39SH,SV,SM,SR00-17

Indoor and Outdoor Air Handlers

Installation, Start-Up and Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . 1,2

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Unit Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

PREINSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18,19

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Shipping Bolt and Screw Removal . . . . . . . . . . . . . . . . 18

Unit Suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Service Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Condensate Drain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

External Vibration Isolators . . . . . . . . . . . . . . . . . . . . . . . 18

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-33

Condensate Drain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Bottom Return Economizer Package (BREP) and

Horizontal Bottom Return Economizer

Package (HBREP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Motorized Outside Air Damper . . . . . . . . . . . . . . . . . . . . 22

Mixing Box Actuator (for 39SH and 39SM Horizontal

Return Units Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

• MIXING BOX ACTUATOR ASSEMBLY

• ACTUATOR INSTALLATION

Mixing Box Air Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

• MIXING BOX MIXED AIR SENSOR BRACKET

ASSEMBLY

• MIXED AND OUTSIDE AIR SENSORS

INSTALLATION

Mixing Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

• MIXING BOX LINKAGE INSTALLATION

(39SH Sizes 00-03)

• MIXING BOX LINKAGE INSTALLATION

(Sizes 04-17)

Install Sheaves on Motor and Fan Shafts . . . . . . . . . 27

•ALIGNMENT

Install V-Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Water and Steam Coil Piping

Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

• GENERAL

• WATER COILS

• STEAM COILS

Coil Freeze-Up Protection. . . . . . . . . . . . . . . . . . . . . . . . . 31

Refrigerant Piping, Direct Expansion

(DX) Coils. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Electric Heaters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Motor Stop/Start Stations . . . . . . . . . . . . . . . . . . . . . . . . . 33

START-UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34,35

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Fan Motor Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

• DETERGENT

Winter Shutdown (Chilled Water Coil Only) . . . . . . . 34

• ANTIFREEZE METHODS OF COIL PROTECTION

• AIR DRYING METHOD OF COIL PROTECTION

•PIPING

Page

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

• FILTER SECTIONS

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

• MOTORS

• BEARINGS

SAFETY CONSIDERATIONS

Air-handling equipment is designed to provide safe and reliable service when operated within design specifications. To

avoid injury to personnel and damage to equipment or property

when operating this equipment, use good judgment and follow

safe practices as outlined below.

DANGER

NEVER enter an enclosed fan cabinet or reach into a unit

while the fan is running.

LOCK OPEN AND TAG the fan motor power disconnect

switch before working on a fan. Take fuses with you and

note removal on tag. Electric shock can cause personal

injury or death.

LOCK OPEN AND TAG the electric heat coil power disconnect switch before working on or near heaters.

Failure to follow these warnings could lead to personal

injury or death.

WARNING

CHECK the assembly and component weights to be

sure that the rigging equipment can handle them safely.

Note also, the centers of gravity and any specific rigging

instructions.

CHECK for adequate ventilation so that fumes will not

migrate through ductwork to occupied spaces when welding or cutting inside air-handling unit cabinet or plenum.

WHEN STEAM CLEANING COILS be sure that the area

is clear of personnel.

DO NOT attempt to handle access covers and removable

panels on outdoor units when winds are strong or gusting

until you have sufficient help to control them. Make sure

panels are properly secured while repairs are being made to

a unit.

DO NOT remove access panel fasteners until fan is completely stopped. Pressure developed by a moving fan can

cause excessive force against the panel which can injure

personnel.

DO NOT work on dampers until their operators are

disconnected.

BE SURE that fans are properly grounded before working

on them.

Failure to follow these warnings could result in personal

injury or equipment damage.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53390006-01 Printed in U.S.A. Form 39S-2SI Pg 1 614 7-08 Replaces: 39S-1SI

CAUTION

Unit Identification — The 39S units are identified by

INTRODUCTION

the 18-digit part number listed on the serial plate. The part

SECURE drive sheaves with a rope or strap before working on a fan to ensure that rotor cannot free-wheel.

DO NOT restore power to unit until all temporary walkways inside components have been removed.

NEVER pressurize equipment in excess of specified test

pressures.

PROTECT adjacent flammable material when welding or

number describes all component, coil, motor, drive, and control

selections.

For further information on unit and component identification, contact your Carrier representative for the AHUBuilder

program. Refer to the 39S Product Data catalog for more information on individual component sections. Refer to Tables 1-4

and Fig. 1-13 for component data.

flame cutting. Use sheet metal or asbestos cloth to contain

sparks. Have a fire extinguisher at hand and ready for

immediate use.

Failure to follow these warnings could result in personal

injury or equipment damage.

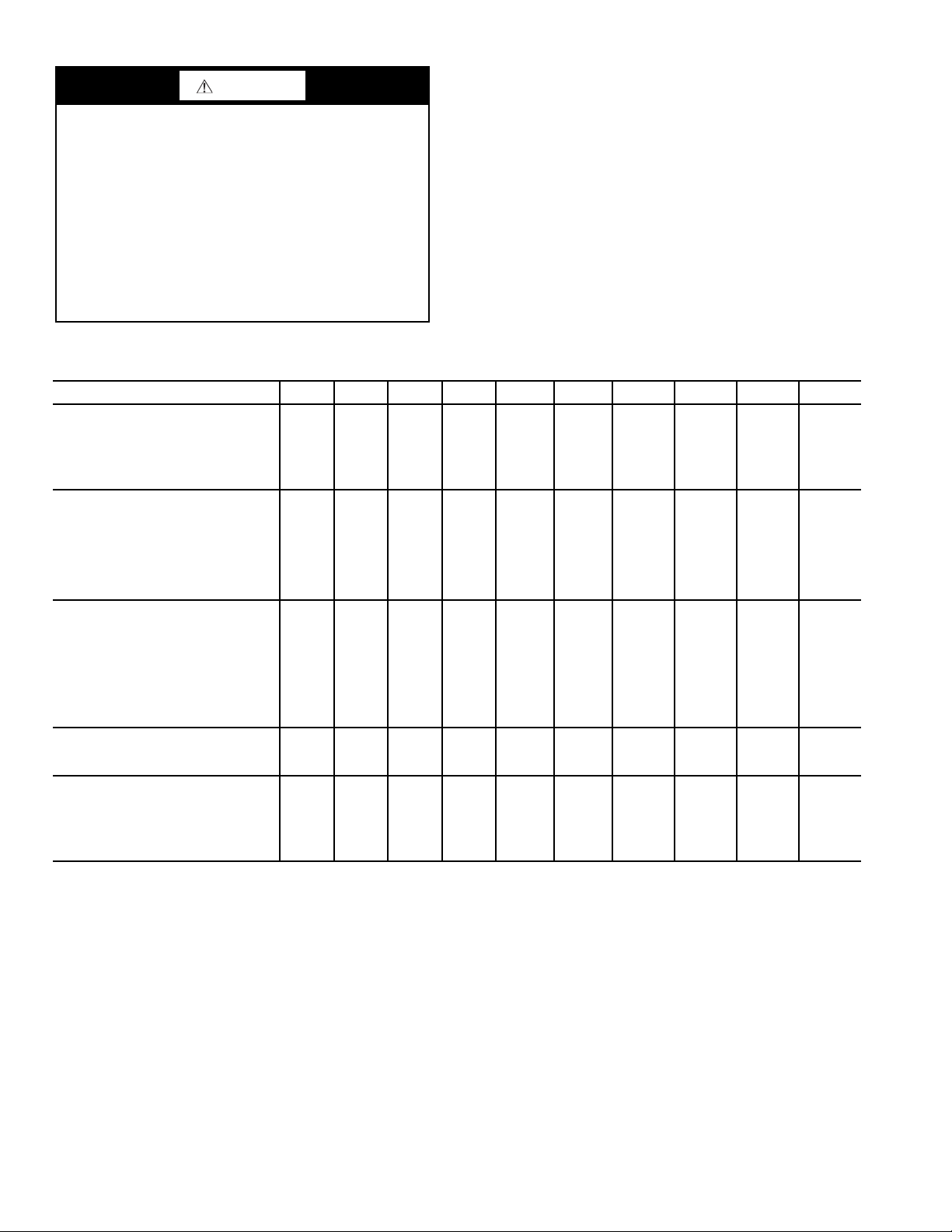

Table 1 — Physical Data — 39SH Coil and Filter Data

39SH UNIT SIZE 00 01 02 03 04 05 07 09 13 17

CHILLED WATER

Nominal Capacity at 400 fpm (cfm) 632 716 800 1224 1612 2000 2916 3832 5500 7084

Face Area (sq ft) 1.58 1.79 2 3.06 4.03 5 7.29 9.58 13.75 17.71

Coil Connection Size (in. OD sweat)

4 Row (Qty)

6 Row (Qty)

HOT WATER

Nominal Capacity at 400 fpm (cfm) 632 716 624 956 1612 2000 2688 3544 5348 6640

Face Area (sq ft) 1.58 1.79 1.56 2.39 4.03 5 6.72 8.86 13.37 16.6

Coil Connection Size (in. OD sweat)

1 Row

2 Row (Qty)

4 Row* (Qty)

6 Row* (Qty)

DIRECT EXPANSION

Nominal Capacity at 400 fpm (cfm) 452 476 820 1220 1612 2000 2864 4088 5500 6640

Face Area (sq ft) 1.13 1.19 2.05 3.05 4.03 5 7.16 10.22 13.75 16.6

Connection Size (in. OD sweat)

(Qty)

Liquid Line

Suction Line

STEAM

Nominal Capacity at 400 fpm (cfm) 632 716 752 1144 1452 1800 2688 3640 5512 7000

Face Area (sq ft) 1.58 1.79 1.88 2.86 3.63 4.5 6.72 9.1 13.78 17.5

FI LT ER D ATA

Size (in.) (Qty) 12x25 12x25 16x32 16x32 20x20

Nominal Face Area (sq ft) 2.08 2.08 3.56 3.56 5.56 5.56 11.56 11.56 18.06 22.5

*4 and 6 row hot water coils have the same face area as 4 and 6 row

chilled water coils.

†Single circuited coil.

**Dual circuited coil.

3

/

3

/

5

/

7

/

3

/

3

/

1

/

3

/

3

4

4

8

8

4

4

4

4

/

3

/

5

/

7

/

3

/

3

/

1

/

3

/

3

4

4

8

8

4

4

4

4

/

3

/

5

/

7

/

3

/

3

/

3

/

3

/

3

4

4

8

8

4

4

8

4

/

4

7

/

8

5

/

8

7

/

8

3

/

4

7

/

8

3

/

8

3

/

4

11/

11/

7

7

7

7

1

7

(2)

/

/

/

/

/

/

11/

8

11/

8

7

11/

11/

11/

11/

/

8

1

/

2

8

8

8

8

2

8

20x20

(2)

11/

8

8

8

8

8

8

8

13/

8

N/A N/A N/A N/A

11/

8

11/

8

13/

8

5

/8†,

1

/2** (2)

11/8†,

7

/8** (2)

16x32 (2)

20x32 (1)

13/

8

15/

8

13/

8

13/

8

15/

8

5

/8†,

1

/2** (2)

13/8†,

7

/8** (2)

16x32 (2)

20x32 (1)

13/

15/

13/

13/

15/

1

/2** (2) 5/8** (2)

15/8 (2)

8

15/8 (2)

8

15/8 (2)

8

15/8 (2)

8

15/8 (2)

8

11/8** (2) 13/8** (2)

20x25 (2)

20x20 (4)

16x20 (2)

16x25 (2)

20x20 (2)

20x25 (2)

®

2

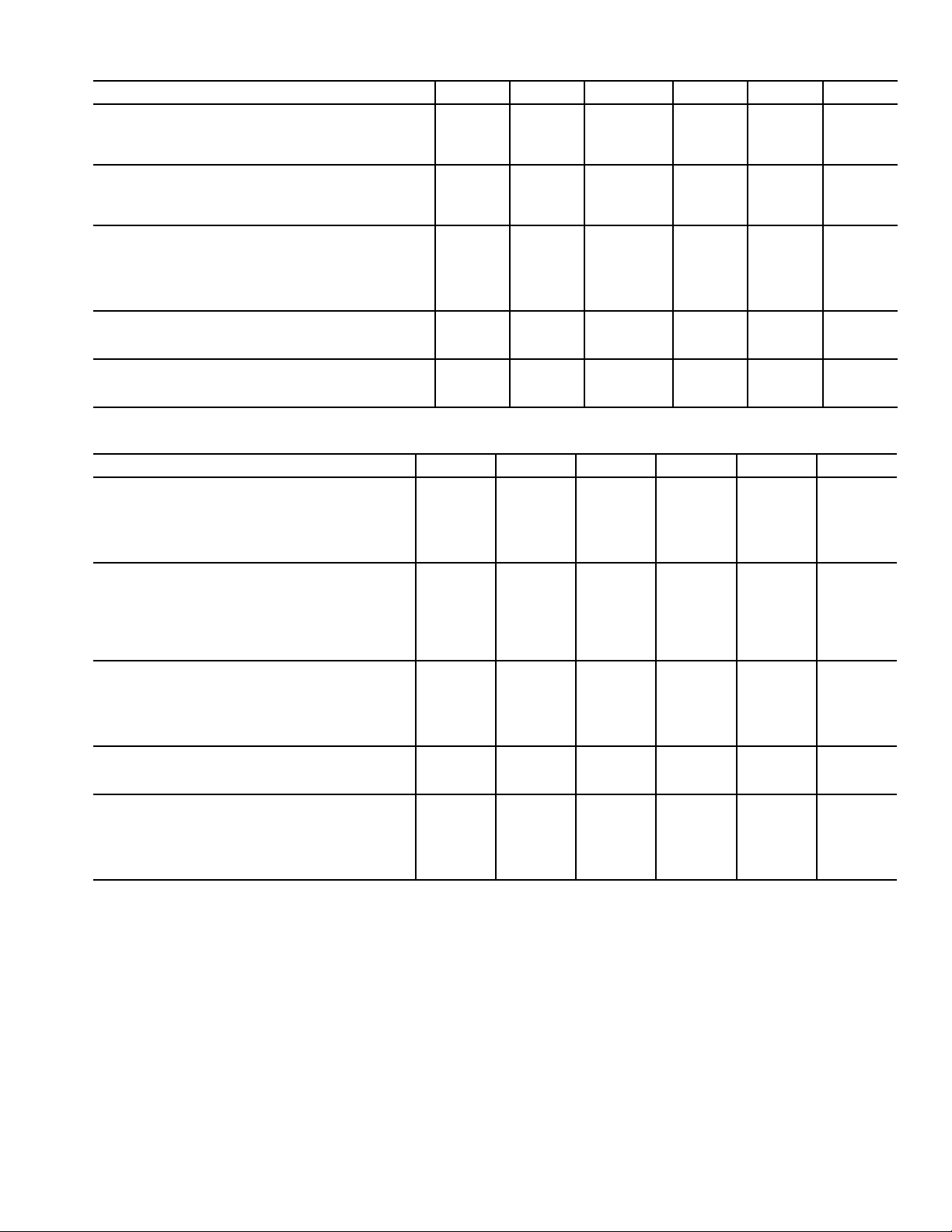

Table 2 — Physical Data — 39SV Coil and Filter Data

39SV UNIT SIZE 02 03 04 05 07 09

CHILLED WATER

Nominal Capacity at 400 fpm (cfm) 1200 1200 1600 2000 2932 3668

Face Area (sq ft) 3 3 4 5 7.33 9.17

Coil Connection Size (in. OD sweat)

3

/

4

3

/

4

7

/

8

11/

8

11/

8

HOT WATER

Nominal Capacity at 400 fpm (cfm) 804 804 964 1276 2292 3124

Face Area (sq ft) 2.01 2.01 2.41 3.19 5.73 7.81

Coil Connection Size (in. OD sweat)

7

/

8

7

/

8

7

/

8

11/

8

11/

8

DIRECT EXPANSION

Nominal Capacity at 400 fpm (cfm) 1200 1200 1600 2000 2932 3668

Face Area (sq ft) 3 3 4 5 7.33 9.17

Connection Size (in. OD sweat) (Qty)

Liquid Line

Suction Line

3

/

8

3

/

4

3

/

8

3

/

4

1

/

2

7

/

8

11/

1

/

2

8

5/8

11/

8

STEAM

Nominal Capacity at 400 fpm (cfm) 624 624 688 1268 1750 2452

Face Area (sq ft) 1.56 1.56 1.72 3.17 4.375 6.13

FI LT ER D ATA

Size (in.) (Qty) 20x20 20x20 22.5x22.5 16x25 (2) 20x25 (4) 20x25 (4)

Nominal Face Area (sq ft) 2.78 2.78 3.52 5.56 13.89 13.89

Table 3 — Physical Data — 39SM Coil and Filter Data

39SM UNIT SIZE 04 05 07 09 13 17

CHILLED WATER

Nominal Capacity at 400 fpm (cfm) 1668 2084 2776 3332 5000 7084

Face Area (sq ft) 4.17 5.21 6.94 8.33 12.5 17.71

Coil Connection Size (in. OD sweat)

4 Row (Qty)

6 Row (Qty) 11/

HOT WATER

Nominal Capacity at 400 fpm (cfm) 1668 2084 2776 3332 5000 7084

Face Area (sq ft) 4.17 5.21 6.94 8.33 12.5 17.71

Coil Connection Size (in. OD sweat)

2 Row (Qty)

4 Row* (Qty)

6 Row* (Qty) 11/

DIRECT EXPANSION

Nominal Capacity at 400 fpm (cfm) 1668 2000 2668 3332 5000 7000

Face Area (sq ft) 4.17 5 6.67 8.33 12.5 17.5

Connection Size (in. OD sweat)

Liquid Line

Suction Line

STEAM

Nominal Capacity at 400 fpm (cfm) 1492 1960 2472 3028 4752 6700

Face Area (sq ft) 3.73 4.9 6.18 7.57 11.88 16.75

FI LT ER D ATA

Size (in.) (Qty) 20x25 (2) 20x25 (2) 16x25 (4) 16x25 (4) 16x20 (2)

Nominal Face Area (sq ft) 6.94 6.94 11.11 11.11 22.5 22.5

*4 and 6 row hot water coils have the same face area as 4 and 6 row

chilled water coils.

7

/

8

8

7

/

8

7

/

8

8

1

/

2

7

/

8

11/

11/

11/

11/

11/

11/

8

8

8

8

8

1

/

2

8

11/

13/

11/

11/

13/

11/

8

8

8

8

8

5

/

8

8

13/

15/

11/

13/

15/

13/

8

8

8

8

8

5

/

8

8

13/

8

15/

8

11/

8

13/

8

15/

8

5

/

8

13/

8

20x20 (2)

16x25 (2)

20x25 (2)

15/8 (2)

15/8 (2)

11/8 (2)

15/8 (2)

15/8 (2)

15/8 (2)

16x20 (2)

20x20 (2)

16x25 (2)

20x25 (2)

13/

11/

1

/2 (2)

7

/8 (2)

5

/8 (2)

8

8

3

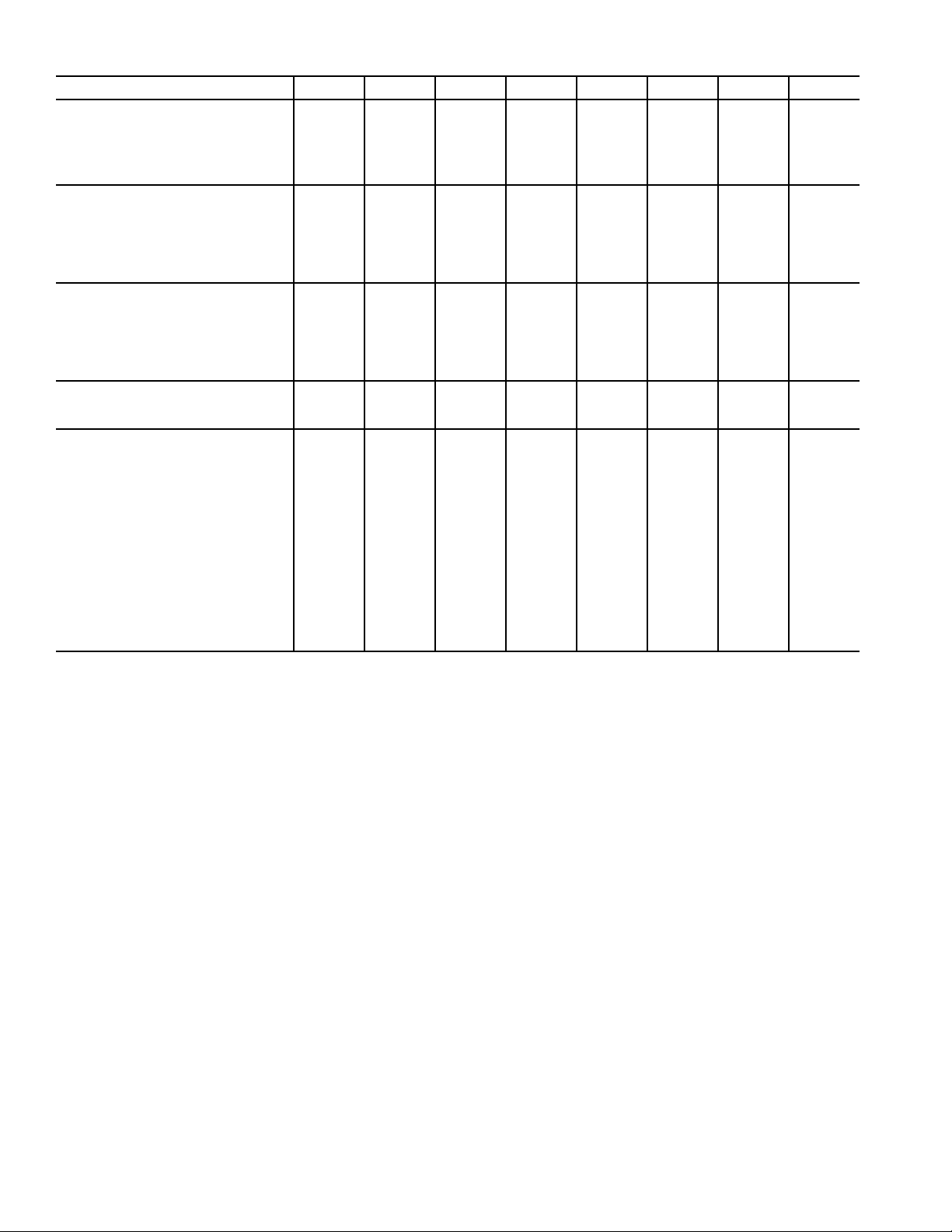

Table 4 — Physical Data — 39SR Coil and Filter Data

39SR UNIT SIZE 02 03 04 05 07 09 13 17

CHILLED WATER

Nominal Capacity at 400 fpm (cfm) 800 1224 1612 2000 3252 3792 5124 7000

Face Area (sq ft) 2 3.06 4.03 5 8.13 9.48 12.81 17.5

Coil Connection Size (in. OD sweat)

4 Row

6 Row

3

/

4

3

/

4

HOT WATER

Nominal Capacity at 400 fpm (cfm) 624 956 1612 2000 3252 3792 5124 7000

Face Area (sq ft) 1.56 2.39 4.03 5 8.13 9.48 12.81 17.5

Coil Connection Size (in. OD sweat)

2 Row

4 Row*

6 Row*

5

/

8

3

/

4

3

/

4

DIRECT EXPANSION

Nominal Capacity at 400 fpm (cfm) 800 1224 1612 2000 3252 3792 5124 7000

Face Area (sq ft) 2 3.06 4.03 5 8.13 9.48 12.81 17.5

Connection Size (in. OD sweat)

(Qty)

Liquid Line

Suction Line

3

/

8

3

/

4

STEAM

Nominal Capacity at 400 fpm (cfm) 752 1144 1452 1800 3088 3576 4956 6768

Face Area (sq ft) 1.88 2.86 3.63 4.5 7.72 8.94 12.39 16.92

FI LT ER D ATA

Single Wall Unit, Throwaway Filter

Size (in.) (Qty) 16x32 16x32 20x20 (2) 20x20 (2) 16x25 (4) 16x25 (4) 16x20 (3)

Nominal Face Area (sq ft) 3.56 3.56 5.56 5.56 11.11 11.11 15 20

Single Wall Unit, Pleated Filter

Size (in.) (Qty) 16x32 16x32 20x24 (1)

Nominal Face Area (sq ft) 3.56 3.56 5.56 5.56 11.11 11.11 15 20

Double Wall Unit,

Pleated and Throwaway Filters

Size (in.) (Qty) 16x32 (1)

10x10 (3)

Nominal Face Area (sq ft) 5.64 5.64 8.75 8.75 15.63 15.63 17.67 23.11

*4 and 6 row hot water coils have the same face area as 4 and 6 row

chilled water coils.

3

/

4

7

/

8

7

/

8

3

/

4

7

/

8

3

/

8

3

/

4

16x32 (1)

10x10 (3)

7

/

8

11/

8

7

/

8

7

/

8

11/

8

1

/

2

7

/

8

16x20 (1)

12x25 (1)

12x20 (1)

16x20 (1)

16x25 (1)

11/

8

11/

8

11/

8

11/

8

11/

8

1

/

2

11/

8

20x24 (1)

16x20 (1)

12x25 (1)

12x20 (1)

16x20 (1)

16x25 (1)

13/

15/

11/

13/

15/

11/

8

8

8

8

8

5

/

8

8

13/

15/

11/

13/

15/

13/

8

8

8

8

8

5

/

8

8

13/

8

15/

8

13/

8

13/

8

15/

8

7

/8 (2)

13/8 (2) 15/8 (2)

16x25 (3)

16x25 (4) 16x25 (4) 16x20 (3)

25x25 (2)

20x25 (2)

25x25 (2)

20x25 (2)

16x25 (3)

16x24 (3)

29x48 (1)

13/

8

15/

8

11/

8

13/

8

15/

8

7

/8 (2)

16x20 (4)

16x25 (4)

16x20 (4)

16x25 (4)

16x20 (4)

16x32 (4)

4

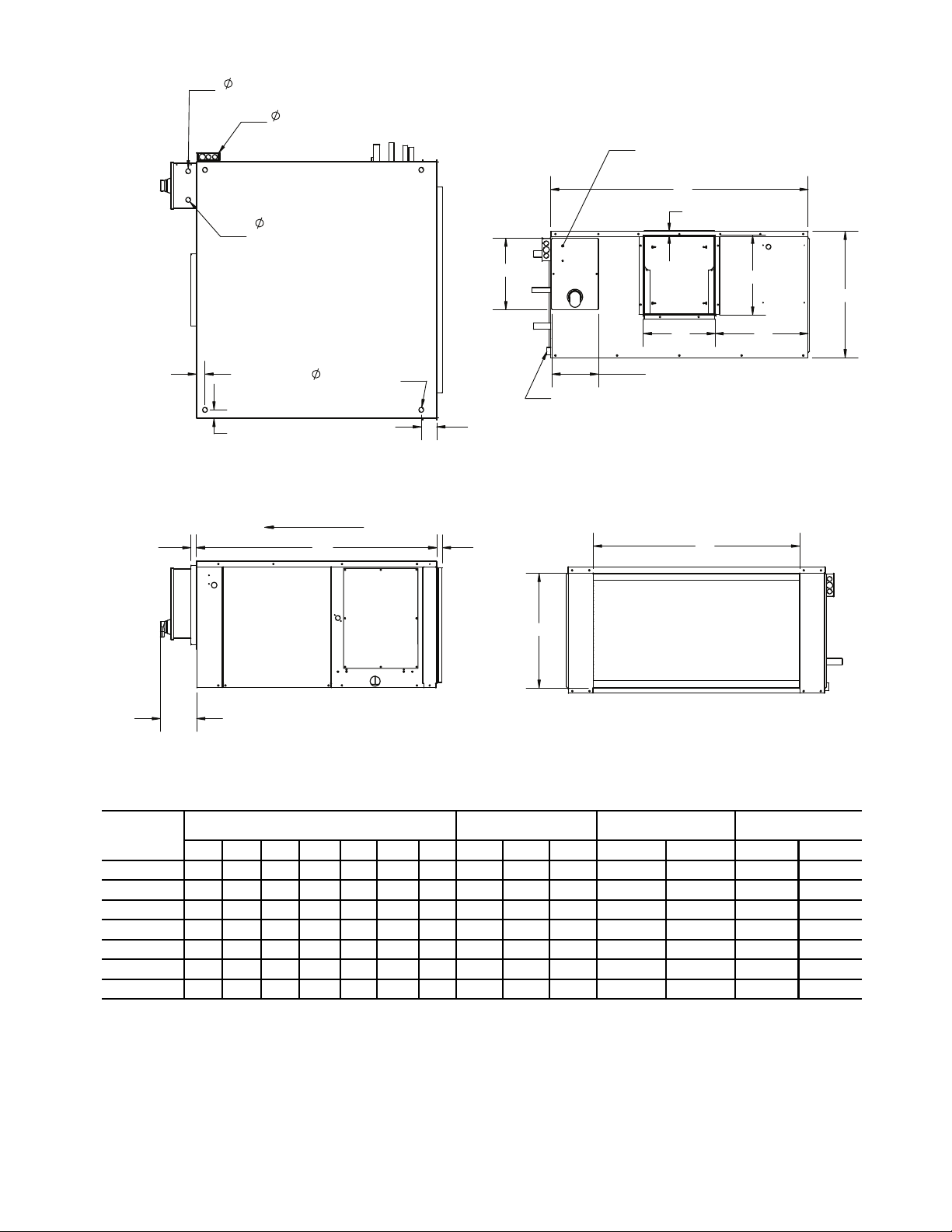

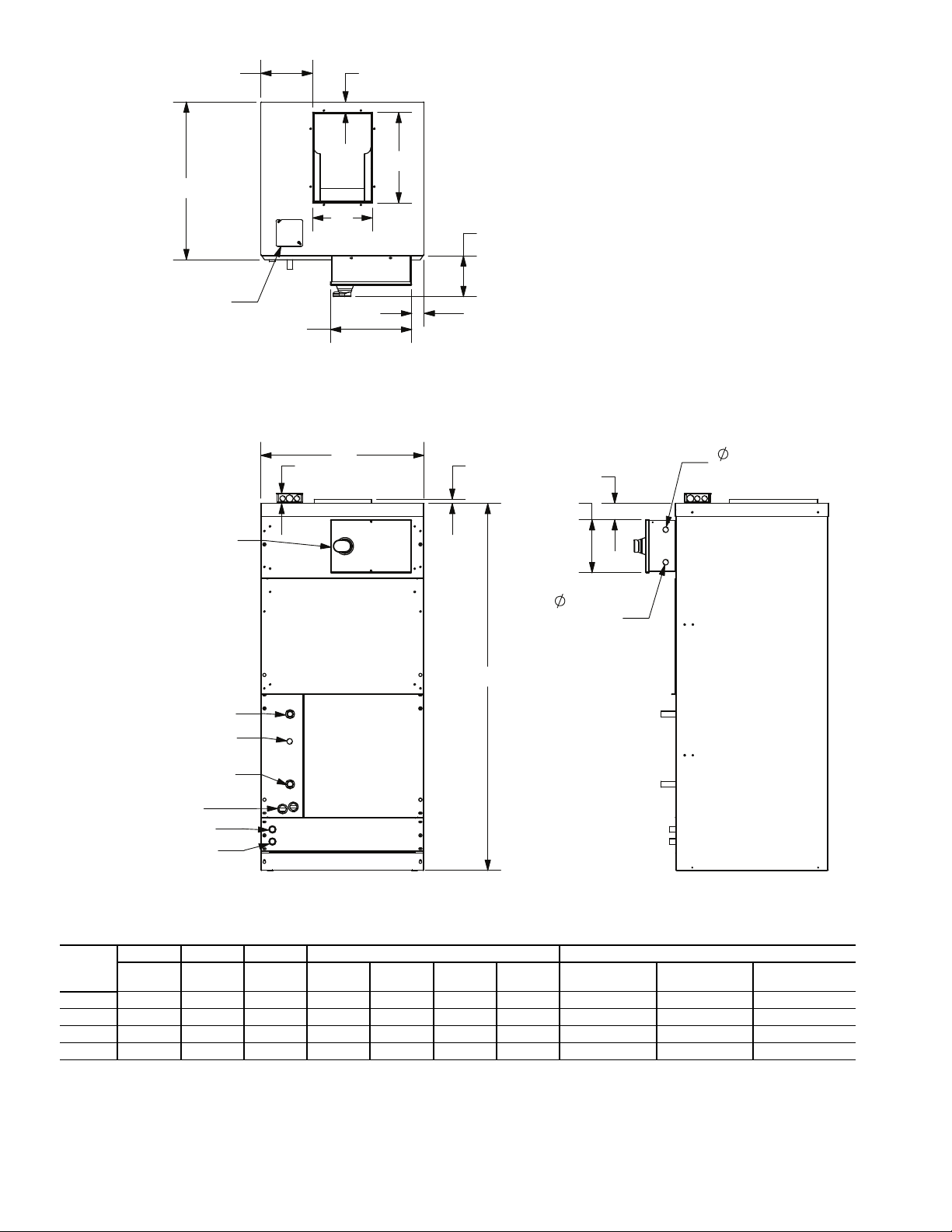

DIMENSIONS (in.)

LEGEND

*"C1" dimension is for standard unit. "C2" dimension is for double wall units.

†Sizes 13 and 17 are twin blowers. Dimension "E" is to closest blower. Dimension "F" and "G" are typical for both fan outlets.

NOTES:

1. Measurements shown in inches.

2. Unit hand is determined by looking into the filters in same direction as airflow. Right hand unit shown for reference.

39SH UNIT

SIZE

UNIT OUTLINE UNIT MOUNTING

BLOWER OPENING

OUTLET

RETURN DUCT

CONNECTION

A B C1* C2* D E H M N P F G K L

00,01

38.0

28.0 14.1 15.1 1.0 9.6 1.0 1.6 2.6 3.3 8.6 10.6 22.0 12.3

02,03

37.1

36.6 18.1 19.0 1.0 14.1 1.0 1.5 1.5 2.9 8.4 10.6 27.6 16.4

04 42.0 45.0 22.1 23.0 1.0 17.9 1.0 1.5 1.5 2.7 9.1 13.8 36.0 20.0

05 42.0 45.0 22.1 23.0 1.0 14.3 1.0 1.5 1.5 2.7 12.5 13.8 36.0 20.0

07,09 52.5 57.0 34.8 34.8 1.0 21.8 9.1 2.8 2.8 2.8

13.4

16.2 48.0 32.2

13 57.5 67.2 43.0 43.0 N/A 11.4† 8.0 3.7 3.7 3.7 16.4

†

(2) 16.4† (2) 57.9 40.4

17 57.5 72.3 48.0 48.0 N/A 14.0

†

13.0 3.7 3.7 3.7 16.4

†

(2) 16.4

†

(2) 66.0 45.7

BTM — Bottom

KO — Knockout

w/o MSS — Without Motor Start/Stop Station

Fig. 1 — 39SH Unit

Airflow

Top View

Left Side View

FILTER

Front View

Rear View

L

K

Motor Start/Stop

Station (opt)

12.51

H

B

C1-2

*

F

G

E

8.12

A

6.35

DD

.875 Power Conn. (w/o MSS)

3/4" FPT

Drain Conn.

(TYP)

P

KO (TYP)

(TOP/BTM)

.875(OPP SIDE)

.875

M (TYP)

(TYP)

Power Conn.

N

.875 24V

Control

Conn.

a39-4122

5

614

DIMENSIONS (in.)

LEGEND

NOTE: Measurements shown in inches.

39SV

UNIT

SIZE

WIDTH DEPTH HEIGHT SUPPLY DUCT CONNECTION SIZES (OD)

A B C D E F G

CW

Supply-ReturnHWSupply-ReturnDXLiquid-Suction

02 22.3 24.0 50.0 6.9 8.5 3.0 11.8

3

/4 - 3/

4

7

/8 - 7/

8

3

/8 - 3/

4

03 22.3 24.0 50.0 6.9 8.5 3.0 11.8

3

/4 - 3/

4

7

/8 - 7/

8

3

/8 - 3/

4

04 25.1 24.3 56.5 8.0 9.1 1.6 13.9

7

/8 - 7/

8

7

/8 - 7/

8

1

/2 - 7/

8

05 29.5 26.0 59.5 8.4 12.6 1.3 13.9 1 1/8 - 1 1/

8

1 1/8 - 1 1/

8

1

/2 - 1 1/

8

CW — Chilled Water MSS — Motor Start/Stop Station

DX — Direct Expansion w/o — Without

HW — Hot Water

D

a39-4065

Fig. 2 — 39SV Unit Sizes 02-05 — Pre-Heat

F

B

4 x 4

J-Box (w/o MSS)

Motor Start/Stop

(MSS) (optional)

12.5

E

Top View

A

1.5

G

6.3

1.9

.8

8.2

24V Control

Conn.

2.5

.875

.875 (OPP SIDE)

Power Conn.

C

Supply Conn. (CW)

Liquid Conn. (DX)

Suction (DX)/

Return (CW)

Conn.

Cond Drain

w/ Aux (3/4" FPT)

Supply Conn. (HW)

Return (HW) Conn.

Front View

6

Right View

DIMENSIONS (in.)

LEGEND

NOTE: Measurements shown in inches.

39SV UNIT SIZE

CONNECTION SIZES (OD)

CW

Supply-ReturnHWSupply-ReturnDXLiquid-Suction

Drain

07 1 1/8 - 1 1/

8

1 1/8 - 1 1/

8

5

/8 - 1 1/

8

0.875

09 1 3/8 - 1 3/

8

1 1/8 - 1 1/

8

1

/2 - 7/8 (2)

0.875

CW — Chilled Water MSS — Motor Start/Stop Station

DX — Direct Expansion w/o — Without

HW — Hot Water

Motor Start/

Stop (opt)

31.00

Iso View

(w/o panels)

Front View

Right View

Top View

4 x 4

J-Box

(w/o MSS)

Power Conn..875

20.316.3

13.3

.875 24V Control Conn.

6.3

2.4

34.2

54.0

(DX) Conn.

20.5

2.3

Return (CW) / Liquid

2.0

1.5

Drain Conn.

Supply Conn. (HW)

Supply (CW) / Suction

10.1

84.4

19.5

.9

(DX) Conn.

Return Conn. (HW)

a39-4066

Fig. 3 — 39SV Unit Sizes 07-09 — Pre-Heat

7

Return Conn. (HW)

Suction (DX)

(MSS) (optional)

/Return (CW) Conn.

Liquid Conn. (DX)

Front View

Supply Conn. (CW)

Top View

Supply Conn. (HW)

Motor Start/Stop

Cond Drain w/ Aux

(3/4" FPT)

A

C

.8

1.5

4 x 4

J-BOX (w/o MSS)

B

E

F

G

D

12.5

6.3

1.9

Right View

2.5

Conn.

24V Control

.875

8.2

.875 (OPP SIDE)

Power Conn.

DIMENSIONS (in.)

LEGEND

NOTE: Measurements shown in inches.

39SV

UNIT

SIZE

WIDTH DEPTH HEIGHT SUPPLY DUCT CONNECTION SIZES (OD)

A B C D E F G

CW

Supply-ReturnHWSupply-ReturnDXLiquid-Suction

02 22.3 24.0 50.0 6.9 8.5 3.0 11.8

3

/4 - 3/

4

7

/8 - 7/

8

3

/8 - 3/

4

03 22.3 24.0 50.0 6.9 8.5 3.0 11.8

3

/4 - 3/

4

7

/8 - 7/

8

3

/8 - 3/

4

04 25.1 24.3 56.5 8.0 9.1 1.6 13.9

7

/8 - 7/

8

7

/8 - 7/

8

1

/2 - 7/

8

05 29.5 26.0 59.5 8.4 12.6 1.3 13.9 1 1/8 - 1 1/

8

1 1/8 - 1 1/

8

1

/2 - 1 1/

8

CW — Chilled Water HW — Hot Water

DX — Direct Expansion w/o MSS— Without Motor Start/Stop Station

a39-4067

Fig. 4 — 39SV Unit — Re-Heat

8

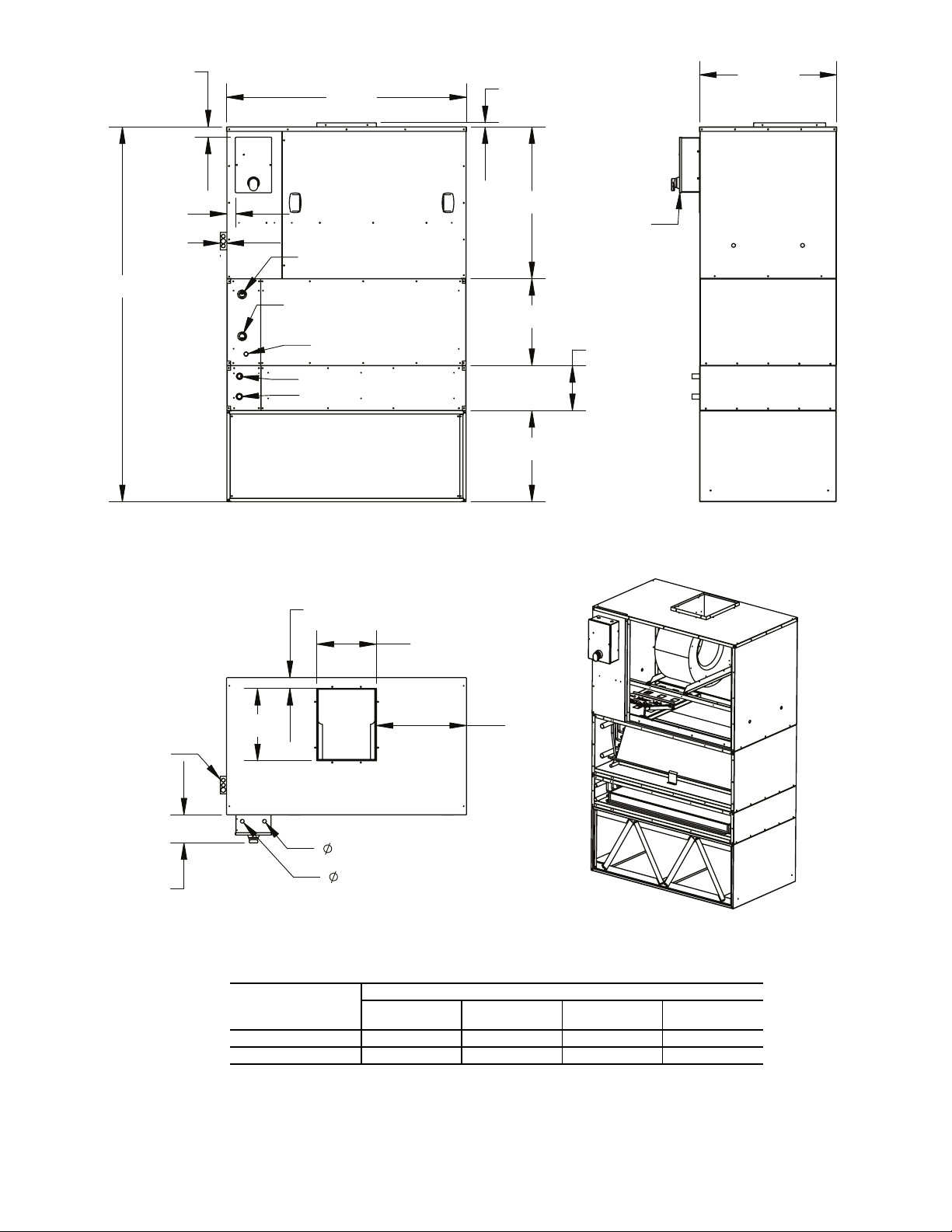

DIMENSIONS (in.)

LEGEND

NOTES:

1. Measurements shown in inches.

2. Hand connections are defined by looking at the filters in the direction of airflow.

3. Coil section and blower ship separately and are installed by others.

4. Blower section may be rotated 180 degrees to relocate supply duct.

39SM

UNIT

SIZE

WIDTH HEIGHT DEPTH

COIL

SECTION

BLOWER

SECTION

MOTOR

START/STOP

(OPT.)

RETURN DUCT

SUPPLY DUCT

(BLOWER OPENING)

SUPPLY

CONN.

RETURN

CONN.

DRAIN

A B C D E F G H I J K L M N O P Q R

04 40.0 53.5 26.0 27.5 26.0 2.8 9.0 36.0 25.5 1.0 2.0 13.6 11.9 1.1 13.1 3.6 20.0 15.2

05 40.0 53.5 26.0 27.5 26.0 2.8 9.0 36.0 25.5 1.0 2.0 13.6 11.9 1.1 13.1 3.6 25.0 15.2

07 50.0 68.5 34.0 34.5 34.0 6.8 13.0 48.0 32.0 1.0 1.0 13.4 16.2 1.2 18.3 3.6 25.0 22.5

09 50.0 68.5 34.0 34.5 34.0 6.8 13.0 48.0 32.0 1.0 1.0 13.4 16.2 1.2 18.3 3.6 30.0 22.5

13 72.0 81.5 34.0 47.5 34.0 6.7 13.0 66.0 45.0 2.0 6.0 16.4 16.4 1.1 14.0 3.6 30.0 23.0

17 72.0 81.5 34.0 47.5 34.0 6.7 13.0 66.0 45.0 2.0 6.0 16.4 16.4 1.1 14.0 3.6 42.6 23.0

CW — Chilled Water

HW — Hot Water

w/o MSS — Without Motor Start/Stop Station

AIR

FILTERS

FLOW

MOTOR

START/STOP (MSS)

(OPT)

H

I

A

K

J

12.51

6.35

VIEWREAR

VIEW

SIZES 04-09

RIGHT

TOP VIEW

CONTROL CONN.

O

.875 24V

L

M

O

N

POWER CONN.

.875 (OPP SIDE)

O

M

L

O

L

N

ACCESS PANEL

C

S

AREA

E

SUPPLY AREA

C

RETURN

S

F

I

L

T

E

R

A

CW/HW

CW/HW

3/4" FPT DRAIN

G

B

P

.98

C

8.18

F

R

Q

.95

D

E

J-BOX (W/O MSS)

.875 POWER

CONN. 4X4

TOP VIEW

SIZES 13, 17

a39-4075

Fig. 5 — 39SM Unit Sizes 04-17 (Vertical Configuration)

9

614

a39-4078

DIMENSIONS (in.)

LEGEND

NOTES:

1. Measurements shown in inches.

2. Hand connections are defined by looking at the filters in the direction of airflow.

3. Coil section and blower ship separately and are installed by others.

4. Blower section may be rotated 180 degrees to relocate supply duct.

39SM

UNIT

SIZE

WIDTH HEIGHT DEPTH

COIL

SECTION

BLOWER

SECTION

MOTOR

START/STOP

(OPT.)

RETURN DUCT

SUPPLY DUCT

(BLOWER OPENING)

SUPPLY

CONN.

RETURN

CONN.

DRAIN

A B C D E F G H I J K L M N O P Q R

04 40.0 27.5 52.0 27.5 26.0 2.7 8.9 36.0 25.5 1.0 2.0 13.6 11.9 1.1 13.1 3.6 20.0 15.2

05 40.0 27.5 52.0 27.5 26.0 2.7 8.9 36.0 25.5 1.0 2.0 13.6 11.9 1.1 13.1 3.6 25.0 15.2

07 50.0 34.5 68.0 34.5 34.0 6.8 12.9 48.0 32.0 1.0 1.0 13.4 16.2 1.2 18.3 3.6 25.0 22.5

09 50.0 34.5 68.0 34.5 34.0 6.8 12.9 48.0 32.0 1.0 1.0 13.4 16.2 1.2 18.3 3.6 30.0 22.5

13 72.0 47.5 68.0 47.5 34.0 6.7 12.9 66.0 45.0 1.0 2.9 16.4 16.4 1.1 14.0 3.6 30.0 23.0

17 72.0 47.5 68.0 47.5 34.0 6.7 12.9 66.0 45.0 1.0 2.9 16.4 16.4 1.1 14.0 3.6 42.6 23.0

CW — Chilled Water

HW — Hot Water

w/o MSS — Without Motor Start/Stop Station

Fig. 6 — 39SM Unit Sizes 04-17 (Horizontal Configuration)

614

10

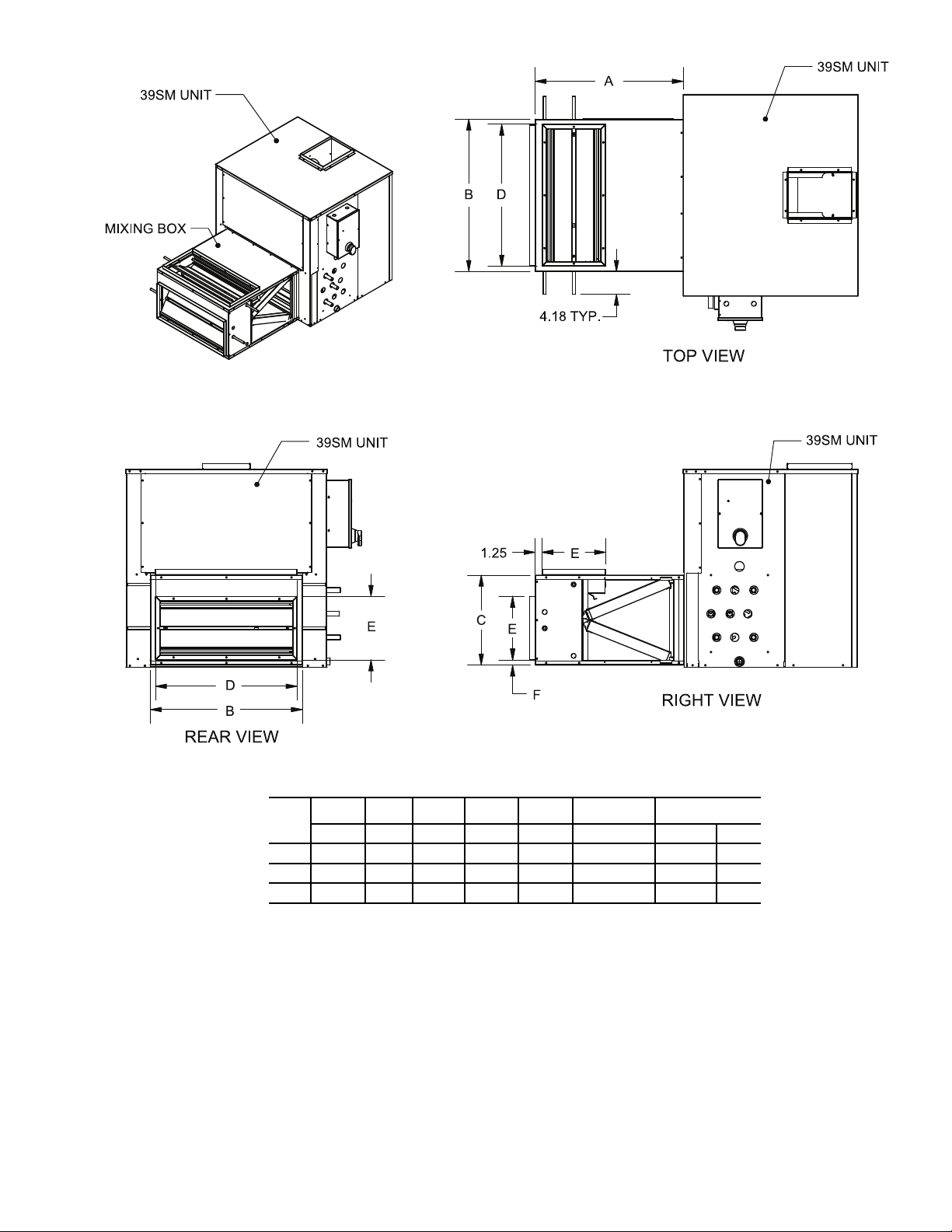

DIMENSIONS (in.)

NOTES:

1. Measurements shown in inches.

2. 39SM unit shown for reference only.

3. Not all components shown for clarity.

4. Optional actuator not shown.

5. Top and rear inlets shown. Bottom and rear inlets are also available.

39SM

UNIT

SIZE

LENGTH WIDTH HEIGHT

DUCT

WIDTH

DUCT

HEIGHT

TOP

CLEARANCE

FILTERS

A B C D E F SIZE QTY

04,05 27.0 36.2 25.5 34.3 15.0 2.0 16 x 32 x 2 2

07,09 32.0 48.2 32.4 46.3 15.0 9.7 20 x 24 x 2 4

13,17 40.0 66.2 45.0 64.3 16.0 15.5 30 x 20 x 2 6

a39-4079

Fig. 7 — 39SM Unit — Mixing Box

11

M

C

B

L

P

HORIZONTAL

DISCHARGE (OPT)

G

F

NO

A

4.0

H

D

F

G

J

K

E

4.0

4.0

DIMENSIONS (in.)

NOTE: Measurements shown in inches.

39SR

UNIT SIZE

A B C D E F G H J K L M N O P

02, 03 67.4 39.6 22.5 12.0 25.8 11.9 8.9 11.0 8.0 35.4 14.2 28.4 2.5 15.3 5.6

04, 05 72.1 48.1 28.5 12.0 34.0 14.1 13.1 11.0 8.0 35.6 18.2 35.8 5.1 17.5 6.2

07, 09 75.0 53.0 42.2 14.0 44.0 16.4 12.1 15.0 8.0 37.2 24.3 46.0 10.1 20.5 3.5

13 75.1 53.0 55.7 14.0 44.0 16.4 19.4 15.0 8.0 37.3 32.7 46.0 23.5 16.8 3.5

17 96.0 76.3 53.3 15.0 62.0 19.6 22.0 15.0 8.0 50.3 47.0 68.2 17.4 27.1 4.1

a39-4068

Fig. 8 — 39SR Unit — Single Wall

614

12

L

M

C

B

P

A

3.0

4.0

G

4.0

F

D

K

H

J

E

HORIZONTAL

DISCHARGE (OPT)

G

F

N

O

DIMENSIONS (in.)

NOTES:

1. Measurements shown in inches.

2. L1 dimension is for horizontal or bottom return economizer package option.

3. L2 dimension is for motorized outside air damper package option.

39SR

UNIT SIZE

A B C D E F G H J K L1 L2 M N O P

02, 03 70.0 42.0 30.5 12.0 26.0 11.9 8.9 10.0 6.0 33.7 17.2 14.2 28.1 8.5 16.6 7.0

04, 05 70.4 50.5 33.6 12.0 34.0 14.1 13.4 10.0 6.0 38.9 21.2 18.2 36.1 4.2 18.6 7.2

07, 09 77.4 55.5 50.9 14.0 44.0 16.4 13.1 15.0 8.0 38.0 35.1 24.3 45.9 19.9 21.2 4.8

13 77.4 55.5 60.6 14.0 44.0 16.4 18.9 15.0 8.0 38.0 48.9 32.8 45.9 29.7 18.3 4.8

17 96.5 76.5 64.1 14.0 62.0 19.0 22.0 15.0 8.0 51.9 48.2 46.9 65.8 24.0 27.3 5.4

a39-4069

Fig. 9 — 39SR Unit — Double Wall

614

13

DIMENSIONS (in.)

39SR UNIT SIZE A B C D E F G

02, 03 30.6 19.9 26.1 2.0 7.7 26.2 19.9

04, 05 39.9 18.0 25.0 1.8 9.9 40.0 22.1

B

A

F

Outdoor Air Hood

Return Air Duct

G

D

E

C

a39-4070

Fig. 10 — 39SR Unit Sizes 02-05 — Horizontal Return Economizer Package

14

DIMENSIONS (in.)

39SR UNIT SIZE A B C D E F

02, 03 32.100 18.940 42.075 17.260 25.950 16.150

04, 05 39.725 22.825 44.025 21.125 27.750 16.250

EF

Return Air

Outdoor Air

C

D

A

B

Fig. 11 — 39SR Unit Sizes 02-05 — Bottom Return Economizer Package

15

LEGEND

DIMENSIONS (in.)

HBREP — Horizontal Bottom Return Economizer Package

39SR UNIT SIZE A B E F G H J

07, 09 13.8 44.1 35.2 34.9 15.4 16.5 48.3

13 18.8 44.1 39.0 48.6 20.1 20.0 48.3

17 19.0 62.9 43.4 45.1 20.1 20.0 66.1

E

H

conversion)

(remove for HBREP

Barometric

Relief Damper

Outdoor Air

Hood

G

F

B (HBREP)

A (HBREP)

J

a39-4072

Fig. 12 — 39SR Unit Sizes 07-17 — Bottom and Horizontal Return Economizer Package

16

C

D

E

F

ROTATING DAMPER

ASSEMBLY

H

G

A

B

REAR ISOMETRIC VIEW

ACTUATOR (OPT)

FRONT ISOMETRIC VIEW

TRANSFORMER (OPT)

MOAD DIMENSIONS (in.)

39SR

UNIT SIZE

A B C D E F G H

02, 03 29.9 19.1 8.7 5.6 24.1 2.9 13.4 10.4

04, 05 37.8 23.5 14.6 5.6 25.3 6.3 17.3 13.8

07, 09 48.8 28.4 17.4 5.6 44.4 2.2 21.8 19.6

13 48.8 34.9 22.3 5.6 40.5 4.1 28.3 25.8

17 30.3 46.8 25.0 5.6 25.2 2.5 38.9 31.8

LEGEND

MOAD — Motorized Outside Air Damper

Fig. 13 — 39SR Unit — Motorized Outside Air Damper

a39-4128

17

PREINSTALLATION

Fig. 14 — Shipping Bolt and Screw Removal

a39-4086

a39-4087

1. Check items received against packing list.

2. Do not stack unit components or accessories during storage. Stacking can cause damage or deformation.

3. If unit is to be stored for more than 2 weeks prior to installation, observe the following precautions:

a. Choose a dry storage site that is reasonably level

and sturdy to prevent undue stress or permanent

damage to the unit structure or components. Do not

store unit on vibrating surface. Damage to stationary bearings can occur. Set unit off ground if in

heavy rain area.

b. Remove all fasteners and other small parts from

jobsite to minimize theft. Tag and store parts in a

safe place until needed.

c. Cover entire unit with a tarp or plastic coverall.

Extend cover under unit if stored on ground.

Secure cover with adequate tiedowns or store

indoors. Be sure all coil connections have protective shipping caps.

d. Monthly — Remove tarp from unit, enter fan

section through access door or through fan inlet,

and rotate fan and motor slowly by hand to redistribute the bearing grease and to prevent bearing

corrosion.

Rigging — Do not remove shipping skids or protective

covering until unit is ready for final placement. Use slings and

spreader bars as applicable to lift unit. Do not lift unit by coil

connections or headers.

Do not remove protective caps from coil piping connections

until ready to connect piping.

Do not remove protective cover or grease from fan shaft un-

til ready to install sheave.

Lay rigid temporary protection such as plywood walkways

in unit to prevent damage to insulation or bottom panel during

installation.

Shipping Bolt and Screw Removal (36SH

Unit) —

and screws are removed and all other bolts and screws are

tight. The red hold-down shipping bolts are located on both

sides of the blower/motor mounting rails and are accessible

through the side access panels. The red sheet metal screws are

located on the discharge duct collar. All red bolts and screws

must be removed for the blower assembly to be isolated from

the cabinet. See Fig. 14.

On 39SH units ensure that all red shipping bolts

Unit Suspension (39SH and 39SM Units) —

Acceptable forms of unit suspension are shown in Fig. 15. A

field-supplied platform mount is recommended, especially for

larger unit sizes. Units can also be supported by suspending the

unit from crossbeams at the joint between each unit component. Since the 39SM units lack a baserail, support members

should also be placed along the airway length of the unit in

order to prevent buckling. Ensure that suspension rods are

secured to adequately support the unit and that the rods extend

entirely through their associated fasteners.

All 39SH units have

top and base panels for suspension rods to pass through, locat-

1

ed 3

/2 in. in from the corners on the center line. It is recom-

mended that an angle iron or Unistrut framing system be used

7

/8 in. knockouts in each corner of their

under the unit for support (these support pieces should extend

approximately 1 in. beyond each end of the unit width).

NOTE: Locate suspension rods so they do not block access

panels or interfere with the electrical, mechanical, or drain

functions of unit.

Service Clearance — Provide adequate space for unit

service access (fan shaft and coil removal, filter removal, motor access, damper linkage access, etc.)

Condensate Drain — To prevent excessive build-up of

condensate in drain pan, adequate trap clearance (trap depth)

must be provided beneath the unit as indicated in Fig. 16. See

Installation, Condensate Drain section for additional details.

External Vibration Isolators — Install vibration

isolators per certified drawings, and in accordance with the job

specifications and the instructions of the vibration isolator

manufacturer. The coil piping must be isolated or have a flexible connection to avoid coil header damage because of unit

motion. A flexible connection should be installed at the fan

discharge.

Figure 15 shows isolation locations for overhead suspension

of unit.

18

Fig. 16 — Condensate Drain

DIFFERENTIAL

Fig. 15 — Unit Suspension

VIBRATION ISOLATORS

(FIELD SUPPLIED)

CEILING – RECOMMENDED

PLATFORM MOUNT

a39-4081

CEILING – ALTERNATE

SUSPENSION RODS WITH NO MOUNT

a39-4088

a39-4125

1

DRAIN NIPPLE

H

FAN OFF

DIFFERENTIAL

2

TRAP CONDITION WHEN FAN STARTS

COOLING COIL

DRAIN PAN

FAN RUNNING AND CONDENSATE DRAINING

INSTALLATION

Condensate Drain —

line at unit drain connection. All 39S units have a 3/4 in. FPT

condensate drain connection.

Measure maximum design negative static pressure upstream from the fan. Referring to Fig. 16, height “H” must be

equal to or larger than negative static pressure at design operating conditions. Prime enough water in trap to prevent losing

seal (Differential 1). When the fan starts, Differential 2 is equal

to the maximum negative static pressure.

Provide freeze-up protection as required.

Install a trapped condensate drain

Bottom Return Economizer Package (BREP)

and Horizontal Bottom Return Economizer

Package (HBREP) (39SR Unit) —

used with 39SR units for automatic sensor-controlled introduction of outdoor air into the system through an electro-mechanically controlled damper.

To install BREP:

1. Check for correct number of parts shown in Fig. 17 and

the following list.

1 – Economizer assembly

1 – Barometric relief hood

1 – Outdoor air hood

1 – Hardware bag

2. Disconnect all power to unit.

3. Remove return air access panel from unit and rear access

panel(s) if applicable as shown in Fig. 18.

4. To assemble the barometric relief hood, the following

will be needed. See Fig. 19.

30 – Screws (type A no. 10 - 16 x

1 – 15 ft gasket (

1 – 15 ft gasket (

a. Take hood bottom and left hood panel, putting the

flange of hood bottom to the inside of left hood

panel and screw into place.

1

/8 in. x 1/2 in.)

1

/8 in. x 3/4 in.)

Economizers are

1

/2 in.)

19

b. Take right hood panel and screw in place like

Fig. 17 — Bottom Return Economizer Package

(BREP) for Sizes 07-17

a39-4089

Fig. 18 — Remove Access Panel(s) from Unit

a39-4090

Fig. 19 — Assemble Barometric Relief Hood

a39-4091

Fig. 21 — Slide Economizer Assembly into Unit

a39-

a39-4092

Fig. 20 — Assemble Outside Air Hood

Step a.

c. Take top rail and place flanges over left hood panel

and right hood panel and secure.

d. Take top panel and do the same as Step c.

e. Take

1

/8 in. x 3/4 in. gasket and place around perimeter of front panel to seal between damper section

and hood.

f. Take front panel and slide inside of left hood panel

and right hood panel and secure.

1

g. Place

/8 in. x 1/2 in. gasket on flanges on hood bottom, left hood panel, right hood panel, and top

panel that attach to the face of the economizer

when installed.

h. Set barometric relief hood to the side for use later.

5. To assemble the outside air hood, the following will be

needed. See Fig. 20.

1

20 – Screws (type A no. 10 - 16 x

1 – 15 ft gasket (

1

/8 in. x 1/2 in.)

/2 in.)

a. Take hood bottom and left hood panel, putting the

flange of hood bottom to the inside of left hood

panel and screw into place.

b. Take right hood panel and screw in place like

Step a.

c. Take top rail and place flanges over left hood panel

and right hood panel and secure.

d. Take side rail and line up to holes in left hood

panel and secure.

e. Repeat Step d for side rail and right hood panel.

f. Take front panel and slide inside of side rails.

g. Take top panel and do the same as Step c.

h. Place

1

/8 in. x 1/2 in. gasket on flanges on hood bottom, left hood panel, right hood panel, and top rail

that attach to the face of the economizer when

installed.

i. Set outside air hood to the side for use later.

6. As shown in Fig. 21, slide economizer assembly into unit

over return opening, but DO NOT insert completely into

unit. Connect low and high voltage wiring to the terminal

block and transformer per wiring diagram shown in

Fig. 22.

20

Fig. 22 — Modulating Gear Economizer with Relief for Sizes 07-17 BREP Units

NOTES:

1. Unit wiring shown as reference only. Check unit wiring for actual unit wiring.

2. Relays 1K and 2K actuate when the outdoor air enthalpy is higher than the return air enthalpy.

3. 1S is an electronic switch which closes when powered by a 24 VAC input.

4. Factory-installed resistor should be removed only if C7400 differential enthalpy sensor is added.

a39-4094

21

7. To install barometric hood:

Fig. 25 — Install Outside Air Hood

a39-4097

Fig. 26 — Slide Economizer into Unit

a39-4098

BAROMETRIC

RELIEF HOOD

Fig. 23 — Install Barometric Relief Hood

a39-

Fig. 24 — 39SR Unit Duct Flange Dimensions for

Horizontal Return Applications

39SR UNIT

SIZE

DUCT FLANGE

DIMENSION (in.)

AB

07,09 13.75 44.25

13 18.75 44.25

17 19.00 63.00

a39-4096

For bottom return applications:

Take the barometric hood and secure to economizer using

screws as shown in Fig. 23.

For horizontal return applications:

a. Connect field-installed horizontal return ductwork

to duct flange. Ensure that bottom return on unit is

capped.

b. Install barometric hood over exhaust opening in

field-installed ductwork. For exhaust and horizontal return opening sizes see duct flange dimensions

in Fig. 24.

8. Install the outside air hood. The upper flange of the

hood should rest against the top of the economizer. See

Fig. 25.

9. Apply

1

/8 x 1/2 in. gasketing along mounting flanges.

Slide economizer assembly fully into unit and secure with

the supplied no. 10-16 x

1

/2 screws. See Fig. 26.

10. Replace all panels and restore power to the unit.

Motorized Outside Air Damper — To install the

motorized outside air damper:

1. Check for correct number of parts shown in Fig. 27 and

the following list.

1 – Hood top

2 – Hood sides

2 – Filter channels

1 – Filter

1 – Filter access panel

1 – Door panel with outside air slide

1 – Adapter panel (provided if necessary)

1 – Hardware bag

2. To assemble outdoor air hood (shown in Fig. 28):

22

a. Secure the filter channels to the hood sides using

the supplied no. 10-16 x

b. Place the hood sides to the inside of the side flange

of the hood top and secure with the supplied

no. 10-16 x

1

/2 screws.

c. Slide the filter inside the filter channels.

d. Place the filter access panel over the hood side

panels and secure with no. 10-16 x

3. Adjust the position of the outside air slides on the door

panel to determine the amount of fresh air provided to the

unit. See Fig. 27.

4. After the slides are in the desired position, secure the

outdoor air hood to the door panel using the provided

no. 10-16 x ½ screws as shown in Fig. 28.

5. Remove the return air access panel from unit and the rear

access panel(s) if applicable as shown in Fig. 29.

6. Locate the adapter panel (provided if necessary). Position

the adapter panel at the top of the return air access panel

under the rooftop unit top panel. Secure the adapter panel

to the rooftop unit using the supplied no. 10-16 x

screws as shown in Fig. 30.

1

/2 screws.

1

/2 screws.

1

/

2

7. Center the door panel over the return-air access opening.

Fig. 30 — Secure Adapter Panel to Unit

a39-4102

Fig. 31 — Secure Door Panel to Unit

a39-4103

Fig. 32 — Actuator Assembly

a39-4104

Fig. 27 — Motorized Outside Air Damper

a39-4099

Fig. 28 — Assemble the Outside Air Hood

a39-4100

Fig. 29 — Remove Access Panel(s) from Unit

a39-4101

8. Align the holes in the top and bottom of the door panel to

the holes in the rooftop unit. Secure the door panel to the

unit using the provided no. 10-16 x

1

/2 screws as shown in

Fig. 31.

Mixing Box Actuator (for 39SH and 39SM Horizontal Return Units Only)

MIXING BOX ACTUATOR ASSEMBLY (Fig. 32 and

33) — To assemble the mixing box actuator:

1. Press logic module onto actuator.

2. Remove lock nut from swivel nut assembly. Place swivel

nut assembly into slot on actuator arm. Hand tighten lock

nut onto swivel nut assembly. Swivel nut assembly will

need to be adjusted once installed for proper actuator

motion.

3. Attach actuator arm assembly to actuator with four 1/4-in.

screws. Arm may need to be repositioned once installed

to ensure proper actuator motion.

23

ACTUATOR INSTALLATION — To install the actuator:

Fig. 35 — Actuator Installation Side View

a39-4107

Fig. 36 — Area A Detailed View

DR4

DR3

DR1

DR2

LINKAGE

ARM

LINKAGE

ROD

a39-4108

Fig. 37 — Area B Detailed View

a39-4109

Fig. 34 — Actuator Installation Front View

a39-4106

Fig. 33 — Assembled Actuator

a39-4105

1. Align actuator so that the actuator linkage arm will have

enough clearance for full range of motion. Refer to

Fig. 34-37. Align center line of the actuator as close to the

centerline of DR4 as possible. See Fig. 36 and 37. Use at

least 4 self-drilling screws to mount directly to top of unit.

2. Place linkage arm assembly (linkage arm and swivel nut

arm) onto DR4 as shown in Fig. 36 and 37. Do not tighten to DR4 as adjustments need to be made.

3. Place linkage rod between actuator arm and linkage arm

on DR4. See Fig. 36. Linkage rod may need to be cut to

length. Ensure actuator arm and linkage arm are parallel.

4. Ensure linkage assemblies are properly secured as shown

in the linkage assembly instructions sent with the unit.

5. Open one set of dampers to 100% open and the other to

100% closed. Ensure actuator motion will operate as

needed and tighten all linkages, swivel assemblies, and

linkage rods into place.

6. Ensure actuator motion opens and closes damper assemblies fully. If not, adjust settings of linkage arm, actuator

arm, swivel nut assemblies, and linkage rods one at a time

until full operation is achieved.

DOOR

(HIDDEN)

VERTICAL

RETURN

B

A

HORIZONTAL

RETURN

24

Mixing Box Air Sensor

Fig. 39 — Mixed Air Sensor Installation

A

A

a39-4111

Fig. 41 — Installing Mixing Box

MIXING

BOX

HANGING

BRACKETS

(1 in. DIA.)

UNIT FILTER

ACCESS DOOR

39SH

UNIT

a39-4113

Fig. 38 — Mixed Air Sensor Bracket

a39-4110

Fig. 40 — Enthalpy Sensor

a39-4112

MIXING BOX MIXED AIR SENSOR BRACKET

ASSEMBLY — To assemble the mixed air sensor bracket

assembly to the mixing box, attach mixed air sensor to mixed

air sensor bracket. See Fig. 38.

MIXED AND OUTSIDE AIR SENSORS INSTALLATION

1. Remove access panel and filters as needed.

2. Place mixed air sensor assembly in airstream as shown in

Fig. 39.

3. Attach to top of unit with self drilling screws.

4. Drill or knockout

to actuator as shown in Fig. 39.

5. Insert snap bushing in hole. Run wires inside unit, along

top of mixing box, between the filter rail and insulation,

and attach to mixed air sensor.

6. Place enthalpy sensor, shown in Fig. 40, in location suitable to meet manufacturer's requirements.

7. Connect all sensors to logic module per manufacturer's

instructions.

8. Test to ensure proper function.

9. Replace all parts and tape or fill any holes or gaps made.

1

/2 in. hole into top of mixing box close

Mixing Box — To install mixing box:

1. Insert rear return duct flanges of unit into opening of

mixing box.

2. Ensure all unit flanges are inside the opening of the mixing box and screw a minimum of three screws into each

of the unit’s four flanges using self-drilling screws.

3. The mixing box should now hang freely from the unit.

NOTE: Hanging brackets (shipped loose), as shown in

Fig. 41, are recommended for 39SH and 39SM unit sizes

07 and above. To install brackets, place in approximate

location and use self-drilling screws to attach to mixing

box. Brackets are sized to allow hanging from Unistrut.

Unistrut should be cut to the length one to two inches

shorter than the width of the mixing box to avoid any interference with the damper linkages.

4. Remove unit filters from unit before start-up.

MIXED

IR SENSOR

SSEMBLY

HOLE

LOCATION

MIXING BOX LINKAGE INSTALLATION (39SH Unit

Sizes 00-03) — To install the mixing box linkage assembly

(sizes 00-03):

1. Check for correct number of parts:

1 – Linkage rod

2 – Linkage arms

2 – Swivel joints

NOTE: A

7

/16 in. box end wrench and/or socket will be

needed for linkage installation.

2. Attach actuator (optional item) to unit with actuator

mounting hardware included with actuator. Actuator

should be mounted on damper rod 1 (DR1) as shown in

Fig. 42.

3. Orientate actuator to avoid interference with linkage

assembly.

4. Ensure dampers are fully closed or open depending on

application, and secure actuator to shaft. Actuator should

open and close dampers fully. Adjust actuator as needed.

25

5. Place a linkage arm onto DR1 and DR2. See Fig. 42 and

Fig. 44 — Linkage Assembly Front View

(Sizes 04-17)

a39-4116

Fig. 45 — Linkage Assembly Side View

(Sizes 04-17)

a39-4117

Fig. 42 — Linkage Assembly Front View

(Sizes 00-03)

VERTICAL

RETURN

HORIZONTAL

RETURN

ACTUATOR

(OPTIONAL)

LINKAGE

ARM

DR2

DR1

LINKAGE ROD

a39-4114

Fig. 43 — Linkage Assembly Side View

(Sizes 00-03)

a39-4115

43 for proper positioning. Ensure that swivel joints are

fully extended to the end of the linkage arm and tighten.

6. Insert linkage rod into swivel joints and tighten. Linkage

rod may need to be cut down to size. Linkage arms

should be parallel.

7. Ensure one set of dampers are fully open and the other

fully closed. Adjust linkage assembly to allow travel

without interference and tighten to DR1 and DR2.

8. The actuator should now be able to power the dampers

fully open and fully closed without interference. Adjust

linkage assemblies as needed.

MIXING BOX LINKAGE INSTALLATION (Sizes 04-

17) — To install the mixing box linkage assembly (sizes

04-17):

1. Check for correct number of parts:

3 – Linkage rods

6 – Linkage arms

6 – Swivel joints

NOTE: A

7

/16 in. box end wrench and/or socket will be

needed for linkage installation.

2. An alternate field-supplied actuator may be installed

directly on the damper shaft if required. If a factorysupplied actuator is ordered for the mixing box, refer to

Mixing Box Actuator section on page 23.

3. Orientate actuator to avoid interference with linkage

assembly. Refer to Fig. 44 and 45.

4. Ensure dampers are fully closed or open depending on

application, and secure actuator to shaft. Actuator should

open and close dampers fully. Adjust actuator as needed.

5. Place a linkage arm onto DR3 and DR2. See Fig. 46 and

47. for proper positioning. Ensure that swivel joints are

fully extended to the end of the linkage arm and tighten.

6. Insert linkage rod into swivel joints and tighten. Linkage

rod may need to be cut down to size. Linkage arms

should be parallel. Assembly should still be loose on

damper rods. This will be linkage assembly no. 1.

7. Place linkage arm onto DR1 and DR2. Ensure swivel

joints are fully extended to the end of the linkage arm and

tighten.

8. Insert linkage rod into swivel joints and tighten. Linkage

rod may need to be cut down to size. Linkage arms

should be parallel.

9. Ensure dampers are fully open or closed and tighten linkage arms to damper rods. Linkage assembly should be

able to open and close dampers fully without interference.

Adjust accordingly.

10. Place linkage arm onto DR3 and DR4. Ensure swivel

joints are fully extended to the end of the linkage arm and

tighten.

11. Insert linkage rod into swivel joints and tighten. Linkage

rod may need to be cut down to size. Linkage arms

should be parallel.

12. Ensure dampers are fully open or closed and tighten linkage arms to damper rods. Linkage assembly should be

able to open and close dampers fully without interference.

Adjust accordingly.

13. Ensure one set of dampers is fully open and the other fully closed. Adjust linkage assembly no. 1 to allow travel

without interference and tighten to DR2 and DR3.

14. The actuator should now be able to power the dampers

fully open and fully closed without interference. Adjust

linkage assemblies as need.

26

Install Sheaves on Motor and Fan Shafts —

Fig. 48 — Determining Sheave-Shaft Overhang

a39-1733

Fig. 46 — Area A Detailed View

DR4

ACTUATOR

(OPTIONAL)

DR3

DR1

DR2

LINKAGE

ARM

LINKAGE

ROD

a39-4118

Fig. 47 — Area B Detailed View

a39-4119

Factory-supplied drives are prealigned and tensioned, however,

Carrier recommends that the belt tension and alignment be

checked before starting the unit. Always check the drive alignment after adjusting belt tension.

When field installing or replacing sheaves, install sheaves

on fan shaft and motor shaft for minimum overhang. (See

Fig. 48.) Use care when mounting sheave on fan shaft; too

much force may damage bearing. Remove rust-preventative

coating or oil from shaft. Make sure shaft is clean and free of

burrs. Add grease or lubricant to bore of sheave before

installing.

ALIGNMENT — Make sure that fan shafts and motor shafts

are parallel and level. The most common causes of misalignment are nonparallel shafts and improperly located

sheaves. Where shafts are not parallel, belts on one side are

drawn tighter and pull more than their share of the load. As a

result, these belts wear out faster, requiring the entire set to be

replaced before it has given maximum service. If misalignment

is in the sheave, belts will enter and leave the grooves at an

angle, causing excessive belt cover and sheave wear.

1. Shaft alignment can be checked by measuring the

distance between the shafts at 3 or more locations. If the

distances are equal, then the shafts will be parallel.

2. Check alignment of sheaves:

Fixed sheaves

sheaves on the shafts, a straightedge or a piece of string

can be used. If the sheaves are properly lined up the string

will touch them at the points indicated by the arrows in

Fig. 49.

Adjustable sheave

sheave on shaft, make sure that the centerlines of both

sheaves are in line and parallel with the bearing support

channel. See Fig. 49. Adjustable pitch drives are installed

on the motor shaft.

— To check the location of the fixed

— To check the location of adjustable

CAUTION

With adjustable sheave, do not exceed maximum fan rpm.

3. Rotating each sheave a half revolution will determine

whether the sheave is wobbly or the drive shaft is bent.

Correct any misalignment.

27

4. With sheaves aligned, tighten cap screws evenly and

PD — Pitch Diameter, inches

Fig. 50 — Fan Belt Tension Data

BELT

CROSS

SECTION

SMALL

SHEAVE

PD RANGE

(in.)

DEFLECTION FORCE — LB

Super

Belts

Notch

Belts

Steel Cable

Belts

Min Max Min Max Min Max

A

3.0- 3.6 3 4

1

/437/851/234

3.8- 4.8 3

1

/2541/261/433/443/

4

5.0- 7.0 4 51/2567/841/451/

4

B

3.4- 4.2 4 5

1

/253/4841/251/

2

4.4- 5.6 51/871/861/291/853/471/

4

5.8- 8.6 63/883/473/8101/8783/

4

C

7.0- 9.4 11

1

/4143/8133/4177/8111/414

9.6-16.0 14

1

/8181/2151/4201/4141/4173/

4

3V

2.65-3.65 3

1

/2537/851/2——

4.12-6.90 4

3

/467/851/477/8——

5V

4.40-6.70 — — 10 15 — —

7.1-10.9 10

1

/2153/4127/8183/4——

11.8-16.0 13 19

1

/215 22 — —

8V

12.5-17.0 27 40

1

/2——— —

18.0-22.4 30 45 — — — —

a39-1

Fig. 49 — Sheave Alignment

progressively.

NOTE: There should be a

1

/8-in. to 1/4-in. gap between

the mating part hub and the bushing flange. If gap is

closed, the bushing is probably the wrong size.

5. With taper-lock bushed hubs, be sure the bushing bolts

are tightened evenly to prevent side-to-side pulley wobble. Check by rotating sheaves and rechecking sheave

alignment.

6. To determine correct belt tension, use the deflection

formula given below and the tension data from Fig. 50 as

follows:

EXAMPLE:

Given

Belt Span 16 in.

Belt Cross-Section A, Super Belt

Small Sheave Pitch Diameter 5 in.

Deflection =

(Belt Span)

64

Solution

1. From Fig. 50 find that deflection force for type A, super

belt with 5-in. small sheave pitch diameter is 4 to 5

1

/2 lb.

2.

Deflection =

3. Increase or decrease belt tension until force required for

1

/4-in. deflection is 51/2 lb.

16

64

Check belt tension at least twice during first operating

day. Readjust as required to maintain belt tension within

the recommended range.

With correct belt tension, belts may slip and squeal

momentarily on start up. This slippage is normal and disappears after unit reaches operating speed. Excessive belt tension

shortens belt life and may cause bearing and shaft damage.

After run-in, set belt tension at lowest tension at which belts

will not slip during operation.

Install V-Belts — When installing or replacing belts, al-

ways use a complete set of new belts. Mixing old and new belts

will result in the premature wear or breakage of the newer

belts.

1. Always adjust the motor position so that V-belts can be

installed without stretching over grooves. Forcing belts

can result in uneven stretching and a mismatched set of

belts.

2. Do not allow belt to bottom out in sheave.

3. Tighten belts by turning motor-adjusting jackscrews.

Turn each jackscrew an equal number of turns.

4. Equalize belt slack so that it is on the same side of belt for

all belts. Failure to do so may result in uneven belt

stretching.

5. Tension new drives at the maximum deflection force

recommended (Fig. 50).

28

Water and Steam Coil Piping Recommendations

53

NOTES:

1. Flange or union is located to facilitate coil removal.

2. Flash trap may be used if pressure differential between steam

and condensate return exceeds 5 psi.

3. When a bypass with control is required.

4. Dirt leg may be replaced with a strainer. If so, tee on drop can

be replaced by a reducing ell.

5. The petcock is not necessary with a bucket trap or any trap

which has provision for passing air. The great majority of high

or medium pressure returns end in hot wells or deaerators

which vent the air.

Fig. 52 — Low, Medium or

High Pressure Coil Piping

a39-4129

Fig. 51 — Water Coil Connection

LEGEND

CW — Chilled Water

HW — Hot Water

LH — Left Hand

RH — Right Hand

a39-4126

GENERAL — Use straps around the coil casing to lift and

place the coil.

CAUTION

To prevent damage to the coil or coil headers: Do not use

the headers to lift the coil. Support the piping and coil connections independently. Do not use the coil connections to

support piping. When tightening coil connections, use a

backup wrench on the nozzles.

Piping practices are outlined in the Carrier System Design

Manual, Part 3, Piping Design.

WATER COILS — Typically, coils are piped by connecting

the supply at the bottom and the return at the top. This is not always the case, especially if the coil hand has been changed in

the field. Coils must be piped for counterflow; otherwise, a capacity reduction of 5% for each coil row will result. To ensure

counterflow, chilled water coils are piped so that the coldest

water meets the coldest air. Hot water coils are piped so that the

warmest water meets the warmest air. Some 39S coils have 3

connections on either side of the coil (for a total of 6 connections). In these cases, the middle connection is used as the re-

For coils used in tempering service, or to preheat outside air,

install an immersion thermostat in the condensate line ahead of

the trap. This will shut down the supply fan and close the outdoor damper whenever the condensate falls to a predetermined

point, perhaps 120 F.

NOTE: Do NOT use an immersion thermostat to override a

duct thermostat and open the steam supply valve.

For vacuum return systems, the vacuum breaking check

valve would be piped into the condensate line between the trap

and the gate valve instead of open to the atmosphere.

Figure 53 illustrates the typical piping at the end of every

steam supply main. Omitting this causes many field problems

and failed coils.

Figure 54 shows the typical field piping of multiple coils.

Use this only if the coils are the same size and have the same

pressure drop. If this is not the case, an individual trap must be

provided for each coil.

Figure 55 shows a multiple coil arrangement applied to a

gravity return, including the open air relief to the atmosphere,

which DOES NOT replace the vacuum breakers.

Figure 56 illustrates the basic condensate lift piping.

turn connection. See Fig. 51.

STEAM COILS — Position the steam supply connection at

the top of the coil, and the return (condensate) connection at the

bottom.

Figure 52 illustrates the normal piping components and the

suggested locations for high, medium, or low-pressure steam

coils. The low-pressure application (zero to 15 psig) can

dispense with the ¼-in. petcock for continuous venting located

above the vacuum breaker (check valve).

Note the horizontal location of the 15-degree check valve,

and the orientation of the gate/pivot. This valve is intended to

relieve any vacuum forming in the condensate outlet of a

condensing steam coil, and to seal this port when steam

pressure is again supplied to the coil. It must not be installed in

any other position, and should not be used in the supply line.

29

NOTES:

1. Flange or union is located to facilitate coil removal.

2. To prevent water hammer, drain coil before admitting steam.

3. Do not exceed one foot of lift between trap discharge and

return main for each pound of pressure differential.

4. Do not use this arrangement for units handling outside air.

Fig. 56 — Condensate Lift to Overhead Return

a39-2365tf.tif

3

NOTES:

1. Flange or union is located to facilitate coil removal.

2. When control valve is omitted on multiple coils in parallel air

flow.

3. When a bypass with control is required.

4. Coils with different pressure drops require individual traps. This

is often caused by varying air velocities across the coil bank.

Fig. 55 — Multiple Coil Low Pressure

Piping Gravity Return

a39-4131

NOTES:

1. A bypass is necessary around trap and valves when continuous operation is necessary.

2. Bypass to be the same size as trap orifice but never less than

1

/2 inch.

Fig. 53 — Dripping Steam Supply to

Condensate Return

a39-2362tf.tif

3

NOTES:

1. Flange or union is located to facilitate coil removal.

2. When a bypass with control is required.

3. Flash trap can be used if pressure differential between supply

and condensate return exceeds 5 psi.

4. Coils with different pressure drops require individual traps. This

is often caused by varying air velocities across the coil bank.

5. Dirt leg may be replaced with a strainer. If so, tee on drop can

be replaced by a reducing ell.

6. The petcock is not necessary with a bucket trap or any trap

which has provision for passing air. The great majority of high

pressure return mains terminate in hot wells or deaerators

which vent the air.

Fig. 54 — Multiple Coil High Pressure Piping

a39-4130

30

Following the piping diagrams in Fig. 52-56, make all con-

nections while observing the following precautions:

• Install a drip line and trap on the pressure side of the

inlet control valve. Connect the drip line to the return

line downstream of the return line trap.

• To prevent scale or foreign matter from entering the control valve and coil, install a

3

/32-in. mesh strainer in the

steam supply line upstream from the control valve.

• Provide air vents for the coils to eliminate noncondensable gases.

• Select a control valve according to the steam load, not

the coils supply connection size. Do not use an oversized

control valve.

• Do not use bushings that reduce the size of the header

return connection. The return connection should be the

same size as the return line and reduced only at the

downstream trap.

• To lift condensate above the coil return line into overhead steam mains, or pressurized mains, install a pump

and receiver between the condensate trap and the

pressurized main. Do not try to lift condensate with

modulating or on-and-off steam control valves. Use only

15-degree check valves, as they open with a lower water

head. Do not use 45-degree or vertical-lift check valves.

• Use float and thermostatic traps. Select the trap size

according to the pressure difference between the steam

supply main and the return main.

• Load variations can be caused by uneven inlet air distribution or temperature stratification.

• Drain condensate out of coils completely at the end of

the heating season to prevent the formation of acid.

Coil Freeze-Up Protection

WATER COILS — If a chilled water coil is applied with outside air, provisions must be made to prevent coil freeze-up.

Install a coil freeze-up thermostat to shut down the system if

any air temperature below 36 F is encountered entering the

water coil. Follow thermostat manufacturer’s instructions.

When a water coil is applied downstream of a directexpansion (DX) coil, a freeze-up thermostat must be installed

between the DX and water coil and electrically interlocked to

turn off the cooling to prevent freeze-up of the water coil.

For outdoor-air application where intermittent chilled water

coil operation is possible, one of the following steps should be

taken:

• Install an auxiliary blower heater in cabinet to maintain

above-freezing temperature around coil while unit is

shut down.

• Drain coils and fill with an ethylene glycol solution suit-

able for the expected cold weather operation. Shut down

the system and drain coils. See Service section, Winter

Shutdown.

STEAM COILS — When used for preheating outdoor air in

pressure or vacuum systems, an immersion thermostat to control outdoor-air damper and fan motor is recommended. This

control is actuated when steam supply fails or condensate temperature drops below an established level, such as 120 to 150 F.

A vacuum breaker should also be used to equalize coil pressure

with the atmosphere when steam supply throttles close. Steam

should not be modulated when outdoor air is below 40 F.

On low-pressure and vacuum steam-heating systems, the

thermostat may be replaced by a condensate drain with a thermal element. This element opens and drains the coil when condensate temperature drops below 165 F. Note that condensate

drains are limited to 5 psig pressure.

INNER DISTRIBUTING TUBE STEAM COILS — The

inner distributing tube (IDT) steam coil used in the 39S airhandling units has an inner tube pierced to facilitate the distribution of the steam along the tube's length. The outer tubes are

expanded into plate fins. The completed assembly includes the

supply and condensate header and side casings which are built

to slant the fin/tube bundle back toward the condensate header.

The slanting of the assembly ensures that condensate will flow

toward the drains. This condensate must be removed through

the return piping to prevent premature failure of the coil. The

fin/tube bundle is slanted vertically for horizontal airflow coils,

and horizontally for vertical airflow coils.

IDT Steam Coil Piping

— The following piping guidelines

will contribute to efficient coil operation and long coil life:

1. Use full size coil outlets and return piping to the steam

trap. Do not bush return outlet to the coil. Run full size to

the trap, reduce at the trap.

2. Use float and thermostatic (F & T) traps only for condensate removal. Trap size selection should be based on the

difference in pressure between the steam supply main and

the condensate return main. It is good practice to select a

trap with 3 times the condensate rating of the coil to

which it is connected.

3. Use thermostatic traps for venting only.

4. Use only

1

/2-in., 15-degree swing check valves installed

horizontally, piped open to atmosphere, and located at

least 12 in. above the condensate outlet. Do not use

45-degree, vertical lift and ring check valves.

5. The supply valve must be sized for the maximum anticipated steam load.

6. Do not drip steam mains into coil sections. Drip them on

the pressure side of the control valve and trap them into

the return main beyond the trap for the coil.

7. Do not use a single trap for two or more coils installed in

series. Where two or more coils are installed in a single

bank, in parallel, the use of a single trap is permissible,

but only if the load on each coil is equal. Where loads in

the same coil bank vary, best practice is to use a separate

trap for each coil.

Variation in load on different coils in the same bank may

be caused by several factors. Two of the most common

are uneven airflow distribution across the coil and stratification of inlet air across the coil.

8. Do not try to lift condensate above the coil return into an

overhead main, or drain into a main under pressure with a

modulating or on/off steam control valves. A pump

and receiver should be installed between the coil condensate traps and overhead mains and return mains under

pressure.

9. Use a strainer (

3

/32-in. mesh) on the steam supply side,

as shown in the piping diagrams, to avoid collection of

scale or other foreign matter in the inner tube distributing

orifices.

NOTE: IDT coils must be installed with the tubes draining

toward the header end of the coil. The IDT steam coils are

pitched toward the header end as installed in the unit.

10. Ensure the AHU (air-handling unit) is installed level to

maintain the inherent slope. Also ensure the unit is installed high enough to allow the piping to be installed correctly, especially the traps which require long drip legs.

11. Do not fail to provide all coils with the proper air vents to

eliminate noncondensable gasses.

12. Do not support steam piping from the coil units. Both

mains and coil sections should be supported separately.

IDT Steam Coil Installation

— Refer to drawings to position

the coils properly with regard to the location of the supply and

return connections. Ensure that the IDT coil is pitched with the

tubes draining toward the header. The AHUs provide proper

coil pitch when the AHU is installed level.

Refer to schematic piping diagrams and piping connection

notes for the recommended piping methods.

31

Refrigerant Piping, Direct-Expansion (DX)

Fig. 58 — Suction Line Riser Piping

a39-516tf.tif

TXV — Thermostatic Expansion Valve

Fig. 57 — Face Split Coil Suction Line Piping

a39-139.tif

Coils —

depending upon the unit size and coil circuiting. Each split requires its own distributor nozzle, expansion valve, and suction

piping. Suction connections are on the air entering side when

the coil is properly installed. Matching distributor connections

for each coil split are on the air leaving side. See unit label or

certified drawing to assure connection to matching suction and

liquid connections.

The lower split of face split coils should be first on, last off.

Row split coils utilize special intertwined circuits; either

split of these row split coils can be first on, last off.

Direct-expansion coils are divided into 1 or 2 splits

CAUTION

Direct-expansion coils are shipped pressurized with dry

nitrogen. Release pressure from each coil split through

valves in protective caps before removing caps.

Do not leave piping open to the atmosphere unnecessarily. Water and water vapor are detrimental to the refrigerant

system. Until the piping is complete, recap the system and

charge with nitrogen at the end of each workday. Clean all

piping connections before soldering joints.

Failure to follow these procedures could result in personal

injury or equipment damage.

SUCTION PIPING — Connect suction piping as shown in

Fig. 57 for face split coil.

EXPANSION VALVE PIPING — Distributor nozzles and

expansion valves sized for acceptable performance for a range

of conditions are factory supplied. Use the AHU (air-handling

unit) selection program in the electronic catalog to select optimal nozzle sizes.

Circuiting selection should result in a circuit loading of 0.8

to 2.0 tons per circuit at design load. Circuit loading must be

evaluated at minimum load to ensure that it does not drop

below 0.6 tons per circuit. Solenoid valves may be used, if necessary, to shut off the refrigerant supply to individual expansion

valves to maintain adequate coil circuit loading.

Compressor minimum unloading and TXV quantity is necessary to determine minimum tonnage per circuit.

Minimum Unloading Equation:

(Tons per Circuit) x (Minimum Unloading)

x (Total no. of TXVs)

no. of TXVs Active

Example:

Condensing Unit: 38ARS012

Minimum Unloading:33%

Coil: 6 row, 11 FPI, Half Circuit

Coil Tons per Circuit: 1.68

Total TXVs: 2

In the first example we will determine the tons per circuit

when both TXVs are active and the compressor is unloaded to

its minimum of 33%.

(1.68 Tons per Circuit) x (33% Minimum Unloading)

=

x (2 TXVs)

2 TXVs Active

Suction line from coil connection to end of the 15-diameterlong riser should be same tube size as coil connection to ensure

proper refrigerant velocity.

maining suction line to compressor for a pressure drop equivalent to 2.0 F. This will provide a total suction line header pressure drop equivalent to approximately 2.5 F. Refer to Fig. 58

for piping risers to the compressor.

sor damage during prolonged light load operation, install an

accumulator in the suction line or a solenoid in the liquid line

of last-on, first off split in row-split applications.

Refer to Carrier System Design Manual, Part 3, and size re-

To minimize the possibility of flooded starts and compres-

(1.68) x (.33) x (2)

=

= .55 tons per circuit at minimum unloading

UNACCEPTABLE

If we install a liquid line solenoid valve before one of the

TXVs and close it so that only one TXV is active when the

compressor is unloaded to its minimum of 33%, we see the

following:

(1.68 Tons per Circuit) x (33% Minimum Unloading)

=

(1.68) x (.33) x (2)

=

= 1.10 tons per circuit at minimum unloading ACCEPTABLE

32

2

x (2 TXVs)

1 TXV Active

1

There are three different options to control tons per circuit