Condensate Drains — Clean all drains and

drain pans at the start of each cooling season. Check the flow

by pouring water into the drain.

TO CLEAN OR REPLACE DRAIN PAN

1. Place a plastic sheet on the floor to catch any water that

may spill from drain pan.

2. Remove the intake grille and distribution assembly (at-

tached). See Fig. 23.

3. Remove the condensate water in the drain pan by letting

water drain into a 3-gallon bucket.

4. Remove the 4 screws holding the drain pan.

5. Carefully hold the drain pan to remove it from the

assembly.

SERVICE

When servicing unit, turn off all electric power to unit

to avoid shock hazard or injury from rotating parts.

Do not vent refrigerant to atmosphere when servicing

unit. Recover refrigerant during system repair or unit

removal.

Before Calling for Service — You may save the cost

of a service call by doing the following:

1. Be sure main power to system is turned on.

2. Press Mode button until OFF is displayed. Wait 5

minutes.

3. Press Mode button until either COOL or HEAT is displayed (as desired).

4. Adjust remote thermostat set point to desired room temperature. If system starts within a few minutes, you may

not need service. If system does not operate properly,check

Table 9 for typical solutions.

IF SYSTEM FAILS TO OPERATE — Be sure:

• unit ON/OFF switch is in ON position

• fuse or circuit breaker is not tripped

FRESH AIR INSTALLATION OPTION

The 40QA units have an installation option which allows

for field installation of fresh air ventilation. Plan your installation carefully. Before you begin, measure carefully and

follow acceptable building practices, NEC, and local codes.

Ventilation-AirAccessory — Referto ventilation air

accessory installation instructions (also see Fig. 24).

Do not use a screwdriver to pry drain pan out of

assembly — it could damage the pan.

16

TROUBLESHOOTING

If the under-ceiling fan coil unit fails to start or operate

properly,sometimes the problem is minor and can be handled

without a service call. Refer to Table 9 for some common

problems, causes, and typical solutions. See Fig. 25 and 26

for additional system troubleshooting details. If the problem

cannot be corrected, contact your local Carrier representative for further assistance.

Table9—Troubleshooting

PROBLEM CAUSE TYPICAL SOLUTION

System does

not start.

System does not

cool properly.

System does not

heat properly.

Ice or frost has

formed on

indoor coil.†

Insufficient

airflow

Blown fuse or circuit breaker tripped at building

power entry.

Indoor and/or outdoor unit disconnect switch is off. Turn on disconnect switch(es).

Thermostat is set to night mode. Cancel mode using Day/Night button on thermostat.

Power failure. Restore power.

Unit is in off mode.

Compressor three-minute timer is running. Wait for 3 minutes.

Temperature is above or below the selected temperature. Select new temperature using the thermostat.

Air filter(s) in indoor unit is dirty or needs to be replaced. Clean or replace air filter(s).

Temperature is set too high or too low.

Outdoor unit outdoor coil restricted. Remove obstruction.

Fan speed is set too low.

Air filter(s) in indoor unit is dirty or needs to be replaced. Clean or replace air filter(s).

Temperature is set too high or too low.

Outdoor unit outdoor coil restricted. Remove obstruction.

Fan speed is set too low.

Outdoor unit outdoor coil is frosted up.

Low outdoor-air temperature. Run system in fan-only mode until frost is gone.

Air filter(s) in indoor unit is dirty or needs

to be replaced.

Air filter(s) in indoor unit is dirty or needs

to be replaced.

Fan coil unit coil is blocked.

Replace fuse or reset circuit breaker.*

Press Mode button on thermostat until thermostat

displays the desired unit mode.

Reset temperature to desired comfort setting

using the thermostat.

Adjust fan speed to high or auto. using the

Fan button on the thermostat.

Reset temperature to desired comfort setting

using the thermostat.

Adjust fan speed to high or auto. using the

Fan button on the thermostat

Check manual defrost timer setting and adjust

as necessary.

Clean or replace air filter(s).

Clean or replace air filter(s).

Clean air discharge louvers.

*If fuse blows or circuit breaker trips again after firststart attempt, DO

NOT attempt to start system again. Contact your local Carrier representative for assistance.

NOTE: See Fig. 3 for dimensions.

Fig. 24 — Field Installation of Ventilation-Air Accessory

†When outdoor temperature is approximately 55 F or below, indoor

REAR VIEW

coil frosting may occur when system is operated in cooling or maximum dehumidification mode.

17

LEGEND AND NOTES (Fig. 25 and 26)

ASM — Air Sweep Motor

ASR — Air Sweep Relay

ASW — Air Sweep Switch

C—Contactor

CAP — Capacitor

CLO — Compressor Lockout

COMP — Compressor Motor

CR — Control Relay

CT — Current Transformer

DFB — Defrost Board (Outdoor Unit)

DFT — Defrost Thermostat

DR — Defrost Relay

DTS — Discharge Temperature Sensor

EQUIP GND — Equipment Ground

FL — Fuse Link

FPT — Freeze Protection Thermostat

FR — Fan Relay

FU — Fuse

GND — Ground

HP — Heat Pump

HPS — High-Pressure Switch

HR — Heater Relay

HTR — Heater

HTT — Heater Temperature Thermostat

IFM — Indoor-Fan Motor

LLPS — Liquid Low Pressure Switch

OFM — Outdoor-Fan Motor

OFR — Outdoor-Fan Relay

NOTES:

1. If any of the original wire furnished must be replaced, it must be

replaced with type 90° C wire or its equivalent.

2. Wire in accordance with National Electrical Code (NEC) and local

codes.

3. Transformer is thermally protected and will reset automatically.

LEGEND

OL — Overload

PCB — Printed Circuit Board

PDR — Pump Delay Relay

PL — Plug

PM — Pump Motor

PSS — Pump Shutoff Switch

RVS — Reversing Valve Solenoid

SC — Start Capacitor

SR — Start Relay

SSDR — Safety Switch Delay Relay

TB — Terminal Block

TDR — Time-Delay Relay

TRAN — Transformer

Terminal (Marked)

Terminal (Unmarked)

Splice

Terminal Block

Factory Wiring

Field Control Wiring

Field Power Wiring

Printed Circuit Board

Accessory or Optional Wiring

4. The IFM(S), OFM and COMP have internal thermal protection.

5. The CLO locks out the COMP to prevent short cycling on COMP

overloads and safety devices. Before replacing CLO check these

devices. Minimum one amp turn required to hold contacts closed.

6. Two 508 long low voltage wiring cables provided with unit.

18

*Heat pump fan coil units only.

Fig. 25 — Typical System Wiring; Cooling-Only Systems or Condensing Unit with

Heat Pump Fan Coil Unit Systems

19

Fig. 26 — Typical System Wiring; Heat Pump Systems

20

PACKAGED SERVICE TRAINING

Our packaged service training programs provide an excellent way to increase your knowledge of the

equipment discussed in this manual. Product programs cover:

• Unit Familiarization • Maintenance

• Installation Overview • Operating Sequence

A large selection of product, theory, and skills programs is available. All programs include a video

cassette and/or slides and a companion booklet. Use these for self teaching or to conduct full training

sessions.

For a free Service Training Material Catalog (STM), call 1-800-962-9212. Ordering instructions are

included.

Copyright 1996 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 3d 2d

PC 111 Catalog No. 534-052 Printed in U.S.A. Form 40QA-3SI Pg 22 4-96 Replaces: 40QA-1SI

I. PRELIMINARY INFORMATION

START-UP CHECKLIST

OUTDOOR UNIT: MODEL NO.

INDOOR UNIT: MODEL NO.

ACCESSORIES: __________________________________________________________________________________

PISTONS (38HDC and 38QRC SYSTEMS ONLY): INDOOR SIZE:

OUTDOOR SIZE (38QRC SYSTEMS ONLY):

REFRIGERANT PIPING: EQUIVALENT LINE LENGTH: (IF OVER 50 FT)*

LIFT: FAN COIL ABOVE OUTDOOR UNIT (IF OVER 25 FT)*?

FAN COIL BELOW OUTDOOR UNIT (IF OVER 25 FT)*?

*APPLIES ONLY TO 38HDC AND 38QRC UNITS USING LONG-LINES APPLICATIONS. MAXIMUM EQUIVALENT

LINE LENGTH FOR 38HDS SYSTEMS IS 50 FT. MAXIMUM LIFT ON 38HDS APPLICATIONS IS 30 FT FROM

LOWEST SYSTEM POINT TO HIGHEST SYSTEM POINT.

SERIAL NO.

SERIAL NO.

PRE-START-UP

INDOOR UNIT (REFER TO OUTDOOR UNIT INSTALLATION INSTRUCTIONS FOR OUTDOOR UNIT

PRE-START-UP FUNCTIONS)

IS THERE ANY SHIPPING DAMAGE?

IF YES, WHERE?

WILL THIS DAMAGE PREVENT UNIT START-UP?

IS POWER SUPPLY CORRECT? (115-V FOR 40QAB024-048, 115 V UNITS; OR 208/230 V FOR

40QAB024-048, 208/230 V UNITS AND ALL 40QAB060 AND 40QAE024-060 UNITS. ALL SYSTEMS REQUIRE

SINGLE-PHASE POWER)

HAS GROUND WIRE BEEN CONNECTED?

HAS THE CORRECT SIZE FUSE OR HACR BREAKER BEEN PROVIDED?

ARE POWER WIRES TO THE UNIT SIZED AND INSTALLED PROPERLY?

IS THE DISCONNECT SWITCH INSTALLED IN SIGHT FROM THE UNIT?

IS THE LOW-VOLTAGE CABLE (INDOOR TO OUTDOOR UNIT) RUN AND CONNECTED PROPERLY?

HAS CONDENSATE DRAIN BEEN RUN, SLOPED, AND TRAPPED PROPERLY?

IS AIR FILTER(S) IN PLACE?

IS UNIT MOUNTED LEVEL?

IS COOLING PISTON INSTALLED (FIG. 13), THE CORRECT SIZE, AND IN THE CORRECT DIRECTION

(38HDC AND 38QRC SYSTEMS ONLY)?

IS HEATING PISTON INSTALLED (FIG. 14), THE CORRECT SIZE, AND IN THE CORRECT DIRECTION

(38QRC SYSTEMS ONLY)?

PIPING

IS A LIQUID LINE SOLENOID INSTALLED IF REQUIRED BY LONG-LINE APPLICATIONS

(38HDC AND 38QRC SYSTEMS ONLY)?

IS FILTER DRIER INSTALLED AT THE OUTDOOR UNIT (38HDC AND 38QRC SYSTEMS ONLY)?

HAVE LEAK CHECKS BEEN MADE AT THE COMPRESSOR, OUTDOOR UNIT, FLARE CONNECTIONS, FILTER

DRIERS, AND FUSIBLE PLUGS WITH A LEAK DETECTOR?†

†FIELD PIPING AND ALL TUBING CONNECTIONS MUST BE LEAK TESTED BY THE PRESSURE METHOD DE-

SCRIBED IN CARRIER GENERAL TRAINING FOR AIR CONDITIONING MANUAL (GTAC2), MODULE 5. USE

R-22 ATAPPROXIMATELY 25 PSIG BACKED UP WITH AN INERT GAS TO REACH A TOTALSYSTEM PRESSURE

NOT TO EXCEED 245 PSIG.

CL-1

START-UP CHECKLIST (cont)

HAS PIPING SYSTEM BEEN EVACUATED TO 1000 MICRONS (IF REQUIRED)?

HAS SYSTEM CHARGE BEEN WEIGHED IN (IF REQUIRED)?

HAVE SERVICE VALVES BEEN FULLY BACKSEATED?

CHECK VOLTAGE: IS VOLTAGE WITHIN RANGE SHOWN FOR UNIT (WITH UNIT OPERATING)?

OUTDOOR INDOOR

START-UP

IF UNIT HAS A CRANKCASE HEATER, HAS IT BEEN ON FOR 24 HOURS?

MEASURE AND RECORD THE:

AIR ENTERING OUTDOOR UNIT:

AIR ENTERING INDOOR UNIT:

DISCHARGE LINE TEMPERATURE:

VAPOR LINE TEMPERATURE:

MEASURE AND RECORD THE:

VAPOR LINE PRESSURE:

DISCHARGE PRESSURE:

F

F

F

F

PSIG

PSIG

Copyright 1996 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 3d 2d

PC 111 Catalog No. 534-052 Printed in U.S.A. Form 40QA-3SI CL-2 4-96 Replaces: 40QA-1SI

Loading...

Loading...