Page 1

iupeeseoeo '6'/

Draw-Thru Central Station Weathermaker

SuPcesfi^cC) ay 0/7/

39B

INDEX

PAGE

PREINSTALLATION

INSTALLATION

Base Unit Assembly

Accessory Assembly

Unit Suspension and Mounting

Piping

Coil Removal and Reversing

Duct Connections

Motor and Drive

Belt Guard

START-UP

SERVICE

Coil Removal

Fan Section Access

Fan Shaft Bearing Replacement

Fan Shaft Removal

Fan Wheel Removal

PREINSTALLATION

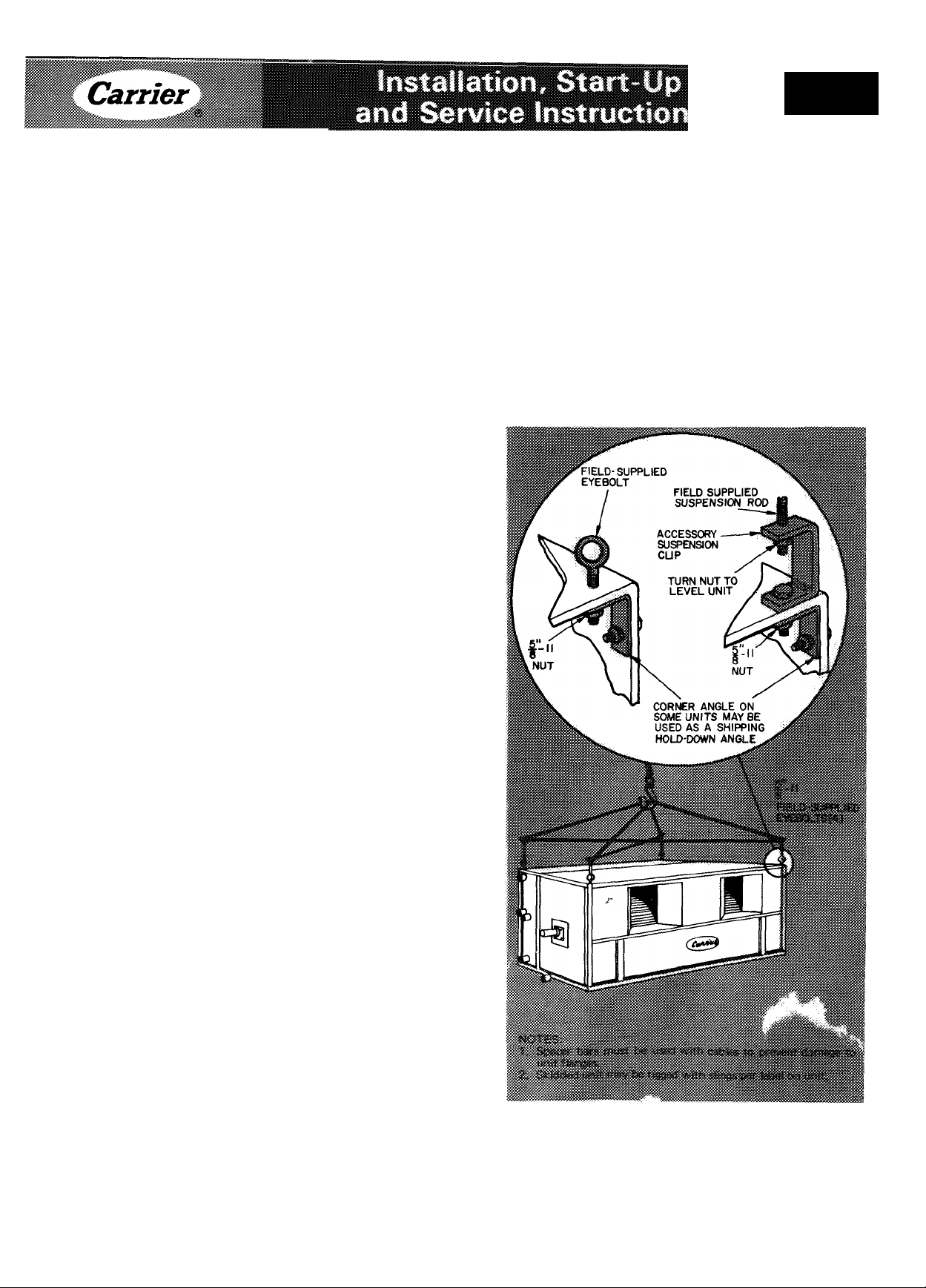

1. Use spacer bars when rigging to avoid bending

unit flanges per Fig. 1.

2. Check items received against packing list and

Tables 1,2, and 3. Notify Carrier at once of

any discrepancy.

3. Examine for damage incurred during shipment.

Especially check for bent fan wheel or shaft

which may result in future vibration problems.

If any damage is found, immediately file claim

with transit company.

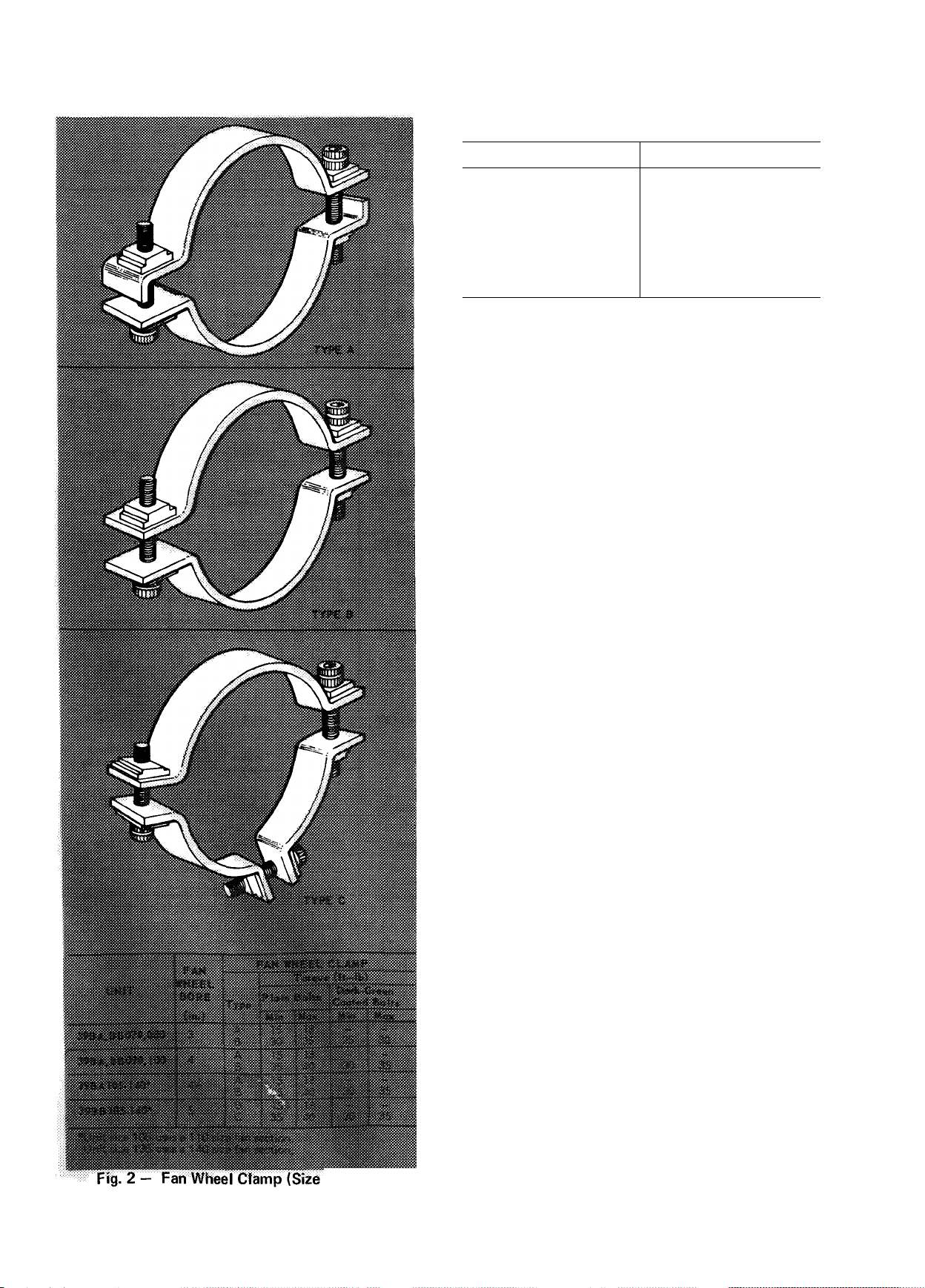

4. Check fan wheel setscrews (sizes 040-060) or

fan wheel clamps (sizes 070-140) for secure

ness. Refer to Table 4 or Fig. 2 respectively.

a. Bolt threads with a dark-green finish require

no lubrication. Carefully lubricate all other

bolt threads with oil. Do not oil fan shaft.

b. Tighten clamps evenly.

5. Exercise care in handling all equipment.

6. If unit is to be stored for more than t, ’o v,eeks

prior to installation, observe the following

precautions:

a. Choose storage site that is kvel and ; +urdy.

to prevent undue stress or permanei t dis

tortion to fan. Do not subject bearings to

direct sunlight or temperatures in excess of

1.

180 F. '

1

6

6

9

14

15

19

19

19

22

22

23

23

23

23

23

24

b.c.Protect bearings and rotating components

against moisture, abrasives and corrosion.

Cover entire unit with a tarp or plastic

coverall. Extend cover under unit if stored

on ground. Moisture and condensation can

cause loosening of internal insulation.

Periodically rotate fan shaft slowly by hand.

Fig. 1 — Rk , and Suspension DetailiS

© Carrier Corporation- 1971

*

Form 39B-1SI

Page 2

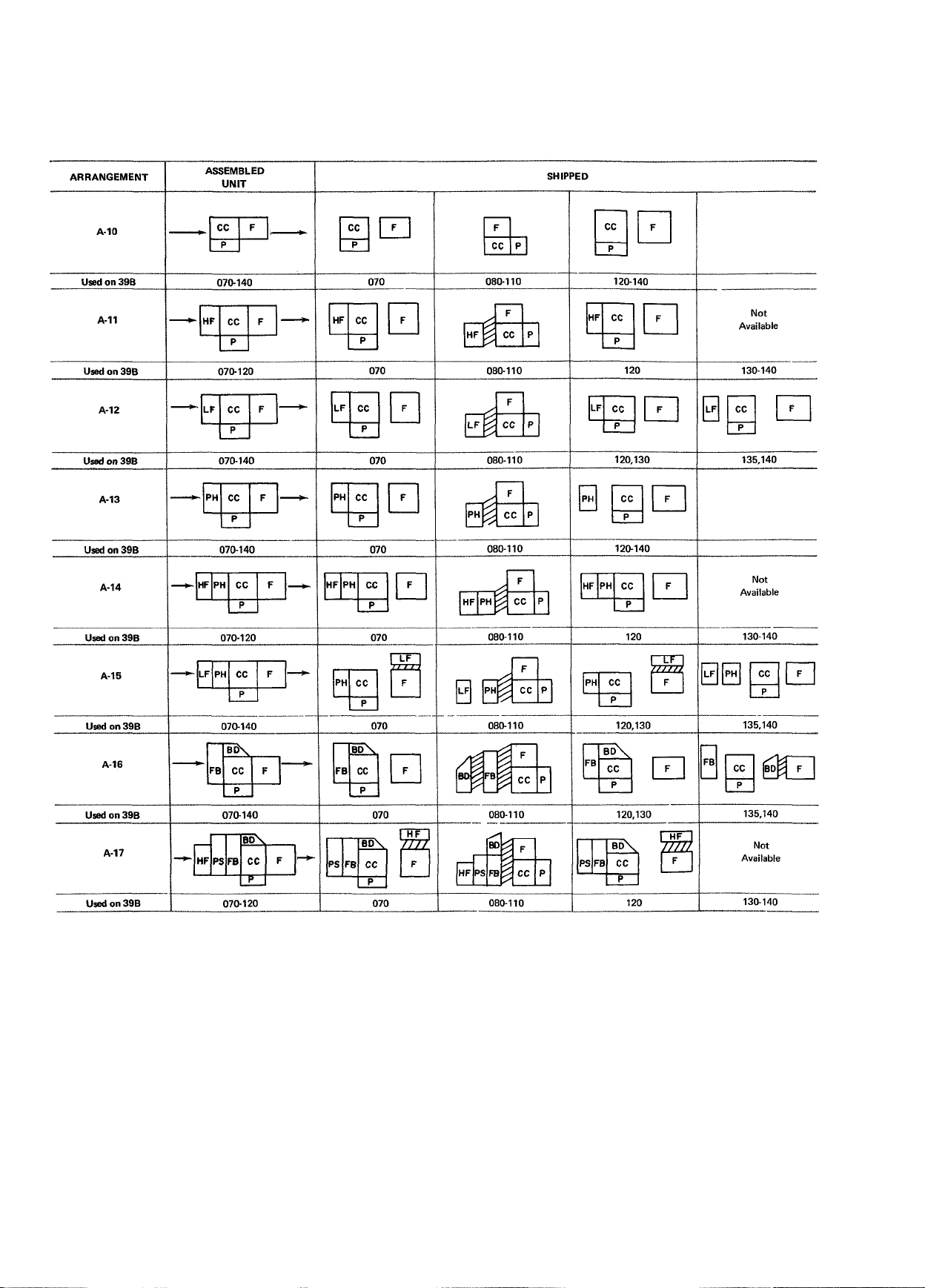

Table 1 — 39B Type "A" Unit Arrangements (Horizontal With Reheat)

Base unit and accessories on 39BA, sizes 040 thru 060 are shipped completely assembled.

Page 3

Table 1 — 39B Type "A" Unît Arrangements (Horizontal With Reheat) (cont)

Base unit and accessories on 39BA, sizes 040 thru 060 are shipped completely assembled.

r

LEGEND

BD — Bypass Duct

CC — Cooling Coil and Reheat

Coil Section

F — Fan Section

FB — Face & Bypass Damper Section

NOTE: Combination mixing box and filter assembly (MB), not shown, is shipped separately.

HF — High-Velocity Filter Section

LF — Low-Velocity Filter Section

P — Base Pan

PD — Preheat Duct Extension

PH — Preheat Coil Section

PS — Plenum Section

Separate Crates or Skids

Location for Shipping only on one Skid.

Page 4

Table 2 ~ 39B Type "B" Unit Arrangements (Horizontal Without Reheat)

Base unit and accessories on 39BA, sizes 040 thru 060 are shipped completely assembled.

ARRANGEMENT

B-10

Used on 39B

B-11

Used on 39B

B-12

Used on 39B

B-13

Used on 39B

ASSEMBLED

UNIT

C

^

070-120

070-120

P

C

F

C

H

P

F

Hcc

SHIPPED

LF

Shipped

Assembled

070-110 Used on 39B

PH

Shipped

Assembled

070-110 Used on 39B

Shipped

Assembled

I

ARRANGEMENT

B-17

Used on 39B

B-18

Used on 39B

B-20

B-21

ASSEMBLED

UNIT

■ p

F

c

F

s

B

c

070-120

P

F

c

L

F

L

F

F

S

B

c

070-120

\

P

F

c

F

S

B

c

070-120

PD BD

070-120 070-110

PD BD

P

S

\

F

P

c

F

B

H

c

Shipped

Assembled

070-110

P

F

c

s

B

c

070-110

Shipped

Assembled

070-110

PD BD

P

F

S

B

«

P

F

s

B

§

SHIPPED

\

IlI

F

N

p

P

s

P

F

s

B

p

s

F

B

P

s

120

F

B

120

120

PD BD

M

120

F

B

PD BD

BD

P

F

s

B

Used on 39B

B-15

Used on 39B

B-16

Used on 39B

070-120 070-110

P

c

H

c

p

070-120 070-110

F

c

F

B

c

070-120 070-120

Shipped

Assembled

120

I

120

Used on 39B 070-120

B-22

Used on 39B 070-120

B-23

Used on 39B

LEGEND

BD — Bypass Duct

— Cooling Coil Section Only P

CC

— Fan Section PD

F

— Face & Bypass Damper Section PH

FB

— High-Velocity Filter Section

HF

LF

PS

NOTE: Combination mixing box and filter assembly (MB), not shown, is shipped separately.

070-110

PD BD

1

___

p

c

B P

s

c

® H

PD BD

F

P

B

H

070-120

V

F

PD BD

p

F

p

c

s

B

c

H

070-110

Shipped

Assembled

070-110

□ □ Separate Crates or Skids

Location for Shipping oniy on one Skid

120

P

F

F

s

B

PD t BD

“

P

H

120

p-y

F

F

B

Page 5

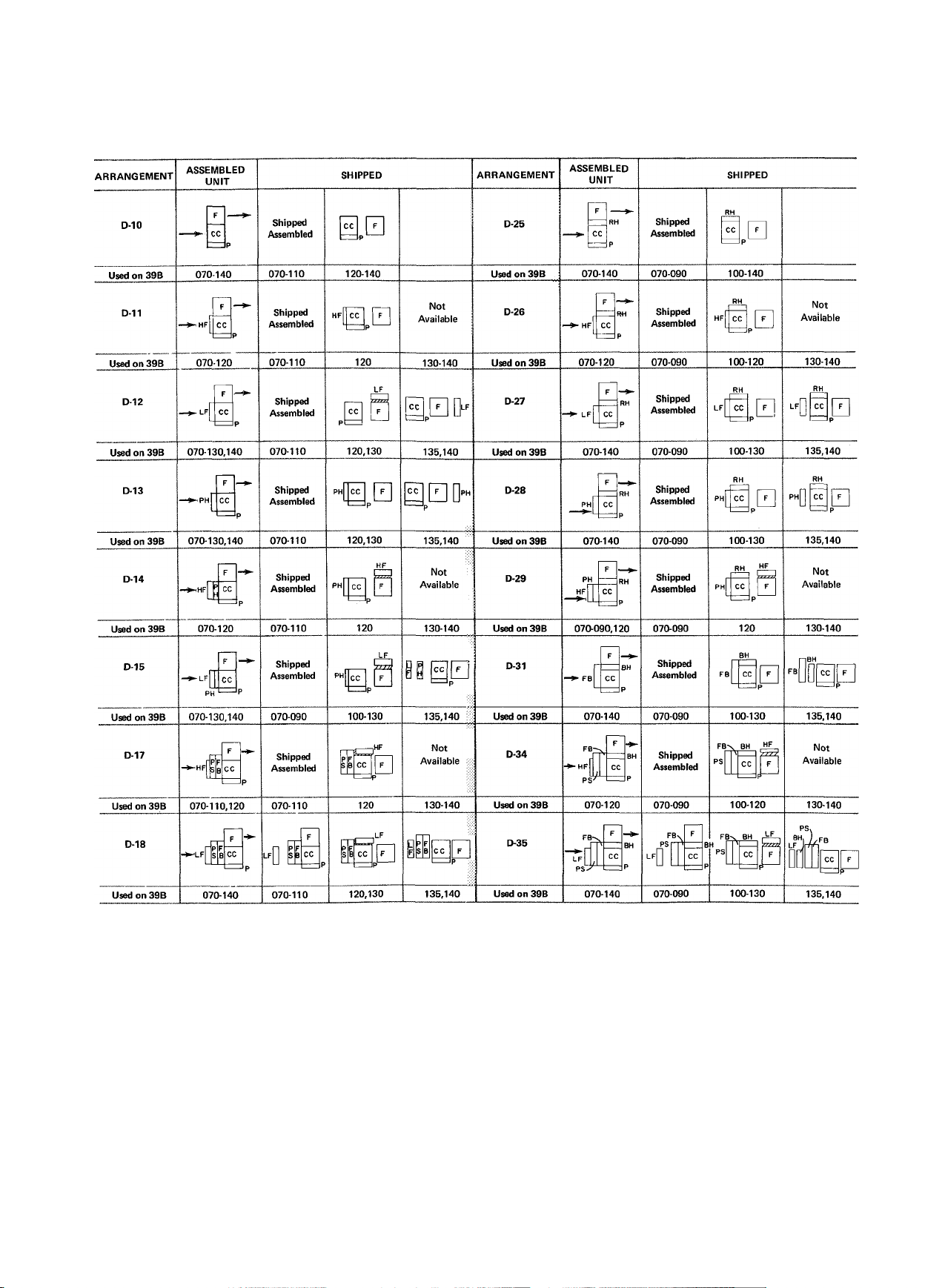

Table 3 — 39B Type "D" Unit Arrangements (Vertical)

Base unit and accessories on 39BA, sizes 040 thru 060 are shipped completely assembled.

LEGEND

BH - Bypass Heat Section LF — Low-Velocity Filter Section

CC — Cooiing Coil Section P — Base Pan

F — Fan Section PH — Preheat Coil Section

FB — Face & Bypass Damper Section PS — Plenum Section

HF — High-Velocity Filter Section RH — Reheat Coil Section

NOTE: Combination mixing box and filter assembly (MB), not shown, is shipped separately.

□ □ Separate Crates or Skids

Location for Shipping only on one Skid

Page 6

Table 4 — Setscrew Torques

076-140)

SETSCREW SIZE

10

1/4 52.7- 71 3 in.-lb

5/16

3/8 168.3-227.7 in.-lb

7/16

1/2

5/8

3/4

INSTALLATION

General

TORQUE

22 5- 30.5 in.-lb

103.7-140.3 in.-lb

22.1- 29 9 ft-lb

32 3- 43 7 ft-lb

78.2-105.8 ft-lb

107.9-146.1 ft-lb

DO NOT

1. Remove protective caps from coil piping con

nections until ready to connect piping.

2. Bend or mutilate coil fins.

3. Remove protective cover or grease from fan

shaft until ready to install sheave.

4. Lift by fan shaft extension or coil connections.

5. Remove fan drive from boxes until ready to

install, to prevent loss of parts and installation

information labeled on boxes.

6. Lift face and bypass damper assembly without

providing support under center of assembly.

DO

1. Use spacer bars per Fig. 1 when rigging to avoid

bending unit flanges.

2. Make piping and duct connections in accord

ance with standard practices. Refer to Carrier

System Design Manual for details.

3. Leave sufficient clearances for:

a. Condensate trap.

b. Removal of fan shaft and coils.

c. Service of filters, fan motor, bearings,

damper linkage, and damper motors (at least

30 inches).

d. Piping to permit removal of fan guard.

Base Unit Assembly (Fan and Coil Sections)

NOTES:

1. Base unit and accessories on 39BA sizes 040

thru 060 (arrangements A, B, and D) are

shipped completely assembled, except for

accessory mixing box which is shipped

separately.

2. More holes may exist than indicated by these

instructions. Use only those which line up.

3. Fastener package is shipped with each fan

section. Sealing compound is shipped inside

belt guard.

4. Remove any accessories attached to base unit

that are not in their final location per Tables 1,

2, and 3.

5. Unit suspension is simplified by completely

assembling units prior to rigging.

6. Unit sizes 130 thru 140 must be assembled on a

platform for suspended applications.

Page 7

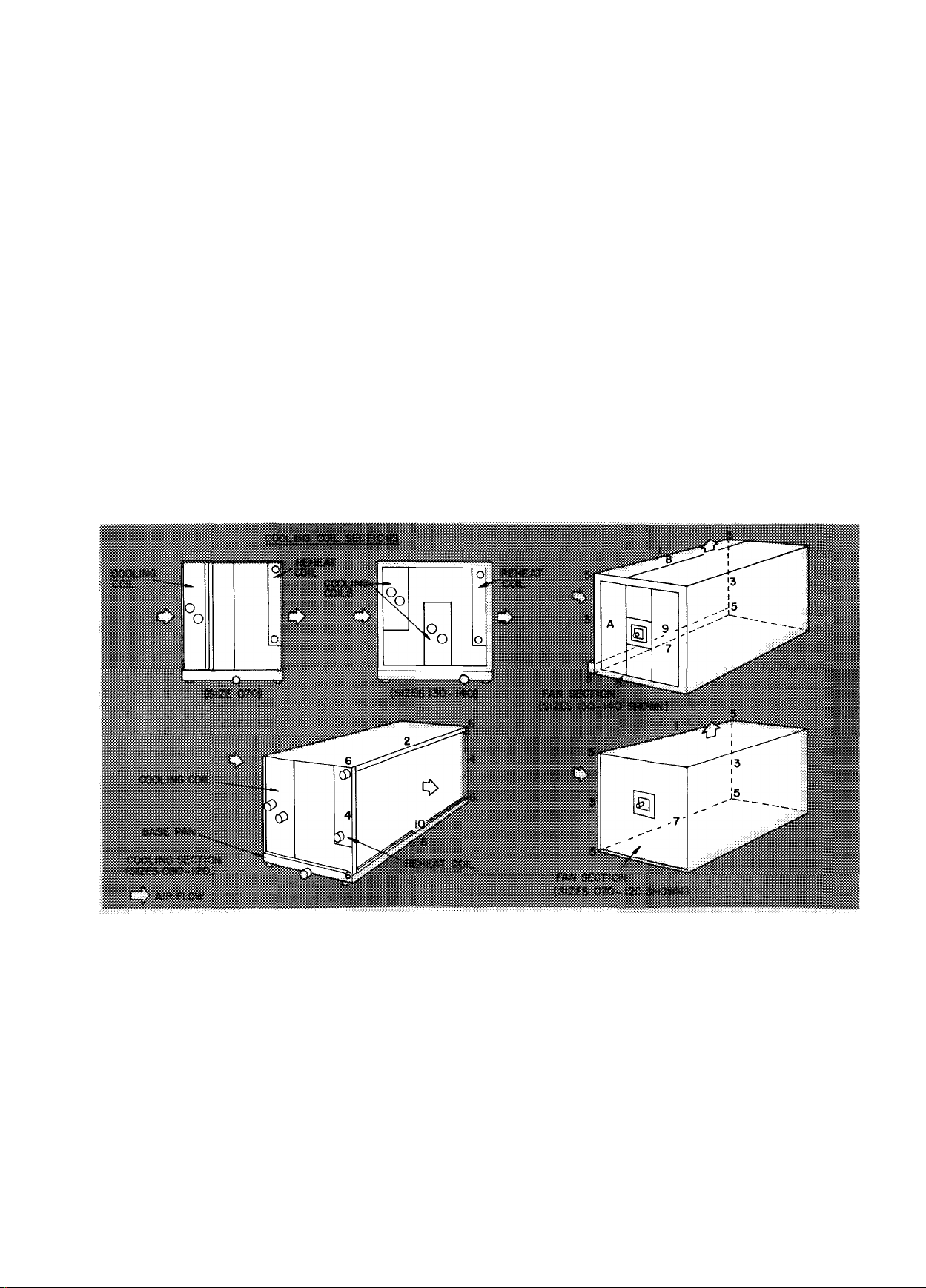

UNITS 39BA,BB SIZES 070 THRU 120 (Arrange

ment A) - Refer to Fig. 3 and Table 1.

1. Remove shipping skid(s) and apply sealing

compound to flanges on air intake side of fan

r

section.

2. Face air intake side of fan section toward air

discharge side of cooling coil section.

3. Fasten flange 1 to 2 with five 3/8-16 x 3/4-in.

hex head cap screws, lockwashers and flange 2

weld nuts.

4. Fasten flanges 3 to 4 with one 3/8-16 x 3/4-in.

hex head cap screw, lockwasher, and hex nut

per two flanges.

5. Fasten corners 5 to 6 with one 3/8-16 x 3/4-in.

hex head cap screw, lockwasher, two plain

washers and hex nut per two corners. Corner

holes are 11/16-in. diameter.

6. Fasten external flange 7 to 8 with three

3/8-16 X 3/4-in. hex head cap screws, lockwashers, and flange 8 weld nuts.

7. Tighten all screws securely.

UNITS 39BA,BB SIZES 130 THRU 140 AND

39BC SIZES 135 AND 140 (Arrangement A) —

Refer to Fig. 3 and Table 1.

1. Follow preceding steps 1 and 2.

2. Remove fan section panels A and B. Provide a

cardboard walkway on fan section bottom to

protect insulation.

3. Fasten flange 1 to 2 with seven 3/8-16 x 3/4-in.

hex head cap screws, lockwashers, and flange 2

weld nuts.

4. Fasten flanges 3 to 4 with five 3/8-16 x 3/4-in.

hex head cap screws, lockwashers, plain

washers, and hex nuts per two flanges.

5. Fasten riser panel 9 to lip 10 with six

1/4-20 X 1/2-in. self-tapping screws and Hp 10

engagement holes.

6. Tighten all screws securely.

7. Remove cardboard walkway from fan section

and replace panels A and B.

Fig. 3 — Base Unit Assembly for 39BA,BB070-140 and 39BC135 and 140 (Arrangement A)

Page 8

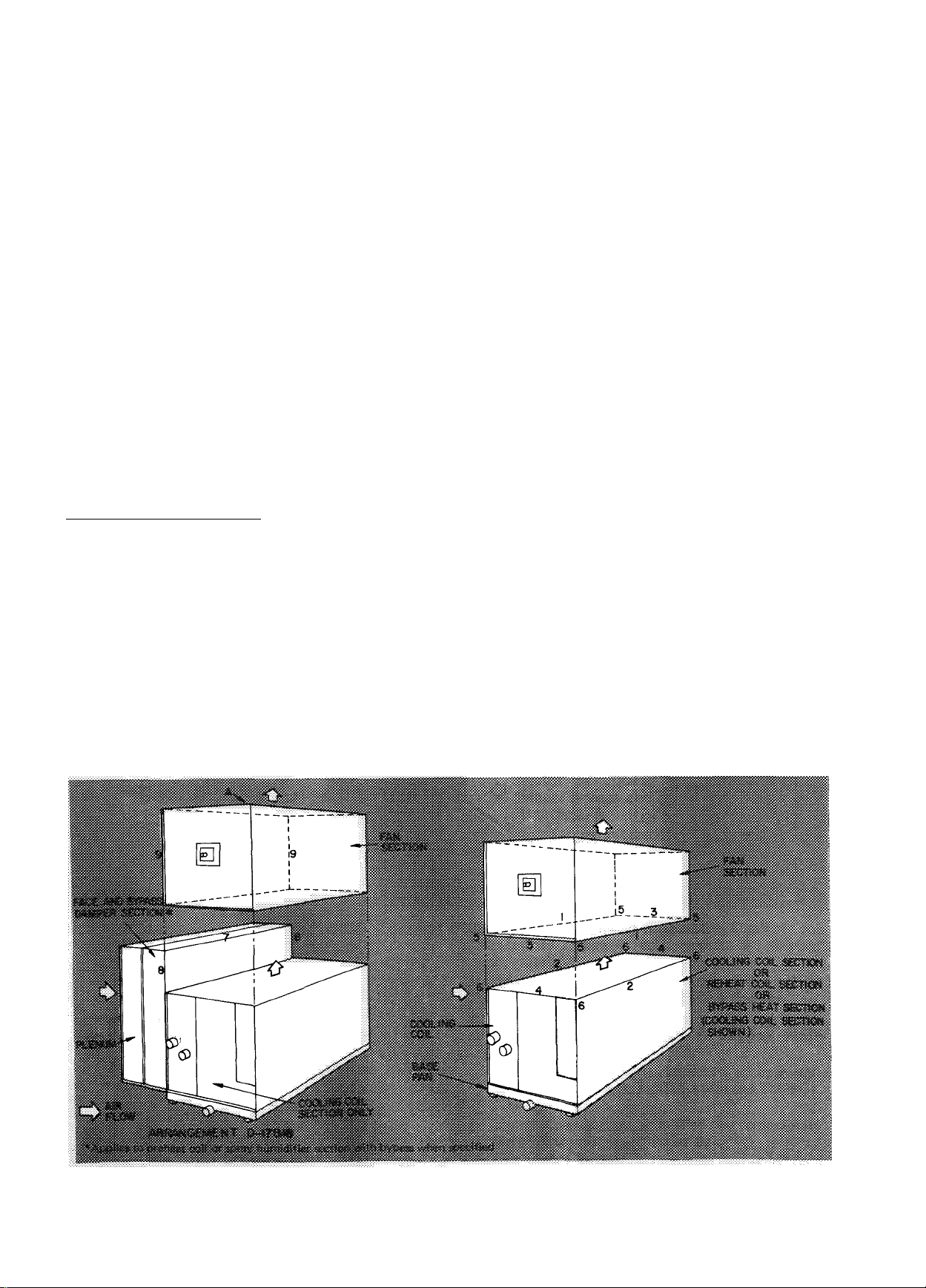

UNITS 39BA,BB SIZES 100 THRU 120 (Arrange

ment D, except D-17 and D-18) — Refer to Fig. 4

and Table 3.

1. Remove shipping skids and apply sealing

compound to flanges on air discharge side of

cooling coil section.

2. Place air intake side of fan section on top of air

discharge side of cooling coil section, reheat

coil section or bypass heat section.

3. Fasten flange 1 to 2 with three 3/8-16 x 3/4-in.

hex head cap screws, lockwashers per two

flanges and flange 2 weld nuts.

4. Fasten flanges 3 to 4 with one 3/8-16 x 3/4-in.

hex head cap screw, lockwasher, and hex nut

per two flanges.

5. Fasten comers 5 to 6 with one 3/8-16 x 3/4-in.

hex head cap screw, lockwasher, two plain

washers, and hex nut per two corners. Corner

holes are 11/16-in. diameter.

6. Tighten all screws securely.

Arrangements D-17 and D-18

1. Follow preceding steps 1 thru 5.

2. Fasten spray humidifier or preheat coil section

with bypass when supplied to cooling coil

section per accessory assembly.

3. Fasten flange 7 to fan section side A with three

1/4-20 X 1/2-in. self-tapping screws and side A

engagement holes.

4. Line up flanges 8 and 9 and drill two engage

ment holes in each flange 9 with a no. 3 drill.

5. Fasten flanges 8 to 9 with two 1/4-20 x 1/2-in.

self-tapping screws per two flanges.

6. Tighten all screws securely.

UNITS 39BA,BB SIZES 130 THRU 140 AND

39BC SIZES 135 AND 140 (Arrangement D, ex

cept D-18) — Refer to Fig. 5 and Table 3.

NOTE: On arrangements D-31and35, sizes 135

and 140 — first fasten bypass heat section to

cooling coil section per Accessory Assembly, then

proceed with following steps;

1. Remove shipping skid(s) and apply sealing

compound to flanges on air discharge side of

cooling coil section.

Place air intake side of fan section on top of air

2.

discharge side of cooling coil section, reheat

coil section, or bypass heat section.

Cooling coil section —

3.

a. Line up side A of fan section with filler

panel and drill eight engagement holes along

bottom edge of side A with a no. 3 drill.

b. Fasten filler panel to side A with eight

1/4-20 X 1/2-in. self-tapping screws.

4. Bypass heat section or reheat coil section.

a. Place filler panel, removed from cooling coil

section per Accessory Assembly, along

flange 7 of accessory section and butt

against fan section per Fig. 5.

b. Drill seven engagement holes along flange 7

with a no. 2 drill.

c. Fasten filler panel to flange 7 with seven

self-tapping screws.

d. Follow preceding steps 3a and 3b.

5. Fasten flange 1 to 2 with five 3/8-16 x 3/4-in.

hex head cap screws, lockwashers, plain

washers, and hex nuts per two flanges.

6. Tighten all screws securely.

Fig. 4 - Base Unit Assembly for 39BA,BB100-120 (Arrangement D)

8

Page 9

Fig. 5 - Base Unit Assembly for 39BA,BB130-140 and 39BC135,140 (Arrangement D)

Arrangement D-18

NOTE: Duct extension is shipped assembled to fan

section.

1. Remove filler panel from cooling coil section

and discard.

2. Fasten spray humidifier or preheat coil section

with bypass when specified or plenum and face

and bypass damper section to cooling coil

section per Accessory Assembly.

3. Remove shipping skid and apply sealing

compound to flanges on air discharge side of

cooling coil section.

4. Place air intake side of fan section on top of air

discharge side of cooling coil section.

5. Fasten flanges 3 to 4 with seven 1/4-20 x 1 /2-in.

self-tapping screws and flange 4 engagement

holes.

6. Fasten flanges 5 to 6 with two 3/8-16 x 3/4-in.

hex head cap screws, lockwashers, plain

washers, and hex nuts per two flanges.

7. Tighten all screws securely.

Accessory Assembly — Refer to Tables 1,2, and 3.

NOTE; More holes may exist than indicated. Use

only those which line up.

BYPASS HEAT SECTION (Arrangements D-31 and

D-35; sizes 135 and 140 only) - Refer to Fig. 6.

1. Remove shipping crate and apply sealing com

pound to flanges on air intake side of accessory.

2. Remove filler panel from cooling coil section

and save for fan section assembly.

3. Place air intake side of accessory on top of air

discharge side of cooling coil section.

4. Fasten flanges 1 to matching flanges of cooling

coil section with five 3/8-16 x 3/4-in. hex head

cap screws, lockwashers, plain washers, and hex

nuts per two flanges.

5. Tighten all screws securely.

Fig. 6 - Assembly of Accessory Bypass Heat Section

(Arrangements D-31, D-35; Sizes 135,140 Only)

BYPASS DUCT (Arrangement A only) — Refer to

Fig. 7.

1. Sizes 080 thru 110 —

a. Place one endpiece on each flange 8 of

cooling coil section, with fiber glass insu

lated sides facing each other. Ensure air

intake side of bypass duct is flush with edge

of flange 9.

b. Fasten flange 1 to 8 with three

1/4-20 X 1/2-in. self-tapping screws and

both flange 8 engagement holes.

c. Fasten tabs 7 to flanges 8 with a

3/8-16 X 3/4-in. hex head cap screw, two

plain washers, and hex nut per tab.

Page 10

Fig. 7 — Assembly of Accessory Bypass Duct — (Arrangement A Only)

d. Fasten flange 2 to matching surface of

cooling coil section with seven

1/4-20 X 1/2-in. self-tapping screws and

matching surface engagement holes.

e. Fasten top panel to each flange 3 and 4 with

two and three 1/4-20 x 1/2-in. self-tapping

screws respectively per end and each

flange 3 and 4 engagement holes.

f. Fasten one angle 5 to each flange 6 with

three 1/4-20 X 1/2-in. self-tapping screws

and flange 6 engagement holes.

g. Tighten all screws securely.

2. Sizes 135 and 140—

a. Place one endpiece on one flange 8 of

cooling coil section with fiber glass insulated

side facing second flange 8.

b. Fasten flange 10 to 8 as follows;

(1) Line up flange 10 and 8. Ensure air in

take side of bypass duct is flush with

edge of flange 9

(2) Drill six engagement holes in flange 8

with a no. 3 drill.

(3) Fasten flange 10 to 8 with six

1/4-20 X 1/2-in. self-tapping screws.

c. Loosely fasten one end of top panel to flange

12 with nine 1/4-20 X 1/2-in. self-tapping

screws and flange 12 engagement holes.

d. Place second endpiece on second flange 8 of

cooling coil section with fiber glass insulated

side facing first endpiece.

e. Loosely fasten remaining end of top panel

with nine 1/4-20 X 1/2-in. self-tapping

screws and flange 12 engagement holes.

f. Loosely fasten front panel to flanges 13

with five 1 /4-20 x 1 /2-in. self-tapping screws

per end and flange 13 engagement holes.

g. Loosely fasten flange 14 to matching edge

of top panel with seven 1/4-20 x 1/2-in.

self-tapping screws and engagement holes

along top panel edge.

h. Fasten flange 10 of second endpiece as

follows:

(1) Line up flange 10 and 8. Ensure air

intake side of bypass duct is flush with

edge of flange 9.

(2) Drill six engagement holes in flange 8

with a no. 3 drill.

(3) Fasten flange 10 to 8 with six

1/4-20 X 1/2-in. self-tapping screws.

i. Fasten flange 11 to matching surface of

cooling coil section as follows:

(1) Line up flange 11 and matching surface.

(2) Drill ten engagement holes in matching

surface with a no. 2 drill.

(3) Fasten flange 11 to matching surface

with ten 1/4-20 X 1/2-in. self-tapping

screws.

j. Tighten aU screws securely.

FACE AND BYPASS DAMPER SECTION; PRE

HEAT COIL SECTION AND/OR SPRAY

HUMIDIFIER SECTION WITH AND WITHOUT

BYPASS (Sizes 070 thru 120) - Refer to Fig. 8.

1. Remove shipping crate(s) and apply sealing tape

to flanges on air discharge side of spray

humidifier section only.

2. Face air discharge side of accessory(ies) toward

air intake side of cooling coil section.

NOTE; Spray humidifier section must be

adjacent to cooling coil section so excess

water can be collected in condensate pan.

Remove factory-installed accessories to do

this and replace same.

10

Page 11

г-

Fig. 8 — Assembly of Accessory Face and Bypass Damper Section; Preheat Coil Section

and/or Spray Humidifier Section with and without Bypass — (Sizes 070-120)

3. Fasten flanges 2 thru 5 of preheat coil or spray

humidifier section without bypass to matching

flanges of cooling coil section with the following:

a. Fasten flanges 2 and 3 with three

3/8-16 X 3/4-in. hex head cap screws per

two flanges and matching flange weld nuts.

b. Fasten flanges 4 and 5 with three 3/8-16 x

3/4-in. hex head cap screws and hex nuts per

two flanges.

4. Duct extension (for accessories with bypass) —

a. Preheat coil section only - Remove two

(size 070) or three (sizes 080 thru 120)

1/4-20x1-in. hex head cap screws, plain

washers, and hex nuts from each flange 6

and 7. Save fasteners for following steps b

and c.

b. Place endpiece having largest holes on side

C, on flange 6 of accessory. Face fiber glass

insulated side toward flange 7 of accessory.

Fasten surface A to flange 6 of spray

humidifier section with one 1/4-20 x 1/2-in.

self-tapping screw and flange 6 engagement

hole. For preheat coil section, use two of

each type of fastener saved from preceding

step a.

c. Place second endpiece on flange 7 of

accessory. Face fiber glass insulated side

toward fiber glass insulated side of first

endpiece. Fasten surface A to flange 7 per

preceding step b.

d. Fasten one angle D to each side E of both

endpieces with two (size 070) or three

(sizes 080 thru 120) 1/4-20 x 1/2-in. self

tapping screws per angle and side E engage

ment holes.

e. Fasten top panel to top of each endpiece

with one (spray humidifier section) or two

(preheat coil section) 1/4-20 x 1/2-in. self

tapping screw(s) per end and engagement

hole(s) in top of each endpiece.

11

Page 12

5. Fasten flanges 1 thru 5 of face and bypass

damper section; preheat coil or spray

humidifier section with bypass as follows:

a. Arrangements A and B — Fasten flange 1 to

matching flange of applicable accessory with

three fasteners per preceding step 3a.

b. Arrangement D — Fasten flange 1 to match

ing flange of fan section or accessory bypass

heat section with three 1 /4-20 x 1 /2-in.

self-tapping screws and matching flange en

gagement holes. Fasten flange 1 to matching

flange of duct extension with three fasteners

per preceding step 3a.

c. Fasten flanges 2 and 3 to matching flanges

of applicable accessory or cooling coil

section with three fasteners per preceding

step 3a.

d. Fasten flanges 4 and 5 to matching flanges

of applicable accessory(ies) and/or coohng

coil section with four (size 070) or five

(sizes 080 thru 120) fasteners per preceding

step 3b.

6. Tighten screws securely.

7. When face and bypass damper section is used

with accessory humidifier, minimum stops may

be required to ensure air flow thru humidifier

at all times. Install stops on damper actuator

linkage as opposed to directly on damper blades

to prevent possible damage.

PREHEAT COIL SECTION, AND/OR SPRAY

HUMIDIFIER SECTION WITH AND WITHOUT

BYPASS (Sizes 130 thru 140) - Refer to Fig. 9.

1. Remove shipping crate and apply sealing tape

to flanges on air discharge side of spray

humidifier section only.

2. Remove coil from preheat section to provide

access to internal flanges 5, 6, and 8.

3. Face air discharge side of accessory(ies) toward

air intake side of cooling coil section.

NOTE; Spray humidifier section must be

adjacent to cooling coil section so excess

water can be collected in condensate pan.

Remove factory-installed accessories to do

this and replace same.

4. Duct extension (for accessories with bypass) —

a. Place one endpiece on each flange 3 of

accessory, with flanges 1 facing each

other.

b. Line up flanges 2 and 3. Drill one (spray

humidifier section) or two (preheat coil

section) engagement holes in flanges 3

with a no. 3 drill.

c. Fasten flanges 2 to 3 with one or two

1/4-20 X 1/2-in. self-tapping screws per

two flanges.

d. Fasten top panel to each flange 1 with two

1/4-20 X 1/2-in. self-tapping screws per

end and both flange 1 engagement holes.

Fig. 9 — Assembly of Accessory Preheat Coil Section and/or Spray Humidifier Section

with and without Bypass (Sizes 130-140)

12

Page 13

5. Fasten flange 4 to matching flange of applicable

accessory (except bypass heat section arranged

for bypass cooling only) with seven 1/4-20

X 1/2-in. self-tapping screws and locknuts.

6. Fasten flange 4 to matching flange of bypass

heat section arranged for bypass coohng only

as follows:

a. Line up flange 4 with matching flange of

accessory.

b. Drill seven engagement holes in matching

flange with a no. 3 drill.

c. Fasten flange 4 to matching flange with

seven 1/4-20 x 1/2-in. self-tapping screws.

7. Fasten flange 5 to matching flange of appli

cable accessory or cooHng coil section with

seven 3/8-16 x 3/4-in. hex head cap screws and

matching flange weld nuts.

8. Fasten flange 6 to matching flange of applicable

accessory with seven 3/8-16 x 3/4-in. hex head

cap screws and matching flange weld nuts.

9. Fasten flange 6 to matching flange of coohng

coil section with seven 1/4-20 x 1/2-in. self

tapping screws and matching flange engage

ment holes.

10. Fasten flanges 7 to matching flanges of appli

cable accessory with two 1/4-20 x 1/2-in. self

tapping screws per two flanges and matching

flange engagement holes (bypass duct) or lock

nuts (duct extension or bypass heat section).

11. Fasten flanges 8 to matching flanges of appli

cable accessory or coohng coil section with

five 3/8-16 X 3/4-in. hex head cap screws and

hex nuts per two flanges.

12. Tighten all screws securely.

13. Replace coil in preheat section.

FACE AND BYPASS DAMPER SECTION

(Size 130 thru 140) - Refer to Eig. 10.

1. FoUow preceding steps 1 and 3.

2. Fasten flange 1 to matching flange of apphcable

accessory (except bypass heat section arranged

for bypass cooling only) with seven 1/4-20

X 1/2-in. self-tapping screws and locknuts.

3. Fasten flange 1 to matching flange of bypass

heat section arranged for bypass coohng only

as follows:

a. Line up flange 1 with matching flange of

accessory bypass heat section.

b. Drill seven engagement holes in matching

flange with a no. 3 drill.

c. Fasten flange 1 to matching flange with

seven 1/4-20 x 1/2-in. self-tapping screws.

4. Fasten flange 2 to matching flange of apph

cable accessory or coohng coil section (preheat

coil section; sizes 135 and 140 excluded) with

seven 3/8-16 x 1-in. hex head cap screws per

flange and matching flange weld nuts.

5. Fasten flange 2 to matching flange of preheat

coil section (sizes 135 and 140) as follows:

a. Line up flange 2 with matching flange of

preheat coil section.

b. Follow preceding steps 3b and 3c (sub

stitute flange 2 for flange 1 in step 3 c).

6. Fasten flange 3 to matching flange of apphcable

accessory or coohng coil section (preheat coil

and cooling coil sections, sizes 135 and 140

excluded) with seven 3/8-16 x 1-in. hex head

cap screws and matching flange weld nuts.

7. Fasten flange 3 to matching flange of preheat

coil section (sizes 135 and 140) with seven

3/8-16 X 1-in. hex head cap screws and hex nuts.

8. Fasten flange 3 to matching flange of coohng

coil section (sizes 135 and 140) with seven

1/4-20 X 1/2-in. self-tapping screws and match

ing flange engagement holes.

9. Fasten flanges 4 to matching flanges of apph

cable accessory (bypass duct excluded) with

two 1/4-20 X 1/2-in. self-tapping screws and

locknuts per flange.

10. Fasten flange 4 to matching flanges of accessory

bypass duct with two 1/4-20 x 1/2-in. self

tapping screws and matching flange engagement

holes.

11. Fasten flanges 5 to matching flanges of apph

cable accessory or coohng coil section with:

five (accessory or coohng coil section —

size 130); five (accessory section —

sizes 135 and 140); six (coohng coil section —

sizes 135 and 140) 3/8-16 x 1-in. hex head cap

screws and hex nuts per two flanges.

12. Tighten all screws securely.

13. When face and bypass damper section is used

with accessory humidifier, minimum stops

may be required to ensure air flow thru

humidifier at all times. Install stops on damper

actuator hnkage as opposed to directly on

damper blades to prevent possible damage.

Fig. 10 — Assembly of Accessory Face and Bypass

Damper Section — (Sizes 130-140)

13

Page 14

FILTER SECTION OR COMBINATION MIXING

BOX AND FILTER SECTION (All sizes and

arrangements, high and low velocity) — Refer to

Fig. 11.

Fig. 11 — Assembly of Acœssory Filter Section or

Combination Mixing Box and Filter Section — (All

Sizes and Arrangements — High-and Low-Velocity)

d. Fasten flange 5 to matching flange of cool

ing coil section (sizes 135 and 140) with

seven 4/4-20 X 1/2-in. self-tapping screws

and matching flange engagement holes.

7. Fasten flanges 2 to matching flanges of appli

cable accessory or cooling coil section with:

three (accessory or cooling coil section —

sizes 070 thru 120); five (accessory or cooling

coil section — size 130) ; five (accessory section

— sizes 135 and 140); or six (cooling coil sec

tion — sizes 135 and 140) 3/8-16 xl-m. hex

head cap screws and hex nuts per two flanges.

8. Tighten all screws securely.

9. Install filter blankoff panels, evenly spaced in

filter tracks, when using high-velocity filters in

low-velocity filter sections or combination

mixing box and filter section to ensure uniform

air distribution.

ATOMIZING SPRAY AND STEAM GRID

HUMIDIFIERS — Normally shipped assembled in

unit. If a separate shipment is made, refer to

Installation Instructions provided with humidifier.

1. Remove shipping skid.

2. Face air discharge side of accessory toward air

intake side of applicable accessory or cooling

coil section.

3. Fasten support legs to low-velocity filter sec

tion or filter section of combination mixing

box and filter section (sizes 070 thru 120 only)

with two hex head cap screws, plain washers

and nuts per leg.

4. Fasten flange 1 to matching flange of applicable

accessory or cooling coil section with three

(sizes 070 thru 120) or seven (sizes 130 thru

140 — preheat coil section sizes 135 and 140

excluded) 3/8-16 x 3/4-in. hex head cap screws

and matching flange weld nuts.

5. Fasten flange 1 to matching flange of preheat

coil section (sizes 135 and 140) per preceding

steps 5a, 3b, and 3c (substitute flange 1 for

flange 2 in step 5a).

6. Fasten flange 5 to matching flange of applicable

accessory or cooling coil section as follows;

a. Fasten flange 5 (sizes 070 thru 120) with

three 3/8-16 X 3/4-in. hex head cap screws

and matching flange weld nuts.

b. Fasten flange 5 to matching flange of appli

cable accessory or cooling coil section

(preheat coil and cooling coil sections,

sizes 135 and 140 excluded) with seven

3/8-16 X 1-in. hex head cap screws and

matching flange weld nuts.

c. Fasten flange 5 to matching flange of pre

heat coil section (sizes 135 and 140) with

seven 3/8-16 X 1-in. hex head cap screws

and hex nuts.

Unit Suspension and Mounting

1. Level unit after mounting to insure proper coil

and base pan drainage.

2. Rig and suspend base unit from same points per

Fig. 1. Note that unit sizes 130 and 140 must

be installed on a suspended platform.

3. Rig and suspend accessory combination mixing

box and filter section as follows:

a. Directly fastened to base unit — Rig and

suspend from two top corners on air-intake

end of accessory. Use one suspension rod

per comer.

b. Remote from base unit — Rig and suspend

from four top corners of accessory. Use one

suspension rod per corner.

VIBRATION ISOLATORS

1. Arrangement A (unit size 070 thru 140). A

minimum of six isolators should be installed for

proper support — one on each comer of coil

section and one on each comer of air discharge

side of fan section. Two additional isolators

may be installed on air-intake side of fan

section.

2. Arrangements B and D (unit sizes 070 thru

140) and all arrangements (unit sizes 040 thru

060) — Four isolators should be installed for

proper support.

3. Two isolators are required under combination

mixing box and filter section for floor mounting.

4. Vibration isolator hangers are required on combi

nation mixing box and filter section for sus

pended applications per preceding steps 2a and

2b, under “Unit Suspension and Mounting.”

£

14

Page 15

OUTDOOR UNITS — Not recommended for

standard units unless following precautions are

taken into consideration. Consult your local

Carrier representative for units specially factory

equipped for outdoor use.

1. Externally insulate all accessories that are not

factory insulated (combination mixing box and

filter section, filter section, and face and bypass

damper section).

2. If outside temperature will be below dew point

of air in unit at any time during operating

season, insulate complete unit externally to

prevent internal condensation. Vapor seal and

weatherproof insulation.

3. Install a crowned waterproof cover on top of

unit to prevent water from collecting or leaking

into unit per Fig. 12. A shed-type cover

(Fig. 13) can be used as an alternate.

Fig. 12 — Crowned-Type Protection Cover —

Field-Supplied

4. Caulk all joints with nonhardening material

such as butyl-rubber or silicone-rubber to pre

vent moisture infiltration.

5. Install a field-supplied rain shield over outside

air damper of combination mixing box and

filter section.

6. Obtain motor manufacturer’s recommendation

for a fan motor type suitable for outdoor use.

7. Install a field-supphed cover over damper link

age to prevent ice and snow from interfering

with operation. Damper motor must be suitable

for outdoor use.

8. If unit is to be subjected to freezing tempera

tures, insulate condensate drain lines and locate

trap indoors to prevent freeze-up.

9. For coil freeze-up protection, refer to 39B, 39C

Operation and Maintenance Book.

Piping — Cod connections are labeled on unit.

GENERAL

1. Pipe unit so that vibration is not transmitted to

or from unit.

2. Allow sufficient clearance for unit piping

connections so that piping will not prevent

removal of fan belt guard.

3. All piping must follow standard piping tech

niques. Refer to Carrier System Design Manual

for details.

DIRECT-EXPANSION COOLING COIL

3 Nozzles

Fig. 13 — Shed-Type Protection Cover

Field-Supplied

Table 5 — Factory-Installed Refrigerant Distributor Nozzles — Standard Direct-Expansion Coils

070 080 090

060

050

UNIT SIZE

Size Coil

In Unit

Qty-Size

In Coil

s

4- And

6-Row

8-Row

040

040

1-G2

1-G2

050

1-G3

1-G3

060

1-G4

1-G4

070 080

1-C4

1-AlO

1-C5

1-A12

090

2-C5

2-A12

100

100

2-C6

2-A12

Refrigerant Distributor Nozzles

1. Check refrigerant distributor nozzle against

design load and note following:

a. Nozzles installed are for minimum rec

ommended coil loading for proper refrig

erant distribution and oil return. For heavier

loads, proper nozzles must be substituted.

b. Nozzle orifice size is stamped on nozzle.

Refer to Table 5 for factory-installed

standard coil nozzles. Refer to Table 6 for

nozzle orifice capacities.

105

130

2-C5

2-A12

no

110 120

2-C6

2-A12

120

2-AlO

3-A12

130

130 130

2-C5

2-A12

2-C5

2-A12

135

no

130 120 130

2-C6 2-C5

2-A12

2-A12

2-AlO

3-A12

140

2-C5

2-A12

1«;

Page 16

Table 6 — Refrigerant Distributor Nozzle Orifice

Capacities (Tons of Refrigeration)

NOZZLE

ORIFICE

NUMBER

2 2.0

2-1/2

3

4 4.0

5 5.0 4.2 3.5

6 6.0 5.0

8 8.0

10 10.0 8.0

12

15 15,0

17

20

25

30

35 i

40 40 0

NOTES:

1 Orifice sizes 2-1/2, 3, 4, 5, 6 and 8 are not available for "A"

nozzles

2. Nozzle designation is stamped on nozzle; "G" indicates 7/8 in.

ODM distributor, "E" indicates 1-1/8 in. ODM distributor, "C"

indicates 1-3/8 in, ODM distributor, "A" indicates 1-5/8 in.

ODM distributor. Therefore, only the nozzles having the same

letter are physically interchangeable.

EVAPORATOR TEMPERATURE

R-12

40 F 30 F 20 F

1.7 1.4 3.2

2.1 1.8

2 5

3.0 2.5 2.1

3.3

6.5

12.0 10.0

12,5 10.0

17.0 14.0

20 0 16.5

21 0

25 0

30.0 25 0

35.0 29 0

33 0

40 F 30 F 20 F 40 F

4.0

4.8 4.0 3.4 3.4

2 8

6.5 5.5 4 6

8.0

4.2

9.5 8.0

5.5 12 5

7.0

15.0

8.0

18.5 15.0

23.0 19 0 15.5

11 5 26.0 21.0 18.0

13.5 31.0 25.0 21.0

17.0

39.0 32.0 27 0 28 0

20.0

45 0

24.0

54 0 44 0 37 0

27.0

60 0 49.0 41 0

R-22

2.7 2.3 2.3

3.3

2 8

6 5 5.5 5.5

6.5

10.5 8.5

12.5 10.5

12 5

37.0 31.0

R-500

30 F

20 F

1.9

1.6

2.4

2 9

4 6 3.8

7.0

8.5

11.0 9.0 7.5

13.5

17,0

19 0 15.5

23.0

33.0 27.0 23.0

39.0

44.0

2.0

2.8 2.4

3 2

4.6

3 9

6.0

5 0

7.0 6.0

11.0 9.5

14 0 11.5

13 0

19 0 15.5

19.0

23 0

32 0 27.0

36 0 30.0

c. Standard coils above size 080 are face split

with the load for each coil divided evenly

between the two or three distributors. Unit

sizes 130, 135 and 140 contain two coils,

each of which are face split. The percentage

of total unit load handled by each distrib

utor is as follows:

(1) Unit sizes 040 thru 080; 100%

(2) Unit sizes 090 thru 120: 50% except

8-row coil on 120

(3) Unit size 120 with 8-row coil: 33-1/3%

(4) Unit size 130; 25%

(5) Unit size 135; 23% for each distributor

of the smaller coil and 27% for each

distributor of the larger coil.

(6) Unit size 140 with 4- and 6-row coil;

20% each distributor of smaller coil; 30%

each distributor of larger coil.

(7) Unit size 140 with 8-row coil: 20% each

distributor of both coils.

2. Factory-installed nozzle should be replaced if

the following relationship is not met;

design load (per distributor) = g 90 to 1 20

nozzle orifice capacity (Table 6)

3. If two nozzles satisfy above relationship,

choose the smaller.

4. Mark final nozzle size, where indicated, on unit

label for future reference. This will show nozzle

size has been checked.

Partial Load Operation — System controls must be

designed with consideration of following:

1. No coil or coil split served by a single refrig

erant distributor and expansion valve can be

expected to operate satisfactorily at less than

50% of design load.

2. As load reduces, a portion of coil surface must

be deactivated so that remaining active coil or

coil splits operate between 50 and 100% of

design load.

3. Face-split coils may be used when air quantity

is constant. In variable volume systems, row-

split coils must be used.

4. If operation must be below 50% of design load,

hot gas bypass must be used. Refer to Carrier

System Design Manual for details.

Suction Piping

1. Connect suction piping per Fig. 14,15 and 16.

2. Suction line from evaporator to end of

15 diameter long riser (located between reducer

fittings) must be sized for high velocity. Refer

to Carrier System Design Manual, Part 3 for

suction pipe sizing charts. This piping length

will normally result in an equivalent length of

20 ft and should be sized for a pressure loss

corresponding to 0.5 F. Remaining suction Mne

should be sized for a pressure drop correspond

ing to 1.5 F for a total suction line pressure

drop corresponding to 2 F.

3. Suction risers must be sized to provide ade

quate oil return at minimum load. When a

suction riser is designed to permit oil return at

minimum load, the pressure drop at full load

may be too great. If this situation occurs, a

double suction riser should be used. Refer to

Carrier System Design Manual for details of

sizing.

Expansion Valve (field-supplied)

1. Expansion valve must satisfy following;

a. Design load per distributor.

b. Available pressure drop.

c. Valve inlet temperature (condensing tem

perature minus subcooUng).

d. Design evaporator temperature.

e. Valve must have non-condensing charge

power element.

f. If selection falls between two valves, choose

smaller.

2. Install expansion valve(s). Refer to Fig. 14, 15

and 16 for proper location of sensing bulb and

equalizer connection.

3. Install condensate pan(s) under expansion

valve(s) per Fig. 17.

1 A

Page 17

a

Fig. 14 — Suction Line Piping — Single Unsplit Coil

Fig. 15 — Suction Line Piping — Face Split Coil

17

Page 18

Fig. 16 — Suction Line Piping — Row-Split Coil

DRILL a SCREW

PAN TO COVER SHEET

DRILL § HOLE

FOR TUBE IN

COIL COVER SHEET

CONDENSATE

PAN

Fig. 17 — Expansion Valve Condensate Pan

CHILLED WATER, HOT WATER AND STEAM

COILS

1. Use unions or flanged coil connections for ease

of service per Fig. 18.

2. Install a tee with a pipe plug at coil connection

to facilitate air blow thru coil for freeze

protection per Fig. 18.

CONDENSATE DRAIN - Connect drain line and

trap per Fig. 19 to condensate drain connection.

Do not reduce pipe size. Run drain line to nearest

open site drain. On unit sizes 070 thru 140, install

a field-supplied cap on unused drain connection.

HUMIDIFIERS — Humidifier water and steam

f

supply must be odor-free and uncontaminated.

Consideration shall be taken by installer as to

corrosive and odor effect from hard or contami

nated water. Carrier assumes no responsibility for

problems caused by inadequate water treatment.

General — It is recommended that a strainer be

installed in supply line. Steam grid humidifiers

require a drain line trap with a water seal to offset

unit negative static pressure. Trap is similar to that

shown in Fig. 19.

Fig. 18 — Coil Connections

18

Page 19

Fig. 19 — Cooling Coil Condensate Piping

Coil Removal and Reversing

1. Remove coil coverplate.

2. Remove air baffle from both ends of coil on

leaving air side.

3. Remove coil hold-down bolts from both ends

of coil.

4. Shde coil out of unit. Lift coils from suspension

points at four corners as close to tube sheets as

possible. Never lift from center. Handle cooling

coils with coil face vertical.

5. Reverse coil per Fig. 20.

6. Reverse steps 1 thru 4 to reinstall. Cooling and

hot water heating coils must be reinstalled so

refrigerant or chilled water supply enters on

air-leaving face of coil and returns on air

entering face. Steam heating coils must be

installed with upper connection for supply and

lower for return. Supply connection has a

raised letter “S” on return-bend type steam

coils. Supply connection is larger than return

on nonfreeze type steam coils.

Motor and Drive

GENERAL

1. Excessive tipping will cause oil loss in sleeve

bearing motors. Follow motor manufacturer’s

recommendations.

2. Check job prints to determine correct motor

mounting position.

3. Drive package numbers are marked on drive

package and label on drive end of fan section.

4. Required center-to-center distance (C/D) be

tween fan and motor shafts is marked on fan

drive package.

5. Refer to Table 7 for motor base used on unit

sizes 070 thru 140. A single bracket is used

universally for unit sizes 040 thru 060. Motors

larger than 50 hp must not be mounted on unit.

Use field-provided, floor-mounted base under

unit and motor.

Table 7 — Motor Base Usage

(Unit Sizes 070 thru 140)

NEMA FRAME

MTR BASE

PART NO.

39BA070-453

39B A110-453

‘Corresponds to frame sizes for open dripproof 1750 rpm motors

only.

HP

RANGE*

V2-2O

25-50

SIZE RANGE

56-256T or

56-286U

284T-326T or

324U-356U

MOTOR BASE

CRADLE DIM. (in.)

16 Vs X 20 V4

23 V4 X 26V

UNIT SIZES 040 THRU 060 - Refer to Fig. 21.

Fig. 20 — Coil Reversing

Duct Connections — Make connections per

accepted design practices. Refer to Carrier System

Design Manual for details.

Fig. 21 — Motor Base (Unit Sizes 040 Thru 060)

Set motor mounting bracket position (min or

1

max) to provide required drive center-to-center

distance.

Install motor on motor mounting and adjusting

2.

brackets with hardware from accessory drive

package.

3. Install adjusting screw, locknuts, and rubber

bumpers (shipped in cloth bag, taped to motor

base) on motor adjusting bracket. Save three

1 ¡4-20 X 1 ¡2-in. self-tapping screws for belt

guard installation.

19

Page 20

4. Remove protective cover and clean grease from

fan shaft with solvent.

5. Apply a light coat of grease or white lead to fan

shaft.

6. Install fan and motor sheaves with correct

angular and parallel alignment per Fig. 22.

Refer to drive package carton for additional

instructions.

Table 8 — Fan Belt Deflection Force I lb)

Fig. 22 — Correct Sheave Aligrirnent

7. Loosen locknut and adjust belt tension by

turning adjusting screws. Refer to Table 8 for

correct belt tension and note following;

a. Correct belt tension is lowest tension at

which belts will not slip during operation.

b. Correct belt tension may cause belts to slip

and squeal briefly on start-up, which is

normal and will disappear after unit has

reached operating speed. Excessive belt

tension will reduce belt life and may cause

bearing and shaft damage.

c. To determine correct belt tension, use the

following formula for deflection forces

shown in Table 8.

^ ^ Belt Span

Deflection = —rrf-—

64

For a belt span of 16 in., small sheave of

5-in. pitch diameter (PD), size 4L belts:

(1) From formula 1/4-in. deflection

24

needed.

(2) From Table 8, deflection force is be

tween 1-7/8 and 2-5/8 lb.

BELT

CROSS

SECTION

PD — Pitch Diameter

SMALL

PD

RANGE

3.0 -3.6

A

3.8 -4.8

5.0 -7.0

3.4 -4.3; 2V4

B

4.4 -5.6

5.8 -8.6

7.0 -9.4

9.6-16.0

2.1 -2.8

4L 3.0 -3.5

3.7 -5.0

DEFLECTION FORCE

Std

Befts

Min

2

2‘/4

2‘6

3

4

6V2

8Va I2V4 11 16

IVs

IVs

Super

Belts

Max Min Max Min

2Vs

2‘6

3 3

3% 5 3V4

3k

3 4

3

4

4k

6

5V4

9

8k

IVs

- —

2Vs

2Ve

Notch

Belts

3

3V4

4

3Vs

3Vs

5k 4k

6 9

7k

11V4 9V4

12k

__

- LBS

Steel Cable

Belts

Min Max

Max

3k

3 k

3k 4k

4k

5Vs

4 k

4k 4k 5k

5k

6k

7

Ilk

13k

14k

18k

—

— -

(3)If necessary, increase or decrease the

tension on belts until the deflection

force is between 17/8 and 2 5/8 lb.

8. Secure locknut and check all bolts on motor

base for secureness.

UNIT SIZES 070 THRU 140 -

1. Adjust motor base prior to mounting motor as

follows:

a. Make cardboard pattern showing distance

from base of motor to shaft center per

Fig. 23.

b. Determine specified motor position and

bolt motor base to fan section with hard

ware from accessory drive package per Fig.

24. Do not tighten until sheaves are aligned.

(1) Locate base adjusting slots in respect to

fan shaft as shown.

(2) Place cardboard pattern on motor base.

(3) Check center-to-center distance

between pattern and fan shaft with

center-to-center distance marked on

drive package carton. Required centerto-center distance should be obtained

with support angle bolts approximately

centered in adjusting slots. This will

permit final adjustment for belt in

stallation and proper tension.

(4) If center-to-center distance is too

short, adjust pivot point upward; if

too long, adjust pivot point down

ward. Refer to Fig. 25.

4

5 k

7 k

8 k

14

17k

Page 21

'Г

Fig. 23 — Cardboard Pattern

sizes 040 thru 060). A pry bar may be used to

support weight of motor.

10. Secure two support angle bolts and loosen

jackscrews.

11. Adjust motor base after mounting motor as

follows:

NOTE: If center-to-center distance was not

properly set before mounting motor, adjust

base height as follows for proper belt tension:

a. Turn jackscrews until they contact motor

base cradle.

b. Block up motor under mounting angle

nearest pivot points to support weight of

motor. Place lever (pry bar or 2 x 4 for

example) under same area.

c. Loosen two support angle bolts, and

adjust jackscrews until two support angle

bolts are approximately centered in ad

justing slots.

d. Remove two pivot point bolts, raise or

lower pivot point to obtain correct

center-to-center distance. Replace pivot

point bolts.

e. Refer to preceding step 9 for final adjust

ment of belt tension.

f. Secure two support angle bolts and two

pivot point bolts, and loosen jackscrews.

Fig. 24 — Location of Adjusting Slots

(Unit Sizes 070 thru 140)

2. Place motor on motor base with maximum

shaft overhang and install hardware from

accessory drive package; tighten securely. Posi

tion small frame motors up to 145 T per

Fig. 25. Note that hold-down bolts for small

frame motors will be smaller in diameter than

mounting angle bolts supplied in motor base,

Fig. 25.

3. Locate mounting angles so motor shaft will

hne up with center of cutout in motor base.

Make certain mounting angles are perpendic

ular to support angles and secure mounting

angle and motor hold-down bolts shown in

Fig. 25.

4. Remove protective cover and clean grease from

fan shaft with solvent.

5. Apply a light coat of grease or white lead to

fan shaft.

6. Install fan and motor sheaves with correct

angular and parallel alignment per Fig. 22.

7. Correct alignment by repositioning motor

base.

8. Secure motor base hold-down bolts.

9. Loosen two support angle bolts per Fig. 24

and adjust belt tension by turning jackscrews.

Follow step 7 of Motor and Drive (imit

Fig. 25 — Small Frame Motor Mounting

(Such as 143T and 145T)

21

Page 22

Belt Guard

UNIT SIZES 040 THRU 120

1. Position belt guard and drill three engagement

holes (sizes 040 thru 060) with a no. 5 drill or

four engagement holes (sizes 070 thru 120)

with a no. 3 drill in side of fan section using

mounting bracket clearance holes as templates.

2. Secure guard to fan section with three

1/4-20 X 1/2-in. self-tapping screws.

UNIT SIZES 130 THRU 140

1. Position belt guard and drill eight engagement

holes with a no. 3 drill in side of fan sectit i,

using mounting bracket clearance holes a:

templates.

2. Secure guard to fan section with eight

1/4-20 X 1/2-in. self-tapping screws.

3. Position two unattached mounting brackets

over unit front or top structural member and

secure to guard with four 1/4-20 x 1/2-in.

self-tapping screws and guard engagement holes.

4. Drill four engagement holes in unit structural

members with a no. 2 drill, using mounting

bracket clearance holes as templates.

5. Secure two mounting brackets to unit struc

tural members with four 1/4-20 x 1/2-in. self

tapping screws.

START-UP

Check List

1. Make certain all construction debris is removed

from unit interior.

2. Check lubrication of fan and motor bearings.

a. Note that bearings are shipped completely

full of grease for corrosion protection and

may run warm temporarily on start-up until

the excess grease has discharged. As a

precaution, cycle unit on and off at oneminute intervals for five minutes.

b. Sleeve bearing motors are normally shipped

with oil reservoir drained. Fill reservoir

before starting motor.

3. Check secureness of bearing locking collars per

Table 4. Refer to Fig. 26 for eccentric type.

Recheck sheave alignment and belt tension.

4.

Make certain fan shaft turns freely and fan

5.

wheels do not rub in housings.

Make certain filters used during building con

6.

struction are replaced with new ones. Refer to

Table 9.

Check direction of rotation and fan speed.

7.

Arrow on fan drive side indicates correct

direction of rotation. Excessive fan speed may

result in condensate carry-over from coohng

cod and/or fan motor overload. Refer to

39B, 39C Operation and Maintenance Instruc

tions for operating Umits.

Fig. 26 — Securing the Bearing Eccentric

Locking Collar

Table 9 — 39B Filters, 2 Inches Thick,

(No.... Size)

UNIT 39B

040 2...16x16

050

060 2...20x25

070

LOW VELOCITY AND

MIXING BOX

2...16x2U

2.. . 20x20

2.. . 20x25

HIGH

VELOCITY

1...16x20

1... 20x25

2...16x25

3...25x20

2 ..16x20

080

090

100

105

and

no

120

130

135 and 140

ЗИ7Ж20

3 .20x25

3...16x20

'6...2Ux2U

3.. .20x25

3.. .16x20

97720x25

3 ..16x20

3...2D72D~

6 ..20x25

9 .16x20

4 ..16x25

36 ..20x20

36...20x25

6... 16x20

8...16x20

8...20x20

14 .16x20

14 . 16x25

24 . 20x20"”"

24 20x25

8. Vibration Check:

NOTE: After final assembly, unit is checked to

ensure vibration level is within tolerance.

If excessive vibration is noted, check following:

Drive alignment

a.

b.

Mismatched belts

Wheel or sheaves loose on shaft

c.

d.

Loose or worn bearings

e.

Loose mounting bolts

f.

Motor out of balance

Sheaves eccentric or out of balance

gh.

Vibration isolators improperly adjusted

i.

Worn or corroded wheel (replace if bad)

Accumulation of material on wheel (mate

j-

rial accumulation should he scraped off).

77

Page 23

SERVICE

Coil Removal

1. Disconnect piping.

2. Remove coil cover panel.

3. Remove air baffle from both ends of coil on

leaving air side.

4. Remove and discard coil shipping hold-down

bolts from both ends of coil.

5. SUde coil out of unit. Handle cooling coils with

coil face vertical. Handle heating coils with coil

face vertical or horizontal. Lift coils from four

suspension points at corners as close to tube

sheets as possible per Fig. 27.

6. Replace in reverse order.

5. Install new bearing and tighten bearing locking

collar setscrews per Table 1 and Fig. 26.

6. Make certain fan wheel does not rub sides of

fan housing after installing new bearings.

7. Recoat fan shaft with a rust inhibitor.

8. Replace sheave, belts, and belt guard.

Fig. 27 — Handling Coil with Face Vertical

Fan Section Access — All fan section sides, front

and top panels may be removed. The panels to be

removed for fan access will depend on unit

location and the amount of access required. Refer

to Fig. 28.

After removing panels, store them properly to

avoid damage to insulation. Before entering fan

section, protect insulation by placing cardboard or

boards on bottom of fan section to serve as a

walkway.

Fan Shaft Bearing Replacement

1. Remove belt guard, belts, and sheave.

2. Loosen bearing locking collar setscrews.

3. Remove bearing hold-down bolts.

4. Remove bearing and observe the following

precautions:

a. Make certain fan shaft surface is clean

between bearing and end of shaft.

b. Block up fan shaft. Do not let fan shaft

drop on bearing support, or let fan wheel

twist or bind between sides of fan housing.

ЧОТГ "rfstv-fx, iiyxiW :}' i-jycia'.'f'.xi

*>t,: r ги>'eij-i y td'.zi ■'tf-,.

Fig. 28 — Removable Panels for Access to

Fan Section

Fan Shaft Removal

1. Remove fan shaft bearings per Fan Bearing

Replacement.

2. Refer to Fan Section Access and remove panels.

3. Loosen fan wheel setscrews (sizes 040 thru 060)

or fan wheel clamps (sizes 070 thru 140).

4. Block up fan wheels within housings to prevent

dropping when shaft is removed.

5. Remove bearing plates and sUde shaft from

unit.

6. Replace shaft in reverse order and replace any

damaged internal insulation. Refer to Fig. 2 or

Table 4.

23

Page 24

Fan Wheel Removal

1. Remove fan shaft bearings per Fan Bearing

Replacement.

2. Remove fan shaft per Fan Shaft Removal.

3. Remove fan discharge ductwork.

4. Remove cutoff plate per Fig. 29 and remove

fan wheel thru housing discharge.

5. Replace any damaged internal insulation.

6. Replace fan wheel in reverse order and note

following;

a. When replacing fan wheels on unit sizes

070 thru 140, ensure balancing reference

marks on wheel (normally a red line)

and clamps line up. Adjust fan clamp

torque per Fig. 2.

b. Adjust cutout clearance per Table 10. For

minor adjustment, loosen screw holding

cutoff clip to fan housing and adjust cutoff

plate. For further adjustment, loosen bear

ings and shift fan shaft.

Table 10 — 39B Cutoff Clearance (in.)

Fig, 29 — Fan Details

UNIT 39B

040 thru 060

070 thru 080

090

100 thru 110

120

130

135 thru 140

1%

%

IMe

1“/з2

2У2

2Уд

3

A

FAN SECTION

В

- -

%

1Мб

IVie

2

2У

2У

С

-

-

-

-

-

3

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to change any product specifications without notice.

CARRIER AIR CONDITIONING COMPANY • SYRACUSE, NEW YORK

Tab 9 Form 39B-1SI Supersedes 39BA041005 Printed in U.S.A. 9-71 Codes C and ME Catalog No. 533-902

Loading...

Loading...