Page 1

Carrier Parkway • Syracuse, N Y 13221

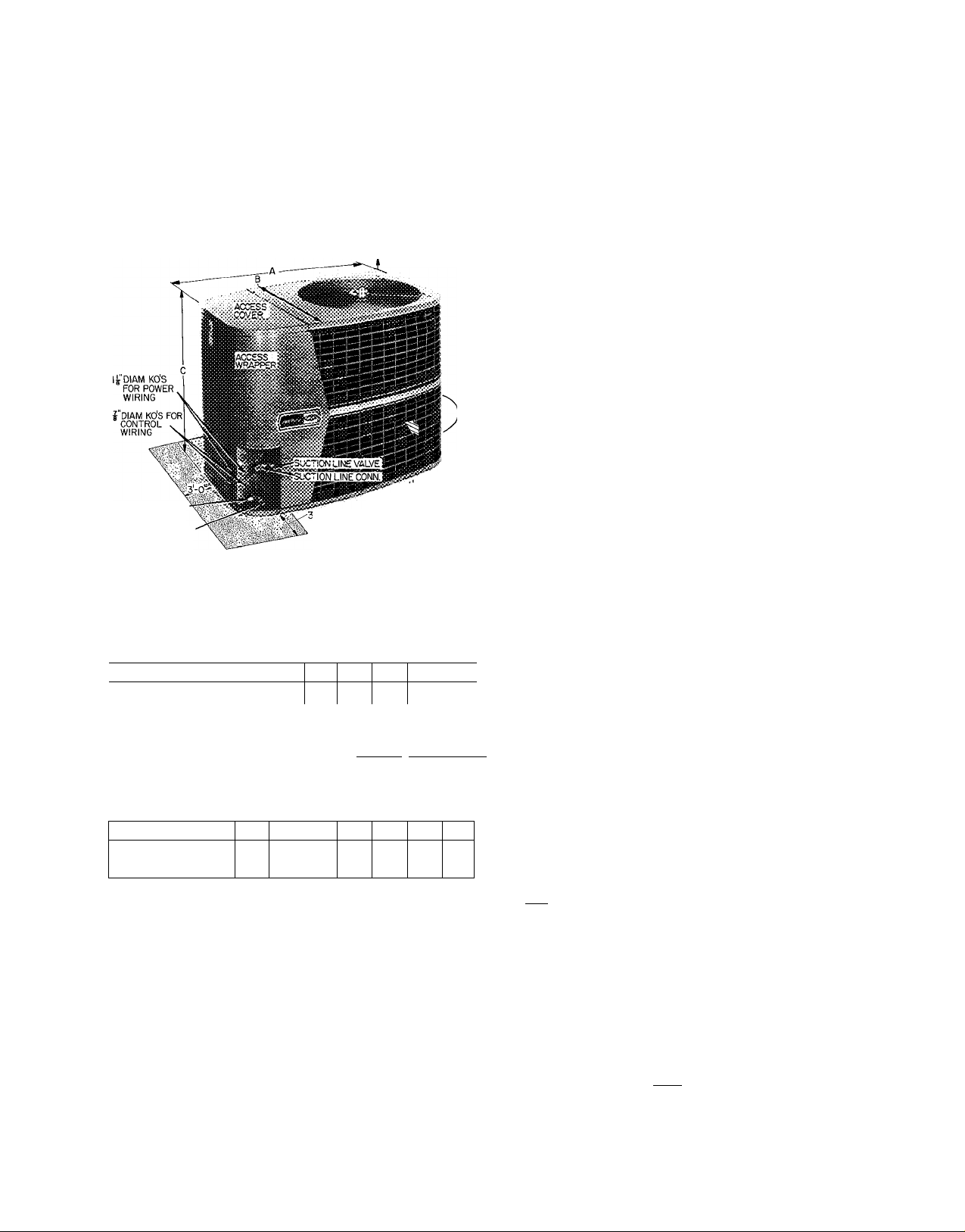

Heat Pump - Outdoor Section

4'0" OVERHEAD SPACE REQ'D

FOR SERVICE AND AIRFLOW

0 AIRFLOW

CLEARANCE

LIQUID LINE CONN

LIQUID LINE VALVE

Certified dimension drawings are available on request

i'-0"(B0TH SIDES)

ra SPACE REQ'D FOR SERVICE

^ AIRFLOW

(BOTH SIDES)

Fig. 1 — Dimensions and Connections (Table 1)

Table 1 — Installation Data (Fig. 1)

UNIT 38CQ

OPER WT (lb)

UNIT DIM. (ft-in.)

Length A

Width B

Height C

REFRIG CONN (in.)

Suction* (ODF)

Liquid* (ODF)

‘Recommended field supplied refrigerant line sizes

UNIT 38CQ 015

SUCTION (in. ODF)

LIQUID (in. ODF)

tMay use 7/8-in accy tubing package (slight capacity loss) See p 3

NOTES:

1 Maximum length of interconnecting tubing is 50 feet

2 Units 38CQ044, 048 factory supplied with 3/4 to 1-1/8 in suc

tion valve adapter (field installed) for field-supplied 1-1/8 in

suction line

; 015 1 Ò20

TÌ45 j_160

I -4^1 -4% 11 -4Vs[ 2-0)41 2-0yB|2-0VB 12-6Vs

Compatible Fitting (Suet) & Flare (Liq)

027

033

166 180

2-10V4

1-10

039

210

048

044

212 220

Ys I % I %

%

020 [027 033

5/

Vs 1 ^4

78

039

044t 048t

V

78

%

%

fZ 1

IVb

INSTALLER'S PRELIMINARY SURVEY

Step 1 — Unpackage Unit — Move heat pump to

final location. Open carton at end marked

“compressor end.” Slide unit from carton taking

special care to not damage service valves or grilles.

Step 2 — Inspect Equipment — File claim with

shipping company if shipment is damaged or

incomplete.

Step 3 — Complete or Consider the Following

before installing the 38CQ unit.

Consult local building codes and National

Electrical Code (NEC) for special installation

requirements.

When installing unit, allow sufficient space for

airflow clearance, wiring, refrigerant piping and

servicing unit. Position unit so water or ice from

roof will not drop directly on top of unit.

Make provisions for condensate drainage and

defrost water disposal whether unit is installed on

ground or roof. (Make sure unit base pan drainage

holes are not blocked.) See Mounting Pad for

details. Roof installation method for 38CQ

depends on building construction and special re

quirements of local codes. Roof must be capable of

supporting unit weight. Maximum allowable ver

tical distance between indoor and outdoor sections

is 50 feet. See Table 2.

Use an indoor coil with a bleed-type expansion

device. (See Table 2 for Carrier approved indoor

sections.) If coil does not have a bleed-type

expansion device, it may be necessary to add an

accessory start capacitor and relay to heat pump.

This would require removing compressor start

thermistor (PTC device) on units so equipped. It is

recommended that 38CQ units be used with

Carrier approved indoor sections, all of which are

equipped with a bypass type AccuRater'^^ (bleed-

type expansion device).

Table 2 — Carrier Approved 38CQ System Data

INDOOR UNIT

OUT

DOOR

UNIT

^ .38CQQ15

38CQ020

38CQ027

38CQ033

38CQ039

38CQ044

38CQ048

‘Indoor units that require replacement of AccuRater refrigerant

control piston for optimum performance when used with specified

outdoor unit The 38CQ048 is factory supplied with no 8 piston for

indoor unit (28MQ048)

REFRIG

ERANT

22

Fan

Coi

4gAQpi8

^^^40AQ024

40AQ024*

40AQ030

40AQ030*

40AQ036^_

40FSJI60|28MQ036

40AQ036*

40FS160

4ÒFSÌ60

40FS160

40FS200

40FS200

28MQ036'

'28MQ042

28MQ042*

28MQg48^

28MQ048''

AccuRafer

Piston

.

.. 6

. 6

.. .Tt...

j HEIGHT (ft)

; Above 1 Be low

II

2

4*

4 .

6*

. If .

7

8*

I

Indoor Unit

Outdoor Unit

50 50

(g) Carrier Corporation 1977

38CQ400105 B

Form 38CQ-6SI

Page 2

MOUIMTirJtTP^

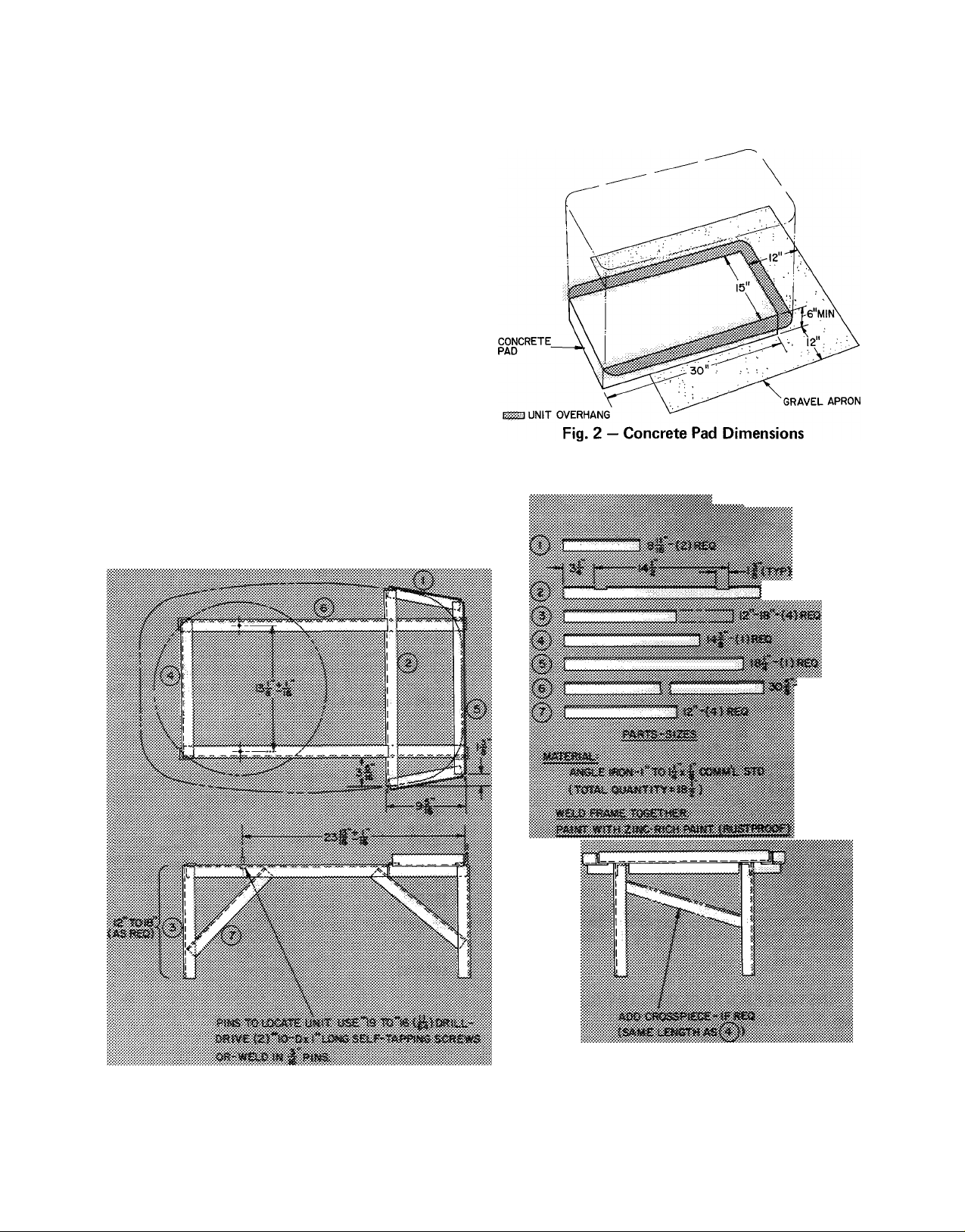

Step 4 — On the Ground: Mount Unit on a Solid,

Level Concrete Pad. See Fig. 2 for pad dimensions.

Position unit so that coil drainage holes in base pan

overhang the pad. Make sure pad does not obstruct

drainage holes (holes drain water during heating

and defrost cycles). Unit can be attached to pad

with mastic adhesive or by drilling holes in base

pan for 1/4-in. mounting bolts.

Construct pad a minimum of 6-in. thick to

provide clearance under holes for drainage and ice

buildup. In areas where prolonged subfreezing

temperature or heavy snows occur; increase clear

ance to 12 to 18 in. by constructing an angle iron

frame to support unit 12 to 18 in. off concrete

base. Cross angle of frame must not obstruct coil

drainage holes. See Fig. 3 for recommended frame

construction. Extend a 12-in. gravel apron around

pad for condensate and defrost water drainage

field.

Step 5 — On the Roof: Mount Unit on a Level

Platform or Frame: Unit must be elevated for

proper clearance as described under ground in

stallation above. Roof design and water drainage

must be planned to prevent unit from setting in

water. Flash all roof openings to prevent leaks.

«AtMtAK'tMV.VA'Kry.-

mtm

Fig. 3 — Heat Pump Mounting Frame

Page 3

PART NO.

38CQ900081

38C 0900111

38CQ900182

38GS900381

38CQ900061

38CQ900091

38RQ900001

38RQ900021

1hH22AG110

Low-Voltage Control — Honeywell Thermostat HH07AT071 and

Thermostat Subbase HH93AZ073 — (Automatic Changeover)

Low-Voltage Control — Honeywell Thermostat HH07AT071 and

Thermostat Subbase HH93AZ075 — (Manual Changeover)

Service Sentry (Six HN65CT002)

Start Capacitor and Relay Package

Flare (3/8-in.) to Compatible (3/8-in.) Couplings (Two-Pack)

Liquid Line Filter-Drier

Emergency Heat Relay (Required with 2 outdoor thermostats.)

(Service Parts)

Outdoor Thermostat (Six 38RQ900032)

Optimizer Control

38CQ900141 Solid State Time Guard (24 volt)

TUBING

PACKAGE

Length

(ft) OD 1 ube End

Liquid

(in.) OD (in.)

38GC900031

38GC900041

38GS900221

38GC900061 35

38GC900191

38GC900071 10

38GC900081

38GC900091 25

38GC900101 35

38GC900m

38CQ900001

38CQ9000n 25

38CQ900021 35

38CQ900031

*Suction line is insulated and has a 90 bend at one end

fFor 5/8-in evaporator connection, cut off 3/4-in end

10

18

25

% %

%

%

Ha

50

18

50

18

50

V4

V

V

4

V

4

V

4

V

4

4

V

4

V

4

___

Table 3 — Accessories

DESCRIPTION

TUBING

Va

Va

Va

Va

Va 4

4

V

4

Va

Va

V

4

Va

Va

Va

ICapacity reduction may occur when 7/8-in accessory tubing is used

on 38CQ044.048

____

Suction*

OD

(in.)

Va V4t Va

Va

Va V4t Va

Va V4Î Va

Va V4t

1 ube bnd

OD (in.)

Evap

V4t

V4

V4 V4

V4

V

4

V4

V

4

V4 V4

Vat

Vai

V

4

4

V4

Vai

V4

Cond

Va

V

4

y

4

y

4

y

4

y

4

y

4

y

4

4

V4

4

UNIT

38CQ015,020

38CQ027,033

38CQ039,044,048

PIPING CONNECTIONS

The 38CQ units can be connected to indoor

units using Carrier accessory tubing package or

field-supplied tubing of refrigerant grade. See

Table 1 (with notes) for unit piping connection

type, size and line size recommendations and

Table 3 for accessory tubing sizes. Maximum

length of refrigerant piping allowed is 50 feet

A capacity reduction will result if accessory

tubing is used in 38CQ044,048 systems. For

example, when a 25-ft, 7/8-in. accessory tubing

package is used, there will be a capacity reduction

of 1-1/2%. For maximum capacity, use 1-1/8 in.

suction line as recommended in Table 1.

When other than 25 ft of interconnecting

piping is used, follow special requirements de

scribed in Refrigerant Charging. Do not use less

than 10 ft of accessory liquid line. Do not cut

5/16-in. or 1/4-in. liquid line. Do not cut 7/8-in.

suction line. Bend or coil to fit.

Do not use damaged or contaminated tubing.

Always evacuate or purge evaporator coil and

tubing system (use field-supplied refrigerant, not

unit refrigerant).

When making tubing connections, be sure to

provide clearance at unit for electrical connections.

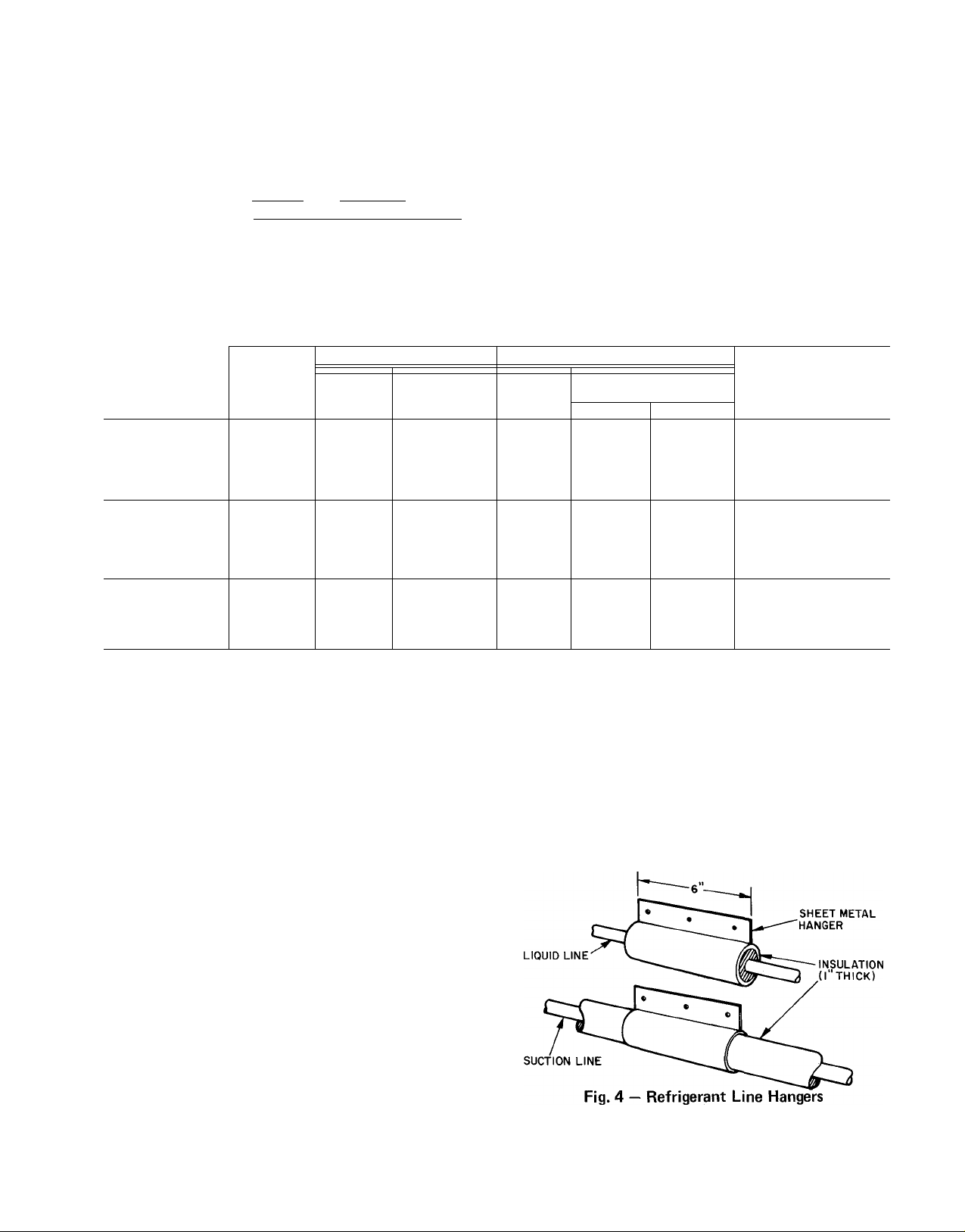

To assure noise-free installation, isolate refrig

erant lines from ductwork and framing or where

they run thru stud spaces, enclosed ceilings or pipe

chases. Use isolation hangers (Fig. 4), as rigid

fastening may transmit pulsations to structure,

creating an objectionable rumble. Do not attach

liquid line to uninsulated suction line. When

running thru structure, surround all lines with 1-in.

insulation to prevent transmission of vibration.

Before Connecting Refrigerant Lines, replace the

AccuRater'^'''^ refrigerant control piston in the

indoor coil as required. See Table 2. The 38CQ048 is

Page 4

factory supplied with a No. 8 AccuRater piston for

installation in 28MQ048. For piston replacement

instructions, see AccuRater’’"''^ Servicing on page 15.

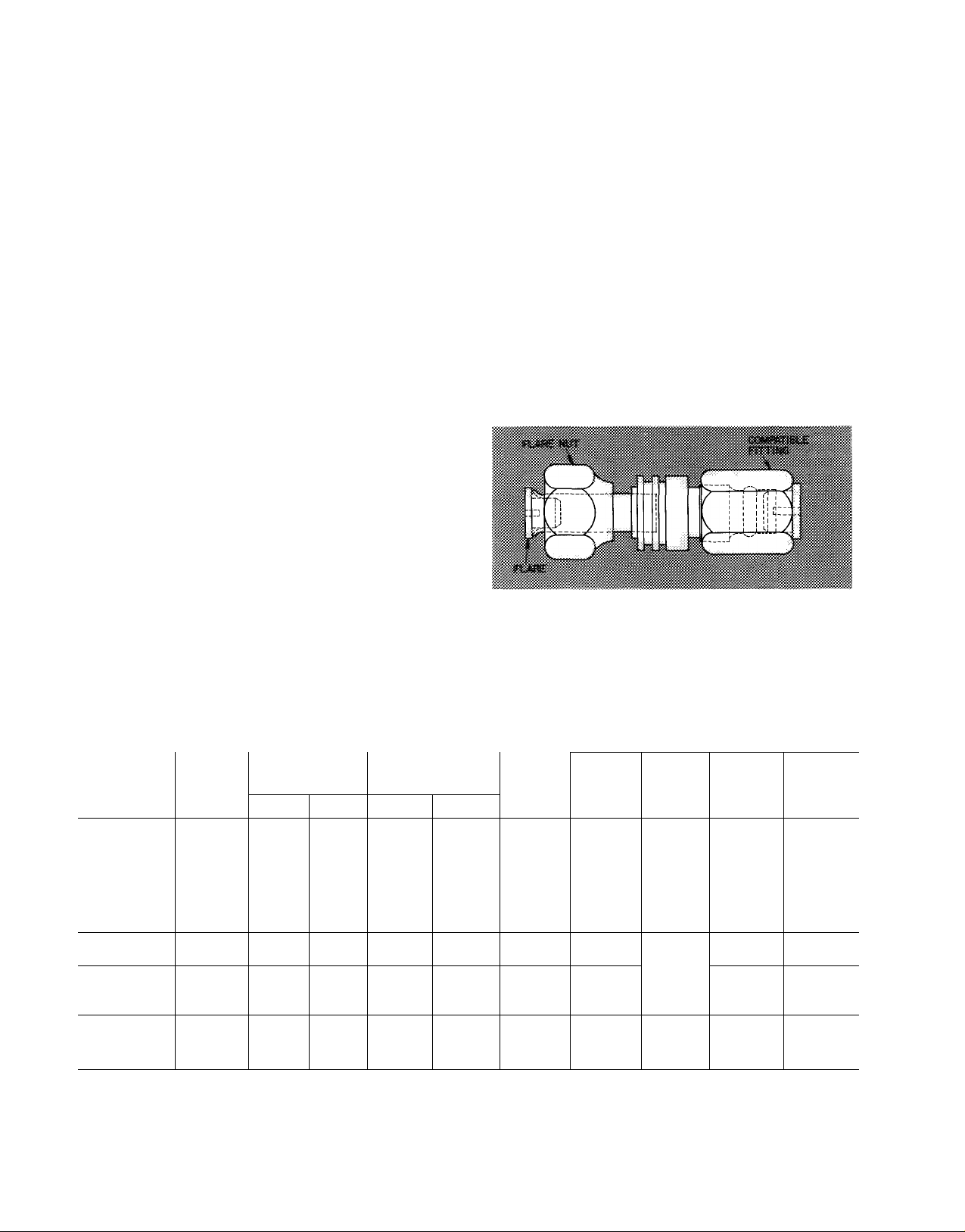

Step 6 — Connect Refrigerant Lines to fittings on

unit suction and liquid service valves (Fig. 1).

Liquid service valve has flare fitting; suction service

valve has Compatible Fitting. Make suction line

connection first. Slide flare nut on liquid line, then

flare and connect liquid line. (Do not disassemble

AccuRater.) Unit Compatible Fitting permits

mechanical (quick-connect) or sweat connection as

described below. It is not necessary to flare system

liquid line if an accessory flare to Compatible

Fitting coupler is used for liquid line connection.

See Accessory Coupler (Fig. 5).

38CQ044,048 UNITS - When using 1-1/8 in.

field-supplied suction line, remove suction line

adapter taped to compressor suction line. Sweat

connect refrigerant suction line to 1-1/8 in. end of

adapter. Connect 3/4-in. end of adapter to unit

suction line Compatible Fitting.

When a 7/8-in. field-supplied suction line is

used on 38CQ039, a field-supplied 3/4-in. to

7/8-in. suction line adapter must be provided (not

required if 38CQ accessory tubing is used).

MECHANICAL CONNECTION TO COMPATIBLE

FITTING (Mate one set of connections at a time.)

1. Loosen nut on Compatible Fitting one turn. Do

not remove.

2. Remove plug and be sure 0-ring is in the groove

inside the Compatible Fitting.

3. Cut tubing to correct length.

4. Insert tube into Compatible Fitting until it

bottoms.

5. Tighten nut until it bottoms on back coupler

flange. Keep tube bottomed in Compatible

Fitting while tightening nut.

SWEAT CONNECTION TO

COMPATIBLE

FITTING (Use refrigerant tubing.)

Remove locking nut,

1.

rubber 0-ring and

Schrader core from valve.

2.

Cut tubing to correct length.

3.

Insert tube in Compatible Fitting. Wrap top and

bottom of service valves in wet cloth to prevent

damage by heat. Solder with low temperature

(450 F) silver alloy solder.

4.

Replace Schrader core.

5.

Evacuate or purge system with field-supplied

refrigerant.

ACCESSORY FLARE TO COMPATIBLE COU

PLER is shown in Fig. 5. Attach flare nut on

coupler to flare fitting on unit liquid service valve.

Connect liquid line to Compatible Fitting using

mechanical or sweat connection. When mechanical

connection is made, use 2 wrenches when tighten

ing Compatible Fitting nut — one to hold coupler

and one to tighten nut. Liquid line must be flared

if coupler is not used.

Fig. 5 — Accessory Coupler

ELECTRICAL DATA AND WIRING

Field wiring must comply with local and

national fire, safety and electrical codes. Voltage to

unit must be within ± 10% of voltage indicated on

Table 4 — Electrical Data (60-Hz)

OPER

UNIT V/PH

38CQ015 41

38CQ020 65 10.3

38CQ027 82

38CQ033

38CQ039

38CQ044

38CQ048 106

38CQ033

38CQ039

38CQ044

38CQ048

38CQ039

38CQ044

38CQ048

FLA — Full Load Amps

LRA — Locked Rotor Amps

RLA — Rated Load Amps

*Permissible limits of the voltage range at which the units will

operate satisfactorily

fRequired when using nonmetallic conduit

^Maximum dual element fuse size

230/1 254 207

200/

230/3

200/3

230/3

VOLTAGE*

Max Min

254 180 87

229 180 87 18.6

254

207 70

COMPR

LRA

88 19.8 2.4 10 36

94

106

79 17.4

87 18.6

67

70

BRANCH CIRCUIT

FAN

FLA

RLA

9.0

17.7 2.4 10 42

22.2

25.0

25.0

13.0/

11.5

15.0

16.7

16.7

.9 14 31

.9 12 40 12

2.4 10 33

2.4

3.0

2.0/

2.0

2.4 12 31

2.4 10 35

3.0 10 35

2.4 12

2.4 12

3.0 12

NOTES:

1 Fan motors are 200-v or 230-v, single phase

2 All units have 24-v control circuit which requires external

power source

3 Copper wire sizes based on 60 C Use copper or copper-clad

aluminum wire only Use latest National Electrical Code for

wire sizing

Power

Wire

Size

(AWG)

8 46

8

12

Max

Ft

Wire

46 8

40 12

41 12

36

36 12 35

Gnd

Wire

Sizef

(AWG)

14 20

10

10

10 50

8 50

12 40

10 40

10 40

12

Max

Fuse

Ampsi

20

40

45

50

30/

25

35

35

V

Page 5

f

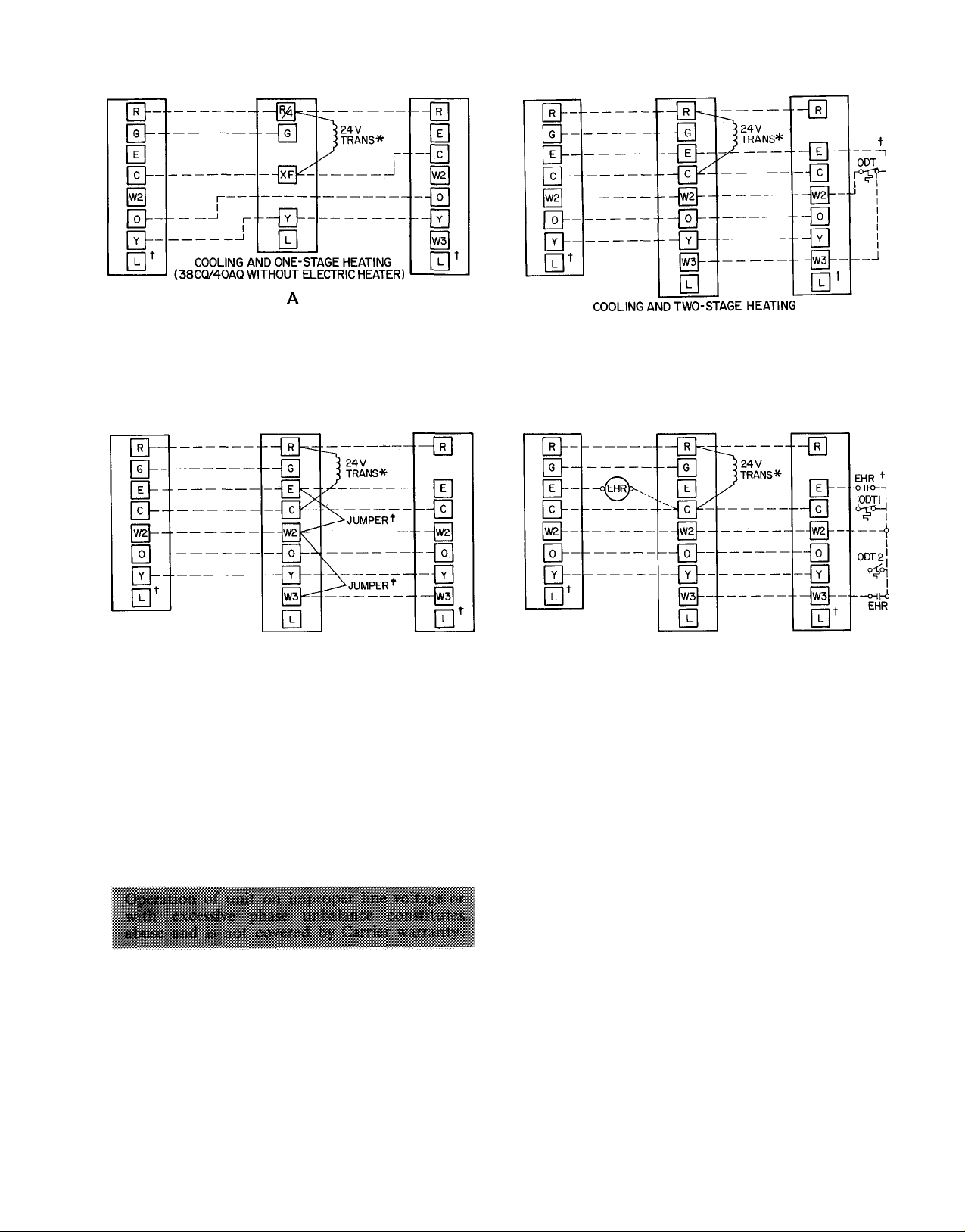

THERMOSTAT

SUBBASE

HH93AZ073 OR

HH93AZ075

40AQ FAN COIL

COOLING CONTROL KIT

TERMINAL BOARD

38CQ

TERMINAL

BOARD

THERMOSTAT

SUBBASE

HH93AZ0730R

HH93AZ075

(38CX) WITH 40AQ OR 40FS/28MQ

EQUIPPED WITH ELECTRIC HEATER;

EMERGENCY HEAT, ONE OUTDOOR THERMOSTAT)

40AQ OR 40FQ

ELECTRIC HEATER

TERMINAL BOARD

38CQ

TERMINAL

BOARD

THERMOSTAT

SUBBASE

HH93AZ073 OR

HH93AZ075

COOLING AND TWO-STAGE HEATING

(38CQ WITH 40AQ OR 40FS/28MQ

EMERGENCY HEAT, NO OUTDOOR THERMOSTATS)

EQUIPPED WITH ELECTRIC HEATER;

40AQ OR 40FQ

ELECTRIC HEATER

TERMINAL BOARD

B

EHR — Emergency Heat Relay

ODT — Outdoor Thermostat

_______

Factory Wiring

_______

Field Wiring

38CQ

TERMINAL

BOARD

THERMOSTAT

SUBBASE

HH93AZ073 OR

HH93AZ075

COOLING AND TWO-STAGE HEATING

EQUIPPED WITH ELECTRIC HEATER;

EMERGENCY HEAT, TWO OUTDOOR THERMOSTATS)

*Transformer (60 va) located in cooling control kit or electric heater

fTerminal L is identified as terminal X on some former thermostats

(Required for accessory Service Sentry)

:|;Remove factory-installed jumpers (connection B) when installing

outdoor thermostats (ODT)

Fig. 6 — Control Circuit Connections

40AQ OR 40FQ

ELECTRIC HEATER

TERMINAL BOARD

(38CQ WITH 40FS/28MQ

38CQ

TERMINAL

BOARD

nameplate. On 3'-phase units, phases must be

balanced within 2%. Contact local power company

for correction of improper line voltage.

When making electrical connections, provide

clearance at unit for refrigerant piping connections.

See Table 4 for recommended wire and fuse sizes.

Step 7 — Install a Branch Circuit Fused Disconnect

of adequate size to handle unit starting current.

Provide a separate fused disconnect for outdoor

unit, indoor unit and for each accessory electric

heater circuit as required. (See Indoor Unit and

Electric Heater Installation, Start-Up and Service

Instructions.) Locate disconnect(s) within sight of

and readily accessible from the unit, per section

440-14 of National Electrical Code (NEC).

Step 8 — Bring Line Power Leads Into Unit —

Extend leads from fused disconnect thru hole

provided in service embossment (Fig. 1) and thru

7/8-in. hole into control box.

Step 9 — Connect Ground Lead to a Ground Lug

in Control Box for safety. Connect power wiring.

See Fig. 7. Splice line power leads to yellow and

black pigtails on single-phase units or to black

pigtails (3) on 3-phase unit. Use wire nuts supplied

with unit. Tape each connection.

Step 10 — See Indoor Unit and Electric Heater

Installation, Start-Up and Service Instructions for

line power wiring details. All control wiring is

shown in this booklet.

Step 11 — Control Power Wiring (24 v) is brought

thru hole in unit service embossment. Fig. 1.

Connect leads to control wiring terminal board

(located on outside of control box) as shown in

Fig. 6.

Page 6

3-PHASE

CONN. TO

FUSED

DISCONNECT

I-PHASE

CONN. TO

FUSED

DISCONNECT

_________

L

------------

BLK-

GROUND LUG

38CQ HEAT PUMP

CONTROL BOX

Fig. 7 — Line Power Connections

BLK-

YEL OR BLK

------

emergency heat switch in the indoor thermostat

subbase. The thermostat locks out compressor and

the relay bypasses the outdoor thermostats for

electric heater operation during heat pump shut

down. When one outdoor thermostat is used, an

emergency heat relay is not required. The emer

gency heat switch in the indoor thermostat subbase

bypasses outdoor thermostat, locks out compressor

and activates electric heater. See 40FS Indoor Unit

and Electric Heater Installation, Start-Up and

Service Instructions for installation of emergency

heat relay.

Use indoor unit transformer as 24-v supply for

system. At least a 60-va transformer is recom

mended. Carrier approved indoor units are

equipped with 60-va transformer. See indoor unit

data.

Use Carrier accessory indoor thermostat

HH07AT071 with HH93AZ073 or HH93AZ075

subbase.

IWITIAL START-UP

The 38CQ unit is equipped with a crankcase

heater. It is recommended that heater be energized

a minimum of 24 hours before starting unit. To

energize heater only, turn the thermostat to OFF

position and close electrical disconnect to heat

pump.

Heat Anticipator Settings for Room Thermostat

(HH07AT071) — Set anticipator settings for room

thermostat according to Table 5. These settings

may be changed slightly to provide a greater degree

of comfort for a particular installation.

Table 5 — Thermostat Anticipator Settings

UNIT

38CQ

015

020

027

033

039

044

048

FIRST-

STAGE

ANTICIPATOR

SETTING

Fixed

INDOOR

UNIT WITH

ELECTRIC

HEATER

40AQ Fan-Coil

with 40AQ Htrs

40FS/28MQ

with 40FQ

Htrs

HTR

KW

5 0

7 5

10 0

15 0

20 0

25 0

30 0

34 0

second-

stage

ANTICIPATOR

SETTINGS

16

33

49

Accessory Outdoor Thermostat provides adjustable

outdoor control of accessory electric heater. This

thermostat makes contact when a drop in outdoor

temperature occurs. It energizes a stage of electric

heat when the outdoor temperature setting is

reached, provided the room thermostat is on the

second stage of heating. One outdoor thermostat is

recommended for each stage of electric heat after

the first stage. Set the outdoor thermostat(s)

progressively lower for each stage. Refer to heat

load of building and unit capacity to determine the

correct outdoor thermostat settings.

The accessory emergency heat relay is required

when 2 outdoor thermostats are used. It is auto

matically energized by the manually operated

Accessory Outdoor Thermostat(s) Installation —

Install outdoor thermostat at a suitable location on

the outside of the control box. Use any free hole

to fasten thermostat bracket. Be sure that engage

ment screw does not interfere with wiring or

components inside of control box Thermostat

bracket may be secured with only one screw;

however, make sure that bracket is firmly attached

to resist vibration forces. If a free hole is not

available, drill hole in control box after assuring

that drilling will not damage any components

inside of box If a second thermostat is used,

follow the procedure outlined above. If there is no

available space on the control box for a second

thermostat, mount the 2 thermostats together.

Connect the 2 thermostats with a machine screw,

lock washer and nut, and then mount assembled

thermostats to the control box (See Fig. 8a).

Route the capillary and attached bulb below the

control box to the upper portion of the outdoor

coil grille. Carefully insert the bulb between the

tube sheet and nearest vertical grille wire. Place the

bulb across the grille and fasten with wire, wire ties

or other suitable fastener (See Fig. 8b). Never

expose bulb to direct sunlight. If necessary, shield

bulb with appropriate material.

Replace access wrapper on unit. Check that

capillary is not pinched by wrapper

To Start Unit — (Make sure crankcase heater has

been energized for 24 hours.) Adjust the thermo

stat as follows:

1. Set selector switch at OFF.

2. Turn on main disconnect switch(es) to indoor

and outdoor units.

3. Set fan switch as desired (ON or AUTO.).

4. Set thermostat dial at desired temperature.

5. Set selector switch at HEAT or COOL.

Check system refrigerant charge. See Refrig

erant Charging.

SERVICE

Refrigerant Charging — The 38CQ units contain

correct operating charge for complete system when

connected to 40FS/28MQ or 40AQ indoor units

with 25 ft of tubing of recommended diameter.

Charge adjustment is required on other systems.

Adjust system charge for refrigerant line lengths

and diameters that differ from 25 ft and 3/8-in.

V

Page 7

OD (liquid line), respectively, using refrigerant

weights shown in table below. (Twenty-five feet of

3/8-in. OD tubing contains 14.4 oz of R-22.) Add

R-22 charge to system if liquid line is over 25 ft;

remove charge if liquid line is shorter than 25 feet.

(

LIQUID LINE 1 OUNCES OF ^22/FT LENGTH

DIAM (in.) OF LIQUID LINE

3/8

5/16

1/4

58

36

21

Table 6 — Service Data

UNIT 38CQ

R-22 CHG

(Ib-oz) 1 4-10 4-1 1 6-5 7-11 7-13 7-10

REFRIG CONTROL A ccuRater*^^

FAN 1 Prope

Cfm

Rpm

Diam (in.) 1 17

Motor Hp

1 015,

1 020

]

1

2600

1/8

2600

027 033 039

(Bypass Type

Her - Direct Drive

2800

1075

17 18 18 16 18

1/4 1/4 1/4

1/4

044

2800 1 2600 3400

048

)

1/2

system before recharging. If system has lost com

plete charge, evacuate system to 500 microns (29.7

in. vacuum) before recharging. Service port connec

tions are provided on liquid and suction line service

valves for evacuation and charging. (See Fig. 32 for

correct service port location on cooling and heating

cycles.) DiaTa-charge charging cylinder is an

accurate device used to recharge systems by

weight. These cylinders are available at refrig

eration supply firms.

To check and/or adjust charge during cooling

season, use correct Cooling Cycle Charging Chart

(Fig. 9, 11, 13, 15, 17, 19, 21,23, 25, 27, 29) and

follow Charging Chart Method below. The charging

chart may also be used as an alternate method of

recharging system.

To check system operation during heating

cycle, use correct Heating Cycle Operation Check

Chart (Fig. 10, 12, 14, 16, 18, 20, 22, 24, 26,28,

30). These charts indicate whether a correct

relationship exists between system operating pres

sures and air temperatures entering indoor and

outdoor units. If pressure and temperature lines do

not intersect on chart, the system refrigerant

When recharging is necessary during heating or

cooling season, weigh in total charge indicated in

Table 6. (Charge must be weighed in during heating

season.) Remove any refrigerant remaining in

charge may not be correct or other system abnor

malities may exist. Do not use Operation Check

Charts to adjust refrigerant charge. Weigh charge

into system.

a. 2 — Thermostat Assembly b. Capillary Tube Routing

^ Fig. 8 — Outdoor Thermostat Installation Details

7

Page 8

COOLING CYCLE CHARGING CHART

METHOD

1. Operate unit a minimum of 10 minutes before

checking charge, and after each charge

adjustment.

2. Measure suction pressure by attaching a gage to

outdoor unit suction valve service port. (See

Fig. 32 for correct service port location on

cooling cycle.)

3. Measure outdoor (coil inlet) air dry-bulb tem

perature with service thermometer.

4. Using a sling psychrometer, measure wet-bulb

temperature of air entering indoor unit.

5. Refer to correct Charging Chart. Locate on

curves where outdoor air dry-bulb and indoor

air wet-bulb temperature lines intersect.

6. From intersect point, project vertically down

ward to chart suction pressure line. Compare

chart suction pressure to unit suction pressure

(Step 2).

7. If unit suction pressure is lower than chart

pressure, add refrigerant to system until chart

pressure is reached. If unit suction pressure is

higher than chart pressure, remove refrigerant

until chart pressure is reached.

340

320

300

3

5

ui

£ 280

o 260

PRESSURE AT SUCTION SERVICE VALVE (PSIG)

Fig. 9 — 38CQ015 with 40AQ018 Cooling Cycle

Charging Chart (R-22)

cr 240

220

20 O'

66 68 70 72 74 76 78 80 82 84 86 88 90

PRESSURE AT SUCTION SERVICE VALVE (PSIG)

Fig. 11 — 38CQ020 with 40AQ024 Cooling Cycle

Charging Chart (R-22)

Fig. 10 — 38CQ015 with 40AQ018 Heating Cycle

Operation Check Chart (R-22)

Fig. 12 — 38CQ020 with 40AQ024 Heating Cycle

Operation Check Chart (R-22)

Page 9

PRESSURE AT SUCTION SERVICE VALVE (PSI6)

Fig. 13 — 38CQ027 with 40AQ024 Cooling Cycle

Charging Chart (R-22)

Fig. 15 — 38CCX)27 with 40AQ030 Cooling Cycle

Charging Chart (R-22)

Fig. 14 — 38CQ027 with 40AQ024 Heating Cycle

Operation Check Chart (R-22)

Fig. 16 — 38CQ027 with 40AQ030 Heating Cycle

Operation Check Chart (R-22)

Page 10

360

Fig. 17 — 38CQ033 with 40AQ030 Cooling Cycle

Charging Chart (R-22)

260-

240-

DRY-BULB TEMP AIR

ENT OUTDOOR UNIT

(F)

WET-BULB TEMP AIR

ENT INDOORUNIT(f:

i8^

340

S» 320

£

^ 300-

o

280

o

220

200

66 68 70 72 74 76 78 80 82 84 86 88 90

PRESSURE AT SUCTION SERVICE VALVE (PSIG)

Fig. 19 - 38CQ033 with 40FS160/28MQ036 or

40AQ036 Cooling Cycle Charging Chart (R-22)

Fig. 18 — 38CQ033 with 40AQ030 Heating Cycle

Operation Check Chart (R-22)

Fig. 20 - 38CQ033 with

40FS160/28MQ036 or 40AQ036

Heating Cycle Operation Check Chart (R-22)

10

Page 11

PRESSURE AT SUCTION SERVICE VALVE (PSIG)

Fig. 21 - 38CQ039 with 40AQ036 or 40FS160/

28MQ036 Cooling Cycle Charging Chart (R-22)

Fig. 23 - 38CQ039 with 40FS160/28MQ042

Cooling Cycle Charging Chart (R-22)

SUCTION PRESSURE AT SERVICE PORT(PSIG)

Fig. 22 - 38CQ039 with 40AQ036 or 40FS160/

28MQ036 Heating Cycle Operation Check Chart

Fig. 24 - 38CQ039 with 40FS160/28MQ042

Heating Cycle Operation Check Chart (R-22)

11

Page 12

PRESSURE AT SUCTION SERVICE VALVE (PSI6)

Fig. 25 - 38CQ044 with 40FS160/28MQ042

Cooling Cycle Charging Chart (R-22)

PRESSURE AT SUCTION SERVICE VALVE (PSIG)

Fig. 27 - 38CQ044 with 40FS200/28MQ048

Cooling Cycle Charging Chart (R-22)

SUCTION PRESSURE AT SERVICE PORT(PSIG)

Fig. 26 - 38CQ044 with 40FS160/28MQ042

Heating Cycle Operation Check Chart (R-22)

Fig. 28 - 38CQ044 with 40FS200/28MQ048

Heating Cycle Operation Check Chart (R-22)

12

Page 13

300

Fig. 29 - 38CQ048 with 40FS200/28MQ048

Cooling Cycle Charging Chart (R-22)

280

260

>240

fE 220

£ 180

140

120

WET-BULB TEMP

AIR ENT

OUTDOOR UNIT{F)

23.5F

15 F

9F

M

-I0.5F

20 30 40 50 60

SUCTION PRESSURE AT SUCTION SERVICE PORT

43F

I

33F

Fig. 30 - 38CQ048 with 40FS200/28MQ048

Heating Cycle Operation Check Chart (R-22)

DRY-BULB TEMP

AIR ENT

INDOOR UNIT (F)

70

Unit Single-Phase Compressors

COMPRESSORS OF THE SPLIT CAPACITOR

(PSC) TYPE require an equalized system pressure

to start. When supply voltage is within 10% limit

and compressor does not start, give compressor a

temporary capacitance boost. See Carrier Standard

Service Techniques Manual, Chapter 2, for details.

Use a 130-mfd start capacitor. Connect wires with

insulated probes to each capacitor terminal. Touch

probes to each side of run capacitor or to

compressor motor terminals R and S. Start com

pressor; pull probes away after 3 seconds Dis

charge start capacitor. Run compressor for 10

minutes, then shut off and allow system pressure

to equalize. Try restarting without boost capacitor.

If after 2 attempts (without boost capacitor) the

compressor does not start, add an accessory start

thermistor (PTC device). If after 2 more attempts

the compressor does not start, remove thermistor

and add an accessory start capacitor relay package.

COMPRESSORS THAT ARE EQUIPPED WITH A

COMPRESSOR START THERMISTOR (PTC

device): if compressor does not start, check the

thermistor with an ohmmeter as described below.

Earlier unit models have a 50-ohm thermistor (with

2-prong connections), later models have a 25-ohm

thermistor (with 3-prong connections). If indoor

coil does not have a bleed-type expansion device, it

may be necessary to remove start thermistor and

replace with accessory start capacitor and relay.

Checking Start Thermistor

1. Shut off all power to unit and wait 5 minutes

for thermistor to cool to outdoor temperature.

2. Measure resistance of thermistor with ohmmeter. Normal resistance readings at 75 F out

door temperature are: 50 to 90 ohms for

50 ohm thermistor; 25 to 50 ohms for 25 ohm

thermistor.

3. If ohmmeter resistance reading is 0 or much

higher than 50 or 90 ohms, the thermistor is

defective and must be replaced.

If start thermistor is good and compressor does

not start, disconnect the thermistor from starting

circuit and give compressor a temporary capaci

tance boost as described above. Run compressor

for 10 minutes, then shut off and allow system

pressure to equalize. Reconnect start thermistor

and try restarting compressor without boost capa

citor. If aher 2 attempts the compressor does not

start, remove thermistor and add an accessory start

capacitor relay package.

13

Page 14

Compressor Removal — See Table 7 for compressor

information and Fig. 31 for component location.

Follow safety codes, and wear safety glasses and

work gloves. Have quenching cloth available

(Step 7).

pressor hold-down bolts are in place. Connect

wiring.

11. Evacuate and recharge unit.

FILTER-DRIER — Install accessory heat pump

filter-drier (Table 3) in system liquid line when

refrigerant system is opened for service as de

scribed under Compressor Removal. Position drier

in liquid line at convenient location. Do not use a

standard single-pass filter-drier.

1. Shut off power to unit. Remove unit top

access cover and rear access wrapper.

2. Remove refrigerant from unit using refrigerant

removal methods described in Carrier Standard

Service Techniques Manual, Chapter 1.

3. Disconnect compressor wiring at compressor

terminal box.

4. Using a tubing cutter, cut suction and dis

charge lines at convenient place near com

pressor for easy reassembly to new compressor

with copper slip couplings.

5. Remove crankcase heater from compressor

base.

6. Remove compressor hold-down bolts and lift

compressor out.

7. Carefully unbraze suction and discharge line

piping stubs from compressor. If oil vapor in

piping stubs ignites, use quenching cloth.

8. Braze piping stubs (removed in step 7) on new

compressor.

9. Clean system. Add new liquid line heat pump

filter-drier as described below.

10. Install new compressor in unit. Braze suction

and discharge lines to compressor piping stubs

(at points where cut, step 4) using field-

supplied copper couplings. Make sure com

Table 7 — Compressor Data

UNIT

38CQ015

38CQ020

38CQ027

38CQ033

38CQ039

38CQ044

38CQ048

38CQ039

38CQ044

38CQ048

38CQ039

38CQ044

38CQ048

‘Refer to Service Parts catalog for replacement compressor

model numbers

V/PH

230/1

200/3

230/3 PG5316HD

PRODUCTION —

Model*

38CQ400994

MD2023HB

MD3023HB

MC3423HB

PC4Ó16HD

PC5316HD

PC5316HD

PF4616HD

PF5316HD

PF5316HD

.

PG4616HD

PG5316HD

Oil Recharge (oz)

20

44

44

44

64

64

64

64

64

64

64

64

64

Pumpdown Procedure (Cooling Cycle) — The

38CQ units may be pumped down in order to

make repairs on low side of system without losing

complete refrigerant charge. Ensure unit is in

cooling mode.

1. Attach pressure gage to suction service valve

service port.

2. Frontseat the liquid line valve.

3. Start unit and run until suction pressure reaches

5 psig (see Caution).

4. Shut unit off and frontseat suction valve.

5. Vent remaining pressure to atmosphere.

FAN COMPARTMENT

-WAY VALVE

CONTROL BOX

DISCHARGE LINE

MUFFLER

(039,044,048)

COMPRESSOR

Fig. 31 — Component Location

14

CONTROL WIRING

TERMINAL BOARD

ACCUMULATOR'

SUCTION LINE

SERVICE VALVE-

LIQUID LINE

SERVICE VALVE

Page 15

Unit Controls and Safety Devices

HIGH-PRESSURE RELIEF VALVE is located in

compressor. Relief valve opens at a pressure differ

ential of approximately 600 psi between suction

(low side) and discharge (high side) to allow

pressure equalization.

INTERNAL CURRENT AND TEMPERATURE

SENSITIVE OVERLOAD resets automatically

when internal compressor motor temperature

drops to a safe level (overloads may require up to

45 minutes to reset). When an internal overload is

suspected of being open, check by using an

ohmmeter or continuity tester. If necessary, refer

to Carrier Standard Service Techniques Manual,

Chapter 2, for complete instructions.

LIQUID LINE LOW-PRESSURE SWITCH (LLPS)

is connected in liquid line to work with compressor

internal thermostat in providing loss-of-charge pro

tection during the heating cycle. Control is

mounted on liquid line.

With a high-side leak, pressure gradually de

creases until low-pressure control stops the com

pressor. (Low-pressure control settings are shown

in Table 8.)

Table 8 — Pressure Switch Settings

UNIT

38CQ

015

020

027

033 20 + 5 5+3

039

044

048

Cut-in (psig) Cutout (psig)

LIQUID LINE

LOW-PRESSURE SWITCH

With a low-side leak there is always some

pressure in the liquid line. However, compressor

motor temperature increases because of in

sufficient suction gas cooling. This causes internal

thermostat to actuate and stop compressor. When

compressor stops, system pressure equalizes and

contacts on pressure control open. The compressor

cannot restart until leak is repaired and system

recharged.

CRANKCASE HEATER is connected across line

side of contactor and operates continuously.

The purpose of the heater is to keep the

crankcase warm during the off cycle and thus

prevent dilution of the oil with refrigerant. This

assures good lubrication and prevents loss of oil

from crankcase during start-up.

If the electrical disconnect switch to the out

side unit has been off for an extended period of

time, the crankcase heater should be energized for

24 hours before starting the compressor

DEFROST CONTROL, consisting of a defrost

timer, defrost thermostat and defrost relay, inter

rupts normal system heating operation every 90

minutes to defrost outdoor coil, if the coil satu

rated suction temperature indicates freezing

temperatures. Defrost control simultaneously stops

outdoor fan, energizes reversing valve solenoid to

return system to cooling cycle (outdoor unit as

condenser, indoor unit as evaporator), and acti

vates accessory electric heater.

For the heat pump to defrost, 2 conditions are

necessary:

1. Defrost timer contacts must be closed.

2. Refrigerant temperature from outdoor unit

must be cold enough to cause defrost ther

mostat contacts to close. Contacts close at 31

(±4) F.

Every 90 minutes of elapsed running time, the

defrost timer contacts close for 10 seconds. If the

defrost thermostat contacts are closed, the unit

defrosts. The defrost timer limits defrosting period

to 10 minutes. Normally the frost is removed and

the defrost thermostat contacts will open to

terminate defrosting before 10 minutes have

elapsed. Defrost thermostat contacts open at 80

(±6) F liquid refrigerant temperature. When de

frosting is terminated, the outdoor fan motor is

energized and reversing valve solenoid is de

energized returning unit to heating cycle.

HEAT PUMP CIRCUITS shown in Fig. 32 are

refrigerant flow diagrams for heating and cooling

cycles.

AccuRater^''^ (Bypass Type) Servicing — See Fig.

33 for bypass type AccuRater components. The

piston has a refrigerant metering hole thru it. The

retainer forms a stop for the piston in the

refrigerant bypass mode, and a sealing surface for

liquid line flare connection. To check, clean or

replace piston:

1. Shut off power to unit.

2. Pump unit down using Pumpdown Procedure

described previously.

3. Remove liquid line flare connection from

AccuRater.

4. Pull retainer out of body being careful not to

scratch flare sealing surface. If retainer does not

pull out easily, carefully use vise grips or pliers

to remove retainer.

5. Slide piston out by inserting a small soft wire,

with small kinks, thru metering hole. Ensure

metering hole, sealing surface around piston

cones and fluted portion of piston are not

damaged.

15

Page 16

SUCTION

SERVICE

PORTAT

SERVICE

VALVE

(HTG CYCLE)

OUTDOOR

COIL

SUCTION

SERVICE

PORT

ACCESSORY

FILTER DRIER

DISCHARGE

SERVICE

PORT AT

SERVICE

VALVE

(HTG CYCLE)

LIQUID LINE

SERVICE

PORT AT

SERVICE

VALVE

(CL6 CYCLE)

ACCESSORY

FILTER DRIER

BYPASS TYPE

ACCURATOR (PERMITS FLOW

IN EITHER DIRECTION)

STRAINERS

ACCUMULATOR

-WAY valve

SUCTION

SERV^ICE

PORTAT

SERVICE

VALVE

(CLG CYCLE)

iUNIT PIPING

HEATING CYCLE

Fig. 32 — 38CQ Refrigerant Flow Diagrams

Fig. 33 — AccuRater^'^ (Bypass Type) Components

6. Clean piston refrigerant metering hole.

7. Replace retainer 0-ring before reassembling

bypass type AccuRater. Carrier O-ring part no.

is99CC501052.

LIQUID LINE STRAINER (protects AccuRater)

made of wire mesh is located in the liquid line

inside 38CQ unit behind liquid line service valve.

Liquid line is belled and sweat connected where

strainer is located. If strainer is plugged, unsweat

belled liquid line connection and replace strainer.

Compatible Fitting Repair

LEAKING MECHANICAL CONNECTION Frontseat outdoor section service valves and relieve

refrigerant pressure in tubing. Back locknut off

Carrier Compatible Fitting onto tube. Cut fitting

between threads and seal ring bead shown in

Fig. 34. Remove tubing section remaining in

threaded portion of fitting. Discard locknut.

Clean, flux, and insert new tube end into

remaining portion of Carrier Compatible Fitting.

Wrap valve base in wet rag. Heat and apply

low-temperature solder (450 F).

COOLING CYCLE

LEAKING SWEAT CONNECTION - Frontseat

service valves and relieve refrigerant pressure in

tubing. Clean and flux area around leak and apply

low-temperature solder (450 F).

Evacuate or purge indoor coil and tubing

system. Add refrigerant charge (seb charging

instructions).

Leaking Flare Connection — Cut and reflare 3/8-in.

system liquid line.

I,

Fig. 34 — Carrier Compatible Fitting

16

Page 17

Outdoor Fan Position — Required fan position is

shown in Fig. 35. Adjust fan by loosening setscrew

and moving fan blades up or down.

Fan Motor Removal

1. Shut off power to unit.

2. Remove unit top access cover and fan grille.

3. Disconnect fan motor wires from fan capacitor

and control relay or contactor. Pull wires out of

control box.

4. Remove fan from motor shaft by loosening

setscrew and pulling upward on fan hub.

5. Remove rain shield from motor shaft by pulling

upward.

6. Loosen bolt holding fan motor to motor

mounting bracket. Remove motor thru top of

unit. To replace motor, place motor on self

positioning motor mounting flanges and re

tighten bolt.

Before replacing fan, ensure rain protector is in

place on motor shaft.

FAN BLADE

MOTOR

setscrew""

Fig. 35 — Condenser Fan Position

MAINTENANCE

Outdoor Coil Cleaning — Inspect coil periodically.

Clean coil with water at the beginning of every

cooling season or more often if required. Use

ordinary garden hose at a pressure high enough to

clean efficiently. For best results, unscrew and

remove unit top cover (grille). Insert hose nozzle

between fan blades and spray coil fins from

inside-to-outside the unit or top to bottom be

tween rows of tubing. If unit has a double-row coil,

loosen screws to separate coils. Pull outer row of

coils away from inner row and flush dirt toward

outside of both coils. Flush dirt from base pan by

spraying water thru top of unit. Avoid splashing

mud on coil or water on fan motor. Make sure

water drainage holes under outdoor coil are not

obstructed.

Lubrication

FAN MOTOR BEARINGS - Oiling holes are

provided at each end of outdoor unit fan motor.

Remove fan motor and lubricate motor with 32

drops (16 drops per hole) of SAE-10 nondetergent

oil at intervals described below:

a. Annually, when environment is very dirty,

ambient temperature is higher than 105 E and

average unit operating time exceeds 15 hours a

day.

b. Every 3 years when environment is reasonably

clean, ambient temperature is less than 105 F

and unit operating time averages 8 to 15 hours

a day.

c. Every 5 years when environment is clean,

ambient temperature is less than 105 F and unit

operating time averages less than 8 hours a day.

COMPRESSOR contains factory oil charge. When

oil is lost, see Table 7 for oil charge and Carrier

Standard Service Techniques Manual, Chapter 1,

page 1-21, for instructions. Use Carrier PP33-1,

Texaco Capella B or Suniso 3G oil.

17

Page 18

00

TROUBLESHOOTING CHART - COOLING CYCLE

Page 19

TROUBLESHOOTING CHART - HEATING CYCLE

Page 20

SI METRIC CONVERSIONS

(°F - 32) X 5/9

= °C

BTU X 1.055 = kJ

BTU/hr X

Tons refrig x 3.517

0.2931 = W

= kW

HP X 0.7457 = kW

kcal/hr X

ft X

1.163

0.3048

ft^x 0.09290

fpm

in X

0.005080

25.4 = mm

in wg 39.2° F x 0.2491

in Hg 32° F X 3.386

CFM X

gpm (U.S.) X

0.0004719

0.06309 = l/s

Ibx 0.4536

lb/in^ X 6.895

OZ. X 0.02835

fluid OZ. (U.S.) X 0.02957 = 1

kcal X

kg f/cm^ X

Metric HP X

4.1855

98.07 = kPa

735.5 = W

pints X 0.4732

= W

= m

= m2

= m/s

= kPa

= kPa

= m^/s

= kg

= kP

= kg

= kJ

= 1

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Tab 12 Form 38CQ-6SI Supersedes 38CQ-4SI Printed in USA 1-77 PC 101 Catalog No 533-854

Book

1 4

Tab 5a

5a

Loading...

Loading...