Page 1

With Product Integrated Controls (PIC)

Installation, Operation, and

Start-Up Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS ...................2

GENERAL ...................................2

INSTALLATION .............................2-64

Service Area Requirements ...................2

Remote Control Box Option ..................2

• REMOTE CONTROL BOX CONDENSATE

PREVENTION

Make Electrical Connections ..................3

Variable Frequency Drives ...................38

Water Valve Assemblies .....................38

• VALVE WIRING

Duct Static Pressure Probe (VAV Units) ......39

Space Temperature Sensor ..................40

Outdoor-Air Temperature Sensor .............42

Mixed-Air Temperature Sensor ...............42

Enthalpy Switch ............................43

• CONTROL RANGES

Supply-Air Temperature Sensor ..............44

Return-Air Temperature Sensor ..............44

Heat Interlock Relay .........................45

Fan Relay ..................................45

Duct High Humidity Switch ..................45

Wall-Mounted Relative Humidity Sensor ......46

Duct-Mounted Relative Humidity Sensor ......47

• LOCATION FOR OUTSIDE AIR RELATIVE

HUMIDITY

• LOCATION FOR RETURN AIR RELATIVE

HUMIDITY

Mixing Box Linkage .........................47

Airflow Switch ..............................48

Low-Temperature Thermostat ................48

Outdoor-Air Thermostat .....................48

Filter Status Switch .........................49

High-Pressure Switch .......................49

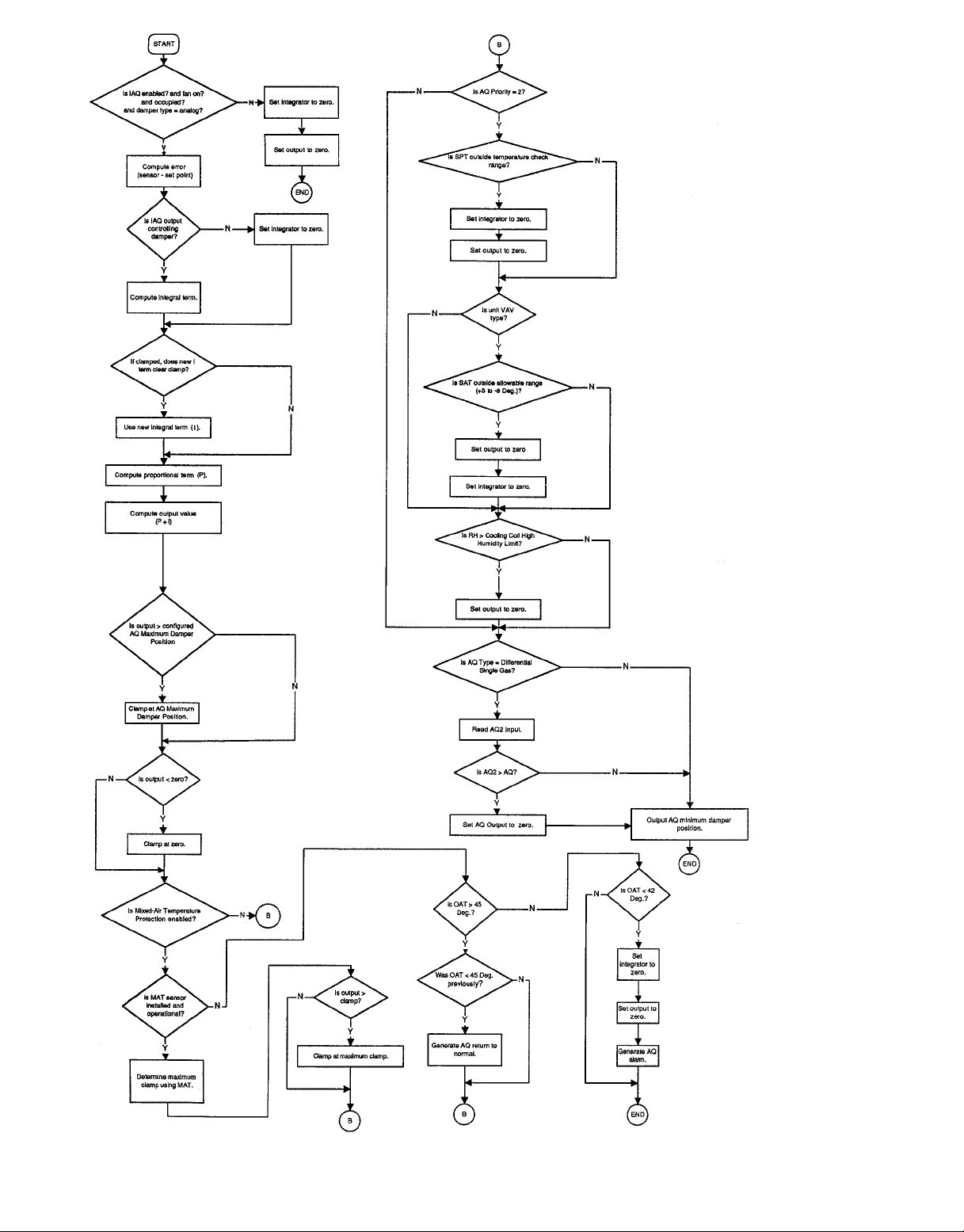

Air Quality Sensors .........................49

Constant Outside Air (OAC) Control ..........50

• PROBE INSTALLATION

• OAC CALIBRATION

• USING OAVP VALUES TO DETERMINE DUCT

AIRFLOW

• FIELD-SUPPLIED OR HIGH-VELOCITY

PRESSURE TRANSDUCERS

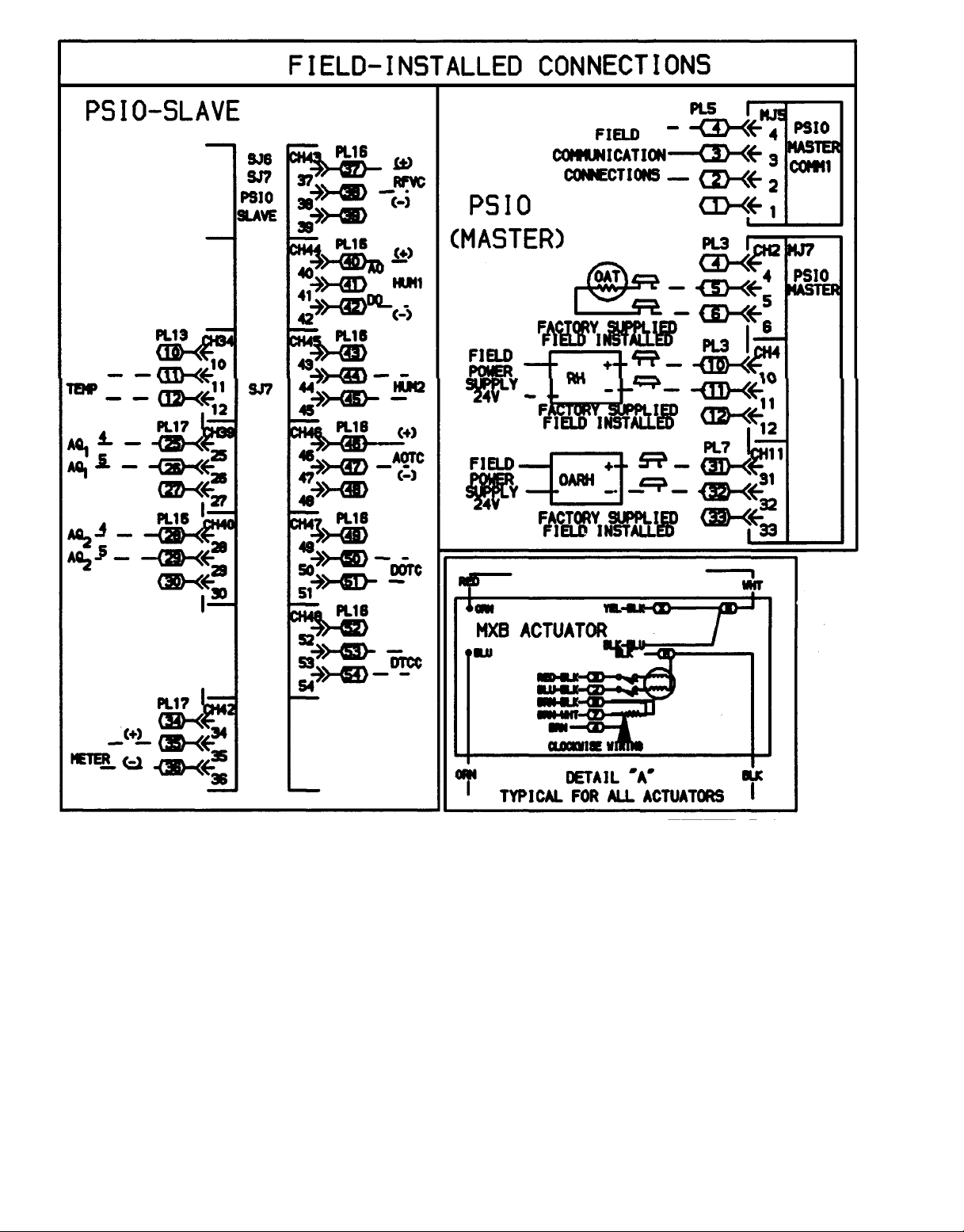

Field Wiring Connections ....................52

• REMOTE LOCAL INTERFACE DEVICE (HSIO)

• RETURN-AIR TEMPERATURE SENSOR,

OUTDOOR-AIR TEMPERATURE SENSOR,

ENTHALPY SWITCH, AND MIXED-AIR

TEMPERATURE SENSOR

• SPACE TEMPERATURE SENSOR (SPT)

• DAMPER ACTUATORS

• SMOKE CONTROL OPTION

• ANALOG DEVICE FOR ANALOG OUTPUT

TEMPERATURE CONTROL

39L,NX

Central Station Air-Handling Units

• DEVICE UNDER DISCRETE OUTPUT

TEMPERATURE CONTROL

• DISCRETE OUTPUT DEVICE UNDER

TIMECLOCK CONTROL

• HUMIDIFICATION DEVICES

• AIR QUALITY SENSOR

• OUTSIDE AIR VELOCITY PRESSURE (OAVP)

SENSOR

• FAN VOLUME CONTROL

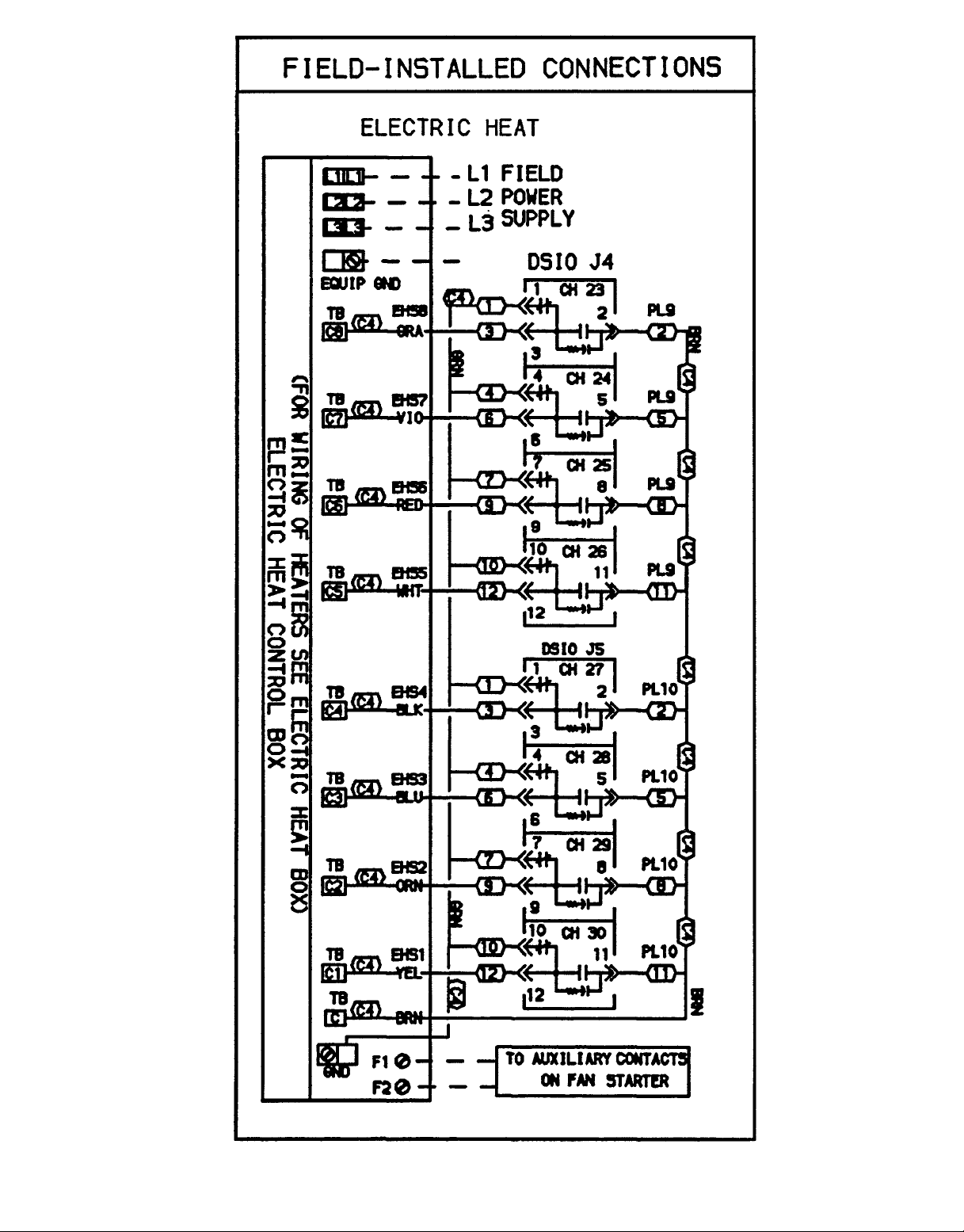

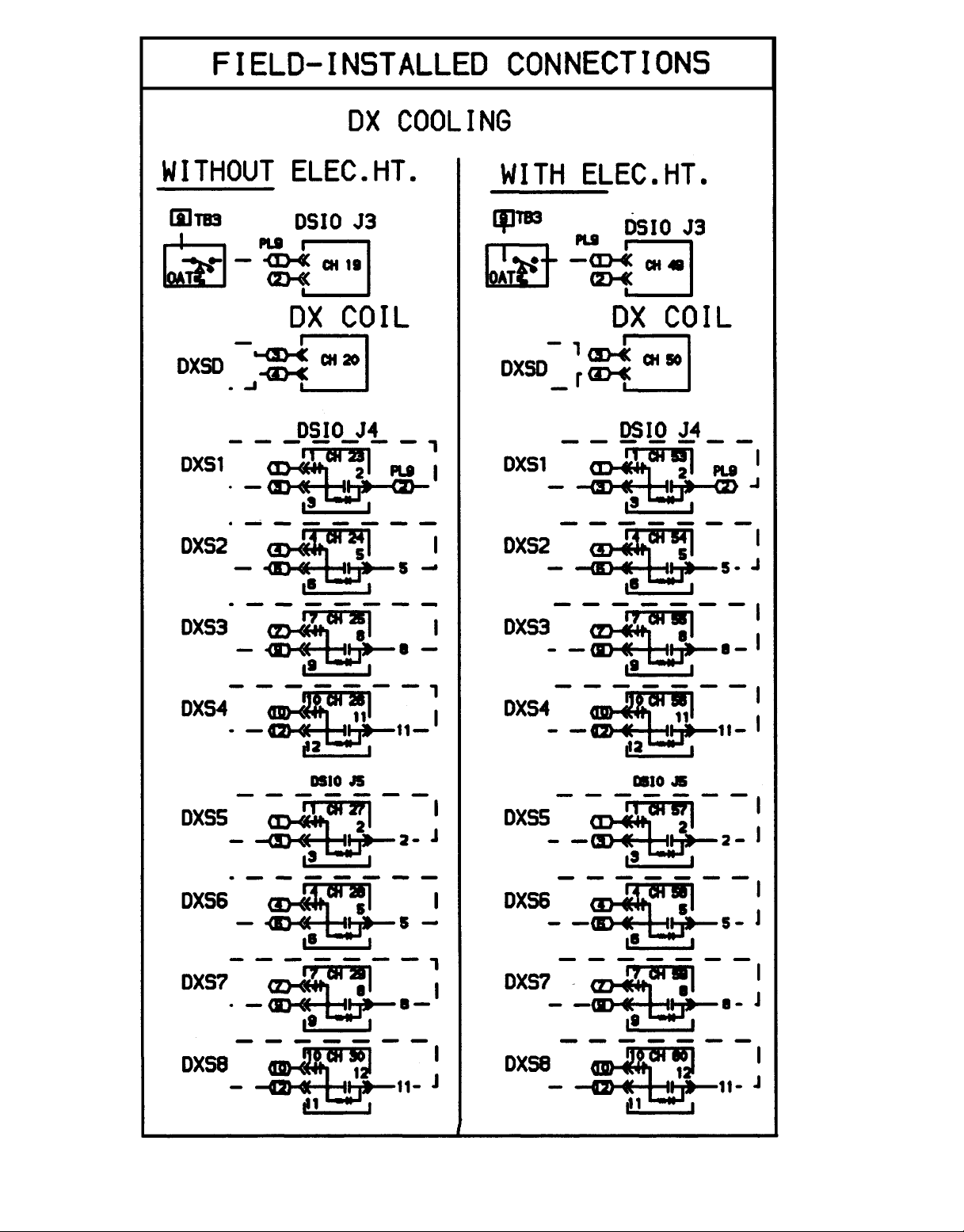

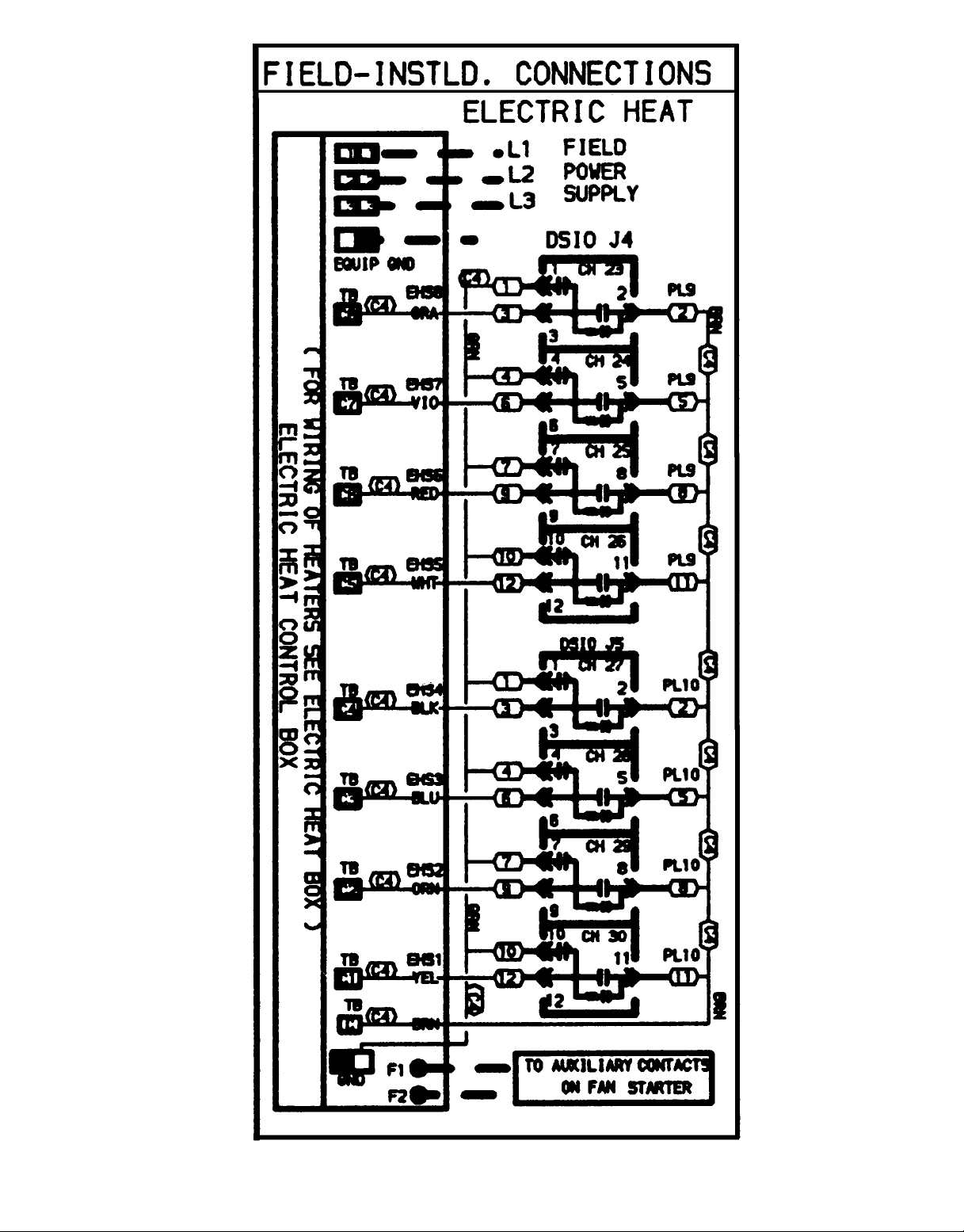

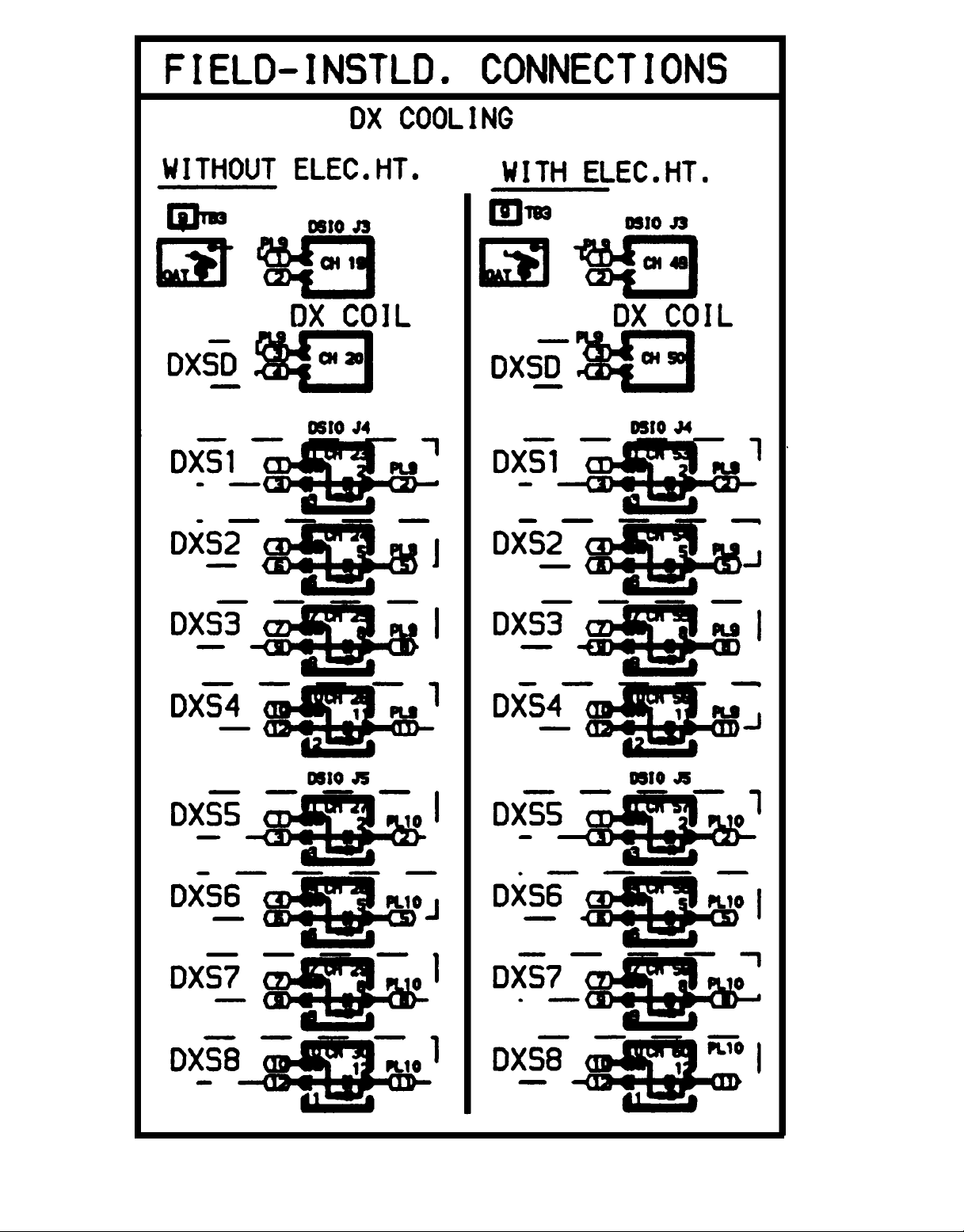

• ELECTRIC HEATER

• CARRIER COMFORT NETWORK INTERFACE

• OUTDOOR-AIR THERMOSTAT

CONTROL SYSTEM .......................64-68

Processor (PSIO Master) and Option (PSIO Slave)

Modules .................................65

Relay (DSIO) Module .......................65

Local Interface Device (HSIO) ...............67

CONTROL OPERATION ...................69-91

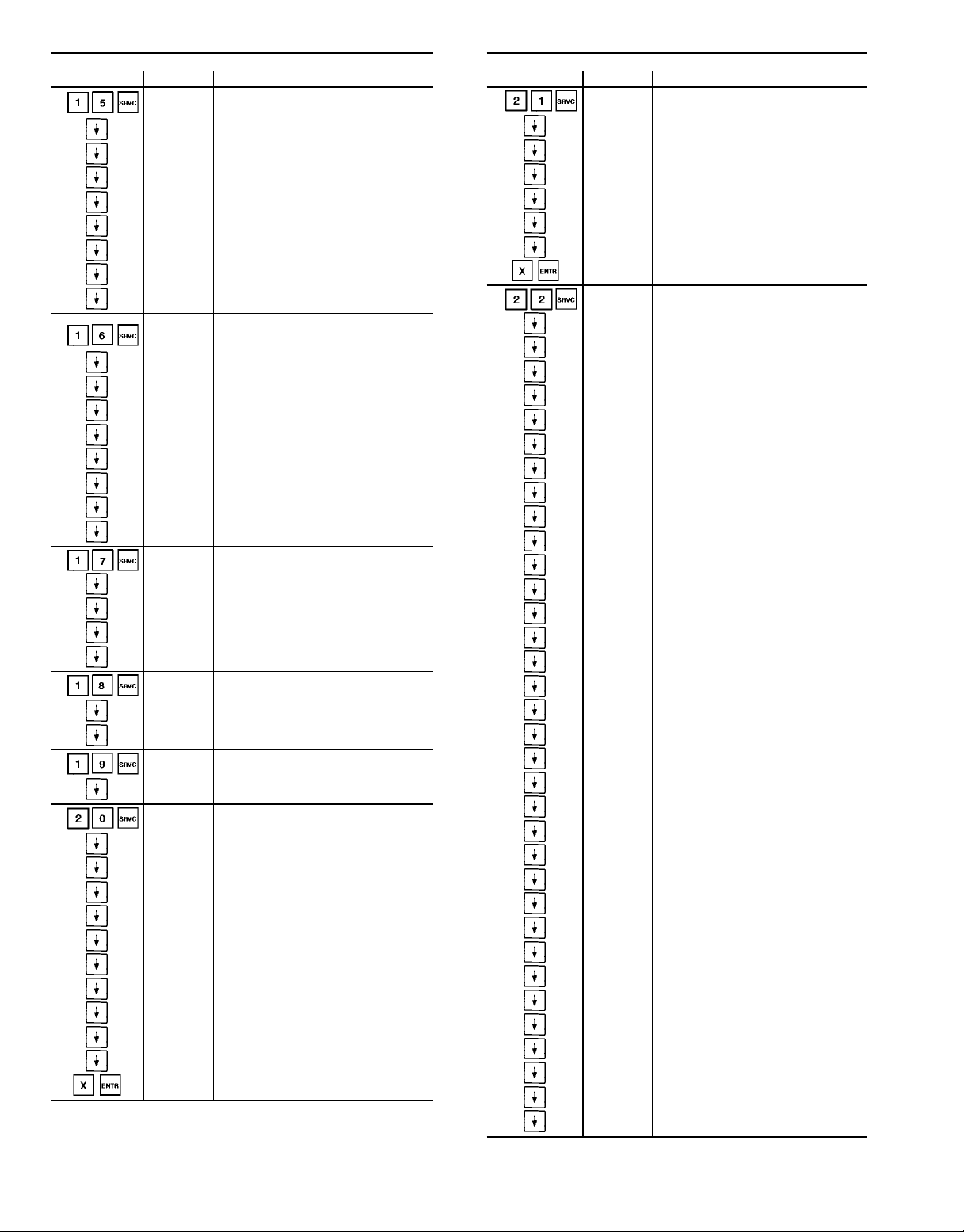

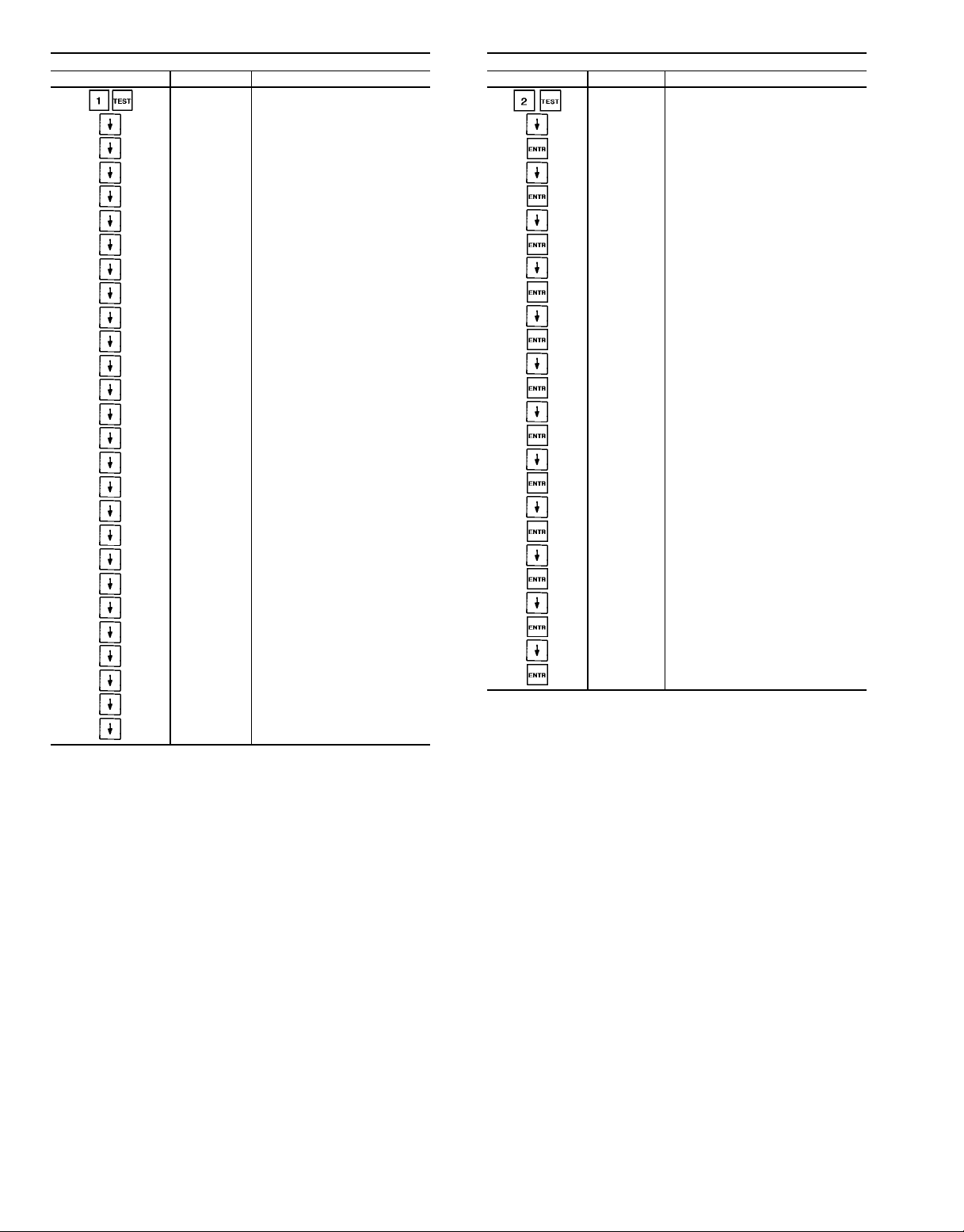

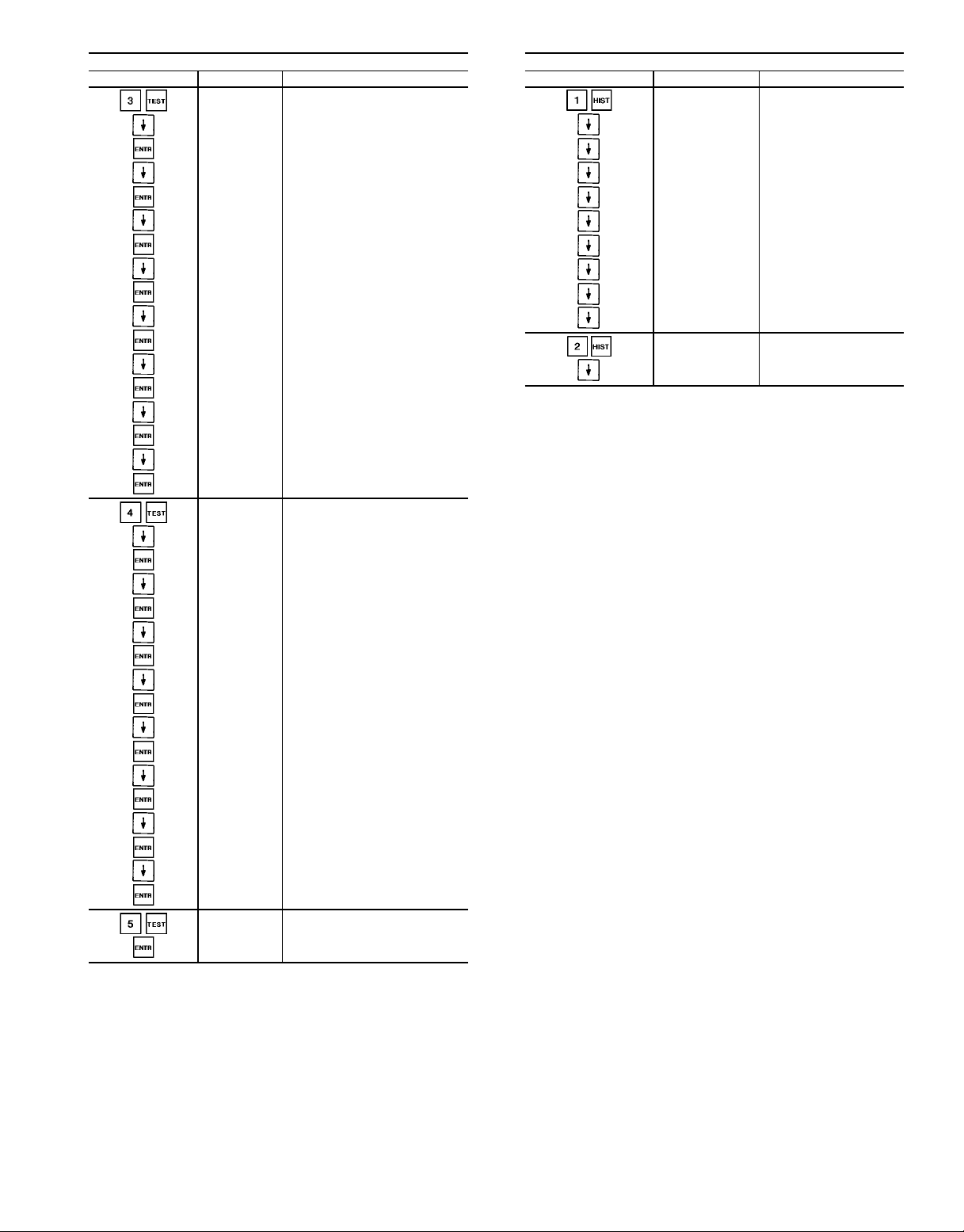

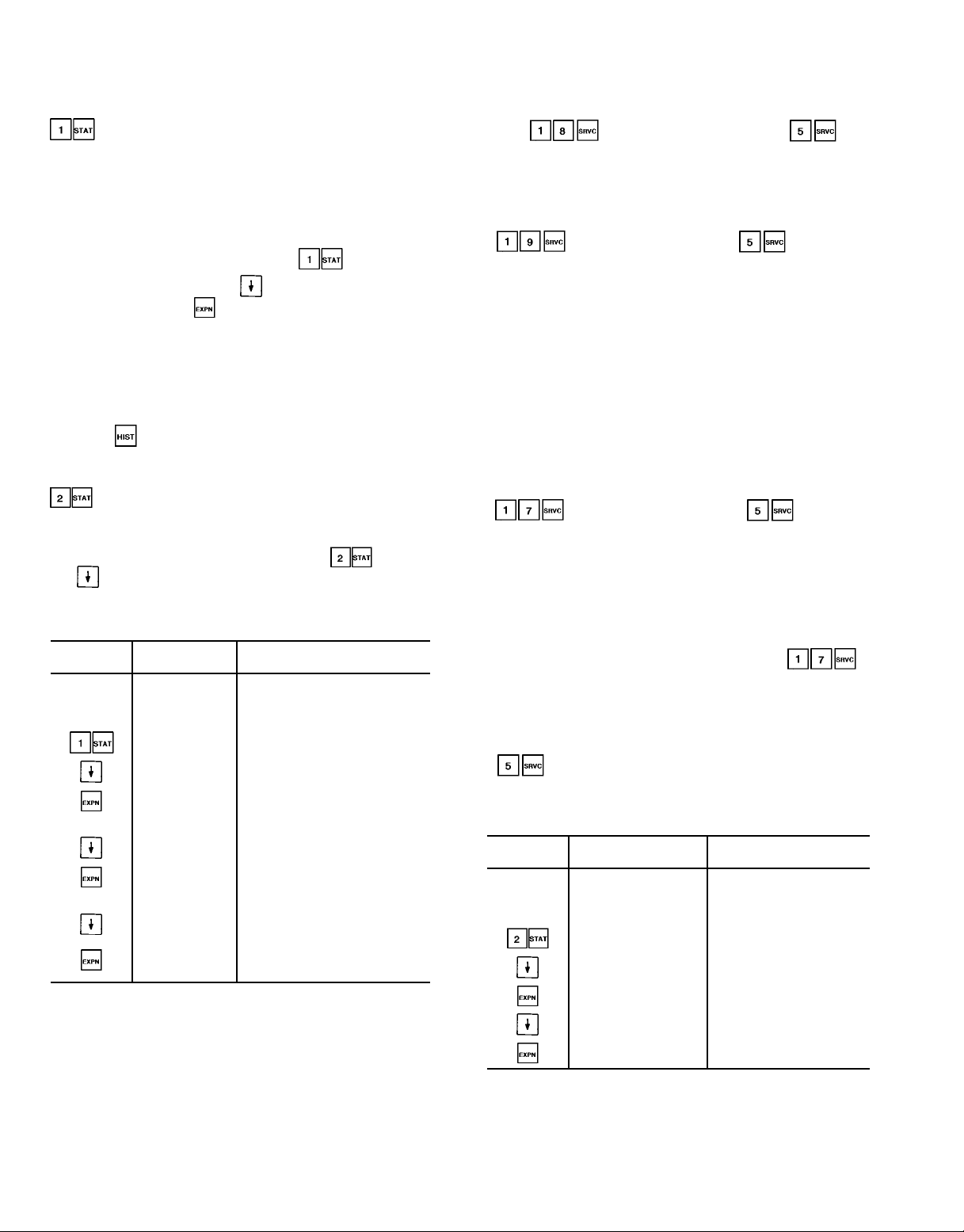

Accessing Functions and Subfunctions .....69

Display Functions ..........................69

• SUMMARY DISPLAY

• STATUS FUNCTION

• HISTORY FUNCTION

• TEST FUNCTION

Programming Functions ...................81

• SERVICE FUNCTION

• SET POINT FUNCTION

• SCHEDULE FUNCTION

CONTROL OPERATING SEQUENCE .......92-102

Constant Volume and Variable Air

Volume Units ............................92

Constant Volume Units Only ................96

Variable Air Volume Units Only .............99

START-UP ..............................103-108

Initial Check ..............................103

Quick Test ................................103

Electronic Valve Actuator Field Test ........108

CONTROL LOOP CHECKOUT ............108,109

To Check Operation of Analog Outputs .....108

VALVE TROUBLESHOOTING .............109-111

General ...................................109

1

⁄2-in. Through 11⁄4-in. Electric Hot Water/Steam

All

Valve Assemblies .......................109

All 11⁄2-in. Through 3-in. Valve Assemblies ..110

CONTROL MODULE

TROUBLESHOOTING ..................111,112

General ...................................111

Module Replacement (PSIO, DSIO) .........112

UNIT TROUBLESHOOTING ...............113-115

METRIC CONVERSION CHART .............116

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 3

Tab 1b

PC 201 Catalog No. 533-913 Printed in U.S.A. Form 39L,NX-2SI Pg 1 3-96 Replaces: 39L,NX-1SI

Page 2

IMPORTANT: This equipment generates, uses, and can

radiate radio frequency energy and if not installed and

used in accordance with these instructions may cause

radio interference. It has been tested and found to comply with the limits of a Class A computing device as

defined by FCC regulations, Subpart J of Part 15, which

are designed to provide reasonable protection against

such interference when operated in a commercial

environment.

SAFETY CONSIDERATIONS

Installation and start-up of air-conditioning equipment can

be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, start up, or service air-conditioning equipment.

When working on air-conditioning equipment, observe precautions in the literature, tags and labels attached to the unit,

and other safety precautions that may apply.

Follow all safety codes, including ANSI (American

National Standards Institute) Z223.1 (latest version). Wear

safety glasses and work gloves.

Disconnect all power to the unit before performing maintenance or service. Unit may automatically start if power

is not disconnected. Electrical shock and personal injury could result.

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other

appliance.

GENERAL

The Product Integrated Control (PIC) option is available

for 39L and 39NX indoor units with a draw-thru configuration. The PIC control box can be supplied as part of a dedicated PIC section; it is factory-installed and wired and has

the same hand (orientation) as the fan section. The control

box can also be shipped separately for remote mounting without a PIC section. For the remote control box option, all connections from the control box to the unit are made to a junction box in the unit’s fan section.

The control box includes electronic modules, fuses, relays, transformers, terminal blocks, low-limit air temperature protection (optional), static pressure transducer (VAV

[Variable Air Volume] units only) and high-pressure switch

(VAV units). An ON/OFF switch is included to shut off the

power to the control box.

PIC environmental limitations are as follows:

Shipping Temperature — −20 to 165 F

Shipping Humidity — 10 to 95%

Operating Temperature — 32 to 125 F

Operating Humidity — 30 to 90%

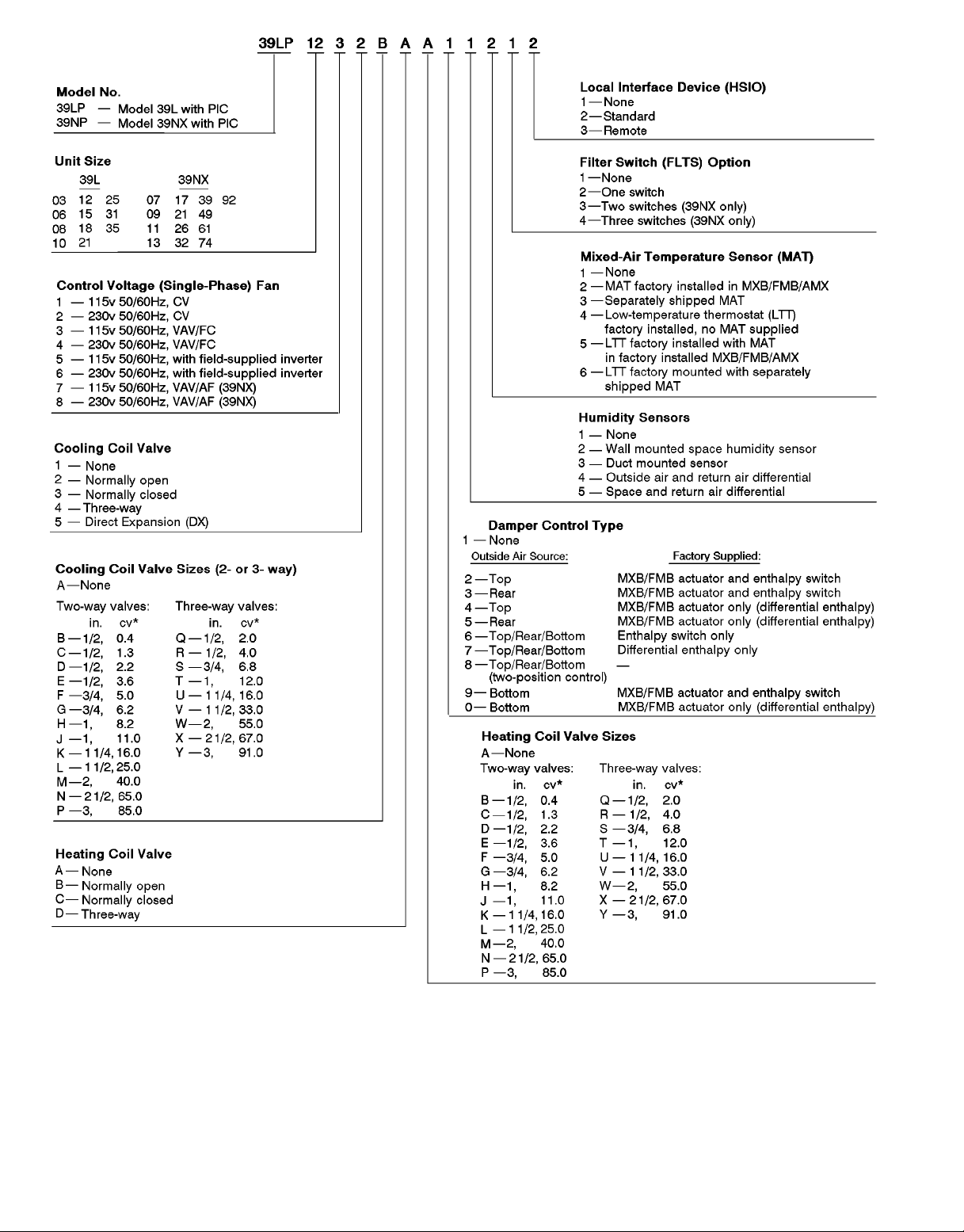

INSTALLATION

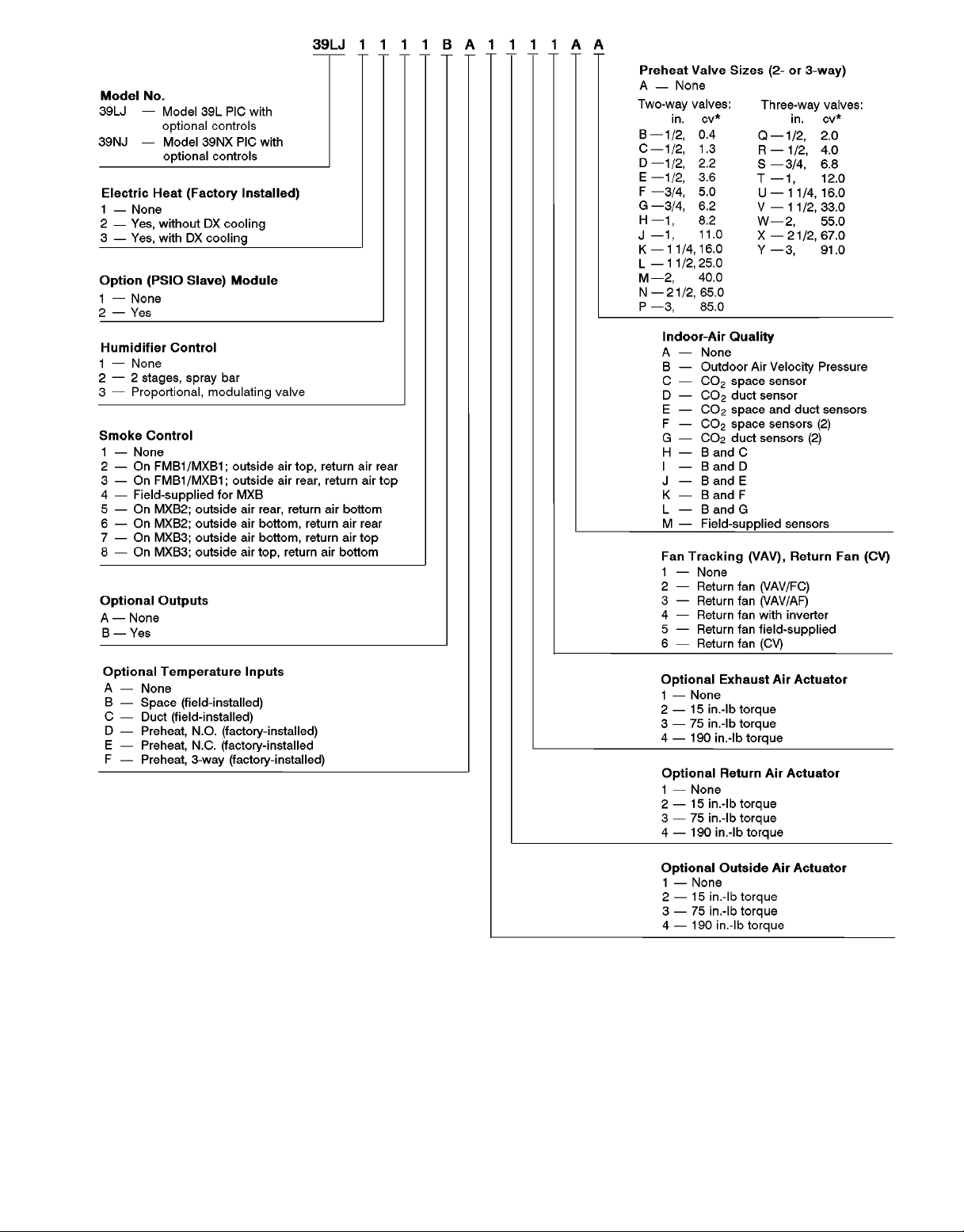

Follow all basic installation instructions for 39L or 39NX

units as described in the 39L or 39NX Installation, Start-Up,

and Service Instructions shipped with the unit. To verify the

PIC and PIC option configurations according to the model

numbers, see Fig. 1 and 2.

Leave protective coverings on the unit until it is installed

inside and protected from the elements, construction debris,

and dirt.

Use one of the keys provided in the 39L or 39NX installation packet (located in fan section) to open the control box

door.Visually inspect all components and wiring for any damage. Remove the valve assembly packages and the sensor

packages from the fan section. For units with PIC sections,

remove protective plastic caps from the bulkhead fittings

(located on the top edge of the control box) and discard.

Verify that the 10.0 amp ON/OFF switch located on the

PIC control box door is in the OFF position. Do not turn the

power supply on at this time.

NOTE: The 39NX and 39L air handlers are designed for indoor applications. Modified units are available for outdoor

applications on pier or slab mounts (not curb mounts). Prod-

uct integrated controls are not available for outdoor applications. Consult your Carrier sales representative for further

details.

ServiceArea Requirements — Article 110-16 of the

NEC (National Electrical Code) describes electrical installation.All 39L and 39NX PIC installations must comply with

the minimum clearances required for electrical installation

as listed in Table 110-16(a) of the code. Make sure to provide the necessary clearance from the PIC unit to any adjoining wall. Refer to the base unit installation instructions

for detailed dimensions for each unit section.

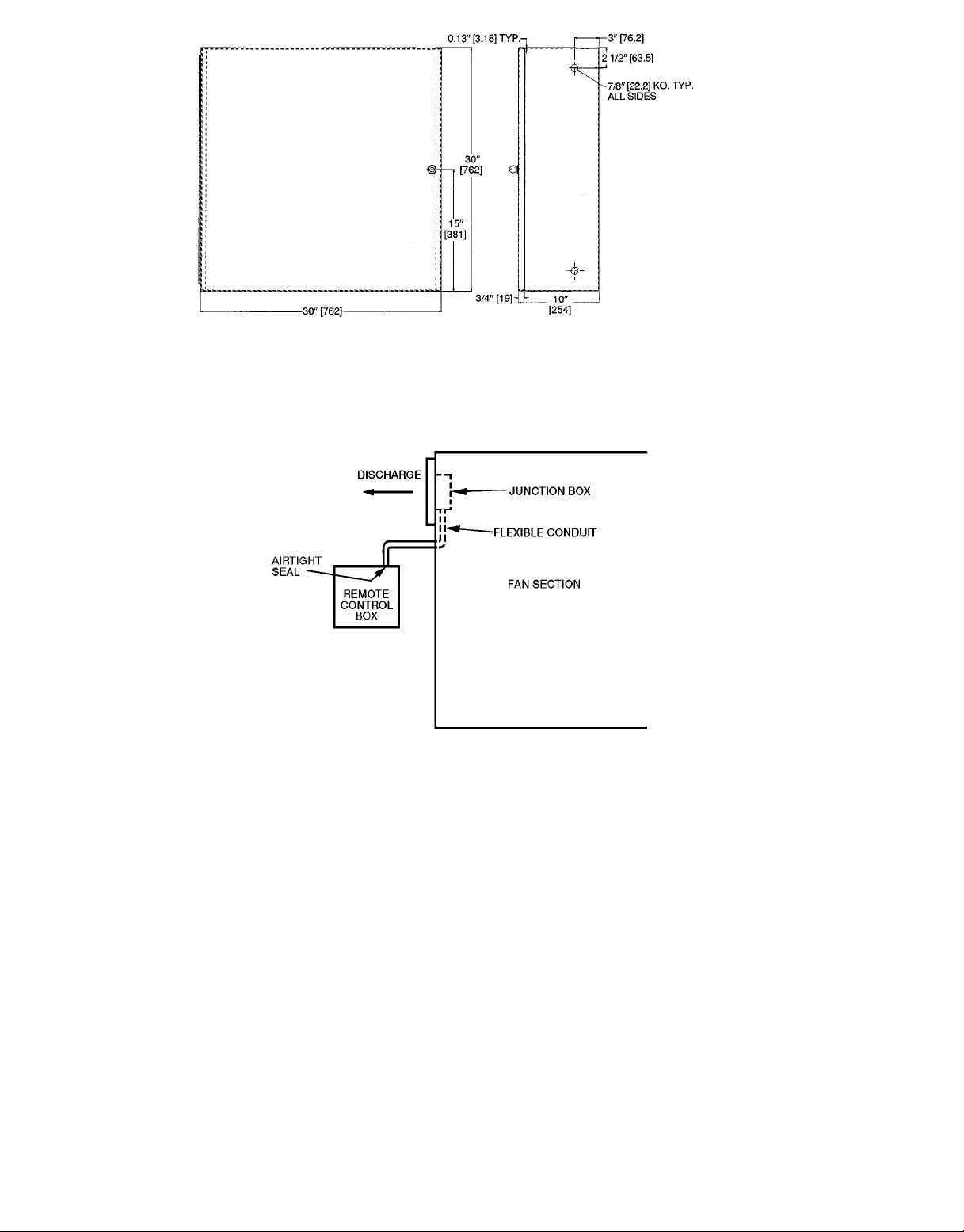

Remote Control Box Option — This option allows

the PIC control box to be mounted away from the unit; the

remote control box (Fig. 3) must be wired to the supply fan

section. Mount the remote control box assembly to the

mechanical room wall near the unit using field-supplied

Unistrutt metal framing or equivalent supports. The control

box has 4 mounting holes in the back of the enclosure for

this purpose.

2

Page 3

Mount the remote control box as follows:

1. Loosen and remove the 4 nuts securing the control panel

in the control box.

2. Remove the control panel from the box; set the panel and

nuts aside for reassembly later.

3. Mount the control box to the Unistrutt support using fieldsupplied fasteners.

4. Locate, mark, and drill pilot holes on the top of the box

for each of the following:

• Motor starter wiring

• Actuator and sensor wires to fan section junction box

• Supply power wires (ac)

• Valve wiring or tubing (water valves, field-supplied

sensors, or other devices)

5. Expand the pilot holes as required. Recommended sizes

are as follows:

• Motor starter wiring —3⁄4in. (5 wires)

• Actuator and sensor wires to fan section junction

box —

3

⁄4in. to 1 in. (number of wires and hole di-

ameter determined by application)

1

• Supply power wires (ac) —

⁄2in. or3⁄4in.

• Valve wiring or tubing — size as required

Fan section panels are provided with pilot holes that can

be drilled or punched to accomodate an electrical conduit

for the remote control box wiring. Where possible, install

the conduit in a panel that will not be removed, such as the

discharge panel. See Fig. 4.

REMOTE CONTROL BOX CONDENSATE PREVENTION — When the remote control box is installed, precautions must be taken to prevent condensation from forming

inside the junction box mounted in the unit’s supply fan section. Standard installation practice is to mount the remote

control box adjacent to the air handling unit and then to enclose the Class II wiring in flexible conduit between the control box and the junction box in the fan section.

The sheet metal housing of the control box is not airtight,

therefore warm, moist air can migrate through the flexible

conduit to the junction box in the fan section. Condensate

can form inside the junction box and possibly on the terminal lugs.

To prevent moist air from migrating through the conduit,

seal the control wires inside the conduit at the remote control box enclosure. See Fig. 4. Use a nonconductive, nonhardening sealant. Permagum (manufactured by Schnee

Morehead) or sealing compound, thumb grade (manufactured by Calgon), are acceptable materials.

MakeElectrical Connections — 39L and 39NX units

have internal control wiring for the operation of the PIC section and its control devices. The control system requires a

dedicated 120 vac or 230 vac (50 or 60 Hz) power circuit

capable of providing a minimum of 10 amps (but not greater

than 20 amps) to the control box. The actual number of controls on one power source depends on the installation and

power circuit requirements. Do not run PIC power wiring in

the same conduit as sensor wiring or control wiring of fieldinstalled devices.

IMPORTANT: To ease installation, control wiring is

located on the service side of the unit with electrical

connectors provided at all unit separation points. If a

unit is separated into pieces for installation, rejoin all

connectors in their original alpha-numeric sequence upon

reassembly. Connectors for vertical fan sections that

are shipped out of the normal operating position must

also be joined at final assembly.

For units with an integral PIC section, all unit factory control wiring is internal. Only a small number of wires must be

field-installed. All internal wiring consists of plenum wires

which enter the rear of the control box through sealed fittings. Control wiring is 18 to 20 gage, 2-conductor twisted

pair.

The electrical power disconnect and fan motor starter are

field-supplied and installed. Connections are provided in the

control box to wire a field-supplied HOA (HANDS/OFF/

AUTOMATIC) switch. If an HOA switch is used, it must be

field-installed in the supply and return fan motor starter circuit. The factory-wired high-pressure switch (variable air volume only) and low-temperature thermostat options are energized when the supply fan circuit is powered.

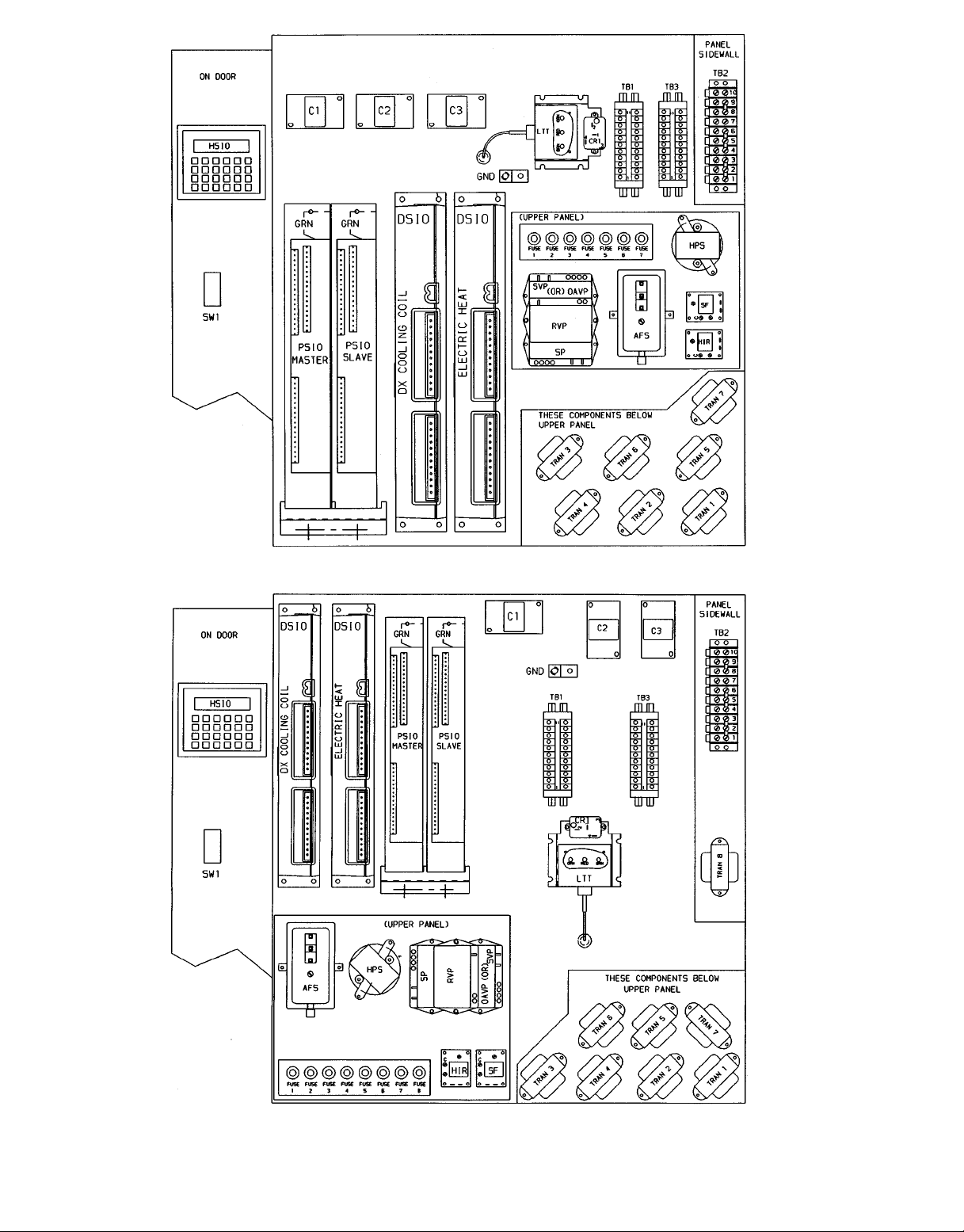

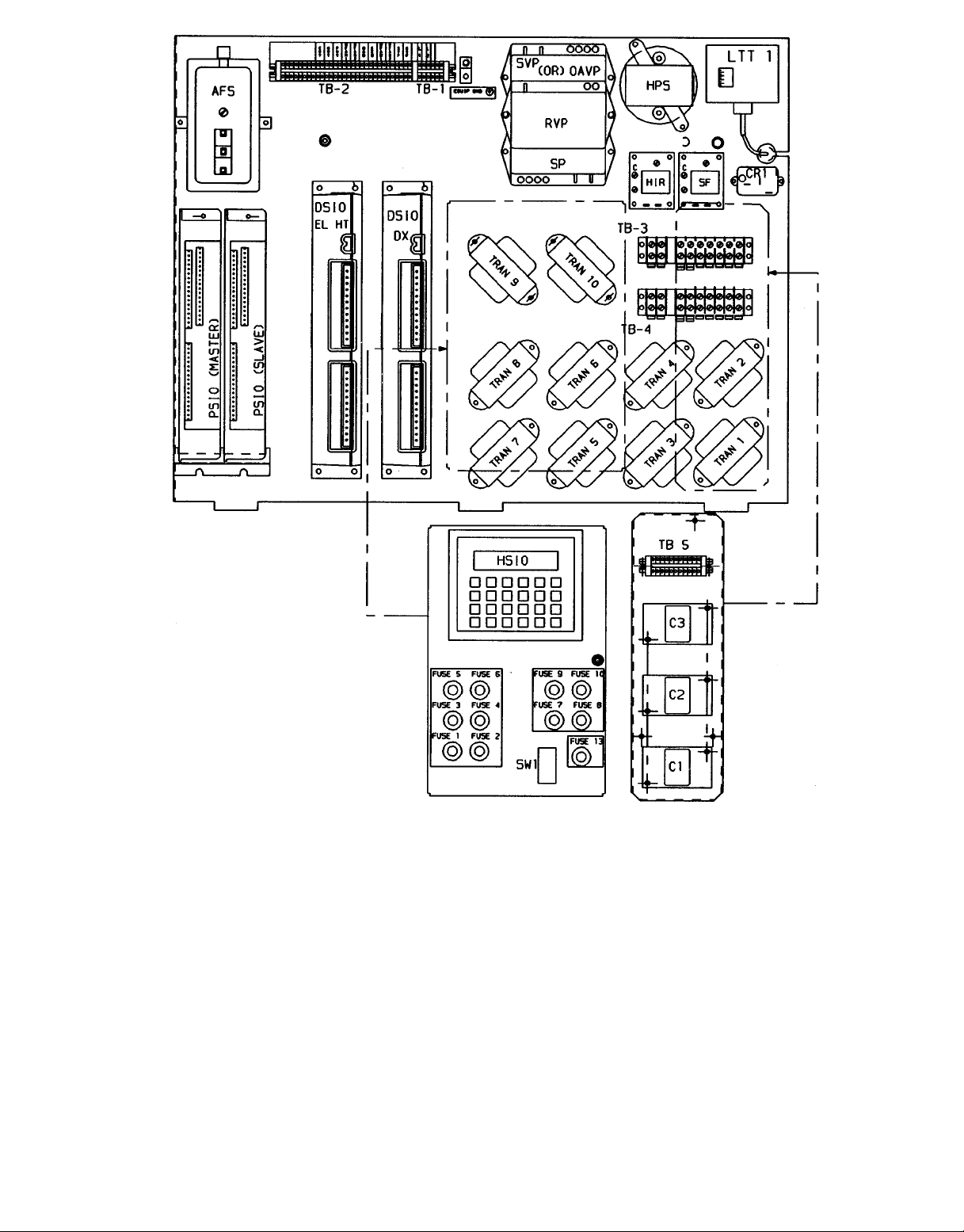

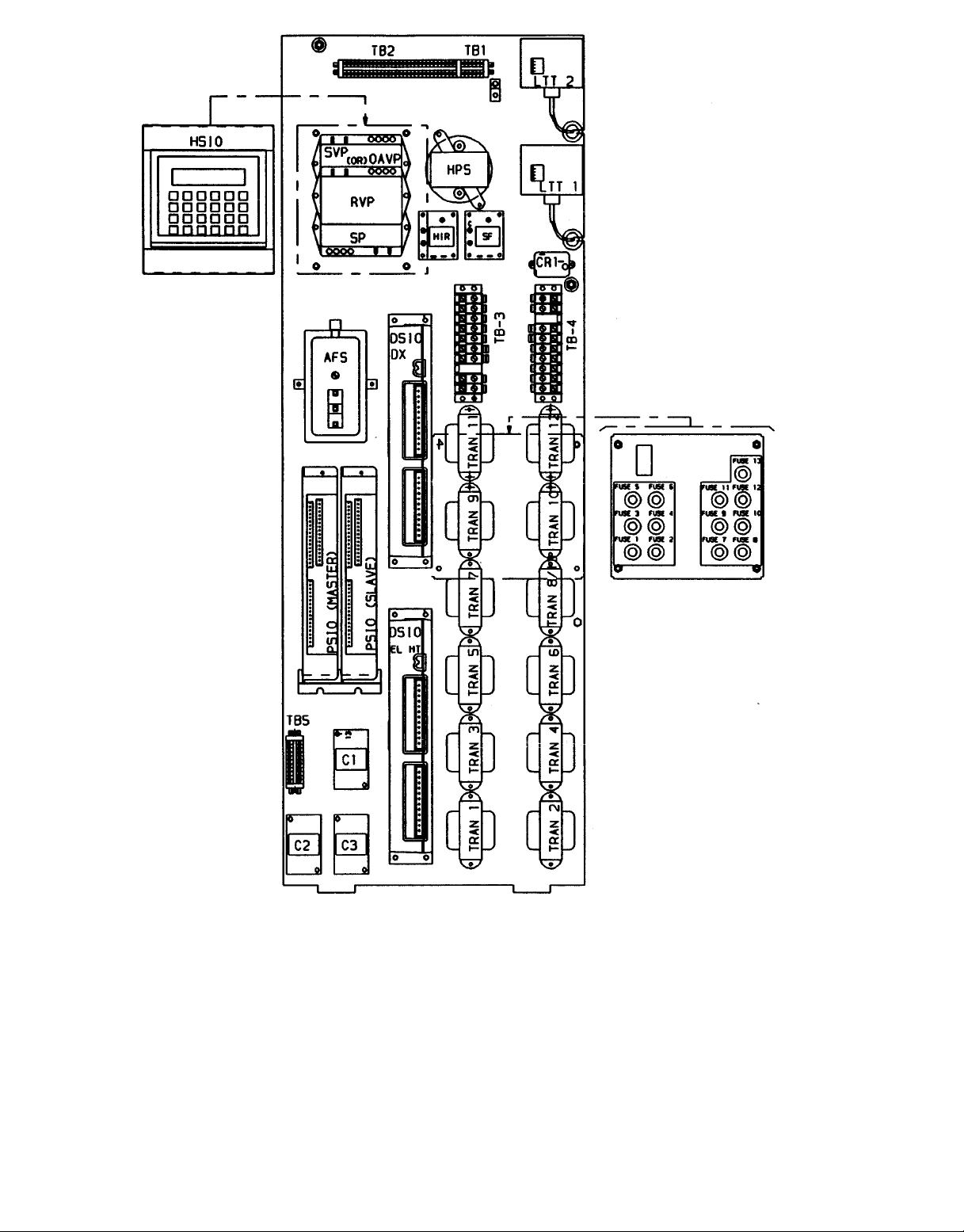

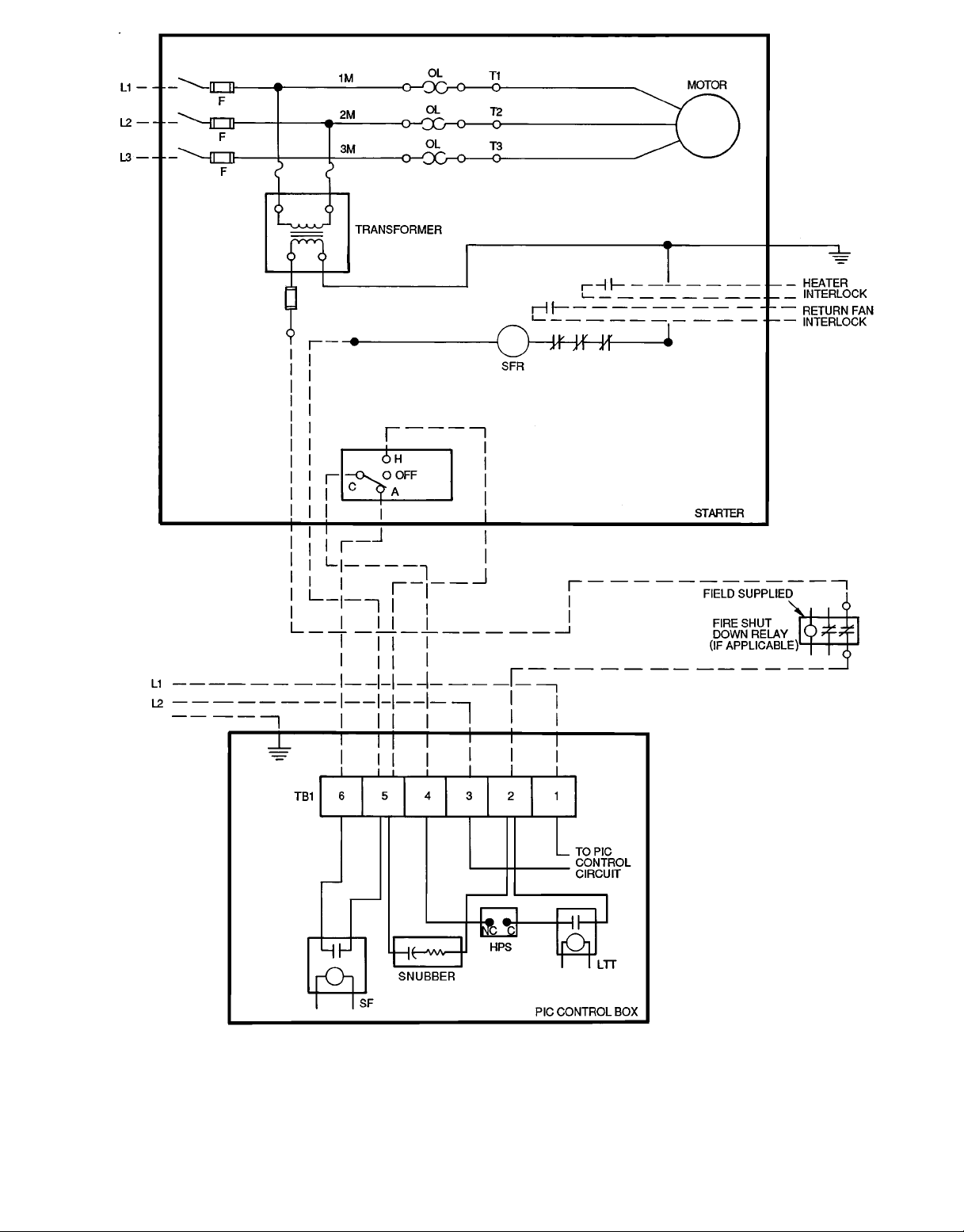

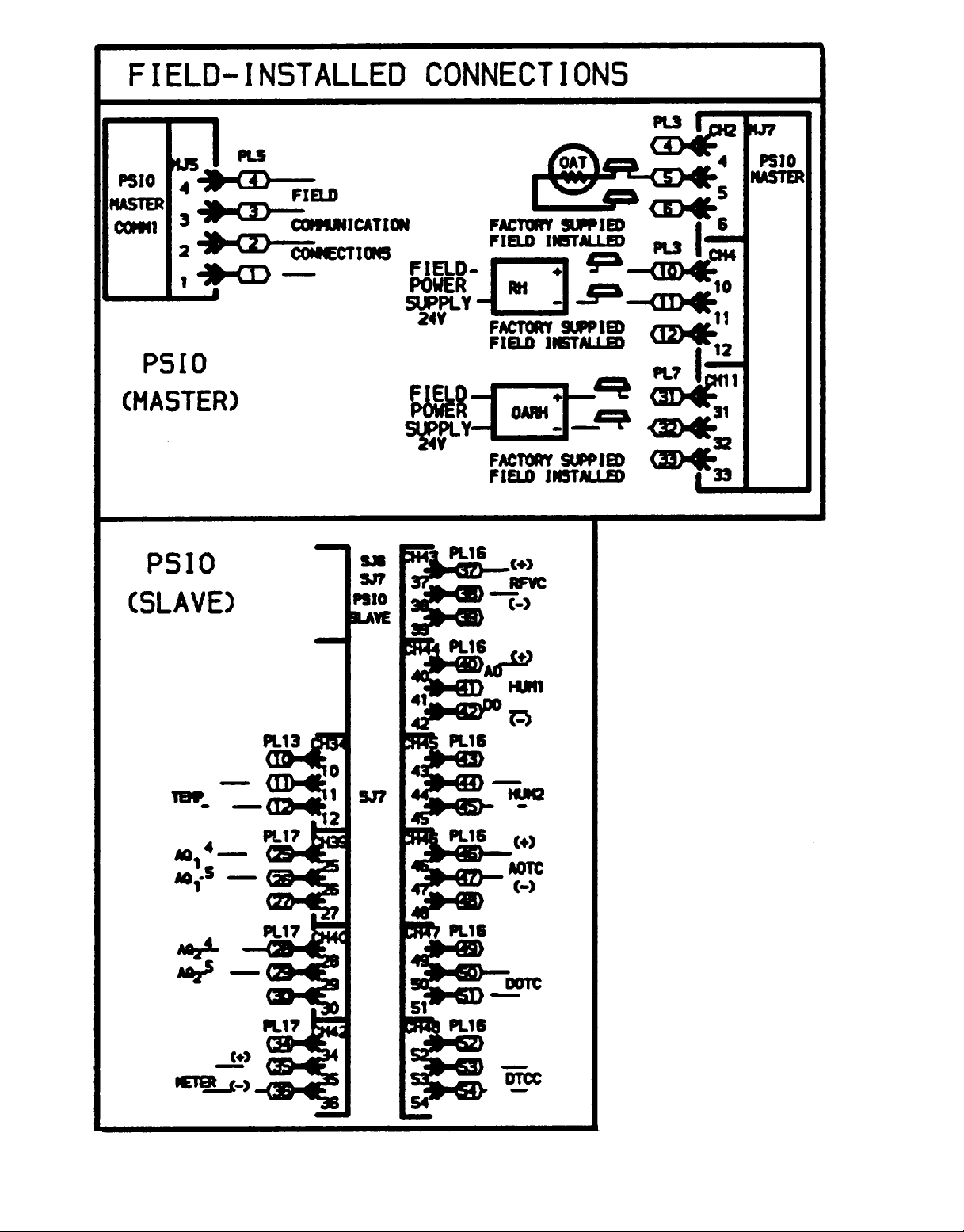

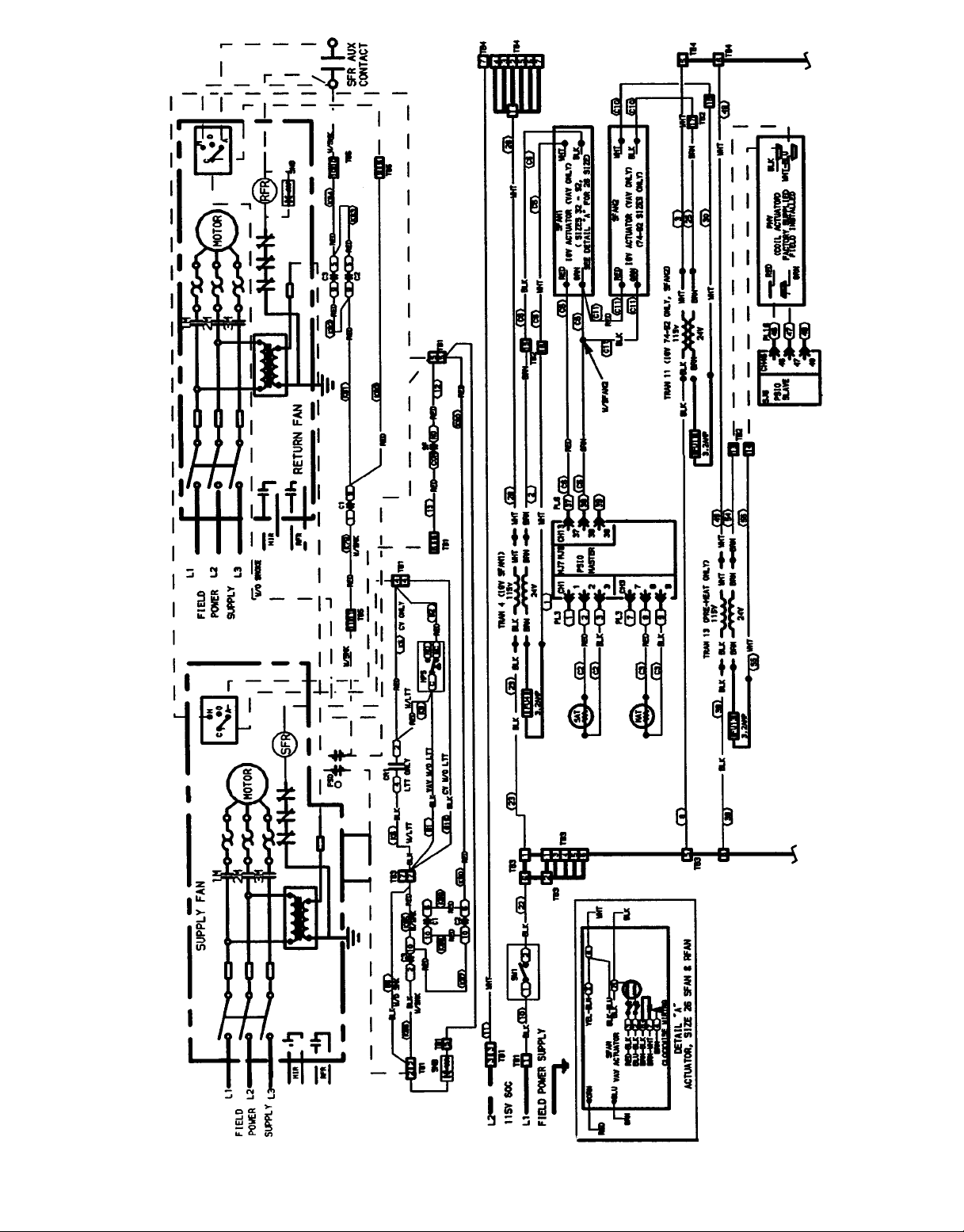

See Fig. 5-7 for control box component arrangements and

Fig. 8 for fan motor wiring. PIC input and output points are

listed in Table 1. Consult the wiring diagram located in the

control box or Fig. 9-12 for further details.

Power is present in the PIC control box in the motor

starter circuit even when the dedicated power to the PIC

control box is off.

The supply and return fan starter circuits are independent

from each other. Either circuit and its related control box

interface can have 24 vac, 120 vac, or 240 vac power.

All options that require a factory-installed transformer

are fused with 3.2 amp fuses on the secondary of each

transformer.

When the control box is shipped separately for remote mounting, all unit wiring terminates in a junction box located in

the fan section. Refer to Fig. 12 for the applicable wiring

diagram and Table 2 for junction box connections.

If the unit is provided with a factory-installed smoke control option, refer to the section titled Field-Wiring Connections, Smoke Control Option, page 54.

All PIC electrical components are UL (Underwriters’Laboratories) listed. The electronic modules are approved under

UL HVACEquipment Standard 873. PIC units are listed and

labeled by ETL (Engineering Testing Laboratory) to comply

with UL Standard 1995 for heating and cooling units, and

comply with NFPA (National Fire Protection Association)

Standard 90A.

3

Page 4

LEGEND

ABX — Air Blender

AF — Airfoil

CV — Constant Volume

IGV — Inlet Guide Vanes

FC — Forward-Curved

FMB — Filter Mixing Box

MXB — Mixing Box

PIC — Product Integrated Controls

VAV — Variable Air Volume

*The cv capacity rating is the flow (gpm) through a valve at 1 psi pres-

sure drop.

Fig. 1 — Basic PIC Order Number

4

Page 5

LEGEND

AF — Airfoil

CV — Constant Volume

DX — Direct Expansion

FC — Forward-Curved

FMB — Filter Mixing Box

MXB — Mixing Box

N.C. — Normally Closed

N.O. — Normally Open

PIC — Product Integrated Controls

VAV — Variable Air Volume

*The cv capacity rating is the flow (gpm) through a

valve at 1 psi pressure drop.

Fig. 2 — PIC Option Order Number

5

Page 6

NOTE: Dimensions in [ ] are in millimeters.

Fig. 3 — Control Box for Remote Mounting

Fig. 4 — Sealing Control Wiring in Flexible Conduit

6

Page 7

LEGEND (Fig. 5-12, Table 2)

AFS — Airflow Switch

AO — Analog Output

AOTC — Analog Output Temperature Control

AQ

AQ

C—Contactor

CCW — Counterclockwise

CH — Channel

CR — Control Relay

CUST — Condensing Unit Status

CV — Constant Volume

CW — Clockwise

CWV — Chilled Water Valve

DHH — Duct High Humidity

DO — Discrete Output

DOTC — Discrete Output Temperature Control

DSIO — Control Module, Electric Heat and/or DX

DTCC — Discrete Time Clock Control

DX — Direct Expansion

DXS — DX Cooling Stage

DXSD — Direct Expansion Cooling Shutdown

EHS — Electric Heaters

ELEC — Electric

ENT — Enthalpy Switch

EQUIP — Equipment

EVAC — Smoke Evacuation Input

EXD — ExhaustAir Damper Actuator

FLTS — Filter Status Switch

FSD — Fire Shutdown Device

FU — Fuse

GND — Ground

HIR — Heat Interlock Relay

HOA — Hand-Off-Auto. Switch

HPS — High-Pressure Switch

HSIO — Keyboard and Display Module

HT — Heat

HUM — Humidifier

HWV — Hot Water Valve

IGV — Inlet Guide Vane Actuator

LTT — Low Temperature Thermostat

MAD — Mixed-Air Damper Actuator

MAT — Mixed-Air Temperature

MPSIO — Master Processor Module

OAD — Outdoor-Air Damper Actuator

OARH — Outdoor-Air Relative Humidity

OAT — Outdoor-Air Temperature

OAVP — Outdoor-Air Velocity Pressure

— Air Quality Sensor, No. 1

1

— Air Quality Sensor, No. 2

2

(Processor Module)

OT — Outside-Air Thermostat

PH — Preheat

PL — Plug Assembly

PRESS — Smoke Pressurization Input

PSIO — Processor Module

PURG — Smoke Purge Input

RAD — Return-Air Damper Actuator

RAT — Return-Air Temperature

RFAN — Return Fan

RFR — Return Fan Relay

RFVC — Return Fan Volume Control

RH — Relative Humidity

RVP — Return Velocity Pressure

SAT — Supply-Air Temperature

SF — Fan Status Relay

SFAN — Supply Fan

SFR — Supply Fan Relay

SMK — Smoke

SNB — Snubber

SP — Static Pressure Transducer

SPSIO — Slave Processor Module

SPT — Space Temperature

SVP — Supply Velocity Pressure

SW — Switch

TB — Terminal Block Terminal

TEMP — Temperature

TRAN — Transformer

VAV — Variable Air Volume

W/ — With

WO/ — Without

(Option Module)

Marked Wire or Cable

Terminal (Marked)

Terminal (Unmarked)

Terminal Block

Splice (Factory)

Splice (Field)

Wiring Factory

Wiring Field Control

Wiring Field Power

Option or Accessory

Common Potential

NOTES:

1. Use copper conductors only.

2. Wire is in accordance with National Electrical Code (NEC).Forlocalcodes,

replace original wires with 90 C wire or its equivalent.

3. Replace wires fromIGV, FLTS,MAT,SAT,OAD,RAD,andELEC HTwith

125 C plenum cable conductor as required.

4. Input channel numbers and points for configuration of the optional

analog output temperature control (AOTC) follow:

CHANNEL SENSOR DESCRIPTION

1 SAT Supply-Air Temperature

2 OAT Outdoor-Air Temperature

3 MAT Mixed-Air Temperature

6 SPT Space-Air Temperature

7 RAT Return-Air Temperature

34 TEMP Preheat or Optional Carrier Sensor

5. Reference for wire markers, where ‘X’ represents a numeral:

X — Item number on wiring harness

BX — Box wire

CX — Cable

KX — Accessory kit wire

7

Page 8

ARRANGEMENT FOR SIZES 03 AND 06

ARRANGEMENT FOR SIZES 08 THROUGH 35

Fig. 5 — PIC Section Control Box Component Arrangements, 39L

8

Page 9

Fig. 6 — PIC Section Control Box Component Arrangement, 39NX Sizes 07-21

9

Page 10

Fig. 7 — PIC Section Control Box Component Arrangement, 39NX Sizes 26-92

10

Page 11

Fig. 8 — Fan Motor Starter Circuit and PIC Control Wiring Interface — PIC Power for

Control Circuit From Dedicated Source

11

Page 12

MODULE,

DEFAULT ADDRESS

PSIO (Processor)

ADDRESS 1

PSIO (Option)

ADDRESS 31

DSIO (Electric Heat)

ADDRESS 19

DSIO (DX without

Electric Heat)

ADDRESS 19

DSIO (DX with

Electric Heat)

ADDRESS 49

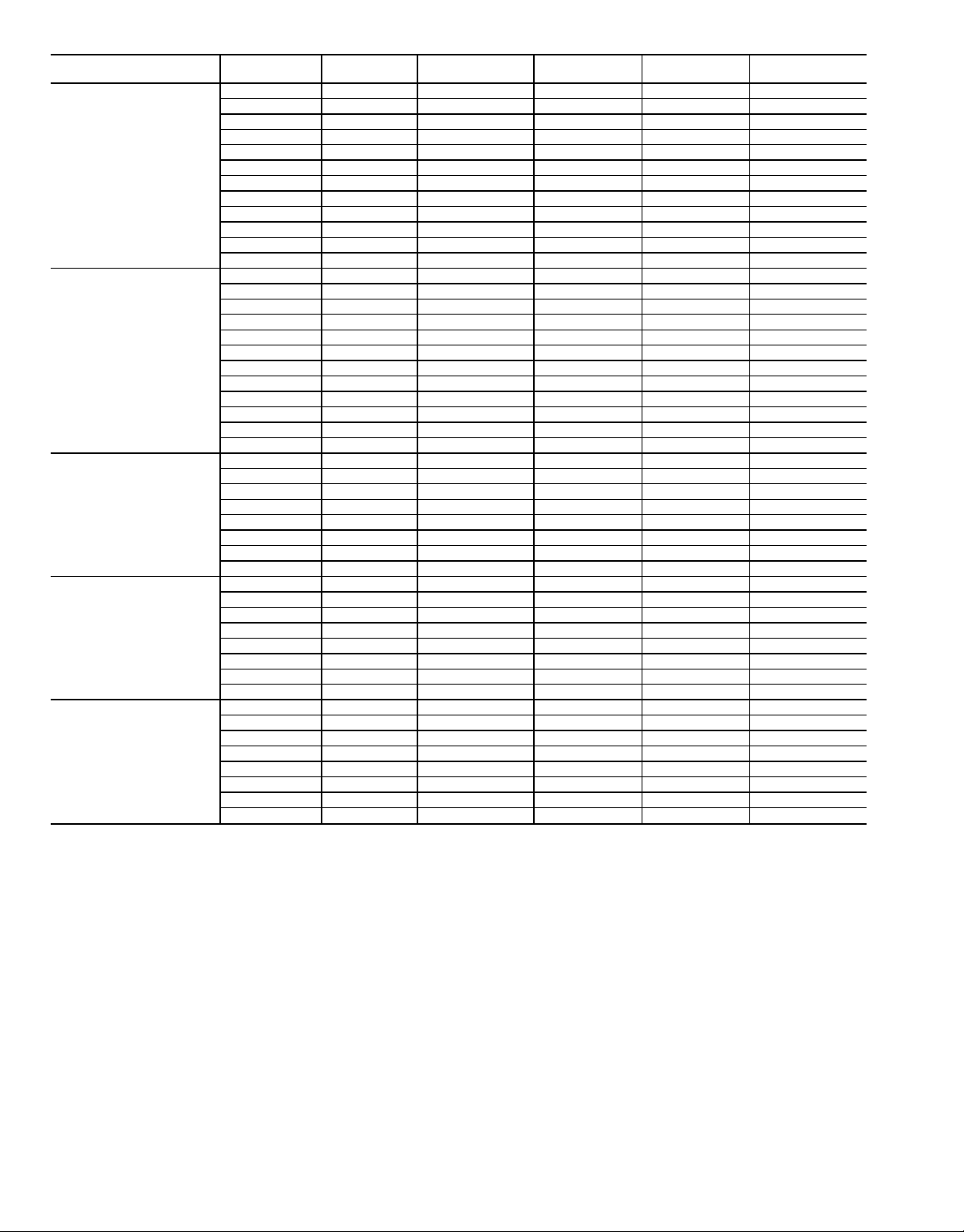

Table 1 — Input and Output Points

INPUT

SAT AI 1 IGV* AO 13

OAT AI 2 MIXD AO, DO† 14

MAT AI 3 HWC AO 15

RH AI 4 CWC AO 16

LTT DI 5 SF DO 17

SPT AI 6 HIR* DO 18

RAT AI 7 — — —

SP* AI 8 — — —

AFS DI 9 — — —

FLTS DI 10 — — —

OARH AI 11 — — —

ENT DI 12 — — —

SVP* AI 31 RFVC* AO 43

RVP* AI 32 HUM1 AO, DO 44

DHH DI 33 HUM2 DO 45

TEMP AI 34 AOTC AO 46

PRES DI 35 DOTC DO 47

EVAC DI 36 DTCC DO 48

PURG DI 37 — — —

FSD DI 38 — — —

AQ1 AI 39 — — —

AQ2 AI 40 — — —

OAVP* AI 41 — — —

METER DI 42 — — —

— — — EHS1 DO 23

— — — EHS2 DO 24

— — — EHS3 DO 25

— — — EHS4 DO 26

— — — EHS5 DO 27

— — — EHS6 DO 28

— — — EHS7 DO 29

— — — EHS8 DO 30

CUST DI 19 DXS1 DO 23

DXSD DI 20 DXS2 DO 24

— — — DXS3 DO 25

— — — DXS4 DO 26

— — — DXS5 DO 27

— — — DXS6 DO 28

— — — DXS7 DO 29

— — — DXS8 DO 30

CUST DI 49 DXS1 DO 53

DXSD DI 50 DXS2 DO 54

— — — DXS3 DO 55

— — — DXS4 DO 56

— — — DXS5 DO 57

— — — DXS6 DO 58

— — — DXS7 DO 59

— — — DXS8 DO 60

INPUT

TYPE

CHANNEL

NUMBER

OUTPUT

OUTPUT

TYPE

CHANNEL

NUMBER

AFS — Airflow Switch (Supply Fan

AI — Analog Input

AO — Analog Output

AOTC — Analog Output Temperature

AQ1, 2 — Air Quality Sensors 1, 2

CUST — Condensing Unit Status

CWC — Chilled Water Coil

DI — Discrete Input

DHH — Duct High Humidity

DO — Discrete Output

DOTC — Discrete Output Temperature

DTCC — Discrete Output Timeclock

*Available on VAV only.

†Discrete output with two-position damper control.

Status Switch)

Control

(Outdoor Air Thermostat)

Control

Control

LEGEND

DXS1-8 — Direct Expansion Cooling

DXSD — Direct Expansion Cooling

EHS1-8 — Electric Heater Stages 1-8

ENT — Enthalpy Switch

EVAC — Evacuation

FLTS — Filter Status Switch

FSD — Fire Shutdown

HIR — Heat Interlock Relay

HWC — Hot Water Coil

HUM1, 2 — Humidity Stages 1, 2

IGV — Inlet Guide Vanes

LTT — Low Temperature Thermostat

MAT — Mixed-Air Temperature

METER — Meter (Pulsed Dry-Contact

Stages 1-8

Shutdown

(also labelled FRZ)

Input)

12

MIXD — Mixed-Air Dampers

OARH — Outdoor-Air Relative Humidity

OAT — Outdoor-Air Temperature

OAVP — Outdoor-Air Velocity Pressure

PRES — Pressurization

PURG — Purge

RAT — Return-Air Temperature

RFVC — Return Fan Volume Control

RH — Relative Humidity

RVP — Return Velocity Pressure

SAT — Supply-Air Temperature

SF — Supply Fan Relay

SP — Static Pressure

SPT — Space Temperature

SVP — Supply Velocity Pressure

TEMP — Optional Temperature Input

Page 13

13

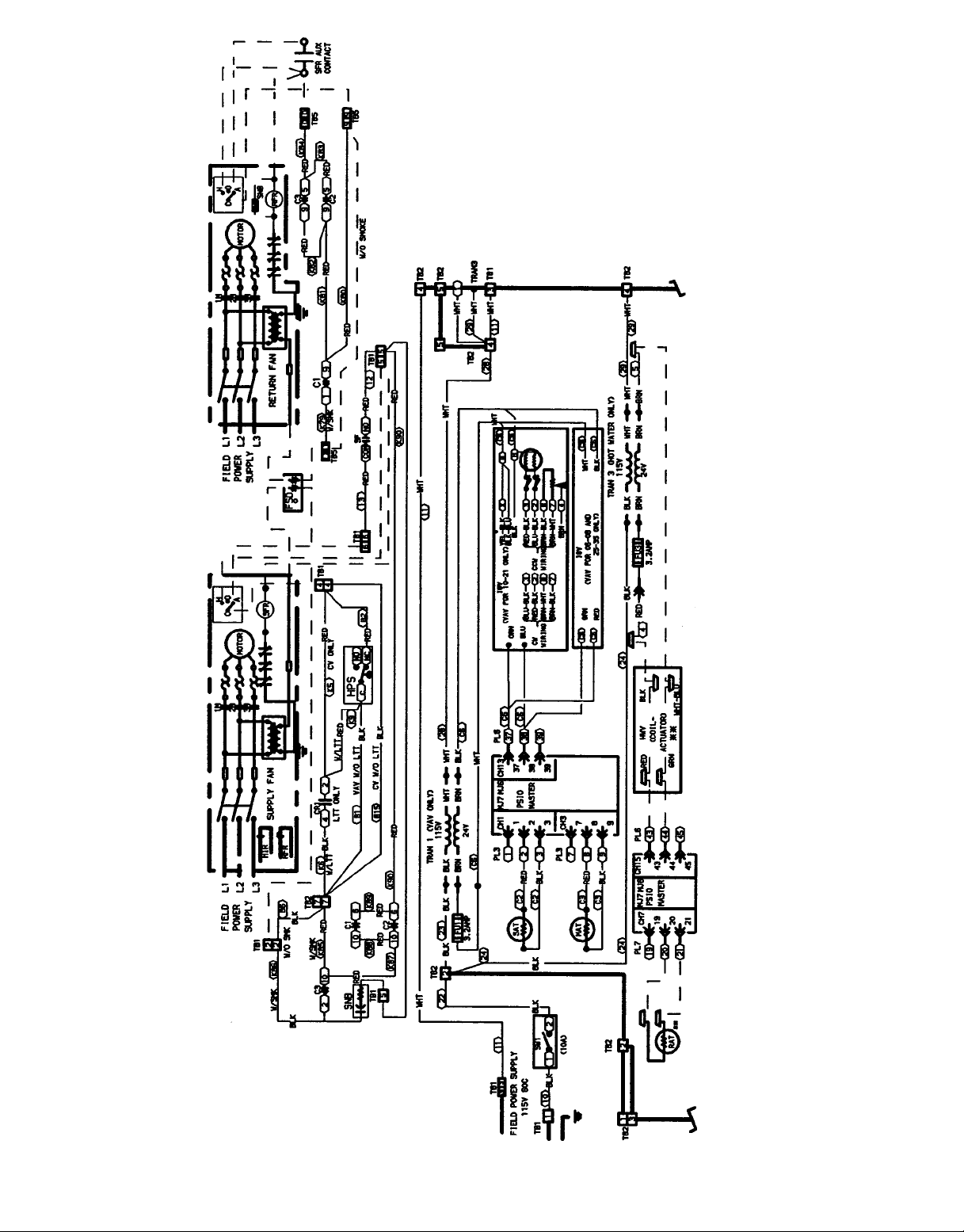

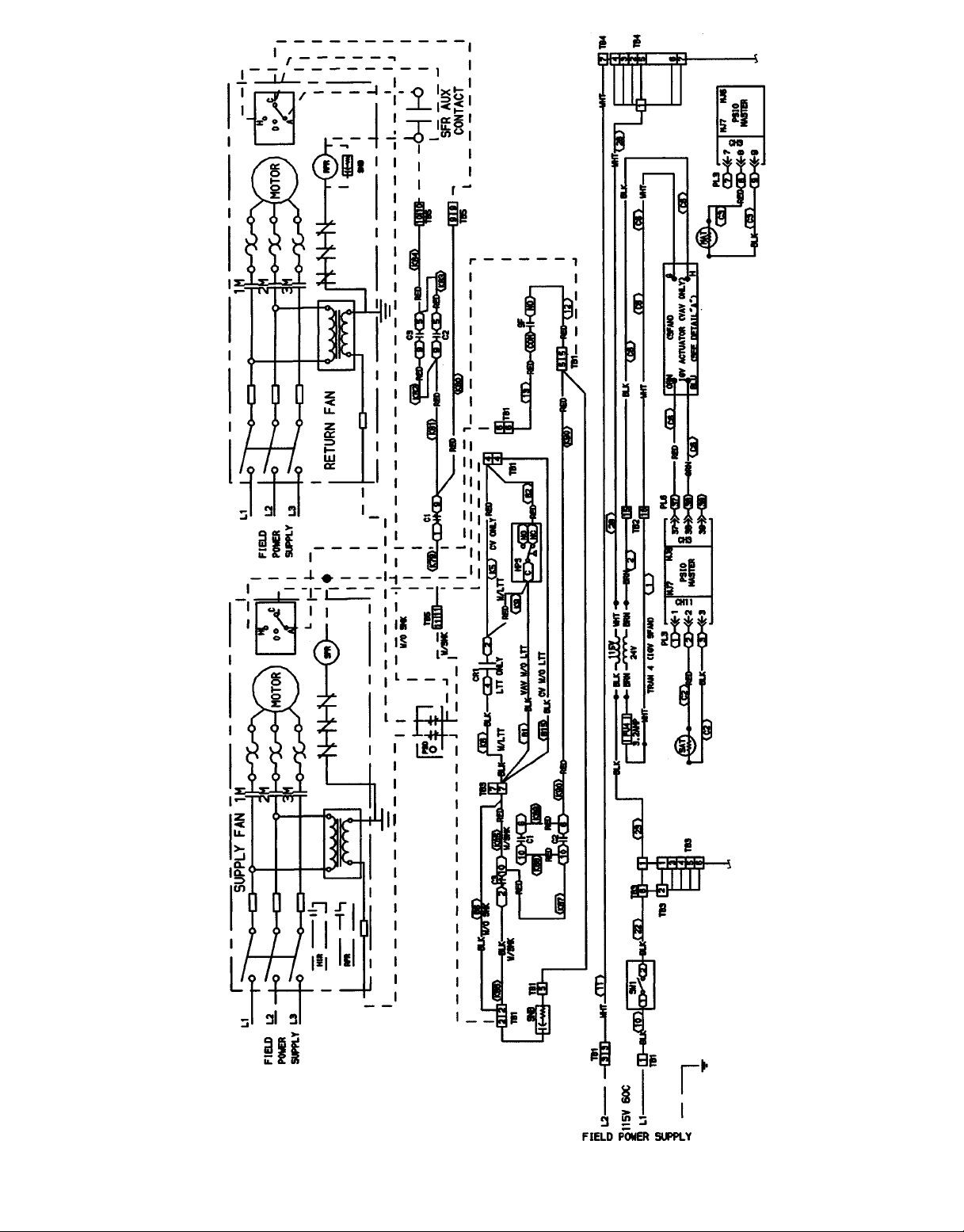

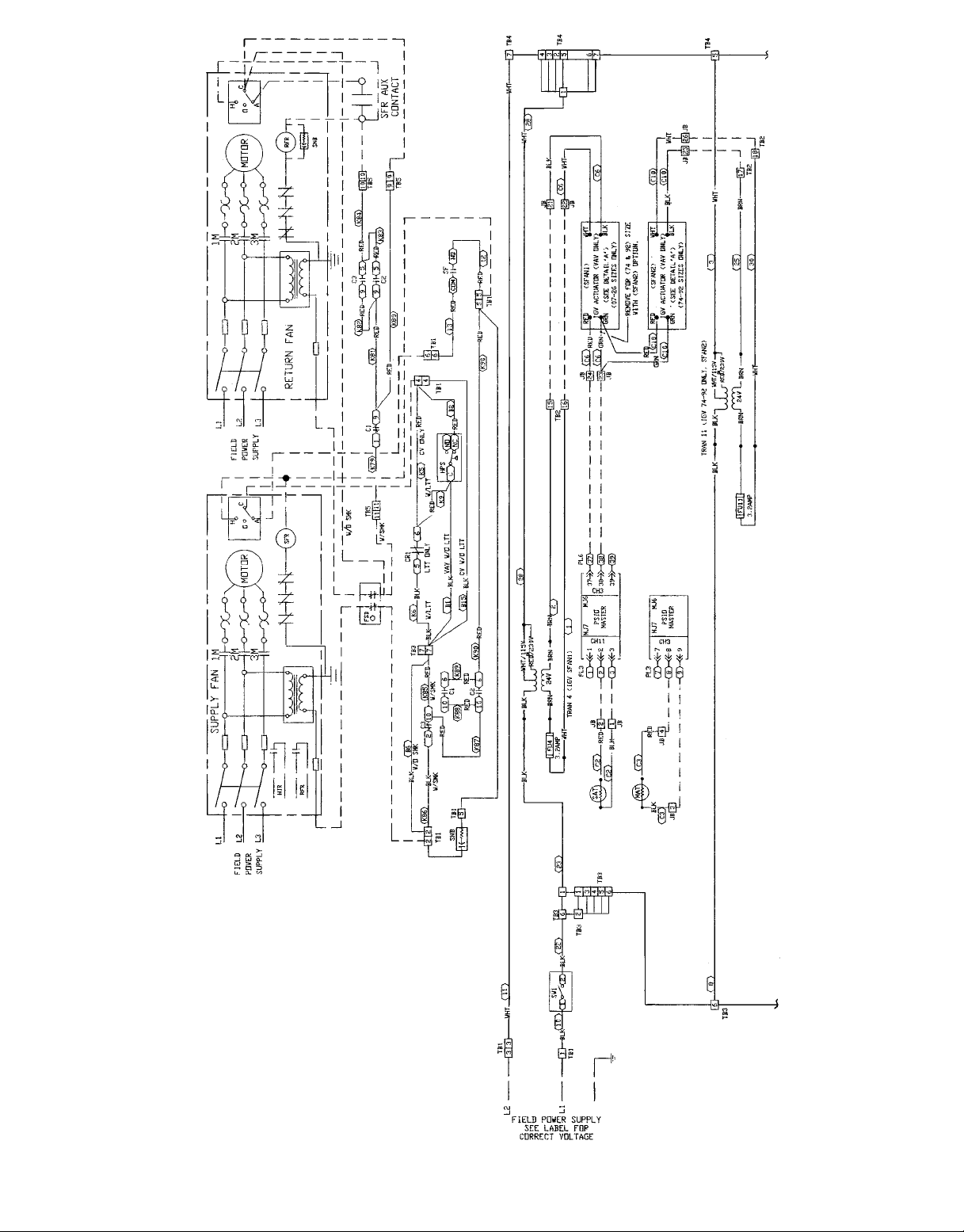

Fig. 9 — Unit Wiring Schematic, 39L Sizes 03-35 (115 v, Typical)

Page 14

14

Fig. 9 — Unit Wiring Schematic, 39L Sizes 03-35 (115 v, Typical) (cont)

Page 15

15

Fig. 9 — Unit Wiring Schematic, 39L Sizes 03-35 (115 v, Typical) (cont)

Page 16

Fig. 9 — Unit Wiring Schematic, 39L Sizes 03-35 (115 v, Typical) (cont)

16

Page 17

Fig. 9 — Unit Wiring Schematic, 39L Sizes 03-35 (115 v, Typical) (cont)

17

Page 18

Fig. 9 — Unit Wiring Schematic, 39L Sizes 03-35 (115 v, Typical) (cont)

18

Page 19

19

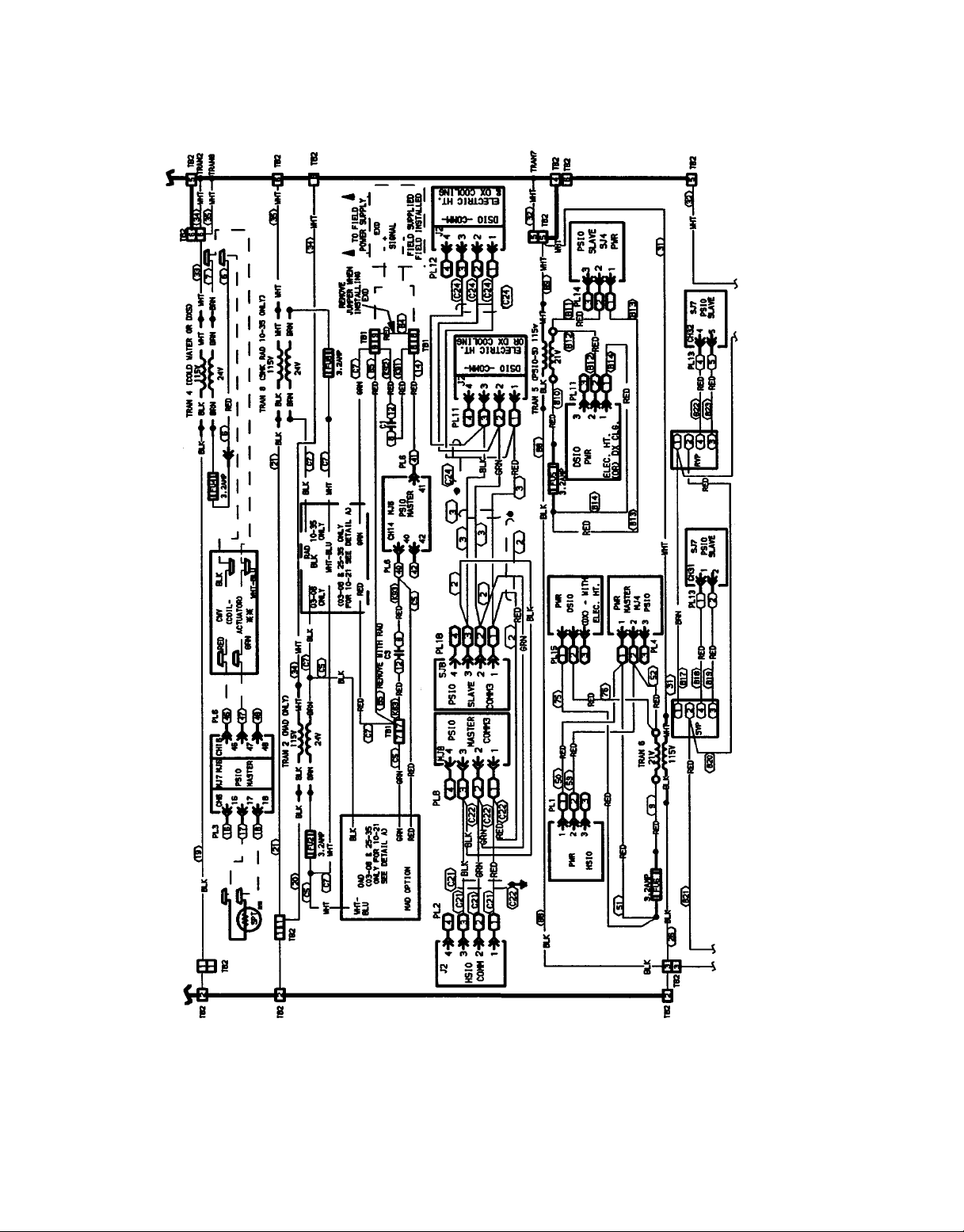

Fig. 10 — Unit Wiring Schematic, 39NX Sizes 07-21 (115 v, Typical)

Page 20

20

Fig. 10 — Unit Wiring Schematic, 39NX Sizes 07-21 (115 v, Typical) (cont)

Page 21

21

Fig. 10 — Unit Wiring Schematic, 39NX Sizes 07-21 (115 v, Typical) (cont)

Page 22

Fig. 10 — Unit Wiring Schematic, 39NX Sizes 07-21 (115 v, Typical) (cont)

22

Page 23

Fig. 10 — Unit Wiring Schematic, 39NX Sizes 07-21 (115 v, Typical) (cont)

23

Page 24

Fig. 10 — Unit Wiring Schematic, 39NX Sizes 07-21 (115 v, Typical) (cont)

24

Page 25

25

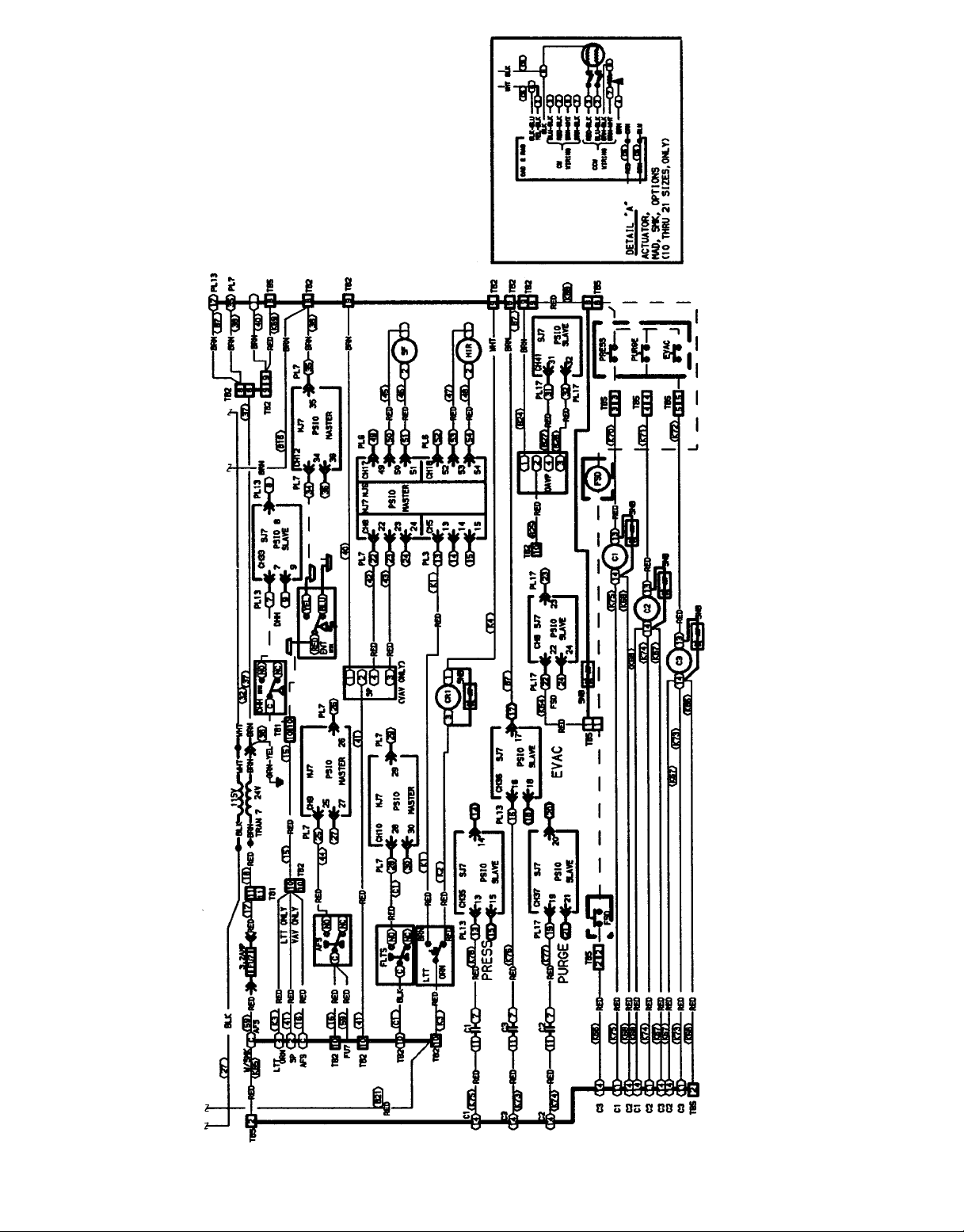

Fig. 11 — Unit Wiring Schematic, 39NX Sizes 26-92 (115 v, Typical)

Page 26

26

Fig. 11 — Unit Wiring Schematic, 39NX Sizes 26-92 (115 v, Typical) (cont)

Page 27

27

Fig. 11 — Unit Wiring Schematic, 39NX Sizes 26-92 (115 v, Typical) (cont)

Page 28

Fig. 11 — Unit Wiring Schematic, 39NX Sizes 26-92 (115 v, Typical) (cont)

28

Page 29

Fig. 11 — Unit Wiring Schematic, 39NX Sizes 26-92 (115 v, Typical) (cont)

29

Page 30

Fig. 11 — Unit Wiring Schematic, 39NX Sizes 26-92 (115 v, Typical) (cont)

30

Page 31

31

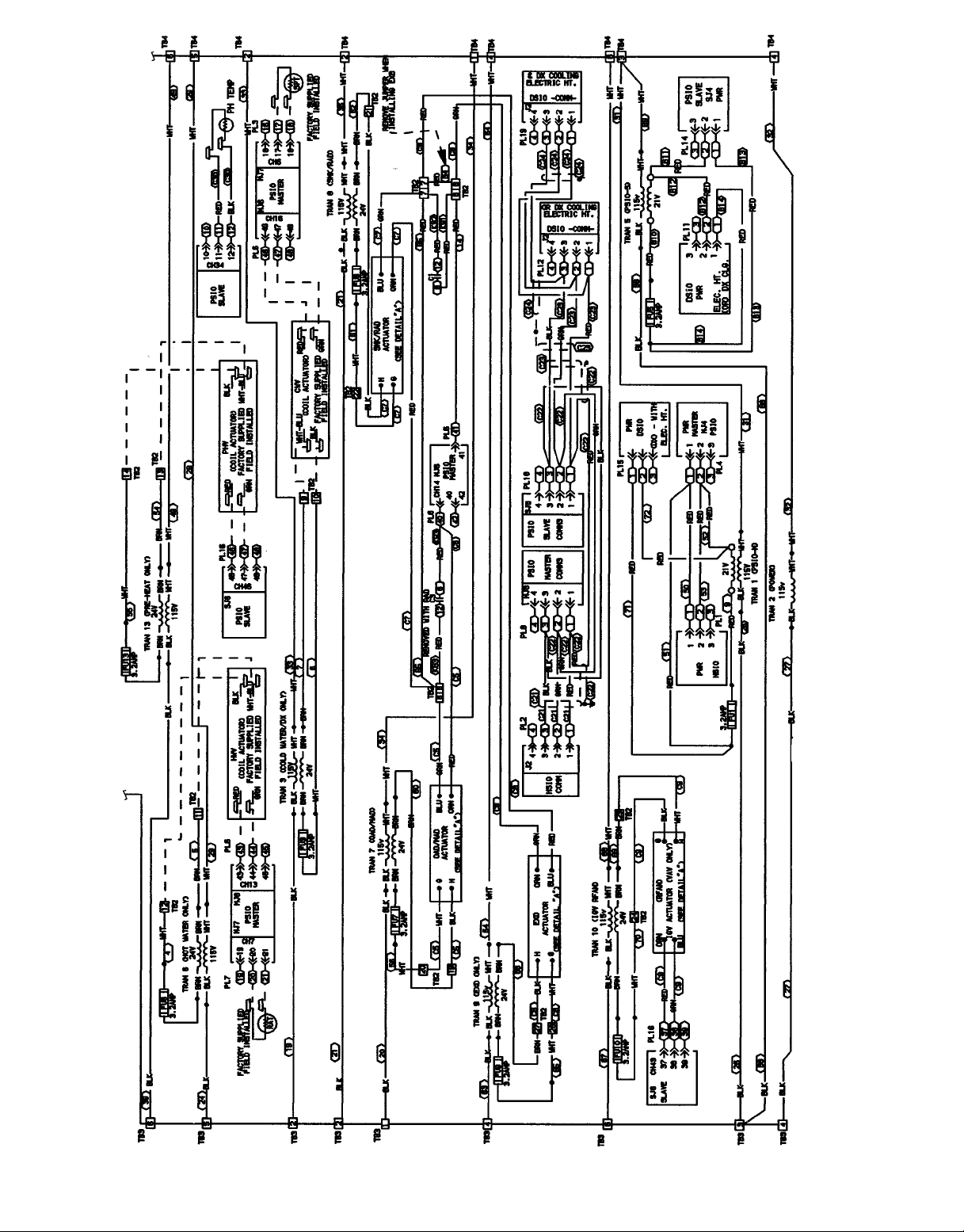

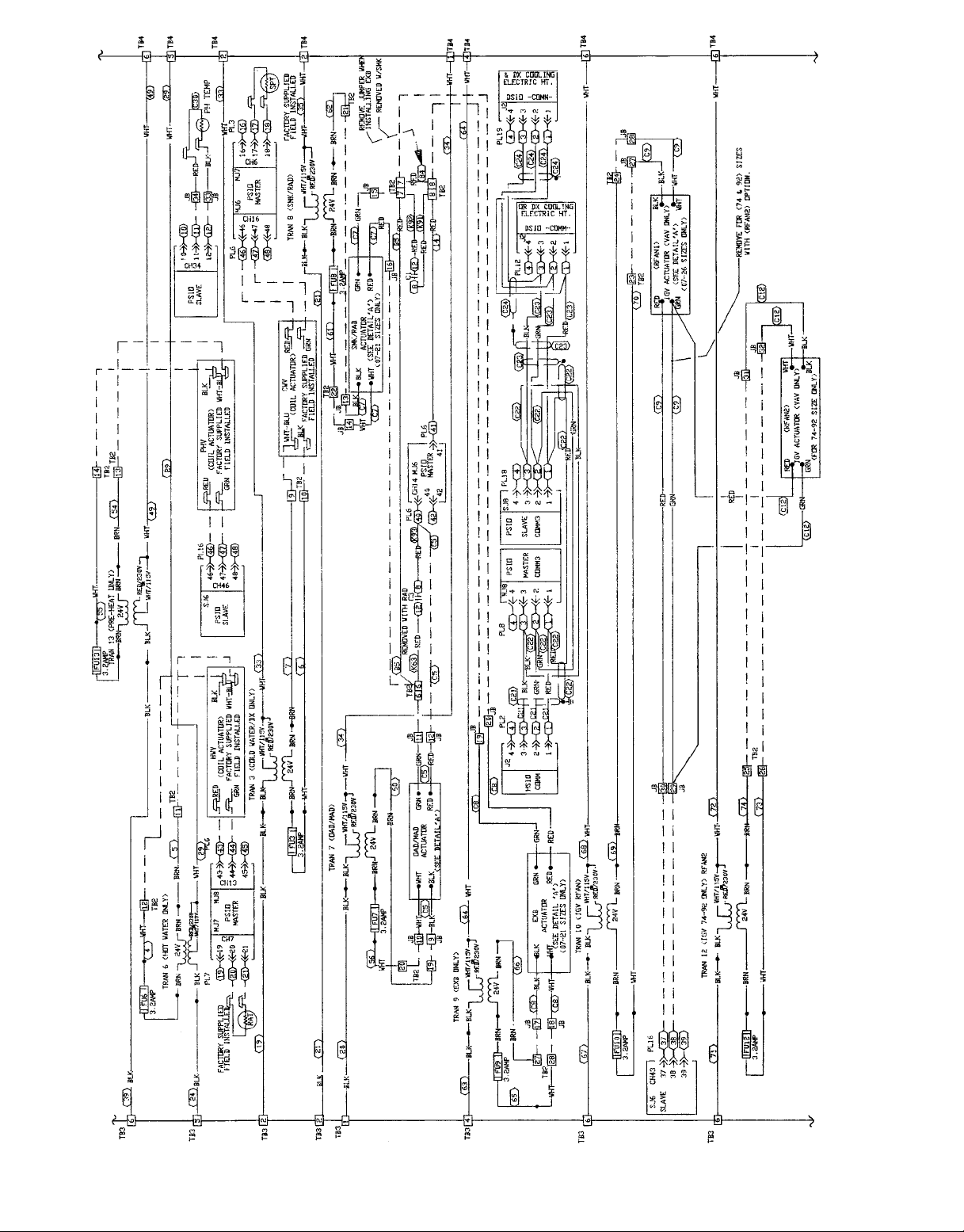

Fig. 12 — Unit Wiring Schematic, 39L and 39NX PIC with Remote Control Box

Page 32

32

Fig. 12 — Unit Wiring Schematic, 39L and 39NX PIC with Remote Control Box (cont)

Page 33

33

Fig. 12 — Unit Wiring Schematic, 39L and 39NX PIC with Remote Control Box (cont)

Page 34

Fig. 12 — Unit Wiring Schematic, 39L and 39NX PIC with Remote Control Box (cont)

34

Page 35

Fig. 12 — Unit Wiring Schematic, 39L and 39NX PIC with Remote Control Box (cont)

35

Page 36

Fig. 12 — Unit Wiring Schematic, 39L and 39NX PIC with Remote Control Box (cont)

36

Page 37

Table 2 — Junction Box Connections for Optional Remote Control Box

REMOTE

CONTROL BOX

LOCATION

MPSIO 2 SAT — BLK 1

MPSIO 3 SAT — RED 2

MPSIO 8 MAT — BLK 3

MPSIO 9 MAT — RED 4

TB3 10 FLTS — BLK 5

MPSIO 28 FLTS — RED 6

TB3 10 LTT — K3 7

MPSIO 13 LTT — K1 8

TB2 19 OAD — BLK 9

TB2 20 OAD — WHT 10

TB2 6 OAD — GRN 11

MPSIO 40 OAD — RED 12

TB2 21 RAD — BLK 13

TB2 22 RAD — WHT 14

TB2 7 RAD — GRN 15

TB2 6 RAD — RED 16

TB2 27 EXD — BLK 17

TB2 28 EXD — WHT 18

TB2 8 EXD — GRN 19

TB2 7 EXD — RED 20

TB2 15 SFAN1 — BLK 21

TB2 16 SFAN1 — WHT 22

MPSIO 38 SFAN1 — GRN 23

MPSIO 37 SFAN1 — RED 24

TB2 17 SFAN2 — BLK 25

TB2 18 SFAN2 — WHT 26

TB2 23 RFAN1 — BLK 27

TB2 24 RFAN1 — WHT 28

SPSIO 38 RFAN1 — GRN 29

SPSIO 37 RFAN1 — RED 30

TB2 25 RFAN2 — BLK 31

TB2 26 RFAN2 — WHT 32

SPSIO 12 PH — BLK 33

SPSIO 11 PH — RED 34

NOTES:

1. Pneumatic tubing to connect the airflow sensor in the fan to the remote control box is bundled with the internal PIC wiring to the junction box,

but does not enter the box. Route tube directly to remote control box along with conduit containing wiring from junction box to remote control box.

2. See Legend on page 7.

CONTROL

BOX

TERMINAL

FAN SECTION

JUNCTION BOX

SIGNAL

JUNCTION

BOX

TERMINAL

37

Page 38

Variable-Frequency Drives — The input signal for

the inverter must be 4 to 20 mA. Use a 2-conductor

20 AWG (American Wire Gage) cable (single twisted pair,

unshielded) to connect the input of the inverter to the output

of the PIC control terminals. See Fig. 8.

Wire the inverter so that if it is placed in the manual or

bypass mode the low temperature thermostat and the highpressure switch (if supplied) are still in the motor control

circuit to protect the unit.

Adjust the minimum inverter speed to provide at least 10%

airflow when inlet guide vanes are at 0% (4 mA) and maximum design airflow when inlet guide vanes are at 100%

(20 mA). Use the local interface device to verify that the

supply fan status ( ) shows the fan is ON and that the

supply fan is operating at the lowest airflow adjustment. In-

crease inverter minimum speed as required. For additional

information, see the Quick Test section on page 103.

Water Valve Assemblies — Water valve assemblies

(Fig. 13) are shipped inside the fan section for field installation. All valve assemblies have electrically powered actuators. Each actuator has an external junction box for field

wiring.The junction box contains 24 vac power wires (WHITE/

BLUE, BLACK) and 4 to 20 mA signal wires (1RED,

−GREEN). The actuators operate the valve through a linear

stroke; if power is lost, a return spring reverses the stroke

and returns the valve stem to the normal position.

VAL VE ACTUATOR

ACTUATOR LINKAGE

VALVE BODY

To prevent electric shock and equipment damage, disconnect the power to the control box before installing

valve assemblies. Turn power switch located on control

box door to OFF.

On installations where valve mounting space is limited,

use unions to couple valve assemblies to water lines. If unions

do not provide sufficient clearance, refer to the Valve

Troubleshooting section, page 109.

On chilled water applications or hot water applications with

1

⁄2to 3-in. valves, the valve actuators can be mounted in

1

any position above the centerline of the valve body.For steam

applications or hot water applications with1⁄2to 11⁄4-in. valves

that have actuators and high-temperature linkage extensions, mount the actuator above the centerline of the valve

body and 45 degrees from vertical. This position helps to

prevent actuator exposure to direct heat convection.

DO NOT install valve assembly where excessive moisture, corrosive fumes, and/or vibration are present.

INSTALL all 2-way valve assemblies so that they close

against system flow. An arrow on the valve body indicates the proper flow direction.

ALWAYS install 3-way mixing valve with 2 inlet flows

and one outlet. Normal flow will be from port B to port

AB with stem up. See Fig. 14.

Fig. 13 — Valve Assembly (T ypical)

Fig. 14 — Three-Way Mixing Valve — Normal Flow,

T ypical Piping

38

Page 39

VALVE WIRING

Valves MUST be connected to the correct processor module terminal to operate properly. Damage to the actuator

may occur if the valve is improperly connected.

Hot WaterValves (Fig. 15) — Using a 4-conductor 20AWG

cable (two twisted pairs, no shield), connect the hot water

valve actuator as follows:

1. Using twist-on wire connectors, connect the BLACK and

WHITE/BLUE leads inside the actuator junction box to

the 24 vac power wires of the cable. Connect the other

ends of the power wires to TB2, pins 11 and 12, in the

PIC control box.

2. Using twist-on wire connectors, connect the RED (1 )and

GREEN (−) leads inside the actuator junction box to the

other 2 wires in the cable. Note the polarity of each wire.

3. Connect the positive signal wire (connected to the RED

lead) to pin 43 on the processor module. Connect the negative signal wire (connected to the GREEN lead) to pin 44

on the processor module.

Chilled Water Valves (Fig. 16) — Using a 4-conductor

20 AWG cable (two twisted pairs, no shield), connect the

chilled water valve actuator as follows:

1. Using twist-on wire connectors, connect the BLACK and

WHITE/BLUE leads inside the actuator junction box to

the 24 vac power wires of the cable. Connect the other

ends of the power wires to TB2, pins 9 and 10, in the PIC

control box.

2. Using twist-on wire connectors, connect the RED (1 )and

GREEN (−) leads inside the actuator junction box to the

other 2 wires in the cable. Note the polarity of each wire.

3. Connect the positive signal wire (connected to the RED

lead) to pin 46 on the processor module. Connect the negative signal wire (connected to the GREEN lead) to pin 47

on the processor module.

Duct Static Pressure Probe (VAV Units) — The

duct static pressure probe is shipped inside the control box.

Select a location in the ductwork where the static pressure

will be representative of the static pressure to be monitored

and maintained (typically 2/3 of the distance down the duct

from the fan). Install the probe with the tip facing the airflow. See Fig. 17.

1

⁄4-in. OD approved polyethylene tubing for up to

Use

50 ft (3⁄8-in. OD for 50 to 100 ft) to connect the probe to the

39L or 39NX unit. Route the tubing back to the mechanical

room and connect the tubing to the bulkhead fitting labelled

H (HIGH), located on the bottom edge of the 39L control

box or top edge of the 39NX control box.

NOTE: If the probe is more than 100 ft from the control

box, it is recommended that the static pressure sensor be removed from the control box and mounted remotely.The sensor should be mounted closer to the probe and then rewired

to the original connections in the control box.

NOTE: Connections for 39NX with integral PIC shown. See wiring

diagrams in Fig. 9 and 12 for terminal connections in 39L control box

and all remote-mount control boxes.

Fig. 15 — Hot Water Valve Wiring

39

Page 40

FACTORY WIRING

FIELD WIRING

NOTE: Connections for 39NX with integral PIC shown. See wiring

diagrams in Fig. 9 and 12 for terminal connections in 39L control box

and all remote-mount control boxes.

Fig. 16 — Chilled Water Valve Wiring

Space TemperatureSensor (Fig. 18) — The space

temperature sensor (SPT) is packaged and shipped inside the

fan section. It is installed on a building interior wall to measure room air temperature.

The wall plate accommodates both the NEMA (National

Electrical Manufacturers’ Association) standard and the

European

use of a junction box to accommodate the wiring is recommended for installation. The sensor can be mounted directly

on the wall, if acceptable by local codes.

DO NOT mount the sensor in drafty areas such as near

heating or air conditioning ducts, open windows, fans,

or over heat sources such as baseboard heaters or radiators.

Sensors mounted in these areas produce inaccurate readings.

1

⁄4DIN (Deutsche Industrie Norm) standard. The

Fig. 17 — Duct Static Pressure Probe

Avoid corner locations. Allow at least 3 ft between the

sensor and any corner. Airflow near corners tends to be reduced, resulting in erratic sensor readings.

The sensor should be mounted approximately 5 ft up from

the floor, in the area representing the average temperature.

Install the sensor as follows:

1. Remove sensor cover. Using a small blade screwdriver,

insert blade into sensor cover latch slot on bottom of slat.

Gently push upward on the screwdriver to release the cover

latch. Rotate the cover forward as the screwdriver is removed.

2. Snap off the wall plate from the base assembly.

3. Feed the wires from the electrical box through the sensor

base assembly.

5

4. Using two 6-32 x

⁄8-in. flat screws, mount the sensor base

assembly to the electrical box.

5. Dress the wires down and inside the perimeter of the sen-

sor base.

6. Attach the wall plate by snapping it onto the sensor base

assembly.

7. Replace the cover by inserting the top inside edge of the

cover over the tab on top of the sensor base assembly and

rotating the cover down. Snap cover on.

Refer to Field Wiring Connections section, page 52 for

wiring instructions and details. See Table 3 for Thermistor

Resistance vs. Temperature Values.

NOTE: Clean sensor with damp cloth only. Do not use

solvents.

40

Page 41

NEMA — National Electrical Manufacturers’ Association

Fig. 18 — Space Temperature Sensor (P/N HH51BX001)

Table 3 — Thermistor Resistance vs. Temperature Values for Space Temperature Sensor, Return-Air

Temperature Sensor, and Supply-Air Temperature Sensor

RESISTANCE

(Ohms)

173,631.0 −30 38,308.7 22 10,698.1 74 3602.5 126 1409.7 178

168,222.0 −29 37,304.0 23 10,459.4 75 3533.4 127 1386.3 179

162,998.0 −28 36,328.8 24 10,226.8 76 3465.9 128 1363.3 180

157,954.0 −27 35,382.1 25 10,000.0 77 3399.8 129 1340.7 181

153,083.0 −26 34,463.0 26 9,778.9 78 3335.2 130 1318.6 182

148,378.0 −25 33,570.7 27 9,563.4 79 3272.0 131 1296.9 183

143,833.0 −24 32,704.2 28 9,353.1 80 3210.1 132 1275.6 184

139,442.0 −23 31,862.8 29 9,148.2 81 3149.6 133 1254.8 185

135,200.0 −22 31,045.7 30 8,948.4 82 3090.4 134 1234.3 186

131,101.0 −21 30,252.0 31 8,753.5 83 3032.5 135 1214.2 187

127,139.0 −20 29,481.1 32 8,563.4 84 2975.8 136 1194.5 188

123,310.0 −19 28,732.2 33 8,378.0 85 2920.3 137 1175.1 189

119,609.0 −18 28,004.6 34 8,197.1 86 2866.0 138 1156.1 190

116,031.0 −17 27,297.7 35 8,020.7 87 2812.9 139 1137.5 191

112,571.0 −16 26,610.8 36 7,848.6 88 2760.9 140 1119.2 192

109,226.0 −15 25,943.4 37 7,680.6 89 2710.0 141 1101.3 193

105,992.0 −14 25,294.7 38 7,516.8 90 2660.2 142 1083.7 194

108,863.0 −13 24,664.2 39 7,356.9 91 2611.4 143 1066.4 195

99,837.3 −12 24,051.4 40 7,200.9 92 2563.7 144 1049.4 196

96,910.2 −11 23,455.6 41 7,048.6 93 2516.9 145 1032.8 197

94,078.4 −10 22,876.5 42 6,900.0 94 2471.2 146 1016.5 198

91,338.6 −9 22,313.4 43 6,755.0 95 2426.4 147 1000.4 199

88,687.3 −8 21,765.9 44 6,613.4 96 2382.5 148 984.7 200

86,121.6 −7 21,233.5 45 6,475.2 97 2339.5 149 969.2 201

83,638.4 −6 20,715.7 46 6,340.3 98 2297.5 150 954.0 202

81,234.8 −5 20,212.2 47 6,208.5 99 2256.3 151 939.1 203

78,908.0 −4 19,722.4 48 6,079.9 100 2215.9 152 924.5 204

76,655.3 −3 19,245.9 49 5,954.3 101 2176.4 153 910.1 205

74,474.2 −2 18,782.4 50 5,831.7 102 2137.7 154 896.0 206

72,362.1 −1 18,331.5 51 5,712.0 103 2099.8 155 882.2 207

70,316.7 0 17,892.8 52 5,595.0 104 2062.6 156 868.6 208

68,335.6 1 17,465.9 53 5,480.8 105 2026.3 157 855.2 209

66,416.7 2 17,050.4 54 5,369.2 106 1990.6 158 842.1 210

64,557.9 3 16,646.1 55 5,260.2 107 1955.7 159 829.2 211

62,756.9 4 16,252.6 56 5,153.7 108 1921.5 160 816.6 212

61,012.0 5 15,869.6 57 5,049.7 109 1887.9 161 804.1 213

59,321.1 6 15,496.8 58 4,948.1 110 1855.1 162 791.9 214

57,682.4 7 15,133.8 59 4,848.8 111 1822.9 163 779.9 215

56,094.3 8 14,780.4 60 4,751.8 112 1791.3 164 768.2 216

54,554.9 9 14,436.4 61 4,657.0 113 1760.4 165 756.6 217

53,062.2 10 14,101.3 62 4,564.4 114 1730.1 166 745.2 218

51,615.9 11 13,775.1 63 4,473.8 115 1700.4 167 734.0 219

50,213.1 12 13,457.3 64 4,385.3 116 1671.3 168 723.1 220

48,853.0 13 13,147.9 65 4,298.9 117 1642.7 169 712.3 221

47,533.9 14 12,846.4 66 4,214.3 118 1614.7 170 701.7 222

46,254.7 15 12,552.8 67 4,131.7 119 1587.3 171 691.3 223

45,013.9 16 12,266.8 68 4,050.9 120 1560.4 172 681.0 224

43,810.3 17 11,988.1 69 3,971.9 121 1534.1 173 671.0 225

42,642.6 18 11,716.6 70 3,894.6 122 1508.2 174 661.1 226

41,509.8 19 11,452.0 71 3,819.1 123 1482.9 175 651.4 227

40,410.5 20 11,194.2 72 3,745.3 124 1458.0 176 641.8 228

39,343.9 21 10,943.0 73 3,673.1 125 1433.6 177 632.4 229

TEMP

(F)

RESISTANCE

(Ohms)

TEMP

(F)

RESISTANCE

(Ohms)

TEMP

(F)

RESISTANCE

(Ohms)

TEMP

(F)

RESISTANCE

(Ohms)

TEMP

(F)

41

Page 42

Outdoor-Air Temperature Sensor (Fig. 19) —

The outdoor-air temperature (OAT) sensor is shipped inside

the fan section. The OAT sensor continuously monitors the

temperature of the air outside the building. The integral shield

prevents ice formation on the sensor conductors. A fieldsupplied conduit junction box is required for installation. See

Fig. 20.

Position the OAT sensor so that it accurately senses only

the outdoor-air temperature. The sensor must be located upstream from outside air dampers and located where it is unaffected by interior and duct temperatures. During the unoccupied (fan off) period the sensor’s location should have a

minimal effect on its readings.

Do not mount the sensor in direct sunlight. Inaccurate readings may result. It may be necessary to field-fabricate a shield

to protect the sensor from direct sunlight.

Do not mount the sensor near the exhaust from airhandling units or compressors, or near leakage drafts of indoor air, or near shrubbery or trees. Inaccurate readings may

result. Do not mount under direct water runoff. Water may

freeze around the sensor in winter and produce a false

reading.

If sensor wire is shielded, strip back the sensor shield and

tape it to prevent contact.

Position the sensor with the slotted end pointed

downward.

The field-supplied junction box housing must be threaded

to screw onto a male

conduit adaptor.The assembledbox and sensor mustbe mounted

parallel to the building wall. See Fig. 20. The sensor can

also be installed on a roof or other location.

For distances up to 500 ft, use 2-conductor 20 AWGcable

to connect the sensor to the PIC terminals. Refer to the Field

Wiring Connections section, page 52 for further wiring instructions. See Table4 for thermistor resistance according to

temperature value.

Table 4 — Thermistor Resistance vs

Temperature Values for Outdoor-Air

RESISTANCE

(Ohms)

168,250 −40 5,000.0 77

121,350 −31 4,028.5 86

88,500 −22 3,265.0 95

65,200 −13 2,663.3 104

48,535 −4 2,185.0 113

36,476 5 1,801.5 122

27,665 14 1,493.0 131

21,165 23 1,244.0 140

16,325 32 1,041.5 149

12,695 41 876.0 158

9,950 50 739.5 167

6,245 68 627.5 176

1

⁄2-in. NPT electrical metal tubing (EMT)

Temperature Sensor

TEMPERATURE

(F)

RESISTANCE

(Ohms)

TEMPERATURE

(F)

Fig. 20 — Outdoor-Air Temperature

Sensor Installation

Mixed-Air Temperature Sensor — The optional

mixed-air temperature sensor (MAT) is factory wired and

installed on all units with a factory-installed mixing box (MXB),

filter mixing box (FMB), or air blender (AMX). On units

without an AMX, MXB, or FMB, the optional MAT is packaged and shipped inside the fan section for field installation.

The field-installed MAT should be mounted downstream

of the return air duct and filters, but as close as possible to

the 39L or 39NX unit.

AVOID repeated bending of copper tubing, as this will

place stress on the sensor element and lead to eventual

breakage.

DO NOT fold or crimp copper tubing.

USE CARE in forming and securing the element.

STRIP back and tape the shield in order to prevent

contact.

Mount field-installed MAT as follows (Fig. 21):

1. Punch a 1-in. diameter hole in the duct and feed the sen-

sor element through the hole. Mount the utility box on

the outside of the duct.

2. Bend the copper tubing surrounding the sensor element

to conform to the area of the duct. Do not bend it to less

1

than 2

⁄2in. diameter on any turn. The sensor element

should be evenly distributed over the entire cross sectional area of the duct.

Existing support structures may be used for the sensor

element, as long as there is no metal-to-metal contact with

the copper tubing, and the mounting does not interfere

with other functions.

3. Use a field-supplied plastic spacer, clamp, and screws to

secure the sensor in the airstream. See Detail A,

Fig. 21.

4. Using 2-conductor 20 AWG plenum-rated cable, connect

the sensor to the PIC control box terminals.

Fig. 19 — Outdoor-Air Temperature Sensor

(P/N HH79NZ023)

42

Page 43

NOTE:This sensor uses a resistance temperature device (RTD)

element. Polarity is not a consideration.

When space does not allow working inside the duct, mount

as follows (Fig. 22):

1. Open a duct penetration on the opposite side of the sensor junction box.

3

2. Wrap the element around a

⁄4-in. PVC pipe, cut holes

near the center of the duct on both sides and feed the pipe

with sensor element through the hole.

3. Secure the seal around the PVC pipe.

NOTE: If local codes do not permit the use of PVC, use

EMT instead.

Refer to Field Wiring Connections section, page 52 for

wiring instructions and details. See Table 5 for RTD resistance vs temperature values.

Table 5 — RTD Resistance vs Temperature Values

for Mixed-Air Temperature Sensor

RESISTANCE

(Ohms)

693 −40 940 50 1223 140

719 −30 970 60 1257 150

745 −20 1000 70 1290 160

772 −10 1031 80 1325 170

799 0 1062 90 1360 180

827 10 1093 100 1395 190

854 20 1125 110 1430 200

883 30 1157 120 — —

912 40 1190 130 — —

TEMP

(F)

RESISTANCE

(Ohms)

TEMP

(F)

RESISTANCE

(Ohms)

TEMP

(F)

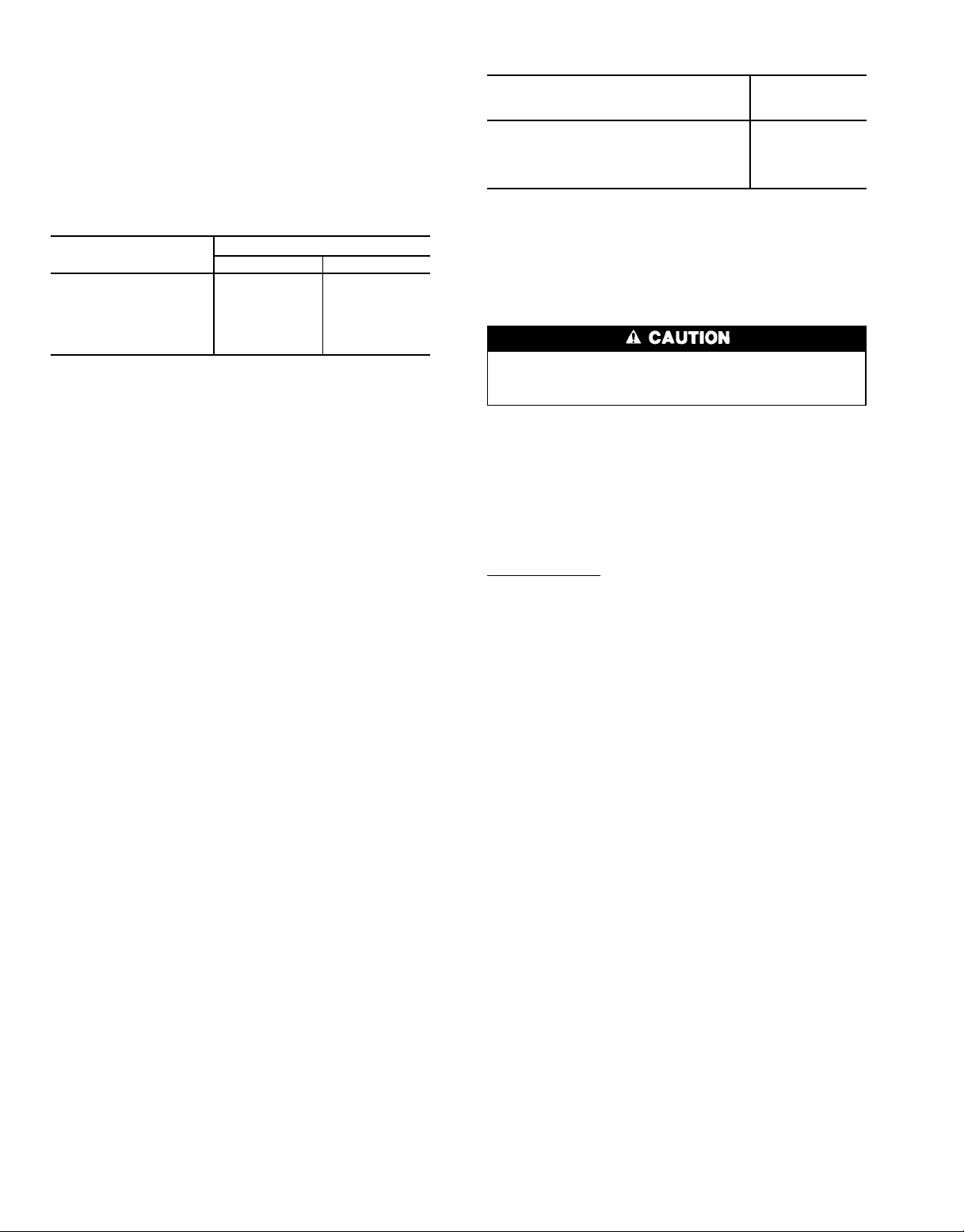

Enthalpy Switch (Fig. 23) — The enthalpy switch and

mounting template are located in a box shipped inside the

fan section.

The enthalpy switch is normally mounted in a horizontal

position with the sensing element exposed to freely circulating outdoor air.

DO NOT install enthalpy switch in locations where excessive moisture, corrosive fumes, and/or vibration are

present.

Fig. 22 — Alternate Mixed-Air Temperature

Sensor Installation

Mount the switch as follows:

1. Position mounting template on duct. Remove adhesive

backing and press template onto outside air duct.

2. Drill four

1

⁄8-in. mounting holes as indicated on the

template.

3. Cut out center portion of duct as outlined on template.

4. Mount controller to duct using screws provided.

If no outside air duct is present, mount the enthalpy switch

on a field-supplied and installed plate upstream of the outside air damper.

Connect the red and blue wires of the enthalpy switch to

the PIC control box terminals. Refer to Field Wiring

Connections section, page 52 for further details.

CONTROLRANGES — See Fig. 24 for control settings and

intermediate settings.

MOUNTING HOLES

Fig. 21 — Mixed-Air Temperature Sensor

(P/N HH79NZ021) Installation

43

Y

E

L

R

E

D

B

L

U

A

Fig. 23 — Enthalpy Switch (P/N HH57AC076)

D

C

B

Page 44

DIAL

SETTING

A

B

C

D

CONTROL SETTINGS

RELATIVE

HUMIDITY (%)

20 50 80

78 F

(26 C)

73 F

(23 C)

68 F

(20 C)

62 F

(17 C)

73 F

(23 C)

68 F

(20 C)

63 F

(17 C)

58 F

(14 C)

68 F

(20 C)

63 F

(17 C)

59 F

(15 C)

53 F

(12 C)

CONTROL

CURVE

A

B

C

D

4. Remove the adhesive backing from the gasket; attach the

gasket to the outside of the junction box, aligning the holes

in the gasket with the holes in the box.

5. Attach the junction box to the duct with the 2 screws

provided.

6. Insert the probe assembly through the compression fitting and into the duct. Tighten screws one half-turn past

finger tight. Do not overtighten.

For distances up to 500 ft, use 2-conductor 20 AWGcable

to connect the sensor to the PIC control box terminals. Refer

to Field Wiring Connections section, page 32 for further details. See Table 3 for thermistor resistance vs. temperature

values.

Fig. 24 — Enthalpy Control Settings

Supply-Air TemperatureSensor (Fig. 25) — The

supply-air temperature sensor (SAT) measures the temperature of the air as it leaves the supply fan. The sensor is factoryinstalled on the fan scroll.

Return-Air Temperature Sensor (Fig. 25) — The

return-air temperature sensor (RAT)is shipped inside the fan

section. It measures the temperature in the return air duct.

Mount the sensor in the middle of the return air duct approximately 4 to 5 ft from the return air damper. The sensor’s probe tip must be within a straight length of duct.

Mount the sensor as follows:

1. Remove the cover of the sensor junction box.

5

2. Drill or punch a

turn air duct as indicated in Fig. 26.

3. Drill or punch 2 holes through the sensor gasket into the

fan scroll.

⁄16-in. hole on the centerline of the re-

Fig. 25 — Supply/Return Air Temperature Sensor

(P/N HH79NZ019)

Fig. 26 — Return-Air Temperature Sensor

Installation

44

Page 45

Heat Interlock Relay (Fig. 27) — The heat interlock

relay (HIR) is factory wired and installed on VAV units only.

It is a single-pole, double-throw (SPDT) relay that provides

normally-open and normally-closed contacts to interface with

air terminal units. It allows the air terminals to open when

the PIC unit goes into the heating mode. The contacts are

silver cadmium oxide and are rated as follows:

48 va at 24 vac and .25 power factor

125 va at 115 vac and .25 power factor

125 va at 230 vac and .25 power factor

The contact terminations are no. 6 screw terminals.

NOTE: The HIR is not used in digital air volume control

(DAV) applications.

SDA 2 02 0

NC

2

COI L

DO NOT install the duct high humidity switch in locations where excessive moisture, corrosive fumes, and/or

vibration are present. Be sure to allow minimum dimensions from the elbows or junctions as indicated in

Fig. 29.

Mount the DHH as follows:

1. Position the mounting template on the duct. Remove adhesive backing and press template onto duct.

2. Drill four

template.

3. Cut out center portion of duct as outlined on template.

4. Mount DHH to duct using screws provided.

For distances up to 500 ft, use 2-conductor 20 AWG

cable to connect the switch to the PIC control box terminals.

Refer to Field Wiring Connections section, page 52 for further details.

The DHH adjustment knob provides settings from 15

to 95% relative humidity, The scale range is marked on the

face of the switch. The high humidity set point should be at

least 65%.

NOTE: The duct high humidity switch has a relative humidity differential of 5%.

1

⁄8-in. mounting holes as indicated on the

1

COM

Fig. 27 — Relay (P/N HK35AB001)

NO

Fan Relay — Thefan relay is factory wired and installed

on all 39L and 39NX units. It is a SPST relay that provides

a normally-open contact. The relay interfaces with the motor starter circuit and automatically starts/stops the fan when

the HOA switch is in the AUTO mode. The contacts are silver cadmium oxide and are rated as follows:

48 va at 24 vac and .25 power factor

125 va at 115 vac and .25 power factor

125 va at 230 vac and .25 power factor

The contact terminations are factory wired to TB1.

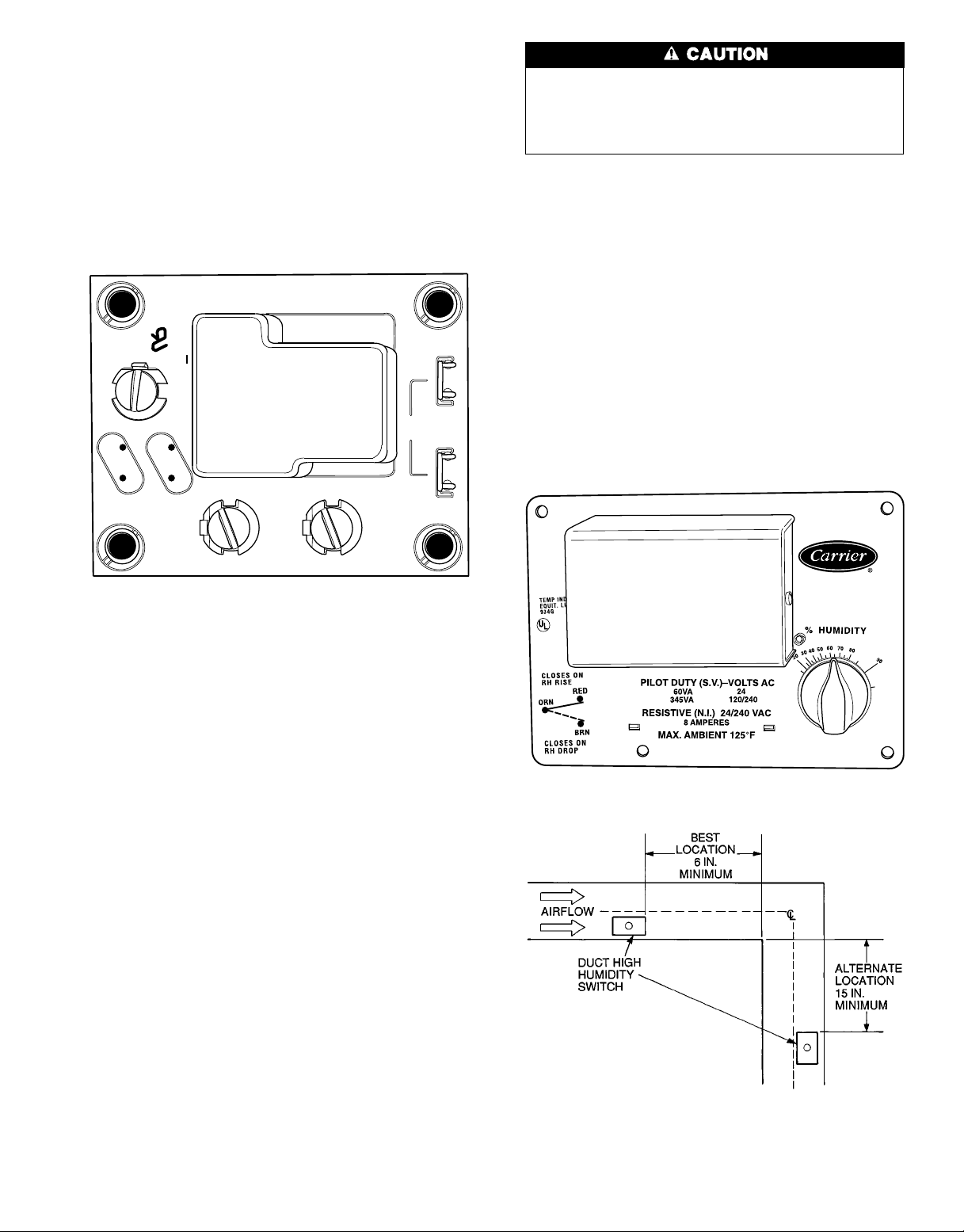

Duct High Humidity Switch (Fig. 28) — The duct

high humidity switch (DHH) is shipped inside the fan section. It is used as a safety input when the humidity control

options have been ordered. The DHH adjustment knob provides settings from 15 to 95% humidity.

Locate the DHH control element in the duct, downstream

of the humidifier. Adjust the DHH to the ASHRAE

(American Society of Heating, Refrigeration, and Air Conditioning Engineers) recommended maximum setting of 80%.

Settings higher than 80% are not recommended.

The DHH is normally mounted in a horizontal position on

the outside surface of the duct with the sensing element exposed to freely circulating air.

Fig. 28 — Duct High Humidity Switch

(P/N HL38ZG024)

45

Fig. 29 — Duct High Humidity Switch

Locations

Page 46

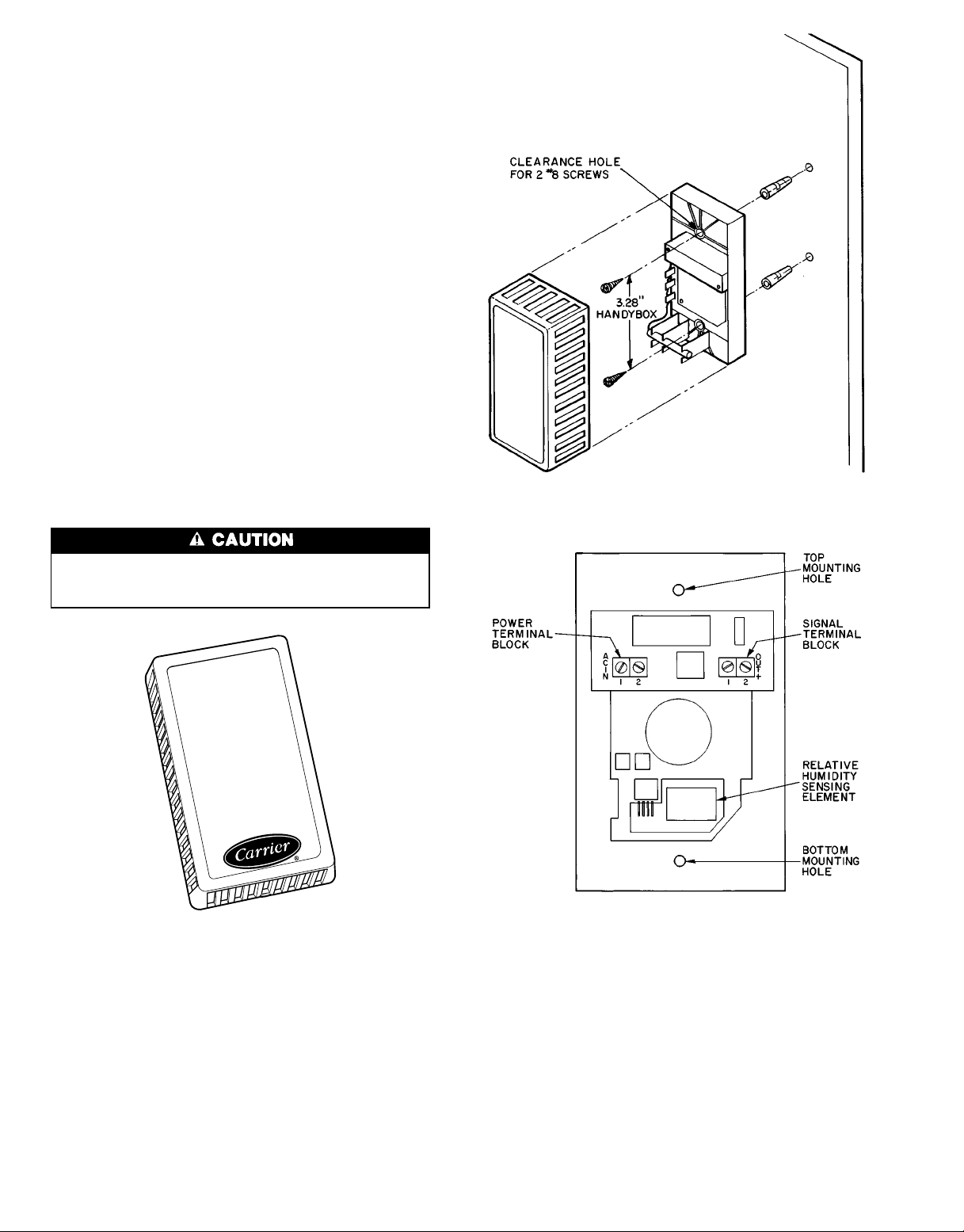

Wall-MountedRelative Humidity Sensor (Fig.30)

The wall-mounted relative humidity sensor is packaged

—

and shipped inside the fan section. It is installed on interior

walls to measure the relative humidity of the air within the

occupied space.

The use of a junction box to accommodate the wiring is

recommended for installation. The sensor may be mounted

directly on the wall, if acceptable by local codes.

DO NOT mount the sensor in drafty areas such as near

heating or air conditioning ducts, open windows, fans, or over

heat sources such as baseboard heaters or radiators. Sensors

mounted in those areas will produce inaccurate readings.

Avoid corner locations. Allow at least 3 ft between the

sensor and any corner. Airflow near corners tends to be reduced, resulting in erratic sensor readings.

Sensor should be vertically mounted approximately 5 ft

up from the floor, beside the space temperature sensor.

Install the sensor using 2 screws and 2 hollow wall anchors (if required); do not overtighten screws. See Fig. 31.

Sensor must be mounted with terminals ACIN and OUT1

located at the top of the sensor as shown in Fig. 32.

For distances up to 500 ft, use 4-conductor 20 AWG

cable (2 twisted pairs, no shield) to connect the sensor to the

PIC control box terminals and power supply. Refer to Field

Wiring Connections section, page 52 for wiring instructions

and details.

The PIC controller has a space relative humidity default

set point of 40%.

Fig. 31 — Wall-Mounted Relative Humidity

Sensor Installation

Never attempt to clean or touch the sensing element with

chemical solvents, as permanent damage to the sensor

will occur.

Fig. 30 — Wall-Mounted Relative Humidity Sensor

(P/N HL39ZZ001)

Fig. 32 — Wall-Mounted Relative Humidity

Sensor Positioning

46

Page 47

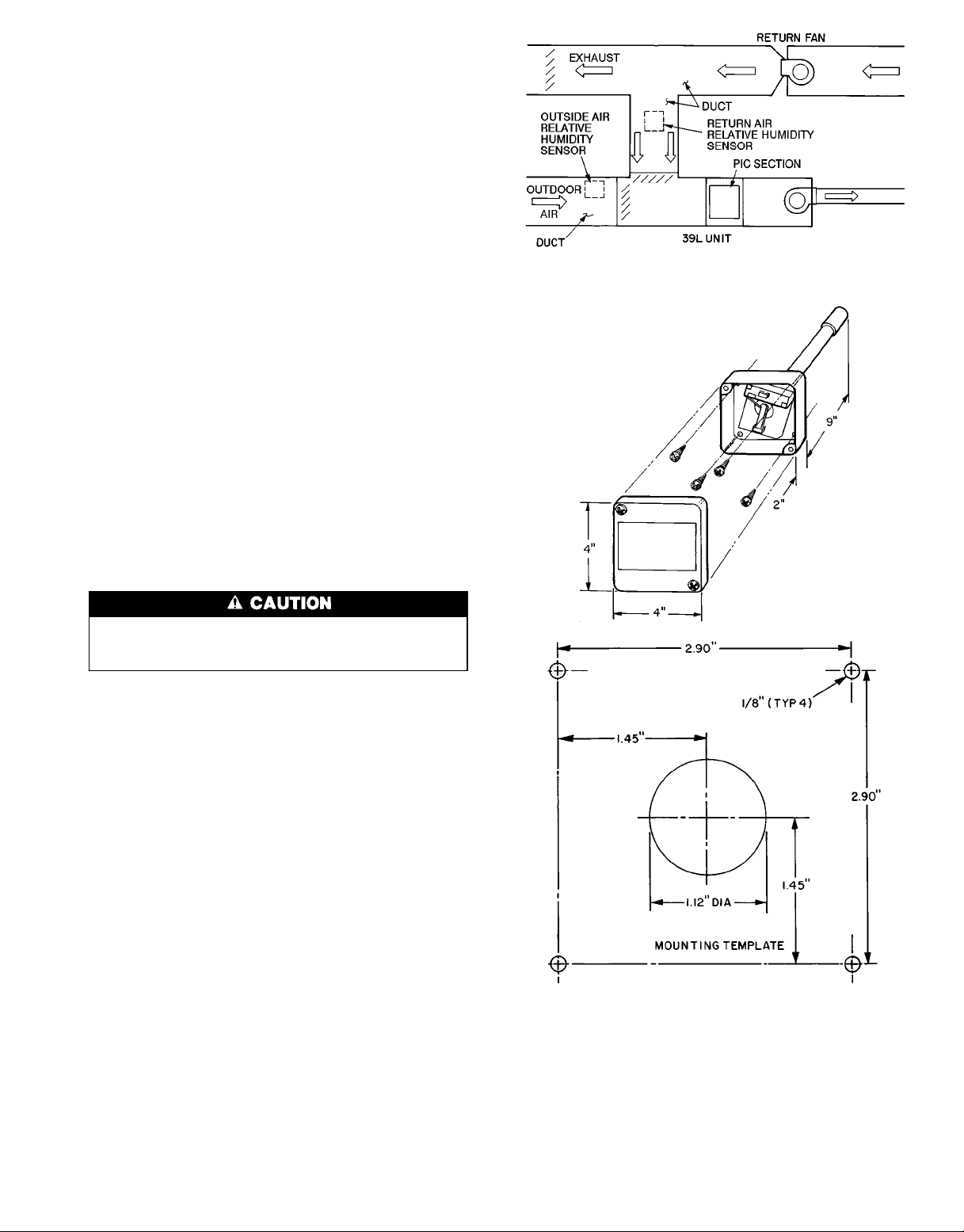

Duct-Mounted Relative Humidity Sensor — The

duct-mounted relative humidity sensor and mounting template are packaged and shipped inside the fan section. The

sensor is installed in either the return air ductwork or in the

outside air ductwork. If 2 relative humidity sensors are ordered for differential enthalpy control, then the sensors must

be installed in both the return air and outside air ducts. If the

sensor is used for control of a humidifier, install the sensor

in the return air duct.

The PIC controller has a return air relative humidity de-

fault set point of 40%.

LOCATION FOR OUTSIDE AIR RELATIVE HUMIDITY

— Locate the sensor where it accurately measures outdoor

conditions, yet is protected from the elements. During the

unoccupied (fan off)period, the sensor’slocation should have

a minimal effect on its readings.

LOCATION FOR RETURN AIR RELATIVE HUMIDITY

— Locate the sensor at least 6 in. upstream or 15 in. downstream of a 90 degree turn in the ductwork. The best location is 15 in. downstream of the 90 degree turn of the duct.

The probe should be mounted in the center of the duct. See

Fig. 33.

Mount the relative humidity sensor (Fig. 34) as follows.

1. Position mounting template on duct.

1

2. Drill four

template.

3. Punch a 1

template.

4. Mount sensor to duct using four no. 8 screws. Install 9-in.

sensor probe into the 1

⁄8-in. mounting holes as indicated on the

1

⁄8-in. hole as indicated on the mounting

1

⁄8-in. hole.

Fig. 33 — Duct-Mounted Relative Humidity

Sensor Locations

Never attempt to clean or touch the sensing element with

chemical solvents, as permanent damage to the sensor

will occur.

MixingBox Linkage — On units with mixing box (MXB)

or filter mixing box (FMB), the actuator and linkage are factory installed. The actuator is directly linked to the outdoorair damper and holds the damper closed. No adjustment is

necessary.

For shipping purposes, the secondary linkage rod connecting the outdoor-air and return-air dampers is factory set

for a closed return-air damper.

Adjust the secondary linkage as follows:

1. Open the door of the MXB or FMB to access the return

air damper crankarm.

NOTE: On MXB/FMB with top outdoor-air damper, it

may be necessary to remove the vertical panel holding

the return-air damper to access the return-air damper

crankarm.

2. Loosen the setscrew on the return-air damper crankarm.

3. Move the damper to its full open position.

4. Secure the setscrew on the return-air damper crankarm.

5. Close the MXB or FMB access door.

Fig. 34 — Duct-Mounted Relative Humidity Sensor

(P/N HL39ZZ002) Installation

47

Page 48

Airflow Switch — The airflow switch (AFS) is a snap-

acting SPDT switch that is factory installed in the PIC control box. It senses the air supplied by the 39L or 39NX unit

and provides the microprocessor module with a 24 vac discrete signal for fan status. See Fig. 35.

Alength of plenum tubing connects the switch to the probe

located on the fan side plate.

The airflow switch range is 0.05 to 2.0 in. wg with a deadband of 0.02 in. wg at minimum set point and 0.1 in. wg at

maximum set point.

ADJUSTMENT

SCREW

C

MANUAL RESET

BUTTON

F

NORMALLY

CLOSED CONTACT

TURN SCREW CLOCKWISE

TO INCREASE AIRFLOW

TURN SCREW COUNTERCLOCKWISE TO DECREASE

AIRFLOW

LOWPRESSURE

INLET

HIGHPRESSURE

INLET

SPDT — Single-Pole, Double Throw

NORMALLY

OPEN CONTACT

MOUNTING BRACKET

CLOSED

CONTACT

SPDT SNAP

ACTING

SWITCH

Fig. 35 — Airflow Switch (P/N HK06WC030)

Low-Temperature Thermostat (Fig. 36 ) — The

optional low-temperature thermostat (LTT) is factory wired

and installed. It is used to protect the chilled water coil from

freezing whenever abnormally cold air passes through the

coil.

The LTT consists of a 20-ft capillary tube that is serpentined in the airstream on the entering side of the chilled water coil. It has a range of 34 to 60 F and is factory set at

35 F.

The LTT is wired in series with the motor starter fan

relay. If any 1-ft section of the capillary tube senses cold air

at or below the thermostat setting, the fan shuts down.Amanual

reset is provided to restart the fan after the abnormal problem is fixed. The temperature setting is field-adjustable.

To adjust the temperature set point, turn the adjustment

screw (located on the top of the case) until the position indicator is at the desired temperature. (A clockwise rotation

increases the set point.)

Fig. 36 — Low-Temperature Thermostat

(P/N HH22CZ001)

than the condensing unit’s minimum temperature. When installed, the thermostat must be set to the minimum operating

temperature of the condensing unit. If the condensing unit

has an optional low-ambient control (Motormastert device),

an outdoor-air thermostat is not required.

The outdoor-air thermostat is an SPST switch; the contacts open on temperature rise and the set point is adjustable

from 45 to 75 F (7.2 to 23.9 C). To increase the set point,

turn the indicator clockwise. See Fig. 37 for thermostat set

point adjustment and mounting hole locations. Thermostat

should be mounted inside condensing unit control box where

it can sense the outdoor air temperature but is protected from

rain and snow.

DO NOT set low-temperature thermostat below 35 F.

Damage to freezestat may result.

If the temperature exceeds the set point by5Formore,

the reset button will restore the circuit.

Outdoor-Air Thermostat (Fig. 37) — Also called

the condensing unit status (CUST) switch, the outdoor air

thermostat is a temperature-actuated switch used in systems

with direct-expansion cooling. The thermostat is fieldinstalled in the outdoor condensing unit to prevent the system from operating when the outdoor-air temperature is lower

Fig. 37 — Outdoor-Air Thermostat (Condensing Unit

Status Switch)

48

Page 49

Filter Status Switch — The filter status switch (FLTS)

is factory-installed in the filter section on all PIC-equipped

units. The switch is a snap-acting SPDT switch. When dirty

filter elements cause the pressure drop across the filter media to exceed the switch setting, the switch closes and sends

an alarm signal to the PIC.

The 39L units use a single switch. In 39NX units, up to

3 switches can be connected in parallel. When the switches

are wired in parallel, it is not possible to isolate an alarm

signal to a single switch.

The FLTS has an operating range of 0.05 to 2.0 in. wg.

Factory settings for the switch are as follows:

Filter Type

Setting (in. wg)

Flat 0.5

Bag/Cartridge 1.0

Final 1.5

The FLTS electrical ratings are as follows:

300 va pilot duty at 115 to 277 vac

10 amps non-inductive to 277 vac

Rated for NO (normally open) and NC (normally closed)

contacts.

High-Pressure Switch (Fig. 38) — The high-

pressure switch (HPS) is factory installed in the PIC control

box on VAV units only. It is a snap-acting SPDT switch with

manual reset that is used to shut down the supply fan whenever the duct pressure reaches the switch setting. The manual

reset is used to restart the fan after the problem has been

corrected.

The switch is factory set at 3.0 in. wg. It has a range of

1.4 to 5.5 in. wg and can be field adjusted for specific

applications.

Adjust the high-pressure switch setting as follows:

1. Loosen conduit enclosure retaining screw, pull firmly on

the bottom end and snap off cover.

2. Raise set point by turning slotted adjustment screw

(located at top of range spring housing) clockwise. Turn

adjustment screw counterclockwise to lower set point.

Fig. 38 — High-Pressure Switch (P/N HH02WC001)

3. To change or check calibration, use a T assembly with

3 rubber tubing leads. Attach one lead to the HPS and

another to an accurate manometer with the appropriate

range. Apply pressure through the third lead and approach set point slowly.

4. Adjust set point to at least 0.5 in. wg greater than configured static pressure set point.

Air Quality Sensors (Fig. 39) — The air quality (AQ)

sensors are shipped inside the fan section for field installation. Two types of sensors are supplied; one sensor monitors

the conditioned air space, and the other sensor monitors the

return air duct. Both sensors use infrared technology to detect the levels of CO2present in the air.

Sensor descriptions and part numbers are shown in

Table 6. To mount the sensor, refer to the installation instructions shipped with the sensor.

Table6—CO

CO2SENSOR ACCESSORY

PART NUMBERS

CGCDXSEN001A00 Wall Mount Sensor (No Display)

CGCDXSEN002A00 Wall Mount Sensor with Display

CGCDXSEN003A00 Duct Mount Sensor (No Display)

CGCDXGAS001A00 Sensor Calibration Service Kit

CGCDXPRM001A00 User Interface Program (UIP)

The CO2sensors listed in Table 6 are all factory set for a

range of 0 to 2000 ppm and a linear voltage output of 2 to

10 vdc. Fig. 40 shows ventilation rates for various CO2set

points when outside air with a typical CO2level of 350 ppm

is used to dilute the indoor air. Refer to the instructions supplied with the CO2sensor for electrical requirements and

terminal locations.

Any changes to the sensor’s factory configuration require

the purchase of the User Interface Program (UIP) or Sensor

Calibration Service Kit, which also contains the UIP.

To accurately monitor the quality of the air in the conditioned air space, locate the sensor near the return air grille

so it senses the concentration of CO

sensor should be mounted at least 1 ft above or 1 ft below

the thermostat to avoid direct breath contact.

Do not mount the space sensor in drafty areas such as near

supply ducts, open windows, fans, or over heat sources. Allow at least 3 ft between the sensor and any corner. Avoid

mounting the sensor where it is influenced by the supply air;

the sensor gives inaccurate readings if the supply air is blown

directly onto the sensor or if the supply air does not have a

chance to mix with the room air before it is drawn into the

return air stream.

To accurately monitor the quality of the air in the return

air duct, locate the sensor at least 6 in. upstream or 15 in.

downstream of a 90 degree turn in the duct. The downstream

location is preferred. Mount the sensor in the center of the

duct.

If the sensor is mounted in the return air duct, readjust the

mixed-air dampers to allow a small amount of air to flow

past the return air damper whenever the mixing box is fully

open to the outside air. If the damper is not properly adjusted to provide this minimum airflow, the sensor may not

detect the indoor-air quality during the economizer cycle.

Sensor Accessories

2

DESCRIPTION

leaving the space. The

2

49

Page 50

Fig. 39 — Air Quality (CO2) Sensor

IN

24 Vac.

OUT

-

+

PRESSURE

LO

HI

SPAN

ZERO

PRESSURE TRANSDUCER :

Part Number :

Range : 0 -

0 . 1 in.

of water

CARRIER

CORPORATION

T40 - 001C - 04 - 012

9A32201

(Wall Mount Version Shown)

CO2CONCENTRATION (PPM)

Fig. 40 — Ventilation Rates Based on CO2Set Point

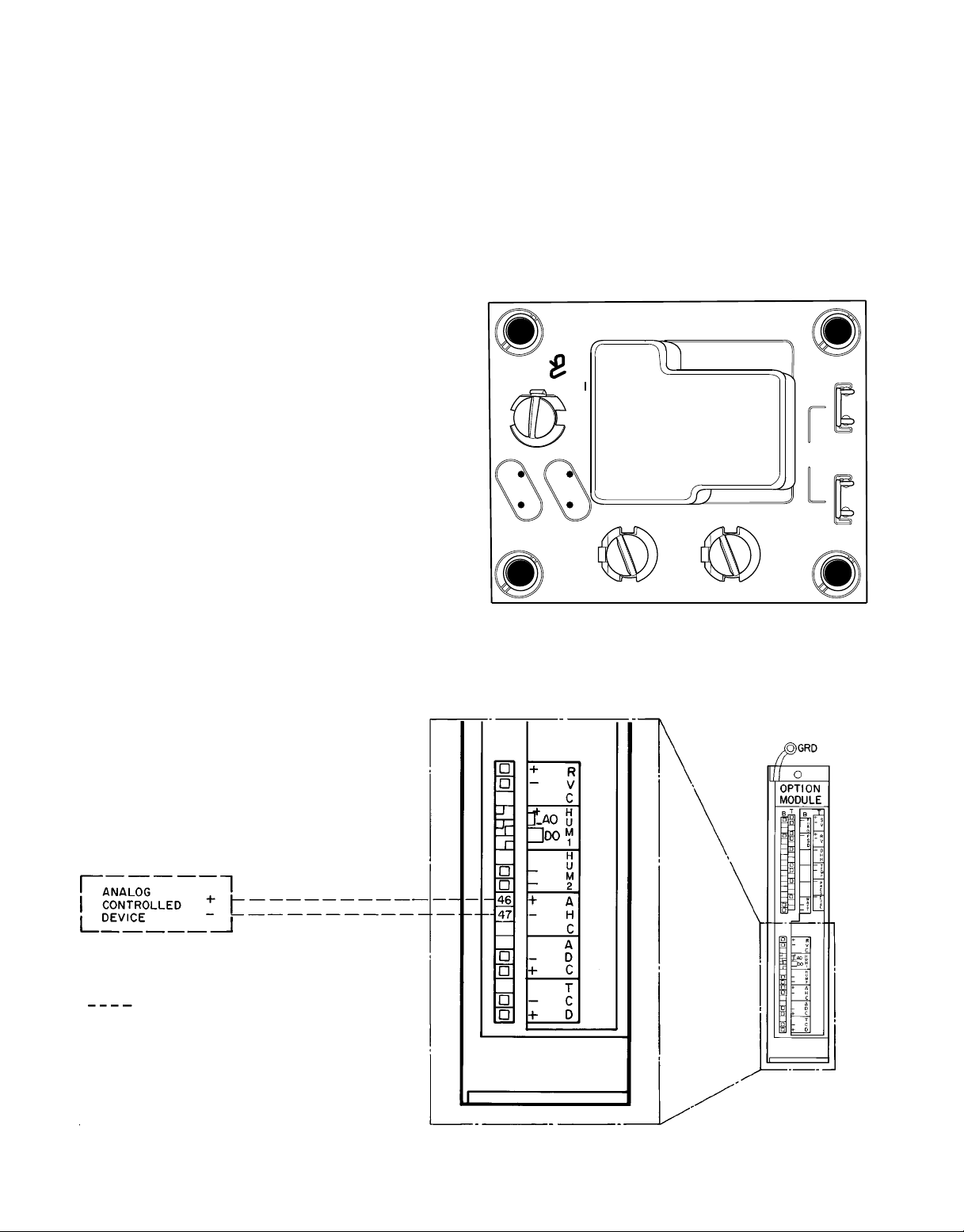

Constant Outside Air (OAC) Control — This fea-

ture ensures a continuous supply of outside air to the unit

and occupied space. The OAC control monitors the outside

air velocity pressure (OAVP) with a probe and pressure transducer.The pressure transducer is factory-installed; the probe

is factory-supplied for field installation in the outside air ducts.

See Fig. 41 and 42.

PROBE INSTALLATION — Locate each probe in a straight

portion of the outside air duct with any dampers, elbows, or

fittings at least 2 diameters away. The probe should be in a

portion of the duct where the airflow is uniform, so that the

probe senses the average air velocity in the duct. The probe

must also be located so that measurements at the probe are

not influenced by the opening or closing of the outdoor-air

dampers.

Install the probe at a 90 degree angle to the airflow and

ensure that the holes in the probe are facing and in line with

the airflow. The probe tube that is closest to the incoming

airflow measures velocity pressure; the rear tube measures

duct static pressure. Use approved plenum tubing to connect

the probe to the bulkhead fittings on top of the control box.

For runs up to 150 ft, use

150 ft, use3⁄8-in. OD tubing. Use at least 25 ft of tubing to

prevent pulsations and erratic operation. Coil any extra tubing if necessary.

installed in the duct and manifolded to obtain a more accurate velocity pressure reading for the entire duct. Manifold

tubing must be larger than the plenum tubing connecting the

If the outside air duct is large, additional probes can be

manifold to the control box. See Fig. 43 and the preceding

for recommended tube sizes.

1

⁄4-in. OD tubing. For runs over

Fig. 41 — OAVP Transducer (P/N HK05ZG004)

Fig. 42 — OAVP Probe (P/N 35DN40007001)

NOTE:High-pressuremanifoldconnectionsshown. Low-pressure connections are identical and must duplicate high-pressure connections.

Fig. 43 — Probe Manifolding

50

Page 51

OAC CALIBRATION — Once the probe and tubing are installed, input the set point to match the probe readings. Before adjusting the OAVP probe, ensure that the supply-air

fan is providing the maximum design airflow and that the

outside-air dampers are adjusted for the design outdoor

airflow intake.

To calibrate the PIC processor to match the probe location, use a precision manometer to measure the velocity pressure in the outdoor air duct at design conditions. Use the

HSIO (local interface device) or Building Supervisor to input the value as the OAVP set point.

Note that the probe does not measure true velocity pressure; when positioned as recommended, the probe measures

a velocity pressure 1.563 times that of the velocity pressure

in the duct. This multiplier (magnification) factor varies with

the probe’s location, and can even be negative if the probe

is located at an elbow or turn. All OAVPvalues displayed on

the HSIO incorporate the multiplier factor to show the true

duct velocity pressure.

If a precision manometer is not available, read the velocity pressure value at the HSIO when the system is running

at maximum design airflow and input that value as the set

point. During normal operation, the velocity pressure is held

constant as the supply fan modulates.

USING OAVP VALUES TO DETERMINE DUCT AIRFLOW — It is possible to determine the airflow (cfm) in the

outside air duct based on the readings obtained by the OAVP

probe. See the following procedure.

Use the HSIO and status function ( ) to display

the outside air velocity pressure (Pv) at the transducer.

If the airflow obtained by the preceding method is different from the design airflow or a measurement obtained with

a balancer, the OAVP probe is not sensing the average duct

velocity and/or the probe’s multiplier factor is effectivelynot

1.563. To match the design or measured airflow to the airflow determined with the preceding formulas, relocate

the probe as recommended or use the HSIO and service

function ( ) to change the probe multiplier

factor.

FIELD-SUPPLIED OR HIGH-VELOCITY PRESSURE

TRANSDUCERS — The default pressure transducer installed at the factory (P/N HK05ZG004) has a range of 0.00

to 0.05 in. wg, which matches an air velocity range of approximately 225 to 680 fpm. The maximum velocity for optimum OAC operation and response, however, is 620 fpm.

If the average duct air velocity is greater than 620 fpm, use

one of the alternate transducers shown in Table 7.

For a field-supplied pressure transducer, use the service

function ( ) to configure the OAC control with

the transducer’s specifications:

OALV = Transducer minimum output voltage

OAHV = Transducer maximum output voltage

OALR = Transducer low pressure

OAHR = Transducer high pressure

(range minimum output) value

(range maximum output) value

Find the average velocity (V) in the duct, in fpm:

4005

=Pv = V

Obtain the cross-sectional area of the duct in sq ft. (A). To

determine the airflow (F) in the duct, in cfm:

VxA=F

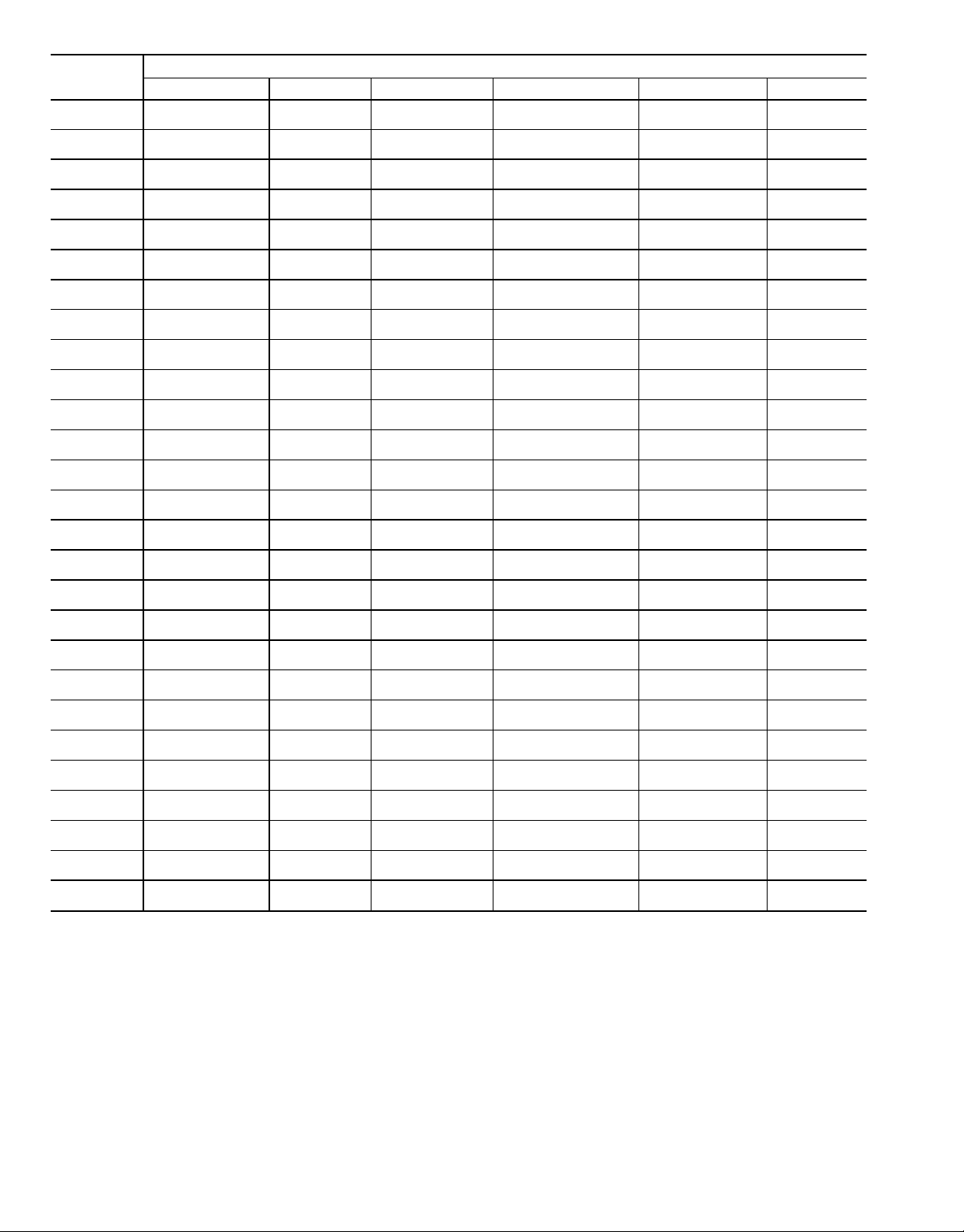

Table 7 — OAC Pressure Transducers

INDICATED VELOCITY

CARRIER

PART NO.

HK05ZG004 T40-005C-04-013 0.00 — 0.05 0.013 — 0.037 0.005 — 0.045 0.008 — 0.024 0.003 — 0.029 360 — 620 225 — 680

HK05ZG005 T40-001C-04-012 0.00 — 0.10 0.025 — 0.075 0.010 — 0.090 0.016 — 0.048 0.006 — 0.057 505 — 875 320 — 960

HK05ZG006 T40-003C-04-015 0.00 — 0.30 0.075 — 0.225 0.030 — 0.270 0.048 — 0.144 0.019 — 0.173 875 — 1520 555 — 1665

MODUS PART

NO.

RANGE

(in. wg)

PRESSURE AT

TRANSDUCER (in. wg)

Optimum

Range

Theoretical

Range

TRUE VELOCITY PRESSURE

IN DUCT (in. wg)

Optimum

Range

Theoretical

Range

VELOCITY IN DUCT

(fpm)

Optimum

Range

Theoretical

Range

51

Page 52

Field Wiring Connections — All field wiring must

comply with National Electric Code (NEC) and all local requirements. The recommended wiring is as follows:

Dampers, actuators, — 4-conductor 20 AWG cable

and valves (2 twisted pairs, unshielded)

Sensors — 2-conductor 20 AWG cable

Refer to Table 8 for recommended brands and part

numbers.

Table 8 — Recommended Sensor and

MANUFACTURER

Alpha 1895 —

American A21501 A48301

Belden 8205 88442

Columbia D6451 —

Manhattan M13402 M64430

Quabik 6130 —

*Within a building.

NOTE: Wiring is 20 gage, 2-conductor twisted cable.

REMOTE LOCAL INTERFACE DEVICE (HSIO) — When

ordered as part of a 39L or 39NX unit, the HSIO is factoryinstalled and fully wired.

To reinstall the HSIO in a remote location away from the

control box, refer to the factory wiring connections in

Fig. 9-12 and proceed as follows:

1. Use a 20 AWG 2-conductor twisted wire pair (Belden

No. 8205 or equivalent) to supply power to the HSIO module. Use a 20AWG 3-conductor cable shielded with drain

wire (Belden No. 8772 or equivalent) for communication

with the HSIO. Cable length must not exceed 1000 ft.

2. Pull the 2 cables (power and signal) through the electri-

cal conduit to the NEMA standard box or HSIO. Leave

approximately 4 ft of wire in the PIC control box for

terminations.

3. Route the cables from the PIC control box to the HSIO

bracket. Secure the HSIO cables to the existing cables

using either tie wraps or by twisting the HSIO cables around

the existing cables. Strip back the jacket 6 in. on each

cable after cutting off the excess. Connect the power cable

at the PIC control box to the existing 3-pin connector hanging at the HSIO bracket. The wires should be terminated

in the screw-type locking clamps on Terminals 1 and 2.

4. Connect the signal cable at the PIC control box to the

existing 4-pin communications connector hanging at the

HSIO bracket. The wires should be terminated in the locking clamps on Terminals 1, 2, and 3. The shield should be

terminated at the HSIO bracket (ground). Be sure to note

the color coding used on the cable for later reference when

terminating the other end of the cable.

5. At the NEMA standard box or HSIO, connect the power

conductors to Pin 1 and 2 of the 3-pin plug. Using the

color coding from the above step, connect the signal cable

to Pin 1, Pin 2, and Pin 3 of the 4-pin communications

connector. Remove the shield and drain wire from this

end of the cable.

6. After the HSIO is installed inside the remote cover, con-

nect the 4-pin and 3-pin plugs to the HSIO.

RETURN-AIR TEMPERATURE SENSOR, OUTDOORAIR TEMPERATURE SENSOR, ENTHALPY SWITCH,

AND MIXED-AIR TEMPERATURESENSOR — Wires are

to be connected to the proper terminals on the processor module. See Fig. 44 for details.

(one twisted pair, unshielded)

Device Wiring

PART NUMBER

Regular* Plenum*

Select a 20 AWG twisted pair, no shield cable. Connect as

per table below:

SENSOR

Return-air temperature sensor (RAT) 20 and 21

Outside-air temperature sensor (OAT) 5 and 6

Enthalpy switch (ENT) 34 and TB2-3

Mixed-air temperature sensor (MAT) 8 and 9

Space temperature sensor (SPT) 17 and 18

NOTE: The MAT is factory wired on all units with a factory-installed

mixing box, filter mixing box, or air blender.

PROCESSOR

MODULE

PIN NO.

SPACETEMPERATURESENSOR (SPT) —The space temperature sensor cover includes terminal block TB1, a jumper

between Pin E2 and Pin E3, and an RJ11 female connector.

The RJ11 female connector connects the service tool with

the Carrier Comfort Network.

Jumper MUST be in place between Pin E2 and Pin E3

or inaccurate readings could result. Ensure that the jumper

is in place before installing the sensor.

Using a 20 AWG twisted pair conductor cable rated for

the application, connect one wire of the twisted pair to

Terminal T1 and connect the other wire to Terminal T2 on

TB1. See Fig. 45.

The other ends of the wires are connected to the processor

(PSIO master) module. As polarity is not a consideration,

connect one wire to Terminal 17 and one wire to Terminal

18 of the processor module.

RJ11 Plug Wiring — Refer to the Carrier Comfort Network

Interface, page 64, for communication bus wiring and cable

selection. The cable selected must be identical to the CCN

communication bus wire used for the entire network.

Cut the CCN wire and strip the ends of the RED, WHITE,

and BLACK conductors. Insert and secure the RED (1)wire

to Pin J2 of the SPT terminal strip TB1. Insert and secure the