Page 1

r«) 11 w<0 11

Carrier Corporation • Syracuse, N.Y. 13221

Fan Sections and Accessory Electric Heaters

CONTENTS

SAFETY CONSIDERATIONS

MODULAR SYSTEM

INTRODUCTION..................................................2,3

INSTALLATION...................................................3-9

Step 1 — Inspect Equipment

Step 2 — Determine Position of Unit by

Airflow Direction.................................................. 3

Step 3 — Assemble Required Unit

Step 4 — Connect Ductwork to Unit

Supply and Return Air Openings

Step 5 — Insulate Ductwork

Step 6 — Install Accessory Cooling

Control Kit (cooling-only applications) ... 9

Step 7 — Install Accessory Humidity

Control Kit (28TQ applications only)

ELECTRICAL DATA AND WIRING ..................9-16

Step 8 — Install Branch Circuit

Disconnect Switch(es) per NEC .........................9

Step 9 — Route Line Power Leads

into Unit

................................................................

Step 10 — Connect Ground Leads

Step 11 — Set Fan Motor Speed(s)

Step 12 — Connect Control Power

Wiring (24-v)

.......................................................

START-UP........................................................... 16

FAN SECTION SERVICE

ELECTRIC HEATER SERVICE.......................... 17

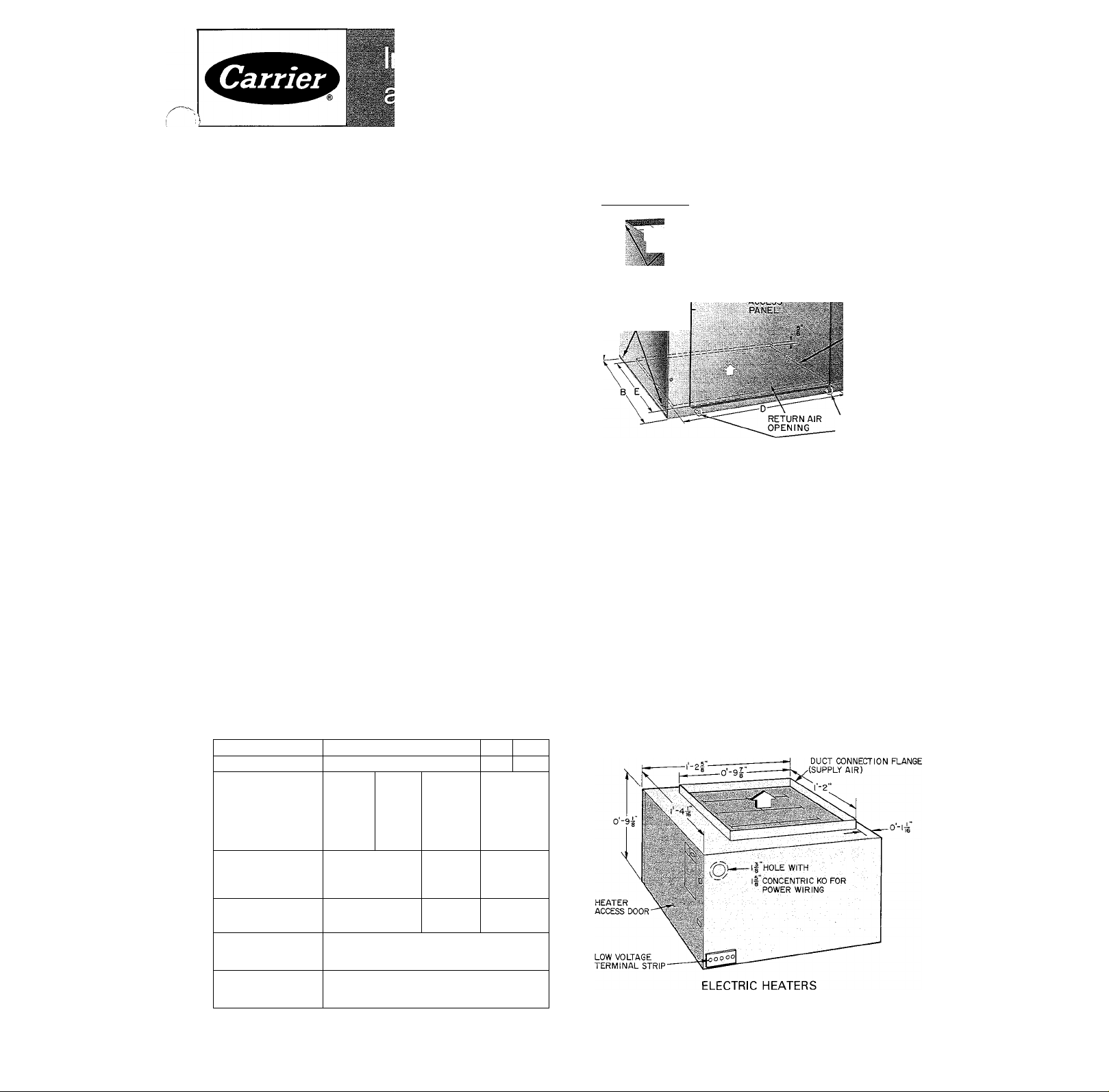

^ Table 1 — Physical Data and Dimensions

MODEL 40FS

OPERATING WT (lb) 60 65 72

FAN

Rpm, 60 Hz

Air Discharge

Nominal Cfm

PSC Motor — Hp

DIMENSIONS (ft-in.)

Length A

Width B

Height C

DUCT INLET (ft-in.)

DUCT OUTLET (ft-in.)

FILTER (1-in. thick)*

No.

Size (in.)

PSC — Permanent Split Capacitor

*40FS units factory equipped with permanent fi Iter and reversible rack with

s/s-in. duct connection flange.

075 1 120 ! 160 200 220

625-800

(2-speed)

Upflow-

Horizontal

750

Mo

2-0’Me

D

E

F

G

...........................

..............................

...................

.....................

................................

..................

..................

..................

...................................

(Fig. 1)

Centrifuga

(1-speed)

Upflow

l-llMe

— Direct Dr

1-9%

-lOMe

-

7%

1-7

1-178

1

800

(3-s

Upflow-[

Hori

1250

Vi

1-7%

975

1150

1

1

0-97s

21x24V4 I 21x203/4 | 21x24V4

ve

-1100

peed)

lownflowzontal

1750 1 2000

9,10

% 1 1

2-0’Me

1-11’/Í6

I

Page

. 2

3

3-7

7,8

8

9

9

10

10

17

40FS FAN SECTION SUPPLY AIR

■

CLEARAtjeSHOLEP

(AONEAGMDE)

FOR ATTACHING

ELEC. HE.?çte

AND C0ÛM3 COI

OR FI LTÉ®

SECTION »

■ ^FILTER RACK MAY BE TURNED OVER TO PROVIDE EXTERNAL |-IN.

DUCT CONNECTION FLANGE.

DUCT CONNECTION „7FLANGE (SUPPLY AIR) O/'^s

f HOLE FOR

CONTROL WIRING

OPENING

k /

HEATER ACCESS DOOR

I HOLE FOR

LINE POWER

/WIRING

ALTERNATE

(INTERNAL) .

, POSITION OF I

FILTER SECTION

FLANGES*

FILTER

'SECTION

PULL RINGS FOR

-FILTER MEDIA

REMOVAL

q¿'(40FS9I6,40FQ9I6,

' ■^I638HQ9000)

. OR

2-04 (40FS920,40FQ920,

—/ 38HQ900I)

0'-9"

l| HOLE WITH CONCENTRIC

KO'S: .

I'i,

FOR POWER WIRING

ELECTRIC HEATERS

(All 38HQ, 40FS,FQ Models except 40FS916320CD

thru JR, 40FS916500EH, GM and HV)

(40FS916320CD thru JR, 40FS916500 EH, GM and HV)

Certified dimension drawings are available on request.

Fig. 1 — Dimensions and Connections

Carrier Corporation 1983

Form 40FS-11SI

Page 2

SAFETY CONSIDERATIONS

Installation and servicing of air conditioning

equipment can be hazardous due to system pres

sure and electrical components. Only trained and

qualified service personnel should install, repair or

service air conditioning equipment.

Untrained personnel can perform basic mainte

nance functions of cleaning coils and filters and

replacing filters. All other operations should be per

formed by trained service personnel. When working

on air conditioning equipment, observe precautions

in the literature, tags and labels attached to the unit

and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and

work gloves. Use quenching cloth for unbrazing

operations. Have fire extinguisher available for all

brazing operations.

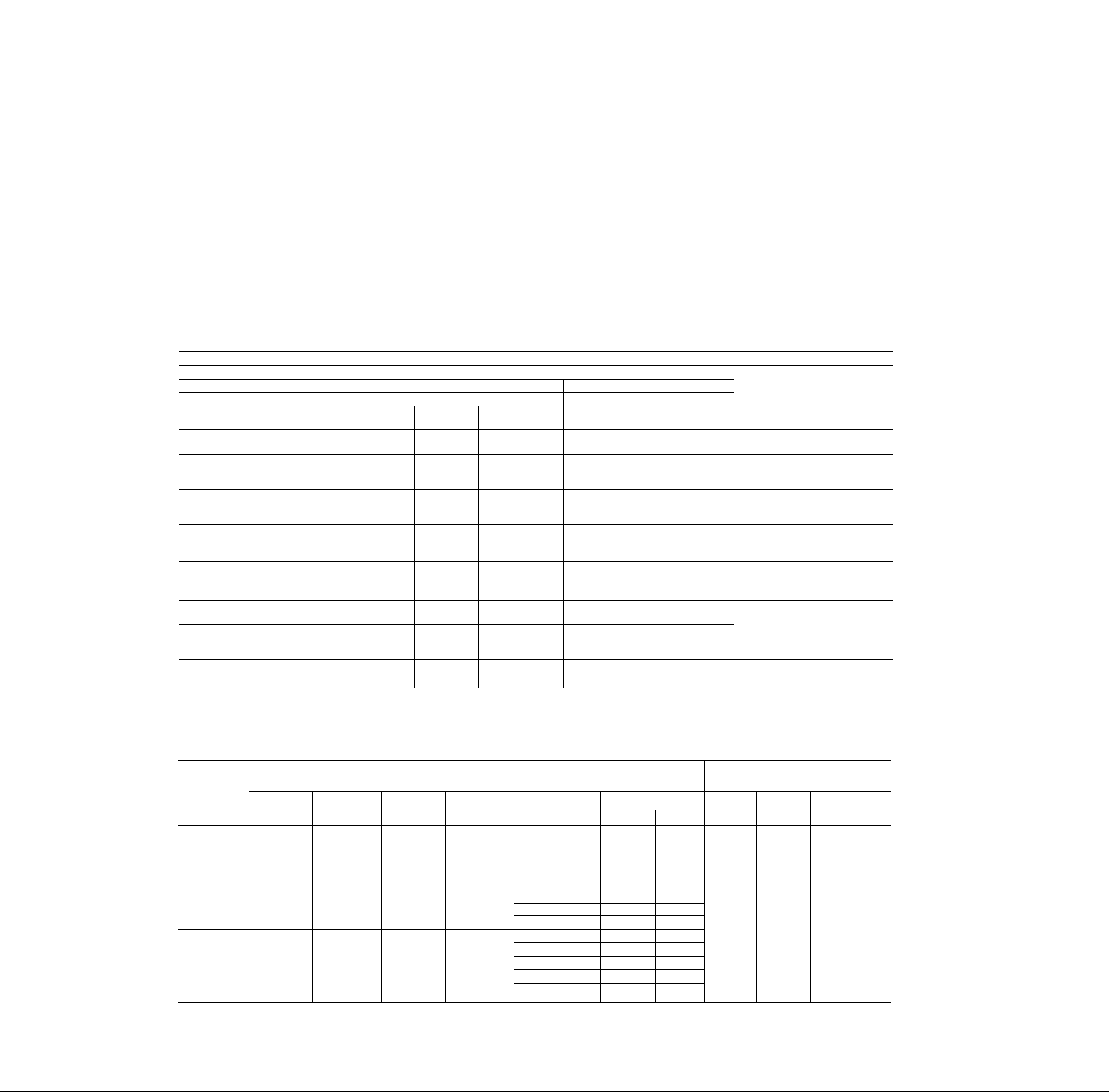

Table 2 — Height Dimensions of Assembled Units

MODULAR UNIT ASSEMBLIES

Cooling and Heating Unit

Cooling Unit 1 —

—

Coil

28H0036020

28HQ042030

28HQ048020

28H0042020

28HQ048020

28HQ060020 28VQ060020 28TQ060

28HQ036020 28VQ036020

28HQ042030

28HQ048020

28HQ042020

28HQ048020

28HQ060020 28VQ060020

-

-

-»

—

- — - -

*Total height may vary slightly depending on electric heater model used.

fLength dimension of assemblies in the horizontal position are same as

height dimension of units assembled for upflow airflow.

iAII height dimensions include 40FS filter section.

28VQ036020

28VQ042030

28VQ048030

28VQ042020

28VQ048020

-

28TQ042

-

-

-

280X036

280X042

-

— — —

28VQ042030

28VQ048030

28VQ042020

28VQ048020

-

- - - -

— — —

-

- - -

— — —

-

- -

- -

W.ARMNCi: llefore performing service or

maintenance operations on unit, turn off main

power switch to unit. Turn off accessoi\ healer

power switch if applicable, filectrical shock

could cause personal injury.

MODULAR SYSTEM INTRODUCTION

Field assemble the required 28 Series directexpansion (encased) coil and/or 40FS,40FQ,38HQ

accessory electric heater to 40FS fan section.

Combine fan section and coil for a split system fan

coil; fan section and accessory electric heater for

an electric furnace; fan section, coil and electric

heater for a heating and cooling unit. (See Table 2

for total height dimension of assembled units.)

Heating Unit

Fan Section

-

■ -

-

-

28VH002/004 40FS075/1 20

28VH002/004 40FS075/120

40FS160

40FS160

40FS200

40FS200.220

40FS160

40FS160

40FS200

40FS200.220

40FS160

40FS200.220

**For use with 38HQ227 and 234 only.

ttTotal height for 28QX coil with fan section and electric heater.

NOTE: 020.030 denotes dimensional variation within 28HQ/VQ models.

Refer to 28HQ/VQ literature for exact dimensions.

TOTAL HEIGHT'i (ft-in.)

Airflow

Upflow

Elec Heater

40FS,FO916

38HQ9000**

40FS.F0916

38HQ9000**

40FS91 6,920

40F0920

38H09001*

40FS91 6,920

40FQ920

38H0900T*

_

-

-

—

40FS,FO916

38H09000**

40FS916,920

40FO920

38HQ9001**

40FS920EH

(or Horizontal)t

3-11’^X6

4-

SM,

4- 3=46

5- OVsft

4- 7’4e

3- 3=46

3-10’/4

3-

7Va

3-1IV,6 3-11V,6

2-4=46

4- 7Ve

— 3-1IV,6 —

Downflow

4- OVe

4-

7Va

4- 3=46

5- 0%tt

4- 8’46

3- 4=46

3-10%

3- 7%

—

Table 3 — Installation and Usage Data (See Modular System Introduction, Page 3)

COIL

FAN

SECTION

40FS075 28VH002

40FS120 28VH004

40FS160

40FS200,

40FS220Í

Upflow

-

280X036,

280X042

*Electric heater for use with 208/230 V, 40FS units only. Refer to Electrical

Data and Wiring, Table 4, for fan section/electric heater usage and com

plete electric heater model numbers.

(Draw-Thru Airflow)

Upflow,

Downflow

-

Upflow

28VQ036,

28VQ042

28VO042,

28VO048,

28V0060

Horizontal

28VH002t

— —

28HO036,

28HO042

28H0042,

28H0048,

28H0060,

280X036,

280X042

Upflow,

Downflow,

Horizontal

-

28TQ042

28TO048,

28T0060

ELECTRIC HEATER*

(Blow-Thru Airflow)

Upflow,

Downflow,

Horizontal

KW

208V

40FS920300EH 7.5

40FS920300EH 7.5

40FS916300 6 - 18.8 8-25

40FS916320

40FS916500

40FO916

38HQ9000**

40FS920300

40FS916320

40FS916500

3.75-15

7.5-22.5

6-18.8

6-15

7.5-22.5

3.75-15

7.5-22.5

40FQ920 7.5-22.5 10-30

38HQ9001**

7.5-18.8

fHorizontal application not recommended for Weathermaster IV system.

iModel 40FS220 not for use with 28QX coil.

**For use with 38HQ227 and 234 only.

Heating

240 V

10.0

10.0 Fig. 2, 3

Unit

Fig. 2, 3

5-20

10-30

8-25

8-20

10-30

Fig. 2, 3

5-20

10-30

10-25

UNIT ASSEMBLY

POSITION

Cooling

Unit

Fig. 4

except dow

Heating and

Cooling Unit

iflow —

Fig. 4 Fig. 5

Fig. 4 Fig. 5

Fig. 5

Page 3

Models 28VQ,HQ coils and 40FS heaters are for

use in cooling-only and/or cooling and electric

heating systems. The 28VQ and HQ coils are also

for use in heat pump systems with 38HQ or 40FQ

electric heaters. Model 28TQ coil is for installation

in 38TQ 2-speed heat pump systems. The 28QX coil

is for solar-assisted heat pump systems. The 28VH

coil application is with Model 40FS075 only.

Fan section, coil and electric heater are tested

and approved for installation in unconditioned

space per ARI Standard (80 F db, 75 F wb indoor

temperature; 80 F db outdoor temperature). Insu

late supply and return air ductwork in uncondi

tioned space. If conditions exceed the ARI Stand

ard, additional insulation with vapor barrier may

be required for the unit.

Fan Sections 40FS can be positioned to discharge

air upward (upflow), horizontally, or downward

^(downflow), except for sizes 075, 120 which cannot

be used in downflow applications, and are suitable

for “Attic-Type” installations.

The 28 Series Coils are approved as draw-thru

(airflow) units only with the 40FS fan section. Install

coils in draw-thru position; heater in blow-thru

position. Therefore, coil must be attached to air inlet

end of fan section. As indicated in Table 3, per

missible coil airflow position(s) in system are:

28TQ — upflow, downflow or horizontal; 28VQ —

upflow or downflow; 28HQ — horizontal; 28QX —

upflow or horizontal; 28VH002 — horizontal or

^upflow with 40FS075 only, upflow with 40FS120

only.

Assembly of coils to 40FS fan section, electric

heater and filter section is described in this booklet.

For further coil information, see 28 Series installa

tion data.

COIL CONDENSATE DRAINAGE (for any unit

assembly installed above an occupied or usable

space) — In addition to normal condensate drain

line connection, install an auxiliary condensate pan

under entire unit assembly. Route drain line to any

drain that is visible to occupant. In 28 VH coil appli

cations, only the drain pan needed should be used.

See 28VH Installation Instructions.

Under prolonged high humidity conditions, elimi

nator plates may be required on downflow applica

tions. Horizontal coil installation may also require

special condensate removal methods. See Coil In

stallation Data.

Accessory Electric Heater is used with 40FS,

208/230-volt fan section. See Electrical Data and

Wiring table for fan section/electric heater usage.

Use electric heater as a blow-thru unit only by

attaching heater to air discharge end of 40FS fan

section in any of the 3 positions. Electric heater

has both heating and cooling controls including a

40-va or 60-va control circuit transformer, indoor

fan relay and low-voltage terminal strip.

MODELS 40FS916320 AND 40FS916500EH,

GM AND HV — These heaters are approved for

downflow usage but require the use of adapters

(downflow support angles) to support fan section

weight. See Installation, Heating Unit Assembly.

Filter Section is shipped taped to air inlet end of

fan section. Filter section includes a reversible

filter rack with 5/8-in. duct connection flanges. On

most unit assemblies the filter section can be

attached to unit with flanges exposed or turned over

so flanges are inside unit. The permanent one-in.

filter media pulls out (Fig. 1) for easy removal and

cleaning.

Cooling Control Kit is an accessory for 40FS,

208/230-volt fan sections used in cooling-only in

stallations. The kit contains a 40-va transformer, fan

deck filler panels, indoor fan relay and low-voltage

terminal strip. See Fig. 11, and cooling control kit

installation on page 9. Because accessory electric

heaters come equipped with cooling controls listed

above (plus required heating controls), a cooling

control kit is not required when electric heater is

used. An accessory humidity control kit is required

for use in 28TQ 2-speed installations. See Step 7

and Fig. 12.

INSTALLATION

Step 1 — Inspect Equipment — File claim with

shipping company if shipment is damaged or

incomplete.

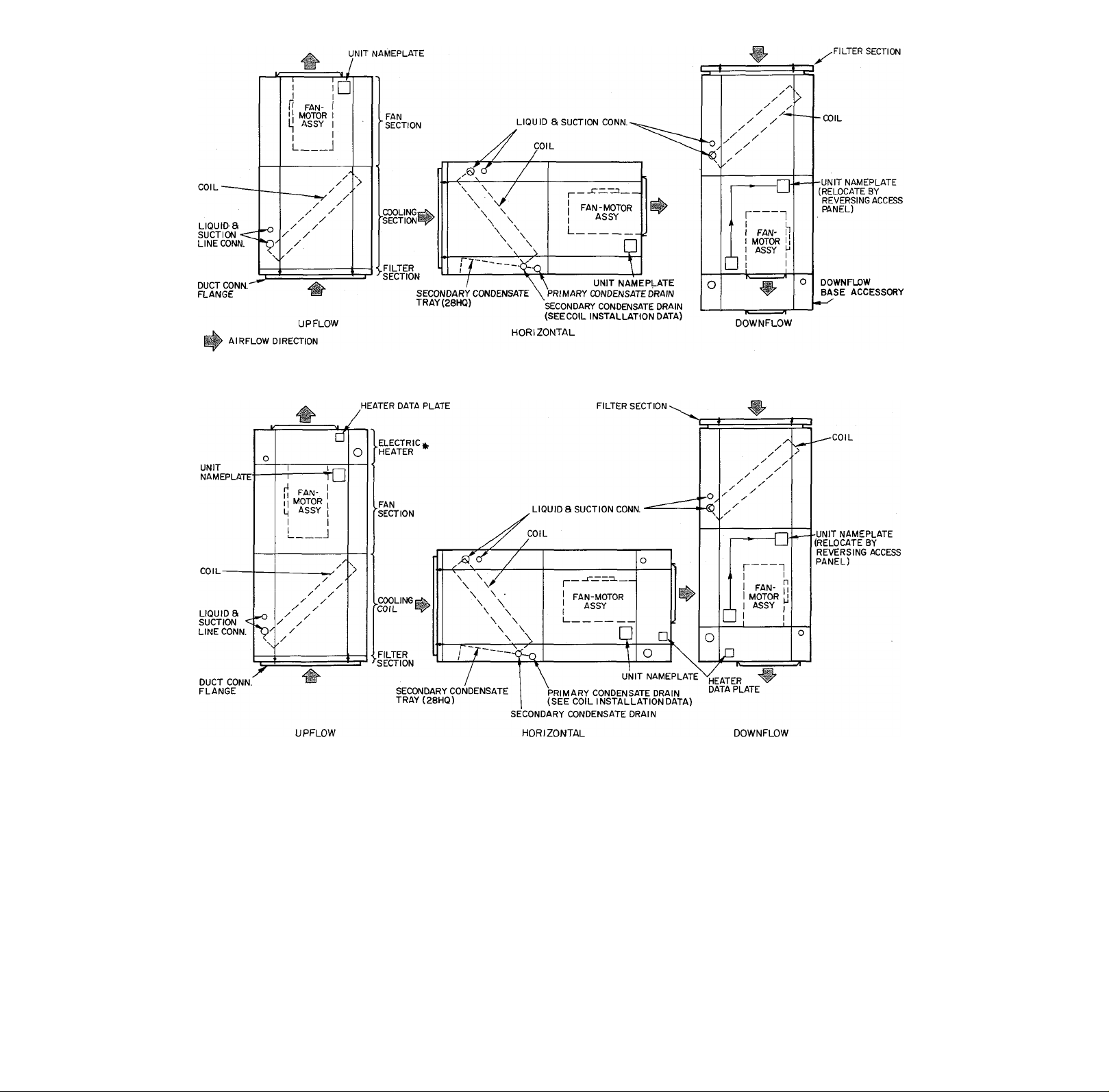

Step 2 — Determine Position of Unit by Air

flow Direction — See Table 3 and Fig. 2, 3, 4 and

5. Ensure access panels on all units face front before

and after unit assembly.

Step 3 — Assemble Required Unit — Follow

assembly procedure below for required unit. On

downflow unit assemblies, loosen or remove fan

motor mounting bolts and rotate fan motor so

oiling holes are a minimum of 45° above horizontal

center line of motor.

Fasteners for assembling units are shipped in a

bag inside of fan section or inside electric heater

enclosure. Use the no. 10 serrated hex head sheet

metal screws (or equivalent) provided, where indi

cated in unit assembly instructions below, to ensure

proper electrical ground continuity.

( .\l NON: \ll coil'« iiiii'l be applied draw-ihru

and l1e:ller.^ blow-ihiii v\heii eombining

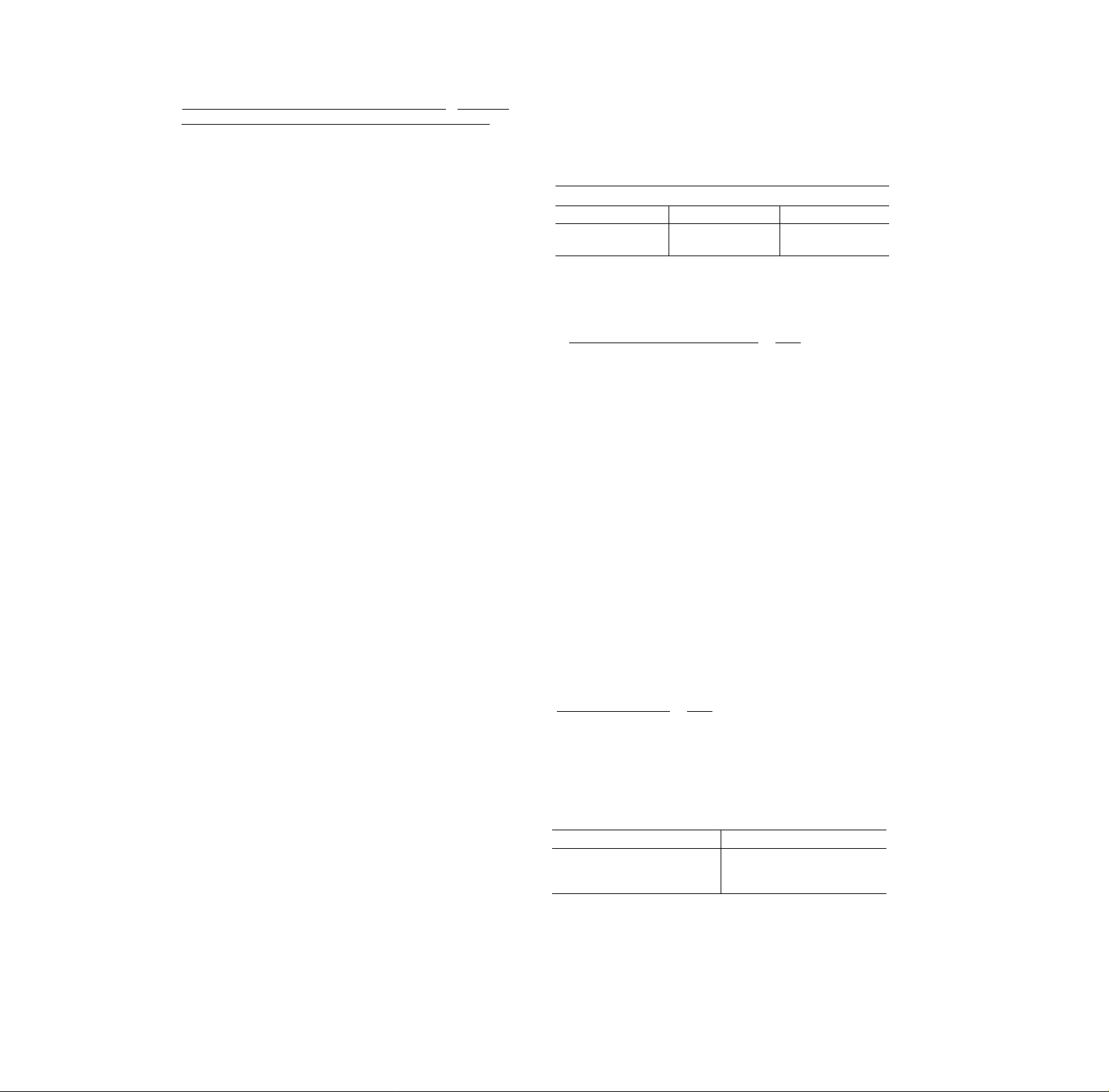

HEATING UNIT ASSEMBLY (Fig. 2)

Electric Heater Models except 40FS916320.

40FS916500EH. GM and HV. and 40FS916500LW

and PA when used with fan sections 40FS075.

-»40FS120. 40FS200 and 40FS220 — Position fan

section for upflow air direction. (Accessory flange

deck40FS900391 or40FS900401 required.) Setelectric heater on air discharge end of fan section.

Attach heater to fan section with 5 no. 8-32 self

threading screws provided. Clearance holes for

screws are provided on each side (2) and hack (1) of

fan section and engagement holes on heater.

Electric Heater Models 40FS916320. 40FS916330

and 40FS9165Q0EH. GM and HV — Position fan

section for upflow air direction. Mount heater on

fan section supply air duct connection flanges, and

attach with 4 sheet metal screws. Four clearance

holes for screws, provided on heater cabinet, can

be used as template for drilling engagement holes

in duct flanges as required. See Fig. 3. Assembly

may be aided by first removing top flange deck

from fan section (2 screws hold flange deck in place).

Assembled heater and flange deck can then be

resecured to fan section. Reposition plug buttons

Page 4

and rubber grommet positions in top flange deck to

accommodate heater fan leads. Install door air seal

strip on fan deck along front edge of heater.

Electric Heater Models 40FS916500LW. and PA

used with Fan Sections 40FS200 and 40FS220 —

Position fan section for upflow air direction.

Assemble flange deck according to instructions

shipped with accessory. Mount heater on fan section

supply air duct connection flanges; attach with 3

no. 8-32 self-threading screws and bracket provided

as shown in Fig. 3.

On all heating unit assemblies, attach filter

section to air inlet (return) end of fan section. The

filter section can be mounted with its 5/8-in. duct

connection flanges inside or outside of fan section.

Filter section is held in place with 4 screws and speed

nuts provided. See Fig. 6. Clearance holes for

screws are provided on each side of filter section.

Speed nuts provide engagement holes on each side

of fan section.

To position heating unit for horizontal airflow,

simply place assembled unit on either left or right

side with access panels at front. Position Model

40FS075 horizontally only with the motor above

the scroll as shown in Fig. 4.

For a downflow heating unit, turn assembled unit

over so fan discharges downward thru electric

heater. Remove fan section access panel. Turn

access panel so Carrier nameplate is in upright

position and replace panel on fan section.

CAU’IION: The electric heater modeK

4ii! II. (I\l. Il\ and 401

are appro\ed for downflow but w ill not support

fan section weight. When assembled unit is used

in downlliiw piisilmn. iiiNtall aCi.eNMii\ i|h\m;-

llow Niippuri ;ingle' li)l b‘J0l).14l tiisiippoii Ian

weight as describeil in Downllow Support

.Angles below.

Downflow Support Angles

1. Position fan-heater combination for upflow

arrangement (Fig. 3). Remove screws (4) secur

ing fan cover; remove and set aside cover.

2. Remove tie angle. Save screws “A” (2).

3. Install accessory fan deck filler panels as de

scribed in instructions shipped with accessory.

Assembly is similar to filler panels on accessory

cooling control kit. See Step 6 and Fig. 11.

4. Position support angles on fan section as shown

in Fig. 11. Reinstall screws “A” securing support

angles and flange deck to fan wrapper.

5. Using screws “B” supplied, attach each angle to

corresponding fan side flange. Holes in side

flanges are clearance holes.

6. Using remaining hole in each angle as a guide

drill a .128 in. diameter hole in front flange of

flange deck. Install screws “C” (supplied) in

these holes to attach angles to front flange.

NOTE: All 3 screws are required in each angle

for proper unit stability.

7. Using the 4 screws removed in step 1, reattach

fan cover so that Carrier nameplate is upside

down. Fan-heater assembly is now ready to be

inverted so that when installed in final loca

tion, nameplate will be right-side up.

The electric heater is equipped with heating

controls as described in Modular System Intro

duction. See Electrical Data and Wiring for wiring

details.

COOLING UNIT ASSEMBLY — Be sure 28 Series

coil is assembledin recommended airflow position;

DRAW-THRU AIRFLOW

Upflow

28TQ.28VQ,

28QX.28VH 28TQ,28VH

Coil casing on most models has sheet metal screw

engagement holes for assembly to fan section.

When engagement holes are not provided, carefully

drill holes where required.

Upflow and Horizontal Cooling Unit — Position

fan section for upflow air direction and coil in

upright position as shown in Fig. 4, page 6. Set fan

section on top of cooling coil casing. Attach fan

section to coil casing with 5 no. 10 hex head sheet

metal screws provided. Clearance holes for screws

are provided on each side (2) and back (1) of fan

section and engagement holes in sides and back of

coil casing. (Drill engagement holes as required).

Before attaching filter section to air inlet (return)

end of coil casing, remove return air duct flange

from coil casing. Be sure to install secondary con

densate tray with lip over edge of condensate pan

(28HQ only). The filter section can be mounted with

its 5/ 8-in. duct connection flanges inside or outside

of coil casing. Filter section is held in place with 4

screws and speed nuts provided (Fig. 6). Engage

ment holes for screws are provided by speed nuts on

each side of coil casing. Drill engagement holes in

each side of coil casing as required.

Use cooling unit as assembled above for hori

zontal airflow. To position unit for horizontal

airflow, place unit on its right side by turning it

clockwise 90°.

Downflow Cooling Unit — Install as accessory

downflow base under fan section to provide a

“firebreak” in accordance with UL requirements.

This base, which is a heater enclosure with no

heating components in it, is shown in Fig. 4. Install

base in the same manner as the heater as described

previously in Heating Unit Assembly. Also see

Fig. 2. The bases are used as follows;

FAN SECTION

40FS160300 40FS900220

40FS200300 40FS900230

40FS220300

Turn fan section (only) over so fan discharges

downward. Remove return air duct flange from

coil casing. Place coil, in an upright position, on air

inlet end (top) of fan section. Attach coil casing to

fan section with 4 no. 10 hex head sheet metal

screws provided. Clearance holes for screws are

provided in each side of fan section and engage

ment holes on sides of coil casing. (Drill engage

ment holes as required).

Downflow

28TQ.28VQ

Horizontal

28HQ,28QX,

USES BASE

40FS900230

Page 5

Set filter section on top of coil section with

filter flanges overlapping coil flanges. Drill 1/8-in.

holes thru coil and filter flanges, and fasten

together with sheet metal screws provided. Do not

drill into filter support rack. See Fig. 6.

Remove fan section access panel. Turn access

panel so Carrier nameplate is in upright position

and replace panel on fan section.

An accessory cooling control kit is required for

208-230-volt upflow, horizontal or downflow

cooling units described above. See cooling control

kit installation. An accessory humidity control

package is required for use with the 28TQ coil in

2-speed applications. See 28TQ installation data.

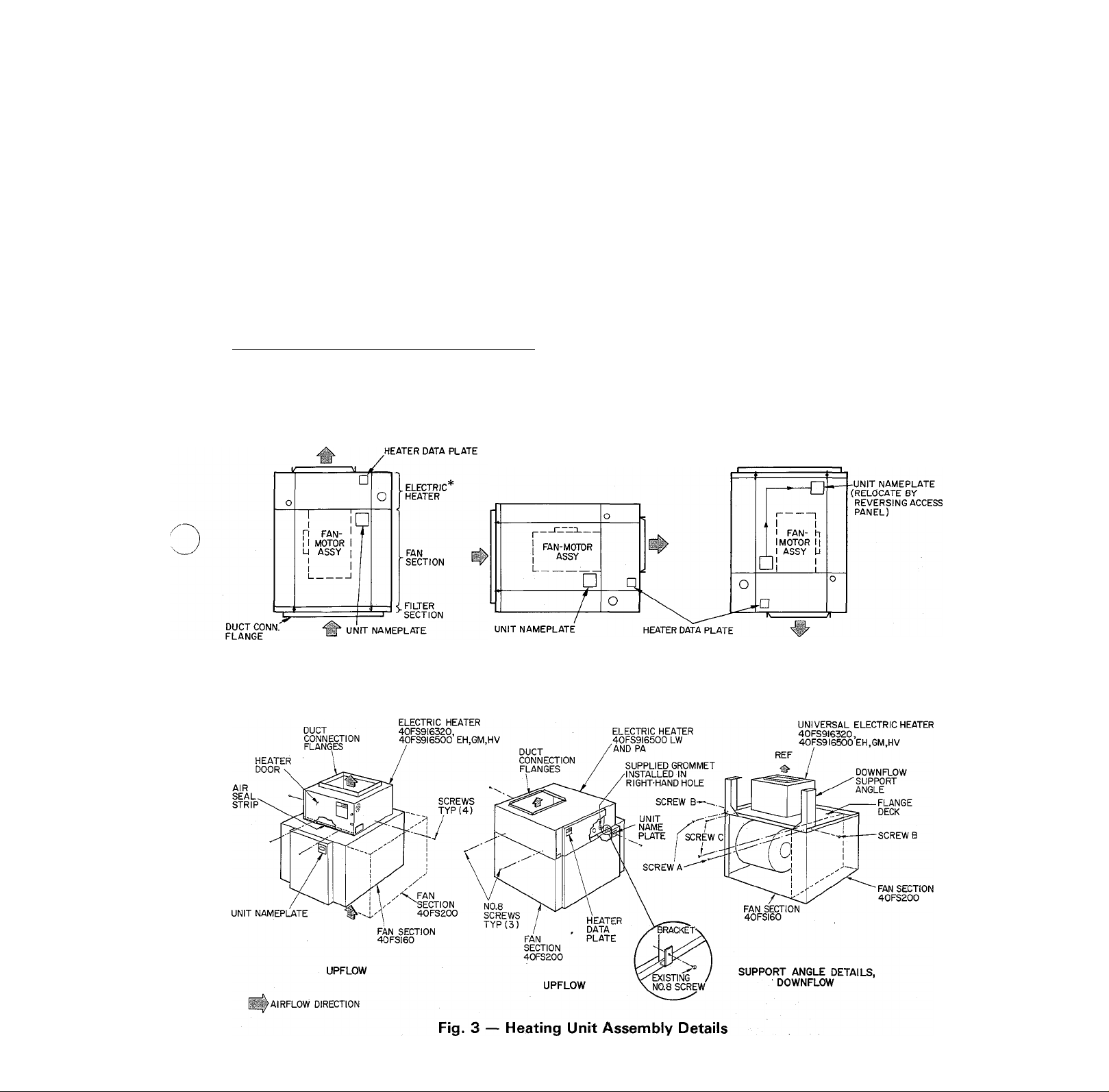

HEATING AND COOLING UNIT ASSEMBLY

— Attach electric heater to fan section as described

under Heating Unit Assembly. However, before

attaching filter section, proceed as follows:

Upflow and Horizontal Heating/Cooling Units —

Position heating unit assembly (Fig. 2, 3) for

upflow air direction and coil in upright position as

shown in Fig. 5 and 7. Set heating unit assembly

on top of cooling coil casing. Attach heating unit

assembly to coil casing with 5 no. 10 hex head sheet

metal screws provided. Clearance holes for screws

are provided on each side (2) and back (1) of fan

section, and engagement holes in side and back of

coil casing. (Drill engagement holes as required).

Before attaching filter section to air inlet (return)

end of coil casing: remove return air duct flange

from coil casing. Be sure to install secondary con

densate tray with lip over edge of condensate pan

(28HQ only). The filter section can be mounted

with its 5/8-in. duct connection flanges inside or

outside of coil casing. Filter section is held in place

with 4 screws and speed nuts provided (Fig. 6).

Engagement holes for screws are provided by speed

nuts on each side of coil casing. Drill engagement

holes in each side of coil casing as required.

Use cooling and heating unit as assembled above

for horizontal airflow. To position unit for hori

zontal airflow, place unit on its right side by turning

it clockwise 90°.

Downflow, Heating/Cooling Unit —^ When

40FS916320, or 40FS916500EH, GM, or HV

heaters are used in this assembly, install accessory

downflow support angles 40FS900241 to support

fan section/coil weight as described on page 3. Turn

fan section/electric heater assembly (Fig. 2, 3) over

so fan discharges downward thru electric heater.

Remove return air duct flange from coil casing.

UPFLOW

airflow direction

HORIZONTAL DOWNFLOW

*ALL HEATER MODELS EXCEPT 40FS9I6320,40FS9I6330 AND 40FS9I6500 LW AND PA. SEE FIG. 3

Fig. 2 — Heating Unit Assembly

Page 6

Fig. 4 — Cooling Unit Assembly

AIRFLOW DIRECTION

♦ heater 40FS9I6320 AND 40FS9I6500 EH,GM AND HV SHOWN INFIG.3

Fig. 5 — Heating and Cooling Unit Assembly

Place coil, in an upright position, on air

inlet end (top) of fan section. Attach coil casing to

fan section with no. 10 hex head sheet metal screws

provided. Clearance holes for screws are provided

on each side of fan section and engagement holes

on sides of coil casing. (Drill engagement holes

as required).

Set filter section on top of coil section with

filter flanges overlapping coil flanges. Drill 1/8-in.

holes thru coil and filter flanges and fasten

together with sheet metal screws provided. Do not

drill into filter support rack. See Fig. 6 and 8,

Remove fan section access panel. Turn access

panel so Carrier nameplate is in upright position

and replace panel on fan section.

The electric heater is equipped with heating

controls and cooling system controls as described

in Modular System Introduction. See Electrical

Data and Wiring, page 9, for wiring details.

Ductwork — Air Ducts should be installed in

accordance with the Standards of the National Fire

Protection Association, NFPA numbers 90A and

90B in compliance with paragraph 46.1-E of the

UL Standard 1096.

All 40FS units with accessory electric heaters

are suitable for installation with 0-in. clearance

from heater cabinet, discharge plenum and duct

work to combustible materials with the following

exceptions: When using 40FS920300PA (30 kw).

Page 7

all 38HQ and 40FQ models, 40FS916320 (11 to

20 kw) with 40FS200 fan section, and all 40FS916500

models, maintaina 1-in.clearance betweendischarge

plenum and ductwork to combustible materials for

a distance of 36-in. from unit. (0-in. clearance to

heater cabinet still permissible.) Use a heater spacer

plate. Carrier Model No. 40FS900310 to maintain

1-in. clearance.

SCREWS (4) SUPPLIED

SCREW CLEARANCE ]

HOLES(8)

FILTER SECTION

(SUPPORT RACK)'

FILTER SECTION

FLANGE MAY BE

POSITIONED INSIDE

(AS SHOWN) OR OUT

SIDE UNIT CASING

FDR DUCT CONN.

SPEED NUTS (4)

SUPPLIED

BOrrOM F..ANGE

ATTACHING FILTER SECTION TO FAN SECTION OR COOLING COIL IN ALL

INSTALLATIONS EXCEPT DOWNFLOW COOLING OR DOWNFLOW COOLING

AND HEATING,____________________________________

To maintain ductwork clearance on upflow in

stallations when heater top is within 3 in. of com

bustible material, set heater spacer plate over heater

discharge air opening. Attach ductwork to heater

flanges. Fig. 9. To maintain ductwork clearance

on downflow installations thru a floor: cut a 16-in. x

12-in. hole thru the floor. Set the spacer plate into

the hole. Place unit into the installed spacer plate

and connect discharge plenum to flanges provided

on heater.

Step 4 — Connect Ductwork to Unit Supply

and Return Air Openings — Duct connection

flanges are provided on fan section when used with

accessory flange deck, cooling coil, electric heater

and filter section, Fig. 1 thru 8. Two instances may

occur when duct connection flanges are not avail

able for use; when cooling unit or cooling and heat

ing unit is assembled for downflow cooling or

downflow cooling and heating with filter section

in place (Fig. 8), when filter section is installed

on fan section or cooling coil with its duct connec

tion flanges in alternate position inside of coil or

fan casing. Field-fabricated duct connections

are then required.

CAU'HON: Do not screw ductwork directly to

filter section. Screws will present removal of

Fig. 6 — Attaching Filter Section

SHEET METAL

SCREWS (2 EACH

SIDE, I ON BACK)

SUPPLIED

SHEET METAL

SCREWS (2 EACH

SIDE, I ON BACK)

SUPPLIED

'2s V

SUPPLY AIR DUCT

'CONNECTION (FLANGES)

.ELECTRIC

HEATER

FAN

SECTION

COIL

SECTION

If necessary, refer to Carrier System Design

Manual, Part 2, for system air duct design. It is

recommended that flexible connectors be used

between ductwork and unit to prevent trans

mission of vibration. (See Ductwork Acoustical

FIELD FABRICATED

SHEET METAL SCREW*

LOCATIONS (2

EACH SIDE) ON

FLANGES FOR

ATTACHING FILTER

SECTION (SEE

FIGS)

SHEET METAL

SCREWS (2 EACH

SIDE, ION BACK)

SUPPLIED

SHEET METAL

SCREWS (2 EACH

SIDE, ION BACK)

SUPPLIED

RETURN AIR DUCT CONN.TO

FILTER SECTION

FILTER

SECTION

O’ AIRFLOW

Fig. 7 —

FILTER

— ^SECTION

RETURN AIR DUCT

CONN. TO FILTER

SECTION

Upflow Heating and Cooling

Unit Assembly

CT AIRFLOW ■ ----------------------- ! SUPPLY AIR DUCT

^

*DRILL THRU FILTER SECTION FLANGES AND CCWLING COIL FLANGES TO ATTACH

FILTER SECTION. DO NOT SCREW DUCTWORK TO FILTER SECTION.

------

J'»CONN. TO HEATER

FLANGES

Fig. 8 — Downflow Heating and Cooling

Unit Assembly

Page 8

Treatment.) When electric heater is installed, use

heat resistant material for flexible connector

between ductwork and unit air discharge con

nection. Ductwork passing thru unconditioned

space must be insulated and covered with vapor

barrier. External ductwork must be insulated and

weatherproofed.

UPFLOW RETURN AIR CONNECTION THRU

THE FLOOR — Size floor opening large enough

to accept flanges on filter section. Make duct flush

with floor. Set unit on floor over opening with

filter section flanges inserted thru floor into duct.

Use fireproof resilient gasket 1/8 to 1/4-in. thick

between duct, unit and floor. For downflow supply

air connection thru the floor, proceed as above,

except size floor opening large enough to accept

flanges on unit air discharge connection. (See

combustible material specifications.)

If a side inlet return air connection is required,

use an accessory return air plenum.

ACCESSORY RETURN AIR PLENUM is avail

able in 2 sizes for use in upflow installations where

side return air inlet is required. A 21-in. wide model,

40FS900-141, is for use with 40FS160 assemblies,

and a 24-1/2 in. wide model, 40FS900-191, is for

use with 40FS200,220 assemblies and 40FS075

assemblies.

duct outlets. Metal duct systems that do not have

one 90° elbow and 10 ft of main duct to first

branch takeoff require internal acoustical insula

tion lining per the following specifications:

Line the inside of plenum, branch runs and

main duct with acoustical insulation in accordance

with the latest edition of SMACNA (Sheet Metal

and Air Conditioning Contractors National Asso

ciation) application standard for duct liner. Duct

liners should be UL classified batts and blankets

with a fire hazard classification marking of

FHC-25/50 or less. Ensure main duct lining is

extended 6 to 8 ft down the duct from plenum.

As an alternate to above, fibrous glass ductwork

may be used if constructed and installed in

accordance with the latest edition of SMACNA

construction standard on fibrous glass duct.

Both acoustical lining and fibrous ductwork shall

comply with National Fire Protection Association

as tested by UL Standard 181 for Class I air ducts.

Set 40FS heating and/or cooling assembly in

place on top of plenum. Cut opening in either side

or back of plenum and make return air ductwork

connection. Return air plenums and typical in

stallation are shown in Fig. 10.

Step 5 — Insulate Ductwork (Thermal and

Acoustical) — Insulate all ductwork passing thru

unconditioned spaces such as hot attics and crawl

spaces. Heat gain due to ductwork transmission

can result in insufficient air supply temperatures at

40FS,FQ OR

38HQ HEATER

40FS FAN SECTION

28VQ COIL

Fig. 9 — Heater Spacer Plate

AIR CLEANER

RETURN

, AIR

40FS ACCESSORY PLENUM

BASEMENT INSTALLATION

Fig. 10 — Accessory Return Air Plenum

Page 9

Step 6 — Install Accessory Cooling Control Kit

on 208/230-volt cooling only applications. As in

dicated on page 3, kit is not required on units

equipped with electric heater. Remove fan section

access panel; unpack and install control kit as

shown in Fig. 11 as follows;

1. Assemble left-hand and right-hand filler panels

using screws provided. Holes in filler panels are

provided to accommodate fan section width.

2. Cut supplied foam seal strip to fit filler panel

standing flange. Apply seal strip to back of

flange.

3. Secure cooling control box to right-hand filler

panel using screws “A” provided.

4. Remove screws “B” securing tie angle to fan

section. Remove tie angle; save screws.

5. Install filler panel/control box assembly on fan

section as shown. Secure, reusing screws “B”

plus screws provided (4 for top of panels to fan

deck; 2 for filler-to-side panels).

6. Route relay wires from control box thru wire

tie on fan assembly to fan speed selector block.

W.ARN'ING: Wires from heater must pass thru

wire tic to prevent wires from rubbing on sharp

Fig. 12 — Humidity Control Kit Installation

(28TQ Applications Only)

ELECTRICAL DATA AND WIRING

Field wiring must comply with local and national

fire, safety and electrical codes. Voltage to

unit must be within ± 10% of voltage indicated on

nameplate (voltage range at which the units will

operate satisfactorily for limited periods of time).

Contact local power company for correction of

improper line voltage.

Operation of unit on improper line \oltagc

constitutes abuse and is not covered by Carrier

Warranty.

7.

To install control box cover (not shown),

secure to hole in right-hand filler panel using

screw provided.

8.

Secure ductwork to fan section flanges (3) and

filler panel standing flange. Review ductwork

information discussed previously.

9.

Install fan section access panel.

Fig. 11 — Fan Section 40FS; Interior Details

Step 7 — Install Accessory Humidity Control

Kit (for 230-v, 28TQ application). See Fig. 12.

Attach supplied bracket to rear of control box using

hole closest to strain relief. Place control box in

upper right-hand corner of 40FS fan section. Secure

control box by fastening bracket supplied to support

bracket of fan section.

See Tables 4 and 5 for recommended wire and

fuse sizes.

Step 8 — Install a Branch Circuit Disconnect

Switch(es) per NEC. One disconnect switch is

required on all unit assemblies except those

which include 40FS916320 (11- to 20-kw) electric

heaters. Standard assemblies using these heaters

require 2 disconnect switches for 2 line power

circuits. If one line power circuit, using one dis

connect, is required, attach an accessory line power

connection conversion lug set (Lug Adapter Kit —

Part No. 40FS900271) to fuse terminals in electric

heater. Installation may be aided by first attaching

adapter lugs to wire then positioning lugs to fuse

block. See Fig. 13C.

Locate disconnect(s) within sight from and readily

accessible from the unit, per section 440-14 of

National Electrical Code (NEC).

Step 9 — Route Line Power Leads Into Unit —

Extend leads from disconnect per NEC thru hole

provided (Fig. 1) into cooling control kit or acces

sory electric heater. (Cooling control kit not

required when heater is used.)

Step 10 — Connect Ground Lead(s) to the

Ground Screw in Cooling Control Kit or

Grounding Lug in Electric Heater Control

Section for safety. Connect power wiring. Fig. 13.

Splice power leads to pigtails in cooling control kit

or connect leads to fuse terminals or terminal board

on electric heater.

When using control kit, splice a power lead to

black transformer pigtail on 230-volt units or red

transformer pigtail on 208-volt units. Cap unused

transformer pigtail.

When using an electric heater on 230-volts,

connect the red transformer pigtail to heater hne

voltage terminal. When using heater on 208-volts,

Page 10

connect blue transformer pigtail to heater line

voltage terminal. See heater label wiring diagram.

Cap unused transformer pigtail.

For splice connections or capping pigtails, use

wire nuts provided: Tape each connection.

Three-speed fan motor on all units (except Model

40FS075) may be connected for high, medium or

low fan speeds as described below. Refer to Table 7

for minimum allowable fan speeds when electric

heaters are used.

Step 11 — Set Fan Motor Speed(s) — High,

medium or low fan speed leads are provided on

motor for choice of fan speeds. Motor leads are

factory connected to fan speed selector block

located on fan housing (Fig. 11 and 13). Selector

block terminal 1 is high fan speed, terminal 2 is

medium fan speed and terminal 3 is low fan speed.

Model 40FS075 utilizes terminals 1 and 2 only.

Line power leads are supplied with cooling

control kit and electric heater for connection to

fan speed selector block as directed in Fig. 13.

Route yellow and black power leads which

extend thru hole in back of cooling control kit to

selector block. Route yellow and black or yellow,

black and red power leads from electric heater thru

power openings (Fig. 15) in bottom of heater

casing and fan section deck to selector block.

One fan speed may be selected for coohng only

unit assembly, heating only or cooling and heating

unit assembly when 40FS916320 or 40FS916500

heater is used.

Two fan speeds may be selected for remaining

combined cooling and heating assemblies; a heating

speed and a cooling speed. (See Table 7 for

Minimum Fan Speeds on heating application.) For

single fan speed operation on these heating only or

heating and cooling assemblies, remove red lead

from heater fan relay terminal 5 or 6. Connect a

black jumper (supplied) between fan relay terminal

6 and fan relay terminal 4 (40FS,FQ916, or

38HQ9000 heaters) or terminal 5 (40FS,FQ920, or

38HQ9001 heaters). Connect black heater lead to

fan speed selector block for speed required. See unit

label diagram for details.

40FQ9I6, OR 38HQ9000

40FS9I6300

,,

___

TO FAN CZ]—RED

SELECTOR ADD

BLK ([!□—BLK-

, REMOVE

factory)

WIRING )

I FACTORY

I WIRING

BLK-

40FQ920, OR 38HQ900I

40FS920300

1

Step 12 — Connect Control Power Wiring

(24-volt) with Cooling Control Kit or Electric

Heater — Use 40- or 60-va transformer supplied

as part of cooling control kit or electric heater

controls as 24-volt supply for system. A onetransformer control wiring hookup is recommended

for ease of installation. When outdoor unit trans

former is used together with control kit (or heater)

transformer, a phasing problem may result. If both

transformers are used, also use a thermostat with

isolating contacts to prevent interconnection of

class 2 (24-v) outputs.

10

Page 11

A. COOLING ONLY UNITS

I-PHASE CONN.

TO DISCONNECT PER NEC

230V OR 208V TAP

I I

BLK RED

J

____

L

( PRIMARY 1

ITRANSFORMERI

UecqndaryJ

f~

YEL

1 /

COM

PL-I PL-2 PL-3

FAN SPEED SELECTOR BLOCK

(I-FAN SPEED OPERATION)

l-PHASECONN. TO DISCONNECT PER NEC

LINE VOLTAGE |

TERMINAL BOARD |

0N5-KWT0I0-KW I

HEATER

CONTACTS

TAPE UNUSED LEADS

FAN

RELAY

(k

GROUND

—I CONN.

B. HEATING ONLY OR HEATING AND COOLING UNITS

(WITH ALL HEATER MODELS EXCEPT 40FS9I6320, 40FS9I6500

I

COOLING

CONTROL

KlTdFAN SPEED

OPERATION)

AND CIRCUIT BREAKER VERSIONS OF ALL 40FQ)

TERMINAL

BOARD 2

TO lO-KW HEATER

GROUND LUG (LOCATED

NEAR TRANSFORMER)

I-PHASE CONN.

TO DISCONNECT PER NEC

ON 8-KW

------

TAPE

UNUSED

LEADS

Q /

230V OR 208V TAP

[transformer

\SEC0NDARY/^

RED

( PRIMARY ^

I

11 I

'

C. HEATING ONLY OR HEATING AND COOLING UNITS

(WITH MODEL 40FS9I6320 HEATER)

1-PHASE CONN. TO DISCONNECT PER NEC

!

1

GROUND

LEAD

1

l-PHASE CONN

1

TO DISCONNECT

1

1

1

1

1

I-PHASE CONN.

TO DISCONNECT PER NEC

L2 LI

U-CKTA—H

*

F5

L_T5n ground lug ( LOCATED NEAR

YELIBLK

FI

F3

1 [-KW TO 30-KW HEATER

-TRANSFORMER)

38HQ HEATERS ONLY

ELECTRIC HEATER

CONTROL BOARD

F2 F4

FUSE BOARD ON

I

COM PL-I

FAN

-PHASE CONN. TO DISCONNECT PER NEC

' 1

GROUND

LEAD

1

PL-2 PL-3

SPEED SELECTOR BLOCK

FAN

motor;

1 1

1 I

l^CKTA^

1 1

F6

BLU

GROUND LUG (LOCATED

NEAR TERMINAL BOARD)

r^-

D. HEATING ONLY OR HEATING AND COOLING UNITS

(WITH MODEL 40FS9I6500 HEATERS)

3-PHASE

FIELD

POWER

CONN.

<^!> <^>

TERMINAL BOARD

18-KW UNITS

10-KW TO

SELECTOR BLOCK TERMINATIONS

COM-COMMON

PL-1 - HIGH

PL-2 - MED

PL-3 - LOWt

Q

230V OR 208V TAP

( PRIMARY ^

iTRANSFOR~MEg

Lseconda’ryJ^

GROUND

m

FUSE BOARD

mn

1 FU2

1 FU3

1 FU4

1 FU5

1 FU6

25-KW AND 30-KW UNITS

------

------

-- 0 I .GROUND LUGS (LOCATED I 0 I

---------^ NEAR FUSE BOARD) ^

TAPE UNUSED

LEAD^

--------------

-----------------

ELECTRIC HEATER

CONTROL BOARD

( l-FAN SPEED OPERATION)

YEL (COOLING a HEATING)

/ s

COM

PL-I PL-2 PL-3

FAN SPEED SELECTOR BLOCK

HEATING ONLY OR HEATING AND COOLING UNITS

/r\

h)-

3-PHASE

FIELD

■■

POWER

CONN.

Line Voltage Connection

Splice Connection

Field Wiring

Factory Wiring

Accessory connection conversion

lug set. See text for power wiring.

o o © <s>

0 0 0 0

STANDARD FUSE BOARD ON ll-KW

TO 20-KW HEATER W/ACCESS.

CONN. CONVERSION LUG SET

—f 0~I GROUND LUG

FAN ’

motor;

(UNITS 40FQ WITH CIRCUIT BREAKERS)

CIRCUIT BREAKER

BOARD (TYP)

I - PHASE FIELD

POWER CONN,

• — GROUND

*Fuses 5 and 6 only on heater models over 20 kw.

tPL-3 not used on Model 40FS075.

NOTES:

1. Branch circuit wiring data as shown in Table 4.

2. Tape or cap all unused wire leads.

3. For 1 fan speed operation, see text for power

wiring.

Fig. 13 — Line Power Connections

11

Page 12

FAN

SECTION

40FS075

^ 40FS120

40FS160

40FS200

or

40FS220

Table 4 — Heater Electrical Data and Usage

Heater

Model

240 V

40FS920300

(1-Ph)

40FS916300 FE 12.0

(1-Ph) FQ 13.0

40FQ916 030

(1-Ph)

38HQ9000

(1-Ph)

40FS920300

(1-Ph)

40FQ920

(1-Ph)

38HQ9001

(1-Ph)

EH 10.0 7.5 1

DL

DX 9.0

EH 10.0 7.5

ET 11.0

GB 14.0

GM 15.0

JR 20 0

LW

Old

060*

020

070*

080*

040

090*

050

100*

61

71 10.0 7.5

81

91

EH 10.0 7.5

ET 11.0 8.3

FE

FQ 13.0

GB 14.0 10.5 1 A 55.5 48.0 2

GM

JR

LW

PA

060

120*

070

130*

080

140*

090

150*

100

160*

01 10.0

11 15.0 11.3

21 20.0 15.0

31

8.0 6.0

25 0

8.0 6.0

10.0 7.5

15.0

20.0

25.0 18.8

8.0

15.0 11.3

20.0 15.0

12.0 9.0

15.0 11.3

20.0

25.0 18.8

30 0

10.0 7.5

15.0 11.3 1 59.5 51.6

20.0

25.0 18.8

30.0

25.0 18.8

ELECTRIC RESISTANCE HEATER (208/240 V)

Kw

No.

208 V 240 V 208 V

A

Htr

Amps

240 V 208 V 240 V

39.6 34.4 4

1 A 33.3 28.9

1

37.5

6.8

A

32.5 6

1 A 41.6 36.1 4

8.3

9.0

9.8

10.5

11.3

150

188

11.3

15.0

6.0

1 A 45.8

1

A 50.0

1 A

1 A

1 A

1 A

104.2

A

1

1

1

A

1

/\

1

/y

1

104.2

1 33.3

A

1

41.6 36.1

/\

1

62.5 54.2

39.7 4

43.4

54.2

47.0

58.3 50.5 2

62.5 54.2 2

72.2

83.3

90.3

33.3

41.6 36.1

54.2

62.5

83.3 72.2

90.3

28.9

1 83.3 72.2

1 A 39.6 34.4 4 6

1

43.6

A

37.8

1 A 47.6 39.4 4 4 65

1

51.6

9.8

A

44.8

1 A 59.5 51.6 2 2

1 A 79.3 68.8

15.0

1 A 99.2

22 b 1 A 119.0 103.2

86.0

1 39.6 34.4

1 79.3

15.0

22.5

7.5

1 Ai

/y

1

119.0 103.2

1 A<

39.6 34.4

A 59.5

1

1 A 79.3

1 99.2

99.2

68.8

86.0

51.6

68.8

Rfi n

Min Wire

Size (AWG)

6

4 4

2 4

2t

ot

6t

6t

4t

6t 6t

2t

4t 4t

It 2t

2t 2t

OOf

Ot

6t

6t

4t

6t

2t

4t

It 2t

2t 2t

4

2 4

It

Ot

oot

4t

6t

2t 2t

4t

n It

2t 2t

oot

Ot

oot

ooot

oot Ot

4t

6t

6t

6t

2t 2t

4t 4t

It It

2t

2t

oot

Ot

Ot

It

Branch Circuit

Max Ft

Wire

208 V

6

80

8 60

6 55 55

6 80

75 45

6

70

100 65

4

75 60

2 85

2

65 65

80 65

It

60 60

6t

60 40

8t

80 50

6t

50 50

85 70

2t

55 55

85 65

65 65

100

Ot

8t

6t

6t

2t

4t

80 65

It

60 60

6t

60 40

80 50

50 50

85 70

55 55

85 65

65 65

80 50

6 75 45

100 60

4

90 55

85 85

2

85 70

85 70

n

90 70

ot

80 50

6t

50 50

6t

90 90

55 55

4t

85

70 70

105 85

Ot

85

It

110 90

90 70

80 50

50 50

90 90

55 55

85 85

70

70

105 85

85 1

70

Min Gnd

Wire Size

208 V

240 V

50

40

10 10 60** 60**

10 10

10 10 60** 45**

10 10

50

10 70 60

8

65

8 10 70

8 8

8 8

70

8 8

6 8 110 100

6

10 10 50** 40**

1_Q

10 60** 50**

8 8 90 80

0

85

0 0

10 10 50** 40**

10 60**

10

8 8 90 80

0

10 60** 60**

10

8 10 70 60

70

8 10 70 70

8

8

8 8 80 70

8

8

6

8 110 100

6 6

6 6

10 10 60**

8 8 90 80

85

70

0

0 0

6

8 110 100

0

10 10 60** 60**

8 8 90 80

0

8 110 100

6

6 150 125

Fuse/CB

Amps

208 V

240 V

50** 40**

. 60** 50**

80

80 70

90

6

150 125

8 110 100

150 125

8 110 100

80 70

90 80

150 125

175 150

60**

150 125

150

175

60

70

80

50?**

12

Page 13

FAN

SECTION

40FS160,

40FS200

or

40FS220

Model

40FS916320

40FS916500

(3-Ph)

Table 4 — Heater Electrical Data and Usage (cent)

ELECTRIC RESISTANCE HEATER (208/240 V)

Kw

240 V 208 V

CD

CP 6.0 4.5 1 A

DA

DF

DL

DX

EH

—

i ETtt

■,__ _

1 FEtt

FQtt

GBtt

; GMtt

GY .

; HJtt 17.0 12.75

HVtt

JFtt 19.0 14.25

JRt+ 20.0

EH

GM 15.0 11.3 1

HV 18.0 13.5 1

LW ■

PA : 30.0 ;

5.0 3.75 1 A

7.0

5.25

7.5 5.63 1 A

8.0 6.0 1 A

9.0 6.75

10.0 7.5 1 A

11.0 8 25

iiiSiiPM

12.0 9.0

13.0 9.75

140 10.5

15.0 11.25

16.0 12 0

18.0 13.5 A

15 0

10.0 7.5 1

18.8

22 5 1

No.

nUfc

Htr

Amps

240 V

208 V 240 V 208 V

Min Wire

Size (AWG)

20.8 18.0 8 10

25.0 21.6 8 8 50 60

1 A 29.2

31.3 27.0

33.3 28.9

1

A

37.5 32.5

41.6

1 A

45.8

A

25.0 21.6

8

20.8 18.0

1

A

50.0

A

29.2 25.2

2

B

20.8 18.0

1 A

54.2

A

33.3 28.9

2

B

20.8 18.0

1

A 58.3

A

37.5 32.5

B

20.8 18.0 10

1

A 62.5 54.2 2

A

41.6

2

B

20.8

1 A

66.7 57.7 2

A 33.3

2

B 33.3

1 A

70.8 61.3

A

35.4

0

B 35.4

1 A

75.0 64.9 1 2 90 85 8 8 100 90

25.2 6 8 70

6

6 6 65 70

6 6 55 65 10

36.1

39.7

4 6

4 6 75 55 8

8 8 50 60

10

43.4 4

6 8 70 50 10 10 45

10

47.0

2

6

10

50.5

2

6 6 55 65 10 10 60 50

36.1

18.0

4 6 80 60 10 10 60 60

10 10 45

28.9 6

28.9

6 8 70 55 10 10

2 2

30.6

6 6

30.6 6 8 65 50 10 10 45 40

37.5 32.5 6 6 55 65 10 10 60 50

B

37.5 32.5 6 6

1 A

79.2 68.5

A

39.6

34.3

B

39.6 34.3 6 6 60 70 10 10 50 45

1 A

83.3 72.2

A

41.6 36.1

2

B

41.6 36.1 6 6 55 65 10 10

24.0 20.8

36.0 31.3

43.3

37.5

2t

6 6

2t

4

8t 8t

6t 8t

6t

1 60.2 52.2 4 4

72.2 62.5 2

Branch Circuit

8 65 50

10 45 55 10 10 30

4

10 45 55 10 10 30

4

6 60 70 10 10 50 45

10 45 55 10 10 30 25

4 100

10 45 55 10 10 30 25

2

2

6 60 70 10 10 50 45

2

1

6 80 60 10 10 60 60

6t

4

Max Ft

Wire

240 V 208 V

60 45

Min Gnd

Wire Size

240 V 208 V 240 V 208 V

Fuse/CB

Amps

10 10 35 30

10 10 40

50

10 10 45 40

10 10 45

10

10 50 45

10 60

60

80

10

10

60

10 70 60

10

10 40

80 8

70

10 70 60

100 70 8 8 80 70

70

8

8

80 70

90 100 8 8 90

55 10

10

30 25

80 90 8 8 90 80

45

90 8 8 100 90

80

65 10 10 50 45

60

70 10 10 50 45

60

80 6 8 110

70

55 60 10 10 60 50

95 6 8

65

110 100 •

60 50

70 60 10 10 40 35

65 40 10 10 60 45

55

55 10

10

60 60

65 65 8 8 90 80

90 55 8

8

100

35

40

50

60

35

25

40

25

80

40

100

90

Two-stage electric heaters. Remaining heaters are singlestage. See Fig. 15.

CB — Circuit Breaker

^Circuit breaker models. All remaining models over 10 kw are in

ternally fused.

tCopper wire sizes based on 75 C; all other copper wire sizes

based on 60C. Use copper wire only.

JCopper wire rated at 75 C and no larger than 00 size must

be used.

**Use fuses only on 40FS91 6300 DL, DX, EH, 40FQ91 6010,020,

40FQ920060 and 40FS920300 EH units.

tfStandard heater models that require 2 line power circuits. Add

accessory conversion lug set for single power circuit operation.

NOTES:

1. Heater models 40FQ916, 40FQ920 and 40FS916320 equipped

with 60-va control circuit transformer. Remaining heater

models have 40-va transformer.

2. Field-selected wire sizes must not create a voltage drop

between power source and unit in excess of 2% of unit

rated voltage.

13

Page 14

THERMOSTAT HHOIAD040 0R042W1TH

HH93AZ040 OR 042 SUBBASE

FAN SECTION

COOLING CONTROL KIT

I l-KW TO 20-KW,

ARRANGEMENT ACOOLING ONLY. (SEE NOTE I BELOW)

THERMOSTAT HH0IAD040 OR 042 WITH jq is-kw

HH93A2040 OR 042 SUS8ASE ELECTRIC HEATER

AND I-STAGEHEATING WITH,8-KW TO 15-KW,

40FS9I6300 OR 40FS920300 HEATER.

(SEE NOTE I BELOW)

THERMOSTAT HH07AT070

SUBBASE HH93AZ080

ARRANGEMENT C- COOLING

AND 2-STAGE HEATING WITH.20-KW TO 30-KW,

40FS9I6300 0R40FS920300 HEATER.

(SEE NOTE I BELOW)

THERMOSTAT HH0IAD04O OR 042 5-KW TO 10-KW,

WITH HH93AZ040 OR 042 SUBBASE ELECTRIC HEATER

20-KW TO 30-KW

ELECTRIC HEATER

LOW-VOLTAGE

TERMINAL BOARD

CONO UNIT

CONO UNIT

40FS9I6320 HEATERS. (SEE NOTE 1 BELOW)

THERMOSTAT HH07AT07I WITH

HH93AZ073 (AUTO. CHANGEOVER)

OR HH93AZ075(MANUAL 40FQ

CHANGEOVER)SUBBASE. ELECTRIC HEATER

(SEE NOTE 2 BELOW.) TERMINAL BOARD

ARRANGEMENT F-COOLING

AND 2-STAGE HEATING-38CQ HEAT PUMP AND

40FQ HEATER (ALL); SUPPLEMENTAL HEAT, NO OUTDOOR

THERMOSTATS.(SEE NOTE I BELOW) REFER TO 38CQ

OR 38RQ HEAT PUMP INSTALLATION INSTRUCTIONS

IF OUTDOOR THERMOSTATS ARE USED.

THERMOSTAT

SUBBASE

HH93ÀZ073

OR HH93AZ075

40AQ.38HQ OR 40FQ

ELECTRIC HEATER

TERMINAL BOARD

38HQ

COMPRESSOR SECTION

TERMINAL BOARD

38CQ0R38RQ

HEAT PUMP

TERMINAL BOARD

40FS9I6320 HEATERS. (SEE NOTE I BELOW)

Eliminate shaded wiring connections for heating only

applications.

CR — Control Relay

ODT — Outdoor Thermostat

SHR — Supplemental Heat Relay

-----------

Factory Wiring

-----------

Field Wiring

*A 40-va transformer is located in cooling control kit and

*

40FS916300,920300 electric heaters. All 40FS916320,330,500

and 40FQ916,920 electric heaters have a 60-va transformer that

is internally fused. All 38HQ heaters have a 75-va transformer

that is internally fused. Do not short secondary terminals.

Fig. 14 — Control Wiring Connections

(38HQ WITH 40AQ OR 40FS/28HQ.VQ

EQUIPPED WITH ELECTRIC HEATER,

SUPPLEMENTAL HEAT,

NO OUTDOOR THERMOSTATS)

REFER TO 38HQ HEAT PUMP INSTALLATION

INSTRUCTIONS IF OUTDOOR THERMOSTATS

ARE USED.

fRemove jumpers from 40FQ heater terminfl board to wire with

outdoor thermostat(s).

^Remove factory-installed jumpers (connection B) when installing

outdoor thermostats (ODT).

NOTES:

1. For simplicity, arrangement identifications below diagrams do

not call out fan section/coil model numbers. See Modular Sys

tem Introduction and Tables 2, 3 and 4 for fan section/coii/

heater models and usage.

2. Thermostat/subbase package numbers: 38CQ900081 for

HH07AT071/HH93AZ073 (auto, changeover); 38CQ900111

for HH07AT071/HH93AZ075 (manual changeover).

3. See Carrier price pages for other approved thermostats.

14

Page 15

Table 5 — Fan Section Electrical Data

FAN SECTION

Branch Circuit

Model

40 FS

Volts

(1-ph)

FLA

Wire

Size*

(AWG)

075

120

160 208/230

200

220

0.9 14

1.5

14

3.5 14

4.5 14

6.9

14

FLA — Full Load Amps

*Copper wire sizes based on 60 C. Use copper wire only.

NOTÉS: 1. See Table 4 for units equipped with electric heaters.

2. When 40FS unit is equipped with electric heater, fan motor line power is

supplied from electric heater line power circuit.

Table 6 — Thermostat Anticipator Settings

Max

Ft

Wire

Fuse

Amps

399 15

240

103 15

80 15

52 15

15

40FS916300

40FQ916

38HQ9000

40FS920300

40FQ920

38HQ9001

HEATER

MODEL

1 St Stage

DL

OX

EH

ET

FE

FQ

GB

GM

JR

LW

010

060

020

070

030

080

040*

090*

050*

100*

61

71

240 V

8.0 6.0

9.0 6.8

10.0 7.5

11.0

12.0 9.0

13.0

14.0 10.5

15.0 11.3

10.0 7.5

15.0

8.0

10.0 7.5

10.0 7.5

10.0 7.5

15.0 11.3

8.0 6.0

10.0 7.5

208 V 240 V 208 V

81 10.0

91

EH

ET

FE

FQ

GB

GM

10.0 7.5

10.0 7.5

11.0 8.3

12.0

13.0 9.8

14.0 10.5

15.0 11.3

JR 10.0 7.5

LW

PA

060

120

070

130

080

140

090*

150*

100*

160*

01

11

21

31

15.0 11.3

20.0 15.0

10.0 7.5

. 10.0 7.5

10.0

15.0

11.3

20.0 15.0

10.0

10.0 7.5

10.0

15.0 11.3

8.3

9.8

11.3

6.0

7.5

9.0

7.5

7.5

7.5

KW

ANTICIPATOR SETTING

2nd Stage 1 St Stage 2nd Stage

__

_

__

— —

— —

— —

—

— —

10.0

10.0

— —

—

5.0

240 V

—

—

—

.16

.16

.16

.16

.16

208 V

.14

.14

.14

.14

.14

.16 .14

—

.16 .14

.16 .14

7.5

7.5

.16

.16

.14

.14

.16 .16

- .16 .16

3.75 .16 .16

240 V

— ,

__

—

—

—

— —

— —

.16

.16

— —

— ' — ■

.16

10.0 7.5 .16* .16* .16* .16*

10.0 7.5 .16* .16*

— —

5.0

—

3.75 .16 .16

.16 .16

.16 .16

.16*

■

-------

— —

.16 .16

10.0 7.5 .16* .16* .16* .16*

— —

—

—

—

— —

— —

10.0

10.0

_

7.5

7.5

10.0 7.5

— —

5.0

3.75

10.0 7.5

10.0

10.0

— —

5.0

7.5

7.5

3.75

10.0 7.5 .16

.16 .14

.16 .14

.16 .14

.16

.16

.14

.14

.16 .14

.16

.14

.16 .14 .16 .14

.32 .28 .16

.16

.16

.16 .16 .16 .16

.16 .16 .16 .16

.16* .16* .16* .16*

.32* .32* .16* .16*

.16

.16

.16 .16 .16 .16

.16 .16 .16

' 10.0 7.5 .16 .16

— —

— —

— —

— —

— —

— —

.16

— —

— —

.16* .16*

208 V

—

—

—

—

—

.14

.14

.16

.16*

—

.14

.14

15

386

Page 16

Table 6 — Thermostat Anticipator Settings (cont)

HEATER

MODEL

40FS916320

40FS916500

1 St Stage

240 V 208 V

CD

CP 6.0 4.5

DA

DF

DL

DX

EH

ET*

FE*

FQ*

GB*

GM*

GY*

HJ*

HV*

JF*

JR*

EH 10.0 7.5

GM

HV

LW

PA

5.0

7.0 5.25

7.5 5.63

8.0 6.0

9.0 6.75

10.0 7.5

6.0 4.5

7.0 5.25

8.0

9.0 6.75 5.0 3.75

10.0 7.5

8.0 6.0 8.0 6.0

8.5 6.38 8.5

9.0

9.5 7.13

10.0 7.5

15.0 11.3

18.0 13.5

12.5 9.4

15.0 11.25 15.0 11.25 .23 .23 .23 .23

KW

2nd Stage 1 St Stage

240 V

3.75

6.0 5.0 3.75

6.75

— —

— — .25

— —

— — .25

— —

— —

—

5.0 3.75

5.0

5.0 3.75

9.0 3.75

9.5 7.13 .25* .25* .25* .25*

10.0

— — .23

— — .23 .23 — —

— —

12.5

208 V

—

3.75

6.38 .25* .25*

7.5

9.4

240 V 208 V

.25

.25

.25

.25

.25

.25*

.25*

.25* .25*

.25* .25*

.25* .25*

.25* .25*

.25*

.25* .25*

.23

.23 .23 .23 .23

*Heaters that may be wired for 1- or 2-stage operation. When wired for 1-stage operation, add first and second stage anticipator settings.

ANTICIPATOR SETTING

2nd Stage

240 V

.25

.25

.25 — —

.25

.25 — —

.25 — —

.25

.25*

.25* .25*

.25* .25* .25*

.23

.23

— —

— —

— —

— —

.25* .25*

.25* .25*

.25* .25*

.25* .25*

.25* .25*

.25*

.25* .25*

— ■ —

— —

208 V

.25*

.25*

Table 7 — Minimum Fan Speeds^

FAN

SECTION

40FS075

40FS120

40FS160

40FS920300 10.0

40FS916300

40FS916320

40FS916500

40FQ916

38HQ90000

Model

or

HEATER

240 V

and

and

and

20

25

10

11

20

10

18

25

30

10

15

to

25

to

15

to

to

to

Kw

208 V

7.5

6.0

8

to

11.3

15

and

18.8

5

3.75

to

7.5

8.75

to

15.0

7.5

to

13.5

18.8

and

22.5

8

6

and

7.5

11.3

to

18.8

‘Minimum fan speed and cfm for safe eiectric heater operation.

MIN

FAN

SPEED

Low

Low

Medium

Low

Medium

Medium

High

Low

Low

MIN

CFM

650

1200

1350

950

950

1000

1400

1130

1130

FAN

SECTION

40FS920300

40FS916320

40FS200

or

40FS220

40FS916500

40FQ920

or 38HQ90001

(W/40FS200)

40FQ920

(W/40FS220)

tMinimum cfm is 1960 (High Speed) when 40FS200/40FQ920 is

used with 38RQ054.

Model

HEATER

240 V 208 V

and

and

20

25

30

11

20

10

18

25

30

10

30

10

30

10

to

to

10

to

to

to

to

Kw

7.5

to

15

18.8

and

22.5

5

3.75

to

7.5

8.25

to

15.0

7.5

to

13.5

18.8

and

22.5

7.5

to

22.5

7.5

to

22.5

MIN

FAN

SPEED

Low

Medium

Low

Medium

Medium

High

Medium

Low

MIN

CFM

1600

1800

1200

1200

1000

1400

1550t

1550

START-UP

Adjust room thermostat as follows:

1. When electric heater is used, set thermostat

anticipator settings according to Table 6. These

settings may be changed slightly to provide a

greater degree of comfort for a particular

installation.

2. Set thermostat selector switch at OFF.

3. Set thermostat fan switch at AUTO, or FAN.

4. Turn on main disconnect switch(es) to unit.

5. Set thermostat dial to the desired temperature

(above or below room temperature).

6. Set selector switch at HEAT or COOL.

7. If necessary, adjust the system airflow (cfm) by

changing fan motor speed. See Electrical Data

and Wiring for fan speed adjustment. Refer to

Table 7 for minimum allowable fan speed when

electric heaters are used.

16

Page 17

FAN SECTION SERVICE

I )¡momiu.v1 pi)w«. i In iill 1'iii.ims K’lmvM’l\ к■inü

Remove unit front access panels for cleaning,

lubrication or parts replacement (Fig. 15).

LOW-VOLTAGE

TERMINAL

STRIP

ELECTRIC

HEATER

FILTER

SECTION

C|>AIRFLJDW T-J

Fig. 15 — Upflow Heating and Cooling Unit

Interior Details (Typical)

USIBLE LINK

LIMIT SWITCH

SEQUENCERS

-TRANSFORMER

■ POWER LEAD ROUTE TO

FAN SPEED SELECTOR

BLOCK

COOLING CONTROL KIT

(NOT REQ'D WHEN ELEC

■ HEATER IS USED; HUMIDITY

CONTROL KIT REQ'D ON

28TQ INSTALLATIONS)

FAN SPEED SELECTOR

BLOCK

FAN WHEEL (BLOWER

ASSEMBLY)

■ CONDENSATE DRAINSHORIZONTAL

INSTALLATIONS

CONDENSATE DRAINSUPFLOW OR DOWNFLOW

INSTALLATIONS

RINGS FOR FILTER

REMOVAL

1. Shut off unit power.

2. Remove fan section access panel.

3. Disconnect motor wires at fan speed selector

block.

4. Where applicable, disconnect wires from cool

ing control box and remove control box.

5. Remove tie angle screws and tie angle (these

screws secure front corners of filler panels to

fan section side panels as shown in Fig. 11).

Remove screws to allow filler panels to be

raised slightly.

6. Grasp blower assembly firmly — left hand on

motor, right'hand on scroll right side inlet.

7. Pull blower assembly forward. Rotate assembly

so that rear drops slightly, allowing assembly to

pass thru front of unit.

8. Reassembly is the reverse of the above pro

cedure. Note that when reassembling, rear

flange of blower outlet sits on top of fan deck,

tab on forward edge of outlet erigages slot in

front of fan deck.

Cleaning — Remove caked-on dirt from fan wheel

and housing with brush; remove grease with mild

solvent. When replacing blower assembly, ensure

fan wheel is centered in housing.

Return Air Filter — Pull rings (Fig. 1) are provided

for removing 1-in. permanent filters. Inspect filter

frequently. Clean filter with a vacuum cleaner or

wash with mild soap and water solution.

A steel rod acting as a media support is

imbedded in the filter. Replace filter so that

support prevents media from being drawn into fan

during operation.

Fan Motors

LUBRICATION — Where oil holes are provided,

remove oil plugs and add 8 drops of SAE 20

nondetergent oil at start of every cooling season.

Replace oil plugs. When motor is removed, reinstall

so that oil holes are at least 45 degrees above

horizontal. Motors without oil holes are factory

lubricated for life of motor.

BLOWER ASSEMBLY REMOVAL (Fig. 11)

( \l I l()\ Blow«.I .i"cmbl\ IS hc.iw aiul ma>

hill Iilv wIkii discim:ia;.d lioin ils inouiiiiMg

Support the asscmbl\ to a\oid injur\ or

ELECTRIC HEATER SERVICE

See Fig. 15 for component location. All service

can be completed with heater in place. Ensure all

power is shut off before servicing.

Limit Switch malfunction prevents heating

element from coming on or causes fusible link to

blow. Replace switch if malfunction occurs.

Sequencer malfunction will cause heater not to

come on or never to shut off — replace sequencer.

Transformer — (40- or 60-va) supplies 24-volt

power for control circuit. Replace transformer if

faulty.

Fan Relay malfunction will cause unit fan not to

run or run continuously — replace relay.

17

Page 18

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book 1 4

Tab 3c

2c

Form 40FS-11 SI Supersedes 40FS-10SI Printed in U.S.A. 386

10-83 PC 101 Catalog No. 534-032

Loading...

Loading...