Carrier 40GXC, 38GXC Cooling, 40GXQ, 38GXQ Heat Service Manual

40GXC / 38GXC Cooling Only

40GXQ / 38GXQ Heat Pump

Inverter---Driven High Wa ll Duct ---Free Spl it System

Sizes 009 to 012

Service Manual

INTRODUCTION

This Service Manual provides the necessary information to service,

repair, and maintain the 38/40GXC(Q).

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 1.........................

MODEL / SERIAL NUMBER NOMENCLATURE 2.........

STANDARD FEATURES AND ACCESSORIES 3...........

SPECIFICATIONS 4...................................

DIMENSIONS 5......................................

CLEARANCES 6.....................................

SYSTEM OPERATING ENVELOPE 7....................

ELECTRICAL DATA 7................................

WIRING 7...........................................

CONNECTION DIAGRAMS 7..........................

WIRING DIAGRAMS 8--9..............................

REFRIGERATION CYCLE DIAGRAM 10.................

REFRIGERANT LINES 11.............................

SYSTEM EVACUATION AND CHARGING 11.............

CONTROL SYSTEM 12--13............................

SEQUENCE OF OPERATION 13........................

MODES OF OPERATION 13--15.........................

TROUBLESHOOTING 16..............................

DIAGNOSTIC CHARTS 23.............................

APPENDIX 24--27....................................

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury, or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory--authorized kits or accessories

when modifying this product. Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in

literature and attached to the unit. Consult local building codes and

National Electrical Code (NEC) for special requirements.

Recognize safety information. This is the safety--alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand these signal words: DANGER, WARNING, and

CAUTION. These words are used with the safety--alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out and

tag switch with a suitable warning label.

WARNING

!

!

MODEL NUMBER NOMENCLATURE

INDOOR UNIT

40 GXQ 1--- 01

009

---

38/40GXQ

Fan Coil Unit

A ir --- C o o l e d Con d e n s e r

Unit Type

GXQ --- He a t P u m p

GXC --- C o o l i n g On l y

Nominal Capacity

009 --- 3 / 4 To n

012 --- 1 T o n

OUTDOOR UNIT

38 GXQ 1--- 01

Unit Type

GXQ --- He a t P u m p

GXC --- C o o l i n g On l y

009

Nominal Capacity

009 --- 3 / 4 To n

012 --- 1 T o n

---

Volt age

1 --- 1 1 5 --- 1 --- 6 0

Volt age

1--- 1 1 5 --- 1 --- 6 0

Week of Manufacture

Year of Manufacture

SERIAL NUMBER NOMENCLATURE

01 06

V

Manufacturing Site

00001

2

Serial Number

STANDARD FEATURES AND ACCESSORIES

Ease Of Installation

Mounting Brackets S

Low Voltage Controls S

Comfort Features

Microprocessor Controls S

Wireless Remote Control S

Rapid Cooling/Heating S

Automatic Air Sweep S

Cold Blow Prevention S

Continuous Fan * S

Auto Restart Feature S

Memory Function S

Auto Changeover S

Energy Saving Features

Inverter Driven Compressor S

Sleep Mode S

24 Hour Stop/Start Timer S

Safety And Reliability

Indoor Unit Freeze Protection S

3MinuteCompressorTimeDelay S

High Compressor Discharge Temperature S

Low Voltage Protection S

Compressor Overload Protection S

Compressor Over current Protection S

IPM Module Protection S

Ease Of Service And Maintenance

Cleanable Filters S

Diagnostic LED’s On Outdoor Board S

Error Messages Displayed Front Panel S

Application Flexibility

Condensate Pump A

Wind Baffle F

Standard Warranty

6 Year Compressor Limited Warranty* S

2 Year Parts Limited Warranty* S

Extended Warranty

6 --- 1 0 Ye a r C o m p r e s s o r O n l y O

2 --- 6 Ye a r P a r t s O n l y O

2 --- 6 Ye a r P a r t s ; 1 --- 6 Y r L a b o r O

2 --- 6 Y r P a r t s ; 6 --- 1 0 Y r C o m p r e s s o r O n l y ; 1 --- 6 Y r L a b o r O

Legend

S Standard

A Accessory

O Optional

F Field Fabricated

* For Residential applications. For Commercial applications, warranty is 1

year for parts and 5 years for compressor.

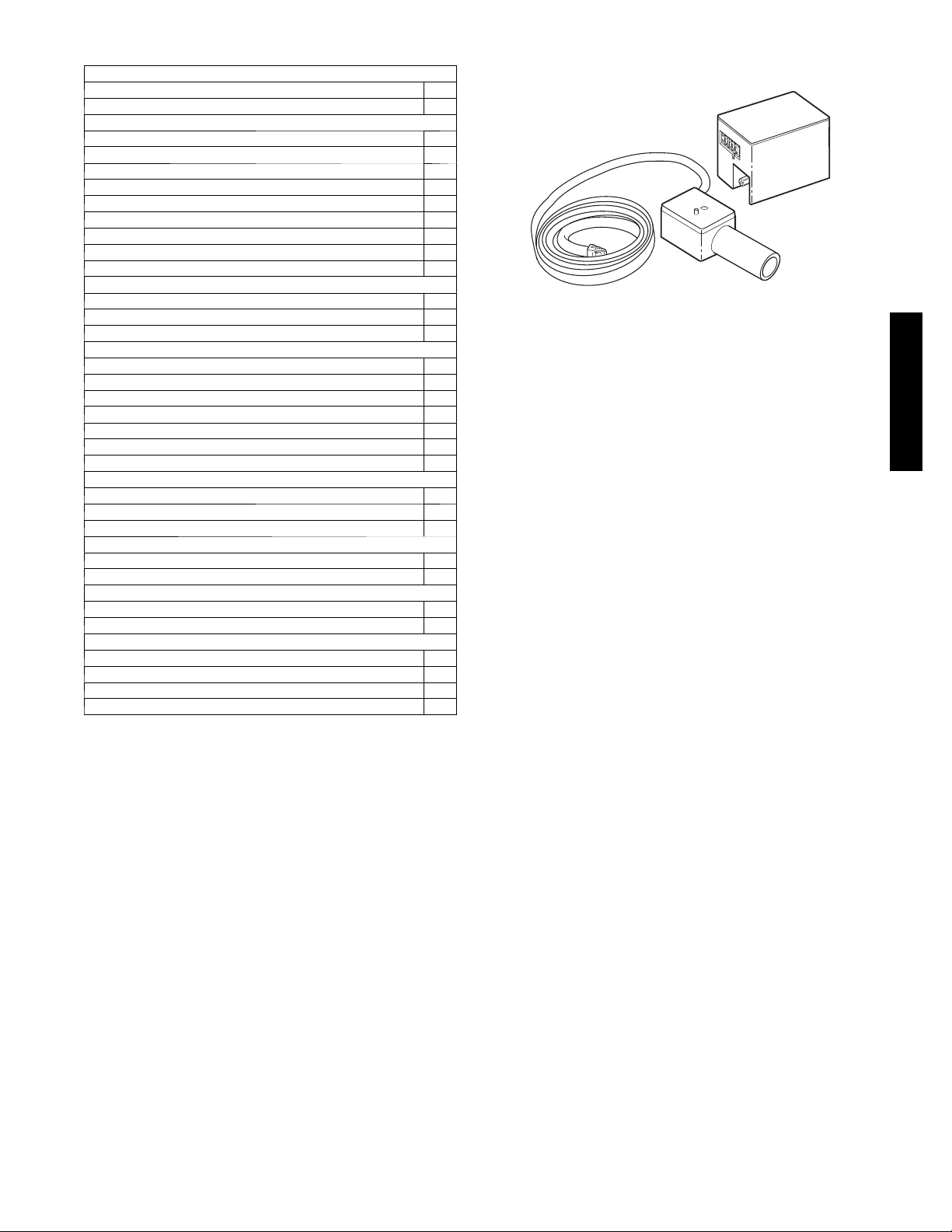

INDOOR UNITS

On high wall fan coils, the condensate pump accessory is

recommended when adequate drain line pitch cannot be provided,

or when the condensate must move up to exit.

The pump has a lift capability of 12 ft (3.6 m) on the discharge side

if the pump is mounted in the fan coil or 6 ft (1.8 m) on the suction

side if the pump is remote mounted.

A07892

Fig. 1 – Condensate Pump Accessory

38/40GXQ

3

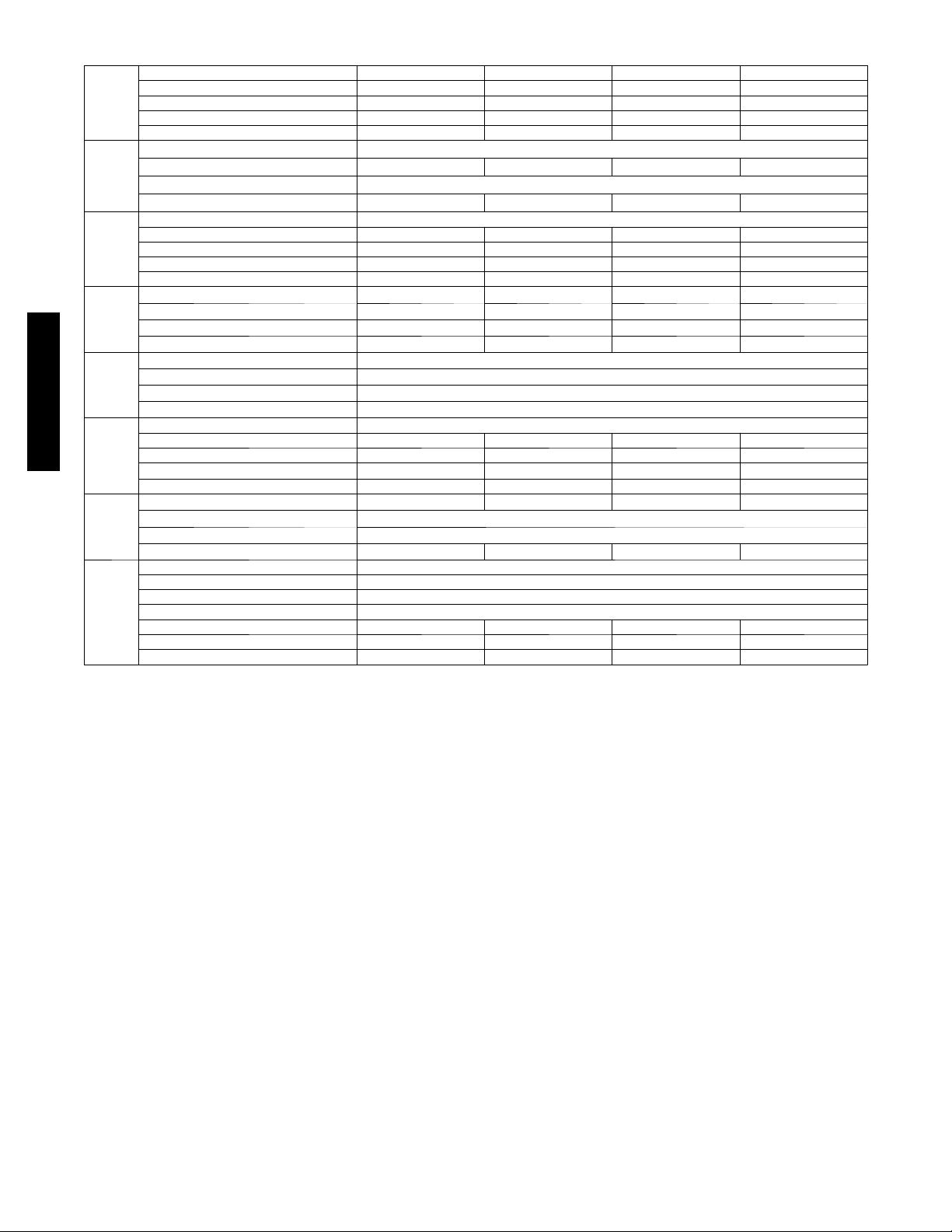

PRODUCT SPECIFICATIONS

System Model Number 53GXC009 --- --- --- 1 5 3 G X C 0 1 2 --- --- --- 1 5 3 G X Q 0 0 9 --- --- --- 1 53GXQ012 --- - -- - -- 1

System Voltage 115 V 115 V 115 V 115 V

Control Voltage 0 --- 2 4 v D C 0 --- 24 v D C 0 --- 2 4 v D C 0 --- 2 4 v D C

Capacity (Btuh) Clg/Htg 8,600/--- 12,000/--- 8,600/10,800 12,000/11,200

System

SEER/HSPF 16/--- 16/--- 16/7.7 16/7.7

Refrigerant Type R---410A

Design Pressure (PSIG) 560 560 560 560

Metering Device Capillary Tube at Outdoor

Refrigerant

Charge (lb) 2.65 2.8 2.65 2.8

Type Twin Rotary Inverter Driven

Model C---6RZ092H1AB C---6RZ092H1AB C---6RZ092H1AB C---6RZ092H1AB

O il C h a r g e (POE --- o z ) 11.6 11.6 11.6 11.6

Rated Current (RLA) 4 3.92 4 3.92

Locked Rotor Amp (LRA) 33 33 33 33

Compressor

Rpm/CFM 830/1060 830/1060 830/1060 830/1060

Diameter (in) .. No. of Blades 15.7 … 3 15.7 … 3 15.7 … 3 15.7 … 3

Motor (hp) 0.04 0.04 0.04 0.04

Motor

Outdoor

Capacitor 2.5µF/450VAC 2.5µF/450VAC 2.5µF/450VAC 2.5µF/450VAC

Face Are a (sq. f t) 3.5

No. Rows 2

Coil

Fins per inch 18

Outdoor

Circuits 2

38/40GXQ

Motor Watts/HP 20/0.027

Rpm/Cfm (High) 1200/290 1350/315 1200/290 1350/315

Rpm/Cfm (Medium) 1060/245 1200/268 1060/245 1200/268

Motor

Indoor

Rpm/Cfm (Low) 700/224 1100/245 700/224 1100/245

Blower Diameter … Length (in) 3.8 … 23 3.6 … 24.3 3.8 … 23 3.6 … 24.3

Face Are a (sq. f t) 2.4 2.4 2.4 2.4

No. Rows 2

Coil

Fins per inch 18

Indoor

Circuits 2 3 2 3

Connection Type Flare

Liquid (Mix Phase) (in) OD 1/4”

Vapor Line (in) OD 1/2”

Condensate Dr ain (in) ID = 1/2” OD=5/8”

Lines

Maximum Length (ft) 65 65 65 100

Refrigerant

Max Lift (Fan Coil Above) (ft) 35 35 35 50

Max Drop (Fan Coil Below) (ft) 35 35 35 50

4

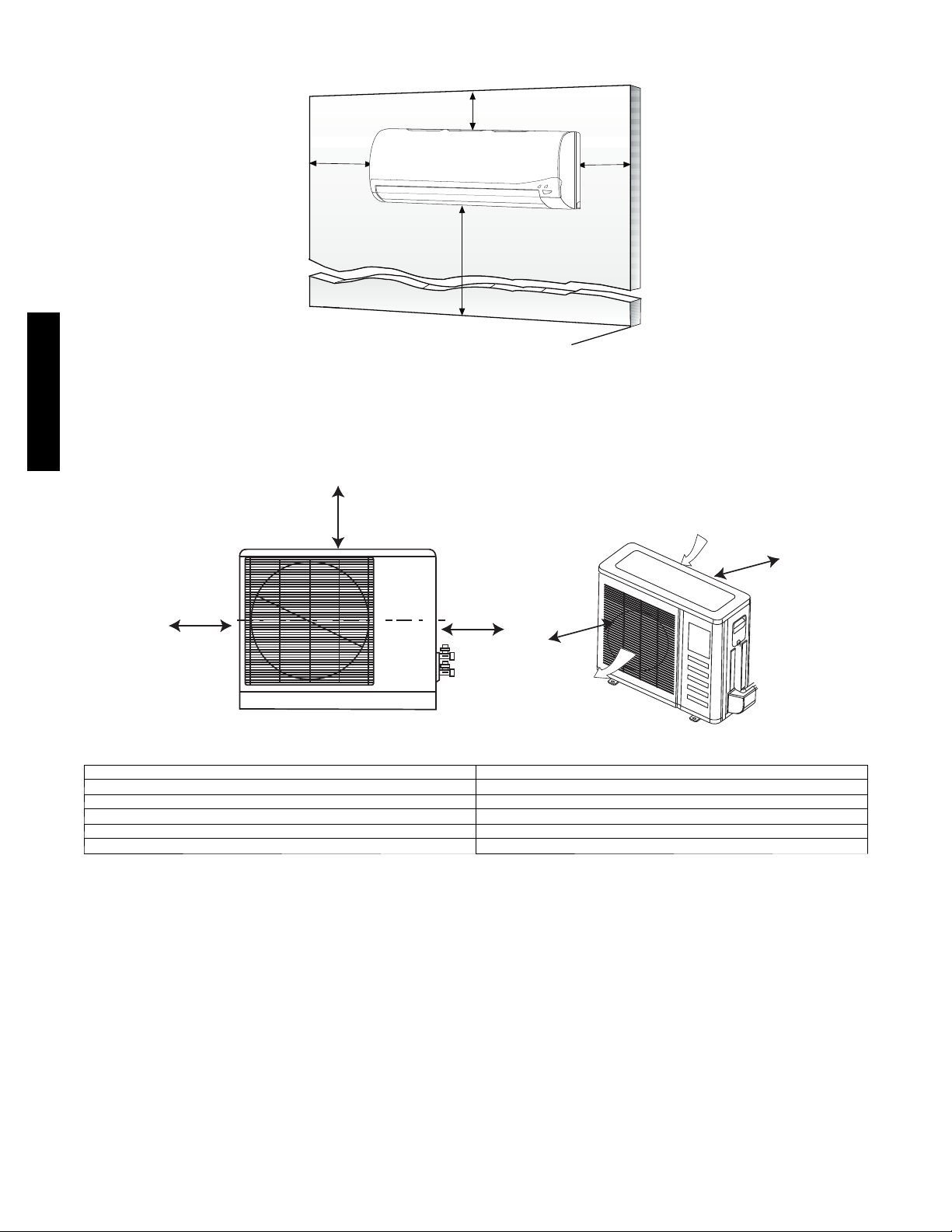

DIMENSIONS -- INDOOR

H

Unit Size

9k 30.3 (770) 9.8 (250) 7.84 (1.99) 18.7 (8.5)

12k 32.7 (830) 11.2 (285) 8.9 (225) 24.2 (11)

In. (mm)

DIMENSIONS -- OUTDOOR

W

W

H

In. (mm)

D

In. (mm)

D

A08289

Net Operating Weight

Lbs. (Kg)

Fig. 2 – Dimensions of Indoor Unit

38/40GXQ

W

D

H

Unit Size

9k & 12k 33.4 (848) 12.6 (320) 21.3 (540) 88 ( 40)

W

In. (mm)

D

In. (mm)

H

In. (mm)

Net Operating Weight

Lbs. (Kg)

Fig. 3 – Dimensions of Outdoor Unit

A08290

5

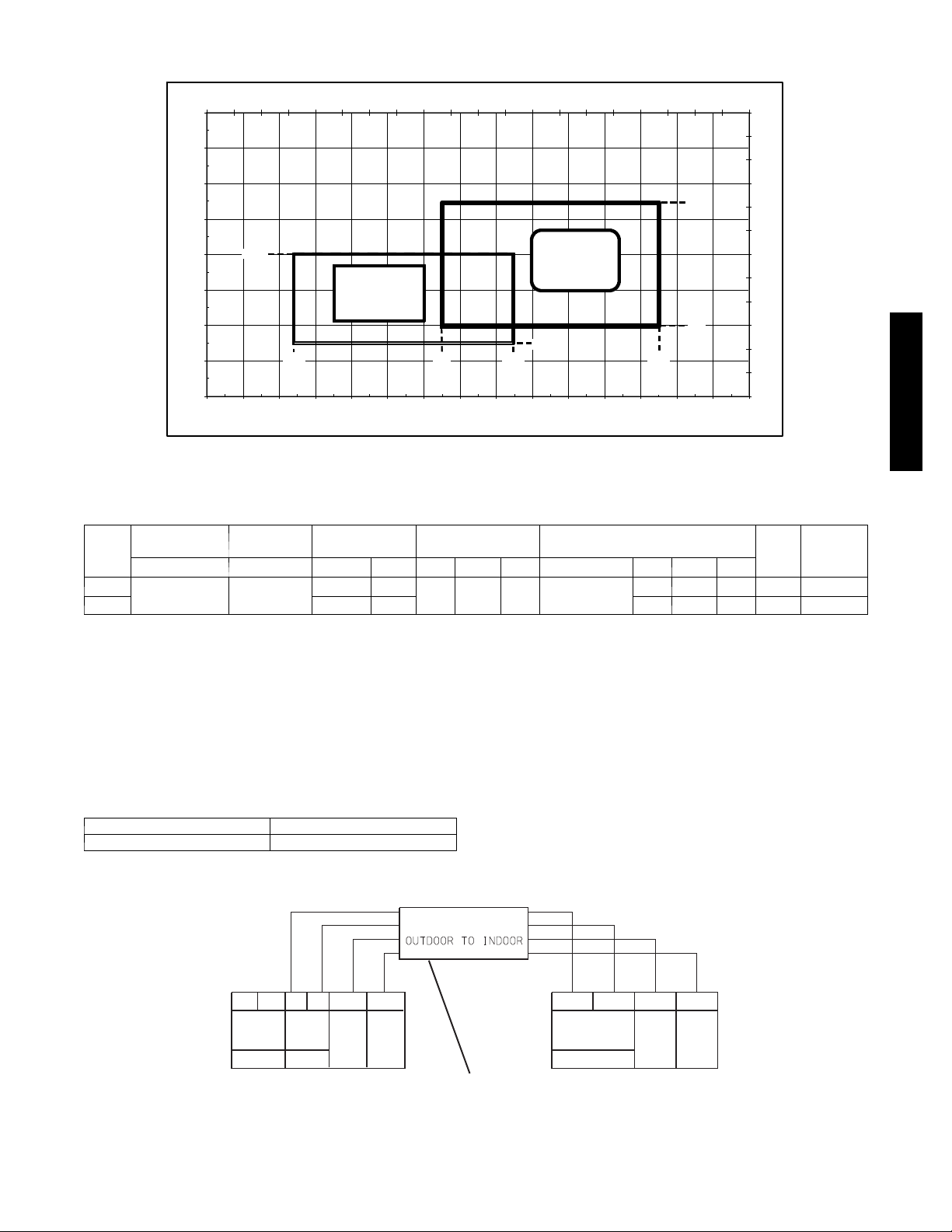

CLEARANCES -- INDOOR

38/40GXQ

CLEARANCES -- OUTDOOR

5

"

(0.13m)

min.

CEILING

6" (0.15m) min.

(1.8m)

6'

FLOOR

Fig. 4 – Indoor unit clearance

5

"

(0.13m)

min.

A07891

A

Air-inlet

E

D

B

C

Air-outlet

A07894

UNIT 12k in. (mm)

A 20 (508)

B 20 (508)

C 24 (610)

D 12 (305)

E 12 (305)

Fig. 5 – Outdoor Unit Clearance

6

38/40GXQ SYSTEM OPERATING ENVELOPE

--- 4 0 --- 3 5 --- 3 0 --- 2 5 --- 2 0 --- 1 5 --- 1 0 --- 5 0 5 1 0 1 5 2 0 2 5 3 0 3 5 4 0 4 5 5 0 5 5 6 0

Outdoor Temperature (_C)

60

55

50

45

40

35

30

25

20

15

10

Indoor Temperature (_C)

5

0

Indoor Temperature (_F)

120

110

100

90

80

70

60

50

40

80_F

14_F

Heating

Continuous

Operation

55_F

75_F

Cooling

Continuous

Operation

55_F

95_F

60_F

115_F

--- 10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140

Outdoor Temperature (_F)

NOTE: Low ambient controls cannot be used with these systems

Fig. 6 – 38/40GXQ System Operating Envelope

ELECTRICAL DATA

UNIT

SIZE

009

012 4.0 33 .45 .027 20 20 25

* Permissible limits of the voltage range at which the unit will operate satisf actorily

{ Indoor fan powered from outdoor un it.

LEGEND

FLA --- F u l l L o a d Am p s

LRA --- L o c k e d R o t o r A m p s

MCA --- Minimu m Circuit Amps

RLA --- RatedLoadAmps

SYSTEM

VOLTAGE

V O L T S --- P H --- H Z MAX/MIN RLA LRA FLA HP W VOLT S FLA HP W

1 1 5 --- 1 --- 6 0 127/104

OPERATING

VOLTAGE*

COMPRESSOR OUTDOOR FAN INDOOR FAN{

4.0 33

.6 .04 30 115

.3 .027 30 20 25

MCA

A09247

MAX

FUSE/CB

AMP

38/40GXQ

WIRING

The main power is supplied to the outdoor unit. The field supplied connecting cable from the outdoor unit to indoor unit consists of four

wires and provides the power for the indoor unit as well as the communication signal between the outdoor unit and indoor unit.

Voltage drop on the connecting cable should be kept to a minimum. Use cable size and max length below:

18 AWG 50 ft. (16 m)

16 AWG 100 ft. (33 m)

CONNECTION DIAGRAMS

CONNECTING CABLE

NL

L

Main Power

Supply

115-1-60

9 &12K Outdoor Unit

Power to

Indoor

Unit

115-1-60

N

GND

Ground Control

S

Use a four (4) Wire Cable

(Do Not use thermostat wire)

Fig. 7 – Connection Diagrams

LN

Power to

Indoor

Unit

115-1-60

9 &12K Indoor Unit

GND

Ground Control

S

A08292

7

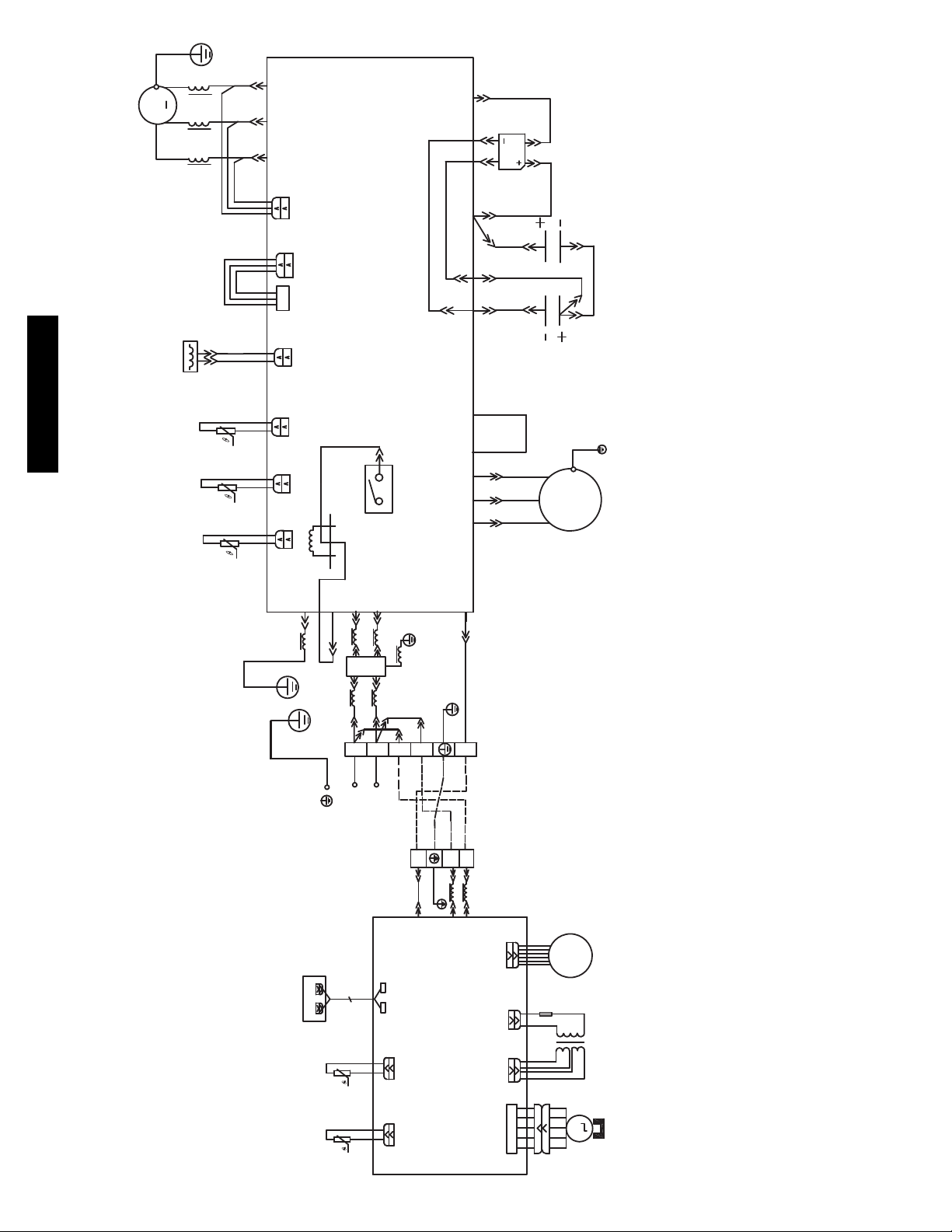

YE/GN

E

COMP

R

C

BLU

BRN

X17

BLU

AC

AC

BRN

FILTER

X9

S

GRN

WHT

GRN

V(X12) W(13)

U(X11)

WHT

CN6

RED

RED

A09344

RED

BLU

BRN

BLK

CAP

2

1

1

2

WHT

CAP

YE/GN

E

O.D. FAN

MOTOR

40GXC009/012---1

COOLING ONLY INDOOR UNIT

115-1-60

BRN

CN8

CN7

CURRENT

SENSOR

COMP.

DISCHARGE

TEMP.

OD AIR

TEMP.

OD COIL

TEMP.

SENSOR

SENSOR

38/40GXC(Q)

SENSOR

RED

YE/GN

CN4

CN1

CN2

CN3

E (X4)

X5

BRN

WHT

FILTER

BRN

MAIN

RELAY

X2 (N)

X3 (L)

WHT

4

3

E

2

1

BLU

L

N

COM NO

YE/GN

L

BRN

BLU

X6

GRN

BLU

X15

X10

X16

X7

X21 X14

X1 (COM)

BLK

YE/GN

S

N

XT2

Fig. 8 – 38--40GXC009/012 Cooling Only Wiring Diagram

L

N

WIRING DIAGRAMS

DISPLAY BOARD

RETURN

AIR TEMP.

ID COIL

TEMP.

FIELD

SENSOR

SENSOR

{

POWER

SUPPLY

X9 X12

XT

BLK

X13

X9 MK1

S

DATA1

YE/GN

N

BLU

N

AP2

BRN

L

ACL1

FAN1

X1 X2

I.D. FAN

MOTOR

TRANSFORMER

38GXC009/012---1

X3

LOUVER MOTOR

8

COOLING ONLY INDOOR UNIT

115-1-60

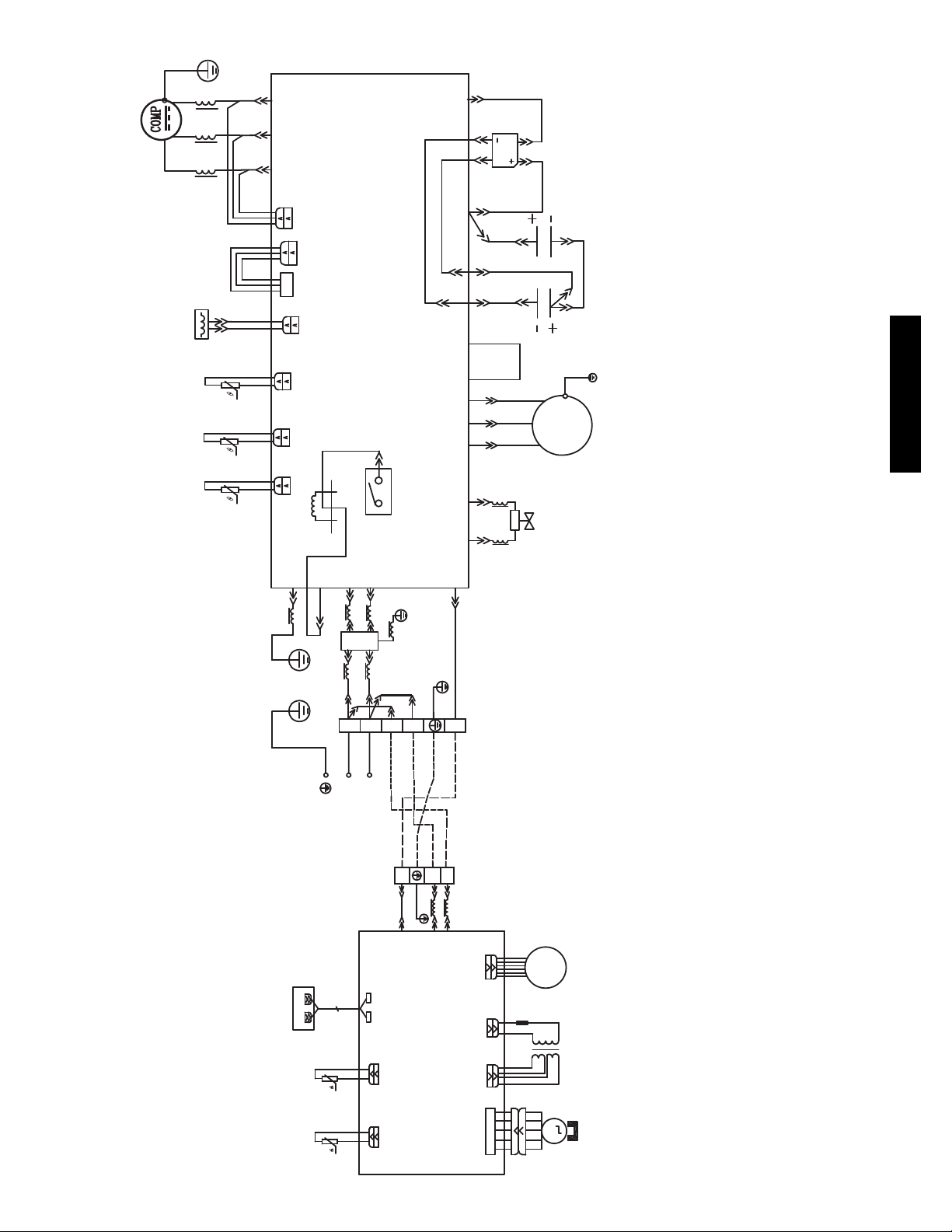

E

R

COMP.

DISCHARGE

OD AIR

OD COIL

YE/GN

C

RED

S

GRN

WHT

CURRENT

SENSOR

TEMP.

SENSOR

TEMP.

SENSOR

TEMP.

SENSOR

RED

GRN

WHT

RED

V(X12) W(X13)

U(X11)

CN6

CN7

CN1

CN2

CN3

CN8

CN4

BRN

MAIN

NO

COM

BLU

BRN

X6

X17

X9

X15

X10

X16

X7

X14

X21

X18

AC

BRN

GRN

BLU

FILTER

BRN

AC

BLU

BLK

RED

BLU

BRN

2

1

CAP

2

CAP

A09345

1

WHT

40GXQ009/012---1

HEATPUMP OUTDOOR UNIT

YE/GN

E

O.D. FAN

MOTOR

115-1-60

38/40GXC(Q)

YE/GN

X4 (E)

DISPLAY BOARD

RETURN

AIR TEMP.

X5

SENSOR

RED

FILTER

BRN

FIELD

POWER

X3 (L)

324

1

L

L

X2 (N)

WHT

E

BLU

N

N

{

SUPPLY

X12

RELAY

X9

YE/GN

XT

X13

X8

X1 (COM)

10BK

BLU

YE/GN

BRN

L

S

N

XT2

4 WAY VALVE

Fig. 9 – 38--40GXQ009/012 Heat Pump Wiring Diagram

L

S

N

BLU

BLK

BRN

YE/GN

N

ACL1

DATA1

FAN1

X2X1

AP2

TC

I.D. FAN

MOTOR

TRANSFORMER

38GXQ009/012---1

HEATPUMP INDOOR UNIT

115-1-60

ID COIL

TEMP.

SENSOR

X9 MK1

WIRING DIAGRAMS (CONT.)

X3

LOUVER MOTOR

9

Loading...

Loading...