Page 1

Number One

AirConditbning

Maker

Division of

Carrier Corporation

Carrier Parkway • Syracus

N Y 13221

t.-

Roll Filter Sections

Central Station Air-Handling Units

INSTALLATION

Step 1 — Verify Shipment with

Shipping Order

Step 2 — Rig Roll Filter Section

Step 3 — Suspend Roll Filter Section....................1

Step 4 — Make Airway Connection

Step 5 — Review RFS Components

Step 6 — Install Power and Control Wires ... 1

Step 7 — Install Roll Filter Media

...............................................

..........................

......................

......................

.........................

Page

1

1

1

1

8

INDEX

START-UP Page

Step 8 — Perform Electrical Control

System Checkout

Replacing Dirty Filter Media

Media Runout Switch

Pressure Switch

Motor Gear-Drive Assembly

Media Tension Brake

Shear Pin

.............................................................

Cleaning and Lubrication

...........................................

SERVICE

...............................

..........................................

...................................................

...............................

..........................................

....................................

9

10

10

11

11

11

11

11

INSTALLATION

Step 1 — Verify shipment with Shipping

Order — Roll filter sections (RFS) are designed to

be bolted to standard Carrier 39E Central Station

Air-Handling Unit section without modification.

They may also be installed in field-fabricated duct

systems. Sections are identified as:

MODEL NO.*

39ER_A (RFS1)

39ED_B (RFSI)

39ED C (RFS3)

39ER_D (RFS5)

39ED_E (RFS5)

39ED F (RFS7)

*Sizes available for each model are shown in Fig

APPLICATION V-PH-HZ

Outdoor, Automatic

Indoor, Automatic

Indoor, Manual

Outdoor, Automatic

Indoor, Automatic

Indoor, Manual

AMPS

120-1-60 3.2 1/10

230-1-50

3

HP

1/10

If shipment is incomplete, contact Carrier. File

damage claims with transportation agency.

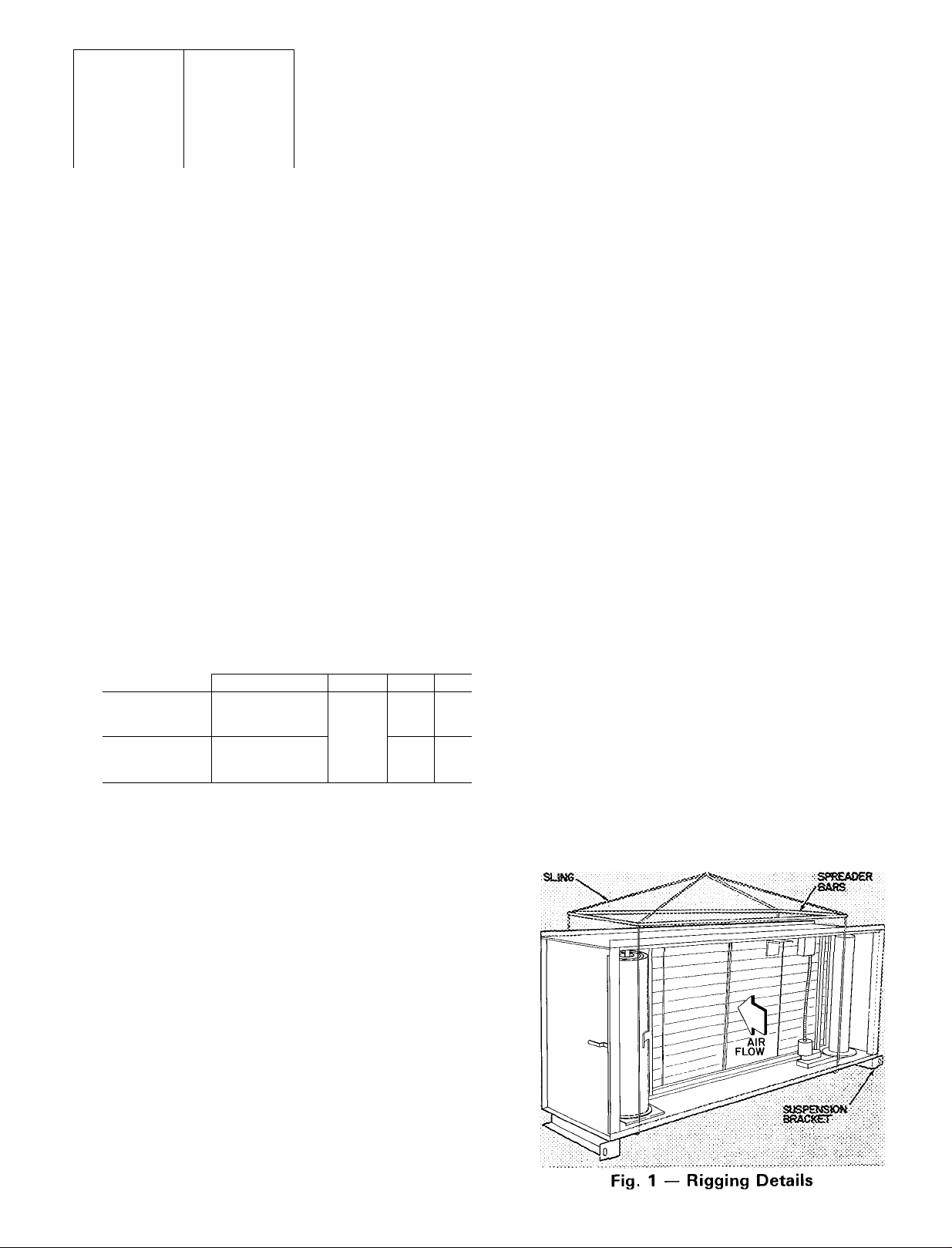

Step 2 — Rig Roll Filter Section — Section is

designed for overhead rigging only. Do not removS

shipping skids until RFS is ready to be moved to

final location. Whenever RFS is moved, use slings

and spreader bars to prevent damage to enclosure

(Fig. 1). Brackets on entering air end of section are

for suspension and are not to be used for rigging.

Refer to base unit installation instructions as

required.

Step 3 — Suspend Roll Filter Section — Sec

tions are supplied with suspension brackets on air

inlet end of channel leg supports (Fig. 1). Unit sizes

08 thru 57 may be suspended by these brackets and

by downstream component bolted to outlet flange.

Size 90 may not be suspended.

Step 4 — Make Airway Connection — Holes in

RFS flanges match holes in 39E base unit sections.

Assemble sections using fasteners shipped in cloth

bag in RFS. For outdoor installation, apply black

caulking gasket on inlet and outlet flanges. Gasket

is shipped in RFS.

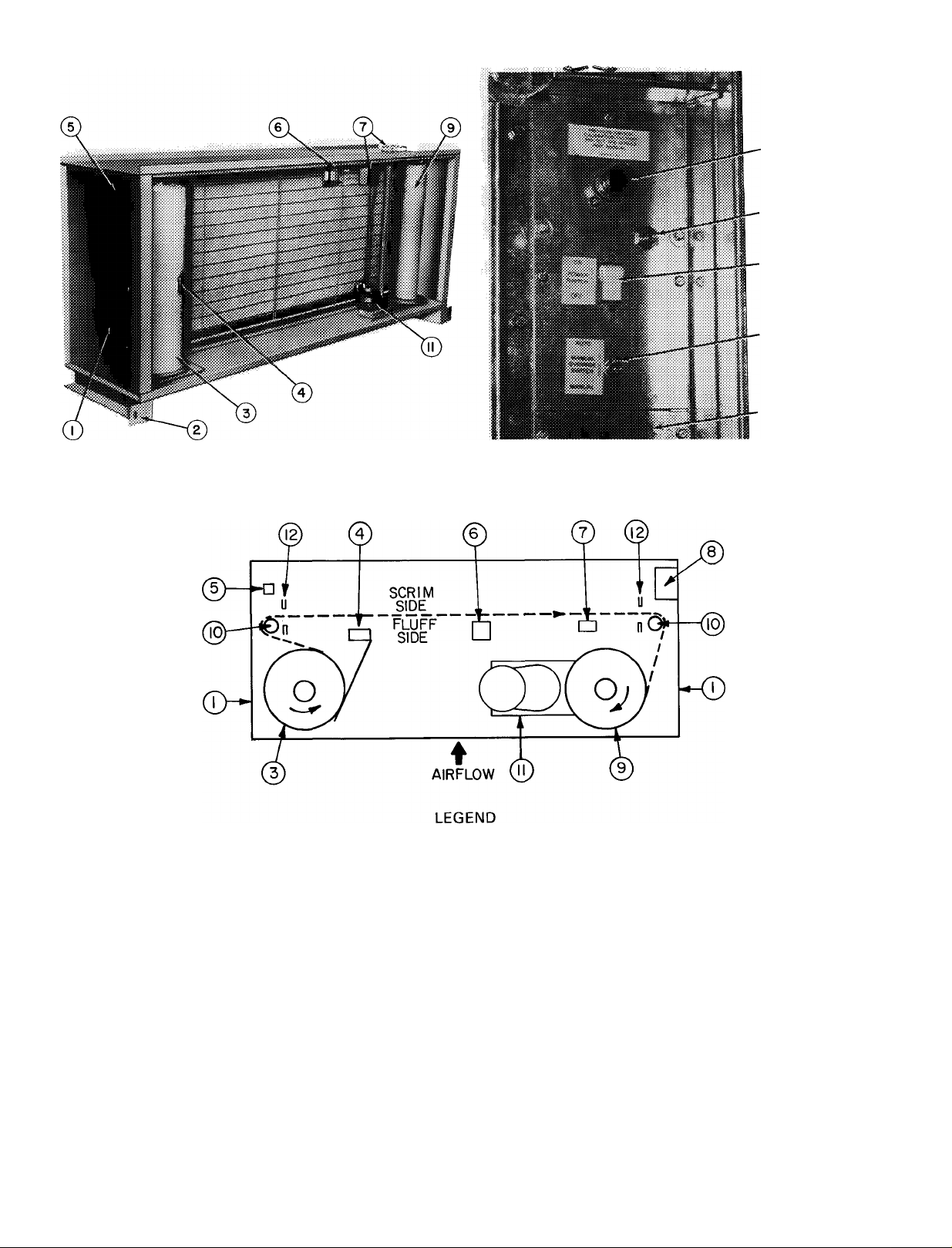

Step 5 — Review RFS Components — Fa

miliarize installer with RFS interior before proceed

ing with installation of power wiring and filter media

roll. This simplifies installation and prevents

damage to equipment. Refer to Fig. 2 thru 5.

Step 6 — Install Power and Control Wires —

Junction box is located on right-hand side of RFS

as shown in Fig. 2 and 3. Install a separate fieldsupplied power disconnect. On 39ER roof-curbed

units, route wires internally. Install all outdoor

wiring in accordance with local codes. Connect to

pigtails LI and L2 provided. Also connect green

ground wire found in junction box.

Tex/ continued on page 8

© Carrier Corporation 1978

Form 39E-11SI

Page 2

CONTROL BOX (ITEM 81 DETAILS

PRESSURE SWITCH

ADJUSTING SCREW

(UNDER RED CAP)

PRESSURE SWITCH

HIGH-PRESSURE

PORT

POWER SWITCH

(ON-OFF)

MANUAL OVERRIDE

SWITCH

(AUTO-MANUAL)

CONTROL BOX

LOWER ACCESS

PANEL

1 — Access Door (both sides)

2 — Suspension Bracket

3 — Supply Spool Assembly

4 — Media Runout Switch

5 — Media Switch

6 — Pulse Generator Switch

7 — Junction Box (position varies; see text)

8 — Control Box

9 — Take-Up Spool Assembly

10 — Idler Shaft (both sides)

Fig. 2 — Roll Filter Section, RFS1 Shown

ROLL FILTER SECTION DESCRIPTION

(Fig, 2 and 3)

........

AU sections have side access

doors hasisg safety latches, A 1 4~in. x 20 lx)ií

prevents door latch from opening unless bolt is

removed. (Do not operate air system when an>

access door is open. Be sure to replace safety bolt

after dootx are closed.) Left-hand door provides

access to roll media supply spool and a media

switch. Right-hand side of section, in addition to

take-up spool and its motorized gear drive, con

tains also a control panel, a field wiring jtmetion

11 — Motor Gear Drive Assembly

12 — Seal (both sides)

-----------

Media Path

box, and where applicable, an mdicator light box

for remote mounting.

The 65-ft of roll media advance from left to

right as shown. ,Medta Is monitored by a runout

switch and a metering device for full span media

travel. Replacement rolls of filter media (65-ftl

may be shipped with section for future use,

i,argest model (39E-90) consists of 2 roll media

assembUes in a common enclosure, lipper assem

bly (slave) Is coupled to lower assembly for

tandem operation by a common control drive

arrangement.

Page 3

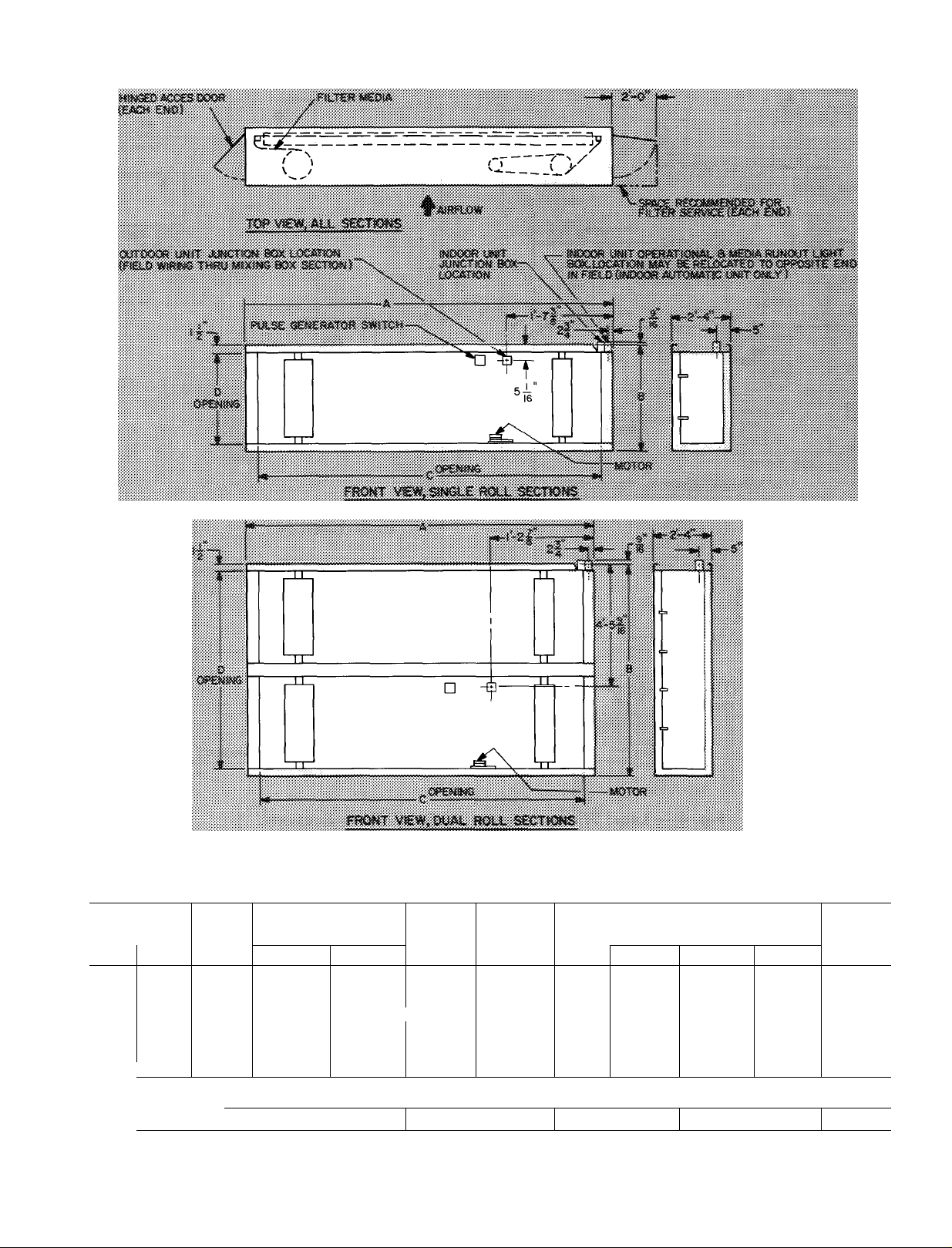

MODEL

SIZE

RFS

RFS — Roll Filter Sections

39E

08 08

10,12 11 6 5,810 6,960 330 1-11-1/2 6-

12

15,18

18

21

26

32

39 39

57 48,57

75,90 91

90

FILTER

AREA

(sq

21 21

26 27 3 13,800 16,560 440 3- 8 832 32 8 16,550 19,860 490 3- 8 9- 9

SINGLE-MEDIA ROLL SECTIONS

CAPACITY

tt)

500 FPM

10 0 5,000 6,000 305 1-11-1/2 5- 11 2-7

19 5 9,750 11,700 375 2-10-1/2 7- 7 3-6

4

43 2 21,600 25,920 510 4-10 962 0 31,000

(cfm)

600 FPM

10,700 12,840 400 2-10-1/2 8-

37,200

WEIGHT

(lbs.

approx)

630 5- 8 11-

MEDIA

ROLL

HEIGHT

(ft-in.) A В

9

3

3

9

9

ROLL FILTER SECTION

2-7

3-6

4-3-1/2 7-9-3/4

4-3-1/2 9-3-3/4

5-5-1/2 9-3-3/4

6-3-1/2 11-3-3/4

DOUBLE-MEDIA ROLL SECTIONS

2

46,100

55,320 825 3- 8

13-3 8-4

Fig. 3 — Physical Data and Dimensions, 39E Roll Filter Sections

DIMENSIONS (ft-in.)

C

5-5-3/4 2-4 100

6-3-3/4 2-4

7-1-3/4

7-9-3/4 3-3

12-9-3/4 8-1

FILTER

FACE

D (sq ft)

3-3

4-0-1/2 27 6

4-0-1/2 33 1

5-2-1/2 43 2

6-0-1/2 62.0

AREA

11 6

19 5

21 4

92.2

Page 4

MEDIA SWITCH

BOX

LI AND L2

- CONNECTIONS

(PIGTAILS)

LI

BLK

sw r

GRY

MS

BLU

MRS i\ o

PINK

i

___

-------------

VIO

115 VOLTS, 60 HZ

230 VOLTS,50 HZ

----------TBI

L2

WHT

BLK

sw

MEDIA RUNOUT

SWITCH BOX

MOTOR CONNECTION

MOTOR CONNECTION

JUNCTION BOX

WIRING JUNCTION

BOX

•JUMPER

TBI TBI

------------

MANUAL UNIT ARRANGEMENT

■YEL (mTr)

----------------

GRY —0

—^ TBI

(INDOOR UNIT ONLY)

LABEL DIAG NO.

60Hz 3INC20-I064

50Hz 3INC 20-1074

Fig. 4 — Label Wiring Diagram, 39E Roll Filter Sections,

Manual, 115-1-60 and 230-1-50

LEGEND

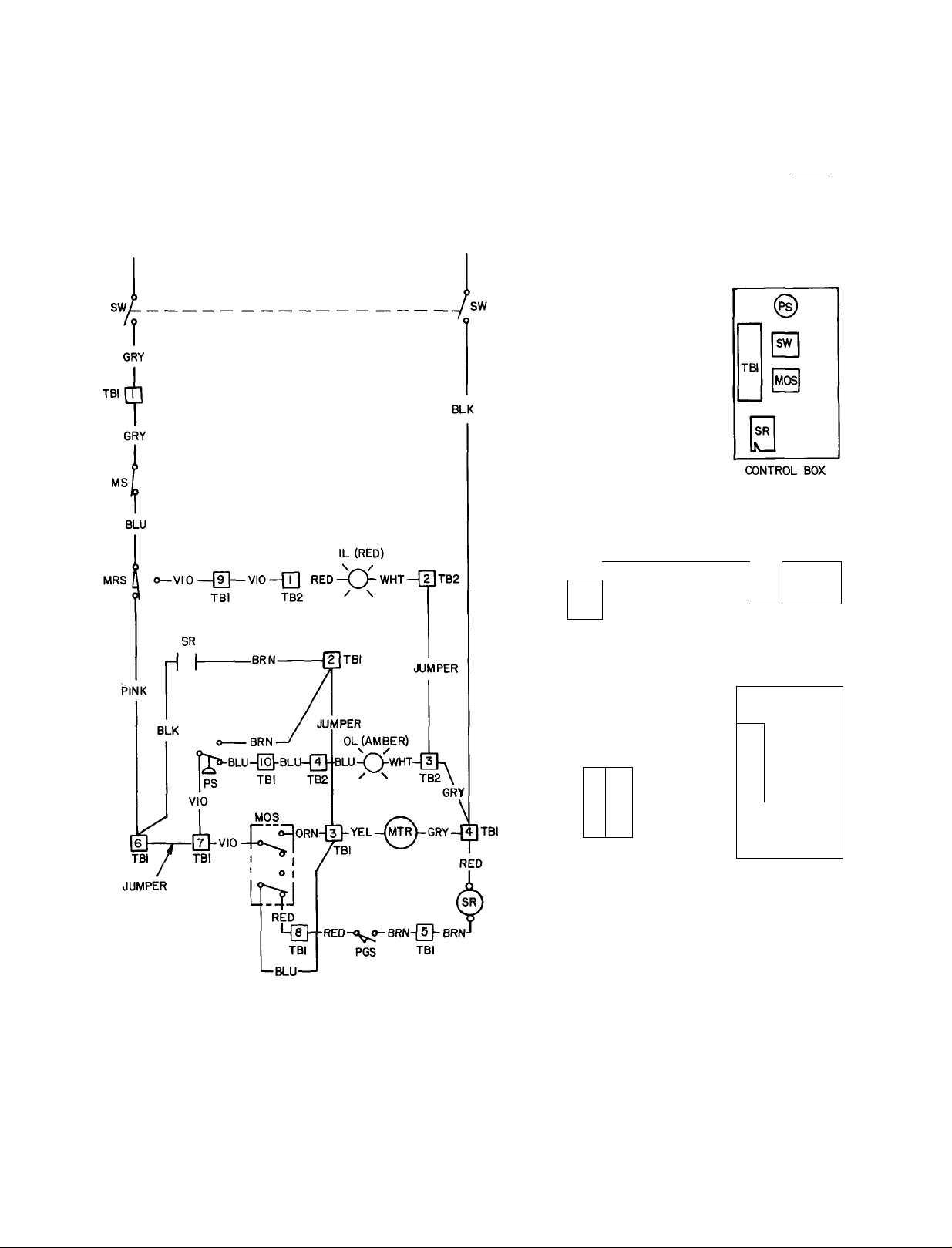

(Fig. 4 and Fig. 5)

IL — Indicating Light

MOS — Manual Override Switch

MRS — Media Runout Switch

MS — Media Switch

MTR — Motor

OL — Operating Light

PGS — Pulse Generator Switch

PS — Pressure Switch

SR — Sequence Relay

SW — On-Off (Power) Switch

TB — Terminal Board

Page 5

f

BLK

115 VOLTS, 60 Hz

230 VOLTS, 50 Hz

L2

WHT

MRS

MEDIA RUNOUT SWITCH

BOX

PGS

PULSE GENERATOR

SWITCH BOX

MOTOR CONNECTION

JUNCTION BOX

INDOOR UNIT COMPONENT ARRANGEMENT

MS

MEDIA SWITCH

BOX

MOTOR

CONNECTIONS

MS

LI a L2 CONNECTION

(PIGTAILS)

ITBEI

WIRING TERMINAL BOX

OL IL

o o

OPERATING a

INDICATING LIGHT

BOX

MEDIA SWITCH

MRS

MEDIA RUNOUT SWITCH

PULSE GENERATOR

BOX

PGS

SWITCH BOX

T

TB

2

WIRING TERMINAL

BOX

OUTDOOR UNIT COMPONENT ARRANGEMENT

BOX

LI AND L2

CONNECTIONS

(PIGTAILS) AND

MOTOR

CONNECTIONS

LABEL DI AG NO

60Hz 3INC20- 1044

50 Hz 3INC20- 1054

Fig. 5 — Label Wiring Diagram, 39E Roll Filter Sections,

Automatic, 115-1-60 and 230-1-50

1 L

OL

O

o

INDICATING LIGHT BOX (REMOTE)

OPERATING a

(OPERATIONAL)

0

0

TBI

|mo s|

0

CONTROL BOX

Page 6

ELECTRICAL COM FOMENT IDENTÍFICATIOM {Rg< 4, 5, 6)

Indksatfng ü^ht OU — Media runout hghi, autoïnaik üecîioas only. Red, acti%atcd by media runout

switch. Illuminates» when filter media on supply

spool is depleted.

Manual Overnde Switch iMOSj — Overrides

automatic advance circuit, activates motor circuit to

permit manual motonr.ed media advancement such

as during media threading operation.

Media Runout Switch |MRS) — Prevents opera

tion of gear motor when supply spool media is de

pleted. Activates red indicating light.

Madia Switch IMS) Desenergizes motor cir

cuit. Allows motor operation from supply side.

Used in conjunction with manual override switch.

Motor {MTRÎ — Operates take-up spool gear

drive to advance filter media, ntermally-protected.

6-rpm, I lô-hp. Gear drive reduces take-up spool

speed to 3 rpm.

Operating light (Ot) — Aatomatic sections only.

Amber, indicates that control switches are in correct

mode, Li^t goes out momentarily when pressure

switch activates motor circuit. If electrical or mech

anical malfunction occurs, light gîses out and stays

out to indicate possible power failure or that pres

sure drop thru airway exceeds air pressure switch

setting due to mechanical failure. Light is re

energized when pressure or power is restored,

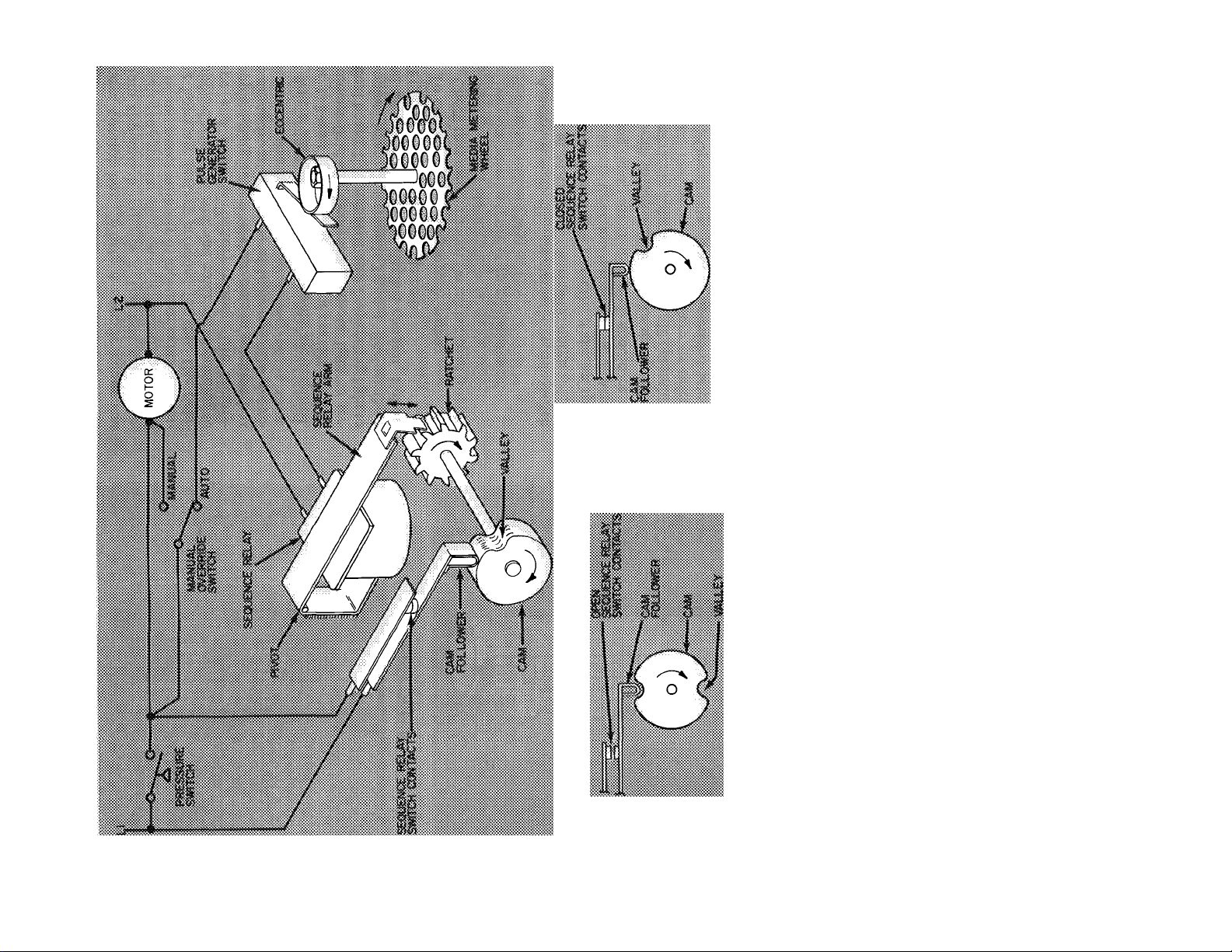

Fulse Gerwmior Switch |PGS> ~- Athomatic

sections only: activated by media metering wheel

cam to operate sequence relay.

Fressure Switch {PS) — Automatic sections only.

Senses pressure drop thru media iu airway. .At preset

pressure (0,5$ in, wg factory setting, adjustable) it

activates motor circuit Camber operating light goes

out). When pressure drops below setting, switch

returns to turn on operating light.

Sequence Relay fSR) — Automatic sections only.

A holding relay that maintains motor operating

mrcait. Senses pulses genmated by pulse ^nerator

switch to advance ratchet cam shaft,

On-Off Switch ISVIQ — Power switch. Controls

all power to motor and control circuit (DPST),

B&WÚ CTS) — Provides quick-connect

termináis for indicator ll^ts or other fmldoonneeted oompoueota,

Ptilsa iSormrator Aaaambly S) Consists

of media metering wheel, pulse generator switch

and sequence relay. Except for making .sure that

media metering wheel tension against media is

suffieient to turn wheel as media passes bv, little or

no service can be performed beyond keeping media

wheel and shaft free of lint and making

sure that electrical connections are intact. The

assembly function.^ a,s follows:

As air pressure increases due to restriction caused

by dirty filtes media, pressure switch closes acti

vating motor to advance media, .Media passing

metering wheel causes wheel to turn. Eccentric

closes pulse generator switch which momcniarily

energizes sequence relay once each rev'olution. Se

quence relay arm advances ratchet wheel one notch

causing relay switch arm cam follower to ride up out

of valley. Sequence relay contacts on relay switch

arm close maintaining pow'er to motor. As media

metering wheel continues to trip sequence relay,

pulses advance ratchet until catn follower drops into

valley thus de-energizing motor power. Media

advancement ceases. Valley-to-valiey interval,

which depends on media metering whxl diameter

and number of valleys. Is “programmed” to operate

motor so that a predetermined length of media h

advanced into airway for full span operation.

Ratchet and cam may be advanced manually (clock

wise} by either turning cam or repeatedly pressing

on sequence coil arm such as when operational

check requires manual advance.

Page 7

ш

_>

SI

E

0)

и

(О

< Е

>- (б

о ™

■н О)

<0 я

® Q

g Ü

«=5

ф л

í>

о. со

(О

03

Page 8

Text continued from page I.

Install remote indicator light box shipped with

outdoor automatic sections per job plans. Indicator

light box on indoor automatic units is fastened

above control box. Where a specific equipment

room application requires it, this box may be re

located to a similar location on left-hand end of RFS

to permit easier visibility of indicator lights. Mount

ing holes are factory provided for this. Use fieldsupplied wiring of type and color corresponding to

type and color of factory wiring. Use factorysupplied plug button to close hole in junction box

resulting from relocation of light box. Do not re

locate junction box.

Where additional indicator lights are required,

use 1 / 2-watt (maximum) lights of correct voltage.

Connect field-supplied media runout light to ter

minal board 2, terminals 1 and 2; operating light to

terminal board 2, terminals 3 and 4. Enclose these

and all wires in rigid or flexible conduit. Follow

NEC and all other applicable codes.

To check that RFS is properly wired:

1. Check that media runout switch is closed (supply

media roll in place).

2. Turn on power supply at fused disconnect.

3. Set media switch (MS) at ON.

4. Automatic section — set manual override switch

(MOS) at MANUAL (automatic only).

5. Set power switch (SW) at ON. Take-up spool

should turn in direction shown in Fig. 2. Amber

operating light (automatic units) should be on.

6. Set on-off switch at OFF. Take-up spool will

stop; operating light will go out. If operation is

incorrect, review wiring procedure or refer to

Service, Operational Checks described later as

required.

Fig. 7 — Threading Details (Step 6)

Step 7 — Install Roll Filter Media — The follow

ing procedure applies to installation of initial roll

filter media as shipped with section. If replacing

dirty filter media, refer to section entitled Replacing

Dirty Filter Media.

1. Open take-up side access door. Set power switch

at OFF, set manual override switch at MAN

UAL (Fig. 2). Open supply side access door. Set

media switch at ON.

2. Begin with lower assembly on dual roll sections.

Lift supply spool shaft upper retainer, swing

out upper end of spool shaft.

3. Install media roll on spool shaft. Note correct

position of roll so that as media unwinds, fluff

side of media will be facing into airstream

(Fig. 2).

4. Untie and remove plastic wrapper from media

roll. Replace upper end of spool shaft in

retainer.

5. Remove threading rod from its storage clips on

supply compartment bulkhead.

6. Locate eyelet end of threading wire lying in

Fig. 8 — Paper Leader Installed on

Take-Up Core (Step 9)

media track. Install threading rod on filter

media paper leader so that threading rod eyelet

is trapped at about midpoint of leader (Fig. 7).

7. Pull take-up end of threading wire so that filter

media passes around supply side idler shaft and

traverses airway from supply side to take-up

side. Be sure that threading rod, paper leader

and filter media pass thru supply side seals with

out force. Check that threading operation

follows route shown in Fig. 2 so that media

emerges thru take-up side seals and around

take-up side idler shaft without wrinkling or

tearing.'

8. Remove threading rod and wire from paper

leader. Replace threading rod on its storage

clips on supply side. Threading wire may be

discarded.

9. Insert leader behind strap on take-up core

(cardboard tube) and fold it over itself as shown

in Fig. 8.

Page 9

10. Set power switch at ON so that take-up spool

makes 2 complete turns. Be sure that paper

leader lies flat against media so that as media

winds around core it does not come loose or

bunch up. Be sure that media is free of wrinkles

and travels without snagging. Again, check that

media is routed as shown in Fig. 2.

11. Dual roll sections — Repeat threading pro

cedure for upper media roll. Note that a second

threading rod and wire are provided. After

upper roll is threaded, about 4 turns of media

will be wound on lower take-up spool. Do not

operate gear motor any more than necessary.

Media cannot be rewound onto supply spool.

12. Set manual override switch at AUTO, as appli

cable. Then set power switch at ON.

13. Perform operational checks as required. Close

and secure access doors. Refer to air handling

unit operating instructions as applicable.

START-UP

Step 8 — Perform Electrical Control System

Checkout — Control system designed and factory

set to provide full-span media advancement when

required. Before performing Operational Check,

and Complete Electrical Check, described below, re

view Roll Filter Description (page 8), Wiring Dia

grams (Fig. 3 and 4) and Component Description.

Be sure that media is correctly installed and routed

as shown in Fig. 2.

cAwmmt mm ^

mm whidi m Siee« Mv&tsm be re-

OPERATIONAL CHECK (all power is off)

1. Automatic Units — set manual override

switch at AUTO.

2. Set media switch at OFF.

3. Turn on power to unit at fused disconnect

switch.

4. Set power switch at ON. Read steps 5, 6 and

7; perform in relatively rapid succession.

5. Set media switch at ON.

Manual Units — Motor should operate.

Automatic Units — Amber operating light

should light up.

6. Automatic Units — Set manual override

switch momentarily at MANUAL. Motor

should operate momentarily.

7. Swing media runout switch arm away from

supply media spool. Depress media runout

switch (micro-switch behind runout arm).

Manual Units — Motor should stop.

Automatic Units — Media runout light (red)

should light up.

8. Release media runout switch. Restore control

circuit to operating status (i.e. media switch at

ON, runout switch at AUTO., power switch at

ON).

COMPLETE ELECTRICAL CHECKOUT to be

performed by a qualified electrician only.

Because it has fewer controls, the complete elec

trical checkout of a manual roll filter section is the

same as the operational check described above. The

following procedure applies to automatic roll filter

section only.

1. Set power switch at OFF. Turn power off at

external fused disconnect switch.

2. Remove access panel below control panel

(Fig- 2).

3. Restore power at fused external disconnect

switch; set power switch at ON.

4. Perform Operational Check described pre

viously as required.

5. Connect a 36-in. (approximate) piece of 3/8-in.

tubing to high-pressure tap on control panel

face (Fig. 2).

6. Blow on tube to close pressure switch to simu

late high pressure caused by dirty filters. Media

advance motor should operate. Refer to Pres

sure Switch Adjustment described later as

required.

7. Maintain pressure on pressure switch long

enough to perform step 8.

8. As media advances, allow media metering wheel

to revolve thru one revolution. This closes pulse

generator switch and energizes sequence relay

(Fig. 5 and 6). Review Pulse Generator Assem

bly description as required.

9. Set power switch at OFF. Shut off power at

fused disconnect.

10. Remove tubing from high-pressure tap.

11. Reset sequence relay by manually turning cam

clockwise until relay switch arm drops into

valley of cam (either cam on sizes 75 and 90).

12. Replace control box cover, restore power at

fused disconnect switch and set all switches

as follows:

Media Switch — ON

Manual Override Switch — AUTO.

Power Switch — ON

13. Roll filter section is again ready for automatic

operation. Check that all is in order. Close and

secure access doors before leaving job site.

Page 10

SERVICE

Replacing Dirty Filter Media — Rethreading

clean media roll is not necessary. When clean media

is to be installed, simply attach leader of clean media

roll to trailer of depleted (dirty) media roll as

follows;

1. Shut off system air fan. Open both side access

doors (Fig. 2). Automatic units — set manual

override switch at MANUAL.

2. Check that supply media roll has been depleted.

Swing media runout arm away from supply

spool and set media switch at ON so that motor

will advance remaining media. When paper

trailer is exposed, release runout arm (stopping

motor). Then set media switch at OFF.

NOTE: If a complete increment of clean media

can be exposed to airway before paper trailer on

supply spool is exposed, adjust media runout

switch as described later so that clean media will

not be wasted.

3. Disengage paper trailer from supply core (card

board tube). Do not operate motor at this time.

4. Lift supply spool upper shaft retainer, swing

out upper end of shaft. Remove the now empty

core from supply spool. Do not damage or dis

card core.

5. Unpack replacement supply media roll, install

it on supply spool. Replace upper end of spool

in retainer. Note correct position of roll so that

as media unrolls fluff side of media will be facing

into airstream (Fig. 2).

6. Connect paper leader of replacement media roll

to paper trailer of depleted media roll by using

threading rod (Fig. 9).

7. Dual-roll sections only — Jog media switch to

expose paper trailer of upper (slave) media roll.

As this is done, be sure that threading rod in

splice in lower media rolls passes smoothly

around supply-side idler shaft and then thru

supply-side seals without snagging or wrinkling.

Repeat steps 2 thru 6 to replace upper media

roll.

8. Set media switch at ON to draw splice(s) across

airway opening. Check that threading rod(s),

splice(s) and media travel smoothly. When

(lower) threading rod and splice reach take-up

side set media switch at OFF.

9. Remove threading rod to disconnect paper

trailer of depleted roll from paper leader of

replacement roll. Replace threading rod on its

storage clips in supply side.

10. Lift take-up spool shaft retainer; swing out

upper end of take-up spool. Remove depleted

media roll from take-up spool. Pack dirty media

roll in now-empty replacement roll carton. Dis

pose of dirty media roll as suitable.

11. Install empty core (cardboard tube removed in

step 4) on take-up spool. Replace upper end of

take-up spool shaft in shaft retainer.

12. Insert leader behind strap on take-up core

(Fig. 8). Fold leader over itself. Note rotation

of take-up spool (Fig. 2).

13. Set power switch at OFF.

14. Set media switch at ON.

15. Jog power switch so that about 2 turns of clean

media roll winds up on take-up spool to secure

paper leader end of roll on to core. On dual-roll

sections this will also advance upper media roll

so that splice will pass thru upper take-up-side

seals, pass around take-up idler shaft and reach

upper take-up spool.

16. Dual roll sections — Disconnect splice in upper

depleted and replacement rolls; connect upper

replacement media roll to upper take-up spool

(i.e. repeat steps 9 thru 15). Be sure that media

travels smoothly and that paper leader is evenly

secured. Replace threading rod in its storage

clips on supply side.

17. Manual Units — Leave media switch at ON. Set

power switch at OFF.

Automatic Units — Set manual override switch

at AUTO. Set media switch at ON, then set

power switch at ON.

18. To check that all is in order, perform Opera

tional Checks as required. Close and secure

access doors before leaving job site.

r

Fig. 9 — Replacement Media Roll Spliced

to Depleted Media Roll

Media Runout Switch (Fig. 2) — Switch is factory

set to prevent media advancement when supply

spool media is depleted. Incorrect setting may

cause excessive media to remain on supply spool

or cause media to be pulled off supply spool core

before shutting off advance cycle.

Runout switch is activated by adjustable bolt on

runout arm when arm is 3/8-in. away from spool

core. To adjust cutout setting:

10

Page 11

1. Loosen adjusting screw locknut.

2. Turn adjustable bolt so that runout switch opens

when runout arm comes within 3/8-in. of core.

3. Tighten adjusting screw locknut. Recheck

setting.

Pressure Switch (Fig. 2) — As filter media be

comes dirty, high-pressure drop thru media reduces

airflow. Pressure switch is factory set at 0.55 in. wg.

Field adjustment should not be necessary. When

pressure sensed by high-pressure fitting on control

panel face reaches this setting, pressure switch shuts

off amber operating light and energizes pulse gener

ator sequence relay and motor. As clean media ad

vances across airway, pressure drop across media

decreases and switch returns to illuminate amber

operating light. To check and/or adjust pressure

switch setting:

1. Shut off system air fan. Open take-up side

access door. Shut off power at fused disconnect.

Set power switch at OFF.

2. Disconnect yellow or gray motor lead at ter

minal board no. 1 (TBl-3 or 4) to prevent motor

operation. Tape off lead.

3. Set power switch at ON. Turn on power at

fused disconnect.

4. Remove red plastic cap from pressure switch to

expose adjusting screw. Do not loosen 1-in. hex

locknut. Nut is locked to provide mechanical

stop for minimum differential pressure setting.

5. Connect a draft gage to high-pressure port on

control panel.

6. Apply controlled pressure gradually to highpressure port until amber operating light goes

out. Note draft gage reading. This is switch set

point (factory setting 0.55 in. wg).

7. Turn adjusting screw counterclockwise to de

crease static pressure setting or clockwise to

increase static pressure setting as required. A

1/2 turn changes setting approximately 0.13

in. wg.

8. Remove draft gage. Replace red plastic cap on

adjusting screw.

9. Shut off power at fused disconnect. Set power

switch at OFF. Reconnect motor lead. Turn on

power at fused disconnect. Set power switch

at ON.

10. Perform any other operational checks as re

quired. Close and secure access door. Restore

air system operation.

Motor Gear-Drive Assembly (Fig. 2 and 10) —

Assembly advances clean media across filter section

airway. It consists of a motor and drive sprocket,

a roller chain and a take-up spool sprocket on a

support plate. Chain tension is factory set so that

deflection of chain at midpoint is 1/4-inch. To ad

just chain tension, loosen motor mounting bolts (3),

reposition motor on slotted mounting holes in

support plate until correct tension is achieved.

Tighten motor hold-down bolts.

MOTOR

SUPPORT PLATE

MOTOR MOUNTING

BOLTS. LOOSEN FOR

TENSION ADJUSTMENT

Fig. 10 — Motor Gear-Drive Details

MOUNTING HOLES (4)

TAKE-UP

SPOOL

SPROCKET

Lubricate chain with a light graphite oil once each

year.

Media Tension Brake (Fig. 11) — Brake is

mounted on bottom panel of supply spool side to

provide tension on supply spool at bottom end of

spool shaft. Two brake shoes held in place by 2

helical springs cause friction (drag) required for

proper media tension. Brake assembly includes

supply spool bearing surface and slotted axis shaft.

Except for making sure that helical springs and shoes

are in tension, no other maintenance is required.

Shear Pin — Take-up spool shaft is fastened to

keeper on take-up spool disk at base of spool by a

bolt and locknut. This bolt acts as a shear pin to pre

vent damage to motor gear-drive. In the event of

mechanical failure which could cause excessive

tension on motor gear-drive, bolt will shear allowing

motor to operate freely and continuously. Eventu

ally, amber operating light will go out (as described

elsewhere) and stay out as indication of malfunction.

Cleaning and Lubrication — The only cleaning

necessary in addition to general housekeeping is

removal of loose fibers around shaft bearings. Shaft

bearings and gear motor require no routine main

tenance. Refer to specific component description for

additional information as required.

BRAKE

SKIES:

Fig. 11 — Media Tension Brake

11

Page 12

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 3

Tab lib

Form39E-11SI Supersedes 31 NA-1 SI

PrintedinUSA 5-78 PC201 Catalog No 533-925

Loading...

Loading...