40GRQ /

High --Wall Ductless Split S

38GRQ

yste

m

Sizes 09 to 18

Owner' s

NOTE: Read the entire instruction manual before starting the

installation.

Please read this Owner’s Information Manual carefully before installing and using this appliance

and keep this manual for future reference.

For your convenience, please record the model and serial numbers of your new equipment in the

spaces provided. This information, along with the installation data and dealer contact information,

will be helpful should your system require maintenance or service.

UNIT INFORMATION

Model #

Serial #

INSTALLATION INFO RMATION

Date Installed

Manual

the environmentally sound refrigerant

NOTE TO EQUIPMENT OWNER:

TABLE OF CONTENTS

SYSTEM REQUIREMENTS 2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Wo

rking temperature range 3

Model numbers

Parts name 4. . . . . . . . . . . . . . . . . . . . . .

Instructions - programming remote and a ir conditioner 5. . . . . . .

Remote controller 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

Lost or damaged remote control 16. . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING AND MAINTENANCE 17. . . . . . . . . . . .

Troubleshooting 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installatio

Tools for installation

INDOOR UNIT INSTALLATION 26. . . . . . . . . . . . . . . . . . . . . .

OUTDOOR UNIT INSTALLATION FOR SINGLE ZONE APLICATIONS

(REFER TO THE 38GJ OWNER'S MANUAL FOR MULTIZONE)

Vacuum pumping

Leakage detection 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking installation 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing unit operation 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring connection pipe 36. . . . . . . . . . . . . . . . . . . . . . . . . . .

Pipe expanding method 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DEALERSHIP CONTACT INFORMATION

Company Name:

Address:

Phone Number:

Technician Name:

. .....................................

n diagram 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

PAGE

. . . . . . . .

. .......

2SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . .

3

24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31

34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

SAFETY CONSIDERAT IONS

-2-

When installing in an application where there is high

electrical frequency all wires should be shielded.

Installing, starting up, and servicing air--conditioning equipment

can be hazardous due to system pressures, electrical components,

and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should

install, start--up, and service this equipment.

Untrained personnel can perform basic maintenance functions such

as cleaning coils. All other operations should be performed by

trained service personnel.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

Follow all safety codes. Wear safety glasses and work gloves. Keep

quenching cloth and fire extinguisher nearby when brazing. Use

care in handling, rigging, and setting bulky equipment.

Read these instructions thoroughly and follow all warnings or

cautions included in literature and attached to the unit. Consult

local building codes and National Electrical Code (NEC) for

special requirements. Recognize safety information. This is the

!

safety--alert symbol

in instructions or manuals, be alert to the potential for personal

injury.Understand these signal words: DANGER, WARNING, and

CAUTION. These words are used with the safety--alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF

position. There may be more than 1 disconnect switch.

Lock out and tag switch with a suitable warning label.

!

. When you see this symbol on the unit and

WARNING

!

WARNING

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Do not bury more than 36 in. (914 mm) of refrigerant pipe

in the ground. If any section of pipe is buried, there must be

a 6 in. (152 mm) vertical rise to the valve connections on

the outdoor units. If more than the recommended length is

buried, refrigerant may migrate to the cooler buried section

during extended periods of system shutdown. This causes

refrigerant slugging and could possibly damage the

compressor at start--up.

CAUTION

SYSTEM REQUIREMENTS

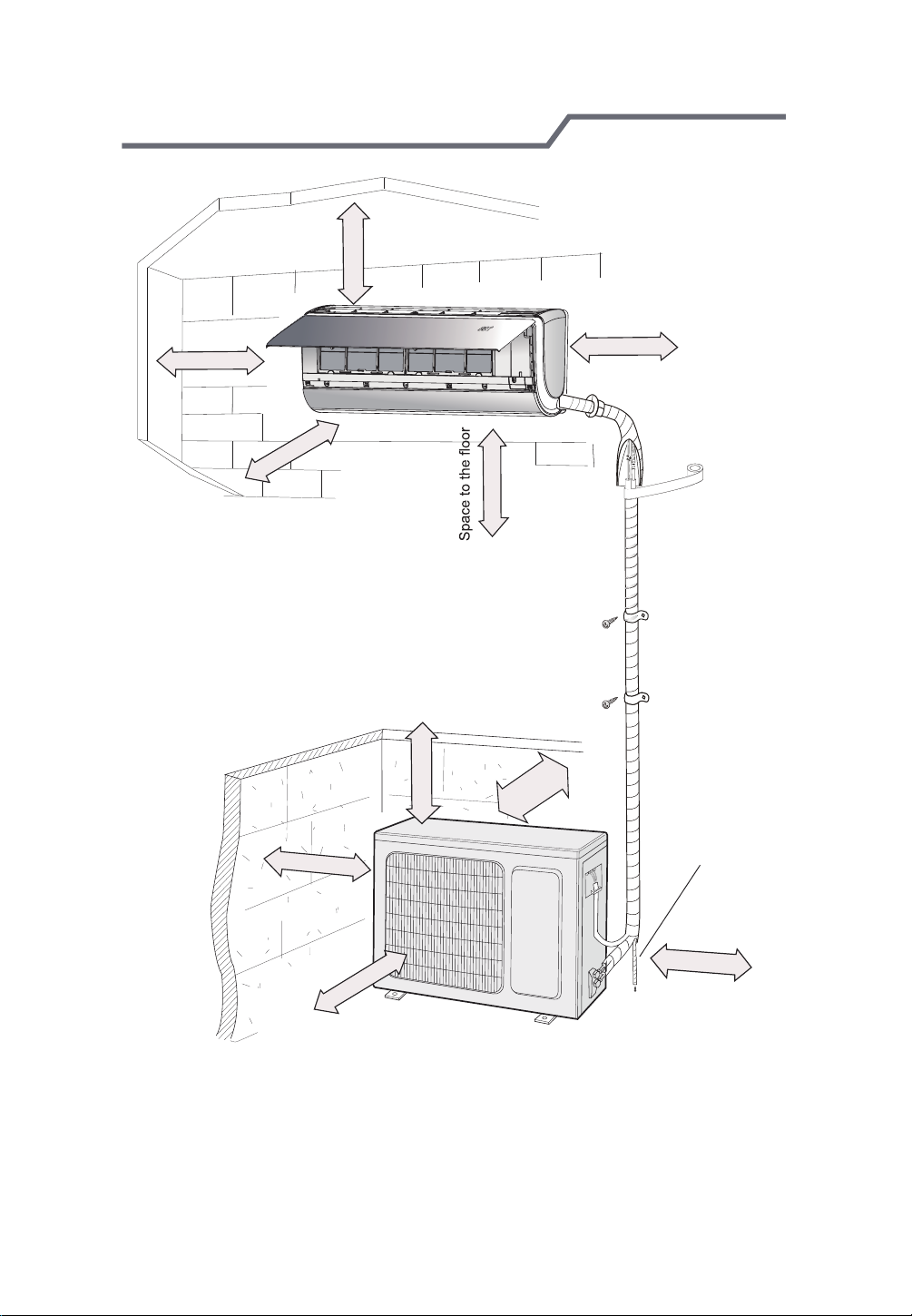

Allow sufficient space for airflow and servicing unit. See Fig. 1

for minimum required distances between unit and walls or

Recommended Connection Method for Power and

cation Wiring (To minimize communication wiring

ence)

Power Wiring:

The main power is supplied to the outdoor unit. The field supplied

connecting cable from the outdoor unit to indoor unit consists of

three (3) wires and provides the power for the indoor unit. Two

wires are high voltage AC power and one is a ground wire.

Consult your local building codes and the NEC (National

Electrical Code) or CEC (Canadian Electrical Code) for special

requirements.

All wires must be sized per NEC or CEC and local codes. Use

Electrical Data table MCA (minimum circuit amps) and MOCP

(maximum over current protection) to correctly size the wires and

the disconnect fuse or breakers respectively.

Per caution note, only copper conductors with a minimum 300 volt

rating and 2/64--inch thick insulation must be used.

Communication Wiring:

A separate shielded copper conductor only, with a minimum 300

volt rating and 2/64--inch thick insulation, must be used as the

communication wire from the outdoor unit to the indoor unit.

To minimize voltage drop of the control wire, use the following

wire size and maximum lengths shown in the chart below:

Wire Size

18 AWG 50 (15)

16 AWG 50 (15) to 100 (30)

Length

ft (m)

ceilings.

Communi-

interfer-

EXPLOSION HAZARD

Failure to follow this warning could

result in death, serious personal injury,

and/or property damage.

Never use air or gases containing

oxygen for leak testing or operating

refrigerant compressors. Pressurized

mixtures of air or gases containing

oxygen can lead to an explosion.

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

S Wires should be sized based on NEC and local codes.

S Use copper conductors only with a minimum 300 volt

rating and 2/64 inch thick insulation.

CAUTION

Working temperature range

-3-

Model Numbers

Model Number Reference

Maximum cooling

Maximum heating

Indoor side DB/WB

80/-(26.7/-)

( )

°F/°C

Outdoor side DB/WB

115/75(46.1/23.9)

75/64.9(23.9/18.3)

(°F/°C)

NOTICE:

The operating temperature range (outdoor temperature) for cooling only unit is

-0.4°F(-18°C) (-30°C)~114.8°F(46°C); for heat pump unit is -22°F ~ 72.5°F(24°C)

Parts name

-4-

Indoor Unit

panel

filter

horizontal louver

air inlet

power wire

remote controller

Outdoor Unit

display

air outlet

power

tem.display

air inlet

Connection wire

air outlet

NOTE:

The illustration above is only a sketch. Different models may be slightly

different.

Instructions - programming remote and air conditioner

-5-

The RF remote control must be synchronized with air conditioner prior to use.

Follow the instructions below.

Note

Synch remote controls within 6.5ft (2m) from air conditioning unit.

While synching, the remote controller and air conditioner should be on standby

status.

Synching remote controller with air conditioner is a one-time requirement.

Programming remote control

. Press standy status on air conditioner.

. Stand near air conditioner while holding remote control. Press standby button on remote.

. Synching will occur automatically.

. If synch does not occur, move closer to unit and repeat steps.

Remote controller

-6-

1

3

7

10

11

14

15

2

4

65

8

9

12

13

16

1 ON/OFF button

+/- button

2

Cool button

3

Heat button

4

Fan button

5

6 I FEEL button

up down swing button

7

8

Mode button

9

Left right swing button

10

T-ON/T-OFF button

11

Clock button

12

X-fan button

13

Air button

14

Light button

15

Sleep button

16

WIFI button

Introduction for icons on display screen

Set fan speed

Operation mode

Auto mode

Cool mode

Dry mode

Fan mode

Heat mode

Set time

Turbo fan speed

X-FAN function

Auto quiet mode

INTELLIGENT

HOUR ON OFF

Quiet mode

Temp. display type

:Set temp.

:Outdoor ambient temp.

WIFI

:Indoor ambient temp.

Send signal

battery power

humidity functions

Temp.display type

Healthy mode

Set temperature

Up & down swing

Left & right swing

46°F (8°C) heating function

child lock

I feel function

Replacing air

Sleep mode

Matching Remote Control

-7-

The RF remote control must be synchronized with air conditioner prior to use.

Follow the instructions below.

Note

Synch remote controls within 6.5ft (2m) from air conditioning unit.

While synching, the remote controller and air conditioner should be on standby

status.

Synching remote controller with air conditioner is a one-time requirement.

Programming remote control

. Press standy status on air conditioner.

. Stand near air conditioner while holding remote control. Press standby button on remote.

. Synching will occur automatically.

. If synch does not occur, move closer to unit and repeat steps.

REMOTE CONTROL FUNCTIONS

-8-

Note:

After the air conditioner has been properly installed, you can use the remote

control to operate the air conditioner. Press the power button on the remote

control. The green indicator light will display on the air conditioner unit.

Follow the instructions for using the remote control.

1

Use the ON/OFF remote button to turn on or turn off the air conditioner.

The button on the remote will display ON when the air conditioner is on.

+/- button

2

The +/- button increases or decreases the temperature setting on the air

conditioning unit. Hold the "+" or "-" for 2s to change the temperature setting.

NOTE: Temperature setting can not be adjusted in "auto mode".

Press the "+" or "-" for setting and adjusting TIMER.

Cool button

3

Press the Cool button to operate in cool mode.

Heat button

4

Press the Heat button to operate in heat mode.

5

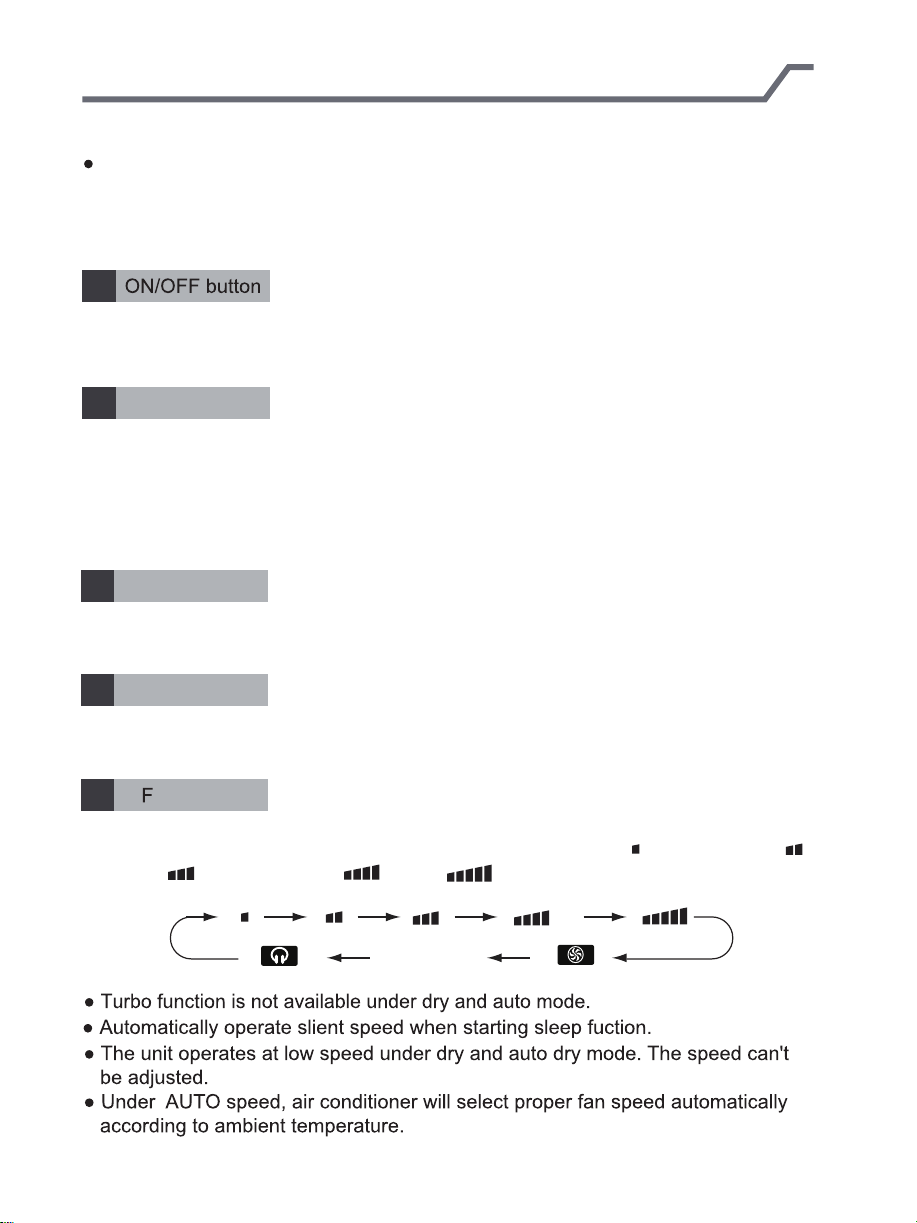

Press the FAN button to adjust the fan circulation speed: low( ), low medium( ),

medium( ), medium high( ), high( ), super, auto and quiet.

Note:

AN button

Auto

REMOTE CONTROL FUNCTIONS

-9-

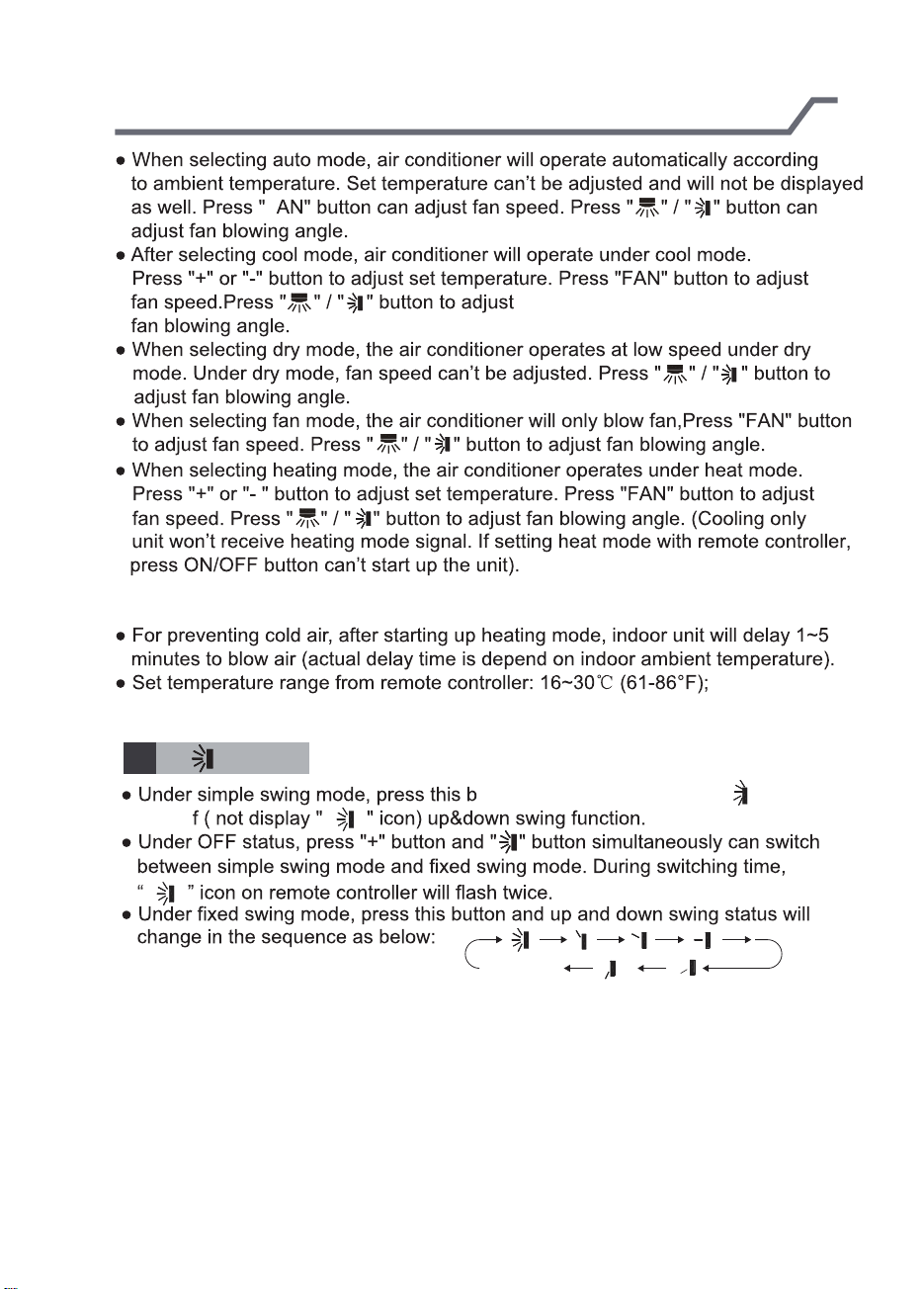

6

7

turn off ( not display " " icon) left&right swing function.

between simple swing mode and fixed swing mode. During switching time,

“ ” icon on remote controller will flash twice.

will change in the sequence as below:

EEL

L

.

.

button

utton can turn on (display " " icon ) or

neously can switch

no display

(stops at current position)

MODE button

8

Press this button to select your required operation mode.

T ANRY AT

REMOTE CONTROL FUNCTIONS

-10-

F

Note:

9

turn of

button

utton can turn on ( display " " icon) or

no display

(horizontal louvers stops

at current position)

REMOTE CONTROL FUNCTIONS

-11-

T-ON/T-OFF button

10

T-ON button

“T-ON” button can set the time for timer on. After pressing this button, " " icon

disappears and the word “ON" on remote controller blinks. Press “+” or “-”button

to adjust T-ON setting. After each pressing “+” or “-”button, T-ON setting will

increase or decrease 1min. Hold “+” or “-”button, 2s later, the time will change

quickly until reaching your required time. Press“T-ON”to confirm it. The word “ON”

will stop blinking. " " icon resumes displaying.Cancel TIMER ON: Under the

condition that T-ON is started up, press “T-ON” button to cancel it.

T-OFF button

“T-OFF” button can set the time for timer off. After pressing this button, " " icon

disappears and the word "OFF" on remote controller blinks. Press "+" or "-" button

to adjust T-OFF setting. After each pressing "+" or "-" button, T-OFF setting

will increase or decrease 1min. Hold "+" or "-" button, 2s later, the time will change

until reaching your required time. Press“T-OFF”to confirm it. The word “ON”will

"OFF" will stop blinking. " " icon resumes displaying. Cancel T-OFF.Under the

condition that T-OFF is started up, press “T-OFF” button to cancel it.

Note:

ff status, you can set T-OFF or T-ON simultaneously.

T-ON or T-OFF, please adjust the clock time.

After starting up T-ON or T-OFF, set the constant circulating valid. After that,

air conditioner will be turned on or turned off according to setting time. ON/OFF

button has no effect on setting. If you don’t need this function, please use remote

controller to cancel it.

CLOCK button

11

Press this button to set clock time. " " icon on remote controller will blink.

Press "+" or "-" button within 5s to set clock time. Each pressing of "+" or "-"

button, clock time will increase or decrease 1 minute. Hold "+" or "-" button, 2s

later, time will change quickly. Release this button when reaching your required

time. Press “CLOCK”button to confirm the time. " " icon stops blinking.

Note:

The interval between two operations can’t exceeds 5s. Otherwise, remote

controller will quit setting status. Operation for TIMER ON/TIMER OFF is

the same.

REMOTE CONTROL FUNCTIONS

-12-

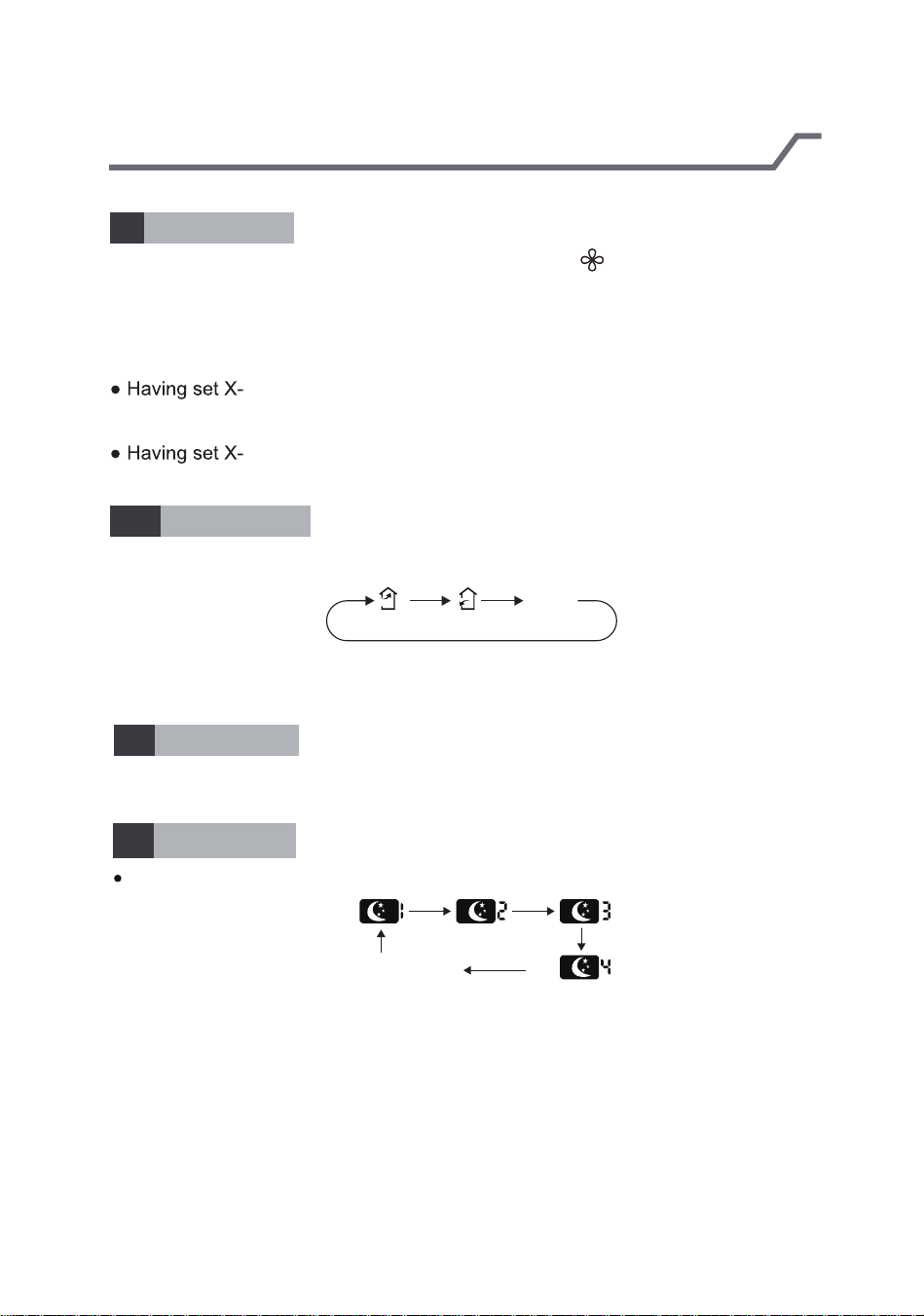

X-FAN button

12

Pressing this button in COOL or DRY mode, the icon " " is displayed and the

indoor fan will continue operation for 2 minutes in order to dry the indoor unit even

though you have turned off the unit. After energization, X-FAN OFF is defaulted.

X-FAN is not available inAUTO, FAN or HEAT mode.

This function indicates that moisture on evaporator of indoor unit will be blowed

after the unit is stopped to avoid mould.

FAN function on: After turning off the unit by pressing ON/OFF

button indoor fan will continue running for about 2 min. at low speed. In this

period, press X-FAN button to stop indoor fan directly.

FAN function off: After turning off the unit by pressing ON/OFF

button, the complete unit will be off directly.

Air button

13

Press this button to select your required operation mode.

cancel

Note:there is no this function for this unit. If press this button,the main unit will click,

but it also runs under original status.

LIGHT button

14

Pressing this button to turn off display light on indoor unit. Press this button again

to turn on display light.

SLEEP button

15

Pressing this button can select Sleep 1, Sleep 2,Sleep 3, Sleep 4 or cancel Sleep

circularly as below:

cancel

REMOTE CONTROL FUNCTIONS

-13-

In Sleep 1 and Sleep 2, the air conditioner will run according to a group of presetting

temperature curves.

Sleep 3 - the sleep curve setting under DIY Sleep mode:

(1) Under Sleep 3 mode, long press "AIR" button, the remote controller will enter

the setting of personalized sleep. In this case, the timer zone of remote controller

will display "1 hr" and the set temperature zone "88" will display the corresponding

temperature of the last set sleep curve and blink (The first entering will display

according to the initial curve setting value of manufacturer);

(2) Press "+" and "-" button to adjust the corresponding temperature. After adjusting,

press "AIR" button to confirm it;

(3) At this time, the timer time on the remote controller will increase automatically by

1hr (that is "2 hr" or "3 hr" … or "8 hr"). The set temperature zone "88" will display the

corresponding temperature of the last set sleep curve and blink;

(4)Repeat step(2) and step (3) until 8-hour temperature setting is finished, then the

sleep curve is set successfully. After that, remote controller will resume displaying the

original timer time and temperature zone will resume displaying the original set

temperature.

Sleep 3 - the sleep curve inquiry under DIY Sleep mode:

User can inquire the set sleep curve according to the setting method of sleep curve.

Enter the setting of personalized sleep but do not change the temperature. Then

press "AIR" button to confirm the setting.

Note: In the above setting or inquiry procedure, if there is no button pressing within

10s, remote controller will automatically exit the sleep curve setting and resume the

HEATING button is pressed during the setting or inquiry procedure, remote controller

original display. If ON/OFF, MODE, TIMER, HUMIDIFY, SLEEP, COOLING or

will also exit the sleep curve setting.

Sleep 4 is Siesta mode. The set temperature will change automatically according to

the features of siesta.

Sleep function will be disabled if the air condition is restarted after power failure;

when sleep function is turned on, quite fan speed will be also turned on.

Sleep function can not be set in AUTO mode.

Wifi button

16

Press this button 3s can set wifi function on or OFF.

At OFF status,press mode button and wifi button,can reset wifi mode parameter.

and open wifi function.

REMOTE CONTROL FUNCTIONS -

-14-

COMBINATION KEYS

X-FAN

This function indicates moisture levels will blow away after unit stops to prevent mold.

1.When X-FAN function is on: Press ON/OFF button (on remote) to turn off the unit.

The indoor fan will run for approximately 2 minutes at low speed. Press X FAN button

to stop indoor fan.

2. When X-FAN function is off: Press ON/OFF button (on remote) to turn off complete unit.

Auto Run

The Auto Run mode automatically adjusts to the room's temperature. The LCD on the

unit does not show the temperature.

Lock

Press "+" and "-" buttons simultaneously to lock or unlock the remote control. If remote

control is locked, the icon will display; when this occurs press any button on the

remote three times. The lock will disappear. If the remote is not locked, the lock

will not appear.

Fahrenheit & Centigrade

Make sure the remote control is off. Press MODE and press "C" or "F" to switch between

fahrenheit and centigrade.

Operating unit

-15-

After initializing unit, press the ON/OFF button on remote control to turn on air

1.

conditioner.

Press "MODE" on remote control to select mode: AUTO, COOL, DRY, FAN, or

2.

HEAT.

Press "+" or " - " button to set temperature. (Temperature can’t be adjusted

3.

under auto mode).

Press "FAN" button to set fan speed: low, low medium, medium, medium high,

4.

high, super, auto and quiet speed.

Press "SWING" button to select fan blowing angle.

5.

Replace batteries in remote control

1. Press the back side of remote control marked

the cover of battery box along the arrow direction.

signal sender battery

reinstall

2. Replace two AAA 1.5V dry batteries, and make

sure the position of "+" polar and "-" polar are

correct.

3. Reinstall the cover of battery box.

Battery level will be displayed on the remote

controller.When " " is flickering, please

Cover of battery box

o

F

replace the batteries, otherwise, remote

controller can’t operate normally.

NOTICE

ntrol signal sender at the receiving

window on indoor unit.

The distance between signal sender and receiving window should be no

more than 26ft(8m), and there should be no obstacles between them.

Signal may be interfered by a fluorescent lamp or wireless telephone;

remote control should be close to indoor unit during operation.

remove

battery level

batteries.

batteries.

remove

s no display, please

replace

Lost or damaged remote control

-16-

If the remote control is lost or damaged, the air conditioner can be turned

off directly from the unit. Lift the display panel on top of the air conditioner,

then press the AUX button to turn on or turn off the air conditioner. If the

air conditioner is on, it will operate through the AUTO MODE.

air conditioner. When the air conditioner is turned on, it will operate in auto

mode.

panel

Display panel

Warning:Use insulated object

to press the auto button

aux. button

CLEANING AND MAINTENANCE

WARNING

Turn off the air conditioner and disconnect the power before cleaning the air

conditioner to avoid electric shock.

r.

Clean surface of indoor unit

When the surface of indoor unit is dirty, it is recommended to use a soft dry cloth

or wet cloth to wipe it.

NOTICE:

CLEANING AND MAINTENANCE

-17-

Open panel

1

2

3

113°F (45°C)

.

WARNING

Clean filter every three months. If dust accumulates quickly, clean filter more

frequently.

4

.

CLEANING AND MAINTENANCE

-18-

Preparing to clean filter

1. Check whether air inlets and air outlets are blocked.

2. Check whether air switch, plug and socket are in good condition.

4. Check whether mounting bracket for outdoor unit is damaged or corroded.

If yes, please contact dealer.

5. Check whether drainage pipe is damaged.

Cleaning unit panel and filter

1. Disconnect power supply.

3. Check whether mounting bracket for outdoor unit is damaged or corroded.

If yes, please contact dealer.

Notice for recovery

1. Many packing materials are recyclable materials.

Please dispose them in appropriate recycling unit.

2. To dispose the air conditioner,please contact local dealer or consultant

service center for the correct disposal method.

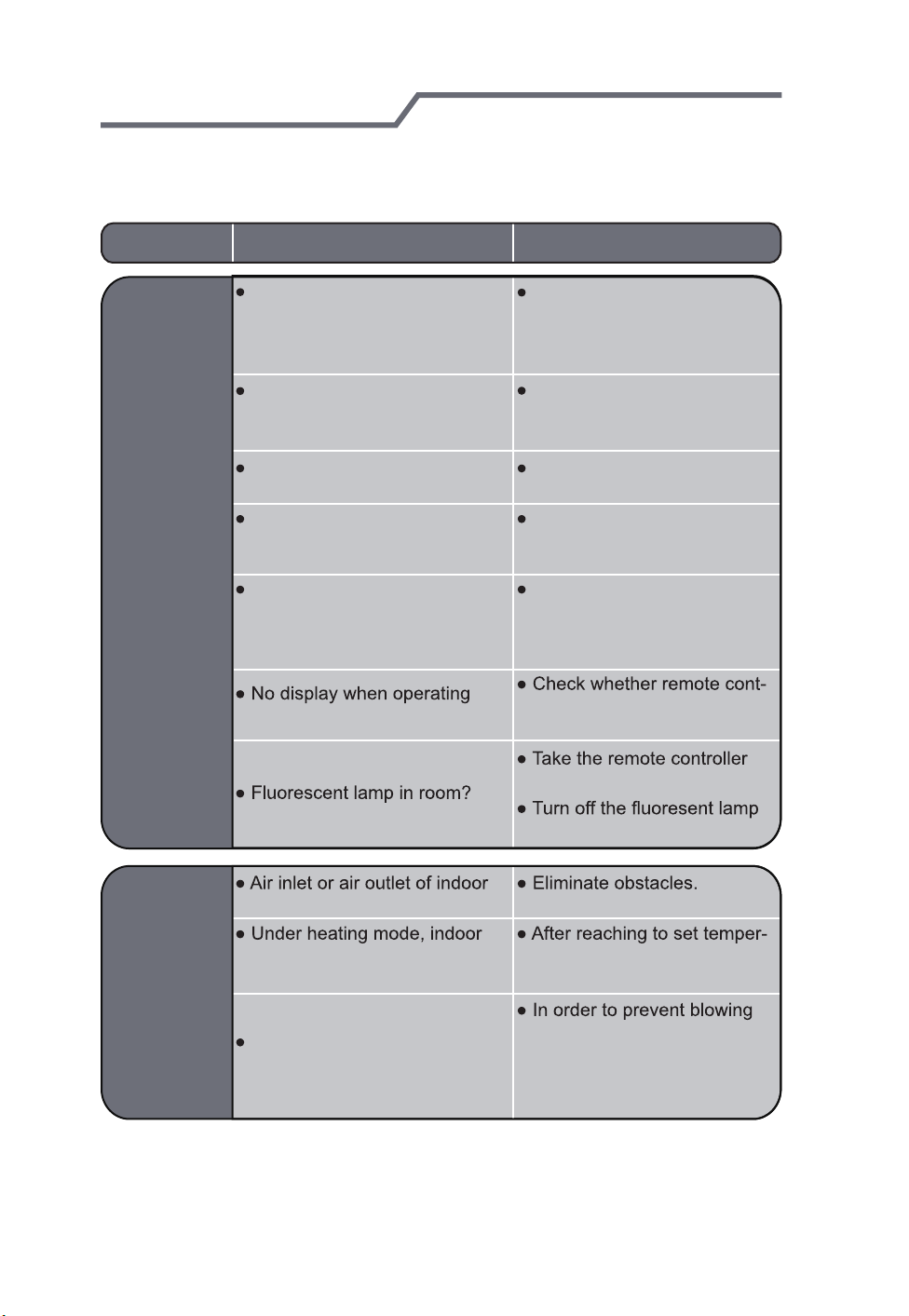

Troubleshooting

-19-

Please identify problems and possible solutions for requesting maintenance

assistance. If problem can not be resolved by following the steps described,

contact your dealer or a qualified professional.

Problem Possible cause Solution

Indoor unit

can’t receive

remote

control's

signal or

remote

control

has no

action.

Determine if interference has

occurred due to severe static

electricity or voltage surge.

Determine if the remote control

is within the signal receiving

range.

Determine if other obstacles

are preventing signal receptivity.

Unit not responding to the

remote control.

Determine if remote control is

working properly. Possible

problems: low sensitivity,

fuzzy display or no display.

remote controller?

Remove the plug from the wall

outlet. Wait three minutes.

Reinsert the plug into the

outlet, then turn the unit on.

Make sure the remote control is

within the receiving range:

26.2ft(8m).

Eliminate possible obstacles that

can block signal reception.

Select proper angle and point

the remote controller at the re ceiving window on indoor unit.

Replace batteries if remote

control performs slowly or

poorly.

roller appears to be damaged.

If yes, replace it.

close to indoor unit.

and then try it again.

Air conditioner

unit does not

release air.

unit is blocked?

temperature is reached to set

temperature?

Heating Mode not starting right

after setting it in the remote

control.

ature, indoor unit will stop bl owing out air.

out cold air, indoor unit will be

started after delaying for sev eral minutes, which is a nor mal phenomenon.

Troubleshooting

-20-

Problems Possible Causes Solutions

Air conditioner does

not start.

Mist is coming

out of indoor

unit's air outlet.

Set temperature can’t

be adjusted.

burnt out?

after stopping operation?

Is remote control function

setting correct?

idity is high?

mode?

exceeds the set temperature

range?

air switch or fuse.

on the unit again.

Occurs if indoor air rapidly cools

down.

temperature and humidity will

be decrease and mist will

disappear.

sted under auto mode.

Please switch the operation

mode if you need to adjust

temperature.

16 ~30 .

After a while, indoor

Cooling or

heating is

inaccurate.

resumes normal.

range? range.

Troubleshooting

-21-

Problems Possible causes Solutions

Sources of foul odors: furniture,

Foul odors

cigarettes, etc.

Air conditioner

suddenly

operates normally

without repair

Outdoor

unit has

vapor

“Water

noise

Cracking

noise

Occurs when there's

interference: thunder, wireless

devices, etc.

Air conditioner unexpectedly

turns on or off and emits an

unfamiliar sound.

The air conditioner makes an

unusual cracking sound.

power, and then turn on the

unit again.

ating mode, it may generate

vapor

the unit, which is a normal

phenomenon.

caused by expansion and/or

contraction of panel or other

parts due to the change of

temperature.

, which is a normal

occurence.

Troubleshooting

-22-

Error Codes

ation of error code.

al, temperature indictor on indoor unit will

Error code

E5

E6

E8

U8

H6

C5

F1

F2

Note: If there are other error codes, please contact qualified professionals for

service.

It can be eliminated after restarting the unit. If not,

It can be eliminated after restarting the unit. If not,

It can be eliminated after restarting the unit. If not,

It can be eliminated after restarting the unit. If not,

It can be eliminated after restarting the unit. If not,

Troubleshooting

WARNING

If incidences

ease turn off air conditioner and discon-

for service.

There’s abnormal sound during operation.

f frequently.

Air conditioner gives off burning smell.

bnormal conditions, it may cause

Installation diagram

-23-

At least 4.9 ft (15cm)

Space to the ceiling

At least 0.49ft (15cm)

Space to the wall

At least 9.8 ft (300cm)

Space to the wall

At least 0.49 ft (15cm)

Space to the obstruction

At least 0.98 ft (30cm)

Space to the wall

At least 6.56 ft (200cm)

Space to the obstruction

At least 8.2 ft (250cm)

Space to the

obstruction

Space to the obstruction

At least 1.64 ft (50cm)

At least

0.98 ft (30cm)

Drainage pipe

At least 1.64ft (50cm)

Space to the

obstruction

Tools for installation

-24-

1 Level meter 2 Screw driver 3 Impact drill

4 Drill head 5 Pipe expander 6 Torque wrench

7 Open-end wrench 8 Pipe cutter 9 Leakage detector

10 Vacuum pump 11 Pressure meter 12 Universal meter

13 Inner hexagon spanner 14 Measuring tape

Note:

INSTALLATION TIPS

Basic requirement

Installing the unit in the following places may cause malfunction. If it is unavoidable, please consult the local

dealer:

1.The place with strong heat sources,

,

or volatile objects spread in the air.

2.The place with high-frequency

devices (such as welding machine,

medical equipment).

3.The place near coast area.

4.

The place with oil or fumes in the air.

5.The place with sulfureted gas.

6.Other places with special circums-

tances.

7.The appliance shall not be installed

in the laundry.

Outdoor unit

will not affect neighborhood.

2. The location should be well ventilated and dry, so the outdoor unit

won't be exposed directly to sunlight or strong wind.

3. The location should be able to withstand the weight of outdoor unit.

4. Make sure that the installation follows the requirement of installation

dimension diagram.

5. Select a location which is out of reach for children and far away from animals

or plants. If it is unavoidable, please add the fence for safety purpose.

Indoor unit

1. There should be no obstruction near air

inlet and air outlet.

2. Select a location where the condensat ion water can be dispersed easily and

won't affect other people.

3. Select a location which is convenient to

connect the outdoor unit and near the

power socket.

4. Select a location which is out of reach

for children.

The location should be able to withstand

5.

the weight of indoor unit and won't incr ease noise and vibration.

6.

The appliance must be installed 2.5m

7. Don't install the indoor unit right above

the electric appliance.

8. Please try your best to keep way from

Grounding requirement

-25-

The Air conditioner must be properly grounded to avoid electric shock.

2. The yellow-green wire in air conditioner is grounding wire, which can't be used

for other purposes.

3. The grounding resistance should comply with national electric safety regulations.

4. The appliance must be positioned so that the plug is accessible.

5. An all-pole disconnection switch having a contact separation of at least 1/8 in (3mm)

in

sure the plug is within reach after installation;

6. Including an air switch with suitable capacity, please note the following table. Air

switch should be included magnet buckle and heating buckle function, it can

protect the circuit-short and overload. (Caution: please do not use the fuse only

for protect the circuit)

For models with a power plug, make

Air-conditioner

09K

12K

18K

Air switch capacity

15A

20A

30A

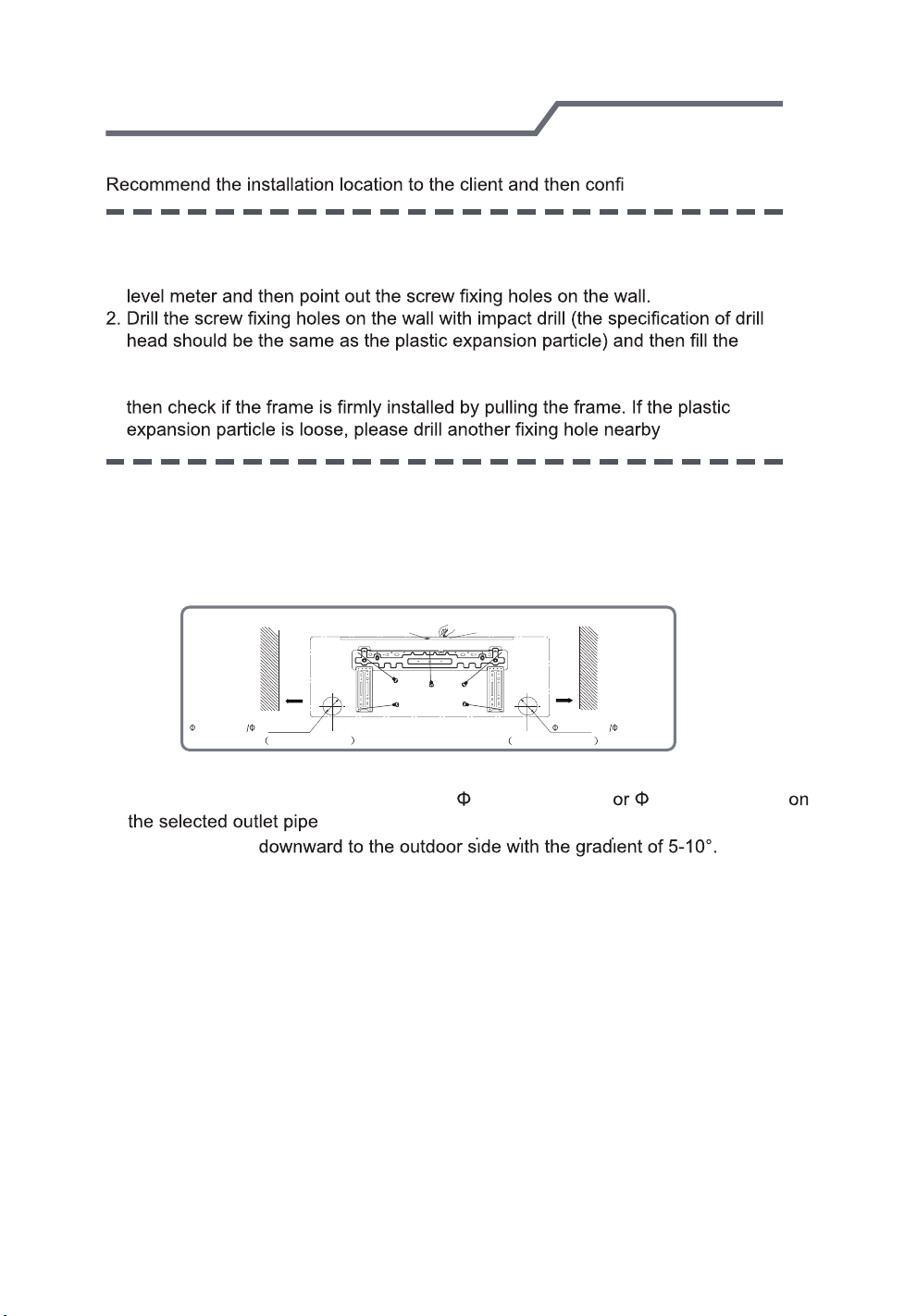

INDOOR UNIT INSTALLATION

-26-

Step one: choosing installation location

rm it with the client.

Step two: install wall-mounting frame

1. Hang the wall-mounting frame on the wall; adjust it in horizontal position with the

plastic expansion particles in the holes.

3. Fix the wall-mounting frame on the wall with tapping screws (ST4.2X25TA) and

.

Step three: open piping hole

1. Choose the position of piping hole according to the direction of outlet pipe. The

position of piping hole should be a little lower than the wall-mounted frame,

shown as below.

Wall

2 1/6 in (55mm) 2 3/4 in (70mm) 2 1/6 in (55mm) 2 3/4 in (70mm)

Mark in the middle of it

Space

to the

wall

above

5 9/10 in

(150mm)

Left

Rear piping hole

Level meter

Rear piping hole

Wall

Space

to the

wall

above

5 9/10 in

(150mm)

Right

2. Open a piping hole with the diameter of 2 1/6 in (55mm) 2 3/4 in (70mm)

position.In order to drain smoothly, slant the piping hole on

the wall slightly

INDOOR UNIT INSTALLATION

-27-

Note:

opening the hole.

The plastic expansion particles are

locally.

Step four: outlet pipe

1. The pipe can be led out in the

direction of right, rear right, left or

rear left.

rear left

right

rear right

left

Indoor

5-10

2. When select leading out the pipe

from left or right, please cut off the

corresponding hole on the bottom

case.

left

outdoor

2 1/6 in (55mm)

2 3/4 in (70mm)

right

cut off

the hole

/

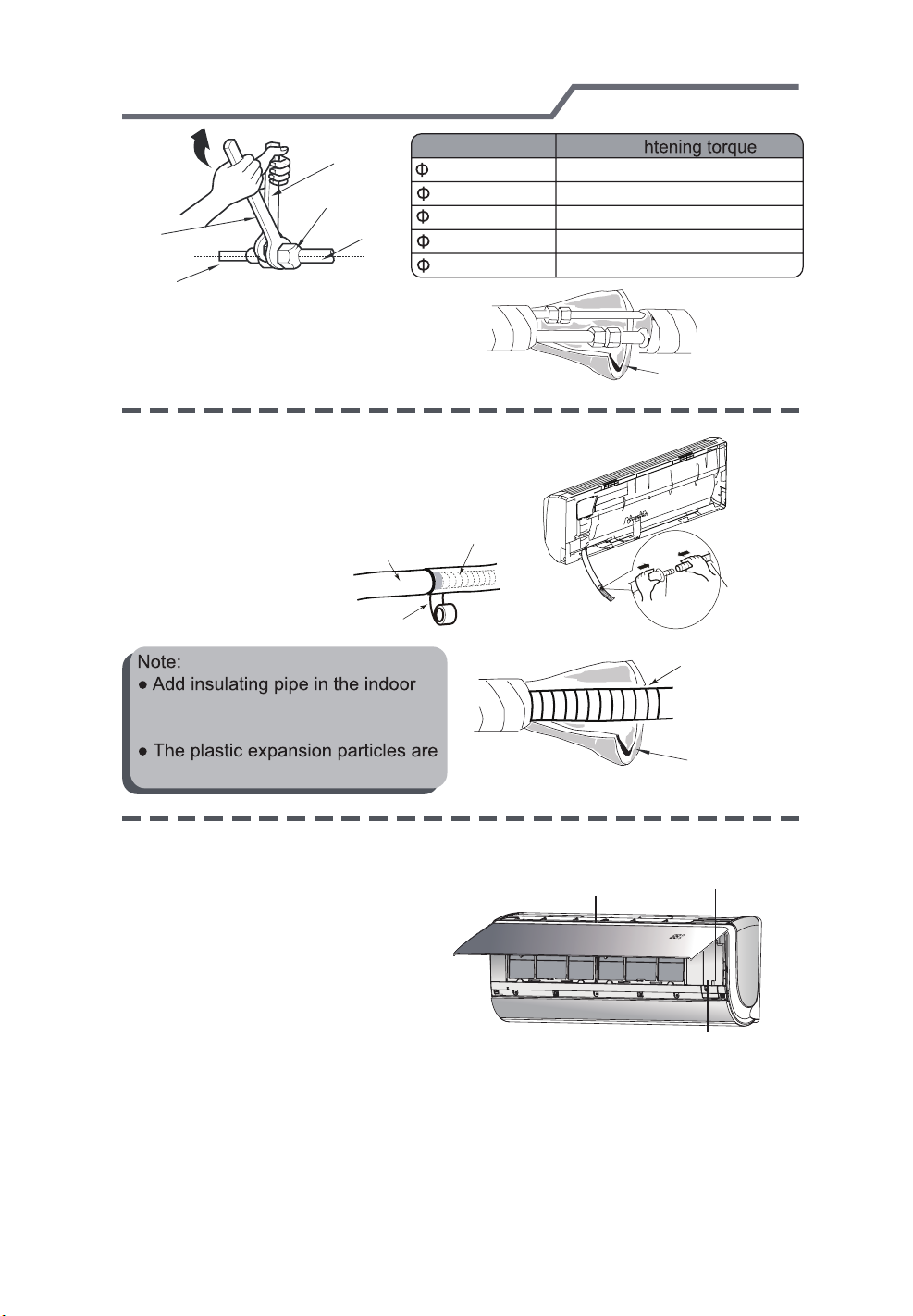

1. Aim the pipe joint at the corresponding

bellmouth.

union nutpipe joint

2. Pretightening the union nut with hand.

3. Adjust the torque force by referring to the following sheet. Place the open-end

wrench on the pipe joint and place the torque wrench on the union nut. Tighten

the union nut with torque wrench.

pipe

INDOOR UNIT INSTALLATION

-28-

open-end

wrench

union nut

Hex nut diameter Tig

1/4 in (6 mm)

3/8 in (9.52 mm)

1/2 in (12 mm)

torque wrench

pipe

5/8 in (16 mm)

3/4 in (19 mm)

indoor pipe

4. Wrap the indoor pipe and joint of con nection pipe with insulating pipe, and

then wrap it with tape.

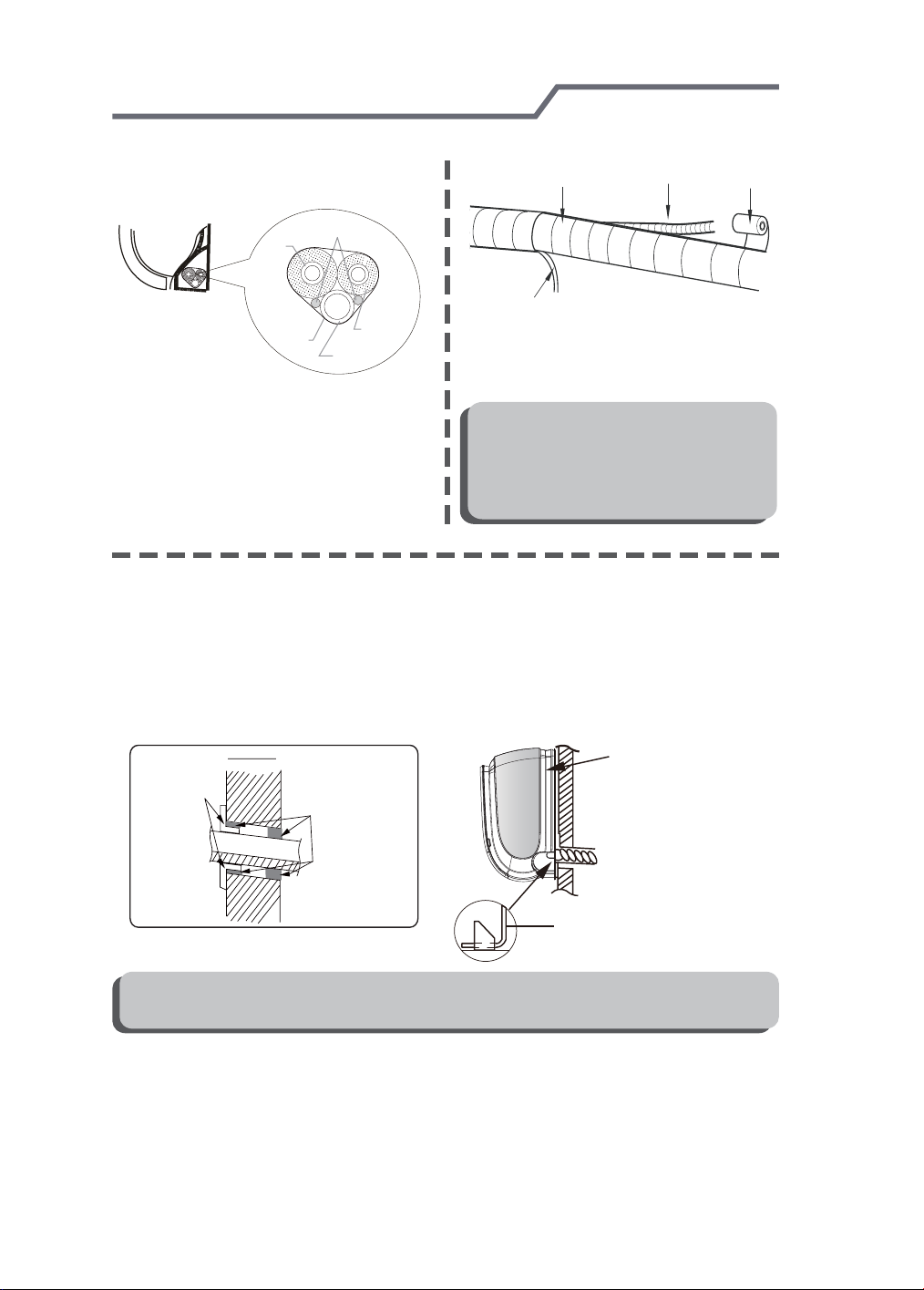

Step six: install drain hose

1. Connect the drain hose to the outlet pipe of

indoor unit.

drain hose

2. Bind the joint with tape.

outlet pipe

tape

20.34~27.12 ft.lb(15~20 N.m)

40.68~54.24 ft.lb(30~40 N.m)

61.02~74.58 ft.lb(45~55 N.m)

81.36~88.14 ft.lb(60~65 N.m)

94.93~101.7 ft.lb(70~75 N.m)

insulating pipe

outlet

pipe

drain hose

drain hose

drain hose in order to prevent

condensation.

not provided.

Step seven: connect wire of indoor unit

1. Open the panel, remove the screw

on the wiring cover and then take

down the cover.

pane

insulating pipe

screw

wiring cover

INDOOR UNIT INSTALLATION

-29-

2. Make the power connection wire go

through the cable-cross hole at the back

cable-cross

hole

the front side.

power connection

wire

with wire clip.After finishing wiring

into the wire-crossing groove as shown in the following figure, in order to avoid

pressing the wire when closing the electric box cover.

L2’

S

L1’

green

red

black

white

(blue)

Outdoor unit connection

(brown)

(yellow-

green)

4.Put wiring cover back and then tighten the screw

5.Close the panel.

Note:

All wires of indoor unit and outdoor uni

t should be connected by a professional.

If the length of power connection wire is insufficient, please contact the supplier

for a new one. Avoid extending the wire by yourself.

For the air conditioner with plug, the plug should be reachable after finishing

installation.

The air switch should be all-pole parting and the contact parting distance should

2/17 in (3mm)

INDOOR UNIT INSTALLATION

-30-

Step eight: bind up pipe

1. Bind up the connection pipe, power

connection pipe

cord and drain hose with the band.

indoor and

indoor unit

2. Reserve a certain length of drain

hose and power cord for installation

when binding them. When binding to

a certain degree, separate the indoor

power and then separate the drain

hose.

outdoor power cord

gas

pipe

band

liquid pipe

drain hose

indoor power cord

3. Bind them evenly.

4. The liquid pipe and gas pipe should

be bound separately at the end.

1RWH

Ɣ7KHSRZHUFRUGDQGFRQWUROZLUH

FDQWEHFURVVHGRUZLQGLQJ

Ɣ7KHGUDLQKRVHVKRXOGEHERXQG

at the bottom.

Step nine: hang the indoor unit

1. Put the bound pipes in the wall pipe and then make them pass through the wall

hole.

2. Hang the indoor unit on the wall-mounting frame.

3. Stuff the gap between pipes and wall hole with sealing gum.

4. Fix the wall pipe.

5.Check if the indoor unit is installed firmly and closed to the wall.

indoor

outdoor

drain hose

upper hook

band

wall pipe

sealing gum

lower hook of

wall-mounting frame

1RWH

Ɣ'RQRWEHQGWKHGUDLQKRVHWRRH[FHVVLYHO\LQRUGHUWRSUHYHQWEORFNLQJ

CAUTION NOTE

-31-

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or improper operation.

In regions with snowfall and cold temperatures, avoid installing the outdoor unit in areas where it can

be covered by snow. If the outdoor unit is installed in areas where heavy snow is expected, a field

supplied ice or snow stand and/or field supplied--installed wind baffle should be installed to protect the

unit from snow accumulation and/or blocked air intake. Blocking the air intake may result in reduced

airflow, significantly reduced performance and damage to the equipment.

CAUTION

OUTDOOR UNIT INSTALLATION FOR SINGLE ZONE APLICATIONS

(REFER TO THE 38GJ OWNER'S MANUAL FOR MULTIZONE)

(select it according to the actual installation situation)

1. Select installation location according to the house structure.

2. Fix the support of outdoor unit on the selected location with expansion screws.

3. Make sure the outdoor unit is mounted level and off the ground in areas where

there is snow.

Note:

installing the outdoor unit.

Make sure the support can withstand at least

four times of the unit weight.

1 1/6 in (3cm)

joint.

3 HP~

6 5/7 HP (2300W~5000W), 6 expansion

screws are needed;

for the unit with cooling capacity of 8 HP~

10 3/4 HP (6000W~8000W), 8 expansion

screws are needed;

for the unit with cooling capacity of 13 2/5 HP

~21 1/2 HP (10000W~16000W)

screws are needed.

,10 expansion

at least 1 1/6 in (3cm) above the floor

Step two: install drain joint

(Only for cooling and heating

unit)

1. Connect the outdoor drain joint into

the hole on the chassis, as shown in

the picture below.

2. Connect the drain hose into the drain

vent.

drain vent

Drain hose

chassis

outdoor drain joint

1. Place the outdoor unit on the

support.

2. Fix the foot holes of outdoor unit

with bolts.

foot holes

foot holes

OUTDOOR UNIT INSTALLATION FOR SINGLE ZONE APLICATIONS

-32-

(REFER TO THE 38GJ OWNER'S MANUAL FOR MULTIZONE)

Step four: connect indoor and outdoor pipes

1. Remove the screw on the right han dle of outdoor unit and then remove

the handle.

screw

handle

3. Pretightening the union nut with

hand.

pipe joint

union nut

2. Remove the screw cap of valve and

aim the pipe joint at the bellmouth of

pipe.

liquid pipe

liquid

gas pipe

valve

gas valve

4. Tighten the union nut with torque

wrench by referring to the sheet

below.

Hex nut diameter Tig

1/4 in (6 mm)

3/8 in (9.52 mm)

1/2 in (12 mm)

5/8 in (16 mm)

3/4 in (19 mm)

20.34~27.12 ft.lb(15~20 N.m)

40.68~54.24 ft.lb(30~40 N.m)

61.02~74.58 ft.lb(45~55 N.m)

81.36~88.14 ft.lb(60~65 N.m)

94.93~101.7 ft.lb(70~75 N.m)

1. Remove the wire clip; connect the po wer connection wire and signal control

wire (only for heating unit) to the wiring

terminal according to the

18K

L1’ S L2’

green

white

(yellow-

(blue)

green)

handle

black

Indoor unit connection

(brown)

L2

black

(brown)

L2

POWER

L1 G

whitered

(blue)

L1

green

(yellowgreen)

、12K

L1’

S

L1

Indoor unit

L2’ G

L2

L1

L2

G

OUTDOOR UNIT INSTALLATION FOR SINGLE ZONE APLICATIONS

-33-

(REFER TO THE 38GJ OWNER'S MANUAL FOR MULTIZONE)

2. Fix the power connection wire and signal control wire with wire clip (only for

cooling and heating unit).

1RWH

Ɣ$IWHUtighteningWKHVFUHZSXOOWKHSRZHUFRUGVOLJKWO\WRFKHFNLILWLV¿UP

Ɣ1HYHUFXWWKHSRZHUFRQQHFWLRQZLUHWRSURORQJRUVKRUWHQWKHGLVWDQFH

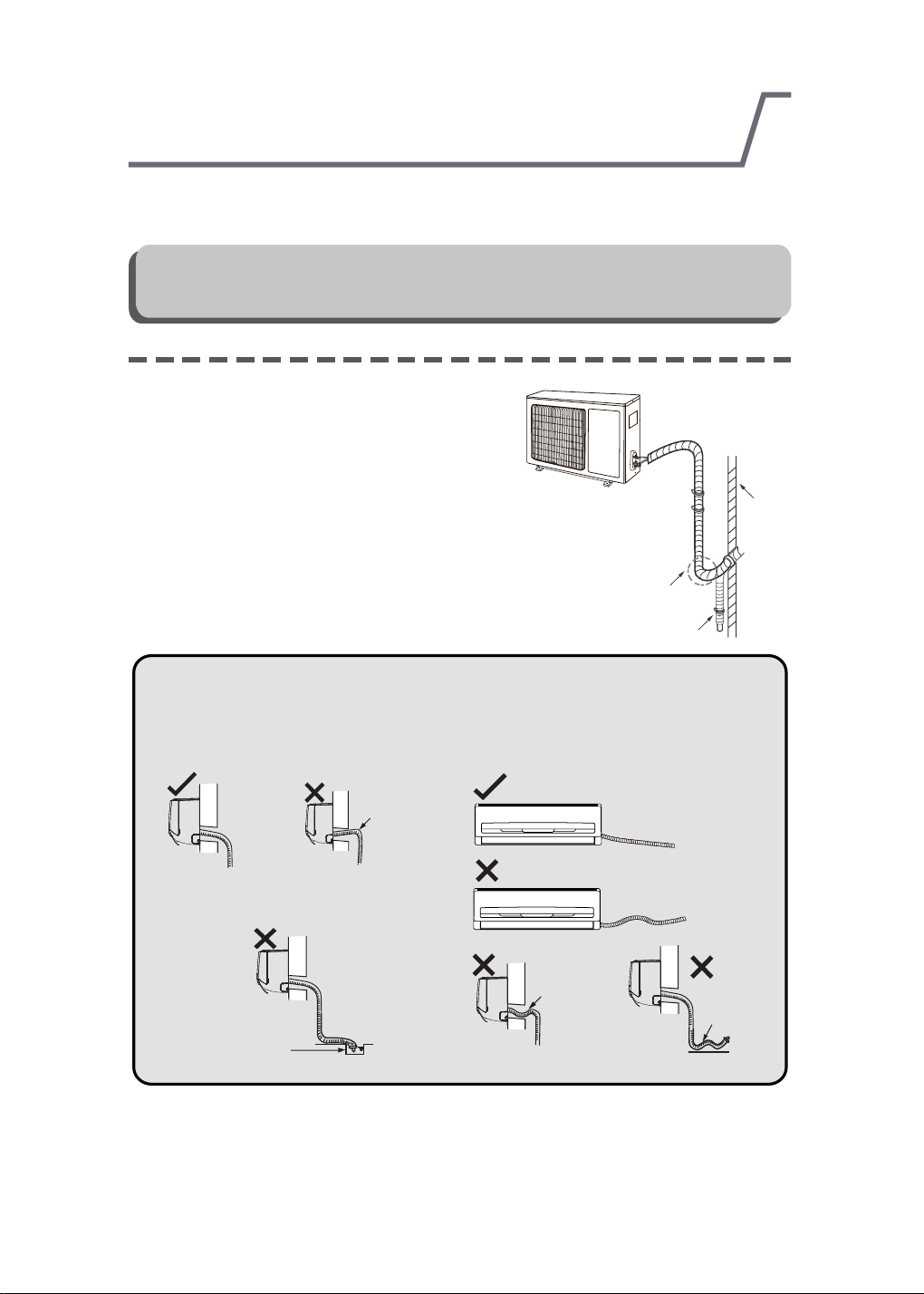

Step six: neaten the pipes

1. The pipes should be placed along the wall,

bent reasonably and hidden possibly. Min.

semidiameter of bending the pipe is 10cm.

2. If the outdoor unit is higher than the wall

hole, you must set a U-shaped curve in the

pipe before pipe goes into the room, in

order to prevent rain from getting into the

room.

U-shaped curve

drain hose

wall

Note:

Ɣ7KHWKURXJKZDOKHLJKWRIGUDLQKRVH

VKRXOGQWEHKLJKHUWKDQWKHRXWOHW

pipe hole of indoor unit.

the drain hose

can't raise

upwards.

Ɣ7KHZDWHURXWOHWFDQWEHSODFHG

in water in order to drain smoothly.

The water outlet

can't be placed

in water

Ɣ6ODQWWKHGUDLQKRVHVOLJKWO\GRZ

QZDUGV7KHGUDLQKRVHFDQWEH

FXUYHGUDLVHGDQGÀXFWXDQWHWF

The drain hose can't be fluctuant

The drain hose

can't be fluctuant

The water

outlet can't be

fluctuant

Vacuum pumping

-34-

Use vacuum pump

1. Remove the valve caps on

the liquid valve and gas

valve and the nut of refri gerant charging vent.

2. Connect the charging hose

RISLH]RPHWHUWRWKHUHIUL

gerant charging vent of gas

valve and then connect the

other charging hose to the

vacuum pump.

2SHQWKHSLH]RPHWHUFRP

pletely and operate for

10-15min to check if the

SUHVVXUHRISLH]RPHWHUUH

mains in -14.5 PSI (-0.1 MPa).

4. Close the vacuum pump

and maintain this status for

1-2min to check if the pres-

VXUHRISLH]RPHWHUUHPDLQV

in -14.5 PSI (-0.1 MPa). If the pressure decreases, there may be leakage.

5HPRYHWKHSLH]RPHWHURSHQWKHYDOYHFRUHRIOLTXLGYDOYHDQGJDVYDOYH

completely with inner hexagon spanner.

6. Tighten the screw caps of valves and refrigerant charging vent.

7. Reinstall the handle.

liquid valve

gas valve

refrigerant charging

vent

nut of refrigerant

charging vent

piezometer

valve cap

vacuum pump

inner hexagon

spanner

close

open

Lo Hi

Leakage detection

1. With leakage detector:

Check if there is leakage with leakage detector.

2. With soap water:

If leakage detector is not available, please use soap water for leakage detection.

Apply soap water at the suspected position and keep the soap water for more

than 3min. If there are air bubbles coming out of this position, there's a leakage.

Checking installation

-35-

Items to be checked Possible problem

The unit may drop, shake or emit noise.

Has the refrigerant leakage been

tested?

Is water drained well?

(heating) capacity.

It may cause condensation and water

dripping.

It may cause condensation and water

dripping.

Is the voltage of power supply according to the voltage marked on the

nameplate?

Is electric wiring and pipeline installed

correctly?

Is the unit grounded securely? It may cause electric leakage.

Is there any obstruction in the air inlet

and outlet?

The dust and sundries caused during

installation are removed?

The gas valve and liquid valve of

connection pipe are open completely?

It may cause malfunction or damaging

the parts.

It may cause malfunction or damaging

the parts.

It may cause malfunction or damaging

the parts.

(heating) capacity.

It may cause malfunction or damaging

the parts.

(heating) capacity.

Testing unit operation

1. Preparation of test operation

2. Method of test operation

operation.

whether the operation is normal or not.

60.8°F (16°C), the air conditioner can’t

start cooling.

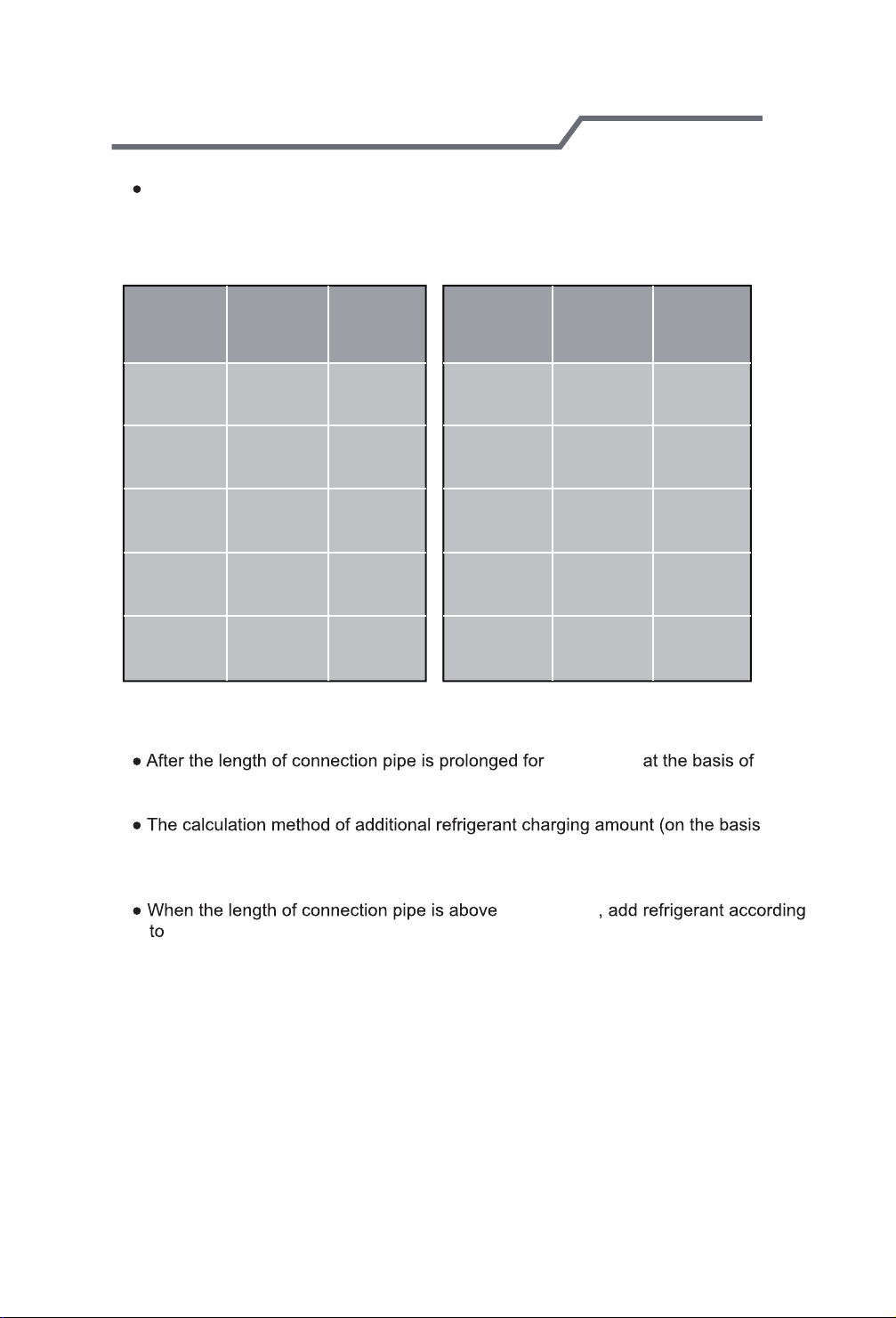

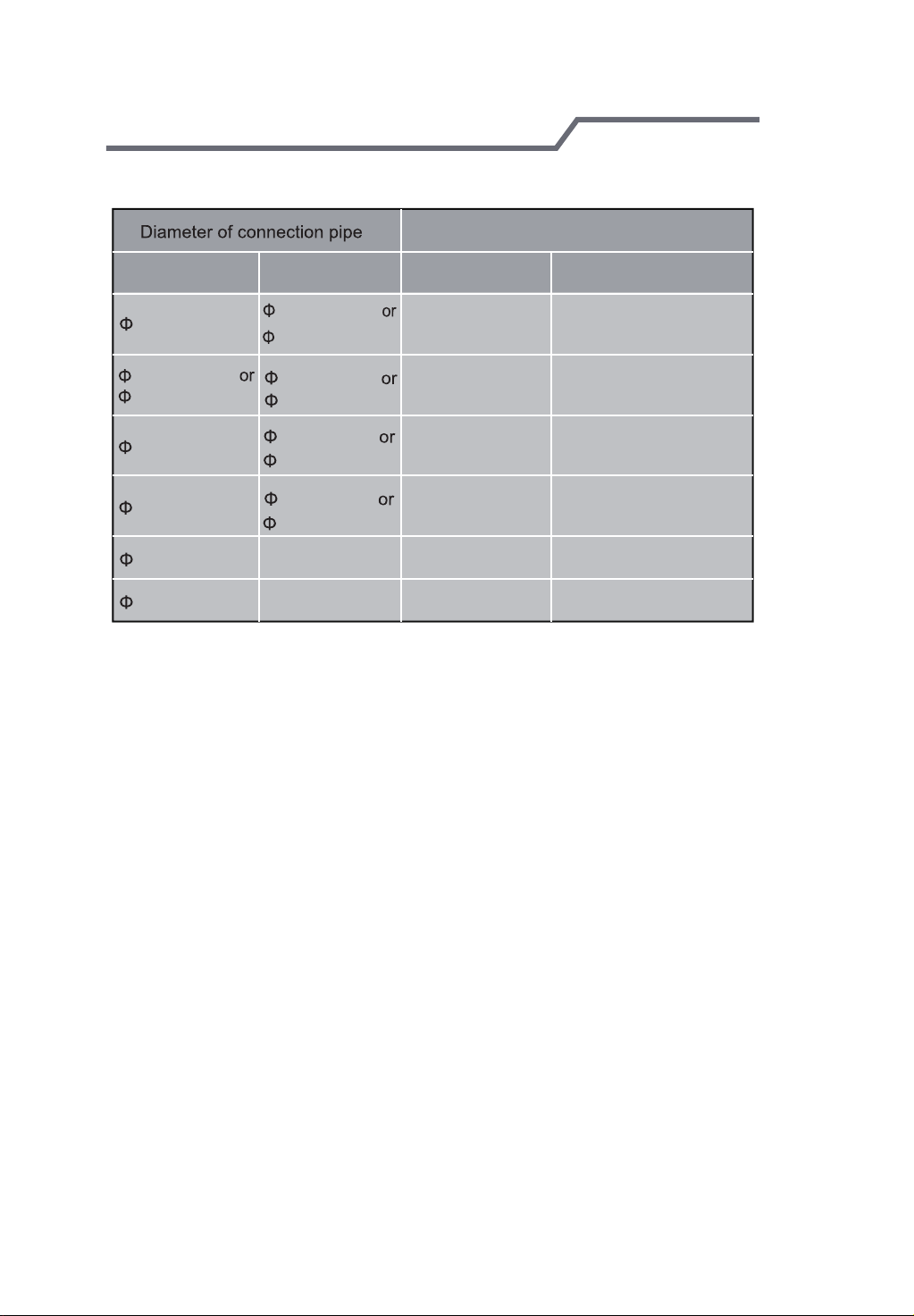

Configuring connection pipe

-36-

1. Standard length of connection pipe

16.4 ft (5 m),24.6 ft (7.5 m),26.2 ft (8 m)

2.Min. length of connection pipe is 9.8 ft (3 m).

3.Max. length of connection pipe and max. high difference.

Cooling

capacity

5000Btu/h

(1465W)

7000Btu/h

(2051W)

9000Btu/h

(2637W)

12000Btu/h

(3516W)

18000Btu/h

(5274W)

4. The additional refrigerant oil and refrigerant charging required after prolonging

connection pipe

standard length, you should add 1/3 in³ (5 ml) of refrigerant oil for each additional

16.4 ft (5 m)

Max length

of connection pipe

49.2 ft (15 m)

49.2 ft (15 m)

49.2 ft (15 m)

65.6 ft (20 m)

82 ft (25 m)

of connection pipe.

Max height

difference

16.4 ft (5 m)

16.4 ft (5 m)

16.4 ft (5 m)

Cooling

capacity

24000Btu/h

(7032W)

28000Btu/h

(8204W)

36000Btu/h

(10548W)

42000Btu/h

(12306W)

48000Btu/h

(14064W)

Max length

of connection pipe

82 ft (25 m)

98.4 ft (30 m)

98.4 ft (30 m)

98.4 ft (30 m)32.8 ft (10 m)

98.4 ft (30 m)32.8 ft (10 m)

32.8 ft (10m)

Max height

difference

32.8 ft (10 m)

32.8 ft (10 m)

65.6 ft (20 m)

65.6 ft (20 m)

65.6 ft (20 m)

of liquid pipe):

Additional refrigerant charging amount = prolonged length of liquid pipe ×

additional refrigerant charging amount per meter

16.4 ft (5 m)

the prolonged length of liquid pipe. The additional refrigerant charging amount

per meter is different according to the diameter of liquid pipe. See the

following sheet.

Configuring connection pipe

-37-

Additional refrigerant charging amount for R410A

Outdoor unit throttle

Liquid pipe(in/mm) Gas pipe(in/mm)

1/4 in (6 mm)

1/4 in (6 mm)

3/8 in (9.52 mm)

1/2 in (12 mm)

5/8 in (16 mm)

3/4 in (19 mm)

7/8 in (22.2 mm)

3/8 in (9.52 mm)

1/2 in (12 mm)

5/8 in (16 mm)

3/4 in (19 mm)

3/4 in (19 mm)

7/8 in (22.2 mm)

1 in (25.4 mm)

1 1/4 in (31.8mm)

_

_

Cooling only(oz/ft (g/m)) Cooling and heating(oz/ft (g/m))

0.2 oz/ft (15 g/m)

0.2 oz/ft (15 g/m)

0.3 oz/ft (30 g/m)

0.6 oz/ft (60 g/m)

2.7 oz/ft (250 g/m)

3.8 oz/ft (350 g/m)

0.2 oz/ft (20 g/m)

0.5 oz/ft (50 g/m)

1.3 oz/ft (120 g/m)

1.3 oz/ft (120 g/m)

2.7 oz/ft (250 g/m)

3.8 oz/ft (350 g/m)

Pipe expanding method

-38-

Note:

Improper pipe expanding is the main cause of refrigerant leakage. Please expand

the pipe according to the following steps:

A: Cut the pipe

E: Expand the port

the distance of indoor unit and

outdoor unit.

pipe

pipe cutter

leaning uneven burr

B: Remove the burrs

prevent the burrs from getting into

the pipe.

pipe

shaper

downwards

hard

expander

mold

pipe

diameter, please refer to the sheet

below:

Outer diameter

(mm (in ))

A(in/mm)

Max Min

1/20 in (1.3 mm) 0.02 in (0.7 mm)

3/50 in (1.6 mm) 1/24 in (1 mm)

0.07 in (1.8 mm)

1/10 in (2.4 mm)

1/24 in (1 mm)

2/25 in (2.2 mm)

F: Inspection

C: Put on suitable insulating pipe

connection pipe and outdoor valve;

install the union nut on the pipe.

union pipe

pipe

If there is any blemish, expand the

port again according to the steps

above.

smooth surface

improper expanding

damaged

leaning

the length is equal

surface

crack uneven

thickness

66129916984

Copyright 2014 Ca rrier Corporation S 7310 W. Morris St. S Indianapolis, IN 46231

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

Edition Date: 11/14

Catalog No: 38-40GR-01OM

Replaces: New

Loading...

Loading...