Page 1

Number One

Air Conditbninq

Maker

Installation, Start-Up ^ ^ 3

Division of

and Service Instructions

Carrier Corporation

Carrier Parkway • Syracuse

SAFETY CONSIDERATIONS

INSTALLATION

Step 1 — Check Equipment and

Jobsite.................................................................1

• UNPACK UNIT

• INSPECT EQUIPMENT

• COMPLETE OR CONSIDER

Step 2 — Make Piping Connections .... 2

• REPLACE THE ACCURATER™

• CONNECT REFRIGERANT LINES

Step 3 — Make Electrical

Connections........................................................5

• INSTALL A BRANCH CIRCUIT

• ROUTE LINE POWER LEADS INTO

• CONNECT GROUND LEAD AND

• CONNECT CONTROL POWER

START-UP

SERVICE.................................................................. 8-10

MAINTENANCE

Installation and servicing of air conditioning

equipment can be hazardous due to system pressure

and electrical components. Only trained and quali

fied service personnel should install, repair or

service air conditioning equipment.

Untrained personnel can perform basic mainten

ance functions of cleaning coils and filters and re

placing filters. All other operations should be

performed by trained service personnel. When

working on air conditioning equipment, observe

precautions in the literature, tags and labels attached

to the unit and other safety precautions that may

apply.

Follow all safety codes. Wear safety glasses and

work gloves. Use quenching cloth for brazing opera-

f N Y 13221

Air-Cooled Condensing Units

INDEX

..................................

.......................................................

SYSTEM REQUIREMENTS

REFRIGERANT CONTROL

PISTON IN THE INDOOR

COIL IF REQUIRED

DISCONNECT PER NEC

UNIT

POWER WIRING

WIRING

...............................................................

......................................................

SAFETY CONSIDERATIONS

Page

1

1-5

6-8

10-12

tions. Have fire extinguisher available for all brazing

operations.

WARJ^iKG; Before performitsg $ervice or

maiatesjaBce operatjojjs vam off

nsBiirt po’»er swiich. to indoor »nfi and outdoor

unit. Turn, off accessory heater poTser switch if

applicable- Electrical siioolc could cause persortal irgnry.

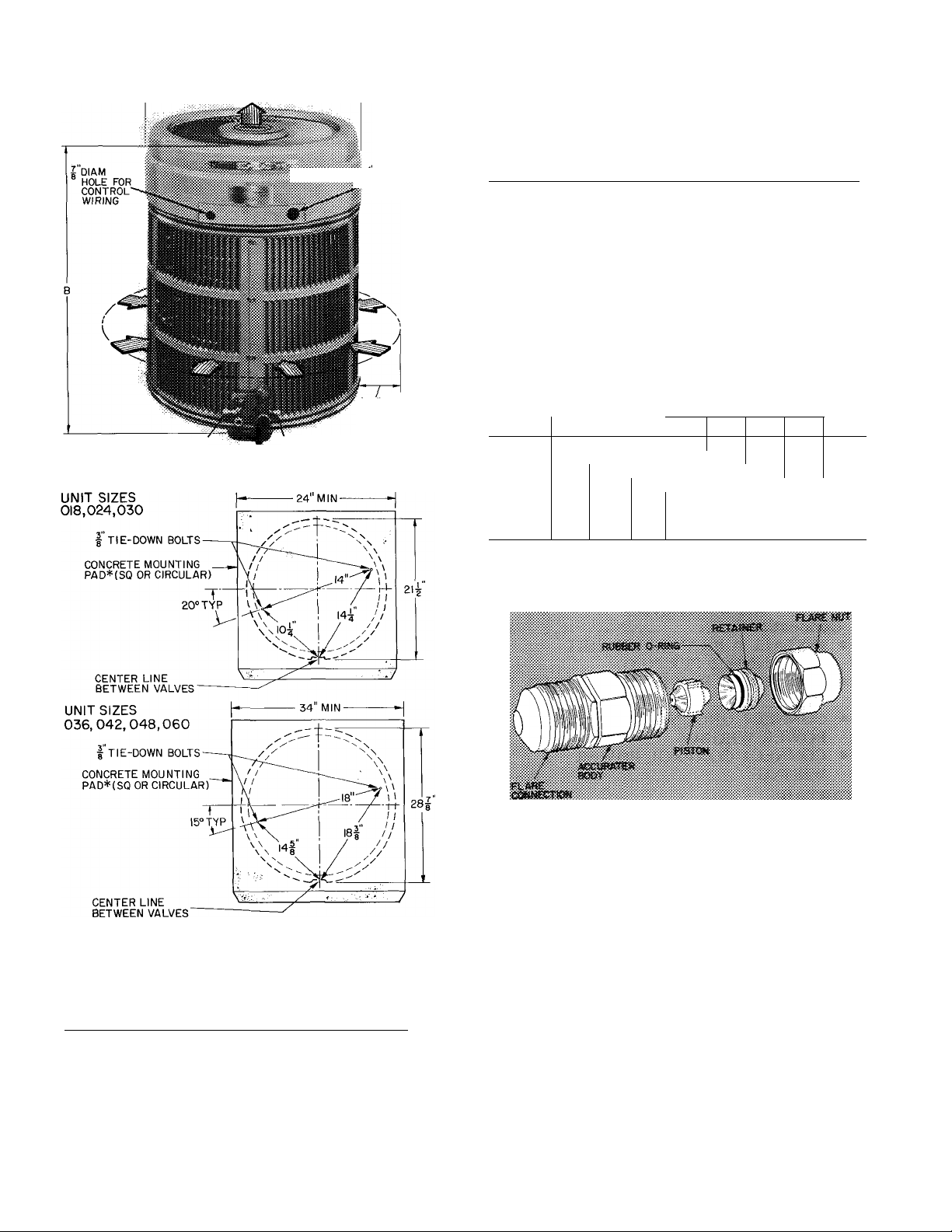

Table 1 — Physical Data (Refer to Fig. 1.)

MODEL 38EC

OPER WT (lb)

DIMENSlbNS (ft-in.)

Diameter A

Height B

CONNECTIONS (in.)

Suction (DDF)

Liquid (DDF)

REFRIG LINES

Suction (in DDF)

Liquid (in DDF)

*Fora1-1/8in suction line on 38EC048,060, a 3/4-in x 1-1/8 in suction

valve connection adapter is available as an accessory See Table 3

018 024

116 130 137 165

2-2-3/8 1 2-8

INSTALLATION

Step 1 — Check Equipment and Jobsite

UNPACK UNIT — Move to final location. Slide

from carton taking special care not to damage serv

ice valves or grilles.

INSPECT EQUIPMENT — File claim with ship

ping company if damaged or incomplete.

COMPLETE OR CONSIDER SYSTEM RE

QUIREMENTS before installation:

Consult local building codes and National Elec

trical Code (NEC) for special installation

requirements.

When installing, allow sufficient space for airflow

clearance, wiring, refrigerant piping and service.

Maintain a minimum of 4 ft clearance from obstruc

tions above and 18 in. on sides of unit. Maintain a

distance of 24 in. between condensing units. Posi

tion so water from roof or eaves does not flow

directly on unit.

Install on a solid, level mounting pad. It is not

necessary to attach unit to pad but if desired or

required by local code, position tiedown bolts in

pad. Fasten unit to pad using 2 holes provided in unit

base. See Fig. 1.

030 036 042 048* 060*

212 230

18|

1-9-3/4

5/8 3/4*

Recommended Field-Supplied Sizes

5/8 1 3/4 I 7/8 I 1-1/8

2-5-1/4

2-2-3/8 1 2-8 1 3-2

3/8

3/S

© Carrier Corporation 1982

Form 38EC-2SI

Page 2

4-0 OVERHEAD SPACE REQUIRED

FOR SERVICE AND AIRFLOW

LIQUID VALVE SERVICE PORT

CONDENSER AIRFLOW

liDIAM HOLE

FOR POWER

WIRING

r-6 AIRFLOW

AND SERVICE

CLEARANCE

SUCTION VALVE SERVICE PORT

orator i^^if^field replacement of piston. Refer to

Table 2. Replace piston, if required, before connect

ing refrigerant lines. Piston replacement instructions

are ineluded in evaporator installation book. After

system installation is complete, use Charging Chart

to check and/or adjust refrigerant charge.

Condensing Units Connected to Carrier-Approved

Evaporators — Condensing units contain correct

system refrigerant charge for operation with evap

orator of the same size when connected by 25 ft

of field-supplied or Carrier accessory tubing.

Check refrigerant charge for maximum efficiency

(see Refrigerant Charging, page 6).

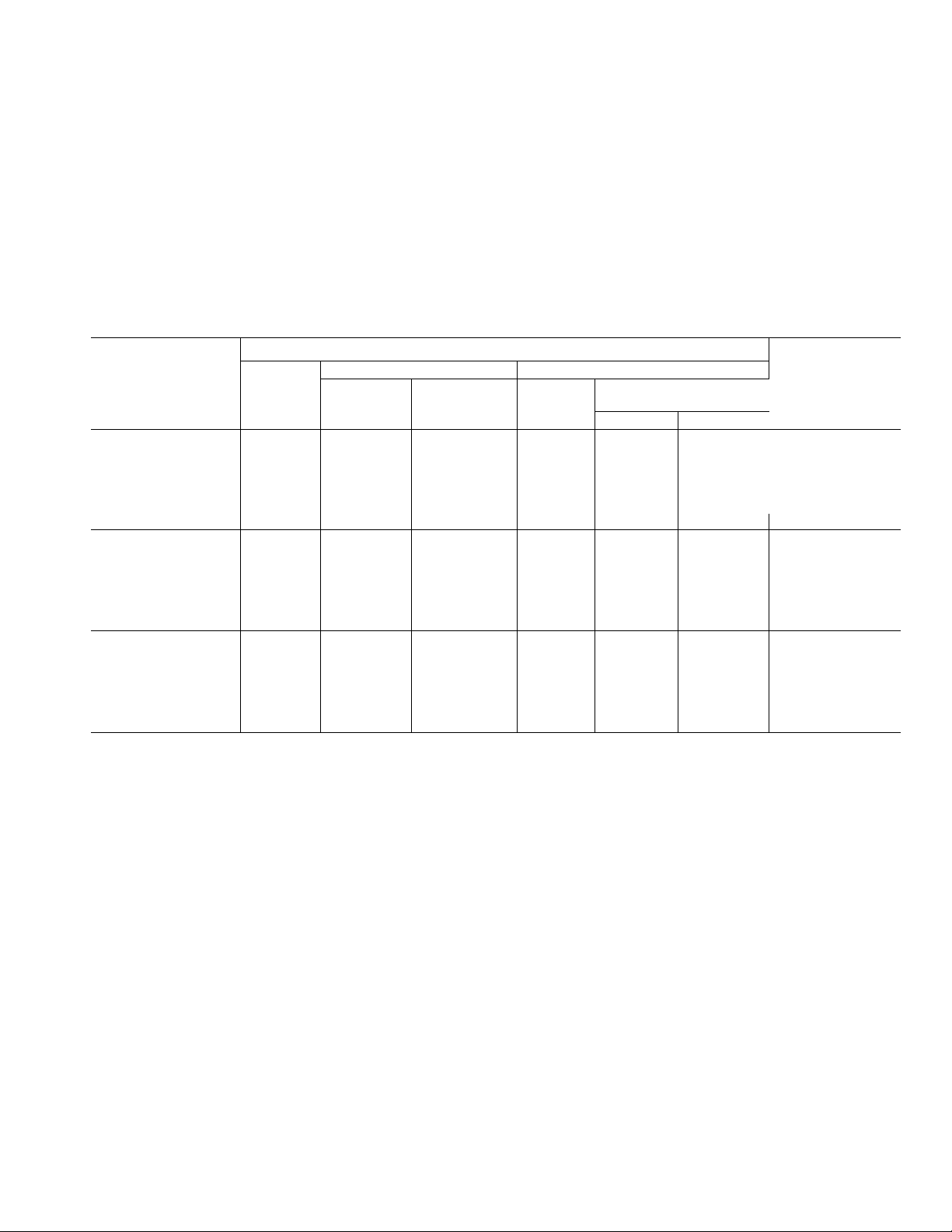

Table 2 — Optimization Chart

(Outdoor air design temperature. db-F.

100 F and below)

COND

UNIT

38EC

018

024

030

036

042

048

060

014 018

—

— —

—

— —

— —

— — —

—

Factory-installed piston Obtain replacement pistons thru

local Carrier distributor

ACCURATER™ piSTON NO.

Evap Size (Coil or Fan Coil)

024 030

46

—

—

TXV

52

SS

—

— —

—

—

57

63

— — ■■■■

— —

036

—

TXV

65

67

- -

042

048 060

— —

— — —

_

TXV

70

TXV

76 78

—

S3 82

— ■ ; 64

—

—

TXV

*CONCRETE PAD SHOULD WEIGH I5 TO 2 TIMES WEIGHT OF UNIT

Certified dimension drawings available on request

Fig. 1 — Dimensions. Connections and

Mounting Pad (Refer to Table 1.)

Carrier Cooling System Capacity Optimization —

AccuRater™ (bypass type) refrigerant control, with

field-replaceable piston (see Fig. 2), is supplied on

evaporator. Use Optimization Chart, Table 2, to

find AecuRater piston size required for eondenser/

evaporator system being installed. Pistons are correetly sized for an evaporator of the same capacity as

the condensing unit, so piston change is not neces

sary. Mix-matching of condensing unit with evap-

Fig. 2 — AccuRater (Bypass Type)

Components

■Step 2 — Make Piping Connections — Con

densing units may be conneeted to evaporator sec

tions using Carrier accessory tubing package (Table

3) or field-supplied tubing of refrigerant grade,

correct size and condition (Table 1). For tubing

requirements beyond 50 ft, obtain information from

local Carrier distributor.

WARNING if

ùt

If 1-1/8 in. tubing is used (38EC048,060), braze

it to theaecessory 1-1 / 8 x 3/4-in. suction eonnection

adapter (Carrier Part No. 28VQ900011) or to eor-

rectly sized field-supplied adapter, then make Com

patible Fitting connections.

Page 3

Table 3 — Accessories

PART NO

HH01AD040

HH93AZ040

HH07AT170

Low-Voltage Control Honeywell Deluxe Thermostat

Thermostat Subbase

Low-Voltage Control

DESCRIPTION

&

HH07AT174

HH93AZ176

HH01AD042

HH93AZ042

HH01YA192

HH93YZ194

38GS900102 Indoor Fan Relay (Six HN61KJ210)

38GS900212

28VQ900011

09WQ036.060 Refrigerant-to-Water Heat Exchanger for Chilled Water Systems All

TUBING

PACKAGES

38LS958151

38LS958201

38LS958251

38LS958301

38LS958351

38LS958401

38LS958501

38LS934151

38LS934201

38LS934251

38LS934301

38LS934351 35 3/8

38LS934401

38LS934501

38LS978151

38LS978201

38LS978251

38LS978301

38LS978351

38LS978401

38LS978501

‘For maximum capacities, use suction line sizes recommended in

Table 1 Use of accessory tubing packages smaller than recom

mended may result in slight capacity loss (see Note 2)

tSuction line is insulated and has a 90 degree bend at one end

JFor 5/8-in evaporator connection, cut off 3/4-in end

Length

Honeywell Thermostat

Thermostat Subbase

Low-Voltage Control Honeywell Thermostat

Thermostat Subbase

Low-Voltage Control Grayson Thermostat

Thermostat Subbase

Low-Voltage Transformer (Six 38GS900091)

Twelve 3/4- x 1-1/8 in Connection Adapters

TUBING

Liquid

(ft)

15 3/8 3/8

20 3/8 3/8

25 3/8

30 5/16

35 5/16

40 5/16

50

15 3/8

20 3/8

25 3/8

30

40 3/8 3/8 3/4 3/4 3/4

50 3/8

15 3/8 3/8

20

25 3/8

30 3/8

35 3/8

40 3/8

50 3/8

OD

(in.)

1/4

3/8 3/8 3/4 3/4 3/4 030, 036

3/8 3/8 7/8 3/4

Tube End

OD (in.)

3/8

3/8 5/8

3/8 5/8

3/8 5/8 3/4t

3/8 5/8

3/8 3/4 3/4 3/4

3/8

3/8 3/4 3/4 3/4

3/8

3/8

3/8 7/8 3/4

3/8 7/8 3/4

3/8 7/8

3/8 7/8 3/4

3/8 7/8 3/4

*

Suctionf

OD

(in )

5/8

5/8 3/4t 5/8

5/8 3/4t 5/8

3/4

3/4 3/4 3/4

3/4

7/8

NOTES

1 Do not cut 3/8-in OD liquid lines to a length shorter than 10

feet Do not cut 5/1 6-or 1/4-in liquid line Do not cut 7/8-in

OD suction lines

2 Field-supplied 1-1/8 in suction line is recommended on

38EC048 and 060 If accessory tubing package is used, a

capacity reduction can result

Tube End

OD (in.)

Evap Cond

3/4t

3/4t 5/8

3/4t 5/8

3/4t

3/4 3/4

3/4

3/4

3/4 3/4

MODEL

38EC

All

048, 060

MODEL

38EC

5/8

018, 024

5/8

5/8

3/4

3/4

3/4

3/4

3/4

3/4

3/4

■ WAHNiKO' IK> HOI Et'RY LiNESETS. if

is for exsojaSod peraaisi. dint

ing vmtn westiher. rdVigoraoi may to

the cookr boiieii ssetioo catismg

sltsggisig m A sksn ruo of kss

3 Ci of Uoesei may in pousni but ihore mmi fee

a 6 m vetiicai rise lo ifee valve cotmociiona oo

tire condeosiog sale.

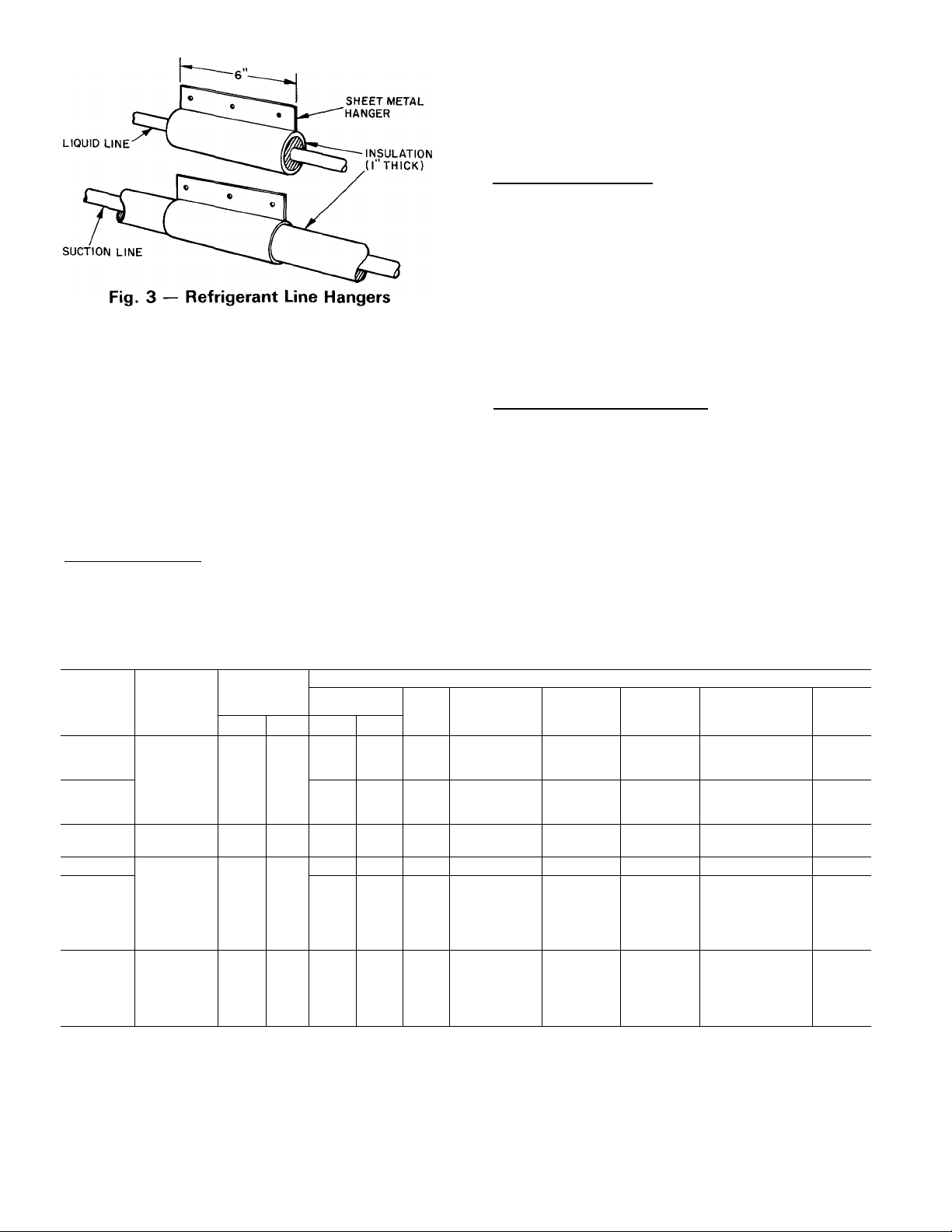

Isolate interconnecting tubing from framing and

ductwork or where tubing runs thru stud spaces, en

closed ceilings or pipe chases. Use isolation type

hanger (Fig. 3) since rigid fastening transmits pulsa

tions to structure, creating objectionable sound.

For maximum capacity on 38EC048 and 060 sys

tems use 1-1/8 in. suction line. A capacity reduction

results if Carrier accessory tubing is used on these

systems. (Example: When a 25-ft accessory tubing

package is used on a 38EC048 system, the smaller

suction line results in a 3% capacity reduction.)

Length of interconnecting tubing may necessitate

refrigerant charge adjustment. Follow special re

quirements described in Start-Up, Refrigerant

Charging, page 6. Do not use less than 10 ft of inter

connecting tubing. On Carrier accessory tubing

packages, do not cut 5/ 16-in. or 1/4-in. liquid line or

7/8-in. suction line. These tubing packages have

swaged ends that, if cut, will not fit into refrigerant

line fittings. Bend or coil excess tubing to fit.

Do not use damaged, undersized or contaminated

tubing. Always evacuate or purge evaporator coil

and tubing system. When purging, use field-supplied

refrigerant, not unit holding charge refrigerant.

Page 4

When making tubing connections, be sure to pro

vide clearance at unit for electrical connections.

REPLACE THE ACCURATER™ REFRIG

ERANT CONTROL PISTON IN THE INDOOR

COIL, if required, before connecting refrigerant

lines. See Carrier Cooling System Capacity Optimi

zation, page 2.

CONNECT REFRIGERANT LINES to fittings on

eondensing unit suction and liquid service valves

(Fig. 1). Unit Compatible Fittings permit mechanical

(quick connect) or sweat connections.

Model 38EC048,060 — When using 1 -1 / 8 in. fieldsupplied suction line, use accessory suction line

adapter. Braze refrigerant suction line to 1-1/8 in.

end of adapter. Allow adapter to cool before insert

ing into valve. Do not allow heat to reach valve as

O-ring damage may result. Connect 3/4-in. end of

adapter to unit suetion line Compatible Fitting.

Connect liquid refrigerant line to unit. If a 7/8-in.

field-supplied suction line is used, provide a fieldsupplied 3/ 4-in. to 7/ 8-in. suction line adapter. (Not

necessary if 38LS accessory tubing is used.)

Mechanical Connection — (Mate one set of connec

tions at a time.)

1. Loosen nut on Compatible Fitting one turn. Do

not remove.

2. Remove plug and be sure O-ring is in the groove

inside the Compatible Fitting.

3. Cut tubing to correct length. Deburr tubing.

4. Insert tube into Compatible Fitting until it

bottoms. Keep tube bottomed in Compatible

Fitting while tightening nut. Tighten nut until it

bottoms on shoulder of fitting or valve.

Sweat Connection or Repair — (Use refrigerant

grade tubing.)

1. Remove locking nut, rubber O-ring and Schrader

core and cap from valve service port.

2. Cut tubing to correct length. Deburr tubing.

3. Insert tube in Compatible Fitting until it bottoms.

Wrap top and bottom of service valves in wet

cloth to prevent damage by heat. Solder with lowtemperature (430 F) solder.

4. Replace Schrader core and cap.

5. Evacuate or purge system using field-supplied

refrigerant.

f

Table 4 — Electrical Data (60 Hz)

COND

UNIT

38EC

018300 41 9 1 14

024300 59 13 3

030300

036300

042310 108

048300

048310

060300

030500 60

036500 74 11 7 12

042510

048500

048510 80 163

060500 136

036600

042610

048600

048610 40 8 1

060600 49

AWG — American \A/ire Gage

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

RLA — Rated Load Amps

‘Permissible limits of the voltage range at which the unit will

operate satisfactorily

fCopper wire sizes based on 60C Use copper or copper-clad

aluminum wire only Use latest NEC for copper-clad aluminum

conductor sizing

V/PH

208-230/1

230/1

208-230/3

460/3

OPER

VOLTAGE*

Max

Min

254

197

254 207

254

197

506 414

Compressor Fan Min Wire

LRA RLA

69 16.2 10

93

145

105

22 9

35 3

150

74

120

41 5 9

38 6 5

60 74 1 2

FLA

Size (AWG)t

1 2 12

20 2

21 7

25 7

20 8

20

94 1 2

120

20

148

20 4

102 12

BRANCH CIRCUIT

Max Wire

(ft)

31 5 14 20

32 7 12 30

46.0 10 35

10

8

8

6

14

12

10

10

10

14 106 9 14 15

14 98 9 14 15

14 87 6 14 15

12

^Required when using nonmetallic conduit

“Maximum dual element size

NOTES

1 Fan motors are 230 v, single phase

2 All units have 24-v control circuit which requires external

power source

35 7

49 9

44.8 8 60 34.5

41 0

51 3

35 3 14 20

40 7

42 9

55 0

50 4

41 2

129 2 12 20 11 3

97 9

Min Gnd

Wire Size}

10

8

10

6

12

12

10

10 35

10

12

Max Fuse or

HACR Type

Ckt Bkr Amps“

45

50 29 5

50

60

25

25

30

45

25 14 9

MCA

12 6

17 8

21.5

27 7

31 0

46 5

13 0

16 6

17 0

20 9

22 8

27 9

8 6

9 3

105

Page 5

Step 3 — Make Electrical Connections — Be

sure field wiring complies with local and national

fire, safety and electrical codes, and that voltage to

unit is within limits shown in Table 4. Contact local

power company for correction of improper line

voltage.

See Tafek 4 ««t »pply i

See Table 4 for recommended wire and fuse sizes.

When making electric connections, provide clear

ance at unit for refrigerant piping connections.

INSTALL A BRANCH CIRCUIT DISCONNECT

PER NEC of adequate size to handle unit starting

current. Locate disconnect within sight from and

readily accessible from the unit, per section 440-14

of National Electrical Code (NEC).

ROUTE LINE POWER LEADS INTO UNIT —

Extend leads from disconnect thru power wiring

hole provided (see Fig. 1) and into unit splice area.

Remove top cover to gain access to unit wiring.

CONNECT GROUND LEAD AND POWER

WIRING — Connect ground lead to a ground lug

in control box for safety. Then connect power wiring.

See Fig. 4. Splice line power leads to yellow and

black pigtails. Use wire nuts and tape at each con

nection. Connect unit wiring to copper or copperclad aluminum power wiring. Do not connect to

aluminum wiring.

CONNECT CONTROE POWER WIRING —

Route 24-v control wires thru control wiring hole

and connect to pigtails supplied with unit (Fig. 1).

Use furnace or fan coil transformer as 24-v (40-va

minimum) supply for system as shown in Fig. 5, or

use accessory transformer shown in Table 3.

THERMOSTAT SUBBASE

HH93AZ042 OR

THERMOSTAT SUBBASE

HH93AZ042 OR

ARRANGEMENT B-ONE TRANSFORMER

(COOLING AND ONE-STAGE HEATING)

THERMOSTAT SUBBASE

HH93AZI76

_LEAVE JUMPER ON

SUBBASE (RH TORO

38EC

5»^ « £ K

MWk MW Mb •! t MV< VWWWM

iifscomiz^

PER

~ -«ROtiRtS V.E&0 ' UJS

MVWT

--

------

ftmwifvni

Fig. 4 — Line Power Connections

__

o

Eili&SS

tsam UNIT

CiMi ìmr

____

^

1

r

_L_

TO IFM LINE

VOLTAGE

POWER

SUPPLY

ARRANGEMENT C-ONE TRANSFORMER

(COOLING AND TWO-STAGE HEATING)

IFR, FS and IFM are located in furnace on heating-cooling

applications If accessory IFR is required for cooling-only

applications, locate IFR in fan coil

c

— Contactor (12-va) Trans — Transformer

— Fan Switch __

FS

HC

— Heating Control v-V Field Splice

IFM — Indoor Fan Motor

IFR

"Connect FS to low-speed indoor fan terminal when 2-speed fan

NOTE Refer to unit wiring label for wire colors C to G and C to Y

connections

Indoor Fan Relay

is used

1 1

1 !

1

1

L

1

ITRWS

HC|

-HC2

FURNACE

________

_________ Factory Wiring

Field Wiring

^ Fig. 5 — Control Circuit Connections

Page 6

START-UP

1. Backseat (open) liquid and suction line service

valves. Open liquid line first to equalize pres

sure and reduce oil flow to suction line.

2. Set thermostat selector switch at OFF.

3. Set room thermostat at desired temperature.

Be sure this temperature is below indoor ambient.

4. Close electrical disconnects energizing entire

system.

5. Set room thermostat at COOL and fan switch at

FAN or AUTO, as desired. Operate unit for 15

minutes; then check system refrigerant charge.

See Refrigerant Charging, discussed later.

Motors and controls are designed to operate satis

factorily in the voltage range shown in Table 4. If

necessary to use manifold gages for servicing, refer

to Carrier Standard Service Techniques Manual,

Chapter 1, Refrigerants, page 1-5, Fig. 8 for bypass

method of returning charge to system. Removal of

liquid line charging hose without following these

precautions could result in some loss of charge.

Refrigerant Charging

ca» саяш flooding.

Table 5 — Service Data

UNIT

38EC

018 3 3

024

030 5 3

036 7.5

042 63

048300 6 1

048310

060

‘Factory refrigerant charge is adequate when evaporator and con

densing unit are the same size and are connected with 25 ft or less

of field-supplied tubing of recommended size or Carrier accessory

tubing

R-22 CHG*

(lb)

3 3 1110/950

72

9 6

CONDENSER

FAN RPM (Hi/Lo)

1075/950

Condensing units contain correct operating

charge for complete system when connected to

Carrier-approved evaporators of same capacity as

condensing unit with 25 ft or less of Carrier accessory

tubing or field-supplied tubing of recommended

size. For every 10 ft of liquid line of recommended

size over 25 ft, add refrigerant charge as follows: .41b

for 3/8-in. line; .28 lb for 5/ 16-in. line. On all other

systems, adjust eharge for correct operation as

applicable.

Service port eonnections are provided on liquid

and suction line service valves for evacuation and

charging. See Fig. 1.

TO CHECK, ADJUST OR REPLACE REFRIG

ERANT CHARGE use method recommended in

Table 6. Details of charging methods are listed

below.

Before recharging system, thoroughly evacuate

system and then weigh in refrigerant charge speci

fied in Table 5. Check or adjust charge as required.

Refer to Carrier Standard Service Techniques

Manual, Chapter 1, Refrigerants, for additional sys

tem evacuation and dehydration instructions.

WEIGHT METHOD — Refer to Table 5 or unit

nameplate for correct system refrigerant charge.

Remove any refrigerant remaining in system before

recharging.

When system is not evacuated, subtract the

following amount from total charge.

38EC018 thru 030 — .10 lb (1.6 oz)

38EC036 thru 060 — .20 lb (3.2 oz)

The Dial-a-charge charging cylinder is an accu

rate device used to recharge system by weight. These

cylinders are available at refrigeration supply firms.

CHARGING CHART METHOD — Use Charging

Chart, Fig. 6, and the following procedure.

1. Operate unit a minimum of 10 minutes before

checking charge.

Measure suction pressure by attaching a gage to

2.

suction valve service port.

Measure suction line temperature by attaching a

3.

service thermometer to unit suction line near suc

tion valve. Insulate bulb, thermocouple or

thermistor for accurate reading.

f:

Table 6 — Refrigerant Charging Methods

roNniilMlT ADJUSTING CHARGE

ALL 1 or

‘Sight glass field supplied and installed in liquid refrigerant line

I METHODS OF CHECKING OR

38EC 1 System Refrigerant Control

1 Non TXV TXV

1 Chargemaster®

1 Charging Chart

Sight

Glass*

METHODS FOR COMPLETE

System Refrigerant Control

Non TXV

Weight Method

plus

Chargemaster or

Charging Chart

RECHARGING

TXV

Weight Method

plus

Sight Glass*

Page 7

(AccuRater™ System)

4. Measure outdoor (condenser inlet) air dry-bulb

temperature with a second thermometer.

5. Refer to Charging Chart (Fig. 6). Find air tem

perature entering condenser and project hori

zontally to curve showing suction pressure (psig

at suction valve).

6. From this intersection, project vertically down

ward to suction line temperature.

7. If unit has a higher suction line temperature than

charted temperature, add refrigerant until

charted temperature is reached.

If unit has a lower suction line temperature than

8.

charted temperature, bleed refrigerant until

charted temperature is reached.

If air temperature entering condenser or pressure

9.

at suction valve changes, charge to new suction

line temperature indicated on chart.

CHARGEMASTER® METHOD — Operate unit

for 10 minutes before using Chargemaster (Carrier

Part No. 38GC680004).

1. Tape Chargemaster feeler bulb to suction line

close to condensing unit. Insulate bulb. Ensure

suction line is clean for good contact with bulb.

(Uninsulated bulb or dirty suction line will seri

ously affect accuracy of temperature readings.)

2. Connect refrigerant drum to Chargemaster inlet

port keeping drum in position for vapor charging.

3. Connect Chargemaster outlet port to unit suction

valve service port.

4. Crack valves on refrigerant drum and Chargemaster to purge lines from drum to suction valve.

After purging lines, close valve on Chargemaster

only.

5. Measure outdoor air dry-bulb temperature.

6. Crack unit suction valve and read evaporator

temperature at red needle position on Chargemaster temperature gage and suction line tem

perature at black needle position.

Enter Chargemaster Charging Chart, Table 7, at

7.

outdoor air temperature (step 5) and evaporator

temperature (step 6). Find the suction line tem

perature required for correct system charge. If

actual suction line temperature (step 6) is higher

than table value, the system is undercharged. If

suction line temperature is lower than table

value, system is overcharged.

EXAMPLE: At outdoor air temperature of 84 F

and evaporator temperature of 43 F, the system

will be correctly charged at 76 F ± 2 F suction

line temperature. See Table 7.

Add charge by slowly opening Chargemaster

valve. If necessary, reduce charge by bleeding at

liquid line service valve. Check outdoor air and

evaporator temperature during procedure. If they

change, refer back to Chargemaster Charging

Chart.

Table 7 — 38EC Chargemaster Charging

Chart (AccuRater System)

OUTDOOR

TEMP

(F)

60

62 30

64 28

66

68 34 43

70 32 41 52

72

74

76

78

80 26

82

m 3Î

86

88 35

90 34

92

94

96 38

98 36

too 42 49 57 65 75

102

104

106

108 43 49

110 41 47 55 63

112

114

Example

EVAPORATOR TEMPERATURE (F)

21

32

27

25 28 31

Suction Line Temperature (F)

40 51

38 39

37 47;

35 45 : 57

31 39 50

37 : 48

30

36 46

29

27 35

33 42

32

29 37

34

60

54 67

44

40

mr

im m

33

37 40 45 48

64

61 72

58

69

56

66

54

63

52

61 72

50

59 68

46

55 63 73 85

44

53 61 70

42

51 59

41

49 57 65

39 47 55

45 53

44 51 59 67

41

39

75

X4£^:«:

48

46

45 51

; ^

81

78 90

68

75

63

72

61

70

55 63 73

61

53

59

57

46 53

50

86

83

80

77

70

68

65

61

59

Page 8

Correct use of Chargemaster ensures that an opti

mum refrigerant charge will be in system when con

ditions and system components are normal.

However, the Chargemaster does not solve or fix

system abnormalities. It indicates correct charge for

condition of the system. It will not make corrections

for dirty filters, slow fans, excessively long or short

suction lines or other abnormal conditions. This

charging device ensures that a correct relationship

exists between outdoor temperature, evaporator

temperature, and suction line temperature on a spe

cific system.

SIGHT GLASS METHOD — (Field-supplied sight

glass installed in liquid line.) A satisfactory oper

ating charge can be obtained on thermal expansion

valve systems only by charging to a clear sight glass.

For optimum charge, increase high-side pressure to

380 ± 10 psig by blocking condenser fan discharge

or air entering condenser. Charge to a clear sight

glass while holding constant high-side pressure. For

peak efficiency, adjust charge to yield a liquid refrig

erant temperature at the evaporator that is approxi

mately the same as outdoor dry-bulb temperature.

CRANKCASE HEATER SWITCH

SUCTION LINE

LOW

PRESSURE

SWITCH

DISCHARGE GRILLE (FAN

MOTOR UNDERNEATH) ^

WIRE ACCESS OPENING

TOP COVER-

HOT GAS

DISCHARGE LINE

CONDENSER COIL

COMPRESSOR

HIGH-

'/ PRESSURE

SWITCH

FAN MOTOR

AND

COMPRESSOR

LEADS

PLASTIC PIN

OF TUBE

lì SUPPORT

SERVICE

Compressor Removal — See Table 8 for com

pressor information and Fig. 7 for component loca

tion. Shut off power to unit. Remove refrigerant

from unit using refrigerant removal methods de

scribed in Carrier Standard Service Techniques

Manual, Chapter 1, Refrigerants. Be sure system

pressure is 0 psig before attempting eompressor

removal.

^ Table 8 — Compressor Data

UNIT PRODUCTION

38EC

018300 AJ8520G

024300

030300 CRF1-0250PFV Ì;

036300 CRJ1-0300PFV 55

042310

048300

048310

060300 PC6416AG

030500

036500

042510

048500 YRD6-0400-TFC

048510

060500

036600

042610

048600

048610

060600

'Refer to Carrier Service Parts Catalog for replacement model

numbers

tWhere piping exceeds 50ft, obtain information from local Carrier

distributor

COMPR*

CRD-0200PFV 55

AV5542E 54

YRD-0400-PFV 72

PC5016BD 66

CRF1-0250-TF5

CRJ1-0300-TF5 55

AV5542E

PY5016BD 66

PY6416AF 66

CRJ1-0300-TFD 55

AV5542E

YRD6-0400-FFD 72 68

PH5016BD

PH6416AF 66 62

OIL CHARGE (oz)t

Initial Recharge

26

55

66

55

54

72

54

66 62

24

51

51

51

50

68

62

62

51

51

50

68

62

62

51

50

Fig. 7 — Condensing Unit 38EC

Component Locations

Follow safety codes. Wear safety glasses and

work gloves. Have quenching cloth available.

CAilTIOMi

m iufeisjg or doroags tmy

1. Remove top cover: remove 3 screws holding

top cover to connector plate; remove third screw

clockwise from connector plate; loosen remain

ing 5 screws; lift cover straight up.

2. Disconnect high- and low-voltage field wiring

and fan motor leads from capacitor and

contactor.

3. Remove 4 screws (38FC018 thru 030) or 8 screws

(38FC036 thru 060) holding discharge grille in

place. Lift grille from unit.

4. Disconnect compressor leads (crankcase heater,

low-pressure switch, if so equipped) from elec

trical components and pull them thru the wire

access opening into the coil section. Lift fan

orifice/control ring after pinching and pressing

down on 3 plastic pins of tube supports.

5. Remove louvered casing by taking out 16 screws

securing it to the cabinet and sliding it away

from the coil.

Page 9

6. Using a midget tubing cutter, cut liquid and

discharge lines on the coil and suction line at a

convenient place for easy reassembly with

copper slip couplings.

After plugging connections, remove condenser

coil by pinching plastic pins of tube supports

that extend into basepan and lift vertically. Set

coil on a clean, flat surface.

Remove compressor holddown bolts and slide

8.

out compressor. Remove crankcase heater, if

so equipped.

9. Carefully unbraze suction and discharge line

piping stubs from compressor after noting posi

tion of stubs to assist when reinstalling.

10. Install new compressor, placing crankcase

heater around compressor, if so equipped. Be

sure compressor holddown bolts are in place.

11. Replace coil; braze suction and discharge lines

to compressor piping stubs (at points where eut.

Step 6); rewire compressor and leak test.

12. Replace fan orifice/control ring; connect com

pressor wires after feeding them thru eontrol

ring; replace fan/grille assembly and rewire;

connect high- and low-voltage power wiring;

and replace louvered casing.

13. Replace top cover by running screws into orifice

loosely and tighten when cover is in plaee.

14. Evacuate and reeharge system.

Filter Drier — Install field-supplied filter drier

(Table 3) in system liquid line when refrigerant

system is opened for serviee as described under

Compressor Removal. Position drier in liquid line

at convenient loeation.

Pumpdown Procedure — The system may be

pumped down in order to make repairs on low side

without losing eomplete refrigerant charge.

1. Attach pressure gage to suction service valve gage

port.

2. Frontseat the liquid line service valve.

3. Start unit and run until suction pressure reaches

5 psig (see Caution).

4. Shut unit off and frontseat suction valve.

5. Vent remaining pressure to atmosphere.

1

Unit Controls and Safety Devices

HIGH-PRESSURE RELIEF VALVE is located in

eompressor. Relief valve opens if system operating

pressure differential between suction and discharge

pressure reaches 400 to 500 psi on all models.

LOW-PRESSURE SWITCH is located on unit

suction line. Low-pressure switch settings are: cut

out, 31 ± 4 psig; cut-in, 60 (+15, -0) psig.

INTERNAL TEMPERATURE AND/OR CUR

RENT SENSITIVE OVERLOADS reset automati

cally when motor internal temperatures drop to a

safe level (overload may require up to 30 minutes to

reset). When internal overload is suspected of being

open, check by using an ohmmeter or continuity

tester. If neeessary, refer to Carrier Standard Serv

ice Techniques Manual, Chapter 2, Eleetrical, for

complete instructions.

INHERENT FAN MOTOR PROTECTION pro

tects motor from abnormal current and temperature.

FAN SWITCH changes to high speed at 90 F ± 5;

changes to low speed at 75 F ± 5.

SOLID-STATE TIME GUARD II CIRCUIT,

if so equipped, protects unit compressor by prevent

ing short cycling. Time Guard II circuit provides a

5 ± 2-minute delay before restarting compressor

after shutdown for any reason. On normal start-up,

the 5-minute delay occurs before thermostat closes.

After thermostat closes, the Time Guard 11 circuit

then provides a 3-second delay to prevent contactor

chattering.

CRANKCASE HEATER keeps the crankcase

warm during the off cycle and thus prevents dilution

of the oil with refrigerant. This assures good lubrieation and prevents loss of oil from crankcase during

start-up.

CRANKCASE HEATER SWITCH (relay for 060,

3-ph, 460-v units only) deaetivates heater when

compressor is operating for maximum energy

efficiency.

START CAPACITOR AND RELAY assure

proper compressor start-up under adverse

conditions.

Page 10

Compatible Fitting Repair

MECHANICAL CONNECTION — Frontseat unit

service valves. Relieve refrigerant pressure from

tubing. Back off locknut from Compatible Fitting

onto tube. Cut fitting between threads and 0-ring

as shown in Fig. 8. Remove tubing section

remaining in threaded portion of fitting. Discard

locknut.

Clean, flux, and insert new tube end into remain

ing portion of Compatible Fitting. Wrap valve in

wet rag. Heat and apply low-temperature (430 F)

solder. Do not overheat valve.

Evacuate or purge evaporator coil and tubing

system. Add refrigerant charge. See Refrigerant

Charging instructions described previously.

Fig. 8 — Repair of Mechanical Connection

Lubrication

■COMPRESSOR contains factory oil charge. Re

place oil when lost. See Table 8 for oil recharge and

refer to Carrier Standard Service Techniques

Manual, Chapter 1, page 1-21, for oil recharg

ing procedure. Use Carrier PP33-1, Texaco WFl-32

or Suniso 3GS oil.

FAN MOTOR BEARINGS are prelubricated for 3

years heavy duty or 5 years normal duty. When

lubrication is necessary, send motor to authorized

motor repair shop.

^Coil Repair — A flare-union coupling repair kit

is available, with instructions, thru Carrier Service

Parts.

Coil Cleaning to be done at the beginning of

each cooling season or more often if required.

Condenser Fan Adjustment — Required fan

position is shown in Fig. 9. Adjust fan by loosening

setscrew(s) and moving fan blade up or down.

Fig. 9 — Condenser Fan Position

Condenser Fan Motor Removal

1. Shut off power to unit. Failure to do so may

result in electric shock or injury from rotating fan

blade.

2. Remove top cover, referring to Compressor

Removal, step 1.

3. Disconnect fan motor leads from control leads.

See Fig. 7.

4. Remove 4 screws (38EC018 thru 030) or 8 screws

(38EC036 thru 060) holding fan motor/discharge

grille in place and lift assembly from unit.

5. Remove Carrier nameplate by straightening

tabs.

6. Remove 4 nuts holding fan motor to discharge

grille. Remove motor and leads.

7. Reassembly is reverse of above procedure. Make

sure fan is positioned correctly as in Fig. 9.

1. Shut off power to unit.

2. Remove louvered casing by taking out 16 screws

securing it to the cabinet and sliding it away from

the coil.

3. Clean coil using vacuum cleaner and its crevice

tool (see Fig. 10). Work crevice tool vertically

making sure tool only touches dirt on fins. To

prevent fm removal, do not “scrub” fins with tool

or move tool horizontally.

4. If oil deposits are present, spray coil with house

hold detergent (Fantastic, Lestoil, 409, or any

similar type). Wait 10 minutes then proceed to

step 5.

Fig. 10 — Crevice Cleaning Tool

10

Page 11

5. Using garden hose, spray coil vertically down

ward with a constant stream of water at moderate

pressure (see Fig. 11). Keep nozzle at a 15 to 20

degree angle, about 3 in. from coil face and 18 in.

from tube. Spray so debris is washed out and

away from coil.

6. Reinstall louvered casing being careful not to

damage coil.

7. Restore power to unit.

Page 12

TROUBLESHOOTING GUIDE

SYMPTOM AND

PROBABLE CAUSE

COMPRESSOR SHUTS OFF. FAN OVERLOAD

OR HIGH-PRESSURE SWITCH CUT OUT, OR

INTERNAL PRESSURE RELIEF OPENS

Condenser Fan On

1. Condenser air restricted or recirculating.

2. Refrigerant overcharge, noncondensables in

system; system restricted.

3. Improper line voltage, loose electrical connec

tions, faulty run capacitor.

Condenser Fan Off

1. Fan slipping on shaft, fan motor bearing stuck,

fan motor defective.

2. Loose electrical connections. Fan motor over

load open.

COMPRESSOR RUNS BUT COOLING IS INSUFFICIENT

1. Low refrigerant charge.

2. Dirty filters, partially restricted airflow (evap

orator coil may be partially iced).

High Suction Pressure

1. Defective compressor valves (accompanied by

low head pressure).

COMPRESSOR SHUTS OFF FROM LOW-PRESSURE SWITCH CUTOUT

Evaporator Fan Runs

1. Low refrigerant charge or restricted evaporator

air.

2. Restricted refrigerant flow.

Evaporator Fan Stopped

1. Evaporator fan-motor defective or inoperative

COMPRESSOR SHUTS OFF WILL NOT RESTART

Contactor Open

1. Burned out transformer, open thermostat circuit,

faulty control relay, open overload

Contactor Closed or Closes Then Opens

1. Compressor power is out, compressor motor is

burned out or internal overloads are open. Time

Guard II circuit faulty.

PROBABLE REMEDY

1. Condenser coil blocked. See Maintenance, Coil

Cleaning. Check airflow clearance (Fig.‘ 1)

2. Review Refrigerant Charging procedures; purge

system, replace filter drier, check refrigerant

control.

3. Review Installation, Step 3; replace capacitor.

1. Tighten fan hub setscrews, see Condenser Fan

Motor Removal.

2. Check unit wiring. Check motor bearings. Re

place motor.

1. Check Refrigerant Charging procedures.

2. Check evaporator air system for dirty filters,

obstruction in ductwork, improper damper

settings. Refer to coil, fan coil or furnace

instructions as applicable.

1. Perform Compressor Replacement procedure.

Recheck system charge.

1. See Compressor Runs But Cooling Is Insufficient

above regarding filters, ductwork, etc

2. Check refrigerant flow device, be sure correct

AccuRaterTf^ or TXV is used.

Check furnace or fan instructions regarding de

fective fan relay, belt adjustment, condition of

motor bearings and overloads, check and tighten

electrical connections, check power supply.

Check control circuit components and wiring.

Refer to unit label diagram, check all conditions.

Refer to Standard System Techniques Manual,

Chapter 2, Electrical.

Check main power supply wiring. Refer to Elec

trical Data table and label diagram. Substitute

Time Guard II with a replacement to verify its

operation. Refer to Standard Service Techniques

Manual, Chapter 2, Electrical.

For replacement items use Carrier Specified Parts

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Book

Tab

1 4

3a 2a

Form 38EC-2SI Supersedes 38EC-1 SI

Printed in U S A 6-82

PC 101 Catalog No 533-848

Loading...

Loading...